Page 1

Installation, Operating and Maintenance Manual

Read And Save These Instructions

Page 2

IMPORTANT WARNINGS

BEFORE INSTALLING OR HANDLING THE APPLIANCE PLEASE CAREFULLY READ

AND FOLLOW THE INSTRUCTIONS AND SAFETY STANDARDS DESCRIBED IN THIS

MANUAL AND ILLUSTRATED BY THE LABELS ON THE MACHINE.

This humidifier produces non-pressurized steam using electrodes immersed in the water

contained in the plastic steam generator cylinder. The electrodes pass electrical current through

the water, to produce steam.

The quality of the water used affects the ability of electrical current to pass through the water, so

the appliance may be supplied with untreated water, as long as this is drinkable and not

demineralized. (Use of softened water is not recommended.)

This appliance has been designed exclusively to directly humidify rooms or ducts, using the

distribution system supplied. It is suitable for this purpose as long as: the installation, use and

maintenance operations are carried out according to the instructions contained in this manual and

on the labels applied internally and externally.

The conditions of the environment and the power supply voltage must comply with the specified

values. All other uses and modifications made to the device which are not authorized by the

manufacturer are considered incorrect. Liability for injury or damage caused by the incorrect use

of the device lies exclusively with the user.

Please note that the machine contains powered electrical devices and hot surfaces. All service

and/or maintenance operations must be performed by qualified personnel who are aware of the

necessary precautions and are capable of performing the operations correctly. Disconnect the

machine from the main power supply before accessing any internal parts. Local safety standards

in force must be applied in all cases.

The humidifier is made up of metallic and plastic parts. All parts must be disposed of in

accordance to local standards on waste disposal.

This product is warranted for 2 years from the date of installation, or 2 years and 1 month (see

page 23 and warranty card) from the date of original shipment, whichever comes first. This

warranty does not cover consumable parts, such as the steam cylinder. Full warranty information

is on a separate registration card supplied with this appliance.

WARNING: Your humidifier requires water to operate. Do NOT mount it above materials or

machinery that could be damaged if a leak occurs. General Filters, Inc. assumes no responsibility

for consequential or inconsequential damage as a result of any leaks.

2

Page 3

Installation, Operating and Maintenance Manual

Table of Contents

1: REMOVE HUMIDIFIER FROM BOX AND OPEN............................................................................. 4

2: MOUNTING THE HUMIDIFIER............................................................................................................ 5

POSITIONING.................................................................................................................................................. 5

OUNTING..................................................................................................................................................... 5

M

3: STEAM DISTRIBUTION ......................................................................................................................... 6

R

OOM DISTRIBUTION..................................................................................................................................... 6

DUCT DISTRIBUTION...................................................................................................................................... 7

STEAM HOSE INSTALLATION.......................................................................................................................... 7

4: PLUMBING................................................................................................................................................ 9

CONNECT WATER DRAIN...............................................................................................................................9

CONNECT WATER FEED................................................................................................................................. 9

5: POWER WIRING.................................................................................................................................... 10

6: CONTROLS WIRING............................................................................................................................. 11

MOUNT THE HUMIDISTAT............................................................................................................................ 11

MOUNT 12500 AIR PRESSURE SWITCH (DS-20 ONLY)................................................................................ 11

CONNECT HOSES. CONNECT HOSE TO SUPPLY PLENUM PROBE. TRIM HOSE TO

LENGTH AND CONNECT TO HIGH PRESSURE INLET TOWARD REAR OF SWITCH.

CONNECT RETURN PLENUM PROBE TO LOW PRESSURE INLET TOWARD FRONT OF

SWITCH........................................................................................................................................................ 11

WIRE THE CONTROLS .................................................................................................................................. 12

7: START-UP AND SHUT-DOWN ............................................................................................................ 13

FIRST START-UP ........................................................................................................................................... 13

STARTING THE UNIT ..................................................................................................................................... 13

HUT-DOWN................................................................................................................................................ 14

S

8. OPERATING PRINCIPLE AND OTHER FUNCTIONS.................................................................... 15

OPERATING PRINCIPLE ................................................................................................................................. 15

9. ALARMS, TROUBLESHOOTING........................................................................................................ 16

10. MAINTENANCE AND SPARE PARTS.............................................................................................. 18

REPLACING THE CYLINDER ......................................................................................................................... 18

MAINTENANCE OF THE OTHER HYDRAULIC COMPONENTS......................................................................... 18

