Page 1

Electronics Technical Information

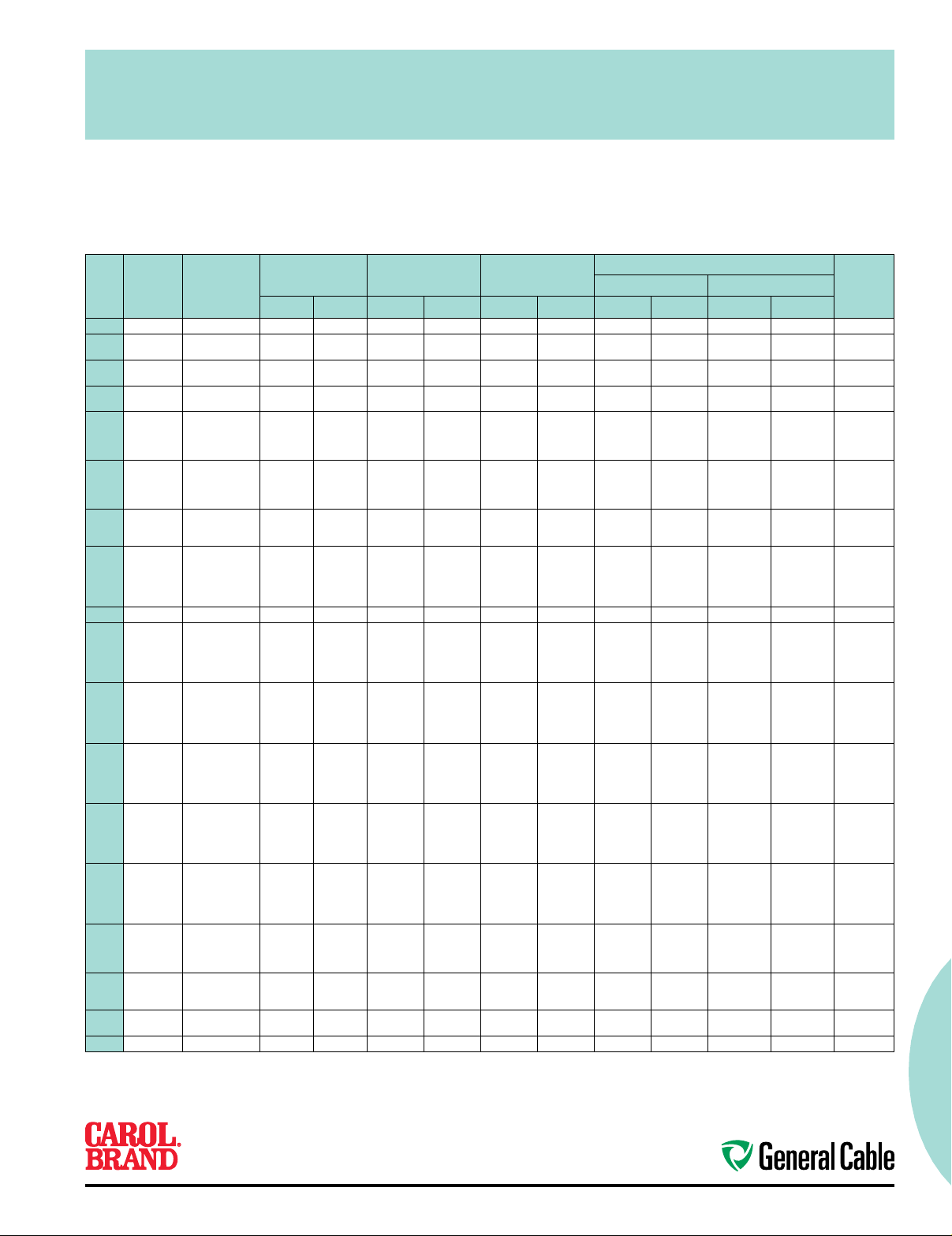

AWG Conductor Chart

COPPER CONDUCTOR DATA

The conductors used by General Cable meet the applicable requirements of ASTM specifications B-3, B-33, B-172, B-173, B-174 and B-286 and

Federal Specification QQ-W-343.

