Page 1

Owner’s Manual

003986

Light Tower

PLT240 LINK Tower

For technical assistance contact:

www.generacmobileproducts.com

Technical Support

1-800-926-9768

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

Use this page to record important information about your Light Tower

(000005)

WARNING

California Proposition 65. This product contains or

emits chemicals known to the state of California to

cause cancer, birth defects, and other reproductive

harm.

Record the information found on your unit data label on

Unit Model Number

Unit Serial Number

this page. See unit serial number location (Unit Serial

Number Locations). The data plate is affixed to the

mast inside the cabinet.

When contacting an Generac Mobile Products

Authorized Dealer about parts and service, always

supply the complete model number and serial number of

the unit.

Operation and Maintenance: Proper maintenance and

care of the Light Tower ensures a minimum number of

problems and keeps operating expenses at a minimum. It

is the operator’s responsibility to perform all safety

checks, to verify that all maintenance for safe operation is

performed promptly, and to have the equipment checked

periodically by a Generac Mobile Products Authorized

Dealer. Normal maintenance, service and replacement of

parts are the responsibility of the owner/operator and, as

such, are not considered defects in materials or

workmanship within the terms of the warranty. Individual

operating habits and usage may contribute to the need

for additional maintenance or service.

ii Owner’s Manual for PLT240 Light Tower

Page 3

Table of Contents

Section 1: Introduction and Safety

Introduction ..........................................................1

Read This Manual Thoroughly ....................................1

How to Obtain Service .................................................1

Safety Rules .........................................................1

General Hazards ..................................................2

Fire Hazards .........................................................2

Electrical Hazards ................................................2

Operating Safety ..................................................2

Positioning the Unit .....................................................2

Starting the Unit ...........................................................3

Raising and Lowering the Mast ...................................3

Service Safety ......................................................3

Safety and Operating Decals ..............................3

Section 2: General Information

Specifications ......................................................5

Section 4:Maintenance

Daily Walk-Around Inspection ......................... 17

General Maintenance ........................................ 17

Preparing for Service .................................................17

Cleaning the Unit .......................................................17

Inspecting the Unit ..................................................... 17

Basic Maintenance Schedule ........................... 17

Winch Use, Operation and Maintenance ......... 18

Prior to Use ............................................................... 18

Operation ................................................................... 18

Maintenance .............................................................. 18

Winch Mechanical Brake ........................................... 18

Jack Maintenance .............................................. 18

Wheel Maintenance ........................................... 18

Section 5:Troubleshooting

Troubleshooting the Lights .............................. 19

Unit Serial Number Locations ............................6

Unit Dimensions ..................................................7

Component Locations .........................................8

Control Panel .......................................................9

Control Panel Components and Functions ..................9

Internal Storage .................................................10

Lifting and Transporting ...................................10

Lifting the Unit ...........................................................10

Transporting the Unit .................................................10

Tying the Unit Down ..........................................11

Section 3:Operation

Operation Configuration ...................................13

LED Lights Only ........................................................13

LED Lights and Auxiliary Power ................................13

Light Tower Setup .............................................13

Raising the Mast ................................................14

Section 6:Wiring Diagrams

AC Wiring ........................................................... 21

Prestart Checklist ..............................................15

Turn Unit ON ......................................................15

Turn Unit OFF .....................................................15

Lowering the Mast .............................................15

Long-Term Storage ............................................16

Owner’s Manual for PLT240 Light Tower iii

Page 4

Table of Contents

This page intentionally left blank.

iv Owner’s Manual for PLT240 Light Tower

Page 5

Section 1: Introduction and Safety

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

(000001)

DANGER

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

(000002)

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

(000003)

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Introduction and Safety

Introduction

Thank you for purchasing a Generac Mobile Products LLC

product. This unit has been designed to provide high

performance, efficient operation, and years of use when

maintained properly.

The information in this manual is accurate based on

products produced at the time of publication. The

manufacturer reserves the right to make technical updates,

corrections, and product revisions at any time without

notice.

Read This Manual Thoroughly

If any section of the manual is not understood, contact your

nearest Generac Mobile Products Authorized Dealer, or

contact Generac Mobile Products Technical Service at 1800-926-9768 or

any questions or concerns.

www.generacmobileproducts.com

with

Safety Rules

The manufacturer cannot anticipate every possible

circumstance that might involve a hazard. The warnings in

this manual, and on tags and decals affixed to the unit are,

therefore, not all inclusive. If using a procedure, work

method or operating technique that the manufacturer does

not specifically recommend, verify that it is safe for others.

Also make sure the procedure, work method or operating

technique utilized does not render the equipment unsafe.

Throughout this publication, and on tags and decals affixed

to the unit, DANGER, WARNING, CAUTION and NOTE

blocks are used to alert personnel to special instructions

about a particular operation that may be hazardous if

performed incorrectly or carelessly. Observe them

carefully. Their definitions are as follows:

The owner is responsible for proper maintenance and safe

use of the equipment. Comply with regulations the

Occupational Safety and Health Administration (OSHA)

has established, or with equivalent standards. Also, verify

that the unit is applied, used, and maintained in accordance

with the manufacturer's instructions and recommendations.