CLEANING THE FILL VALVE......................................................................................................................... 18

C

LEANING THE DRAIN VALVE..................................................................................................................... 19

HYDRAULIC PARTS ...................................................................................................................................... 19

PARE PARTS................................................................................................................................................ 20

S

11. WIRING DIAGRAM.............................................................................................................................. 21

12. TECHNICAL SPECIFICATIONS ....................................................................................................... 22

D

IMENSIONS AND WEIGHTS .......................................................................................................................... 22

3

Page 4

1: Remove Humidifier

From Box And Open

Twist GeneralAire brand badge on the front

cover of the cabinet to uncover the hidden

capture screw underneath the right side.

Remove capture screw using a phillips

screwdriver. (take care not to lose the screw)

Lift cabinet front cover upward about 1” and then

pull forward to remove.

Your Elite Steam humidifier will consist of:

For duct mounted applications:

1 - Steam humidifier unit

1 - Duct steam nozzle

6' - 7/8" ID steam hose

2 - Steam hose clamps

7' - 5/16" ID condensate hose

1 - Condensate hose clamp

1 – 800 UST Saddle valve kit

1 – Wall / Duct Mount Humidistat

1 – 12500 Air Pressure Switch

1 – Water supply tube kit

3 - Screws and anchors

1 - Fill connector

1 – 10’ coil low voltage wire

For room mounted applications:

1 - Steam humidifier unit with blower attached

1 – 800 UST Saddle valve kit

1 – Wall / Duct Mount Humidistat

1 – Water supply tube kit

3 - Screws and anchors

1 - Fill connector

1 – 10’ coil low voltage wire

IMPORTANT: BEFORE beginning installation:

Check for shipping damage to cartons. Mark the shipping waybill accordingly.

Open cartons and check for any hidden damage. Mark the shipping waybill accordingly.

Check packing slip to insure all items have been received. Notify General Filters, Inc. within one

week of any shortages or damaged parts.

4

Page 5

Installation, Operating and Maintenance Manual

2: Mounting The Humidifier

Positioning

The humidifier unit should be mounted as close as

possible to the steam distributor nozzle or blower unit to

minimize steam hose length and condensate losses.

The unit has been designed for wall-mounting, and the

wall must be able to support the weight of the unit in

normal operating conditions (See bottom of page).

The metal cabinet of the humidifier heats up during

operation, and the rear part in contact with the wall may

reach temperatures of over 140°F. Make sure the

humidifier is mounted level and plumb, and that the

minimum clearances, as shown at right, are maintained

to allow room for maintenance operations and ventilation.

Mounting

The humidifier must be wall-mounted using three screws: two upper

screws, for fastening the support bracket, and one lower, central

screw, to fasten the unit into place. To the right is the template for the

mounting holes.

Fasten the bracket supplied with the humidifier to the wall (see

below); making sure that it is level. If the unit is to be mounted to a

block wall, use the plastic screw anchors (5/16”) and screws (3/16” x

2”) supplied.

Hang the humidifier on the bracket using the mating bracket located

on the top edge of the back of the humidifier. Fasten the humidifier

to the wall using the central hole in the rear part of the base; this can

be easily reached from underneath the unit.

Height: 24-3/8”

Width: 14-1/8”

Depth: 10-1/4”

Weight dry: 29.7 lbs.

Weight wet: 36.4 lbs.

5

Page 6

3: Steam Distribution

Room Distribution

The room distribution unit is used to distribute the steam directly into the room, and is supplied

premounted to the top of the humidifier.

The drawing shows the minimum distances required to prevent humidified air from coming into

contact with persons, or surfaces before the steam has been totally absorbed by the air.

6

Page 7

Installation, Operating and Maintenance Manual

Duct Distribution

If a duct steam distribution nozzle is to be used, selected an accessible location on the duct,

allowing at least 18” of straight duct (no elbows or obstructions) after the point where the nozzle will

be installed and the clearances can be maintained as per the following drawings.

To mount the steam distributor nozzle, cut or drill a 2-1/2” hole in the duct. Apply caulk to the

mounting plate of the nozzle. Attach the nozzle to the duct using 4 #10 sheet metal screws

(supplied). Nozzle must be level with condensate outlet to bottom.

