General ABGA18TATA, ABGA24TATA, ABGA30TATA, ABGA36TATA, ABGA45TATA Service Manual

...

Multi Air Conditioning System for Buildings

R407C

HEAT PUMP & COOLING ONLY TYPE

SERVICE MANUAL

1. TEST RUN

CONTENTS

1-1 TEST RUN METHOD..................................................................................................

1-1-1 PROCEDURE......................................................................................................

1-1-2 TEST RUN FROM REMOTE CONTROLLER......................................................

1-1-3 TEST RUN CONTROL.........................................................................................

2. FUNCTION OF PRINTED CIRCUIT BOARD

2-1 ELECTRIC CONTROL BLOCK DIAGRAM...............................................................

2-2 PCB LAYOUTS..........................................................................................................

2-2-1 INTDOOR UNIT..................................................................................................

2-2-2 OUTDOOR UNIT................................................................................................

2-2-3 REMOTE CONTROLLER...................................................................................

2-3 ELECTRIC CONTROL FUNCTION TABLE..............................................................

2-3-1 INDOOR UNIT....................................................................................................

2-3-2 OUTDOOR UNIT................................................................................................

2-4 FUNCTION AND SETTING OF EACH SWITCH.......................................................

2-4-1 INDOOR UNIT....................................................................................................

2-4-2 OUTDOOR UNIT................................................................................................

01-01

01-01

01-02

01-02

02-01

02-02

02-02

02-03

02-04

02-05

02-05

02-06

02-07

02-07

02-08

2-4-3 REMOTE CONTROLLER...................................................................................

3. OUTDOOR UNIT OPERATION CONTROL

3-1 OUTDOOR FAN SPEED CONTROL FUNCTION OPERATION...............................

3-2 ELECTRONIC EXPANSION VALVE CONTROL......................................................

3-3 4-WAY VALVE DELAY SWITCHING FUNCTION (REVERSE CYCLE)...................

3-4 BASE HEATER FUNCTION (OPTION).....................................................................

3-5 DE-ICING OPERATION.............................................................................................

3-6 BELT HEATER..........................................................................................................

3-7 DEFROSTING (REVERSE CYCLE)..........................................................................

3-7-1 DEFROSTING OPERATION..............................................................................

3-7-2 DEFROSTING FLOW-CHART........................................................................... 03-03

3-8 PROTECTION FUNCTION........................................................................................

3-8-1 COMPRESSOR PROTECTION FUNCTION...................................................... 03-04

3-8-2 PRESSURE SWITCH PROTECTION.................................................................

3-8-3 DISCHARGE TEMPERATURE PROTECTION..................................................

02-09

03-01

03-01

03-01

03-02

03-02

03-02

03-02

03-02

03-04

03-04

03-04

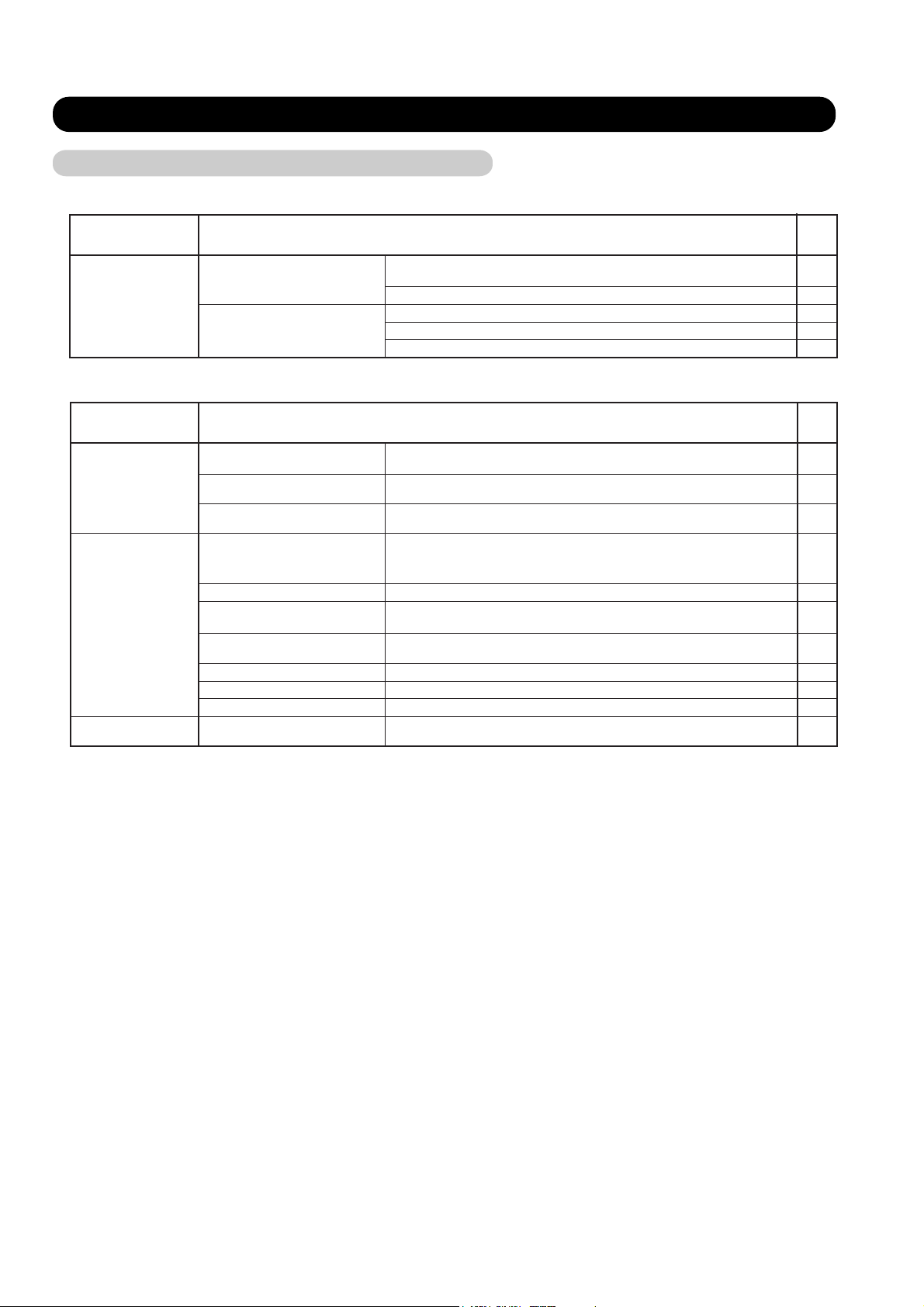

CONTENTS

4. INDOOR UNIT OPERATION CONTROL

4-1 FAN CONTROL.........................................................................................................

4-1-1 FAN SPEED SETTING.......................................................................................

4-1-2 "AUTO" POSITION.............................................................................................

4-2 MASTER CONTROL.................................................................................................

4-2-1 "AUTO" POSITION............................................................................................. 04-02

4-2-2 "COOL" POSITION............................................................................................. 04-04

4-2-3 "HEAT" POSITION.............................................................................................. 04-05

4-2-4 "FAN" POSITION................................................................................................ 04-05

4-3 LOUVER CONTROL..................................................................................................

4-3-1 ADJUSTING THE DIRECTION OF AIR CIRCULATION..................................... 04-06

4-3-2 SWING OPERATION.......................................................................................... 04-07

4-4 DRAIN PUMP OPERATION......................................................................................

4-5 FUNCTION.................................................................................................................

4-5-1 AUTO RE-START................................................................................................ 04-09

4-5-2 INDOOR HEAT EXCHANGER DE-ICING FUNCTION....................................... 04-09

4-5-3 SET TEMPERATURE COMPENSATION THE OPERATION START................ 04-09

4-5-4 COLD AIR DISCHARGE PREVENTION FUNCTION......................................... 04-10

4-5-5 ENERGY SAVE FUNCTION............................................................................... 04-10

4-6 TIMER CONTROL......................................................................................................

4-6-1 ON / OFF TIMER................................................................................................. 04-11

4-6-2 WEEKLY TIMER................................................................................................. 04-11

04-01

04-01

04-01

04-02

04-06

04-09

04-09

04-11

4-7 SETTING THE ROOM TEMPERATURE DETECTION LOCATION..........................

5. TROUBLE SHOOTING

5-1 INDOOR UNIT...........................................................................................................

5-2 OUTDOOR UNIT.......................................................................................................

5-3 REMOTE CONTROL UNIT.......................................................................................

5-4 WORKING INSPECTION..........................................................................................

5-5 SYMPTOMS AND CHECK ITEMS............................................................................

5-6 NORMAL OPERATION DISPLAY............................................................................

6. INSTALLATION

6-1 PRECAUTIONS FOR INSTALLATION.....................................................................

6-2 ADDITIONAL CHARGE CALCULATION.................................................................

6-3 ELECTRICAL WIRING SETTING.............................................................................

6-3-1 SIMULTANEOUS OPERATION.........................................................................

6-3-2 INDIVIDUAL OPERATION.................................................................................

6-4 ADDRESS SETTING.................................................................................................

6-5 PUMP DOWN METHOD............................................................................................

04-12

05-01

05-02

05-03

05-04

05-04

05-05

06-01

06-06

06-07

06-07

06-08

06-09

06-10

7. REFRIGERANT CAUTION

CONTENTS

7-1 WHAT IS CFC / HCFC / ?...........................................................................................

7-2 CHARACTERISTICS OF R22 AND R407C...............................................................

7-3 DIFFERENCE FROM CONVENTIONAL MODEL (R22) AND PRECAUTIONS........

7-4 TOOLS........................................................................................................................

7-5 PRECAUTIONS FOR INSTALLATION...................................................................... 07-04

7-6 PRECAUTIONS FOR DERVICING............................................................................ 07-04

8. APPENDING DATA

8-1 REFRIGERANT PIPE DIAGRAM..............................................................................

8-1-1 SIMULTANEOUS OPERATION.........................................................................

8-1-2 INDIVIDUAL OPERATION..................................................................................

8-2 CHARACTERISTICS OF SENSORS........................................................................

8-3 WIRING DIAGRAM....................................................................................................

8-3-1 OUTDOOR UNIT................................................................................................

8-3-2 INDOOR UNIT....................................................................................................

8-4 PCB CIRCUIT DIAGRAM..........................................................................................

8-4-1 OUTDOOR UNIT................................................................................................

8-4-2 INDOOR UNIT....................................................................................................

07-01

07-01

07-02

07-03

08-01

08-01

08-02

08-03

08-04

08-04

08-08

08-14

08-14

08-16

8-5 MODEL DESIGNATION............................................................................................

9. DISASSEMBLY ILLUSTRATION & PARTS LIST

9-1 OUTDOOR UNIT........................................................................................................

9-2 INDOOR UNIT............................................................................................................

08-22

09-01

09-11

1. TEST RUN

1. TEST RUN

1-1 TEST RUN METHOD

1-1-1 PROCEDURE

Turn Power On

Procedure

1. Turn power on

Operation Check

Procedure

1. Operate all of

the indoor units

2. Operate

the outdoor unit

3. Remote controller

Outdoor unit

Indoor unit

Abnormal noise

and abnormal vibration

Water drain

Check intake

and exhaust air temperatures

Compressor operation

Fan rotation

Abnormal noise

and abnormal vibration

Check high pressure

and low pressure

Check discharge pipe temperature

Check suction pipe temperature

Check heat exchanger temperature

Operate the remote controller

Check item

Supply power to the crankcase heater for 12 hours prior to

the start of operation if the outdoor temperature is lower than 21°C

There are not instrument anomalies.

There are not instrument anomalies.

Blinking Operation indicator and Timer indicator alternately.

The middle of the screen displays time.(Wired Remote Controller)

Check item

There are no abnormal noise or abnormal vibration.

Check the indoor units for water leaks.

Drain the water without accumulating.

Intake - exhaust air temperature differential is 10°C and over (Cooling),

15°C and over. (Heating).

The compressor operates.

Run the indoor units one at a time,

and make sure that the corresponding outdoor units also run.

Check the operation in each fan mode.

There are no abnormal noise or abnormal vibration.

Cooling : low pressure 0.3 - 0.5 Mpa (approx.)

Heating : high pressure 1.6 - 2.2 Mpa (approx.)

Below 125°C

Operation by remote control can be performed by each remote controller.

