General Eastern MMY245 Operating Manual

DewPro MMY245

Installation and Operation Manual

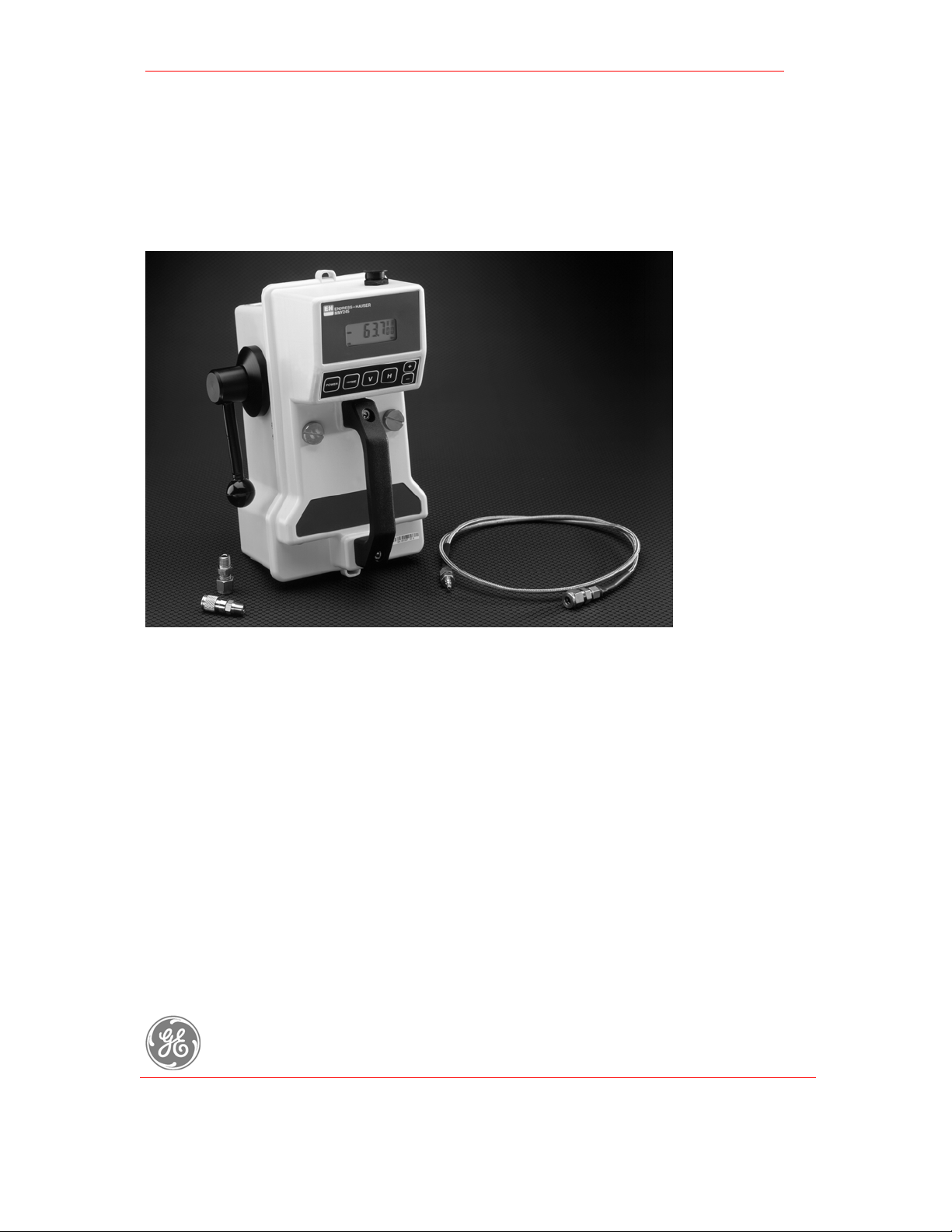

DewPro MMY 245

Portable Moisture Analyzer

Installation and Operation Manual

GE General Eastern

GE Measurement & Sensing Technologies

GE General Eastern

DewPro MMY245

Installation and Operation Manual

General Notes

Attention!

This is a portable moisture analyzer. The success and accuracy of moisture measurements and of field

validation depends on the integrity of the care exercised in operating this equipment. All fittings and

tubing should be tightened properly and examined prior to each use for thread or quick connect fitting

damage, leaks or crimped hoses. If any damage is suspected, do not place the unit in service until the

suspected damage is repaired. DO NOT alter or modify any of the supplied components. This will not

only void the Warranty but could rupture components causing injury or death. Tampering with internal

components will likely produce errors in the instrument readings.

