Humi

Lab

Relativ

e Humidity Generator

Oper

ator’s Manual

500 Research Drive

Wilmington MA 01887-4498

Tel: 800-33HUMID (800-334-8643)

Fax: 978-203-1919 www.generaleastern.com

Safety:

T

his manual as well as safety labels posted on the instrument use the following safety

alerts to draw your attention to special safety instructions that should be followed.

C

CAU

TION:

W

ARNING:

AUTI

Hazards or unsafe practices could result in electrical shock, minor

injury, or product damage.

W

AR

Refer to accompanying document for additional information.

ON

NING

ALERT

A

LERT:

W

indows and Windows XP are trademarks of Microsoft Corp.

The information in this manual is believed to be reliable. However, GE General Eastern makes no warranty, expressed or implied, as to its

accuracy and assumes no liability arising out of its use by others. We reserve the right to change this manual without prior notice.

Document No. A40241708

Revision B.00 ECO #6498

June 2004 Printed in U.S.A

Copyright © 2003, 2004 GE General Eastern

Earth ground connection; removal could result in electrical shock,

minor injury, or product malfunction.

GE General Eastern

500 Research Drive

Wilmington, MA 01887

Tel: 978 203 1900

Fax: 978 203 1919

Email: generaleastern@ge.com

Web: www.generaleastern.com

C

ONTENTS

INTRODUC

CHAPTER 1 — INST

CHAPTER 2 — OPERATION

TION

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

About GE General Eastern - - - - - - - - - - - - - - - - - - - - - - 1

Overview of the Humilab - - - - - - - - - - - - - - - - - - - - - - - 2

About this Owner’s Manual - - - - - - - - - - - - - - - - - - - - - - 2

ALLATION AND INITIAL SETUP

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Pre-Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Components shipped with the Humilab - - - - - - - - - - - - - - - 4

System diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Place the Humilab at its operating site - - - - - - - - - - - - - - 6

Connect a dry gas source (optional) - - - - - - - - - - - - - - - - 6

Electrical connections - - - - - - - - - - - - - - - - - - - - - - - - 8

Rear input/output fitting connections - - - - - - - - - - - - - - - - 9

Initial setup and water fill - - - - - - - - - - - - - - - - - - - - - 11

Chilled mirror setup - - - - - - - - - - - - - - - - - - - - - - - - 12

Initialize the dew point sensor - - - - - - - - - - - - - - - - - 12

Clean and balance the dew point sensor - - - - - - - - - - - - 13

Shipping the Humilab - - - - - - - - - - - - - - - - - - - - - - - 15

- - - - - - - - - - - - - - - - - - - - - - - - 16

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Front panel displays and switches - - - - - - - - - - - - - - - - - 17

Performing routine calibrations - - - - - - - - - - - - - - - - - - - 20

Chamber response time - - - - - - - - - - - - - - - - - - - - - - 21

- - - - - - - - - - - - 4

CHAPTER 3 — USING THE P

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Installing the Prostep software - - - - - - - - - - - - - - - - - - - 23

Running Prostep - - - - - - - - - - - - - - - - - - - - - - - - - - 24

CHAPTER 4 — T

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Divided flow - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

The Humilab chilled mirror controller - - - - - - - - - - - - - - - 31

HEORY OF OPERATION

What is optical condensation hygrometry? - - - - - - - - - - - 32

General description of the chilled mirror hygrometer system - - 33

Chilled mirror hygrometer system theory of operation - - - - - 33

ROSTEP SOFTWARE

- - - - - - - - - - - - - - - - - 30

- - - - - - - - - - - - 22

CHAPTER 5 — MAINTENANCE AND T

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

Basic maintenance - - - - - - - - - - - - - - - - - - - - - - - - 35

Reference measurement maintenance - - - - - - - - - - - - - - 36

Mirror maintenance - - - - - - - - - - - - - - - - - - - - - - - - - 36

Cleaning the sensor mirror - - - - - - - - - - - - - - - - - - - 36

Balancing the sensor optics - - - - - - - - - - - - - - - - - - - 37

Field replacement of the sensor mirror - - - - - - - - - - - - - - 40

Annual recertification - - - - - - - - - - - - - - - - - - - - - - - - 41

Troubleshooting the Humilab, system diagnostics - - - - - - - - - - 41

Is the system operating correctly? - - - - - - - - - - - - - - - - 41

ROUBLESHOOTING

- - - - - - - - 35

APPENDIX A — SPEC

APPENDIX B — HUMILAB CHILLED MIRROR H

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45

System components - - - - - - - - - - - - - - - - - - - - - - - - - 45

Front panel operation and displays - - - - - - - - - - - - - - - - - 46

Displays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

Switches - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 48

Option selections using the display switch - - - - - - - - - - - - 49

A simplified explanation of the option selection system - - - - - 49

A more rigorous explanation of the option selection system - - - 50

RS-232c re-programming mode - - - - - - - - - - - - - - - - - - - 52

The Main Menu - - - - - - - - - - - - - - - - - - - - - - - - - 53

Scale outputs - - - - - - - - - - - - - - - - - - - - - - - - - - 53

Set balance type - - - - - - - - - - - - - - - - - - - - - - - - - 54

Set RS-232 units - - - - - - - - - - - - - - - - - - - - - - - - - 55

Display option - - - - - - - - - - - - - - - - - - - - - - - - - - 56

Set averaging - - - - - - - - - - - - - - - - - - - - - - - - - - 57

Service and troubleshooting procedures - - - - - - - - - - - - - - - 58

Helpful hints - - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

Time response - - - - - - - - - - - - - - - - - - - - - - - - - - 61

Mirror cleanliness - - - - - - - - - - - - - - - - - - - - - - - - 61

APPENDIX C — CONFIGURING THE R

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

Establishing RS-232 communications - - - - - - - - - - - - - - - - 65

Using RS-232C communications - - - - - - - - - - - - - - - - - - 66

RS-232C operate mode - - - - - - - - - - - - - - - - - - - - - 66

Computer connections - - - - - - - - - - - - - - - - - - - - - 67

IFICATIONS

- - - - - - - - - - - - - - - - - - - - - 43

YGROMETER DETAILS

S-232 INTERFACE

- - - - - - - - - 65

- - 45

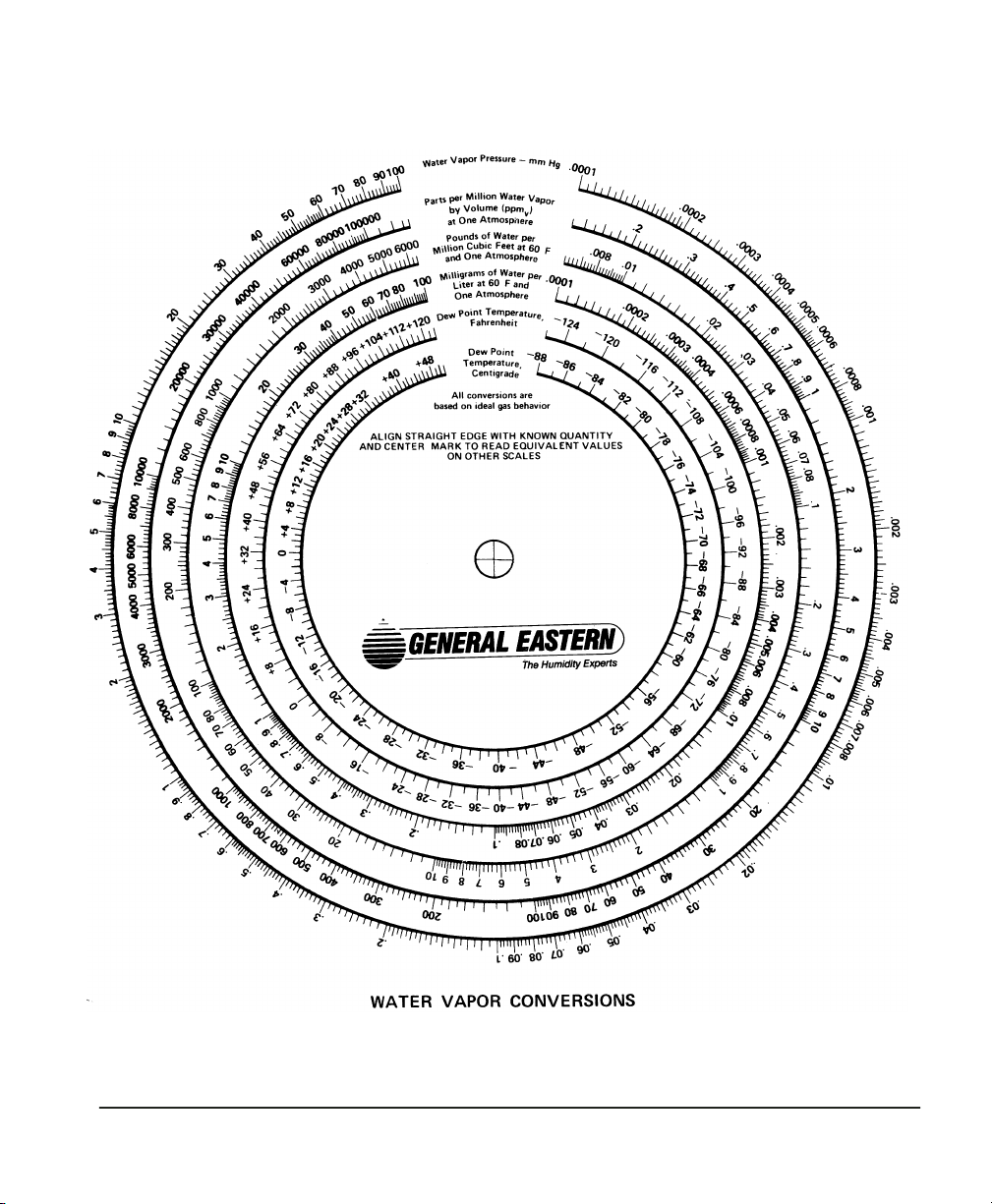

APPENDIX D — HUMIDITY EQUATIONS AND CONVERSION CHAR

APPENDIX E — W

ARRANTY INFORMATION AND RETURN PROCEDURES

TS

- 68

73

Ab

out GE General Eastern

GE General Eastern is devoted to the design and manufacture of

accurate, reliable and rugged humidity measuring equipment. We

specialize in providing solutions for applications where humidity

measurements are critical.

There are many ways to make humidity measurements, and no

single humidity sensor meets all requirements for all applications.

Our variety of sensor types — including chilled mirror, lithium

chloride, capacitive oxide, capacitive-resistive, resistance polymer,

and wet bulb — can precisely determine dew point, parts per million

by volume, mixing ratio, absolute humidity, relative humidity, and

other parameters.

In keeping with GE General Eastern’s philosophy of providing the

best solutions to humidity measurement problems, we offer the

following products and services:

• high quality state-of-the-art instrumentation to assure

excellent performance

• a broad range of humidity instruments capable of covering

virtually any humidity measurement application

• full applications assistance to help you choose the sensor that

is best for your needs

• worldwide superior service, should it ever be needed

If you have questions about a particular measurement problem, we

invite you to call and discuss your application with one of our

engineers. Call 800-33HUMID (800-334-8643). If you’re calling

from Massachusetts or outside the United States, call

978-203-1900. Our fax number is 978-203-1919.

GE General Eastern’s website (www.generaleastern.com) has information about our other products as well as technical papers and

applications notes on humidity measurements.

Intr

oduction

Intr

oduction

Page

1

Ov

erview of the Humilab

T

he Humilab Relative Humidity Generator is designed to perform

U.S. National Institute of Standards and Technology (N.I.S.T.) traceable calibration of RH instruments and/or several smaller transmitters.

The Humilab design is based on the proven divided flow technology. Divided flow in the time domain excels as a reliable

method for accurately controlling relative humidity at a fixed

temperature. Temperature stability is ensured by a water jacket

surrounding the calibration chamber.

Continuous digital control, using a built-in GE General Eastern

N.I.S.T. traceable chilled mirror dew point hygrometer, makes the

Humilab a traceable relative humidity transfer standard with which

to calibrate other devices. Calibrations meeting the requirements of

ANSI Z540-l-1994, MIL-STD 45662A, 10CFR-50, and ISO 9001 may

be performed.

