Page 1

www.discount-equipment.com

Discount-Equipment.com

Owner’s Manual

Light Tower

MLT6SC

006446

######

SA VE THIS MANUAL FOR FUTURE REFERENCE

Page 2

Discount-Equipment.com is your online resource for commercial and industrial

Discount-Equipment.com

quality parts and equipment sales.

Locations:

Florida (West Palm Beach): 561-964-4949

Outside Florida TOLL FREE: 877-690-3101

Need parts? Check out our website at www.discount-equipment.com

Can’t find what you need?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and fill out

the request form.

Please have the machine model and serial number available in order to help us get

you the correct parts. One of our experienced staff members will get back to you with

a quote for the right part that your machine needs.

We sell worldwide for the br

Diamond

Chicago Pneumatic, Allmand Brothers, Essick, Miller Spreader, Skyjack, Lull, Skytrak,

Tsurumi, Husquvarna/Target, Whiteman-Concrete/Mortar, Stow-Concrete/Mortar, Baldor,

Wacker, Sakai, Snorkel, Upright, Mi-T-M, Sullair, Neal, Basic, Dynapac, MBW, Weber,

Bartell, Bennar Newman, Haulotte, Ditch Runner, Blaw-Knox, Himoinsa, Best, Buddy,

Crown, Edco, Wyco, Bomag, Laymor, Terremite, Barreto, EZ Trench, Takeuchi, Basic, Bil-

Jax, Curtis, Gehl, Heli, Honda, ICS/PowerGrit, Puckett, Waldon, ASV, IHI, Partner, Imer,

Clipper, MMD, Koshin, Rice, Gorman Rupp, CH&E, Cat Pumps, Comet, General Pump,

Giant,AMida, Coleman, NAC, Gradall, Square Shooter, Kent, Stanley, Tamco, Toku, Hatz,

Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air, Small Line, Wanco, Yanmar

Products, Magnum, Airman, Mustang, Power Blanket, Nifty Lift, Atlas Copco,

ands: Genie, Terex, JLG, MultiQuip, Mayco, Toro/Stone,

Page 3

Use this page to record important information about your Light Tower

(000393)

WARNING

Operating, servicing and maintaining this

equipment can expose you to chemicals

including engine exhaust, carbon monoxide,

phthalates, and lead, which are known to the

State of California to cause cancer and birth

defects or other reproductive harm. To

minimize exposure, avoid breathing exhaust,

do not idle the engine except as necessary,

service your equipment in a well-ventilated

area and wear gloves or wash your hands

frequently when servicing your equipment.

For more information go to

www.P65Warnings.ca.gov.

(000394)

WARNING

Breathing diesel engine exhaust exposes you

to chemicals known to the State of California

to cause cancer and birth defects or other

reproductive harm.

• Always start and operate the engine in a

well-ventilated area.

• If in an enclosed area, vent the exhaust to

the outside.

• Do not modify or tamper with the exhaust

system.

• Do not idle the engine except as necessary.

For more information go to

www.P65Warnings.ca.gov/diesel.

Discount-Equipment.com

Record the information found on your unit data label on this

Unit Model Number

Unit Serial Number

Engine Model

Number

Engine Serial

Number

Generator Model

Number

Generator Serial

Number

MLT6SC

C1.1—EJ501-2055

201CSA5412

page. See Unit Serial Number Locations.

Engine and generator serial numbers are located on separate

data plates affixed to the engine and generator respectively.

When contacting a Generac Mobile Products Authorized

Service Dealer (GMP ASD) about parts and service, always

provide the unit model and serial number.

Operation and Maintenance: Proper maintenance and care of

the light tower ensures a minimum number of problems and

keeps operating expenses at a minimum. It is the operator’s

responsibility to perform all safety checks, to verify that all

maintenance for safe operation is performed promptly, and to

have the equipment checked periodically by a Generac Mobile

Products Authorized Dealer. Normal maintenance, service and

replacement of parts are the responsibility of the owner/

operator and, as such, are not considered defects in materials

or workmanship within the terms of the warranty. Individual

operating habits and usage may contribute to the need for

additional maintenance or service.

ii Owner’s Manual for MLT6SC Light Tower

Page 4

Table of Contents

Discount-Equipment.com

Section 1: Introduction and Safety

Introduction ..........................................................1

Read This Manual Thoroughly ....................................1

How to Obtain Service .................................................1

Safety Rules .........................................................1

General Hazards ..................................................2

Explosion and Fire Hazards ................................2

Trailer Hazards .....................................................2

Electrical Hazards ................................................3

Battery Hazards ...................................................3

Fuel Hazards ........................................................4

Engine Safety .......................................................4

Operating Safety ..................................................4

Positioning the Unit .....................................................4

Starting the Unit ...........................................................4

Raising and Lowering the Mast ...................................5

Service Safety ......................................................5

Section 3:Operation

Light Tower Setup .............................................25

Prestart Checklist ..............................................26

Raising the Mast—Manual Winch .................... 26

Raising the Mast—Electric Winch (If Equipped)

