Page 1

iQ2000 Portable Generator

000853

(000209b)

WARNING

Loss of life. This product is not intended to

be used in a critical life support application.

Failure to adhere to this warning could result

in death or serious injury.

Owner’s Manual

MODEL:________________________

SERIAL:________________________

DATE PURCHASED:______________

Register your Generac product at:

WWW.GENERAC.COM

1-888-GENERAC

(1-888-436-3722)

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

Table of Contents

(000393)

WARNING

Operating, servicing and maintaining this

equipment can expose you to chemicals

including engine exhaust, carbon monoxide,

phthalates, and lead, which are known to the

State of California to cause cancer and birth

defects or other reproductive harm. To

minimize exposure, avoid breathing exhaust,

do not idle the engine except as necessary,

service your equipment in a well-ventilated

area and wear gloves or wash your hands

frequently when servicing your equipment.

For more information go to

www.P65Warnings.ca.gov.

Section 1 Introduction and Safety 1

Introduction ..................................... 1

Safety Rules .................................... 1

Safety Symbols and Meanings ........ 1

Exhaust and Location Hazards ....... 2

Electrical Hazards ...........................3

Fire Hazards .................................... 3

Standards Index .............................. 3

Section 2 General Information and

Setup .............................................. 4

Know Your Generator ..................... 5

Emissions ........................................ 5

Connection Plugs ............................ 6

PowerDial ........................................ 6

PowerBar ........................................ 6

Economy Switch .............................. 6

Generator Status Lights ..................6

Run Time Display ............................ 6

Fuel Sensor and Fuel Gauge .......... 7

Remove Contents from Carton ....... 7

Add Engine Oil ................................7

Fuel ................................................. 8

Section 3 Operation .......................9

Operation and Use Questions .........9

Before Starting Engine ....................9

Prepare Generator for Use ..............9

Grounding the Generator When Used

as a Portable ...................................9

Know Generator Limits ....................9

Transporting/Tipping of the Unit ....10

Starting Pull Start Engines .............10

Restarting Hot Engines ..................11

Low Oil Level Shutdown System ...11

Parallel Operation ..........................11

Parallel Reset Procedure ...............12

Section 4 Maintenance and

Troubleshooting ..........................13

Maintenance ..................................13

Maintenance Schedule ..................13

Preventive Maintenance ................13

Engine Maintenance ......................13

Storage ..........................................16

Troubleshooting .............................17

Page 3

Section 1 Introduction and Safety

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

(000001)

DANGER

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

(000002)

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

(000003)

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

DANGER

Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide. This is

a poison you cannot see or smell.

NEVER use inside a home

or garage, EVEN IF doors

and windows are open.

Only use OUTSIDE and

far away from windows,

doors, and vents.

000657

Introduction

Thank you for purchasing a Generac Power

Systems Inc. product. This unit has been

designed to provide high-performance, efficient operation, and years of use when maintained properly.

If any section of the manual is not understood,

contact your nearest Independent Authorized

Service Dealer (IASD), or contact Generac

Customer Service at 1-888-GENERAC (1888-436-3722), or www.generac.com with any

questions or concerns.

The owner is responsible for proper maintenance and safe use of the equipment. Before

operating, servicing or storing this generator:

• Study all warnings in this manual and on

the product carefully.

• Become familiar with this manual and the

unit before use.

• Refer to Introduction and Safety for instructions on final assembly procedures. Follow

the instructions completely.

Save these instructions for future reference.

ALWAYS supply this manual to any individual

that will use this machine.

The information in this manual is accurate

based on products produced at the time of

publication. The manufacturer reserves the

right to make technical updates, corrections,

and product revisions at any time without

notice.

NOTE: Notes contain additional information

important to a procedure and will be found

within the regular text of this manual.

These safety warnings cannot eliminate the

hazards that they indicate. Common sense

and strict compliance with the special instructions while performing the action or service

are essential to preventing accidents.

Safety Symbols and Meanings

Safety Rules

The manufacturer cannot anticipate every

possible circumstance that might involve a

hazard. The warnings in this manual, and on

tags and decals affixed to the unit are, therefore, not all inclusive. If using a procedure,

work method or operating technique that the

manufacturer does not specifically recommend, verify that it is safe for others. Also

make sure the procedure, work method or

operating technique utilized does not render

the equipment unsafe.

Throughout this publication, and on tags and

decals affixed to the generator, DANGER,

WARNING, CAUTION and NOTE blocks are

used to alert personnel to special instructions

about a particular operation that may be hazardous if performed incorrectly or carelessly.

Observe them carefully. Their definitions are

as follows:

Owner’s Manual for Portable Generator 1

Asphyxiation. Running engines produce carbon

DANGER

monoxide, a colorless, odorless, poisonous gas.

Carbon monoxide, if not avoided,

will result in death or serious injury.

• If you start to feel sick, dizzy, or weak after

the generator has been running, move to

fresh air IMMEDIATELY. See a doctor, as

you could have carbon monoxide poisoning.

(000103)

Page 4

(000179b)

DANGER

Asphyxiation. The exhaust system must be properly

maintained. Do not alter or modify the exhaust system

as to render it unsafe or make it noncompliant with

local codes and/or standards. Failure to do so will

result in death or serious injury.

DANGER

(000116)

DANGER

Electrocution. Turn utility and emergency

power supplies to OFF before connecting power

source and load lines. Failure to do so will result

in death or serious injury.

(000146)

WARNING

Equipment and property damage. Do not alter

construction of, installation, or block ventilation for

generator. Failure to do so could result in unsafe

operation or damage to the generator.

(000178a)

Asphyxiation. Always use a battery operated carbon

monoxide alarm indoors and installed according to

the manufacturer’s instructions. Failure to do so

could result in death or serious injury.

WARNING

(000250)

WARNING

Equipment and property damage. Do not operate unit on

uneven surfaces, or areas of excessive moisture, dirt, dust

or corrosive vapors. Doing so could result in death, serious

injury, property and equipment damage.

(000111)

WARNING

Moving Parts. Keep clothing, hair, and appendages

away from moving parts. Failure to do so could

result in death or serious injury.

(000142a)

Personal injury. Do not insert any object through the

air cooling slots. Generator can start at any time and

could result in death, serious injury, and unit damage.

WARNING

Risk of injury. Do not operate or service this machine

if not fully alert. Fatigue can impair the ability to service

this equipment and could result in death or serious

injury.

(000215)

(000103)

DANGER

Asphyxiation. Running engines produce carbon

monoxide, a colorless, odorless, poisonous gas.

Carbon monoxide, if not avoided,

will result in death or serious injury.

Asphyxiation. The exhaust system must be properly

as to render it unsafe or make it noncompliant with

local codes and/or standards. Failure to do so will

result in death or serious injury.

(000178a)

Asphyxiation. Always use a battery operated carbon

monoxide alarm indoors and installed according to

the manufacturer’s instructions. Failure to do so

could result in death or serious injury.

WARNING

Electrocution. Water contact with a power source,

if not avoided, will result in death or serious injury.

(000104)

Injury and equipment damage. Do not use generator

as a step. Doing so could result in falling, damaged

parts, unsafe equipment operation, and could result

in death or serious injury.

• For safety reasons, it is recommended that

the maintenance of this equipment be performed by an IASD. Inspect the generator

regularly, and contact the nearest IASD for

parts needing repair or replacement.

• Point muffler exhaust away from people

and occupied buildings.

• Minimum generator placement distance of

five feet from windows, doors, or openings

in walls with engine exhaust directed away

from occupied buildings and if possible

downwind.

(000216)

Exhaust and Location Hazards

DANGER

maintained. Do not alter or modify the exhaust system

(000179b)

WARNING

Hot Surfaces. When operting machine, do not

touch hot surfaces. Keep machine away from

combustables during use. Hot surfaces

could result in severe burns or fire.

WARNING

2 Owner’s Manual for Portable Generator

WARNING

(000108)

Equipment and property damage. Do not alter

WARNING

construction of, installation, or block ventilation for

generator. Failure to do so could result in unsafe

operation or damage to the generator.

• If you start to feel sick, dizzy, or weak after

the generator has been running, move to

fresh air IMMEDIATELY. See a doctor, as

you could have carbon monoxide poisoning.

(000146)

Page 5

Electrical Hazards

(000144)

DANGER

Electrocution. Contact with bare wires,

terminals, and connections while generator

is running will result in death or serious injury.

(000104)

DANGER

Electrocution. Water contact with a power source,

if not avoided, will result in death or serious injury.

(000145)

DANGER

Electrocution. In the event of electrical accident,

immediately shut power OFF. Use non-conductive

implements to free victim from live conductor. Apply

first aid and get medical help. Failure to do so will

result in death or serious injury.

(000105)

DANGER

Explosion and Fire. Fuel and vapors are extremely

flammable and explosive. Add fuel in a well

ventilated area. Keep fire and spark away. Failure to

do so will result in death or serious injury.

(000199)

DANGER

Explosion and Fire. LP vapors are extremely ammable

and explosive. Do not use or store LP cylinder in a

building, garage, or enclosed area except as authorized

by NFPA 58 or B149.2 (Canada). Failure to do so will

result in death or serious injury.

(000166b)

Explosion and Fire. Do not overfill fuel tank. Fill to

1/2 inch from top of tank to allow for fuel expansion.

Overfilling may cause fuel to spill onto engine causing

fire or explosion, which will result in death or

serious injury.

(000174)

DANGER

Risk of fire. Allow fuel spills to completely dry

before starting engine. Failure to do so will

result in death or serious injury.

(000142a)

Personal injury. Do not insert any object through the

air cooling slots. Generator can start at any time and

could result in death, serious injury, and unit damage.

• The National Electric Code (NEC) requires

the frame and external electrically conductive parts of the generator be properly connected to an approved earth ground. Local

electrical codes may also require proper

grounding of the generator. Consult with a

local electrician for grounding requirements

in the area.

