E4-1111H-GE

DEW POINT MONITOR

Operator’s Manual

The information in this manual is believed to be reliable.

However, General Eastern makes no warranty, expressed or implied, as to its accuracy and assumes no

liability arising out of its use by others. We reserve the

right to change this manual without prior notice.

Document No. A40232856/A00 ECO #5521

October 31, 2001 Printed in U.S.A.

Copyright

2001 General Eastern Instruments

The Humidity Experts

General Eastern Instruments

20 Commerce Way, Woburn, MA 01801-1057

Tel: (781) 938-7070 Fax: (781) 938-1071

Safety:

This manual as well as safety labels posted on the instrument use the

following safety alerts to draw your attention to special safety instructions

that should be followed.

CAUTION

CAUTION: Hazards or unsafe practices could result in electrical shock, minor

injury, or product damage.

WARNING

WARNING: Refer to accompanying document for additional information.

ALERT:

ALERT

Earth ground connection; removal could result in electrical shock,

minor injury, or product malfunction.

CONTENTS

CHAPTER 1 — INTRODUCTION

About General Eastern - - - - - - - - - - - - - - - - - - - - - - 1

Overview of the E4-1111H-GE - - - - - - - - - - - - - - - - - - 1

The humidity sensor - - - - - - - - - - - - - - - - - - - - - - - 3

Theory of operation - - - - - - - - - - - - - - - - - - - - - - - - 3

CHAPTER 2 — INSTALLATION

Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Input power - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Wiring the outputs - - - - - - - - - - - - - - - - - - - - - - - - 9

Sensor information - - - - - - - - - - - - - - - - - - - - - - - 12

Sensor replacement - - - - - - - - - - - - - - - - - - - - - - - 13

CHAPTER 3 — OPERATION

General information - - - - - - - - - - - - - - - - - - - - - - - 15

Control switches - - - - - - - - - - - - - - - - - - - - - - - - 15

RS-232C data outputs - - - - - - - - - - - - - - - - - - - - - - 17

Helpful hints for operating the unit - - - - - - - - - - - - - - - 17

The PACER Cycle - - - - - - - - - - - - - - - - - - - - - - - - 21

CHAPTER 4 — PROGRAMMING

General information - - - - - - - - - - - - - - - - - - - - - - - 23

RS-232C programming - - - - - - - - - - - - - - - - - - - - - 23

CHAPTER 5 — SERVICE

Minor maintenance of sensor optics - - - - - - - - - - - - - - - 31

Field replacement of sensor mirror - - - - - - - - - - - - - - - 32

Test and calibration - - - - - - - - - - - - - - - - - - - - - - - 35

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - 35

- - - - - - - - - - - - - - - - - - - - - - - 31

- - - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - - - 7

- - - - - - - - - - - - - - - - - - - - - 15

- - - - - - - - - - - - - - - - - - - 23

APPENDIX A — SPECIFICATIONS

APPENDIX B — WARRANTY AND RETURN PROCEDURE

- - - - - - - - - - - - - - - - - - 39

- - - - - - 41

APPENDIX C — HUMIDITY EQUATIONS AND CONVERSION CHART

APPENDIX D — CONFIGURING THE RS-232 INTERFACE

APPENDIX E — GLOSSARY

- - - - - - - - - - - - - - - - - - - - - 53

- - - - - - 49

45

FIGURES

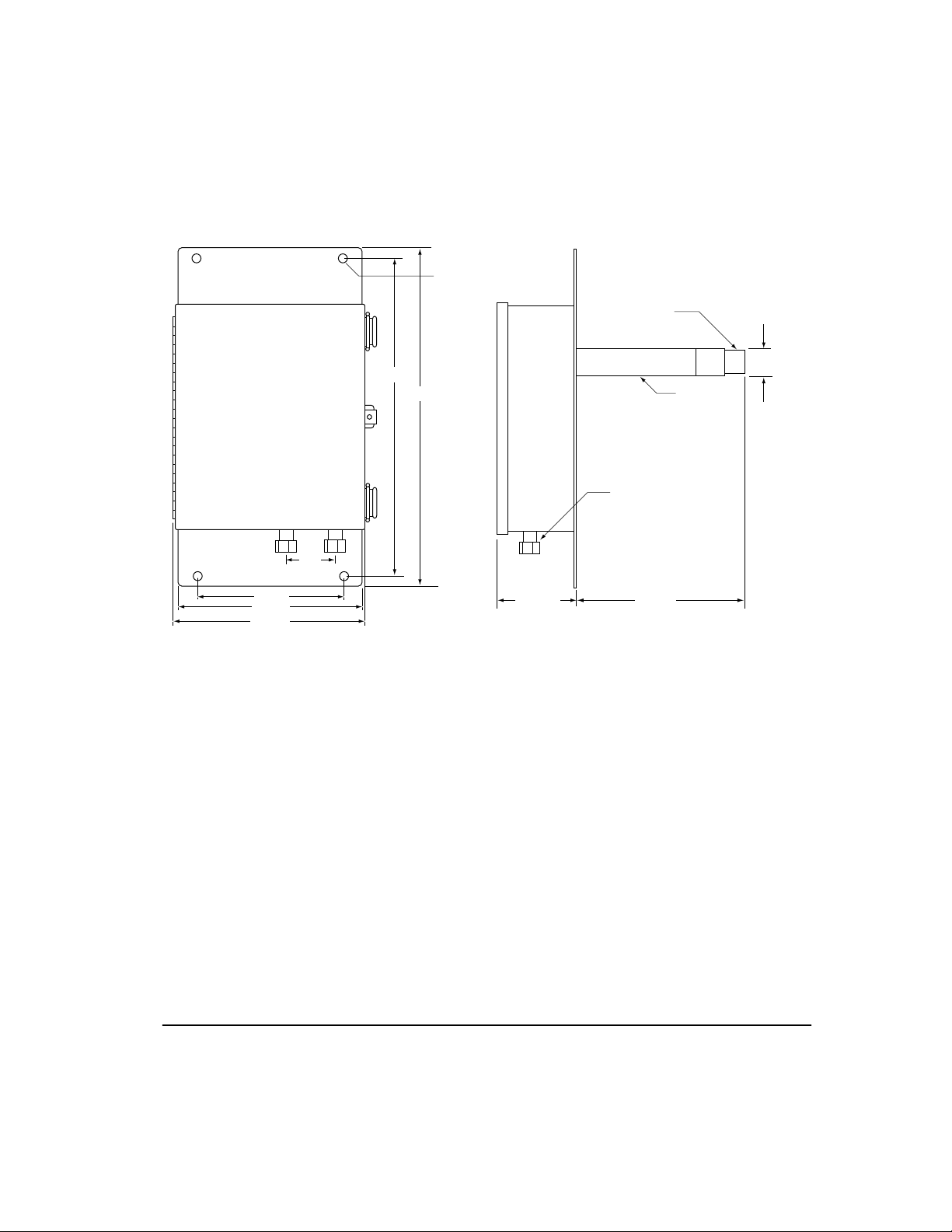

Figure 1 Dimensions

Figure 2 The chilled-mirror hygrometer

Figure 3 Front view

Figure 4 Side view

Figure 5 Rear view

Figure 6 PC Board

Figure 7 Wiring and sensor replacement

Figure 8 DIP Switches

Figure 9 The PACER cycle

Figure 10 Results of the PACER cycle

Figure 11 Scaling parameters

Figure 12 Balance adjustment screw locations

Figure 13 Using a Resistance Decade Box

- - - - - - - - - - - - - - - - - - - - - - - 3

- - - - - - - - - - - - - - 4

- - - - - - - - - - - - - - - - - - - - - - - 7

- - - - - - - - - - - - - - - - - - - - - - - - 8

- - - - - - - - - - - - - - - - - - - - - - - - 9

- - - - - - - - - - - - - - - - - - - - - - - 10

- - - - - - - - - - - - - 11

- - - - - - - - - - - - - - - - - - - - - 16

- - - - - - - - - - - - - - - - - - - 21

- - - - - - - - - - - - - - - 22

- - - - - - - - - - - - - - - - - - - 25

- - - - - - - - - - - - - 37

- - - - - - - - - - - 32

Chapter 1 — Introduction

About General Eastern

General Eastern is devoted solely to the design and manufacturing

of accurate, reliable and rugged humidity measuring equipment.

We specialize in providing solutions for applications where

humidity measurements are critical.

There are many ways to make humidity measurements, and no one

humidity sensor meets all requirements for all applications. Our

variety of sensor types — including chilled mirror, lithium chloride,

resistance polymer, and wet bulb — can precisely determine dew

point, parts per million by volume, percent relative humidity, and

other parameters.

In keeping with General Eastern’s philosophy of providing the best

solutions to humidity measurement problems, we offer the

following products and services:

• high quality state-of-the-art instrumentation to assure excellent performance

• a broad range of humidity instruments capable of covering virtually any humidity measurement application

• full applications assistance to help you choose the sensor that

is best for your needs

• full and superior service, should it ever be needed

If you have questions about a particular measurement problem, we

invite you to call and discuss your application with one of our engineers. Call 800-225-3208 (if you’re calling from Massachusetts or

outside the United States, call 781-938-7070). Our fax number is

781-938-1071.

Overview of the E4-1111H-GE

The General Eastern E4-1111H is a multi-purpose chilled-mirror

hygrometer, suitable for use in a variety of applications. The unit

measures dew/frost point from –25°C to +65°C (–13°F to +149°F).

Chapter 1 — Introduction

1

The E4-1111H is designed for wall or surface mounting. It is

housed in a gasketed NEMA-4 aluminum enclosure, suitable for

industrial environments.

A 4–20mA analog output is provided as well as an RS-232C

communications port.

A red indicator light shows when

indicator light shows that the unit’s

tion (see “The PACER Cycle” beginning on page 21).

The monitor utilizes advanced microprocessor control and includes

General Eastern’s patented Programmable Automatic Contaminant

Error Reduction (PACER) system to insure accuracy.

Detailed specifications are given in Appendix A, beginning on

page 39.

