Page 1

Manual Part No. 75239

DIAGNOSTIC REPAIR

MANUAL

Air-Cooled

Recreational Vehicle

Generators

Printed in I! A.

Page 2

FOREWORD

This DIAGNOSTIC REPAIR MANUAL has been prepared especially for the pur

pose of familiarizing service personnel with the operational analysis,

troubleshooting, testing, disassembly and repair of the Series NP45G, NP55G and

NP65G recreational vehicle generators.

Keep the Manual in a safe place and refer to it as often as necessary. The

Manual contains important technical data and should be referred to whenever the

need for such information arises.

Every effort has been expended to ensure the information in the Manual is

both accurate and current. However, the manufacturer reserves the right to

change, alter, or otherwise improve his product at any time without prior notice.

Page 3

_________________TABLE OF

CONTENTS

Page

Wiring Diagram eind Eiectricai Schematic

Expioded View of Sheet Metai

Expioded View of Base and Puiiey..................................28

Exploded View of Generator and Panel

Electrical Formulas...........................................................32

Specifications....................................................................33

.........................................

......................

..........................

26

30

Generator Fundamentals

Introduction........................................................................2

Electro-Magnetic Induction...............................................2

A Simple a-c Generator

A More Sophisticated a-c Generator

Generator Block Diagram.................................................3

....................................................

...............................

2

2

Introduction to Troubleshooting

Introduction.......................................................................4

Tools and Test Equipment

Rotor Rotational Speed....................................................4

Relationship of Voltage and Frequency

Generator a-c Connection System

Effects of Engine Power...................................................5

Effects of Dirt and Moisture on RV Generators

...............................................

.........................

..................................

.............

5

5

11

Troubleshooting the RV Generator

Introduction.......................................................................12

Problem No. 1- Engine Won’t Crank

Problem No. 2- Engine Cranks, Won’t Start

Problem No. 3- Engine Cranks and Starts, Shuts

Down When Start/Stop Switch is Released

Problem No. 4- Engine Starts Hard, Runs Rough

Problem No. 5- Engine Won’t Shut Down

Problem No. 6- Loss of Generator a-c Output................19

...............................

.......................

Engine Troubieshooting

General...............................................................................23

Checking Engine Compression

Check Engine Ignition

Check Carburetion............................................................23

Other Problems that Might Affect Engine Operation.. 23

4

......................................................

.......................................

Adjustments

General...............................................................................24

Engine Governor Adjustments

Voltage Regulator Adjustment.........................................24

5

Automatic Choke Adjustment

........................................

..........................................

...................

....................

..........

Page

13

15

17

18

18

23

23

24

25

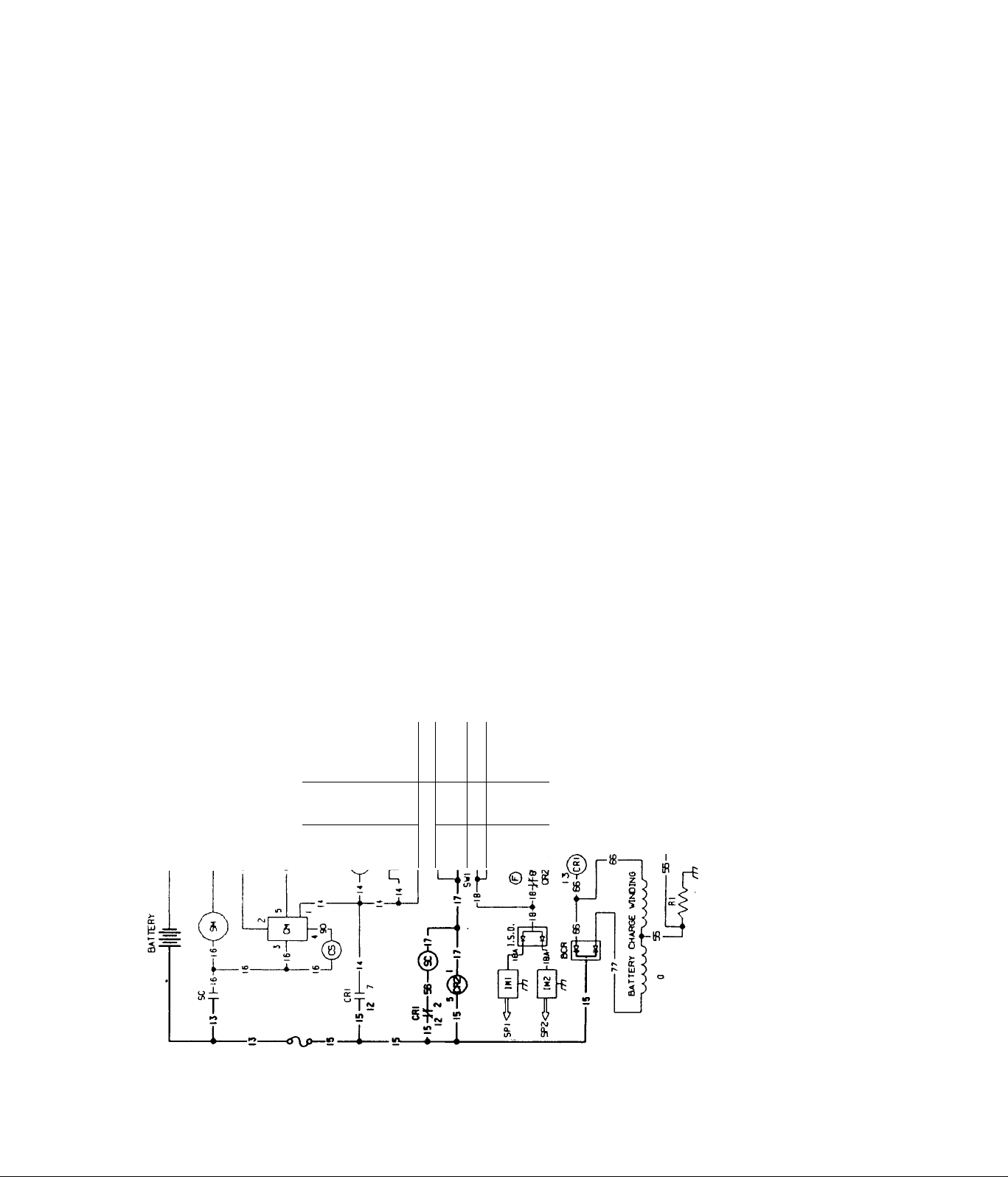

Operational Analysis of D-C Controi System

Introduction.......................................................................6

Circuit Condition- Engine Shut Down.............................6

Circuit Condition- Engine Cranking

Circuit Condition- Startup and Running

Circuit Condition- Normal Shutdown..............................8

................................

.........................

6

7

Insulation Resistance Tests

General...............................................................................9

The Hi-Pot Tester

Testing Stator Insulation..................................................9

Testing Rotor Insulation for Breakdown.........................10

Cleaning the Generator

Drying the Generator

..............................................................

....................................................

........................................................

9

10

10

Page 4

GENERATOR FUNDAMENTALS

Introduction

It has long been known that a relationship exists between

magnetism and electricity. Revolving fieid a-c generators

depend on this relationship for their operation. The ser

vice technician must understand that relationship. This

section of your DIAGNOSTIC REPAIR MANUAL will

familiarize you with the basic fundamentals of generator

operation.

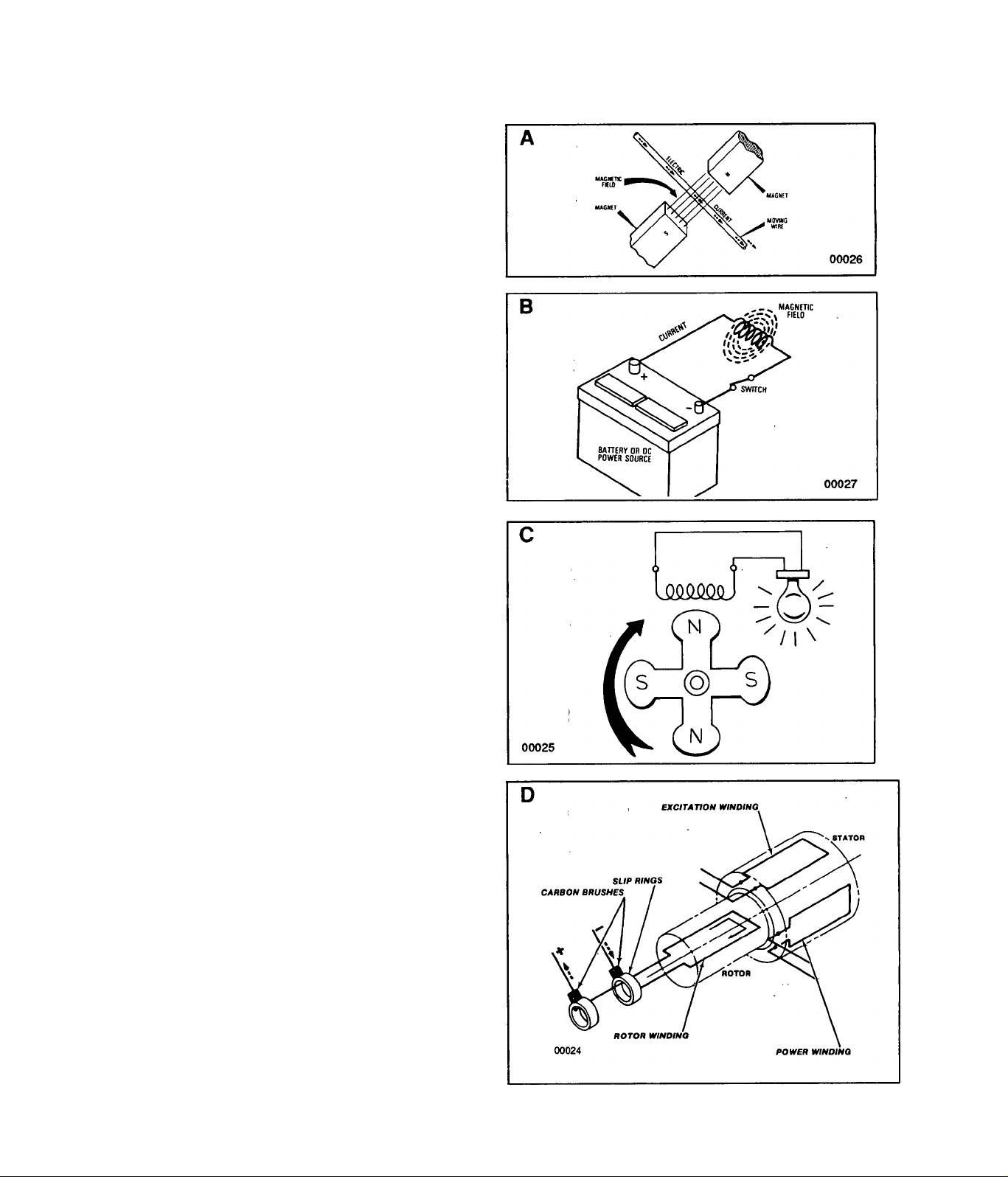

Electro-Magnetic Induction

A Magnetism Creates Electricity: - When a wire or

coii of wire is moved through a magnetic field, an electri

cal voltage is aeated in that wire. If the ends of the wire

are joined to complete a circuit, electrical current will flow

in the wire. The direction that current flows in the wire

depends on the polarity of the magnetic field.

B Current Flow Creates a Magnetic Field: - When

ever electrical current flows through a wire or coil of wire,

a magnetic field is created around that wire. The strength

of the field depends on the amount of current flow and

the number of coils or loops in the wire.

C A simple a-c generator consists of a spinning mag

netic field called a ROTOR and stationary coil of wire

called a STATOR. As the Rotor spins, its lines of mag

netic force cut across the stationary Stator. When the

ends of the Stator winding are connected across a load

(such as a light bulb) to complete the circuit, current will

flow through the circuit. In this simple generator, the

Rotor is a permanent magnet. The amount of voltage and

current flow induced into the Stator windings depends on

(a) the Rotor’s magnetic field strength, (b) Rotor rotational

speed, and (c) the number of turns of wire in the Stator.

A More Sophisticated a-c Generator

D A more sophisticated generator is equipped with a

Stator a-c power winding and a Stator excitation winding.

Regulated direct current from the excitation winding flows

through carbon brushes which slide on metallic slip rings

and then through the Rotor windings. Regulated current

flow through the Rotor creates a regulated magnetic field

strength. In turn, the regulated magnetic field strength

induces a regulated voltage into the stationary Stator;

winding. !

