Page 1

Owner’s Manual

For

DF7500 Dust Suppression System

009111

For technical assistance contact:

Register your Generac product at:

www.generacmobileproducts.com

WWW.GENERAC.COM

Technical Support

1-888-GENERAC

1-800-926-9768

(1-888-436-3722)

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

Use this page to record important information about your Generac Mobile Product

Unit Model Number

Unit Serial Number

Date Purchased

Record the information found on your unit data label on this

page. See

Engine and generator serial numbers are located on separate

data plates affixed to the engine and generator respectively.

When contacting a Generac Mobile Products Authorized

Service Dealer (ASD) about parts and service, always supply

the complete model number and serial number of the unit.

Operation and Maintenance: Proper maintenance and care of

the generator ensures a minimum number of problems and

keeps operating expenses at a minimum. It is the operator’s

responsibility to perform all safety checks, to verify that all

maintenance for safe operation is performed promptly, and to

have the equipment checked periodically by an ASD. Normal

maintenance, service and replacement of parts are the

responsibility of the owner/operator and, as such, are not

considered defects in materials or workmanship within the

terms of the warranty. Individual operating habits and usage

may contribute to the need for additional maintenance or

service.

Unit and Serial Number Locations.

WARNING

CANCER AND REPRODUCTIVE HARM

www.P65Warnings.ca.gov.

(000393a)

ii Owner’s Manual for DF700 Dust Suppression System

Page 3

Table of Contents

Section 1: Introduction and Safety

Introduction ..................................................................1

Read This Manual Thoroughly ....................................1

How to Obtain Service .................................................1

Safety Rules .................................................................1

Safety Symbols and Meanings ...................................1

General Hazards ...........................................................2

Electrical Hazards ........................................................2

Service Safety ..............................................................2

Operating Safety .........................................................3

Positioning the Unit .....................................................3

Starting the Unit ...........................................................3

Trailer Hazards .............................................................4

Towing Safety ...............................................................4

Hitch and Coupling ......................................................4

Running Lights ............................................................4

Wheels and Tires .........................................................4

Safe Towing Techniques .............................................4

Reporting Trailer Safety Defects ................................4

Safety and Operating Decals ......................................5

Section 2: General Information

Specifications ...............................................................7

Unit Dimensions ...........................................................8

Component Locations .................................................9

Control Panel ..............................................................10

Control Panel Components and Functions ................10

Unit and Serial Number Locations ...........................10

Connecting Water Supply .........................................11

Connecting Power Supply .........................................11

Using Transport Locks ..............................................12

Disengaging Transport Locks ....................................12

Engaging Transport Locks .........................................12

Towing the Unit .........................................................12

Lifting the Unit ...........................................................13

Tying the Unit Down ..................................................13

Section 3: Operation

Operation and Use Questions ..................................17

Before Starting ...........................................................17

Starting the Unit .........................................................18

Stopping the Unit .......................................................18

Tilting Blower .............................................................19

Rotating Blower .........................................................19

Automatic Oscillation ................................................19

Section 4: Maintenance and

Troubleshooting

Daily Walk-Around Inspection ..................................21

General Maintenance .................................................21

Preparing for Service .................................................21

Inspecting the Unit .....................................................21

Cleaning the Unit .......................................................21

Emptying Water Circuit .............................................22

Cleaning Water Filters ...............................................22

Inlet Filter ...................................................................22

Nozzle Filter ..............................................................22

Nozzle Cleaning .........................................................22

Lubrication .................................................................23

Jack Maintenance ......................................................23

Trailer Wheel Bearings ..............................................23

Wheel Maintenance ....................................................23

General Troubleshooting ..........................................24

Owner’s Manual for DF7500 Dust Suppression System 1

Page 4

This page intentionally left blank

2 Owner’s Manual for DF7500 Dust Suppression System

Page 5

Section 1: Introduction and Safety

Introduction and Safety

Introduction

Thank you for purchasing a Generac Mobile Products LLC

product. This unit has been designed to provide high

performance, efficient opera tion, and years of use when

ma inta ine d p rope rly.

The information in this manual is accurate based on

products produced at the time of publication. The manufacturer reserves the right to make technical updates,

corrections, and product revisions at any time without

notice.

Read This Manual Thoroughly

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

If any section of this manual is not understood, contact your

nearest Generac Mobile Products Authorized Service Dealer

(ASD), or contact Generac Mobile Products Technical Service

at 1-800-926-9768 or www.generacmobileproducts.com

with any questions or concerns.

The owner is responsible for proper maintenance and safe

use of the equipment. Comply with regulations the Occupational Safety and Health Administration (OSHA) has

established, or with equivalent standards. Also, verify that

the unit is applied, used, and maintained in accordance with

the manufacturer's instructions and recommendations. Do

nothing that might alter safe application/usage and render

the unit in noncompliance with the aforementioned codes,

standards, laws, and regulations

Save these instructions for future reference. This manual

contains important instructions for the unit that should be

followed during setup, operation and maintenance of the

unit and battery. ALWAYS supply this manual to any individual that will use this machine.

.

How to Obtain Service

When the unit requires servicing or repairs, contact an

ASD for assistance. Service technicians are factorytrained and are capable of handling all service needs. For

assistance locating a dealer, go to https://www.gener-

acmobileproducts.com/parts-service/find-service.

