Page 1

Owner’s Manual

For

Diesel Generator

MLG8 • MLG15 • MLG20 • MLG20ICAN

MODEL NUMBER: _________________________

SERIAL NUMBER: _________________________

DATE PURCHASED:________________________

Register your Generac product at:

WWW.GENERAC.COM

1-888-GENERAC

(1-888-436-3722)

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

(000004)

WARNING

California Proposition 65. Engine exhaust and some

of its constituents are known to the state of California

to cause cancer, birth defects, and other reproductive

harm.

(000005)

WARNING

California Proposition 65. This product contains or

emits chemicals known to the state of California to

cause cancer, birth defects, and other reproductive

harm.

ii Owner’s Manual for Mobile Generator

Page 3

Table of Contents

Introduction and Safety

Introduction .......................................................1

Read This Manual Thoroughly ..........................1

Safety Rules ......................................................1

General Hazards ...............................................2

Explosion and Fire Hazards ..............................2

Trailer Hazards ..................................................3

Electrical Hazards .............................................3

Battery Hazards ................................................4

General Information

Component Locations .......................................5

Unit and Serial Number Locations ....................6

Engine Oil Recommendations ...........................6

Coolant Recommendation .................................6

Main Control Panels ..........................................7

Operation

Prestart Checklist ..............................................9

Starting the Unit ................................................9

Emergency Stop Switch ..................................10

Automatic Shutdown .......................................10

Voltage Regulator ...........................................11

Derating for Altitude ........................................11

Wet Stacking ...................................................11

Receptacle Panel ............................................11

Shutting Down the Unit ...................................11

Towing the Unit ...............................................11

Lifting the Unit .................................................12

Maintenance

Emissions Information .................................... 13

Daily Walk Around Inspection ......................... 13

General Maintenance ..................................... 13

Basic Maintenance Schedule ......................... 13

Jack Maintenance ........................................... 16

Side-Wind Models ...........................................16

Top-Wind Models ............................................ 16

Trailer Wheel Bearings ................................... 16

Lower Radiator Hose Heater Option - Use

and Maintenance ............................................ 17

Wiring Diagrams and Service Log

AC Wiring Diagram W/3-30A, 1-50A Outlets .. 19

AC Wiring Panel Options ................................ 20

AC Wiring Diagram - MLG 8 ........................... 21

DC Wiring Diagram - MLG 8 and MLG15 ....... 22

DC Wiring Diagram - MLG 20 ......................... 23

Trailer Harness ............................................... 24

Service Log ..................................................... 25

Owner’s Manual for Mobile Generator iii

Page 4

This page intentionally left blank.

iv Owner’s Manual for Mobile Generator

Page 5

Section 1 Introduction and Safety

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

(000001)

DANGER

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

(000002)

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

(000003)

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Introduction

Thank you for purchasing a Generac Mobile Products

LLC product. This unit has been designed to provide

high-performance, efficient operation, and years of use

when maintained properly.

The information in this manual is accurate based on

products produced at the time of publication. The

manufacturer reserves the right to make technical

updates, corrections, and product revisions at any time

without notice.

Read This Manual Thoroughly

Introduction and Safety

If any section of the manual is not understood, contact

your nearest Generac Mobile Products Authorized

Dealer, or contact Generac Mobile Products (GMP)

Customer Service at

www.generacmobileproducts.com with any questions

or concerns.

The owner is responsible for proper maintenance and

safe use of the equipment. Before installing, operating, or

servicing this generator:

Save these instructions for future reference. This manual

contains important instructions for the generator that

should be followed during installation, operation and

maintenance of the generator and batteries. ALWAYS

supply this manual to any individual that will use this

machine.

1-800-926-9768, or

Safety Rules

The manufacturer cannot anticipate every possible

circumstance that might involve a hazard. The warnings

in this manual, and on tags and decals affixed to the unit

are, therefore, not all inclusive. If using a procedure, work

method or operating technique that the manufacturer

does not specifically recommend, verify that it is safe for

others. Also make sure the procedure, work method or

operating technique utilized does not render the

equipment unsafe.

Throughout this publication, and on tags and decals

affixed to the unit, DANGER, WARNING, CAUTION and

NOTE blocks are used to alert personnel to special

instructions about a particular operation that may be

hazardous if performed incorrectly or carelessly. Observe

them carefully. Their definitions are as follows:

NOTE: Notes contain additional information important to

a procedure and will be found within the regular text of

this manual.

These safety warnings cannot eliminate the hazards that

they indicate. Common sense and strict compliance with

the special instructions while performing the action or

service are essential to preventing accidents.

Owner’s Manual for Mobile Generator 1

Page 6

Introduction and Safety

Asphyxiation. Running engines produce

carbon monoxide, a colorless, odorless,

poisonous gas. Carbon monoxide, if not

avoided, will result in death or serious injury.

(000103)

DANGER

(000107)

WARNING

Hearing Loss. Hearing protection is

recommended when using this machine.

Failure to wear hearing protection could

result in permanant hearing loss.

(000111)

WARNING

Moving Parts. Keep clothing, hair, and

appendages away from moving parts. Failure

to do so could result in death or serious injury.

(000108)

WARNING

Hot Surfaces. When operating machine, do not

touch hot surfaces. Keep machine away from

combustibles during use. Hot surfaces

could result in severe burns or fire.

WARNING

In case of an emergency, press the

emergency stop button to stop the engine

immediately. Failure to do so could result

in death or serious injury.

(000298)

CAUTION

(000291)

Equipment damage. Do not attempt to start or operate

a unit in need of repair or scheduled maintenance.

Doing so could result in serious injury, death, or

equipment failure or damage.

WARNING

WARNING

Risk of injury. Do not operate or service this

machine if not fully alert. Fatigue can impair the

ability to service this equipment and could result

in death or serious injury.

(000215)

(000182)

WARNING

CAUTION

(000229)

Equipment or property damage. Do not block

air intake or restrict proper air flow. Doing so

could result in unsafe operation or damage

to unit.

(000105)

DANGER

Explosion and Fire. Fuel and vapors are

extremely flammable and explosive. Add fuel

in a well ventilated area. Keep fire and spark

away. Failure to do so will result in death

or serious injury.

WARNING

Fire risk. Fuel and vapors are extremely

flammable. Do not operate indoors. Doing so

could result in death, serious injury, or

property or equipment damage.

(000281)

(000147)

WARNING

Risk of Fire. Unit must be positioned in a

manner that prevents combustible material

accumulation underneath. Failure to do so

could result in death or serious injury.

General Hazards

Explosion and Fire Hazards

2 Owner’s Manual for Mobile Generator

Page 7

Trailer Hazards Electrical Hazards

WARNING

Trailer must be securely coupled to the hitch

and chains correctly attached. Uncoupled or

unchained towing could result in death or serious

injury.

(000233)

WARNING

Do not operate this unit while transporting.

Doing so could result in death or serious

injury.

(000231)

(000234a)

WARNING

Crushing hazard. Verify unit is properly secured

and on level ground. An unsecured unit can

suddenly roll or move, causing death or serious

injury.

WARNING

Property or Equipment Damage. Tighten wheel lug

nuts after first 50 miles to factory specifications.

Failure to do so could result in death, serious injury,

property or equipment damage.

(000235)

(000145)

DANGER

Electrocution. In the event of electrical accident,

immediately shut power OFF. Use non-conductive

implements to free victim from live conductor. Apply

first aid and get medical help. Failure to do so will

result in death or serious injury.

(000104)

DANGER

Electrocution. Water contact with a power

source, if not avoided, will result in death

or serious injury.

