Power Washer

Operator’s Manual

000263

MODEL:________________________

SERIAL:________________________

DATE PURCHASED:______________

Register your Generac product at:

register.generac.com

1-888-922-8482

Operator’s Manual for Power Washer i

SAVE THIS MANUAL FOR FUTURE REFERENCE

Table of Contents

(000393a)

WARNING

CANCER AND REPRODUCTIVE HARM

www.P65Warnings.ca.gov.

Section 1 Introduction and Safety 1

Introduction .....................................1

Safety Rules .................................... 1

Safety Symbols and Meanings ........ 2

Section 2 General Information and

Setup ..............................................3

Know Your Power Washer .............. 3

Emissions Information ..................... 3

Remove Contents from Carton .......4

Assembly ......................................... 4

Add Engine Oil ................................ 4

Check Pump Oil .............................. 5

Fuel .................................................5

Water Supply ................................... 5

Connect Water Supply .................... 6

Connect Lance and High-Pressure

Hose to Spray Gun ..........................6

Spray Gun ....................................... 6

How to Use Nozzles ........................ 6

Section 3 Operation .......................8

Operation and Use Questions .........8

Before Starting Engine ....................8

Prepare Power Washer for Use .......8

Apply Detergent .............................10

Rinsing ...........................................10

Clean Detergent Siphoning Tube ..10

Automatic Cool Down System

(Thermal Relief) .............................11

Section 4 Maintenance and

Troubleshooting ..........................12

Maintenance ..................................12

Maintenance Schedule ..................12

Preventive Maintenance ................12

Engine Maintenance ......................14

Service Spark Plug ........................15

Storage ..........................................16

Troubleshooting .............................18

Notes .............................................19

Section 1 Introduction and Safety

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

(000001)

DANGER

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

(000002)

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

(000003)

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Introduction and Safety

Introduction

Thank you for purchasing a Generac Power

Systems Inc. product. This unit has been

designed to provide high performance,

efficient operation, and years of use when

maintained properly.

If any section of the manual is not understood,

contact your nearest Independent Authorized

Service Dealer (IASD), or contact Generac

Customer Service at 1-888-GENERAC (1888-436-3722), or http://www.generac.com/

with any questions or concerns.

The owner is responsible for proper

maintenance and safe use of the equipment.

Before operating, servicing or storing this

power washer:

• Study all warnings in this manual and on

the product carefully.

• Become familiar with this manual and the

unit before use.

• Refer to the Assembly section of the

manual for instructions on final assembly

procedures. Follow the instructions

completely.

Save these instructions for future reference.

ALWAYS supply this manual to any individual

that will use this machine.

The information in this manual is accurate

based on products produced at the time of

publication. The manufacturer reserves the

right to make technical updates, corrections,

and product revisions at any time without

notice.

Safety Rules

The manufacturer cannot anticipate every

possible circumstance that might involve a

hazard. The warnings in this manual, and on

tags and decals affixed to the unit are, therefore, not all inclusive. If using a procedure,

work method or operating technique that the

manufacturer does not specifically recommend, verify that it is safe for others. Also

make sure the procedure, work method or

operating technique utilized does not render

the equipment unsafe.

Throughout this publication, and on tags and

decals affixed to the generator, DANGER,

WARNING, CAUTION and NOTE blocks are

used to alert personnel to special instructions

about a particular operation that may be hazardous if performed incorrectly or carelessly.

Observe them carefully. Their definitions are

as follows:

Owner’s Manual for Power Washer 1

NOTE: Notes contain additional information

important to a procedure and will be found

within the regular text of this manual.

These safety warnings cannot eliminate the

hazards that they indicate. Common sense

and strict compliance with the special instructions while performing the action or service

are essential to preventing accidents.

Introduction and Safety

Asphyxiation. Running engines produce

carbon monoxide, a colorless, odorless,

poisonous gas. Carbon monoxide, if not

avoided, will result in death or serious injury.

(000103)

DANGER

(000104)

DANGER

Electrocution. Water contact with a power

source, if not avoided, will result in death

or serious injury.

(000105)

DANGER

Explosion and Fire. Fuel and vapors are

extremely flammable and explosive. Add fuel

in a well ventilated area. Keep fire and spark

away. Failure to do so will result in death

or serious injury.

(000106b)

Fluid Injection. This machine produces

high-pressure fluid streams that can pierce

skin. Fluid injection could result in death or

serious injury.

WARNING

(000110)

WARNING

Risk of Fire. Hot surfaces could ignite

combustibles, resulting in fire. Fire could

result in death or serious injury.

(000101)

WARNING

Vision Loss. Eye goggles are required to be

worn when using this machine. Failure to wear

eye goggles could result in permanent

vision loss.

(000107)

WARNING

Hearing Loss. Hearing protection is

recommended when using this machine.

Failure to wear hearing protection could

result in permanant hearing loss.

(000108)

WARNING

Hot Surfaces. When operating machine, do not

touch hot surfaces. Keep machine away from

combustibles during use. Hot surfaces could

result in severe burns or fire.

(000109)

WARNING

Risk of Fire. Verify machine has properly

cooled before installing cover and storing

machine. Hot surfaces could result in fire.

(000111)

WARNING

Moving Parts. Keep clothing, hair, and

appendages away from moving parts. Failure

to do so could result in death or serious injury.

(000112)

WARNING

Risk of Falling. Use of machine creates wet

areas and trip hazards. Be aware of work area

conditions. A fall could result in death

or serious injury.

(000114)

WARNING

Risk of Falling. Do not use this machine or

any components on elevated surfaces.

Doing so can result in a fall, serious injury,

or death.

(000113)

WARNING

Recoil Hazard. Recoil could retract unexpectedly

if water pressure is not properly relieved from

pump, creating kickback. Kickback could result

in death or serious injury.

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

(000115)

WARNING

Moving Parts. Do not wear jewelry when

starting or operating this product. Wearing

jewelry while starting or operating this product

could result in death or serious injury.

(000117c)

Personal injury. Risk of fluid injection.

Do not aim spray gun at people, animals,

electrical devices, or fragile items. Keep out

of reach of children. Failure to do so

could cause death or serious injury.

WARNING

WARNING

Environmental Hazard. Always recycle batteries at an

official recycling center in accordance with all local

laws and regulations. Failure to do so could result in

environmental damage, death or serious injury.

(000228)

(000244)

WARNING

Personal Injury / Equipment Damage. Place wand in

holster and verify that handle is locked into place

before moving. Failure to do so could result in death,

serious injury, or equipment damage.

Safety Symbols and Meanings

2 Owner’s Manual for Power Washer

Section 2 General Information and Setup

000264

A

B

C

D

E

F

G

I

J

L

M

N

O

P

R

S

T

U

U

H

K

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

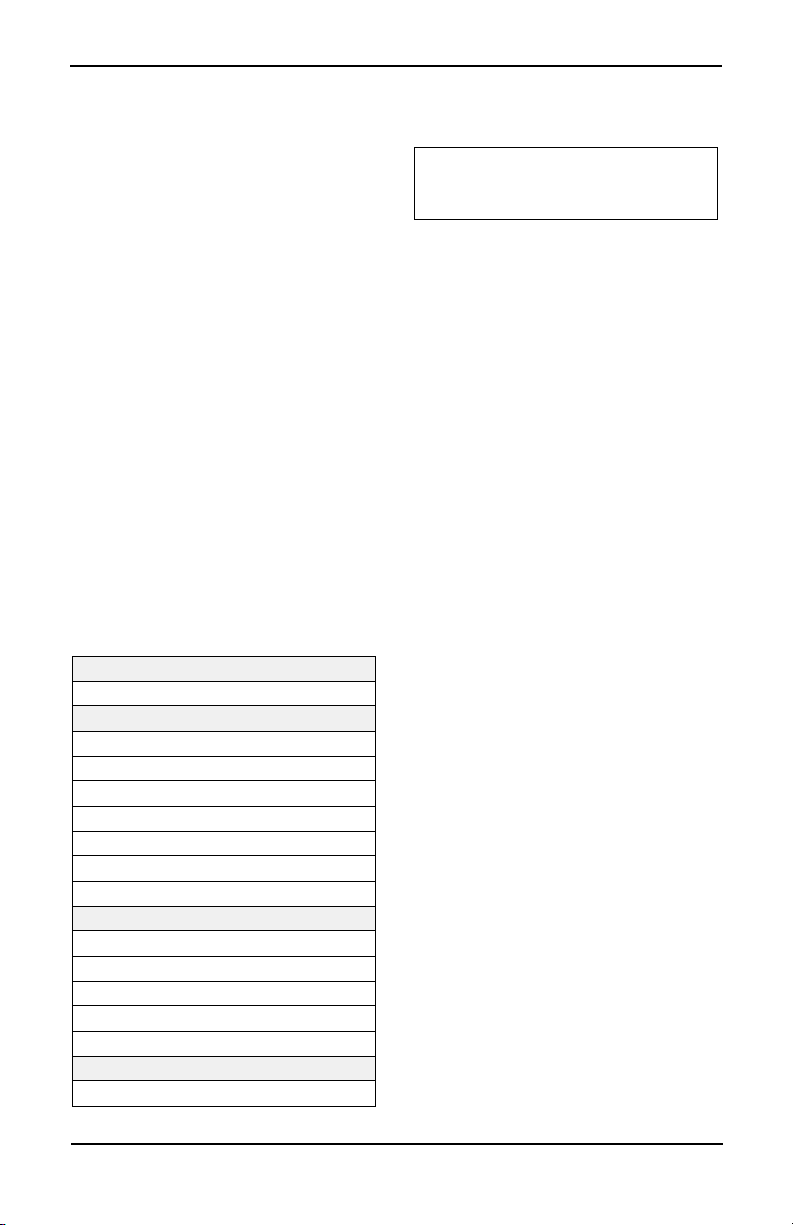

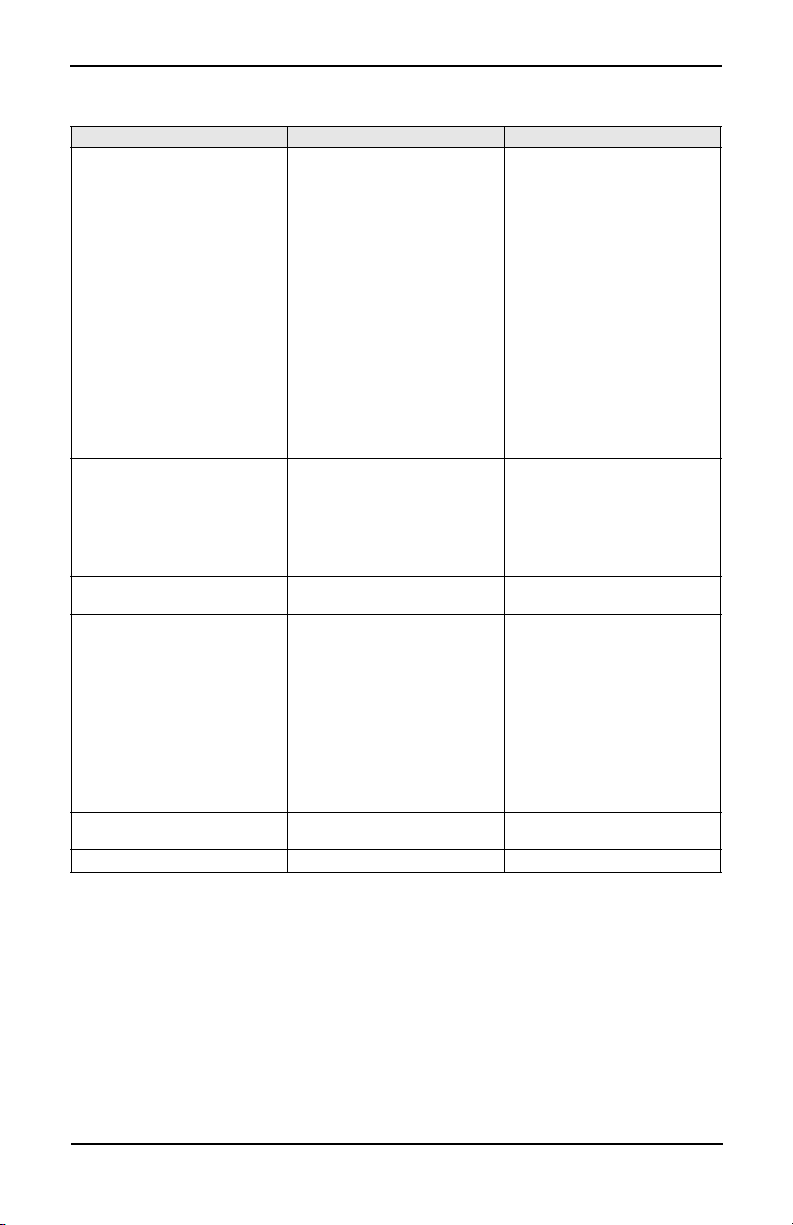

Table 2-1. Power Washer Components

A Spray Gun

B Lance with Quick Connect

C High-Pressure Hose

D Recoil Starter

E Oil Fill

F Air Filter

G High-Pressure Pump

H Thermal Relief Valve

I Engine On/Off Switch

J Unloader Valve

K High-pressure Outlet

L Water Inlet

M Fuel Tank

N Fuel On/Off Valve

O Choke

PBelt Guard

R Nozzles

S Adjustable Side Handle

T Oil Drain Plug

U Serial Number Location.

