Page 1

MODELS GA50A14, GA50A22, GA50A20

Features

Lifetime Filter System never needs replacing

Electronically removes dust, mites, pollen, pet dander, tobacco smoke, cooking smoke

and grease, mold, fungi, bacteria, viruses and more, down to 0.01 micron

Light Weight Aluminum Collecting Cells are durable and easy to maintain

Cell Guide ensures proper placement of collecting cells

Activated Carbon Filters remove unpleasant odors

Electronic Air Proving Switch for quick wiring

Dual Indicator Lights show Air Cleaner is working at a glance

Galvanized Steel Cabinet for solid vertical or horizontal installation

Durable Scratch-Resistant powder coat paint finish resists corrosion

OWNER’S MANUAL

ELECTRONIC AIR CLEANERS

IMPORTANT: PLEASE READ MANUAL BEFORE OPERATING UNIT

Page 2

IMPORTANT: Please read entire instructions before

installing the Electronic Air Cleaner.

CONTENTS

SAFETY CONSIDERATIONS 2

WHAT THE ELECTRONIC AIR CLEANER DOES 2

BENEFITS 2

HOW IT WORKS 2

SPECIFICATIONS 3

COMPONENTS 3

INSTALLATION 3-5

Static Pressure 3

Location 3

Installation Location With Humidifier 4

Installation Location With Air Conditioner 4

Electronic Air Cleaner Installation 5

Wiring 5

SYSTEM CHECK 5

OPERATION 6

WHITE DUST 6

MAINTENANCE 6

Cell and Prefilter Cleaning 6

Activated Carbon Filter Replacement 6

SERVICE 7-10

Quick Check 7

Testing For High Voltage At Power Board 7

Measuring High Voltage At Power Board 7

Replacing Performance Light 7

Replacing A Power Board 8

Testing Air Proving Switch (APS) 8

Replacing An Air Proving Switch (APS) 8

Testing The 24 V Transformer 8

Replacing The 24 V Transformer 8

Setting Voltage Of Power Board 9

Setting Voltage Without High Voltage Meter 9

Testing For Voltage At The Cell 9

Testing Cell For Bad Contacts 9

Testing Cell with an Ohmmeter 9

Removing Power Box 10

Replacing A Tungsten Ionizing Wire 10

EXPLODED VIEW 10

PARTS LIST 11

TROUBLESHOOTING GUIDE 12

WARRANTY 15

Certified for shock and electrical fire hazard only.

SAFETY CONSIDERATIONS

Read and follow instructions carefully. Follow all local

electrical codes during installation. All wiring must conform

to local and national electrical codes. Improper wiring or

installation may damage Air Cleaner.

Understand the signal words WARNING and

CAUTION which are present in the Owner’s Manual.

WARNING and CAUTION signifies a hazard which

could result in property damage, personal injury or death.

WARNING

Before beginning any installation or modification, be

certain that the main line electrical disconnect switch is

in OFF position. Electric shock could result. Tag

disconnect switch with suitable warning labels.

Installation and servicing of Electronic Air

Cleaners can be hazardous. Only trained and qualified

service personnel should install, repair, or service

Electronic Air Cleaners.

Homeowners or untrained personnel can perform

the basic maintenance functions of cleaning and

replacing filters.

When working on air cleaning equipment, observe

precautions in the manual, labels attached to the unit,

and other safety precautions that may apply. Follow

all safety codes. Wear safety glasses and work gloves.

WHAT THE ELECTRONIC AIR CLEANER DOES

Your High Efficiency Electronic Air Cleaner has been

designed to remove atmospheric and household dust, coal

dust, insecticide dust, mites, pollen, mold spores, fungi,

bacteria, viruses, pet dander, cooking smoke and grease,

tobacco smoke particles, and more down to .01 micron

(.01 micron = 1/2,540,000 of an inch).

BENEFITS

Helps provide relief for allergy or asthma suffering.

Helps prevent damaging black dust from staining walls

and furnishings, reducing the amount of time and

money spent cleaning and redecorating.

Helps eliminate unpleasant odors (with use of optional

Carbon Filters).

Helps protect heating/cooling equipment, prolonging

the operating efficiency.