(000144)

DANGER

Electrocution. Contact with bare wires,

terminals, and connections while generator

is running will result in death or serious injury.

(000152)

DANGER

Electrocution. Verify electrical system is

properly grounded before applying power.

Failure to do so will result in death or serious

injury.

(000123)

DANGER

Electrocution. Turn utility supply OFF before

working on utility connections of the transfer

switch. Failure to do so will result in

death or serious injury.

(000150)

DANGER

Electrocution. Never connect this unit to the electrical

system of any building unless a licensed electrician

has installed an approved transfer switch. Failure to

do so will result in death or serious injury.

(000164)

WARNING

Electrical shock. Disconnect battery ground

terminal before working on battery or battery

wires. Failure to do so could result in death

or serious injury.

Introduction and Safety

Owner’s Manual for Mobile Generator 3

Page 8

Introduction and Safety

(000188)

DANGER

Electrocution. Do not wear jewelry while

working on this equipment. Doing so will

result in death or serious injury.

(000137a)

WARNING

(000162)

WARNING

Explosion. Do not dispose of batteries in a fire.

Batteries are explosive. Electrolyte solution can cause

burns and blindness. If electrolyte contacts skin or eyes,

flush with water and seek immediate medical attention.

(000163a)

WARNING

Risk of burn. Do not open or mutilate batteries.

Batteries contain electrolyte solution which can

cause burns and blindness. If electrolyte contacts

skin or eyes, flush with water and seek immediate

medical attention.

WARNING

Environmental Hazard. Always recycle batteries at an

official recycling center in accordance with all local

laws and regulations. Failure to do so could result in

environmental damage, death or serious injury.

(000228)