Identification Label (not shown) – located

*

*

Owner’s Manual for Power Washer 3

on engine blower housing

Detergent Siphoning Tube/Filter (not

shown)

Figure 2-1.Features and Controls

Know Your Power Washer

Read this manual thoroughly before

assembling and operating this unit. Save this

manual for future and immediate reference.

Replacement owner’s manuals are available

at www.generac.com.

Emissions Information

The U.S. Environmental Protection Agency

(and California Air Resource Board for

equipment certified to CA standards) requires

that this engine comply with exhaust and

evaporative emission standards. Locate the

emissions compliance decal on the engine to

determine what standards the engine meets,

and to determine which emissions warranty

applies. The engine is certified to meet the

applicable emission standards on gasoline. It

is important to follow the maintenance

specifications in the Maintenance section to

verify that the engine complies with the

applicable emission standards for the duration

of the product’s life. This engine utilizes lean

carburetion settings and other systems to

reduce emissions. Tampering with or altering

the emission control system may increase

emissions and may be a violation of Federal

or California Law. Acts that constitute

tampering include but are not limited to:

• Removal or alteration of any part of the

intake, fuel, or exhaust systems.

• Altering or defeating the governor linkage

or speed-adjusting mechanism to cause

the engine to operate outside its design

parameters.

Have the engine inspected and repaired by a

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

000265

000266

000115

servicing dealer if these symptoms develop:

• Hard starting or stalling after starting

• Rough idle

• Misfiring or backfiring under load

• Afterburning (backfiring)

• Black exhaust smoke or high fuel

consumption

NOTE: Maintenance, replacement, or repair of

emissions control devices and systems may

be performed by a small engine repair

establishment or individual. To be covered by

warranty, all emissions control service work

must be performed by a factory authorized

dealer. See emissions warranty for further

details.

Remove Contents from Carton

1. Open carton completely by cutting each

corner from top to bottom.

2. Remove and verify carton contents prior to

assembly. Carton contents should contain

one each of the following:

• Main Unit

• High-pressure Hose

• Siphon Hose & Filter

• Spray Gun

• Lance with Quick Connect Fitting

• Oil Bottle

• Parts Bag (includes):

– Owner’s Manual

– Owner’s Registration Card

– Bag of Colored Nozzles

3. Call Generac Customer Service 1-888-

436-3722 with the unit model and serial

number for any missing carton contents.

4. Record model, serial number, and date of

purchase on front cover of this manual.

Figure 2-2.Insert Nozzles (number may

2. Place spray gun and nozzle extension into

spray gun holder.

vary)

3. See Figure 2-3 Attach siphon tube.

Figure 2-3.Siphon Tube Location

Add Engine Oil

1. Place power washer on a flat, level

surface.

2. Clean area around oil fill and remove

orange oil fill cap/dipstick (Figure 2-4).

Assembly

Call Generac Customer Service at 1-888-4363722 for any assembly issues or concerns.

Please have model and serial number

available.

1. Insert color-coded nozzles in spaces

provided (Figure 2-2).

3. Using oil funnel (optional), slowly pour oil

NOTE: On some units there is more than one

oil fill location. In these instances it is only

necessary to use one of the oil fill points.

4. Check periodically until the oil level is

4 Owner’s Manual for Power Washer

Figure 2-4.Fill Engine Oil

into oil fill opening. See Engine Oil

Recommendations.

between "L" and "H" on the dipstick

(Figure 2-5). DO NOT OVERFILL.

NOTE: Any attempt to crank or start the

000116

000267

000268

(000105)

DANGER

Explosion and Fire. Fuel and vapors are

extremely flammable and explosive. Add fuel

in a well ventilated area. Keep fire and spark

away. Failure to do so will result in death

or serious injury.

000117

engine before it has been properly serviced

with the recommend oil may result in engine

failure.

5. Replace oil fill cap/dipstick and fully

tighten.

Figure 2-5.Safe Operating Range

Check Pump Oil

1. Place power washer on a flat, level

surface.

2. Clean area around oil fill and remove

vented cap/dipstick (Figure 2-1).

Fuel

Fuel requirements are as follows:

• Clean, fresh, unleaded gasoline.

• Minimum rating of 87 octane/87 AKI (91

RON).

• Up to 10% ethanol (gasohol) is acceptable.

• DO NOT use E85.

• DO NOT use a gas oil mix.

• DO NOT modify engine to run on alternate

fuels.Stabilize fuel prior to storage.

1. Verify unit is OFF and cooled for a

minimum of two minutes prior to fueling.

2. Place unit on level ground in a well

ventilated area.

3. Clean area around fuel cap and remove

cap slowly.

4. Slowly add recommended fuel. Do not

overfill.

Figure 2-6.Check Pump Oil

3. Check to confirm oil level is within the

markings on the dipstick (Figure 2-5). If oil

is required, see Maintenance section. DO

NOT OVERFILL.

4. See Preventive Maintenance for additional

information.

5. Install oil dipstick until finger tight.

6. Clean up any spilled oil.

Figure 2-7.Pump Oil Dipstick

Owner’s Manual for Power Washer 5

5. Install fuel cap.

NOTE: Allow spilled fuel to evaporate before

starting unit.

Water Supply

NOTE: DO NOT run unit without sufficient

water supply. Failure to follow water supply

requirements will void unit warranty.

Water supply must meet the following requirements:

• DO NOT siphon standing water for the

water supply.

• Water temperature must be less than 100

°F (38 ºC).

• Water supply hose length must not exceed

50 ft (15.2 m).

• Water must be greater than 3.8 gallons per

minute (17.3 liters per minute) and no less

than 30 psi (206.8 kPa).

• DO NOT use a one-way valve, vacuum

breaker, or check valve in any part of the

water supply.

Figure 2-8.Add Recommended Fuel

Connect Water Supply

000270

A

B

000120

000269

000123

000125

1. Remove and discard shipping cap from

the pump water inlet.

2. Run water supply for 30 seconds prior to

connection to eliminate debris.

3. See Figure 2-9. Inspect inlet screen (A) for

debris. Clean screen or replace as

necessary. DO NOT run power washer if

inlet screen is damaged or missing.

Figure 2-9.Connect Water Supply

4. Connect water supply hose to pump water

inlet (A) and hand-tighten.

5. Connect high-pressure hose to pump (B).

Connect Lance and HighPressure Hose to Spray Gun

1. See Figure 2-10. Connect lance to spray

gun and hand-tighten.

Spray Gun

Become familiar with spray gun trigger and

locking system prior to use.

See Figure 2-12. With unit OFF, hold spray

gun and squeeze trigger to learn how trigger

mechanism and locking system can be

activated and deactivated.

Figure 2-12.Spray Gun (Typical)

3. Turn ON the water, squeeze the trigger to

purge the pump system of air.

4. Verify spray gun is OFF with lock engaged

before starting power washer.

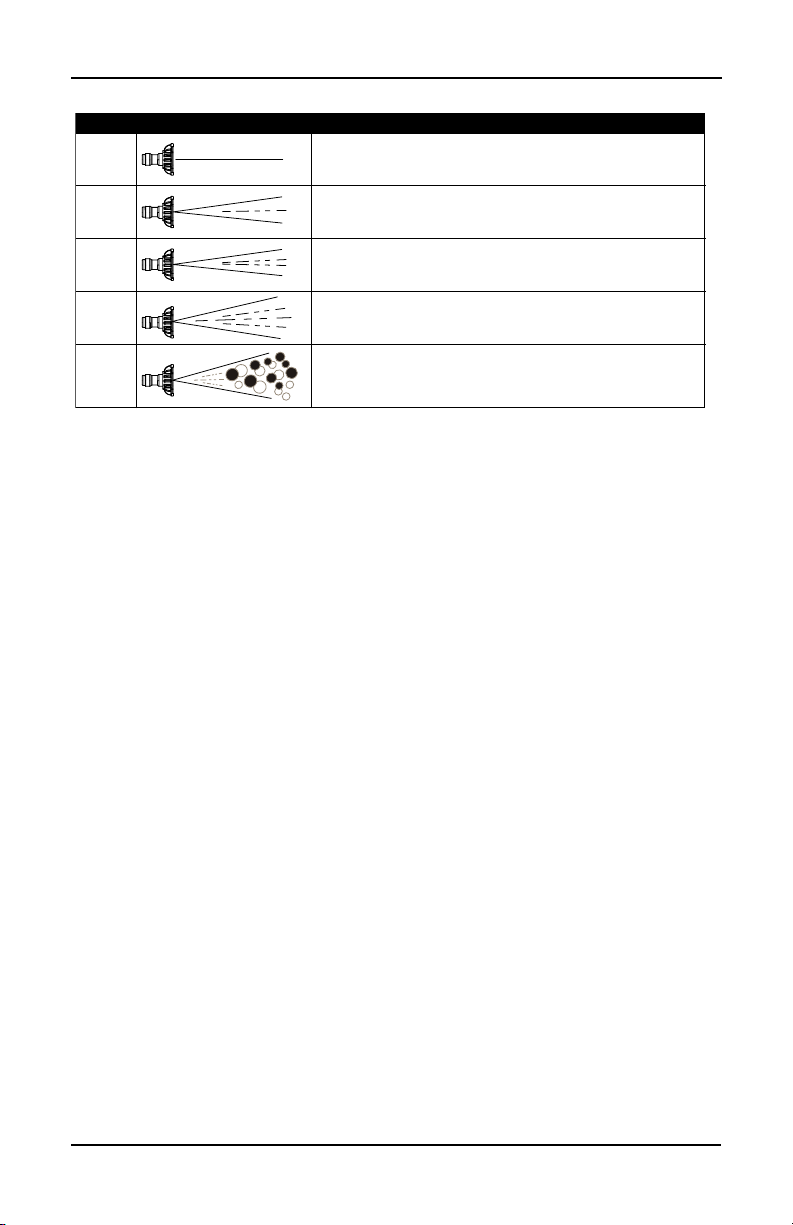

How to Use Nozzles

1. See nozzle selection guide and select

correct nozzle for task.

2. See Figure 2-13. Pull back quick–connect

collar and install nozzle.

