Page 1

Owner’s Manual

004806

Discount-Equipment.com

Water Trailer

MWT500

www.discount-equipment.com

SA VE THIS MANUAL FOR FUTURE REFERENCE

Page 2

Discount-Equipment.com is your online resource for commercial and industrial

Discount-Equipment.com

quality parts and equipment sales.

Locations:

Florida (West Palm Beach): 561-964-4949

Outside Florida TOLL FREE: 877-690-3101

Need parts? Check out our website at www.discount-equipment.com

Can’t find what you need?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and fill out

the request form.

Please have the machine model and serial number available in order to help us get

you the correct parts. One of our experienced staff members will get back to you with

a quote for the right part that your machine needs.

We sell worldwide for the br

Diamond

Chicago Pneumatic, Allmand Brothers, Essick, Miller Spreader, Skyjack, Lull, Skytrak,

Tsurumi, Husquvarna/Target, Whiteman-Concrete/Mortar, Stow-Concrete/Mortar, Baldor,

Wacker, Sakai, Snorkel, Upright, Mi-T-M, Sullair, Neal, Basic, Dynapac, MBW, Weber,

Bartell, Bennar Newman, Haulotte, Ditch Runner, Blaw-Knox, Himoinsa, Best, Buddy,

Crown, Edco, Wyco, Bomag, Laymor, Terremite, Barreto, EZ Trench, Takeuchi, Basic, Bil-

Jax, Curtis, Gehl, Heli, Honda, ICS/PowerGrit, Puckett, Waldon, ASV, IHI, Partner, Imer,

Clipper, MMD, Koshin, Rice, Gorman Rupp, CH&E, Cat Pumps, Comet, General Pump,

Giant,AMida, Coleman, NAC, Gradall, Square Shooter, Kent, Stanley, Tamco, Toku, Hatz,

Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air, Small Line, Wanco, Yanmar

Products, Magnum, Airman, Mustang, Power Blanket, Nifty Lift, Atlas Copco,

ands: Genie, Terex, JLG, MultiQuip, Mayco, Toro/Stone,

Page 3

(000393)

WARNING

Operating, servicing and maintaining this

equipment can expose you to chemicals

including engine exhaust, carbon monoxide,

phthalates, and lead, which are known to the

State of California to cause cancer and birth

defects or other reproductive harm. To

minimize exposure, avoid breathing exhaust,

do not idle the engine except as necessary,

service your equipment in a well-ventilated

area and wear gloves or wash your hands

frequently when servicing your equipment.

For more information go to

www.P65Warnings.ca.gov.

Use this page to record important information about your unit

Discount-Equipment.com

Unit Model Number

Unit Serial Number

Engine Model

Number

Engine Serial

Number

Generator Model

Number

Generator Serial

Number

Record the information found on your unit data label on

this page. See Unit Serial Number Locations.

Engine and generator serial nu mbe rs are located on da ta

plates affixed to the engine and generator, respectively.

When contacting a Generac Mobile Products Authorized

Service Dealer (GMP ASD) about parts and service,

always provide the unit model and serial number.

Operation and Maintenance: Proper maintenance and

care of the unit ensures a minimum number of problems

and keeps operating expenses at a minimum. It is the

operator’s responsibility to perform all safety checks, to

verify that all maintenance for safe operation is

performed promptly, and to have the equipment checked

periodically by a GMP ASD. Normal maintenance,

service, and replacement of parts are the responsibility of

the owner/operator and, as such, are not considered

defects in materials or workmanship within the terms of

the warranty. Individual operating habits and usage may

contribute to the need for additional maintenance or

service.

ii Owner’s Manual for MWT500 Water Trailer

Page 4

Table of Contents

Discount-Equipment.com

Section 1: Introduction and Safety

Introduction ..........................................................1

Read This Manual Thoroughly ....................................1

How to Obtain Service ............ ... ... ... .... ... ... ... .... ... ... ... ..1

Safety Rules .........................................................1

General Hazards ..................................................2

Electrical Hazards ................................................2

Explosion and Fire Hazards ................................2

Trailer Hazards .....................................................2

Fuel Hazards ........................................................3

Engine Safety .......................................................3

Operating Safety ..................................................3

Towing Safety ......................................................4

Hitch and Coupling .... ... ... ............................................4

Running Lights ............................................................4

Wheels and Tires ........................................................4

Safe Towing Techniques ........................................... ..4

Section 4: Maintenance

Basic Schedule ..................................................13

Engine and Water Pump ...................................13

Long-Term Storage ...................................................13

Jack ....................................................................14

Side-Wind Models . .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ...14

Top-Wind Models ......................................................14

Section 5:Troubleshooting

Section 6:Wiring Diagrams

Trailer .................................................................17

Wiring Harness—Electric Brake Option ..........18

Section 7:Service Log

Reporting Trailer Safety Defects ........................4

Section 2: General Information

Unit Specifications ..............................................5

Unit Serial Number Locations ............................6

Component Locations .........................................7

Trailer Tongue and Storage Bin ..................................7

Filling and Discharging Water .....................................8

Section 3: Operation

Preparing Unit for Use .........................................9

Using Valves and Cam Locks .............................9

Filling Water Tank ................................................9

Hydrant as Fill Source ........ .... ... ... ...............................9

Reservoir as Fill Source ............................................10

Discharging Water from Tank ...........................10

Using Rear Spray Bar ...............................................10

Using 2-Inch Flexible Spray Hose .......... ... ... .... ... ......10

Using 5/8-Inch Flexible Spray Hose ..........................11

Using Gravity Drain Bibb ...........................................11

Adjusting Rear Spray Bar .................................11

Draining Water from System ............................12

Owner’s Manual for MWT500 Water Trailer iii

Page 5

Section 1: Introduction and Safety

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

(000001)