The included Prostep software allows you to use your PC to upload

a control profile via the RS-232 port, enabling an entire calibration

cycle to be run.

Ab

out this Owner’s Manual

T

his manual provides the information you will need to set up, use,

and maintain the Humilab Relative Humidity Generator. Please

read and follow these instructions carefully to ensure that the

instrument provides the precise and reliable humidity measurement and control that you have come to expect from GE General

Eastern.

Page

F

Icons

2

our categories of information are presented with an accompa-

nying icon for quick identification.

The exclamation mark within a triangle indicates that the accompanying information is important to the correct operation of the

equipment. You should take particular care to observe this information because it ensures optimum operation and avoids potential

damage to the unit.

Intr

oduction

T

he lightning bolt within a triangle indicates that the accompanying information is important to the safety of the operator. Failure

to heed this information will place the operator in danger. This

symbol must not be ignored.

The ground symbol indicates points that must be connected to

earth ground. Failure to connect, or removal, could result in electrical shock, minor injury, or product malfunction.

The pointing hand icon is used to indicate information that is

related or simply additional to the surrounding text. This information is not required for proper operation, nor will any harm arise

from not applying this information.

Intr

oduction

Page

3

Chapter 1 — Inst

Intr

oduction

T

his chapter explains site requirements for the Humilab system,

what is shipped with the unit, how to install the Humilab, and how

to set it up and perform the necessary procedures to ensure efficient and reliable operation to meet your calibration requirements.

Pr

e-Installation

Bef

ore you proceed to install your Humilab, ensure that you have

chosen a site suitable for the effective and efficient operation of the

instrument.

A location should be found for the Humilab where the ambient

temperature is reasonably constant. This is usually the case in a

calibration laboratory. Ideally, the room should be stable within

±1°C, between 20°C and 30°C. Ensure that the table or lab bench is

level.

The water jacket surrounding the test chamber and the 1/2” thick

Lexan cover above it effectively isolate the chamber from

short-term temperature fluctuations. However, longer term

changes in room ambient temperature may cause a temporary

chamber error until the system equilibrates to the new ambient

temperature. Therefore, temperature stability of the room is important.

allation and Initial Setup

Components

Page

4

CA

UTION:

T

wo people are required for moving this system.

shipped with the Humilab

T

he following items are packaged with the Humilab:

• cover (removed for shipment)

• Certificate of Conformance

Chapter 1 — Installation and Initial Setup

Optional

equipment

•

maintenance kit

(Additional kits are available through G

•

mixing/workspace plate

• desiccant cartridges (2)

• rubber stopper

• AC power cord

• RS-232 cable

• mating analog output connector

• transportation case

• CD-ROM containing this manual, HCON Humidity Conversion software, and Prostep software

•

temperature bath/circulator (for maintaining a stable chamber temperature from 20°C to 30°C)

If an item is missing, contact GE General Eastern. Our phone

number and address are found on page 1.

EI’s Service Department)

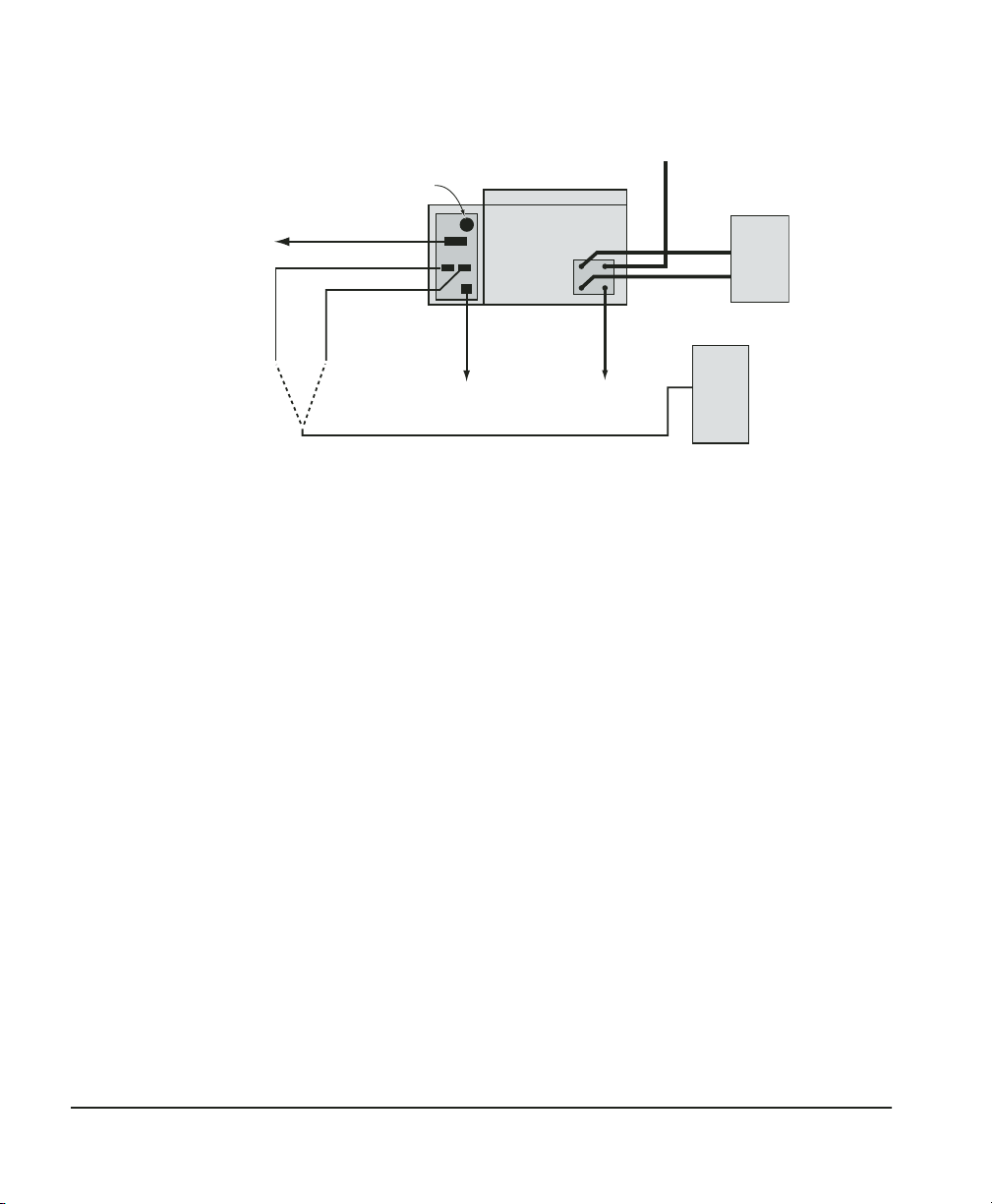

System diagr

Chapter 1 — Installation and Initial Setup

am

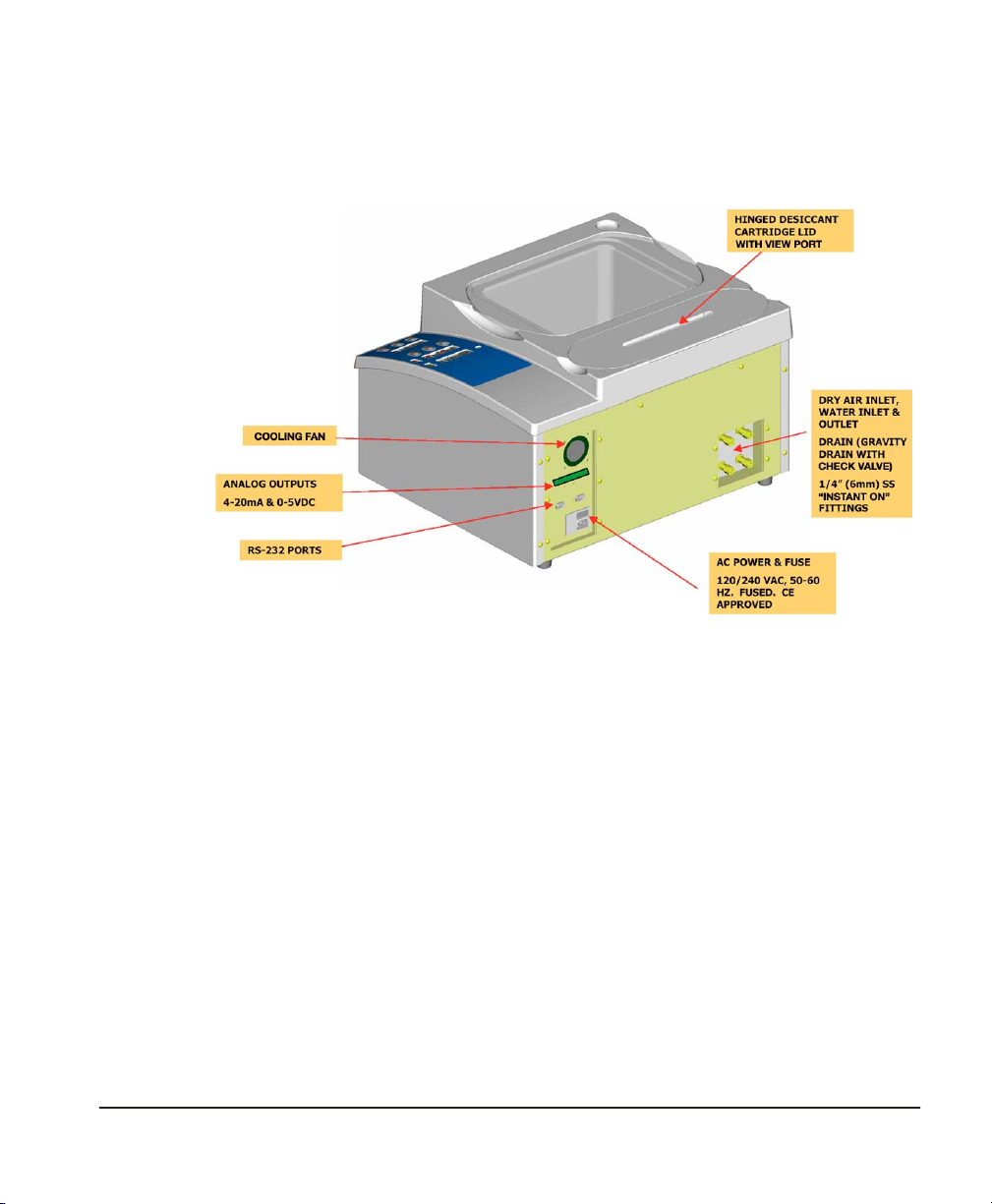

Interconnection of the HumiL

Figure 1.

ab’s components is shown in

Page

5

Analog

outputs

Cooling fan

Reference port

Controller port

Humilab

(rear view)

Dry air input (optional)

Neslab

Chiller

(optional)

Inst

allation

Place the

Humilab at its

operating site

Carefull

room behind the unit to make the necessary gas, drain, and

optional chiller connections on the back panel. The two data cables

(an RS-232 cable and an analog output cable) can also be installed

at this point.

Connect

a dry

gas source

(optional)

A dry gas source can be utilized to impro

desiccant material and provide the user with less frequent desiccant replacement.

The HumiLab does not require an external dry gas source to

operate. The unit is equipped with a desiccant cartridge that

provides the Humilab with a –40°C dew point dry gas. The unit is

designed to operate for approximately 24 hours of continuous

usage (at an ambient humidity less than 50%) before having to

replace the desiccant.

AC power

y move the Humilab to its intended site. Leave enough

Drain

Figure 1 — System interconnection diagram

PC

ve the longevity of the

Page

Gas r

equirements.

be –40°C or lower for operation over the full specified range.

6

If a dry gas source is used, the frost point should

Use

Chapter 1 — Installation and Initial Setup

clean, oil-free gas, regulated at 1 to 2 psig at 5 lpm (minimum).

Connect the dry air or dry nitrogen source using the 1/4”

“instant-on” DRY AIR IN connector on the rear of the unit. See

Figure 2, Humilab Rear View.