(Check by noise of operation.)

check

field

check

field

01-01

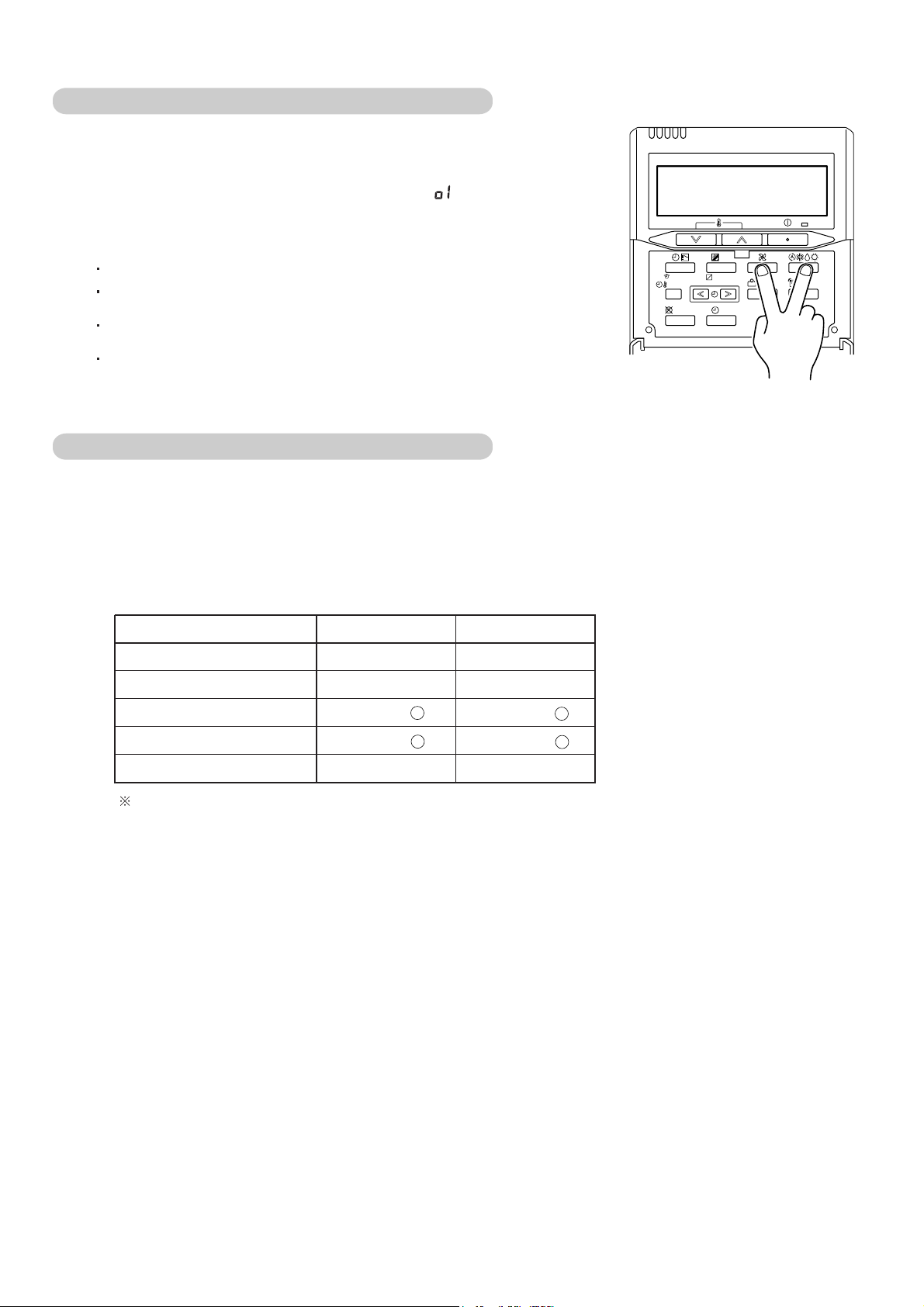

1-1-2 TEST RUN FROM REMOTE CONTROLLER

UTB -YUB / GUB

Standard wired remote controller

Stop the indoor unit. Push the FAN CONTROL button and

MASTER CONTROL button simultaneously for more than two seconds.

The air conditioner will start to conduct a test run and " " will display on

the remote controller display.

However, the SET TEMP./DAY setting button does not have function,

but all other buttons, displays, and protection functions will operate.

Perform the test operation for 60 minutes.

To stop test run, push the START/STOP button of the standard wired remote

controller.

CLOCK ADJUST

SET BACK

DELETE SET

For the operation method, refer to the operating manual and perform operation

check.

Check that there are no abnormal sounds or vibration sounds during test run

operation.

1-1-3 TEST RUN CONTROL

When the test run signal is transmitted from standard wired controller.

(1) The test run operation starts all of the indoor unit connected remote controller and the compressor and fan is

controlled to a maximum flow, regardless of the temperature condition.

(2) De-frosting and frost prevention operation has priority over item(1).

(3) After 60 minutes passes, the test run stops.

Test running initialization is shown below.

DAY

DAY OFF

ENERGY

SAVE

THERMO

SENSOR

Operating Mode Cooling Heating

Fan speed Hi Hi

Room Temperature Indication 18 30

Vertical Air Direction Panel

Horizontal Air Direction Panel

Swing

Position

Position

1

3

OFF OFF

Position

Position

4

3

Please refer to '4-3 LOUVER CONTROL' in this manual and find the definition

for air direction panel position.

01-02

2. FUNCTION OF PRINTED CIRCUIT BOARD

2. FUNCTION OF PRINTED CIRCUIT BOARD

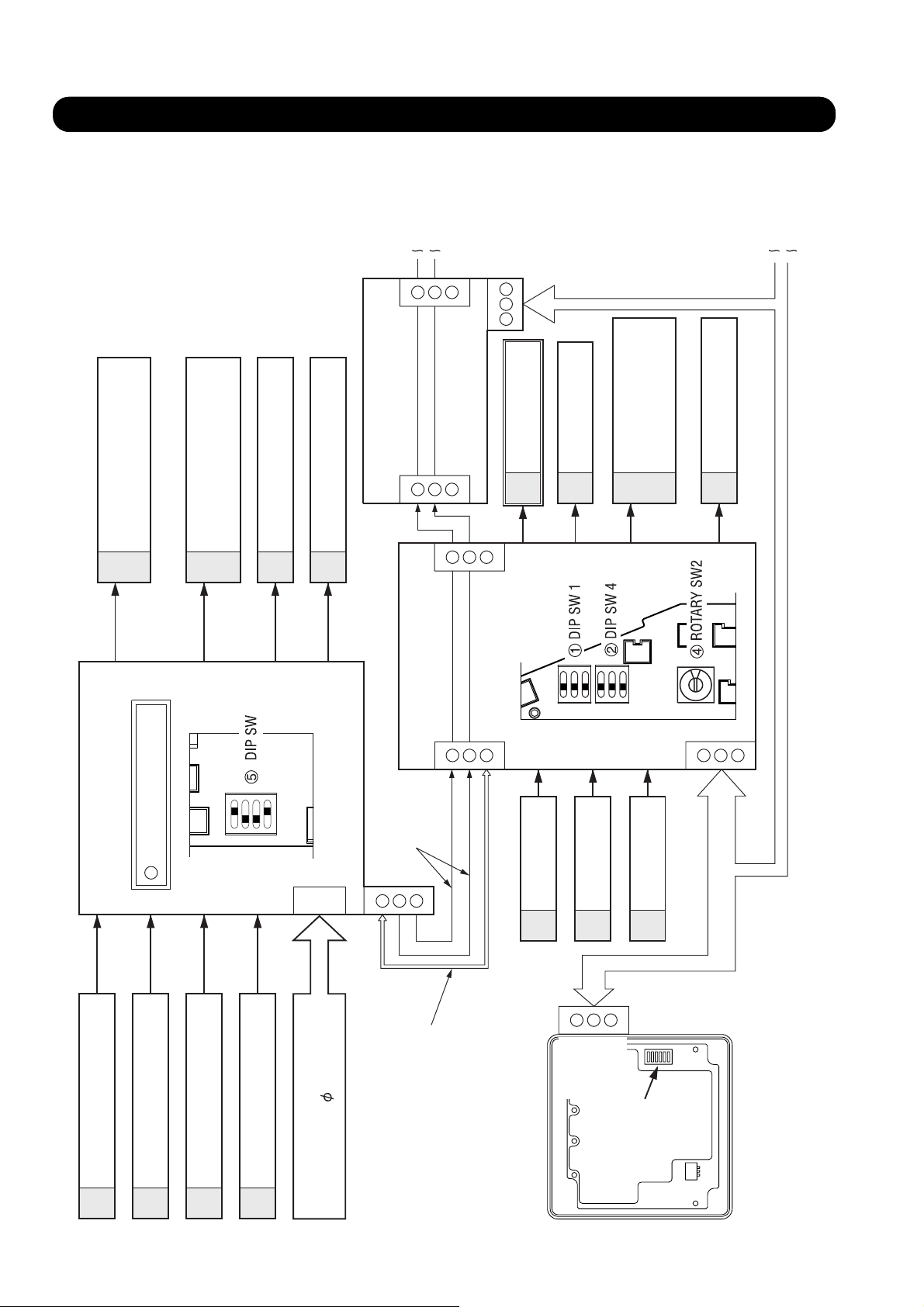

2-1 ELECTRIC CONTROL BLOCK DIAGRAM

Indoor unit

power supply

to others

Remote control

unit terminal

321

321

Indoor unit

to others

321

(EX : Master unit)

Control Circuit Board

Louver step motor

Vertical (UP/DOWN)

Horizontal(RIGHT/LEFT)

123

O

F

F

(7) Indoor fan motor

123

O

(8)

F

F

(9) Drain pump

0

(6) Indicator display

Control Circuit Board

(EX : Slave unit)

INDOOR UNIT No. 1

321

Outdoor fan motor x 2

(Left fan & Right fan)

(17)

Compressor x 2

(Crankcase heater)

(18)

(19) 4-way valve

(20) Electronic expansion valve

INDOOR UNIT No. 0

321

F

F

O

(4)

Control Circuit Board

123

4

OUTDOOR UNIT

LED Display No.1~ No.6

6

Power supply

321

(5)

1

2

(16)

3

(10)

Room thermistor

(1)

(2) Pipe thermistor

(3) Float switch

Remote controller signal

(11)

321

GND

Signal

+B(12V)

UTB-YUB

Pressure switch control

AC POWER SUPPLY INPUT

380V- 415V 3 50Hz

(12) Discharge temp. thermistor

(13) Condenser temp. thermistor

(14) Outdoor temp. thermistor

(15)

Communication of signal

REMOTE CONTROL UNIT

DIP-SW1

(3),(6),(8),(9),(19)is different on the model.

