Page 1

Surface Mount Models: Flush Mount Models:

004996-0 004997-0 Standard Annunciator

004998-0 004999-0 Annunciator w/Remote Relay Panel

PM-DCP 20-light

Remote Annunciator

Owner’s Manual

GEN.

RUN.

PRESSURE

GENERAC

LOW

OIL

BATTERY

CHARGER

FAILURE

PRE - ALARMS

HIGH

WATER

TEMP.

LOW

BATTERY

VOLTAGE

LOW

WATER

TEMP.

HIGH

BATTERY

VOLTAGE

LOW

FUEL

®

POWER SYSTEMS

1 AMP

RPM

SENSOR

LOSS

LOW

OIL

PRESSURE

RESET

ALARM

OVER

CRANK

HIGH

WATER TEMP

LOW WATER

LEVEL

RE-ARM

HORN

OVER

SPEED

EMERGENCY

STOP

GEN.

POWER

NOT

IN

AUTO

POWER MONITOR

TEST

ON

OFF

SYSTEM

READY

LINE

POWER

REMOTE START

COMMS.

OK

0A6733

ON

OFF

Page 2

20-light Remote Annunciator

DETAILED SPECIFICATIONS

ENVIRONMENTAL SPECIFICATIONS

Temperature -20°C to +50°C

Humidity 0 to 95% Non Condensing

POWER SUPPLY REQUIREMENTS

Power Supply Source Generator Battery to comply

with NFPA

Nominal Supply +12 to +24VDC

Transient protection Spikes clamped to 40V

Power Usage 150mA maximum.

Battery Supply cable 2 wire - DC resistance less

than 7 Ohms per conductor.

Fuse on front panel 1 Amp

COMMUNICATION WITH GENERATOR CONTROL

SYSTEM

Communication link 2 wire RS485 fully isolated.

Communication cable 2 wire—twisted pair with

overall screen.

Cable size 24 AWG 0-250 feet. 18 AWG

0-1,200 feet.

Baud rate 4800, N, 8, 2.

NOTE:

1. The RS485 cable should not be run in the same

conduit, or in the same grouping as any high voltage or other “noisy” electrical conductors.

2. Avoid running the RS485 cable through any “high

noise” environments.

INTERFACE WITH OTHER EQUIPMENT

Alarm Relay Output 1 pair N/O Volt-free contacts-

100mA, 24V DC

AGENCY COMPLIANCE

NFPA-110 Yes

NFPA-99 Yes

TRANSPORTATION AND STORAGE

Temperature -20°C to +80°C

Humidity 0-95% Non Condensing

Detailed Specifications ..................................................2

Environmental Specifications ........................................2

Power Supply Requirements..........................................2

Communication With Generator Control System ..........2

Interface With Other Equipment ....................................2

Agency Compliance ......................................................2

Transportation and Storage ..........................................2

Packaging and Mounting................................................3

Annunciator Panel Mounting..........................................3

System Specification ......................................................3

Active/Passive Mode ......................................................3

Setting to Passive Mode ................................................4

Hardware Functional Description ..................................4

Generator Stop Signals..................................................4

Warning Indicators ........................................................4

Generator Power............................................................5

Line Power ....................................................................5

Battery Charger AC Failure............................................5

System Status Indicators ..............................................5

System Ready................................................................5

Communication OK........................................................6

Audible Annunciator ......................................................6

Test Switch ....................................................................6

Re-Arm Horn Switch ......................................................6

Reset Switch ..................................................................6

Relay Output ..................................................................6

Software Specification....................................................6

Serial Interface ..............................................................6

Request Frequency........................................................6

Operator Functions ........................................................6

Error Handling................................................................6

Hardware Watchdog ......................................................6

Troubleshooting ..............................................................7

Notes ................................................................................8

Electrical Data ................................................................9

Exploded Views & Parts Lists......................................12

2 Generac®Power Systems, Inc.

Page 3

20-light Remote Annunciator

Generac®Power Systems, Inc. 3

PACKAGING AND MOUNTING

Enclosure type Sheet metal box.

Base panel Generac part #0A6985/0A7437

Front panel Generac part #0A6988/0A7443

Panel overlay Generac part #0A6733

Mounting Flush or Wall.