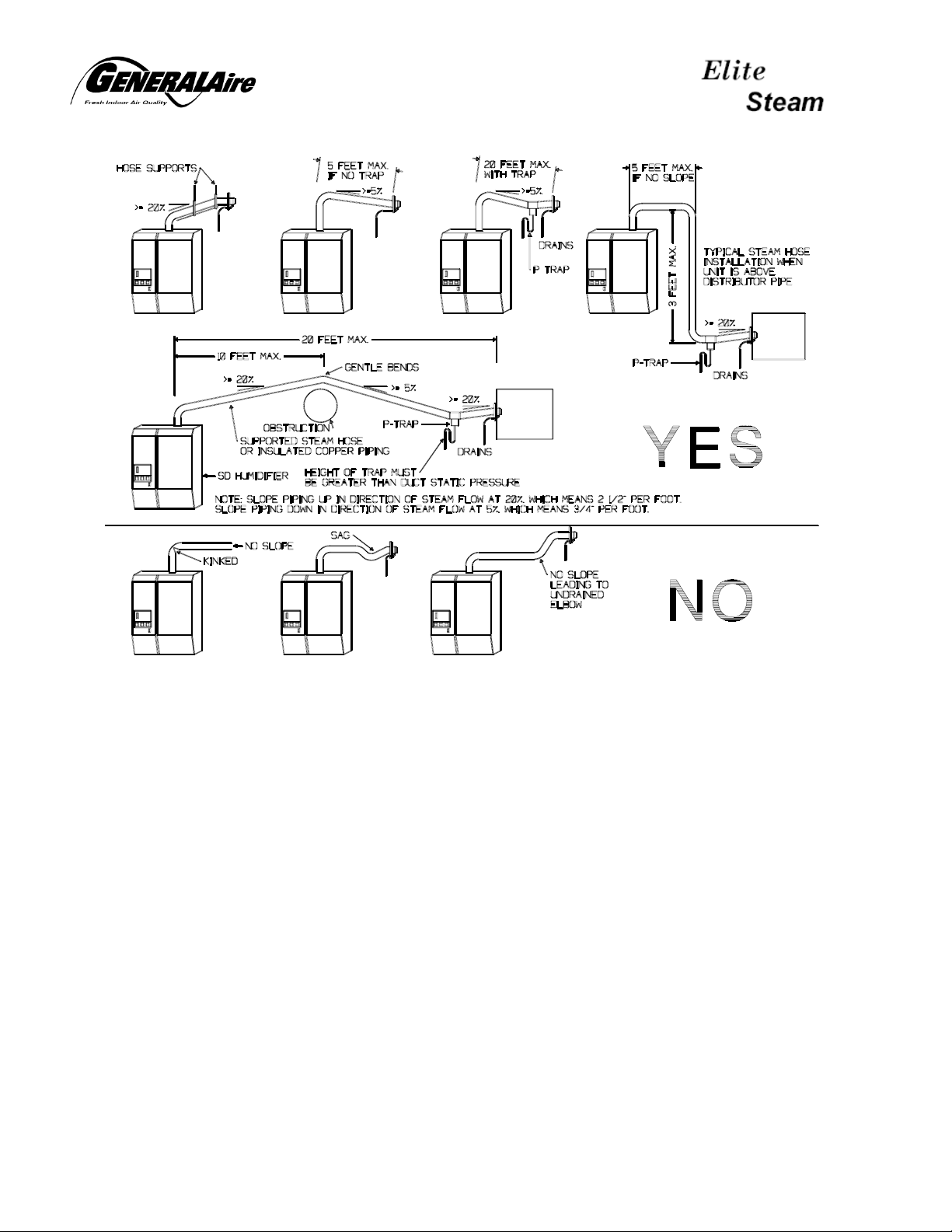

Steam Hose Installation

The humidifier must be connected to the distributor nozzle

using the GeneralAire hose supplied or other hose suitable

for use with steam and condensate. The use of unsuitable

tubing may cause weakening and cracking and consequently

steam leaks.

Installation of the steam hose is absolutely critical.

95% of all operational problems are traced back to

improper hose installation.

Steam must flow through the hose, and condensate must flow back. Avoid any kinks, sags or

areas where condensate can become trapped as it will impede the free flow of steam, putting

pressure on the humidifier cylinder.

The steam hose must slope 20% up and away from the humidifier or 5% down and away.

7

Page 8

If necessary, support the steam hose using braces or other

supports. DO NOT try to pipe the steam to two different

ducts or air handlers.

