General Eastern MMY2650 Operating Manual

GE

Measurement & Control Solutions Moisture

HygroGuar d MMY 2650

Installation and Operation Manual

63005131 Rev. D

September 2010

GE

Measurement & Control Solutions

HygroGuard MMY 2650

General Eastern Trace Moisture Analyzer

Installation and Operation Manual

63005131 Rev. D

September 2010

www.gesensinginspection.com

©2010 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Contents

Chapter 1. Features

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Available Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.1 Connection Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.2 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Equipment Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2. Installation

2.1 Mounting the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.1 In-Line Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.2 Bypass Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.3 Mounting in a Sample System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.4 Probe Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2 Opening the Wall-Mount Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3 Mounting the Wall-Mount Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4 Mounting the Panel-Mount Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5.1 Connecting the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5.2 Connecting the Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5.2aAC Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5.2bDC Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5.3 Connecting Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5.3aRelays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5.3bCurrent Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5.3cVoltage Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.5.4 Auxiliary Input Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.5.4a4 to 20mA Loop-Powered Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.5.4bActive 4 to 20mA Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.6 Connecting RS-485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.6.1 Components Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.6.1aConnections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

HygroGuard MMY 2650 Installation and Operation Manual iii

Contents

Chapter 3. Programming and Operation

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2 Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3 Standard Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.4 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.5 LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.6 The Programming Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6.1 Moving Through the Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6.2 Entering Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6.3 “Display Only” Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.6.4 Function Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.6.5 Accessing the Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.6.6 Locking the Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.6.7 Unlocking the Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.6.8 Matrix Field Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.7 Analog Output Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.8 Relay Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Chapter 4. Calibration

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 5. Troubleshooting and Maintenance

5.1 General Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1.1 Invalid Loop Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1.2 Slow Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1.3 Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.1.1 Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.1.2 Correcting Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.2 Signal Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3 Probe Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

iv HygroGuard MMY 2650 Installation and Operation Manual

Contents

Appendix A. Specifications

A.1 MMY 2650 Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.1.1 Electronics:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.1.2 Standard Inputs: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.1.3 Optional Input: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.1.4 Moisture Probe: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.1.5 User Interface: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.1.6 Display:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.1.7 EMI/RFI/ESD Protection: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.1.8 Units of Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A.1.8aMoisture: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A.1.8bTemperature: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A.1.8cPressure:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A.1.9 Analog Outputs: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A.1.10Digital Outputs: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A.1.11Serial Output: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A.1.12Serial Communication:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.1.13Program: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.1.14Data: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.1.15Operating and Storage Temperature: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.1.16Supply Voltage:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.1.17Power Consumption: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.1.18Enclosure: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.1.19Cable Entry: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.1.20Weight: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A.2 Panel Mount Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

A.2.1 Material: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

A.2.2 Dimensions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

A.2.3 Depth: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

A.2.4 Panel cutout:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

A.2.5 Wiring: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

A.2.6 Mounting: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

A.2.7 Front Panel Surface: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

HygroGuard MMY 2650 Installation and Operation Manual v

Contents

A.3 DY 5xx Probe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A.3.1 Sensing Element: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A.3.2 DP Range:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A.3.3 DP Accuracy: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A.3.4 DP Repeatability: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A.3.5 ppmv Range:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A.3.6 Standard Operating Temperature:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A.3.7 Standard Operating Pressure:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A.3.8 Probe/Analyzer Signal Transmission: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A.3.9 Sensor Electronics:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A.3.10Probe Tube:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

A.3.11Standard Probe Mounting: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

A.3.12Optional Probe Mounting: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

A.3.13Weight: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

vi HygroGuard MMY 2650 Installation and Operation Manual

Preface

Information Paragraphs

• Note paragraphs provide information that provides a deeper understanding of the

situation, but is not essential to the proper completion of the instructions.

• Important paragraphs provide information that emphasizes instructions that are

essential to proper setup of the equipment. Failur e to follow these instructions car efully

may cause unreliable performance.

• Caution! paragraphs provide information that alerts the operator to a hazardous

situation that can cause damage to property or equipment.

• Warning! paragraphs provide information that alerts the operator to a hazardous

situation that can cause injury to personnel. Cautionary information is also included,

when applicable.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county, state and

national codes, regulations, rules and laws related to safety and safe

operating conditions are met for each installation.

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance with local

codes, standards, regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic modes of

operation. As equipment can move suddenly and without warning, do

not enter the work cell of this equipment during automatic operation,

and do not enter the work envelope of this equipment during manual

operation. If you do, serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF and

locked out before you perform maintenance procedures on the

equipment.

HygroGuard MMY 2650 Installation and Operation Manual ix

Preface

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the

auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment applicable

to the auxiliary equipment. Examples include safety glasses, protective headgear, safety

shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the

equipment.

Environmental Compliance

Waste Electrical and Electronic Equipment (WEEE) Directive

GE Measurement & Control Solutions is an active participant in Europe’ s Waste Electrical

and Electronic Equipment (WEEE) take-back initiative, directive

2002/96/EC.

The equipment that you bought has required the extraction and use of natural resources for

its production. It may contain hazardous substances that could impact health and the

environment.

In order to avoid the dissemination of those substances in our environment and to diminish

the pressure on the natural resources, we encourage you to use the appropriate take-back

systems. Those systems will reuse or recycle most of the materials of your end life

equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please

contact your local or regional waste administration.

Visit http://www.gesensing.com/environment/weee.htm

and more information about this initiative.

x HygroGuard MMY 2650 Installation and Operation Manual

for take-back instructions

Chapter 1. Features

Chapter 1. Features

1.1 Overview

The MMY 2650 is a moisture analyzer designed to operate with trace moisture probes

DY5x7 and DY5x2. The unit offers an optional input that can be used for pressure

compensation or any other sensor. The standard product comes with one current output

(0–20 mA or 4–20 mA), a system alarm relay, and three adjustable relays, all with

single-pole double-throw contacts, selectable fail-safe mode, and adjustable hysteresis.

One or two additional current outputs are available as options. A display and five push

buttons form the user interface for data display, and selection of units, ranges, setpoints,

and special functions.

The MMY 2650 is to be used only as specified by the factory. Use other than as specified

may impair the safety precautions of the system.

1.2 Available Versions

The MMY 2650 is available in two mounting versions: wall mount and panel mount.

This manual generally describes the installation and wiring of the wall-mount version.

Specific instructions for the panel-mount version are given where necessary.

The panel-mount version is available with or without a protective and lockable door

covering the unit’s controls.