When contacting an ASD about parts and service, always

supply the complete model and serial number of the unit

as given on the data decal located on the unit. Record

the model and serial numbers in the spaces provided on

the front cover of this manual.

(000100a)

Safety Rules

The manufacturer cannot anticipate every possible circumstance that might involve a hazard. The warnings in this

manual, and on tags and decals affixed to the unit are,

therefore, not all inclusive. If using a procedure, work

method or operating technique that the manufacturer does

not specifically recommend, verify it is safe for others. Also

make sure the procedure, work method or operating technique utilized does not render the equipment unsafe.

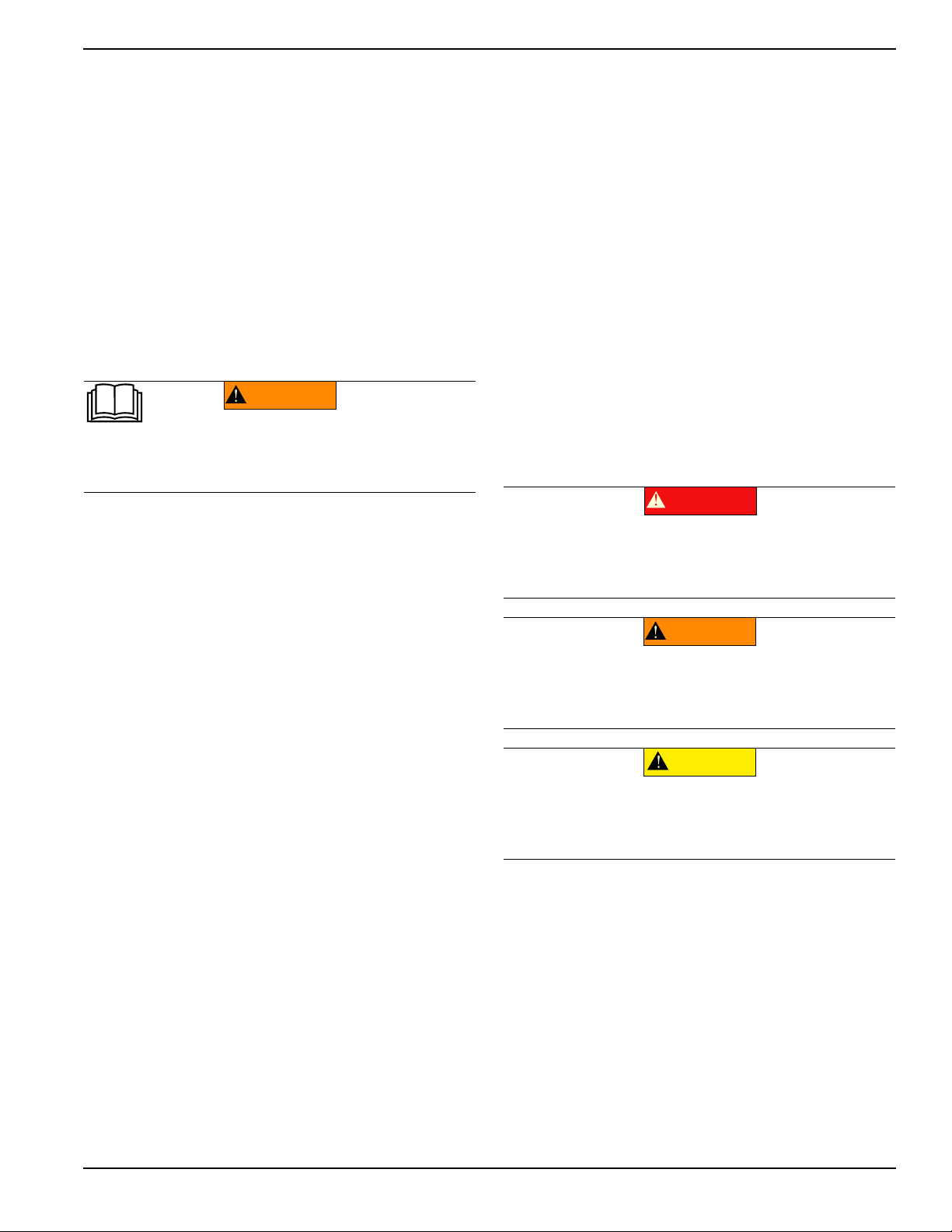

Safety Symbols and Meanings

Throughout this publication, and on tags and decals affixed

to the unit, DANGER, WARNING, CAUTION and NOTE

blocks are used to alert personnel to special instructions

about a particular operation that may be hazardous if

performed incorrectly or carelessly. Observe them carefully. Their definitions are as follows:

DANGER

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

(000001)

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

(000002)

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

(000003)

NOTE: Notes contain additional information important to

a procedure and will be found within the regular text of

this manual.

These safety alerts cannot eliminate the hazards that they

indicate. Common sense and strict compliance with the

special instructions while performing the action or service

are essential to preventing accidents.

