Page 1

INSTALLATION GUIDE

Horizontal

series

HRV MODEL 8160and MODEL 8220

ERV MODEL 3160and MODEL 3220

Page 2

2

About Us

GeneralAire offers you a complete range of products designed to improve indoor air quality, and

that provides a wide selection of accessories to facilitate installation.

Our vision – To offer a complete range of GeneralAire products that satisfy environmental

concerns.

Whether your needs involve ventilation, purification, humidification or filtration, GeneralAire has

the customized solution for you, with its range of quality products backed by the best warranty

in the industry.

Installation

1. Ventilation needs

2. Types of installation

3. GeneralAire HRV/ERV systems

4. Finding a suitable installation area for the HRV or ERV

5. Installation of the HRV/ERV

6. Rigid duct

7. Insulated flex from unit to outside wall

8. Condensation drain line

9. Devoted electric receptacle

10. Outside fresh air and exhaust air hoods

11. Fresh air and exhaust air grilles

12. Benefits of the DuotrolTMsystem

13. Balancing the unit

Functions and Controls

14. Controls and wiring

Technical Information

15. Troubleshooting

16. Wiring diagram

17. Maintenance

18. Specification and technical information

Peace of Mind

All GeneralAire products are

backed by the best limited

warranty in the industry, for

your peace of mind.

You benefit from a lifetime warranty on

the core, a 10-year warranty (5 years +

5 years prorated) on our ventilation

motors, a 5-year warranty on the

enthalpic core, and a 5-year warranty

on all other components. So you can

breathe easy.

3

3

6

6

7

7

8

9

10

11

12

13

14

15

19

20

21

22

INFORMATION FOR INSTALLERS PAGE

INFORMATION FOR HOME OWNERS AND INSTALLERS PAGE

INFORMATION FOR HOME OWNERS AND INSTALLERS PAGE

INSTALLATION

GUIDE

Page 3

3

Determine your

ventilation needs

installation

How much fresh air do I need? Good air

quality is based in part on the capacity

of the home’s ventilation system.

Usually, the HRV’s or ERVs capacity is

measured in CFM (cubic feet per

minute) or L/s (Liters per seconds) of

fresh air being distributed in the living

space. The room count calculation or the

air change per hour method shows you

how to determine your ventilation needs.