HOW IT WORKS

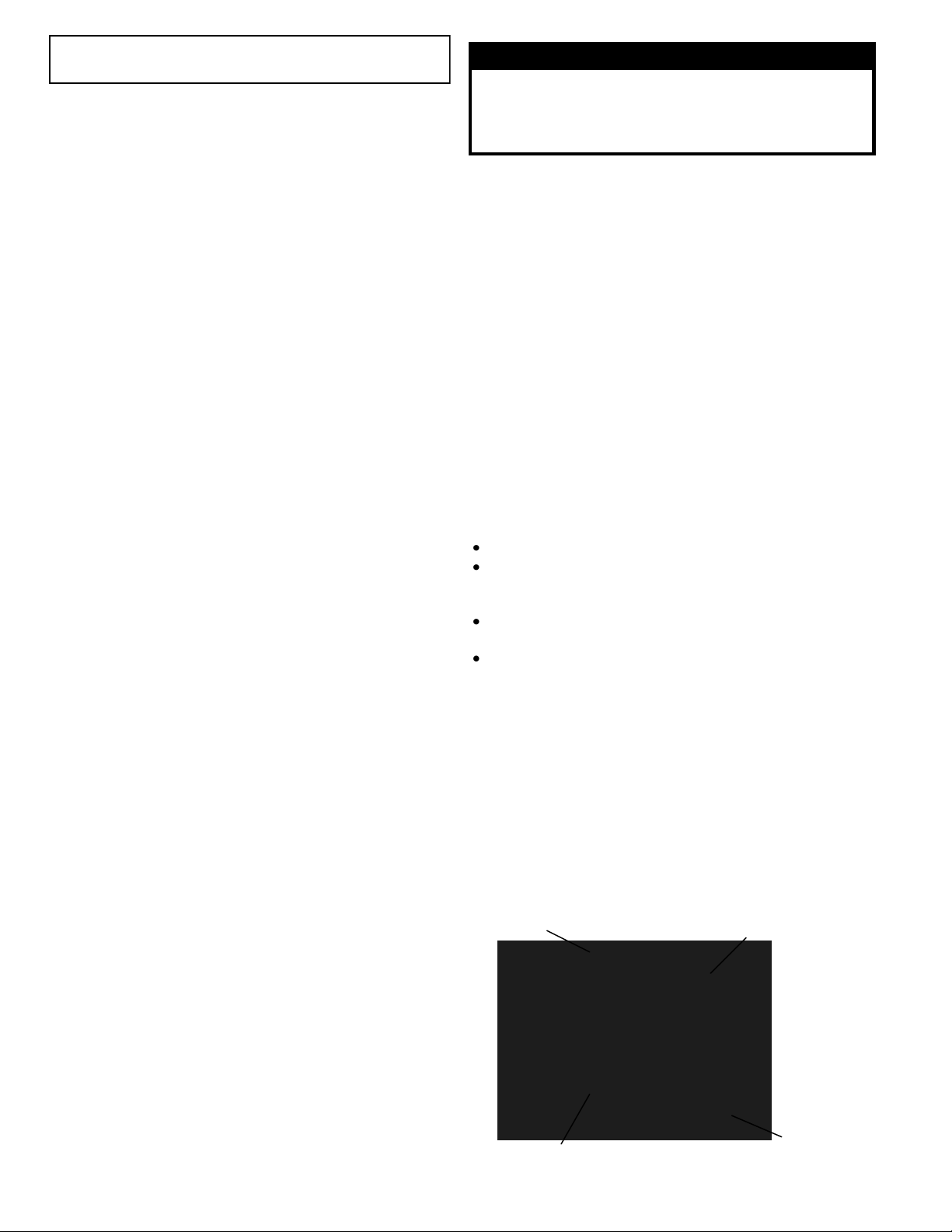

The High Efficiency Electronic Air Cleaner operates on

the principle of electrostatic precipitation. Millions of

airborne pollutants are carried through the return air ducts

of the heating/cooling system and treated through four

stages of filtration.

The prefilters (2) remove all large visible particles such

as lint. Smaller particles then pass through a two-stage

electrostatic collecting cell (2). First, particles are given a

powerful positive electrical charge by the ionizing wires.

Second, charged particles move into the collecting area

2 Prefilter

1 Dirty Air

4 Collecting Cell Plates

6 Clean Air to Heating/

Cooling System

3 Ionizing Section

Fig. 1

5 Carbon Filters (3)

(optional)

2

Page 3

Table 1 — SPECIFICATIONS

MODEL GA50A14 GA50A20 GA50A22

House Size Area

Airflow

Duct Size

Unit Weight

Input Voltage

Power Consumption

Options Included

<3000 ft²

<278.70 m²

up to 1400 CFM

up to 2380 m³/hr

16 x 25 in

40.5 x 63.5 cm

37 lbs

16.8 kg

120 V 60 Hz 120 V 60 Hz 120 V 60 Hz

30 Watts 30 Watts 30 Watts

Carbon Filters

Air Switch

where they are attracted to a series of grounded plates.

Pollutants are held in this section like a magnet until

washed away during cleaning. Lastly, clean air passes

over activated carbon filters (3) for odor removal .

The Electronic Air Cleaner, available in three models

with air flow capacities of up to 1400 and 2000 CFM

(2380 and 3400 m³/hr), is adaptable to all residential

forced air heating or cooling systems.

COMPONENTS

Cabinet: Constructed of heavy gauge galvanized steel

to resist corrosion and provide trouble-free installation.

Holes are provided to facilitate mounting to the ductwork

or air handling equipment.

Power Box: Removable. Contains the power switch,

performance indicator light, safety interlock switch, high

voltage power board, air proving switch and high voltage

contacts.

The power board is uniquely equipped with a variable

resistor (potentiometer) to adjust high voltage output.

Output has been pre-set for optimum efficiency. As

voltage varies in extreme conditions of dryness, humidity

or proximity to hydro towers, raising or lowering

potentiometer allows for proper voltage output.

Air Proving Switch (APS): Integrated. Automatically

cycles Air Cleaner on and off with the system fan. The

APS will detect airflow (fan on) and energize the Air

Performance Indicator Light

ON/OFF Switch

Power Box

Cabinet

Door

Collecting Cells (2)

Fig. 2

Prefilters (2)

Activated Carbon

Filters (3)

<3000 ft²

<278.70 m²

up to 1400 CFM

up to 2380 m³/hr

20 x 20 in

51.0 x 51.0 cm

37 lbs

16.8 kg

Carbon Filters

Air Switch

>3000 ft²

>278.70 m²

up to 2000 CFM

up to 3400 m³/hr

20 x 25 in

51.0 x 63.5 cm

41 lbs

18.6 kg

Carbon Filters

Air Switch

Cleaner.

Collecting Cells: Consist of an ionizing section and a

plate section. The arrow on the cell must point toward the

system fan.

Prefilters: Constructed of aluminum mesh, to prevent

lint and large particles from entering the collecting cells.

Carbon Filters: Remove odors. Must be replaced every

six months - not washable. Maximum of (3) carbon filters

can be used at same time.

INSTALLATION

Static Pressure

The static pressure drop across the Air Cleaner will

vary with CFM and whether the optional carbon filters

have been installed in the unit.

100% Air Flow

No Carbon

0.158 0.250 0.030 0.060

100% Air Flow

With Carbon

40% Air Flow

No Carbon

40% Air Flow

With Carbon

Table 2 — Pressure Drop (Inches WC)

Location

The Air Cleaner must only be installed in the return

air duct, as close to the fan compartment as possible.

This location provides the most even airflow across the

collecting cells and allows the Air Cleaner to keep the

system motor and blower clean. The installation can be

vertical or horizontal. When choosing a location, there

must be adequate room to wire the Air Cleaner and

remove prefilters, collecting cells and power box for

maintenance.

Note: Once Air Cleaner has been installed, do not allow

the placement of any device such as a new hot water

heater, water softener, gas pipe, or electrical cable to be

put 2 ft. in front of or within 6 in. (15 cm) from top of Air

Cleaner, in order to allow removal of filters and Air

Cleaner parts, which are necessary for maintenance or

servicing.

