Page 1

Model Elite Steam Humidifiers

User Manual

Manual d’utilisation

Read and Save These Instructions

Lire et Conserver Ces Instructions

Revision 4.0

Manufacturers of Whole House Residential Indoor Air Quality Products.

Humidifiers - Dehumidifiers - Air Cleaners - UV Air Purifiers - Heat/Energy Recovery Ventilators

www.generalfilters.com

Page 2

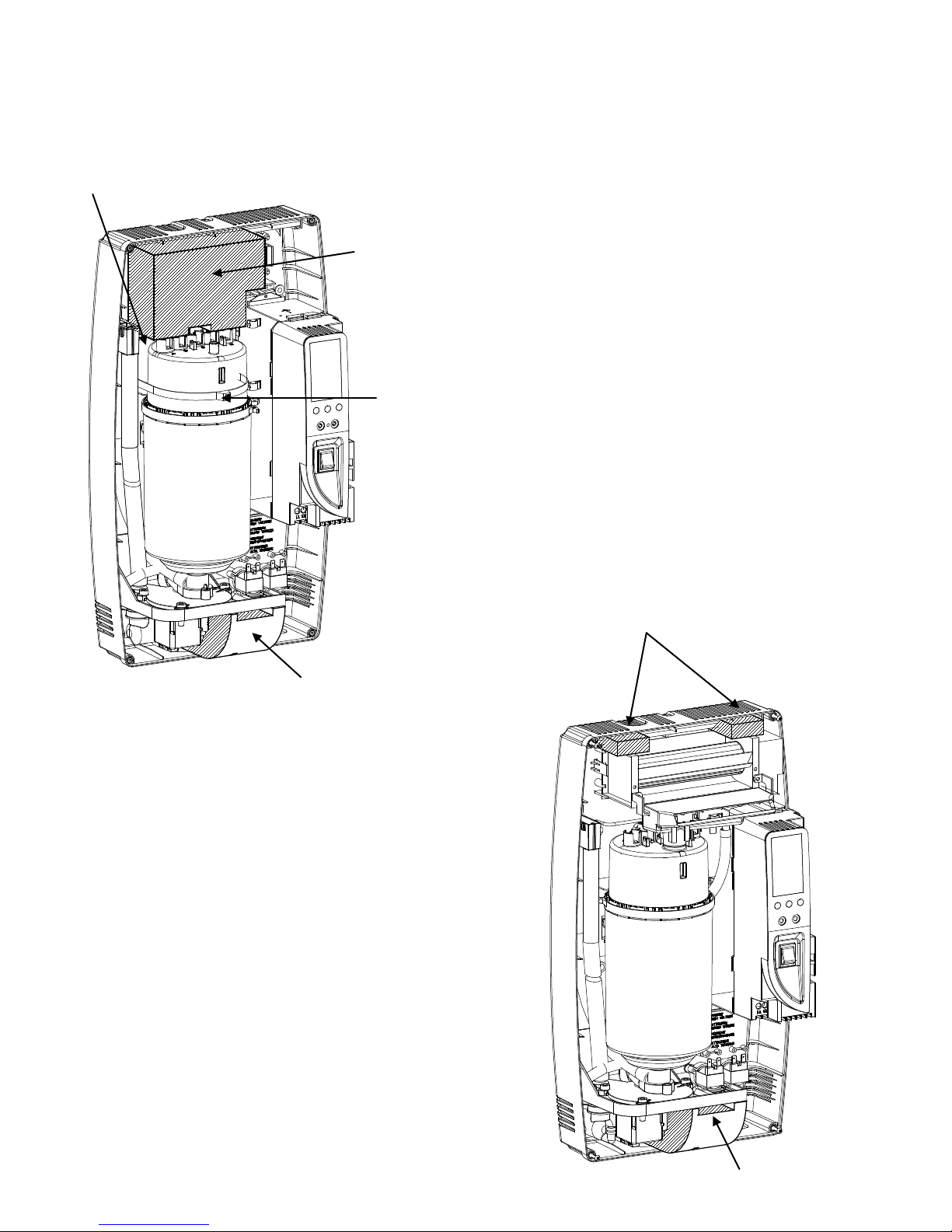

LATCH THE CYLINDER CLAMP

REMOVE BEFORE INSTALLING

REMOVE BEFORE INSTALLING

REMOVE BEFORE INSTALLING

REMOVE BEFORE INSTALLING

REMOVE BEFORE INSTALLING

Warning

If present, remove the following items:

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

1

Page 3

IMPORTANT WARNINGS

BEFORE INSTALLING OR HANDLING THE HUMIDIFIER PLEASE CAREFULLY READ AND F OLLOW THE INSTRUCTIONS

AND SAFETY STANDARDS DESCRIBED IN THIS MANUAL AND ON THE LABELS ATTACHED TO THE Elite Steam.

CAUTION: ALWAYS DISCONNECT THE MAIN POWER

Elite Steam produces non-pressurized steam by means of electrodes immersed in the water contained in the plastic steam

generator cylinder. Electric current passes through the water between the electrodes, heating the water into steam, which is then

used to humidify the air.

The quality of the water used affects the operation of this unit, so the Elite Steam may be supplied with untreated water, as long as

this is drinkable and not softened or demineralized. The water converted into steam is automatically replaced through an electric fill

valve. Periodically, based on the water quality, the unit will also drain some water to dilute the build-up of minerals in the steam

generator. In cases of high water mineral content, an activated carbon filter is series with a particulate filter, no more than 5 microns

is suggested.

This humidifier has been designed exclusively to directly humidify rooms or ducts, using a distribution system. The installation, use

and maintenance operations must be carried out according to the instructions contained in this manual and on the labels applied

internally and externally.

IMPORTANT: BEFORE beginning installation:

• Check for shipping damage to cartons. Mark the shipping waybill accordingly.

• Open cartons and check for any hidden damage. Mark the shipping waybill accordingly.

• Check packing slip to ensure all items have been received. Notify GENERAL FILTERS, INC. of any shortages or damaged

parts. You must notify General Filters, Inc. within 5 working days of any shortages.

CAUTION: ELECTRIC SHOCK HAZARD! The humidifier has components under power inside!

CAUTION: SCALDING HAZARD! The humidifier has hot parts ( 100°C/ 212°F)

WARNING: Install the humidifier out of the reach of children.

The humidifier must be installed in accordance with all local and national standards.

All service and/or maintenance operations must be performed by qualified personnel who are aware of the necessary

precautions and are capable of performing the operations correctly.

Disconnect the humidifier from the main power supply before accessing any internal parts.

The conditions of the environment and the power supply voltage must comply with the specified values listed on the data

label in the humidifier.

All other uses and modifications made to the humidifier that are not authorized by the manufacturer are considered

incorrect, and the manufacturer assumes no liability for the consequences of any such unauthorized use.

Please note that the humidifier contains powered electrical devices and hot surfaces.

The humidifier is made of metallic and plastic parts. All parts must be disposed of according to the local and national

standards for waste disposal.

WARNING: Your humidifier requires water to operate. Do NOT mount it above materials or machinery that could be

damaged if a leak occurs. General Filters, Inc. assumes no responsibility for consequential or inconsequential damage as

a result of any leaks.

BEFORE OPENING OR SERVICING THE HUMIDIFIER!

We wish to save you time and money!

We can assure you that the thorough

reading of this manual will guarantee

correct installat ion and saf e use of the

product described.

Disposal of the parts of the humidifier:

of according to the local sta ndard s on waste disposal.

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

the humidifier is made up of metallic and plastic parts. All parts must be disposed

2

Page 4

CONTENTS

1. HOW THE ELITE STEAM WORKS 4

1.1 B

1.2 C

1.3 C

ASIC OPERATION 4

YLINDER LIFE 5

ALCULATING HUMIDITY LOAD 5

2. MODELS 6

3. INSTALLATION 7

3.1 P

3.2 M

3.3 P

3.4 S

3.5 P

3.6 C

3.7 W

OSITIONING 7

OUNTING 7

LUMBING 9

TEAM DISTRI B U TI O N 10

OWER WIRING 13

ONTROL WIRING 13

IRING CONNECTIONS: 15

4. START-UP 16

4.1 S

4.2 T

4.3 S

4.4 S

TARTUP CHECKLIST 16

HE ELITE STEAM CONTROLLER 16

TARTING ELITE STEAM 16

TARTING WITH A NEW CYLINDER 16

5. OPERATING ELITE STEAM 17

5.1 D

5.2 C

5.3 A

5.4 R

5.5 U

5.6 A

ISPLAYING INFORMATION 17

HANGING THE MAXIMUM PRODUCTION 17

CTIVATING MANUAL DRAIN 17

ESETTING THE HOUR COUNTER 17

SING THE GFX3 HUMIDISTAT 18

LARMS 18

6. TROUBLE SHOOTING 19

7. MAINTENANCE 20

7.1 P

7.2 C

7.3 R

ERIODIC CHECKS 20

YLINDER MAINTENANCE 20

EPLACEMENT PARTS 21

8. TECHNICAL SPECIFICATIONS 22

9. LIMITED WARRANT Y 23

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

3

Page 5

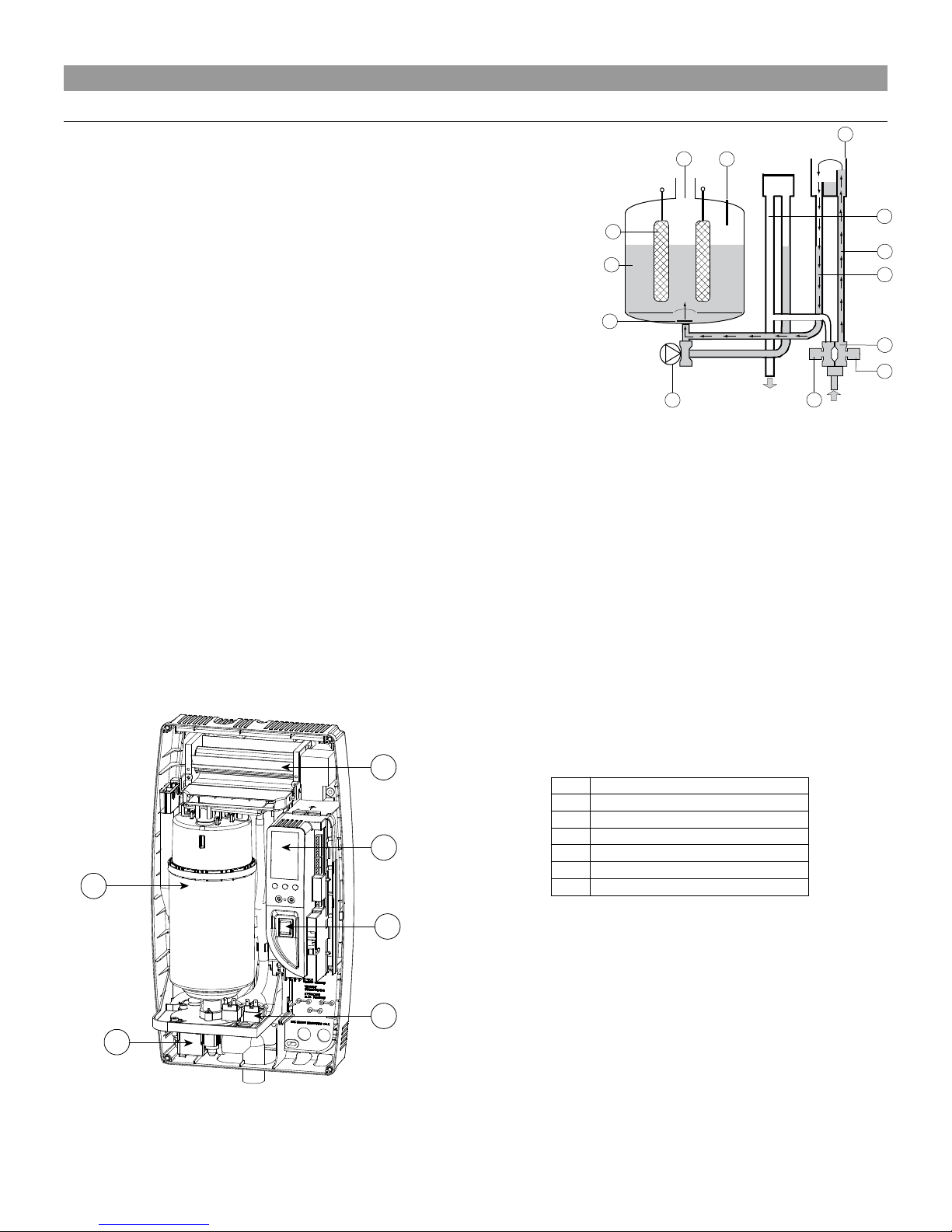

No.

Description

A

Steam generator cylinder

B

Room blower/manifold (optional)

C

User interface/display

D

On/Off, SET buttons

E

Fill & tempering valves

F

Drain pump

Tab. 1.a

Fig. 1.a

HL

DP

DT

EVF

8

9

3

13

6

10

2

4

1

11

7

12

5

A

F

B

C

D

E

1. HOW THE ELITE STEAM WORKS

1.1 Basic Operation

Elite Steam is an electrode humidifier. It produces steam for humidification by

passing electric current through the water between metal electrodes in the

plastic steam generator cylinder. There are no heating elements. Steam output

is directly proportional to the conductivity of the water, and the amount of

electrode immersed in the water.

On a call for humidity, the Elite Steam controller will open the water fill valve (1)

and allow water to enter the cylinder. A flow restrictor (4) prevents the unit from

filling too quickly or with too much pressure. The water flows up the fill tube (2)

and into the fill cup (3). W ater then flows over the dam in the f ill cup (3), which

creates a 1” air gap to prevent backflow of contaminated water into the feed

lines, and through the fill tube (6) and into the bottom of the steam cylinder (5).

Any backflow or overflow of water travels through the overflow hose (13) to the

drain.

As the water fills the cylinder, it will reach the electrodes (7) and current will

begin to flow. As the water continues to fill the cylinder, the current will

increase, and this is monitored by an amperage transformer connected to one of the power wires and located on the

electronic controller. When the desired current is reached, the fill valve will close (1) and the water will then begin to warm

and produce steam. If the water reaches the cylinder full probes (9) or if current rises too much, the drain pu mp (11) will be

activated to drain awa y some water and reduce the current flow to acc eptable levels. Note that, any time the drain pump is

activated, the tempering valve (10) will be opened for tempering the hot drained water down to 140 degrees F / 60 degrees C

in accordance to local and national standards.