The following data covers the more commonly used conductor constructions in the electrical and electronics industry. Special constructions, not

shown, are available or can be designed to meet specific requirements. It is suggested that the General Cable Product Engineering Department be

contacted before a specification is finalized.

(2)

BREAK STR.

LBS

340.00

303.00

214.00

194.00

135.00

122.00

133.00

112.00

84.20

75.90

90.20

71.60

53.20

48.60

45.10

33.20

30.60

34.00

28.00

–

21.00

19.20

21.30

17.90

21.60

13.60

14.00

13.50

13.10

13.60

8.28

8.56

8.88

8.56

8.30

5.21

5.38

5.59

5.25

5.25

3.28

3.28

3.21

4.10

3.24

2.13

2.13

–

–

1.30

–

–

–

–

–

–

–

–

–

–

–

3.157

5.020

7.983

12.690

19.430

30.890

49.120

78.100

124.200

197.500

314.500

(4)

AWG STRANDING

7/40

32

Solid

30

7/38– Bu

Solid

28

7/36– Co

Solid

27

7/35– Co or Bu

Solid

7/34

26

10/36

19/38

Solid

7/32

24

16/36

19/36

Solid

7/30

22

19/34

Solid

7/28

10/30

20

19/32

26/34

Solid

19

Solid

7/26

16/30

18

19/30

41/34

Solid

19/294

19/.0117

16

26/30

65/34

Solid

7/.0242

19/274

14

19/.0147

41/30

Solid

7/.0305

19/254

12

19/.0185

65/30

Solid

7/.0385

19/.0234

10

37/.0169

105/30

7/.0486

19/.0295

8

133/29

168/30

19/.0374

133/27

6

266/30

133/25

4

420/30

665/30

2

(1) Bu - Bunched; Co - Concentric; Eq - Equilay; Ro - Rope; Un - Unilay

(2) Typical DC resistance values for uninsulated wires. Multiply by 1.04 for typical values after insulation

(3) Values are for tinned, heavy tinned, prefused, overcoated or topcoated conductors

(4) Does not meet UL conductor stranding requirements

TYPE

STRANDING

Co or Bu

–

Co or Bu

Bu

Bu or Co

–

Co or Bu

Bu

Co or Bu

–

Co or Bu

Bu or Eq

–

Co or Bu

Bu

Co, Bu or Eq

Bu

–

–

Co or Bu

Bu

Co, Bu or Eq

Bu

–

Bu or Eq

Bu

Bu

Bu

–

Co

Co, Eq or Un

Bu

Bu

–

Bu

Co, Eq or Un

Cu

Bu

–

Co

Bu

Co

Bu

Bu

Bu or Eq

Ro 19 x 7/29

Ro 7 x 24/30

Bu

Ro 19 x 7/27

Ro 7 x 38/30

Ro 19 x 7/25

Ro 7 x 60/30

Ro 19 x 35/30

DIAMETER

(1)