POWER

BALANCE

is applied and a green

function is in opera-

System

Components

Physical

description

The complete system is packaged with the following items:

• The electronic monitor with integrated dew point sensor and

filter

• Operator’s manual

• Certification that the unit is traceable to the National Institute

of Standards and Technology

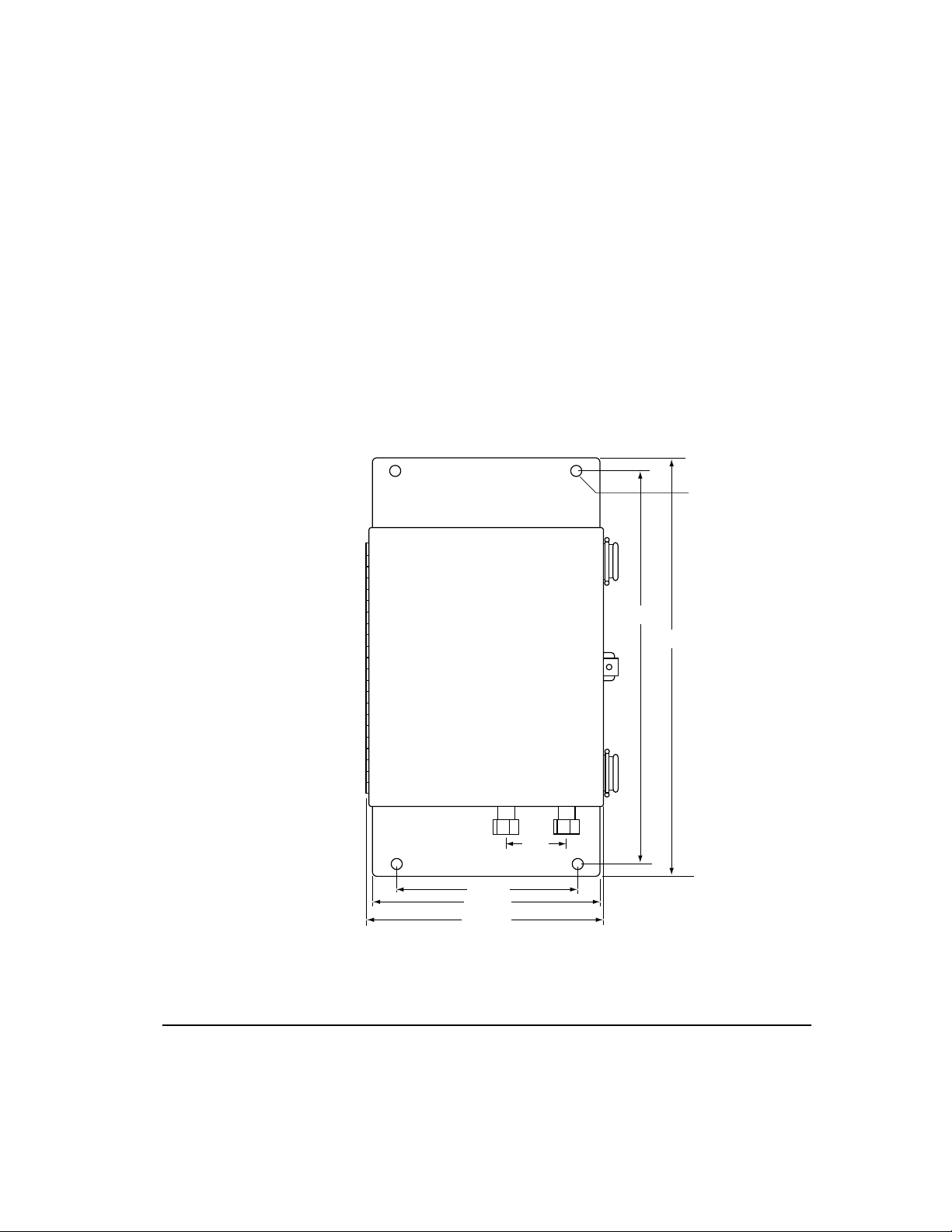

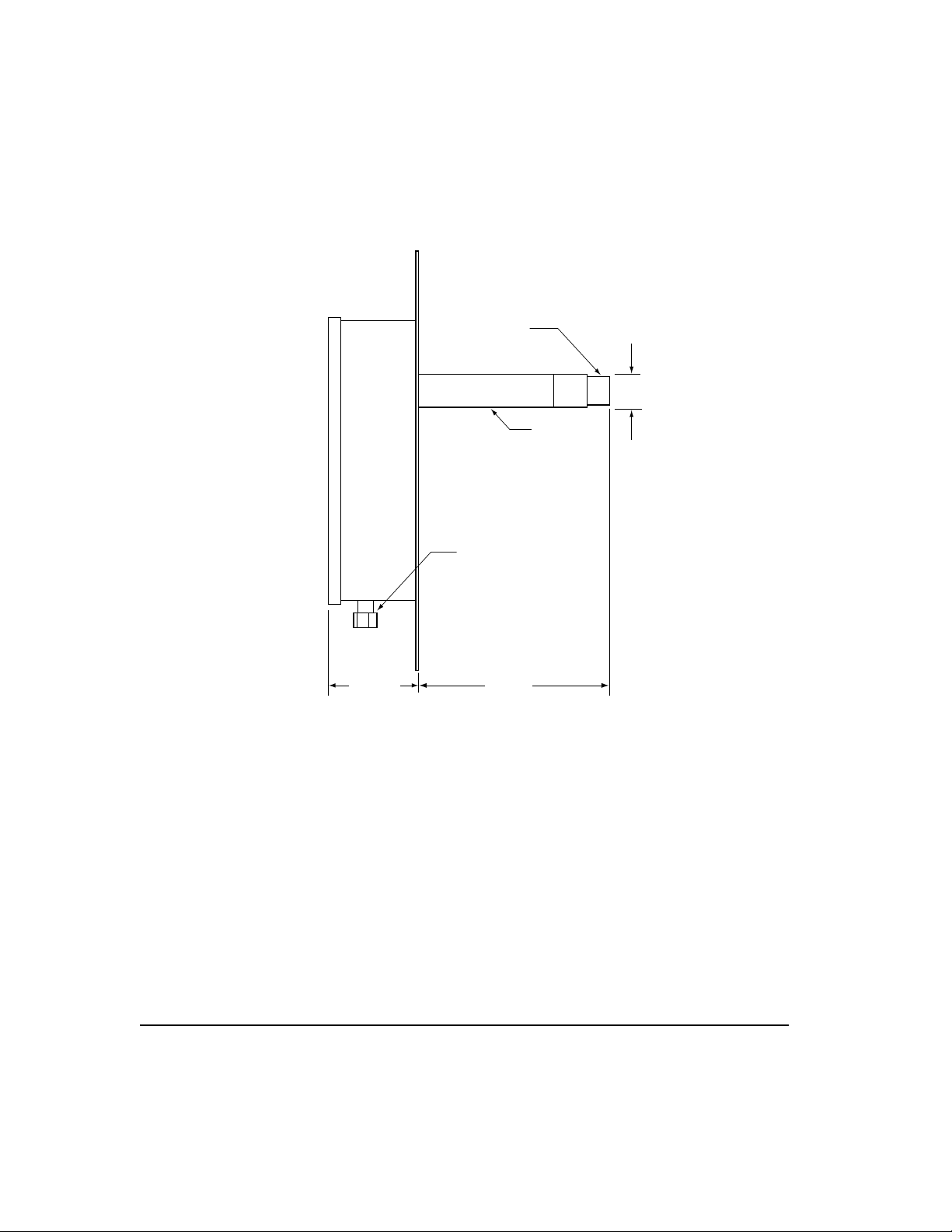

The E4-1111H is designed for surface mounting on a vertical wall

or panel. The unit’s dimensions are shown in Figure 1 in inches

(cm).

2

E4-1111H-GE Operator’s Manual

)

n

Ø 0.50 (12.7

4 plcs

3

Removable filter

17.36 (44.1)

2.75

(70)

8 (20.3)

10 (254)

10.5 (267)

The humidity sensor

The monitor is configured with a General Eastern 1111H

single-stage chilled-mirror dew point sensor. The sensor provides

data to the electronics unit that calculates humidity.

18.4 (468)

dimensions in

inches (mm)

4.25 (108)

Sensor Probe

1/2" Conduit fittings

Figure 1 — Dimensions

9.2 (237)

Figure 1 — Dimensions

1.5 (39)

dimensions i

inches (mm)

Theory of operation

What is Optical

Condensation

Hygrometry?

Chapter 1 — Introduction

Optical condensation hygrometry is a precise technique for determining the water vapor content in gases by directly measuring dew

point or frost temperatures. Using this technique, a metallic mirror

is cooled until it reaches a temperature at which a thin layer of

condensation begins to form on it. The dew layer is detected optically, and the mirror is held at that temperature. The mirror

temperature, measured with a platinum resistance thermometer, is

r

an accurate indicator of the dew or frost point. Because these

hygrometers are so accurate, they are widely used as a standard in

many of the world’s metrology laboratories.

How do General

Eastern

hygrometers

function?

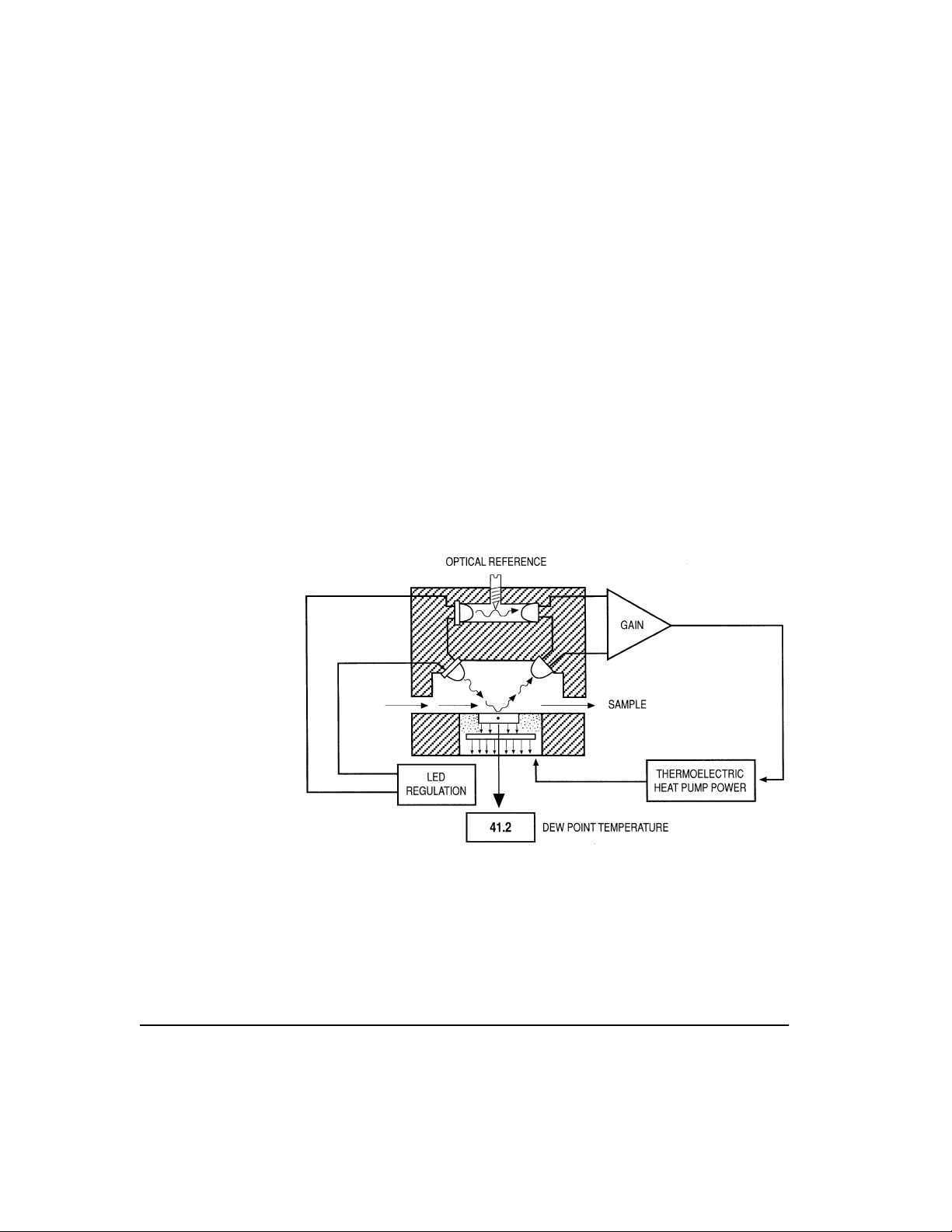

Figure 2 illustrates how General Eastern hygrometers detect and

measure dew point. The condensate mirror is illuminated with a

high-intensity, solid state, light emitting diode (LED). A photodetector monitors the LED light reflected from the mirror. The photodetector is fully illuminated when the mirror is clear of dew, and it

receives less light as dew forms. A separate LED and photodetector

pair are used as a known reference to compensate for any thermally

induced changes in the optical components. The photodetectors

are arranged in an electrical bridge circuit, the output current of

which is proportional to the light reflected from the mirror. The

bridge output controls the electrical current to the thermoelectric

cooler.

