Page 1

F-

ALTERNATOR

DIAGNOSTIC REPAIR

MANUAL

%■

Printed in U.S.A.

GENERAC

P.O. Box 8, Waukesha, Wisconsin 53186

50357

Page 2

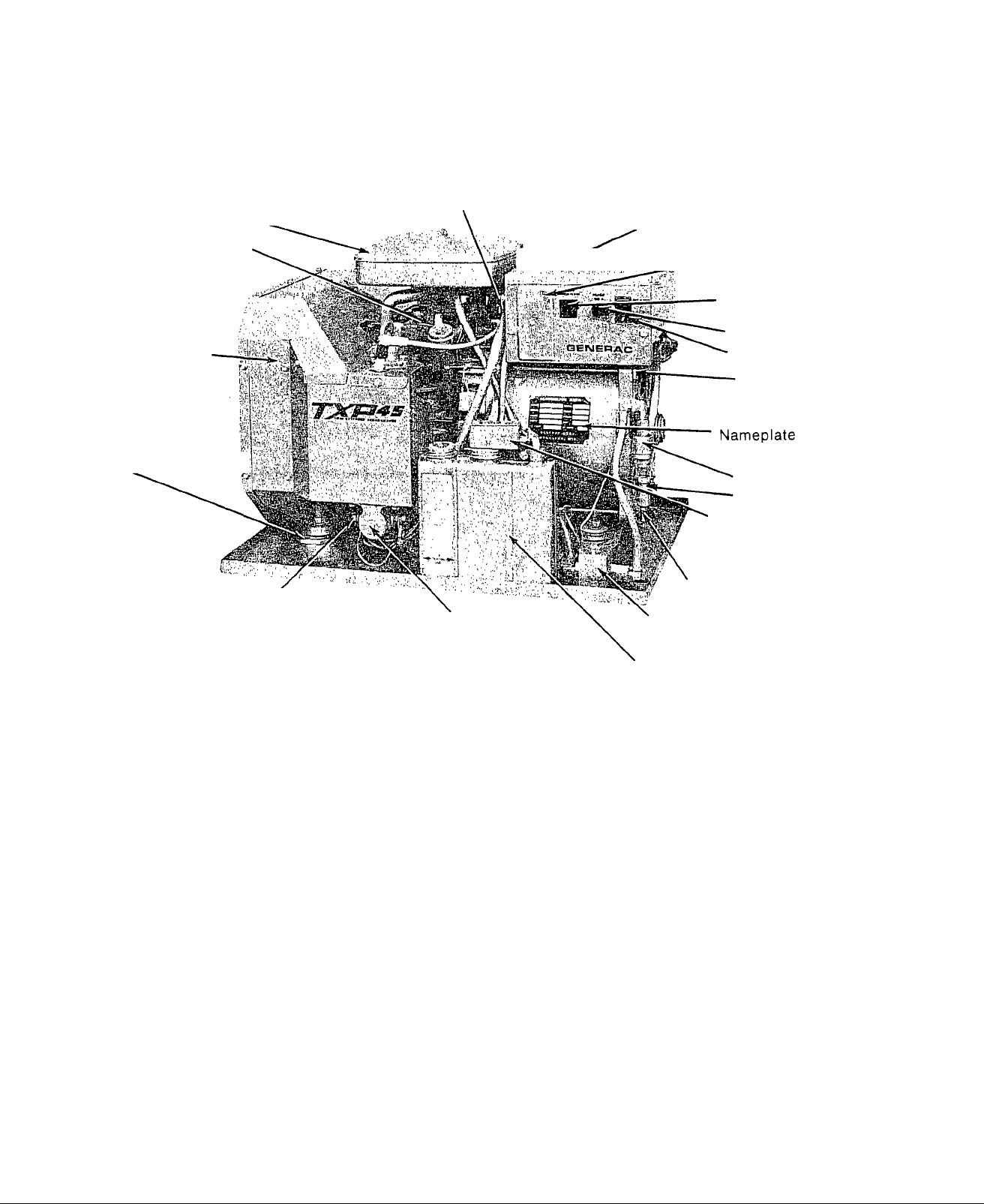

Engine Air Cleaner

Conduit Clamp

Button Plug

(Optional location of conduit clamp)

Oil Dipstick

Blower Shroud

Vibration Dampener

POSITIVE Battery

Cable Connection

Starter Solenoid

Figure 1. NOMENCLATURE

I Customer Wiring Connection

—■ Access Panel

Main Circuit Breaker

15 amp Fuse

Start/Stop Switch

NEGATIVE Battery

Cable Connection

Solenoid Operated

Fuel Shutoff Valve

Lowo7L¡^'""®'

Shutdown Switch

Customer Fuel Supply

Line Connection

Fuel Pump

Oil Make Up Tank

(2 quart)

Page 3

PART I

GENERAL

Section Title Page

1 Specifications.........................................................................................................................................................

Difference Data......................................................................................................................................................

Engine Lubrication................................................................................................................................................‘'■2

Electrical Test Specifications.............................................................................................................................. ■'•2

Torque Values........................................................................................................................................................‘'•2

Engine Specifications............................................................................................................................................

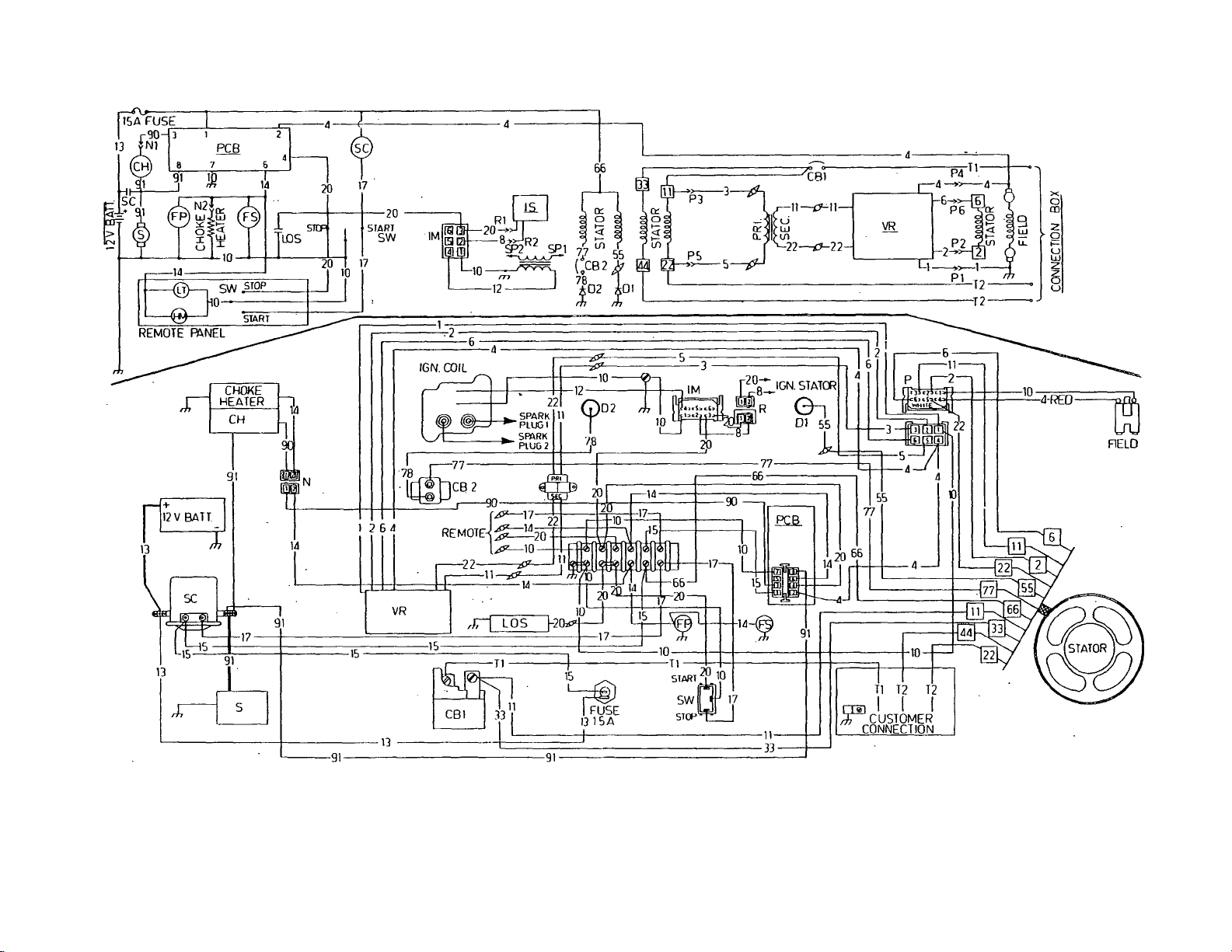

2 Wiring Diagram (Model 6931-0)............................................................................................................................2.1

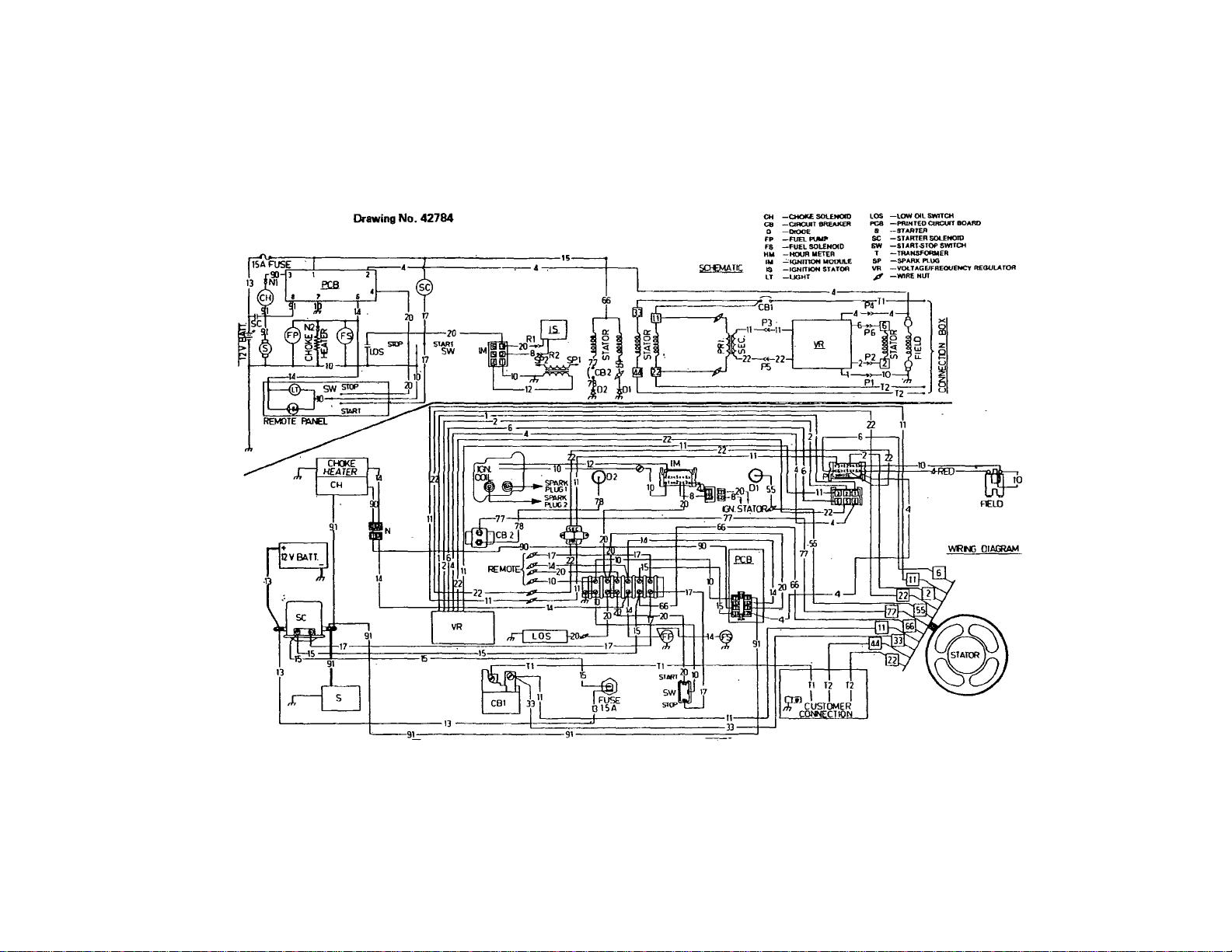

Wiring Diagram......................................................................................................................................................2.2

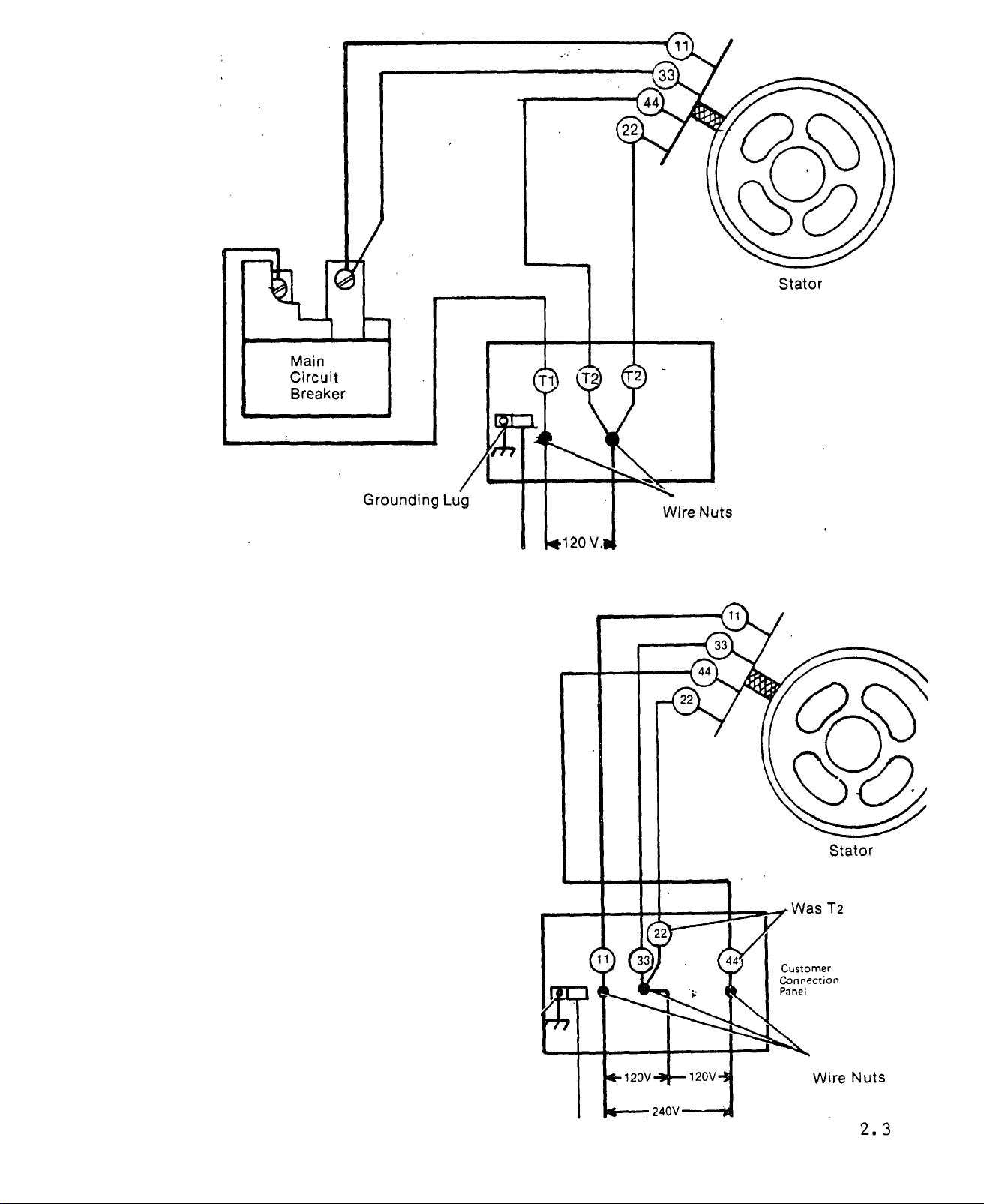

Factory Equipped Customer Wiring Connections

TXP Reconnected for 120/240 Volt Output...........................................................................................................2.3

..........

...............................................................................

2.3

Page 4

SPECIFICATIONS

Model No.