3

Page 4

Fig. 3 — DIMENSIONS

MODEL

GA50A14

GA50A22

GA50A20

DIMENSIONS — in (cm)

A B C D E F G H

19.8

(50.4)

24.7

(62.8)

24.7

(62.8)

15.9

(40.5)

20.8

(52.9)

20.8

(52.9)

26.1

(66.3)

21.2

(53.9)

25.8

(65.4)

13.6

(34.6)

18.0

(45.7)

18.0

(45.7)

24.1

(61.2)

18.7

(47.5)

23.3

(59.1)

1.0

(2.5)

1.3

(3.2)

1.3

(3.2)

26.6

(67.7)

21.7

(55.2)

26.3

(66.8)

25.8

(65.4)

21.2

(53.9)

25.8

(65.4)

Fig. 4 — AIR CLEANER INSTALLATION LOCATION

Fig. 4 — AIR CLEANER INSTALLATION LOCATION

Allow 24 in (600 mm) clearance for cleaning air cleaner. Allow 6 in. (150 mm) clearance for power box removal.

Allow 24 in (600 mm) clearance for cleaning air cleaner. Allow 6 in. (150 mm) clearance for power box removal.

Installation Location With Humidifier

A humidifier should be installed in the furnace warm

air duct. However, it may be installed in the return duct

without causing problems to the Air Cleaner. Care must

be taken to ensure that the humidifier does not leak, as

this may cause arcing and a mineral deposit to build up

on the collecting cells.

An atomizing type humidifier should be installed

downstream from the Air Cleaner. If the atomizing type

humidifier is installed upstream, high humidity, salts and

minerals may decrease the efficiency of the collecting

cells and cause service problems.

If the atomizing type humidifier must be installed

upstream, the following precautions should be taken:

1. Atomizing type humidifier must be installed as far

from the Air Cleaner as possible.

2. Collecting cells must be washed frequently to prevent

a mineral deposit build-up.

Installation Location With Air Conditioner

Whenever possible, the Air Cleaner should be

installed upstream of the cooling coil. This location will

clean the air before it reaches the evaporator coil.

4

Page 5

Electronic Air Cleaner Installation

1. Remove existing equipment filter. Thoroughly clean

fan compartment and ductwork where Air Cleaner is

to be installed.

2. Open access door. Slide filters and collecting cells

out of cabinet.

3. Place cabinet in ductwork. Holes are provided to

attach cabinet to ductwork or equipment. If the

adjoining ductwork is flanged, install the screws so

that the screw heads are inside the cabinet. This will

help prevent damage to prefilter and carbon filters

during removal for cleaning. Never put screws or

rivets into the removable power box.

When the air duct does not fit the Air Cleaner

opening, a gradual transition is recommended to

reduce air turbulence though the air Air Cleaner and

to increase its efficiency. There should not be more

than 20º of expansion used on each side of the

transition fitting. Do not reduce ductwork to a smaller

Air Cleaner or it will increase the velocity of airflow.

4. If the Air Cleaner is installed adjacent to an elbow or

angle fitting, turning vanes are recommended to

improve air distribution across the collecting cells.

5. After the Air Cleaner has been installed, seal seams

airtight with duct tape or caulking to prevent dust

from entering the system.

6. Replace the prefilters in the track on the air entering

side. Place the carbon filters evenly spaced in the

track on the air exiting side. The collecting cells are

placed between the tracks, with the arrow on cell

pointing towards the fan. The cell handle may need

to be repositioned if the airflow is in a different

direction than the left to right set up. The handle

should face the door. Close access door.

Wiring

WARNING

Electrical shock can cause injury or death. Be certain

main line disconnect switch is off before wiring.

Wiring should only be performed by qualified

personnel only. All wiring must comply with all applicable

codes and standards. The voltage of the power source

must match the voltage indicated on the Air Cleaner. The

Air Cleaner must operate ONLY when the system fan is

running. Make sure the Air Cleaner is properly grounded.

If the air cleaner is equipped with a cord and plug the

air cleaner can be plugged into an outlet within 6 feet of

the unit. Do not use an extension cord if the outlet is too

far away. Have an electrician wire in a new outlet closer

to the air cleaner.

If the air cleaner is not equipped with a cord then wire

the Air Cleaner directly to a 120 V power source

preferably to the same source that is supplying power to

the furnace or air handler. The APS will power the Air

Cleaner when there is sufficient airflow to activate the

sensor. See Fig 5.

Note: The power switch will be lit even if there is no

airflow.

If the unit is to be wired to the EAC contacts on the

system module check that there is sufficient voltage to

the EAC contacts with the fan operating in all conditions.

Some systems do not power the contacts on low speed.

SYSTEM CHECK

Perform the following system check before operation.

1. Replace prefilters, collecting cells and carbon filters.

Close access door.

2. Turn Air Cleaner power switch ON. Ensure system

fan is operating. Both the power switch light and

performance indicator light should be lit. The power

switch light indicates the Air Cleaner has unit voltage.

The performance indicator light shows that the Air

Cleaner is operating.

Fig. 5 — Air Cleaner Schematic (with Air Proving Switch)

5

Page 6

Note: There may be some arcing or snapping sounds

from the collecting cells. This is normal when the unit is

new. In about 2 weeks, as the sharp edges of the cells

become smoother, the arcing will disappear.

OPERATION

The Air Cleaner will run as long as there is adequate

airflow through the ducts. The Air Cleaner will not run if

the system fan is off. For proper operation, follow these

simple steps:

1. Run heating/cooling system fan continuously, and on

low speed if available.

2. Remove furniture or carpets which block return air

grilles throughout your house, so that air moves

freely to the furnace/ air conditioner.

3. Check for proper operation of the system fan.

WHITE DUST

After installation of the Air Cleaner, you may notice

some white dust on tabletops and shelves. Most large

particles such as lint, are too heavy to remain airborne

and tend to settle quickly, never reaching the air cleaner.

This white visible dust is normally referred to as

“clean dust.” As the Air Cleaner is removing the dark and

staining particles from the air, the lint will also be cleaner.

Lint dust is most noticeable on dark furnishings; in

homes containing new carpeting; and where there is a lot

of household traffic from occupants and pets. To reduce

lint dust, use continuous fan operation and keep return

vents unrestricted to create an efficient airflow.

Note: The Air Cleaner does NOT produce more lint or

dust.

MAINTENANCE

It is important to follow a scheduled maintenance for

maximum performance of the Air Cleaner.

CAUTION

Make sure to turn Air Cleaner and system fan OFF

before performing any maintenance or removing any

components.

3. Rinse cells well with hot water (maximum 120°F/49°

C).

4. To remove contaminate from the ionizing wires use

an old toothbrush. Slide the brush bristles over the

wire and gently drag the brush up and down the wire

once. Be very careful when cleaning the wires as

they become very brittle with age.