Figure 2 — Humilab rear view (gas, A/C, and signal connections)

Chapter 1 — Installation and Initial Setup Page 7

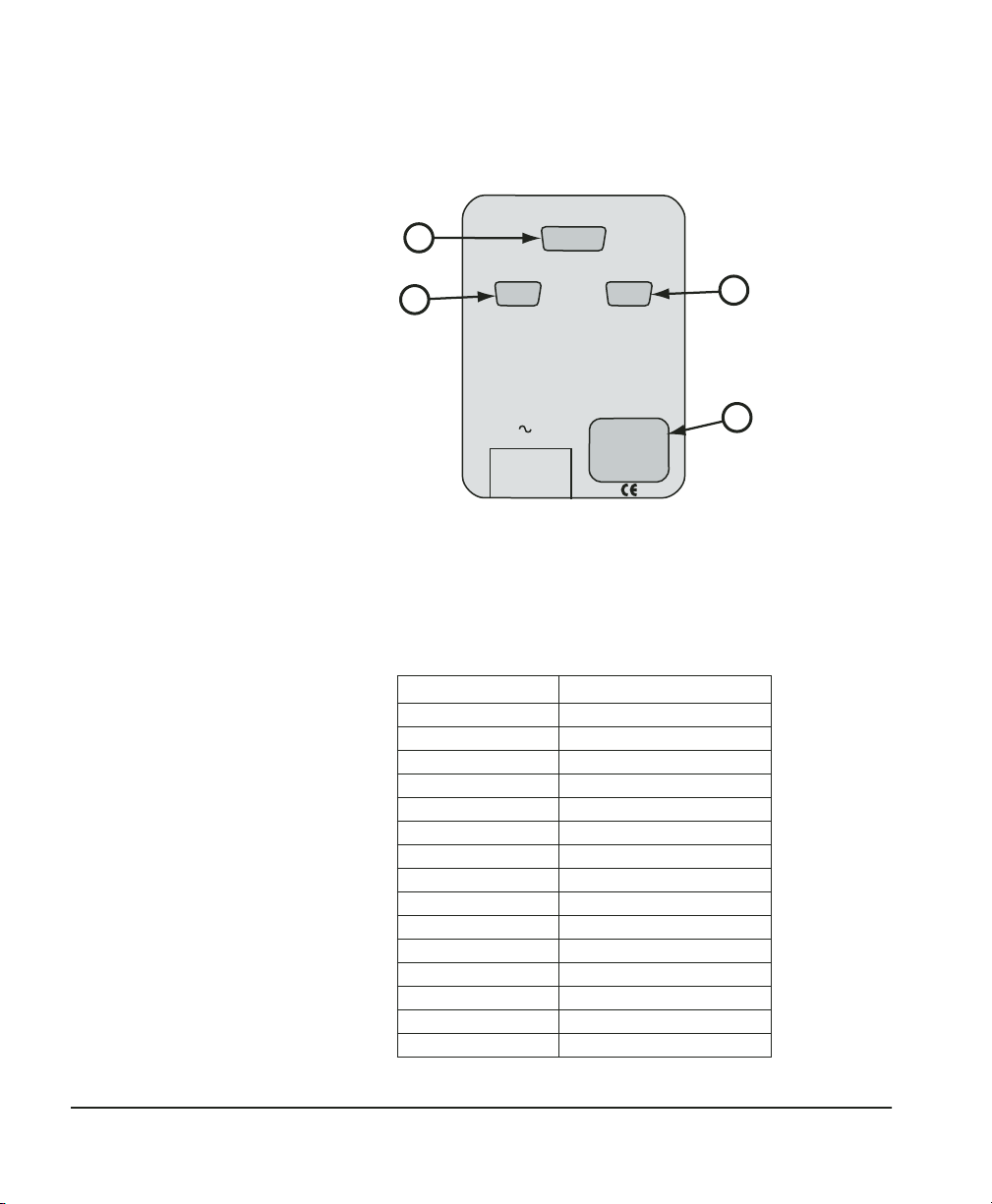

Electrical connections

s

Electrical connections to the Humilab are made on the rear panel

as shown in Figure 3.

A

B

ANALOG OUTPUTS

REFERENCE RS-232 CONTROLLER RS-232

LINE

Figure 3 — Humilab electrical connection

C

D

A. Analog outputs. Analog outputs are available to the operator via

the DB-15 connector located on the rear I/O panel. A cable suitable

for connecting to a terminal block is included. The connector

pinout is listed below.

DB-15 Pin No. Function

1 RH 4–20 mA (+)

2 RH 0–5 V (+)

3 Temp 4–20 mA (+)

4 N/C

5 Temp 0–5V (+)

6 Status

7 N/C

8 N/C

9 Service

10 Gnd (Rtn)

11 N/C

12 N/C

13 N/C

14 N/C

15 N/C

Page 8 Chapter 1 — Installation and Initial Setup

B. RS-232 Reference Port. This connector is used for diagnostics

s

when the LOOP switch is in the OPEN LOOP position. In CLOSED

LOOP mode, it transmits the digital outputs of the hygrometer: dew

point, temperature, and RH.

C. RS-232 Controller Port. This connector is used when down-

loading humidity profiles from Prostep into the HumiLab.(see

Chapter 3).

D. AC receptacle. The AC input power is connected to the power

receptacle. The input voltage is noted on the label to the right. The

input voltage is configured at the factory and must be determined

prior to shipment.

Power Requirements 103–127 VAC

48–66 Hz, 80 VA max

Fuse Type 1A Type T .5A Type T

E. Cooling fan (not visible). The fan is used for cooling the elec-

tronics. The fan must stay clean and clear of any obstruction to

prevent damage to the internal electronics.

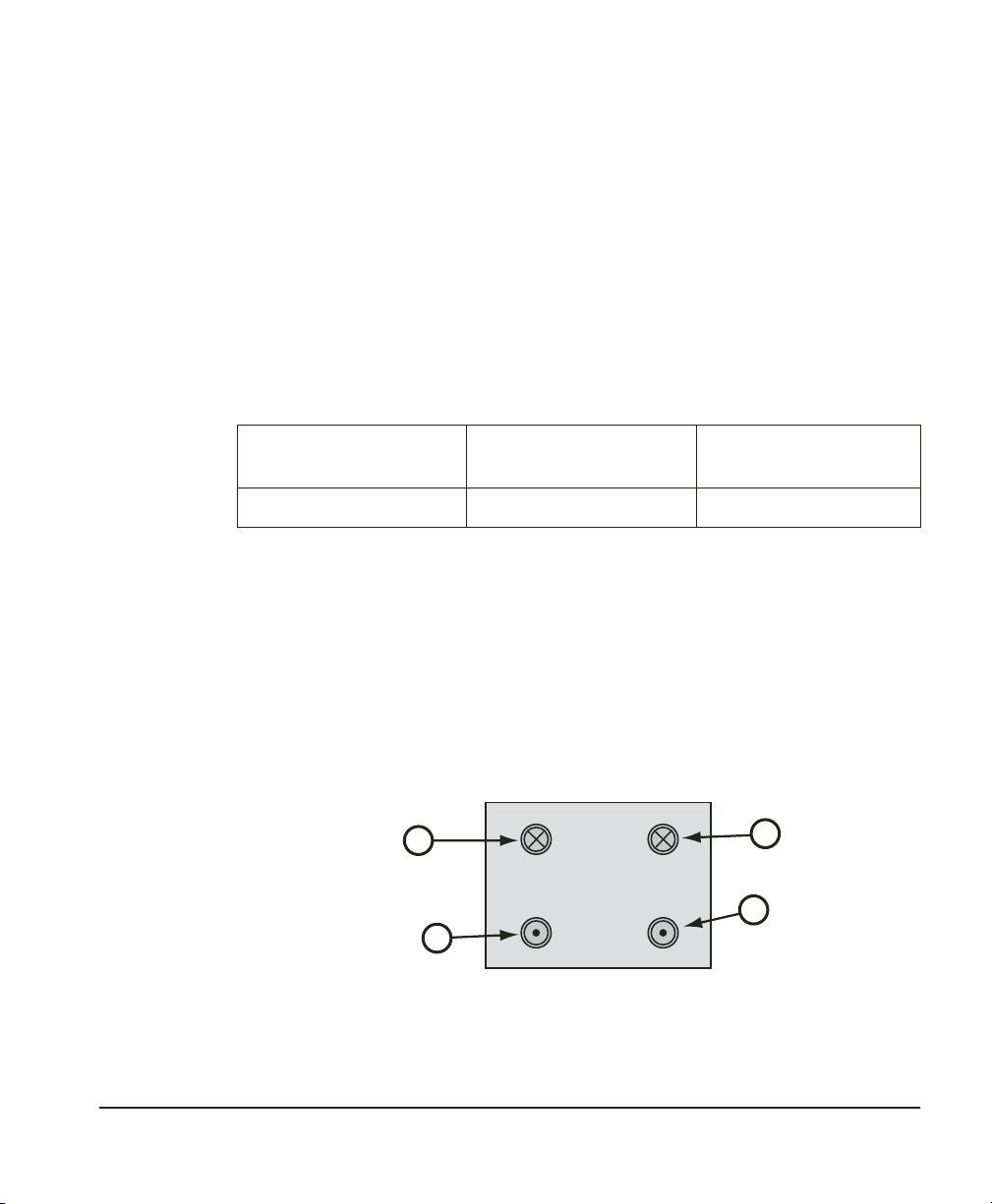

Rear input/output fitting connections

Mechanical connections to the Humilab are made on the rear panel

as shown in Figure 4.

B

COOLANT IN DRY AIR IN

COOLANT OUT DRAIN

C

Figure 4 — Humilab mechanical connection

198–264 VAC

48–66 Hz, 80 VA max

A

D

Chapter 1 — Installation and Initial Setup Page 9

A. Dry air in. A dry air supply can be connected to this port. The

dew point of the dry air must be at or below –40°C for proper

full-range operation. The flow rate requirement is 1 to 2 psig at 5

liters per minute (minimum). If a dry air supply is not available,

then this port must be left open to the atmosphere. The internal

pump will draw the ambient air through the desiccant cartridge to

supply the HumiLab with the proper supply of dry air.

B. Coolant In. For optimum performance, an optional temperature

bath/circulator should be connected to provide a stable water and

chamber temperature. Connect the chiller’s output port to this

Coolant In port.

C. Coolant Out. Connect the temperature bath/circulator’s input port

to the coolant-out port of the HumiLab.

D. Drain. This port allows the operator to easily drain the saturator

before transporting or storing the unit. Simply place a 1/4” tube

into a bucket and press the other end into the drain fitting until it

stops. Water will immediately begin to drain into the bucket. To

remove the tube from the fitting, depress the black outer ring and

pull out the tubing. A built-in check valve prevents water from

running out of the drain port when the tubing is not in place.

Coolant

connections

Page 10 Chapter 1 — Installation and Initial Setup

The HumiLab is equipped with 1/4” “instant on” coolant fittings

that require no tools for installation. These fittings will accept many

types of hard-wall tubing such as Teflon, stainless steel, or

Impolene. To insert the tubing, simply press the tubing into the

connector as far as it will go. Pull gently on the tubing to ensure

the connections are secure.

To remove the tubing from the “Instant On” fittings, simply depress

the black outer ring and pull the tubing out. The coolant fittings

are equipped with built-in check valves that enable the operator to

easily remove the coolant lines with minimal fluid loss.

If the optional chiller is used to accurately control the chamber

temperature, connect the chiller output to the “Coolant In” fitting

on the HumiLab and connect the chiller inlet to the “Coolant Out”

fitting.

Initial setup and water fill

Distilled water is recommended for trouble-free operation. Always

add water with the power turned off (the water level may pulse up

and down during normal operation). After the water chamber has

been filled (or refilled), allow sufficient time (typically one hour) to

equilibrate the water temperature.

1. Set up the unit on a flat surface.

2. Pour in one gallon of clean distilled water.

3. Install the drain line in the rear drain port, and drain out

enough water (about one cup) to ensure that the drain line is

full of water. This procedure is needed for proper water level

indication.

4. Remove the drain line and pour in an additional 1¼ gallons of

distilled water. Wipe up any spillage.