Battery Hazards

Always recycle batteries in accordance with local laws

and regulations. Contact your local solid waste collection

site or recycling facility to obtain information on local

recycling processes. For more information on battery

recycling, visit the Battery Council International website

at: http://batterycouncil.org

4 Owner’s Manual for Mobile Generator

Page 9

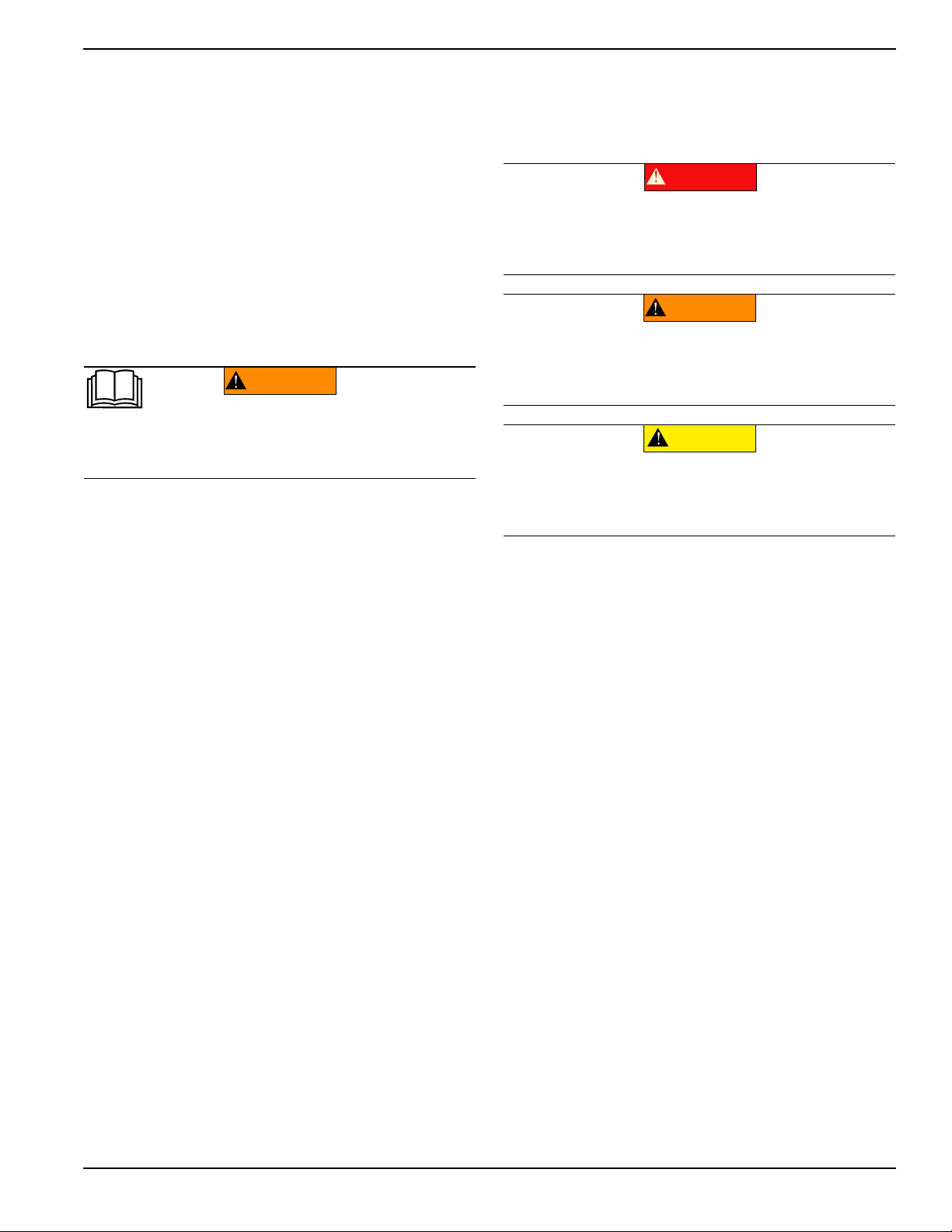

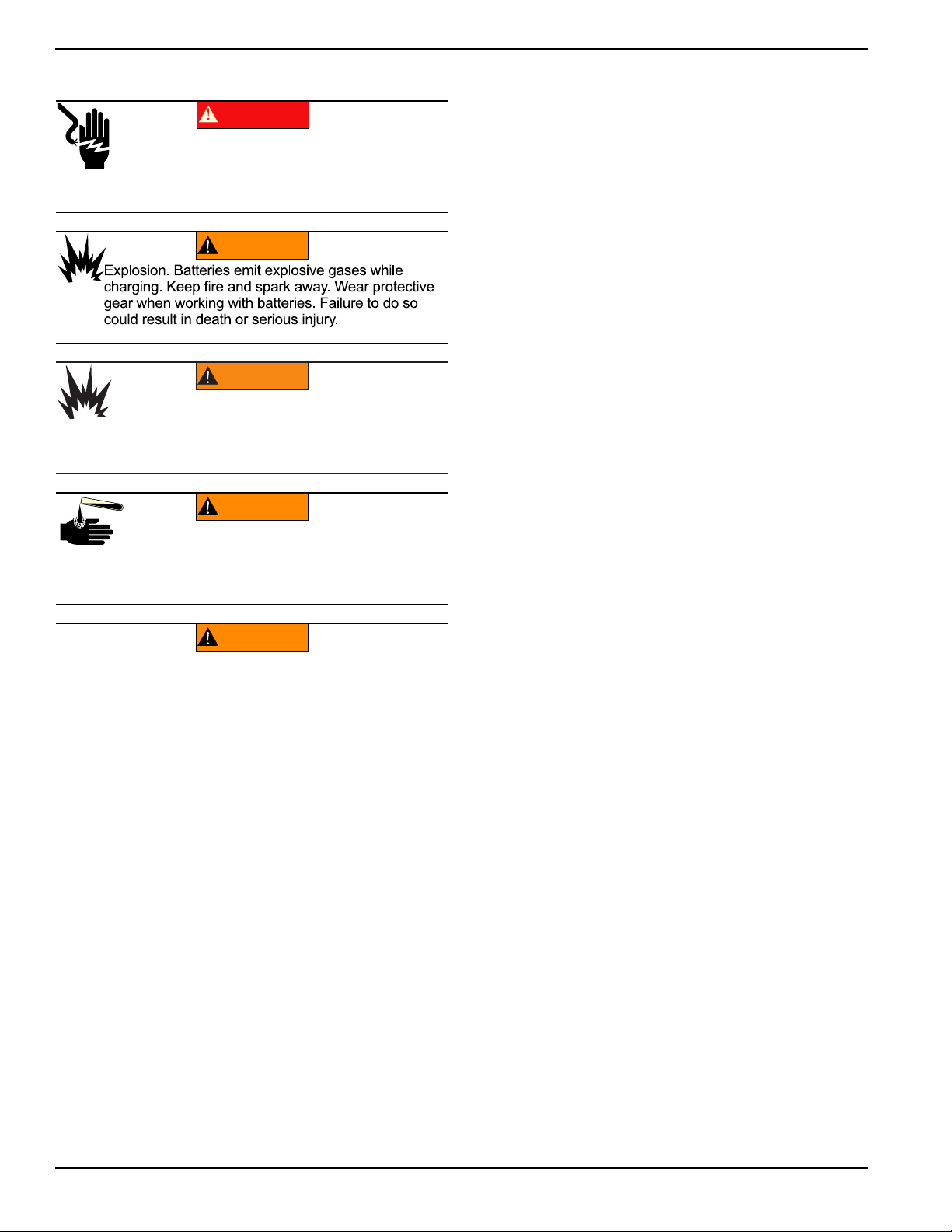

Section 2 General Information

C

B

A

G

H

E

D

F

Component Locations

General Information

Figure 2-1. Component Locations

Table 2-1. Generator Components

Fuel Filler Location (under door)

A

Radiator Access Panel

B

Control Panel Locations (under door)

C

Emergency Stop Switch (on MLG8 units,

D

switch is located on front panel)

Receptacle Panel (not available on MLG8 units)

E

Ground Studs (2)

F

Safety Chains

G

Tongue Jack

H

Owner’s Manual for Mobile Generator 5

Page 10

General Information

003550

A

B

(000149)

DANGER

Risk of poisoning. Do not use mouth to

siphon coolant. Doing so will result in

death or serious injury.

(000154)

WARNING

Risk of burns. Do not open coolant system

until engine has completely cooled.

Doing so could result in serious injury.

(000165)

CAUTION

Do not use any chromate base rust inhibitor with

propylene glycol base antifreeze, boosters or

additives. Doing so will cause overheating.

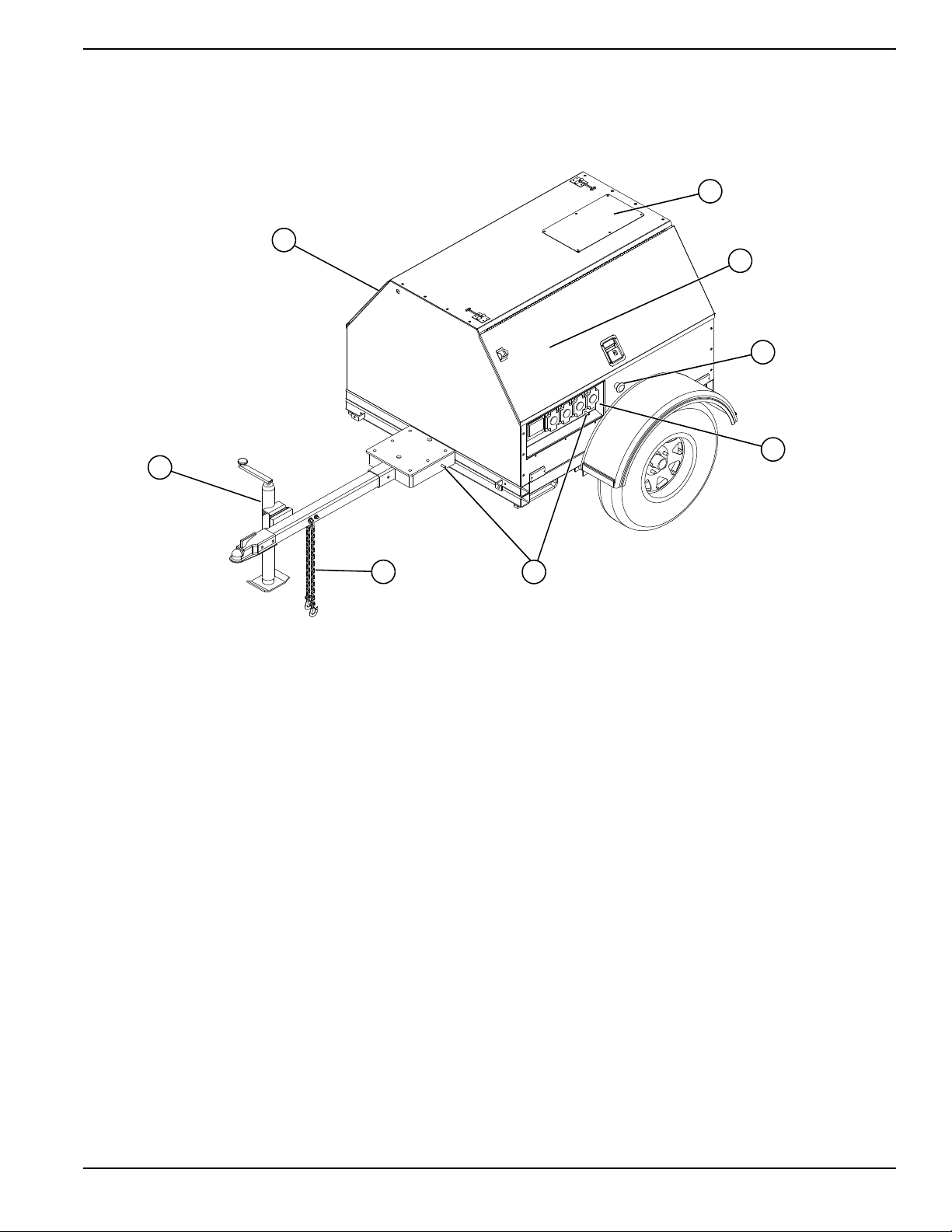

Unit and Serial Number Locations

See Figure 2-2 to locate the unit ID tag (A) and Vehicle

Identification Number (VIN) tag (B). Important

information, such as the unit model number, serial

number, VIN and tire loading information is found on

these tags. Record the information from these tags so it

is available if the tags are lost or damaged. When

ordering parts or requesting assistance, you may be

asked to provide this information.

Figure 2-2. Unit and Serial Number Locations

Engine Oil Recommendations

To maintain the product warranty, the engine oil should

be serviced in accordance with the recommendations of

this manual.

The engine has been filled with factory engine oil of a

grade recommended by the engine supplier.

Use a high quality detergent oil with an appropriate

classification and viscosity for the engine type and

ambient temperature conditions. Consult your Generac

Mobile Products Authorized Dealer or the applicable

engine service manual for engine oil recommendations.

