Page 1

DRY AIR PAC™

FACTORY MUTUAL APPROVED

AIR DRYING UNITS FOR REFRIGERATED AREA AND

DRY PIPE SPRINKLER SYSTEMS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

MODELS DAP500, DAP1000 & DAP2000

ENGINEERED COMPRESSED AIR DRYING SYSTEMS FOR COLD

STORAGE/ FREEZER ROOM DRY PIPE SPRINKLER SYSTEMS

MODEL NUMBER SYSTEM

CAPACITY

DAP500 500 GALLON 2 10 375LBS

DAP1000 1000 GALLON 5 20 500LBS

DAP2000 2000 GALLON 5 27 550LBS

COMPRESSOR

HORSEPOWER

DRYER RATING

SCFM

APPROXIMATE

SHIPPING WT.

N:\Work\Engineering\Product Files\DRY AIR PAC \INSTRUCTIONS\DAP-INSTRUCTION MANUAL011606 revision.doc

Page 2

INSTALLATION

1. Install DRY AIR PAC in a clean, dry location, with ambient temperatures at all times

above 50o F., adjacent to the sprinkler system piping outside the cold room.

NO MORE THAN 3 SYSTEMS ARE TO BE CONNECTED TO A SINGLE DRY AIR PAC;

CAPACITY OF EACH SYSTEM SHOULD NOT EXCEED THE RATED CAPACITY OF

THE DRY AIR PAC. The unit must be accessible at the front for servicing all major

components. The unit should be leveled and anchored to the floor (the vibration isolators

supplied with the unit MUST be utilized). If the location is below freezing at any time the

unit must be enclosed in a separate, heated enclosure to keep the temperature above 50o

F.

NOTE:

Do not install the Dry Air Pac in an area where ammonia vapors or similar

contaminants exist. The equipment and desiccant can be damaged by ammonia and

other vapors. Locate the Dry Air Pac to ensure no ammonia or other vapors are drawn

into the intake.

2. The unit has been filled with oil for test purposes, it is strongly recommended to change this

oil after the initial run in period on site. 2 Quarts of oil are shipped with each Dry Air Pac for this

purpose. When adding or replacing oil only use General Part Number ACPO1Q Specially

Formulated Compressor Oil.

Oil requirements are as follows:

DAP500 22ounces

DAP1000 Approximately 1 1/2 quarts (middle of oil level window)

DAP2000 Approximately 1 1/2 quarts (middle of oil level window)

Lightweight lubricants should not be used nor heavy gear oils.

3. Connect proper supply voltage to the starter line terminals in the control panel.

Note: Wire size must be capable of carrying the unit load, without dropping the

voltage at the terminals below normal operating levels. Double check incoming wire

size; if there are any questions please call us, we can assist you in ensuring you have

selected the correct size. Be sure the control power transformer has its primary side jumpers

connected to match the incoming supply voltage. Each unit is run at the factory and results noted

for reference so if there are any questions please contact the factory. Motor rotation will always

need to be checked. After connecting the power, use the on/off switch on the front of the unit to

turn on the compressor briefly to check rotation. An indicating arrow is on the compressor

flywheel. If rotation is not correct on three phase units, reverse any two leads. On single phase

units refer to the motor nameplate, however it should not require changing as it has been run at

N:\Work\Engineering\Product Files\DRY AIR PAC \INSTRUCTIONS\DAP-INSTRUCTION MANUAL011606 revision.doc

Page 3

the factory. If you feel this is required please consult with factory personnel as there may have

been changes made to the unit, which should be discussed with the factory PRIOR TO starting

the unit. Please ensure sufficient power is available at the unit. Long feed line runs can cause

voltage drops, which can affect the performance of the unit and damage the motor.

ONLY QUALIFIED ELECTRICAL PERSONNEL SHOULD CONNECT THE UNIT.

4. Each DRY AIR PAC is shipped with desiccant installed. The unit will need to be run for a

minimum of 8 hours PRIOR TO any air being used from the Dry Air Pac in the sprinkler

system. Air should be bled from the tee after the regulator in an amount to allow the compressor

to run NO MORE than 4 times per hour.

NOTE: If you are connecting to an old piping system there may be existing le aks in the

system which cause the compressor to cycle more frequently than 4 times per hour. If this is

the case there are three suggestions: 1. Fix the leaks. 2. Add a second DRY AIR PAC to

provide enough air to bring the cycle times back to less than 4 times per hour. 3. Add a

receiver, which can act as a storage buffer to supply more air to the system. This should be

discussed with the factory personnel, as it will only work in cases where minor leaks are

involved.