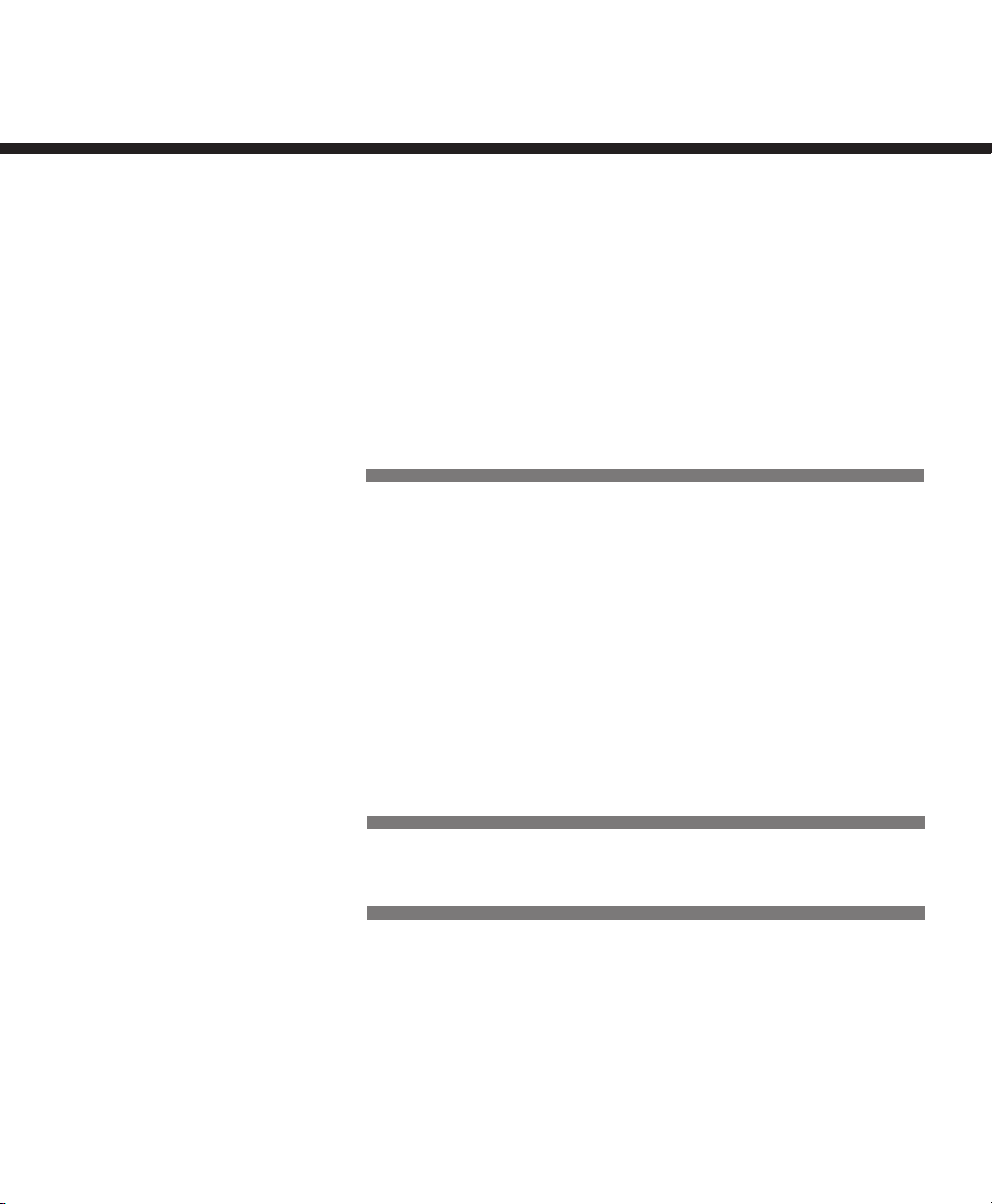

Independent system

installation

This application uses a

devoted duct system for the

supply and the exhausting

of stale air accumulated

in the home.

It is recommended to install

fresh air grilles in all

bedrooms and living areas. Exhaust

the stale air from the bathroom,

kitchen and laundry room.

Independent System

A. Room count calculation

B. Air change per hour method

2. Types of Installation

1.Ventilation Needs

LIVING SPACE

Master Bedroom

With Basement

Without Basement

Single Bedroom

Living Room

Dinning Room

Family Room

Recreation Room

Other

Kitchen

Bathroom

Laundry Room

Utility Room

TOTAL cu ft x 0.35 per hr = total

Take total and divide by 60 to get CFM

Number of Rooms CFM (L/s) CFM Required

x 20 cfm (10 L/s)=

x 20 cfm (10 L/s)=

x 10 cfm (5 L/s)=

x 10 cfm (5 L/s)=

x 10 cfm (5 L/s)=

x 10 cfm (5 L/s)=

x 10 cfm (5 L/s)=

x 10 cfm (5 L/s)=

x 10 cfm (5 L/s)=

x 10 cfm (5 L/s)=

x 10 cfm (5 L/s)=

TOTAL ventilation requirement (add last column)=

1 CFM = 0.47189 L/s

1 L/s = 3.6 m

3

/hr

Example: 25' x 40' house with basement

1,000 sq. ft. x 8' high x 2 (1st floor + basement) = 16,000 cu. ft.

16,000 cu. ft. x 0.35 ACH = 5,600 cu. ft.

