Page 1

SPLIT TYPE

AIR CONDITIONER

CEILING

type (50Hz)

Models

Indoor unit Outdoor unit

ABHA36LAT

ABHA45LAT

AOHA36LATL

AOHA45LATL

CONTENTS

SPECIFICATIONS

DIMENSIONS

REFRIGERANT SYSTEM DIAGRAM

CIRCUIT DIAGRAM

ERROR CONTENTS

PARTS (INDOOR UNIT)

PARTS (OUTDOOR UNIT)

STANDARD ACCESSORIES

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . .

. . . . .

. . . . . . .

. . . .

1

2

4

5

7INDOOR PCB CIRCUIT DIAGRAM

10OUTDOOR PCB CIRCUIT DIAGRAM

13

16

21

25

Page 2

SPECIFICATIONS

ELECTRICAL DATA

TYPE

INDOOR UNIT ABHA36LAT

OUTDOOR UNIT AOHA36LATL AOHA45LATL

COOLING CAPACITY

HEATING CAPACITY

POWER SOURCE

RUNNING CURRENT

INPUT WATTS

E.E.R.

MOISTURE REMOVAL

AIRCIRCULATION INDOOR

AIRCIRCULATION OUTDOOR

MAXIMUM CURRENT

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling & Heating

ABHA45LAT

10.0 kW 12.5 kW

11.2 kW

230 V 50 Hz 230 V 50 Hz

13.6 A

13.2 A

3.11 kW

3.02 kW

3.21 kW/kW

3.71 kW/kW

3.0 L/hr

6,600 m3/hr

19.0 A

14.0 kW

17.0 A

16.5 A

3.89 kW

3.77 kW

3.21 kW/kW

3.71 kW/kW

4.5 L/hr

2,250 m3/hr2,020 m3/hr

6,600 m3/hr

20.0 A

FAN MOTOR

INDOOR UNIT

OUTDOOR

UNIT

Discrimination

High speed

Med speed

Low speed

Quiet

Discrimination

Upper fan

Lower fan

MFH-45RV

1,100 r.p.m.

910 r.p.m.

750 r.p.m.

650 r.p.m. 680 r.p.m.

MFE-60PO

850 r.p.m. 850 r.p.m.

750 r.p.m.

MFH-45RV

1,200 r.p.m.

1,000 r.p.m.

830 r.p.m.

MFE-60PO

750 r.p.m.

COMPRESSOR AND REFRIGERANT

Hermetic type, Inverter,

TYPE

DISCRIMINATION

WEIGHT (with oil)

STANDARD REFRIGERANT

REFRIGERANT TYPE

MAX PIPE LENGTH 50 m

MAX PIPE HEIGHT 30 m

Pipe length

FULL CHARGE

ADDITIONAL CHARGE 50 g/m

20 m

30 m

40 m

50 m 4,850 g

4 poles, 3 phase,

DC motor, Twin Rotary

DA420A3F-21ZA

23.7 kg

3,350 g

R410A

3,350 g

3,850 g

4,350 g

NOISE LEVEL

High speed

INDOOR UNIT

OUTDOOR UNIT

Note : Static pressure : 30Pa

Duct length : Inlet 1m, Outlet 2m

Med speed

Low speed

Quiet

Cooling

Heating

DIMENSIONS

INDOOR UNIT H x W x D

H x W x DOUTDOOR UNIT

WEIGHT

INDOOR UNIT Gross / Net

OUTDOOR UNIT

Gross / Net

47 dB

43 dB

37 dB

32 dB 34 dB

54 dB 55 dB

55 dB 56 dB

240 x 1,660 x 700 mm

1,290 x 900 x 330 mm

58 kg / 44 kg

107 kg / 98 kg

49 dB

45 dB

39 dB

2007.10.29 1

Page 3

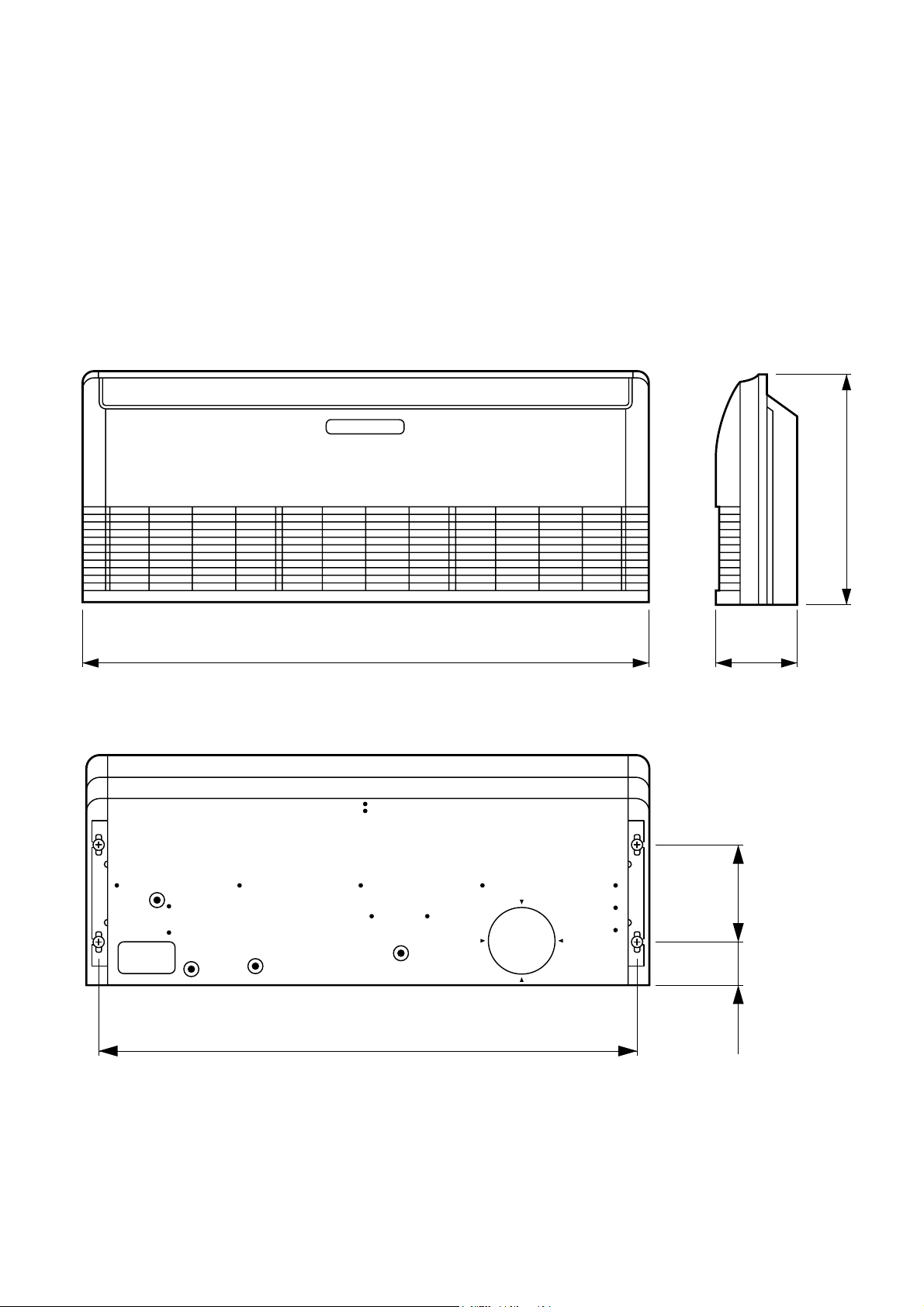

DIMENSIONS

INDOOR UNIT

(Unit : mm)

700

1,660 240

1,600

2007.10.29 2

130 300

Page 4

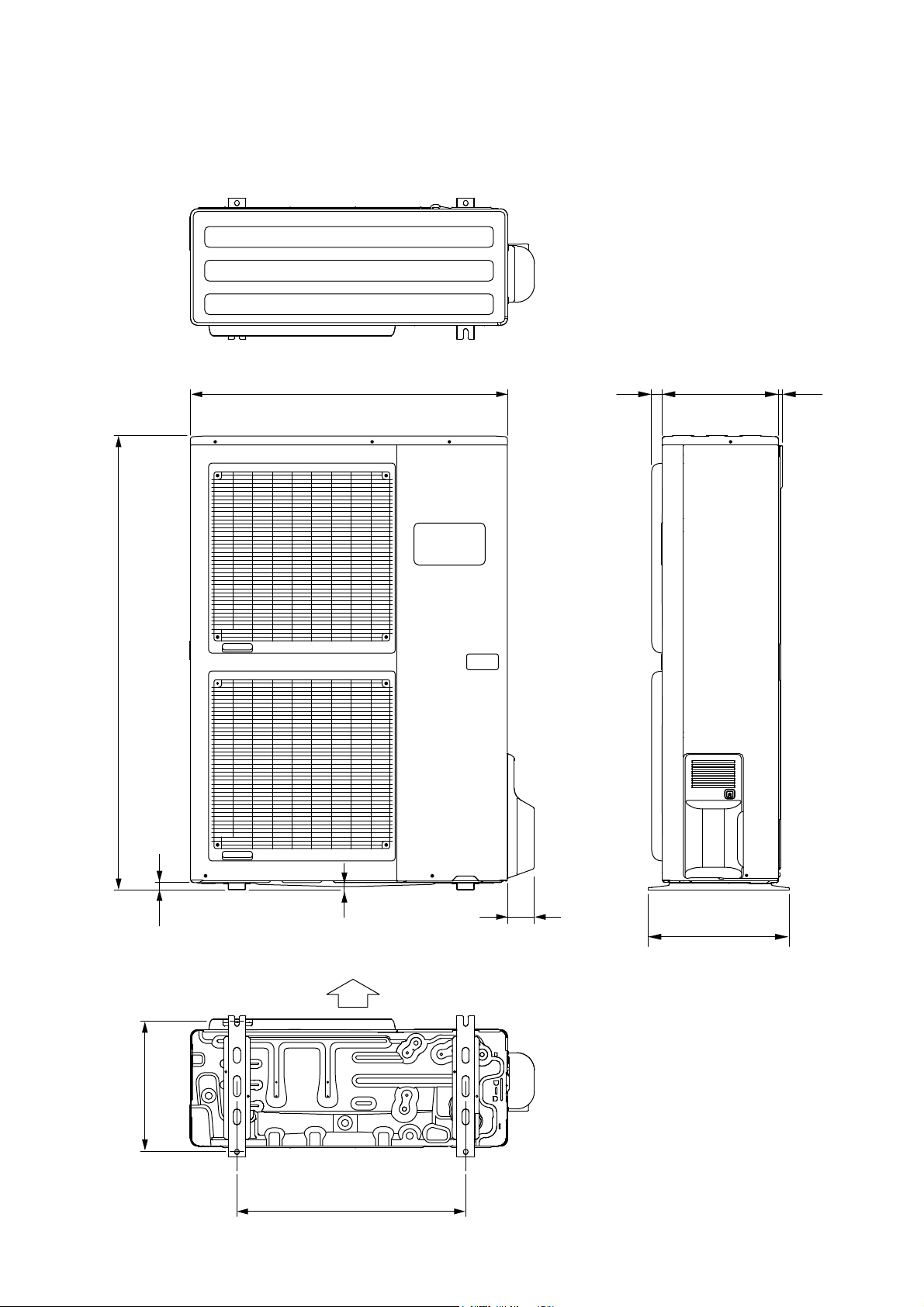

OUTDOOR UNIT

(Unit : mm)