5. The DRY AIR PAC is supplied with a removable, threaded inlet air filter so that if the AHJ

requires the air to be drawn from the cold room this can be done. These units have been FM

Approved with air NOT being drawn from the freezer room. Therefore WE DO NOT

RECOMMEND they be connected to the freezer room. The Dry Air Pac is designed so

that performance will not be adversely affected with the filter left in place directly on the

compressor. If connected in the cold room, the piping back to the compressor must be 1 1/2”

minimum pipe size for this run, bushed down directly at the compressor inlet elbow. This pipe

must be heat traced and insulated. The filter should be mounted on the inlet end of this pipe

directly in the cold room. The interconnecting piping should be clean of any foreign matter,

which may be drawn into the compressor and cause damage.

6. There is a 1/2” pipe plug installed in the outlet tee. This is provided as a point to install a dew

point monitoring device, should you require one. This is after the regulator and gives you the

pressure dew point of the system. Be careful to follow the dew point monitor manufacturer’s

recommendations as far as installation is concerned.

7. The DRY AIR PAC outlet is from the combination particulate filter with pressure regulator,

mounted on the right lower side of the unit facing the control panel. Connect this outlet to the

sprinkler system air inlet.

8. The DRY AIR PAC has a UL/FM approved Air Maintenance Device built into the unit. It

will require adjustment of the regulator to your system requirements. It replaces the final

regulator, which should be left fully open once the Air Maintenance Device has been adjusted

and valved into the line. If connecting more than one system to the unit, the Air Maintenance

N:\Work\Engineering\Product Files\DRY AIR PAC \INSTRUCTIONS\DAP-INSTRUCTION MANUAL011606 revision.doc

Page 4

Device should be left valved out of the system and the individual AMD’s used to control each

system should be utilized.

NOTE: Leaks in the piping system will affect the pump up time of the system. The DRY

AIR PAC has been factory tested to produce the published capacity.

9. An integral electronic drain valve is installed on each unit. The drain is pre-set when the unit

leaves the factory. If necessary you can adjust the time between openings and the length of time

the valve is open using the control knobs located above the hour meter on the front of the

control panel. Under normal circumstances the maximum time between openings should be

sufficient. If more frequent openings are required due to excessive compressor operation simply

decrease the duration between openings. The On/Off - Manual Test switch can be used to

check operation.

START UP

AS NOTED PREVIOUSLY - The unit must run for a minimum of 8 hours PRIOR TO any air

being taken from the Dry Air Pac into the sprinkler system. Air should be bled from the tee after

the regulator in an amount to allow the compressor to run NO MORE than 4 times per hour for

this period.

1. With all the connections made as described in INSTALLATION, the unit is ready to

start. With the valve ahead of the coalescing filter closed, turn the unit on with the switch

on the front of the control panel. The compressor should start to fill the receiver tank

and the tank pressure gauge on the front of the control panel should indicate the

pressure. The unit should pressurize the receiver to approximately 100psig and then shut

off.

Note:

Do not adjust the pressure switch on the unit. It is factory set at the values required for

correct operation of the unit. Warranty may be void if the pressure switch is reset.

The unloader line will operate to bleed off the pressure in the line from the compressor to the

receiver inlet so that the compressor does not start loaded. Air will exhaust from the small valve

at the side of the switch immediately after the compressor is shut off. This should not occur

when the compressor is running or for long periods of time after the compressor shuts off. If

this occurs, contact the factory.

2. Open the valve ahead of the coalescing filter and pressurize the rest of the DRY AIR PAC.

The Air Maintenance Device should be in bypass mode, with the 3/4” valve open.

N:\Work\Engineering\Product Files\DRY AIR PAC \INSTRUCTIONS\DAP-INSTRUCTION MANUAL011606 revision.doc

Page 5

3. The outlet valve should now be open to allow air to begin to purge into the sprinkler system.

The final regulator is factory set to 40 psig. The regulator should always be set to maintain

pressure on the drying tower between 70 to 100 psig. At no time should the regulator be

opened to bleed all pressure off the drying system, as this will adversely affect drying quality.

4. Open an inspection test point on the far end of the sprinkler system to allow the current wet

ai r in the sprinkler system to be purged out of the system. This leak should be adjusted to allow

the compressor to run, after filling the system to pressure, NO MORE than 4 times per hour.

Allow this to run for 24 hours then close the inspection test port to allow the system to function

normally.

5. The automatic drain is set to a mid position at the factory. You should not need to adjust this

frequency or duration but if you do, be aware that the quicker the cycle and the longer the open

time, the more air will be used and the less will be available at the unit outlet. A light on the

control panel will indicate when the drain is operating. A length of tubing is provided at the drain

valve outlet for piping to a convenient drain water disposal position.

