Page 1

CASSETTE TYPE AIR CONDITIONER

TECHNICAL MANUAL

FUJITSU GENERAL LIMITED

Page 2

BACK

NEXT

CASSETTE TYPE AIR CONDITIONER

1. FEATURES AND OPERATION

2. SPECIFICATIONS

3. OUTLINES AND DIMENSIONS

4. D ATA

5. REFRIGERANT SYSTEM DIAGRAM

6. CIRCUIT DIAGRAM

7. NOISE LEVEL MEASUREMENT

8. PRECAUTIONS ON INSTALLATION

9. TROUBLESHOOTING

10. OPTIONAL PARTS

Page 3

BACK

NEXT

1 FEATURES AND OPERATION

1.1 MODEL IDENTIFICATION

1.2 APPLICATION MODEL

1.3 FEATURES OF EACH MODEL

1.4 EASY OPERATION BY REMOTE CONTROLLER

1.4.1 WIRELESS TYPE CONTROL FUNCTIONS

1.4.2 LCD WIRED TYPE CONTROL FUNCTIONS

2 SPECIFICATIONS

2.1 AU18, 18R, 25, 25R, 30, 30R (1-PHASE 50Hz)

2.2 AU25, 36, 36R, 45, 45R (3-PHASE 50Hz)

2.3 AU25, 25R, 36, 36R (1-PHASE 60Hz)/AU45, 45R (3-PHASE 60Hz)

3 OUTLINES AND DIMENSIONS

3.1 GRILLE

3.2 INDOOR UNIT FOR AU18, 18R, 25, 25R

3.3 INDOOR UNIT FOR AU30, 30R, 36, 36R, 45, 45R

3.4 OUTDOOR UNIT FOR AO18, 18R, 25, 25R, 25(3)

3.5 OUTDOOR UNIT FOR AO30, 30R, 36, 36R, 45, 45R

4 D ATA

4.1 PERFORMANCE CURVE

4.1.1 AU18, 25

4.1.2 AU25(3)

4.1.3 AU18R,25R

4.1.4 AU30, 36, 45(3)

4.1.5 AU30R, 36R, 45R(3)

4.1.6 PIPE LENGTH FOR AU18, 18R, 25, 25R, 25(3), 30, 30R

4.1.7 PIPE LENGTH FOR AU36, 36R, 45(3), 45R(3)

4.2 TEMPERATURE RANGE

4.3 REFRIGERANT CHARGING

4.4 AIR VELOCITY DISTRIBUTION

4.4.1 AU18

4.4.2 AU25

4.4.3 AU30

4.4.4 AU36

4.4.5 AU45

4.5 DUCT CONNECTION

4.5.1 OUTLET AIR FOR AU30, 30R, 36(3), 36R(3), 45(3),45R(3)

4.5.2 FRESH AIR FOR AU30, 30R, 36(3), 36R(3), 45(3),45R(3)

Page 4

BACK

NEXT

5 REFRIGERANT SYSTEM DIAGRAM

5.1 AU18/AO18

5.2 AU18R/AO18R

5.3 AU25/AO25, AU25(3)/ AO25(3)

5.4 AU25R/AO25R

5.5 AU30/AO30

5.6 AU30R/AO30R

5.7 AU36/AO36

5.8 AU36R/AO36R (50Hz)

5.9 AU36R/AO36R (60Hz)

5.10 AU45/AO45

5.11 AU45R/AO45R

6 CIRCUIT DIAGRAM

6.1 OVERALL CIRCUIT DIAGRAM

6.1.1 AU18/AO18, AU25/AO25 (Inside power supply)

6.1.2 AU18/AO18, AU25/AO25 (Outside power supply)

6.1.3 AU25(3)/AO25(3) (Low ambient cooling model)

6.1.4 AU18R/AO18R, AU25R/AO25R

6.1.5 AU30/AO30 (Low ambient cooling model)

6.1.6 AU30R/AO30R

6.1.7 AU36/AO36, AU45/AO45 (50Hz)

6.1.8 AU36/AO36, AU45/AO45 (50Hz) (Low ambient cooling model)

6.1.9 AU36/AO36R, AU45R/AO45R (50Hz)

6.2 INDOOR PRINTED CIRCUIT BOARD CIRCUIT DIAGRAM

6.2.1 AU18, 25 (Inside power supply)

6.2.2 AU18, 25, 30, 36, 45

6.2.3 AU18R, 25R, 30R, 36R, 45R

6.3 OUTDOOR PRINTED CIRCUIT BOARD CIRCUIT DIAGRAM

6.3.1 AO18R, 25R

6.3.2 AO30R

6.3.3 AO36R, 45R (50Hz)

6.4 WIRELESS REMOTE CONTROLLER CIRCUIT DIAGRAM

6.5 LIQUID CRYSTAL WIRED REMOTE CONTROLLER CIRCUIT DIAGRAM

7 NOISE LEVEL MEASUREMENT

7.1 NOISE LEVEL CHECK POINTS

7.2 NOISE LEVEL CURVE

Page 5

BACK

NEXT

8 PRECAUTIONS ON INSTALLATION

8.1 INSTALLAITION MANUAL

8.1.1 AU18, 25, 25(3)

8.1.2 AU18R, 25R

8.1.3 AU30, 36, 45 (50Hz)

8.1.4 AU30R, 36R, 45R (50Hz)

8.1.5 AU36R, 45R (60Hz)

8.1.6 AU36R, 45R (60Hz)

8.2 LIQUID CRYSTAL WIRED REMOTE CONTROL INSTALLATION

9 TROUBLESHOOTING

9.1 WIRELESS REMOTE CONTROL MODEL

9.2 LIQUID CRYSTAL WIRED REMOTE CONTROL MODEL

9.3 CARE AND MAINTENANCE

10 OPTIONAL PARTS

10.1 WIRELESS REMOTE CONTROL MODEL

10.2 LIQUID CRYSTAL WIRED REMOTE CONTROL MODEL

Page 6

BACK

NEXT

1.1 MODEL IDENTIFICATION

INDOOR UNIT

1

A

TYPE

AU: CASSETE

OUTDOOR UNIT

1

2 10

2

U

DESTINATION

MARKET REGIONS

T: 50Hz FUJITSU

(AUSTRALIA)

Y: 50Hz FUJITSU

3

T

3

4

1

CAPACITY RANK

BTU/h

18: 18000

24: 24000

25: 25000

30: 30000

36: 36000

45: 45000

4

5

5

8

FUNCTION

TYPE

R: REVERSE

CYCLE

A: COOLING

ONLY

6

6

A

CONTROL

METHOD

(REMOTE

CONTROL)

L: WIRED

S: WIRELESS

78L9

7

S

SHOWING

MINOR

CHANGES

8

C

SPECIAL

METHOD

3: 3-PHASE

9

3

A

TYPE

AO: OUT-

DOOR

O

DESTINATION

MARKET REGIONS

T: 50Hz FUJITSU

(AUSTRALIA)

Y: 50Hz FUJITSU

T

1

CAPACITY RANK

BTU/h

18: 18000

24: 24000

25: 25000

30: 30000

36: 36000

45: 45000

8

A

FUNCTION

TYPE

R: REVERSE

CYCLE

A: COOLING

ONLY

W

SHOWING

COMPRESSOR

USED

A

SHOWING

MINOR

CHANGES

SPECIAL

METHOD

FUNCTION

3: 3-PHASE

L: LOW AMBIENT

TEMPERATURE

COOLING

OPERATION

Page 7

BACK

NEXT

1.2 APPLICATION MODEL

TYPE MODEL NAME

AU18/AO18 AUY18ASC/AOY18AWA AUY18ASD/AOY18AWDL

AU18R/AO18R AUT18RLC/AOT18RWBL AUY18RLC/AOY18RWBL

AU25/AO25 AUT25ASC/AOT25AWA AUY25ASC3/AOY25ACA3L

AUY25ASC/AOY25AWA AUY25ASD3/AOY25ACD3L

AUY25ASD/AOY25AWDL

AU25R/AO25R AUT25RLC/AOT25RWDL AUY25RLD/AOY25RWDL

AUY25RLC/AOY25RWDL

AUY18RLD/AOY18RWDL

AU30/AO30 AUY30ASC/AOY30ABAL

AU30R/AO30R AUY30RLC/AOY30RBFL

AU36/AO36 AUY36ASC3/AOY36ACA3L AUT36ASC3/AOT36ACA3

AU36R/AO36R AUT36RLC3/AOT36RCB3L AUY36RLC3/AOY36RCB3L

AU45/AO45 AUY45ASC3/AOY45ACA3L AUT45ASC3/AOT45ACA3

AU45R/AO45R AUT45RLC3/AOT45RCB3L AUY45RLC3/AOY45RCB3L

Page 8

BACK

NEXT

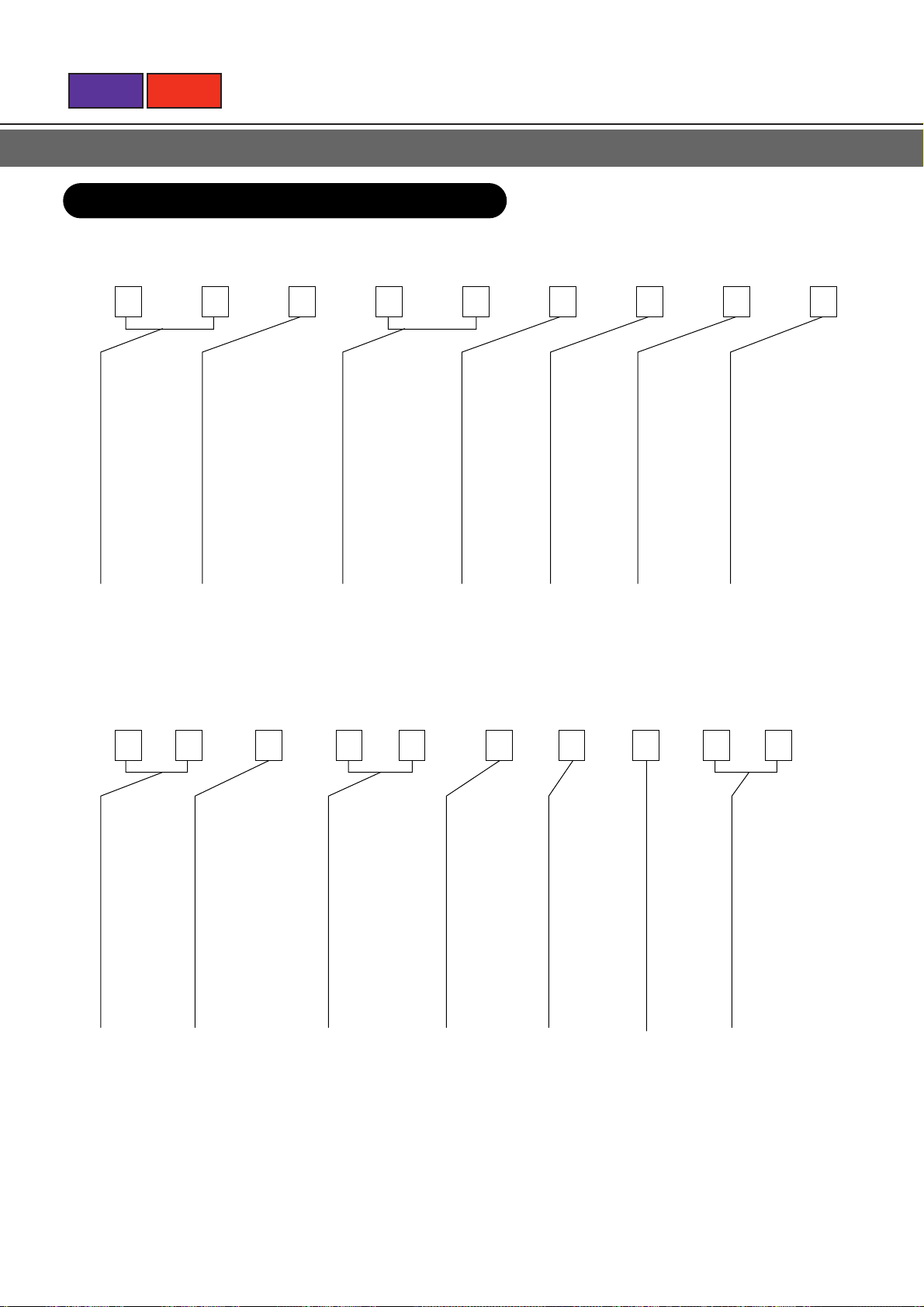

1.3 FEATURES OF EACH MODEL

Cassette type

AU18 AU18R

AU25 AU25R

AU25(3) AU30R

AU30 AU36R(3)

AU36(3) AU45R(3)

AU45(3)

Wireless remote

controller

Liquid crystal wired

remote controller

Auto restart

Auto louver

Auto fan speed

Dry

Off timer

On timer

Sleep

Program timer

Repeat timer

Zone control

Energy save

Simultaneous 16 air

conditioners control

Twin remote control

Auto change

Low ambient operation

( )

Function

Refer to the item 1.4.1 on page XX.

Refer to the item 1.4.2 on page XX.

In the event of a temporary power failure, the air conditioner

will automatically restart in the same operating mode as

before, once the power supply is restored.

The louver automatically swings to right and left. The

direction and the angle of the air flow can be easily

changed.

The optimum fan speed is available with the difference

between the indoor temperature and the setting

temperature.

The computer effectively dehumidifies the air.

(Air conditioner will operate with gentle cooling operation.)

When the timer reaches the set time, the air conditioner will

be turned off.

When the timer reaches the set time, the air conditioner will

be started.

The microcomputer gradually changes the room

temperature automatically to afford a comfortable night's

sleep.

Combines the OFF timer and the ON timer for one cycle.

(OFF

Æ ON or ON Æ OFF) Starts operation from the OFF

timer or ON timer, whichever is closer to the current time.

Combines the operation of the OFF timer and ON timer (the

cycle described in the PROGRAM timer above) so they

repeat the same cycle every day. Starts operation from the

OFF timer or ON timer, whichever is closer to the current

time.

When the ZONE CONTROL button is pressed while multiple

air conditioners are being centralized controlled, only the

preset air conditioners stop.

The energy conservation mode (ENERGY SAVE) raises the

set temperature slightly in the cooling mode and lowers the

set temperature in the heating mode, using a computer

program to economically control the operation of the unit.

One remote controller can control up to 16 air conditioners.

All the air conditioners can be operated with the same

setting.

Two remote controllers can be connected to one air

conditioner unit. The air conditioner operation contents are

the remote controller setting contents set later. (Both remote

controllers show the same display.)

In the auto mode, the air conditioner switches automatically

between cooling and heating, keeping the room at or around

the set temperature.

Cooling capacity is variable over a wide range, so the inside

environment stays comfortable with very little variation in

temperature or humidity.

NOTE: The parenthesis ( ) shows that the function is installed or not according to models.