Page 5

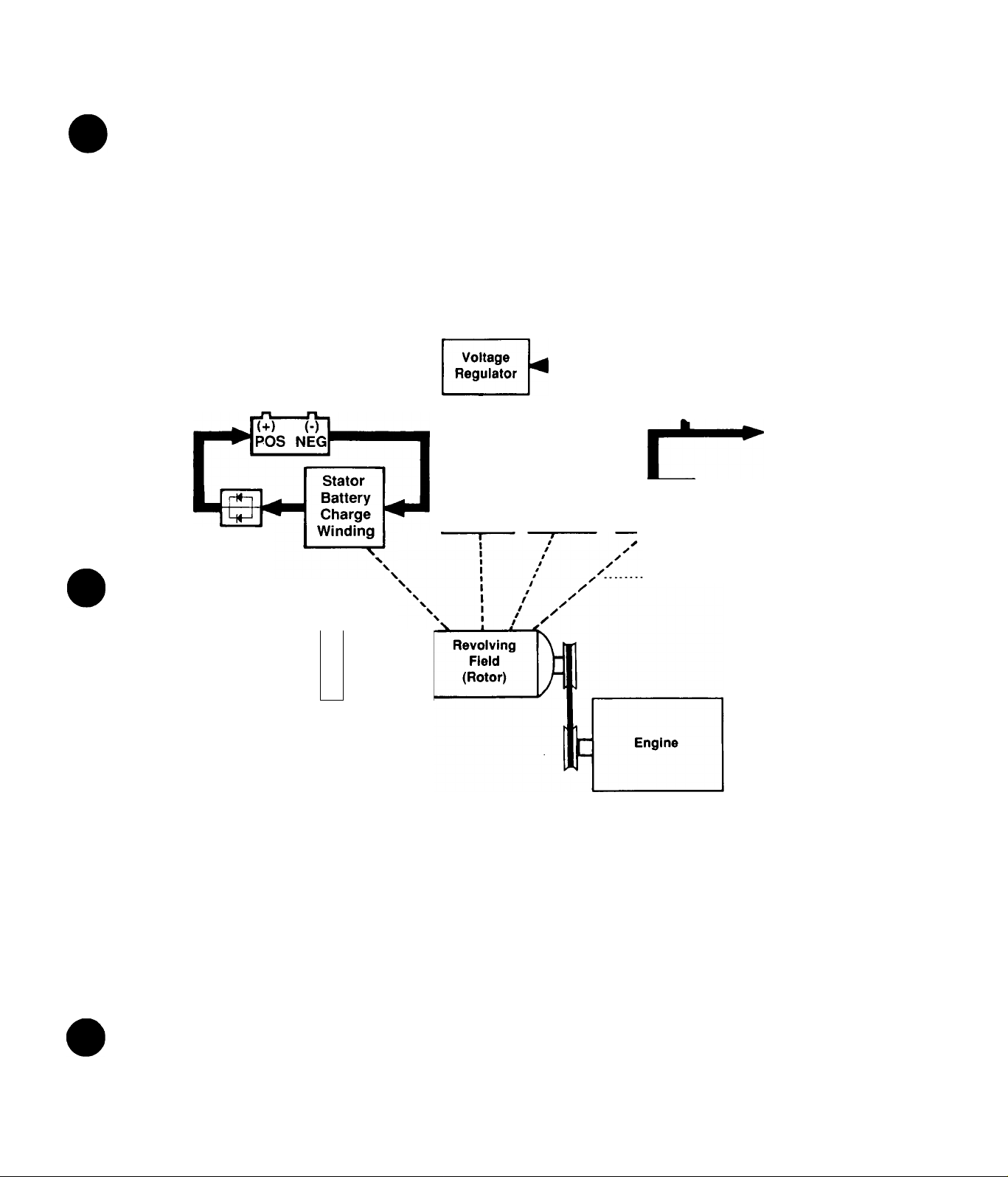

Generator Block Diagran^

E The Rotor (spinning fieid) is driven by the engine,

through a belt and pulley arrangement to maintain a fixed

operating speed. The Rotor’s magnetic field cuts across,

(a) a Stator a-c power winding, (b) a Stator excitation

winding, and (c) a Stator battery charge winding, to

induce a voltage Into those windings.

1. Stator Battery Charge Winding: Rectified direct

current output from this winding is delivered to the gen

erator’s 12-volts battery, to maintain battery state-ofcharge.

2. Stator a-c Power Winding:- The a-c output from this

winding is used to supply electrical power to connected

electrical loads.

3. Excitation Winding:- Output from this winding is

delivered to an Electronic Voltage Regulator, where it is

rectified and, based on a-c power winding sensing sig

nals, regulated. The regulated, rectified current flows

through the brushes and slip rings and into the Rotor

windings. Because the current flow is regulated, the

Rotor’s magnetic field strength Is regulated. In turn, be

cause the field strength is regulated, the voltage induced

into the Stator windings is regulated.

BATTERY

CHARGE

DIODE

00023

12 VOLTS

BATTERY

8

■T—f—L_r—\

Ü

Slip Rings \

Stator

Excitation

Winding

Stator a-c

Power

Winding

1

Stator a-c

Power

Winding

-r

Magnetic Field

Customer

Load

Connections

Page 6

INTRODUCTION TO TROUBLESHOOTING

Introduction

A typical RV generator set does not have a large number

of parts. However, the parts are expensive. For that

reason, a parts replacement method of troubleshooting is

not cost effective. A basic understanding of generators is

essential to good troubleshooting, i.e., why they behave

or don’t behave as they should. This section will introduce

the technician to some of the fundamentals of

troubleshooting.

DANGER!: Recreational vehicle generators produce

extremely high and dangerous voltages. Use ex

treme care when working on or around the gener

ator. Contact with live wires and terminals will cause

extremely hazardous and possibly lethal electrical

shock. Only personnel who have been thoroughly

trained In the maintenance of RV generators should

attempt to troubleshoot, test, repair or service a gen

erator.

Tools and Test Equipment

The generator service technician should have a well

stocked tool box having a good selection of common hand

tools. Such a tool box should contain wrenches in both

metric and english sizes. Also recommended is a good

nut driver set.

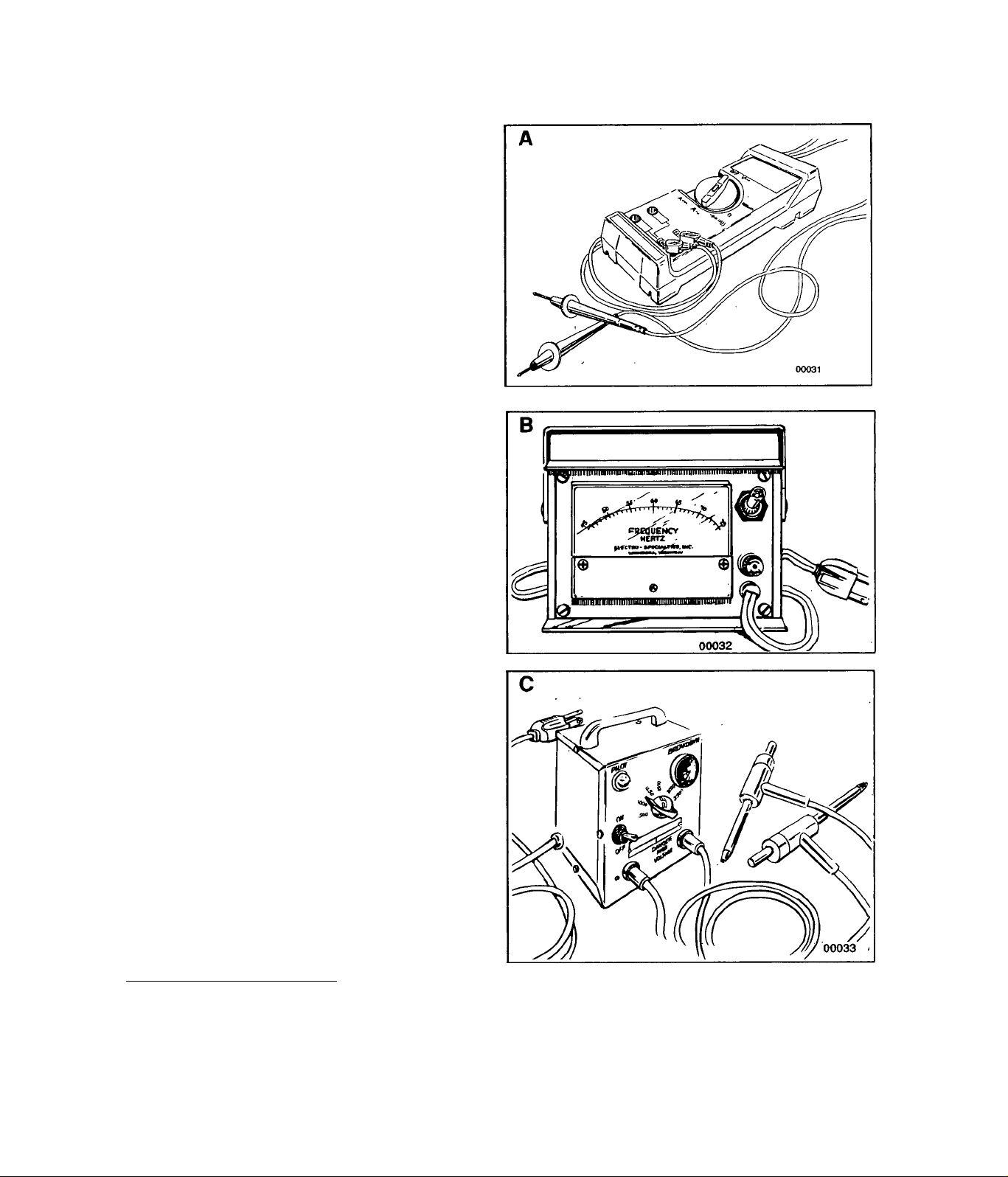

A Volt-Ohm-Milliammeter:-An accurate volt-ohm-mil-

liammeter (VOM) is essential for the troubleshooting and

testing of generators. Simply having a VOM is not

enough. The technician must understand electricity, must

be familiar with electrical circuits, must be able to read

wiring diagrams/electrical schematics, and must know

how tio use the VOM.

B Frequency Meter:- This test device permits the gen

erator’s a-c ou^ut frequency, in HERTZ or CYCLES PER

SECOND, to be read. Measurement of frequency is re

quired for precise adjustment of engine-generator speed.

Also see ROTOR ROTATIONAL SPEED.

C Insulation Resistance Tester:- Also called a "Hl-

POT", this device permits generator Stator and Rotor

winding insulation to be tested for breakdown. Use the

Hi-Pot tester to test resistance between parallel stator

windings, between isolated windings, and the resistance

of all windings to ground. See also EFFECTS OF DIRT

AND MOISTURE ON GENERATORS.

NOTE: An electrical LOAD BANK Is also recom

mended for generator testing and adjustment. The

Load Bank permits a known electrical load to be ap

plied to the generator, for the purpose of testing/adjustlng unit operation under load.

__________________

Rotor Rotational Speed

The generator’s revolving field on Series NP45G, NP55G

and NP65G generators is a 2-pole type, having a single

north and a single south magnetic pole. The Rotor is en

gine driven through a belt and pulley arrangenrient. Such

a 2-pole Rotor must be operated at 3600 rpm to supply

an a-c frequency output of 60 Hz. The belt and pulley ar

rangement pro>4des a speed reduction, so that engine

speed can be reduced while driving the Rotor at its re

quired operating speed. The following formulae apply

Page 7

when determining a-c frequency, Rotor rpm and number

of Rotor poles.

rpm X No. of Rotor Poles

Frequency = 2 x 60

2 X 60 X Frequency

RPM = No. of Rotor Poles

not be able to handle loads within the generator's rated

capacity. Problems with generator a-c output are oftencaused by an engine problem.

NOTE: A shorted condition In one or more con

nected electrical loads or In generator windings can

dramatically Increase the power demands on the

driving engine. Such shorted conditions may

present the same symptoms as an underpowered

engine.

________________________________________

2 X 60 X Frequency

Rotor Poles= rpm

Relationship of Voltage and Frequency

Engine governed speed and a-c voltage are adjusted with

no electrical loads applied to the generator (no-load).

That is, the a-c voltage is set at a fixed ratio to a-c

frequency. Recommended frequency and voltage set

tings are as follows:

Set Frequency to:

Set Voltage to;