BE SURE TO PIPE THIS DISCHARGE TO A POSITION WHERE THE DISCHARGED

AIR AND WATER WILL NOT BE A HAZARD TO PERSONNEL.

6. Once the system is filled the Air Maintenance Device will need to have the 3/4” valve closed,

the two 1/4” valves opened and the regulator set for final system maintenance pressure. The

final regulator should then be opened to full to allow the Air Maintenance Device to be the

controller.

7. REMEMBER - After the 24-hour period, close the inspection port.

OPERATION

The following is a description of the operation of the DRY AIR PAC.

Typically air is drawn into the compressor intake through the threaded inlet filter. . These units

have been FM Approved with air NOT being drawn from the freezer room. Therefore

WE DO NOT RECOMMEND they be connected to the freezer room. If required by the

AHJ, air is drawn in from the cold room through the inlet filter installed inside the cold room.

This air then travels to the compressor intake via 1 1/2” minimum line size piping.

Upon reaching the compressor, it is drawn into the compressor intake and compressed through

the compression cycle and then discharged into the intercooler. The air then crosses over into

the air cooled aftercooler where ambient air being pulled over the coil cools the hot compressed

air. Water in the compressed air will now drop out of the air as it cools and drops down into the

receiver. A check valve in this line prevents any back flow to the compressor. The water settles

N:\Work\Engineering\Product Files\DRY AIR PAC \INSTRUCTIONS\DAP-INSTRUCTION MANUAL011606 revision.doc

Page 6

into the bottom of the receiver and is discharged from the receiver when the automatic drain

valve opens.

This air then leaves the receiver and goes into the coalescing filter where it has entrained oil

removed. This air then travels to the dryer inlet. The air is diverted to the corresponding tank via

two solenoid valves. The air travels upwards through the desiccant bed and exits through the

top of the tank. A portion of this dried air is diverted to the opposite tank via the purge valve

and gauge/orifice combination. The pressure gauge setting is factory set (see following settings

for each model). If re-setting is required, consult the factory for assistance. The purge air enters

the top of the tower and travels in a downward direction to pick up the water molecules from

the desiccant as the pressure drops to atmosphere. The wet purge air then exits the bottom of

the tank and is vented to atmosphere via the purge mufflers. These mufflers act to quiet the

discharging air and also reduce the noise when the towers depressurize. These mufflers are

removable for cleaning with soap and water periodically. Cleaning will ensure no build up, which

will create back pressures in the tanks and decrease dryer performance. Both inlet and outlet of

the tanks have screens to retain the desiccant. The exiting air then goes to the Air Maintenance

Device. (See Start Up above for operating positions). From the Air Maintenance Device the air

goes into the final filter regulator. The air up to this point has been at 70 – 100 psig. When it

leaves the filter regulator it is reduced to system pressure.

NOTE: THE DRYER MUST OPERATE AT THE HIGHER PRESSURE IN ORDER TO

FUNCTION CORRECTLY. THE AIR MAINTENANCE DEVICE REGULATOR MUST

BE SET AND VALVED INTO THE SYSTEM.

SETTING PURGE PRESSURE

The purge pressure set valve is located between the two tanks just over the top of the control

panel. This valve is pre-set at the factory, however should it need to be adjusted for any reason,

the following listing shows the correct set pressures.

DAP500 20psig

DAP1000 30psig

DAP2000 27psig

COALESCING FILTER - OPERATION

The coalescing filter is there to protect the desiccant dryer from oil carryover from the

compressor. The filter has a built in differential pressure indicator with three color bands. Green

is normal condition, yellow is warning that the element is going to need to be replaced, and red

indicates the filter is overdue for replacement.

N:\Work\Engineering\Product Files\DRY AIR PAC \INSTRUCTIONS\DAP-INSTRUCTION MANUAL011606 revision.doc

Page 7

The filter has a built in automatic drain, which in normal service will expel accumulated oil or

moisture from the bottom of the bowl. The drain can be tested by pushing up on the needle

valve stem, which is in the mouth of the black outlet nipple on the bottom of the filter.

N:\Work\Engineering\Product Files\DRY AIR PAC \INSTRUCTIONS\DAP-INSTRUCTION MANUAL011606 revision.doc

Page 8

SERVICE KITS ARE AVAILABLE AS DETAILED BELOW. MODEL AND SERIAL

NUMBERS ARE REQUIRED WHEN ORDERING SERVICE KITS

KIT# KSMB01 Compressor Intake Filter Element(s),

Coalescing Filter Element, Particulate

After Filter Element and Compressor Oil

KIT# KAMA01 Same as Kit # KSMB01 and full

desiccant charge for both dryer towers

OPERATING SEQUENCE - DRYER

The dryer operates on a 4-minute total cycle. There are four valves at the inlet manifold, and

four at the outlet manifold. The timing cycle diagram shows the sequence of operation of the

four inlet valves. The outlet valves are check valves, which sequence automatically with the

operation of the inlet valves. SV1 and SV2 are the inlet valves to the towers, SV3 and SV4 are

the opposite purge valves such that when the left tower is drying and its inlet valve is open, the

purge valve on that tower is closed.

