Page 1

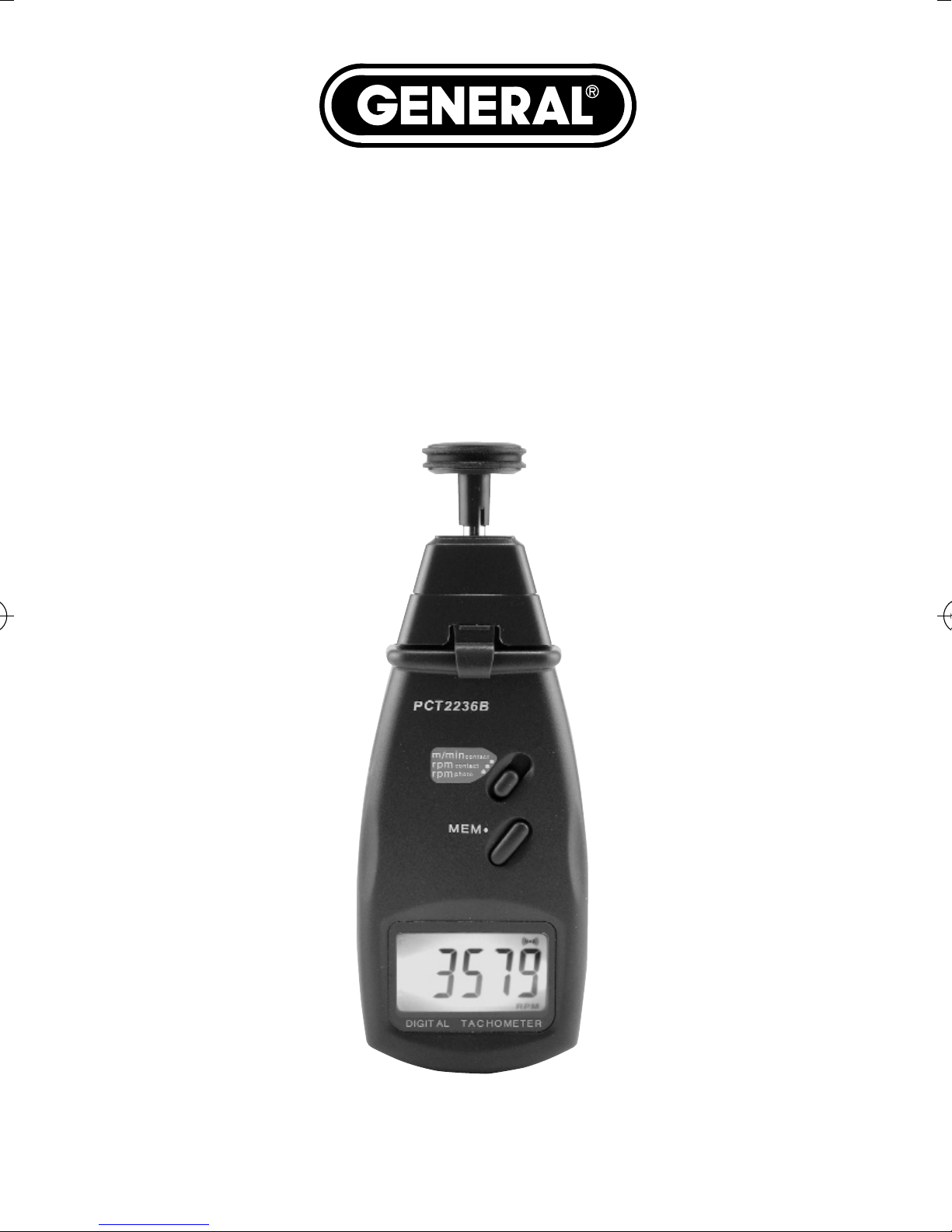

PCT2236B

Please read this manual carefully and thoroughly before using this product.