HygroGuard MMY 2650 Installation and Operation Manual 1

Chapter 1. Features

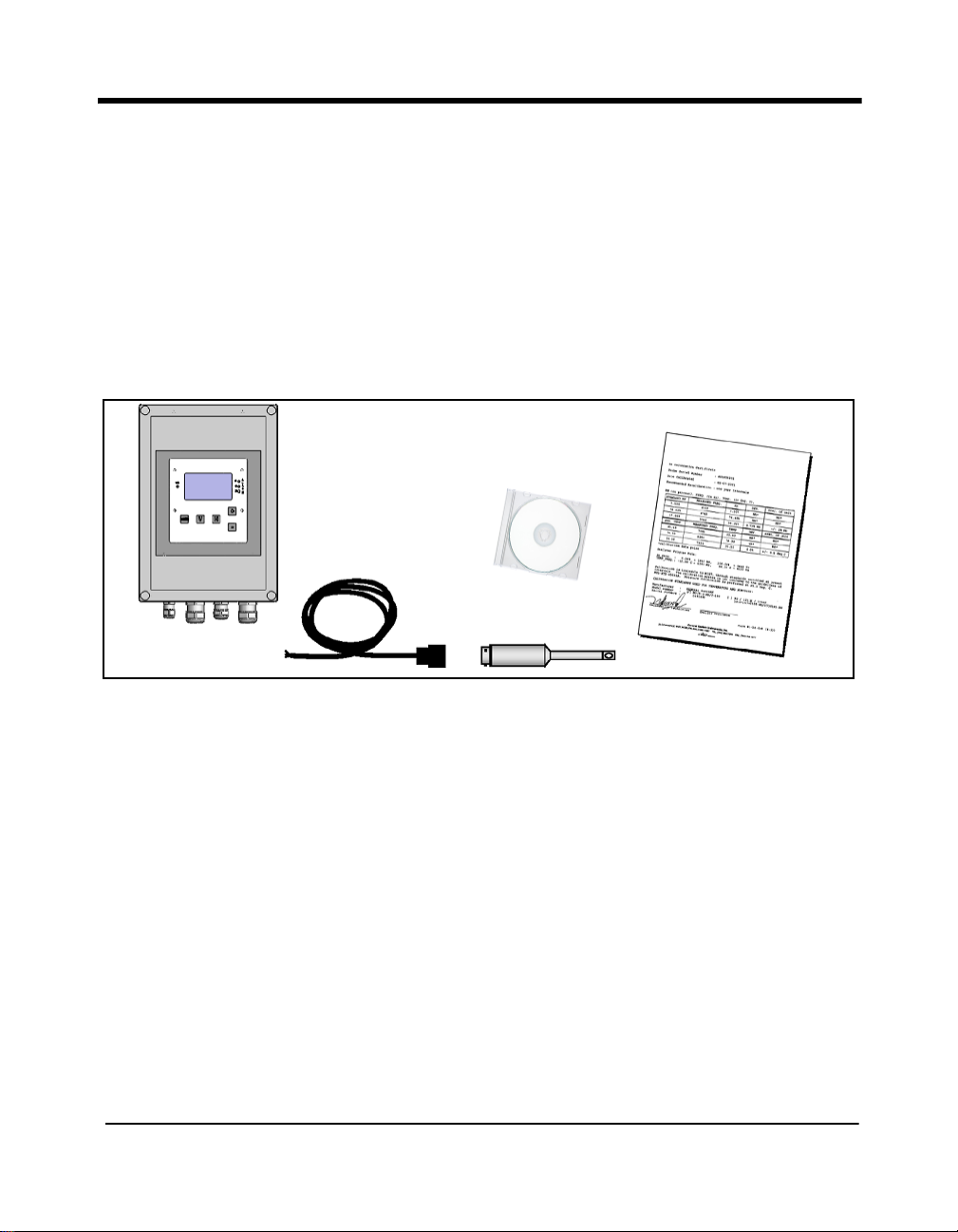

1.3 Unpacking and Inspection

Examine the shipping carton for broken or open packing, distortion, o r any other eviden ce

of mishandling. If inspection indicates damage to the unit or any of its components, notify

the carrier promptly and request an inspection.

Move the carton to a clean work area and unpack the unit. The carton should contain:

• MMY 2650 analyzer • CD with Manual

• DY5xx probe with its cable • Calibration certificate

Figure 1: Unpacking the Components

2 HygroGuard MMY 2650 Installation and Operation Manual

Chapter 1. Features

1.3.1 Connection Cable

Configuration information for the cable connecting the MMY 2650 to the DY5 probe is

shown below:

7C2550-X

2C2550-X

7 C2550- 0 Model Number Example

Cable with multi-pin connector and tinned ends; for use

with probe DY5-X7 25XXX

Cable with spade lugs and ferrule ends; for use with

probe DY5-X2 25XXX

Cable Length

0 5 ft.

Other length; specify r equir ed le ngth (Be lden 8723 o r

L

equivalent)

For probes with a junction box (DY-502), the factory provides five feet of cable at no

charge.

1.3.2 Theory of Operation

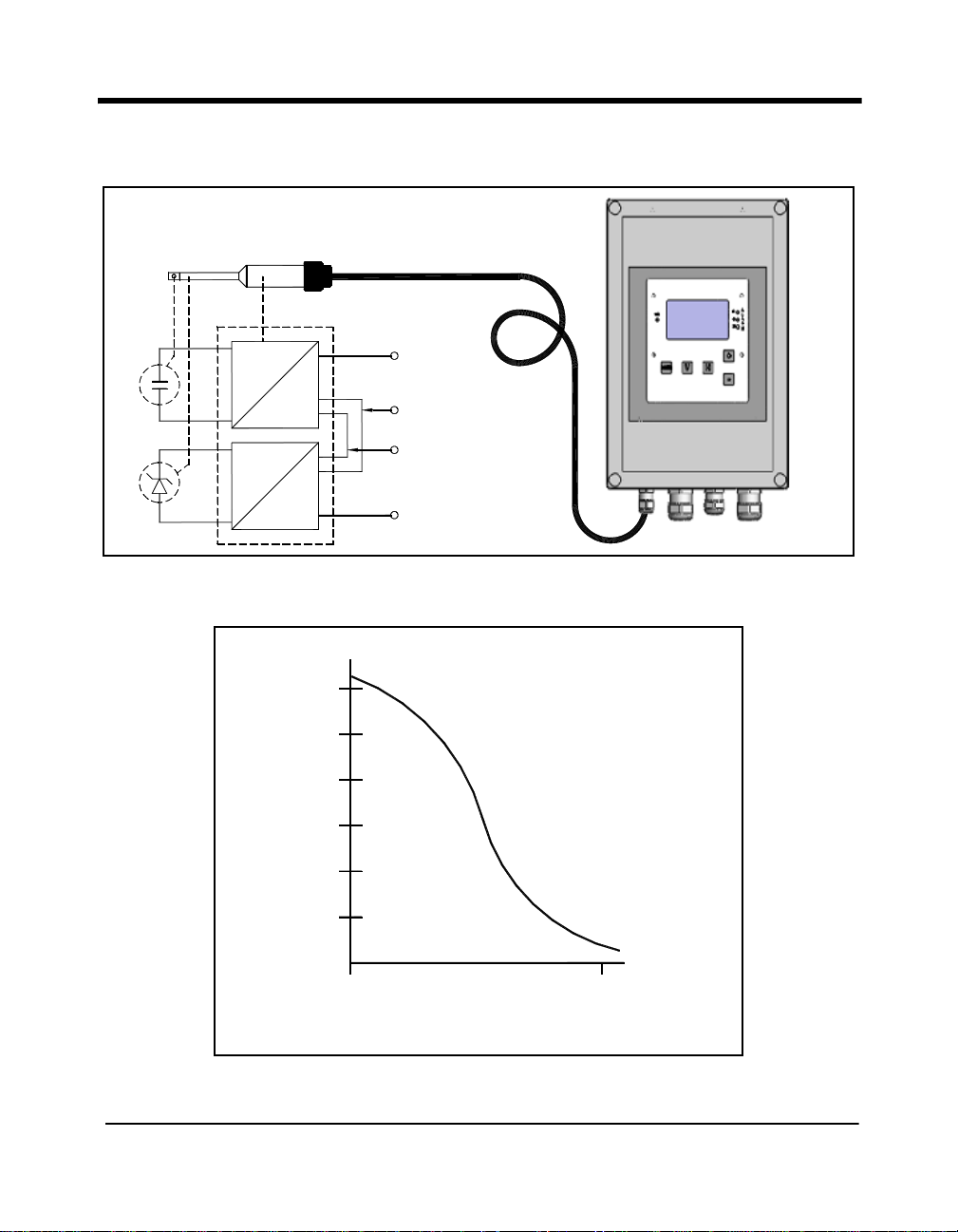

Moisture and temperature sensor signals are converted within the probe to frequencies,

allowing the use of shielded four-wire cable up to 1000 feet in length without noise

interference. The raw frequencies can be displayed for troubleshooting, calibration and

function control.

The DY5xx probe is calibrated against known dew point temperatures referenced by a

NIST-certified chilled mirror instrument. The sensor senses the water vapor pressure

independent of the carrier gas. Other units of measure are derived using the temperature

measurement, where necessary.