Coolant Recommendation

Consult your Generac Mobile Products Authorized

Dealer or the applicable engine service manual for

engine coolant recommendations. See table below for

mixtures:

Freezing Point °F (°C)

Water (% Volume) 60 50 40 30

Anitfreeze (% Volume) 40 50 60 70*

-12

(-24)

* Maximum freeze protection is at 70%.

-34

(-36)

-54

(-48)

-90

(-67)

6 Owner’s Manual for Mobile Generator

Page 11

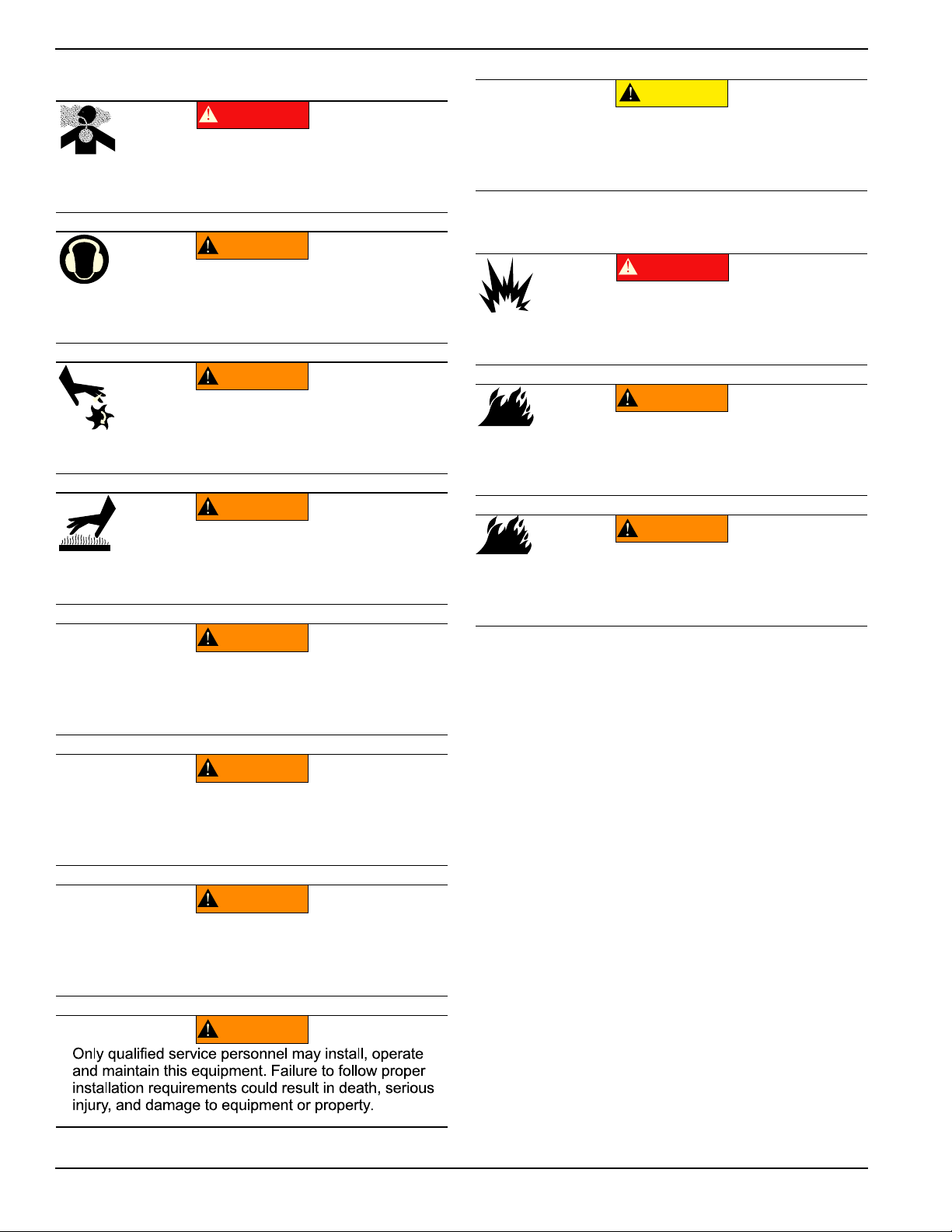

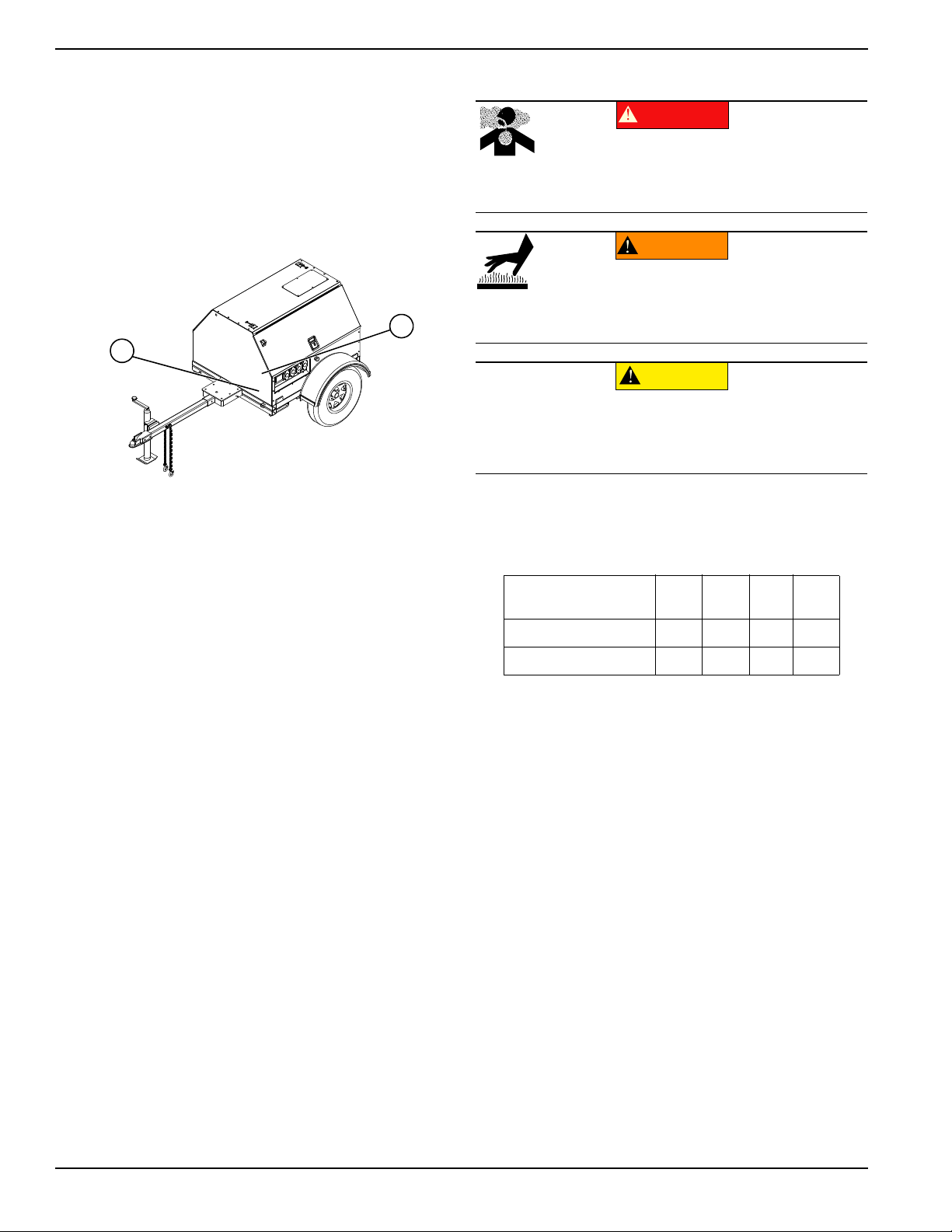

Main Control Panels

120VAC120VAC

120VAC120VAC

240VAC240VAC

TURNTURN

MAINMAIN

BREAKERBREAKER

OFFOFF

120VAC120VAC

BREAKERBREAKER

120VAC120VAC

BREAKERBREAKER

240VAC240VAC

MAIN CIRCUITMAIN CIRCUIT

BREAKERBREAKER

240VAC240VAC

BREAKERBREAKER

GLOW PLUGGLOW PLUG

INDICATORINDICATOR

OFFOFF

RUNRUN

STARTSTART

GLOWGLOW

PLUGSPLUGS

NEUTRAL BONDED TO FRAMENEUTRAL BONDED TO FRAME

I

O

I

O

ON

ON

20 20

0

0 00 0

HOURS

ON

ON

TURN MAIN

BREAKER OFF

MAIN

BREAKER

240V

OFF

RUN

START

GLOW

PLUG

NEUTRAL BONDED TO FRAME

ON ON

0 0 00 0

HOURS

MLG8

MLG15 • MLG20 • MLG20ICAN

A

C

D

F

G

B

E

H

I

F

D

E

A

B

General Information

Figure 2-3. Control Panel Component Locations

Table 2-2. Control Panel Components

Circuit Breaker Indicator Light

A

Main Circuit Breaker

B

240VAC Circuit Breaker

C

Key Switch

D

Glow Plug Indicator

E

Engine Hour Meter

F

240V Twist-Lock Receptacle

G

120V GFCI Receptacles

H

120V Breaker

I

Owner’s Manual for Mobile Generator 7

Page 12

General Information

This page intentionally left blank.

8 Owner’s Manual for Mobile Generator

Page 13

Section 3 Operation

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

Asphyxiation. Running engines produce

carbon monoxide, a colorless, odorless,

poisonous gas. Carbon monoxide, if not

avoided, will result in death or serious injury.

(000103)

DANGER

CAUTION

(000230)

Equipment Damage. Do not continuously

crank engine for more than ten seconds.

Doing so will lead to overdischarge of batteries

and starter seizure.

003552

A

Operation

Prestart Checklist

Before starting the unit, all items in the prestart checklist

must be completed.

• Verify all maintenance procedures are up to date.

For more information, see General Maintenance

and Basic Maintenance Schedule.

• Verify the unit is level.

• Verify there is no water inside, on, or near the unit.

Dry if needed.

• For grounding requirements, follow any local, state,

or National Electrical Code (NEC) guidelines.

• Verify the key switch is OFF (O).

• Verify all circuit breakers are OFF (O).

• Inspect all electrical cords; repair or replace any

that are cut, worn, or bare.

• Verify oil, coolant, and fuel levels are correct, per

the engine manufacturer manual.

• Verify battery connections are secure.

• Turn the battery disconnect switch ON, if equipped.

• Inspect the engine fan belt tension and condition.

• Inspect the engine fan guard.

• Inspect the engine exhaust system for loose or

rusted components.

• Verify the radiator and surrounding shroud are

clear of debris.

• Verify all covers are in place and secure.

• Verify the emergency stop switch is pulled out.

Starting the Unit

NOTE: If the engine was run out of fuel or the fuel tank

was drained, it may be necessary to bleed the fuel lines.

See the engine operator’s manual supplied with the unit.

1. Verify the main circuit breaker and individual circuit

breakers for each of the receptacles are OFF (O).

NOTE: When the red Turn Main Breaker Off light is

illuminated, the main circuit breaker must be turned to

OFF (O).

2. See Figure 3-1. Turn the key on the key switch to

GLOW PLUG (A) and hold the key in place for five

seconds, or until the glow plug indicator turns red.

Figure 3-1. Activate Glow Plug

Owner’s Manual for Mobile Generator 9

Page 14