※

02-01

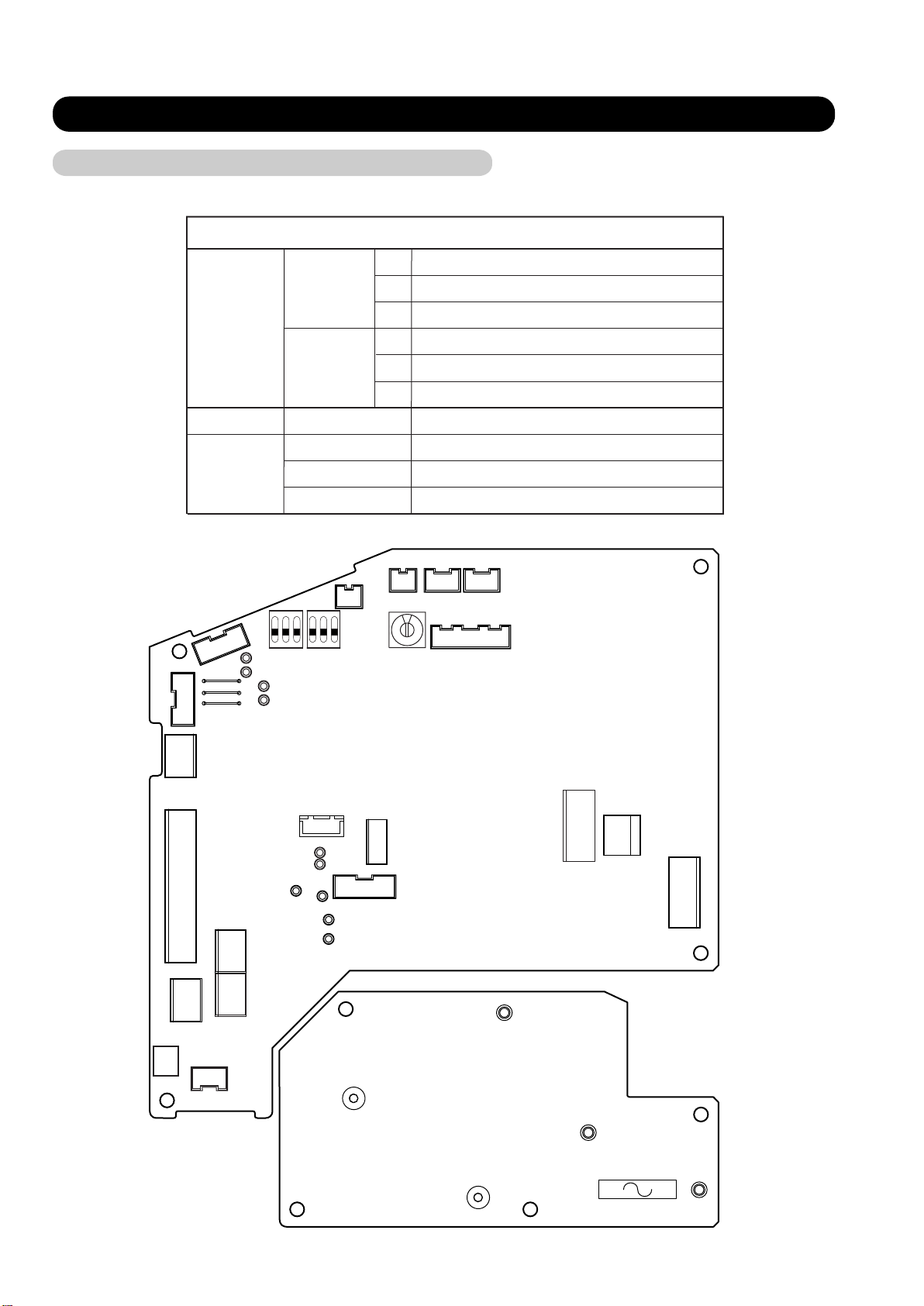

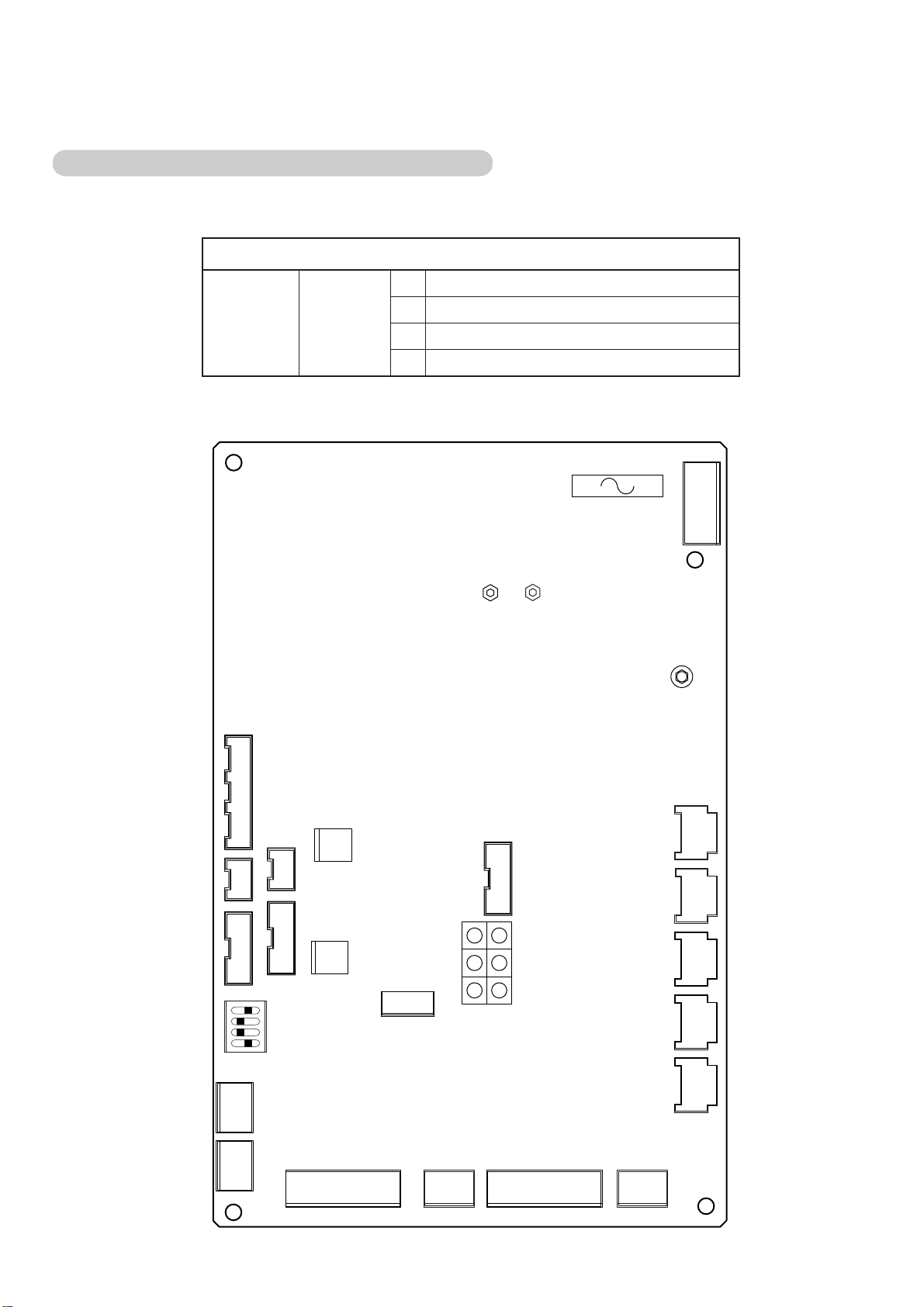

2-2 PCB LAYOUTS

2-2-1 INDOOR UNIT

DIP SW

Rotary SW

Jumper

wire

(RED)

CN11

JM1

JM2

JM3

CN10

123

O

SW1 SW4

W1

W2

W3

W4

F

F

SW 1

SW 4

SW 2

JM 1

JM 2

JM 3

123

O

F

F

CN7

(BLACK)

Indoor unit

Ceiling height setting

1

Room temp correct coefficient of heating 1

2

Room temp correct coefficient of heating 2

3

Auto restart validity / invalidity

1

Indoor unit fan speed switch 1

2

Indoor unit fan speed switch 2

3

Select No. of indoor unit

Forbidden

Room temp correct coefficient of cooling

De-icing prevent temp

CN8

CN15 CN17

(RED)

(BLACK)

0

SW2

(BLACK)

CN13

(WHITE)

CN16

(WHITE)

CN14

W8

W7

CN9

CN18

(WHITE)

E101

(GREEN)

W104

(BLACK)

W6

W5

CN5

(WHITE)

CN6

CN19

CN4

(WHITE)

CN12

SW3

W10

W9

(BLUE)

W103

(WHITE)

(RED)

CN2

W102

(WHITE)

CN3

F101

(3150mA)

T 3.15A 250V

CN1

W101

(BLACK)

(BLACK)

02-02

2-2-2 OUTDOOR UNIT

DIP SW

SW 1

Outdoor unit

Forced defrost

1

Defrost temperature selected

2

Pump down

3

Outdoor fan-low sound

4

T 6.3A 250V (6300mA)

F1

W2

W1

(RED)

(PINK)

(BLUE)

CN9 TH

(RED)

(WHITE)

CN10 COMP.A

(RED)

CN18 COMP.B

CN19 P.SW-B

(BLUE)

CN8 FLASH

EV.B

EV.B

AC IN

(BLACK)

CN7

(GREEN)

E

CN20

(BLACK)

CN21

(BLUE)

(WHITE)

CN11 EEV.A

4

3

2

SW1

1

CN22

MAIN RELAY.A

CN23

MAIN RELAY.B

(RED)

CN12 EEV.B

F

F

O

(RED)

(BLUE)

(WHITE)

CN13 P.SW-A

(WHITE)

CN3 FANMOTOR-1

LED2 LED3

(WHITE)

LED1

CN14 TEST

(YELLOW)

LED5 LED6

LED4

(RED)

CN2 FANCAPA-1

CN16 FANMOTOR-2

CN6

HEATER.A

CN5

4WV.B

CN4

4WV.A

(YELLOW)

(YELLOW)

(RED)

(WHITE)

CN15 FANCAPA-2

02-03

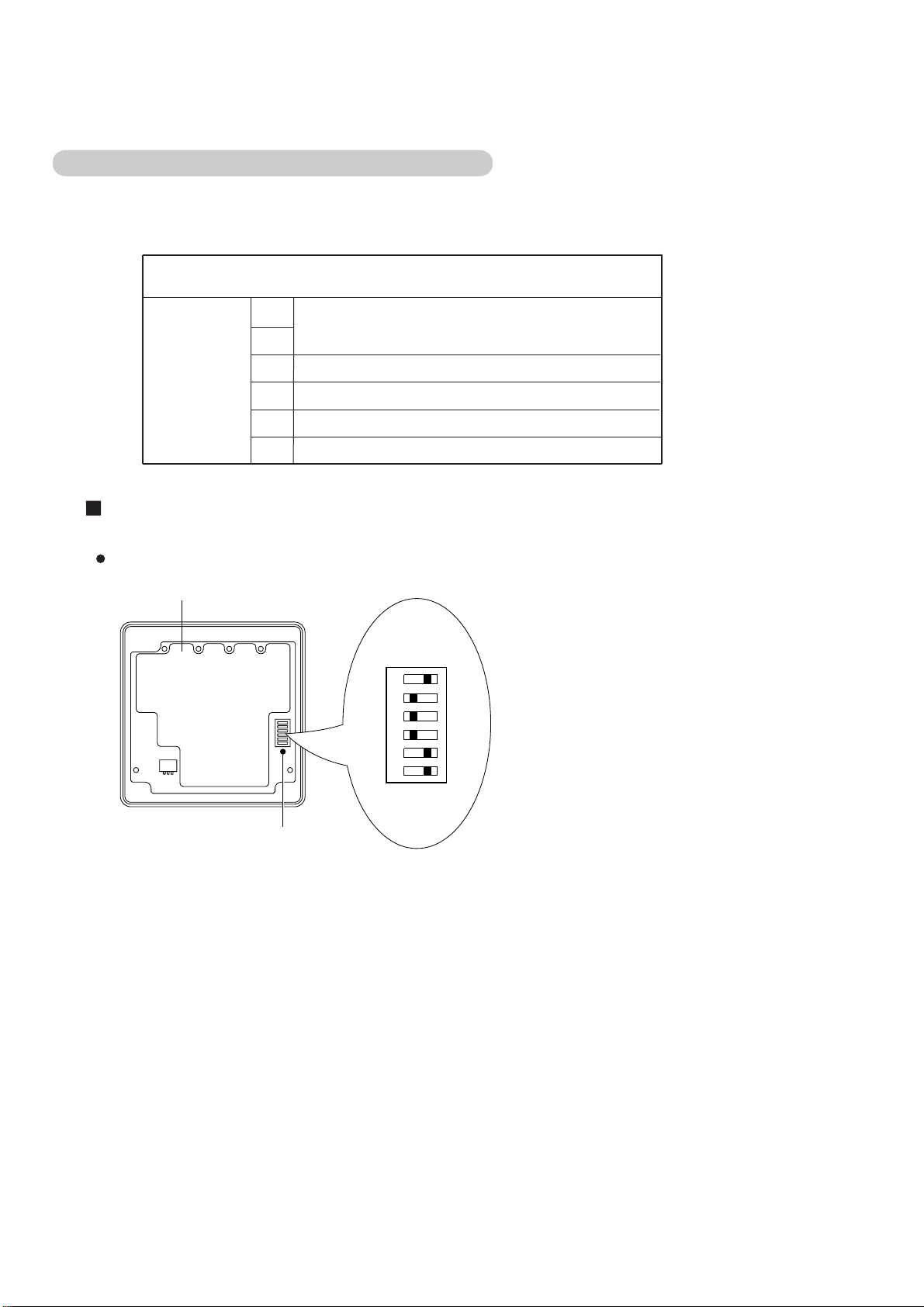

2-2-3 REMOTE CONTROLLER

1

2

3

DIP SW

4

5

6

SWITCH POSITION

Wired remote controller

Front case (back side)