• Use a ground fault circuit interrupter in any

damp or highly conductive area (such as

metal decking or steel work).

• Once generator has been started outside,

connect electrical loads to extension

cord(s) inside.

Fire Hazards

WARNING

• Do not operate the generator if connected

electrical devices overheat, if electrical output is lost, if engine or generator sparks or if

flames or smoke are observed while unit is

running.

• Keep a fire extinguisher near the generator

at all times.

Standards Index

1. National Fire Protection Association

(NFPA) 70: The NATIONAL ELECTRIC

CODE (NEC) available from www.nfpa.org

2. National Fire Protection Association

(NFPA) 5000: BUILDING CONSTRUCTION AND SAFETY CODE available from

www.nfpa.org

3. International Building Code available from

www.iccsafe.org

4. Agricultural Wiring Handbook available

from www.rerc.org, Rural Electricity

Resource Council P.O. Box 309 Wilmington, OH 45177-0309

5. ASAE EP-364.2 Installation and Mainte-

nance of Farm Standby Electric Power

available from www.asabe.org, American

Society of Agricultural & Biological Engineers 2950 Niles Road, St. Joseph, MI

49085

6. CSA C22.2 100-14 Electric motors and

generators for installation and use, in

accordance with the Rules of the Canadian Electrical Code

7. ANSI/PGMA G300 Safety and Perfor-

mance of Portable Generators. Portable

Generator Manufacturer’s Association,

www.pgmaonline.com

This list is not all inclusive. Check with the

Authority Having Jurisdiction (AHJ) for any

local codes or standards which may be applicable to your jurisdiction.

DANGER

Owner’s Manual for Portable Generator 3

Page 6

Section 2 General Information and Setup

000581

17

14

15

12

18

16

13

20

7

10

3

1

2

8

6

9

54

11

000662

19

000662

Figure 2-1. Features and Controls

TABLE 1. Generator Components

1 Parallel Ready 120 Volts AC Duplex

Outlet

2 Turbo/Standard/Economy Switch

3PowerBar

4 Grounding Location

5 Reset Button

6 Overheat LED (red)

7 Overload LED (red)

8 Low Oil LED (orange)

9 Ready to Load LED (green)

10 Fuel Gauge

11 Run Time Display

12 Muffler/Spark Arrestor

13 Fuel Cap (with vent)

14 Recoil Handle

15 Carrying Handle

16 Power Dial

17 Service Door

18 Air Intake

19 Data Label Location

20 Oil Fill

4 Owner’s Manual for Portable Generator

Figure 2-2. Control Panel

Figure 2-3. Data Label Location

000579

003039

Page 7

Know Your Generator

(000100a)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

Emissions

The United States Environmental Protection

Agency (US EPA) (and California Air

Resources Board (CARB), for engines/equipment certified to California standards) requires

that this engine/equipment complies with

exhaust and evaporative emissions standards. Locate the emissions compliance decal

Replacement owner’s manuals are available

at www.generac.com.

on the engine to determine applicable standards. For emissions warranty information,

please reference the included emissions warranty. It is important to follow the maintenance

specifications in the manual to ensure that the

engine complies with the applicable emissions

standards for the duration of the product’s life.

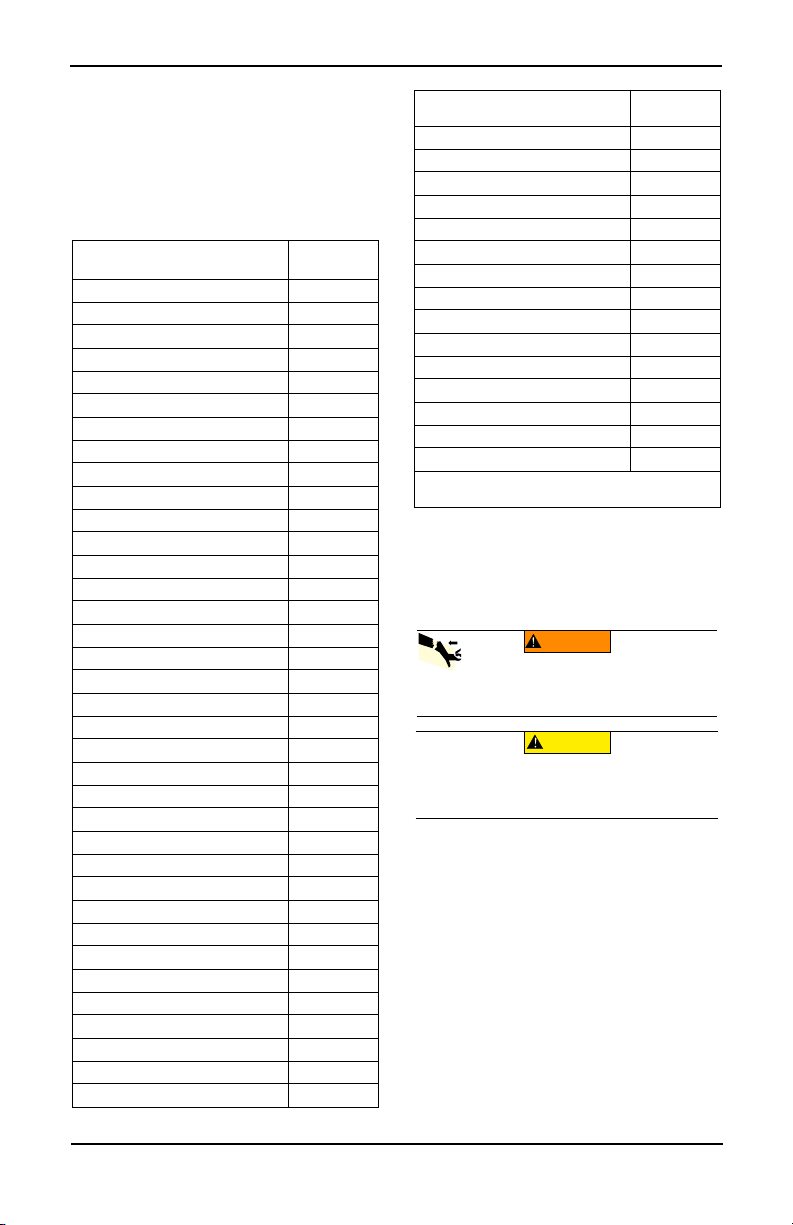

TABLE 2. Product Specifications

Generator Specifications

Rated Power 1600 W

Surge Power 2000 VA

Rated AC Voltage 120V

Rated AC Load at 120V 13.3 Amps**

Rated Frequency 60 Hz

Dimensions L x W x H (in/mm) 20.0 x 12.6 x 16.9 (507.4 x 320.8 x 428)

Unit Weight (dry) 46.2 lb. (19.3 kg)

** Operating Temperature Range: -13 deg. C (8 deg. F) to 40 Deg. C (104 Deg. F). When operated

above 25 deg. C (77 deg. F) there may be a decrease in power.

** Maximum wattage and current are subject to, and limited by, such factors as fuel Btu content, ambi-

ent temperature, altitude, engine condition, etc.. Maximum power decreases about 3.5% for each

1,000 feet above sea level; and will also decrease about 1% for each 6° C (10° F) above 16° C (60°

F) ambient temperature.

Engine Specifications

Engine Type Single Cylinder, 4-stroke

Displacement 80 cc

Spark Plug Part Number 0K91470141

Spark Plug Type NHSP LDE6RTC

Spark Plug Gap (in/mm) 0.023-0.027 (0.6-0.7)

Fuel Capacity / Type 4.0 L (1.06 gal) / Unleaded

Oil Type

Oil Capacity 0.38 L (0.4 qt.)

Run Time at 25% Load 7.7 Hours

Add Engine Oil

See

Owner’s Manual for Portable Generator 5

Page 8

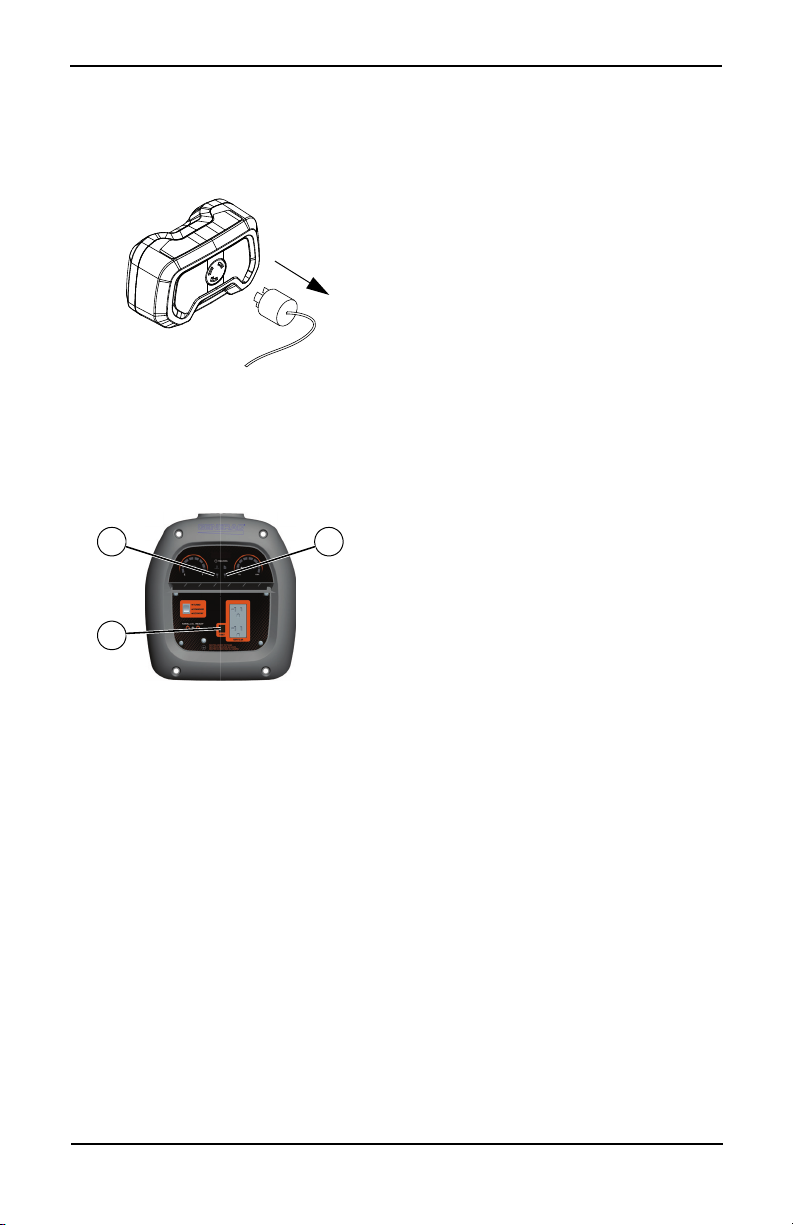

Connection Plugs

000424

000663

2

1

3

120 VAC, Duplex Receptacle

The 120 Volt outlet is overload protected by

the inverter module electronic control. See

Figure 2-4. Each receptacle will power 120

Volt AC, single phase, 60 Hz electrical loads

requiring up to 1600 watts (1.6 kW).