Periodically, based on the incoming water conductivity, the unit will run drain pump (11) and drain some water to reduce the

mineral concentration. Every 120 hours the unit automatically drains to remove mineral sediment on the bottom of the

cylinder. A strainer (12) in the cylinder helps to prevent mineral debris from jamming the drain pump (11).

In case Elite Steam remains powered but idle, i.e. without producing steam, for more than 72 hours (3 days), the cylinder will

be emptied to not have stagnant water inside.

If there is no water in the cylinder, there will be no current flow and no steam production. The electrodes do not burn out, but

they will eventually become completely coated with mineral and the cylinder will then need to be replaced. Cleaning cylinders

may cause electrode damage, therefore voiding its warranty. See 7.2.2 maintenance section on page 21.

Fig. 1.b

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

4

Page 6

Table 1.2 Pounds of Moisture / Hour / Cubic Foot *

Indoor Air

Temp °F

35%

Indoor RH%

40%

45%

50%

68

0.00015

0.00018

0.00021

0.00024

70

0.00017

0.00020

0.00023

0.00026

72

0.00019

0.00022

0.00025

0.00028

100%

20%

Fig. 1.c

1.2 Cylinder Life

1.2.1 Basics of the Steam Cylinder

The Steam Cylinder is the engine of the humidifier. As the humidifier operates water is evaporated and minerals are left

behind. Much of these minerals are removed through the c ylinder drain. Some are depos ited on the walls of the cylinder and

the cylinder electrodes. When a lower section of the electrodes develop a thick coating, the water level is raised to expose

clean electrode surface. Eventually minerals cover the electrodes’ entire length with a thick coating and little electrical current

can pass between them resulting in poor steam output. The humidifier can sense the low amperage and will display the E6

Cylinder Exhausted error code. There are several factors that influence cylinder life.

1.2.2 Water

Characteristics of water influence cylinder life and can vary greatly from place to place. Total mineral content of the water is

important. Equally important is what minerals are present in the water. Most water conditions result in flaky scale that

eventually fills the bottom of the cylinder until it can no longer function. Water with high silica content can result in a thin

glass-like coating on the electrodes that is highly insulating resulting in shorter cylinder life. Only cold wa ter is to be used.

Water conductivity that is not matched to the correct cylinder will shorten cylinder life.

1.2.3 Water Filtration

Typically additional filtration of the incoming water supply is not necessary. If, however, mineral content is known to reduce

cylinder life excessively or if cylinder life proves insufficient then water filtration c an be added. In most cas es the addit ion of a

two element water filter can improve cylinder life. The filter should contain an activated carbon element and a particul ate filter

element rated for 5 microns or less. Micron is a size measurement. The filter system should have a flow rate of at least 2

gpm. The activated carbon will absorb much of the mineral content while the particulate filter will catch any granular material

or sediment. It is important to remember that the increase in cylinder life will be accompanied by the need to replace filter

elements with each cylinder change.

1.2.4 Humidity Load and Cylinder Life

Humidity load demands have an effect on cylinder life. Normal installations where humidity capacity is properly sized require

only intermittent periods where full humidifier capacity is required. This allows the water level in the cylinder to be increased

only as electrode segments become insulated. This tends to maximize cylinder life.

Extraordinary installations that require constant operation at full capacity reduce cylinder life. The water level in the

cylinder is, on average, much higher, and the electrodes become completely insulated mo re quickly. Installations like this

may result in cylinder life of less than 1000 hours.

The importance of providing adequate humidifier capacity should not be underestimated.

1.2.5 Maximum Production

Another factor affecting cylinder life is the maximum production setting. A higher production

rate will result in a shorter cylinder life. For this reason DS-25 and RS-25 units are preset from

the factory at 70%. Further reductions in Maximum Production will extend cylinder life.

See Figure 1.c.

1.2.6 Structures Under Construction

In high end construction projects, humidification is often required while the structure is being finished. Humidification is

necessary to protect and stabilize wood floors, trim and decoration. Humidification load, however, in an unfinished structure

may be five to eight times higher than when finished. Elite Steam humidifiers may be operated while construction is underway

but, reduced cylinder life is to be expected and budgeted for. Good practice dictates that the steam cylinders also be

replaced once the project is complete.

1.3 Calculating Humidity Load

1.3.1 Steps to Determine Humidity Load

*Based on .5 air changes per hour.

Total Square Footage

x Average Ceiling Height

x Factor From Table 1.2

x 1.05 for each Fireplace

Humidity Load in lbs./hour

x 2.88 convert to gallons/day

Gallons per Day Humidity Load

Cylinder

Life

* Based on .5 air charges per hour.

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

5

Page 7

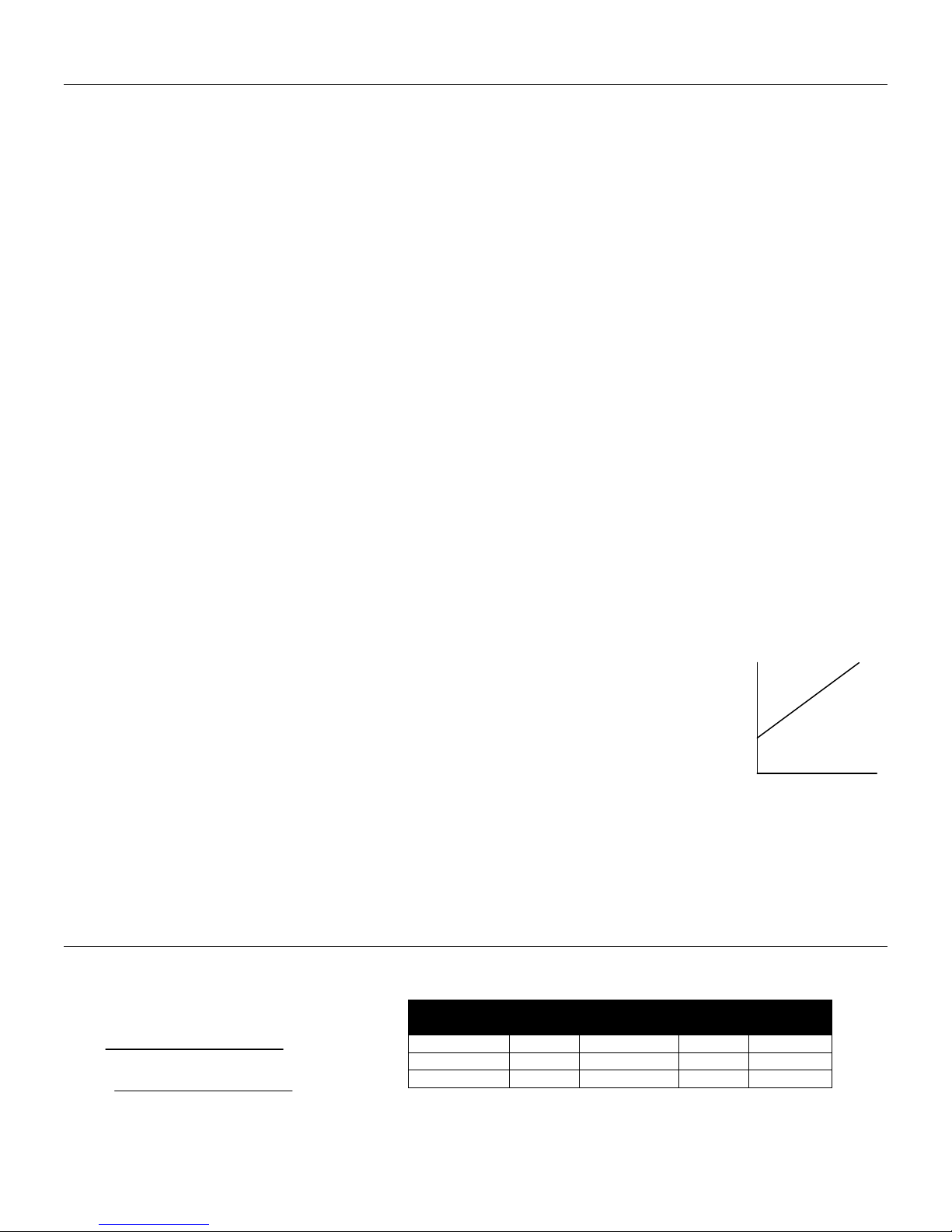

PART NUMBER

DESCRIPTION

PARTS INCLUDED

RS 15P

Fig. 2.b

Room steam discharge, 15 gallons

per day (5.5 Lbs per hour) 115-120v

Complete Humidifier. GFX3 humidistat, code valve, water fill

connector, water supply tubing

RS 25

Fig. 2.b

Room steam discharge, 35 gallons

per day (12 Lbs per hour) 220-240v

Complete Humidifier. GFX3 humidistat, code valve, water fill

connector, water supply tubing

DS 15P

Duct steam injection 15 gallons Humidifier only,

hour) 115-120v

Humidifier only, Kit select ion r equir ed

Fig. 2.a

per day (12 Lbs per hour) 220-240v

Kit selection required

DMNKIT

Duct mount kit

8 ft. steam hose, nozzle, GFX3 humidistat, code valve,

tubing, air proving pressure switch.

wall sleeve with 120v blower and grille pkg.

RMB 3 5

Remote mount blower

12 ft. steam hose, GFX3 humidistat, code valve, condensate

wall sleeve with 240v blower and grille pkg.

2. MODELS

There are two basic models available in two voltages. Duct models require selection of an additional kit.

Duct Steam Injection Room Steam Discharge

Fig. 2.a

DS 25

(not shown)

RMB 1 5

(not shown)

(not shown)

EDMK4

(not shown)

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

Kit selection requ ired per day (5.5 Lbs per

Duct steam injection 35 gallons

Remote mount blower

kit for DS 15

kit for DS 25

Economy Duct mount kit 4 ft. steam hose, nozzle, 5 ft. condensate hose, fill connector,

Fig. 2.a Fig. 2.b

MODEL LIST

Humidifier only,

water fill connector, condensate hose, water supply

12 ft. steam hose, GFX3 humidistat, code valve, condensate

hose, water fill connector, water supply tubing, and thru-the

hose, water fill connector, water supply tubing, and thru-the

air proving pressure switch (Humidistat not included)

