Page 1

POWER SYSTEMS, INC.

H-100 Control Panel

®

Technical Manual

This manual should remain with the unit.

Page 2

IMPORTANT SAFETY INSTRUCTIONS

H-100 Control Panel Technical Manual

SAVE THESE INSTRUCTIONS – The manufacturer suggests that these rules for safe operation

be copied and posted in potential hazard areas. Safety should be stressed to all operators

and potential operators of this equipment.

Study these SAFETY RULES carefully before installing, operating, or servicing this equipment. Become

familiar with this manual and all literature pertaining to the generator set and related equipment. This

equipment can operate safely, efficiently, and reliably

only if it is properly installed, operated, and maintained. Many accidents are caused by failing to follow

simple and fundamental rules or precautions.

Generac cannot anticipate every possible circumstance that might involve a hazard. The warnings in

this manual, and on tags and decals affixed to the

equipment, are, therefore, not all inclusive. If using

a procedure, work method, or operating technique

the manufacturer does not specifically recommend,

ensure that it is safe for others. Also make sure the

procedure, work method, or operating technique utilized does not render the equipment unsafe.

GENERAL HAZARDS

For safety reasons, the manufacturer recommends

•

that this equipment be installed and serviced by

an Authorized Service Dealer or other qualified

electrician or installation technician who is familiar with applicable codes, standards, and regulations. The operator also must comply with all such

codes, standards, and regulations.

When working on this equipment, remain alert

•

at all times. Never work on the equipment when

physically or mentally fatigued.

Inspect the equipment regularly, and promptly

•

repair or replace all worn, damaged or defective

parts, using only factory-approved parts.

Before performing any maintenance on the gen-

•

erator or any related equipment, disconnect the

generator’s battery cables and remove panel fuse

to prevent accidental startup. Disconnect the cable

from the battery post, indicated by a NEGATIVE,

NEG, or (–) first. Reconnect that cable last.

Do not handle any kind of electrical device while

•

standing in water, while barefoot, or while hands or

feet are wet. DANGEROUS ELECTRICAL SHOCK

MAY RESULT.

If people must stand on metal or concrete while

•

installing, operating, servicing, adjusting, or repairing this equipment, place insulative mats over a

dry wooden platform. Work on the equipment only

while standing on such insulative mats.

Wire gauge sizes of electrical wiring, cables, and

•

cord sets must be adequate to handle the maximum electrical current (amperage) to which they

will be subjected to.

Before installing or servicing this equipment, make

•

sure that all power voltage supplies are positively

turned off at their source. Failure to do so will result

in hazardous and possibly fatal electrical shock.

When installed with an automatic transfer switch,

•

the generator may crank and start anytime, without warning. To prevent injuries caused by sudden

start-up, disable the generator’s automatic start

circuit before working on, or around, the unit.

Then, place a “Do Not Operate” tag on the generator control panel and on the transfer switch.

In case of an accident caused by electric shock,

•

immediately shut down the source of electrical

power. If this is not possible, attempt to free the

victim from the live conductor. AVOID DIRECT

CONTACT WITH THE VICTIM. Use a nonconducting implement, such as, a rope or board, to free

the victim from the live conductor. If the victim

is unconscious, apply first aid and get immediate

medical help.

Never wear jewelry when working on this uipment.

•

Jewelry can conduct electricity, resulting in electric

shock, or may get caught in moving components,

causing injury.

FIRE HAZARDS

ELECTRICAL HAZARDS

Generators produce dangerous electrical voltages

•

and can cause fatal electrical shock. Avoid contact

with bare wires, terminals, connections, etc., while

the generator and related equipment are running.

Ensure all appropriate covers, guards, and barriers are in place before operating the equipment.

If working around an operating unit, stand on an

insulated, dry surface to reduce potential shock

hazards.

• For fire safety, the generator and related equipment must be installed and maintained properly.

Installation always must comply with applicable

codes, standards, laws, and regulations. Adhere

strictly to local, state, and national electrical

and building codes. Comply with regulations the

Occupational Safety and Health Administration

(OSHA) has established. Also, ensure that the

equipment is installed in accordance with the

manufacturer’s instructions and recommendations. Following proper installation, do nothing

that might alter a safe installation and render the

unit in noncompliance with the aforementioned

codes, standards, laws, and regulations.

Page 3

Table of Contents

H-100 Control Panel Technical Manual

Table of Contents

Safety Rules ........................................ Inside Front Cover

General Information ......................................................... 2

Introduction .................................................................... 2

Features .......................................................................... 2

Panel Setup ..................................................................... 2

Changing the Controller Configuration ........................2

Customization .............................................................. 2

The Measurement “Engine” ............................................. 3

Analog Channels .......................................................... 3

Analog Maths ............................................................... 3

Analog Alarms .............................................................4

Other Analog Options ..................................................5

Analog Sensor Ratings ................................................. 5

Output Functions ............................................................5

Spare Analog Channels ................................................ 5

Engine Management ........................................................ 6

Generator Parameters ..................................................6

Engine Settings ............................................................6

Starting and Stopping - Sequence Diagrams ................... 7

Voltage Regulator (Option) .............................................. 8

Governor (Speed Regulator) Option ................................ 8

Trending .........................................................................9

Remote Trending ......................................................... 9

Local Trending ...........................................................10

GenLink Local Trending Setup .................................. 10

Trigger/Collection Type ..............................................13

The ILC ......................................................................... 10

The Front Panel Display ................................................ 11

Left Display ................................................................ 11

Right Display ............................................................. 11

Left Display Pages ...................................................... 11

Right Display Pages .................................................... 13

Alarms .......................................................................13

Engine ........................................................................... 14

Status ............................................................................16

Service .......................................................................... 17

Generator ...................................................................... 18

Diagnostics ....................................................................19

Exercise/HTS ................................................................ 21

The Control Panel ......................................................... 23

The Alarm Log .............................................................. 23

The Event Log ............................................................... 23

Maintenance Settings .................................................... 24

Air/Fuel Ratio Control (Option) .....................................24

2

I

T Current Monitoring (Option) ................................... 24

Internal Exercise Function ............................................25

QuietTest® Setup Using GenLink ..................................25

Normal Exercise Setup Using GenLink ......................... 26

QuietTest® Setup Using Front Panel .............................. 27

Set Date and Time ........................................................ 33

Date and Time Setup Using GenLink ......................... 33

Date and Time Setup Using Front Panel .................... 33

Adjust Display Contrast ................................................ 34

Enable Generac Commercial Transfer Switch (HTS) .... 35

HTS Setup Using GenLink .........................................35

HTS Setup Using Front Panel ....................................35

Communications ........................................................... 37

Remote Annunciator Connection (Option) .....................37

New Generation GenLink (NGG) ................................... 37

GenLink Relay Control .............................................. 37

Set Engine Hours .......................................................37

Absolute Maximum Ratings ....................................... 37

Environmental Ratings ..............................................37

Appendix ............................................................................ 38

Appendix A — Analog Functions ...................................38

Appendix B — H-100 General I/O and Connector

Information ........................................... 40

H-100 Analog Inputs .................................................. 40

H-100 Digital Outputs ................................................41

H-100 Digital Inputs .................................................. 41

H-100 Digital Output Functions ................................. 42

H-100 Connector Pin Descriptions ............................46

Appendix C — Miscellaneous H-100

Internal Alsrms/Warnings ......................47

Notes ...................................................................................48

AUTHORIZED SERVICE

DEALER LOCATION

To locate the nearest AUTHORIZED SERVICE

DEALER, please call this number:

1-800-333-1322

DEALER LOCATION INFORMATION

CAN BE OBTAINED AT THIS NUMBER,

or visit the website at www.generac.com.

1

Page 4

General Information

H-100 Control Panel Technical Manual

INTRODUCTION

The H-100 Control Panel is an electronic control box

that functions as an advanced standby generator

controller. Its technology is based on the flagship PMDCP system with all its flexibility included. A familiar

user interface in the form of GenLink®-DCP is used

to program, monitor and change the parameters in

the unit. The interface appears the same as it does

for the PM-DCP.

Specialized programs are built into the H-100 Control

Panel to allow customers to configure spare I/O to

their own needs. For example, built in Integrated

Logic Controller (ILC) logic can eliminate the need

for ancillary external controllers. Everything can be

user customized from measurements to alarms to

the screen displays.

Why do we do this? Having one set of control firmware buys us the economy of scale which can be

passed on to the customer. It also has great technical

advantages. The H-100 Control Panel and all PM-DCP

products are built around a common “core” of firmware. This provides EVERY product with the same

technical tools. For example, both the H-100 Control

Panel and PM-DCP products can call out for assistance via a modem, every product can provide trending data for its measured parameters, any measured

value can be setup to create alarms or warnings, each

product has a built in ILC, etc. H-100 Control Panel

is very flexible.

FEATURES

Local/remote connection to a PC for GenLink®-

•

DCP communication.

Interface with up to four Generac Commercial

•

Transfer Switches (HTS).

Interface with up to two Remote Annunciator

•

Panels.

Customizable display.

•

New Generation GenLink.

•

Built-in Frequency and Voltage controller.

•

External modem option with dialout capability

•

upon alarm.

Communication via standard CAN bus and Modbus

•

protocols.

Programmable I/O channel properties.

•

Programmable alarm/warnings.

•

Alarm and event logging with time stamping.

•

Parameter logging and trending both to file and

•

graphical.

Built-in diagnostics.

•

Internal ILC for combinatorial logic functions

•

including analog inputs.

Spare customer programmable Analog input capac-

•

ity.

Spare customer programmable Digital I/O capac-

•

ity.

•

Firmware can be updated via Telephone line.

2

PANEL SETUP

CHANGING THE CONTROLLER

CONFIGURATION

The H-100 Control Panel controller is setup in the

factory to match the product it is shipped with and

generally no changes are required. For spares purposes the controller can be re-configured in the field

using the GenLink software tool and a PC.

If you need to change the function of the panel the

best way to get a basic setup for a product is to use

GenLink to download a “product file”. This will setup

all the basic parameters and just leave customization

and calibration to be done. Product files are available

on the web site for downloading cross referenced to

product serial numbers/generic product types. The

manufacturer does not recommend changing the

settings individually for a product as this is laborious and prone to human error. Some of the settings

require detailed knowledge of things like governor

settings which are not easily discernable.

Some configurations are changeable from the H-100

Control Panel touch pad and displays. These configurations will be described later and include:

Setting Display Contrast

•

Setting System Time and Date

•

Setting up/Enabling Internal Exercise

•

Enabling Interface with Generac Commercial

•

Transfer Switch (HTS)

CUSTOMIZATION

The controller is designed to be very flexible and

allow great levels of customization via the GenLink

tool. Once you have customized your controller, you

should save the settings away to floppy or hard disk

for backup. This can be done during the customization process, or at any time subsequent to customization by uploading the settings from the controller to

GenLink and then saving them to disk. The digital

outputs can be set to turn on from any one of a list

of functions, or they can be used as part of the builtin ILC. The digital inputs can be moved, inverted,

renamed, given delay times, made alarms, used

in the ILC, logged/not logged, etc. Refer to the section “MEASUREMENT ENGINE” for details. Analog

inputs are dealt with in the same section.

There are some parameters which are specific to the

product, such as an engine controller or transfer

switch. These are all customizable via GenLink. Refer

to the relevant section for details.

Page 5

THE MEASUREMENT "ENGINE"

The measurement “engine” is the key feature of the

system. All the inputs to the controller are processed

by this module. Each physical input is measured and

the result processed by an individual set of rules that

are set via a PC and GenLink. Normally, a product

is delivered with the inputs and outputs pre-configured and nothing needs to be done, however the

manufacturer has provided complete flexibility to

each measurement (except where product safety is

concerned). The inputs are divided into analog and

digital channels.