0 min 2 min 4 min

A

B SV1

A

B SV2

A

B X SV3 X

A SV4

B X X

A=VALVE CLOSED B=VALVE OPEN X = 15 seconds

With the unit turned on and the tank pressurized, air is ready to be used from the unit. As air is

withdrawn from the unit into the sprinkler system, the pressure will drop and the pressure switch

will start the compressor. As the compressor runs, the dryer is energized. The drying tower is

indicated by a light on the front of the panel, as shown in the mimic panel. The drying tower will

show tank pressure and the opposite tank, when purging will show no pressure; when

repressurizing prior to switch over, it will show tank pressure. The purge valve can only be

N:\Work\Engineering\Product Files\DRY AIR PAC \INSTRUCTIONS\DAP-INSTRUCTION MANUAL011606 revision.doc

Page 9

adjusted during the time the off line tower is purging and is showing no pressure. At this time, if

necessary, adjust the purge pressure to the value in the above table. The dryer cycle timer runs

only when the compressor is running and accumulates time so that the length of the cycle on any

one tower does not get out of line with its normal operation and does not saturate one desiccant

bed.

The frequency of change for the oil, filter elements and desiccant is highly dependent upon the

following:

Number of times the unit has to operate to satisfy the system air requirement. The tighter

the system, the less the unit will have to run.

Cleanliness of the environment in which the compressor is located.

Maintenance schedule for the equipment.

As the desiccant will degrade (age) slightly over time, it is recommended that the desiccant be

changed once every year.

Consult the factory for type and quantity per unit.

ADDITIONAL SPECIFICATIONS

MODEL COMPRESSOR

HP

DAP500 2 10 2.9 AMPS 5.8 AMPS 12 GA 12 GA

DAP1000 5 20 6.2 AMPS 12.4 AMPS 12 GA 10 GA*

DAP2000 5 27 6.2 AMPS 12.4 AMPS 12 GA 10 GA*

*IF UNDER 50’ RUN 12 GA CAN BE USED HOWEVER, CHECK VOLTAGE WHILE RUNNING TO ENSURE NO

UNDERVOLTAGE CONDITION EXISTS. FOR RUNS OVER 100’ INCREASE WIRE SIZE TO CORRECT FOR VOLT

DROPS.

DRYER

RATING

CFM

CURRENT

LOAD 460V

CURRENT

LOAD 230V

WIRE SIZE

460V

WIRE SIZE

230V

N:\Work\Engineering\Product Files\DRY AIR PAC \INSTRUCTIONS\DAP-INSTRUCTION MANUAL011606 revision.doc

Page 10

DESICCANT REPLACEMENT

NOTE: You will need the following in order to service the unit:

Annual Service Kit - “General” part number: KAMA01

1. Close the outlet valve of the unit and turn the power to the unit off.

2. Depressurize the unit completely by opening the petcock on the bottom of the receiver and

checking the pressure gauges to ensure all air is removed. If air remains in the desiccant tanks,

pull on the relief valve toggles to depressurize the tanks.

ALL PRESSURE MUST BE OUT OF THE UNIT PRIOR TO WORKING ON THE

UNIT.

3. The tanks have separate desiccant fill and drain ports at the top and bottom.

TANK OUTLET

FILL PORT

DRAIN PORT

TANK INLET

4. Once the pressure has been removed from each tank, remove the lower (drain) port plug.

Desiccant will start to drop out of the 1/2” port. It is easiest to vacuum the desiccant out with a

shop vac; however, the desiccant will drop out of the tower. You may have to probe the outlet

with a thin probe in order to keep the desiccant from jamming together at the port. The

desiccant is white in color; yellow means the desiccant has oil on it.

5. Ensure that all desiccant is removed from the tower. Replace the plug ensuring the threads

are cleaned and re-doped with thread sealant before replacing.

CHECK the condition of the lower desiccant. As flow is upward through the bed, the lower

desiccant will see any major contaminants and any carryover from the inlet filter if this has not

been serviced correctly. Oil on the lower desiccant means that the filter element has been over

saturated allowing oil to be carried over into the desiccant bed.

N:\Work\Engineering\Product Files\DRY AIR PAC \INSTRUCTIONS\DAP-INSTRUCTION MANUAL011606 revision.doc

Page 11

CHECK the filter drain and element before putting the new desiccant into the towers.