Caution!

Before using or installing the DewPro MMY 245, please read all instructions.

Safety!

The DewPro MMY 245 Portable Moisture Analyzer is designed for connection to pressurized

gaseous systems. Be certain to de-pressurize the system before connecting or disconnecting the hoses

or fittings to the analyzer or at the process connection.

Disclaimer

General Eastern Instruments, Inc. reserves the right to change or modify our products in appearance or performance specifications at any time

and without notice. Therefore, information in this document is subject to change without notice and does not represent a commitment on the

part of General Eastern Instruments, Inc.

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and

recording, for any purpose without the express written permission of General Eastern Instruments, Inc.

Technical Assistance

If you should have any questions regarding the product described in this document, or need further

assistance, please contact your local General Eastern Instruments (GEI) representative or the factory at

800-33HUMID (800-334-8643). When contacting the factory for technical support, please have your

serial number ready. This number is located inside the unit and can be accessed by loosening the two

knurled screws on the top of the unit.

Serial Number: _______________________________

GE General Eastern

DewPro MMY245

Installation and Operation Manual

TABLE OF CONTENTS

1 General System Information __________________________________________________3

1.1 Unpacking and Inspection_________________________________________________________3

1.2 System Description_______________________________________________________________4

1.2.1 Portable Trace Moisture Analyzer ______________________________________________________ 4

1.2.1.1 Versatility_____________________________________________________________________ 4

1.2.1.2 Safety ________________________________________________________________________ 4

1.2.1.3 User Friendly Operation__________________________________________________________ 4

1.2.2 Field Validator _____________________________________________________________________ 5

1.3 Theory of Operation _____________________________________________________________5

1.3.1 Sensor Theory______________________________________________________________________ 5

1.3.2 Sample System Operation_____________________________________________________________ 5

1.3.3 Software Features ___________________________________________________________________ 6

1.3.4 Sample Conditioning Practices and Precautions____________________________________________ 6

1.3.4.1 Internal Construction ____________________________________________________________ 6

1.3.4.2 Avoid Liquid Samples ___________________________________________________________ 6

1.3.4.3 Avoid High Temperatures ________________________________________________________ 6

1.3.4.4 Avoid High Pressure Samples _____________________________________________________ 6

1.3.4.5 Hazardous Gas Handling _________________________________________________________ 6

1.3.4.6 Avoid Particulate Contamination___________________________________________________ 6

1.3.4.7 Avoid Corrosive Chemicals _______________________________________________________ 7

1.3.4.8 Avoid Ambient Air _____________________________________________________________ 7

1.3.4.9 Piping Recommendations_________________________________________________________ 7

Dimensions _________________________________________________________________________7

Basic Operation ________________________________________________________________8