Wattage Capacity

Voltage Output

Amperes

Frequency

Phase(s)

Voltage Regulation

Driven Speed

Battery Charging

Amperes

Gross weight (wet)

Engine Type ■ ■

Engine Horsepower

Bore

Stroke

6931-0 6931-1 6931-2

4500

120/240*

37.5 at 120 Volts - 18.75 at 240 Volts

60 Hz

1-Phase

120 Volts ( + 27o) AC at 60 Hertz

1800 rpm

0-10 Amperes at 12 Volts DC

215 Pounds

2-Cylinder, 4-Cycle, Aluminum

Approximately 10 at 1800 rpm

3.44 Inches (87.3 mm)

2.16 Inches (54.7 mm)

Displacement

Valves

Stellite exhaust valves - Valve ro

tators on exhaust valves

40 Cu, In, (656 cc)

Governed Speed 1800 rpm

Air Cleaner

Crankcase Oil

Capacity

Oil Make-up System

Ignition System

Dry paper element, oil foam pre-cleaner

56 Ounces (3% Pints')

Maintains crankcase oil level at about

48 Ounces (3 Pints)

Solid state capacitor discharge type

Starting System 12 Volt DC electric (Ring Gear)

Cranking Current

Approximately 90 amperes nominal

*As shipped, alternator provides 120 volts AC only. Unit is

reconnectable to supply 120 and 240 volts AC. See Page 2,3.

DIFFERENCE DATA

Model 6931-0 - Rigid coupling between engine drive shaft and rotor

Model 6931-1 - Added a flexible coupling between engine drive shaft

___________________

and rotor

_________________________________________________________

Model 6931-2 t New rotor with improved 4-pole laminations. New im

proved blower housing with heavier sheet metal. New

_________________

improved inertia ring.with increased mass.

______________________________

Issued 6-78

1.1

Page 5

ENGINE LUBRICATION

Use any high quality detergent oil

having a classification which inc

ludes ’’Service MS, SC, SD or SE”,

No special additives should be used.

ELECTRICAL TEST SPECIFICATIONS

RECOMMENDED SAE VISCOSITY GRADES

1 1

100

60

°C-30

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

-20 10 10

80

30 40

20

*If not available, a synthetic oil may be used

having — 5W-20, 5W-30 or 5W-40 viscosity.

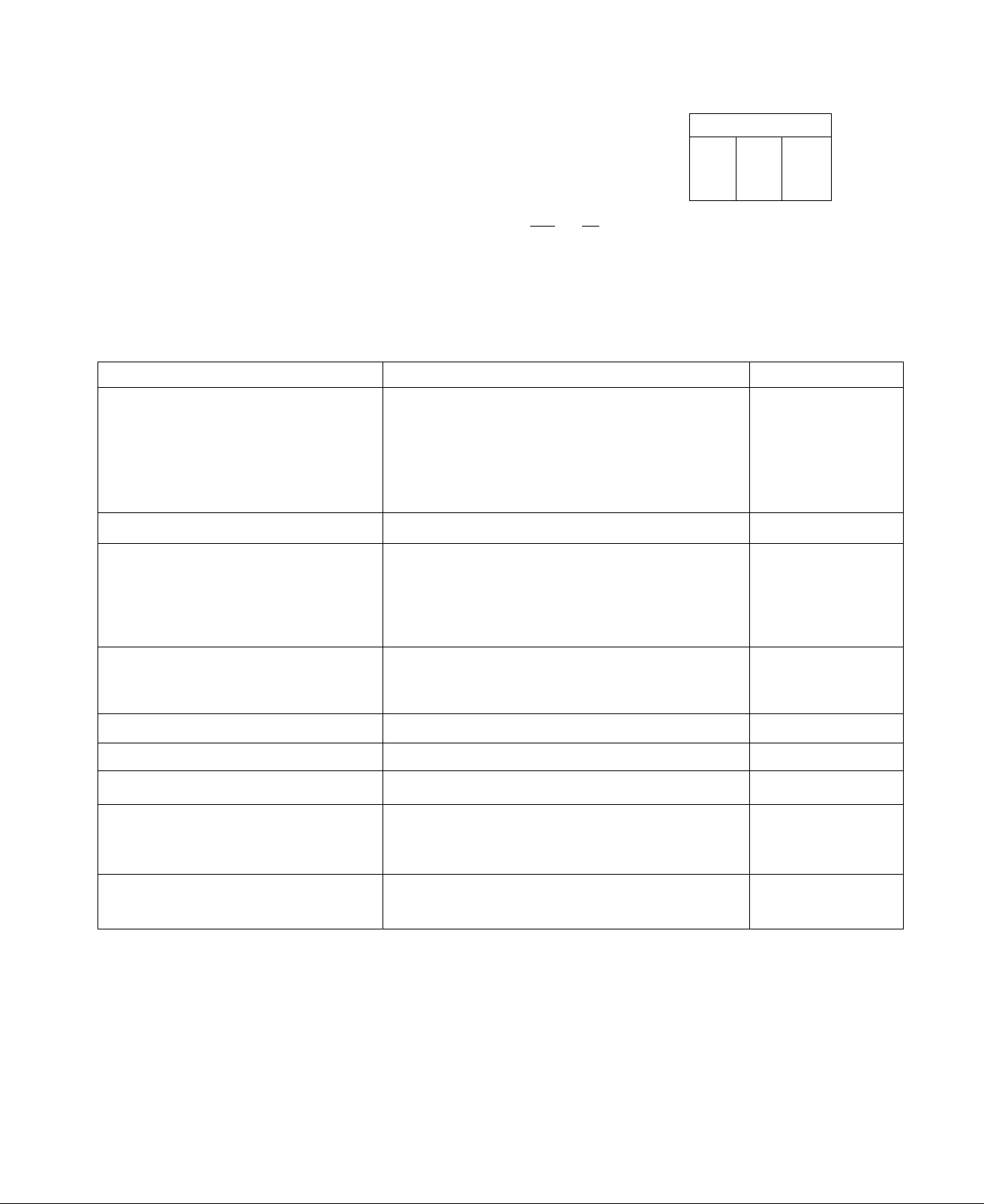

COMPONENT

Stator Windings

AC Power Windings

AC Power Windings

Excitation Windings

Battery Charge

Windings

Rotor

Ignition Stator

Charge Coil

Trigger Coil

Ignition Stator Voltage

Input to Printed

Circuit Board

Fuel Pump DC Resistance

Spark Timing

Choke Heater

TEST POINTS

Wire #11 - Wire #22

Wire #33 - Wire #44

White receptacle Pin #2 -Pin #6,

Wire #55 - Ground

Wire #77 - Ground

Brush terminals or Slip Rings

Ignition Module Receptacle Pin

#2 - Ground

Ignition Module Receptacle Pin

#3 - Ground

PGB Pin #4 - Ground

Fuel Pump terminal to ground

Wire #77 - Ground

TEST VALUE

0,42 Ohms

0,42 Ohms

2,30 Ohms

0,20 Ohms

0, 20 Olmns

13,00 Ohms

225.00 Ohms 4

6,00 Ohms

0.5-1.5 Volts

50,00 Ohms

26 BTDG

30.00 ohms

Sensing Transformer

Secondary Winding

Primary Winding

Field Boost Voltage

(While Cranking)

Wire #11 - Wire #22

White receptacle Pin #3 - #5

White receptacle Pin #4 - Ground

NOTE;-Either of two transformer makes may be used. The Wescoil transformer

has a primary winding resistance of 745-825 Ohms and a secondary winding

resistance of 1603-2169 Ohms, The CoilTran transformer has a primary resis

tance of 824-1114 Ohms and a secondary resistance of 1222-1654 Ohms.

1.2

See NOTE

See NOTE

9 - 12 VDG

Page 6

TORQUE VALUES

STANDARD TORQUE VALUES

Grade 2

BOLT SIZE

1/4-20 5 4

1/4-28

5/16-18 11 8

5/16-24

3/8-16

3/8-24 23 17 35

7/16-14

7/16-20

1/2-13

1/2-20 55 42

9/16-12

9/16-18 78

5/8-11

5/8-18

3/4-10

3/4-16

DRY LUB

6 5 10 7 12

13 10

20

32

36

49

70

92

105

165 125

180

1525

27

38

54 110 84

60 120

71

81

140 295

All Values in FOOT-POUNDS

TORQUE VALUES + 5 PER CENT

DRY

17 13 21

19 15 24

31

49 38

55

75

85 65 105

150

170

270 205

Grad

8

----------

LUB DRY

6

24

27

42

58

93 150 115

115 185 145

130 210 160

230

Grade 7

LUB

10

16

18

38 29

43

61

68

93 - 72

135 105

330

365

33

47

52 78

■ 80

250

280

Grade 8

DRY

8

9

27

49

105

120 90

155

170 132

210 165

240 185

375

420 320

■ LUB

12 9

14

24 18

44

70

11

21

34

38

54

60

82

120

290

7/8-9 200

7/8-14

1-8

1-14^ 340 260 680

SPECIAL TORQUES

Connecting Rod.

Cylinder Head (Torque in staggered.sequence)

Spark Plug.:.

Starter Motor Mounting Bolts..,i.............................................. .........................................160 In.-Lbs.

Engine Base

Sump (7 bolts)....

Crankcase Cover (7 bolts).

Governor Lever Lock Nut...,.

Fan to Engine Shaft Capscrew (Grade 5)-(Apply Loc^Tite

601 to capscrew threads:)

Flex Coupling to Rotor Hub Capscrews (Model 6931-2) -

(Apply LocTite 601 to capscrew, threads)................................................................. 19 Ft.-Lbs.

Flex Coupling to Fan Capscrews (Model 6931-2) - (Apply

LocTite 601 to capscrew threads).....................................................................................

.........

.....................................................................................................................

..............................

225 170 435 335

300

GRADE

BOLT HEAD

SYMBOL

.........

................................................ 200 In. -Lbs.

155 395 305 530

585 450

230

590 455

510

795 610

O

.

........................................................................••..190 In.-Lbs.

..................................

.(......I-............................................. 160 In.-Lbs.

.............................................................................

...........................................................................................

..................

..........

......................................................... 19 Ft.-Lbs.

..........

405

©

............

.......140 In.-Lbs.

605

670 515

905 695

..160 In.-Lbs.

300 In.-Lbs.

100 In.-Lbs.

19 Ft.-Lbs.

455

Issued 6-78 1»3

Page 7

ENGINE SPECIFICATIONS

Spark Plug Gap

Crankshaft End Play..

Governed Idle Speed Adjustment...............................................................................................

Valve Clearance (with springs installed)................................................................Intake .005"-. 007"

Valve Seat Angle...........................................................................................................Intake - .30

Valve Seat.Width...............................................................................................

Valve Seat Margin................................................................................................Not less than 1/64'

Valve Clearance (springs not installed).,......

Crankshaft Reject Sizes.........................................................................................PTO Journal 1.376'

Cylinder Boi'e Standard Diameter

Ring Gap Reject Sizes (Top and center compression)......................................................................0.035'

Ring to Ring Groove Maximum Clearance

Maximum Piston Pin Out-of-Roundness....................................................................................,0,0005'

Crankpin Bearing Hole Rejection Size........................................................................................

Piston Pin Bearing Hole Rejection Size...;,.......................................................,,,,.,.,,.....0,802'

Camshaft Rejection Sizes (Gear and. Shaft Journals).......................................................................0,623'

Cylinder Bore Maximum Out-of-Roundness,

Cylinder Bore Oversizes when honing..........................................................

..................................................................................................................................

.............................................................................................

.........................................................

...................................................................................

(oil Ring)................................................................................ .......0.045'

........................................................................................

(Cam Lobes)

.........................................................................

.........................................................................0,0025'

........

0.002"-0.008"

1400 rpm*

Exhaust .007"-.009"

Exhaust - 45

...................

Intake .007"-.009'

0,010" above standard

0.020" above standard

0.030" above standard

3/64"- 1/16’

Exhaust ,009"-.Oil'

Crankpins 1.622'

..... 3.4375**

...1.252'

0.030"

0.007'

1.124'

*Adjust carburetor idle screw to 900 rpm

**Resize if worn 0.003" or more

1.4

Issued 6-78

Page 8

CM

(O

s

<

oc

(3

<

o

CD

z

SCHEMATIC

tH

I

CNJ

WIRING DIAGRAM

E

MODEL 6931 -0

legend

CH~ cnoke So/enold

CB— Circuit Breaker

D— Diode

PP— Fuel. Pump

FS— Fuel Solenoid

HM— Hour Meter

IM— Ignition Module

IS— Ignition Stator

UT— Light

LOS— Low Oil Switch

FCB— Printec? Circuit Board

S— Starter

SC— Starter Solenoid

SW— Start-Stop Switch

T— Transformer

SP— Spark Plug

VR— Voltage/Frequency Regulator

^ — Wire Nut

WIRING DIAGRAM

00

CO

X)

0)

. d

CO

CO

I

Page 9

ro

to

WIRING DIAGRAM

W

in

0

0)

a-

OJ

■o

oo

I

MODEL 6931-1

6931-2

)

),

Page 10

Factory Equipped Customer Wiring Connections

120VoitsOniy

PROCEDURE

1. Disconnect wires No. 11 and No. 33 at

main circuit breaker,

2. Disconnect wire No. Ti at main cir

cuit breaker and discard.

3. Route wires No. 11 and 33 (discon

nected from main circuit breaker) to

customer connection panel.

4. Connect customer wiring as shown

to obtain both 120 and 240 volts A-C.

XR

Main

Circuit

Breaker

Main Circuit Breaker is Not Connected

TXP RECONNECTED FOR 120/240 VOLT OUTPUT

Issued 3-78

Grounding Lug

Page 11

PART II

TROUBLE DIAGNOSIS

Section Title Page

3 DIAGNOSTIC FLOW CHARTS

Engine Won’t Crank....................................................................................................................3.1

Engine Cranks, Won’t Start.........................................................................................................3.2

Engine Starts Hard, Runs Rough............................................................................................... 3.5

Switch Set to STOP, Engine Keeps Running..............................................................................3.7

A-C Voltage Low..........................................................................................................................3.8

A-C Power Low............................................................................................................................3.9

A-C Voltage High.........................................................................................................................3.9

No A-C Voltage..........................................................................................................................3.10

4 DIAGNOSTIC TESTS

Test 1-15 Amp Fuse..................................................................................................................4.1

Test 2 - Battery............................................................................................................................4.1

Test 3 - Start/Stop Switch............................................................................................................4.2

Test 4 - Starter Solenoid

Test 5 • Starter Motor...................................................................................................................4.4

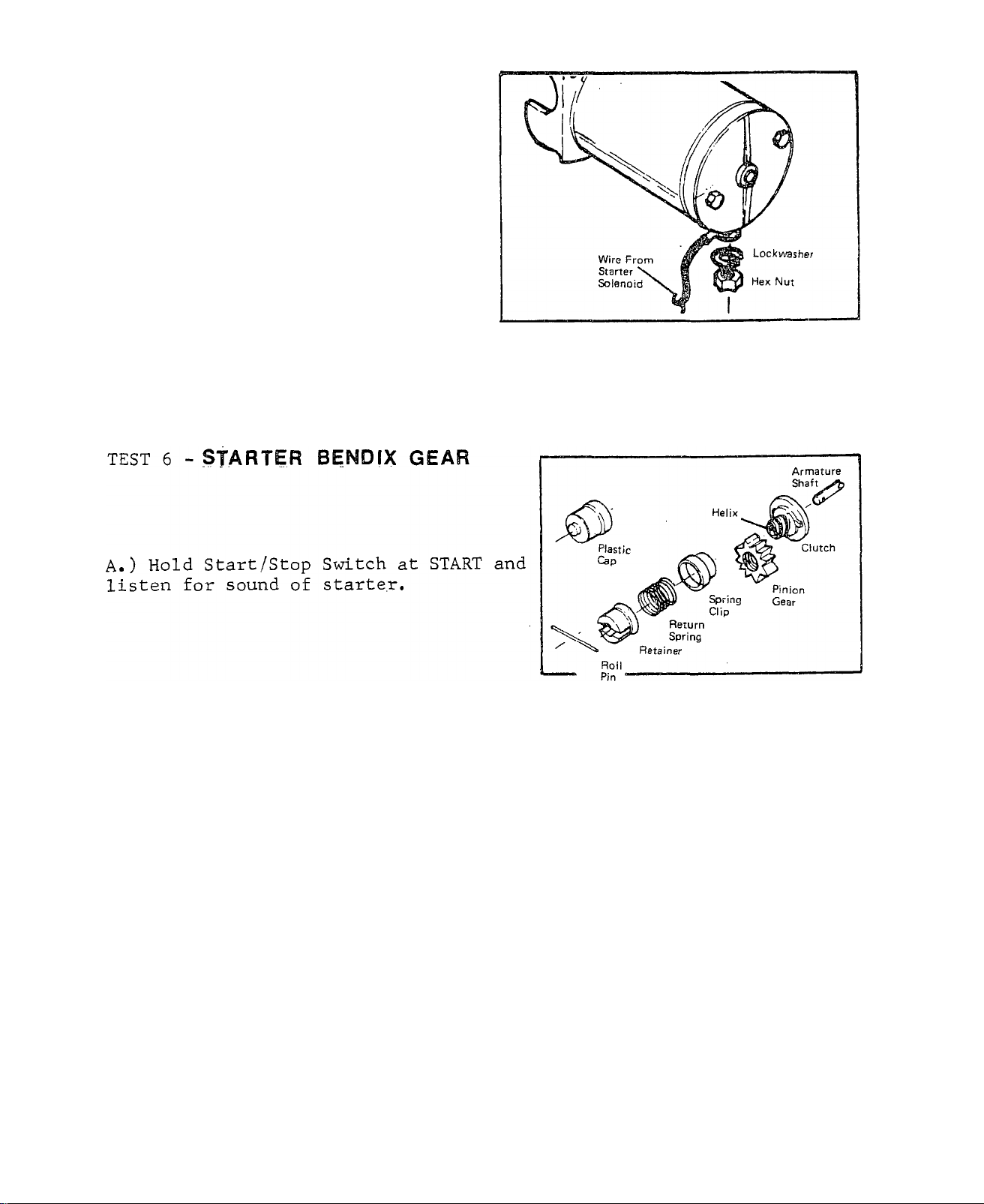

Test 6 - Starter Bendix Gear........................................................................................................4.4