Figure 2-4. 120 VAC, Duplex Receptacle

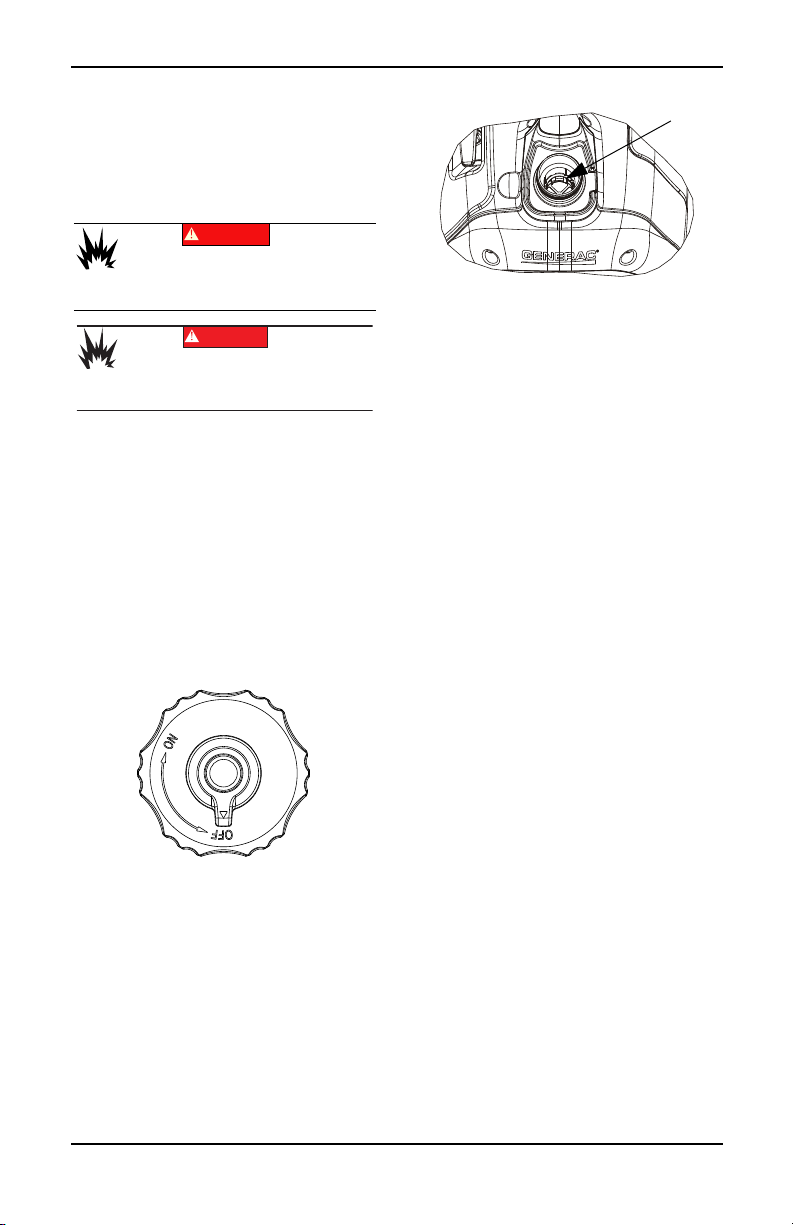

PowerDial

The PowerDial controls the ON/OFF functions, choke and fuel valve operation. See Fig-

ure 2-5.

• The START position (1) is used to start the

engine. In this position, the fuel is on and

the choke is fully on (closed).

• The RUN position (2) for normal operation

and to gradually reduce the use of the

choke.

• The STOP position (3) stops the engine

and shuts off fuel flow.

Figure 2-5. PowerDial (example)

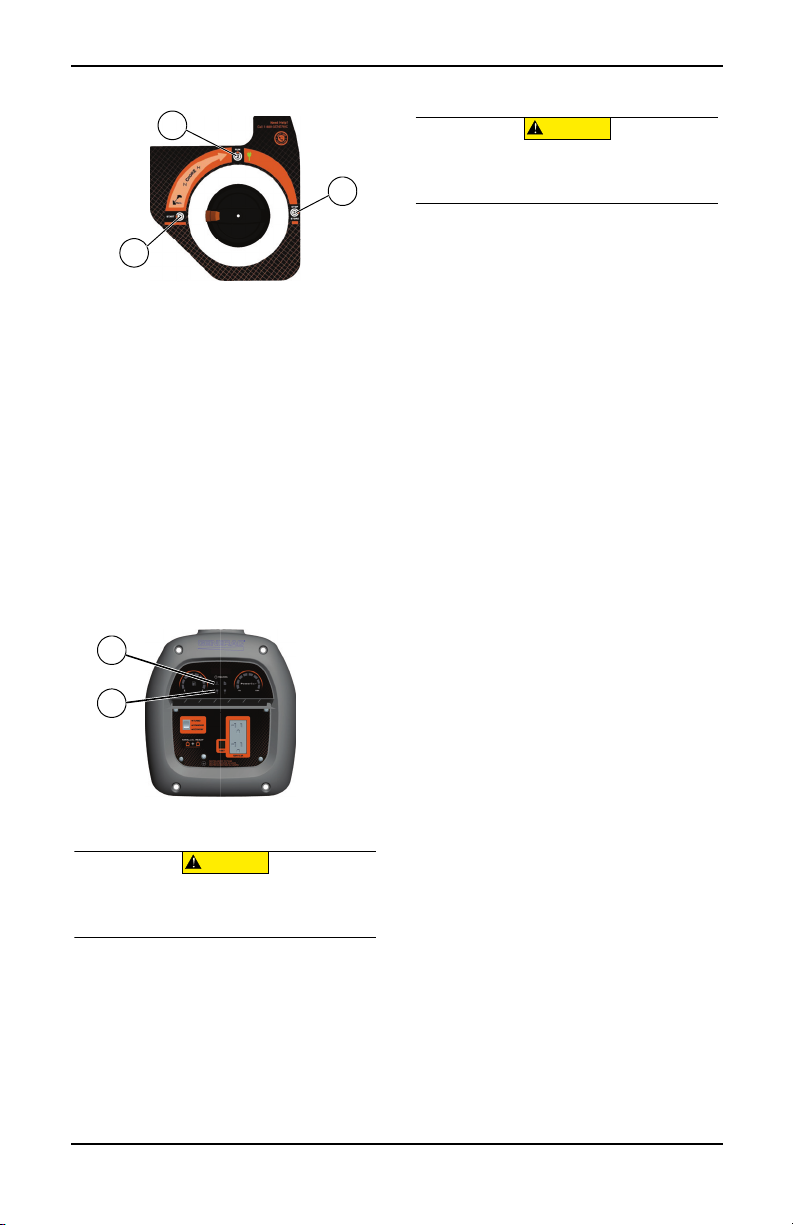

PowerBar

See Figure 2-6. The PowerBar (8) indicates

the amount of power being used from the generator. Each section is approximately 12.5%.

Economy Switch

The economy switch has 3 modes of operation:

• Economy: The quietest mode and best

when running appliances or equipment that

are resistive loads (non-motor starting),

(example: TV, video game, light, radio).

• Standard: Best when running a both inductive (motor-starting loads) and resistive

(non-motor starting loads), especially when

these loads are turning on and off (example: RV, air conditioner, hairdryer).

• Turbo: Best when running inductive loads

(appliances or equipment with motor-starting) that are continually running (examples:

drill, blender, saw).

Generator Status Lights

See Figure 2-6.

• Overheat LED (red): Illuminates when unit

temperatures exceed normal operating

conditions (1). The ready LED will turn off

and the inverter will cut power to the outlets. Check for airflow obstructions at front

and rear panels. The engine will remain

running to cool the unit with the overheat

LED illuminated. Once the unit has reached

normal operating temperatures, the overheat LED will turn off. The reset button

must then be pressed for 1 second and

released to clear the fault and restore output power.

• Low Oil Level LED (orange): Illuminates

when oil level is below safe operating level.

Engine shuts down (2).

• Ready LED (green): Indicates output from

generator (3) (unless there is a low oil or

overload condition).

• Overload LED (red): Indicates system

overload (4). During motor starting it is normal for the overload LED to illuminate for a

few seconds. If LED stays illuminated and

the ready LED turns off, the engine will continue to run without output power. Remove

all applied loads and determine if attached

devices exceed recommended output

power. Review for any faulty or shorted

connections. Press and hold the reset button for 3 seconds and release. The red

overload LED should turnoff. Loads can be

re-applied once the green ready LED illuminates. If the red LED returns, contact an

IASD.