Weight requirements None

Manuals Yes - Operator guide

ANNUNCIATOR PANEL MOUNTING

NOTE:

For ALL models installation must always comply

with applicable codes, standards, laws and regulations. Adhere strictly to local, state and national

electrical and building codes. Comply with regulations the Occupational Safety and Health

Administration (OSHA) has established. Also, the

generator and related components must be installed

completely in conformance with the manufacturer’s

instructions and recommendations. Following proper

installation, do nothing that might alter a safe installation and render the unit in non-compliance with

such codes, standards, laws and regulations.

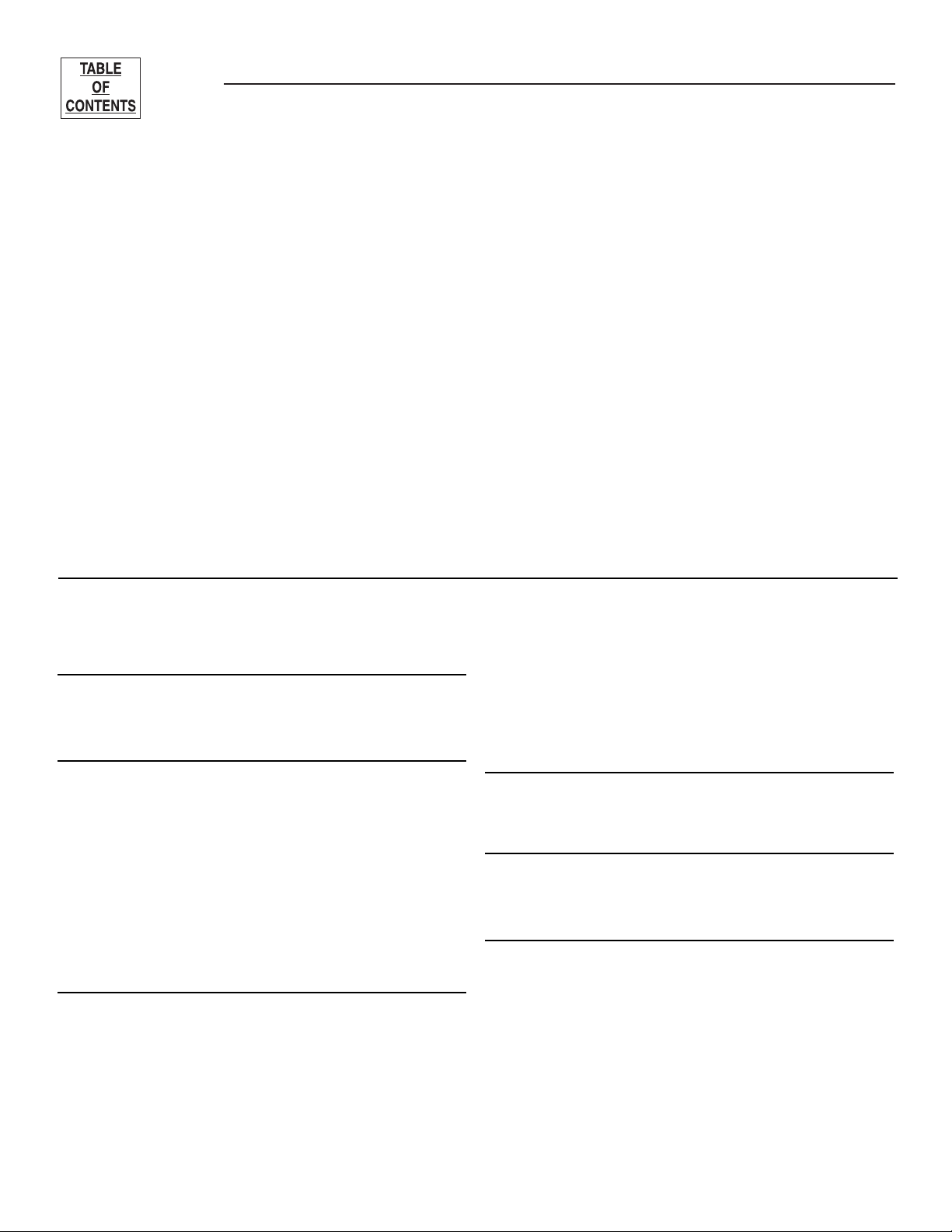

The Remote Annunciator panels (Models 004997-0 and

004999-0) are intended for flush mounting. Panel

mounting dimensions are shown in the illustration

below. The panel can be installed behind a cutout in an

existing sheet metal panel by using the four mounting

holes in its front panel. For wall mounting, use a square

outlet box behind the annunciator panel.