2.1 Operating Controls ______________________________________________________________8

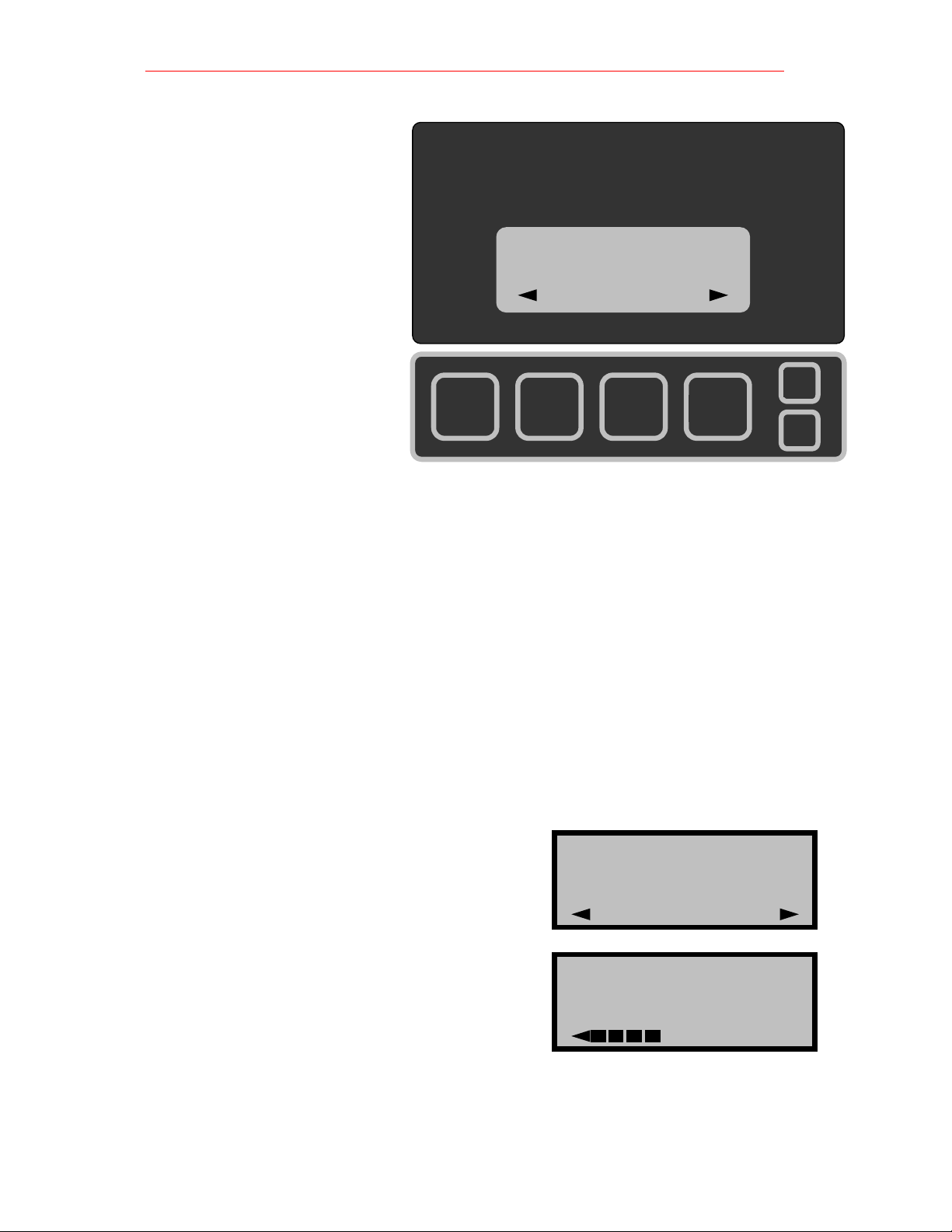

2.2 Display Elements ________________________________________________________________8

2.3 Basic Sampling or Spot-Checking __________________________________________________9

2.4 General Operation Practice _______________________________________________________9

2.4.1 Mapping spot check route____________________________________________________________ 10

2.4.2 Temporary Monitoring ______________________________________________________________ 10

2.4.3 Moisture Measurement Practice _______________________________________________________ 10

2.4.3.1 Checking Dryer Performance_____________________________________________________ 10

2.4.3.2 Quality Assurance _____________________________________________________________ 11

2.5 Instrument Setup / Programming _________________________________________________11

2.5.1 Matrix Orientation _________________________________________________________________ 11

2.5.2 Special Functions of the Push Buttons __________________________________________________ 13

2.5.3 Function Guide ____________________________________________________________________ 13

2.5.4 Matrix Field Details ________________________________________________________________ 13

2.5.5 Special Output and Input Functions ____________________________________________________ 15

2.5.6 Interconnection ____________________________________________________________________ 16

2.5.6.1 External Power Option__________________________________________________________ 16

2.5.6.2 External Scalable Input Option.___________________________________________________ 16

2.5.6.3 Voltage Inputs ________________________________________________________________ 16

2.5.6.4 Output connections ____________________________________________________________ 17

3 Troubleshooting ___________________________________________________________17

3.1 General Troubleshooting Practice _________________________________________________17

3.2 Error Codes ___________________________________________________________________18

4 Field Validator Operation ___________________________________________________ 19

GE General Eastern

DewPro MMY245

Installation and Operation Manual

4.1 Optimum Validation Practice _____________________________________________________20

4.2 MMY 3 Transmitter Preparation__________________________________________________21

4.3 Validator Connection Options ____________________________________________________21

4.3.1 Transmitter Vent (series) Connection___________________________________________________ 22

4.3.2 Vacuum Application Connection ______________________________________________________ 22

4.3.3 Parallel Connection_________________________________________________________________ 23

4.3.4 Closed Loop Connection ____________________________________________________________ 24

4.4 Field Validator Setup____________________________________________________________25

4.4.1 Matrix Orientation _________________________________________________________________ 25

4.4.2 Single Point Validation Function Guide_________________________________________________ 26

4.4.3 Two-point Validation Function Guide __________________________________________________ 26

5 Troubleshooting Validator Operation __________________________________________27

6 Instrument Specifications____________________________________________________28

7 Appendix _________________________________________________________________29

GE General Eastern

2

DewPro MMY245

Installation and Operation Manual

1 General System Information

1.1 Unpacking and Inspection

Upon receipt of the DewPro® MMY245, examine the shipping carton for broken or open packing,

distortion, or any other evidence of mishandling. If inspection indicates damage to the unit or any of its

components, notify the carrier (within 15 days of delivery) and request an inspection. Move the carton

to a clean work area and unpack. The carton you receive should contain:

DewPro® MMY245

Installation and Operation Manual

All MMY 245 accessories ordered as separate line items

Compare the model number with the product structure below to ensure proper receipt of order. If an

error should be discovered, do not put the instrument into service and contact the factory immediately.

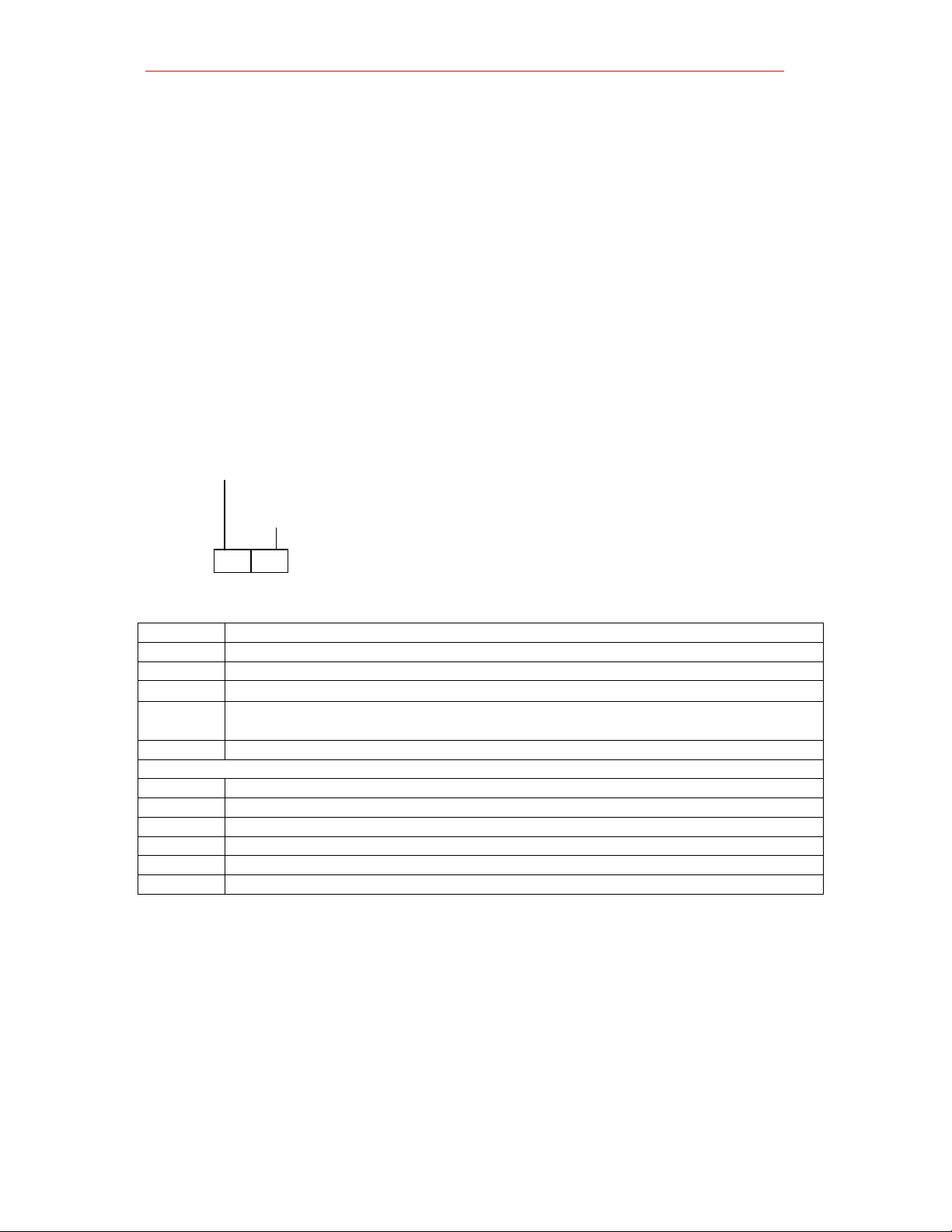

Product Structure

1 Certification

R Standard

Y Other

2 Pressure Compensation

R Basic configuration

P Pressure sensor built-in for ppm compensation

MMY245-

Accessories

Part No. Description

63005033 Carrying case including shoulder strap

63005032 Shoulder strap

63004006

63004005

Cable assembly, MMY 245 to DewPro

Connector/cable assembly, RS485 DewPro

installation in the transmitter for external connection to P/N 63004006)