Run Time Display

See Figure 2-6. At startup the Run Time Display (7) shows the total engine hours of the

unit, then transitions to show the Run Time

Remaining.

6 Owner’s Manual for Portable Generator

Page 9

Figure 2-6. Status Indicators

003040

6

5

1

3

7

4

2 8

001792

Fuel Sensor and Fuel Gauge

See Figure 2-6. The fuel sensor (5) and gas

gauge (6) indicate fuel remaining in the internal fuel tank. The Run Time Clock displays the

amount of run time remaining for the current

fuel level and applied load.

NOTE: The run time clock will update if load is

changed to reflect different fuel consumption.

Add Engine Oil

CAUTION

Engine damage. Verify proper type and quantity of

engine oil prior to starting engine. Failure to do so

could result in engine damage.

NOTE: The generator is shipped without oil in

the engine. Add oil slowly and verify oil level

often during filling process to ensure overfilling

does not occur.

1. Place generator on a level surface.

2. Clean area around oil fill and oil drain plug.

3. Remove oil fill cap and wipe dipstick clean.

See Figure 2-7.

(000135)

Remove Contents from Carton

1. Open carton completely by cutting each

corner from top to bottom.

2. Remove and verify carton contents prior to

assembly. Carton contents should contain

the following:

TABLE 3. Accessories

Item Qty.

Main Unit 1

Owner’s Manual 1

SAE 30 Oil 1

Oil Funnel 1

Product Registration Card 3

Service Warranty 1

Emissions Warranty 1

3. Call Generac Customer Service 1-888GENERAC (1-888-436-3722) with the unit

model and serial number for any missing

carton contents.

4. Record model, serial number, and date of

purchase on front cover of this manual.

000804

Figure 2-7. Remove Dipstick

4. Screw funnel into oil fill opening. Add recommended engine oil as necessary. Climate determines proper engine oil

viscosity. See chart to select correct viscosity.

NOTE: Use petroleum based oil (supplied) for

engine break-in before using synthetic oil.

SAE 30

10W-30

Synthetic 5W-30

000399

5. To check oil level, remove funnel and

insert dipstick into oil filler neck without

screwing it in. See Figure 2-8.

.

Figure 2-8. Safe Operating Range

Owner’s Manual for Portable Generator 7

Page 10

6. Remove dipstick and verify oil level is

(000105)

DANGER

Explosion and Fire. Fuel and vapors are

extremely flammable and explosive. Add fuel

in a well ventilated area. Keep fire and spark

away. Failure to do so will result in death

or serious injury.

(000166b)

Explosion and Fire. Do not overfill fuel tank. Fill to

1/2 inch from top of tank to allow for fuel expansion.

Overfilling may cause fuel to spill onto engine causing

fire or explosion, which will result in death or

serious injury.

001112

000820

within safe operating range.

NOTE: Verify oil level often during filling process to ensure overfilling does not occur.

7. Install oil fill cap/dipstick and hand-tighten.

Fuel

DANGER

Fuel requirements are as follows:

• Clean, fresh, unleaded gasoline.

• Minimum rating of 87 octane/87 AKI (91

RON).

• Up to 10% ethanol (gasohol) is acceptable.

• DO NOT use E85.

• DO NOT use a gas oil mix.

• DO NOT modify engine to run on alternate

fuels. Stabilize fuel prior to storage.

1. Verify unit is OFF and cooled entirely prior

to fueling.

2. Place unit on level ground in a well venti-

lated area.

3. Clean area around fuel cap and turn vent

on fuel cap to ON. See Figure 2-9.

Figure 2-10. Internal Fuel Tank Level

NOTE: Allow spilled fuel to evaporate before

starting unit.

IMPORTANT NOTE: It is important to prevent gum deposits from forming in fuel

system parts such as the carburetor, fuel

hose or tank during storage. Alcoholblended fuels (called gasohol, ethanol or

methanol) can attract moisture, which

leads to separation and formation of acids

during storage. Acidic gas can damage the

fuel system of an engine while in storage.

To avoid engine problems, the fuel system

should be emptied before storage of 30

days or longer. See the Storage section.

Never use engine or carburetor cleaner

products in the fuel tank as permanent

damage may occur.

Figure 2-9. Fuel Cap

4. Turn cap slowly to remove.

5. Slowly add recommended fuel. DO NOT

overfill.

— Fill to red insert inside filler neck. See

Figure 2-10.

6. Install fuel cap.

7. Turn vent on fuel cap to OFF for transpor-

tation and storage.

8 Owner’s Manual for Portable Generator

Page 11

Section 3 Operation

(000179b)

DANGER

Asphyxiation. The exhaust system must be properly

maintained. Do not alter or modify the exhaust system

as to render it unsafe or make it noncompliant with

local codes and/or standards. Failure to do so will

result in death or serious injury.

WARNING

(000118a)

Risk of fire. Do not use generator without

spark arrestor installed. Failure to do so

could result in death or serious injury.

(000178a)

Asphyxiation. Always use a battery operated carbon

monoxide alarm indoors and installed according to

the manufacturer’s instructions. Failure to do so could

result in death or serious injury.

WARNING

(000110)

WARNING

Risk of Fire. Hot surfaces could ignite

combustibles, resulting in fire. Fire could

result in death or serious injury.

(000108)

WARNING

Hot Surfaces. When operating machine, do not

touch hot surfaces. Keep machine away from

combustibles during use. Hot surfaces could

result in severe burns or fire.

(000136)

CAUTION

Equipment and property damage. Disconnect electrical

loads prior to starting or stopping unit. Failure to do so

could result in equipment and property damage.

Operation and Use Questions

Call Generac customer service at 1-888-GENERAC (1-888-436-3722) with questions or

concerns about equipment operation and

maintenance.

Before Starting Engine

1. Verify engine oil level is correct.

2. Verify fuel level is correct.

3. Verify unit is secure on level ground, with

proper clearance and is in a well ventilated

area.

Prepare Generator for Use

Asphyxiation. Running engines produce

carbon monoxide, a colorless, odorless,

poisonous gas. Carbon monoxide, if not

avoided, will result in death or serious injury.

Owner’s Manual for Portable Generator 9

DANGER

(000103)

Grounding the Generator When Used as a Portable

The generator is equipped with a terminal for

the connection of a grounding electrode system. Article 250.34 (A) does not require the

frame of the generator to be connected to a

grounding electrode system when the generator only supplies power to cord and plug connected equipment through the receptacles on

the generator.

When the generator supplies power to a 3pole manual transfer switch or distribution

panel boards for temporary power, a grounding electrode system shall be installed and

connected to the grounding electrode terminal

on the generator. See NEC 250.30, 250.34

and 250.52 for clarification.

See Figure 3-1.

• Neutral Bonded to Frame

000808

Figure 3-1. Grounding the Generator

Know Generator Limits

Overloading a generator can result in damage

to the generator and connected electrical

devices. Observe the following to prevent

overload:

• Add up the total wattage of all electrical

devices to be connected at one time. This

total should NOT be greater than the generator's wattage capacity.

• The rated wattage of lights can be taken

from light bulbs. The rated wattage of tools,

appliances, and motors can be found on a

data label or decal affixed to the device.

• If the appliance, tool, or motor does not

give wattage, multiply volts times ampere

rating to determine watts (volts x amps =

watts).

• Some electric motors, such as induction

types, require about three times more watts

of power for starting than for running. This

surge of power lasts only a few seconds

when starting such motors. Make sure to

allow for high starting wattage when selecting electrical devices to connect to the generator:

1. Figure the watts needed to start the largest

motor.

Page 12

2. Add to that figure the running watts of all

(000183)

WARNING

Recoil Hazard. Recoil could retract unexpectedly.

Kickback could result in death or serious injury.

(000136)

CAUTION

Equipment and property damage. Disconnect electrical

loads prior to starting or stopping unit. Failure to do so

could result in equipment and property damage.

other connected loads.

Wattage Reference Guide is provided to assist

in determining how many items the generator

can operate at one time.

NOTE: All figures are approximate. See data

label on appliance for wattage requirements.

Wattage Reference Guide

Device Running

*Air Conditioner (12,000 Btu) 1700

*Air Conditioner (24,000 Btu) 3800

*Air Conditioner (40,000 Btu) 6000

Battery Charger (20 Amp) 500

Belt Sander (3") 1000

Chain Saw 1200

Circular Saw (6-1/2") 800 to 1000

*Clothes Dryer (Electric) 5750

*Clothes Dryer (Gas) 700

*Clothes Washer 1150

Coffee Maker 1750

*Compressor (1 HP) 2000

*Compressor (3/4 HP) 1800

*Compressor (1/2 HP) 1400

Curling Iron 700

*Dehumidifier 650

Disc Sander (9") 1200

Edge Trimmer 500

Electric Blanket 400

Electric Nail Gun 1200

Electric Range (per element) 1500

Electric Skillet 1250

*Freezer 700

*Furnace Fan (3/5 HP) 875

*Garage Door Opener 500 to 750

Hair Dryer 1200

Hand Drill 250 to 1100

Hedge Trimmer 450

Impact Wrench 500

Iron 1200

*Jet Pump 800

Lawn Mower 1200

Light Bulb 100

Microwave Oven 700 to 1000

*Milk Cooler 1100

Oil Burner on Furnace 300

Watts

Oil Fired Space Heater (140,000

Btu)

Oil Fired Space Heater (85,000 Btu) 225

Oil Fired Space Heater (30,000 Btu) 150

*Paint Sprayer, Airless (1/3 HP) 600

Paint Sprayer, Airless (hand-held) 150

Radio 50 to 200

*Refrigerator 700

Slow Cooker 200

*Submersible Pump (1-1/2 HP) 2800

*Submersible Pump (1 HP) 2000

*Submersible Pump (1/2 HP) 1500

*Sump Pump 800 to 1050

*Table Saw (10") 1750 to 2000

Television 200 to 500

Toaster 1000 to 1650

Weed Trimmer 500

* Allow 3 times the listed watts for starting these

devices.