5. Install the dry line, connecting to a source of dry air, if available (–40°C DP dry air or nitrogen, 15–16 psig, 4–5 l/m flow).

If running from a desiccant cartridge, make sure the cartridge

is fully seated and the desiccant color is a minimum of 75%

blue throughout the length of the tube. Replace the cartridge

or desiccant if necessary.

6. Install the unit’s cover.

7. Install the power cord and turn the unit on. Set the controller

to 80–90% RH.

8. Check the water fill level indicator and make sure the level

has not increased above the fill line and that the overflow line

does not leak water (front left-hand corner of unit). If the

water fill level rises sharply or the overflow tube leaks, check

the wet gas tube inlet ports for obstructions.

9. Run the unit for 15–30 minutes and inspect for the absence of

water in the bottom of the wet line ports located at the bottom of the tank I/O block (near 1111H sensor). If water is

present, soak it up with a cotton swab or absorbent cloth, napkin or towel.

10. Perform mirror cleaning and balance procedure as described

in “Mirror maintenance” on page 36.

Chapter 1 — Installation and Initial Setup Page 11

Chilled mirror setup

The GE General Eastern HumiLab is shipped with the chilled

mirror sensor (1111H-SR) and temperature probe (T-100) already

installed.

Initialize the

dew point

sensor

Although it was initialized at the factory, the dew point sensor

bridge should be initialized again to compensate for any change

during shipment. This is accomplished by cleaning and balancing

the sensor as described below. Figure 7, shows the location of the

switches and LEDs on the front panel. Chapter 2 contains a

complete description of the operating procedures.

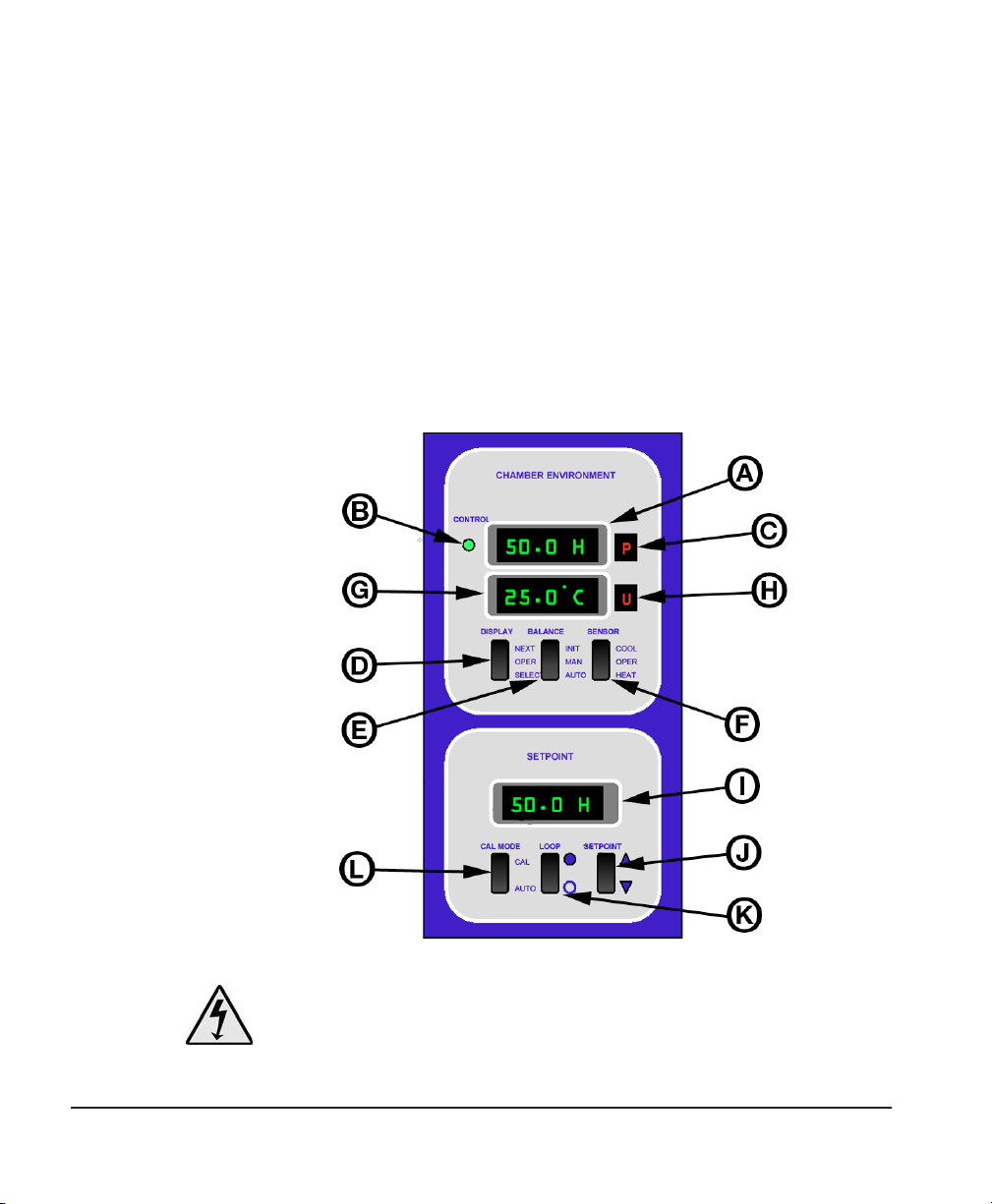

Figure 5 — Front Panel Controls

1. Plug the A/C power cord into a wall socket.

Page 12 Chapter 1 — Installation and Initial Setup

2. Turn ON the power switch located on the back right side of

the Humilab near the bottom.

The digital LED displays will light, and the generator will go

through a self check cycle. The letter “P” (for Pacer®) will be lit

on the front panel (C in Figure 5). (See Appendix B, page 45

for information on the Pacer feature.)

3. Wait for the Pacer cycle to complete (approximately three

minutes).

4. On the front panel, set the LOOP switch (K) to the CLOSED

LOOP position. (Depress the top of the rocker switch, toward

the filled circle.)

Clean and

balance the

dew point

sensor

The next steps are required to clean and rebalance the dew point

sensor. This normalizes the system, and prepares it for proper operation.

1. Press the SENSOR switch (F) to the HEAT position.

2. Open the test chamber cover and remove the white dust

cover.

3. Locate the sensor cleaning solution (in the GE General Eastern Maintenance Kit). Wet a cotton swab with the blue cleaning solution, and rub it lightly over the mirror. Lightly buff

the mirror dry with a clean, dry swab. Note: If you don’t have

the supplied cleaning solution, a solution of two parts rubbing alcohol to one part distilled water may be substituted.

4. Replace the sensor cover. Be sure that the cover is installed so

that the sensor balance screw aligns with the hole in the

cover.

Do not attempt to operate the sensor without the cover. It is

an optical device and will be offset by overhead light.

5. A vertical LED light bar indicates balance status. Either 3, 2, 1,

or zero horizontal bars will be lit. Locate the Balance, or Bias,

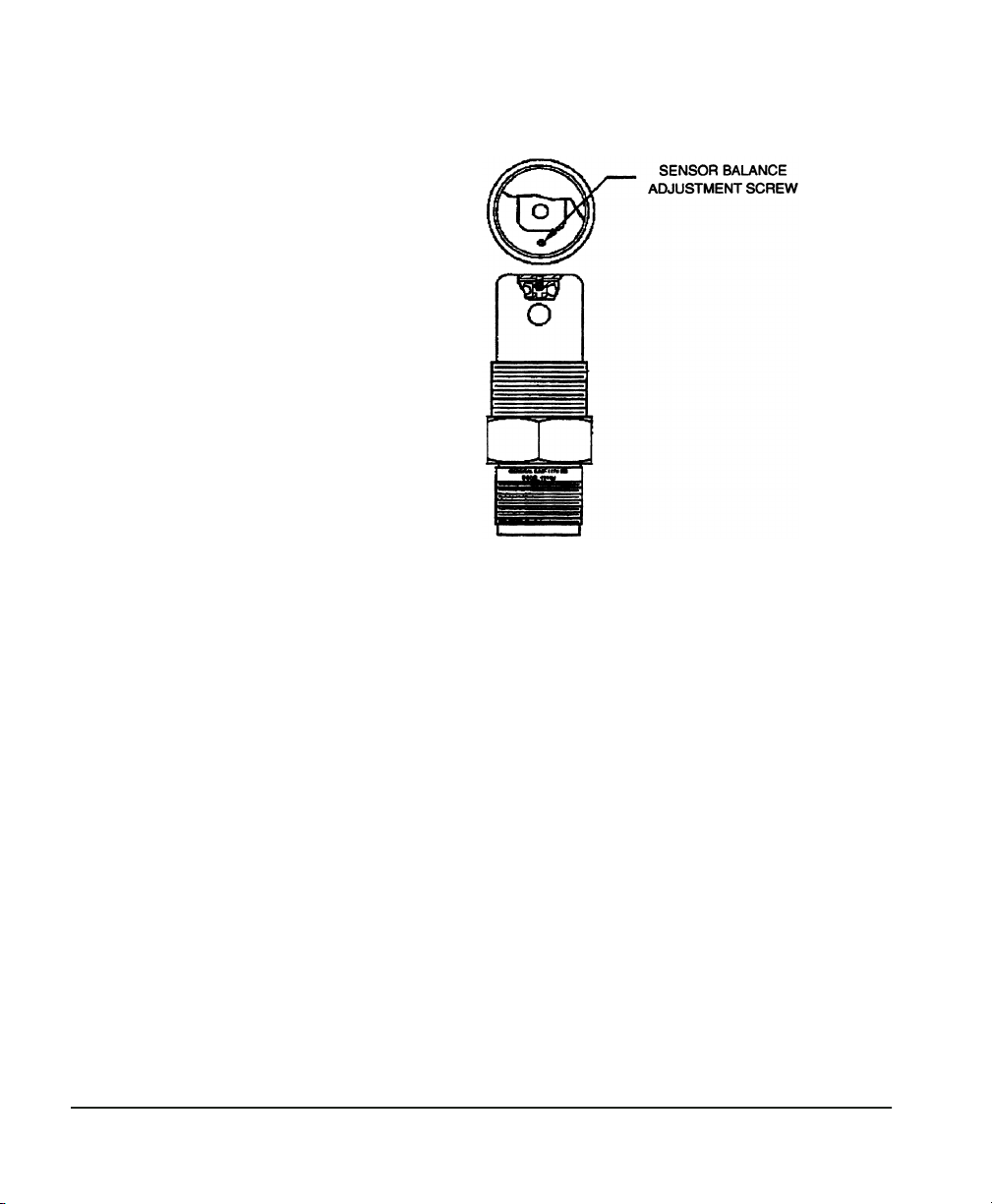

adjustment screw at the top of the sensor. See Figure 6. Using

the small screwdriver supplied in the maintenance kit, slowly

rotate the screw until only the bottom bar is illuminated. (The

Chapter 1 — Installation and Initial Setup Page 13

number of bars is increased when you turn the screw counterclockwise.) The optical bridge has now been balanced.

Figure 6 — 1111H Sensor Balance Adjustment Screw Location

6. Place the HEAT switch back in the OPERATE position.

7. Run the instrument through another Pacer cycle. (Momentarily press the INITiate switch.)

The letter “P” will light, and the displays will be frozen for several minutes as the cycle proceeds. At the end of that time,

the “P” will go out, and the left-hand displays will read the

actual percent R.H. and temperature in the test chamber.

8. Use the SETPOINT switch to select 30% RH by pressing on the

upper or lower side of the switch as required.

The display will scroll, one decade at a time, to the desired

reading. Release the switch when that point is reached.

9. Run the chamber for at least one hour, until the water surrounding the chamber assumes ambient laboratory temperature and the temperature equilibrates to ±0.2°C or better.

10. Use the SETPOINT switch to select 00.0 %RH and allow 30 to

45 minutes for the chamber to dry down.

Page 14 Chapter 1 — Installation and Initial Setup

Shipping the Humilab

This procedure describes the process the customer should follow

before shipping the HumiLab to an off site location or shipping the

unit back to GE General Eastern.