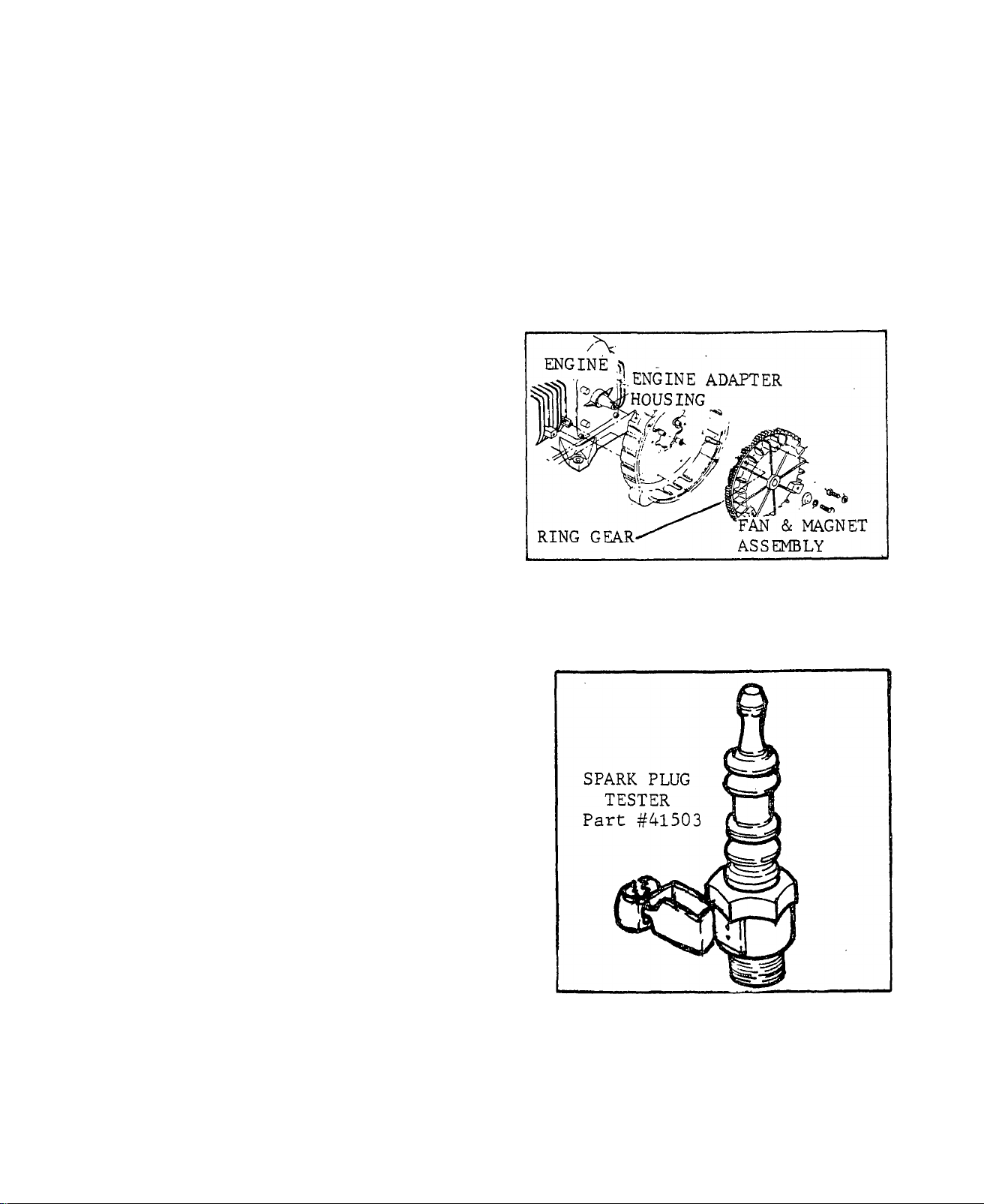

Test 7 - Starter Ring Gear............................................................................................................4.5

Test 8 - Check Spark...................................................................................................................4.5

Test 9 - Oil Make-up Tank...........................................................................................................4.6

Test 10 - Low Oil Switch..............................................................................................................4.6

Test 11 - Spark Plug....................................................................................................................4.7

Test 12 - Ignition Module.............................................................................................................4.7

Test 13 - Ignition Stator................................................................................................................4.8

Test 14 - ignition Coil...................................................................................................................4.8

Test 15 - Low Fuel Level..............................................................................................................4.9

Test 16 - No Fuel Flow...............................................................................................................4.10

Test 17 - 4 Amp Fuse.................................................................................................................4.10

Test 18 - Printed Circuit Board....................................................................................................4.11

Test 19- Fuel Filter.....................................................................................................................4.11

Test 20 - Fuel Shutoff Solenoid.................................................................................................4.12

Test 21 - Fuel Pump...................................................................................................................4.12

Test 22 - Check Installation........................................................................................................4.13

Test 23 - Carburetor...................................................................................................................4.14

Test 24 - Compression...............................................................................................................4.15

Test 25 - Head Gasket...............................................................................................................4.15

Test 26 - Valves.........................................................................................................................4.15

Test 27 - Rings...........................................................................................................................4.15

Test 28 - Cylinder.......................................................................................................................4.15

Test 30 - Choke..........................................................................................................................4.16

Test 31 - Pre-Choke...................................................................................................................4.17

Test 32 - Governor.....................................................................................................................4.17

Test 33 - Frequency...................................................................................................................4.18

Test 34 - Excitation Windings.....................................................................................................4.19

Test 35 - Carbon Buildup...........................................................................................................4.19

Test 36 - Cutput Voltage............................................................................................................4.19

Test 37 - Sensing Transformer

Test 38 - Main Circuit Breaker...................................................................................................4.21

Test 39 - Rotor...........................................................................................................................4.21

Test 40 - Field Boost..................................................................................................................4.22

Test 41 - Stator...........................................................................................................................4.23

Test 42 - Charging Cutput..........................................................................................................4.23

Test 43 - Circuit Breaker........................................................................................................... 4.24

Test 44 - Diodes D1 and D2.......................................................................................................4.24

Test 45 - Stator Battery Charge Windings..................................................................................4.25

................................

..................................................................................................

'..............................................................................4.3

4.20

Page 12

DIAGNOSTIG FLOW CHARTS 3

IMTRODUCTION

Use these FLOW CHARTS in conjunction with the detailed instructions for

each test in Section 4, Test numbers assigned In the FLOW CHART are id

entical to the test numbers assigned to specific tests in Section 4.

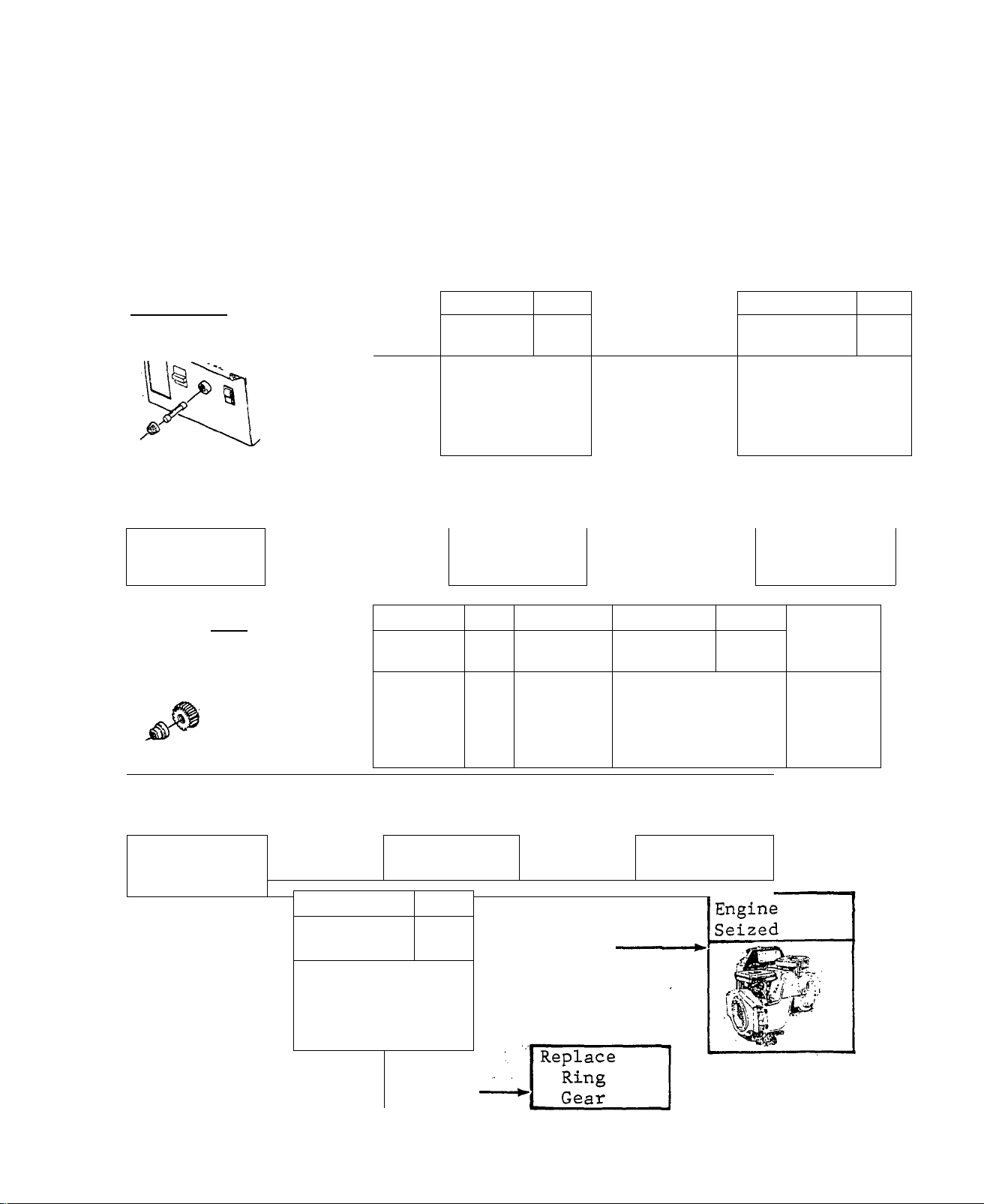

ENGINE WON’T CRANK

TEST 1 Page

15 Amp

Fuse

-------1-------

CHECKS

BAD

f

Replace

Fuse

TEST 6

Starter

Bendix

Gear

«i^'^Retalner

Pin

Gear

CHECKS

BAD

t

Replace

Bendix

Gear

CHECKS'

GOOD

Page

4.4

Clutch

4.1

CHECKS

GOOD

CHECKS

■ GOOD

Test 7

Starter

Ring Gear

TEST 2 Page

Battery

4.1

■ CHECKS

GOOD

CHECKS

BAD

Recharge or

Replace

TEST 5 Page

STARTER

4.4

MOTOR

CHECKS

TEST 4

Starter

Solenoid

GOOD

CHECKS

CHECKS

BAD

1

Replace Replace

Motor

Solenoid

Page

4.5

CHECKS

GOOD

BAD

t

TEST 3

Page

4.3

Start/Stop

Switch

CHECKS

BAD

Replace

Switch

^CHECKS

GOOD

Paee

4.2

Issued 3-78

CHECKS

BAD

3.1

Page 13

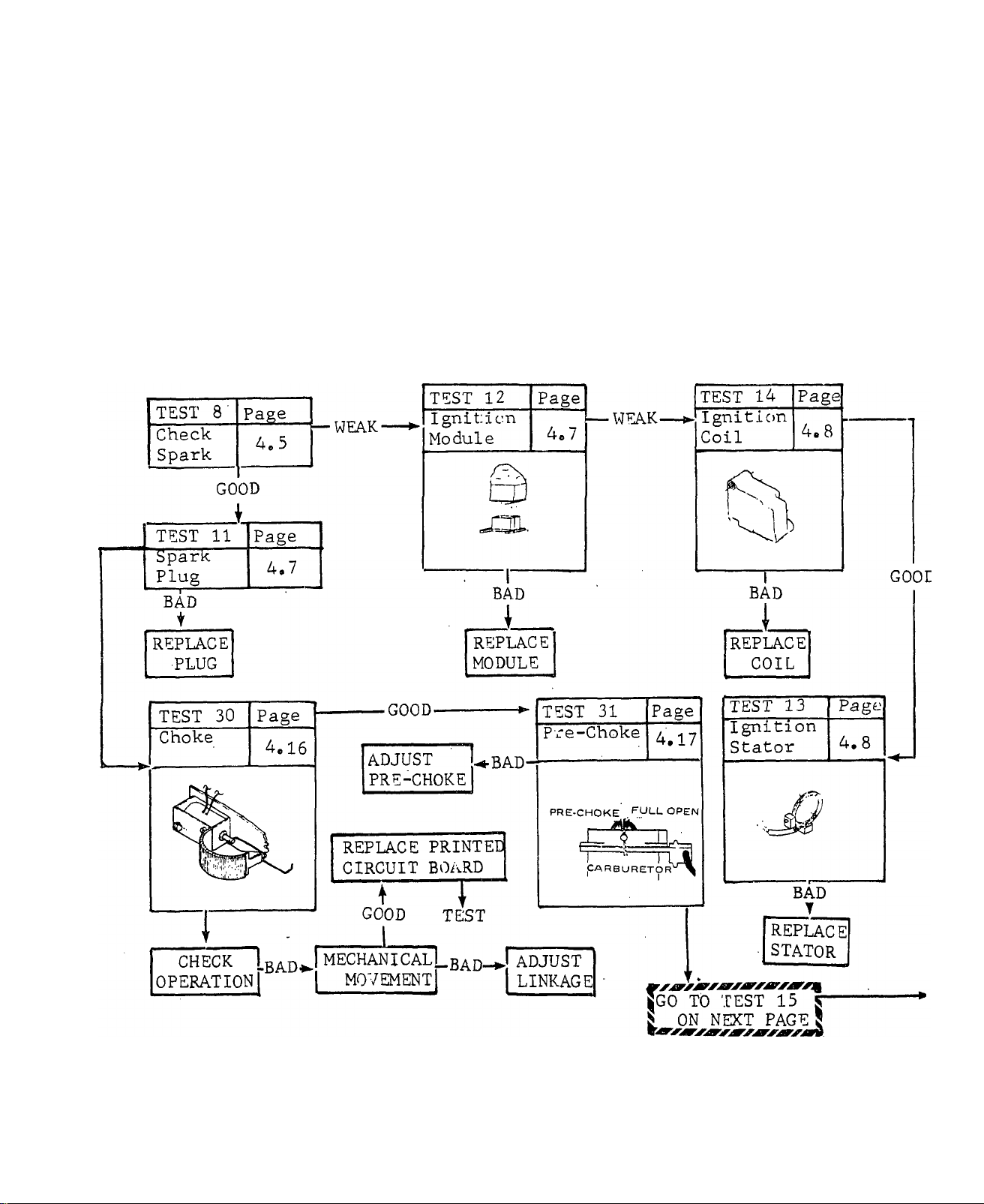

ENGINE CRANKS , WON’T START

TEST 8 Page

Check

Spark

TEST 13

Ignition

Stator

4.5

Page

4.8

NO

SPARK

•GOOD-

TEST 9

Oil

Make-Up

Tank

TEST 12

Ignition

Module

LOW

FILL

TANK

Page

4.6

—GOOD

4.7

-------

-GOOD-

TEST 10

Low Oil

Switch 4.6

Page

4

BAD

I

REPAIR/

REPLACE

TEST 11

Spark

Plug

Page

4.7

GOOD

BAD

__L

Replace

Stator

TEST 14

Ignition

Coil

GOOD

BAD

BAD

I

Replace

Module

[Replace

Coil

^jlF SPARK CHECKS GOOD,«

^ GO TO TEST 15 3

BAD

Replace

Plug

3.2

Issued 3-78

Page 14

______________________

TEST 15

Low Fuel

Level

.

To Vthicii

Engintf

Page

To Alternitor

Engine

4.9

— GOOD

TEST 16

No Fuel

Flow

Page

4.10

-BAD

TEST 17

4 Amp

Fuse

Page

4.10

___________

TEST 20

Fuel

Shutoff

Solenoid

Fuel ^

T«ik В

FILL

TANK

S ^‘Pe

Д Nipple

^<^Anti ■ Siphon

Holes

LOW

i

Page

4.12

Pipe Cep

■GOOD.