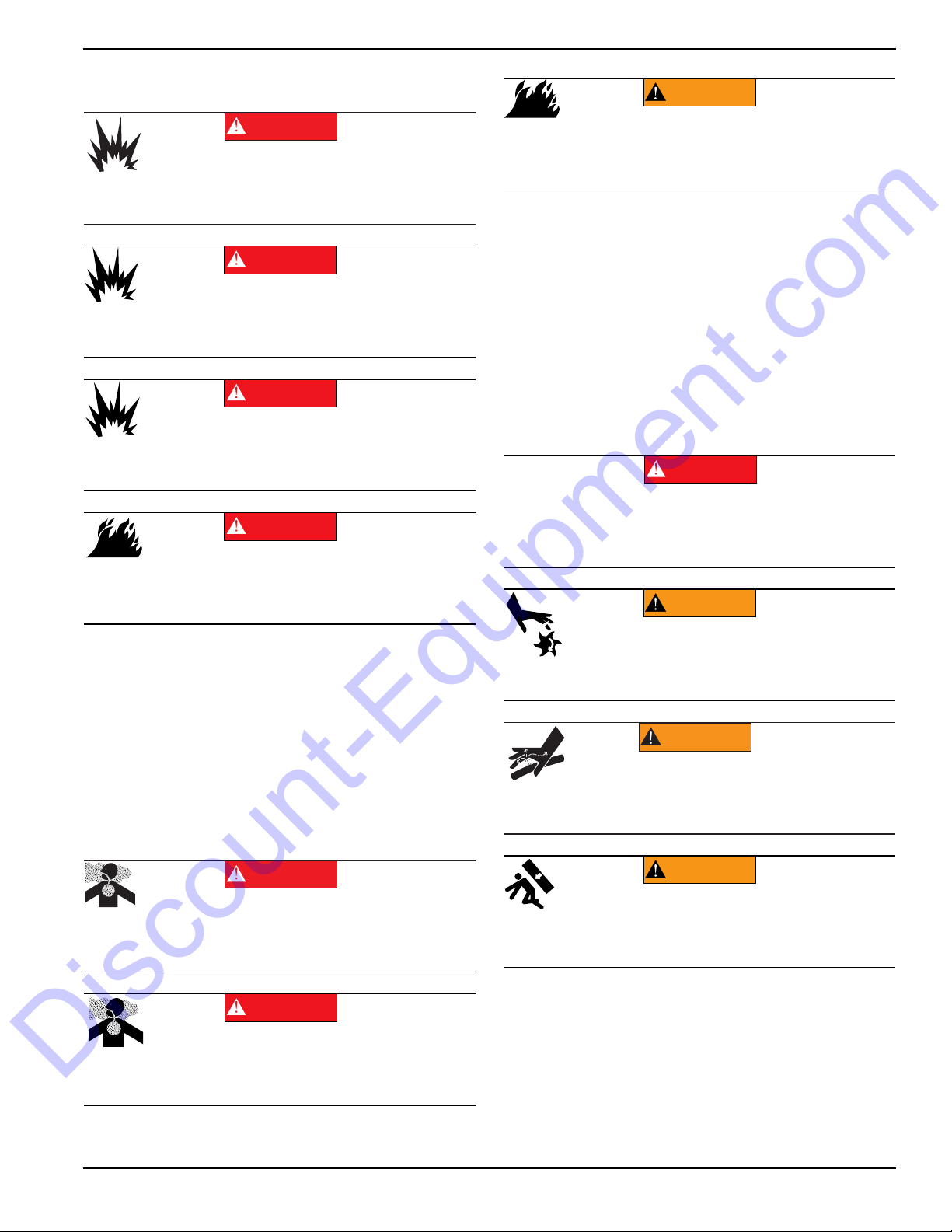

DANGER

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

(000002)

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

(000003)

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Discount-Equipment.com

Introduction and Safety

Introduction

Thank you for purchasing a Generac Mobile Products, LLC

product. This unit has been designed to provide high

performance, efficient operation, and years of use when

maintained properly.

The information in this manual is accurate based on

products produced at the time of publication. The

manufacturer reserves the right to make technical update s,

corrections, and product revisions at any time without

notice.

Read This Manual Thoroughly

The owner is responsible for proper maintenance and safe

use of the equipment. Comply with regulations the

Occupational Safety and Health Administration (OSHA)

has established, or with equivalent standards. Also, verify

the unit is applied, used, and maintained in accordance with

the manufacturer's instructions and recommendations. Do

nothing that might alter safe application/usage and render

the unit in noncompliance with the aforementioned codes,

standards, laws, and regulations

.

Safety Rules

The manufacturer cannot anticipate every possible circumstance that might involve a hazard. The alerts in this

manual, and on tags and decals affixed to the u nit, are not

all inclusive. If using a procedure, work method, or operating technique that the manufacturer does not specifically

recommend, verify that it is safe for others and does not

render the equipment unsafe.

Throughout this publication, and on tags and decals affixed

to the unit, DANGER, WARNING, CAUTION, and NOTE

blocks are used to alert personnel to special instructions

about a particular operation that may be hazardous if

performed incorrectly or carelessly. Observe them

carefully. Alert definitions are as follows:

Save these instructions for future reference. This manual

contains important instructions for the unit that should be

followed during setup, operation, and maintenance of the

unit and battery. ALWAYS supply this manual to any

individual who will use this machine.

How to Obtain Service

When the unit requires servicing or repairs, contact a

Generac Mobile Products Authorized Dealer for assistance.

Service technicians are factory-trained and are capable of

handling all service needs.