1. Remove A/C power from the unit and disconnect the dry gas

supply.

2. Connect a 1/4" O.D. drain line to the drain port located in the

rear of the unit. For customer convenience, an impolene drain

line is provided. Otherwise any 1/4" hard wall tubing will do.

3. Visually interrogate the unit through the fill port to determine if all the water has been removed. If water is still visible,

then the unit may have to be tilted towards the back and to

the left with the drain tube still attached.

4. The temperature bath/circulator lines need to be drained

prior to shipment. Insert the drain tube provided into the

COOLANT OUT port connector. Insert a short 1/4" tube into the

COOLANT IN port connector. This will allow the coolant to be

removed from the temperature coil. This will prevent the temperature coil from freezing during transport and possibly

causing damage to the unit. A slightly pressurized air line

could be used to help facilitate the draining process.

5. Place the mix tray inside of the chamber and fill the chamber

with bubble-pak to prevent any sensor damage and keep the

tray from moving during shipment. Place the cover on top.

Place the rubber stopper (supplied) into the fill port located at

the top front left corner.

6. Place the HumiLab into the transportation case (supplied).

The unit is now ready to be transported.

Chapter 1 — Installation and Initial Setup Page 15

Introduction

Chapter 2 — Operation

The Humilab is very simple to operate. Minimal operator training is

required for successful calibration of humidity recorders, transmitters, or hand-held portables. Typically, only the R.H. setpoint

selector switch is used in a calibration. All other switches are set as

desired and then left in position.

Front panel switch settings are described in this chapter. More

detail is available in Appendix B. For quick reference, the following

settings are typical for most applications:

• Power Switch: ON (mounted on rear of unit)

• Sensor Switch: OPERate

• Display Switch: OPERate

• Loop Switch: Closed Loop (Set to the filled-in circle) for operation; Open Loop (open circle) for uploading profiles

• Balance Switch: Center position

• Auto/Cal Switch: OPERate

• Setpoint: Set to desired chamber humidity

Page 16 Chapter 2 — Operation

Front panel displays and switches

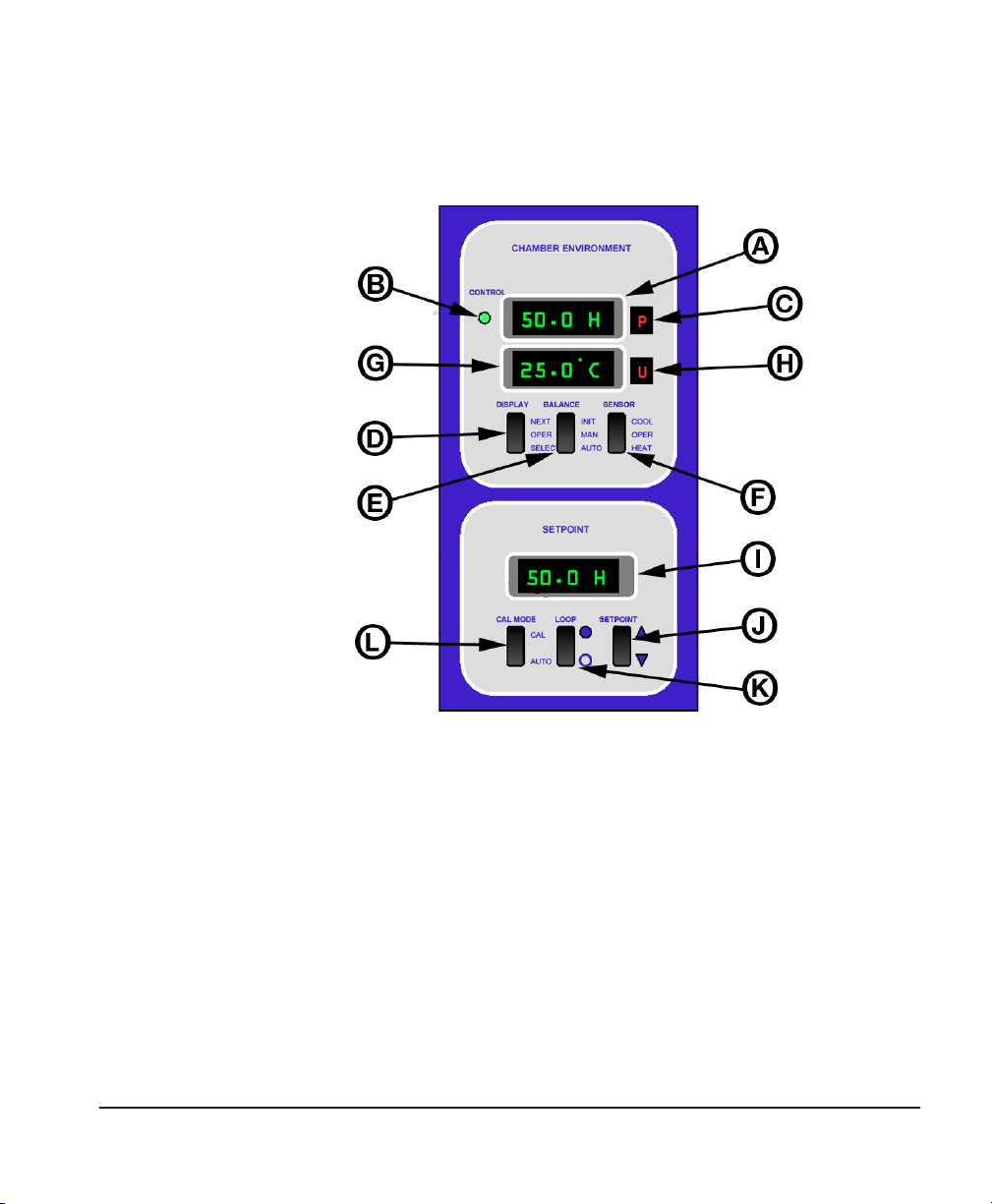

Refer to Figure 7 as you review the following descriptions of the

front panel displays and selector switches.

Figure 7 — Front Panel Controls

The Humilab, as shipped, is set up by the factory for normal operation. The two upper digital displays read Percent RH and Temperature in °C. The lower digital display shows the desired chamber set

point.With the exception of the setpoint selector switch, the other

front panel switches are seldom used in day-to-day operation.

However, they are included in case you wish to make changes to

normal default operation and for system testing.

Appendix B contains information on changing factory-set defaults.

A. HUMIDITY Display. This display is shipped from the factory set

for percent relative humidity. Please refer to Appendix B for more

information.

Chapter 2 — Operation Page 17

If you wish to perform dew point calibrations in the test chamber,

the display may be reprogrammed to read dew point.

B. CONTROL STATUS Indicator. The green control indicator advises

you that the control loop that maintains the dew layer on the

chilled mirror is operating correctly, and that there is a proper layer.

When lit, you may consider it to be an indication that the chilled

mirror humidity measurement is valid. Conversely, if the green

indicator is not lit, you should wait until it lights before performing

calibrations.

C. STATUS Window (humidity). A green letter “S” (for Service) in this

window advises the operator that the sensor mirror has become

contaminated, and requires cleaning.

If you are readjusting the sensor optical balance, a light bar appears

in this window. See “Balancing the sensor optics” on page 37 for

details.

This window will show various indications while reprogramming

the display units or analog outputs. See Appendix B.

D. DISPLAY Switch. The DISPLAY Switch is normally used in the

center OPERate position.

This rocker switch is used to reprogram measurement units and to

check the scale factor of analog outputs.

In the standard configuration, the analog output scale factors can

only be changed using the RS-232 port, to ensure that they are not

changed accidentally. If you wish to reconfigure the system so that

these parameters can be changed via the front panel, see Appendix

B.

E. BALANCE Switch. This switch is normally operated in the lower

AUTOmatic position.

In the AUTO position, the instrument will go through a normal

Pacer® cycle every 12 hours, rebalancing the dew point sensor

bridge and determining whether it requires cleaning.

In the MANual center position, there will be no automatic Pacer

cycles, only those initiated manually (if desired).

Page 18 Chapter 2 — Operation

In the manual position, you will never see the “S”ervice light displayed, telling you that the sensor mirror needs cleaning.

The upper (INITiate) momentary position manually triggers a Pacer

cycle.

F. SENSOR Switch. The SENSOR switch is typically kept in the center

OPERate position.

This switch allows you to over-ride the automatic mirror control

loop, and force the mirror temperature up or down, causing it to

heat or cool. These are test positions used for sensor diagnostics.

G. TEMPERATURE Display. As shipped from the factory, this display

reads temperature in °C. It may be factory or field programmed to

read °F if desired. See Appendix B.

H. STATUS WINDOW (Temperature). This window provides the oper-

ator with programming status for the Temperature display when

programming Units or Outputs. See Appendix B.

I. SETPOINT Display. This display window shows the relative

humidity setpoint that has been programmed in the chamber.

J. SET (SETPOINT) Switch. This switch allows you to select a

humidity setpoint in the display window. Scroll to the desired value

by incrementing or decrementing, one decade at a time, until the

desired value is reached.

K. LOOP SELECT Switch. This selector is normally kept in the Closed

Loop position (up, toward the filled-in circle).

In the Closed Loop position the chilled mirror hygrometer controls

the chamber relative humidity. In the Open Loop position, you can

download humidity profiles from the Prostep software program,

and you can perform diagnostics if necessary (see Chapter 3).

L. CAL/AUTO Switch. This switch is typically kept in the center posi-

tion.

When this switch is pressed into the momentary CALibrate setting,

the system begins the automatic 9-hour recalibration cycle.

Chapter 2 — Operation Page 19

If you ever accidentally switch the Humilab to the “CAL” mode,

simply shut the power OFF and then ON using the power switch

(on the rear panel) to reset to normal operation.

Performing routine calibrations

The unit has been calibrated at the factory. Field calibration is only

required if the measured humidity deviates from the setpoint

humidity by more than 1% RH after one hour.

With the selector switches preset to the proper positions for normal

operation, calibration may be performed as follows:

1. Insert the item(s) to be calibrated into the Humilab humidity

chamber. Run power cables via the top cover to the transmitter.

2. Select the proper RH Setpoint.

When this switch is held up (for higher humidity) or down (for

lower humidity), the digital set point display will scroll toward

the desired set point. First the least significant decade will

change, and then successively more significant decades will

change. Release the switch when the desired humidity is reached.

It may be easier to stop a few counts before the desired reading,

and allow the least significant unit display to move in 0.1%

R.H. steps to the set point.

3. Allow 40 to 60 minutes equilibration time.

The R.H. in the Humilab cavity will gradually move toward the

set point. For the first 20–30 minutes, there will be no

closed-loop feedback. After the loop is controlled, a correction

will be made every 5 minutes.

4. Calibrate as required.

Relative humidity is a function of temperature as well as moisture

content. If you are calibrating a device (such as a humidity transmitter) that generates heat, locate it near the center of the cavity.

This will allow the HumiLab’s temperature sensor to quickly

sense the temperature change and correct for it.

Page 20 Chapter 2 — Operation

Chamber response time

Due to the large cavity size, typical response time will be approximately 30–40 minutes. At the end of that period, the RH in the test

chamber will be within 1% RH of the set point. After that time, the

two will track each other within the accuracy specification of the

instrument.

Chapter 2 — Operation Page 21

Chapter 3 — Using the PROSTEP software

Introduction

This chapter describes the use of GE General Eastern’s Prostep software to set up a calibration test profile.

Prostep software generates humidity/temperature profiles to

control the Humilab. It is supplied with the Humilab system on a

CD-ROM. Using Prostep, a complete automatic test profile (relative

humidity vs. time, with ramps and step changes) may be created

using an IBM-compatible computer. The profile may then be used

for automatic calibration of the devices in the Humilab cavity. See

Figure 8 for a sample humidity profile.

In addition to creating humidity profiles for use in the Humilab,

the PROSTEP software can be configured to generate temperature

control commands/profiles to the recirculating water bath chiller,

remotely operate the Humilab, customize the Humilab calibration

sequence, and collect humidity and temperature data from the

reference hygrometer. This section will detail the creation,

uploading, and operation of humidity profiles and datalogging

features only. Consult the factory for more advanced operational

detail.