5,600 cu. ft./60 minutes = 93 CFM

93 CFM is your ventilation need

Page 4

4

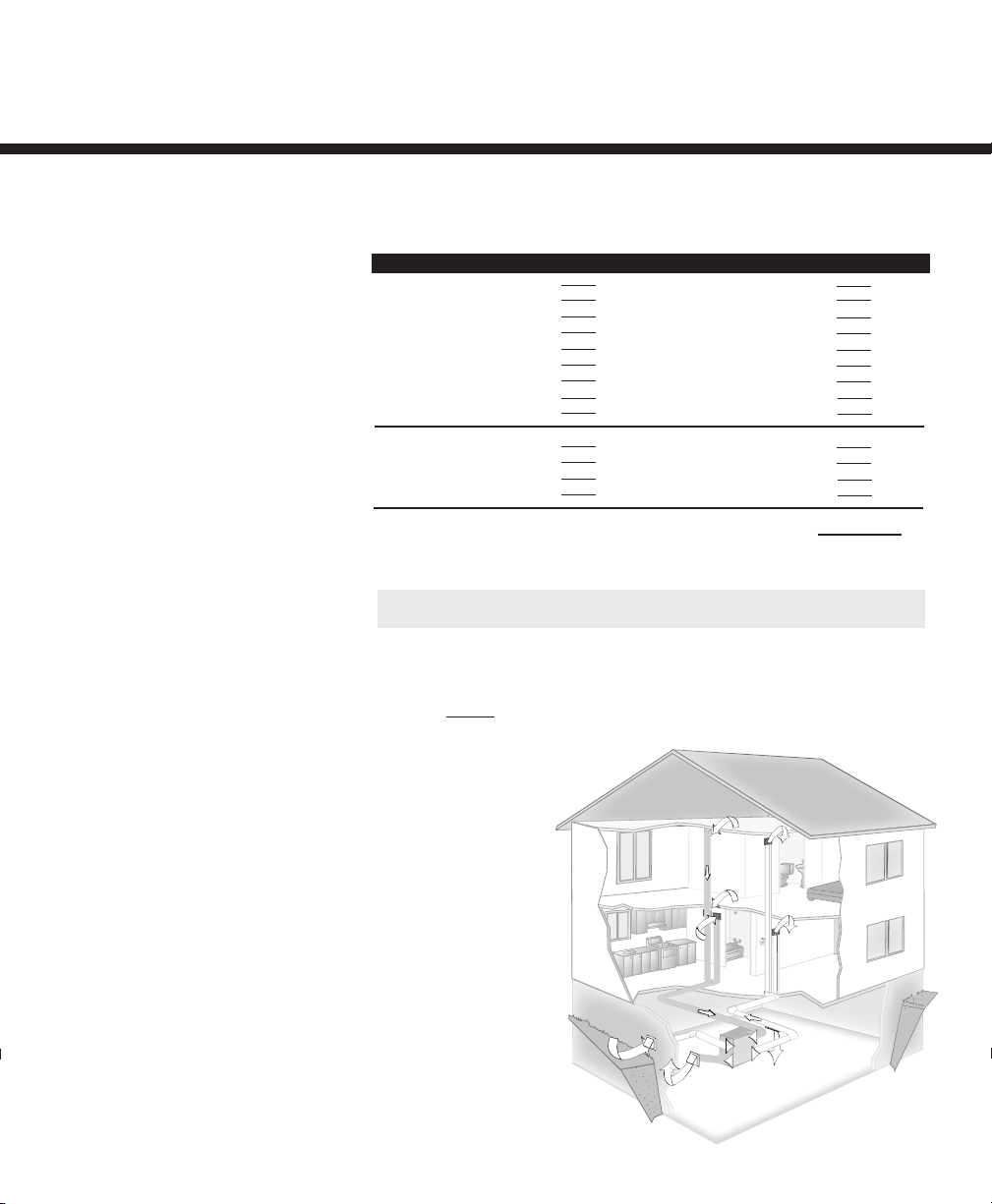

4" to 12" maximum

Indirect Connection - Breathing Tee

Indirect Connection - Return Air Grille

2. Types of Installation (continued)

Exhaust at the

source and supply

in the return

installation

This application uses a

devoted duct system for the

exhausting of stale air accumulated

in the home. The fresh air is dumped into

the return air duct and is distributed thru

the home by the existing supply air

ductwork of the forced air system.

Make sure when using this application that

your fresh air duct connection to the forced

air system return air duct is at least 3' from

the forced air system. You should check

with your local code or the forced air

system’s manufacturer.

Forced Air System

6'

18"

*For minimum distance between return and forced air

system, check with your local building codes and forced

air system manufacturer.

HRV/ERV

From Bathroom or

Kitchen

To living space

There are different practices used to combine HRV or ERV to a forced air system.

3'

Exhaust at the source

A Breathing Tee is a ventilation air supply

duct with an open tee located before the

connection to the return air duct. It allows

the HRV to function without supply air flow

rates being affected by the forced air

system’s fan speed.

Leaving a gap in the ventilation air supply

duct in place of the breather tee is

acceptable but not recommended.

With the return air grille approach, HRV or

ERV ventilation supply air is “dumped”near

a grille (between 4" and 12") in the return

air duct upstream of the recirculation fan.

*See your local code before making an installation.