Flush Mounting Dimensions

The Remote Annunciator panels (Models 004996-0, and

004998-0) are mounted using any combination of the

mounting holes in the back panel of the box itself.

Surface Mount Dimensions

SYSTEM SPECIFICATION

The 20-light remote annunciator panel (RAP) directly

interacts with Generac’s control systems, and provides

remote monitoring and annunciation of 17 generator

parameters, two system-level warnings - System Ready

and Communications OK, and one spare channel.

Power to the RAP is supplied from the generator battery

(+12VDC to +24VDC) via a 2-wire link.

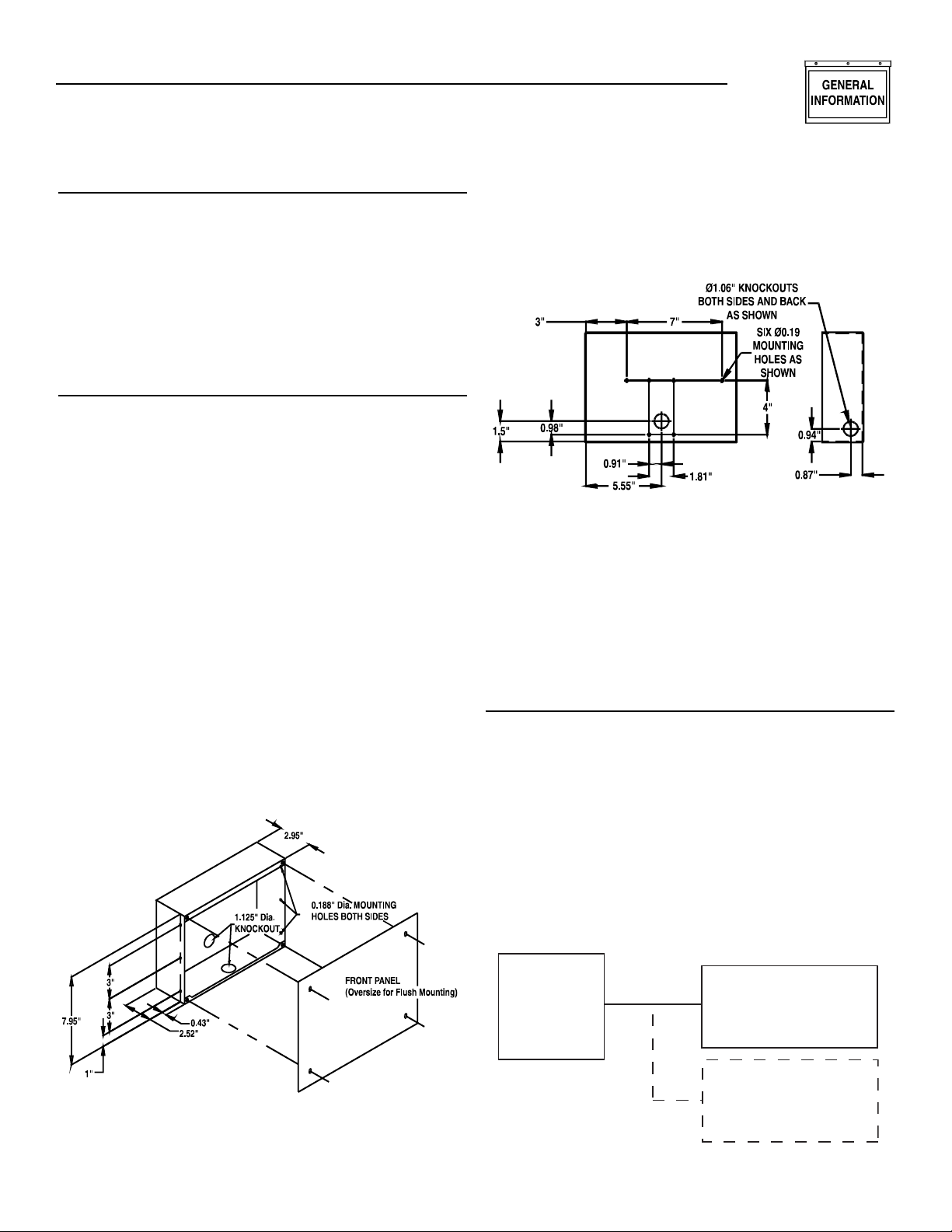

ACTIVE/PASSIVE MODE

The 20-light remote annunciator can be set to operate in

either ACTIVE or PASSIVE mode. In ACTIVE mode, it is

a modbus master and will request data from the DCP.

The DCP must be set as a slave port. In PASSIVE mode,

it is a modbus slave and must be connected to a master

port on the DCP; or, it can be hooked onto a masterslave link as a pure listening device. This method allows

for the connection of more than one annunciator.

An annunciator connected to an engine controller would

be a master.

Annunciator Connected to Engine Controller

PM-GC

(Slave)

Annunciator

(Master)

Slave

Page 4

4 Generac®Power Systems, Inc.

An annunciator connected to a system controller would

be a slave.

Annunciator Connected to System Controller

DO NOT set the PM-GC to a modbus master port.

This connection will not work.

SETTING TO PASSIVE MODE

To set the 20-light annunciator to passive mode, simply

connect an 18 to 22 gauge wire between header positions J3-1 and J3-2.

NOTE:

1. It is not recommended to connect more than a

total of two 20-light remote annunciator panels.

(one set to active mode, one set to passive mode)

2. Up to four remote relay panels can be used with

the two 20-light remote annunciators.

HARDWARE FUNCTIONAL DESCRIPTION

The Remote Annunciator Panel communicates with the

control system and updates the light panel and audible

annunciator as described below.

GENERATOR STOP SIGNALS

These lights will flash when any alarm occurs and the

horn will sound as follows:

The ‘Re-Arm Horn' switch can be used to turn off and