5. If dirt remains on the cell plates, let the cells soak in a

solution of DAX Detergent and water for 30 minutes.

6. Tilt cells on 45° angle on their short side, with arrows

pointing sideways. Allow to dry completely,

approximately 8-10 hours. A hair dryer may be used

to speed up drying time.

7. To wash prefilters, spray with DAX Detergent, rinse

and let dry. Do not wash in the same water as

collecting cells.

8. Do not place the cells in the air cleaner if they are

wet.

9. Place cells and prefilters back into cabinet. Close

door and turn power switch ON. If the performance

light does not come on or arcing occurs, turn Air

Cleaner OFF and allow air from system fan to dry

cells completely.

CAUTION

Damage to cells may occur if improperly handled or

washed. Do not wash cells in a dishwasher. Never use

any object to clean between the cell plates, as this may

cause damage to plates or ionizing wires. Never place

cell in oven to dry. The edges of the cell may be sharp handle with care.

Activated Carbon Filter Replacement

Carbon filters help remove odors from the air. If the

Air Cleaner has been equipped with optional carbon

filters, they should be replaced every 3 - 6 months. Filters

are NOT washable. Replacements are available through

Cell And Prefilter Cleaning

The collecting cells and prefilters must be cleaned on a

regular basis for the Air Cleaner to function at its peak of

efficiency. The frequency of cleaning will vary from one

house to another. On average, the cells should be

cleaned every 3 months.

1. Remove access door, collecting cells and prefilters.

2. Place cells in a laundry tub. Rinse with hot water and

spray completely with DAX Detergent (or a nonchlorine, non-corrosive, non-abrasive liquid

household detergent. Allow detergent to run down

both sides of plates and ionizing wires. Let stand for

5 minutes or fill up laundry tub with water and DAX

Detergent, and dunk cells up and down until water is

dirty.

Fig. 6 — DAX Detergent and Carbon Filters are

DAX 32 oz Spray Bottle Part #9900

Replacement Carbon Filters:

GA50A14 Set of 3 Part #EAC14-12

GA50A20, GA50A22 Set of 3 Part #EAC20-12

6

Page 7

your installer or dealer. To replace filters, perform the

following functions:

1. Turn Air Cleaner power switch OFF.

2. Turn off system fan.

3. Open access door.

4. Remove collecting cells from Air Cleaner.

5. Remove the used carbon filters from Air Cleaner.

6. Put new carbon filters into Air Cleaner. Space filters

evenly across the discharge opening of Air Cleaner.

Never put more than 3 carbon filters in the Air

Cleaner, as this may cause a problem with airflow.

SERVICE

WARNING

Electronic Air Cleaners use high voltage (low

amperage). Only trained personnel should perform

service. USE CAUTION! Electric shock can cause injury

or death.

CAUTION

For most troubleshooting the cells should be

removed from the Air Cleaner. A short in one of the

cells will cause the power board to shutdown and the

performance light will stay off. Unless otherwise directed

remove the cells from the unit when testing.

The Air Cleaner when operating normally, with the

fan running, should have both the switch light and the

performance indicator light ON. If the fan is running and

the lights are not on see the Troubleshooting Guide for

probable causes and remedies.

WARNING

When performing LIVE tests in the power box NEVER

touch any parts other then what are mentioned in the

tests. Components carry dangerous voltages and

extreme care must be taken.

Quick Check (Power Light ON, Performance Light OFF)

1. Make sure the system fan is ON. Remove both

cells.

2. Close the door. If the light is still out, check the

power board for an arc to ground at HV1 or HV2. If

there is a good arc and no performance light then

replace the light. If the light comes on check the

cells for a fault.

3. If there is no arc, test the output voltage of the

transformer. If there is transformer output replace

the power board

4. If there is no transformer output, check for output of

the APS.

5. If there is output from the APS replace the

transformer and retest the power board for an arc.

6. If there is no output from the APS, jumper terminals

3 & 4 on the APS and retest the output. If there is

APS output with the jumper, replace the APS.

7. If there is no output from the APS check the output

voltage from the on/off switch.

8. If there is no voltage from the switch, test the input

to the switch. If there is input replace the switch. If

there is no input to the switch check the interlock

switch and the supply voltage.

Testing For High Voltage At Power Board

With the collecting cells out of the unit, the door on

the unit and the system fan on high speed, turn the Air

Cleaner ON.

With a long shafted screwdriver, with a plastic

handle, short between the grounded side of the power

box and the HV1 terminal of the power board.

If you draw a good spark, there is high voltage from

the power board.

Measuring High Voltage At Power Board

A high voltage meter capable of measuring up to

10,000 VDC is required to test the voltage.

1. The Air Cleaner should be ON with the cells installed,

the door closed and the system fan running. The Air

Cleaner should be on at least 5 minutes to allow

voltage to stabilize. The cells and ionizing wires must

be clean.

2. Remove the cover from power box.

3. Connect the ground of the high voltage meter to an

unpainted surface in the power box.

4. Check terminals HV1 and HV2 on the power board to

determine if voltage is present. See Table 3 for

values..

5. If no voltage is present, remove both cells from the

Air Cleaner and replace door.

a. Check the voltage at HV1 and HV2 again.

b. If voltage is present, the problem is with one of

the cells or the wiring to the copper contacts.

c. With a flashlight, look into the cabinet to check

condition of the copper contacts.

d. If the contacts are not bent, replace one cell and

retest voltage. If cell is OK, test the other cell. If

the problem is with a cell, see Troubleshooting

Guide.

e. If there is no voltage with both cells removed,

check the power board, APS and transformer to

make sure that they are functioning correctly.

6. If there is voltage present, but the performance light

does not come on, replace light.

7. High voltage can be adjusted with high voltage

potentiometer if required. See Table 3.

Replacing A Performance Light

Before replacing the performance light, turn OFF

power to the Air Cleaner at the source.

1. Remove the power box cover.

2. Disconnect the performance light wiring connected to

the LED terminals on the power board. Carefully cut

the wire ties from the wire bundle.

7

Page 8

3. Push the light out through front of power box.

4. Push the new light into the power box.

5. Connect the wiring to the LED terminals on the power

board. P3 - red; P4 - black. Route the wires away

from the high voltage wires or contacts.