400

Transporting/Tipping of the Unit

Do not store or transport the unit at an angle

greater than 15 degrees.

Starting Pull Start Engines

1. Turn fuel cap vent ON. See Figure 2-9.

2. See Figure 3-2. Rotate the PowerDial to

START (1).

3. Switch Economy switch to TURBO.

4. Firmly grasp recoil handle and pull slowly

until increased resistance is felt. Pull rapidly up and away.

10 Owner’s Manual for Portable Generator

Page 13

Figure 3-2. PowerDial Positions

000663

2

1

3

003039

A

B

(000136)

CAUTION

Equipment and property damage. Disconnect electrical

loads prior to starting or stopping unit. Failure to do so

could result in equipment and property damage.

(000136)

CAUTION

Equipment and property damage. Disconnect electrical

loads prior to starting or stopping unit. Failure to do so

could result in equipment and property damage.

5. See Figure 3-2. When engine starts, rotate

PowerDial to RUN (2). Choke operation is

reduced as PowerDial is rotated towards

RUN. If engine falters, rotate PowerDial

counterclockwise to START (1) to increase

choke. When engine runs smoothly, rotate

back to RUN.

NOTE: If engine fires, but does not continue to

run, rotate the PowerDial to START and

repeat starting instructions.

IMPORTANT NOTE: Do not overload generator or individual panel receptacles. See

Figure 3-3. If an overload occurs, the over-

load LED (A) will illuminate and AC output

ceases. Press and hold the reset button for

3 seconds to reset the fault condition while

the unit is running. Read Know Generator

Limits carefully.

.

Figure 3-3. Shutdown Fault

Generator Shut Down

1. Shut off all loads and unplug electrical

loads from generator panel receptacles.

2. Let engine run at no-load for several minutes to stabilize internal temperatures of

engine and generator.

3. See Figure 3-2 Rotate PowerDial clockwise to STOP (3).

4. Turn fuel cap OFF.

Restarting Hot Engines

1. See Figure 3-2. Turn PowerDial counterclockwise, from STOP until just past RUN.

This will open the fuel valve and permit

starting.

2. Firmly grasp recoil handle and pull slowly

until increased resistance is felt. Pull rapidly up and away.

3. Turn PowerDial clockwise to RUN.

Low Oil Level Shutdown System

The engine is equipped with a low oil level

sensor that shuts down the engine automatically when the oil level drops below a specified level to prevent engine damage. See

Figure 3-3 (B). The engine will not run until the

oil has been filled to the proper level.

If the engine shuts down and there is sufficient

fuel, check engine oil level.

Parallel Operation

For output power up to 3200W, two iQ2000

inverters can operate in parallel using Generac’s Smart Parallel Kit (optional). See the

Smart Parallel Kit Operator ’s Manual or contact an IASD.

NOTE: All connections to the parallel kit

should be made while both inverters are

turned off and all loads disconnected.

1. The economy switch for both units must be

matching and set to either standard or

turbo.

2. Make appropriate parallel connections to

the 120V duplex outlets on each iQ2000

inverter as outlined in the owner’s manual

supplied with the kit.

NOTE: Do not disconnect any parallel kit connections once the units are running.

3. Start both units per starting instructions.

Once the green output indicator illuminates, devices can be connected and

turned on using the parallel kit outlet.

4. Follow Generator Shut Down instructions.

NOTE: Load applied to the parallel kit is not to

exceed 3200 watts.

NOTE: Only use Generac approved parallel

kit.

Owner’s Manual for Portable Generator 11

Page 14

Parallel Reset Procedure

003594

003039

1

3 2

1. Turn OFF all loads applied to generators.

2. See Figure 3-4. Remove the 30A plug from

parallel kit. DO NOT unplug parallel kit

from generators.

.

Figure 3-4. Remove 30A Plug

3. See Figure 3-5. Press and hold the Reset

button (1) on unit A for three (3) seconds,

then release.

4. See Figure 3-5. Wait for the red Overload

light (2) to turn OFF and the green Ready

light (3) to turn ON.

.

Figure 3-5. Reset Button and Status Lights

5. See Figure 3-5. Repeat steps 3 and 4 for

unit B.

6. Insert 30A plug into parallel kit.

7. Apply loads. After each load is applied,

observe power usage displayed on Powerbar. DO NOT exceed 100%.

NOTE: See Figure 3-5. If red Overload light (2)

persists after five (5) attempts, contact Generac customer service at 1-888-GENERAC (1888-436-3722).

12 Owner’s Manual for Portable Generator

Page 15

Section 4 Maintenance and Troubleshooting

(000142a)

Personal injury. Do not insert any object through the

air cooling slots. Generator can start at any time and

could result in death, serious injury, and unit damage.

Maintenance

Regular maintenance will improve performance and extend engine/equipment life.

Generac Power Systems, Inc. recommends

that all maintenance work be performed by an

Independent Authorized Service Dealer

(IASD). Regular maintenance, replacement,

or repair of the emissions control devices and

systems may be performed by any repair shop

or person of the owner’s choosing. To obtain

emissions control warranty service free of

charge, the work must be performed by an

IASD. See the emissions warranty.

NOTE: Call 1-888-GENERAC (1-888-436-

3722) with questions about component

replacement.

Maintenance Schedule

Follow maintenance schedule intervals,

whichever occurs first according to use.

NOTE: Adverse conditions will require more

frequent service.

NOTE: All required service and adjustments

should be each season as detailed in the following chart.

At Each Use

Check engine oil level

Every 50 Hours

Clean/Replace Air Filter**

Every 100 Hours or Every Season*

Change oil ǂ

Replace Spark Plug

Clean Spark Arrestor

Valve Clearance Adjustment

Every 200 Hours or Every Season

Inspect/clean air cleaner filter**

Replace Fuel Filter +

ǂ Change oil after first 30 hours of operation,

then every season.

+ To be performed by IASD

* Change oil every month when operating

under heavy load or in high temperatures.

** Clean more often under dirty or dusty oper-

ating conditions. Replace air filter parts if

they cannot be adequately cleaned.

*** Check valve clearance and adjust if neces-

sary after first 50 hours of operation and

every 100 hours thereafter.

Preventive Maintenance

Dirt or debris can cause improper operation

and equipment damage. Clean generator

daily or before each use. Keep area around

and behind muffler free from combustible

debris. Inspect all cooling air openings on

generator.

WARNING

• Use a damp cloth to wipe exterior surfaces

clean.

• Use a soft bristle brush to loosen caked on

dirt, oil, etc.

• Use a vacuum to pick up loose dirt and

debris.

• Low pressure air (not to exceed 25 psi)

may be used to blow away dirt. Inspect

cooling air slots and openings on generator.

These openings must be kept clean and

unobstructed.

NOTE: DO NOT use a garden hose to clean

generator. Water can enter engine fuel system

and cause problems. If water enters generator

through cooling air slots, some water will be

retained in voids and crevices of rotor and stator winding insulation. Water and dirt buildup

on generator internal windings will decrease

insulation resistance of windings.

Engine Maintenance

WARNING

Accidental start-up. Disconnect spark plug wires when

working on unit. Failure to do so could result in death

or serious injury.

Engine Oil Recommendations

To maintain the product warranty, the engine oil

should be serviced in accordance with the recommendations of this manual. For your convenience, maintenance kits designed and intended

for use on this product are available from the

manufacturer that include engine oil, oil filter, air

filter, spark plug(s), a shop towel and funnel.

These kits can be obtained from an Independent

Authorized Service Dealer (IASD).

(000141)

Owner’s Manual for Portable Generator 13

Page 16

.

(000139)

WARNING

Risk of burns. Allow engine to cool before

draining oil or coolant. Failure to do so could

result in death or serious injury.

001792

SAE 30

10W-30

Synthetic 5W-30

000399

Inspect Engine Oil Level

Inspect engine oil level prior to each use, or

every 8 hours of operation.

1. Place generator on a level surface.

2. Clean area around oil fill, and oil drain

plug.

3. Remove oil fill cap and wipe dipstick clean.

See Figure 4-1.

7. Replace oil fill cap and hand-tighten.

NOTE: Some units have more than one oil fill

location. It is only necessary to use one oil fill

point.

Change Engine Oil

WARNING

Accidental start-up. Disconnect spark plug wires when

working on unit. Failure to do so could result in death

or serious injury.

When using generator under extreme, dirty,

dusty conditions, or in extremely hot weather,

change oil more frequently.

NOTE: Don’t pollute. Conserve resources.

Return used oil to collection centers.

Change oil while engine is still warm from running, as follows:

1. Place generator on a level surface.

2. Disconnect the spark plug wire from the

spark plug and place the wire where it

cannot contact spark plug.

3. Clean area around oil fill and oil drain plug.

4. Remove oil fill cap and wipe dipstick clean.

Screw funnel into oil fill opening. See Fig-

ure 4-3.

(000141)

000804

Figure 4-1. Engine Oil Fill

4. To check oil level, insert dipstick into oil

filler neck without screwing it in. See Fig-

ure 4-2.

Figure 4-3. Oil Fill Opening With Funnel

5. Tip unit and drain oil completely into a suitable container.

6. Once oil is sufficiently drained from unit, tip

unit back to a level position.

7. Add recommended engine oil as necessary.

8. To check oil level, remove funnel and

insert dipstick into oil filler neck without

screwing it in. See Figure 4-2.

9. Remove dipstick and verify oil level is

within safe operating range.

NOTE: Verify oil level often during filling process to ensure overfilling does not occur.

10. Replace oil fill cap and hand-tighten.

Figure 4-2. Safe Operating Range

5. Remove dipstick and verify oil level is

within safe operating range.

6. Add recommended engine oil as necessary.

NOTE: Verify oil level often during filling process to ensure overfilling does not occur.