Do nothing that might alter safe application/usage and

render the unit in noncompliance with the aforementioned

codes, standards, laws, and regulations

Save these instructions for future reference. This manual

contains important instructions for the unit that should be

followed during setup, operation and maintenance of the

unit and battery. ALWAYS supply this manual to any

individual that will use this machine.

.

How to Obtain Service

When the unit requires servicing or repairs, contact a

Generac Mobile Products Authorized Dealer for assistance.

Service technicians are factory-trained and are capable of

handling all service needs. For assistance locating a dealer,

www.generacmobleproducts.com/parts-service/

go to

.

find-service

Products Authorized Dealer about parts and service,

always supply the complete model number and serial

number of the unit as given on its data decal located on

the unit. Record the model number and serial numbers in

the spaces provided on the inside front cover of this

manual.

Owner’s Manual for PLT240 Light Tower 1

When contacting an Generac Mobile

NOTE: Notes contain additional information important to

a procedure and will be found within the regular text of

this manual.

These safety alerts cannot eliminate the hazards that they

indicate. Common sense and strict compliance with the

special instructions while performing the action or service

are essential to preventing accidents.

Page 6

Introduction and Safety

(000111)

WARNING

Moving Parts. Keep clothing, hair, and

appendages away from moving parts. Failure

to do so could result in death or serious injury.

(000108)

WARNING

Hot Surfaces. When operating machine, do not

touch hot surfaces. Keep machine away from

combustibles during use. Hot surfaces could

result in severe burns or fire.

WARNING

Risk of injury. Do not operate or service this machine

if not fully alert. Fatigue can impair the ability to service

this equipment and could result in death or serious

injury.

(000215)

WARNING

Do not operate this unit while transporting. Doing so

could result in death or serious injury.

(000231)

(000234a)

WARNING

Crushing hazard. Verify unit is properly secured and

on level ground. An unsecured unit can suddenly roll

or move, causing death or serious injury.

CAUTION

(000306)

Equipment Damage. Failure to perform a daily

inspection could result in damage to the unit.

(000110)

WARNING

Risk of Fire. Hot surfaces could ignite

combustibles, resulting in fire. Fire could

result in death or serious injury.

(000354)

DANGER

Electrocution. In the event of electrical accident,

immediately shut power OFF and disconnect unit

from source. Use non-conductive implements to free

victim from live conductor. Apply first aid and get medical help.

Failure to do so will result in death or serious injury.

(000104)

DANGER

Electrocution. Water contact with a power

source, if not avoided, will result in death

or serious injury.

(000152)

DANGER

Electrocution. Verify electrical system is

properly grounded before applying power.

Failure to do so will result in death or serious

injury.

(000188)

DANGER

Electrocution. Do not wear jewelry while

working on this equipment. Doing so will

result in death or serious injury.

DANGER

Electrocution. DO NOT use the unit if

electrical cord is cut or worn through. Doing

so will result in death or serious injury.

(000263a)

(000260a)

High Voltage. Verify area above unit is clear

of overhead wires and obstructions. Contact

with high-voltage power lines will result in

death or serious injury.

DANGER

General Hazards

Electrical Hazards

Fire Hazards

2 Owner’s Manual for PLT240 Light Tower

Operating Safety

Positioning the Unit

•

The area immediately surrounding the unit should be

dry, clean, and free of debris.

•

Position and operate the unit on a firm, level surface.

•

If the unit requires external grounding (using the

grounding stud on the control panel), follow any

local, state, and National Electrical Code (NEC)

guidelines when connecting.

Page 7

Introduction and Safety

DANGER

Electrocution. DO NOT use the unit if

electrical cord is cut or worn through. Doing

so will result in death or serious injury.

(000263a)

WARNING

Electrocution. Do not set up or operate

this unit if severe weather is expected.

Lightning strikes can kill or cause severe injury

even if you are not touching the unit.

(000296)

WARNING

(000345)

Personal Injury. Do not set-up or operate unit

in high winds. Doing so could result in death,

serious injury, property, or unit damage.

WARNING

Personal Injury. Stop immediately if the mast hangs

up or the winch cable develops slack. Excess slack

could cause the mast to collapse, resulting in personal

injury or equipment damage.

(000265)

WARNING

Personal injury. Use caution when winding

winch cable. Failure to do so could result

in serious injury.

(000391)

Starting the Unit

DO NOT start a unit in need of repair.

•

Raising and Lowering the Mast

IMPORTANT NOTE: Unit wind rating is 45 mph.

DO NOT

all electrical components are shut down.

•

ALWAYS

in damp conditions. Do not service the unit if your

skin or clothing is wet. Do not allow water to collect

around the base of the unit.

•

DO NOT

power washers, or steam cleaners. Water may

collect in the unit, causing damage to electrical parts.

•

Replace all missing and hard to read decals. Decals

provide important operating instructions and warn of

dangers and hazards.

•

Wear heavy leather gloves when handling winch

cables. Never let cables slip through bare hands.

•

Only use mild soap and water to clean the lens covers.