INSTALLATION

GUIDE

Page 5

5

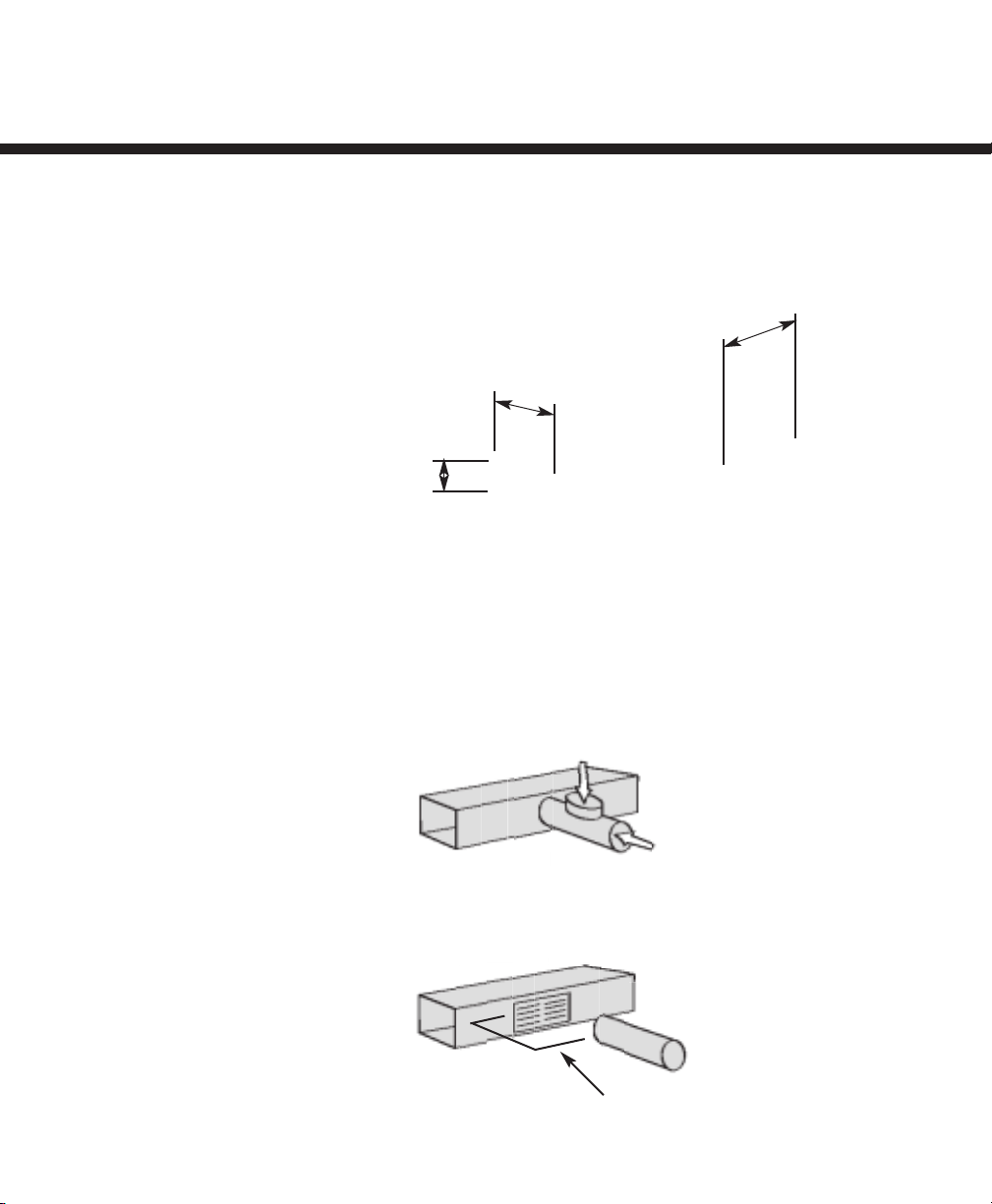

Exhaust and

supply in the return

installation

When using this

application make sure

that there is at least

6' between the fresh

air and exhaust air

connections of the

HRV or ERV in the return

air duct.

Supply air from HRV or ERV must be at

least 3' from the forced air system. Can

be different from a region to an other.

You should check with your local code

or the forced air system’s

manufacturer.

Note

to installer

Fresh air must always be down-stream

from the exhaust air in the return air

duct of the forced air system.

Exhaust from the return

and supply in supply

installation

When using this application make sure

that the Supply air from HRV or ERV is

at least 3' from the forced air system.

Can be different from a region to an

other.You should check with your local

code or the forced air system’s

manufacturer.

2. Types of installation (continued)

Simplified Connection

Forced Air System

6’

18”

HRV / ERV

6’

3’

Exhaust and supply in the return

Forced Air System

6’

18”

HRV / ERV

Exhaust from return and supply in supply

FOR MINIMUM DISTANCE BETWEEN

RETURN AND FORCED AIR SYSTEM

Check with your local building codes and force air system manufacturer.

To living space

Page 6

Installation Kit

Included in the installation kit:

• 4 Collars

• 2 Flexible Vinyl Ducts

• 1 Condensation Drain Line

• 1 Drain Adapter with Nut

• 4 Tie Wraps (30”)

• 16 screws (#10 x 5/8")

• 4 screws (#10 x 1")

• 4 Washers

TIPS

to installer

Removing the core unit will facilitate

your job.

Figure 3.1 Pull out the inserts first then use the straps to lift the unit out of the box.

3. GeneralAire HRV/ERV systems

4. Finding a suitable installation area for HRV or ERV

Figure 3.2 Installation kit is shipped inside the unit.

Figure 3.3 Installation kit.

The HRV or ERV units should be installed in a mechanical room or as close to an outside

wall as possible. This would assure a short run of insulated flexible duct.

The HRV or ERV unit must always be installed in an area where the air is tempered to avoid

freezing of the condensate line. The contractor should install the unit in area that is very

accessible to allow the homeowner easy access for maintenance.

It is very important to install an electric receptacle (115v) near the HRV or ERV, a separate

circuit breaker is also recommended. You should have access to a condensate drain near

the HRV or ERV to avoid the use of condensate pump.

INSTALLATION

GUIDE

6

Page 7

The SPMTMsystem is supplied

with the HRV or ERV to allow

one person mounting of unit.

SPM

TM

attachment system

The entire line of

GeneralAire HRV/ERV

products is designed for

installation by a single

person. “Single Person

Mounting

TM

” will enable you

to save time and effort by offering

you a variable attachment system

and maximizing your basement

space.

TIPS

to installer

If unit is not level, improper

drainage will occur and could lead

to moisture and leakage problems.

TIPS

to installer

It is recommended to use

approximately 16" of flexible duct

(supplied in kit) between the HRV

or ERV and your rigid duct (see

figure 6.1). The flex duct is

mounted the same way to the HRV

or ERV as the insulated flex close

on step 6 (see figure 6.2).

figure 5.1 Place HRV/ERV on a stepladder.

figure 5.2 Attach your four straps to the

floor joist making sure that you attach

thru the washers and the grommets.

figure 5.3 Pull on the middle strap and

gently push upward on the unit. Then

repeat procedure on other side.

figure 5.4 When completing the

procedure make sure that the HRV or

ERV is leveled.

5. Installation of the HRV/ERV

6. Rigid duct

figure 6.1 Mount flex to HRV/ERV.

figure 6.2 Mount flex to rigid duct.

7

Page 8

ISF

TM

collar system

(Patent Pending Technologies)

Quick and simple to install

thanks to our revolutionary

“Insert Slide and FixTM”

collar system.

The “ISFTM” collar system enables you to

manipulate duct within your reach and

then insert the collar to the HRV/ERV

by sliding it in place, for a better and

quicker installation.