31900 330 12

1,290

21

9

77

400

Air Flow

370

650

2007.10.29 3

Page 5

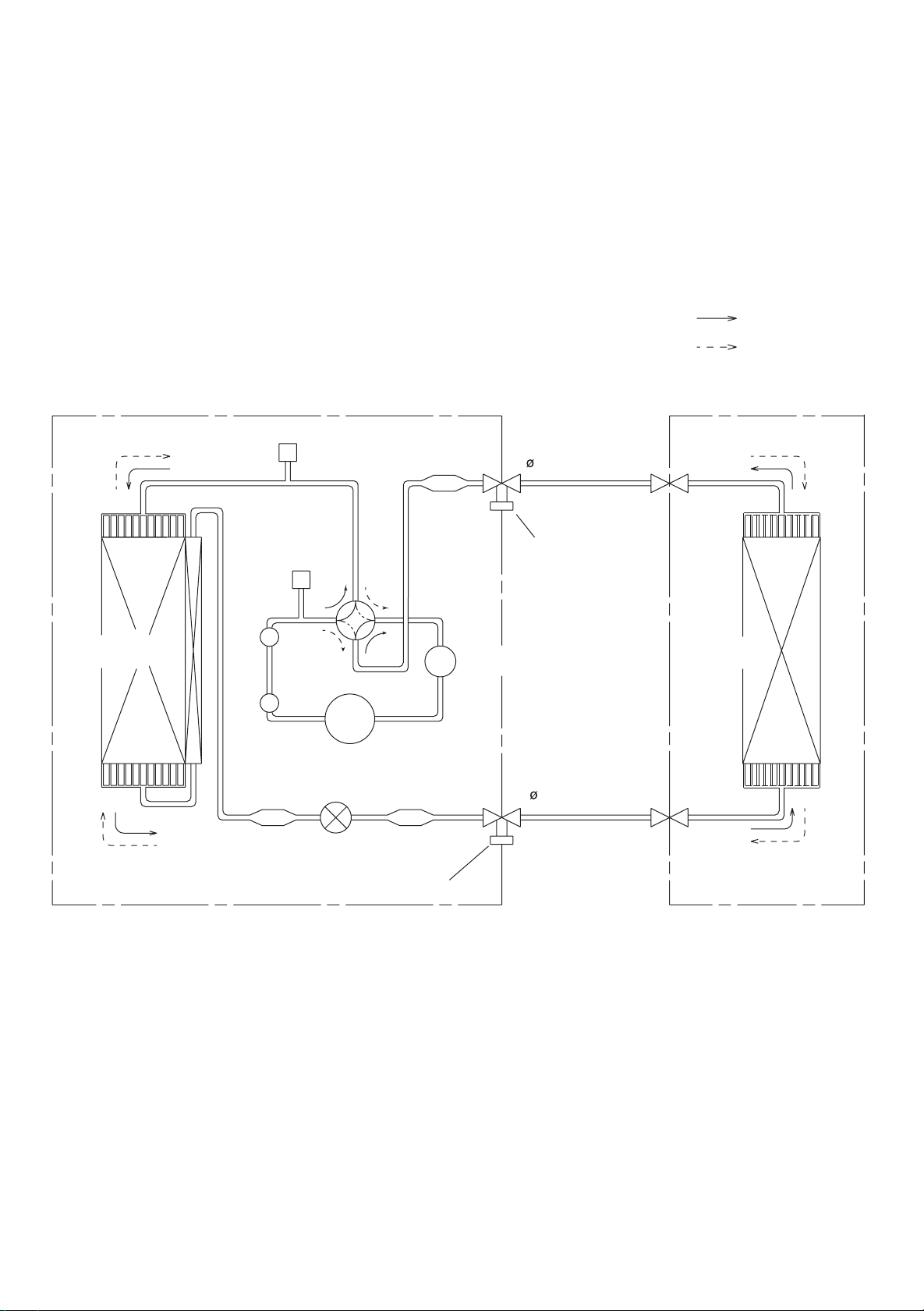

REFRIGERANT SYSTEM DIAGRAM

Refrigerant direction

: Cool

: Heat

OUTDOOR UNIT INDOOR UNIT

Condenser

High

Pressure

Switch

Muffler x 2

Strainer

Pressure

Check Valve

4-way

Valve

Compressor

Expansion

Valve

Strainer

Accumulator

Strainer

Charging Valve

Refrigerant Pipe

15.88mm (5/8")

Charging

Valve

Evaporator

Refrigerant Pipe

9.52mm (3/8")

2006.10.29 4

Page 6

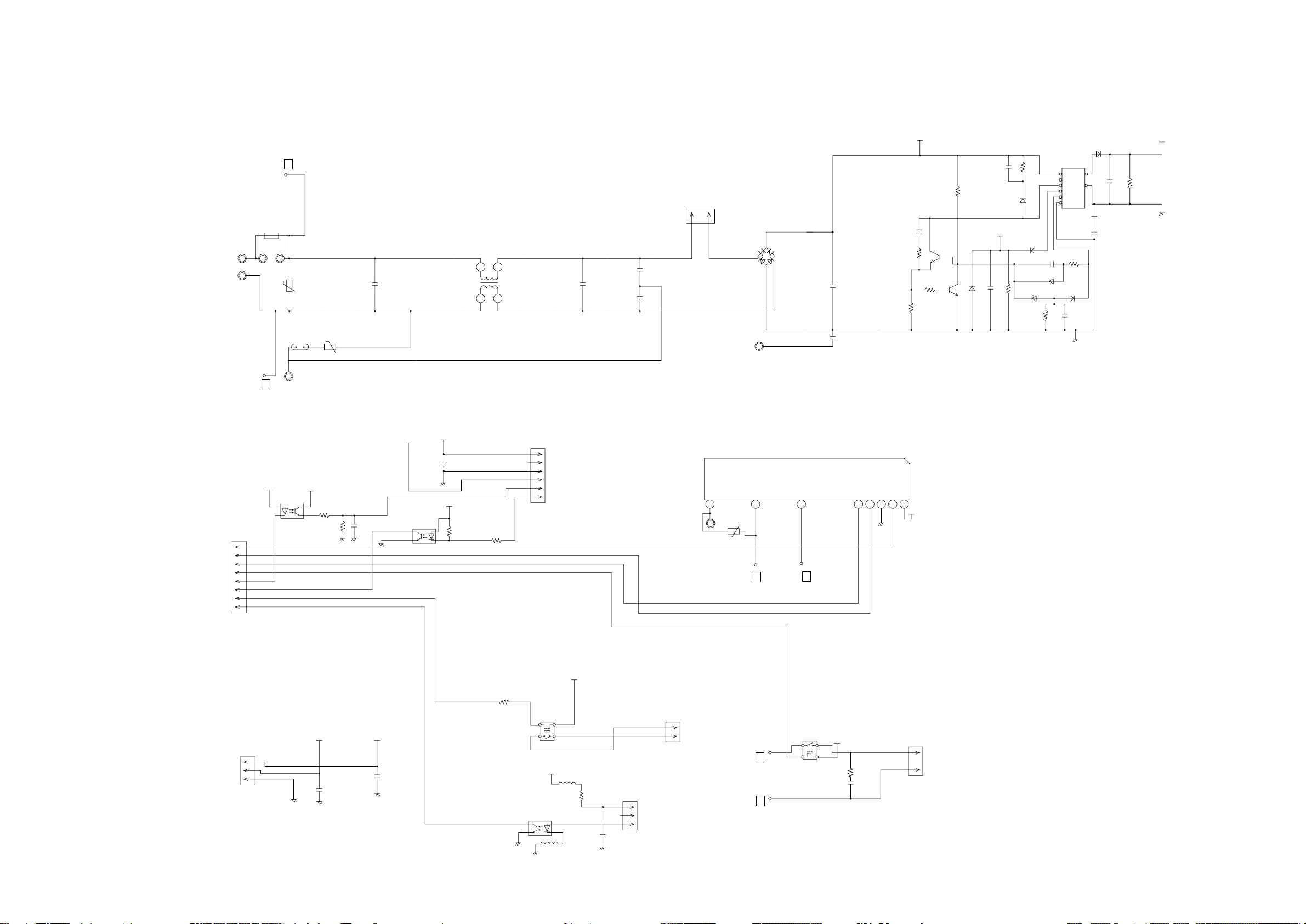

CIRCUIT DIAGRAM

INDOOR UNIT OUTDOOR UNIT

STEP MOTOR

( RIGHT / LEFT )

STEP MOTOR

( UP / DOWN )

DC FAN MOTOR

F M

GREEN

/ YELLOW

OUTDOOR TH.

COMPRESSOR TH.

HEAT SINK TH.

HIGH PRESSURE SWITCH

RED

RED

BLACK

BLACK

RED

SOLENOID COIL

4WV

FAN MOTOR 1

BLACK

WHITE

YELLOW

BROWN

RED

F M

FAN MOTOR 2

BLACK

WHITE

YELLOW

BROWN

RED

BROWN

BLUE

ORANGE

YELLOW

WHITE

F M

EXPANSION

VALVE COIL

E V

WHITE

BLACK

YELLOW

ORANGE

ORANGE

BLACK

TM102

TM101

BLACK

BROWN

BLACK

RED

BLUE

RED

2

1

1

CN24

2

1

1

CN21

2

121

1

CN22

2

2

1

2

1

2

CN23

121

CN26

U

W305

V

W304

FUSE

F4 T 5A - 250V

W

W303

1

2

CN407

3

4

CONTROLLER PCB ASSY

5

( MAIN PCB )

W12

W13

W21

W22

W16

W17

W10

W11

FUSE

F2 T 3.15A - 250V

CN1

2

1

4

3

RED

BROWN

BLACK

2

1

3

1 2

3

CN1

1

1

W9

POWER SUPPLY PCB ASSY

W3

GREEN

W6

W7

WHITE

BLACK

PIPE TH.

