Page 1

SG010

SG015

Standby Power Rating

10KW 60 Hz

15KW 60 Hz

Liquid Cooled Gas Engine Generator Sets

Prime Power Rating

7.2KW 60 Hz

11KW 60 Hz

Power Matched

GENERAC MMC 4G15 ENGINE

Naturally Aspirated

FEATURES

■ INNOVATIV E DESIGN & PROTOTYPE TESTING are key

components of GENERAC'S success in "IMPROVING POWER BY

DESIGN." But it doesn't stop there. Total commitment to component

testing, reliability testing, environmental testing, destruction and life

testing, plus testing to applicable CSA, NEMA, EGSA, and other

standards, allows you to choose GENERAC POWER SYSTEMS

with the confidence that these systems will provide superior

performance.

■ TEST CRITERIA:

✓ PROTOTYPE TESTED

✓ SYSTEM TORSIONAL TESTED

✓ ELECTRO-MAGNETIC INTERFERENCE

✓ NEMA MG1 EVALUATION

✓ MOTOR STARTING ABILITY

✓ SHORT CIRCUIT TESTING

✓ UL 2200 COMPLIANCE AVAILABLE

■ SOLID-STATE, FREQU EN CY COMPENSATED VOLTAGE

REGULATION. This state-of-the-art power maximizing regulation

system is standard on all Generac models. It provides optimized

FAST RESPONSE to changing load conditions and MAXIMUM

MOTOR STARTING CAPABILITY by electronically torque-matching

the surge loads to the engine.

■ SINGLE SOURCE SERVICE RESPONSE from Generac's dealer

network provides parts and service know-how for the entire unit,

from the engine to the smallest electronic component. You are never

on your own when you own a GENERAC POWER SYSTEM.

■ GEN ERAC TRANS FER SWITC HES, SWITC HGEAR AND

ACCESSORIES. Long life and reliability is synonymous with

GENERAC POWER SYSTEMS. One reason for this confidence is

that the GENERAC product line includes its own transfer systems,

accessories, switchgear and controls for total system compatibility.