*Llne-to-Neutral Voltage

60.5 to 63.5 Hz

121 to 127 volts*

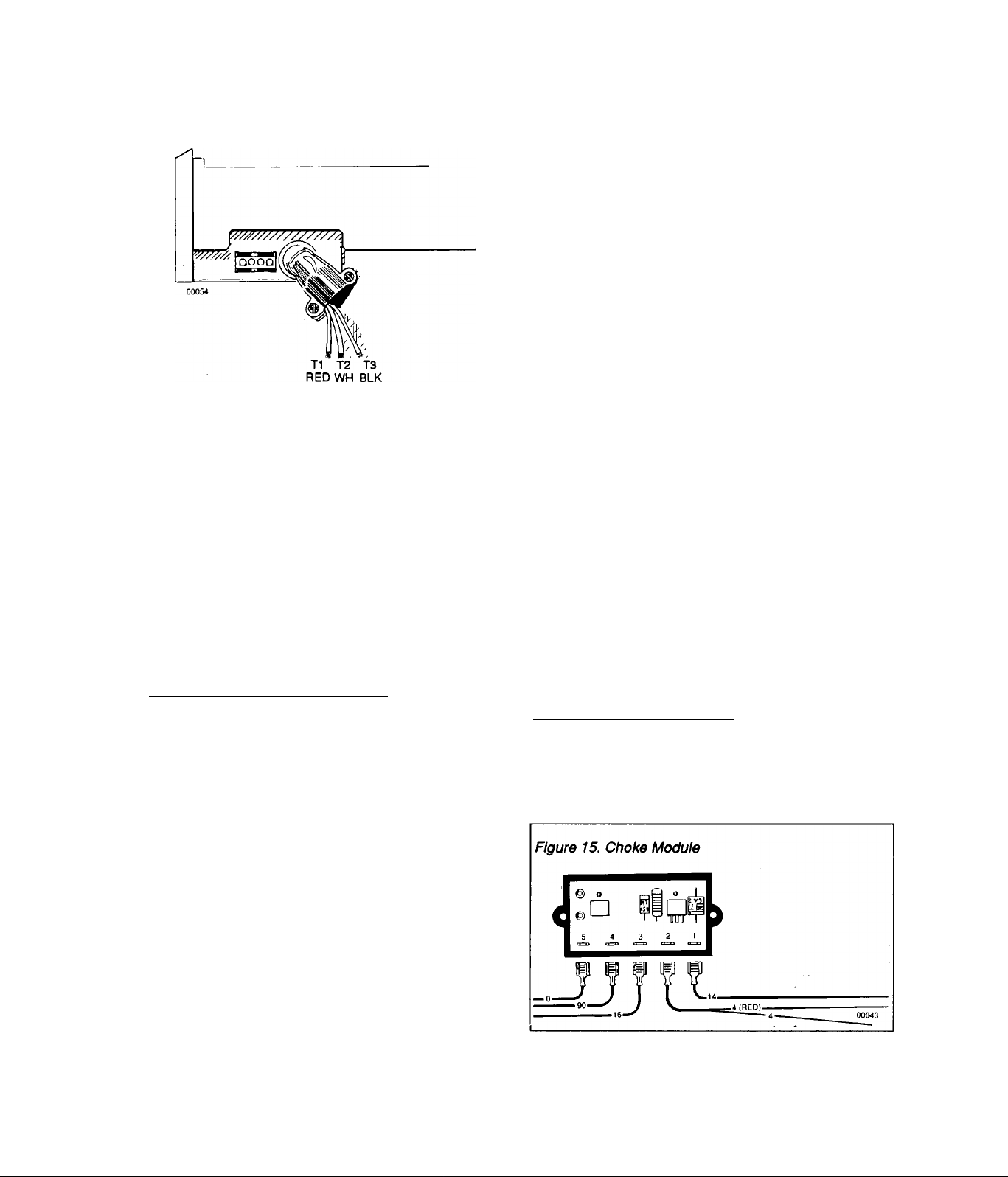

Generator a-c Connection System

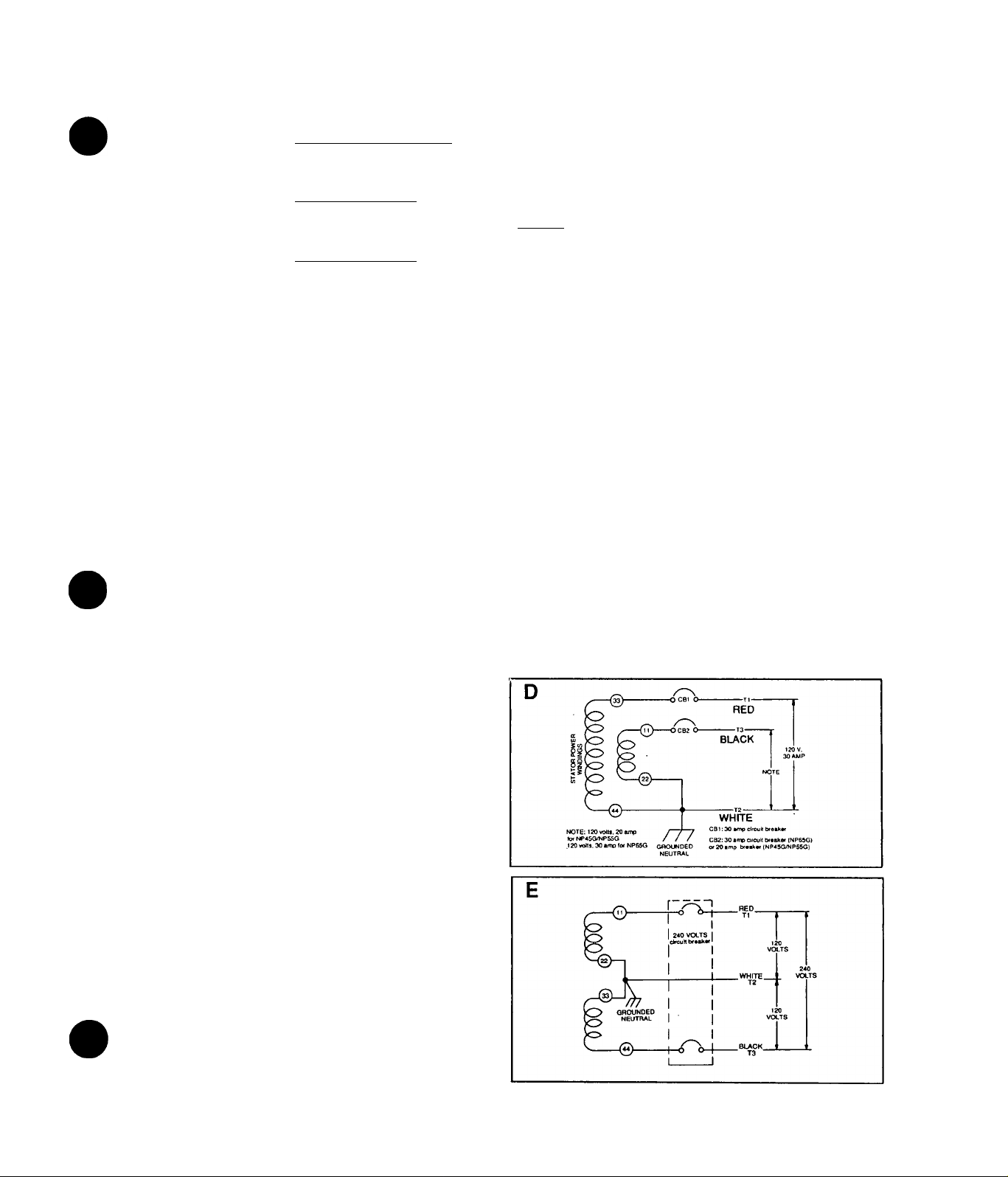

D Series NP45G, NP55G and NP65G RV generators

are equipped with dual Stator a-c power windings. These

windings may be connected in parallel to provide a 120votts a-c output as shown. Note that customer loads of

up to 30 a-c amperes may be connected across Wires T1

(red) and T2 (white); loads up to 20 a-c amperes across

wires T2 (white) and T3 (black).

E The generator’s a-c output leads may be reconnected

in series, to supply a dual voltage (120 and/or 240 volts)

a-c output. When this is done, connect 240 volts a-c

loads across T1 (red) and T3 (black); 120 volts across T1

(red) and T2 (white) or T3 (black) and T2 (white). T2 is

the neutral wire.

Effects of Dirt and Moisture oh RV

Generators

If moisture is permitted to remain in contact with gener

ator windings, some of that moisture may be retained in

cracks and voids of the winding insulation. This will

cause a reduced insulation resistance. However,

prolonged exposure to moisture resistance of stator and

rotor winding Insulation. Dirt can make the problem

worse, since it tends to hold moisture into contact with

windings. Salt (as from sea air) also makes the problem

worse, since salt will absorb moisture from the air. When

salt and moisture combine, they form a good electrical

conductor.

Because of the detrimental effects of dirt and moisture,

the generator should be kept as clean and as dry as

possible. Stator and rotor windings should be tested

periodically, using an insulation resistance tester (Hi-Pot

or megohmmeterX If insulation resistance is excessively

low, drying may be required to remove moisture. After

drying, a second test of insulation resistance is still low

after drying, replacement of defective windings may be

necessary.

Effects of Engine Power

The generator engine must develop sufficient power to

operate the generator under varying electrical loads. The

greater the wattage (amperage) demands ot connected

electrical loads, the greater the engine power needs. As

a general rule, approximately 2 engine horsepower is

ne^led for each 1000 watts (1.0 kW) of generator power

output.

If the generator’s wattage/amperage capacity is ex

ceeded, engine power may not be adequate to handle

the increased load. The result will be a decrease in

engine rpm, a corresponding decrease In generator a-c

output voltage and frequency, and internal generator

overheating.

A badly worn engine, one that has lost compression, or

one with defective fuel. Ignition or air Intake system may

Page 8

OPERATIONAL ANALYSIS OF D-C CONTROL SYSTEM

Introduction

This section of your Manual is intended to familiarize the

reader with how the RV generator’s d-c control system

functions. The d-c control system provides the means to

obtain engine cranking, engine ignition and fuel flow, car

buretor choking, field boost and battery charging. If

problems with any of these functions are encountered,

the technician must have a working knowledge of how the

system operates.

Circuit Condition- Engine Shut Down

A With engine stopped, the circuit condition may be

described as follows:

1. Battery voltage is available to the normally-open

Starter Contactor (SC) contacts. The contacts are open

and the circuit is incomplete.

2. Battery voltage is available through a 15 amp Fuse (FI)

and to the normally open contacts of Control Relay (CR1).

These contacts are open and the circuit is incomplete.

3. Battery voltagte is available through Fuse (Ft), through

the normally-closed contacts of Control Relay (CR1),

through the Starter Contactor (SC) coil, and to the

Start/Stop Switch (SW1). However, the Switch contacts

are open and the circuit is incomplete.

4. Battery voltage is available through Fuse (F1), through

the Control Relay (CR2) actuating coil, and to the

Start/Stop Switch (SW1). However, the Switch contacts

are open and the circuit is incomplete.

5. Battery voltage is available to the Battery Charge Rec

tifier (BCR), via Wire #13, 15 amp Fuse (FI), Wire #15,

and to a Battery Charge Rectifier (BCR). However, BCR

diode action inhibits Current flow.

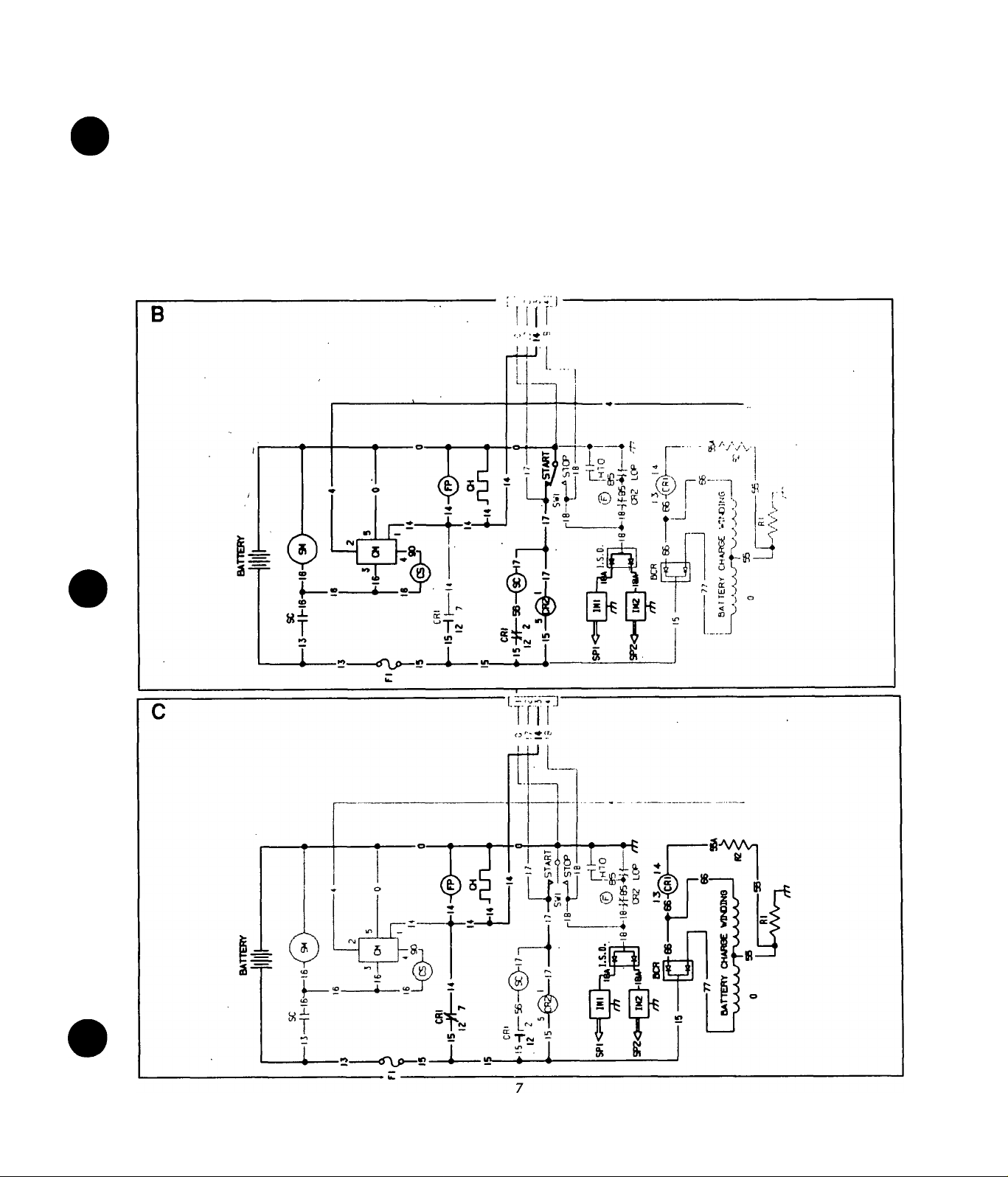

Circuit Condition- Engine Cranking

B When the Start/Stop Switch is held at its START posi

tion, the following sequence of events occurs

1. Start/Stop Switch closure connects the Control Relay

(CR2) and the Starter Contactor (SC) actuating coils to

frame ground.

2. The Starter Contactor (SC) energizes and its contacts

close to deliver battery voltage to (a) Starter Motor (SM)

and (b) a Choke Solenoid (CS) and (c) a Choke Module

(CM). The following events then occur:

a. Starter Motor (SM) energizes and the engine

cranks.

b. Battery voltage is delivered to the Choke Module

(CM), via Wire 16, the Choke Solenoid coil, and Wire

90. Choke Module (CM) action opens and closes

this circuit to ground at a rate dependent on ambient

temperature, to energize and de-energize the Choke

. Solenoid. Choke Solenoid (CS) opens and closes

the carburetor choke.

c. Battery voltage delivered to the Choke Module

(CM) is delivered to the generator Rotor windings via

a Field Boost Resistor and Diode (housed in the

Choke Module), Wire 4 and the Rotor brushes and

slip rings. This is field boost.

"1

-

7 ^

>-

&

►-

■t° Ife

-gAAAn

&

LEGEND

BCRc

. BATTERY CHARGE RECTIFIER

CIRCUIT BREAKER- 30 AMP

CB1 a

CIRCUIT BREAKER

CB2a

CH -

. CHOKE HEATER

CM c

.CHOKE MODULE

I CONTROL RELAY

CR1 -

. CONTROL RELAY

CR2-

. CHOKE SOLENOID

CS -

FI a

FUSE- 15 amp

FP -

FUEL PUMP

GROUND TERMINAL

QT HM c

. HOURMETER (Optional)

IGNITION MAGNETO

IMI IM2.

IGNITION MAGNETO

K3NmON SHUTDOWN

ISD.

RUN LIGHT

LI -

. LOW OIL PRESSURE, SWITCH

. LOP-

RESISTOR-1 ohm, 25 watt

R1 -

SC - STARTER CONTACTOR

SM - STARTER MOTOR

SW1 - START/STOP SWITCH

SPI - No. 1 SPARK PLUG

SP2 - No. 2 SPARK PLUG

TC o TERMINAL CONNECTOR

- WIRE NUT CONNECTION

Page 9

d. Battery voltage is delivered through a diode

(housed in the Choke Module) and to the Wire 14 cir

cuit. Wire 14 is now electrically hot, to operate (a) a

Fuel Pump (FP), (b) a Choke Heater (CH), and (c)

an "Engine Run" lamp on the optional remote panel.

3. Control Relay (CR2) energizes, its nonnaiiy-closed

contacts open and the Wire 18 circuit is effectiveiy iso

lated from frame ground. Ignition can now occur, since

that circuit Is now open to ground.

4. With automatic choking, and with fuel flow and ignition

available, the engine will start.

5. Engine oli pressure buildup opens the Low Oil Pres

sure Swritch (LOP).

Circuit Condition- Startup and Running

C When engine fires and starts, the operator will release

the Start/Stop Switch. Circuit condition may then be

described as follows:

1. When a-c output from the generator's Battery Charge

Winding reaches approximately 9-12 volts a-c. Control

Relay (CR1) energizes and its normally open contacts

close, to deliver battery voltage to the Wire 14 circuit (Fuel

Pump and Choke Heater actions continue).