COMBINATION

CONTACT/

NON CONTACT

LASER TACHOMETER

USER’S MANUAL

Page 2

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Key Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

What’s in the Case. . . . . . . . . . . . . . . . . . . . . . . . . 4 – 5

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Setup Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Install Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operating Instructions . . . . . . . . . . . . . . . . . . . . 7 – 15

Simulate Making, Storing and

Recalling RPM Measurements

in Contact Mode. . . . . . . . . . . . . . . . . . . . . . 7 – 10

Measuring Rotating Speeds

in Contact Mode. . . . . . . . . . . . . . . . . . . . . 11 – 12

Measuring Linear Speeds . . . . . . . . . . . . . . . . . 12

Measuring Surface Dimensions . . . . . . . . 12 – 13

Making RPM Measurements in

Non-Contact Mode. . . . . . . . . . . . . . . . . . . 13 – 15

Storing and Recalling RPM Measurements

in Non-Contact Mode. . . . . . . . . . . . . . . . . . . . . 15

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 16 – 17

Maintenance Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Warranty Information. . . . . . . . . . . . . . . . . . . . . 18 - 19

Return for Repair Policy . . . . . . . . . . . . . . . . . . . . . . 19

2

Page 3

INTRODUCTION

Thank you for purchasing General Tools & Instruments’

PCT2236B Combination Contact/Non-Contact Laser

Tachometer. Please read this user’s manual carefully and

thoroughly before using the instrument.

The PCT2236B is a general-purpose instrument that can

measure the rotational speed of a motor’s or generator’s

spinning shaft using either a contact or non-contact technique.

In non-contact measurement mode, the instrument bounces a

laser beam off a piece of reflective tape that has been affixed to

the shaft and uses an integrated photocell to count the number

of reflections produced per minute. In contact measurement

mode, the instrument uses dedicated fittings that measure the

speed of the shaft by rotating along with it. In contact mode, the

PCT2236B also can measure the linear speed of a moving

surface (such as a conveyor belt or the circumference of a

wheel) and the dimensions of stationary objects.

In both operating modes, measurements are displayed in real

time on a 0.7 in. (18mm) high backlit liquid-crystal display and

stored in memory. Up to 96 measurements of rpm or linear

speed can be stored, indexed and recalled, along with the last

value, the minimum value and the maximum value of a series.

In non-contact mode, the tachometer can measure the speeds

of shafts spinning at up to 99,999 rpm. In contact mode, the

instrument can measure rotational speeds from 0 to 20,000 rpm,

linear speeds from 5cm/min (2 in./min) to 2km/min (6,562

ft./min), and lengths from 5cm to 10km (2 in. to 6.2 miles).

The PCT2236B is powered by four “AA” batteries (included) or

an optional 6V AC/DC adapter.

3

Page 4

KEY FEATURES

• Measures rotational speeds using contact or non-contact

technique

• Autoranging is automatic

• Includes fittings for measuring the speed of a rotating shaft and

the linear speed of a conveyor

• Wide measurement range and high resolution

• Backlit 0.7 in. (18mm) high display supports work in low light

• Stores and indexes up to 96 measurements

• Memorizes the last, minimum and maximum values of a series

of measurements

• Also measures any dimension of a stationary object, in meters

• One-handed operation

• Auto power off function extends battery life

SAFETY INSTRUCTIONS

Spinning shafts and fast-moving conveyor belts can be

dangerous. When using the tachometer, take care not to let your

fingers, hands, hair or clothing make contact with moving parts.

LASER WARNING NOTE!

Do not point laser directly at eye.

Use caution around reflective surfaces.

Keep out of reach of children.

WHAT’S IN THE CASE

The PCT2236B comes fully assembled in a carrying case

along with the following accessories (see Figure 1):

4

•

Page 5

• Three rubber fittings—called

rpm adapters

—for making

contact with the end of a rotating shaft of a motor or

generator. Two have cone-shaped rubber tips that fit into a

hollowed (concave) end of a metal shaft; one (B) has a large

cone compatible with a 1/2 in. diameter shaft, the other (J)

has a smaller cone that fits

into shafts 1/4 in. across. The

third (K) fitting has its own

hollowed end; it is designed

to fit over a 1/4 in. diameter

shaft with a flat or slightly

convex end.

• One rubber/plastic fitting (the

surface speed wheel A) for

making contact with a

surface in linear motion. The

surface speed wheel has a

1/8 in. slot into which moving

wire, cable or rope fits snugly.