Owner’s Manual for DF 7500 Dust Suppression System 1

Page 6

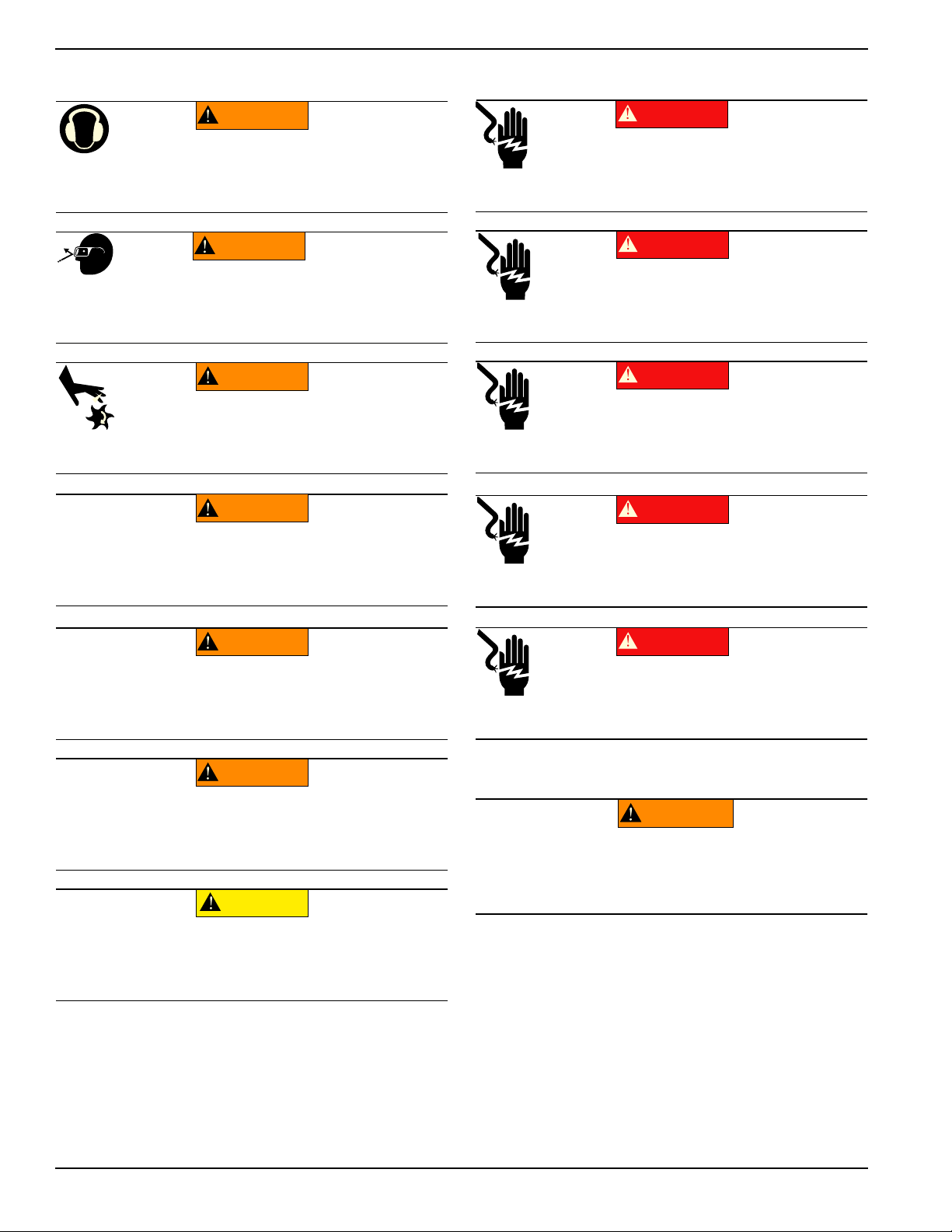

Introduction and Safety

General Hazards Electrical Hazards

WARNING

Hearing Loss. Hearing protection is

recommended when using this machine.

Failure to wear hearing protection could

result in permanant hearing loss.

(000107)

WARNING

Vision loss. Eye protection is required when

operating unit. Failure to wear appropriate eye

protection could result in vision loss or serious

injury.

(000407)

WARNING

Moving Parts. Keep clothing, hair, and

appendages away from moving parts. Failure

to do so could result in death or serious injury.

(000111)

WARNING

CAUTION

Equipment damage. Do not attempt to start or operate

a unit in need of repair or scheduled maintenance.

Doing so could result in serious injury, death, or

equipment failure or damage.

(000291)

DANGER

Electrocution. In the event of electrical accident,

immediately shut power OFF. Use non-conductive

implements to free victim from live conductor. Apply

first aid and get medical help. Failure to do so will

result in death or serious injury.

(000145)

DANGER

Electrocution. Water contact with a power

source, if not avoided, will result in death

or serious injury.

(000104)

DANGER

Electrocution. Verify electrical system is

properly grounded before applying power.

Failure to do so will result in death or serious

injury.

(000152)

DANGER

Electrocution. Do not wear jewelry while

working on this equipment. Doing so will

result in death or serious injury.

(000188)

WARNING

Risk of injury. Do not operate or service this machine

if not fully alert. Fatigue can impair the ability to service

this equipment and could result in death or serious

injury.

(000215)

WARNING

Equipment damage. Only qualified service personnel may

install, operate, and maintain this equipment. Failure to follow

proper installation requirements could result in death, serious

injury, and equipment or property damage.