Mobile Products Authorized Dealer about parts and

service, always supply the complete model number and

serial number of the unit as given on the data decal

located on the unit (see Figure 2-1). Record the model

number and serial numbers in the spaces provided on the

inside front cover of this manual.

Owner’s Manual for MWT500 Water Trailer 1

When contacting a Generac

NOTE: Notes contain additional information important to

a procedure and will be found within the regular text of

this manual.

These safety alerts cannot eliminate the hazards that they

indicate. Common sense and strict compliance with the

special instructions while performing the action or service

are essential to preventing accidents.

Page 6

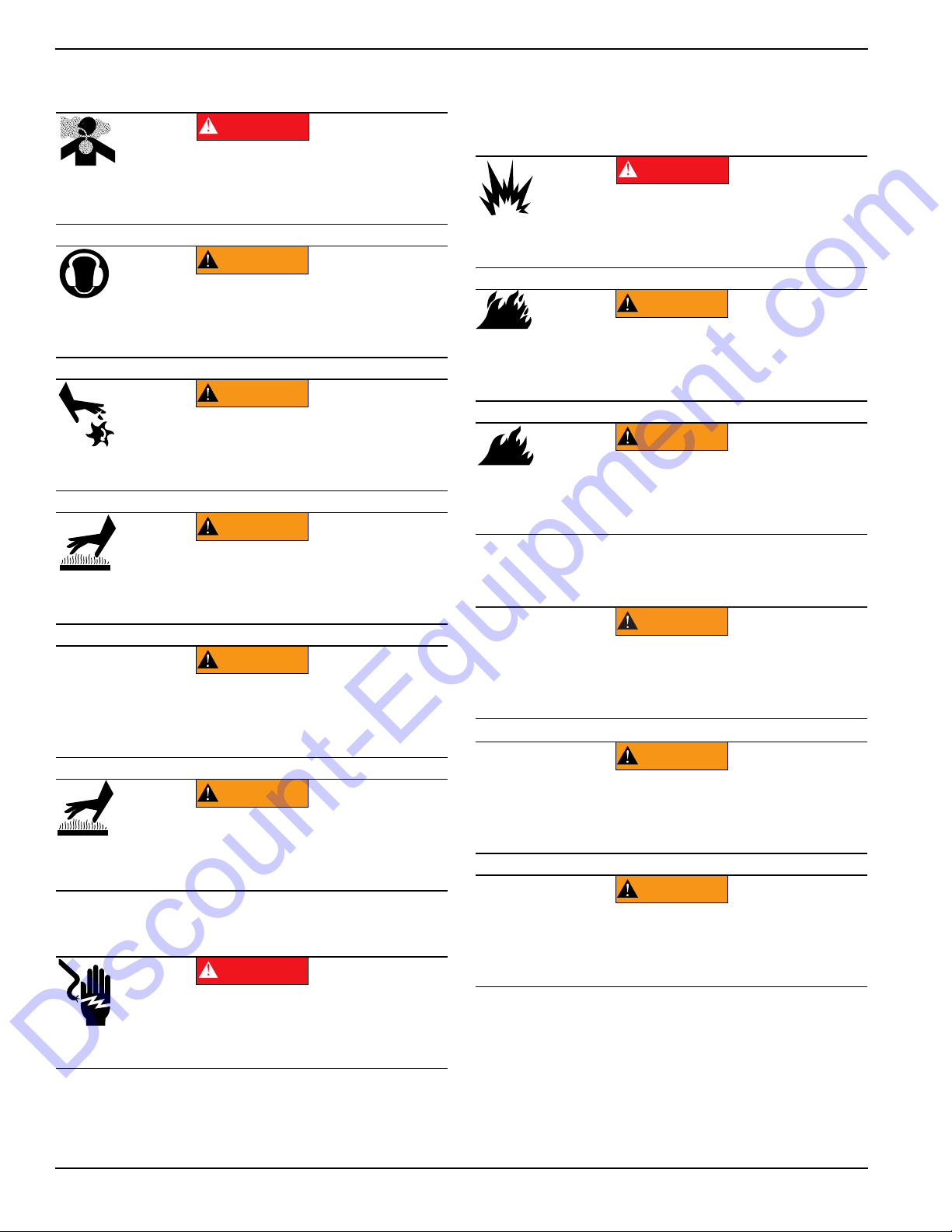

Introduction and Safety

Asphyxiation. Running engines produce

carbon monoxide, a colorless, odorless,

poisonous gas. Carbon monoxide, if not

avoided, will result in death or serious injury.

(000103)

DANGER

(000107)

WARNING

Hearing Loss. Hearing protection is

recommended when using this machine.

Failure to wear hearing protection could

result in permanant hearing loss.

(000111)

WARNING

Moving Parts. Keep clothing, hair, and

appendages away from moving parts. Failure

to do so could result in death or serious injury.

(000108)

WARNING

Hot Surfaces. When operating machine, do not

touch hot surfaces. Keep machine away from

combustibles during use. Hot surfaces could

result in severe burns or fire.

WARNING

Risk of injury. Do not operate or service this machine

if not fully alert. Fatigue can impair the ability to service

this equipment and could result in death or serious

injury.

(000215)

(000139)

WARNING

Risk of burns. Allow engine to cool before

draining oil or coolant. Failure to do so could

result in death or serious injury.

(000104)

DANGER

Electrocution. Water contact with a power

source, if not avoided, will result in death

or serious injury.

(000105)

DANGER

Explosion and Fire. Fuel and vapors are

extremely flammable and explosive. Add fuel

in a well ventilated area. Keep fire and spark

away. Failure to do so will result in death

or serious injury.