re-arm the horn, or the alarms can be fully acknowledged using the ‘Reset' switch.

The ‘Reset' switch will turn off and re-arm the horn, and

any flashing lights will switch to the ON state until the

alarms are no longer present at the generator control

panel.

NOTE:

1. Alarm condition MUST be reset at the generator

set control panel.

2. When this annunciator is used in a Modular Power

System (MPS), an alarm on any one of the generators will cause the above lights to light, and alarm

to sound.

WARNING INDICATORS

These lights will flash when any alarm occurs and the

horn will sound according to the following table:

These alarms will be latched/not latched by the RAP

according to the above table. They can be acknowledged

at the RAP using the ‘Reset' switch—the active lamps

will then stop flashing and remain in the ON state until

the alarm signal clears from the generator control

panel. The ‘Reset' switch will also turn off and re-arm

the horn.

NOTE:

1. These lamps can only be fully reset when the

alarm state is no longer active and “Reset” has

been pressed at both the generator control panel

and the RAP.

Alternatively, at any time the horn can be turned

OFF and re-armed with the ‘Re-Arm Horn’ switch.

2. When this annunciator is used in a Modular Power

System (MPS), a warning on any one of the generators will cause the above lights to light, and

alarm to sound (if the warning is audible).

!

20-light Remote Annunciator

Annunciator Light Light Audible

Color Alarm

RPM Sensor Loss Red Yes

Overcrank Red Yes

Overspeed Red Yes

Low Oil Pressure Red Yes

High Water Temp/Low Water Level Red Yes

Emergency Stop Red Yes

Annunciator Light Light Audible Latched

Color Alarm

Pre-low OIl Pressure Yellow Yes Yes

Pre-high Water Temp Yellow Yes Yes

Pre-low Water Temp Yellow Yes Yes

Pre-low Fuel Yellow Yes Yes

Battery Charger AC Failure Yellow Yes No

Low Battery Voltage Yellow Yes No

High Battery Voltage Yellow No No

Generator Run Yellow No No

Generator Power Yellow No No

Not in Auto Red Yes No

PM-SC

(Master)

Annunciator

(Slave)

Slave

DANGER

Page 5

Generac®Power Systems, Inc. 5

20-light Remote Annunciator

GENERATOR POWER

This light indicates different things depending on the

type of system it is attached to.