TIPS

to installer

To ensure a better installation and to

avoid an undesired bend in the duct,

align the duct with the collar before

securing over the four hooks.

The installer can now beneficiate from the ISFTMcollar system for its flex duct installation to

the unit. Take four collars out of the unit. Insert the flex over the interior flange of the collar.

Make sure that flex is pushed all the way, so the four tabs on the collar hooks on to the flex.

Seal with tie wrap (4 tie wraps supplied with unit). Pull insulation over the interior flange.

Pull vapor barrier over outer flange on the collar and seal with duct tape.

Once insulated flex is attached to the collar, slide collar in keeper section, fixed collar to the

unit with four screws supplied in installation kit.

Insert the threaded drain adapter thru the bottom of the HRV or ERV and hand tighten the

plastic nut supplied with the drain kit.

7. Insulated Flex from Unit to Outside Wall.

figure 7.1 ISFTMcollar system - removable part.

figure 7.2 Insert vinyl duct over the

hooks and seal with a 30" tie wrap.

figure 7.3 Insert insulation inside

the collar.

figure 7.5 Slide collar on the unit.

figure 7.6 Fix and secure with two screws supplied.

figure 7.4 Finish by taping the duct on

the collar.

INSTALLATION

GUIDE

8

Page 9

9

Sloped Drain Pan

drainage system

GeneralAire HRV/ERV units

are equipped with an easy-

access sloped drain pan.

Excess condensation that

might accumulate inside the unit

migrate to the centre of the drain pan

to be evacuated.

8. Condensation Drain Line

Insert the threaded drain adapter thru the bottom of the HRV or ERV and hand tighten the

plastic nut supplied with the drain kit.

Install the condensate line (10 feet included in drain kit). Insert condensate tubing by pushing

clear plastic line over drain adapter. Make condensate trap by looping the clear plastic tubing.

This procedure is to avoid foul odor to enter the HRV or ERV.

figure 8.1 Hand screw the drain adapter

figure 8.2 Insert condensate line.

figure 8.3 Make a loop in condensate line.

figure 8.4 Use a condensate pump if

you don’t have access to the floor drain.

Page 10

INSTALLATION

GUIDE

Insert the power cord on top of the unit.

Press fir

mly to make sure the power cord is

secure.

figure 9.1 HRV/ERV’s Power Cord

It is recommended that the HRV or ERV have

a devoted receptacle with 115v. It is not

recommended to connect unit with an

extension cord. If no receptacle is available

please call an electrical contractor and have

one installed.

figure 9.2 Electric Wall Outlet

9. Devoted Electric Receptacle

10

Page 11

10. Outside Fresh Air and Exhaust Air Hoods

figure 10.1 Locating outside hoods.

72"

18"

figure 10.4 Install outside hoods.

figure 10.2

Insert vinyl duct over the hooks. Fix the

collar on the floor joist.

figure 10.3

Insert insulation inside the collar and

finish by taping the vapor barrier on

the collar.

11

TIPS

to installer

To make your installation easier use our

double collar to install your flex pipe

with the outside hoods (figure 12.2).

TIPS

to installer

We manufacture a wide selection of:

• Insulated flexpipe

• Hoods

TIPS

to installer

Extend the sheet metal sleeve 1.5"

inside the home. Attach GeneralAire

specialty ISF

TM

collar to sheet metal

sleeve.