Operation

003553

A

003554

A

WARNING

In case of an emergency, press the

emergency stop button to stop the engine

immediately. Failure to do so could result

in death or serious injury.

(000298)

CAUTION

(000246)

Equipment Damage. The emergency stop switch

is not to be used to power down the unit under

normal operating circumstances. Doing so will

result in equipment damage.

E

M

E

R

G

E

N

C

Y

S

T

O

P

002815

3. See Figure 3-2. As soon as it is glowing, turn the

key to START (A) and hold it until the engine

cranks and starts running.

Figure 3-2. Crank Engine to Start

4. See Figure 3-3. Release the key, it will move to

RUN (A).

Emergency Stop Switch

The unit is equipped with one emergency stop switch.

For location of the emergency stop switch, see

Component Locations. The switch can be accessed

and activated with all doors closed and locked.

Figure 3-3. Release Key

NOTE: For cold weather conditions, see the engine

operator’s manual for appropriate glow plug interval.

NOTE: If oil pressure is not obtained within 15 seconds

after the key is switched to RUN, the low oil automatic

shutdown will turn off the fuel supply, stopping the

engine. Check the oil level and turn the key to OFF to

reset the oil pressure timer before attempting to restart

the engine.

Activate the emergency stop switch by pushing the

button in until it locks down. This will trip the main circuit

breaker which will open the contact, disconnecting the

load to the connection lugs. This will also open the fuel

circuit, shutting down the engine. The emergency stop

fault will be displayed on the control panel. The switch

will remain closed until it is pulled out.

Figure 3-4. Emergency Stop Switch

Automatic Shutdown

5. Once the engine is running, allow it to reach

normal operating temperature before switching on

any loads.

10 Owner’s Manual for Mobile Generator

This unit is equipped with a low oil pressure and high

coolant temperature automatic shutdown system. This

system will automatically shut off the fuel supply to stop

the engine if oil pressure drops too low or the engine

exceeds normal operating temperature. Return the

switch to OFF to reset the unit after the cause of

shutdown has been determined.

Page 15

Voltage Regulator

003555

A

This unit is equipped with an electronic voltage regulator.

The voltage regulator controls the output of the generator

by regulating the current into the exciter field. The

regulator has three screwdriver adjustable

potentiometers that may be adjusted for voltage, stability

and voltage roll-off (U/F). The voltage regulator is

adjusted before shipment from the factory. Contact

Generac Mobile Products for additional information

before attempting to adjust the voltage regulator.

Derating for Altitude

All units are subject to derating for altitude and

temperature; this will reduce the available power for

operating tools and accessories connected to the

receptacles. Typical reductions in performance are 2-4%

for every 1000 ft (305 m) of elevation and 1% per 10ºF

(5.6ºC) increase in ambient air temperature over 72ºF

(22ºC).

Wet Stacking

The unit is powered by a diesel engine. Diesel engines

are susceptible to wet stacking if lightly loaded. Wet

stacking occurs when an engine is run at less than 30%

of its full load capacity, causing unburned fuel to

accumulate in the exhaust system. Wet stacking can be

detected by continuous black exhaust when the unit is

under a constant load. It can also cause fouling of

injectors and buildup on engine valves. Diesel engines

operate properly when applied loads are between 30%

and 100% capacity. Appropriate generator sizing is

determined by the anticipated load. If the unit is in a wet

stack condition, load the unit heavily for five hours or until

the exhaust is clear.