Figure 2 — The chilled-mirror hygromete

A large bridge current develops when the mirror is dry, causing the

mirror to cool toward the dew point. As dew begins to form on the

mirror, less light is reflected, and the bridge output decreases. This,

in turn, causes a decrease in cooling current. A rate feedback loop

4

E4-1111H-GE Operator’s Manual

5

within the amplifier ensures critical response, causing the mirror to

stabilize quickly at a temperature that maintains a thin dew or frost

layer on the mirror surface. A precision thermometer element

embedded within the mirror directly monitors this dew point

temperature.

Using General

Eastern

Hygrometers as a

standard for

calibration

An optical condensation hygrometer such as the E4-1111H can be

sent to the National Institute of Standards and Technology (NIST)

in Gaithersburg, Maryland for calibration against the NIST standard. A calibrated instrument can then be used as a transfer standard in local laboratories to calibrate lower echelon instruments.

Hygrometers used as calibration standards must have the following

characteristics:

• The mirror thermometer must have suitable long-term accuracy (such as that obtained with a platinum resistance thermometer).

• A means must be provided for viewing the dew or frost formation on the mirror.

Chapter 1 — Introduction

6

E4-1111H-GE Operator’s Manual

Mounting

)

Chapter 2 — Installation

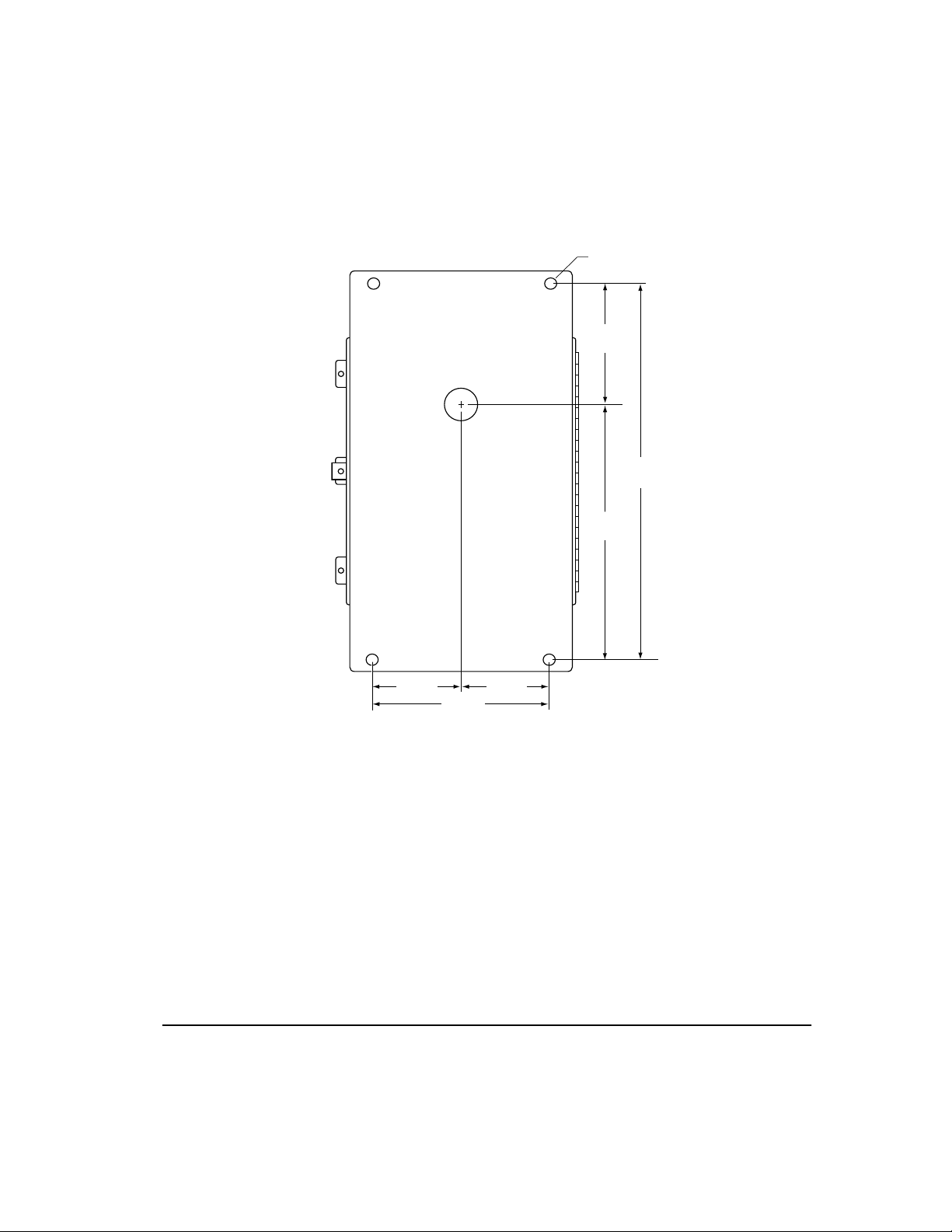

Mount the E4-1111H on a vertical surface using the four mounting

holes at the corners of the unit. Provide adequate space below the

unit for cabling, and to the left of the unit to allow the door to open

fully. The sensor module protrudes from the rear of the unit into

the measurement space. Mounting dimensions are shown in

Figures 3, 4 and 5.

Ø 0.50 (12.7

4 plcs

17.36 (44.1)

18.4 (468)

dimensions in

inches (mm)

Figure 3 — Front view

8 (20.3)

10 (254)

10.5 (267)

2.75

(70)

Chapter 2 — Installation

7

n

Removable filter

Sensor Probe

1.5 (39)

Input power

1/2" Conduit fittings

dimensions i

inches (mm)

4.25 (108)

9.2 (237)

Figure 4 — Side view

The E4-1111H is available in versions wired for 115, 230, and 100

VAC. The 230 VAC version is double-fused.

The unit’s voltage and frequency rating and tolerances, as well as

fusing data, are listed inside the unit.

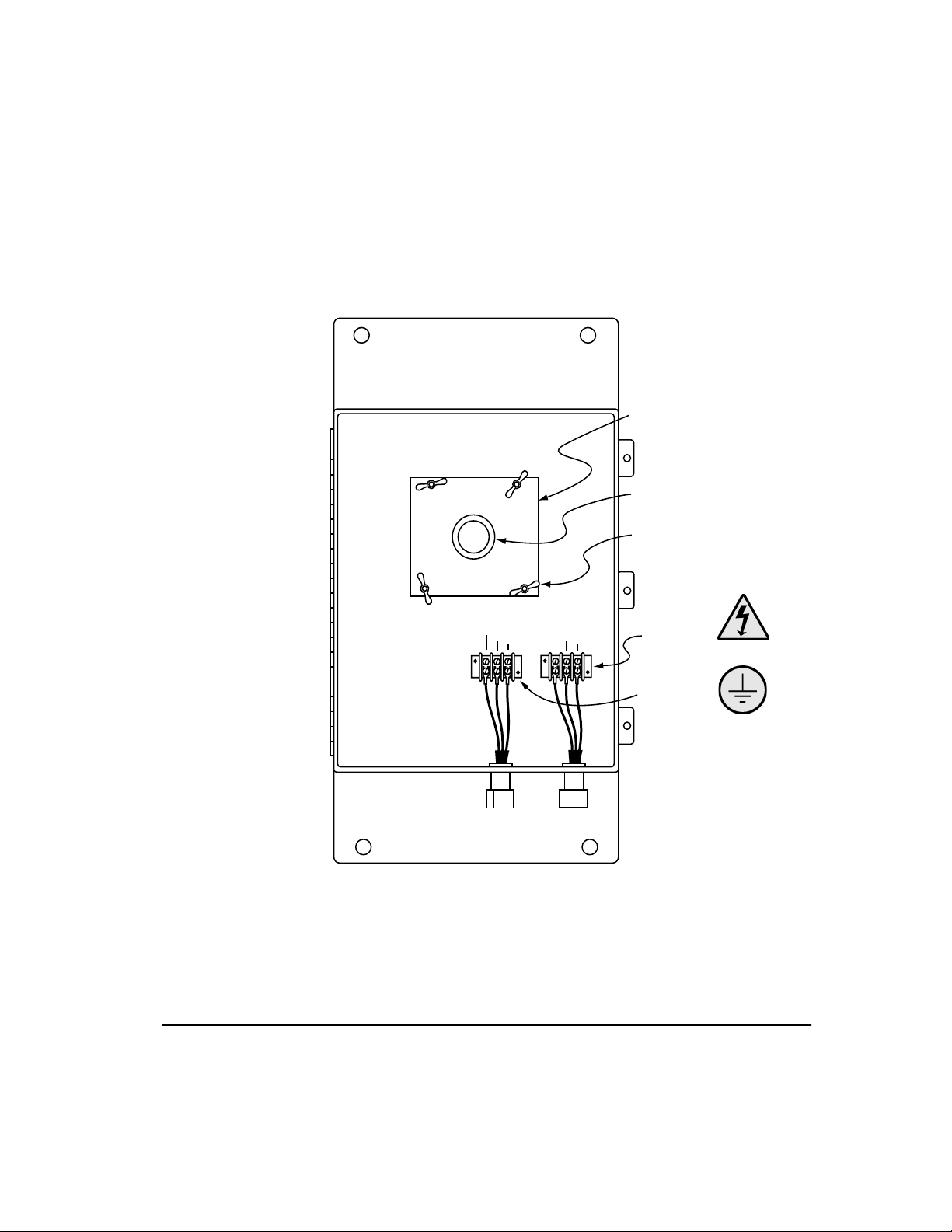

Input power wiring enters through the bottom edge of the unit and

connects to the right-hand terminal block as shown in Figure 7.

