Page 1

3-AXIS USB

VIBRATION/ACCELERATION

DATA LOGGER

USER’S MANUAL

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

VB10

Please read this manual carefully and thoroughly before using this product.

Page 2

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 –3

Key Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 –4

What’s In the Package . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 –5

Setup Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 10

Activate Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Install Software . . . . . . . . . . . . . . . . . . . . . . . . . . 6 –8

Configure Data Logger . . . . . . . . . . . . . . . . . . . 8 – 10

Deploy Data Logger . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . 11 – 12

Monitoring Device Status . . . . . . . . . . . . . . . . . . . . 11

Starting & Stopping Data Logging . . . . . . . . . 11 – 12

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Downloading Data and Using the Software . . . . . . 12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Return for Repair Policy . . . . . . . . . . . . . . . . . . . . . . . . . 15

INTRODUCTION

Thank you for purchasing General Tools & Instruments’ VB10

3-Axis USB Vibration/Acceleration Data Logger. Please read this

user’s manual carefully and thoroughly before using the product.

2

Page 3

The VB10 system has three components:

1. A USB memory stick (data logger) with three precision on-board

microelectronic gravitational force sensors (accelerometers).

The data logger is designed to be attached to an operating

piece of equipment (a motor, for example) and left in place to

measure and record the equipment’s acceleration in three

dimensions over an extended period of time.

2. A pedestal with magnets and screw holes for firmly mounting

the data logger to the piece of equipment.

3. A Windows-compatible graphics application that can download

thousands of stored or real-time acceleration readings to a PC

from the data logger via its USB interface. Using powerful

analysis tools in the software, an engineer or technician can

assess the health or diagnose any performance problems of the

equipment by relating the acceleration data to physical

manifestations such as vibration, motion and tilt.

KEY FEATURES

• Three accelerometers precisely measure acceleration on x, y

and z axes

• Data logger stores up to 327,600 data points in flash memory

• One button starts/stops data logging without PC

• Plug-and-play USB 2.0 interface; no need for cables, cradles or

docks

• Mounting pedestal with magnets and three screw holes

• Included PC interface/analysis software can download recorded

data or acquire real-time data or real-time frequency data

• Software is used to set system clock, operating mode (normal,

time-triggered or motion measuring), sampling rate and axial

high/low alarm thresholds

3

Page 4

• Powerful analysis modes, including Fast Fourier Transform

frequency conversion and time-domain analysis

• One-click exporting of tabular data to .txt file or graph to printer

• Red and green LEDs indicate device status (recording, not

recording, battery low, memory full)

• Powered by high-capacity, long-life, non-rechargeable Li-ion

battery

WHAT’S IN THE PACKAGE

The VB10 system comes in a white box. Inside the box are:

• The USB data logging device with a pre-installed battery that

requires activation

• A mounting pedestal

• An extension cable with a full-size USB plug at one end and a

full-size USB jack at the other

• A mini-disc containing the .exe file of the Shock Software V2.1

application and a pdf explaining how to install and use it

• A hard copy of this user’s manual

PRODUCT OVERVIEW

Fig. 1 below and on the next page shows all controls, indicators

and physical structures on the data logger and pedestal.

A. Logging start/stop button

B. Green Rec LED

C. Red Alm LED

D. USB plug

E. Transparent plug cap

F. Battery compartment

4

USB DATA LOGGER

F

Page 5

G

H

K

I

PEDESTAL (TOP) PEDESTAL (BOTTOM)

J

G. Locking thumbscrew

H. Data logger clamp

I. Pedestal

J. Magnets

K. Screw mounting holes

SETUP INSTRUCTIONS

ACTIVATE BATTERY

1. Use a very small Phillips-head screwdriver to remove the two

silver screws securing the grey battery compartment cover

(Fig. 1, Callout F) to the bottom of the data logger. Set the

screws aside, taking care not to lose them.

2. Carefully remove the battery compartment cover to expose the

“1/2AA” battery inside.

3. Remove the battery from the well. If the battery is covered by a

transparent plastic cover, remove and discard it. If not, proceed

to the next step.

4. Insert the battery in the well cathode (- side) first.

5. Replace the battery compartment cover and secure it with the

two silver screws.

5

Page 6

INSTALL SOFTWARE

1. Remove the Shock Software V2.1 mini-disc from its protective

sleeve and place it in the tray of your PC’s CD/DVD drive with

the label facing up. Close the tray.

2. On the AutoPlay screen that appears next, click on “Open folder

to view files”

3. The next screen will indicate that there are two files on the

disc: <Shock Software V2.1 Instructions.pdf> and <Shock V2.1

Setup.exe>. Before installing the application, General

recommends that you copy the pdf to your hard drive to make

the software instructions available without having to re-load the

disc. You may also want to print out the instructions for off-line

reference.

4. Double-click <Shock V2.1 Setup.exe>. The screen below will

appear.

6

Page 7

5. Click Next to call up

the screen at right.