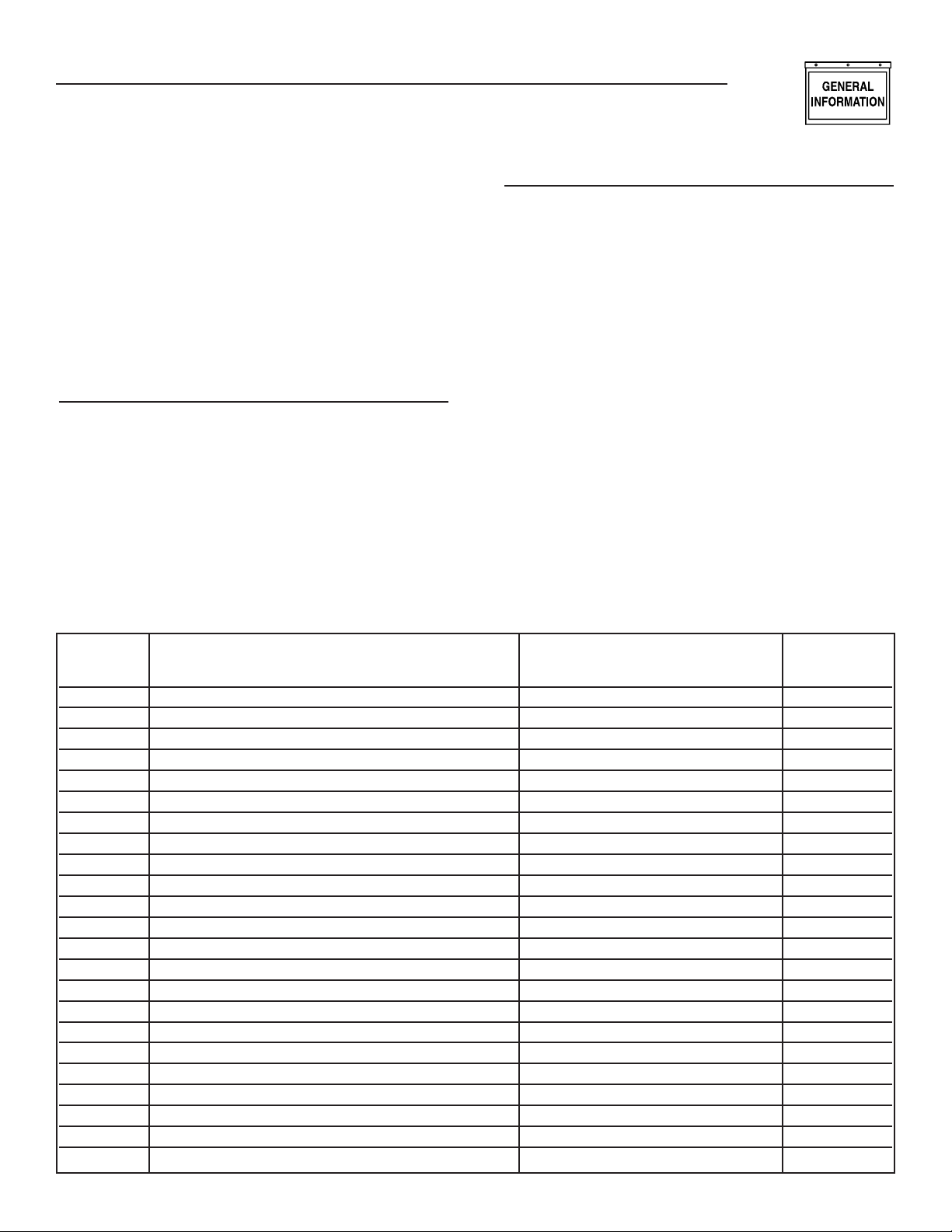

ANALOG CHANNELS

There are 23 analog channels of which 14 have fixed

functions. The remaining 9 channels are split between

product specific inputs (such as oil temperature),

and customer spares. The exact split depends on the

product. Table 1 shows the channel allocation.

Some of the 14 fixed channels are “DERIVED” readings in that they are calculated from the other readings. For example, power is calculated from both voltage and current. These are not real hardware channels, but they result in an analog reading that can be

treated as a “fixed channel” just like any other.

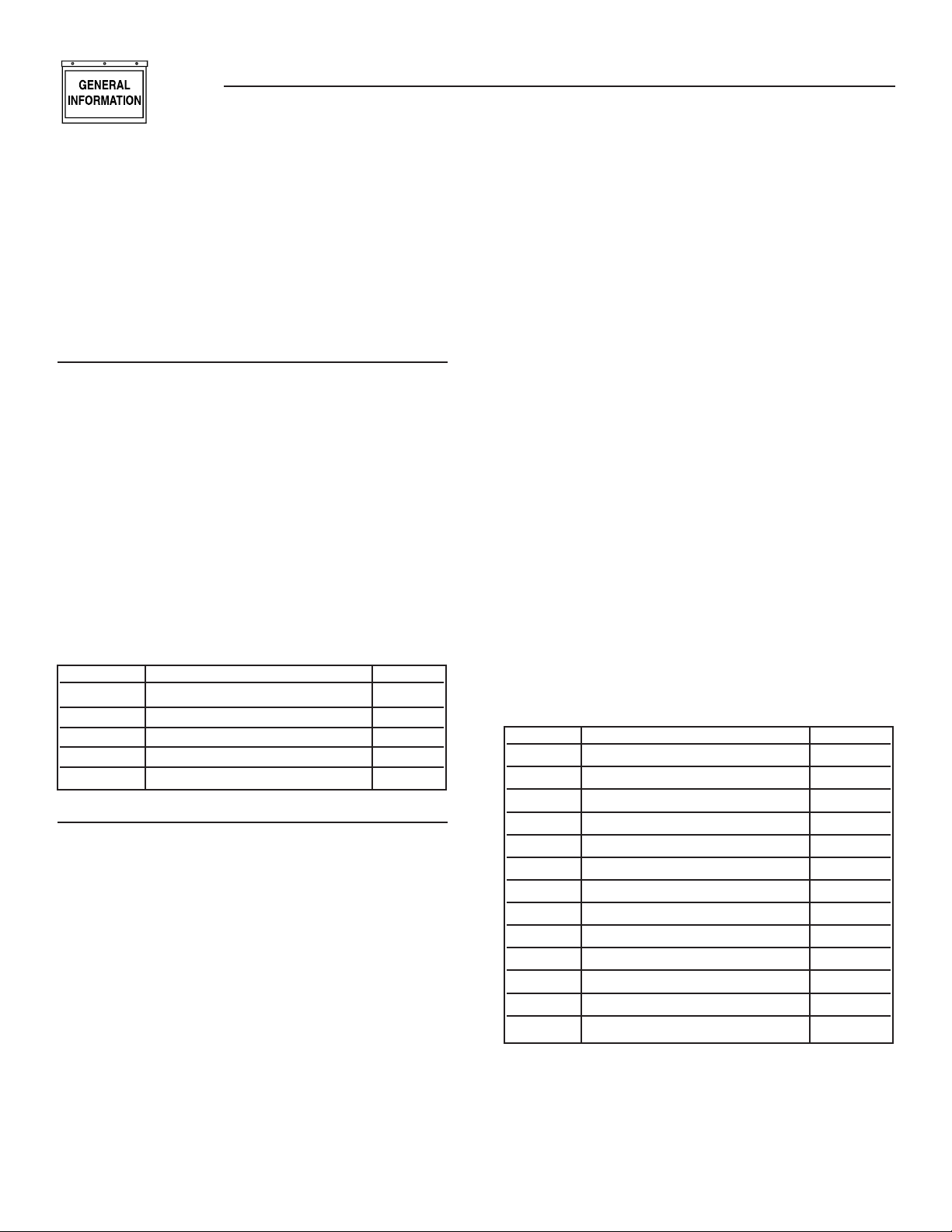

Table 1

General Information

H-100 Control Panel Technical Manual

ANALOG MATHS

Each of the 23 channels is processed by a set of measuring rules using constants that are set via GenLink.

Usually these constants can be changed by the customer. In the following illustration, the measurement

is represented by M and the GenLink constants are

in italics. The measurement is processed in the following order and the result is then stored for customer display or use.

M = M * Calibration Factor

This is used to calibrate out any reading inaccuracies where calibration factor is a number such that

1024 is equivalent to 1, so it’s really M * calibration

factor/ 1024. GenLink will hide this computation so

you can enter floating point numbers such as 1.1 or

0.987 etc.

THEN

M = M processed by function x:

CPU

Channel Derived

No. Channel Title Update Rate Value

7 User Configurable #1 (Usually Oil Temp) 3.84 ms No

8 User Configurable #2 (Usually Coolant Temp) 3.84 ms No

9 User Configurable #3 (Usually Oil Pressure) 3.84 ms No

10 User Configurable #4 (Usually Coolant Level) 3.84 ms No

11 User Configurable #5 (Usually Fuel level) 3.84 ms No

12 User Configurable #6 - Spare - 3.84 ms No

13 User Configurable #7 (Usually throttle position) 3.84 ms No

14 Special Oxygen sensor 3.84 ms No

15 Special Battery charge sensor 3.84 ms No

16 Battery Voltage/ PSU voltages 3.84 ms No

1 Generator Phase A RMS Current Phase A ZERO CROSSING No

2 Generator Phase B RMS Current Phase B ZERO CROSSING No

3 Generator Phase C RMS Current Phase C ZERO CROSSING No

- Generator average current Every Phase ZERO CROSSING Yes

4 Generator Phase A RMS Voltage Phase A ZERO CROSSING No

5 Generator Phase B RMS Voltage Phase B ZERO CROSSING No

6 Generator Phase C RMS Voltage Phase C ZERO CROSSING No

- Generator average voltage Every Phase ZERO CROSSING Yes

- Total Generator Power KW Every Phase ZERO CROSSING Yes

- Total Generator Power Factor Every Phase ZERO CROSSING Yes

- Generator Frequency Every Phase ZERO CROSSING Yes

- RPM #1 4 - 8 ms variable (geared) Yes

- Oxygen sensor zero crossings Every O2 ZERO CROSSING No

3

Page 6

General Information

H-100 Control Panel Technical Manual

Where x can be:

1. THERMISTOR

2. CURRENT

3. LINEAR

4. PRESSURE

5. UNALTERED

6. POLY_3RD

7. POLY_2ND

8. POLY_1ST

9. POLY_1ST_N1

10. POLY_1ST_N2

11. CAL_SCALE

12. CFM_SENSOR

13. GEN_FP_POLY

The function x may use any of the coefficients 1,2,3

and in some cases will use calibration factor as a 4th

coefficient (in this case use scaling factor for calibration). The coefficients are used to allow adjustment

of the basic functions to cater for future or alternate

sensors. They perform different tasks in different

functions, see APPENDIX A for further details. Note

that if calibration factor is used as a coefficient, it will

be shown (and entered) by GenLink as (actual coefficient/1024).

For example, if the coefficient is -378, it will be displayed as -0.36914.

THEN

M =M * Scaling Factor:

Where scaling factor is a number such that 1024 is

equivalent to 1, so it’s really M * scaling factor/1024.

GenLink will hide this computation so you can enter

floating point numbers such as 2.1 or 0.987 etc.

ANALOG ALARMS

Each of the 23 channels is processed by a set of

alarm rules using constants that are set via GenLink.

Usually these constants can be changed by the

customer. Note that all alarms will be entered into

the alarm log and will operate the audible alarm.

Warnings will operate the audible alarm also, and will

be put in the alarm log. The following list shows the

alarm properties.

Types

This section is used to turn alarms and warnings on

or off and define if the input must be greater than a

value (GT) or less than a value (LT). There can be up

to 2 alarms and 2 warnings, of which there can be a

maximum of 2 GT or LT types.

Setpoints

There can be up to 4 setpoints to support 2 alarms

and 2 warnings, of which there can be a maximum of

2 GT or LT types. The setpoints are in the same units

that the measurement is displayed in.

Delay Time

There are 2 delay fields that can be set with different times in each. Any or none of these times can be

applied to any of the alarms or warnings via GenLink

radio buttons.

For example, a measurement may have to be greater

than the setpoint for 1 second to cause an alarm, or

less than another setpoint for 2 seconds to cause a

warning. The resolution of this time interval is 0.1

seconds.

Hysteresis

Applied hysteresis in display or final units (for example battery voltage is displayed in units of 1/100ths

of a volt). When an alarm/warning has gone active,

the hysteresis is subtracted from the GT setpoint or

added to the LT setpoint to calculate the modified

setpoint needed to make the alarm go inactive.

Shutdown

When set, this alarm condition (alarms only, not

warnings) has been selected to shutdown the engine.

Dialout

When this field is set, the dialout feature is selected.

If an alarm or warning occurs for this channel the

processor will automatically call for assistance via

telephone (if the external modem option is fitted).