Page 2

APPLICATION

& ENGINEERING DATA

SG010 / SG015

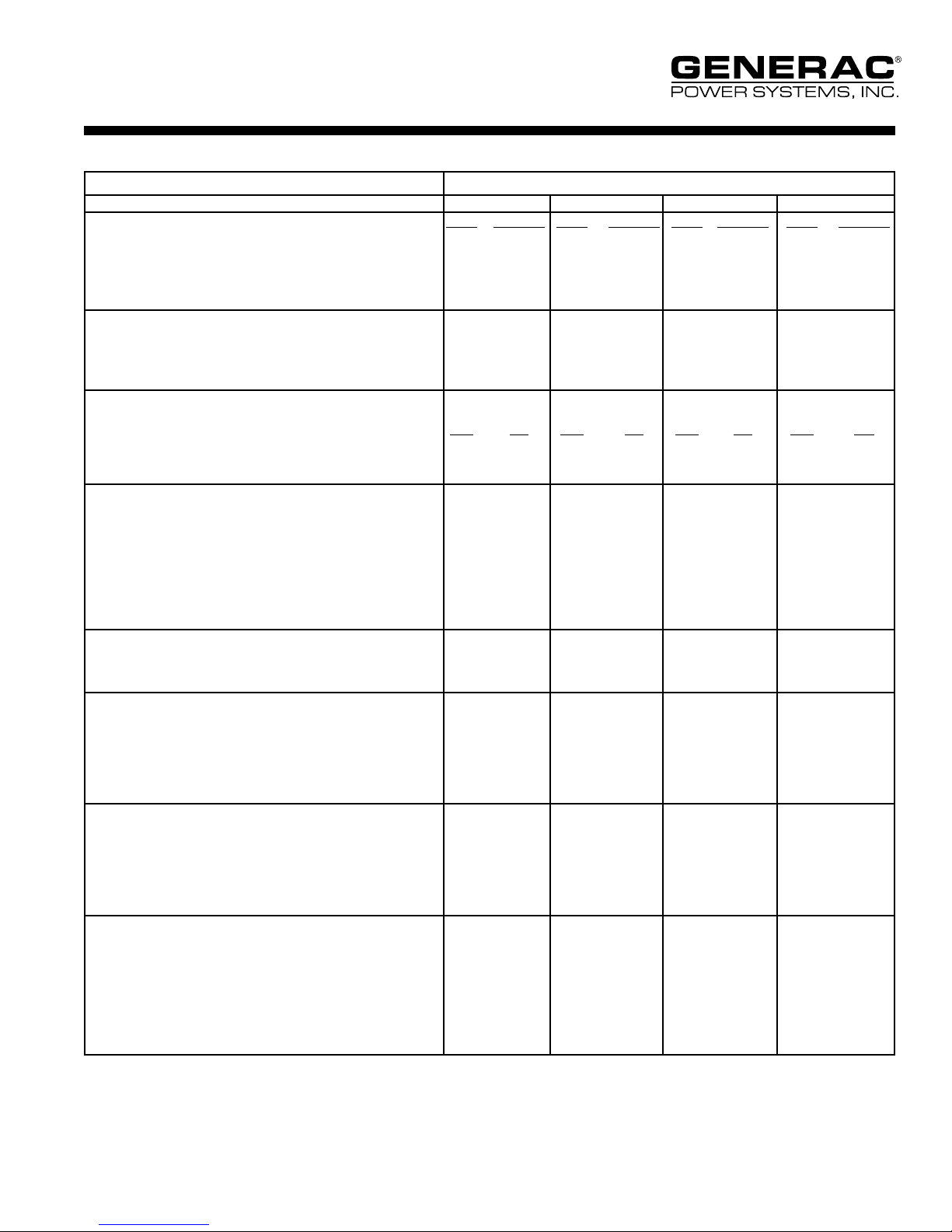

GENERATOR SPECIFICATIONS

TYPE ................................................................. Two-pole, revolving field

ROTOR INSULATION ..................................................................Class F

STATOR INSULATION .................................................................Class F

TOTAL HARMONIC DISTORTION ..................................................

TELEPHONE INTERFERENCE FACTOR (TIF) ................................

ALTERNATOR ...........................................Self-ventilated and drip-proof

BEARINGS (PRE-LUBED & SEALED) .................................................1

COUPLING .............................................................. Direct, Flexible Disc

LOAD CAPACITY (STANDBY) .......................................................100%

NOTE: Emergency loading in compliance with NFPA 99, NFPA

110, paragraph 5-13.2.6. Generator rating and performance in

accordance with ISO8528-5, BS5514, SAE J1349, ISO3046 and

DIN6271 standards.

EXCITATION SYSTEM

DIRECT ............................................................. DC excitation system ✓

Low-velocity brushes and slip rings ✓

REGULATION ................................................................... Solid-state ✓

.................................................................................... +2% regulation ✓

<5%

<50

GENERATOR FEATURES

ENGINE SPECIFICATIONS

MAKE .................................................................................... GENERAC

MODEL ................................................................................. MMC 4G15

CYLINDERS ............................................................................... 4 in-line

DISPLACEMENT ................................................... 1.5 Liter (91.5 cu. in.)

BORE .........................................................................75.5 mm (2.97 in.)

STROKE ........................................................................82 mm (3.23 in.)

COMPRESSION RATIO ..................................................................9.4:1

INTAKE AIR ...............................................................Naturally Aspirated

NUMBER OF MAIN BEARINGS ...........................................................5

CONNECTING RODS .............................................. 4-Drop forged steel

CYLINDER HEAD .....................................................................S.O.H.C.

PISTONS ..................................................................... 4-Aluminum Alloy

CRANKSHAFT ...........................................................Drop Forged Steel

VALVE TRAIN

LIFTER TYPE ...............................................................Rocker Arm Type

INTAKE VALVE MATERIAL .....................High Temperature Alloy Forged

EXHAUST VALVE MATERIAL ................High Temperature Alloy Forged

VALVE SEATS ..................................................................... Replaceable

ENGINE GOVERNOR

❐ ELECTRONIC ...................................................................... Standard

FREQUENCY REGULATION, NO-LOAD TO FULL LOAD

STEADY STATE REGULATION ...............................................+0.25%

... Isochronous

■ Four pole, revolving field generator, directly connected to the engine

shaft through a heavy-duty, flexible disc for permanent alignment.

■ Generator meets the temperature rise standards for class "F"

insulation as defined by NEMA MG1-32.6.

■ All prototype models have passed a three-phase symmetrical short

circuit test to assure system protection and reliability.

■ All prototype models are tested for motor starting ability by

measuring the instantaneous voltage dip with a waveform data

acquisition system.

