Page 1

Manual Part No. 94468-A

SERVICE

Manual

COMPUTER

CONTROLLED

VARIABLE

SPEED RV

GENERATORS

Series NP-30G and NP-40G

P. O. Box 8

PH ONE: (414) 544-4811

Printed In U.S.A.

Waukesha, Wisconsin 53187

_________

FA X: (414) 544-4851

REVISED: 05/16/96

Page 2

SAFETY

Throughout this publication, ’DANGERl" and "CAUTiONI" blocks are used to alert the mechanic to special

Instructions concerning a particular service or operation that might be hazardous if performed Incorrectly or

carelessly. PAY CLOSE ATTENTION TO THEM.

DANGER!

UNDER THIS HEADING WILL BE FOUND SPECIAL INSTRUCTIONS WHICH, IF NOT COMPLIED WITH,

COULD RESULT IN PERSONAL INJURY OR DEATH.

CAUTION!

Under this heading will be found special instructions which, if not complied with, couid result in damage

to equipment and/or property.

These ‘Safety Alerts” alone cannot eliminate the hazards that they signal. Strict compliance with these special

Instructions plus ‘common sense” are major accident prevention measures.

NOTICE TO USERS OF THIS MANUAL

This SERVICE MANUAL has been written and published by Generac to aid our dealers’ mechanics and company

service personnel when servicing the products described herein.

It Is assumed that these personnel are familiar with the servicing procedures for these products, or like or similar

products manufactured and marketed by Generac. That they have been trained in the recommended servicing

procedures for these products. Including the use of common hand tools and any special Generac tools or tools

from other suppliers.

Generac could not possibly know of and advise the service trade of all conceivable procedures by which a

service might be performed and of the possible hazards and/or results of each method. We have not undertaken

any such wide evaluation. Therefore, anyone who uses a procedure or tool not recommended by Generac must

first satisfy himself that neither his nor the products safety will be endangered by the service procedure selected.

All information. Illustrations and specifications in this manual are based on the latest product information

available at the time of publication.

When working on these products, remember that the electrical system and engine Ignition system are capable

of violent and damaging short circuits or severe electrical shocks. If you intend to perform work where electrical

terminals could be grounded or touched, the battery cables should be disconnected at the battery.

Any time the Intake or exhaust openings of the engine are exposed during service, they should be covered to

prevent accidental entry of foreign material. Entry of such materials will result In extensive damage when the

engine Is started.

During any maintenance procedure, replacement fasteners must have the same measurements and strength as

the fasteners that were removed. Metric bolts and nuts have numbers that indicate their strength. Customary bolts

use radial lines to indicate strength while most customary nuts do not have strength markings. Mismatched or

Incorrect fasteners can cause damage, malfunction and possible injury.

REPLACEMENT PARTS

Components on Generac recreational vehicle generators are designed and manufactured to comply with

Recreational Vehicle Industry Association (RVIA) Rules and Regulations to minimize the risk of fire or explosion.

The use of replacement parts that are not In compliance with such Rules and Regulations could result In a fire or

explosion hazard. When servicing this equipment it is extremely important that all components be properly

Installed and tightened. If improperly Installed and tightened, sparks could ignite fuel vapors from fuel system

leaks.

Page 3

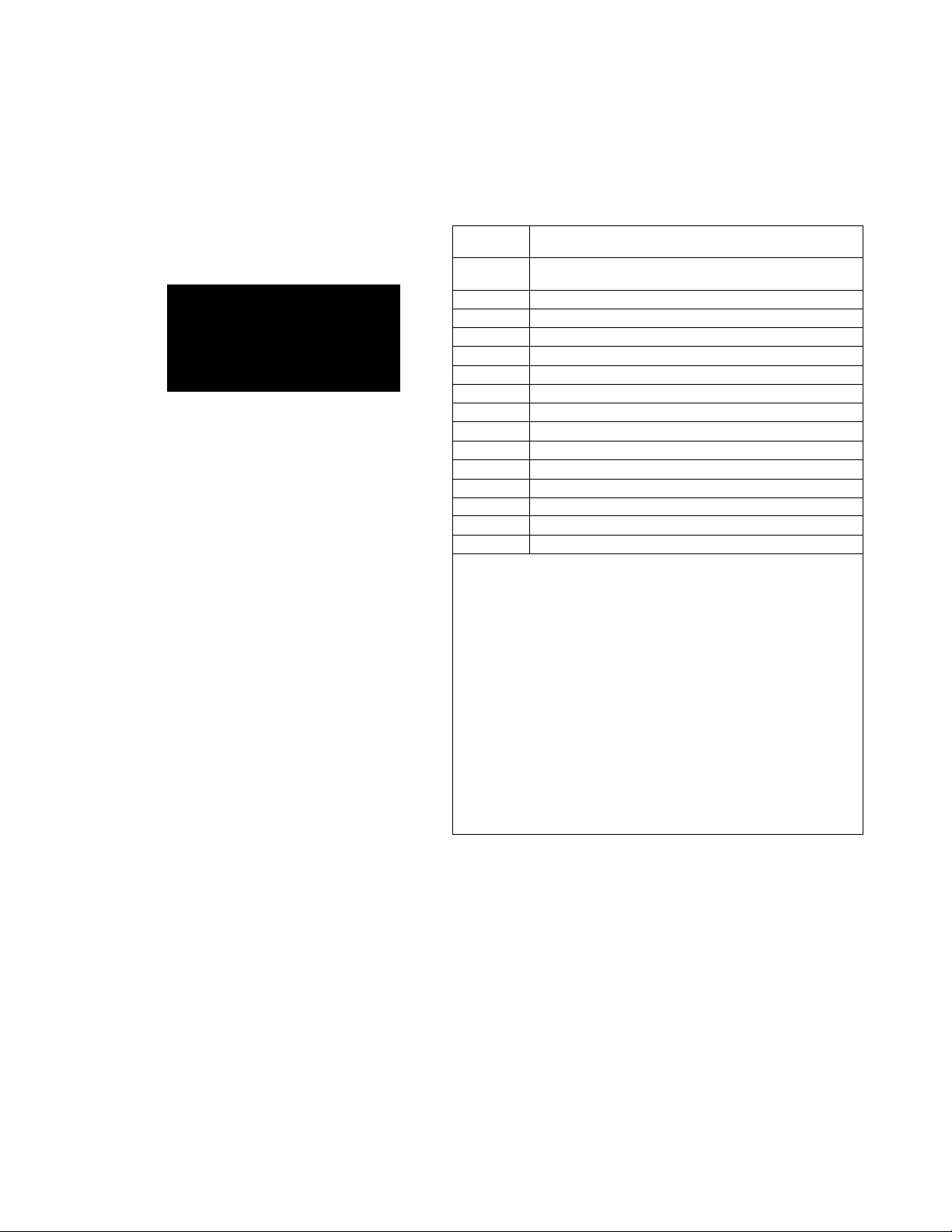

PART

TITLE

SERVICE

MANUAL

COMPUTER

CONTROLLED

VARIABLE

SPEED RV

GENERATORS

Series NP-30G and NP-40G

1

2

3

4

5

6

7 TROUBLESHOOTING

8

THE AC GENERATOR

ENGINE MECHANICAL

GASOLINE FUEL SYSTEM

GASEOUS FUEL SYSTEM

ENGINE OIL & COOLING SYSTEM

ENGINE ELECTRICAL SYSTEM

SPECIFICATIONS & CHARTS

Page 4

Part 1

THE AC

GENERATOR

COMPUTER

CONTROLLED

VARIABLE

SPEED RV

GENERATORS

Series NP-30G and NP-40G

SECTION

1.2

1.3

1.4

1.5

1.6

1.7

TITLE

TaEnE!53tT5i?TOnï55mÇÏTRB"

GENERATOR MAJOR COMPONENTS

OPERATIONAL ANALYSIS

INSULATION RESISTANCE

COMPONENTS TESTING

CONTROL PANEL

SHEET METAL

Page 5

Section 1.1- GENERATOR FUNDAMENTALS

Magnetism

Magnetism can be used to produce electricity and

electricity can be used to produce magnetism.

Much about magnetism cannot be explained by our

present knowledge. However, there are certain patterns

of behavior that are known. Application of these behavior

patterns has led to the development of generators, mo

tors and numerous other devices that utilize magnetism

to produce and use electrical energy.

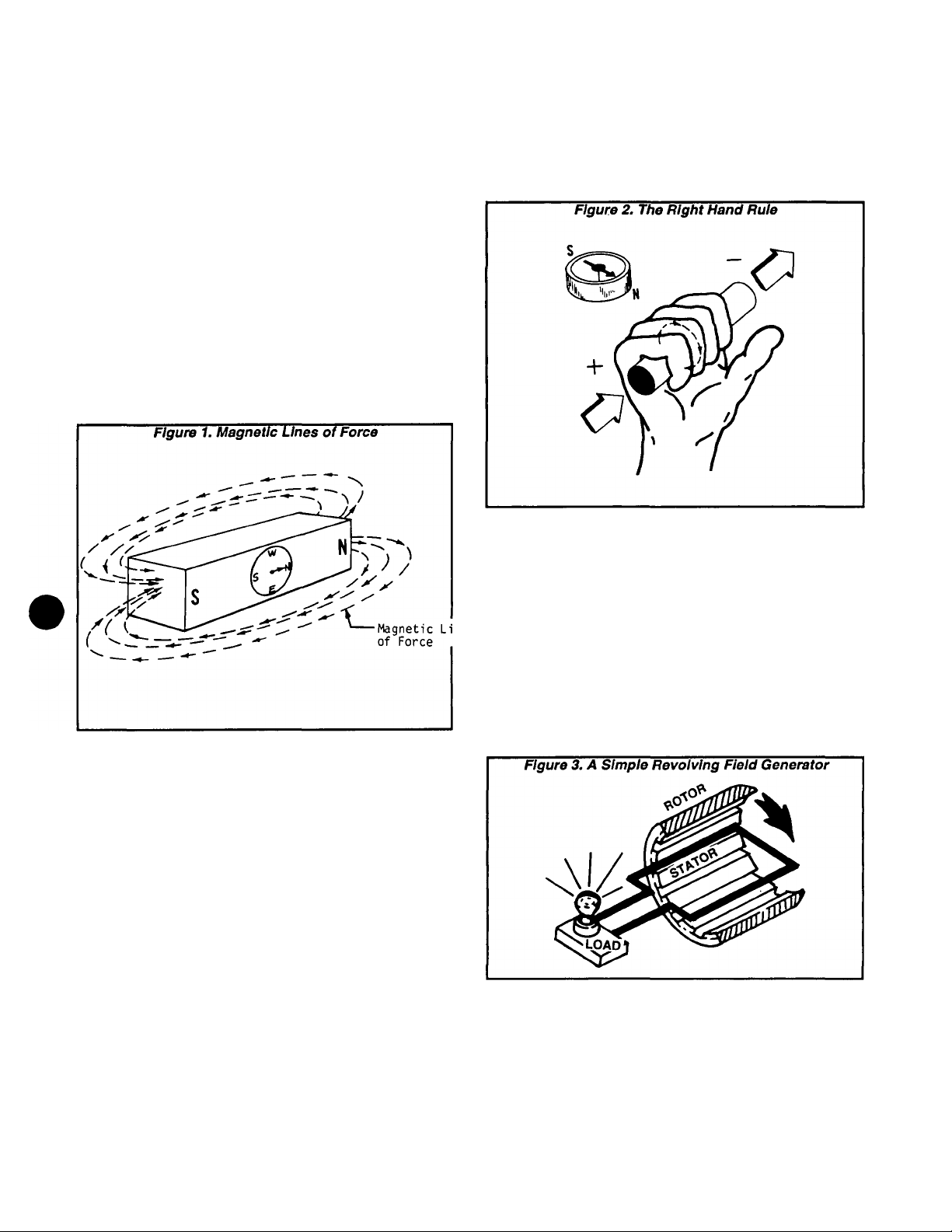

See Figure 1. The space surrounding a magnet Is

permeated by magnetic lines offeree called "flux“. These

lines offeree are concentrated at the magnet’s north and

south poles. They are directed away from the magnet at

Its north pole, travel In a loop and re-enter the magnet at

Its south pole. The lines of force form definite patters

which vary In Intensity depending on the strength of the

magnet The lines of force never cross one another. The

area surrounding a magnet In which Its lines offeree are

effective Is called a "magnetic field".

Like poles of a magnet repel each other, while unlike

poles attract each other.

Electromagnetic Fields

AM conductors through which an electric current Is

flowing have a magnetic field surrounding them. This

field Is always at right angles to the conductor. If a

compass Is placed near the conductor, the compass

needle will move to a right angle with the conductor. The

following rules apply:

NOTE: The "right hand rule" Is based on the "current

flow" theory which assumes that current flows from

positive to negative. This Is opposite the "electron"

theory, which states that current flows from negative to

positive.

Electromagnetic induction

An electromotive force (EMF) or voltage can be pro

duced In a conductor by moving the conductor so that it

cuts across the lines of force of a magnetic field.

Similarly, if the magnetic lines of force are moved so

that they cut across a conductor, an EMF (voltage) will

be produced In the conductor. This Is the basic principal

of the revolving field generator.

Figure 3, below. Illustrates a simple revolving field

generator. The permanent magnet (Rotor) Is rotated so

that its lines of magnetic force cut across a coll of wires

called a Stator. A voltage Is then Induced into the Stator

windings. If the Stator circuit Is completed by connecting

a load (such as a light bulb), current will flow in the circuit

and the bulb will light.

□ The greater the current flow through the conductor,

the stronger the magnetic field around the conduc

tor.

□ The Increase In the number of lines of force Is di

rectly proportional to the Increase In current flow

and the field Is distributed along the full length of the

conductor.

D The direction of the lines of force around a conduc

tor can be determined by what Is called the "right

hand rule". To apply this rule, place your right hand

around the conductor with the thumb pointing In the

direction of current flow. The fingers will then be

pointing in the direction of the lines of force.

Alternating Current

A simple generator consists of a coil of wires called a

Stator and a magnetic field called a Rotor. As the Rotor’s

magnetic field cuts across the Stator coll, a voltage Is

induced into the Stator windings. The amount of Induced

voltage is equal to the strength of the magnetic field.

Page 1.1-1

Page 6

Section 1.1- GENERATOR FUNDAMENTALS

Alternating Current (Continued)

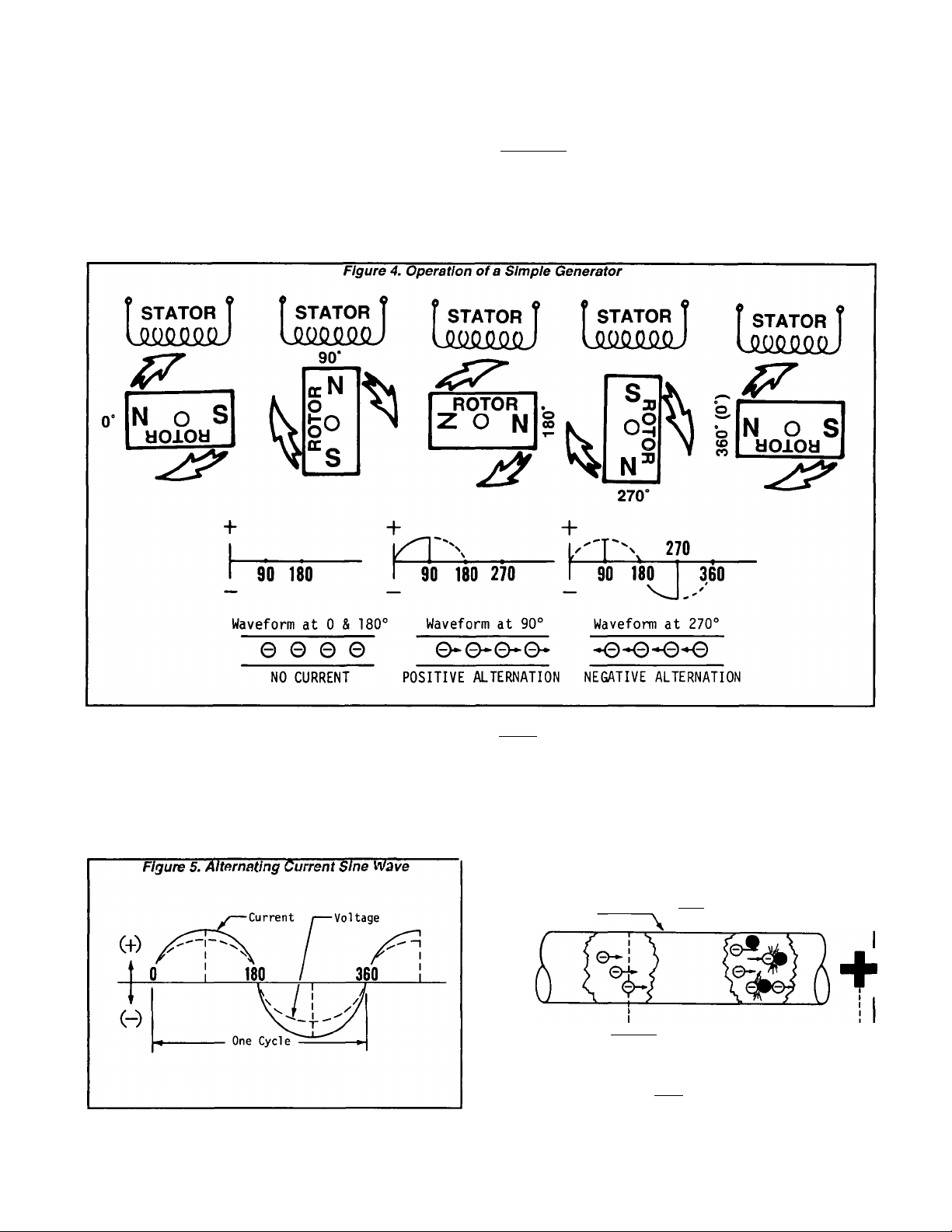

See Figure 4. The current alternates according to the

position of the Rotor’s poles in relation to the position of

the Stator. At 0* and again at 180*, no current flow Is

produced. At 90’ of Rotor rotation, current flow reaches

a maximum positive value. Rotor rotation to 270’ brings

another maximum flow of current. However, at 270’ the

current flow has reversed In polarity and now flows in the

opposite direction.