• Three 24 in. (6mm) long

strips of 1/2 in. (12mm) wide

adhesive reflective tape

• Three spare Phillips head

screws

• Four “AA” batteries

• This user’s manual

5

Fig. 1

1/2" RUBBER RPM ADAPTER

INSERTED IN BLACK PLASTIC SLEEVE

SURFACE

SPEED

WHEEL

1/4" RUBBER

RPM ADAPTER

RPM ADAPTER WITH HOLLOWED END

FOR 1/4" DIAMETER SHAFTS WITH

FLAT OR CONVEX END

(A)

(B)

(K)

(J)

Page 6

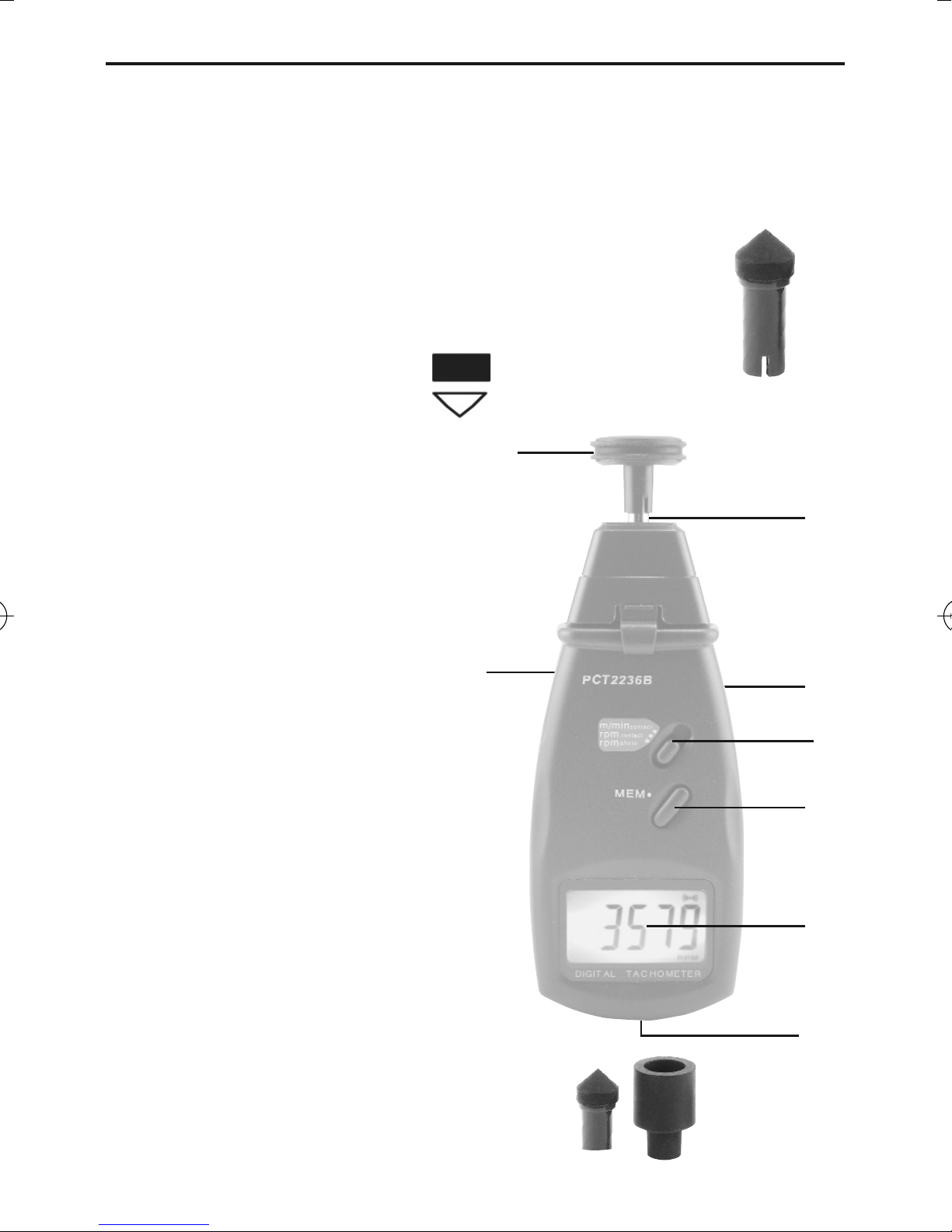

PRODUCT OVERVIEW

Figure 2 shows all of the controls and indicators and other

physical features of the PCT2236B. Familiarize yourself with

their names and locations before continuing.