TEST 19

Fuel

Filter

”F“

GOOD

GO TO

TEST 23

Page

4.11

-.GOOD

BAD

I

REPLACE

FUSE

TEST 18

Printed

Circuit

Board

и ~ c=3 p|n

GOOD

Page

4.11

GOOD

REPLACE

SOLENOID

TEST 21

Fuel

Pump

BAD

Page.

4.12

GOOD.

■ BAD-

------------------

TEST 22

Check

Installation

,| REPLACE

BAD

REPLACE

FILTER

PUMP

1

—I—

BAD

REPLACE

BOARD

Page

4.13

SIF TEST 1.6 IS GOOD,t

3 GO TO TEST 23 (

Issued 3-18 3.3

Page 15

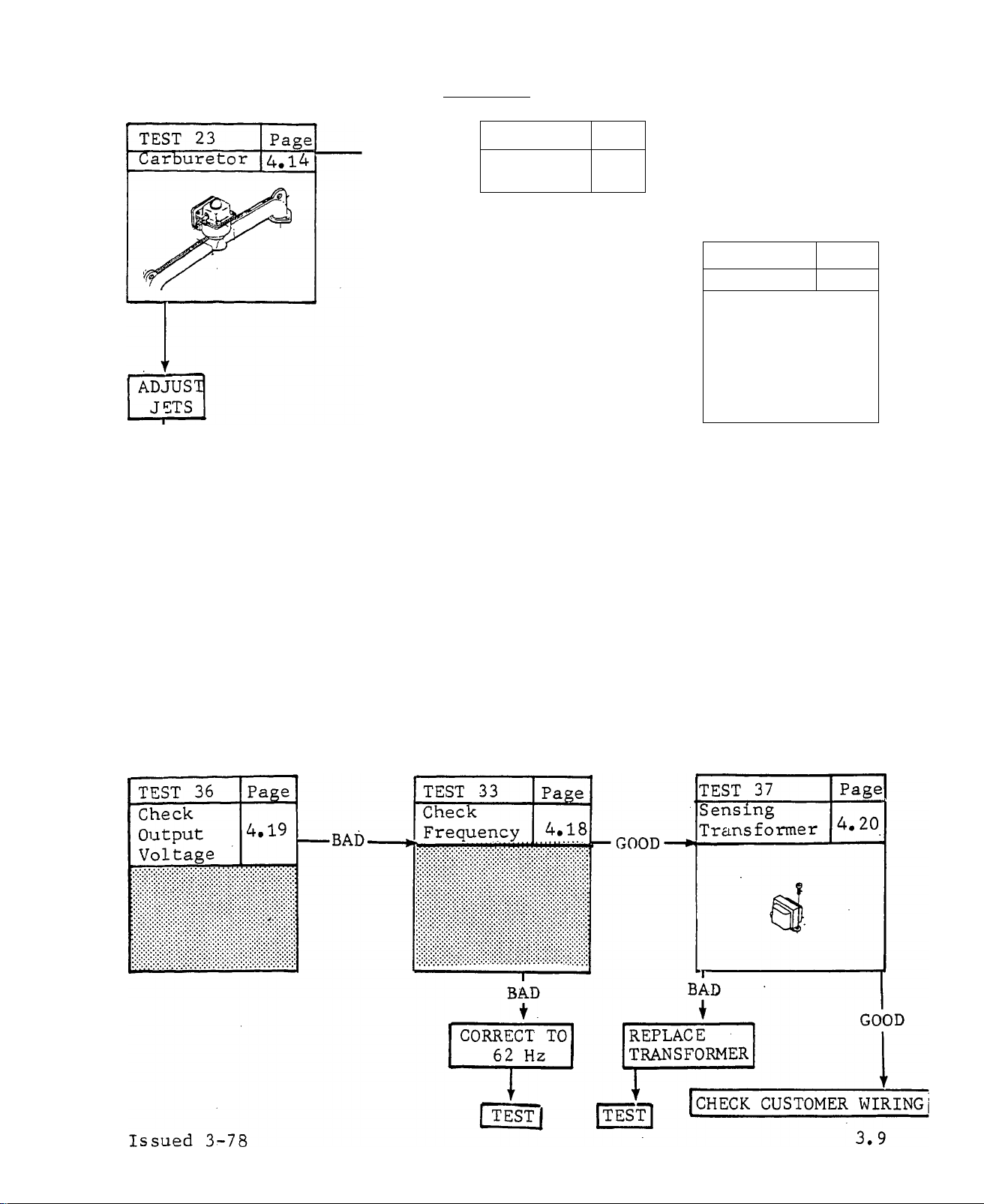

TEST 23

Carburetor

J / ^

Page

4.14

TEST 24

COMPRESSION

Page

4.15

BAD

TEST

GOOD

REPLACE

GASKET

ADJUST

JETS

’

FLOAT

SEAT

FLOAT

LEVEL [

-BAD J replace

|. SEAT

1

hBAD-

NO

■ CHANGE’

I adjust"

'I FLOAT.

-8^,TEST

REPIACE

CARBURETOR

TEST

,1 TEST

BAD

1 TEST

TEST 26

VALVES

1

-------

TEST.

TEST 28

CYLINDER t4.15

1 REPAIR 1

_Page_

Page

4.15

3.4

T.EST.

TEST 27

RINGS

h:

Page

4.15

REPLACE I

GOOD

■ GOOD

GOOD

-»‘I GO TO TEST 29§i

_ - --

_ - .

Issued 3-78

Page 16

ENGINE STARTS HARD - RUNS ROUGH

Issued 6-78

3.5

Page 17

TEST 15.

Low Fuel

Level

Page

4.9

■ GOOD

TEST 16 Page

Fuel Flow

4.10

BAD

-GOOD-

TEST 23

Carburetor

Page

4.14

TEST-^

TEST-*-

FILL

TANK

REPLACE

FILTER

REPLACE

SOLENOID

TEST 19

Fuel

Filter

TEST 20

Fuel

Shutoff

Solenoid

Page

4.11

9

[adjustI

Ijets

BAD^

REPLACE

CARBURETOR

-TEST

CHECK

REPLACE

SEAT

-TEST

Page

FLOAT

VALVE

■ BAD*.

4.12

ADJUST

FLOAT

-TEST,

1 ■

FLOAT

LEVEL BAD-^

TEST-*-

3.6

REPLACE

PUMP

TEST 21

Fuel

Pump

TEST 22

check

Installation

Pagè

4.12

Page

4.13

TEST 32

Gove mor

"^8 COMPRESSION "

Page

4.17

’change'

BAD

I

ADJUST

GOVERNOR

5 GO TO TEST 24 I

Issued 3-78

NO

Page 18

TEST 24

Compression

-—BAD

TEST 25 .

Head Gasket

Page

4,15

TEST 26

Valves

Page

4.15

BAD

REFI ACE

GASKET

TEST

GOOD-

TEST 27

Rings

REELAGEl

R-INGS

BAD

GOOD

REPAIR

''

TEST

Page

4.15

BAD

1

Issued 6-78

TEST.

SWITCH SET TO STOP - ENGINE KEEPS RUNNING

TEST 3

Start/Stop

Switch

Page

4.2

-BAD

I REPLACE

■ *" SWITCH

3.7

Page 19

A-C VOLTAGE LOW

TEST 33

Check

Frequency

BAD

TEST 32 Page

Governor

Page

4.18

4.17

■ GOOD

¡testI

REPLACE

STATOR

■ GOOD-

REPLACE VOLTAGE

REGULATOR

3.8

Issued 6-7 8

Page 20

A-C POWER LOW

GOOD

T

TEST

NO .

■ CHANGE'

TEST 35

Page

Carbon

Build-up

.4.19

DE-CARBONIZE

- HEAD

TEST

NO

CHANGE

NO ‘

-CHANGE-

TEST 32

Governor

(^

Page

4.17

sf^ ^

TEST

A-C VOLTAGE HIGH

Page 21

NO A-C voltage,

TEST 36

Page

Cheek

Output

4.19

Voltage

GOOD

I

CHECK CUSTOMER

WIRING

TEST

TEST 38

Main

Circuit

Breaker

BAD

REPLACE

CIRCUIT

BREAKER

~T~

TEST

Page

TEST 29

Rotor

Page

4.21

4.21

-GOOD■

BAD.

I

REPLACE

ROTOR

TEST

GOOD

TEST 41

Stator

REPLACE

STATOR

TEST.

Page

4.23

GOOD

CHECK WIRE

#14 '

[testI-

-BAD.

CHECK VOLTAGE

TO ROTOR

------------1------------BAD

_L_

CHECK #4 WIRE

FOR 12 VOLTS'

-----------

1

----------------

GOOD

I

REPLACE

PRINTED

CIRCUIT

BOARD

3.10

Issued 3-78

Page 22

DIAGNOSTIC TESTS

TEST 1 - l.S.AMP -FUSE

Remove and visually inspect the 15

amp fuse. A more thorough check may

be made with a Volt-Ohm-Milliammeter,

a_s foil o\vs :

1. Set VOM to ''+nC" and to ”Rxl”

scale.

2. Connect test probes together and

’’Zero" the meter.

3. Touch test probes to the fuse

ends - meter needle should swing up

scale and indicate "Zero” ohms. If

needle does not move upscale, replace

the fuse.

RESULTS: 1.) Fuse tests bad.............Install new 15 Amp Fuse

2.) Fuse tests good

...............................

.....Continue tests in "Diagnostic

4

Flow Charts", Section 3

TEST 2 - BATTERY

Check battery condition, as well as

the condition, cleanliness and sec

urity of battery cables and.connec

tions.

RESULTS: 1.) Battery, cables or connections

test bad.......................................

2.) Battery, cables and connections

test good

..................................................

.....Replace or repair the defec

tive component

Continue tests in "Diagnostic

Flow Charts", Section 3

Issued 3-78

4.1

Page 23

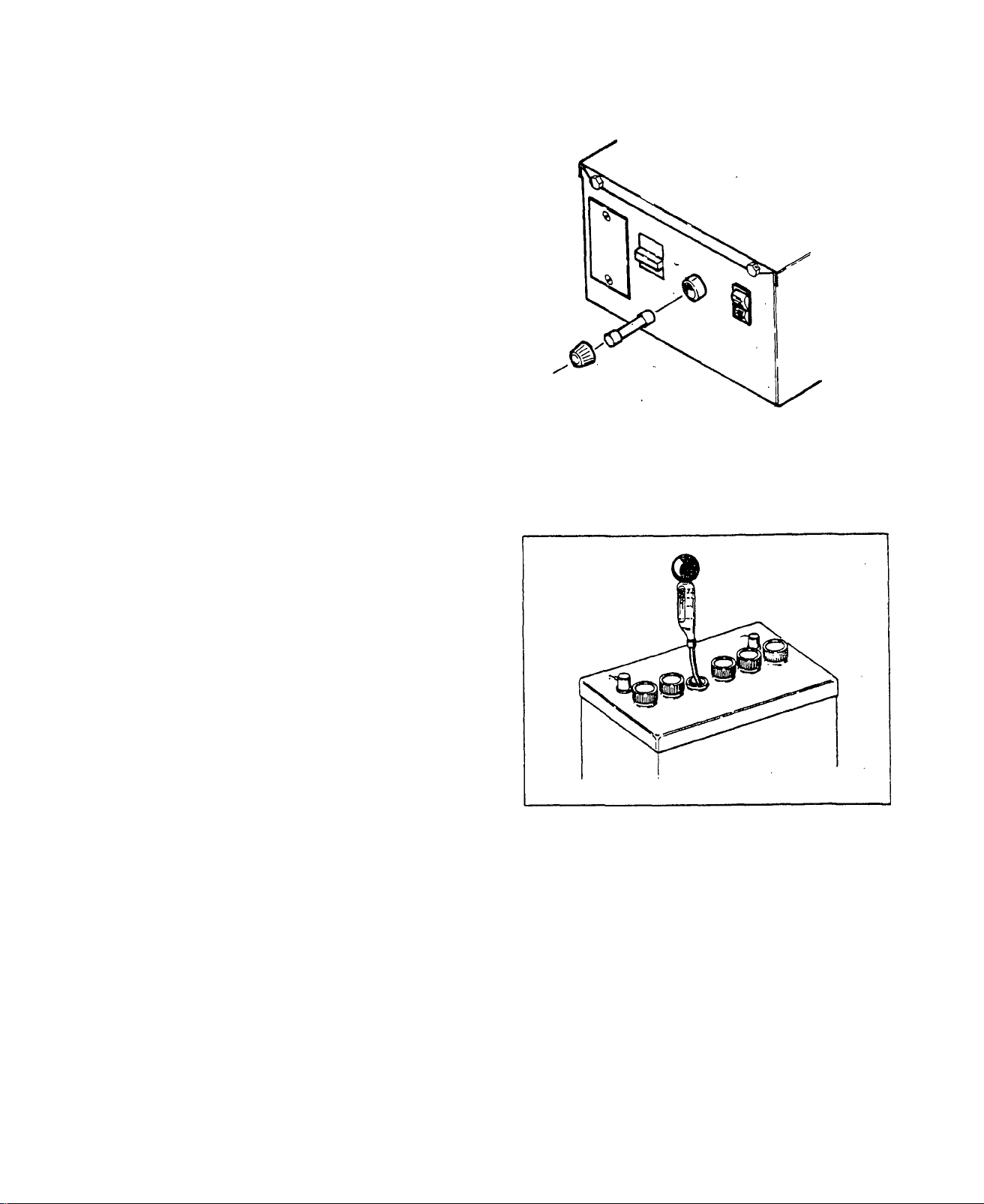

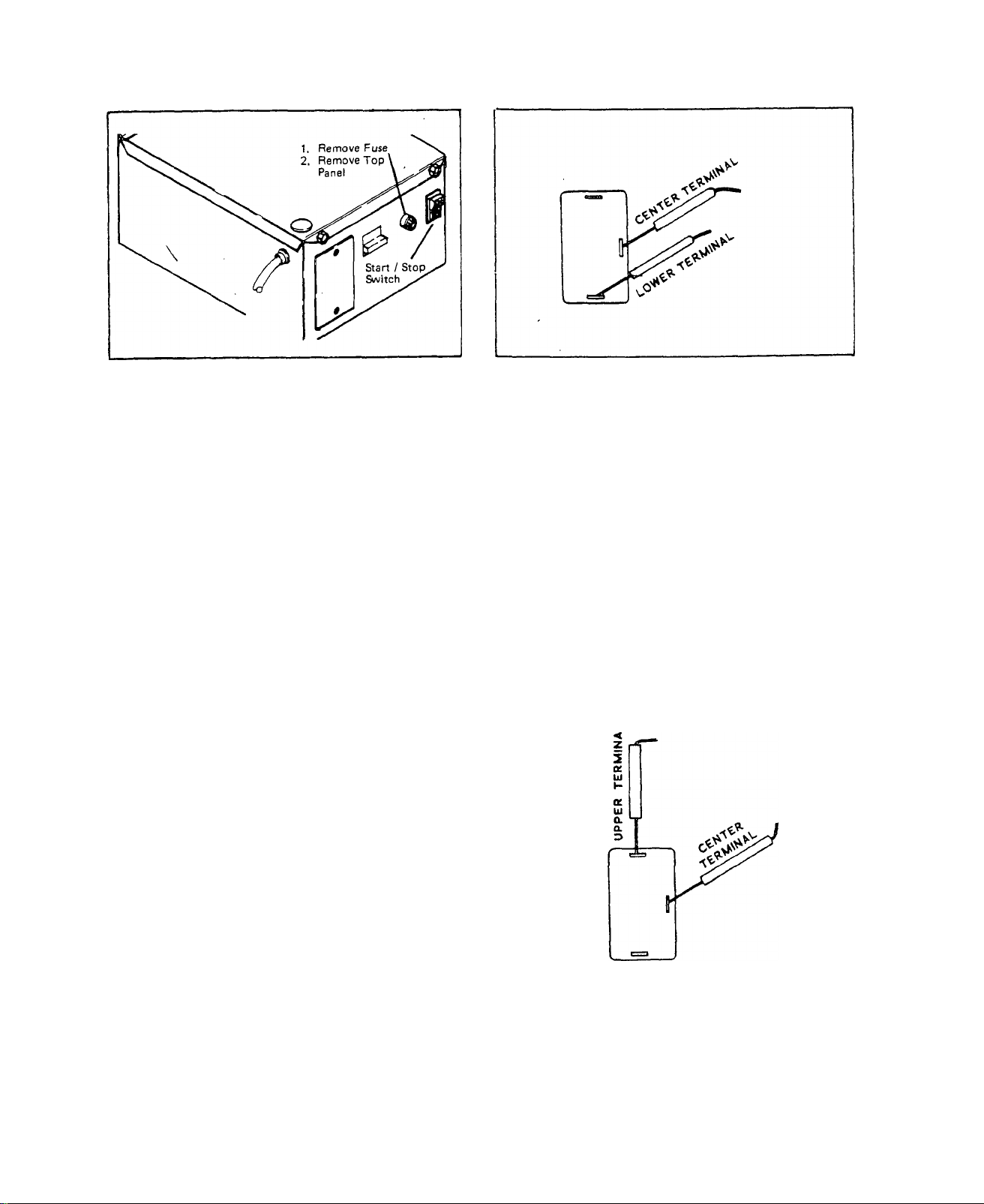

TEST 3 -START - STOP SWITCH

/^5

Remove the 15 amp Fuse to disconn

ect the starting circuit. Then re

move 2 screws that retain the top

panel. Finally, remove the top

panel.