Figure 2-10.Connect Lance

2. See Figure 2-11. Connect high-pressure

hose to base of spray gun.

Figure 2-11.Connect High-Pressure Hose

6 Owner’s Manual for Power Washer

to Spray Gun

3. Release quick-connect collar to secure

4. Verify nozzle is locked in place.

Figure 2-13.Insert Nozzle

nozzle.

Blast

Pressure

Nozzle

(Red)

Strip

Pressure

Nozzle

(Yellow)

Clean

Pressure

Nozzle

(Green)

Wash

Pressure

Nozzle

(White)

Detergent

Nozzle

(Black)

Nozzle Selection Guide

MAXIMUM - Higher pressure and lower flow for stubborn or hard to reach

surface such as second story surfaces, paint removal, oil stains, rust removal

or other stubborn substances (tar, gum, grease, wax, etc.).

MEDIUM - Higher pressure and medium flow for removing stains on hard

porous surfaces such as concrete driveways, garage floors and brick patios.

GENERAL - Medium pressure and medium flow for most all purpose cleaning

such as home siding, brick patios, wood decks, driveways and

sidewalks, garage floors, etc.

DELICATE - Lower pressure and higher flow for gentle cleaning of cars/trucks,

boats, RV’s, patio furniture, lawn equipment, etc.

DETERGENT ONLY (BLACK), Only use power washer safe detergents/soaps

to help break down stubborn dirt and grime on a variety of surfaces.

000245

Owner’s Manual for Power Washer 7

Operation

Asphyxiation. Running engines produce

carbon monoxide, a colorless, odorless,

poisonous gas. Carbon monoxide, if not

avoided, will result in death or serious injury.

(000103)

DANGER

(000110)

WARNING

Risk of Fire. Hot surfaces could ignite

combustibles, resulting in fire. Fire could

result in death or serious injury.

(000108)

WARNING

Hot Surfaces. When operating machine, do not

touch hot surfaces. Keep machine away from

combustibles during use. Hot surfaces could

result in severe burns or fire.

000271

A

B

OFF

ON

000128

Section 3 Operation

Operation and Use Questions

Call Generac customer service at 1-888-4363722 with questions or concerns about unit

operation and maintenance.

Before Starting Engine

1. Verify engine oil level is correct.

2. Verify fresh fuel level is correct.

3. Verify all fittings and couplers are properly

secured.

4. Verify sufficient water supply is properly

connected.

5. Verify unit is secure on level ground, with

proper clearance and is in a well ventilated

area.

Prepare Power Washer for Use

1. Place unit on level ground, within the

specified clearance required.

2. Connect appropriate water supply.

Power Washer Placement for Use

• Only use the unit outdoors. Verify exhaust

gas does not enter a confined area through

windows, doors, ventilation intakes.

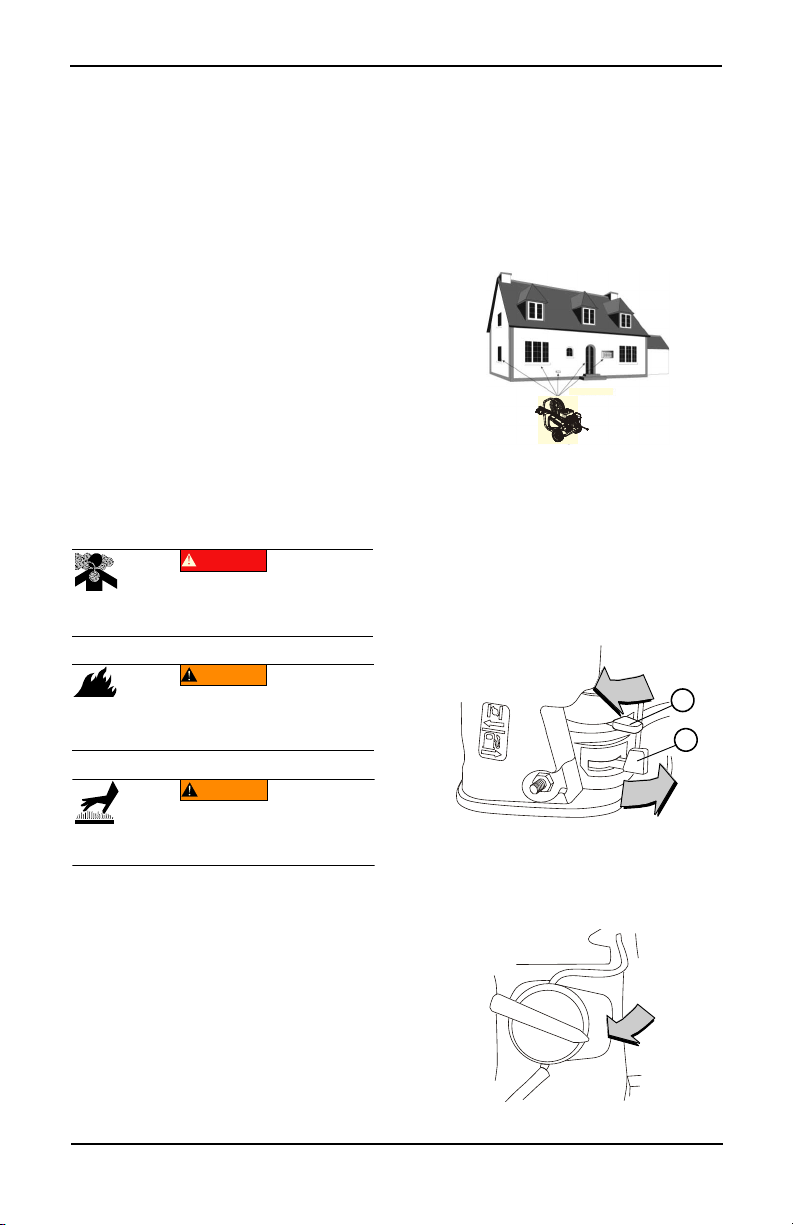

•See Figure 3-1 Keep at least 5 ft (1.5 m) of

clearance on all sides of power washer

including overhead from dwellings and

combustibles, when in use.

Figure 3-1.Five Feet of Minimum Clearance

Power Washer Start-Up

NOTE: DO NOT run power washer without a

sufficient water supply turned ON. Damage to

equipment resulting from failure to follow this

instruction will void warranty.

1. Connect a sufficient water supply.

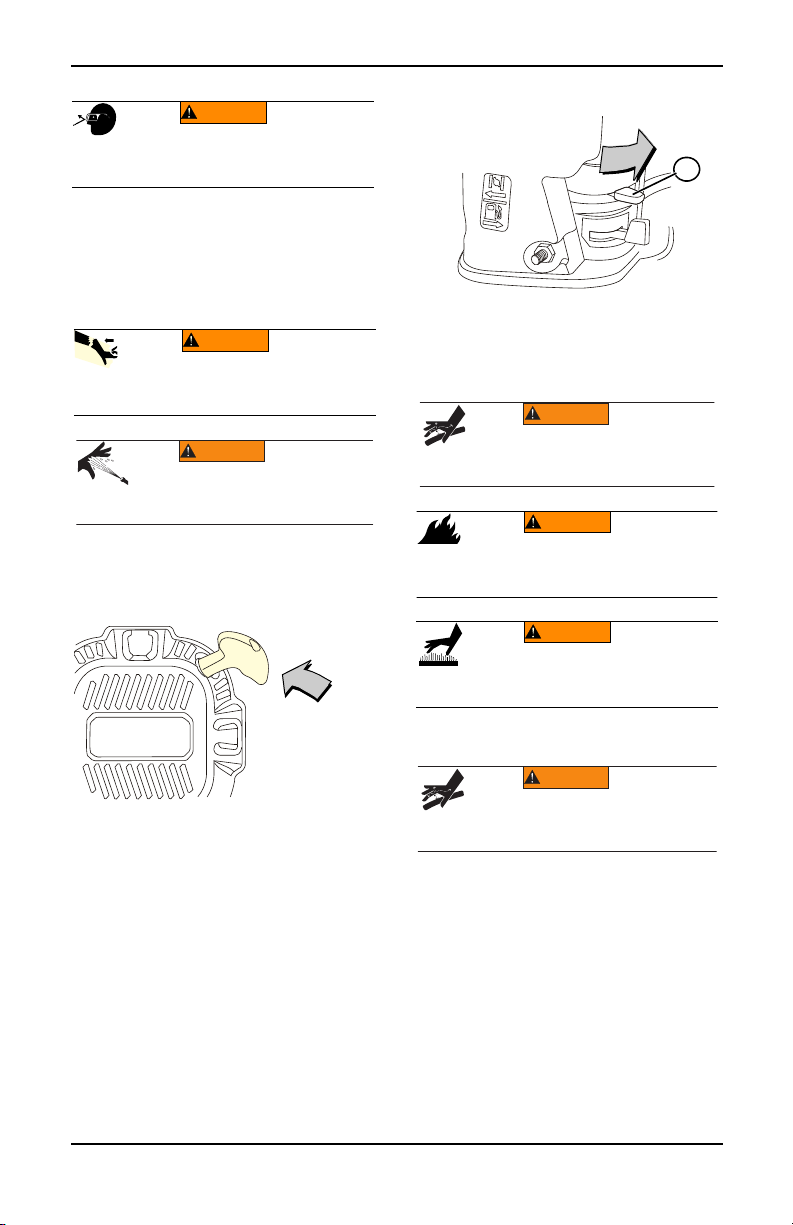

2. See Figure 3-2. Move fuel valve (B) to ON.

3. Move choke lever (A) to CLOSE.

Figure 3-2.Fuel Valve and Choke

NOTE: For warm engine, verify choke lever is

It is a violation of California Public Resource

Code, Section 4442, to use or operate the

engine on any forest-covered, brush-covered,

or grass-covered land unless the exhaust

system is equipped with a spark arrester, as

defined in Section 4442, maintained in

effective working order. Other states or federal

jurisdictions may have similar laws.

Only operate power washer outdoors in a well

ventilated area. Never operate power washer

indoors, or in a confined space. Be aware of

building openings and ventilation systems

where exhaust may enter during use.

• Verify power washer is placed on level

ground to avoid tipping during operation.

8 Owner’s Manual for Power Washer

in OPEN position.

4. See Figure 3-3. Turn engine switch ON.

Figure 3-3.Engine Switch

000127

5. Relieve spray gun pressure.

(000101)

WARNING

Vision Loss. Eye goggles are required to be

worn when using this machine. Failure to wear

eye goggles could result in permanent

vision loss.

(000113)

WARNING

Recoil Hazard. Recoil could retract unexpectedly

if water pressure is not properly relieved from

pump, creating kickback. Kickback could result

in death or serious injury.

(000117c)

Personal injury. Risk of fluid injection.

Do not aim spray gun at people, animals,

electrical devices, or fragile items. Keep out

of reach of children. Failure to do so

could cause death or serious injury.

WARNING

000129

000127

A

(000106b)

Fluid Injection. This machine produces

high-pressure fluid streams that can pierce

skin. Fluid injection could result in death or

serious injury.

WARNING

(000110)

WARNING

Risk of Fire. Hot surfaces could ignite

combustibles, resulting in fire. Fire could

result in death or serious injury.

(000108)

WARNING

Hot Surfaces. When operating machine, do not

touch hot surfaces. Keep machine away from

combustibles during use. Hot surfaces could

result in severe burns or fire.

(000106b)

Fluid Injection. This machine produces

high-pressure fluid streams that can pierce

skin. Fluid injection could result in death or

serious injury.

WARNING

6. Secure unit from movement when pulling

recoil.

7. See Figure 3-4. Firmly grasp the recoil

handle. Pull slowly until resistance is felt.

Then pull rapidly to start engine.

After engine-start attempt, if engine fails to

run, always point spray gun in safe direction,

and squeeze spray gun trigger to release

high-pressure.