Electrical Units

AMPERE;

The rate of electron flow in a circuit is represented by

the AMPERE. The ampere is the number of electrons

flowing past a given point at a given time. One AMPERE

Is equal to Just slightly more than six thousand million

billion electrons per second.

With alternating current (AC), the electrons flow first

In one direction, then reverse and move In the opposite

direction. They will repeat this cycle at regular intervals.

A wave diagram, called a “sine wave“ shows that current

goes from zero to maximum positive value, then reverses

and goes from zero to maximum negative value. Two

reversals of current flow Is called a cycle. The number of

cycles per second Is called frequency and is usually

stated in "Hettz".

Page 1.1-2

VOLT:

The VOLT is the unit used to measure electrical PRESSURE, or the difference In electrical potential that causes

electrons to flow. Very few electrons will flow when

voltage is weak. More electrons will flow as voltage

becomes stronger. VOLTAGE may be consdiered to be

a state of unbalance and current flow as an attempt to

regain balance. One volt is the amount of EMF that will

cause a current of 1 ampere to flow through 1 ohm of

resistance.

Figure 6. Electrical Units

Conductor of a

Circuit

AMPERE - Unit measuring rate of

L.

OHM - Unit measuring resistance

or opposition to flow

current flow (nunfcer of elec

trons past a given point)

■ VOLT - Unit measuring force or

_____

difference in potential

causing current flow

Page 7

Section 1.1- GENERATOR FUNDAMENTALS

OHM:

The OHM Is the unit of RESISTANCE. In every circuit

there Is s natural resistance or opposition to the flow of

electrons. When an EMF Is applied to a complete circuit,

the electrons are forced to flow In a single direction

rather than their free or orbiting pattern. The resistance

of a conductor depends on (a) Its physical makeup, (b)

Its cross-sectional area, (c) Its length, and (d) Its temper

ature. As the conductor’s temperature Increases, Its re

sistance Increases In direct proportion. One (1) ohm of

resistance will permit one (1) ampere of current to flow

when one (1) volt of electromotive force (EMF) Is applied.

Ohm’s Law

A definite and exact rela

tionship exists between

VOLTS, OHMS and AMPERES.

The value of one can be calcu

lated when the value of the

other two are known. Ohm’s

Law states that In any circuit

the current will Increase when

voltage Increases but resis

tance remains the same, and

current will decrease when re

sistance Increases and volt

age remains the same.

If AMPERES Is unknown while VOLTS and OHMS are

known, use the following formula:

i AMPS

\(l)

OHMS j

(R)y

The magnetic field around the conductor Induces elec

tromotive forces that cause current to keep on flowing

while voltage drops. The result Is a condition In which

voltage leads current When a conductor Is formed Into

a coll, the magnetic lines of force are concentrated In the

center of the coll. This Increased density causes an

Increase In magnetically Induced EMF without Increas

ing current Thus, colls cause Inductive reactance.

Inductive reactance can also be caused by placing an

Inductlonmotoronthe circuit which utilizes the current’s

magnetic field for excitation.

AMPERESs VOLTS

■ÖHMS"

If VOLTS is unknown while AMPERES and OHMS are

known, use the following formula:

VOLTS 3 AMPERES X OHMS

If OHMS Is unknown but VOLTS and

AMPERES are unknown, use the following:

OHMS: VOLTS

AMPERES

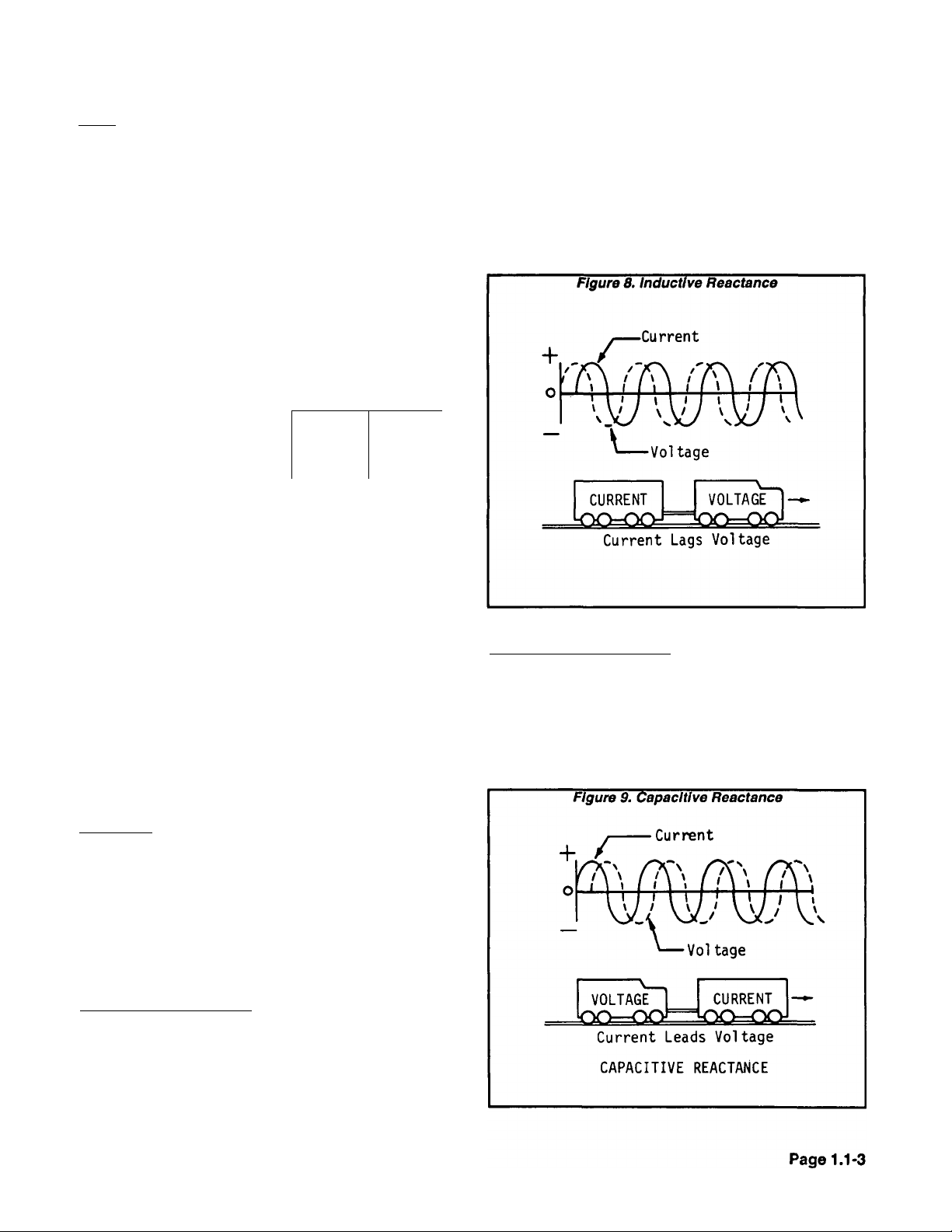

Reactance in AC Circuits

GENERAL:

When direct current (DC) Is flowing, the only opposi

tion to current flow that must be considered is resistance

(ohms). This Is also true of alternating current (AC) when

only resistance type loads such as heating and lamp

elements are on the circuit In such a case, current will

be In phase with voltage- that Is, the current sine wave

will coincide In time with the voltage sine wave.

However, two factors In AC circuits called INDUCTIVE

and CAPACITIVE REACTANCE will prevent the voltage

and current sine waves from being In phase.

INDUCTIVE REACTANCE:

This condition exists when current lags behind volt

age (Figure 8). As current flows In a circuit, magnetic

lines offeree are created at right angles to the conductor.

The continuous changes In current value (from positive

to negative) cause these magnetic lines to collapse and

build up continuously.

CAPACITIVE REACTANCE:

This condition occurs when current leads voltage (Fig

ure 9). It might be thought of as the ability to oppose

change In voltage. Capacitance exists In a circuit when

certain devices are (a) capable of storing electrical

charges as voltage Increases and (b) discharging these

stored charges when the voltage decreases.

Page 8

Section 1.1- GENERATOR FUNDAMENTALS

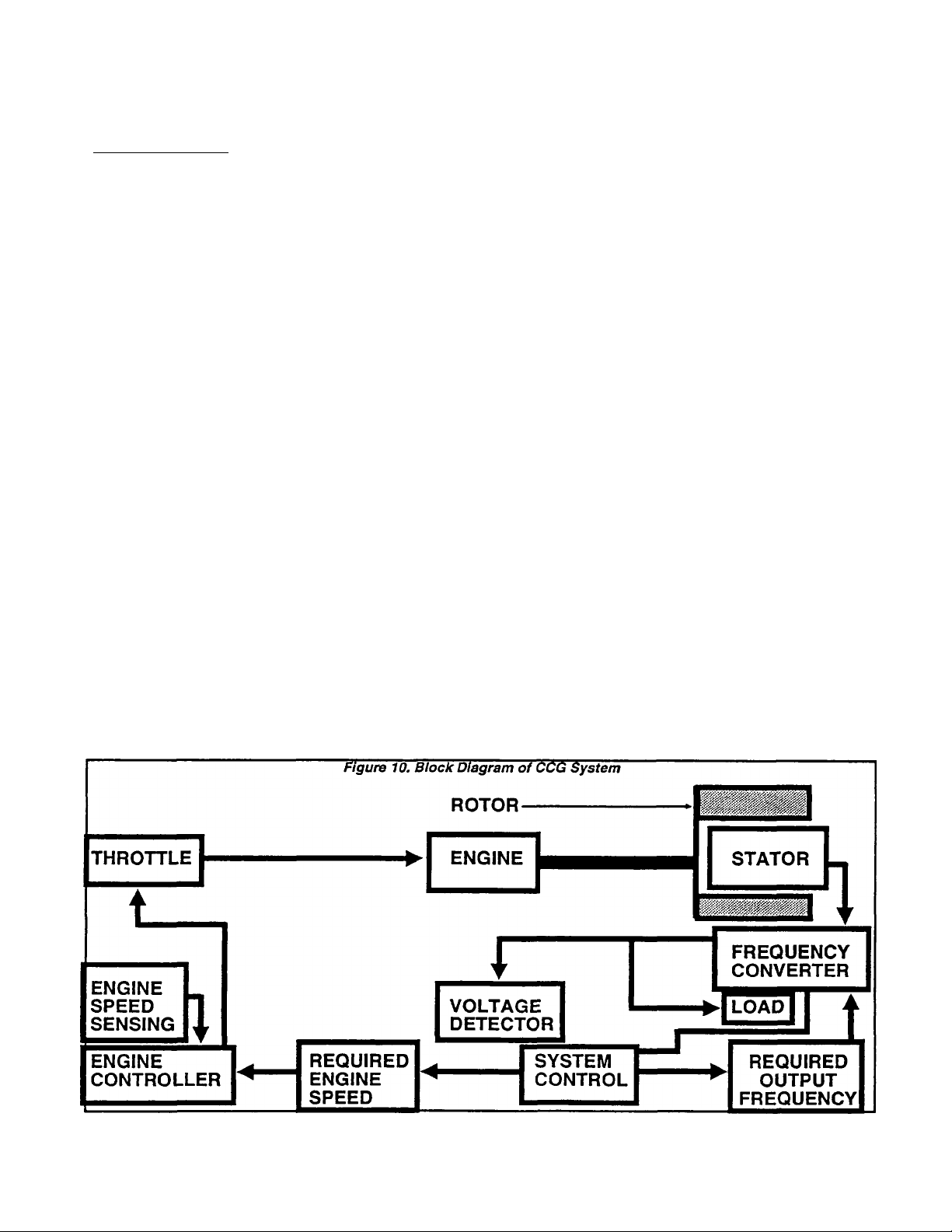

introduction to CCG’s

WHAT IS A "CCG"?:

The initials “CCG” stand for “computer con

trolled generator“. Such units are different from

conventional generators in that the performance of

the engine and AC generator are more accurately

matched over a wide range of power needs. The

CCG’s provide greater efficiency of both the engine

and the generator while maintaining electrical out

put within an acceptable voltage and frequency

band.

CCG units have the ability to operate the engine

over a wide range of speeds, while conventional

generators will deliver correct AC frequency and

voltage only at a fixed rpm. The unit’s electrical

output is fed through an AC-AC converter which

reconstructs electrical waveforms to the correct

output frequency.

Unlike conventional AC generators, the CCG can

match engine speed to load requirements. This

provides several advantages, as follows:

П Smaller engines can be used to produce more

power than on a conventional generator, since

it can be allowed to run at a higher speed.

□ When the load is reduced, the engine can run

at slower than the usual speeds. This improves

fuel economy and reduces engine noise.

□ The CCG unit can be operated closer to its peak

power point at all times, because output volt

age and current are functions of engine speed.

This allows fora much more compact generator

design.

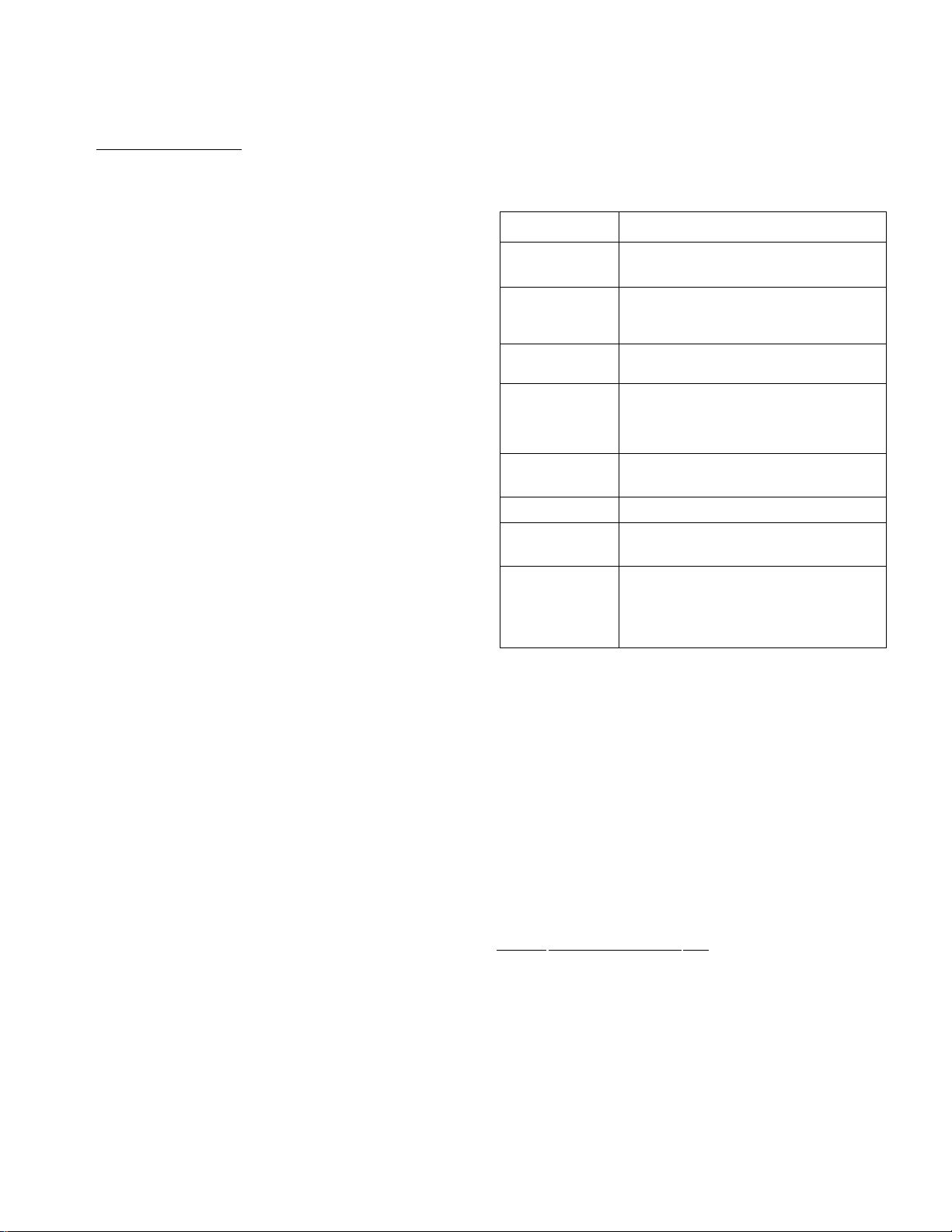

CCG SYSTEM OVERVIEW:

Figure 10 is a block diagram of the CCG system.

The major elements of the system are represented

in the diagram. Operation of the system may be

described briefly as follows:

1. The engine is directly coupled to a permanent

magnet type Rotor, so the Rotor runs at the same

speed as the engine.

2. As the Rotor turns. Its magnetic field cuts across

the Stator windings to induce a voltage into the

Stator.

a. The Stator is a 2-phase type with center tap.

b. Stator AC output frequency Is between 336 and

540 Hertz. This corresponds to engine speeds of

2520 to 4050 rpm.

c. The load requires a nominal AC frequency of

60 Hertz. Thus, the generated frequency Is six to

nine times the desired range.

3. A Frequency Converter changes the high fre

quency output to a useful frequency, I.e., one that

is compatible with load requirements of about 60

Hertz.

4. A Voltage Detector circuit senses load voltage

and signals a System Control circuit.

5. The System Control circuit establishes the RE

QUIRED ENGINE SPEED for correct voltage and

delivers an output to an Engine Controller.

6. The Engine Controller adjusts the engine’s

Throttle to change engine speed and establish the

correct AC output voltage.

7. The following facts should be apparent:

□ LOAD FREQUENCY IS CONTROLLED BY THE

“FREQUENCY CONVERTER“ DEVICE.

□ VOLTAGE IS CONTROLLED BY A “SYSTEM

CONTROL“ CIRCUIT WHICH CHANGES EN

GINE SPEED TO MAINTAIN A CONSTANT

VOLTAGE AT VARYING ELECTRICAL LOADS.

Page 1.1-4

Page 9

Section 1.1- GENERATOR FUNDAMENTALS

Why Variable

Most electrical loads will operate satisfactorily

only within a relatively small voltage band. In order

to provide useful voltage at larger load currents, It

is necessary to increase engine speed.

In conventional AC generators, some form of

voltage regulation Is needed to provide correct

voltage in the full range of load current. This Is

often accomplished by regulating excitation cur

rent to the Rotor (fíelo) which then regulates the

strength of the Rotor’s magnetic field. The voltage

Induced Into the Stator windings Is proportional to

the strength of the Rotor’s magnetic field.

