GE

Sensing

Portable and Precise

Humilab™

General Eastern Relative

Humidity Generator and

Calibration Chamber

Humilab is a General Eastern

product. General Eastern has joined

other GE high-technology sensing

businesses under a new name_GE

Industrial, Sensing.

• Primary standard: Integrated chilled mirror and

platinum RTD constantly measure test conditions

• Precise: ±0.2% RH stability

• Accurate: ±1% RH from 10% to 70% RH and ±1.5% RH

from 70% to 90% RH

• Versatile: 10% to 90% RH and 20°C to 30°C

• Self-contained operation: Equipped with desiccant and

water reservoir

• Connects to temperature bath/circulator to

standardize test conditions

• Connects to dry compressed air to extend desiccant

life indefinitely

• Records and documents: 0 to 5 VDC, 4 to 20 mA

analog outputs and RS-232 digital data stream

• Fast response: 10 minutes for 63% step change and

30 minutes to full stability

• Quality design: Stainless steel chamber

• Instant-on fittings for external dry air, circulation of

temperature controlled water and reservoir drain

• Cost effective: Ability to calibrate several %RH

instruments at once

• Ease of operation: Set to value you need by the front

panel or via PROSTEP software for ramp and soak

profiles

• Bright, easy to read control panel

• Equipped with transportation case

g

GE

Sensing

Document and Standardize

• Calibration labs

• HVAC and BAS transmitters

• Pharmaceutical instruments

• %RH data loggers

• %RH recorders

• Industrial humidity probes

• Test humidity sensors

• Metrological and radiosonde sensors

The Humilab employs the time-proportioned divided flow

method to generate relative humidity values from 10%

to 90% RH. Unlike other humidity chambers that use

secondary %RH sensors, pressure transducers or

wet/dry bulb temperature sensors, the Humilab has a

built-in primary humidity reference standard. %RH is

calculated from the fundamental chilled mirror dew

point and platinum RTD temperature measurements. The

chilled mirror sensor and RTD are in the same

environment as the devices under test. The relative

humidity is controlled, regulating a fraction of a constant

flow of dry air through a saturator. The dry air is

produced with an internal pump and desiccant cartridge.

The air streams are temperature-conditioned and mixed

to maintain the desired RH level in the test chamber.

Repeatable and Economical

The Humilab is a NIST-traceable relative humidity

generator and calibration chamber that is continuously

monitored and controlled by a chilled mirror hygrometer

and precision RTD. The system is water jacketed for

thermal stability and facilitates cost-effective

calibrations of relative humidity sensors, probes,

transmitters, recorders and data loggers.

Since the volumetric mixing ratio is a time-based control,

the system is highly repeatable. The chamber is

sufficiently sized for several test articles at once. The

Humilab has an inlet for dry compressed air, which

extends the life of the desiccant indefinitely. The water

jacket may be connected to a temperature-controlled

water bath/circulator to provide standardized test

Primary NIST-Traceable Calibration

The system is supplied with a certificate of calibration

and functional test data.