RESULTS: 1.) Switch tests Bad..

2.) Switch tests Good.

Connect the VOM test probes to the

Switch terminals as shown at right.

Hold Start./Stop Switch at START meter needle should not move.

Set the switches of a Volt-Ohm-

Milliammeter to and to ''Rxl"

scale. Connect meter test probes

together and ”Zero" the meter.

Connect the meter test.probes to

the switch center and lower termi

nals, as shown above. Meter needle

should not move. Hold Switch at

STA.RT position - meter needle

should, move upscale, to "zero”.

Hold switch at STOP - meter needle

should drop all the way downscale

to "Infinity”.

.

......................

......................

Install a new switch

Continue tests

Release the Switch to NEUTRAL po

sition - the meter needle, should

not move.

Hold the Switch at STOP - the. meter

needle should swing upscale and. ind'

icate "zero" ohms.

RESULTS: 1.) Switch tests Bad..

2.) Switch tests Good.

4.2

.Install a new Sta.rt/Stop Switch

.Reconnect wires to Switch

Install top panel

Install 15 Amp Fuse

Continue Tests

Issued 3-78

Page 24

TES T 4 - STARTER SOLENOID

A.) Set the Start/Stop Switch to

START position and back to NEUTRAL

several times. An audible "click”

should be heard as the solenoid

actuates^

RESULTS: !.) Solenoid actuates, but

engine does not crank

...............................

Continue- ttst (Paragraph "B")

2.) Solenoid does not actuate,..Continue test (Paragraph "D")

B. ) Set VOM to "+DC" and to a scale greater than 12 Volts DC. Connect

the NEGATIVE (pr COMMON) test probe to. ground. Connect the POSITIVE (+)

test probe to the battery cable connection on the starter solenoid. The

meter needle should indicate 12 volts DC.

RESULTS: 1.) Meter reads 12 VoltsContinue test (Paragraph "C")

2.) Meter indicates less

than 12 Volts..............................................Check for open or shorted wire

or loose connections between

battery and starter solenoid

C. ) Connect POSITIVE (+) meter probe to starter cable connection on

starter solenoid. Connect NEGATIVE (or COMMON) test probe to ground.

Hold Start/Stop Switch at START - meter should indicate 12 volts DC.

RESULTS: 1.) Meter does not indicate

12 Volts...............................................

..Install new starter solenoid

2.) Meter reads 12 Volts and

solenoid checks good.......Continue tests in "Diagnostic

Flow Charts", Section 3

D. ) Set VOM to "+DC" so that 12 Volts can be read. Connect, meter POS

ITIVE (+) probe to one of the small terminals on the starter solenoid.

Connect the remaining test probe to ground. Meter should read.12. Volts.

With NEGATIVE (or COMMON) test probe still connected to ground, conn

ect POSITIVE (+) test probe to the other small terminal. Meter should

indicate 12 volts DC.

RESULTS.: 1.) Meter indicates 12. Volts

from BOTH small terminals

to ground

.............

Continue tests in. "Diagnostic

Flow Charts", Section 3

Meter does NOT read 12

2.)

Volts.........................................................Retest battery, 15 Amp Fuse

and Start/Stop Switch. Wlien

sure that these components

are good, and 12 volts is not

obtained from both small ter

minals, replace solenoid,

Issued 3-78

4.3

Page 25

TEST 5 - STARTED MOTOR

A.) Set VOM to ”+DC" and to a high

enough DC volts scale to permit

reading 12 volts. Connect the POS

ITIVE test probe to starter cable

connection at the starter. Connect

the NEGATIVE (or COMMON) test lead

to ground,then hold Start/Stop

Switch at START. Starter should

run and meter should read 12 Volts.

RESULTS: 1.) Meter, indicates .12.. Volts,

■ but starter does not run...... Replace starter

2.) Starter runs........................................................Continue tests in "Diagnostic

Flow Charts", Section 3

RESULTS: 1.) Starter motor can be heard

running without load,

L'OOCAOOOOO .Continue checks in Paragraph

IfRtt

'B

2.) Starter runs and cranks the

engine

.....................................................

...Continue tests in. "Diagnostic

Flow Charts", Section 3

B. ) Remove starter. Inspect pinion gear for damage or excessive wear,

RESULTS: 1.) Starter pinion gear damaged,

..................................................

2.) Starter Pinion gear is good,.................................................Continue test (Para

C. ) Without installing starter, connect starter cable from starter sol

enoid to starter terminal post. Hold Start/Stop Switch at START. The

starter pinion gear should move outward on the clutch.

4.4

Replace

graph C)

Issued 3-78

Page 26

RESULTS: 1.) Starter Pinion Gear does

not move outward.............................

2.) Pinion Gear does move out

ward.’

..................................................

TEST 7 - STARTER RING GEAR

A.) Inspect Starter Ring Gear for

damaged teeth.

.

.

Inspect helix on clutch for

freedom of operation. If

sticking due to dirt, clean

entire starter drive. If

any parts are damaged or

worn, replace.

.Continue tests in ’’Diagnos

tic Flow Charts", Section 3

RESULT: 1.^ Ring. Gear damaged,

2.) Ring Gear Good....

TEST 8 -CHECK SPARK

A.) Remove lead from one spark plug.

Connect the lead to Spark Plug test-

er,

plug tester clamp to a clean, paint-

free ground. Crank the engine - a

sharp, "snappy" spark should be seen.

Repeat the test for the remaining

spark plug. _______________________

NEVER crank the engine, with a spark

plug or spark plug lead removed, un

less the spark plug or.lead Is conn

ected to a clean ground. Failure to

ground the plug or lead can damag.e.

the ignition coil. _______________________________

Part No. 41503. Attach the spark

^CAUTION

.Replace

.Continue tests in "Diagnostic

Flow Chart", Section 3

RESULT: 1,)A sharp, snappy spark is NOT

observed...

2.)A sharp, snappy spark is ob

served.

........

...........................................

.....

..................................................

Issued 3-78

.Continue tests in "Diagnostic

Flow Charts", Section 3

.Continue tests in "Diagnostic

Flow Charts", Section 3 4^5

Page 27

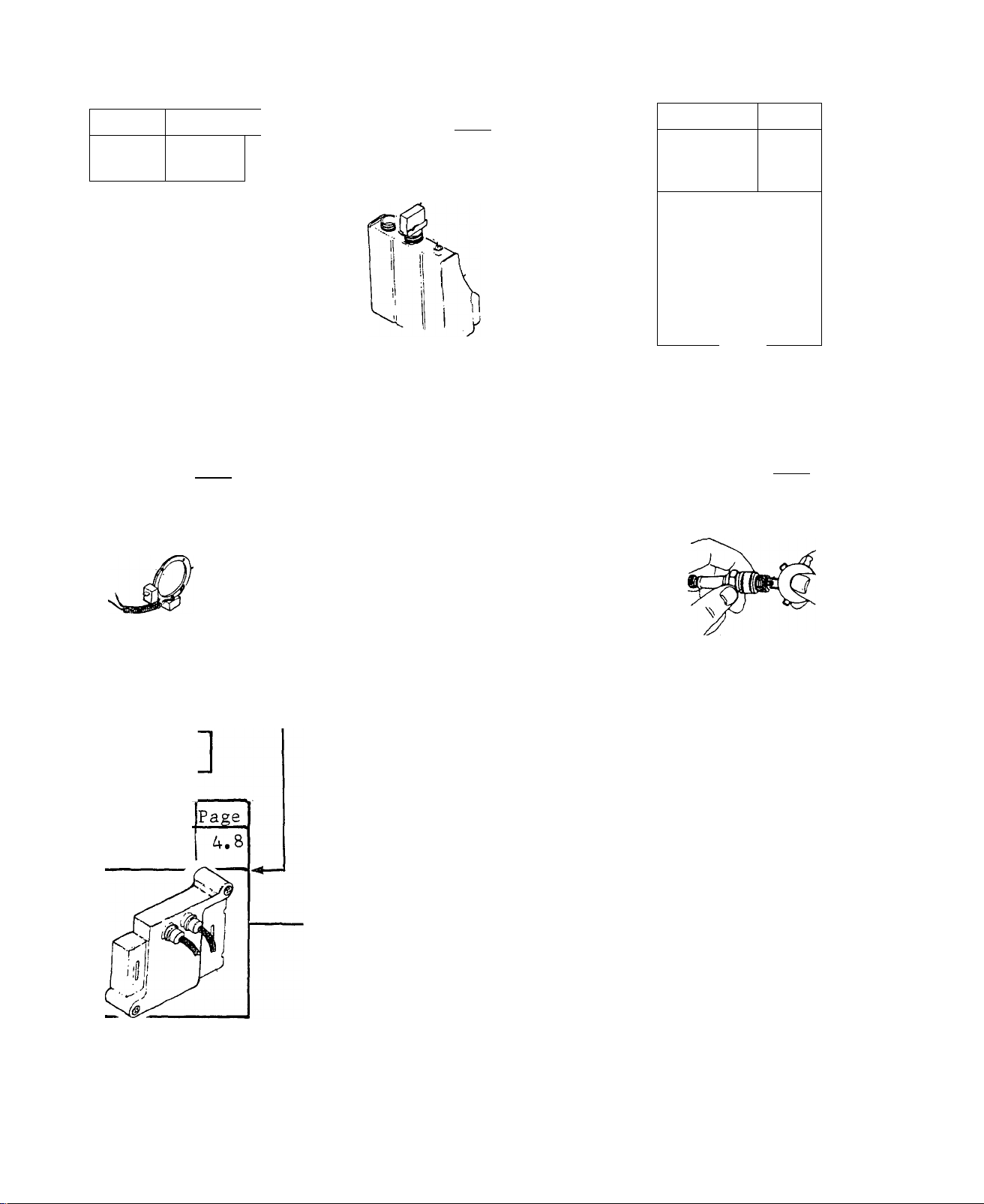

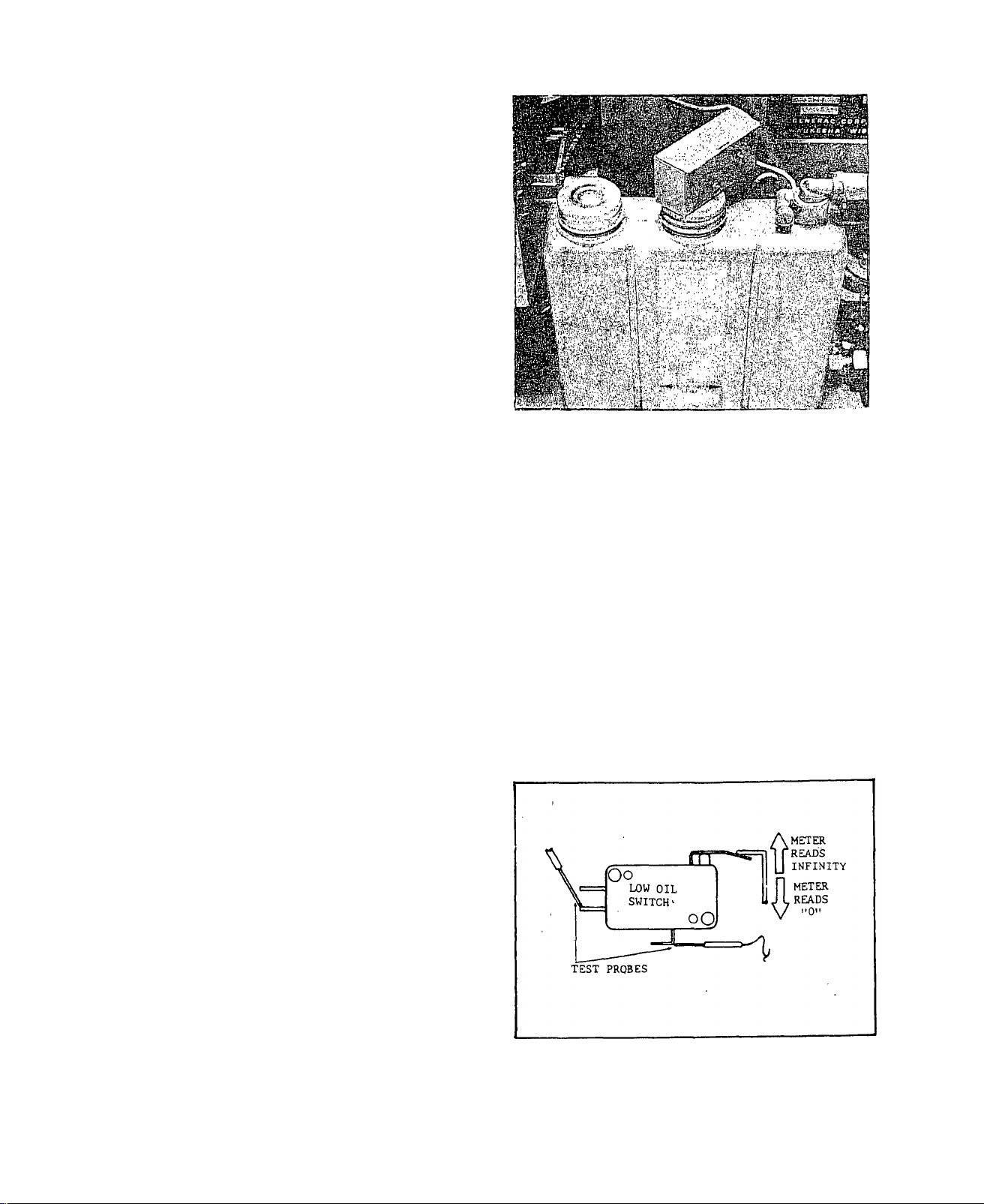

TEST 9 -OIL MAKE-UP TANK

A.) Check Oil level in Oil Make-up

Tank. If oil level is near OIL

CHANGE LEVEL arrows, refill tank

with same, type and grade of oil

used in engine crankcase.

RESULTS: 1.) Oil level LOW..

2.) Oil level.GOOD.

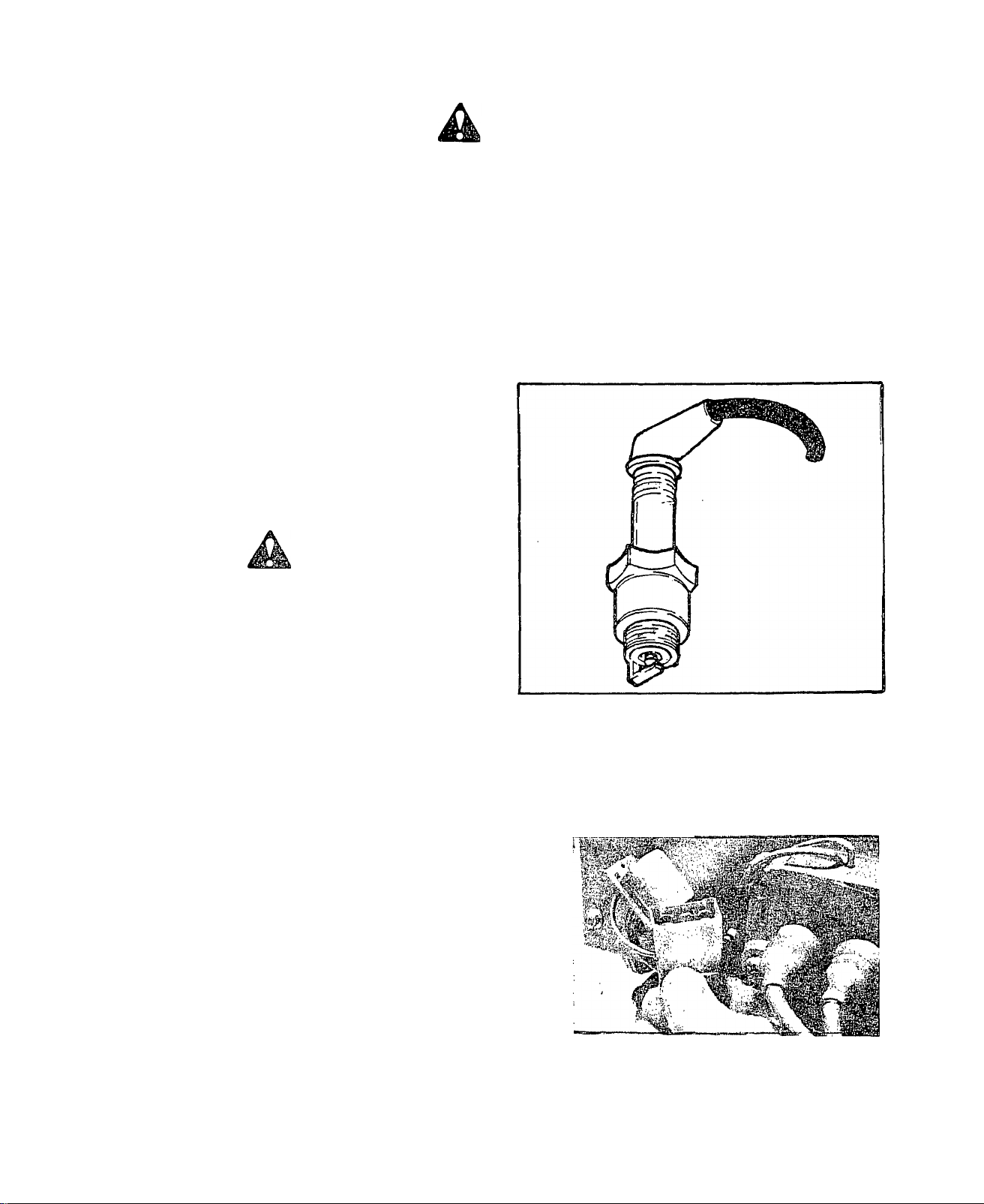

TEST 10 - LOW OIL SWITCH

A.) Remove one screw that retains the Low Oil Switch Cover. Move Cover

out of the way.