2. The Starter Contactor (SC) and Control Relay (CR2)

circuits to ground are opened.

Page 10

3. Starter Contactor (SC) de-energizes and its contacts

open to effect the following

a. Starter Motor (SM) de-enerizes and cranking

ends.

b. Carburetor choking terminates.

c. Field Boost ends.

d. Power to the Wire 14 circuit through the Choke

Module ends.

4. Control Relay (CR2) de-energizes and its normallyclosed contacts close. However, the ignition circuit to

ground is held open by Low Oil Pressure Switch (LOP)

action and engine ignition continues.

5. Stator Battery Charge Winding (rectified) output is

delivered to the generator battery.

Circuit Condition- Normal Shutdown

D Closure of the Start/Stop Switch (SW1) to its STOP

position grounds the engine ignition circuit, ignition ter

minates and the engine shuts down. As engine speed

decreases. Low Oil Pressure Switch (LOP) closure main

tains the ignition ground condition.

Page 11

r

INSULATION RESISTANCE TESTS

General

Refer to EFFECTS OF DIRT AND MOISTURE ON RV

GENERATORS (Page 5). The resistance of rotor and

stator windings should be tested periodically, using a

"Hi-Pot" resistance tester.

CAUTION!: When using the Hl-Pot (Insulation Resis

tance) tester, follow the tester manufacturer’s In

structions carefully. Improper use of the tester can

result in serious damage to the generator. Do not

apply voltage in excess to those recommended in

this Manual to Stator or Rotor windings.

____________

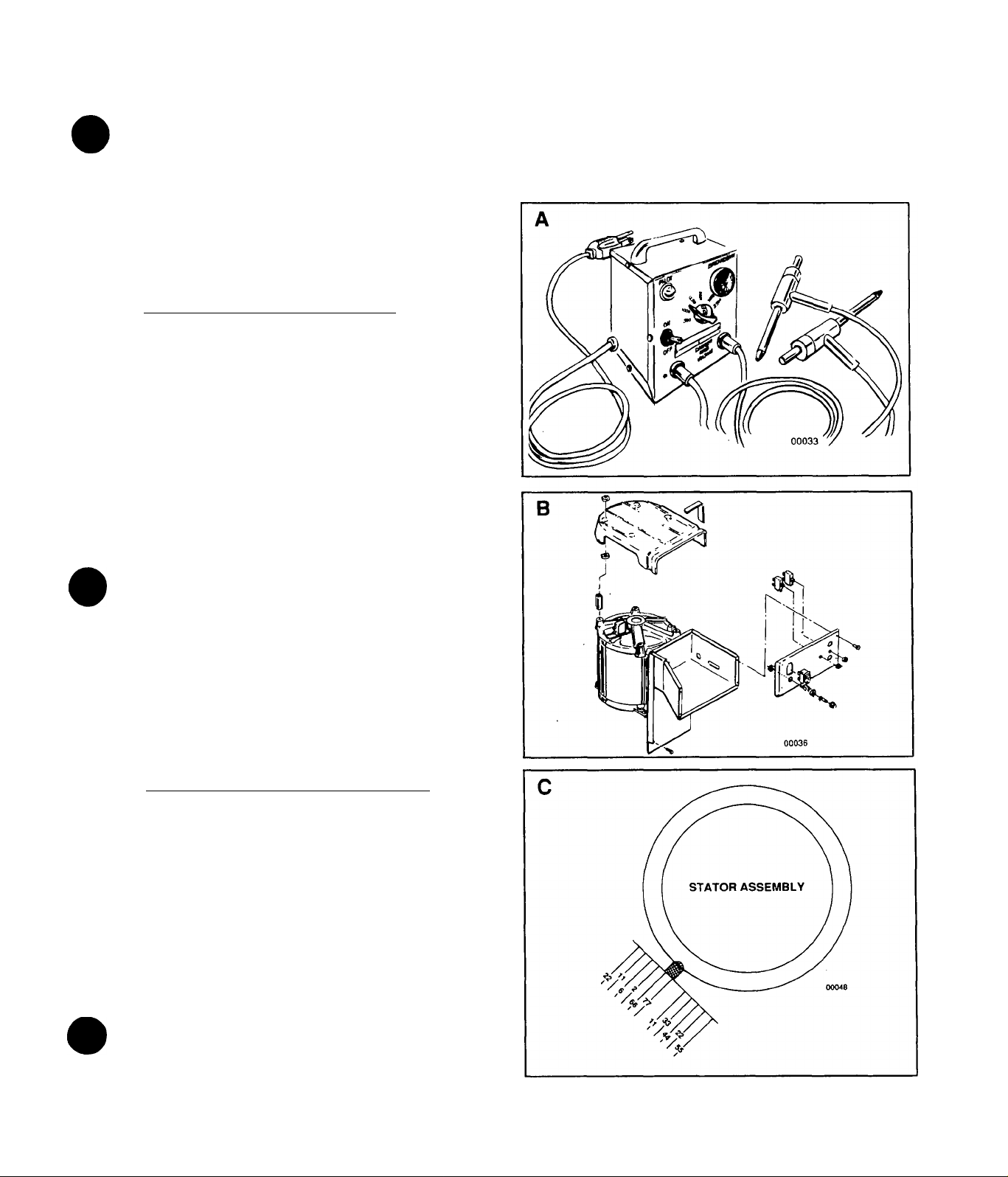

The Hi-Pot Tester

A The Hi-Pot tester shown is oniy one of many brands

available. It is equipped with an On/Off switch. Thepiiot

Lamp glows to indicate tester power is availabie. The

breakdown tamp will light to Indicate failure of the winding

being tested.

Testing Stator insuiation

6 Gain Access to Stator Leads: Remove screws that

retain the front panel to the panel housing. Remove the

generator cover. Inside the panel housing, locate the

Electronic Voltage Regulator and the 30-amp Circuit

Breaker (CB1).

4. Tum tester switch ON and check that Pilot Lamp is ON.

Then, set Voltage Selector Switch to 2000 volts. Observe

the BREAKDOWN lamp, wait one second, then turn

tester switch OFF.

C Disconnect Stator Leads: Disconnect Stator a-c

output wires 11 and 22 from the Electronic Voltage

Regulator terminals. Disconnect Stator Wire 33 from the

30-amp Breaker (CB1). Separate wires 22 and 44 at their

junction. Finally, disconnect Stator Excitation Wiriding

Wires 2 and 6 from the Electronic Voltage Regulator

terminals.

DANGER!: Follow the Instructions carefully. Wire

terminal ends must not be touching any part of the

generator when Hl-Pot voltage Is applied. Do not

exceed the recommended voltages. Apply voltage

to windings for a maximum of 1 second only.

Test All Stator Windings to Ground: Connect terminal

ends of Stator a-c output Wires 11, 22, 33, 44, 2 and 6

tightly together. Make sure no terminal end is in contact

with the generator frame. Then proceed as follows:

1 .Connect RED test lead of Hi-Pot tester to joined ter

minal ends of Wires 11,22, 33, 44, 2 and 6.

2. Connect the BLACK test lead to a dean, painted frame

ground (on generator Stator can).

3. Turn Hi-Pot tester switch OFF. Then plug tester into a

120 voits wall socket and set its Voltage Selector Switch

to 500 volts.

CAUTION!: IN STEP 4, DO NOT APPLY VOLTAGE

LONGER THAN ONE MINUTE.

Page 12

Test Between Isolated Windings:- To test between iso

lated Stator windings, proceed as follows:

1. Connect RED lead of Hi-Pot tester to terminal end of

Wire 11, BLACK test lead to Wire 2 terminal end.

2. Turn tester switch ON and check that Pilot Light is ON.

3. Set Voltage Selector Switch to 1500 voits- APPLY

VOLTAGE FOR ONE SECOND ONLY. Observe tester

Breakdown lamp. Turn tester switch OFF and reset Vol

tage Selector Switch to 500 volts.

Test Between Parallel Windings:- Test between paral

lel Stator windings as follows:

1. Set tester Voltage Selector Switch to 500 volts.

2. Connect tester RED test lead to Wire #11, BLACK test

lead to Wire 33.

3. Turn tester switch ON and check that Pilot Light is ON.

4. Apply voltage for one second while observing the

Breakdown lamp. Then, turn tester switch OFF.

RESULTS: If tester Breakdown lamp comes ON

during any one second test, clean and dry the stator.

Then, repeat the breakdown test. If Breakdown lamp

Illuminates after drying, replace the Stator Assemb

ly-

Testing Rotor Insulation for Breakdown

D Remove generator cover to gain access to the Rotor

slip rings and brushes. ,

E Remove all wires that connect to the Brushes. Then,

test Rotor insulation as follows:

1. Connect tester RED test lead to the positive {+) Rotor

slip ring (nearest the Rotor bearing).

2. Connect BLACK test lead to a clean frame ground.

3. Turn tester switch OFF.

4. Plug tester into a 120 volts wall socket.

5. Set Voltage Selector Switch on tester to 500 volts.

6. Turn tester switch ON and check that Pilot Light is ON.

7. Set Voltage Selector Switch to 1250 volts and observe

the tester breakdown lamp. Then, turn tester switch OFF.

RESULTS:- If tester breakdown lamp lllumlates

during the 1 second test, drying of the generator may

be necessary. After drying, repeat the Hl-Pot test. If

Rotor windings fall the second test (after drying),

replace the Rotor assembly.

Cleaning the Generator

Removed caked on or greasy dirt with a soft brush or a

clean, damp doth. A vacuum system may be used to pick

up loosened dirt. Loose dust and dirt may also be

removed using low pressure, dried air (25 psi maximum).

CAUTION!: Do NOT use a forceful spray of water to

clean generator. Some of the water will be retained

on generator windings and will cause serious

problems.______________________________________

Drying the Generator

1. Open the main drcuit breaker or main line switch. NO

ELECTRICAL LOADS MUST BE CONNECTED TO

GENERATOR WHILE DRYING.

2. Remove the generator cover (see illustration "B" on

previous page).

3. Disconnect Wire #4 from the Electronic Voltage

Regulator.

4. Provide an external source to blow warm, dry air

through the generator. Do NOT exceed 185' F. (85* C.).

5. Start the engine, let it run for 2 to 3 hours.

6. Stop the engine and retest Stator and Rotor windings.

10

Page 13

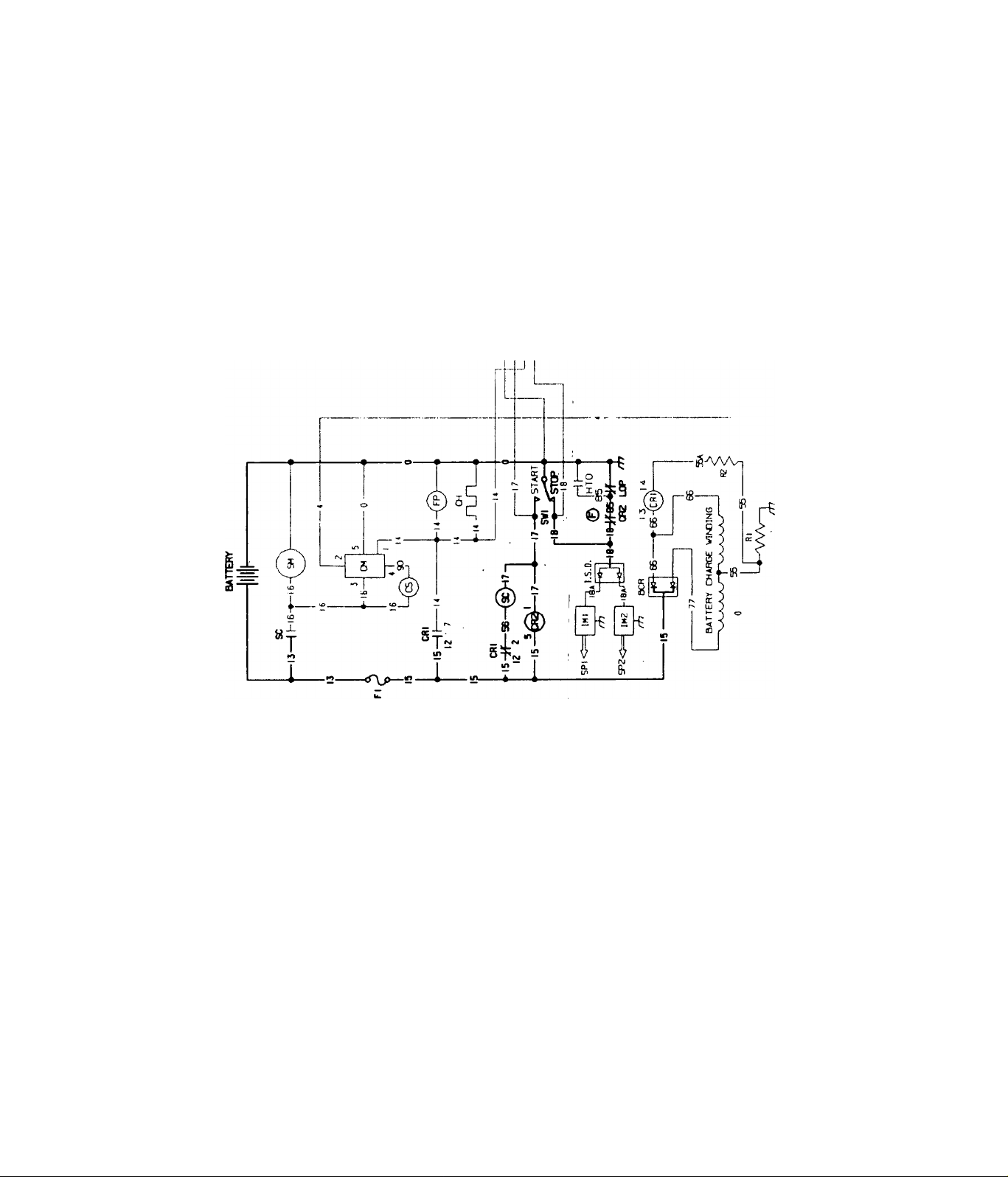

WIRING DIAGRAM & ELECTRICAL SCHEMATIC

11

Page 14

TROUBLESHOOTING THE RV GENERATOR

Introduction

The service technician can use this troubieshooting guide

to determine the cause of existing problems. Six common

problems are covered in this section. Problems are not

arranged in any particuiar sequence.