Other chemicals may damage the lens covers.

perform even routine maintenance unless

use extreme care when servicing this unit

wash the unit with high pressure hoses,

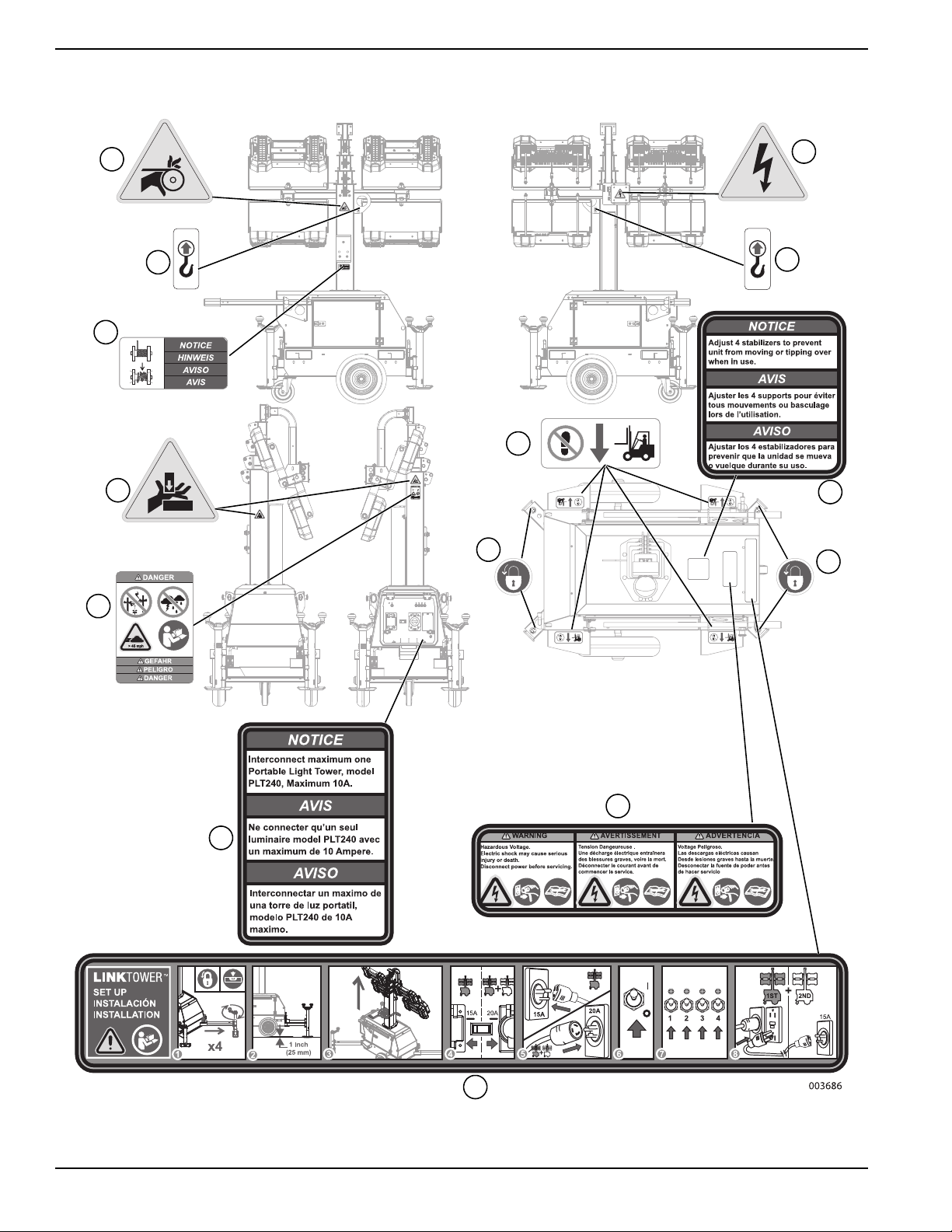

Safety and Operating Decals

See Table 1-1 and Figure 1-1. This unit features numerous

safety and operating decals. These decals provide

important operating instructions and warn of dangers and

hazards. The following diagrams illustrate decal locations

and descriptions.

Replace any missing or hard-to-read decals and use care

when washing or cleaning the unit. Decal part numbers

can be found in the parts manual at

www.generacmobileproducts.com.

• ALWAYS extend the outriggers and level the unit

before raising the mast. DO NOT retract the

outriggers while the mast is up.

• Keep area around the unit clear of people while

raising and lowering the mast.

• ALWAYS lower the mast when not in use.

Service Safety

This unit uses high voltage circuits capable of causing

serious injury or death. Only a qualified and licensed

electrician should troubleshoot or repair problems

occurring in this equipment.

Table 1-1. Decal Descriptions

ID Description

1 Warning—Entanglement Hazard

2 Lifting Point

3 Notice—Correctly Wind Winch

4 Warning—Crushing Hazard

Danger—Electrical Storms, High Wind and Overhead

5

Wires

6 Notice—Interconnect (located on flat beneath right

side receptacles)

7 Quick Start Guide

Warning—Hazardous Voltage: Disconnect Before

8

Servicing

9 Lock Stabilizing Feet

10 Forklift Pocket: Not a Step

11 Notice—Adjust Four Stabilizers

12 Warning—Electric Shock Hazard

•

Before servicing the unit, verify the main breaker

switch and circuit breakers are in the OFF (O)

position, and the shore power cord is disconnected.