Speed Control?

The CCG uses a Rotor having a fixed and perma

nent magnetic field. The strength of this magnetic

field Is fixed and cannot be regulated.

The output voltage on CCG generators tends to

droop with Increasing electrical loads. The SYS

TEM CONTROLLER maintains a constant AC out

put voltage by Increasing engine and Rotor speed

as the load current increases, to offset this Inherent

voltage droop.

The SYSTEM CONTROLLER also selects the cor

rect number of generator pulses which are com

bined to form each 60 Hertz "half-cycle“.

Page 10

Section 1.1- GENERATOR FUNDAMENTALS

Page 1.1-6

Page 11

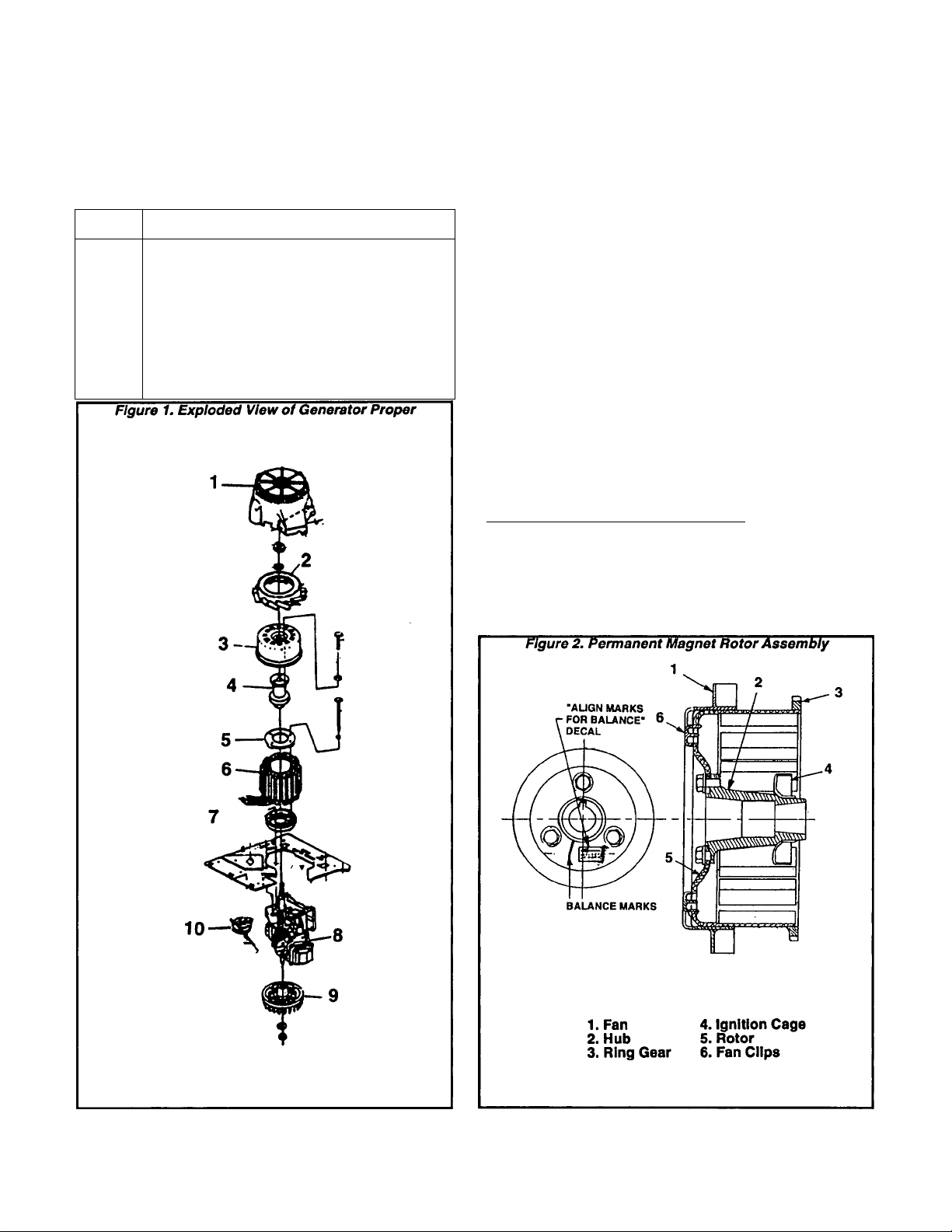

Section 1.2- MAJOR GENERATOR COMPONENTS

Introduction

Major components of the generator proper are

shown in Figure 1, beiow. Externai sheet metal and

other unrelated components are omitted from the

drawing for clarity. These parts are:

ITEM

1

2

3

4

5

6

7

8

9

10

NOMENCLATURE

Upper Fan Housing

Upper Cooling Fan

Permanent Magnet Rotor

Rotor Hub

Stator Retaining Ring

Stator Assembly

Stator Adapter

Engine

Lower Fan & Flywheel

Stepper Motor

Upper Fan Housing

As its name implies, this component houses and

shields the upper cooling fan. See Figure 1, Item

1.

Upper Cooling Fan

The Cooling Fan draws air Into the generator

through slots in the Upper Fan Housing. It Is fas

tened to and rotates with the Permanent Magnet

Rotor.

Permanent Magnet Rotor

Sixteen permanent magnets have been affixed to

the Rotor. A starter ring gear is welded to the

Rotor. The Rotor and Hub are balanced at the fac

tory as an assembly and must be replaced as an

assembly.

NOTE: The hub MUST be properly aligned during

reassembiy. The mounting bolt, housing opening

and magnet must be properly aligned. In addition,

match marks between the Hub and Rotor must be'

aiigned as indicated by an “ALIGN MARKS FOR

BALANCE” decal. During assembiy, use care to

avoid damage to the Ignition Sensor.______________

DANGERI

THE PERMANENT MAGNET ROTOR PRODUCES

AN EXTREMELY STRONG MAGNETIC FORCE.

USE CARE DURING INSTALLATION TO AVOID

PINCHED FINGERS.

Page 1.2-1

Page 12

Section 1.2- MAJOR GENERATOR COMPONENTS

Rotor Hub

See Figure 2. The Rotor Hub Is balanced with the

Rotor and must be replaced with the Rotor as an

assembly. Part of the engine ignition system is

pressed onto the Hub and can be replaced only as

part of the Rotor and Hub assembly.

Stator Retaining Ring

The Stator Retaining Ring is made of dIe-cast

aluminum. Four hex head capscrews with

lockwashers pass through holes in the Retaining

Ring, to retain the Stator Assembly to the Stator

Adapter (Item 7, Figure 1).

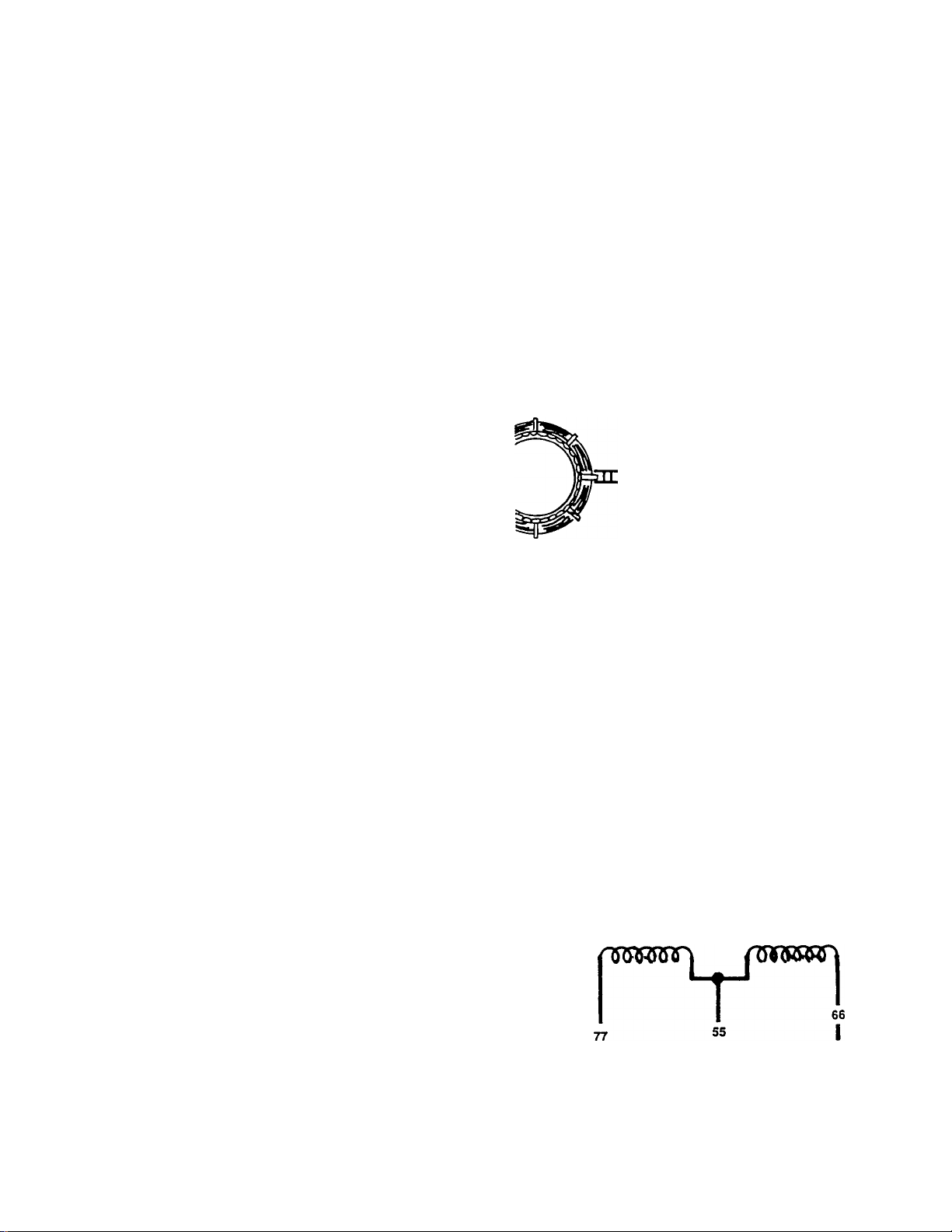

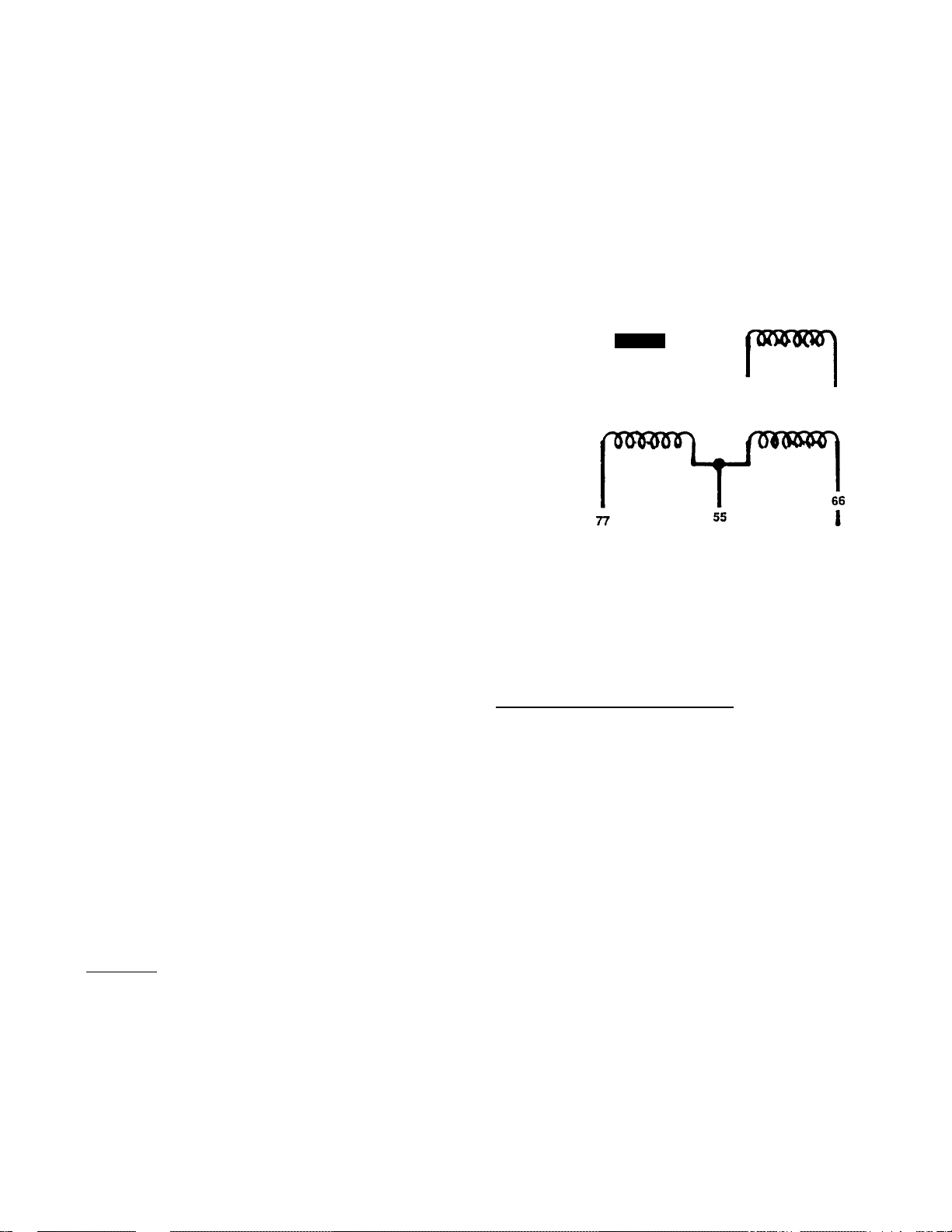

Stator Assembly

The 2-phase Stator is made up of eight (8) wind

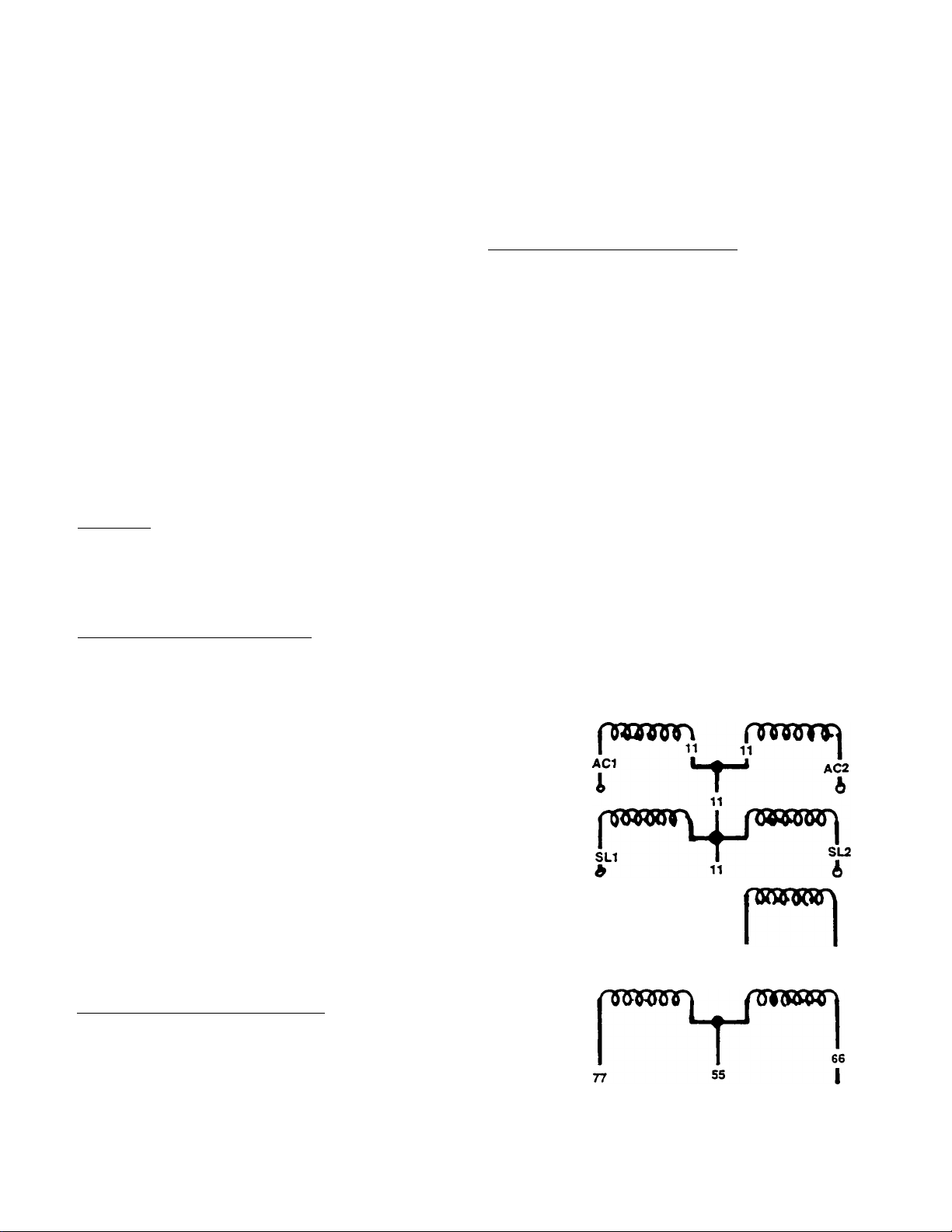

ings, with leads brought out as shown in figure 3.

Figure 4 is a schematic representation of each sta

tor winding. Note that there are four (4) power

phase windings (Leads AC2, AC1, SI2, SI1 and 11);

a timing winding (Leads TIM1 and TIM2); a power

supply winding (Leads PS1, PS2); and a dual bat

tery charge winding (Leads 55, 66, 77).

The Stator produces a frequency of 336 to 540

Hertz, which corresponds to engine speeds

between 2520 and 4050 rpm. This means the gen

erated frequency is between six and nine times

the desired frequency of about 60 Hertz.

Stator Adapter

The Adapter Is retained to the engine by means

of four hex head capscrews. The Stator Is retained

to the Stator Adapter and Is “sandwiched'' between

the Adapter and the Stator Retaining Ring.