6. Replace cover.

7. Return power to Air Cleaner. Test light.

Replacing A Power Board

Before replacing the power board, turn OFF power to

the Air Cleaner at the source or remove the plug.

1. Remove the power box cover.

2. Disconnect wiring from the LED, HV1, HV2 and 24 V

terminals. Make note of position of wires.

3. Remove the three hex nuts from the power board.

4. Remove the power board from the studs.

5. Place the new board onto studs with the 24 volt input

close to the transformer.

6. Replace the hex nuts removed in Step 3. Ensure the

star washer is in place over the steel spacer at the

ground location on the power board. For proper

grounding the washer must be located on the top of

the steel spacer, under the power board.

7. Reconnect wiring to LED, HV1, HV2, and 24 V

terminals on the new power board. See Fig. 5.

8. Return power to Air Cleaner. Test power board.

9. Replace power box cover.

Note: The power board has been set before shipping. It

is not usually necessary to reset the voltage to the new

load. If you do need to adjust the voltage refer to Setting

Voltage of Power Board section for more information.

Testing Air Proving Switch (APS)

The APS sensor must sit in the plastic bushing to

operate correctly. The sensor is very sensitive and

operation may be affected by cold ambient temperatures,

an air exchanger, or a fresh air duct connected to the

return air duct just upstream of the Air Cleaner.

The APS uses a Triac in its output circuit, which

affects the voltage sine wave. Using a regular digital

voltmeter may give a false reading. To check the output

from the APS, use a true RMS (root mean square) meter

to measure the output at terminals 1 and 4 of the APS.

The output should be between 105 and 115 VAC,

depending on the airflow across the sensor.

A 125 volt neon lamp may be used to test the output

of the APS. Place the leads of the lamp across terminals

1 and 4 of the APS. If the lamp lights, the voltage is

sufficient for operation. Do not use performance light.

When the Air Cleaner is turned on without airflow, the

APS sensor heats up, and after 20-30 seconds opens the

circuit to turn off the power board. When the fan starts up

(the sensor is cooled), the circuit will close, the power

board is turned on, and the performance light will come

on.

The light on the power switch will be lit even when

the APS is open.

If the power board fails to come on with the fan on,

check that the sensor is properly set down, to the bottom

of the plastic bushing, in the front of the power box. To

check the APS for proper operation remove the collecting

cells, turn the unit ON without the fan on. The power

board should come on immediately, and then turn off in

20-30 seconds as the sensor heats up. To check sensor,

blow directly on it lightly. This should activate the power

board within 10 seconds. Service the sensor carefully.

The sensor leads are 120 V. If the APS does not turn the

power board and performance indicator on, by-pass the

APS by placing a jumper between wires 3 & 4 on the

APS. This removes the APS from the circuit.

See Troubleshooting Guide for more information.

Note: If the air flow through the Air Cleaner is less than

360 CFM the APS sensor may not have enough air flow

to activate the Air Cleaner. See Wiring for information

how to wire the Air Cleaner to the EAC module of the

system. In very low air applications the Air Cleaner may

need to be wired through the EAC contacts and the APS

disabled by connecting wires 3 & 4 together.

If there is no EAC module or it is not powered on low

speed then a relay will have to be installed to activate the

Air Cleaner when the fan starts. The APS will have to be

disabled.

Replacing An Air Proving Switch (APS)

Before replacing the APS, turn OFF the power to the

Air Cleaner at the source.

1. Disconnect wiring from terminals 1, 2, 3, and 4 on the

APS. See Fig. 5.

2. Remove the circuit board from the studs by removing

the two nuts. Do not remove the spacers.

3. Install the new APS on the studs and secure with the

nuts. Ensure sensor protrudes only to the bottom of

the plastic bushing.

4. Connect wiring to terminals on APS. See Fig. 5.

Wiring from the power switch is connected to

terminals 2 and 3. Wiring to the transformer is

connected to terminals 1 and 4.

5. Test the new APS.

Testing The 24 V Transformer

1. Remove power box cover.

2. Disconnect the leads of the 24 V transformer from

the power board. See Fig. 5. Do not short leads.

3. The Air Cleaner should be ON. The system fan

should be running on high speed. The access door

should be closed.

4. Measure voltage across the leads with a voltmeter.

Voltage should read 25 - 28 VAC.

5. If no voltage is present, check operation of the APS.

6. Reconnect leads to the power board.

7. Replace power box cover.

Replacing The 24 V Transformer

Before replacing the transformer, check the

resistance across the power board 24 V input terminals,

8

Page 9

without the transformer connected. Resistance should

read above 20K ohms with an analog meter and above

4M ohms with a digital meter. If the resistance readings

are below these values, the power board may be the

cause of the transformer failure.

Before replacing the 24 V transformer, turn OFF power to

the Air Cleaner at the source.

1. Remove power box cover.

2. Disconnect the secondary leads from the transformer

to the 24 V terminals on the power board. See Fig. 5.

3. Cut the primary leads (to the APS) close to the

transformer or disconnect leads from the APS.

4. Remove the 2 hex nuts and washers from the

transformer studs.

5. Remove the transformer.

6. Place new transformer over studs and re-install 2 star

washers and hex nuts to secure into place.

7. Connect secondary leads (white) to the 24 V

terminals on the power board (P1 & P2).

8. Wire nut primary leads from APS (cut in Step 3) to

the primary leads of the new transformer or connect

primary leads to APS terminals 1 & 4.

9. Replace power box cover.

10. Turn ON the power to the Air Cleaner and test.

Setting Voltage Of Power Board

Voltage on the power board may drop below required

level when installation area is too damp, too cold, or if

there is a leakage of water from a humidifier. Voltage on

power board may be too high when installation area is

too dry or too hot, or home is in close proximity to hydro

towers or situated in remote farm land areas. By

adjusting the HV Adj. potentiometer, the voltage can be

set to optimum level. A high voltage meter capable of

measuring 10,000 VDC is required. To test and adjust

voltage level, perform the following procedure:

1. Turn the Air Cleaner OFF.

2. Remove the power box cover.

3. Connect the ground of the high voltage meter to an

unpainted surface in the power box.

4. Turn ON the Air Cleaner and wait 5 minutes before

checking voltages to allow voltages on cells to

stabilize. The cells and ionizing wires must be clean.

5. Measure the voltages at HV1 and HV2 on the power

board.