Owner’s Manual for PLT240 Light Tower 3

Page 8

Introduction and Safety

7

9

9

5

4

3

2

1

12

2

10

8

6

11

Figure 1-1. Decal Locations

4 Owner’s Manual for PLT240 Light Tower

Page 9

Section 2: General Information

Specifications

DESCRIPTION PLT240-LED

Dimensions

See Unit Dimensions.

Weights

Operating Weight 558 lbs (252.6 kg)

Lighting

Lighting Type Light-Emitting Diode (LED)

LED Driver (4) Mean Well HLG-320H-30A

Lumens 88,000

AC Distribution

Circuit Breaker Size 15A / 20A Main Breaker

Amperage Selection 15A / 20A

120V-20 Amp GFCI Receptacle 1

Power Selection Switch 1

120V-20 Amp Twist Lock Inlet 1

120V-15 Amp Inlet 1

Chassis

Number of Axles 1

Tire Size 3.5 x 8 in. (89 x 203 mm)

Locking Caster Size 6 in. (152 mm)

Maximum Cargo Capacity 180 in. (81.7 mm)

Specifications are subject to change without notice.

General Information

Owner’s Manual for PLT240 Light Tower 5

Page 10

General Information

003622

Unit ID Tag

(Located on mast inside cabinet)

xxxxx

Unit Serial Number Locations

See Figure 2-1 to locate the unit ID tag on the unit. Important information, such as the unit serial number, model

number, and tire loading information are found on these tags. Record the information from these tags so it is available

if the tags are lost or damaged. When ordering parts or requesting assistance, you may be asked to provide this

information.

Figure 2-1. Unit Serial Number Locations

6 Owner’s Manual for PLT240 Light Tower

Page 11

Unit Dimensions

003440

C

B

A

D

E

F

General Information

Figure 2-2. Unit Dimensions

ABCDEF

PLT240

(1.37 m)

54 in.

77.5 in.

(1.96 m)

Specifications are subject to change without notice.

16 ft.

(4.88 m)

31.5 in.

(0.80 m)

57 in.

(1.45 m)

74 in.

(1.88 m)

Owner’s Manual for PLT240 Light Tower 7

Page 12

General Information

003443

F

E

C

D

B

A

H

I

J

K

L

G

Component Locations

Figure 2-3. Component Locations—Front and Left Side

A. Forklift pockets / tie-down locations G. LED Drivers (inside cabinet)

B. Swiveling caster (lockable) H. Lockable storage access door (2)

C. Control panel I. Outrigger and jack (4)

D. Water protection shield J. Handle (2)

E. Quick start guide K. Winch

F. LED fixtures (4) L. Lifting eye

8 Owner’s Manual for PLT240 Light Tower

Page 13

General Information

ON

15A

20A

OFF

ON

OFF

20A OUT15A IN 20A IN

1 2 3 4

003389

G

F

E

DC

B

A

Control Panel

IMPORTANT NOTE: If the control panel is ever removed, replace the gasket behind control panel and the gasket

between the water ingress cover and control panel.

Control Panel Components and Functions

(A) Main circuit breaker

Resettable main circuit breaker for the LED lights and

120V/20A GFCI receptacle.

(B) Input power selector switch

Allows the operator to select the input (shore power)

source.

• Choose the 15A setting if the unit will be operated

as a stand-alone light source.

• Choose the 20A setting if auxiliary equipment or a

second PLT240 will be connected to the unit.

See (C) and (G) for more information.

(C) 120VAC-20A plug (shore power input)

Provides a connection point for 120VAC-20A shore power

input to the LED lamps and GFCI receptacle. Requires

NEMA L5-20P connection.

(D) Mast light circuit breakers

Individual circuit breakers for the LED light fixtures.

Figure 2-4. Control Panel

(E) 120VAC/20A GFCI convenience receptacle (5-20R)

Customer convenience receptacle for use in connecting

auxiliary equipment. Includes a Ground Fault Circuit

Interrupter (GFCI) test and reset button. Requires NEMA

5-20P or 5-15P connection.

(F) Electrical ground connection (Optional)

An electrical grounding stud for connecting an earth

ground to the unit if required. Follow local, state, or

National Electrical Code (NEC) guidelines.

(G) 120VAC-15A plug (shore power input)

Provides a connection point for 120V-15A input power for

the LED lamps only. NEMA 5-15 plug. Requires NEMA 515P connection.

Owner’s Manual for PLT240 Light Tower 9

Page 14

General Information

003545

A

(000108)

WARNING

Hot Surfaces. When operating machine, do not

touch hot surfaces. Keep machine away from

combustibles during use. Hot surfaces could

result in severe burns or fire.

003542

B

A

C

D

Internal Storage

See Figure 2-5. The interior of the cabinet can be used

for storing nonflammable items such as shore power

cords, small equipment, or tools when the unit is not in

operation. Locking doors (A) on each side of the cabinet

provide access to the cabinet interior.

NOTE: Cabinet is not waterproof.

Figure 2-5. Internal Storage

4. Close and lock both access doors and the control

panel.

5. See Figure 2-6. To lift the unit, use one of the

following methods:

• Attach slings, chains or hooks directly to the central

lift point (A). Verify the LED fixtures will not be

damaged when lifting.