Consult the factory if any oil is in the towers.

6. Remove the upper plug from the fill port.

7. Using “General” part number 34006-50, refill the tower with new, white desiccant.

NOTE:

Only add desiccant beads to towers when refilling. Avoid adding chips and dust, which may be

in the bottom of the bag of desiccant, to the towers.

8. Reinstall the fill port ensuring that you clean the threads and re-dope prior to installation.

9. Remove and replace the pre & afterfilter elements prior to putting the unit back in service.

This is accomplished by unscrewing the bowls and following the kit instructions to replace the

elements. We would be happy to look at the old elements if you feel there is any question as to

the condition. Please contact the factory for shipping instructions. Replace the filter bowls and

tighten securely prior to re-pressurizing the unit.

10. Turn the power back on to the unit (see 11.).

11. Open the discharge valve of the unit, then the valve ahead of the coalescer, turn power back

on to the unit and allow the unit to repressurize.

12. Operate the drain valve manually to bleed air to force the dryer through a full cycle to

ensure that the towers pressurize and repressurize correctly and go through their cycle. This is

simply a check to see that the unit is operating normally. The unit is now ready to go back in

operation.

Run the unit for the 8 hours as above in INSTALLATION, item 4, before letting air feed back

into the system.

NOTE:

The purge mufflers must be removed during the first 2 hours of the 8-hour break-in period

detailed above. Reinstall the mufflers only after 2 hours of operation.

Once this has been done, valve the unit back into the system.

Should you have any questions, please call the factory and ask for Customer Service at 1800-345-8207.

N:\Work\Engineering\Product Files\DRY AIR PAC \INSTRUCTIONS\DAP-INSTRUCTION MANUAL011606 revision.doc

Page 12

TROUBLE SHOOTING GUIDE

PROBLEM PROBABLE CAUSE SOLUTION

POOR DEWPOINT

PERFORMANCE

Check to see that Air

Check compressor output to

Check no leaks have

Excessive water &/or oil in

Low purge flow . Check purge pressure setting.

Desiccant contamination. Check compressor intake is

Check when the last time the

Check condition of coalescing

High inlet temperature to

EXCESSIVE PRESSURE

DROP

Low pressure on desiccant

dryer.

dryer.

dryer.

Low inlet pressure. See alternatives above.

Switching valve failure. Check tower-operating

Desiccant breakdown.

Dryer is set to operate at 70 to

100 psig. Re-set regulator on

DAP Air Maintenance Device

to hold back pressure on dryer

side to normal settings.

Maintenance Device bypass

valve has not been opened.

ensure compressor is running

normally.

developed in DAP system

such as drain valve sticking

open, filter drain valves

sticking open, etc.

Check coalescing filter &

automatic drain operation.

not in an area where

chemicals can be drawn into

the intake filter with air.

desiccant was changed.

Recommended frequency of

change, 1 to 2yrs.

filter element and drain.

sequence to verify and identify

which valves are operating.

Change desiccant.

N:\Work\Engineering\Product Files\DRY AIR PAC \INSTRUCTIONS\DAP-INSTRUCTION MANUAL011606 revision.doc

Page 13

EXCESSIVE PRESSURE

DROP (continued)

Clogged filters. Change filter elements.

Valve shut. Open valve.

SWITCHOVER FAILURE Electric power loss. Turn dryer off; check

connections to cam timer and

inlet to unit.

Solenoid valve failure. Check valve operating

sequence. Replace valve.

REPRESSURIZATION

FAILURE OR PURGE

Purge flow control valve

orifice clogged.

Clean or replace.

FAILURE/TOWER

BACKPRESSURE

Failed check valve. Replace.

Purge exhaust solenoid valve

failure.

Turn dryer off, check

connections to cam timer,

inspect valve and solenoid,

replace if necessary.

Purge exhaust muffler

Clean or replace.

clogged.

THANK YOU FOR USING OUR PRODUCTS, WE APPRECIATE YOUR BUSINESS.