6

Page 8

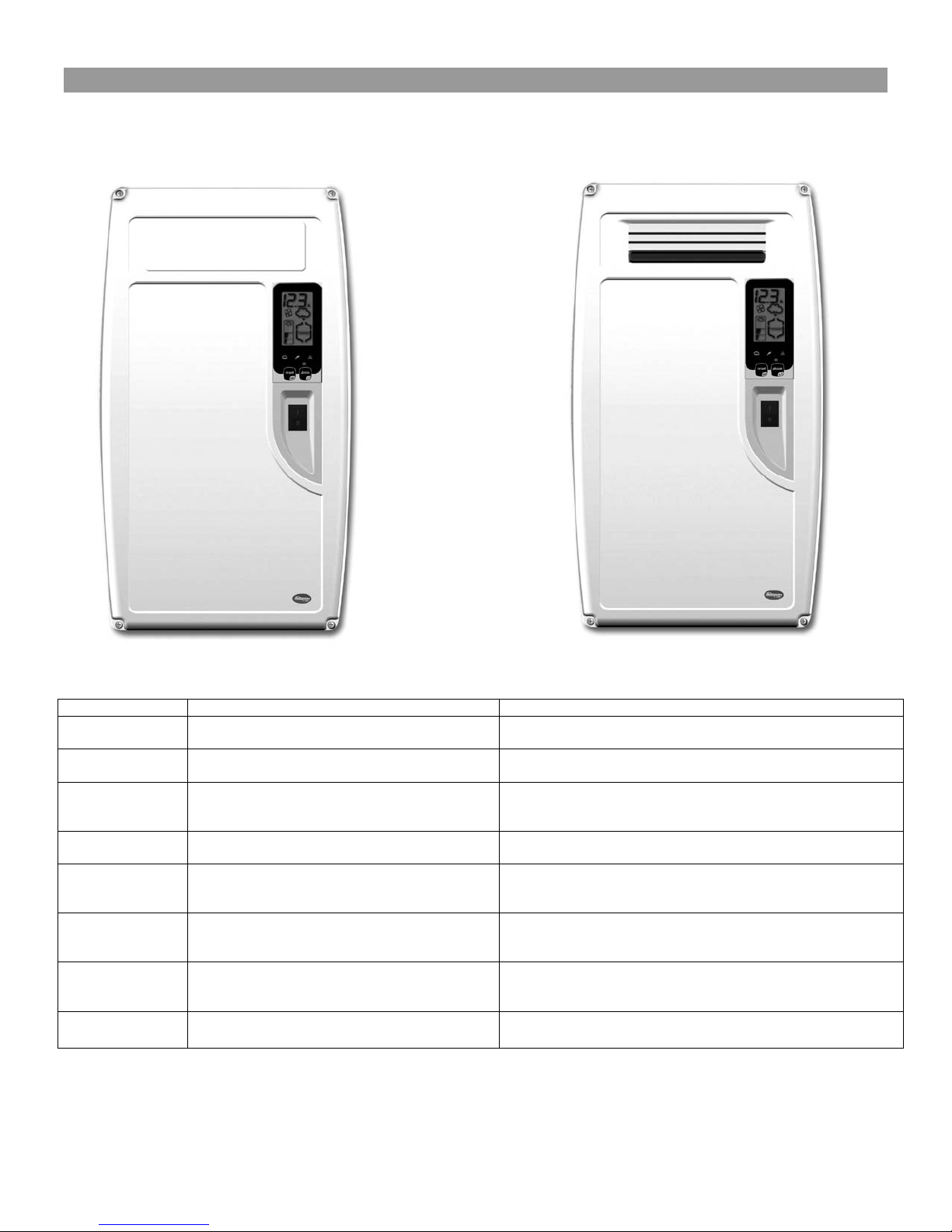

3. INSTALLATION

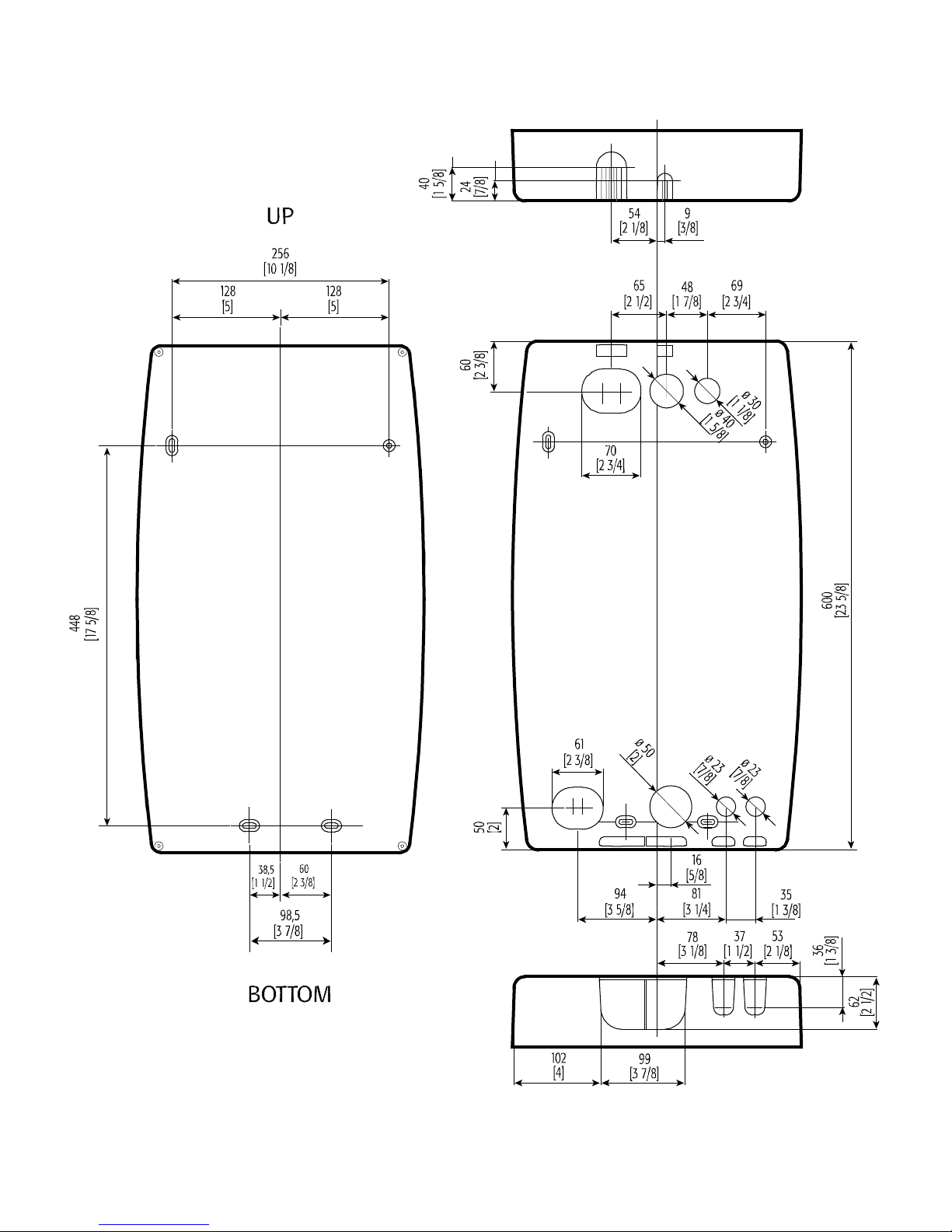

Millimeters

Inch

A

(150 mm)

6”

B

(150 mm)

6”

C

(150mm)

6”

D

(150 mm)

6”

E

(600 mm)

24” F max. 0.2°

Tab. 3.a

Fig. 3.a

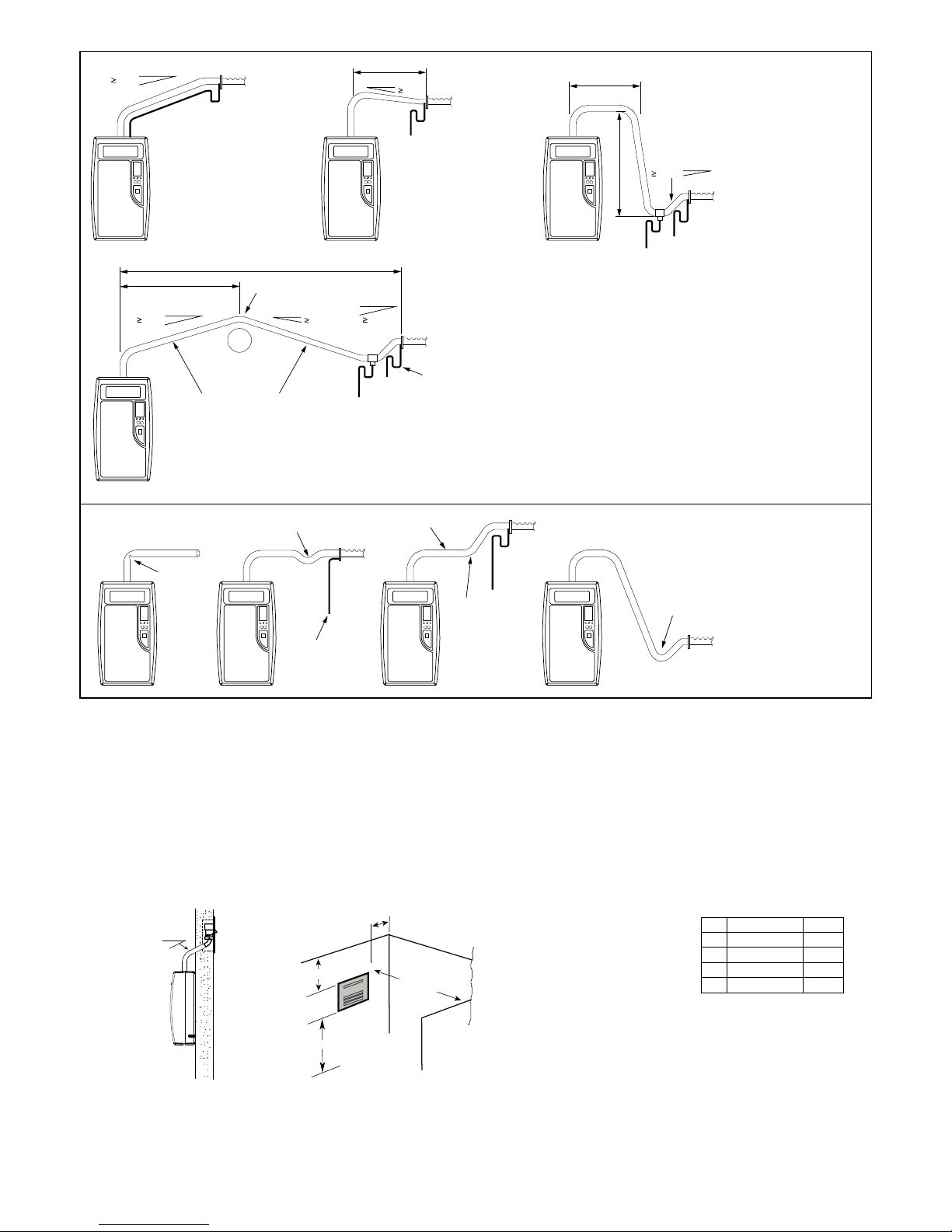

Duct Steam Injection

C

D

Fig. 3.b

Millimeters

Inch

A

150 mm

6”

B

1800 mm

72”

C

1800mm

72”

D

600 mm

24”

Tab. 3.b

Room Steam Discharge

Millimeters

Inch A 341 mm

13.5“

B

204 mm

8.1“

C

600 mm

23.7“

Kilograms

Pounds

Weight empty

8kg

18 lbs

Weight packaged

10kg

22 lbs

Weight i nstalled with water

12kg

26 lbs

Unit Dimensions: Duct and Room Units

Fig. 3.c

3.1 Positioning

The Elite Steam has been designed for wall mounting and, since it is an atmospheric

steam humidifier, should be placed close to the point where the steam will be used, to

minimize the steam hose length (and the amount of condensate). Certain clearances

must be maintained around the unit for safety and maintenance.

3.2 Mounting

3.2.1 Removing the front cover

The front cover is secured by four screws located at the four corners of the unit. Use a

Phillips head screwdriver to remove the four cover screws. Then simply pull the front cover

away from the back part of the unit. Return it in reverse order.

Be careful not to over-tighten the screws.

Fig. 3.d

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

Fig. 3.e

Tab. 3.c

7

Page 9

3.2.2 Fastening to the wall

Drill the wall according to the drilling template supplied; then secure Elite Steam firmly to the wall using the screws and

anchors supplied.

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

Fig. 3.f

8

Page 10

3.3 Plumbing

Hydrogen ions (pH)

7 8.5 Hydrogen ions (pH)

7 8.5

Specific conductivity (R,20°C)

μS/cm

300

Specific conductivity (R,20°C)

μS/cm

125

500

Dry residue at 180°C

mg/l

(*)

(*) Dry residue at 180°C

mg/l

(*)

(*)

Total hardness

mg/l CaC³O

150

400 Total hardness

mg/l CaC³O

0

200

Temporary hardness

mg/l CaC³O

=

200 Temporary hardness

mg/l CaC³O

=

150

Iron + Manganese

mg/l F e + Mn

=

0.2 Iron + Manganese

mg/l F e + Mn

=

0.2

Chlorides

ppm Cl

=

30 Chlorides

ppm Cl

=

20

Chlorides

mg/Si2O

=

20 Chlorides

mg/Si2O

=

20

Chlorine residue

mg/l Cl-

=

0.2 Chlorine residue

mg/l Cl-

=

0.2

Calcium sulphate

mg/l CaS4O

=

100 Calcium sulphate

mg/l CaS4O

=

60

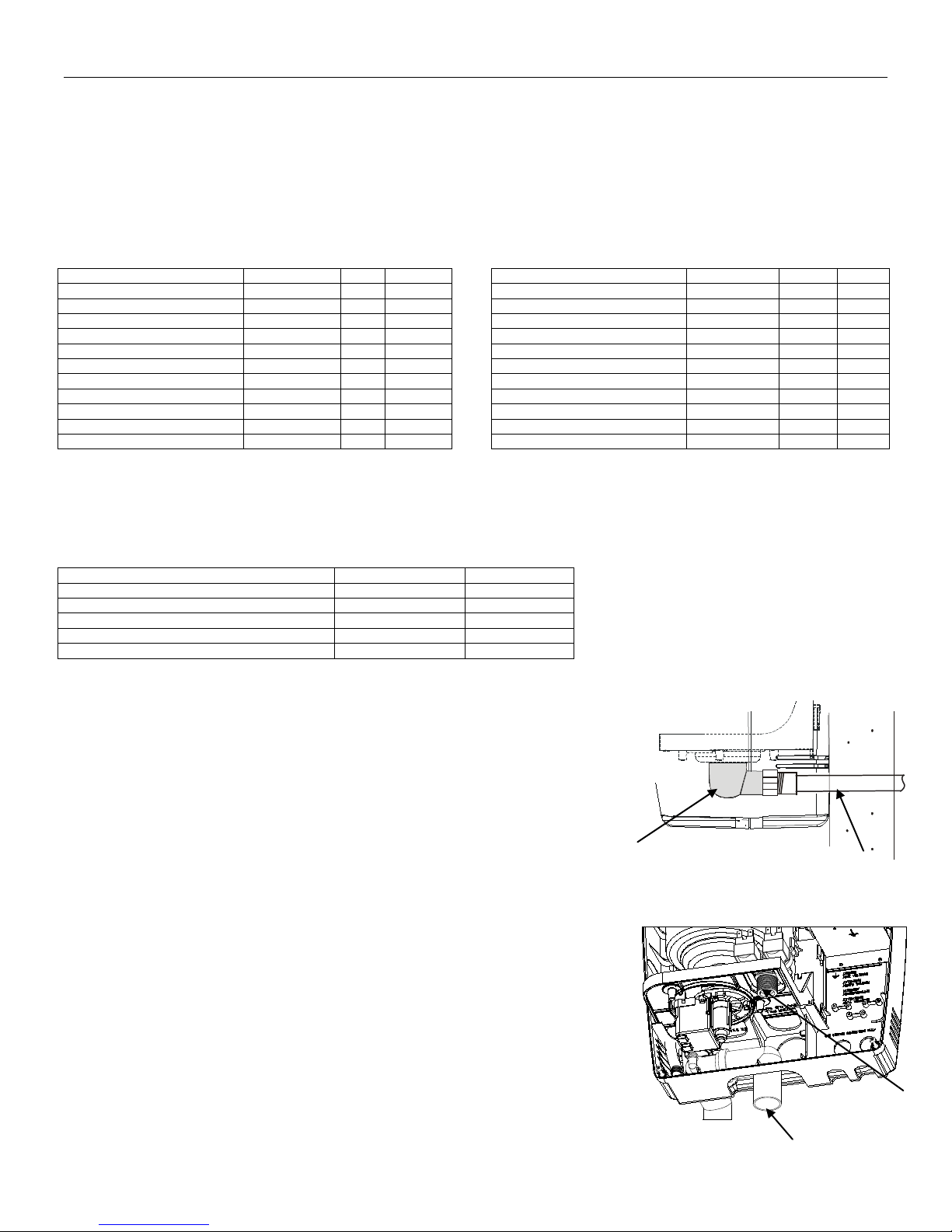

ELITE STEAM models

Conductivity μS/cm

Steam Cylinder

DS25, RS25, DS25LC, RS25LC, DS35, RS35

300-1250

35-14

DS25, RS25, DS25LC, RS25LC, DS35, RS35

125-500

35-15

DS15P, RS15P, DS15, RS15

125-1250

15-14

DS20A, RS20A

300-1250

20-14A

DS20A, RS20A

125-500

35-14

Fill valve and filter

Fig. 3.g

Extension tube

Water drain outlet

3.3.1 Water Characteristic Requirements

The humidifier must be supplied with water with the following characteristics:

• pressure between 20psi and 110psi or 0.1 and 0.8 MPa (1 and 8 bar)

• temperature between 33°F and 104°F or 1°C and 40°C

• flow-rate minimum of 0.45 L/min or 0.21gpm

• hardness no greater than 40°fH (equal to 400 ppm³ of CaCO), conductivity: from 125 to 1250 μS/cm

• absence of organic compounds

• the characteristics of the water of supply must fall within the following limits:

LIMIT VALUES FOR LOW SALT CONTENT WATER LIMIT VALUES FOR LOW NORMAL WATER

Units Min Max Units Min Max

Total dissolved solids (c R) mg/l (*) (*) Total dissolved solids (c R) mg/l (*) (*)

Tab.3.d Tab.3.e

(*) Values dependent on the specific conductivity: in general: cR~=0.65*σR, 20°C; R180~=0.9*σR, 20°C

Note: There is no relationship between the hardness and conductivity of water.