14 Owner’s Manual for Portable Generator

11. Wipe up any spilled oil.

12. Properly dispose of oil in accordance with

all applicable regulations.

000822

Page 17

Air Filter

000666

ABA

C

D

000211

000668

A

B

C

D

Engine will not run properly and may be damaged if run with a dirty air filter. Service air filter more frequently in dirty or dusty conditions.

To service air filter:

1. See Figure 4-4. Turn knob and remove

service door (A).

2. Unscrew bolt (B) and remove air filter

cover (C).

3. Wash filter (D) in soapy water. Squeeze

dry in clean cloth (DO NOT TWIST).

4. Clean air filter cover before re-installing it.

NOTE: To order a new air filter, contact the

nearest authorized service center at 1-888GENERAC (1-888-436-3722).

Figure 4-4. Air Filter Assembly

Service Spark Plug

To service spark plug:

1. Clean area around spark plug.

2. Remove and inspect spark plug.

3. Inspect electrode gap with wire feeler

gauge and reset spark plug gap to 0.6 -

0.7mm (0.024 - 0.028 in). See Figure 4-5.

Inspect Muffler and Spark Arrester

NOTE: It is a violation of California Public

Resource Code, Section 4442, to use or operate the engine on any forest-covered, brushcovered, or grass-covered land unless the

exhaust system is equipped with a spark

arrester, as defined in Section 4442, maintained in effective working order. Other states

or federal jurisdictions may have similar laws.

Contact original equipment manufacturer,

retailer, or dealer to obtain a spark arrester

designed for exhaust system installed on this

engine.

NOTE: Use ONLY original equipment replacement parts.

Inspect muffler for cracks, corrosion, or other

damage. Remove spark arrester, if equipped,

inspect for damage or carbon blockage.

Replace parts as required.

Inspect Spark Arrester Screen

Hot Surfaces. When operating machine, do not

touch hot surfaces. Keep machine away from

combustibles during use. Hot surfaces could

result in severe burns or fire.

WARNING

(000108)

Clean Spark Arrestor Screen (50

State)

The engine exhaust muffler has a spark arrestor screen. Inspect and clean the screen every

100 hours of operation or once each year,

whichever comes first.

To service spark arrestor:

1. See Figure 4-6. Remove the clamp (A) to

remove retainer (B).

2. Slide spark arrestor screens (C) out from

the muffler outlet tube (D).

3. Inspect screens and replace if torn, perforated or otherwise damaged. Do NOT use

a defective screen. If screen is not damaged, clean with a commercial solvent.

4. Replace the screens, and retainer, and

secure with clamp.

Figure 4-5. Spark Plug

NOTE: Replace spark plug if electrodes are

pitted, burned or porcelain is cracked. Use

ONLY recommended replacement plug. See

Specifications.

4. Install spark plug finger tight, and tighten

an additional 3/8 to 1/2 turn using spark

plug wrench.

Owner’s Manual for Portable Generator 15

Figure 4-6. Spark Arrestor Screen

Page 18

Val ve Cle aranc e

(000181)

WARNING

Vision Loss. Eye protection is required to avoid

spray from spark plug hole when cranking engine.

Failure to do so could result in vision loss.

Important: Please contact an Independent

Authorized Service Dealer for service assistance. Proper valve clearance is essential for

prolonging the life of the engine.

Check valve clearance after the first fifty-hours

of operation. Adjust as necessary.

• Intake — 0.10 ± 0.02mm (cold), (0.004" ±

0.001" inches)

• Exhaust — 0.10 ± 0.02mm (cold) (0.004" ±

0.001" inches)

Storage

General

Explosion and Fire. Fuel and vapors are extremely

flammable and explosive. Store fuel in a well

ventilated area. Keep fire and spark away. Failure

to do so will result in death or serious injury.

Risk of Fire. Verify machine has properly

cooled before installing cover and storing

machine. Hot surfaces could result in fire.

It is recommended to start and run the generator for 30 minutes, every 30 days. If this is not

possible, refer to the following list to prepare

unit for storage.

• DO NOT place a storage cover on a hot

generator. Allow unit to cool to room temperature before storage.

• DO NOT store fuel from one season to

another unless properly treated.

• Replace fuel container if rust is present.

Rust in fuel will cause fuel system problems.

• Cover unit with a suitable protective, mois-

ture resistant cover.

• Store unit in a clean, dry area.

• Always store generator and fuel away from

heat and ignition sources.

DANGER

(000143)

WARNING

(000109)

2. Remove spark plug.

3. Pour tablespoon (5-10cc) of clean engine

oil or spray a suitable fogging agent into

cylinder.

4. Pull starter recoil several times to distribute oil in cylinder.

5. Install spark plug.

6. Pull recoil slowly until resistance is felt.

This will close valves so moisture cannot

enter engine cylinder. Gently release

recoil.

Change Oil

Change engine oil before storage. See,

Change Engine Oil.

Prepare Fuel System/Engine for

Storage

Fuel stored over 30 days can go bad and

damage fuel system components. Keep fuel

fresh, use fuel stabilizer.

If fuel stabilizer is added to fuel system, prepare and run engine for long term storage.

Run engine for 10-15 minutes to circulate stabilizer throughout fuel system. Adequately

prepared fuel can be stored up to 24 months.

NOTE: If fuel has not been treated with fuel

stabilizer, it must be drained into an approved

container. Run engine until it stops from lack

of fuel. Use of fuel stabilizer in fuel storage

container is recommended to keep fuel fresh.

1. Change engine oil.

16 Owner’s Manual for Portable Generator

Page 19

Troubleshooting

PROBLEM CAUSE CORRECTION

Engine won't start. 1. PowerDial turned off.

2. Out of fuel.

3. Defective spark plug.

4. Plugged fuel filter.

5. Defective or stuck PowerDial

assembly.

6. Incorrect engine oil level.

7. Defective ignition coil.

8. Fuel cap vent OFF.

9. Carb is flooded.

10. Throttle plate closed.

1. Turn on PowerDial.

2. Fill fuel tank.

3. Replace spark plug.

4. Contact IASD.

5. Contact IASD.

6. Check/fill engine oil.

7. Contact IASD.

8. Turn fuel cap vent ON.

9. Drain carb.

10. Open throttle plate (push

toward back of unit).

Engine starts, then shuts

down.

Engine will not start; or

starts and runs rough.*

No AC output. 1. Generator is overloaded.

Fuel leaks from drain

hoses.

* Engine speed increases and decreases — This is normal as generator starts up and loads vary.

1. Out of fuel.

2. Incorrect engine oil level.

3. Contaminated fuel.

4. Defective low oil level switch.

5. Fuel cap vent OFF.

1. Choke is stuck or left on.

2. Dirty or clogged air filter.

3. Defective or dirty spark plug.

4. Dirty fuel filter.

5. Dirty or gummed up carburettor.

6. Unit not warmed up.

7. Fuel cap vent OFF.

2. Inverter module is overheated.

3. Short circuit in electrical

device.

4. Defective inverter assembly.

1. Carburetor drain in bowl is not

closed.

1. Fill fuel tank.

2. Check engine oil level.

3. Contact IASD.

4. Contact IASD.

5. Turn fuel cap vent ON.

1. Turn choke off.

2. Clean or replace air filter.

3. Replace spark plug.

4. Replace fuel and fuel filter.

5. Clean carburetor.

6. Gradually adjust PowerDial

and reduce choke until engine

runs smoothly in RUN position.

7. Turn fuel cap vent ON.

1. Disconnect all loads. Shut

down generator to reset module. Reduce loads, restart

generator.

2. Verify service door is ON. Let

cool 15 minutes by running

engine without AC output.

Press and hold Reset button

on control panel, restart generator.

3. Verify condition of extension

cords and items being powered. Press and hold Reset

button on control panel.

4. Contact IASD.

1. Turn valve clockwise to close.

Owner’s Manual for Portable Generator 17

Page 20

Part No. 10000011496 Rev. B 12/15/2017 ©2017 Generac Power Systems, Inc. All rights reserved

Specifications are subject to change without notice.

No reproduction allowed in any form without prior

written consent from Generac Power Systems, Inc.

Generac Power Systems, Inc.

S45 W29290 Hwy. 59

1-888-GENERAC (1-888-436-3722)

Waukesha, WI 53189

www.generac.com

Page 21

Generador portátil iQ2000

000853

ADVERTENCIA

(000209b)

Fallecimiento. Este producto no se ha diseñado

para que se utilice en aplicaciones de apoyo

vital crítico. En caso de hacerlo, podría

provocar la muerte o lesiones graves.