• Use a forklift. Approach the forklift pockets (B) only

from the side as shown. Avoid approaching the unit

at an angle, as this can permanently damage the

forklift pockets, wheels, or cabinet. Make sure any

obstructions are clear of the forklift tines before

lifting.

The LED drivers are mounted inside the cabinet behind a

heat guard at the back of the unit (control panel end). The

drivers become very hot during operation. Use care when

adding or removing items from internal storage, and

avoid touching the heat guard. Verify heat guard vents

are clear of obstructions.

Transporting the Unit

See Figure 2-7. Wheelbarrow-style handles (C) are

Figure 2-6. Lifting The Unit

provided for maneuvering the unit at the work site. Pull

the spring-loaded knobs (D) and fully extend each

Lifting and Transporting

This unit is equipped with a lifting eye and forklift pockets

handle. Then release the spring-loaded knobs to lock the

handles in place.

for lifting the unit on and off a transporting vehicle.

Wheels and handles are provided for manually

maneuvering the unit at the work site.

IMPORTANT NOTE: This unit is not designed to be

towed. Never attempt to tow this unit behind a

vehicle.

Lifting the Unit

NOTE: Always remain aware of people and objects

around the unit while preparing, maneuvering, and lifting

the unit.

1. Verify the equipment being used to lift the unit is in

good condition and has sufficient capacity. For

Figure 2-7. Extending the Handles

approximate weights, refer to Specifications.

2. Verify the mast is completely lowered.

3. Verify the outriggers and jacks are fully retracted.

10 Owner’s Manual for PLT240 Light Tower

003541

Page 15

See Figure 2-8. The chassis is equipped with a

003515

E

swiveling caster at the rear. Step on the brake (E) to lock

the caster and prevent the wheel from rotating. Raise the

brake to unlock the caster.

Figure 2-8. Swiveling Caster

Tying the Unit Down

When securing the unit for transportation, verify the

equipment being used to fasten the unit is in good

condition and has sufficient strength to hold the unit in

place during transport.

See Figure 2-6. Tie-down straps, ropes, or chains may

be passed through the forklift pockets (B). The holes in

the forklift pockets may also be used to secure the unit

for transport.

General Information

Owner’s Manual for PLT240 Light Tower 11

Page 16

General Information

This page intentionally left blank.

12 Owner’s Manual for PLT240 Light Tower

Page 17

Section 3: Operation

Asphyxiation. Do not connect any enginepowered equipment or fired air heaters to the

convenience receptacle(s), even with proper

ventilation. Carbon monoxide, if not avoided,

will result in death or serious injury.

(000353)

DANGER

(000260a)

High Voltage. Verify area above unit is clear

of overhead wires and obstructions. Contact

with high-voltage power lines will result in

death or serious injury.

DANGER

WARNING

(000345)

Personal Injury. Do not set-up or operate unit

in high winds. Doing so could result in death,

serious injury, property, or unit damage.

WARNING

Electrocution. Do not set up or operate

this unit if severe weather is expected.

Lightning strikes can kill or cause severe injury

even if you are not touching the unit.

(000296)

Operation Configuration

Before setting up the unit, determine if the unit will

operate as a standalone light tower, or if export power will

be required.

If the unit will be operated as a standalone light tower,

either the 120V-15A or 120V-20A input power plugs can

be used.

If export power is required, or a second link tower will be

connected (via the 120V GFCI receptacle), 120V-20A

input power is required.

NOTE: Shore power cords are not included with this unit

and must be supplied by the end user. See Table 1 for

recommended cable size and length.

Table 1 - Recommended Shore Power Cable

Size and Length

Operation

Light Tower Setup

Suggested Power Cables and Lengths

50 ft. (15.2 m) 10/3—(L5-20P – L5-20R)

100 ft. (30.5 m) 12/3—(5-15P – 5-15R)

Maximum Distance - One LINK Tower

400 ft. (121.9 m) cable size 10/3—(L5-20P – L5-20R)

OR

300 ft. (91.4 m) cable size 12/3—(5-15P – 5-15R)

Maximum Distance - Two LINK Towers

300 ft. (91.4 m) cable size 10/3—(L5-20P –L5-20R)

to first LINK Tower

(first LINK Tower must be powered by 20A circuit)

AND

200 ft. (61 m) cable size 12/3—(5-15P–5-15R)

to second LINK Tower

LED Lights Only

Connect the unit to either a 120VAC-15A supply or

120VAC-20A supply using either input power plug.

LED Lights and Auxiliary Power

1. Connect the unit to a 120VAC-20A supply using

the NEMA L5-20 plug.

2. Connect auxiliary equipment to the 120VAC GFCI

convenience receptacle.

IMPORTANT NOTE: Unit wind rating is 45 mph.

1. For maximum light coverage, position the unit at

ground level or in a spot higher than the area being

illuminated by the lamps.

NOTE: The mast extends up to 16 ft (4.88m).

2. Place the unit on firm ground that is relatively flat

(less than 5° grade). Use the handles to rotate the

unit until the lights face the desired direction.