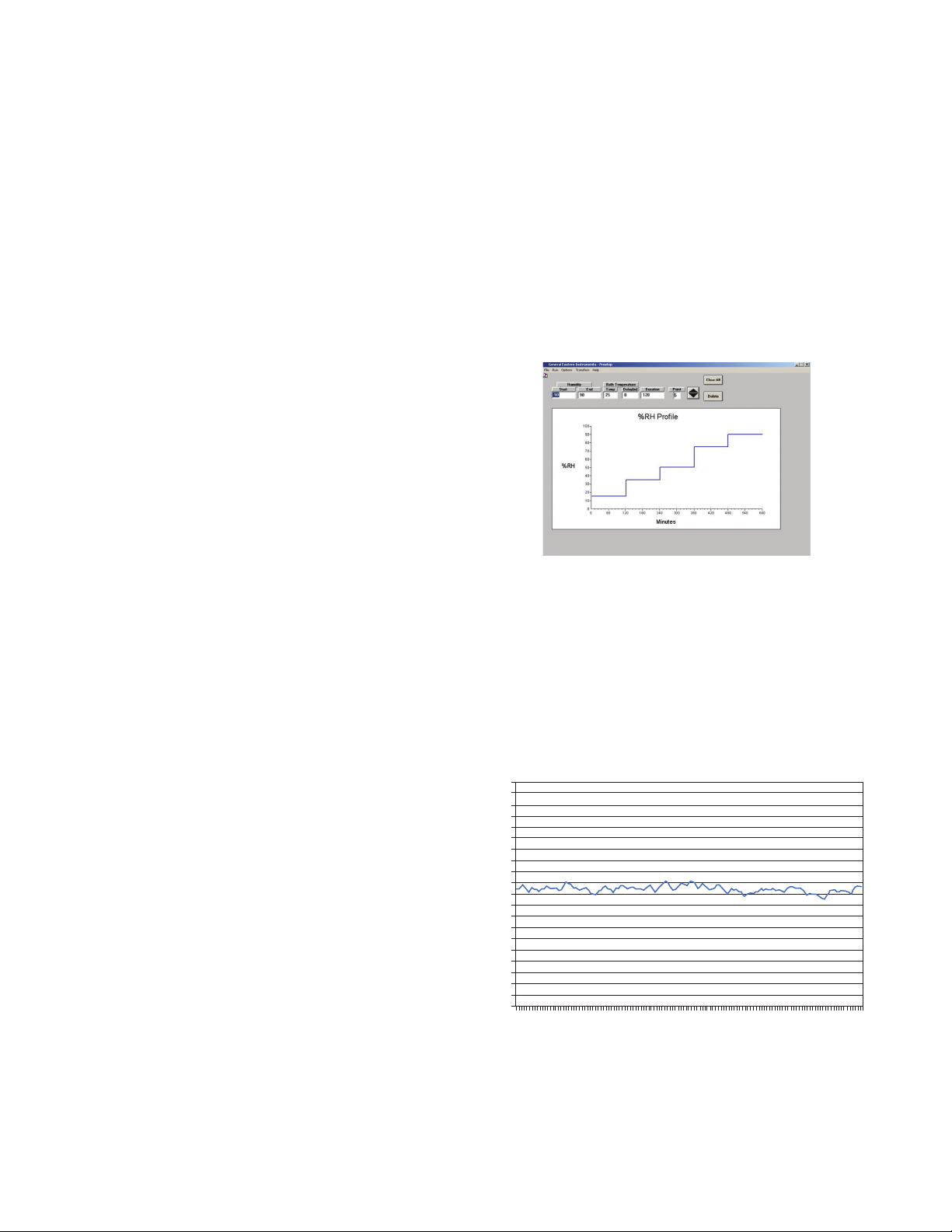

Prostep software enables “ramp and soak” humidity and temperature

prof iles to be loaded into the Humilab. Prostep also features data

logging. The chamber conditions are recorded as time-based ASCII data,

which can be opened in spreadsheet programs such as Excel.

conditions. The test chamber has been thermally

mapped to confirm temperature uniformity of better

than 0.2°C. Humilab provides analog and digital outputs

(RS232) to facilitate data logging and recording. The %RH

set point can be selected from the front panel or ramp

and soak profiles may be uploaded to the Humilab using

Prostep software. Prostep also provides data logging via

the RS232 data port. Test data may be saved to a PC as

ASCII data, which can be imported into standard

spreadsheet programs such as Excel.

The graph above was produced with data from the Humilab. The

calibration system provides stability of better than ±0.2% RH.