Dialout can be selected either for warnings, alarms,

neither, or both. There is a predefined and prioritized

list of 10 phone numbers that will be tried. The controller expects GenLink to answer the call and log the

fault. It is possible for the customer to program any

Modbus device with a modem to respond to the call.

Active When

You can select other criteria to determine when

alarms and warnings become active. This is further

divided in that you can define these criteria independently for LT and GT alarm types.

ALWAYS ENABLED = This alarm or warning is

always enabled under every circumstance.

HOLD OFF = Alarms/Warnings with this qualification only become active after a programmable hold

off time has been met. The hold off timer starts after

the engine has started. Stopping the engine cancels

the hold off timer.

4

Page 7

General Information

H-100 Control Panel Technical Manual

IMMEDIATE = Alarms/Warnings with this qualification only become active immediately after the engine

has started.

Sensor Failure Check

When this field is set, the input sensor is checked

for short circuit or open circuit failure. Normally

each of the inputs are conditioned externally to be 420mA current loops. Any currents outside this range

indicate a sensor failure. This will cause an alarm to

occur. The alarm can be selected to shut down the

engine if so desired via the next field. The alarm will

be entered in the alarm log.

Shutdown on Sensor Failure

When this field is set, the engine will shut down if

there is a sensor failure. If the field is unchecked, the

failure will just cause an alarm message to appear

and the audible alarm to sound. The alarm will be

entered in the alarm log.

OTHER ANALOG OPTIONS

Event Log

When set, the channel measurement is compared to

the setpoint with either the GT or LT options. Once

the condition is met (eg measurement GT setpoint)

the event is logged along with a date/time stamp into

the volatile memory based event log. Six other parameters that can be chosen by the customer will also be

logged. Volatile means that when power is removed

from the unit, the memory will be lost.

OUTPUT FUNCTIONS

Output functions are flags that are set/reset by the

internal program to indicate a certain status, for

example “Engine Running”. The Measurement Engine

allows these flags to be treated as “channels” that can

be made into alarms/warnings, display messages,

operate real outputs and also be fed as inputs to the

ILC. For example, use the “Ready To Start” output

function to operate a relay by mapping it to a physical

output via GenLink, or you could feed it into the ILC

to do combinatorial logic.

See TABLE OF OUTPUT FUNCTIONS in appendix

B.

SPARE ANALOG CHANNELS

Depending upon the particular configuration of your

product, the following input channels may be available for custom measurements:

Channel # Normal function

4 Coolant level

5 Fuel Level

6 Spare

7 Throttle position

8 Oxygen sensor 0-1Vdc

9 Battery charge current 0-5Vdc

Analog Outputs

There are no analog outputs available for customization.

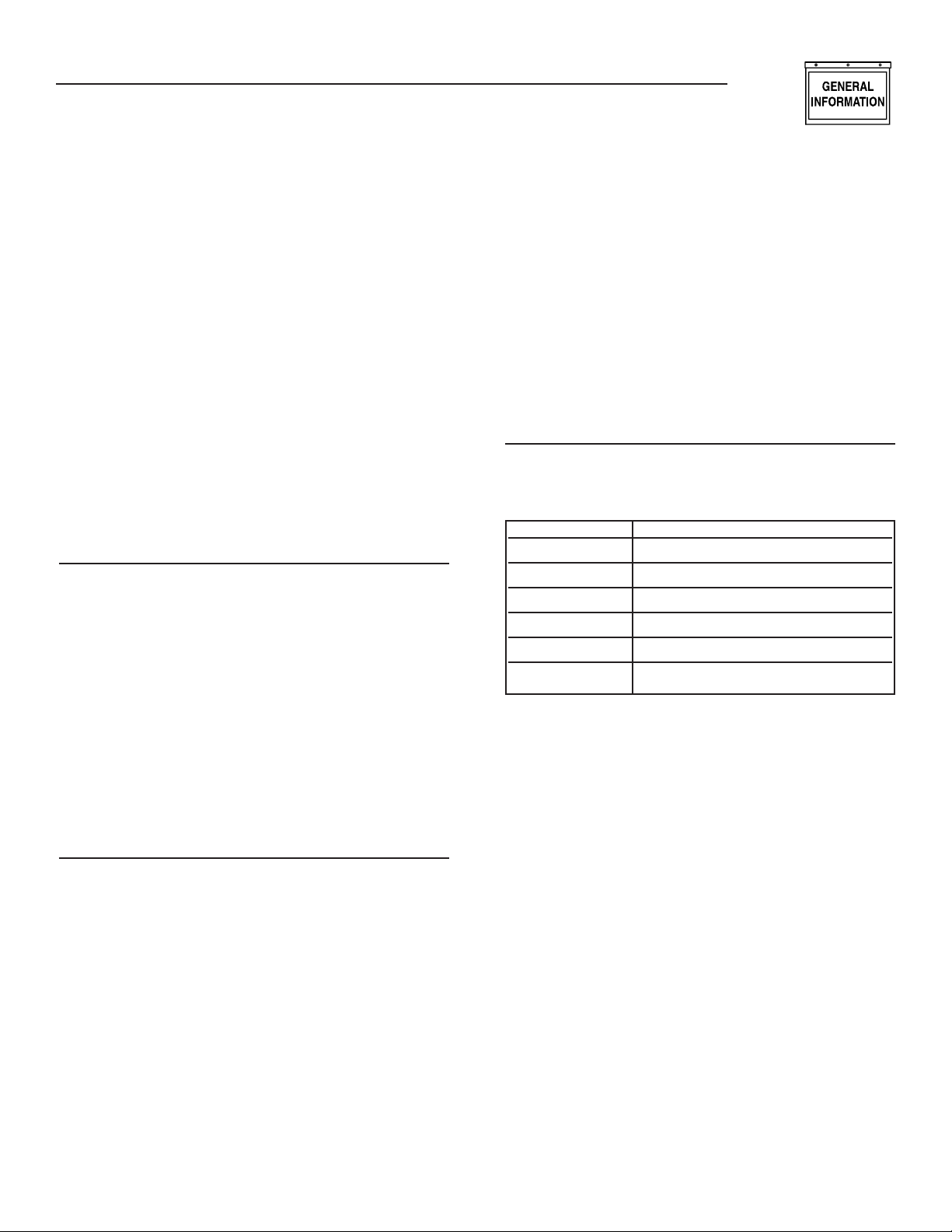

ANALOG SENSOR RATINGS

Typically the sensors used by the manufacturer have

the following ratings:

Temperature 35 - 300 deg. F

Pressure 0 - 150 psi

5

Page 8

General Information

H-100 Control Panel Technical Manual

ENGINE MANAGEMENT

The engine management module is very similar to

that used in the manufacturer's other products. It

controls engine cranking, engine starting, engine

running and engine stopping. These functions are

performed to a set of “rules” that can be customized

via parameters from GenLink. In turn, the module

needs to know certain things about the engine which

it expects to be programmed in from GenLink.

GENERATOR PARAMETERS

Engine Flywheel Teeth — Number of flywheel teeth

•

or pulses per revolution for RPM input. RPM 1 is

used for the engine controllers.

CT Ratio/Generator — Current Transformer ratio

•

for the generator. This value is the result from

reducing the CT ratio. E.G. If the CT ratio is

100 amps to 5 amps, the resulting value is 20.

Normally, the CT ratio will be x amps to 1 amp on

H-100 Control Panels.

Generator Phase Configuration — Select either

•

single-phase or three-phase configuration depending on how the unit is supplied.

60 Hertz RPM — The engine RPM needed to supply

•

60 Hertz power.

Quiet-Test® RPM — The engine RPM used when

•

running Quiet-Test®.

Number PARAMETER UNITS

1 Engine Flywheel Teeth Teeth

2 CT Ratio - Generator 3 Generator Phase Configuration 1 or 3

4 60 Hertz RPM RPM

5 Quiet-Test® RPM RPM

ENGINE SETTINGS

All of the following times are in seconds:

•

Preheat Time — The time preheat is applied for

before cranking if enabled.

•

Start Detection RPM — The Engine must reach this

RPM before disengaging the starter.

•

Crank Time — The maximum time in seconds that

each crank will last

•

Alarm Hold-off Time — The time after starting at

which the hold-off alarms become enabled.

•

Engine Warmup Time — The engine will run for

at least this time before issuing the “Accept load”

signal.

•

Target Frequency — The target generator frequency

(Hz).

•

Target Voltage — The target generator voltage

(RMS).

Preheat Enable — The following four options are

•

selectable (only for Diesel):

- Preheat disabled.

- Preheat during cranking.

- Preheat before and during cranking.

- Preheat before and during cranking and until

load ready.

The Preheat output pin shares its function with the

Air/Fuel Solenoid output. You must choose one of

the two functions as follows:

- To select Air/Fuel - set the “Diesel” parameter on

the governor settings page to “No”. Set Preheat to

“Disabled”

- To select Preheat - set the “Diesel Y/N” parameter on the governor settings page to “Yes”. Set

Preheat to one of the enable selections.

Engine Cooldown Time — The generator will run

•

for at least this time after remote start becomes

inactive.

Pause Between Cranks Time — The time between

•

each successive crank operation.

Number of Start Attempts — The maximum num-

•

ber of times the engine will attempt to start (crank)

before faulting out with overcrank.

Load Accept Frequency — The generator must

•

reach this frequency before issuing the “Accept

load” signal.

Load Accept Voltage — The generator must reach

•

this voltage before issuing the “Accept load” signal.

Number PARAMETER UNITS

1 Preheat Time (S)econds

2 Start Detection RPM RPM

3 Crank Time S

4 Alarm Hold-off Time S

5 Engine Warmup Time S

6 Target Frequency Hz

7 Target Voltage Vrms

8 Preheat Enable -

9 Engine Cooldown Time S

10 Pause Between Cranks Time S

11 Number of Start Attempts -

12 Load Accept Frequency HZ

13 Load Accept Voltage Vrms

6

Page 9

H-100 Control Panel Technical Manual

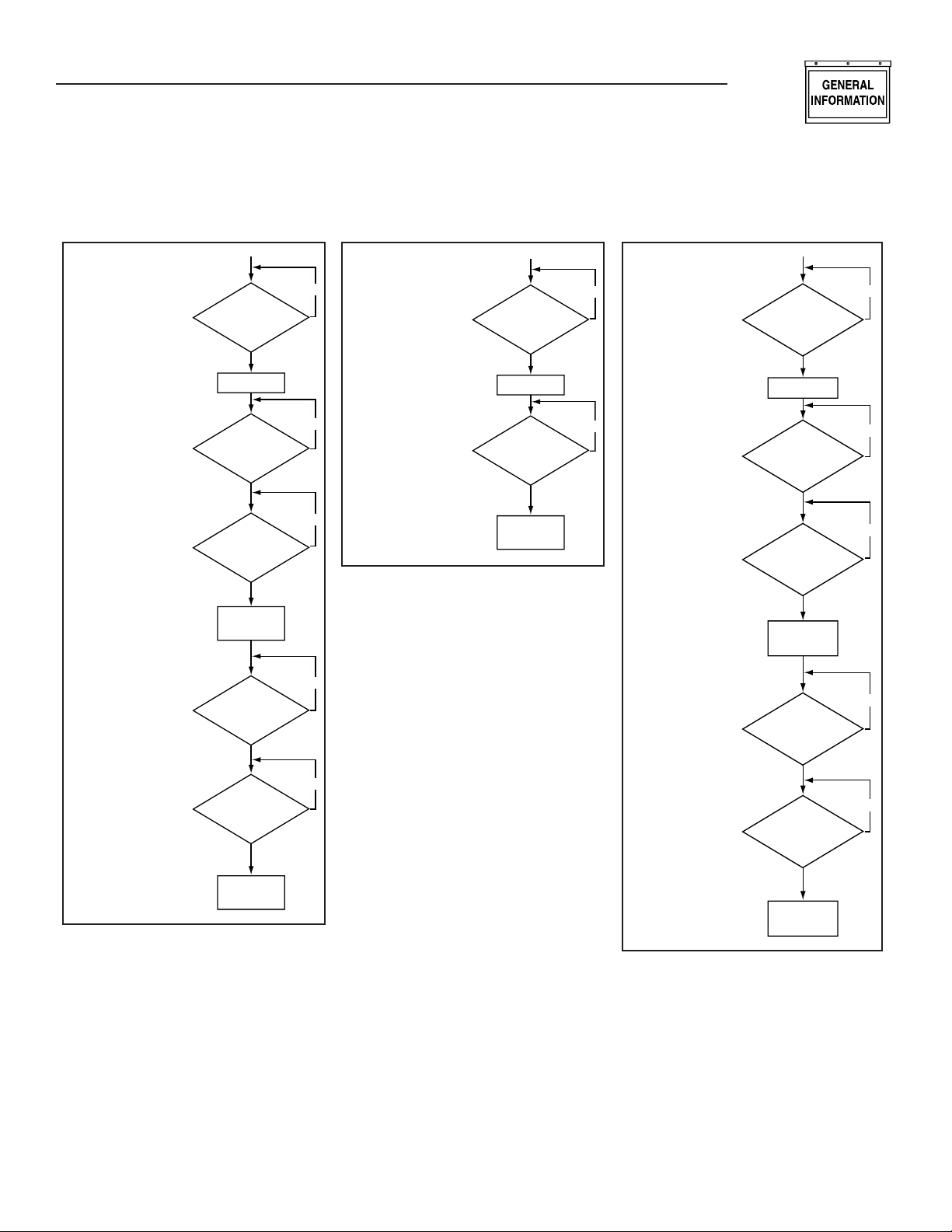

STARTING AND STOPPING - SEQUENCE DIAGRAMS

General Information

2-wire Remote Starting and

Stopping Sequence

Keyswitch in Auto Position

NOTE: Shutdown Alarms will

cause the engine to turn off

or not start.

