Page 1

SPLIT TYPE

AIR CONDITIONER

CASSETTE

Models

Indoor unit Outdoor unit

AUH30LUAS

AUH36LUAS

AOH30LMBWL

AOH36LMBWL

type

(50Hz)

CONTENTS

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

REFRIGERANT SYSTEM DIAGRAM . . . . . . . . . . . . . 4

CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . 7OUTDOOR PCB CIRCUIT DIAGRAM

ERROR CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . .

DISASSEMBLY ILLUSTRATION . . . . . . . . . . . . . . . . . 12

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

STANDARD ACCESSORIES . . . . . . . . . . . . . . . . . . . 22

10

6INDOOR PCB CIRCUIT DIAGRAM . . . . . . . . . . . . . .

Page 2

SPECIFICATIONS

TYPE

INDOOR UNIT

OUTDOOR UNIT

COOLING CAPACITY

HEATING CAPACITY

ELECTRICAL DATA

POWER SOURCE

RUNNING CURRENT

INPUT WATTS

E.E.R.

STARTING CURRENT

MOISTURE REMOVAL

AIRCIRCULATION-Hi

(kW/kW)

COMPRESSOR

TYPE

COOLING

HEATING

COOLING

HEATING

COOLING

HEATING

( /hr)

(m3/hr)

COOLING & HEATING

AUH30LUAS AUH36LUAS

AOH30LMBWL AOH36LMBWL

8.5 kW 10.0 kW

10.0 kW 11.2 kW

230V 50Hz

12.5 A 17.6 A

12.4 A 15.2 A

2.86 kW

2.84 kW 3.49 kW

2.97

3.52

15 A

3.0

Total enclosed type, 4 poles,

Inverter, Twin Rotary

4.01 kW

2.49

3.21

15 A

4.0

1,550

TYPE

INDOOR UNIT

OUTDOOR UNIT

NOISE LEVEL

HI-SPEED

INDOOR UNIT MED-SPEED

LO-SPEED

OUTDOOR UNIT

Note : Static pressure : 30Pa

Duct length : Inlet 1m, Outlet 2m

COOL

HEAT

REFRIGERANT CHARGE (R410A)

MAX PIPE LENGTH

MAX PIPE HEIGHT

PIPE LENGTH 15 m

20 m

FULL CHARGE

AMOUNT

ADDITIONAL REFRIGERANT

30 m

40 m

50 m

COOLING & HEATING

AUH30LUAS AUH36LUAS

AOH30LMBWL AOH36LMBWL

48.0 dB

44.0 dB

41.0 dB

53.0 dB

55.0 dB

2,200 g

2,400 g

2,800 g

3,200 g

3,600 g

40 g / m

54.0 dB

55.0 dB

50 m

30 m

DISCRIMINATION

REFRIGERANT R410A

FAN MOTOR

DISCRIMINATION

HI-SPEED

INDOOR UNIT

OUTDOOR UNIT

MED-SPEED

LO-SPEED

S-LO-SPEED

DISCRIMINATION

COOL

HEAT

DIMENSIONS

INDOOR UNIT H x W x D

H x W x DOUTDOOR UNIT

WEIGHT

INDOOR UNIT GROSS / NET

GROSS / NETOUTDOOR UNIT

TNB220FPBM9

2,200 g

MFA-54PZM

600 r.p.m.

490 r.p.m.

420 r.p.m.

300 r.p.m.

MFE-60PO

850 r.p.m.

900 r.p.m.

296 x 830 x 830 mm

830 x 900 x 330 mm

52 / 37 kg

70 / 64 kg

2005.12.12 1

Page 3

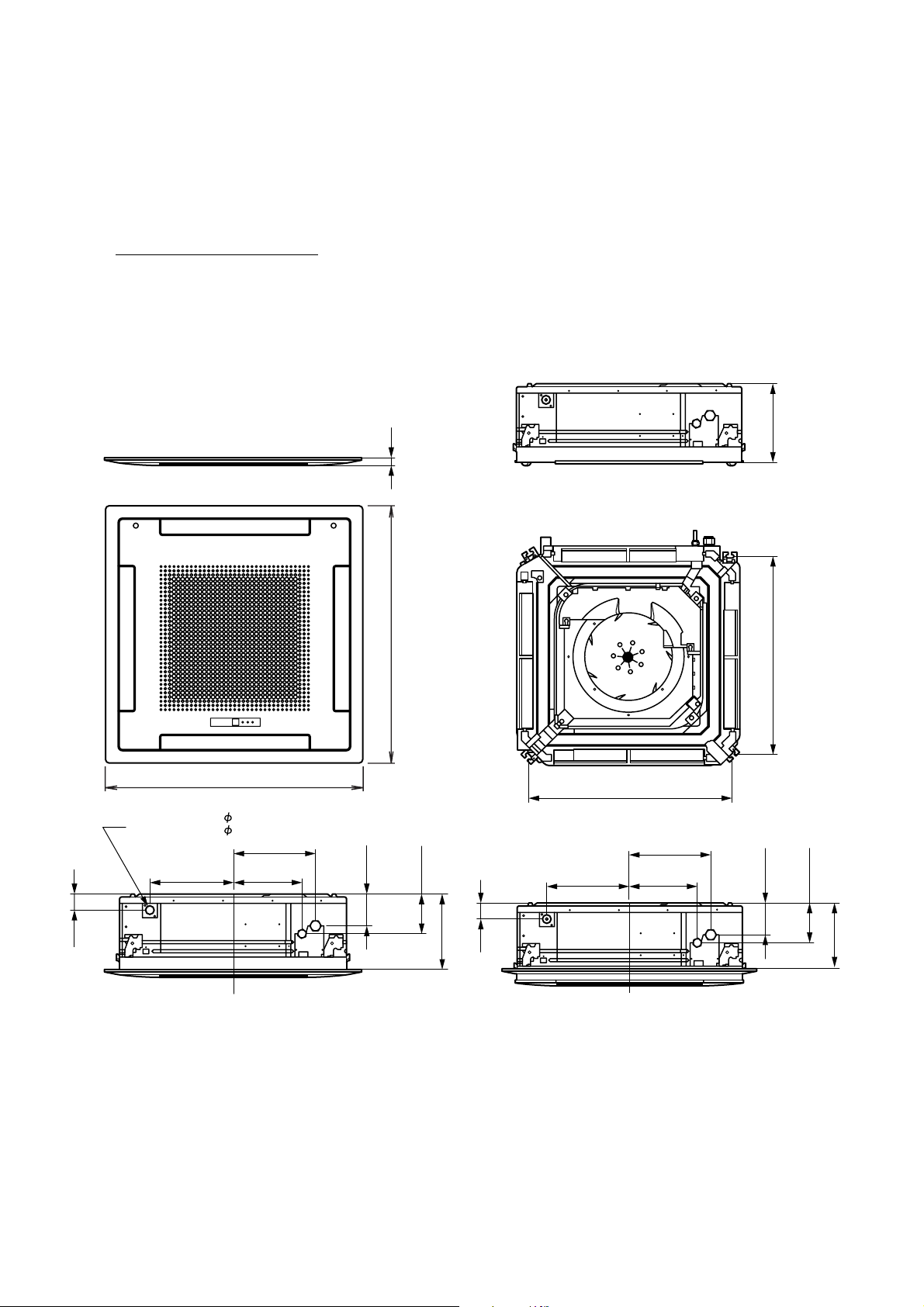

DIMENSIONS

(Unit : mm)

INDOOR UNIT

Models : AUH30LUAS

AUH36LUAS

940

Drain Inside Dia. 32

Outside Dia. 37

305.5 248.5

298.5

30

940

750

298.5

120

(Small pipe)

(Large pipe)

150

305.5 248.5

296

750

120

150

(Large pipe)

(Small pipe)

60

(Drain pipe)

285

2005.12.12 2

60

(Drain pipe)