Lower Fan & Flywheel

The Lower Fan and Flywheel are retained to the

engine PTO shaft by means of a conical washer and

an Ml 6-1.50 hex nut. When assembling, tighten the

flywheel nut to 75 foot-pounds.

Engine

The engine is a single cyclinder, overhead valve

type manufactured by Generac Corporation. De

pending on the specific generator Model Number,

either a GN-190 or a GN-220 engine is used on

NP-30 and NP-40 RV generators.

sponse to changes In AC output voltage. Thus, In

response to decreasing AC output voltages, the

Motor will increase the throttle setting and engine

speed will Increase. Conversely, Increasing AC

output voltages will cause the Motor to decrease

throttle setting and engine speed will decrease.

Figure 3. Stator Pictorial View

-66 (BROWN)-

—77 (BROWN) T1M1 (ORANGE)

—TM2 (GRAY)

-PS1 (BROWN)-

-AC2 (YELLOW)

-AC1 (GRAY)—

-SL1 (ORANGE)—

-----

SL2 (BROWN)-------------

Figure 4. Schematic- Stator Windings

POWER

PHASE 1

POWER

PHASE 2

AC1 aC2

I ! I

POWER I TIMING

SUPPLY I I

PS1 PS2

C «r ® ®

-55 (BLACK)

--------

»<§)

H T1M1 (

PS2 (YELLOW)

■11 (BLUE)

---------

AC2

I (7»CT«r|

II è

b

SL2

è

Stepper Motor

The Stepper Motor (Figure 5, next page) consists

of a stepper motor along with a gear and cam

arrangement which allows motor movement to

change the engine carburetor throttle setting. The

Motor Is controlled by output signals from the Com

puter Control Circuit Board, which calculates the

number of steps the stepper needs to take and

generates the required signals to the Motor. The

circuit board signals the Motor to actuate in re

Page 1.2-2

BATTERY

CHARGE

Page 13

Section 1.2- MAJOR GENERATOR COMPONENTS

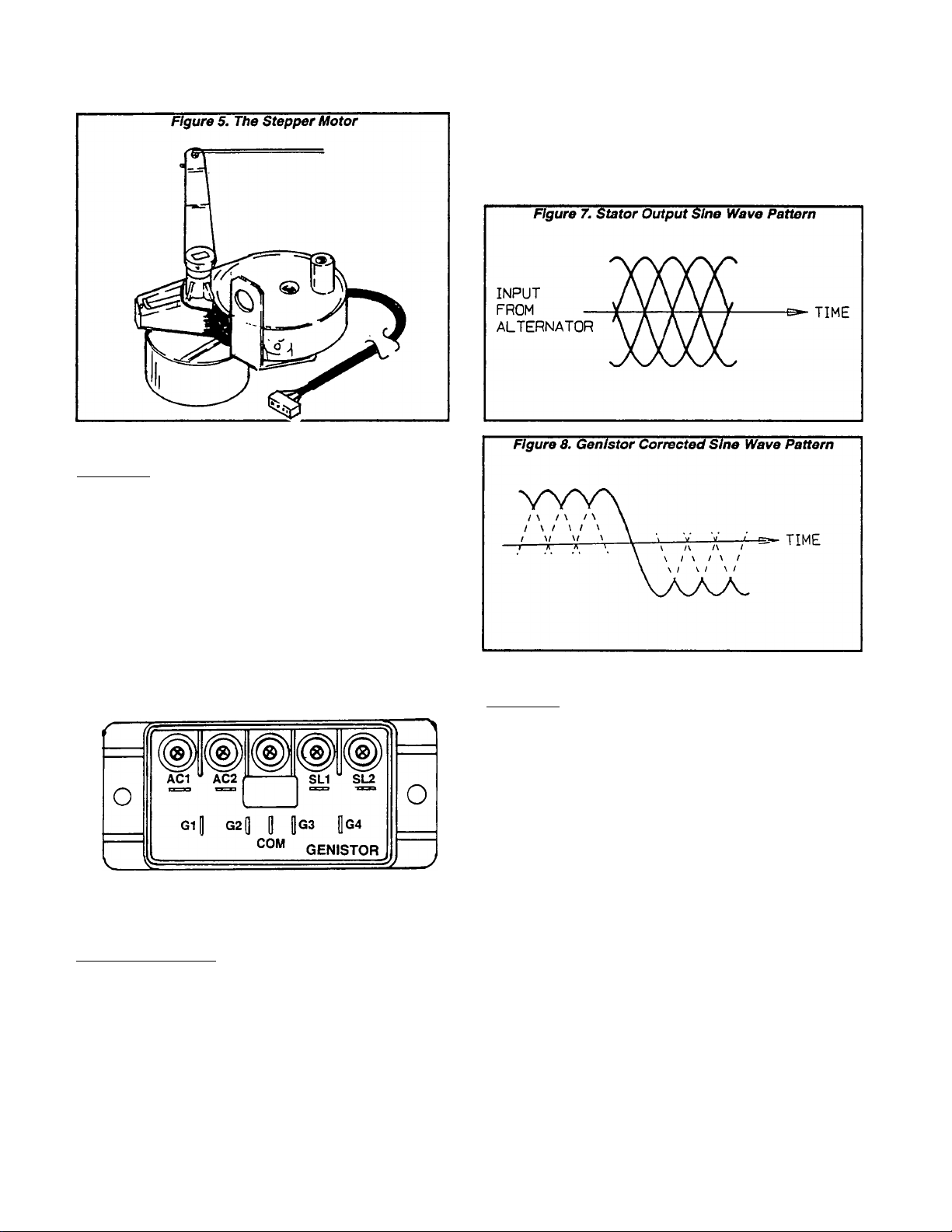

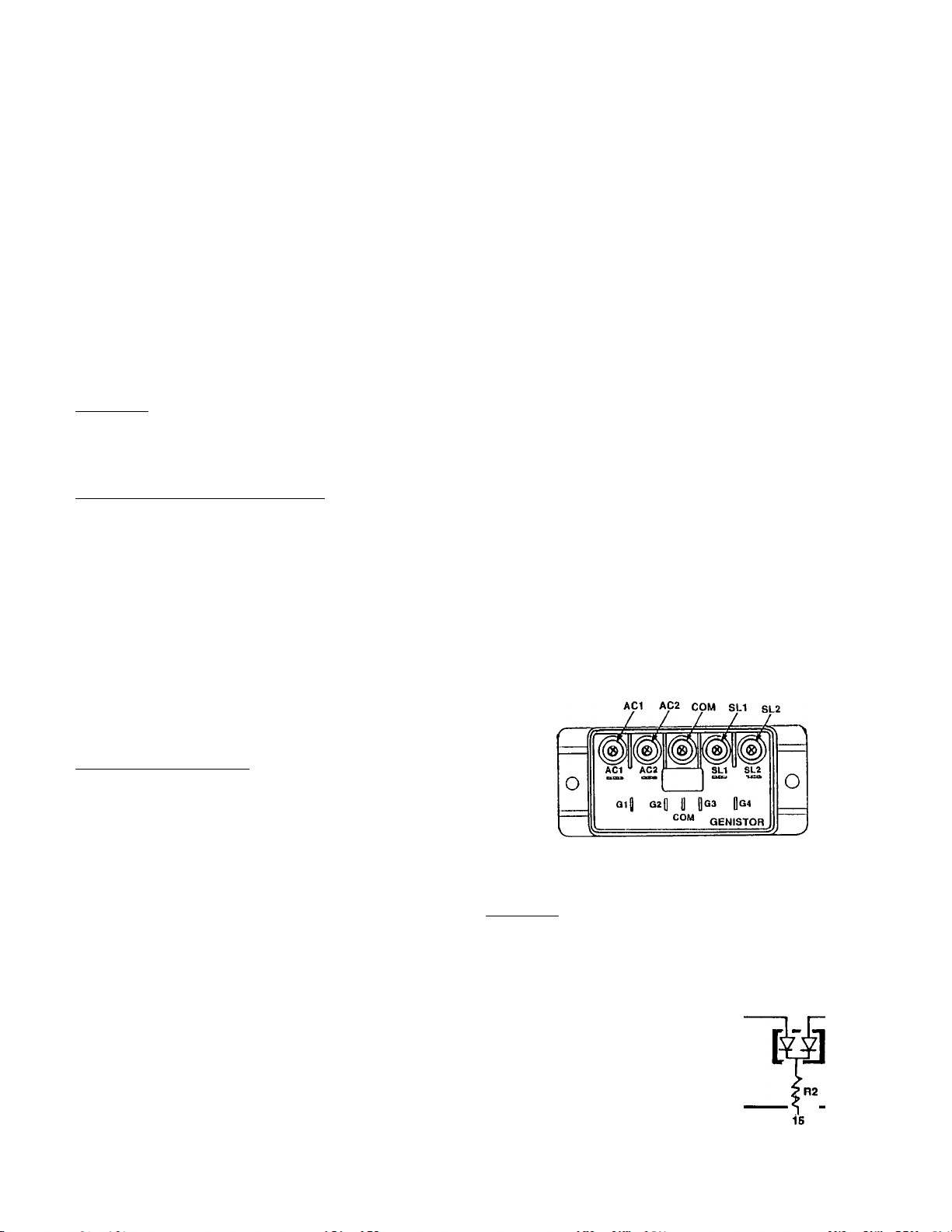

The Genistor

GENERAL:

See Figure 6. The GENISTOR is often called a

“frequency converter“ (also see "Introduction to

CCG’s“ on Page 1.1-4). its function is to change the

high frequency AC output of the Stator (336-540

Hertz) to a useful frequency (about 56-60 Hertz).

The Genistor has no intelligence of Its own. It is

simply a high speed switcning device which is

controlled by the CCG circuit board.

Switching signals from the CCG circuit board are

also delivered to the Genistor. These signals

switch the Genistor on and off as required, result

ing In a sine wave output to the load as shown in

Figure 8.

Figure 6. The dtenhtor

GENISTOR THEORY:

The purpose of a “frequency converter“ is to

divide the Stator AC output frequency by an inte

gral factor to provide a useful output frequency.

Each of the four half-phases of the center-tapped

Stator Is Genistor-controlled.

Figure 7 shows the sine wave output from the

2-phase Stator windings. This output Is delivered

to the Genistor switching module.

The CCG Circuit Board

GENERAL:

The CCG circuit board has several functions as

follows:

1. It controls the operation of the “frequency con

verter“ (Genistor).

2. It controls AC output voltage under all load

requirements by controlling engine speed.

3. It protects the system against various faults.

FREQUENCY CONTROL:

The CCG board will adjust the number of alterna

tor cycles In one output cycle to control AC output

frequency. The number of cycles is based on en

gine rpm and the output frequency will be main

tained in the 55-65 Hertz band.

The board uses a "zero crossing" detector to

synchronize an internal clock. The frequency of the

Stator’s waveform is measured and, with

referencve to the required output frequency, a “freguency divisor" is calculated. The circuit board

then signals the Genistor (frequency converter) to

switch on and off at the proper times so that fre

quency Is maintained in the 55-65 Hertz band.

Page 1.2-3

Page 14

Section 1.2- MAJOR GENERATOR COMPONENTS

The CCG

VOLTAGE CONTROL:

The CCG circuit board utilizes a closed-loop,

proportional-derivative controller which regulates

RMS voltage by changing engine speed. The sys

tem maintains output voltage at about 115 volts at

the lowest rpm and 120 volts up to the maximum

rpm.

The board controls a Stepper Motor (Figure 5),

which moves the throttle. The board calculates the

number of steps the Motor needs to take and sig

nals the Motor to move. Motor movement changes

throttle position and changes In engine speed re

sult.

FAULT PROTECTION:

The CCG board has the ability to detect several

fault conditions and shut the engine down, as fol

lows:

1. Overvoltage:- If the output voltage exceeds 127

VAC for longer than 15 seconds, the board will turn

AC output power off and shut the engine down.

2. Undervoitage:- If output remains below about 96

VAC longer than 15 seconds, an overload condition

probably exists. The board will then turn AC output

off and shut the engine down.

3. Overspeed:- if engine speed exceeds 4500 rpm,

shutdown will occur.

4. Failure of the Genistor (frequency converter) will

result in engine shutdown.

5. Loss of output to any circuit connected to the

board will result in engine shutdown.

Circuit Board (Continued)

CIRCUIT BOARD CONI

The board Is equipped with eight (8) connection

points (receptacles). These are identified as

"CONNr through "CONNS". See Figure 9.

CONNECTOR

CONNI

CONNECTIONS:

FUNCTION

Six-pin connector Interconnects

with speed control Stepper Motor.

CONN2

12-pin connector is NOT used on

RV units. An orange jumper wire

is connected across Pins 5 & 11.

CONN3

7-pin connector interconnects with

the Genistor.

CONN4

4-pln receptacle for connection of

the Stator power supply leads

(PS1, PS2) and the Stator timing

leads (TIM1, TIM2).

CONNS Single point connection for Stator

lead No. 11 (blue).

CONN6 Interconnects with the Genistor.

CONN7 Single point connector Is NOT

used on RV units.

CONNS Single point connector for Wire 18B.

Interconnects with Engine Cont

roller circuit board, allows the

CCG board to shut the engine down.

-O

-Ó

Figure 9. the CÔà Circuit Board

0 0 ^

C0NN4

CDNN8 CDNN7

CDNN5

a

u

JSl

_______________

Ì i

□

o

o

CGNN3 CDNN6

lij Itl lil Ui lli'ururuu umuuiuiuniniimui Ui'Ul uul

mfamfsifsifiifgifaifgimfiimfsimmisifCTm ijunj

■~L0r'

Page 1.2-4

Page 15

Section 1.3- OPERATIONAL ANALYSIS

General

Figure 1, below, is a block diagram of the com

puter controlled RV generator. The diagram la In

tended only for the purpose of Illustrating genera

tor operation. Refer to the actual wiring diagram for

wiring interconnections.

Operational Description

1. The PERMANENT MAGNET ROTOR Is directly

coupled to the ENGINE and rotates at the same

speed as the engine.

2. As the ROTOR turns, its magnetic field cuts

across a number of STATOR windings, to Induce a

voltage Into those windings. A voltage Is induced

Into the following STATOR windings:

a. Phase 1 and 2 of the STATOR POWER WIND

INGS (output leads AC1-AC2 and SL1-SL2).

b. The STATOR POWER SUPPLY WINDING with

output leads PS1-PS2.

c. The STATOR TIMING WINDING (output leads

TIM1-TIM2).

d. STATOR BATTERY CHARGE WINDING with

output leads 55,66 and 77.

Figure 1. Block Diagram- AC Generator System

3. STATOR BATTERY CHARGE WINDING o^ut Is

delivered to the unit battery via a BATTERY

CHARGE RECTIFIER (BCR) and a 1 OHM, 50 WATT

RESISTOR. The circuit Is completed through the

battery to frame ground and back to the BATTERY

CHARGE WINDING via Wire 55.

4. STATOR TIMING WINDING output is delivered to

the CCG CIRCUIT BOARD. The circuit board mea

sures the frequency of the waveform and calcu

lates a "frequency divisor" to maintain a useable

frequency to the CUSTOMER CONNECTION re

gardless of rpm.

5. The STATOR POWER SUPPLY WINDING output

Is delivered to the CCG CIRCUIT BOARD. This is

the power supply for operation of the circuit board

and GENISTOR.

6. STATOR POWER WINDING OUTPUT (Phase 1

and 2) Is delivered to a GENISTOR. The GENISTOR

is a nIgh-speed switching device which is con

trolled by the CCG board.

7. The CCG CIRCUIT BOARD senses voltage and

frequency and then acts to control voltage and

frequency as follows:

STATOR

POWER

WINDING

AC1-AC2

WÀ‘§Ê2

STATOR

POWER

WINDING

SL1-SL2

STATOR

POWER

SUPPLY

WINDING

PS1-PS2

STATOR

TIMING

WINDING

TIM1-TIM2

WIRE18B

.(ENGINE

SHUTDOWN)

STATOR

BATTERY

CHARGE

WINDING

66-77

MAGNETIC

FIELD

PERMANENT

MAGNET

ROTOR

ENGINE

Page 1.3-1

Page 16

Section 1.3- OPERATIONAL ANALYSIS

Operational Description (Continued)

a. The circuit board senses actual voltage and b. The CCG board <

"compares“ it to a pre-set “reference“ voltage of

about 115-120 volts AC.

0) If voltage Is low, the board will signal a STEPPER

MOTOR to change engine throttle setting and In

crease speed until the desired voltage level Is

reached.

If voltage goes high, the board will signal the

STEPPER MOTOR to reduce engine throttle setting

until the desired voltage level Is obtained.

(3) Engine speed Is variable and Is used to control

output voltage and may range from about 2520 to

4050 rpm.

acting on the GENISTOR.

(1) The GENISTOR is a high speed switching

device.

(2) The CCG board signals the Genistor to switch

generator waveforms on and off at the proper

times. In order to maintain a frequency In the

55-65 Hertz band.

8. The CCG circuit board can protect the system

against some faults by shutting the engine down,

wire 18B is the “engine shutdown“ lead that connectcts this system to the Engine Controller circuit

board. See “FAULT PROTECTION“, Page 1.2-4.

controls AC frequency by

Page 1.3-2

Page 17

Section 1.4- INSULATION RESISTANCE

Dirt and Moisture

If moisture Is permitted to remain In contact with the

generator Stator windings, some of It will be retained In

voids and cracks of the winding Insulation. This can

eventually cause a reduction In Insulation resistance and

generator output may be affected.

Winding Insulation In Generac generators Is moisture

resistant. However, prolonged exposure to water, high

humidity, salt air, etc., will gradually reduce the resis

tance of winding Insulation.

Dirt can make the problem even worse, since It tends

to hold moisture Into contact with the windings. Salt, as

from sea air, can also worsen the problem, since salt

tends to absorb moisture from the air. When salt and

moisture combine, they make a good electrical conduc

tor.

Because of the detrimental effects of water, dirt and

salt, the generator should be kept as dry and as clean as

possible. Stator windings should be tested periodically

using a Hi-Pot tester or a Megohmmeter. If insulation

resistance is low, drying of the unit may be necessary. If

resistance is still low after drying, the defective Stator

should be replaced.