Page 12

INSTALLATION

GUIDE

12

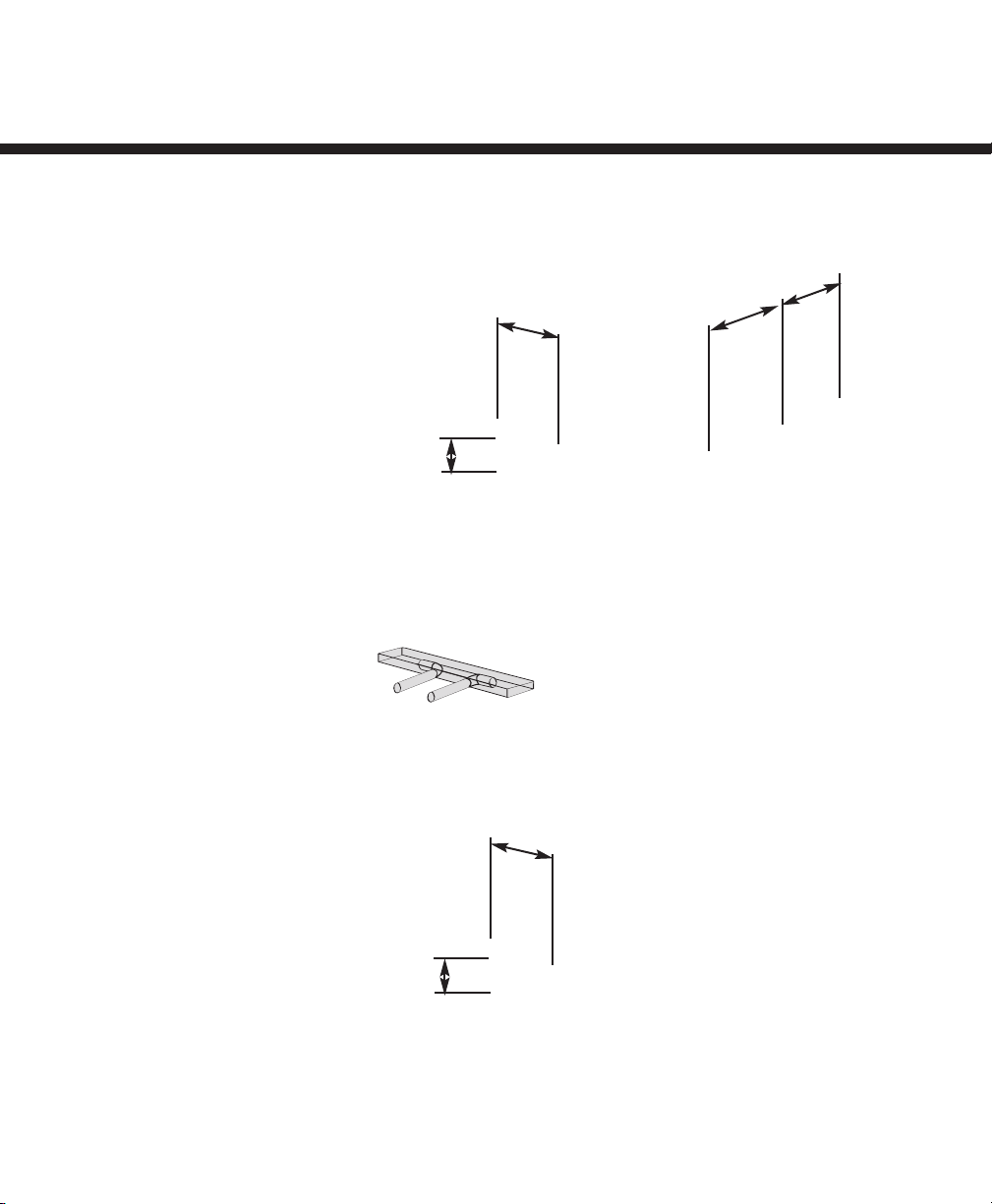

11. Fresh Air and Exhaust Air Grilles

It is recommended to exhaust the stale air from the bathroom, kitchen, laundry room and

storage room. These areas have been found to be the most pollutant areas in a home.

For the kitchen we recommend the use of GeneralAire’s grease filter grilles.

It is recommended to install fresh air grilles in all bedrooms and living areas. The exhaust air

grilles should be located in the bathrooms, kitchen, laundry room and storage room. Grilles are

usually installed 12" from the ceiling.

GeneralAire grilles are recommended for quiet air diffusion (4, 5, 6 and 8 inches are offered).

The grilles combined with our GeneralAire 4" space saving grille adapters (stack head elbow)

makes for easy and time saving installation.

TIPS

to installer

Note: It is not recommended to

exhaust your clothes dryer, your kitchen

exhaust hood or your central vacuum

cleaner thru your ventilation system.

Save Time and Space...

with GeneralAire’s Stack Head Elbow

available to fit your needs. Ask your

local distributor for more information

on our full range of accessories.

We manufacture a wide selection of:

• Duct

• Stack Head Elbow

• Grilles

figure 11.1 Grille.

figure 11.2 Stack head elbow.

figure 11.3 Insert grille.

Page 13

13

Intermittent:

When the selector switch is in the intermittent position the HRV or ERV will only run

when there is a call for ventilation by any control. At that time the unit will run on high speed until the

condition is satisfied.

Continuous:

When the selector switch is in the continuous position the HRV or ERV will run

continuously on low speed except when there is a call for override by any control.

Off:

When the selector switch is in the off position the HRV or ERV will not come on even if there’s a

call for ventilation by any control.

INTER.:

Selects the exhaust air motor

CONT.:

Selects both exhaust and fresh air motors

OFF:

Selects the fresh air motor

+ Button:

Increase the speed of the selected motor.

- Button:

Decrease the speed of the selected motor.

DuoTrol

TM

balancing system

(Patent Pending Technologies)

Silent and economical... By

reducing motor speed to

balance the unit, you avoid

the noise that would be

produced by balancing

dampers.

In addition, with this

technology the unit will consume

less energy.

Mode

selector

• Intermittent

• Continuous

• Off

Balancing

control

• Intermittent

• Continuous

• Off

• Increase Speed

• Decrease Speed

Acts as a mode selector

Acts as a balancing control

(see instructions)

12. Benefits of the DuotrolTMSystem

figure 12.1 DuotrolTMSystem

The DuotrolTMlets contractor set speed of the motors for balancing purposes

(Exhaust air, Fresh air and Both motors).

GeneralAire’s Duotrol

TM

balancing system (patent pending) is state of the art technology

simplified for quick and easy installation for the contractor’s peace of mind.The Duotrol

TM

serves two purposes.

Page 14

INSTALLATION

GUIDE

TIPS

to installer

As mentioned in the section, the

DuotrolTMSystem has two different

purposes.

1. Mode Selector

2. Balancing Mode

The light indicator shows you in which

mode the DuotrolTMSystem is in.