The first step in troubleshooting is to identify your par

ticular problem. When you have identified your problem,

locate that problem in the troubleshooting guide on this

page. When working your way through the step-by-step

procedure for that problem, start at Step 1 and follow

through the step-by-step procedure. Each step is ar

ranged in a definite sequence, from the more probabie/easiest to check to the less probable/more complex

to check. When the cause of the problem is found and

corrected, stop the test.

Follow the step-by-step procedures carefully. After com

pleting each test, read the TEST RESULTS. Some test

resuits may instruct you to skip certan steps and proceed

to a new step number.

Problem No. 1- Engine Won’t Crank

Step 1- Check 15 amp Fuse FI

Step 2- Check Battery

Step 3- Check Starter Contactor SC

Step 4- Check Starter Motor SM

Step 5- Check Start/Stop Switch SW1

Step 6- Check Control Relay CR1

Problem No. 2- Engine Cranks, Won’t Start

step 1- Check Fuel Quantity

Step 2- Check Fuel Shutoff Valves

Step 3- Check Fuel Flow

Step 4- Check Fuel Filter

Step 5- Check Fuel Pump

Step 6- Check Engine Ignition System

Step 7- Test Choke Module

Step 8- Check Automatic Choke Operation

Step 9- Check Engine Compression/Condition

Step 10- Test Control Relay CR2

Problem No. 3- Engine Cranks and Starts,

Shuts Down When Start/Stop Switch is

Released

Step 1 - Check Engine Oil Level

Step 2- Check Oil Pressure Switch

Step 3- Check Control Relay CR1

Step 4- Check Stator Battery Charge Windings

Step 5- Check Resistor R1

Problem No. 4- Engine Starts Hard, Runs

Rough

Step 1- Check Engine Ignition System

Step 2- Check Carburetion

Step 3- Check Engine Compression

Step 4- Test Automatic Choke

Problem No. 5- Engine Won’t Shut Down

Step 1 - Check Start/Stop Switch

Step 2- Check Wire #18 & #0

Step 3- Check Engine Ignition System (I.S.D.)

Problem No. 6- Loss of Generator a-c Out

put

Step 1- Check Circuit Breakers CB1/CB2

Step 2- Check Vehicle Wiring

Step 3- Check a-c Voltage and Frequency

Step 4- Check Load Voltage and Frequency

Step 5- Check/Adjust Engine Governor

Step 6- Check Field Boost Circuit

Step 7- Check Stator Excitation Windings

Step 8- Check Stator a-c Power Windings

Step 9- Check Rotor (Field) Circuit

Step 10- Check Voltage Regulator Sensing

Step 11- Check/Adjust Voltage Regulator

12

Page 15

TROUBLESHOOTING GUIDELINES

Problem No. 1- Engine Won’t Crank

step 1- Check 15 amp Fuse F1

Test Procedure: Remove Fuse FI from generator panel

and Inspect fuse element. If necessary, use a Volt-Ohm-

Mllllammeter (VOM) to check fuse for continuity.

Test Results:A. Fuse FI checks GOOD: Go to Step 2

B. Fuse FI Is open: Replace Fuse FI. If engine cranks

normally STOP.

Step 2- Check Battery

Test Procedure:- Perform the following checks/tests on

the generator battery:

1. Inspect battery terminals (posts) and cables. Cable

clamps and connections must be clean and tight. Glean

and/or tighten cable clamps and connections as neces

sary. Replace any defective cables.

2. Use an automotive type battery hydrometer to test bat

tery STATE OF CHARGE. Follow the hydrometer

manufacturer’s instructions carefully. Write down the

specific gravity of the electrolyte fluid in each battery cell.

Write down the specific gravity reading of each cell as the

reading is taken. Return the electrolyte fluid to the cell

from which it was removed. If the hydrometer used does

not have a percentage of charge scale, compare the read

ings obtained with the following:

SPECIFIC GRAVITY PERCENT OF CHARGE

1.260

1.230

1.200

1.170

If necessary, use an automotive type battery charger to

recharge the battery to a 100% state of charge.

100%

75%

50%

25%

Step 3- Check Starter Contactor SC

Test Procedure:- Starter Contactor operation may be

tested as follows:

1. See Figure 1. Connect the positive (+) test lead of a d-

c voltmeter to the Wire 56 terminal of the Starter Contac

tor. Connect the meter negative (-) test lead to a clean

frame ground. The voltmeter should indicate battery vent

age (12 volts d-c).

Test Results:

A. Battery voltage NOT indicated: Go to Step 6

B. Battery voltage was indicated: Continue test

2. Connect the positive (+) test lead of a d-c voltmeter to

the Wire 16 terminal stud of the Starter Contactor; con

nect negative (-) test lead to a dean frame ground. Zero

volts should be indicated.

3. With d-c voltmeter still connected to the Wire 16 ter

minal stud and frame ground, disconnect Wire 17 from its

terminal stud on Starter Contactor. Connect a jumper wire

from the Wire 17 terminal stud (on Starter Contactor) to

a clean frame ground. The d-c voltmeter should indicate

battery voltage and engine should crank.

Test Results:

A. Battery voltage GOOD and engine cranks, but will not

crank with Start/Stop Switch: Go to Step 5

B. Battery voltage GOOD, engine does NOT crank: Go

to Step 4

C. Zero battery voltage with jumper wire connected and

engine does not crank; Replace Starter Contactor SC.

DANGER!: Storage batteries give off EXPLOSIVE

hydrogen gas while charging. Completely remove

the battery from the vehicle before attempting to

recharge It. Charge the battery only In a well venti

lated space where explosive gases cannot accumu

late and present the danger of explosion. Do not per

mit smoking, open flame or sparks in the vicinity

while charging a battery.

3. If the difference in specific gravity between the highest

and lowest reading cell is 0.050 (50 points) or greater, the

battery is nearing the end of its usefui life and should be

replaced. However, if the lowest reading cell has a

specific gravity of less than 1.200, recharge the battery

and then repeat the specific gravity test. If, after charg

ing, the difference between the highest and lowest read

ing cell is still 0.050 (50 points), replace the battery.

Test Results:A. Normal engine cranking occurs: STOP tests

B. Battery checks GOOD, no cranking; Go to Step 3.

_________________________

Step 4- Check Starter Motor SM

Test Procedure:- Connect a jumper cable to the large

battery cable terminal stud (Wire 13) of the Starter Con

13

Page 16

tactor and to the cable terminal on Starter Motor. Engine

should crank.

Test Results:

A. Engine cranks normally but does not crank when using

the Start/Stop Switch: Go to Step 5.

B. Engine does NOT crank: Replace Starter Motor SM

C. Engine cranks normally with jumper cable and with

Start/Stop Switch: STOP tests.

2. Connect a jumper wire between the Start/Stop Switch

Wire 17 terminal and a clean frame ground connection.

Engine should crank and start. Disconnect jumper wire to

terminate cranking when engine starts. To stop the en

gine, connect jumper wire to Wire 18 terminal of

Start/Stop Switch and to frame ground.

Test Results:

A. Engine cranks, starts and shuts down normally when

using jumper wire, but not when using Start/Stop Switch:

Replace Start/Stop Switch.

B. Engine will not crank when using jumper wire: Go to

Step 6.

C. Engine cranks and stops normally when using jumper

wire and with Start/Stop Switch: STOP tests.

Step 6- Check Control Relay CR1

NOTE: See WIRING DIAGRAM & ELECTRICAL

SCHEMATIC on Page 11. Two different types of Con

trol Relay CR1 are used on the NP series generators,

Identified In the Wiring Diagram as "CRI" and "AlternateCRl". Also see Figures 4 and 5

NOTE: For Starter Motor SM testing and repair In-

Structlons, refer to ENGINE SERVICE MANUAL.

Step 5- Check Start/Stop Switch SW1

Test Procedure:- See Figure 3. Test the Start/Stop

Switch as follows:

1, Set a Volt-Ohm-Milliammeter (VOM) to its "Rxl" scale

and zero the meter. Connect one VOM test lead to the

Wire 0 terminal of Start/Stop Switch; connect second

meter test lead to a clean frame ground. The VOM should

indicate continuity.

Test Results:

A. VOM does NOT indicate continuity: Repair or replace

Wire 0 between Switch and frame ground connection, as

necessary.

B. VOM indicates continuity: Continue test.

Test Procedure:- See Figure 4 or 5. Test the Relay as fol

lows:

1. Connect the positive (+) test lead of a d-c voltmeter to

CRI terminal 12 (Wire 15 terminal): connect the negative

(-) test lead to a clean frame ground. Meter should indi

cate battery voltage. If alternate CRI is installed, connect

meter positive (+) test lead to Relay terminal 9 (Wire 15

terminal).

Test Results:

A. Battery voltage is indicated; Continue test

B. Battery voltage is NOT indicated:- Repeat Step 1. Also

check Wire 15 between Relay CRI and Fuse FI for open

or disconnected condition; Wire 13 between Fuse FI and

Starter Contactor SC for open; and positive (+) battery

cable to Starter Contactor SC.

2. Connect the positive (+) test lead of a d-c voltmeter to

CRI terminal 2 (Wire 56 terminal); negative (-) test lead

to frame ground. If alternate CRI is installed, connect

meter positive (+) test lead to Relay terminal 3 (Wire 56

terminal). Battery voltage should be indicated.

Test Results:

A. Battery voltage NOT indicated: Replace Control Relay

CRI

B. Battery voltage was indicated: Repeat Steps 1 through

5. Refer to WIRING DIAGRAM (Page 11) and test wires

for open or shorted condition.

14

Page 17

Figure 4. Control Relay CR1

3D

n

56 15 I 55A

_U

12 14

7 P rO

14 66

___

I I 1_

4]

13

00047

Test Results:

A. Fuel Shutoff Valve(s) are closed: Open all valves

B. Shutoff valves are open, engine wili not start: Go to

Step 3

Step 3- Check Fuel Flow (Gasoline System Only)

Test Procedure:- Disconnect fuel line at engine car

buretor inlet. Crank engine and check fuel flow from open

end of disconnected line.

Test Results:

A. Fuel Flow is inadequate: Go to Step 4

B. Fuel flow checks GOOD: Go to Step 6

Step 4- Check Fuei Filter (Gasoline System Only)

Test Procedure:- See Figure 6. if fuel flow to carburetor

is low, try a new fuel filter. Make sure arrow on filter body

points in direction of flow toward carburetor. With new fil

ter installed, recheck fuel flow as outlined in Step 3.

Test Results:

A. Fuel flow is normal: STOP tests

B. Fuel flow still inadequate: Go to Step 5

Problem No. 2 - Engine Cranks, Won’t Start

step 1 - Check Fuel Quantity

Test Procedure: When troubleshooting a problem, the

most simple causes are often overlooked. If engine

cranks normally but won’t start, check that adequate

supply of the proper fuel is available. Many RV generator

Installations with shared fuel tank utilize a generator fuel

pickup tube thatis shorter than the vehicle engine's fuel

pickup tube. For that reason, the generator will "run out

of gas" while fuel is still available for the vehicle engine.

Test Results:

A. Fuel quantity is adequate: Go to Step 2.

B. Inadequate fuel in tank: Fili fuei tank.

Step 2 - Check Fuel Shutoff Valves

Test Procedure: The fuel supply line in the vehicie may

be equipped with one or more fuei shutoff valves. If

engine will not start, check that all fuel supply valves are

open.

Step 5- Check Fuel Pump (Gasoline System Only)

Test Procedure:- Locate the 4-tab terminal connector to

which Wires 14 connects. Locate Wire 14 from Fuel Pump

on the terminal connector. Connect the positive (+) test

lead of a d-c voltmeter to the Fuel Pump’s Wire 14 ter

minal; connect negative (-) test lead to a clean frame

ground. Crank engine- the voltmeter should indicate bat

tery voltage and the Fuel Pump should operate.

Test Results:

A. Battery voltage is indicated and Fuel Pump operates,

but still no start: Go to Step 6

B. No battery voltage indicated and Fuel Pump does not

operate: Go to Step 7

15

Page 18

Step 6- Check Engine Ignition System

Test Procedure:- Refer to section in this Manual entitled

ENGINE TROUBLESHOOTING. Also refer to the EN

GINE SERVICE MANUAL, if necessary.

Test Results:

A. Ignition System checks GOOD: Go to Step 7

B. Ignition System checks BAD: Repair or replace defec

tive component(s) mas necessary

Figure 7. Choke Module

© o

©L3

Step 7- Test Choke Module

NOTE: The following procedure will test the Wire 14

diode, the field boost diode, and the field boost

resistor. To test these components. It Is recom

mendecf that a Volt-Ohm-Mllllammeter having a

DIODE TEST capability be used. The solid state cir

cuit that regulates automatic choke opening and

closing cannot be tested In the field. That circuit will

be tested In Step 8 by observing choke operation,

Test Procedure:- See Figure 7. Disconnect ail wires from

Choke Moduie terminals to prevent interaction. Then,

proceed as follows:

1. To test the Wire 14 diode, connect one VOM test lead

to Terminal 3 of the Choke Module; connect second test

lead to ,Terminal 1. Observe the meter reading. Then,

reverse the test leads (reverse the d-c polarity) across

those Choke Module terminals and again observe the

reading. At one polarity, the VOM should read infinity. At

the opposite polarity, the VOM should indicate the for

ward resistance of the 6 amp, 100 volts diode in the Wire

14 circuit. If using a VOM having the diode test feature,

allowable voltage drop across the diode is 0.6 to 0.8 volt.

2. To test the Field Boost diode and resistor, connect one

VOM test lead to Choke Module Terminal 3, the second

test lead to Terminal 2. Note the meter reading. Then,

reverse the test leads (reverse polarity) and again ob

serve the VOM reading. At one polarity, the meter should

indicate infinity. At the opposite polarity, the meter should

read the forward resistance of the diode plus the resis

tance of the Field Boost Resistor. If a VOM having the

diode test feature is used, allowable voltage drop will be

0.6 to 0.8 volts PLUS the voltage drop across the resis

tor.

f

00043

Step 8- Check Automatic Choke Operation

Test Procedure;- See Figure 8. Crank engine while ob

serving choke operation. The Choke Solenoid CS should

pull in to close choke for about 0.2-0.4 seconds, should

then de-energize to open choke for about 2 seconds. This

cyclic action should occur while the engine is cranking. If

Choke Solenoid does not actuate, check for binding. Also

check for proper choke adjustment (see ADJUSTMENTS

section).

