Page 1

MC ALTERNATOR

DIAGNOSTIC REPAIR MANUAL

ISSUED JANUARY 1979

P.0, BOX 8, WAUKESHA. WISCONSIN 53186

PRINTED IN U.S.A.

51834

Page 2

This Repair Manual is provided to aid the technician in the

analysis and repair of malfunctions that might occur in the

MC alternator or its engine. Keep the Manual in a safe place

and refer to it whenever necessary.

All information, illustrations and specifications contained

in this Manual are based on the latest product information

available at the time of publication. Generac reserves the

right to make changes in any product at any time without no

tice.

GENERAC

P.O.BOX 8

WAUKESHA. WISCONSIN 53186

Page 3

PART I

GENERAL

Section 1.1

1.1.1

1.1.2

1.1.3

1.1.4

• 1.1.5

1.1.6

Section 1.2

Section 1.3

SPECIFICATIONS

Model Numbers

Fuels and Oils

Torque Specifications (General)

Torque Specifications (Special)

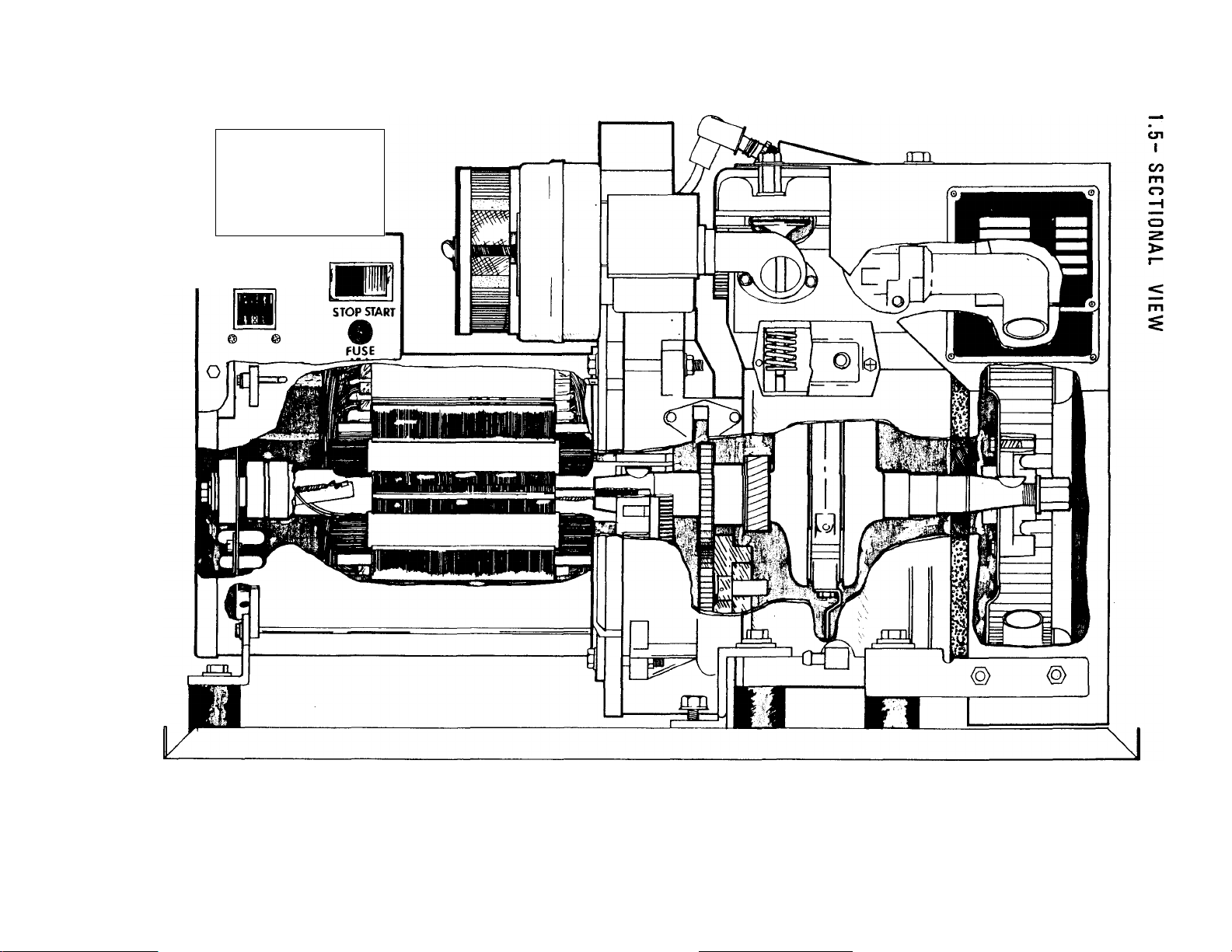

Sectional View

Engine Specifications

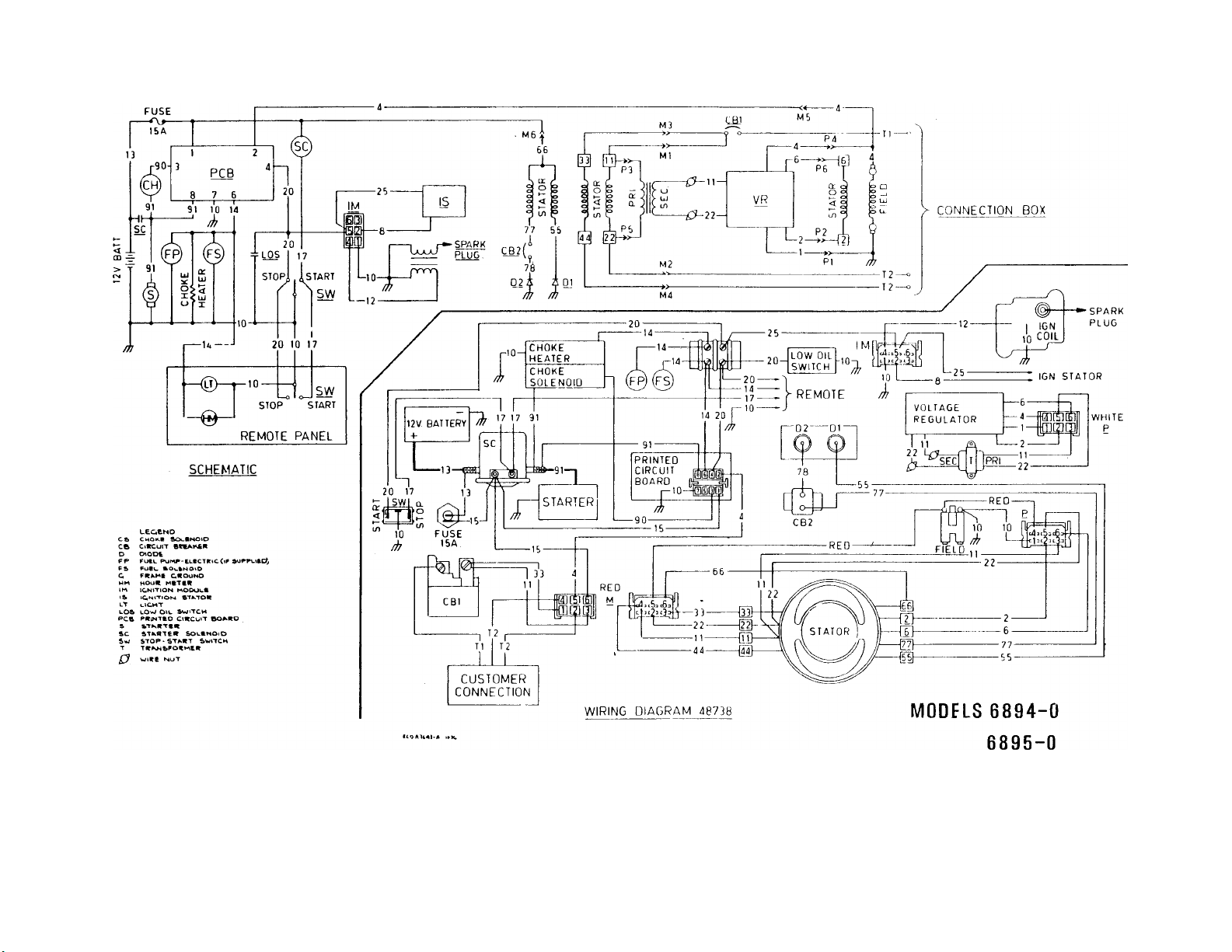

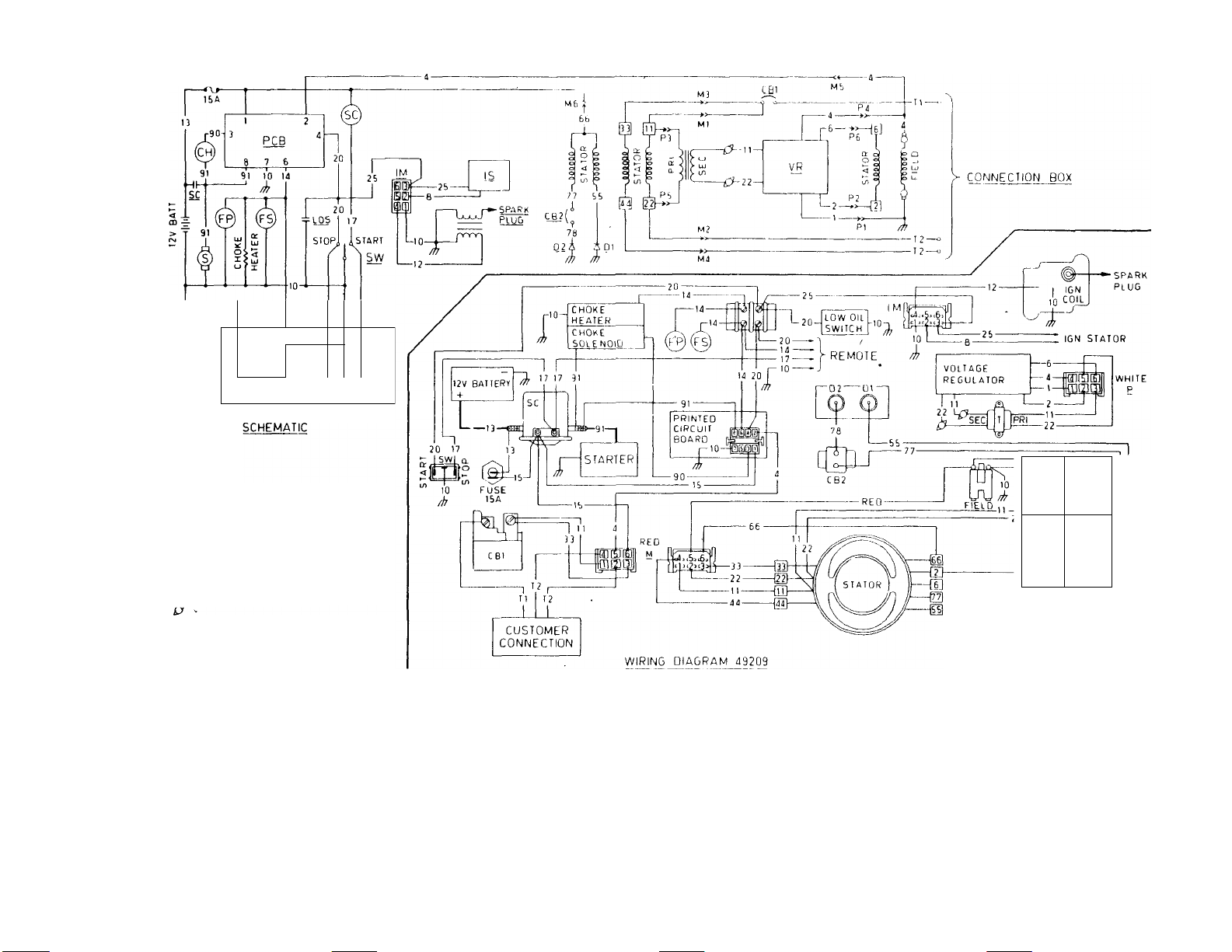

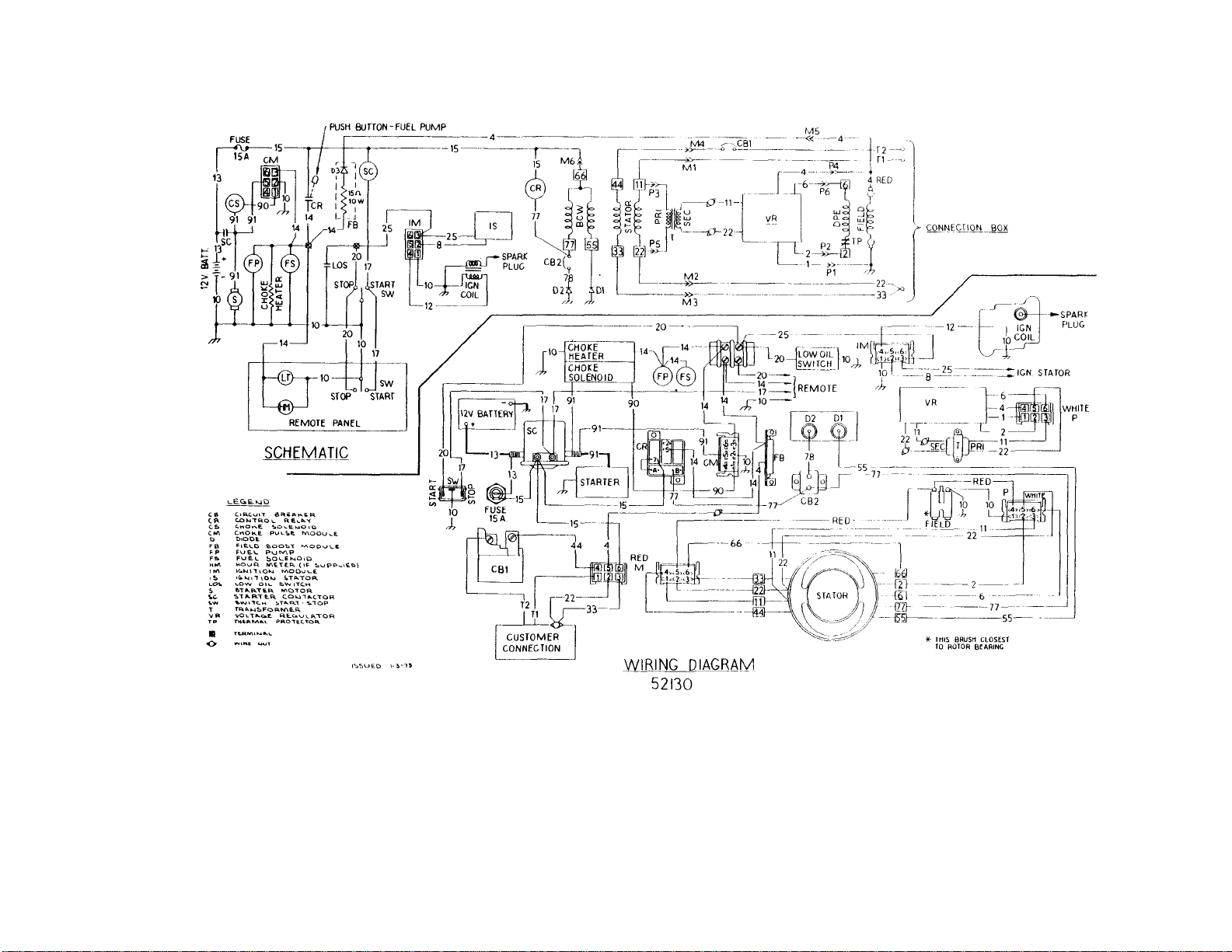

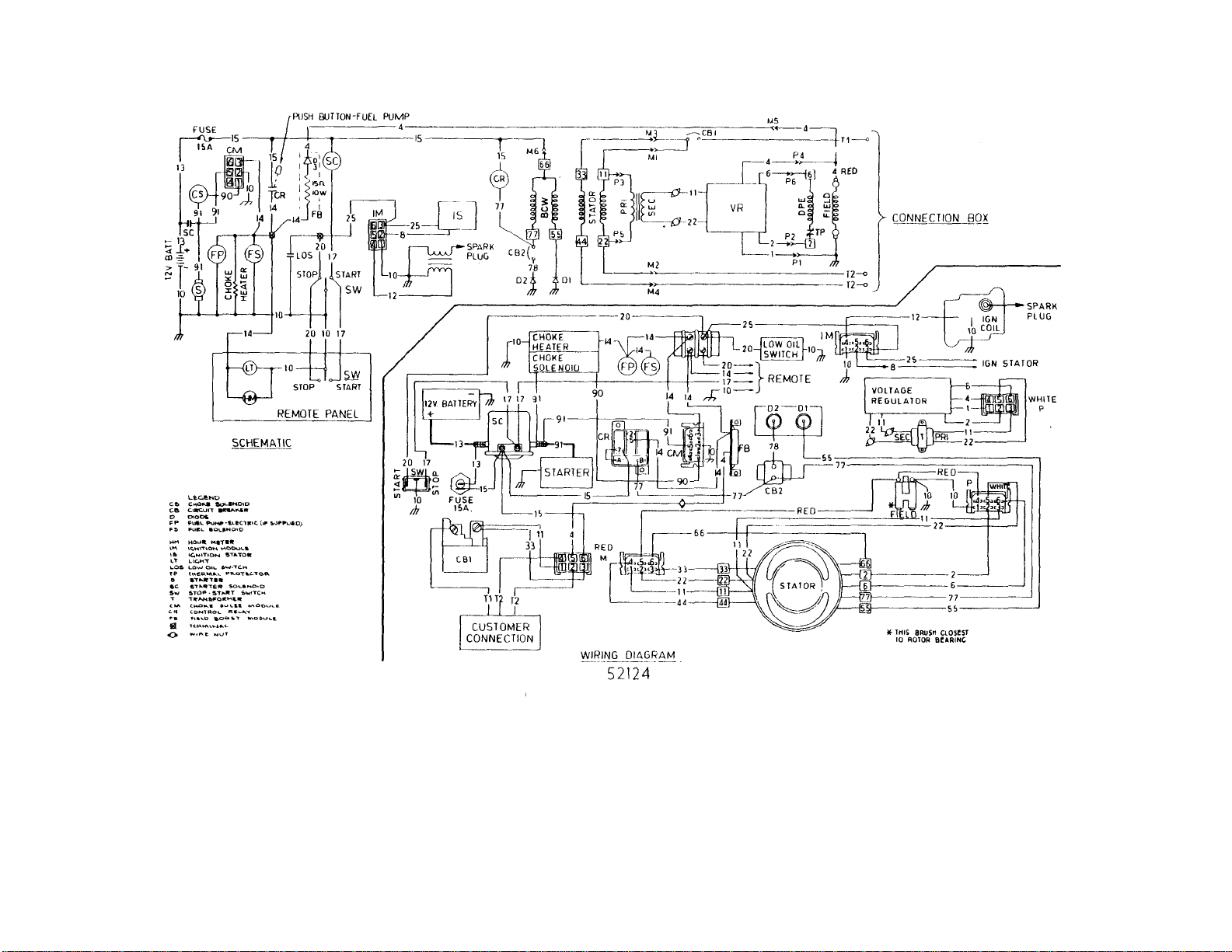

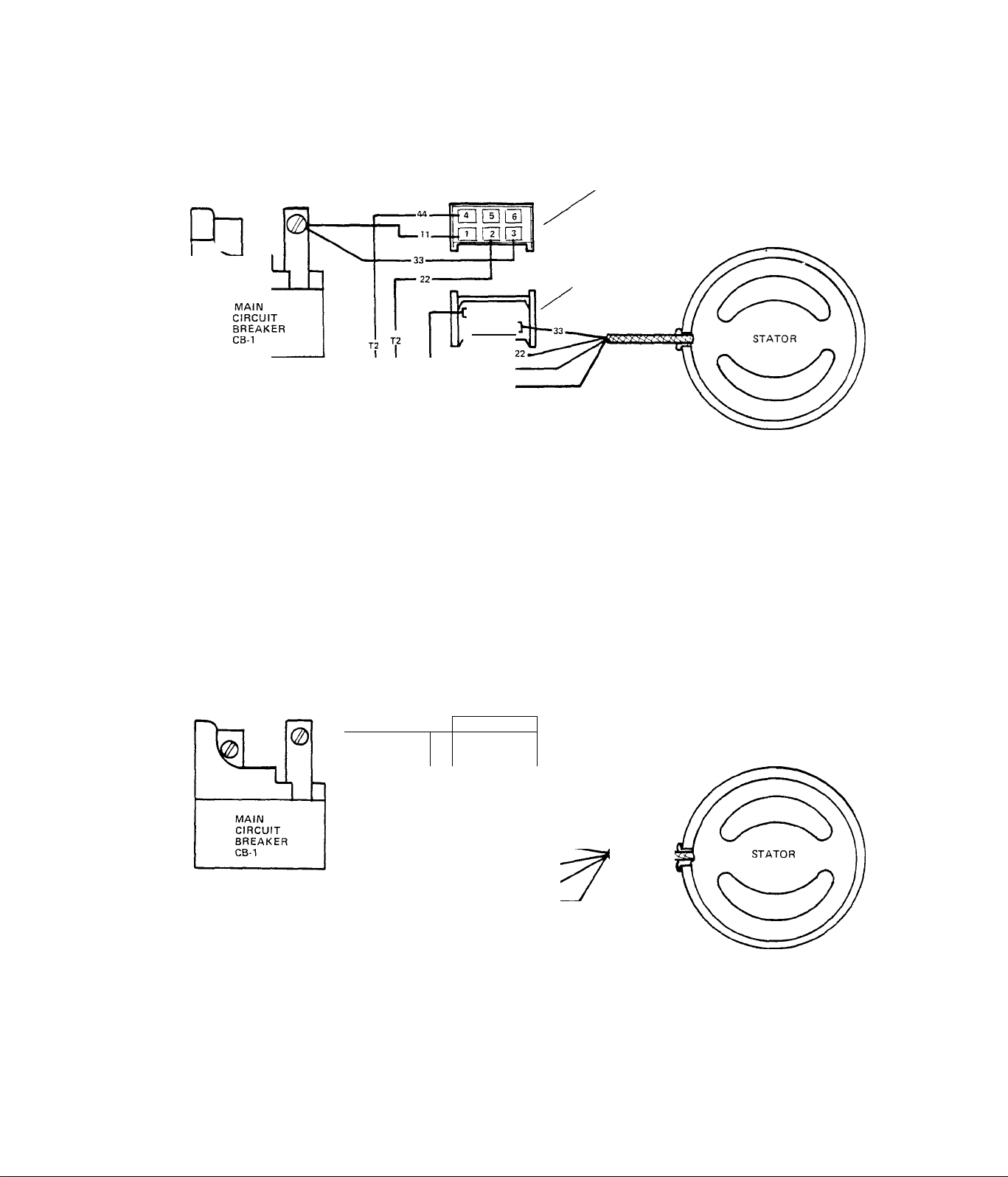

WIRING DIAGRAMS

SPECIAL TOOLS

Page 4

SPECIFICATIONS

1.1.T-M0DEL NUMBERS

SECTION 1.1

Model No,

Wattage Capacitv

Voltage

MC-35

6894

3500 3500 3800

120* 120* 120*

Maximum Amperes 29,2 at 120 V, 31,7 at 120 V.

Phase 1-Phase 1 1-Phase 1-Phase 1-Phase

Frequency

Voltage

Regulation

Solid state voltage regulator maintains 120 Volts AC

(±27o) at 60 Hertz

MC-35

6895

MC-38

6938

MC-38

69 39

MC-40

6896

3800 4000

120* 120*

33.3 at 120 V.

1 -Phasel_1-Phase

60 Hertz at 3600 rpm

Batterv Charge 0-10 Amperes at 12 Volts DC

Gross Weight

(wet)

Engine Part No,

Bore

Stroke

Displacement

48078 48078

Approximately 127 pounds

48078 48078 48078

78 mm

62 mm

296 cc

Governed Speed 3720 rpm at no-load

Ignition System

Starting System

Cranking Current

Average Fuel

Consumption

Type of Fuel

Pump

Mech,

12 Volt DC electric (Ring Gear)

Approximately 0,70 Gallons per Hour

Elec, Mech,

Solid State

Approximately 90 Amperes

Elec, Mech, ■ Elec,

MC-40

6897 ..