PIPE MID. TH.

S ( S )

ACTPM

WHITE

L1

L2

-

+

1

1

2

2

3

3

4

4

5

5

6

6

P

N

WHITE

BLACK

BROWN

RED

ORANGE

YELLOW

CN106

1

22

1

2

3

1

2

3

4

5

6

7

1

2

3

1

2

1

2

GRAY

GRAY

BLACK

BLACK

BROWN

1

RED

2

ORANGE

3

WHITE

4

BLUE

5

PURPLE

6

GRAY

7

RED

1

WHITE

2

BLACK

3

RED

WHITE

BLACK

PIPE TH.

ROOM TH.

INDICATOR PCB ASSY

1

2

3

4

5

6

7

8

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

TERMINAL

1

3

2

TO REMOTE CONTROL UNIT

( OPTION )

TERMINAL

1 2 3

DISCHARGE TH.

COMPRESSOR

R ( R )

C M

C ( T )

TERMINAL

BROWN

CHOKE

COIL

POSISTOR

M

M

1

2

3

4

5

1

2

3

4

5

BROWN

1

RED

2

ORANGE

3

YELLOW

4

WHITE

5

BROWN

1

RED

2

ORANGE

3

YELLOW

4

WHITE

5

BLACK

BLACK

1

2

1 2

CN5

1

1

2

2

3

3

CN12

4

4

5

5

1

1

2

2

3

3

4

4

5

5

CONTROLLER

PCB ASSY

CN11CN9

( MAIN PCB )

1

1 2

1

2

CN7 CN8

1

2

1

2

CN13

CN14

3

1

2

CN10

1 2

1 2

GRAY

1

1 2

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

BROWN

YELLOW

WHITE

BLACK

RED

1

1

2

2

3

3

4

4

5

5

6

6

F101

FUSE

3.15A

CN105

250V

E101 E102

CN4 CN1

34567

34567

GRAY

2

GRAY

GRAY

GRAY

GRAY

3 4 567

34567

CN104

POWER SUPPLY

PCB ASSY

CN102

1

2

3

8

8

GRAY

GRAY

8

8

CN103

1 2

1 2

1

1 2

1

CN101

2

GRAY

GRAY

2

CN108

1

CN6 CN3

3

3

GRAY

3

3

W105

W102

W101

2

1 2

2

CN34

2

2

WHITE

BROWN

1

CN25

CN800

CN801

3

3

BLACK

W8

BLUE

BLACK

2

2

CN37

CN30

CN27

W200

W1

BLACK

1

2

1

2

3

1

2

3

4

5

6

7 7

1

2

3

4

5

6

7

1

2

3

4

5

6

W2

1

2

1

2

3

1

2

3

4

5

6

1

2

3

4

5

6

7

1

2

3

4

5

6

WHITE

GREEN

GREEN

WHITE

WHITE

COIL

2007.10.29 5

EARTH

FUSE

10A

FUSE

25A

RED

1

2

3

N

L

EARTH

POWER SOURCE

Page 7

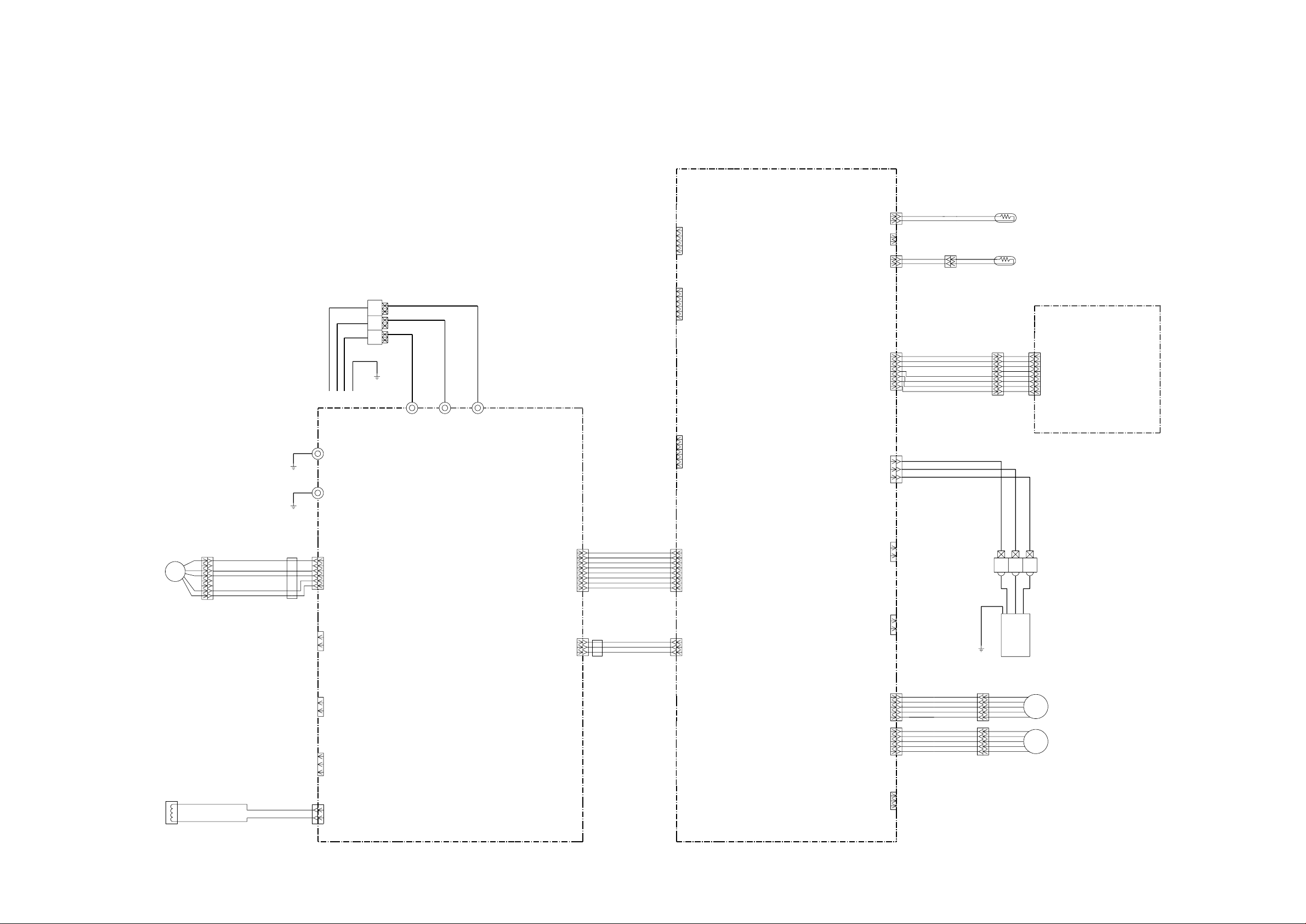

INDOOR PCB CIRCUIT DIAGRAM

CONTROL UNIT

ABHA36LAT : EZ-0061EHSE

ABHA45LAT : EZ-0061DHSE

CN2-1

CN2-2

CN2-3

CN2-4

CN2-5

CN2

B5P-SHF-1AA

WHITE

CN8

B02B-XASK-1-A

WHITE

CN7

B02B-XAYK-1-A

YELLOW

CN5

B02B-XAKK-1-A

BLACK

CN8-1

CN8-2

CN7-1

CN7-2

CN5-1

CN5-2

BLACK

BLACK

BLACK

BLACK

GRAY

GRAY

ROOM TH.

PIPE TH. ( M I D )

DC FAN MOTOR

F M

1

UL1015 AWG22 RED

2

3

UL1015 AWG22 BLACK

UL1015 AWG22 WHITE

4

5

6

UL1015 AWG22 YELLOW

7

UL1015 AWG22 BROWN

8

DRAIN PUMP

E I B OUT

UL1015 AWG16

GREEN

UL1015 AWG16

GREEN

EMI FILTER

ATFC-25-15-12

2 TURN

E I B I N

TERMINAL BOARD

OUTDOOR UNIT

E101

E102

CN105-6

CN105-5

CN105-4

CN105-3

CN105-2

CN105-1

CN106-1

CN106-2

CN103-1

CN103-2

CN102-1

CN102-2

CN102-3

3

2(N)

1

UL1015 AWG20 BLACK

UL1015 AWG20 WHITE

W101

W102

POWER SUPPLY PCB ASSEMBLY

K06AL-0606HSE-P0

CN105

B5P6-VH-B

WHITE

CN106

B2P3-VH-B-E

BLUE

CN103

B2B-XH-AM

WHITE

CN102

B3B-XH-AM

WHITE

UL1015 AWG20 RED

W105

CN104

B08B-PASK-1

WHITE

CN101

B03B-PASK-1

WHITE

CN104-1

CN104-2

CN104-3

CN104-4

CN104-5

CN104-6

CN104-7

CN104-8

CN101-1

CN101-2

CN101-3

POWER DRIVE

UL1430 AWG26 GRAY

UL1430 AWG26 GRAY

UL1430 AWG26 GRAY

UL1430 AWG26 GRAY

UL1430 AWG26 GRAY

UL1430 AWG26 GRAY

UL1430 AWG26 GRAY

UL1430 AWG26 GRAY

DC SUPPLY

UL1430 AWG26 GRAY

UL1430 AWG26 GRAY

UL1430 AWG26 GRAY

EMI FILTER

ZCAT1518-0730

2 TURN

CN15-1

CN15-2

CN15

CN15-3

CN15-4

B06B-XASK-1-A

WHITE

CN15-5

CN15-6

CONTROLLER PCB ASSEMBLY ( MAIN PCB )