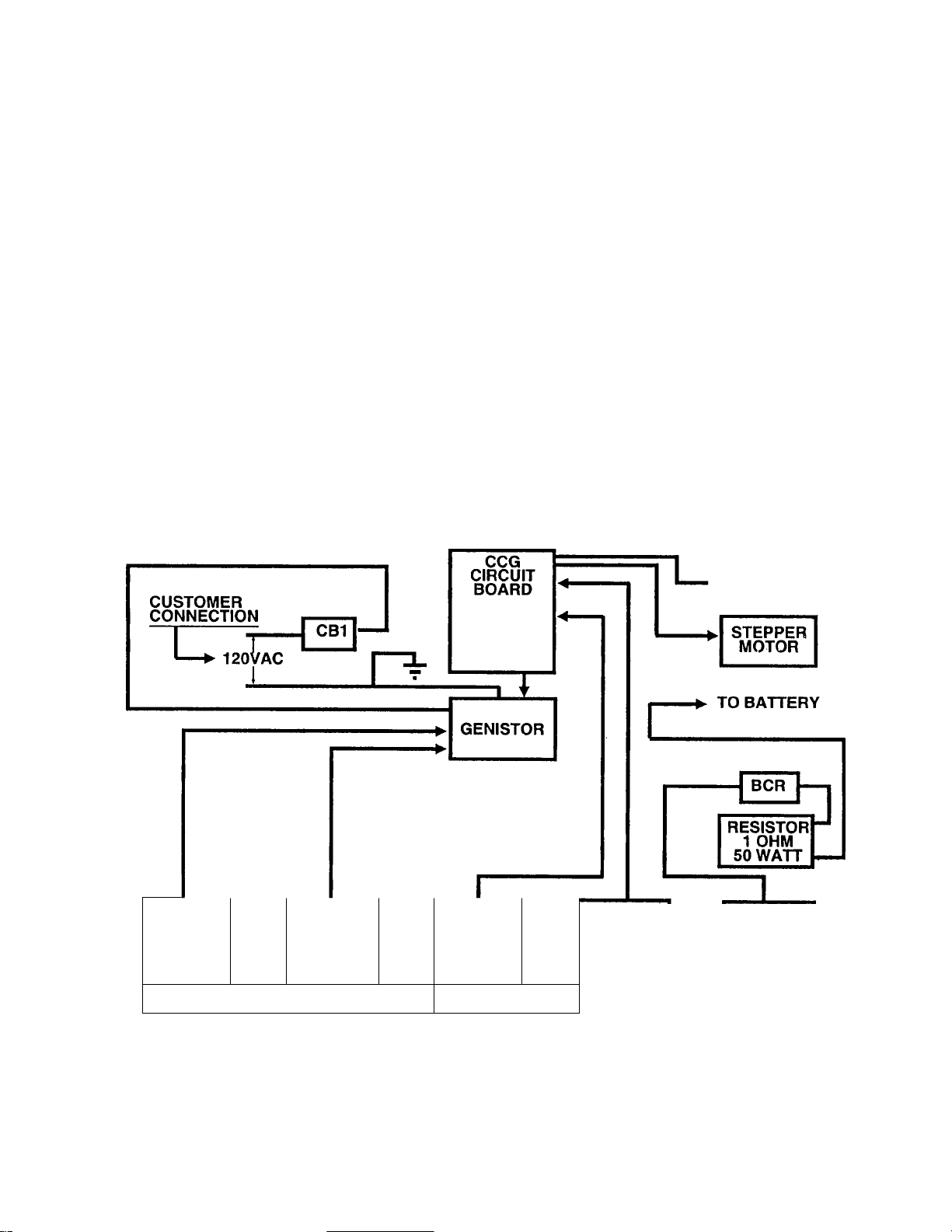

Insuiation Resistance Testers

One kind of Insulation resistance tester Is shown in

Figure 1, below. Other types are commerlally available.

The type shown has a "Breakdown” lamp which turns on

to indicate an Insulation breakdown during the test.

One common type of tester is the "Megohmmeter"

which measures resistance in "Megohms".

NO. COLOR CONNECTS TO

U

77

66

55

SL2

SL1

AC2

AC1

PS1

TIM1

PS2

TIM2

Blue

Brown

Brown

Black

Brown

Orange

Yellow

Gray

Brown

Orange

Yellow

Gray

Main Circuit Breaker CB1

Battery Charge Rectifier BCR

Battery Charge Rectifier BCR

Grounding Terminal

Genistor fG)

Genistor (G)

Genistor (G)

Genistor (G)

CCG Circuit Board (CCB)

CCG Circuit Board i CCB)

CCG Circuit Board l CCB)

CCG Circuit Board (CCB)

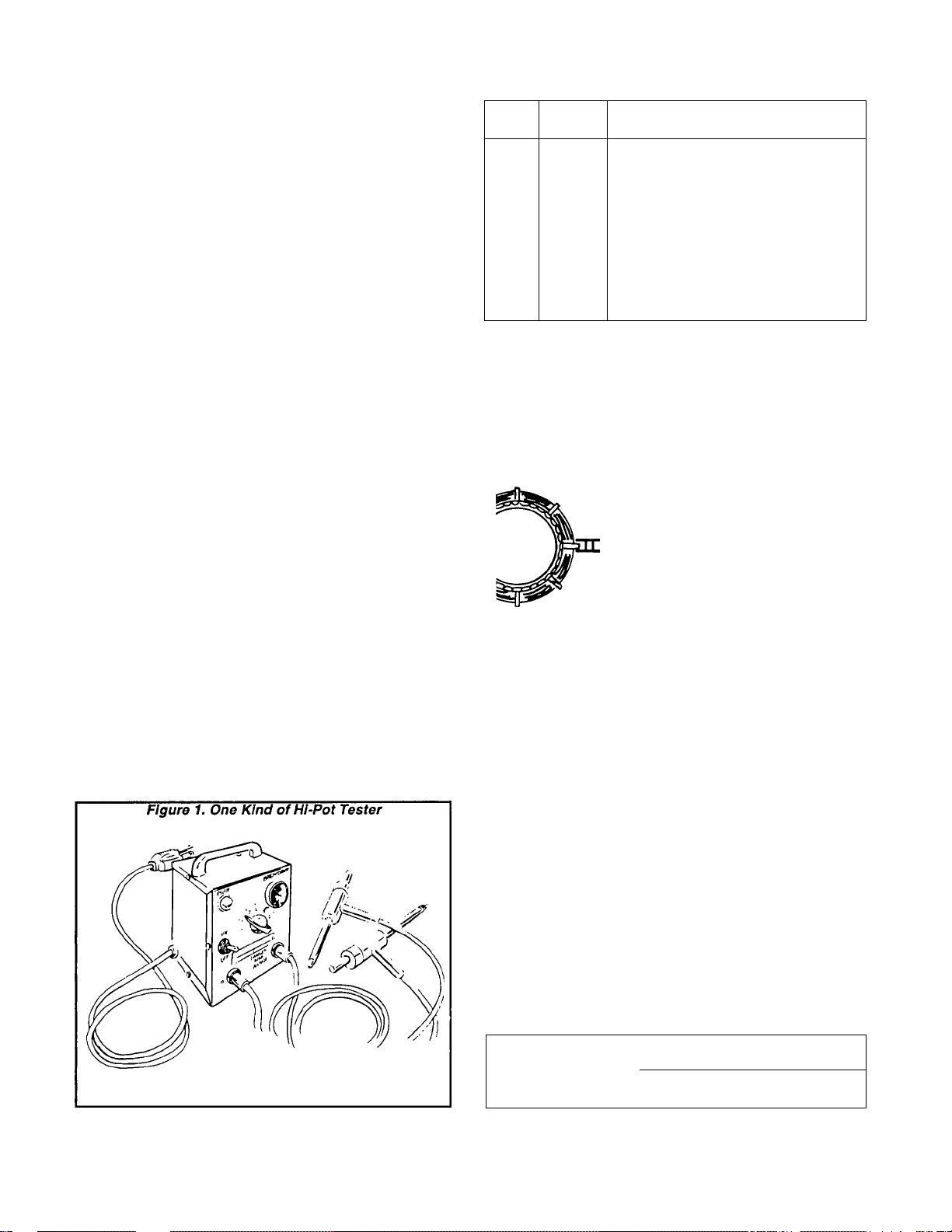

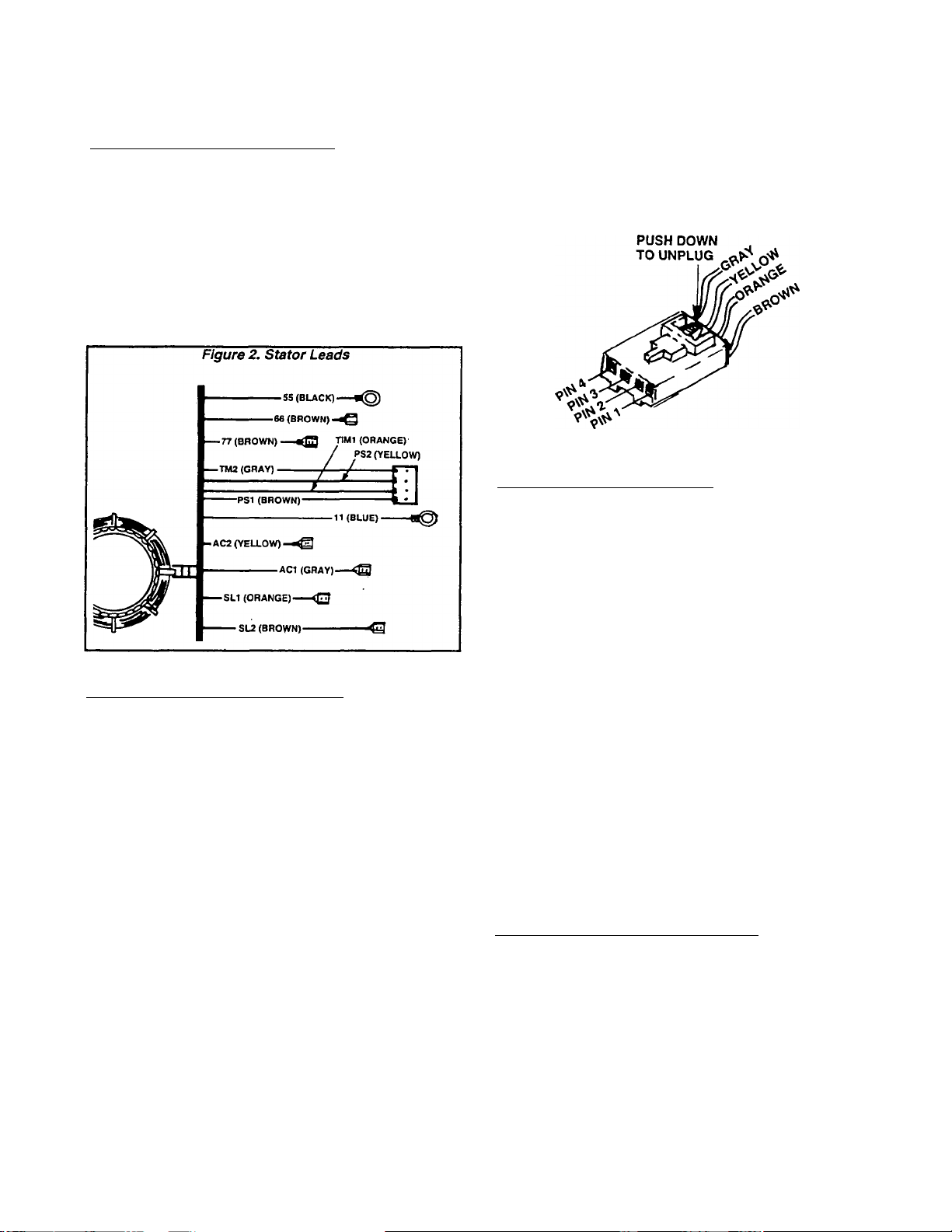

Figure 2. Stator Leads

— 55 (BLACK)-*^)

-66 (BROWN)

— 77 (BROWN) —(ORANGE)

PS2 (YELLOW)

—TM2 (GRAY) -

-PS1 (BROWN)I (BLUE) —«0)

-AC2 (YELLOW)

-AC1 (GRAY)—

-SL1 (ORANGE)^—

CAUTION!

When using a Megohmmeter or any other tester,

be sure to follow the manufacturer’s instructions

carefully. All Stator leads must be isolated from

other components, especially circuit boards, be

fore performina tests. The high voltages used In

testing Insuiation resistance will damage elec

tronic components.

Stator Leads

The following leads are brought out of the Stator and

connected to various components in the unit:

-----

SL2 (BROWN)

-------------

■^0

Preparation for Tests

See Stator leads CHART above. Disconnect and Iso

late all Stator leads. ALL STATOR LEADS MUST BE

DISCONNECTED AND ISOLATED BEFORE STARTING

THE TESTS.

Test Aii Stator Windings to Ground

Connect the ends of all Stator leads together. Make

sure none of the leads are touching any terminal or any

part of the generator.

Connect one Tester probe to the Junction of all Stator

leads; the other Tester probe to a clean frame ground on

the Stator. Apply a voltage of 1000 volts for about 1

second.

Follow the tester manufacturer’s Instructions care

fully. Some "Hl-Pot" testers are equipped with a "Break

down" light which will turn ON to indicate an Insulation

breakdown.

A

"Megger" (Megohmmeter) will Indicate the "meg

s’’ of resistance. Normal Stator winding Insulation

ohms"

resistance is on the order of "millions of ohms" or "meg

ohms". The MINIMUM acceptable Insulation resistance

reading for Stators can be calculated using the following

formula.

MINIMUM INSULATION

RESISTANCE

(In “megohniis")

GENERATOR RATED VOLTS

-

------------------------------------------ +1

1000

Page 1.4-1

Page 18

Section 1.4- INSULATION RESISTANCE

Test All Stator Windings to

Ground (Continued)

EXAMPLE: Generator rated voltage Is "120 VAC".

Divide ■

obtain

the unit Is "1.12 megohms".

120 by 1000 to obtain "0.12". Add “1" to

"1.12 . Minimum Insulation resistance for

.

..............................................■

Test for Shorts Between Windings

Figure 2 on the previous page shows the Stator leads

that are brought out of the Stator. Figure 3 is a schematic

representation of the eight (8) Stator windings. To test

for shorts between windings, proceed as follows:

1. Make sure all Stator output leads are isolated from

each other and from the frame.

2. POWER PHASE TO TIMING WINDINGS:- Connect one

tester probe to Stator lead No. 11, the other test probe to

Stator lead TIM1. Apply a voltage of 1000 volts. The

Tester will Indicate a breakdown if the windings are

shorted together.

3. POWER PASE TO POWER SUPPLY WINDINGS: Con

nect one tester probe to Stator lead No. 11, the other

tester probe to Stator lead PS1. Apply 1000 volts. If a

breakdown Is Indicated, the windings are shorted to

gether.

4. POWER PHASE TO BATTERY CHARGE WINDINGS:Connect one tester probe to Stator Lead No. 11, the other

probe to Stator lead No. 55. Apply 1000 volts. If break

down Is Indicated, the windings are shorted together.

5. TIMING TO POWER SUPPLY WINDING:- Connect one

tester probe to Stator lead No. TM1, the other test probe

to Stator lead No. PS1. Apply 1000 volts. If breakdown is

Indicated, the windings are shorted together.

6. TIMING TO BATTERY CHARGE WINDING:- Connect

one test probe to Stator lead No. TIM1, the other test

probe to Stator lead No. 55. Apply 1000 volts. If break

down is Indicated the windings are shorted together.

7. POWER SUPPLY TO BATTERY CHARGE WINDING:Connect one test probe to Stator lead No. PS1, the other

probe to Stator lead No. 55. Apply 1000 volts. If break

down is indicated, the windings are shorted together.

Results of Tests

1. If testing Indicates that Stator windings are shorted to

ground, the Stator should be cleaned and dried. The

Insulation resistance tests should then be repeated. If,

after cleaning and drying, the Stator again fails the test,

replace the Stator assembly.

2. If testing Indicates that a short between windings

exists, clean and dry the Stator. Then, repeat the tests. If

Stator fails a second test (after cleaning and drying),

replace the Stator assembly.

Cleaning the Generator

GENERAL:

If testing indicates that the insulation resistance is

below a safe value, the winding should be cleaned.

Proper cleaning can be accomplished only while the

generator is disassembled. The cleaning method used

should be determined by the type of dirt to be removed.

Be sure to dry the unit after it has been cleaned. An

electric motor repair shop may be able to assist with

cleaning. Such shops are often experienced in special

problems (sea coast, marine, wetland applications, etc.).

Figure 3. Schematic- Stator Windings

pravm ппушт|

POWER

PHASE 1

POWER ^

PHASE 2

BATTERY

CHARGE

AC1

I

SL1

à

POWER

f

SUPPLY

PS1 PS2 .

О ^ О

11

AC2

h

SL2

h

TIMING

TIMI T1M2

USING SOLVENTS FOR CLEANING:

A solvent is generally required when dirt contains oil

or grease. Only petroleum distillates should be used to

clean electrical components. Recommended are safety

type petroleum solvents having a flash point greater than

100’ F. (38* C.).

Use a soft brush or cloth to apply the solvent. Use care

to avoid damaging magnet wire or winding Insulation.

After cleaning, dry all components thoroughly with mois

ture-free, low pressure compressed air.

DANGER!

DO NOT WORK WITH SOLVENTS IN ANY EN

CLOSED AREA. ALWAYS PROVIDE ADEQUATE

VENTILATION. FIRE, EXPLOSION OR OTHER

HEALTH HAZARDS MAY EXIST UNLESS ADE

QUATE VENTILATION IS PROVIDED. WEAR EYE

PROTECTION. WEAR RUBBER GLOVES TO PRO

TECT THE HANDS.

CAUTIONI

Some generators use epoxy or polyester base

winding varnishes. Use solvents that do not at

tack such materials.

Page 1.4-2

Page 19

Section 1.4- INSULATION RESISTANCE

Drying the Generator

GENERAL:

If testing Indicates that the insulation resistance of a

winding Is below a safe value, the winding should be

dried before operating the unit Some recommended

drying methods include (a) heating units and (b) forced

air.

HEATING UNITS:

If drying Is needed, the generator can be enclosed In

a covering. Heating units can then be Installed to raise

the temperature about 15’-18* F. (8*-10* C.) above ambi

ent.