4000

120*

48078

'Factory connected for 120 Volt AC output only. Unit is reconnectable

to provide dual voltage output.

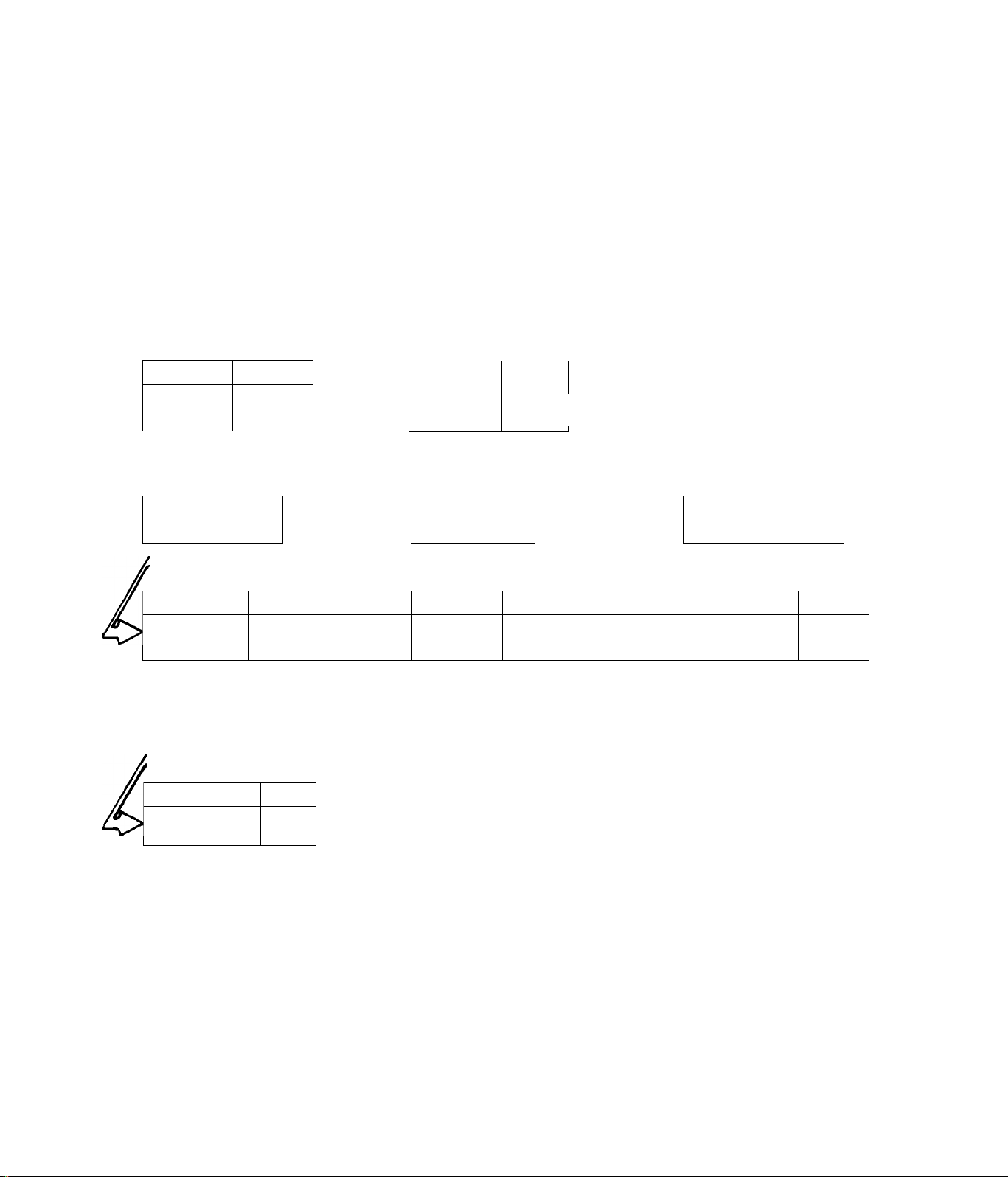

1.1.2-FUELS AND OILS

RECOMMENDED FUEL

Use NON-LEADED gasoline. Leaded REGULAR grade gasoline is an acceptab

le substitute. Do not use any highly leaded, premium gasoline,

RECOMMENDED OIL

I

Use oil classified ”For Service SC,

SD or SE”, as shown in the CHART at

USE OIL CLASSIFIED "FOR SERVICE SC, SD, or SE"

---------------------------------------

USE SAE 10 W

Of 10W-30OIL

^-----------------------------

USE SAE 30 OIL

USE SAE 20 W

or 10W-30 OIL

right.

-10“F. 10“F. 32'F.

■22^C. •12.2'^C. O'C.

TEMFERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

1,1-1

Page 5

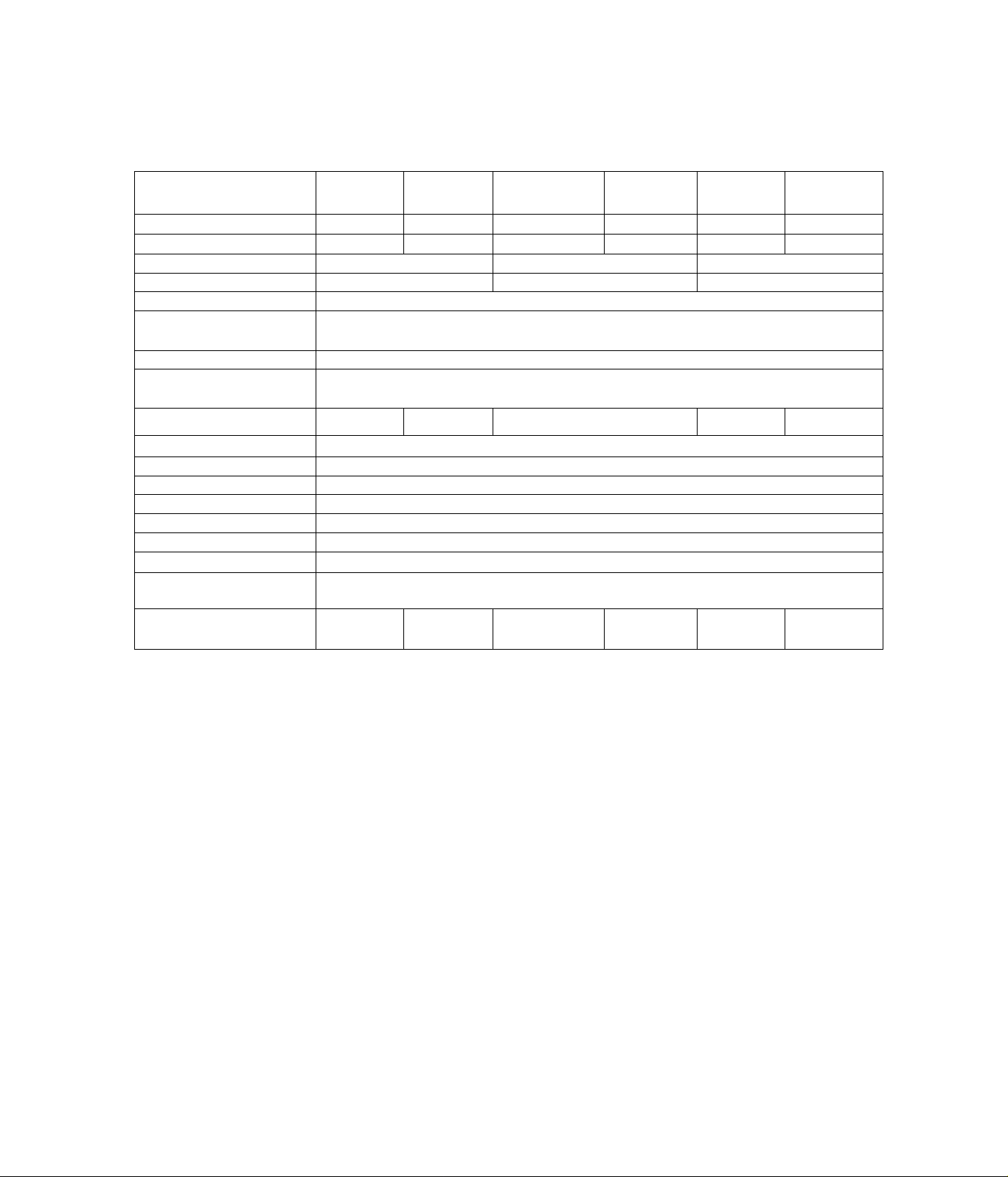

1.1.3- TORQUE SPECIFICATIONS (GENERAL)

STANDARD TORQUE VALUES

Grade 2

BOLT SIZE

1/4-20

1/4-28

5/16-18

5/16-24

3/8-16

3/8-24

7/16-14

7/16-20

1/2-13

1/2-20

9/16-12

9/16-18

5/8-11 92

5/8-18 105

3/4-10

3/4-16 180 140

7/8-9

7/8-14

1-8 300

1-14

DRY LUB

5

6

11

13 10

20

23 17

32

36 27

49

55

70

78

165 125

200

225

340 260

15

25

38

42 85

54 110

60

71

81

155

170

230

All Values in FOOT-POUNDS

DRY

4

5 10

8 17

19

31 24

35

49

55 42

75

120

150

170

270

295 230

395

435

590

680

Grade 5

LUB

8

13 21

15

27

38

58

65

84

93

115

130

205

305

335

455

5.10

DRY LUB

6 10

7

12

24

38 29

43

61 47

68

93 72

105

135

150

185

210

330

365

530'

585 450

795 610

Grade 7

16 24

18

33

52

80

105

115

145

160

250

280 420

405

DRY LUB

8

9 14

12

27

44 34

49

70 54

78

105

120 90

155 120

170

210

240

375 290

605 455

670

905 695

Grade 8

9

11

18

21

38

60

82

132

165

185

320

515

GRADE

BOLT HEAD

SYMBOL

o

1.1.4- TORQUE SPECIFICATIONS (SPECIAL)

Spark Plug

Cylinder Head Bolts

Connecting Rod Cap Bolts

Engine Gear Cover Bolts

Blower Fan (Special M14 Hex Nut)

Rotor Bolt

Mechanical Fuel Pump Bolts

INCH-POUNDS FOOT-POUNDS

216-264

264-348

216-264

90-110

600-660 50-55

180-200

25-30

18-22

22-29

18-22

7.5-9

15-17

1.1-2

Page 6

г=

ID

о о

о о

^ BREAKER ^

—

о

—J

U)

I

Page 7

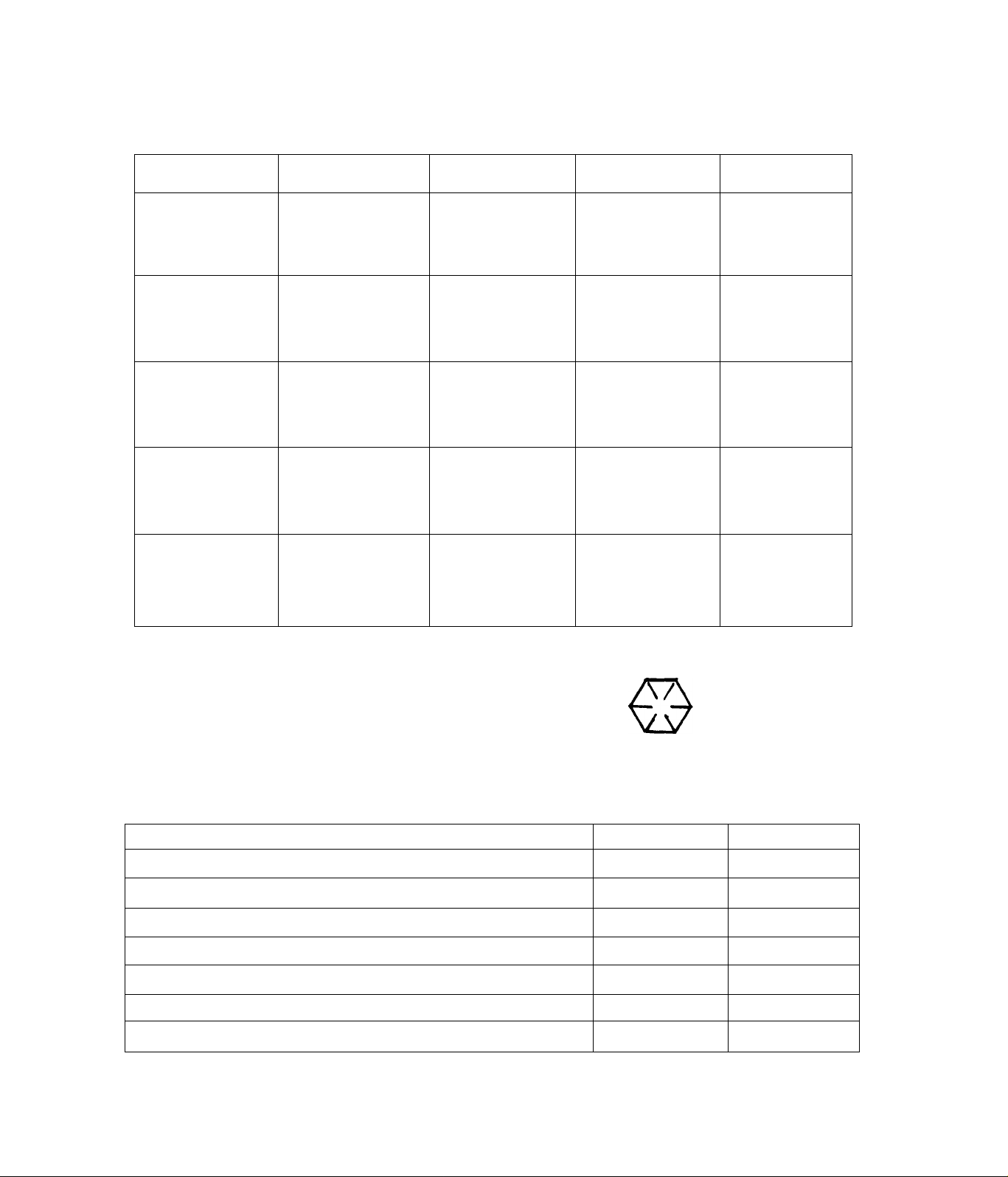

1.1.6-ENGINE SPECIFICATIONS

INCHES METRIC

Spark Plug Gap

Valve Spring Length

Valve Spring Compression Length

Valve Seat Width

Valve Tappet Clearance

Crankshaft End Play

Piston Diameter (at skirt)

Piston Pin Diameter

Width of Compression Grooves

Width of Oil Ring Groove

Width of Compression Rings

0.035

0.009 mm

1.2995 33.000 mm

1.0236

0.039-

26.000 mm

1-2 mm

0.079

0.0039-

0.1-0.2 mm

0.0078

0.0039-

0.1-0.3 mm

0.0118

3.067-

3.068

0.7080-

0.7086

0.0797-

0.0805

0.1584-

0.1593

0.0775-

0.0784

77.91-

77.93 mm

17.989 mm-

18.000 mm

2.025 mm-

2.045 ram

4.025 mm-

4.045 mm

1.970 mm-

1.990 mm

Width of Oil Ring

Ring End Gap

Maximum Permissible Out-of-Roundness

of Crankpin

Connecting Rod to Crankpin Clearance

Valve Spring Force

0.1560-

0.1570

0.0078-

0.0157

3.970 mm-

3.990 mm

0.2 - 0.4

mm

0.002 0.05 mm

0.001-

0.002

14.81-

19.76 lbs

0.030-

0.050 mm

kilograms

6.72-8.96

1.1-4

Page 8

K>

I

6896- 0

6897- 0

co

гп

о

g i

>r

Isa

CD

XI

>

CD

Page 9

N5

ro

FUSE-

m

—14

--

@—

iTt>

L&ceND

C6 ChO«.B SOvKNOlO

c& c>*cutT BrmAiKClt

O OiOOB

FP FoCL Pur^-ei.CCTRlC(ir »OPPl^tfcO^

F& FuBc BOwBnO'D

C FKikHt C«OUNO

>4M hOU« MtT«H

IM iCNiTlOM N\OOOUt

vS STikTO«

l-T CICMT

LOW OlC BW>TCm

»cm p«iNTto Cimcj'T mo*^«o

s m-TK«!««

sc «Tk.«Te<« &OLBNo>o

Sw BTOP-ST^RT Switch

i^imi tmut

-----

1

REMOTE PANEL

STO

0 1

7

0 1

2

o—

—o

c

TART

p

tu

----

1

1 e

ffh

-2

------

6

MODELS 6894-1,-2

6895- 1,-2

6896- 1,-2

6897- 1,-2,-3

6938- 0

6939- 0

Page 10

ю

I

со

о

о

оо

to

о

со

Page 11

N>

i

4ï^

О

О

05

ОО

СО

I

Page 12

RED CONNECTOR PLUG

0

RED RECEPTACLE

oKslCel

CjlLjlCa

11 '—

T1

120

V.

CUSTOMERS

CONNECTIONS

FACTORY WIRING CONNECTIONS

120 VOLTS ONLY

1

44

22

V

120VT 120V.

•—4*—>

-240V, -

CUSTOMER

CONNECTIONS

-CD □ d]

j

-----

-L

[4] rs: Cel

RED CONNECTOR

PLUG

RED

RECEPTACLE

N

RECONNECTED FOR

120/240 VOLT

OUTPUT

1.2-5

Page 13

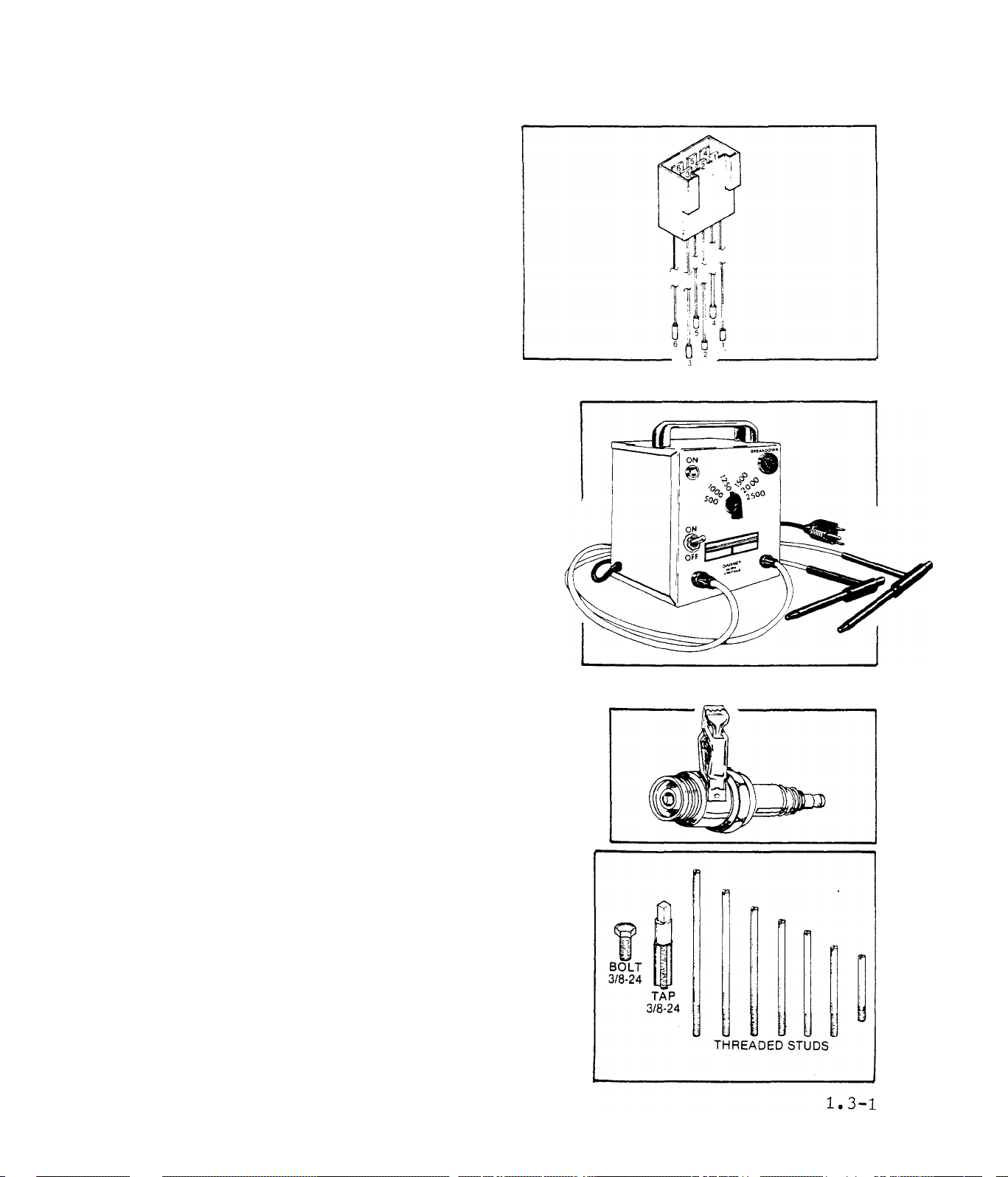

SECTION 1.3

SPECIAL TOOLS

ELEHTRICAL TEST PLUG

The Electrical Test Plug facilit

ates the testing of electrical

components in circuits that pass

through the red and white stator

can receptacles, or through the

Ignition Module receptacle. Use

the Test Plug in any diagnostic

test that calls for connection of

the VOM test probes to pins in

these receptacles. Order Part No.

27069.

INSULATION BREAKDOWN TESTER

Resistance testing of alternator compon

ents with an Ohmmeter is generally valid.

Such resistance tests will nearly always

indicate the presence of an open or shor

ted condition. However, some malfunctions

do not become evident until an electrical

load is applied across the defective'com

ponent. The insulation breakdown tester

permits a component to be tested under a

simulated load condition, by applying a

selected voltage to the component. Follow

the tester manufacturer’s instructions

strictly when using the tester.

SPARK T.ESTER

The Spark Tester is used to check for pro

per ignition spark with the engine cranking.

Order Part' No. 41503.

ROTOR REMOVAL KIT

The Rotor Removal Kit consists of a 3/8-24

TAP, 3/8-24 BOLT, and threaded studs o'f

varying lengths. The kit is used for remo

val of the rotor. Order Part No. 41079.

Page 14

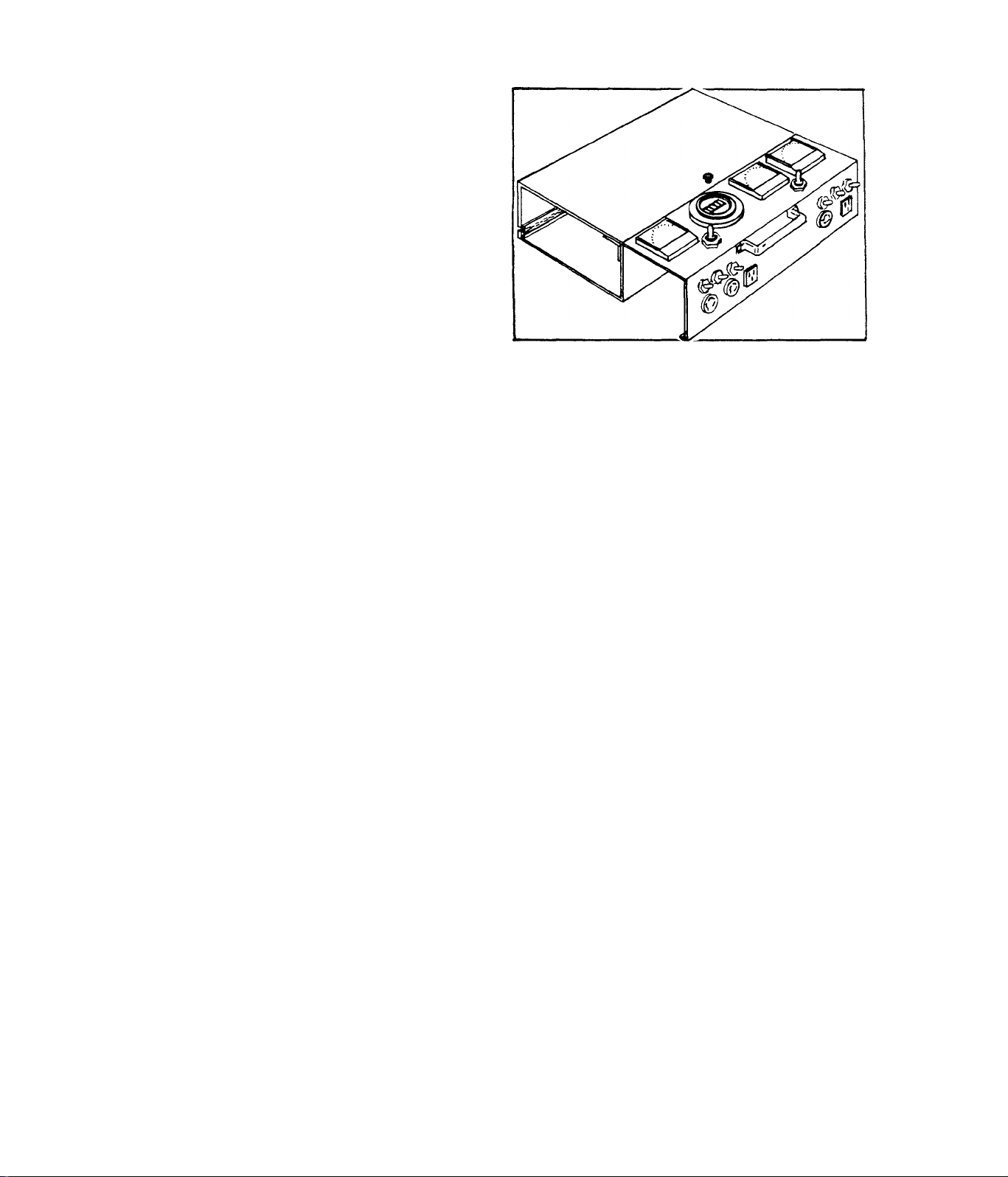

LOAD BANK

The Load Bank is used to apply an

electrical load to alternators..

The unit is equipped with a Volt

meter, Ammmeter and Frequency Me

ter, as well as the necessary

switches for selecting the desir

ed load. Specify Model No. 5515,

1.3-2

Page 15

PART II

TROUBLE DIAGNOSIS

Section 2.1

2.1.1

Section 2.2

Section 2,3

- DIAGNOSTIC FLOW CHARTS

- Introduction

Engine won’t Crank

Engine Cranks, won’t Start

Engine starts hard - Runs Rough

Switch set to STOP - Engine Keeps Running

AC Voltage Low

AC Power Low

AC Voltage High

No AC Voltage

- Diagnostic Tests

- Battery Charge Circuit Tests

Page 16

SECTION 2.1

DIAGNOSTIC FLOW CHARTS

2.1.1-INTROUUCTION

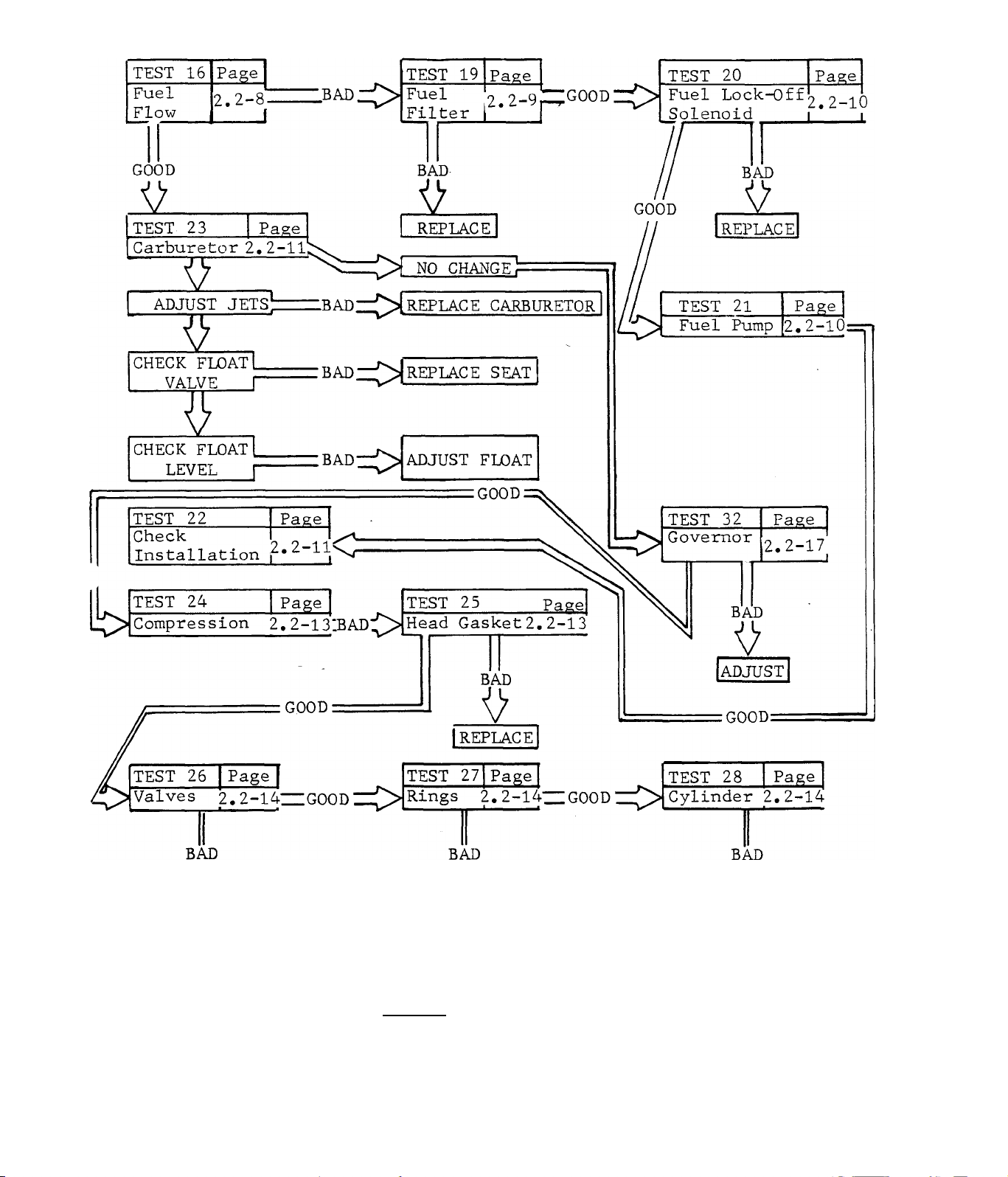

The DIAGNOSTIC FLOW CHARTS that follow are intended for use with the

DIAGNOSTIC TESTS in Section 2.2, Test numbers assigned in the FLOW

CHART are identical to the numbers assigned to specific tests in Sec

tion 2.2.

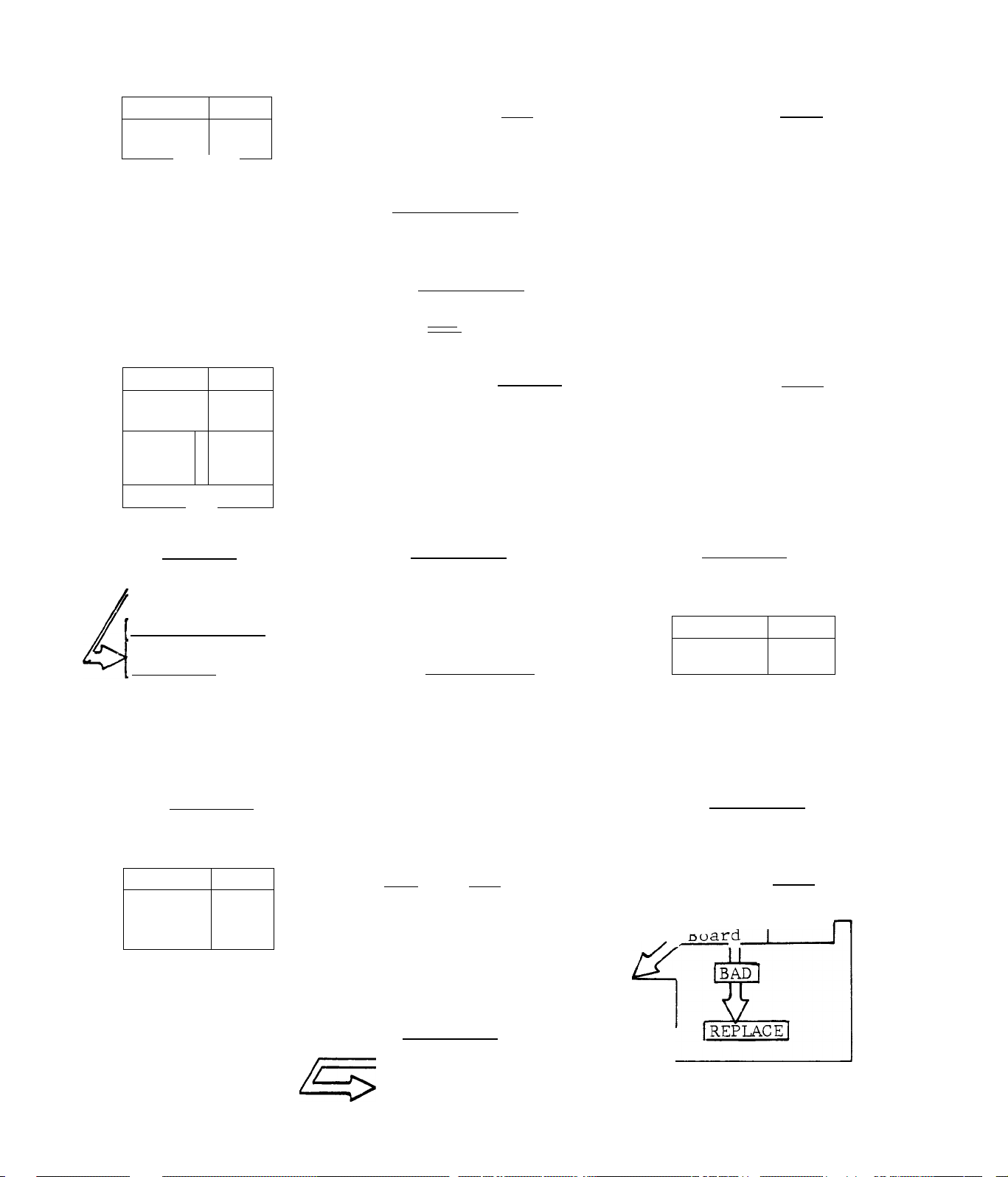

ENGINE WON’T CRANK

TEST 1

15 Amp

Page

2.2-1

Fuse

BAD

Replace Rise

TEST 4

Starter

Solenoid

I i

|Repl

TEST 7

Page 1

2.2-2|iGOODZ^

ace

Page]

Starter

Ring Gear

______

BAD

9 0/,

1

“GOODI^

'GOOD

1

TEST 2 Page

Battery

9.2-1*—GOOD--^ Start/Stop

2.2-1

BAD

<>

Recharge or

Replace

;GOOD

TEST 5

Starter

Motor

L___1

--------1

Replace

ENGINE

SEIZED

Page 1

2.2-3 |—■ GOODI^

GOOD

7F1

idJ

ll

BAD

TEST 3

Cr-r,- i-^U

Switch

~1 r

Page

2.2-2

BAD

Replace Switch

TEST 6 Page

Starter

Drive Gear

2.2-4

Replace

n

Replace

0

Repair

or

Replace

Page 17

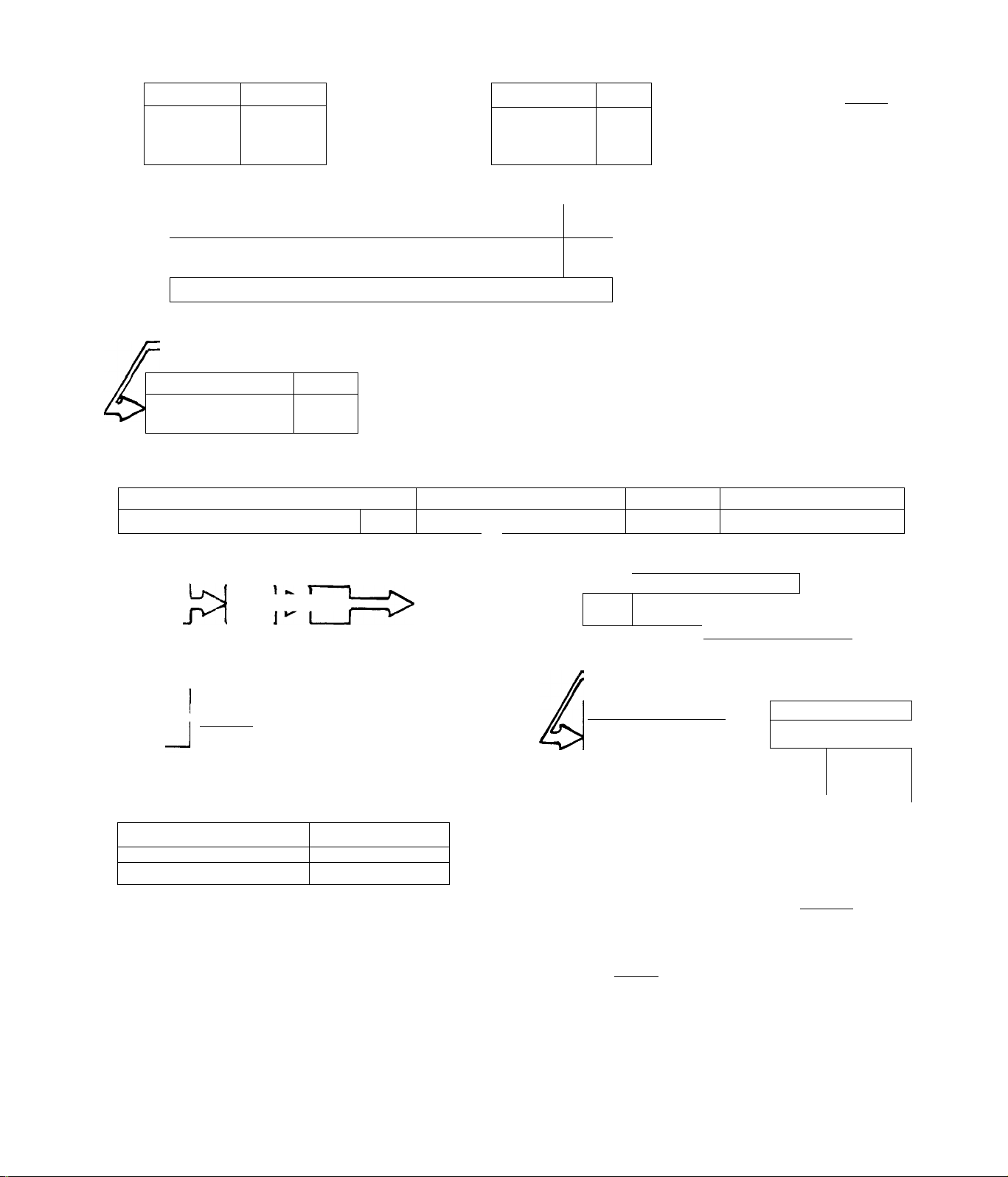

ENGINE CRANKS, WON’T START

TEST 8

Check

Spark

Page

2.2-^’

If

IF SPARK CHECKS GOOD

GO TO TEST 15

TEST 11

Spark

Plug

Page

2.2-5

BAD

TEST 9

________ _______

OIL LEVEL LOW |

iz

IFILL TANK

........-nnnn-

TEST 12

Ignition

Module

IbadI

Page

Page I

2.2-6 ^GOOD =CH

TEST 10

Low Oil

Switch

ba:

REPAIR/REPLACE

TEST 13

Ignition

Stator

IBAD

Page

2.2-5

D

Page

2.2-6

n

n

Replace

TEST 14 Page

Ignition *2 2-7

Coil I * I

I

I REPLACE

TEST 16

No Fuel

Flow

Page

2.2-8

|Replace|

IF SPARK CHECKS GOOD I

O

TEST 17

4 Amp

.BAD Fuse

;GOOD:

GO TO TEST 15

:G00D:

Page

2.2-8

r

:good:

5

¡Replace

TEST 15

Low Fuel

LOW

FILL TANK

TEST 18

Printed

Circuit

Page

2.2-8

Page

2.2-9

GO TO TEST

23

2.1-2

BAD

Except 6897-4

See Section 2.4

IREFIACEI

;G00D;

GO TO TEST 19

Page 18

TEST 19

Fuel

Filter

Page

2.2-9

IGOOD;

TEST 20

Fuel

Lock-Off ;

Solenoid

Page

L2-10

____

TEST 21

Fuel

Pump |2.2-lC

1

Page

bad!

REPLACE

TEST 22 Page

Check

Installation_

IF FUEL FLOW IS GOOD

GO TO TEST 23

--------------------

2.2-11

2

ADJUST

JETS

test:! BAD

1 .

D

BA

T

REPLACE

:GOOD:

TEST 23 Pagel

Carburetor 2.2-11”^^^

u

REPLACE

CARBURETOR

CHANG E¡f>

TEST

BAD

2

REPLACE

TEST 24 Page

L

Compression!.2-13

GOOD

ICO TO TEST 29

Iz

CHECK

FLOAT Z^BAD^Z^^

SEAT

0

CHECK 1

FLOAT ::;>bad;i::>

LEVEL

REPLACE

SEAT

ADJUST

KLOAT i

LEVEL

GO TO TEST 27

TEST

;BAD

TEST 25 page! ^

Vi n A J _ I

Head

Gasket^

_____

| o

Iz

BAD

2

REPLACE

GASKET

5

Itest

TEST 26| Page

Valves 2.2-14

iz

REPAIR

I

[TEST

2.1-3

Page 19

IF COMPRESSION IS GOOD, GO TO TEST 29r

TEST 27

Rings 2

.. 1 i ’

BAD

V

REPIACE

17

TEST

Page

-.2-14

■good:

TEST 28 Page

Cylinder 2.2-14

\ I I ‘ *

BAD

REPAIR

TEST 29

77

TEST

ENGINE STARTS HARD - RUNS ROUGH

Timing

Page

Z.2-14

2.1-4

Page 20

A

REPAIR

REPLACE

SWITCH SET TO STOP - ENGINE KEEPS RUNNING

TEST 3 jPagej

Replace Switch

REPAIR

2.1-5

Page 21

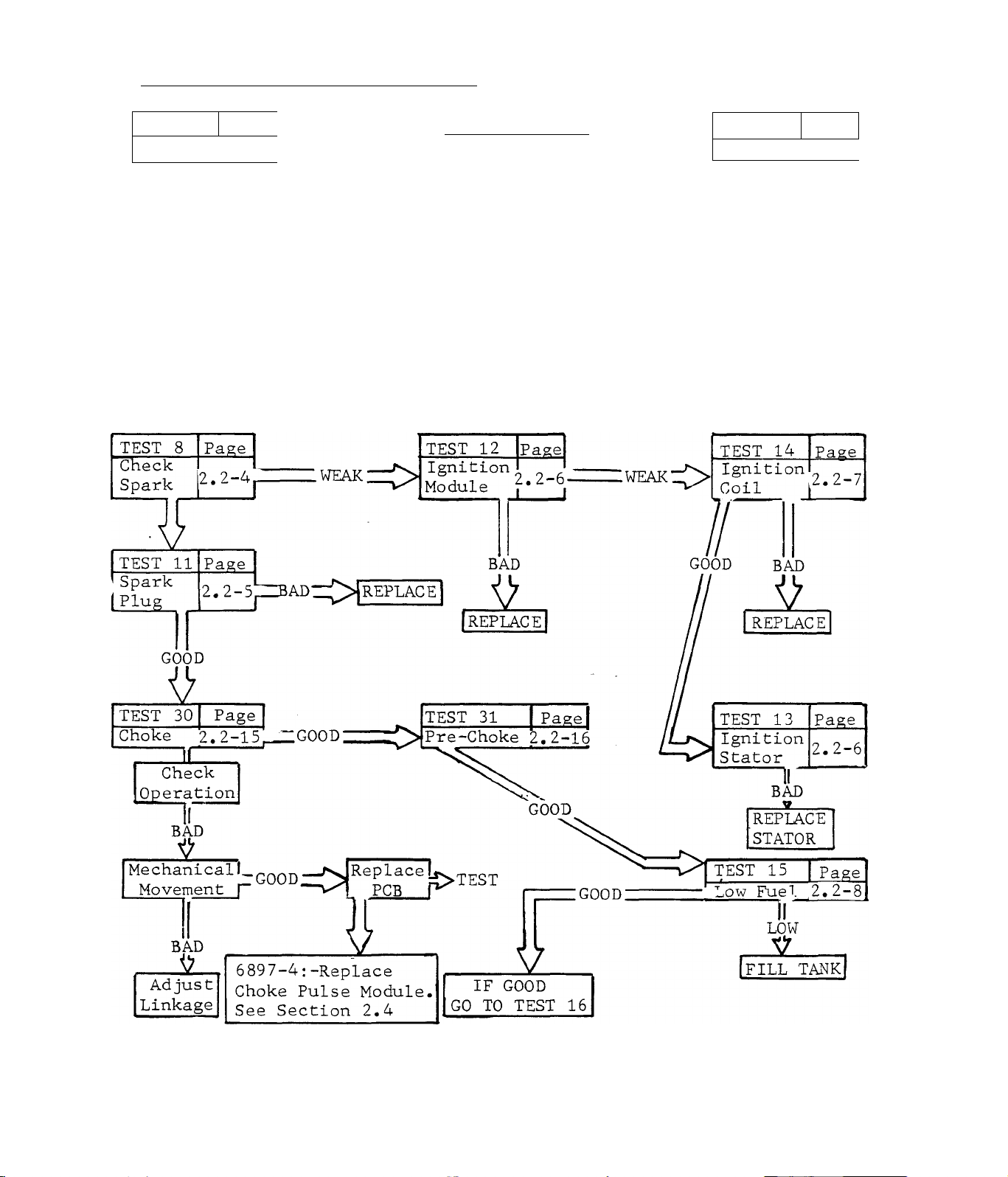

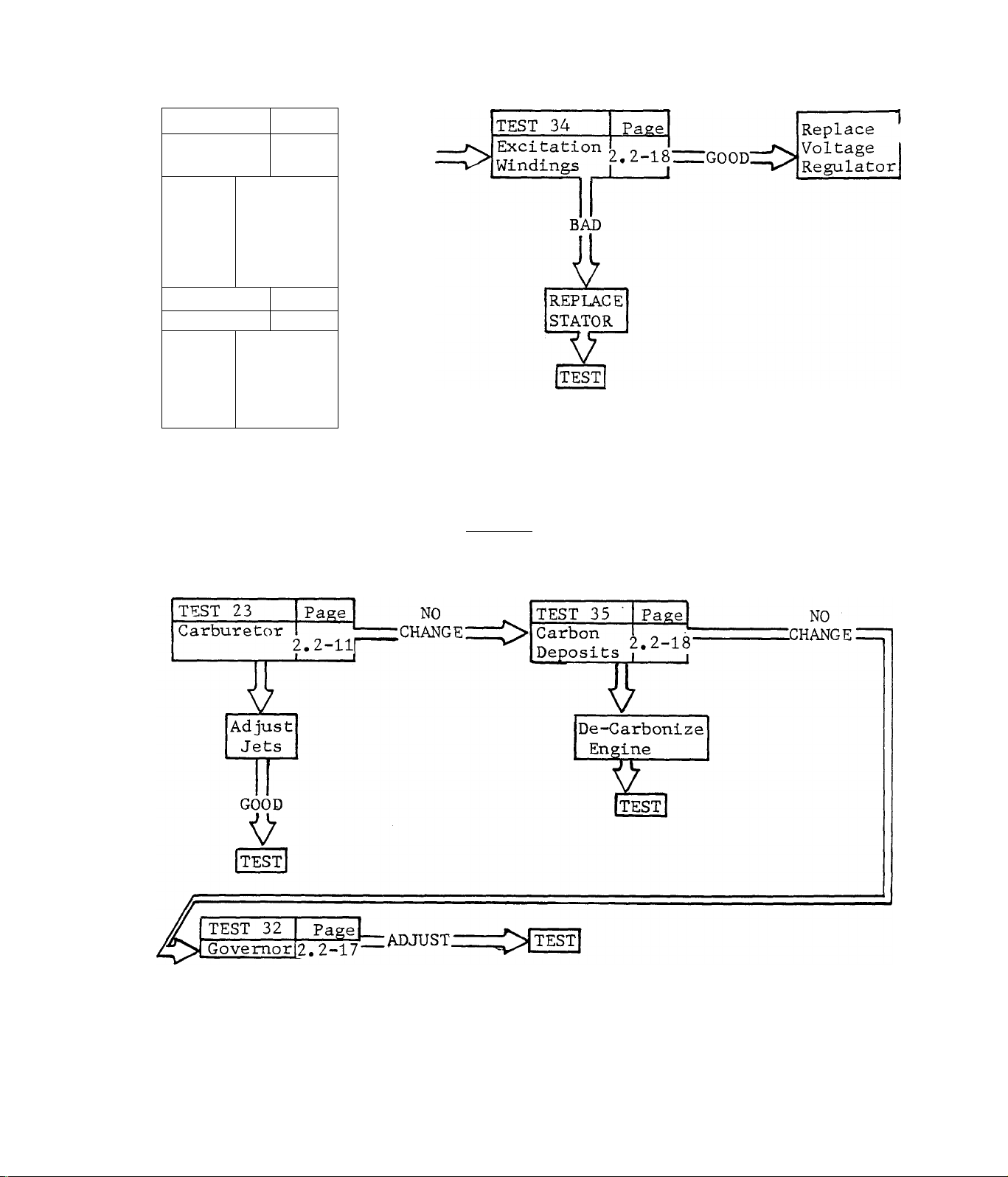

A-C VOLTAGE LOW

TEST 33

Check

Frequency

B/1Id

TEST 32

Governor

Bi

<

2.2-17

____

2.2-17

L

Page

:good

i

Page

A-C POWER LOW

2*1-6

Page 22

A-C VOLTAGE HIGH

TEST 36

Check

Output ;

Voltage

TEST 36

Check

Output

Voltage

Page

>.2-19

____

Page

^2-19

ZZBAD

1

CHECK CUSTOMER WIRING|<r^IZZZ.GOOD

NO A-C VOLTAGE

TEST 38

Main

Circuit .