ABHA36LAT : K06AK-0607HSE-C1

ABHA45LAT : K06AK-0606HSE-C1

CN13

B07B-PASK-1

WHITE

CN3-1

CN3-2

CN3

CN3-3

CN3-4

B06B-PASK-1

WHITE

CN3-5

CN3-6

CN4-1

CN4-2

CN4-3

CN4-4

CN4-5

CN4-6

CN4-7

CN4-8

CN1-1

CN1-2

CN1-3

CN4

B08B-PASK-1

WHITE

CN1

B03B-PASK-1

WHITE

CN14

B03B-XAKK-1-A

BLACK

CN6

B02B-PAMK-1

GREEN

CN10

B02B-PAOK-1

ORANGE

CN11

B05B-XASK-1-A

WHITE

CN12

B05B-XARK-1-A

RED

CN13-1

CN13-2

CN13-3

CN13-4

CN13-5

CN13-6

CN13-7

CN14-1

CN14-2

CN14-3

CN6-1

CN6-2

CN10-1

CN10-2

CN11-1

CN11-2

CN11-3

CN11-4

CN11-5

CN12-1

CN12-2

CN12-3

CN12-4

CN12-5

UL1430 AWG28 BROWN

UL1430 AWG28 RED

UL1430 AWG28 ORANGE

UL1430 AWG28 WHITE

UL1430 AWG28 BLUE

UL1430 AWG28 PURPLE

UL1430 AWG28 GRAY

FRESH AIR

UL1430 AWG28 BROWN

UL1430 AWG28 RED

UL1430 AWG28 ORANGE

UL1430 AWG28 YELLOW

UL1430 AWG28 WHITE

UL1430 AWG28 BROWN

UL1430 AWG28 RED

UL1430 AWG28 ORANGE

UL1430 AWG28 YELLOW

UL1430 AWG28 WHITE

1

1

BROWN

RED

2

2

3

3

ORANGE

4

4

YELLOW

WHITE

5

5

BLUE

6

6

PURPLE

7

7

8

8

GRAY

UL1430 AWG22 RED

UL1430 AWG22 WHITE

1

2

EARTH WIRE

REMOTE CONTROL UNIT

( OPTION PARTS )

BROWN

RED

ORANGE

YELLOW

WHITE

BROWN

RED

ORANGE

YELLOW

WHITE

INDICATOR PCB ASSEMBLY

K04GN-0402HSE-D0

CN201-1

CN201-2

CN201-3

CN201-4

CN201-5

CN201-6

CN201-7

CN201-8

CN201

JC25-08HG

WHITE

UL1430 AWG22 BLACK

TERMINAL BOARD

3

LOUVER

M

U - D

LOUVER

M

L - R

CN108

CN108-1

CN108-2

B2P3-VH-B

WHITE

NORMAL COIL

RELY41-22

22mH

2.2A

UL1015 AWG20 WHITE

UL1015 AWG20 WHITE

2007.10.29 6

B03B-XARK-1-A

CN9

CN9-1

CN9-2

CN9-3

RED

FLOAT SWITCH

Page 8

INDOOR UNIT

CONTROLLER PCB ASSEMBLY ( MAIN PCB )

ABHA36LAT : K06AK-0607HSE-C1

ABHA45LAT : K06AK-0606HSE-C1

CN1

B03B-PASK-1

DC SUPLLY

CN2

B5P-SHF-1AA

TEST

CN3

B06B-PASK-1

SP PCB

CN4

B08B-PASK-1

POWER DRIVE

CN6

B02B-PAMK-1

FRESH AIR

CN10

B02B-PAOK-1

HEATER

1

2

3

1

2

3

4

5

1

2

3

4

5

6

1

2

3

4

5

6

7

8

13.5V

1

2

1

2

5V

13.5V

13.5V

13.5V

5V

C1

10/

50V

R15 - R18

10K <1/10W> x 4

5V

10K <1/10W> x 3

R24

R23

+

R26

10K

<1/10W>

<1/10W>

1SS355

NJM7812

1

D1

1SS355

I C2

NJM7805

1

I

R32

R67 1.0K

<1/10W>

5V

R30

10K

<1/10W>

D4

I C8

I

G

5V

12V

3

O

G

2

+

5V

3

O

C3

2

0.01

<F>

R19

R22

1.0K <1/10W> x 4

R66

C35 C12

R25

1.0K

<1/10W>

R31

10K

<1/10W>

5V

R34

R33

1.0K

10K

<1/10W>

R27

330

<1/10W>

C2

10/

50V

R20

R21

1.0K <1/10W> X 3R63

R64

1000P <R> x 3

<1/10W>

1

C15

0.01

<F>

C17

0.01

<F>

C18

0.01

<B>

CUSTOM CODE

CUSTOM CODE

HEATING FAN DELAY

R65

C37

C14

1000P

<R>

0.1

<F>

C11

5V

R29

R28

390

10K

<1/10W>

3

2

Q1

DTC124EKA

C16

0.01

<F>

5V

C32

+

100/

6.3V

C4 - C7

0.01 <F> x 4

JM1

JM2

JM3

C33

0.1

<F>

<1/10W>

Q3

DTC124EKA

3

2

5V

R1 - R3

10K <1/10W> x 3

C28

0.1

<F>

R70

10K

1

R4 - R6

1.0K <1/10W> x 3

8

7

6

5

SW1

CFS-0402MC

I C3

13.5V

uLN2003

9

SK

I 1

16

O1

I 2

O2

15

I 3

14

O3

I 4

13

I 5

O4

12

O5

I 6

I 7

11

O6

10

O7

8

GND

1

2

3

4

5

6

7

C8 - C10

0.1 <F> x 3

4

3

2

1

C36

0.47

<F>

5V

I C1

uPD78F0535

34

AVREF

39

I C

RST

36

43

P00

44

P01

P02

45

46

P03

33

P10

32

P11

31

P12

30

P13

29

P14

28

P15

27

P16

26

P17

18

P20

19

P21

20

P22

21

P23

22

P24

P25

23

P30

11

12

P31

13

P32

14

P33

38

XT1

37

XT2

41

X1

X2

40

AGND

25

9

GND0

42

GND1

R11 - R14

10K <1/10W> x 4

R7 - R10

1.0K <1/10W> x 4

AVDD

VDD0

VDD1

35

10

24

15

P34

16

P35

P36

17

57

P40

58

P41

59

P42

P43

60

P44

61

62

P45

63

P46

64

P47

P50

1

2

P51

3

P52

4

P53

5

P54

6

P55

P56

7

8

P57

53

P64

54

P65

55

P66

56

P67

47

P70

48

P71

49

P72

P73

50

51

P74

52

P75

2007.07.29 7

3

2

1

X1

5.00MHz

<CSTLS>

C19 - C22

0.1 <F> x 4

JM5

0R0

JM6

0R0

C31

0.01

<F>

R45

10K

<1/10W>

R46

1.0K

<1/10W>

C27

0.1

<F>

5V

R56

100K

<1/10W>

0.1 <F>

R37

10K

<1/10W>

C38

1

2

3

5V

FLOAT SWITCH

CN9

B03B-XARK-1-A

I C7

S80842

2

3

NC

VDD

1

4

OUT GND

R40

10K

<1/10W>

1

CS

VCC

2

SK

DO

3

D I

NC

6

GND

NC

I C5

BR93L56RF

DTC124EKA

1

5V

ROOM TH.

1

CN8

2

C25

50V

12V

R48

10K

1

2

3

4

5

6

7

10/

I C4

1

2

1

2

5V

+

DAN217U

13.5V

SK

O1

O2

O3

O4

O5

O6

O7

GND

B02B-XASK-1-A

PIPE TH. ( ENT )

CN7

B02B-XAYK-1-A

PIPE TH. ( MID )

CN5

B02B-XAKK-1-A

5V

R49 - R51

10K <1/10W> x 3

C26

0.01

<F>

D2

1 2

3

9

16

15

14

13

12

11

10

8

12V

R52

10K

<1/10W>

D3

D1FS4A

FLASH

CN15

5V

B06B-XASK-1-A

1

2

3

4

5

6

INDICATOR

CN13

B07B-PASK-1

1

2

3

4

5

6

7

CN14

B03B-XAKK-1-A

REMOTE CONTROL UNIT

1

2

3

CN11

B05B-XASK-1-A

LOUVER ( UP / DOWN )

1

2

3

4

5

1

2

3

4

5

CN12

B05B-XARK-1-A

LOUVER ( RHIGT / LEFT )

C29

0.1

<F>

C30

0.1

<F>

C34

0.1

<F>

NC

R57

1.0K

<1/10W>

R58

1.0K

<1/10W>

R62

1.0K

<1/10W>

R41 1.0K

<1/10W>

R43

10K

<1/10W>

R59

10K

<1/10W>

R60

49.9K

<1/10W>

R61

49.9K

<1/10W>

5V

R44

10K

<1/10W>

5V

C23

8

C13

4

0.1

7

5

<F>

0.01

<F>

5V

R55

10K

<1/10W>

R36

Q2

3

0R0

C24

1000P

<R>

7

BA10393F

1

BA10393F

R47

390

<1/10W>

R35

1.0K

<1/10W>

R42

47

<1/10W>

6

-

5

+

I C6-2

2

-

3

+

I C6-1

13.5V

12V

R54

15.4K

<1/10W>

R53

28K

<1/10W>

<1/10W>

B Z

2

BZ1

PKM13EPYH-4000-A0

uLN2003

1

I

2

I

I

3

4

I

5

I

I

6

I

7

Page 9

INDOOR UNIT

POWER SUPPLY PCB ASSEMBLY

K06AL-0606HSE-P0

L

I C26-14

F101

3.15A - 250V

<BET>

FH102

VA101

470V

<TNR>

PFC5000-0702F

x 2

SA101

RA-362M

VA102

470V

<TNR>

C101

0.22

<LE>

W101

BLACK

W102

WHITE

FH101

LF101

ELF20N018A

1

2

4

3

C104

0.22

<LE>

C105

0.01

<YE>

C106

0.01

<YE>

NORMAL COIL

2

1

CN108

B2P3-VH-B

E102

GREEN

<RS-2W>

C108

4700

D102

1SR139-600

15V

+

R110

10K

<1/10W>

R103

62K

ZFT22B03

2

3

5

6

7

8

D106

D1FL20U

C110 0.047 <ECQB>

D103

D1FL20U

D104

MTZJ5.1B

<1/4W>

R109

330

D1FL20U

+

T101

D105

C111

100/

25V

D108

D2FL20U

12

10

1000/

A

C113

25V

C114

0.01

<KH>

C115

0.01

<KH>

R108

100

<1/2W>

13.5V

R111

+

10K

<1/10W>

340V

<ECQM>

R104

330K

<2W>

C109

220P/

2.0kV

R105

1.5

75

Q101

2SC5354

2

3

2SC1815

R107

100

<1/10W>

1

Q102

1

2

3

D107

RD16M

<B1>

C112

330/

25V

D101

1

D3SB60

3

2

4

C107

+

270/

450V

<ECKE>

<RS-2W>

R106

<RS-2W>

C118

0.01

<KH>

POWER DRIVE

B08B-PASK-1

SERIAL I N

SERIAL I NT

SERIAL ON

DRAIN PUMP

DC FAN-OUT

DC FAN-FEEDBACK

EX. SIGNAL-OUT

EX. SIGNAL-I N

DC SUPPLY

I C26-10

CN104

CN101

B03B-PASK-1

E101

N

GREEN

CN105

B5P6-VH-B

6

5

4

3

2

1

G5NB-1A

4

2

I C101

TLP621

<GB>

4

3

<AG601>

DC FAN MOTOR

K101

1

3

L102

BLm18

5V

<AG601>

1

2

L103

BLm18

13.5V

R112

330

<1/10W>

C116

0.01

<B>

CN102

B3B-XH-AM

3

2

1

2

1

E I B I N

W105

CN103

B2B-XH-AM

8

RED

SERIAL

E I B OUT

VA103

470V

<TNR>

IC26-14

7

L

IC26-14

L

IC26-10

N

IC26-10

I C 105

H I 2002R

101418

6

N

K102

G5NB-1A

342

1

13.5V

5 4 3 2

3 2 1

5 4

RC101

120/

0.2

1

5V

CN106

B2P3-VH-B-E

2

1

DRAIN PUMP

C119

0.01

<KH>

I C103

TLP621

<GB>

4

3 2

340V

15V

1

A

R114

4.7K

<1/10W>

R115

6.8K

<1/4W>

R113

330

<1/10W>

15V

5V

1

2

3

4

5

6

7

8

1

2

3

1

2

TLP621

I C104

<GB>

15V

4

3

R116

1.0K

<1/4W>

R117

<1/4W>

5V

C121

0.1

<F>

820

+

C117

100/

25V

AA

13.5V

C120

0.1

<F>

2007.07.29 8

Page 10

TO CONTROLLER PCB ASSEMBLY

( OPERATE )

