Page 1

Owner’s Manual

For

Diesel Generator

MDG25IF4

008730

For technical assistance contact:

www.generacmobileproducts.com

Technical Support

1-800-926-9768

Register your Generac product at:

WWW.GENERAC.COM

1-888-GENERAC

(1-888-436-3722)

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

Use this page to record important information about your Mobile Generator

(000394)

WARNING

Breathing diesel engine exhaust exposes you

to chemicals known to the State of California

to cause cancer and birth defects or other

reproductive harm.

• Always start and operate the engine in a

well-ventilated area.

• If in an enclosed area, vent the exhaust to

the outside.

• Do not modify or tamper with the exhaust

system.

• Do not idle the engine except as necessary.

For more information go to

www.P65Warnings.ca.gov/diesel.

(000393a)

WARNING

CANCER AND REPRODUCTIVE HARM

www.P65Warnings.ca.gov.

Record the information found on your unit data label on this

Unit Model Number

Unit Serial Number

Engine Model

Number

Engine Serial

Number

Generator Model

Number

Generator Serial

Number

Date Purchased

page. See

Engine and generator serial numbers are located on separate

data plates affixed to the engine and generator respectively.

When contacting a Generac Mobile Products Authorized

Service Dealer (GMP ASD) about parts and service, always

supply the complete model number and serial number of the

unit.

Operation and Maintenance: Proper maintenance and care of

the generator ensures a minimum number of problems and

keeps operating expenses at a minimum. It is the operator’s

responsibility to perform all safety checks, to verify that all

maintenance for safe operation is performed promptly, and to

have the equipment checked periodically by a GMP ASD.

Normal maintenance, service and replacement of parts are the

responsibility of the owner/operator and, as such, are not

considered defects in materials or workmanship within the

terms of the warranty. Individual operating habits and usage

may contribute to the need for additional maintenance or

service.

Unit and Serial Number Locations.

ii Owner’s Manual for MDG25IF4

Page 3

Table of Contents

Section 1: Introduction and Safety

Introduction ..................................................................1

Read This Manual Thoroughly ....................................1

How to Obtain Service .................................................1

Safety Rules .................................................................1

Safety Symbols and Meanings ...................................1

General Hazards ...........................................................2

Trailer Hazards .............................................................2

Electrical Hazards ........................................................3

Explosion and Fire Hazards ........................................3

Battery Hazards ............................................................4

Fuel Hazards .................................................................4

Engine Safety ...............................................................4

Operating Safety ..........................................................5

Positioning the Unit .....................................................5

Towing Safety ...............................................................5

Hitch and Coupling ......................................................5

Safe Towing Techniques .............................................5

Reporting Trailer Safety Defects ................................5

Safety and Operating Decals ......................................6

Section 2: General Information

Specifications .............................................................11

Unit Dimensions .........................................................12

Component Locations ...............................................13

Control Panel ..............................................................14

Unit and Serial Number Locations ...........................16

Altitude and Temperature Limitations .....................16

PowerZone® Controller .............................................17

Controller Features and Functions ............................18

Operator Screens ......................................................18

Maintenance Screens ................................................20

Generator Summary ..................................................20

Engine Tab ................................................................20

Generator Tab ...........................................................20

Alarms Tab ................................................................21

Input/Output Tab .......................................................21

Scheduler Tab ...........................................................22

Status Tab .................................................................22

Generator Monitoring ................................................22

Engine Monitoring .....................................................22

PowerZone Controller Information Displays,

Functions, and Reset .................................................22

Voltage Selector Switch ............................................22

Section 3: Operation

Pre-start Checklist ..................................................... 23

Manually Starting the Unit .........................................23

AUTO (Remote) Starting the Unit .............................24

Wet Stacking .............................................................. 25

Cold Weather Operation ............................................25

Using a Booster Battery or Charger (if equipped) ..26

Generator Output Connections ................................ 26

Generator Cam Lock Connections (If Equipped) ....27

Using the Voltage Selector Switch ...........................28

Fine Voltage Adjustment ...........................................28

Voltage Regulator ...................................................... 28

Achieving 240V Three-Phase in 208V Three-Phase

(Parallel Low Wye) Configuration .............................28

Changing Back to 208V Configuration ...................... 29

Customer Convenience Receptacles .......................29

Main Circuit Breaker ..................................................29

Transfer Switch ..........................................................30

AUTO Exercise Timer ................................................ 30

Accessing the Configuration Menu ............................ 30

Set the Controller Clock ............................................ 31

Set the Schedule .......................................................31

Setting Up a Daily Scheduled Run ............................ 31

Set the Unit to AUTO Mode .......................................31

Shutting Down the Unit .............................................31

Emergency Stop Switch ............................................32

Idle Switch .................................................................. 32

Using the ECU Override Switch ................................ 32

Towing the Unit ..........................................................32

Lifting the Unit ............................................................33

Section 4: Maintenance

Emissions Information ..............................................35

Maintenance ...............................................................35

Daily Walk Around Inspection ..................................35

Belt Tensioners ..........................................................35

General Maintenance .................................................35

Owner’s Manual for MDG25IF4 1

Page 4

Engine Oil Recommendations .................................. 36

Recommended Oil Types ......................................... 36

Coolant Recommendation ........................................ 36

Basic Maintenance Schedule ................................... 36

Engine Break-In Requirements ................................ 37

Resetting Maintenance Alarms ................................ 37

Checking Generator Drive Plate Torque ................. 38

Jack Maintenance ...................................................... 38

Side-Wind Models ..................................................... 38

Top-Wind Models ...................................................... 38

Trailer Wheel Bearings .............................................. 38

Section 5: Troubleshooting

General Troubleshooting .......................................... 39

Section 6: Wiring Diagrams and Service Log

Wiring Diagram - 3 Position AC Box ........................ 41

Wiring Diagram - 4 Position AC Box ........................ 42

Wiring Diagram - Receptacles .................................. 43

Wiring Diagram - Engine Heater ............................... 43

Wiring Diagram - Wiring Buck (If Equipped) ........... 44

Wiring Diagram - Power Zone PMG ......................... 44

Wiring Diagram - Power Zone Control Box ............. 45

Wiring Diagram - Trailer Lights ................................ 46

Wiring Diagram - Brake Wiring ................................. 47

Wiring Diagram - 12V Battery Charger .................... 48

Wiring Diagram - Power Zone Low Oil Level

(If Equipped) ............................................................... 48

Service Log ................................................................ 49

2 Owner’s Manual for MDG25IF4

Page 5

Section 1: Introduction and Safety

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

(000001)

DANGER

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

(000002)

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

(000003)

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Introduction and Safety

Introduction

Thank you for purchasing a Generac Mobile Products LLC

product. This unit has been designed to provide high

performance, efficient operation, and years of use when

maintained properly.

The information in this manual is accurate based on

products produced at the time of publication. The

manufacturer reserves the right to make technical

updates, corrections, and product revisions at any time

without notice.

Read This Manual Thoroughly

If any section of this manual is not understood, contact your

nearest Generac Mobile Products Authorized Service Dealer

(GMP ASD), or contact Generac Mobile Products Technical

Service at 1-800-926-9768 or

www.generacmobileproducts.com

concerns.

The owner is responsible for proper maintenance and safe

use of the equipment. Comply with regulations the

Occupational Safety and Health Administration (OSHA)

has established, or with equivalent standards. Also, verify

that the unit is applied, used, and maintained in accordance

with the manufacturer's instructions and recommendations.

Do nothing that might alter safe application/usage and

render the unit in noncompliance with the aforementioned

codes, standards, laws, and regulations

Save these instructions for future reference. This manual

contains important instructions for the unit that should be

followed during setup, operation and maintenance of the

unit and battery. ALWAYS supply this manual to any

individual that will use this machine.

with any questions or

.

When contacting a GMP ASD about parts and service,

always supply the complete model number and serial

number of the unit from the data decal located on the unit.

Record the model number and serial numbers in the

spaces provided on the inside front cover of this manual.

Safety Rules

The manufacturer cannot anticipate every possible

circumstance that might involve a hazard. The warnings in

this manual, and on tags and decals affixed to the unit are,

therefore, not all inclusive. If using a procedure, work

method or operating technique that the manufacturer does

not specifically recommend, verify it is safe for others. Also

make sure the procedure, work method or operating

technique utilized does not render the equipment unsafe.

Safety Symbols and Meanings

Throughout this publication, and on tags and decals affixed

to the unit, DANGER, WARNING, CAUTION and NOTE

blocks are used to alert personnel to special instructions

about a particular operation that may be hazardous if

performed incorrectly or carelessly. Observe them

carefully. Their definitions are as follows:

How to Obtain Service

When the unit requires service or repairs, contact a

Generac Mobile Products Authorized Service Dealer

(GMP ASD) for assistance. Service technicians are

factory-trained for all service needs.

To locat e a GMP ASD, go to:

www.generacmobileproducts.com/parts-service/

find-service

Owner’s Manual for MDG25IF4 1

NOTE: Notes contain additional information important to

a procedure and will be found within the regular text of

this manual.

These safety alerts cannot eliminate the hazards that they

indicate. Common sense and strict compliance with the

special instructions while performing the action or service

are essential to preventing accidents.

Page 6

Introduction and Safety

Asphyxiation. Running engines produce

carbon monoxide, a colorless, odorless,

poisonous gas. Carbon monoxide, if not

avoided, will result in death or serious injury.

(000103)

DANGER

DANGER

Asphyxiation. Do not operate unit without

a properly functioning exhaust system.

Doing so will result in death or serious injury.

(000340)

(000209b)

WARNING

Loss of life. This product is not intended to

be used in a critical life support application.

Failure to adhere to this warning could result

in death or serious injury.

(000107)

WARNING

Hearing Loss. Hearing protection is

recommended when using this machine.

Failure to wear hearing protection could

result in permanant hearing loss.

(000407)

WARNING

Vision loss. Eye protection is required when

operating unit. Failure to wear appropriate eye

protection could result in vision loss or serious

injury.

(000111)

WARNING

Moving Parts. Keep clothing, hair, and

appendages away from moving parts. Failure

to do so could result in death or serious injury.

(000108)

WARNING

Hot Surfaces. When operating machine, do not

touch hot surfaces. Keep machine away from

combustibles during use. Hot surfaces could

result in severe burns or fire.

