Page 1

GASEOUS GENERATOR

Discount-Equipment.com

MGG155 • MGG210

OPERATING MANUAL

00620

www.discount-equipment.com

35319 C 05/16

Page 2

Discount-Equipment.com is your online resource for commercial and industrial

Discount-Equipment.com

quality parts and equipment sales.

Locations:

Florida (West Palm Beach): 561-964-4949

Outside Florida TOLL FREE: 877-690-3101

Need parts? Check out our website at www.discount-equipment.com

Can’t find what you need?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and fill out

the request form.

Please have the machine model and serial number available in order to help us get

you the correct parts. One of our experienced staff members will get back to you with

a quote for the right part that your machine needs.

We sell worldwide for the br

Diamond

Chicago Pneumatic, Allmand Brothers, Essick, Miller Spreader, Skyjack, Lull, Skytrak,

Tsurumi, Husquvarna/Target, Whiteman-Concrete/Mortar, Stow-Concrete/Mortar, Baldor,

Wacker, Sakai, Snorkel, Upright, Mi-T-M, Sullair, Neal, Basic, Dynapac, MBW, Weber,

Bartell, Bennar Newman, Haulotte, Ditch Runner, Blaw-Knox, Himoinsa, Best, Buddy,

Crown, Edco, Wyco, Bomag, Laymor, Terremite, Barreto, EZ Trench, Takeuchi, Basic, Bil-

Jax, Curtis, Gehl, Heli, Honda, ICS/PowerGrit, Puckett, Waldon, ASV, IHI, Partner, Imer,

Clipper, MMD, Koshin, Rice, Gorman Rupp, CH&E, Cat Pumps, Comet, General Pump,

Giant,AMida, Coleman, NAC, Gradall, Square Shooter, Kent, Stanley, Tamco, Toku, Hatz,

Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air, Small Line, Wanco, Yanmar

Products, Magnum, Airman, Mustang, Power Blanket, Nifty Lift, Atlas Copco,

ands: Genie, Terex, JLG, MultiQuip, Mayco, Toro/Stone,

Page 3

WARNING

Discount-Equipment.com

CALIFORNIA PROPOSITION 65 WARNING: Engine exhaust and some of its constituents

are known to the state of California to cause cancer, birth defects, and other reproduc-

tive harm. (000004)

WARNING

CALIFORNIA PROPOSITION 65 WARNING: This product contains or emits chemicals

known to the state of California to cause cancer, birth defects, and other reproductive

harm. (000005)

WARNING

ENVIRONMENTAL HAZARD: Always recycle batteries at an official recycling center in

accordance with all local law and regulations. Failure to do so could result in environ-

mental damage, death or serious injury. (000228)

ii

Page 4

Introduction

Discount-Equipment.com

This manual provides information and procedures to safely operate and maintain the Generac Mobile Products unit.

For your own safety and protection from physical injury, carefully read, understand, and observe the safety instructions

described in this manual. Keep a copy of this manual with the unit at all times. Additional copies are available from

Generac Mobile Products. The information contained in this manual was based on machines in production at the

time of publication. Generac Mobile Products reserves the right to change any portion of this information without

notice.

Read all of the manuals included with the unit. Each manual details specific information regarding items such as

setup, use and service requirements. An engine operator’s manual provides detailed operation and maintenance

procedures for the engine. Additional copies of the engine operator’s manual are available from the engine

manufacturer.

DO NOT MODIFY or use this equipment for any application other than for which it was designed.

Only a trained and licensed electrician should perform wiring and connections to unit. Wiring must be in compliance

with National Electrical Code (NEC), state and local regulations, and Occupational Safety and Health Administration

(OSHA) guidelines.

Engine Make:__________________________________________

Engine Serial Number:___________________________________

Engine Model Number: __________________________________

Generator Make: _______________________________________

Generator Model Number: ________________________________

Generator Serial Number: ________________________________

Unit Model Number:_____________________________________

Unit Serial Number: _____________________________________

Dealer Name:__________________________________________

Dealer Phone Number: __________________________________

iii

Page 5

Table of Contents

Discount-Equipment.com

Section 1 - Safety

Safety Notes ....................................................................................................................................... 1

Operating Safety................................................................................................................................. 1

Engine Safety ..................................................................................................................................... 2

Service Safety .................................................................................................................................... 2

Towing Safety.....................................................................................................................................3

Reporting Trailer Safety Defects ........................................................................................................ 3

Section 2 - General Information

Specifications ..................................................................................................................................... 5

Unit Dimensions .................................................................................................................... 6

Engine Oil Recommendations ............................................................................................... 6

Coolant Recommendation ..................................................................................................... 7

Unit Serial Number Locations.............................................................................................................7

Component Locations......................................................................................................................... 8

Unit Set Up ....................................................................................................................................... 14

Well Site Approval ............................................................................................................... 14

Fuel Connections................................................................................................................. 14

LP Liquid Connections (Liquid Withdrawal System)............................................................ 17

Valve and Fitting Pipe Equivalents ...................................................................................... 19

Electrical Connections ......................................................................................................... 19

Dual Fuel System ............................................................................................................................. 20

Natural Gas (Well Gas) Fuel System .................................................................................. 20

LP Liquid Withdrawal Fuel System...................................................................................... 20

DC Fuses.......................................................................................................................................... 20

Generator and Load Compatibility....................................................................................................20

Engine/Generator Protective Devices .............................................................................................. 21

Digital Controller ............................................................................................................................... 21

Setting the Clock ................................................................................................................. 22

Section 3 - Operation

Prestart Checklist ............................................................................................................................. 23

Manually Starting the Unit ................................................................................................................ 23

Natural Gas (Well Gas) Start Up .........................................................................................23

LP Liquid Start Up ............................................................................................................... 24

Auto (Remote) Starting the Unit ....................................................................................................... 24

Parallel Setup and Operation ........................................................................................................... 24

Operation Checks.............................................................................................................................25

Overcrank Shutdown ........................................................................................................................ 25

Derating for Altitude..........................................................................................................................26

Generator Output Connections......................................................................................................... 26

Customer Convenience Receptacles ............................................................................................... 27

Main Circuit Breaker ......................................................................................................................... 28

Frame Ground Connection .................................................................................................. 28

Battery Disconnect Switch................................................................................................... 28

Shutting Down the Unit.....................................................................................................................28

Emergency Stop Switch ................................................................................................................... 29

Towing the Trailer.............................................................................................................................29

Section 4 - Maintenance

Emissions ......................................................................................................................................... 31

Maintenance Tasks .......................................................................................................................... 31

Daily Walk Around Inspection.............................................................................................. 31

Check Fuel System ............................................................................................................. 31

Check Engine Fluids............................................................................................................ 31

Changing the Oil.................................................................................................................. 32

v

Page 6

Adding Coolant .................................................................................................................... 33

Discount-Equipment.com

Integrated Electronic Pressure Regulator (IEPR) Maintenance and Inspection.................. 33

Checking/Draining Oil Build-Up in the Vaporizer Regulator ................................................34

Maintenance Schedule ..................................................................................................................... 34

Battery Inspection................................................................................................................ 36

Battery Replacement ........................................................................................................... 37

Other Maintenance Checks ................................................................................................. 38

Jack Maintenance............................................................................................................................. 39

Side-Wind Models ............................................................................................................... 39

Top-Wind Models ................................................................................................................ 39

Trailer Wheel Bearings ..................................................................................................................... 39

Section 5 - Troubleshooting

Problems and Solutions....................................................................................................... 41

Section 6 - Wiring Diagrams

AC Wiring - MGG155 (120V GCB) ...................................................................................................53

AC Wiring - MGG210 (120V GCB) ...................................................................................................54

AC Wiring - MGG155 (24V GCB) ..................................................................................................... 55

AC Wiring - MGG210 (24V GCB) ..................................................................................................... 56

DC Wiring - MGG155 (120V GCB)...................................................................................................57

DC Wiring - MGG210 (120V GCB)...................................................................................................58

DC Wiring - MGG155 (24V GCB).....................................................................................................59

DC Wiring - MGG210 (24V GCB).....................................................................................................60

CAN Parallel Communication Connection - MGG155 and MGG210 ............................................... 61

vi

Page 7

SAFETY NOTES

Discount-Equipment.com

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.

This manual contains DANGERS, WARNINGS, CAUTIONS, NOTICES and NOTES which must be

followed to prevent the possibility of improper service, damage to the equipment, personal injury or death.

The following formatting options will apply when calling the readers attention to the DANGERS, WARNINGS, CAUTIONS, NOTICES and NOTES.

INDICATES A HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN

Indicates a hazardous situation which, if not avoided, could result in death or serious

Indicates a hazardous situation which, if not avoided, could result in minor or moderate

Section 1 - Safety

DANGER

DEATH OR SERIOUS INJURY. (000001)

WARNING

injury. (000002)

CAUTION

injury. (000003)

Indicates a hazardous situation which, if not avoided, could result in property or equipment

damage.

Note: Notes contain additional information important to a procedure and will be found within the regular text body

of this manual.

OPERATING SAFETY

Before using the unit, be sure you read and understand all of the instructions. This equipment was

designed for specific applications; DO NOT modify or use this equipment for any application other than

which it was designed for. Equipment operated improperly or by untrained personnel can be dangerous.

Read the operating instructions and familiarize yourself with the location and proper use of all instruments

and controls. Inexperienced operators should receive instruction from someone familiar with the equipment

before being allowed to operate or set up the unit. The following points should be practiced at all times:

• The area immediately surrounding the unit should be dry, clean, and free of debris.

• Position and operate the unit on a firm, level surface.

• DO NOT start a unit in need of repair.

• If the unit is equipped with a frame grounding stud, follow any local, state, and National Electrical

Code (NEC) guidelines when connecting.

• DO NOT operate the unit on a combustible surface.

• DO NOT operate a unit while tired, distracted, or under the influence of drugs or alcohol.

• Keep all body parts, clothing and other loose items away from moving parts.

• All fuel types are potentially FLAMMABLE and/or EXPLOSIVE and should be handled with care.

Comply with all laws regulating the storage and handling of fuels. Inspect the unit’s fuel system

frequently and correct any leaks immediately. Fuel supply lines must be properly installed, purged,

and leak tested according to applicable fuel-gas codes before placing the equipment into service.

35319 C MGG155/210 Operating Manual 1

Page 8

Safety

Discount-Equipment.com

• DO NOT smoke around the unit.

• Shut the engine down if any of the following conditions exist during operation:

1. Noticeable change in engine speed.

2. Loss of electrical output.

3. Equipment connected to the unit overheats.

4. Sparking occurs.

5. Engine misfires or there is excessive engine/generator vibration.

6. Protective covers are loose or missing.

7. If the ambient air temperature is above 120°F (49°C).

ENGINE SAFETY

Internal combustion engines present special hazards during operation and fueling. Failure to follow the

safety guidelines described below could result in severe injury or death. Read and follow all safety warnings

described in the engine operator's manual. A copy of this manual was supplied with the unit when it was

shipped from the factory.

• DO NOT run engine indoors or in an area with poor ventilation unless exhaust hoses are used. Engine

exhaust contains carbon monoxide, a deadly, odorless and colorless gas which, if inhaled, can cause

nausea, fainting or death. Verify engine exhaust cannot seep into closed rooms or ventilation

equipment.

• DO NOT touch or lean against hot exhaust pipes or engine components.

• DO NOT clean air filter with gasoline or other types of low flash point solvents.

• DO NOT operate the unit without a functional exhaust system.

• Prolonged exposure to sound levels in excess of 85 dB(A) can cause permanent hearing loss. Wear

hearing protection when working around a running engine.

• Batteries contain sulfuric acid which can cause severe injury or death. Sulfuric acid can cause eye

damage, burn flesh or eat holes in clothing. Protective eye wear and clothing are necessary when

working on or around the battery. Always disconnect the negative (-) battery cable from the

corresponding terminal before performing any service on the engine or other components.

• DO NOT remove the radiator cap while the engine is hot.

• Keep area around exhaust pipes and air ducts free of debris to reduce the chance of an accidental fire.

SERVICE SAFETY

All service work must be performed by qualified personnel who are familiar with the equipment. Only a

qualified electrician should troubleshoot or repair electrical problems occurring in this equipment. Follow the safety guidelines described below to prevent hazardous situations which could result in severe

injury or death.

• DO NOT wash the unit with high pressure hoses, power washers, or steam cleaners. Water may

collect in the unit, causing damage to electrical parts.