A. Surface Speed Wheel

B. 1/2" Rubber RPM Adapter

(shown inserted

in plastic sleeve)

C. Tachometer Shaft

D.

Measurement

Button

(on right side)

E. Function Switch, labeled

“

m, m/min, rpm

”

F.

MEM

Button

G. Display Window

H. Battery Compartment Cover

(in back)

I. Jack for 6-V AC/DC Adapter

(on left side)

J. 1/4" Rubber RPM Adapter

K. 1/4" Rubber RPM Adapter

with hollowed end

L. Refelctive Tape (on spinning

motor or generator shaft)

M. Reflected Laser Light

(to internal photosensor)

Fig. 2. The PCT2236B’s

controls and indicators

and other physical features

6

SURFACE

SPEED WHEEL

C

D

E

F

G

H

K

J

I

B

L

M

A

Fig. 2

1/2" RPM ADAPTER

INSERTED IN BLACK

PLASTIC SLEEVE

Page 7

SETUP INSTRUCTIONS

INSTALL BATTERIES

To gain access to the battery compartment, remove the

Phillips head screw securing its cover in the back of the

instrument (callout H of Fig. 2). Slide the cover down and away

from the unit. Then install four “AA” batteries in the correct

orientation, using the polarity marks on the inside of the

compartment as a guide. Don’t forget to install the batteries

over the ribbon, which makes it easier to remove them later.

Replace the battery compartment cover, tucking the end of the

ribbon under it, and secure it with the Phillips head screw.

OPERATING INSTRUCTIONS

SIMULATE MAKING, STORING AND RECALLING RPM

MEASUREMENTS IN CONTACT MODE

Before using the PCT2236B on actual equipment, General

suggests that you familiarize yourself with the way the

instrument measures, stores and recalls speeds by spinning

the tachometer’s shaft by hand. By simulating readings you

can expect to see in practice, you will safely gain expertise

that will save you time later.

To get started, make sure the black plastic sleeve (see

Fig. 1 (B) ) is installed on the tachometer’s shaft (callout C of

Fig. 2), with the slot of the sleeve over the shaft’s metal pin.

Cradle the tachometer in your right hand. Move the function

switch (callout E of Fig. 2) to either the “

m/min

” or “

rpm

”

position. Then press the

Measurement button o

n the right

side of the instrument (callout D of Fig. 2) with your right

7

Page 8

thumb. Note that this illuminates the display window. The

display should show “0”, either with the letters “

rpm

” directly

below it or with the letters “

m/min

” below it to the left,

depending on the position of the function switch.

To simulate a speed measurement

, keep the tachometer

cradled in your right hand and spin its shaft by “flicking” it

with the middle two fingers on your left hand while pressing

the

Measurement button with your right thumb. Note how

the display tracks the force of yo

ur flicks, and also how the

instrument powers off whenever the

Measurement button

if released (this “dead man switch” feature extends batt

ery

life considerably).

To simulate storing measurements

, keep the

Measurement button dep

ressed with your right thumb while

you make three simulated speed measurements, as follows:

• Flick the shaft with your left index finger once. Store the

displayed reading by pressing the

MEM button w

ith your

left thumb.

• Flick the shaft again to make another simulated

measurement. Store this reading by pressing the

MEM

button

aga

in.

• Flick the shaft a third time and store the third reading as

well by pressing the

MEM button.

After simulating and storing three measurements, release

the

Measurement button

and do not press it again until

instructed to.

8

Page 9

To simulate recalling stored measurements

, press the

MEM

button once and hold it. This illuminates the display,

which now shows the highest of the three readings you have

just stored. Note that if you continue

holding the

MEM button,the display

alternates between showing the highest

value and the letters “

UP

”, signifying the

maximum speed.

Also note that releasing the

MEM button

pow

ers off the display and the instrument.

Now press the

MEM button twice and

hold it. This again illuminates the display,

but now it shows the last reading you stored, indicated by and

alternating with the letters “

LA

”.