8

E4-1111H-GE Operator’s Manual

n

Ø

0.50 (12.7)

4 plcs

5.63

(143)

I+

Wiring the outputs

The E4-1111H’s output terminals are located inside the unit’s front

door. Cabling is brought in through the bottom edge of the unit

and connected to terminal blocks as shown in Figure 7.

Analog humidity

output

The humidity output provides a 4–20mA analog signal (500 Ohms

maximum load). Connect to the terminals labelled

the left-hand terminal block.

4 (10.15)

8 (20.3)

4 (10.15)

11.73

(298)

17.36

(441)

dimensions i

inches (mm)

Figure 5 — Rear view

and

RTN

on

Chapter 2 — Installation

9

d

The humidity units and scaling may be set using the RS-232C port.

See “Chapter 4 — Programming” beginning on page 23 for details.

.

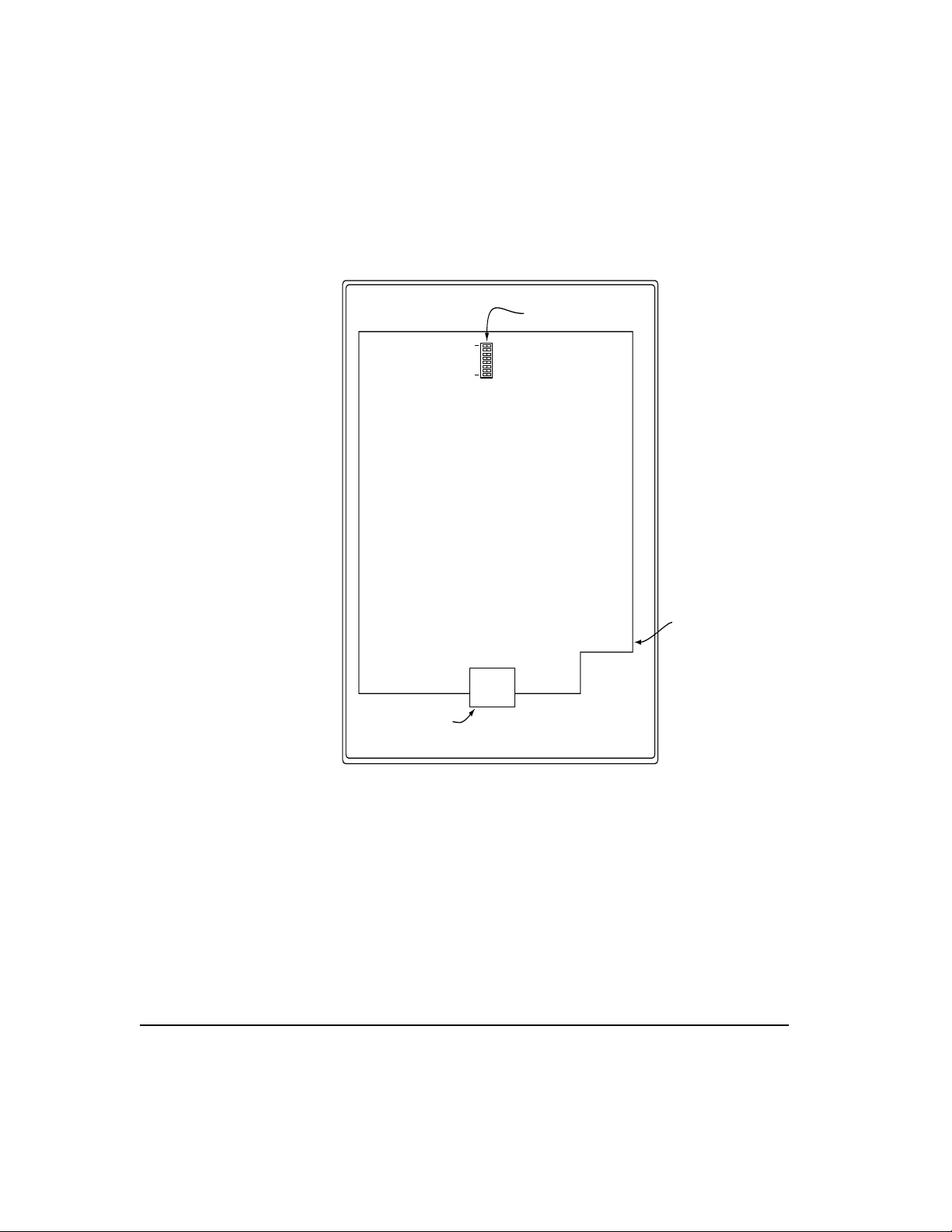

DIP switches

RS-232 Connector

Switch 1

Right Side (closed)Left Side (open)

Switch 8

PC Boar

Figure 6 — PC Board

Service output

10

The

SRVC

output provides a TTL-compatible signal that indicates

that the mirror needs cleaning (see page 31).

Connect to the terminals labelled

SRVC

and

Figure 7.

E4-1111H-GE Operator’s Manual

RTN

as shown in

RS-232C

connector

The RS-232C connector is located at the bottom edge of the PC

board (see Figure 6). It provides RS-232C digital communications

between the unit and an RS-232C terminal or a PC running in

terminal emulation mode.

Sensor mounting

plate

Sensor cable

connection

Wing nuts (4 plcs)

SRVC

RTN

L (line)

I+

Ground

N (neutral)

AC power

Chapter 2 — Installation

Outputs

Figure 7 — Wiring and sensor replacement

The connector is a standard 25-pin D connector. For connection to

another RS-232C device, the cable is wired as shown below. Pin

connections are given for both 25-pin and 9-pin devices.

11

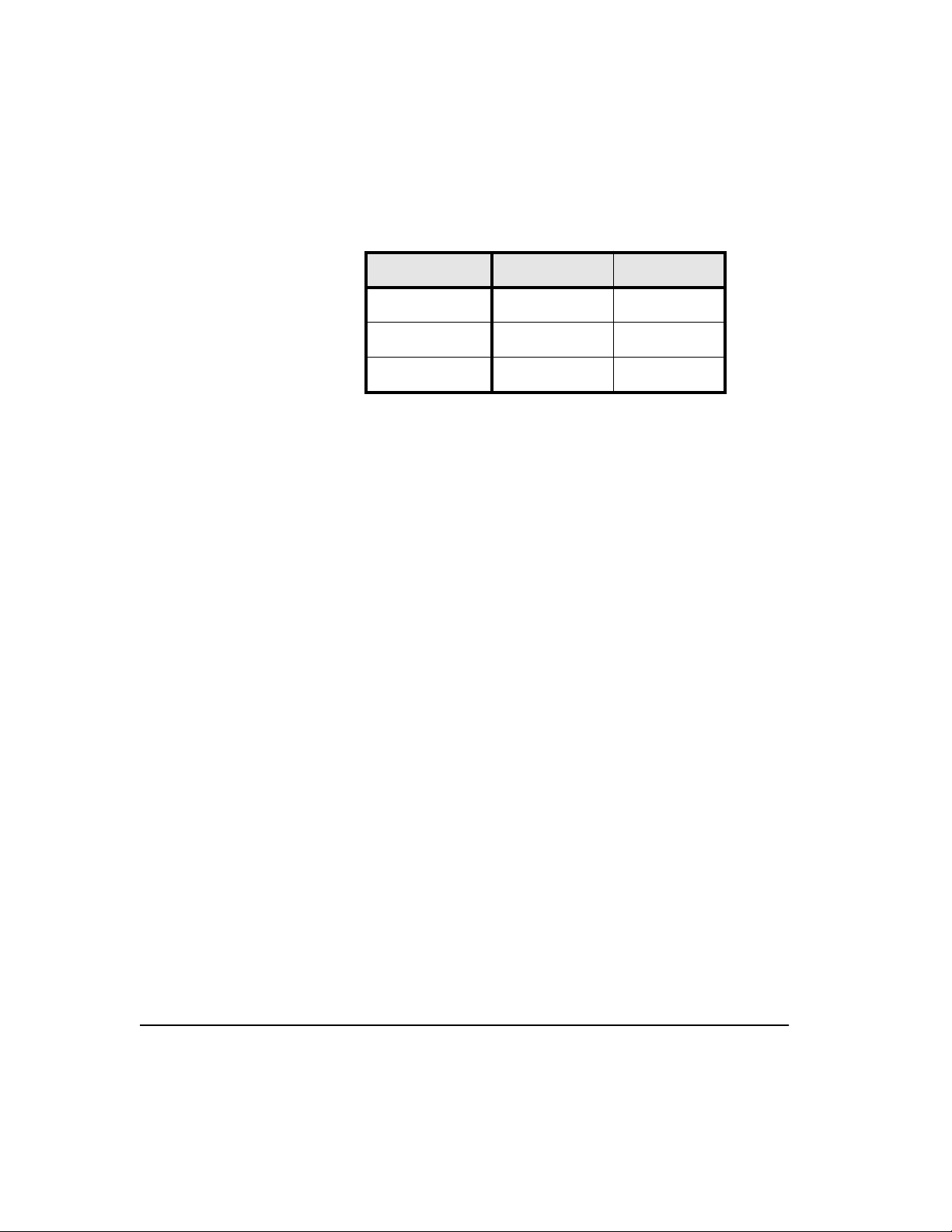

E4-1111H

25-pin device 9-pin device

232

323

775

The baud rate of the data is 1200. The format of the data is 8 data

bits, 1 stop bit, and no parity.

The unit can communicate with a handheld RS-232C terminal or a

personal computer running in terminal emulation mode. See

Appendix D for a BASIC computer program that can be used for

simple RS-232C communications between the unit and your PC.

Handshaking.

to

NO HANDSHAKE

In order to enable handshaking, the RS-232C menu must be

accessed through the RS-232C port. See “Handshake control” on

page 28 for details. To implement handshake control using

Clear-To-Send and Ready-To-Send, use pins 4 and 5. Applying 8

volts (

transmit.

3) to Pin 5 of the RS-232C connector allows the unit to

±

The default handshaking protocol for the unit is set

.

Sensor information

Filter

Requirements

Flow Rate

12

The E4-1111H is equipped with a submicron Teflon filter to avoid

particulate contamination and to protect the sensor from the presence of liquid water. In many applications, the filter requires periodic inspection and replacement. Typical applications might

require replacement twice a year.

It is important to have adequate flow through the sensor. Too little

flow can slow the response (particularly at very low frost points).

E4-1111H-GE Operator’s Manual

Too much flow can cause instability of the control system at high

dew points and can reduce the depression capability of the cooling

pump at very low dew points. Too much flow also accelerates the

rate of system contamination. A flow rate of 2 to 2.5 ft

over 1 liter/min) is ideal for most applications. In many cases, flow

rates between 0.2 and 5 ft

Sensor replacement

If it necessary to remove the sensor module, follow the steps below:

1. Disconnect the line power from the unit.

2. Open the front door.

3. Unplug the sensor cable from the end of the sensor probe as

shown in Figure 7.