Remote start

contacts

CLOSED?

Start the Engine

At

load accept

limits?

Warmup timer

expired?

Issue load

accept signal

Remote start

contacts

OPEN?

Exercise without transfer

starting and stopping sequence

NO

keyswitch in auto position.

NOTE: Shutdown Alarms will

NO

cause the engine to turn off

or not start.

NOTE: A Remote Start signal

will terminate exercise and

proceed to normal running mode.

NO

NO

Time to

exercise?

Start the Engine

Exercise

time

expired?

Stop the Engine

Loss of utility with HTS

starting and stopping

NO

sequence keyswitch in

auto position.

NOTE: Shutdown Alarms will

cause the engine to turn off

or not start.

NO

HTS indicates

loss of Utility?

Start the Engine

At

load accept

limits?

Warmup timer

expired?

Command HTS

to transfer to

Generator Power

HTS indicates

return of

Utility?

NO

NO

NO

NO

Cooldown

timer expired?

Stop the Engine

NO

NO

Cooldown

timer expired?

Stop the Engine

7

Page 10

General Information

H-100 Control Panel Technical Manual

VOLTAGE REGULATOR (OPTION)

All panels include automatic voltage regulation as

standard. There are various settings that can be

made to the voltage regulator via GenLink. The settings are normally factory preset and are shown here

for completeness.

Voltage KP/KI/KD — Voltage regulation stability

•

constants.

PMG — YES indicates a Permanent Magnet Excited

•

alternator.

VF Corner 1 / 2. — These are used for v/f control

•

to reduce the output voltage when a large load is

applied that slows down the generator. If the frequency drops below these setpoints, the voltage

is reduced proportionally as the frequency drops

according to the Volts per Hertz ratio.

Panel Type — Indicates the panel type that the H-

•

100 Control Panel has been programmed to be. It

will normally be H-100.

Volts per Hertz — Number of volts to reduce the

•

generator voltage for each hertz below VF Corner

1 frequency.

AVR Dump Improve — Makes the regulator mod-

•

ule increase the gain temporarily on a load dump

to improve the transient voltage response.

Unit Rated Power — This is the generator’s rated

•

power in kW.

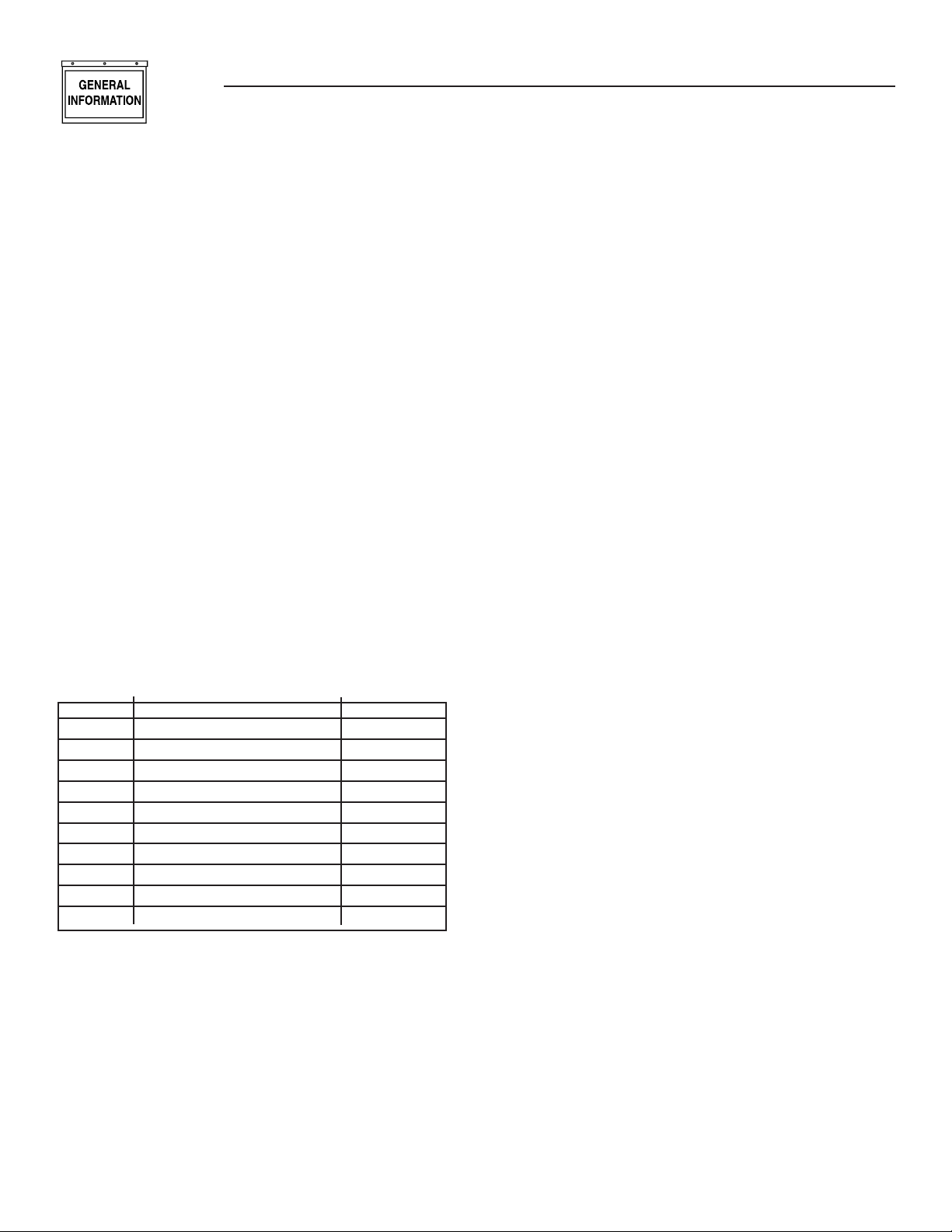

Voltage Regulator (Option) Chart

NO. PARAMETER UNITS

1 Voltage KP -

2 Voltage KI -

3 Voltage KD -

4 PMG Y/N

5 VF Corner 1 Hertz

6 VF Corner 2 Hertz

7 Panel Type -

8 Volts per Hertz V/Hertz

9 AVR Dump Improve Y/N

10 Unit Rated Power kW

GOVERNOR (SPEED REGULATOR)

OPTION

All panels include automatic frequency (speed) regulation as standard. There are various settings that

can be adjusted for the governor via GenLink, these

include the target frequency. The settings are normally factory preset and are shown here for completeness, they do not apply to all governor types.

Standby KP,KI,KD — Frequency regulation stability

•

constants used for normal mode operation.

QuietTest® KP,KI,KD — Frequency regulation sta-

•

bility constants used for QuietTest® mode operation.

Actuator Type — Indicates the type of governor

•

actuator. The following types are available:

- POWERFLOW — Barber Coleman Powerflow,

voltage driven without position feedback

- BOSCH GAS — Bosch Butterfly, current driven

with position feedback

- LINEAR CURRENT — Linear, Current Driven

without position feedback

- DETROIT DIESEL — Detroit diesel PWM Driven

- BOSCH HORIZONTAL DIESEL — Bosch Diesel

Arm with Horizontal Connecting Rod and current

driven with position feedback

- BOSCH VERTICAL DIESEL — Bosch Diesel Arm

with Vertical Connecting Rod and current driven

with position feedback

Actuator Offset — Number corresponding to lowest

•

actuator position (Close Throttle).

Actuator Fullscale — Number corresponding to

•

highest actuator position (Open Throttle).

Actuator Normal Start Position — The position

•

the actuator will be parked at from start up until

the “Start detection RPM” is reached. If “soft start”

is enabled, this is also the maximum position of

the throttle until the Target Frequency - 3 Hz is

reached. Therefore, if “soft start” is enabled, the

actuator start position MUST be high enough to

reach, Target Frequency - 3 Hz.

Actuator QuietTest® Start Position — The position

•

the actuator will be parked at from start up until

the “Start detection RPM” is reached. If “soft start”

is enabled, this is also the maximum position of the

throttle until the QuietTest® Target Frequency - 3

Hz is reached. Therefore, if “soft start” is enabled,

the actuator start position MUST be high enough

to reach, QuietTest® Target Frequency - 3 Hz.

Soft Start Time — The time to stay at each soft

•

start step before moving on to the next step. ( Only

applies if soft start is enabled ).

Soft Start Frequency — An entry of 0 Hz disables

•

soft start. Any other value enables soft start which

ramps up the generator frequency at a rate determined by “Soft Start Time” to minimize smoke.

This value selects the first frequency to target after

start up. Once this frequency is attained, the generator will hold this frequency for the “Soft Start

Time” and then move to the next step. Each step

is 3 Hz higher with the final step being “Target

Frequency” - 3 Hz. Each step is held for the “Soft

Start Time”. During soft start, the throttle will not

be allowed to exceed the “Actuator Start Position”.

Diesel — Indicates if this is a diesel powered gen-

•

erator. This modifies such features as frequency

control, and others.

8

Page 11

Dump Enable — Indicates if extra load dump gov-

•

ernor compensation is desired to reduce increase

in frequency caused by drop in load. The following

three selections are available:

- No Dump — No additional compensation.

- Dump — Reset governor algorithm when load

dump detected.

- Dump & Hold — Same as Dump, but also hold

throttle closed until frequency back in range.

Engine Linearization — Selects engine torque

•

to actuator position translation curve for Bosch

Actuators.

0 = No conversion - torque = position

1 = Butterfly Actuator with minimum position

same as unpowered actuator

2 = Diesel arm with Horizontal rod

3 = Diesel arm with Vertical rod

4 = Same as 1, but minimum position at actuator

mechanical stop

5 = Same as 4, but with limited position resolu-

tion of 1

6 = Same as 4, but with added energy to accom-

modate throttles that normally operate in the

nearly closed position at no load

Integral limit/Antiwindup — Choose whether to use

•

an integral limit or an anti-windup strategy.

YES = integral limit

NO = anti-windup

Limit/windup parameter — If “Integral Limit” is

•

selected, this is the maximum value the integral

is allowed. If “Anti-Windup” is selected, this is the

integral value above which the anti-windup algorithm becomes active.

Pwm Counts per ampx10 — Number of PWM

•

counts required to drive one tenth of an amp into

a linear current driven actuator. This only applies

to the “Linear Current” actuator type.

Desynch Offset — Offset of –0.9 to +0.9 Hertz to be

•

applied to the target frequency to improve passive

synchronizing by Automatic Transfer Switches. If

an in-phase or synchronized transfer is required,

use this setting to adjust the generator frequency

to 0.1 Hz above nominal Utility frequency.

