Page 1

Power Manager Integrated Controller

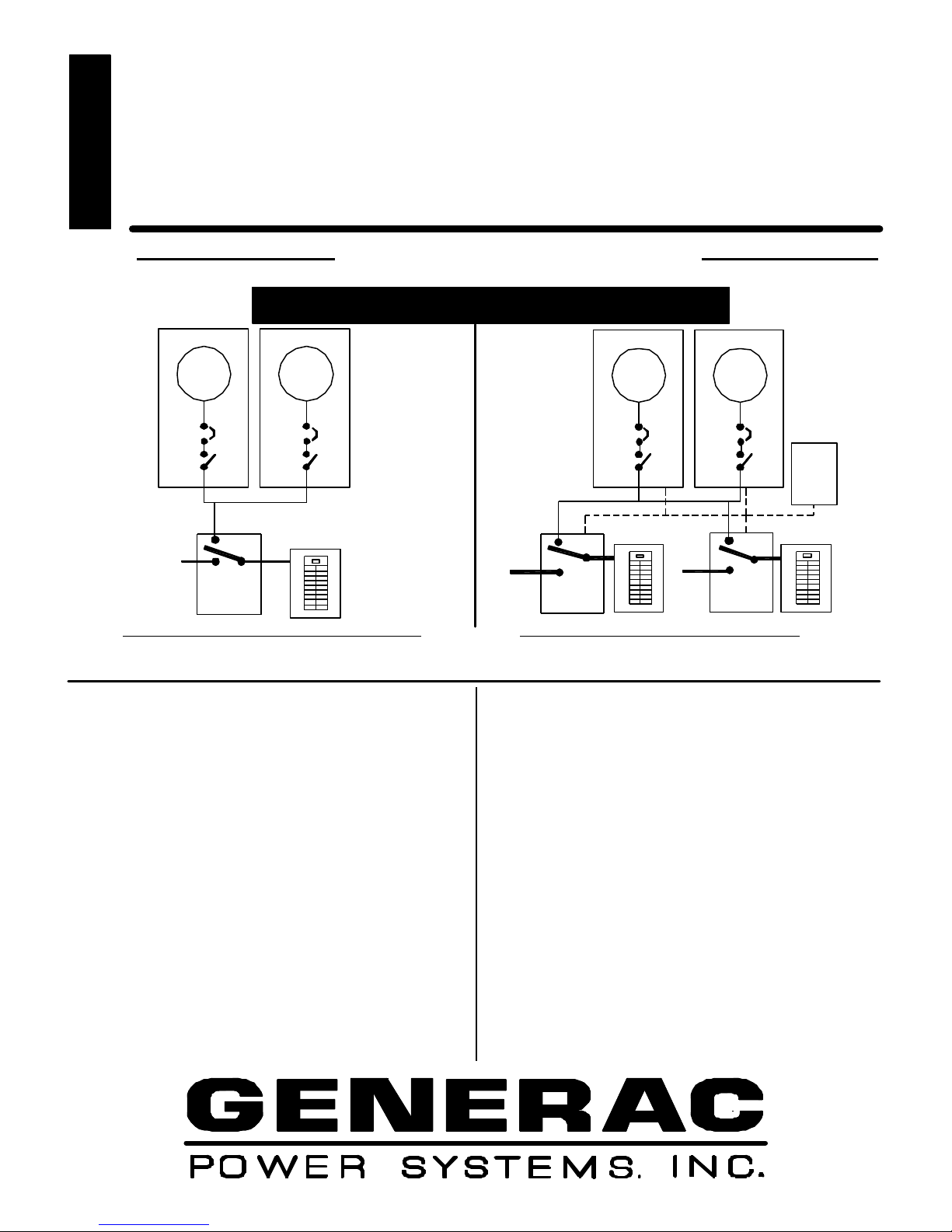

Layout

Power Manager System Controller Layout

FEATURES

Modular Power

System (MPS)