51.0

50.9

50.8

50.7

50.6

50.5

50.4

50.3

50.2

50.1

50.0

49.9

49.8

49.7

49.6

49.5

49.4

49.3

49.2

49.0

18:49

18:51

18:52

18:54

18:56

18:57

18:59

19:01

19:03

19:04

19:06

19:08

19:09

19:11

19:13

19:14

19:16

19:18

19:19

19:21

19:23

19:24

19:26

19:28

19:29

19:31

19:33

19:35

19:36

19:38

19:40

19:41

19:43

19:45

19:46

19:48

19:50

19:51

19:53

19:55

19:57

19:58

20:00

20:02

20:03

20:05

20:07

GE

Sensing

Humilab

Specifications

%RH Range

10% to 90% RH at 77°F (25°C)

Temperature Range

60°F to 86°F (20°C to 30°C)

May be used with temperature controlled water

bath/circulator. Humidity limited by surface temperature

of internal walls and cover (dew point in chamber must

be less than interior surface temperature to avoid

condensation).

Response Time

10 minutes for 63% step change. 30 to 40 minutes to full

stability.

Accuracy

±1% RH from 10% to 70% RH and 1.5% RH from 70% to

90% RH

±0.3°F (0.15°C) dew point and 0.3°F (0.15°C) dry bulb at

77°F (25°C)

Analog Output

Two-user scalable 4 to 20 mA/0 to 5 VDC signals for

temperature, humidity and temperature

Power

115 or 230 VAC ±10%, 50/60 Hz. Single phase

Digital Interface

(2) RS232 ports. Reference and generator interface

Prostep Software

Windows®95/98 and above required. Supplied on

CD-ROM with operation manual (PDF), and HCON

Humidity Conversion Software

Approvals

CE approved

Certifications

Supplied certificate of NIST traceability and functional

test data

Display

(3) LEDs, 0.5 in (12.7 mm) high 7 segment. Displays of set

point (%RH), actual %RH and temperature. 0.1%

RH/°C/°F resolution

Workspace Dimensions

11 in x 9 in x 6.5 in (279.4 mm x 228.6 mm x 165.1 mm)

approximately 644 in3(10.6 liters)

Overall Dimensions

23 in long x 19 in wide x 13 in high

(548.2 mm x 482.6 mm x 330.2 mm)

Chamber Material

Stainless steel with aluminum I/O block

Water Jacket

Stainless steel. Water capacity 2.2 gallons (8.3 liters)

Mechanical I/Os

Fill port. 1/4 in (6.35 mm) OD tubing instant-on fittings for

water circulation (inlet and outlet), water drain (enables

water to be gravity drained) and dry air inlet

(compressed dry air to be regulated to <5 psi)

Weight

66 lbs (30 kg) dry weight

19 in

(482.6 mm)

23 in

(548.2 mm)

13 in

(330.2 mm)

GE

Sensing

g

Humilab

Specifications

©2004 GE. All rights reserved.

920-075B

All specifications are subject to change for product improvement without notice.

Humilab™ is a trademark of GE. Windows®is a registered trademark of Microsoft

Corporation, which is not affiliated with GE, in the U.S. and other countries. Lexan

®

is a registered trademark of GE Plastic. GE® is a registered trademark of General

Electric Co.

Electrical I/Os

Power_IEC receptacle. Sub-DB-15 for analog outputs.

Sub-DB-9 for RS232

Water Capacity Indicator

Liquid sight glass-color indicator

Desiccant

Indicating type. Bright blue when dry. Pink when

saturated. Chamber runs 24 hours at 50% RH and 77°F

(25°C) on a new charge of desiccant. Dry compressed

(-40°F/-40°C dew points or drier) extends desiccant life

indefinitely

Ordering Information

HUMILAB-115

115 VAC, 50 to 60 Hz

HUMILAB-230

230 VAC, 50 to 60 Hz

CAL-3

Prepaid three year annual calibration service. 20%

savings over standard recertification costs

Accessories

RTE

Temperature controlled refrigeration and heating bath

circulator

DES-CAR

Spare desiccant cartridge

B-DES

Bulk desiccant, 5 lb (2.27 kg)

HLAB-CVR

Spare Lexan®cover (may be drilled to accommodate

various probes)

www.gesensing.com

Loading...

Loading...