Figure 8 — Sample Humidity Profile

Computer

requirements

Page 22 Chapter 3 — Using the PROSTEP software

Prostep requires a computer system with the following characteristics:

• IBM-compatible 286 or higher machine

• RS-232 serial port

• at least 512K of RAM

• at least 1Mb of hard disk space

A DB-9 male to DB-9 female cable is supplied, along with a standard

RS-232 cable and null modem adapter.

If your computer has only USB ports in place of serial comm ports,

you will need to use a USB-to-serial converter, available from

computer supply houses.

Computer

communication

port settings

Connecting the

host computer

Set your IBM compatible computer’s serial communications port

settings as follows. (In Windows, go to Settings, control panel,

system, device manager, ports, communications port, port settings)

Bits per second: 1200

Data Bits: 8

Parity: None

Stop Bits: 1

Flow Control: None

Controlling Humilab. For communication to the Humilab controller

(uploading/downloading humidity profiles), connect the host

computer COM port connector to the 9-pin RS-232 CONTROLLER

connector on the rear of the Humilab.

Datalogging. For datalogging with PROSTEP, connect the host

computer COM port connector to the 9-pin RS-232 REFERENCE

connector on the rear of the Humilab. The Humilab must be in

closed loop operation.

Installing the Prostep software

Load the supplied CD-ROM and open the folder containing the

software. Double click on SETUP.EXE and follow the on-screen

directions.

Chapter 3 — Using the PROSTEP software Page 23

Running Prostep

To start the program, click on start, Programs, Prostep, and

Prostep.

Screens shown in this manual represent the appearance of Prostep

running under Windows XP, and will differ with other operating

systems.

Note: The HumiLab’s LOOP switch must be in the OPEN LOOP posi-

tion (open circle) when uploading Prostep humidity profiles. It

must be in the CLOSED LOOP position (filled-in circle) to run a

profile in normal operation.

PROSTEP

communication

settings

The profile

screen

Prior to communication with the Humilab, verify the communication settings in PROSTEP. Under Options > Communications Setup,

verify the following:

Baud rate: 1200

Flow Control: Off

Stop Bits: 1

Data Bits: 8

Com Port: 1–4 (matched to host computer)

Parity: none

The main profile screen is used for entering and modifying the

Humilab’s humidity profile. A profile must be uploaded to the

Humilab before it can be used, and can be downloaded back into

the PC for further editing. Use the File menu to manage the loading

and storing of multiple profiles. To customize the profile display,

see the Options / Scale Graph menu below.

The profile is specified by a number of setpoints. Each setpoint

specifies a bath temperature (if configured) and a programmable

humidity ramp as shown in Figure 9. Six items may be specified for

each setpoint:

Page 24 Chapter 3 — Using the PROSTEP software

D

20°C

40% RH

C

SETPOINT

Temp

3

B

30°C

E

80% RH

R.H.

F

time

A

A setpoint sequence number

B bath temperature

C an optional delay before the humidity

change is initiated (to allow for temperature

stabilization)

D initial humidity

E final humidity

F duration of the humidity ramp

Figure 9 — A typical setpoint and its values

Click on the large up and down arrows on the screen to step

through the list of setpoints, and enter the data for each setpoint.

The File menu

The File menu accesses standard Windows functions for:

• creating a new profile

• loading a existing profile

Chapter 3 — Using the PROSTEP software Page 25

• saving the current profile

• saving the current profile under a new name or file format

• selecting a folder for holding the profile data or datalog file

• exiting the program

The Run menu

The Options

menu

The Run menu contains the following choices:

Run Profile. Runs the profile most recently downloaded to the

Humilab.

Collect data. Collect RH, temperature, and/or DP data for Humi-

Lab operation. (See options > Setup Datalogging Parameters).

Halt Test. Stops running the current profile.

The Options menu accesses all of the setup and configuration

items:

Scale Graph. Sets the parameters for the main screen profile

display:

• units and maximum/minimum values for humidity and temperature (units set to %RH for typical Humilab profile)

• time scale

Page 26 Chapter 3 — Using the PROSTEP software

• graph colors.

Set up Communications. Sets the comm port parameters:

• baud rate: 1200

• flow control: None

• stop bits: 1

• data bits: 8

• parity: not checked

• comm port number: 1

Set up Data Logging Parameters. Sets units and formats for

logged data.

Before using this screen, make the following settings:

• set Predefined Groups to M4

• set BBox Port to –1

Chapter 3 — Using the PROSTEP software Page 27

A list displays all parameters to be logged, showing all configured

data for each. To change one, select the line with the mouse. Data

from that line will appear in the edit line, above. Make changes and

click on Edit to store the changes. Click on Remove to delete the

selected line. To add a new line, enter the data and click on Add.

When finished, click on Done.

• Unit Number: If more than one unit is connected, each can be

selected for configuration

• Enabled check box: must be checked to allow datalogging

• the Comm Port that the Humilab or BlackBox is connected to

• Channel base Address: default = 48

• Unused Channel Number: the number of the first Black Box

channel that is not in use

• Log Interval: the time between logged items (hh:mm:ss)

• Append to File check box: adds new data to end of existing

file if checked

Page 28 Chapter 3 — Using the PROSTEP software

The Transfers

menu

The Transfers menu allows moving a profile between the computer

and the Humilab.

Upload Profile. Send the current profile from the PC to the

Humilab.

Download Profile. Transfer a profile from the Humilab to the PC

The Help menu

The Help menu supplies on-line instructions for using the Prostep

software.

Chapter 3 — Using the PROSTEP software Page 29

Chapter 4 — Theory of Operation

A

Overview

Divided flow

The Humilab Relative Humidity Generator uses a divided flow

method to accurately generate a selected relative humidity in a

large test chamber. The selected humidity is controlled using a GE

General Eastern Chilled Mirror Hygrometer System. This chapter

describes divided flow and the chilled mirror controller.

The Humilab’s chamber RH is controlled by time proportioning a

fraction of an air stream through a saturator and a desiccant. The

saturated air mixes with the dry air to produce the desired RH

value in the chamber. Figure 10 shows the basic block diagram of

the Humilab’s operation.

-40°C DP

ir supply

(optional)

Desiccant

Cartridge

Dry gas

temperature coil

(surrounding chamber)

Water jacket

Pum

p

Solenoid

valve

Wet

gas

in

Te st

chamber

Figure 10 — Basic Block Diagram

Dry

gas

in

Sparger

(bubbles air

through water)

The operator selects the desired relative humidity on the front

panel, using the increment/decrement switch to scroll to the value.

The selected RH determines the duty cycle of a solenoid operated

Page 30 Chapter 4 — Theory of Operation

wet air/dry air valve.

The time required for one complete cycle of operation is 1 second.

During that period, the on-off duty cycle determines the ratio of

wet air to dry air, which, in turn, determines the percent relative

humidity in the test chamber. When the valve is ON, wet air is

generated and flows into the chamber. When the valve is OFF, dry

air flows into the chamber. Figure 11 shows how the wet/dry air

ratio is proportional to the relative humidity.

Figure 11 — Wet/Dry Air Selection

During the wet air portion of the cycle, the air is thoroughly saturated by an efficient diffuser. It then passes into the test chamber.

During the remainder of the cycle, the dry air enters the chamber,

after having first been completely temperature stabilized so that it

is virtually the same temperature as the water in the jacket

surrounding the chamber. This stabilization ensures that there is

very little temperature gradient between the incoming air and the

chamber itself.

The Humilab chilled mirror controller

A GE General Eastern chilled mirror dew point hygrometer is built

into the Humilab, providing continuous closed loop feedback to

control the relative humidity of the test chamber. This device

provides a fundamental, N.I.S.T. traceable measurement of the

chamber dew point. See Appendix B for more detailed information

on the operation of the chilled mirror hygrometer.

Mounted inside the test chamber is a chilled mirror dew point

sensor, bringing chamber dew point information to the hygrometer.

Chapter 4 — Theory of Operation Page 31

Also mounted within the test chamber is a platinum RTD air

temperature sensor, providing air temperature information (dry

bulb) to the chilled mirror hygrometer. A microprocessor calculation converts the chamber dew point and air temperature data to

percent relative humidity.

A microprocessor-based relative humidity controller receives the

RH information. It also looks at the RH setpoint which has been

selected on the front panel by the operator. If there is a difference

between the two readings, the controller adjusts the ratio of wet to

dry air entering the test chamber, at 5-minute intervals. This closed

loop operation ensures that the resulting relative humidity in the

chamber remains within ±0.2% R.H. of the chilled mirror hygrometer reading.

A multi-point calibration of the test chamber against the built in

chilled mirror has been performed at the factory, at 10% R.H. increments. At each point, a correction factor, determined by the actual

dew point and temperature measurement, has been stored in

non-volatile memory. Thus, the test chamber has acquired the

accuracy and N.I.S.T. traceability of the fundamental chilled mirror

hygrometer. If desired, this automatic calibration of the test

chamber against the chilled mirror hygrometer may be repeated at

any time in the field.

What is optical

condensation

hygrometry?

Page 32 Chapter 4 — Theory of Operation

Optical condensation hygrometry is a precise technique for determining the water vapor content in gases by measuring dew or frost

temperatures. Because these hygrometers are so accurate, they are

widely used as a standard in many of the world’s metrology laboratories.

Optical condensation hygrometry works on the chilled-mirror principle and provides a fundamental measurement of dew/frost point

temperature. A metallic mirror surface is cooled until it reaches a

temperature at which condensation begins to form on it. The dew

layer is optically detected and the mirror is held at that temperature. The mirror temperature, measured with a platinum resistance

thermometer, is an accurate indicator of the dew or frost point.

General

description of

the chilled

mirror

hygrometer

system

The Humilab includes a general purpose chilled mirror dew point

system that utilizes advanced microprocessor control. It is supplied

with GE General Eastern’s patented PACER® (Programmable Automatic Contaminant Error Reduction). See Appendix B, page 62, for

information on the Pacer feature. The Chilled Mirror Hygrometer

System also provides 4-20mA and 0-5 VDC analog outputs and

RS232C communications. For detailed Chilled Mirror Hygrometer

System Specifications, refer to Appendix A.

The Humilab Chilled Mirror System measures humidity in dew/

frost point or relative humidity (RH). It also measures temperature

in °C or °F. It accepts inputs from the Model 1111H chilled mirror

dew point sensor and the Model T-100E temperature sensor. These

are located within the test chamber.

Chilled mirror

hygrometer

system theory

of operation

The Humilab Chilled Mirror System operation is illustrated in

Figure 12 on page 34, which shows the way in which the chilled

mirror hygrometer detects and measures dew point. The condensate detection mirror is illuminated with a high intensity, solid

state, light emitting diode (LED). A photodetector monitors the LED

light reflected from the mirror. A separate LED and photodetector

combination are used to compensate for any thermally induced

changes in the optical components.

The photodetectors are arranged in an electrical bridge circuit, and

the photo-detector is fully illuminated when the mirror is clear of

dew. As dew forms on the mirror, the photodetector receives less

light due to scattering losses. Since the bridge output current is

proportional to the light received, a large bridge current develops

whenever the mirror is dry. The bridge output is amplified and

used to control the direct current to the thermoelectric cooler,

causing the mirror to cool toward the dew point.

As dew begins to form on the mirror, the optical bridge output is

reduced due to a reduction in detected light. This in turn, causes a

decrease in cooling current. A rate feedback loop within the amplifier ensures critical response, and the system quickly stabilizes at a

condition where a thin dew or frost layer is maintained on the

mirror surface (i.e., the dew or frost point). Thus, the mirror temper-

For detailed information on the chilled mirror hygrometer, refer to

Appendix B.

Chapter 4 — Theory of Operation Page 33

Figure 12 — Chilled Mirror Sensor Block Diagram

ature is always at the dew point of the gas being measured, and it

follows the dew point if it changes. A precision thermometer

element embedded within the mirror directly monitors this dew

point temperature and provides a continuous readout to the user.