The condensate hose should be trapped as shown in the two

drawings above. This is to prevent steam from flowing

through it. The condensate is wasted, either to the nipple on

top of the humidifier, or to a separate drain. DO NOT put

condensate into the humidifier fill cup.

Hose clamps are provided for the 7/8” I.D. steam hose as

well as for the 5/16” condensate hose. DO NOT reduce the

size of the steam hose, use valves or otherwise restrict

the free steam flow.

WARNING: the length of the steam hose should be less than 12 feet.

8

Page 9

Installation, Operating and Maintenance Manual

4: Plumbing

Connect Water Drain

The humidifier periodically drains some hot water to

remove mineral build-up in the steam cylinder. This

water is generally in the range of 140 to 200°F, so the

drain piping must be CPVC or copper.

The drain line should be 1-1/2” diameter CPVC. Slip the

1-1/2” pipe over the drain outlet on the bottom of the

humidifier as shown at right. Do not glue to the

humidifier.

A trap must be used in the drain line directly below the

humidifier to prevent flash steam from rising into the

humidifier unit and condensing on components.

WARNING: Failure to install a drain trap as

instructed will void the warranty.

Instant maximum drain water flow = 0.40 gpm

Connect Water Feed

A plastic and brass quick connect fitting is supplied for

connection of the water feed line. This fitting includes a

¼” O.D. compression fitting which mates to standard ¼”

O.D. plastic or copper tubing.

Inside the fill valve connection is a plastic strainer which

must be removed for periodic maintenance. Make sure

that your installation will allow the plastic fitting to be

removed for maintenance.

WARNING: Hand tighten only.

DO NOT USE DEMINERALIZED WATER.

Instant maximum feed water flow = 0.30 gpm

9

Page 10

5: Power Wiring

Feed power wiring through strain relief in bottom of

humidifier and tighten around wiring cable.

Connect power wires into terminals N and L. A green/yellow

ground terminal (which is also the chassis ground) is provided

for connection of the ground wire.

Power supply Rated specifications

Voltage (1)

(V - Type)

230 – 1 N 10.4 2.40 7 12 AWG 15A / quick blow

current (2)

(A)

power (2)

(kW)

Steam output

(lbs/hr)

wire size

power fuses (4)

(A / type)

wiring diagram

See end of

manual

10

Page 11

Installation, Operating and Maintenance Manual

6: Controls Wiring

Mount The Humidistat

Please refer to the installation Instructions included with the Humidistat.

Mount 12500 Air Pressure Switch (DS-20 Only)

Mount Air Flow Switch on a vertical surface. Switch must be oriented vertically with the hose

connections pointed down. Do not mount switch on or in warm air plenum. Use care when

locating mounting holes so as not to damage furnace electronics, fuel lines, combustion chamber,

etc.

Mount Plenum Probes. Select locations on supply and return plenums so length of supplied hose

will be sufficient and does not kink. Drill ¼” hole and insert long end of probe into duct. Use two

sheet metal screws to secure probe.

Connect hoses. Connect hose to supply plenum probe. Trim hose to length and connect to high

pressure inlet toward rear of switch. Connect return plenum probe to low pressure inlet toward

front of switch.

11

Page 12

Wire The Controls

Two pigtail wires are provided inside the

electrical compartment of the humidifier. This

“AB” to “AB” circuit is the low-voltage control

for the humidistat and air pressure switch.

The humidifier will run when the AB-AB

Circuit is completed.

24 volt A.C. to power the E1 Humidistat may

be pulled from the “G” and “GND” terminals.

The AB-AB circuit is completed through the

12500 Pressure Switch (“NO”, “C” terminals)

and the E1 Humidistat (“OUT” terminals).

If it is desired for the humidifier to activate the

heating fan during a call for humidity use the

second wiring scheme below.

terminal function electrical specifications

+VR

SET

AB

AB

G

GND

Enabling jumper external N/O contact; R

Input from humidistat remote

enabling input

24V AC power supply for E1

Humidistat and relay

external N/O contact; R

Output V

=50 ; V

max

=50 ; V

max

=24Vac; LOAD

max

=10Vdc; I

max

=24Vdc; I

max

=500mA ac

max

12

=1mAdc

max

=10mAdc

max

Page 13

Installation, Operating and Maintenance Manual

7: Start-Up And Shut-Down

Important Warnings:

Before starting, check that the humidifier is in perfect condition, that there are no water

leaks and that the electrical parts are dry;

Do not connect power if the humidifier is damaged or even partially wet;

When installation is completed, flush the supply tubing for several minutes by piping water

directly into the drain, without sending it into the humidifier. This will eliminate any scale

or construction dirt that may cause foam when boiling.