250

Page 4

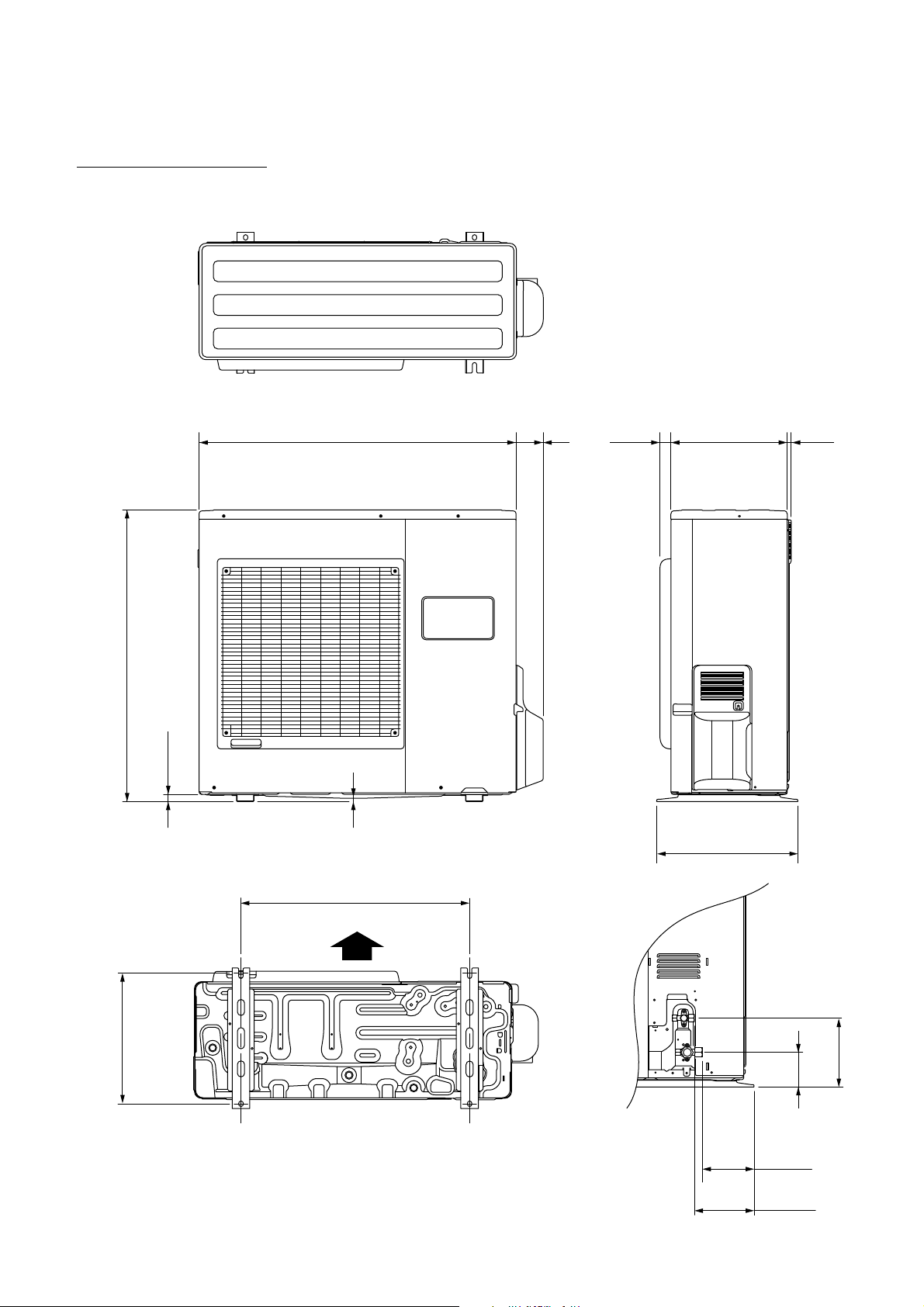

OUTDOOR UNIT

Models : AOH30LMBWL

AOH36LMBWL

(Unit : mm)

77900

33031 12

830

21

9

400

650

Air Flow

370

2005.12.12 3

196

99

147

170

Page 5

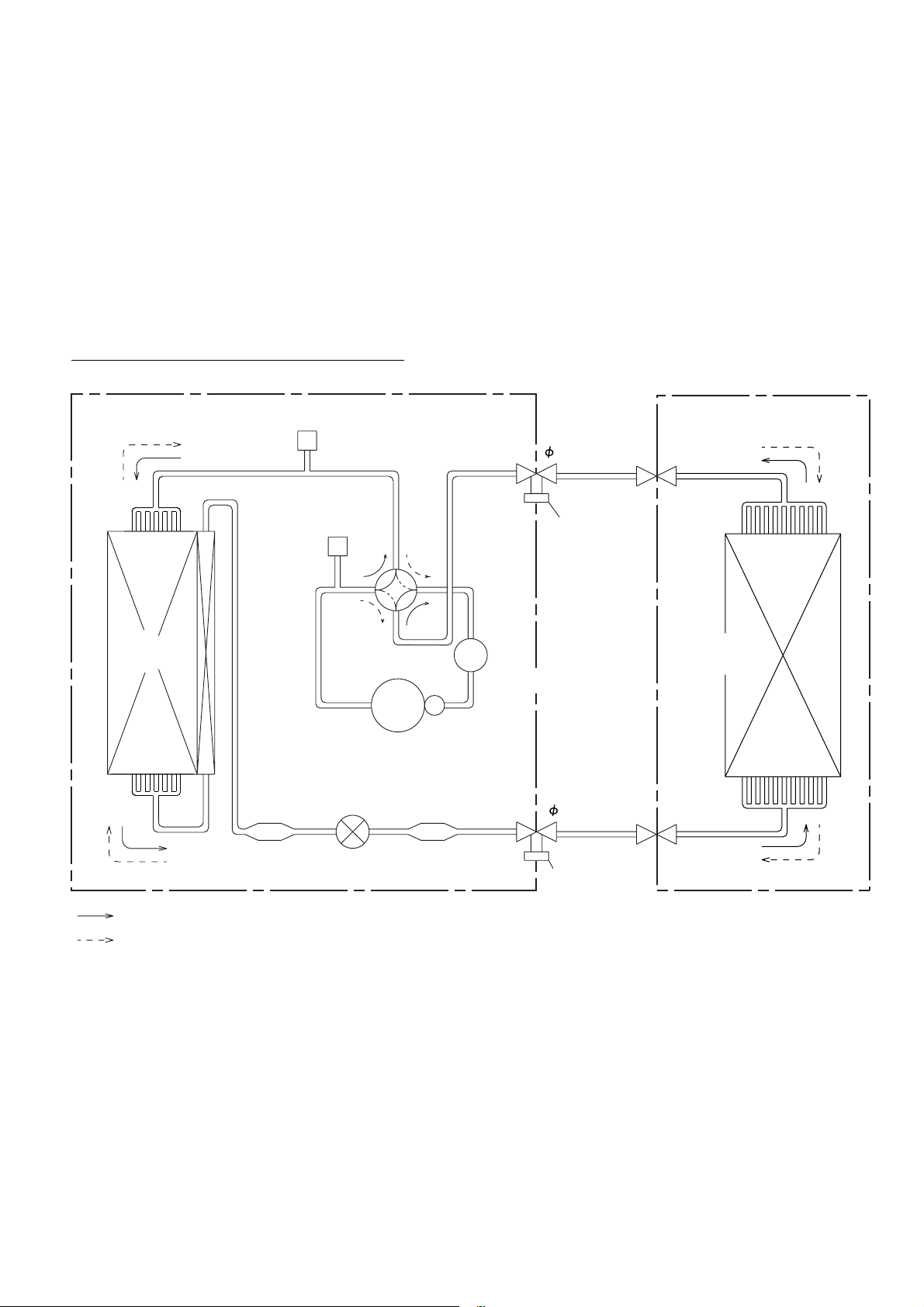

REFRIGERANT SYSTEM DIAGRAM

Models :

AUH30LUAS / AOH30LMBWL

AUH36LUAS / AOH36LMBWL

OUTDOOR UNIT

Condenser

Pressure

Check Valve

High Pressure

Switch

4-way

Valve

INDOOR UNIT

Refrigerant Pipe

15.88mm (5/8")

Charging

Valve

Evaporator

Accumulator

Compressor

: COOL

: HEAT

Strainer

Expansion

Valve

Refrigerant Pipe

9.52mm (3/8")

Strainer

Charging Valve

2005.12.12 4

Page 6

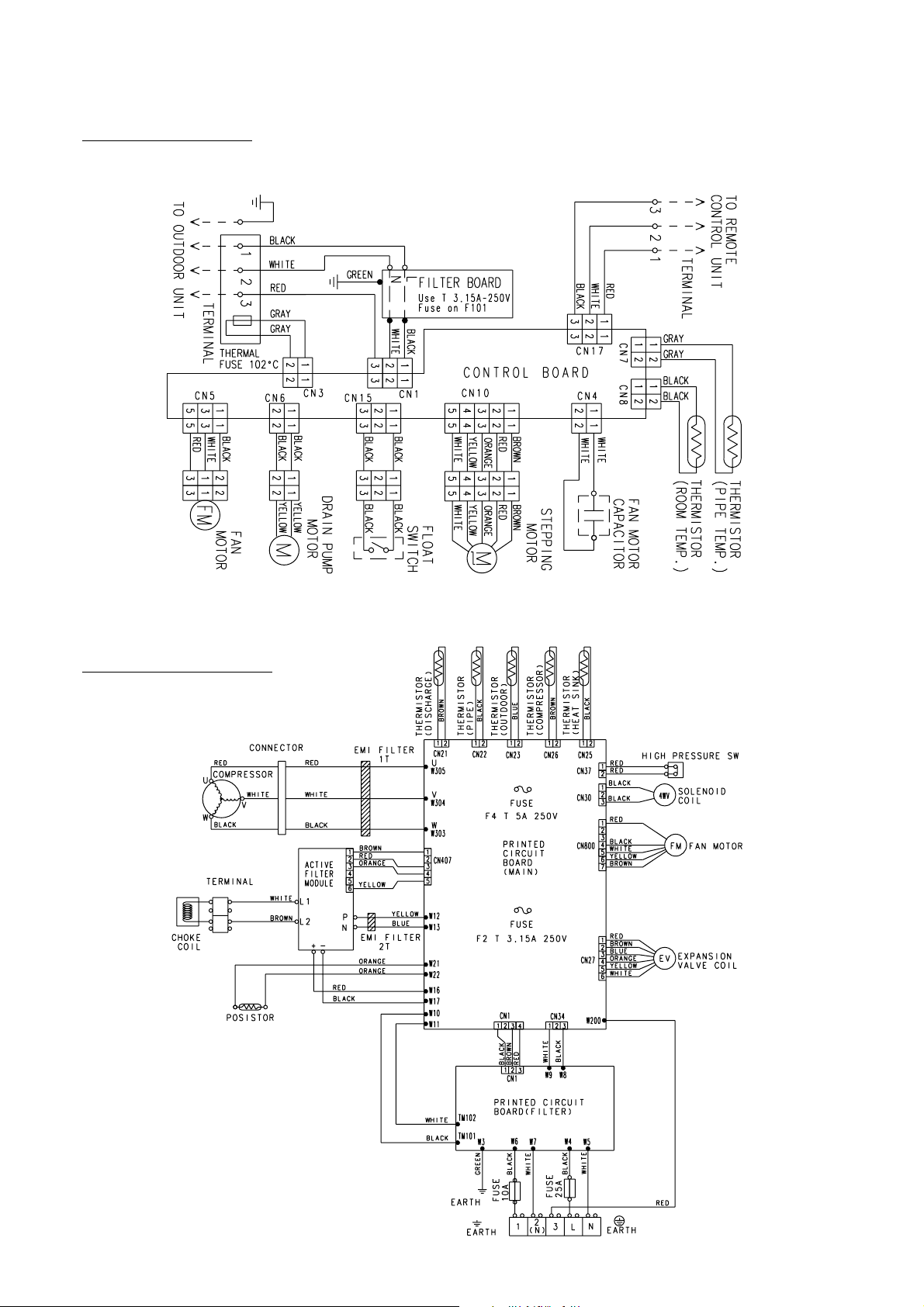

CIRCUIT DIAGRAM

Models : AUH30LUAS

AUH36LUAS

Models : AOH30LMBWL

AOH36LMBWL

2005.12.12 5

Page 7

INDOOR PCB CIRCUIT DIAGRAM

CONTROLLER PCB ASSEMBLY ( MAIN PCB )