Receptacle Panel

This unit is equipped with a receptacle panel for running

accessories or tools from the generator. Power is

supplied to the receptacles any time the engine is

running and the main circuit breaker is switched to ON

(I). Each receptacle has an individual circuit breaker,

located inside the cabinet under a flip-up cover. Each

circuit breaker corresponds with the receptacle located

below it on the receptacle panel.

Should the main breaker, or any of the individual circuit

breakers trip, remove some of the load to the receptacles

before turning them back on.

NOTE: To ensure proper grounding, anytime the

generator is providing power to any equipment or load

panels that do not have a grounded plug, a ground wire

must be added between the equipment and the

grounding stud on the receptacle panel per the National

Electrical Code (NEC), state and local regulations.

Operation

Figure 3-5. Receptacle Panel Grounding Stud

A Receptacle Panel Grounding Stud

Shutting Down the Unit

Check with personnel using power supplied by the unit

and let them know the power is going to be turned off.

Verify the power shut down will not create any hazards by

accidentally turning off equipment that needs to be kept

on (pumps, compressors, lights, etc.). When you have

finished using the unit, proceed with shut down as

follows:

1. Remove all loads from the receptacles.

2. Switch the individual circuit breakers for each

receptacle to OFF (O).

3. Switch the main circuit breaker to OFF (O).

4. Turn the key switch to OFF.

NOTE: For extended storage time, disconnect the

battery. For extended storage requirements, see the

engine operator’s manual.

Towing the Unit

Once the engine is shut down, follow these steps to

prepare the unit for towing.

1. Verify the unit is OFF.

2. Use the jack to raise or lower the trailer onto the

hitch of the towing vehicle. Lock the hitch coupling

and attach the safety chains or cables to the

vehicle. Raise the jack foot completely.

3. Connect any trailer wiring to the tow vehicle. Check

for proper operation of the directional and brake

lights.

4. Verify all doors are properly latched.

5. Check for proper inflation of the trailer tires. Proper

inflation is specified on each tire.

Owner’s Manual for Mobile Generator 11

Page 16

Operation

WARNING

Personal injury. Excessive weight. Use only

appropriate lifting eyes and lifting equipment to

lift unit. Improper lifting techniques could result in

equipment damage, death or serious injury.

(000224)

003556

A

B

6. Check the wheel lugs. Tighten or replace any lugs

that are loose or missing. If a tire has been

removed for axle service or replaced, tighten the

lugs, in the order shown, to the following

specifications:

a. Start all lug nuts by hand.

b. First pass tighten to 20-25 ft-lbs

(27-33 Nm).

c. Second pass tighten to 50-60 ft-lbs

(67-81 Nm).

d. Third pass tighten to 90-120 ft-lbs

(122-162 Nm).

3. Use the forklift pockets with care. Approach the

unit as perpendicular as possible to avoid

damaging the unit. Verify any obstructions are

clear of the forklift tines before lifting.

Figure 3-7. Standard Forklift Pockets

002394

Figure 3-6. Lug Sequence

NOTE: After first road use, repeat tightening procedure.

Maximum recommended speed for highway towing is 45

mph (72 km/h). Recommended off-road towing speed is

not to exceed 10 mph (16 km/h).

Lifting the Unit

When lifting the unit, attach any slings, chains or hooks

directly to the central lift point.

1. Verify the equipment being used to lift the unit has

sufficient capacity. For approximate weights, see

the applicable product spec sheet.

2. Always remain aware of people and objects around

the unit while moving.

Figure 3-8. Optional Lift Structure

A Forklift Pockets

B Central Lift Point

12 Owner’s Manual for Mobile Generator

Page 17

Section 4 Maintenance

CAUTION

(000306)

Equipment Damage. Failure to perform a

daily inspection could result in damage to

the unit.

Maintenance

Emissions Information

For emissions information, see the OEM engine manual.

bar reaches the red section on the gauge (20 in.

O).

H

2

• Check wheel lugs. see Towing the Unit.

• Check coolant level daily. See the engine

Daily Walk Around Inspection

Look for conditions that could hinder performance or

safety, such as (but not limited to) oil/coolant/fuel

leakage, blocked vents, loose/missing hardware, and

electrical connections.

Visually inspect the fan belt for cracks, fraying,

stretching, and verify the belt is properly seated in the

pulley grooves. Replace the belt according to the

manufacturer’s recommendations.

General Maintenance

Poorly maintained equipment can become a safety

hazard. In order for the equipment to operate safely and

properly over a long period of time, periodic maintenance

and occasional repairs are necessary. Never perform

routine service (oil/filter changes, cleaning, etc.) unless

all electrical components are OFF. Before servicing the

unit, always follow the instructions listed below.

• Verify the key is removed.

• Verify the circuit breakers are OFF (O).

• Activate (push in) the emergency stop switch.

• Disconnect the negative (-) terminal on the battery.

operator’s manual for coolant recommendations

and proper mixture.

– Coolant is checked visually by inspecting the

level in the coolant overflow jug located near the

radiator.

– Normal operating level is between the FULL and

ADD markings on the overflow jug, also known

as the normal range.

– When engine is stopped and completely cool,

coolant may be added directly to the coolant

overflow jug.

• Check the oil level daily. See the engine operator’s

manual for the proper viscosity grade of oil,

including special operating conditions such as a

change in season or climate.

–Do not start the unit if the engine oil level is

below the ADD mark on the dipstick.

– Normal operating level is in the cross-hatch

pattern between the FULL and ADD markings on

the dipstick.

– Add oil only if the oil level is below the ADD mark

on the bottom of the cross-hatch pattern on the

dipstick.

– Do not overfill the crankcase.

• Check the fuel level.

NOTE: During the first 100 hours of operation, avoid

long periods of no load or sustained maximum load

operation. If the unit is to run for longer than five minutes

without a load, shut the engine OFF.

• Attach a “Do Not Start” sign to the control panel.

This will notify everyone that the unit is being

serviced and will reduce the chance of someone

inadvertently trying to start the unit.

• Do not wash the unit with a high pressure hose or

with any kind of power washer.

• Do not wash the engine block or fuel tank with a

power washer or steam cleaner. Water may enter

the cabinet and collect in the generator windings or

other electrical parts, causing damage. Water will

also pool on top of fuel tank and mix with any

environmentally hazardous fluids that may be

present, such as engine oil and coolant.

Basic Maintenance Schedule

See the original equipment manufacturer’s operating

manual for a complete list of maintenance requirements.

Failure to comply with the procedures as described in the

engine operator manual will nullify the warranty,

decrease performance and cause equipment damage or

premature equipment failure. Maintenance records may

be required to complete a warranty request.

• If the unit is stored outside, check for water inside

the cabinet and generator before each use. If wet,

dry the unit thoroughly before starting.

• Inspect condition of electrical cords. Do not use the

unit if insulation is cut or worn through.

• Verify the condition of the air filter by viewing the

level of the vacuum draw on the filter minder

gauge. Replace the air filter when the yellow center

Owner’s Manual for Mobile Generator 13

Page 18

Maintenance

Table 4-1. Basic Maintenance Schedule - MLG8

Item

Drain Water Separator

Inspect/Adjust Belt

Inspect/Clean Fuel Filter

Inspect/Replace Air Filter

Replace Engine Oil*

Check Radiator and Hose Clamps

Replace Engine Oil Filter*

Replace Fuel Filter

Clean Water Separator

Replace Fan Belt

Check/Clean Battery

Inspect/Adjust Valve Clearance

Replace Engine Coolant

Replace Radiator Hose Clamps

* Actual oil life and change intervals should be determined through oil sampling and analysis in extreme conditions.