N:\Work\Engineering\Product Files\DRY AIR PAC \INSTRUCTIONS\DAP-INSTRUCTION MANUAL011606 revision.doc

Page 14

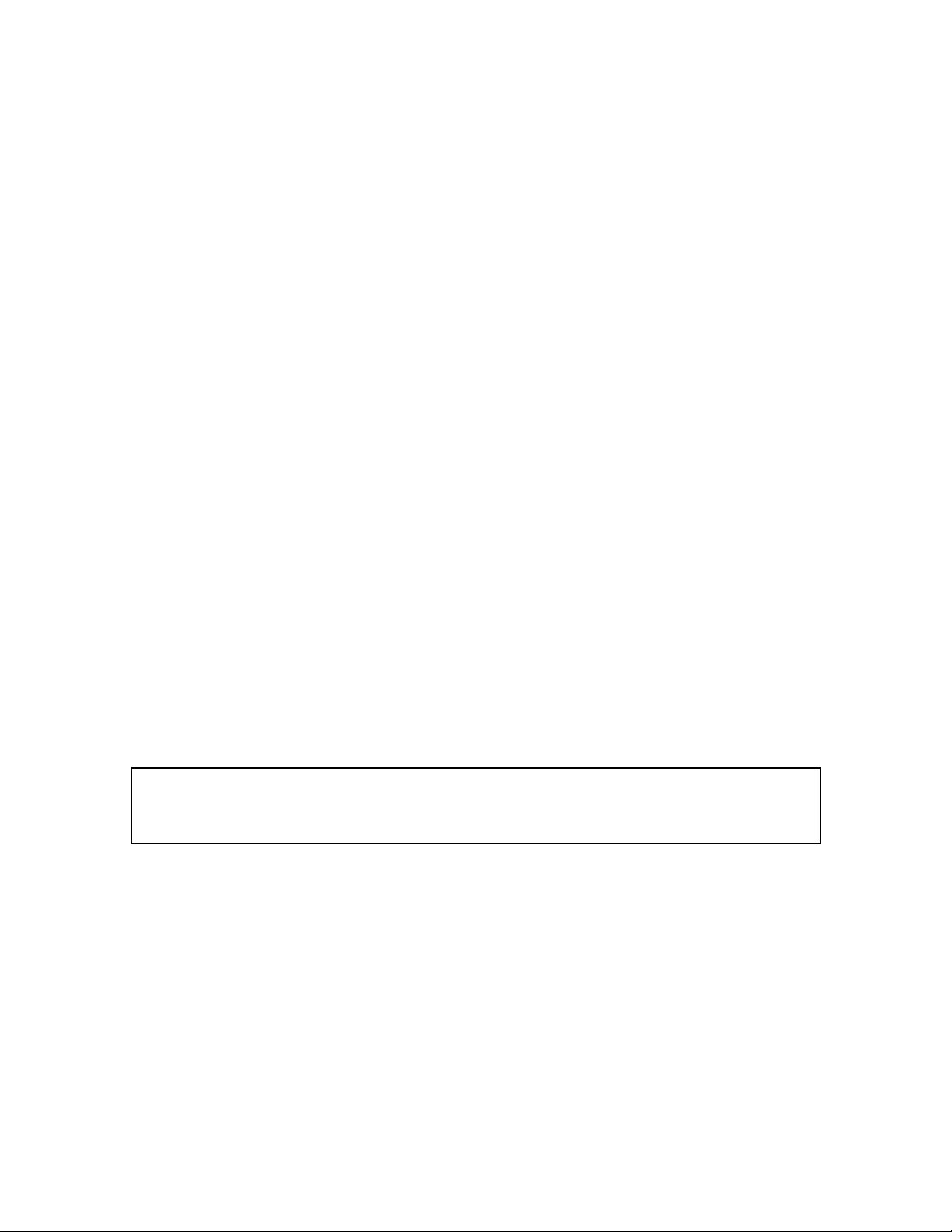

UL/FM APPROVED

AIR MAINTENANCE DEVICE

STANDARD ON DRY AIR PACS

NOTE 1

IF REQUIRED BY AHJ, CONNECT TO

COLD ROOM WITH MINIMUM OF 1 1/2" PIPE SIZE

BUSHED DOWN AT COMPRESSOR INLET

THIS PIPE MUST BE HEAT TRACED AND INSULATED.

CONTROL PANEL CUSTOMER CONNECTION AREA

NOTE 2

AMBIENT TEMPERATURE

MUST REMAIN OVER

50 DEGREES F. AT ALL TIMES

1" THICK VIBRATION ISOLATION PADS SHIPPED WITH UNIT.

UNIT MUST BE MOUNTED ON VIBRATION PADS.