Before starting the humidifier, check the following:

The water, electrical and steam distribution connections have been made according to the

instructions contained in this manual;

The water shut-off valve to the humidifier is open;

The external main power fuses or breakers are installed and intact;

All wiring connections to the unit and inside the unit are tight;

The pigtail control wires are connected properly to the humidistat and air flow switch and

that these are both closed indicating a demand for humidity and air flow in the duct;

The steam hose is clear and properly sloped;

The condensate return hose from the distributor is installed, trapped and open to drain;

The drain tubing is correctly connected, trapped and open to drain;

First start-up

When first starting the unit with a clean empty cylinder, the humidifier will operate using a special

start-up routine designed to concentrate the minerals in the water for maximum efficiency. If the

water is very good (low mineral content) this process may take up to several hours before the full

rated production of steam is reached.

Starting the unit

On the right side, rear of the humidifier cabinet are two rocker switches. One is marked I and O;

this is the On/Off switch (I=On, O=Off). Next to it is the manual drain switch.

To start the humidifier, simply press the top of the On switch (I). If the unit does not

start operating, then check the control devices wired between the pigtail control wires

to be sure they are closed, completing the control circuit.

ON

13

Page 14

Once started, the LEDs on the control panel at the bottom

front of the humidifier will glow to indicate operation

LED Position Means

Green Left Power on

Yellow Center Humidification in progress

Red Right Signals and alarms. These are indicated by specific flashes.

Sequence Of LED Flashes On Start-Up

On start-up, the humidifier performs a sequence of flashes of the LEDs on the front panel. Please

note that the green LED remains on for the entire time the machine is on, irrespective of the

operating status. The sequence consists of the following operations:

1. Power connected: the yellow and red LEDs remain off for 1 second;

2. Initialization: the yellow and red LEDs flash a number of times to indicate the version of the

program that the board is configured with; this occurs once each time the machine is started;

a. First the yellow LED - the number of flashes indicates the tens (0=no flash);

b. Then the red LED - the number of flashes indicates the units (0=no flash); example:

version 1.1: 1 flash of the yellow LED, then 1 flash of the red LED;

c. Once the sequence of flashes corresponding to the unit is completed, the LEDs remain

off for 3 seconds, followed by the start of operation.

3. Operation: the humidifier starts operation; the yellow LED indicates that production is in

progress, as shown by the following table:

Yellow LED Production

Off 0%

1 flash 1% to 19%

2 flashes 20% to 29%

3 flashes 30% to 39%

… …

9 flashes 90% to 99%

Always on 100%

Remark: the transient production is signalled by short flashes: on and off twice in 1 second; each

sequence of flashes repeats continuously and, between one sequence and the next one, the yellow

LED stays off for 3 seconds.

Indication Of An Alarm

When an alarm occurs, the red LED starts to flash. The number of the flashes followed by a pause

indicates specific alarms. See ALARMS, TROUBLESHOOTING.

Shut-Down

During seasonal shut-down or shut-down for maintenance, the humidifier should be placed out-ofservice.

14

Page 15

Installation, Operating and Maintenance Manual

If during a shut-down the cylinder needs to be emptied, (which is recommended for seasonal

shut down) press the drain button (down arrow) and hold until the water has been completely

emptied, before disconnecting power from the unit.

In the event of a malfunction of the drain valve, the cylinder can be emptied by lifting it from the

bottom connection and slowly pouring the water into the drain pan.

Press the bottom of the On/Off rocker switch (O) and check that the

LEDs on the display panel are all out.

open the main power switch to the humidifier;

close the water shut-off valve to the humidifier.

OFF

8. Operating Principle And Other Functions

Operating principle

On a call for humidity, a power contactor closes

and sends power to the electrodes (11) in the

plastic cylinder (10). After a short delay, the fill

valve (1) opens and water flows into the fill cup

(3 to 7), covering the conductivity probes (6).

The controller reads the water conductivity and

remembers it. Water then flows through the

tubing (4) and into the bottom of the cylinder

(12) by gravity. As it rises over the electrodes

(11), electric current begins to flow through the

water and the water warms. Eventually the

water begins to boil into steam, which exits the

cylinder (9) into the steam hose and then into

the air duct. The steam output is directly

proportional to the amount of electrode covered

by water. If the amperage rises too high, the

controller will open the drain valve (14) and

drain off some water. As water is boiled off, the

fill valve (1) will open and replace it. As water is

boiled off, mineral will begin to build up in the

cylinder, so periodically the controller will open the drain valve (14) and drain some of the mineral

laden water away and replace it with fresh water. If the water rises too high, or foaming occurs,

this is detected by the cylinder full electrodes (8).