( TIMER )

( LOUVER )

( LOUVER )

( 5V )

( REMOTE CONTROL )

( GND )

( MANUAL AUTO SWITCH )

INDOOR UNIT

INDICATOR PCB ASSEMBLY

K04GN-0402HSE-D0

R201

330 <1/4W>

R202

330 <1/4W>

BROWN

RED

ORANGE

YELLOW

WHITE

BLUE

PURPLE

GRAY

CN201

08/08 JC/XMR

1430 L=300

1

2

3

4

5

6

7

8

R203

330 <1/4W>

SW201

EVQPAG04K

1

2

5V

D205 EBR3864X <RED>

D206 EMPG3863X <GREEN>

D207 EMAA3863X <ORANGE>

C202

C201

+

10/

3

4

16V

0.1

<F>

JM201

PHA201

P I C-37143TH5

2

VCC

OUT

1

GND

3

2007.07.29 9

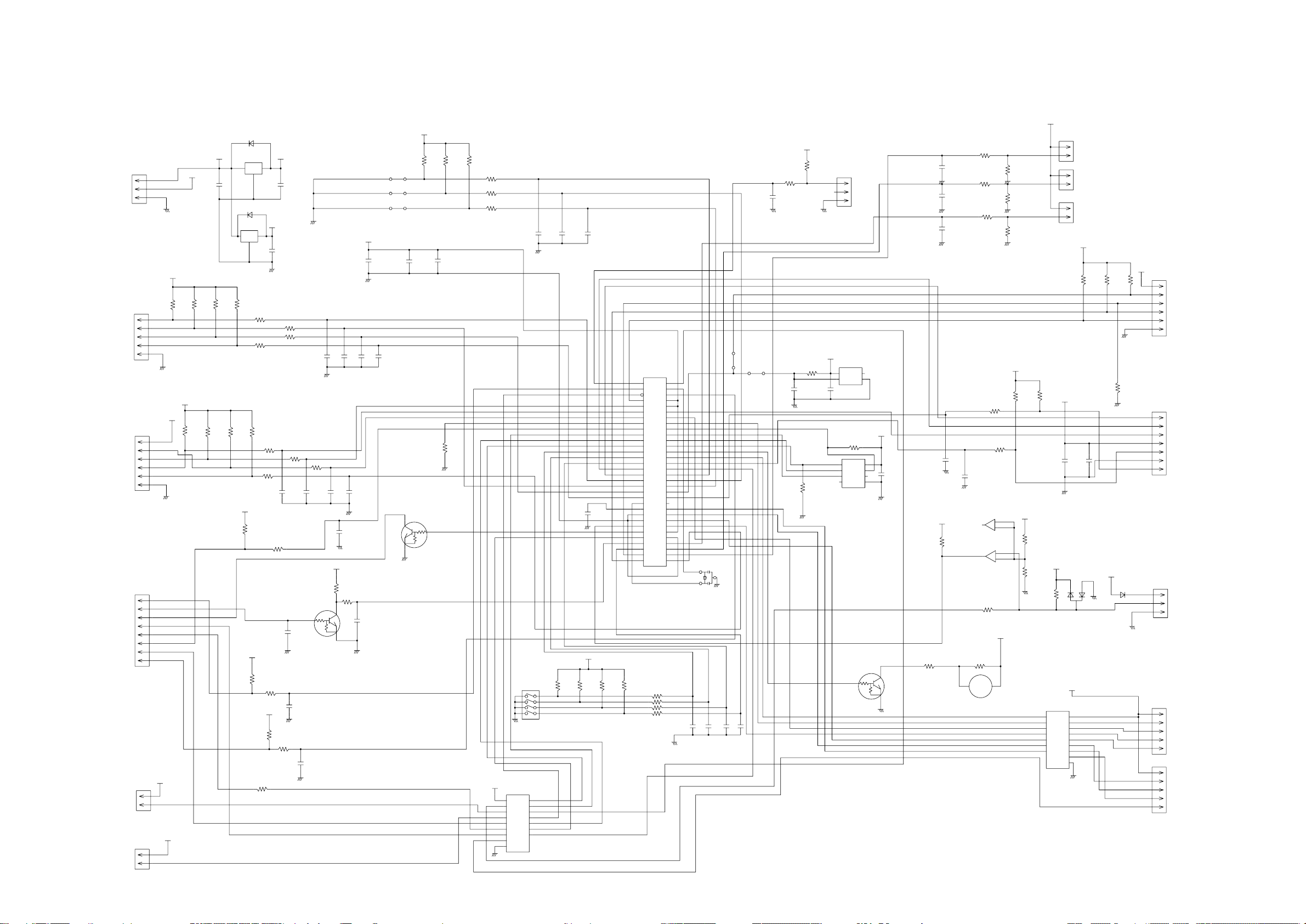

Page 11

POWER SOURCE

230V

50Hz

INDOOR UNIT

N

L

3

2

(N)

1

5P TERMINAL

HP-T3061-3

UL1015

TLC 25A - 250V, B

AWG12

( 250V 25A )

WHITE

UL1015

AWG12

BLACK

UL1015

AWG20

RED

UL1015

AWG20

WHITE

UL1015

AWG20

BLACK

F202

FSL 250 10 ( EM )

( 250V 10A )

OUTDOOR PCB CIRCUIT DIAGRAM

INVERTER ASSEMBLY

AOHA36LATL : EZ-00603HUE

AOHA45LATL : EZ-00604HUE

F201

EMI FILTER 1

TFC-25-15-12A

UL1015

AWG12

BLACK

UL1015

AWG20

BLACK

1T

UL1015

AWG16

GREEN

EARTH

W1

B

W6

B

POWER SUPPLY PCB ASSY

W2

B

W7

B

W3

B

K04BA-0401HUE-P0

B3B-XASK-1-A

03 VH / SIN

1015 L=250

CN1

WHITE

CT OUT

TM101

TM102

W9

W8

B

B

1

2

3

UL1015 AWG14 BLACK

UL1015 AWG14 WHITE

UL1015 AWG20 WHITE

UL1015 AWG20 BLACK

UL1007 AWG24 BLACK

UL1007 AWG24 BROWN

UL1007 AWG24 RED

W10

B

W11

B

CN34

1

B2P3-VH-B-Y

YELLOW

3

CN1

03 XA / 172520

1

1007 L=180

WHITE

3

4

AC VOLT I N

CT

W16

W17

W21

W22

CHOKE COIL

L=0.3MH

30A

UL1015

AWG14

EMI FILTER 2

TFC-25-15-12A

2T

BROWN

+

UL1015

AWG14

RED

B

UL1015

AWG14

BLACK

B

UL1015

AWG20

ORANGE

B

UL1015

AWG20

ORANGE

B

ZPR0YCE400A300

-

UL1015

AWG14

BROWN

L1 L2

ACTPM

SACT32010F1

P

N1

1

2

3

4

5

6

EMI FILTER 3

TFC-25-15-12A

2T

UL1015 AWG14 YELLOW

UL1015 AWG14 BLUE

UL1007 AWG24 BROWN

UL1007 AWG24 RED

UL1007 AWG24 ORANGE

UL1007 AWG24 YELLOW

W12

B

W13

B

CN407

06 PH / 172520

1

1007 L=480

WHITE

3

4

5

ACTPM CONTROL

W305

W304

W303

B

B

B

UL1015 AWG14 RED

UL1015 AWG14 WHITE

UL1015 AWG14 BLACK

C M

COMPRESSOR

DC FAN MOTOR 1

DC FAN MOTOR 2

EXPANSION VALVE

4-WAY VALVE

PRESSURE SWITCH

COMPRESSOR TH.

HEAT SINK TH.

DISCHARGE TH.

PIPE TH.

OUTDOOR TH.

PIPE ( MID ) TH.

F M

F M

M

BLACK

BLACK

BROWN

BROWN

BLACK

BLACK

BROWN

BROWN

BLACK

BLACK

BLUE

BLUE

BLACK

BLACK

RED

BLACK

WHITE

YELLOW

BROWN

RED

BLACK

WHITE

YELLOW

BROWN

RED

BROWN

BLUE

ORANGE

YELLOW

WHITE

RED

RED

W200

B

1

2

CN800

3

4

B07B-XASK-1-A

5

WHITE

6

7

1

2

3

CN801

4

B07B-XAKK-1-A

5

BLACK

6

7

1

2

CN27

3

4

B06B-XARK-1-A

5

RED

6

1

CN30

179844-1

3

WHITE

1

CN37

2

B02B-XARK-1-A

RED

CN26

B02B-XAMK-1-A

1

GREEN

2

CN25

B02B-XAKK-1-A

1

BLACK

2

CN21

1

B02B-XH-AM-Y

2

YELLOW

1

CN22

2

B2B-XH-AM-R

RED

1

2

CN23

B02B-XAEK-1-A

BLUE

1

2

CN24

B2B-XH-AM

WHITE

SERIAL

CONTROLLER PCB ASSY ( MAIN PCB )

AOHA36LATL : K06DZ-0601HUE-C1

AOHA45LATL : K06DZ-0600HUE-C1

CN601

B10B-PASK-1

MAIN FLASH

WHITE

1

5V

2

GND

3

TAUX

4

TTXD

5

TRXD

TMODE

6

TAUX3

7

TCK

8

/ TRES

9

/ TICS

10

2007.07.29 10

Page 12

AC VOLT I N

B2P3-VH-B-Y

SERIAL

4-WAY VALVE

PRESSURE SWITCH

B02B-XARK-1-A

COMPRESSOR TH.