(000182a)

CAUTION

Equipment or property damage. Do not block air

intake or restrict proper air flow. Doing so could

result in unsafe operation or damage to unit.

(000229)

DANGER

Electrocution. DO NOT use the unit if

electrical cord is cut or worn through. Doing

so will result in death or serious injury.

(000263a)

Service Safety

WARNING

Before servicing unit, shut unit down, turn water supply

OFF, and disconnect unit from power source. Failure

to do so could result in death, serious injury, or

equipment damage.

(000586)

2 Owner’s Manual for DF 7500 Dust Suppression System

Page 7

Introduction and Safety

Operating Safety

Positioning the Unit

WARNING

Crushing hazard. Verify unit is properly secured and

on level ground. An unsecured unit can suddenly roll

or move, causing death or serious injury.

(000234a)

WARNING

Personal injury. Only use water from controlled, reliable

sources. Uncontrolled water could contain bacteria. Inhaling

mist containing bacteria could result in death, or serious

injury.

WARNING

Personal injury. Keep people and pets away from work

area. Failure to do so could result in death or serious

injury.

(000584)

(000420)

Lifting Hazards

WARNING

Personal injury. Failure to properly connect

lifting cables, chains, or straps could result in

death, serious injury, or property damage.

(000346)

WARNING

Personal Injury. Do not use lifting eye if there are signs

of damage or corrosion. Doing socould result in death,

serious injury, or property damage.

(000433)

WARNING

Personal Injury. Do not use lifting eye other than as

directed. Doing so could result in death, serious injury,

or property damage.

(000434)

WARNING

WARNING

Personal injury. Never direct air jet toward people or animals.

Shut unit OFF immediately if people or animals enter the

work area. Failure to do so could result in death or serious

injury.

•

The area immediately surrounding the unit should

be dry, clean, and free of debris.

(000585)

• If the unit is equipped with a frame grounding stud,

follow any local, state, and National Electrical Code

(NEC) guidelines when connecting.

Starting the Unit

DANGER

Electrocution. DO NOT use the unit if

electrical cord is cut or worn through. Doing

so will result in death or serious injury.

(000263a)

WARNING

CAUTION

Equipment damage. Do not attempt to start or operate

a unit in need of repair or scheduled maintenance.

Doing so could result in serious injury, death, or

equipment failure or damage.

(000291)

Personal Injury. Verify all fasteners are properly

tightened prior to lifting unit. Failure to do so could

result in death, serious injury, or property damage.

(000351)

Owner’s Manual for DF 7500 Dust Suppression System 3

Page 8

Introduction and Safety

Trailer Hazards

WARNING

Personal injury. Trailer must be securely coupled to

the hitch with the chains correctly attached. Uncoupled

or unchained towing could result in death or serious

injury.

WARNING

Personal injury. Do not operate unit during transport.

Doing so could result in death, serious injury, or

property damage.

WARNING

Crushing hazard. Verify unit is properly secured and

on level ground. An unsecured unit can suddenly roll

or move, causing death or serious injury.

WARNING

Property or Equipment Damage. Tighten wheel lug

nuts after first 50 miles to factory specifications.

Failure to do so could result in death, serious injury,

property or equipment damage.

IMPORTANT NOTE: See original trailer operating

manual for additional safety information.

(000233a)

(000231a)

(000234a)

(000235)

• Connect safety chains in a crossing pattern under

the tongue with enough slack to permit turning and

to hold tongue up if trailer comes loose.

• Before towing the trailer, verify that the weight of

the trailer is equal across all tires. On trailers with

adjustable height hitches, adjust the angle of the

trailer tongue to keep the trailer as level as

possible.

Running Lights

Verify directional and brake lights on the trailer are

connected and working properly.

Wheels and Tires

Inspect trailer tires for wear and proper inflation.

•

• Verify wheel lug nuts are present and tightened to

the specified torque.

Safe Towing Techniques

Practice turning, stopping, and backing up in an

•

area away from heavy traffic prior to transporting

the unit.

• Maximum recommended speed for highway towing

is 45 mph (72 km/h). Recommended off-road towing speed is 10 mph (16 km/h) or less, depending

on terrain.

• When towing, maintain extra space between vehi-

cles and avoid soft shoulders, curbs, and sudden

lane changes.

Towing Safety

Towing a trailer requires care. Both the trailer and vehicle

must be in good condition and securely fastened to each

other to reduce the possibility of an accident. Some states

require that large trailers be registered and licensed. Contact your local Department of Transportation office to check

on license requirements for your particular unit.

Towing Vehicle

DO NOT exceed the towing vehicle’s gross vehicle weight

rating (GVWR).

Hitch and Coupling

Verify the hitch and coupling on the towing vehicle

•

are rated equal to, or greater than, the trailer's

gross vehicle weight rating (GVWR).

• Verify the trailer hitch and the coupling are compat-

ible. Verify the coupling is securely fastened to the

vehicle.

• DO NOT tow trailer using defective parts. Inspect

the hitch and coupling for wear or damage.

Reporting Trailer Safety Defects

If you believe your trailer has a defect which could cause

a crash or could cause injury or death, you should immediately inform the National Highway Traffic Safety Administration (NHTSA) in addition to notifying Generac Mobile

Products LLC.