®

MPSG350

350 kW

Standby Power Rating Prime Power Rating

350 KW 60 Hz 280 KW 60 Hz

Powered with Generac’s 13.3 Natural Gas Engine

Diesel Generator

GEN

Circuit

Breaker

Contactor

UTILITY

Transfer Sw

Control

W/ Integral

Diesel Generator

GEN

Circuit

Breaker

Contactor

Distribution

Cab

n The Generac Modular Paralleling system utilizes

multiple small generators in a side by side parallel

arrangement to achieve a larger combined power

output.

n The proven 13.3 liter Generac generators can be

combined up to 10 units to provide from 300 kW to 1

megawatts of reliable power.

n Paralleling System Features. The paralleling function is

controlled by Generac’s field proven Power Manager

Control utilizing contractor switching technology

resulting in cost effective reliable paralleling. The MPS

control system provides automatic synchronization,

adjustable load sharing between generators, reverse

power protection and load shedding contacts.

n The optional cable interconnect cabinet is furnished with

bus bar and lugs to allow easy cabling between the

multiple gensets. Recommended for 3 or more gensets.

n The Generac “Power Manger Generator controller”

provides complete engine monitoring and control along

Diesel Generator

Diesel Generator

GEN GEN

UTILITY

Circuit

Breaker

Contactor

ATS

PMSC

Controller

Cabinet

Distribution

Cab

Circuit

Breaker

Contactor

Control Wires

Distribution

Cab

UTILITY

ATS

with alarm function and communication ability via a

RS232 with a modem link to Generac’s Genlink

software or Modbus control. A RS485 link is also

available.

n Flexibility. The Modular Power systems flexibility allows

for a wide variety of configurations, including single or

multiple automatic transfer switch arrangements roof

application where better weight distribution is required

and areas with specific height or depth limitations.

Since MPS gensets need not be located together, space

can be utilized wherever it is available. Smaller units

are also easier to transport and place on the jobsite.

n Redundancy. N+1 means greater reliability with MPS.

Backup power during scheduled maintenance.

Simplified service which reduces maintenance costs.

n Single source service response from Generac’s dealer

network provides parts and service support for the entire

unit. You are never on your own when you own a

Generac Power System

Page 2

APPLICATION

Ratings definitions

: See Generac Power Systems "

Power Rating Guidelines

" for specific definitions and application guidelines of the Standby Power, Prime Power and Continuous Power

& ENGINEERING DATA

MPSG 350

Modular Paralleling System

MPSG 350

System Description

The Generac control system consists of the Power Manager™

System Controller (PM-SC) or the Power Manager Integrated

Controller ()PM-IC) along with the Power Manager Generator

Controller (PM-GC). For single transfer switch installations with

the Generac Transfer Switch, the PM-IC is integral with the

transfer switch. For multiple transfer switch installations, the

PM-SC interfaces with the PM-GC to provide start/stop

commands based on utility power, proportional load sharing

and safe paralleling of each individual genset to the main bus or

transfer switch. Each individual genset has a built in heavy duty

switch to complete the paralleling operation. This switch and

it's control system replace the high cost switchgear and motor

operated circuit breakers associated with standard paralleling

systems.

System Components

Power Manager Generator Controller (PM-GC)

This control is installed on the generator set and monitors

all the engine parameters, including oil pressure, coolant

temperature, overspeed, kW and power factor.

It also controls the governor, voltage regulator and

the synchronizing connection to the bus.

Paralleling Switch

Installed in the generator set connection box

Heavy duty 3 pole solenoid actuated, mechanically

held, with emergency trip to off position

Rated at 400 amps and 1000 amps continuous

35,000 and 42,000 amps interrupting capacity

Built in arc suppression

Power Manager System Control (PM-SC)

Up to 3 primary transfer switches with up to 6 individual

steps for load sequencing, application or shedding with

assignable kW values for each step in addition to the

critical load ATS.

Unlimited number of secondary slave switches

The PM-SC is in an enclosure se parate from the transfer

switches.