Anti-foam procedure

Some types of supply water foam during operation. When the humidifier detects the presence of

foam, a special drain/fill procedure is activated to eliminate the foam. The procedure consists of

repeated draining, and in more critical situations complete draining of the cylinder.

Automatic draining of the cylinder for extended shut-down

If the humidifier remains powered but there is no call for humidity for a period of more than 7 days,

the water contained inside the cylinder is completely drained. This function prevents the corrosion

and rusting of the electrodes.

15

Page 16

9. Alarms, Troubleshooting

Alarms are indicated on the front display panel by a sequence of flashes of the red alarm LED. In the

event of more than one alarm, these are indicated in sequence. Even if no longer active, the

alarm status continues to be displayed by the flashing of the LED and the operation of the

humidifier is stopped while the alarm is still present. To clear the inactive alarms, the humidifier

must be turned off, and then on again. Active alarms cannot be reset by restarting the

machine.

LED flash modes: slow flashes - 1 flash every 2 seconds; quick flashes - 2 flashes per second;

the signals are repeated continuously, and the LED stays off for 3 seconds between one signal

and the next.

Display Causes Solution Action

Current overload in

the electrodes;

probable fault in the

2 quick flashes

red LED

3 quick flashes

red LED

2 slow flashes

red LED

3 slow flashes

red LED

4 slow flashes

red LED

5 slow flashes

red LED

6 slow flashes

or 3 quick

flashes

red LED

9 slow flashes

electrodes or water

temporarily too

conductive

(especially on restart after a brief

pause)

High level is

indicated but no

amperage draw is

present

End of cylinder life Turn the machine off and replace the cylinder

No water

Excessive reduction

in steam output

Drain malfunction

Internal memory

error

Cylinder full with

humidifier off-duty

Drain part of the water and re-start

With the machine off and disconnected from the main power

supply, check the condition of the cylinder and the electrical

connections

Check that the supply water tubing to the humidifier and the

internal tubing are not blocked or bent and that there is proper

pressure;

Check the operation of the supply valve;

Check that the steam outlet does not have excessive backpressure, preventing the flow of water into the cylinder by

gravity;

Check that the steam outlet hose is not choked or that there

are pockets of condensate

End cylinder life or alternatively water with excessive foam

Check the water drain circuits and the correct operation of the

drain valve

Contact the Dealer

Turn off the machine and check whether the full electrovalve

leaks or there is some condensate entering the cylinder from

the steam distributor

Total

shut-

down

Total

shut-

down

Signal

only

Total

shut-

down

Total

shut-

down

Total

shut-

down

Total

shut-

down

Total

shutdown

16

Page 17

Installation, Operating and Maintenance Manual

Troubleshooting table

Problem Causes Solution

The humidifier does

not turn on

The humidifier does

not start operation

The humidifier fills

with water without

producing steam

Breaker opens

The humidifier wets

the duct

The humidifier wets

the floor below

1. No electrical power;

2. On/Off switch of the humidifier in Off

position (O);

3. Improper connection;

4. Blown fuses;

5. Transformer fault;

6. Humidistat or air flow switch not closed

1. Humidistat or air flow switch open;

2. The humidistat has not been connected

correctly;

3. Humidistat fault

1. Too much backpressure in steam hose;

2. Cylinder drain screen blocked;

3. Lime scale in the fill cup;

4. Drain valve malfunction

Circuit breaker is under-rated Check that the thermal-magnetic overload

1. The distributor is not installed correctly;

2. Humidifier over-sized;

3. Humidifier active when the fan in the

duct is off

1. The humidifier drain is blocked;

2. The supply water or overflow circuit has

leaks;

3. The steam outlet pipe is not properly

fastened to the cylinder

1. Check the external fuses and breakers

and for power at the humidifier;

2. Turn the On/Off switch On (I);

3. Check that the power wires are properly

inserted in the terminal block;

4. Check the condition of fuses f1/f2/f3;

5. Check that the voltage across the

secondary winding of the transformer is

24vac

6. Jump out airflow & humidistat

1. Fix or replace humidistat or air flow switch;

2. Check the external wiring

1. Check that the steam outlet pipe is not

bent or choked;