GREEN LIGHT

Mode Selector

YELLOW LIGHT

Balancing Mode

Using the

Selector Switch

to installer

When on Balancing Mode, the Selector

Switch allows you to choose the motor

you want to set.

Closed Duotrol Cover

1. INTER (Exhaust Motor)

2. CONT (Both Motors)

3. OFF (Supply Motor)

or

Open Duotrol Cover

1. UP (Exhaust Motor)

2. MIDDLE (Both Motors)

3. DOWN (Supply Motor)

13. Balancing the unit

Step 1: Press the (+) and (–) buttons simultaneously until you

see the yellow light. Once the indicator light turns yellow you

are in balancing mode.

Step 2: When in balancing mode the selector switch becomes

the motor selector switch. INTER (Right Motor), CONT (Both

Motors) and OFF (Left Motor)

Step 3: Once the total cfm needed is determined, you can

start balancing the HRV/ERV.Set your fresh air supply by

selecting the “OFF” position on the Duotrol

TM

. Install your

magnehelic gauge and air flow grid in the fresh air duct.

Step 4: Press the (–) button to decrease the cfm or press the

(+) button to increase the CFM.

Step 5: Then perform the same operation on the stale air side

by selecting the “INTER” position on the Duotrol

TM

.

Step 6: The “CONT” position will allow you to adjust the cfm

on both motors proportionately (if necessary).

Step 7: Once this is completed, you have set the high speed

on your HRV/ERV. To lock balancing mode you must press (+)

and (–) buttons simultaneously and release. The indicator light

will turn green to indicate normal operation mode.

Step 8: Once high speed is set and locked, switch to

continuous on the Duotrol

TM

. By using (+) and (-) buttons set

low speed on the HRV/ERV.

Step 9: Select the mode of operation.

(Intermittent, Recirculation or Continuous Ventilation)

figure 13.1 DuotrolTMSystem

figure 13.2 Magnehelic Gauge with Air Flow Grid

figure 15.6 Selector Switch

figure 13.3 Magnehelic Gauge with Air Flow Grid

figure 13.4 Inserting Air flow grid in duct

figure 13.5 Seal Air flow grid in duct with duct tape.

14

Page 15

14. Controls and Wiring

GeneralAire’s DC1allows the homeowner control of the indoor humidity level.

The DC1 is a two wires connection. On the Duotrol

TM

System and the DC1 are

R and G terminal connections on the lower right hand side of the control board.

DC1

DEHUMIDISTAT

Features

• Dehumidistat to select the humidity level

figure 14.1 DC1

figure 14.2 Duotrol

TM

Range of controls

The entire range of GreenThinker

TM

model controls is offered with

features making your

ventilation system simple,

easy to operate and backed

by a 5-year limited warranty.

15

Page 16

INSTALLATION

GUIDE

16

Page 17

17

GeneralAire’s DC4E allows the homeowner control of the indoor humidity level by offering

four selections of operation. The controller allows the homeowner to select the humidity

percentage, fan speed, operation mode and cycles per hour.

The above controller have four wires connection. On the Duotrol

TM

System and DC4E use

R, G, B and W terminal connections on the lower right hand side of the control board.

DC4E

ELITE DEHUMIDISTAT

Features

• Dehumidistat to select the humidity level

• Speed Control (Off, Normal and Reduced)

• Mode Control (Intermittent and Continuous Ventilation)

• Cycles per hour (0/0, 20/40 and 30/30)

• Light On Override

• Maintenance Light Reminder

figure 14.7 DC4E

figure 14.8 Duotrol

TM

CYCLES

0

20/40

30/30

Allows the homeowner to select cycles per hour

Normal operation mode

20 minutes on high speed and 40 minutes on previously set mode of operation

30 minutes on high speed and 30 minutes on previously set mode of operation

MAINTENANCE

Light indicator:

14. Controls and Wiring (continued)

Shows homeowner when HRV or ERV needs to be maintain.

Page 18

INSTALLATION

GUIDE

18

14. Controls and Wiring (continued)

GeneralAire’s TR3 allows the homeowner controls of the indoor humidity level in rooms

were more humidity is produced (Ex. bathroom and kitchen).

The

TR3 allows the homeowner to override the DC Dehumidistat to high speed for a

determined length of time (20min, 40min and 60min).

The

TR3 is a three wires connection. On the low voltage control board use R, G and B

terminal connection on the top right hand corner of the board.

figure 14.9 TR3

figure 14.10 Duotrol

TM

TR3

TIMER CONTROL

Feature

• 20/40/60 minutes exchange

To operate:

Press the PUSH button once,the light indicator will blink one time.

The unit will operate at high speed for 20 minutes.

Press the indicator light until it blinks twice, the unit will operate

at high speed for 40 minutes.

Press the indicator light until it blinks 3 times, the unit will operate

at high speed for 60 minutes.

(Pressing the button gives you the first blink.)

Page 19

19

PROBLEMS

• HRV or ERV not running

• Air is too dry

• Air too humid

SOLUTIONS

• Verify breaker in electrical box

• Verify that dehumidistat or switch on HRV or ERV are

activated to supply power to unit.

• Unplug HRV or ERV verify if controller is wired correctly to

the connection box on the side of the unit.