■ All models utilize an advanced wire harness design for reliable

interconnection within the circuitry.

■ Magnetic circuit, including skewed stator design, provides a minimal

level of waveform distortion and an electromagnetic interference

level which meets accepted requirements for standard AM radio, TV,

and marine radio telephone applications.

■ Voltage waveform deviation, total harmonic content of the AC

waveform, and T.I.F. (Telephone Influence Factor) have been

evaluated to acceptable standards in accordance with NEMA

MG1-32.

■ Alternator is self-ventilated and drip-proof constructed.

■ Fully life-tested protective systems, including "field circuit and

thermal overload protection" and optional main-line circuit breakers

capable of handling full output capacity.

■ System Torsional acceptability confirmed during Prototype Testing.

■ Generac H-100 Digital Control Panel

LUBRICATION SYSTEM

TYPE OF OIL PUMP .......................................................................Gear

OIL FILTER .................................................................Full flow, cartridge

CRANKCASE CAPACITY ............................................. 3.8 Liters (4 qts.)

COOLING SYSTEM

TYPE OF SYSTEM ...................................Pressurized, closed recovery

WATER PUMP ..................................................... Pre-lubed, self-sealing

TYPE OF FAN ............................................................................. Pusher

NUMBER OF FAN BLADES ..................................................................6

DIAMETER OF FAN ....................................................380 mm (15.0 in.)

COOLANT HEATER ............................................................120V, 500 W

FUEL SYSTEM

FUEL

❐ Natural Gas or L.P. Vapor ................................................. Standard

❐ L.P. Liquid Withdrawal ........................................................ Optional

CARBURETOR .......................................................................Down draft

SECONDARY FUEL REGULATOR ....... Nat. Gas or L.P. Vapor Systems

HOT WATER VAPORIZER..................... L.P. Liquid Withdrawal Systems

AUTOMATIC FUEL LOCKOFF SOLENOID.............................. Standard

OPERATING FUEL PRESSURE VAPOR SYSTEMS ........7" to 15" H2O

ELECTRICAL SYSTEM

BATTERY CHARGE ALTERNATOR ............................. 15 Amps at 12 V

STARTER MOTOR ...........................................................................12 V

RECOMMENDED BATTERY ............................(1) - 12 V, 530 CCA, 26F

GROUND POLARITY ................................................................Negative

Rating definitions - Standby: Applicable for supplying emergency power for the duration of the utility power outage. No overload capability is available for this rating. (All ratings in accordance with

BS5514, ISO3046 and DIN6271). Prime (Unlimited Running Time): Applicable for supplying electric power in lieu of commercially purchased power. Prime power is the maximum power available at

variable load. A 10% overload capacity is available for 1 hour in 12 hours. (All ratings in accordance with BS5514, ISO3046, ISO8528 and DIN6271).

Page 3

SG010 / SG015

OPERATING DATA

STANDBY PRIME

SG010 SG015 SG010 SG015

GENERATOR OUTPUT VOLTAGE/KW-60Hz NG/LP Rated AMP NG/LP Rated AMP NG/LP Rated AMP NG/LP Rated AMP

120/240V, 1-phase, 1.0 pf 10 41.7 15 62.5 7.2 30.0 11 45.8

120/208V, 3-phase, 0.8 pf 10 34.7 15 52.1 7.2 25.0 11 38.2

120/240V, 3-phase, 0.8 pf 10 30.1 15 45.2 7.2 21.7 11 33.1

277/480V, 3-phase, 0.8 pf 10 15.1 15 22.6 7.2 10.8 11 16.6

MOTOR STARTING KVA

Maximum at 35% instantaneous voltage dip

with standard alternator; 60 Hz 20 29 20 29

FUEL

Fuel consumption—60 Hz—100% Load N.G. L.P. N.G. L.P. N.G. L.P. N.G. L.P.

ft.3/hr. 185 77 265 110 145 60 204 85

m3/hr. 5.2 2.2 7.5 3.1 4.1 1.7 5.8 2.4

COOLING

Coolant capacity System lit.(US gal.) 6.6 (1.75) 6.6 (1.75) 6.6 (1.75) 6.6 (1.75)

Engine lit.(US gal.) 0.9 (0.25) 0.9 (0.25) 0.9 (0.25) 0.9 (0.25)

Radiator lit.(US gal.) 6.6 (1.75) 6.6 (1.75) 6.6 (1.75) 6.6 (1.75)