Models : AUH30LUAS

AUH36LUAS

THERMAL FUSE

GRAY

UL1015 AWG18 BLACK

UL1015 AWG18 WHITE

OUTDOOR UNIT

GRAY

CN3-2

CN3-1

CN3

53406-9910

TM101

TM102

UL1015

AWG16

GREEN

FAN CAPACITOR

8uF 400VAC

UL1015 AWG18 RED

TERMINAL BOARD

1

2

3

POWER SOURCE

230V

50Hz

R1 3.3

<RC - 5W>

F101

L

3.15A

<BET>

FH102

FH101

N

SA101

RA-362M

E101 W103 W104

F M

FAN MOTOR

E

D1

D3SB60

C5

+

100/

450V

VA102

470V

<TNR>

VA101 470V

<TNR>

UL1015

AWG18

UL1015 AWG18 WHITE

UL1015 AWG18 RED

UL1015 AWG20

WHITE

UL1015 AWG20

WHITE

UL1015 AWG20

BLACK

UL1015 AWG20

WHITE

UL1015 AWG20

RED

BLACK

DRAIN PUMP

M

YELLOW

YELLOW

R4 330K

<SPRH - 2W>

Q1

2SC4236

R3 100

<1/10W>

R2 1.5

<RS - 2W>

ELF20N018A

C102

0.22

<LE>

LF101

CN1

B3P5-VH-B-C

BLACK

CN4

B2P3-VH-B-Y

YELLOW

Q2

2SC1815

CN1-1

CN1-2

CN1-3

CN4-1

CN4-2

CN5-1

CN5-2

CN5-3

CN5

B3P5-VH-B

UL1015 AWG22

BLACK

UL1015 AWG22

BLACK

C6

4700P

<ECQM>

C7 0.047

<ECQB>

D2

D1FL20U

D3

MTZJ5.1B

R7 330

<1/4W>

C103

0.01

<KH>

C104

0.01

<KH>

JM5

R5 62K

<RS - 2W>

D5

1SR139-600

D10

1SR139-600

+

C105

0.022

C101

<YE>

0.22

C106

<LE>

0.022

<YE>

JM8

CN6-2

CN6-1

CN6

B2P3-VH-B-E

BLUE

SW1

DSS803

NO.1

NO.2

NO.3

R6 100

<1/2W>

D4

D1FL20U

C8

100/

6.3V

C3 0.22 <RE>

R88 120

<RS - 1/2W>

SWITCHING TRANSFORMER

ZFT29B01

PRIMARY

K4

G5NB-1A

DC12V

CN9 B5P-SHF-1AA

CN9-1

CN9-2

TEST

AUTO RESTART

ROOM TEMPERATURE CORRECTION

( HEATING OPERATION )

ROOM TEMPERATURE CORRECTION

( HEATING OPERATION )

CN9-3

CN9-4

CN9-5

R15 - R17

10K <1/10W> x 3

CUSTOM CODE CHANGER

CUSTOM CODE CHANGER

CUSTOM CODE CHANGER

T1

D6

D2FL20U

SECONDARY

C54

0.01

<F>

VA1 470V

<TNR>

14

10

5V

R93 R94 R95 R96

SSR1

G3MC-202PL-VD

5V

R39

R38 R37

JM1

JM2

JM3

14V

C9

+

1000

/25V

R8 10K

<1/10W>

R29 - R32

10K <1/10W> x 4

C

SW2

DRS4016-5

I C10 H I 2002

10K <1/10W> x 4

+

-

VA2 470V

<TNR>

5V

10K <1/10W> x 3

I C11-1

BA10358

1

5V

R18 - R20

1.0K <1/10W> x 3

I C2

12V

7812

O

I

G

C11

+

10/

25V

I C3

7805

I

8

4

2

1

5V

O

G

C13

0.1

<F>

R35 1.0K <1/10W>

R36 1.0K <1/10W>

5V

1

4

C17

0.01

<F>

14V

NC

NC

NC

K 4

R21 - R24

10K <1/10W> x 4

R25 - R28

1.0K <1/10W> x 4

R42 1.0K <1/10W>

R41 1.0K <1/10W>

R40 1.0K <1/10W>

3

+

2

-

C21

0.01 <F> x 3

10K <1/10W> x 4

C14

100/

6.3V

R97

R98

C15

+

0.1

<F>

R59

5V

NC

R33 1.0K <1/10W>

R34 1.0K <1/10W>

C29

C28 C27 C26

0.01 <F> x 4

10

7

I C5 (1/7)

uPA2003GR

R14 10K

5

<1/10W>

2

5V

R10

10K

<1/10W>

14V

11 6

12

13 4

14 3

15 2

Q3

DTC124EKA

9

5

8

I C5 (5/7)

uPA2003GR

C22 - C25

0.01 <F> x 4

C30

R9 390

<1/10W>

0.01 <F> x 3C10 C12

R99

C47

0.1

<F>

CR1

0.01

<F>

C19C20

JM10

CR6

0.01

<F>

1

2

3

54

55

66

65

74

68

75

7

4

67

33

71

72

56

57

58

59

41

42

63

40

39

38

37

36

43

44

45

46

19

20

21

2005.12.12 6

I C 1

P15

P16

P17

uPD780058BGC

-131-8BT-A

P122

P123

P05

P04

VDD0

VDD1

AVRF0

AVRF1

AVSS

VSS0

VSS1

I C

XT2

P124

P125

P126

P127

P65

P66

P02

P64

P63

P62

P61

P62

P67

P30

P31

P32

P40

P41

P42

70

1

2

P10

P11

P70

P71

P72

P131

P46

P24

P23

P47

P57

P56

P50

P27

P26

P25

P22

P21

P20

P130

P00

P121

P36

P33

P01

P55

P120

P37

P35

P34

P03

P12

P13

P14

P52

P53

P54

P45

P44

P43

XT1

P51

RESET

X2X1

69

3

X1

CSTS0500MG03-T

AUH30LUAS : K01AL-0500HSE-C1

AUH36LUAS : K01AL-0501HSE-C1

76

C32

1000P

<R>

77

C35

1000P

<R>

8

9

10

6

25

15

14

26

R100 10K <1/10W>

35

34

27

18

17

16

13

12

11

5

61

10

53

7

11

6

50

16

1

47

5V

C41

+

10/

25V

62

CR5

1000P

<R>

32

52

51

49

48

64

78

79

80

29

NC

CR2 CR3 CR4

30

NC

31

NC

10K <1/10W> x 3

24

23

22

C31

0.01

<F>

73

28

NC

R55

10K

<1/10W>

60

C44

0.1

<F>

R58 10K <1/10W>

R75 10K <1/10W>

R76 10K <1/10W>

R44 1.0K

<1/10W>

R46 1.0K

<1/10W>

R50 10K <1/10W>

4

3

2

1

I C7 BR93L46RF

R77 - R79

10K <1/10W> x 3

1 16

7 10

5 12

14V

9

13

4

3

2

15

1

I C4 (7/7)

uPA2003GR

R57 1.0K

<1/10W>

R56

I C6 (3/7)

uPA2003GR

B Z

C42 0.01

<F>

R54 47

<1/10W>

5

4

3

2

R81 1.0K <1/10W>

R72 1.0K <1/10W>

R71 1.0K <1/10W>

C16

C43

0.01

0.01

<F>

<F>

RJ1 1.0K

<1/10W>

C49

5V

0.01

<F>

I C8

PST600C

DO

VCC

D I

NC

CK

NC

GND

CS

I C5 (1/7) uPA2003GR

116

14

16

8

14V

BZ1

PKM13EPY-4000

R53 10K

<1/10W>

12

13

I C6 (4/7)

14

uPA2003GR

15

CR7

0.01

<F>

R70 R69 R80

5V

RJ2

10K

<1/10W>

5V

1

3

2

5V

8

7

C39

0.1

6

<F>

5

5V

NC

NC

5V

NC

R60

NC

10K

<1/10W>

Q5

2SC2712

5V

C40

0.01

<F>

R67 1.0K

<1/10W>

5V

NO3 FAN DELAY CHANGER

(HEATING OPERATION)

NO2 FAN CHANGER

NO1 REMOTE CONTROL

FUNCTION REVERSED

CN15-1

CN15-2

CN15-3

CN15 B3B-XARK-1-A RED

C45

0.1

<F>

R43 10K

<1/10W>

(1%)