Set VOM to "+DC" and to "Rxl" scale. Connect meter test probes and zero

the meter. Connect one meter test probe to lower left switch terminal

and remaining probe to ground terminal (bottom of switch). With switch

actuating lever DOWN (low oil condition), meter needle should swing up

scale to "Zero". If meter

A.) Remove one screw that retains the Low Oil Switch Cover. Move Cover

out of the way to.expose switch terminals.

Set VOM to "+DC" and to "Rxl"

scale. Connect meter test probes

and "zero" thé meter. Connect

one test probe to lower left

switch terminal. Connect remain

ing test probe to ground. With

switch actuating lever DOWN (low

oil level), meter needle should

swing upscale to "zero". With

switch actuating lever UP (norm

al oil level), meter needle should

drop all the way downscale to

"infinity". MAKE SURE GROUND WIRE

BETWEEN SWITCH BOTTOM TERMINAL AND OIL FILLER. NECK BRACKET SCREW IS

TIGHT.

.Refill tank

.Continue tests in "Diagnostic

Flow Charts", Section 3

4.» 6

Issued 3-78

Page 28

CAUTION

Before installing Low Oil Switch Cover, make sure the float arm is

riding on top of the switch actuating lever. If float arm has dropped

off of switch actuating lever, engine will not shut down when oil

level in tank is low.

RESULTS:.!.) Switch tests Bad

2.) Switch tests.Good...............Continue tests in "Diag

TEST 11 -SPARK PLUG

A,) Remove one spark plug. Connect

spark plug wire to plug. Ground

spark plug against engine. Hold

Start/Stop Switch at START and ob

serve spark plug. A sharp, snappy

spark should be seen. Repeat test

for second spark plug.

CAUTION

NEVER crank engine with a spark

plug or spark plug wire removed,

unless the spark plug or wire is

connected to a clean ground.

Failure to ground the plug or

lead can damage the Ignition coil,

............................................................

Replace Switch

nostic Flow Charts", Sec

tion 3

RESULTS: 1.) Sharp, snappy spark is

NOT observed.

2.) Sharp, snappy spark IS

observed,.

Test 12 - IGNITION MODULE “

A.) Unplug the Ignition Module

from its receptacle. Inspect the

connector pins in the module and

module receptacle - make sure

the pins are not bent or pushed

in. Install a new (or "shop") ig

nition module and check for norm

al spark.

RESULTS: 1.) Normal "hot" sparking...................................................Install a new Ignition

2.) Normal sparking NOT observed.... Continue tests in"Diagnos-

.........

....

........................................

......

.................................................................. .Continue tests in

.Replace spark plug

"Diagnostic* Flow

Charts", Section 3

Module, continue tests

tic Flow Charts", Section 3

Issued 3-78

Page 29

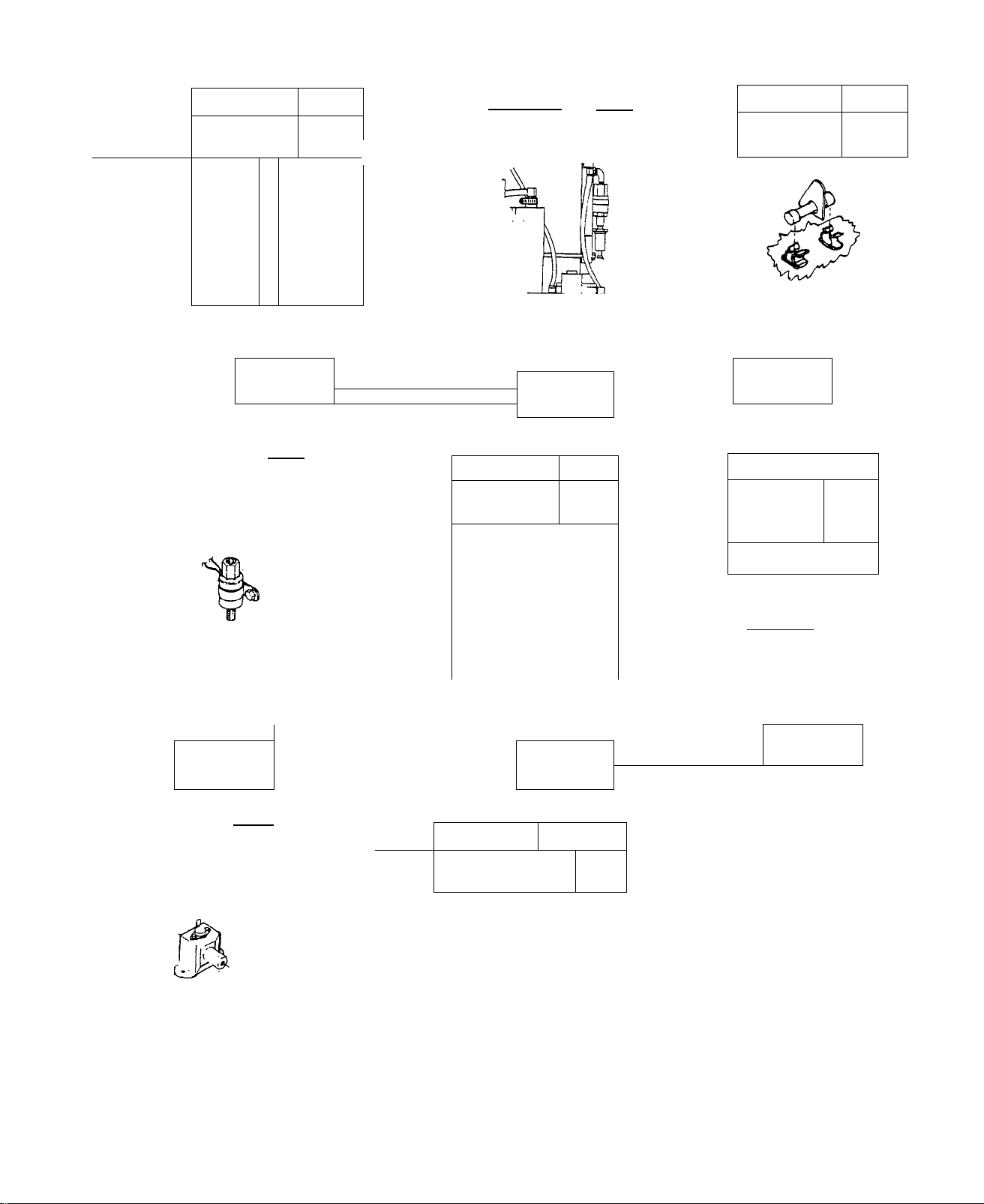

TEST 13 - IGNITION STATOR

A.) Remove the wire nut from Wire

No. 20.at the Low Oil Switch. Dis

connect the wire, to prevent inter

action. Then proceed a.s. follows:

^

a. Set VOM to ”Rxl00" and to ”+DC”.

Zero the meter. Connect one meter

^ A test probe to Pin No. 2 of the Ig-

cJwoj/nition Module receptacle. Connect

the second test probe to ground.

^v> Meter needle, should swing upscale

R^-^j^nd read appro.ximately 225 Ohms

(+10'^°)* This is the Ignition State

Charge Coil resistance.

RESULTS: 1.) Tests Bad

.......................................

2.) Tests Good

Reconnect Wire No. 20 at the

fore proceeding to next test

TEST 14 - IGNITION COIL

Set

A.)

MT

n

’+DC", then zero the meter. Conn

to "Rxl" scale and to

VOM

ect one meter test probe to Pin 4

of the Ignition Module receptacle.

Connect the remaining test probe

to Ignition Module receptacle Pin

1. Meter needle should swing up

scale and indicate the Ignition

Coil primary winding resistance

(about 0.5 Ohms).

.......................

b. S'et the VOM to ”+DC" and to ’’Rxl”

scale. Again zero the meter. Connect

one meter test probe to Ignition

Module receptacle Pin No. 3, and the

second probe to ground. Meter needle

should swing upscale and,read approx

imately 6 Ohms. This is the Ignition

Stator Trigger Coil resistance.

.

...........

,Install new Ignition Stator

.Continue tests in "Diagnostic

Flow Chart", section 3

Low Oil Switch and retain with wire nut be-

, Also install Ignition Module,.

4.8

Issued 3-78

Page 30

RESULTS: 1.) Checks BAD................................................Replace Ignition Coil

2.) Checks Good...........................................Continue with Paragraph "B"

B.) Set VOM to "RxlOO" scale and zero

the meter. Unplug both spark plug

wires from Ignition Coil, and in

sert the two meter test probes as

shown. Meter needle should indicate

secondary winding resistance, about

6500 ohms.

RESULTS: 1.) Checks Bad.............Replace. Ignition Coil

2.) Checks Good...

................................

Continue with Paragraph "C"

C.) Set VOM to ”Rxl0,000" scale and zero the meter. Connect one

meter test probe to Ignition Coil as in Paragraph ”B”, but conn

ect the second probe to ground. Meter needle shonld not swing

upscale (infinity).

RESULTS: 1.) Meter swings upscale.... Replace Ignition Coil

TEST

2.) Meter does not move

15 -LOW FUEL LEVEL

...........................

A.) Check fuel level in gas. tank.

The vehicle engine fuel pickup

tube in the tank, is usually sev

eral inches longer than the alter

nator pickup tube. This means that,

even if adequate fuel is available

for vehicle engine operation, the

fuel may be below the alternator fuel

pickup tube.

Continue with tests in

"Diagnostic Flow Charts",

Section 3

To Vehicle

Engine

Fuel

Tankik p

\1

Installation Of Second

Fuel Pick Up Tube In

Tank Outlet.

To Alternator

Engine

Pipe

Nipple

Variable

Potentiometer ^

_L

\ Anti-Siphon

■^Holes

1'

3 in.

♦

Pipe Cap

To Alternator

Engine

3 In

Fuel Pickup/Float

B.

Assembly

To Vehicle

Engine

Fuel Gauge

Connection

Fuel

Quantity

Float

Issued 3-78

4.9

Page 31

TEST 16 -NO FUEL FLOW

At carburetor inlet, spread clamp

and slide it down the fuel inlet

hose. Disconnect the hose from in

let fitting - BE CAREFUL NOT TO

BREAK THE FITTING. Hold open end

of fuel hose over a suitable con

tainer. Hold Start/Stop Switch,at

START to crank engine. Check for

fuel flow from fuel inlet hose.

DANGER

A’

Gasoline vapors are highly flammable and. explosive. Do not Jbermit

smoking, open flame or sparks in the vicinity while checking for

fuel flow.

RESULTS: 1.) Fuel.. Flow Bad.............................................

2.) Fuel Flow Good

TEST 17-4 AMP FUSE

A.) Remove 15 Amp fuse to disconn

ect starting, circuit. Remove the

2 screws that retain the top panel.

Remove the top panel.

........................................

B.) Remove the 4 Amp Fuse from the

Printed Circuit Board. Check visu

ally for an open fuse element. Set

VOM to "+DC" and to "Rxl" scale.

Zero the meter. Connect meter test

probes to both ends of fuse. Meter

needle should swing upscale and in

dicate "zero".

Continue tests in "Diagnostic

Flow Charts", Section 3

Continue tests in "Diagnostic

Flow Charts", Section 3

RESULTS: 1.) Fuse checks Good

2.) Fuse checks Bad..................................Replace Fuse

4.10

...................................

Continue tests in

Diagnostic Flow Charts"

Section 3

Issued 3-78

Page 32

TEST 18 - PRINTED CIRCUIT BOARD

A.) Depress locking tangs of Print

ed Circuit Board connector plug and

disconnect plug from its receptacle.

On the connector plug, locate Pin #

4 to which Wire #20 attaches. Set

the VOM switches to ’.’AC" and to 2,5

Volts, Connect one VOM test probe to

Connector plug Pin #4 and the other

test probe to ground. Crank the eng

ine - Tneter needle should swing up

scale and indicate approximately 0,5

volts AC (pulsing voltage),

RESULTS: 1,) Meter indicates 0,5 Volts

2,) Meter does not indicate,,

0,5 volts

B.) Plug printed circuit board

connector plug in. Locate Wire

#14 connection at terminal strip.

Set VOM to "+DC" and to ''50V'

scale. Connect POSITIVE (+) meter

test probe to terminal strip wire

#14 connection and other test

probe to ground. Crank the engine.

Meter should indicate battery vol

tage (9-12 volts DC),

RESULTS: 1,) Meter indicated 12 volts,

2,) Meter did NOT indicate,,.

12 volts

TEST 19 - FUEL FILTER

,Go to Paragraph ”B”

.Check Wire #20 between Print

ed Circuit Board and Terminal

Strip, and between Terminal

Strip and Ignition Module for

open or shorted condition.

• Continue tests in ’’Diagnostic

Flow Charts”, Section 3

Check Wire. #14 between Terminal

Strip and Printed Circuit Board

for open or shorted condition.

If not open or shorted, replace

Printed Circuit Board,

#

Remove and replace the In-Line

Fuel Filter, Make sure arrow on

Fuel Filter points towards the

solenoid-operated Fuel Shutoff

Valve, Repeat TEST 16 on Page

4.10 (No Fuel Flow).

Issued 3-78

Page 33

RESULTS: 1.) Fuel Flow Good,

engine still won't start

2. ) Fuel Flow Bad

........................................................

............................................

3. ) Fuel Flow Good and engine

starts..........................Repair completed,

TEST 20 - FUEL SHUTOFF SOLENOID

A.) Disconnect Fuel Shutoff Solenoid

Wire #14 at the Fuel Pump terminal.

Crank the engine for 2 or 3 seconds,

then touch the terminal end of Wire

#14 to the Fuel Pump terminal. Fuel

Shutoff Solenoid should actuate and

sound of Fuel Pump should change not

iceably.

RESULTS; 1.) Fuel Shutoff Solenoid did

not actuate

............................................

2.) Fuel Shutoff Solenoid

actuated

................................................

Go to TEST 23

Go to TEST 20

dis-

continue tests

•Replace Fuel Shutoff Solenoid

.Continue tests in "Diagnostic

Flow Charts", Section 3

TEST 21 - FUEL PUMP

A.) Disconnect BOTH Wires #14 at the

Fuel Pump terminal. Set VOM to "+DC"

and to "Rxl" scale. Zero the meter.

Connect one meter test probe to the

Fuel Pump connection terminal and the

remaining test probe to ground. Meter

needle should swing upscale and read

approximately 50 Ohms.

RESULTS: 1») Pump tests Good

................................................

Go to-Paragraph "B"

2.) Pump tests Bad^..............................................Replace Fuel Pump

B.) Reconnect both Wires #14 to Fuel Pump connection terminal,

engine and listen for sound of fuel pump.

RESULTS: 1.) Pump does not pulse.......................................Go to Paragraph "C"

2.) Pump pulses normally

............................

..Continue tests in "Diagnostic

Flow Charts", Section 3

Crank the

4.12

Issued 3-78

Page 34

•C.) Disconnect Wire #14 at Fuel Pump

terminal. Set VOM to ”+DC” and to 50

Volt scale. Connect the POSITIVE (+)

meter test probe to the terminal end

of Wire #14. Connect the COMMON test

probe to ground. Crank the engine -

meter needle should deflect upscale

and indicate battery voltage (about

12 volts DC).

RESULTS: 1.) Meter does NOT read 12 volts............................................*...Go to Paragraph ”D’

2.) Meter indicates 12 volts, but pump

does not pulse when Wire #14 is

connected to its terminal.'......................................................Replace Fuel Pump

D,) Check Wire #14, between the Fuel

Pump and terminal strip in control

panel, for open or shorted condition.

RESULTS: 1.) Wire #14 checks Good

2.) Wire #14 checks Bad..................................................Repair/Replace Wire #14

TEST 22 -CHECK INSTALLATION

Does the installation include a second in-line fuel filter? If so,, check

the filter for clogging. If a shutoff valve is installed in the fuel

supply line, make sure the valve is open. Finally, make sure the air in

let opening in the door is large enough. An insufficient supply of cool

ing air will result in high compartment temperatures and possible fuel

line vapor lock. Refer to INSTALLATION MANUAL, RECREATIONAL VEHICLE ALT

ERNATORS (Part No. 49204).