Coolant flow/min. 60 Hz lit.(US gal.) 25 (6.6) 25 (6.6) 25 (6.6) 25 (6.6)

Heat rejection to coolant 60 Hz BTU/hr. 48,000 72,000 35,000 53,000

Cooling air flow 60 Hz m

3

/min. (cfm) 40 (883) 40 (883) 40 (883) 40 (883)

COMBUSTION AIR REQUIREMENTS

Flow at rated power 60 Hz m

EXHAUST

Exhaust flow at rated output 60 Hz m

3

/min. (cfm) 0.8 (29) 1.2 (41) 0.6 (22) 0.9 (32)

3

/min. (cfm) 2.7 (96) 3.9 (137) 2.1 (75) 3.0 (32)

Max. recommended back pressure Kpa (Hg) 5.0 (1.5") 5.0 (1.5") 5.0 (1.5") 5.0 (1.5")

Exhaust temp. at rated output oC (oF) 593 (1100) 621 (1150) 566 (1050) 593 (1100)

Exhaust outlet size N.P.T. (female) 1.5" 1.5" 1.5" 1.5"

ENGINE

Rated RPM 60 Hz 1800 1800 1800 1800

HP at rated KW 60 Hz 15 23 11 17

Piston speed 60 Hz m/min. (ft./min.) 295 (969) 295 (969) 295 (969) 295 (969)

BMEP (psi) 60 Hz - psi 77 116 55 85

POWER ADJUSTMENT FOR AMBIENT CONDITIONS

Temperature

-3% for every 10

o

C above - °C 40 25 40 25

-1.5% for every 10oF above - °F 104 77 104 77

Altitude

-3% for every 300 m above - m 913 150 913 150

-3% for every 1000 ft. above - ft. 3000 500 3000 500

Page 4

STANDARD ENGINE & SAFETY FEATURES

SG010 / SG015

■ High Coolant Temperature Automatic Shutdown

■ Low Coolant Level Automatic Shutdown

■ Low Oil Pressure Automatic Shutdown

■ Overspeed Automatic Shutdown (Solid-state)

■ Crank Limiter (Solid-state)

■ Oil Drain Extension

■ Radiator Drain Extension

■ Factory-Installed Cool Flow Radiator

■ Closed Coolant Recovery System

■ UV/Ozone Resistant Hoses

■ Rubber-Booted Engine Electrical Connections

■ Isochronous Governor

■ Fuel Lockoff Solenoid

■ Low Coolant Temperature

OPTIONS

■ OPTIONAL FUEL ACCESSORIES

❍ Flexible Fuel Lines

❍ L.P. Liquid Withdrawal

❍ Automatic Gaseous Dual Fuel

■ OPTIONAL EXHAUST ACCESSORIES

❍ Critical Exhaust Silencer

■ OPTIONAL ELECTRICAL ACCESSORIES

❍ Battery, 12 Volt, 75 A.H., 27F

❍ Battery Heater

❍ 2A Battery Charger

❍ 10A Dual Rate Battery Charger

■ Secondary Fuel Regulator (N.G. and L.P.)

■ Low Fuel Pressure Alarm

■ Stainless Steel Flexible Exhaust Connection

■ Battery Charge Alternator

■ Battery Cables

■ Battery Tray

■ Vibration Isolation of Unit to Mounting Base

■ 12 Volt, Solenoid-Activated Starter Motor

■ Air Cleaner

■ Fan Guard

■ Control Console

■ Radiator Duct Adapter

❍ Oil Make-Up System

❍ Oil Heater

❍ 5 Year Warranties

❍ Export Boxing

❍ Heavy Duty Air Cleaner

❍ Engine Block Heater

■ OPTIONAL ENCLOSURE

❍ Weather Protective

❍ Sound Attenuated

❍ Alluminum

❍ Enclosed Muffler

■ OPTIONAL ALTERNATOR ACCESSORIES

❍ Alternator Strip Heater

❍ Alternator Tropicalization

❍ Main Line Circuit Breaker

■ CONTROL CONSOLE OPTIONS

• see Digital Controller H-100 specification 0172110SBY

■ ADDITIONAL OPTIONAL EQUIPMENT

❍ Automatic Transfer Switch

❍ 20 Light Remote Annunciator

❍ Alarm Relay Panels

❍ Unit Vibration Isolators (Pad/Spring)