3. Lock the swiveling caster.

4. Return the handles to the stored position.

5. A grounding stud is located on the control panel.

For grounding requirements, follow local, state, oil

and gas or petrochemical plant grounding, MSHA,

OSHA, CSA, IEC, IEEE, NFPA, ABS Marine and

Maritime guidelines as applicable.

Owner’s Manual for PLT240 Light Tower 13

Page 18

Operation

003544

B

A

WARNING

Tipping hazard. Extend the outriggers and level the unit

before raising the mast. Keep the outriggers extended

while the mast is up. Failure to do so could cause the unit

to tip and fall and could result in death or serious injury.

(000266)

002994

DETAIL C

STOP

B

C

A

WARNING

Personal Injury. Stop immediately if the mast hangs

up or the winch cable develops slack. Excess slack

could cause the mast to collapse, resulting in personal

injury or equipment damage.

(000265)

6. See Figure 3-1. Pull the locking pins (A) on the

four outriggers (B) and pull each outrigger out until

the spring loaded locking pin snaps back into

place.

Figure 3-1. Set Up Outriggers and Jacks

7. Rotate each jack handle clockwise to start leveling

the unit. Adjust all four jacks by rotating their

handles clockwise until the wheels and caster are

not touching the ground.

8. Before raising the mast, it may be necessary to

adjust the LED fixtures. The LED fixtures may be

adjusted up, down, left or right by simply aiming

them in the desired direction.

Raising the Mast

IMPORTANT NOTE: The mast is intended for use

ONLY to support the LED fixtures. Do not use the

mast as a hoist or for any other purpose.

1. Set up and level the unit. See Light Tower Setup.

x

Figure 3-2. Pulley Locations

2. See Figure 3-2. Check the mast cables for

excessive wear or damage. Verify the cables are

properly centered in each pulley (A). Check the

electrical cord for damage.

Stand, facing the winch, at the location indicated

3.

with the black “X” in

4.

Use the winch (B) to slowly extend the mast, making

sure that the coiled electrical cord is extending at

the top sections of the mast. STOP extending the

mast when the colored mark (C) on the second mast

section is visible as seen in Detail C.

Figure 3-2.

14 Owner’s Manual for PLT240 Light Tower

IMPORTANT NOTE: Contact a Generac Mobile

Products Authorized Dealer immediately if the mast

hangs up or the winch cable develops slack.

Page 19

5. See Figure 3-3. Verify cable winds evenly around

WARNING

(000372)

Machine damage. Do not extend the mast beyond

the colored mark. Overextension can stretch or

break electrical cables or winch cables, and may

damage mast hardware.

WARNING

Personal injury. Use caution when winding

winch cable. Failure to do so could result

in serious injury.

(000391)

004887

A

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

winch drum as shown (A) to prevent cable

damage.

Operation

Prestart Checklist

Before starting the unit, all items in the prestart checklist

must be completed.

Verify all maintenance procedures are up to date. For

more information, refer to General Maintenance and

Basic Maintenance Schedule.

Verify the unit is level.

Verify the unit is dry. Look for water inside or near the

unit; dry if needed.

For grounding requirements, follow any local, state,

oil and gas or petrochemical plant grounding, MSHA,

OSHA, CSA, IEC, IEEE, NFPA, ABS Marine and

Maritime guidelines as applicable.

Verify the main breaker switch is OFF (O).

Verify all circuit breakers are OFF (O).

Figure 3-3. Winch Cable Alignment

Inspect all electrical cords; repair or replace any that

are cut, worn, or bare.

Verify all winch cables are in good condition and

centered on each pulley. Do not use if cables are

kinked or beginning to unravel.

Verify all covers and guards are in place and properly

secured.

Verify cords are routed properly through the water

protection shield.

If using 20A shore power, verify convenience

receptacle is functional.

Owner’s Manual for PLT240 Light Tower 15

Page 20

Operation

DANGER

Electrocution. DO NOT use the unit if

electrical cord is cut or worn through. Doing

so will result in death or serious injury.

(000263a)

WARNING

Personal Injury. Stop immediately if the mast hangs

up or the winch cable develops slack. Excess slack

could cause the mast to collapse, resulting in personal

injury or equipment damage.

(000265)

Turn Unit ON

1. Plug in any equipment or another LINK tower.

2. Press the plug power selection switch to select

either 15A or 20A power source. Switch position

MUST match the connected input source.

3. Connect a 20A or 15A shore power cord,

depending on plug power selection switch position

and input source from previous step.

4. Turn the main breaker switch ON.

5. Turn each mast light circuit breaker ON. The LED

lamps will illuminate.

6. Start auxiliary equipment (if powered by the 20A

inlet).

NOTE: It may be necessary to leave some lights off if the

export current exceeds 12A.

Long-Term Storage

Perform the following steps if the machine is to be stored

for an extended period (for example, more than one

year).

1. Verify all circuit breakers are OFF (O).

2. Verify the unit is unplugged.

3. Lower the mast.

4. Retract the outriggers and handles.

5. Clean the unit inside and out.

6. Close and lock the storage access panels.

7. Store the unit indoors, if possible, in a secure, dry

location.

Perform a visual inspection of all electrical connections,

LED lights, winch cables, and mast before returning the

unit to service.