Remote controller

Dual remote controller setting

Group control setting

Model setting

Auto changeover setting

Memory backup setting

DIP Switch

ONOFF

1

2

3

4

5

6

02-04

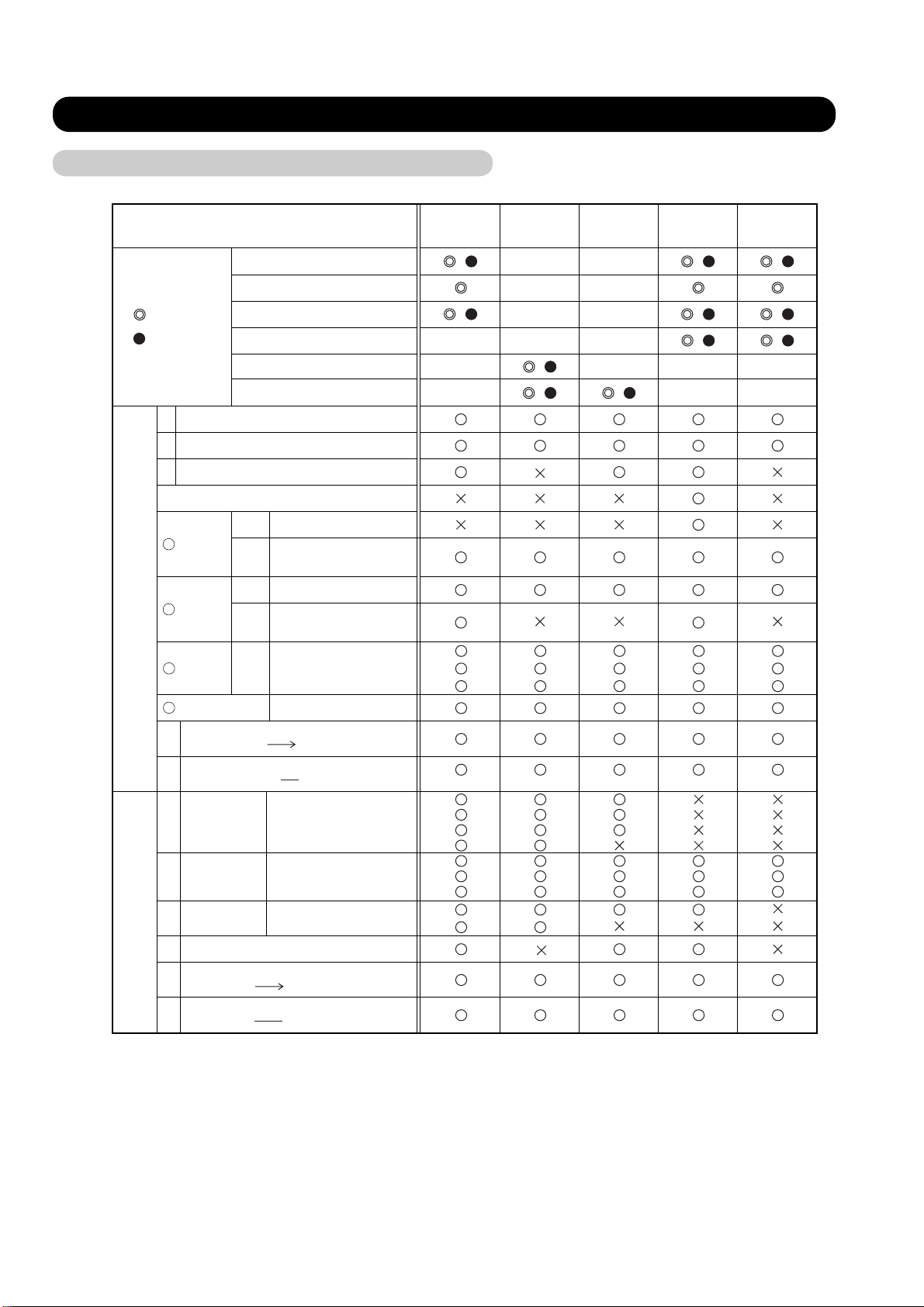

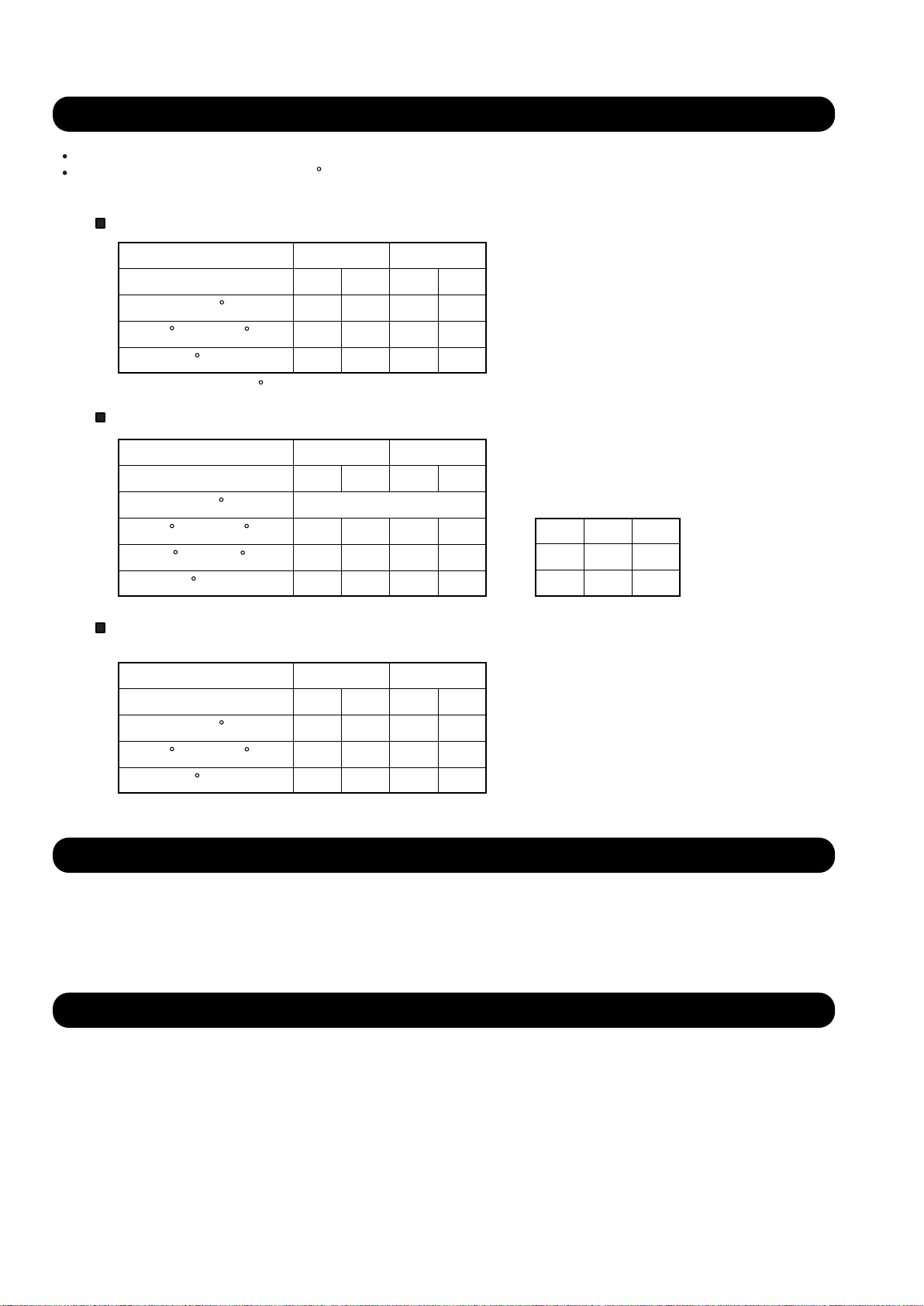

2-3 ELECTRIC CONTROL FUNCTION TABLE

2-3-1 INDOOR UNIT

INDOOR UNIT TYPE

MODEL CODE

: Simultaneous

: Individual

(1) Room Thermistor (Sensor)

(2) Pipe Thermistor (Sensor)

(3) Float Switch Control

Thermal Fuse (Within Terminal board)

No. 1 High Ceiling mode

1

DIP SW1

2

DIP SW4

INPUT

3

Jumper

4

Rotary SW

Signal Transmitter-Receiver Signal

(4)

(Outdoor unit Indoor unit )

Remote controller signal

(5)

(Remote control Indoor unit )

Indicator

(6)

Display LED

Indoor Fan

(7)

Motor Speed

Louver Motor

(8)

(9) Drain Pump

(10)

Signal Transmitter-Forward Signal

OUTPUT

(Indoor unit Outdoor unit)

(11)

Remote controller signal

(Indoor unit Remote Control)

No. 2 Compensation Heating 1

No. 3 Compensation Heating 2

No. 1 Auto restart

No. 2 Indoor Fan Table 1

No. 3

Indoor Fan Table 2

JM 1

Remote controller type

JM 2

Compensation Cooling

JM 3

De-icing Prevent temp.

Select No. of indoor unit

• Operation

• Timer

• Swing (UP/DOWN)

• Swing (RIGHT/LEFT)

• High

• Med

• Low

Vertical (UP/DOWN)

Horizontal (RIGHT/LEFT)

45

36

30

25

24

18

Ceiling

Universal

Floor / Ceiling

Cassette

(compact)

Cassette

Duct

(Standard Static

Pressure)

02-05

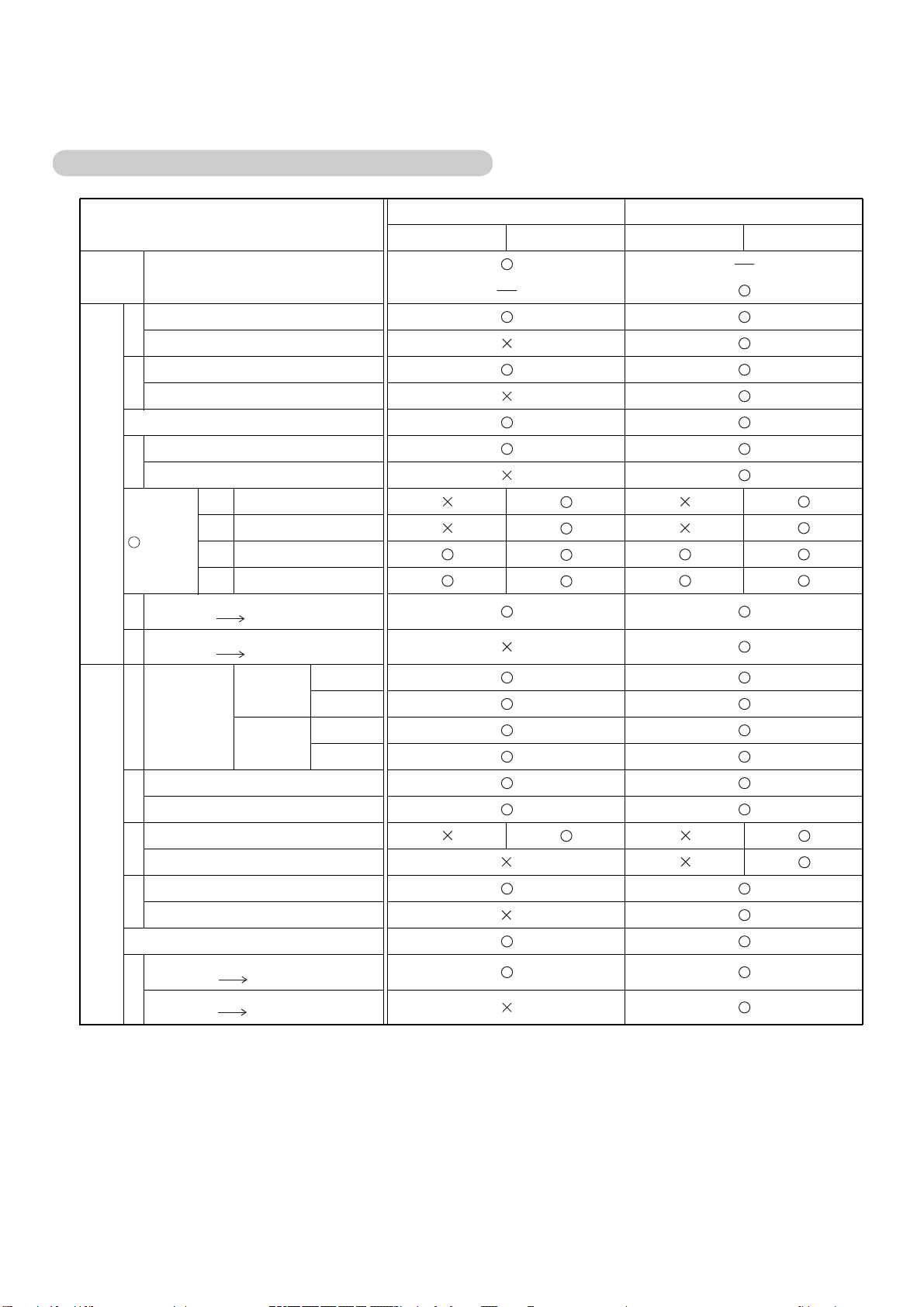

2-3-2 OUTDOOR UNIT

MODEL

CODE

INPUT

OUTDOOR UNIT TYPE

90

90 (45 x 2)

(12)

Discharge Temp. Thermistor A

(11)

Discharge Temp. Thermistor B

(13)

Condensor Temp. Thermistor A

(11)

Condensor Temp. Thermistor B

(14)

Outdoor Temp. Thermistor

(15)

Pressure Switch A

(11)

Pressure Switch B

Defrost temp. Selected

No.1

Forced Defrost

5

DIP SW

(10)

Serial Transmitter-Forward Signal A

(Indoor unit Outdoor unit)

Serial Transmitter-Forward Signal B

(Indoor unit Outdoor unit)

(17)

Outdoor Fan

Motor Speed

No.2

Pump down

No.3

Outdoor Fan-low sound

No.4

Fan motor 1

High

Low

Simultaneous Type

Cooling only Heat pump

Individual Type

Cooling only Heat pump

Fan motor 2

(18)

Compressor A

(11)

Compressor B

(19)

4-Way Valve A

(11)

4-Way Valve B

OUTPUT

(20)

Electronic Expansion Valve A

(11)

Electronic Expansion Valve B

LED Display No. 1 ~ No. 6

(4) Remote Transmitter-Receiver Signal A

(Indoor unit Outdoor unit)

Remote Transmitter-Receiver Signal B

(Indoor unit Outdoor unit)

High

Low

02-06

2-4 FUNCTION AND SETTING OF EACH SWITCH

2-4-1 INDOOR UNIT

DIP SWITCH SETTING

1. SW1 setting

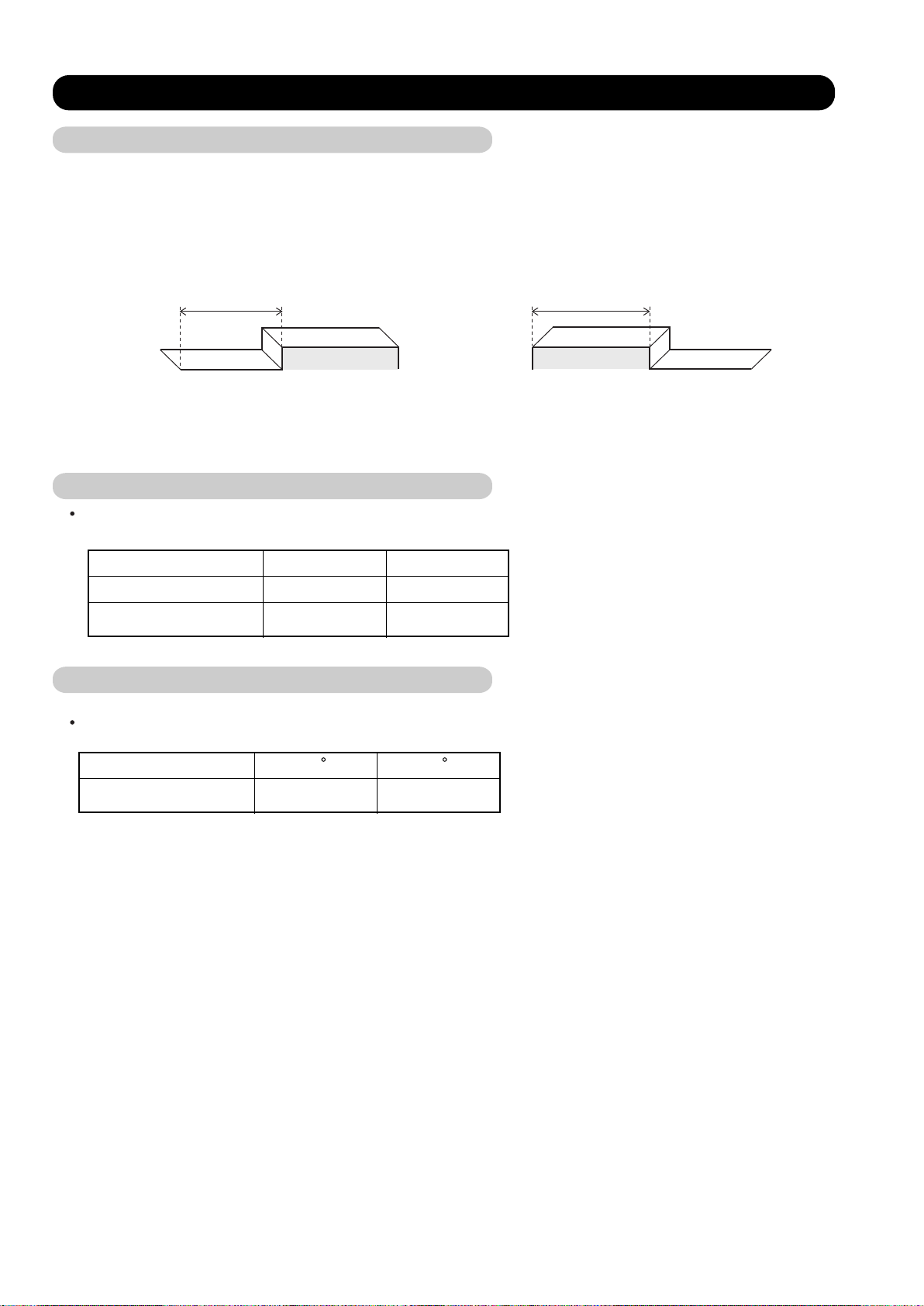

1-1 Ceiling height setting

CEILING HEIGHT SETTING (CASSETTE TYPE)

SW1-1

OFF

ON High ceiling

This function is validity only large cassette type

1-2 Room temperature correct coefficient of heating

Decide the heating temperature correct coefficient value for room temperature thermistor.

The overall temperature increases when a larger coefficient value is used.

HEATING TEMPERATURE CORRECTION

SW1-2 SW1-3

OFF

ON OFF

OFF

Ceiling height mode

Standard

OFF

ON

2. SW4 setting

2-1 Auto restart validity / invalidity

Control the auto restart function by turning this switch ON/OFF.