General Information

H-100 Control Panel Technical Manual

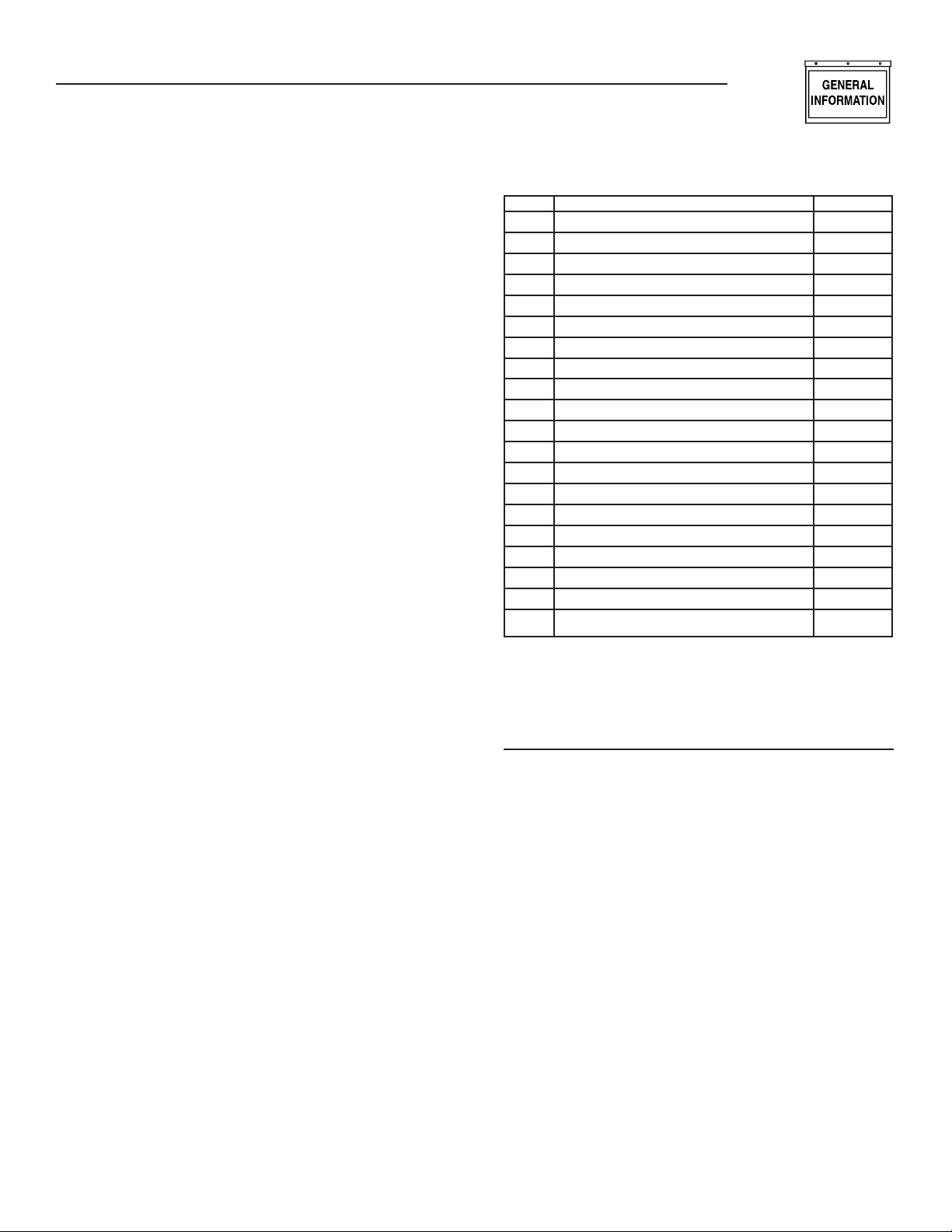

Governor (Speed Regulator) Option Chart

NO. PARAMETER UNITS

1 Standby KP -

2 Standby KI -

3 Standby KD -

4 QuietTest® KP -

5 QuietTest® KI -

6 QuietTest® KD -

7 Actuator Type -

8 Actuator Offset -

9 Actuator Fullscale -

10 Actuator Normal Start Position -

11 Actuator QuietTest® Start Position -

12 Soft Start Time Seconds

13 Soft Start Frequency Hz

14 Diesel Y/N

15 Dump Enable -

16 Engine Linearization -

17 Integral limit/Antiwindup Y/N

18 Limit / windup parameter -

19 Pwm Counts per ampx10 -

20 Desynch Offset Hz

TRENDING

Just like in the PM-DCP, there are two types of trending available - Remote and Local.

REMOTE TRENDING

GenLink performs remote trending by polling the

controller for the selected data at the desired rate.

Up to 8 analog channels can be monitored at a 0.3

second rate. If a faster rate is desired, reducing the

number of analog channels monitored will allow for a

0.1 second rate. The polling rate can be varied from

0.1 seconds to several hours. GenLink can save the

data to a file and/or display it as a near real-time

graph. The file is MS Excel compatible ( CSV format

). Examples of things you can trend are the generator

frequency response (in 0.1 second steps) to a block

load or Generated power over a day.

9

Page 12

General Information

H-100 Control Panel Technical Manual

LOCAL TRENDING

Local trending is done inside the controller where up

to 1000 samples can be stored in memory. GenLink

provides an interface to select the analog channels to

be trended, the rate to be sampled at, and optional

triggers to be used to specify when to sample. Up to 6

analog channels can be sampled. However, the 1000

samples are divided by the number of channels. For

example, there will be 1000 samples of 1 channel or

only 166 samples of each of 6 channels. The analog

samples can be sampled at one of three basic polling

rates: Low Speed, Mid Speed, and High Speed. For

the Low Speed and Mid Speed modes, there are also

several settings that can be used to determine when

to sample. GenLink can save the data to a file and/or

display it as a snap-shot graph. The file is MS Excel

compatible ( CSV format ).

GENLINK LOCAL TRENDING SETUP

When setting up the local trending, verify that the

“Armed” box is unchecked and press “Apply”. To

change the settings with the trending armed may

result in corrupted data. Select a rate at which to

take samples.

Low Speed rate samples the processed analog

•

channel values at a rate that is able to be set in

increments of 0.1 seconds.

Mid Speed rate is about 2 milliseconds which

•

captures the new analog channel value as soon

as it is processed by the measurement and alarm

modules.

High Speed rate is 0.4 milliseconds and is reserved

•

for the raw AC wave forms of generator voltage and

current.

There are 6 pull-down boxes that allow the selection of

up to 6 analog channels. All channel pull-down boxes

after the first pull-down box with NULL CHANNEL

selected are ignored. If High Speed is selected, the

pull-down boxes are not used. Instead, there are 6

check boxes that can be used to select which voltage

and current lines are to be trended.

The “Capture When” pull-down box allows the trending to be limited to the engine running or engine being

stopped. If the “Stop at End of Buffer” box is selected,

then the trending will start when the “Capture When”

condition is true and stop when the 1000 samples

have been taken.

Any digital or analog channel can be used as an event

trigger. The event trigger needs to be set up in that

channel's setup screen. Checking the “Capture Only

When Trigger is True” box will cause the samples to

only be taken while the event trigger is true. Checking

the “Capture on Shutdown Alarm” will cause the samples to start upon the setting of a shutdown alarm.

The event trigger can be used to start sampling, stop

sampling, or center the sampling by selecting the

appropriate radio button:

10

No Trigger

The event trigger is ignored and samples are continually being placed into the buffer.

Pre-Trigger

Samples are continually being placed into the buffer

until the event trigger becomes true. Then no more

samples are placed into the buffer.

Post-Trigger

No samples are placed into the buffer until the event

trigger becomes true. Then samples are placed in the

buffer until it is full.

Pre- and Post-Trigger

Samples are continually being placed in the buffer

until the event trigger becomes true. This point is

considered ½ of the buffer. Samples continue to be

placed into the buffer until it is full.

Pressing the “View” button will show a graph of

the samples in the buffer at the time the button is

pressed. The graph has a “Save” button that allows

the user to save the data out to a file in a MS Excel

compatible ( CSV ) format.

THE ILC

The built-in ILC uses simple combinatorial logic to

generate digital outputs and limited generator control. The ILC uses ladder logic for programming,

and a separate offline programming tool is available to generate the ILC programs. These are then

downloaded via GenLink and are started or stopped

by means of a checkbox on the GenLink ILC page.

Once downloaded and started, they will remain active

unless they are stopped via GenLink, even if power

is cycled.

The I/O scan time of the ILC is about 100 ms worst

case. This means that all inputs and outputs are

scanned within 100 ms. Also, the ILC processes

one rung every 5 ms, so 5 rungs will take 25 ms.

However, this is in parallel with the I/O scan and not

added to it.

The offline tool uses graphic symbols to design the

“rungs” of the ladder logic. The rungs are simple and

can only have 2 combinatorial elements in them, but

by the use of “soft contacts” the output of one rung

can be fed into the input of another to provide more

combinations. As well as the logical combinations,

there are also analog comparisons, counters and timers available for use in the rungs. As an example this

allows the following type of logic to be built:

IF (in automatic) AND (engine running) AND (air

temperature >25 deg) FOR (20 seconds) THEN

OPERATE (output 7).

Page 13

General Information

H-100 Control Panel Technical Manual

Generator control is limited to the following output

options (referred to as “Hooks”).

1. Use Keyswitch

2. Force Off – cleared with “Use Keyswitch” hook

3. Force Manual – cleared with “Use Keyswitch”

hook

4. Force Auto – cleared with “Use Keyswitch” hook

5. Force Dialout

6. Halt ILC

7. Force Alarm/Warning #1

8. Force Alarm/Warning #2

9. Force Remote Start

For detail in programming the ILC, refer to the ILC

manual.

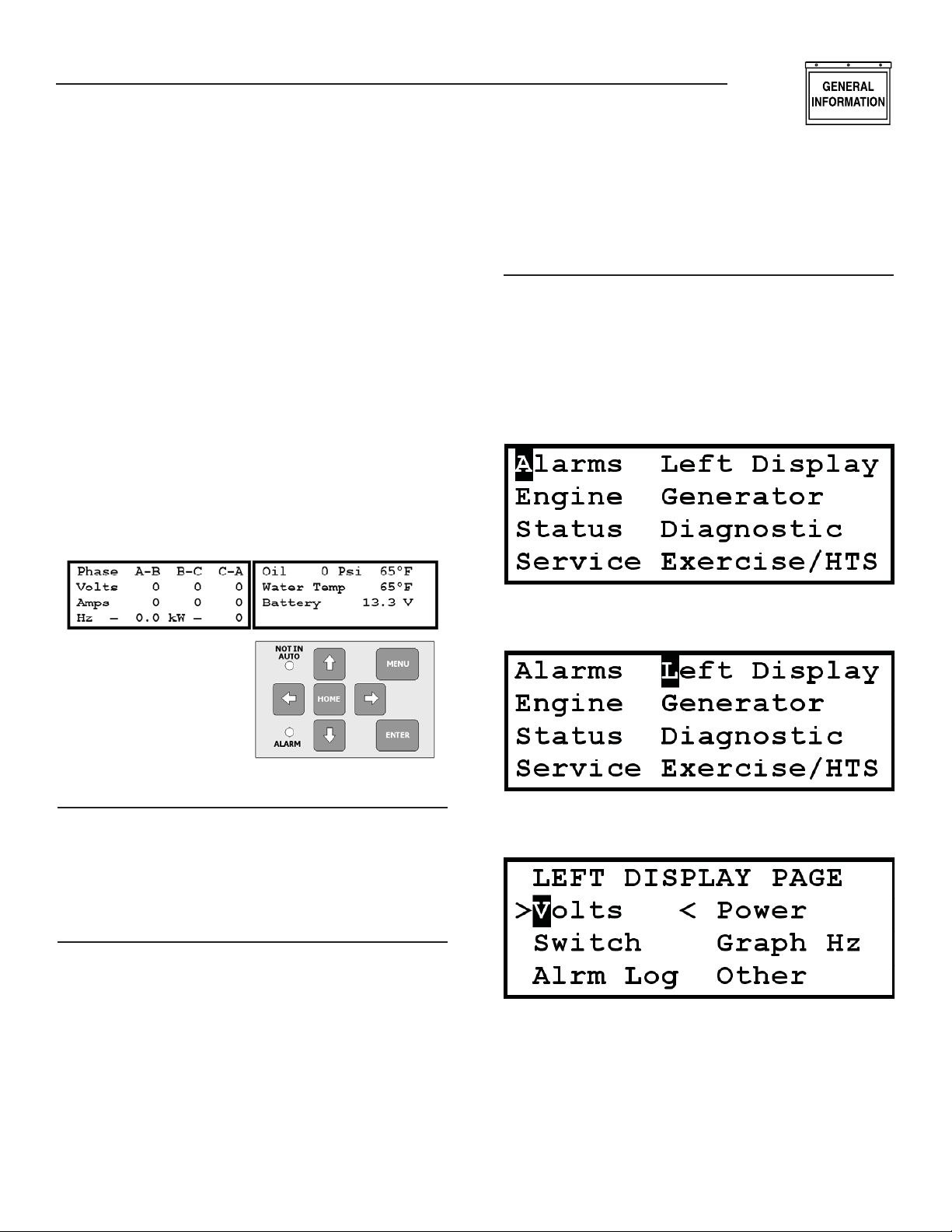

THE FRONT PANEL DISPLAY

The front panel display consists of two LCD displays

that are 4 rows of 20 characters each and a key pad

with seven buttons and two LEDs.

field. Moving off an edit field while in edit mode automatically enters the value displayed. Also, while in

edit mode, pressing the Home button will return the

parameter to the last value entered.