Water Conductivity must be matched by specifications of the steam cylinder. Check or know the water conductivity of

the proposed site before installation. Replace the steam cylinder before startup if not correct. See Table 3.f right.

Tab.3.f

The following water types are not acceptable:

1. Softened water as this will lead to foam, electrode corrosion and greatly shortened

cylinder life.

2. Water containing disinfectants or corrosion inhibiters, as these are potential irritants.

3. Industrial water, boiler water or water from cooling circuits.

4. Any potentially chemically or bacteriologically contaminated water.

5. Heated water.

3.3.2 Water Supply Connection

We recommend the connection between the fill valve and the water supply line by a

soft poly hose capable of absorbing the water hammering in order to avoid damage to

the fill valve itself. The water line may be routed through the back or through the

bottom of the unit. With poly tubing, a tubing support must be used to prevent tubing

collapse and leaks. The fitting then threads onto the fill valve inlet located on the

bottom of the humidifier using a 3/4” G connection. Note that there is a strainer built

into the fill valve fitting underneath the unit, which will require periodic

cleaning, so be sure to allow clearance for access.

9

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

Fig. 3.h

Water drain

Page 11

3.3.3 Water Drain

Airflow 1000 cfm min.

Airflow

Min 8”

Height >8”

=

=

Airflow

1000 cfm min.

1/3 Height

Airflow

1000 cfm min.

=

=

8” min

24” min

Upstream

36”min

Downstream

Millimeters

Inch

B

50 mm

1.96”

C

56 mm

2.20”

E

100 mm

3.93”

F

G

22 mm

0.86”

H

∅ 30 mm

∅ 1.18”

I

12 or 22 mm

0.47 or 0.87”

Fig. 3.j

Important: Do NOT install into duct that has interior insulation.

Air Brake

Figure 3.h.2.

The Elite Steam also requires a connection to a drain. The drain line may be routed out the

back or bottom of the unit using the included angle fitting. The drain line can be 1-1/4” PVC,

CPVC or polypropylene. The drain line is not glued or otherwise attached to the humidifier so

it must be supported by itself. A coupling should be used. The Elite Steam includes a drain

tempering valve that runs whenever the drain pump runs and flushes cool water into the drain

line to insure the drain water temperature never exceeds 60°C or 140°F.

The drain water characteristics are:

• Drain Flow Rate – See Technical Specifications (Section 8 / pg 24)

• Connection 32mm or 1 1/4”

• Temperature 60°C or 140°F

min. 5°

NOTE: Drain line must be trapped under the unit to prevent flash steam from condensing in

4

the unit cabinet, as seen in figure 3.h.2.

3.3.4 Drain Connections

When using a rear outlet drain passing through drywall, we suggest using a 1 1/4” extension tube type SJ (see Fig. 3.f).

When using a bottom outlet drain, attach the included 90° fitting to the drain outlet. The drain outlet may be rotated. Then

connect a 1 1/4” trap adaptor to connect to drain pipe.

IMPORTANT WARNING: The drain pipe must be free without back pressure. We recommend an external anti-flooding

device not supplied to protect from faults of external hydraulic circuits.

3.3.5 Condensate Pump

When using a Condensate Pump, ensure pump selected is capable of handling 7.0 GPM for up to 10-15 seconds.

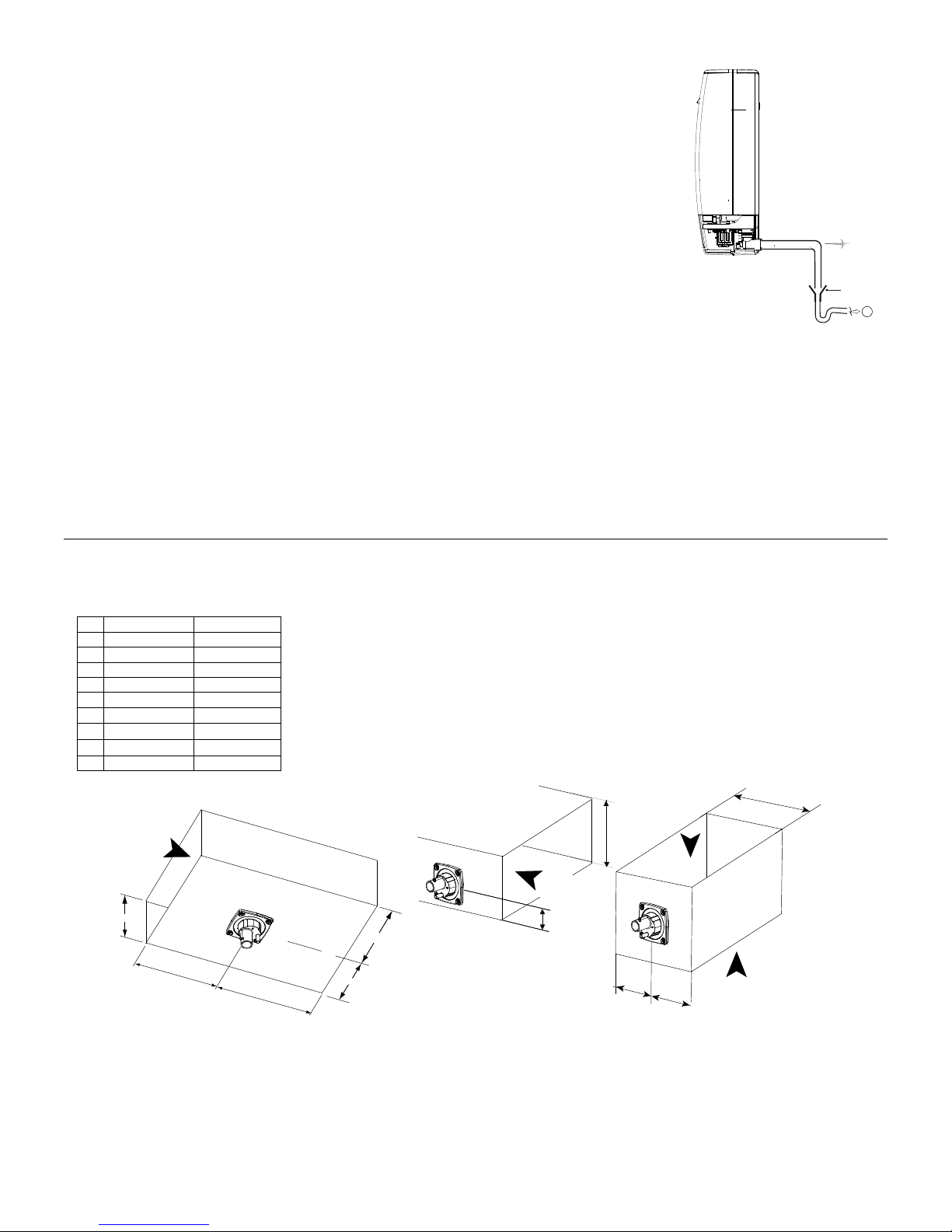

3.4 Steam distribution

3.4.1 Duct steam injection (Additional kit required)

The maximum allowed duct static pressure is 2 in WC.

The Elite Steam duct injection models include a plastic duct injection nozzle. See Fig. 3.i

5

A 31.5 mm 1.24”

D 57.5 mm 2.26”

∅ 8 mm ∅ 0.31”

∅

∅

Fig. 3.i

Important: Do NOT install into duct that has interior insulation.

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

10

Page 12

3.4.2 Duct Distri bution (Additional kit required)

If a duct steam distribution nozzle is to be used, select an accessible location on the duct, allowing at least 36” of straight duct (no

elbows or obstructions) after the point where the nozzle will be installed and the clearances can be maintained as per the following

drawings. See Fig.3.j To mount the steam nozzle, cut or drill a 2-1/2” hole in the duct. Apply caulk to the mounting plate of the

nozzle. Attach the nozzle to the duct using 4 #10 sheet metal screws (supplied). Nozzle must be level or vertical with condensate

outlet to the bottom.

IMPORTANT: Allow 1 M (3 feet ) of straight duct downstream of the distributor pipes and no z z les for absorption of the steam.

Always allow 0.6M (2 feet) of straight duct upstream of the distributor pipes for evaporation of the steam. Turbulent air flow may

require longer lengths

.

Optional stainless steel duct distributor pipe:

Fig. 3.j

To install the distributor pipes:

1. Cut a round hole in the side of the duct to match the steam pipe and condensate return.

2. Apply silicone sealant to the mounting plate and inser t the pipe through the hole and secure it with

sheet metal screw s. See F ig. 3.k

3. Connect the steam and condensate hoses using the hose cla mps suppl ied.

(Note: end support bracket supplied only with 36” and longer distributors.)

3.4.3 Return Condensate Connection

The return condensate hose from the nozzle, etc. must be trapped. Coil the hose into a vertical loop

and secure it below the nozzle, etc. This trap prevents steam from being released into the cabinet.

The hose end may be run through the knockout at the top of the humidifier and be inserted into the

hole located on top of the fill cup. The hole may be enlarged to suit. See Fig.3.l.

25-12 STEAM CYLINDER HOSE ADAPTER

Fig. 3.l

3.4.4 Steam Hoses

IMPORTANT WARNING: NINETY PERCENT (90%) OF ALL OPERATION PROBLEMS ARE CREATED BY IMPROPER STEAM

PIPING FROM THE HUMIDIFIER UNIT TO THE DUCT DISTRIBUTOR PIPES.

To avoid these problems, remember one simple fact when running the steam hose: steam naturally flows up hill, and condensate

naturally flows downhill. Run the steam hose or piping to avoid any kinks, sharp elbows, or low spots that could collect or restrict the

flow of steam to the distributor pipe, or the flow of condensate back to the humidifier. Support the hose adequately to avoid sags.

The following diagrams are to provide you with some guidelines. If you have a situation you are unsure of, please contact the factory

for instructions .

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

11

Page 13

20%

YES

NO

≥20%

A

C

B

D

Millimeters

Inch A 150 mm

6”

B

1800 mm

72” C 600 mm

24” D 2100 mm

84”

Fig. 3.n

IF NO TRAP

1,5 m (5 FT max.)

5%

WITH TRAP

1,5 m (5 FT max.)

IF NO SLOPE

20%

0,9 m (3 FT max.)

3 m (10 FT max.)

1,5 m (5 FT max.)

20% 20%

SUPPORTED STEAM HOSE

AND/ORCOPPER PIPE

NOTES:

• SLOPEPIPING UPIN DIRECTION OF STEAM FLOWAT 20% OR GREATER, WHICH MEANS 65,5mm x305mm (2 1/2” PER FOOT);

• SLOPEPIPING DOWN IN THE DIRECTION OF STEAM FLOWAT 5% OR GREATER, WHICH MEANS 20mm x 305mm (3/4” PER FOOT);

• MAX. LENGTH OF RUBBER STEAM HOSE IS 3 m (10 FT).

• HEIGHT OF P-TRAPSMUSTBE GREATER THAN THE D UCT STATIC PRESSURE.

NO SLOPE

KINKED

GENTLE BEND

OBSTRUCTION

SAG

5%

NO TRAP

DRAINS

P - TRAP

NOTE: HEIGHT OF TRAPSMUSTBE GREATER

THAN THE DUCT STATIC PRESSURE

NO SLOPE

UNDRAINED

ELBOW

TYPICAL INSTALLATION

WHEN UNIT IS ABOVE

THE DISTRIBUTORPIPE

DRAINS

UNDRAINED

ELBOW

NO DISTRIBUTION

PIPE DRAIN

Fig. 3.m

IMPORTANT: Maximum length of rubber steam hose is 4m (12 feet.). Insulated copper tubing may be up to 6m (20feet) in

length. In all cases, minimize sharp bends and elbows. Use 2 - 45° elbows instead o f 90°s.

Hose inner diameter = 7/8” (22 mm); Hose outer diameter = 1-1/4” (30 mm).

3.4.4 Remote Mount Blower

Remote Mount Blowers, are used to distribute the steam directly into the room. The drawings show the minimum recommended

distances to avoid the flow of humidified air from coming into direct contact with persons, lights, electrical appliances, and surfaces

before the steam has been totally absorbed by the environment. For further details on the assembly, the electrical connections and

the use of a Remote Mount Blower, please refer to the specific instruction manual.