6. Adjust the HV Adj. potentiometer until the voltage

reading matches the voltage in Table 3. Adjusting the

potentiometer clockwise decreases the voltage and

turning counter-clockwise increases the voltage.

7. Turn OFF the Air Cleaner.

Model Maximum Voltage

on Plates (KVDC)

Maximum Voltage

on Ionizer (KVDC)

8. Remove the high voltage meter.

9. Replace the power box cover.

10. Turn ON the Air Cleaner.

Setting Approximate Voltage Without High Voltage

Meter

A high voltage meter should be used to set the high

voltage. If one is not available, this method can be used.

This will only set an approximate voltage. After using this

method, the voltage should be reset with a high voltage

meter as soon as possible.

1. Remove power box cover.

2. Turn the HV Adj. potentiometer fully counter-

clockwise. The Air Cleaner may arc or snap at this

point.

3. Turn the HV Adj. potentiometer back, clockwise, until

the arrow is between 6 and 8 on the dial or on the +

side of the half way point.

4. Replace power box cover.

Testing for Voltage At The Cell

1. Open access door to Air Cleaner.

2. The cells must be in the Air Cleaner for this test and

the system fan should be on high speed.

3. Turn the Air Cleaner ON and press the safety

interlock switch lever.

4. Place a plastic handled screwdriver into the direction

arrow slot. Do not apply excessive force.

5. If there is a good snap then there is high voltage at

the cell.

Testing Cell For Bad Contacts

1. Open access door to Air Cleaner.

2. The cells must be in the Air Cleaner for this test and

the system fan should be on high speed.

3. Turn the Air Cleaner ON and press the safety

interlock switch lever.

4. Place a plastic handled screwdriver into the direction

arrow slot. Do not apply excessive force.

5. There should be an initial snap when the plates are

shorted, then no sound. If a hissing occurs, then

there is a bad contact. Look along the top of the cell,

with the short still in place. If there is a small arc

between the cell top and copper contact, then that is

the bad contact. Pull cell out and gently pull the

copper contact down.

6. If an arc is not seen and there is a bad contact, then

the problem may be an internal contact in one of the

cells.

7. Let up on safety interlock.

8. Close access door.

See below for additional testing.

GA50A14 4.8 - 5.3 (HV1) 7.2 - 8.0 (HV2)

GA50A20, GA50A22 4.8 - 5.2 (HV1) 7.2 - 7.8 (HV2)

Table 3 — Power Board Voltage Settings (with load)

The voltage will be higher without the cells in the unit.

Testing Cell with an Ohmmeter

To test the cell for a dead short or a bad contact an

ohmmeter can be used. Always discharge the cell with

a screw driver before testing with an ohmmeter.

9

Page 10

1. With the ohmmeter set on its lowest scale take a

reading between the top center contact of the cell

and the ionizing fingers on the bottom of the cell. You

should have continuity. If you do not then there is a

bad contact between the center contact and the top

set of ionizing fingers.

2. Test the resistance between the top center contact

and the cell frame. You should read infinite

resistance. If not you have a short in the ionizing

section.

3. Take a reading between the two outside contacts on

the top of the cell. You should have continuity. If you

do not then there is a bad contact between one of the

contacts to the live cell plate. Test each top outside

contact to the last plate in the cell to determine which

contact is not mating properly.

4. Test the resistance between the outside contacts and

the cell frame. You should read infinite resistance. If

not you have a short in the collecting section.

5. If you have a bad contact adjust the internal contacts

within the cell until contact is made.

Removing Power Box

1. Turn the main system switch OFF or disconnect the

power cord.

2. Remove the power box cover.

3. If the unit does not have a cord disconnect the

source wires to the Air Cleaner. Cap off the wires so

the system can still be operated.

4. Remove the two nuts holding the power box to the

cabinet.

5. Slide the power box forward then up to remove it

from the cabinet.

6. If you are removing the power box for any length of

time tape a cover over the top opening to prevent air

from entering into the system.

Replacing A Tungsten Ionizing Wire

Replacement wires are cut to the correct length and

have eyelets at each end for easy replacement.

1. Turn OFF power to Air Cleaner.

2. Remove cell from Air Cleaner.

3. Remove all parts of broken wire from the cell. If

necessary, the cell may be used temporarily with one

wire missing until a replacement is received.

4. Place one end of the loop over the finger at the

bottom of the cell.

5. Using needle-nose pliers, grip the other end of wire,

near the bottom of the top loop. Pull the wire up

toward the top finger. As you apply tension, the

bottom finger will give, allowing the placement of the

loop around the top finger.

6. Install cell in Air Cleaner.

7. Return power to Air Cleaner.

8. Test cell for proper operation.

Fig. 7 — Exploded View

# Part Description

1 On/Off Switch

2 Safety Interlock Switch

3 Performance Indicator Light (Green LED)

4 Air Proving Switch

5 24 Volt Transformer

6 Power Board

7 Fibreboard (with 4 Copper Contacts)

8 Copper Contact

9 Cord Assembly (Optional)

10 Cover for Power Box

11 Power Box Complete (No Cover)

12 Carbon Filters (Set of 3)

13 Prefilter

14 Cell Guide (Plastic)

15 Collecting Cell

16 Cell Handle

17 Door (with Plastic Clip & Handle)

18 Door Handle (Plastic)

19 Ionizing Wire

20 Male & Female Door Clip Set

21 Door Label (Important… Wait 15 Seconds)

22 Door Label (Cleaning Instructions)

23 Dax Detergent

Use Part Numbers When Ordering (See next page)

10

Page 11

Parts List

Use the diagram on the preceding page to identify the part which is required. To order

parts call the number listed at the bottom of the page or call your local contractor.