R45 49.9K

<1/10W>

(1%)

14V

CN10-1

CN10-2

CN10-3

CN10-4

CN10-5

R61 10K

<1/10W>

3

1

Q6

2

2SC2712

R51 1.0K

<1/10W>

10K <1/10W>

x 3

SW4

DSS803

UL1430 AWG22

UL1430 AWG22

C34

0.1

<F>

C37

0.1

<F>

Q4

DTC124EKA

R49 1.0K

<1/10W>

C38

0.01

<F>

UL1430 AWG28

CN10

B5B-XASK-1-A

5V

R63 15.4K

<1/10W>

(1%)

3

2

5V

R52

10K

<1/10W>

R68 10K

<1/10W>

C1 0.1

<F>

NO.3

NO.2

NO.1

BLACK

BLACK

CN14

B4B-XH-AM

R47 390

5V

<1/10W>

5V

R48

10K

<1/10W>

BROWN BROWN

RED RED

ORANGE ORANGE

YELLOW YELLOW

WHITE WHITE

R64 28K

<1/10W>

(1%)

12V

1

R65 390

<1/10W>

R62 4.7K

<1/10W>

I C11-2

BA10358

12V

7

D7

DA226U

+

-

5V

FLOAT SWITCH

BLACK

BLACK

5

6

CN14-4

CN14-3

CN14-2

CN14-1

12V

HA

JEM-A

12V

L2 0.022

<DSS306>

R66 10K

<1/10W>

5V

CN8

CN7

L4 0.022

<DSS306>

B2B-XASK-1-A

CN8-1 BLACK

CN8-2 BLACK

CN7-1 GRAY

CN7-2 GRAY

B2B-XAKK-1-A BLACK

M

CN17 B3B-XAKK-1-A BLACK

CN17-1

CN17-2

CN17-3

L3 0.022

<DSS306>

LOUVER

( UP / DOWN )

UL1430 AWG22 RED

UL1430 AWG22 WHITE

UL1430 AWG22 BLACK

ROOM TEMPERATURE THERMISTOR

PIPE TEMPERATURE THERMISTOR

TERMINAL BOARD

3 2

1

REMOTE CONTROL UNIT

Page 8

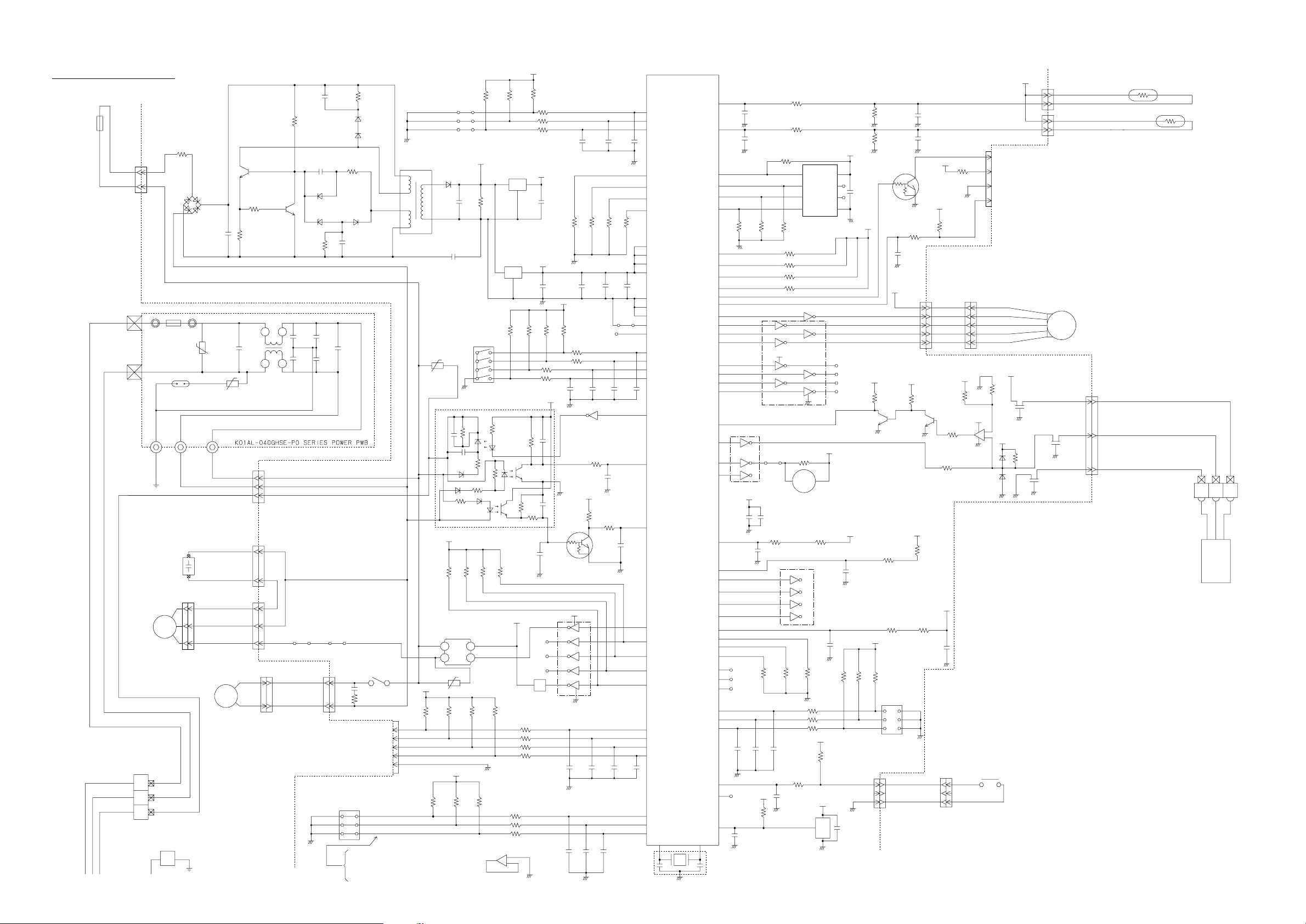

OUTDOOR PCB CIRCUIT DIAGRAM

Models : AOH30LMBWL

AOH36LMBWL

AC230V

50Hz

INDOOR UNIT-A

INDOOR UNIT-B

INDOOR UNIT-C

INDOOR UNIT-D

UL1015

AWG14

BLACK

UL1015

L

AWG14

WHITE

N

UL1015

AWG20

BLACK

L

N

UL1015

AWG20

BLACK

UL1015

AWG20

WHITE

TLC 25A-250V, B

<250V 25A>

FSL 250 10 (EM)

<250V 10A>

3

EMI FILTER

UL1015

L

N

3

L

N

3

L

N

3

AWG20

BLACK

UL1015

AWG20

WHITE

UL1015

AWG20

BLACK

UL1015

AWG20

PINK

UL1015

AWG20

BROWN

ZCAT1518

-0730

1 TURN

UL1015

AWG20

YELLOW

UL1015

AWG20

WHITE

UL1015

AWG14

F201

BLACK

F202

UL1015

AWG20

RED

UL1015

AWG20

WHITE

EMI FILTER

ZCAT1518-0730

1 TURN

UL1015

AWG20

BLACK

UL1015

AWG16

GREEN

B

W4

B

W6

W5

W7

W3

B

B

B

POWER SUPPLY PCB

K04BA-0401HUE-P0

E

03 VH / S I N

1015 L250

CN1

B3B-XASK-1-A

WHITE

CT OUT

TM101

TM102

W9

W8

UL1015 AWG14 BLACK

UL1015 AWG14 WHITE

B

UL1015 AWG20 WHITE

B

UL1015 AWG20 BLACK

2

3

EMI FILTER

TFC25-15-12

2 TURN

UL1007 AWG24 BLACK1

UL1007 AWG24 BROWN

UL1007 AWG24 RED

INVERTER ASSEMBLY

AOH30LMBWL : EZ-00500HUE

AOH36LMBWL : EZ-00501HUE

W10

B

W11

B

CN34

B2P3-VH-B-Y

YELLOW

1

AC I N

3

CN1

03 XA / 172520 1007 L180

WHITE

1

CT

3

4

W16

W17

B

B

UL1015

AWG14

RED

UL1015

AWG14

BLACK

UL1015

AWG14

WHITE

L1 L2

ACTPM

I C404

SACT32010A

-

CHOKE COIL

L=0.3mH 30A

UL1015

AWG14

BROWN

P+

N1

N2

I O

1

2

3

4

5

6

UL1015 AWG14 YELLOW

UL1015 AWG14 BLUE

EMI FILTER

TFC25-15-12

2 TURN

UL1007 AWG24 BROWN

UL1007 AWG24 RED

UL1007 AWG24 ORANGE

UL1007 AWG24

YELLOW

W12

B

W13

B

CN407

06 PH / 172520 1007 L480

1

WHITE

3

4

5

ACTPM CONTROL

W305

W304

W303

B

B

B

RED

WHITE

BLACK

UL1015 AWG14 x 3

2

3

1 1

2

3

RED

WHITE

BLACK

C. M.

COMPRESSOR

DC FAN MOTOR

EXPANSION VALVE-A

EXPANSION VALVE-B

EXPANSION VALVE-C

EXPANSION VALVE-D

PRESURE SWITCH-1

PRESURE SWITCH-2

COMP. TEMPERATURE

HEAT SINK TEMPERATURE

DISCHARGE TEMPERATURE

PIPE TEMPERATURE

OUTDOOR TEMPERATURE

2-WAY VALVE-A TEMP.

3-WAY VALVE-A TEMP.