1 3

Page 9

BACK

NEXT

1.4 EASY OPERATION BY REMOTE CONTROLLER

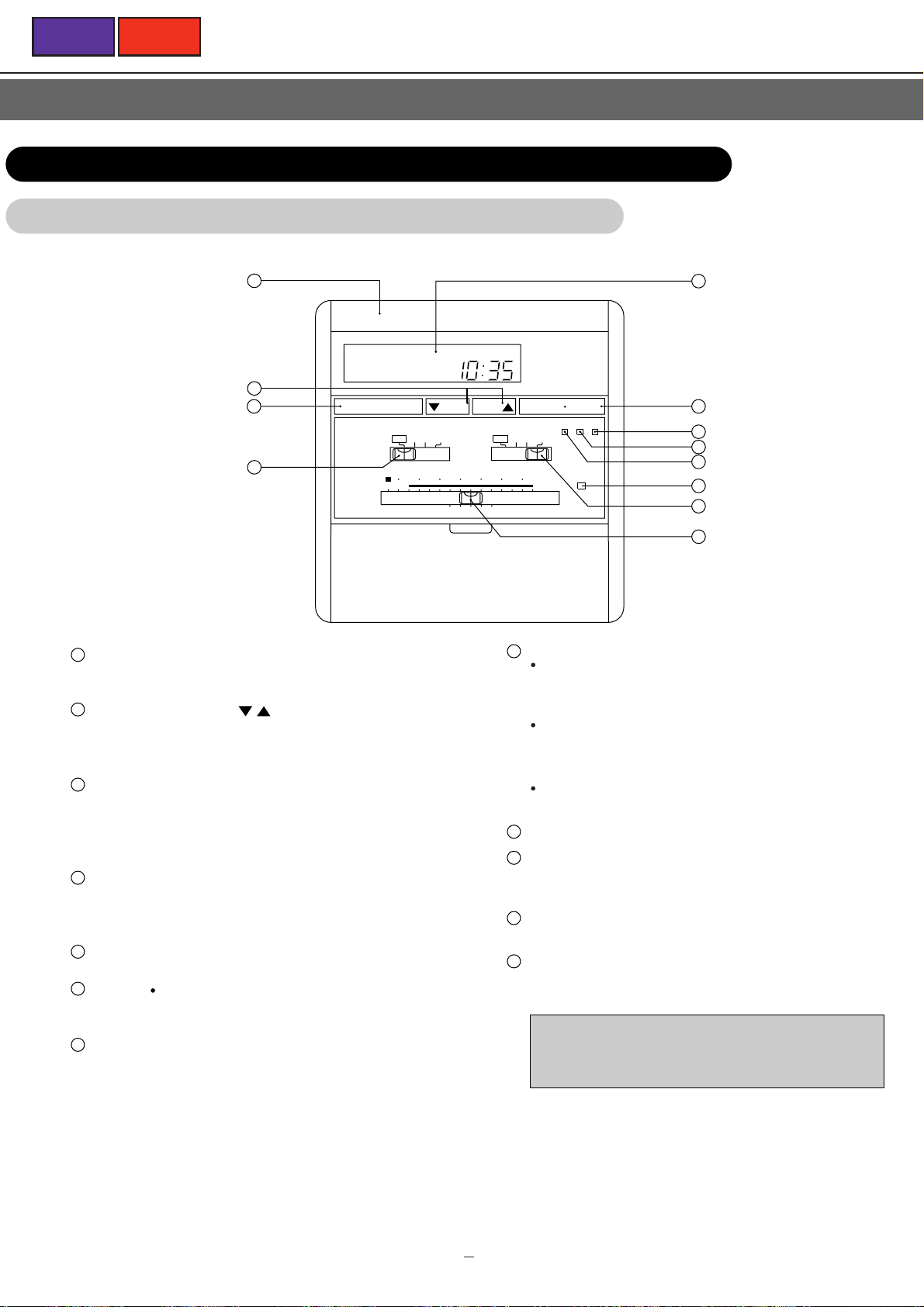

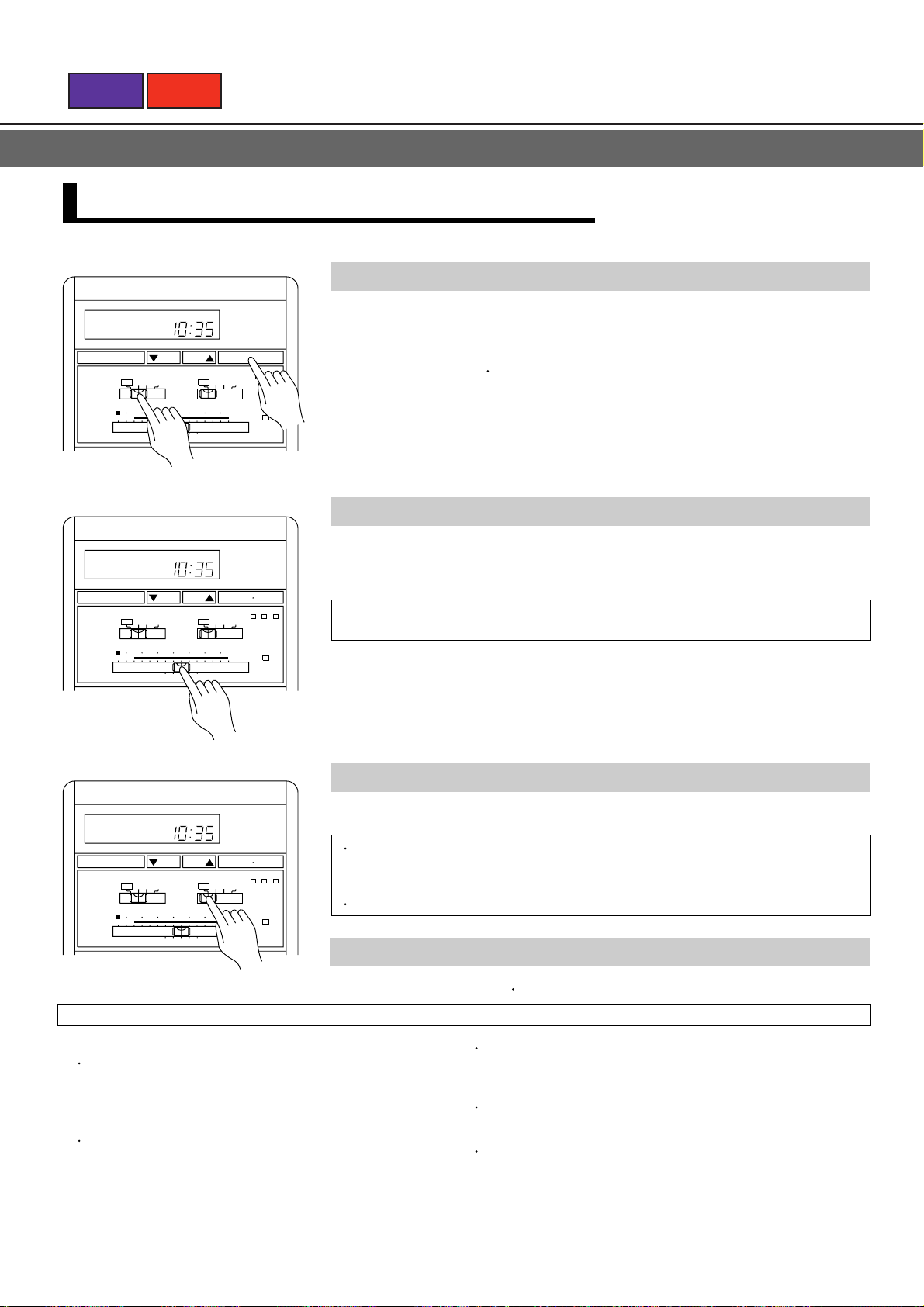

1.4.1 WIRELESS REMOTE CONTROLLER

1

NON STOP CLOCK

2

1

Signal Transmitter

3

4

TIMER SET

AUTO AUTO

MASTER

CONTROL

THRTMOSTAT

Transmits control signals to the air conditioner.

2

SET TIME Buttons

/

( )

Use to make timer settings, to change the time, and to

set the clock to the current time.

3

TIMER Button

Use to select the various timer modes(OFF timer, ON

timer, PROGRAM timer, SLEEP timer, NON-STOP

operation).

4

MASTER CONTROL Switch

Use to select the various operating modes (AUTO,

COOL, DRY, FAN).

5

Remote Control Unit Display (LCD)

6

START

STOP Button

Press to start and stop operation.

7

ACL Button

5

6

7

8

9

10

11

LOW MED

26

28

START STOP

TIME ADJUST

TEST RUN

HIGH

LOUVER

30

ACL

TIME

COOL

DRY

FAN

FAN

CONTROL

18

20

22

24

19 21 23 25 27

12

8

TEST RUN Button

This button is used when installing the air conditioner,

and should not be used under normal conditions,

since it will cause the air conditioner's thermostat

function to stop operating properly.

If this button is pressed during normal operation, the

unit will switch to test operation mode, and the room

unit's operation lamp and timer lamp will begin to flash

simultaneously.

To stop the test operation mode, press the Operation

Stop button to stop the air conditioner.

9

TIME ADUST Button

10

LOUVER Button

Press it start and stop auto louver operation.

Press it to turn on and press again to turn off.

11

FAN CONTROL Switch

Use to select the fan speed (AUTO, LOW, MED,HIGH).

12

THERMOSTAT Control Switch

Use to set the desired room temperature.

Depending on the conditions in your room, the

displayed temperature may differ from the actual room

temperature.

1 4

Page 10

BACK

TIMER SET

TIME

START STOP

NON STOP CLOCK

SLEEP

TIMER

PROGRAM

OFF ON

1

2

3

NEXT

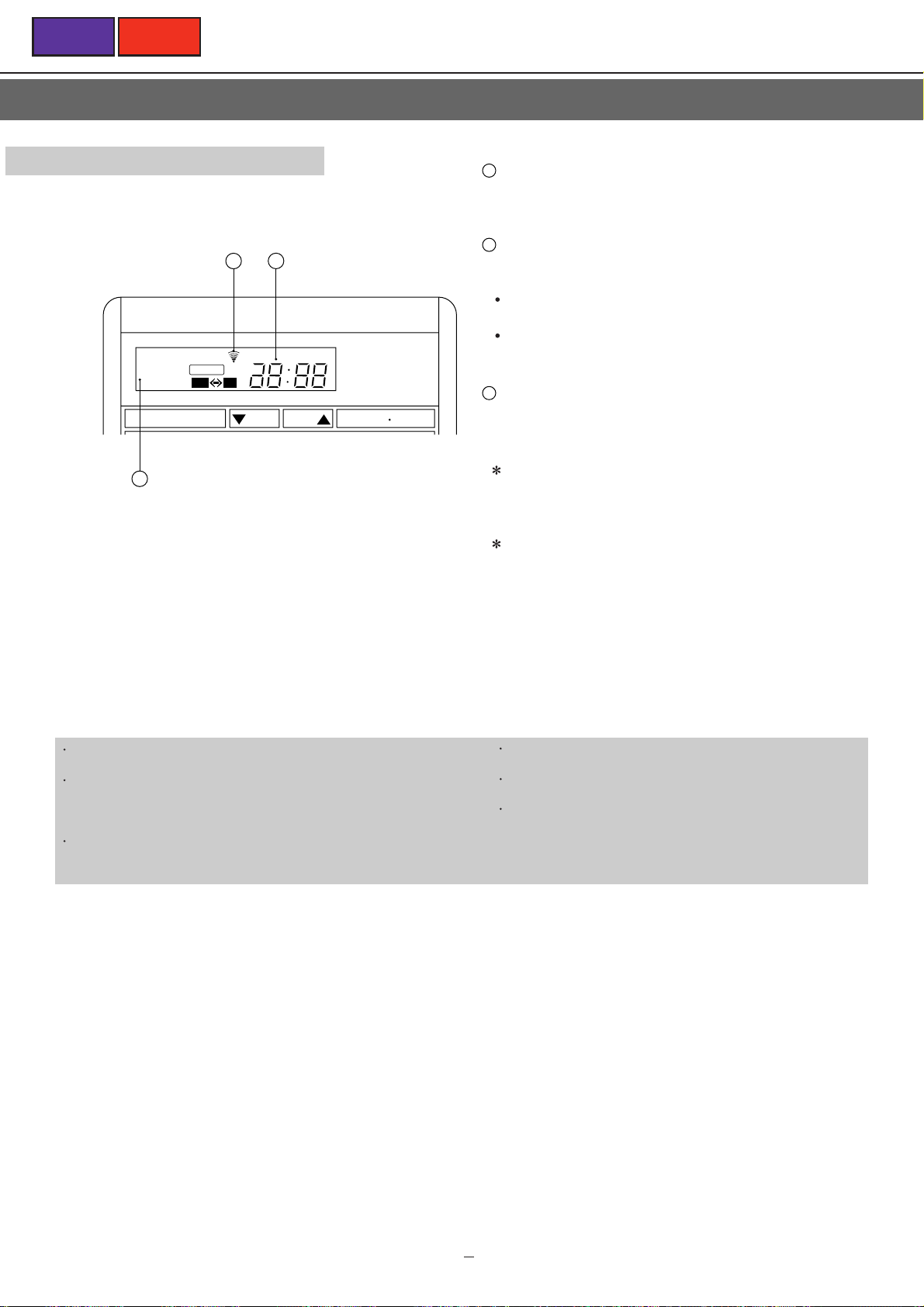

Remote Control Unit Display

Indicates the timer setting.

1

Transmit Indicator

This indicator is displayed when a signal is sent to the

air conditioner.

2

Time Display

Indicates either the current time or the timer setting (24hour display,from 0:00 to 23:59).

When the word "CLOCK" is shown, the display

indicates the current time.

When the word " TIMER " is shown, the display

indicates the timer setting.

2

Time Mode Display

Indicates the timer mode (OFF timer, ON timer,

PROGRAM timer, SLEEP timer, NON-STOP).

When the remote control unit's batteries run low, the

display (especially the transmit indicator) will become

faint. Use this as a guide to indicate when batteries

should be replaced.

To facilitate explanation, the accompanying illustration

has been drawn to show all possible indicators ; in actual

operation, however, the display will only show those

indicators appropriate to the current operation.

Signals will not be transmitted properly if a wall, curtain, or other

object is between the air conditioner and the remote control unit.

The air conditioner may fail to operate properly if strong direct

light is allowed to strike the signal receiver. Use a curtain to

shade strong sunlight from windows, and place strong lamps at

a distance away from the signal receiver.

If another electric appliance is operated by the remote control

unit move the appliance away or consult with authorized service

personnel.

Do not place the remote control unit in locations where it may be

subjected to heat from direct sunlight or from heating apparatus.

Do not subject the remote control unit to strong impacts, and do

not allow water or other liquids to splash on it.

When the remote control unit is used in rooms furnished with

instant-lighting type fluorescent lamps, the air conditioner may

fail to receive control signals correctly.Consult with authorized

service personnel when purchasing a new fluorescent lamp.

1 5

Page 11

BACK

NEXT

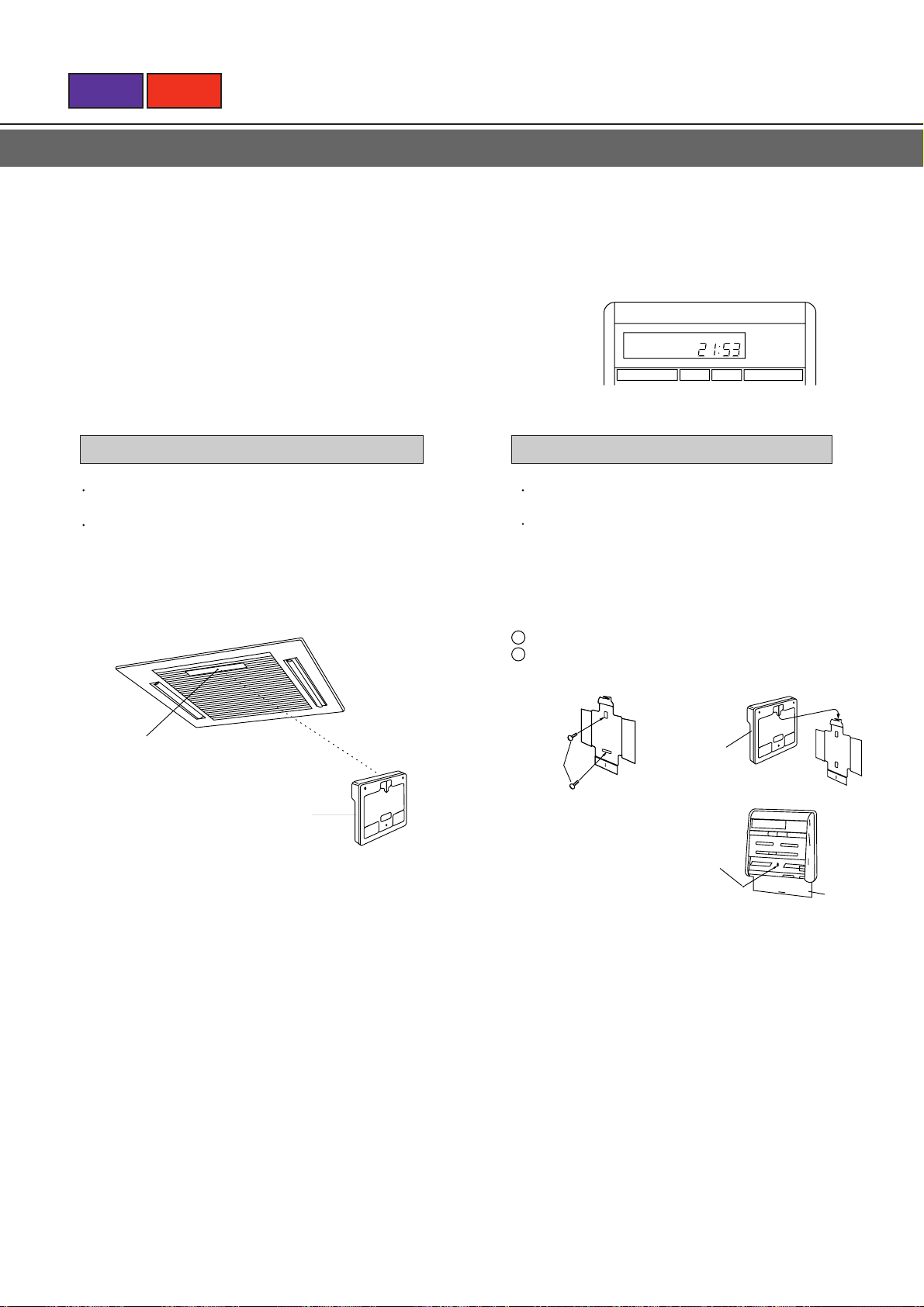

PREPARATION

Prepare the Remote Control Unit

Load batteries in the remote control unit and set the clock to the current time.

Set the Current TimeLoad Batteries (R6P / LR6 x 4)

Pull the battery cover in the direction of the

1

arrow to open it.

Press the TIME ADJUST button.

1

(Use the tip of a pen, etc., to press the button.)

CLOCK

Insert batteries, taking care to align the and

2

-

polarities correctly.

Push the battery cover in the direction of the

3

arrow to close it.

CAUTION!

Take precautions to prevent infants from accidentally swallowing

batteries.

When not using the remote control unit for an extended period,

remove the batteries to avoid possible leakage and damage to

the unit.

If leaking battery fluid comes in contact with your skin, eyes, or

mouth, immediately wash with copious amounts of water, and

consult your physician.

Dead batteries should be removed quickly and disposed of

properly, either by placing in a public battery collection

receptacle, or by returning to a properly equipped dealer.

Do not attempt to recharge dry batteries.

NOTE:

Never mix new and used batteries, or batteries of different

types.

Batteries should last about one year under normal use. If the

remote control unit's operating range becomes appreciably

reduced, replace the batteries and press the ACL button with

the tip of a ballpoint pen or other small object.

+

TIMER SET

AUTO AUTO

COOL

DRY

VASTER

CONTROL

FAN

FAN

CONTROL

TIME

START STOP

TIME ADJUST

LOW MED

HIGH

TEST RUN

ACL

TIME ADJUST

button

<Remote Control Unit Display>

The current time display will flash.

CLOCK

Press the SET TIME buttons to set the display

2

to the current time.

button: Press to advance the time setting.

button: Press to reverse the time setting.

(The time setting will be changed by 1 minute each time

a button is pressed; the time setting will change

continuously in 10-minute increments when a button is

held depressed.)

<Remote Control Unit Display>

The current time display will flash.

CLOCK

TIMER SET

(Example: When the display is set to 21:53)

TIME

START STOP

Page 12

BACK

NEXT

Press the TIME ADJUST button once again.

3

<Remote Control Unit Display>

The current time display will stop flashing.

CLOCK

To Use the Remote Control Unit

Install the remote control so that the front is facing the

photocell.

Install the remote control with a distance of 7 m

between the remote control and the grille photocell as

the criteria.

However, when installing the remote control, check that

it operates positively.

Photocell

Remote control unit

Remote Control Unit Holder

This holder allows the remote control unit to be

mounted on a post or wall.

If the holder is installed in a place that allows the

signals from the remote control unit to be properly

received by the main unit, the air conditioner can be

controlled without removing the remote control unit

from its holder.

1

Installing the holder.

2

Setting the remote control unit.

Remote

Screw

(

medium

)

control

unit

Machine screw

(

)

small

Hook

Battery

cover

Page 13

THRTMOSTAT

MASTER

CONTROL

FAN

CONTROL

AUTO AUTO

COOL

18

19 21 23 25 27

DRY

FAN

LOW MED

HIGH

TIME ADJUST

TEST RUN

ACL

LOUVER

TIMER SET

TIME

START STOP

NON STOP CLOCK

20 22

24

26 28

30

1

2

THRTMOSTAT

MASTER

CONTROL

FAN

CONTROL

AUTO AUTO

COOL

18

19 21 23 25 27

DRY

FAN

LOW MED

HIGH

TIME ADJUST

TEST RUN

ACL

LOUVER

TIMER SET

TIME

START STOP

NON STOP CLOCK

20

22 24

26 28

30

THRTMOSTAT

MASTER

CONTROL

FAN

CONTROL

AUTO AUTO

COOL

18

19 21 23 25 27

DRY

FAN

LOW MED

HIGH

TIME ADJUST

TEST RUN

ACL

LOUVER

TIMER SET

TIME

START STOP

NON STOP CLOCK

20

22 24

26

28 30

BACK

NEXT

AUTOMATIC OPERATION

During AUTO operation, the operating mode (cooling, etc.) will be selected automatically in accordance with room temperature

conditions at the time operation is started.

To Select Mode Operation

Set the MASTER CONTROL switch to the AUTO position.

1

Press the START STOP button.

2

Operation will start (operation will not start if the ON timer has been set).

<Indoor Unit Display>

The OPERATION indicator lamp will light.

To Set the Thermostat

Set the THERMOSTAT control to the desired position.

Range of temperature settings:

19, 21, 23, 25, 27˚C

To Set the Fan Speed

Set the FAN CONTROL switch to the desired position.

When the FAN CONTROL switch is set to the AUTO position,

the optimum fan speed will be selected automatically in accordance with room

temperature and other conditions.

To Stop Operation

Press the START STOP button.

About Automatic Operation

When the room temperature is 2°C higher than the set

temperature, the mode will switch between cooling and dry.

Most effective cooling will be produced by setting the FAN

CONTROL to HIGH.

During dry mode operation, FAN setting is switched to LOW for

gentle cooling effect, and the room fan may stop rotating

temporarily.

Cooling Operation

Dry Operation

2

C

Setting temperature

Thermostat control

Page 14

BACK

NEXT

MODE OPERATION (COOL, DRY)

Use the dry mode when you wish to eliminate room humidity without lowering the room temperature excessively.

To Select Mode Operation

NON STOP CLOCK

Set the MASTER CONTROL switch to the desired position (COOL,

1

TIMER SET

AUTO AUTO

MASTER

CONTROL

THRTMOSTAT

18

START STOP

TIME

TIME ADJUST

TEST RUN

COOL

DRY

FAN

20 22

19 21 23 25 27

1

FAN

CONTROL

24

26 28

LOW MED

30

ACL

HIGH

LOUVER

2

DRY).

Press the START STOP button.

The unit will start operating in the selected mode (operation will not start if the ON

timer has been set).

<Indoor Unit Display>

The OPERATION indicator lamp will light.

To Set the Thermostat

NON STOP CLOCK

TIMER SET

AUTO AUTO

MASTER

CONTROL

THRTMOSTAT

18

NON STOP CLOCK

TIMER SET

AUTO AUTO

MASTER

CONTROL

THRTMOSTAT

18

Set the THERMOSTAT control to the desired position.

2

START STOP

TIME

TIME ADJUST

TEST RUN

COOL

DRY

FAN

20

22 24

19 21 23 25 27

FAN

CONTROL

26 28

LOW MED

30

ACL

HIGH

LOUVER

Range of temperature settings: 18 to 30˚C

To Set the Fan Speed

Set the FAN CONTROL switch to the desired position.

START STOP

TIME

TIME ADJUST

TEST RUN

COOL

DRY

FAN

20

22 24

19 21 23 25 27

FAN

CONTROL

LOW MED

26

28 30

ACL

HIGH

LOUVER

When the FAN CONTROL switch is set to the AUTO position, the optimum fan

speed will be selected automatically in accordance with room temperature and

other conditions.

During the dry mode, fan speed is set automatically and cannot be changed.

To Stop Operation

Press the START STOP button.

About Mode Operation

Cooling

When using the cooling mode, set the temperature to a value

lower than the actual current room temperature. If it is set higher

than the current room temperature, the unit will not enter the

cooling mode and only the fan will operate.

Drying

In the dry mode, since preference will be given to removing

humidity, the room temperature may not be lowered to the

selected value.

When using the dry mode, set the temperature to a value lower

than the actual current room temperature. If it is set higher than

the current room temperature, the unit will not enter the dry

mode.

In the dry mode, the optimum fan speed will be set automatically

and cannot be changed. The fan will emit a very weak stream of

air.

In the dry mode, the room fan may occasionally stop in order to

prevent room humidity from rising.

Page 15

BACK

NEXT

MODE OPERATION (FAN)

Use this mode when you wish to recirculate the air in your room.

To Select Mode Operation

Set the MASTER CONTROL switch to the FAN position.

NON STOP CLOCK

1

TIMER SET

AUTO AUTO

COOL

MASTER

CONTROL

THRTMOSTAT

18

NON STOP CLOCK

TIMER SET

AUTO AUTO

MASTER

CONTROL

THRTMOSTAT

18

NON STOP CLOCK

START STOP

TIME

TIME ADJUST

TEST RUN

DRY

20

FAN

CONTROL

22 24

19 21 23 25 27

FAN

1

LOW MED

26

28 30

ACL

HIGH

LOUVER

2

Press the START STOP button.

2

Operation will start (operation will not start if the ON timer has been set).

<Indoor Unit Display>

The OPERATION indicator lamp will light.

To Set the Fan Speed

Set the FAN CONTROL switch to the desired position.

START STOP

TIME

TIME ADJUST

TEST RUN

COOL

DRY

FAN

20

22

19 21 23 25 27

FAN

CONTROL

24 26

LOW MED

28 30

ACL

HIGH

LOUVER

When the AUTO fan speed is selected in the FAN mode, the fan speed will

automatically be set on MED.

To Stop Operation

Press the START STOP button.

TIMER SET

AUTO AUTO

COOL

MASTER

CONTROL

THRTMOSTAT

18

DRY

20

FAN

CONTROL

22

19 21 23 25 27

FAN

24 26

TIME

START STOP

TIME ADJUST

LOW MED

HIGH

28 30

TEST RUN

LOUVER

ACL

NOTE:

Do not allow the air conditioner's air stream to directly strike a kerosene or other space heater.

Incomplete combustion or fires may result.

Page 16

BACK

NEXT

TIMER OPERATION

Press the START•STOP button; after the unit starts operation perform the following procedure:

OFF Timer/ON Timer

TIMER

OFF

TIMER SET

TIME

START STOP

Example: To set for OFF timer

TIMER

ON

TIMER SET

TIME

START STOP

1

Press the TIMER button, so that the timer mode display shows only

OFF or ON.

The timer will start operating (if the ON timer has been set, the unit will stop

operating).

<Indoor Unit Display>

The TIMER indicator lamp will light.

Each time the button is pressed the timer function changes in the following order:

RESET SLEEP OFF ON

PROGRAM (OFF ON, OFF ON)

Example: To set for ON timer

TIMER

OFF

TIMER SET

TIME

START

STOP

Example: To set the ON timer to turn

the air conditioner off at

00:00

To Confirm or Change Settings Before

Starting Operation

To confirm settings

Press the TIMER button once. (The timer

setting information will be displayed for 15

seconds after the TIMER button is

pressed.)

To change settings

Confirm the settings as noted above, then

press the SET TIME button and TIMER

button as necessary to change the

desired timer setting. (The timer settings

will be displayed for 15 seconds after the

button is pressed.)

After confirming or changing the settings,

press the START•STOP button to start

operation.

Press the SET TIME buttons to adjust the time (the accompanying

2

illustration shows the OFF timer).

Button: Press to advance the time setting.

Button: Press the reverse the time setting.

(Each time a button is pressed the time will change in 5-minute increments; when

held depressed the time will change continuously in 10-minute increments.)

To Change the Timer Setting During

Operation

Operate as noted in step 2.

To Change the Timer Mode During

Operation

Press the TIMER button and set the unit to

the desired mode.

To Cancel the Timer Mode During

Timer Operation

Press the TIMER button and set the display

to "NON STOP" (the unit will switch to nonstop operation).

To Stop Operation During Use of

Timer Mode

Press the START•STOP button.

During operation of the ON timer, the

indoor unit's OPERATION indicator lamp

will not light (the TIMER indicator lamp

will light instead).

When the time reaches the set value, the

unit will start operation and the

OPERATION indicator lamp will light.

Page 17

BACK

NEXT

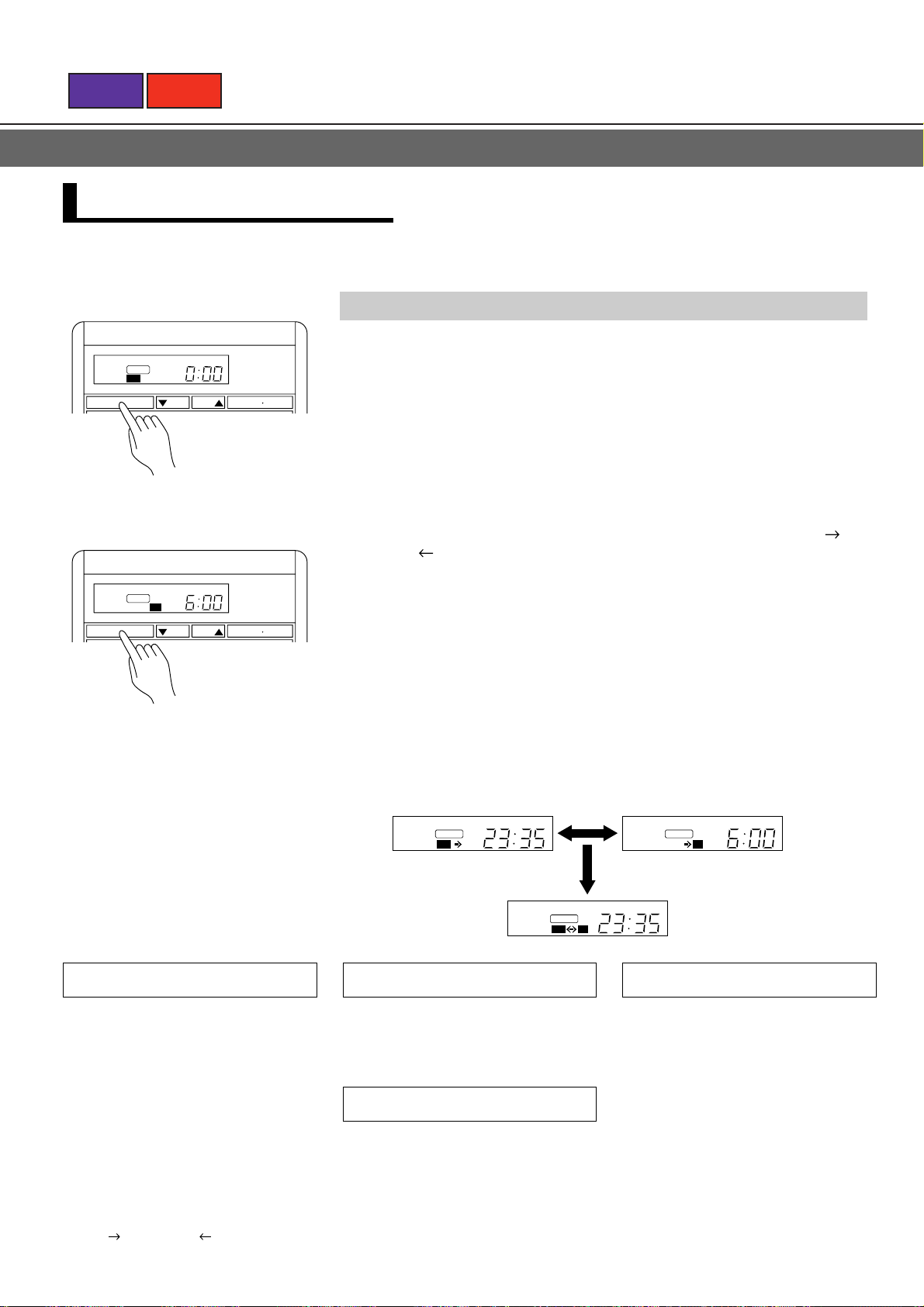

PROGRAM TIMER

Press the START•STOP button; after the unit starts operation perform the following procedure:

To Use the PROGRAM Timer

Press the TIMER button to select the "OFF" and "ON" timer modes

1

TIMER

OFF

TIMER SET

TIME

START STOP

To select OFF timer mode

and make the respective timer settings.

Press the TIMER button so that the display shows OFF ON

2

or OFF ON as desired.

TIMER

ON

TIMER SET

TIME

START STOP

To select ON timer mode

To Confirm or Change Settings Before

Starting Operation

See TIMER OPERATION

To Change Settings After Starting

Operation

<Remote Control Unit Display>

For 15 seconds, the display will switch between the "OFF timer" time and the "ON

timer" time. Then, it will switch to display the time setting for the timer operation

which will function first (the one closest to the current actual time).

<Indoor Unit Display>

The TIMER indicator lamp will light.

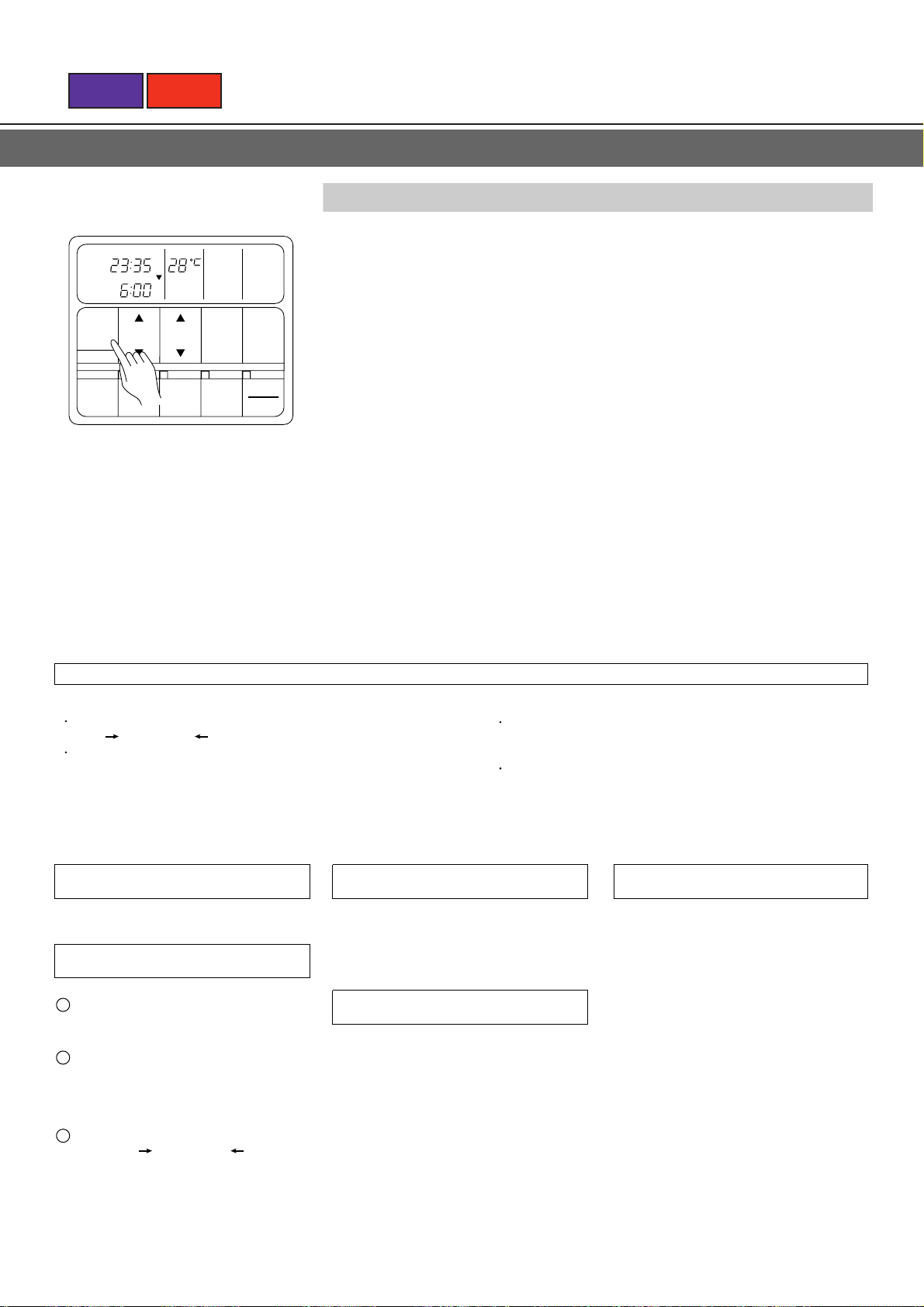

(Example: To set the OFF timer for 23:35 and the ON timer for 6:00)

Displayed

alternately

PROGRAM

TIMER

OFF

PROGRAM

TIMER

ON

After 15 seconds

TIMER

PROGRAM

OFF ON

To Change the Timer Mode During

Operation

Press the TIMER button and set the unit to

the desired mode.

To Stop Operation During Use of

Timer Mode

See TIMER OPERATION

1 Follow the instructions in step 1 of p.15 to

display the timer mode whose time

setting you wish to change.

2.Follow the instructions in step 2 to p.15 to

change the timer setting.

To change both the OFF timer and ON

timer settings, perform both of the above

steps 1,2 for each setting.

3.Press the TIMER button to display either

"OFF ON" or "OFF ON".

To Cancel the Timer Mode During

Timer Operation

Press the TIMER button and set the display

to "NON STOP" (the unit will switch to non

stop operation).

Page 18

BACK

NEXT

SLEEP TIMER OPERATION

The SLEEP timer is different from other timer functions, in that it is used to set the amount of time the air conditioner operates

until it turns off (in the example shown, the air conditioner will turn off two hours after the current time).

Press the START•STOP button; after the unit starts operation perform the following procedure:

To Use the SELECT Timer

Press the TIMER button, so that the timer mode display shows only

1

SLEEP.

SLEEP

TIMER

OFF

TIMER SET

TIME

START STOP

<Indoor Unit Display>

The TIMER indicator lamp will light.

SLEEP

TIMER

OFF

TIMER SET

Example: To set the SLEEP timer

to turn the air conditioner

off after two hours.

TIME

START STOP

Press the SET TIMER buttons to adjust the time (the accom-

2

panying illustration shows the SLEEP timer).

Button: Press to advance the time setting

Button: Press to reverse the time setting

(Each time a button is pressed the time will change in 5-minute increments; when

held depressed the time will change continuously in 10-minute increments.)

To Confirm or Change Settings Before Starting Operation

See TIME OPERATION

To Change the Timer Setting During Operation

Operate as noted in step 2.

To Change the Timer Mode During Operation

Prese the TIMER button and set the unit to the desired mode.

To Cancel the Timer Mode During Timer Operation

Press the TIMER button and set the display to "NON STOP" (the unit will switch to

non-stop operation).

To Stop Operation During Use of Timer Mode

See TIME OPERATION

About the SLEEP Timer

This function changes the room thermostat setting over time, to

prevent excessive room cooling while you sleep. After the set time

has elapsed, the air conditioner operation turns off automatically.

During cooling and dry operation

When the sleep timer is set, the thermostat setting is raised 1°C

each hour. After the thermostat setting has been raised a total

of 2°C, that setting is maintained for the remainder of the set

time, and operation is then stopped.

SLEEP Timer setting

1 hour

Set time

1

c

Stop

2

c

Page 19

BACK

NEXT

HOW TO CONTROL AIR DIRECTION

The power must be turned on in order to adjust the louver direction (attempting to move the

louvers by hand could result in damage).

CAUTION!

During cooling operation, if the louvers are adjusted to blow air directly downward for extended

periods of time, water may condense on the outlet port and louvers, and drip onto the floor.

Horizontal AUTO LOUVER

When the remote control unit's LOUVER button is pressed,

the automatic louver lamp lights and the direction of air flow

changes automatically between up and down.

Louver can be stopped at any position when the switch is

pressed to turn it off.

Horizontal louvers

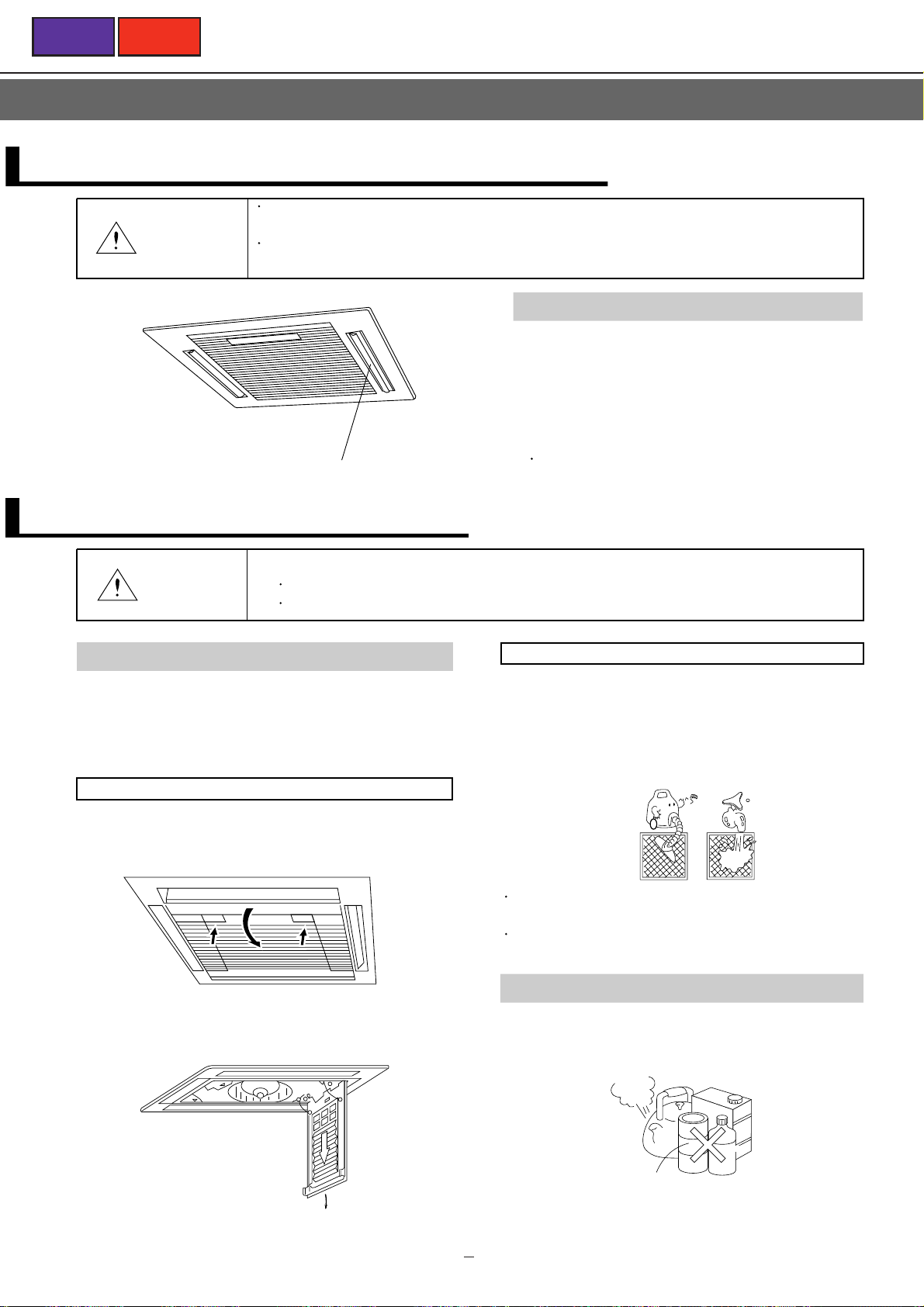

CARE AND MAINTENANCE

Before cleaning the unit, be sure to stop the unit and disconnect the power supply.

CAUTION!

Cleaning the Air Filter

A clogged air filter reduces the airflow and weakens the

cooling effect. If the air filter remains clogged, it may cause

a defect.

How to remove the air filter

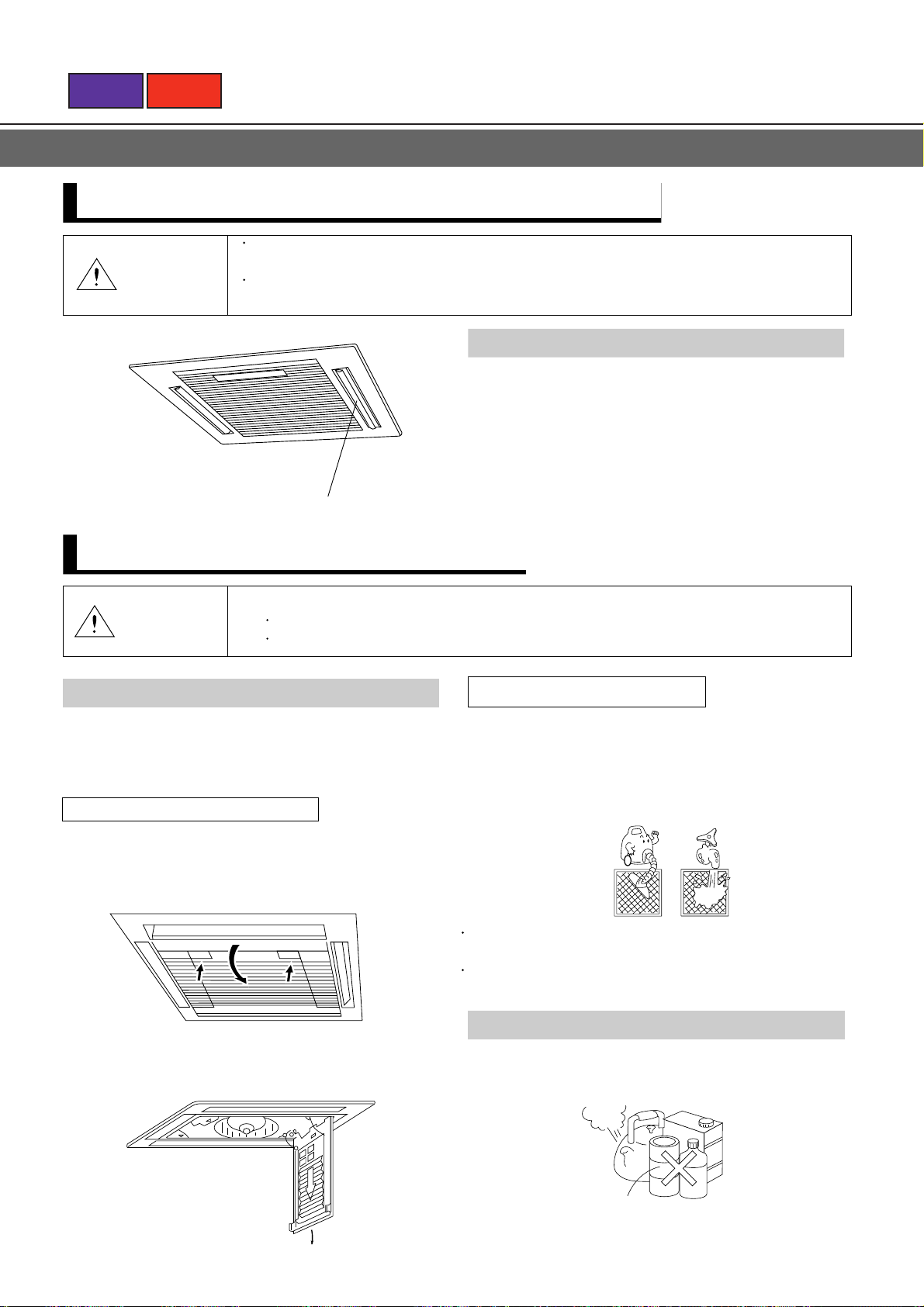

1. Push the intake grille pushbuttons two places until

you hear a "click".

Open the intake grille.

PUSH

Turn off the electrical breaker.

A fan operates at high speed inside the unit, and personal injury could result.

PUSH

How to clean the air filter

Clean the dust from the air filter by washing the filter with

water or blow it away with a vacuum cleaner. If the air filter

is very dirty, rinse the filter with warm or cool water mixed

with synthetic detergent and then wash the detergent

solution away with clean water and dry it.

Do not dry the air filter by exposing it to direct sunlight

or fire. This may damage the filter.

Avoid using hot water (40˚C or higher) to wash the

filter. This may damage the filter.

2. Pull the air filter once downward.

The air filter then comes out.

Cleaning the Indoor Unit

Wipe the cabinet with a dry soft cloth or clean with a cloth

dipped in hot water.

Use of a synthetic detergent is effective for cleaning.

Gasoline

Hot

Water

Polishing powder

Do not use gasoline, thinner, alcohol, benzine, chemicals,

polishing powder, etc. to clean the cabinet.

Benzine

Page 20

BACK

NEXT

ERRORS AND SELF DIAGNOSIS

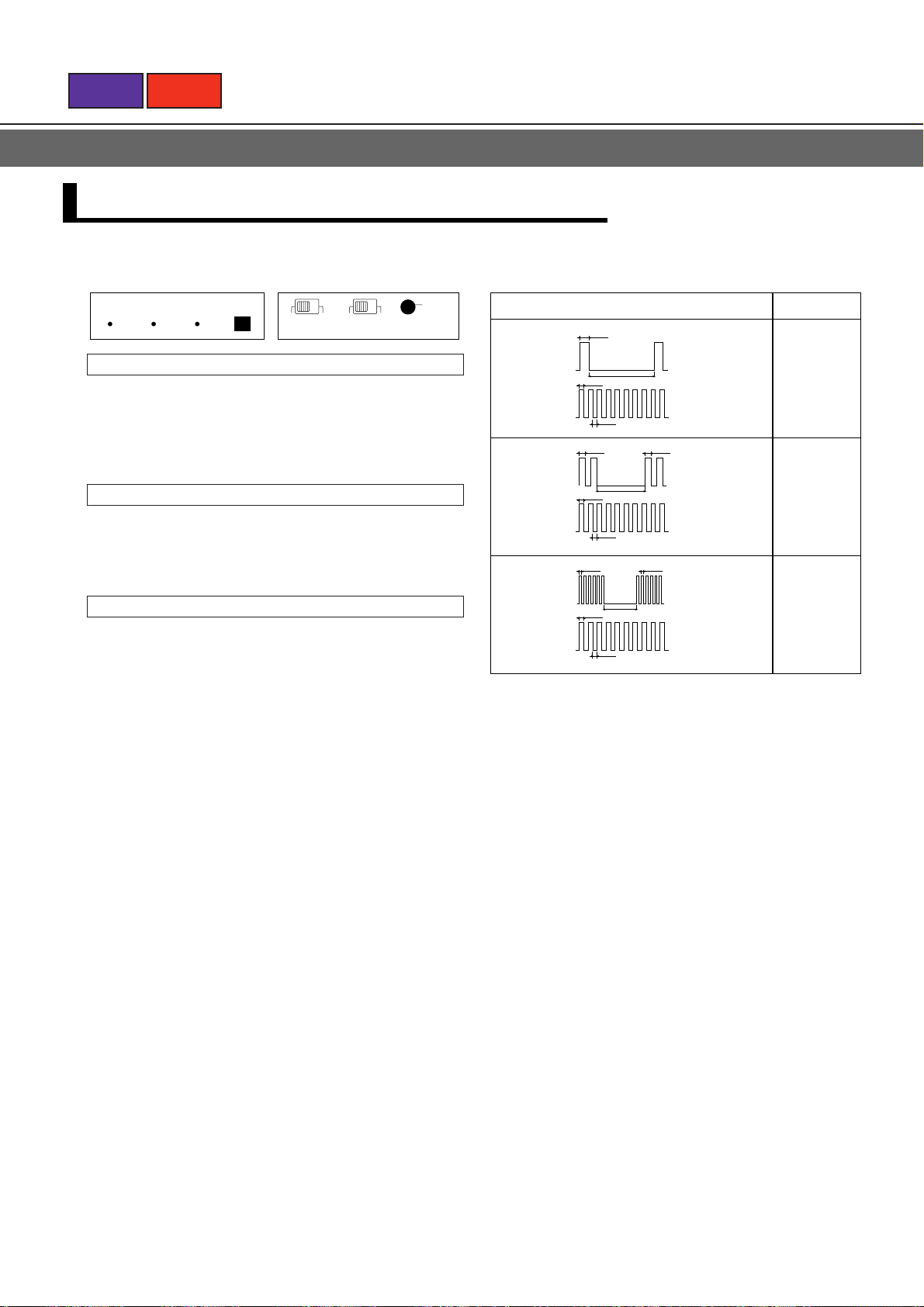

Operation can be checked by lighting and flashing of the grille display section OPERATION and TIMER lamps.

Perform judgment in accordance with the following:

MANUAL

OperationTimerLouver

OFF

POWER

ON

NORMAL

AUTO

RESTART

AUTO

Power ON

When the power is turned on, the grille display section

OPERATION and TIMER lamps flash quickly and

alternately.

When operation starts thereafter, flashing stops.

Test running

When the air conditioner is run by pressing the remote

control unit test running button, the OPERATION and

TIMER lamps flash slowly at the same time

Error

The OPERATION and TIMER lamps operate as follows

according to the error contents.

OPERATION

LAMP

TIMER

LAMP

OPERATION

LAMP

TIMER

LAMP

OPERATION

LAMP

TIMER

LAMP

Error display Error contents

0.5sec

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

0.1sec

0.1sec

0.5sec

0.1sec

5sec

0.1sec

0.5sec

5sec

0.1sec

0.5sec

5sec

0.1sec

0.5sec

Single quick

flash

repeated

0.1 sec ON/

OFF repeated

Two quick

flashes

repeated

0.1 sec ON/

OFF repeated

Six quick

flashes

repeated

0.1 sec ON/

OFF repeated

Room

temperature

thermistor

abnormal

temperature

detected

Piping

thermistor

abnormal

remperature

detected

Float switch

ON for 3

minutes or

longer

Page 21

BACK

NON STOP

OFF ON

TIMER

PROGRAM

REPEAT

FAN AUTO

FAN HIGH

FAN MED

FAN LOW

AUTO

HEAT

FAN

COOL

CLOCK

TIMER

TEMP

SET

TIME

ENERGY

SAVE

ZONE

CONTROL

LOUVER

START

STOP

TIMER

MODE

CLOCK ADJUST

FAN

CONTROL

MASTER

CONTROL

DEFROST TEST

OFF

ON

ON

OFF

SET

TEMP

1

2

3

4

5

6

7

89

10

11

12

13

14

Remote Controller

Display

NEXT

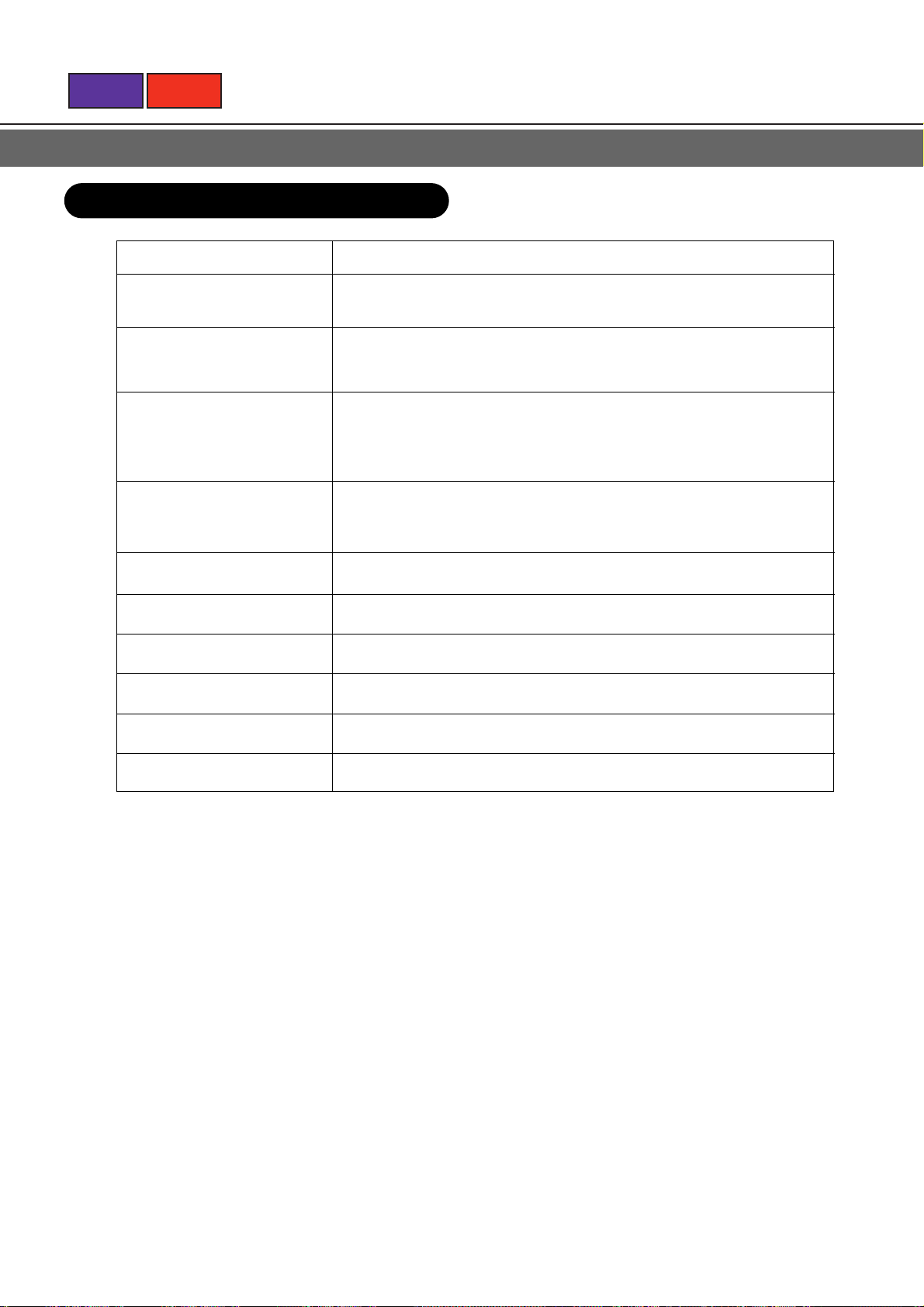

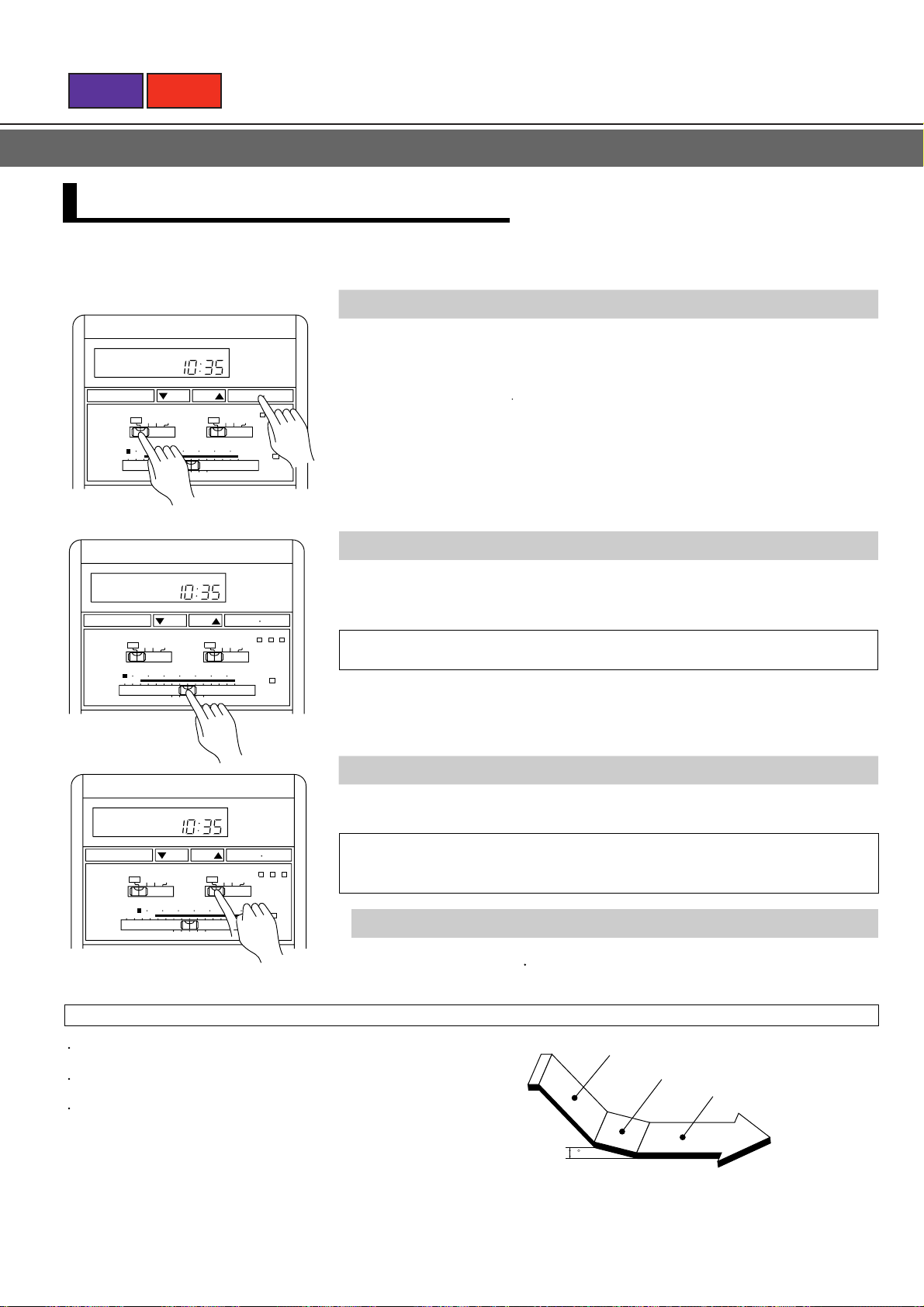

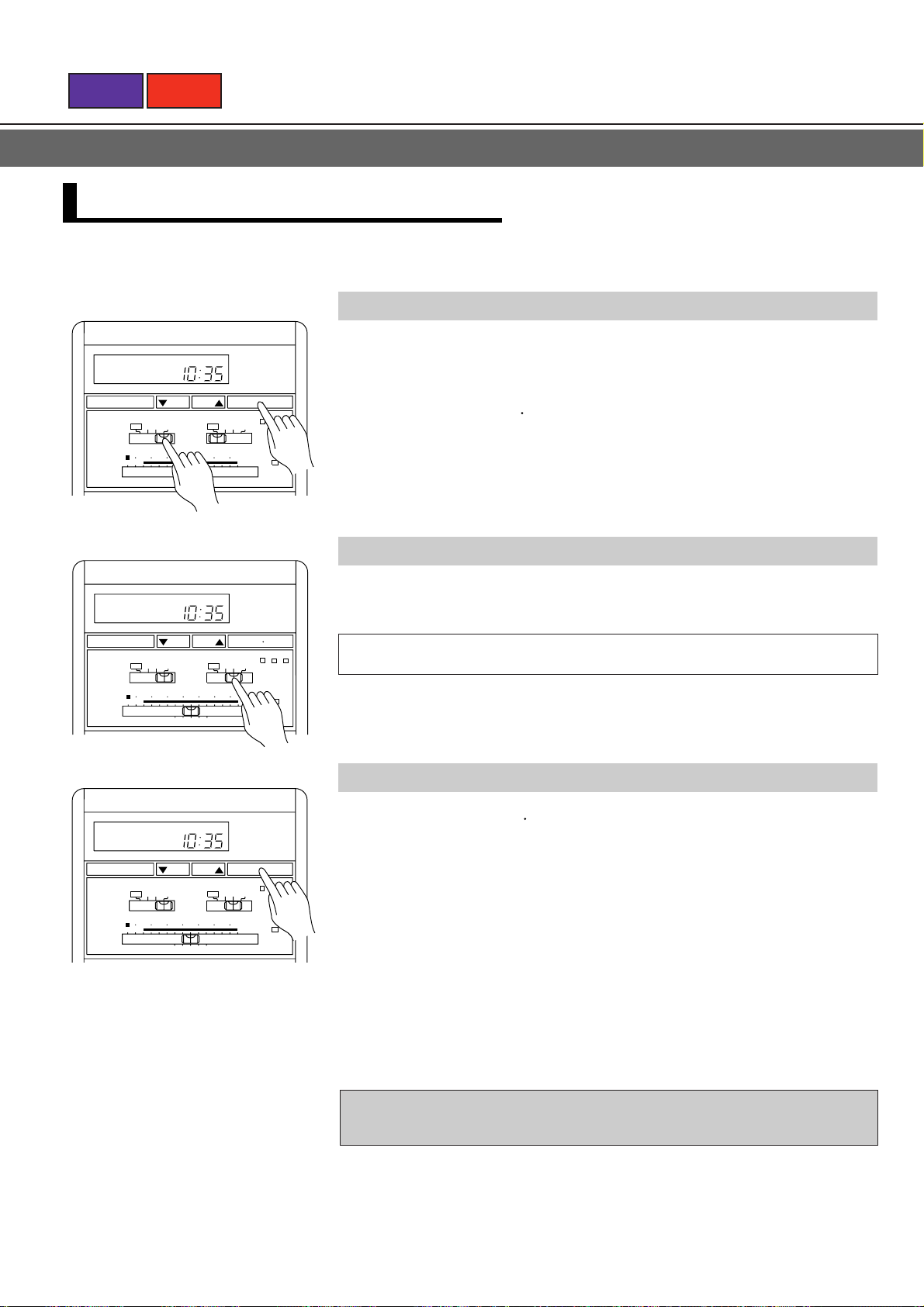

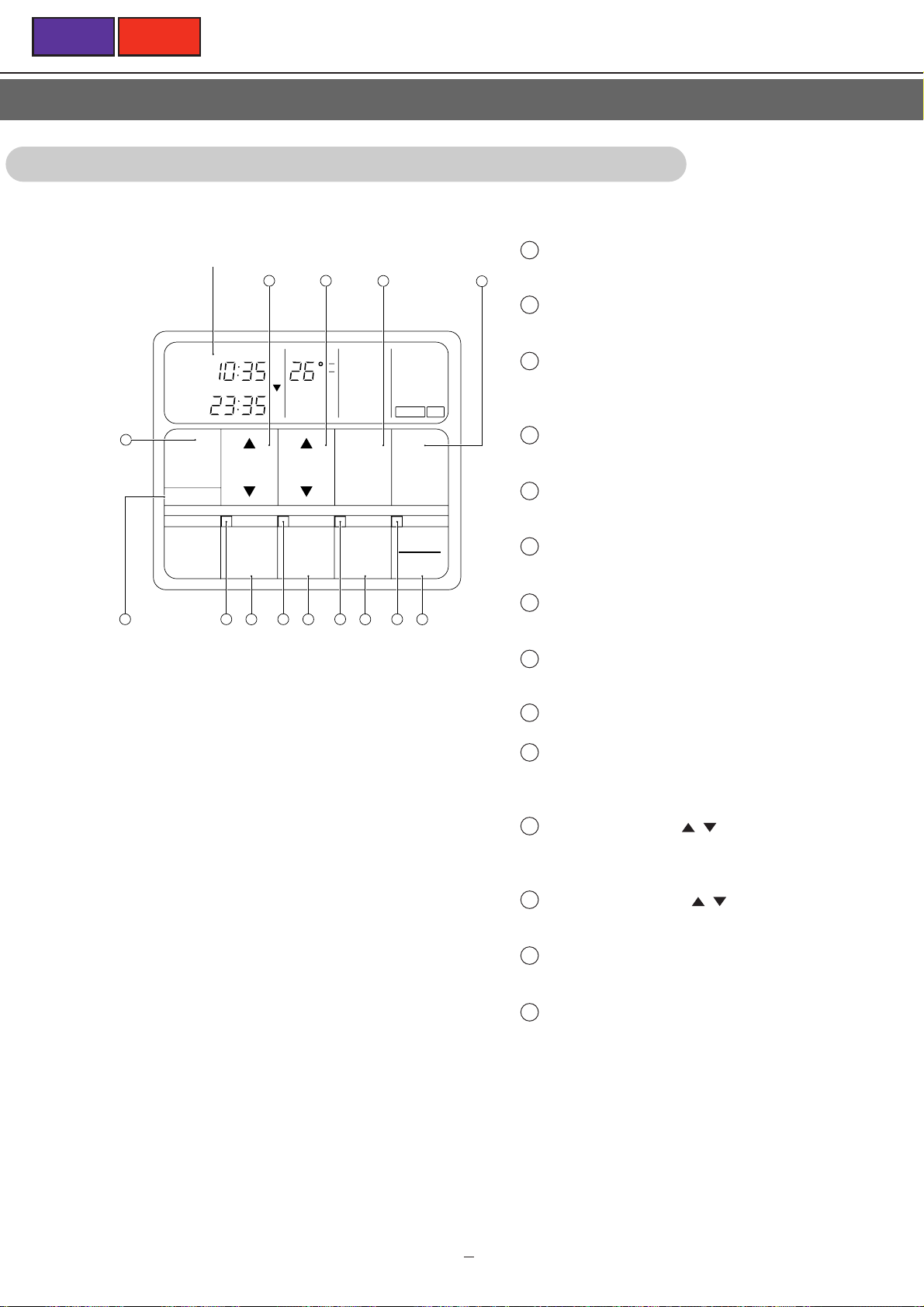

1.4.2 LIQUID CRYSTAL REMOTE CONTROLLER

START/STOP Button

1

Press to start and stop operation.

2

Operation Lamp

Lights up during operation and when the timer is on

3

LOUVER Button

Press it start and stop auto louver operation. Press it to

turn on and press again to turn off.

4

LOUVER Lamp

Lights up during auto louver operation.

For explanatory purposes, the figure showing

the remote controller display shows all

possible displays.

The actual display shows only that area that

is being adjusted or used.

5

ZONE CONTROL Button

Use to turn the zone control on and off.

6

ZONE CONTROL Lamp

Lights up when the unit is in the zone control mode.

ENERGY SAVE Button

7

Turns the energy efficient mode on and off.

8

ENERGY SAVE Lamp

Lights up when the unit is in the energy save mode.

9

CLOCK ADJUST Button

10

TIMER MODE Button

Use to change timer modes (NON STOP, OFF TIMER,

ON TIMER, PROGRAM TIMER, REPEAT TIMER).

11

SET TIME Button ( / )

Use to change the timer settings,

and to set the current time.

12

SET TEMP. Button ( / )

Use to change the temperature setting.

13

FAN CONTROL Button

Use to select the fan speed (AUTO, HIGH, MED, LOW).

1 16

14

MASTER CONTROL Button

Use to select the various operating modes (AUTO,

HEAT, FAN, COOL).

Page 22

BACK

NON STOP

OFF ON

TIMER

PROGRAM

REPEAT

FAN AUTO

FAN HIGH

FAN MED

FAN LOW

AUTO

HEAT

FAN

COOL

CLOCK

TIMER

TEMP

DEFROST TEST

OFF

ON

ON

OFF

4 5

6

7

321

NEXT

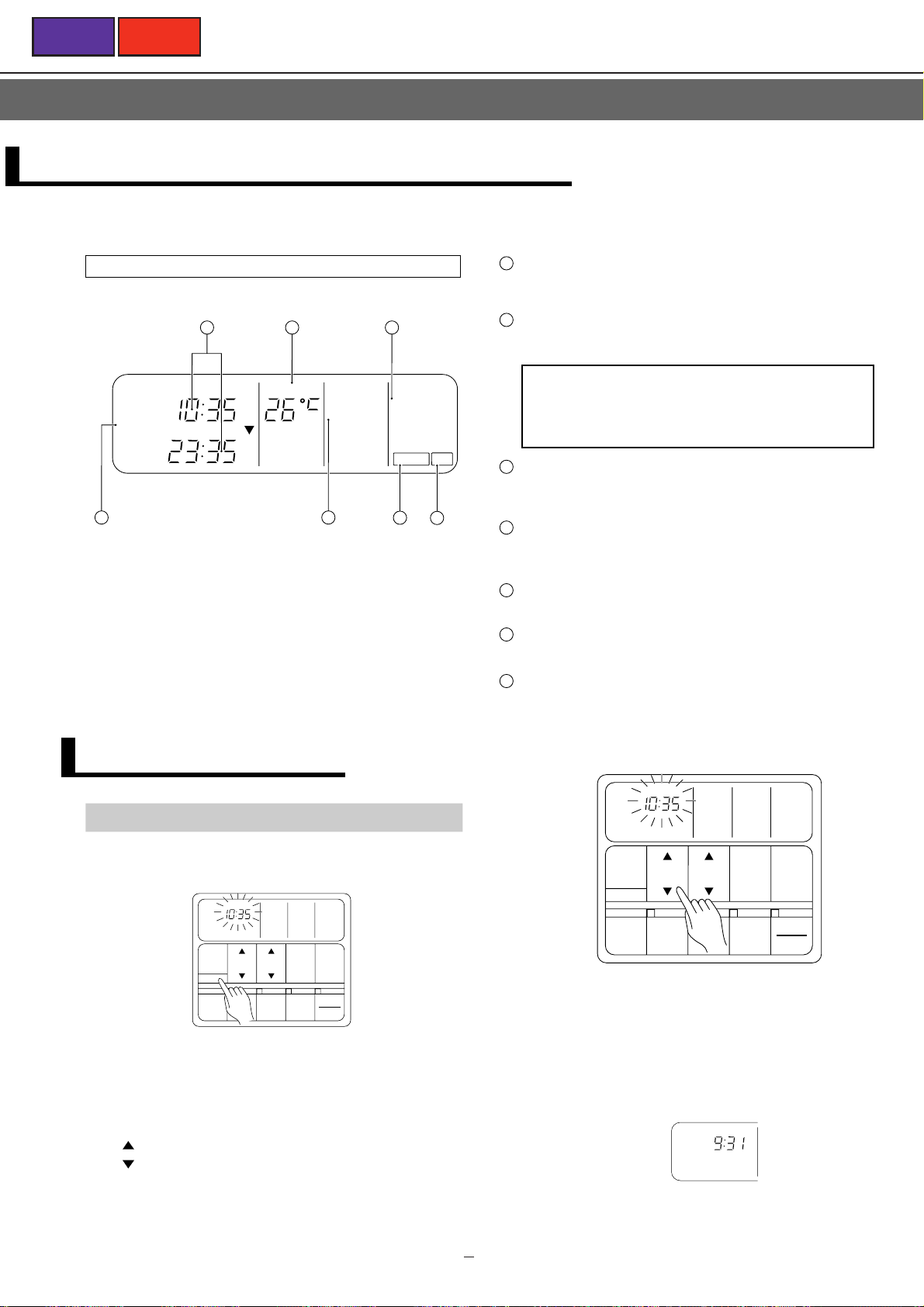

NAME AND FUNCTION OF PARTS

1

Remote Controller Display

* For explanatory purposes, the above figure shows all

possible displays. The actual display shows only that

area being adjusted or used.

Clock Display (CLOCK/TIMER)

Displays current or timer times (0:00 to 23:59).

2

Set Temperature Display (TEMP.)

Displays the set temperature.

Depending on the usage circumstances of the unit

(room width, outdoor temperature etc.)l, the displayed

temperature may differ from the actual room

temperature.

3

Operation Mode Display

Displays the operation mode (AUTO, HEAT, FAN,

COOL).

4

Timer Mode Display

Displays the timer mode (NON STOP, OFF TIMER, ON

TIMER, PROGRAM, REPEAT).

5

Fan Speed Display

Displays the current fan speed.

6

DEFROST Display

Displayed during defrosting.

7

TEST Display

Displayed during test operation.

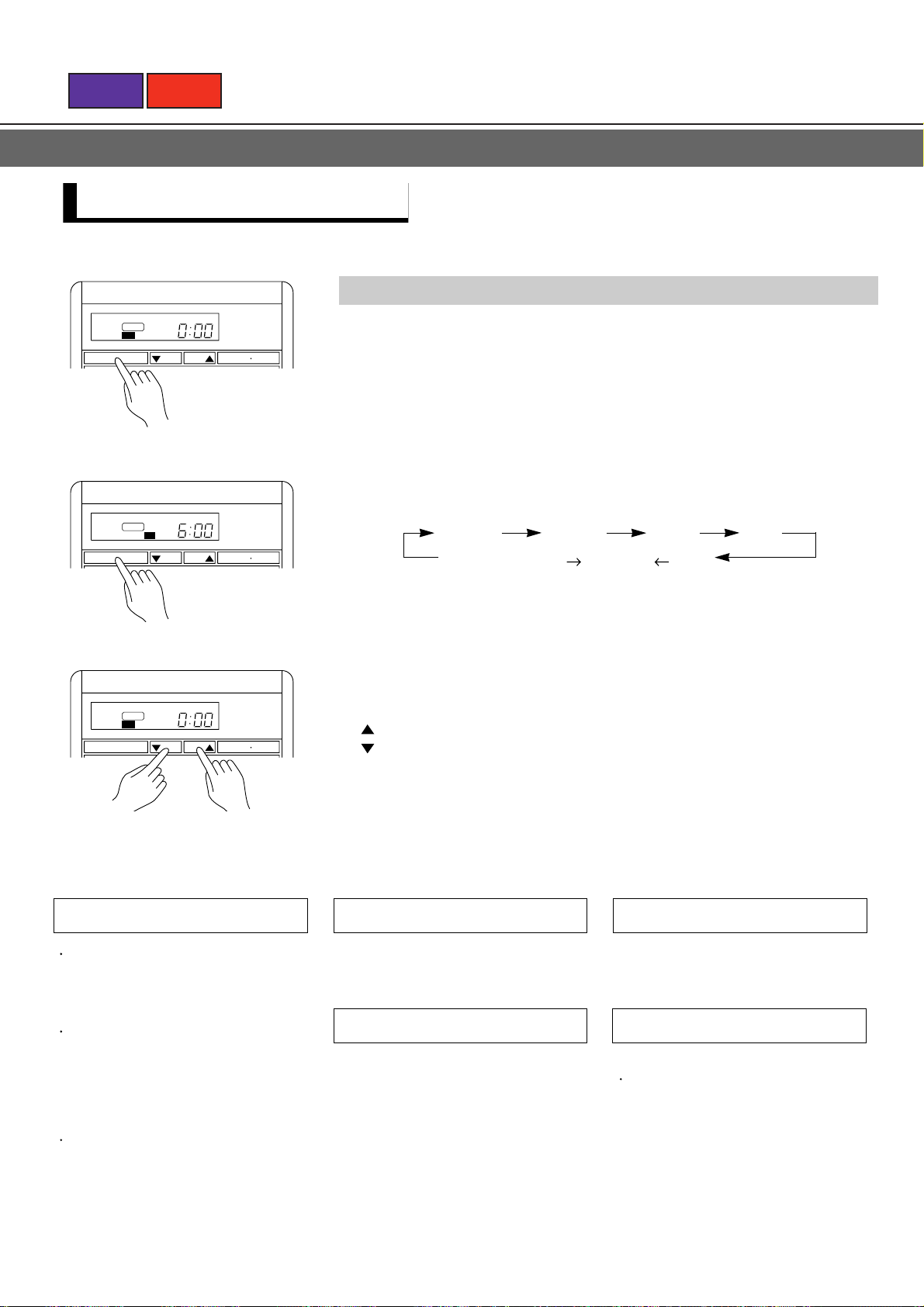

PREPARATION

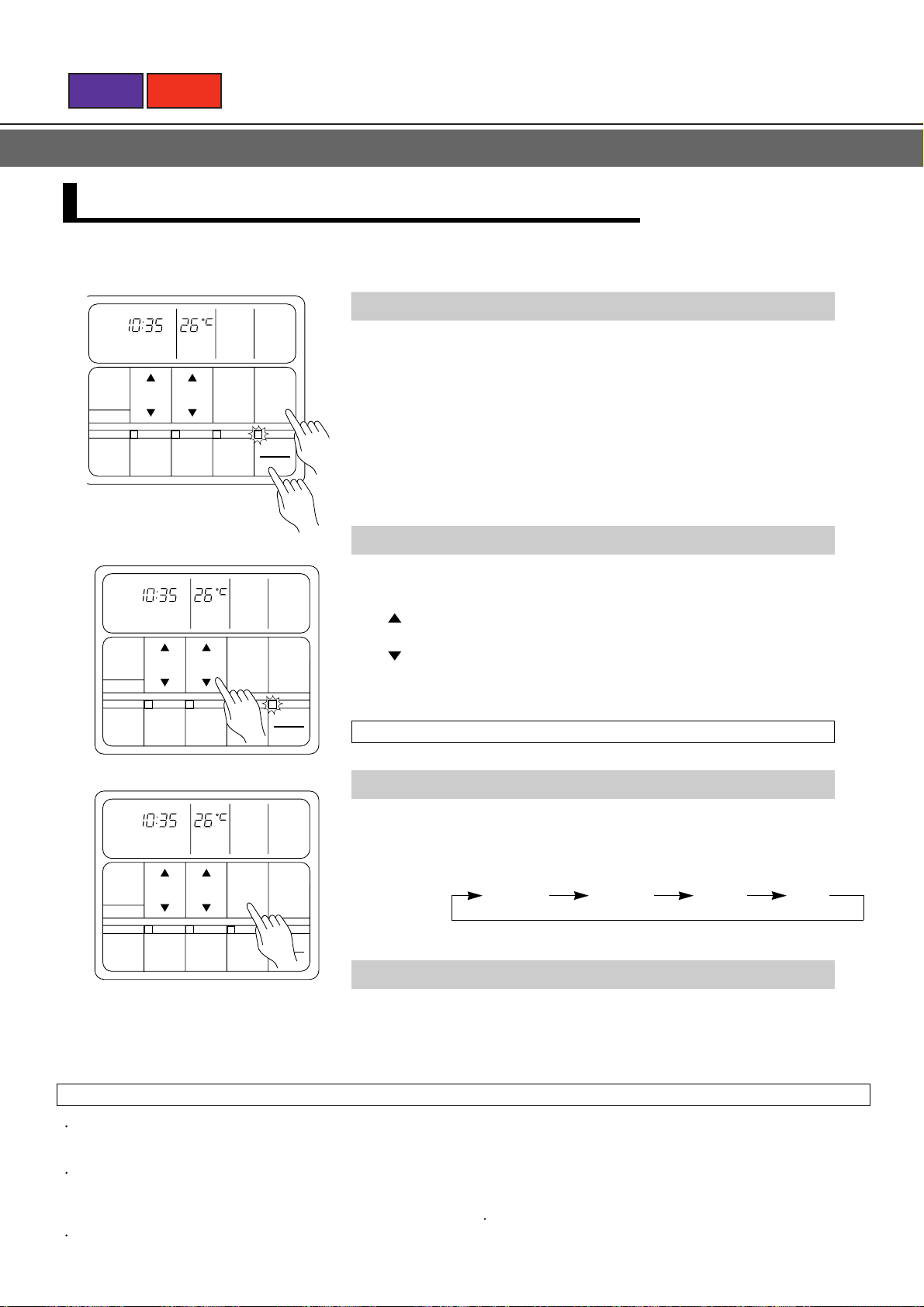

Set the Current Time

Press the CLOCK ADJUST button for more

1

than three seconds.

CLOCK

TIMER

SET

MODE

TIME

CLOCK ADJUST

ENERGY

SAVE

<Remote Controller Display>

The current time display will flash.

Press the SET TIME button and set the time.

SET

TEMP

ZONE

CONTROL

FAN

CONTROL

LOUVER

MASTER

CONTROL

START

STOP

2

: Use to advance the time forward.

: Use to turn the time back.

(Press once to move the time 1 minute; hold down and

the time will move 10 minutes at a time.)

CLOCK

TIMER

MODE

CLOCK ADJUST

SET

TIME

ENERGY

SAVE

CONTROL

SET

TEMP

ZONE

FAN

CONTROL

LOUVER

MASTER

CONTROL

START

STOP

<Remote Controller Display>

The current time display will flash.

Press the CLOCK ADJUST button again.

3

<Remote Controller Display>

The current time display will stop flashing.

CLOCK

Example: Set the time to 9:31.

1 17

Page 23

BACK

NEXT

AUTO CHANGEOVER OPERATION

NON STOP

TIMER

MODE

CLOCK ADJUST

NON STOP

TIMER

MODE

CLOCK ADJUST

SET

TIME

ENERGY

SAVE

SET

TIME

ENERGY

SAVE

SET

TEMP

ZONE

CONTROL

SET

TEMP

ZONE

CONTROL

FAN HIGH

FAN

CONTROL

LOUVER

FAN HIGH

FAN

CONTROL

LOUVER

AUTOCLOCK TEMP

MASTER

CONTROL

START

STOP

AUTOCLOCK TEMP

MASTER

CONTROL

START

STOP

1

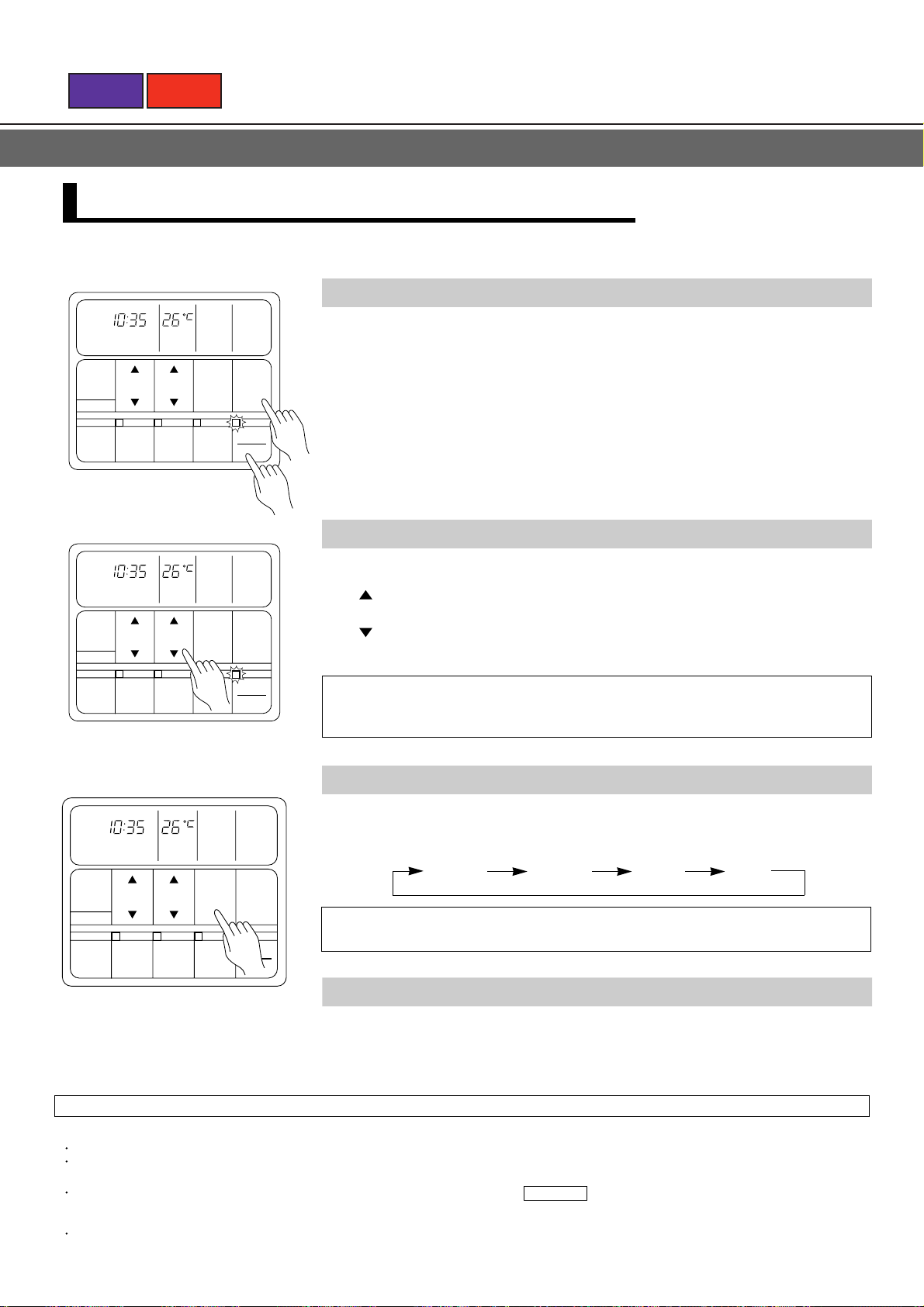

To Select AUTO CHANGEOVER Operation

Press the START/STOP button.

1

The unit will start and the operation lamp will light up.

Press the MASTER CONTROL button to select AUTO.

2

The operating mode "AUTO" will appear alone in the display.

2

To Set the Thermostat

Set the SET TEMP. button to the desired temperature.

: Use to raise the set temperature.

(Press the button once to raise the temperature 1°C).

: Use to lower the set temperature.

(Press the button once to lower the temperature 1°C).

The temperature can be set 18 to 30°C .

To Change the Fan Speed

NON STOP

TIMER

MODE

CLOCK ADJUST

SET

TIME

ENERGY

SAVE

SET

TEMP

ZONE

CONTROL

FAN HIGH

FAN

CONTROL

LOUVER

AUTOCLOCK TEMP

MASTER

CONTROL

START

STOP

Press the FAN CONTROL button to select the fan speed.

Every time you press the FAN CONTROL button, the speed changes as shown.

To Stop Operation

Press the START/STOP button.

<Remote Controller Display>

The display contents disappear and only the current time is displayed.

About AUTO CHANGEOVER Operation

When AUTO CHANGEOVER operation is selected, the air

conditioner selects the appropriate operating mode (Cooling or

Heating) in response to your room's temperature.

When AUTO CHANGEOVER operation first selected, the fan

will operate at very low speed for about one minute, during

which time the unit detects the room conditions and selects the

proper operating mode.

When the air conditioner has adjusted your room's temperature

to near the thermostat setting, it will begin monitor operation. In

AUTO HIGH MED LOW

the monitor operation mode, the fan will operate at low speed. If

the room temperature subsequently changes, the air conditioner

will once again select the appropriate operation (Heating, Cooling)

to adjust the temperature to the value set in the thermostat.

(The monitor operation range is ±2°C relative to the thermostat

setting.)

If the mode automatically selected by the unit is not what you

wish, see MODE OPERATION and select one of the mode operation

(HEAT, COOL, FAN).

Page 24

BACK

NEXT

MODE OPERATION (HEAT, COOL)

Steps are recorded by the unit, after entering in this information, you need only press the START/STOP button to control the unit.

NON STOP

CLOCK TEMP

TIMER

MODE

CLOCK ADJUST

NON STOP

CLOCK TEMP

TIMER

MODE

CLOCK ADJUST

SET

TIME

ENERGY

SAVE

SET

TIME

ENERGY

SAVE

SET

TEMP

ZONE

CONTROL

SET

TEMP

ZONE

CONTROL

FAN HIGH

FAN

CONTROL

LOUVER

FAN HIGH

FAN

CONTROL

LOUVER

COOL

MASTER

CONTROL

START

STOP

COOL

MASTER

CONTROL

START

STOP

1

To Select Mode Operation

Press the START/STOP button.

1

The unit will start and the operation lamp will light up.

Press the MASTER CONTROL button.

2

Select either HEAT or COOL.

2

To Set the Thermostat

Set the SET TEMP. button to the desired temperature.

: Use to raise the set temperature.

(Press the button once to raise the temperature 1°C ).

: Use to lower the set temperature.

(Press the button once to lower the temperature 1°C ).

Range of temperature setting:

For heating mode....................................................................... 16 to 30°C

For cooling mode........................................................................ 18 to 30°C

To Set the Fan Speed

NON STOP

CLOCK TEMP

TIMER

MODE

CLOCK ADJUST

SET

TIME

SET

TEMP

FAN HIGH

FAN

CONTROL

COOL

MASTER

CONTROL

Press the FAN CONTROL button to select the fan speed.

Every time you press the FAN CONTROL button, the speed changes as shown.

AUTO HIGH MED LOW

When the AUTO fan speed is selected in the heating or cooling modes, the fan

speed will vary with room conditions.

ENERGY

SAVE

ZONE

CONTROL

LOUVER

START

STOP

To Stop Operation

Press the START/STOP button.

<Remote Controller Display>

The display contents disappear and only the current time is displayed.

About Mode Operation

Heating

Always set the temperature higher than the current room temperature. If it is set lower than the current room temperature, heating will not start.

For about 3 to 5 minutes after starting heating, the fan will operate very slowly, then switch to the selected fan setting.

This period allows the indoor unit's heat-exchanger to perform before emitting warm air.

During defrosting, the heating mode will be temporarily interrupted. DEFROST will be shown on the remote controll er display.

Cooling

Always set the temperature lower than the current room temperature. If it is set higher than the current room temperature, the unit will not enter

the cooling mode and only the fan will operate.

Page 25

BACK

NEXT

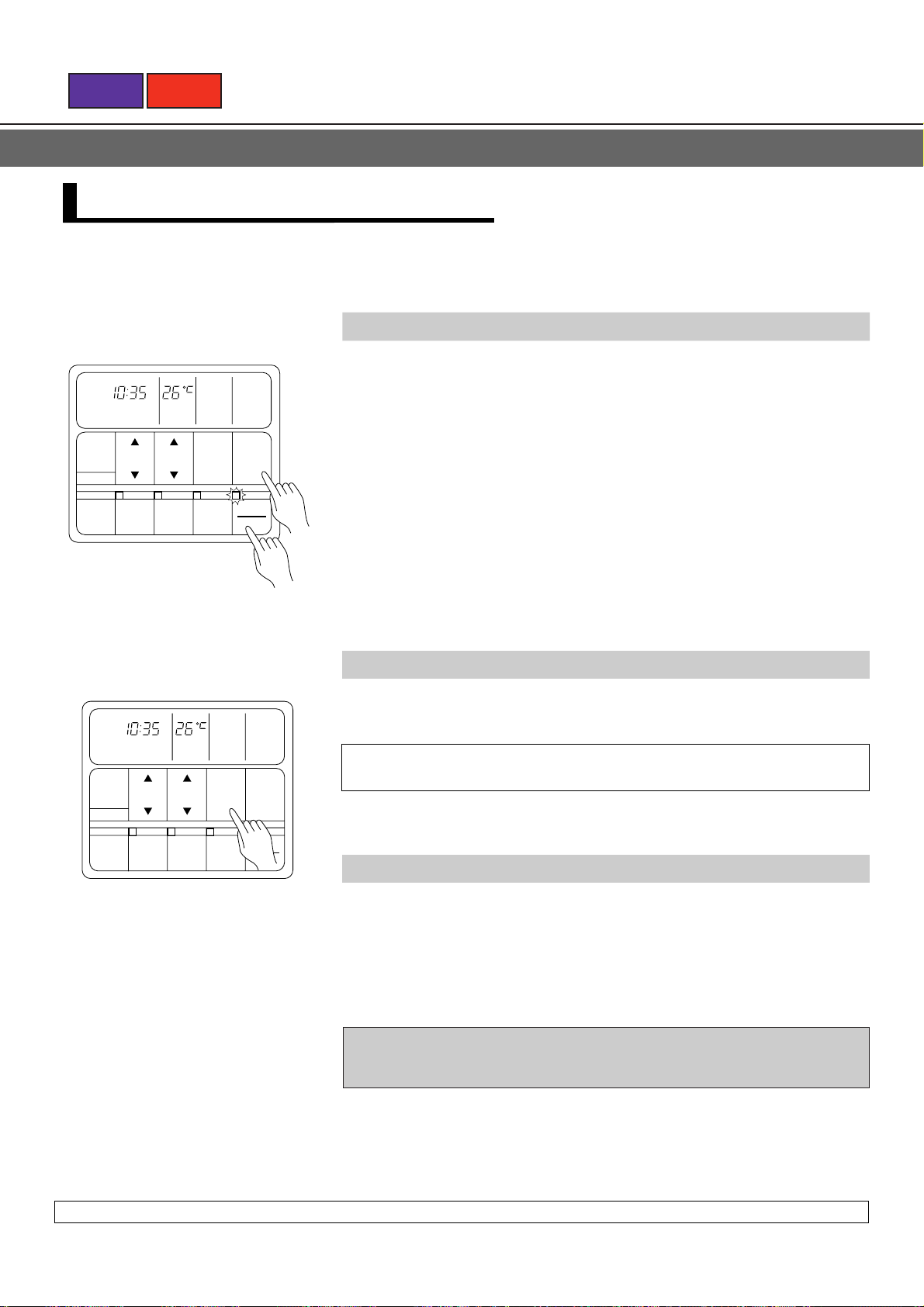

MODE OPERATION (FAN)

Steps are recorded by the unit, after entering in this information, you need only press the START/STOP button to control the unit

To Select MODE Operation

NON STOP

CLOCK TEMP

TIMER

MODE

CLOCK ADJUST

NON STOP

TIMER

MODE

CLOCK ADJUST

SET

SET

TIME

TEMP

ENERGY

ZONE

SAVE

CONTROL

CLOCK TEMP

SET

TIME

SET

TEMP

FAN HIGH

FAN

CONTROL

LOUVER

FAN HIGH

FAN

CONTROL

FAN

MASTER

CONTROL

START

STOP

FAN

MASTER

CONTROL

1

2

Press the START/STOP button.

1

The unit will start and the operation lamp will light up.

Press the MASTER CONTROL button to select FAN mode.

2

To Set the Fan Speed

Press the FAN CONTROL button to select the fan speed.

When the AUTO fan speed is selected in the FAN mode, the fan speed will

automatically be set on MED.

ENERGY

SAVE

ZONE

CONTROL

LOUVER

START

STOP

To Stop Operation

Press the START/STOP button.

<Remote Controller Display>

The display contents disappear and only the current time is displayed.

NOTE:

Do not allow the air conditioner's air stream to directly strike a kerosene or other space heater.

Incomplete combustion or fires may result.

About Mode Operation

The room temperature cannot be adjusted in the FAN mode. (The room temperature is not displayed on the remote controller.)

Page 26

BACK

NEXT

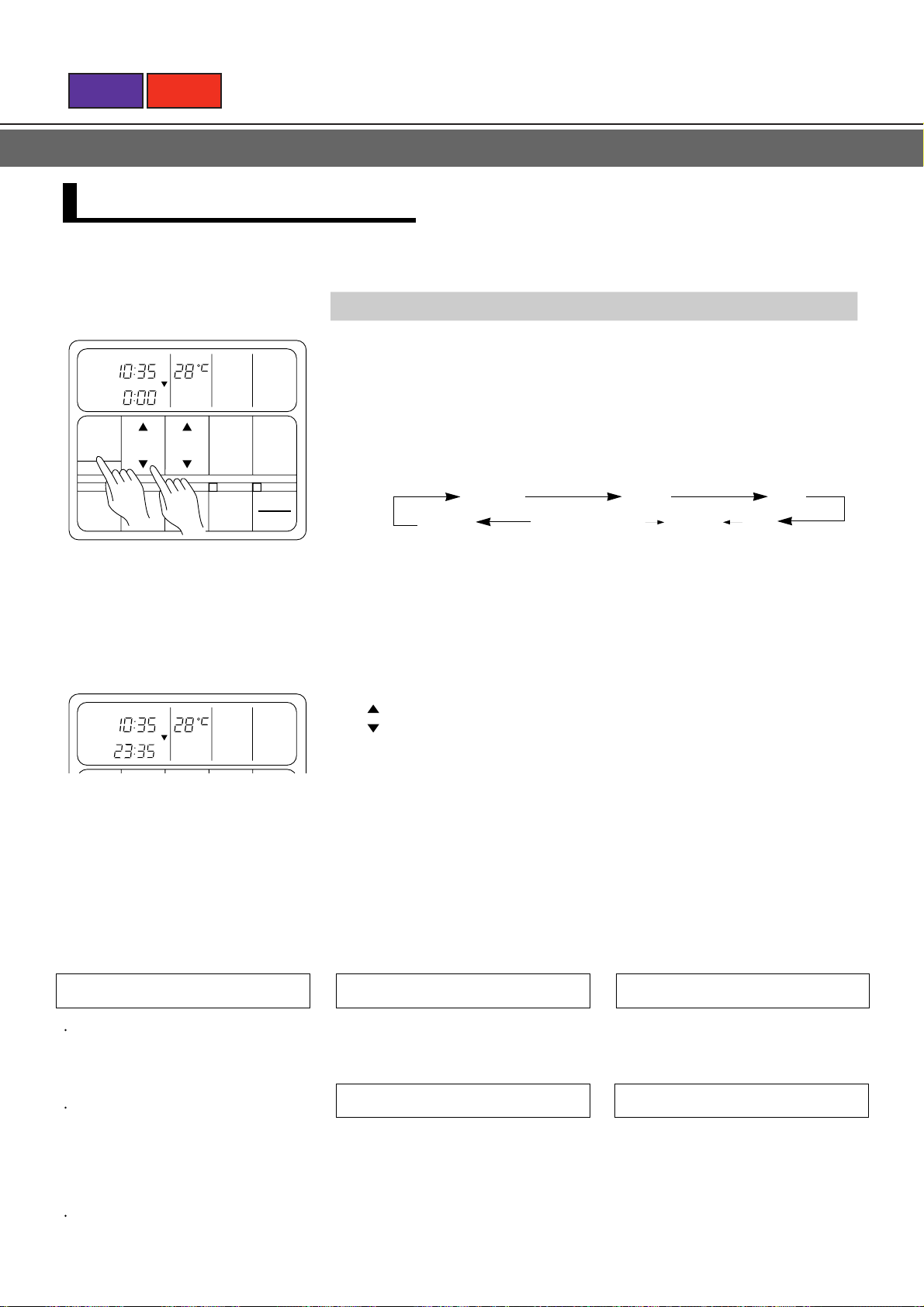

TIMER OPERATION

Press the START/STOP button; after the unit starts operation perform the following procedure:

OFF Timer/ON Timer

CLOCK

OFF

TIMER

TIMER

TIMER

MODE

CLOCK ADJUST

1

ENERGY

SAVE

CLOCK

OFF

TIMER

TIMER

TIMER

MODE

Example: Setting the OFF TIMER

CLOCK ADJUST

SET

TIME

SET

TIME

to

TEMP

OFF

ON

ON

OFF

SET

TEMP

ZONE

2

CONTROL

TEMP

OFF

ON

ON

OFF

SET

TEMP

23:35.

FAN HIGH

FAN

CONTROL

LOUVER

FAN HIGH

FAN

CONTROL

COOL

MASTER

CONTROL

START

STOP

COOL

MASTER

CONTROL

Press the TIMER MODE button and display

either OFF Timer or ON Timer.

1

The timer will start operating.

(If you set the ON timer, the air conditioner will stop operating).

Each time the button is pressed the timer function changes in the foollowing order:

RESET OFF ON

REPEAT PROGRAM (OFF

Press the SET TIME button and set the timer time.

2

: Use to advance the time forward.

: Use to turn the time back.

(Press once to move the time 1 minute; hold down and the

time will move 10minutes at a time.)

ON,OFF ON)

1

ENERGY

SAVE

ZONE

2

CONTROL

LOUVER

START

STOP

To Confirm or Change Settings Before

Starting Operation

To confirm settings

Press the TIMER MODE button once.

(The timer setting information will be

displayed for 15 seconds after the TIMER

MODE button is pressed.)

To change settings

Confirm the settings as noted above, then

press the SET TIME button and TIMER

MODE button as necessary to change the

desired timer setting. (The timer settings

will be displayed for 15 seconds after the

button is pressed.)

After confirming or changing the settings,

press the START/STOP button to start

operation.

To Change the Timer Settings During

Operation

Operate as noted in step 2.

To Change the Timer Mode During

Operation

Press the TIMER MODE button and set the

unit to the desired mode.

To Cancel the Timer Mode During

Timer Operation

Press the TIMER MODE button and set the

display to "NON STOP" (the unit will switch

to non-stop operation).

To Stop Operation During Use of

Timer Mode

Press the START/STOP button.

Page 27

BACK

NEXT

PROGRAM Timer/REPEAT Timer

CLOCK

TIMER

PROGRAM

TIMER

MODE

CLOCK ADJUST

ENERGY

SET

TIME

2

SAVE

TEMP

OFF

ON

SET

TEMP

ZONE

CONTROL

FAN HIGH

FAN

CONTROL

LOUVER

COOL

MASTER

CONTROL

START

STOP

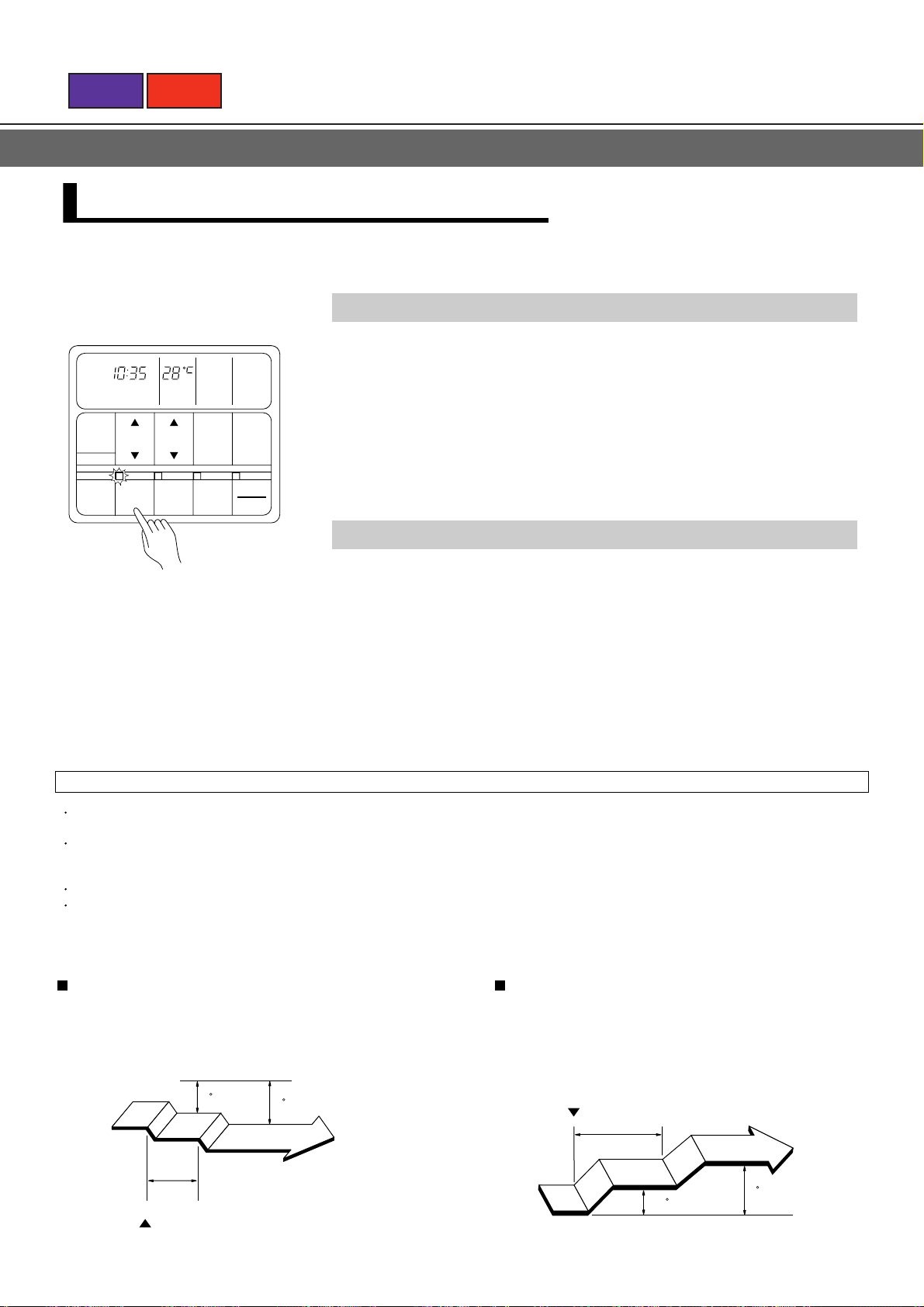

Example:

If the OFF timer is set at 23:35 and the

ON timer at 6:00, and the unit is in the

PROGRAM timer mode.(Select the

REPEAT timer mode,

REPEAT" is

shown on the display.)

About Timer Operation

Setting the timer time.

1

Follow steps 1 and 2 See TIME OPERATION and set the times for the ON timer

and OFF timer modes.

Press the TIMER MODE button until the "PROGRAM" or "REPEAT"

2

mode display is shown.

PROGRAM Timer

Combines the OFF timer and the ON timer for one cycle.

(OFF

Starts operation from the OFF timer or the ON timer, whichever

is closer to the current time.

To Confirm or Change Settings Before

Starting Operation

See TIME OPERATION

To Change Settings After Starting

Operation

1

Follow the instructions in step 1 to display

the timer mode whose time setting

you wish to change.

2

Follow the instructions in step 2 to change

the timer setting.

To change both the OFF timer and ON

timer settings, perform both of the above

steps 1,2 for each setting.

Press the TIMER MODE button to display

3

either "OFF ON" or "OFF ON".

ON, or OFF ON)

To Change the Timer Mode During

Operation

Press the TIMER MODE button and set the

unit to the desired mode.

To Cancel the Timer Mode During

Timer Operation

Press the TIMER MODE button and set the

display to "NON STOP" (the unit will switch

to non stop operation).

REPEAT Timer

Combines the operation of the OFF timer and the ON timer (the

cycle described in the PROGRRAM timer above) so they repeat

the same cycle every day.

Starts operation from the OFF timer or the ON timer, whichever

is closer to the current time.

To Stop Operation During Use of

Timer Mode

Press the START/STOP button.

Page 28

BACK

NEXT

ENERGY SAVE OPERATION

To Use the ENERGY SAVE

NON STOP

CLOCK TEMP

TIMER

SET

MODE

CLOCK ADJUST

About the ENERGY SAVE

TIME

ENERGY

SAVE

SET

TEMP

ZONE

CONTROL

FAN HIGH

FAN

CONTROL

LOUVER

COOL

MASTER

CONTROL

START

STOP

Press the ENERGY SAVE button.

The unit will run in the ENERGY SAVE mode.

To Stop the ENERGY SAVE

Press the ENERGY SAVE button one more time.

The ENERGY SAVE mode will be turned off.

<Remote Controller Display>

The ENERGY SAVE light goes off, and the unit will return to the former operating

conditions.

The energy conservation mode (ENERGY SAVE) raises the set temperature slightly in the cooling mode and lowers the set temperature in the

heating mode, using a computer program to economically control the operation of the unit.

If you press the ENERGY SAVE button while the air conditioner is on, it will change to the conservation mode. If you press the ENERGY SAVE

button while the unit is in the timer mode (ON timer, PROGRAM timer, or REPEAT timer), the unit will go into the conservation mode when the

unit starts with the timer.

If you turn off the air conditioner while in the conservation mode, the mode will be shut off.

The temperature set on the remote controller will not change if the energy save mode is used.

When Heating

After the ENERGY SAVE button is pressed, the set temperature

will be lowered about 1°C every 30 minutes. When it has lowered

a total of 2°C, then it will hold that temperature.

1

c

30 min.

2

c

When Cooling

After the ENERGY SAVE button is pressed, the set temperature

will be raised about 0.5°C every 30 minutes. When it has gone up

a total of 1°C, then it will hold that temperature.

Set to the ENERGY SAVE mode.

30 min.

1

0.5

c

c

Set to the ENERGY SAVE mode.

Page 29

BACK

NEXT

HOW TO CONTROL AIR DIRECTION

The power must be turned on in order to adjust the louver direction (attempting to move the

CAUTION!

louvers by hand could result in damage).

During cooling operation, if the louvers are adjusted to blow air directly downward for extended

periods of time, water may condense on the outlet port and louvers, and drip onto the floor.

Horizontal AUTO LOUVER

When the remote control unit's AUTO LOUVER button is

pressed, the automatic louver lamp lights and the direction

of air flow changes automatically between up and down.

Louver can be stopped at any position when the switch is

pressed to turn it off.

Horizontal louvers

During heating, point the louvers down so that warn air

reaches the floor.

CARE AND MAINTENANCE

Before cleaning the unit, be sure to stop the unit and disconnect the power supply.

CAUTION!

Cleaning the Air Filter

A clogged air filter reduces the airflow and weakens the

cooling effect. If the air filter remains clogged, it may cause

a defect.

How to remove the air filter

1. Push the intake grille pushbuttons two places until

you hear a "click".

Open the intake grille.

PUSH

Turn off the electrical breaker.

A fan operates at high speed inside the unit, and personal injury could result.

PUSH

How to clean the air filter

Clean the dust from the air filter by washing the filter with

water or blow it away with a vacuum cleaner. If the air filter

is very dirty, rinse the filter with warm or cool water mixed

with synthetic detergent and then wash the detergent

solution away with clean water and dry it.

Do not dry the air filter by exposing it to direct sunlight

or fire. This may damage the filter.

Avoid using hot water (40˚C or higher) to wash the

filter. This may damage the filter.

2. Pull the air filter once downward.

The air filter then comes out.

1 24

Cleaning the Indoor Unit

Wipe the cabinet with a dry soft cloth or clean with a cloth

dipped in hot water.

Use of a synthetic detergent is effective for cleaning.

Gasoline

Hot

Water

Polishing powder

Do not use gasoline, thinner, alcohol, benzine, chemicals,

polishing powder, etc. to clean the cabinet.

Benzine

Page 30

100 to 120

Hook shaft

Hook

BACK

NEXT

CARE AND MAINTENANCE

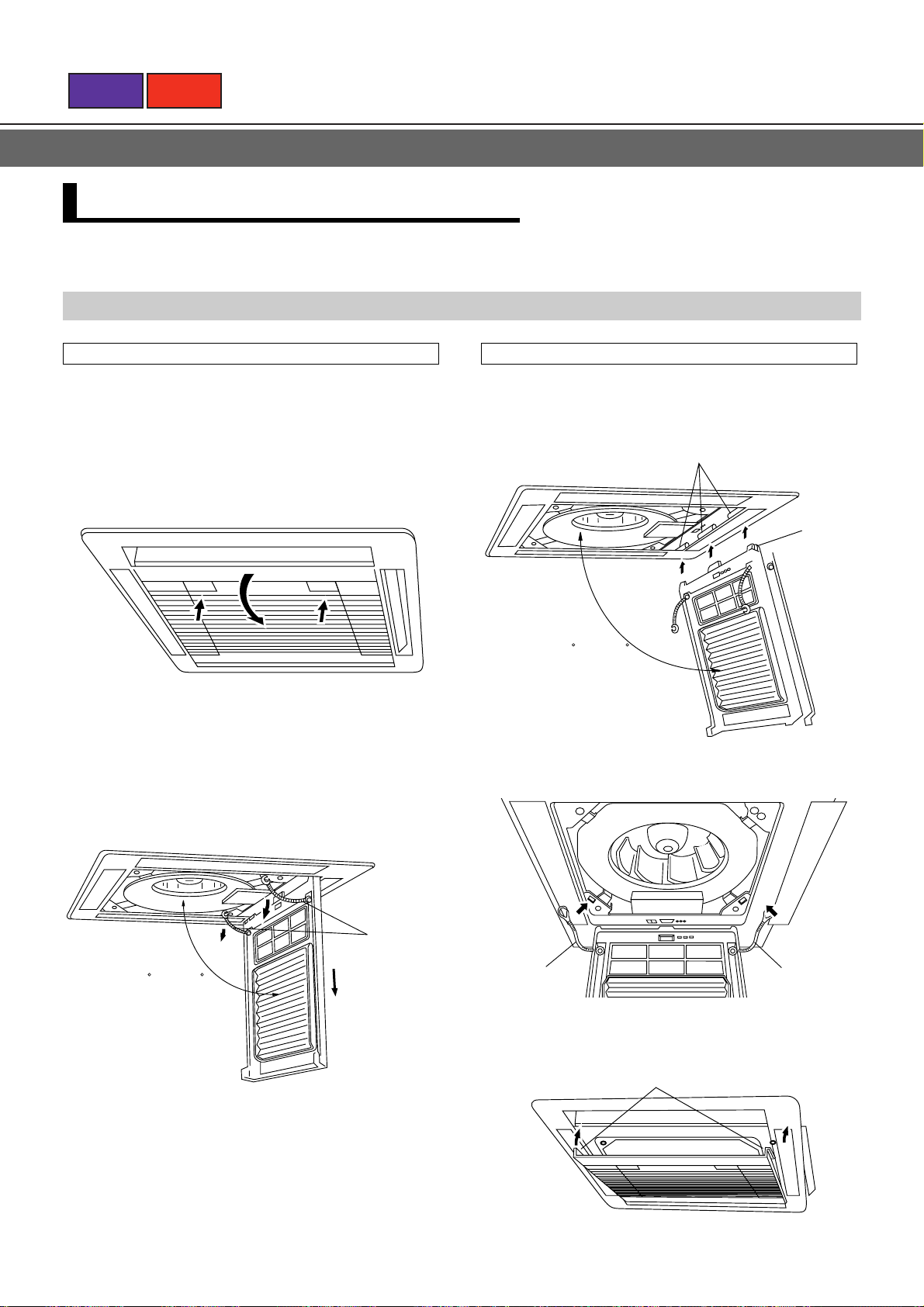

REMOVING / INSTALLING THE INTAKE GRILLE

Removing the intake grille

1. Push the intake grille pushbuttons (two places)

until you hear a "click".

Open the intake grille.

PUSH

PUSH

2. Remove the wire (hanger).

Removing the intake grille by opening it 100° to 120°.

Installing the intake grille

1. Tilt the intake grille 100

° to 120° and hook the

three hooks to the intake grille hook shaft.

2. Install the wire (hanger).

100 to 120

Wire

(

hanger

)

Wire

(

hanger

)

Wire

(

hanger

)

3. Push the intake grille pushbuttons (two places)

until you hear a "click".

Intake grille hooks

PUSH

PUSH

4. Hook the intake grille hooks to the grille

assembly.

Page 31

BACK

NEXT

ERRORS AND SELF DIAGNOSIS

CLOCK

OFF

ON

TIMER

MODE

CLOCK ADJUST

SET

TIME

ENERGY

SAVE

TEMP

ZONE

CONTROL

SET

FAN

CONTROL

LOUVER

MASTER

CONTROL

START

STOP

If there is a problem with the air conditioner, it will stop

running and "EE:EE"will be displayed instead of the clock.

1. If the operation lamp is on then press the

START/STOP button to turn it off.

2. Press the ENERGY SAVE and the ZONE

CONTROL buttons at the same time for more

than three seconds to start the self diagnosis

check.

An error code will be displayed in the clock

display area.

3. Press the ENERGY SAVE and the ZONE

CONTROL buttons again for more than three

seconds to end the self diagnosis check.

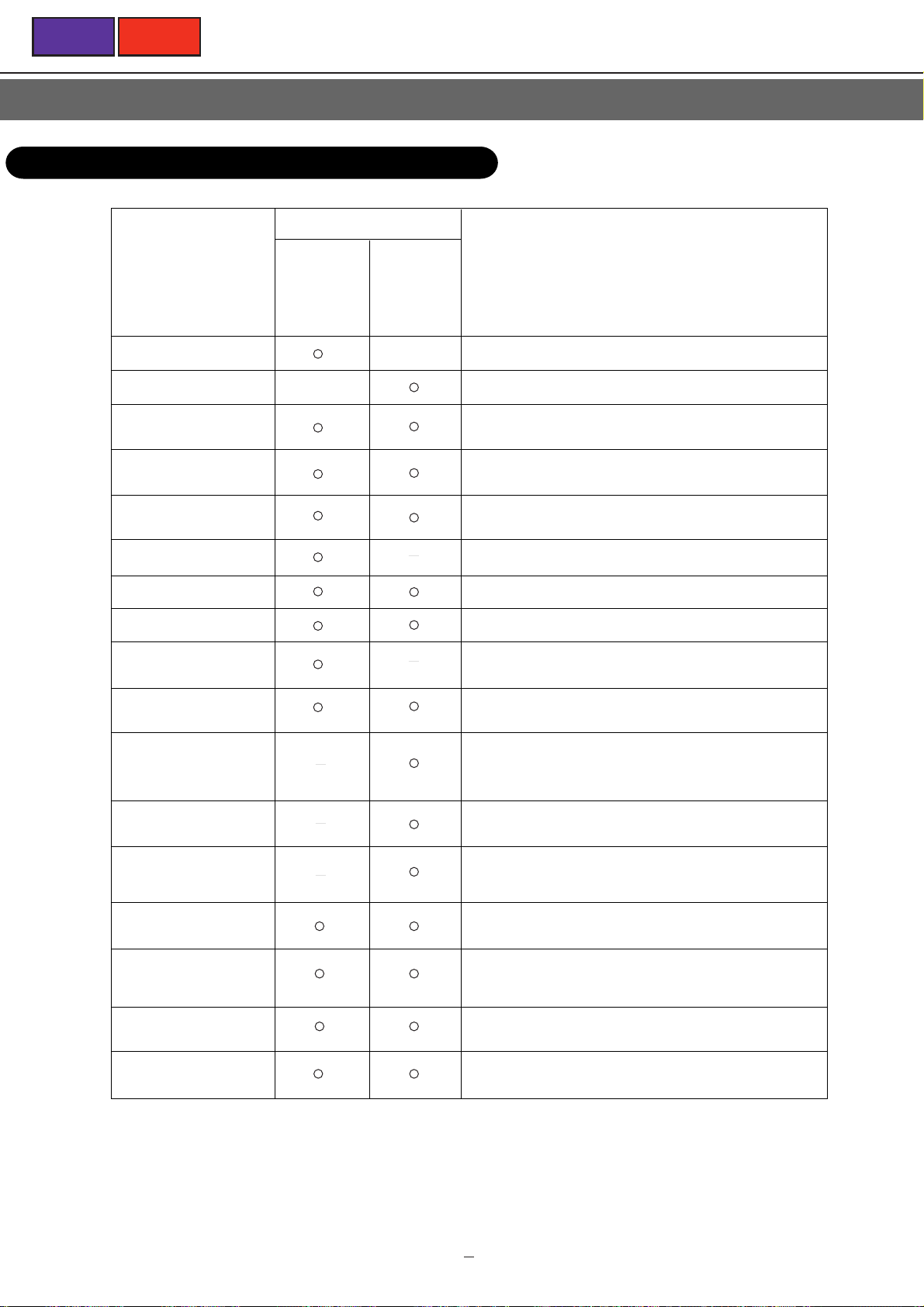

Error code Error

Communication error

(

indoor unit remote controller

Communication error

(

indoor unit outdoor unit

Room temperature sensor open.

Room temperature sensor shorted.

Indoor heat exchanger temperature

sensor open.

Indoor heat exchanger temperature

sensor shorted.

Outdoor heat exchanger temperature

sensor open.

Outdoor heat exchanger temperature

sensor shorted.

Float switch operated.

Outdoor temperature sensor open.

Outdoor temperature sensor shorted.

Discharge pipe temperature

sensor open.

Discharge pipe temperature

sensor shorted.

High pressure abnormal.

Discharge pipe temperature abno

rmal.

)

)

OPERATION DETAILS

Please read and understand the following details regarding this air conditioner.

Operation and Performance

Heating Performance

This air conditioner uses a heat pump which absorbs

heat from outside air and brings it indoors. As a result,

its heating performance is reduced as the temperature

of outside air drops. If you find that insufficient room

heat is produced, we recommend that you use the air

conditioner together with other heating appliances.

Heat-pump type air conditioners use warm-air

recirculation to warm your entire room. As a result,

some time will be required after starting operation until

your entire room becomes warm.

Microcomputer-controlled Automatic Defrosting

When the outside temperature is low and the humidity high,

frost will collect on the outside unit, reducing heater

efficiency. When this happens, the computer will

automatically start the defrost cycle. During the defrost

cycle, the indoor fan will shutdown and DEFROST will be

displayed on the remote controller. It will take anywhere

from 4 to 15 minutes before the air conditioner starts up

again.

When both indoor and outdoor temperatures are high during

use of the heating mode, the outdoor unit's fan may stop at

times.

When the outdoor temperature drops, the outdoor unit's fans

may switch to Low Speed, or one of the fans may stop

intermittently.

When Indoor and Outdoor Temperatures are High

Low Ambient Cooling

1 26

Page 32

BACK

NEXT

SYSTEM OPERATION

There are different ways the unit can be controlled.

<Spare Remote Controller>

Two remote controllers can be connected to one air

conditioner unit. The air conditioner operation contents

are the remote controller setting contents set later.

(Both remote controllers show the same display.)

To Use the ZONE CONTROL

NON STOP

CLOCK

TIMER

TIMER

MODE

CLOCK ADJUST

SET

TIME

ENERGY

SAVE

TEMP

OFF

ON

ON

OFF

SET

TEMP

ZONE

CONTROL

FAN HIGH

FAN

CONTROL

LOUVER

COOL

MASTER

CONTROL

START

STOP

When the ZONE CONTROL button is pressed while multiple air conditioners

are being centralized controlled, only the preset air conditioners stop.

Press the ZONE CONTROL button.

Preset units will stop.

To Stop the ZONE CONTROL

Press the ZONE CONTROL button one more time.

Those units that were stopped will start again.

<Control Several Units with just one Remote

Controller>

One remote controller can control up to 16 air conditioners.

All the air conditioners can be operated with the same

setting.

Unit No. 1 Unit No. 2 Unit No. 16

Auto Restart

When the air conditioner power was temporarily turned off by a power failure, etc., it will

restart automatically after the power recovers. (Operated by settings before the power failure.)

Page 33

BACK

NEXT

2. SPECIFICA TIONS

2.1 AU18, 18R, 25, 25R, 30, 30R, 1-PHASE 50Hz

MODEL

Capacity

Power supply 1 ~ 220-240V 50Hz

Total

input

Total

current

EER

Starting current A

Indoor

unit

Grille

Outdoor

unit

Refrigerant

circuit

Condition

Piping

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Fan speedHiMed

Air

circulation

Noise level

(Sound

pressure)

Heat exchanger

Fan type x Q' ty

Fan motor output kW

Operation control

Dimensions

Weight kg Net/Gross

Dimensions

Weight kg Net/Gross

Fan speed

Air circulation Hi

Noise level dB

Heat exchanger

Fan type x Q 'ty

Fan motor output kW

Compressor type

Protection

Dimensions

Weight kg Net/Gross

Disch. pressure kg/cm

Suct. pressure kg/cm

Discharge temp. ˚C

Suction temp. ˚C

Refr. pipe length m

Disch. air temp.

Indoor

entering

air temp.

Ourdoor

entering

air temp.

Refrigerant charge kg(lb)

Pipe O D

size

Connection method

Between

kW

BTU/h

kW

BTU/h

kW

kW

A

A—

kW/kW

kW/kW —

r.p.m.

r.p.m.

r.p.m.

Low

Hi

Med

Low

Hi

Med

Low

H mm(inch)

W mm(inch)

D mm(inch)

H mm(inch)

W mm(inch)

D mm(inch)

Low

H mm(inch)

W mm(inch)

D mm(inch)

Cool

Heat

Cool

Heat

Liquid

Gas

Pipe length

Hi

Height

3

m

/h

3

m

/h

3

m

/h

dB

dB

dB

r.p.m.

r.p.m.

3

m

/h

kW 1.875 2 2.7Motor output

2

G

2

G

˚C

DB/WB ˚C

DB/WB ˚C

DB/WB ˚C

DB/WB ˚C

mm(inch)

mm(inch)

m

m

AU 18 AU 18R AU 25 AU 25R AU 30 AU 30R

5.25 - 5.40

17,900 - 18,400

—

—

2.05 - 2.15

—

10.0 - 10.5

2.56 - 2.51

66 / 74 68 / 76 67 / 75 68 / 76 94 / 108 96 / 110

Cooling Cooling Heating Cooling Cooling Heating Cooling Cooling Heating

19.8 19.1 19.7

5.0 5.2 4.5

99 90 85

9

13 13.5 41 14 13 42 11 12 45

1.14 (2.51) 1.65 (3.63) 1.95 (4.29) 2.07 (4.55) 1.80 (3.97) 2.20 (4.85)

5.10 - 5.15

17,400 - 17,500

5.20 - 5.25

17,700 - 17,900

1.95 - 2.05

1.95 - 2.05

9.6 - 10.2

9.6 - 10.1

2.62 - 2.51

2.67 - 2.56

50

500

430

360

1,000

850

700

41.5

37.0

34.0

0.037 0.050

216 (8 - 1/2") 302 (11-7/8")

26 / 33 38 / 45

740

280

2,590

56

Propeller x 1

0.060 x 1

Internal protector (OCR), High pressure relief valve

643 (25 - 5/16")

840 (33 - 1/16")

336 (13 - 1/4")

Max. 25 Max. 30 Max. 25

CASSETTE TYPE

7.00 - 7.10

23,900 - 24,200

—

—

2.64 - 2.77

—

12.8 - 13.2

—

2.65 - 2.56

—

Plate fin coil

Tubo fan x 1

Remote control

800 (31 - 1/2")

800 (31 - 1/2")

80 (3 - 5/32")

950 (37 - 13/32")

950 (37 - 13/32")

Plate fin coil

Hermetic (Recipro)

19.9

4.9

90

4

20.0 / (15.0)

15.88 (5/8")

6.95 - 7.05

23,700 - 24,100

7.60 - 7.85

25,900 - 26,800

2.60 - 2.73

2.45 - 2.55

12.7 - 13.0

11.4 - 11.8

2.67 - 2.58

3.10 - 3.08

61

580

510

430

1,200

1,025

850

45.0

42.0

39.0

6.5 / 11

20.1 21.2

4.9 4.0

101 81

9 1.0

5

27.0 / 19.0

35.0 / 24.0

7.0 / 6.0

9.53 (3/8")

Flare

Max.15

8.60 - 8.80

29,400 - 30,000

—

—

3.00 - 3.10

—

14.7 - 15.2

—

2.87 - 2.84

—

Propeller x 2

1,152 (45 - 11/32")

370 (14 - 9/16")

18.5

5.2

90

87 0.5

8.60 - 8.80

29,400 - 30,000

8.80 - 9.10

30,000 - 31,000

3.00 - 3.10

2.70 - 2.80

14.7 - 15.2

13.6 - 14.0

2.87 - 2.84

3.26 - 3.25

67

460

380

320

1,200

950

700

44.5

42.5

40.5

790

510

5,900

57

0.063 x 2

940 (37")

17.8 17.1

5.0 3.9

85 100

510

2 1

Page 34

BACK

NEXT

2.2 AU25, 36, 36R, 45, 45R 3-PHASE 50Hz

MODEL

Capacity

Power supply 3 ~ 380 - 415V 50Hz

Total

input

Total

current

EER

Starting current A

Indoor

unit

Grille

Outdoor

unit

Refrigerant

circuit

Condition

Piping

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Fan speed

Air

circulation

Noise level

(Sound

pressure)

Heat exchanger

Fan type x Q' ty

Fan motor output kW

Operation control

Dimensions

Weight kg Net/Gross

Dimensions

Weight kg Net/Gross

Fan speed

Air circulation Hi

Noise level dB

Heat exchanger

Fan type x Q 'ty

Fan motor output kW

Compressor type

Protection

Dimensions

Weight kg Net/Gross

Disch. pressure kg/cm

Suct. pressure kg/cm

Discharge temp. ˚C

Suction temp. ˚C

Refr. pipe length m

Disch. air temp.

Indoor

entering

air temp.

Ourdoor

entering

air temp.

Refrigerant charge kg(lb)

Pipe O D

size

Connection method

Between

kW

BTU/h

kW

BTU/h

kW

kW

A

A—

kW/kW

kW/kW —

r.p.m.

Hi

r.p.m.

Med

Low

r.p.m.

Hi

Med

Low

Hi

Med

Low

H mm(inch)

W mm(inch)

D mm(inch)

H mm(inch)

W mm(inch)

D mm(inch)

Low

H mm(inch)

M mm(inch)

L mm(inch)

Cool

Heat

Cool

Heat

Liquid

Gas

Pipe length

3

m

/h

m3/h

3

/h

m

dB

dB

dB

Hi

r.p.m.

r.p.m.

3

m

/h

kW 1.870

2

G

2

G

˚C

DB/WB ˚C

DB/WB ˚C

DB/WB ˚C

DB/WB ˚C

mm(inch)

mm(inch)

Height

m

m

AU 25(3) AU 36(3) AU 36R(3) AU 45(3) AU 45R(3)

7.00 - 7.10

23,900 - 24,200

—

—

2.54 - 2.64

——

4.4 - 4.6

—

2.76 - 2.69

580

510

430

1,200

1,025

850

45.0

41.0

38.0

0.037 0.061 0.070

216 (8 - 1/2") 302 (11 - 7/8")

26 / 33 38 / 45

740 790

280

2,590

Propeller x 1

0.060 x 1

Internal protector (OCR) Internal protector (OCR), High pressure relief valve

643 (25 - 5/16")

840 (33 - 1/16")

336 (13 - 7/32")

67 / 57 94 / 108 95 / 110 102 / 116 108 / 122

Cooling Cooling Cooling Heating CoolingCooling Heating

19.6 18.8

4.8 5.1 5.0

84 90 95

15 6

14 11 12 42 12 12 46

2.03 (5.07) 2.15 (4.74) 2.8 (6.17) 3.15 (6.94) 3.4 (7.49)

15.88 (5/8") 19.05 (3/4")

Max. 35 Max. 50

3.73 - 3.80

2.76 - 2.76

35,200 - 36,000

—

—

6.4 - 6.4

—

—

57.5 58.056

CASSETTE TYPE

10.5 - 10.7

36,000 - 36,500

3.88 - 3.95

3.18 - 3.25

6.6 - 6.6

6.1 - 5.8 7.4 - 7.4

2.65 - 2.66

3.30 - 3.29

42 5532

570

470

380

1,400

1,150

900

49.0

45.0

42.5

Plate fin coil

Tubo fan x 1

Remote control

800 (31 - 1/2")

800 (31 - 1/2")

80 (31 - 5/32")

950 (37 - 13/32")

950 (37 - 13/32")

6.5 / 11

Plate fin coil

Hermetic (Recipro)

1.9

10

27.0 / 19.0

20.0 / (15.5)

35.0 / 24.0

7.0 / 6.0

9.53 (3/8")

Flare

Max. 30

510

Propeller x 2

0.063 x 2

1,152 (45 - 11/32")

940 (37")

370 (14 - 9/16")

16.820.2 19.0

4.4

80

18

5

12.4 - 12.710.3 - 10.5

42,500 - 43,500

—

—

—

—

—

—

5.0

90 90

46,000 - 47,000

4.45 - 4.57

7.5 - 7.5

2.79 - 2.78

680

570

490

1,700

1,500

1,200

53.5

50.0

46.5

790

5,5005,900

59.0

2.7Motor output

18.7

13.4 - 13.7

4.23 - 4.35

3.17 - 3.15

510

20.4

4.8 4.0

100

73

2 2

Page 35

BACK

NEXT

2.3 AU25, 25R, 36, 36R, 1-PHASE / AU45,45R 3-PHASE 60Hz

MODEL

Capacity

Power supply 1 ~ 220V 60Hz 3 ~ 220V 60Hz

Total

input

Total

current

EER

Starting current A

Indoor

unit

Grille

Outdoor

unit

Refrigerant

circuit

Condition

Piping

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Fan speed

Air

circulation

Noise level

(Sound

pressure)

Heat exchanger

Fan type x Q' ty

Fan motor output kW

Operation control

Dimensions

Weight kg

Dimensions

Weight kg

Fan speed

Air circulation Hi

Noise level dB

Heat exchanger

Fan type x Q 'ty

Fan motor output kW

Compressor type

Protection

Dimensions

Weight

Disch. pressure

Suct. pressure kg/cm

Discharge temp. ˚C

Suction temp. ˚C

Refr. pipe length m

Disch. air temp.

Indoor

entering

air temp.

Ourdoor

entering

air temp.

Refrigerant charge kg(lb)

Pipe O D

size

Connection method

Between

W

W

W

W

A

A—

W/W

W/W —

Hi

r.p.m.

r.p.m.

Med

Low

r.p.m.

mm(inch)

mm(inch)

mm(inch)

Net/Gross

mm(inch)

mm(inch)

mm(inch)

Net/Gross

Hi

mm(inch)

mm(inch)

mm(inch)

Net/Gross

kg/cm

Gas

Height

3

m

/h

3

m

/h

3

m

/h

dB

dB

dB

r.p.m.

3

m

/h

kW 2 3.5 4.54Motor output

2

G

2

G

˚C

DB/WB ˚C

DB/WB ˚C

DB/WB ˚C

DB/WB ˚C

mm (inch)

mm (inch)

m

m

Hi

Med

Low

Hi

Med

Low

H

W

D

H

W

D

Low r.p.m.

H

M

L

kg

Cool

Heat

Cool

Heat

Liquid

Pipe length

AU 25 AU 25R AU 36 AU 36R AU 45 (3) AU 45R (3)

5,600

—

3,030

—

13.9

1.85

1,200

1,025

46.0

43.0

39.0

0.037 0.061

216 (8 - 1/2") 302 (11 - 7/8")

26 / 33 38 / 45

740

—

2,590

56 (COOL) 58 (HEAT) 58

Propeller x 1

0.060 x 1

643 (25 - 5/16")

840 (33 - 1/16")

336 (13 - 1/4")

67 / 75 68 / 76 94 / 108 96 / 110 102 / 115 108 / 122

Cooling Cooling Heating Cooling Cooling Heating Cooling Cooling Heating

24 25.3 21

5.2 5.3 4.0

96 108 74

7

15 15 45 12 14 46 12 14 46

1.75 (3.86) 2.07 (4.56) 2.2 (4.85) 2.6 (5.73) 3.35 (7.39) 3.60 (7.94)

15.88 (5/8") 19.05 (3/4")

Max. 15

Max. 25 Max. 50

7,500

3,250

2,700

15.2

12.7

1.73

2.78

66

580

510

430

850

280

Internal protector (OCR), High pressure relief valve

21.0 / (15.5) 21.0 / (15.5)

CASSETTE TYPE

9,000

—

4,600

—

21.5

—

1.96

—

77

560

510

460

1,400

1,250

1,100

48.5

46.0

43.5

Plate fin coil

Tubo fan x 1

Remote control

800 (31 - 1/2")

800 (31 - 1/2")

80 (3 - 5/32")

950 (37 - 3/32")

950 (37 - 13/32")

6.5 / 11

5,900 5,500

Plate fin coil

Hermetic (Recipro)

23

5.3

95

7

5

46.0 / 24.0

7.0 / 6.0

9.53 (3/8")

Flare

8,500

10,500 14,000

3,650

17.5

1.85

2.88

790

Propeller x 2

0.063 x 2

1,152 (45 - 11/32")

940 (37")

370 (14 - 9/16")

23 20

5.5 4.5

95 90

10 1

Max. 30

—

—

—

—

—

23.5

5.0

100

515 1

10,000

5,550