CAUTION

(000291)

Equipment damage. Do not attempt to start or operate

a unit in need of repair or scheduled maintenance.

Doing so could result in serious injury, death, or

equipment failure or damage.

WARNING

WARNING

Risk of injury. Do not operate or service this machine

if not fully alert. Fatigue can impair the ability to service

this equipment and could result in death or serious

injury.

(000215)

(000182a)

WARNING

Equipment damage. Only qualified service personnel may

install, operate, and maintain this equipment. Failure to follow

proper installation requirements could result in death, serious

injury, and equipment or property damage.

CAUTION

(000229)

Equipment or property damage. Do not block air

intake or restrict proper air flow. Doing so could

result in unsafe operation or damage to unit.

WARNING

Personal injury. Trailer must be securely coupled to

the hitch with the chains correctly attached. Uncoupled

or unchained towing could result in death or serious

injury.

(000233a)

Personal injury. Do not operate unit during transport.

Doing so could result in death, serious injury, or

property damage.

(000231a)

WARNING

(000234a)

WARNING

Crushing hazard. Verify unit is properly secured and

on level ground. An unsecured unit can suddenly roll

or move, causing death or serious injury.

WARNING

Property or Equipment Damage. Tighten wheel lug

nuts after first 50 miles to factory specifications.

Failure to do so could result in death, serious injury,

property or equipment damage.

(000235)

General Hazards

Trailer Hazards

2 Owner’s Manual for MDG25IF4

Page 7

Electrical Hazards Lifting Hazards

(000145)

DANGER

Electrocution. In the event of electrical accident,

immediately shut power OFF. Use non-conductive

implements to free victim from live conductor. Apply

first aid and get medical help. Failure to do so will

result in death or serious injury.

(000104)

DANGER

Electrocution. Water contact with a power

source, if not avoided, will result in death

or serious injury.

(000144)

DANGER

Electrocution. Contact with bare wires,

terminals, and connections while generator

is running will result in death or serious injury.

(000152)

DANGER

Electrocution. Verify electrical system is

properly grounded before applying power.

Failure to do so will result in death or serious

injury.

(000123)

DANGER

Electrocution. Turn utility supply OFF before

working on utility connections of the transfer

switch. Failure to do so will result in death or

serious injury.

(000150)

DANGER

Electrocution. Never connect this unit to the electrical

system of any building unless a licensed electrician

has installed an approved transfer switch. Failure to

do so will result in death or serious injury.

WARNING

Explosion. Batteries emit explosive gases.

Always disconnect negative battery cable

first to avoid spark. Failure to do so could

result in death or serious injury.

(000238)

WARNING

Personal injury. Failure to properly connect

lifting cables, chains, or straps could result in

death, serious injury, or property damage.

(000346)

WARNING

Personal Injury. Do not use lifting eye if there

are signs of damage or corrosion. Doing so

could result in death, serious injury, or

property damage.

(000433)

WARNING

Personal Injury. Do not use lifting eye other

than as directed. Doing so could result in

death, serious injury, or property damage.

(000434)

WARNING

Personal Injury. Verify all fasteners are properly

tightened prior to lifting unit. Failure to do so could

result in death, serious injury, or property damage.

(000351)

(000105)

DANGER

Explosion and Fire. Fuel and vapors are

extremely flammable and explosive. Add fuel

in a well ventilated area. Keep fire and spark

away. Failure to do so will result in death

or serious injury.

WARNING

Fire risk. Fuel and vapors are extremely

flammable. Do not operate indoors. Doing so

could result in death, serious injury, or

property or equipment damage.

(000281)

(000147)

WARNING

Risk of Fire. Unit must be positioned in a

manner that prevents combustible material

accumulation underneath. Failure to do so

could result in death or serious injury.

Introduction and Safety

Explosion and Fire Hazards

Owner’s Manual for MDG25IF4 3

Page 8

Introduction and Safety

(000188)

DANGER

Electrocution. Do not wear jewelry while

working on this equipment. Doing so will

result in death or serious injury.

(000137a)

WARNING

Explosion. Batteries emit explosive gases while charging.

Keep fire and spark away. Wear protective gear when

working with batteries. Failure to do so could result in

death or serious injury.

(000162)

WARNING

Explosion. Do not dispose of batteries in a fire. Batteries

are explosive. Electrolyte solution can cause burns and

blindness. If electrolyte contacts skin or eyes, flush with water

and seek immediate medical attention.

(000163a)

WARNING

Risk of burn. Do not open or mutilate batteries.

Batteries contain electrolyte solution which can

cause burns and blindness. If electrolyte contacts

skin or eyes, flush with water and seek immediate

medical attention.

WARNING

Environmental Hazard. Always recycle batteries at an

official recycling center in accordance with all local

laws and regulations. Failure to do so could result in

environmental damage, death or serious injury.

(000228)

(000192)

DANGER

Explosion and fire. Fuel and vapors are extremely

flammable and explosive. No leakage of fuel is

permitted. Keep fire and spark away. Failure to do

so will result in death or serious injury.

(000174)

DANGER

Risk of fire. Allow fuel spills to completely dry

before starting engine. Failure to do so will

result in death or serious injury.

Battery Hazards

Fuel Hazards

• DO NOT fill fuel tank near an open flame, while

smoking, or while engine is running. DO NOT fill

tank in an enclosed area with poor ventilation.

• DO NOT operate with the fuel tank cap loose or

missing.

Engine Safety

Internal combustion engines present special hazards

during operation and fueling. Failure to follow the safety

guidelines described below could result in severe injury or

death. Read and follow all safety alerts described in the

engine operator's manual. A copy of this manual was

supplied with the unit when it was shipped from the factory.

Always recycle batteries in accordance with local laws

and regulations. Contact your local solid waste collection

site or recycling facility to obtain information on local

recycling processes. For more information on battery

recycling, visit the Battery Council International website

at: http://batterycouncil.org

• DO NOT run engine indoors or in an area with poor

ventilation. Verify engine exhaust cannot seep into

closed rooms or ventilation equipment.

• DO NOT clean air filter with gasoline or other types

of low flash point solvents.

• DO NOT operate the unit without a functional

exhaust system.

• Shut the engine down if any of the following

conditions exist during operation:

• Abnormal change in engine speed.

• Loss of electrical output.

• Equipment connected to the unit overheats.

• Sparking occurs.

• Engine misfires or there is excessive engine/

generator vibration.

• Protective covers are loose or missing.

• Ambient air temperature is above 120°F (49°C).

4 Owner’s Manual for MDG25IF4

Page 9

Introduction and Safety

(000234a)

WARNING

Crushing hazard. Verify unit is properly secured and

on level ground. An unsecured unit can suddenly roll

or move, causing death or serious injury.

Operating Safety

Positioning the Unit

•

The area immediately surrounding the unit should

be dry, clean, and free of debris.

• If the unit is equipped with a frame grounding stud,

follow any local, state, and National Electrical Code

(NEC) guidelines when connecting.

Towing Safety

Towing a trailer requires care. Both the trailer and vehicle

must be in good condition and securely fastened to each

other to reduce the possibility of an accident. Some states

require that large trailers be registered and licensed.

Contact your local Department of Transportation office to

check on license requirements for your particular unit.

Hitch and Coupling

•

Verify the hitch and coupling on the towing vehicle

are rated equal to, or greater than, the trailer's

Gross Vehicle Weight Rating (GVWR).

• Verify the trailer hitch and the coupling are

compatible. Verify the coupling is securely fastened

to the vehicle.

• DO NOT tow trailer using defective parts. Inspect

the hitch and coupling for wear or damage.

• Connect safety chains in a crossing pattern under

the tongue.

• Before towing the trailer, verify the weight of the

trailer is equal across all tires. On trailers with

adjustable height hitches, adjust the angle of the

trailer tongue to keep the trailer as level as

possible.

Safe Towing Techniques

•

Practice turning, stopping and backing up in an

area away from heavy traffic prior to transporting

the unit.

• Maximum recommended speed for highway towing

is 45 mph (72 km/h). Recommended off-road

towing speed is 10 mph (16 km/h) or less,

depending on terrain.

• When towing, maintain extra space between

vehicles and avoid soft shoulders, curbs and

sudden lane changes.

Reporting Trailer Safety Defects

If you believe your trailer has a defect which could cause

a crash or could cause injury or death, you should

immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying Generac

Mobile Products LLC.

If NHTSA receives similar complaints, it may open an

investigation; and if it finds that a safety defect exists in a

group of vehicles, it may order a recall and remedy

campaign. However, NHTSA cannot become involved in

an individual problem between you, your GMP ASD, or

Generac Mobile Products LLC.

To contact NHTSA, you may either call the Auto Safety

Hotline toll-free at 1-888-327-4236 (TTY:1-800-424-9153),

go to http://www.safercar.gov; or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain other information about motor vehicle

safety from http://www.safercar.gov.

Owner’s Manual for MDG25IF4 5

Page 10

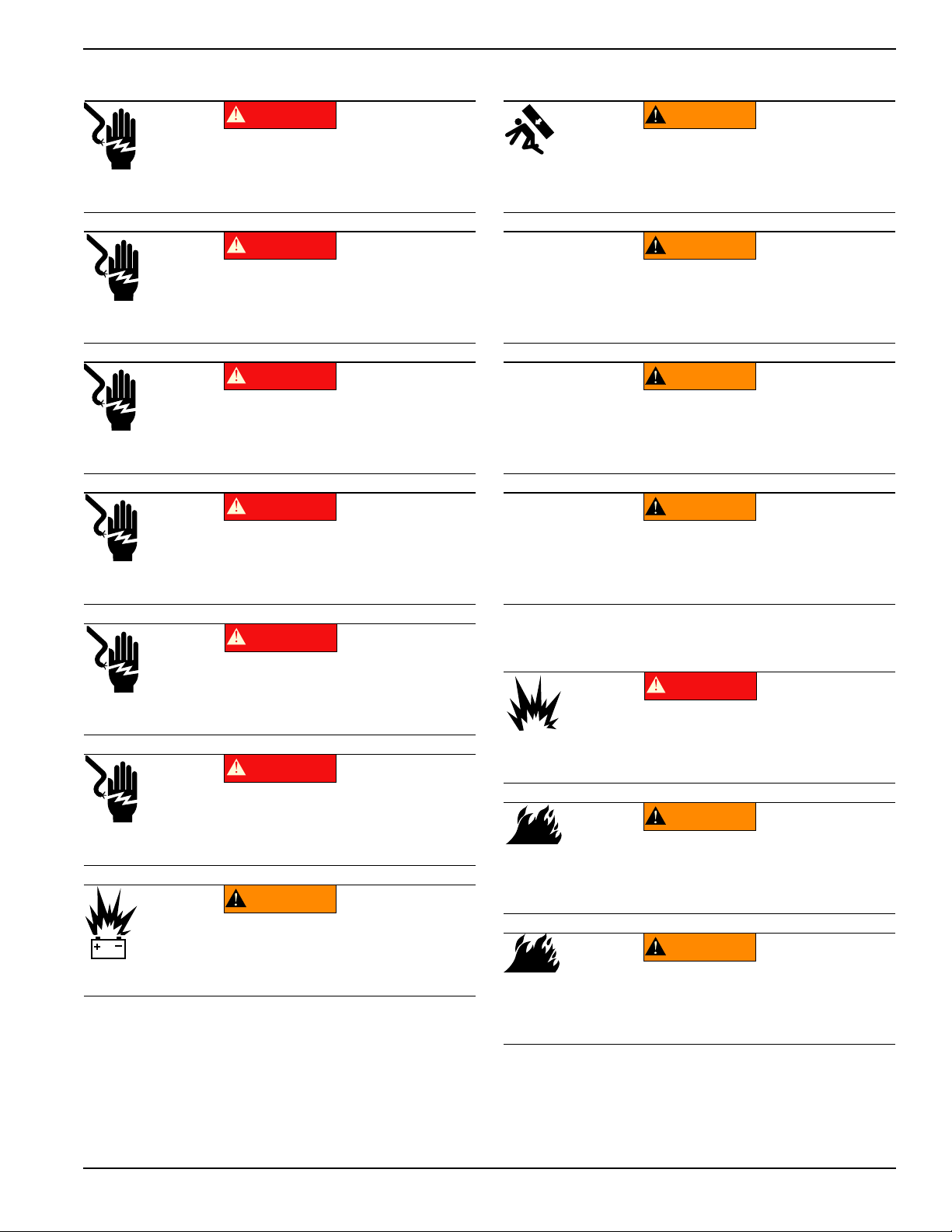

Introduction and Safety

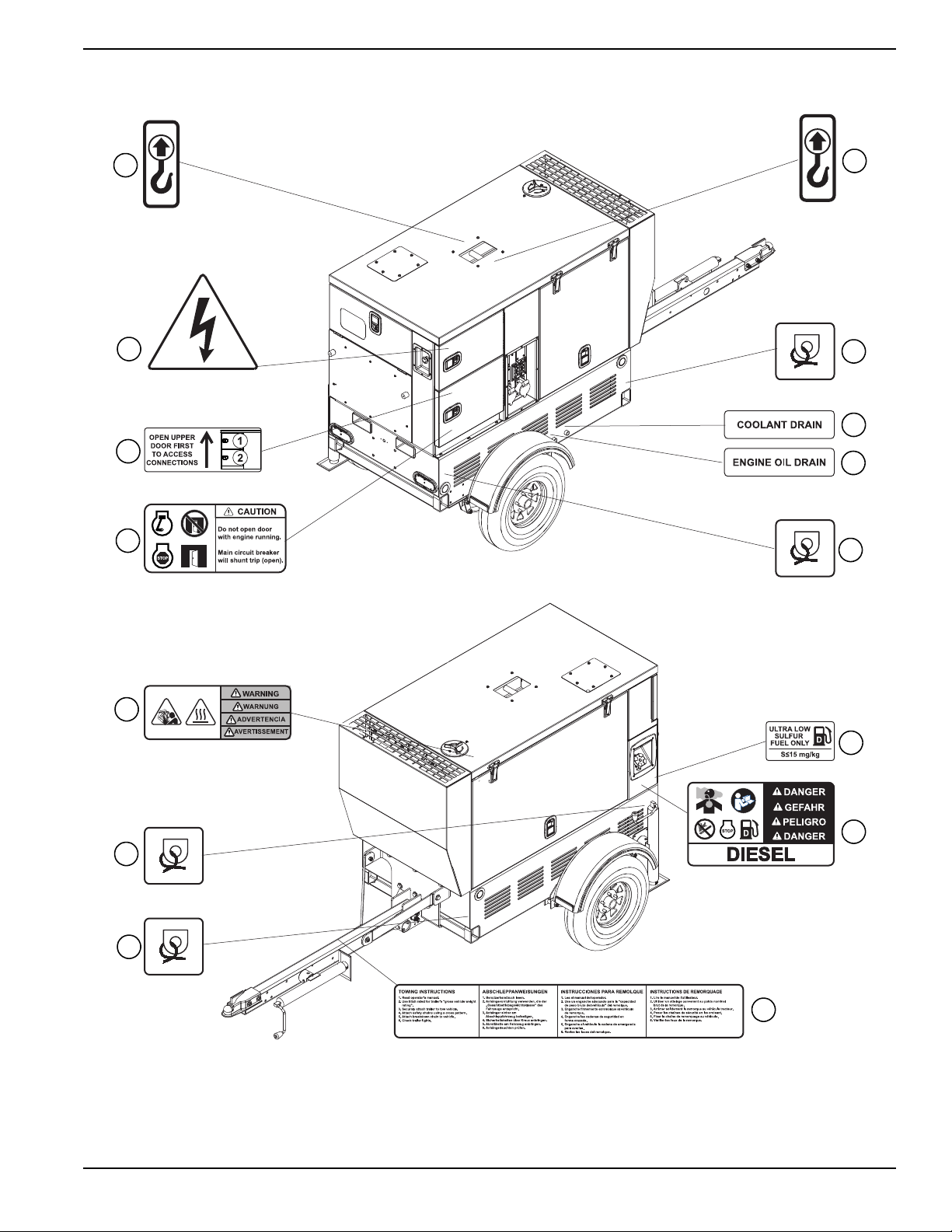

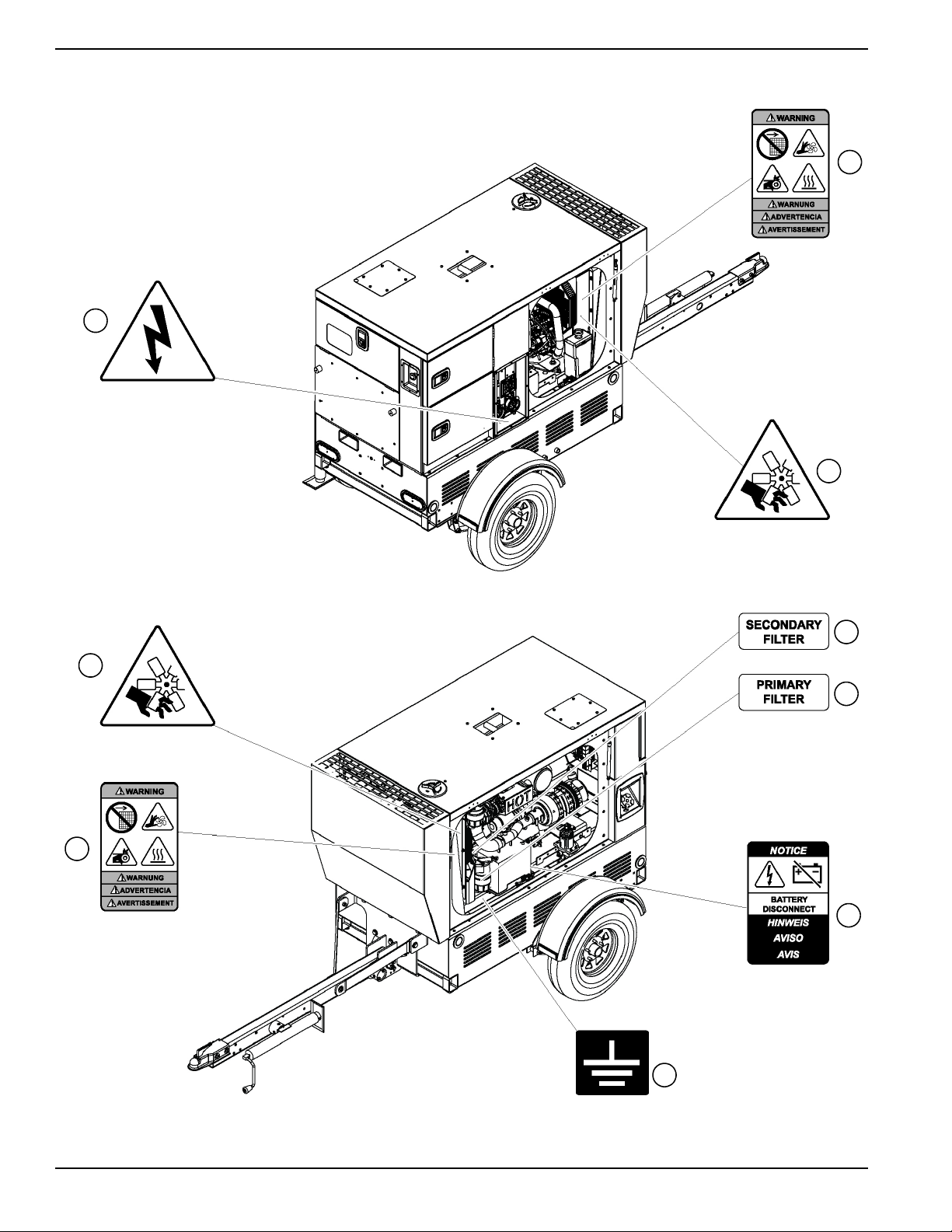

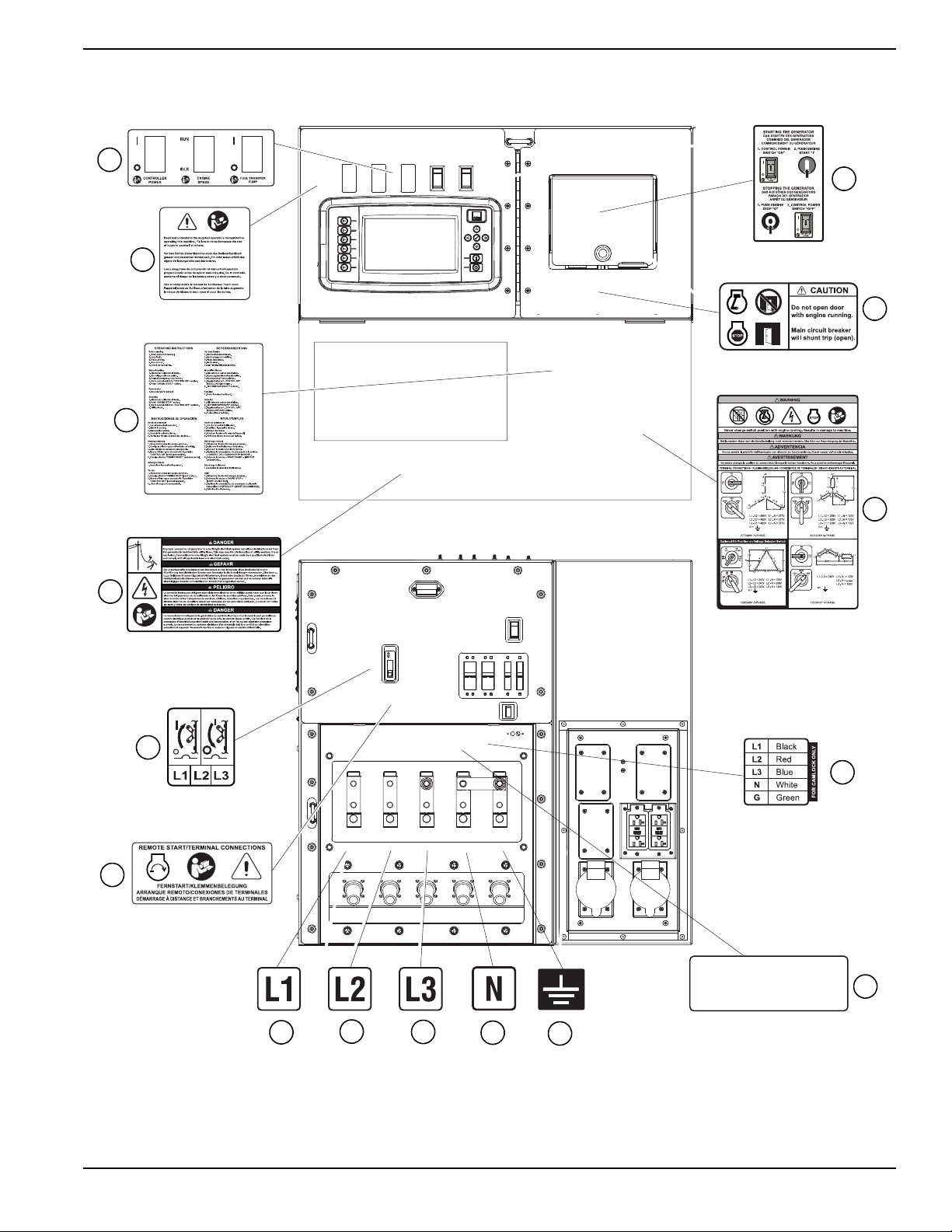

Safety and Operating Decals

This unit features numerous safety and operating decals.

These decals provide important operating instructions and

warn of dangers and hazards. The following diagrams

illustrate decal locations and descriptions.

Replace any missing or hard-to-read decals and use care

when washing or cleaning the unit. Decal part numbers

can be found in the parts manual at

www.generacmobileproducts.com.

Table 1-1. Decal Descriptions

ID Description

1 Lifting Point

2 Tie-Down Location

3 Coolant Drain

4 Engine Oil Drain

5 Ultra Low Sulfur Fuel Only

6 Diesel Fuel

7 Towing Instructions

8 Hot Coolant Under Pressure, Hot Surface

9 Do not Open Door with Engine Running

10 Open Upper Door First

11 Electric Shock Hazard

12 Warning

13 Moving Parts

14 Secondary Filter

15 Primary Filter

16 Battery Disconnect

17 Electrical Ground

18 Ground Output Connection

19 Starting and Stopping the Generator

20 Do not Open Door with Engine Running

21 Terminal Connections (Voltage Selector Switch)

22 CAN Lock Connectors

23 Connection Terminal Lugs

24 Remote Start Terminal Connections

25 Circuit Breaker

26 Electrical Backfeed Danger

27 Operating Instructions

28 Read and Understand Owner’s Manual

29 Buttons Below Controller

30 Neutral

31 Neutral Bonded to Frame

6 Owner’s Manual for MDG25IF4

Page 11

Introduction and Safety

1

11

10

9

8

7

6

5

2

4

3

2

007607

2

2

1

Figure 1-1. Exterior Decals

Owner’s Manual for MDG25IF4 7

Page 12

Introduction and Safety

007608

12

13

11

13

14

15

16

17

12

Figure 1-2. Interior Decals

8 Owner’s Manual for MDG25IF4

Page 13

10000023204

NEUTRAL (L0) BONDED TO FRAME

NULLLEITER (L0) AM RAHMEN ANGESCHLOSSEN

NEUTRO (L0) CONECTADO AL BASTIDOR

POSITION NEUTRE

(L0)

LORSQUE FIXÉ AU CADRE

29

28

27

26

24

18

22

21

20

19

007609

23

23

23

25

30

31

Introduction and Safety

Figure 1-3. Control Panel Decals

Owner’s Manual for MDG25IF4 9

Page 14

Introduction and Safety

This page intentionally left blank.

10 Owner’s Manual for MDG25IF4

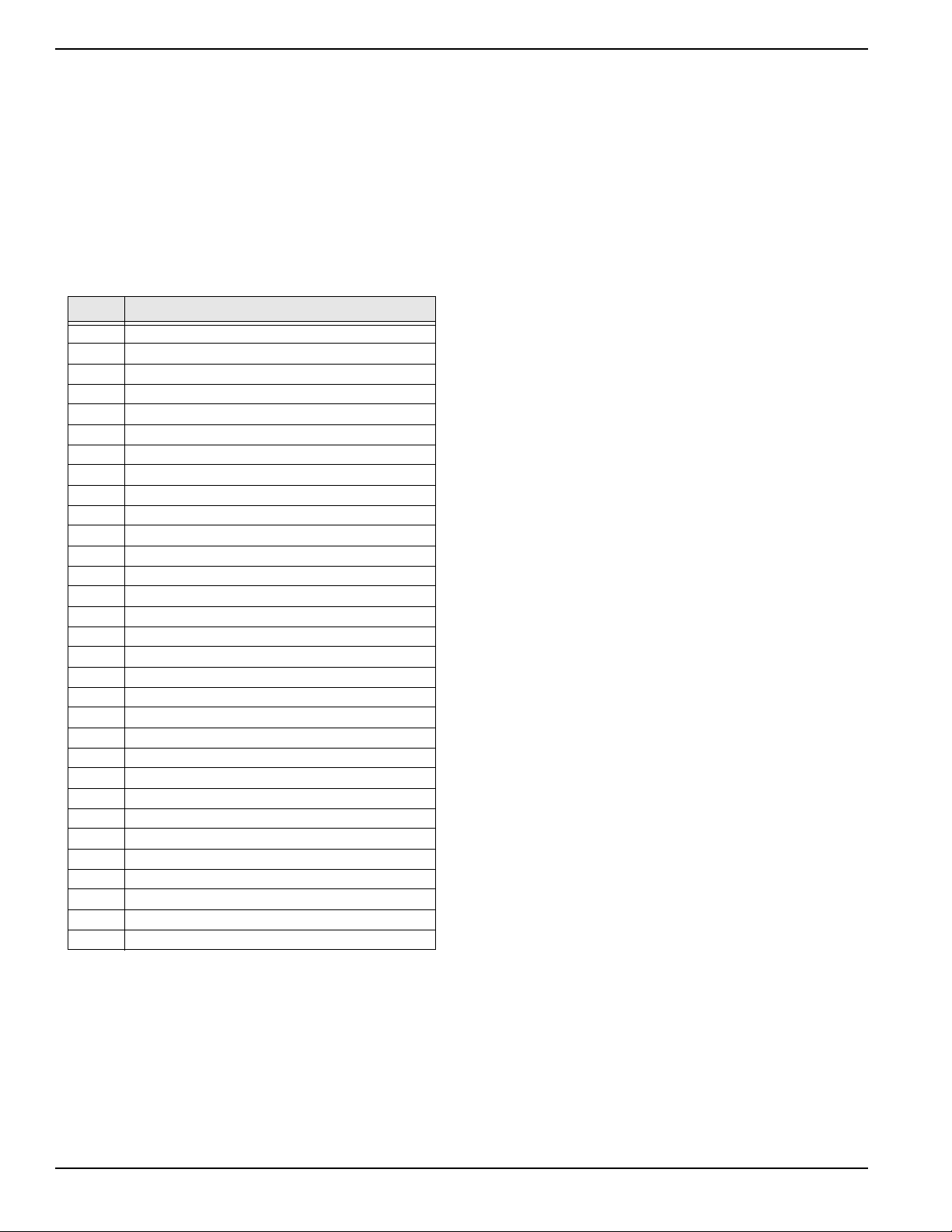

Page 15

Section 2: General Information

Specifications

Description Units MDG25DF4

Engine

Make —

Model — 4LE2T

EPA Tier — Tier 4 Final

Rated Engine Power Output hp (kW) 33.5 (25)

Engine Speed rpm 1800

Fuel consumption—100%: Standby / Prime gph (Lph) 2.3 (8.6) / 2.0 (7.4)

Fuel consumption—75%: Standby / Prime gph (Lph) 1.7 (6.5) / 1.6 (6.1)

Fuel consumption—50%: Standby / Prime gph (Lph) 1.2 (4.4) / 1.1 (4.2)

Battery voltage V (quantity per unit) 12 (1)

Battery rating CCA 720

Isuzu

General Information

®

Generator

Make — Marathon Electric

Model — 282PSL1705

Power output 3Ø standby kW (kVA) 25 (31)

Current output 3Ø standby - 480V (208V) A 37 (86)

Power output 3Ø prime kW (kVA) 20 (25)

Current output 3Ø prime - 480V (208V) A 30 (70)

Power output 1Ø standby kW (kVA) 25 (25)

Current output 1Ø standby - 240V A 104

Power output 1Ø prime kW (kVA) 20 (20)

Current output 1Ø prime - 240V A 83

Power Factor kW (kVA) 1 (1Ø) / 0.8(3Ø)

Frequency Hz 60

Weights

Dry weight—skid mounted lb (kg) 1,977 (896)

Operating weight—skid mounted lb (kg) 2,373 (1,076)

Dry weight—trailer mounted lb (kg) 2,246 (1,018)

Operating weight—trailer mounted lb (kg) 2,642 (1,198)

Capacities

Usable fuel gal (L) 48 (181)

Coolant system gal (L) 4.4 (16.7)

Oil qts (L) 11 (10.4)

Maximum run time hours 24

AC Distribution

Circuit breaker size A 125

Owner’s Manual for MDG25IF4 11

Page 16

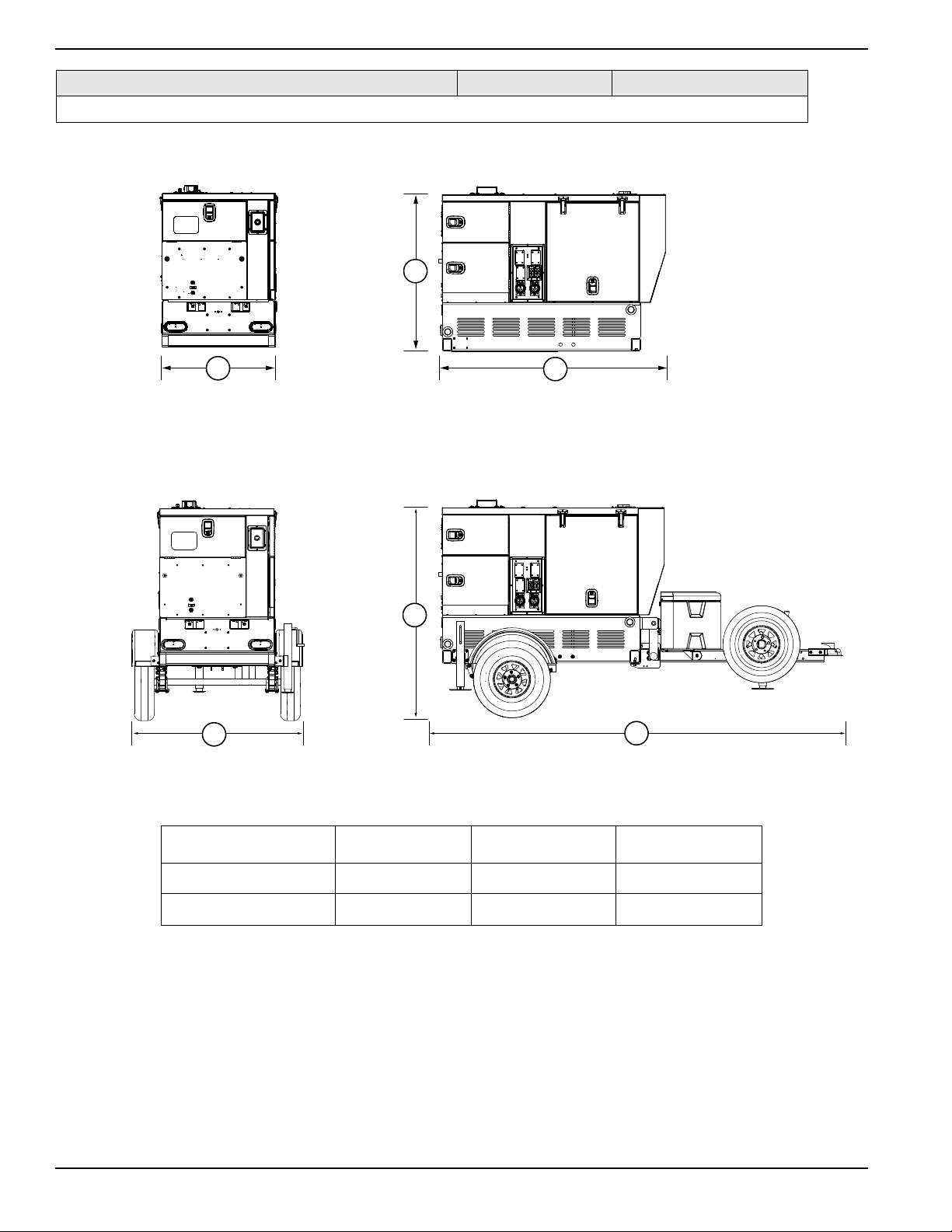

General Information

A

B

C

A

B

C

008731

Description Units MDG25DF4

Specifications are subject to change without notice. Refer to the product specification sheet for complete list.

Unit Dimensions

Figure 2-1. Unit Dimensions

AB C

Skid Mounted 35 in (0.89 m) 48 in (1.22 m) 70 in (1.78 m)

Trailer Mounted 53 in (1.35 m) 65 in (1.65 m) 129 in (3.28 m)

12 Owner’s Manual for MDG25IF4

Page 17

Component Locations

J

008734

C

N

E

D

F

G

H

B

A

I

M

K

L

General Information

Figure 2-2. Component Locations

A Central Lift Point H Alternator

B Fuel Fill I Manual Holder

C Air Filter J Coolant Overflow Container

D Generator (located behind air filter) K Oil Drain

E Battery L Coolant Drain

F Primary Fuel Filter M Control Panel

G Secondary Fuel Filter N Fork Pockets

Owner’s Manual for MDG25IF4 13

Page 18

General Information

007612

A

B

H

G

D

E

F

C

Control Panel

Figure 2-3. Control Panel (rear of unit)

A Voltage Selector Switch E Option

B Emergency Stop Button F Option

C

PowerZone

®

Controller

G

Run/Idle Switch

D Power Switch H Fuel Transfer Pump Switch

14 Owner’s Manual for MDG25IF4

Page 19

General Information

007613

A

B

C

D

E

F

H

G

I

J

K

L

Figure 2-4. Control Panel (right side of unit)

A Main Circuit Breaker I Cam Lock Connection Lugs (5) (if equipped)

B Control Panel Lights (3) J Ground Connection Lug

C 50A Circuit Breakers (2) K Connection Lugs

D Service Lights Switch L Remote Start Terminal Block

E 20A Circuit Breakers (2)

F Lug Door Safety Switch

G 120V GFCI Receptacles (2)

H 120V/240V Twist-Lock Receptacles (2)

Owner’s Manual for MDG25IF4 15

Page 20

General Information

B

A

007614

Unit and Serial Number Locations

See Figure 2-5 to locate the unit ID tag (A) and vehicle

identification number (VIN) tag (B). Important information

such as the unit model number, serial number, VIN, and

tire loading information are listed on these tags. Record

the information from these tags in the event the tags are

lost or damaged. This information may be needed when

ordering parts or requesting assistance.

Figure 2-5. Unit and Serial Number Locations

Altitude and Temperature Limitations

All units are subject to derating for altitude and

temperature. Derating reduces the available power for

operating tools and accessories connected to the outlets.

For the MDG25, the engine can provide full prime power

up to an altitude of 10,000 ft (3048 m). The maximum air

temperature at which the unit can provide full prime

power is defined in Table 2-2. If the unit is operated

beyond this limit at full power, the coolant temperature

will exceed the maximum allowable limit of 235°F (113°C)

and cause the engine to shut down.

Table 2-2. Altitude and Temperature Limitations

Model

MDG25

Maximum Altitude

Prime

Power

10,000 ft

(3048 m)

Standby

(1371 m)

Power

4500 ft

Maximum Air

Temp erature

111 ° F

(44 °C)

16 Owner’s Manual for MDG25IF4

Page 21

General Information

A

007615

B

C

D

E

F

G

H

I

J

K

L

M

N

PowerZone® Controller

The PowerZone controller is an auto start controller that

monitors the unit and indicates operational status and

fault conditions. The controller can be programmed to

automatically start or stop based on time schedule, fault

condition, or load demand.

The controller constantly monitors vital generator and

engine functions for a number of preprogrammed alarm

and fault conditions. When a fault condition occurs, the

engine can shut down automatically and the display

screen will show the fault that caused the shut down. The

fault condition must be resolved to resume unit operation.

This controller records a history of unit performance,

which may be viewed at any time and will not be lost

when the controller is powered down.

NOTE: See Controller Features and Functions for

descriptions of the callouts below.

Figure 2-6. PowerZone Controller Layout

A Fuel Transfer Pump Switch H Voltage Adjust Button

B Engine Speed Switch I Generator Button

C Navigation Buttons J Engine Button

D Engine START Button K Home Button

E Engine STOP Button L Controller Power Switch

F AUTO or MANUAL Mode Button M N/A

G Alarm Mute Button N N/A

Owner’s Manual for MDG25IF4 17

Page 22

General Information

GEN

WARNING

Personal injury. Press the emergency stop button to

stop the engine immediately in case of an emergency.

Failure to do so could result in death or serious injury.

(000298a)

CAUTION

(000246)

Equipment Damage. The emergency stop switch is

not to be used to power down the unit under normal

operating circumstances. Doing so will result in

equipment damage.

Manual Mode

3 PHASE

Volts

Amps

480

128

%

0

10

100

110

20

30

40

50

60

70

80

90

Time to Empty

15 hr

Full

3/4

1/2

1/4

Empty

74

%

GEN

V

+

-

002787

Controller Features and Functions

These buttons are used to enter the various operator

screens from any other screen. The operator screens

consist of four screens: Home ( ), Engine ( ),

V

Generator ( ), and Voltage Adjust ( ). See

Operator Screens.

Fuel Transfer Pump Switch

Used to allow fuel into the engine.

Engine Speed Switch

Provides engine overspeed protection.

Navigation Buttons

Used to navigate through the various operator screens.

Engine START Button

Press the engine START (I) button while the controller is

in MANUAL mode to start the unit. If there are no

shutdown errors and the engine satisfies the start status

the unit will start. If the controller is in AUTO mode, the

engine START (I) button has no effect.

Engine STOP Button

-

+

Generator Button

Press to display the Generator Screen.

Engine Button

Press to display the Engine Screen.

Home Button

Press to display the Home Screen.

Controller Power Switch

Use this switch to start up and shut down the controller.

This switch should not be turned off when the unit is

running.

Operator Screens

The operator screens display the most relevant and

critical information needed to properly configure and

utilize a unit. From these four screens, the operator can

access the engine, generator, and power transmission

information necessary to operate the unit under normal

conditions.

Home Screen

The home screen is the controller’s default screen and

automatically displays after the controller is powered up

and the unit management software is loaded. It displays

a live readout of the kW meter, percent of load used

(gauge), selected phase, volts and amps being produced

by the generator, and the fuel level with time until empty.

The controller will automatically return to this screen from

any other screen after a period of inactivity.

Press the engine STOP (O) button to shut down the unit

and put the controller into STOP mode, whether in

MANUAL mode or AUTO mode.

AUTO or MANUAL Mode Button

Changes the startup and shutdown modes of the unit.

The unit enters MANUAL mode when pressed once. The

unit enters AUTO mode when pressed and held for five

seconds. If in AUTO mode, pressing once will return the

unit to MANUAL mode.

Alarm Mute Button

Silences the audible alarm. Additional action will be

required to fully disable the active alarm.

Voltage Adjust Button

Press to display the Voltage Adjust Screen.

18 Owner’s Manual for MDG25IF4

Figure 2-7. Home Screen

Engine Screen

The engine screen displays the oil pressure, coolant

temperature, and battery voltage on three main gauges.

An hour gauge displaying the total run time on the engine

is below the gauges. The hour gauge also displays

maintenance alarm status at the bottom of the screen,

with the time remaining (black text) or the time passed

(red text), a scheduled maintenance task, along with the

description of the maintenance procedure, and the action

that will take place when the timer trips the alarm.

Page 23

General Information

002788

Manual Mode

GEN

V

+

-

Parallel Low Zig-Zag

L1 (U)

L2 (W)

N

Volt Volt Amp kW

L1-L2 L1

L2-L3 L2

L3-L1 L3

IE

0

0

0

0

0

0

0

0

50

25

0.0

0.0

0.0

AmpVolt

Freq

0

10

20

30 40

50

60

70 0

88

175

263

350 0

13

25

38

50

002789

Manual Mode

40 60

20

80

170

190 210

230

20 30

10

40

50.9

100

PSI

0 0 3 2 5 1 5

214

0

250

°F

Hrs

13.8

V

Shutdown

Electrical Trip

50150

Warning

0

GEN

Oil press. Coolant Temp. Battery

V

-

+

Maintenance

Alarm Hours Description Action

1 174 To Service Oil Maintenance

2 174 To Service Fuel Maintenance

3 174 To Service Air Maintenance

Figure 2-8. Engine Screen

NOTE: If the measured value is outside the range of a

gauge, the needle will not be displayed. The digital value

below the gauge will still show the measured value.

• Oil Press: Displays engine oil pressure. Current

coolant temperature displays directly below the

gauge at all times. The gauge registers oil pressure

between 0–100 psi (0–689 kPa). Normal operating

pressure is between 35–80 psi (241–552 kPa).

• Coolant Temp: Displays engine coolant

temperature. Current coolant temperature displays

directly below the gauge at all times. The gauge

displays coolant temperature between 150–250 °F

(66–121 °C). Normal operating temperature of the

unit is between 180–200 °F (82–93 °C) with an

average ambient air temperature of 70 °F (21 °C).

• Battery: Displays the engine battery voltage.

Current battery voltage displays directly below the

gauge at all times. The gauge displays battery

voltage between 0–50V. A normal reading is 12–

14V on 12 volt systems and 24–26V on 24 volt

systems (with the engine running).

Generator Screen

The generator screen displays the average voltage

frequency, volts and amps from the generator, as well as

line-to-line voltage, and individual line-to-neutral voltage,

amperage, and power (kW). This screen also displays

the generator winding configuration set by the voltage

selector switch in the lower right corner.

Figure 2-9. Generator Screen

NOTE: When loading the generator, it is important to

observe the amperage to determine the load balance on

each line of the generator. Minor load imbalances,

usually 10% or less, will not cause problems. Every effort

should be made to distribute the load equally between all

lines.

• Freq: Displays the output frequency in Hertz (Hz).

Normal operating frequency is 60 Hz.

• Volt s: Displays the nominal voltage in volts (V).

• Amps: Displays the AC output amperage

produced by the generator in amps (A).

Additional information can be found on the electric power

table at the bottom-left side of the screen. This provides

an overview of all three lines and average voltage and

amperage readouts.

Voltage Adjust Screen

The unit automatically fine tunes voltage upon start-up

after the output voltage is selected and the unit is started.

See Voltage Selector Switch. The voltage can be

manually fine tuned as needed. See Fine Voltage

Adjustment.

The voltage adjust screen displays the line-to-neutral and

line-to-line voltage averages. The operator can

electronically adjust the voltage within limits to prevent

under-voltage or over-voltage conditions using the onscreen instructions. This feature replaces a traditional

potentiometer.

Owner’s Manual for MDG25IF4 19

Page 24

General Information

Manual Mode

GEN

V

+

-

Voltage Adjust

- Press , voltage will begin flashing

- Use and arrows to adjust voltage

- Press to confirm new voltage. Numbers will stop flashing

V

L-N Average

L-L Average

V

277

480

002803

SITE GENSET

07:10

480V/277V 3-Phase

Return Delay 10:00:00

Total

kWh+

kVAh

kVArhpf

kVAr

kVA

kW

%

0.0

0.0

0.0

%

0.0

0.0

0.0

0.0

0.00

0.0

0.0

Hz

kW

kVAr

Energy Generator

002790

GEN

V

+

-

SITE GENSET

7741 \ 7740

07:10

480V/277V 3-Phase

Status

Schedule

I/O

AlarmsEngine Generator

1/9

Engine Starts

Fuel Used

Fuel Remaining

US Gal

Litre

Hrs

RPM

0

00000 00

Oil press. Coolant Temp.

Charge AltBatteryOil Temp

Fuel Level

0

°F V

%

0

°FPSI

0.0

V

0.0

00.00

0

10

20 30

40

50

0

10

20 30

40

50

0

2

46

8

10 -50

0

50 150

200

250 0

20

40 60

80

100

10

30

90

70

50

1

3

5

7

9

100

-50

0

50 150

200

250

100

CAN

0

3

6

9

12 15

18

21

24

27

15

30

33

36

007616

GEN

V

+

-

SITE GENSET 7741 \ 7740

07:10

480V/277V 3-Phase

StatusSchedule

I/O

AlarmsEngine

Generator

1/9

L1-L2

L2-L3

L3-L1

L1

L2

L3

IE

Volt Volt Amp kW kVA kVAr pf

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0

0

0

0

00

0

0

0

0

L1-L2 L2-L3 L3-L1 Hz

FreqVoltVoltVolt

0

100

200

300

400

500

600

0

100

200

300

400

500

600 0

100

200

300

400

500

600 0

10

20

30 40

50

60

70

007617

Figure 2-10. Voltage Adjust Screen

Maintenance Screens

All of the data inputs from the engine, generator, inputs/

outputs, schedule, and PowerZone controller are visible

on the maintenance screens.

The information displayed on the maintenance screens

can be used to identify, diagnose, and troubleshoot unit

shutdown conditions and poor unit performance. The

maintenance screens can be accessed from any

operator screen by pressing any directional arrow (▲, ►,

▼, ◄).

The bottom of the screens have a list of available tabs,

with the currently displayed tab highlighted in blue. The

tabs can be selected by using the ► or ◄ buttons. The

current/available pages are displayed to the left of the

tabs. The pages within a tab can be viewed by using the

▲ and ▼ buttons. Whenever a new tab is selected, the

current page will always be page one.

Generator Summary

The generator summary can be found at the top of all

maintenance screens and provides an overview of the

system.

Engine Tab

The engine tab contains maintenance and

instrumentation data gathered from the engine. Above

the engine analog meters is a row of alarm icons. Each

icon can be one of three colors: gray (inactive), yellow

(warning), or red (shutdown). The alarm icons from left to

right are: water in fuel, emission filter, engine air inlet

temperature, charge alternator, oil pressure, fuel level,

battery voltage, coolant temperature, and ECU lamp.

NOTE: The content may change depending upon the

selected engine and the features supported by the

engine.

Figure 2-12. Engine Tab Screen

Generator Tab

The generator tab contains maintenance and

instrumentation data gathered from the generator. Each

page highlights different data gathered by the generator,

with the analogue meters changing accordingly. The last

two pages display the information in the bar graph. The

bar graph is blue for positive and red for negative. For the

power factor bar graph, blue is for lagging pf and red is

for leading pf.

NOTE: The content may change depending upon the

selected generator and the features supported by the

generator.

Figure 2-11. Generator Summary Screen

20 Owner’s Manual for MDG25IF4

Figure 2-13. Generator Tab Screen

Page 25

Alarms Tab

GEN

V

+

-

SITE GENSET 7741 \ 7740

07:10

480V/277V 3-Phase

Return Delay 10:00:00

0.0

Hz

Total Generator

kWh+

kVAh

kVArh

kW

kVA

kVAr

pf

0.0

0.0

0.0

0.0

0.0

0.0

0.00

0.0

%

%

0.0

kW

kVAr

StatusSchedule

I/O

AlarmsEngine Generator

1/2

Warning Shutdown Electrical Trip

Engine

002793

GEN

V

+

-

SITE

GENSET

7741 \ 7740

07:10

480V/277V 3-Phase

Return Delay 10:00:00

0.0

Hz

Total Generator

kWh+

kVAh

kVArh

kW

kVA

kVAr

pf

0.0

0.0

0.0

0.0

0.0

0.0

0.00

0.0

%

%

0.0

kW

kVAr

Status

Schedule

I/O

AlarmsEngine Generator

2/2

Warning

Shutdown

Shutdown

Shutdown

Shutdown

Shutdown

Shutdown

Shutdown

Shutdown

Shutdown

Shutdown

Shutdown

Shutdown

This is an event index 1

This is an event index 2

This is an event index 3

This is an event index 4

This is an event index 5

This is an event index 6

This is an event index 7

This is an event index 8

This is an event index 9

This is an event index 10

This is an event index 11

This is an event index 12

This is an event index 13

1 01/01/1970 00:00:01 0:00

2 02/06/1970 11:45:55 0:00

3 01/01/1970 00:00:00 0:00

4 01/01/1970 00:00:00 0:00

5 01/01/1970 00:00:00 0:00

6 01/01/1970 00:00:00 0:00

7 01/01/1970 00:00:00 0:00

8 01/01/1970 00:00:00 0:00

9 01/01/1970 00:00:00 0:00

10 01/01/1970 00:00:00 0:00

11

12 01/01/1970 00:00:00 0:00

13 01/01/1970 00:00:00 0:00

01/01/1970 00:00:00 0:00

Index Date Time Hrs Event Details

002794

GEN

V

+

-

SITE GENSET 7741 \ 7740

07:10

480V/277V 3-Phase

Return Delay 10:00:00

0.0

Hz

Total

Generator

kWh+

kVAh

kVArh

kW

kVA

kVAr

pf

0.0

0.0

0.0

0.0

0.0

0.0

0.00

0.0

%

%

0.0

kW

kVAr

StatusSchedule

I/O

AlarmsEngine Generator

1/38

Digital Inputs

Ip Description Active State Ip Description Active State

A

B

C

D

E

F

H

I

J

G

K

002795

The alarms tab displays warnings, electrical trip,

shutdown alarms, and any engine diagnostic trouble

codes (DTC) that are occurring or have occurred. The

first page displays the alarms that are currently active

and organizes them by alarm type.

Figure 2-14. Alarms Tab Screen (Page One)

General Information

Figure 2-15. Alarms Tab Screen (Page Two)

To scroll down within the event log, press the ENTER ()

button. The scroll bar will activate and change to blue.

Press the ▲ or buttons to scroll up or down in the

event log. Press the ENTER () button again when

finished.

Table 2-3. Diagnostic Trouble Codes

Alarm

Typ e

Warning Yellow/Black

Electrical

Trip

Shutdown Red/Black

ECU

Code

Color–

Background/Text

Purple/Black

Blue/White

Graphic

Warning

Electrical Trip

Shutdown

Engine

The second page of the alarms tab shows the event log

with a list of events, including normal operation events

and alarm notifications. The most recent events are listed

first. All indexed events include the date and time of the

event, and hours of runtime on the engine when it

occurred, along with the event name or alarm type and

details.

Input/Output Tab

The input/output (I/O) tab shows a list of digital inputs and

outputs connected to the controller, whether they are

active or not, and the current state (open/closed status)

of the input and output.

Figure 2-16. Input/Output Tab Screen

Owner’s Manual for MDG25IF4 21

Page 26

General Information

GEN

V

+

-

SITE GENSET 7741 \ 7740

07:10

480V/277V 3-Phase

Return Delay 10:00:00

0.0

Hz

Total Generator

kWh+

kVAh

kVArh

kW

kVA

kVAr

pf

0.0

0.0

0.0

0.0

0.0

0.0

0.00

0.0

%

%

0.0

kW

kVAr

StatusSchedule

I/O

AlarmsEngine Generator

1/1

Warning

Warning

Warning

ActionDescription

Alarm Hours Date Time

Maintenance

Scheduler Enabled to run Reserved Reserved

Event Week Day Start Stop Duration Event Week Day Start Stop Duration

250 hr Maint. - Refer to Manual

500 hr Maint. - Refer to Manual

3000 hr Maint. - Refer to Manual

1 250:00

2 500:00

3 3000:00

All Monday 00:00 00:00 0:00

All Monday 00:00 00:00 0:00

All Monday 00:00 00:00 0:00

All Monday 00:00 00:00 0:00

All Monday 00:00 00:00 0:00

All Monday 00:00 00:00 0:00

All Monday 00:00 00:00 0:00

All Monday 00:00 00:00 0:00

9

10

11

12

13

14

15

16

All Monday 00:00 00:00 0:00

All Monday 00:00 00:00 0:00

All Monday 00:00 00:00 0:00

All Monday 00:00 00:00 0:00

All Monday 00:00 00:00 0:00

All Monday 00:00 00:00 0:00

All Monday 00:00 00:00 0:00

All Monday 00:00 00:00 0:00

1

2

3

4

5

6

7

8

002796

GEN

V

+

-

SITE GENSET 7741 \ 7740

07:10

480V/277V 3-Phase

Return Delay

10:00:00

0.0

Hz

Total Generator

kWh+

kVAh

kVArh

kW

kVA

kVAr

pf

0.0

0.0

0.0

0.0

0.0

0.0

0.00

0.0

%

%

0.0

kW

kVAr

StatusSchedule

I/O

AlarmsEngine Generator

1/1

- DCD

- DSR

- DTR

- RTS

- CTS

Model

Link Quality

100%

Application

USB ID

Supervisor State:

Engine State:

Load State:

Protections:

Logging

Log Dest:

Log Mode:

USB drive:

Host IP:

Host Port:

Slave IP:

Slave Port:

Total mem

Log mem free

Log Time:

Bootloader

Analogue

Engine:

Model

Application

USB ID

Bootloader

Ethernet

002797

WARNING

Electric Shock. Never change the voltage

selector switch while the engine is running or

the controller is on. Doing so could result in

death, serious injury or equipment

damage.

(000302)

Scheduler Tab

The scheduler tab shows the current configuration and

status of the scheduler, located below the generator

summary. The maintenance configuration status and time

remaining until an alarm, electrical trip, or shutdown will

be displayed at the bottom of the screen. The lamp(s) to

the left shows the configuration status of the

maintenance alarm, not the alarm condition.

Figure 2-17. Schedule Tab Screen

Status Tab

Engine Monitoring

Engine information is displayed on both the engine

operator screen and engine tab within the Maintenance

Screens. See Engine Tab.

PowerZone Controller Information Displays, Functions, and Reset

The PowerZone controller constantly monitors vital

generator and engine functions for a number of

operation, alarm, and fault conditions. When a fault

condition occurs, the engine shuts down automatically

and the main display shows the fault that caused the

shutdown. The fault condition must be resolved to

resume operation. Press the ENTER () button to reset

the controller and resume operation.

Voltage Selector Switch

The status tab contains the status and configuration of

the controller, firmware, and data connections.

Figure 2-18. Status Tab Screen

Generator Monitoring

Generator information is displayed on both the generator

button screen and generator tab within the Maintenance

Screens. See Generator Tab.

The voltage selector switch mechanically configures the

main windings of the generator to provide a Hi Wye, Low

Wye, Zig Zag or Delta (if equipped) configuration

providing single and three phase voltage output to the

main breaker. Voltage ranges are selected by rotating the

handle on the switch to the desired voltage.

The voltage selector switch is equipped with a lockout

mechanism to prevent unauthorized changing of the

voltage setting by locking the handle in place.

See Using the Voltage Selector Switch for instructions

on switching the voltage.

22 Owner’s Manual for MDG25IF4

Page 27

Section 3: Operation

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

CAUTION

(000291)

Equipment damage. Do not attempt to start or operate

a unit in need of repair or scheduled maintenance.

Doing so could result in serious injury, death, or

equipment failure or damage.

WARNING

(000147)

WARNING

Risk of Fire. Unit must be positioned in a

manner that prevents combustible material

accumulation underneath. Failure to do so

could result in death or serious injury.

Asphyxiation. Running engines produce

carbon monoxide, a colorless, odorless,

poisonous gas. Carbon monoxide, if not

avoided, will result in death or serious injury.

(000103)

DANGER

WARNING

Fire risk. Fuel and vapors are extremely

flammable. Do not operate indoors. Doing so

could result in death, serious injury, or

property or equipment damage.

(000281)

82%

Image File Transer...

002804

Operation

Pre-start Checklist

All items in the pre-start checklist must be completed

before starting the unit. This checklist applies to both

manual and remote starting of the unit.

Verify all maintenance procedures are up to date. For

more information, see General Maintenance and

Basic Maintenance Schedule.

Verify the unit is level.

Verify there is no water inside, on, or near the unit;

dry if needed.

For grounding requirements, follow any local, state,

or National Electrical Code (NEC) guidelines.

Verify the control power switch is OFF (O).

Verify all circuit breakers are OFF (O).

Inspect all electrical cords; repair or replace any that

are cut, worn, or bare.

Verify oil, coolant, and fuel levels are correct, per the

engine manufacturer’s manual.

Verify battery connections are secure.

Turn the battery disconnect switch ON (if equipped).

Verify engine fan belt tension and condition are within

spec.

Verify engine fan belt guard is installed and secure.

Check engine exhaust system for loose or rusted

components.

Verify the radiator and surrounding shroud are clear

of debris.

Verify all covers are in place and secure.

Owner’s Manual for MDG25IF4 23

Verify all electrical connections at the connection

lugs, if equipped, are tight and wired correctly.

Verify the voltage selector switch is set to the desired

voltage and locked.

Verify the emergency stop switch is pulled out.

Verify all doors on the unit are closed.

Manually Starting the Unit

All units equipped with the PowerZone controller will

initially start up in STOP mode. Proceed as follows to

start the generator in MANUAL mode:

1. Set the control power switch to ON (I).

2. The display screen will show the pre-start

diagnosis, and the controller will load the unit

management software.

Figure 3-1. Pre-start Screen

3. The home screen will be displayed when the

software is loaded, and the controller will be in

STOP mode as indicated at the top of the screen.

Press the AUTO or MANUAL mode ( ) button to

enter MANUAL mode.

Page 28

Operation

Stop Mode

3 PHASE

Volts

Amps

0

0

0.0 kW

%

0

10

100

110

20

30

40

50

60

70

80

90

Time to Empty

15 hr

Full

3/4

1/2

1/4

Empty

74

%

GEN

V

+

-

002805

the generator, depending on the type of engine

governing used.

11. If all wiring connections have been made correctly,

switch the main circuit breaker to ON (I), and then

add any loads attached to the receptacles by

switching the respective circuit breaker to the ON

(I) position. A slight change in engine sound when

a load is applied to the unit is normal.

AUTO (Remote) Starting the Unit

AUTO mode is used when the unit is started from a

location other than the control panel by using a transfer

Figure 3-2. Home Screen

NOTE: The controller can be started from any screen

when it is in MANUAL mode.

4. Pressing the green engine START (I) button on the

controller will initiate the startup procedure and

start the engine, if there are no engine faults

preventing the unit from starting.

NOTE: It may take a few seconds for the engine to run

smoothly and reach its governed operating speed. During

this time, the screen will show a voltage different from the

voltage set with the voltage selector switch.

5. If the engine does not start after the first cranking

attempt, the engine will pause for 15 seconds to

allow the starter to cool. The display screen will

show MANUAL MODE - CRANK REST at the top

of the screen. The engine will make two more

attempts to start for a total of three crank cycles.

6. If the engine does not start and run within three

crank cycles, the display screen will show the fail to

start alarm. The starting sequence can be repeated

after the starter has had a minimum of two minutes

to cool. Pressing the ENTER () button will clear

the alarm and reset the controller.

NOTE: The engine controller may skip the preheat

engine steps on some of the larger models.

7. Once the engine starts, it begins speeding up to a

constant 1800 RPM. The engine may hunt or

change speeds until operating speed is reached.

The engine will be warmed up and the operator

screens will show engine and generator operating

parameters after a few minutes of operation.

8. Check the generator for excessive noise or

vibration and any coolant, oil, or fuel leaks before

applying any loads.

9. Verify the AC output voltage is correct. See Fine

Voltage Adjustment.

10. Verify the frequency (Hz) is correct on the

24 Owner’s Manual for MDG25IF4

generator screen. The frequency should read

approximately 60 Hz with no loads connected to

switch. AUTO (remote start) is the normal setting when

the unit is being used as a standby power supply. Review

the Pre-start Checklist and Manually Starting the Unit

before putting the unit in AUTO mode. Follow all safety

warnings and review all information on isolating the

generator with a transfer switch if the unit is to be used as

a standby power supply. See AUTO Exercise Timer,

then proceed as follows:

1. Perform a manual start of the unit at least once to

verify the engine is operating correctly.

2. To check the remote start circuit, remove the wires

from the remote start terminal block. Press the

AUTO or MANUAL mode ( ) button, and the

display screen will show auto mode at the top of

the screen.

3. Attach a jumper wire (minimum 16 gauge) across

the two terminals on the remote start terminal

block. This applies a ground to the PowerZone

controller to close the starting circuit contacts. The

engine will crank, start, and run.

4. Remove the jumper wire from the remote start

terminal block and the engine will stop. Reconnect

any necessary wires from the remote start switch

(transfer switch) to the remote start terminal block.

5. Verify the unit is in AUTO mode. The display

screen should show AUTO mode at the top of the

screen.

6. Switch the main circuit breaker ON (I).

7. Secure the unit by closing and locking all access

doors.

8. The unit is now ready for remote starting.

See Figure 3-3. The remote start terminal block provides

a connection for installation of a remote start switch

which will allow the unit to be started by a remote drycontact closure switch. For location of the remote start

terminal block, see Figure 2-4.

Before entering AUTO mode, verify the contacts on any

remote switch linked to the unit are open. If the contacts

on a remote switch are closed, the engine will crank and

start when AUTO mode is entered. Attach the switch

leads to the two unused terminals (A) on the unit’s

remote start terminal block.

Page 29

Figure 3-3. Remote Start Terminal Block

A

002806

DANGER

Explosion. Do not use ether when starting an

engine equipped with glow plugs or an air intake

heater. Doing so could cause an explosion, which

will result in death or serious injury.

(000583)

008744

Wet Stacking

The unit is powered by a diesel engine. Diesel engines

are susceptible to wet stacking if lightly loaded. Wet

stacking occurs when an engine is run at less than 30%

of its full load capacity, causing unburned fuel to

accumulate in the exhaust system. Wet stacking can be

detected by continuous black exhaust when the unit is

under a constant load. It can also cause fouling of

injectors and buildup on engine valves. Diesel engines

operate properly when applied loads are between 30%

and 100% capacity. Appropriate generator sizing is

determined by the anticipated load. If the unit is in a wet

stack condition, load the unit heavily for five hours or until

the exhaust is clear.

Operation

shore power 120V electrical connection that can be

found in the convenience receptacle. The crankcase

ventilation heater is powered by the generator and will

stay on when the engine is operating in cold weather

conditions.

Figure 3-4. Cold Weather Starting Guidelines

A No Aids

B Electric Air Heat

C Block Heat

D Ether

Cold Weather Operation

Use cold weather starting aids as needed according to

Figure 3-4. Follow supplier instructions for starting aids

provided on engine. A booster battery can be connected

if needed (see Using a Booster Battery or Charger (if

The engine may be equipped with optional equipment,

such as a coolant heater, oil pan heater, crankcase

ventilation heater, battery heater or fuel heater as cold

weather starting aids.

See Figure 3-4. Starting aids are required below

32°F (0°C). They will enhance starting performance

below these temperatures and may be needed to start

applications that have high parasitic loads during

cranking and start acceleration to idle. Other cold

weather starting aids are required at temperatures below

-13°F (-25°C) or at altitudes above 5000 ft (1500 m).

The use of correct grade oil (see Recommended Oil

Types) is critical to achieving adequate cold weather

cranking speed. Synthetic oils have improved flow at low

temperatures.

The oil pan heater, battery heater and fuel filter heater (if

equipped) are activated with a thermostat and will turn on

and off as needed. The coolant heater is powered by a

Owner’s Manual for MDG25IF4 25

equipped)).

NOTE: Turn key to ON but do not crank engine until

Engine Preheat Indicator goes off.

NOTE: Additional information on cold weather operation

is available from your local GMP ASD.

E Electric Air Heat and Block Heat

F Ether and Block Heat

Page 30

Operation

(000137a)

WARNING

Explosion. Batteries emit explosive gases while charging.

Keep fire and spark away. Wear protective gear when

working with batteries. Failure to do so could result in

death or serious injury.

(000138a)

WARNING

(000167a)

CAUTION

Equipment damage. Do not make battery

connections in reverse. Doing so will result

in equipment damage.

004507

004508

(000237)

DANGER

Electrical backfeed. Use only approved switchgear to

isolate generator from the normal power source.

Failure to do so will result in death, serious injury,

and equipment damage.

(000157)

DANGER

Electrocution. Do not disable or modify the

connection box door safety switch. Doing so

will result in death or serious injury.

Using a Booster Battery or Charger (if equipped)

See Figure 3-6. A 12 volt booster battery can be

connected in parallel with battery(ies) on the unit to aid in

cold weather starting. ALWAYS use heavy-duty jumper

cables.

Series:

• Amps = Same as single battery

• Volts = Twice as a single battery

Parallel:

• Amps = Twice as a single battery

• Volts = Same as single battery

Figure 3-6. Parallel

1. Connect booster battery or batteries to produce the

required system voltage.

NOTE: To avoid sparks, do not allow the free ends of

jumper cables to touch engine.

2. Connect one end of jumper cable to the POSITIVE

(+) post of the booster battery.

3. Connect the other end of the jumper cable to the

POSITIVE (+) post of battery connected to starter.

4. Connect one end of the other jumper cable to the

NEGATIVE (-) post of the booster battery.

5. Complete the hookup by making the last

connection of the NEGATIVE (-) cable to a good

ground on the engine frame and away from the

battery(ies).

6. Start the engine. Disconnect jumper cables

immediately after engine starts. Always disconnect

NEGATIVE (-) cable first.

Generator Output Connections

Figure 3-5. Series

26 Owner’s Manual for MDG25IF4

Page 31

The installation should be in compliance with the national

(000156)

DANGER

Electrocution. Before connections are made to

the unit, verify the main circuit breaker and

battery disconnect switch are OFF. Failure to do

so will result in death or serious injury.

(000155a)

WARNING

Electric shock. Only a trained and licensed electrician

should perform wiring and connections to unit. Failure

to follow proper installation requirements could result in

death, serious injury, and equipment or property damage.

007618

B

A

(000156)

DANGER

Electrocution. Before connections are made to

the unit, verify the main circuit breaker and

battery disconnect switch are OFF. Failure to do

so will result in death or serious injury.

(000237)

DANGER

Electrical backfeed. Use only approved switchgear to

isolate generator from the normal power source.

Failure to do so will result in death, serious injury,

and equipment damage.

WARNING

Electric Shock. Verify all connections to the

cam lock receptacles are made to one side

only. Failure to do so could result in death,

serious injury and property damage.

(000308)

(000155a)

WARNING

Electric shock. Only a trained and licensed electrician

should perform wiring and connections to unit. Failure

to follow proper installation requirements could result in

death, serious injury, and equipment or property damage.

L1

L2

L3

N (Neutral)

G (Ground)

Black

Red

Blue

White

Green

007619

A

electrical code (NEC), state, and local regulations.

See Figure 3-7. The unit is equipped with connection

lugs (A), located on the lower portion of the control box

behind the lug box door. The lugs provide connection

points to attach external loads to the generator. A large

decal on the inside of the connection lug door details the

proper connections for selected voltages.

Connections to the lugs should be made by running the

power cables up through the opening in the bottom of the

box.

Operation

Generator Cam Lock Connections (If Equipped)

IMPORTANT NOTE: Do not make any connections

directly to the lugs without routing the cables

through the opening. Use a hex-wrench to tighten the

cable connections.

The connection lug door is equipped with safety interlock

switches that will trip the main circuit breaker and disable

the voltage regulator if the door is opened while the unit

is operating.

A ground connection (B) is located next to the connection

lugs. The unit must be connected to ground for proper

operating safety. The generator neutral is bonded to

ground when it is shipped from the factory. The bonding

plate must be removed when the generator is used as a

standby power source.

See Figure 3-8. The unit may be equipped with cam lock

connections (A) located below the receptacles. These

receptacles provide connection points to attach external

loads to the generator. A decal below the cam lock

connections details the proper connections for selected

voltages.

Connections should be made by plugging power cables

equipped with series 16 taper nose 400A/600V cam lock

plugs into the cam lock receptacles. Secure the

connection by rotating the plug a 1/2 turn to the right.

Figure 3-7. Generator Connection Lugs

Owner’s Manual for MDG25IF4 27

Figure 3-8. Cam Lock Connections

Page 32

Operation

(000157)

DANGER

Electrocution. Do not disable or modify the

connection box door safety switch. Doing so

will result in death or serious injury.

WARNING

Electric Shock. Never change the voltage

selector switch while the engine is running or

the controller is on. Doing so could result in

death, serious injury or equipment

damage.

(000302)

Manual Mode

GEN

V

+

-

Voltage Adjust

- Press , voltage will begin flashing

- Use and arrows to adjust voltage

- Press to confirm new voltage. Numbers will stop flashing

V

L-N Average

L-L Average

V

277

480

002803

V

+

-

WARNING

Electric Shock. Never change the voltage