Power Manager Integrated Control (PM-IC)

Integrated Control (IC) is installed in the same enclosure

as the single Generac Transfer Switch

Transfer Switch (PM- IC System )

1000 amp,1600 amp, 2600 amp (UL)3200 Amp (non UL)

For smaller switch ratings use the PM-SC control

42,000 AIC – 1000 Amp, 65,000 AIC – 1600 Amp,

85,000 AIC – 2600 - 3200 Amp

NEMA 12/3R enclosure

66"H x 36"W x 30" D – 1000 Amp

78"H x 48"W x 24" D – 1600 Amp

80” H x 48” W x 48” D – 2600 –3200 Amp

Wire access – top, side, bottom

NEMA 3R or 4X Optional

Wt. 1250 lbs. –1000-1600 Amp. 1850 lbs. 2600-3200 Amp

Connection Cabinet ( Optional )

NEMA 12/3R

80” H x 48” W x 48” D

Lug capacity –16 for Generator Controller (GC), 12 for

ATS. Each lug accepts (4) #4 to 750 MCM ( see Dwg. OD4482)

Floor mounting

Aluminum or Copper Wire compatible – 4500 amp bus

Sequence of Operations

1. The PM-IC or a transfer switch in the PM-SC configuration

detects a Utility failure and issues a start command. In the

PM-IC, the command goes direct to each PM- GC and with

multiple transfer switches the command goes to the PM-SC

which then issues a start command to the PM-GC's

2. Each Generator will start on its own.

3. The first generator that attains rated frequency and voltage

is connected to the main bus or transfer switch terminals via

the paralleling switch n the individual genset.

4. The remaining generators will synchronize with the bus and

the respective paralleling switch will close into the bus.

5. When all the gensets are paralleled to the main bus, the

System or Integrated Controller will signal the transfer switch

to transfer to the load. If multiple transfer switches are

installed, the PM-SC will connect these switches in 3

separate programmed steps.

6. If a NFPA requirement for 10 second start exists, the first

unit connects to the bus. This causes the controller in a

separate emergency transfer switch to immediately transfer

to the NFPA load.

7. If a single generator fails, load shed contacts are available to

disconnect selected non critical loads.

8. If load conditions are reduced, (night time operation)

selected generators can be programmed off line.

9. When Utility supply returns, the PM-SC or PM-IC will issue

commands to transfer loads back to the Utility. If then issues

commands to the individual PM-GC’s to disconnect from the

bus. Each PM-GC will operate its generator for the cooldown period and then issue a shutdown command.

Features: PM-IC & PM-SC

Programmable and viewable via Genlink

Provides up to 3 load shed contacts

Failsafe protective functions for reverse

`` Exercise controller

Ratings. Prime Power is not available at this time for MPS units.

power and synchronous paralleling control.

Backup battery

RS232 for Modem connection

RS485 Data Highway

System Configuration

Any KW configuration that equals the required load kW

can be used. The following page details a common

engine configuration and the most economical

configuration utilizing the MG150, MG200. But,

depending on load parameters any number of units up to

10 can be paralleled together.

Additional units and transfer switches can easily be added

at a later date.

Page 3

TOTAL SYSTEM PARAMETERS

1.0% for every 10 º F above

Output Voltage 60 Hz.

120/208

277/480

600 421

Combinations

350 kW 437.5 kVA

Rated Amps

1214

526

1 - 200 kW, 1 - 150 kW

MPSG350

Motor Starting

Inst Dip

kVA

15%

20%

25%

30%

35%

208 Volt Parallel Wye Network 480 Volt Series Wye Network

415

581

711

784

Alternator Parameters

Alternator Models

Sub Transient Reactance

Transient Reactance

Synchronous Reactance

Zero Sequence Reactance

Neg Sequence Reactance

Time Constant Seconds

Phase Sequence

Voltage Balance

Max Harmonics

Efficiency % @

60% Load

80% Load

100% Load

Engine Fuel Consumption @

% of Rated Load

25%

50%

75%

100%

Engine Cooling

Heat Rejection to Coolant( Full Load )

Coolant Capacity (total)

Inlet Cooling Air CFM

Maximum External Press Drop on Rad

Max air temp to radiator º F (derates apply)

Max ambient temperature º F (derates apply)

1,206,000 BTU/Hr. Total for the 2 units 1@ 700,000 btu/hr 1@ 506,000btu/Hr.