• For a PowerManager System Controller (PM-SC with

external transfer switch(es)), generator power is

defined as any one or more generators in the system

running and connected to the generator bus.

• For a PowerManager Integrated Controller (PM-IC

with integrated transfer switch), it represents the status of the generator’s side auxiliary contact of the

internal transfer switch. This shows whether the load

is powered by the generator.

• For a non-paralleling engine controller (PM-GC

WITHOUT internal transfer switch), it represents the

status of the input 4 (TB2-5) to the generator DCP.

This should be connected to the generator side auxiliary contact of the external transfer switch. A closure

to ground will cause the light to illuminate. This

shows whether the load is powered by the generator.

• For an engine controller that is part of an MPS system

(PM-PC), generator power represents the state of the

internal contactor that the generator is connected to.

• For a Utility paralleling engine controller (PM-GCF),

generator power represents the status of the generator side auxiliary contact of the internal transfer

switch. This shows whether the load is powered by

the generator.

LINE POWER

This light indicates different things depending on the

type of system it is attached to.

• For a PowerManager System Controller (PM-SC with

external transfer switch(es)), line power represents

the auxiliary input C (TB6-4).

• For a PowerManager Integrated Controller (PM-IC

with integrated transfer switch), it represents the status of the utility side auxiliary contact of the internal

transfer switch. This shows whether the load is powered by the utility.

• For a non-paralleling engine controller (PM-GC

WITHOUT internal transfer switch), it represents the

status of the input 3 (TB2-4) to the generator DCP.

This should be connected to the utility side auxiliary

contact of the external transfer switch. A closure to

ground will cause the light to turn ON. This shows

whether the load is power by the utility.

• For an engine controller that is part of an MPS system

(PM-PC), line power is not used.

• For a Utility paralleling engine controller (PM-GCF), it

represents the status of the utility side auxiliary contact of the internal transfer switch. This shows

whether the load is powered by the utility.

BATTERY CHARGER AC FAILURE

This light annunciates upon loss of 120 VAC power supply to the battery charger. This requires an AC relay

with normally closed contacts connected in the circuit

feeding power to the battery charger.

NOTE:

To prevent false alarms caused by brief power outages or load switching, a time delay AC relay

(approximately 30 second delay) is suggested.

SPARE

The spare indicator can be activated from the DCP by

using the programmable logic controller (PLC) feature.

SYSTEM STATUS INDICATORS

These lamps are for Status indication only—the normal

condition is ON.

SYSTEM READY

The System Ready is defined as ALL “in service” generators are ready to start, run, and supply power. Any

generators manually declared as “out of service” will not

affect this LED.

Upon a loss of System Ready, the annunciator will

respond as follows:

1. The System Ready LED will begin to flash.

2. The alarm will sound.

The “Re-arm Horn” switch can be used to turn off and

re-arm the horn, or the alarm can be fully acknowledged using the reset switch at which time the System

Ready LED will turn off and remain off until the System

Ready status is returned.

Annunciator Light Light Audible

Color Alarm

System Ready Green Yes

Communication OK Green Yes

Line Power Green No

Spare Green No

Page 6

6 Generac®Power Systems, Inc.

COMMUNICATION OK

This LED will be on as long as there is proper communication between the Remote Annunciator Panel and the

generator control system.

When communication failure occurs, the RAP will flash

the communication LED, and sound the horn. The rate

of flashing will be indicative of the cause of error.

1. No reply from the generator control system Frequency = one second on/one second off.

2. Consecutive data errors Frequency = 0.5 second on/two seconds off.

This alarm condition can be acknowledged at the RAP

using the “reset” switch - the horn will be turned off and

re-armed, and the communication OK light will continue to flash until proper communication returns.

AUDIBLE ANNUNCIATOR

See System Status Indicators chart for alarm occurrences.

TEST SWITCH

While the test switch is pressed, all lights will light and

the horn will sound. When released the lights will return

to their original status. During this test, communication

to the generator control system will be suspended.

RE—ARM HORN SWITCH

The re-arm horn switch will silence the horn and rearm it for new alarm occurrences.