Test Results:

A. Choke operation checks GOOD, engine still won’t

start: Go to Step 9

B. Choke operation checks BAD: Try adjusting choke- if

it still does not operate, replace Choke Module

NOTE: The Field Boost Resistor is rated 47 ohms at

2 watts (plus or minus 10%). The Field Boost diode

Is rated 1 amp at 600 volts.

3. The Choke Module circuit includes a metal oxide Varis

tor, rated 22 volts, 0.6-0.8 Joule. There is no good method

of testing a Varistor in the field. Typically, when a Varis

tor fails it will overheat and melt. Inspect the Choke

Module- if evidence of overheating and melting is ob

served, replace the Choke Module.

Test Results:

A. All Choke Module tests are GOOD: Go to Step 8

B. Choke Moudle tests BAD: Replace Choke Module

_________________________

Step 9- Check Engine Compresslon/Condition

Test Procedure:- Refer to section entitled ENGINE

TROUBLESHOOTING. If necessary, also refer to the EN

GINE SERVICE MANUAL.

Test Results:

A. Engine^Checks GOOD: Go to Step 10

B. Engine checks BAD; Repair/replace engine as neces

sary

16

Page 19

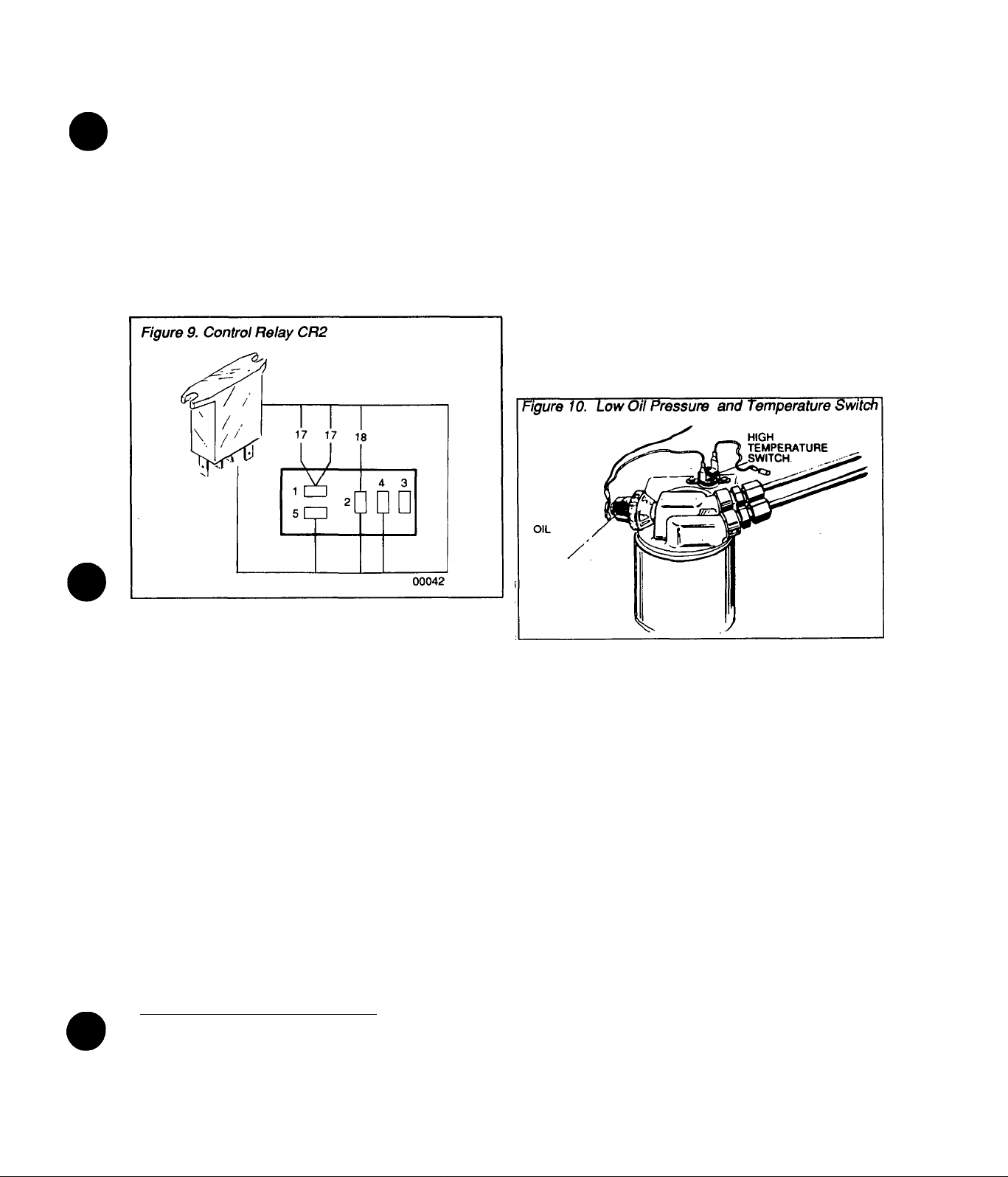

step 10- Test Control Relay CR2

Test Procedure:- See Figure 9. Disconnect Wire 18 from

Reiay Terminai 2 and Wire 85 from Terminai 4, to prevent

interaction. Set a VOM to its "Rxl" scaie and zero the

meter. Then, connect the VOM test ieads aaoss Reiay

Terminais 2 and 4- the meter needie shouid swing ups-

caie (continuity). Hoid Start/Stop Switch at START to

crank engine- the VOM needie shouid drop aii the way

downscaie (infinity).

Test Results:

A. Control Relay CR2 checks GOOD; Repeat Steps 1

through 9

B. Control Relay CR2 checks BAD: Replace Relay CR2

Step 2 - Check Oil Pressure Switch

Test Procedure: Set a VOM to its "Rxl" scale and zero

the meter. Disconnect Wire 85 from the Switch terminal,

then test the Low Oil Pressure Switch (Fig. 10) as follows:

1. Connect one VOM test lead to the switch terminal, the

remaining test lead to a clean frame ground. Meter

should indicate continuity.

2. Crank engine. The VOM needle should drop all the

way downscale (infinity) as oil pressure inaeases.

3. If the engine starts and runs, hold terminal end of Wire

85 into firm contact with a dean frame ground. Engine

should shut down.

Test Results:

A. Oil Pressure Switch checks GOOD: Go to Step 3.

B. Oil Pressure Switch checks BAD: Replace switch.

Problem No. 3- Engine Cranks and Starts,

Shuts Down When Start/Stop Switch is

Released

Step 1- Check Engine Oil Level

Test Procedure:- Check engine oil level as outlined in

Owner’s Manual. If oil level is low, sufficient oil pressure

to open the Low Oil Pressure Switch contacts will not be

developed. With Start/Stop Switch at START, Control

Relay CR2 action will open the engine ignition circuit to

ground. However, as soon as the Start/Stop Switch is

released, CR2 contacts will close and closure of the Low

Oil Pressure Switch contacts will close the ignition circuit

to ground and ignition will terminate. The result will be an

ehgine'shutdown as soon as the Start/Stop Switch is

released.

Test Results:-

A. Oil level is LOW: Add oil as required (don’t forget Oil

Makeup Tank)

B. Oil level is GOOD: Go to Step 2

NOTE: You may wish to check engine oil pressure.

See ENGINE SERVICE MANUAL for Oil pressure

check procedures and specifications.

______________

Step 3- Check Oil Temperature Switch

Test Procedure: Set a VOM to its "Rxl" scale and zero

the meter. Disconnect Wire 85 from the Switch terminal,

then test the Oil Temperature Switch (Fig. 10) as follows:

1. Connect one VOM test lead to the switch terminal, the

remaining test lead to a clean frame ground. Meter

should indicate continuity.

2. If the engine starts and runs, hold terminal end of Wire

85 into firm contact with a dean frame ground. Engine

shouid shut down.

Test Results:

A. OifTemperature Switch contacts check GOOD: Go to

Step 4.

B. Oil Temperature Switch contacts check BAD: Check

wiring.

17

Page 20

Step 4 - Check Control Relay CR1

Test Procedure: Refer to Step 6 under Problem No. 1.

Test Results:

A. Control Relay CR1 checks GOOD: Go to Step 5.

tion. Set a VOM to Ks "Rxl" scale and zero the meter.

Connect the first meter test probe to the Wire 55 terminal

of Resistor. Connect second test probe to a clean frame

ground. Meter should indicate about 1 ohm (plus or minus

5%).

B. Control Relay CR1 checks BAD: Replace Control

Relay CR1.

Step 5 - Check Stator Battery Charge Windings

NOTE: The Volt-Ohm-Mllllammeter (VOM) used to

test Stator windings must be accurate. Recommended Is a digital meter of high accuracy.

Test Procedure: Disconnect Wires 66 and 77 (Fig. 11)

from the Battery Charge Rectifier BCR terminais. Set a

VOM to its "Rxl" scaie and zero the meter. Connect the

meter test ieads across the terminal ends of Wires 66 and

77, just removed from Battery Charge Rectifier BCR. The

VOM should indicate Stator Battery Charge Winding

resistance, as follows:

Series NP45G = 0.12 ohm

Series NP55G = 0.09 Ohm

Series NP65G = 0.07 ohm

All test readings are plus or minus 10%.

Now, set the VOM to its "Rxl 0,000" scale and zero the

meter. Connect one VOM test lead to terminal end of

Wire 66, remaining test lead to a dean frame ground. No

upscale movement of the meter should be noted (infinity).

Test Results:

__________

Test Results:

A. Resistor R1 checks GOOD: Repeat Steps 1 through 4

under Problem No. 3.

B. Resistor R1 checks BAD: Replace Resistor R1.

Figure 12. Resistor R1

X BATTERY CHARGE

7 WINDING

-T

55

00053

R1

66

rh GROUND

Problem No. 4 - Engine Starts Hard, Runs

Rough

Step 1 - Check Engine Ignition System

A. Battery Charge Winding checks GOOD: Go to Step 6

B. Battery Charge Winding checks BAD: Replace Stator

Assembly.

Test Procedure: Inside the generator panel, locate

Resistor R1 (Fig. 12). Test wire 0 (between Resistor R1

and frame ground connection) for an open condition.

Correct open condition, if necessary, before proceeding.

Disconnect Wire 55 form the Resistor to prevent interac

Test Procedure: Refer to ENGINE TROUBLESHOOT

ING section. Also see ENGINE SERVICE MANUAL.

Test Results:

A. Ignition system checks GOOD: Go to Step 2.

B. Ignition system checks BAD: Repair or replace defec

tive component(s).

Step 2 - Check Carburetlon

Test Procedure: See ENGINE TROUBLESHOOTING

section. Also see ENGINE SERVICE MANUAL.

Test Results:

A. Checks GOOD: Go to Step 3.

B. Checks BAD: Adjust, repair or replace as necessary.

Step 3 - Check Engine Compression

Test Procedure: Refer to ENGINE TROUBLESHOOT

ING section. Also see ENGINE SERVICE MANUAL.

Test Results:

A. Engine checks GOOD: Go to Step 4.

B. Engine checks BAD: Repair as required.

18

Page 21

Step 4 - Test Automatic Choke

Step 2 - Check Wire 18

Test Procedure: Refer to Steps 7 and 8 of Problem No.

2 for automatic choke system test procedures. See AD

JUSTMENTS section as well.

Test Results:

A. Choke tests GOOD; Repeat Steps 1 thru 3.

B. Choke tests BAD: Repair, adjust or replace defective

component(s) as necessary.

Problem No. 5 - Engine Won’t Shut Down

Step 1 - Check Start/Stop Switch.

Test Procedure: Test the Start/Stop Switch (Fig. 13) as

follows;

1. Check Wire 0 (between Start/Stop Switch and ground

terminai QT) for open condition. Ground connection

must be good before proceeding.

2. Disconnect Wires 17 and 18 from Switch terminals, to

prevent interaction.

3. Set VOM "Rxl" scale and zero the meter.

4. Connect one meter probe to the Wire 17 terminal, and

connect the remaining test probe to Wire 0 (ground)

terminal. Meter should indicate infinity.

5. Actuate the Switch to its START position. Meter

should read continutity.

6. Release Switch. Meter should indicate infinity.

Test Procedure: Refer to WIRING DIAGRAM, Page 11.

Test Wire 18 between Ignition Shutdown Module ISD and

Start/Stop Switch for open or shorted condition. Also

check Wire 18 between Start/Stop Switch and Control

Relay CR2 for open or shorted condition.

Test Results:

A. Wire 18 checks GOOD: Go to Step 3.

B. Wire 18 checks BAD: Repair or replace.

Step 3 • Check Engine Ignition System

Test Procedure: See ENGINE TROUBLESHOOTING

section in this Manual. Also see ENGINE SERVICE

MANUAL.

Test Results:

Repair or replace defective ignition components as

necessary.

Problem No. 6 - Loss of Generator a-c

Output

step 1 - Check Circuit Breakers CB1/CB2

Test Procedure: Try resetting applicable circuit breaker.

If this does not correct the problem, use a VOM to test

the circuit breakers.

Test Results:

A. Problem is corrected by resetting Breaker: STOP test.

7. Set Switch to STOP. Meter should indicate infinity.

8. Connect one meter probe to the Wire 18 terminal of

Switch, and connect the remaining test probe to Wire 0

(ground) terminal. With Switch at START, VOM should

indicate infinity. Hold Switch at STOP and meter should

read continuity.

Test Results:

A. Start/Stop Switch SW1 checks GOOD: Go to Step 2.

B. Circuit Breaker tests GOOD, still little or no a-c output:

Go to Step 2.

C. Circuit Breaker tests BAD: Replace Circuit

Breaker(s).

Step 2 - Check Vehicle Wiring

Test Procedure: Check vehicle a-c wiring and a-c dis

tribution components.

Test Results:

A. Vehicle wiling checks GOOD: Go to Step 3

B. Vehicle wiring checks BAD; Repair or replace as

needed.

Step 3 - Check a-c Voltage and Frequency

Test Procedures: Check generator a-c output voltage

frequency (Fig. 14) as follows:

1. Disconnect generator a-c output leads T1 (red), T2

(white) and T3 (black) in the junction box where they

connect to vehicle wiring.

2. Connect an accurate a-c voltmeter and frequency

meter across generator a-c output leads T1 (red) and T2

(white).