Use the Browse

button if you want to

save the Shock

software somewhere

other than the

ProgramFiles folder.

Otherwise,

click Next.

6. On the Ready to

Install screen at

right, click Install.

7. While the software

installs, you will see

the screen at right.

7

Page 8

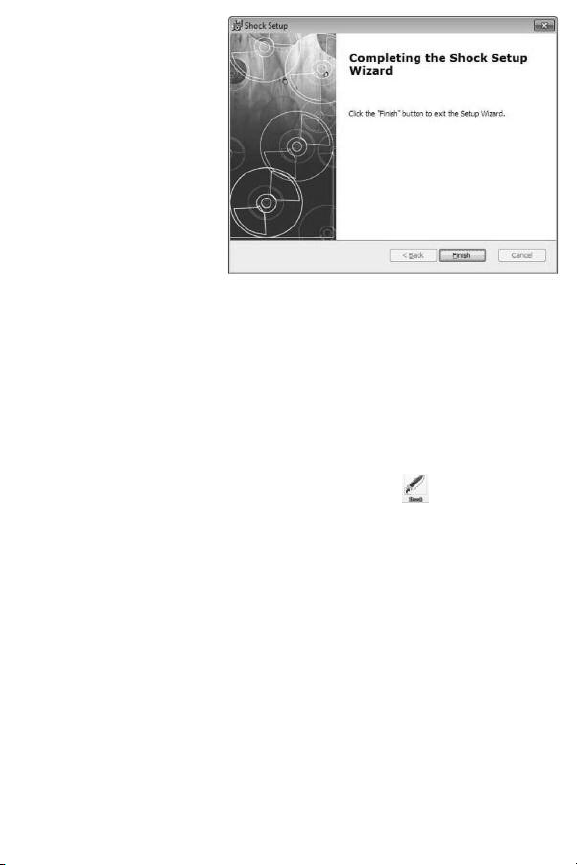

8. When installation is

complete, click

Finish to exit the

Shock Setup Wizard.

CONFIGURE DATA LOGGER

The next two steps in the setup process install a software driver

for the USB data logger, and configure the unit to your data

logging preferences.

Remove the transparent plug cap (Fig. 1, Callout E) from the data

logger to prepare it to be plugged into a USB port of your

computer.

Note that the software installation has added a icon to your

desktop. To facilitate access to the program, right-click on the

icon and pin it to both your Start button and the Quick Start area

at the left of your taskbar. You can now eject the Shock Software

mini-disc and store it with your other important software.

Plug the data logger into an available USB port of your computer.

If your computer is a laptop and the only available USB jack does

not have enough vertical clearance to accommodate the logger

without mechanically stressing its USB plug, do not plug the

logger directly into the jack. You do not want the plug of the logger

to support any of the weight of the laptop. If that is the case, plug

the data logger into the jack of the included USB extension cable

and insert the plug of the extension cable into the computer’s

USB jack.

8

Page 9

The first time you plug the data logger into your computer, your

system tray will notify you that the computer is “Installing Device

Driver Software”. When the notification disappears, open the

Shock program by selecting it via your Start button, clicking on its

icon on your taskbar, or double-clicking its desktop icon.

If the software has installed correctly and you have plugged the

data logger into a working USB port of your computer, the screen

at right will

appear on your

computer’s

display.

To configure the

data logger,

begin by selecting

the System

Parameter

pulldown of the

File menu at

upper left. This

will call up the

screen at right.

9

Page 10

Of all the options available on this screen, there is only one you

should initially change from the default value: Interval Time.

General suggests that you change this value (more commonly

called Sampling Time) from 50ms to 500ms to avoid filling up the

on-board flash memory with redundant information (nearly

identical samples taken too close together in time). Note that the

Current Time and Start Record Time fields have already been

synchronized to your PC’s clock. You can always change the other

default values later, after you have gained some experience

operating the VB10 system and the Shock software.

After you have changed the Interval Time to 500ms, click OK at

the bottom left of the screen to save the settings.

DEPLOY DATA LOGGER

To obtain accurate readings, the data logger must be securely

attached to the equipment whose vibration or motion history you

wish to log and analyze.

The data logger fits snugly in the supplied mounting pedestal. To

insert the logger in the pedestal, turn the locking thumbscrew

(Fig. 1, Callout G) to loosen it, raise the clamp (Fig. H), insert the

logger, lower the clamp over it, and turn the thumbscrew to

secure the clamp.

There are three ways to attach the pedestal and data logger to the

equipment whose acceleration is to be measured: 1) Using the

three magnets on the back of the pedestal (Fig. 1, Callout J);

2) Using screws or bolts (not included) to permanently attach the

pedestal to the equipment through the three holes in the pedestal

(Callout K); 3) Gluing the pedestal to the equipment.

10

Page 11

OPERATING INSTRUCTIONS

MONITORING DEVICE STATUS

The VB10 uses two colored LEDs to indicate its working status.

The table below describes the meaning of four LED flashing

patterns and any action to be taken in response.