( Factory setting)

( Factory setting)

Coefficient value

+ 2 deg

- 2 deg

0 deg

+ 4 degON ON

AUTO RESTART SETTING

SW4-1

OFF

ON Validity

Please set it in the same way when remote control is a group control.

*

2-2 Indoor unit fan speed switch

This switch can select fan speed corresponding to each model.

Large ceiling type

AB30

OFF ONSW4-2

SW4-3

Large cassette type

AU25

SW4-2

SW4-3

ON

ON

( Factory setting)

Auto restart

Invalidity

AB36 AB45

AU30

OFF

ON

OFF

ONOFF OFF

AU36

ON

OFF

AU45

OFF

OFF

02-07

JUMPER WIRE SETTING

( Factory setting)

JP

JM1

JM2

JM3

Forbidden

Room temperature correct

coefficient of cooling

indoor heat exchange icing, the

de-icing operation temperature.

Function

ROTARY SW SETTING

SW2 Setting

Sets the unit number of the indoor unit to MASTER or SLAVE.

Master setting

0

Master

Indoor unit A

Other Slave setting

1

Slave

Indoor unit B

2-4-2 OUTDOOR UNIT

Connect Disconnect

Type with sensor

0°C +2°C

Set-up 2°C - Reset 6°C Set-up 4°C - Reset 8°C

2

Slave

Indoor unit C

3

Slave

Indoor unit D

DIP SWITCH SETTING

SW1 setting

1. Forced defrost

This function first melts the outdoor heat exchange ice and inspects the pressure and temperature when

servicing and maintaining the outdoor unit at heating operation.

( Factory setting)

SW1-1

OFF

ON

2. Defrost temperature selected

The Defrost start operation temperature can be changed according to the outside air temperature region

environment.

SW1-2

OFF

ON

Forced defrost

Defrost start

( Factory setting)

Defrost temperature selected

-10°C

-7°C

02-08

3. Pump down (pressure SW mode)

This function disables the pressure switch when operation is stopped by low pressure switch and pump

down is not longer possible.

( Factory setting)

SW1-3

Pump down

OFF

ON

4. Outdoor fan-low sound

Set the outdoor fan noise value [2dB (A)] to the low-noise mode. (See page 03-01 "OUTDOOR FAN SPEED

CONTROL FUNCTION OPERATION".)

SW1-4

Outdoor fan-low sound

OFF

ON

2-4-3 REMOTE CONTROLLER

DIP SWITCH SETTING

SW1 setting

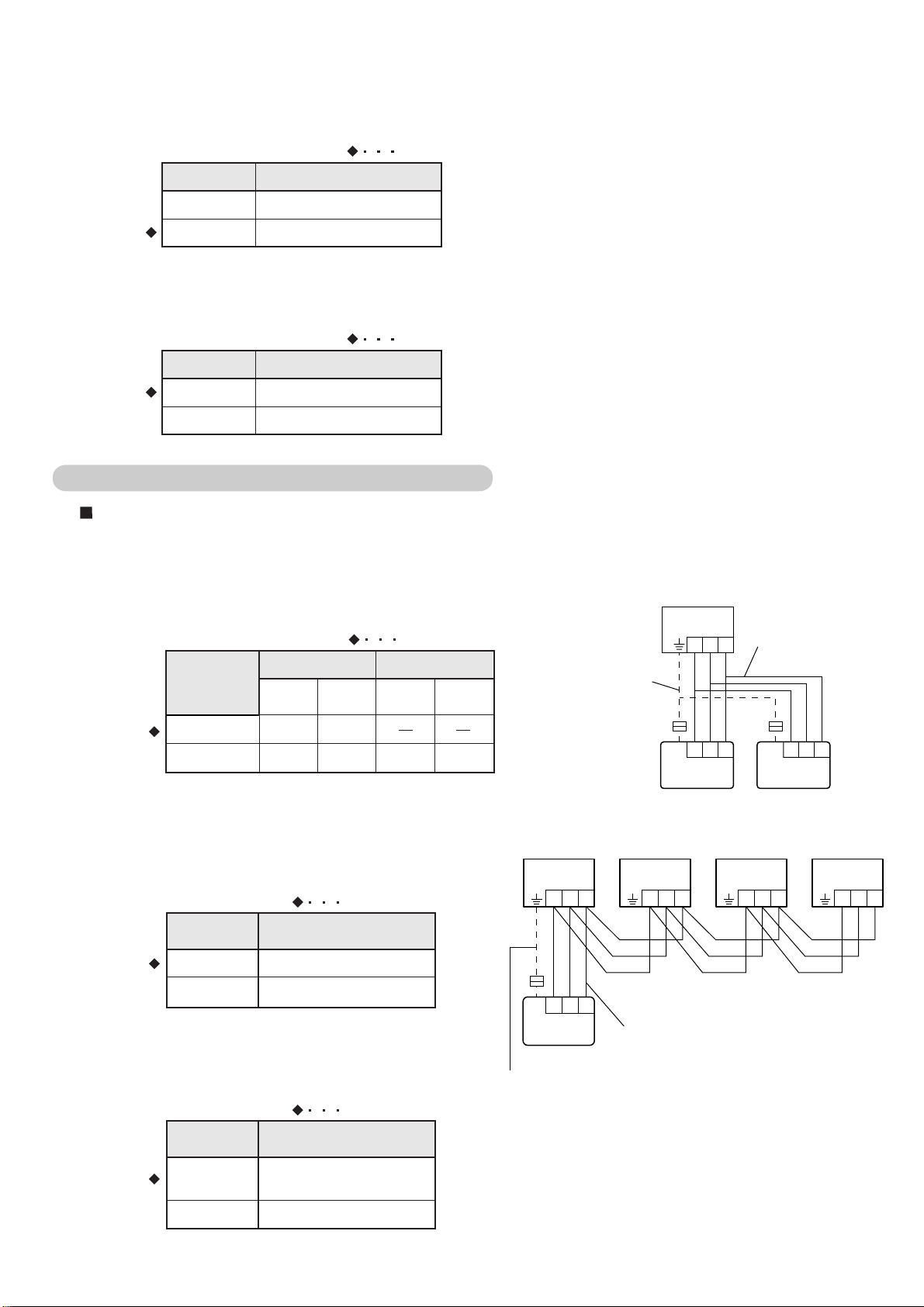

1-1 Dual remote controller setting

Set the remote controller DIP switch No.1 and 2

according to the following table.

Number of

remote

controller

Master unit Slave unit

SW1-1 SW1-2 SW1-1 SW1-2

Operate

Release

( Factory setting)

Standard

Fan-low sound

( Factory setting)

When ground wire

is necessary

Indoor unit

1 2 3

Remote controller cable

1 (Normal)

2 (Dual)

ON

OFF

OFF

OFF

ON ON

1-2 Group control setting

Number of indoor unit connection (One/Multiple)

This is switched according to the number of

connected indoor units.

( Factory setting)

SW1-3

OFF

Number of indoor unit

One unit connection

ON Multiple unit connection

1-3 Model setting

The system type of the outdoor unit can be selected by

setting up DIP switch No.4 as follows.

( Factory setting)

SW1-4

OFF

Heat Pump model or

Heat Recovery model

Model

Remote controller

123

123

Remote controller

When ground wire is necessary

123 123 123

Remote

controller cable

1 231 23

Slave unitMaster unit

Indoor unit 2Indoor unit 1Indoor unit 0 Indoor unit 3

ON Cooling only model

02-09

1-4 Auto changeover setting

Selecting auto changeover validity / invalidity.

( Factory setting)

SW1-5

OFF

ON Validity

Auto changeover

Invalidity

1-5 Memory backup setting

Set to ON to use batteries for thr memory backup.

If batteries are not used, all of the settings stored in memory will be deleted if there is a power failure.

( Factory setting)

SW1-6

OFF

ON Validity

Memory backup

Invalidity

02-10

3. OUTDOOR UNIT OPERATION CONTROL

3. OUTDOOR UNIT OPERATION CONTROL

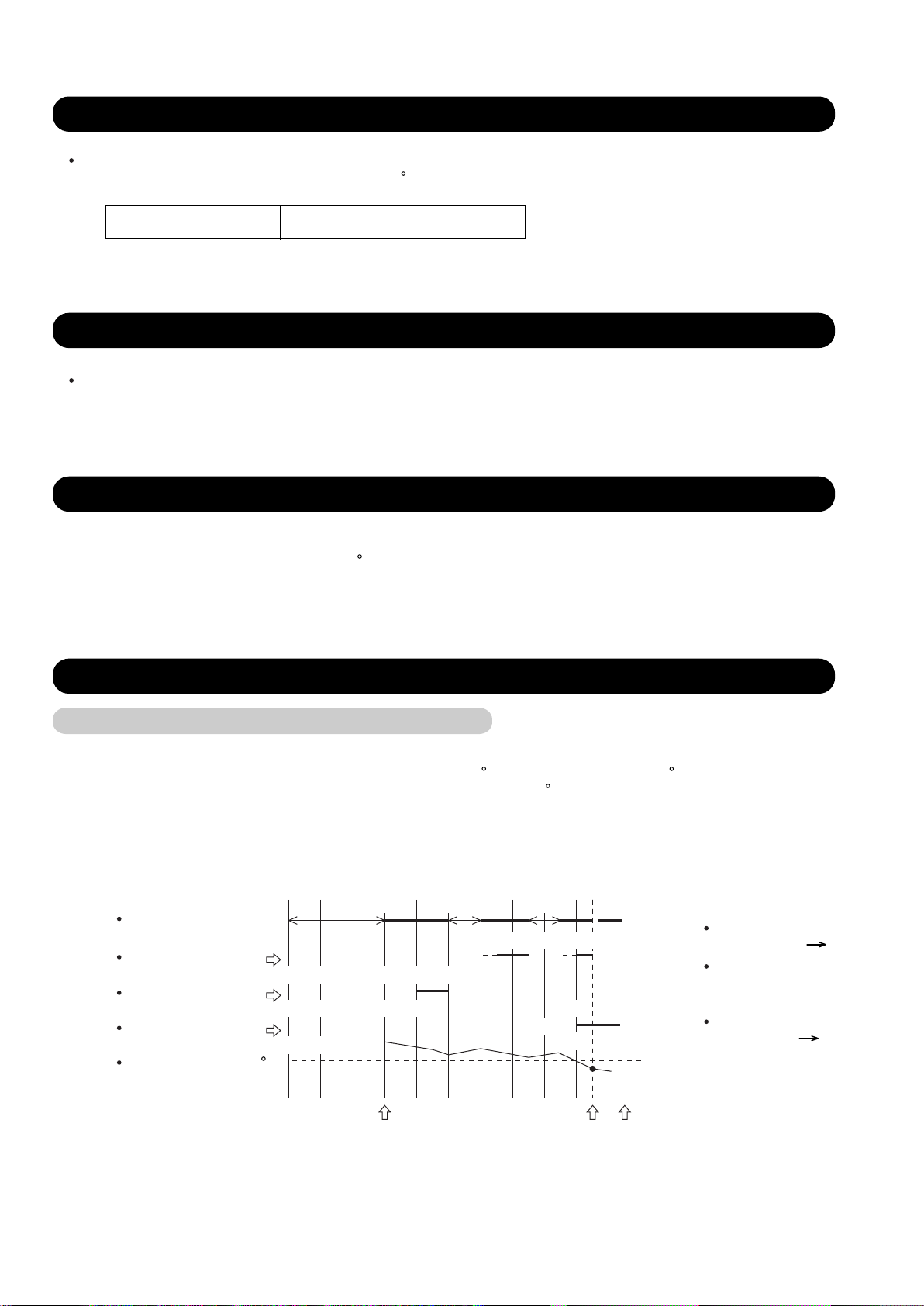

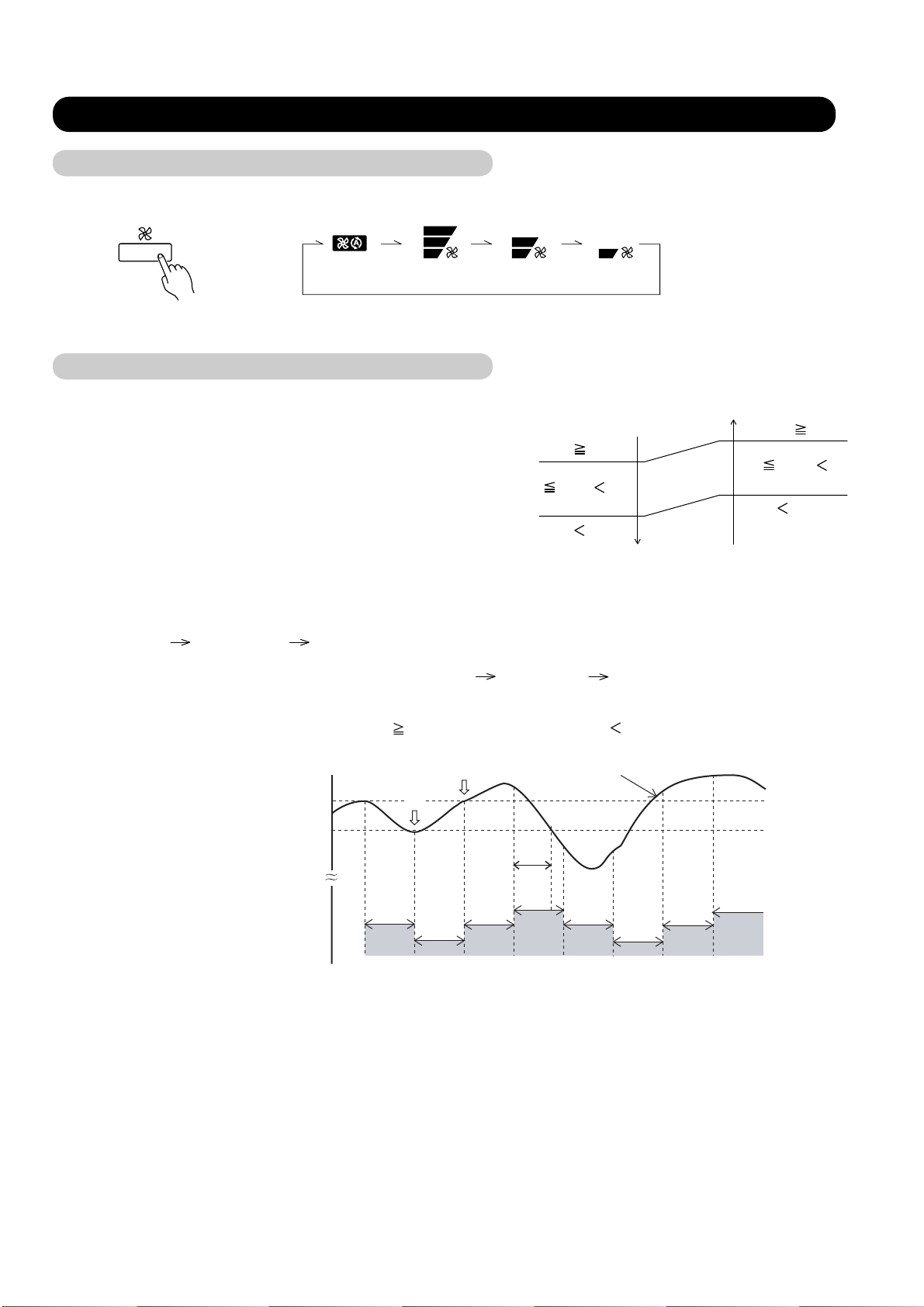

3-1 OUTDOOR FAN SPEED CONTROL FUNCTION OPERATION

The Outdoor Fan speed operates in the following mode, depending on the outside temperature condition.