LEFT DISPLAY PAGES

The left display has five “fixed” parameter pages:

System Voltages, System Power, Transfer Switch

Mimic Diagram, Generator Frequency Graph, and

System Alarm Log. A sixth page is selectable, but has

no function at this time. The left display page is determined by selecting the right display menu item, “Left

Display”. To change the left display, do the following:

Press the “MENU” button.

Press the button to move to the “Left Display”

field.

LEFT DISPLAY

The left display is used to display a “fixed” set of

parameter pages and has no cursor or entry fields.

The key pad has no direct control of its contents. Its

contents are determined by a menu selection on the

right display.

RIGHT DISPLAY

The right display has several pages and responds

directly to the key pad. There are two “quick” buttons

on the key pad that are used to go directly to either

the Home page or the Menu page. The Enter button

is used to enter and exit edit mode, operate an output override, or select another page. When not in edit

mode, the arrow buttons are used to navigate around

the page to either an edit field or a control field.

When in edit mode, the up/down buttons slew up or

down through the available values and the right/left

buttons are used to change to a different digit or edit

Press the “ENTER” button to display the “Left

Display” menu page.

The “>…..<” indicates which page is currently displayed on the left display. Use the arrow buttons to

move the cursor to the desired page name and press

the “ENTER” button. The left display will change

to the new page and the “>…..<” will move to the

selected page name.

11

Page 14

General Information

H-100 Control Panel Technical Manual

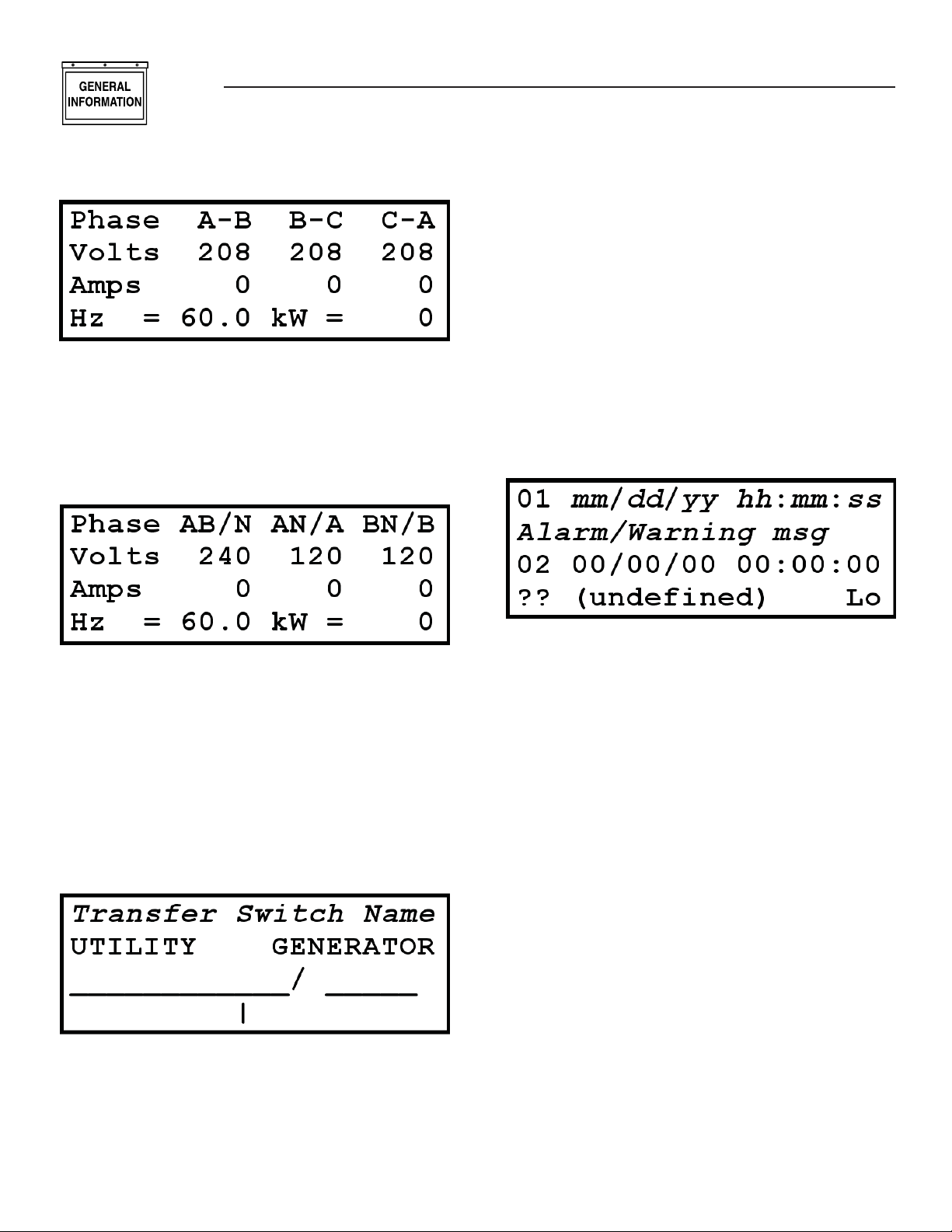

> Volts <

This is a typical three phase System Voltages page.

LINE 1: Phase titles for the voltage and current.

LINE 2: Line-to-line voltages in Volts RMS.

LINE 3: Line currents in Amps RMS.

LINE 4: Generator frequency in Hz and total system

power in kilowatts.

LINE 1: “Transfer Switch Name” indicates which

switch inputs are being displayed such as “From

HTS #1”. To select a switch to display, select the

switch number on the HTS page (refer to the Right

Display Pages - Exercise/HTS page). If there are

no HTS switches connected, then the Line Power

and Generator Power inputs are displayed and the

“Transfer Switch Name” is “From Line/Gen Inputs”

LINE 2: Title line showing the left side is the Utility

switch and the right side is the Generator switch.

LINE 3: Character graphics showing the switch

states – open or closed.

LINE 4: Character graphics indicating the load coming off the bottom of the diagram.

> Alrm Log <

This is a typical single phase System Voltages page.

LINE 1: Phase titles for the voltage and current

– voltage title/current title.

LINE 2: Line-to-line voltage for AB and Line-toNeutral voltage for A and B in Volts RMS.

LINE 3: Neutral current and Line currents in Amps

RMS.

LINE 4: Generator frequency in Hz and total system

power in kilowatts.

> Switch <

This is the Transfer Switch Mimic Diagram page.

It shows the position of the Utility Switch and the

Generator Switch. This depicted display shows the

Utility switch closed and the Generator switch open.

There can be up to 4 HTS switches connected to the

generator.

This is the System Alarm Log page. It displays the last

20 alarms or warnings that occurred with a time and

date stamp. Two records are displayed at a time.

LINE 1/3: The record’s alarm or warning number

(lowest number being the most recent) followed by the

date and time that the alarm or warning occurred.

LINE 2/4: The alarm or warning description message. The depicted display shows a basic format in

place of the first record and an empty record for the

second. The records scroll up at about a 4 second

rate.

The message format symbols are explained below:

First 2 characters:

?? – Empty slot

Wr – Warning

Al – Non-shutdown alarm

SD – Shutdown alarm

Last 2 Characters:

Sn – Sensor failure

Hi – Tripped by being greater than threshold

Lo – Tripped by being less than threshold

– (blank) Internal alarm or warning

12

Page 15

General Information

H-100 Control Panel Technical Manual

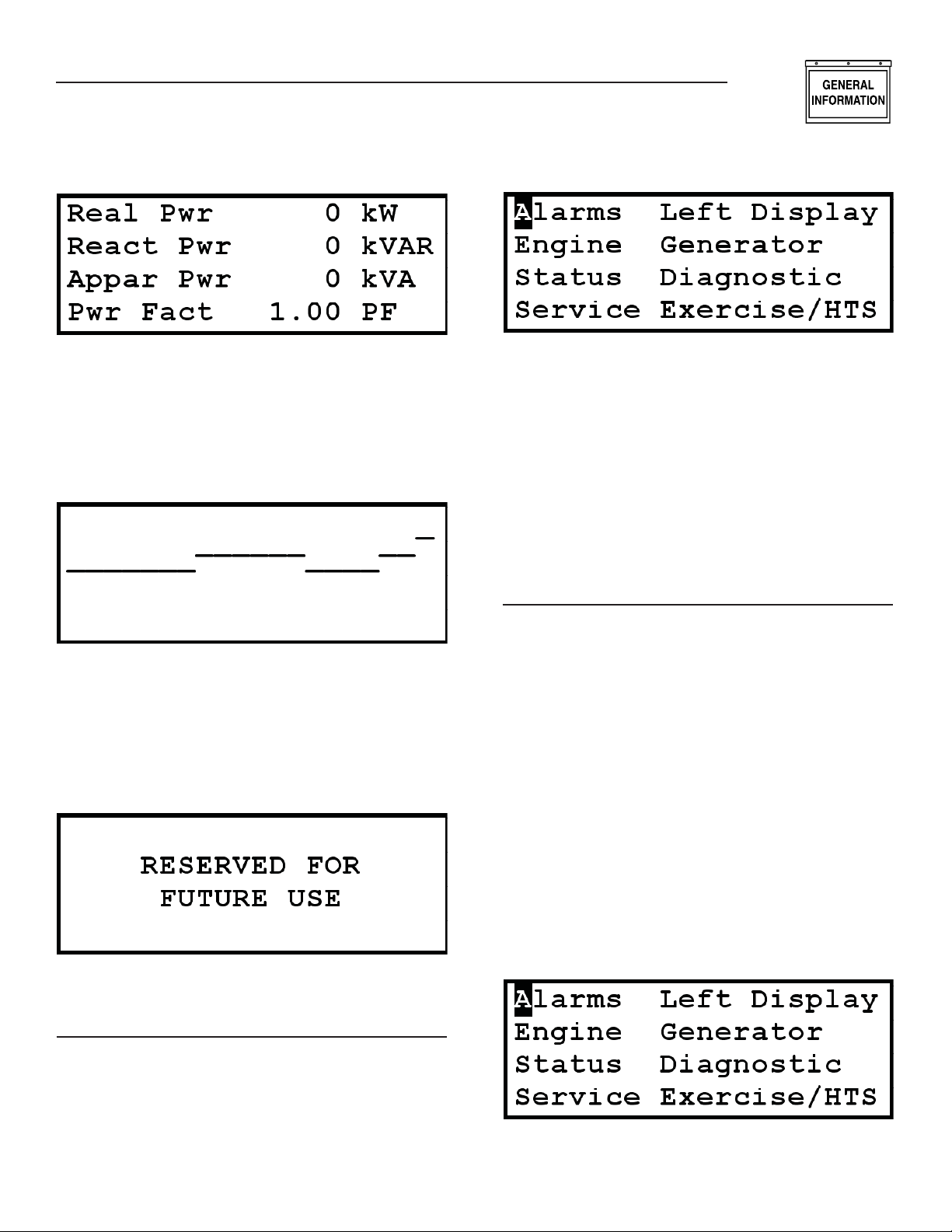

> Power <

This is a typical System Power page.