.............................................................................27

Starting the Unit ................................................28

Preparing for Start-Up (with Power Zone Control-

ler, If Equipped) .................................................29

Select AUTO or MANUAL Mode ...............................29

Manually Starting the Unit ................................29

Light Operation ..................................................29

Light Operation (With Power Zone Controller, If

Equipped) ........................................................... 30

Engine Derating .................................................30

Wet Stacking ......................................................30

Dusk to Dawn Sensor .......................................31

Towing Safety ......................................................6

Hitch and Coupling ......................................................6

Running Lights ............................................................6

Wheels and Tires ........................................................6

Safe Towing Techniques .............................................6

Reporting Trailer Safety Defects ........................6

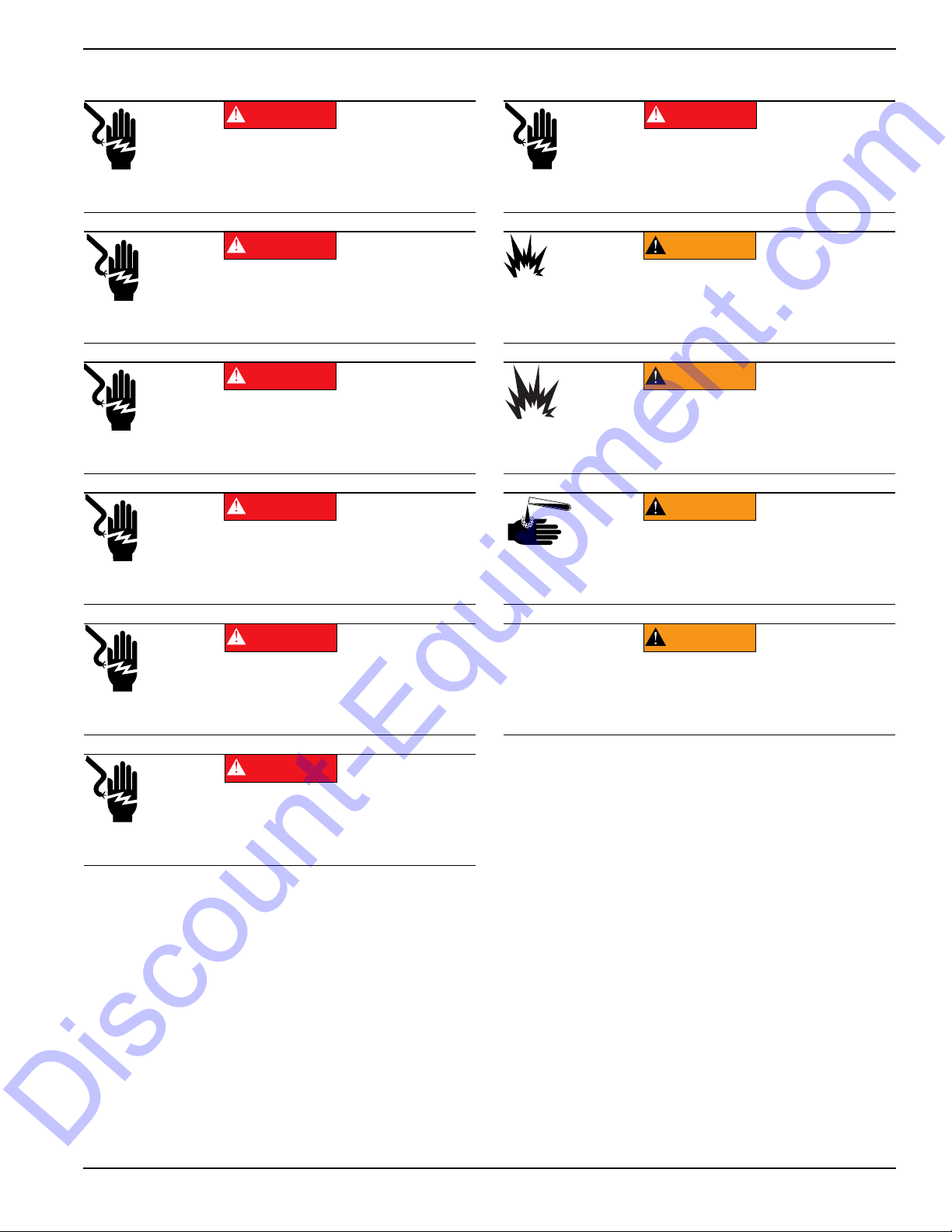

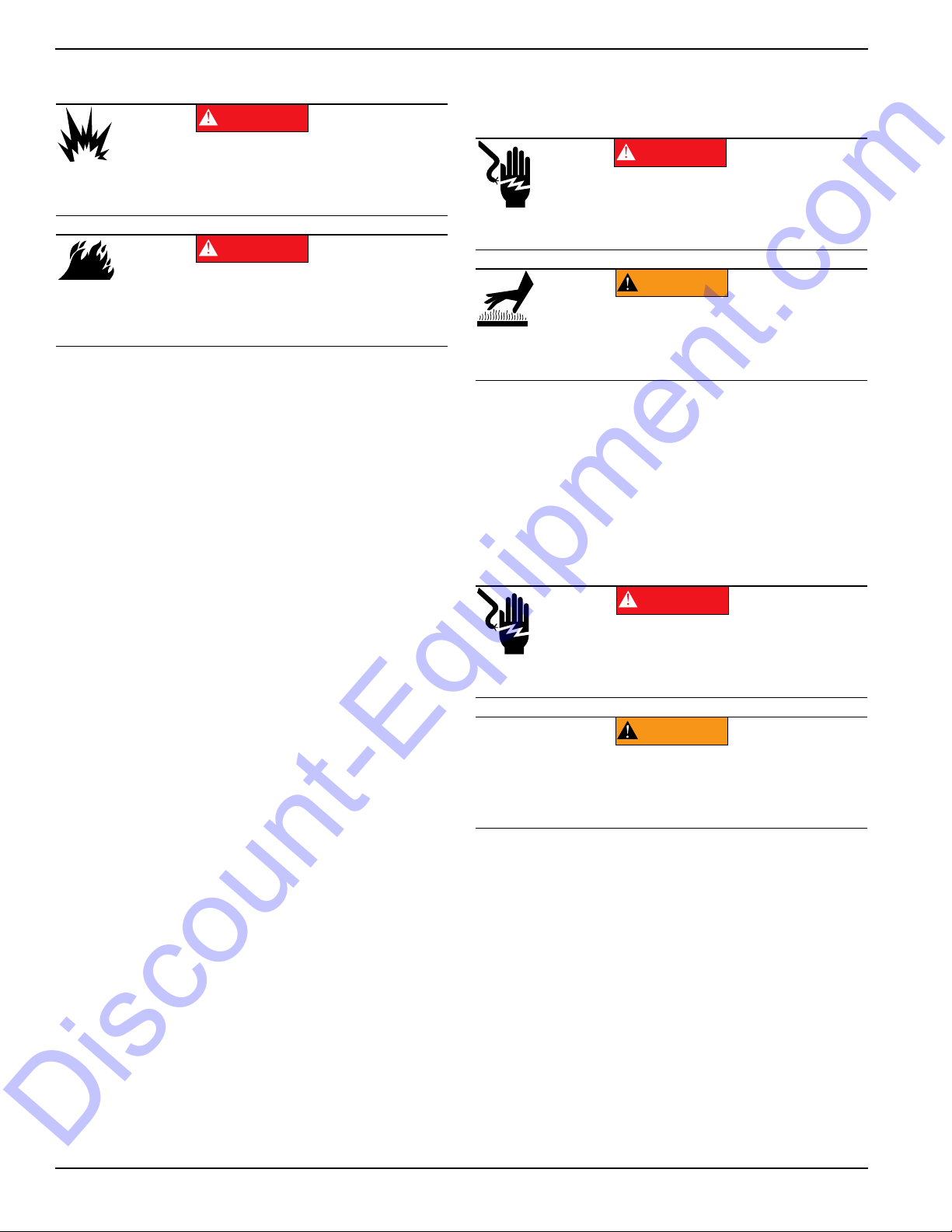

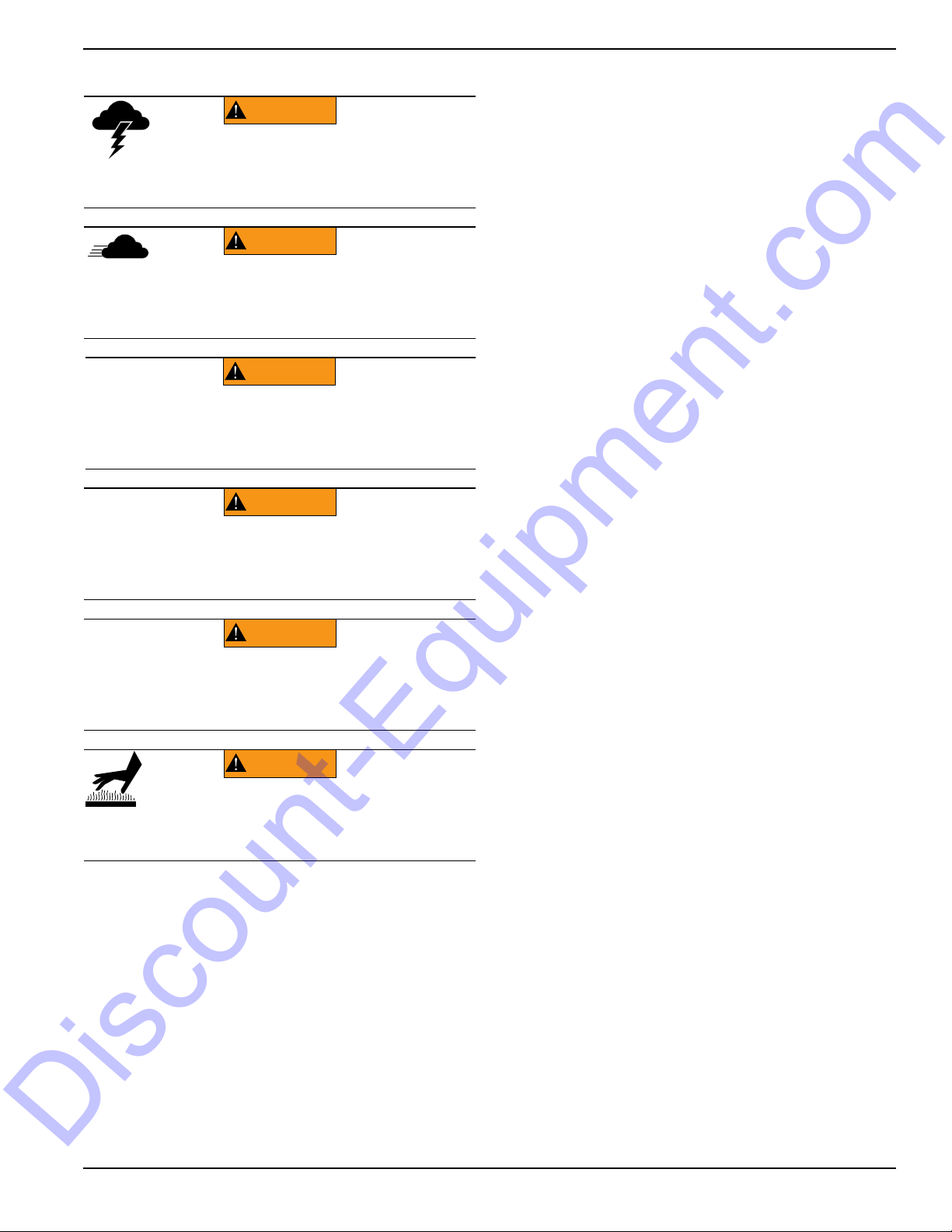

Safety and Operating Decals ..............................7

Section 2: General Information

Specifications ....................................................11

Unit Serial Number Locations ..........................12

Trailer Tongue Storage and Tow Positions .....13

Place Trailer Tongue in Tow Position ........................13

Place Trailer Tongue in Storage Position ..................14

Unit Dimensions ................................................15

Component Locations .......................................16

Control Panel .....................................................18

Control Panel Features and Functions ......................18

Customer Convenience Outlets .......................31

Shutting Down the Unit .....................................31

Shutting Down the Unit (with Power Zone Con-

troller, If Equipped) ...........................................31

Automatic Shutdown .................................................31

Lower Radiator Hose Heater (If Equipped) .....31

Tandem Tow (If Equipped) ............................... 32

Telemetry (If Equipped) ....................................32

Spark Arrester (If Equipped) ............................ 32

Lowering the Mast—Manual Winch ................. 32

Lowering the Mast—Electric Winch

(If Equipped) ......................................................33

Manually Lowering the Mast ...................................... 33

Towing the Unit .................................................33

Lifting the Unit ...................................................34

Tying the Unit Down ..........................................34

Power Zone–DLA (If Equipped) ........................19

Controller Features and Functions ............................19

Operator Screens ......................................................20

Owner’s Manual for MLT6SC Light Tower iii

Page 5

Section 4:Maintenance

Discount-Equipment.com

Emissions Information ......................................35

Daily Walk-Around Inspection ..........................35

General Maintenance .........................................35

Preparing for Service ................................................ 35

Cleaning the Unit ...................................................... 35

Inspecting the Unit .................................................... 35

Basic Maintenance Schedule ...........................36

Resetting the Maintenance Alarms

(If Equipped) .......................................................38

Manual Winch: Use, Operation, and

Maintenance .......................................................38

Prior to Use ............................................................... 38

Operation .................................................................. 38

Maintenance ............................................................. 38

Electric Winch: Use, Operation, and

Maintenance .......................................................38

Winch Mechanical Brake .......................................... 39

Jack Maintenance ..............................................39

Trailer Wheel Bearings ......................................39

Section 5:Troubleshooting

General Troubleshooting ..................................41

Troubleshooting the Lights ..............................42

Section 6:Wiring Diagrams

Mast Junction Box Wiring and Light

Connections .......................................................43

AC Wiring Diagram ............................................44

DC Wiring Diagram ............................................45

DC Wiring - Electric Winch Option ...................46

Trailer Lights Wiring ..........................................47

Section 7:Service Log

iv Owner’s Manual for MLT6SC Light Tower

Page 6

Section 1: Introduction and Safety

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

(000001)

DANGER

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

(000002)

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

(000003)

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Discount-Equipment.com

Introduction and Safety

Introduction

Thank you for purchasing a Generac Mobile Products LLC

product. This unit has been designed to provide high

performance, efficient operation, and years of use when

maintained properly.

The information in this manual is accurate based on

products produced at the time of publication. The

manufacturer reserves the right to make technical updates,

corrections, and product revisions at any time without

notice.

Read This Manual Thoroughly

If any section of the manual is not understood, contact your

nearest Generac Mobile Products Authorized Service

Dealer with any questions or concerns.

The owner is responsible for proper maintenance and safe

use of the equipment. Comply with regulations the

Occupational Safety and Health Administration (OSHA)

has established, or with equivalent standards. Also, verify

that the unit is applied, used, and maintained in accordance

with the manufacturer's instructions and recommendations.

Do nothing that might alter safe application/usage and

render the unit in noncompliance with the aforementioned

codes, standards, laws, and regulations

Save these instructions for future reference. This manual

contains important instructions for the unit that should be

followed during setup, operation and maintenance of the

unit and battery. ALWAYS supply this manual to any

individual that will use this machine.

.

Safety Rules

The manufacturer cannot anticipate every possible

circumstance that might involve a hazard. The warnings in

this manual, and on tags and decals affixed to the unit are,

therefore, not all inclusive. If using a procedure, work

method or operating technique that the manufacturer does

not specifically recommend, verify that it is safe for others.

Also make sure the procedure, work method or operating

technique utilized does not render the equipment unsafe.

Throughout this publication, and on tags and decals affixed

to the unit, DANGER, WARNING, CAUTION and NOTE

blocks are used to alert personnel to special instructions

about a particular operation that may be hazardous if

performed incorrectly or carelessly. Observe them

carefully. Their definitions are as follows:

How to Obtain Service

When the unit requires servicing or repairs, contact a GMP

ASD for assistance. Service technicians are factory-trained

and are capable of handling all service needs. For

assistance locating a dealer, go to

www.generacmobleproducts.com/parts-service/find-

service. When contacting a Generac Mobile Products

Authorized Service Dealer about parts and service, always

supply the complete model number and serial number of

the unit as given on its data decal located on the unit.

Record the model number and serial numbers in the

spaces provided on the inside front cover of this manual.

Owner’s Manual for MLT6SC Light Tower 1

NOTE: Notes contain additional information important to

a procedure and will be found within the regular text of

this manual.

These safety alerts cannot eliminate the hazards that they

indicate. Common sense and strict compliance with the

special instructions while performing the action or service

are essential to preventing accidents.

Page 7

Introduction and Safety

Asphyxiation. Running engines produce

carbon monoxide, a colorless, odorless,

poisonous gas. Carbon monoxide, if not

avoided, will result in death or serious injury.

(000103)

DANGER

(000107)

WARNING

Hearing Loss. Hearing protection is

recommended when using this machine.

Failure to wear hearing protection could

result in permanant hearing loss.

(000111)

WARNING

Moving Parts. Keep clothing, hair, and

appendages away from moving parts. Failure

to do so could result in death or serious injury.

(000108)

WARNING

Hot Surfaces. When operating machine, do not

touch hot surfaces. Keep machine away from

combustibles during use. Hot surfaces could

result in severe burns or fire.

WARNING

Risk of injury. Do not operate or service this machine

if not fully alert. Fatigue can impair the ability to service

this equipment and could result in death or serious

injury.

(000215)

(000139)

WARNING

Risk of burns. Allow engine to cool before

draining oil or coolant. Failure to do so could

result in death or serious injury.

(000105)

DANGER

Explosion and Fire. Fuel and vapors are

extremely flammable and explosive. Add fuel

in a well ventilated area. Keep fire and spark

away. Failure to do so will result in death

or serious injury.

(000147)

WARNING

Risk of Fire. Unit must be positioned in a

manner that prevents combustible material

accumulation underneath. Failure to do so

could result in death or serious injury.

(000110)

WARNING

Risk of Fire. Hot surfaces could ignite

combustibles, resulting in fire. Fire could

result in death or serious injury.

WARNING

Personal injury. Trailer must be securely coupled to

the hitch with the chains correctly attached. Uncoupled

or unchained towing could result in death or serious

injury.

(000233a)

Personal injury. Do not operate unit during transport.

Doing so could result in death, serious injury, or

property damage.

(000231a)

WARNING

(000234a)

WARNING

Crushing hazard. Verify unit is properly secured and

on level ground. An unsecured unit can suddenly roll

or move, causing death or serious injury.

WARNING

Property or Equipment Damage. Tighten wheel lug

nuts after first 50 miles to factory specifications.

Failure to do so could result in death, serious injury,

property or equipment damage.

(000235)

Discount-Equipment.com

General Hazards

Explosion and Fire Hazards

Trailer Hazards

2 Owner’s Manual for MLT6SC Light Tower

Page 8

Electrical Hazards Battery Hazards

(000145)

DANGER

Electrocution. In the event of electrical accident,

immediately shut power OFF. Use non-conductive

implements to free victim from live conductor. Apply

first aid and get medical help. Failure to do so will

result in death or serious injury.