Outdoor Fan speed switching has a ±1 C differential relative to the following temperature setting table.

Simultaneous type : Cooling operation

OUTDOOR DIP SW 1- 4

Outdoor Fan motor

T > 25 C

>

25 C

Simultaneous type : Heating operation

OUTDOOR DIP SW 1- 4

Outdoor Fan motor

16 C

Individual type : Cooling and heating operations

OUTDOOR DIP SW 1- 4

Outdoor Fan motor

10 C

T > 16 C

11 C

T > 10 C

=

>

T > 11 C

=

>

=

9 C

>

T

=

T C : Outdoor Temperature thermistor

T > 9 C

>

T

=

:

Common mode

OFF

Right LeftRight Left

Hi Hi

OFF ON

Intermittent operation

OFF ON

Hi STOP

Lo LoLo Lo

Lo STOPLo STOP

Right LeftRight Left

Lo STOPLo STOP

Lo LoLo Lo

Hi STOPHi Hi

Right LeftRight Left

ON

Intermittent operation:

The outdoor fan repeatedly operates

at the following timing:

Right LeftTime

STOP STOP2 min.

Lo Lo10 sec.

Hi STOPHi Hi

Lo LoLo Lo

Hi STOPHi Hi

26 C

T > 26 C

>

T > 10 C

=

>

10 C

=

T

3-2 ELECTRONIC EXPANSION VALVE CONTROL

Control process of electronic expansion valve and each thermistor detection temperature

To control the quantity of super heat constant, the electronic expansion valve is controlled by the difference between

thermistor detection temperature of outdoor temperature and discharge thermistor detection temperature.

3-3 4-WAY VALVE DELAY SWITCHING FUNCTION(REVERSE CYCLE)

When heat operation is stopped, 4-way valve is stopped 2 min. 35 sec later.

03-01

3-4 BASE HEATER FUNCTION(OPTION)

When the outdoor temperature is minus, turn ON to warm the outdoor unit drain pan and positively discharge the drain

water when the outdoor temperature thermistor is 2 C or lower and the operating mode is HEAT.

CN6 OUT-PUT MAXIMUM HEATER OUTPUT 100W

(CN6 FOR OUTDOOR UNIT PRINTED CIRCUIT BOARD)

3-5 DE-ICING OPERATION

To prevent outdoor heat exchanger icing at heating operation heating overload, after the compressor and outdoor fan

have been operated for two hours, the compressor is stopped for 3 minutes and the outdoor fan is de-iced at Hi.

3-6 BELT HEATER

Belt heater is installed around the compressor.

When the outdoor temperature is less than 21 C, oil is fallen in the compressor and the refrigerant is melted into oil and

oil may be diluted, then the bearing metal etc. of the compressor motor is easy to damage when starting the compressor.

To prevent the above, the crank case heater is installed. The heater operates under the compressor halt.

3-7 DEFROSTING(REVERSE CYCLE)

3-7-1 DEFROSTING OPERATION

Defrosting operation

1.

When the outdoor piping thermistor detection temperature is -7 C (DIP SW : ON) or less (-12 C or less for 10 minutes

after switching from one room operation to two rooms operation, and -7 C after 10 minutes and in one room operation) after timer of 6 minutes timer or 10 minutes timer, besides 40 minutes timer are up, defrosting starts.

Defrosting start condition

0 102030

30 10ON OFF

Comp. A1 (ON/OFF)

6 minutes timer

(Comp. OFF is less than 20 min.)

10 minutes timer

(Comp. OFF is more than 20 min.)

40 minutes timer

(Comp. total operation time)

Outdoor pipe : - 8 C

thermistor

(20) (15) (5)

40 50 60 70 80 90 100 (Min.)

ST TU STRS RS

ST TU 0RS 6 0 6

ST 10

TU40RS

[Note]

ST : Timer Start

(Comp. A OFF ON)