Operation

Figure 3-5.Fuel Valve and Choke

• If engine fails to start after six pulls, move

choke lever to OPEN position, and repeat

steps 6 through 9.

Power Washer Shut Down

Figure 3-4.Engine Recoil

8. Return recoil handle slowly. DO NOT let

recoil snap back against recoil housing.

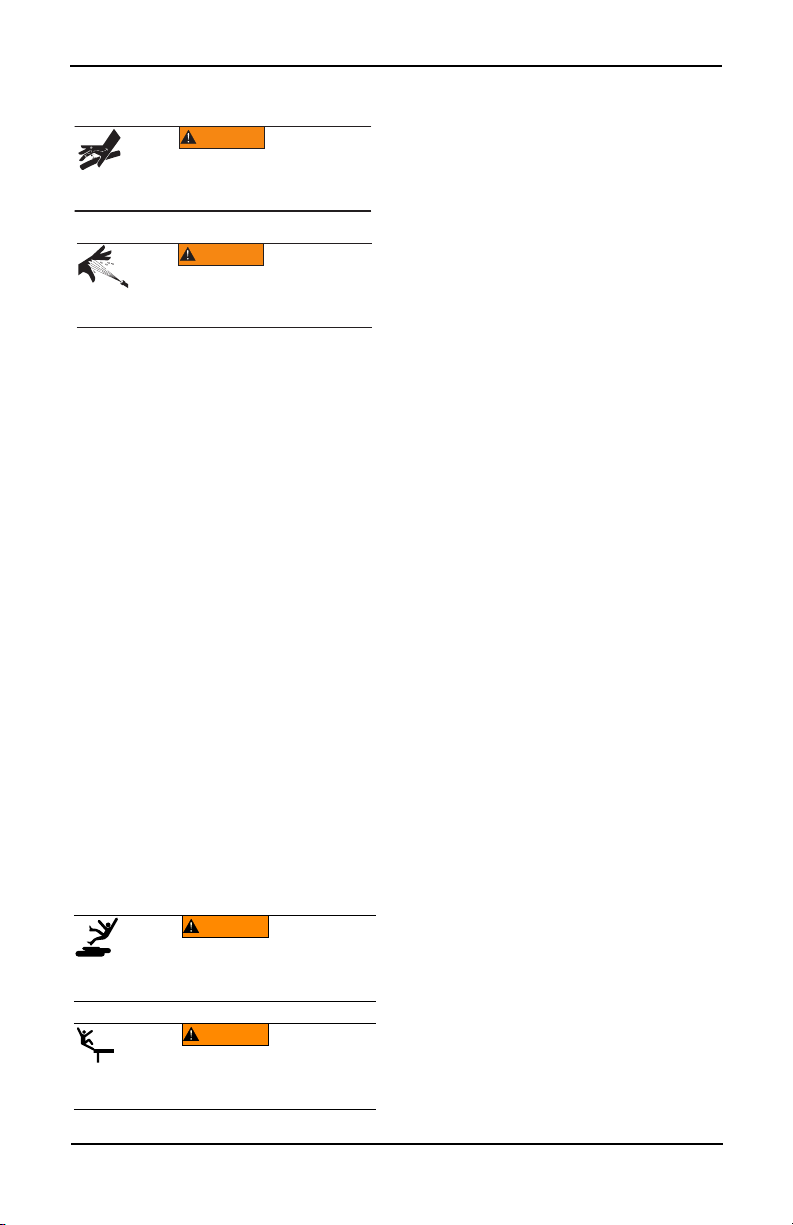

9. See Figure 3-5. When engine starts, slowly

move choke lever to OPEN position (A) as

engine warms. If engine falters, move

choke lever to CLOSE position, then to

OPEN position.

Owner’s Manual for Power Washer 9

IMPORTANT: Spray gun traps high-pressure

water, even when engine is stopped and water

is disconnected. Always point spray gun in

safe direction, and squeeze spray gun trigger

to release high-pressure. Engage trigger lock

when not in use.

1. Release spray gun trigger.

2. Turn engine switch OFF.

3. Squeeze spray gun trigger and release

high-pressure water.

4. Engage trigger lock.

5. Turn water supply OFF.

NOTE: Keep high-pressure hose connected to

pump and spray gun while system is

pressurized.

Operation

(000106b)

Fluid Injection. This machine produces

high-pressure fluid streams that can pierce

skin. Fluid injection could result in death or

serious injury.

WARNING

(000117c)

Personal injury. Risk of fluid injection.

Do not aim spray gun at people, animals,

electrical devices, or fragile items. Keep out

of reach of children. Failure to do so

could cause death or serious injury.

WARNING

(000112)

WARNING

Risk of Falling. Use of machine creates wet

areas and trip hazards. Be aware of work area

conditions. A fall could result in death

or serious injury.

(000114)

WARNING

Risk of Falling. Do not use this machine or

any components on elevated surfaces.

Doing so can result in a fall, serious injury,

or death.

Apply Detergent

NOTE: DO NOT use caustic liquid with power

washer. Use ONLY power washer safe

detergents. Follow manufacturer instructions

on detergent label.

Apply detergent as follows:

1. Prepare detergent solution as required by

job.

2. Make sure siphoning tube remains fully

submerged into the detergent.

3. When inserting the siphon into a detergent

solution bottle, route the tube so as to

keep it from inadvertently contacting the

hot muffler.

4. Verify black detergent nozzle is installed.

NOTE: Detergent cannot be applied with highpressure nozzle (Yellow, White, Green or

Red). Only use black nozzle with detergent.

5. Start engine.

6. Firmly grasp spray gun with both hands

when using high-pressure spray to avoid

injury when spray gun kicks back.

7. Apply a high-pressure spray to a small

area and then inspect surface for damage.

If no damage is found, continue to apply

detergent.

8. Apply detergent to a dry surface, start at

lower portion of area to be washed and

work upward using long, even,

overlapping strokes.

IMPORTANT: Flush the detergent siphoning

system after each use. Contact an authorized

dealer or qualified service center with

questions.

Rinsing

1. Remove black detergent nozzle from

lance.

2. Select and install desired high-pressure

nozzle.

3. Point spray gun in safe direction and

squeeze trigger to flush remaining

detergent from system.

4. Keep spray gun a safe distance from area

you plan to spray.

5. Firmly grasp spray gun with both hands

when using high-pressure spray to avoid

injury when spray gun kicks back.

6. Apply a high-pressure spray to a small

area and then inspect surface for damage.

If no damage is found, continue rinsing.

7. Start at top of area to be rinsed, working

down with same overlapping strokes as

used for cleaning.

Clean Detergent Siphoning Tube

Flush detergent siphoning tube after each

use, before stopping the engine.

1. Place detergent siphoning tube/filter in

bucket of clean water.

2. Remove high-pressure nozzle from nozzle

extension.

3. Select and install black detergent nozzle.

4. Flush for 1-2 minutes.

5. Shut engine OFF.

6. Point spray gun in a safe direction,

squeeze spray gun trigger to release

retained high water pressure. Engage

trigger lock.

After Each Use

DO NOT allow water to remain in unit for long

periods of time. Sediments or minerals can

deposit on pump parts and freeze pump.

Follow these procedures after every use:

1. Shut engine OFF.

2. Turn water supply OFF.

3. Point spray gun in a safe direction, and

squeeze trigger to relieve trapped

pressure.

4. Let engine cool.

5. Disconnect hoses from spray gun and

high-pressure outlet on pump. Drain water

from hoses, spray gun, and lance. Use a

rag to wipe off components.

6. Verify engine start switch and fuel valve is

OFF.

7. Pull recoil handle approximately six times

to remove remaining liquid from pump.

8. Store unit in a clean, dry area.

NOTE: If storing for more than 30 days, see

Storage section.

10 Owner’s Manual for Power Washer

Automatic Cool Down System (Thermal Relief)

When power washer runs for 3-5 minutes

without spray gun activation, circulating water

in pump can reach temperatures above 133°F

(56.1 ºC). Thermal relief system engages to

cool pump by discharging warm water onto

ground.

Operation

Owner’s Manual for Power Washer 11

Maintenance and Troubleshooting

Section 4 Maintenance and Troubleshooting

Maintenance

Regular maintenance will improve performance and extend engine/equipment life.

Generac Power Systems, Inc. recommends

that all maintenance work be performed by an

Independent Authorized Service Dealer

(IASD). Regular maintenance, replacement,

or repair of the emissions control devices and

systems may be performed by any repair shop

or person of the owner’s choosing. To obtain

emissions control warranty service free of

charge, the work must be performed by an

IASD. See the emissions warranty.

Power washer warranty does not cover items

subjected to operator abuse or negligence. To

receive full warranty value, operator must

maintain power washer as instructed in this

manual, including proper storage as detailed

in Storage.

NOTE: Call 1-888-GENERAC (1-888-436-

3722) with questions about component

replacement.

NOTE: All required service and adjustments

should be each season, as detailed in

Maintenance Schedule.

Maintenance Schedule

Follow maintenance schedule intervals,

whichever occurs first according to use.

NOTE: Adverse conditions will require more

frequent service.

First 5 Hours

Change engine oil

Every 8 Hours or Daily

Inspect/clean water inlet screen*

Inspect high-pressure hose

Inspect detergent siphoning hose/filter

Inspect spray gun and assembly for leaks

Clean debris

Inspect engine oil level

Inspect pump oil level

Every 50 Hours or Every Season

Check/clean water inlet screen**

Check/clean air filter**

Change pump oil**

Change engine oil**

Inspect muffler and spark arrester*

Every 100 Hours or Every Season

Service spark plug

* Clean if clogged. Replace if perforated or

torn.

** Service more often under dirty or dusty

conditions.

Preventive Maintenance

Dirt or debris can cause improper operation

and equipment damage. Clean power washer

daily or before each use. Keep area around

and behind muffler free from combustible

debris. Inspect all cooling air openings on

power washer.

• Use a damp cloth to wipe exterior surfaces

clean.

• DO NOT insert any objects through cooling

air openings.

• Use a soft bristle brush to loosen caked on

dirt, oil, etc.

• Use a vacuum to pick up loose dirt and

debris.

Inspect and Clean Inlet Screen

Inspect inlet screen on pump water inlet.

Clean clogged screen and replace screen if

damaged.

Inspect High-Pressure Hoses

High-pressure hoses can develop leaks from

wear, kinking, or abuse. Inspect hoses before

each use. Inspect for cuts, leaks, abrasions,

bulging, and damage or movement of

couplings. If these conditions exist, replace

hose immediately.

NOTE: DO NOT repair high-pressure hose.

Replace with hose that meets or exceeds

maximum pressure rating of unit.

Inspect Detergent Siphoning Tube

Inspect filter on detergent tube and clean if

clogged. Tube should fit tightly on barbed

fitting. Examine tube for leaks or tears.

Replace filter or tube if either is damaged.

Inspect Spray Gun

See Figure 4-1.

NOTE: Replace spray gun immediately if it

fails any test steps.

1. Verify spray gun hose connection is

secure.

2. Squeeze and release trigger.

NOTE: Trigger should spring back into place

and lock when released.

12 Owner’s Manual for Power Washer

Figure 4-1.Test Spray Gun (typical)

000123

(000106b)

Fluid Injection. This machine produces

high-pressure fluid streams that can pierce

skin. Fluid injection could result in death or

serious injury.

WARNING

000109

000131

000275

000268

Nozzle Maintenance

A pulsing sensation felt when squeezing spray

gun trigger may be caused by excessive

pump pressure. Typical causes of excessive

pump pressure are nozzle clog or restriction.

Immediately clean nozzle as follows:

1. Turn engine and water supply OFF.

NOTE: Keep high-pressure hose connected

to pump and spray gun while system is

pressurized.