2-WAY VALVE-B TEMP.

3-WAY VALVE-B TEMP.

2-WAY VALVE-C TEMP.

3-WAY VALVE-C TEMP.

2-WAY VALVE-D TEMP.

3-WAY VALVE-D TEMP.

M

M

M

4-WAY VALVE

F. M.

M

RED

BROWN

BLUE

ORANGE

YELLOW

WHITE

RED

BROWN

BLUE

ORANGE

YELLOW

WHITE

RED

BROWN

BLUE

ORANGE

YELLOW

WHITE

RED

YELLOW

BLUE

BLACK

GRAY

BROWN

ORANGE

GREEN

BLACK

WHITE

WHITE

WHITE

WHITE

WHITE

BLACK

GREEN

GREEN

GREEN

GREEN

GREEN

BLACK

BLUE

BLUE

BLUE

BLUE

BLUE

BLACK

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

BLACK

RED

RED

RED

RED

RED

RED

RED

RED

BLACK

WHITE

YELLOW

BROWN

RED

BROWN

BLUE

ORANGE

YELLOW

WHITE

BLACK

BLACK

RED

RED

RED

RED

BROWN

BROWN

BLACK

BLACK

BROWN

BROWN

BLACK

BLACK

BLUE

BLUE

B

W200

SERIAL-A

B

W201

SERIAL-B

B

SERIAL-C

W202

B

W203

SERIAL-D

1

CN800

2

3

B7B-XASK-1-A

4

WHITE

5

6

7

1

CN27

2

3

B6B-XARK-1-A

4

RED

5

6

1

CN50

2

06 XA / 172520 1007

4

WHITE

5

6

7

1

CN51

3

06 XA / 172520 1007

4

GREEN

5

6

7

1

CN52

2

06 XA / 172520 1007

BLUE

5

6

7

8

1

CN30

3

179844-1 WHITE

1

CN37

2

B2B-XARK-1-A RED

1

CN36

2

B2B-XASK-1-A WHITE

1

CN26

2

B2B-XAMK-1-A GREEN

CN25

1

2

B2B-XAKK-1-A BLACK

1

CN21

2

B2B-XH-AM YELLOW

1

CN22

2

B2B-XH-AM RED

CN23

1

2

B2B-XAEK-1-A BLUE

1

CN39

3

08 XA / 172520 1007

4

WHITE

5

6

7

8

9

1

CN40

2

08 XA / 172520 1007

4

RED

5

6

7

8

9

CONTROLLER PCB ASSEMBLY

AOH30LMBWL : K04AW-0509HUE-C1

AOH36LMBWL : K04AW-050AHUE-C1

SUB-FLASH

MAIN-FLASH

CN602

B10B-PASK-1

WHITE

CN601

B10B-PASK-1

WHITE

1

5V

2

GND

3

TAUX

4

TTXD

5

TRXD

6

TMODE

7

TAUX3

8

TCK

/ TRES

9

10

/ T I CS

1

5V

2

GND

3

TAUX

4

TTXD

5

TRXD

6

TMODE

7

TAUX3

8

TCK

/ TRES

9

10

/ T I CS

2005.12.12 7

Page 9

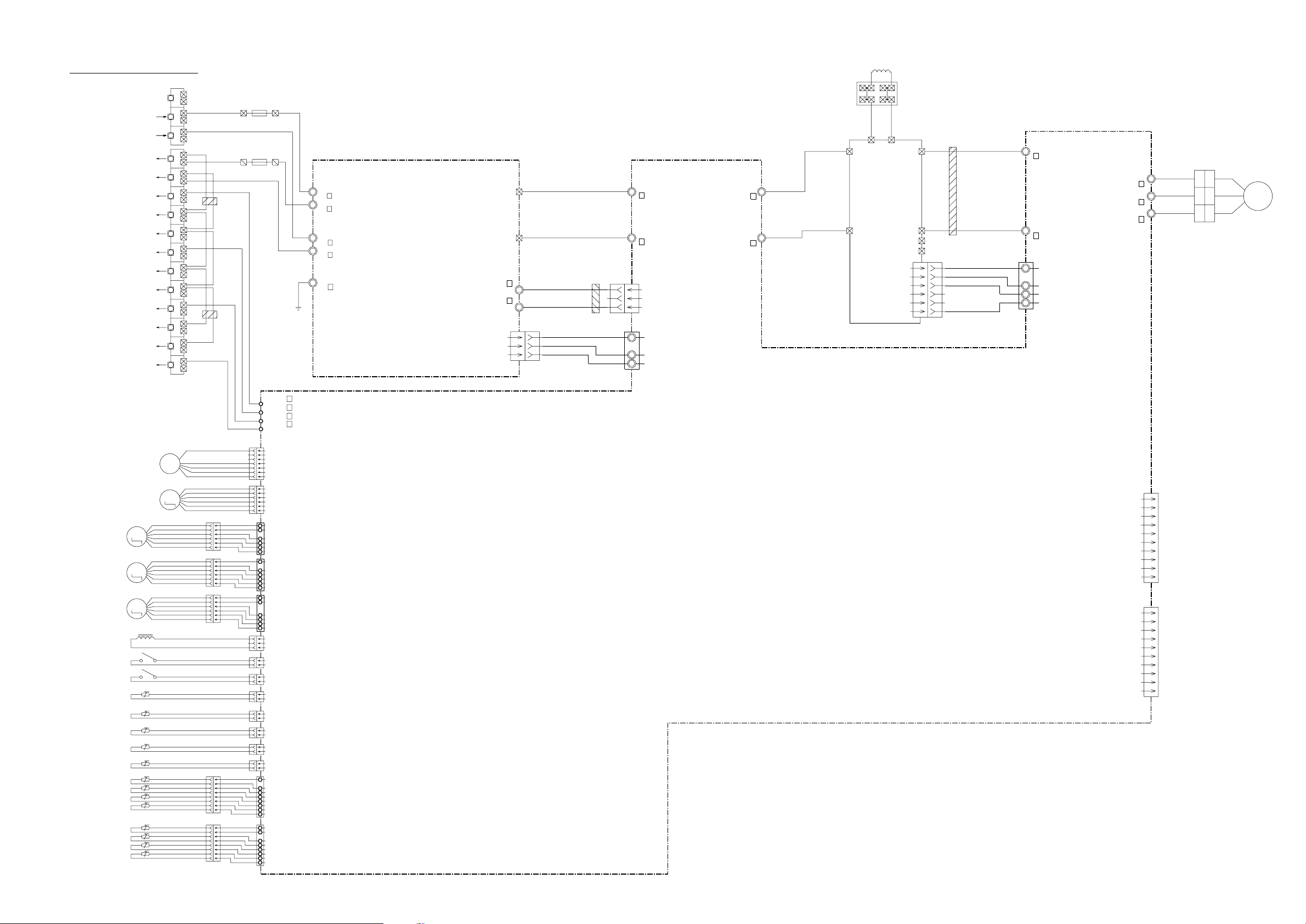

Models : AOH30LMAWL

AOH36LMAWL

CONTROLLER PCB ASSEMBLY

AOH30LMBWL : K04AW-0509HUE-C1

AOH36LMBWL : K04AW-050AHUE-C1

JM156

10K <1/10W>

x 2

P-AN-HT

P-CMPTH

P-AN-TT

P-AN-TA

P-AN-TD

SW1

6

5

4

DSS803

C53

C180

10K <1/10W> x 2

R16

3

2

1

1.0K

<1/10W>

x 2

0.022 <F> x 2

JM106

5V

R17

R34

R35

P-S I

P-S I1

P-POWER

5V

R11

C40 0.1

<F>

0.1 <F> x 2

C78

C77

MICOM-MAIN

MICOM-SUB

MB90460

R195

17

P62

16

P46

2

35

P12

3

P50

P37

59

P36

58

P40

60

MD2

21

34

P11

47

P26

27

P02

28

P03

29

P04

30

P05

31

P06

32

P07

33

P10

57

C

41

P20

P21

42

43

P22

P23

44

10

P57

9

P56

8

P55

7

P54

5

P52

6

P53

4

P51

22

X0

23

X1

3

1

X1

8.00MHz

<EF0EC>

2

I C 1

AVCC

RSTX

AGND

VCCP63

AVR

MD0

MD1

GND

GND

56

11

25

P00

P01

26

40

P17

36

P13

37

P14

38

P15

39

P16

12

45

P24

46

P25

50

P30

51

P31

52

P32

53

P33

54

P34

55

P35

14

P60

15

P61

18

20

64

P44

63

P43

62

P42

61

P41

P45

19

48

P27

13

24

49

C79

0.1

<F>

0.1 <F> x 2

C19

R608 10K <1/10W>

U

X

V

Y

W

Z

1

R72 1.0K

<1/10W>

C17

0.01

<F>

R36 1.0K

<1/10W>

W107

WHITE

W108

VIOLET

CN34

B2P3-VH-B-Y

YELLOW

AC VOLT I N

W200

SERIAL-A

RED

CN30

179844-1

WHITE

4-WAY VALVE

CN37

B2B-XARK-1-A

RED

PRESSUR SW1

CN26

B2B-XAMK-1-A

GREEN

COMP. TH.

CN25

B2B-XAKK-1-A

BLACK

HEART SINK

CN21

B2B-XH-AM

YELLOW

DISCHARGE TH.

CN22

B2B-XH-AM

RED

PIPE TH.

CN23

B2B-XAEK-1-A

BLUE

OUTDOOR TH.