B02B-XAMK-1-A

HEAT SINK TH.

B02B-XAKK-1-A

DISCHARGE TH.

PIPE TH.

OUTDOOR TH.

B02B-XAEK-1-A

W22

ORANGE

W21

ORANGE

W10

BLACK

W11

WHITE

CN34

YELLOW

W200

CN30

179844-1

WHITE

CN37

CN26

GREEN

CN25

BLACK

CN21

B2B-XH-AM

YELLOW

CN22

B2B-XH-AM

CN23

CONTROLLER PCB ASSEMBLY ( MAIN PCB )

AOHA36LATL : K06DZ-0601HUE-C1

AOHA45LATL : K06DZ-0600HUE-C1

R51 27K

5V

<1/10W>

R55

R56 27K

1.0K

R50 10K

<1/10W>

<1/10W>

R52

1.0K

C51

0.022

<F>

<1/10W>

1

3

Q51

2SC2412K

2

<BQ>

<1/10W>

JM156

x 2

C53

<F>

C180

0.022

P-S I

P-S I1

P-POWER

P-AFE

P-AFDC

P-CP-POS

C95

100P

<CH>

<1/10W>

<1/10W>

VOLTAGE LOCK OUT

C35, C26

0.01 <F>

R113

1.0K

R114

27K

VA103

470V

<TNR>

MAIN CURRENT

2

+

3

-

D101

D25XB60

18

14 10 5 432 1

1

4

7

HY I C1

HU2001

C115

0.1

<HCP>

6

B

W16

RED

B

W17

BLACK

5V

2

543

18

B

B

4

12V

B

B

PFC5000

-0702

FH2

3

1

3

1

2

K101 DW12D1

PFC5000

F4

-0702

T 5A

FH1

250V

SERIAL

RED

B

2SC2412K <BQ>

100K <2W>

12V

D28

SLR-332VR

<RED>

12V

R43 2.2K

<1/4W>

1C

2C

15

3C

14

4C

13

5C

12

6C

11

7C

10

COM

9

I C3

uLN2003A

1B

116

2B

2

3

3B

4B

4

5B

5

6

6B

7B

7

8

E

JM157

P-FM1SEL

P-V2

P-4WV-AC

P-LED

P-PR

P-SO1

P-SO

1

2

CR5

RE1202

K17 G5NB-1A

3

12V

124

4WV

D153, D152,

D151, D150

SLR-332VR

<RED> x 4

5V

2.2K

1

2

R91

1

2

1

2

1

2

1

2

1

2

R90

L202

BL02Rn1

5V

BL02Rn1

RED

RED

<1/10W>

x 2

C71

L201

4.75K 1%

4.75K 1%

38.3K 1%

1.0K <1/10W> x 2

R93

R92

0.1

C70

0.01 <F> x 2

R100

13K

<1/10W>

R98

<1/10W>

R63

13K

<1/10W>

R65

<1/10W>

R67

<1/10W>

<F>

x 2

<1/10W>

<1/10W>

<1/10W>

<1/10W>

<1/10W>

C73

R101

10K

R99

10K

R62

10K

R64

10K

R66

10K

C72

PR-SW

C60

1.0

<F>

C61

1.0

<F>

C37

1.0

<F>

C38

1.0

<F>

C39

1.0

<F>

5V

C91

0.1

<F>

8 VCC

4

7

5

<1/10W>

THERMISTOR

I C201

BR93L56RF-WE2

1

CS

2

DO

SK

3

NC

D I

6

GND

NC

R206

10K

EEPROM

P-E2PCS1

P-E3PSK1

P-E2PD I 1

C56

1.0K

<1/10W>

P-SWPRS1

P-SWPRS2

P-CMPTH

P-AN-HT

P-AN-TD

P-AN-TT

P-AN-TA

6

5

4

SW1

DSS803

AOHA36LATL

CN24

B2B-XH-AM

PIPE ( MID ) TH.