HygroGuard MMY 2650 Installation and Operation Manual 3

Chapter 1. Features

(Frequency)

Moisture

(Frequency)

Temperature

Pt1000

f

V

–

f

V

+

Dew Point–80°C

1kHz

Frequency Hz

5kHz

2kHz

3kHz

4kHz

20°C

6kHz

1.3.2 Theory of Operation (cont.)

Figure 2: Theory of Operation

4 HygroGuard MMY 2650 Installation and Operation Manual

Figure 3: Typical Moisture Sensor Calibration Curve

1.4 Equipment Drawings

Chapter 1. Features

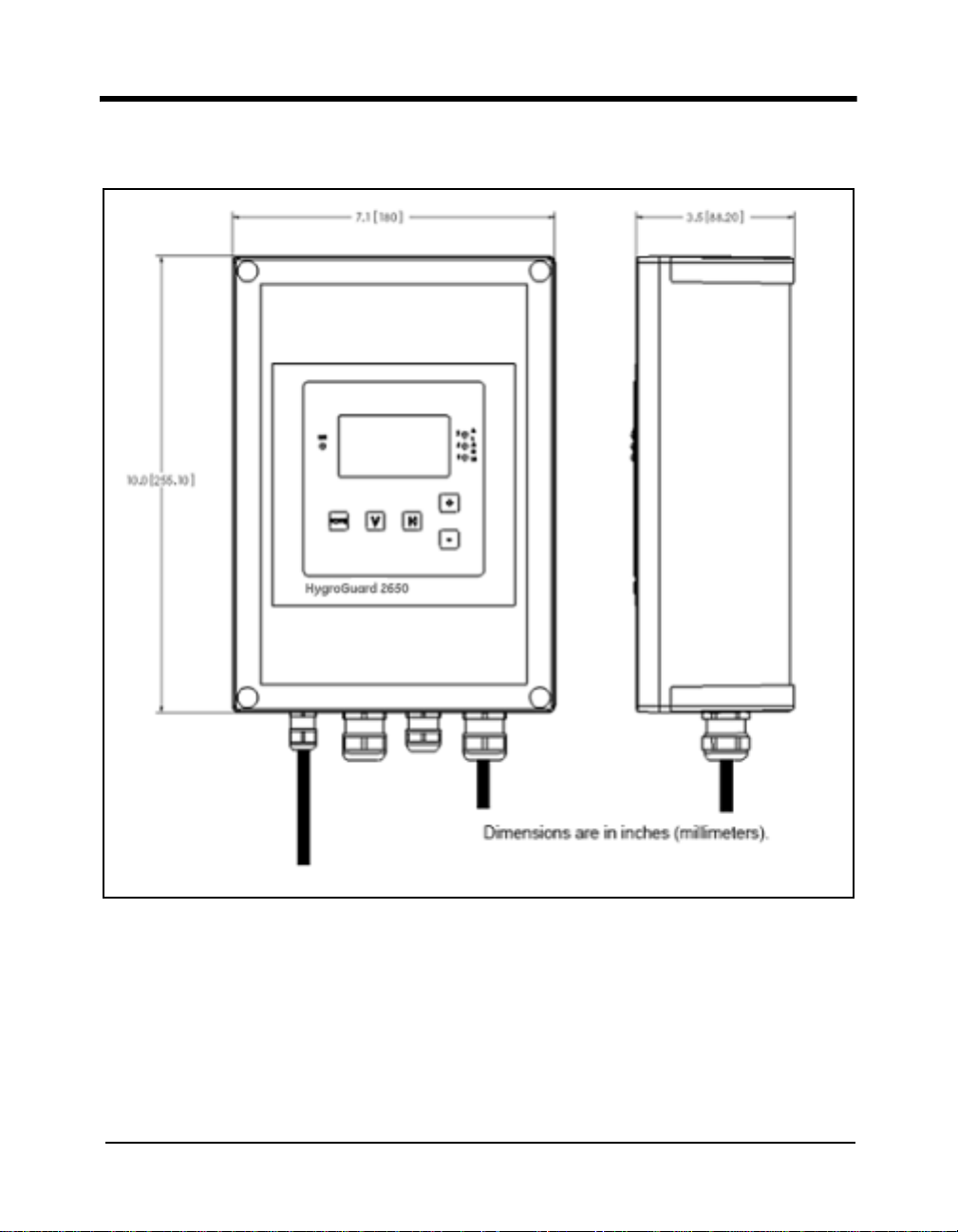

Figure 4: MMY 2650 Analyzer

HygroGuard MMY 2650 Installation and Operation Manual 5

Chapter 1. Features

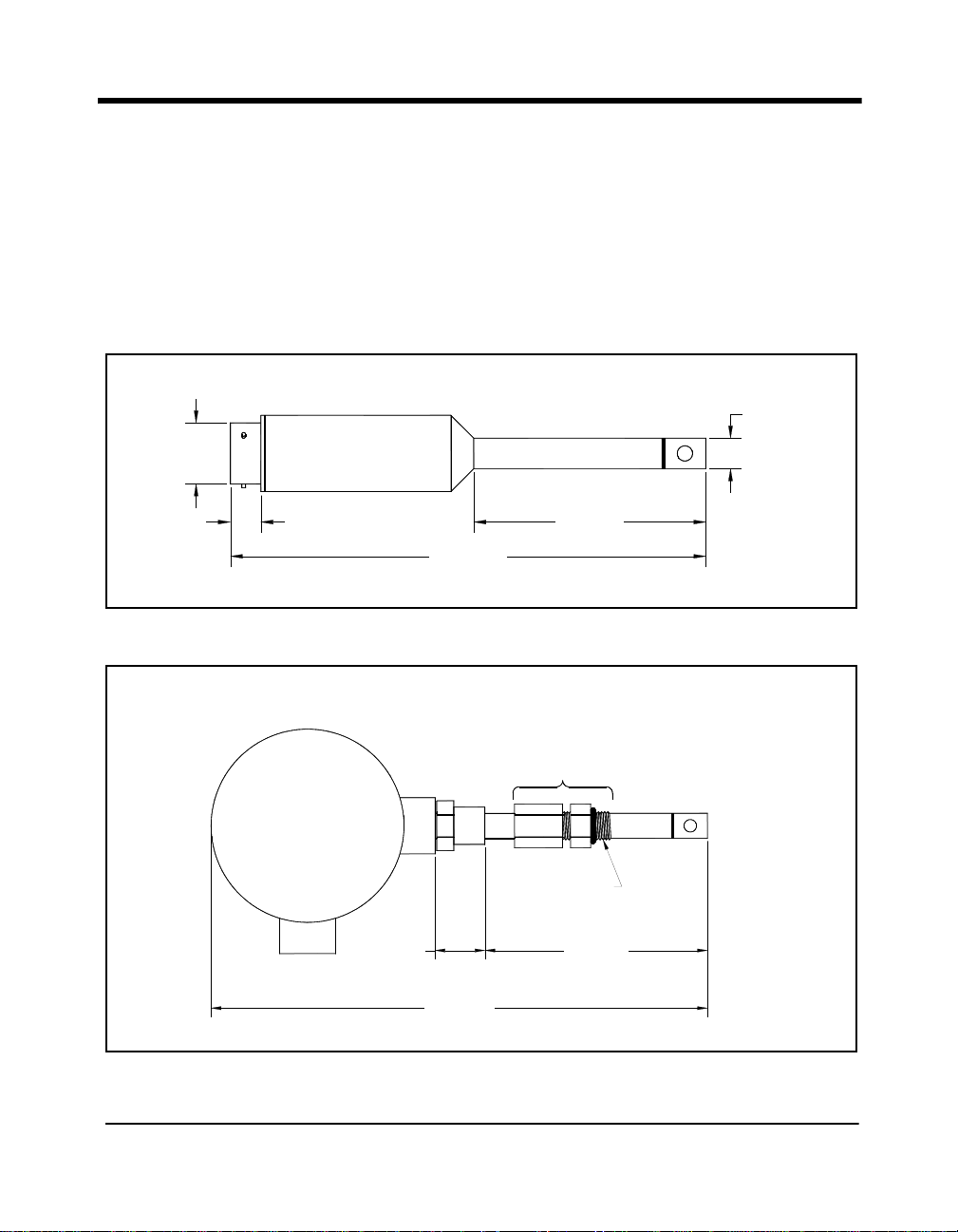

Ø1.0

(25)

3.8 (97)

Ø0.5

(13)

7.8 (198)

0.5 (13)

Dimensions are in inches (millimeters).

4.5 (114)

Dimensions are in inches (millimeters).

10.0 (254)

1/2" MNPT

1.0 (25)

Probe Mounting Adapter

1/2" FNPT

Conduit Connection

1.4 Equipment Drawings (cont.)

• The DY 507 probe uses a removable cable and connector.

• The DY 502 probe cable is wired to an attached junction box for use in hazardous

areas.

• The standard mounting adapter for the DY-series probe is a 1/2” tube compression

fitting by 1/2” MNPT.

Figure 5: DY 507 Probe

6 HygroGuard MMY 2650 Installation and Operation Manual

Figure 6: DY 502 Probe

1.4 Equipment Drawings (cont.)

Connectors

Wiring

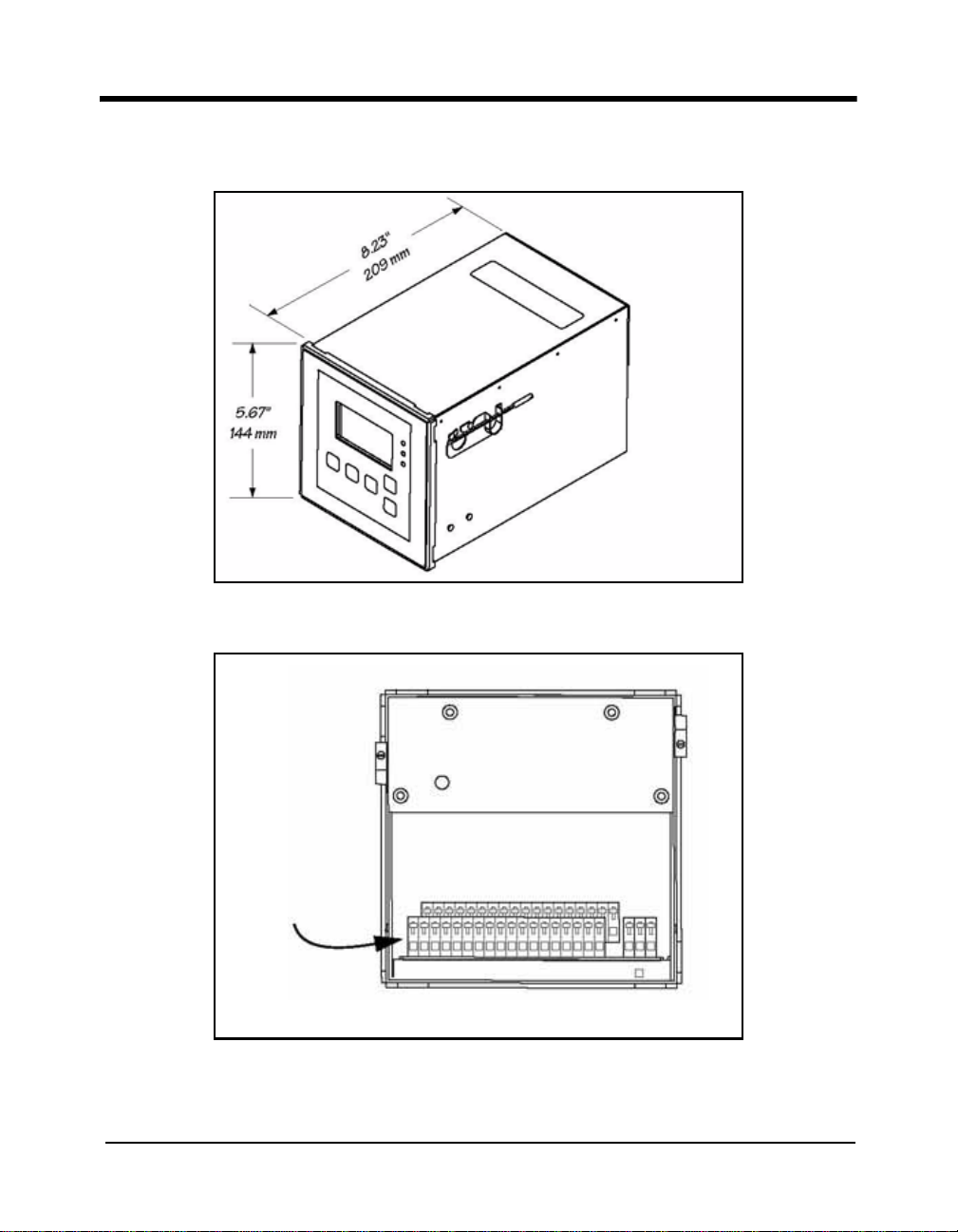

Figure 7: MMY 2650 Panel Mount Version

Chapter 1. Features

HygroGuard MMY 2650 Installation and Operation Manual 7

Figure 8: MMY 2650 Panel Mount Version (rear view)

Chapter 1. Features

8 HygroGuard MMY 2650 Installation and Operation Manual

Chapter 2. Installation

Pipe

Probe

1"

Probe

Pipe

1”

Chapter 2. Installation

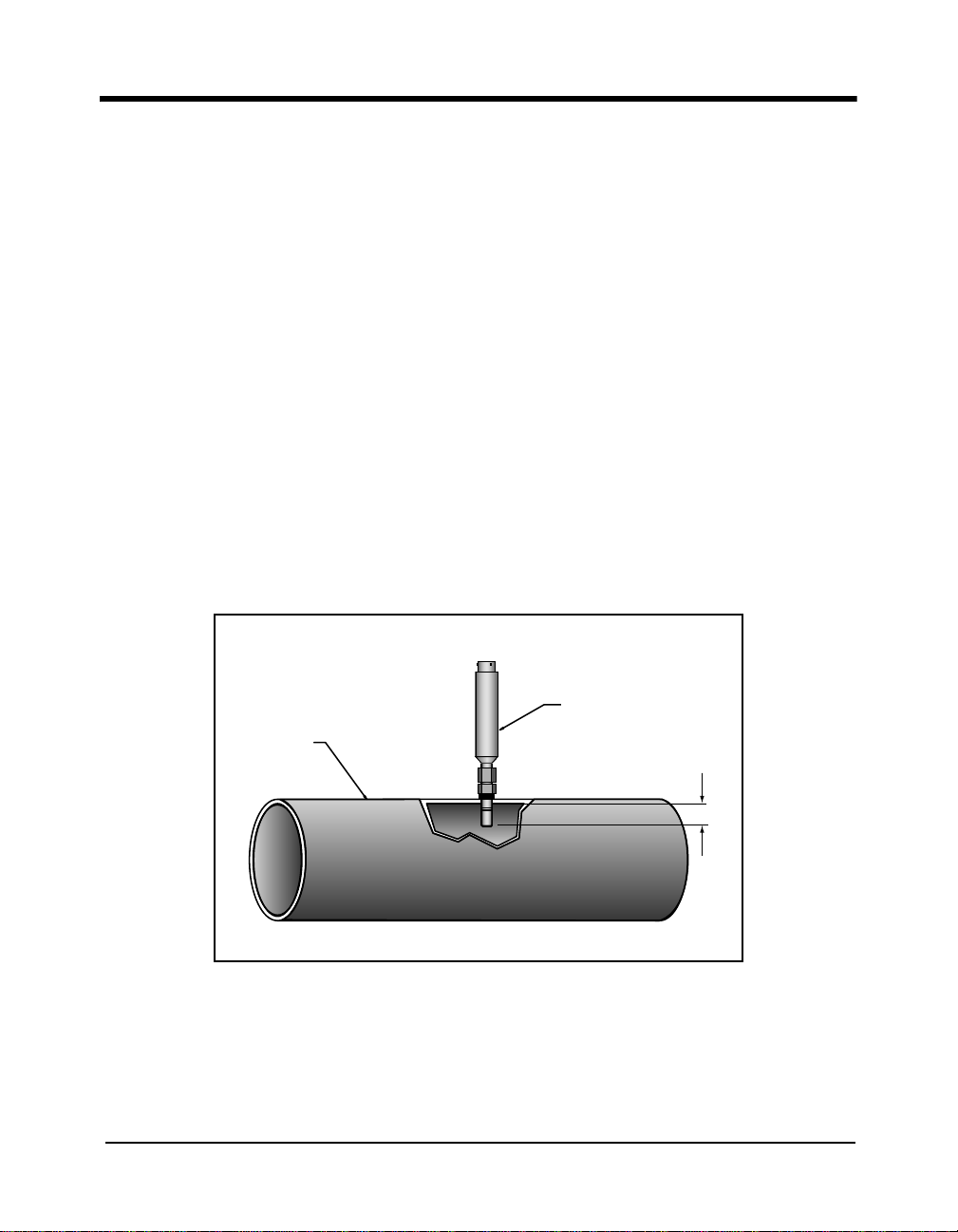

2.1 Mounting the Probe

2.1.1 In-Line Mounting

Mount the probe vertically so that the sensor tip points down. The probe is typically

mounted in a H” pipe thread connection. Insure that the tip of the probe does not touch the

inside wall of the pipe.

Adjust the stainless steel ferrule for a probe insertion length of at least 1” and tighten the

compression fitting as follows:

1. Hand-tighten the nut.

2. Using a wrench, tighten the nut one and one-half additional turns.

With this procedure, the fitting is sealed and can withstand pressure to 3000 psig.

Figure 9: Probe Mounting

HygroGuard MMY 2650 Installation and Operation Manual 9

Chapter 2. Installation

Probe

Main

process

stream

Shutoff valves

the upstream valve and

Probe

Shutoff Valves

Main

Process

Stream

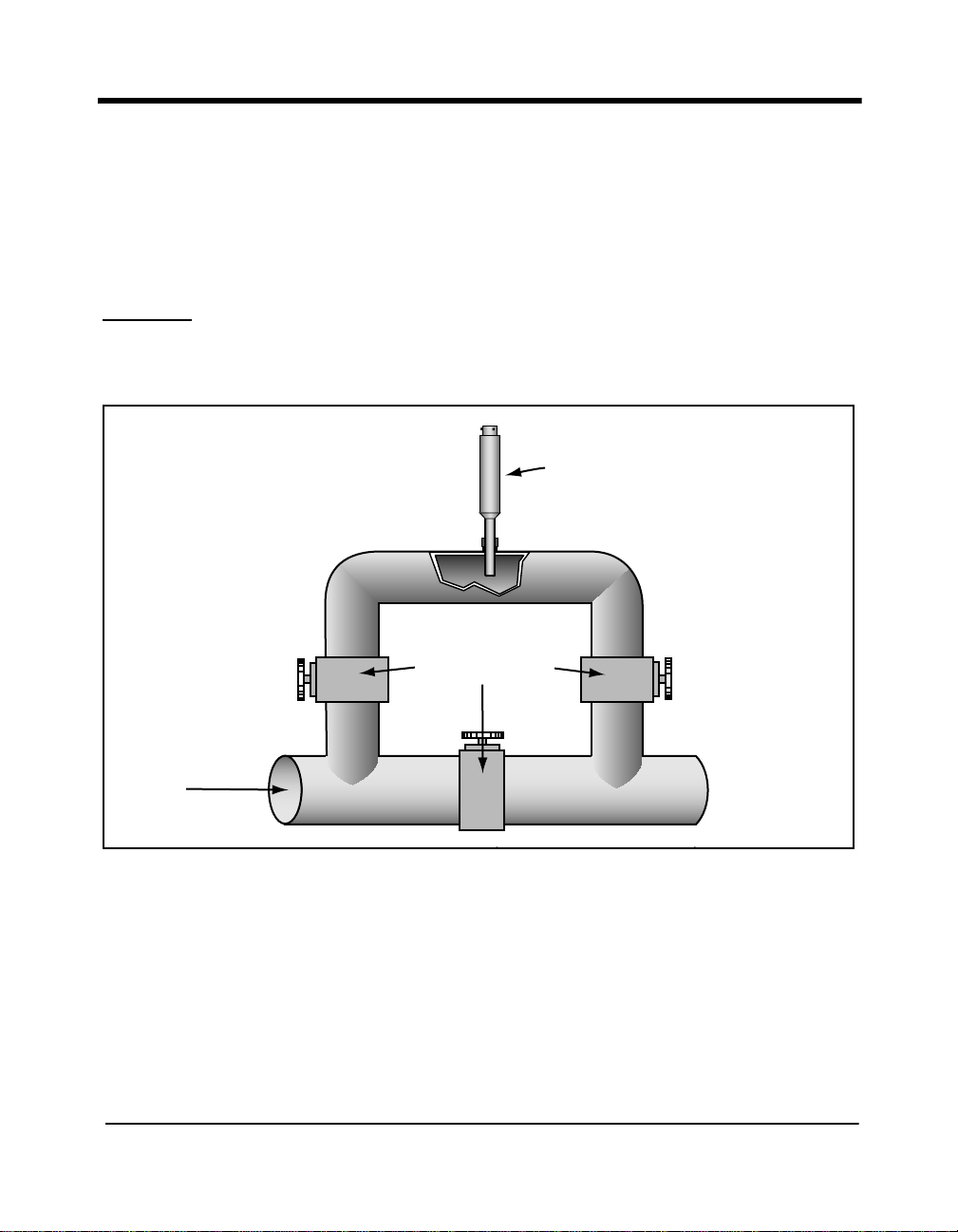

2.1.2 Bypass Mounting

Using a bypass line assures no interruption of the process stream while the probe is being

serviced. T o mount the probe in a bypass, the above procedure for in-line mounting should

be followed. Exercise caution when reopening the bypass after a probe has been serviced

as this may contaminate the main stream.

CAUTION!

Before servicing the probe, close the upstream valve and the proces s

stream valve to depressurize the bypass; then close the system’s

downstream valve.

Figure 10: Bypass Mounting

10 HygroGuard MMY 2650 Installation and Operation Manual

Chapter 2. Installation

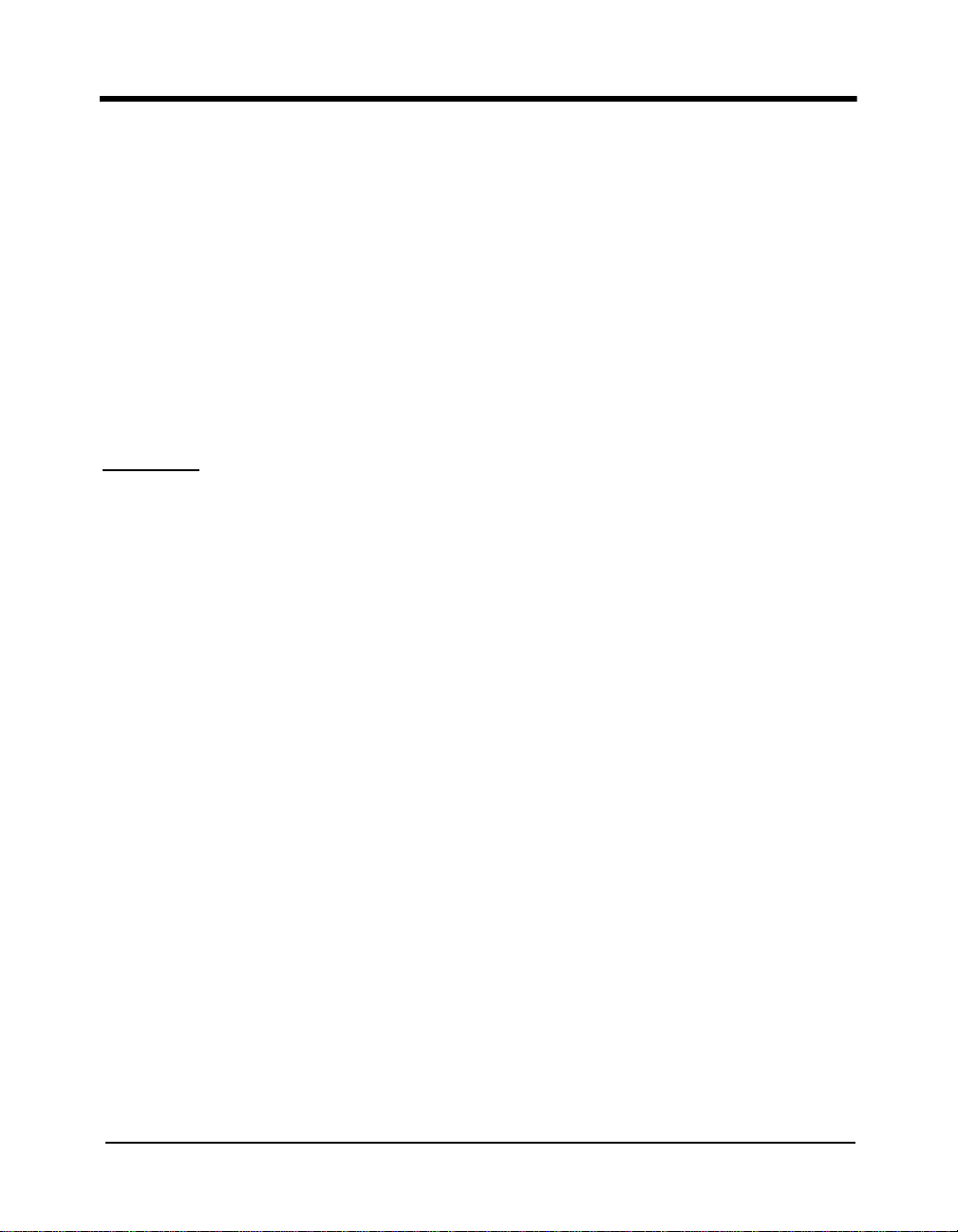

2.1.3 Mounting in a Sample System

If the gas velocity or temperature in your application exceeds the probe specifications in

Appendix A or if particulates are entrained in the stream, a sample system should be used.

In a sample system with low dew points, all wetted parts should be of stainless steel. (For

further details, refer to the General Hints for Trace Moisture Measurement manual.)

While the measured value of the probe is not flow-sensitive, the flow rate in a sample cell

influences the response time of the system. A flow rate of 1 to 5 SCFH through the flow

cell is ideal. In addition, the sample gas temperature in the flow cell must remain above the

dew point temperature to prevent condensation. (If the dew point is greater than 0°C,

maintaining a +10°C (18°F) difference is recommended.)

WARNING!

Before removing the probe, insure that the flow cell is not under

pressure!

Removing the probe when pressure exists in the flow cell could result

in an extremely dangerous situation, threatening to both life and

limb!

Figure 11 on page 12 illustrates a basic sample system.

HygroGuard MMY 2650 Installation and Operation Manual 11

Chapter 2. Installation

Probe

Valve 1

Valve 2

Flow Cell

Flow

Intake towards the middle of the

p

ipe diameter is recommended.

I

s

I

a

N

t

a

o

Probe

Flow

Valve 1

Valve 2

Flow Cell

Intake toward the middle of the

pipe diameter is recommended.

See note below.

2.1.3 Mounting in a Sample System (cont.)

Measurement Options

• If measurement is desired under system pressure:

Valve 1 is fully open and the sample flow is regulated by Valve 2.

• If measurement is desired under atmospheric pressure:

Valve 2 is fully open and the sample flow is regulated by Valve 1.

Note: At least five feet of 1/4” tubing, if vented to the atmosphere, will ensure accuracy

of sample in the flow cell.

12 HygroGuard MMY 2650 Installation and Operation Manual

Figure 11: Basic Sample System

Chapter 2. Installation

2.1.4 Probe Mounting Hardware

The following fittings are available for the DY 5xx probe. A 316 stainless steel ferrule is

provided for use in pressurized systems. For non-pressurized systems, a nylon ferrule is

available.

• ½” tube by ½” or ¾” MNPT compression fitting; ferrule

• ¾” x 16 “O” ring fitting x ½” tube 316 DD compression fitting

• For metric systems, a compression fitting with gasket and

G ½ thread, DIN-ISO 228, is available.

Figure 12: Compre ssion Fitting

HygroGuard MMY 2650 Installation and Operation Manual 13

Chapter 2. Installation

2.2 Opening the Wall-Mount Enclosure

To access the mounting points and electrical connections, open the case as follows (refer

to Figure 13 below):

1. Ensure that no electrical power is present at the analyzer.

2. Loosen the four plastic screws securing the cover to the enclosure and remove the

cover.

Note: The cover contains electronic components and is connected to the body of the

analyzer.

Figure 13: Opening the Wall-Mount Enclosure

14 HygroGuard MMY 2650 Installation and Operation Manual

Chapter 2. Installation

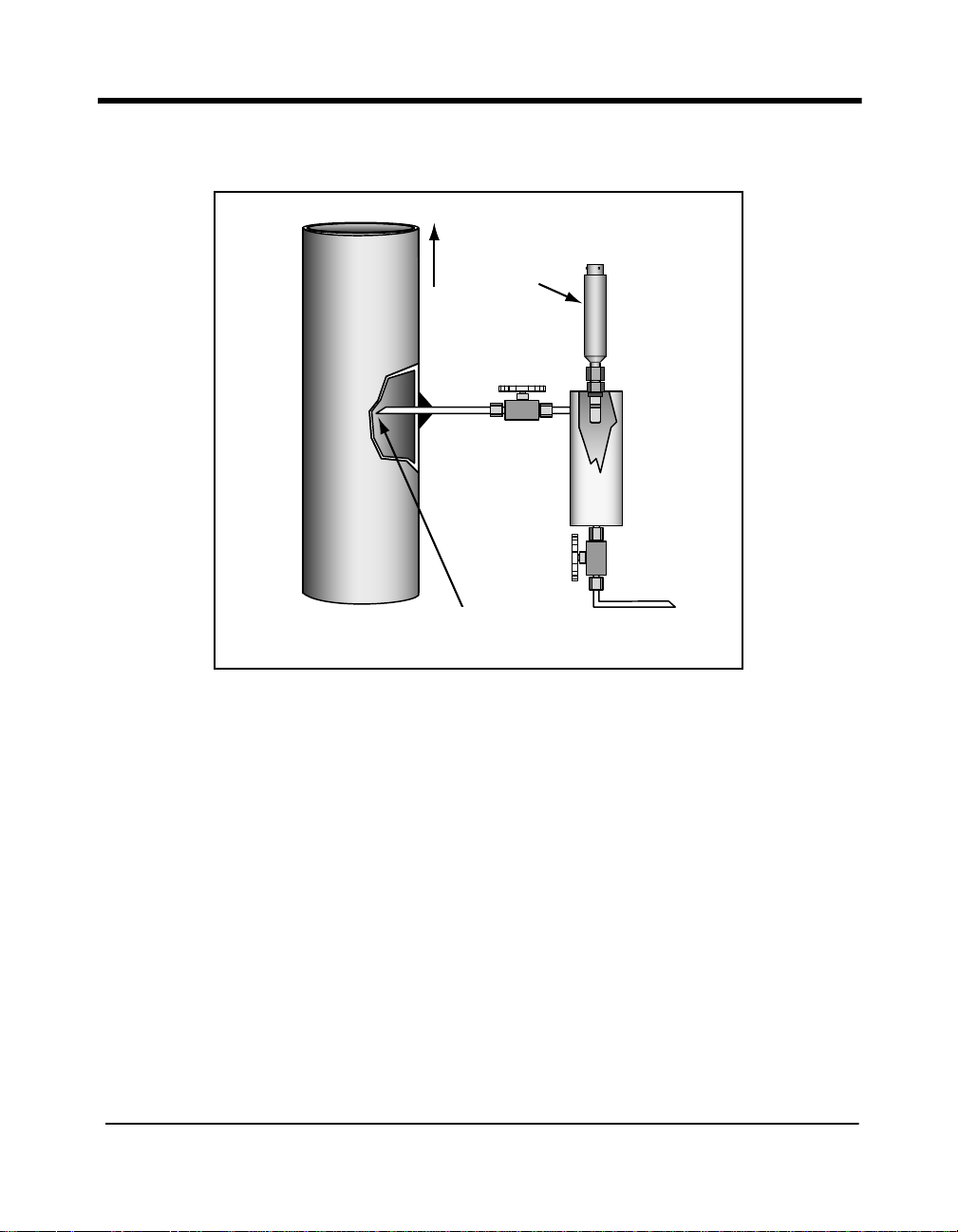

2.3 Mounting the Wall-Mount Enclosure

The MMY 2650 analyzer is for indoor use only. It should be mounted with appropriate

hardware, and all wiring should conform to local electrical codes and standards.

A drilling template for locating the 2650’s mounting holes is supplied with the unit.

Choose mounting hardware appropriate for your application.

Locate the analyzer module so that the probe cable length will not exceed 1000 feet.

1. Remove the cover as described in the previous section.

2. Mount the analyzer as shown in Figure 14 below.

Note: Insert the upper screw into the mounting hole and tighten it. Finally, insert the two

lower screws.

3. Replace the cover (Maximum torque = 1.2 N-m (12.2 Kg-cm)).

T o dismount the instrument, remov e the cover. Remove the lower mounting screws. Then,

remove the top mounting screws.

Figure 14: Mounting the Wall-Mount Enclosure

HygroGuard MMY 2650 Installation and Operation Manual 15

Chapter 2. Installation

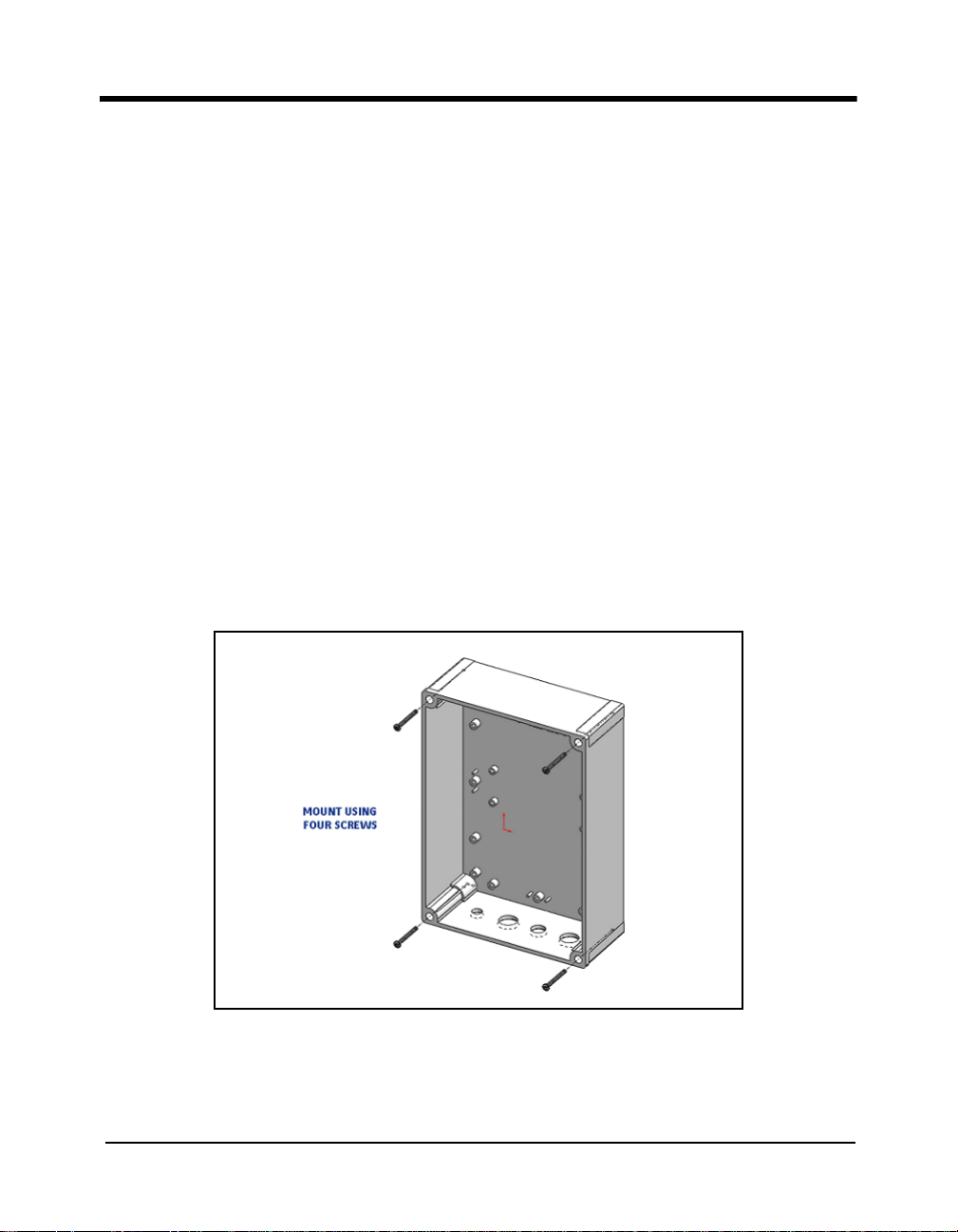

2.4 Mounting the Panel-Mount Enclosure

The panel-mount version of the MMY 2650 is for indoor use only and is designed to be

mounted in a square cutout in an equipment panel. The unit accommodates a wide range

of panel thicknesses. Mount the unit as described below:

1. Make a cutout in the panel measuring 5.4 3” by 5.43”

(138 by 138 mm).

2. Slide the unit into the cutout from the front of the panel.

3. From the rear side of the panel, slide the two mounting clamps into place on each side

of the unit (see Figure 7 on page 7).

4. Tighten each clamp screw from the rear using a long screwdriver.

2.5 Wiring

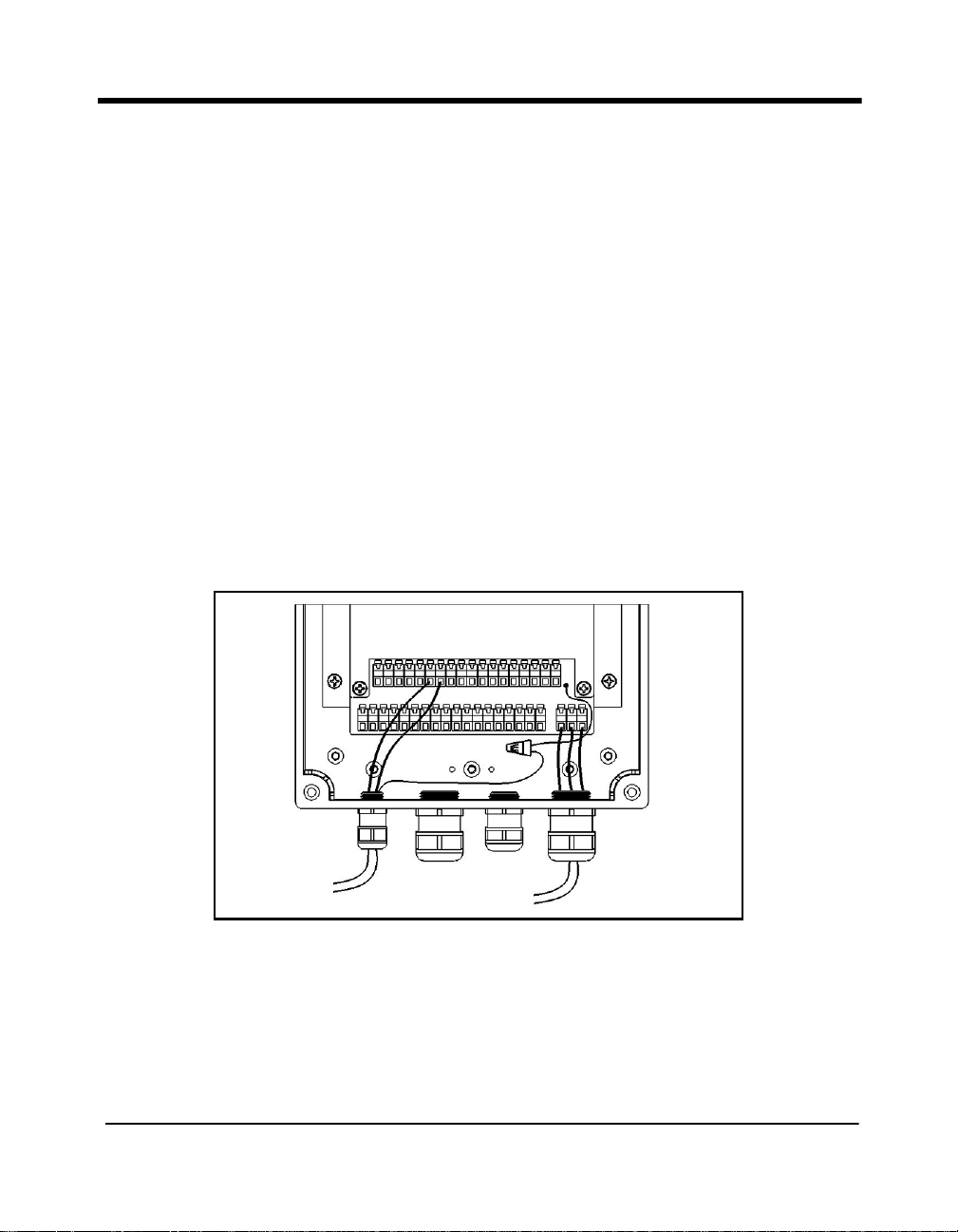

Figure 15 below shows the MMY 2650 wiring compartment, showing typical connections

for power and the DY 5xx probe.

Figure 15: Wiring Compartment

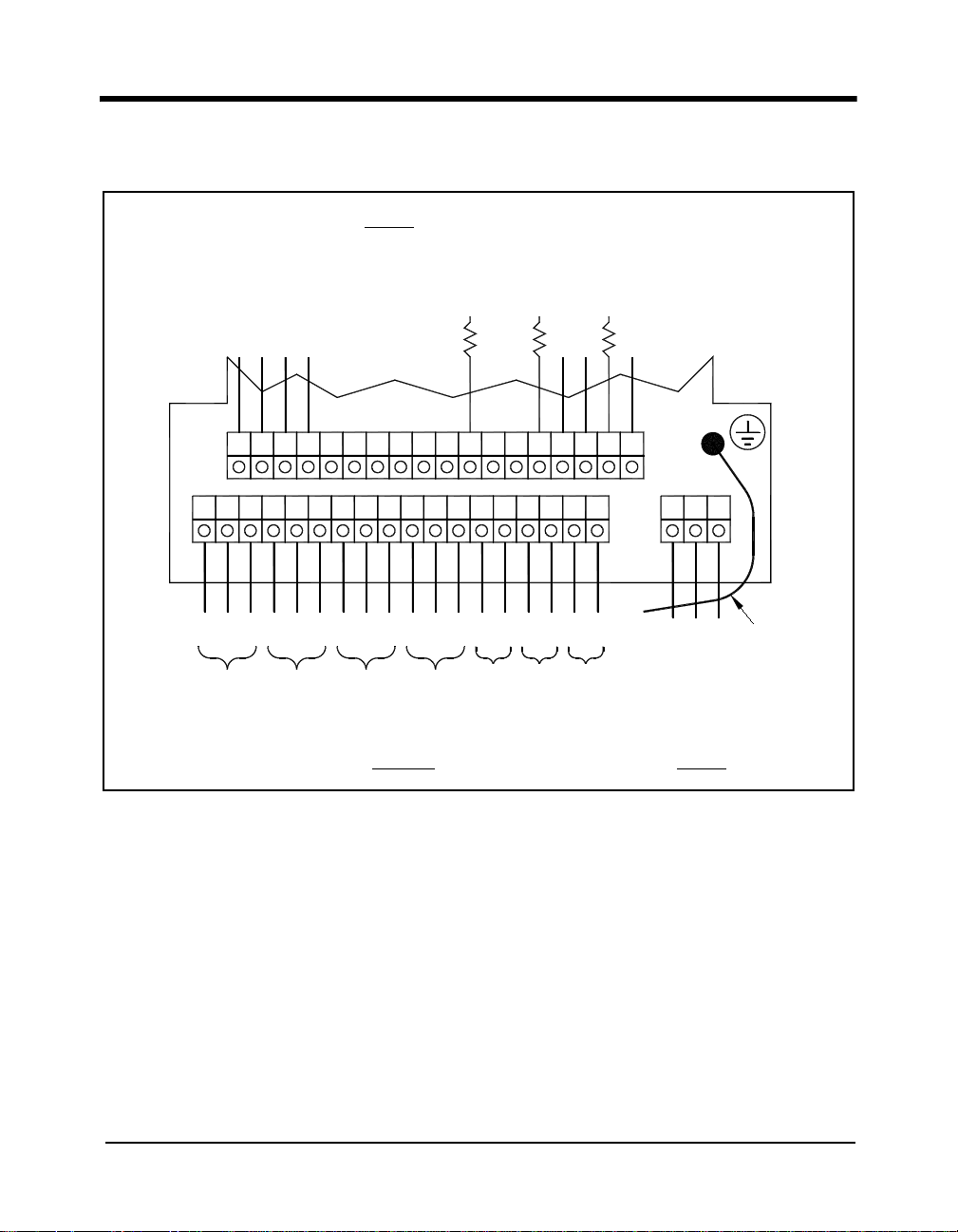

Figure 16 on pag e 17 shows the complete wiring diagram for the 2650. Wiring for the

probe, power and outputs are shown in the following sections.

Wiring for the Panel Mount version is the same, except that the wiring connections are

accessed from the rear of the unit.

16 HygroGuard MMY 2650 Installation and Operation Manual

2.5 Wiring (cont.)

249 Ohms

–

Current Out 2

32

16

CRelay 2

Relay 1

NC

NO

NC

C

Current Out 1

Relay 4

Relay 3

Outputs

NC

NC

NO

NO

C

+

+

NO

C

–

249 Ohms

(–) (Probe Black)

FRQ2 (Probe White)

FRQ1 (Probe Green)

+8.2V (Probe Red)

51 2 34

19 2120 27

6 7 9810

24

22 23 2625

131211 14 15

2928 30 31

Inputs

Ground Wire

Earth Ground

Current Out 3

Power

L1 or (+)

+

–

Cable Shield

L2/Neutral or( –)

249 Ohms

+Ch. 3 Input 0–5V

1817

3533 34 36

213

+15 VDC Out

(–)

Chapter 2. Installation

Figure 16: Wiring Connections

HygroGuard MMY 2650 Installation and Operation Manual 17

Loading...

Loading...