Manual del usuario

MODELO: __________________________

SERIE: ____________________________

FECHA DE LA COMPRA: _____________

Registre su producto Generac en:

WWW.GENERAC.COM

1-888-GENERAC

(1-888-436-3722)

GUARDE ESTE MANUAL PARA PODER CONSUL TARLO EN EL FUTURO

Page 22

Índice de contenidos

Sección 1 Introducción

y seguridad .................................... 1

Introducción .................................... 1

Normas de seguridad ...................... 1

Símbolos de seguridad

y significados ................................... 1

Peligros derivados de las emisiones

de escape y la ubicación ................. 2

Peligros eléctricos ...........................3

Peligros de incendio ........................ 3

Índice de normas ............................. 3

Sección 2 Información general y

configuración ................................4

Conozca su generador .................... 5

Emisiones ........................................ 5

Enchufes de conexión ..................... 6

Selector de potencia ....................... 6

Barra de potencia ............................ 6

Interruptor de ahorro ....................... 6

Luces de estado del generador ....... 6

Pantalla de tiempo de

funcionamiento ................................ 7

Sensor de combustible e indicador

de combustible ................................7

Sacar el contenido de la caja .......... 7

Añadir aceite de motor .................... 7

Combustible .................................... 8

Sección 3 Funcionamiento ...........9

Preguntas sobre uso

y funcionamiento .............................9

Antes de arrancar el motor ..............9

Preparación del generador

para su uso ......................................9

Conexión a tierra del generador

cuando se utiliza como aparato

portátil ..............................................9

Conozca los límites del generador ..9

Transporte o inclinación de

la unidad ........................................10

Arranque de motores con el

tirador de arranque ........................11

Volver a arrancar motores

calientes ........................................11

Sistema de cierre por nivel bajo

de aceite ........................................12

Funcionamiento en paralelo ..........12

Procedimiento de reinicio

paralelo ..........................................12

Sección 4 Mantenimiento

y solución de problemas ............13

Mantenimiento ...............................13

Programa de mantenimiento .........13

Mantenimiento preventivo .............13

Mantenimiento del motor ...............14

Almacenamiento ............................16

Solución de problemas ..................18

El funcionamiento, reparación y mantenimiento de

este equipo puede exponerlo a productos químicos

entre los que se incluyen gases de escape del motor,

monóxido de carbono, ftalatos y plomo, los cuales

son considerados por el Estado de California como

causantes de cáncer y malformaciones congénitas y

otros daños reproductivos. Para minimizar los efectos

de la exposición a tales sustancias, evite respirar

gases de escape, no deje que el motor funcione al

ralentí excepto si fuera necesario, realice las tareas

de mantenimiento del equipo en un área bien ventilada

y lleve guantes o lávese las manos con frecuencia

cuando realice tareas de mantenimiento en el equipo.

Si desea obtener más información, vaya a

www.P65Warnings.ca.gov.

ADVERTENCIA

(000393)

Page 23

Sección 1 Introducción y seguridad

(000001)

PELIGRO

Indica una situación peligrosa que, si no se evita, ocasionará la

muerte o lesiones graves.

(000002)

ADVERTENCIA

Indica una situación peligrosa que, si no se evita, podría

ocasionar la muerte o lesiones graves.

(000003)

PRECAUCIÓN

Indica una situación de riesgo que, si no se evita, puede

producir lesiones leves o moderadas.

000657

Asfixia. Los motores funcionando producen

monóxido de carbono, un gas incoloro, inodoro, y

venenoso. El monóxido de carbono, si no se evita,

ocasionará la muerte o lesiones graves.

(000103)

PELIGRO

Introducción

Gracias por haber adquirido un producto de

Generac Power Systems Inc. Esta unidad se

ha diseñado para proporcionar un

funcionamiento eficiente, de alto rendimiento

y con una vida útil larga si se conserva

adecuadamente.

ADVERTENCIA

Consulte el manual. Lea y comprenda completamente

el manual antes de usar el producto. No comprender

completamente el manual puede provocar la muerte o

lesiones graves.

(000100a)

Si no entendiera alguno de los apartados de

este manual, póngase en contacto con el

servicio técnico independiente autorizado más

cercano, o con el servicio de atención al

cliente de Generac llamando al 1-888GENERAC (1-888-436-3722), o visitando

www.generac.com para plantear cualquier

pregunta o duda que tenga.

El propietario es responsable del

mantenimiento adecuado y del uso seguro del

equipo. Antes de poner en funcionamiento,

revisar o guardar el generador:

• Revise atentamente todas las advertencias

que aparecen en este manual y en el

producto.

• Familiarícese con este manual y con la

unidad antes de utilizarla.

• Consulte Introducción y seguridad para

obtener instrucciones sobre los

procedimientos de montaje. Siga

estrictamente las instrucciones.

Guarde estas instrucciones para consultarlas

en el futuro. Entregue SIEMPRE este manual

a cualquier persona que utilice la máquina.

La información que aparece en este manual es

precisa y está basada en productos fabricados

en el momento en el que se editó esta

publicación. El fabricante se reserva el derecho

de hacer las actualizaciones técnicas, las

correcciones y las revisiones de los productos

que considere necesarias sin previo aviso.

Normas de seguridad

El fabricante no puede prever todas las

posibles circunstancias que pueden suponer

un peligro. Por tanto, las advertencias de este

manual, y de las etiquetas y los adhesivos

pegados en la unidad no incluyen todos los

peligros. Si se utiliza un procedimiento, método

de trabajo o técnica de funcionamiento no

recomendados específicamente por el

fabricante, compruebe que sean seguros para

otros usuarios. También asegúrese de que el

procedimiento, método de trabajo o técnica

operativa utilizados no disminuyan la seguridad

del generador.

En esta publicación y en las etiquetas y

adhesivos pegados en el generador, los

bloques PELIGRO, ADVERTENCIA,

PRECAUCIÓN y NOTA se utilizan para alertar

al personal sobre instrucciones especiales

relacionadas con un funcionamiento que

puede ser peligroso si se realiza de manera

incorrecta o imprudente. Léalos atentamente y

respete sus instrucciones. Sus definiciones son

las siguientes:

NOTA: Las notas incluyen información

adicional importante para un procedimiento y

se incluyen en el texto normal de este manual.

Estas advertencias de seguridad no pueden

eliminar los peligros que indican. Para evitar

accidentes, es importante el sentido común y

el seguimiento estricto de las instrucciones

especiales cuando se realice la acción o la

operación de mantenimiento.

Símbolos de seguridad y significados

Usar un generador en interiores LO PUEDE MATAR EN

MINUTOS.

Los gases de escape del generador contienen monóxido

de carbono. Este es un veneno que no se puede ver u oler.

NUNCA lo use dentro de una

casa o garaje, AUNQUE la

puerta y las ventanas se

encuentran abiertas.

¡PELIGRO!

Use únicamente en

EXTERIORES, y alejado

de ventanas, puertas y

ventilaciones.

Manual del usuario del generador portátil 1

Page 24

• Si empieza a sentirse enfermo, mareado o

(000179b)

PELIGRO

Asfixia. El sistema de escape debe mantenerse

adecuadamente. No altere ni modifique el sistema

de escape ya que podría hacer que su funcionamiento

sea inseguro o que no cumpla con los códigos

y/o normativas locales. En caso de hacerlo, podría

provocarse la muerte o lesiones graves.

(000104)

PELIGRO

Electrocución. Si no se evita el contacto del agua

con una fuente de alimentación, ocasionará la

muerte o lesiones graves.

(000116)

Electrocución. APAGUE el suministro de alimentación

de emergencia y de la red eléctrica antes de conectar

la fuente de alimentación y las líneas de carga.

En caso de no hacerlo, podría provocar la

muerte o lesiones graves.

PELIGRO

ADVERTENCIA

(000146)

Daños a los equipos y la propiedad. No altere la

construcción, instalación, o bloquee la ventilación

para el generador. No hacer esto puede provocar el

funcionamiento inseguro o dañar el generador.

(000178a)

Asfixia. En interiores, utilice siempre una alarma

de monóxido de carbono alimentada por pilas e

instalada de acuerdo con las instrucciones de los

fabricantes. En caso de no hacerlo, podría

provocarse la muerte o lesiones graves.

ADVERTENCIA

(000250)

Daños a los equipos y a la propiedad. No use la unidad

sobre superficies desparejas, o en zonas con exceso de

humedad, suciedad, polvo, o vapores corrosivos. Hacerlo

puede ocasionar la muerte, lesiones graves y daños al

equipo.

ADVERTENCIA

Piezas en movimiento. Mantenga la ropa, cabello,

y extremidades alejados de las piezas en

movimiento. No hacerlo puede ocasionar la

muerte o lesiones graves.

(000111)

ADVERTENCIA

(000108)

ADVERTENCIA

Superfcies calientes. Al usar la máquina, no toque

las superfcies calientes. Mantenga la máquina

alejada de los combustibles durante el uso. Las

superfcies calientes pueden ocasionar quemaduras

graves o incendio.

(000142a)

ADVERTENCIA

Lesiones personales. No inserte objetos a través de las ranuras

de enfriamiento de la unidad. El generador puede arrancar en

cualquier momento y provocar la muerte, lesiones graves y

daños en la unidad.

ADVERTENCIA

Riesgo de lesión. No opere ni proporcione servicio a esta

máquina si no está completamente alerta. La fatiga puede

desvirtuar la capacidad para proporcionar servicio a este

equipo y puede ocasionar la muerte o

lesiones graves.

(000215)

ADVERTENCIA

Lesiones o daños al equipo. No use el generador

como un escalón. Hacerlo puede ocasionar caídas,

piezas dañadas, funcionamiento inseguro del

equipo, la muerte o lesiones graves.

(000216)

Asfixia. Los motores funcionando producen

monóxido de carbono, un gas incoloro, inodoro, y

venenoso. El monóxido de carbono, si no se evita,

ocasionará la muerte o lesiones graves.

(000103)

PELIGRO

(000179b)

PELIGRO

Asfixia. El sistema de escape debe mantenerse

adecuadamente. No altere ni modifique el sistema

de escape ya que podría hacer que su funcionamiento

sea inseguro o que no cumpla con los códigos

y/o normativas locales. En caso de hacerlo, podría

provocarse la muerte o lesiones graves.

ADVERTENCIA

(000146)

Daños a los equipos y la propiedad. No altere la

construcción, instalación, o bloquee la ventilación

para el generador. No hacer esto puede provocar el

funcionamiento inseguro o dañar el generador.

(000178a)

Asfixia. En interiores, utilice siempre una alarma

de monóxido de carbono alimentada por pilas e

instalada de acuerdo con las instrucciones de los

fabricantes. En caso de no hacerlo, podría

provocarse la muerte o lesiones graves.

ADVERTENCIA

débil después de que el generador haya

estado funcionando, salga INMEDIATAMENTE para respirar aire fresco. Consulte

con un médico ya que podría haberse

intoxicado con monóxido de carbono.

• Por razones de seguridad, se recomienda

que el mantenimiento de este equipo sea

efectuado por un distribuidor autorizado

independiente. Revise el generador

periódicamente y póngase en contacto con

el servicio técnico más cercano para

conocer qué piezas deben repararse o

sustituirse.