• ALWAYS use extreme caution when servicing this unit in damp conditions. Do not service the unit if

your skin or clothing is wet. Do not allow water to collect around the base of the unit.

• Replace all missing and hard to read decals. Decals provide important operating instructions and

warn of dangers and hazards.

• ALWAYS turn the battery disconnect switch to the OFF position before performing any service on the

engine, generator, or any other components. Remove the negative (-) battery cable from the

corresponding terminal if the unit is to be stored or transported.

2 MGG155/210 Operating Manual 35319 C

Page 9

• DO NOT start the unit under load. The main circuit breaker must be in the open position (press the

Discount-Equipment.com

right I/O button on the controller) when starting the unit.

TOWING SAFETY

Towing a trailer requires care. Both the trailer and vehicle must be in good condition and securely fastened

to each other to reduce the possibility of an accident. Some states require that large trailers be registered

and licensed. Contact your local Department of Transportation office to check on license requirements for

your particular unit.

• Verify the hitch and coupling on the towing vehicle are rated equal to, or greater than, the trailer's

Gross Vehicle Weight Rating (GVWR).

• Check trailer tires for wear and proper inflation.

• DO NOT tow trailer using defective parts. Inspect the hitch and coupling for wear or damage.

• Verify the trailer hitch and the coupling are compatible and the coupling is securely fastened to the

vehicle.

• Verify the directional and brake lights on the trailer are connected and working properly.

• See Towing the Trailer. Verify wheel lug nuts are present and tightened to the specified torque.

• Maximum recommended speed for highway towing is 45 mph (72 km/h). Recommended off-road

towing speed is 10 mph (16 km/h).

Safety

• When towing, maintain extra space between vehicles and avoid soft shoulders, curbs and sudden

lane changes. Practice turning, stopping and backing up in an area away from heavy traffic prior to

transporting unit.

• Wipe the coupler clean and apply fresh grease each time the trailer is towed to eliminate squeaking.

• Connect safety chains in a crossing pattern under the tongue and ATTACH THE BREAKAWAY

CABLE TO THE REAR BUMPER OF THE TOWING VEHICLE. Do not attach the cable to the trailer

hitch.

• The trailer is equipped with hydraulic or electric surge brakes. Verify proper operation of the brakes

by braking the vehicle at a slow speed before entering traffic. Both the trailer and the vehicle should

brake smoothly. If the trailer seems to be pushing, check the level in the brake fluid reservoir, if

equipped.

REPORTING TRAILER SAFETY DEFECTS

If you believe your trailer has a defect which could cause a crash or could cause injury or death, you should immediately

inform the National Highway Traffic Safety Administration (NHTSA) in addition to notifying Generac Mobile Products

LLC.

If NHTSA receives similar complaints, it may open an investigation; and if it finds that a safety defect exists in a group

of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become involved in an individual

problem between you, your Independent Authorized Service Dealer, or Generac Mobile Products LLC.

To contact NHTSA, you may either call the Auto Safety Hotline toll-free at 1-888-327-4236 (TTY:1-800-424-9153),

go to http://www.safercar.gov; or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain other information about motor vehicle safety from http://www.safercar.gov.

35319 C MGG155/210 Operating Manual 3

Page 10

Safety

Discount-Equipment.com

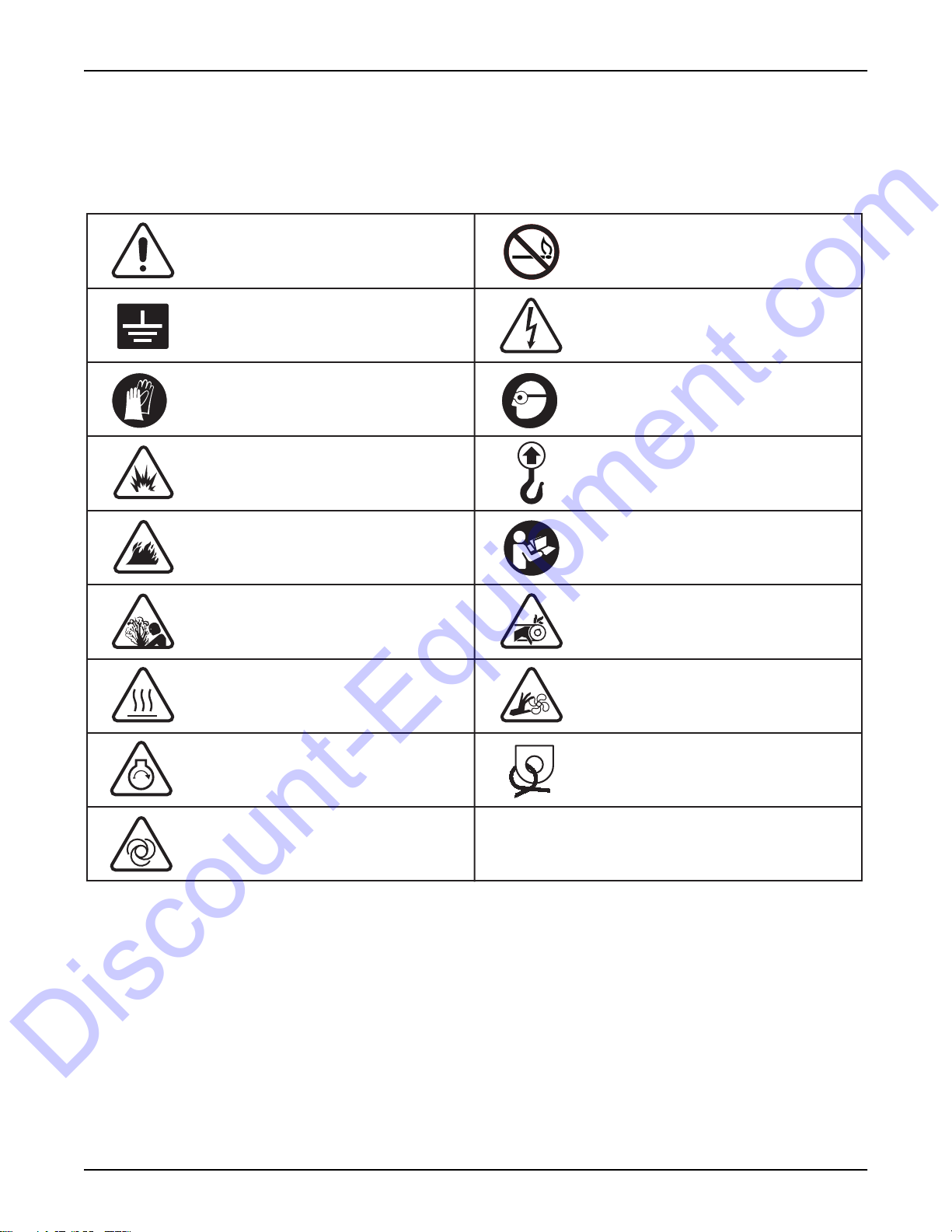

SAFETY SYMBOL SUMMARY

The safety and operating decals affixed to the unit provide important instructions and warn of dangers and hazards.

Replace any missing or hard-to-read decals and use care when washing or cleaning the unit. Decal placement and

part numbers can be found in the online parts manual at www.generacmobileproducts.com. Below is a summary of

the intended meanings for the symbols used on the decals.

Safety alert symbol; used to alert

you to potential personal

injury hazards.

No open flames.

Unit electrical ground.

Wear protective gloves.

Explosion hazard.

Fire hazard.

Burn/scald hazard;

pressurized steam.

Hot surface(s) nearby.

Dangerous voltage may be

present.

Use protective eyewear.

Lift here only.

Read and understand the

supplied operator’s manual

before operating unit.

Belt/entanglement hazard; keep

body parts clear of this area.

Fan hazard; keep body parts

clear of this area.

Engine starting/remote starting point.

Engine can start automatically.

4 MGG155/210 Operating Manual 35319 C

Anchor/tie down point.

00844

Page 11

Section 2 - General Information

Discount-Equipment.com

SPECIFICATIONS

GENERAC MODEL MGG155 MGG210

Engine

Make/Brand............................................................................. PSI ..........................................PSI

Model ......................................................................................D081TIC..................................D111TIC

Induction System ....................................................................Turbo CAC ..............................Turbo CAC

Horsepower - Prime - Natural Gas hp (kW) ..........................239 (178) ................................. 302 (225)

Horsepower - Standby - LP Liquid hp (kW) ...........................200 (149) .................................272 (203)

Operating Speed rpm .............................................................1800 ........................................ 1800

Displacement in

Cylinders - qty .........................................................................6 .............................................. 6

Spark plug gap in (mm)..........................................................0.015 (.4) .................................0.015 (.4)

Fuel Consumption (NG) - 100% load ft

Fuel Consumption (NG) - 75% load ft

Fuel Consumption (NG) - 50% load ft

Fuel Consumption (LP) - 100% load gal/hr (L/hr)..................15.4 (58.3) ...............................19.2 (72.7)

Fuel Consumption (LP) - 75% load gal/hr (L/hr)....................11.8 (44.7) ...............................14.7 (55.6)

Fuel Consumption (LP) - 50% load gal/hr (L/hr)....................8.3 (31.4) .................................10.2 (38.6)

Battery Type - Group Number .................................................8D............................................8D

Battery Voltage (quantity per unit)...........................................12V (2) .................................... 12V (2)

Battery Voltage (series connection) ........................................24V..........................................24V

Battery Rating .........................................................................1100CCA................................. 1100CCA

3

(L) ..............................................................494 (8.1) ..................................673 (11.0)

3

/hr (m3/hr) ..............1092 (30.9) .............................. 1431 (40.5)

3

/hr (m3/hr) ................858 (24.3) ................................ 1112 (31.5)

3

/hr (m3/hr) ................625 (17.7) ................................ 794 (22.5)

Generator

Make/Brand............................................................................. Stamford..................................Stamford

Model ......................................................................................UCI274E-311...........................UCI274G-311

Type, Insulation....................................................................... Brushless, H............................Brushless, H

See the data plate on the generator for rated watts, amperes, frequency, voltage, phase and other important information.

Generator Set (Engine/Generator)

3Ø - Continuous - Natural Gas kW (kVA) ..............................100 (125) ................................. 137 (171)

3Ø - Standby - LP Liquid kW (kVA) ........................................ 108 (135).................................139 (173)

Amps - 3Ø Continuous - Natural Gas (480V/277) A ...............150 .........................................206

Amps - 3Ø Standby - Natural Gas (480V/277) A ....................214 .........................................278

Amps - 3Ø Standby - LP Liquid (480V/277) A .......................162 .......................................... 209

Frequency Hz .........................................................................60 ............................................ 60

Power Factor........................................................................... 0.8 ..........................................0.8

AC Distribution

Circuit Breaker Size A............................................................. 200 ..........................................400

Voltage Regulation..................................................................Digital ......................................Digital

Voltages Available 3Ø .............................................................480 (277/480)..........................480 (277/480)

Capacities

Coolant (incl. engine) qt (L) ...................................................20 (18.9)..................................22 (20.8)

Oil (incl. filter) qt (L) ...............................................................7.2 (6.81).................................7.6 (7.19)

Weights

Operating Weight, Skid Mounted lbs (kg) .............................7245 (3286).............................7290 (3307)

Operating Weight, Trailer Mounted lbs (kg) ..........................9645 (4375) .............................9890 (4486)

Trailer

Number of Axles......................................................................2 ..............................................2

Capacity - Axle Rating lbs (kg) ............................................... 7000 (3175).............................7000 (3175)

Tire Size in .............................................................................16 ............................................ 16

Brakes - Standard ...................................................................Electric ....................................Electric

Hitch - Standard ......................................................................3" lunette ring ..........................3" lunette ring

Maximum Tire Pressure psi ...................................................80 ............................................80

Specifications are subject to change without notice.