Finally, press the

MEM button th

ree times and hold it. This

retrieves the slowest of the three speeds you measured and

stored. This value is shown alternating with the letters “

dn

”,

signifying the minimum speed.

To try out other memory-related features,

you can now press the

Measurement

button o

n the right side. Now press the

MEM button

once, twice and three times (holding it in each

time) and note from the display that all three of your stored

measurements have been erased (indicated by “

0.0

” readings

for

UP, dn

and

LA

). You can confirm this by pressing and holding

the

MEM button until

the display begins counting down from

20. When the count reaches 0, the display immediately switches

to showing the letters “

AN

” on the left side and a number (in

this case, “0”) on the right. (The letters “

AN

” are an

abbreviation for the Ancient Greek word for “recall.”)

9

Page 10

To complete this simulation exercise and put your new

expertise to the test, make and store a set of five simulated

measurements by hand-spinning the tachometer’s shaft and

using the

MEM button. Then

, remembering not to press the

Measurement button, press

and hold the

MEM button as

ma

ny times as needed to make the display go into countdown

mode.

Note that because you have stored five measurements, the

display will read “

AN 5

” once the countdown reaches zero. If

you release the

MEM

button and th

en press and hold it again,

the display will first read “1” and then the value of the first of

the five measurements you stored. If you release the

MEM

button

an

d then press and hold it again, the display will then

show “2”, followed by the value of your second measurement.

Release, press and hold again, and the display will show “3”,

followed by the value of your third measurement. By repeating

this sequence, you can retrieve up to 96 measurements in the

order in which they were stored. Once all of the stored

measurements have been displayed, the tachometer will

return to the mode in which pressing the

MEM

button once,

twice or three times calls up the minimum, maxim

um and

last values of the set of measurements you have stored.

With this simulated experience under your belt, you can now

confidently measure the rotational speed of a spinning motor or

generator shaft, or the linear speed of virtually any conveyor

belt.

10

Page 11

MEASURING ROTATING SPEEDS IN CONTACT MODE

To measure the speed of a rotating shaft

, first make sure

that the black plastic sleeve (see Fig. 1 (B) ) is installed on the

tachometer’s shaft (callout C of Fig. 2), with the slot of the

sleeve over the shaft’s metal pin. To measure the speed of a

motor’s or generator’s shaft with a hollowed (concave) end,

determine which of the two supplied cone-tipped rpm

adapters (see Fig. 1) fits more snugly in the hollow. Push the

flat end of that adapter into the end of the plastic sleeve. Then

slide the function switch on the front panel (callout E of Fig.2)

to the “

rpm

” position.

Cradle the tachometer in your right hand. While pressing the

Measurement

button on the right side of the instrument with

your right thumb, gently push the cone-tipped end of the rpm

adapter into the cavity at the end of the spinning motor or

generator shaft whose speed you wish to measure. Take care

to keep the two shafts aligned. When the displayed reading

has stabilized, and while keeping the

Measurement button

depressed with your right thumb, press the

MEM button

on

the front panel with your left thumb to store the measurement.

Make and store as many measurements as you wish, using

the lessons learned during the simulation exercise.

If the end of the shaft whose speed you want to measure is

flat or slightly convex and has a diameter of 0.25 in, locate the

rubber fitting with a 1/4 in. diameter hole at its wider end.

Insert the narrow end of this fitting into the black plastic

sleeve on the instrument’s shaft. Make sure the function

switch is set to “

rpm

”. Then, while cradling the tachometer in

your right hand, carefully push the other end of the fitting

11

Page 12

around the end of the motor or generator shaft. Take care to

line up the shafts of the equipment and the tachometer. Using

the

Measurement

and

MEM buttons

, make and store as

many readings of rotational speed as you wish.

MEASURING LINEAR SPEEDS

To measure the linear speed of a conveyor belt

, remove

the plastic sleeve and any rubber fitting inserted in it from the

tachometer’s metal shaft. Locate the surface speed wheel and

install it on the tachometer’s shaft, sliding the slot in the

wheel’s stem over the tachometer shaft’s metal pin.