Breaker

Page

^2-20

____

1

:good:

TEST 37

Sensing

Transformer

BAD

Replace

Transformer

TEST

TEST 39

check Rotor2 2-20“

j Paee

12.2-19

J_____

Pag£

GOOD

<>

Check Customer

____

Wiring

TEST

TEST 40

Check Field

Boost

Check Wire ^^0-

No. 14

____

Page

2.2-21lC>

BAD

iZ

REPLACE

TEST

CHECK VOLTAGE* _

TO ROTOR I

\ t

BAD

0

Jcheck No. 4 Wire

1 for 12 Volts

^~li

GOOD

BAD

¡REPLACE

¡TEST

IGOOD

testIcT^

,

________Iz__________

.•Replace Printed

"[Circuit Board

■ 2.1-7

Page 23

SECTION 2.2

DIAGNOSTIC TESTS

TEST 1-15 AMPFUSE

Remove and visually inspect the 15

Amp Fuse. Replace, if Fuse element

has melted. A more thorough check

may be made with a Volt-Ohm-Milli-

ammeter, as follows

1. )-Set VOM to ”+DC” and to "Rxl”

scale.

2. )-Connect meter test probes and

”Zero’^ the meter.

3. )-Connect meter test probes to

Fuse ends. Meter needle should

swing upscale to ’^0” ohms (continu

ity). If meter needle does not move

upscale, replace the Fuse.

RESULTS:-Fuse tests bad

Fuse tests good

TEST 2-BATTERY

Check Battery condition, as well as

the condition, cleanliness and sec

urity of battery cables and connec

tions .

RESULTS:-Battery, cables or connections,

check bad

Battery, cables or connections,

check good

............

.......

.

.Install new 15 Amp Fuse

.Continue tests

.Recharge or replace de

fective Battery. Repair,

clean or replace defect

ive cables or connection

.Continue tests

2.2-1

Page 24

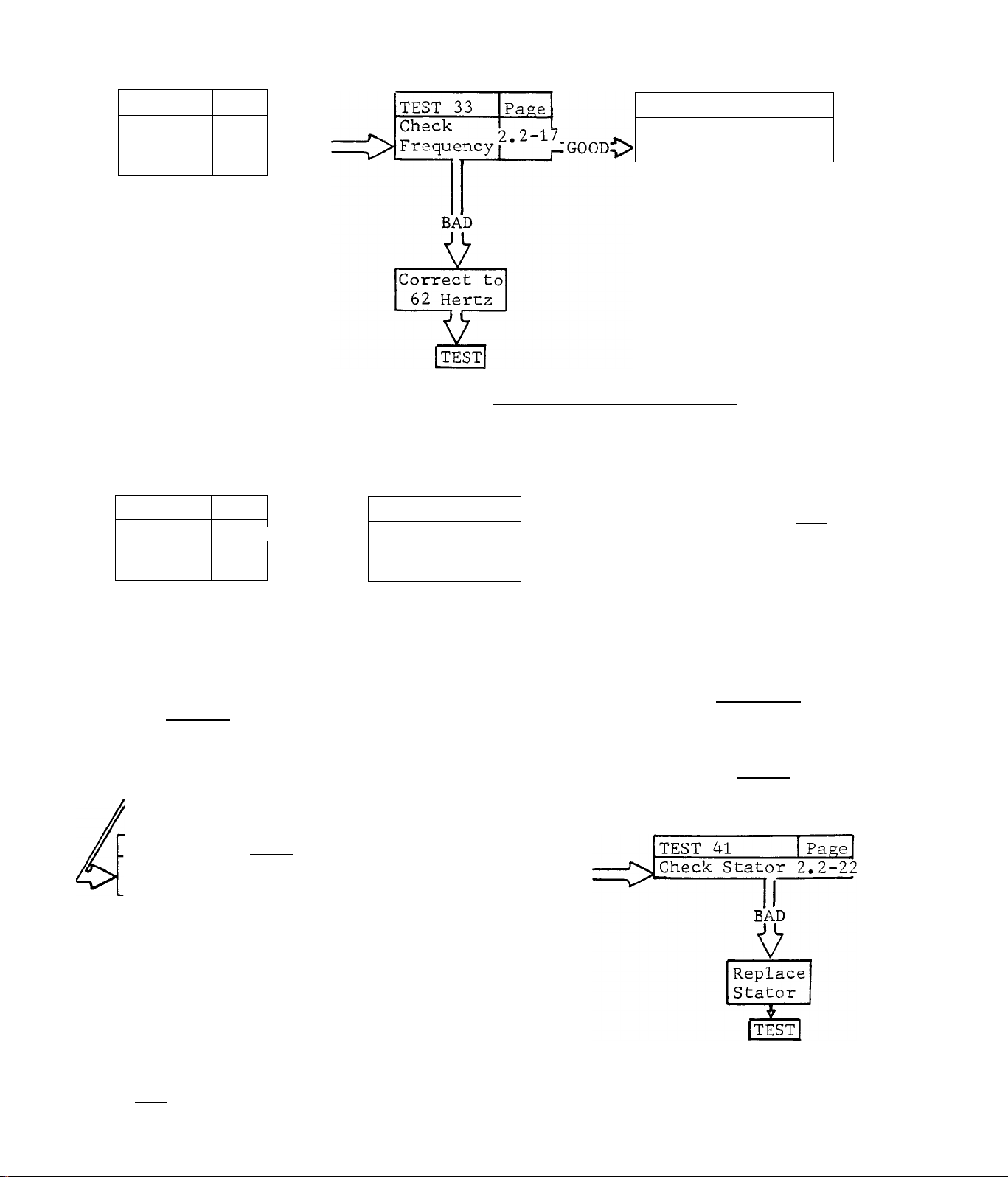

TEST3-ST0P/START SWITCH

Left Hand

10 (Ground)

Remove 15 Amp Fuse to disconnect

starting circuit. Remove panel

top cover. Disconnect wires from

switch terminals to prevent int

eraction. Set VOM to "+DC” and to

"Rxl” scale, then zero the meter.

Connect meter test probes to the

switch center and right hand ter

minals (as viewed from switch

rear). Meter needle should not

TT,^-<rQ H QT.ri rph at START - meter

Connect VOM test probes to Switch

center and left terminals (as vi

ewed from switch rear). Hold the

Switch at START - meter needle

should not move. Release the Switch

to NEUTRAL - meter needle should

not move. Hold the Switch at STOP needle should swing upscale to ”0",

.Install new Stop/Start Switch

.Connect Switch wires, install

top panel and 15 Amp Fuse,

Continue tests.

A.)- Set Stop/Start Switch to START

and back to NEUTRAL several times.

An audible ’’click" should be heard

as the solenoid actuates.

2.2-2

Page 25

RESULTS:- Solenoid actuates, engine

does not crank

...............

Continue tests in Paragraph B

Solenoid does not actuate.•...Continue tests in Paragraph D

B. )- Set VOM to ”+DC” and to a scale greater than 12 Volts DC. Connect

the NEGATIVE (COMMON) test probe to ground. Connect the POSITIVE (+)

probe to the battery cable connection on the solenoid. Meter should in

dicate approximately 12 Volts DC.

RESULTS: - Meter reads 12 Volts DC

Meter reads less than 12

.....

....

Continue tests in Paragraph C

.Check for open or shorted wire

Volts DC (or loose connection) between

Battery and Starter Solenoid

C. )- Connect POSITIVE (+)'meter test probe to starter cable connection

on solenoid. Connect NEGATIVE (COMMON) probe to ground. Hold Stop/Start

Switch at START - meter should indicate approximately 12 Volts DC.

RESULTS:- Meter does not read

12 Volts DC.....

Meter reads 12 Volts and

..........

.....

...Install new Starter Solenoid

Continue tests in DIAGNOSTIC

Solenoid checks good FLOW CHARTS

D. )- Set VOM to ”+DC” and to a scale greater than 12 Volts. Connect the

meter POSITIVE (+) test probe to one of the small terminals on the sol

enoid. Connect the remaining probe to ground. Meter needle should read

approximately 12 Volts DC. With one probe'still connected to ground,

connect the remaining terminal to the other small terminal on the solen

oid - meter should indicate approximately 12 Volts DC.

RESULTS:- Meter indicates 12 Volts......Continue tests

Meter does NOT read 12 Volts..Repeat Tests 1, 2 and 3. When

sure that these tests are good

and 12 Volts is not indicated

in Test 4.D., replace solenoid

TEST 5-STARTER MOTOR

Set VOM to ”-hDC” and to a scale

greater than 12 Volts DC. Conn

ect VOM positive (4-) test probe

to the Starter terminal lug and

COMMON (-) test probe to frame

ground. Hold Stop/Start switch

at START. Meter should indicate

approximately 12 Volts DC and

starter motor should run.

Starter runs.................................Continue tests

Meter indicates 12 Volts DC,

Starter does not run

.......................

Meter does not indicate 12 Volts

........

Replace Starter

Check Starter cable

2.2-3

Page 26

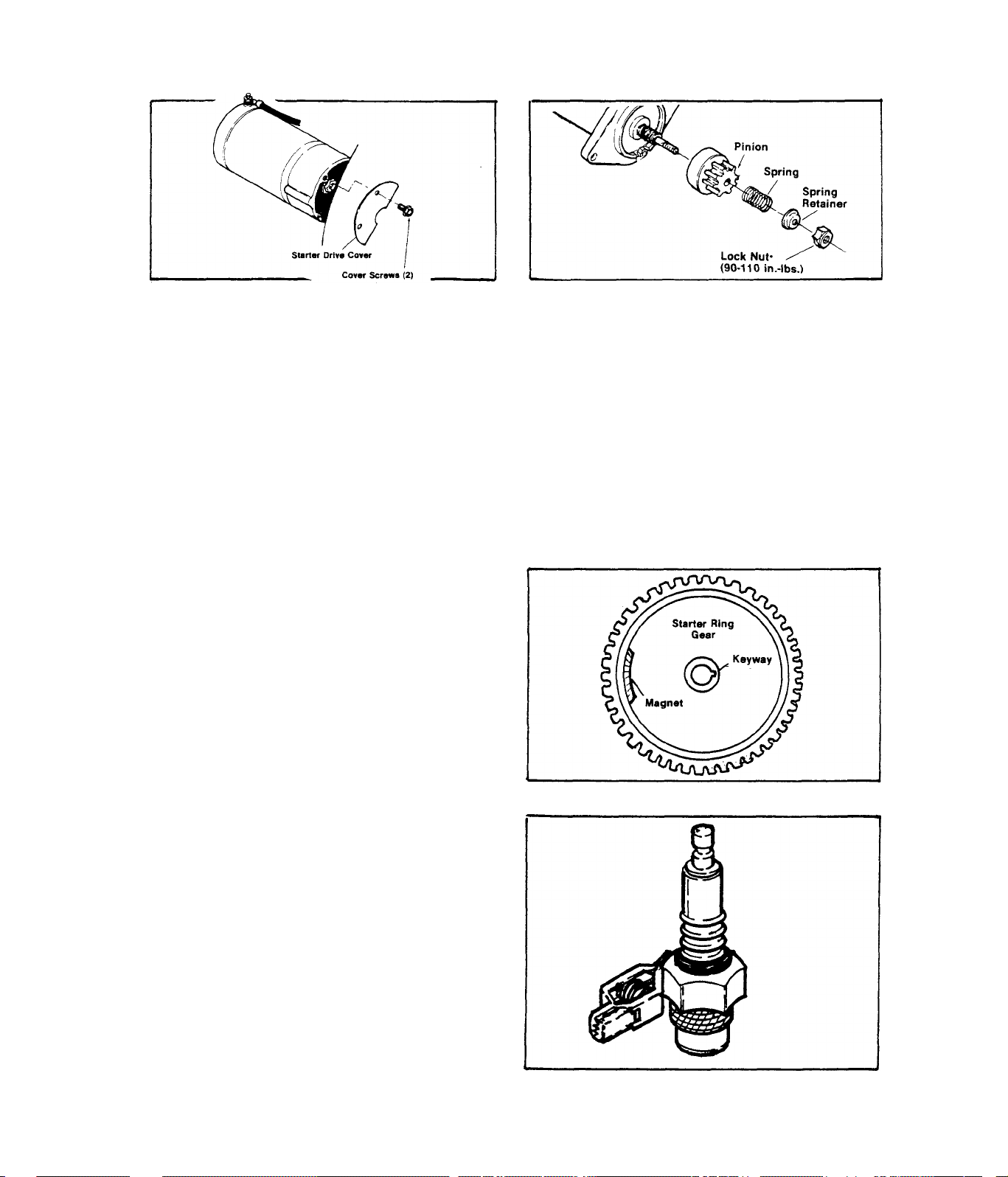

TEST 6-STARTER DRIVE GEAR

A.)-Hold Stop/Start switch at its

START position and listen for the

starter motor. If motor runs free

B,)-Visually check Starter pinion

for damage, if damaged, replace

pinion.

ly (without load), remove Starter

drive cover.

C,)-To replace Starter pinion assembly, remove lock nut, spring retain

er, and pinion. Install a new pinion, spring, spring retainer and lock

nut. Tighten lock nut to 90-110 inch-pounds, DO NOT LUBRICATE PINION

SPLINES,

RESULTS:- Starter drive checks good

Starter drive is defective.,,,,,,,.................

.................

.Continue tests

Replace

TEST 7-STARTER RING GEAR

Inspect Starter Ring Gear for dam

age, Ring Gear and Fly^dieel are

heat shrunk onto Rotor aaaembly.

If replacement is necessary, ent

ire assembly must be replaced.

TEST 8-CHECK SPARK

Disconnect spark plug lead from

engine spark plug and connect to

Spark Tester (Part No, 41503).

Connect Tester clamp to engine

spark plug. Crank engine - spark

tester should emit a blue, snappy

spark.

RESULTS:- Spark tests good...

.

.......

...Go to Test 15

Spark tests bad,

......

2.2-4

Continue tests

.....

........

Page 27

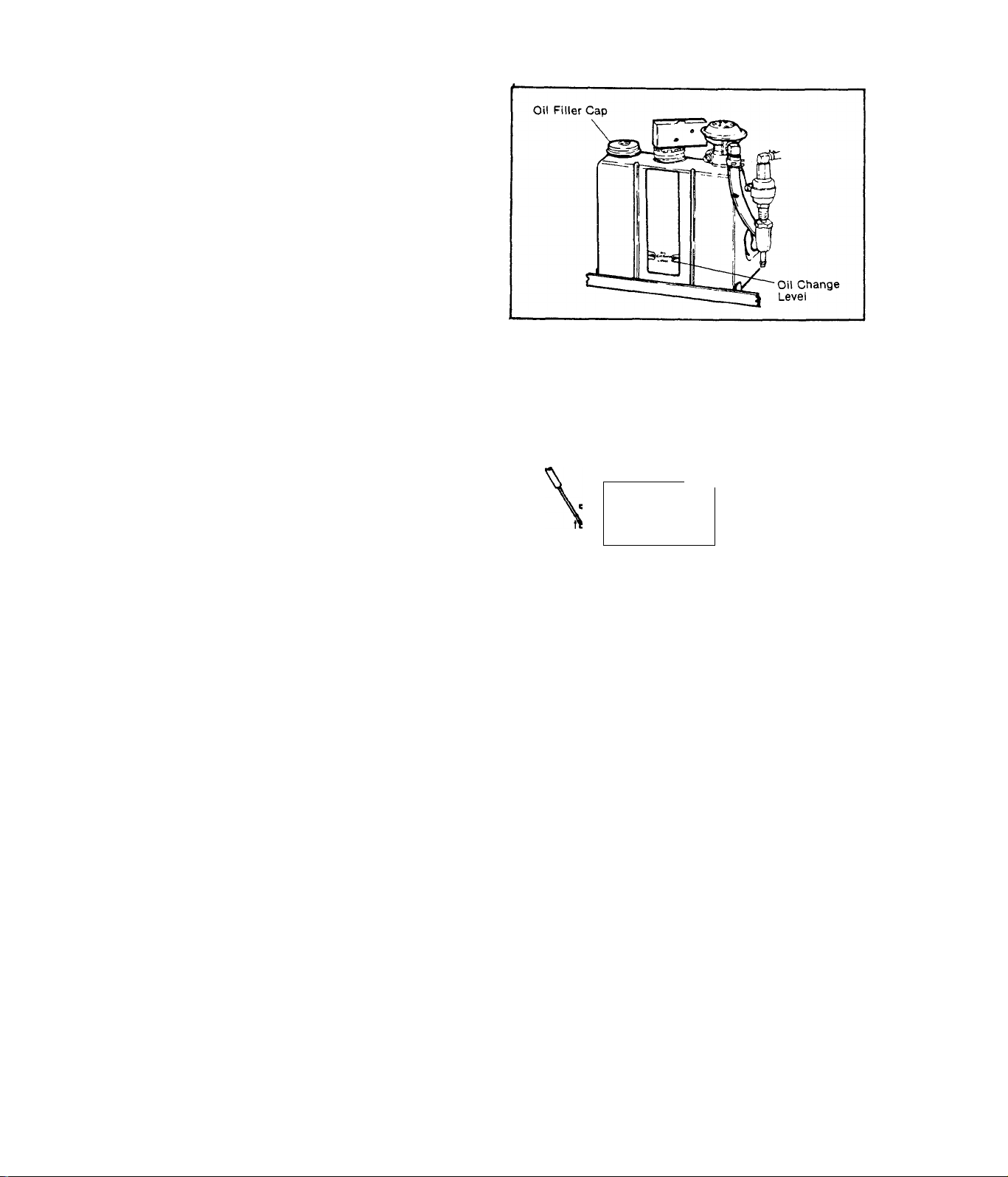

TEST 9-OIL MAKE-UP TANK

Check oil level in Oil Make-Up

Tank. If oil level is below OIL

CHANGE LEVEL arrows, fill tank

with recommended engine oil and

recheck for proper start.

TEST 10-LOW OIL SWITCH

Remove Low Oil Switch Cover and

slide it down the Switch wires

to expose the Switch terminals.

Set VOM to "+DC" and to "Rxl"

scale, then zero the meter. Con

nect one meter test probe to the

lower terminal on side of switch.

Connect remaining test probe to

ground terminal on bottom of the

switch. Move switch actuating le

ver DOWN (simulated low oil cond

ition) - meter needle should

swing upscale to ”0”. Raise the

switch actuating lever (FULL con

dition) - meter needle should

drop downscale to infinity.

Oo

LOW OIL

SWITCH'

TEST PROBES

mr^

ooj

A

METER

READS

INFINITY

METER

READS

V

•0"

RESULTS:- Switch tests bad..

Switch tests good.

A

CAUTION

.Replace switch

.Continue tests

When reassembling Switch cover, make sure float arm is in place

on top of switch actuating lever, or switch will not function.

TEST 11-SPARK PLUG

Remove engine spark plug. With spark plug lead connected to plug, ground

the spark plug against the engine block and crank engine. Spark plug

should emit a sharp, snappy, blue spark,

RESULTS;- Spark Plug bests bad..,....................Replace Spark Plug

Spark Plug checks good,,,.,,,.................

Continue tests

2.2-5

Page 28

TEST 12- IGNITION MODULE

Unplug the Ignition Module from

its receptacle on the side of the

stator can. Carefully inspect mo

dule and receptacle pins for. dam

age, bending or "pushing out"

from their retainers. Plug in a

known good "shop" module and

check for normal sparking at the

spark plug.

Ignition

Module

Ignition Module

Receptacle

RESULTS:- Ignition Module tests good

Ignition Module tests bad

........................Replace

TEST 13- IGNITION STATOR

A. )-Trig;g£r Coil:- Set VOM to "+DC"

and to "Rxl" scale. Zero the meter.

On the DC Control Board, unplug the

connector plug from its receptacle

to prevent interaction. Also unplug

the Ignition Module from its recep

tacle. Insert one meter test probe

into Pin No. 3 of the Ignition Mod

ule Receptacle. Connect tha remain

ing test probe to frame ground. The

meter needle should swing upscale

and read Trigger Coil resistance (a-

bout 7 Ohms),

RESULTS:- Meter needle does not move.

Meter needle swings upscale,

and indicates approximately

7 Ohms resistance

................

.Check Wire No. 25 between

Ignition Module receptacle

and Ignition Stator for an

"open" condition. If Wire

No. 25 is good, replace

Ignition Stator

.Continue checks

Continue tests

Trigger

Coil

B.)- Charge Coil:- Set VOM to "+DC" and to "RxlO" scale, then zero the

meter. Insert one meter test probe into Pin No, 2 of the Ignition Mod

ule receptacle. Connect the remaining test probe to frame ground. The

meter needle should swing upscale.and indicaie approximately 250 Ohms

resistance.

2.2-6

Page 29

RESULTS;— Meter needle does not move«

..Check Wire No, 8, between

Ignition Module receptacle

and Ignition Stator Charge

Coil for an ''open” condit

ion, If Wire No, 8 checks

good, replace Ignition Sta

tor,

Meter indicates approximately 250.

..Continue checks

Ohms

REINSTALL CONNECTOR PLUG INTO DC CONTROL BOARD RECEPTACLE AND IGNITION

MODULE INTO ITS RECEPTACLE BEFORE CONTINUING.

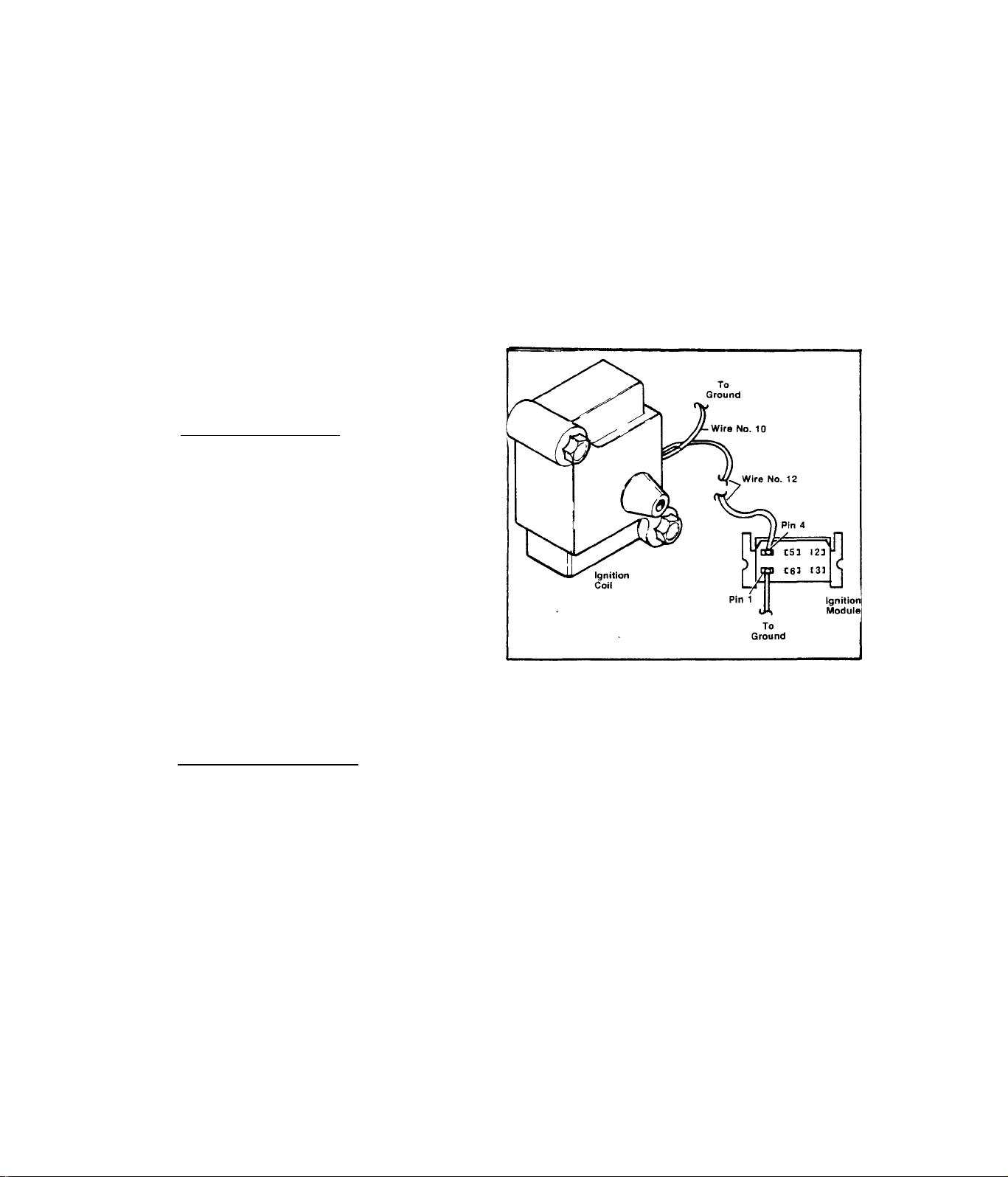

TEST 14- IGNITION COIL

A.)- Primary Winding;- Set VOM to

"Rxl” scale and to ''+DC”. Zero the

meter. Connect the positive (+)

test probe into Pin 4 of the Igni

tion Module receptacle. Connect

the negative (common) test probe

to frame ground. Meter needle

should swing upscale to nearly "O",

RESULT;- Meter needle does not move.............Replace Ignition Coil

Meter indicates nearly "O”.....................Continue test

B,)- Secondary winding; - Set VOM to '’RxlK” and to "+DC”. Zero the met

er. Install spark plug lead into Ignition Coil. Connect one meter test

probe to spark plug end of spark plug lead and the remaining probe to

frame ground. Meter needle should swing upscale and indicate approxim

ately 5000 Ohms (+10%).

RESULT;- Meter needle does not move.......Check spark plug lead for

open condition. If lead is

good, replace Ignition Coil

Meter reads approximately.....................Continue test

5000 Ohms

CAUTION

To prevent damage to Ignition Coil, make sure spark plug, lead and

spark plug are installed and grounded to engine before cranking.

2.2-7

Page 30

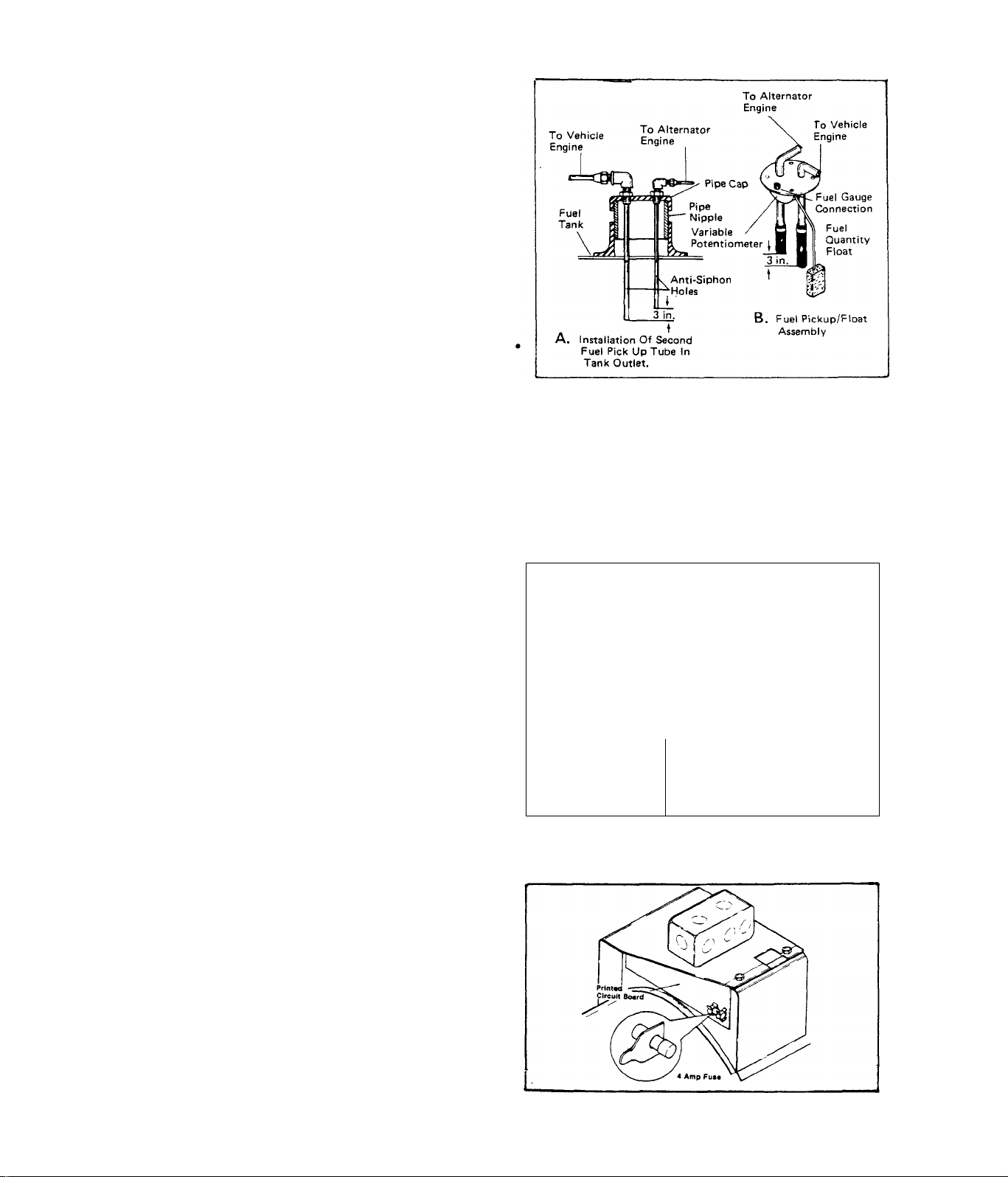

TEST 15:- LOW FUEL

The motor home engine and the alt

ernator engine should "share” the

vehicle fuel tank, through a dual

fuel pickup tube arrangement. See

illustration at right. To prevent

the alternator from depleting the

fuel tank, the alternator fuel

pickup tube is usually several in

ches shorter than the vehicle eng

ine tube. Thus, the alternator may

be "out-of-gas" while the vehicle

engine has a sufficient fuel supply

Make sure the alternator fuel supply line is NOT connected into the ve

hicle engine fuel supply line. If the vehicle engine is running, the

alternator engine may be starved of fuel. When the vehicle engine is

not running, the alternator may drain the vehicle engine fuel line (and

even the vehicle engine carburetor). The latter will result in hard

starting of the vehicle engine.

TEST 16:-NO FUEL FLOW

Disconnect fuel line at Carburetor

inlet fitting. Place open end of

fuel line into a suitable contain

er, then crank engine. Fuel should

pump from open end of fuel line.

If little or no fuel comes from

fuel line, check in-line filter for

clogging. Replace fuel line and fi

lter, if filter is clogged.

RESULTS:- Little or no fuel flow observed

Fuel flow is good

...........................

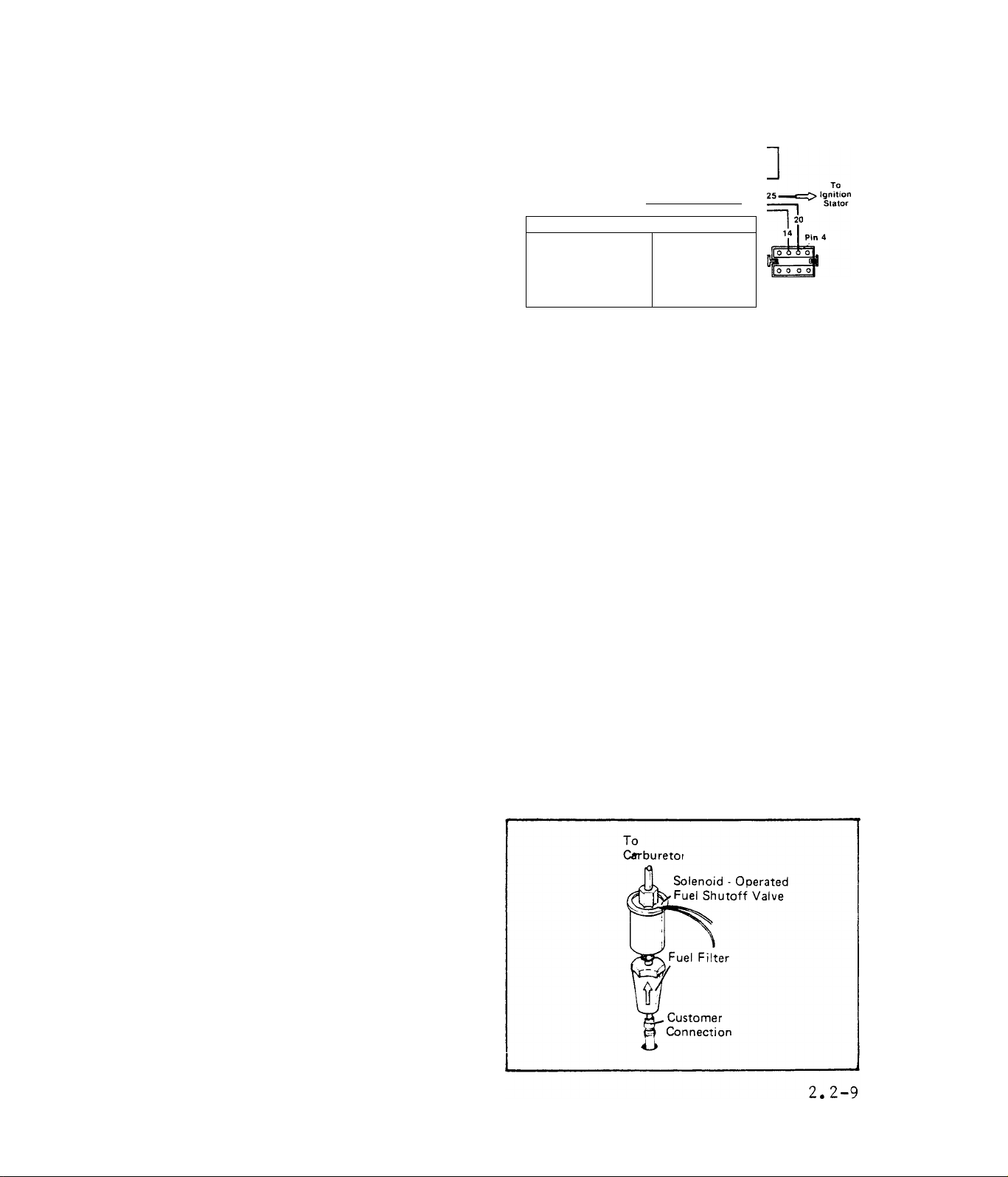

TEST 17:- 4 AMP FUSE

The 4 Amp Fuse is equipped with a

Fuse Puller Tab for easy removal.

Remove the Fuse from the Printed

Circuit Board and test in same

manner as 15 Amp Fuse (Test 1). If

Fuse is defective, replace.

(NOTE:-Model 6897-4 has no 4 Amp

Fuse. See Section 2.4.)

2.2-8

__

i 1

3>

j "

■j

'I'

>

.............

_

----

CARBURETOR

- IN-LINE FILTER

— FUEL LINE

Continue tests

Go to Test 23

Page 31

TEST 18;- PRINTED CIRCUIT BOARD

A.)- Depress Printed Circuit Board

connector plug locking tangs and

remove connector plug. On the conn

ector plug, locate Pin 4 to which

Wire No. 20 attaches. Set VOM to AC

and to the 2.5 volt scale. Connect

one meter test probe to connector

plug Pin 4, Connect the other test

probe to frame ground. Crank engine.

Meter should indicate a small puls

ing voltage. This is the pulsing

voltage from the Ignition .Stator

trigger coil, which energizes circ

uit board components.

Wir« No. 14

Connection

m

terminal

Strip

, ■ ■■■ ■ ■ —Q— . ■ ■ -1

rs —^ \— ^ -1

__________________________________________

Printed Circuit Board

H

I Module

CD

- EDflO

Ignition

__J— O

1--1 —' jc 0 o'olj

Connector Plug

Receptacle

Connector

Plug (viewed

from Wire end)

NOTE:- For Model 6897-4, refer

to Section 2,4,

RESULTS:- Meter indicates pulsing voltage

.........

.,,Continue tests

No pulsing voltage indicated,..Check Wire No. 20, between

connector plug and terminal

strip, and Wire No. 25 betw

een terminal strip and Igni

tion module for open or shor

ted condition

See illustration above. Locate the Wire No, 14 connection at terminal

strip. Plug the Printed Circuit Board connector plug into its recept

acle. Set VOM to '’+DC” and to "50V” scale. Connect positive ( + ) meter

test probe to terminal strip Wire No. 14 connection. Connect remain

ing test probe to frame ground. Crank the engine. Meter should swing

upscale and indicate 9-12 Volts DC.

RESULTS:- Meter indicated 9-12 Volts

....

Continue tests in Diagnostic

Flow Charts

Meter did NOT read 9-12 Volts..Check Wire No. 14 (between

PCB and terminal strip) for

open or short. If wire is

good, replace Circuit Board

TEST 19:- FUEL FILTER

Remove and replace fuel filter.

Make sure arrow on filter body-

points toward the solenoid oper

ated Fuel Shutoff Valve. Repeat

Test 16 (NO FUEL FLOW).

Page 32

TEST 20;- FUEL LOCK-OFF SOLENOID

A.)- Locate Wire No. 14 between the

Fuel Lock-Off Solenoid and terminal

strip. Disconnect the wire at its

terminal strip connection. Crank en

gine. While cranking, touch Wire No.

14 to its terminal strip connection.

Fuel solenoid should actuate. If the

unit has an electric fuel pump, a

noticeable change in fuel pump sound

will be detected.

RESULT:- Solenoid did not actuate.,.,,

.............

Go to Paragraph B

Solenoid actuates....Continue tests in DIAGNOSTIC FLOW CHARTS

B.)- Disconnect Fuel Lock-Off Solenoid Wire No, 14 at the terminal st

rip, Set VOM to "+DC” and to ”Rxl” scale. Zero the meter. Connect one

meter test probe to the terminal end of Wire No, 14, Connect the rem

aining test probe to frame ground. Meter needle should swing upscale

to indicate resistance of solenoid windings.

RESULT:- Meter did not swing upscale,

.Check Wire No, 14 between sol

enoid and terminal strip for

open condition. Also check the

solenoid ground wire and conn

ection

Meter needle swung upscale,,,

.Replace Fuel Lock-Off Solenoid

and solenoid did not actuate

in Paragraph A

TEST 21:- FUEL PUMP

UNITS WITH ELECTRIC FUEL PUMP

A.)- Disconnect Wire No, 14 at the Fuel Pump, Set VOM to ”+DC' and to

”Rxl” scale. Zero the meter. Connect one meter test probe to the Fuel

Pump Wire No, 14-, Connect the remaining test probe to frame ground.

Meter needle should swing upscale and indicate approximately 50 Ohms',

RESULT:- Pump tests good

Pump test^ bad,

..........................

......

.........................

Go to Paragraph B

Replace pump

C,)- Set VOM to "+DC" and to 50V scale. Disconnect Wire No, 14 at the

Fuel Pump, Connect POSITIVE (+) meter test probe to terminal end of Wire

No. 14, Connect COMMON test probe to frame ground. Crank the engine -

meter needle should deflect upscale and read approximately 12 Volts DC

(battery voltage),

RESULT:- Meter needle daes NOT swing upscale

Meter indicated approximately 12 Volts

2.2-10

.......

.....

Go to Paragraph C

Replace Fuel Pump

Page 33

C.)- Check Wire No. 14, between Fuel Pump and terminal strip, for open

or shorted condition,

RESULT:- Wire No. 14 checks good

Wire No. 14 cheeks bad

............

............

UNITS WITH MECHANICAL FUEL PUMP

Disconnect Piomp Outlet Line at the

carburetor inlet. Connect a press

ure gauge to the line. Disconnect

Pump Inlet Line at the £ue-l lock-

off solenoid and immerse line in

clean gasoline. Crank engine. The

pressure gauge should indicate 1-

3 psi.

RESULT:- Pressure gauge read 1-3 psi

Pressure gauge does -not read 1-3 psi

Repair/replace Wire No. 14

........

Continue Diagnostic tests

Continue Diagnostic Tests

...........

Replace Pump

TEST 22;- CHECK INSTALLATION

Check alternator installation for:-

1. )- Any other filter screens in the fuel supply line from gas tank.

If other filters are found, check for clogging.

2. )- A Shutoff Valve in the fuel supply line. Make sure Shutoff Valve

is OPEN.

3. )- Anything that might restrict cooling air flow, such as air inlet

or exhaust openings too small, clogged air inlet screening, etc.

If cooling air flow is inadequate, interior compartment tempera

tures will be high resulting in possible fuel line vapor lock,

4. )- Alternator fuel pump located too high above fuel supply tank.

Maximum vertical lift for MC units with an electric pump is app

roximately 18 inches, for mechanical fuel pumps approximately 9

inches.

TEST 23- CARBURETOR

This test covers the procedures for adjustment of the carburetor Idle

Speed Stop Screw, Idle Mixture Adjusting Screw, and High Speed Jet Ad

justing Screw. In addition to these adjustments, the float valve and

its seat should be checked, as well as the float level.

2.2-11

Page 34

A.)-Turn High Speed Jet Adjusting

Screw clockwise until it just bot

toms. DO NOT USE EXCESSIVE FORCE.

Then turn High Speed Jet Adjusting

Screw counterclockwise about

turns. Perform the same initial ad

justment on the Idle Mixture Adjust

ment Screw. This initial adjustment

should permit the engine to be star

ted and warmed up.

Automatic Choke

. High Speed Jet

Adjusting Screw

Throttle Lever

Idle Mixture

Adjusting Screw

RESULTS:- Engine starts

Engine will not start

.............................

....................

Go to Paragraph B

Go to Paragraph D

B. )- Set VOM to "250V,” scale and to "AC". Connect the meter test leads

to a convenient AC outlet powered by the alternator. Hold the Carburet

or Throttle Lever against its Idle Speed Stop Screw, Adjust Idle Speed

Stop Screw until meter indicates 60 Volts a-c. When a 60 Volt reading

is obtained, turn Idle Mixture Adjusting Screw until voltage starts to

drop off. Then turn the screw in the opposite direction until voltage

reading again starts to decrease. Finally, reverse direction again and

turn the screw until the highest voltage reading is obtained. Release

Throttle Lever and let engine accelerate and stabilize,

C. )- With engine running at governed speed, apply a normal load to the

alternator. Connect an accurate frequency meter to the unit’s a-c out

put, Turn the High Speed Jet Adjusting' screw slowly clockwise then

counterclockwise until the highest frequency is obtained. When the Jet

is set for the highest possible frequency, turn adjusting screw count

erclockwise 1/8 turn.

RESULTS:- Engine starts and runs normally............Discontinue Tests

Engine will not start or starts and runs

rough

.....................................

Go to Paragraph D

D.)- Remove Fuel Bowl from Carbur

etor Body. Inspect Float Valve,

Seat and Gasket for damage, dirt

or wear. Replace defective compon

ents. Also check for proper Float

setting. Top of Float should be

0.070 - 0.110 inch below Carburet

or Body mounting Flange. See illu

stration at right.

2.2-12

Page 35

RESULT:- Float Valve, Seat, Gasket and

Float level are good

Float Valve, Seat, Gasket or

Float level check bad

TEST 24:- COMPRESSION

A.)-Insert a standard compression

gauge into engine spark plug hole.

Open throttle wide open and crank

engine. Compression should be app

roximately 75-85 psi (cold) or 95105 psi (hot).

.........

........

-...Continue Diagnostic Tests

-Replace or adjust, then test

COMPRESSION

GAUGE

SPARK PLUG

REMOVED

RESULT:- Compression reading good

Compression reading low.......................Continue tests

B,)- Squirt a few drops of clean engine oil into spark plug hole on en

gine cylinder head. Repeat compression test. If compression reading is

higher than was obtained in Paragraph A, ring or cylinder wear is indi

cated, If little or no difference in compression was noted, trouble may

be due to head gasket leakage, worn valves, etc.

RESULT:- Noticeable increase in

compression obtained...............

Little or no increase in compression.

TEST 25:- HEAD GASKET

Crank the engine. A "hissing" sound

at the spark plug indicates the plug

is loose or broken. Likewise, "hiss

ing" at the cylinder head indicates

loose head nuts or a leaking head

gasket. Tighten loose spark plug, re

place broken spark plug using a new

plug gasket. If cylinder head leaks,

check for warped cylinder head and

for a defective head gasket. Refer to

engine section of manual and to TORQ

UE SPECIFICATIONS (SPECIAL).

......................