As

Required

Every 200

Hours

Every 400

Hours

Every 500

Hours

Every 800

Hours

Every Two

Years

Table 4-2. Basic Maintenance Schedule - MLG15

Item

Drain Water Separator

Check/Replace Air Cleaner Element

Replace Engine Oil and Filter*

Inspect/Clean Solenoid Fuel Pump Filter

Inspect/Adjust Belt

Check Radiator and Hose Clamps

Replace Fuel Filter

Inspect/Adjust Valve Clearance

Check/Clean Battery

Replace Engine Coolant

Replace Radiator Hose Clamps

* Actual oil life and change intervals should be determined through oil sampling and analysis in extreme conditions.

As

Required

First 50

Hours

Every 250

Hours

Every 500

Hours

Every 24

Months

14 Owner’s Manual for Mobile Generator

Page 19

Table 4-3. Basic Maintenance Schedule - MLG20

Maintenance

Item

Drain Water Separator

Check Coolant Level

Inspect Belt

Replace Engine Oil*

Replace Engine Oil Filter*

Replace Fuel Filters

Adjust/Replace Belt

Replace Air Cleaner

Check/Clean Battery

Check/Adjust Valve Clearance

Replace Radiator Hose Clamps

Replace Engine Coolant

* Actual oil life and change intervals should be determined through oil sampling and analysis in extreme conditions.

As

Required

Every 250

Hours

Every 500

Hours

Every 1000

Hours

Every 12

Months

Owner’s Manual for Mobile Generator 15

Page 20

Maintenance

002823a

002824a

002825a

Jack Maintenance

The following procedures should be performed annually.

Side-Wind Models

•

The internal gearing and bushings of the jack must

be kept lubricated. Apply a small amount of

automotive grease to the internal gearing by

removing the jack cover, or if equipped, use a

needle nose applicator or standard grease gun on

the lubrication point found on the side of the jack

near the crank. Rotate the jack handle to distribute

the grease evenly.

• A lightweight oil must be applied to the handle unit

at both sides of the tube.

• If equipped, the axle bolt and nut assembly of the

caster wheel must also be lubricated with the same

lightweight oil.

Top-Wind Models

•

Apply a lightweight oil to the screw stem.

Figure 4-1. Lubrication Points

Trailer Wheel Bearings

The trailer axles are equipped with a grease fitting to

allow lubrication of the wheel bearings without the need

to disassemble the axle hub. To lubricate the axle

bearings, remove the small rubber plug on the grease

cap, attach a standard grease gun fitting to the grease

fitting and pump grease into the fitting until new grease is

visible around the nozzle of the grease gun. Use only a

high quality grease made specifically for lubrication of

wheel bearings. Wipe any excess grease from the hub

with a clean cloth and replace the rubber plug when

finished. The minimum recommended lubrication is every

12 months or 12,000 miles (19,312 km). More frequent

lubrication may be required under extremely dusty or

damp operating conditions.

16 Owner’s Manual for Mobile Generator

Page 21

Lower Radiator Hose Heater Option -

WARNING

Personal Injury. Do not modify the location of the

lower radiator hose heater. Improper use of hose

heater could result in personal injury or engine

damage.

(000339)

Use and Maintenance

The following points should be followed when operating a

unit equipped with a lower radiator hose heater.

• Verify the cooling system is full of the proper

mixture of water and engine coolant before each

heater use.

• The heater is designed for all-night operation,

however, 2-5 hours of heating just prior to starting

is usually sufficient for proper engine starting.

• The unit must be level to maintain proper

orientation of the heater while it is in operation.

• Use only an undamaged, outdoor rated, three-

prong grounded 120VAC extension cord with a

minimum amperage rating of 10A. Connect the

cord to a properly grounded 120VAC, GFCI

receptacle.

• Before starting the engine, unplug the extension

cord from the power, then unplug the heater

cordset from the extension cord.

Maintenance

Owner’s Manual for Mobile Generator 17

Page 22

Maintenance

This page intentionally left blank.

18 Owner’s Manual for Mobile Generator

Page 23

Wiring Diagrams and Service Log

Section 5 Wiring Diagrams and Service Log

AC Wiring Diagram W/3-30A, 1-50A Outlets

10

BLOCK 1

TERMINAL

RED

3

WHT

RED

2

WHT

1

GRN/YEL

GROUND

BONDED TO

BLK

RED

BLK

RED

BLK

RED

BLK

RED

50 AMP

CIRCUIT

50 AMP

CIRCUIT

30 AMP

CIRCUIT

BLK

RED

BREAKER

BLK

RED

BREAKER

BLK

RED

BREAKER

BLK

RED

50 AMP

TWIST LOCK

RECEPTACLE

50 AMP

TWIST LOCK

30 AMP

TWIST LOCK

WHT

GRN

WHT

GRN

RECEPTACLE

WHT

GRNGRN

WHT

7

8

9

BLK

4

5

6

BLK

MAIN

CIRCUIT

100 AMP

BREAKER

BLK

L1

N1

GEN

RED

L2

GRN

GROUND

BONDED TO

GRN

GROUND

BONDED TO

30 AMP

CIRCUIT

BREAKER

BLK

RED

20 AMP

CIRCUIT

20 AMP

CIRCUIT

BREAKER

BREAKER

30 AMP

TWIST LOCK

RECEPTACLE RECEPTACLE

BLK

WHT

G.F.I.

20 AMP

RED

WHT

G.F.I.

20 AMP

RECEPT. RECEPT.