Set the function switch to the “

m/min” position

. Then,

cradling the tachometer in your right hand, press the edge of

the surface wheel against the moving object whose linear

speed you wish to measure. Note that the circumference of

the wheel has a 1/8-in.-wide slot into which wire, cable or

rope of that diameter fits snugly.

Taking care to keep the tachometer perpendicular to the

moving conveyor, use the function and

MEM buttons

to make

and store as many measurements of linear speed as you wish.

Linear speed measurements of moving objects obtained by

placing them in contact with the outer diameter of the surface

speed measurements are accurate as displayed. However, to

compensate for the smaller inner diameter of the wheel within

its slot, measurements made by placing wire, cable or rope

within the slot should be multiplied by 0.9.

MEASURING SURFACE DIMENSIONS

The PCT2236B can also serve as a metric ruler. To operate it in

that mode, move the function switch to the “m” position and

12

Page 13

install the surface speed wheel directly onto the instrument’s

metal shaft.

Cradling the tachometer in your right hand and pressing and

holding the

Measurement button

, roll the wheel across

the length, width or depth of the object you wish to measure.

The displayed value represents the dimension measured, in

meters. Measurements made in this mode of operation cannot

be stored, and disappear from the display when the

Measurement button

is released.

MAKING RPM MEASUREMENTS IN

NON-CONTACT MODE

To use the PCT2236B to make non-contact rpm

measurements, you must first remove the black plastic

housing at the top of the instrument that covers the laser light

source and lens.

To prepare to remove the housing, first remove the black

plastic sleeve and any rpm adapter attached to it (callout B of

Fig. 2) from the tachometer’s shaft (callout C). Then remove

the Phillips head screw securing the housing via a flange to

the back of the tachometer. Next, carefully lift both plastic

flanges (front and back) that keep the housing in place. Once

you have unsnapped the housing, pull it up and over the

tachometer’s shaft and place it to one side. Note that when

you now press the

Measurement

button, a red laser light

shines out of the top of the PCT2236B.

13

Page 14

Caution

: The Phillips head screws securing both the housing

and the battery compartment cover are not equipped with

retainers, so they are easy to lose. The PCT2236B includes

three spare screws designed to serve both purposes.

To measure the rotational speed of a motor/generator shaft:

1. Identify the target.

Determine whether there is a larger

surface to measure than the shaft itself. If some thing with a

larger diameter (for example, a fan or a wheel of any type)

is attached to the shaft, use any flat part of its surface as

the measurement target instead.

2. Prepare the target.

Either unplug the generator/motor or

make sure that it cannot be turned on remotely or turn on

automatically. Scrape the target area clean enough so a

piece of tape will stick to it. If the target area is naturally

reflective, cover it with black tape or paint.

3. Attach reflective tape to the target.

Cut a 1/2 in. square

piece of reflective tape, remove its backing, and apply it to

the target area.

4. Make the measurement.

Turn on the motor or generator.

Cradling the tachometer in your right hand, move it as close

to the shaft as possible, but no closer than 2 inches away.

Position the instrument so its main axis is aligned with the

end of the shaft. Using your right thumb, press the Measure

button (callout 1-4) while shining the red laser beam on the

reflective tape. Confirm that the tachometer is receiving a

signal by checking that the (( )) Monitor Indicator icon flashes

on the display each time the beam hits the moving tape.

When the display reading stabilizes, release the Measure

button.

14

Page 15

STORING AND RECALLING RPM

MEASUREMENTS IN NON-CONTACT MODE

To store and recall non-contact rpm measurements, use the

same procedures for contact rpm measurements that you

simulated beginning on p. 8.

As in contact measurement mode, in non-contact mode

individual measurements or series of measurements can only

be stored while the

Measurement

button is pressed and held.

When the

Measurement

button is released, the contents of

the instrument’s memory are frozen. When the

Measurement

button is pressed again, the memory’s contents are erased.

15

TWO MEASUREMENT TIPS

1. If your motor/generator’s shaft spins slowly

(i.e., at

less than 50 rpm), getting an accurate reading may

require placing one or more additional squares of

reflective tape on the target. Begin by adding a second

square of tape on the circumference of the target 180º

from the first square (at 6 o’clock relative to 12

o’clock). Then perform Step 4 above, but divide the

display reading by two to account for the presence of

the second square. If the result is still unsatisfactory,

add another two pieces of tape at 3 o’clock and 9

o’clock and perform Step 4, but now divide the display

reading by four.