12V

B

B

PFC5000

-0502

FH2

3

1

B

CR5

RE1202

1

2

5V

1

2

R91

L202

BL02Rn1

1

2

1

2

1

2

1

2

1

2

F4

T 5A

250V

JM1

SERIAL

2.2K <1/10W>

x 2

R90

5V

L201

BL02Rn1

C162

0.1

<F>

C163

0.1

<F>

C164

0.1

<F>

C165

0.1

<F>

C166

0.1

<F>

PFC5000

-0502

FH1

K17 G5NB-1A

3

12V

1

C71 C70

R100 6.65K

<1/10W>

(1%)

R98 1.0K

<1/10W>

(1%)

R63 6.65K

<1/10W>

(1%)

R65 4.75K

<1/10W>

(1%)

R67 38.3K

<1/10W>

(1%)

VA103

470V

<TNR>

2

4WV

4

R93

R92

0.1 <F>

x 2

0.01 <F> x 2

18

1.0K <1/10W>

C73

C72

R101 10K

<1/10W>

R99 10K

<1/10W>

R62 10K

<1/10W>

R64 10K

<1/10W>

R66 10K

<1/10W>

8

x 2

PR-SW

HY I C 1

HU2001

14

7

SLR-332VR

<RED> x 4

C60

0.1

<F>

C61

0.1

<F>

C37

0.1

<F>

C38

0.1

<F>

C39

0.1

<F>

R51 4.7K

5V

<1/10W>

R52

5 4 3 2

10

6

12V

12V

5V

D28

SLR-332VR

<RED>

R43 2.2K

<1/4W>

13

4C

12

5C

11

6C

7C

10

COM

5V

C91

0.1

<F>

1

2345

1B

2B

3B

4B

5B

6B

7B

E

I C3

uLN2003A

I C201

BR93L56RF-WE2

8

VCC

DO

4

7

NC

5

GND

R206 10K

<1/10W>

1.0K

R50 10K

<1/10W>

<1/10W>

1

C51

0.022

<F>

1

2

3

4

5

6

7

89

JM157

1

CS

2

SK

D I

3

6

NC

EEPROM

THERMISTOR

R55 1.0K

<1/10W>

1

P-FM1SEL

P-V2

P-4WV-AC

P-LED

P-PR

P-SO1

P-SO

P-E2PCS1

P-E2PSK1

P-E2PDI 1

P-SWPRS1

P-SWPRS2

P-CMPTH

P-AN-HT

P-AN-TD

P-AN-TT

P-AN-TA

R56 27K

<1/10W>

3

Q51

2

2SC2412K <BQ>

FM2FDBK

SUB-CLH

P-FM2POW

P-POWER

P-AN-CT

P-FM1POW

TTXD-1

TAUX3-1

P-AFS

P-CP-POS

P-S I

P-SO

P-PR

P-LED

P-4WV-AC

P-V2

P-TRIP

P-EPV-A

P-EPV-B

P-EPV-C

P-EPV-D

2005.12.12 8

P-AFE

P-AFDC

P-CP-POS

C18

5V

C16

4.7/50V

<PS>

5V

R158

10K

<1/10W>

SW2

KSM0632B

5V

+

C20

4.7/50V

<PS>

R126 - R128

10K <1/10W> x 3

R73 82K

<1/10W>

+

2

SUBNCVCC

1

I C6

BD4742G

C95

100P

<CH>

VOUT

GND

R113

1.0K

<1/10W>

<1/10W>

TAUX-1

P-E2PCS1

P-FM1SEL

FM1FDBK

P-E2PD I1

P-E2PSK1

P-AFDC

P-AFE

P-U

P-X

P-V

P-Y

P-W

P-Z

SUB-FWD

SUB-BKWD

TMODE-1

P-SWPRS2

P-SWPRS1

TCK-1

TRXD-1

5

4

3

YELLOW

BLUE

VILTAGE LOCK OUT

10K <1/10W> x 2

C35 - C36

0.01 <F> x 2

5V

R102

22K

3

<1/10W>

1

R114

R103 4.7K

2

27K

<1/10W>

Q91

2SC242K

<BQ>

R6R1

100K <2W> x 2

R3 100

Q1

2SC4236

<1W>

2

1

3

R140 1.2

D10

<2W>

D1

D1FL20U

P-AFS

RSTX-1

5V

B

W14

W15

B

I C400-1

5V

uPC393

R407

R403

I C400-2

uPC393

15V

I C11-1

uPC393

1

-

+

R2 1.0K

<RS - 3W>

C1

220P

<BN>

C2 0.047

<ECQB>

D2

D1FL20U

C3 <PJ>

RD5.6ES

<B2>

100/16V

R4 330 <1/4W>

R411 22K

<1/10W>

C416

1000P

<B>

TAUX-1

TTXD-1

TRXD-1

TMODE-1

TAUX3-1

TCK-1

RSTX-1

C201 - C205 500/450V x 6

R201

+

220K

<2W>

+ +++

SMOOTHING CIRCUIT

C409

10/25V

<PS>

15V

+

8

2

-

1

7

15V

2

3

+

-

+

C88

<F>

4

C412

0.1

<F>

0.1

R435

3

6

5

C414

0.01

<F>

C87

330P <B>

C89

470P

<B>

SW POWER SUPPLY

T1

JPZ-200

16

15

13

12

10

9

D100

D1FL20U

+

P-U

P-V

P-W

P-X

P-Y

P-Z

P-TRIP

P-FM1POW

FM1FDBK

FM2FDBK

ACTPM CONTROL

2

3

2

1

Q401

DTC124EUA

R605

22K

<1/10W>

AA

270 <1/10W>

(1%) x 2

5V

10K <1/10W> x 5

R604

FLASH-MAIN

15V

x 2

R441

D82

21 1

R108

2.87K

<1/10W>

(1%)

D1FL20U x 2

D8

D7

I C407 uPC24M18

D401

D1FL

20U

18V

C415

1

0.01

<F>

Q403

3

DTA143

C413

0.01

<F>

A

A

5V

R601

R602

R400

(1%)

R440

180K <RN - 1/2W>

<1/10W>

R406

2.94K 2.87K

<1/10W>

R401

R105

R5 10K

C406

+

220/50V

<PJ>

CN407

06 PH / 172520

1007 L480

WHITE

1

A

2

3

4

5

5V

1

2

3

4

5

6

7

8

9

10

R402 3.3K

<1/4W>

D402

RD3.3ES

<B2>

1.0K <1/10W>

x 2

C411

0.01 <F>

DAN217U x 2

D81

2

3 3

COMP POSITION DETECT

1

2

3

6

7

8

15V

+

C7

220/

35V

18V

R437

R438

R21

R603

R20

10K

<1/10W>

C116

0.1 <HCP>

FH3

PFC5000

-0502

F2

T 3.15A

250V

FH4

PFC5000

-0502

L100

BL02Rn1

(1%)

R104

x 2

(1%)

(1%)

R106

195K <RN - 1/2W>

(1%)

2.49K

<1/10W>

(1%) R87 2.94K

R107

680

C5 <PJ>

C4 <PJ>

470/25V

<1/10W>

I C8

TA7805

1

G

+ +

+

2

18V

1 3

I O

G

2

ACTPM

CONTROL

TAUX

TTXD

TRXD

TMODE

TAUX3

TCK

/ TRES

/ TICS

CN601

B10B-PASK-1

WHITE

R370 - R374 <2W> x 5

R375 - R379 <2W> x 5

195K <RN - 1/2W>

x 6

R360 39

<1/2W>

<1/10W>

12V

5V

3I O

U1JU44 x 3

R340

R341

R342

R343

R344

R345

C6 <PJ>

100/16V

(1%)