63002013 Connector/cable assembly, external power and non-I.S. outputs.

Gas Connection Accessories

63000598 Gas Inlet and outlet connection, ¼” tube 316 SS

63002201 Gas Inlet and outlet connection, 6mm tube 316 SS

63002199 Gas inlet, 3 ft. PFA hose with quick connect set and ¼” tube process connection

63002200 Gas inlet and outlet connection, ¼” tube PFA

63005036 Coalescing Filter for Glycol Contactor Applications

63005037 Pressure Regulator for samples greater than 125 psig.

MMY 30, RS485 cable

(RS 485 communication cable for

GE General Eastern

3

DewPro MMY245

Installation and Operation Manual

1.2 System Description

1.2.1 Portable Trace Moisture Analyzer

The DewPro MMY 245 Moisture Analyzer is designed primarily as a portable moisture instrument

that can be used in a variety of gaseous applications. The portable unit can be used to quickly spot

check the performance of dryers for compressed air, natural gas. Checking pure gas supplies, accurately

testing SF6 gas in high power switchgear and transformers, gasified LNG, breathing air or oxygen and

many other applications are easy with the MMY 245 portable analyzer.

This is a well balanced, compact, easy to use versatile analyzer complete with all the units of measure

and connectability required to keep track of the moisture critical processes in your facility. The rugged

DewPro

MMY 245 case has been selected to provide the maximum protection for the internal

components in most any industrial environment where it is used.

With the MMY 245 Portable Moisture Analyzer, measurement time is typically 5 minutes. The sensor

is kept in a very dry desiccated environment with the dry-down taking place while the instrument is

inactive or being transported to the next measurement point. For complete instrument specifications,

see Section 6.

1.2.1.1 Versatility

The variety of applications in which the DewPro MMY 245 can be used is limited only by its range of

operation for moisture and pressure and by the chemical nature of the gas sample. The unit is designed

to be used for dry samples having a dew point temperature below freezing at the pressure of the sample

introduced to the unit. Some typical applications are listed below:

Desiccant dried air Dried Natural Gas Argon gas for welding

Nitrogen gas supplies Breathing air SF

Helium gas supplies Oxygen gas supplies Hydrogen cooling loops

Instrument air Glove box gas purifier loops Ethylene Production

Heat treating atmosphere

Gas Bottle filling operations … and many others.

generators

The processes listed above often require many different units of measure and the MMY 245 is able to

provide readouts in most of the common units necessary for these applications. The unit of measure is

simply selected from the operating keypad. An optional pressure sensor will automatically correct for

changes in pressure that occur in a given stream or when spot-checking several sample points

throughout a facility or process.

gas for switchgear

6

1.2.1.2 Safety

The DewPro MMY 245 has been designed to meet or exceed the FM requirements for Class I,

Division 1 environments for portable instruments.

1.2.1.3 User Friendly Operation

The normal method of measurement is to connect the DewPro MMY 245 to the process sample tap via

a short flexible high-pressure hose that employs a quick-connect fitting. The sample valve on the

process piping is opened to start a sample flow to the unit. After allowing the sample flow to purge the

hose for 15-30 seconds, the handle on the side of the analyzer is rotated up to the vertical position. This

directs the sample across the sensor. The power button is pressed and the readout provides the moisture

value in the desired unit of measure.

The analyzer is programmed using the keypad and a matrix to select the moisture unit of measure,

temperature unit of measure and other operating parameters. An optional pressure sensor can provide

real time correction for concentration units of measure. In lieu of the optional sensor, a pressure

constant can provide the proper value with known pressure conditions.