FORCED AIR:

Portable forced air heaters can be used to dry the

generator. Direct the heated air Into the generator’s air

intake openings. Run the unit at no-load. Air temperature

at the point of entry Into the generator should not exceed

150* F. (66* C.).

Page 20

Section 1.4- INSULATION RESISTANCE

Page 1.4-4

Page 21

Section 1.5- COMPONENTS TESTING

Introduction

Problems that occur In the computer-controlled

RV generator generally Involve the following sys

tems or components:

1. The engine.

2. The Speed Control System.

3. The AC Generator.

4. The Genistor.

5. Battery Charge Circuit.

6{ CCG Circuit Board.

7. Wiring Harness and Front Panel.

This Section will discuss test procedures for the

following components. Also see Part 8 of this

Manual, “TROUBLESHOOTING".

1. The AC Generator (Stator).

2. The Genistor.

3. Battery Charge Circuit.

4. CCG Circuit Board.

Stator Assembly

GENERAL:

For additional information on the Stator, refer to

the following:

1. “ Stator Assembly“ on Page 1.2-2.

2. Section 1.4, “INSULATION RESISTANCE“.

SYMPTOMS OF STATOR FAILURE:

A. If the engine starts but the Stepper Motor does

not move, and shutdown occurs after several sec

onds, look for the following:

1. Broken or shorted Power Supply winding

(Wires PS1 and PS2).

2. Broken or shorted Timing winding (Wires TIM1

and TIM2).

NOTE: If the Power Supply windina Is shorted to

ground, a burned area on the CCG circuit board

mircult board ground track) may be visible. If the

Timing winding Is shorted to ground, the circuit will

probably be damaged but bum-up may not be vls-

A short circuit between windings.

□

□

NOTE: The resistance of Stator windings Is very

low. Some meters will not read such alow resis

tance and will simply Indicate “continuity". Recom

mended Is a high quality, digital type meter capable

of reading very low resistances.

TESTING POWER PHASE WINDINGS:

A. Refer to Figures 1 and 2. To test the Power

Phase windings for an open circuit condition, pro

ceed as follows:

1. Disconnect the following wires:

a. Lead “AC1" (Gray) at the Genistor.

b. Lead “AC2” (Yellow) at the Genistor.

c. Lead “SL1" (Orange) at the Genistor.

d. Lead “SL2" (Brown) at the Genistor.

e. Lead No. 11 (Blue) at the Main Circuit Breaker

(CB1).

2. Make sure all of the disconnected leads are

isolated from each other and are not touching the

frame during the test.

3. Set a VOM to its "Rxl" scale and zero the

meter.

4. Connect one VOM test lead to Lead No. 11

. Then, connect the remaining test lead as

K

s:

a. To Lead AC1 and note the resistance reading,

b. To Lead AC2 and note the resistance reading,

c. To lead SL1 and note the resistance reading,

d. To lead SL2 and note the resistance reading.

NOMINAL RESISTANCE- POWER PHASE WINDINGS

Figure 1. Schematic- Stator Windings

POWER

PHASE 1

POWER

PHASE 2

0.30 to 0.42 ohm

B. If the engine shuts down but speed did NOT

exceed 4500 rpm, look for the following:

1. One of the main windings (Power Phase 1 or

2) is open.

2. One of the main windings (Power Phase 1 or

2) is shorted to ground.

TESTING THE STATOR WITH A VOM:

A Volt-Ohm-Milliammeter (VOM) can be used to

test the Stator windings for tne following faults:

□ An open circuit condition.

□ A "short-to-ground“ condition.

BATTERY

CHARGE

nSGfiSIPr

PS1

c

POWER

SUPPLY

TIMING

TIMI T1M2

Page 1.5-1

Page 22

Section 1.5- COMPONENTS TESTING

Stator Assembly (Continued)

TESTING POWER PHASE WINDINGS

B. To test the Power Phase windings for a "short-toground* condition, proceed as follows:

1. Make sure all leads are Isolated from each other and

are not touching the frame.

2. Set a VOM to its *Rx10,000" or "RxlK* scale and

zero the meter.

3. Connect one VOM test lead to the terminal end of

Lead" AC1", the other test lead to a clean frame ground

on the Stator.

a. The meter should read "infinity".

b. Any reading other than "infinity" indicates a

"short-to-ground* condition.

TESTING POWER SUPPLY WINDINGS:

A. To test the Power Supply winding for an open circuit

condition, proceed as follows:

1. Disconnect the 4-pin connector from "CONN4" of

the CCG circuit board. See Rgure 3.

a. Stator lead "PS1* (Brown) connects to Pin 1 of

the connector.

b. Stator lead "PS2* (Yellow) connects to Pin 3 of

the connector.

2. Set a VOM to its *Rx1* scale and zero the meter.

3. Connect one VOM test lead to Pin 1 (Lead PS1Brown), the othet test lead to Pin 3 (Lead PS2-Yellow).

The meter should indicate the resistance of the Power

Supply winding.

NGS (CONT’D): NOTE: Any reading other than "Infinity'' Indicates

the winding Is shorted to ground. If winding Is open

or shorted, the Stator should be replaced.

TESTING THE TIMING WINDING:

A. To test the Stator Timing winding for an open circuit

condition, proceed as follows:

1. Disconnect the 4-pin connector from "CONN4" of

the CCG circuit board. See Rgure 3.

a. Stator lead TIM1 (Orange) connects to Pin 2 of the

4-pin connector.

b. Stator lead TIM2 (Gray) connects to Pin 4 of the

4-pin connector.

2. Set a VOM to its *Rx1 * scale and zero the meter.

3. Connect one VOM test lead to Pin 2 (Lead TIM1Orang^; connect the other test lead to Pin 4 (Lead

TIM2- Gray). The meter should Indicate the Stator

Timing winding resistance.

B. To test the Timing winding for a "short-to-ground"

condition, proceed as follows:

1. Set the VOM to its "Rx10,000* or "Rx1K" scale and

zero the meter.

2. Connect one VOM test lead to Pin 2 of the 4-pin

connector (Lead TIMI-Orange).

3. Connect the other test lead to a clean frame ground

on the Stator. The meter should read "Infinity". Any

reading other than "Infinity" Indicates the Timing

winding is shorted to ground.

Figures. "CONN4“4-Pin Connector

NOMINAL RESISTANCE

STATOR TIMING WINDING

0.35-0.44 ohm

NOMINAL RESISTANCE

POWER SUPPLY WINDING

0.35-0.44 ohm

B. To test the Power Supply winding for a “short-toground" condition, proceed as follows:

1. Set the VOM to its “Rx10,000" or "RxlK" scale and

zero the meter.

2. Connect one VOM test lead to Pin 1 (Lead PS1Brown). Connect the other test lead to a clean frame

ground on the Stator. The meter should read "infinity".

Page 1.5-2

SHORT CIRCUIT BETWEEN WINDINGS:

To test for a short circuit between windings, proceed

as follows:

1. Set a VOM to its "Rx10,000" or "RxlK" scale and

zero the meter.

2. Connect one meter test lead to Stator lead PS1

(Brown).

3. Connect the remaining test lead to Stator lead AC1

(Gray). The meter should read "Infinity*. Any reading

other than "infinity" indicates a shorted condition and

the Stator should be replaced.

Page 23

Section 1.5- COMPONENTS TESTING

4. Connect one VOM test lead to Stator lead AC1,

the other test lead to Stator lead 77. The VOM

should read "Infinity“.

5. Connect one VOM test lead to Stator lead AC1,

the other test lead to Stator lead TIM1. The meter

should read “Infinity”.

6. Connect one test lead to Stator lead PS1, the

other to Stator lead TIM1. “Infinity" should be

Indicated.

7. Connect one test lead to Stator lead PS1, the

other to Stator lead 77. The VOM should read

"Infinity".

8. Connect one VOM test lead to Stator lead TIMI,

the other test lead to Stator lead 77. “Infinity"

should be Indicated.

Genistor

GENERAL:

The “Genistor" or "Triac Module" is the FRE

QUENCY CONVERTER for the generator. For addi

tional Information on the Genistor, refer to "The

Genistor" on Pages 1.2-3 and 1.2-4.

SYMPTOMS OF GENISTOR FAILURE:

If the engine shuts down but speed did not ex

ceed 4500 rpm, the following problems may exist:

1. Loss of the "Gate" connection (G1 through G4)

between the CCG circuit board and the Genistor.

2. Although the correct “Gate" signal Is received

from the CCG board, one or more switches are not

gating.

3. The Genistor is not gating properly, I.e., one or

more switches are permanently turned on.

4. Open circuit or loss of connection(s) between

Stator and Genistor (Leads AC1, aC2, SLI, SL2,

22).

5. Open circuit or loss of connection between

Genistor and CCG circuit board (Leads AC1, AC2,

SL1,SL2).

TESTING THE GENISTOR:

Disconnect ail wires from the Genistor before

attempting to test it.

RESISTANCE READING

"COM" to G1 s 20-60 Ohms

"COM" to G2 > 20-60 Ohms

"COM" to G3 o 20-60 Ohms

"COM" to G4 B 20-60 Ohms

3. Set the VOM to its “Rx1” scale and zero the

meter. Then connect the VOM test leads across

the “COM" terminal and the center screw. The

VOM should read “continuity”.

4. Now, connect the VOM test leads across the fol

lowing terminals and screws:

a. Across AC1 screw to AC1 terminal should

read “continuity”.

b. Across AC2 screw to AC2 terminal should

read “continuity”.

c. Across SLI screw to SLI terminal should read

“continuity”.

d. Across SL2 screw to SL2 terminal should read

“continuity”.

5. Set the VOM to its “Rxl 0,000” or “RxlK” scale

and zero the meter. Then, connect the VOM test

leads across each of the screws. There should be

no continuity between any of the screws (“infini

ty”).

NOTE: The resistance reading between any two of

the screws on the Genistor is in the neighborhood

of about 1 megohm (about 1 million amps). If the

Genistor failed any of the proceeding tests, it

should be replaced.

f^lgure 4. Genistor Test Points

CAUTIONI

DO NOT attempt to test the Genistor until ALL

leads have been disconnected. The genistor

MUST be completely disconnected from the cir

cuit If testing is accomplished with any leads

connected, alftest results are Invalid.

See Figure 4. To test the Genistor, proceed as

follows:

1. Set a VOM to a resistance scale that will allow a

range of about 20-60 ohms to be read. Zero the

meter.

2. Connect one VOM test leads to the "COM" termi

nal and the other test lead to Terminals G1, G2, G3

and G4 one at a time. Read the resistance as the

meter is connected to G1, to G2, to G3, and to G4.

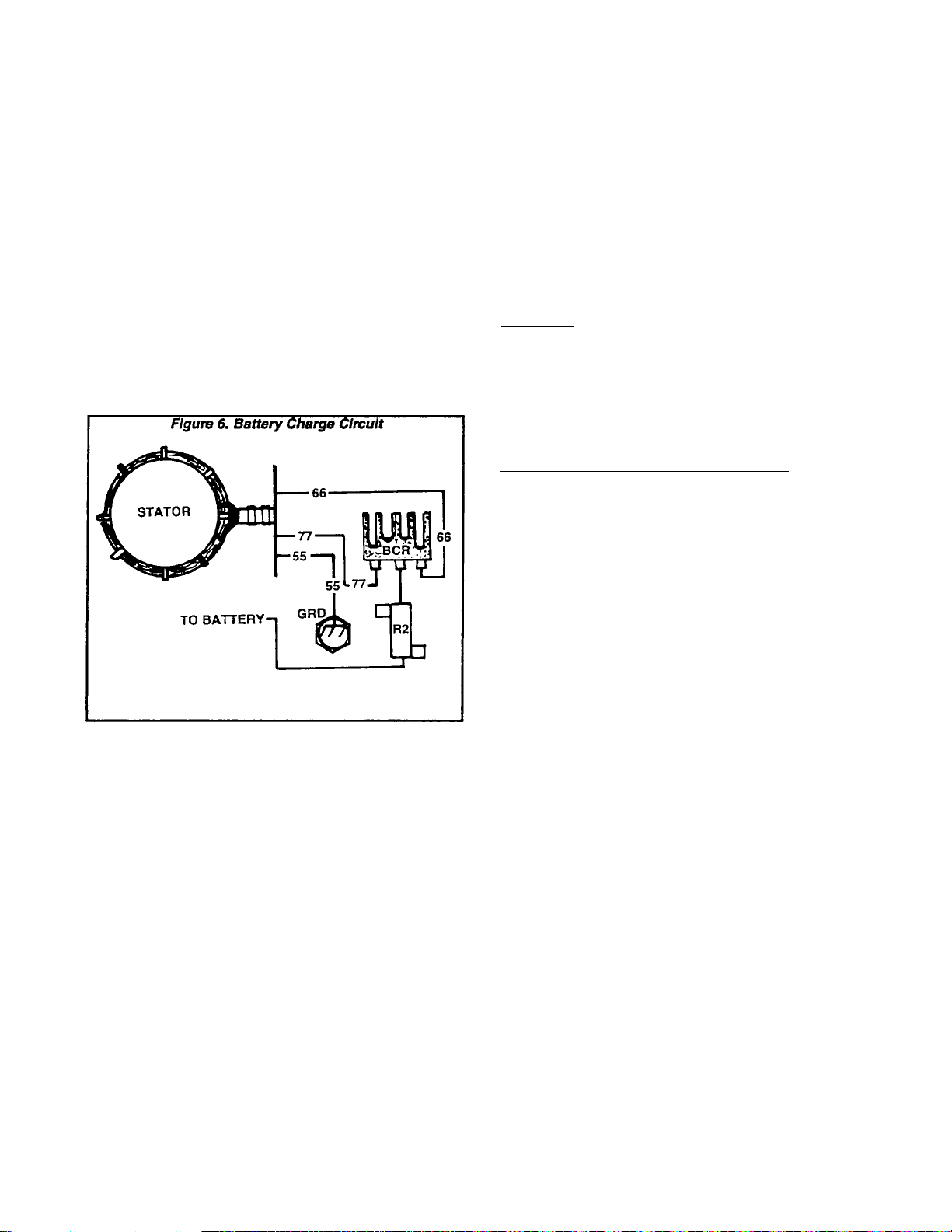

Testing the Battery Charge Circuit

GENERAL:

The Stator Is equipped with

dual battery charge windings.

These windings deliver an AC

output to a Battery Charge Rec

tifier (BCR) which rectifies it

changes It to direct current or

É

C). The direct current Is deliv

ered to the unit battery, to main

tain the battery in a charged

state while the unit Is running.

figure 5,

BATTERY CHARGE

WINDING

Page 1.5-3

BCR

Page 24

Section 1.5- COMPONENTS TESTING

Testing the Battery Charge Circuit

(Continued)

SYMPTOMS OF CIRCUIT FAILURE:

It is difficult to determine if the battery charm

circuit is operating without testing for correct volt

age. If you suspect the battwery charge circuit Is

defective, the following symptoms will usually

point to a cause of the problem. See Figure 6.

1. If no AC voltage can be measured across Stator

connections at the Battery Charge Rectifier (BCR),

an open circuit condition probably exists in Wire 66

(Brown), or Wire 77 (Brown).

2. If AC voltage is available to the Wire 66 and 77

terminals at the battery Charge Rectifier, but no

voltage or a low voltage Is measured between the

BCR’s Wire 55 terminal and ground, the Battery

Charge Rectifier (BCR) Is defective.

TESTING THE BATTERY CHARGE CIRCUIT:

Test the Battery Charge winding as follows:

1. Disconnect Wire 77 at the Battery Charge Recti

fier (BCR).

2. Disconnect Stator output Wire 66 at the Battery

Charge Rectifier (BCR).

3. Disconnect Wire 55.

4. Set a VOM to its ”Rx1" scale and zero the meter.

5. Connect the VOM test leads across Wires 77 and

55, then across Wires 66 and 55. Note the resis

tance reading in both cases. Replace Stator As

sembly, If defective.

BATTERY CHARGE WINDING RESISTANCE

ACROSS WIRES 66 TO 55 s 0.037-0.042 Ohm

ACROSS WIRES 77 TO 55 s 0.037-0.042 Ohm

6. Use a VOM to measure AC voltage at the Wires

66 and 77 terminals of the Battery Charge

Rectifier, with the unit running. If no AC voltage is

measured, an open circuit exists in the wire 66 or

77 circuit.

7. With engine running, use a VOM to check for DC

voltage between the Battery Charge Rectifiers

Wire 55 and frame ground. If AC voltage was pre

sent in step 6, but DC voltage is NOT present in

this stem, the Battery Charge Rectifier (BCR) is

d6f6CtiVG.

Testing the CCG Circuit Board

GENERAL:

It is difficult if not impossible to test the CCG

circuit board in the field. Generally, if the other

components in the AC generator system have

tested good, you may assume that any problem is

In the CCG circuit board.

NOTE: Also refer to “CCG Circuit Board" on Pages

Ï.2-4, 1^-5, and 1^-6.

SYMPTOMS OF CIRCUIT BOARD FAILURE:

1. If the engine starts, but the Stepper Motor does

not move, and engine shuts down after several

seconds, the CCG circuit board’s micro-controiler

may not be operating.

2. A failure of the circuit board’s Stepper Motor

drive can result in the following:

a. Engine starts, but Stepper Motor does not

move. The engine accelerates uncontrollably

and shuts down when engine speed exceeds

4500 rpm.

b. Engine starts, but Stepper Motor does not

move. The following symptoms occur:

(1) Engine appears to operate too slowly.

(2) Engine is not able to handle the load and unit

operates at low AC output voltage.

(3) After several seconds under load, AC output

voltage is turned off (overload condition).

3. If the engine can be started, but shuts down after

several seconds, a timing detection faiiure may

have occured (Timing winding. Wires TIM1, T1M2).

4. if the engine speed and output voltage are erratic

under constant load, but the AC output does not

turn off intermittently, erratic timing detection may

have occured (Timing winding. Wires TIM1, TIM2).

NOTE: Timing detection Involves the circuit

board’s ability to detect "zero crosslrws" of the

sine wave (see “Alternating Current", Pages 1.1-1

and 1.1-2). The CCG clrculfboard must detect both

zero VOLTAGE and zero CURRENT crossings If the

system Is to operate properly. This “zero crossing“

detector Is used to synchronize an Internal clock

on the circuit board. The frequency of the Input

waveform la measured by the circuit board and

checked against a "reference“ frequency. The

board then calculates a frequency divisor. By

counting “zero voltage crossings“, an Internal reterence output polarity Is generated. The Genistor

switch with the maximum potential In the direction

of the Internal reference Is gated.

