Page 1

Fresh Indoor Air Quality

READ AND SAVE THESE INSTRUCTIONS

R

900 SERIES

INSTALLER: PLEASE FILL OUT AND MAIL WARRANTY CARD AFTER INSTALLATION IS

COMPLETE. LEAVE INSTALLATION INSTRUCTIONS WITH HOME OWNER

PRECAUTION: The installer should be an experienced service technician. Disconnect electrical power before

beginning installation. Do not install where temperatures fall below 32 degrees F or where plenum temperatures

exceed 150 degrees F. When wiring into a multi-speed blower circuit see Step 9D.

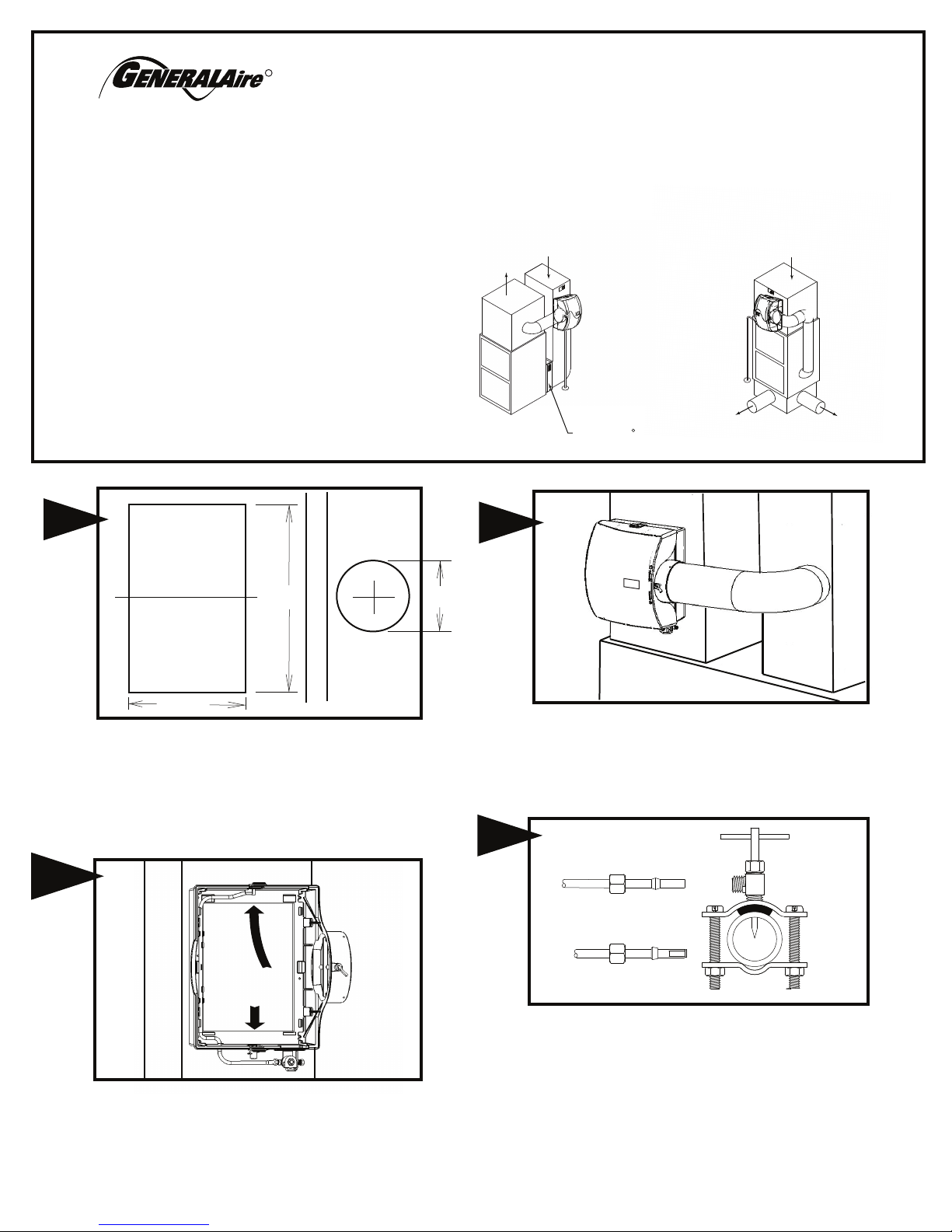

INSTALLATION: The humidifier may be mounted with the 6" outlet to

the right or left by inverting the cabinet and reversing the positions of

the distributor trough and drain pan. The humidifier may be mounted

on the warm or return air plenum with equal efficiency.

See Typical Installations.

ADDITIONAL MATERIALS THAT MAY BE NECESSARY:

1. 1/4" diameter plastic supply tubing or 1/4" copper

supply tubing for hot water applications

2. 6" diameter galvanized by-pass pipe

3. electrical wire and wire nuts

4. current sensing relay (G.F. Model #GA50 suggested)

5. #8 self piercing sheet metal screws

1

WARM AIR

3

UP FLOW

RETURN AIR

DRAIN

GENERALAire AC SERIES

HIGH EFFICIENCY AIR CLEANER

R

FLOW-THROUGH

BYPASS HUMIDIFIER

FOR INSTALLATION ON A VERTICAL

PLENUM SURFACE OF ANY

FORCED AIR FURNACE

RETURN AIR

DRAIN

WARM AIR

DOWN FLOW

WARM AIR

12”

8-7/8”

The GeneralAire model 900 may be installed on either the supply or

return plenum of a forced air handling system. Select a location for the

humidifier that allows for service and maintenance. Cut out a rectangle

8-7/8” wide by 12“ tall. Extend horizontal centerline of cut out to the

adjacent plenum. Cut a 6” hole 10” to 15” from side of humidifier, on

cabinet centerline, using connecting collar as guide. The bypass is

reversible and can be mounted on the right or left side of the

humidifier.