(000147)

WARNING

Risk of Fire. Unit must be positioned in a

manner that prevents combustible material

accumulation underneath. Failure to do so

could result in death or serious injury.

(000110)

WARNING

Risk of Fire. Hot surfaces could ignite

combustibles, resulting in fire. Fire could

result in death or serious injury.

WARNING

Personal injury. Trailer must be securely coupled to

the hitch with the chains correctly attached. Uncoupled

or unchained towing could result in death or serious

injury.

(000233a)

(000234a)

WARNING

Crushing hazard. Verify unit is properly secured and

on level ground. An unsecured unit can suddenly roll

or move, causing death or serious injury.

WARNING

Property or Equipment Damage. Tighten wheel lug

nuts after first 50 miles to factory specifications.

Failure to do so could result in death, serious injury,

property or equipment damage.

(000235)

Discount-Equipment.com

General Hazards

Explosion and Fire Hazards

Electrical Hazards

Tr ailer Hazards

2 Owner’s Manual for MWT500 Water Trailer

Page 7

Fuel Hazards

(000105)

DANGER

Explosion and Fire. Fuel and vapors are

extremely flammable and explosive. Add fuel

in a well ventilated area. Keep fire and spark

away. Failure to do so will result in death

or serious injury.

(000143)

DANGER

Explosion and Fire. Fuel and vapors are extremely

flammable and explosive. Store fuel in a well

ventilated area. Keep fire and spark away. Failure

to do so will result in death or serious injury.

(000192)

DANGER

Explosion and fire. Fuel and vapors are extremely

flammable and explosive. No leakage of fuel is

permitted. Keep fire and spark away. Failure to do

so will result in death or serious injury.

(000174)

DANGER

Risk of fire. Allow fuel spills to completely dry

before starting engine. Failure to do so will

result in death or serious injury.

(000179b)

DANGER

Asphyxiation. The exhaust system must be properly

maintained. Do not alter or modify the exhaust system

as to render it unsafe or make it noncompliant with

local codes and/or standards. Failure to do so will

result in death or serious injury.

Asphyxiation. Running engines produce

carbon monoxide, a colorless, odorless,

poisonous gas. Carbon monoxide, if not

avoided, will result in death or serious injury.

(000103)

DANGER

(000147)

WARNING

Risk of Fire. Unit must be positioned in a

manner that prevents combustible material

accumulation underneath. Failure to do so

could result in death or serious injury.

DANGER

Not for human consumption. Water in tank is not

potable. Using tank water for human consumption

will result in death or serious injury.

(000361)

(000111)

WARNING

Moving Parts. Keep clothing, hair, and

appendages away from moving parts. Failure

to do so could result in death or serious injury.

(000117b)

Personal injury. Rick of fluid injection.

Do not aim spray gun at people, animals,

electrical devices, or fragile items. Keep out

of reach of children. Failure to do so

may cause death or serious injury.

WARNING

WARNING

Personal injury. Failure to properly connect

lifting cables, chains, or straps could result in

death, serious injury, or property damage.

(000346)

Discount-Equipment.com

Introduction and Safety

• DO NOT clean air filter with gasoline or other types

of low flash point solvents.

• Shut off engine if any of the following conditions

exist during operation.

• Abnormal change in engine speed

• Loss of pumping output

• Sparking occurs

• Engine misfires or there is excessive engine

vibration

Operating Safety

• DO NOT operate with the fuel tank cap loose or

missing.

Engine Safety

Internal combustion engines present special hazards

during operation and fueling. Failure to follow the safety

guidelines described below could result in severe injury or

death. Read and follow all safety alerts described in the

engine operator's manual. A copy of this manual was

supplied with the unit when it was shipped from the factory .

• The area immediately surrounding the unit should

be dry, clean, and free of debris.

• Position and operate the unit on a firm, level

surface.

• Always keep water tank cover in place.

• DO NOT enter tank.

Owner’s Manual for MWT500 Water Trailer 3

Page 8

Introduction and Safety

WARNING

Personal injury. Trailer must be securely coupled to

the hitch with the chains correctly attached. Uncoupled

or unchained towing could result in death or serious

injury.

(000233a)

WARNING

Property or Equipment Damage. Tighten wheel lug

nuts after first 50 miles to factory specifications.

Failure to do so could result in death, serious injury,

property or equipment damage.

(000235)

Discount-Equipment.com

• DO NOT drive over hoses while pressurized or

while pump is running.

• NEVER leave unit unattended while pump is

running.

• DO NOT start a unit that needs repair.

Towing Safety

Towing a trailer requires care. Both the trailer and vehicle

must be in good condition and securely fastened to each

other to reduce the possibility of an accident. Some states

require large trailers to be registered and licen sed. Contact

your local Department of T ransportation of fice to check on

license requirements for your particular unit.

Hitch and Coupling

•

Verify the hitch and coupling on the towing vehicle

are rated equal to, or greater than, the trailer's

Gross Vehicle Weight Rating (GVWR).

• Verify the trailer hitch and the coupling are

compatible. Make sure the coupling is securely

fastened to the vehicle.

• DO NOT tow trailer using defective parts. Inspect

the hitch and coupling for wear or damage.

• Connect safety chains in a crossing pattern under

the tongue. Attach breakaway cable to rear

bumper of towing vehicle. Do not attach cable to

trailer hitch.

• Before towing the trailer, verify the weight of the

trailer is equal across all tires. On trailers with

adjustable height hitches, adjust the angle of the

trailer tongue to keep the trailer as level as

possible.

Safe Towing Techniques

•

Practice turning, stopping, and backing up in an

area away from heavy traffic prior to transporting

the unit.

• Maximum recommended speed for highway towing

is 45 mph (72 km/h). Recommended off-road

towing speed is 10 mph (16 km/h) or less,

depending on terrain.