1-200 kW plus 1 - 150 kW 520 mm PMG Generac Alternators

0.16

0.23

3.1

0.07

0.18

0.0078

CBA

0.5%

3.50%

208 Volts 1.0 PF 480 Volts 1.0 PF

90.40% 90.70%

90.70% 91.10%

90.50%

Natural Gas 950 BTU /Cu.Ft

kW Cu Ft / Hr Therms/Hr.

87.5 11.49

175

262.5

350

15.4 gallons for the 2 units 77 Gallons per unit

34,400 for the 3 units 17,200 for each unit

0.5 inches H2O

1,209

2,329

3,429

4,467

350 kW

140 º F

120 º F

Combustion Air Requirements

Flow at Rated Power ( cfm)

1174 cfm Total. 618 cfm + 556 cfm

Exhaust

Exhaust Flow @ FL

Exhaust Temperature ( Average)

Exhaust Outlet per engine

Power Adjustments

Temperature 2% for every 10 º C above

Altitude 0.7% for every 100 m above

2.0% for every 1000 ft above

* Note: Temperatures will require necessary derates be applied. Unless otherwise noted, all data at 480 volt wye - 1.0 PF.

4017 CFM for the 2 units 2257 CFM + 1760 CFM

1128

1 @ 4.0" NPT

350 kW Standby

40 º C

104 º F

1066 Meters

3500 Feet

459

637

804

958

1098890

90.90%

22.12

32.58

42.44

Page 4

INTERCONNECTION DIAGRAM

GENERAC POWER SYSTEMS, INC. MPSG350

The PM-SC can control 3 transfer switches and any number of

the size and number of wires for the specific application.

1 - 200 kW 13.3 Liter

The PM-IC is part of the

Generac Transfer Switch

©

Typical Installations

Standard Enclosed units shown.

PMIC Power Manager Integrated Control PMSC Power Manager System Control

Generator Generator

powerpower

control

Power Manager

Integrated

Control

Transfer

Switch

control

A connection box for the power wires is an option.

+ 1 - 150 kW 13.3 Liter Gas

Powered Generator

Modules

Generator Generator

Gen Bus or

Connection

Cabinet (Opt)

ATS ATSATS

Control Wiring

Power Wiring

slave switches. The main connection box would be configured for

Electrical

Connections

AIR AND

EXHAUST

OUTLET

TOP SIDE

TOP VIEW

13.3 LITER

this area

Power

Manager

System

Control

(PM-SC)

Sound attenuated package adds an

additional 26" to the length.

Units can also be non-enclosed for

indoor installations.

AIR AND

EXHAUST

OUTLET

TOP SIDE

TOP VIEW

13.3 LITER

Electrical

Connections

this area

Minimum Clearance

between units

Area Space Requirements.

Units can be placed end to end, side by side or wherever room is available. The transfer switch or switches are generally placed

close to the main electric service. Consult State, Federal and Local codes for specific installation requirements.

Power Connections are in one area in the left rear quadrant of the genset.

All controls are through a single 2 wire RS485 connection that can be daisy chained between generators.

GENERAC

POWER SYSTEMS,INC.

P.O.BOX 8 WAUKESHA, WI. 53187

262-544-4811 FAX 262-544-0770

2003 GENERAC POWER SYSTEMS, INC. All rights reserved. All specifications subject to change without notice. Bulletin # 0168230SBY MW 06-28-03

DISTRIBUTED BY:

Loading...

Loading...