2

1

2

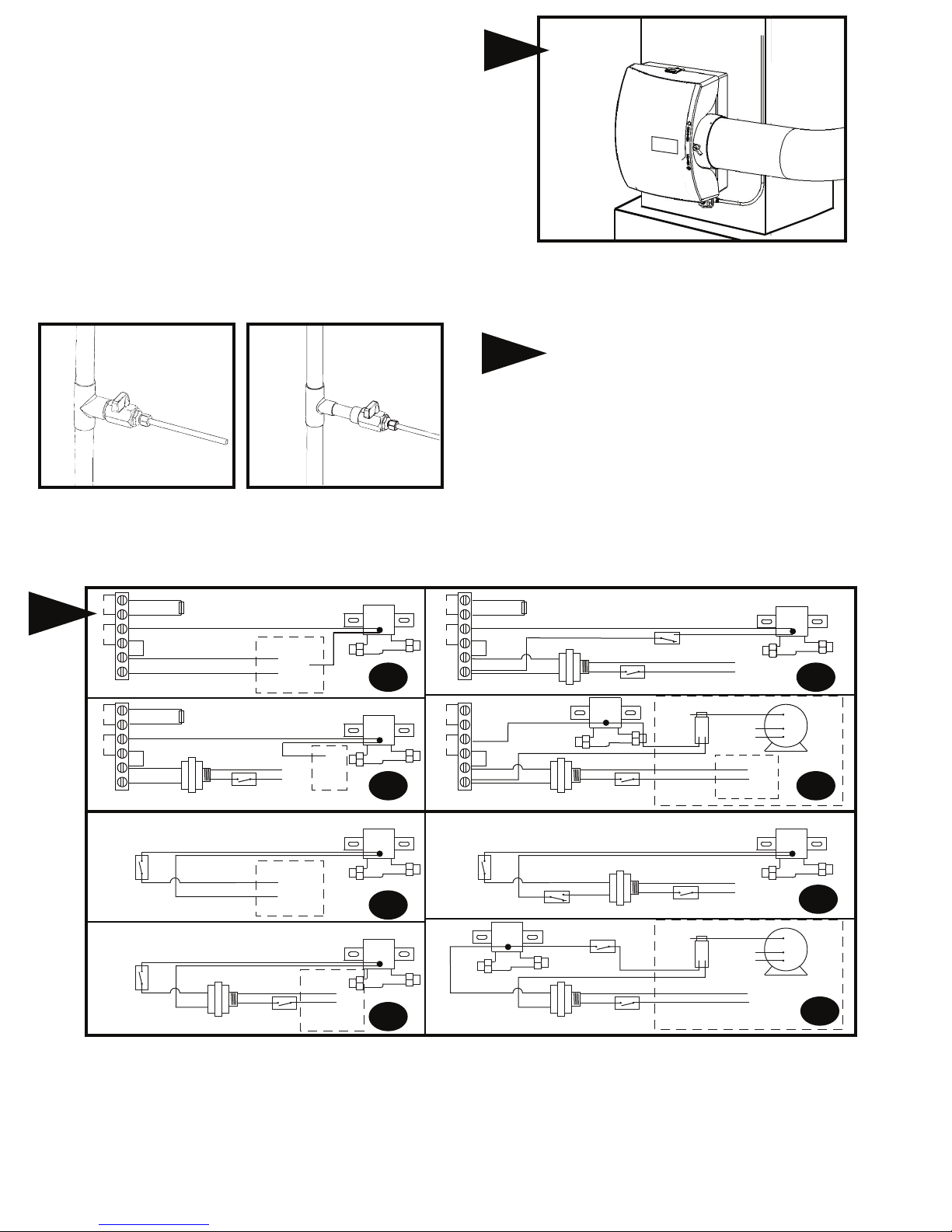

Humidifier is self retaining. Slide top side in first, then slide chassis

down. Level chassis and install center screws. If by-pass pipe installs to

opposite side of chassis, bend clip on chassis, remove side discharge,

and reinstall discharge to opposite side of chassis. Install remaining four

corner screws.

6”

Connect by-pass pipe to collar and humidifier cabinet. Using

holes at top and bottom of side panel discharge, pierce 2 self

tapping screws through by-pass pipe.

4

Mount the self tapping saddle valve or code valve on either a cold

or a hot water pipe. A side or top mount is best to avoid clogging

from pipe sediment. Connect 1/4” O.D. tubing to the saddle valve.

Copper tubing requires a brass compression nut and brass sleeve.

Plastic tubing requires a brass insert inside the tubing, a plastic

sleeve on the outside with a brass compression nut.

NOTE: DO NOT USE PLASTIC TUBING ON HOT WATER OR IN

CONTACT WITH ANY HOT PLENUM SURFACE OR DUCT.

INSTALLATION OF THIS SADDLE VALVE MUST MEET OR

EXCEED LOCAL CODES AND ORDINANCES.

COPPER

TUBING

PLASTIC

TUBING

FORM NO. 900-18 REV. F

Page 2

GCV3412 CODE VALVE INSTALLATION INSTRUCTIONS

Copper Pipe

1. Turn off water supply.

2. Clean pipe, fittings and valve with sandpaper or wire brush.

3. Apply a thin layer of flux to all surfaces to be soldered.

4. Assemble valve to pipe and/or fittings.

5. Cooling the valve by wrapping a wetted rag around the valve is

optional.

6. Heat the joints with a torch. Apply solder to each joint. Continue to

apply heat sufficient to keep solder liquid.

7. After solder has filled entire joint area, remove heat and allow joint

to cool. Do not move or disturb.

8. Slide compression nut over 1/4” copper tube followed by

compression sleeve.

9. Insert tube into valve fully and tighten nut.

10. Turn on water supply and check for leaks.

*CODE VALVE IS INCLUDED WITH AUTOMATIC MODELS ONLY

3/4” TEE

1/2” TEE

5

Connect 1/4" water supply tube to brass filter at inlet of solenoid.

NOT USE PLASTIC TUBING IN CONTACT WITH ANY HOT PLENUM

SURFACE OR DUCT. IF USING PLASTIC TUBING, USE TUBE INSERT

P189 AND PLASTIC COMPRESSION SLEEVE P190 (AVAILABLE AS

PART OF ASSEMBLY 747-38 TUBING KIT).

6

Turn damper knob to winter (open) position. Turn on water supply and check

operation of humidifier. Set humidistat to a demand setting. With the furnace

off, the solenoid valve should be closed. Start the furnace, the solenoid valve

should open when the blower or burner circuit is energized. Check flow of

water through distributor trough and evaporator pad. The standard GA4231

(YELLOW) orifice will supply approximately 3.5 GPH of water at a line water

pressure of 60 psi. For low water pressures (20-40 psi) a larger (ORANGE)

orifice GA4299 is available to provide the same flow. Leave humidistat set at

the recommended setting.

Connect drain hose to 1/2" spout on humidifier cabinet using hose clamp.

Run 1/2" hose to suitable drain such as floor drain, sewer or laundry sink.

Be sure hose has continuous slope and is not kinked at any point.

DO

7

SNSR

HUM

AC N

AC L

SNSR

HUM

AC N

AC L

HUMIDISTAT

HUMIDISTAT

OUTDOOR TEMP. SENSOR

WIRE JUMPER

WIRE JUMPER

OUTDOOR TEMP. SENSOR

WIRE

JUMPER

727-58 24 V. TRANSFORMER

24 V. TRANSFORMER

ON-OFF SWITCH

FURNACE

CONTROL BOARD

C

24v.

60CY.

R

N

115v.

(HOT)

60CY.

FURNACE

CONTROL BOARD

C

24v.

60CY.

HUM

ON-OFF SWITCH

W

W

FURNACE

BOARD

FURNACE

BOARD

(HOT)

ACC

EAC

24v.

60CY.

24V. SOLENOID VALVE

24V. SOLENOID VALVE

24V. SOLENOID VALVE

24V. SOLENOID VALVE

C

115v.

60CY.

7A

7C

7E

7G

SNSR

HUM

AC N

AC L

SNSR

HUM

AC N

AC L

HUMIDISTAT

OUTDOOR TEMP. SENSOR

WIRE

JUMPER

727-58 24 V. TRANSFORMER

24V. SOLENOID VALVE

OUTDOOR TEMP. SENSOR

WIRE

JUMPER

727-58 24 V. TRANSFORMER

C

12500 AIR

PRESSURE SWITCH

24V. SOLENOID VALVE

24 V. TRANSFORMER

ON-OFF SWITCH

NO

24 V. TRANSFORMER

HUMIDISTAT

ON-OFF SWITCH

C

PRESSURE SWITCH

ON-OFF SWITCH

12500 AIR

GA50

CURRENT

SENSING

RELAY

ON-OFF SWITCH

GA50

CURRENT

SENSING

RELAY

NO

L2

115v.

60CY.

(HOT)

L1

FURNACE

COMMON LEAD

C

(HOT)

L2

115v.

60CY.

(HOT)

L1

FURNACE

COMMON LEAD

C

(HOT)

115v.

60CY.

24V. SOLENOID VALVE

7B

C

HI

LO

115v.

60CY.

7D

24V. SOLENOID VALVE

C

HI

LO

MULTI

SPEED

BLOWER

MOTOR

7F

MULTI

SPEED

BLOWER

MOTOR

7H

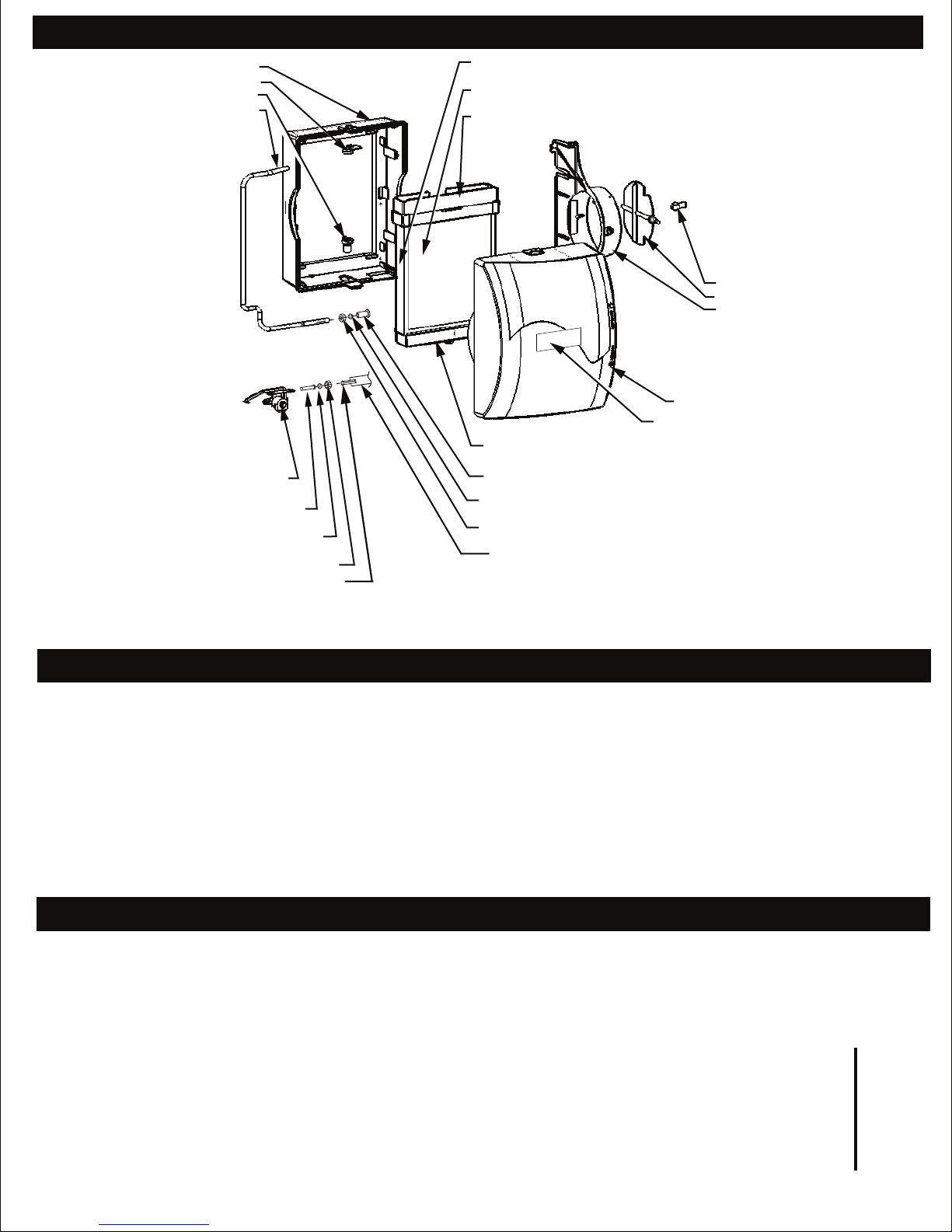

7A-7D Electronic Humidistat

7A - To furnace control board 24 volts

7B - To constant power using 24V transformer and pressure switch

7C - To furnace control board 115 volts with 24V transformer

7D - To constant power using 24V relay and current sensing relay

7E-7H Manual Humidistat

7E - To furnace control board 24 volts

7F - To constant power using 24V transformer and pressure switch

7G - To furnace control board 115 volts with 24V transformer

7H - To constant power using 24V relay and current sensing relay

Page 3

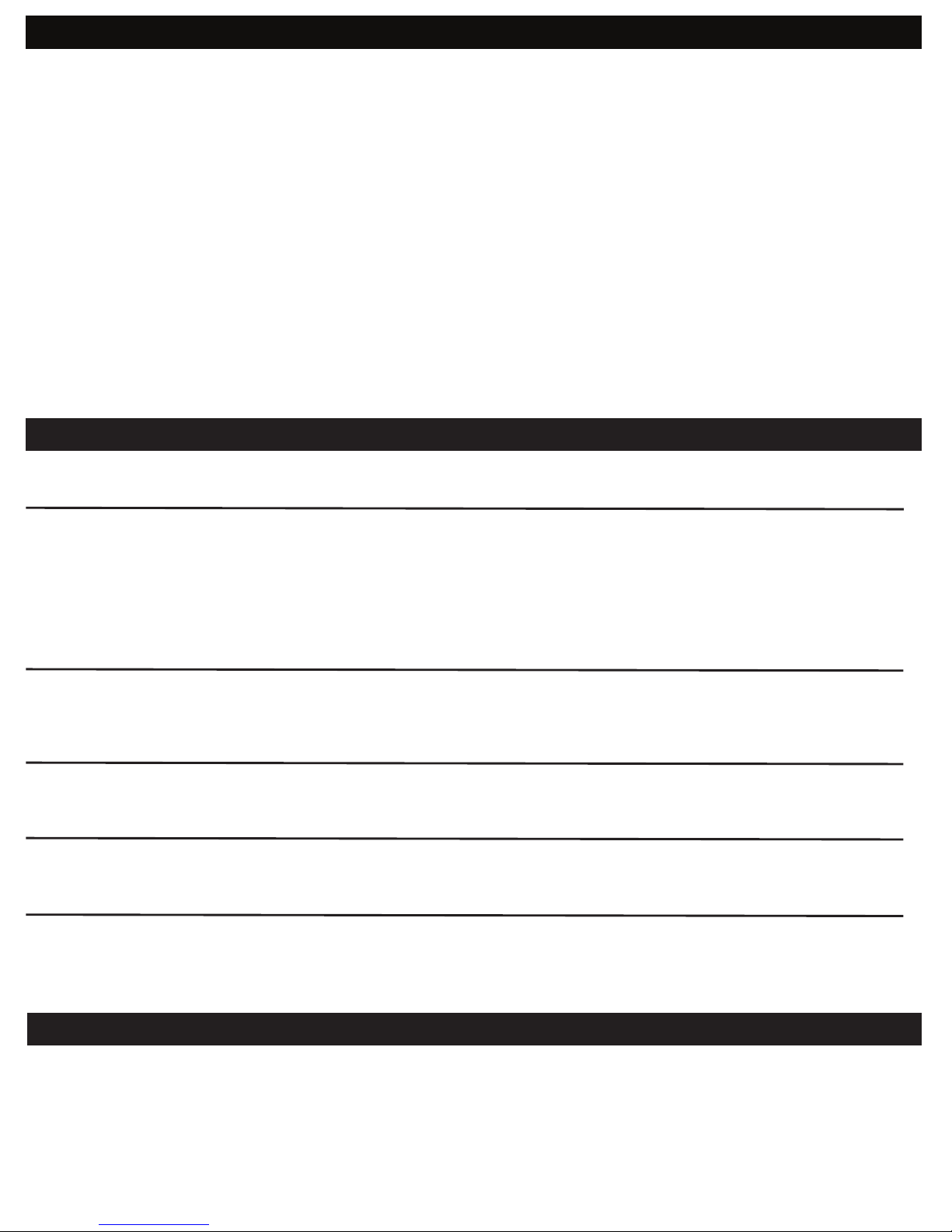

900-1 CHASSIS

900-9 NOZZLE

900-10 SPOUT

GA4266 DISTRIBUTOR TUBE

GA4040 SOLENOID VALVE ASM

GA4004 STAINER SCREEN

P102 COMPRESSION SLEEVE

P101 COMPRESSION NUT

P189 BRASS TUBE INSERT

PARTS LIST FOR HUMIDIFIER

900-40 PAD RAIL

GA-19 EVAPORATOR PAD

900-15 DISTRIBUTOR TROUGH

900-14 DRAIN PAN

GA4231 YELLOW ORIFICE

P102 COMPRESSION SLEEVE (BRASS)/P190 COMPRESSION SLEEVE (PLASTIC)

P101 COMPRESSION NUT

747-38 TUBING KIT (AVAILABLE)

900-11 DAMPER KNOB

900-28 DAMPER DISK

900-2 SIDE PANEL DISCHARGE

900-13 COVER

900-71 NAMEPLATE

LIMITED WARRANTY

This humidifier, if properly registered by the return of the warranty registration card to the manufacturer, is warranted to the consumer against defects in

materials and workmanship for a period of ten years from the date of installation. Evaporator pads, water strainers or metering orifices are not covered by this

limited warranty or any other warranties. Any other defective parts will be repaired without charge except for removal, reinstallation and transportation costs. To

obtain repair service under this limited warranty, the consumer must send the defective part or the complete humidifier to the manufacturer.

THERE ARE NO EXPRESS WARRANTIES COVERING THIS HUMIDIFIER OTHER THAN AS SET FORTH ABOVE, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED. THE MANUFACTURER ASSUMES NO LIABILITY IN

CONNECTION WITH THE INSTALLATION OR USE OF THIS PRODUCT, EXCEPT AS STATED IN THIS LIMITED WARRANTY. THE MANUFACTURER WILL

IN NO EVENT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

This limited warranty gives you specific legal rights, and you may also have other rights which vary from state to state. Some states do not allow either

limitations on implied warranties, or exclusions from incidental or consequential damages, so the above exclusion and limitation may not apply to you.

Any questions pertaining to this limited warranty should be addressed to the manufacturer. (U.S.A.: The manufacturer has elected not to make available the

informal dispute settlement mechanism which is specified in the Magnuson-Moss Warranty Act.)

CARE AND MAINTENANCE

Your humidifier is engineered to give helpful and trouble-free humidification. For maximum efficiency the following cleaning procedures should be

carried out at the end of each heating season:

1. Turn off water supply and electrical power to humidifier.

2. Remove cover, distributor trough, evaporator pad and drain pan. Clean excessive mineral deposits from the distributor

trough, drain pan, pad rails, and humidifier cabinet. A solution of 1/2 vinegar & 1/2 water will help loosen mineral deposits.

Replace humidifier evaporator pad if necessary. (Part number GA19) Install trough and drain pan.

3.

Replace cover. Replace evaporator pad yearly for peak performance.

4. In heavy mineral areas or if the solenoid valve fails to function disconnect the 1/4” water supply line from the solenoid valve.

Carefully pull the strainer screen (P.N. GA4004) from the valve body (P.N. 900-6). Clean the mineral deposits from all

parts.

If the orifice is clogged, it may be opened by inserting a small pin. Reinsert the filter into the orifice fitting and screw the

brass strainer body into the solenoid valve.

5. Reconnect the 1/4” water line to the solenoid valve if necessary. Turn on the water supply and check all points for leakage.

The operation of the unit may be checked by starting the furnace. The humidifier operates only when the furnace blower is

running or the burner circuit is energized. The humidifier is now ready for operation.

6. During the summer, turn off water supply and electrical power to humidifier. Close air damper.

AT

OUTSIDE

TEMPERATURE

RECOMMENDED

SETTING

-20°F -29°C 15%

-10°F -23°C 20%

0°F -18°C 25%

+10°F -12°C

+20°F - 7°C

30%

35%

+30°F - 1°C 40%

Page 4

HOW THE HUMIDIFIER WORKS

The operating principle of the humidifier is based on the most efficient and economical means of evaporating water to the air. The humidifier uses only 2.5 watts

of electrical power during operation, less than the smallest household light bulb. The heat necessary for evaporating water is produced by the furnace.

The water supply to the humidifier is controlled by the electric solenoid valve. The humidistat connected in series with the solenoid provides low voltage control

of the humidifier. The humidistat is designed for wall mounting in the living area or surface mounting on the return air duct. ELECTRICAL RATING: 24 VAC / 60

Hz.

Water flows through a strainer, is metered through an orifice to provide the proper amount of water, and is supplied to the evaporator pad by the distributor

trough. Approximately 200 CFM of air is by-passed from the warm air plenum through the humidifier and returned to the cold air plenum. Moisture is evaporated

to the air passing through the evaporator pad. Minerals are not blown into the air stream as occurs in atomizing humidifiers; they are left on the evaporator pad

where a high percentage is carried off with the waste water.

When the humidifier is installed and operating, no adjustments are necessary other than setting the control knob on the humidistat to the desired level of

humidification. Leave knob on the humidifier in "HI" or "WINTER" position. To turn the humidifier off, close water supply valve, switch electrical power off and turn

humidistat off. If furnace is used for summer cooling or ventilating set air damper on "LOW" or "SUMMER".

DO NOT SET RELATIVE HUMIDITY TOO HIGH DURING COLD WEATHER. EXCESSIVE HUMIDITY MAY CAUSE CONDENSATION ON WINDOWS OR IN

WALLS. REFER TO RECOMMENDED SETTINGS AS DESCRIBED IN THE HUMIDISTAT OWNERS MANUAL.

TROUBLESHOOTING

SYMPTOMS

Humidier will not operate

Proper voltage present at solenoid

valve (24 VAC) but no water ow

Humidier runs without

furnace operation or humidier

never shuts o

Too much humidity in home and/or

condensation on windows

Where can I purchase

replacement parts?

* Humidistat is generally located on furnace return plenum or on an inside wall in the living space.

1. Set thermostat to operate both furnace burner and blower. Operation may be necessary for system power.

2. Humidity level in home may be higher than humidistat setting. Increase humidity setting on humidistat.*

3 . Verify water supply is on.

4. Check for voltage at the solenoid valve. Voltage should be 24VAC. Bypass the humidistat if necessary to isolate

the solenoid valve circuit.

5. Verify wiring of humidier and humidistat.

1. Verify water supply is on

2. Verify metering orice is not obstructed. Very hard water with high mineral content may restrict the metering

orice in as little as one heating season. Replace metering orice if restricted. (part number GA4231)

1. Verify humidier and humidistat wiring. Humidier should operate with furnace burner or blower cycle.

1. Reduce the setting on the humidistat. Refer to CARE AND MAINTENANCE section of this manual to estimate a

humidity setting for the home based on outside temperature. *

1. Replacement parts can purchased through your authorized GeneralAire contractor or visit www.GeneralAire.com

for more information.

DIAGNOSTIC STEP

USA CUSTOMERS

General Filters, Inc.

43800 Grand River Ave.

Novi, MI 48375

www.GeneralAire.com

Engineering@generalfilters.com

Toll Free (866) 476-5101

TECHNICAL SUPPORT

CANADIAN CUSTOMERS

Canadian General Filters, Ltd.

400 Midwest Rd.

Toronto, ON M1P3A9 Canada

www.CGFProducts.com

Sales@cgfproducts.com

Tel. (416) 757-3691

Page 5

Model No.

Loose (0.75 AC/H)

GPD

Average (0.50 AC/H) Tight (0.30 AC/H)

Elite 570

12

800 sq. ft.

1200 sq. ft.

2000 sq. ft.

Elite 900

17

1115 sq. ft.

1650 sq. ft.

2800 sq. ft.

Elite 1000

18

1175 sq. ft.

1770 sq. ft.

3000 sq. ft.

Outside Design Temp 0° F (-18° C)

Outside Design R.H. 70% R.H.

Inside Design Temp. 70° F (21° C)

Inside Design R.H. 30% R.H.

Air Changes/hour (AC/H) 0.30

Ceiling Height 8 ft

Furnace Plenum Temp. 120° F (49° C)

Furnace run time for 8hr/1 day

calculating sq. ft.

15 1/2”

17 1/2”

13”

ELITE 900 HUMIDIFIER SPECIFICATIONS

Model 900A (GFI#5720) includes:

Humidier components: GA19 Vapor pad, GA4040 solenoid assembly, Integral Bypass Damper

Accessories: GFX3 Automatic Digital Humidistat, 24V Transformer, Code Valve, Saddle Valve

Model 900M (GFI#5725) includes:

Humidier Components: GA19 Vapor Pad, GA4040 Solenoid Assembly, Integral Bypass Damper

Accessories: Manual Humidistat, 24V Transformer, Saddle Valve

Expected Humidity Performance Coverage in Square Feet Based on Construction Type

HUMIDIFIER PACKAGED COMPONENT ACCESSORIES

Humidifier Performance Baseline Criteria

12”

8-7/8”

Humidier Chassis with plenum

cut out shown as dashed lines

Page 6

Product Information:

Serial Number: _____________________________________________________________

Model: ____________________________________________________________________

Install Date: Month _______________ Day ______________ Year _____________

Owner Information:

Name: _____________________________________________________________________

Address: ___________________________________________________________________

Address 2: __________________________________________________________________

City: _______________________ State: ___________ Zip Code: ____________________

Phone: _____________________________________________________________________

Email: ______________________________________________________________________

WARRANTY REGISTRATION

Contractor Information:

Contractor Name: _____________________________________________________________

Address: ____________________________________________________________________

Address 2: ___________________________________________________________________

City: _____________________ State: ___________ Zip Code: _______________________

Contractor Phone: ____________________________________________________________

Contractor Email: _____________________________________________________________

You may register online at www.GeneralAire.com or mail form below

Mail Form To:

General Filters, Inc

Attn: Warranty Dept.

43800 Grand River Ave.

Novi, MI 48375

Fresh Indoor Air Quality

R

cut along dashed line

cut along dashed line

USA CUSTOMERS

General Filters, Inc.

43800 Grand River Ave.

Novi, MI 48375

www.GeneralAire.com

Engineering@generalfilters.com

Toll Free (866) 476-5101

CANADIAN CUSTOMERS

Canadian General Filters, Ltd.

400 Midwest Rd.

Toronto, ON M1P3A9 Canada

www.CGFProducts.com

Sales@cgfproducts.com

Tel. (416) 757-3691

TECHNICAL SUPPORT

Page 7

Qualité de l’air frais intérieur

LIRE ET REGISTRER CES INSTRUCTIONS

R

SÉRIE 900

INSTALLATEUR : VEUILLEZ REMPLIR ET POSTER LA CARTE DE GARANTIE UNE FOIS

L’INSTALLATION TERMINÉE. LAISSER LES DIRECTIVES

D’INSTALLATION AU PROPRIÉTAIRE DE LA MAISON.

PRÉCAUTION : L’installateur doit être un technicien qualifié et expérimenté. Couper l’alimentation électrique avant

de commencer l’installation. Ne pas installer l’appareil dans un endroit où la température peut descendre sous

0 °C (32 °F) ou si la température du plénum dépasse 66 °C (150 °F). Lors d’un branchement à un circuit de

ventilateur à plusieurs vitesses, voir l’étape 9D.

INSTALLATION : L’humidificateur peut être installé avec la sortie de 15 cm

(6 po) à droite ou à gauche en inversant le boîtier et l’emplacement de la

goulotte du distributeur et du bac de récupération. L’humidificateur fournit

le même rendement, qu’il soit installé sur un plénum d’air chaud ou sur un

plénum de reprise d’air. Voir l’installation typique.

MATÉRIAUX SUPPLÉMENTAIRES POUVANT ÊTRE NÉCESSAIRES :

1. tuyau d’alimentation en plastique ou en cuivre de 6 mm (1/4 po) de

diamètre pour l’alimentation en eau chaude

2. tuyau de dérivation galvanisé de 15 cm (6 po)

3. fils électriques et coinceurs à câble

4. relais du détecteur de surcharge (G.F. modèle nº GA50 suggéré)

5. vis autotaraudeuse nº 8

1

30,5 cm

(12 po)

15,2 cm

(6 po)

VERS LE HAUT

RETOUR D’AIR

AIR CHAUD

DÉBIT D’AIR

3

DRAIN

FILTRE À AIR À HAUT RENDEMENT

GENERALAire

®

DE SÉRIE AC

HUMIDIFICATEUR À

CIRCULATION DIRECTE

POUR UNE INSTALLATION SUR LA

SURFACE VERTICALE DU PLÉNUM

DE N’IMPORTE QUEL APPAREIL DE

CHAUFFAGE À AIR CHAUD

DRAIN

AIR CHAUD

PROPULSÉ

RETOUR D’AIR

DÉBIT D’AIR

VERS LE BAS

AIR CHAUD

2

22,5 cm

(8-7/8 po)

Le modèle 900 de GeneralAire peut être installé sur le plénum

d’alimentation ou de retour d’un système à air propulsé. Choisir

un emplacement pour l’humidificateur qui permette un accès

facile pour les réparations et l’entretien. Couper une section

carrée de 22,5 cm de largeur x 30,5 cm de hauteur (8-7/8 po x

12 po). Prolonger la ligne horizontale centrale de la section vers

le plénum adjacent. Découper un trou de 15,2 cm (6 po) à

environ 25 à 38 cm (10 à 15 po) du côté de l’humidificateur, au

centre du boîtier, en utilisant le collier de connexion comme

gabarit. La dérivation est réversible et peut être montée du côté

droit ou gauche de l’humidificateur.

1

2

L’humidificateur se retient automatiquement. Faire glisser d’abord

la partie supérieure, puis faire glisser le cadre vers le bas. Mettre

le cadre de niveau et visser la vis centrale. Si le tuyau de

dérivation est installé du côté opposé du cadre, plier la bride du

cadre, enlever le tuyau de sortie et le réinstaller du côté opposé

du cadre. Visser les quatre vis restantes dans les coins.

Raccorder le tuyau de dérivation au collier et au boîtier

de l’humidificateur. Visser deux (2) vis autotaraudeuses

dans les trous en haut et en bas du panneau latéral de

sortie et à travers le tuyau de dérivation.

4

Installer le robinet-vanne à étrier autotaraudeur ou la vanne-code sur un

tuyau d’eau froide ou d’eau chaude. Un montage latéral ou sur le dessus est

idéal pour éviter un engorgement causé par les sédiments du tuyau.

Raccorder un tuyau d’un diam. ext. de 6 mm (1/4 po) au robinet-vanne à

étrier. Les tuyaux en cuivre exigent un écrou à compression et un manchon

en laiton. Les tuyaux en plastique exigent un insert en laiton à l’intérieur des

tuyaux et un manchon en plastique à l’extérieur avec un écrou à

compression.

REMARQUE : NE PAS UTILISER DE TUYAUX EN PLASTIQUE AVEC DE

L’EAU CHAUDE OU SUR UNE SURFACE DE CONTACT CHAUDE DE

PLÉNUM OU DE CONDUIT. L’INSTALLATION DE CE ROBINET-VANNE

À ÉTRIER DOIT RESPECTER OU DÉPASSER LES EXIGENCES DES

CODES LOCAUX ET AUTRES ORDONNANCES.

TUYAU EN

CUIVRE

TUYAU EN

PLASTIQUE

Page 8

Tourner le bouton du registre à la position hiver (ouvert).

Ouvrir l’alimentation en eau et vérifier le fonctionnement de

l’humidificateur. Régler l’humidistat en mode de demande. Lorsque

l’appareil de chauffage est éteint, la vanne électromagnétique doit

être fermée. Démarrer l’appareil de chauffage, la vanne

électromagnétique devrait s’ouvrir lorsque le circuit du ventilateur ou

du brûleur est activé. Vérifier le débit d’eau passant par la goulotte du

distributeur et le tampon d’évaporation. L’orifice jaune standard

GA4231 fournit environ 13,2 l/h (3,5 gal/h) d’eau à une ligne de

pression de 206 kPa (60 lb/po2). Si la pression d’eau est faible (137 à

275 kPa/20 à 40 lb/po2), un orifice orange plus grand GA4299 est

offert afin de fournir le même débit. Laisser l’humidistat au réglage

recommandé.

Raccorder le tuyau d’évacuation au bec de 13 mm (1/2 po) situé sur

le boîtier de l’humidificateur en utilisant un collier de serrage.

Acheminer un boyau de 13 mm (1/2 po) vers un drain adéquat,

comme un drain de sol, d’égout ou d’évier de lavage. S’assurer que le

boyau est en pente continue et n’est déformé en aucun point.

6

5

7A

7C 7D

7

(CHAUD)

115 V

60 Hz

COMMUTATEUR DE

MARCHE-ARRÊT

FIL COMMUN

APPAREIL DE CHAUFFAGE

C

HAUT

BAS

GA50

RELAIS DU

DÉTECTEUR

DE

SURCHARGE

GA50

RELAIS DU

DÉTECTEUR

DE

SURCHARGE

MOTEUR DE

VENTILATEUR

À PLUSIEURS

VITESSES

AC L

AC N

HUM

SNSR

VANNE ÉLECTROMAGNÉTIQUE DE 24 V

727-58 TRANSFORMATEUR DE 24 V

(CHAUD)

C

115 V

60 Hz

COMMUTATEUR DE

MARCHE-ARRÊT

COMMUTATEUR DE

MARCHE-ARRÊT

AC L

AC N

HUM

SNSR

VANNE ÉLECTROMAGNÉTIQUE DE 24 V

727-58 TRANSFORMATEUR DE 24 V

727-58 TRANSFORMATEUR DE 24 V

7B

L1

C

NO

L2

AC L

AC N

HUM

SNSR

(CHAUD)

115 V

60 Hz

COMMUTATEUR DE

MARCHE-ARRÊT

12500

PRESSOSTAT D’AIR

VANNE ÉLECTROMAGNÉTIQUE DE 24 V

DÉTECTEUR DE TEMPÉRATURE EXTÉRIEURE

CAVALIER

R

CARTE DE CIRCUITS

IMPRIMÉS DE L’APPAREIL

DE CHAUFFAGE

C

24 V

60 Hz

AC L

AC N

HUM

SNSR

VANNE ÉLECTROMAGNÉTIQUE DE 24 V

Blanc

(W)

DÉTECTEUR DE TEMPÉRATURE EXTÉRIEURE

DÉTECTEUR DE TEMPÉRATURE EXTÉRIEURE

DÉTECTEUR DE

TEMPÉRATURE EXTÉRIEURE

N

W

24 V

60 Hz

ACC

CHAQUE

(CHAUD)

C

115 V

60 Hz

COMMUTATEUR

DE MARCHE-

ARRÊT

FIL COMMUN

APPAREIL DE CHAUFFAGE

C

HAUT

BAS

MOTEUR DE

VENTILATEUR

À PLUSIEURS

VITESSES

VANNE ÉLECTROMAGNÉTIQUE DE 24 V

HUMIDISTAT

TRANSFORMATEUR DE 24 V

(CHAUD)

C

115 V

60 Hz

VANNE ÉLECTROMAGNÉTIQUE DE 24 V

VANNE ÉLECTROMAGNÉTIQUE DE 24 V

TRANSFORMATEUR DE 24 V

L1

C

NO

(CHAUD)

L2

115 V

60 Hz

COMMUTATEUR DE

MARCHE-ARRÊT

12500

PRESSOSTAT D’AIR

TRANSFORMATEUR DE 24 V

HUM

C

24 V

60 Hz

VANNE ÉLECTROMAGNÉTIQUE DE 24 V

HUMIDISTAT

HUMIDISTAT

HUMIDISTAT

7E

7G

7F

7H

7A à 7D Humidistat électronique

7A – Vers la carte de circuits imprimés de l’appareil de chauffage

de 24 volts

7B – Vers la source d’alimentation constante utilisant un

transformateur de 24 V et un manostat

7C – Vers la carte de circuits imprimés de l’appareil de chauffage

de 115 volts avec un transformateur de 24 V

7D – Vers la source d’alimentation constante utilisant un relais et un

relais du détecteur de surcharge de 24 V

7E à 7H Humidistat manuel

7E – Vers la carte de circuits imprimés de l’appareil de chauffage de

24 volts

7F – Vers la source d’alimentation constante utilisant un

transformateur de 24 V et un manostat

7G – Vers la carte de circuits imprimés de l’appareil de chauffage de

115 volts avec un transformateur de 24 V

7H – Vers la source d’alimentation constante utilisant un relais et un

relais du détecteur de surcharge de 24 V

CAVALIER

INSTRUCTIONS D’INSTALLATION DE LA VANNE-CODE GCV3412

Tuyau en cuivre

1. Couper l’alimentation en eau.

2. Nettoyer le tuyau, les raccords et la vanne avec du papier abrasif

ou une brosse métallique.

3. Appliquer une fine couche de flux sur toutes les surfaces devant

être soudées.

4. Fixer la vanne au tuyau ou aux raccords.

5. Refroidir la vanne en l’enveloppant d’un chiffon humide est une

possibilité.

6. Chauffer les joints avec un chalumeau. Souder chaque joint.

Continuer d’appliquer suffisamment de chaleur pour garder la

soudure à l’état liquide.

7. Lorsque la soudure a entièrement rempli l’espace du joint, retirer

la chaleur et laisser le joint refroidir. Éviter de déplacer ou de

toucher le joint.

8. Faire glisser un écrou à compression sur le tuyau en cuivre de

6 mm (1/4 po), puis le manchon de compression.

9. Insérer entièrement le tube dans la vanne et serrer l’écrou.

10. Ouvrir l’alimentation en eau et vérifier qu’il n’y a pas de fuites.

*LA VANNE-CODE EST FOURNIE AVEC LES MODÈLES

AUTOMATIQUES UNIQUEMENT

Raccorder le tuyau d’alimentation en eau de 6 mm (1/4 po) du filtre en

laiton à l’entrée de la vanne électromagnétique. NE PAS UTILISER

DE TUYAUX EN PLASTIQUE SUR UNE SURFACE DE CONTACT

CHAUDE DE PLÉNUM OU DE CONDUIT. SI UN TUYAU EN

PLASTIQUE EST UTILISÉ, UTILISER LE SUPPORT À TUYAU P189

ET LE MANCHON DE COMPRESSION POUR PLASTIQUE P190.

CAVALIER

CARTE DE

CIRCUITS

IMPRIMÉS DE

L’APPAREIL DE

CHAUFFAGE

CARTE DE CIRCUITS

IMPRIMÉS DE L’APPAREIL

DE CHAUFFAGE

CARTE DE

CIRCUITS IMPRIMÉS

DE L’APPAREIL DE

CHAUFFAGE

CAVALIER

T de 19 mm

(3/4 po)

T de 13 mm

(1/2 po)

Page 9

900-11 BOUTON DU REGISTRE

900-28 DISQUE DU REGISTRE

900-2 ÉVACUATION PAR LE

PANNEAU LATÉRAL

900-40 RAIL DU TAMPON

GA-19 TAMPON D’ÉVAPORATION

900-15 GOULOTTE DU DISTRIBUTEUR

900-13 COUVERCLE

900-14 BAC DE RÉCUPÉRATION

GA4231 ORIFICE JAUNE

P102 MANCHON DE COMPRESSION (LAITON)/

P190 MANCHON DE COMPRESSION (PLASTIQUE)

P101 ÉCROU DE COMPRESSION

747-38 TROUSSE POUR TUYAUTERIE (VENDUE SÉPARÉMENT)

900-71 PLAQUE SIGNALÉTIQUE

LISTE DES PIÈCES POUR L’HUMIDIFICATEUR

RÉGLAGE

RECOMMANDÉ

TEMPÉRATURE

EXTÉRIEURE

Votre humidificateur est conçu pour fournir une humidification d’appoint sans problèmes. Pour bénéficier d’un fonctionnement maximum, suivre les étapes de

nettoyage ci-dessous à la fin de chaque saison froide :

1. Fermer l’alimentation en eau et en électricité de l’humidificateur.

2. Enlever le couvercle, la goulotte du distributeur, le tampon d’évaporation et le bac de récupération. Nettoyer les dépôts

excessifs de minéraux de la goulotte du distributeur, du bac de récupération, des rails du tampon et du boîtier de

l’humidificateur. Une solution moitié vinaigre, moitié eau aide à déloger les dépôts de minéraux.

3. Remplacer le tampon d’évaporation de l’humidificateur si nécessaire (réf. GA10). Installer la goulotte et le bac de récupération.

Remettre le couvercle. Remplacer le tampon d’évaporation chaque année pour assurer un fonctionnement optimum

.

4. Dans les endroits riches en minéraux ou si la vanne électromagnétique est défaillante, déconnecter la ligne d’alimentation en

eau de 6 mm (1/4 po) de la vanne électromagnétique.

Retirer avec précaution le filtre à tamis (réf. GA4004) du corps de la vanne (réf. 900-6). Éliminer les dépôts de minéraux de

toutes les pièces. Si l’orifice est bloqué, on peut l’ouvrir en y insérant une petite tige. Réinstaller le filtre dans le raccord de

l’orifice et visser le corps du filtre en laiton dans la vanne électromagnétique.

5. Raccorder la conduite d’eau de 6 mm (1/4 po) à la vanne électromagnétique au besoin. Ouvrir l’alimentation en eau et vérifier

tous les points de fuite.

Le fonctionnement de l’appareil peut être vérifié en démarrant l’appareil de chauffage. L’humidificateur fonctionne uniquement

lorsque le ventilateur de l’appareil de chauffage est en marche ou que le circuit du brûleur est activé. L’humidificateur est

maintenant prêt à fonctionner.

6. Pendant la période estivale, fermer l’alimentation en eau et en électricité de l’humidificateur. Fermer le registre à air.

SOIN ET ENTRETIEN

GARANTIE LIMITÉE

Cet humidificateur, lorsqu’il est enregistré correctement en retournant la carte d’enregistrement de la garantie au fabricant, est garanti au consommateur contre

tout défaut de matériaux et de main-d’œuvre pour une période de dix (10) ans à partir de la date d’installation. Les tampons d’évaporation, les filtres à eau ou

les plaques ne sont pas couverts par cette garantie limitée ou par toute autre garantie. Toute autre pièce défectueuse sera réparée sans frais, hormis les coûts

de désinstallation, de réinstallation et de transport. Pour obtenir un service de réparation avec cette garantie limitée, le consommateur doit envoyer la pièce

défectueuse ou l’humidificateur au fabricant.

AUCUNE AUTRE GARANTIE QUE LA PRÉSENTE NE COUVRE CET HUMIDIFICATEUR, LES GARANTIES IMPLICITES DE QUALITÉ MARCHANDE OU

D’ADAPTATION À UN USAGE PARTICULIER SONT EXPRESSÉMENT EXCLUES. LE FABRICANT NE PEUT ÊTRE TENU RESPONSABLE DE

L’INSTALLATION OU DE L’UTILISATION DE CE PRODUIT, SAUF DE LA MANIÈRE INDIQUÉE DANS LA PRÉSENTE GARANTIE LIMITÉE. LE FABRICANT

NE PEUT EN AUCUN CAS ÊTRE TENU RESPONSABLE DES DOMMAGES ACCESSOIRES OU INDIRECTS.

Cette garantie limitée vous donne des droits légaux spécifiques, et vous pouvez jouir d’autres droits, lesquels varient d’une juridiction à l’autre. Certaines

juridictions ne permettent pas de limites sur les garanties implicites ou d’exclusions pour les dommages accessoires ou indirects; les exclusions

susmentionnées peuvent donc ne pas s’appliquer dans votre cas.

Toute question relative à cette garantie limitée doit être soumise au fabricant. (É.-U. : Le fabricant a choisi de ne pas divulguer les termes de l’accord spécifiés

dans le « Magnuson-Moss Warranty Act ».)

-29 °C -20 °F 15 %

-23 °C -10 °F 20 %

-18 °C 0 °F 25 %

-12 °C +10 °F 30 %

-7 °C +20 °F 35 %

-1 °C +30 °F 40 %

900-1 CADRE

900-9 GICLEUR

900-10 BUSE

GA4235 TUBE DE DISTRIBUTEUR

GA4040 VANNE ÉLECTROMAGNÉTIQUE ASM

GA4004 FILTRE À TAMIS

P102 MANCHON DE COMPRESSION

P101 ÉCROU DE COMPRESSION

P189 INSERT EN LAITON

Page 10

Le principe de fonctionnement de l’humidificateur est basé sur la façon la plus efficace et la plus économique d’évaporer l’eau dans l’air. L’humidificateur utilise

uniquement 2,5 watts de courant électrique lorsqu’il fonctionne, c’est-à-dire moins que la plus petite ampoule électrique de votre maison. La chaleur nécessaire

pour l’évaporation de l’eau est produite par l’appareil de chauffage. L’alimentation en eau vers l’humidificateur est contrôlée par la vanne électromagnétique.

L’humidistat connecté en série avec la vanne électromagnétique fournit un contrôle de basse tension à l’humidificateur. L’humidistat est conçu pour une

installation murale dans un endroit habité ou sur le conduit de reprise. CARACTÉRISTIQUES ÉLECTRIQUES : 24 V c.a./60 Hz

L’eau s’écoule par une crépine, est mesurée par un orifice pour fournir la quantité adéquate et alimente le tampon d’évaporation par la goulotte du distributeur.

Environ 5,66 mètres cubes (200 CFM) par minute sont dérivés du plénum d’air chaud, passent par l’humidificateur et sont renvoyés au plénum d’air froid.

L’humidité est évaporée dans l’air en passant par le tampon d’évaporation. Les minéraux ne sont pas soufflés dans le courant d’air, comme c’est le cas avec

les humidificateurs à pulvérisation; ils restent sur le tampon d’évaporation où un fort pourcentage est évacué avec les eaux usées.

Lorsque l’humidificateur est installé et fonctionne, aucun réglage n’est nécessaire sauf le réglage du niveau voulu d’humidification par le bouton de commande

sur l’humidistat. Laisser le bouton de l’humidificateur à la position HAUT (HI) ou HIVER (WINTER). Pour éteindre l’humidificateur, fermer la vanne

d’alimentation en eau, mettre hors tension et fermer l’humidistat. Si l’appareil de chauffage est utilisé pendant l’été pour refroidir ou aérer, régler le registre à la

position BAS (LOW) ou ÉTÉ (SUMMER).

NE PAS RÉGLER L’HUMIDITÉ RELATIVE TROP HAUT PENDANT LA PÉRIODE HIVERNALE. UNE HUMIDITÉ EXCESSIVE PEUT ENTRAÎNER DE LA

CONDENSATION SUR LES FENÊTRES OU SUR LES MURS. SE RÉFÉRER AUX RÉGLAGES RECOMMANDÉS DÉCRITS DANS LE MANUEL DE

L’UTILISATEUR DE L’HUMIDISTAT.

FONCTIONNEMENT DE L’HUMIDIFICATEUR

DÉPANNAGE

SYMPTÔMES

ÉTAPES DU DIAGNOSTIC

L’humidicateur ne fonctionne pas

L’humidicateur fonctionne alors que

l’appareil de chauage est éteint, ou

l’humidicateur ne s’éteint jamais

La tension au niveau de la vanne

électromagnétique est bonne (24 V c.a.),

mais l’eau ne coule pas

Taux d’humidité trop élevé dans la maison

ou présence de condensation sur les fenêtres

1. Régler le thermostat de manière à faire fonctionner l’appareil de chauage et le ventilateur; il peut être nécessaire que

ces appareils fonctionnent pour alimenter le système.

2. Le niveau d’humidité de la maison peut être plus élevé que le réglage de l’humidistat. Augmenter le réglage d’humidité

de l’humidistat.*

3. S’assurer que l’alimentation en eau est ouverte.

4. Vérier la tension au niveau de la vanne électromagnétique. La tension doit être de 24 V c.a. Contourner l’humidistat si

nécessaire pour isoler le circuit de la vanne électromagnétique.

5. Vérier le câblage de l’humidicateur et de l’humidistat.

1. S’assurer que l’alimentation en eau est ouverte.

2. Vérier que l’orice de mesure n’est pas obstrué. De l’eau très dure ayant un taux élevé de minéraux peut obstruer

graduellement l’orice de mesure, dans certains cas en une seule saison. Remplacer l’orice de mesure s’il est obstrué

(réf. GA4231).

1. Vérier le câblage de l’humidicateur et de l’humidistat. L’humidicateur doit fonctionner lorsque le brûleur ou le

ventilateur de l’appareil de chauage fonctionne.

1. Réduire le réglage de l’humidistat. Consulter la section SOIN ET ENTRETIEN de ce manuel pour déterminer le réglage

de l’humidistat de votre maison selon la température extérieure.*

*L’humidistat est généralement placé sur le plénum de retour d’air de l’appareil de chauage ou dans un mur d’un espace d’habitation.

Où peut-on acheter des pièces de rechange?

1. Des pièces de rechange peuvent être achetées auprès de votre installateur GeneralAire autorisé ou visiter le

www.GeneralAire.com pour obtenir de plus amples informations.

CLIENTS AUX É.-U.

General Filters, Inc.

43800 Grand River Ave.

Novi, MI 48375, É.-U.

www.GeneralAire.com

Engineering@generalfilters.com

Numéro sans frais : 866-476-5101

CLIENTS AU CANADA

Canadian General Filters, Ltd.

400 Midwest Rd.

Toronto, ON M1P3A9 Canada

www.CGFProducts.com

Sales@cgfproducts.com

Tél. : 416-757-3691

ASSISTANCE TECHNIQUE

Page 11

39,4 cm

(15-1/2 po)

44,5 cm

(17-1/2 po)

33 cm

(13 po)

CARACTÉRISTIQUES DE L’HUMIDIFICATEUR ELITE 900

Le modèle 900A (GFI nº 5720) inclut :

Composants de l’humidicateur : GA19 tampon d’évaporation, GA4040 ensemble de la vanne électromagnétique, registre de

dérivation intégral

Accessoires : GFX3 Humidistat numérique automatique, transformateur de 24 V, vanne-code, vanne à étrier

Le modèle 900M (GFI nº 5725) inclut :

Composants de l’humidicateur : GA19 tampon d’évaporation, GA4040 ensemble de la vanne électromagnétique, registre de

dérivation intégral

Accessoires : Humidistat manuel, transformateur de 24 V, vanne à étrier

Performance d’humidité prévue selon la supercie en mètres carrés/pieds carrés et le type de construction

ACCESSOIRES DES COMPOSANTS DE L’HUMIDIFICATEUR EMBALLÉ

30,5 cm

(12 po)

22,5 cm

(8-7/8 po)

Nº de modèle

Faible (0,75 CAH)

GPD

Moyen (0,50 CAH) Élevé (0,30 CAH)

Elite 570

12

74 m

2

/800 pi

2

111 m2/1200 pi

2

186 m2/2000 pi

2

Elite 900

17

104 m

2

/1115 pi

2

153 m2/1650 pi

2

260 m2/2800 pi

2

Elite 1000

18

109 m

2

/1175 pi

2

164 m2/1770 pi

2

279 m2/3000 pi

2

Température de calcul – extérieure -18 °C (0 °F)

HR de calcul – extérieure HR de 70 %

Température de calcul – intérieure 21 °C (70 °F)

HR de calcul – intérieure HR de 30 %

Changements d’air/heure (CAH) 0,30

Hauteur du plafond 2,43 m (8 pi)

Température du plénum de

l’appareil de chauage 49 °C (120 °F)

Durée de fonctionnement de l’appareil

de chauage pour calculer la supercie 8 h/jour

Performance d’humidité prévue selon la superficie en mètres carrés/pieds carrés et le type de construction

Critères de base de la performance de l’humidificateur

Cadre de l’humidicateur avec

la découpe du plénum illustrée

en lignes pointillées

Page 12

Renseignements sur le produit :

Numéro de série : ____________________________________________________________

Modèle : ___________________________________________________________________

Date d’installation : Mois _______________ Jour ______________ Année ____________

Renseignements sur le propriétaire :

Nom : _____________________________________________________________________

Adresse : __________________________________________________________________

Adresse 2 : ________________________________________________________________

Ville : ____________________ État/Province : ___________ Code postal : ___________

Téléphone : ________________________________________________________________

Courriel : __________________________________________________________________

ENREGISTREMENT DE LA GARANTIE

Renseignements sur l’installateur :

Nom : _____________________________________________________________________

Adresse : __________________________________________________________________

Adresse 2 : ________________________________________________________________

Ville : ____________________ État/Province : _____________ Code postal : _________

Téléphone : ________________________________________________________________

Courriel : __________________________________________________________________

Le produit peut être enregistré en ligne au www.GeneralAire.com

ou par la poste en envoyant le formulaire ci-dessous

Poster le formulaire à :

General Filters, Inc

Attn: Warranty Dept.

43800 Grand River Ave.

Novi, MI 48375, É.-U.

découper le long de la ligne pointillée

découper le long de la ligne pointillée

CLIENTS AUX É.-U.

General Filters, Inc.

43800 Grand River Ave.

Novi, MI 48375, É.-U.

www.GeneralAire.com

Engineering@generalfilters.com

Numéro sans frais : 866-476-5101

CLIENTS AU CANADA

Canadian General Filters, Ltd.

400 Midwest Rd.

Toronto, ON M1P3A9 Canada

www.CGFProducts.com

Sales@cgfproducts.com

Tél. : 416-757-3691

ASSISTANCE TECHNIQUE

R

Qualité de l’air frais intérieur

Loading...

Loading...