2. If bright ambient light is preventing the PCT2236B

from receiving the reflected beam, try shading the target.

Page 16

SPECIFICATIONS

Parameter Specification— Specification—

Contact Mode Non-contact mode

Rotational Speed 0 to 20,000 rpm/±0.05% 2.5 to 99,999 rpm/±0.05% of

Measurement Range/Accuracy of reading plus one digit reading plus one digit

Rotational Speed 0.1 rpm for readings below 999.9 rpm; 1 rpm for readings above

Measurement Resolution 1,000 rpm

Linear Speed 5cm/min (2 in./min) N/A

Measurement Range to 2km/min (6,562 ft./min)

Length Measurement Range 5cm to 10km (2 in. to 6.2 miles) N/A

Detection Distance N/A 5 to 50cm (2 to 20 in.)

Sampling Time 0.8 seconds at speeds over 60 rpm

Memory Capacity 96 measurements

Recallable Measurements Maximum, minimum, last values

Page 17

17

SPECIFICATIONS (continued)

Parameter Specification

Microcontroller Single custom chip

Time Base Quartz crystal

Display Type 5-digit yellow-green backlit liquid crystal

Display Height 0.7 in. (18mm)

Dimensions 8.27 x 2.91 x 1.18 in. (210 x 74 x 30mm)

Weight 7.76 oz. (220g), including batteries

Power Source Four “AA” batteries

Current Consumption 65mADC

Operating Temperature Range 32º to 122ºF (0º to 50ºC) @ up to 80% relative humidity

Page 18

MAINTENANCE TIPS

The PCT2236B requires no regular maintenance other than

light cleaning of the housing and display with a soft, dry cloth.

When the text “

LO

” appears on the display, it’s time to change

the PCT2236B’s four “AA” batteries because their total

potential has fallen below 4.5 volts. To do so, follow the Setup

Instructions on p. 7.

Remove the batteries whenever the instrument is expected to

sit idle for an extended period of time (six months or more).

WARRANTY INFORMATION

General Tools & Instruments’ (General’s) PCT2236B

Combination Contact/ Non-Contact Laser Tachometer is

warranted to the original purchaser to be free from defects in

material and workmanship for a period of one year. Subject to

certain restrictions, General will repair or replace this

instrument if, after examination, the company determines it to

be defective in material or workmanship.

This warranty does not apply to damages that General

determines to be from an attempted repair by non-authorized

personnel or misuse, alterations, normal wear and tear, or

accidental damage. The defective unit must be returned to

General Tools & Instruments or to a General-authorized service

center, freight prepaid and insured.

Acceptance of the exclusive repair and replacement remedies

described herein is a condition of the contract for purchase of

this product. In no event shall General be liable for any

incidental, special, consequential or punitive damages,

18

Page 19

or for any cost, attorneys’ fees, expenses, or losses alleged to

be a consequence of any damage due to failure of, or defect in

this product including, but not limited to, any claims for loss of

profits.

RETURN FOR REPAIR POLICY

Every effort has been made to provide you with a reliable

product of superior quality. However, in the event your

instrument requires repair, please contact our Customer

Service to obtain an RGA (Return Goods Authorization) number

before forwarding the unit via prepaid freight to the attention

of our Service Center at this address:

General Tools & Instruments

80 White Street

New York, NY 10013

212-431-6100

Remember to include a copy of your proof of purchase, your

return address, and your phone number and/or e-mail

address.

19

Page 20

GENERAL TOOLS & INSTRUMENTS

80 White Street

New York, NY 10013-3567

PHONE (212) 431-6100

FAX (212) 431-6499

TOLL FREE (800) 697-8665

e-mail: sales@generaltools.com

www.generaltools.com

PCT2236B User’s Manual

Specifications subject to change without notice

©2011 GENERAL TOOLS & INSTRUMENTS

NOTICE - WE ARE NOT RESPONSIBLE

FOR TYPOGRAPHICAL ERRORS.

MAN#PCT2236B 3/22/11

Loading...

Loading...