RESET SWITCH

The reset switch is used to acknowledge any active

alarms. It will re-set any flashing light to ON (steady)

condition (or OFF for normally on lights). If the alarm

no longer exists and it has also been latched OFF at the

generator control panel (pre-alarm indicators only) the

active light will go OFF. It will also silence the horn and

re-arm it for new alarm occurrences.

NOTE:

Pre-alarm conditions MUST be reset at the generator

set control panel.

RELAY OUTPUT

The RAP will also provide a pair of Normally Open contacts which will mimic the status of the Audible alarm

(Horn). The relay output is fail-safe (i.e. DC supply failure will reset the relay to OFF, which will close the contacts).

SOFTWARE SPECIFICATION

In general terms, the RAP polls the generator control

system. The generator control system returns an ASCII

text string which represents the status of the indicator

lights on the panel display.

SERIAL INTERFACE

Default 4800,n,8,2

NOTE:

Set the DCP port to these settings.

REQUEST FREQUENCY

Once per three seconds.

OPERATOR FUNCTIONS

Switches will be scanned every 1/10 second.

ERROR HANDLING

An error will be reported by flashing the

Communication OK light—the rate of flashing will be

indicative of the cause of the error.

1. No reply from generator control system—frequency

one second on/one second off.

2. Consecutive data errors—frequency 0.5 seconds

on/two seconds off.

HARDWARE WATCHDOG

Will reset the CPU if :

a. Supply voltage at CPU drops below 4.65VDC.

b. CPU activity stops for 15 seconds.

20-light Remote Annunciator

Page 7

Generac®Power Systems, Inc. 7

20-light Remote Annunciator

TROUBLESHOOTING GUIDE

No LEDs are lit. 1. Check for proper battery supply at J1 pins 3 and 4.

• J1 pin 3 should be + Battery (12 or 24 volts).

• J1 pin 4 should be – Battery.

• Refer to the “power supply requirements” section at the

beginning of the manual for cable specifications.

2. Check the 1 Amp panel fuse, replace if necessary.

The “Communication OK” 1. Does the RS485 communications cable meet specifications.

LED is flashing at the rate: Refer to the “Communication with generator control system”

one second on/one second off section at the beginning of the manual.

2. Check that the RS485 connections are connected properly.

• RS485+ connected to J1 pin 1.

• RS485– connected to J1 pin 2.

• Shield is connected correctly. Refer to the wiring schematic for

your particular model located in this manual. Note the screen

should be connected on one end only.

3. Check for proper installation of the RS485 cable between the annunciator and the generator’s control system. Is this cable sharing a conduit

or running next to any high voltage or other “noisy” electrical lines?

4. Check that the DCP port is set to 4800, N, 8, 2.

5. Use GenLink communication diagnostics to check if data is being sent

or received via the Tx and Rx check boxes. Go to pull-down menu for

diagnostics and select “Com Ports”. Select the port the R.A. is connected to (normally port 0) and look to see if the check boxes change

state. If not, data is not being transmitted/received, check the cabling.

If data is being received, check the baud rate, etc.

The “Communication OK” 1. Does the RS485 communications cable meet specifications?

LED is flashing at the rate: Refer to the “Communication with generator control system”

0.5 seconds on/two seconds off section at the beginning of the manual.

2. Is the cable shield connected correctly? Refer to the wiring schematic

for your particular model located in this manual. Note that the

screen should be connected on one end only.

3. Check for proper installation of the RS485 cable between the annunciator and the generator’s control panel. Is this cable sharing a conduit

or running next to any high voltage or other “noisy” electrical lines?

4. Check that the DCP port is set to 4800, N, 8, 2.

5. Use GenLink communication diagnostics to check if data is being sent

or received via the Tx and Rx check boxes. Go to pull-down menu for

diagnostics and select “Com Ports”. Select the port the R.A. is connected to (normally port 0) and look to see if the check boxes change

state. If not, data is not being transmitted/received, check the cabling.

If data is being received, check the baud rate, etc.

Page 8

8 Generac®Power Systems, Inc.

20-light Remote Annunciator

Page 9

Generac®Power Systems, Inc. 9

(CONNECT SCREEN AT ONE END ONLY)

(

O

N

M

M

/

V

E

O

U

C

O

O

0V

N

S

-

5+

ST

P

/

O

S

S

G

O

C

O

85-

85

6

5

8

S

O

+

US

P

O

-

S

T

U

P

0

S

O

C

SC

0

S

9

S

S

ARM

O

20-light Remote Annunciator

Wiring Diagram - Drawing No. 0E5616

ARD

R B

IAT

N

TE ANN

EM

SE I/

F

E O/

F

RN +5 O/P

H

RN O/P

H

E

RE

TE

V O

RE-ARM H

R

EXTERNAL ALAR

XTERNAL ALAR

CREEN-SPAR

CREE

BATT

BATT +12

485

R

24

RS48

T

2

E

P

V

T

E

RN

-

21

2

ET

E

ET

E

2

E

2

27

2

2

P

A

.

P

RN

1

+

24 V

REEN

4

4

V

2

REEN

NLY.

R

T T

ENERAT

NNE

TEM

Y

L

NTR

T THE

END

NNE

N THI

WER

PPLY

HE

Page 10

10 Generac®Power Systems, Inc.

20-light Remote Annunciator

Wiring Diagram - Drawing No. 0E5617

Page 11

Generac®Power Systems, Inc. 11

20-light Remote Annunciator

Wiring Diagram - Drawing No. 0E5617

Page 12

ITEM PART NO. QTY. DESCRIPTION

1 0A6985 1 PANEL ANNUNCIATOR REAR

2 0A6388D 1 ASSY, 20LT MODBUS ANNUN G-PNL

4 040213 6 PCB SUPPORT SNAP-IN 1/4"

5 0A6990 1 SUPPORT, PC BOARD

6 036901 4 SCREW PPHM #6-32 X 3/8

7 0A6988 1 PANEL ANNUNCIATOR FRONT

8 0A6733 1 DECAL ANNUNCIATOR PANEL

10 061284 3 SWITCH ROCKER SPST 10@125V SPD

11 032300 1 HOLDER FUSE

12 044299 1 FUSE 1A X AGC1

13 061286 1 SOUNALERT, BUZZER

14 065511 1 PLUG PANEL PLASTIC 1/2"

16 056892 4 SCREW CRIMPTITE 10-24 X 3/8

17 025034 2 PLUG STEEL 1.0625

18 0E5620 1 HARNESS,10 WIRE REMOTE ANN

19 022985 4 WASHER FLAT #6 ZINC

20 022155 4 WASHER LOCK #6

21 022188 4 NUT HEX #6-32 STEEL

22 0F0168 1 DECAL MODEL NO. 04996-0

23 0D4462 1 DECAL,WIRING,REMOTE ANNUNCIATOR

6

0

0

0

8

J

0

0

3

3

0

3

8

6

6

5

9

0

12 Generac

®

Power Systems, Inc.

20-light Remote Annunciator

Assembly - Drawing No. 0F0169

1

1

1

2

1

21

2

1

2

1

2

1

Page 13

Generac®Power Systems, Inc. 13

ITEM PART NO. QTY. DESCRIPTION

1 0A7437 1 PANEL ANNUNCIATOR REAR

2 0A6388D 1 ASSY, 20LT MODBUS ANNUN G-PNL

4 040213 6 PCB SUPPORT SNAP-IN 1/4"

5 0A6990 1 SUPPORT, PC BOARD

6 036901 4 SCREW PPHM #6-32 X 3/8

7 0A7438 1 PANEL ANNUNCIATOR FRONT

8 0A6733 1 DECAL ANNUNCIATOR PANEL

10 061284 3 SWITCH ROCKER SPST 10@125V SPD

11 032300 1 HOLDER FUSE

12 044299 1 FUSE 1A X AGC1

13 061286 1 SOUNALERT, BUZZER

14 065511 1 PLUG PANEL PLASTIC 1/2"

16 036918 4 SCREW PPHM #8-32 X 1/2

17 025034 1 PLUG STEEL 1.0625

18 0E5620 1 HARNESS,10 WIRE REMOTE ANN

19 022985 4 WASHER FLAT #6 ZINC

20 022155 4 WASHER LOCK #6

21 022188 4 NUT HEX #6-32 STEEL

22 0F0172 1 DECAL MODEL NO. 04997-0

23 0D4462 1 DECAL,WIRING,REMOTE ANNUNCIATOR

]

0

0

8

6

J

0

5

8

3

3

0

9

6

3

3

20-light Remote Annunciator

Assembly - Drawing No. 0F0173

2

1

2

OTHER SIDE OF PANEL

-

1

1

1

1

1

1

-

Page 14

ITEM PART NO. QTY. DESCRIPTION

1 0A6985 1 PANEL ANNUNCIATOR REAR

2 0A6388D 1 ASSY, 20LT MODBUS ANNUN G-PNL

3 0A9036B 1 8CH REM RLY PNL MODBUS RRP G-P

4 040213 12 PCB SUPPORT SNAP-IN 1/4"

5 0A6990 2 SUPPORT, PC BOARD

6 036901 8 SCREW PPHM #6-32 X 3/8

7 0A6988 1 PANEL ANNUNCIATOR FRONT

8 0A6733 1 DECAL ANNUNCIATOR PANEL

10 061284 3 SWITCH ROCKER SPST 10@125V SPD

11 032300 1 HOLDER FUSE

12 044299 1 FUSE 1A X AGC1

13 061286 1 SOUNALERT, BUZZER

14 065511 1 PLUG PANEL PLASTIC 1/2"

16 056892 4 SCREW CRIMPTITE 10-24 X 3/8

17 025034 2 PLUG STEEL 1.0625

18 0E5620 1 HARNESS,10 WIRE REMOTE ANN

19 022985 8 WASHER FLAT #6 ZINC

20 022155 8 WASHER LOCK #6

21 022188 8 NUT HEX #6-32 STEEL

22 0F0174 1 DECAL MODEL NO. 04998-0

23 0D4461 1 DECAL,WIRING,REMOTE RELAY PNL

24 0D4462 1 DECAL,WIRING,REMOTE ANNUNCIATOR

6

0

3

6

0

6

9

5

8

J

0

0

0

C

3

3

8

O

G

0

T

14 Generac

®

Power Systems, Inc.

20-light Remote Annunciator

Assembly - Drawing No. 0F0175

2

TE RELAY PANEL WIRIN

REM

LIGH

2

1

2

1

1

1

1

2

1

21

1

Page 15

Generac®Power Systems, Inc. 15

ITEM PART NO. QTY. DESCRIPTION

1 0A7437 1 PANEL ANNUNCIATOR REAR

2 0A6388D 1 ASSY, 20LT MODBUS ANNUN G-PNL

3 0A9036B 1 8CH REM RLY PNL MODBUS RRP G-P

4 040213 12 PCB SUPPORT SNAP-IN 1/4"

5 0A6990 2 SUPPORT, PC BOARD

6 036901 8 SCREW PPHM #6-32 X 3/8

7 0A7438 1 PANEL ANNUNCIATOR FRONT

8 0A6733 1 DECAL ANNUNCIATOR PANEL

10 061284 3 SWITCH ROCKER SPST 10@125V SPD

11 032300 1 HOLDER FUSE

12 044299 1 FUSE 1A X AGC1

13 061286 1 SOUNALERT, BUZZER

14 065511 1 PLUG PANEL PLASTIC 1/2"

16 036918 4 SCREW PPHM #8-32 X 1/2

17 025034 1 PLUG STEEL 1.0625

18 0E5620 1 HARNESS,10 WIRE REMOTE ANN

19 022985 8 WASHER FLAT #6 ZINC

20 022155 8 WASHER LOCK #6

21 022188 8 NUT HEX #6-32 STEEL

22 0F0176 1 DECAL MODEL NO. 04999-0

23 0D4461 1 DECAL,WIRING,REMOTE RELAY PNL

24 0D4462 1 DECAL,WIRING,REMOTE ANNUNCIATOR

]

0

0

6

J

5

3

8

0

3

3

0

9

6

3

3

3

C

8

20-light Remote Annunciator

Assembly - Drawing No. 0F0177

2

1

OTHER SIDE OF PANEL

2

-

1

1

4

1

1

-

Page 16

GENERAC®POWER SYSTEMS, INC.

P.O. BOX 8 • WAUKESHA, WI 53187

PH: (414) 544-4811 • FAX: (414) 544-4851

Part No. 0F0270 Revision 0 (03/29/04)

Printed in U.S.A.

Loading...

Loading...