2. Clean the filter;

3. Clean the fill cup;

4. Check for the presence of 24vac at the

drain electrovalve and/or replace drain

electrovalve

switch is rated for a current of at least 1.5

times the rated current of the humidifier

1. Check that the steam distributor is

installed correctly;

2. Change humidifier model;

3. Check the connection and condition of the

airflow switch

1. Clean the drain in the bottom tank;

2. Check the entire water circuit;

3. Check the fastening of the pipe clamps on

the steam outlet

17

Page 18

10. Maintenance And Spare Parts

Replacing The Cylinder

WARNING: the cylinder may be hot. Allow it to cool before touching it or use protective

gloves.

To access the cylinder:

Completely drain the water contained in the cylinder (see Shut-down);

Turn the humidifier off and open the external disconnect;

Open and remove the cover (see Removal and reassembly of the front cover);

Remove the steam hose from the cylinder outlet;

Disconnect the electrical connections from the power and high level electrodes;

Unlock the cylinder from its holding arm and lift it up to remove it;

Insert the new cylinder in the humidifier by performing the previous operations in reverse.

(Make sure electric connection is tight, failure to do so may cause equipment damage, fire, or

bodily injury.)

Maintenance Of The Other Hydraulic Components

WARNINGS:

• When cleaning the plastic components do not use detergents or solvents;

• Scale can be removed using a solution of 5% phosphoric acid and then rinsing with

water (Lime-A-Way or CLR may also be used).

The steam humidifier has just one part that requires periodical replacement: the steam

production cylinder. This operation is necessary when mineral deposits that form inside the

cylinder prevent the sufficient passage of current. This situation is displayed by the control with an

alarm signal. The frequency of this operation depends on the supply water: the higher the content

of mineral, the more frequently the cylinder will need

replacing.

Cleaning The Fill valve

After shutdown and removal of the steam cylinder, shut off

the water supply to the humidifier, disconnect the water

supply and remove the fill valve from the humidifier.

Remove the inlet strainer by reaching up into the fill valve

inlet with a pair of needle nose pliers and pulling out the

strainer by its tab. Clean the fill valve and inlet strainer using

the same solution as used to clean the steam humidifier, but DO NOT soak the solenoid coil in

fluid. Reinstall the fill valve.

WARNING: When cleaning the fill valve, do NOT poke or probe flow regulator with any

object which may enlarge the orifice. The flow regulator must meter water flow precisely or

shortened cylinder life may result.

18

Page 19

Installation, Operating and Maintenance Manual

Cleaning The Drain Valve

Remove the drain valve group and disassemble it.

Clean all parts in the same way as the fill valve,

reassemble and reinstall.

After cleaning and reassembly, restart your humidifier

according to the Startup Instructions contained in this

manual.

Hydraulic Parts

No. Description

1 Fastening o-ring for s/d (supply - drain)

manifold

2 Supply/drain manifold

3 Water fill valve

4 Drain valve

5 Fill cup supply hose

6 Cylinder supply hose

7 Overflow hose

8 Fill cup with conductivity probes

9 Base / drain pan

Clean the drain pan and fill cup of any deposits and check

that the water flows freely from the fill cup to the drain.

Check that there are no blockages or solid particles and

that the conductivity measuring electrodes are clean.

Remove any impurities and rinse.

See spare parts list on page 20

19

Page 20

Fuses in the auxiliary circuits

The dimensions of these are 10.3x38 mm and are contained in cartridge-type fuse holders; to

check the condition of the fuses, check continuity using a tester.

Use fuses with the settings indicated in the following table.

Fuses 1- 2

Fuse 3 * 2A slow blow

* 5 x 20 mm, only on the control board.