Go to Test 29

Go to Test 27

Go to Test 25

2.2-13

Page 36

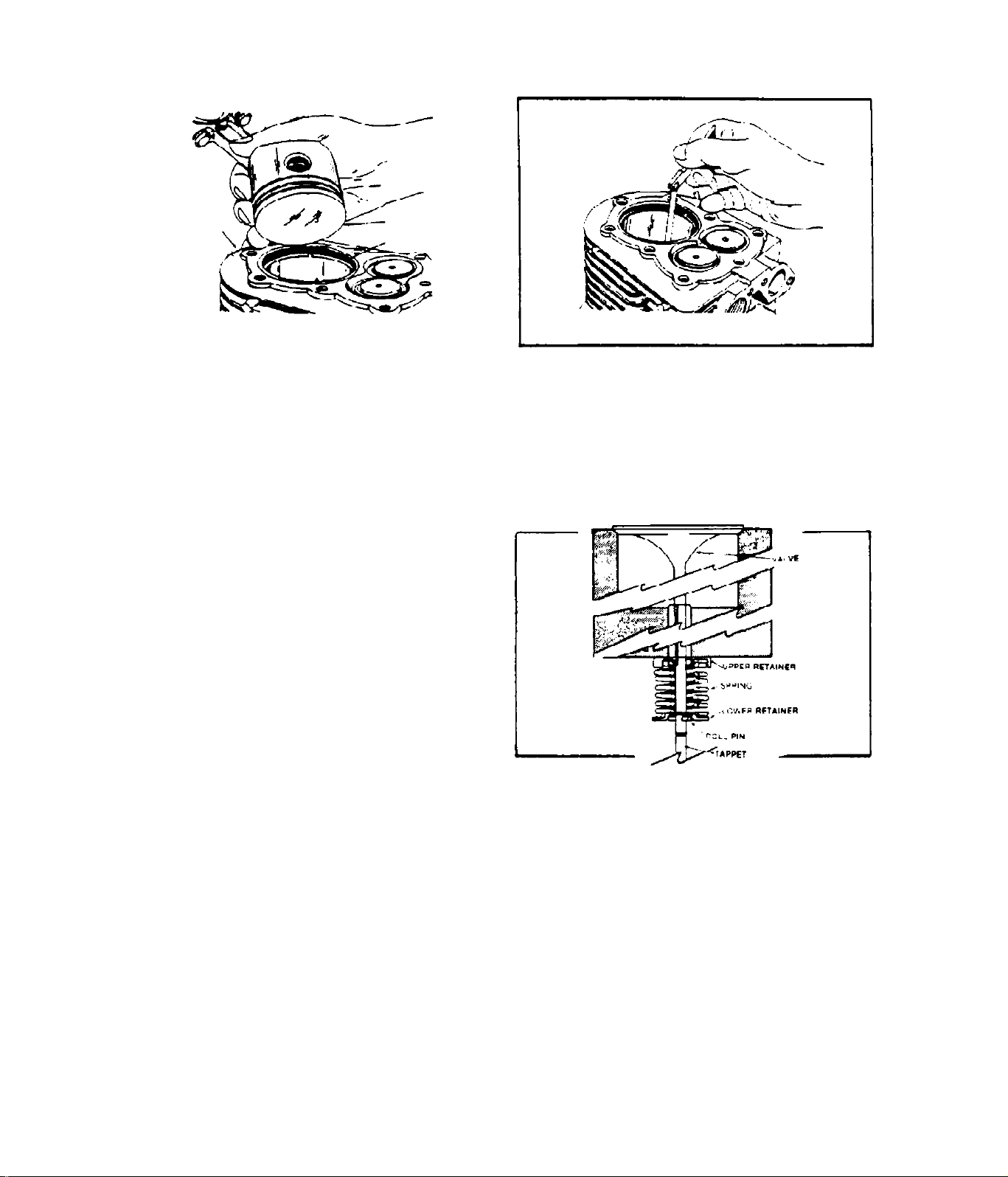

TEST 26:- VALVES

Remove valves. Clean all parts in

non-flammable solvent. Remove all

carbon. Replace damaged or distor

ted valves. If valves are useable,

lap them as outlined in engine se

ction. Check for correct tappet

clearance as outlined in engine

section of manual.

TEST 27:- RINGS

Check for broken or worn rings.

Check ring clearance-in piston

grooves and ring gap. Refer to

engine section of manual.

Valve

Roller Spring Retainer

Valve Spring

Valve Spring Retainer

Tappet

TEST 28:- CYLINDER

Inspect cylinder walls for burning, scoring, or scratching. Check cylin

der inner diameter. Refer to engine section of manual for inspection

requirements.

TEST 29:- TIMING

This Pol« Must Attract Th«

North Soaking Poia Ot A

Magnatic Compass

The ignition magnet is retained to

the fan with a special adhesive

which is cured at 300°F. for 1 hour

(or 265°F. for 1% hours) after ins

tallation. The ring gear is heated

and pressed over the fan and magnet

assembly. The entire assembly is

then balanced as a unit, and finally heated and epoxied into place over

the rotor shaft. Any damage to the

Rotor, Fan, Magnet or Ring Gear is

cause for replacement of the entire

assembly.

2.2-14

Magnai Location astabilshas

Timing At 21* BTDC

Page 37

Timing is established at 21 BTDC by the physical location of the magnet

on the fan. Thus any damage that results in a physical change in the

magnet's location will cause an "out-of-time" condition. Check for a da

maged key or keyway that might have caused slippage of the fan on the

rotor shaft.

TEST 30:- CHOKE

A.)-Crank the engine. The Choke

Solenoid should pulse from Choke

OPEN to Choke CLOSED position at

a rate dependent on ambient tem

perature.

RESULTS:- Choke movement is good

Choke does not move

.............

Go to Test 31, PRE-CHOKE

.......................

Go to Paragraph B

B.)-Check the Choke assembly for

binding or sticking caused by im

proper alignment, dirt, etc. Move

Choke back and forth with fingerthere should be no evidence of

binding or sticking.

RESULTS:- Choke is binding..,

Choke moves freely,

.Adjust or clean choke linkage

............

Go to Paragraph C

C.)- Loosen the two Solenoid Adjusting screws. Adjust axial movement

of solenoid plunger so that, with carburetor choke plate closed, the

choke solenoid plunger is bottomed. Tighten the two adjusting screws

and check again for correct choke action,

RESULTS:- Choke solenoid pulls in normally..............Go to Test 31

Solenoid does not pull in,................Go to Paragraph D

2.2-15

Page 38

D.)-Set VOM to ”+DC'’ and to ”50V.”

scale. Connect the positive (+)

meter test probe to the Wire No. 91

terminal on the choke solenoid and

the remaining test probe to frame

ground. Crank the engine - meter

needle should swing upscale and in

dicate a steady 12 Volts DC.

RESULTS:- Meter does not indicate IZ Volts....Check Wire No. 91 for an

open or shorted condition

Meter indicates 12 Volts DC................Go to Paragraph E

E.)- Set VOM to "+DC” and to ”50V.'' scale. Connect the positive ( + ) me

ter test probe to the Wire No. 90 terminal on the choke solenoid and

the common (-) test probe to frame ground. Crank the engine - meter nee

dle should indicate a pulsing voltage as choke pulses open and closed.

RESULTS:- No meter needle movement

Meter test is good but choke

does not actuate.....................Replace Choke assembly

TEST 31:- PRE-CHOKE

With the choke Bi-Metal at ambient

temperature, the carburetor choke

plate should be approximately 1/8

inch away from its full open posi

tion (toward the closed position).

If necessary, loosen the bi-metal

adjusting screws and move the bi

metal to obtain this setting. This

is the "Pre-Choke" position.

......

Replace Printed Circuit Board

(Model 6897-4:-Replace Choke

Pulse Module [CM]. See Sect-

jL 2 ^ )

2.2-16

Page 39

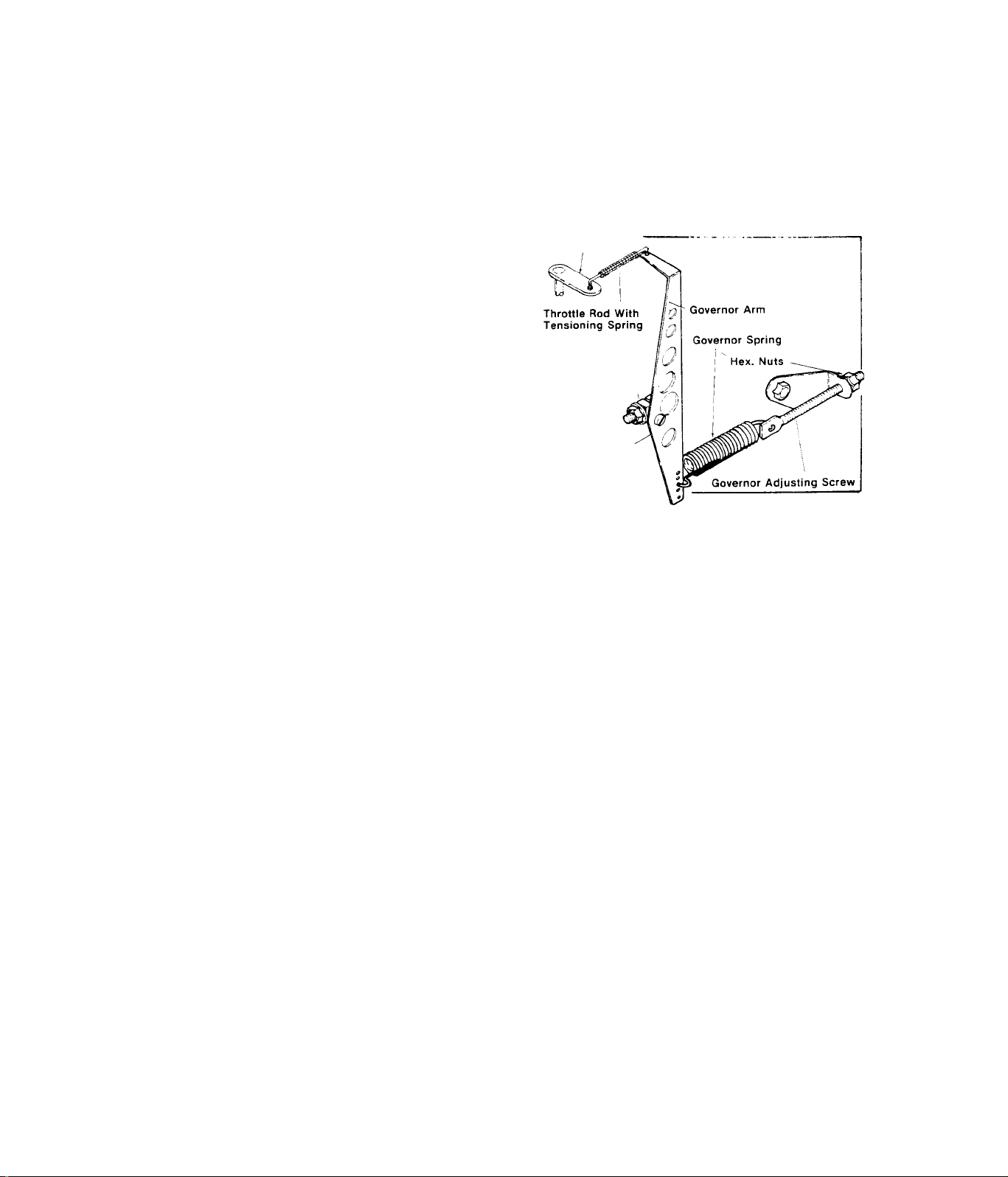

TEST 32;- GOVERNOR

A.)- Adjust Carburetor as outlined in Test 23, The Carburetor must be

adjusted BEFORE attempting to adjust the Governor,

RESULT Problem is corrected...........................Test completed

Engine ’’hunts’’ and/or a-c voltage

or frequency is incorrect.................Go to Paragraph B

_ Carburetor

Throttle Lever

B,)-Make sure Governor Spring is

connected to Governor Arm and to

Governor Adjusting Screw, Loosen

Engine Governor Shaft Clamp Nut

and turn Engine Governor Shaft

counterclockwise as far as it

Engine Governor

Shaft Clamp Bolt,

Nut and Washers

will go. Then tighten Governor

Shaft Clamp Nutand torque to 110

inch-pounds.

Engine Governor

Shaft

RESULT:- Engine runs normal, provides

62 Hertz at no—load..........................Test completed

Engine hunts and/or a-c voltage

or frequency is incorrect

................

Go to Paragraph C

C,)- With engine running, adjust hex nuts at end of Governor Adjust

ing Screw to obtain 62 Hertz at no-load. One hex nut serves as a jam

nut - make sure this nut is tight when 62 Hertz is obtained,

RESULT:- Engine runs normal,,,,.,,"...................Test completed

Engine hunts

...............

Set Carburetor for richer mixture

NOTE

All mechanical governors have a normal offspeed fluctuation,

This is the reaction time of the governor,

TEST 33;- CHECK FREQUENCY

Use an accurate Frequency Meter to check alternator output frequency.

Frequency should be 62 Hertz at no-load. With a normal electrical load

applied, frequency should be 59-62 Hertz and stable (disregarding the

normal offspeed fluctuation).

2.2-17

Page 40

TEST 34:- EXCITATION WINDINGS

Remove the

assembly.

alternator front panel

Disconnect the white connector plug

from its receptacle on the stator

can. On the receptacle, locate Pin

No. 2 and 6 to which Wires No. 2

and 6 attach. Set VOM to ”+DC’' and

to "Rxl” scale, then zero the meter.

Connect one meter test probe to re

ceptacle Pin No, 2, Connect the re

maining test probe to receptacle Pin

No. 6. Meter needle should swing up

scale and read approximately 1,1

Ohms, This is the resistance of the

excitation winding,

RESULT;- Meter needle does not move

Windings check good

..............

....................

,,,Continue diagnostic tests

Replace stator

TEST 35:- CARBON DEPOSITS

Excessive carbon buildup in the engine combustion section can serious

ly affect engine power. Carbon deposits should be removed every 500

operating hours, whenever the cylinder head is removed, or when prob

lems are encountered. Refer to the engine section of Manual for cylin

der head removal and installation procedures. Cylinder head bolts must

be properly located and properly torqued.

RESULT:- Power output is normal............

Problem is still encountered,

2.2-18

......

........

Discontinue tests

Continue diagnostic tests

Page 41

TEST 36:- CHECK VOLTAGE

Disconnect customer wiring from

Wires No. T1 and T2 in alternator

connection box. Check a-c voltage

output at Wire No. T1 and junction

of Wires T2. Reading should be ap

proximately 125 Volts a-c at no-load

and 115-125 Volts a-c under load.

RESULT:- Vol.tage output bad,,

Voltage checks good.

.Continue diagnostic tests

.....Check customer wiring

NOTE

Alternators are factory connected to provide a 120 Volt a-c output

only. Some units may have been reconnected to supply 120/240 Volts

a-c. See Page 1.2-3.

TEST 37;- SENSING TRANSFORMER

White Connector Plug

A./-Remove 2 wire nuts that connect

wires No. 11 and 22, between Sensing

Transformer and Voltage Regulator.

Disconnect the wires. Set VOM to

”+DC” and to ”Rxl00" scale, then ze

ro the meter. Connect meter test

probes across wires No, 11 and 22

from the Sensing Transformer. Meter

needle should swing upscale and indi

cate secondary winding resistance.

See illustration at right.

Winding Wescoil Coiltran

Primary 785 ohms 969 ohms

Secondary 1886 ohms 1438 ohms

Resistance (± 15%)

RESULT;- Secondary winding resistance checks good

Meter needle does not swing upscale

.......

...

Go to Paragraph В

Replace Transformer

B.)- Unplug the white connector plug from its receptacle on the stator

can. Set VOM to ”-t-DC” and to ”RxlO, 000" scale. Zero the meter. Connect

one meter test probe to white connector plug Pin No. 3. Connect the re

maining probe to white connector plug Pin No. 5, Meter needle should

swing upscale and indicate PRIMARY winding resistance. See illustration

above right.

2.2-19

Page 42

RESULT:- Primary windiag rasistance. checks good..Check customer wiring

Primary winding resistance is bad,.......Replace Transformer

NOTE

The Sensing Transformer secondary windings MUST connect to the

Voltage Regulator, The primary windings..must connect to the

white connector plug. In most cases, primary and secondary wi

ndings will be identified when replacing a Transformer. If the

windings are not identified, check winding resistance. The

winding having the HIGHEST resistance is the SECONDARY winding.

TEST 38:- MAIN CIRCUIT BREAKER

Set VOM to ”+DC" and to "Rxl" scale.

Zero the meter. See illustration at

right. Connect VOM test probes acr

oss the Main Rreaker teat points.

Meter needle should swing upscale to

zero with Main Breaker ON, When the

Breaker is set .to OFF, needle should

drop all the way downscale (infinity),

RESULT:- Main Breaker cheeks good.

Main Breaker feeafes bad.

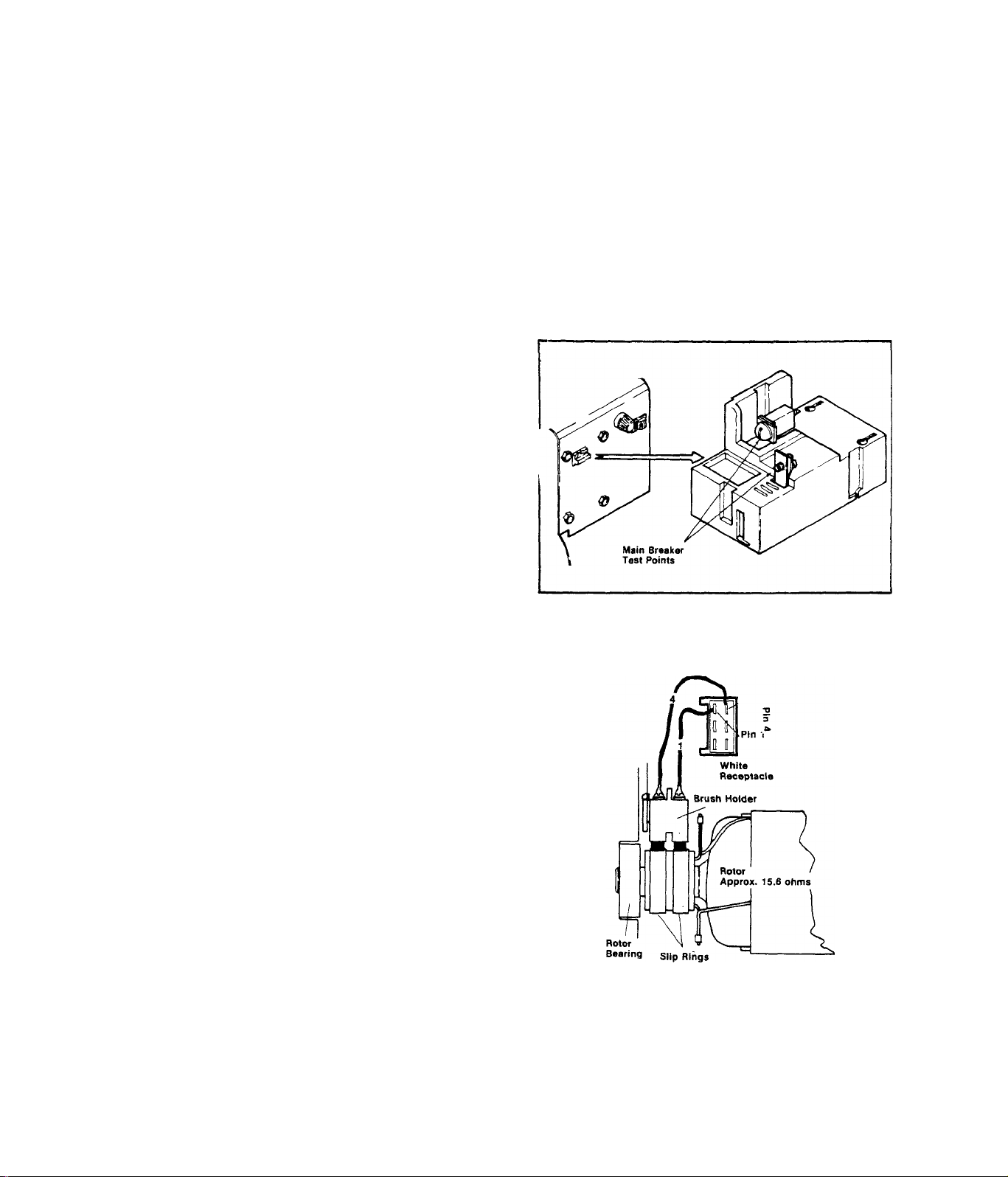

TEST 39:- CHECK ROTOR

A.)-Disconnect the white connect

or plug from its receptacle on the

stator can. Set VOM to "+DC” and

to "Rxl” scale, then zero the met

er. Connect the positive (+) meter

test probe to white receptacle Pin

4, Connect the common (-) probe to

receptacle Pin 1, Meter needle

should swing upscale and indicate

rotor winding resistance (approxi

mately 15,6 Ohms),

RESULT:- Rotor checks good

Rotor checks bad..

.Continue diagnostic tests

..........Replace Breaker

....

Go to Test 40

,Go to Paragraph B

2.2-20

Page 43

rotor checks bad in Paragraph A, check Wires No. 1 and 4 for an

open or shorted condition. Inspect brushes - replace if cracked, chipp

ed or less than 5/16 inch long. Inspect slip rings and clean with fine

sandpaper, if necessary. Make sure brushes are making good contact with

slip rings. Finally, recheck rotor winding resistance at Pins 1 and 4

of white receptacle as outlined in Paragraph A.

RESULT:- Wires, slip rings and brushes

check good but rotor still

checks bad......................................Replace rotor

Wires, slip rings or brushes

check bad............................Repair, clean or replace

TEST 40:-CHECK FIELD BOOST refe?^to^Section^rr)^°'^'^^^ 6897-4

Unplug the Ignition Module to pre

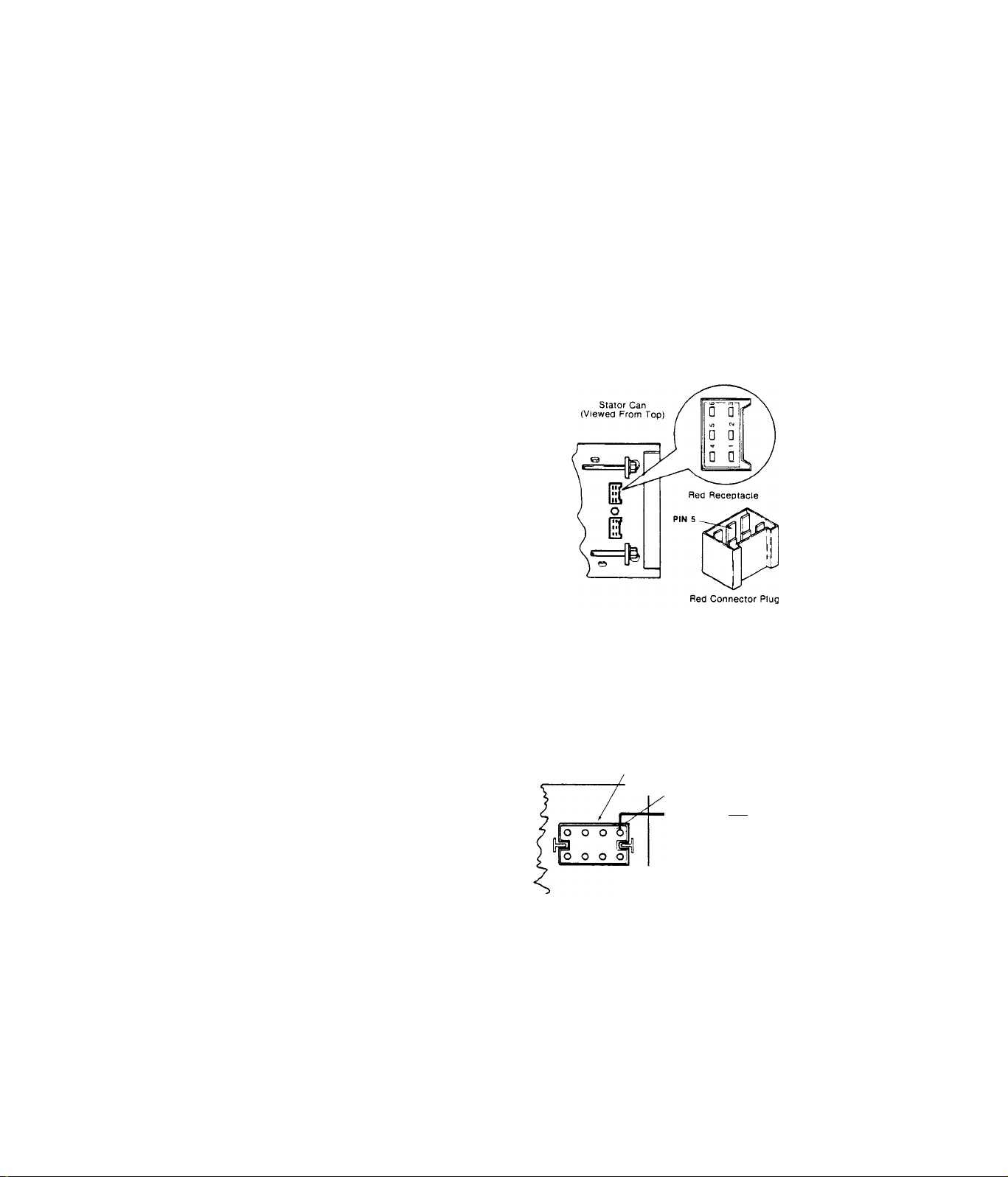

vent the engine from starting. Al

so unplug the red connector plug

from its receptacle on the stator

can. Set VOM to ”+DC" and to any

scale that will permit 12 Volts to

be read. Connect the positive (+)

meter test probe to red connector

plug Pin 5, Connect the negative

(-) test probe to frame ground.

Crank the engine - meter needle

should swing upscale and indicate

approximately 9-12 Volts d-c,

RESULT:- No field boost valtage indicated

Field boost voltage checks good

B,)-Unplug connector plugs from

the Printed Circuit Board and from

the red receptacle on stator can.

Set VOM to "+DC” and to "Rxl” sca

le, then zero the meter. Connect

one meter test probe to Pin No, 2

of the printed circuit board conn

ector plug. Connect second test

probe to Pin No, 5 of the red con

BOTH CONNECTOR PLUGS VIEWED FROM WIRE END

nector plug. Meter needle should

swing all the way upscale to zero.

RESULT:- Meter indicated, zero,

...

.

Meter did not swing upscale,

..........

....

Continue diagnostic tests

Printed Circuit Board

Connector Plug

Go to Paragraph B

Pin No.2

Red Connector Plug

(On Stator Can)

Wire No.4

k -■ Pin No. 5

.Replace printed circuit board

.Repair/replace Wire No, 4 or

defective connector plug

2.2-21

Page 44

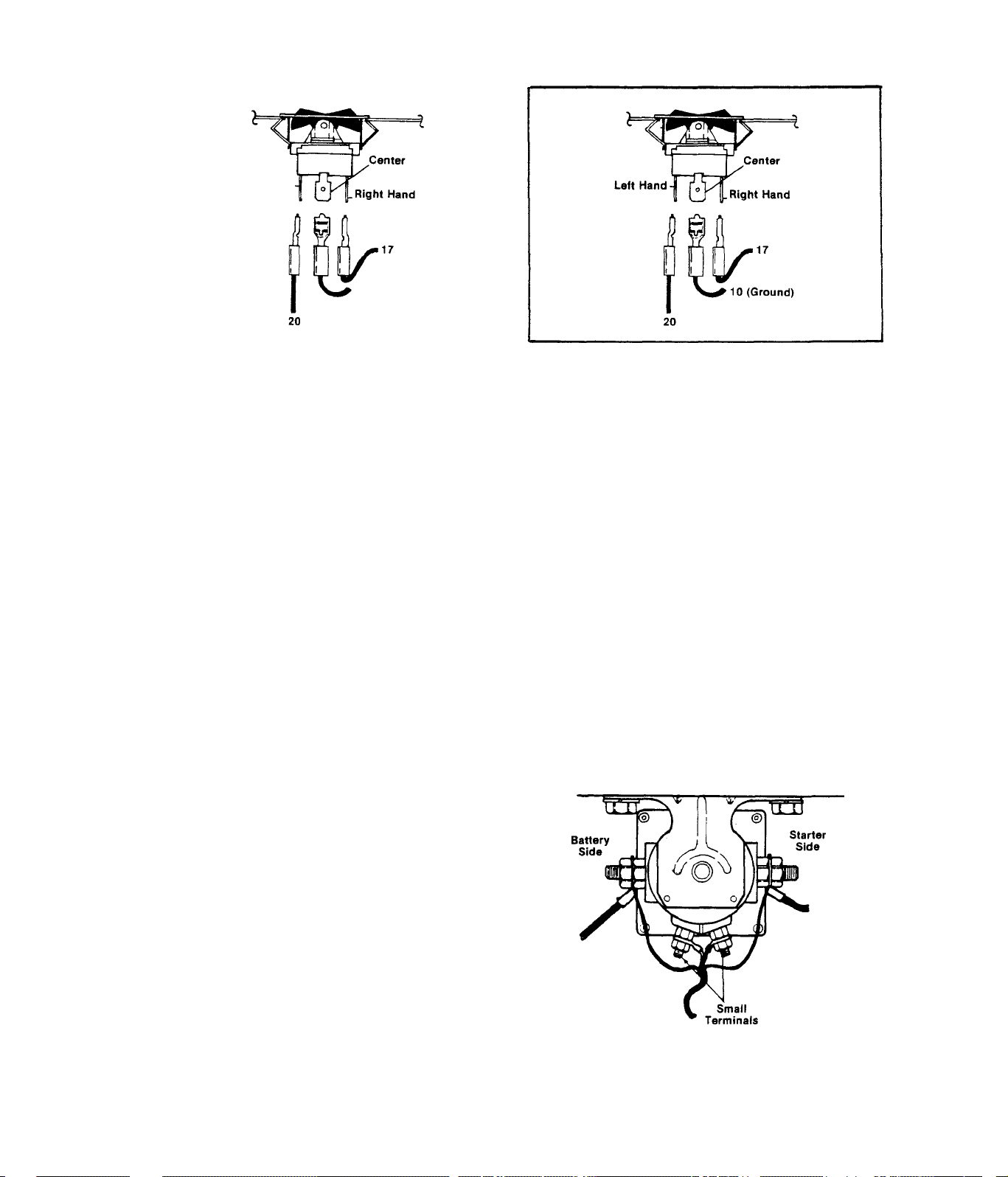

TEST 41:-CHECK STATOR

A.)- Set VOM to ”+DC" and to ”Rxl”

scale, then zero the meter. Connect

meter test probes to Pins 1 and 2

of red receptacle on stator can. Me

ter needle should swing upscale and

indicate approximately 0,42 Ohms.

RESULT, - Meter needle did not move

...................

Replace stator

Checks good................................Go to Paragraph B

B, )- With VOM still set to ”-l-DC” and to ”Rxl” scale, connect meter test

probes to red receptacle Pins 3 and 4, Meter needle should swing up

scale and indicate approximately 0.42 Ohms.

RESULT:- Meter needle did not move

Checks good..-. ....

............ .Go to Paragraph C

....................

Replace stator

C. )- Set VOM to ”+DC” and to ”Rxl0,000” scale, then zero the meter.

Connect one meter test probe to red receptacle Pin 1 and the second test

probe to frame ground. Meter needle should not move. Repeat test with

one test probe connected to red receptacle Pin 3 and the second probe

to frame ground. Meter needle should not move,

RESULT:- Meter needle moved upscale

.................

..Replace stator

Checks good........................Continue diagnostic tests

2.2-22

Page 45

SECTION 2.3

BATTERY CHARGE CIRCUIT

CHARRING CURRENT

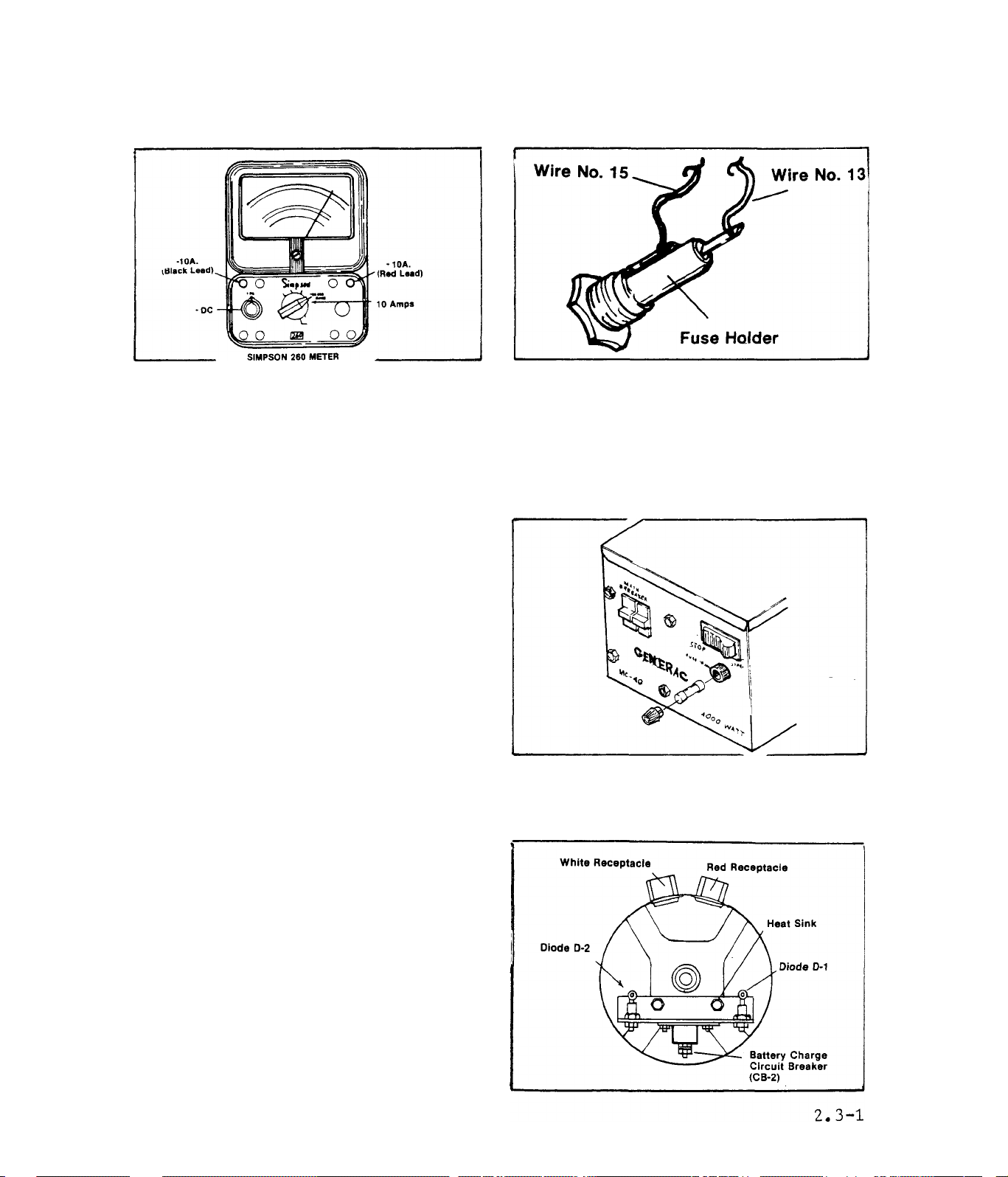

1,)- Plug the black (-) test lead

into the "-10A" jack on the VOM.

Plug the red (+) test lead into

the "+10A" jack on the meter. Set

the meter range switch to ”10 Amps”

(dual position with 10 MA).

2.)-Locate the 15 Amp Fuse inside

the alternator control panel. Co

nnect the red meter test probe to

the Wire 15 terminal on the Fuse

Holder, Connect the black test

probe to the Wire 13 terminal on

the Fuse Holder.

TESTS

3.)-Start the alternator. With

the engine running, remove the 15

Amp Fuse from its holder. With

the Fuse removed, the alternator

should indicate a current output

dependent on battery condition.

RESULT:- Ammeter indicates a current output..........Discontinue tests

No current output indicated.,.,

CIRCUIT BREAKER CB-2

Disconnect Wires No, 77 and 78 from

the battery charge circuit breaker

(CB-2). Set VOM to ”+DC” and to ”Rxl”

scale, then zero the meter. Connect

the meter test probes to the circuit

breaker terminal studs. Meter needle

should swing upscale to zero. If it

does not swing upscale, replace the

circuit breaker.

...............

Continue tests

Page 46

DIODES D1 ANDD2

A.)- Disconnect Wire No. 78 at the

circuit breaker CB-2, Set the VOM

to '*+DC” and to ’’Rxl” scale. Zero

the meter. Connect the positive (+)

test probe to Wire No. 78 from the

Diode D-2. Connect the common (-)

test probe to frame ground. Meter

needle should not move. Set meter

to ”-DC", or reverse the meter test

probes. Meter needle should swing

upscale to some mid-scale reading

(approximately 7-12 Ohms).

RESULT:- Diode D-2 tests good...... Reconnect Wire 78,

Diode D-2 tests bad

.....

....

............

go to Paragraph B

.Replace Diode D-2

B.)- Set VOM to ”+DC” and to ”Rxl” scale, then zero the meter. Connect

the positive (+) test probe to the Diode D-1 terminal end. Connect the

common (-) test probe to frame ground. Meter needle should not move.

Set meter to ”-DC” or reverse the test probes. Meter needle should move

upscale.

RESULT:- Diode D-1 tests good.....

Diode D-1 tests bad.............

.....................

...........

...Replace Diode D-1

Continue tests

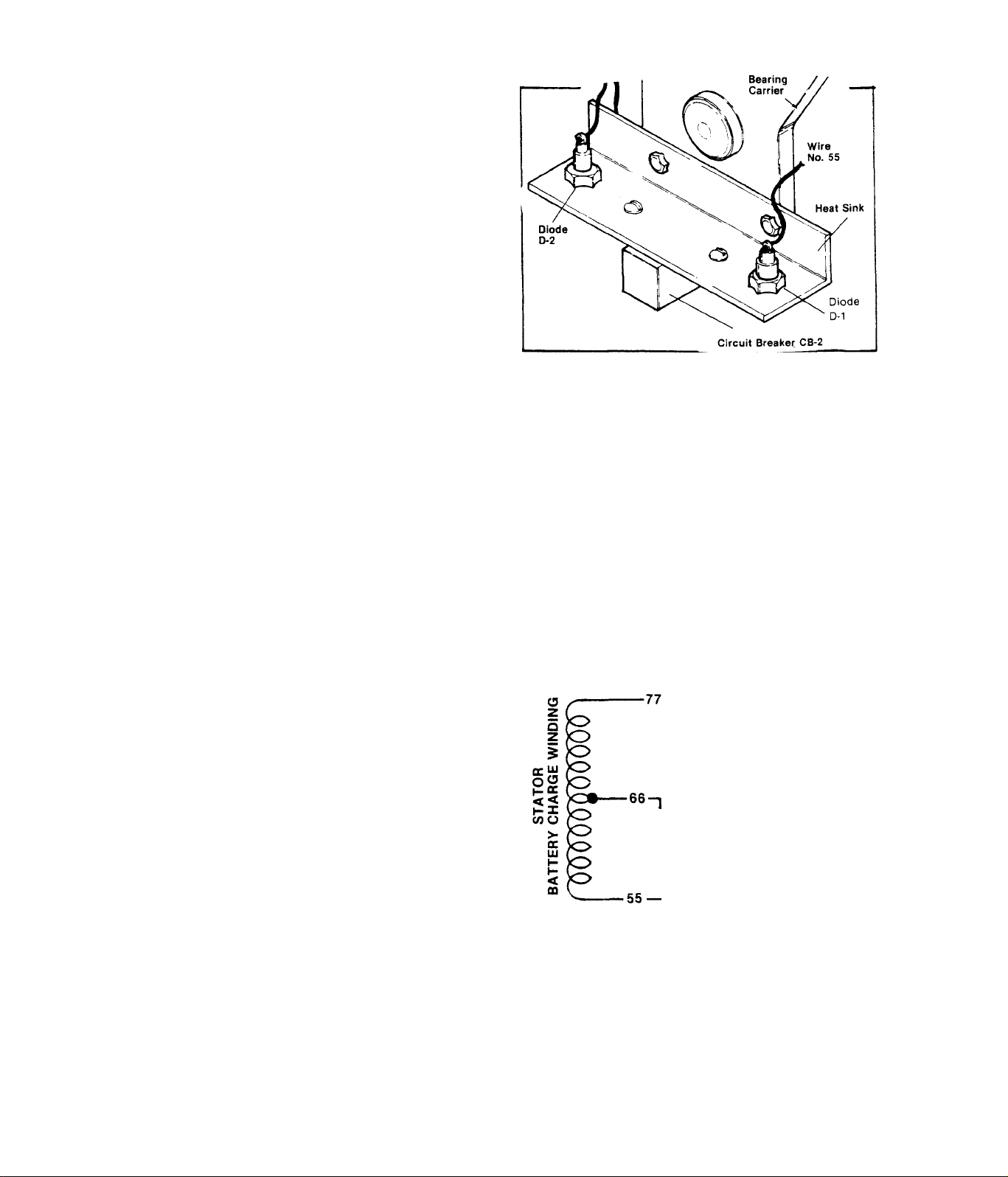

STATOR BATTERY CHARGE WINDINGS

Disconnect Wire 77 from Circuit Break

er CB-2, Unplug the red connector plug

from its receptacle on the stator can.

To

CB-2

Set VOM to "+DC” and to ”Rxl" scale,

then zero the meter. Connect one meter

test probe to Wire 55 at the Diode D-1

.08 ohm.

Pin 6

terminal. Connect second test probe to

Pin 6 of the red receptacle. Meter

needle should swing upscale (approxim

ately ,08 Ohm). Repeat test with meter

.08 ohm.

€ 0

0 0

RECEPTACLE

00

RED

test probe connected to red receptacle

Pin 6 and Wire 77 - meter should indi

cate approximately .08 Ohm,

To

•DIODE D-1

RESULT; Both meter readings were approximately

.08 Ohm

............................................

Meter needle did not indicate .08 Ohm

2.3-2

..........

Test good

Replace stator

Page 47

SECTION 2.4

MODEL 6897-4

2.4.1-GENERAL

2.4.1.1-INTRODUCTION

The Model 6897-4 (MC-40) alternator incorporates several new components

in its DC control system. The new components replace the printed circu

it board used on earlier models. They will improve starting and simpli

fy component testing, removal and replacement. New components are:-

1. )- Choke Pulse Module (CM)

2. )- Control Relay (CR)

3. )- Field Boost Module (FB)

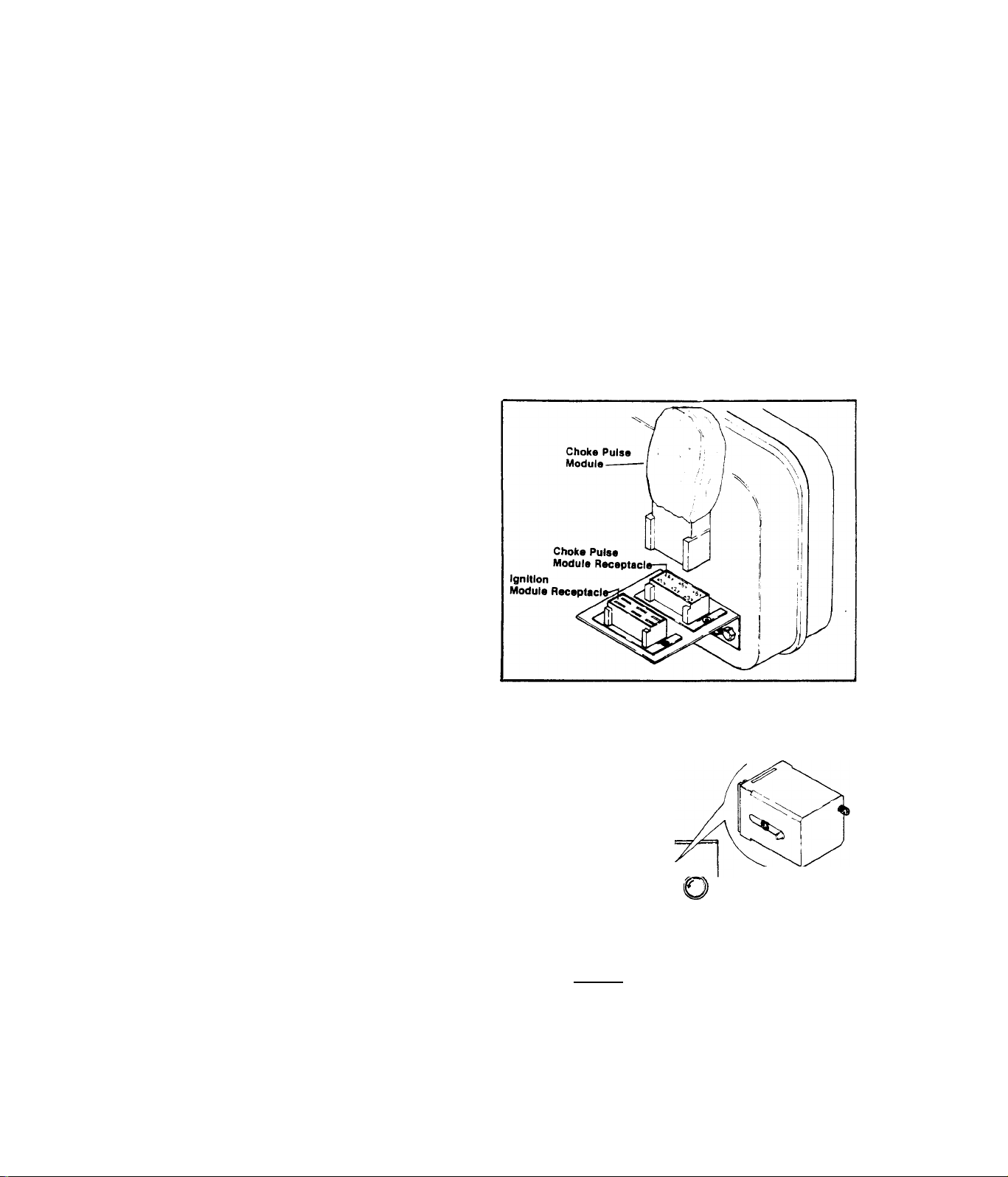

2.4.1.2-CHOKE PULSE MODULE

The Choke Pulse Module performs

several important functions, rel

ated to engine starting. These

functions are:-

1. )-Provides the necessary compo

nents for delivery of a pulsing

voltage to the automatic choke

solenoid during cranking.

2. )-Provides the required circui

try for energizing the fuel lockoff solenoid and (electric) fuel

pump during cranking, before the

control relay (CR) is energized.

2.4.1.3-CONTROL RELAY (CR)

The Control Relay (CR) is equipped

with a pushbutton for manually cl

osing the CR contact. The pushbut

ton can be identified by the words

FUEL PUMP on the unit control pan

el. To prime the carburetor prior

to cranking the engine, depress

the pushbutton. This action will

energize the Fuel Lockoff Solenoid

open and operate the (electric)

Fuel Pump. After a start, the CR

remains energized to hold the Fuel

Lockoff Solenoid open and operate

the Fuel Pump. (While cranking,

part of the Choke Pulse Module cir

cuit performs the latter function.)

MAIN

BREAKER

O

® -©

Q 4000 O I MC-40

WATT "

O

STOP STAUT

------------

Control Relay (CR)

'

2.4-1

Page 48

2.4.1.4-FIELD BOOST MODULE (FB)

Many alternators rely on residual

or ’’stored" magnetic energy to

provide the initial magnetic field

around the rotor windings. Residu

al magnetism can be lost due to

shock or physical damage.

The MC alternator is equipped with

a Field Boost Module (FB) which

supplies battery current to the

rotor windings during each start.

2.4.2- CIRCUIT OPERATION

Battery power is available through Wire No. 13, the 15 Amp Fuse, and

Wire No. 15 to the Control Relay (CR) contacts. When the push button

(FUEL PUMP) is depressed, the CR contacts close. This completes the

12 Volt DC circuit through Wire No. 14, the Fuel Lockoff Solenoid (FS),

Fuel Pump (FP), and the Choke Heater to frame ground. The Fuel Lockoff

Solenoid is energized open and the Fuel Pump operates.

2.4-2

Page 49

2.4.2.2-CRANKING

the 15 Amp Fuse, Wire No. 15, the Starter Contactor (SC), and Wire

No. 17. When the Stop/Stairt Sx<rLtch is set to START position,, the cir

cuit is completed through Wire No. 10 to frame ground. The Starter

Contactor (sc) energizes and its contacts close. With the SC contacts

closed, several events occur as follows

1, )- Battery power is supplied through Wire No. 91 to the Starter Mo

tor and to frame ground. The engine cranks,

2, )- Battery power is supplied through Wire No. 91, through the Choke

Solenoid (CS), Wire No. 90, and to Pin No. 1 of the Choke Pulse

Module (cm). Solid state components within the CM open and close

this circuit through CM Pin No. 2 and Wire No. 10 to ground, at

a rate dependent upon ambient temperature. The Choke Solenoid

(CS) is thus pulsed and the automatic choke operates at a rate

dependent on ambient temperature,

3, )- Battery power is supplied across the closed SC contacts, through

Wire No. 91, to Pin No, 5 of the Choke Pulse Module (CM), The

circuit is completed within the CM, through Pin No. 3, through

Wire No. 14, the Fuel Lockoff Solenoid (FS), the Fuel Pump (FP),

Choke Heater and through Wire No, 10 to frame ground. The Choke

Heater energizes, the Fuel Lockoff Solenoid (FS) opens, and the

Fuel Pump (FP) operates,

4, )- As the engine cranks, the Ignition Stator (IS) supplies a volt

age pulse to the Ignition Module (IM). The Ignition Module in

turn supplies a timed voltage pulse to the Ignition Coil primary

winding. The buildup and collapse of this voltage pulse induces

a voltage into the Ignition Coil secondary winding to fire the

spark plug.

5, )- Battery power is supplied through Wire No, 14 to the Field Boost

(FB) module. A 15 Ohm, 10 Watt resistor reduces this voltage and

a Diode (D3) ensures correct polarity. The reduced voltage is

delivered to the rotor windings via Wire No. 4, 243

Page 50

2.4.2.3- RUNNING

Releasing the Stop/Start Switch to NEUTRAL opens the DC circuit from

the battery. Wire No. 13, 15 Amp Fuse, Wire No. 15, Starter Contactor

(sc), and Wire No. 17. The SC de-energizes and its contacts open to

terminate cranking and choke operation. The Control Relay (CR) is held

energized by AC output from the Battery Charge Windings, and the CR

contacts close. Battery power is delivered through the closed CR cont

acts to the Fuel Pump (FP), Fuel Lockoff Solenoid (FS), and Choke Heat

er to maintain engine operation. The Ignition System continues to func

tion and Field Boost current is still available.

2.4.2.4-SHUTDOWN

2.4-4

Page 51

When the Stop/Start Switch is set to STOP, Ignition Stator (IS) output

from Wire No. 25, Ignition Module (IM) Pin No. 3, Wire No. 25 to the

Terminal Block and Wire No. 20 is delivered to frame ground. Ignition

terminates and the engine shuts down. The Control Relay de-energizes

and its contacts open to close the Fuel Lockoff Solenoid (FS) and ter

minate Fuel Pump (FP) operation,

2.4.3- DIAGNOSTIC TESTS

2.4.3.1- CHOKE PULSE MODULE

METHOD 1:- Install a known good Choke Pulse Module, Crank engine,

RESULT:- Choke operates normally...........Replace Choke Pulse Module

Engine starts.

Choke does not function and/or

....

Continue Diagnostic Tests,

no start Section 2,1

METHOD 2:- A.)-

Unplug Choke Pulse Module, Set VOM

to "+DC” and to ”50V." scale.

Connect positive (+) meter test

probe to Module receptacle Pin No,

1, common (-) test probe to frame

Choke Pulse

Module

ground. Crank engine. Meter should

indicate 9-12 Volts DC. This is

the input voltage to the Choke Pu

lse Module,

Choke Pulse

B, )-Plug Choke Pulse Module into

its receptacle. Set VOM to ”+DC"

Module Receptacle-

Ignition

Module ReceptacI

and to "50V,” scale. From bottom

of receptacle, connect positive (+)

meter test probe into receptacle

Pin No. 1 and common (-) test probe

to frame ground. Crank engine. The

meter should indicate a pulsing

voltage and choke solenoid should

pulse.

C. )-Plug Choke Pulse Module into its receptacle. Set VOM to "+DC" and

to '’50V,” scale. From bottom of Module receptacle, connect positive

meter test probe to receptacle Pin No. 3, Connect common (-) test pr

obe to frame ground. Crank engine. Meter should indicate approximate

ly 12 Volts DC.

RESULTS:-All tests were good..,.Continue diagnostic tests. Section 2.1

Test A checked bad

....

Check Wire No. 90 between receptacle

and Choke Solenoid, Choke Solenoid,

Wire No, 91 between Choke Solenoid and

Starter Solenoid (SC), Starter Solenoid

(SC)

Test B checked bad

....

Replace Choke Pulse Module (CM)

Test C checked bad,,,,.Replace Choke Pulse Module (CM)

2.4-5

Page 52

2.4.3.2- CONTROL RELAY (CR)

Refer to 2.4.1,3 and 2,4.2, this Section, If engine starts and then

shuts down, the problem may be caused by the Control Relay (CR). Pro

ceed as follows to check the Control Relay

A. )-With unit battery properly connected, depress Fuel Pump button.

The Fuel Lockoff Solenoid should open and Fuel Pump should operate.

RESULT :-Checks good,...........................

Checks bad

.........

Check 15 Amp Fuse and priming circuit -

Go to Paragraph B

See 2.4.2.1, PRIMING

B. )-Crank engine while holding Fuel Pump button depressed. Continue

to hold button in after engine starts, then release.

RESULT:-Engine starts and runs normally,

shuts down after button is rel-

.........

Go to Paragraph C

eased

No change - engine starts then,..Continue Diagnostic Tests,

shuts down as before

C. )-Set VOM to "AC", Connect one me

ter test probe to Pin No. 7 of the

Section 2,1

CONTROL RELAY RECEPTACLE

VIEWED FROM WIRE END

CR receptacle. Connect remaining

test probe to receptacle Pin B, then

crank engine. Meter should indicate

approximately 10-12 Volts AC,

RESULT:- Checks good

Checks bad

....

Check wires 15 and 77-

.....

Replace CR

If wires check good,

replace stator assembly

2.4.3.3- FIELD BOOST MODULE

A.)-Unplug red receptacle from its

receptacle on stator can. Set VOM

to "-HDC" and to any scale that

will permit 12 Volts to be read.

Connect the positive (+) meter test

probe to red connector plug Pin No,

5, Connect the common (-) probe to

frame ground. Depress the Fuel Pump

button - meter should indicate app

roximately 9-12 Volts DC.

RESULT:-Checks bad,.....Go to Para

graph B

Checks good

....

Continue

tests. Section

2.1

2.4-6

Page 53

B,)-Set VOM to ”+DC” and to any

scale that will permit 12 Volts

to be read. Connect the positi

ve meter test probe to the Wire

No. 4 connection at Field Boost

Module, Connect the common (-)

test probe to frame ground. De

press the Fuel Pump button- the

meter should indicate 9-12 Volts

DC.

RESULT;-No voltage indicated........................Go to Paragraph C

Voltage is indicated, but none

....

.Repair/replace Wire No. 4

in Paragraph A between red receptacle and Field

Boost Module

C,)-Set VOM to ”+DC” and to any scale that will permit 12 Volts DC to

be read. Connect the positive (+) meter test probe to the Wire No. 14

connection at Field Boost Module, Connect the common (-) test probe

to frame ground. Depress the Fuel Pump button. Meter needle should iftdicate 9-12 Volts DC.

RESULT:-Normal DC voltage indicated

but not in Paragraph B

No voltage indicated

..........Check Wire No. 14 between

.......

Replace Field Boost Module

the Field Boost Module and the

Control Relay (CR)

2.4-7

Page 54

PART III

DISASSEMBLY &

Section 3.1

3.1.1

3.1.2

3.1.3

Section 3.2

3.2.1

3.2.2

3.2.3

Section 3.3

3.3.1

'3.3.2

3.3.3

BLOWER SHROUD SECTION

Disassembly

Inspection and Repair

Reassembly

ALTERNATOR SECTION

Disassembly

Inspection and Repair

Reassembly

ENGINE SECTION

Disassembly

Inspection and Repair

Reassembly

REPAIR

Page 55

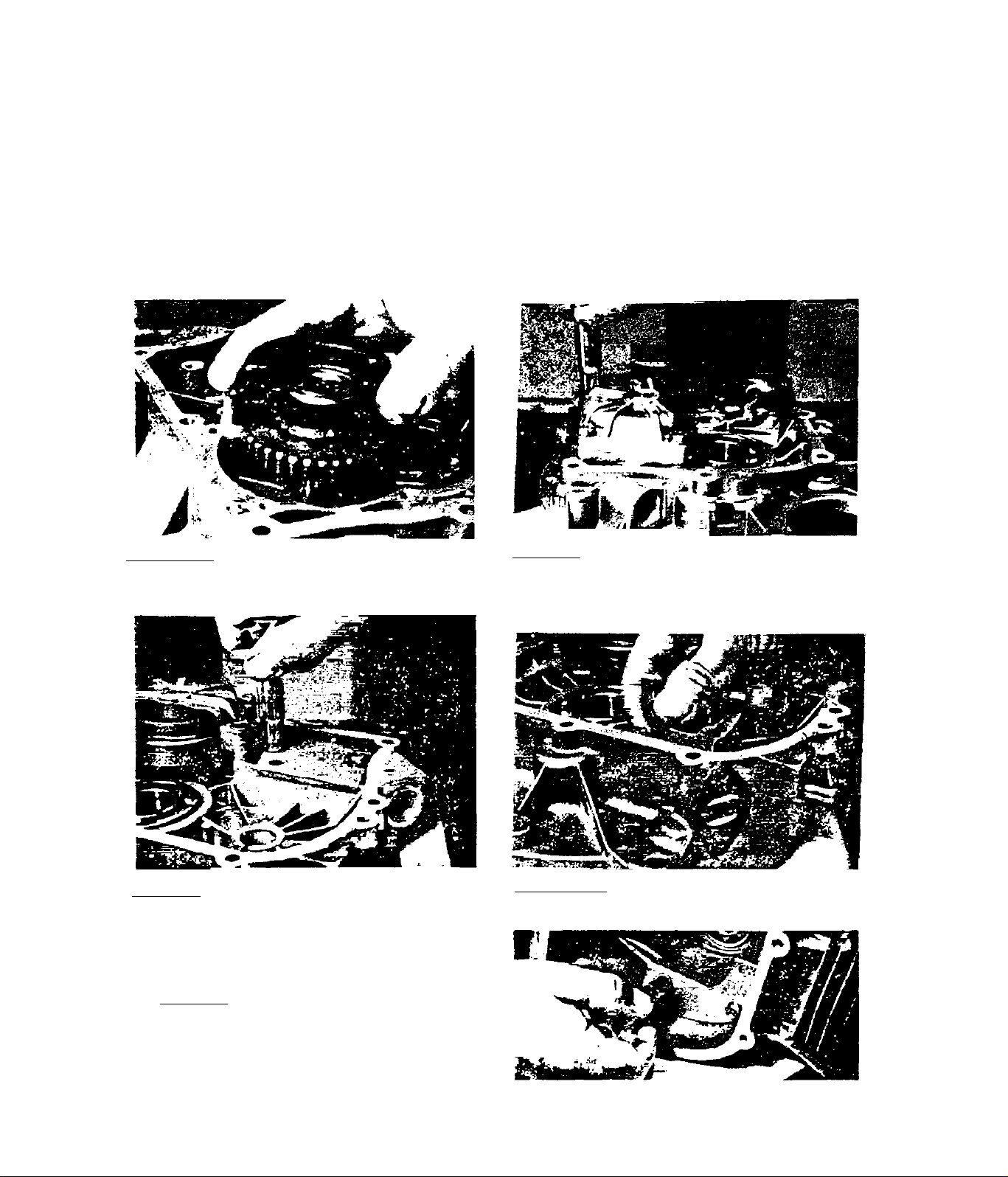

3.1.1-D1SASSEM<^LY

SECTION 3.1

BLOWER SHROUD SECTION

3.1 .1 .1 -IT.sp R 5/16 Inch nut driver

to remove screws and flat washers

Chat retain blower shroud end pan

el. Remove end panel.

3.1.1.3-Insert a screwdriver into a

cooling air slot of engine adapter

housing to prevent ring gear from

Cuming.

3.1.1.2-Reiiiuve philllps head screws

that retain blower inlet ring. Rem

ove blower inlet ring.

3.1.1.4-While preventing ring gear

from turning, remove the special M-

14 hex nut that retains the blower

fan hub to engine Caper shaft.

3.1.1.5-Tnstall three 5/16-24 bolts

into threaded holes of blower fan

huh. Install a puller as shoi^n at

right and pull blower fan and blow

er fan hub free of engine taper

shaft.

3.1-1

Page 56

2#_l_Ll2_6-Use a lO nim \^пгRт^ch to rem

ove blower, scroll bolts nearest the

pngine taper shaft. The bolt at low

er right comer of blower scroll ex

tends through the shrouding and is

retained by a lock washer, flatwasher and hex nut on shroud exterior.

Use a 7/16 inch wrench to remove the

bolt and nut.

3.1.1,7-RemoVP four MlO bolts and

four lockwashers that retain Che cy

linder head cover. Remove cylinder

head cover.

Wmm

3.1.1.8-Remove two M8 socket head 3.1.1.9-Remove bolt and washer Chat

capscrews that retain the exhaust

pipe to engine.

retains housing and exhaust pipe

support to vibration dampener.

il

3.1,1,lU-Use a nut driver to remove

screws that retain blower housing

upper ends to engine. Remove blower

housing.

3.1-2

Page 57

3.1.2-INSPECTION AND REPAIR

Clean and degrease all components, including sheet metal* Inspect all

parts as follows

1*)- Carefully check all sheet metal for cracks or other damage. Repair

or replace damaged sheet metal*

2. )- Inspect all weld nuts.

3. )- Check foam rubber gaskets on blower shroud sheet metal* Replace

all damaged strips.

4. )- Inspect blower fan for cracks or other damage. Replace, if damaged.

5. )- Inspect blower fan hub. Replace, if cracked or damaged or if key

way is worn* Also check key and key^^ay on engine taper shaft*

3.1.3-REASSEMBLY

3.1.3.1-Retain blower shroud and 3.1.3.2-Retain blower shroud at

blower scroll to cylinder block

with two M5 X 10 mm capscrews and

Inckwashers. Tighten capscrews to

90-110 inch-pounds.

3.1.3.3-With exhaust pipe u-bolt

and housing and exhaust pipe sup

port loosely retained by 2 hex

nuts, lockwashers and flatwashers,

retain housing and exhaust pip«

support to engine base and vibrat

ion damper.

both sides of cylinder block

with M6 X 15 mm long capscrews,

Inckwashers and flatwashers.

3.1-3

Page 58

3.1» 3,4-Loosoly retain blower hou

sing support to opposite vibration

damper with capscrew, lockwasher

and flatwasher.

3,1,3,^"Retain blower housing and

scroll to blower housing support

(installed in previous step) ^^th

b-20 X ^ inch long bolt and flaLwasher and a hex nut, flatwasher

and lockwasher. Tighten the hex

nut. Finally, tighten all bolts that

thread into the vlhratlon dampers.

3,1,3,6-Slide exhaust pipe down

through blower housing ^nd through

exhaust pipe u-bolt. Install exha

ust flange gasket. Retain exhaust

pipe to exhaust flange with an M8

X 50 ram long and an M8 x 20 mm long

socket head capscrew and lockwash-

prs.

3,1,3,8"Retaln cylinder head cover

with four MlO X 20 mill long bolts

and lockwashers. Tighten bolts to

12 foot-pounds. TnsLall all No. 10-

32 screws that retain head cover to

blower housing.

3,1,3,7"Tightcn exhaust pipe u-bolt

hex niiLs,

3.1-4

Page 59

3^1,3>9-Align keyway in blower fan

hub wlCh drive key on engine shaft.

Install blower fan over engine

shaft. Make sxire drive key and key

way are engaged. Install special M-

14 hex nut and flatwasher. Prevent

crankshaft from turning, then torq

ue hex nut to 50-55 foot-pounds.

3.It 3#11-Install blower shroud end

panel. Retain with No. 10-32 screws

and flatwasherst

3.1.3.lO-jnstall inlet ring as

sho\smi. Retain w1 th No. 6-32 x

3/8 inch long screws and lock-

washers.

3.1-5

Page 60

3.2.1-DISASSEMBLY

SECTION 3.2

ALTERNATOR SECTION

3#2»1«1-At the terminal strip, dis

connect Che Wire No. 20 chat comes

Truiu the low oil level shutdown sw

itch.

3.2.1.3“Remove 4 screws that retain

irront panel. Remove front panel.

3.2.1.2“Loo3en oil line clamp at

oil make-up pump. Slide clamp down

hose, then disconnect hose from

pump fitting.

3,2,1.6-Unplug the red connector

plug from Its stator can recepLacle,

Also remove ground wire, retained

by panel divider screw.

3.2.1.5-Remove screws that retain

rear panel. Remove rear panel.

3.2.1.6-Remove end panel.

3.2-1

Page 61

3.2,1,7~St:raighCpn brush holdei'

locking tangs on bearing carrier,

Kemove brush holder from carrier.

Remove brush leads from brushes

and remove brush holder and brus

hes .

3,2.1,9-Remove two bottom stator 3,2.1,10-Remove 6 screws that ret-

bolts and stator bolt bar.

3,2,1»d-Remove al temator support

to vibration dampener bolts.

aln bearing carrier to stator can,

Remove bearing carrier, using a

puller.

3,2,1.11-Ramove 2 upper stator

bolts and stator holt bar.

3.2-2

3,2.1.12-RGmove panel divider. The

stator can may now be removed as

well.

Page 62

3»2., 1« 13-Remove starter cable at

the starter terminal.

3.2.1.14-Cur Wires No. 8 and 25

that go to the ignition stator.

3.2.1.15-At the terminal strip,

disconnect the wire from the fuel

lockoff solenoid.

3.2.1.l7-Rcmovc bolts, nuts and

washers that retain the adapter

casting. Remove carburetor to

intake manifold nuts, then rem

ove adapter casting.

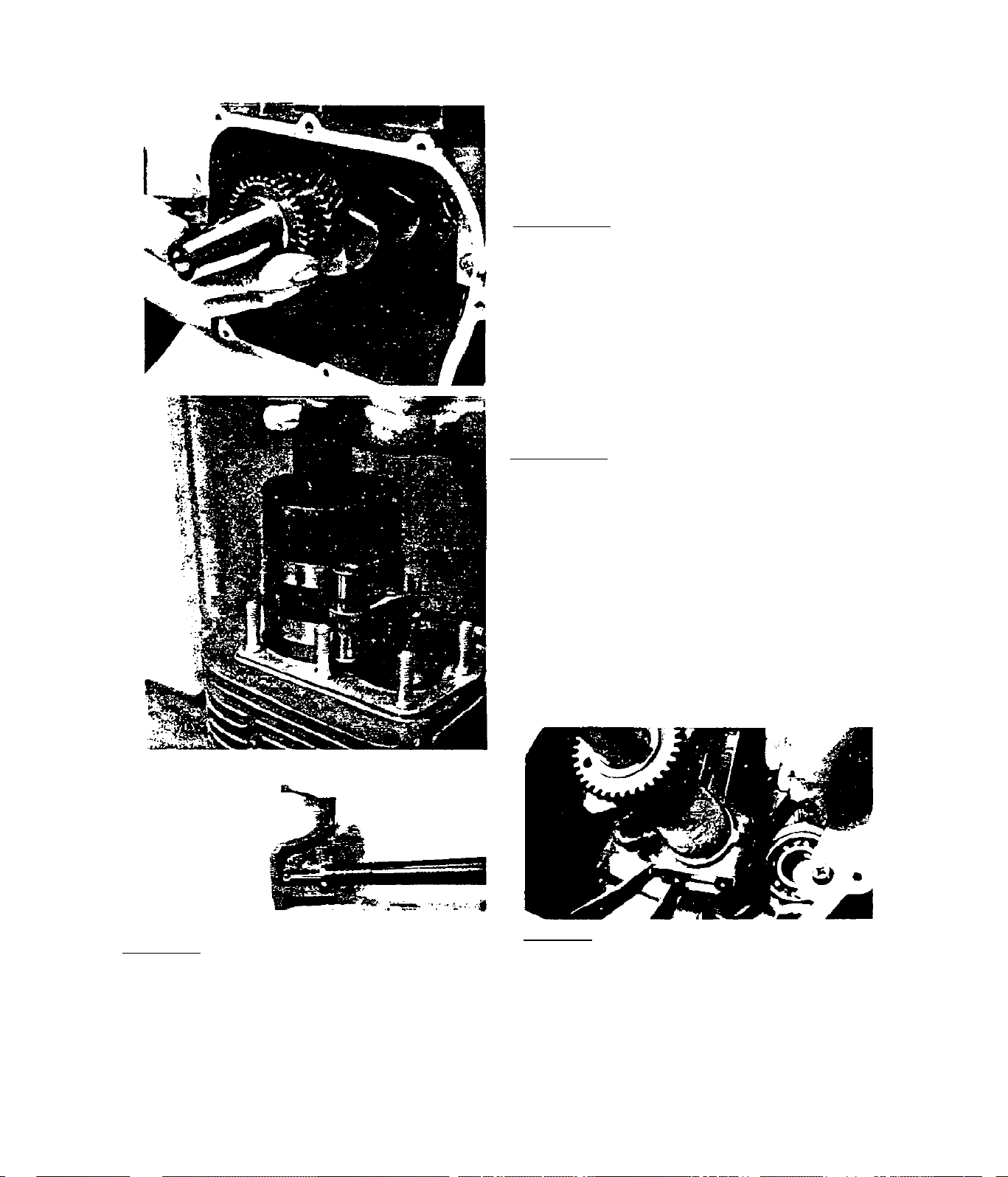

3.2.1.19-Use rotor removal kit

to remove rotor. (See Section

1.3, SPECIAL TOOLS.) Use the

5/16-24 tap from kit to cut

threads in totor as shown at

right.

3.2.1.16-Remove fuel Line at carb

uretor. Carburetor to intake luaui-

fold iiuLs may also be loosened at

this time. These nuts will be cionipletely rpTTioved prior to removal

of the adapter casting (Step 3.2.

1.17).

3.2.1.18-Remove -rotor bolt.

3.2-3

Page 63

3,2,1,20~SelQcc a stud from the

kit that is long enough so that,

when the stud is threaded into

the engine crankshaft, the slot

ted end of the stud will extend

approximately Inch into the

rotor shaft. Thread the stud in

to the engine crankshaft.

3,2,1,22-Remove the ignition stat

or.

3,2,1,21-Thread the 5/16-24 bolt

(included with rotor removal kit)

into the rotor shaft until It Is

fiinnly seated against the stud.

Tighten the bolt against the stud

and tap the bolt head with a mal

let, Continue tightening and cap

ping until rotor is free. Remove

Che rotor and fan assembly.

3.2.2-INSPECTION AND REPAIR

3,2,2,1- GENERAL

Inspect wiring for pinching, obvious damage, defective insulation.