Page 34 Chapter 4 — Theory of Operation

Chapter 5 — Maintenance and

Introduction

Troubleshooting

There are two levels of maintenance on the Humilab: basic system

maintenance and reference measurement maintenance.

Basic

maintenance

The following should be checked (every few hours, until the

requirements for your particular application determine a different

schedule):

• check the water level surrounding the calibration chamber

• check the desiccant condition and replace if it has turned

pink

Verifying water level. Water should be added to maintain the level

in the green area of the water level indicator. Be sure to use only

distilled water, and be careful not to accidentally spill water in the

test chamber. If you do spill any water, wipe it up completely.

The water level may pulse up and down while the Humilab system

is operating.

Verifying desiccant condition. Prior to each use of the HumiLab,

verify that the desiccant cartridge contains active desiccant material. The desiccant contains an indicating material which turns

from blue to pink as the desiccant is exhausted. Replace or regenerate the desiccant granules before the cartridge is completely

exhausted.

To regenerate the desiccant, the granules may be spread in layers

one granule deep and heated for 1 hour at 210° C or 425° F. The

regenerated material should be placed in the original glass or metal

container and sealed while hot. Do not overheat the desiccant.

Replacement desiccant can be obtained from GE General Eastern.

Chapter 5 — Maintenance and Troubleshooting Page 35

Reference

measurement

maintenance

The following should be performed as required to maintain the

accuracy needed for your particular application:

• periodic mirror cleaning

• balancing the sensor optics

Details for these procedures are given below.

Problems not resolved by these procedures require the attention of

a person with more in-depth knowledge. The chilled mirror

hygrometer sensor (Model 1111H) generally requires the most

attention because it is the most intricate component of the

Humilab. Information addressing these problems is contained in

Appendix B.

Mirror maintenance

Some Humilab owners routinely perform a mirror cleaning before

each calibration run for best possible system operation. While this

is truly optimum, it is theoretically possible (and generally most

practical) to operate until the system tells you that the mirror needs

cleaning by lighting the letter “S” (for Service) in the Status

window.

In normal operation, the green “CONTROL STATUS” indicator on the

left hand side of the front panel will be lit. The Control Status light

tells you that everything is normal with regard to the control loop

that determines the mirror dew layer.

If the Service indicator adjacent to it does light, momentarily activate the Pacer® switch. A letter “P” will appear in a window on the

front panel. If the Service light goes out after several minutes (at

the end of the Pacer cycle), continue normal operation. If the

Service light remains on after the end of the Pacer cycle, it is an

indication that the sensor mirror requires cleaning. A fine layer of

dust or other contaminant has gradually built up on the surface,

and it must be removed.

Cleaning the

sensor mirror

Page 36 Chapter 5 — Maintenance and Troubleshooting

Periodically inspect and maintain the chilled mirror hygrometer

sensor (1111H) optics as described in the following paragraphs.

These procedures can be done at any time but are only necessary

when an “S” appears on the status display, indicating that service is

required.

Under normal conditions, the chilled mirror hygrometer is

self-checking and self-balancing. However, there are occasions

when particulate matter and water-soluble contaminants reduce

sensor mirror reflectance and system accuracy. Clean the sensor

mirror according to the procedure below.

1. Deactivate the sensor cooler by setting the Electronics front

panel Sensor switch to the HEAT position.

2. Open the sensor by removing the sensor cover.

3. Moisten a cotton swab with a cleaning solution suitable for

mirrors, such as the blue cleaning solution in the GE General

Eastern maintenance kit, or dilute methanol or rubbing alco

hol.

Do not use Q-tips or other swabs that contain oils.

4. Clean the mirror with a few light wipes. If the sensor has been

exposed to significant contamination, clean the other optical

surfaces in the sensor and the sensor cavity itself.

5. Replace the sensor cover. Leave it in the Open position, with

the large holes allowing maximum air into the sensor cavity

for fastest response time.

6. Return switches to normal, initiate a Pacer cycle, and continue

operation.

-

Balancing the

sensor optics

Chapter 5 — Maintenance and Troubleshooting Page 37

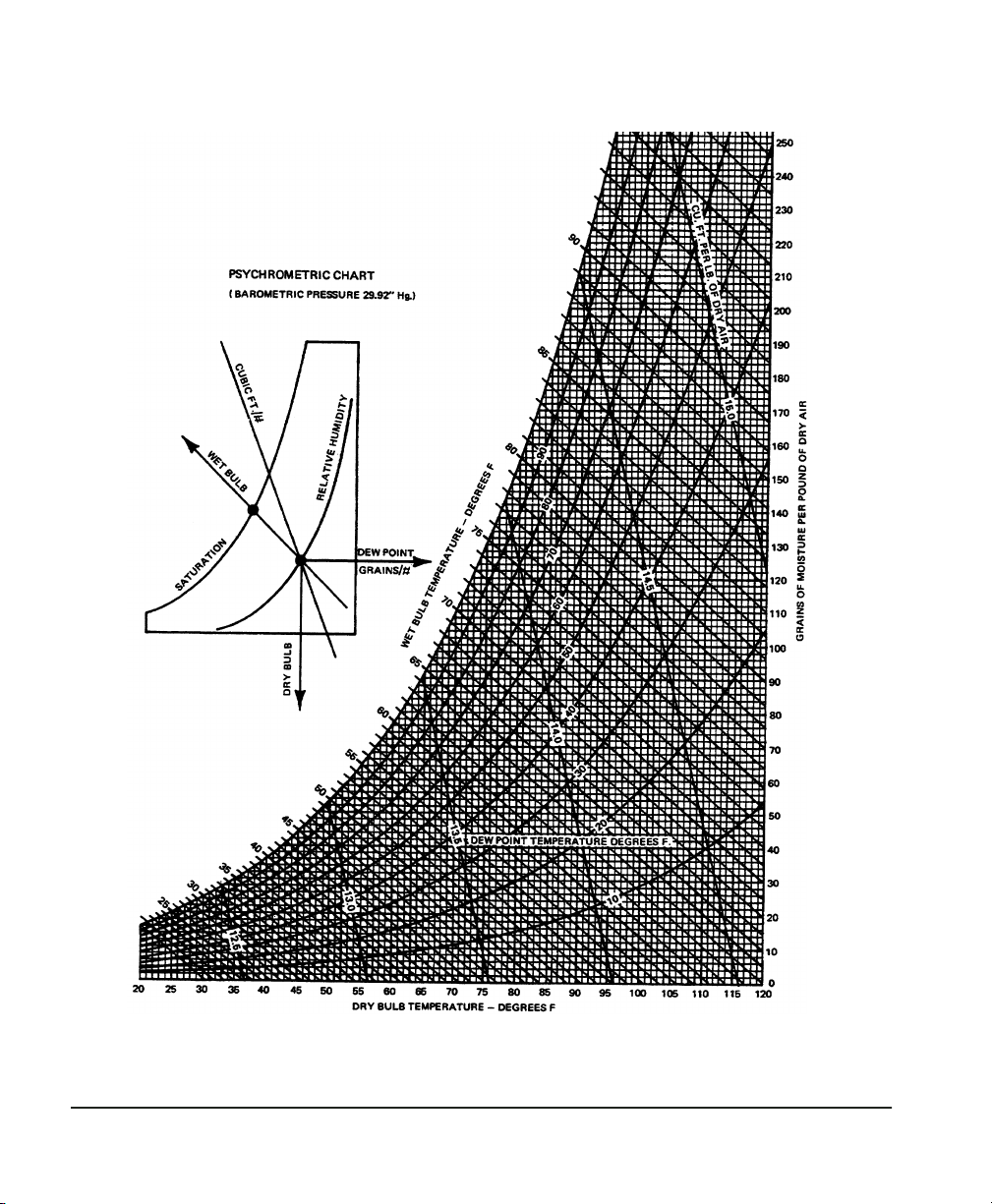

If the service (“S”) flag reappears after a Pacer cycle, even after

performing the mirror cleaning procedure above, check the sensor

optics balance adjustment. Improper adjustment of the optical

balance is the most common cause of instrument malfunction.

Also, new systems may require an optical balance adjustment after

one or two months of operation.

Never perform the Optical Balance Adjustment without first cleaning the mirror.

Place the sensor switch on HEAT, wait one minute, then observe the

segment display. If only the bottom segment bar is lit, the sensor is

properly balanced. Otherwise, balance the sensor according to the

procedure below.

1. Clean the mirror as described earlier in this chapter. Make

sure you replace the sensor cover when checking the balance.

If no bars are lit or more than one bar is lit, go to Step 2. If one

bar is lit, go to Step 3.

2. If no bars are lit, turn the balance screw on the sensor

COUNTERCLOCKWISE until only the bottom bar is lit.

If more than one bar is lit, turn the balance screw CLOCK-

WISE until only the bottom bar is lit. (For the adjustment

screw, see Figure 6 on page 14.)

Be sure to cover the mirror cavity while adjusting the balance

screw, since ambient light can cause an offset.

3. The sensor is balanced when one bar is lit. Replace the sensor

cover, if necessary, and make sure one bar is still lit. If not,

repeat Step 2, since you were allowing some light to enter the

cavity. Place the Sensor switch back to OPERATE to stop heating the mirror.

4. Initiate a Pacer cycle by switching the Balance switch to INIT.

At the completion of the cycle, the Humilab Chilled Mirror

Hygrometer System is properly balanced. Figure 13 on the

next page diagrams the complete balancing procedure.

Page 38 Chapter 5 — Maintenance and Troubleshooting

Figure 13 — Mirror Check and Mirror Sensor Balancing Procedure

Chapter 5 — Maintenance and Troubleshooting Page 39

Field

replacement of

the sensor

mirror

One advantage of using a GE General Eastern chilled mirror dew

point sensor is you can replace the mirror yourself. A sensor does

not have to go back to the factory for replacement of the reflective

surface, but of course you can return it for factory service if

desired. A mirror may require replacement for these reasons:

• The reflective surface may be gradually abraded by sharp par-

• The mirror surface may be accidentally scratched or gouged

Replacing the sensor mirror. Required equipment: Torque driver, set

to 20-30 inch-ounces of torque. You can order a GE General

Eastern type TW-1 torque driver if needed.

1. Open the sensor by removing the sensor cover.

2. Unscrew the old mirror, using a 3/16-inch (0.187) hex socket.

3. The kit supplied by the factory contains the replacement mir-

4. Use a toothpick or similar tool to place a small amount of

5. Carefully screw in the new mirror and tighten to the proper

6. Carefully clean the mirror surface, using a cotton swab and

7. Replace the cover and return the sensor to normal operation.

ticles.

during use or cleaning.

Discard the old mirror.

ror and a container of white thermal compound for proper

heat transfer. Complete instructions are also included in the

kit.

thermal compound in the hole into which the mirror is tightened. (Do not apply the compound to the mirror stem.) Do

not use an amount large enough to leak out when the mirror

is tightened. Do not allow any compound on the mirror surface, as it is very difficult to remove completely.

torque.

The mirror protrudes only about 1/16-inch above the surface.

Ensure that the hex socket does not slip off while tightening, as

this may mar the new mirror or mar the vapor barrier.

the cleaning solution supplied in the maintenance kit. Alternatively, you can use distilled water or diluted rubbing alcohol.

Under some circumstances, a new mirror may operate in a

somewhat unstable manner for the first one to two hours.

Page 40 Chapter 5 — Maintenance and Troubleshooting

Annual recertification

A dated Certificate of Conformance has been supplied with the

Humilab system from the factory. This document indicates traceability to the National Institute of Standards and Technology

(N.I.S.T.), in Gaithersburg, MD, USA. Under most regulatory standards, this certification is good for one year from date of issue. If

your regulations require that the Humilab be re-certified annually,

there are two methods you should consider.

• Return the unit to GE General Eastern for re-certification

• Have it re-certified in your standards laboratory if adequate

traceable standards are available.

Troubleshooting the Humilab, system diagnostics

Is the system

operating

correctly?

The Setpoint display (lower right) shows the R.H. that you have set

the test chamber to. The Humidity display (upper left) shows the

actual R.H. in the chamber, as read by the chilled mirror hygrometer. Do they agree within the instrument specifications?

Set Point RH and Actual RH do not Agree within Specifications.