2. Relieve spray gun water pressure.

3. Remove nozzle from lance.

4. See Figure 4-2. Use a paper clip to remove

debris.

5. See Figure 4-3. Remove lance from spray

gun and back flush thoroughly.

6. Install nozzle on lance.

7. Install lance on spray gun.

Maintenance and Troubleshooting

8. Verify hose is connected to pump water

inlet, and high-pressure hose is connected

to spray gun and pump.

9. Turn water ON.

10. Start engine.

11. Test power washer by operating with each

quick connect nozzle.

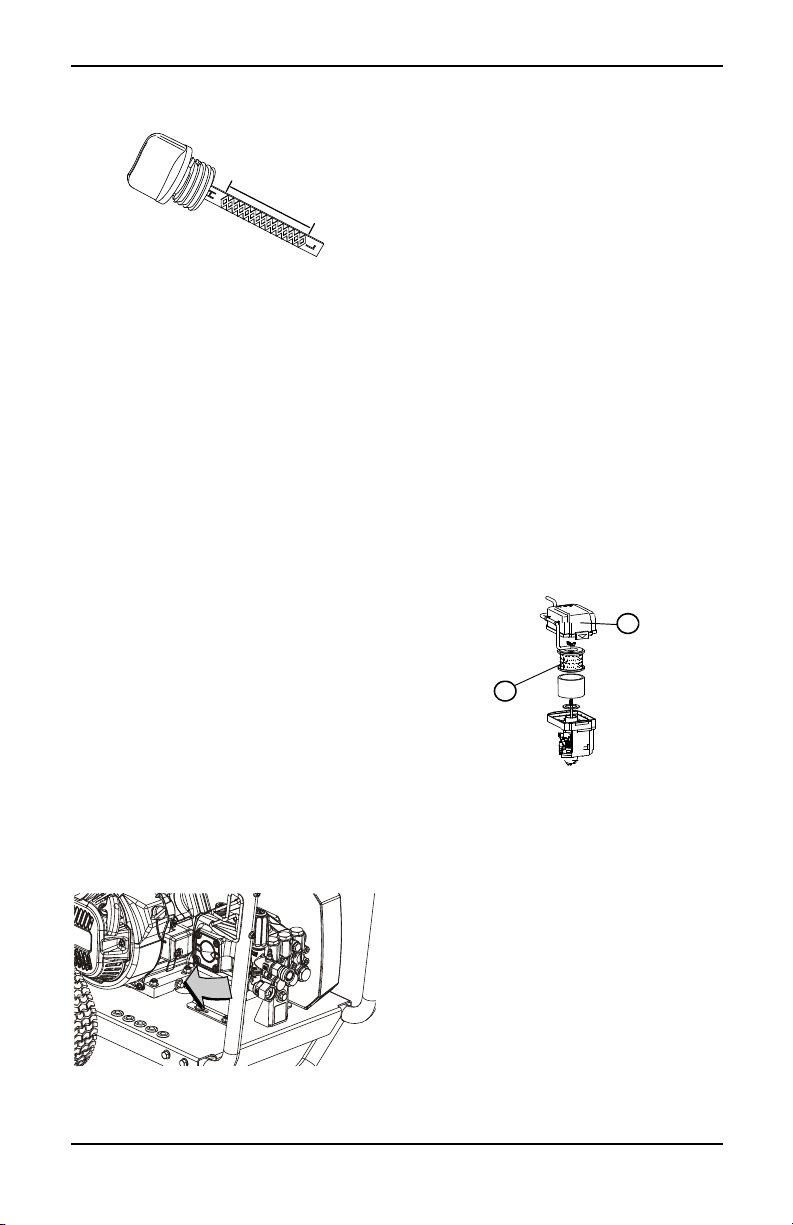

Change Pump Oil

1. Clean area around oil drain plug (Figure 2-

1).

2. Place a small pan under oil drain plug to

catch oil.

3. Remove oil drain plug. Drain oil

completely.

4. Install oil drain plug. Do not over tighten.

5. Clean area around pump oil dipstick.

6. Fill pump with SAE 15W40 non-detergent

oil. Oil level must be within markings on

dipstick (Figure 2-5). Do not overfill.

7. Install oil dipstick until finger tight.

8. Clean up any spilled oil.

Figure 4-4.Drain Pump Oil

Figure 4-5.Pump Oil Dipstick

Belt Replacement

Figure 4-2.Remove Debris

Figure 4-3.Back Flush Lance

Owner’s Manual for Power Washer 13

It may be necessary to replace belt if it breaks

or if there is a sudden loss of pressure:

1. Remove belt guard

2. See Figure 4-6. Loosen nuts (A) and

tensioning bolt (B).

Maintenance and Troubleshooting

000272

A

B

000273

000274

A

000130

SAE 30*

5W-30

10W-30**

000115

Figure 4-6.Loosen Nuts

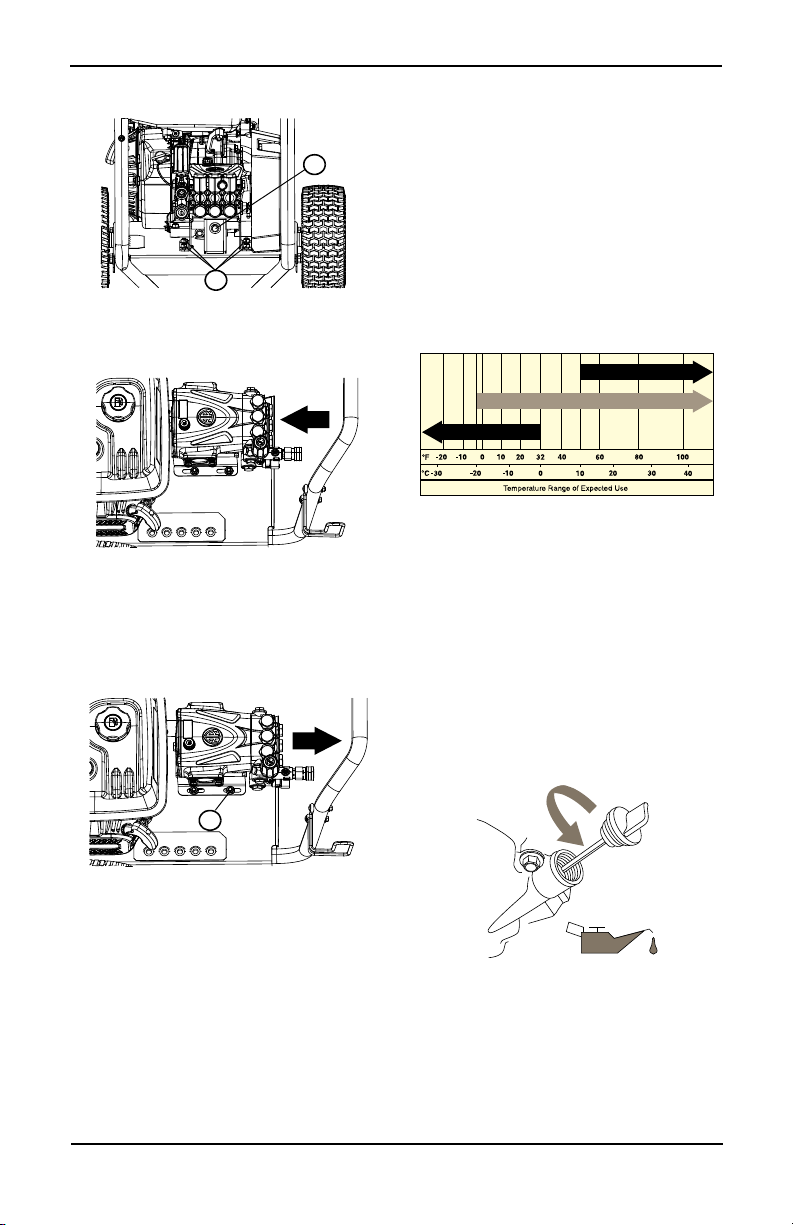

3. Push pump toward engine (Figure 4-7).

Figure 4-7.Push Pump Toward Engine

4. Remove old belt and install new belt.

5. See Figure 4-8 Pull pump away from

engine so bolt is approximately 2/3 of the

way through the pump bracket slot (A).

Tighten bolt.

Engine Maintenance

Engine Oil Recommendations

To maintain the product warranty, the engine

oil should be serviced in accordance with the

recommendations of this manual. For your

convenience, maintenance kits designed and

intended for use on this product are available

from the manufacturer that include engine oil,

oil filter, air filter, spark plug(s), a shop towel

and funnel. These kits can be obtained from

an Independent Authorized Service Dealer

(IASD).

Climate determines proper engine oil

viscosity. See chart to select correct viscosity.

Figure 4-9. Oil Viscosity

* Below 50°F (10°C) use of SAE 30 will result

in hard start.

** Above 80°F (27°C) use of 10W30 may

cause increased oil consumption. Inspect

oil level more frequently.

Inspect Engine Oil Level

Inspect engine oil level prior to each use, or

every 8 hours of operation.

1. Place power washer on a level surface.

2. Clean area around oil fill.

3. See Figure 4-10. Remove oil fill cap and

wipe dipstick clean.

Figure 4-8.Pull Pump Away From Engine

6. Tighten tensioning bolt (B) (page 14). The

pulleys should be aligned within 1° of each

other and the new belt should be

tensioned to ~90.5 lbs. (1/8” deflection

under 8.3 lbs. with a tension gauge).

7. Tighten all four nuts (A) (page 14).

8. Replace belt guard before running unit.

14 Owner’s Manual for Power Washer

Figure 4-10. Engine Oil Fill

4. See Figure 4-11. Screw dipstick into filler

neck.Verify proper oil level on dipstick.

Figure 4-11. Safe Operating Range

000116

000276

000277

A

B

5. Add recommended engine oil as

necessary.

6. Replace oil fill cap and hand-tighten.

NOTE: Some units have more than one oil fill

location. It is only necessary to use one oil fill

point.

Change Engine Oil

When using power washer under extreme,

dirty, dusty conditions, or in extremely hot

weather, change oil more frequently.

NOTE: Don’t pollute. Conserve resources.

Return used oil to collection centers.

Change oil while engine is still warm from

running, as follows:

1. Place power washer on a level surface.

2. Disconnect the spark plug wire from the

spark plug and place the wire where it

cannot contact spark plug.

3. Clean area around oil fill, and oil drain

plug.

4. Remove oil fill cap.

5. See Figure 4-12. Remove oil drain plug (A)

and drain oil completely into a suitable

container.

6. Install oil drain plug and tighten securely.

7. See Figure 4-11. Slowly pour oil into oil fill

opening until oil level is between L and H

marks on dipstick. DO NOT overfill.

8. Install oil fill cap, and finger tighten.

9. Wipe up any spilled oil.

10. Properly dispose of oil in accordance with

all applicable regulations.

Maintenance and Troubleshooting

Air Filter

Engine will not run properly and may be

damaged if run with a dirty air cleaner. Service

air cleaner more frequently in dirty or dusty

conditions.