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

Tab. 3.g

12

Page 14

Fig. 3.o

Fig. 3.q

L1 L2

Fig. 3.r

Fig. 3.t

Fig. 3.u

Fig. 3.v

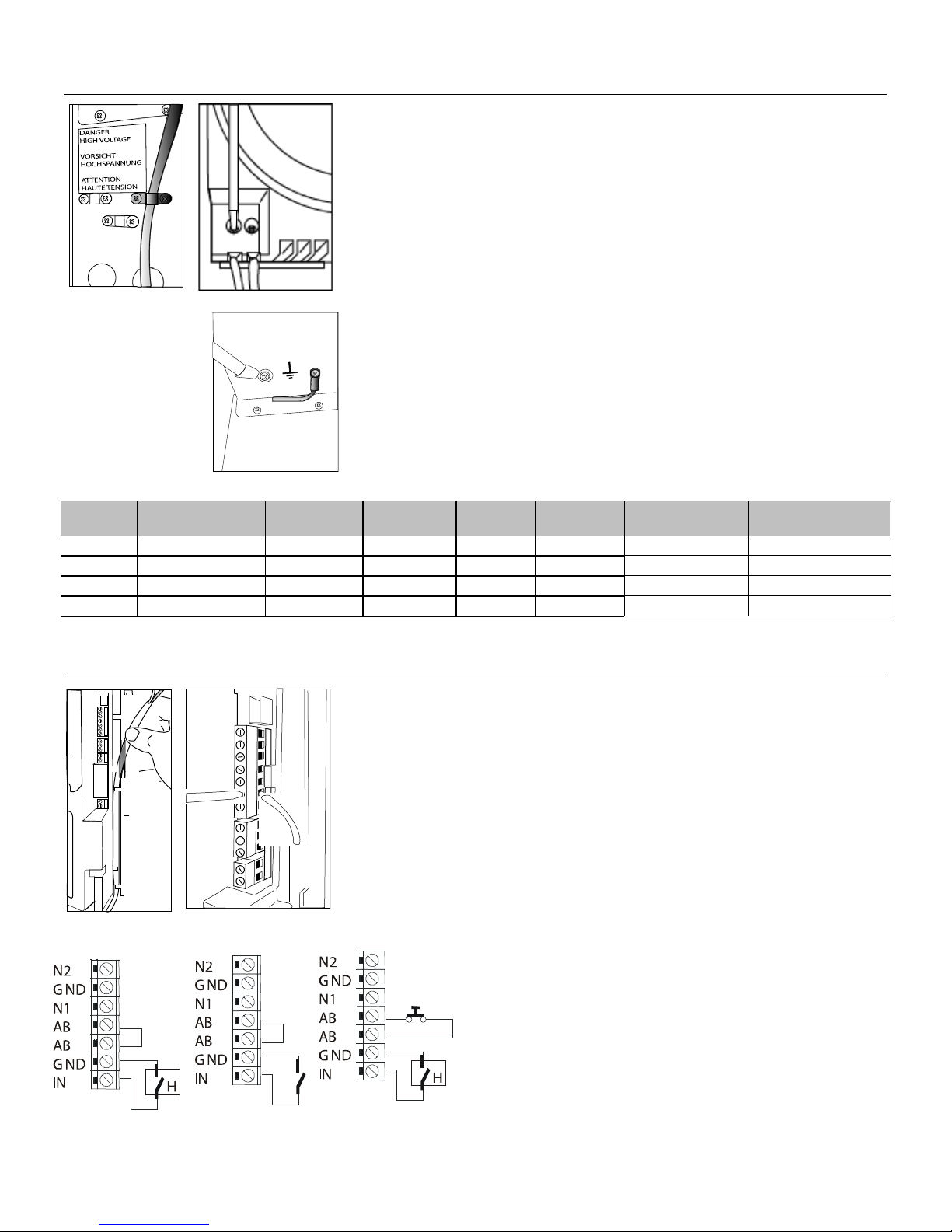

3.5 Power wiring

Check that the power supply voltage to be connected matches the value indicated on

the rating plate inside the electrical panel.

Insert the power and ground connection cables into the ele ct rical panel co mpart men t

using the strain reliefs supplied, and connect to the terminals. An external fused

disconnect must be installed. See Fig. 3.o

All wiring must be in accordance with local, state and national electric codes.

NOTE: to avoid unwanted interference, the power cables should be kept separate

from any control wiring.

NOTE: Tolerance allowed on main voltage =-15% to +10%.

Fig. 3.p

Connect power wires to the power terminal block located at the bottom left of the

control module, polarity does not matter. See Fig. 3.p

Connect the ground wire to the unit’s chassis ground, located just behind the power

wiring terminal block. See Fig. 3.q

Model

DS15 110V ac 50/60Hz 5.5 2.5 1.80 16.40 AWG10

RS15 110V ac 50/60Hz 5.5 2.5 1.80 16.40 AWG10

DS35 230V ac 50/60Hz 12 5.4 3.89 16.95 AWG10

RS35 230V ac 50/60Hz 12 5.4 3.89 16.95 AWG10

Power supply

(single phase)

Steam Output

(lbs/hr)

Steam Output

(kg/h)

POWER

(kW)

CURRENT

(A)

EXTERNAL

POWER WIRES

3.6 Control wiring

Elite Steam allows connection of any simple or automatic humidistat, and safety

devices such as high-limit humidistat, air flow proving switch, and remote on/off.

The humidifier is operated by the closing of a mechanical humidistat H, or by the

closing o f a voltag e-free remote contact, or alternatively by a combination of both. The

most common is a combination of a humidistat and pressure switch. The diagrams

in the figures show the connections to be made on the terminal block, in case of:

Fig. 3.u Operation performed by a simple enabling contact;

Fig. 3.t Operation controlled by an external mechanical humidistat;

Fig. 3.v A combination of both humidistat and pressure switch (most common).

Contact AB-AB:

• closed: humidifier enabled to produce steam (production starts when humidistat

closes);

• open: steam production is immediately stopped.

The remote on/off contact is usually a series of external potential-free contacts that

Fig. 3.s

enable the humidifier to produce steam when all of them are closed, indicating the

duct/AHU is ready to accept steam. Connect the 12500 Pressure

Switch NO and C terminals to the AB-AB contacts.

For example,

• fan contact closes when fan is running;

• downstream cooling coil contact closes when coil is off;

• etc.

Contact IN-GND:

• closed: steam production starts if contact AB-AB is closed

• open: steam production is stopped after 5 sec.

EXTERNAL FUSE (A)

OR BRAKER

25

25

25

25

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

13

Page 15

N2

GND

N1

AB

AB

GND

IN

NO

C

NC

C

NO

GND

24V

AC L

AC N

HUM

SNSR

OUTDOORTEMP. SENSOR

(not used in manual mode)

Elite Steam

ON DIP

1 2 3 4

ADCD

DIP SWITCH SETTNGS

FOR HUMIDISTAT ONLY OPERATION

ON

OFF

OFF

ON

Fig. 3.w

Fig. 3.x

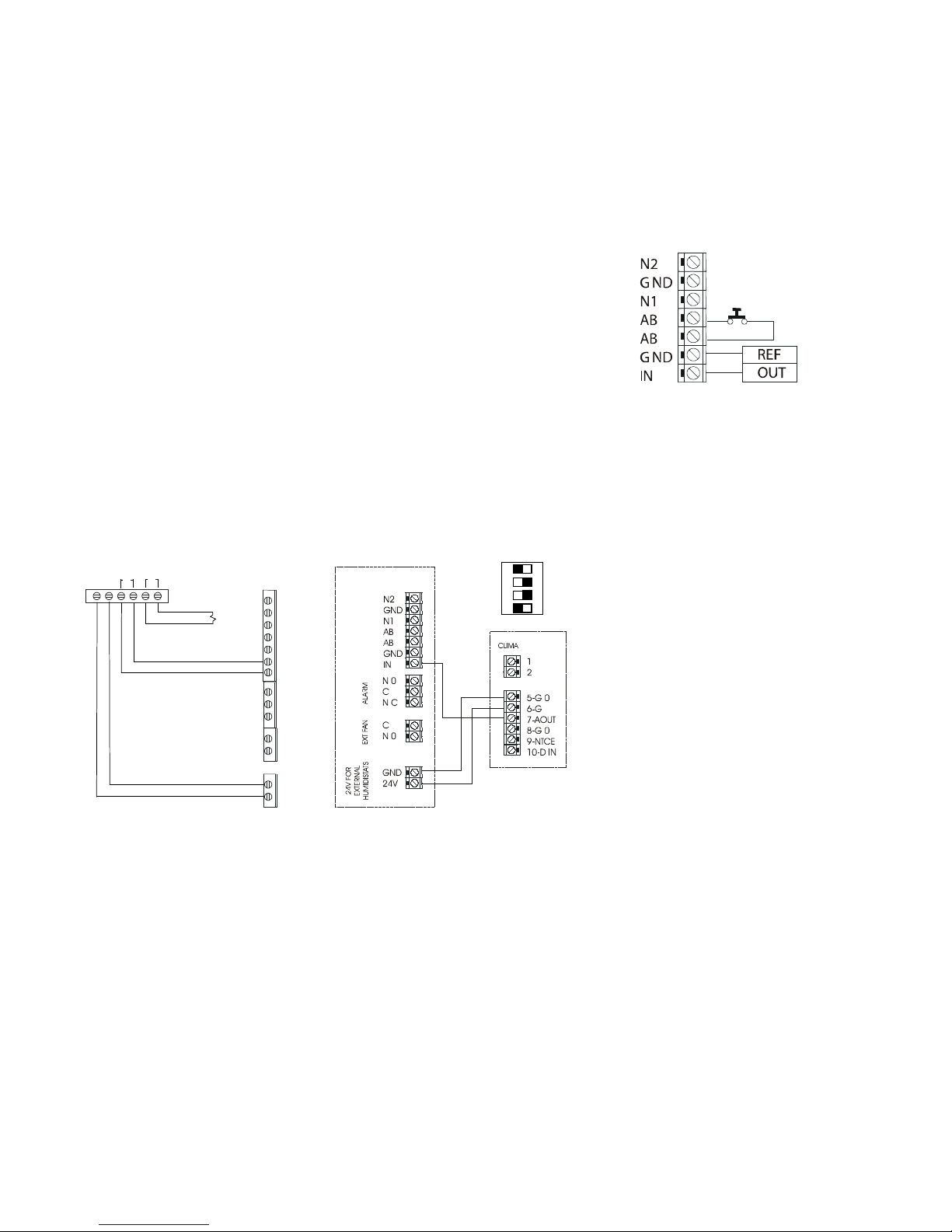

3.6.1 Connect the GFX3 Humidistat for On/Off Operation:

1. Remove the humidistat from the base, squeeze the louvered base at the top and bottom. To remove the humidistat from

the wall, lift up on the humidistat and pivot top away from wall.

2. Before wall mounting, please remove the black foam gasket.

3. Before return air duct mounting, please remove the breakout piece.

4. If return air duct mounting, route wires between humidistat and base.

5. Mount the sensor outside the house. Do not mount on South side of the house or in direct sunlight. Place at least 4 feet

away from any exhaust vent. If in air intake, place 1 foot or closer to outside wall. Place at least 6” higher than possible

snow. Do not route sensor wire near high voltage wires.

6. Connect the GND-IN terminals on the humidifier to the HUM terminals on the GFX3 Humidistat. Connect the GND-24V

terminals to the ACL-ACN terminals on the GFX3 Humidistat. see Fig.3.x

3.6.2 Modulating Operation

Connect an external 0...10 Vdc modulating input between terminals IN-GND. Connect any

Safety Switches (high-limit, air flow switch, remote on/off) in series to terminals AB-AB. If

no safety switches are used, then a jumper must be installed between AB-AB. DO NOT

PRESSURE

SWITCH

apply any voltage to AB-AB.

3.6.3 Connect the GFX50 humidistat for Modulating Operation

To select signal modulating see Fig 3.y Connect the power supply to the GFX50 G and G

EXTERNAL

REGULATOR

O terminals, using the terminal GND and 24V on the Elite Steam. Note MODULATING

OPERATION requires a change in signal type. See SEC. 5.1.1 page 19.

Connect an external signal to the

AOUT in

GFX50.

GFX50 using the terminal IN from the Elite Steam and

See the diagram below.

GFX3 HUMIDISTAT GFX50 HUMIDISTAT AIR CONDITIONER RELAY INTERLOCK

3.6.4 Safety and High Limit Switches

Remove the jumper between terminals AB-AB and connect any simple high-limits, air flow switch, 12500 pressure switch, and

remote contacts in series to terminals AB-AB; otherwise, if no such dry contacts are available, the jumper must remain in place

between terminals AB-AB. DO NOT apply any voltage to AB-AB.

Thread the control wiring through the bottom of the unit, and the strain relief (see photo at top of previous page), and then up the

side of the control module to the top right wiring terminal blocks. Connect the control wiring to the control wiring terminal blocks

found at the top right side of the control module.

3.6.5 Air Conditioner Relay Interlock

Auxiliary DPDT safety relay: Use this method in the following situations:

1. To prevent the air conditioner from running when there is a call from humidity. The DPDT relay will open the “Y” circuit and close

the “G” circuit for operation while a call for humidity is present. Demand for humidity will override call for cooling.

2. In systems using a thermostat where G and Y are a single circuit. The DPDT relay will allow blower operation to occur without

back-feeding the compressor.

Do not use this method when simultaneous humidification and cooling will be desired. Use a high limit humidistat in to avoid

condensation in ductwork.

The humidistat should be set to OFF during the air conditioning season if humidification is not desired.

For variable speed or DC systems, consult furnace manufacturer

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

Fig. 3.y

Fig. 3.z

.

14

Page 16

3.7 Wiring Connections:

Terminals

Functions

Electrical specifications

L1-L2 -GROUND

Power supply and Ground connections

Power supply 110 VAC 1-phase 50-60Hz 1.86kW or 230VAC 1phase 50-60Hz 4.05kW

KEY

Programming port

Connecting to Programming port or supervisor

AB-AB

Remote enabling input

Imposes an external NO contact ; Rmax=300 Ohm; Vmax=33 Vdc;

Imax=6mAdc; humidifier enabl ed = contact cl ose d

IN-GND

Control signal input

If programmed 0...10V:

Input impedance 10 kohm

Imax = 5mA Rmax = 300 Ohm

NC-C-NO

NC alarm contact

NO alarm contact

250V; 8Amp max with resistive load; 4 Amp max with inductive

load

24GND

Power for external humidistat

Power supply for external humidistat 24 Vac; 2 Watt

KEY FOR PROGRAMMING PORT:

DP = DRAIN PUMP

DT = DRAIN TEMPERINGVALVE

HL = HIGH-LEVELSENSOR

EVF = FILL VALVE

CONNECT ED

TO GROUND

POWER SUPPLY

(110VAC 1-PHASE 50-60 HZ

OR

230 VAC 1-PHASE50-60HZ)

24VACFOR

EXTERNAL

HUMIDISTATS

EXTERNALDUCT FAN

ALARM

HUMIDISTAT

AIR PRESSURE SWITCH

PROGRAMMING

PORT

IN GND AB AB N1 GND N2

NO C

NC C NO

24Vac GND

KEYBOARD

EXT FAN ALARM

KEY

HL

N

EVF

DP

N

F

INT

FAN

E1

E2

L1 L2

8

2

4

EMBEDDED

BLOWER

ON-OFF

BOTTON

6

EXTERNAL FUSED

DISCONNECTTO BE

INSTALLED(NOT

SUPPLIED) RESPECT

LOCAL CODES

HL

STEAM

BOILER UNIT

DP

DT EVF

DRY CONTACTS,

If programmed ON-OFF:

Vmax 33Vdc

Common alarm contact

load

NO-C External fan relay 250V; 8Amp max with resistive load; 4 Amp max with inductive

3.7.1 Wiring diagram of controller

EXTERNAL FAN

HOOKUP

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

Fig. 3.z.1

15

Page 17

2.