If NHTSA receives similar complaints, it may open an

investigation; and if it finds that a safety defect exists in a

group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become involved in an

individual problem between you, your GMP ASD, or Generac Mobile Products LLC.

To contact NHTSA, you may either call the Auto Safety

Hotline toll-free at 1-888-327-4236 (TTY:1-800-424-9153),

go to http://www.safercar.gov; or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain other information about motor vehicle

safety from http://www.safercar.gov.

4 Owner’s Manual for DF 7500 Dust Suppression System

Page 9

Introduction and Safety

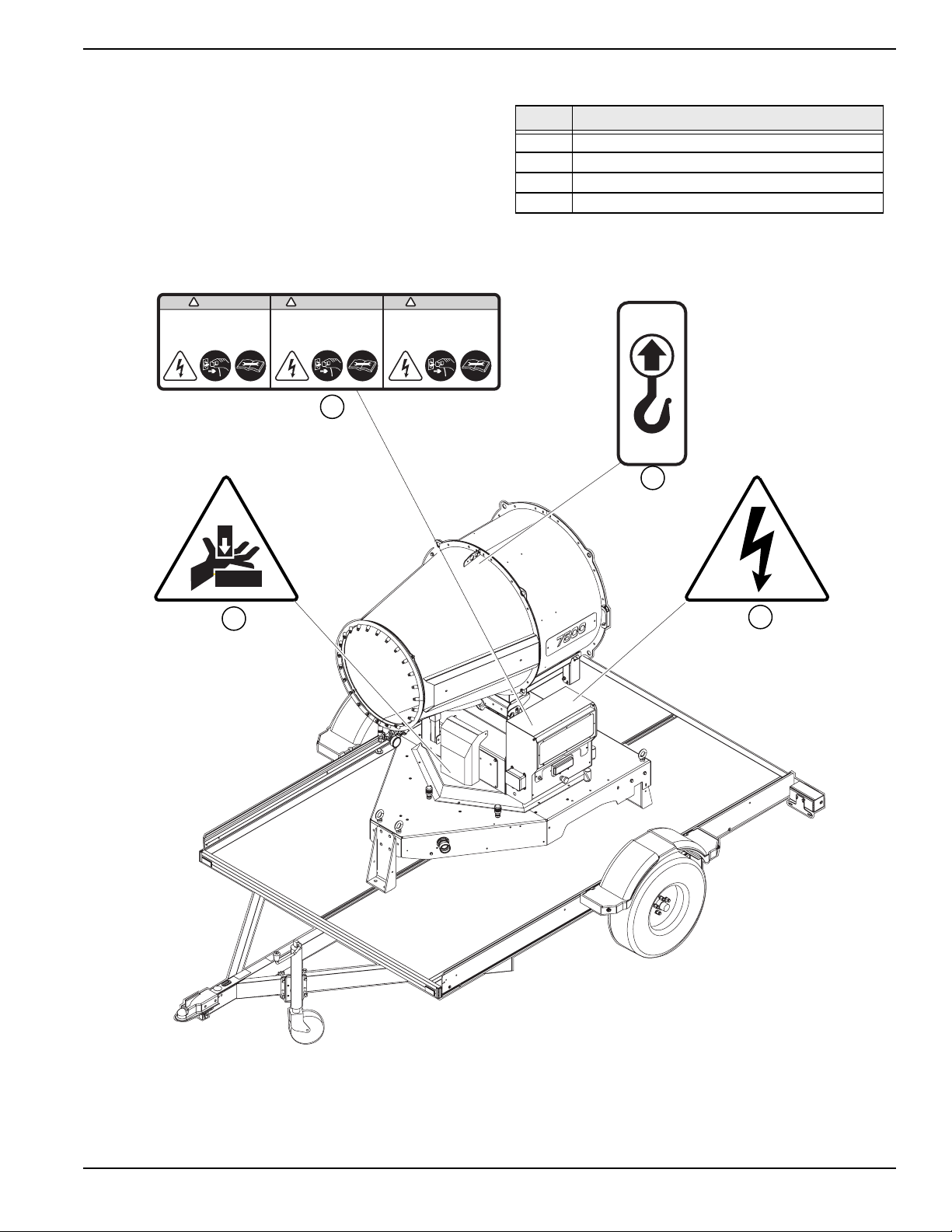

Safety and Operating Decals

This unit features numerous safety and operating decals.

These decals provide important operating instructions and

warn of dangers and hazards. The following diagrams

illustrate decal locations and descriptions.

Replace any missing or hard-to-read decals and use care

when washing or cleaning the unit. Decal part numbers

can be found in the parts manual at www.generacmobile-

products.com.

WARNING

Hazardous Voltage.

Electric shock may cause serious

injury or death.

Disconnect power before servicing.

! !!

AVERTISSEMENT

Tension Dangeureuse .

Une décharge électrique entraînera

des blessures graves, voire la mort.

Déconnecter le courant avant de

commencer le service.

1

ADVERTENCIA

Voltage Peligroso.

Las descargas eléctricas causan

Desde lesiones graves hasta la muerte.

Desconectar la fuente de poder antes

de hacer servicio

Table 1-1. Decal Descriptions

ID Description

1 Electric Shock Hazard

2 Central Lift Point

3 Electric Shock Hazard

4 Hand Crush

2

4

3

Figure 1-1. Safety Decal Locations

IMPORTANT NOTE: See original trailer operating manual for trailer safety and operating decal information.