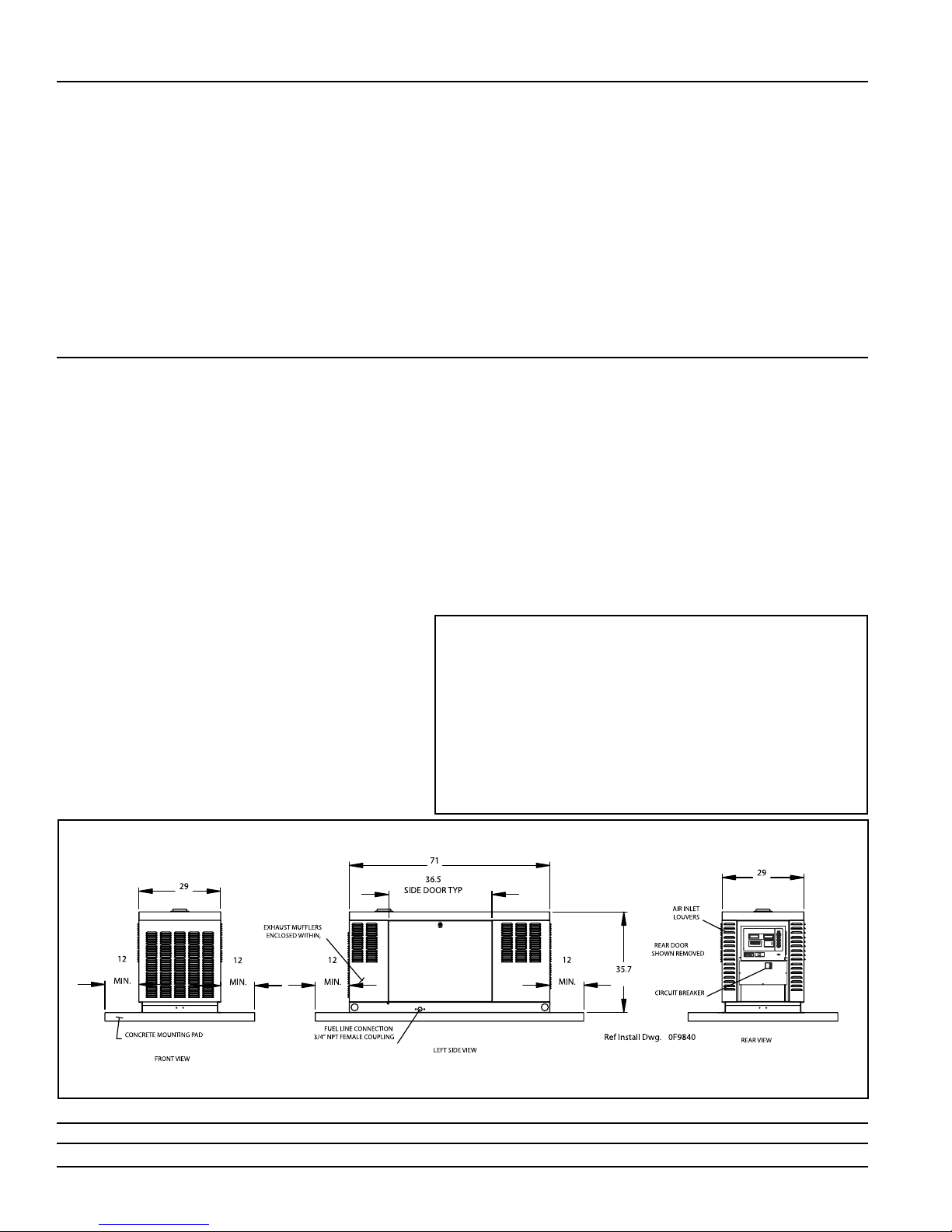

Design and specifications subject to change without notice. Dimensions shown are approximate. Contact your Generac dealer for certified drawings. DO NOT USE THESE DIMENSIONS FOR INSTALLATION PURPOSES.

Distributed by:

mm [in]

GENERAC® POWER SYSTEMS, INC. • P.O. BOX 8 • WAUKESHA, WI 53187

262/544-4811 • FAX 262/544-4851

Bulletin 0172500SBY / Printed in USA 12.05, rev: 01.06

WEIGHT: 1650 lbs.

© 2006 Generac Power Systems, Inc. All rights reser ved. All specifications subject to change without notice.

Loading...

Loading...