TU : Timer UP

6,10,40 after the

setting time passed

RS : Reset

(Comp. A ON OFF

Operation

start

03-02

Defrost

start

END

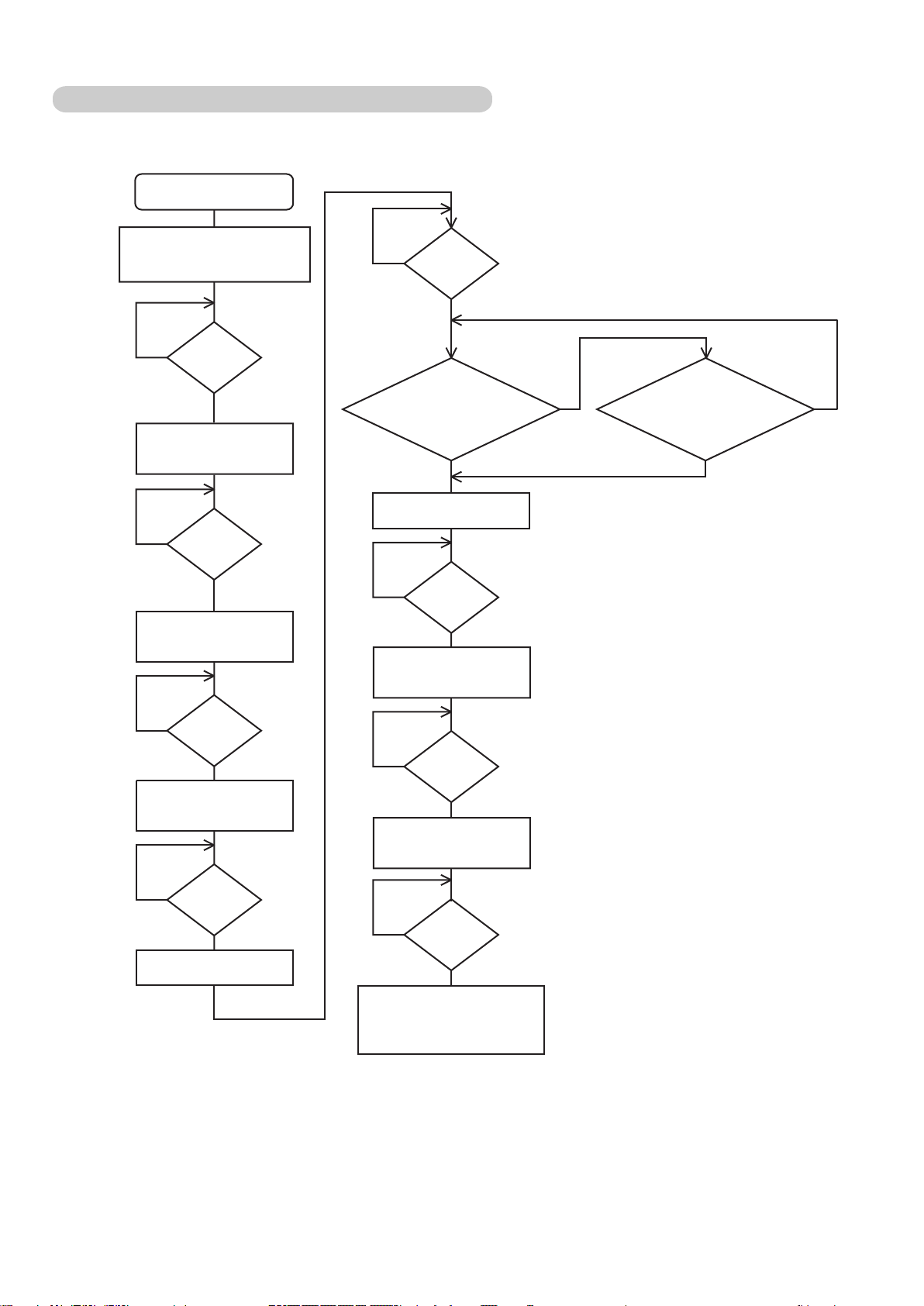

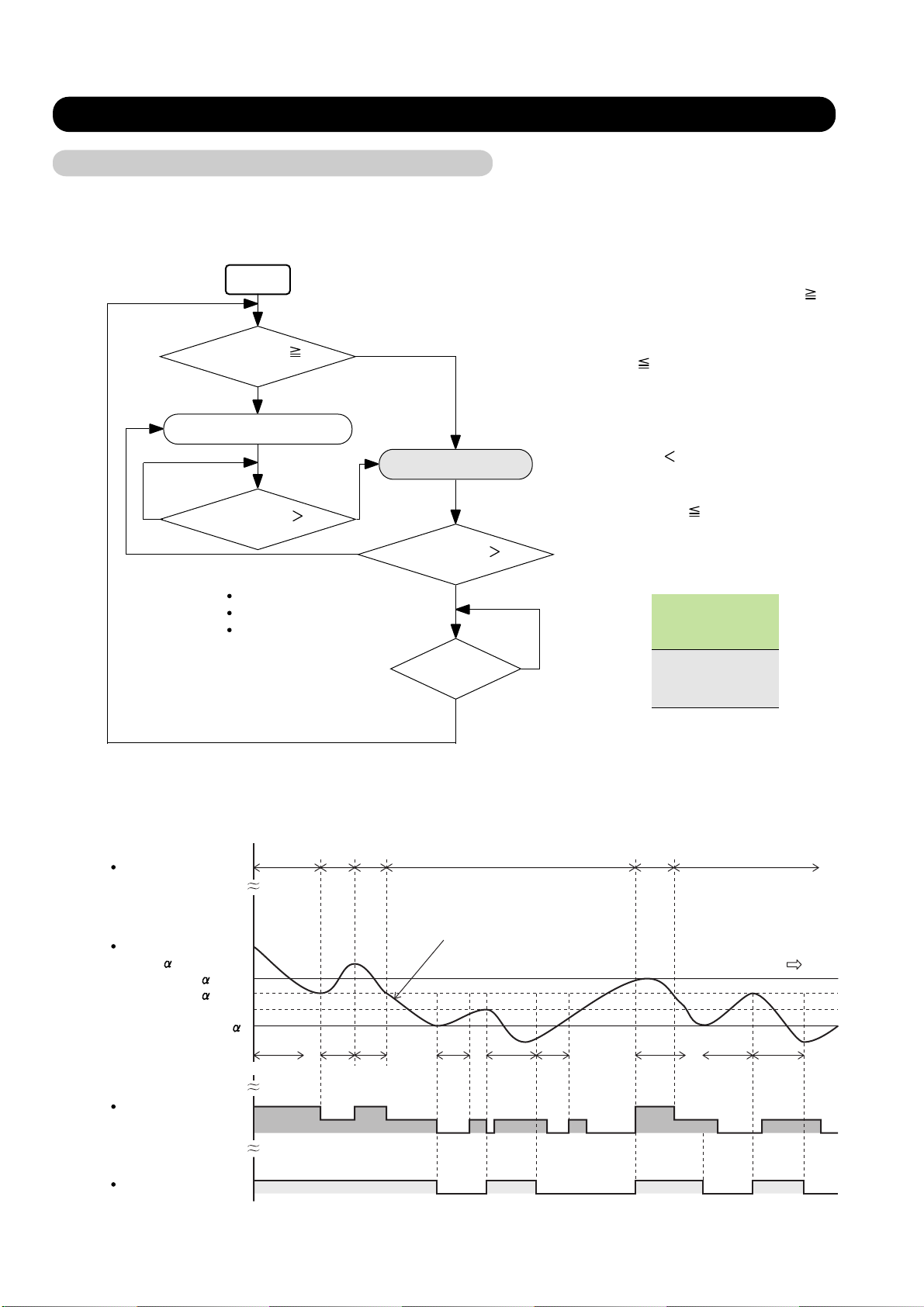

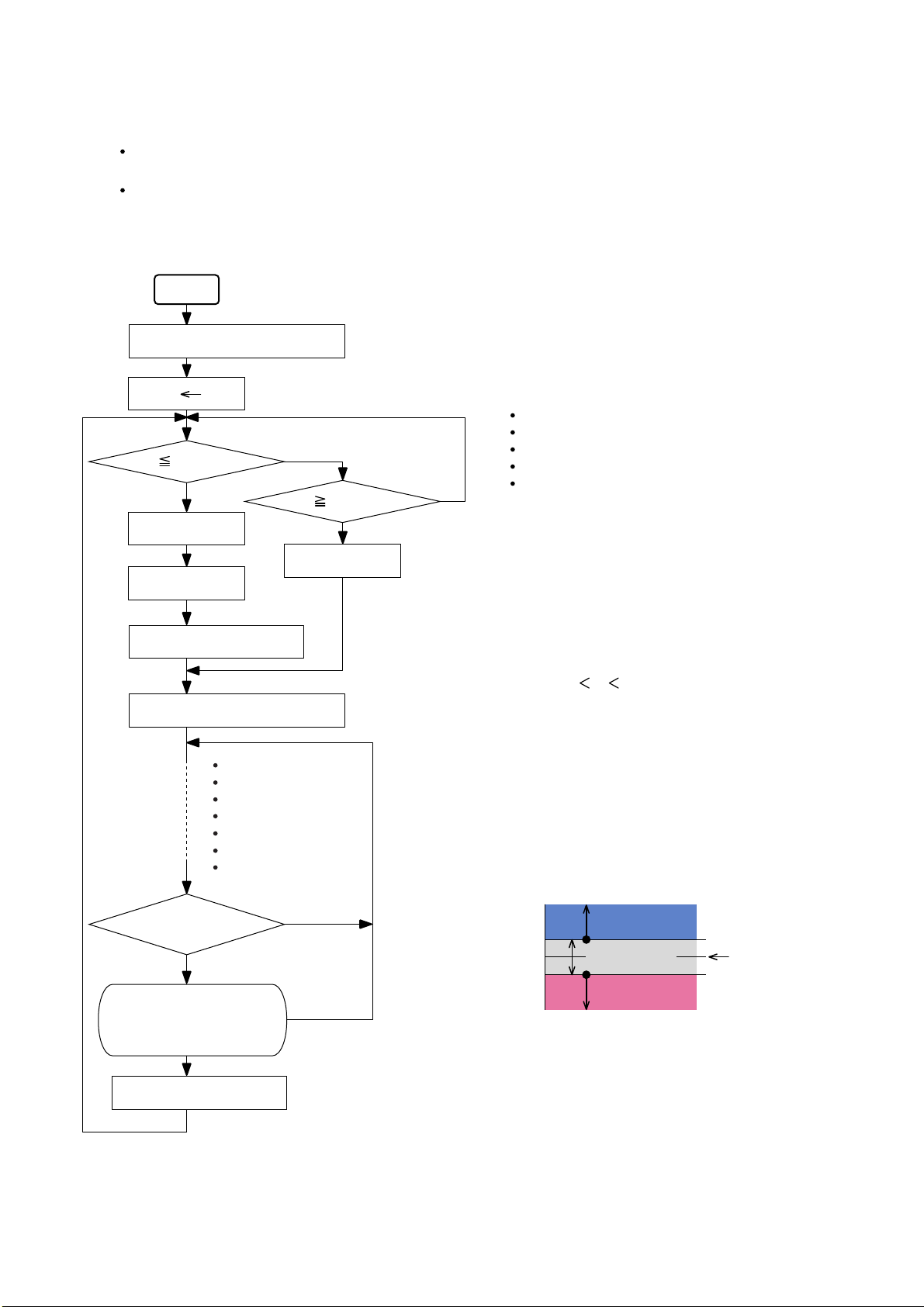

3-7-2 DEFROSTING FLOW-CHART

2. Defrosting flow-chart

Defrosting starts

Compressor : OFF

Indoor fan motor : OFF

No

3 seconds

Mask

Yes

Expansion valve

is controlled

No

25 seconds

Mask

Yes

4-way valve

is switched. (OFF)

1 minute

No

Mask

Yes

Is the piping

thermistor detection

temp. more than

10°C ?

Compressor : OFF

No

3 seconds

Mask

Yes

Expansion valve

is controlled

No No

Have 15 minutes

passed since defrosting

starts ?

Yes

No

3 seconds

Mask

Yes

Expansion valve

No

25 seconds

Mask

Yes

is controlled

4-way valve

is switched. (ON)

No

3 seconds

Mask

Yes

Compressor : ON

No

3 seconds

Mask

Yes

After this the unit follows

conventional operation.

(Defrosting is finished)

3. DEFROSTING FINISH

Defrosting is performed after the compressor is turned on and one minute mask is finished.

It will be completed when the outdoor piping thermistor temperature is 10°C or more or time

of 15 minutes timer is up.

03-03

3-8 PROTECTION FUNCTION

3-8-1 COMPRESSOR PROTECTION FUNCTION

1. THREE MINUTES DELAY FUNCTION (3ST)

The outdoor unit does not operate for three minutes

after the power switch is turned on. (Compressor protection, breaker off prevention, etc.)

Compressor ON/OFF control

3ST

ON

OFF

Note:

When test operation is performed during continuous heating operation, it takes some time until air blows out from the

indoor unit because "Three minutes delay" and "Cold air discharge prevention" have priority over TEST operation.

2. THREE MINUTES CONTINUOUS FUNCTION (3HT)

The unit continues to run for three minutes after the compressor starts.

3HT

ON

OFF

3-8-2 PRESSURE SWITCH PROTECTION

To prevent the refrigerant liquid from returning to the compressor during cooling operation, the following operations are

performed.

Pressure SW

Pressure value (kgf/cm

Function operation

2

)

ON OFF

Compressor stop

3 or moreUp to 2

Normal operation

(Reset)

3-8-3 DISCHARGE TEMPERATURE PROTECTION

The following operations are performed for compressor body heating protection

Discharge temperature

Function operation

125 C 95 C

Compressor stop

Normal operation

(Reset)

03-04

4. INDOOR UNIT OPERATION CONTROL

4. INDOOR UNIT OPERATION CONTROL

4-1 FAN CONTROL

4-1-1 FAN SPEED SETTING

Fan speed setting

Press the FAN CONTROL button to set the fan speed.

AUTO

HIGH MED LOW

4-1-2 "AUTO" POSITION

41°C

THE °C

Fan speed zone

Hi zone

Med zone

Low zone

TR-TS 3°C

2°C TR-TS 3°C

TR-TS 2°C

When the room

temperature increases

TIME -->

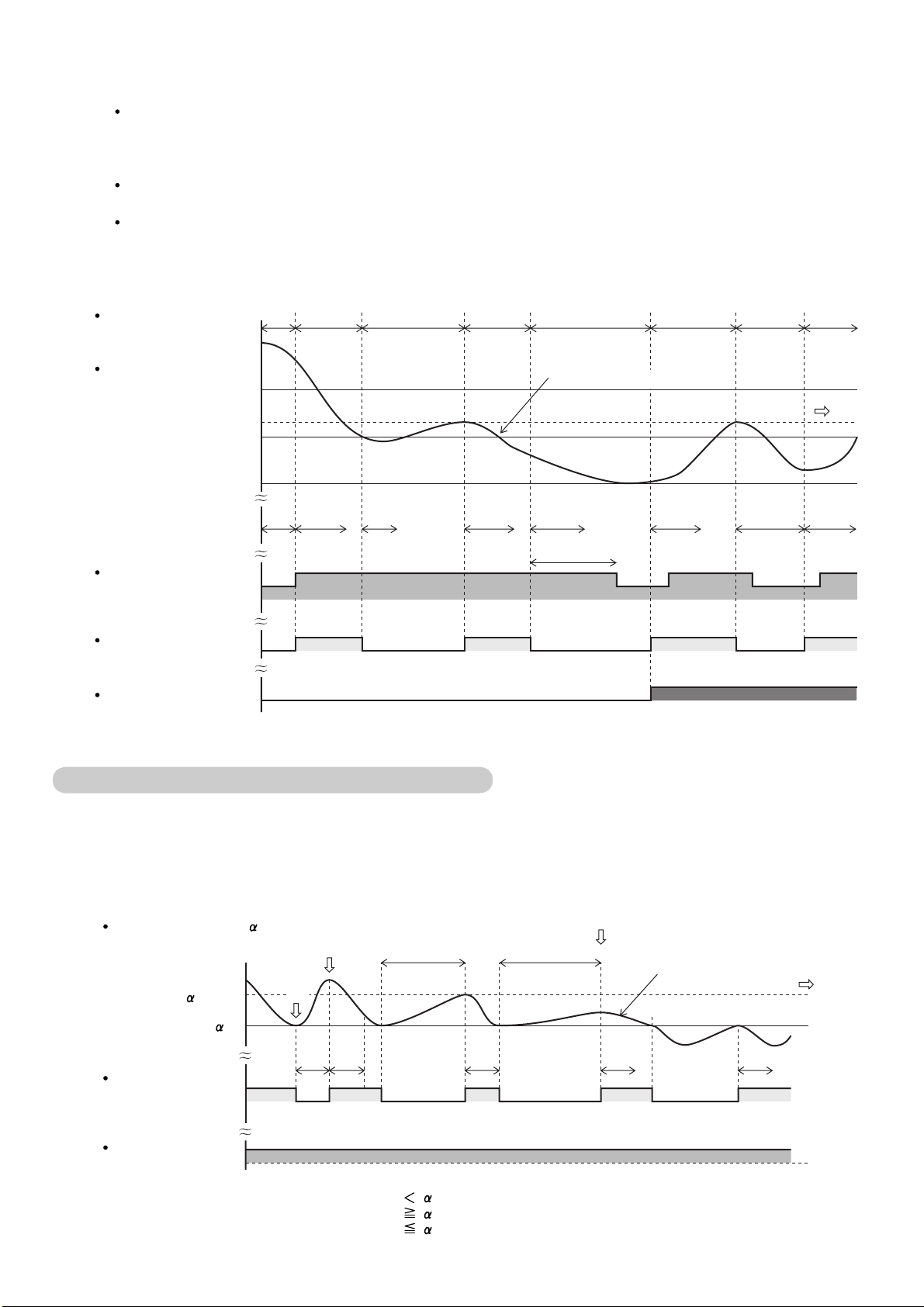

1. COOLING OPERATION

The fan speed is determined automatically in accordance

with the condition "(TR(corrected room temperature) - TS

(corrected set temperature)" as shown on the right.

However, the fan speed zone is determined in the manner

as the room temperature increases for the following cases.

(1) When the TS is changed.

(2) When the operation mode is changed from other mode to "COOL".

(3) When the fan control is changed from other position to "AUTO".

2. HEATING OPERATION

(1) When the indoor heat exchanger temperature reaches 47°C or more, the fan speed switches to the next higher position.

("LOW" "MED", "MED" "HIGH").

(2) When the indoor heat exchanger temperature drops below 41°C while the refrigerant circulation of the indoor unit is ON,

the fan speed switches to the next lower position ("HIGH" "MED", "MED" "LOW").

(3) After switching the fan speed, it does not switch again within 2 minutes.

(4) When "FAN CONTROL" is switched from a set fan speed to "AUTO" after the cold air prevention is released , the fan of

indoor unit will start at "MED" speed for THE or at "LOW" speed for THE .

An example for heat operation

Indoor heat

•

exchanger

temperature (THE °C)

47°C

41°C

41°C

(1)

(2)

TR-TS 2°C

1°C TR-TS 2°C

TR-TS 1°C

When the room

temperature decreases

(3)

Indoor fan speed

•

mode

4. FAN OPERATION

The indoor fan rotates continuously at "Lo" speed.

HI

MED

LOW

OFF

2min.

04-01

2min.

2min.

2min.

2min.

4-2 MASTER CONTROL

4-2-1 "AUTO" POSITION

A: COOLING & DRY operation (COOLING ONLY MODEL)

Operation flow chart

Room temp.

COOLING OPERATION

Yes

Room temp.

START

NO

Ts+2°C ?

Yes

Room temp.

control

NO

Ts+ 1°C ?

Yes

3-min. ST Protection

3-min. HT Protection

Room temperature control

DRY OPERATION

Room temp.

Ts+ 2°C ?

NO

Compressor

off ?

Yes

NO

(1) When starting yhe operation at "AUTO" or

when switched to "AUTO" from other modes,

if the room temperature is higher than the set

temperature +2°C (Room temp. Set temp.

(Ts) +2°C), "COOL"mode is set automatically

and an air conditioner operates until the room

temperature reaches the condition "Room

temp. Set temp. (Ts) +1°C".

(2) When the room temperature is less than the

set temperature (Ts) +2°C at the start of operation or changing into "AUTO", or after the

room temperature reaches the condition "Room temp. Set temp. (Ts)+2°C", the unit is

changed into the "DRY" mode.