90212_A_08.27.12

GRN

GRN

Owner’s Manual for Mobile Generator 19

Page 24

Wiring Diagrams and Service Log

AC Wiring Panel Options

BLK

BLK

RED

RED

50 AMP

TO MAIN BREAKER

TO NEUTRAL

TO GROUND

TO MAIN BREAKER

BREAKER

CIRCUIT

BLK

RED

20 AMP

BREAKER

CIRCUIT

BLK

RED

20 AMP

BREAKER

CIRCUIT

BLK

RED

WHT

GRN

BLK

RED RED

20 AMP

BREAKER

CIRCUIT

BLK

RED

BLK

RED

50 AMP

240 VOLT

RECEPTACLE

20 AMP

20 AMP

CIRCUIT

BREAKER

CB CB

CIRCUIT

BREAKER

TWIST-LOCK

GRN GRN

20 AMP

240 VOLT

TWIST LOCK

RECEPTACLE

GRN

20 AMP

240 VOLT

TWIST LOCK

RECEPTACLE

GRN

20 AMP

240 VOLT

TWIST LOCK

RECEPTACLE

WHT

BLK

GRN

G.F.I

20 AMP

OUTLET

RED

GRN

G.F.I

20 AMP

OUTLET

BLK

RED

BLK

RED

BLK

90319_ORG_07.06.11

50 AMP

CIRCUIT

30 AMP

CIRCUIT

30 AMP

CIRCUIT

BLK

REDRED

BREAKER

BLK

REDRED

BREAKER

BLK

RED

BREAKER

BLKBLK

RED

BLK

BLK

BLK

RED

RED

BLK

WHT

WHT

WHT

WHT

TO MAIN BREAKER

2x5-20R, 3xL6-20R, 1x50A

WHT

TO NEUTRAL

TO GROUND

BLK

RED

WHT

GRN

BLK

RED

RED

30 AMP

CIRCUIT

BREAKER

BLK

BLK

RED

RED

30 AMP

CIRCUIT

BREAKER

BLK

BLK

RED

RED

30 AMP

CIRCUIT

BREAKER

BLK

BLK

RED

RED

30 AMP

CIRCUIT

BREAKER

240 VOLT

240 VOLT

240 VOLT

240 VOLT

30 AMP

TWIST-LOCK

30 AMP

TWIST-LOCK

30 AMP

TWIST-LOCK

30 AMP

TWIST-LOCK

WHT

GRN

RECEPTACLE

WHT

GRN

RECEPTACLE

WHT

GRN

RECEPTACLE

WHT

GRN

RECEPTACLE

2x5-20R, 4xL14-30R

WHT

WHT

BLK

BLK

20 AMP

CIRCUIT

BREAKER

RED

CB CB

20 AMP

CIRCUIT

BREAKER

GRN

G.F.I

20 AMP

OUTLET

RED

GRN

G.F.I

20 AMP

OUTLET

90321_ORG_07.06.11

240 VOLT

240 VOLT

240 VOLT

50 AMP

TWIST LOCK

30 AMP

TWIST LOCK

30 AMP

TWIST LOCK

RECEPTACLE

RECEPTACLE

RECEPTACLE

GRN GRN GRN

WHT

WHT

WHT

WHT

TO MAIN BREAKER

BLK

RED

BLK BLK

50 AMP

BREAKER

CIRCUIT

BLK BLK

30 AMP

BREAKER

CIRCUIT

BLK

RED

30 AMP

BREAKER

CIRCUIT

RED RED

REDRED

240 VOLT

REDRED

240 VOLT

BLK

RED

240 VOLT

BLKBLK

50 AMP

TWIST-LOCK

30 AMP

TWIST LOCK

30 AMP

TWIST LOCK

WHT

RECEPTACLE

WHT

GRN GRN

RECEPTACLE

WHT

GRN

RECEPTACLE

WHT

GRN

30 AMP

240 VOLT

TWIST LOCK

RECEPTACLE

WHT

WHT

GRN

G.F.I

20 AMP

OUTLET

RED

GRN

G.F.I

20 AMP

OUTLET

90320_ORG_07.06.11

2x5-20R, 3xL14-30R, 1x50A

TO NEUTRAL

TO GROUND

WHT

30 AMP

BREAKER

CIRCUIT

GRN

BLK

BLK

CB

20 AMP

CIRCUIT

BREAKER

RED

RED

CB

20 AMP

CIRCUIT

BREAKER

240 VOLT

30 AMP

TWIST LOCK

WHT

G.F.I

20 AMP

G.F.I

20 AMP

RECEPTACLE

OUTLET

OUTLET

GRN

GRN

GRN

WHT

2x5-20R, 3xL6-30R, 1x50A

TO NEUTRAL

TO GROUND

WHT

GRN

30 AMP

BREAKER

CIRCUIT

BLK BLK

RED

CB

20 AMP

CIRCUIT

CB

20 AMP

CIRCUIT

BREAKER

BREAKER

90318_ORG_07.06.11

20 Owner’s Manual for Mobile Generator

Page 25

AC Wiring Diagram - MLG 8

MAIN

CIRCUIT

BREAKER

40 AMP

2 POLE

L1

GRN

GEN

L2

RED

RED

BLK

BLK

RED

WHT

WHT

WHT

TERMINAL

BLOCK 1

10

9

8

7

6

5

4

3

2

1

Wiring Diagrams and Service Log

RED

240 VOLT

30 AMP

CIRCUIT

BREAKER

240 VOLT

30 AMP

TWIST LOCK

RECEPTACLE

20 AMP

G.F.I.

OUTLET

GRN

20 AMP

G.F.I.

OUTLET

GRN

GRN/YEL

CB

20 AMP

CIRUIT

BREAKER

CB

20 AMP

CIRUIT

BREAKER

90732_A_07.25.16

Owner’s Manual for Mobile Generator 21

Page 26

Wiring Diagrams and Service Log

DC Wiring Diagram - MLG 8 and MLG15

RED

RED

BLK

MAIN

CIRCUIT

BREAKER

40 AMP

2 POLE

GRN

L1

GEN

L2

BLK

RED

WHT

WHT

WHT

TERMINAL

BLOCK 1

10

9

8

7

6

5

4

3

2

1

RED

240 VOLT

30 AMP

CIRCUIT

BREAKER

240 VOLT

30 AMP

TWIST LOCK

RECEPTACLE

20 AMP

G.F.I.

OUTLET

GRN

20 AMP

G.F.I.

OUTLET

GRN

GRN/YEL

CB

20 AMP

CIRUIT

BREAKER

CB

20 AMP

CIRUIT

BREAKER

90732_A_07.25.16

22 Owner’s Manual for Mobile Generator

Page 27

DC Wiring Diagram - MLG 20

90733_A_07.25.16

WARNING

LIGHT

“TURN MAIN

BREAKER OFF”

BLK

NO

NC

C

MAIN BREAKER

AUX SWITCH

GLOW PLUGS

BLU

B TERM

R TERM

SOLENOID

RED (HOLD)

WHT (PULL)

BLK (COM)

ORN

BRN

BLK

CONTROL

RESISTANCE

BLU

BLU

DOME

LIGHT

R1

R2

B

BR

ACC

C

STARTER SWITCH

GRN

BLU

RED

GRN

RED

BLK

B

B

S

STARTER

RED

BATTERY 12V

EMERGENCY

STOP

SWITCH

1

4

3

2

N.C.

N.C.

VIO/WHT

VIO

RED

TIME

DELAY

RELAY

1

2

3

5

6

OVERHEAT

WARNING

SWITCH

(NORMAL

OPEN TYPE)

PUR

PNK

OIL

PRESSURE

WARNING

SWITCH

(NORMAL

CLOSED TYPE)

FUSE

SWITCH

RED

10 AMP

CIRCUIT

BREAKER

BLK

HOUR

FUEL

PUMP

RED

RED

BLK

BLK

Wiring Diagrams and Service Log

Owner’s Manual for Mobile Generator 23

Page 28

Wiring Diagrams and Service Log

GN

YL

BN

WT

MARKER

LAMP

AMBER

TRAILER

PLUG

RIGHT

TAIL/TURN

LAMP

LAMP

PLATE

LICENSE

MARKER

LAMP

RED

BK

BK

BK

BK

RD

WT

BK

SPLICE

SPLICE

SPADE

SPADE

LAMP

TAIL/TURN

LEFT

RDWTBK

SPADE

YL

BN

WT

SPADE

SPADE

WT

BK

BN

WT

SPLICE

GN

RING

MARKER

LAMP

AMBER

MARKER

LAMP

RED

BK

BK

BK

BK

SPLICE

SPLICE

SPADE

SPADE

BN

WT

WT

WT

BN

BN

90341_B_12.20.13

Trailer Harness

24 Owner’s Manual for Mobile Generator

Page 29

Wiring Diagrams and Service Log

OIL GRADE: _____________________________________ BRAND: __________________________________

COOLANT MIXTURE: _____________________________ BRAND: __________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

Date

Hours to

Service

Oil Level

Coolant

Level

Date

Hours to

Service

Oil Level

Coolant

Level

Service Log

Owner’s Manual for Mobile Generator 25

Page 30

Wiring Diagrams and Service Log

This page intentionally left blank.

26 Owner’s Manual for Mobile Generator

Page 31

Page 32

Part No. 10289 Rev. M 09/09/16

©2016 Generac Mobile Products LLC. All rights reserved

Specifications are subject to change without notice.

No reproduction allowed in any form without prior written

consent from Generac Mobile Products LLC.

Generac Mobile Products

215 Power Drive, Berlin, WI 54923

GeneracMobileProducts.com │800-926-9768 │920-361-4442

Loading...

Loading...