LINE 1: Total system real power in kW.

LINE 2: Total system reactive power in kVAR.

LINE 3: Total system apparent power in kVA.

LINE 4: Total system power factor.

> Graph Hz <

This is the Generator Frequency Graph page. This

graph provides a coarse representation of the generator frequency. The graph scrolls from right to left at 2

characters per second (last 10 seconds of data on the

display). The bottom of the graph is 50 Hz and the

top is 70 Hz. There are 32 levels between bottom and

top. Therefore, each level is approximately 0.6 Hz.

> Other <

This is the Other page. At this time, it has no function

and serves as a place holder.

Press the “MENU” button:

Use the arrow keys to move the cursor to the desired

menu item and then press the “ENTER” button. Most

menu items have multiple pages under them. When

that is the case, there is a “More (x-y)” field at

the lower right hand corner of the page where “x” is

the page number and “y” is the total number of pages

available under this menu item. To move forward or

backward through the pages, the cursor is placed

on the or character using the arrow buttons

and the “ENTER” button is pressed. When a page is

first displayed, the cursor normally starts on the

character to promote ease of scanning through the

pages.

ALARMS

There are three System Alarm and Warning pages.

Each page is capable of displaying three alarms or

warnings. If there are more than nine total alarms

and warnings to list, then only the most recent nine

will be visible. All alarms and warnings remain in the

list until they are cleared. Warnings clear when they

are no longer active. Normal Alarms clear when they

are no longer active and have been acknowledged.

Shutdown alarms clear only after the key switch has

been placed in the OFF position and they are no longer active. There are a few shutdown alarms that will

only clear after a power cycle of the controller and

they are no longer active. Besides using the menu to

get to the alarm pages, the right display immediately

changes to the first alarm page when an alarm or

warning first becomes active. If a shutdown alarm is

active and an alarm or warning is not acknowledged,

the displays will flash with the Alarm LED.

Do the following to view the alarm/warnings pages:

Press the “MENU” button.

RIGHT DISPLAY PAGES

The right display is menu based with eight main menu

items: System Alarm and Warning pages, Engine

Parameter pages, System Status pages, Maintenance

Status Pages, Left Display Menu page, Generator

Parameter pages, System Diagnostic pages, and

Internal Exercise and HTS pages. To select a page for

the right display, do the following:

13

Page 16

General Information

H-100 Control Panel Technical Manual

Press the “ENTER” button.

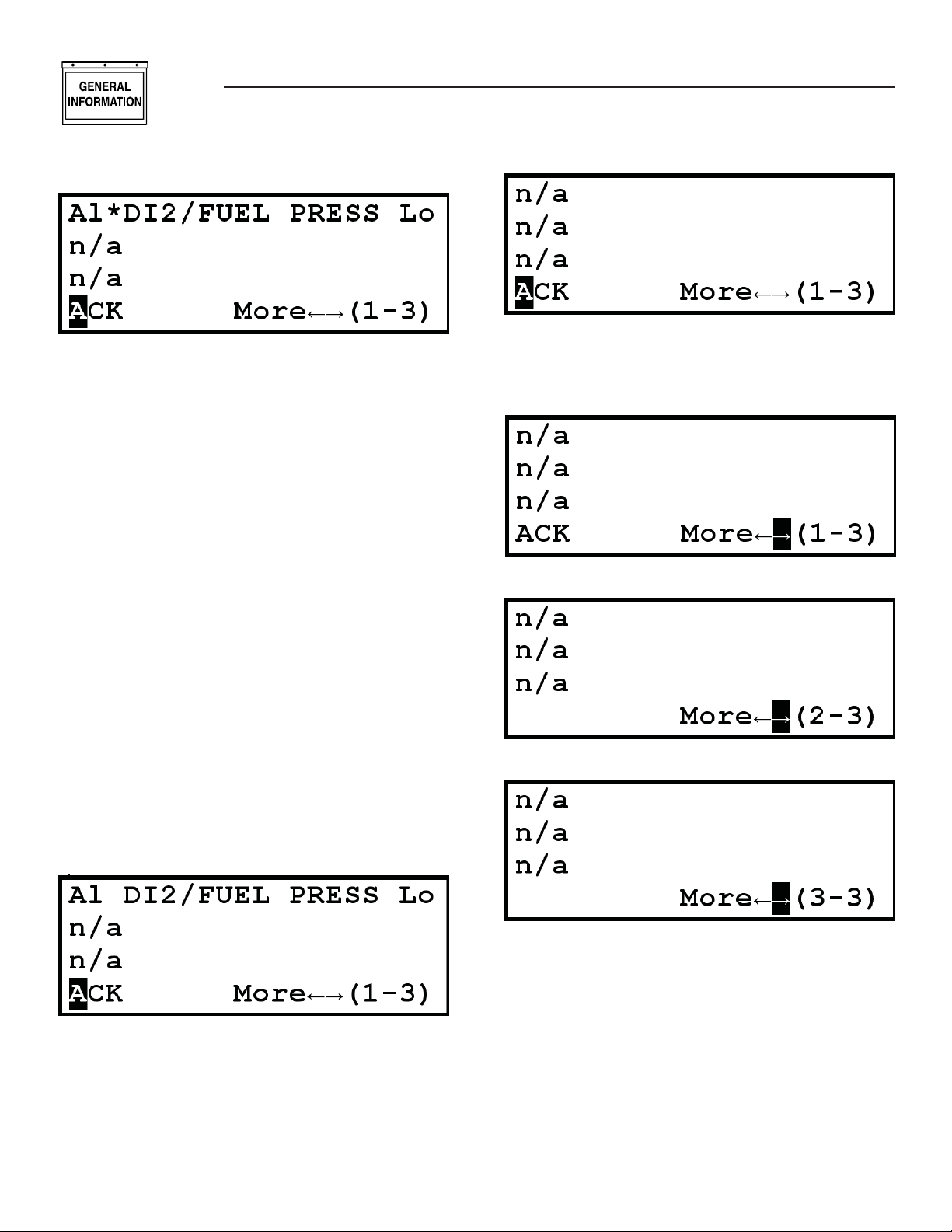

This is a typical System Alarm and Warning page.

The n/a indicates there is not an alarm or warning

to display on that line. As depicted, this display indicates a Fuel Pressure alarm for low pressure. This

would be a common alarm for a system that has the

gas line turned off. The “Al” indicates it is an alarm.

The “*” indicates the alarm has not been acknowledged. The “DI2/FUEL PRESS” message indicates it

is a fuel pressure alarm (DI2 was included in the text

by the user to indicate it is Digital Input #2). The “Lo”

indicates the alarm was tripped because the input

value fell below a set threshold.

The message format symbols are explained below:

First 2 characters:

Wr – Warning

Al – Non-shutdown alarm

SD – Shutdown alarm

Third Character:

* – Has not been acknowledged

Last 2 Characters:

Sn – Sensor failure

Hi – Tripped by being greater than threshold

Lo – Tripped by being less than threshold

(blank) – Internal alarm or warning

Press the “ENTER” button while the cursor is on

"ACK" to acknowledge the alarm.

The alarm has cleared since the gas pressure is now

adequate.

Move the cursor to the on the bottom line by pressing the button twice or the button once.

Press the “ENTER” button to see the next page.

Press the “ENTER” button to see the next page.

The “*” is now gone since the alarm has been

acknowledged.

Turn the gas line on.

14

ENGINE

There are four Engine Parameter pages. In most H100 Control Panels, there are spare analog channels

available or unused analog channels. They can be

displayed on these pages. If they are not configured,

they will not be displayed.

Do the following to view the engine parameter pages:

Press the “MENU” button.

Page 17

Press the button.

Press the “ENTER” button.

General Information

H-100 Control Panel Technical Manual

This is a typical second engine parameter page. The

first two values on this page are not able to be configured as other values.

LINE 1: Engine RPM

LINE 2: Battery Voltage in Volts DC.

If any of these signals are not configured, they will

display “n/a” for their value.

LINE 3: Normally Battery Charger Current (Analog

Channel #9). If it is not configured, the line will be

blank.

LINE 4: “More” field to allow page selection.

Press the “ENTER” button.

This is a typical first engine parameter page. The

three values on this page are not able to be configured

as other values.

LINE 1: Oil Temperature (Analog Channel #1) in

degrees Fahrenheit.

LINE 2: Oil Pressure (Analog Channel #3) in pounds

per square inch.

LINE 3: Coolant Temperature (Analog Channel #2)

in degrees Fahrenheit.

LINE 4: “More” field to allow page selection.

If any of these signals are not configured, they will display “n/a” for their value such as the Oil Temperature

shown above.

Press the “ENTER” button.

This is a typical third engine parameter page.

LINE 1: Total number of hours the engine has run.

LINE 2: Coolant Level Sensor (Analog Channel #4)

reading in steps 0 - 1023.

LINE 3: Often the Fuel Level Sensor (Analog Channel

#5) reading in %. As depicted, Analog Channel #5 is

not configured – leaving the line blank.

LINE 4: “More” field to allow page selection.

Press the “ENTER” button.

This is a typical fourth engine parameter page.

LINE 1: Auxiliary Analog Channel input (Analog

Channel #6).

LINE 2: Throttle Position Sensor (Analog Channel

#7) reading in steps 0 - 1023.

LINE 3: Emissions Sensor (Analog Channel #8)

reading. As depicted, Analog Channels #6 and #8 are

not configured – leaving the lines blank.

LINE 4: “More” field to allow page selection.

15

Page 18

General Information

H-100 Control Panel Technical Manual

STATUS

There are two System Status pages. These pages

show the system status, system time, and system

versions.

Do the following to view the system status pages:

Press the “MENU” button.

Press the button twice.

Press the “ENTER” button.

This is a typical first System Status page.

LINE 1: Engine Running Status. It can have the following values:

“Stopped, Key SW Off”

The engine is stopped and the key switch is in the

OFF position.

“Running from Manual”

The engine is starting or running and the key switch

is in the MANUAL position.

“Running from 2-wire”

The engine is starting or running because the 2-wire

start signal was activated and the key switch is in the

AUTO position.

“Running from serial”

The engine is starting or running because the GenLink

commanded it to start and the key switch is in the

AUTO position.

“Running exercise”

The engine is starting or running because internal

exercise was activated and the key switch is in the

AUTO position.

“Stopped, Key SW Auto”

The engine is stopped and the key switch is in the

AUTO position.

“Running, QuietTest”

The engine is starting or running because QuietTest®

was activated and the key switch is in the AUTO position.

“Running, HTS Xfer SW”

The engine is starting or running because the HTS(s)

indicated a need for the generator power and the key

switch is in the AUTO position.

LINE 2: Generator Status. It can have the following

values:

“Resetting”

The generator control system is resetting.

“Stopped”

Generator is stopped and not preheating.

“Stopped, Preheating “

Generator is stopped and preheating.

“Cranking”

Generator is starting and not preheating.

“Cranking, Preheating”

Generator is starting and preheating.

“Pause between starts”

Generator is pausing between consecutive start

attempts.

“Started,not to speed”

Generator is started, but has not attained normal

running speed yet.

“Warming, Alarms Off “

Generator is started and is up to speed, but is waiting

for warmup timer to expire.

“Warmed Up,Alarms Off ”

Generator is started and warmed up, but the hold-off

alarms are not yet enabled.

“Warming, Alarms On”

Generator is started and the hold-off alarms are

enabled, but is waiting for warmup timer to expire.

16

Page 19

General Information

H-100 Control Panel Technical Manual

“Warmed Up, Alarms On”

Generator is started, warmed up, and the hold-off

alarms are enabled.

“Running,cooling down”

Generator is still running, but waiting for cool down

timer to expire.

“Stopping”

Generator is running down after being turned off

normally.

“Stopping due to Alrm”

Generator is running down after being turned off due

to a shutdown alarm.

“Stopped due to Alarm”

Generator is stopped due to a shutdown alarm.

LINE 3: System Time and Date. It is able to be

changed on this page by using the arrow buttons to

go from field to field or to modify a field in edit mode

and the “ENTER” button to enter and exit edit mode.

There are five editable fields: Hours, Minutes, Month,

Day, and Year. The day of the week will change as the

displayed date is changed. See the “SET DATE AND

TIME” section of this manual for details.