Page 1.5-4

Page 25

Section 1.5- COMPONENTS TESTING

TESTING THE CIRCUIT BOARD;

There Is no practical way of testing the CCG

circuit board In the field. Read "SYMPTOMS OF

CIRCUIT BOARD FAILURE" carefully. Test the Sta

tor, the Genistor, and the Battery Charge circuit as

outlined In this Section. Also perform a resistance

test of the Stepper Motor (see Part 7, "THE VARI

ABLE SPEED SYSTEM") and observe Its operation

If possible.

Inspect wiring and wiring connections between

the CCG circuit board and the Genistor as follows

(refer to appropriate wiring diagram):

1. Check wires G1 through G4 (and Wire 22) for

proper connections at circuit board and at the

Genistor.

2. Use a VOM to check Wires G1 through G4 (and

Wire 22) for continuity.

3. Check Wires AC1, AC2, SL1 and SL2 (between

circuit board and Genistor) for proper connections.

4. Use a VOM to check Wires AC1, AC2, SL1, SL2

(between circuit board and Genistor) for condlnu-

Ity.

If all tests are completed and no problem Is found

on other components of the system, replace the

CCG circuit board and check unit operation.

Page 1.5-5

Page 26

Section 1.5- COMPONENTS TESTING

Page 1.5-6

Page 27

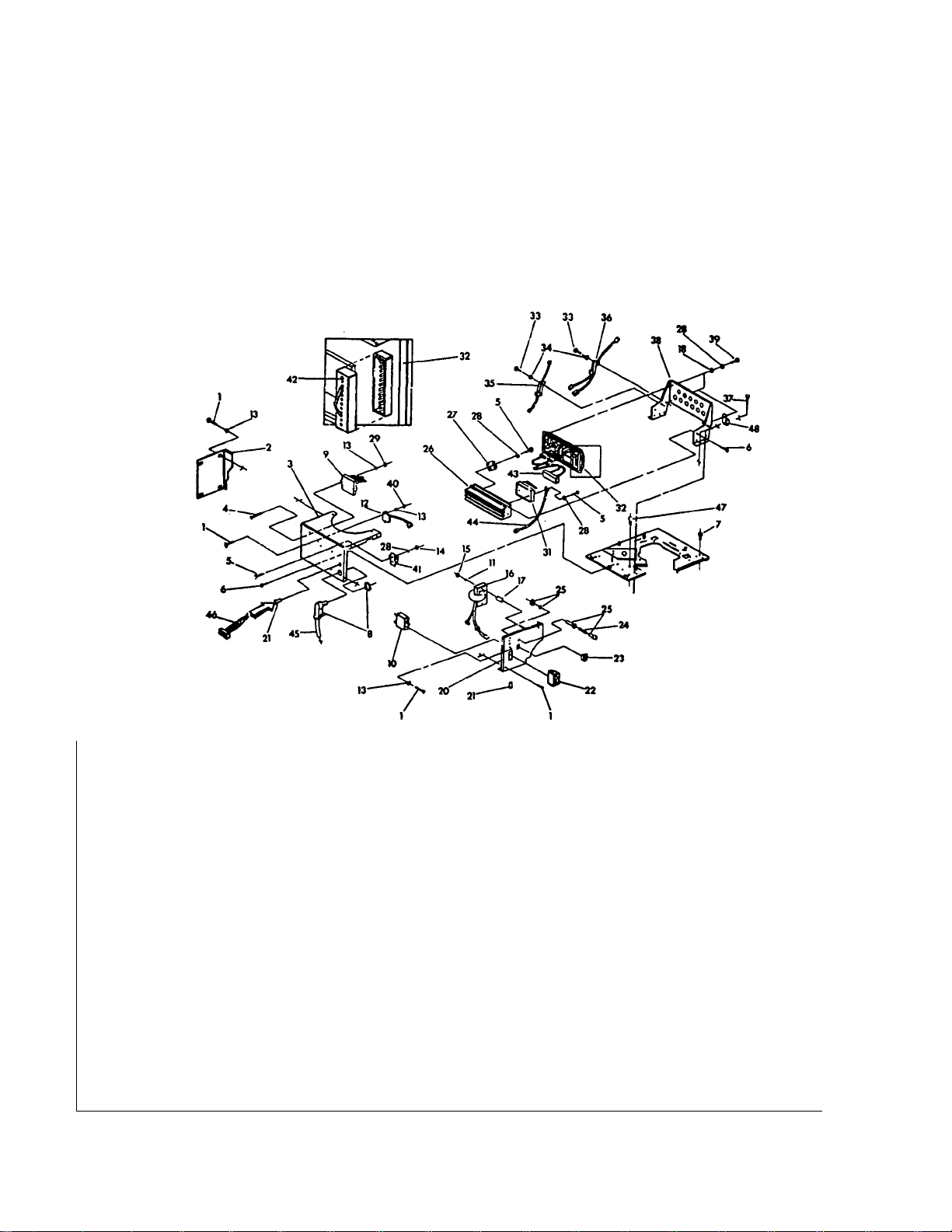

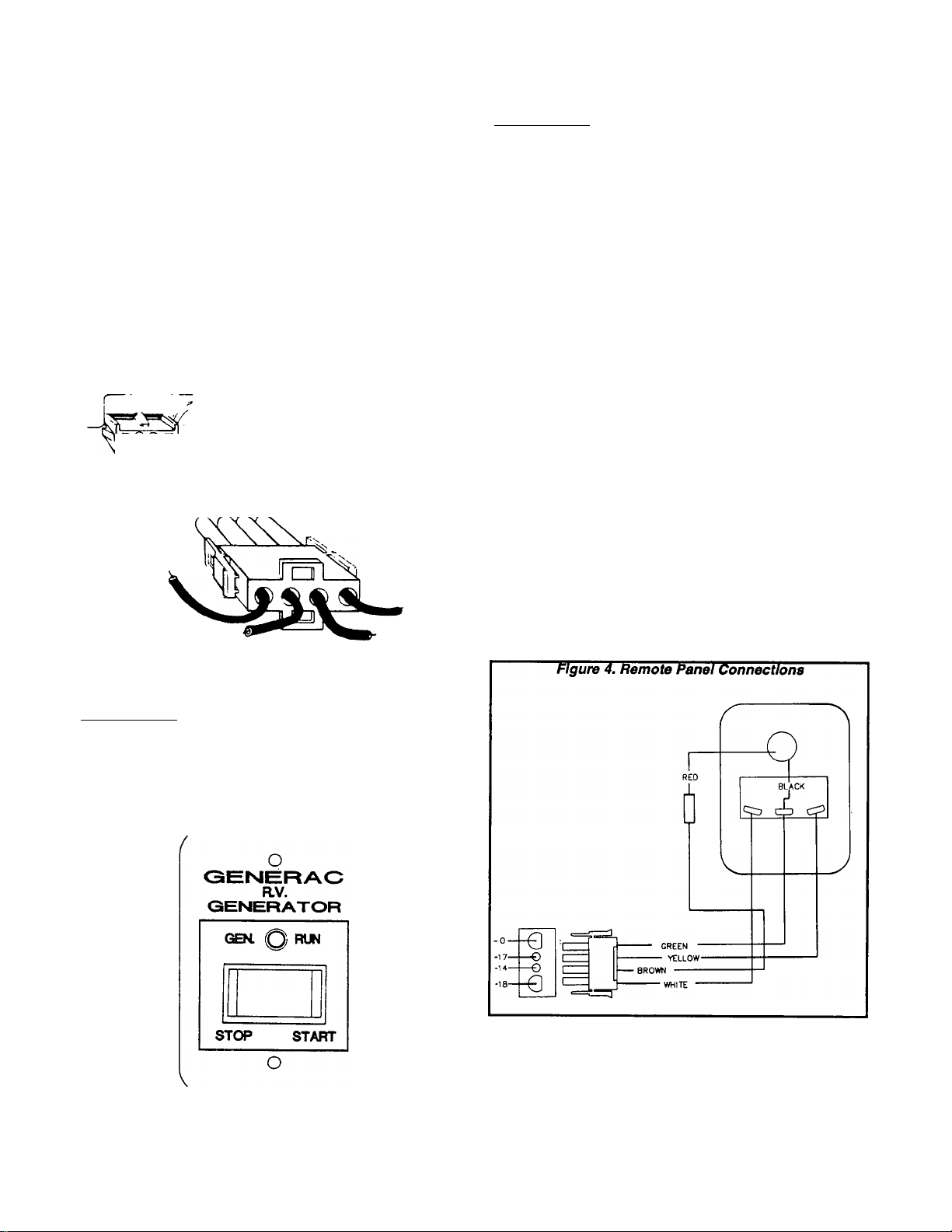

Section 1.6- CONTROL PANEL

Construction

The panel Is constructed of sheet metal and Includes

a panel box, a panel back cover and a front control panel.

The panel box Is retained to an enolne-generator divider

plate by five MS screws. Removal of these screws will

permit the panel to be removed from the divider plate and

set out of the way with connecting wires still attached.

This will allow access to components housed In the

control panel.

Figurer 1. Exploded View of Control Panel

Components

A heat sink bracket Is attached to the engine-generator

divider plate, for attachment of a heat sink to which a

CCG circuit board and Genistor are mounted. See Items

26,31,32 and 38 In the Exploded View of Control Panel.

Other components are also shown In the Exploded View.

Many of tnese components are part of the "ENGINE

ELECTRICAL SYSTEM" (Part 6 of this manual).

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13 8

14

15

16

17

18

20

21

22

23

24

25

QTY

6

1

1

2

5

8

1

1

1

1

2

1

2

2 M6 Hex Nut

1

2

4

1

2

1

1

1

1

M5 Pan Head Machine Screw

Engine Controller Circuit Board

DESCRIPTION

Back Panel Cover

Control Panel Box

No. 10-32 Pan Head Screw

M4 Pan Head Screw

M5 Screw

Snap Bushing

90’ Connector

25 amp circuit breaker

M6 Lockwasher

Ignition Module 38

M5 Lockwasher

M4 Hex Nut

Ignition Coll Assembly

Ignition Coll Spacer

No. 8 Flatwasher 44 1 Ground Wire

Front Control Panel 45 1

Snap Bushing 46

Start-Stop Switch

Fuel Primer Switch

15 amp Fuse

Fuse Holder

ITEM

26 1

27 1

28 9

29 2

31 1

32 1 CCG Printed Circuit Board

33 4 M3 Pan Head Screw

34 4 M3 Lockwasher

35

36 1 500 ohm Power Resistor

37 4 M6 Screw

39 4

40 2

41 1 Terminal Block

42

43 1 Genistor Harness

47

48 2 Wiring Harness Clamp

49 1 Panel Harness (Not Shown)

QTY

1 1 ohm Power Resistor

1 Heat Sink Bracket

1 12-pln Connector

1 Remote Panel Harness

1

DESCRIPTION

Heat Sink

Battery Charge Rectifier

M4 Lockwasher

No. 10-32 Hex Nut

Genistor

M4 Pan Head Screw

M5 Hex Nut

Customer Wiring Harness

Snap Bushing

Page 1.6-1

Page 28

Section 1.6- CONTROL PANEL

Page 1.6-2

Page 29

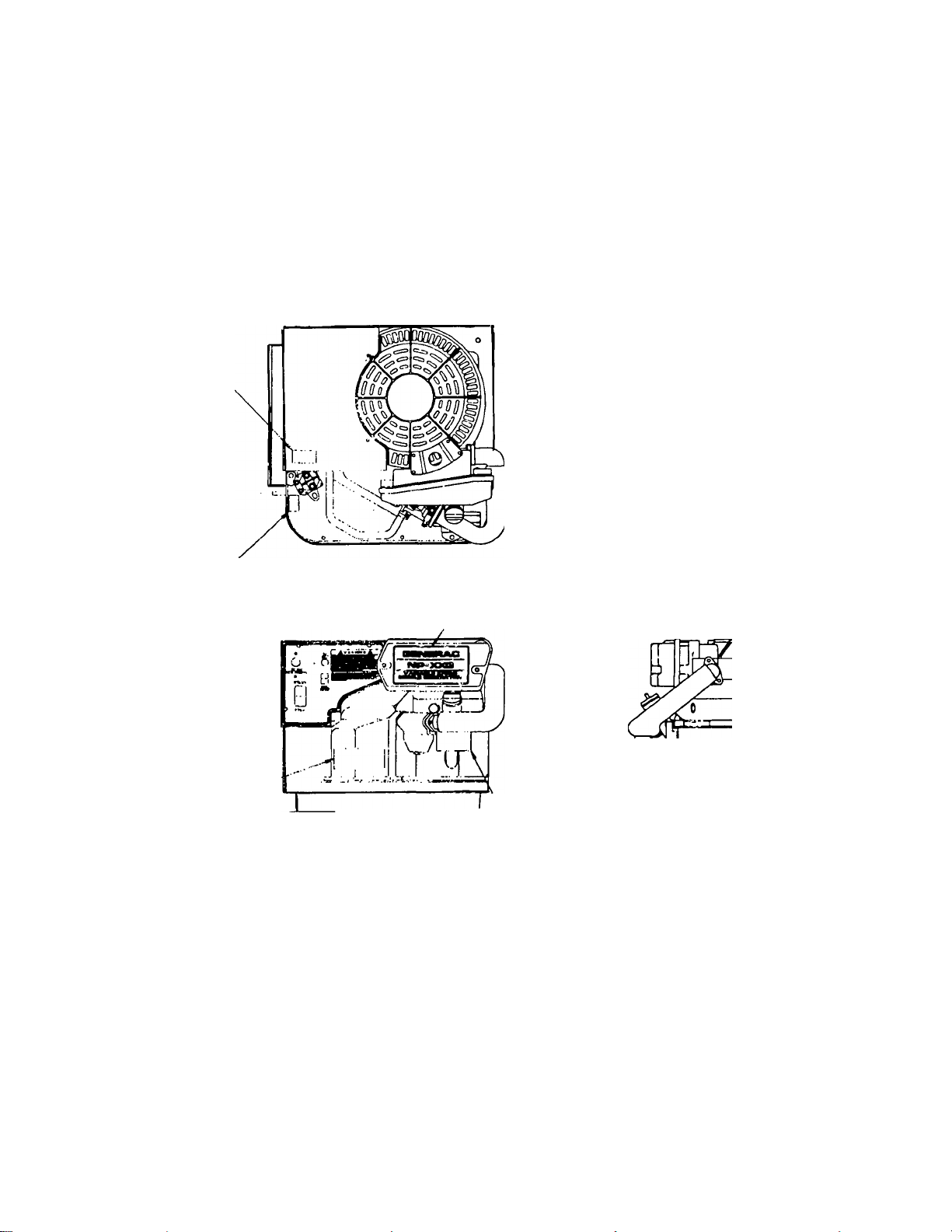

Section 1.7- SHEET METAL

See ‘Exploded View of Sheet Metal" on next page. A

General

DIVIDER PLATE (Item 1 )separate8 the AC generator com

ponents from the engine. The engine Itself Is enclosed

by a BASE HOUSING WRAPPER (ftem 4), a FRAME (Item

24), and a BELLY PAN (Item 23). These components are

sealed by means of rubber SEALS (Items 3), to prevent

the escape of gases.

NP-30/NP-40 Generator

CONTROL PANEL

BOX

DIVIDER PLATE

The LOWER FAN attaches to the engine shaft and Is

enclosed In a LOWER FAN HOUSING (Item 19). Air Is

drawn Into the enclosed area around the engine and

forced out of the LOWER FAN HOUSING.

Removal of sheet metal will be necessary for many

repairs and for replacement of most parts.