<1/10W>

220/16V

+

C418 <PJ>

10/35V

R86

R111

R89

R112

R110

R88

D301D303 D302

x 3

330K

47/35V

<PJ> x 3

<1/10W>

0.1 <F> x 3

+

C305

C323

+

C322

C304

+

R362 R363 R361

C321

C303

1.0K <1/10W> x 6

C311 - C316 1000P <B> x 6

DC FAN1

DTA143EUA

x 2

Q800

3

2

R803

10K

1

<1/10W>

C801

R804 1.0K

0.01

<1/10W>

<B>

C324 - C326

0.1 <F> x 3

15V

Q801

2

5V5V

1 2

C332

0.1

<F>

VN I

UP

1

2

VNC

VP I

C IN

VUFB

3

CFO

4

VUFS

VP

5

6

VP I

7

VVFB

WN

VVFS

8

9

WP

10

VP I

11

VPC

12

VWFB

VWFS

13

I PM

I C310 PS21869-A

C33

0.01

<F>

15V

1

R801 1.0K <1/2W>

3

C800

+

100/

16V

3

<PJ>

D803

DAN217U

15V

C333

47/

35V

+

14

15

16

17

FO

18

19

UN

20

VN

21

P

22

23

U

24

V

25

W

26

N

R40 1.0K

<1/10W>

L800

BL02Rn1

R802

560

<1/4W>

L300

BL02Rn

R302 1.0K

<1/10W>

C327

0.022 <F>

5V

R33

10K

<1/10W>

C802

0.1

<F>

C328

2200P

<B>

INVERTER

1

2

3

4

5

6

7

B

W305

RED

B

W304

WHITE

W303

BLACK

B

CN800

B7B-XASK-1-A

WHITE

DC FAN MOTOR-1

A

CN1

03 XA / 172520

1007 L180

WHITE

CT

CN27

B6B-XARK-1-A

RED

EXPANSION VALVE-A

CN50

06 XA / 172520

1007 L300

WHITE

P-AN-CT

P-EPV-A

P-EPV-B

P-EPV-C

P-EPV-D

P-EPV1-A

P-EPV1-B

P-EPV1-C

P-EPV1-D

C804

R808 1.0K

0.01

<1/10W>

<B>

E.E.-VALVE

JM152 - JM155

R807

10K

<1/10W>

D61

DAN217U

1.5K <1/10W> x 4

R97

R96

R95

R94

D804

DAN217U

12V

5V5V

1 2

3

C803

25V1

100/16V <PJ>

3

3

O1

I 1

6

O2

I 2

11

O3

I 3

16

14

O4

I 4

1

COM1

GND1

8

COM2

GND2

12

10

NC1

GND3

15

NC2

13

GND4

I C4 TD62064

C29

0.1

<F>

2

7

9

4

5

12V

5V

1

2

3

4

1

2

3

4

5

6

Page 10

Models : AOH30LMBWL

AOH36LMBWL

POWER SUPPLY PCB ASSEMBLY

K04BA-0401HUE-P0

TM100

POWER SOURCE

230V

50Hz

TO INDOOR UNIT

EARTH

AC VOLT OUT

BLACK

WHITE

W4

W5

W6

BLACK

W7

WHITE

W3

GREEN

W8

BLACK

W9

WHITE

L1

RCH4730-021PF07

VA101

B

470V

<TNR>

VA102

470V

C101

3.3

<LE>

<TNR>

B

SA100

RA-302M

B

B

B

B

B

C104

0.033

<YE>

C105

0.033

<YE>

C106

3.3

<LE>

L2

N300300K1D7C

C107

3.3

<LE>

CT1

CT-1B

D60

5V

DAN217U

C60

220/16V

<PJ>

R60 1.0K

<1/10W>

(1%)

L4

RCH4730-021PF07

+

VR1

B2K

R61 3.74K

<1/10W>

(1%)

C111

3.3

<LE>

R68 22K

<1/10W>

C64

0.1

<F>

C65

0.1

<F>

5V

B

B

CN1

B3B-XASK-1-A

WHITE

1

2

3

TM101

TM102

CT OUT

2005.12.12 9

Page 11

ERROR CONTENTS

SUMOTUWETH FR

SA

(indoor unit)

CAUTION

Supply power to the crankcase heater for at least 12 hours

before the start of operation in winter.

(1) Stop the air conditioner operation.

(2) Press the master control button and the fan control button simultane-

ously for 2 seconds or more to start the test run.

Test run display

(3) Press the start/stop button to stop the test run.

[SELF-DIAGNOSIS]

When the error indication "E:EE" is displayed, follow the following items to

perform the self-diagnosis. "E:EE" indicates an error has occurred.

1. REMOTE CONTROLLER DISPLAY

(1) Stop the air conditioner operation.

(2) Press the set temperature buttons simultaneously for 5 sec-

onds or more to start the self-diagnosis.

Refer to the following tables for the description of each error code.

Error code Error contents

13

14

15

16

17

18

19

1A

1b

1c

1d

1E

1F

Outdoor unit doesn't accept the signal from

indoor unit.

Excessive outdoor pressure (permanent stop)

Compressor temperature sensor

Pressure switch error

IPM error

CT error

Active filter module (AFM) error

Compressor does not operate

Outdoor unit fan error

Communication error

(inverter multicontroller)

2 way valve sensor error

Expansion valve error

Connection indoor unit error

Unit number (usually 0)

Error code

Ex. Self-diagnosis

(3) Press the set temperature buttons simultaneously for 5 sec-

onds or more to stop the self-diagnosis.

Error code Error contents

01

02

03

04

05

06

08

09

0A

0c

11

12

Indoor unit doesn't accept the signal from

outdoor unit.

Room temperature sensor open

Room temperature sensor short-circuited

Indoor heat exchanger temperature sensor open

Indoor heat exchanger temperature sensor shortcircuited

Outdoor heat exchanger temperature sensor

Power source connection error

Float switch operated

Outdoor temperature sensor

Discharge pipe temperature sensor

Model abnormal

Indoor fan abnormal

1c, 1d, 1E, 1F errors are only for multi type.

2. CHECKING DRAINAGE

To check the drain, remove the water cover and fill with 2 to 3 of water as

shown in figure.

The drain pump operates when operating in the cooling mode.

Drain pipe

Water cover

Watering pot

2005.12.12 10

Page 12

ERROR CONTENTS

(outdoor unit)

CAUTION

Always turn on the power 12 hours prior to the start of the

operation in order to ensure compressor protection

1. Make a TEST RUN in accordance with the in stallation instruction sheet for the indoor unit.

2. OUTDOOR UNIT LEDS

When a malfunction occurs in the outdoor unit, the LED on the circuit

board lights to indicate the error. Refer to the following table for the description of each error according to the LED.

LED

1 flash

2 flash

3 flash

4 flash

7 flash

8 flash

9 flash

12 flash

13 flash

14 flash

15 flash

16 flash

5 sec. ON/

1 sec. OFF

repeated

lighting

Communication error

(Indoor unit - Outdoor unit)

Discharg pipe temperature sensor

Outdoor heat exchanger temperature sensor

Outdoor temperature sensor

Compressor temperature sensor

Heat sink temperature sensor

Pressure switch abnormal

IPM error

Compressor rotor position cannot detect

Compressor cannot operate

Outdoor fan abnormal (upper fan)

Outdoor fan abnormal (lower fan)

Protect operation

No error

Error contents

SPECIAL INSTALLATION

SETTING

PUMP DOWN (Refrigerant collecting operation)

Perform the following procedures to collect the refrigerant when moving

the indoor unit or the outdoor unit.

(1) Press the push-button switch (SW2) on the circuit board once.

The LED on the circuit board starts flashing (one second ON/one second OFF). This indicates the start of PUMP DOWN operation.

When the switch is pressed while the compressor is in operation, PUMP

DOWN operation starts automatically.

When the switch is pressed while the compressor is in stop, the compressor starts to operate automatically, and then move on to PUMP

DOWN operation.

(2) PUMP DOWN operation continues for about 1 minute. When PUMP

DOWN operation is completed, the compressor stops automatically.

Then close the 2-way valve and 3-way valve immediately.

(3) Turn the power off.

PUMP DOWN SW (SW2)

2005.12.12 11

DANGER

This part (Choke coil) generates high voltages.

Never touch this part.

Page 13

DISASSEMBLY ILLUSTRATION

Models :

AUH30LUAS

AUH36LUAS

481

481-1

481

481

2005.12.12 12

Page 14

Models :

AUH30LUAS

AUH36LUAS

479

460-1

462

187

460-2

467

127

835

482

835 803

798

484

244

465

164

474

168

484

484

464

484

814

563

834-1

514

223

477

457

476-2

117-3

337-1

197

146-1

565

337-2

146-2

197

337-1

160

457

2005.12.12 13

Page 15

Models :

AUH30LUAS

AUH36LUAS

138

187

146-1

184-1

235

146-2

564

47-1

896

2005.12.12 14

735

Page 16

Models :

AUH30LUAS

AUH36LUAS

2005.12.12 15

Page 17

Models : AOH30LMBWL

AOH36LMBWL

1

6

3

4

7

2

2005.12.12 16

5

Page 18

Models : AOH30LMBWL

AOH36LMBWL

10

9

15

13

14

11

17

18

8

2005.12.12 17

Page 19

Models : AOH30LMBWL

AOH36LMBWL

26

23

19

22

31

24

25

27

29

28

20

12

12

30

18

2005.12.12 18

Page 20

Models : AOH30LMBWL

AOH36LMBWL

38

37

36

35

33 34

2005.12.12 19

Page 21

PARTS LIST

INDOOR UNIT

Ref.

Description

No.

34 Capacitor (Fan Motor) 9900270162

47-1 Rubber (Discharge Pipe) 313194159807

61 Decoration Plate 9363131000

71 Holder (Hook) 9362782005

93 Filter 9362766005

117-3 Hexagon Nut 301721180114

122 Holder (Louver Supporter) 9362799003

127 Drain Hose 9362784009

138 Separate wall 9362737005

143-1 Clamp NK-3 313361274700

146-1 Evaporator-A Assy 9373799054

146-2 Evaporator-B Assy 9373800057

160 Kit (Drain Pan Sub Assy) 9370934014

164 Motor, Induction 9601915010

168 Cabinet-E 9362735001

184-1 Thermistor Spring-A 313728262708

187 Clamp No. 1219 313361271706

195 Binder-C 313361275805

197 Wind Guide Board 9373444015

223 Control Box 9362762007

226 Motor Gear 9362764001

234 Room Temp. Thermistor 9703299025

235 Pipe Temp. Thermistor 9703297014

236 Controller PCB Assy 9705914056

240 Remote Control Unit 9372266052

244 Pipe Cover Assy 9362819015

337-1 RFM (Eva. )-A 9362749008

337-2 RFM (Eva. )-B 9362750004

338 Motor Holder 9362765008

381 Locking Spacer 313209391506

457 RFM (Drain Pan) 9362757003

460-1 Pump Cover-A 9362775007

9900270162

313194159807

9363131000

9362782005

9362766005

301721180114

9362799003

9362784009

9362737005

313361274700

9373799054

9373800057

9370934014

9601915010

9362735001

313728262708

313361271706

313361275805

9373444015

9362762007

9362764001

9703299025

9703297014

9705914049

(K01AL-0500HSE-C1)

9372266052

9362819015

9362749008

9362750004

9362765008

313209391506

9362757003

9362775007

Part No.

AUH36LUASAUH30LUAS AUH36LUASAUH30LUAS

(K01AL-0501HSE-C1)

Ord.

Q'ty

Ref.

Description

No.

472-5 RFM (Grille)-E 9362742009

474 Turbo Fan Assy 9362803014

476-2 Washer (Turbo Fan) 9362756006

477 Bellmouth-B 9362774000

479 Float Switch 9703285004

481 Insulation (Grille)-A 9362780001

481-1 Insulation (Grille)-B 9362781008

482 Pump Unit 9703125010

484 Hook 9362736008

487 Hinge Wire (Grille) 9362754002

488 Drain Pan Plug 313005174654

514 Control Box Cover 9362763004

522 Joint Gear 9362772006

541 Terminal Plate 9363642001

542 Panel Base 9362759014

543 Holder (Panel Frame) 9362761017

544 Holder (Panel Base) 9362760010

545 Panel Frame 9362758017

563 Inner Box 9362768009

564 Bypass Pipe-A Assy 9371323053

565 Evaporator Holder Assy 9362802017

628 Locking Spacer-B 313005446558

690 Joint-A 9362773003

692 Joint Shaft 9362771009

705 Louver Assy 9362836012

710 Intake Grille 9362767019

735 Distributor Assy 9371325132

777-1 Hook (Grille)-A 9362779012

777-2 Hook (Grille)-B 9362778015

798 Drain Pump Holder 9362753005

803 Cabinet-D 9362734004

814 Cabinet-C 9362733007

9362742009

9362803014

9362756006

9362774000

9703285004

9362780001

9362781008

9703125010

9362736008

9362754002

313005174654

9362763004

9362772006

9363642001

9362759014

9362761017

9362760010

9362758017

9362768009

9371323053

9362802017

313005446558

9362773003

9362771009

9362836012

9362767019

9371325132

9362779012

9362778015

9362753005

9362734004

9362733007

Part No.

Ord.

Q'ty

460-2 Pump Cover-B 9362776004

462 Panel (Top) Assy 9362806015

464 Cabinet-A Assy 9362800013

465 Cabinet-B Assy 9362801010

467 Drain Port 9362786003

468 M10 Nut-A (Large) 313005446653

469 M10 Nut-B (Small) 313005446759

472-1 RFM (Grille)-A 9362738002

472-2 RFM (Grille)-B 93627390099362739009

472-3 RFM (Grille)-C 9362740005

472-4 RFM (Grille)-D 9362741002

9362776004

9362806015

9362800013

9362801010

9362786003

313005446653

313005446759

9362738002

9362740005

9362741002

2005.12.12 20

815-1 Terminal-3P 9306489069

815-2 Terminal-3P 9703345012

834-1 Cover (Wire)-A 9362789004

834-2 Cover (Wire)-B 9362788007

835 Cushion (Pump) 9362777001

847 Louver Supporter 9362770019

858 Spring (Grille) 9362755009

875 Power Supply PCB Assy 9704561220

876-2 Motor, Step 9900362027

896 Coupling Pipe Assy 9373038221

982-1 Clamp (Cord) 9356857009

When you order parts, please make a photocopy of this page and

fill the number of the parts in the "Order" column.

9306489069

9703345012

9362789004

9362788007

9362777001

9362770019

9362755009

9704561220

9900362027

9373038221

9356857009

Page 22

OUTDOOR UNIT

Ref.

No.

Description

AOH30LMBWL

1

Top Panel Sub Assy 9374417025

2

Front Panel 9374094066

3

Fan Guard 9374330010

4 Grip Side 9374173013

5

Service Panel Sub Assy 9374415038

6 Right Panel Sub Assy 9374416066

7

Emblem Rear 9372171011

8 Propeller Fan Assy 9366378020

9 Motor, Induction 9601882015

10 Condenser-A Assy

11 Coil Choke 9703458019

12 Strainer Assy 9372524015

13 Separate Wall Assy 9374629022

14 Cap Foot 9374345014

15 Base Assy 9374166084

17 3-Way Valve Assy (3/8) 9372205044

18 3-Way Valve Assy (5/8) 9372205075

19 Check Joint Assy 9372802038

20 Compressor Assy 9373711018

22 4-Way Valve 9900164010

9374417025

9374094066

9374330010

9374173013

9374415038

9374416066

9372171011

9366378020

9601882015

9374433056

9703458019

9372524015

9374629022

9374345014

9374166084

9372205044

9372205075

9372802038

9373711018

9900164010

Part No.

AOH36LMBWL

9374433056

Ord.

Q'ty

23 Solenoid 9900165055

24 Pressure Switch

25 Inlet Pipe Cond A Assy 9373461067

26 Inlet Pipe Cond B Assy

27 Outlet Pipe Cond A Assy

28 Expansion Valve Assy 9370947113

29 Coil (Expansion Valve) 9900057039

30 Distributor

31 Discharge Pipe A Assy 9372264126

33 Terminal 2P 9701971015

34 Terminal 5P 9900203023

35 ACTPM 9703457012

36 Holder Thermo 9372797013

37 Inverter PCB Assy 9705642164

38 Power PCB Assy 9705647022

---- Fuse 25A-250V 0600086039

---- Fuse 3.15A-250V 0600222512

---- Fuse 5A-250V 0600222529

---- Thermistor (Outdoor Temp.) 9703516078

---- Heat Exchanger Thermistor 9704220042

---- Thermistor (Discharge) 9704219114

---- Compressor Thermistor 9900156022

---- Thermistor 9704265012

---- Heatsink Thermistor 9900311018

---- Transformer 9702334024

---- Varistor 0000361224

---- Arrester 0600280147

---- Relay 9900117016

---- Relay 9900007010

---- Switch Push 9703476013

9900165055

9900186012

9373461067

9373463054

9374266050

9370947113

9900057039

9369128004

9372264126

9701971015

9900203023

9703457012

9372797013

9705642157

9705647022

0600086039

0600222512

0600222529

9703516078

9704220042

9704219114

9900156022

9704265012

9900311018

9702334024

0000361224

0600280147

9900117016

9900007010

9703476013

9900186012

9373463054

9374266050

9369128004

---- Switch Slide 9701392018

---- Drain Pipe (I-Type) 9301102000

---- Drain Pipe Packing 9301143003

---- Drain Cap 313166024302

9701392018

9301102000

9301143003

313166024302

2005.12.12 21

When you order parts, please make a photocopy of this page and

fill the number of the parts in the "Order" column.

Page 23

STANDARD

ACCESSORIES

INDOOR UNIT ACCESSORIES

Name and Shape

Coupler heat

insulation

Q’ty

For indoor side pipe joint

2

Application

Screw

Special nut A

(large flange)

Special nut B

(small flange)

Template

Binder

Blower cover insulation

Hook wire

For installing the remote

2

controller

For installing indoor unit

4

For installing indoor unit

4

For ceiling hole cutting

1

For remote controller and

remote controller cord

1

binding

(small)

For discharged air

2

For installing intake grille

2

Remote

controller

Remote controller cord

2005.11.24 22

1

For connecting the remote

controller

1

Page 24

WARNING

1

For the air conditioner to operate satisfactorily. install it as outlined in this installation instruction sheet.

2

Connect the indoor unit and outdoor unit with the room air conditioner piping and cords available standards parts. This

installation instruction sheet describes the correct connections using the installation set available from our standard parts.

3

Installation work must be performed in accordance with national wiring standards by authorized personnel only.

4

Also, do not use an extension cord.

5

Do not turn on the power until all installation work is complete.

6

Do not purge the air with refrigerants but use a vacuum pump to vacuum the installation.

7

There is not extra refrigerant in the outdoor unit for air purging.

8

Use a vacuum pump for R410A exclusively.

9

Using the same vacuum pump for different refrigerants may damage the vacuum pump or the unit.

10

Use a clean gauge manifold and charging hose for R410A exclusively.

11

If refrigerant leaks while work is being carried out, ventilate the area. If the refrigerant comes in contact with a flame, it

produces a toxic gas.

Be careful not to scratch the air conditioner when handling it.

After installation, explain correct operation to the customer, using the operating manual.

Let the customer keep this installation instruction sheet because it is used when the air conditioner is serviced or moved.

STANDARD PARTS

The following installation parts are furnished.

Use them as required.

Name and Shape Q'ty Application

Drain pipe

1

For outdoor unit drain

piping work (May not be

Drain cap

supplied, depending on

the model.)

2

Insulation (seal)

For filling in a gap at the

entrance of connection

1

cords

CONNECTION PIPE REQUIREMENT

CAUTION

The maximum lengths of this product are shown in the following table. If the units are further apart than this, correct

operation can not be guaranteed.

Model Type

30,000 BTU/h class

36,000 BTU/h class

45,000 BTU/h class

Use pipe with water-resistant heat insulation.

9.52 mm (3/8 in.) 15.88 mm (5/8 in.)

Diameter

Liquid Gas

Pipe length

MAX.

50 m

70 m

MIN.

5 m 30 m

CAUTION

Install heat insulation around both the gas and liquid pipes. Failure to do so may cause water leaks.

Use heat insulation with heat resistance above 120 C. (Reverse cycle model only)

In addition, if the humidity level at the installation location of the refrigerant piping is expected to exceed 70%, install heat

insulation around the refrigerant piping. If the expected humidity level is 70-80%, use heat insulation that is 15 mm or thicker

and if the expected humidity exceeds 80%, use heat insulation that is 20 mm or thicker.

If heat insulation is used that is not as thick as specified, condensation may form on the surface of the insulation.

In addition, use heat insulation with heat conductivity of 0.045 W/(maK) or less (at 20 C).

Maximum height

(between indoor

and outdoor)

2006.01.04 23

Page 25

0511G2943

Loading...

Loading...