GE General Eastern

4

DewPro MMY245

Installation and Operation Manual

1.2.2 Field Validator

This portable unit can validate the readings of permanently installed GEI loop-powered dew point

transmitters while they are in the loop, simply by connecting the MMY 245 to the DewPro’s

monitoring the same sample. This is accomplished by monitoring the same sample as the transmitter by

connecting to its outlet. Either a single-point or two-point validation mode can be selected via the

keypad and matrix. An RS-485 connection between the portable and the transmitter provides for digital

correction of the transmitter’s calibration data. The procedure takes from one to four hours and

eliminates transmitter downtime and reduces the need for sending transmitters back to the factory for

recalibration. The complete description of this feature can be found in section 4 of this manual. This

validation is not a field calibration technique since most calibrations require the standard to be four

times more accurate than the device under test. The MMY 245 does not have that accuracy advantage

and should be used to adjust transmitters in the field with this in mind.

outlet and

1.3 Theory of Operation

The DewPro MMY 245 operates as a self-contained moisture analyzer system comprised of a sensor,

electronics, power source, and sample system.

The sensor is an advanced Planar Gold/Aluminum Oxide sensor designed to respond quickly to changes

in measuring conditions. It has been used extensively in trace moisture analyzers for several years. This

trusted sensor is resistant to contamination and has proven to be a rugged and stable platform for

consistent results in measurement accuracy and reliability.

The electronics package was designed using the basic DewPro

to the introduction of the portable configuration. With proven reliability and ruggedness and with the

addition of memory and energy management components, the MMY 245 provides the flexibility

required for many applications.

Four standard “D” cell batteries supply the power for the MMY 245. Standard alkaline batteries are

included and are recommended for replacement.

The internal sample system provides for purging the hoses after they are connected to the sample tap

and then directs the sample across the sensor.

technology developed four years prior

1.3.1 Sensor Theory

The Planar Gold / Aluminum Oxide sensor is a capacitance based technique for detecting the moisture

content in gaseous samples. This sensor is manufactured using semiconductor techniques on wafers of

ceramic substrate. The sensor is manufactured by depositing a pure aluminum layer over gold contact

pads on a ceramic substrate. The aluminum is partially anodized using a proprietary process and a thin

film of permeable gold is deposited over the oxide layer. The aluminum oxide is a porous insulator and

provides a space for moisture molecules to reside at equilibrium with the sensor environment. The

permeable gold conductive layer allows moisture molecules to move freely into or out from the oxide

layer and acts as one plate of the capacitor. The aluminum layer beneath the oxide acts as the opposing

plate for the capacitor. After the sensors are created on the wafer, they are diced apart and each sensor

is then bonded to a pressure rated feed-through on a probe. The probe supports the sensor in the process

environment for which it is rated.

1.3.2 Sample System Operation

The main component of the sample system in the DewPro MMY 245 is essentially a valve. The valve

emulates a four-way process valve during operation. In the “dry” or horizontal position, the sensor is

exposed to a very dry, -85° to –95°F, (-65° to –72°C) dew point environment created by a very strong

desiccant. This keeps the sensor dry and ready to measure. Any sensor will respond quickly to

increasing moisture and dries down much more slowly. In the “measure” or vertical position of the

valve handle, the sample stream is directed across the sensor to allow the measurement to be made.

Just as in a four-way process valve, there is a second function in operation concurrent with the “flow”

description above. When in the “dry” position, the passage for the sample connection inlet is connected

to the outlet for purging the connecting hoses. This purging operation is critical for making the

measurement as quickly as possible since a fresh sample is transferred to the immediate sensor location

GE General Eastern

5

DewPro MMY245

while the sensor itself is kept dry and ready to measure. Purging for 3-5 minutes is recommended. In

the “measure” position of the valve handle, the desiccant chamber is closed from any possible contact

with the incoming sample gas. This prevents the desiccant from being contaminated or consumed too

quickly. The desiccant should last several months under daily use for several readings per day.

An optional pressure transducer can be ordered to provide pressure information to the electronics for

compensation of readings in concentration units of measure. These units of measure require a total

pressure value to correctly compute the proper moisture reading. The pressure information can be

displayed and used for correction of the moisture reading from this pressure sensor or from a direct

input of a constant value as selected using the keypad.

Installation and Operation Manual

1.3.3 Software Features

The software architecture is based on a matrix of operating parameters. Each parameter setting

determines the function of the software to display and compute the proper moisture value, to control

outputs and to communicate with field mounted MMY series transmitters. The matrix settings also

determine how to treat optional inputs and when they should be used in the computation of a moisture

value. The complete operation of the matrix is described in the Instrument Setup portion of the Basic

Operation, Section 2 in this manual.

1.3.4 Sample Conditioning Practices and Precautions

1.3.4.1 Internal Construction

All the wetted surfaces of the MMY 245 DewPro are electro-polished non-hygroscopic metal

components of either stainless steel or anodized aluminum. Introducing clean samples will prevent

these surfaces from becoming contaminated.