• When towing, maintain extra space between

vehicles and avoid soft shoulders, curbs, and

sudden lane changes.

Reporting Trailer Safety Defects

If you believe your trailer has a defect which could cause

a crash or could cause injury or death, you should

immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying Generac

Mobile Products LLC.

If NHTSA receives similar complaints, it may open an

investigation; and if it finds that a safety defect exists in a

group of vehicles, it may order a recall-and-remedy

campaign. However, NHTSA cannot become involved in

an individual problem between you, your dealer, or

Generac Mobile Products LLC.

To contact NHT SA, you may either call the Auto Safety

Hotline toll-free at 1-888-327-4236 (TTY :1-800-424-9153),

go to www.safercar.gov; or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

Y ou can also obtain other inform ation about motor vehicle

safety from www.safercar.gov.

Running Lights

Verify directional and brake lights on the trailer are

connected and working properly.

Wheels and Tires

Check trailer tires for wear and proper inflation.

•

4 Owner’s Manual for MWT500 Water Trailer

Page 9

General Information

Discount-Equipment.com

Section 2: General Information

Unit Specifications

DESCRIPTION UNITS MWT500

Engine

Make/Brand — Honda

Model — GX120

Horsepower—Prime hp (kW) 3.5 (2.6)

Operating Speed rpm 3600

Fuel Consumption—100% Prime gph (Lph) 0.18 (0.68)

Fuel Consumption—75% Prime gph (Lph) 0.14 (0.53)

Fuel Consumption—50% Prime gph (Lph) 0.09 (0.34)

Pump

Make/Brand — Tsurumi

Model — TE2-50HA

Type — Centrifugal

Fitting Type — 2 in. cam and groove

Water Tank

Capacity gal (L) 500 (1895)

Fill Rate — 3-4 min. full tank at full throttle

Dimensions

L x W x H in (m) 160 x 77 x 64 (4.06 x 1.96 x 1.63)

Weights

Trailer w/ Empty Water Tank lbs (kg) 1747 (792)

Trailer w/ Full Water Tank lbs (kg) 5747 (2607)

Capacities

Fuel Tank gal (L) 0.66 (2.50)

Maximum Pump Output Fuel Volume gpm (Lpm) 137 (517)

Maximum Lift Suction ft (m) 28 (8.5)

Total Dynamic Head ft (m) 115 (35)

Maximum Pressure psi (kPa) 49.7 (343)

Maximum Pump Speed rpm 4000

Trailer

Number of Axles quantity 2

Capacity—Axle Rating lbs (kg) 3500 (1588)

Tire Size — ST225/75D15

Brakes — Hydraulic

Hitch—Standard — 3 in. Tow Ring

Maximum Tire Pressure psi (kPA) 65 (448)

Specifications are subject to change without notice.

Owner’s Manual for MWT500 Water Trailer 5

Page 10

General Information

MAGNUM POWER PRODUCTS LLC

Manufactured by

A wholly owned subsidiary of

Generac Power Systems, Inc.

215 Power Drive • Berlin, WI 54923

1-800-926-9768

MODEL

kg lbs

SERIAL NUMBER

MADE IN USA

Unit ID Tag

SEE OWNER’S

MANUAL FOR

ADDITIONAL

INFORMATION

VOIR LE

MANUEL DE

L’USAGER

POUR

PLUS DE

RENSEIGNEMENTS

MANUFACTURED BY/FABRIQUE PAR: Magnum Power Products LLC DATE: 00/0000

GVWR/PNBV: 000KG (0000LBS) COLD INF. PRESS./

PRESS. DE

V.I.N./N.I.V.:

00000000000000000

TYPE:

TRAILER

MODEL:

XXX000

GAWR / PNBE TIRE / PNEU RIM / JANTE GONF A FROID - KPA(PSI/LPC) SGL / DUAL

EACH

AXLE

THIS VEHICLE CONFORMS TO ALL APPLICABLE STANDARDS PRESCRIBED UNDER THE U.S. FEDERAL MOTOR VEHICLE SAFETY STANDARDS(FMVSS) AND CANADIAN

MOTOR VEHICLE SAFETY REGULATIONS IN EFFECT ON THE DATE OF MANUFACTURE.

CE VEHICULE EST CONFORME A TOUTES LES NORMES QUI LUI SONT APPLICABLES EN VERTU DU REGLEMENT SUR LA SECURITE DES VEHICULES AUTOMOBILES DU CANADA EN VIGUEUR A LA DATE SA

FABRICATION.

The weight of cargo should never exceed 0000KG (0000LBS)

Le poids du chargement ne doit jamais depasser 0000KG (0000LBS)

VIN Tag

TIRE AND LOADING INFORMATION

RENSEIGNEMENTS SUR LES

PNEUS ET LE CHARGEMENT

004796

Discount-Equipment.com

Unit Serial Number Locations

See Figure 2-1 for unit ID and Vehicle Identification Number (VIN) tags. Im portant inform ation, such as the un it serial

number, model number, VIN, and tire loading information display on the tags. Record the information from these tags

so it is available if the tags are lost or damaged. When ordering parts or requesting assistance, you may be asked to

provide this information.

Figure 2-1. Serial Number Locations

6 Owner’s Manual for MWT500 Water Trailer

Page 11

Component Locations

005408

A

B

C

D

E

Discount-Equipment.com

Trailer Tongue and Storage Bin

General Information

Figure 2-2. Trailer Tongue and Storage Bin

Item Description

A Side pivot bolts

B Center pivot bolt

C Tongue hardware holes

D Tongue brace

E Storage bin

Owner’s Manual for MWT500 Water Trailer 7

Page 12

General Information

A

B

F

H

C

D

L

J

M

N

G

E

K

Discount-Equipment.com

Filling and Discharging Water

Figure 2-3. Components for Filling and Discharging Water Tank

004807

Item Description

A

B

C

D

E

F

G

H

J

K

L

M

N

Tank cover

Supply pipe

Rear spray bar

Fitting for 5/8 in. flexible hose

Upper manifold—two locations, fitted with end-plugs and cam-locks

Va lve 1

Access hole—fitted with plug

Va lve 2

Va lve 3

Pump housing drain—fitted with plug

Va lve 4

Lower manifold—fitted with end-plug and cam-lock

Gravity drain bibb

8 Owner’s Manual for MWT500 Water Trailer

Page 13

Section 3: Operation

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

005805

A

B

005806

A

B

Discount-Equipment.com

Preparing Unit for Use

Unit ships from factory with hoses and accessories inside

tank. Remove hoses and accessories from tank before

using equipment. Make sure all items are secured in the

storage bin before moving or towing.

See Figure 2-2. Prepare unit for use as follows.

1. Verify unit is on a level surface and wheels are

blocked.

2. Loosen both side pivot bolts.

3. Secure tongue to base of tank fill pipe with a rope

or chain.

4. Loosen center pivot bolt and remove tongue brace

and hardware from trailer frame.

5. Carefully lower tongue.

6. Install tongue hardware to indicated holes.

Operation

See Figure 3-2. All cam locks have two positions:

Opened and closed.

Figure 3-2. Opened Cam Lock (A) and Closed

(Secured) Cam Lock (B)

Filling Water Tank

Fill water tank only with polyethylene-compatible fluids.

Filling tank with incompatible chemicals will result in tank

leaking or failure.

The tank is NOT fire resistant. Do not expose tank to

open flame or excessive heat.

Protect tank from sharp impacts, especially in cold

temperatures.

NOTE: Do not reuse nylock nuts.

7. Tighten tongue hardware and pivot bolts to 80-109

ft-lbs (108-148 Nm).

Using Valves and Cam Locks

See Figure 3-1. Valves have two positions: opened,

which allows water to flow through the valve; and closed,

which stops water flow at the valve.

Hydrant as Fill Source

1. See Figure 2-3. Remove tank cover. Open valve 1.

Close valves 2, 3, and 4. Close gravity drain bibb.

2. Attach hydrant adapter to hydrant. Attach threaded

end of 2 in. rigid fill-hose to hydrant adapter.

3. On the upper manifold, open one cam-lock fitting

and remove the end-plug. Attach cam-lock end of 2

in. rigid fill-hose to the manifold, then close camlock fitting. Eliminate bends and kinks in hose.

4. Slowly open hydrant valve.

The tank begins to fill through the supply pipe.

5. Fill tank to desired level, then close hydrant valve,

then close valve 1.

6. Remove 2 in. rigid fill-hose from hydrant and allow

hose to drain. Remove hydrant adapter. Remove

hose from upper manifold cam-lock fitting. Place

hose and hydrant adapter in storage bin.

7. Close upper manifold end-plug. Secure cam-lock

fitting on end-plug. Close tank cover.

Figure 3-1. Opened Valve (A) and Closed Valve (B)

Owner’s Manual for MWT500 Water Trailer 9

Page 14

Operation

(000385)

Personal Injury. Do not reach into pump

housing with engine running. Doing so will

result in death or serious injury.

DANGER

DANGER

Not for human consumption. Water in tank is not

potable. Using tank water for human consumption

will result in death or serious injury.

(000361)

(000117b)

Personal injury. Rick of fluid injection.

Do not aim spray gun at people, animals,

electrical devices, or fragile items. Keep out

of reach of children. Failure to do so

may cause death or serious injury.

WARNING

WARNING

Equipment damage. Do not allow pump to run dry.

Doing so will cause the pump to overheat and could

cause equipment damage.

(000380)

WARNING

Equipment damage. Running pump with closed

valves will cause pump to overheat and could result

in equipment damage.

(000381)

WARNING

Personal injury and equipment damage. Do not drive

over pressurized hoses. Doing so could cause hose

rupture and result in personal injury and equipment

damage.

(000382)

Discount-Equipment.com

Reservoir as Fill Source

1. See Figure 2-3. Remove tank cover . Open valve 1.

Close valves 2, 3, and 4. Close gravity drain bibb.

2. On the lower manifold, open the cam-lock fitting

and remove the end-plug. Attach cam-lock end of 2

in. rigid fill-hose to the manifold.

3. Attach basket strainer to threaded end of 2 in. rigid

fill-hose.

4. Place hose in water.

5. Prime the pump:

a. Remove plug of access hole.

b. Pour water into access hole, filling the pump

housing.

c. Start the engine.

The tank begins to fill through the supply pipe.

6. Fill tank to desired level, then shut off engine.

7. Close valve 1. Remove 2 in. rigid fill-hose from

lower manifold and allow hose to drain. Place hose

in storage bin.

8. Close lower manifold end-plug. Secure cam-lock

fitting on end-plug. Close tank cover.

Discharging Water from Tank

Using Rear Spray Bar

1. Position trailer for proper use of rear spray nozzles.

2. See Figure 2-3. Open valve 4. Close valves 1, 2,

and 3. Close gravity drain bibb.

3. Start engine.

4. Open valve 2. Water begins discharging through

nozzles of rear spray bar.

NOTE: The spray pattern is adjustable. See Adjusting

Rear Spray Bar.

5. When tank is empty, shut off engine and close

valves 2 and 4.

Using 2-Inch Flexible Spray Hose

1. See Figure 2-3. Close valves 1, 2, 3, and 4. Close

gravity drain bibb.

2. Remove one upper manifold end-pl ug. Attach camlock fitting of 2 in. flexible spray hose to manifold

and secure the cam-lock fitting. Eliminate bends

and kinks in hose. Close nozzle of hose.

3. Open valve 4.

4. Start engine.

The hose pressurizes and is ready for use.

NOTE: T wist hose to turn on and of f, and to adjust spr ay

pattern.

5. When tank is empty , shut of f engine. Remove ho se

from upper manifold and allow hose to drain.

Return hose to storage bin.

6. Secure end-plug to upper manifold (B) and secure

cam-lock fitting.

7. Close valve 4.

10 Owner’s Manual for MWT500 Water Trailer

Page 15

Operation

WARNING

Personal Injury. Do not adjust spray nozzles, valves,

or hoses when pump engine is running. Doing so

could result in death or serious injury.

(000383)

004812

A

B

C

Discount-Equipment.com

Using 5/8-Inch Flexible Spray Hose

1. See Figure 2-3. Close valves 1, 2, 3, and 4. Close

the gravity drain bibb.

2. Remove one upper manifold end-plug. Attach

5/8 in. flexible spray hose to fitting of upper

manifold. Eliminate bends and kinks in hose.

3. Open valve 4.

4. Start engine.

5. Open valve 3. The hose pressurizes and is ready

for use.

6. After tank is empty, shut off engine. Remove hose

from upper manifold and allow hose to drain.

Return hose to storage bin.

7. Close valves 3 and 4.

Using Gravity Drain Bibb

1. See Figure 2-3. Close valves 1, 2, 3, and 4.

2. Attach 5/8 in. flexible spray hose to gravity drain

bibb (H). Eliminate bends and kinks in hose.

3. Open gravity drain bibb.

Water begins discharging through spray hose.

4. After tank is empty, close gravity drain bibb.

Remove hose from gravity drain bibb and allow

hose to drain. Return hose to storage bin.

Adjusting Rear Spray Bar

See Figure 3-3. The rear spray bar d ischa rg es water in a

fan-shaped pattern. The pattern can be adjusted by

twisting one or both spray nozzles.

Figure 3-3. Rear Spray Bar

Item Description

A

Total spray width, as shipped from factory:

approximately 32 ft (9.75 m)

B

C

Spray angle of each nozzle, as shipped from

factory: 120°

Nozzles (two): Twist one or both to adjust

spray angle and total spray width

Owner’s Manual for MWT500 Water Trailer 11

Page 16

Operation

Discount-Equipment.com

Draining Water from System

The tank, pump housing, and hoses must be completely

drained under either of the following conditions.

• Ambient temperature is expected to drop below

32°F (0°C).

• Unit is being put in storage for long period of time.

Drain the tank, pump housing, and hoses as follows.

1. Using the trailer jack, lower the front of the trailer

as much as possible.

2. See Figure 2-3. Open gravity drain bibb. Open

valve 4. Allow water to completely drain from tank

and lower manifold.

3. Close valve 4.

4. Using the trailer jack, raise the front of the trailer

until the engine is at a slight angle.

5. Remove pump housing drain plug. Allow water to

completely drain from pump housing.

6. Close pump housing drain plug.

7. Close valves 1, 2, 3, and 4. Remove one upper

manifold end-plug. Remove plug of access hole.

8. Using an air compressor, blow air into pump

housing. Water remaining in outlet-side of pump

and hose discharges through manifold.

9. Secure end-cap to upper manifold.

10. Open valv e 2.

11. Using an air compressor, blow air into pump

housing.

Water remaining in supply hose to rear spray-bar

discharges through rear spray nozz les .

12. Leave gravity drain bibb open to allow residual

water to drain from tank.

12 Owner’s Manual for MWT500 Water Trailer

Page 17

Section 4: Maintenance

CAUTION

(000306)

Equipment Damage. Failure to perform a daily

inspection could result in damage to the unit.

WARNING

Personal Injury. Do not perform maintenance

procedures while pump is running. Doing so could

result in death or serious injury.

(000384)

Discount-Equipment.com

Keep unit free of mud, oil, and chemicals. Do not spray

water on engine or surge brake coupler. Immediately

replace decals that are missing or hard to read.

For maintenance assistance, contact

Generac Mobile Products Technical Service at 1-800-9269768 or www.generacmobileproducts.com

a GMP ASD or

.

Maintenance

Engine and Water Pump

For engine or water pump maintenance schedules and

procedures, consult the appropriate OEM manual.

Long-Term Storage

If the unit will be stored for an extended period of time,

certain precautions must be taken to ensure reliable start

up in the future.

Consult the pump instruction manual and engine owner’s

manual for long term storage procedures.

NOTE: This water trailer is designed for specific

applications. Do not modify or use this unit for any

application other than which it was designed for.

Basic Schedule

Item Daily 3 Months /

1000 Miles

Check engine oil level in engine X

Check hoses, valves, and

couplings for leaks or bulges

Check brake fluid level in surge

brake coupler or battery connections on electric-brake models

Check trailer tires for inflation, wear X

Check trailer lights and wiring X

Ensure hoses and accessories are

accounted for and securely fastened

to storage bin

Check lug nuts on trailer wheels for

tightness

X

X

X

X

Check hardware, tighten, or loose or

missing components

Grease trailer axle bearings X

Owner’s Manual for MWT500 Water Trailer 13

X

Page 18

Maintenance

A

B

B

A

B

A

A

A

Discount-Equipment.com

Jack

See Figure 4-1. Perform maintenance on the jacks at

least once per year, as described.

equipped, the axle bolt and nut assembly of the caster

wheel must also be lubricated with the same light weight

oil.

Top-Wind Models

Apply a lightweight oil to screw stem.

Figure 4-1. Grease and Oil Points

Item Description

A

B

Side-Wind Models

Lubricate internal gears and bushings: Apply a small

amount of automotive grease to internal gears by

removing the jack cover, or, if equipped, use a needlenose applicator or standard grease gun on the lubrication

point found on the side of the jack near the crank. Rotate

jack handle to distribute grease evenly. A lightweight oil

must be applied to handle unit at both sides of the tube . If

Oil point

Grease point

14 Owner’s Manual for MWT500 Water Trailer

Page 19

Section 5: Troubleshooting

Discount-Equipment.com

Problem Possible Cause Solution

Troubleshooting

Engine does not start, or it

starts but runs roughly

Pump not operating

Weak discharge flow

1. Dirty ai r filter.

2. No fuel.

3. Stale fuel.

4. Spark plug wire not connected to plug.

5. Bad spark plug.

6. Water in fuel.

7. Excessively rich fuel mixture.

8. Impeller obstructed.

9. Dirty fuel filter.

1. Ai r leak in suction hose.

2. Suction and/or discharge hoses blocked.

3. End of suction hose not submerged.

4. Total head exceeds pump capacity.

1. Air leak (intake) at suction side.

2. Reduced engine power output.

3. Damaged mechanical seal.*

4. Suction lift too high.

5. Suction hose too long or hose diameter

too small.

6. Leaking discharge hose or connection.

7. Impeller obstructed.

8. Worn impeller.**

1. Clean or replace air filter.

2. Add fuel.

3. Replace with fresh fuel.

4. Connect wire to spark plug.

5. Replace spark plug.

6. Drain fuel tank; add fresh fuel.

7. Contact GMP ASD.

8. Clean impeller.

9. Replace fuel filter.

1. Check su ction hose and connections for

leaks. Tighten or repair.

2. Check hoses and strainer. Clear

obstructions.

3. Increase suction hose length or move

pump closer to water.

4. Reduce total head or choose a different

pump for the task.

1. Check su ction hose and connections for

leaks. Tighten or repair.

2. Contact authorized servicing dealer.

3. Replace mechanical seal.

4. Lower suction lift.

5. Shorten suction hose, or increase hose

diameter.

6. Check discharge hose and connection for

leaks. Tighten or repair.

7. Clean impeller.

8. impeller.

1. Air leak (intake) at suction side.

2. Insufficient priming water inside pump

casing.

Pump does not prime water,

or priming takes a long time

Oil leak at muffler or air

cleaner

Water leak between engine

and pump

* Mechanical seal damage may be caused by normal wear, overheating, or pumping incompatible fluids.

** Excessive impeller wear is primarily due to cavitation. Causes include restricted suction and excessive suction lift.

*** Total suction head should not exceed 26 ft (8 m).

3. Water drain plug is loose.

4. Engine malfunction.

5. Damaged mechanical seal.

6. Incorrectly sized suction hose.

7. Suction hose is too long.

8. Excessive suction lift. ***

1. Check oil le vel for over-fill.

2. Engine failure .

1. Damage d mechanical seal. 1. Replace mechanical seal.

1. Check su ction hose and connections for

leaks. Tighten or repair.

2. Add priming water.

3. Tighten water drain plug.

4. Contact authorized servicing dealer.

5. Replace mechanical seal.

6. Use correct suction hose.

7. Move pump closer to water.

1. Adjust oil level.

2. Repair or replace.

Owner’s Manual for MWT500 Water Trailer 15

Page 20

Section 6: Wiring Diagrams

Discount-Equipment.com

Trailer

TRAILER

PLUG

GRN

YEL

BRN

Wiring Diagrams

WHT

AMBER

MARKER

LAMP

BLK

WHT

BLK

WHT

AMBER

MARKER

LAMP

TO

MOUNTING

STUD

STOP-TURN

SIGNAL LAMP

(LEFT)

PLATE

LAMP

Owner’s Manual for MWT500 Water Trailer 17

YEL

BRN

WHT

WHT

TO

MOUNTING

STUD

GRN

BRN

STOP-TURN

SIGNAL LAMP

(RIGHT)

90228_ORG_05.09.12

Page 21

Wiring Diagrams

Discount-Equipment.com

Wiring Harness—Electric Brake Option

SPLICE

BRAKE

BRAKE

SPLICE

SPLICE

BRAKE

SPLICE

SPLICE

SPLICE

SPLICE

WT

BL

SINGLE AXLE

BRAKE BRAKE

SPLICE

SPLICE

SPLICE

BRAKE

SPLICE

SPLICE

WT

WT

BL

BL

BL

TANDEM AXLE

TRI-AXLE

FRAME GND

WT

BATTERY

SPLICE

SPLICE

BL

WT BK

BKBL

BREAKAWAY

90286_E_03.18.14

SWITCH

18 Owner’s Manual for MWT500 Water Tr ailer

Page 22

Service Log

Discount-Equipment.com

Section 7: Service Log

OIL GRADE:_______________________ _______________ BRAND: _________________________________ _

COOLANT MIXTURE (IF APPLICABLE: ________________ BRAND: __________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

Date

Hours to

Service

Oil Level

Coolant

Level (if

applicable)

Date

Hours to

Service

Oil Level

Coolant

Level (if

applicable)

Owner’s Manual for MWT500 Water Trailer 19

Page 23

www.discount-equipment.com

Discount-Equipment.com

Part No. 40859 Rev. N 11/082017

©2017 Generac Mobile Products, LLC

All rights reserved.

Specifications are subject to change without notice.

No reproduction allowed in any form without prior written consent

from Generac Mobile Products, LLC.

Loading...

Loading...