...................................................

Continue tests in”Diagnos-

Issued 3-78

tic Flow Charts", Section 3

4.13

Page 35

TEST 23 - CARBURETOR

Ad just Jets: Turn Needle Valve

clockwise until it just closes DO NOT TURN IN TOO FAR, OR JET

MAY BE DAMAGED. Then open needle

valve l\ turns (counterclockwise).

Close Idle Valve in same manner,

then open 1^ turns. This initial

adjustment will permit the engine

to be started and warmed up.

With engine running, hold the throttle lever against the Idle Stop. Set

the Idle Speed Adjusting Screw to obtain 1400 rpm. Turn Idle Valve SLOW

LY clockwise to obtain 1400 rpm, 93 volts AC, or 46 Hz. Then turn Idle

Valve SLOWLY clockwise (lean mixture) until engine misses or engine

speed slows. Finally, turn Idle Valve one-half turn counterclockwise.

Hold throttle lever against idle

stop and turn Idle Speed Adjust

ing Screw to obtain 900 rpm (30

Hertz or 60 Volts a-c). Then bend

Governed Idle Tab (see illustrat

ion at right) to obtain 1400 rpm

(93 Volts a-c or 46 Hertz).

___________________

NOTE

Governed idle must be adjusted

for proper operation. The smaller

spring keeps the engine on govern

nor, even at idle speed. Idle

speed should not be lower then

1100 rpm, 73 volts or 37 Hz.

Release throttle lever and let'engine accelerate to governed speed.

Apply a load to the alternator, between'3000 and 4500 watts. Turn

Needle valve SLOWLY clockwise (lean mixture) until voltage reading

starts to drop off. Then turn Needle Valve counterclockwise until

the highest voltage reading is obtained. When the highest voltage

is obtained, turn the Needle Valve counterclockwise an additional

1/8 of a turn.

Check Float Valve and Seat; Refer to engine section of this Manual

for procedures. Inspect float valve and its seat for damage, dirt

or wear.

Check Float Level; Refer to engine section of this Manual for pro

cedures .

4.14

Issued, 3-78

Page 36

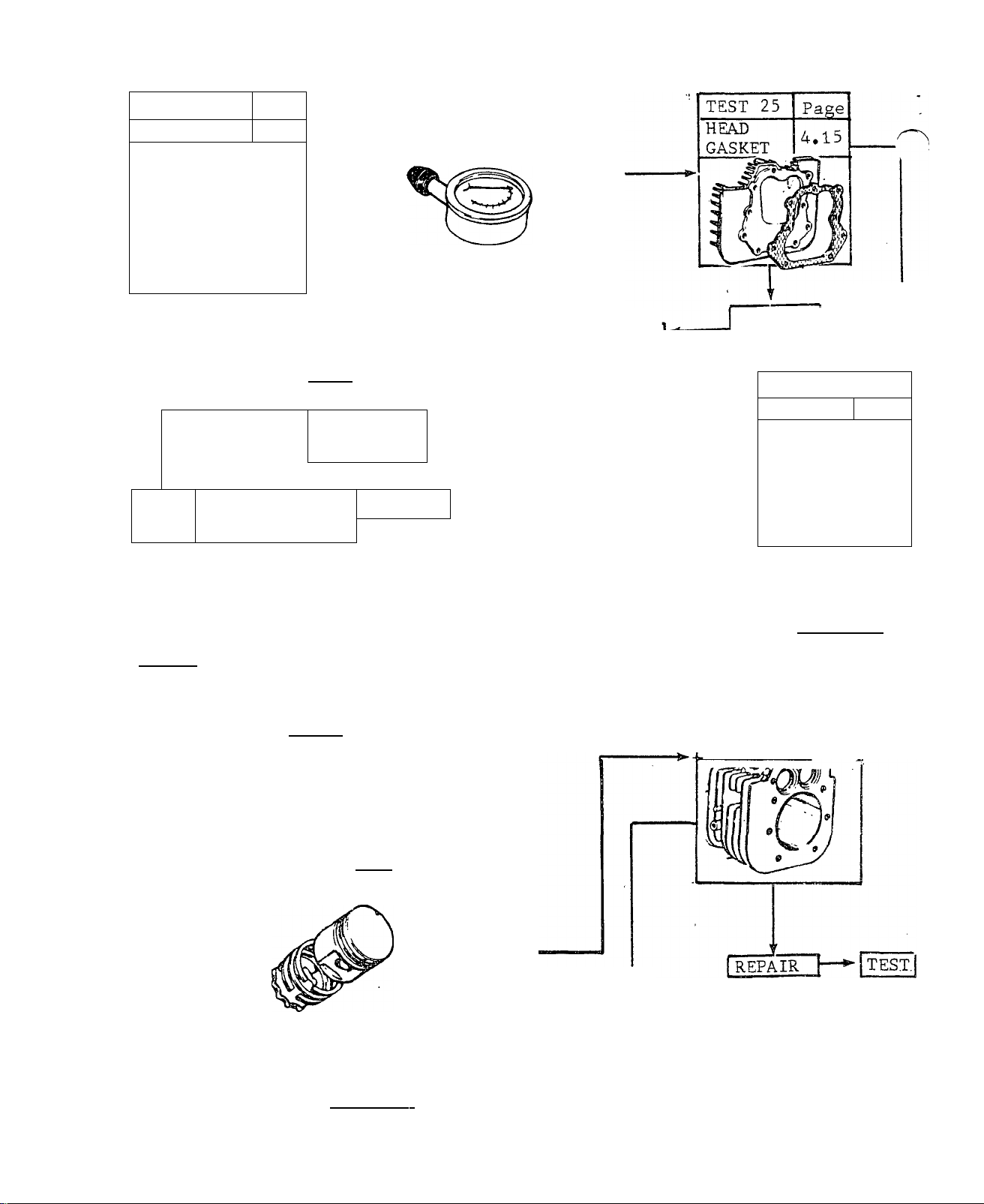

TEST 24 - COMPRESSION

A. ) Use a standard compression gauge.

Insert end of gauge into spark plug

hole. Open throttle wide open and

crank the engine. Repeat compression

check for second cylinder. There

should be no more than a 25 per cent

difference in compression between

the two cylinders. A greater pressure

difference indicates loss of compress

ion.

COMPRESSION

GAUGE

SPARK PLUG

REMOVED

RESULTS: 1.) Compression Low

...........................

Paragraph ’’B”

2.) Compression Good....Go to

Test 29

B. ) Squirt a few drops of oil into the

spark plug opening of one cylinder.

Repeat compression Test of Paragraph

’’A” above. If compression is higher

than was obtained in "A”, RING or CYL

INDER wear is indicated. If little or

no difference in compression is noted,

compression loss is due to a leaking

HEAD GASKET, FAULTY VALVES, etc.

Repeat Paragraph "B" for second cylinder,

RESULTS: 1.) Compression Increased,.Go

to Test 27 and 28

2.) No increase

........................................

to Tests 25 and 26

TEST 25 HEAD GASKET

Go to

Go

#

Refer to ENGINE REPAIR section of this Manual.

TEST 26 VALVES

Refer to ENGINE REPAIR section of this Manual.

TEST 27 RINGS

Refer to ENGINE REPAIR section of this Manual.

TEST 28 CYLINDER

Refer to ENGINE REPAIR section of this Manual.

Issued 3-78

4.15

Page 37

TEST 30 CHOKE

A.) Hold the Start/Stop Switch at

START position and crank engine.

While the engine is cranking, the

Choke Solenoid should pulse., the

choke from a ”No-Choke” to a

’’Choke’’ position, at a rate dep

endent on ambient temperature.

RESULTS: 1.) Choke Movement Good

2.) Choke does not move

B.) Inspect the Choke Assembly and Linkage for binding caused by im

proper choke support alignment, dirt, etcJ Push the Choke back and

forth with your finger - no mechanical binding or sticking should be

observed.

RESULTS; 1.) Choke is Binding.........................................Adjust or clean choke linkage

Choke moves freely

C.) Loosen the two solenoid adjusting screws. Adjust solenoid axial

movement so that, with the carburetor choke valve closed, the choke

solenoid plunger is bottomed. Tighten the two adjusting screws, and

check again for correct choke action.

RESULTS; 1.) Solenoid pulls in normally

2.) Solenoid does not operate normally...Go to Paragraph ”D”

D.) A small 2-wire disconnect is located adjacent to the Choke assembly.

Wire #90, from the Printed Circuit Board to the Choke Solenoid, and

Wire #14, from the Printed Circuit Board to the Choke Bi-Metal, can be

disconnected here. The following test is a check of the Printed Circuit

Board, which governs Choke pulsing action.,

............................................

...........................................

............................

...................................................

Go to Paragraph ”C” •

Go to Test 31

Go to Paragraph ”B”

Go to Test 31

CAUTION

The VOM positive (+) test probe MUST be connected to the Wire #90

pin on the FEMALE half of the disconnect. This is wire #90 from the

Printed Circuit Board. DO NOT connect the test probe to the male

half of the disconnect (wire. #90 from the Choke Solenoid). Wire #

90, from the Choke Solenoid to the male half of the disconnect, is

HOT while the engine is being cranked. Connection of the VOM to the

Wire #90 MALE disconnect pin will seriously damage the meter as

soon as the engine is cranked.

4.16

Issued 6-78

Page 38

Unplug the mating halves of the

small disconnect. Locate the male

and female pins that connect Wire

#90 from the Choke SOLENOID (NOT

from the Choke Bi-Metal). Set the

VOM to ”+.DC” and to ”Rxl” scale,

then zero the meter. Connect the

POSITIVE (+) meter test probe to

the FEMALE Wire #90 pin, NOT TO

THE MALE WIRE #90 PIN. Connect the

common (-) test probe to ground.

Crank the engine. Meter needle

should swing upscale, then drop

downscale in a pulsing cycle.

RESULTS: 1.) Meter needle does NOT move

2.) Check is Good, but on sub

sequent tests Choke does not

operate normally

TEST 31 PRE-CHOKE

A.) With the Choke Bi-Metal cold

(ambient temperature)., the carbu

retor Choke Valve should be app

roximately 1/8 inch away from its

vertical position, and towards a

CHOKE position. If necessary,

loosen the Bi-Metal, adjusting

screws and move the Bi-Metal to

obtain this setting. This is the

"Pre-Choke” position.

TEST 32 GOVERNOR

..................................

................

..Replace Printed Circuit Board

Replace Choke Assembly

A.) Adjust Carburetor jets and Governed Idle as outlined in Test 23,

CARBURETOR. These adjustments must be completed before attempting to

adjust the Governor.

RESULTS: 1.) Problem, is corrected.....................................................................Test Completed

2.) Engine "hunts" ,and/or AC Voltage

or Frequency is incorrect...........................................Go to Paragraph "B"

Issued 6-78

4.17

Page 39

B.) Loosen Governor Lever Nut,

Push Governor Lever all the way

counterclockwise to open thrott

le wide open. Hold the Governor

Lever in this position, then ro

tate the Governor shaft all the

way counterclockwise, as far as

it will go. Tighten the Governor

Lever Nut to 100 inch-pounds.

RESULTS: 1.) Engine runs normal, provides

62 Hz at "No-Load"..............................................................Test Completed

2.) Engine "hunts" and/or AC Voltage

or Frequency is incorrect......................................................Go to Paragraph "C"

C.) With engine running, turn

Governor Adjusting Nut to ob

tain 62 Hz at "No-Load".

Governor tab should be bent to

apply slight tension to governed

idle spring at 1860 rpm (62 Hz

or 124 volts), with no electrical

loads applied. Spring should be

loose when loads are applied.

Governed

IdleTang

Governor

Shaft

Governor

Lever Nut Governor

Lever

;

Idle Speed

Adjustment Screw

Carburetor Body

Throttle Lever/

Governor Adjustincj Nut

NOTE

The Governed Idle spring, prevents engine speed surging and "hunting"

during "No-Load" conditions. When an electrical load is applied, the

spring will normally become loose and ineffective.

TEST 33 FREQUENCY

A.) Use an accurate Frequency Meter to check alternator output frequen

cy. The Model 5515 Load Bank is equipped with a frequency meter, as well

as provisions for reading voltage and amperage. Frequency should be 63

Hz (63 cps) at "no-load". With an electrical, load applied, frequency

should be 59-63 Hz and stable. (All mechanical governors have a normal

ffspeed" fluctuation, which is the reaction time of the governor.)

'o

RESULTS: 1.) Frequency checks Bad

......................................

Continue tests in "Diagnostic

Flow Charts", Section 3

2.) Fi'equency Checks Good

...............................

Continue tests in "Diagnostic

Flow Charts", Section 3

4.18

Issued 6-78

Page 40

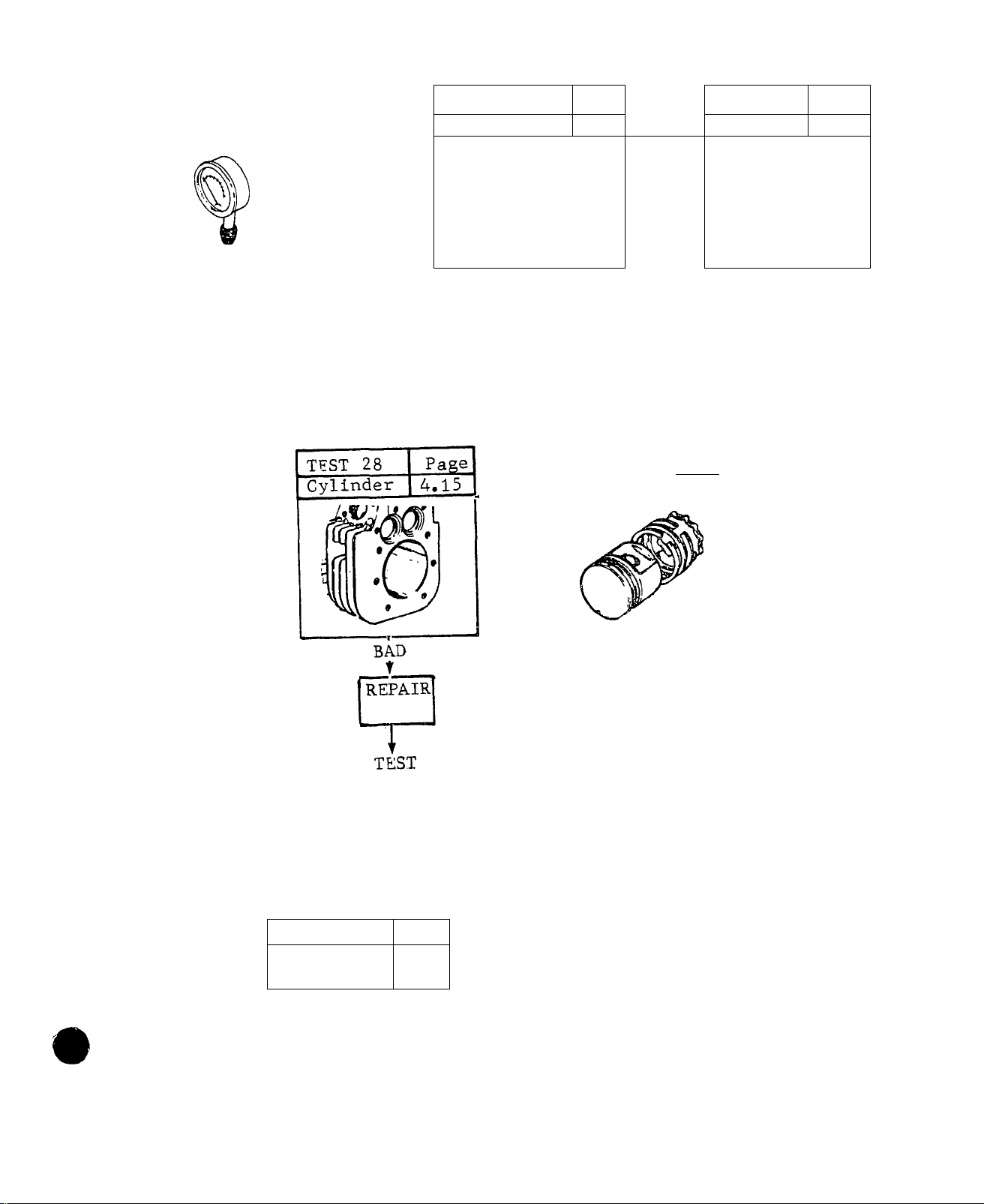

TEST 34 - EXCITATION WINDINGS

A. .) Remove Control Panel top cover.

Locate the white connector plug at

the rear of the panel. Unplug the

connector from its receptacle. Set

VOM to '’+DC” and to ”Rxl" scale,

then zero the meter. Connect one

meter test probe to receptacle pin

#2. Connect the second test probe

to receptacle pin #6. Meter needle

should swing upscale and indicate

about 1.8 to 2.5.ohms. This is the

resistance of the stator excitation

winding..

RESULTS: 1.), Windings check Bad.