Maintenance

3.

Display is amperage (default)

4.

Steam is being produced

5.

Cylinder filling

6.

Foaming

7.

Water presence inside the cylinder

9.

LEDs indicate: power (yellow), operation (green) and alarms (red)

10.

Drain button for manual draining of cylinder and confirming parameter values

12.

Reset button to reset alarms and access parameters

13.

Level of output: 33%, 66%, 100%

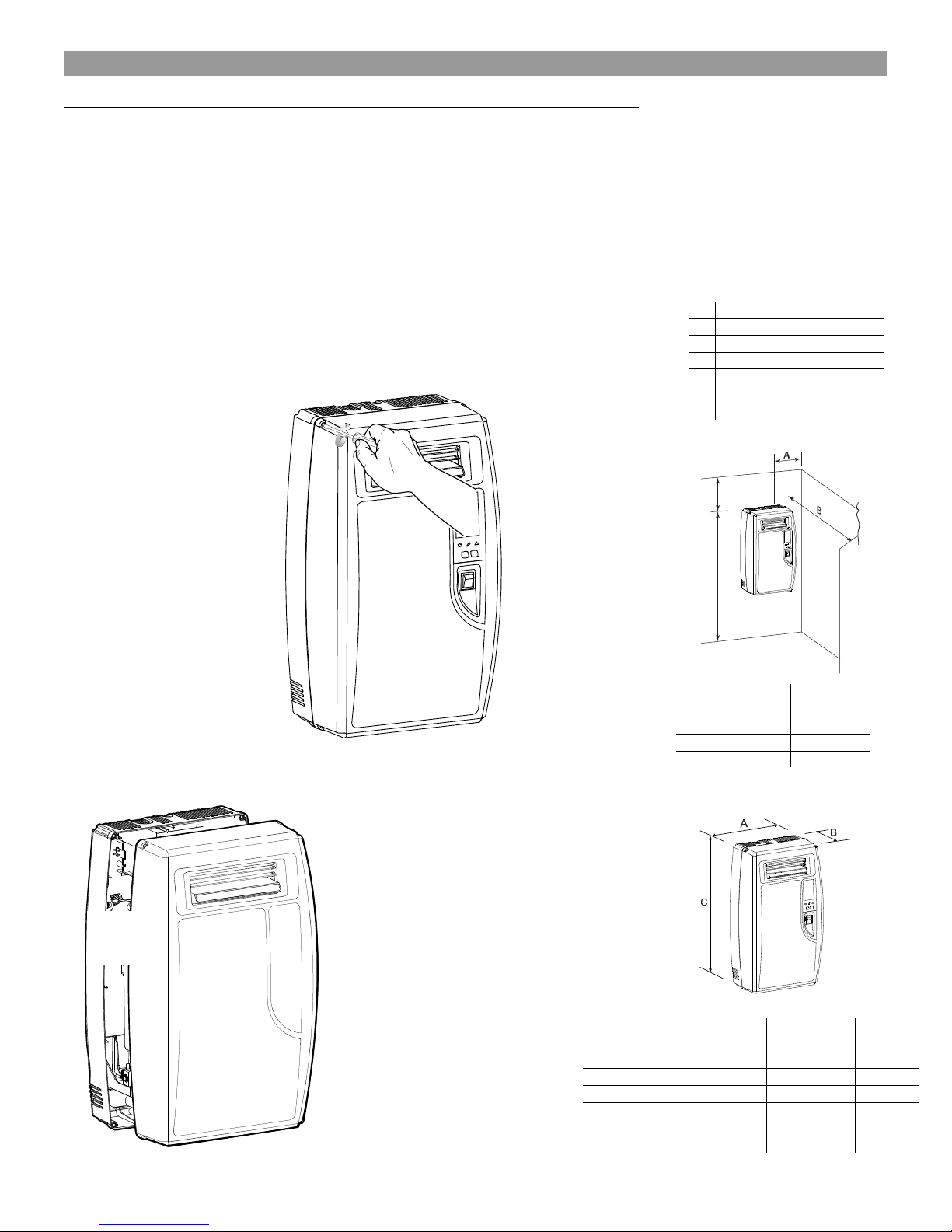

1

2

4

5

6

9

10

12

13

14

11

3

7

8

4. START-UP

IMPORTANT WARNINGS:

1. Before starting, check that the humidifier is in perfect condition, that there are no water leaks and that the electrical parts

are dry;

2. Do not connect power if the humidifier is damaged or even partially wet!

When installation is completed, flush the supply pipe for around 10 minutes by piping water directly into the drain, without sending it

into the humidifier; this will eliminate any scale or residues that may cause foam when boiling.

4.1 Startup Checklist

Before starting the humidifier, the follow ing shou ld be chec ke d:

• Water is connected, the line has been flushed, and external valves are open.

• Drain is connected, run to an open drain, and has a trap under the unit.

• Electricity is connected in accordance with instructions, local codes and data labels in the unit.

• The power fuses are installed and intact.

• All control wiring is done and tested.

• Airflow switch is wired to open on air flow loss.

• Hi-limit humidistat is wired to open on humidity rise above set point.

• Unit wires have been checked to make sure they and all connectors are tight from shipping.

• The steam hose(s) are run correctly with no sags or kinks and sloped properly according to the manual.

• Condensate hoses are run correctly with no sags or kinks and sloped properly according to the manual.

4.2 The Elite Steam Controller

The Elite Steam controller features a comprehensive information display that shows the operation of the system at a glance:

1. Display is % of nominal capacity

8. Cylinder draining

11. ON/OFF button

14. Fan relay is activated

The Elite Steam is now ready to operate.

4.3 Starting Elite Steam

• Insure that the external power is turned on.

• Push the top part of the On/Off button so that the I part is in. The yellow Power LED will be

lit. The Elite Steam is now ready to operate.

• When there is a call for humidity, Elite Steam will close its power relays and send power to

the electrodes in the plastic steam generator. The green Operation LED will light, indicating

that operation has begun.

4.4 Starting with a new cylinder

When starting with a new cylinder, you should activate the cylinder cleaning function as follows:

1. Switch Elite Steam off.

2. Press and hold both buttons, “reset” and “drain”, and switch Elite Steam back on. When the

wrench blinks then release the two buttons.

3. Press and hold “reset” until the display shows 04.

WARNING: DO NOT confirm any value higher than 04. If 05 or higher is displayed, press “reset” until the display goes back to

the normal operating mode and restart from step

4. Press “drain” (minimum 1 second): the cleaning starts and the display shows PC.

During the cleani ng, the electrodes are power ed and water is filled in until it touches the high-level sensor or the phas e current equals 20A,

whichever occurs first. After either of the events is detected, the boiler is fully discharged with the electrodes un-powered (the drain pump and

the drain tempering valve are activated for 3 minutes). W arming the filling water helps washing out any mould releas e or dirt. General Filters,

Inc. recommends doing two cleanings when starting a new boiler. After the cleaning ends, the humidi fier starts the regular duty. When starting

the unit with a new or emp t y cylinder, it m ay tak e a s ignif icant a mount of time (ho urs) f or the uni t to bui ld u p en ough mine ral con centration to

reach rated capacity. This time can be shortened by the addition of Alka-Seltzer through the steam outlet on top of the cylinder.

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

16

Page 18

5. OPERATING ELITE STEAM

5.1 Displaying Information

By pressing the “reset” button for 2 seconds, the display will loop from amperage to production in % of the maximum production to

the hour counter and back to amperage:

Fig. 5.a

1. Amperage: it is the value of the current that flows through the water making it boiling off (default display)

2. Production %: it is the current production expressed as a percentage of the humidifier’s capacity

3. Hour counter, expressed in tens; for instance, when the display shows 13 the real hour value will be between 130 and 139

hours.

5.1.1 Select Signal Type

The Elite Steam is preset for the included GFX3 humidistat (signal type 0). If the included humidistat is used, this section may be

omitted. If another humidistat is used, review this section to see if changes are needed.

1. Switch Elite Steam off.

2. Press and hold both buttons “reset” and “drain” and switch Elite Steam back on. When the wrench blinks,

release the

2 buttons.

3. Press “Reset” until the display shows 02. WARNING: DO NOT confirm any value higher than 04. If 05 or higher is

displayed, press “Reset” until the display goes back to the normal operating mode and restart from step 1.

4. Press “drain” (minimum 1 second) to confirm: the display shows “P1” then the current signal type and “set”

5. Press “Reset” to change signal type between 0 and 1:

0 = On-Off humidistat such as the GeneralAire “M” or “GFX” series humidistat.

1 = external 0...10 Vdc modulating signal such as the GeneralAire

®

ADCD series humidistat

6. Press “drain” (minimum 1 second) when done to confirm the new value of P1 and exit to the normal operatin g mode.

7. Switch Elite Steam off: you can now proceed with connecting the control wiring.

5.2 Changing The Maximum Production

The maximum production can be adjusted between 20% to 100% of the nominal production in steps of 5% in order to suit the

environmental characteristics. DS25 and RS25 Maximum production is factory set at 70%.

1. Switch Elite Steam off.

2. Press both and hold both buttons “Reset” and “Drain” , and switch Elite Steam back on. When the wrench blinks;

release the 2 buttons.

3. Press “reset” until the display shows 01. WARNING: DO NOT confirm any value higher than 04. If 05 or higher is displayed,

press "Reset" until the display goes back to the normal operating mode and restart from step 1.

4. Press “drain” (minimum 1 second) the display shows “P0” then the current Maximum Production Percent and “set”.

5. Press “reset” to change the Maximum Production in steps of 5% between 20% and 100%.

6. Press and hold “drain” (minimum 1 second) when done to confirm the new Maximum Production and exit to the normal

operating mode.

5.3 Activating Manual Drain

Press and hold the “drain” button on the front of the unit until the cylinder is drained. Note: Water will continue to flow from the

tempering valve after the cylinder is empty.

5.4 Resetting the hour counter

The hour counter should be reset every time the cylinder is changed in order to reset and r estart the internal maintenance timer:

1. Switch Elite Steam off.

2. Press and hold both buttons “Reset” and “Drain” and switch Elite Steam back on. When the branch

buttons.

3. Press and hold “reset” until the display shows 03. WARNING: DO NOT confirm any value higher than 04. If 05 or higher is

displayed, press “reset” until the display goes back to the normal operating mode and restart from step 1.

4. Press “drain” (minimum 1 second) to confirm: the hour counter will be reset at once and Elite Steam will go back to the normal

operating mode.

blinks; release

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

17

Page 19

5.5 Using the GFX3 Humidistat

play

Led

Relay

--

Remote on-off open

Unit disabled

Off

Off EE

Internal memory error

Unit disabled

On

On E0

Control board configuration not valid

Unit disabled

On

On

Turn off, check control boar d, reprogram

E1

High current alarm

Unit disabled

On

On

Turn off, check connections, check

electrodes, no electrodes short-circuited)

E2

Low production, low supply water

Unit disabled.

On

On

Check supply water conductivity (too

E3

Press “reset/sel” key for 1 seconds to reset.

Off

Off

Change cylinder (not urgent)

timeout)

(critical performance detected)

produce the demand, otherwise turn off and then on.

reset/sel

cylinder”)

Resetting the hour counter”)

176 °F / 80 °C)

decreases below 176 °F / 80 °C.

the controller.

Suggested

Setting

Outdoor

Temperatures

15%

-20˚F -29˚C

20%

-10˚F -23˚C

25%

0˚F -18˚C

30%

+10˚F -12˚C

35%

+20˚F - 7˚C

40%

+30˚F - 1˚C

Press to select OFF, MANUAL or AUTO mode (if outd oor s ensor is connected).

OFF mode: The humidifier is turned off.

MANUAL mode: The GFX3 will work to maintain the single humidity selected. You can set

your desired humidity level by pressing

or . The humidifier will turn ON or OFF

according to your manual setting. (The humidifier will operate when the measured relative

humidity falls more than 2% below the set point.) Humidity will have to be lowered when

weather is colder or if condensation is suspected.

AUTO mode: The GFX3 will automatically raise the humidity as the outdoor temperature

increases. This provides the highest possible humidity. The GFX3 will automatically lower the humidity as temperatures drop. This

minimizes the risk of condensation on cold surfaces like windows. You can adjust the Auto Humidity Index Set Point from 0 (low) to

10 (high) by pressing or . The Humidity Index is based on the outdoor temperature and indoor humidity. The humidifier will

switch ON/OFF according to the calculated auto humidity index set point. Lower Index settings are for older homes with less

insulation and vapor barriers. Higher Index settings are for newer homes with complete vapor barriers, triple pane windows and high

R value insulation. If condensation occurs reduce Index setting by 2 points until condensation stops.

NOTE If the outdoor temperature sensor fails, flashes and the unit will default to MANUAL mode.

To toggle between indoor / outdoor temperature and indoor humidity: Press .

To change the temperature unit: Press °C / °F.

To set the temperature / humidity offset in MANUAL or AUTO mode:

1. Simultaneously press and when viewing the temperature or humidity reading.

2. Use

3. Press and simultaneously or wait 5 seconds to confirm and move onto the next setting.

or to change the setting (-3 to 3).

WARNING: Do not allow excess humidification. Excess humidity can cause condensation and enable mold and mildew growth.

5.6 Alarms

In the event of an alarm, the red alarm LED will flash, the alarm relay will close, and the alarm code will flash in the display. Multiple

alarms will flash in sequence, alternating with the main display. Pressing the sel button for 2 seconds will reset the alarms, although

still active alarms will continue to display.

Dis

Description Action Red

Alarm

Notes

conductivity or excessive

foam/limescale in the cylinder

Cylinder almost exhaus ted, already

used for 20 00 hrs

E4 Fill alarm, unable or slow fill

(current does not increase within

timeout)

E5 Drain alarm, unable to drain

(current does not decre ase wi thi n

E6 Cylinder exhausted

E7 Foam detected

E8 Cylinder lifetime expired (3000 hours) Unit disabled: Reset the hour counter (read chap.

E9 High controller temperature (above

Press “reset/sel” key for 1 seconds to reset.

Press “reset/sel” key for 1 seconds to reset, otherwise

the warning will be reset automatically every 10

minutes until the supply water is available again.