"Room Temp. Set Temp. (Ts) +2°C

Cool

Ts +2°C

Dry

Ts°C

Cooling or Dry temperature control operation time chart

Operation mode

Set temperature

(Ts = T )

T +2°C

T +1°C

Indoor fan

motor

Compressor

0.5°C

SET

LOW

OFF

ON

OFF

COOL DRY COOL

R

T Room temperature

T

3HT 2min 2min 3ST 3HT 3ST 3HT 3ST 3HT

DRY

COOL DRY

TIME

04-02

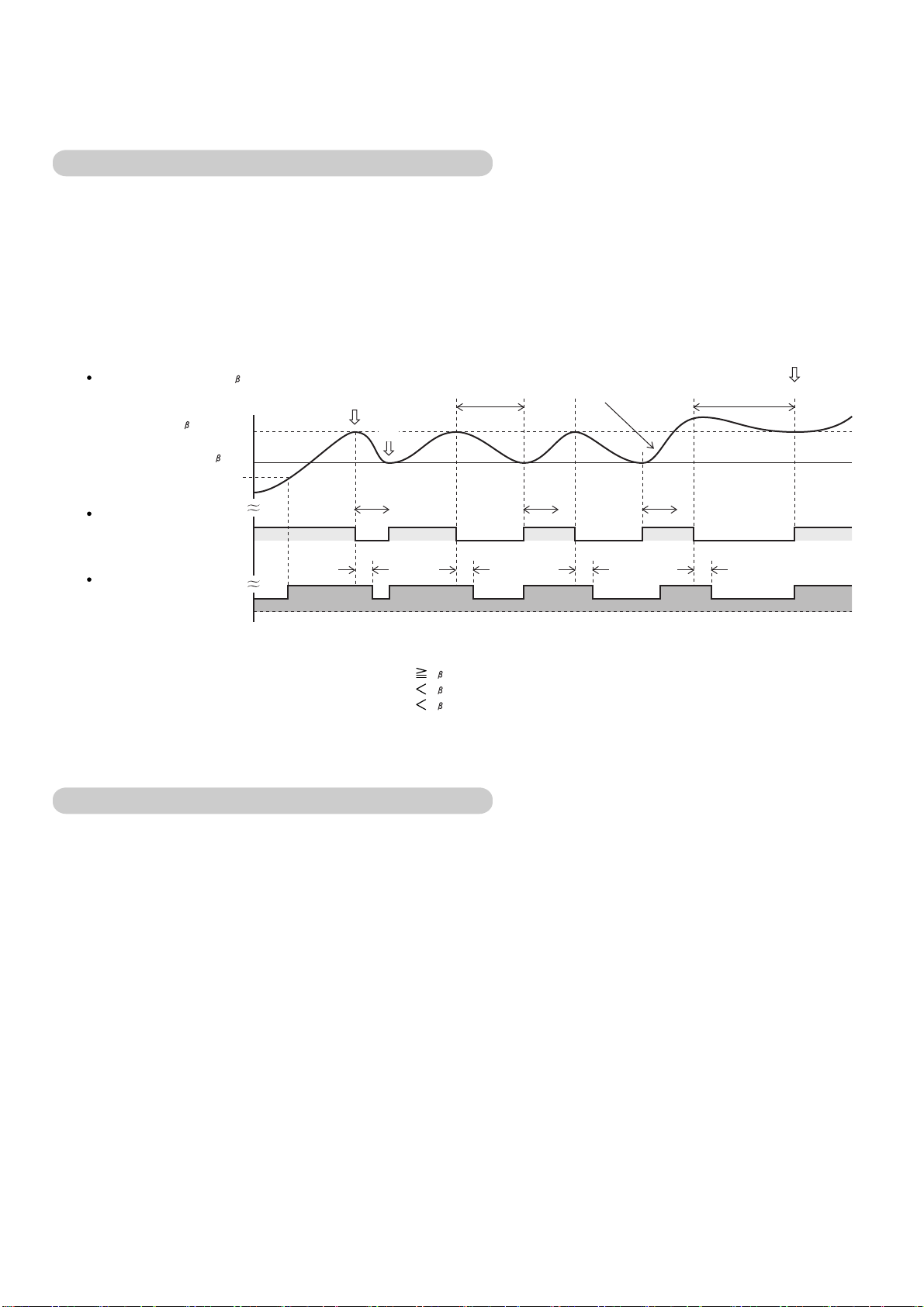

B: AUTO CHANGEOVER operation [REVERSE CYCLE]

When AUTO CHANGEOVER operation is selected, the air conditioner selects the appropriate operation mode

(Cooling or Heating) in response to your room's temperature.

When AUTO CHANGEOVER operation first selected, the fan will operate at very LOW speed for about one minute,

during which time the unit detects the room conditions and selects the proper operating mode.

(1)

Auto changeover flow chart

Monitoring (Room temperature detection)

The monitoring is that the indoor fan motor rotates intermit-

START

tently (0.5 sec ON at Low / 2.0 sec OFF) for 60 seconds to

detect the room temperature (Tr) after the unit starts with

the MASTER CONTROL of AUTO.

(1) Monitoring (one minute timer)

In case that the 3-min delay function actuates or is actuating the monitoring continues until the 3-min delay function

is expired and furthermore 30 seconds elapses.

(2)

(3)

Tr (Tsa+2)°C

NO

Yes

Cooling

NO

During the monitoring :

Indoor fan motor

Outdoor fan motor Hi

Outdoor fan motor Lo

: S-Lo

: OFF

: OFF

4-way valve

Conpressor

(2)

Auto operation

: OFF

The cooling operation starts when the monitoring is

expired and then the detected room temperature (Tr) is

given in the formula [Tr (Tsa+2)°C].

Tsa Ts

Tr (Tsa-2)°C

Yes

Heating

Tsa=Ts+CC

The heating operation starts when the monitoring is

expired and then the detected room temperature (Tr) is

4-way valve is turned on

given in the formula [Tr (Tsa-2)°C].

The monitoring continues when the detected room temperature (Tr) is given un the following formula.

[(Tsa-2)°C Tr (Tsa+2)°C]

The compressor is turned on.

The cooling or heating operation is performed in accordance with the microcomputer functions such as thermostat control, 3-min delay function, etc.

When the compressor continues to be in the OFF state for

Thermostat control

3 min. SH

6 minutes by the thermostat control in either of the cooling

or heating, it is switched to the monitoring.

3 min. ST

De-icing function

Cold air prevention

Overload protection

Defrost operation

Room temperature (T ) control zone

R

Is the

compressor turned

off ?

Yes

Does the com-

pressor continue to be

NO

NO

Cool

Monitoring

Heating

Tsa+2°C

Tsa°C

Tsa-2°C

turned off more than 6

minutes ?

Yes

4-way valve is turned off.

(3) Tsa : Set temperature in AUTO operation

During cooling operation or after switching to monitoring from cooling operation, Tsa is identical to the temperature (Ts)

selected out of the THERMOSTAT.

04-03

During heating operation or after switching to monitoring from heating operation, “Tsa” is a value which the heating correction coefficient (CC) is added to the temperature (Ts) select out of the THERMOSTAT.

(Tsa=Ts+CC)

[Heating correction coefficient (CC) : See page 02-07]

When the set temperature of the THERMOSTAT (Ts) is changed, the last temperature has priority over the former set

temperature.

Even though the set temperature is changed to switch from cooling to heating or from heating to cooling, such a switching is carried out after the compressor continues to be in the OFF state for 6 minutes by the thermostat control.

An example for AUTO CHANGEOVER TEMPERATURE CONTROL time chart

Operation mode

(Moni.: Monitoring)

Set temperature

Indoor fan

•

motor

Compressor &

Outdoor fan

4-Way valve

Ts+2°C

0.5°C

Ts

Ts–2°C

SET

S-LOW

OFF

ON

OFF

ON

OFF

Moni.

Cool Moni. Moni.

Cool

Moni.Heat Heat

TR Room temperature

1min. 3HT 3HT 3HT

3ST 3ST 3ST 3ST

Comp. OFF 6min.

TIME

4-2-2 "COOL" POSITION

1.

When using the cooling mode, set the temperature to a value lower than the current room temperature.

2. If it is set higher than the current room temperature the unit will not enter the cooling mode and only the fan will operate.

An example for COOLING TEMPERATURE CONTROL time chart (Manual setting)

Set temperature (Ts=T Correction)

T +0.5°C

(a)

T °C

Compressor

ON

3ST

OFF

Indoor fan

ON

OFF

(a) Compressor turned OFF :T TR

(b) Compressor turned ON

(c) Compressor turned ON

(b)

3~6 min.

Less than 6 min.

3HT 3HT 3HT 3HT

(b)

R

:T T +0.5°C

R

:T T

(In case of 3 to 6 minutes)

(In case that the compressor stops more than 6 minutes)

(C)

TR

TIME

04-04

4-2-3 "HEAT" POSITION

1. Set the temperature higher than the current room temperature. If it is set to a lower temperature, heating will not

start.

2. For about 3 ~ 5 minutes after the start of heating, the fan will operate very slowly, and then switch to the selected fan

setting. This period allows the indoor unit's heat exchanger to warm-up before emitting warm air.

3. During defrosting, the OPERATION indicator lamp flashes 3 sec. ON and 1 sec. OFF, and the heating operation is

temporarily interrupted.

An example for HEATING TEMPERATURE CONTROL time chart (Manual setting)

Set temperature (Ts=T Correction)

(a)

3~6 min.

TR

Less than 6 min.

(C)

Compressor

Indoor fan

¥

speed mode

T +0.5°C

T °C

27°C

ON

OFF

SET

S-LOW

OFF

Cold air prevention

(a) Compressor OFF R

(b) Compressor ON R

(c) Compressor ON R (When the compressor stops after less than 6min.)

(b)

3ST

20sec.

: T T +0.5°C

: T T

: T T +0.5°C

3HT

20sec. 20sec.

3HT

4-2-4 "FAN" POSITION

1. In this position, the fan operates alone to circulate air. The room temperature will not be changed.

2. Operates at the air flow set in the FAN CONTROL mode.

3. When only the "FAN" mode is being used, setting to "AUTO" is equivalent to set it at "MED".

20sec.

04-05

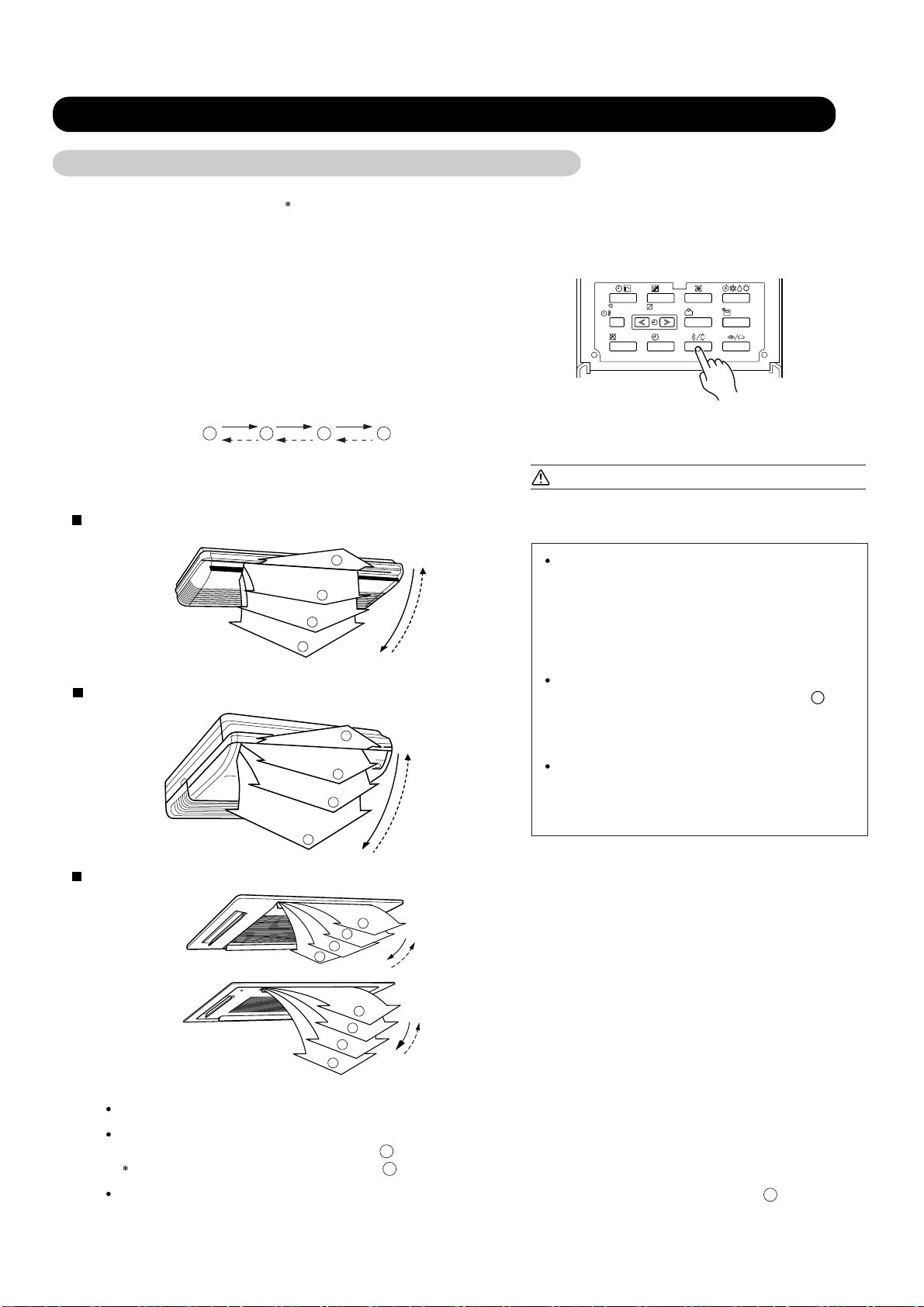

4-3 LOUVER CONTROL

4-3-1 ADJUSTING THE DIRECTION OF AIR CIRCULATION

Instructions relating to heating ( ) are applicable only to "HEAT

PUMP MODEL".

Begin air conditioner operation before performing this procedure.

Vertical Air Direction Adjustment

This instructions are applicable to "CEILING SUSPENSION

TYPE", "FLOOR CONSOLE/UNDER CEILING DUAL TYPE" and

"CASSETTE TYPE".

Press the VERTICAL AIR FLOW DIRECTION SET button.

Each time the button is pressed, the air direction range will

change as follows:

1 2 3 4

The remote controller's display does not change.

CEILING SUSPENSION TYPE

1

2

3

4

FLOOR CONSOLE/UNDER CEILING DUAL TYPE

1

2

3

4

DAY

CLOCK ADJUST

DAY OFF

ENERGY

SET BACK

DELETE SET

SAVE

THERMO

SENSOR

Example : When set to vertical air direction.

DANGER!

Never place fingers or foreign objects inside the

outlet ports could cause personal injury.

Always use the remote controller's AIR FLOW

DIRECTION button to adjust the UP/DOWN

air direction flaps or RIGHT/LEFT air direction

louvers. Attempting to move them manually

could result in improper operation; in this case,

stop operation and restart. The flaps should begin to operate properly again.

During use of the Cooling mode, do not set

the UP/DOWN air direction flaps in the position for long periods of time, since water vapor

may condense near the outlet port and drops

of water may drip from the air conditioner.

When used in a room with infants, children,

elderly or sick persons, the air direction and

room temperature should be considered carefully

when making settings.

4

CASSETTE TYPE

1

2

3

4

1

2

3

4

Use the air direction adjustments within the ranges shown above.

The vertical airflow direction is set automatically as shown, in accordance with the type of operation selected.

During Cooling mode : Horizontal flow

During Heating mode : Downward flow

1

4

During AUTO mode operation, for the first minute after beginning operation, airflow will be horizontal ; the air

direction cannot be adjusted during this period.

04-06

1

Loading...

Loading...