To service air cleaner:

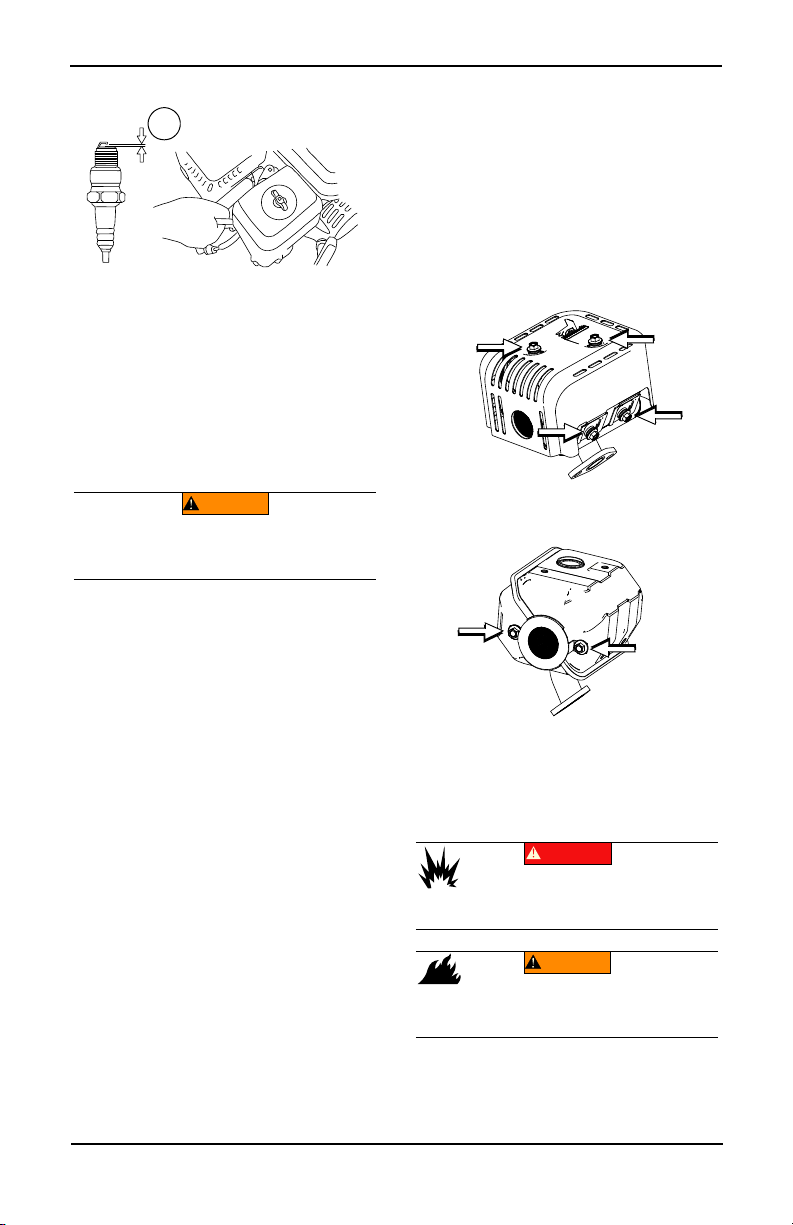

1. See Figure 4-13. Remove air cleaner cover

(A).

2. Remove filter element(s) (B).

3. Inspect filter element(s) and replace if

damaged. To order replacements, contact

Generac Customer Service at 1-888GENERAC (888-436-3722) for the name

of your nearest IASD.

4. Clean foam filter element in warm soapy

water. Rinse, and allow to dry thoroughly.

Dip in clean engine oil and squeeze out

excess oil.

5. Tap paper filter element several times on

hard surface to remove dirt. Compressed

air (not exceeding 30 psi (207 kPa) can

also be used to blow through filter element

from the inside.

6. Use a clean, damp cloth to wipe dirt from

inside air cleaner cover.

7. Put cleaned or new filter element(s) in

place. Verify gasket is in place (if

equipped).

8. Install air cleaner cover. Tighten air

cleaner screws or fasteners securely.

Figure 4-13.Air Filter Assembly

Service Spark Plug

To service spark plug:

1. Clean area around spark plug.

2. Remove and inspect spark plug.

3. See Figure 4-14. Inspect electrode gap

with wire feeler gauge and replace spark

plug if gap (A) is not within specification

listed on Product Specifications Sheet.

Figure 4-12.Oil Drain Plug

Owner’s Manual for Power Washer 15

Maintenance and Troubleshooting

000134a

A

(000102)

WARNING

Accidental Start-up. Disconnect spark plug wire when

working on unit. Failure to do so could result in death

or serious injury.

000135

000136

(000105)

DANGER

Explosion and Fire. Fuel and vapors are

extremely flammable and explosive. Add fuel

in a well ventilated area. Keep fire and spark

away. Failure to do so will result in death

or serious injury.

(000109)

WARNING

Risk of Fire. Verify machine has properly

cooled before installing cover and storing

machine. Hot surfaces could result in fire.

Figure 4-14. Spark Plug

NOTE: Replace spark plug if electrodes are

pitted, burned or porcelain is cracked. Use

ONLY recommended replacement plug. See

Product Specifications Sheet.

4. Install spark plug finger tight, and tighten

an additional 3/8 to 1/2 turn using spark

plug wrench.

Inspect Engine Spark

1. Disconnect spark plug wire from spark

plug.

2. Secure spark plug wire where it cannot

contact spark plug.

3. Test spark plug with approved spark plug

tester.

NOTE: DO NOT inspect for spark with spark

plug removed.

Inspect Muffler And Spark Arrestor

NOTE:

It is a violation of California Public

Resource Code, Section 4442, to use or

operate the engine on any forest-covered,

brush-covered, or grass-covered land unless

the exhaust system is equipped with a spark

arrestor, as defined in Section 4442, maintained

in effective working order. Other states or

federal jurisdictions may have similar laws.

NOTE: Call 1-888-GENERAC (1-888-436-

3722) with questions about component

replacement.

NOTE: Use ONLY original equipment

replacement parts.

Inspect muffler for cracks, corrosion, or other

damage. Remove spark arrestor, if equipped,

inspect for damage or carbon blockage. If

replacement parts are required.

16 Owner’s Manual for Power Washer

Inspect Spark Arrestor Screen

(if equipped)

1. Loosen fasteners and remove heat shield

from muffler. See Figure 4-15.

2. Loosen fasteners and remove spark

arrester from muffler. See Figure 4-16.

3. Inspect spark arrester. Replace if torn,

perforated or otherwise damaged (part

number 0K1851).

4. If screen is not damaged, clean it with a

commercial solvent and replace.

Figure 4-15.Heat Shield Fasteners

Figure 4-16.Spark Arrestor Fasteners

Storage

General

• DO NOT place a storage cover on a hot

power washer. Allow unit to cool to room

temperature before storage.

• DO NOT store fuel from one season to

another unless properly treated.

Maintenance and Troubleshooting

• Replace fuel container if rust is present.

Rust in fuel will cause fuel system

problems.

• Cover unit with a suitable protective,

moisture resistant cover.

• Store unit in a clean and dry area.

• Always store power washers and fuel away

from heat and ignition sources.

Winter Storage

NOTE: If pump saver is not available, connect

a 3-foot section of garden hose to water inlet

adapter. Pour RV-antifreeze (antifreeze

without alcohol) into hose. Pull recoil handle

twice. Disconnect 3-foot hose.

• Store unit in a clean and dry area.

NOTE: If not using power washer for more

than 30 days, prepare engine and pump for

storage.

Prepare Fuel System for Storage

Fuel stored over 30 days can go bad and

damage fuel system components. Keep fuel

fresh, use fuel stabilizer.

If fuel stabilizer is added to fuel system,

prepare and run engine according to Power

Washer Start-Up. Run engine for 2 minutes to

circulate stabilizer throughout fuel system.

Adequately prepared fuel can be stored up to

24 months.

NOTE: If fuel has not been treated with fuel

stabilizer, it must be drained into an approved

container. Run engine until it stops from lack

of fuel. Use of fuel stabilizer in fuel storage

container is recommended to keep fuel fresh.

Protect unit from freezing temperatures as

follows:

1. Shut engine OFF.

2. Turn fuel valve to OFF.

3. Turn water supply OFF.

4. Point spray gun in a safe direction, and

squeeze trigger to relieve trapped

pressure.

5. Let engine cool.

6. Disconnect hoses from spray gun and

high-pressure outlet on pump. Drain water

from hoses, spray gun, and lance. Use a

rag to wipe off components.

7. Empty pump of all remaining liquids.

8. Pull recoil handle approximately six times

to remove remaining liquid from pump.

9. Winterize pump with Generac Pump

Shield™ (P/N 0L2414). This minimizes

freeze damage and lubricates pistons and

seals.

NOTE: If Generac Pump Shield™ is not

available, connect a 3 ft (1 m) section of

garden hose to water inlet adapter. Pour RVantifreeze (alcohol free antifreeze) into hose.

Pull recoil handle twice. Disconnect hose.

10. Store unit in a clean and dry area.

Prepare Engine for Storage

1. Change engine oil.

2. Remove spark plug.

3. Pour a tablespoon (5-10cc) of clean

engine oil or spray a suitable fogging

agent into cylinder.

4. Pull starter recoil several times to

distribute oil in cylinder.

5. Install spark plug.

6. Pull recoil slowly until resistance is felt.

This will close valves so moisture cannot

enter engine cylinder. Gently release

recoil.

Change Oil

Change engine oil before storage. See

Change Engine Oil.

Prepare Pump for Storage

NOTE: If not using power washer for more

than 30 days, prepare engine and pump for

storage.

Protect unit from freezing temperatures.

Failure to do so will permanently damage

pump and render unit inoperable. Freeze

damage is not covered under warranty.

Owner’s Manual for Power Washer 17

Maintenance and Troubleshooting

Troubleshooting

PROBLEM CAUSE CORRECTION

Pump fails to produce

pressure, has erratic pressure,

chattering, loss of pressure,

low water volume.

Detergent fails to mix with

spray.

Engine runs well at no-load,

but bogs when load is applied.

Engine will not start, or starts

and runs rough.

Engine shuts down during

operation/

Engine lacks power. 1. Dirty air filter. 1. Replace air filter.

1. Low pressure nozzle

installed.

2. Water inlet is obstructed.

3. Inadequate water supply.

4. Inlet hose kinked or

leaking.

5. Clogged hose inlet screen.

6. Water supply is over 100 ºF

(37.8 ºC).

7. High-pressure hose is

obstructed, or leaks.

8. Spray gun leaks.

9. Nozzle is obstructed.

10. Pump is faulty.

11. B elt is wor n

1. Detergent siphoning tube is

not submerged.

2. Detergent siphoning tube/

filter is obstructed or

cracked.

3. High-pressure nozzle

installed.

1. Engine speed too low. 1. Contact authorized

1. Low oil level, “Oil Alert

System”.

2. Dirty air filter.

3. Out of fuel

4. Stale fuel.

5. Spark plug wire not

connected to plug.

6. Bad spark plug.

7. Water in fuel.

8. Excessively rich fuel

mixture.

9. Engine switch OFF.

1. Out of fuel. 1. Fill fuel tank.

1. Replace with high-pressure

nozzle.

2. Clean inlet.

3. Provide adequate water

flow.

4. Straighten inlet hose, patch

leak.

5. Inspect and clean inlet

hose screen.

6. Provide cooler water

supply.

7. Clear obstructions or

replace hose.

8. Replace spray gun.

9. Clean nozzle.

10. Contact authorized

servicing dealer.

11. Contact local service

facility to replace belt

1. 1. Insert detergent

siphoning tube into

detergent.

2. Clean or replace filter/

detergent siphoning tube.

3. Install low-pressure nozzle.

servicing dealer.

1. Fill crankcase to proper

level.

2. Clean or replace air filter.

3. Fill fuel tank.

4. Replace with fresh fuel.

5. Connect wire to spark plug.

6. Replace spark plug.

7. Drain fuel tank, replace

with fresh fuel.

8. Contact authorized

servicing dealer.

9. Turn engine switch ON.

18 Owner’s Manual for Power Washer

Notes

Owner’s Manual for Power Washer 19

20 Owner’s Manual for Power Washer

Part No. 0L1528 Rev. C 09/20/2018 ©2018 Generac Power Systems, Inc. All rights reserved Specifications are subject to change without notice. No reproduction allowed in any form without prior written consent from Generac Power Systems, Inc.