LINE 4: “More” field to allow page selection.

Press the “ENTER” button.

SERVICE

There are four Maintenance Status pages. The first

three pages show the status of the scheduled maintenance items. The fourth page allows changing of the

display contrast.

Do the following to view the service pages:

Press the “MENU” button.

Press the button three times or the button

once.

Press the “ENTER” button.

This is a typical second System Status page.

LINE 1: Firmware and Hardware release versions.

LINE 2: Configuration File identifier – serial num-

ber, model number, or text.

LINE 3: ILC program name. This text string is blank

or blocks (as shown above) when there is no ILC

program loaded.

LINE 4: ILC program running status followed by the

“More” field to allow page selection.

This is a typical first Maintenance Status page. Each

line displays a maintenance item that has been set

up via GenLink. The value displayed is the approximate % of life remaining before maintenance should

be performed. Refer to the Maintenance setup using

GenLink.

Press the “ENTER” button.

This is a typical second Maintenance Status page.

17

Page 20

General Information

H-100 Control Panel Technical Manual

Each line displays a maintenance item that has

been set up via GenLink. The value displayed is the

approximate % of life remaining before maintenance

should be performed. Refer to the Maintenance setup

using GenLink.

Press the “ENTER” button.

This is a typical third Maintenance Status page. Each

line displays a maintenance item that has been set

up via GenLink. The value displayed is the approximate % of life remaining before maintenance should

be performed. Refer to the Maintenance setup using

GenLink.

Press the “ENTER” button.

Press the button and then the button.

Press the “ENTER” button.

This is a typical fourth Maintenance Status page. The

first line is the display contrast. The display contrast

is able to be changed on this page. However, changing

this setting can result in the display becoming nonreadable. Use caution. Use the arrow buttons to go to

the contrast field. Press the “ENTER” button to enter

edit mode. Use the arrow buttons to change the contrast value (range is 00 to 37). Pressing the “HOME”

button while in edit mode will return the value to the

last entered value. Press the “ENTER” button to exit

edit mode.

GENERATOR

There are three Generator Parameter pages – voltage

parameters, power parameters, and i2t parameters.

Do the following to view the generator parameter

pages:

Press the “MENU” button.

This is a typical first Generator Parameter page for a

three phase system.

LINE 1: Phase titles for the voltage and current.

LINE 2: Line-to-Line voltages in Volts RMS.

LINE 3: Line currents in Amps RMS.

LINE 4: Generator frequency in Hz followed by the

“More” field to allow page selection.

The voltages can be converted to values representing

the line-to-neutral voltages by changing the title line

(first line) using edit mode. Use the arrow buttons

to move to one of the title fields – A-B, B-C, or C-A.

Press the “ENTER” button to enter edit mode. Use

the up or down arrow button to change the display to

A-N, B-N, and C-N. Press the “ENTER” button to exit

edit mode. The same process is followed to return to

line-to-line displays. This also affects the left display

voltage page.

18

Page 21

This is a typical first Generator Parameter page for a

single phase system.

LINE 1: Phase titles for the voltage and current

– voltage title/current title.

LINE 2: Line-to-Line voltage for AB and Line-toNeutral voltage for A and B in Volts RMS.

LINE 3: Neutral current and Line currents in Amps

RMS.

LINE 4: Generator frequency in Hz followed by the

“More” field to allow page selection.

Press the “ENTER” button.

This is a typical second Generator Parameter page for

a three phase system.

LINE 1: Total system real power in kW.

LINE 2: Total system power factor.

LINE 3: Percentage of the system rated power being

used.

LINE 4: The “More” field to allow page selection.

General Information

H-100 Control Panel Technical Manual

This is a typical third Generator Parameters page. It

graphically displays the percent of i2t thermal limit

currently attained. If the limit is exceeded, an alarm

will be set and the generator will shutdown to protect

the alternator. This display will then show % Temp

>Over Limit<”. GenLink can provide more information regarding actual limits exceeded. This page is

disabled if the i2t function is disabled.

DIAGNOSTICS

There are six System Diagnostic pages. They are digital inputs page, digital outputs page, two analog input

pages, RS-232 communications status page, and RS485 communications status page.

Do the following to view the diagnostics pages:

Press the “MENU” button.

This is a typical second Generator Parameter page for

a single phase system.

LINE 1: Phase titles for the power and power factor

– Total, A-Neutral, B-Neutral.

LINE 2: Real power in kW – Total system, A-Neutral,

B-Neutral.

LINE 3: Power Factor – Total system, A-Neutral, BNeutral.

LINE 4: The “More” field to allow page selection.

Press the “ENTER” button.

Press the button twice and the button.

Press the “ENTER” button.

19

Page 22

General Information

H-100 Control Panel Technical Manual

This is a typical first System Diagnostics page. It displays ten of the discrete inputs into the H-100 Control

Panel. Inputs to the controller are internally pulled

to 5 v, so to activate an input you must short it to

ground.The following names are normally assigned

to these inputs:

#1 Key switch in AUTO position

#2 Key switch in MANUAL position

#3 Emergency Stop Active

#4 Remote 2-wire start Active

#5 Battery Charger Failure

#6 Rupture Basin or Low Fuel Pressure

#7 Transfer Switch in Line Power Position

#8 Transfer Switch in Emergency Power Position

#9 Modem is connecting or connected

#10 Modem is present

Press the “ENTER” button.

This is a typical second System Diagnostics page.

It displays ten of the discrete outputs out of the H100 Control Panel. Outputs from the controller are

generally open collector. This means that they sink

current through a load and you will NOT see any voltage change on them when they are activated, unless

they are connected to a load. These outputs can be

temporarily inverted from this page. Extreme caution

should be exercised while inverting outputs since it

can result in operation of starters, fuel solenoids, etc.

To invert an output, use the arrow buttons to position

the cursor on the output value to be inverted. Press

the “ENTER” button. The output will be inverted for

approximately 2 seconds and then return to normal

control. Only one output can be inverted at a time and

leaving the page cancels all output inversions.

The following names are normally assigned to these

outputs:

#1 Key switch in AUTO position

#1 Activate Starter Relay

#2 Activate Fuel Relay

#3 Activate Alarm/Warning Relay (Buzzer)

#4 Activate Gas Relay on 13.3L Engines

#5 Auxiliary Discrete Output #1

#6 Auxiliary Discrete Output #2

#7 Auxiliary Discrete Output #3

#8 Auxiliary Discrete Output #4

#9 Activate Ignition Module on 13.3L Engines

20

#12 Activate Emissions Module or Preheat

Press the “ENTER” button.

Press the “ENTER” button.

The above two pages are typical System Diagnostics

Analog Input pages. The analog channel values that

are displayed are the “raw” unprocessed data and

are 10 bit numbers ranging from 0 - 1023 representing a voltage or current on the analog input channel.

The following names are normally assigned to these

inputs:

PAGE 3-6 LINE 2:

#1 A current (CT1)

#2 B current (CT2)

#3 C current (only three phase) (CT3)

PAGE 3-6 LINE 3:

#4 A-B voltage (A-N if single phase) (Vsense1)

#5 B-C voltage (B-N if single phase) (Vsense2)

#6 C-A voltage (only three phase) (Vsense3)

PAGE 3-6 LINE 4:

#7 Oil Temperature (AN1)

PAGE 4-6 LINE 1:

#8 Coolant Temperature (AN2)

#9 Oil Pressure (AN3)

#10 Coolant Level (AN4)

PAGE 4-6 LINE 2:

#11 Fuel level (AN5)

#12 Auxiliary Analog Input (AN6)

#13 Throttle Position Sensor (AN7)

PAGE 4-6 LINE 3:

#14 Emissions Oxygen Sensor (AN8)

#15 Battery Charger Current (AN9)

#16 Battery Voltage

Page 23

General Information

H-100 Control Panel Technical Manual

Press the “ENTER” button.

Press the “ENTER” button.

The above two pages are typical of communications

diagnostics, one page for each port. The LCD display

will show four lines of information about the port:

LINE 1: Will show the type of port protocol that has

been selected. It will also show the Modbus address

(if appropriate) and whether the port is RS-232 or

RS-485.

LINE 2: Will show the settings for the port such as

baud rate, bits per character, stop bits, and parity.

LINE 3: Shows a live update of counts of messages

transmitted, received, and errors.

LINE 4: Shows a mimic of LED’s for TX, RX, and

ERR. For example, the TX LED lit (T*) means the H100 Control Panel is transmitting. Not lit (T-) means

it is not transmitting.

Press the button.

Press the “ENTER” button.

This is a typical first Internal Exercise and HTS

page.

LINE 1: Indicates if internal exercise is enabled. This

field is editable.

LINE 2: Day of week and time of day to start the

exercise weekly. These fields are editable.

LINE 3: How much time remains before exercise is

completed. It starts with 20 minutes.

LINE 4: The “More” field to allow page selection.

Press the “ENTER” button.

EXERCISE/HTS

There are four pages under this menu item – two for

internal exercise and two for HTS. This is where the

internal exercise can be setup and enabled (see the

Exercise Setup Using Front Panel section) and the

HTSs can be enabled and monitored.

Do the following to view the internal exercise and

HTS pages:

Press the “MENU” button.

This is a typical second Internal Exercise and HTS

page.

LINE 1: Indicates if QuietTest® is enabled. This field

is editable.

LINE 2: Can be used to start a 20 minute exercise

period right now. This field is editable.

LINE 3: Indicates if the HTS switches should be

exercised during normal exercise mode. This field is

editable.

LINE 4: The “More” field to allow page selection.

Press the “ENTER” button.

21

Page 24

General Information

H-100 Control Panel Technical Manual

This is a typical third Internal Exercise and HTS

page.

LINE 1: The left side shows the HTS switch number

that the data on this page applies to. This field is

editable in that switch numbers 1 – 4 can be selected.

The Switch number selected on this page also selects

the switch to use for the Left Display Switch Mimic

diagram if that switch is enabled. In addition, it is the

selected switch number for the next page, and for the

remote annunciator lights for generator power and

line power. The right side of the first line is the mode

that the HTS is in. It can have the following values:

“Disabled”

This switch is not present in the system.

“Enabled”

This switch is present in the system and operating

normally.

“Fast Test”

The “FAST TEST” button on the HTS has been

pressed and fast test is being executed.

“Norm Test”

The “TEST” button on the HTS has been pressed and

normal test is being executed.

“No Comms”

This switch is present in the system, but not communicating.

“Xfer Exer”

The system is running in exercise and is exercising

the HTS as well.

“Exercise”

The system is running in exercise, but is not exercising the HTS.

LINE 2: The left side is the status of the HTS. It can

have the following values:

“Idle”

HTS is waiting for conditions to change. No action is

being taken.

“Error”

HTS controller has detected an error.

“TDN”

22 22

HTS is in Time Delayed Neutral position.

“Synching”

HTS is waiting for Generator and Utility to become

synchronized before changing switch position.

“SB4 Xfer”

HTS has activated the “Signal Before Transfer” relay.

“Cls Gen SW”

HTS is closing the Generator side of the switch.

“Cls Util SW”

HTS is closing the Utility side of the switch.

“Opn Gen SW”

HTS is opening the Generator side of the switch.

“Opn Util SW”

HTS is opening the Utility side of the switch.

“No Utl/Coms”

HTS has detected loss of utility and communications

with the H-100 Control Panel.

“No Comms”

HTS has detected utility present, but loss of communications with the H-100 Control Panel.

“Pwr Cycled”

HTS has been power cycled and is awaiting reconfiguration commands from H-100 Control Panel.

“SW Disabled”

HTS indicates that it is disabled.

The right side is the Utility frequency from the HTS

in Hz.

LINE 3: The HTS backup battery voltage in Volts DC

followed by the Utility voltage from the HTS in Volts

RMS.

LINE 4: The HTS firmware version number followed

by the “More” field to allow page selection.

Press the “ENTER” button.

This is a typical fourth Internal Exercise and HTS

page. The left side of the first line shows the HTS

switch number that the data on this page applies to.

This field is editable in that switch numbers 1 – 4

can be selected. The Switch number selected on this

Page 25

General Information

H-100 Control Panel Technical Manual

page also selects the switch to use for the Left Display

Switch Mimic diagram if that switch is enabled. In