2.) Windings check Good

....................................................................

.............................

.....................................Continue tests in

''Diagnostic Flow Charts", Section 3

B. ) Set the. meter swLtches ..to "+DC!' and to "Rxl0,000" scale. Zero the

meter. Connect one teat, probe to white receptacle pin #2, and the other

test probe to ground. Meter needle should not move.

RESULTS: 1.) Meter needle swings upscale

2.) Meter needle does not move

..............................................

..................................................

...Replace stator

"Diagnostic Flow Charts", Section 3

TEST 35 - CARBON BUILDUP

A.) Excessive carbo.n buildup in the engine combustion chamber can ser

iously affect engine power. Carbon deposits should be removed every

500 hours of operation, or whenever the cylinder heads are removed. If

engines are run at a steady load, it may be necessary to remove carbon

more often. Refer to ENGINE REPAIR section of this Manual for cylinder

head removal and installation procedures. When reinstalling cylinder

heads, bolts must be installed in the proper location on the head and

the cylinder head must.be properly torqued.

Replace Stator

Continue tests in

TEST 36 - OUTPUT VOLTAGE

A,.) Use an accurate voltmeter or

the Model 5515 Load Bank to check

output voltage. When using a volt

meter, connect one meter test

probe to alternator output lead T1

and the remaining test probe to 2

output leads T2. Voltage should he.

approximatel.y 125 volts at "no-load",

and.115 - 125 volts AC under load.If

voltage checks good, check frequency.

Issued 6-78

4.19

Page 41

TEST 37 - SENSING TRANSFORMER

Either of 2 Sensing Transformers may be used. I4ien checking Transform

er windings for an open condition, resistance readings obtained should

be as shown in the following CHART:

TRANSFORMER

MAKE

WesCoil

CoilTran

RESIS.TANCE [in OHMS)

Primary Secondary

745-825

824-1114

1603 - 2169

1222 - 1654

A.) Remove wire nuts that retain

wires #11 and #22, between the

Transformer and Voltage Regulator

Disconnect the wires. Set VOM to

”+DC’ and to ’’RxlOO” scale. Zero

the meter. Connect one meter test

probe to Wire #11, and the second

test probe to Wire #22. Meter

needle should swing upscale and

indicate resistance for SECONDARY

Sensing

Transformer

With Wires To

Secondary

Winding

winding.

RESULTS: 1.) Checks Good.

Continue tes.ts in "Diagnos

tic Flow Charts", Section 3

2,) Checks Bad..

.Replace Sensing Transformer

B. ) Set VOM to "+DC" and to "Rxl0,000" scale. Zero the meter. Connect

one meter test probe to Wire #11. Connect the second test probe to

Ground. Meter needle should NOT move. Any needle movement indicates a

shorted condition.

White ' Pin No. 5

Receptacle

Pins No. 3 and

No. 5 to Primary

Winding of

Transformer

---------------

RESULTS: 1.) Tests Good....

...............................................................

Continue tests in "Diag

nostic Flow Charts"

2.) Tests Bad...................................................................Replace Transformer

C. ) Unplug the white connector plug from its receptacle. Set the VOM

to "+DC" and to "RxlOO" scale. Zero the meter. Connect one meter test

probe to White receptacle Pin #3. Connect the second test probe to

white receptacle Pin #5. Meter needle should swing upscale and indic

ate resistance shown in CHART for PRIMARY winding,

RESULTS: 1.) Tests Good......................................................Continue tests in "Diagnostic

Flow Charts", Section 3

2.) Tests Bad

...................................................

Replace Transformer

D. ) Set VOM to "+DC" and to "Rxl0,000" scade. Zero the meter. Connect

one meter test probe to white receptacle Pin #3. Connect the remain

ing test probe to Ground. .Meter.needle should not move.Any movement

of the needle indicates a shorted condition.

RESULTS. 1.) Tests Good......................................................Continue tests in "Diagnostic

Flow Charts", Section 3

2.) Tests Bad

....................................................

Replace Transformer

4o20 Issued 6-78

Page 42

TEST 38 - MAIN CIRCUIT BREAKER

NOTE

If the alternator has. been re.eonnected to provide a dual voltage

of 120 and 240 volts, the Main Circuit Breaker will be disconnec

ted from the circuit. See WIRING DIAGRAMS, Section 2.

A.) Disconnect wires from Main

Circuit Breaker terminals ”A" and

”B", to prevent interaction. Set

VOM to "-)-DC" and to "Rxl" scale.

Zero the meter. Connect one meter

test probe to Terminal ”A" and

one probe to Terminal . ”B’.', With

the Circuit Breaker ON, meter

needle should swing upscale and

indicate ZERO ohms. With Breaker

OFF, meter needle, should drop all

the way downscale to !.'Infinity”,

TEST 39 - ROTOR

A.) Use a ^ inch nut driver to re

move the No. 8-32 screw that reta

ins the Brush Inspection Cover to

the Rear Bearing Carrier. Remove

the Brush Inspection Cover, Set a

VOM to "Rxl" scale and to "+DC".

Zero the meter. Connect one meter

test probe to the brush terminal

furthest from the Brush Inspection

Cover opening. Connect the . s.e-cond

test probe to Ground, Meter needle

should swing upscale and indicate

approximately 13 Ohms. (+10 %). •

■ RESULTS: 1.) Tests Good...,,

2.) Tests Bad,

B.) Use a \ inch nut. driver to re

move the Brush terminal screws, as

well as the Brush Holder reta.Lning

screws. With VOM set to. "+DG" and

to "Rxl" scale, repeat the test of

Paragraph "A" directl.y on the Rotor

Slip Rings, Meter needle should, swing

upscale and indicate, approximately 13

Ohms (+ 10%).

..............................

.Continue tests in "Diagnostic

Flow Charts", Section 3

.Go to Paragraph "B"

Issued 6-78

4.21

Page 43

RESULTS: 1.) Tests Good

..............................................

Go to Paragraph ’’C”

2.) Tests Bad.............................................Replace Rotor

C.) Inspect Brushes and Slip Rings. Replace Brushes if cracked, broken

or less than 5-/16 inch long. If Slip Rings aire dirty or tarnished,

clean with fine sandpaper. DO NOT USE EMERY CLOTH.Then repeat Test "A”.

RESULTS: 1.) Tests Good............................................Continue Tests in "Diagnostic Flow

Chart", Section 3

2.) Tests Bad

..........................................

Replace Rotor Assembly

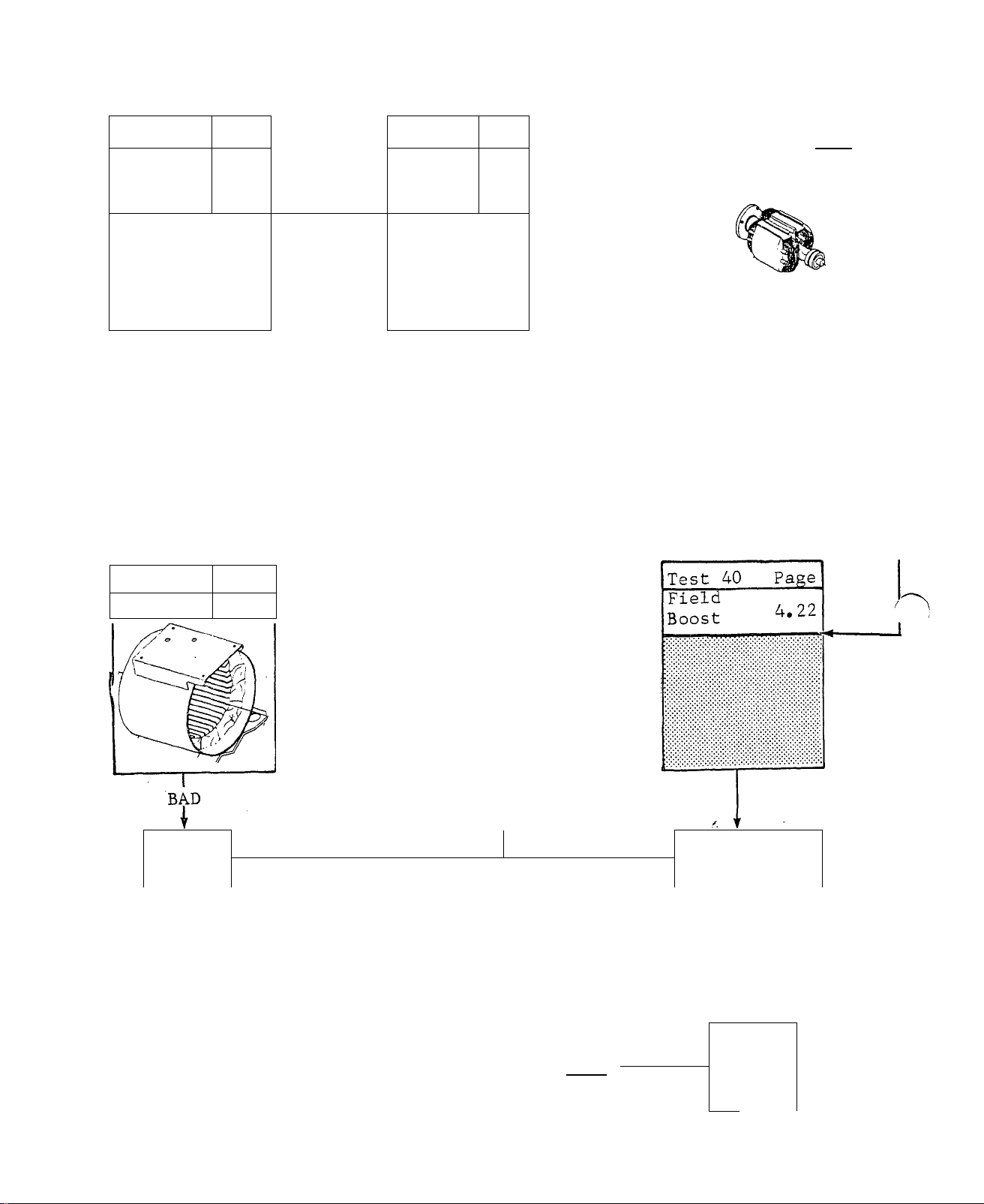

TEST 40 - FIELD BOOST

A,) Unplug the Ignition Module

from its receptacle to prevent the

engine from starting. At the rear

Pin No. 4

of the control panel (on the panel

floor), disconnect the white conn

ector plug from its receptacle.

Set the VOM to "+DC" and to a scale

that will permit 12 volts to be

read. Connect the Positive (+) test

probe to white receptacle Pin #4

and the COMMON test probe to Ground.

Crank the engine. Meter should indi

White

Receptacle

Field Boost:

From PCB Pin No. 2, to

White Receptacle Pin No. 4,

to Brushes & Slip Rings,

To Rotor Windings.

cate about 9-12 volts DC. Reconn

ect the white connector plug before

proceeding.

RESULTS: 1.) Checks Good

...............................

Continue|with "Diagnostic Flow

Charts", Section 3

2.) Checks Bad

.............................

Go to Paragraph "B"

B.) Unplug the connector plug from the Printed Circuit Board and from

the white.receptacle. Set VOM to "+DC" and to "Rxl" scale. Zero the

meter. Connect one meter test probe to printed circuit board connect

or plug (Pin #2). Connect the second test probe to white receptacle

connector plug (Pin #4). Meter needle should swing all the way upscale

to "zero

RESULTS; 1.) Wire #4 checks good..............................................Replace Printed Circuit

Board

2.) Wire #4 checks Bad............Repair/replace Wire #4

RESULTS: 1.) Checks Good, but checked Bad

in Paragraph "A"

..........................................

Check Wire #4, between the

.Printed Circuit Board and

white receptacle

2.) Checks Bad.

.Replace Printed Circuit

Board

4.22 Issued 6-78

Page 44

TEST 41 - STATOR

A.) Disconnect Wires #11 and #33

from the Main Circuit Breaker, Dis

connect two Wires #T2 from customer

wiring. The two wires #T2 are also

labelled.#22 and #44. Set VOM to

''+DC” and to "Rxl" scale. Zero the

meter. Connect meter test probes to

Wires #11 and #22, and. observe the

reading. Then connect test probes

to Wires #33 and #44 and observe

the reading. In each case, the meter

needle should swing upscale, to app

roximately 0,42'Ohms.

RESULTS: 1.) Tests indicate open.

2.) Tests Good.

B.) Set VOM to ”+DC” and to ”Rxl0,000!’ scale. Zero the meter. Connect

one meter test probe to Wire. #11..Connect the second test probe to

Ground. Observe meter. Then connect one test probe to Wire #33 and the

other test probe to Ground, In each case, the meter needle, must not

move (Infinity). Any movement of the meter needle indicates a "shorted”

condition.

RESULTS : 1.) Tests indicate "sho.rt"..............................

2.) Tests Good

................................................

............

.Disassemble, alternator. Test

stator with VOM and with an

Insulation Breakdown Tester.

Replace, if defective.

,Go to Paragraph "B"

Di.sas,semble. alternator. Test

stator with VOM and with an

Insulation Breakdown Tester,

Replace if defective,

...Continue tests in "Diagnost

ic Flow Charts", Section 3

Battery Charge Tests

TEST 42 - CHARGING OUTPUT

A.) Disconnect Wire #66 at the

control panel Terminal Strip. Then

connect an Ammeter in series with

the disconnected Wire #66 and the

Terminal Strip connection. Start

the alternator. The Ammeter, should

indicate an output, dependent upon

battery condition.

Issued 6-78

Page 45

RESULTS: 1.) Ammeter indicates discharge or

no output............................................................................

2.) Ammeter indicates a charge

..................................................

Go to Test 43

Discontinue tests

Disconnect Ammeter from circuit and reconnect Wire #66 to Terminal

Strip before proceeding.

TEST 43 - CIRCUIT BREAKER

A.) Disconnect Wires #77 and #78

from the Circuit Breaker. . Set VOM

to ”+DC” and to "Rxl*' scale, and

zero the meter. Connect meter

test probes to Circuit Breaker

terminal studs. Meter needle should

swing upscale to "zero".

RESULTS: 1.) Checks Good........................................................I....G0 to Test 44

2«) Checks Bad,

................................................................Replace Circuit Breaker

Battery Charge

Circuit Breaker

TEST 44 - DIODES D1 & D2

A.) Disconnect Wire #78 at the

battery charge circuit breaker.

Set VOM to "+DC" and to "Rxl"

scale, then zero the meter.

Connect the Positive (+) »test

probe to Wire #78 from Diode D2.

Connect the COMMON (-) test

probe to Ground. Meter, needle

should not move. Set meter to

"-DC" (or reverse the test prob

es). Meter needle should swing

(Looking Rearward From Front of Control Panel)

upscale to some raid-scale read

ing (approximately 7 - 1.2. Ohms).

RESULTS: 1.) Tests Good.

.Reconnect Wire #78. to. circuit

Breaker, go to Paragraph "B"

2,). Tests Bad,.

.Replace Diode D2

B.) Remove wire nut and disconnect Wire #55, near Diode. Dl. Set VOM

to "+DC" and to "Rxl" scale. Zero, the mater. 'Connect the. Positive ( + )

test probe to Wire #55 from Diode Dl. Connect the COMMON (-) test

probe to Ground. Meter needle should.not move. Set VOM to "-DC" (or

reverse the test probes). Meter needle should swing upscale, to some

mid-scale reading (approximately 7- 12 Ohms).

Control Panel Top

4.24

Issued 6-78

Page 46

RESULTS; 1.) Tests Good......................................Reconnect Wire #55, retain with

wire nut. Go to Test 45

2.) Tests Bad........................................

Replace Diode Dl

TEST 45 -STATOR BATTERY CHARGE WINDINGS

A.) Remove the 15 Amp Fuse. Discon

nect Wire #77 from Battery Charge

Circuit Breaker, Remove wire nut

from the Wire #55 connection, near

Diode Dl, then disconnect the wires.

Set VOM to ”+DC” and to "Rxl” scale.

Zero the meter. Connect one meter

test probe to Wire #55, Connect the

other test probe to Wire #77, Meter

Battery

Charge Circuj^

Breaker

needle should swing upscale and in

dicate approximately 0,20 Ohms.

Wire No. 78

RESULTS

1, ) Tests Good,

2. ) Tests Bad..

.Go to Paragraph ’’B”

.Replace Stator

B.) With 15 Amp Fuse still removed, set VOM to "+DC" and to *'RxlO,000"

scale. Zero the meter. Connect one meter test probe to Wire #55, and

the other test probe to Ground, Meter needle should not move (infinity),

RESULTS; 1,) Meter needle moved upscale

2,) Meter needle did not move,,,

..............................................

........................................

Wire No. 77

^ Nut

Wire

No 55

Shorted condition indi

cated, replace Stator

.Checks Good

Issued 6-78

4.25

Page 47

PART III

ALTERNATOR REPAIR

Section Title Page

5 CONTROL PANEL

Customer Wiring Connections................................................................................................5.1

Voltage Regulator................................................................................................................... 5.1

Printed Circuit Board............................................................................................................... 5.3

Diodes D1 and D2...................................................................................................................5.4