4. Unscrew the four wing nuts shown in Figure 7.

5. Carefully remove the sensor module.

3

/h (a little

3

/h (0.1 and 2.5 liter/min) may be used.

13

Chapter 2 — Installation

14

E4-1111H-GE Operator’s Manual

Chapter 3 — Operation

General information

Operating instructions fall into three categories:

• normal operation

• setup and programming

• system maintenance

Normal operation of the unit’s controls is described in the next

section.

Setup and programming involves customizing the unit for specialized applications, and is not required for many conventional applications. The unit is shipped properly programmed to meet the

customer’s requirements (see Appendix A). Complete programming

instructions are given in Chapter 4, beginning on page 23.

Maintenance involves manually testing the unit’s cooling capacity,

clearing the mirror, and other operations that might be required on

a regular basis, or when a problem is suspected, depending on the

application.

An RS-232C-compatible device, such as a laptop computer, can be

connected to the unit to perform programming and configuration

functions. The RS-232C port can also be used to send data

measured by the unit to an external computer or other device.

Control switches

Control switches are located at the top edge of the PC board,

within the red switch module containing eight DIP switches.

Switches are number from 1 to 8, with Switch 1 at the top and

Switch 8 at the bottom as shown in Figure 8.

Chapter 3 — Operation 15

)

s

Switch 1

Switch 2

Switch 3

Left Side

(contacts open)

Switch 4

Switch 5

Switch 6

Switch 7

Switch 8

Right Side

(contacts closed

Figure 8 — DIP Switche

All switches are normally set to the open position, with the

left-hand side depressed. Press the right hand side to activate a

function as described below. (Switches 5–8 are not used).

Switch Function Left side pressed Right side pressed

1 Mirror cooling Normal Cool the mirror.

2 Mirror heating Normal Heat the mirror.

3 Initiate PACER

cycle

4 Automatic

Normal Initiate one PACER

cycle.

Normal Periodic PACER cycles.

PACER cycles

The PACER cycle for automatically cleaning the sensor mirror is

described in “The PACER Cycle” beginning on page 21.

To initiate a single PACER cycle, press Switch 3 to the right and

then return it to the normal position.

To cause automatic PACER cycles at a programmable periodic rate,

set Switch 4 to the right. See “Setting the balance interval.” beginning

on page 26 for programming the rate.

16 E4-1111H-GE Operator’s Manual

RS-232C data outputs

See “RS-232C connector” on page 11 for details on hardware,

cabling and protocols for establishing RS-232 communications with

the monitor. RS-232 communications can be divided into two

sections: Operate Mode and Programming Mode.

Operate Mode

While the unit is in Operate Mode, the RS-232C port can provide

any data that is available. The data available for this model is as

follows:

DP C=xxxx

DP F=xxxx

The data output by the unit can be modified in two ways:

• the user can customize the data output to a subset of the

above (See “RS-232C programming” on page 23.)

• the user can enter commands via the RS-232C port to obtain

immediate output of a single parameter (See “Outputting data

‘on command’” on page 28.)

Programming is described in “Chapter 4 — Programming” beginning

on page 23.

Helpful hints for operating the unit

Time response

At dew points above 0°C, the system stabilizes within a few seconds

at a consistent dew or frost layer. Once the system is stable valid

readings may be taken.

When the system is operating at very low frost points (below

–40°C), extra care may be required when interpreting readings

because of the slower response of the system. Time response

depends on a number of factors including dew/frost point, slew

rate, upstream filtering, and flow rate.

• As the dew/frost point becomes lower, water molecules in the

air sample become scarcer, and it takes longer to condense a

frost layer on the mirror sufficiently thick to establish an equilibrium condition.

Chapter 3 — Operation 17

• Temperature slew rate is dependent on dew point and depression (the temperature difference between the mirror and the

sensor body); at higher dew points and moderate depressions,

it is typically 1.5°C/second. At lower dew points and/or larger

depressions, slew rate becomes progressively slower.

• Flow rate affects response by determining the rate at which

water vapor is supplied or carried off.

There is, of course, a trade-off between response time, control

system stability, and sensitivity to contamination.

Supercooled dew

points

Contamination

Slightly below the freezing point, water can exist in a supercooled

liquid state for extended periods of time. Extra care may be needed

when making measurements in the frost point region of 0 to –20°C,

because the mirror temperature may temporarily stabilize at the

supercooled dew point, 0.5 to 1°C below the actual frost point.

To assure that the unit is operating in the ice phase within this

temperature range, allow the instrument to operate continuously.

Before manually clearing a frost layer, take a reading, and afterwards allow sufficient time to reform a stable frost layer before

taking further readings.

Mirror Cleanliness. Proper operation of a condensation hygrometer

depends on the condition of the mirror surface. In general, accuracy

is reduced when contaminants accumulate on the mirror.

However, the mirror does not have to be microscopically clean. In

fact, the mirror performs best a few hours after cleaning, when

nucleation sites have formed. On an unscratched, freshly cleaned

mirror, there are relatively few nucleation sites on which dew or

frost deposits can form, and more time is required to collect a

condensation layer at low frost points. Also, overshoot may occur,

which can cause oscillations as the temperature stabilizes.

Particulate contaminants.

water may accumulate on the mirror surface, but does not affect

the instrument accuracy until the mirror reflectance is reduced

substantially. In many cases, particulates improve instrument

response by providing condensation sites.

Particulate matter that is insoluble in

18 E4-1111H-GE Operator’s Manual

Water-soluble contaminants.

Contaminants which readily

dissolve in water, such as naturally occurring salts, are detrimental

to accurate vapor concentration measurement by any condensation method. These materials readily go into solution with the

water condensate on the mirror surface, and then reduce the vapor

pressure in accordance with Raoult’s Law. As the concentration

increases with time, the saturation vapor pressure of the liquid

solution decreases.

The unit responds to this lower vapor pressure by elevating the

mirror temperature in order to maintain a vapor pressure that is in

equilibrium with the partial pressure of atmospheric water vapor.

The measured dew point, therefore, drifts upward above the true

dew point. Because the measurement error increases gradually, it

often goes undetected.

To determine whether dissolved contaminants are affecting dew

point measurement, perform the following steps:

1. Note the indicated dew point

2. Clean the mirror

3. Balance the detector by initiating a PACER cycle

4. Measure the dew point again

If the new reading is lower than the first reading, it is likely that

soluble material was present in sufficient quantity to cause a

measurement error.

Gaseous contaminants.

When a gaseous material that has a higher

condensation temperature than that of water is present (even in

very low concentrations), the unit will eventually control on that

material, rather than on water. The system then displays the

condensation temperature of the contaminant, not of water. Such

material accumulates on the mirror only when chilled. In the

normal atmosphere, gaseous contaminants do not have a detectable effect.

Minimizing the effects of contaminants.

1. Use the PACER feature to reduce the effect of contaminants on

the unit’s performance.

2. Reduce the gas flow rate to reduce the rate of accumulation of

contaminants on the mirror.

Chapter 3 — Operation 19

3. Clean the mirror according to the recommended optics clean-

ing procedure. See “Cleaning the sensor mirror” on page 31. To

determine the proper cleaning interval for a given set of conditions, take a dew point reading before and after the cleaning.

Any appreciable shift indicates that under these conditions,

the mirror should be cleaned more often.

Mirror Flooding

Sample line

maintenance

Pressure effects

If there is an abrupt transition from dry to moist conditions (particularly when accompanied by a transition from cold to warm

temperatures), the mirror may accumulate an overload of moisture.

It then may take several minutes before the sensor dries out and

valid readings can be obtained. The drying process can be accelerated by setting DIP Switch 2 to

sensor.

Contaminated sample lines slow the unit’s response time and can

cause erroneous readings, usually on the high side. Clean the

sample lines as often as necessary. To determine the required

cleaning frequency, take dew point readings before and after

cleaning the lines, sensor cavity, and mirror. If the two readings

differ appreciably, the sampling lines should be cleaned more often.

To reduce the rate of contamination, reduce flow and/or install a

filter upstream.

If the pressure of the gas is increased or reduced from atmospheric

pressure, but the mixing ratio (moisture content) stays constant,

the dew point is correspondingly increased or decreased. The

monitor displays the dew/frost point at the pressure to which the

sensor chamber is exposed. The sensor location and hookup

arrangement can influence the pressure. The dew point change due

to pressure change can be calculated by using Dalton’s Law and the

Smithsonian Tables or a proper nomograph. Appendix C contains

basic data for these calculations. Request a copy of General

Eastern’s Humidity Handbook for additional detailed information.

HEAT, to temporarily heat the

20 E4-1111H-GE Operator’s Manual

The PACER Cycle

General Eastern has developed and patented a compensation technique called PACER (Programmable Automatic Contaminant Error

Reduction) that is very effective in reducing the Raoult Effect error

associated with soluble contaminants, particularly for near-ambient

dew points. The PACER cycle replaces the AUTO balance cycle

available on earlier General Eastern products.

Figure 9 — The PACER cycle

The PACER cycle, diagrammed in Figure 9, begins with a coalescence period, during which the mirror is cooled well below the dew

point of the sample gas, condensing out a large amount of water.

This excess water easily dissolves any water-soluble contaminants.

The mirror is then heated. During the heating phase, the large

puddles of water gradually evaporate, carrying increasingly heavy

concentrations of salt as the puddles become smaller. Finally, when

all the puddles have evaporated, dry “islands” of crystallized salt

are left on the mirror. The area between the islands (80-85% of the

mirror surface) is now clean and shiny, whereas before the PACER

cycle it may have been completely covered. The total amount of

contamination has not been reduced, but instead redistributed as

Chapter 3 — Operation 21

shown in Figure 10, with more clean mirror surface available for

dew formation.

Before

Pacer Cycle

After

Pacer Cycle

Figure 10 — Results of the PACER cycle

22 E4-1111H-GE Operator’s Manual

Chapter 4 — Programming

General information

The E4-1111H-GE is programmed at the factory to display and

output the data required for most applications. In many cases, no

further programming is required.

Programming allows control of two major items:

• the analog outputs

• the digital (RS-232C) outputs

Programming is most easily accomplished using a computer or data

terminal connected to the RS-232C data port.

Note that commands issued to the unit through the RS-232C port

would usually come from a manually operated computer or terminal

as described below. For specialized automated operation, commands

could also be issued autonomously by a properly programmed computer.

RS-232C programming

Programming of the unit using the RS-232C channel is accomplished by a series of menus described in this section. The menus

can be accessed by a computer or data terminal connected to the

unit’s RS-232C data port. The Data Terminal Emulator included in

Windows software provides a very convenient means of controlling

the unit.

The programming menus are not available while BALANCE mode is

active. (Switch 3 in closed position)

When programming menus are active, the sensor cooling is deactivated and the sensor mirror is allowed to rise to ambient temperature.