Generac Power Systems, Inc.

S45 W29290 Hwy. 59

1-888-GENERAC (1-888-436-3722)

Waukesha, WI 53189

www.generac.com/pro

Lavadora a presión

Manual del operador

000263

MODELO: ________________________

SERIE: __________________________

FECHA DE COMPRA: ______________

Registre su producto Generac en:

register.generac.com

1-888-922-8482

Operator’s Manual for Power Washer i

GUARDE ESTE MANUAL PARA REFERENCIA EN EL FUTURO

Índice de contenidos

Ñ

Sección 1 Introducción y seguridad

1

Introducción .................................... 1

Reglas de seguridad ....................... 1

Símbolos de seguridad y significado 2

Sección 2 Información general y

configuración ................................3

Conozca su lavadora a presión ....... 3

Información sobre emisiones ..........3

Retiro del contenido de la caja ........ 4

Armado ........................................... 4

Añadir aceite de motor .................... 5

Comprobar el aceite de la bomba ... 5

Combustible .................................... 6

Suministro de agua ......................... 6

Conexión del suministro

de agua ........................................... 6

Conexión de la manguera y la lanza de

alta presión ..................................... 7

Pistola de pulverización .................. 7

Cómo usar las boquillas .................. 7

Sección 3 Funcionamiento ...........9

Preguntas sobre uso y funcionamiento

9

Antes de poner en marcha

el motor ............................................9

Preparación de la lavadora a presión

para el uso .......................................9

Aplicación de detergente ...............11

Enjuague .......................................12

Limpieza del tubo de sifón para deter-

gente ..............................................12

Sistema de enfriamiento automático

(Alivio térmico) ...............................12

Sección 4 Mantenimiento y solución

de problemas ...............................13

Mantenimiento ...............................13

Programa de mantenimiento .........13

Mantenimiento preventivo .............13

Mantenimiento del motor ...............16

Mantenimiento de la bujía .............17

Almacenamiento ............................18

Resolución de problemas ..............20

ADVERTENCIA

PRODUCE CÁNCER Y

OS REPRODUCTIVOS

DA

www.P65Warnings.ca.gov.

(000393a)

Sección 1 Introducción y seguridad

(000100a)

ADVERTENCIA

Consulte el manual. Lea y comprenda

completamente el manual antes de usar el

producto. No comprender completamente el

manual puede provocar la muerte o lesiones

graves.

(000001)

PELIGRO

Indica una situación peligrosa que, si no se evita, ocasionará la

muerte o lesiones graves.

(000002)

ADVERTENCIA

Indica una situación peligrosa que, si no se evita, podría

ocasionar la muerte o lesiones graves.

PRECAUCIÓN

Indica una situación de riesgo que, si no se evita, puede

producir lesiones leves o moderadas.

(000003)

Introducción y seguridad

Introducción

Muchas gracias por comprar un producto de

Generac Power Systems Inc. Esta unidad ha

sido diseñada para brindar alto rendimiento,

funcionamiento eficiente, y años de uso si se

mantiene apropiadamente.

Si no se comprende alguna parte de este

manual, comuníquese con el concesionario

autorizado independiente (IASD) más cercano

o comuníquese con Servicio al cliente de

Generac llamando al 1-888-GENERAC (1-888436-3722), o visite http://www.generac.com/

para todas las preguntas o inquietudes que

puedan surgir.

El propietario es responsable del mantenimiento apropiado y del uso seguro del equipo.

Antes de operar, poner en funcionamiento o

almacenar esta lavadora a presión:

• Estudie atentamente todas las

advertencias indicadas en este manual y

en el producto.

• Familiarícese con este manual y la unidad

antes del uso.

• Consulte la sección Armado del manual

para obtener las instrucciones sobre los

procedimientos de armado finales. Siga las

instrucciones completamente.

Guarde estas instrucciones para referencia en

el futuro. SIEMPRE suministre este manual a

la persona que va a usar esta máquina.

La información que aparece en este manual

es precisa y está basada en productos fabricados en el momento en el que se editó esta

publicación. El fabricante se reserva el

derecho de hacer las actualizaciones

técnicas, las correcciones y las revisiones de

los productos que considere necesarias sin

previo aviso.

Reglas de seguridad

El fabricante no puede prever todas las

circunstancias probables que podrían

involucrar un peligro. Las advertencias de

este manual y los rótulos y etiquetas

adhesivas fijados en la unidad, por lo tanto, no

incluye todas las reglas de seguridad. Si usa

un procedimiento, método de trabajo o técnica

de funcionamiento que el fabricante no

recomienda específicamente, verifique que

sea seguro para los demás. Asegúrese

también de que el procedimiento, método de

trabajo o técnica de funcionamiento utilizado

no convierta el funcionamiento del equipo en

inseguro.

En toda esta publicación, en los rótulos y en

las etiquetas adhesivas fijadas en la lavadora

a presión, los bloques de PELIGRO, ADVERTENCIA, PRECAUCIÓN y NOTA se usan

para alertar al personal sobre instrucciones

especiales acerca de una determinada

operación que puede ser peligrosa si se

efectúa de manera incorrecta o imprudente.

Respételos cuidadosamente. Sus definiciones

son las siguientes:

Manual del propietario de la lavadora a presión 1

NOTA: Las Notas contienen información adicional importante para un procedimiento y se

encuentran dentro del texto de este manual.

Estas advertencias de seguridad no pueden

eliminar los peligros que indican. El sentido

común y el cumplimiento estricto de las

instrucciones especiales mientras se

desarrolla la acción o el mantenimiento son

esenciales para la prevención de accidentes.

Introducción y seguridad

Asfixia. Los motores funcionando producen

monóxido de carbono, un gas incoloro, inodoro, y

venenoso. El monóxido de carbono, si no se evita,

ocasionará la muerte o lesiones graves.

(000103)

PELIGRO

(000104)

PELIGRO

Electrocución. Si no se evita el contacto del

agua con una fuente de alimentación,

ocasionará la muerte o lesiones graves.

(000105)

PELIGRO

Explosión e incendio. El combustible y los vapores son

extremadamente inflamables y explosivos. Añada

combustible en una zona bien ventilada. Mantenga

alejados el fuego y las chispas. No hacerlo puede

ocasionar la muerte o lesiones graves.

ADVERTENCIA

Inyección de líquido a presión. Esta máquina genera

flujos de líquido a alta presión que pueden penetrar

en la piel. El líquido a presión, si penetra en la piel,

puede ocasionar la muerte o lesiones graves.

(000106b)

(000110)

ADVERTENCIA

Riesgo de incendio. Las superfcies calientes

pueden encender combustibles, produciendo un

incendio. El incendio puede ocasionar la muerte

o lesiones graves.

(000101)

ADVERTENCIA

Pérdida de visión. Se requiere el uso de gafas de

seguridad al usar esta máquina. No usar gafas de

seguridad puede ocasionar pérdida de visión

permanente.

(000107)

ADVERTENCIA

Pérdida auditiva. Recomendamos protectores de

oído al usar esta máquina. No usar protectores de

oído puede ocasionar pérdida auditiva permanente.

(000108)

ADVERTENCIA

Superfcies calientes. Al usar la máquina, no toque

las superfcies calientes. Mantenga la máquina

alejada de los combustibles durante el uso. Las

superfcies calientes pueden ocasionar quemaduras

graves o incendio.

(000109)

ADVERTENCIA

Riesgo de incendio. Verifque que la máquina se

haya enfriado apropiadamente antes de instalar una

cubierta y almacenar la máquina. Las superfcies

calientes pueden ocasionar un incendio.

Piezas en movimiento. Mantenga la ropa, cabello,

y extremidades alejados de las piezas en

movimiento. No hacerlo puede ocasionar la

muerte o lesiones graves.

(000111)

ADVERTENCIA

(000112)

ADVERTENCIA

Riesgo de caídas. El uso de la máquina crea zonas

mojadas y riesgos de disparo. Esté atento a las

condiciones de la zona de trabajo. Una caída

puede ocasionar la muerte o lesiones graves.

(000114)

ADVERTENCIA

Riesgo de caídas. No use esta máquina o

cualquiera de sus componentes en superficies

elevadas. Hacerlo puede ocasionar una caída,

lesiones graves o la muerte.

(000113)

ADVERTENCIA

Riesgo de la cuerda de arranque. La cuerda de

arranque se puede retraer inesperadamente si la presión

de agua no se alivió de la bomba apropiadamente,

creando un contragolpe. El contragolpe puede

ocasionar la muerte o lesiones graves.

(000100a)

ADVERTENCIA

Consulte el manual. Lea y comprenda

completamente el manual antes de usar el

producto. No comprender completamente el

manual puede provocar la muerte o lesiones

graves.

(000115)

ADVERTENCIA

Piezas en movimiento. No use alhajas cuando ponga

en marcha o trabaje con este producto. Usar alhajas

al poner en marcha o trabajar con este producto

puede ocasionar la muerte o lesiones graves.

ADVERTENCIA

Peligro ambiental. Siempre recicle las baterías en un

centro de reciclado oficial de acuerdo con todas las leyes

y reglamentos locales. No hacerlo puede ocasionar daños

ambientales, la muerte o lesiones graves.

(000228)

(000244)

ADVERTENCIA

Lesiones/Daños al equipo. Coloque la varilla en el

portador y verifique que el asa esté trabada en su

lugar antes de mover. No hacerlo puede ocasionar la

muerte, lesiones graves y daños al equipo.

Símbolos de seguridad y significado

2 Manual del propietario de la lavadora a presión

ADVERTENCIA

Lesiones personales. Riesgo de penetración de líquidos.

No apunte con la pistola pulverizadora a personas,

animales, dispositivos eléctricos o artículos frágiles.

Mantenga la máquina fuera del alcance de los niños.

En caso de no hacerlo, podría causar la muerte o

lesiones graves.

(000117c)

Sección 2 Información general y configuración

000264

Å

B

C

D

E

F

G

I

J

L

M

N

O

P

R

S

T

U

U

H

K

(000100a)

ADVERTENCIA

Consulte el manual. Lea y comprenda

completamente el manual antes de usar el

producto. No comprender completamente el

manual puede provocar la muerte o lesiones

graves.

Tabla 2-1. Componentes de la lavadora a

presión

Å Pistola de pulverización

B Lanza con conector rápido

C Manguera de alta presión

D Cuerda de arranque

E Llenado de aceite

F Filtro de aire

G Bomba de alta presión

H Válvula de alivio térmico

I Interruptor encendido/apagado del motor

J Válvula del descargador

K Salida de alta presión

L Entrada de agua

M Tanque de combustible

Válvula de encendido/apagado del

N

combustible

O Cebador

PCorrea

R Boquillas

S Asa lateral ajustable

T Tapón por vaciado de aceite

U Ubicación del número de serie

*

*

Manual del propietario de la lavadora a presión 3

Etiqueta de identificación (no se muestra) -

ubicada en la carcasa del ventilador del

motor

Filtro/Tubo del sifón del detergente (no se

muestra)

Figura 2-1. Controles y funciones

Conozca su lavadora a presión

Lea este manual detenidamente antes de

armar y poner en funcionamiento esta unidad.

Guarde este manual para referencia

inmediata y en el futuro. Los manuales del

propietario de repuesto están disponibles en

www.generac.com.

Información sobre emisiones

La Agencia de Protección Ambiental (EPA) de

los EE. UU. (y la Junta de Recursos del Aire

de California [CARB] para los equipos

certificados conforme a las normas de

California) requiere(n) que este motor cumpla

las normativas sobre el escape de gases y

emisiones por evaporación. Ubique en el

motor la etiqueta adhesiva sobre

cumplimiento de las normas referidas a

emisiones para determinar las normativas que

cumple el motor, y para determinar las

emisiones que incluye la garantía. El motor

está certificado de acuerdo con las normas de

emisiones de gasolina aplicables. Es

importante seguir las especificaciones sobre

mantenimiento en la sección Mantenimiento

para asegurarse de que el motor cumple con

las normas de emisiones aplicables durante la

vida útil del producto. Este motor utiliza un

ajuste de carburación pobre y otros sistemas

para reducir las emisiones. Manipular o alterar

el sistema de control de emisiones puede

aumentar el nivel de emisiones y podría

constituir una infracción de la Ley Federal o

de California. Los actos que constituyen

manipulación incluyen, aunque no se limitan

a, los que se especifican a continuación:

• Supresión o alteración de cualquiera de las

(000100a)

ADVERTENCIA

Consulte el manual. Lea y comprenda

completamente el manual antes de usar el

producto. No comprender completamente el

manual puede provocar la muerte o lesiones

graves.

000265

000266

piezas de los sistemas de entrada de aire,

combustible o sistema de escape de

gases.

• Alterar o interferir en el acoplamiento del

regulador o el mecanismo de ajuste de

velocidad para hacer que el motor funcione

fuera de los parámetros de diseño.

El motor debe ser inspeccionado o reparado

por un distribuidor de servicio si se presentan

los siguientes síntomas:

• Problemas de arranque o atasco tras el

arranque

• Ralentí brusco

• Fallos de encendido o detonaciones bajo

carga

• Postcombustión (detonaciones)

• Formación de humo de escape negro o

alto consumo de combustible

NOTA: El mantenimiento, la sustitución o

reparación de los dispositivos y sistemas de

control de emisiones puede ser llevada a

cabo por una persona o por un

establecimiento pequeño de reparación de

motores. Para que puedan ser cubiertos por

la garantía, todos los trabajos de

mantenimiento de control de emisiones deben

ser llevados a cabo por un distribuidor

autorizado por fábrica. Consulte la garantía de

emisiones para obtener información más

detallada.

Retiro del contenido de la caja

1. Abra la caja completamente cortando

cada esquina de arriba abajo.

2. Retire y verifique el contenido de la caja

antes del armado. La caja debe contener

uno de cada uno de los siguientes

componentes:

• Unidad principal

• Manguera de alta presión

• Manguera y filtro del sifón

• Pistola de pulverización

• Lanza con conector rápido

• Botella de aceite

• Bolsa de piezas

– Manual del propietario

– Tarjeta de registro del cliente

– Bolsa con boquillas de colores

3. Llame al Servicio al cliente de Generac al

1-888-436-3722 con el número de modelo

y número de serie de la unidad para

cualquier artículo que falte en la caja.

4. Registre el modelo, el número de serie y la

fecha de compra en la tapa de este

manual.

Armado

Llame al servicio al cliente de Generac al 1888-436-3722 para comunicar cualquier

problema o duda referente el armado. Tenga

disponible a mano el modelo y el número de

serie.

1. Inserte las boquillas de colores en los

espacios que se proporcionan (Figura 2-2).

Figura 2-2. Insertar boquillas (el número

2. Coloque la pistola de pulverización y la

extensión de la boquilla en el soporte de la

pistola de pulverización.

3. Consulte la Figura 2-3. Conecte el tubo de

sifón.

Figura 2-3. Ubicación del tubo de sifón

puede variar)

4 Manual del propietario de la lavadora a presión

Añadir aceite de motor

000115

000116

000267

000268

1. Coloque la lavadora a presión en una

superficie plana y nivelada.

2. Limpie la zona de llenado y retire el tapón/

varilla de medición de llenado de aceite de

color naranja (Figura 2-4).

Comprobar el aceite de la bomba

1. Coloque la lavadora a presión en una

superficie plana y nivelada.

2. Limpie la zona de llenado de aceite y retire

la varilla/tapón venteado (Figura 2-1).

Figura 2-4. Añadir aceite de motor

3. Con un embudo (opcional), eche el aceite

en la abertura de llenado de aceite.

Consulte Recomendaciones sobre el

aceite de motor.

NOTA: Algunas unidades tienen más de una

ubicación de llenado de aceite. En estos

casos, solo es necesario usar uno de los

puntos de llenado de aceite.

4. Compruebe de vez en cuando hasta que

el nivel de aceite esté ente la “L” y la “H”

de la varilla (Figura 2-5). No lo llene en

exceso.

NOTA: Cualquier intento de arrancar o girar el

motor antes de que se haya puesto a punto

con el aceite recomendado puede causar una

falla en el motor.

5. Instale la tapa de llenado/varilla de

medición y apriete con la mano.

Figura 2-5. Rango de funcionamiento

seguro

Figura 2-6. Comprobar el aceite de la

3. Compruebe que el nivel de aceite se

encuentra dentro de las marcas de la

varilla de medición (Figura 2-5). Si es

necesario añadir aceite, consulte la

sección Mantenimiento. NO LO LLENE

EN EXCESO.

4. Consulte Mantenimiento preventivo para

obtener información adicional.

5. Coloque la varilla de medición de aceite

hasta que quede bien apretada.

6. Limpie el aceite que haya podido quedar

derramada.

Figura 2-7. Va rilla d e medici ón de aceite d e

bomba

la bomba

Manual del propietario de la lavadora a presión 5

Combustible

(000105)

PELIGRO

Explosión e incendio. El combustible y los vapores son

extremadamente inflamables y explosivos. Añada

combustible en una zona bien ventilada. Mantenga

alejados el fuego y las chispas. No hacerlo puede

ocasionar la muerte o lesiones graves.

000117

000270

Å

B

Los requisitos para el combustible son los

siguientes:

• Gasolina limpia, fresca y sin plomo.

• Calificación mínima de 87 octanos/87 AKI

(91 RON).

• Es aceptable hasta un 10 % de etanol

(gasohol).

• NO use E85.

• NO use una mezcla de gasóleo.

• NO modifique el motor para que funcione

con combustibles alternativos. Añada un

estabilizador de combustible antes de

almacenarlo.

1. Verifique que la unidad esté APAGADA y

que se enfríe durante un mínimo de dos

minutos antes de volver a echar

combustible.

2. Coloque la unidad en terreno nivelado en

una zona bien ventilada.

3. Limpie la zona alrededor de la tapa de

combustible y retire la tapa lentamente.

4. Añada lentamente el combustible

recomendado. No lo llene en exceso.

Suministro de agua

NOTA: NO haga funcionar la unidad sin un

suministro de agua suficiente. No respetar los

requisitos de suministro de agua anulará la

garantía de la unidad.

El suministro de agua debe cumplir los

siguientes requisitos:

• NO haga sifón con agua estancada para el

suministro de agua.

• La temperatura del agua debe ser inferior a

100 ºF (38 ºC).

• El largo de la manguera de suministro de

agua no debe superar los 50 pies (15,2 m).

• El agua debe superar 3,8 galones por

minuto (17,3 litros por minuto) y no estar

por debajo de 30 psi (206,8 kPa).

• NO use una válvula de una vía, rompedor

de vacío, o válvula de retención en ninguna

parte del suministro de agua.

Conexión del suministro de agua

1. Retire y deseche la tapa de transporte de

la entrada de agua a la bomba.

2. Haga correr agua durante 30 segundos

antes de la conexión para eliminar

residuos.

3. Consulte la Figura 2-9. Inspeccione el

tamiz de entrada (A) para comprobar si

hay residuos. Limpie o sustituya el tamiz

según sea necesario. NO haga funcionar

la lavadora a presión si falta el tamiz de

entrada o está dañado.

Figura 2-8. Añadir el combustible

5. Instale la tapa de combustible.

NOTA: Permita que el combustible derramado

se evapore antes de poner en marcha la

unidad.

6 Manual del propietario de la lavadora a presión

recomendado

Figura 2-9. Conexión del suministro

4. Conecte la manguera de suministro de

agua a la entrada de agua de la bomba

(A) y apriete con la mano.

5. Conecte la manguera de alta presión a la

bomba (B).

de agua

Conexión de la manguera y la

000120

000269

000123

000125

lanza de alta presión

1. Consulte la Figura 2-10. Conecte la lanza

en la pistola de pulverización y apriete con

la mano.

Figura 2-10. Conexión de la lanza

2. Consulte la Figura 2-11. Conecte la lanza

en la pistola de pulverización y apriete con

la mano.

3. Conecte el agua y apriete el gatillo para

purgar de aire el sistema de la bomba.

4. Verifique que la pistola de pulverización

esté en OFF con el seguro enganchado

antes de poner en marcha la lavadora a

presión.

Cómo usar las boquillas

1. Consulte la guía de selección de boquillas

y seleccione la boquilla correcta para cada

tarea.

2. Consulte la Figura 2-13. Tire hacia atrás

del collar de conexión rápida e instale la

boquilla.

Figura 2-13. Insertar boquilla

3. Libere el collar de conexión rápida para

fijar la boquilla.

4. Verifique que la boquilla esté bloqueada

en su lugar.

Figura 2-11. Conexión de la manguera y la

lanza de alta presión

Pistola de pulverización

Familiarícese con el disparador y el sistema

de seguro de la pistola de pulverización antes

del uso.

Consulte la Figura 2-12. Con la unidad

apagada sostenga la pistola de pulverización

y apriete el gatillo para aprender como se

puede activar y desactivar el mecanismo del

gatillo y el sistema de seguro.

Figura 2-12. Pistola de pulverización

Manual del propietario de la lavadora a presión 7

(típica)

Guía para selección de la boquilla

Boquilla de

presión de

chorro fuerte

(Roja)

Boquilla de

presión para

franjas

(Amarilla)

Boquilla de

presión para

limpieza

(Verde)

Boquilla de

presión para

lavado

(Blanca)

Boquilla para

detergente

(Negra)

MÁXIMA - Presión más alta y caudal más bajo para superficies resistentes o difíciles de alcanzar

como las de segundo piso, remoción de pintura, manchas de aceite, remoción de óxido, y otras

sustancias resistentes (alquitrán, caucho, grasa, cera, etc.).

MEDIA - Presión más alta y caudal medio para quitar manchas en superficies duras porosas como

aceras de concreto, pisos de garaje y patios de ladrillo.

GENERAL - Presión y caudal medios para la mayor parte de la limpieza de propósitos múltiples como

los revestimientos de casas, patios de ladrillo, plataformas de madera, aceras y veredas, pisos de

garaje, etc.

DELICADO - Presión más baja y caudal más alto para limpieza suave de automóviles/camionetas,

botes, vehículos recreativos, muebles de patio, equipos de jardinería, etc.

ÚNICAMENTE DETERGENTE (NEGRA) - Use detergentes/jabones seguros para la hidrolavadora para

ayudar a disgregar suciedad o mugre resistente sobre diferentes superficies.

000245

Manual del propietario de la lavadora a presión 8

Funcionamiento

Asfixia. Los motores funcionando producen

monóxido de carbono, un gas incoloro, inodoro, y

venenoso. El monóxido de carbono, si no se evita,

ocasionará la muerte o lesiones graves.

(000103)

PELIGRO

(000110)

ADVERTENCIA

Riesgo de incendio. Las superfcies calientes

pueden encender combustibles, produciendo un

incendio. El incendio puede ocasionar la muerte

o lesiones graves.

(000108)

ADVERTENCIA

Superfcies calientes. Al usar la máquina, no toque

las superfcies calientes. Mantenga la máquina

alejada de los combustibles durante el uso. Las

superfcies calientes pueden ocasionar quemaduras

graves o incendio.

000271

Sección 3 Funcionamiento

Preguntas sobre uso y funcionamiento

Llame al Servicio al cliente de Generac al

1-888-436-3722 con las preguntas o dudas

acerca del funcionamiento y mantenimiento

de la unidad.

Antes de poner en marcha el motor

1. Verifique si el nivel de aceite de motor es

correcto.