MODELS DAP 500, 1000 & 2000

500

1000

2000

A

17 5/8"

17 5/8"

B

18"

18"

44"

44"

AIR

OUT

DRY AIR

OUTLET

D

in

Z

1

B

C

in

2

in

TEST PORT

A

DRY AIR OUTLET

in

G

in

E

in

F

in

1. COALESCING FILTER - AHEAD OF DRYER.

2. FILTER REGULATOR, AFTERFILTER - AFTER DRYER.

AIR FLOW

OVER

AFTERCOOLER

12" MIN

TO WALL

NOTE

in

DIMENSIONS

C

D

69 1/2"

72 1/2"

13"

13"

E

F

23 1/2"

23 1/2"

10"

10"

G

Z

Revisions

1/2" FPT

1/2" FPT

Title:

DRY AIR PAC OUTLINE DIMENSIONS

DAPOL

General Air Products

Date:

Drawn By:

Drawing #

8/15/96

RGP

G-9646

Rev#

Rev Date:

Scale:

6

7/22/97

NTS

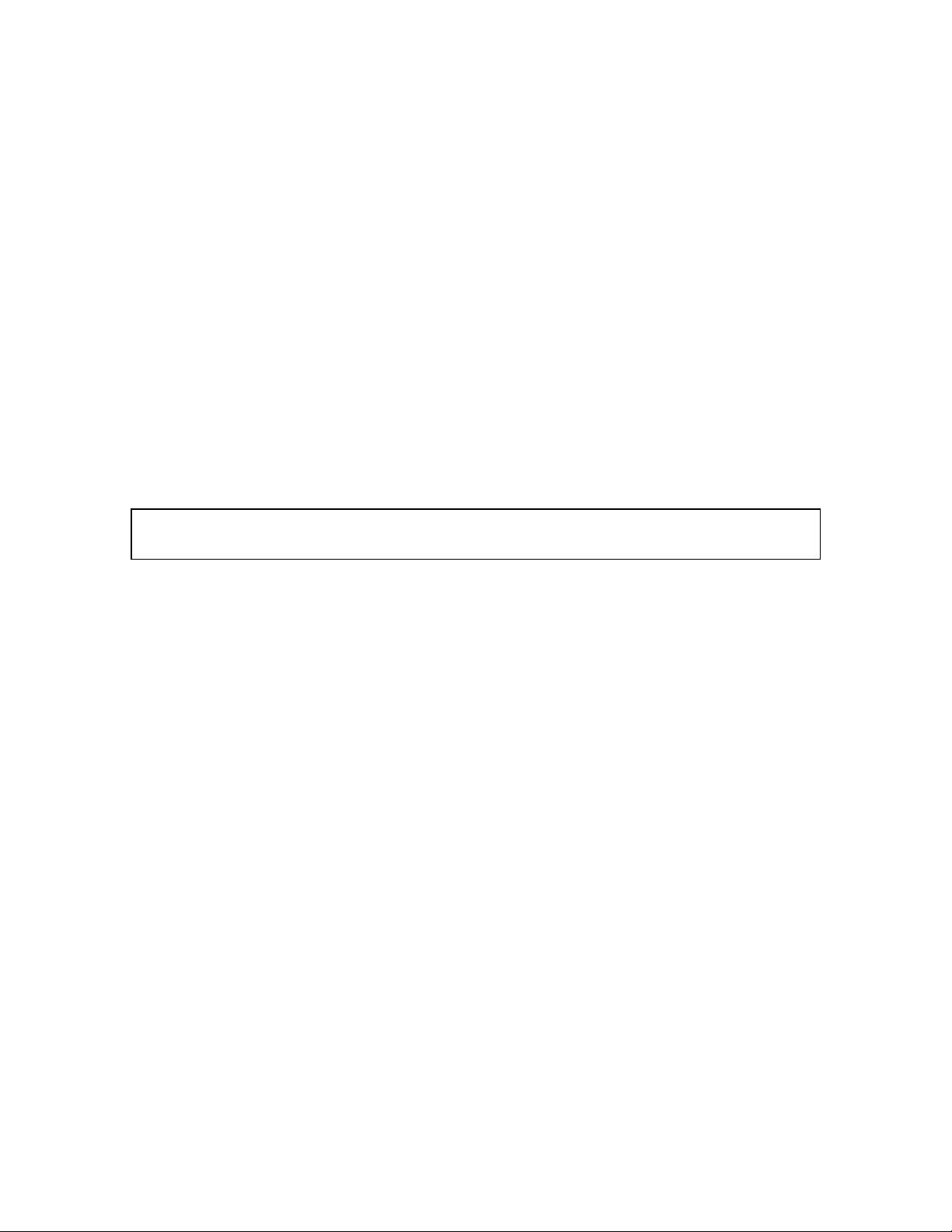

Page 15

SEE TRANSFORMER CONNECTIONS

FOR 575V, 460V OR 230V 60Hz OR 50Hz VOLTAGES

FUSE BLOCKS

POWER INPUT FROM CUSTOMER

A

B

C

A

TRANSFORMER

2

1

2

7

TIMER MOTOR

LT3 L.TOW

B

A

B

3

1

A

B

MOTOR STARTER

MS1

7

1

4

OL

MS

3

11

10

LT

SV

9

TIMER CAMS

7

7

CAM MICRO SWITCH CONNECTIONS

ARE AS FOLLOWS:

BOTTOM CONNECTION IS COMMON

MIDDLE CONTACT IS NORMALLY CLOSED

TOP CONACT IS NORMALLY OPEN

8

RT

SV

2

LT4 R.TOW

TRANSFORMER

TRANSFORMER

TIMER MOTOR

STARTER

HOUR METER

DVA TIMER

LIGHTS DOOR

POWER

SWITCH

DVA

SWITCH

DVA

DV

SV

DAP 3 PHASE POINT TO POINT.TCW

1

2

2

2

2

2

2

2

2

POWER

SWITCH

4 SOL VALVES

JUMPER

JUMPER

JUMPER

JUMPER

JUMPER

JUMPER

JUMPER

JUMPER

5

TIMER

BLACK

DV

62YELLOW

LT

PV

LT1 COMP

LT2 DRAIN

RT

PV

POWER SWITCH

1

3

DVA SW

COMMON

2

3

FOR TIMER

PRESSURE SW

POWER SW

PRESSURE SW

LT-1

DVA TIMER

DVA SW

LT-2

DVA SW

TIMER CAM

3

3

3

4

4

5

6

6

7

STARTER

JUMPER

JUMPER

JUMPER

STARTER

JUMPER

JUMPER

HOUR METER

DVA BOX

JUMPER

JUMPER

DVA TIMER

TIMER MOTOR

STARTER

1

3

2

6

DVA SWITCH

3

Revisions

5

5

REV 7: 8/24/99 ADDED

575V

REV 8:01/19/01 CLARIFIED

TIMER CONNECTIONS

Title:

4

PS

2

2

HOUR

METER

General Air Products

Date:

8/23/96

Drawn By:

Drawing #

DRY AIR PAC ELECTRICAL - POINT TO POINT

RGP

E-9645

3

Rev#

Rev Date:

Scale:

4

8

01/19/01

NTS

Page 16

CUSTOMER

CONNECTIONS

(SEE NOTE 1)

SEE ACCEPTABLE VOLTAGES

L1

L2

L3

M-1

MS

FU-A

SS-1

(LIGHTED)

ON

OFF

3

PL-1

PS

AUTO

MS

1

G

MANUAL

7

FU-1

4

3

1

5

6

CAM TIMER

MTR

NO

CAM1

C

NC

115 V

HM

FU-B

TRANSFORMER

(SEE NOTE 2)

4

4

2

5

6

YELLOW

6

6

11

10

BLACK

MS

DVA

TIMER

BOARD

GROUND

CONTROL POWER SWITCH

2

"POWER ON" LIGHT

PRESSURE SWITCH

OL

MOTOR STARTER

COMPRESSOR LIGHT

HOUR METER

DRAIN VALVE TIMER

AUTOMATIC DRAIN VALVE

DRAIN VALVE LIGHT

CAM TIMER

RIGHT TOWER LIGHT

RIGHT TOWER INLET VALVE

LEFT TOWER INLET VALVE

LEFT TOWER LIGHT

DAP 3 PHASE ELEC SCHEME.TCW

NO

CAM2

NC

C

NO

CAM3

C

NC

NOTES:

1) INPUT VOLTAGE IS CONNECTED TO L1, L2 AND L3 CONNECTIONS ON THE MOTOR STARTER.

2) TRANSFORMER CONNECTIONS ARE DETERMINED BY SUPPLY VOLTAGE.

3) CAM TIMER MICRO-SWITCH CONNECTIONS ARE: BOTTOM CONTACT IS COMMON,

MIDDLE CONTACT IS NORMALLY CLOSED, TOP CONTACT IS NORMALLY OPEN.

ACCEPTABLE VOLTAGES:

DAP500B, DAP1000B AND DAP2000B: 460V/230V/208V/3PH/60HZ

DAP500B-5, DAP1000B-5 AND DAP2000B-5: 575V/3PH/60HZ

DAP500B-50: 190V/200V/208V/220V/380V/400V/415V/3PH/50HZ

DAP1000B-50 AND DAP2000B-50: 190V/200V/208V/220V/380V/400V/415V/440V/3PH/50HZ

9

8

REV 1: 2/24/06: ADDED

ACCEPTABLE VOLTAGES

TITLE

SIZE

A

SCALE

LEFT TOWER PURGE VALVE

RIGHT TOWER PURGE VALVE

GENERAL AIR PRODUCTS

ELECTRICAL SCHEMATIC

3 PHASE DRY AIR PAC

DRAWN BY:

NTS

DPH

DWG NO

DATE:

E-204028

05/03/04

SHEET

REV

1

1 of 1

Loading...

Loading...