Chapter 4 — Programming 23

Main menu

(software

version 2.0)

The main menu is the starting point for all programming functions.

To access the main menu from normal operating mode, press ESC

(hex 1B) twice on your terminal. To return to the main menu from

any sub-menu, press E on your terminal one or more times until

the main menu is displayed. The main menu will contain some or

all of the following choices, depending on the model:

1) Scale Outputs 2) Set Balance Type 3) Set RS-232 Units

4) Display Option 5) Set Averaging 6) Calibrate Output1

E) Exit

Press the digit or letter corresponding to the item you wish to

program.

When finished, press E from the main menu to return to OPERATE

mode. Note that several seconds may be required for the system to

respond and provide data on the RS-232 terminal or the main

display.

Each menu item is described in detail in the sections following.

Function 1:

Scale outputs

From the main menu, press 1 to assign and scale the analog

outputs. The current output selection(s) and scaling are displayed,

followed by the Scale Outputs menu:

OUTPUT1:

DP C:

HIGH = 75 LOW = -45

1) OUTPUT1 E) EXIT

Scaling Output1. Press 1 to access the Output1 menu, which

controls the Humidity output. The text OUTPUT1: is displayed,

followed by the menu listed below:

OUTPUT1:

0) DPC 1) DPF E) EXIT

24 E4-1111H-GE Operator’s Manual

Select a humidity parameter to be output, or press E to exit and

return to the previous menu. If you select a parameter, the unit will

also ask for the analog output scaling values (full-scale high and

low values for the analog outputs).

HIGH =

Enter the value that should cause full-scale output (20mA), and

press RETURN.

LOW =

Enter the value that should cause 4mA output, and press RETURN.

The unit will again display the newly entered values and the Scale

Outputs

menu. Check the values, and press E to exit back to the

main menu. When the unit returns to operating mode, the analog

output voltage will vary with the measured humidity as shown in

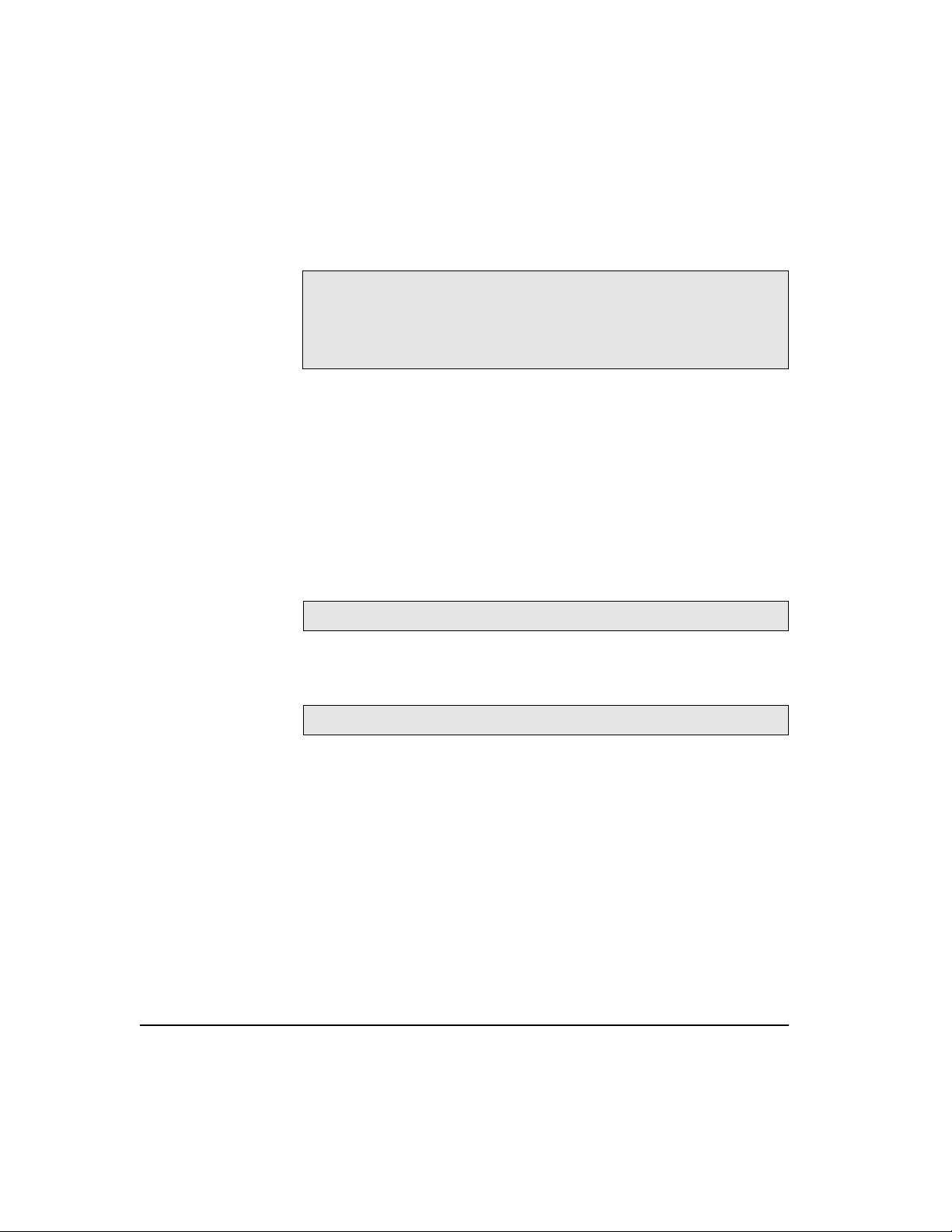

Figure 11.

Analog

output

20mA

4mA

Humidity

Low High

Figure 11 — Scaling parameters

Function 2:

Set balance type

Chapter 4 — Programming 25

From the main menu, press 2 to change the type of balance used,

to adjust the balance interval, or to remotely initiate a balance

cycle. The current balance state is displayed, followed by the

Balance Type menu.

BALANCE TYPE = Pacer

DAY = 0

HOUR = 12

1) Pacer Bal 2) Auto Bal 3) Set Interval

4) Initiate Balance E) Exit

Selecting the balance type. Press 1 to set the type of balance to

PACER (the default) or 2 to set the type of balance to AUTO.

Note: In the E4-1111H, only the PACER cycle type is available, even

though the older AUTO cycle can be selected. Do not use the AUTO

setting. See “The PACER Cycle” on page 21.

Setting the balance interval. To set the balance interval, press 3.

The balance interval is specified in days and hours, and the interval

will be the sum of the days and the hours entered. The following

will appear:

DAY =

Type a value for the number of complete days between balance

cycles and press RETURN. The following will appear:

HOUR =

Type a value from 1 to 24 for the number of hours between

balance cycles, and press RETURN.

The new interval will be displayed, and the unit will return to the

Balance Type menu.

26 E4-1111H-GE Operator’s Manual

Examples:

Day = 0 Balance every 12 hours

Hour = 12

Function 3:

Set RS-232 Units

Day = 1

Hour = 0

Day = 5

Hour = 12

Balance every 24 hours

Balance every 5½ days

Initiating a single balance cycle. Press 4 to manually initiate a

balance cycle. The unit will return to normal operating mode at the

completion of the cycle.

Press E to return to the main menu.

From the main menu, press 3 to customize the RS-232C data

output. This menu selects the units to be output and the handshaking status. The currently selected units and handshaking

status are displayed, followed by the Set RS-232 Units menu.

Selected Units = 1,2

Handshake = Disabled

1) Data 2) Handshake (Toggle) 3) Exit

Selecting output data. Press 1 to configure the RS-232C data

output units. The following menu is displayed:

1) Select Units 2) User Prompt E) Exit

Press 1 to select the parameters to be displayed. The following

menu is displayed:

1) DPC 2) DPF 3) None E) Exit

Press numbers individually to add the designated parameter to the

RS-232C data output. Press the digit for “None” to turn off all data

outputs, or to clear the list before adding parameters.

Chapter 4 — Programming 27

Outputting data ‘on command’. A feature of the E4-1111H allows

the unit to output data only when commanded or “prompted” by

the user or by an external device. When a command code is

received by the unit while operating in this mode, the data associated with that code will be output.

To configure the unit to output data on command, press 2 from the

above menu to select User Prompt. The current user-prompt

status is displayed, and a sub-menu allows the status to be

changed.

Status = Disabled

ALLOW USER TO PROMPT FOR DATA

1) Enable 2) Disable E) Exit

Press 1 to enable the user prompt for data. Press E twice to return

to OPERATE Mode. To return to normal operation, access the above

menu and press 2 to disable this function.

While the unit is set to output data ‘on command,’ data will be

output only when requested by the user prompt.

To output dew point in °C, enter the prompt “D1”.

Handshake control. From the Set RS-232C units menu, press 2

to change the handshake protocol. The default is “no handshake.”

The unit will ask for a password before allowing the handshaking

protocol to be changed.

Enter Access Code:

Type the code word “ACCESS”. The status will be changed and the

new status will be displayed. Press E to return to the main menu.

Function 5:

Set Averaging

28 E4-1111H-GE Operator’s Manual

From the main menu, press 5 to set the data averaging parameter.

This number determines how many dew point readings are averaged to determine the reading that is output. The number may

range between 1 and 20. The factory default is 20. The current

value is displayed, followed by a menu:

Number of Points = 20

1) Set Average E) Exit

Press 1 to change the number of points to be averaged. The current

averaging value is displayed:

VALUE =

Type a value between 1 and 20 and press RETURN. The new value

is displayed. Press E to Exit.

Function 6:

Calibrate

Output1

To calibrate the unit’s Output1 (humidity), the following equipment

is required:

•4½-digit voltmeter

• 0.01%, 100-Ohm precision resistor

CAUTION

Please consult the factory before attempting to calibrate

the outputs of the unit. All analog outputs are factory

calibrated and normally do not require calibration or

field adjustment.

From the main menu, press 6 to calibrate the HUMIDITY output.

The analog outputs are calibrated at the factory and normally

never require recalibration. To protect against inadvertent calibration, this function is protected by a password. The following is

displayed, allowing the password to be entered:

Enter Access Code:

Chapter 4 — Programming 29

Type the code “ACCESS”. The Calibrate Output1 menu is

displayed:

1) Calib Output 2) Check Output E) Exit

Calibrating the current output. Disconnect all devices from the

unit’s humidity output. Connect the 100-Ohm precision resistor

across I+ and RTN terminals. Connect the voltmeter across the

resistor leads. Set the voltmeter to 4 volts full scale.

From the above menu, press 1 to calibrate the humidity current

output. The unit passes a current through the resistor, generating a

voltage measured by the voltmeter. Multiply this voltage by 10 to

convert it to milliamps of current in the resistor, and enter the

result:

VALUE =

For example, if the voltmeter reads 1.6421 volts, type 16.421 and

press RETURN.

The unit passes a new current through the resistor, and asks for a

new reading to be entered. Type the new voltage (times 10) and

press RETURN. The unit recalibrates its HUMIDITY output and

returns to the Calibrate Output1 menu.