1

2

<1/10W>

3

2

<1/10W>

1

<1/10W>

R35

10K

<1/10W>

R68 4.75K

<1/10W>

1%

R16

2.2K

R17

1.8K

R18

1.0K

5V

R11, R195

P-V2

<1/10W>

R34

1.0K

10K <1/10W> x 2

C40 0.1

<F>

C77

0.1

<F>

P-AN-TT2

P-AN-HT

P-CMPTH

P-AN-TT

P-AN-TA

P-AN-TD

FM2FDB

SUB-CLK

P-FM2POW

P-POWER

P-AN-CT

P-FM1POW

TTXD-1

TAUX3-1

P-AFS

P-CP-POS

5V

P-S I

P-SO

P-PR

P-LED

P-4WV-AC

P-TRIP

P-EPV-A

P-EPV-B

P-EPV-C

P-EPV-D

1

MB90462

17

16

2

35

3

59

58

60

21

34

47

27

28

29

30

31

32

33

57

41

42

43

44

10

9

8

7

5

6

4

22

23

3

2

I C1

P63

P62

P46

P12

P50

P37

P36

P40

MD2

P11

P26

P02

P03

P04

P05

P06

P07

P10

C

P20

P21

P22

P23

P57

P56

P55

P54

P52

P53

P51

X0

X1

X1

8.00MHz

<EFO>

MICOM-MAIN

P-AN-TT2

C78

0.1

<F>

AVCC

RSTX

AGND

VCC

P00

P01

P17

P13

P14

P15

P16

AVR

P24

P25

P30

P31

P32

P33

P34

P35

P60

P61

MD0

MD1

P44

P43

P42

P41

P45

P27

GND

GND

C79

<F>

56

11

25

26

40

36

37

38

39

12

45

46

50

51

52

53

54

55

14

15

18

20

64

63

62

61

1

19

48

13

24

49

0.1

0.1 <F> x 2

R608 10K <1/10W>

U

X

V

Y

W

Z

R36

1.0K

<1/10W>

C19

R72 1.0K

<1/10W>

C17

0.01

<F>

5V

C18

C16

4.7/

50V

<PS>

5V

R158

10K

<1/10W>

SW2

KSM0632B

+

<PS>

C20

4.7/

50V

5V

+

2

1

Q1

2SC5354

R140 1.2

TAUX-1

P-E2PCS1

P-FM1SEL

FM1FDB

P-E2PD I1

P-E2PSK1

P-AFDC

P-AFE

P-U

P-X

P-V

P-Y

P-W

P-Z

R126 - R128

10K <1/10W> x 3

SUB-FWD

SUB-BKWD

TMODE-1

P-SWPRS2

P-SWPRS1

TCK-1

TRXD-1

R73 82K

<1/10W>

5

SUB

VCC

4

VOUT

3

GND

NC

I C6

BD4742G

<1/2W>

R407, R403

10K <1/10W>

x 2

5V

R102

3

<1/10W>

1

2

R103

4.7K

<1/10W>

Q91

x 2

R6

R1

2

1

3

D1

D1FL20U

5V

W12

YELLOW

W13

BLUE

x 2

15V

22K

4.7/50V <PS>

R3 100

<1W>

D10

RD5.6ES

R4 330

<1/4W>

P-AFS

RSTX-1

I C400-1

5V

uPC393

I C400-2

uPC393

I C11-1

uPC393

1

R115 1M

<1/10W>

R2 1.0K

<RS-3W>

C2 0.047

D1FL20U

<B2>

100/16V

R411

<1/10W>

C416

1000P

TAUX-1

TTXD-1

TRXD-1

TMODE-1

TAUX3-1

TCK-1

RSTX-1

B

B

-

+

220P

<BN>

<ECQB>

<PJ>

22K

<B>

DTC124EUA

R201

220K

<2W>

660/450WV x 3

1

7

15V

2

3

C90

+

+

C201

C202

C203

SMOOTHING CIRCUIT

15V

R408

C409

6.65K

10/

<1/10W>

25V

1%

<PS>

15V

+

2

-

3

+

6

-

5

+

C412

+

0.1

<F>

C88

0.1

<F>

1.0K <1/10W>

C411

C414

0.01

0.01

<F>

<F>

2

C89

470P

<B>

DAN217U x 2

C87

330P

COMP POSITION DETECT

<B>

SW POWER SUPPLY

T1

JPZ-200

16

C1

15

13

12

10

9

D1

D100

C3

D1FL20U

+

220/

35V

P-U

P-V

P-W

P-X

P-Y

P-Z

P-TRIP

P-FM1POW

FM1FDB

P-FM2POW

FM2FDB

C7

ACTPM CONTROL

Q403

DTA143

2

3

2

1

A

A

Q401

R437,

R438

270 <1/10W>

1% x 2

5V

10K <1/10W> x 5

R605

22K

<1/10W>

R604

R21

FLASH-MAIN

+

R402

2.2K

<1/4W>

D402

RD3.3ES

<B2>

R435, R441

x 2

1

2

3

D81, D82

1

2

3

6

7

8

15V

+

D1FL20U

18V

C415

1

3

C413

0.01

<F>

A

R603

R602

R20

10K

<1/10W>

C116

0.1

<HCP>

R400R440

180K <RN-1/2W>

2.87K

R406

R401

2.94K

1

3

R108

2.87K

<1/10W>

R5

10K

<1/10W>

D8

D7

I C407 uPC24M18

D401

C406

+

220/

x 3

50V

<PJ>

CN407

06 PH / 172520

1007 L=480

WHITE

18V

0.01

<F>

A

A

5V

5V

R601

10

1%

3

4

5

3

4

5

6

7

8

9

1% x 2

<1/10W> 1%

<1/10W> 1%

470/

25V

<PJ>

1

2

1

2

R104

R106

C4

+

1

FH3

PFC5000

-0702

F2

T 3.15A

250V

FH4

PFC5000

-0702

L100

1% x 2

195K <RN-1/2W>

R87 2.94K

R105 2.94K

<1/10W> 1%

R107 680

C5

220/

16V

<PJ>

I C8

TA7805

1

O

G

+

2

3

I

O

G

2

D110

ZP1027

ACTPM

CONTROL

TAUX

TTXD

TRXD

TMODE

TAUX3

TCK

/ TRES

/ TICS

CN601

B10B-PASK-1

WHITE

MAIN-FLASH

<1/10W> 1%

<1/10W> 1%

12V

+

5V

3I

+

<PS>

18V

C418

35V

<PS>

A

100/

16V

10/

C6

R360 39

1.0K

<1/10W>

x 6

195K <RN-1/2W> x 6

R86

R111

R112

R89

R110 R88

<1/2W>

0.1 <F> x 3

330k

<1/10w> x 3

D301

R361

C323

D302

C322

U1JU44 x 3

D303

R340

R341

R342

R343

R344

R345

P-EPV-A

P-EPV-B

P-EPV-C

P-EPV-D

P-EPV1-A

P-EPV1-B

P-EPV1-C

P-EPV1-D

R363

R362

C321

C311

1000P <B> x 6

Q800

DTC143

EUA

2

C801

0.01

<F>

DC FAN-2

Q802

DTC143EUA

2

C804

0.01

<F>

P-AN-CT

JM152

JM153

JM154

JM155

C312

47/35V

<PJ> x 3

+

C305

+

C304

+

C303

C313

Q801

DTA143

3

R803

1

<1/10W>

R804

1.0K

<1/10W>

3 2

1

<1/10W>

EE-VALVE

15V

C332

0.1

L300

BL02Rn1

<F>

0.1 <F> x 3

C324

C325

C326

C316

C314

C315

15VDC FAN-2

1

2

<1/2W>

3

5V

5V

1 2

10K

D803

DAN217U

15V

Q803

1

DTA143

3

5V

R807

10K

<1/10W>

R808

1.0K

DAN217U

1.5K <1/10W> x 4

R97

R96

R95

R94

C333

47/

+

35V

1

UP

2

VP I

3

VUFB

4

VUFS

5

VP

6

VP I

VVFB

7

8

VVFS

9

WP

10

VP I

11

VPC

12

VWFB

13

VWFS

I C310

PS21267-AP

C33

0.01

<F>

L800

BL02Rn1

R801

1.0K

C800

100/

16V

<PJ>

3

R805

1.0K

<1/2W>

D804

DAN217U

5V

D61

12V

14

VN I

VNC

15

16

C IN

17

CFO

18

FO

19

UN

20

VN

21

WN

22

P

23

U

24

V

25

W

26

N

R40 1.0K

<1/10W>

15V

C802

<F>

R802

+

560

<1/4W>

L801

BL02Rn1

15V

C805

0.1

<F>

5V

1 2

1

2

3

TD62064

3

I 1

I 2

6

11

I 3

I 4

14

COM1

1

COM2

8

10

NC1

NC2

15

0.1

3

I C4

R370, R371, R374

R375, R376, R379

0.018 <2W> x 6

R302 1.0K

<1/10W>

C328

2200P

<B>

C327

0.022 <F>

5V

R33 10K

<1/10W>

R806 560

<1/4W>

+

5V

C803 <PJ>

100/16V

C29

R69

0.1

1M

<F>

<1/10W>

12V

2

O1

7

O2

9

O3

16

O4

4

GND1

5

GND2

12

GND3

13

GND4

B

B

B

1

CN800

B07B-XASK-1-A

2

WHITE

3

4

DC FAN

5

6

7

1

CN801

B07B-XAKK-1-A

2

BLACK

3

4

DC FAN

5

6

7

1

2

3

4

CN27

1

B06B-XARK-1-A

RED

2

3

EXPANSION VALVE-A

4

5

6

W305

RED

W304

WHITE

W303

BLACK

INVERTER

CN1

03 XA / 172520

1007 L=180

WHITE

CT

MOTOR-1

MOTOR-2

2007.07.29 11

Page 13

OUTDOOR UNIT

POWER SUPPLY PCB ASSEMBLY

K04BA-0401HUE-P0

TM100

POWER SOURCE

230V

50Hz

TO INDOOR UNIT

EARTH

AC VOLT OUT

BLACK

WHITE

W1

W2

W6

BLACK

W7

WHITE

W3

GREEN

W8

BLACK

W9

WHITE

L1

RCH3818-022PF07

VA101

B

470V

<TNR>

VA102

470V

C101

1.0

<LE>

<TNR>

B

SA100

RA-302M

B

B

B

B

B

C104

0.033

<YE>

C105

0.033

<YE>

C106

1.0

<LE>

L2

N200500K1D7C

C107

3.3

<LE>

CT1

CT-1B

D60

5V

DAN217U

C60

220/16V

<PJ>

R60 680

<1/10W>

(1%)

L4

RCH3818-022PF07

+

R61 3.74K

<1/10W>

(1%)

C111

2.2

<LE>

R68 22K

<1/10W>

VR1

KVSF687

AC202

C64

0.1

<F>

C65

0.1

<F>

5V

TM101

B

BLACK

TM102

B

WHITE

CN1

B03B-XASK-1-A

WHITE

1

2

3

CT OUT

2007.07.29 12

Page 14

ERROR CONTENTS

INDOOR UNIT

(Troubleshooting with the indoor display)

Troubleshooting at the display is possible either on the wired or wireless

remote control.

FILTER lamp (Orange)

TIMER lamp (Green)

OPERATION lamp (Red)

The OPERATION, TIMER and FILTER lamp operate as follows table according to the error contents.

Error contents

Indoor signal error

Wired remote controller abnormal

Indoor room temperature sensor error

Indoor heat exchanger temperature

sensor (middle) error

Indoor heat exchanger temperature

sensor (inlet) error

Float switch operated

Outdoor discharge pipe temperature

sensor error

Outdoor heat exchanger temperature

sensor (outlet) error

Outdoor temperature sensor error

Heatsink thermistor error

Compressor temperature sensor error

2-way valve temperature sensor error

3-way valve temperature sensor error

Outdoor heat exchanger temperature

sensor (middle) error

Indoor manual auto switch abnormal

Power supply frequency detection

error

IPM protection

CT error

Compressor location error

Outdoor fan error

Connected indoor unit abnormal

Outdoor unit computer communication

error

Indoor fan abnormal

Discharge temperature error

Excessive high pressure protection on

cooling

4-way valve abnormal

Pressure switch abnormal

Compressor temperature error

Active filter abnormal

PFC circuit error

OPERATION

lamp (RED)

(2 times)

(2 times)

(2 times)

(2 times)

(3 times)

(3 times)

(3 times)

(3 times)

(3 times)

(3 times)

(3 times)

(3 times)

(4 times)

(4 times)

(5 times)

(5 times)

(5 times)

(5 times)

(5 times)

(5 times)

(6 times)

(7 times)

(7 times)

(7 times)

(7 times)

(7 times)

(8 times)

(8 times)

TIMER lamp

(GREEN)

(8 times)

(2 times)

(3 times)

(4 times)

(6 times)

(2 times)

(3 times)

(4 times)

(7 times)

(8 times)

(2 times)

(4 times)

(2 times)

(3 times)

(5 times)

(6 times)

(7 times)

(8 times)

(2 or 3 times)

(2 times)

(3 times)

(4 times)

(5 times)

(6 times)

(2 or 3 times)

(4 times)

FILTER lamp

(ORANGE)

(2 times)

(3 times)

(4 times)

OUTDOOR UNIT LEDS

Make a TEST RUN in accordance with the

installation instruction sheet for the indoor unit.

When a malfunction occurs in the outdoor unit,

the LED on the circuit board lights to indicate the error.

Refer to the following table for the description of each

error according to the LED.

LED

1 flash

2 flash

3 flash

4 flash

5 flash

7 flash

8 flash

9 flash

12 flash

13 flash

14 flash

15 flash

16 flash

5 sec. on/

1 sec. off

repeat

1 sec. on/

1 sec. off

repeat

off

Error contents

Communication error

(Indoor unit - Outdoor unit)

Discharg pipe temperature sensor

Outdoor heat exchanger temperature (outlet) sensor

Outdoor temperature sensor

Outdoor heat exchanger temperature (mid) sensor

Discharge pipe temperature abnormal6 flash

Compressor temperature sensor

Heat sink temperature sensor

Pressure switch abnormal

Compressor temperature abnormal10 flash

IPM error

Compressor rotor position cannot detect

Compressor cannot operate

Outdoor fan abnormal (upper fan)

Outdoor fan abnormal (lower fan)

Protect operation

Pump down operation

No error

: 0.5s ON/0.5s OFF (Flash) : OFF

2007.10.29 13

Page 15

WIRED REMOTE CONTROL

If an error occurs, the following display will be shown.

("EE" will appear in the set room temperature display.)

If "CO" appears in the unit number display, there is a remote control error.

Refer to the installation instruction sheet included with the remote control.

Unit number

Error code

SUMOTUWETH FR

Error code Error contents

01

13

26

27

00

02

04

28

09

0C

06

0A

15

1d

1E

29

20

2A

17

18

1A

1b

1F

1c

12

0F

24

2c

16

2b

19

25

Serial reverse transfer error

Serial forward transfer error

Communication error ( Main PCB Display PCB )

Communication error ( Display PCB Main PCB )

Wired remote controller abnormal

Indoor room temperature sensor error

Indoor heat exchanger temperature sensor (middle) error

Indoor heat exchanger temperature sensor (inlet) error

Float switch operated

Outdoor discharge pipe temperature sensor error

Outdoor heat exchanger temperature sensor (outlet) error

Outdoor temperature sensor error

Compressor temperature sensor error

2-way valve temperature sensor error

3-way valve temperature sensor error

Outdoor heat exchanger temperature sensor (middle) error

Indoor manual auto switch abnormal

Power supply frequency detection error

IPM protection

CT error

Compressor location error

Outdoor fan error

Connected indoor unit abnormal

Outdoor unit computer communication error

Indoor fan abnormal

Discharge temperature error

Exessive high pressure protection on cooling

4-way valve abnormal

Pressure switch abnormal

Compressor temperature error

Active filter abnormal

PFC circuit error

SA

2007.08.06 14

Page 16

SPECIAL INSTALLATION SETTING

PUMP DOWN (Refrigerant collecting operation)

Perform the following procedures to collect the refrigerant

when moving the indoor unit or outdoor unit

1. When the product is stopped:

Press the PUMP DOWN switch on the outdoor unit.

1

(The LED on the outdoor unit circuit board starts flashing.)

(1 sec. on / 1 sec. off repeated)

2

The pump down operation (cooling operation) begins

right away. After oparation starts, close the three-way

valve (liquid).

3

After 2 - 3 minutes, operation stops. Close the three-way

valve (gas) within one minute after operations stops.

4

The LED will go out three minutes after it stops.

Disconnect the power supply after confirming that the

LED has gone out.

2. When the product is operating:

1

Press the PUMP DOWN switch on the outdoor unit.

The LED on the outdoor unit circuit board starts flashing

( 1 sec. on / 1 sec. off repeated), and operation stops.

At this point, recovery has not been completed, so do not

close the three-way valves. (liquid and gas)

2

The pump down operation (cooling operation) begins after three minutes. Close the three-way valve

(liquid) after operation starts.

PUMP DOWN SW (SW2)

DANGER

This part (Choke coil) generates high voltages.

Never touch this part.

3

After 2 - 3 minutes, operation stops. Close the three-way

valve (gas) within one minute after operations stops.

4

The LED will go out three minutes after it stops. Disconnect the power supply after confirming that the LED

has gone out.

*When the pump down operation is repeated, temporarily disconnect the

power supply after opening the closed valves (both liquid and gas).

Reconnect the power supply after 2 - 3 minutes and perform the pump

down operation.

*When the start of the operation after pump down operation has been

completed, temporarily disconnect the power supply after opening the

closed valves (both liquid and gas).

Reconnect the power supply after 2-3 minutes and be sure to perform a

test operation for cooling.

3-way valve

(Liquid)

6.35 mm (1/4 in.)

Blank

cap

Spindle (Hexagon wrench)

9.52 mm (3/8 in.)

12.70 mm (1/2 in.)

15.88 mm (5/8 in.)

19.05 mm (3/4 in.)

Charging port cap

Outdoor unit

20 to 25 N-m (200 to 250 kgf-cm)

20 to 25 N-m (200 to 250 kgf-cm)

25 to 30 N-m (250 to 300 kgf-cm)

30 to 35 N-m (300 to 350 kgf-cm)

35 to 40 N-m (350 to 400 kgf-cm)

10 to 12 N-m (100 to 120 kgf-cm)

6 to 7 N-m (60 to 70 kgf-cm)

Connecting pipe

3-way valve

Charging port

Tightening torque

Blank cap

Hexagon wrench

Use a 4 mm

hexagon wrench.

3-way valve

(Gas)

2007.03.07 15

Cap

Page 17

PARTS

INDOOR UNIT

3

1

15

16

18

2

14

17

15

19

4

11

9

6

8

14

7

5

13

Ref. Description Part number

1 Kit (Base Sub Assy) 9371360010

2 Panel Left Sub Assy 9360427014

3 Kit (Panel Right Assy) 9371361017

4 Cover (Top) 9359737001

5 Intake Grille 9359738008

6 Air Filter 9359739005

7 Filter Guide R 9359692003

8 Filter Guide L 9359693000

9 Front Panel 9359734000

10 Indicator PCB Assy 9705891036

11 PCB Holder 9359736004

12 Receiver Cover 9359714002

13 Hole Cover 9359691006

14 Hinge Plate (Grille) 9359694007

15 Hanger Bracket 9359742005

16 Cover (Decoration)-R 9359744009

17 Cover (Decoration)-L 9359745006

18 Kit (Side Cover R) 9371364018

19 Kit (Side Cover L) 9371365015

20 Badge 9359735090

9

10

11

12

20

2007.10.29 16

Page 18

INDOOR UNIT

Drain pan

Flap

Ref.

Description Part number

2 Panel Left Sub Assy 9360427014

3 Kit (Panel Right Assy) 9371361017

21 Evaporator Assy 9372585078

22 Distributor Assy 9371325378

23 Coupling Pipe Assy 9373038405

24 Kit (Panel pipe-L) Sub Assy 9371362014

25 Kit (Panel pipe-R) Sub Assy 9371363011

26 Reinforcement Metal 9359697008

Drain Pan Sub Assy 936042901827

28 Flap Assy 9359731009

29 Bushing 9359733003

30 Flap Spring 9359730002

31 Sector Gear 9359729006

32 Pinion 9359728009

33 Motor Base 9359727002

34 Step Motor V 9900297015

35 Kit (Separate Wall Sub Assy) 9371366029

36 Pipe Fixture Metal 9359688006

-- Drain Cap 9358746004

-- Pipe Thermistor 9900022020

-- Thermistor Spring A

313728262708

28

24

27

33

35

23

25

22

21

36

26

29

28

2

27

3

30

31

33

34

32

3

28

2007.10.29 17

Page 19

51

INDOOR UNIT

Louver Base Sub Assy

47

48

43

41

Ref. Description Part number

41 Louver Base Sub Assy 9360432025

42 Louver 9359719007

43 Rod (Motor) 9359723004

44 Louver Link 9359726005

45 Louver Base 9359718000

46 Louver Spring 9359720003

47 Louver Stopper 9359724001

48 Louver Rod 9359725008

49 Step Motor H 9900297015

50 Louver Insulation R 9359721000

51 Louver Insulation L 9359722007

44

46

45

49

42

50

2007.10.29 18

Page 20

INDOOR UNIT

Fan motor

73

67

74

74

61

73

72

63

63

61

71

72

69

70

68

62

Ref. Description Part number

61 Motor Mount 9377999016

62 Fan Motor Assy 9602389018

63 Motor Band A assy 9374647019

64 Motor Band B 9374648023

65 Reinforcement Motor Band 9378000018

66 Rubber 9385102002

67 Casing 9359704003

68

Kit (Cover Casing) Sub Assy

69 Sirocco Fan Assy 9359701002

70 Joint Assy 9378038011

71 Shaft 9359707004

72 Shaft Holder Bracket 9359686002

73 Bearing B Assy 9357921006

74 Shaft Holder Fixture 9359687009

9371367019

66

62

64

2007.10.29 19

64

65

Page 21

Ref. Description Part number

81 Control Box Assy 9377912015

82 Control Box A 9359712008

83 Control Box B 9359713005

84

Controller PCB Assy (36LATN)

84

Controller PCB Assy (45LATN)

85 Power Supply PCB Assy 9707398076

86 Terminal 3P 9703345012

87 Terminal 3P 9306489045

88 Reactor Assy 9707457018

89 Rubber Bushing 9357376004

91 Cord Clamp-A 9359820017

92 Cord Clamp-B 9359821014

93 Reactor Assy 9707457018

94 Room Thermistor 9703299025

95 Wire Assy (Connector) 9707442021

96 Wire Assy (Connector) 9703339028

97 Wire Assy (Connector) 9702319014

98 Wire Assy (Connector) 9702318017

99 Remote Control 9315885012

100 Remote Control Holder 9305642014

9707393088

9707393071

INDOOR UNIT

Control unit

100

99

97

87

98

95

96

84

85

94

88

89

91

86

92

81

2007.10.29 20

82

83

Page 22

PARTS

OUTDOOR UNIT

1

3

2

6

4

3

7

5

Description Parts numberRef.

1 Top Panel Sub Assy

2 Front Panel

3 Fan Guard

4 Grip Side

5

Service Panel Sub Assy

6 Right Panel Sub Assy

7 Valve Cover

-- Emblem Rear 9372171011

9374417025

9374094028

9374330010

9374173013

9374415069

9374416141

9374174010

2007.10.29 21

Page 23

OUTDOOR UNIT

12

11

13

16

10

10

9

15

14

Description Parts numberRef.

9 Propeller Fan Assy

10 Motor DC Brushless

11 Condenser A Assy

12 Condenser B Assy

13 Sepa Wall

14 Cap Foot

15 Base Assy

16 Coil Choke 9703458019

9366378020

9601882015

9374433018

9374434015

9374629015

9374345014

9374166046

2007.02.06 19

2007.10.29 22

Page 24

OUTDOOR UNIT

22

21

58

56

23

20

24

55

25

42

54

26

19

Description Parts numberRef.

17 3-Way Valve Assy

18 3-Way Valve Assy

19 Compressor Assy

20 Accumulator Assy

21 Solenoid

22 Pressure Switch

23 4-Way Valve

24 Check Valve Assy

25 Coil (Expansion Valve)

26 Strainer Assy

42 Expansion Valve Assy

54 Compressor Cover A

55 Compressor Cover B

56 Compressor Cover C

57 Compressor Cover D

58 Solenoid 9900165055

2007.10.29 23

9377958013

9377959010

9378035010

9375250034

9900165055

9900186012

9970035029

9374274017

9900197025

9372524039

9370947175

9374430109

9374431106

9372067086

9375382025

17

18

57

Page 25

Description Parts numberRef.

27 Inverter Box A

28 Inverter Box B

29 Inverter Box C

30 Inverter Box Duct

31 Inverter Box Cover

32 Heat Sink B

33 ACTPM

36 Posistor

37 Inverter PCB Assy (36)

37 Inverter PCB Assy (45) 9707537017

38 Power PCB Assy

39 Clamp (Cord)

40 Terminal

41 Fuse (Small)

43 Thermistor (Dischage)

44

Thermistor (Heat Exchanger)

45 Thermistor (Out Temp)

46 Compressor Thermistor

47 Heatsink Thermistor

48 Wire (Pressure Switch)

50

Thermistor (Heat Exchanger)

51 Fuse Holder (Small) 0501456016

52 Fuse Holder (Large)

53 Fuse Holder (Large) 0600086039

9374603015

9374625017

9374605026

9374609017

9374608010

9374607020

9707592016

9704265012

9707537024

9705647022

9356857009

9900203023

0600086039

9704219084

9900374037

9900378035

9900156060

9900311018

9367595051

9900403010

0501454012

33

37

OUTDOOR UNIT

31

38

27

(Connector : Black)

47

46

45

29

32

(Green)

44

30

(Blue)

43

(Red)

50

(Yellow)

(White)

41

51

53

40

39

36

28

52

(Connector

: Red)

48

2007.10.29 24

Page 26

STANDARD ACCESSORIES

INDOOR UNIT

Name and Shape Q'ty Part numberApplication

Drain hose

insulation

VT wire

Coupler heat insulator

(large)

Coupler heat insulator

(small)

Nylon fastener

Special nut A

(large flange)

Special nut B

(small flange)

Installation

template

Auxiliary pipe

assembly

1

1

2

1

Large

4

Small

4

4

4

1

1

Adhesive type 70 x 230

For fixing the drain hose

L 280 mm

For indoor side pipe joint

(large pipe)

For indoor side pipe joint

(small pipe)

For fixing the coupler heat

insulator

For installing indoor unit

For installing indoor unit

For positioning the indoor unit

For connecting the piping

9360464002

313806350303

9350716029

9352766015

9301501001

312300787605

313005446653

313005446759

9360022004

9374714025

Remote

control

Remote control

holder

Battery

Tapping screw

For air conditioner operation

1

For installing remote control

1

on the wall

For remote control

2

For mounting the remote

2

control holder

OUTDOOR UNIT

Name and Shape Q'ty Part numberApplication

Drain pipe

Drain cap

For outdoor unit drain piping work

(May not be supplied, depending on

1

the model)

2

9315885012

9305642014

0600185534

0700019098

9303029015

313166024302

Installation

(seal)

For filling in a gap at the entrance of

1

connection cords

2007.10.29 25

9374756018

Page 27

0709G3269

Loading...

Loading...