Owner’s Manual for DF 7500 Dust Suppression System 5

Page 10

Introduction and Safety

This page intentionally left blank.

6 Owner’s Manual for DF 7500 Dust Suppression System

Page 11

General Information

Section 2: General Information

Specifications

Description Units DF7500

Electric Connection A Inlet plug three phase 32

Voltage V 240

Hertz Hz 32

Smallest Generator Required kW 32 three-phase

Fan Power kW 7.5

Pump Power kW 2.2

Water Connection - 1” hose barb

Water Consumption gal/min (L/min) 13.7 (52)

Inlet Pressure psi (bar) 1.45 (.1) - 5.8 (.4)

Inlet Water Filter micron/mesh 180/80

Number of Nozzles 24

Rotation Angle Range degrees 335

Tilt Angle degrees 0-40

Noise Level DB @ 22 ft (7 m) 84

Maximum Horizontal Range (without wind) ft (m) 98-131 (30-40)

Maximum Vertical Range (without wind) ft (m) 52 (16)

Maximum Covered Area acre (m2) 1.13 (4,600)

Weights

Skid Mounted lb (kg) 1,993 (904)

Trailer Mounted lb (kg) 2,373 (1,076)

Dimensions

Skid Mounted L x W x H ft (m) 10.83 (3.30) x 6 (1.83) x 7.15 (2.18)

Trailer Mounted L x W x H ft (m) 102 (31) x 178 (52) x 104 (32)

Specifications are subject to change without notice. Refer to the product specification sheet for complete list.

Unit Dimensions

A 6 ft (1.83 m)

B 10.83 ft (3.3 m)

C 7.15 (2.18)

A

Figure 2-1. Unit Dimensions

Owner’s Manual for DF7500 Dust Suppression System 7

C

B

009031

Page 12

General Information

Component Location

I

A

B

E

F

C

D

A

A

J

Figure 2-2. Component Locations

A Lifting Eye F Radio Control Receiver

B Nozzles G Water Inlet Filter

C Water Flow Control Valves H Water Inlet Connection

D Working Range Limiter Pins I Transport Safety Locks

E Control Panel J Electrical Socket

Control Panel

G

C

D

B

A

N

M

F

E

I

K

L

H

J

Control Panel Components and Functions

A Manual Control Switch

B Oscillation System Switch

C Hour Meter

D Water Pump Switch

E Fan Switch

F Phase Controller Error Lamp

G Phase Controller Switch

H Input Switch

I Button Emptying Water Circuit

J Blower Tilting Lever

K Fan Motor Protection Circuit Breaker

L Water pump Protection Circuit Breaker

M Emergency Stop Button

N Oscillation System Protection Circuit Breaker

G

H

009032

Figure 2-4. Control Panel

8 Owner’s Manual for DF7500 Dust Suppression System

Page 13

General Information

Transmitter Unit

C

A

B

D

I

G

Figure 2-4. Transmitter Unit

Unit and Serial Number Locations

See Figure 2-5 to locate the unit ID tag (A) and vehicle

identification number (VIN) tag (B). Important information

such as the unit model number, serial number, VIN, and

tire loading information are listed on these tags. Record

the information from these tags in the event the tags are

lost or damaged. This information may be needed when

ordering parts or requesting assistance

L

E

F

J

H

K

Transmitter Unit Components and Functions

A Fan ON

B Fan OFF

C Pump ON

D Pump OFF

E Oscillation system ON

F Oscillation system OFF

G Fan and pump ON

H All devices OFF

I Tilting Up

J Tilting Down

K Main ON-OFF switch (on back)

L Transmission battery status

Connecting Water Supply

WARNING

Personal injury. Only use water from controlled, reliable

sources. Uncontrolled water could contain bacteria. Inhaling

mist containing bacteria could result in death, or serious

injury.

(000584)

B

A

009111

Figure 2-5. Unit and Serial Number Locations

NOTE: DO NOT run unit without sufficient water supply.

Failure to follow water supply requirements will void

warranty.

Water supply must meet the following requirements:

• Water must be greater than 15 gallons per minute

(52 liters per minutes) and no less than 14 psi (1

bar).

• Water supply hose length must not exceed 50 ft

(15.2 m).

• Water temperature must be less than 100°F

(38°C).

• DO NOT siphon standing water for the water

source.

• Use only controlled water from reliable sources.

• DO NOT use a one-way valve, vacuum breaker, or

check valve in any part of the water supply.

Owner’s Manual for DF7500 Dust Suppression System 9

Page 14

General Information

1. Run water 30 seconds prior to connection to eliminate debris.

2. See Figure 2-6. Connect a hose to 1” water inlet

(A) and hand-tighten.

A

009111

Figure 2-6. Water Connection

Connecting Power Supply

DANGER

Electrocution. In the event of electrical accident,

immediately shut power OFF. Use non-conductive

implements to free victim from live conductor. Apply

first aid and get medical help. Failure to do so will

result in death or serious injury.

(000145)

IMPORTANT NOTE: See generator operator’s manual

for proper installation procedure to generator.

1. Install power cable wires (A) to three phase, 240

volt power source.