LED Status Indication Recommended Action

Both LEDs off Battery not Check battery installation

detected or dead or install fresh battery

Green Rec LED Logger is recording To change the flashing interval,

flashes once every enter the Shock software’s Setup

10 seconds (default), menu by selecting System

with Red Alm LED Parameter from the File menu.

off Then adjust the value in the box

labeled LED Twinkle Cycle.

Red Alm LED

flashes once every

30 seconds, with

Green Rec LED off

Both LEDs flash

Data logger memory Download recorded data

alternately once

is full

every 60 seconds

Low battery

(automatically stops

data logging, with no

loss of data)

Install fresh battery

STARTING & STOPPING DATA LOGGING

To start data logging with the VB10 plugged into a USB port

of your computer, press and hold the yellow Logging start/stop

button (Fig. 1, Callout A) until the green Rec LED flashes four

times.

To stop logging with the VB10 plugged in, briefly press the

Logging start/stop button. This will cause the red Alm LED to flash

four times.

11

Page 12

To start data logging with the VB10 operating in standalone

mode (unplugged from your computer), briefly press the

Logging start/stop button. This will cause the green Rec LED to

flash four times.

To stop logging with the VB10 operating in standalone mode,

briefly press the Logging start/stop button. This will cause the red

Alm LED to flash once. The two LEDs will then alternate flashing

until each has flashed four times.

CALIBRATION

To calibrate the VB10, unplug the unit from your computer and

place it on a flat, level surface. Then press and hold the Logging

start/stop button until the green Rec LED flashes four times. The

self-calibration cycle may take a few minutes, and it is complete

when the red Alm LED flashes four times. Do not touch the unit

during calibration, and try not to miss the red Alm LED flashing to

indicate completion of the cycle.

Note: If the battery is removed from the data logger while it is

recording or before it has been configured using the software, the

data logger must be reconfigured before it can be reactivated. If it

is not reconfigured, the data logger will remain in standby mode.

Replacement batteries (Part No. BA10) are available from General.

DOWNLOADING DATA AND USING THE SOFTWARE

For detailed operating instructions, refer to the <Shock Software

V2.1 Instructions.pdf> found on the mini-disc.

Use the following diagram (also printed on

the battery compartment cover) to correlate

x-, y- and z-axis readings with the orientation

of the data logger.

12

Page 13

SPECIFICATIONS

Acceleration Measurement Range: -16g to 16g

Acceleration Accuracy: ±0.5g

Acceleration Resolution: 0.0039g

Frequency Range: 0 to 60Hz

Data Logging Capacity: 327,600 data points in 16MByte flash

memory

User-selectable Sampling Time: 50ms to 24hours

Interface: USB 2.0

Software Compatibility: Windows XP/Vista/WIN7/WIN8

Power Source: 3.6V/1200mA “1/2AA” non-rechargeable Li-ion

battery

Maximum Continuous Logging Time: 60 hours

Operating Temperature : 32° to 113°F (0° to 45°C) @5 to 95%RH,

non-condensing

Storage Temperature: -4° to 140°F (-20° to 60°C) @≤85%RH

(without battery)

Dimensions (including pedestal):

4.45 x 2.13 x 1.28 in. (113 x 54 x 32.5mm)

Weight (without battery): 2.6 oz. (73.5g)

13

Page 14

WARRANTY INFORMATION

General warrants its instruments and accessories, and digital

tools products against defects in material or workmanship for one

year from the date of purchase unless otherwise stated on the

packaging, manual, and/or marketing materials. General also

warrants its non-digital tools products against defects in material

or workmanship on a limited lifetime term.

General will replace or repair the defective unit, at its option,

subject to verification of the defect.

This warranty does not apply to defects resulting from abuse,

neglect, accident, unauthorized repair, alteration, or unreasonable

use of the product. It also does not cover products purchased

from unauthorized distributors. A proof of purchase must

accompany each warranty claim.

Any implied warranties arising from the sale of a General product,

including but not limited to implied warranties of merchantability

and fitness for a particular purpose, are limited to the above.

General shall not be liable for loss of use of the product or other

incidental or consequential damages, expenses, or economic loss,

or for any claim of such damage, expenses, or economic loss.

State laws vary. The above limitations or exclusions may not apply

to you.

For more details or to file a warranty claim, contact General Tools

& Instruments Technical Support at

techsupport@generatools.com.

14

Page 15

RETURN FOR REPAIR POLICY

Every effort has been made to provide you with a reliable product

of superior quality. However, in the event your instrument requires

repair, please contact our Customer Service to obtain an RGA

(Return Goods Authorization) number before forwarding the unit

via prepaid freight to the attention of our Service Center at this

address:

General Tools & Instruments

75 Seaview Drive

Secaucus, NJ 07094

212-431-6100

Remember to include a copy of your proof of purchase, your

return address, and your phone number and/or e-mail address.

15

Page 16

General Tools & Instruments

GeneralToolsNYC

Visit us at www.TestEquipmentDepot.com

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Loading...

Loading...