Turn Unit OFF

Check with personnel using lights and auxiliary power

supplied by the unit and let them know the power is going

to be turned off. Verify the power shutdown will not create

hazards by turning off equipment that may be in use

(lights, tools, etc.).

1. Turn off and disconnect any auxiliary equipment.

2. Switch lights OFF using the individual mast light

breakers.

3. Switch main breaker OFF (O).

4. After the unit shuts down, disconnect the shore

power cord.

Lowering the Mast

1. Shut down the lights. See Turn Unit OFF.

2. Lower the mast.

3. Use the winch handles to lower the mast to its

lowest position. Verify the electrical cord does not

get caught in, or pinched by, the mast while it is

being lowered.

IMPORTANT NOTE: Contact an Generac Mobile

Products Authorized Dealer immediately if the mast

hangs up or the winch cable develops slack.

16 Owner’s Manual for PLT240 Light Tower

Page 21

Section 4: Maintenance

CAUTION

(000306)

Equipment Damage. Failure to perform a daily

inspection could result in damage to the unit.

Maintenance

Daily Walk-Around Inspection

Perform a walk-around inspection of the unit every day

before starting the unit. Look for conditions that could

hinder performance or safety, such as (but not limited to)

damaged or missing parts and hardware, and loose or

broken electrical connections.

General Maintenance

Poorly maintained equipment can become a safety

hazard. In order for the equipment to operate safely and

properly over a long period of time, periodic maintenance

and occasional repairs are necessary. DO NOT perform

routine service unless all electrical components are OFF.

Regular maintenance will improve performance and

extend engine/equipment life. Generac Mobile Products

LLC recommends all maintenance work be performed by

an Generac Mobile Products Authorized Dealer.

Inspecting the Unit

•

If the unit is stored outside, check for water inside

the cabinet and control panel cover before each

use. If wet, dry the unit thoroughly before starting.

• Inspect condition of electrical cords. DO NOT use

the unit if insulation is cut or worn through.

• Verify winch cables are in good condition and

centered on each pulley. DO NOT use a cable that

is kinked or starting to unravel.

• Verify the wheels and locking caster are present

and in serviceable condition.

Basic Maintenance Schedule

Use Table 4-1 and Table 4-2 as guides for regular

maintenance intervals. For additional guidance, contact a

Generac Mobile Products Authorized Dealer.

Table 4-1. Basic Maintenance Guide

Item

Check Tires for Wear

Check All Electrical Connections

Daily

Preparing for Service

Before servicing the unit, always follow the instructions

listed below.

1. Verify the main breaker switch and lamp switches

are OFF.

2. Disconnect shore power from the unit.

3. Disconnect linked units.

4. Attach a DO NOT USE sign to the control panel.

This will notify everyone that the unit is being

serviced and will reduce the chance of someone

inadvertently trying to start the unit.

Cleaning the Unit

Always clean the unit after each use to remove dust,

grease, mud, or spilled fuel or oil. Use soft, clean rags to

wipe the cabinet exterior and control panel. Low-pressure

compressed air (less than 40 PSI [276 kPa]) can also be

used to remove dust and debris from the cabinet interior.

This unit contains sensitive electronic components that

can be damaged by high pressure, heat and moisture.

Do not wash the unit with a high pressure hose or power

washer. Water may enter the cabinet and collect in the

control panel or other electrical parts, causing damage.

Inspect Light Tower Winch For Proper Operation

Owner’s Manual for PLT240 Light Tower 17

Page 22

Maintenance

Winch Use, Operation and

Maintenance

Prior to Use

Inspect winch cable and replace if damaged.

•

• Check mounting hardware for proper tightness and

tighten if necessary.

• Gears, ratchet pivot point and shaft bushings must

be kept lubricated with a thin film of oil or grease.

Operation

Raising the Mast:

1. The cable must be securely fastened to the winch

drum.

2. Always be sure the cable is undamaged. Contact

Generac Mobile Products to order a replacement

cable if necessary.

3. Referring to the LIFT/LET DOWN decal on the

winch, rotate handle according to the specified

direction to lift. The ratchet MUST make a loud

clicking sound while winding the cable.

Lowering the Mast:

Referring to the LIFT/LET DOWN decal on the winch,

rotate handle according to the specified direction to

lower. No clicking will be heard while lowering the mast

because the automatic brake system is activated.

Maintenance

The following procedures should be performed at least

annually:

1. Lubricate winch gears and bushings. Apply a thin

film of grease to the gear teeth, and oil the

bushings as needed.

2. Lubricate the ratchet pawl pivot point with a thin oil.

Winch Mechanical Brake

The mechanical brake generates heat when loads are

lowered and the wire cable is powered out. Care must be

taken to avoid overheating the mechanical brake.

Whine or chatter associated with a new mechanical

brake is normal and typically disappears with use.

Overheating the mechanical brake may result in

permanent damage to, or failure of, the brake. Replace

any damaged brake components before resuming use of

the winch.

Table 4-2. Winch Preventative Maintenance Schedule

Maintenance

Activity

Check Fasteners

Clean And Grease

Brake Assembly

Visually Check

Winch And Control

After First

Operation

Before

Each Use

Semi-

Annually

Jack Maintenance

Before each use, check each jack foot for damage and

remove any mud or debris. The jacks must be clean and

in good operating condition to properly support the unit.