35319 C MGG155/210 Operating Manual 5

Page 12

General Information

Discount-Equipment.com

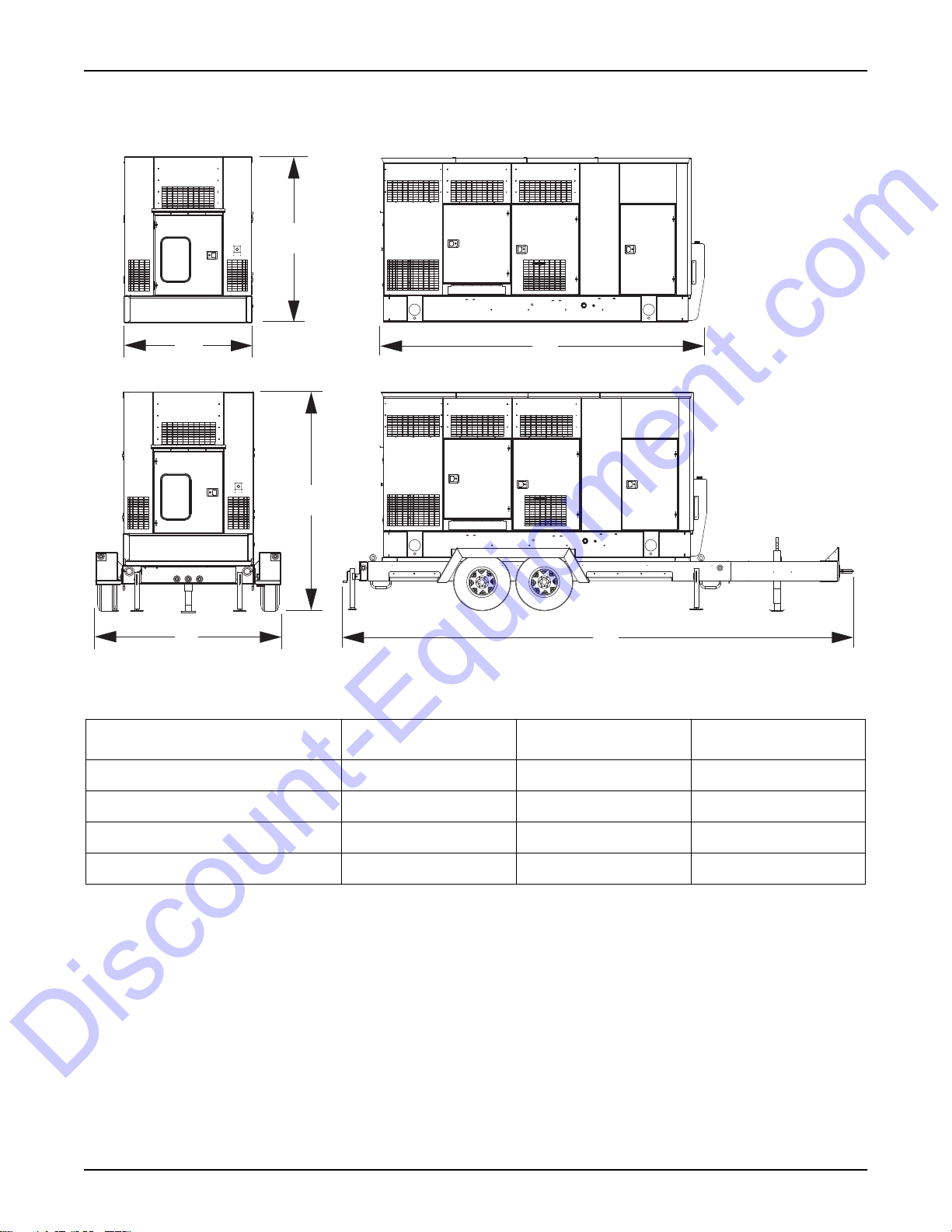

Unit Dimensions

B

A

B

A

Figure 1 - Unit Dimensions

ABC

MGG155 - Skid Mounted 66 in. (1.67 m) 92 in. (2.33 m) 169 in. (4.29 m)

C

C

02020

MGG155 - Trailer Mounted 102 in. (2.59 m) 124 in. (3.15 m) 269 in. (6.83 m)

MGG210 - Skid Mounted 66 in. (1.67 m) 92 in. (2.33 m) 201 in. (5.10 m)

MGG210 - Trailer Mounted 102 in. (2.59 m) 124 in. (3.15 m) 269 in. (6.83 m)

Specifications are subject to change without notice.

Engine Oil Recommendations

To maintain the product warranty, the engine oil should be serviced in accordance with the recommendations of this

manual. For your convenience, Generac Maintenance Kits are available that include engine oil, oil filter, air filter,

spark plug(s), a shop towel and funnel. These kits can be obtained from an Independent Authorized Service Dealer

(IASD).

The engine has been filled with factory engine oil of a grade recommended by the engine supplier. The manufacturer

recommends an initial oil and filter change after the first 50 hours (or first three months) of service operation. Use a

high quality detergent oil with an appropriate classification and viscosity for the engine type and ambient temperature

conditions. See Specifications for oil capacity.

6 MGG155/210 Operating Manual 35319 C

Page 13

General Information

Discount-Equipment.com

• SAE 15W-40 low ash

• API CD/CF or higher

Coolant Recommendation

See the OEM engine manual for coolant type. Normally a 50/50 mix of coolant and water is required. Coolant system

capacity is listed in Specifications.

DANGER

RISK OF POISONING. DO NOT USE MOUTH TO SIPHON COOLANT. DOING SO WILL

RESULT IN DEATH OR SERIOUS INJURY. (000149)

WARNING

DO NOT open coolant system until engine has completely cooled. Doing so could

result in serious injury. (000154)

CAUTION

Do not use any chromate base rust inhibitor with propylene glycol base antifreeze, boosters

or additives. Doing so will cause overheating. (000165)

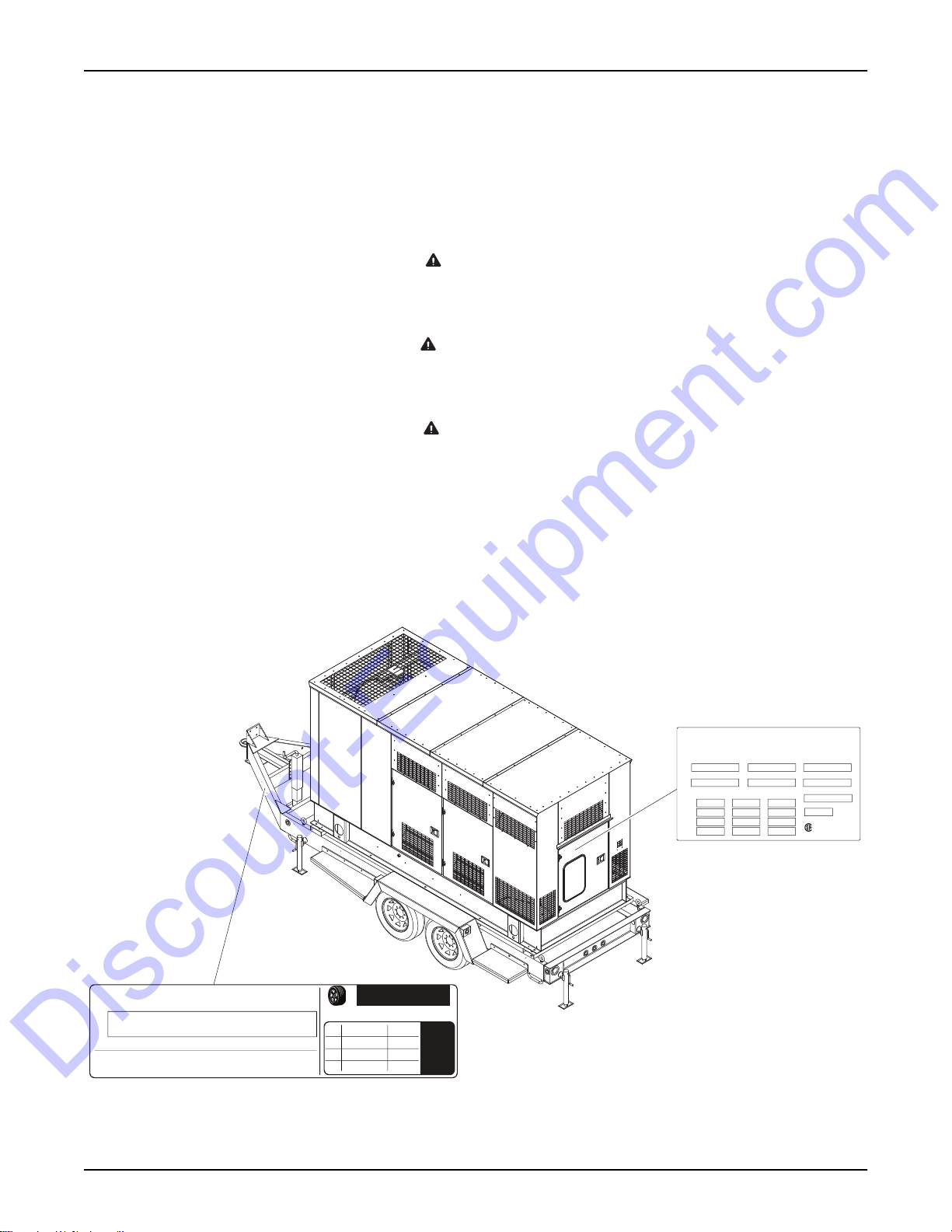

UNIT SERIAL NUMBER LOCATIONS

See Figure 2 to locate the unit ID tag and Vehicle Identification Number (VIN) tag on the unit. Important information,

such as the unit serial number, model number, VIN and tire loading information are found on these tags. Record the

information from these tags so it is available if the tags are lost or damaged. When ordering parts or requesting

assistance, you may be asked to provide this information.

UNIT ID Tag

Manufactured by Generac Mobile Products LLC,

a subsidiary of Generac Power Systems, Inc.

(920) 361-4442 (800) 926-9768

Country of Origin

Manufacturing Code

1 ph. 1.0PF 3 ph. .8PF 3 ph. 1.0PF

KW

KVA

V

A

Model

Weight (lbs/kg) RPM/Frequency

Located on control panel

(behind door)

Serial Number

Rating

FOR ELECTRICAL EQUIPMENT

Ins. Class

ONLY. POUR MATERIAL

ELECTRIQUE SEULEMENT.

209649

Form: SFC626B

VIN Tag

MANUFACTUREDBY/FABRIQUE PAR: Generac Mobile Products LLC DATE: 00/0000

GVWR/PNBV: 000KG (0000LBS) COLDINF. PRESS./

PRESS.DE

GAWR / PNBE TIRE / PNEU RIM / JANTE GONF A FROID - KPA(PSI/LPC) SGL / DUAL

EACH

AXLE

THIS VEHICLE CONFORMS TOALLAPPLICABLE STANDARDS PRESCRIBED UNDER THE U.S. FEDERAL MOTOR VEHICLE SAFETY STANDARDS(FMVSS)AND CANADIAN

MOTOR VEHICLE SAFETY REGULATIONS IN EFFECT ONTHE DATE OF MANUFACTURE.

CE VEHICULE EST CONFORMEATOUTES LES NORMES QUI LUI SONT APPLICABLES EN VERTU DU REGLEMENT SUR LA SECURITE DES VEHICULESAUTOMOBILES DU CANADA EN VIGUEUR A LA DATE SA

FABRICATION.

00000000000000000

V.I.N./N.I.V.:

XXX000

MODEL:

TYPE: TRAILER

TIRE AND LOADING INFORMATION

RENSEIGNEMENTS SUR LES

The weight of cargo should never exceed 0000KG (0000LBS)

Le poids du chargement ne doit jamais depasser 0000KG (0000LBS)

PNEUS ET LE CHARGEMENT

RENSEIGNEMENTS

SEE OWNER’S

MANUAL FOR

ADDITIONAL

INFORMATION

VOIR LE

MANUEL DE

L’USAGER

POUR

PLUS DE

02063

Figure 2 - Serial Number Locations

35319 C MGG155/210 Operating Manual 7

Page 14

General Information

Discount-Equipment.com

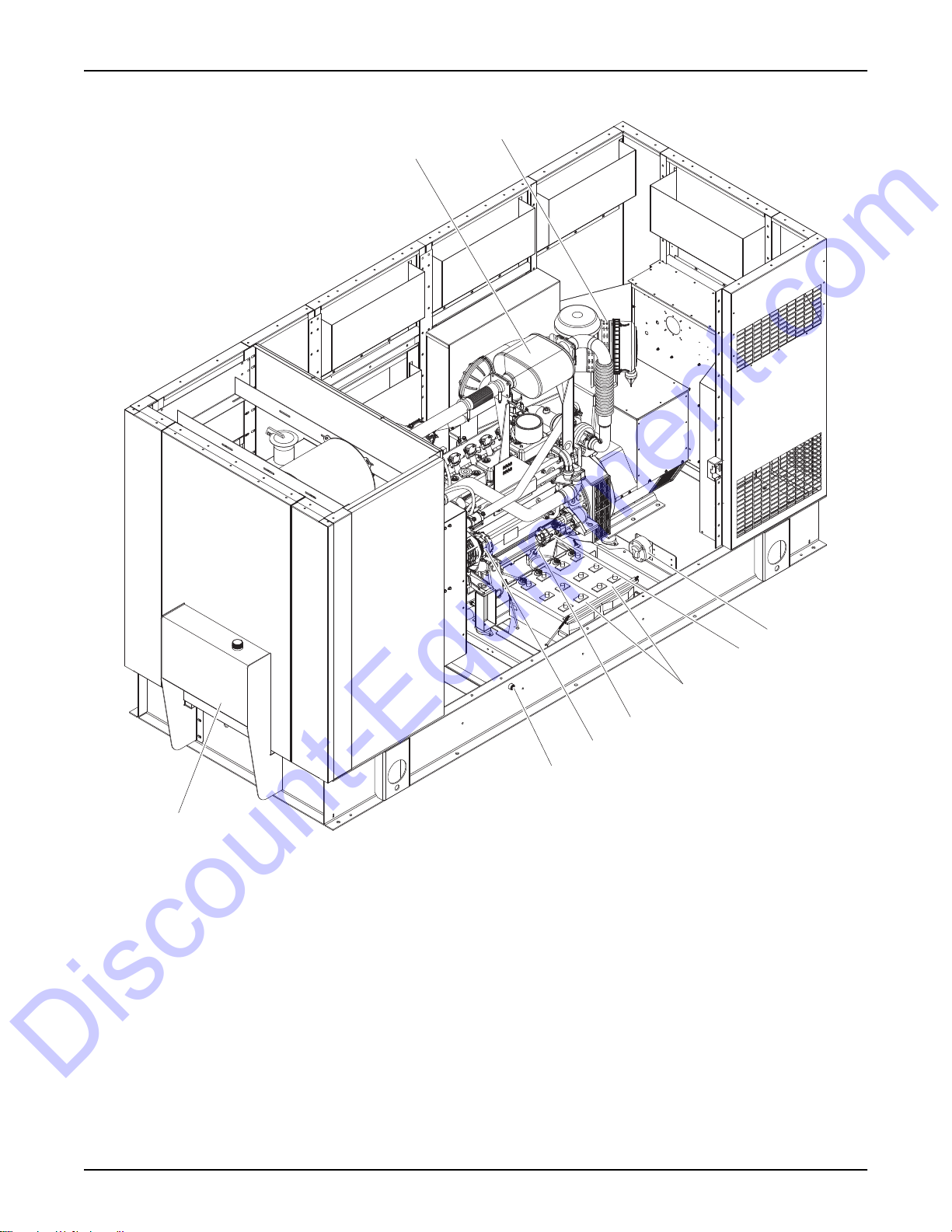

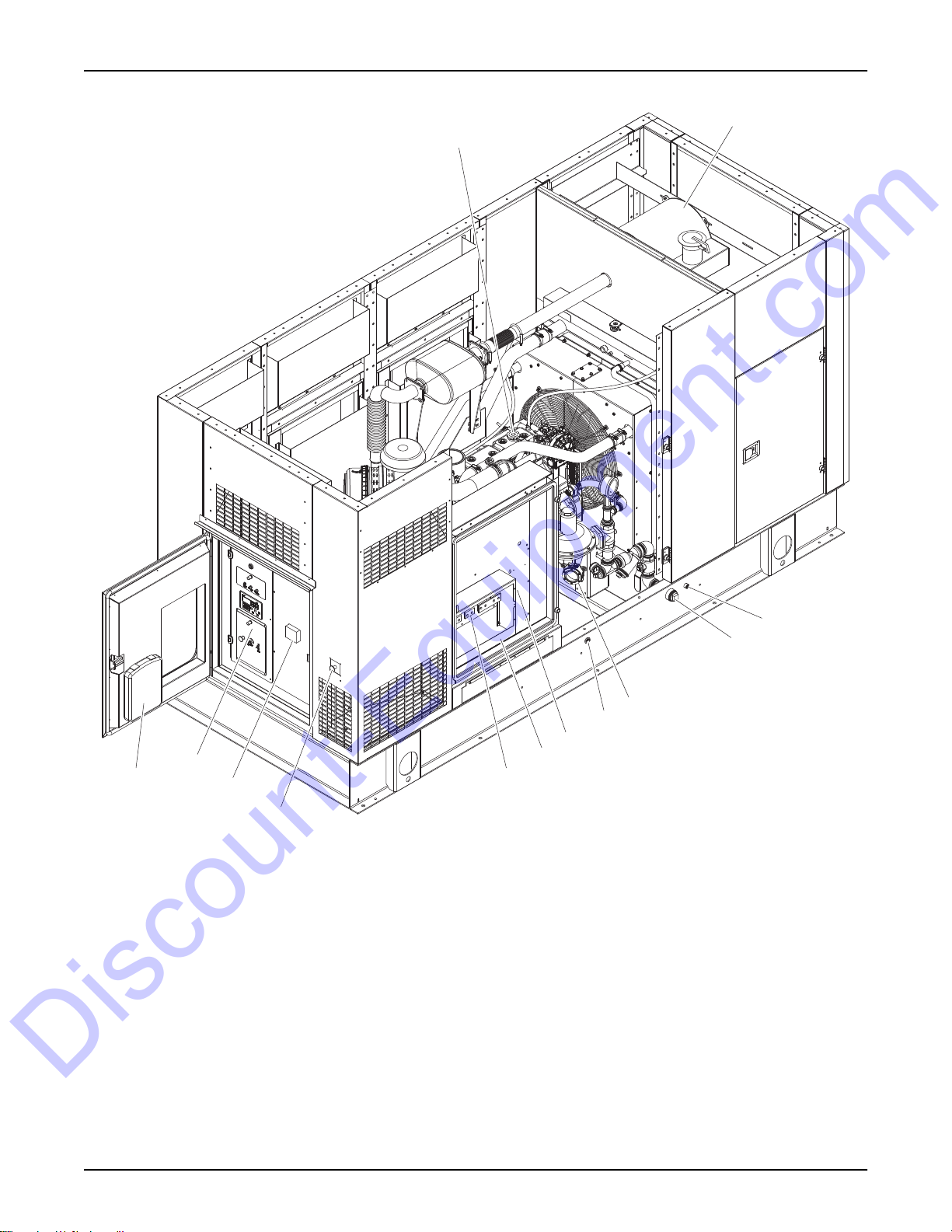

COMPONENT LOCATIONS

2

1

7

8

9

Figure 3 - MGG155 - Left Side

1. Catalyst exhaust muffler 6. Dipstick

2. Air filter 7. Alternator

3. Battery disconnect switch 8. Coolant drain

4. Starter 9. Oil reservoir

5.

12 volt batteries (2)

3

4

5

6

02032

8 MGG155/210 Operating Manual 35319 C

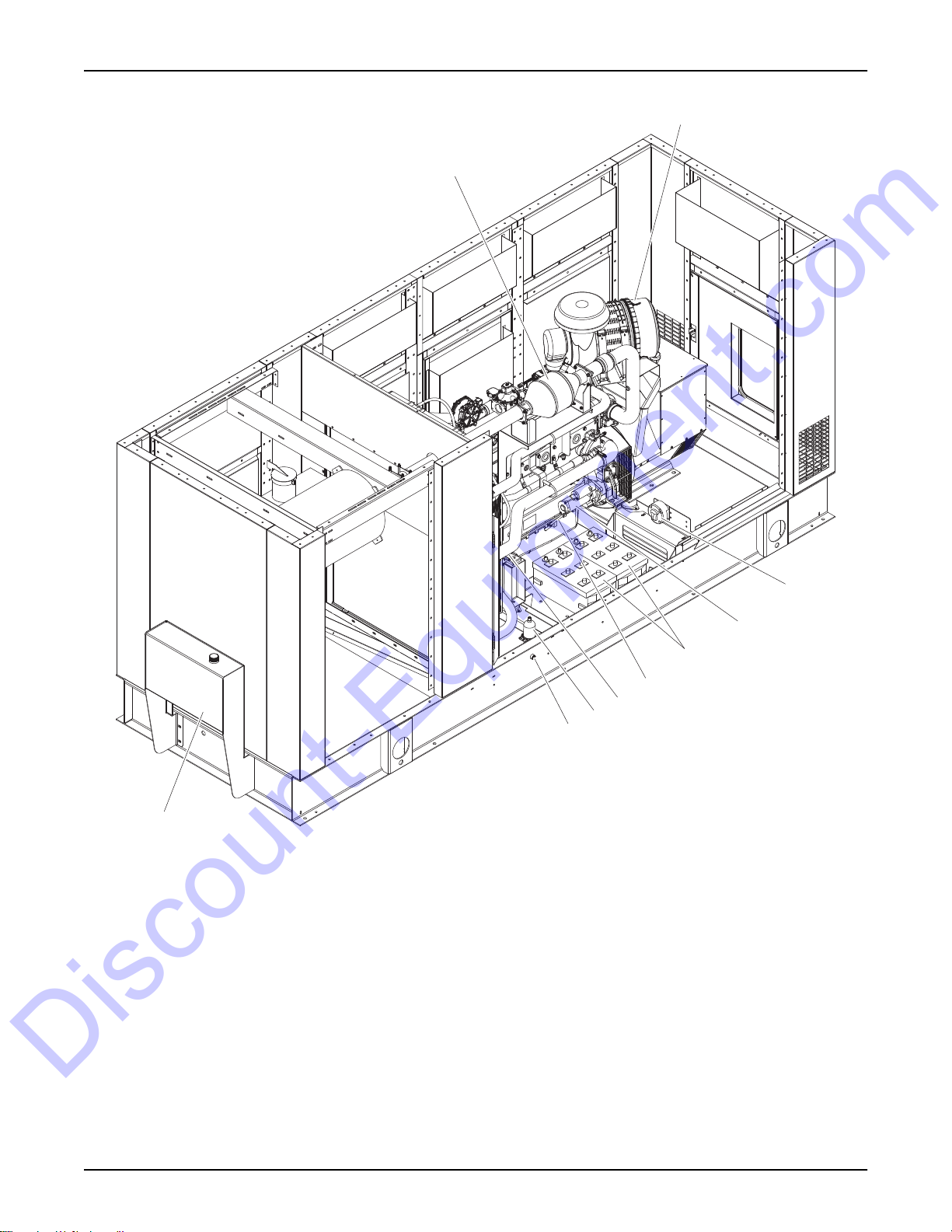

Page 15

General Information

Discount-Equipment.com

2

1

6

7

8

9

10

Figure 4 - MGG210 - Left Side

1. Catalyst exhaust muffler 6. Dipstick

2. Air filter 7. Alternator

3. Battery disconnect switch 8. Engine heater (optional)

4. Starter motor 9. Coolant drain

5. 12 volt batteries (2) 10. Oil reservoir

3

4

5

02033

35319 C MGG155/210 Operating Manual 9

Page 16

General Information

Discount-Equipment.com

2

1

5

6

7

13

12

11

10

Figure 5 - MGG155 and MGG210 - Right Side (MGG155 Shown)

1. Oil fill cap 8. Customer connection box

2. Silencer 9. Generator output connections

3. LP (liquid) inlet 10. Emergency stop switch

4. Natural gas (well gas) inlet 11. Main circuit breaker

5. Oil level controller 12. Control panel (see Figure 7)

6. Oil drain 13. Manual holder

7.

Customer convenience receptacles

8

9

3

4

02034

10 MGG155/210 Operating Manual 35319 C

Page 17

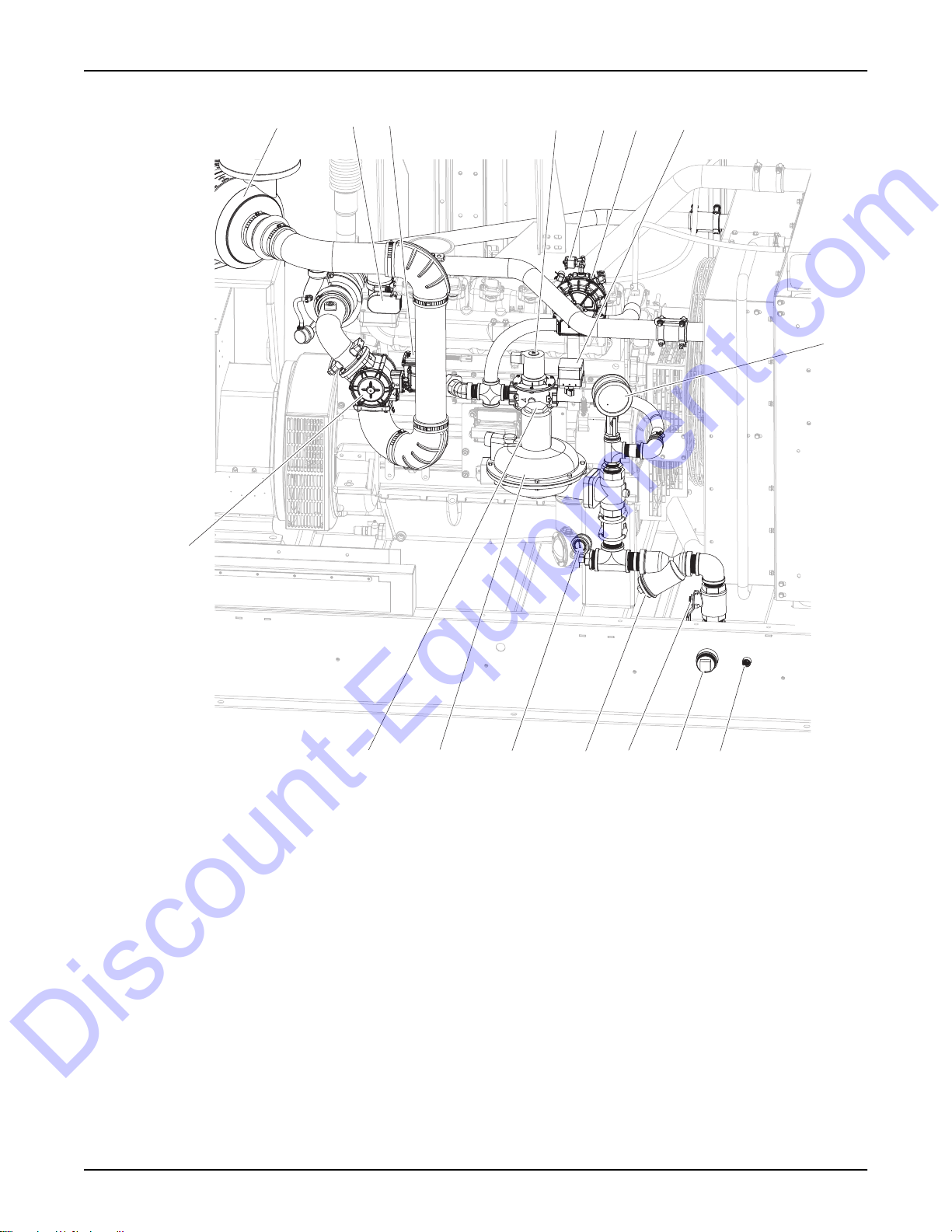

General Information

Discount-Equipment.com

3

1

2

654

7

8

16

15

Figure 6 - Fuel System (MGG155 Shown)

1. Air filter 9. LP liquid inlet

2. Electronic throttle control 10. Natural gas (well gas) inlet

3. Integrated electronic pressure regulator 11. Manual ball valve (natural gas)

4. Natural gas lock-off 12. Strainer access

5. LP liquid lock-off 13. Pressure gauge (psi)

6. Vaporizer 14. Pressure regulator

7. Pressure switch 15. Access for regulator adjustment

8. Pressure gauge (inch WC) 16. Fuel/air mixer

14

13

12

11

10

9

00720

35319 C MGG155/210 Operating Manual 11

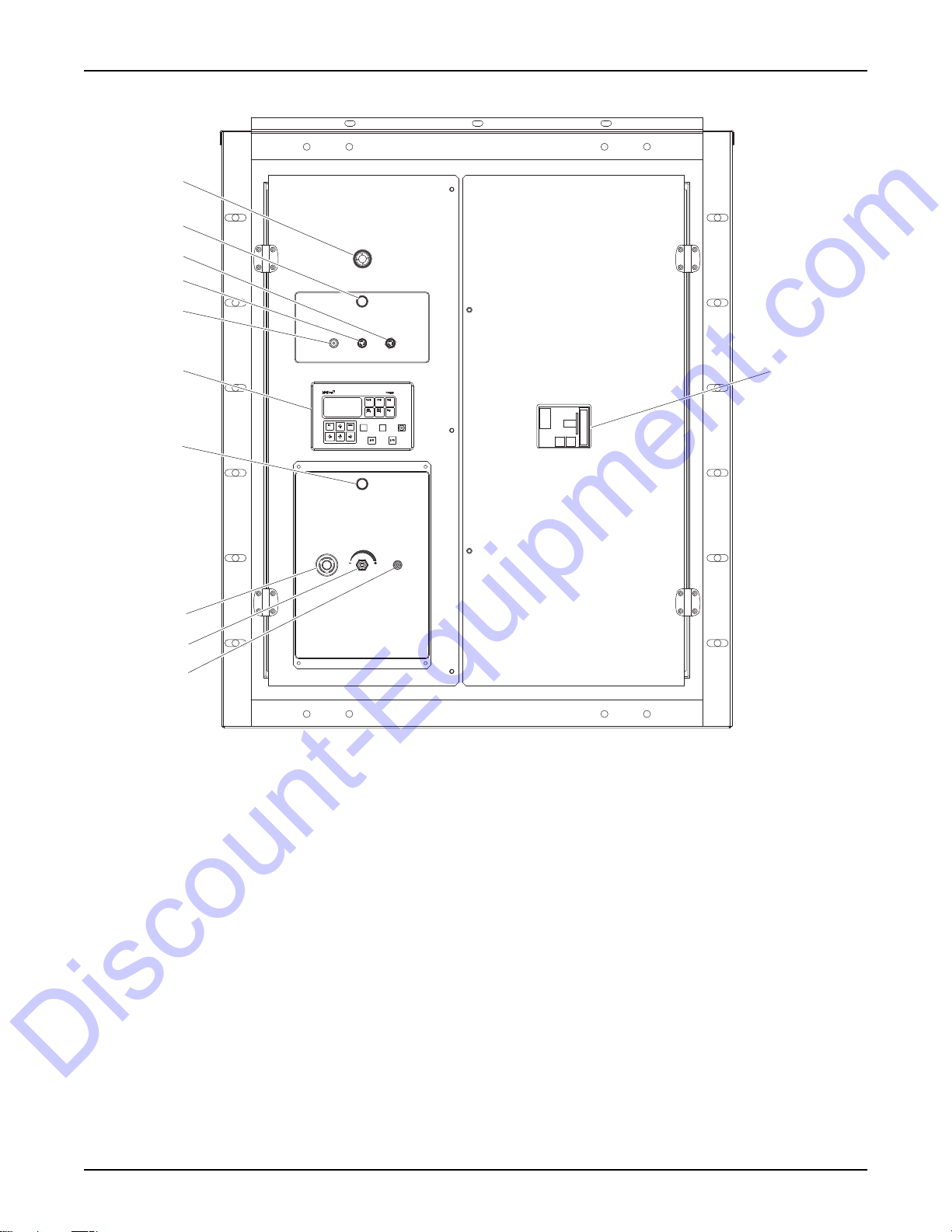

Page 18

General Information

EMERGENCY STOP

VOLTAGE

ADJUST

OFF

ON

PANEL

LIGHTS

Discount-Equipment.com

CONTROL PANEL

1

2

3

4

5

DC CIRCUIT

BREAKER

6

CONTROLLER

PANEL

LIGHT FUSE

FUSE

10

2

EMERGENCY STOP

VOLTAGE

ADJUST

ON

OFF

PANEL

LIGHTS

7

8

9

00578

Figure 7 - MGG155 and MGG210 Control Panel

1. Alarm horn 6. Digital controller

2. Panel light 7. Emergency stop switch (not on all units)

3. Panel light fuse (10A) 8. Voltage adjustment

4. Controller fuse (5A) 9. Panel lights switch

5. DC circuit breaker 10. Main circuit breaker

12 MGG155/210 Operating Manual 35319 C

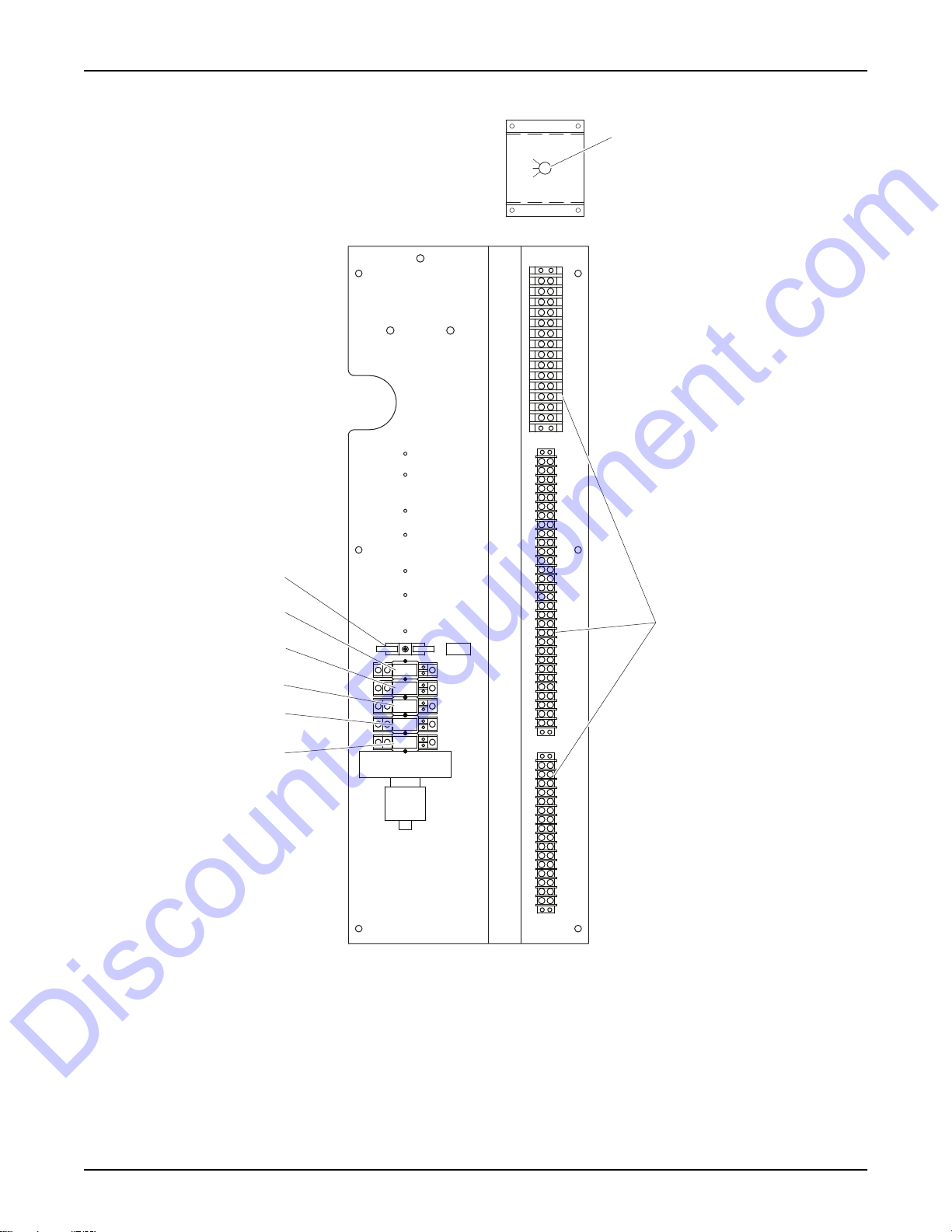

Page 19

ELECTRICAL PANEL

Discount-Equipment.com

General Information

FUEL SELECT SWITCH

AUTO

NG

LP

TB1

1" X 2" WIREWAY

8

TB2

1

7

2

6

SR

5

4

3

FR

STR

CBCR

CBOR

iG-AVRi

iG-AVRi

TRANS/LV

5A FUSE

F3

TB3

02031

Figure 8 - Electrical Panel (Located Behind Control Panel Door)

1. Fuel select switch 5. Shunt trip relay

2. Terminal block (3) 6. Fuel relay

3. Circuit breaker open relay 7. Starter relay

4. Circuit breaker closed relay 8. Relay protection fuse (5A)

35319 C MGG155/210 Operating Manual 13

Page 20

General Information

Discount-Equipment.com

UNIT SET UP

This unit is designed to operate with natural gas or well gas as the primary fuel and LP liquid as the secondary fuel.

For units operating on well site gas, a well test must be performed prior to installation of the unit.

Well Site Approval

A well gas chromatography analysis must be performed prior to installation of the unit. A copy of the test report must

be sent to, and preapproved by, Generac Power Systems. If the unit is moved to a new location, a new well test

must be performed. For more information, contact Generac Mobile Products Technical Support.

The unit should be installed, serviced, tested, adjusted, and otherwise prepared for use by an Independent Authorized

Service Dealer. The owner is responsible for ensuring the unit emission control system meets all applicable state

and local regulations.

WARNING

Risk of Fire. Unit must be positioned in a manner that prevents combustible material

accumulation underneath. Failure to do so could result in death or serious injury.

(000147)

Fuel Connections

Almost all operation problems are related to the installation techniques used. DO NOT guess, be sure pipe size is

adequate for required flow rate. See Table 1, Table 2 and Table 3.

Natural Gas Connections

Follow the steps below:

1. Before connecting the natural gas fuel line to the unit, apply pipe sealant to the NPT threads of the fitting at

the end of the fuel line.

Note: Do not apply pipe sealant to the flared (flanged) end of the fitting.

2. Connect the fuel line to the two inch inlet, located on the right side of the unit’s frame.

3. Be certain that all connections are sealed and no leaks are present. The installer must verify that all gas

connections comply with all building codes.

4. Verify fuel supply pressure is adequate.

Purging the Natural Gas Fuel Line

After initial setup, it may be necessary to purge the natural gas fuel line before operating the unit. LP liquid must be

available as a secondary fuel to perform this procedure.

1. Open the control door located at the back of the unit.

2. Remove the three screws securing the left control panel door. A Fuel Select switch is located behind the

door. See Figure 8.

3. Move the Fuel Select switch to the LP or AUTO position.

14 MGG155/210 Operating Manual 35319 C

Page 21

General Information

Discount-Equipment.com

FUEL SELECT SWITCH

AUTO

NG

LP

00651

Figure 9 - Fuel Select Switch

4. Apply pipe sealant to the NPT threads of the pipe fitting at the end of the natural gas fuel line. Connect the

fuel line to the two inch inlet located on the right side of the unit’s frame.

Note: Do not apply pipe sealant to the flared (flanged) end of the fuel pipe.

5. Apply pipe sealant to the NPT threads of the pipe fitting at the end of the LP liquid fuel line. Connect the fuel

line to the 1/2 inch inlet located on the right side of the unit’s frame.

6. Be certain that all connections are sealed and no leaks are present. The installer must verify that all gas

connections comply with all building codes.

7. Verify fuel supply pressure is adequate.

Formula Example:

If a unit has a 160 hp engine 60 feet from the supply, the engine needs 10,000 BTU/hr per hp to run efficiently. For

natural gas fuel, there are 1015 BTU/ft3. From Table 1, a 60 foot run requires a minimum 1 inch pipe at full engine load.

160 hp x 10,000 BTU/Hr per hp = 1,600,000 BTU’s / per hour for proper operation

1,600,000

1, 015

Note: The incoming pressure must be approximately 20 psi to unit.

= 1576 cubic feet per hour

35319 C MGG155/210 Operating Manual 15

Page 22

General Information

Discount-Equipment.com

Table 1 - Natural Gas Flow Rate (ft3 / m3 Per Hour) per Pipe Length

Pipe

Length

1/2 in

(1 cm)

3/4 in

(2 cm)

1 in

(3 cm)

1−1/4 in

(3 cm)

1−1/2″

(4 cm)

Iron Pipe Size

2 in

(5 cm)

2−1/2 in

(6 cm)

3 in

(8 cm)

3–1/2 in

(9 cm)

4 in

(10 cm)

5 in

(13 cm)

6 in

(15 cm)

10 ft

(3 m)

20 ft

(6 m)

25 ft

(8 m)

30 ft

(9 m)

35 ft

(11 m)

40 ft

(12 m)

45 ft

(14 m)

50 ft

(15 m)

60 ft

(18 m)

70 ft

(21 m)

80 ft

(24 m)

90 ft

(27 m)

100 ft

(30 m)

125 ft

(38 m)

150 ft

(46 m)

200 ft

(61 m)

300 ft

(91 m

400 ft

(122 m)

500 ft

(152 m)

1,000 ft

(305 m)

1,500 ft

(457 m)

2,000 ft

(610 m)

2,723 ft

(830 m)

1,926 ft

(587 m)

1,722 ft

(525 m)

1,572 ft

(479 m)

1,456 ft

(444 m)

1,362 ft

(415 m)

1,284 ft

(391 m)

1,218 ft

(371 m)

1,112 ft

(339 m)

1,029 ft

(314 m)

963 ft

(294 m)

908 ft

(277 m)

861 ft

(262 m)

770 ft

(235 m)

703 ft

(214 m)

609 ft

(186 m)

497 ft

(151 m)

431 ft

(131 m)

385 ft

(117 m)

272 ft

(83 m)

222 ft

(68 m)

193 ft

(59 m)

5,765 ft

(1,757 m)

4,076 ft

(1,242 m)

3,646 ft

(1,111 m)

3,328 ft

(1,014 m)

3,082 ft

(939 m)

2,883 ft

(879 m)

2,718 ft

(828 m)

2,578 ft

(786 m)

2,354 ft

(717 m)

2,179 ft

(664 m)

2,038 ft

(621 m)

1,922 ft

(586 m)

1,823 ft

(556 m)

1,631 ft

(497 m)

1,489 ft

(454 m)

1,289 ft

(393 m)

1,053 ft

(321 m)

912 ft

(278 m)

815 ft

(248 m)

577 ft

(176 m)

471 ft

(144 m)

408 ft

(124 m)

10,975 ft

(3,345 m)

7,760 ft

(2,365 m)

6,941 ft

(2,116 m)

6,336 ft

(1,931 m)

5,866 ft

(1,788 m)

5,487 ft

(1,672 m)

5,174 ft

(1,577 m)

4,908 ft

(1,496 m)

4,480 ft

(1,366 m)

4,148 ft

(1,264 m)

3,880 ft

(1,183 m)

3,658 ft

(1,115 m)

3,471 ft

(1,058 m)

3,104 ft

(946 m)

2,834 ft

(864 m)

2,454 ft

(748 m)

2,004 ft

(611 m)

1,735 ft

(529 m)

152 ft

(46 m)

1097 ft

(334 m)

896 ft

(273 m)

776 ft

(237 m)

22,804 ft

(6,951 m)

16,125 ft

(4,915 m)

14,422 ft

(4,396 m)

13,166 ft

(4,013 m)

12,189 ft

(3,715 m)

11,402 ft

(3,475 m)

10,750 ft

(3,277 m)

10,198 ft

(3,108 m)

9,310 ft

(2,838 m)

8,619 ft

(2,627 m)

8,062 ft

(2,457 m)

7,601 ft

(2,317 m)

7,211 ft

(2,198 m)

6,450 ft

(1,966 m)

5,888 ft

(1,795 m)

5,099 ft

(1,554 m)

4,163 ft

(1,269 m)

3,606 ft

(1,099 m)

3,225 ft

(983 m)

2,280 ft

(695 m)

1,862 ft

(568 m)

1,612 ft

(491 m)

34,398 ft

(10,485 m)

24,323 ft

(7,414 m)

21,755 ft

(6,631 m)

19,860 ft

(6,053 m)

18,386 ft

(5,604 m)

17,199 ft

(5,242 m)

16,215 ft

(4,942 m)

15,383 ft

(4,689 m)

14,043 ft

(4,280 m)

13,001 ft

(3,963 m)

12,161 ft

(3,707 m)

11,466 ft

(3,495 m)

10,878 ft

(3,316 m)

9,729 ft

(2,965 m)

8,881 ft

(2,707 m)

7,692 ft

(2,345 m)

6,280 ft

(1,914 m)

5,439 ft

(1,658 m)

4,865 ft

(1,483 m)

3,440 ft

(1,049 m)

2,809 ft

(856 m)

2,432 ft

(741 m)

66,973 ft

(20,413 m)

47,357 ft

(14,434 m)

42,358 ft

(12,911 m)

38,667 ft

(11,786 m)

35,799 ft

(10,912 m)

33,487 ft

(10,207 m)

31,572 ft

(9,623 m)

29,951 ft

(9,129 m)

27,342 ft

(8,334 m)

25,314 ft

(7,716 m)

23,679 ft

(7,217 m)

22,324 ft

(6,804 m)

21,179 ft

(6,455 m)

18,943 ft

(5,774 m)

1,292 ft

(394 m)

14,976 ft

(4,565 m)

12,228 ft

(3,727 m)

10,589 ft

(3,228 m)

9,471 ft

(2,887 m)

6,697 ft

(2,041 m)

5,468 ft

(1,667 m)

4,736 ft

(1,444 m)

107,577 ft

(32,789 m)

76,068 ft

(23,186 m)

68,037 ft

(20,738 m)

62,109 ft

(18,931 m)

57,502 ft

(17,527 m)

53,788 ft

(16,395 m)

50,712 ft

(15,457 m)

48,110 ft

(14,664 m)

43,918 ft

(13,386 m)

40,660 ft

(12,393 m)

38,034 ft

(11,593 m)

35,859 ft

(10,930 m)

34,019 ft

(10,369 m)

30,427 ft

(9,274 m)

27,776 ft

(8,466 m)

24,055 ft

(7,332 m)

19,641 ft

(5,987 m)

17,009 ft

(5,184 m)

15,214 ft

(4,637 m)

10,758 ft

(3,279 m)

8,784 ft

(2,677 m)

7,607 ft

(2,319 m)

191,989 ft

(58,518 m)

135,757 ft

(41,379 m)

121,424 ft

(37,010 m)

110,845 ft

(33,786 m)

102,622 ft

(31,279 m)

95,994 ft

(29,259 m)

90,504 ft

(27,586 m)

85,860 ft

(26,170 m)

78,379 ft

(23,890 m)

72,565 ft

(22,118 m)

67,878 ft

(20,689 m)

63,996 ft

(19,506 m)

60,712 ft

(18,505 m)

54,303 ft

(16,552 m)

49,571 ft

(15,109 m)

42,930 ft

(13,085 m)

35,052 ft

(10,684 m)

30,356 ft

(9,253 m)

27,151 ft

(8,276 m)

19,199 ft

(5,852 m)

15,676 ft

(4,778 m)

13,576 ft

(4,138 m)

282,890 ft

(86,225 m)

200,034 ft

(60,970 m)

178,915 ft

(54,533 m)

163,327 ft

(49,782 m)

151,211 ft

(46,089 m)

141,445 ft

(43,112 m)

133,356 ft

(40,647 m)

126,512 ft

(38,561 m)

115,489 ft

(35,201 m)

106,922 ft

(32,590 m)

100,017 ft

(30,485 m)

94,297 ft

(28,742 m)

89,458 ft

(27,267 m)

80,013 ft

(24,388 m)

73,042 ft

(22,263 m)

63,256 ft

(19,280 m)

51,648 ft

(15,742 m)

44,729 ft

(13,633 m)

40,007 ft

(12,194 m)

28,289 ft

(8,622 m)

23,098 ft

(7,040 m)

20,003 ft

(6,097 m)

396,270 ft

(120,783 m)

280,205 ft

(85,406 m)

250,623 ft

(76,390 m)

228,787 ft

(69,734 m)

211,815 ft

(64,561 m)

198,135 ft

(60,392 m)

186,804 ft

(56,938 m)

177,217 ft

(54,016 m)

161,777 ft

(49,310 m)

149,776 ft

(46,652 m)

140,103 ft

(42,703 m)

132,090 ft

(40,261 m)

125,312 ft

(38,195 m)

112,082 ft

(34,163 m)

102,317 ft

(31,186 m)

88,609 ft

(27,008 m)

72,349 ft

(22,052 m)

62,656 ft

(19,098 m)

56,041 ft

(17,081 m)

39,627 ft

(12,078 m)

32,355 ft

(9,862 m)

28,021 ft

(8541 m)

724,020 ft

(220,681 m)

511,959 ft

(156,045 m)

457,910 ft

(139,571 m)

418,013 ft

(127,410 m)

387,005 ft

(117,959 m)

362,010 ft

(110,341 m)

341,306 ft

(104,030 m)

323,791 ft

(98,692 m)

295,580 ft

(90,093 m)

273,654 ft

(83,410 m)

255,980 ft

(78,023 m)

241,340 ft

(73,560 m)

228,955 ft

(69,785 m)

204,784 ft

(62,418 m)

186,941 ft

(56,980 m)

161,896 ft

(49,346 m)

132,187 ft

(40,291 m)

114,478 ft

(34,893 m)

102,392 ft

(31,209 m)

72,402 ft

(22,068 m)

59,116 ft

(18,019 m)

51,196 ft

(15,605 m)

1,181,799 ft

(360,212 m)

838,658 ft

(255,623 m)

747,435 ft

(227,818 m)

682,312 ft

(207,969 m)

631,698 ft

(192,542 m)

590,900 ft

(180,106 m)

557,105 ft

(169,806 m)

528,517 ft

(161,092 m)

482,467 ft

(147,056 m)

446,678 ft

(136,148 m)

417,829 ft

(127,354 m)

393,933 ft

(120,071 m)

373,718 ft

(113,909 m)

334,263 ft

(101,883 m)

305,139 ft

(93,006 m)

264,258 ft

(80,546 m)

215,766 ft

(65,765 m)

186,859 ft

(56,955 m)

167,132 ft

(50,942 m)

118,180 ft

(36,021 m)

96,493 ft

(29,411 m)

83,566 ft

(25,471 m)

16 MGG155/210 Operating Manual 35319 C

Page 23

General Information

Discount-Equipment.com

LP Liquid Connections (Liquid Withdrawal System)

Use the following chart to determine the supply pipe size for LP liquid.

Formula Example:

If a unit has a 135 hp engine 80 feet from the supply, the engine needs 449 ft3/hr of LP vapor to run efficiently. For

liquid propane vapor fuel, there is 2500 BUT/ft3. From Table 2, an 80 foot run requires a minimum 1/4 inch pipe at

full engine load.

3

2500 ft

*Cubic feet of vapor at 60°F (16°C) per gallon of liquid at 60°F (16°C).

/hr x 449 ft3/hr = 1,122,500 BTU/ft

3

449 ft

/hr

36.39*

= 12.33 gallons per hour

3

35319 C MGG155/210 Operating Manual 17

Page 24

General Information

Discount-Equipment.com

Liquid

Propane

Flow

10 gal/hr

(38 L/hr)

15 gal/hr

(57 L/hr)

20 gal/hr

(76 L/hr)

40 gal/hr

(151 L/hr)

60 gal/hr

(227 L/hr)

80 gal/hr

(303 L/hr)

100 gal/hr

(379 L/hr)

120 gal/hr

(454 L/hr)

140 gal/hr

(530 L/hr)

160 gal/hr

(606 L/hr)

180 gal/hr

(681 L/hr)

200 gal/hr

(757 L/hr)

240 gal/hr

(908 L/hr)

280 gal/hr

(1,060 L/hr)

300 gal/hr

(1,136 L/hr)

350 gal/hr

(1,325 L/hr)

400 gal/hr

(1,514 L/hr)

1/4 in

(0.6 cm)

Schedule Schedule Schedule Schedule Schedule Schedule Schedule

40 80 40 80 40 80 40 80 40 80 40 80 40 80

729 ft

(222 m)

324 ft

(99 m)

182 ft

(55 m)

46 ft

(14 m)

20 ft

(6 m)

11 ft

(3 m)

(2 m)

416 ft

(127 m)

185 ft

(56 m)

104 ft

(32 m)

(8 m)

(3 m)

(2 m)

7 ft

(1 m)

- - 23 ft

- - 15 ft

- - 13 ft

- - - - 37 ft

- - - - 30 ft

- - - - 21 ft

- - - - 15 ft

- - - - 13 ft

------38 ft

------30 ft

26 ft

11 ft

6 ft

4 ft

Table 2 - LP Liquid Line Sizing Chart

Iron Pipe Size

3/8 in

(1 cm)

----------- -

----------- -

825 ft

(251 m)

205 ft

(62 m)

92 ft

(28 m)

51 ft

(16 m)

33 ft

(10 m)

(7 m)

(5 m)

(4 m)

521 ft

(159 m)

129 ft

(39 m)

58 ft

(18 m)

32 ft

(10 m)

21 ft

(6 m)

15 ft

(5 m)

9 ft

(3 m)

8 ft

(2 m)

1/2 in

(1 cm)

3/4 in

(2 cm)

1 in

(3 cm)

1-1/4 in

(3 cm)

1-1/2 in

(4 cm)

Distance

----------

745 ft

(227 m)

331 ft

(101 m)

187 ft

(57 m)

119 ft

(36 m)

83 ft

(25 m)

61 ft

(19 m)

47 ft

(14 m)

(11 m)

(9 m)

(6 m)

(5 m)

(4 m)

504 ft

(154 m)

224 ft

(68 m)

127 ft

(39 m)

81 ft

(25 m)

56 ft

(17 m)

41 ft

(12 m)

32 ft

(10 m)

25 ft

(8 m)

20 ft

(6 m)

14 ft

(4 m)

10 ft

(3 m)

9 ft

(3 m)

------- -

------- -

735 ft

(224 m)

470 ft

(143 m)

326 ft

(99 m)

240 ft

(73 m)

184 ft

(56 m)

145 ft

(44 m)

118 ft

(36 m)

81 ft

(25 m)

60 ft

(18 m)

52 ft

(16 m)

(12 m)

(9 m)

537 ft

(164 m)

343 ft

(105 m)

238 ft

(73 m)

175 ft

(53 m)

134 ft

(41 m)

106 ft

(32 m)

86 ft

(26 m)

59 ft

(18 m)

44 ft

(13 m)

38 ft

(12 m)

28 ft

(9 m)

22 ft

(7 m)

----- -

----- -

----- -

813 ft

(248 m)

623 ft

(190 m)

491 ft

(150 m)

399 ft

(122 m)

277 ft

(84 m)

204 ft

(62 m)

177 ft

(54 m)

130 ft

(40 m)

99 ft

(30 m)

618 ft

(188 m)

473 ft

(144 m)

373 ft

(114 m)

303 ft

(92 m)

211 ft

(64 m)

155 ft

(47 m)

135 ft

(41 m)

99 ft

(30 m)

75 ft

(23 m)

--- -

--- -

--- -

--- -

--- -

--- -

785 ft

(239 m)

578 ft

(176 m)

433 ft

(132 m)

623 ft

(190 m)

459 ft

(140 m)

344 ft

(105 m)

--

--

980 ft

(299 m)

794 ft

(242 m)

How to use chart:

1. Having determined the required flow at point of use, locate this flow in the left hand column. If this falls between

two figures, use the larger of the two.

2. Determine total length of piping required from source to point of use.

18 MGG155/210 Operating Manual 35319 C

Page 25

General Information

Discount-Equipment.com

3. Read across chart from left (required flow) to right to find the total length which is equal to, or exceeds, the

distance from source to use.

4. From this point, read up to find the correct size of pipe required.

Valve and Fitting Pipe Equivalents

Table 3 - Valve & Fitting Pipe Equivalents

Equivalent Length Of Steel Pipe

Nominal Pipe Size (NPT)

Fitting

45° Screwed

Elbow

90° Screwed

Elbow

Screwed T

Thru Run

Screwed T

Thru Branch

Screwed

Globe Valve*

Screwed

Angel Valve*

Flanged

Globe Valve*

Flanged

Angle Valve*

3/4 in

(2 cm)

1 in

(3 cm)

1-1/4 in

(3 cm)

1-1/2 in

(4 cm)

2 in

(5 cm)

2-1/2 in

(6 cm)

3 in

(8 cm)

Schedule Schedule Schedule Schedule Schedule Schedule Schedule

40 80 40 80 40 80 40 80 40 80 40 80 40 80

1.2 ft

(0.4 m)

1.8 ft

(0.5 m)

1.4 ft

(0.4 m)

4.6 ft

(1.4 m)

14.0 ft

(4.3 m)

11.0 ft

(3.4 m)

0.9 ft

(0.3 m)

1.6 ft

(0.5 m)

1.3 ft

(0.4 m)

4.0 ft

(1.2 m)

10.0 ft

(3.0 m)

8.0 ft

(2.4 m)

- - - - - - 30.0 ft

- - - - - - 12.0 ft

1.3 ft

(0.4 m)

2.3 ft

(0.7 m)

1.7 ft

(0.5 m)

5.6 ft

(1.7 m)

21.0 ft

(6.4 m)

13.0 ft

(4.0 m)

1.2 ft

(0.4 m)

2.1 ft

(0.6 m)

1.6 ft

(0.5 m)

5.3 ft

(1.6 m)

16.0 ft

(4.9 m)

10.0 ft

(3.0 m)

1.7 ft

(0.5 m)

3.1 ft

(0.9)

2.4 ft

(0.7 m)

7.9 ft

(2.4 m)

24.0 ft

(7.3 m)

10.5 ft

(3.2 m)

1.5 ft

(0.5 m)

2.9 ft

(0.9)

2.3 ft

(0.7 m)

7.3 ft

(2.2 m)

19.0 ft

(5.8 m)

8.5 ft

(2.6 m)

2.0 ft

(0.6 m)

3.7 ft

(1.1 m)

2.8 ft

(0.9 m)

9.3 ft

(2.8 m)

39.0 ft

(11.9 m)

20.0 ft

(6.1 m)

(9.1 m)

(3.7 m)

1.8 ft

(0.5 m)

3.4 ft

(1.0 m)

2.6 ft

(0.8 m)

8.6 ft

(2.6 m)

27.0 ft

(8.2 m)

16.0 ft

(4.9 m)

24.0 ft

(7.3 m)

10.0 ft

(3.0 m)

2.6 ft

(0.8 m)

4.6 ft

(1.4 m)

3.6 ft

(1.1 m)

12.0 ft

(3.7 m)

42.0 ft

(12.8 m)

32.0 ft

(9.8 m)

4.10 ft

(1.2 m)

14.5 ft

(4.4 m)

2.4 ft

(0.7 m)

4.4 ft

(1.3 m)

3.3 ft

(1.0 m)

11.0 ft

(3.4 m)

34.5 ft

(10.5 m)

26.5 ft

(8.1 m)

34.0 ft

(10.4 m)

12.0 ft

(3.7 m)

3.0 ft

(0.9 m)

5.3 ft

(1.6 m)

4.2 ft

(1.3 m)

15.0 ft

(4.6 m)

24.0 ft

(7.3 m)

7.5 ft

(2.3 m)

2.8 ft

(0.9 m)

5.1 ft

(1.6 m)

4.0 ft

(1.2 m)

14.0 ft

(4.3 m)

20.0 ft

(6.1 m)

6.0 ft

(1.8 m)

- - 46.0 ft

- - 19.0 ft

3.8 ft

(1.2 m)

6.9 ft

(2.1 m)

5.4 ft

(1.6 m)

17.0 ft

(5.2 m)

46.0 ft

(14.0 m)

19.0 ft

(5.8 m)

(14.0)

(5.8 m)

3.7 ft

(1.1 m)

6.5 ft

(2.0)

5.0 ft

(1.5 m)

16.0 ft

(4.9 m)

39.0 ft

(11.9 m)

16.0 ft

(4.9 m)

39.0 ft

(11.9 m)

16.0 ft

(4.9 m)

* Reg O A7500 series valves.

Electrical Connections

Class 1 wiring methods must be used for field wiring connections to terminals of a class 2 circuit. It is the responsibility

of the owner/operator to arrange for these procedures to be performed by a licensed electrical contractor and ensure

conformance to all applicable codes, including local codes specific to your municipality/city/county and state. Wire

size and insulation type should be as required by National Electrical Code (NEC), state and local regulations.

DANGER

ELECTROCUTION. NEVER CONNECT THIS UNIT TO THE ELECTRICAL SYSTEM OF

ANY BUILDING UNLESS A LICENSED ELECTRICIAN HAS INSTALLED AN APPROVED

TRANSFER SWITCH. FAILURE TO DO SO WILL RESULT IN DEATH OR SERIOUS

INJURY. (000150)

35319 C MGG155/210 Operating Manual 19

Page 26

General Information

Discount-Equipment.com

WARNING

Only qualified service personnel may install, operate and maintain this equipment.

Failure to follow proper installation requirements could result in death, serious injury,

and damage to equipment or property. (000182)

DANGER

ELECTROCUTION. VERIFY ELECTRICAL SYSTEM IS PROPERLY GROUNDED

BEFORE APPLYING POWER. FAILURE TO DO SO WILL RESULT IN DEATH OR

SERIOUS INJURY. (000152)

DUAL FUEL SYSTEM

This unit is equipped with a dual fuel system. This type of fuel system allows the unit to run on either natural gas

(primary) or LP liquid (secondary). In the event that the primary source becomes unavailable, the unit will automatically

switch to the secondary source. It can do so while in operation.

Natural Gas (Well Gas) Fuel System

Natural gas is supplied from a utility supply line or well site in its vapor state through in-ground piping. The vapor

enters the large fuel inlet located on the right side of the unit frame.

LP Liquid Withdrawal Fuel System

LP is supplied as a liquid in pressurized tanks. The liquid must be converted to its gaseous state before it is introduced

into the engine carburetor. The unit is equipped with a vaporizer converter to accomplish this. The LP liquid enters

the fuel system through the small fuel inlet located on the right side of the frame. As the liquid passes through the

vaporizer, heated engine coolant is passed through the vaporizer to provide the necessary heat for conversion of

the fuel from a liquid to a gaseous state.

DANGER

EXPLOSION AND FIRE. FUEL AND VAPORS ARE EXTREMELY FLAMMABLE AND

EXPLOSIVE. ADD FUEL IN A WELL VENTILATED AREA. KEEP FIRE AND SPARK

AWAY. FAILURE TO DO SO WILL RESULT IN DEATH OR SERIOUS INJURY. (000105)

IMPORTANT: THIS UNIT IS NOT DESIGNED TO OPERATE ON LP VAPOR. If your LP supply tank does

not have a liquid withdrawal system, a licensed LP supply company will need to install the correct fitting to

allow for it. For special fuel system configurations, contact Generac Mobile Products Technical Support.

DC FUSES

Located inside the control panel, the fuses protect the control panel wiring and components from damaging overload.

For fuse location and identification, see Figure 7.

GENERATOR AND LOAD COMPATIBILITY

This unit is a revolving field, alternating current type generator set. The generator is designed to supply electrical

power for the operation of compatible electrical loads.

The generator must be fully compatible with the rated voltage, phase rotation, and frequency of the connected

electrical loads. The generator, connected electrical devices, or both, can be damaged if voltage, phase, and frequency

are not compatible.

See the data label affixed to the unit for rated AC voltage, wattage, amperage, number of phases, etc.

20 MGG155/210 Operating Manual 35319 C

Page 27

General Information

Discount-Equipment.com

ENGINE/GENERATOR PROTECTIVE DEVICES

The unit may be required to operate for long periods of time without an operator on hand to monitor operating

conditions. For this reason, the unit has numerous sensors to provide the control panel with the information it needs

to protect both the engine and generator. The control panel is designed to shut down the engine if potentially damaging

conditions occur. These conditions can include low oil pressure, high coolant temperature, low coolant level, engine

overspeed, over or under voltage, over or under frequency, etc. These settings are configured at the factory and can

be changed/adjusted by an Independent Authorized Service Dealer if required.

DIGITAL CONTROLLER

The generator leaves the factory with the controller warning set at 105% load and shutdown set at 110% load. The

unit is equipped with a digital controller with paralleling capabilities. The paralleling feature allows the operator to

synchronize multiple controllers and distribute the load between units. Contact Generac Mobile Products Technical

Support for more information about this feature.

21

20

19

2

1

1718

16

Figure 10 - Digital Controller Pushbuttons and LEDs

3

4

1112131415

5

6

7

8

9

10

01754

1. Horn Reset: Deactivates the horn (audible alarm).

2. Mode ←: Cycles backward through genset operation modes.

3. Mode →: Cycles forward through genset operation modes.

4. Fault Reset: Acknowledges faults and alarms.

5. Start: Starts the genset in manual (MAN) mode.

6. Stop: Stops the genset in manual (MAN) mode.

7. Bus: Green LED is on if bus voltage is present and within limits.

8. GCB ON: Green LED is on if generator circuit breaker feedback is active. Flashes during synchronizing.

9. Genset Failure: Red LED starts flashing when any failure occurs. After Fault Reset button is pressed,

changes to steady light (if an alarm is still active) or is off (if no alarm is active).

35319 C MGG155/210 Operating Manual 21

Page 28

General Information

Discount-Equipment.com

10. Gen Voltage Present: Green LED is on if generator voltage is present and within limits.

11. GCB ON (I)/OFF (O): Opens and closes (synchronizes) the generator circuit breaker in manual MAN mode.

12. MCB ON: Green LED is on if the mains circuit breaker feedback is active. Flashes during reverse synchro-

nizing (synchronizing of the loaded genset back to the restored mains).

13. MCB ON (I)/OFF (O): Opens and closes (synchronizes) the mains circuit breaker in manual MAN mode.

14. Mains Voltage Present: Green LED is on if voltage on the mains terminals is present (in SPI and SPtM).

LED is not active in MINT, COX.

15. Mains Failure: Red LED starts flashing when the mains failure occurs and genset does not run, changes to

steady light when the genset starts, and then turns off when the mains restores.

16. →: Moves history record displayed columns to the right, five percent increase of edited setpoint’s value

(step given by the setpoint range), go back from Alarm list.

17. ↓: Select the setpoint, select the screen, select history record or decrease setpoint value.

18. ←: Moves history record displayed columns to the left, five percent decrease of edited setpoint’s value (step

given by the setpoint range), view Alarm list from measurement screens.

19. ↑: Select the setpoint, select the screen, select history record or increase setpoint value.

20. Esc:

21. Enter:

Where Function

Measurement screens,

Alarm list

Setpoints screen Go to Menu screen; within setpoint group, go to group list

Setpoint edit Leave setpoint edit without changes

History screen Go to Menu screen

FastEdit screen FastEdit exit (to previous measurement screen) without changes

Language screen Language screen exit (to Menu) without save

Where Function

Menu screen Go to selected display group (Measurement CU, Measurement IO.)

Measurement screens,

Alarm list

Setpoints screen Go to selected setpoint group

Setpoint edit Start setpoint edit/save changes

History screen Go to the first column of the first history record

FastEdit screen FastEdit exit (to previous measurement screen) with setpoint change

Language screen Language screen exit (to Menu) and save selection

Go to MENU screen

Go to FastEdit screen, hold Enter button for four seconds, then it is

possible to adjust selected setpoint. (Typically Base load for standard

SPtM.)

For more detailed controller information, see the controller operator guide included with the unit.

Setting the Clock

To set the clock on the digital controller, press Esc, then select Setpoints>Date/Time>Time. Press Enter. Use the up

and down arrows to adjust the settings, then press Enter.

22 MGG155/210 Operating Manual 35319 C

Page 29

Section 3 - Operation

Discount-Equipment.com

The operation of this unit should only be performed by an authorized operator; that is, someone who has been

properly trained by an Independent Authorized Service Dealer. Contact your local Independent Authorized Service

Dealer for assistance in training authorized operators. Read the operating manual thoroughly and understand all

instructions before operating the equipment.

The following instructions assume that the unit has been properly set up, serviced, tested, adjusted, and otherwise

prepared for use by an Independent Authorized Service Dealer. Read the safety information carefully before

attempting to operate this equipment.

PRESTART CHECKLIST

When the initial installation is complete, these checks must be performed before starting the engine. These checks

are not required before each start, only after the initial installation.

CAUTION

Do not apply high voltage to windings in moisture-saturated conditions. Serious damage to

genset and property can result. (000153)

Note: These precautions are extremely critical in locations such as seaboard installations and other high humidity

areas. Some installations will be in environments that are much more corrosive than others.

Verify battery disconnect switch is turned ON.

Verify unit is positioned in a stable manner.

Verify proper clearance on all sides and top of enclosure.

Verify unit is a safe distance from any flammable or combustible material.

Verify no load is connected to unit.

Inspect the engine and genset and verify there are no loose wires or components. Tighten if

necessary.

Verify engine oil level is correct. See Check Engine Fluids.

Verify engine coolant level is correct. See Adding Coolant.

Verify the controller is in STOP mode by pressing the STOP button.

Verify the fuel valve is open and the pressure and flow rate are correct.

Remove all tools, rags, etc. from inside the unit enclosure. Close and secure all enclosure doors prior

to starting the unit.

MANUALLY STARTING THE UNIT

This unit is designed to operate on Natural Gas (NG)/well gas or LP liquid. At oil well sites, LP liquid is typically used

to start the unit until the pump jack brings the well gas (natural gas) up to the surface. The unit fuel system will detect

when there is sufficient pressure to switch to natural gas as the primary fuel source.

Natural Gas (Well Gas) Start Up

If there is sufficient pressure in the well gas fuel line (10-20 psi [69-138 kPa]), the unit can be started directly on well

gas. Follow the steps below:

1. Open the manual ball fuel valve located just inside the frame. See Fuel System (MGG155 Shown).

2. Check for fuel leaks.

3. Press the START on the digital controller. The controller will sense the type of fuel entering the system and

will display “ALI NG Fuel Select”.

Note: If the unit will not start, verify the Fuel Select switch is set to NG or AUTO. See Figure 9.

35319 C MGG155/210 Operating Manual 23

Page 30

Operation

Discount-Equipment.com

LP Liquid Start Up

4. Open the LP liquid tank supply valve and the natural gas manual fuel valve (see Figure 6 for location). If

any leaks are detected, correct them immediately.

5. Press the START button on the digital controller.

6. When the natural gas pressure reaches 10-20 psi (69-138 kPa), move the Fuel Select switch to the NG

position. (You may have to toggle the switch between NG and LP until the unit runs smoothly on NG.)

7. Move the switch to AUTO.

Note: It will not be necessary to purge the fuel lines after shutting the unit down for maintenance or service unless

the fuel lines have been disconnected.

When the unit reaches operation speed, verify the voltage setting is correct and adjust if necessary. If the engine

fails to start, see Troubleshooting.

AUTO (REMOTE) STARTING THE UNIT

Connect the remote start contact to the remote start terminals on the terminal block (#12 and #34). Follow all NEC,

state and local regulations.

Note: The bonding plate may need to be removed. See Figure 12 for bonding plate location.

A ground connection is located next to the lugs. The generator neutral is bonded to ground when it is shipped from

the factory. The bonding plate may need to be removed if the generator is used as a standby power source.

INSTALLATION SHOULD BE IN COMPLIANCE WITH THE NATIONAL ELECTRICAL CODE (NEC), STATE AND

LOCAL REGULATIONS.

02022

Figure 11 - Terminal Block

PARALLEL SETUP AND OPERATION

The unit can be operated in parallel with other parallel-capable units. To ensure the units to be used in parallel are

appropriate for the load, contact Generac Mobile Products Technical Support at 1-800-926-9768.

Before running units in parallel, make sure each unit is operating properly. Set up auto (remote) starting on each unit.

Paralleling Two Units

Using the provided CAN parallel cable, connect one end of the cable to the terminal block of the first unit and the

other end to the terminal block of the second unit. Match each wire with the corresponding color wire connected to

the terminal block; yellow to yellow, green to green, black (shield) to black. Connect the provided 120 ohm resistor

24 MGG155/210 Operating Manual 35319 C

Page 31

Operation

Discount-Equipment.com

to the unused terminals on both units as shown on the decal located below the terminal blocks.

Paralleling More Than Two Units

To parallel more than two units, connect another CAN parallel cable from the unused terminal on the second unit

(remove resistor, if necessary) to a terminal on the next unit. Continue chaining the parallel units. Connect the resistors

to the unused terminals on the first and last units in the series.

Once the units are set up in parallel, they will share the load evenly during normal operation. If parallel units are in

auto mode and one unit is shut down, the load will transfer to the remaining units on line. If all paralleled units are

in manual mode, press the GCB (Generator Circuit Breaker) button on the controller, and the load gradually transitions

to the other units.

Note: When one or more units shut down, any remaining units will shut down if the increase in proportional load is

greater than what the unit is rated for. Contact Generac Mobile Products Technical Support to verify the units to be

used in parallel are appropriate for the planned load.

OPERATION CHECKS