A

009116

Figure 2-7. Electrical Connection

2. See Figure 2-10. Verify input switch (B) is in the

OFF position.

3. Verify emergency stop button (C) is in the out

armed position. If the emergency stop button is

engaged, twist the emergency stop button clockwise to release.

DANGER

Electrocution. Verify electrical system is

properly grounded before applying power.

Failure to do so will result in death or serious

injury.

(000152)

DANGER

Electrocution. Water contact with a power

source, if not avoided, will result in death

or serious injury.

(000104)

DANGER

Electrocution. Turn utility and emergency

power supplies to OFF before connecting

power source and load lines. Failure to do so

will result in death or serious injury.

(000116)

WARNING

Electric shock. Only a trained and licensed electrician

should perform wiring and connections to unit. Failure

to follow proper installation requirements could result in

death, serious injury, and equipment or property damage.

(000155a)

B

C

008780

Figure 2-8. Emergency Stop Button

4.

See

Figure 3-4

. Connect power cable to socket (D)

IMPORTANT NOTE: Installations must be comply

with national, state, and local codes.

10 Owner’s Manual for DF7500 Dust Suppression System

Figure 2-9. Electrical Connection

D

008950

Page 15

General Information

Using Transport Locks

See Figure 2-10. Transport locks (A) (B) must be

disengaged prior to operation

IMPORTANT NOTE: Verify transport locks are

engaged prior to transporting the unit.

Disengaging Transport Locks

1. Remove transport locking pin (A) from transport

lock support.

2. Lift transport locking pin (B) to raised position

Engaging Transport Locks

1. Shut off manual oscillation. See Control Panel.

2. Lower blower completely. See Control Panel.

3. See Figure 2-10. Align holes in actuator supports

(A).

4. Insert transport locking pin through holes (A) and

secure with cotter pin.

5. Rotate blower to forward position.

6. Insert transport lock (B) into hole in base.

Lifting the Unit

WARNING

Personal injury. Failure to properly connect

lifting cables, chains, or straps could result in

death, serious injury, or property damage.

(000346)

WARNING

Personal Injury. Do not use lifting eye if there are signs

of damage or corrosion. Doing socould result in death,

serious injury, or property damage.

(000433)

WARNING

Personal Injury. Do not use lifting eye other than as

directed. Doing so could result in death, serious injury,

or property damage.

(000434)

WARNING

B

A

008784

Figure 2-10. Transport Locks

Towing the Unit (if equipped)

See trailer operator’s manual for proper towing setup and

procedure.

Personal Injury. Verify all fasteners are properly

tightened prior to lifting unit. Failure to do so could

result in death, serious injury, or property damage.

(000351)

1. Verify equipment being used to lift the unit is in

good condition and has sufficient capacity. For

approximate weights, refer to Specifications.

2. Engage transport locks. See Using Transport

Locks.

3.

Remain aware of people and objects around the unit

while preparing, maneuvering, and lifting the unit.

• When lifting the unit, attach any slings, chains, or

hooks directly to the four lifting points (A). The

central lift point is located on top of the enclosure,

connected to a lift structure inside the unit.

• Use fork lift pockets (B) with care. Avoid

approaching unit at an angle as this can damage

the forklift pockets. Verify obstructions are clear of

the forklift tines before lifting.

A

A

B

Figure 2-11. Lifting Points

Owner’s Manual for DF7500 Dust Suppression System 11

008776

Page 16

General Information

This page intentionally left blank.

12 Owner’s Manual for DF7500 Dust Suppression System

Page 17

Section 3: Operation

)

g

Operation

DANGER

Electrocution. In the event of electrical accident,

immediately shut power OFF. Use non-conductive

implements to free victim from live conductor. Apply

first aid and get medical help. Failure to do so will

result in death or serious injury.

(000145)

DANGER

Electrocution. Verify electrical system is

properly grounded before applying power.

Failure to do so will result in death or serious

injury.

(000152)

DANGER

Electrocution. Water contact with a power

source, if not avoided, will result in death

or serious injury.

(000104)

WARNING

Consult Manual. Read and understand manual

completely before using product. Failure to

completely understand manual and product

could result in death or serious injury.

(000100a)

Operation and Use Questions

Contact your nearest Generac Mobile Products Authorized

Service Dealer (ASD), or contact Generac Mobile Products

Technical Service at 1-800-926-9768 or

www.generacmobileproducts.com with any questions or

concerns about unit operation and maintenance.

Before Starting

1. Place unit on flat ground in a well ventilated area.

2. Place barriers 6 ft (2 m) around unit to prevent

unauthorized personnel from nearing unit.

3. See Figure 3-1. Verify sufficient water supply is

properly connected to water inlet (A). For water

requirements, see Connecting Water Supply.

WARNING

CAUTION

Equipment damage. Do not attempt to start or operate

a unit in need of repair or scheduled maintenance.

Doing so could result in serious injury, death, or

equipment failure or damage.

(000291)

WARNING

Before servicing unit, shut unit down, turn water supply

OFF, and disconnect unit from power source. Failure

to do so could result in death, serious injury, or

equipment damage.

(000586)

WARNING

Personal injury. Keep people and pets away from work

area. Failure to do so could result in death or serious

injury.