• Verify low voltage box (Duotrol

TM

)on the unit

• Increase humidity level on dehumidistat.

• Switch ventilation mode from continuous to intermittent

• Install a GeneralAire humidifier

• Reduce the humidity level on the controller.

•Verify if dryer is venting in basement.

•Verify if heating wood is stored in basement.

•Wait for outside temperature to change.

Ex. Summer can be extremely humid.

•Verify balancing of the HRV or ERV.

Peace of Mind

Ensure your comfort in the

years to come by using

GeneralAire systems and

accessories to install any

ventilation, humidification,

purification or filtration product.

Need help? You benefit from certified

customer service ready to guide you in

the installation or operation of your

GeneralAire system.

Call: 1-248-476-5100

15. Troubleshooting

Page 20

INSTALLATION

GUIDE

20

Standard Forced Air

Interlocking Wiring

A relay is normally used when tying a

ventilation system onto forced air

distribution system. Our Duotrol System

is equipped with an internal relay that

will activate the forced air system’

ventilator when there is a demand from

the HRV/ERV. The Duotrol System will

activate the INTERLOCK relay during the

following modes: Continuous, Override,

Recirculation and Defrost. See wiring

diagram.

Alternate Forced Air

Interlocking Wiring

Some forced air system thermostat will

activate the cooling system when tied

using the “Standard forced air

interlocking wiring”.

If you have identify this type of

thermostat you must proceed with the

“A lternate forced air wiring”.

Locating the

Wiring Diagram

to installer

Wiring diagram for the entire line of

professional and furnace models

are placed on the back of each

exhaust motor bracket.

16. Wiring Diagram

Standard Forced Air Interlock Wiring

Alternate Forced Air Interlock Wiring

*Before tying the HRV/ERV to a

forced air system, always refer to

system’s manual or manufacturer.

Page 21

21

FMA

TM

maintenance system

In order to improve air quality

and offer the best possible

air quality in your home,

GeneralAire has developed

one of the first maintenance

service systems in the

industry.The “Filter Maintenance

AdviserTM” will remind you by e-mail

when the filter of your HRV/ERV system

must be replaced, to maximize its

performance and efficiency.

For more information call:

1-248-476-5100

When should I Service my

HRV/ERV?

service and accessories

HEAT RECOVERY CORE UNIT

Once a year or as needed,

vacuum the four surfaces,

let soak in warm water for

three hours, then spray

rinse and let dry.

FILTERS

Four times a year or as needed, vacuum

the filters. Replace filters once a year.

INSIDE THE UNIT

Once a year or as needed, clean the

interior of the unit (walls and drain pan)

with a mild and non abrasive soap. It is

recommended to use products that are

environmentally-friendly.

ENERGY RECOVERY CORE UNIT

Once a year or as needed, vacuum the

four surfaces.

Note

to installer

IMPORTANT : ALWAYS UNPLUG HRV OR

ERV DURING SERVICING

17. Maintenance

figure 17.1 Slide Out the Filters

figure 17.2 Vacuum the Filters

figure 17.3 Slide out the Energy Core

figure 17.4 Wash the Walls of the Unit

Page 22

PROFESSIONAL,DELUXE AND FURNACE MODELS

INSTALLATION

GUIDE

22

Easy Access Door

removable top hinge door

Note

to installer

All GeneralAire products are backed by the

best limited warranty on the market.

GeneralAire reserves the right to modify a

product, without prior notice, whether in

design, colour or specifications, in order to

offer at all times a quality product that is

highly competitive.

Please consult local authorities to find out

whether the installation of electrical

products requires the services of a

certified technician or electrician.

23

7

/

8

"

21

1

/

2

"

18. Specification and Technical Information

Certified Products and Proud Member of These Associations

SPECIFICATIONS

Size

Heat exchanger (L x H x W)

CFM

Type of heat exchanger

Exchange surface

Power consumption

Defrost type

Certification

02280618

23

Unit Housing

20 gauge powder coat steel 20 gauge powder coat steel

Unit Housing

20 gauge powder coat steel 20 gauge powder coat steel

7/8

" x 21

1/2

" x 11

3/8

" 23

7/8

" x 21

1/2

" x 16

1/2

"

"51 x "21 x "21"01 x "21 x "21

022 ot 05061 ot 03

wolf-ssorcwolf-ssorc

104 ft

2

150 ft

2

W 051W 031

tsuahxEtsuahxE

HVI,CCSA

US

HVI,CCSA

US

SPECIFICATIONS

Size

Heat exchanger (L x H x W)

CFM

Type of heat exchanger

Exchange surface

Power consumption

Defrost type

Certification

02230613

23

7/8

" x 21

1/2

" x 11

3/8

" 23

7/8

" x 21

1/2

" x 16

1/2

"

"51 x "21 x "21"01 x "21 x "21

022 ot 05061 ot 03

wolf-ssorcwolf-ssorc

104 ft

2

150 ft

2

W 051W 031

tsuahxEtsuahxE

C

CSA

CSU

CSA

US

8160 11

3

/

8

"

8260 16

1

/

2

"

3160 11

3

/

8

"

3220 16

1

/

2

"

*

Loading...

Loading...