1.3.4.2 Avoid Liquid Samples

Avoid ANY liquid exposure of the sample lines and the instrument. Liquids will damage the unit and

void the Warranty.

1.3.4.3 Avoid High Temperatures

Avoid high or low temperatures. The MMY 245 can be operated over a temperature range of 4°F to

104°F (-20° C to +40° C). Operating the unit at higher temperatures can damage the sensor and the

electronics. The LCD is not likely to work if the unit is operated below the normal stated range.

1.3.4.4 Avoid High Pressure Samples

The maximum inlet pressure rating for the MMY 245 is 150 PSIG or 10 Bar. If the process or sample

pressure is greater than this, a pressure regulator should be used to drop the pressure to within the

instruments range.

1.3.4.5 Hazardous Gas Handling

When making connections to samples of flammable or hazardous gases, exercise care to insure leak

free connections. Be aware that leaks can create fire, explosive or toxic conditions that should be

avoided. The MMY 245 is designed to meet Class I, Division 1, Group B-G environments; but the

integrity of the sample connections to the instrument is the responsibility of the user.

1.3.4.6 Avoid Particulate Contamination

A sample contaminated with particulates will deposit some of this material inside the unit producing

more surface area and sites where moisture could be trapped. This could result in higher than actual

readings. If the sample contains particulates or aerosols, it must be filtered to remove this

contamination.

GE General Eastern

6

DewPro MMY245

Installation and Operation Manual

1.3.4.7 Avoid Corrosive Chemicals

Introducing corrosive chemicals can pit or corrode the internal components and can damage the sensor.

Avoid attempting measurements in streams containing chlorine, HCl, and other strong acid or base

gases.

1.3.4.8 Avoid Ambient Air

The MMY 245 is a trace moisture analyzer. Ambient air can contain as much as 2% water. The

instrument is capable of measuring down to sub ppm

the operating handle in the measure position when not connected to a sample flow. Ambient air

exposure over long periods of time can move large amounts of moisture into the measurement cell and

eventually cause the sensor to drift.

moisture in samples to 150 psig, so avoid leaving

v

1.3.4.9 Piping Recommendations

Connection the MMY 245 to the process or sample tap in the proper manner will insure the most

accurate measurements. Connecting tubing should be made from materials that are non-hygroscopic

and capable of handling the sample pressure. Keeping the length of connecting tubing as short as

possible will allow faster readings since the moisture in the sample arrives quicker than with longer

lines. Materials that are recommended include stainless steel, and PFA tubing especially for dew points

below –65°C, Copper and PTFE tubing. Rubber, Tygon and other plastic or polymer tubing is NOT

recommended for ANY application. Insure that all connections at the sample tap and at the instrument

are leak tight.

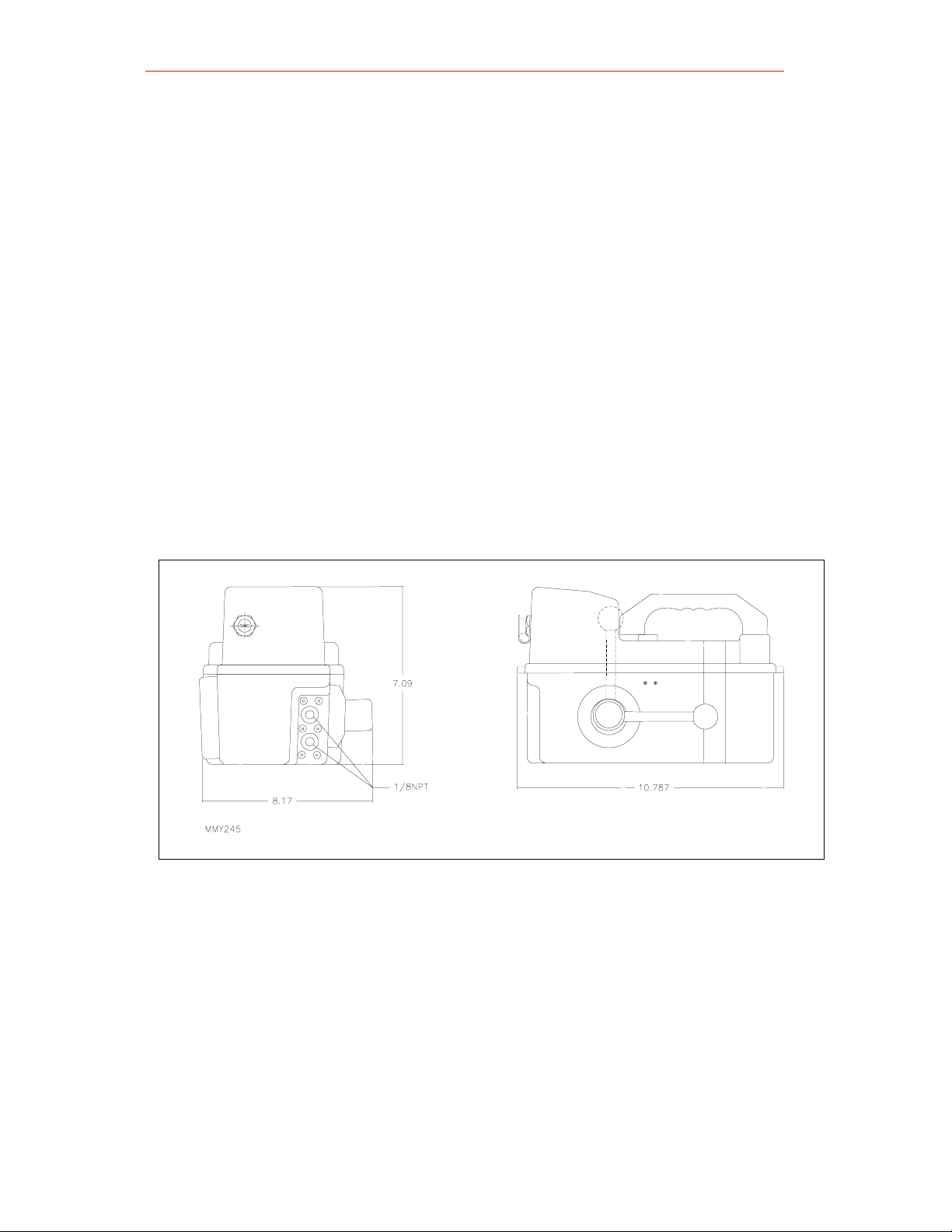

1.4 Dimensions

Figure 1

GE General Eastern

7

DewPro MMY245

V H

V H

V

V

2 Basic Operation

The MMY 245 operation is simple and

intuitive. Provide the instrument with a

sample of gas and direct it to the

sensor using the handle on the side of

the instrument, apply power and let the

analyzer tell you when the

measurement is stable and should be

taken.

The instrument operates best when

measuring pressurized samples over a

range of 20-150 psig. Satisfactory

measurements can be made at lower

pressures, even at vacuum, although a

longer time may be required since

there are not as many exchanges per

minute at these lower pressures.

Techniques for these low-pressure

measurements will be discussed later

in this manual.

POWER

Installation and Operation Manual

0

-

HOME

Figure 2

H

+

-

2.1 Operating Controls

The electronic operating controls for the MMY 245 are found directly in front of the carrying handle

and the flow path control is located on the left side of the instrument. This “operating handle” of the

instrument puts the sensor into a desiccant environment or directs the flow of the sample across the

sensor.

The electronic controls provide access to the analysis of the sample. These electronic controls consist of

six membrane switches (see Figure 2) located below the digital display and are used to power the unit

and control the various functions of the unit. The POWER key will turn the unit on or off. The HOME

key will display the matrix position V0 H0 or alternately V4 H0. Pressing the V and H keys advances

the vertical or horizontal position within the matrix and the display will show the contents of that

position. Pressing the + and – keys increments or decrements the value in the matrix cell described in

the right side of the display. These matrix and operating functions will be described on succeeding

pages.

2.2 Display Elements

There are three distinct display elements consisting of a large

digital readout where values are shown, a smaller digital

section to the right where four characters are displayed

showing the location in the matrix where the values are

generated, and a bar graph across the bottom.

The MMY 245 takes the guesswork out of waiting for the

measurement to stabilize. The instrument display (see

Figure3) includes a rate-of-change bar graph indicating a

reading is changing or stable. A changing reading will cause

the bar graph to include additional segments in any portion

of the bottom of the display. The direction and amplitude

illustrated by the arrows indicate the required change in the

reading. This feature allows the operator to know the reading

has stabilized and can be recorded correctly. Below, several

different measurement techniques are discussed from the perspective of connecting the sample to the

unit; but the basics of operation remain the same.

-48.6

Stable Reading

-48.6

Reading Still Changing

Figure 3

0 0

0 0

GE General Eastern

8

Loading...

Loading...