19

Page 22

3. Start the generator engine, let it stabilize and warm up

at NO-LOAD.

Figure 14. Test Points fora-c Voitage/Frequency

4. Read the no-load a-c voltage and frequency. Indicated

readings should be 124 volts at 62 Hz.

Test Results:

A. Voltage and Frequency check GOOD: Go to Step 4.

B. Voltage and Frequency are both high or low: Go to

Step 5.

time. This total should be less than the generator’s rated

wattage/amperage capacity. Reduce electrical loading

as necessary.

B. A ground fault condition may exist in the generator or

on one or nwre connected electrical loads. This can

increase current flow dramatically and may cause circuit

breakers to trip. See INSULATION RESISTANCE

TESTS on Page 9.

C. Loss of engine power may have occurred. Check

engine for adequate air flow, clogged air cleaner, incor

rect ignition timing, mechanical failure, incorrectly ad

justed carburetor, etc. Complete repairs to engine as

necessary.

Step 5 - Check/Adjust Engine Governor

Test Procedure: If the no-load voltage and frequency

are both correspondingly high or low, adjustment of the

engine governor may be required. See ADJUSTMENTS

section. Following governor adjustment to the correct a-c

frequency, the a-c voltage must be checked. If engine

speed (frequency) is correct but a-c voltage is not, adjust

ment of the Electronic Voltage Regulator may be re

quired.

Test Results:

A. Voltage and Frequency are correct: STOP tests.

C. Low or no a-c voltage: Go to Step 6.

D. Frequency GOOD, Volts HIGH: Go to Step 10.

Step 4 • Check Load Voltage and Frequency

NOTE: If the no-load voltage and frequency were

within specified limits but operational problems

occur when electrical loads are applied, check the

a-c voltage and frequency under load.

Test Procedure: Proceed as follows:

1. Check that load leads are properly connected to a-c

output terminals T1 (red), T2 (white) and T3 (black).

2. Connect an accurate a-c voltmeter and frequency

meter to a-c output leads. Connect meters across leads

T1 (red) and T2 (white).

3. Start the generator engine, let it stabilize and warm up.

Then, turn ON electrical loads by whatever means

provided (such as doubie throw switch or circuit breaker).

Apply loads as dose as possible to the unit’s rated

maximum continuous wattage/amperage capacity.

4. With rated loads applied, check the a-c voitage and

frequency readings. Voitage shouid be at least 116 volts;

frequency should be at least 58 Hz (or higher).Test

Results: If voltage and frequency are good at no-load

but drop excessively when electrical loads are applied,

check the following.

________________

B. Voitage/Frequency still incorrect. Go to Step 6.

Step 6 - Check Field Boost Circuit

NOTE: Some "residual" magnetism Is normally

present in the Rotor (revolving field). This residual

magnetism should be adequate to create the neces

sary "pickup" voltage In the Stator windings. For

that reason, failure of the Field Boost function will

not usually cause a problem unless the Rotor's

residual magnetism Is also lost.

Test Procedure: Test the Field Boost circuit as follows

(Figure 15):

1. Disconnect Wires 4 from Pin 2 of the Choke Module

CM.

___________________

A. Generator may be overloaded. Add up the wattage or

amperage of all electrical loads being operated at one

20

Page 23

2. Connect the positive (+) test iead of the a d-c voitnieter

to Pin 2 of Choke Moduie CM. Connect negative (-) test

iead to a ciean frame ground.

3. Crank the engine. The voitmeter should indicate about

7-10 volts d-c with engine cranking.

Test Results:

A. Engine won’t crank: Go to Problem No. 1.

B. Engine cranks but no d-c voltage is indicated: Replace

Choke Module CM and recheck for proper voltage. If

voltage is good, STOP test.

C. Engine cranks and normal voltage is indicated: Con

tinue test.

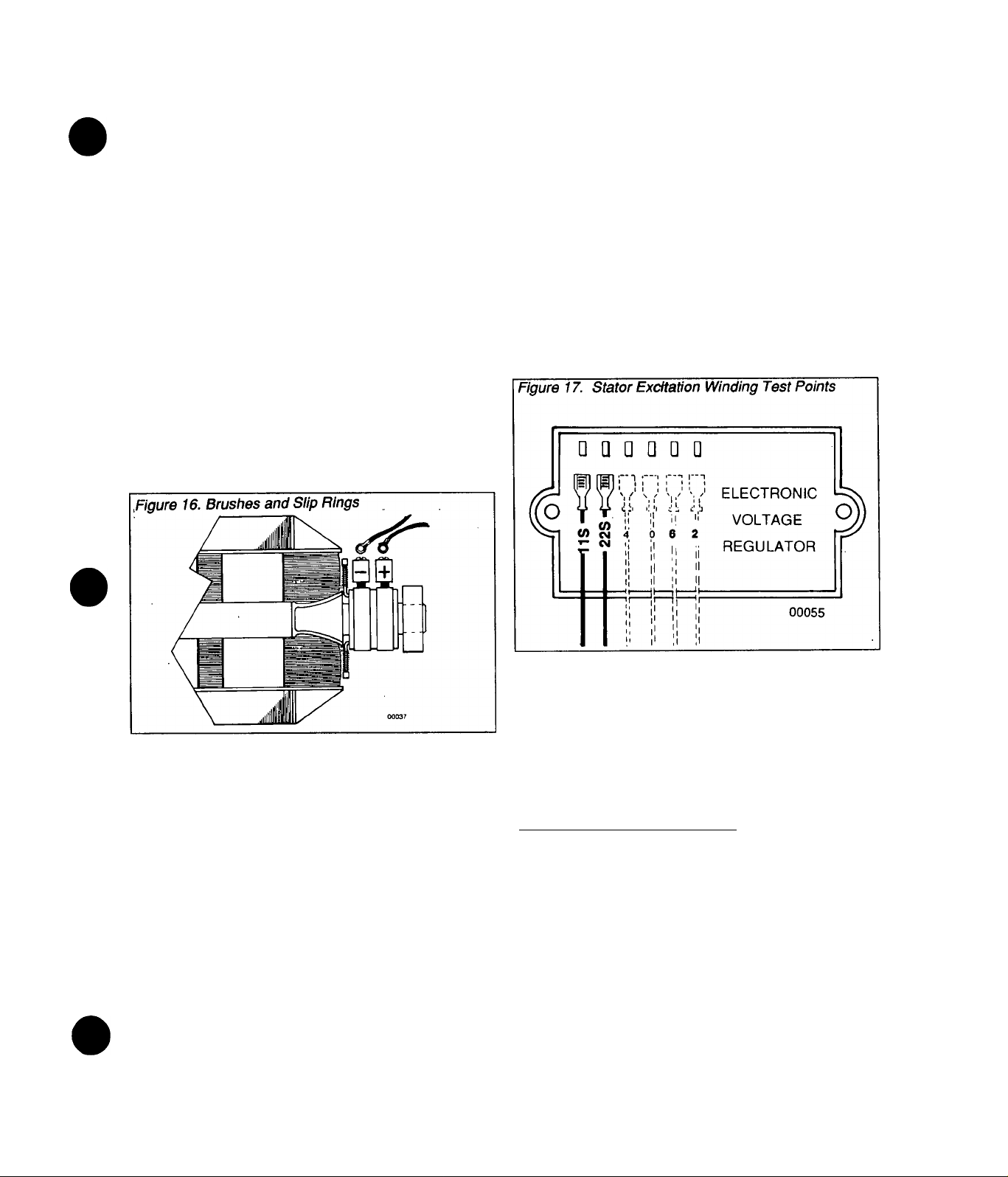

4. Gain access to Brushes and Slip Rings (Fig. 16).

5. Connect the positive lead of a d-c voltmeter to the

terminal of the positive (+) brush (RED lead connection).

Connect voltmeter test lead to a clean frame ground.

6. Crank engine. The voltmeter should indicate about

7-10 volts d-c with engine cranking.

Step 7 - Check Stator Excitation Windings

Test Procedure: Disconnect Stator Excitation Winding

output leads 2 and 6 (Fig. 17) from the Electronic Voltage

Regulator. Set a VOM to its "Rxl" scale and zero the

meter. Connect VOM test leads across terminal ends of

Wires 2 and 6. The VOM needle should swing upscale

and Indicate the following resistance:

NP45G Units = 2.2 Ohms

NP55G Units = 1.8 ohms

NP65G Units = 1.6 ohms

*AII resistance values are plus or minus 10%.

Now, set the VOM to its "Rxl 0,000" scale and again zero

the meter. Connect one VOM test lead to Wire 2, and the

remaining test lead to a dean frame ground. You should

not detect any upscale movement (infinity) of the VOM

needle.

Test Results:

A. Engine won’t crank: Go to Problem No. 1

B. Engine cranks and no d-c voltage indicated, but volt

age was indicated in Item 3 of test: Repair or replace

Wire 4 between Choke Module CM and the positive (+)

brush.

C. Engine cranks and normal voltage indicated: Go to

Step 7.

Test Results:

A. Excitation windings check GOOD: Go to Step 8. .

B. Excitation windings check BAD: Replace Stator As

sembly.

NOTE: Also see INSULATION RESISTANCE TESTS

on Page 9. Typically, In the above test, a low resis

tance indicates a shorted condition; a high reslstance Indicates an open condition.

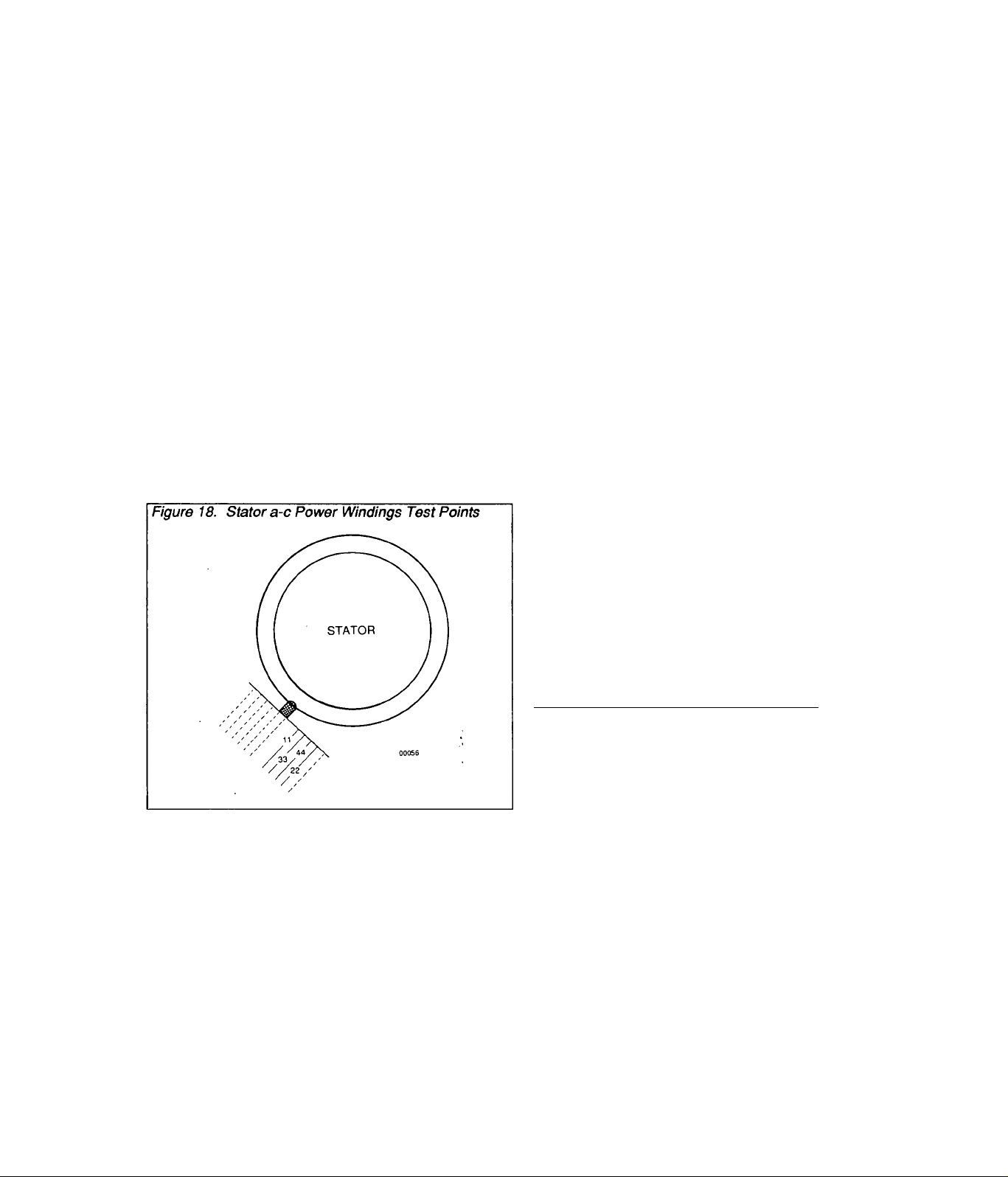

Test 8 ■ Check Stator a-c Power Warnings

Test Procedure:, Test the Stator (Fig. 18) a-c power

windings as follows:

1. Disconnect a-c power winding output leads 11 and 22

from the Electronic Voltage Regulator.

2. Disconnect a-c power winding output lead 33 from

Circuit Breaker CB1.

3. At the wire nut junction of a-c output leads 22 and 44,

separate the two wires.

_________________

21

Page 24

4. Set a VOM to its "Rx1" scale and zero the meter.

Connect VOM test leads across wire ends of Wires 11

and 22 and note the resistance reading, in ohms. Resis

tance should be as follows (plus or minus 10%);

NP45G Units = 0.4 ohms

NP55G Units = 0.3 ohms

NP65G Units = 0.2 ohms

5. Connect VOM test leads across wire ends of Wires 33

and 44. Again, note the resistance. Resistance should

be the same as in Item 4 above.

6. Set VOM to its "Rxl 0,000” scale and zero the meter.

Connect one VOM test lead to Wire 11 and the second

test lead to frame ground. The VOM needle should not

move upscale (infinity). Now, connect one test lead to

Wire 33 and the second lead to frame ground. Meter

should indicate infinity.

Test Results:

A. Power Windings check GOOD: Go to Step 9.

B. Power Windings check BAD: Replace Stator Assemb

ly-

2. Set a VOM to its "Rxl: scale and zero the meter.

Connect VOM positive (+) test lead to the positive (■<-) Slip

Ring (nearest the Rotor bearing). Connect negative (-)

VOM test lead to the negative (-) Slip Ring. Meter should

indicate the following resistance (plus or minus 10%) at

20°C (68®F).