ROCKER COVER

COVER

OIL FILTER buy il

AIR CLEANER

/

I ...r

OIL FILL TAG

ionoanjiiJ

Page 1.7-1

Page 30

Section 1.7- SHEET METAL

Parts List for Exploded View of Sheet Metal

ITEM

1 1

2

3

4

5 26

6

7

8

9 5

10

12 1

13

14 1 3/8"-16 Capscrew 38 1 Snap Bushing

15

16

17

18

19

20

21 1

22 1

23

24

25

QTY

Engine-Generator Divider Plate

1 Engine Upper Wrapper

1 Rubber Seal

1

2 Customer Mounting Ralls

4 M8 Lockwasher 32 1 Starter Contactor Insulator Boot

4

7 M6 Lockwasher 35 4

1

1 3/8” Lockwasher 39

1 3/8” Hex NHut 40

1 Air Outlet Deflector 41 1

1 Exhaust Muffler

1

1 45 1 Grounding Strap

1 Belly Pan 49 1 Muffler Lower Insulation

1

1

DESCRIPTION ITEM QTY DESCRIPTION

Grounding Strap

1/4” Lockwasher

Seal Retainer

M8 Flatwasher

No. 8 Hex Nut

M6-1.00 Capscrew

Lockwasher

Muffler Heat Shield

Base Housing Wrapper

M5 Screw 30

M8-1.25 Capscrew

M8-1.25 Capscrew

Spark Arrestor

Exhaust Clamp

Lower Fan Housing

Carburetor Baffle SKlrt

Rocker Cover Cover

Spark Plug Side Skirt 48

Frame

Grounding Strap

26 1

27 1 Fuel Pump

28 2 Barbed 90* Fitting

29

31

33 1 Oil Filter Opening Seal

34 1

36 1 Fuel Line

37

42

44

47

50 1 Muffler Upper Insulation

3 1/4”-20 Hex Nut

3

1 Starter Contactor

2 Hose Clamp

7 Lockwasher

1 No. 8 Hex Nut

2

1

1

1 Muffler Hanger Bracket

Page 1.7-2

Page 31

Section 1.7- SHEET METAL

Exploded View of Sheet Metal

g 53 s ■«

Page 1.7-3

Page 32

Section 1.7- SHEET METAL

Page 1.7-4

Page 33

SECTION

TITLE

Part 2

ENGINE

MECHANICAL

COMPUTER

CONTROLLED

VARIABLE

SPEED RV

GENERATORS

Series NP-30G and NP-40G

2.1

2.2

2.3

2.4

GENERAL INFORMATION

VALVE TRAIN

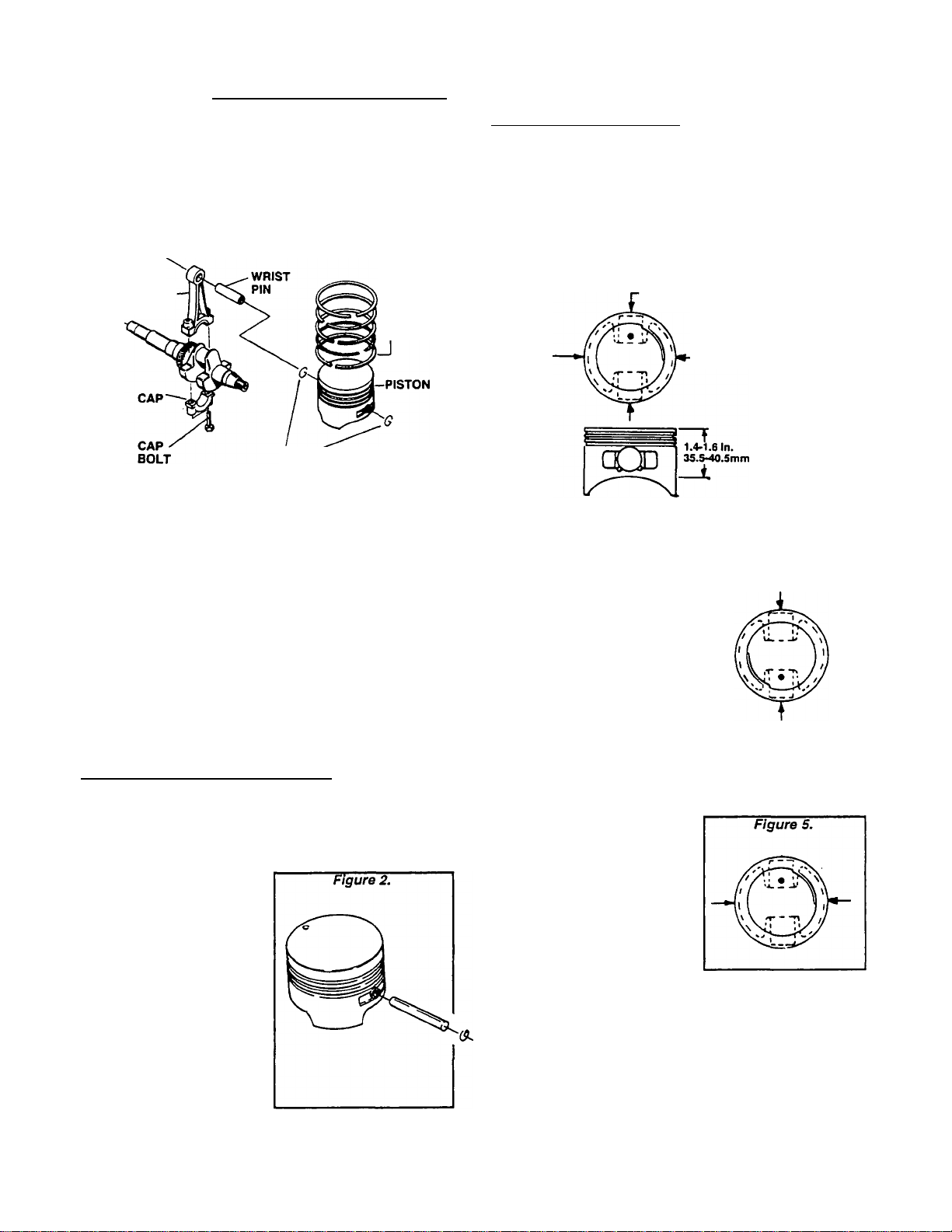

PISTON, RINGS, CONNECTING ROD

CRANKSHAFT & CAMSHAFT

Page 34

Section 2.1- GENERAL INFORMATION

Introduction

The engine used on Series NP-30G and NP-40G recre

ational vehicle AC generators Is a Generac Series GN190

or GN220, vertical shaft, single cylinder, overhead valve

type.

These engines are not equipped with a mechanical

engine governor. Instead, variable engine speeds are

controlled by a computer circuit board. The circuit board

signals a stepper motor to move the carburetor throttle

linkage.

4-Cycle Engine Theory

GENERAL;

Series GN190 and GN220 engines require four (4)

strokes or cycles to complete one power cycle. This is

often called the ''4-stroke, 5-event" cycle. The 4 strokes

and 5 events that occur are (1) Intake, (2) compression,

(3) Ignition, (4) power and (5) exhaust

INTAKE STROKE (Figure 1):

The Intake valve is open. The exhaust valve Is closed.

The piston travels downward, creating a suction which

draws the air-fuel mixture from the carburetor Into the

cylinder and Just above the piston.

COMPRESSION STROKE (Figure 2):

As the piston reaches bottom dead center (BOC), the

Intake valve closes. The exhaust valve remains closed,

as well. The piston starts to move outward in the cylinder.

Since both valves are closed, the air-fuel mixture In the

cylinder Is compressed.

POWER STROKE (Figure 3);

Both valves remain closed. At some point before the

piston reached top dead center (TDC), the spark plug

fires to ignite the fuel-air mixture. The piston moves to

its top dead center position and the burning, expanding

gases of combustion force the piston downward.

EXHAUST STROKE (Figure 4):

The expanding gases of combustion force the piston

downward to its bottom dead center (BOC) position. The

exhaust valve then opens, as the piston starts its move

ment toward top dead center (TDC). Piston movement

then forces the exhaust gases out through the open

exhaust valve. The 4-stroke cycle of events then starts

over again.

TIMING;

Valve timing and Ignition timing must be precisely

controlled If the engine Is to operate properly and effi

ciently. Intake and exhaust valves must open and close

In a precise timed sequence If the four strokes are to

occur. Ignition must occur at exactly the correct piston

position, just prior to the start of the power stroke.

Timing of valve opening and closing, as well as of spark

occurence. Is given in relation to the piston position and

the degrees of crankshaft rotation.

Ignition Is timed to occur several degrees before top

dead center (TDC) of the piston, to allow time for the

air-fuel mixture to ignite and start to bum before the

piston reaches top dead center

There must be no leakage past the valves in their

closed position or compression will not develop. Like

wise, there must be no leakage past the piston-

Figure 3. Power Stroke

Page 35

Section 2.1- GENERAL INFORMATION

Recommended Fuels

GASOLINE FUEL SYSTEMS:

For models equipped with a gasoline fuel system, the

use of clean, fresh, UNLEADED, regular grade gasoline

Is recommended. Unleaded gasoline burns cleaner, ex

tends engine life, and promotes better starting by reduc

ing carbon deposits In the combustion chamber.

Leaded "Regular* grade gasoline may be used if un

leaded gasoline Is not available.

The use of gasohol is NOT recommended. If it must be

used, it should not contain more than 10 percent ethanol.

When gasoline containing ethanol is used, special care

Is required when preparing the unit for storage (see

"Storage Instructions").

DO NOT USE GASOLINE CONTAINING METHANOL.

DO NOT MIX OIL WfTH THE GASOLINE.

DANGERl

GASOLINE IS EXTREMELY FLAMMABLE AND

ITS VAPORS ARE EXPLOSIVE. DO NOT PERMIT

SMOKING, OPEN FLAME, SPARKS OR ANY

SOURCE OF HEAT IN THE VICINITY WHILE HAN

DLING GASOLINE. AVOID SPILLAGE OF GASO

LINE ON A HOT ENGINE. THERE MUST BE NO

LEAKAGE OF GASOLINE INTO THE RV GENER

ATOR COMPARTMENT.

GASEOUS FUEL SYSTEMS:

Some RV generator models may be equipped with an

LP or natural gas fuel system. The use of such gaseous

fuels may result in a slight power loss as compared to

gasoline. However, that disadvantage is usually com

pensated for by the many advantages offered by such

fuels. Some of these advantages are:

Recommended Engine Oil

Use a clean, high quality, detergent oil that Is

classified "For Service SC, SD, SE, SF or SG". Use

no special additives with the oil.

G During summer months (above 32* F. or 0* C.), use

SAE 30 oil. SAE 10W-30 oil Is an acceptable substi

tute.

G During winter months (below 32* F. or 0* C.), use SAE

5W-20 or 5W-30 oil.

G DONOTUSESAE10W-40OIL.

Engine crankcase oil capacity without oil filter change

is about 29 fluid ounces (850ml).

Engine crankcase oil capacity (with oil filter change)

is about 1 U.S. quart (946ml).

Change engine oil and the oil filter after the first eight

(8) hours of operation. Thereafter, change engine oil and

oil filter every 50 operating hours.

NOTE: Additional Information on the engine oil

system can be found In Part 5 of this manual,

"Engine Oil and Cooling System".

Storage Instructions

PREPARATION FOR STORAGE:

The engine should be started at least once every

seven (7) days and allowed to run for at least thirty (30)

minutes. If this cannot be done and the engine is to

remain unused longer than thirty (30) days. It must be

prepared for storage. To prepare the unit for storage,

proceed as follows:

1. Start the engine and let It warm up.

2. After engine Is thoroughly warmed up, shut It down.

D A low residue content which results In minimum

carbon formation In the engine,

n Reduced sludge buildup in the engine oil.

n Reduced burning of valves as compared to gasoline.

D No "washdown" of the engine cylinder wall during

cranking and startup.

D Excellent anti-knock qualities,

n A nearly homogenous mixture in the engine cylin

der.

□ Fuel can be stored for long periods without break

down.

DANGERl

GASEOUS FUELS ARE HIGHLY VOLATILE AND

THEIR VAPORS ARE EXPLOSIVE. LP GAS IS

HEAVIER THAN AIR AND WILL SETTLE IN LOW

AREAS. NATURAL GAS IS LIGHTER THAN AIR

AND WILL ACCUMULATE IN HIGH AREAS. EVEN

THE SLIGHTEST SPARK CAN IGNITE THESE

FUELS AND CAUSE AN EXPLOSION. THE USE

OF LEAK DETECTORS IS RECOMMENDED

WHEN GASEOUS FUELS ARE USED. ALL

CODES, STANDARDS AND REGULATIONS PER

TAINING TO THE INSTALLATION AND USE OF

GASEOUS FUELS MUST BE COMPLIED WITH.

NOTE: If the unit Is equipped with a gasoline fuel

system and GASOHOL was used as a fuel, turn off

the supply of fuel to the engine and let It run out of

gas.

3. While engine Is still warm from running, completely

drain the oil. Then, refill with the recommended oil. See

"Recommended Engine Oil".

4. Attach a tag to the engine Indicating the viscosity and

classification of the oil m the crankcase.

5. Remove the spark plug and pour about one (1) ounce

(15ml) of clean, fresh engine oil into the spark plug

threaded opening. Crank the engine several times to

distribute the oil, then Install and tighten the spark plug.

6. Remove the battery and store It In a cool, dry room on

a wooden board. Never store the battery on any concrete

or wood floor.

7. Clean and wipe the generator exterior surfaces.

RETURN TO SERVICE AFTER STORAGE:

To return the unit to service after storage, proceed as

follows:

1. Verify that the correct oil is In the engine crankcase by

checking the tag on the engine (see "Recommended

Engine Oil".) If necessary, drain oil and refill with the

recommended oil.

Page 2.1-2

Page 36

Section 2.1- GENERAL INFORMATION

2. Check the battery. Fill all battery cells to the proper

level with distilled water. DO NOT USE TAP WATER IN

THE BATTERY. If necessary, recharge the battery to a

100 percent state of charge or replace It, If defective.

3. Turn OFF all electrical loads. Start the engine at no-

load and let It warm up.

4. Apply electrical looads to at least 50% of the unit’s

rated capacity.

5. When engine Is thoroughly warmed up, turn off or

disconnect all electrical loads. Then, shut the engine

down.

THE UNIT IS NOW READY FOR SERVICE.

Engine Tuneup

The following procedure may be used as a minor

tuneup. On completion of the procedure, the engine

should run properly. If It does not run properly, additional

checks and repairs are required.

1. Service and repair engine air cleaners, as necessary.

2. Check engine oil level and condition of oil. Add or

change oil as required.

3. Remove shrouding and clean away dirt from the en

gine cylinder head and cooling fins.

4. Check fuel filters and clean or replace as necessary.

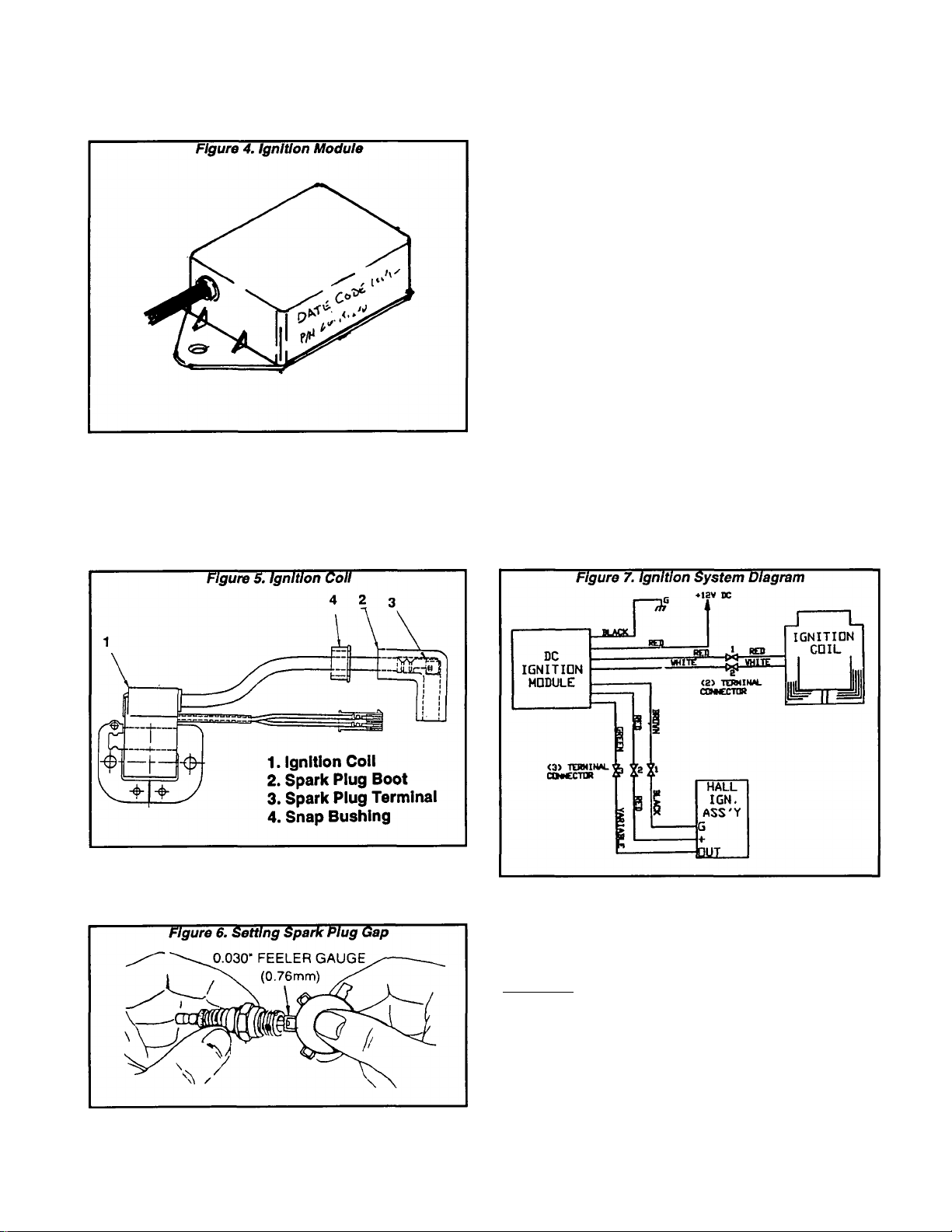

5. Replace the spark plug with a Champion RC12YC (or

equivalent) plug.

a. Set spark plug gap to 0.030 Inch (0.76mm).

b. Install new plug and tighten to 13 foot-pounds (1.8

N-m).

c. If a torque wrench Is not available, tighten spark

plug as tight as possible with fingers and then

(1) If plug is RE-USED, tighten about 1/4 turn more

with a wrench.

(2) If plug Is NEW, tighten it about 1/2 turn more with

a wrench.

6. Check that wiring Is free of breaks, abrasions and are

properly routed.

7. Check for spark as outlined in "Ignition“ section of Part

6 of this manual.

8. Run engine, adjust carburetor If necessary and check

operation.

Page 2.1-3

Page 37

Section 2.1- GENERAL INFORMATION

Exploded View of Engine Long Block

ITEM

QTY

DESCRIPTION ITEM

1 1 (jonneciihg Hd'd &

2 1

3

4 2

5

6

7 2

8

10 1

11 1

12

13

14

15 4

16

17 3

18

19

21 1

22 1

23 1

24 1

25 1

26

27

1

1

1

1

Crankshaft & Gear Assembly

1 Sleeve Bearing

2

1

4

1

1

Crank Case Flange Gasket

Oil Pressure Spring Retainer

Oil Pressure Relief valve Ball

4

M6 Screw & Lockwasher

1

Piston Pin 32

Piston Ring Set (STD)

1/4“ Pipe Plug

Breather Cover

Piston

Piston Pin Retainer

Oil Breather Separator

Crankcase Assembly 41

Crankshaft Oil Seal 43 2

Breather Baffle Cup 44

M6 Screw

Lockwasher

Dowel Sleeve

Camshaft Assembky

Cylinder Head Gasket

Oil Pressure Spring

Thread Forming Bolt 54

Oil Filter Adapter

28 6 M8-1.25 Capscrew

29 1

30

2

Oil Pressure Switch

Valve Spring Retainer

NOTE 1Item 36 Includes valve seats and guides.

QTY DESCRIPTION

2

vaive spring

1 Dowel Pin

33 1

34

36 1

37 1

38

39 2

40

42 1

2

1

2 Tappet

1

Inner Oil Pump Rotor

Connecting Rod Bolt

Cylinder Head (see NOTE 1)

Exhaust Valve

Intake Valve

Push Rod

Oil Pickup Screen

Rocker Cover Gasket

Pivot Ball Stud

45

46

2

2

1

Rocker Arm

Rocker Arm Nut

Puch Rod Guide Plate

47 5 Head Bolt

48 1 Rocker Cover

49

50

51 1

52 1

53 2

55 1

56 2

57

58 1