Press “reset/sel” key for 1 seconds to reset

The warning is automatically reset if Elite Steam can

Press “

The warning is automatically reset if the temperature

” key for 1 seconds to reset

cylinder (no limescale bridges between

low?), replace the cylinder.

On On Check water supply and fill valve; check

On On Check drain pump and drain connection

Off Off Change cylinder (urgent)

Off Off If it continues, do some cleaning cycles

On On Change the cylinder if necessary

Off Off Check the ambient temperature, replace

drain pump for leakage

(read chap. “

Starting with a new

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

18

Page 20

Problem

Causes

Solutions

The humidifier does not start

1. Remote ON/OFF contact open

1. Close ON/OFF contacts

The humidifier fills with water

1. High steam back pressure

1. Check that the steam hose is not kinked or sagging,

The humidifier wets the duct

1. The distributor is not installed correctly (too

1. Check that the steam distributor is installed correctly

ventilation in the duct

The humidifier wets the floor

1. The humidifier drain is blocked

1. Clean the drain assembly and pan

Problem

Causes

Solutions

Water in the cylinder turns

1. Minerals in the cylinder have overand are deteriorating the

1. Check for sags & kinks that could trap condensate in the

steam hoses that could cause a back pressure on the

5. Correct installation problems and replace cylinder.

Heavy arcing occurs within

1. The feed water contains large a m ounts of I ron,

1. Contact the factory for an optional drain timer to force

not damaged in shipping.

Humidifier continuously fills

ains without producing

4. Consider using a mix of demineralized water with raw

d. If feed water

contains silica or nitrates, install a 1 micron water filter.

6. TROUBLE SHOOTING

The humidifier does not turn on 1. No electrical power

operation

without producing steam

below

2. On/off switch of the humidifier in position 0

(open)

3. Control connectors improperly connected

4. Blown fuses

5. Transformer failure

2. The humidistat has not been connected

correctly

3. Humidistat failure

4. Control signal not compatible with the type set

5. Value measured by the sensor/s higher than

the corresponding set point

2. Fill valve strainer clogged

3. Mineral in the fill cup

4. Drain pump valve leaking

near the top of the duct or the condensate return

is blocked)

2.Air flow rate is too low

3.Humidifier active when the fan in the duct is off

2. The supply water or overflow circuit has leaks

3. The condensate drain pipe does not bring the

water back to the drain pan

4. The steam hose is not properly fastened to the

cylinder

5. The bushing and / or O-ring at the base of the

cylinder are missing or not properly seated.

1. Check the safety devices upstream from the humidifier

and the presence of power

2. Close the switch on the panel: position I

3. Check that connectors are properly inserted in terminal

block

4. Check the condition of fuses

5. Check that the proper voltage is connected and turned on

2. Check the external connection

3. Replace the humidistat

trapping condensate

2. Clean the fill valve strainer

3. Clean the fill cup

4. Check for voltage at the drain pump valve and/or drain

pump replacement

2. Increase air flow in duct or decrease PO maximum steam

production setting

3. Check the connection of the device (flow switch or

differential pressure switch) controlling the humidifier to the

2. Check the entire water circuit

3. Check the correct position of the condensate drain hose

in the drain pan

4. Check the fastening of the hose clamps on the steam

outlet

5. Lift out the cylinder and check to see the bushing and / or

O-ring are properly seated. See illustration page 21.

Tab. 6.a

black

hours of startup

and dr

steam

concentrated

electrodes.

Copper or other conductive contaminants.

1. Mineral has bridged between the electrodes.

2. There is back pressure from the steam hoses

or duct.

3. The flow regulator in the fill valve is broken or

out of place.

4. Water conductivity is very high.

5. Water is foaming excessively.

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

cylinder.

2. Check the duct static pressure.

3. Check the fill valve and inlet strainer.

4. Check the drain pump operation.

additional drains to control the minerals.

2. If you are using a softener. Discontinue use.

3. Check the electrodes in the cylinder to be sure they were

1. Clean or replace the cylinder.

2. Check the steam hoses for kinks or gullies t hat might be

trapping condensate.

3. Replace the fill valve.

water.

5. Check cylinder - replace if exhauste

Tab. 6.b

19

Page 21

20%100%

Maximum Production

Cylinder

life

Fig. 7.b.

Fig. 7.c.

Bushing

Red O-Ring

7.1 Periodic checks

• After one hour of operation: Check that there are no significant water leaks.

• Every fifteen days or no more than 300 operating hours: Check operation, that there are no significant water leaks and the

general condition of the cylinder. Check that during operation there is no arcing between the electrodes.

• Every three months or no more than 1000 operating hours: Check operation, that there are no significant water leaks and, if

necessary, replace the cylinder. Check that there are no blackened parts of the cylinder. If there are blackened parts of the

cylinder, check the condition of the electrodes, and if necessary replace the cylinder.

• Annually or no more than 2500 operating hours: Replace the cylinder.

CAUTION: ALWAYS DISCONNECT THE M AIN POWER BEFORE DOING MAINTENANCE!

CAUTION: always disconnect the main power before touching the cylinder in the event of leaks, as current may flow through the water.

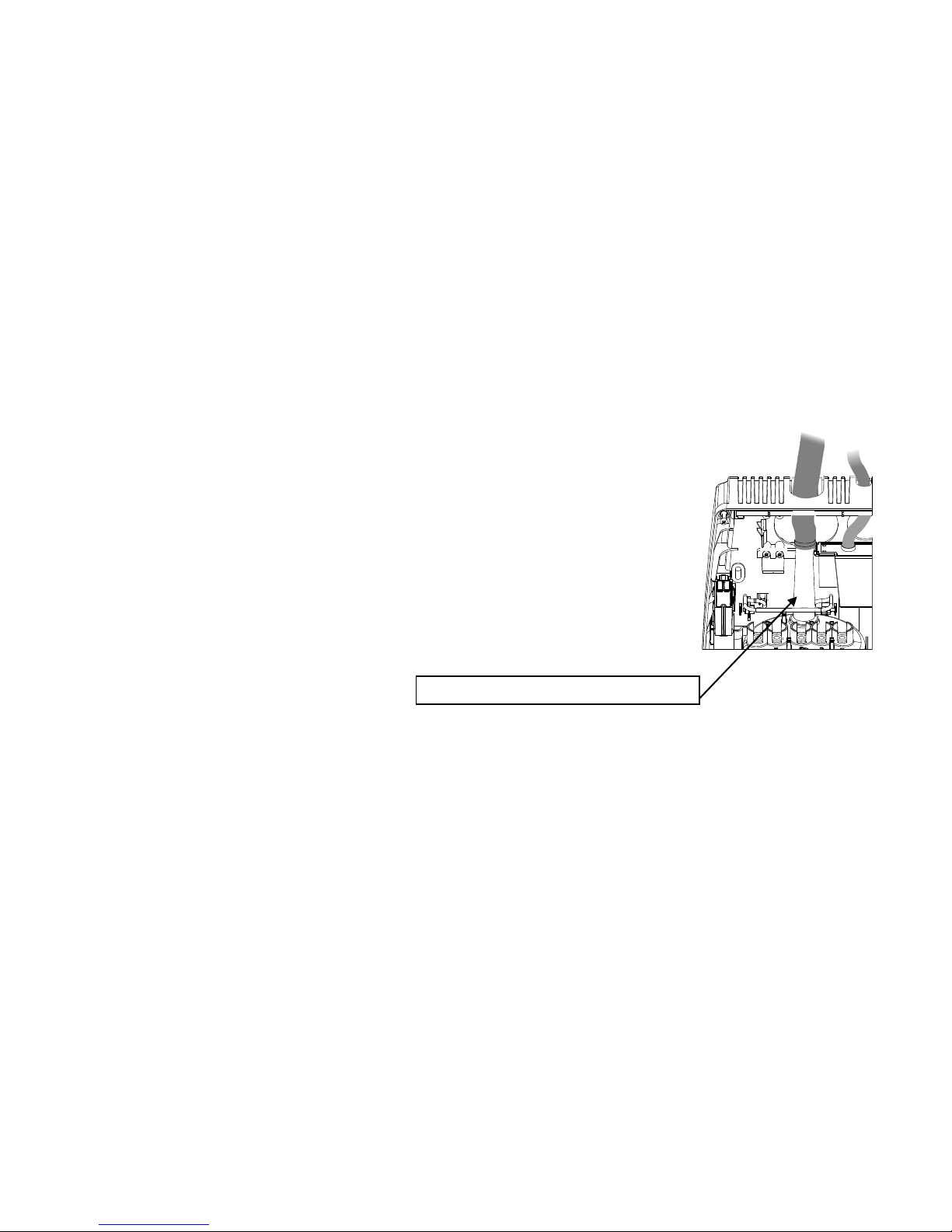

7.2 Cylinder maintenance

The life of the cylinder depends on a number of factors, including: the amount and type of mineral in the water, the correct use and

sizing of the humidifier, and the output, as well as careful and regular maintenance. Another factor affecting cylinder life is

Maximum Production, the higher the production rate the shorter the cylinder life; for this reason the DS-25 and RS-25 are preset

from the factory at 70%. Further reductions in maximum production will extend cylinder life. See figure 7.a

IMPORTANT WARNINGS

The humidifier and its cylinder contain live electrical components and hot surfaces, and therefore all service

and/or maintenance operations must be performed by expert and qualified personnel, who are aware of the

necessary precautions. Before performing any operations on the cylinder, check that the humidifier is

disconnected from the power supply. Remove the cylinder from the humidifier only after having drained it

completely using the manual “drain” butt on or procedure. Check that the model and the power supply voltage

of the new cylinder correspond to the data on the rating label.

7.2.1 Replacing the cylinder

IMPORTANT WARNING: the cylinder may be hot. Allow it to cool before touching it or use protective gloves.

Fig. 7.a

To replace the cylinder:

1. Completely drain the cylinder by pressing and holding the “drain” button until the cylinder is empty;

2. Turn the humidifier off and disconnect the main power;

3. Remove the cover;

4. DS Models:

o Remove the steam hose from the cylinder;

o Flip up the cylinder holdi ng brack et and lift t he cylinder out of the unit;

o Disconnect the steam hose adapter from the cylinder and lift the cylinder out of the unit. Bushing and O-ring

may fall out with cylinder removal. If so, re-seat a NEW O-ring and existing bushing back in the base.

5. RS Models:

o Undo the 2 bolts of the embedded fan;

o Flip up the cylinder holding bracket;

6. Disconnect the distributor from the cylinder and lift the cylinder out of the unit;

7. Set bushing to side. Do NOT discard bushing. Dispose of red O-Ring.

8. Disconnect the electrical connections from the top of the cylinder;

9. Ensure NEW O-ring and bushing are properly re-seated before inserting new cylinder. See figure 7.c.

10. Install the new cylinder in the humidifier by performing the prev ious oper atio ns in rever se

CAUTION: Do not tighten the 7/8” hose clamp so tight that it crushes the cylinder outlet

WARNING: Electrical connections to the cylinder must be tight or possible fire hazard may result.

Threaded nuts on power wires must be connected with 44 in-lbs ± 10% (5 Nm ± 10%).

7.2.2 Maintenance of the other plumbing components IMPORTANT WARNINGS:

• External power must always be disconnected when performing any maintenance on the humidifier.

• When cleaning the plastic components do not use detergents or solvents;

• Scale can be removed using a solution by using vinegar or a weak solution of acetic acid and a soft brush; then rinse the

cylinder thoroughly with fresh water.

Cleaning the fill valve:

After having disconnected the cables and the hoses, remove the valve and check the condition of the inlet filter; clean if

necessary using the same cleaning solution as for the steam cylinder and a soft brush.

Cleaning the drain pump:

Remove the valve body, clean if necessary using the same cleaning solution as for the steam cylinder and a soft brush.

Cleaning the drain pan:

Clean the pan of any mineral deposits and check that the water flows freely from the pan to the drain at the drain pump.

Cleaning the supply, fill, overflow pipes: Check that these are clear and clean or replace if necessary.

IMPORTANT WARNING: after having replaced or checked the plumbing, check that components have been reconnected correctly

with the proper seals. Re-start the humidifier and perform a number of cleaning cycles (from 2 to 4, read chap. “Starting with a new

cylinder”), then check for any water leaks.

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

7. MAINTENANCE

AKA: Gasket

REPLACE WITH NEW

KEEP AND

RE-SEAT

20

Page 22

7.3 Replacement Parts

12

12

4

5

1

3

8

6

14

10

11

7

9

12

2

15

Item

Part No.

Description

1

See the table below

Steam generator cylinder

7801

3

7551

35-18 ON/OFF SWITCH FOR CH SERIES

7535

35-2 ROOM BLOWER ASSEMBLY 230/1 FOR CH SERIES

5

7544

35-19 BLOWER FILTER KIT FOR CH SERIES

7802

7803

25-3 FILL SOLENOID VALVE + DRAIN TEMPERING 230 V FOR DRAIN PUMP

7804

15-7 KIT FOR DRAIN PUMP 110V

7805

9

7542

35-21 90 DEGREE DRAIN ADAPTER FOR CH SERIES

10

7806

25-2 FILL TANK + PLUG FOR DRAIN PUMP

12

7553

35-25 COVER HOLDING SCREWS FOR CH SERIES

14

15

7811

25-50 WIRING KIT FOR UNIT WITH DRAIN PUMP

16

Item

Part No.