NP45G Units =13.9 ohms

NP55G Units = 15.5 ohms

NP65G Units = 11.1 ohms

3. Reassemble Brushes and Brush Holder, retain Brush

Holder and Wires. Make sure Brushes are properly

seated in Brush Holder and are contacting the Slip Rings

properly. Rotate Rotor several times to seat Brushes

against Slip Rings.

Test Results:

A. Rotor circuit checks GOOD: Go to Step 10.

B. Rotor circuit tests BAD: Repair or replace defective

wire(s) or brushes. Replace defective Rotor Assembly.

Step 10 - Check Voltage Regulator Sensing

NOTE: Sensing signals to the Electronic Voltage

Regulator are delivered via Wires 11 and 22. Loss of

these sensing signals to the Regulator due to an

open or shorted condition (in a non-compensated

Regulator) normally means a "Full Field" condition

and resultant high a-c voltage output. However, the

NP series generators are equipped with a VoHage

Regulator that provides automatic protection

against an open sensing circuit and the resultant

high voltage condition. Should sensing wires 11 or

22 open, Voltage Regulator action will automatically

open the Excitation circuit to the Rotor and a-c

output voltage will drop dramatically. Total a-c volt

age output from the Stator a-c power windings will

be a result of residual Rotor magnetism only.

Step 9 - Check Rotor (Field) Circuit

Test Procedure: Use a VOM to test Wire 4, between

Electronic Voltage Regulator and Choke Module for open

or shorted condition. Wire 4 between Choke Module and

Brushes was previously tested in Step 6. Then, inspect

brushes and slip rings and test Rotor as follows:

1. Remove Wires 4 and 0 from Brushes, then remove

Brush Holder. Inspect Brushes and Brush Holder.

Replace if cracked, damaged, worn excessively, etc.

Inspect Slip Rings. If they are dull or tarnished, polish

with fine sandpaper. DO NOT USE ANY METALLIC

GRIT TO CLEAN SLIP RINGS. Use low pressure air (25

psi or less) to blow away cleaning residue.

Test Procedure: Recheck Wires 11 and 22, between the

Electronic Voitage Regulator and the Stator, as outlined

in Step 8.

Test Results:

A. Wires 11 and/or 22 indicate open or shorted condition:

Repair or replace wires as necessary.

B. Wires 11 and 22 check GOOD: Go to Step 11.

Step 11- Check/Adjust Voltage Regulator

Test Procedure: Refer to ADJUSTMENTS section.

With correct a-c frequency indicated, try adjusting the

Voltage Regulator. Frequency and voltage must both be

within the specified limits.

Test Results:

A. Frequency GOOD, cannot adjust in the correct volt

age: Replace the Voltage Regulator, adjust and test unit.

B. Frequency and Voltage both GOOD: STOP tests.

22

Page 25

ENGINE TROUBLESHOOTING

General

Most problems pertinent to engine operation may be clas

sified as one (or a combination) of №e following:

1. Will not start

2. Hard Starting

3. Lack of power

4. Vibration

5. Overheating

6. High oil consumption

When the cause of a problem is not readily apparent, per

form a check of the engine’s Compression, Ignition and

Carburation systems. Checkout of these systems, if per

formed in a systematic manner, can usually be done in a

few minutes. It is the fastest and surest method of finding

the cause of a problem.

What appears to be an engine problem may sometimes

be caused by the system that the engine is driving. For

example, overloading the generator (exceeding its wat

tage capacity) can cause the same indications as an un

derpowered engine. A shorted condition in the generator

or in electrical loads connected to the generator can also

appear to be an underpowered engine.

Checking Engine Compression

For instructions and information on checking engine com

pression, refer to the ENGINE SERVICE MANUAL. If

compression is poor, look for:

1. Loose spark plug(s)

2. Loose cylinder head bolts

3. Blown head gasket(s)

4. Burned valves or valve seats

5. Insufficient valve tappet clearance

6. Warped cylinder head(s)

7. Warped valve stems

8. Worn cylinder bore and/or rings

9. Broke connecting rod(s)

Check Engine ignition

Checkout and servicing of the engine ignition system is

discussed in detail, in the ENGINE SERVICE MANUAL.

To check ignition system operation, connect a SPARK

TESTER to the end of a the Spark Plug wires. Then, crank

the engine with both spark plugs removed. If a hot blue

spark jumps the Spark Tester gap, you may assume the

Ignition System is working properly. If spark jumps the

Tester gap, you may wish to try new spark plugs. If spark

does NOT jump the Tester gap, look for:

1. Defective gnition Module(s) IM1 and IM2

2. Defective Ignition Shutdown Module ISD

3. Defective Control Relay CR2

NOTE: If engine runs but misses during operation,

check to see If Ignition System Is at fault by connect

Ing the Spark Tester between the high tension Spark

Plug wire and the Spark Plugs. A spark miss will be

readily apparent

Check Carburetion

See TROUBLESHOOTING GUIDELINES. Before

making a carburetion check, make sure (a) an adequate

supply of fuel is available, (b) all fuel shutoff valve(s) are

open, and (c) fuel flow is adequate. Try adjusting the en

gine carburetor. Check automatic choke operation and

make sure the choke is adjusted property. If engine will

not start, remove and Inspect the Spark Plug.

If Spark Plug is WET, look for:

1. Overchoking

2. Excessively rich fuel mixture

3. Water in fuel

4. Intake valve stuck open

If Spark Plug is DRY, look for:

1. Leaking carburetor gasket(s)

2. Dirty or gummy carburetor

3. Intake valve stuck closed

4. Inoperative fuel pump

A simple check to determine if fuel is reaching the com

bustion chamber is to remove the spark plugs and pour

a small amount of gasoline through the Spark Plug hole.

Install and tighten Spark Plugs. Crank engine. If engine

fires a few times and then stops, look for the same con

ditions as a dry plug.

Other Problems that Might Affect Engine

Operation

1. Hard Starting or Will Not Start

a. Loose drive belts or pulleys- these can cause a

"backlash" effect that will counteract engine cranking

effort.

b. Starting under load- attempting to start with heavy

electrical loads applied can often cause problems.

c. Shorted condition in the generator or in connected

electrical loads can impose a heavy load on the en

gine, thus preventing start.

2. Vibration

a. Check for defective or damaged pulleys, drive

belts, or Rotor.

b. Check for loose mounting bolts and tighten.

3. Power Loss ■

a. Check for binding or drag in drive train (pulleys

and belts)

b. Check for defective Rotor bearing.

c. Check for Rotor contact with Stator windings.

d. Check for excessive drive belt tension.

4. Noise

a. Check for a damaged Rotor and/or Stator

b. Check for loose or damaged pulleys and drive

belts.

23

Page 26

ADJUSTMENTS

General

This section is inciuded with other a-c generator informa

tion, because the covered information is so important to

proper generator operation and correct a-c output. The

engine governor adjustment may belong in the ENGINE

SERVICE MANUAL. However, that adjustment is so

important to correct a-c output frequency and voltage that

it is included here.

Adjustments included in this section include thefollowing:

1. Engine governor adjustment.

2. Voltage Regulator adjustment

3. Automatic Choke adjustment.

NOTE: An optional LP gas (propane) fuel system Is

available for use with the NP series generators.

Instructions for the installation and adjustment of

the LP gas conversion kit are Included with the kit.

Engine Governor Adjustment

A Also see ROTOR ROTATIONAL SPEED on Page 4

of this Manual. The engine governor is generally ad

justed to deliver a generator a-c output frequency of

61-62 Hz, with no electricai loads connected to the gen

erator. Following the no-load adjustment of engine

speed, unit operation shouid be checked with a ioad

applied. Adjust the engine governor as foiiows:

6. Check a-c frequency; it should be 61 -63 Hz. If not, turn

ADJUSTER NUT until frequency is correct.

7. With governed speed at 61-63 Hz (no-load), check

voltage reading. Voltage should be 122-126 volts. If not,

adjustment of the Voltage Regulator is required.

1. Visually inspect ANTI-LASH SPRING, make sure it is

not broken or disengaged. Spring ends must be hooked

into GOVERNOR LEVER at bottom end and into car

buretor THROTTLE LEVER at top.

2. Loosen GOVERNOR CLAMP NUT.

3. Push spring end of GOVERNOR LEVER ail the way

up, to wide open throttle position. While holding the

LEVER down, insert a screwdriver into siotted end of

GOVERNOR SHAFT and rotate SHAFT fuliy

counterclockwise. Then, tighten the GOVERNOR

CLAMP NUT to 100 inch-pounds of torque.

CAUTION!: Governor shaft MUST be rotated fully

counterclockwise with throttle wide open or full

governor travel will not be reached. Governor clamp

nut must be tight Or full governor travel may be lost

due to vibration.

4. Connect an accurate a-c frequency meter and

voltmeter across generator a-c output leads T2 (white)

and T3 (black) for Series NP45G/NP55G; or across ieads

T1 (red) and T2 (white) for Series NP65G. See Step 3

under Probiem No. 6 on Page 19. (Check A-C VOLTAGE

AND FREQUENCY).

5. Start the engine. Let it stabilize and warm up for a few

minutes with NO ELECTRiCAL LOADS APPLiED TO

GENERATOR.

__________________________________

Voltage Regulator Adjustment

CAUTION: DO NOT adjust the Voltage Regulator

until a-c output frequency Is correct. See ENGINE

GOVERNOR ADJUSTMENT.

B Check that a-c frequency is correct, as outiined in

ENGiNE GOVERNOR ADJUSTMENT. If frequency Is

within stated limit (61-63 Hz), a-c voltage output should

be 122-126 volts. If voltage is not correct, adjust the

Voitage Regulator by turning the VOLTAGE ADJUST

potentiometer slowly until a-c voltage Is within the stated

limits. Voltage regulator is mounted in the generator

24

Page 27

Automatic Choke Adjustment

C Check automatic choke operation and (if necessary)

adjust the choke as foiiows:a. Check Choke Operation:- Crank the engine whiie ob

serving automatic choke operation, initiaily, the Choke

Soienoid shouid energize to dose choke for about 0.2 to

0.4 seconds and then de-energize for about 2 seconds to

open the choke. This open/ciose cycie shouid repeat itseif untii the engine starts and cranking is terminated.

b. Pre-Choke Adjustment:- With engine cold and Choke

Solenoid NOT actuated, check that carburetor choke

plate is about 1/8 Inch away from its full open position. If

necessary to obtain the desired setting, use needle nose

pliers to bend tip of BI-METAL.

c. Choke Solenoid Adjustment:- Loosen screws that

retain the CHOKE SOLENOID to its retaining bracket.

Slide the CHOKE SOLENOID in the slotted holes to ad

just axial movement of the SOLENOID plunger. Adjust

the axial movement so that, with the carburetor choke

plate closed, the CHOKE SOLENOID plunger Is just bot

tomed in the solenoid coil (plunger at full actuated posi

tion). With choke plate closed and plunger bottomed in

the coil, tighten the two screws. Then, crank engine and

check choke operation.

25

Page 28

Drawing No. 75464

Page 29

Exploded View of Sheet Metal

Drawing No. 75464

'EM

1

2

3 67198-N

4

5

6

7 74904

8 56892

9

10

11

12

13

14

15

16

17

18

19 73191

20

21

22

23 11-74260

24

25

26

27 22717-B 1 GROMMET. Rubber

28

29 67866

30 74955

31 74965

32

33

34 48031-E

35

36 74956

37 42907

38

39

40

41

42 29289

43

PART NO.

67877 1

67890

74915 1 SCREEN, Air Inlet

63036 6

70520

74903

74916

74908 8

73190

73189

73188

74902

43146 4

22097 4 LOCKWASHER- M6

48571

22129 2

75246

74900

73186

23484-D 1

22717-A 2 GROMMET, Rubber

22447 1

40936

47662-BB

46509

08-74260

09-74260

48031-D

73132

REQ’D DESCRIPTION

1 ENGINE ASSY (See EXPLODED VIEW OF V-TWIN

ENGINE)

KEY. Woodruff- 6 X 25

1 WASHER, Belleville

1

1

22

1 MODULE, Shorting

1

1

1 WRAPPER- No. 2 Cylinder

1

1

2 WRAPPER, Barrel

1

2

4

1 WIRE ASSY- No. 16

1 COVER, Starter

1

1

1

1

1

1 CLAMP, Hose

1

1 BRACKET, Oil Makeup Pump

1

1

1

1 WIRE ASSY (Ground)-15" long

2 CLAMP, Hose

2 TAPE, Foam

2 BOOT, Spark Plug

NUT, Hex-M20-1.50

SCREW (Crlmptite)- No. 8-32 x 1/4"

HOUSING, Engine Top

SCREW (Crlmptite)- No. 10-32 x 3/8"

SCROLL, Flywheel

COVER, Base #2

SCREW (Taptite)- M5 x 10mm

COVER. Valley

WRAPPER- No. 1 Cylindert

CAPSCREW, Hex Head- M6-1.00 x 10mm

COVER, Base- No. 1 Cylinder

CAPSCREW, Hex Head- M8-1.25 x 10mm

LOCKWASHER- M8

SCREW (Taptite)- 3/8"-16 x 1/4"

WRAPPER, Crankcase

BUSHING, Snap

O-RING

PROBE, Oil Makeup

RETAINER, Oil Makeup Probe

WASHER (Shakeproof)- M6

SCREW, Socket Head- M6-1.00 x 8mm

HOSE- 5/16" ID

CAPSCREW, Hex Head- M8-1.25 x 16mm

PUMP, Oil Makeup

WIRE ASSY (Ground)- 5.5" long

27

Page 30

Drawing No. 75218

28

Page 31

Exploded View of Base & Pulleys

Drawing No. 75218

ART NO.

1 72372 1

2

72382

3 38353

25017 4

4

22237 12

5

22241

6

7

72391

73147 2

8

45771

9

10 52858

11 51730

12 29459

75215

13

14

73146

15 75209

73174

16

67897 1

17

55173

18

19 72383

56892

20

75224-A

21

A

V

75224-B

75224-C

73106-A 1

ZZ

73106-B

73106-C

75216

23

24 49451

25 42633

26 72381

27 73118

28 74906

74908 9

29

72375

30

31 73185

32 22097

74909

33

75242