Wheel Maintenance

Before each use, check each wheel for cuts, damage,

cracks, or embedded objects. Verify all fasteners are

present and tight.

NOTE: Do not get oil or grease on the brake mechanism.

18 Owner’s Manual for PLT240 Light Tower

Page 23

Section 5: Troubleshooting

(000343)

Electrocution. Potentially lethal voltages are present

in this equipment. Render the equipment safe before

attempting repairs or maintenance. Failure to do so

will result in death or serious injury.

DANGER

Troubleshooting the Lights

Problem Possible Cause Solution

Troubleshooting

IMPORTANT NOTE: Only a qualified electrician should

troubleshoot or repair electrical problems occurring in this

equipment. Contact Generac Mobile Products Technical

Service at 1-800-926-9768 for assistance if you have any

questions, or if problems persist.

LED Mast Lights

Do Not Turn On

Extension cord too long

Faulty electrical

connection

Faulty main breaker

switch

Faulty mast light circuit

breaker(s)

Faulty LED driver

Supply power breaker

tripped

Extension cord gauge

too small

Reduce length or increase gauge of extension cord. See

Section 3.

Verify connectors within following sections are properly seated and there

are no loose connections:

• Mast junction box

• 12 pin connector

• LED drivers (4)

• Mast light circuit breakers (4)

• Input power selector switch

• Main breaker switch

Replace main breaker switch

Replace mast light circuit breaker(s)

Verify driver input voltage from light switch is 120VAC ±10VDC. If output

voltage from LED Driver (at 12 pin connector) is less than 24VDC, replace

LED driver.

Reset supply power breaker.

Use larger extension cord.

Table 1 in

Leave light off for a few minutes to reset protection; then restart lights.

LED Mast Lights

are Flashing

Main Breaker

Switch Trips when

Applying Load

LED driver overheated

Voltage is too low Raise voltage to 90VAC

Connected load (through

GFCI) too large

Verify nothing is obstructing airflow to driver. Check for accumulated dust

or dirt on driver; remove using clean, dry cloth.

Reduce size of connected load or reduce the number of lights in use.

Owner’s Manual for PLT240 Light Tower 19

Page 24

Troubleshooting

This page intentionally left blank.

20 Owner’s Manual for PLT240 Light Tower

Page 25

Section 6: Wiring Diagrams

BK/OR

14

RD/OR

14

14

BK/BL

14

14

14

14

14

RD/BL

BK/WT

RD/WT

BK/YL

RD/YL

12

12

12

12

GN/YL

GN/YL

GN/YL

GN/YL

RD

BK

14

14

DRIVER 4

BN

BL

12

12

DRIVER 3

RD

BK

14

14

BN

BL

12

12

GN/YL

12

RD

BK

14

14

DRIVER 2

BN

BL

12

12

GN/YL

12

RD

BK

14

14

DRIVER 2

BN

BL

12

12

GN/YL

12

TB B4

12

YL BK

12

5A

LIGHT #4

TB B3

12

BK BK

12

5A

LIGHT #3

TB B2

12

BL BK

12

5A

LIGHT #2

TB B1

12

OR BK

12

5A

LIGHT #1

NEUTRAL GND

L1

12

BL

12

BL

12

BL

12

BL

TB A4

TB A3

TB A2

TB A1

75018_A_06.28.16

VIEW FACING MAST BOX

12

34

N

N

N

N

NEUTRAL BAR

ISOLATED

12

12

12

12

12

12

120V/20A Edison Inlet

L1

NEUTRAL

GND

N WT

L2

BK

GN/YL

NWT

120V/20A Edison Inlet

GN/YL

GND

NEUTRAL

L1

BK

L1

2-POLE

CIRCUIT

BREAKER

15A

20A

L1.1

BK

L2.1

BK

12

12

DPDT

SELECT

SWITCH

BK

BK

12

12

L3

DPDT

SELECT

SWITCH

BK

12

L4

BK

12

GFCI

120V/20A 5-20R

12 POSITION

CONNECTOR

B

A

1 234

56 7 89101112

MAST COIL CORD

MAST JUNCTION BOX

BK/OR

RD/OR

BK/BL

RD/BL

14

14

14

14

14

14

141414

BK

WT

BK

WT

BK/WT

RD/WT

BK/YL

RD/YL

BK

WT

BK

WT

LIGHT #1

LIGHT #2

LIGHT #3

LIGHT #4

GN/YL

12

GROUND BAR

GN/YL 12

AC Wiring

Wiring Diagrams

Owner’s Manual for PLT240 Light Tower 21

Page 26

Wiring Diagrams

This page intentionally left blank.

22 Owner’s Manual for PLT240 Light Tower

Page 27

Page 28

Part No. 54800 Rev. C 06/01/17

©2017 Generac Mobile Products

All rights reserved.

Specifications are subject to change without notice.

No reproduction allowed in any form without prior written

consent from Generac Mobile Products.

Generac Mobile Products

215 Power Drive, Berlin, WI 54923

GeneracMobileProducts.com │800-926-9768 │920-361-4442

Loading...

Loading...