30 E4-1111H-GE Operator’s Manual

Chapter 5 — Service

Minor maintenance of sensor optics

Periodically inspect and maintain the sensor optics as described in

the following paragraphs.

Cleaning the

sensor mirror

Balancing the

sensor optics

Under normal conditions, the system is self-checking and

self-balancing. However, there are occasions when particulate

matter and water-soluble contaminants reduce sensor mirror

reflectance and system accuracy. See “Contamination” on page 18.

When necessary, clean the sensor mirror, following the procedure

below.

1. Deactivate the sensor cooler, by placing DIP Switch 2 to HEAT

(press the right-hand side).

2. Open the sensor by removing the sensor filter.

3. Moisten a cotton swab with a cleaning solution suitable for

mirrors, such as the blue cleaning solution in the General Eastern maintenance kit, or dilute methanol or alcohol. Clean the

mirror with a few light wipes. If the sensor has been exposed

to significant contamination, clean the other optical surfaces

in the sensor and the sensor cavity itself.

4. Replace the sensor filter.

5. Return switches to normal.

6. Initiate a PACER cycle by closing Switch 3 and then returning

it to the open position

If the service “SRVC” TTL output reappears after a PACER cycle

(even after performing the mirror cleaning procedure above) check

the sensor balance adjustment. Improper adjustment of the optical

balance is the most common cause of instrument malfunction. In

addition, new systems may require an optical balance adjustment

after one or two months of operation. Always clean the mirror as

described above before performing an optical balance.

Chapter 5 — Service 31

1. Clean the mirror as described in “Cleaning the sensor mirror”

on page 31, if you have not already done so.

2. Set DIP Switch 2 to HEAT (right-hand position) and wait one

minute for any condensation to evaporate.

Be sure to cover the optical cavity with your hand to prevent

ambient light from affecting the sensor balance.

3. Observe the green BALANCE LED at the bottom of the unit. If

the LED is illuminated, the sensor is properly balanced. If not,

balance the sensor using the following steps.

4. Turn the balance screw on the sensor COUNTERCLOCKWISE

until the BALANCE light goes out. The location of the balance

adjustment screw is shown in Figure 12.

5. Slowly turn the balance screw CLOCKWISE until the BALANCE

light just comes on.

6. Replace the sensor filter and verify that the BALANCE LED

remains illuminated.

7. Return DIP Switch 2 to the normal (left) position to stop heating the mirror.

8. Initiate a PACER cycle by switching DIP Switch 3 to the right,

and then returning it to the left.

Sensor balance

adjustment screw

(shown with filter

removed)

Figure 12 — Balance adjustment screw locations

At the completion of the PACER cycle, the system is properly

balanced. For more information on the PACER cycle, see “The

PACER Cycle” on page 21.

Field replacement of sensor mirror

One advantage of the General Eastern chilled mirror dew point

sensor is that the mirror is user-replaceable. The sensor does not

have to be returned to the factory for replacement of the reflective

32 E4-1111H-GE Operator’s Manual

surface, but of course you can return it for factory service, if

desired.

A mirror may require replacement for any of the following reasons:

• The mirror is constructed of silver/rhodium plated copper.

Copper provides excellent thermal conductivity to the platinum thermometer. However, some gas constituents, such as

sulfur dioxide (SO2) may react with the copper and eventually

pit the surface or form a copper sulfate coating.

• The reflective surface may be gradually abraded by sharp dirt

particles in the gas being measured.

• The mirror surface may be accidentally scratched or gouged

during use or cleaning.

If the sensor mirror has reacted with a corrosive material in the gas

sample, such as an acid or sulfur compound, it should be replaced

with a solid platinum mirror to remove any possibility of copper

corrosion.

In extreme cases, a solid platinum mirror can make possible a

successful application of chilled mirror technology. For example,

measurements in tobacco factories and malting houses have drastically improved after this change, since both locations have sample

gas constituents that attack copper.

In addition, fine scratches can be buffed out of a solid platinum

surface, restoring the mirror to new condition, since it is of solid

construction.

Replacing the

sensor mirror

Chapter 5 — Service 33

Required equipment: torque driver, set to 20-30 inch-ounces of

torque. General Eastern’s type TW-1 is recommended.

The kit supplied by the factory contains the replacement mirror, a

container of white thermal compound for proper heat transfer, and

(in some models) a mylar washer that is to be placed under the

mirror.

1. Open the sensor by removing the sensor filter.

2. Unscrew and discard the old mirror, using a 3/16-inch (0.187)

hex socket.

3. Use a toothpick or similar tool to place a small amount of thermal compound in the hole supporting the mirror.

CAUTIONS:

Do not apply thermal compound to the mirror stem.

Do not use an amount large enough to leak out when

the mirror is tightened.

Do not allow any compound to get on the mirror sur-

face, as it is very difficult to remove completely.

4. Carefully screw in the new mirror and tighten to the proper

torque as specified for the particular sensor.

5. Carefully clean the mirror surface, using a cotton swab and the

General Eastern cleaning solution supplied with the maintenance kit. Distilled alcohol or diluted alcohol is also acceptable.

6. Replace the filter and return the sensor to normal operation.

Under some circumstances, a new mirror may operate in a

somewhat unstable manner for the first hour or two.

Modification for platinum mirror. If you choose to upgrade from

the standard plated copper mirror to the solid platinum mirror in

the field, a circuit board change must also be made within the

E4-1111H. Capacitor C4 must be increased from 33 microfarads to

approximately 68 microfarads to avoid instability in the control

loop. This change can be accomplished either by replacing C4 with

a larger capacitor, or by adding a 33 microfarad capacitor in parallel

with C4 using the designated pads on the circuit board.

If you received a system that had a platinum mirror installed at the

factory, an additional 33 microfarad capacitor has already been

added in parallel with C4.

If you purchase a platinum mirror to replace a standard mirror, you

can return the unit to the factory for a no-charge circuit board

modification. If you prefer to install the modification, General

Eastern will supply a field modification kit at no charge. A trained

electronic technician with soldering skills is required for proper

circuit board modification.

34 E4-1111H-GE Operator’s Manual

Test and calibration

The procedures in this section effectively test and/or calibrate the

following aspects of the monitor:

• Startup and power supply voltage

• Normal sensor operation

• Digital and analog outputs

• No heating or cooling

The unit has been completely tested and calibrated at the factory,

and is ready to plug in and operate. As shipped, it meets all of our

published specifications and has been checked out at a number of

points against a dew point system that has been certified by the

U.S. National Institute of Standards and Technology (NIST). A certificate of Compliance is supplied with the unit to indicate traceability.

There are no calibration adjustments in the instrument that affect

the measured readings. The reading is determined directly from the

mirror temperature measured by the platinum Resistance Temperature Detector (RTD), which is controlled automatically at the dew

point.

The analog outputs provided for recording or controlling are

produced by a digital-to-analog converter. This converter can be

adjusted as specified in the analog output calibration procedures.

See “Function 6: Calibrate Output1” on page 29.

Troubleshooting

Red POWER

indicator doesn’t

light when

powered up

Incorrect dew

point measured

Chapter 5 — Service 35

1. Check the AC line supply. Make sure both ends are connected

and that the unit is connected to a proper source of AC voltage.

2. Check the fuse. Make sure the proper fuse size is installed.

Make sure the fuse is not open.

If the dew/frost point reads incorrectly, first check the standard

preventive maintenance items:

1. Clean the mirror. See “Cleaning the sensor mirror” on page 31.

2. Balance the sensor optics. See “Balancing the sensor optics” on

page 31.

If the above procedures do not correct the problem, verify that the

platinum resistance thermometer in the sensor is reading correctly

with the following steps:

1. Disconnect the 6-pin J9 connector from the main circuit board

in the unit. After J9 has been disconnected, and after the sensor mirror has stabilized at ambient temperature, the measured dew point should equal the ambient temperature.

2. Check this temperature reading against another reliable thermometer placed near the dew point sensor.

3. If the platinum resistance thermometer is faulty, return the

sensor to General Eastern for factory service.

An alternative method for checking the accuracy of the unit’s electronics is to use a precision resistance decade box in place of the

platinum thermometer. Wire the decade box to the unit’s sensor

connector as shown in Figure 13, and verify that the resistance

settings shown in the table produce the temperatures shown.

36 E4-1111H-GE Operator’s Manual

Figure 13 — Using a Resistance Decade Box

No analog output

No digital

RS-232C output

Chapter 5 — Service 37

If there is no analog output, check the analog output scaling. See

“Function 1: Scale outputs” on page 24.

Check the output scaling for the RS-232C port. See “Function 1:

Scale outputs” on page 24.

No cooling and/

or heating

The RS-232 or analog output can be used to indicate whether or

not cooling and heating are operating correctly. If DIP Switch 2 is

set to HEAT, the displayed temperature should increase. If Switch 1

is set to COOL, the temperature should decrease.

The following procedure can be used to determine whether or not

the sensor thermoelectric cooler has failed.

1. Disconnect the sensor from the sensor cable.

2. Using a jumper wire, connect pins A and B of the 1123HK

cable or 1 and 9 of the D-2K cable at the sensor end of the

cable connector.

3. Connect a digital voltmeter across resistor R28 on the main

circuit board.

4. Set DIP Switch 1 to COOL (press the right-hand side). The voltage should read approximately 0.22 (±0.02) VDC. Return the

switch to its normal position.

5. Set DIP Switch 2 to HEAT (press the right-hand side). The voltage should read 0.06 (±0.01) VDC with the opposite sign from

the previous reading. Return the switch to its normal position.

If the above voltages read correctly, the instrument is operating

correctly and the sensor thermoelectric cooler is likely to have

failed. Return the system to General Eastern for factory service.

38 E4-1111H-GE Operator’s Manual

Appendix A — Specifications

PERFORMANCE

Accuracy: Dew/Frost point:

[complete system at 25°C (77°F)]

Sensitivity:

Repeatability:

Hysteresis:

Measurement range:

Measurement capability:

(at 25°C ambient air temp.)

Full-Scale analog output range: –45°C to +75°C (–49°F to +167°F) dew/frost point

Response time:

Dew/frost point cooling rate: 1.5°C (2.7°F)/sec [typical, above 0°C (32°F)]

Update time:

± 0.2°C (± 0.36°F)

> 0.05°C (0.09°F)

± 0.05°C (±0.09°F)

None

–25°C to +65°C (–13°F to +149°F) dew/frost point

2 sec

Appendix A — Specifications 39

FUNCTIONAL

Analog output:

4–20mA DC, 500 Ohm maximum load

Standard Analog Scaling (field or factory programmable):

–45 to +75°C (–49 to +167°F)

Digital output:

RS-232C

Alarms: Service alarm: TTL compatible. Service flag also available on

RS-232C output.

Balance status:

Power:

Green indicator light. Balance (PACER) flag also

available on RS-232C output.