Spare parts

Duct Steam Nozzle 20-1

Steam Hose 20-2

Condensate Hose 20-3

Fill Connector 20-4

Fill Cup 20-5

Drain Valve 20-6

Internal Tubing Kit 20-7

Power Transformer 208-230/24v. 20-8

Control board with LED support panel 20-9

Fill Valve 20-10

Steam Cylinder 20-14

Self Tapping Saddle Valve Kit 800-UST

Water Supply Tubing Kit 747-38

Humidistat H-86

Air Pressure Switch 12500

1A fast-blow

Description Code

20

Page 21

Installation, Operating and Maintenance Manual

11. Wiring Diagram

RS-20 ONLY

FAN

LNGND

F2

GO

TAM

L1

RELAY 2

F1

MS

G

TP

Drain

Switch

Manual

TP

ON

GND

FUSE

DR

EV2

G

EV1

EV3

CONTROL

INPUT

POWER

G

LS

MODULE

LS

CS

CS

EXTERNAL

SIGNALS

ID2

ID1

GND

SCR-

SCR+

V

DIP

Switch

G

R

{

RELAY 1

AB

N1

SET

+VR

JUMPER

FACTORY

AB

GND

Module

ON/OFF

REMOTE

Display

CS

FILL

CUP

LS

UNIT

STEAM

BOILER

FILL

DRAIN

VALVE

VALVE

21

Page 22

12. Technical Specifications

Model

rated power supply voltage (Vac) 230

steam connection (φ inches)

steam outlet pressure limits (inches w.c.) 0 to 8” w.c.

operating conditions

storage conditions

index of protection IP20

auxiliary voltage / frequency (V - Hz) 24 Vac, 50/60 Hz

maximum auxiliary power (VA) 25 VA

instant steam production

power consumed at rated voltage (kW) 2.40 kW 2.40 kW

duct steam nozzle High

steam hose High temperature EPDM

water pressure 15 to 150 psi

water conductivity 125 to 1250 micromhos

room blower unit air volume N/A 100 CFM

room blower unit power consumption N/A 30 Watts

room blower unit noise level N/A 50 dBA

(1) the average steam production is affected by factors such as: ambient temperature, water quality, steam distribution system

(1)

(lbs/hr)

DS-20

Duct Kit

7/8”

temperature 34 to 104 °F,

humidity 10 to 60% RH

temperature 14 to 158 °F,

humidity 5 to 95% RH

noncondensing

7 lbs/hr 7 lbs/hr

temperature

plastic

RS-20

Fan Kit

N/A

Dimensions and weights

A 14-1/8”

B 10-1/4”

C 24-3/8”

packaged 40 lbs.

empty 29.7 lbs.

Wet * 36.4 lbs.

*: in normal operating conditions,

filled wi t h wa t er

RS-20 (due to

blower)

add 9” high

add 10 lbs.

22

A

B

C

Page 23

Installation, Operating and Maintenance Manual

LIMITED WARRANTY

The DS-20 and RS-20 humidifiers, if properly registered by the return of the attached warranty

registration to General Filters, Inc., are warranted to the consumer against defects in materials

and workmanship for a period of two years from the date of installation, so long as the product

has been installed and operated in accordance with all appropriate manuals and wiring

diagrams. Replacement or routinely replaceable parts such as steam cylinders and gaskets,

are not covered by this limited warranty or any other warranties. Any other defective parts will

be repaired without charge except for removal, reinstallation and transportation costs. To

obtain repair service under this limited warranty, the consumer must send the defective part to

General Filters, Inc.

THERE ARE NOT EXPRESS WARRANTIES COVERING THIS HUMIDIFIER OTHER THAN

AS SET FORTH ABOVE. THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED IN DURATION TO TWO YEARS.

THE MANUFACTURER ASSUMES NO LIABILITY IN CONNECTION WITH THE

INSTALLATION OR USE OF THIS PRODUCT, EXCEPT AS STATED IN THE LIMITED

WARRANTY. THE MANUFACTURER WILL IN NO EVENT BE LIABLE FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES.

This limited warranty gives you specific legal rights, and you may also have other rights which

vary from state to state. Some states do not allow either limitations on implied warranties, or

exclusions from incidental or consequential damages, so the above exclusion and limitation

may not apply to you.

Any questions pertaining to this limited warranty should be addressed to General Filters, Inc.

General Filters, Inc. has elected not to make available the informal dispute settlement

mechanism which is specified in the Magnuson-Moss Warranty Act.

General Filters, Inc. Canadian General Filters, Inc.

43800 Grand River 39 Crockford Blvd.

Novi, MI 48375-1115 Scarborough, ON M1R 3B7

www.generalfilters.com

www.cgfproducts.com

23

Page 24

Form 20-17 rev. B

General Filters, Inc.

43800 Grand River

Novi, MI 48375-1115

WWW.GeneralAir.com

CGF Products

39 Crockford Blvd

Scarborough, ON M1R 3B7

CANADA

WWW.CGFProducts.com

USA

24

Loading...

Loading...