# Part Description

1 On/Off Switch

2 Safety Interlock Switch

3 Performance Indicator Light (Green LED)

4 Air Proving Switch

5 24 Volt Transformer

6 Power Board

7 Fibreboard (with 4 Copper Contacts)

8 Copper Contact

9 Cord Assembly (Optional)

10 Cover for Power Box

11 Power Box Complete (No Cover)

12 Carbon Filters (Set of 3)

13 Prefilter

Type 11A

GA50A14

EAC14-01 EAC14-01 EAC14-01

EAC14-02 EAC14-02 EAC14-02

EAC14-03 EAC14-03 EAC14-03

EAC14-04 EAC14-04 EAC14-04

EAC14-05 EAC14-05 EAC14-05

EAC14-06 EAC20-06 EAC20-06

EAC14-07 EAC22-07 EAC20-07

EAC14-08 EAC14-08 EAC14-08

EAC14-09 EAC14-09 EAC14-09

EAC14-10 EAC22-10 EAC14-10

EAC14-11 EAC22-11 EAC20-11

EAC14-12 EAC20-12 EAC20-12

EAC14-13 EAC22-13 EAC20-13

Type 12A

GA50A22

Type 18A

GA50A20

14 Cell Guide (Plastic)

15 Collecting Cell

16 Cell Handle

17 Door (with Plastic Clip & Handle)

18 Door Handle (Plastic)

19 Ionizing Wire

20 Male & Female Door Clip Set

21 Door Label (Wait 15 Seconds...)

22 Door Label (Cleaning Instructions)

EAC14-14 EAC14-14 EAC14-14

EAC14-15 EAC22-15 EAC20-15

EAC14-16 EAC14-16 EAC14-16

EAC14-17 EAC20-17 EAC20-17

EAC14-18 EAC14-18 EAC14-18

EAC14-19 EAC20-19 EAC20-19

EAC14-20 EAC14-20 EAC14-20

EAC14-21 EAC14-21 EAC14-21

EAC14-22 EAC14-22 EAC14-22

23 Dax Detergent 9900 9900 9900

11

Page 12

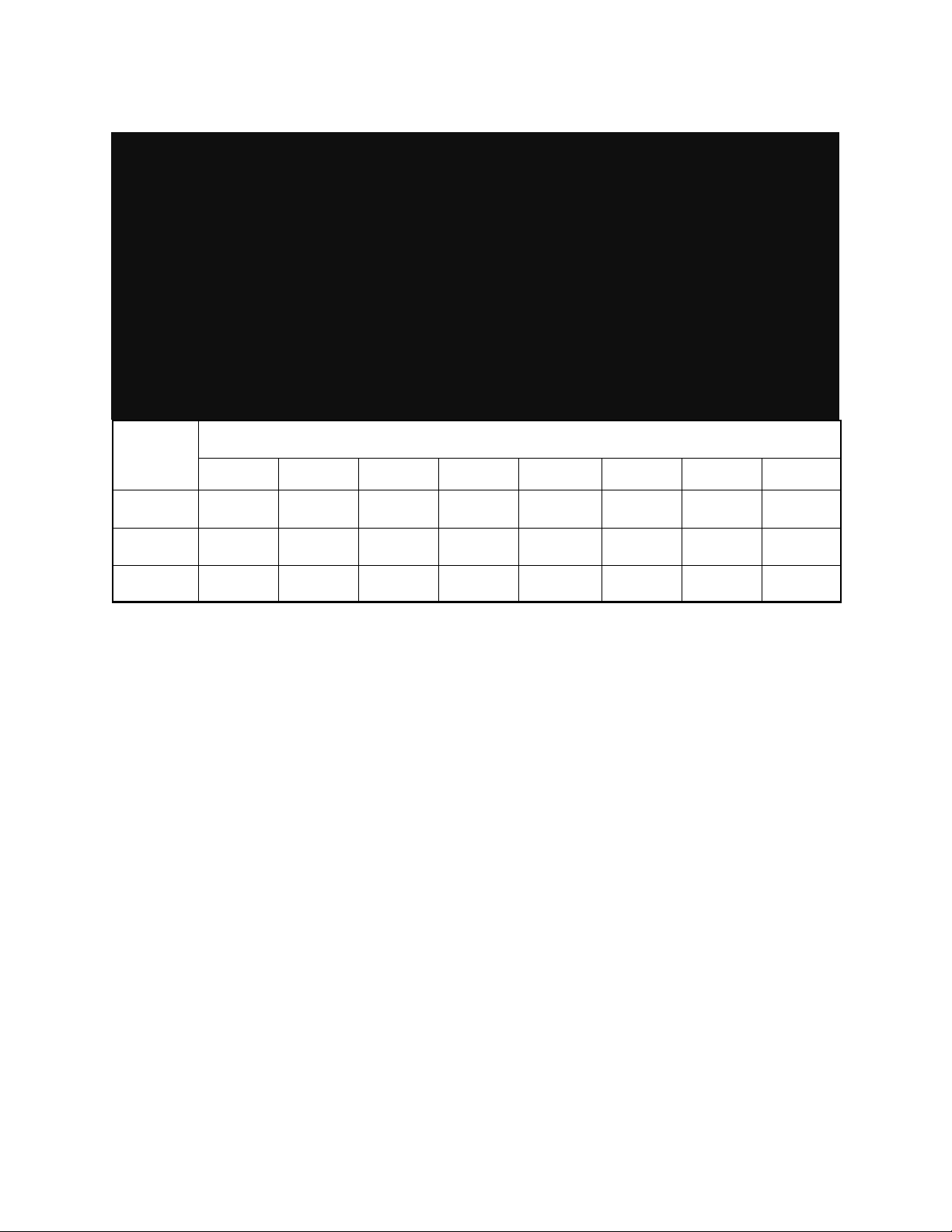

Table 4 — TROUBLESHOOTING GUIDE

PROBLEM PROBABLE CAUSE REMEDY

System fan is not on. Turn system fan on.

Unit does not function

correctly. Power light

and performance indicator light are OFF.

Unit does not function

correctly. Power light is

ON and performance

indicator light is OFF.

Power light is OFF and

performance indicator

light is ON.

Cell makes loud hissing

noise or causes radio

interference.

Cells arcing excessively

(power light and performance indicator light

ON or flashing).

Cells arcing excessively

at top of cell near copper contacts (power

light and performance

indicator light ON).

Cells not collecting dirt

(power light and performance indicator light

ON).

Ozone odor

White dust

Wiring improperly connected. Check wiring or if plug is inserted and receptacle is powered.

Defective power switch. Check power switch for continuity with ohmmeter. Replace if defective.

Defective safety interlock. Remove door and press safety interlock with a screwdriver. If lights

Short in cells due to:

1. Broken ionizing wire.

2. Large particles wedged between cell plates.

3. Cells washed recently and are still wet.

4. Cell end plate insulator is dirty or damaged.

5. Cell plate(s) are bent.

Defective performance indicator light. Determine whether high voltage is present by testing power board. If

Defective power board. Adjust high voltage potentiometer on power board counter-clockwise. If

Air Proving Switch (APS) sensor is burnt out. Remove power box lid and blow lightly for 10 seconds on APS sensor

Air Proving Switch is not getting enough air

across the sensor.