110, 115 or 230 VAC (+/– 10%), 50-60 Hz, 35 Watts

maximum, 250V 3AG 2A SB double fuses

Operating ranges:

Dew point sensor

Ambient temperature: –20°C to +80°C (–4°F to + 176°F)

pressure: –14.7 to 300 psig (0 to 22 bar)

Electronics:

Ambient temperature: –20°C to +75°C (–4°F to +167°F)

relative humidity 85% maximum

PHYSICAL

Dimensions:

Weight:

Shipping Weight:

Environmental:

10.5"W x 18.4"H x 4.25"D (267 x 468 x 108 mm)

not including sensor

12 lbs (5 kg)

14 lbs (5.5 kg)

Surface-mount, industrial environment (NEMA-4)

40 E4-1111H-GE Operator’s Manual

Appendix B — Warranty and return

procedure

Warranty

General Eastern (the Seller) warrants equipment of its manufacture

against defective materials or workmanship for a period of one year

from date of shipment. Liability of the Seller under this warranty is

limited, at Seller’s option, to:

• Repair or replacement of defective parts at no charge

• Credit adjustment, not to exceed original sales price

This warranty is subject to the following conditions:

• Prompt notification to Seller upon discovery of defects or missing items

• Obtaining a Return Authorization Number from Seller to

return defective items to plant as directed

• Return of equipment with freight charges prepaid, or as otherwise agreed

Defects caused by negligence, misuse, improper installation, accident or unauthorized repair or alteration by buyer or user, or any

modification, such as changing range resistors, may void this

warranty.

This warranty does not include mechanical parts failing from

normal usage, nor does it cover limited-life electrical components

which deteriorate with age.

This warranty is in lieu of all other warranties, expressed or

implied, including the implied warranty of fitness for a particular

purpose to the original Purchaser or to any other person. Seller

shall not be liable for consequential damages of any kind.

Damaged

Shipments

Appendix B — Warranty and return procedure 41

In case of shipping damage, it is the Buyer’s responsibility to file a

claim. The Buyer should inspect the shipping container upon

receipt and note any evidence of damage on the freight waybill. If

concealed damage is found after opening the container, the

customer should file a claim with the carrier at once. The customer

must retain the shipping container and all materials during the lifetime of the warranty.

Repaired

Equipment

Instrument

Return Procedure

All repairs are warranted for 90 days. Only the repairs and components replaced as part of these repairs are covered by this warranty.

Other repairs or defective parts are covered by the original

warranty, if applicable.

The aforementioned provisions do not extend the original warranty

of any article which has been either repaired or replaced by the

Seller.

All General Eastern instruments are fully tested and calibrated prior

to shipment. Should a problem with the operation of the equipment arise, follow the procedure below:

1. Contact the factory to discuss the problem. In countries other

than the U.S., the local agent can also be contacted. Sometimes

a problem can be resolved by a change in operating procedure

or an adjustment to the equipment.

2. If the equipment must be returned to the factory, obtain a

return authorization number from General Eastern, and reference the number on the return shipping papers. A written

description of the problem should also be included with the

instrument.

3. If equipment is not covered by General Eastern’s Warranty Policy, a purchase order should be submitted with the equipment

returned. The order should cover one of the following:

a. Open order, authorizing repair of equipment to meet pub-

lished specs. Repair costs will be billed on an actual basis,

but will not exceed 50% of the replacement cost without

prior customer approval.

b. Order that is not to exceed $500.00 or 30% of the

replacement cost, whichever is higher. If repair costs

exceed this amount, the customer will be quoted costs

before the work is done.

c. Order to cover cost of test and evaluation only. Amount

based on type of equipment returned. General Eastern will

42 E4-1111H-GE Operator’s Manual

evaluate but not repair the unit. General Eastern will call

the customer to discuss the evaluation and quote the cost

of repair or replacement.

To expedite repairs and reduce costs, General Eastern recommends options (a) or (b).

4. After receiving a Return Authorization Number, the equip-

ment must be returned freight prepaid.

5. General Eastern reserves the right to apply a minimum service

charge in cases where an instrument is returned for repairs or

recalibration, but does not require service.

Returning equipment without a Return Authorization number and

Purchase Order significantly delays turnaround time and incurs

additional costs. To expedite repairs and reduce costs, please follow

the above instructions.

Note: General Eastern guarantees NIST traceability and operation

within stated specifications. However, claims regarding accuracy or

traceability will be covered under warranty only when verified at

General Eastern, or by a fully independent testing laboratory. Examples of independent labs are: National Institute of Standards and

Technology in the U.S., and the National Physical Laboratory (NPL)

in the U.K.

Appendix B — Warranty and return procedure 43

44 E4-1111H-GE Operator’s Manual

Appendix C — Humidity equations and

conversion chart

The following symbols appear in the equations below:

e

= Vapor Pressure, millibars

e

= Vapor Pressure with respect to ice, millibars

i

e

= Vapor Pressure with respect to water, millibars

w

e

= Saturation vapor pressure, ice, millibars

is

e

= Saturation vapor pressure, water, millibars

ws

P

= Total Pressure, millibars

T

= Temperature, °C

T

= Ambient temperature, °C

a

T

= Dew point temperature, °C

d

T

= Frost point temperature, °C

f

Vapor Pressure

Appendix C — Humidity equations and conversion chart 45

Saturation vapor pressure with respect to water is a function of

temperature only and is given by the following:

17.502T

e

Saturation vapor pressure with respect to ice requires a minor

adjustment of the constants as given by the following:

e

In addition to yielding saturation vapor pressure as a function of

ambient temperature, the above equations also yield ambient

vapor pressure as a function of dew/frost point.

The total pressure of a gas mixture is equal to the sum of the partial

pressure each gas would exert, were it to occupy the same total

volume, according to Dalton’s law.

ws

is

6.1121

6.1115

exp=

exp=

--------------------------

240.97 T+

22.452T

--------------------------

272.55 T+

(2)

(1)

Humidity

Relative Humidity is defined as the ratio of the water vapor pressure (e) to the saturation vapor pressure (es) at the prevailing

ambient or dry bulb temperature (Ta):

()

e

%RH 100

Absolute humidity is expressed as water vapor density: water vapor

mass per unit volume of dry air, according to the following:

------

m

Water vapor content expressed as parts per million by volume is

given by the following:

PPM

Expressing water vapor content as parts per million by weight (or

mixing ratio) requires multiplication of the above by the ratio of

the molecular weight of water to that of air as given by the

following:

PPM

==

216.7eT

g

----------------------------=

3

T 273.16+

=

V

W

----

e

()

6

-----------------------

10

PeT

0.622 10

=

s

d

eTd()

()–

×

100

d

6

------------

Pe–

e

wTd

-------------------

e

()

wsTa

e

(3)

(4)

(5)

(6)

A graphical humidity conversion chart is given below.

46 E4-1111H-GE Operator’s Manual

Appendix C — Humidity equations and conversion chart 47

48 E4-1111H-GE Operator’s Manual

Appendix D — Configuring the RS-232

interface

The E4-1111H is configured as Data Terminal Equipment (DTE).

The following pins are used on the RS-232 interface:

2 - Transmitted data (TXD)

3 - Received data (RXD)

7 - Signal ground (GND)

To send the output of the monitor to a terminal or a terminal

emulator, use the cable arrangement shown below.

Some communications protocols require that the following pins

also be used:

4 - Request to send (RTS)

5 - Clear to send (CTS)

6 - Data set ready (DSR)

20 - Data terminal ready (DTR)

The unit, as shipped from the factory, has pins 4 and 5 connected

and pins 6 and 20 connected via jumpers JPR4 and JPR5, generating the appropriate control signals for devices requiring these

Appendix D — Configuring the RS-232 interface 49

lines. If you want independent control over these signals, JPR4 and

JPR5 can be removed. These jumpers are located on the printed

circuit board and are clearly marked.

If you wish to interface the unit to Data Communications Equipment (DCE), use the cable configuration shown below.

In order to communicate with the unit, you need a standard serial

interface card installed in your computer. If your computer has one

serial card, it is addressed as COM1. If there is a second serial card,

it is addressed as COM2. You must also have a cable with the

following connectors:

• A 25-pin male D connector connecting to the monitor

• A 25-pin female D connector connecting to the computer

Only pins 2, 3, and 7 are used by the monitor. They are connected

straight through: 2 to 2, 3 to 3, and 7 to 7.

After you have installed the serial card and connected the cable,

you can use the Terminal program in Windows 3.1 to easily

communicate with the unit. If Windows is not available, you can

use the following BASIC program to interface to the instrument:

10 ON ERROR GOTO 90

20 OPEN COM1: 1200,N,8,1,CS,DS,CD AS #1

30 OPEN SCRN: FOR OUTPUT AS #2

40 B$ = INKEY$: IF B$ <> THEN GOTO 100 CHECK KEYBOARD

50 IF EOF(1) THEN 40 CHECK END OF TRANSMISSION

60 A$ = INPUT$(LOC(1),#1) GET DATA FROM PORT

70 PRINT #2,A$; DISPLAY DATA FROM SERIAL PORT

50 E4-1111H-GE Operator’s Manual

80 GOTO 40 REPEAT LOOP

90 CLOSE: GOTO 20 ERROR, CLOSE AND REPEAT

100 IF B$<>CHR$(27) THEN PRINT $1,B$;: GOTO 50 CHECK FOR ESCAPE

110 FOR I=1 TO 5 SEND BURST OF ESCAPE CHAR UNTIL RECOGNIZED

130 PRINT #1, CHR$(27)

150 LINE INPUT #1, A$ GET STRING

160 IF INSTR(A$, VERSION ) THEN 210

170 IF INSTR(A$, SCALE ) THEN 210

180 IF INSTR(A$, CALIBRATE ) THE 210

190 NEXT I

210 GOTO 70

Notes:

Line 20: Serial input = COM1, baud rate = 1200, parity = NONE, no.

of data bits = 8, no. of stop bits = 1, timeout = 10

SECONDS

, set to file #1.

Line 30: File #2 set as the video display terminal.

Line 40: Input from keyboard. If there is no input then continue. If

there is input, send it to E4-1111H and to video display

terminal.

To send data to your printer, insert the following line in the

program:

75 LPRINT A$

For further information on interfacing, refer to the factory or to the

Electronic Industries Association (EIA) standard for interfacing.

Appendix D — Configuring the RS-232 interface 51

52 E4-1111H-GE Operator’s Manual

Appendix E — Glossary

depression

capability

PACE R

parameter

scaling

The temperature difference by which the chilled mirror can be

lowered from the ambient temperature.

General Eastern’s patented Programmable Automatic Contaminant

Error Reduction system, which consolidates soluble contaminants

to reduce their effect on system accuracy. See “The PACER Cycle” on

page 21.

A measured quantity available for display by the unit, such as Dew

Point in °C, Humidity in Grams/Kilogram, or Pressure in Bar.

The process of selecting the maximum and minimum output

values of a chosen parameter.

Appendix E — Glossary 53

54 E4-1111H-GE Operator’s Manual

Loading...

Loading...