Description

1

7523

15-14 CYLINDER STD. CONDUCTIVITY 110/ 1 5.5 LBS/ HR DS15P, RS15P, DS15, RS15

1

7524

35-14 CYLINDER STD. CONDUCTIVITY 230/1 12 LBS/HR DS25, RS25, DS25LC, RS25LC

1

1

7516

20-14A CYLINDER STD. CONDUCTIVITY 230/1 7 LBS/HR DS20A, RS20A

7552

35-16 INTERNAL FILTER AND GASKET KIT FOR CYLINDER

Expanded View of Bushing

16

& O-Ring Placement

2

4

6 7536 35-20 INTERNAL STEAM DISTRIBUTOR MANIFOLD FOR CH SERIES

7

8

11

7800

7534 15-2 ROOM BLOWER ASSEMBLY 110/1 FOR CH SERIES

25-1 CONTROL MODULE 5.4 kg/h 230V WITH DRAIN PUMP

15-5 CONTROL MODULE 2.5 kg/h 110V WITHN DRAIN PUMP

15-6 FILL SOLENOID VALVE + DRAIN TEMPERING 110 V FOR DRAIN PUMP

25-7 KIT FOR DRAIN PUMP 230V

7807 25-4 ROOM TUBING KIT FOR DRAIN PUMP

7808 25-5 DUCT TUBING KIT FOR DRAIN PUMP

7809 25-6 BOTTOM TANK FOR DRAIN PUMP

7810 25-8 DRAIN TANK + PLUG FOR DRAIN PUMP

7815 25-12 STEAM CYLINDER HOSE ADAPTER

7685 BUSHING KIT FOR 15 & 25 MODEL STEAM HUMIDIFIERS (BUSHING & O-RING)

7543 35-15 CYLINDER LOW CONDUCTIVITY 230/1 12 LBS/HR DS25, RS25, DS25LC, RS25LC

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

21

Page 23

5.5 lbs/hr (2.5 kg/h): 110 VAC 1-phase 50-60 Hz, 1.86 kW

12 lbs/hr (5.4 kg/h): 230 VAC 1-phase 50-60 Hz, 4.05 kW

Steam pressure

3.81 in WC / 950 Pa

For duct only

24” x 14” x 8” (600 x 341 x 204 mm)

Weight empty/packaged/installed

with water

18/22/26 lbs. (8/10/12 kg)

IP20

Electrode power cables

12 AWG

Power relays

2 x 30 Amp

on board

Screw

Input water type

Potable water

no demin. or softened water

Conductivity range

125-1250 µS/cm

Special cylinders for cond. < 350

1/4” O.D. Compression

Water fill - instant flow

0.09 – 0.16 gpm

(0.35 – 0.60 l/min)

32 mm O.D. (1.25”)

unit.

Drain water temp

< 140°F

(< 60°C)

drain tempering device

Initial Max drain rate - 7 gpm (26.2 l/min) (w/ full cylinder –

one minute period starting with full cylinder)

71 cfm

(120 m³/hr)

RS485

Steam flows, VAC, kW

8. TECHNICAL SPECIFICATIONS

Notes

Dimensions (mm )

IP class

Ground connection

Water fill connection

Drain connection

Drain flow

Embedded fan flow

Serial communication

(Height x Width x Depth)

Adapter to ¾” FPS

Adjustable from horizontal to

vertical.

May be from back or bottom of

for the first 10-15 seconds of drain cycle)

Average drain rate – 3.1 gpm (11.7 l/min) (measured over a

Direct Room Discharge Only

Unit Voltages

Primary 120 / 240 Volts AC

Control Wiring 12 Volts DC

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

22

Page 24

9. LIMITED WARRANTY

DS and RS Residential Humidifiers, if properly registered by the return of the page 25 warranty registration to General Filters, Inc.,

are warranted to the consumer against defects in materials and workmanship for a period of two years from the date of installation,

so long as the product has been installed and operated in accordance with all appropriate manuals and wiring diagrams in a

residential structure.

Install ation in comm ercial, industrial or office building will void all warranties. Installation to a water source that does not meet unit

specification will void all warranties. Replacement of routinely replaceable parts such as steam cylinders and gaskets, are not

covered by this limited warranty or any other warranties.

Any other defective parts will be repaired without charge except for removal, reinstallation and transportation costs. To obtain repair

service under this limited warranty, the consumer must send the defective part to General Filters, Inc.

THERE ARE NO EXPRESS WARRANTIES COVERING THIS HUMIDIFIER OTHER THAN AS SET FORTH ABOVE. THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY

EXCLUDED. THE MANUFACTURER ASSUMES NO LIABILITY IN CONNECTION WITH THE INSTALL ATION OR USE OF THIS

PRODUCT, EXCEPT AS STATED IN THE LIMITED WARRANTY. THE MANUFACTURER WILL IN NO EVENT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. This limited warranty gives you specific legal rights, and you may also have other

rights which vary from state to state. Some states do not allow either limitations on implied warranties, or exclusions from incidental

or consequential damages, so the above exclusion and limitation may not apply to you.

Any questions pertaining to this limited warranty should be addressed to General Filters, Inc. General Filters, Inc. has elected not to

make available the informal dispute settlement mechanism which is specified in the Magnuson-M oss Warranty Act.

Register your warranty online USA: www.generalfilters.com / Support Center

Register your warranty online Canada: www.cgfproducts.com / Warranty Regist rat ion

GENERAL FILTERS, INC CANADIAN GENERAL FILTERS, INC

43800 GRAND RIVER AVENUE 400 MIDWEST ROAD

NOVI, MI. 48375 TORONTO, ON M1P3A9

www.generalfilters.com www.cgfproducts.com

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

23

Page 25

FERMER LA BRIDE DU BALLON

RETIRER AVANT INSTALLATION

RETIRER AVANT INSTALLATION

RETIRER AVANT INSTALLATION

RETIRER AVANT INSTALLATION

RETIRER AVANT INSTALLATION

Mise en garde

Si présents, retirer les éléments suivants:

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

24

Page 26

MISES EN GARDE IMPORTANTES:

AVANT D’INSTALLER OU DE MANIPULER L'HUMIDIFICATEUR, LIRE ET SUIVRE ATTENTIVEMENT LES INSTRUCTIONS ET

LES INDICATIONS DE SÉCURITÉ DÉCRITES DANS CE MANUEL ET SUR LES ÉTIQUETTES APPLIQUÉES SUR L’Elite Steam.

TOUJOURS COUPER L’ALIMENTATION PRINCIPALE AV ANT D’OUVRIR OU DE RÉPARER L'HUMIDIFICATEUR!

Elite Steam produit de la vapeur non-pressurisée à l’aide d’électrodes immergées dans de l’eau contenue dans un ballon plastique

générateur de vapeur. Le courant électrique circule à travers l’eau entre les électrodes, réchauffant ainsi l’eau pour créer de la

vapeur, qui est ensuite utilisée pour humidifier l’air.

La qualité de l’eau utilisée est importante pour le fonctionnement de l’unité. Elite Steam doit être alimenté avec de l’eau non-traitée,

tant qu’elle est potable ni adoucie ni déminéralisée. L’eau transformée en vapeur est automatiquement remplacée à travers une

vanne électrique de remplissage. L'unité évacuera également de l’eau périodiquement, en fonction de la qualité de l’eau, pour

éliminer l’accumulation de minéraux dans le générateur de vapeur. En cas de présence importante de minéraux dans l’eau, un filtre

à charbon actif est doté d’un filtre à particules infér ieur s à 5 microns .

Cet humidificateur a été exclusivement conçu pour humidifier directement des pièces ou des conduits, par l’utilisation d’un système

de distribution. Les opérations d’installation, d’utilisation et de maintenance doivent être effectuées dans le respect des instructions

contenues dans ce manuel et sur les étiquettes appliquées à l’intérieur ou à l’extérieur.

ATTENTION: AVANT de commencer l’installation :

• Contrôler l'absence de dommages dus au transport sur les cartons d'emballages. Remplir la lettre de transport en conséquence.

• Ouvrir les cartons et vérifier l’absence de tout dommage caché. Remplir la lettre de transport en conséquence.

• Contrôler le bon de livraison pour vérifier que tous les articles ont bien été reçus. Avertir GENERAL FILTERS, INC. en cas

d’absence de pièces ou de pièces endommagées. Vous devez aviser General Filters, Inc. dans les 5 jours ouvrables

en cas de pièces manquantes.

ATTENTION : RISQUE DE CHOC ÉLECTRIQUE! L’humidificateur contient des éléments sous tension!

ATTENTION : RISQUE DE BRÛLURES! L’humidificateur contient des élém en ts chau d s (100°C / 212°F )

MISE EN GARDE: Installer l’humidificateur hors de la portée des enfants.

L’humidificateur doit être installé en accord avec les normes nationales et locales.

Toute opération d’entretien et/ou de maintenance doit être effectuée par un personnel qualifié ayant conscience des

précautions nécessaires et étant capable d’effectuer ces opérations correctement.

Débrancher l’humidificateur de l’alimentation électrique avant d’accéder aux parties internes.

Les conditions environnementales et la tension de l’alimentation électrique doivent respectées les valeurs spécifiées sur

l'étiquette des données de l’humidificateur.

Toute autre utilisation ou modification effectuée sur l’humidificateur non autorisée par le fabricant est considérée comme

impropre, le fabricant ne pourra être tenu pour responsable des conséquences de cette utilisation non autorisée.

Veuillez noter que l’humidificateur contient des dispositifs électriques et des surfaces chaudes.

MISE EN GARDE: Votre humidificateur a besoin d’eau pour fonctionner. Ne PAS le monter au-dessus de matériaux ou de

machines pouvant être endommagés suite à des fuites. General Filters, Inc. ne pourra être tenu pour responsable en cas

de dommages collatéraux ou non causés par une fuite.

We wish to save you time and money!

We can assure you that the thorough

reading of this manual will guarantee

correct installat ion and saf e use of the

product described.

Élimination des pièces de l’humidificateur: l’humidificateur est constitué de pièces métalliques et plastiques. Toutes les

pièces doivent être éliminées selon les normes locales d‘él imin at ion des d éch ets.

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

25

Page 27

CONTENU

1. MODE DE FONCTIONNEMENT DE L’ELITE STEAM 1

1.1 F

1.2 D

1.3 C

ONCTIONNEMENT DE BASE 1

UREE DE VIE DU BALLON 2

ALCUL DE LA CHARGE D’HUMIDITE 2

2. MODÈLES 3

3. INSTALLATION 4

3.1 M

3.2 M

3.3 P

3.4 D

3.5 C

3.6 C

3.7 B

ISE EN PLACE 4

ONTAGE 4

LOMBERIE 6

ISTRIBUTION DE LA VAPEUR 7

ABLES D’ALIMENTATION 10

ABLES DE COMMANDE 10

RANCHEMENTS DES CABLES: 12

4. DÉMARRAGE 13

4.1 L

4.2 L

4.3 D

4.4 D

ISTE DE CONTROLE AVANT DEMARRAGE 13

E CONTROLEUR ELITE STEAM 13

EMARRAGE DE L’ELITE STEAM 13

EMARRAGE AVEC UN NOUVEAU BALLON 13

5. FONCTIONNEMENT DE L’ELITE STEAM 14

5.1 A

5.2 M

5.3 A

5.4 R

5.5 U

5.6 A

FFICHAGE DES INFORMATIONS 14

ODIFICATION DE LA PRODUCTION MAXIMUM 14

CTIVATION DE LA VIDANGE MANUELLE 14

EMISE A ZERO DU COMPTEUR HORAIRE 14

TILISATION DE L’HYGROSTAT GFX3 15

LARMES 15

6. RÉSOLUTION DES PROBLÈMES 16

7. MAINTENANCE 17

7.1 C

7.2 M

7.3 P

ONTROLES PERIODIQUES 17

AINTENANCE DU BALLON 17

IECES DETACHEES 18

8. SPÉCIFICATIONS TECHNIQUES 19

9. GARANTIE LIMITÉE 20

Elite Steam +030222075 Rev. 4.0 – 2 Mar. 2015

26

Page 28

1. MODE DE FONCTIONNEMENT DE L’ELI TE S TEAM

N°

Description

A

Ballon générateur de vapeur

B

Souffleur/collecteur (en option)

C

Interface utilisateur/écr an

D

Bouton d’allumage/extincti on, de séle ctio n.

de température

F

Pompe d’évacuation

Tab. 1.a

A

F

B

C

D

E

HL

DP

DT

EVF

8

9

3

13

6

10

2

4

1

11

7

12

5

Fig. 1.a

1.1 Fonctionnement de Base

Elite Steam est un humidificateur à électrode. Il produit de la vapeur pour

l’humidification en faisant circuler du courant électrique à travers de l’eau entre

des électrodes en métal dans le ballon générateur de vapeur en plastique. Il

n’y a aucun élément de chauffage. La sortie de vapeur est directement

proportionnelle à la conductivité de l’eau et à la quantité d'électrodes

immergées dans l'eau.

Lors d’une demande d’humidité, le contrôleu r d’Elite Steam ouvrira la vanne de

remplissage (1) et permettra à l’ eau d’entrer dans le ballo n. Un limiteur de débit

(4) empêche l’unité de se remplir trop rapidement ou avec trop de pression.

L’eau coule dans le tuyau de remplissage (2) et dans la c oupelle de rempli ssage

(3). L’eau passe ensui te le barrage dans la coupelle de remplissage (3), ce qui

crée un premier intervalle d’ai r qui empêche le reto ur d’eau conta minée dans les

lignes d’alimentation, et dans le tube de re mplis sage (6 ) et dans le f ond du bal lon

à vapeur (5). Tout retour ou débordement d’eau es t transporté à tra vers le tuyau

d’évacuation (13) jusqu’à l’évacuation.

Quand l’eau remplira le ballon, elle atteindra les él ectrodes (7) et le courant co mmencera alors à circuler. A mesu re que l’eau

remplira le ballon, le courant d’augmentera. Tout ceci contrôlé par un transformateu r d’intensité connecté à l’un des câbles

d’alimentation et placé sur le contrôleur élect ronique. Une fois le courant souhaité atteint, la van ne de remplis sage se fermera

(1) et l’eau commencera alors à se réchauf f er et à produire de la vape ur. Si l’ eau attei nt l es c apteurs de ballon pl ei n (9) ou s i l e

courant augmente trop rapidement, la pompe d’évacuation (11) s’activera pour évacuer de l’eau et réduire la circulation de

courant jusqu’à un niveau acceptable. Veuillez noter qu’à, chaque fois que la pompe d’évacuation est activée, la soupape

d’équilibrage de température (10) s’ouvrira pour tempérer l’eau chaude jusqu’à 140 °F / 60°C conformément aux normes locales

et nationales.

En fonction de la conductivité de l’eau, l’unité actionnera périodiquement la pompe d’évacuation (11) et évacue ra un peu

d’eau pour réduire la concentration en minéraux. Toutes les 120 heures, l’unité se vidangera automatiquement pour éliminer

les sédiments minéraux au fond du ballon. Une pass oire (12) présente dans le ballon aide à prévenir l'encombrement de la

pompe d’évacuation par des dépôts de minéraux.

Si Elite Steam reste allumé mais en défaut, c’est-à-dire sans production de vapeur, le ballon devra être vide pendant plus de