in mm circ. mils sq. mm lbs/Mft kg/km Ω/Mft Ω/km Ω/Mft Ω/km

.0096 .254 100 .051 .21 .31 176.00 577.00 164.00 538.00 1.986

.010

.012

.01264

.015

.0142

.017

.016

.019

.0193

.021

.0201

.024

.024

.025

.025

.030

.0315

.032

.038

.037

.040

.039

.0359 .912 1,032 .653 3.90 5.80 – – 8.05 26.40 38.950

.0403

.048

.0475

.050

.049

.0508

.057

.0585

.0606

.060

.0641

.073

.071

.074

.077

.0808

.092

.0905

.0925

.094

.1019

.116

.117

.112

.126

.146

.144

.169

.174

.188

.213

.222

.257

.270

.338 8.59 42,000 33.72 213.0 317.00 .18 .59 – –

.254

.305

.321

.381

.361

.432

.404

.483

.490

.533

.511

.610

.610

.635

.643

.762

.800

.813

.965

.940

1.02

.940

1.024

1.22

1.207

1.27

1.244

1.29

1.45

1.50

1.54

1.52

1.63

1.85

1.80

1.88

1.96

2.05

2.34

2.299

2.35

2.388

2.588

2.95

2.97

2.84

3.20

3.71

3.66

4.293

4.42

4.775

5.41

5.64

6.53

6.850

AREA WEIGHT

100

.051

112

.057

159

.081

175

.089

202

.102

220

.111

253

.128

278

.141

250

.127

304

.154

404

.205

448

.227

400

.201

475

.241

643

.324

700

.355

754

.382

1,020

.519

.562

1,111

.507

1,000

.616

1,216

.523

1,290

.823

1,620

.897

1,770

.810

1,600

.963

1,900

.824

1,627

2,580

2,426

2,601

2,600

2,581

4,110

4,100

3,831

4,106

4,100

6,530

6,512

6,088

6,503

6,500

10,380

10,376

10,404

9,361

10,500

16,534

16,535

16,983

16,800

26,576

26,818

26,600

42,615

1.31

1.23

1.32

1.32

1.31

2.08

2.08

1.94

2.08

2.08

3.31

3.30

3.08

3.30

3.29

5.26

5.25

5.27

4.74

5.32

8.38

8.38

8.61

8.51

13.33

13.60

13.49

21.61

21.29

.30

.35

.48

.55

.61

.69

.77

.87

.78

.97

1.22

1.38

1.25

1.48

1.94

2.19

2.35

3.10

3.49

3.14

3.84

3.28

4.92

5.55

5.01

5.95

5.09

7.81

7.52

8.02

8.15

8.20

12.4

12.7

12.1

12.7

12.9

19.8

20.2

19.4

20.2

20.8

31.4

32.0

32.0

29.2

33.8

50.1

50.0

54.0

53.4

81.1

84.1

83.2

135.0

140.0

.45

.52

.72

.82

.91

1.04

1.14

1.29

1.15

1.44

1.82

2.05

1.64

2.20

2.89

3.26

3.50

4.61

5.19

4.67

5.71

4.88

7.32

8.26

7.45

8.85

7.08

11.60

11.20

11.90

12.10

11.90

18.50

18.90

18.00

18.90

19.20

29.50

30.10

28.90

30.10

31.10

46.80

47.60

47.60

43.40

49.20

74.50

74.40

80.40

79.00

121.00

125.00

124.00

201.00

208.00

TIN COATING

113.00

106.00

70.80

67.50

55.60

53.80

44.50

42.50

47.30

38.90

27.20

25.70

29.50

24.90

16.70

16.60

15.50

10.50

10.30

11.40

9.48

11.30

6.77

6.45

7.15

6.10

7.08

4.47

4.82

4.39

4.39

4.47

2.68

–

3.05

2.73

2.81

1.69

–

1.87

–

1.82

–

–

–

–

1.10

–

–

.71

.70

–

.43

.44

.29

.28

D.C. RESISTANCE 20°C

(3)

BARE OF SILVER COATING

371.00

348.00

232.00

221.00

182.00

176.00

146.00

139.00

155.00

128.00

89.20

84.20

96.80

81.70

54.80

54.40

50.80

34.40

33.80

37.40

31.10

37.10

22.20

21.20

23.40

20.00

23.20

14.70

15.80

14.40

14.40

14.70

8.79

10.00

9.22

5.54

6.13

5.97

3.61

2.33

2.30

1.41

1.44

.95

.92

104.00

92.60

65.30

59.30

51.40– 169.00– 6.331

41.00

37.30

40.40

34.10

25.70

23.10

27.50

21.80

16.20

14.80

13.80

10.10

9.33

10.40

8.53

6.39

5.55

6.48

5.46

6.60

4.16

4.27

4.13

3.99

4.16

2.52

–

2.61

2.71

–

2.61

2.53

1.59

–

1.64

1.70

–

1.64

1.64

–

1.00

–

1.00

–

.98

–

1.25

.99

–

.65

–

.65

–

.40

200

Loading...

Loading...