Off board 24V transformer is not working. Verify output of transformer. Replace if necessary.

Defective power switch. Verify output of switch. Replace if necessary.

Defective power switch light. Replace power switch.

Internal cell contacts are not touching plates. Test contacts and repair.

Copper contacts on high voltage tray not making

good connection on cell.

Cells wet from washing. Allow cells to dry completely.

Particles lodged in cell or broken ionizing wire. Wash cell. Shake particle out of cell. Replace wire, if necessary.

Ducts were not cleaned prior to installation of air

cleaner.

Cell plates are bent. Remove cells and adjust to original spacing using needle-nose pliers.

Dirty cells. Wash cells and clean ionizing wires.

Voltage is too high. Adjust high voltage potentiometer on power board clockwise.

High voltage wires are on wrong copper contact. Reposition high voltage wires on proper contact (see Fig. 5).

Internal contact on cell out of alignment. Realign cell contact.

Humidifier (if installed) is leaking water on air

cleaner.

Copper contact on high voltage contact board

are broken or bent upward.

Arrow on cells not pointing towards fan blower. Reposition cell handle and place cell in properly.

System fan is on “Automatic” setting (air cleaner

not on continuously)

Not enough voltage on collecting cells. Adjust high voltage potentiometer counter-clockwise on power board.

Cell plates are bent. Straighten with needle-nose pliers.

Loose or broken ionizing wire. Replace wires.

Dirty cells. Wash cells and clean ionizing wires.

Air Cleaner is on when system fan is not run-

ning. Air cleaner wired incorrectly or air proving

switch is defective.

Incoming voltage is higher than 120V. Adjust high voltage potentiometer clockwise on power board.

Air Cleaner is oversized for house. Not enough

airflow to cover surface area of cells.

Home is extremely dry. Repair or install central humidifier.

Clean lint dust too heavy to remain airborne. Keep fan running continuously. Ensure that return air grilles are not

Gaps around Air Cleaner. Seal or use duct tape around Air Cleaner cabinet.

come on, bend interlock lever towards front and close door.

1. Remove wire or wire fragments. Replace.

2. Shake large particles out or wash cell.

3. Allow cells to dry completely.

4. Clean or replace end plate insulator.

5. Straighten plates with pliers.

voltage is present, replace indicator light.

high voltage is not present, replace power board.

at bottom of power box. If light does not come on, replace APS.

Check that sensor is located in the plastic bushing at the front of the

power box.

Check that the return duct is installed flush to the top and front edge of

the Air Cleaner duct opening.

Ensure there is a minimum of 360 CFM of air to the air cleaner.

With needle-nose pliers, gently pull contacts down or replace contacts.

Clean ducts.

Repair humidifier. If possible, move humidifier to different location.

If possible, pull down contacts with needle-nose pliers or remove power

box and replace contacts.

Use “Fan On” system fan setting for continuous fan operation.

Check operation and wiring of air switch and air cleaner.

Use correct size of Air Cleaner.

obstructed.

12

Page 13

Cleaning Record

The collecting cells and prefilters must be cleaned on a regular basis for the Air Cleaner to

function at its peak of efficiency. The frequency of cleaning will vary from one house to

another. On average, the cells should be cleaned every 3 months.

Use the chart below to keep track of your cleaning schedule.

DATE CLEANED DATE CLEANED DATE CLEANED

13

Page 14

NOTES:

14

Page 15

ELECTRONIC AIR CLEANER

LIMITED FIVE YEAR WARRANTY

Electronic Air Cleaners, if properly registered by the return of the attached warranty registration to

General Filters, Inc., are warranted to the consumer against defects in materials and workmanship for

a period of five years from the date of installation, so long as the product has been installed and

operated in accordance with all appropriate manuals and wiring diagrams. Replacement or routinely

replaceable parts such as prefilters, ionizing wires or carbon filters, are not covered by this limited

warranty or any other warranties. Any other defective parts will be repaired without charge except for

removal, reinstallation and transportation costs. To obtain repair service under this limited warranty,

the consumer must send the defective part to General Filters, Inc.

THERE ARE NOT EXPRESS WARRANTIES COVERING THIS ELECTRONIC AIR CLEANER

OTHER THAN AS SET FORTH ABOVE. THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED. THE MANUFACTURER

ASSUMES NO LIABILITY IN CONNECTION WITH THE INSTALLATION OR USE OF THIS

PRODUCT, EXCEPT AS STATED IN THE LIMITED WARRANTY. THE MANUFACTURER WILL IN

NO EVENT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

This limited warranty gives you specific legal rights, and you may also have other rights which vary

from state to state. Some states do not allow either limitations on implied warranties, or exclusions

from incidental or consequential damages, so the above exclusion and limitation may not apply to you.

Any questions pertaining to this limited warranty should be addressed to General Filters, Inc. General

Filters, Inc. has elected not to make available the informal dispute settlement mechanism which is

specified in the Magnuson-Moss Warranty Act.

G

GFI-SASD2-Rev-G.pub

Rev. G 04/11

Page 16

ATTENTION INSTALLER

IMPORTANT WIRING INFORMATION

This Electronic Air Cleaner is equipped with an Air Proving Switch (APS). The

recommended source for the input voltage to the Air Cleaner is from the same

source that is supplying the heating/cooling equipment, providing it is the

same voltage as the Air Cleaner. The Air Cleaner should be wired directly to

the power source. The APS will power the Air Cleaner when there is sufficient

airflow to activate the sensor.

If you wish to wire the Air Cleaner to the EAC / Accessories Module on the

circuit board of the furnace or air handler, ensure that there is 115 Volt output

from these terminals, when the unit is run manually and is running on low

speed. Some manufacturers do not supply full output voltage to the terminals

in the low speed mode, so the Air Cleaner will not function. The green

Performance Indicator Light will not turn on.

The Air Cleaner performs best when the system fan is on “FAN ON” or

“Continuous” mode, and is run on the low speed. Check the output of the

terminals with a volt meter when running on low speed, before wiring the Air

Cleaner to the circuit board.

The Air Cleaner must be wired to operate only when the system fan is on.

See page 5 of the Owner’s Manual for more information on wiring.

Loading...

Loading...