Actuate the setpoint select switch. You will instantaneously get a

reading in the Setpoint display window that is the actual value

needed to generate the previously displayed setpoint. That is, it is

the R.H. value selected by the SETPOINT switch (plus or minus a

correction value).

Set Point RH and the Corrected Reading Differ by more than 5%.

Check the following to determine the source of the problem.

• Is a green letter “S” illuminated in the window to the right of

• Did you fill the reservoir with water and run a calibrate cycle

the Control Status light?

If so, the mirror needs cleaning due to buildup of dust on the

surface. See mirror cleaning instructions earlier in this chapter.

without an adequate waiting period for the water temperature

to completely equilibrate to ambient?

Chapter 5 — Maintenance and Troubleshooting Page 41

If that is possible, run it again with a stable water supply.

• Relative humidity is a function of temperature. Are you calibrating devices in the chamber that generate heat?

If you are, try to locate the heat producer adjacent to the temperature sensor in the center of the chamber. This way, the system

will correct for it automatically.

• Is the green Control Status indicator off?

If so, the chilled mirror is not tracking the chamber. See the section on page 59 in Appendix B on chilled mirror hygrometer

system troubleshooting.

Page 42 Chapter 5 — Maintenance and Troubleshooting

Appendix A — Specifications

% RH range 10 to 90% RH at 77°F (25°C)

Temperature range 68 to 86°F (20 to 30 °C) May be used with Tempera-

ture-Controlled Water Bath/Circulator. Humidity limited by

surface temperature of internal walls and cover (dew point

in chamber must be less than interior surface temperature

to avoid condensation).

Response time 10 minutes for 63% step change. 30–40 minutes to full

stability

Accuracy ±1% RH from 10% to 70% RH

±1.5% RH from 70 to 90% RH

±0.3°F (0.15°C) dew point at 77°F (25°C)

±0.3°F (0.15°C) dry bulb at 77°F (25°C)

Analog outputs Two (humidity and temperature), each user-scalable,

4–20mA/0–5VDC

Power 115 or 230 VAC ±10%, 50/60Hz single phase

Digital interface Two RS-232 ports for reference and generator interface

Prostep software Windows 95/98 or above required. Supplied on CD ROM

with Operator’s Manual (PDF) and HCON Humidity Conversion Software.

Approvals CE approved. Certifications supplied: Certificate of NIST

traceability and functional test data

Display Three LEDs, 0.5" (1.3cm) high, 7-segment

Shows Set Point (%RH), Actual % RH, and Temperature

0.1% RH/°C/°F resolution

Workspace dimensions 11" by 9" by 6.5" (28 by 23 by 16.5 cm)

Approx. 644 in3 (10.6 liters)

Overall dimensions 23"L by 19"W by 13"H (58 by 48 by 33 cm)

Appendix A — Specifications Page 43

Materials Chamber: stainless steel

I/O block: aluminum

Water jacket: stainless steel

Water capacity 2.2 gallons (8.3 liters)

Mechanical I/O Fill port

Fittings: 1/4" OD tubing, instant-on fittings for: water circulation (inlet and outlet); water drain (for gravity draining);

and dry air inlet (compressed dry air to be regulated to < 5

PSI)

Weight 66 lbs (30 kg) dry weight

Electrical I/O Power: IEC receptacle

Analog outputs: DB-15

RS-232: DB-9

Water capacity indicator Liquid sight glass – color keyed indicator

Desiccant Indicating type (bright blue when dry; pink when satu-

rated). Chamber runs 24 hours at 50% RH and 77°F (25°C)

on a new charge of desiccant. Dry compressed air (–40°F /

–40°C Dew Point or drier) extends life indefinitely.

Page 44 Appendix A — Specifications

Appendix B — Humilab chilled mirror

hygrometer details

Introduction

A general description of the Humilab chilled mirror is presented in

Chapter 4. In most installations this general description is

completely adequate. However, some applications may require

system modification to meet specialized needs. This appendix

describes how to make these changes. It also provides more

detailed information on the Humilab mirror system, its maintenance, and troubleshooting.

Because of the delicate and critical nature of the chilled mirror

components, this information is intended for trained electronics

technicians. If you are not comfortable performing procedures in

this appendix, contact GE General Eastern for assistance.

Chapter

organization

This is a large appendix consisting of the following sections:

• A list of the Humilab Chilled Mirror System Components

• Front Panel Operation

• Using the DISPLAY Switch to Set Defaults (Select Options)

• RS-232 Communications (Windows Terminal Program)

• Using RS-232 Communications to modify Humilab Operations

• Output Terminal Connections

• Service and Troubleshooting Procedures

• Helpful Hints

System components

The Humilab chilled mirror system consists of the following items:

• Electronics Module (as part of the Humilab)

Appendix B — Humilab chilled mirror hygrometer details Page 45

• A dew point sensor (GE General Eastern Model 1111H)

• A Temperature Sensor (GE General Eastern Model T-100E)

• Interconnecting cables (part of the Humilab)

Front panel operation and displays

The front panel was discussed in Chapter 2 from a daily operations

standpoint. This section repeats some of this information (for quick

reference), but also supplies additional information.

Figure 7 on page 17 shows the front panel layout. The panel

contains digital dew point and control status displays and three

operating switches: SENSOR, BALANCE and DISPLAY. The lettered

sections below correspond to the labels in page 17.

A

B,C

D

E

DEW POINT display — The DEW POINT display shows the dew or frost point in

Celsius or Fahrenheit units.

CONTROL/STATUS display — The CONTROL/STATUS display includes a green

control light and a seven-segment display. The control lights comes on when

the system detects both a stable dew or frost layer and a stable dew point

temperature. The seven-segment display indicates as follows:

P

Programmable Automatic Contaminant Error Reduction

(PACER®) mode or Automatic Balance (AUTO) mode is in

operation.

S

Service — The system optics require service, cleaning, or

adjustment.

(bars) Indicates the approximate amount of condensation on the

sensor mirror. (Only seen in HEAT or COOL mode.)

DISPLAY Switch — This is a three-way switch that selects:

NEXT A momentary position used when viewing or changing

OPERATION Normal operation.

SELECT A momentary position used when viewing or changing dis-

played unit, output unit and scaling or alarm units and limits.

BALANCE switch — This is a three-way switch that selects:

AUTO The Pacer/Auto cycle occurs at a pre-selected interval.

Page 46 Appendix B — Humilab chilled mirror hygrometer

MANUAL No PACER cycle unless manually initiated.

INIT

F

SENSOR Switch — This is a three-way position switch that selects:

HEAT Allows the mirror to be cleared of condensation in order to

No PACER cycle unless manually initiated.

check for proper control loop operation.

OPERATION Normal operation.

COOL

A momentary position that forces maximum cooling in

order to check depression capability.

Displays

Main display. The upper display can show R.H. or Dew Point °C or

°F. The front panel DISPLAY switch is used to determine which

parameter is displayed. The factory default for the Humilab is

%R.H. The lower display shows temperature in °C or °F. The factory

default is °C.

Control status display. The CONTROL STATUS display includes a

green control light and a green, seven segment LED display. The

control light comes on when the system detects both a stable dew

or frost layer and a stable dew/frost point temperature. The green

LED can read as follows:

P - Programmable Automatic Contaminant Error Reduction

(PACER®) mode or Automatic Balance (AUTO) mode is in operation.

S - Service. The system optics require service, cleaning, or adjust-

ment.

U - In Units Select mode when using the DISPLAY switch

O - In Output Select mode when using the DISPLAY switch

Horizontal bars indicate the approximate amount of condensation

on the sensor mirror when the SENSOR switch is in HEAT or COOL.

It is an indication of dew layer thickness on the mirror.

See the information starting on page 49 in this appendix for information on using the DISPLAY switch for re-programming Units,

Outputs, or Alarms.

Appendix B — Humilab chilled mirror hygrometer details Page 47

Switches

Display switch. The DISPLAY switch is a three-way switch that

selects:

NEXT - A momentary position used when viewing or changing

displayed units, output units and scaling.

OPER - Normal operation.

SELECT - A momentary position used when viewing or changing

displayed units, output units and scaling.

Display switch operation. The DISPLAY switch is used to change the

units displayed in the main display, view or change units for the

analog output(s). In the Default mode, as shipped from the factory,

the actual analog output scaling can only be modified via the

RS-232 port, to avoid accidentally changing them when changing

displayed units at the front panel. (See “RS-232c re-programming

mode” on page 52 of this appendix.)

Balance switch. The BALANCE switch is a three-way switch that

selects:

INIT - A momentary position that initiates a balance cycle, either

PACER or AUTO.

MAN - No balance cycle unless manually initiated, using INIT.

AUTO - The PACER/AUTO cycle occurs automatically at a

pre-selected interval.

See “Set balance type” on page 54 for details on resetting the balance

interval via RS-232 communication.

Sensor switch. The SENSOR switch is a three-way switch that

selects:

COOL - A momentary position that initiates maximum cooling of

the chilled mirror sensor in order to verify its depression capability.

OPER - Normal operation.

HEAT - An on position that initiates heating of the chilled mirror

sensor in order to clear it of dew or frost and verify proper control

loop operation.

Page 48 Appendix B — Humilab chilled mirror hygrometer

Option selections using the display switch

The DISPLAY switch is used in conjunction with the three green

LED displays (the Units portion of the main display, the parameter

annunciator, and the Control Status display). It has a central rest

position, OPER(ate), and two momentary positions, NEXT and

SELECT. In general, NEXT allows you to get into Option Selection

mode, scroll through various portions of the menu, and scroll

through digits and characters to set values. SELECT allows you to

select which area to access and to set values and characters.

A simplified

explanation of

the option

selection

system

The DISPLAY switch provides you with several main menus. In

sequence, these are:

UNITS on the top display

UNITS on the bottom display

OUTPUTS on the top display

OUTPUTS on the bottom display

Menu navigation.

It’s easier than it might first appear to move about and select

options. Follow the three-step process below.

1. Press NEXT until you see one of the above main menus that

you want. When you get to the one you wish to see, press

Select. This action puts you IN that main menu, and you can

proceed to scroll through it until you see the submenu you

want.

2. When you see it, press SELECT. You are now IN that submenu.

By pressing NEXT, you can scroll through it and find the

parameter you wish to select.

3. When you find the one you want, save it by pressing SELECT.

Indications on the front panel will guide you. It may sound

complicated, but once you have done it a few times, it will

seem very logical.

It is suggested that you now proceed to try it intuitively. The indicators will help you, and you may not need to use the manual. If

you do run into trouble, consult the following sections.

Appendix B — Humilab chilled mirror hygrometer details Page 49

• To begin programming the Electronics Module, press the DIS-

PLAY switch to NEXT. (You may have to keep the switch

pressed for 1-2 seconds in order to see a change.)

• The Electronics Module will leave Operate mode, enter Program mode and display the first of the three main functions.

While you are programming the Electronics Module, it will not

display or output measurement data.

• Press NEXT to display the next menu or option.

• Hold the switch in the NEXT position to scroll through all the

options available. When you get to the end, the Electronics

Module will return to Operate mode.

• Press SELECT to access the displayed function or accept a setting displayed on the main display.

The following two sections map out the functions available in

Program mode along with the state of the three green LED’s at each

step.

• N will display the next function or scroll through alphanumeric values. Depress NEXT for 1-2 seconds

• S will access a function or accept a new value. Depress NEXT

for 1-2 seconds

A more

rigorous

explanation of

The following description describes the DEFAULT programming

sequence for a unit as shipped from the factory. If the behavior of

the DISPLAY switch has been modified, using the RS-232C port, the

description may not be accurate.

the option

selection

system

Page 50 Appendix B — Humilab chilled mirror hygrometer

Default operation.

• From OPERATE mode, Press N.

• The main display and parameter annunciator blank, and the

CONTROL STATUS display shows “U” in the upper display. If

you press S, you can scroll through all the parameters available for display and select one. For now, press N. You can now

do the same for the bottom display.

• The CONTROL STATUS display shows “O”, and the parameter

annunciator shows “Humidity.” If you press S, you can view

the parameter for the Humidity output and the scaling. For

now, press N. You can now do the same for the bottom display.