• Coloque el sistema de escape del silenciador

lejos de la gente y de los edificios habitados.

• La distancia de colocación mínima del

generador es de cinco pies (1,5 metros) de

ventanas, puertas o aperturas de paredes

con la salida de gases del motor colocada

en el sentido contrario a los edificios

habitados y a la dirección del viento.

Peligros derivados de las emisiones de escape y la ubicación

2 Manual del usuario del generador portátil

• Si empieza a sentirse enfermo, mareado o

débil después de que el generador haya

estado funcionando, salga INMEDIATAMENTE para respirar aire fresco. Consulte

con un médico ya que podría haberse

intoxicado con monóxido de carbono.

Page 25

Peligros eléctricos

(000144)

PELIGRO

Electrocución. El contacto con cables, terminales y

conexiones peladas mientras el generador está

funcionando provocará la muerte o lesiones graves.

(000104)

PELIGRO

Electrocución. Si no se evita el contacto del agua

con una fuente de alimentación, ocasionará la

muerte o lesiones graves.

(000145)

PELIGRO

Electrocución. En caso de un accidente eléctrico, APAGUE

de inmediato la alimentación eléctrica. Use implementos no

conductores para liberar a la víctima del conductor. Aplique

primeros auxilios y obtenga ayuda médica. No hacerlo

ocasionará la muerte o lesiones graves.

(000166b)

PELIGRO

Explosión e incendio. No sobrepase el nivel del depósito de

combustible. Llene el depósito y deje sin llenar media pulgada

(127 mm) de la parte superior del mismo para que quede espacio

para la expansión del mismo. Si lo llena en exceso puede hacer que

el combustible se derrame en el motor provocando un incendio o

explosión, lo cual podría provocar la muerte o lesiones graves.

(000142a)

ADVERTENCIA

Lesiones personales. No inserte objetos a través de las ranuras

de enfriamiento de la unidad. El generador puede arrancar en

cualquier momento y provocar la muerte, lesiones graves y

daños en la unidad.

• El Código Eléctrico Nacional (NEC por sus

siglas en inglés) exige que la estructura y los

componentes conductores de electricidad

del generador estén correctamente

conectados a una toma de tierra aprobada.

Es posible que los códigos eléctricos locales

también exijan una conexión a tierra

adecuada del generador. Consulte con un

electricista local cuáles son los requisitos de

conexión a tierra de su zona.

• Utilice un interruptor de circuito por fallo en

la conexión a tierra en todas las zonas

húmedas o altamente conductoras (como

tarimas metálicas o estructuras de acero).

• Una vez que el generador se haya

arrancado en el exterior, conecte las

cargas eléctricos a los cables alargadores

del interior.

Peligros de incendio

Explosión e incendio. El combustible y los vapores son

extremadamente inflamables y explosivos. Añada

combustible en una zona bien ventilada. Mantenga alejados

el fuego y las chispas. No hacerlo puede ocasionar la muerte

o lesiones graves.

Explosión e incendio. Los vapores de LP son extremadamente

inflamables y explosivos. No use o almacene el cilindro de LP

en un edificio, garaje o zona confinada excepto según lo

autorizado por la norma NFPA 58 o B149.2 (en Canadá). No

hacerlo ocasionará la muerte o lesiones graves.

PELIGRO

(000105)

PELIGRO

(000199)

• No utilice el generador si los dispositivos

eléctricos conectados se sobrecalientan, si

se pierde la potencia eléctrica, si el motor o

el generador producen chispas o si se

detectan llamas o humo mientras la unidad

está funcionando.

• Tenga un extintor cerca del generador en

todo momento.

Índice de normas

1. Asociación nacional de protección contra

incendios (NFPA, por sus siglas en inglés)

70: El CÓDIGO ELÉCTRICO NACIONAL

(NEC por sus siglas en inglés) disponible

en www.nfpa.org

2. Asociación nacional de protección contra

incendios (NFPA, por sus siglas en inglés)

5000: CÓDIGO DE SEGURIDAD Y

CONSTRUCCIÓN DE EDIFICIOS

disponible en www.nfpa.org

3. Código de Construcción Internacional

disponible en www.iccsafe.org

4. Manual de Cableado Agrícola disponible

en www.rerc.org, Rural Electricity

Resource Council P.O. Box 309

Wilmington, OH 45177-0309

5. ASAE EP-364.2 Instalación y

mantenimiento de energía eléctrica de

emergencia en granjas disponible en

www.asabe.org, Sociedad Americana de

Ingenieros Agrícolas y Biológicos, 2950

Niles Road, St. Joseph, MI 49085

6. CSA C22.2 100-14 Motores y generadores

eléctricos para su uso e instalación

siguiendo las normativas del Código

eléctrico canadiense.

7. ANSI/PGMA G300 Seguridad y

rendimiento de generadores portátiles.

Asociación de fabricantes de generadores

portátiles, www.pgmaonline.com.

Esta lista no incluye todas las normas

aplicables. Consulte con la autoridad que

tenga jurisdicción (AHJ, por sus siglas en

inglés) si existe cualquier código local o

normativa que pueda ser de aplicación en su

jurisdicción.

PELIGRO

Riesgo de incendio. Deje que los derrames de

combustible se sequen completamente antes de

poner en marcha el motor. No hacerlo ocasionará

la muerte o lesiones graves.

Manual del usuario del generador portátil 3

(000174)

Page 26

Sección 2 Información general y configuración

17

14

15

12

18

16

13

20

7

10

3

1

2

8

6

9

54

11

000662

19

000581

000662

Figura 2-1. Funciones y controles

TABLA 1. Componentes del

generador

1 Salida de CA dúplex de 120 voltios

compatible con modo paralelo

2 Interruptor turbo/estándar/ahorro de energía

3 Barra de potencia

4 Ubicación de la conexión a tierra

5 Botón Restablecer

6 LED indicador de sobrecalentamiento (rojo)

7 LED indicador de sobrecarga (rojo)

8 LED indicador de nivel bajo de aceite

(naranja)

9 LED que indica Listo para cargar (verde)

10 Medidor de combustible

11 Pantalla de tiempo de funcionamiento

12 Supresor/Dispositivo antichispas

13 Tapón de combustible (con ventilación)

14 Cuerda de arranque

15 Asa de transporte

16 Selector de potencia

17 Puerta de mantenimiento

18 Entrada de aire

19 Ubicación de la placa de datos

20 Llenado del aceite

4 Manual del usuario del generador portátil

Figura 2-2. Panel de control

Figura 2-3. Ubicación de la placa de datos

000579

003039

Page 27

Conozca su generador

(000100a)

ADVERTENCIA

Consulte el manual. Lea y comprenda completamente

el manual antes de usar el producto. No comprender

completamente el manual puede provocar la muerte o

lesiones graves.

En la Web de Generac (www.generac.com)

puede encontrar manuales del usuario de

reemplazo.

Emisiones

La Agencia de Protección Ambiental (EPA) de

los EE. UU. (y la Junta de Recursos del Aire

de California [CARB] para los motores/

equipos certificados conforme a las normas

de California) requiere(n) que este motor/

equipo cumpla las normas para el escape y

las emisiones que se evaporan. Ubique en el

motor la etiqueta adhesiva sobre

cumplimiento de las normas referidas a

emisiones para determinar las normas

correspondientes. Para información sobre la

garantía de emisiones, consulte la garantía de

emisiones que se incluye. Es importante

seguir las especificaciones de mantenimiento

del manual para asegurar que el motor

cumpla las normas de emisiones aplicables

durante la vida útil del producto.

TABLA 2. Especificaciones del producto

Especificaciones del generador

Potencia nominal 1600 W

Potencia pico 2000 VA

Tensión de CA nominal 120V

Carga de CA nominal a 120V 13,3 Amps**

Frecuencia nominal 60 Hz

Medidas (largo x ancho x alto) mm/pulgadas 507,4 x 320,8 x 428 (20,0 x 12,6 x 16,9)

Peso de la unidad (Seco) 19,3 kg (46,2 lb)

** Intervalo de temperaturas de funcionamiento: -13 ºC (8 ºF) a 40 ºC (104 ºF). Durante el

funcionamiento con temperaturas superiores a 25º C (77º F), es posible que la potencia disminuya.

** La corriente y la potencia en vatios máximas están sujetas y limitadas por factores como el

contenido de BTu del combustible, la temperatura ambiente, la altitud, el estado del motor, etc.

La potencia máxima disminuye un 3,5% por cada 1.000 pies (304,8 metros) sobre del nivel del mar

y también disminuye un 1 % aproximadamente por cada 6º C (10º F) por encima de los 16º C

(60º F) de temperatura ambiente.

Especificaciones del motor

Tipo de motor Monocilíndrico, 4 ciclos de recorrido

Cilindrada 80 cc

Número de pieza de la bujía 0K91470141

Tipo de electrodos de la bujía NHSP LDE6RTC

Separación de los electrodos de la bujía

(mm/pulg)

Capacidad de combustible / Tipo 4,0 L (1,06 gal) / Sin plomo

Tipo de aceite

Capacidad de aceite 0,38 L (0,4 qt.)

Tiempo de funcionamiento a 25% de carga 7,7 horas

0,023-0,027 (0,6-0,7)

Añadir aceite de motor

Consulte

Manual del usuario del generador portátil 5

Page 28

Enchufes de conexión

000424

000663

2

1

3

Toma de corriente doble ICFT de

120 VCA

La salida de 120 voltios está protegida contra

sobrecargas mediante el control electrónico

del módulo del convertidor. Consulte la

Figura 2-4. Cada toma alimentará cargas

eléctricas de 120 Voltios CA, monofásicas, de

60 Hz que requieran una corriente de 1600

vatios (1,6 kW).

Interruptor de ahorro

El interruptor de ahorro tiene 3 modos de

funcionamiento: