GeneralAire 1000, 1000A, 1000M Installation & Owner's Manual

Installation & Owners Manual

Model 1000 (A & M)

Humidifier

GFI #5730 & 5735

• Installationbyanyoneotherthanaqualiedcontractorvoidsthewarranty.

• Productdesignedforresidentialinstallationonly.Commercialinstallationvoidswarranty.

• Modicationoralterationofproduct,parts,installationinstructionsorlocalsafetycodesvoidswarranty.

• Readourfullwarrantypolicyattheendofthisdocument.

Breathe Healthier

Please Read And Save These Instructions

Canadian General Filters, Ltd.

400 Midwest Rd.

Toronto, ON M1P3A9 Canada

Toll Free: (888) 216-9184

www.cgfproducts.com

General Filters, Inc.

43800 Grand River Avenue

Novi, Michigan 48375

Toll Free: (866) 476-5101

www.generalaire.com

2

Model 1000 Humidier Installation Manual

Breathe Healthier! Residential Whole-House Indoor Air Quality

Table of Contents

Specications 3

Unit Location 3

Additional Materials That May Be Necessary: 3

Installation 4-5

Installing The Control 5-6

Final Steps Of Installation 7

How The Humidier Works 7

Maintenance 8

Parts Drawing 8

Humidier Chassis Cut Out 9

Inside Your Box 9

Trouble Shooting 10

FAQ’s 10-11

Limited Warranty 12

Model 1000 Table of Contents

WARNING!

This symbol indicates: IMPORTANT INSTRUCTIONS!

Failure to heed them can result in serious injury or death.

CAUTION!

This symbol indicates: IMPORTANT INSTRUCTIONS!

Failure to heed them can result in serious injury or material property damage.

!

!

3

www.generallters.com

Model 1000 Humidier Installation Manual

Unit Location

• For installation on a vertical surface of the warm air plenum of any forced air furnace.

• WARNING: Disconnect electrical power before beginning installation.

• Do not install where temperatures fall below 32°F / 0° C or where plenum temperatures exceed 200° F / 93° C.

For maximum evaporative capacity, install this humidier on the warm air supply plenum.

Additional Materials That May Be Necessary:

1. 1/4" Diameter plastic supply tubing for cold water applications, or 1/4" copper supply tubing for hot water applications

2. Current sensing relay (Model #GA50 - GFI #7026) / or single pole single throw isolation relay

3. Junction box, 115V grounding outlet, cover and wire

4. 1/2” I.D. Drain hose / 3/4" PVC drain

5. #8 Self-piercing sheet metal screws

6. Misc. wire and connectors

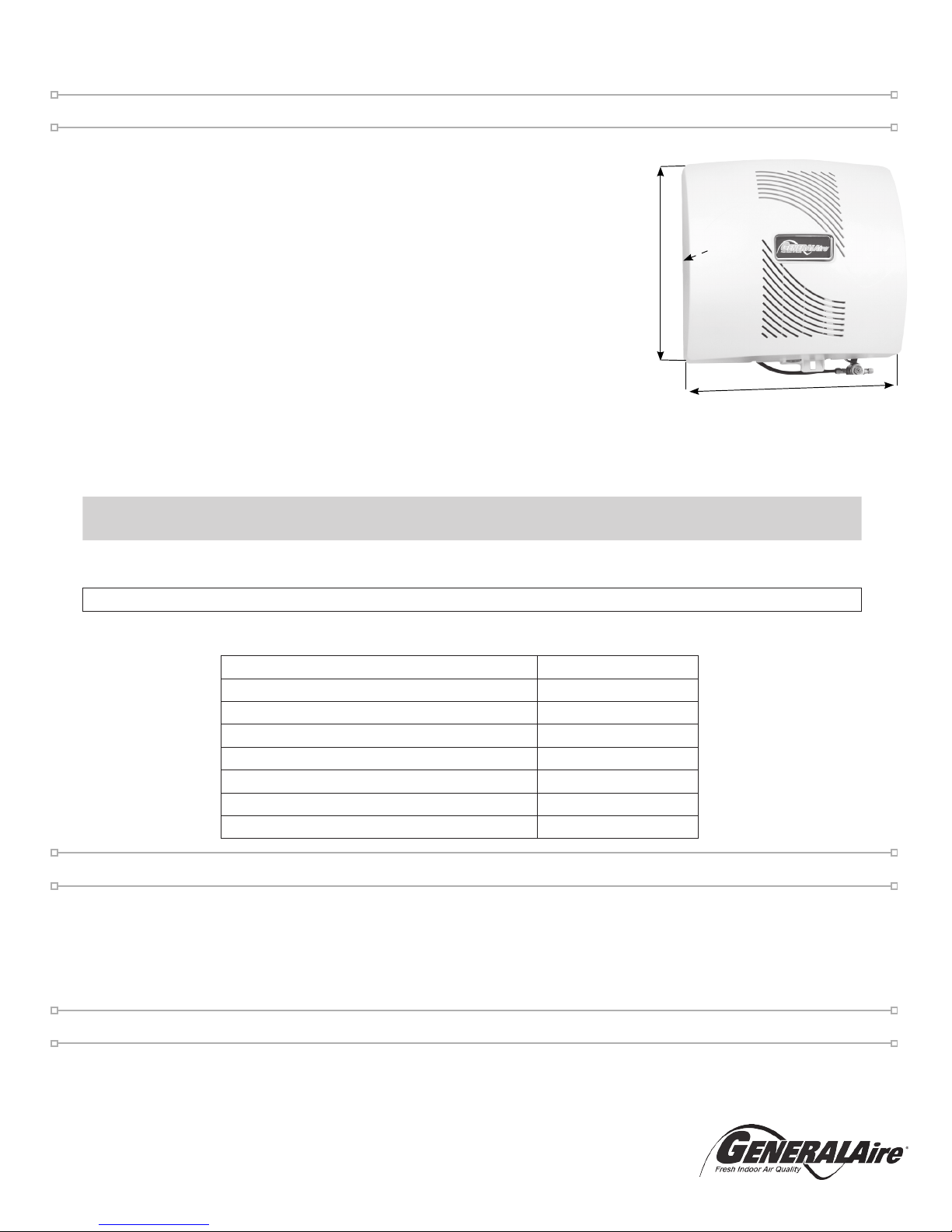

Specifications

• Model: 1000 (A & M) Elite Flow Through Humidiers (GFI #5730 & #5735)

• Type: Fan Powered Flow Through

• GPD: 18 Based on 120° F / 49° C Plenum Temperature

• Warranty (Years): 10

• Replacement Vapor Pad®: GA19 (GFI#7919) (Replace 1-2 times per season)

• Dimensions (Inches): 16 W x 16-1/2 H x 10-1/2 D

• Weight (Pounds): 15

• Home Size (Sq. Ft.): To 3,000

• Installation: Warm Air / Return Air Plenum

• Plenum Opening (Inches): 14-1/8 W X 12 H

• Pallet Qty: 24

• Cabinet Construction: UV-Stable Automotive Grade Plastic

• Humidistat (Included): “M” Models: MHX3C / “A” Models: GFX3

• Voltage: 120VAC

• In The Box: “M” Models: MHX3C / “A” Models: GFX3 (Incuded) Humidier,

Humidistat, Control Bypass Damper, 24V Transformer, Solenoid Valve, Vapor Pad®, Saddle Valve, (GCV3412 Code Valve A Models), Installation Instructions, Template, Parts.

!

16” W

16-1/2” H

10-1/2” D

Expected Humidity Performance Coverage in Square Feet Based on Construction Type

Model No. GPD

Loose

(0.75 AC/H)

Average

(0.50 AC/H)

Tight

(0.30 AC/H)

Elite 570 12 800 Sq. Ft. 1200 Sq. Ft. 2000 Sq. Ft.

Elite 900 17 1115 Sq. Ft. 1650 Sq. Ft. 2800 Sq. Ft.

Elite 1000 18 1175 Sq. Ft. 1770 Sq. Ft. 3000 Sq. Ft.

Outside Design Temperature 0° F / -18° C

Outside Design R.H. 70% R.H.

Inside Design Temperature 70° F / 21° C

Inside Design R.H. 30% R.H.

Air Changes/hour (AC/H) 0.30

Ceiling Height (Feet) 8

Furnace Plenum Temperature 120° F / 49° C

Furnace Run Time For Calculating Sq. Ft. 8 Hour /1 Day

Humidifier Performance Baseline Criteria

4

Model 1000 Humidier Installation Manual

Breathe Healthier! Residential Whole-House Indoor Air Quality

Installation

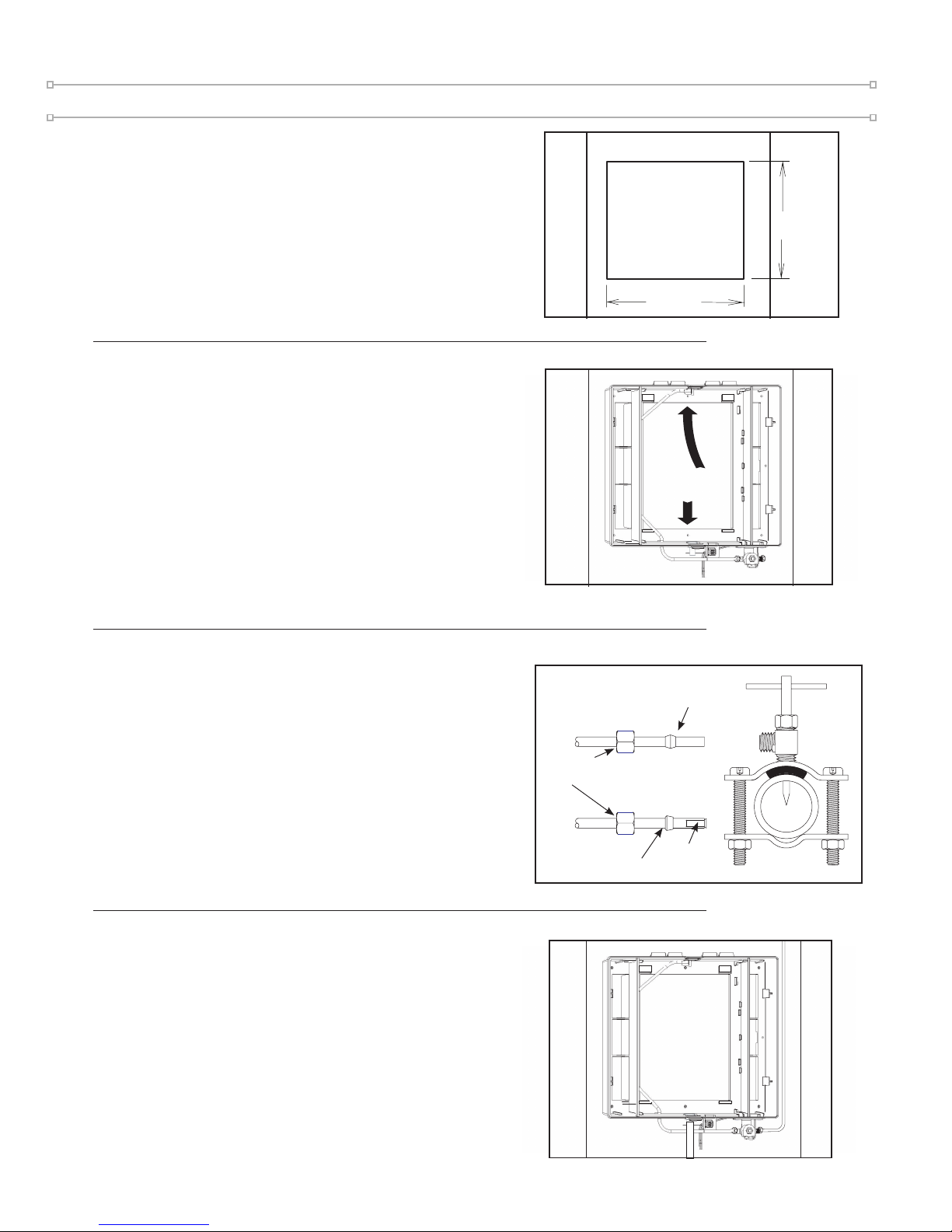

1. Select a location on the vertical surface of warm air plenum

of a forced air handling system for mounting humidier that

allows for service and maintenance. Do not install humidier

where the blanked off ends of a cooling coil will restrict air

ow to the humidier. Cut out a square section 12-1/8” tall

by 14-1/8” wide as shown.

2. Open the cover and remove the evaporator pad assembly.

The humidier chassis is self retaining. Slide the top side

in rst, then slide the chassis down. Level the chassis and

install the eight screws (included).

3. Mount the self tapping saddle valve on either a cold or a hot

water pipe. A side or top mount is best to avoid clogging

from pipe sediment. Connect 1/4” O.D. tubing to the saddle

valve. Copper tubing requires a brass compression nut and

brass sleeve. Plastic tubing requires a brass insert inside the

tubing in addition to a plastic ferrule and brass nut.

CAUTION: do not use plastic tubing on hot water or in

contact with any hot plenum surface or duct. Installation

of this saddle valve must meet or exceed local codes and

ordinances.

4. Connect 1/4" water supply tube to inlet of solenoid.

Connect drain hose to 1/2" spout on humidier cabinet using

hose clamp if necessary. Run 1/2" hose to suitable drain

such as oor drain, sewer or laundry sink. Be sure hose has

continuous slope and is not kinked at any point.

!

1

2

4

12-1/8”

14-1/8”

COPPER

TUBING

PLASTIC

TUBING

Plastic

Sleeve

Brass

Insert

Brass

Sleeve

Compression

Nut

5

www.generallters.com

Model 1000 Humidier Installation Manual

5. GCV3412 Code Valve Installation Instructions*

Copper Pipe:

1. CAUTION: Turn off water supply.

2. Clean pipe, ttings and valve with sandpaper or wire brush.

3. Apply a thin layer of ux to all surfaces to be soldered.

4. Assemble valve to pipe and/or ttings.

5. Cooling the valve by wrapping a wetted rag around the valve is optional.

6. WARNING: For your safety, this should be performed by a

licensed contractor only. Heat the joints with a torch. Apply solder to

each joint. Continue to apply heat sufcient to keep solder liquid.

7. After solder has lled entire joint area, remove heat and allow joint to cool. Do

not move or disturb.

8. Slide compression nut over 1/4” copper tube followed by compression sleeve.

9. Insert tube into valve fully and tighten nut.

10. Turn on water supply and check for leaks.

*Code Valve Is Included With Automatic Models Only

Installation Cont.

!

!

1/2” TEE

3/4” TEE

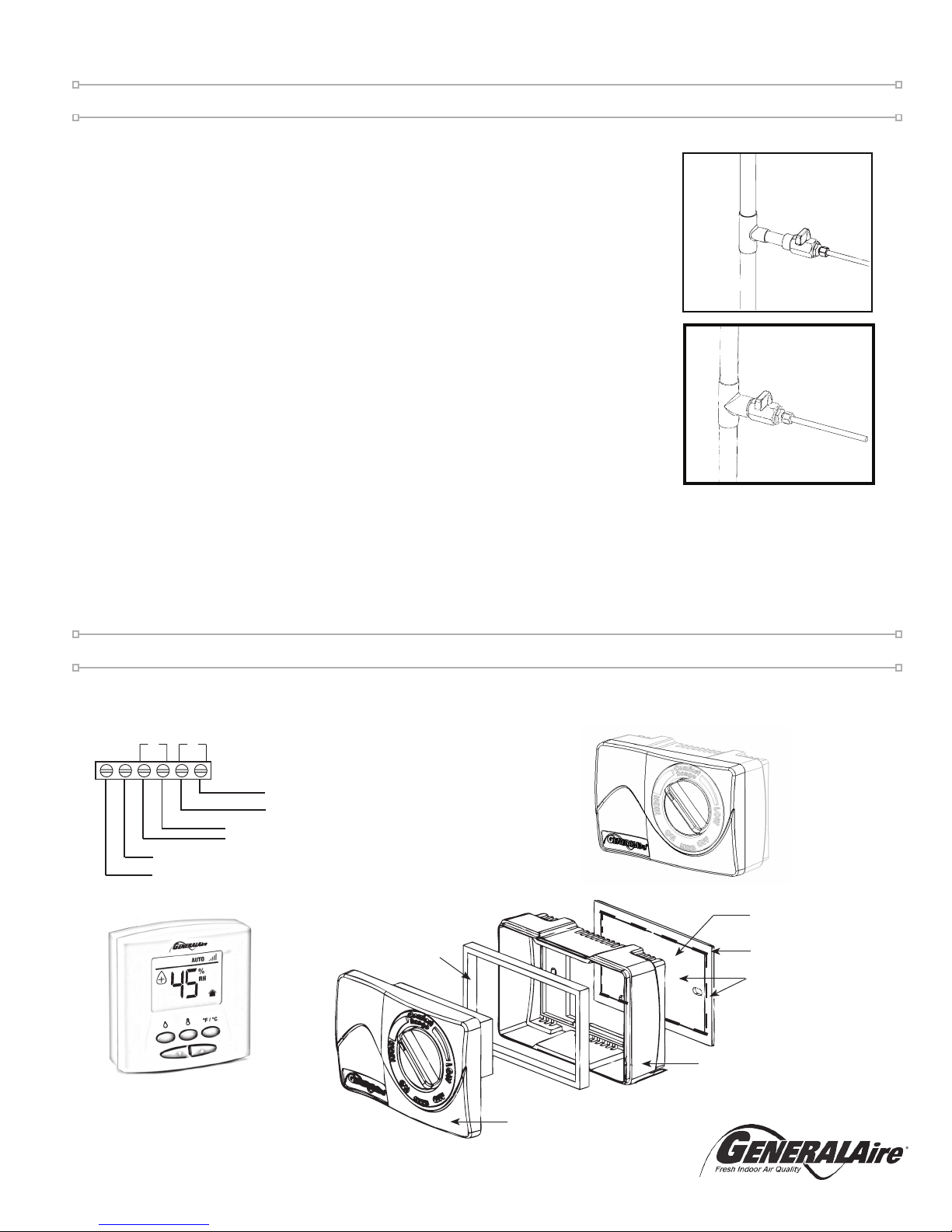

Installing The Control

GFX3 (Automatic Models) MHX3C (Manual Models)

24V OUTPUT FROM HUMIDIFIER (RED WIRES) OR

727-58 24 V. TRANSFORMER WITH CONSTANT POWER

OR 24 VAC POWER SUPPLY WITH CONSTANT POWER

HUMIDIFIER CONTROL LEADS

(YELLOW WIRES)

OUTDOOR TEMP. SENSOR

(NOT USED IN MANUAL MODE)

AC L

AC N

HUM

SNSR

Thin Gasket

Face

FIG. 1

WALL MOUNT: Use

Outer & Inner Portions

DUCT MOUNT: Use

ONLY Outer Portion

Mounting

Base

Thick Gasket

DUCT MOUNT ONLY

Loading...

Loading...