(000104)

DANGER

Electrocution. Water contact with a power

source, if not avoided, will result in death

or serious injury.

(000144)

DANGER

Electrocution. Contact with bare wires,

terminals, and connections while generator

is running will result in death or serious injury.

(000152)

DANGER

Electrocution. Verify electrical system is

properly grounded before applying power.

Failure to do so will result in death or serious

injury.

(000188)

DANGER

Electrocution. Do not wear jewelry while

working on this equipment. Doing so will

result in death or serious injury.

DANGER

Electrocution. DO NOT use the unit if

electrical cord is cut or worn through. Doing

so will result in death or serious injury.

(000263a)

(000188)

DANGER

Electrocution. Do not wear jewelry while

working on this equipment. Doing so will

result in death or serious injury.

(000137a)

WARNING

Explosion. Batteries emit explosive gases while charging.

Keep fire and spark away. Wear protective gear when

working with batteries. Failure to do so could result in

death or serious injury.

(000162)

WARNING

Explosion. Do not dispose of batteries in a fire. Batteries

are explosive. Electrolyte solution can cause burns and

blindness. If electrolyte contacts skin or eyes, flush with water

and seek immediate medical attention.

(000163a)

WARNING

Risk of burn. Do not open or mutilate batteries.

Batteries contain electrolyte solution which can

cause burns and blindness. If electrolyte contacts

skin or eyes, flush with water and seek immediate

medical attention.

WARNING

Environmental Hazard. Always recycle batteries at an

official recycling center in accordance with all local

laws and regulations. Failure to do so could result in

environmental damage, death or serious injury.

(000228)

Discount-Equipment.com

Introduction and Safety

Owner’s Manual for MLT6SC Light Tower 3

Always recycle batteries in accordance with local laws and

regulations. Contact your local solid waste collection site

or recycling facility to obtain information on local recycling

processes. For more information on battery recycling, visit

the Battery Council International website at: http://

batterycouncil.org

Page 9

Introduction and Safety

(000192)

DANGER

Explosion and fire. Fuel and vapors are extremely

flammable and explosive. No leakage of fuel is

permitted. Keep fire and spark away. Failure to do

so will result in death or serious injury.

(000174)

DANGER

Risk of fire. Allow fuel spills to completely dry

before starting engine. Failure to do so will

result in death or serious injury.

(000260a)

High Voltage. Verify area above unit is clear

of overhead wires and obstructions. Contact

with high-voltage power lines will result in

death or serious injury.

DANGER

(000277)

WARNING

Burn hazard. Never operate lights with a

damaged or missing lens cover. Lamps are

hot and pressurized while in use. Unprotected

lamps can shatter, causing severe injury.

DANGER

Electrocution. DO NOT use the unit if

electrical cord is cut or worn through. Doing

so will result in death or serious injury.

(000263a)

CAUTION

(000291)

Equipment damage. Do not attempt to start or operate

a unit in need of repair or scheduled maintenance.

Doing so could result in serious injury, death, or

equipment failure or damage.

WARNING

Discount-Equipment.com

Fuel Hazards

• DO NOT fill fuel tank near an open flame, while

smoking, or while engine is running. DO NOT fill

tank in an enclosed area with poor ventilation.

• DO NOT operate with the fuel tank cap loose or

missing.

Engine Safety

Internal combustion engines present special hazards

during operation and fueling. Failure to follow the safety

guidelines described below could result in severe injury or

death. Read and follow all safety alerts described in the

engine operator's manual. A copy of this manual was

supplied with the unit when it was shipped from the factory.

Operating Safety

Positioning the Unit

The area immediately surrounding the unit should

•

be dry, clean, and free of debris.

• Position and operate the unit on a firm, level

surface.

• If the unit is equipped with a frame grounding stud,

follow the National Electrical Code (NEC), state,

and local regulations when connecting.

Starting the Unit

• DO NOT run engine indoors or in an area with poor

ventilation. Make sure engine exhaust cannot seep

into closed rooms or ventilation equipment.

• DO NOT clean air filter with gasoline or other types

of low flash point solvents.

• DO NOT operate the unit without a functional

exhaust system.

• Shut the engine down if any of the following

conditions exist during operation:

• Noticeable change in engine speed.

• Loss of electrical output.

• Equipment connected to the unit overheats.

• Sparking occurs.

• Engine misfires or there is excessive engine/

generator vibration.

• Protective covers are loose or missing.

• Ambient air temperature is above 120°F (49°C).

4 Owner’s Manual for MLT6SC Light Tower

Page 10

Introduction and Safety

WARNING

Electrocution. Do not set up or operate

this unit if severe weather is expected.

Lightning strikes can kill or cause severe injury

even if you are not touching the unit.

(000296)

WARNING

(000297)

> 60 mph> 60 mph

Do not set up the unit if high winds

are expected. High winds can cause the

unit to tip or fall, causing severe injury

or machine damage.

(000279)

Personal injury or equipment damage. Do not raise

or lower the mast while the unit is operating.

Doing so can break the lenses and cause the

lamps to shatter.

WARNING

WARNING

Personal Injury. Stop immediately if the mast hangs

up or the winch cable develops slack. Excess slack

could cause the mast to collapse, resulting in personal

injury or equipment damage.

(000265)

WARNING

Tipping hazard. Extend the outriggers and level the unit

before raising the mast. Keep the outriggers extended

while the mast is up. Failure to do so could cause the unit

to tip and fall and could result in death or serious injury.

(000266)

(000278)

WARNING

Burn hazard. Lamps become extremely hot

while in use. Allow 10–15 minutes for cooling

before handling or lowering mast. Touching a

hot lens or fixture can cause severe burns.

Discount-Equipment.com

Raising and Lowering the Mast

Service Safety

This unit uses high voltage circuits capable of causing

serious injury or death. Only a qualified and licensed

electrician should troubleshoot or repair problems

occurring in this equipment.

•

Before servicing the unit, verify the Control Power

switch and circuit breakers are in the OFF (O)

position, and the negative (-) terminal on the battery

is disconnected.

service (oil/filter changes, cleaning, etc.) unless all

electrical components are shut down.

•

ALWAYS

unit in damp conditions. Do not service the unit if your

skin or clothing is wet. Do not allow water to collect

around the base of the unit.

•

DO NOT

power washers, or steam cleaners. Water may

collect in the unit, causing damage to electrical parts.

•

Replace all missing and hard to read decals. Decals

provide important operating instructions and warn of

dangers and hazards.

•

Wear heavy leather gloves when handling winch

cables. Never let cables slip through bare hands.

•

Only use mild soap and water to clean the lens covers.

Other chemicals may damage the lens covers.

use extreme caution when servicing this

wash the unit with high pressure hoses,

DO NOT

perform even routine

Keep area around the unit clear of people while

•

raising and lowering the mast.

• ALWAYS lower the mast when not in use.

• The tower extends up to 23 ft (7 m). Verify area

above trailer is open and clear of overhead wires

and obstructions.

• If for any reason any part of mast hangs up or

winch cable develops slack while raising or

lowering tower, STOP immediately! Contact a

Generac Mobile Products Authorized Service

Dealer.

• NEVER remove safety pin or pull mast locking pin

while tower is up.

Owner’s Manual for MLT6SC Light Tower 5

Page 11

Introduction and Safety

Discount-Equipment.com

Towing Safety

Towing a trailer requires care. Both the trailer and vehicle

must be in good condition and securely fastened to each

other to reduce the possibility of an accident. Some states

require that large trailers be registered and licensed.

Contact your local Department of Transportation office to

check on license requirements for your particular unit.

Hitch and Coupling

Verify the hitch and coupling on the towing vehicle

•

are rated equal to, or greater than, the trailer's

Gross Vehicle Weight Rating (GVWR).

• Verify the trailer hitch and the coupling are

compatible. Make sure the coupling is securely

fastened to the vehicle.

• DO NOT tow trailer using defective parts. Inspect

the hitch and coupling for wear or damage.

• Connect safety chains in a crossing pattern under

the tongue.

• Before towing the trailer, verify that the weight of

the trailer is equal across all tires. On trailers with

adjustable height hitches, adjust the angle of the

trailer tongue to keep the trailer as level as

possible.

Reporting Trailer Safety Defects

If you believe your trailer has a defect which could cause

a crash or could cause injury or death, you should

immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying Generac

Mobile Products LLC.

If NHTSA receives similar complaints, it may open an

investigation; and if it finds that a safety defect exists in a

group of vehicles, it may order a recall and remedy

campaign. However, NHTSA cannot become involved in

an individual problem between you, your dealer, or

Generac Mobile Products LLC.

To contact NHTSA, you may either call the Auto Safety

Hotline toll-free at 1-888-327-4236 (TTY:1-800-424-9153),

go to http://www.safercar.gov; or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain other information about motor vehicle

safety from http://www.safercar.gov.

Running Lights

Verify directional and brake lights on the trailer are

connected and working properly

Wheels and Tires

•

Check trailer tires for wear and proper inflation.

• Verify wheel lug nuts are present and tightened to

the specified torque.

Safe Towing Techniques

Practice turning, stopping and backing up in an

•

area away from heavy traffic prior to transporting

the unit.

• Maximum recommended speed for highway towing

is 45 mph (72 km/h). Recommended off-road

towing speed is 10 mph (16 km/h) or less,

depending on terrain.

• When towing, maintain extra space between

vehicles and avoid soft shoulders, curbs and

sudden lane changes.

6 Owner’s Manual for MLT6SC Light Tower

Page 12

Introduction and Safety

######

1

SET UP

AUFSTELLUNG

INSTALACIÓN

INSTALLATION

X

2

2

C

B

4

5

6

TAKE DOWN

ABBAU

DESINSTALACIÓN

DÉMONTAGE

15 MIN

STOP

1 3 4

X

2

1 Inch

(25 mm)

x3

3

2

B

A

A

C

SET UP

AUFSTELLUNG

INSTALACIÓN

INSTALLATION

TAKE DOWN

ABBAU

DESINSTALACIÓN

DÉMONTAGE

4

X

2

3

B

A

C

IOI

O

I

O

I

O

15 MIN

STOP

X

2

2

1 Inch

(25 mm)

x3

3

B

4

A C

0°±5°

1

IOI

O

I

O

I

O

STOP

65

1 2

1

2

006447

Discount-Equipment.com

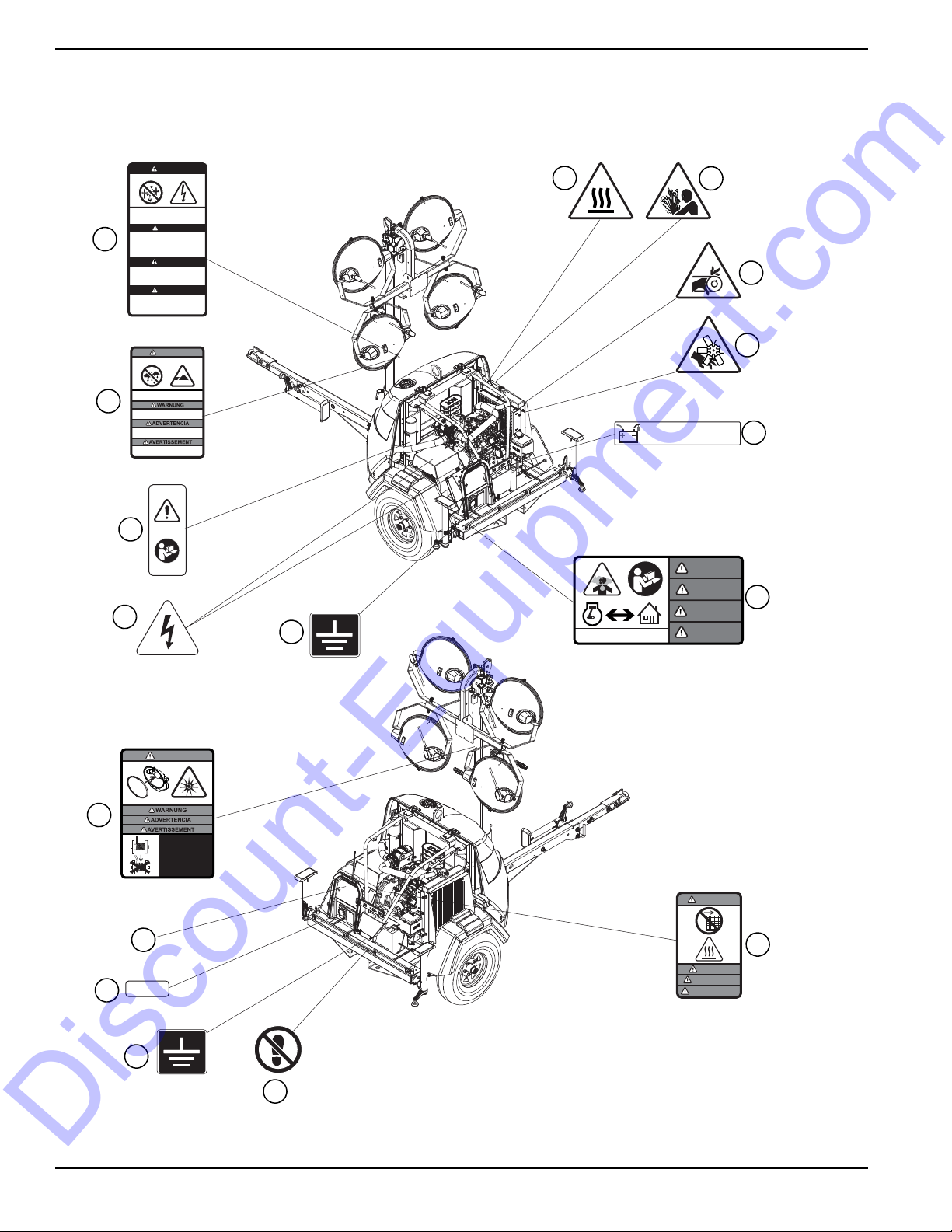

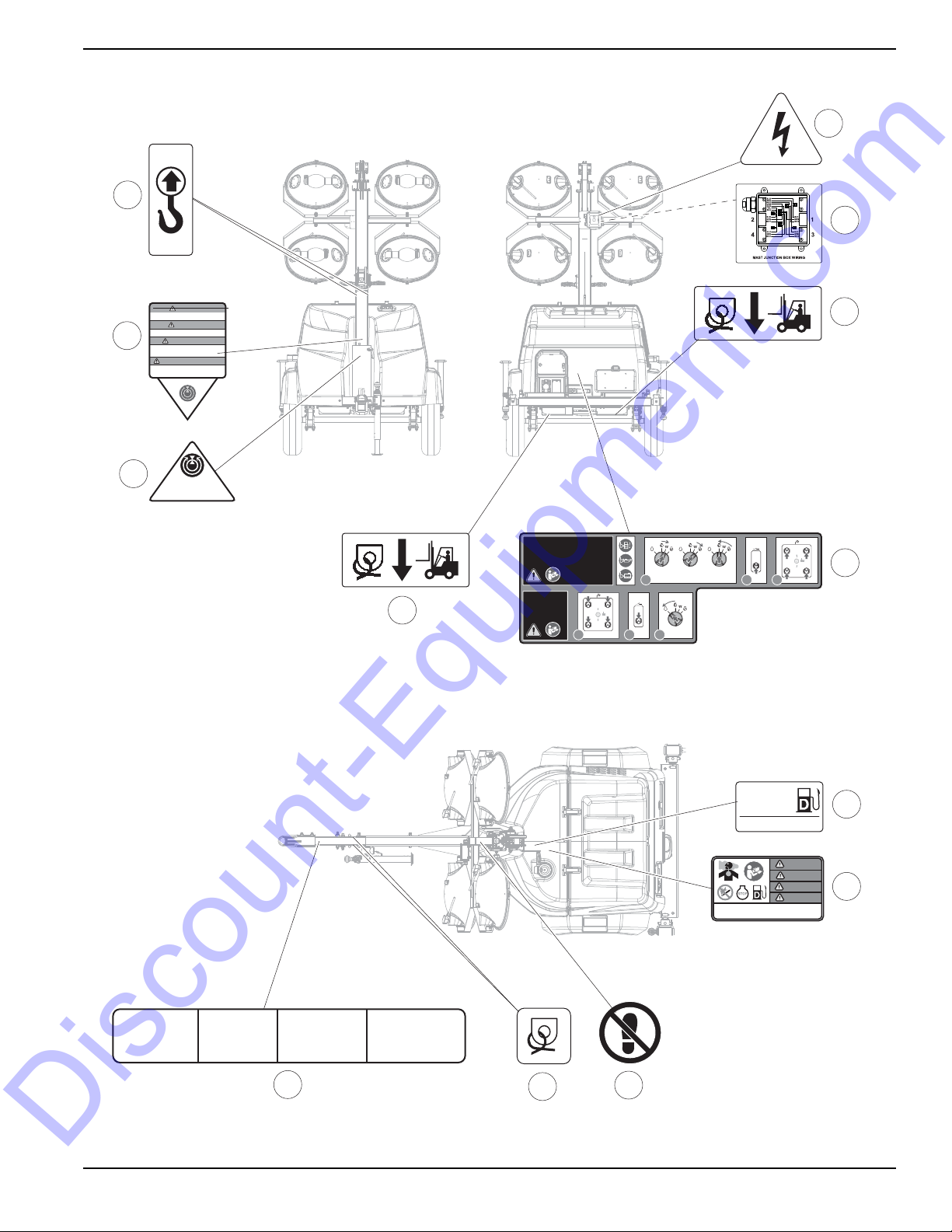

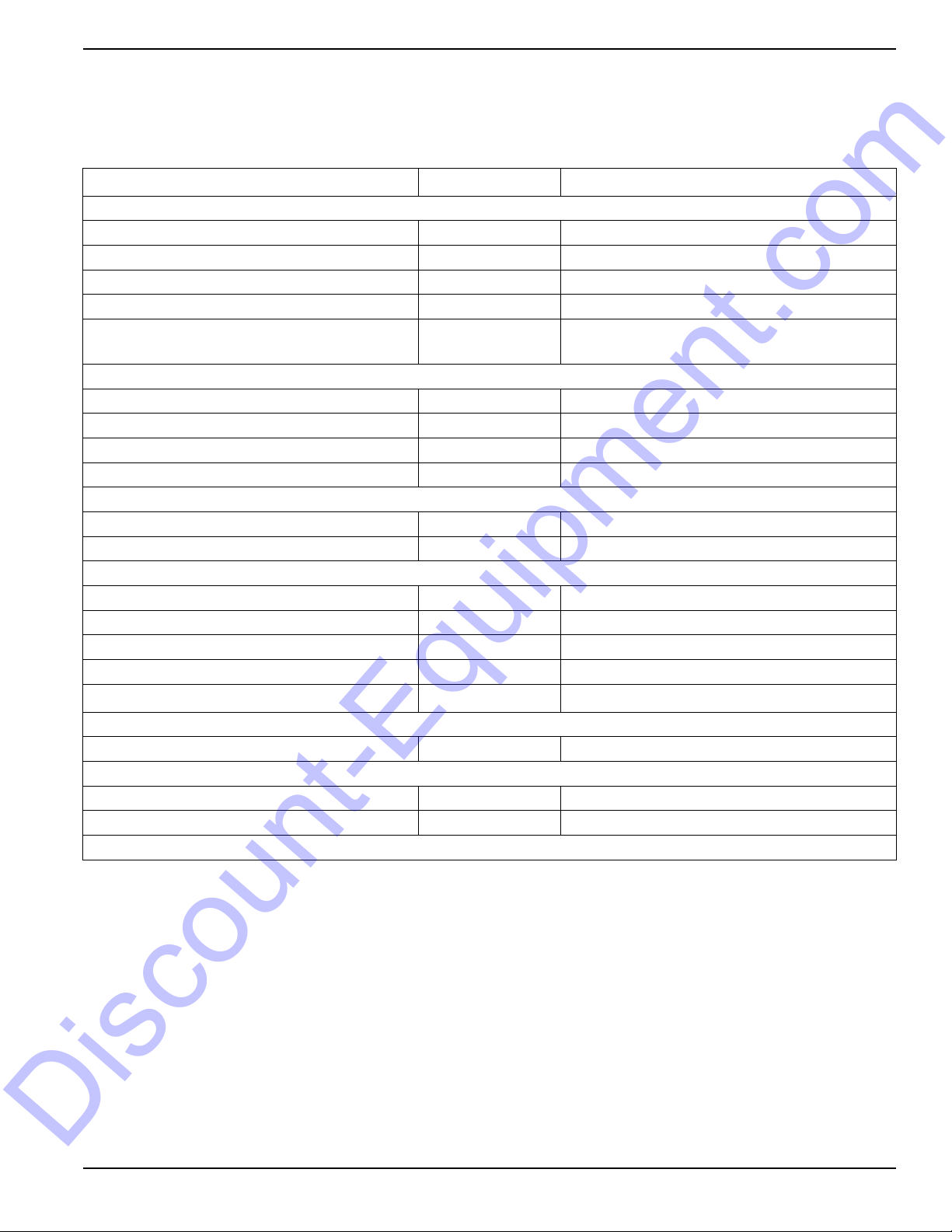

Safety and Operating Decals

See Figure 1-1 through Figure 1-3. This unit features

Replace any missing or hard-to-read decals and use care

when

washing or cleaning the unit. Decal part numbers

can be found in the parts manual.

numerous safety and operating decals. These decals

provide important operating instructions and warn of

dangers and hazards. The following diagrams illustrate

decal locations and descriptions.

ID Description ID Description

1 Setup and Take-Down Instructions (Electric) 15 Control Panel Label (not shown)

2 Setup and Take-Down Instructions (Manual) 16 Neutral Bonded to Frame

3 Danger—Overhead Power Lines 17 Not A Step

4 Warning—Electrical Storms and High Wind 18 Warning—High Temperature: Do Not Remove Guard

5 Owner’s Manual Location 19 Mast Junction Box Wiring (inside)

6 Electric Shock Hazard 20 Warning—Do Not Retract Outriggers With Tower Up

7 Warning—Pressurized Liquid 21 Stowed Position

8 Warning—Hot Surface 22 Lifting Point

9 Warning—Entanglement Hazard 23 Forklift and Tie-Down Point

10 Warning—Cutting Hazard 24 Engine Operation

11 Disconnect Battery Before Servicing 25 Ultra Low Sulfur Diesel Fuel Only

12 Danger—Carbon Monoxide 26 Danger—Fuel and Fueling Hazards

13 Electrical Ground Connection 27 Tie-Down Point

14 Danger—Ultraviolet Radiation / Winch Operation 28 Towing Instructions

0°±5°

Owner’s Manual for MLT6SC Light Tower 7

Figure 1-1. Decal Locations (1 of 3)

Page 13

Introduction and Safety

######

WARNUNG

ADVERTENCIA

AVERTISSEMENT

WARNING

Débrancher la batterie avant de faire l’entretien.

Disconnect battery before servicing.

Vor der Instandsetzung die Batterieverbindungen lösen.

Desconecte la batería

antes de realizar el servicio técnico.

CARBON MONOXIDE

DANGER

GEFAHR

PELIGRO

DANGER

WARNING

NOTICE

HINWEIS

AVI SO

AVI S

Nicht bei Windgeschwindigkeit von mehr

als 95 km/h oder bei Gewitter aufstellen.

No instalar cuando el viento exceda los

95 km/h o durante tormentas eléctricas.

Ne pas installer dans des vents excédant

60 mph ou pendant les orages electriques.

DO NOT set up unit in winds exceeding

60 mph, or during electrical storms.

ELECTRICAL STORMS & HIGH WIND

> 60 mph> 60 mph

WARNING

Der kontakt mit elektrischen

Hochspannungsleitungen kann zu schweren

oder lebensgefährlichen Verletzungen

führen. Den Beleuchtungswagen nie direkt

unter Hochspannungsleitungen aufstellen.

El contacto con las líneas electricas

elevadas podría causar lesiones serias o la

muerte. No posicione la torre de iluminación

debajo de líneas electricas.

Le contact avec des câbles électriques

suspendus causera des blessures graves ou

la mort. Ne pas positionner la tour

lumineuse sous des câbles électriques.

Contact with overhead electrical power lines

will cause serious injury or death. Do not

position light tower under electrical power lines.

OVERHEAD POWER LINES

DANGER

GEFAHR

PELIGRO

DANGER

NEUTRAL BONDED TO FRAME

NULLLEITER AM RAHMEN ANGESCHLOSSEN

NEUTRO CONECTADO AL BASTIDOR

POSITION NEUTRE LORSQUE FIXÉ AU CADRE

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

13

006448

Discount-Equipment.com

Figure 1-2. Decal Locations (2 of 3)

8 Owner’s Manual for MLT6SC Light Tower

Page 14

######

S≤15 mg/kg

ULTRA LOW

SULFUR

FUEL ONLY

1. Read operator's manual.

2. Use hitch rated for trailer's "gross vehicle weight

rating".

3. Securely attach trailer to tow vehicle.

4. Attach safety chains using a cross pattern.

5. Attach breakdown chain to vehicle.

6. Check trailer lights.

TOWING INSTRUCTIONS INSTRUCCIONES PARA REMOLQUE

1. Lea el manual del operador.

2. Use un enganche adecuado para la “capacidad

de peso bruto del vehículo” del remolque.

3. Enganche firmemente el remolque al vehículo

de remolque.

4. Enganche las cadenas de seguridad en

forma cruzada.

5. Enganche al vehículo la cadena de emergencia

para averías.

6. Revise las luces del remolque.

ABSCHLEPPANWEISUNGEN

1. Lire le manuel de l’utilisateur.

2. Utiliser un attelage convenant au poids nominal

brut de la remorque.

3. Arrimer solidement la remorque au véhicule tracteur.

4. Poser les chaînes de sécurité en les croisant.

5. Fixer la chaîne de remorquage au véhicule.

6. Vérifier les feux de la remorque.

INSTRUCTIONS DE REMORQUAGE

1. Benutzerhandbuch lesen.

2. Anhängevorrichtung verwenden, die der

„Gesamtbetriebsgewichtsklasse” des

Fahrzeugs entspricht.

3. Anhänger sicher am

Abschleppfahrzeug befestigen.

4. Sicherheitsketten über Kreuz anbringen.

5. Abreißkette am Fahrzeug anbringen.

6. Anhängerleuchten prüfen.

DANGER

GEFAHR

PELIGRO

DANGER

DIESEL DIESEL

SHUTDOWN

ABSCHALTUNG

APAGADO

ARRÊT

I

O

1 3

MAIN

BREAKER

240V

I

O

2

I

O

IOI

O

STOP

3

ENGINE OPERATION

MOTORBETRIEB

OPERACIÓN DEL MOTOR

FONCTIONNEMENT DU MOTEUR

1

ACTIVATE

GLOW PLUGS

<15 SEC.

CRANK ENGINE

TO START

RELEASE

KEY

MAIN

BREAKER

240V

I

O

32

IOI

O

IOI

O

MANUAL LOCATED

INSIDE HOOD

STOP

STOP

STOP

STOP

Nicht zurückziehen Ausleger mit Turm auf.

No retraiga estabilizadores con la torre de

arriba.

Ne pas retirer les stabilisateurs avec la

tour vers le haut.

DO NOT retract outriggers with tower up.

WARNING

WARNUNG

ADVERTENCIA

ADVERTISSEMENT

21

22

24

23

17

27

28

25

26

20

6

23

19

Stowed Position

Verstauposition

Posición de estibación

Position de rangement

006449

Discount-Equipment.com

Introduction and Safety

Owner’s Manual for MLT6SC Light Tower 9

Figure 1-3. Decal Locations (3 of 3)

Page 15

Section 2: General Information

Discount-Equipment.com

Specifications

DESCRIPTION UNITS MLT6SC

Engine

EPA Tier — Tier 4 Final

Fuel Consumption—100% Prime gph (Lph) 0.74 (2.80)

Battery Type—Group Number — 24

Battery Voltage quantity per unit 12 (1)

Battery Rating cold-cranking

amp-hours

Generator

Output - Standby kW (kVA) 6.0 (6.0)

Output Voltage volts 120/240, single phase

Output Amperes 120V (240V) amperes 20 (25)

Frequency Hz Hertz 60

Weights

Dry Weight lbs (kg) 1316 (597)

Operating Weight lbs (kg) 1586 (719)

Capacities

Fuel Tank Volume gal (L) 40.75 (154.26)

Usable Fuel Volume gal (L) 39.9 (151.04)

Coolant (including engine) qt (L) 5.0 (4.7)

Oil (including filter) qt (L) 4.6 (4.4)

Maximum Run Time hours 59

440

General Information

AC Distribution

Circuit Breaker Size amperes 30

Trailer

Hitch—Standard — 2 in. ball

Maximum Tire Pressure psi (kPA) 50 (345)

Specifications are subject to change without notice.

Owner’s Manual for MLT6SC Light Tower 11

Page 16

General Information

######

VIN Tag

Unit ID Tag

(Located on top of control box)

Serial Number

V

A

Model

KVA

Manufacturing Code

1 ph. 1.0PF 3 ph. .8PF 3 ph. 1.0PF

KW

Country of Origin

Weight (lbs/kg) RPM/Frequency

Rating

Ins. Class

FOR ELECTRICAL EQUIPMENT

ONLY. POUR MATERIAL

ELECTRIQUE SEULEMENT.

209649

Form: SFC626B

Manufactured by Generac Mobile Products LLC

(920) 361-4442 (800) 926-9768

TIRE AND LOADING INFORMATION

RENSEIGNEMENTS SUR LES

PNEUS ET LE CHARGEMENT

SEE OWNER’S

MANUAL FOR

ADDITIONAL

INFORMATION

VOIR LE

MANUEL DE

L’USAGER

POUR

PLUS DE

RENSEIGNEMENTS

MANUFACTURED BY/FABRIQUE PAR: Generac Mobile Products LLC

DATE: 00/0000

GVWR/PNBV: 000KG (0000LBS)

COLD INF. PRESS./

PRESS.DE

V.I.N./N.I.V.:

00000000000000000

TYPE: TRAIL ER

MODEL:

XXX000

GAWR / PNBE TIRE / PNEU RIM / JANTE GONFA FROID - KPA(PSI/LPC) SGL / DUAL

EACH

AXLE

THIS VEHICLE CONFORMS TO ALL APPLICABLE STANDARDS PRESCRIBED UNDER THE U.S. FEDERAL MOTOR VEHICLE SAFETY STANDARDS(FMVSS) AND CANADIAN

MOTOR VEHICLE SAFETY REGULATIONS IN EFFECT ONTHE DATE OF MANUFACTURE.

CE VEHICULE EST CONFORME A TOUTES LES NORMES QUI LUI SONT APPLICABLES EN VERTU DU REGLEMENT SUR LA SECURITE DES VEHICULES AUTOMOBILES

DU CANADA EN VIGUEUR A LA DATE SA FABRICATION.

The weight of cargo should never exceed 0000KG (0000LBS)

Le poids du chargement ne doit jamais depasser 0000KG (0000LBS)

006450

Discount-Equipment.com

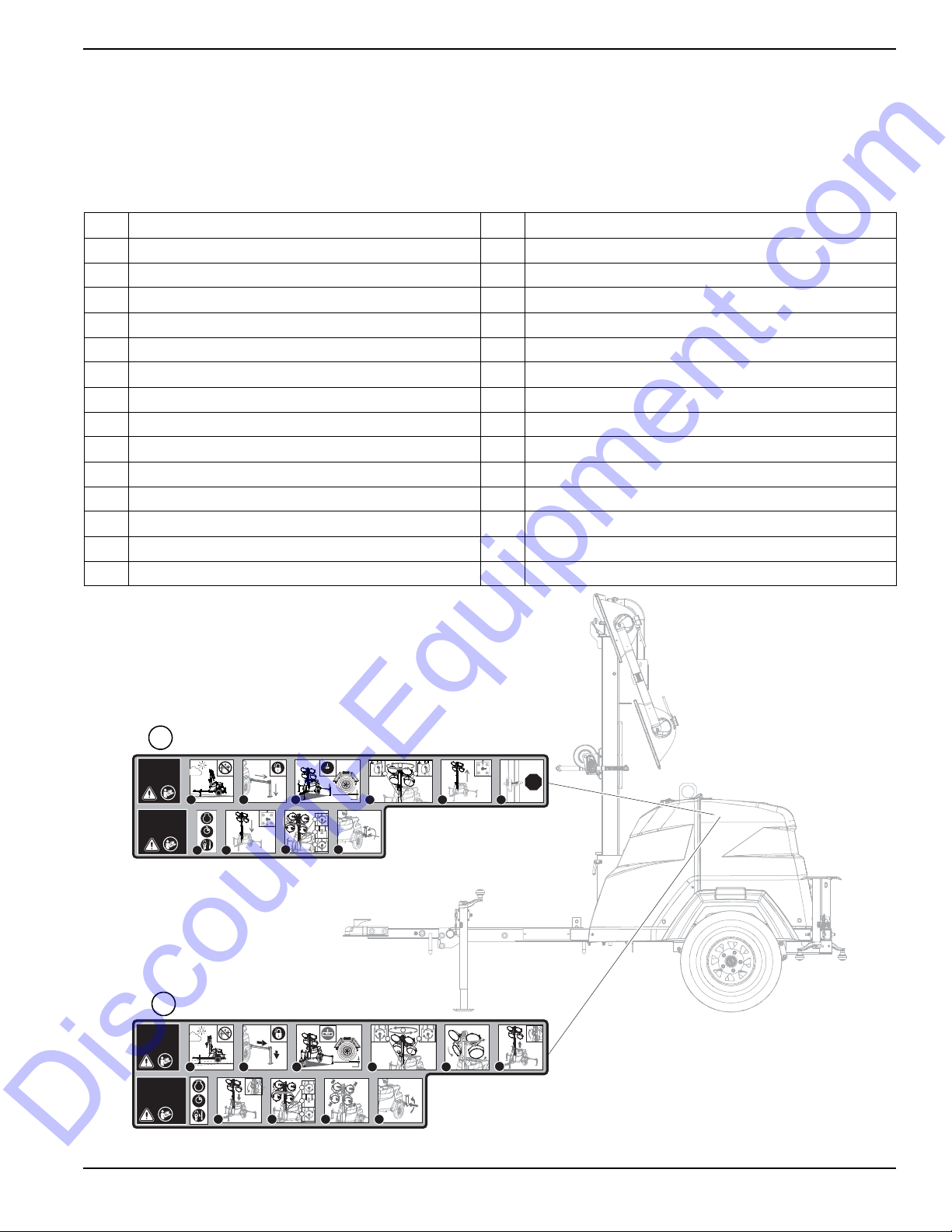

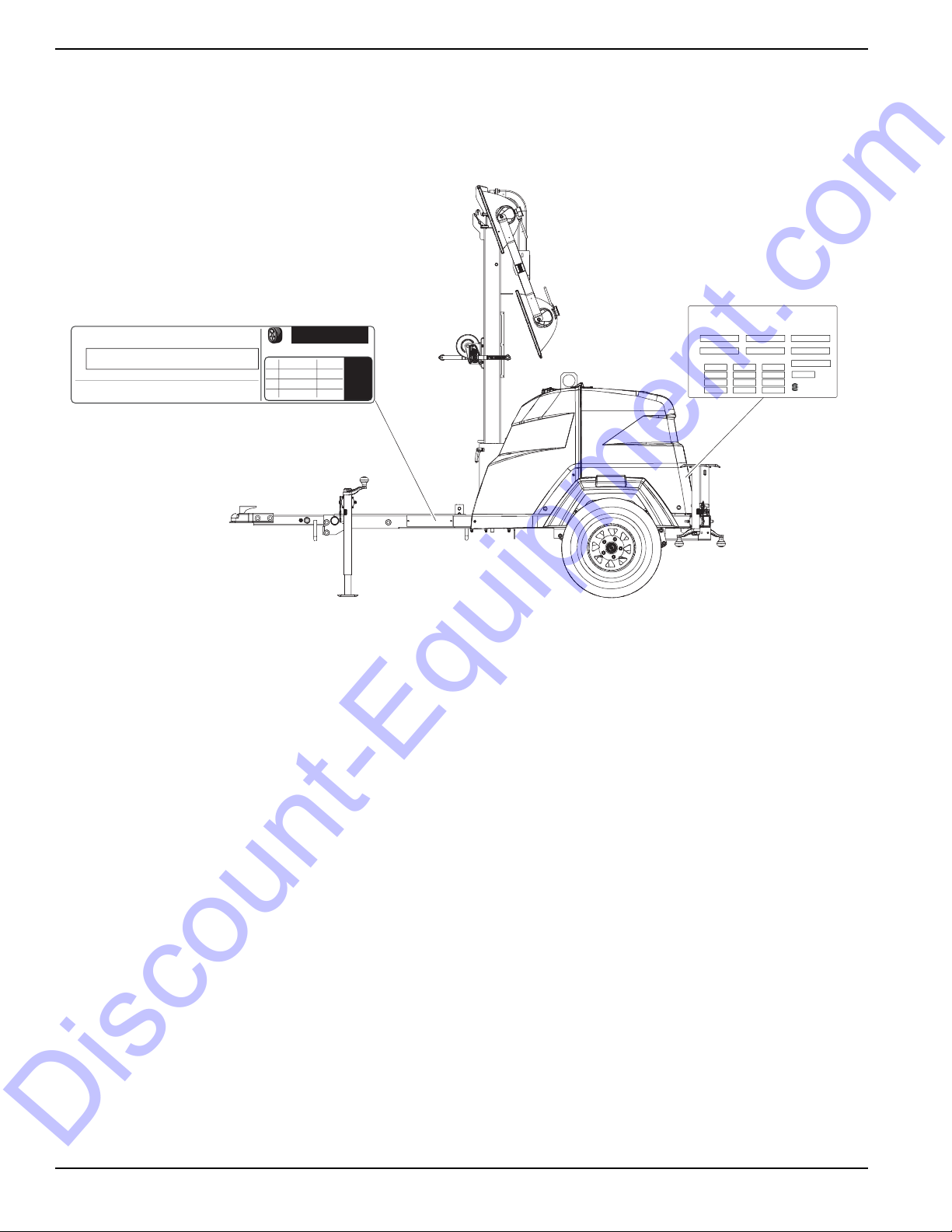

Unit Serial Number Locations

Refer to the illustration to locate the unit ID tag and Vehicle Identification Number (VIN) tag on the unit. Important

information, such as the unit serial number, model number, VIN and tire loading information are found on these tags.

Record the information from these tags so it is available if the tags are lost or damaged. When ordering parts or

requesting assistance, you may be asked to provide this information.

Figure 2-1. Serial Number Locations

12 Owner’s Manual for MLT6SC Light Tower

Page 17

Trailer Tongue Storage and Tow

A

B

C

003517

D

CAUTION

(000313)

Pinching and crushing hazard. To avoid

possible injury, keep fingers away from pivot

point when folding or unfolding trailer tongue.

003519

Discount-Equipment.com

Positions

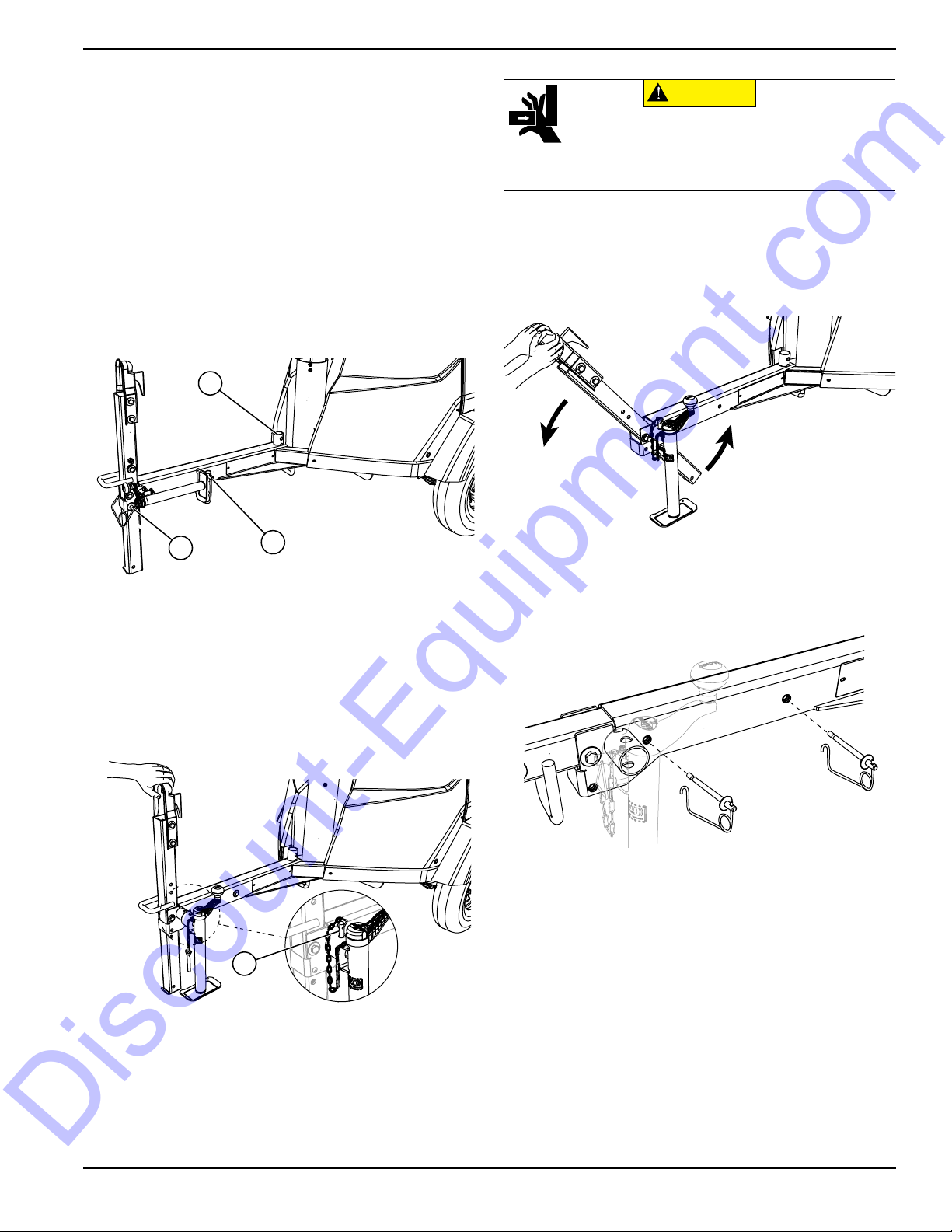

The trailer tongue is designed to fold upright for shipping

and storage.

IMPORTANT NOTE: Do not attempt to tow the unit with

trailer tongue in the storage position.

Place Trailer Tongue in Tow Position

1. Verify unit is on a level surface and wheels are

blocked.

NOTE: See Figure 2-2. Unit ships from factory with jack

in the storage location (A).

General Information

6. See Figure 2-4. Using both hands, slowly lower

trailer tongue into tow position.

NOTE: Varying levels of effort may be required

depending on terrain.

003591

Figure 2-2. Jack and Pin Locations

2. Remove clevis securing jack parallel to ground.

3. Remove jack from tongue weldment. Hold jack

vertically and extend until weldment on jack is

aligned with tongue weldment.

4. See Figure 2-3. Install jack and secure with clevis

(D).

Figure 2-4. Lower Trailer Tongue into Tow Position

7. See Figure 2-5. Install pins as shown to secure

trailer tongue in tow position.

003592

Figure 2-5. Install and Secure Pins

5. See Figure 2-2. Remove pins (B) and (C).

Figure 2-3. Jack Installed

Owner’s Manual for MLT6SC Light Tower 13

Page 18

General Information

003593

A

B

C

CAUTION

(000313)

Pinching and crushing hazard. To avoid

possible injury, keep fingers away from pivot

point when folding or unfolding trailer tongue.

003520

A

B

C

Discount-Equipment.com

Place Trailer Tongue in Storage Position

1. Verify unit is on a level surface and wheels are

blocked.

2. See Figure 2-6. Extend jack (A) enough to allow

minimum effort to pivot trailer tongue into storage

position.

Figure 2-6. Extend Jack and Remove Pins

3. Remove pins (B) and (C) from trailer tongue.

003591

Figure 2-8. Install Pins and Rotate Jack

6. Remove clevis and remove jack (A) from tongue

weldment.

7. Completely retract jack.

8. Rotate jack 90° counterclockwise, place jack on

tongue weldment, and install clevis to secure jack

parallel to ground.

4. See Figure 2-7. Pivot trailer tongue into storage

position.

NOTE: Varying levels of effort may be required

depending on terrain.

Figure 2-7. Pivot Trailer Tongue Into Storage Position

5. See Figure 2-8. Install pins (B) and (C) at locations

shown to secure trailer tongue in storage position.

14 Owner’s Manual for MLT6SC Light Tower

Page 19

Unit Dimensions

A

B

D

C

E

006451

Discount-Equipment.com

General Information

Figure 2-9. Unit Dimensions

ABCDE

MLT6SC 118 in. (3 m) 101 in. (2.6 m) 23 ft. (7 m) 57 in. (1.5 m) 120.5 in. (3.1 m)

Specifications are subject to change without notice.

######

Owner’s Manual for MLT6SC Light Tower 15

Page 20

General Information

######

006452

B

F

C

D

G

H

A

D

E

Discount-Equipment.com

Component Locations

Figure 2-10. Component Locations—Front and Left Side

A. Grounding studs:

Interior: On enclosure floor behind controller

Exterior: On bumper

B. Outriggers and jacks (2) F. Mast rotation knob

C. Fuel fill G. Winch

D. Tie-down location H. Lights (4)

16 Owner’s Manual for MLT6SC Light Tower

E. Tongue jack

Page 21

General Information

######

J

K

L

L

M

N

P

006453

Discount-Equipment.com

Figure 2-11. Component Locations—Rear and Right Side

J. Central lift point M. Tandem tow mount (optional—not shown)

K. Engine/radiator access hood N. Hood latch

L. Forklift pocket P. Key start controller

or Power Zone-DLA controller (optional—not shown)

Owner’s Manual for MLT6SC Light Tower 17

Page 22

General Information

STOP

15 SEC.

MAX.

12V

DC CIRCUIT

BREAKER

AC CIRCUIT

BREAKER

120V

I

O

I

O

I

O

I

O

MAIN

BREAKER

240V

I

O

AC CIRCUIT

BREAKERS

DC CIRCUIT

BREAKER

MAST LIGHT CIRCUIT BREAKERS

MAIN CIRCUIT

BREAKER

CONTROL

POWER

A

004385a

B

C

C

D

E

F

G

H

I

K

F

E

A

B

I

H

J

Controller with Power Zone (If Equipped) Controller without Power Zone

Discount-Equipment.com

Control Panel

Figure 2-4. Control Panel

Control Panel Features and Functions

(A) DC circuit breaker

Resets the DC electrical circuit that powers the control

panel and engine components.

(B) AC circuit breaker

Resets the AC electrical circuit that powers the control

panel.

(C) Mast light toggle switch/circuit breakers (4)

Power switches with internal breakers dedicated to

individual lights

(D) Mast switch (if equipped)

Raises and lowers the mast on units equipped with an

electric winch.

(E) 120V/20A GFCI outle t

Customer convenience outlet for use in connecting

auxiliary equipment such as fans, pumps, drills. Includes

a Ground Fault Circuit Interrupter (GFCI) test and reset

button.

(F) 240VAC/30A twist-lock outlet

Customer convenience outlet for use in connecting

auxiliary equipment such as fans, pumps, drills.

(G) Engine hour meter

Displays number of hours the engine has run.

(H) Main circuit breaker

240V/30A breaker which disconnects power from the

lights and control panel.

(I) Control power switch

Turns the engine ON and OFF.

(J) Power Zone controller

Monitors the unit and indicates operational status and

fault conditions.

(K) Mast light circuit breakers (4)

Power switches with internal breakers dedicated to

individual lights

18 Owner’s Manual for MLT6SC Light Tower

Page 23

General Information

Select

H

G

F

E

D

C

B

A

002353

Discount-Equipment.com

Power Zone–DLA (If Equipped)

The Power Zone–DLA is an AUTO start controller that

monitors the unit and indicates operational status and

fault conditions. The controller can be programmed to

automatically start or stop based on time schedule, fault

condition, or load demand.

The controller constantly monitors vital generator and

engine functions for a number of preprogrammed alarm

and fault conditions. When a fault condition occurs, the

engine will be shut down automatically and the LCD

window will show the fault that caused the shutdown. To

resume operation, the fault condition must be corrected.

This controller also records a history of unit performance,

which may be viewed at any time and will not be lost

when the controller is powered down.

Figure 2-5. Power Zone–DLA Layout

Controller Features and Functions

(A) The Liquid Crystal Display (LCD) Window

This window displays the various operating screens. By

viewing these screens, the operator can monitor both the

engine and generator status while the unit is running.

(B) Select LED

This LED illuminates when the unit is running in AUTO

mode.

(C) Start LED

This LED illuminates when the unit is running in MANUAL

mode.

(D) Start Button

This button starts the engine if there are no shutdown

errors and the engine is in “ready to start” status.

(E) Stop Button

This button shuts down the unit and puts the controller

into STOP mode, whether in MANUAL mode or AUTO

mode.

(F) Stop LED

This LED illuminates when the unit is in STOP mode and

flashes when an Electrical Trip and Shutdown Fault has

occurred.

(G) Select Button

This button confirms entries chosen in the various edit

menus and screens.

(H) Menu Navigation

These buttons (↑, ↓) are used to navigate through the

various operator screens. They are also used to raise

and lower the mast on units equipped with an electric

winch.

NOTE: To prevent damage to the generator and

connected equipment, remove all loads from the

generator by opening all circuit breakers (turn OFF [O])

before pressing the STOP button.

Owner’s Manual for MLT6SC Light Tower 19

Page 24

General Information

002354

002544

002990

002327

Discount-Equipment.com

Operator Screens

See Figure 2-6. The operator screens display the most

relevant and critical information an operator will need to

properly configure and use the unit. From these six

screens, the operator can access information necessary

to operate the unit under normal conditions.

Figure 2-6. Operator Screens Location

Home Screen

See Figure 2-7. The Home screen is the default screen

of the controller and displays after the controller is

powered up and the unit management software is

loaded. It displays the controller mode, total operating

hours, hours left until the next service interval, engine

operating status, and engine RPM. If the unit is in AUTO

mode, the Home screen may also display whether the

scheduler or “dusk to dawn” are enabled.

Battery Voltage Screen

See Figure 2-8. Displays the engine battery voltage. A

normal reading is 12-14V on 12 volt systems (with the

engine running).

Figure 2-8. Battery Voltage Screen

Lights Screen

See Figure 2-9. The Lights screen enables the operator

to turn the lights on and off. Refer to Light Operation for

more information.

Figure 2-7. Home Screen

20 Owner’s Manual for MLT6SC Light Tower

Figure 2-9. Lights Screen

Page 25

General Information

002980

002981

002328

002329

Discount-Equipment.com

Line Amperage Screen

See Figure 2-10. The Line Amperage screen displays

the AC output amperage produced by the generator in

Amps (A). The load balance for each line (L1 and L3) is

displayed in both numerical and graphical form. It is

important to maintain a balanced load distribution

between lines for optimum generator performance.

Figure 2-10. Line Amperage Screen

Generator Screen

See Figure 2-11. The Generator screen displays the

average line voltage, frequency (in Hertz), and power

factor for the generator while in operation.

Dusk to Dawn Screen

NOTE: This feature will only work in AUTO mode.

See Figure 2-12. The Dusk to Dawn screen enables or

disables the “dusk to dawn” function. This function uses a

photo sensor to detect the surrounding light level,

automatically starting the engine and turning the lights on

at dusk. The engine will run and the lights will remain

illuminated until dawn.

Figure 2-12. Dusk to Dawn Screen

Figure 2-11. Generator Screen

Scheduler Screen

NOTE: This feature will only work in AUTO mode.

See Figure 2-13. The Scheduler screen enables the

operator to program specific times for the lights to turn on

and off. Once programmed, the Scheduler will start the

engine and illuminate the lights until the designated

shutdown time.

Figure 2-13. Scheduler Screen

Owner’s Manual for MLT6SC Light Tower 21

Page 26

General Information

002329

002544

003780

Discount-Equipment.com

Maintenance Screens

See Figure 2-14. The information displayed on the

maintenance screens can be used to identify, diagnose

and troubleshoot unit shutdown conditions and poor unit

performance..

Figure 2-14. Maintenance Screens

Icon Description

Home screen

Alarms screen

Maintenance screen

Home Screen

See Figure 2-15. The Home ( ) screen is the default

screen of the controller and displays after the controller

has powered up. The controller automatically returns to

Home from any other screen after a period of inactivity.

Figure 2-15. Home Screen (MANUAL Mode Shown)

Alarms Screen

See Figure 2-16. The Alarms ( ) screen displays all the

alarms, warnings, and engine Diagnostic Trouble Code

(DTC) faults. When an alarm occurs, the controller

automatically switches to this screen and remains there

until the alarm is cleared. The Stop LED also flashes.

Event log screen

About screen

To enter the navigation menu, use the following

procedure:

1. Press both the ↑ and ↓ buttons simultaneously.

2. To select the required icon, press the ↑ button to

cycle right and the ↓ button to cycle left until the

desired operator screen section is reached.

3. Once the desired icon is at the top, press the

Select () button to enter that operator screen

section.

NOTE: Every time the operator screens are entered, the

home icon will be located at the top of the screen.

Figure 2-16. Alarms Screen

• Warnings are non-critical alarm conditions and do

not affect the operation of the generator system.

They serve to draw the operator’s attention to an

undesirable condition. By default, warning alarms

are self-resetting when the fault condition is

removed.

• Electrical trips stop the generator in a controlled

manner. On initiation of the electrical trip condition,

the controller de-energizes all the outputs,

including the lights, to remove the load from the

generator. Once this has occurred, the controller

starts the cooling timer and allows the engine to

cool off-load before shutting down the engine.

• Shutdown alarms stop the generator immediately.

On initiation of the shutdown condition, the

controller de-energizes all the outputs, including

the lights, to remove the load from the generator.

22 Owner’s Manual for MLT6SC Light Tower

Page 27

General Information

003781

003782

Discount-Equipment.com

Once this has occurred, the controller shuts the

generator set down immediately to prevent further

damage.

• DTC faults are displayed by the controller.

Table 2-1. Possible DTC Faults

Fault DTC Description

Check Engine

Fault

Low Oil Pressure Engine oil pressure has fallen below

Underspeed Engine speed has fallen below its

Overspeed Engine speed has risen above its

Low Fuel Level Engine’s fuel level has fallen below its

Battery Under/

Over Voltage

To view the active alarms, repeatedly press the ↑ and ↓

buttons until the LCD window displays the alarm.

Continue to press the ↑ and ↓ buttons to cycle through

the alarms.

To exit the alarm screen, press the ↑ and ↓ buttons

simultaneously to enter the navigation menu. Once

entered, cycle to the desired operator screen.

A fault not recognized by the controller

has been detected. Contact the engine

manufacturer for support.

its configured low oil pressure alarm

level.

configured underspeed alarm level.

configured overspeed alarm level.

configured low fuel level alarm.

Engine’s DC supply has fallen below

or risen above its configured alarm

level.

Maintenance Screen

See Figure 2-17. The Maintenance screen ( ) displays

the maintenance alarms configured into the controller.

The three alarms are for servicing the fuel filter, oil filter,

and air filter.

Figure 2-17. Maintenance Screen

Event Log Screen

See Figure 2-18. The controller’s event log ( ) displays

a list of the last 15 recorded electrical trips or shutdown

events and the engine hours at which they occurred.

Once the log is full, any subsequent electrical trip or

shutdown alarm overwrites the oldest entry in the log.

Therefore, the log always contains the most recent

shutdown alarms.

NOTE: The alarm condition must be corrected before a

reset will take place. If the alarm condition remains, it is

not possible to reset the unit. The exception to this is the

Low Oil Pressure alarm and similar ‘active from safety on’

alarms, as the oil pressure is low with the engine at rest.

To clear alarms that stop the generator, refer to

Resetting the Maintenance Alarms (If Equipped).

NOTE: The LCD backlight is on if the unit has sufficient

voltage while the unit is turned on, unless the unit is

cranking. In this case, the backlight is turned off.

If the controller is left in STOP mode for a period of

inactivity, the controller enters POWER SAVE mode. To

‘wake’ the controller, press the Stop (O) button.

Owner’s Manual for MLT6SC Light Tower 23

To view the event log:

1. Press both ↑ and ↓ buttons simultaneously to

2. Cycle to the event log section and press the Auto

3. Repeatedly press the ↑ or ↓ buttons until the LCD

Continuing to press down the ↑ or ↓ buttons will cycle

through past alarms. Eventually the most recent alarm

will display and the cycle begins again.

To exit the event log, press the ↑ and ↓ buttons

simultaneously to enter the navigation menu. Once

entered, cycle to the desired operator screen.

Figure 2-18. Event Log Screen

display the navigation menu.

button to enter.

window displays the desired event.

Page 28

General Information

003783

Discount-Equipment.com

About Screen

See Figure 2-19. The About ( ) screen contains

information about the controller such as the controller’s

date and time, the product and USB identification

number, and the application and engine version.

Figure 2-19. About Screen

24 Owner’s Manual for MLT6SC Light Tower

Page 29

Section 3: Operation

A

E

G

B

F

D

C

006454

(000260a)

High Voltage. Verify area above unit is clear

of overhead wires and obstructions. Contact

with high-voltage power lines will result in

death or serious injury.

DANGER

WARNING

(000297)

> 60 mph> 60 mph

Do not set up the unit if high winds

are expected. High winds can cause the

unit to tip or fall, causing severe injury

or machine damage.

Discount-Equipment.com

Light Tower Setup

Operation

DETAIL B

DETAIL C

DETAIL D

1”

DETAIL E

Figure 3-1. Set Up Outriggers and Jacks

2. See Figure 3-1. Place the unit on firm ground that

is relatively flat (less than 5° slope), and then block

the wheels to keep it from moving. This will make it

easier to level the unit.

3. Pull the locking pin (A) on the tongue jack (E) and

rotate the jack 90°. Reinstall the locking pin. Rotate

the jack handle clockwise to raise the trailer tongue

off the towing vehicle.

4. A grounding stud (B) is located on the rear frame of

5. See Details C—D. Pull the locking pins (C) on the

1. For maximum light coverage, position the unit at

NOTE: The mast extends up to 23 ft (7m).

Owner’s Manual for MLT6SC Light Tower 25

ground level or in a spot higher than the area being

illuminated by the lamps.

the trailer near the left side outrigger. For

grounding requirements, follow local, state, and

National Electrical Code (NEC) regulations.

outriggers (D) and pull each outrigger out until the

spring loaded locking pin snaps back into place.

Pull the locking pin on each outrigger jack (F) and

rotate each jack 180° so the jack pad is facing

down. Reinstall the locking pin.

Page 30

Operation

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

DANGER

Electrocution. DO NOT use the unit if

electrical cord is cut or worn through. Doing

so will result in death or serious injury.

(000263a)

WARNING

Tipping hazard. Extend the outriggers and level the unit

before raising the mast. Keep the outriggers extended

while the mast is up. Failure to do so could cause the unit

to tip and fall and could result in death or serious injury.

(000266)

DETAIL D

STOP

A

D

B

C

002532

Discount-Equipment.com

6. See Detail E. Rotate each jack handle clockwise to

start leveling the trailer. Adjust all three jacks by

rotating their handles clockwise until they are firmly

in contact with the ground. Continue until the

wheels are approximately one inch (2.5 cm) off the

ground (G).

7. Before raising the mast, it may be necessary to

adjust the lamps. The lamps may be adjusted up,

down, left or right by simply aiming them in the

desired direction.

Prestart Checklist

Before starting the unit, all items in the prestart checklist

must be completed. This checklist applies to both manual

and remote starting of the unit.

Verify all maintenance procedures are up to date. For

more information, refer to General Maintenance and

Basic Maintenance Schedule.

The unit must be level.

The unit must be dry. Look for water inside or near

the unit; dry if needed.

For grounding requirements, follow the local, state,

or National Electrical Code (NEC) regulations.

Verify the Control Power switch is in the OFF (O)

position.

Verify all circuit breakers are in the OFF (O) position.

Raising the Mast—Manual Winch

1. Set up and level the unit. See Light Tower Setup.

Inspect all electrical cords; repair or replace any that

are cut, worn, or bare.

Verify all winch cables are in good condition and

centered on each pulley. Do not use if cables are

kinked or beginning to unravel.

Check oil, coolant, and fuel levels. For more

information, refer to General Maintenance.

Verify battery connections are secure.

Turn the battery disconnect switch on, if equipped.

Check the engine fan belt tension and condition.

Check the engine fan belt guard.

Check the engine exhaust system for loose or rusted

components.

Verify all covers are in place and secure.

26 Owner’s Manual for MLT6SC Light Tower

Figure 3-2. Pulley Locations - Manual Winch

Page 31

Operation

WARNING

Tipping hazard. Do not extend the mast beyond the

colored mark on the second mast section. The unit

can become unstable and tip or fall, causing injury.

(000262)

WARNING

Personal Injury. Stop immediately if the mast hangs

up or the winch cable develops slack. Excess slack

could cause the mast to collapse, resulting in personal

injury or equipment damage.

(000265)

(000279)

Personal injury or equipment damage. Do not raise

or lower the mast while the unit is operating.

Doing so can break the lenses and cause the

lamps to shatter.

WARNING

DANGER

Electrocution. DO NOT use the unit if

electrical cord is cut or worn through. Doing

so will result in death or serious injury.

(000263a)

WARNING

Tipping hazard. Extend the outriggers and level the unit

before raising the mast. Keep the outriggers extended

while the mast is up. Failure to do so could cause the unit

to tip and fall and could result in death or serious injury.

(000266)

DETAIL C

STOP

DETAIL B

A

C

B

002533

D

Discount-Equipment.com

2. See Figure 3-2. Check the mast cables for

excessive wear or damage. Verify the cables are

properly centered in each pulley (A). Check the

electrical cord for damage.

3. Rotate the mast by loosening the mast rotation

knob (C) at the bottom of the mast. Turn the mast

until the lights face in the desired direction, and

then tighten the mast rotation knob to secure the

mast in position.

Using both hands, rotate the winch (B) to slowly

4.

extend the mast, making sure that the coiled

electrical cord is extending at the top sections of the

mast. STOP extending the mast when the colored

mark (D) on the second mast section is visible as

seen in Detail D.

Raising the Mast—Electric Winch

(If Equipped)

1. Set up and level the unit. See Light Tower Setup.

IMPORTANT NOTE: Contact a Generac Mobile

Products Authorized Service Dealer immediately if

the mast hangs up or the winch cable develops

slack.

Owner’s Manual for MLT6SC Light Tower 27

Figure 3-3. Switch & Pulley Locations - Electric Winch

Page 32

Operation

WARNING

Tipping hazard. Do not extend the mast beyond the

colored mark on the second mast section. The unit

can become unstable and tip or fall, causing injury.

(000262)

WARNING

Personal Injury. Stop immediately if the mast hangs

up or the winch cable develops slack. Excess slack

could cause the mast to collapse, resulting in personal

injury or equipment damage.

(000265)

(000279)

Personal injury or equipment damage. Do not raise

or lower the mast while the unit is operating.

Doing so can break the lenses and cause the

lamps to shatter.

WARNING

002752

Discount-Equipment.com

2. See Figure 3-3. Check the mast cables for

excessive wear or damage. Verify the cables are

properly centered in each pulley (A). Check the

electrical cord for damage.

3. Rotate the mast by loosening the mast rotation

knob at the bottom of the mast (D). Turn the mast

until the lights face in the desired direction and

then tighten the mast rotation knob to secure the

mast in position.

4. Start unit according to Manually Starting the Unit.

Press and hold the winch control switch (Detail B)

5.

upward to telescope the mast to the desired height.

While doing so, verify that the coiled electrical cord is

extending at the top sections of the mast. STOP

extending the mast when the colored mark (C) on the

second mast section is visible as seen in Detail C.

IMP O R TAN T N O T E : A limit switch on the main mast

section will disconnect power to the upper electric

winch to prevent overextending the mast.

1. See Figure 3-4. Verify the main circuit breaker and

individual circuit breakers for each of the lights are

OFF (O).

Figure 3-4. Circuit Breakers in OFF (O) Position

2. See Figure 3-5. Turn the key on the Engine Start

switch to the right GLOW PLUG position and hold

the key in place for five seconds.

IMPORTANT NOTE: Contact a Generac Mobile

Products Authorized Service Dealer immediately if

the mast hangs up or the winch cable develops

slack.

Starting the Unit

NOTE: If the engine was run out of fuel or the fuel tank

was drained, it may be necessary to bleed the fuel lines.

Refer to the engine operator’s manual supplied with the

unit.

28 Owner’s Manual for MLT6SC Light Tower

Figure 3-5. Activate Glow Plug

3. See Figure 3-6. Turn the key to the right START

position and hold it until the engine cranks and

starts running.

Figure 3-6. Crank Engine

Page 33

Operation

CAUTION

(000230)

Equipment Damage. Do not continuously crank

engine for more than ten seconds. Doing so will lead

to overdischarge of batteries and starter seizure.

002354

(000277)

WARNING

Burn hazard. Never operate lights with a

damaged or missing lens cover. Lamps are

hot and pressurized while in use. Unprotected

lamps can shatter, causing severe injury.

Discount-Equipment.com

4. See Figure 3-7. Release the key, it will move to the

RUN position.

Figure 3-7. Release Key

Preparing for Start-Up (with

Power Zone Controller, If

Equipped)

NOTE:

drained, it may be necessary to bleed the fuel lines before

starting. Refer to the engine manual supplied with the unit.

If the engine was run out of fuel or the fuel tank was

Manually Starting the Unit

STOP mode is the default start-up setting for all units

equipped with the Power Zone–DLA. Use the following

procedure to start the generator in MANUAL mode.

1. Verify the 240VAC outlet breaker is switched OFF

(O).

2. Switch the main circuit breaker ON (I).

3. Verify that the Load Sense switch is OFF.

4. When the controller powers up, the Home screen

displays on the LCD screen and the Stop LED

illuminates to indicate that the controller is in STOP

mode. Press the Start button to initiate the startup

procedure. Assuming there are no existing engine

faults, the engine will start and the Start LED will

illuminate.

NOTE: The engine can be started from any screen. It

may take a few seconds for the engine to run smoothly

and reach its governed operating speed.

5. If the engine does not start after the first cranking

attempt, the engine will pause for 15 seconds to

allow the starter to cool. The controller backlight

will go out. The engine will make two more

attempts to start for a total of three crank cycles.

6. If the engine does not start and run within three

starting cycles, the LCD screen will display the

“Fail to Start” alarm. The starting sequence can be

repeated after the starter cools for at least two

minutes. Pressing the Stop (O) button will clear the

alarm and reset the controller.

Select AUTO or MANUAL Mode

See Figure 3-8. Using the arrows on the Power Zone–

DLA, select either AUTO or MANUAL on the Home

screen.

• AUTO mode is required for programming

automatic start and stop times (see Scheduler

Screen), or enabling the “dusk to dawn” sensor

(see Dusk to Dawn Sensor).

• MANUAL mode is used for on-demand control of

the lights and convenience outlets.

Figure 3-8. Select AUTO or MANUAL Mode

Owner’s Manual for MLT6SC Light Tower 29

Light Operation

1. Verify the unit is ON and running smoothly.

2. See Figure 3-9. Switch the main circuit breaker (A)

ON (I).

3. Switch the individual circuit breakers for the lights

(B) ON (I), one at a time.

4. The ballast indicator lights will turn on and continue

to get brighter as the lights warm up, and then

remain on. This confirms power is coming from the

ballasts to the lights.

Page 34

Operation

003991

A

B

(000278)

WARNING

Burn hazard. Lamps become extremely hot

while in use. Allow 10–15 minutes for cooling

before handling or lowering mast. Touching a

hot lens or fixture can cause severe burns.

(000278)

WARNING

Burn hazard. Lamps become extremely hot

while in use. Allow 10–15 minutes for cooling

before handling or lowering mast. Touching a

hot lens or fixture can cause severe burns.

Discount-Equipment.com

Figure 3-9. Light Switches and Breaker

NOTE: If an indicator light does not turn on, see

Troubleshooting or contact a Generac Mobile Products

Authorized Service Dealer.

NOTE: The lights require a warm up period of 5-15

minutes before they reach full output. If the lights are shut

down, they require a cool down period of approximately

ten minutes before they can be switched on again.

To turn the light(s) ON, press the Select () button. To

turn the light(s) OFF, press the Select () button.

NOTE: The light tower uses four 1000W or 1050W

bulbs. When checking or replacing the bulbs, wipe them

with a clean cloth to avoid leaving any grease, oil residue

or fingerprints on the glass. Any residue can create a hot

spot on the bulb, causing premature bulb failure.

Figure 3-10. Lights Screen

Engine Derating

All units are subject to derating for altitude and

Light Operation (With Power

Zone Controller, If Equipped)

See Figure 3-10. The lights are turned on and off using

the Power Zone–DLA. To view the light screen, press the

↑ button three times from the Home screen.

NOTE: The lights can only be turned ON and OFF while

the unit is running in MANUAL mode. They operate

automatically in AUTO mode.

1. Once the engine is up to temperature and running

smoothly, switch the main circuit breaker ON (I).

30 Owner’s Manual for MLT6SC Light Tower

temperature. Derating reduces the available power for

operating tools and accessories connected to the outlets.

For every increase in 1000 ft (305 m) of elevation, engine

performance for this unit typically drops between 2% and

4%. Also, engine performance decreases about 1% for

every 10ºF (5.6ºC) increase in ambient air temperature

over 72ºF (22ºC).

Wet Stacking

The unit is powered by a diesel engine. Diesel engines

are subject to “wet stacking” if lightly loaded. Wet

stacking occurs when an engine is run at less than 30%

of its full load capacity, causing unburned fuel to

accumulate in the exhaust system. Wet stacking can be

detected by continuous black exhaust when the unit is

under a constant load. It can also cause fouling of

injectors and buildup on engine valves. Diesel engines

operate properly when applied loads are between 30%

and 100% capacity. Appropriate generator sizing is

Page 35

Operation

A

B

002535

Discount-Equipment.com

determined by the anticipated load. If the unit is in a wet

stack condition, load the unit heavily for five hours or until

the exhaust is clear.

Dusk to Dawn Sensor

This unit is equipped with a “dusk to dawn” photo sensor

to detect the surrounding light level, automatically

starting the engine and turning the lights on at dusk. The

engine will run and the lights will remain illuminated until

dawn.

To prepare the sensor for use, perform the following

procedure at the time of day you want the lights to turn

on:

1. Verify the Power Zone–DLA is set up and the unit

is ON.

2. Slide the light shield bracket up, decreasing the

sensor’s exposure to light, until the lights turn ON.

3. Tighten screws on shield.

Customer Convenience Outlets

See Figure 3-11. The unit is equipped with convenience

receptacles for powering accessories or tools from the

generator. Power is supplied to the receptacles any time