(000420)

WARNING

Personal injury. Only use water from controlled, reliable

sources. Uncontrolled water could contain bacteria. Inhalin

mist containing bacteria could result in death, or serious

injury.

(000584

A

009111

Figure 3-1. Water Connection

4. Turn on water supply.

5. See Figure 3-4. Open water control valves (B).

B

008796

Figure 3-2. Water Control Valves

Owner’s Manual for DF7500 Dust Suppression System 17

Page 18

Operation

6. See Figure 3-3. Verify power source is properly

connected to socket (C). For power requirements

and setup, see Connecting Power Supply.

C

008950

Figure 3-3. Electrical Connection

IMPORTANT NOTE: For grounding requirements, follow National Electrical Code (NEC), state, and local regulations.

7. See Figure 3-4. Verify transport lock (D) and (E)

are disengaged. For more information, see Using

Transport Locks.

H

G

F

E

C

A

D

B

I

008780

Figure 3-5. Control Panel

Stopping the Unit

NOTE: See Figure 3-5. Stop the unit at any time by

pressing emergency stop (A).

Shut down the unit in the following sequence:

1. Shut off oscillation system (F).

2. Shut off water pump (E).

3. Shut off fan (D).

4. Shut off input switch on control panel (B).

B

A

008784

Figure 3-4. Transport Safety Locks

Starting the Unit

1. See Figure 3-5. Verify emergency switch (A) is in

the out, armed position. If emergency switch is not

armed, twist counterclockwise to reset.

2. Turn input switch (B) ON.

3. Set manual control switch (C) to MANUAL.

4. Press fan (D) ON.

5. Press water pump (E) ON.

6. If using automatic oscillation system, press

oscillation system (F) ON.

NOTE: If using automatic oscillation, system must be set

up prior to operation. See Automatic Oscillation.

Tilting the Blower

NOTE: Transport locks must be disengaged before tilting

the blower. See Using Transport Locks.

See Figure 3-5. Use control panel tilting lever (I) or

remote control tilt buttons to adjust tilt 0 to 40°.

Manual Rotation

NOTE: Transport locks must be disengaged before

rotating blower. See Using Transport Locks.

1.

See

Figure 3-5

2. See Figure 3-6 Use handle (A) to rotate blower.

. Verify oscillation is switched OFF (F).

A

NOTE: If the fan does not start and phase controller

error lamp (G) is lit, turn phase controller switch (H) to

PHASE SRT or PHASE SRT then restart fan.

18 Owner’s Manual for DF7500 Dust Suppression System

Figure 3-6. Manual rotation

009116

Page 19

Operation

Automatic Oscillation

NOTE: Transport locks must be disengaged before

using oscillation system. See Using Transport Locks.

See Figure 3-7. When the oscillation system is set to

ON, blower rotation is controlled by the placement of

limiting pins (A). Oscillation range can be adjusted by

moving limiting pins to any hole (B) in the deck. When

micro switch (C) contacts a limiting pin the blower

reverses direction.

C

A

Figure 3-7. Automatic Oscillation

1. Turn OFF oscillation system. See Control Panel.

2. Manually rotate blower to the extreme the blower

should rotate to the left.

3. Install limiting pin (B) into nearest hole (B) to the

left of micro switch (C).

4. Manually rotate blower to the extreme the blower

should rotate to the right.

5. Install limiting pin (B) into nearest hole (B) to the

right of micro switch (C).

6. Turn ON oscillation system. See Control Panel.

B

008805

NOTE: If radio control fails at any time, switch control

switch (A) to MANUAL CONTROL.

1. See Figure 3-8. Move control switch (A) to RADIO

CONTROL.

2. Verify emergency switch (B) is in the out, armed

position. If emergency switch is not armed, twist

counterclockwise to reset.

A

B

008780

Figure 3-8. Control Panel

3. See Figure 3-9. Switch main on-off switch (A) on

back of transmitter to ON.

G

B

F

C

D

E

NOTE: When shutting down the unit, switch off

G

automatic oscillation first. See Stopping the Unit for

proper shutdown sequence.

Using the Transmitter

The operator using the radio control system must:

• Understand transmitter and machine functions.

• Visually follow machine movements activated by

transmitter.

• Switch off transmitting unit whenever suspending

the job.

Figure 3-9. Transmitter

4.

Select fan on/off (B), pump on/off (C), oscillation on/

off (D), tilting up/down (E), or fan and pump on (F).

NOTE: If LED (G) does not flash or flashes weakly when

a button is pressed, the battery needs to be replaced.

A

009034

• Remember the transmitter can activate machine

movements even in indoor locations away from the

receiving unit.

• Never leave the transmitter unattended.

• Avoid using radio control inside shielded areas.

NOTE: Pushing the stop button on the control panel

immediately disables all radio control.

5. Use macro button (G) to automatically switch off

oscillation, pump, and fan in the proper shutdown

sequence.

• Replace batteries when discharged.

Owner’s Manual for DF7500 Dust Suppression System 19

Page 20

Operation

This page intentionally left blank.

20 Owner’s Manual for DF7500 Dust Suppression System

Page 21

Maintenance and Troubleshooting

)

Section 4: Maintenance and Troubleshooting

Preparing for Service

WARNING

Before servicing unit, shut unit down, turn water supply

OFF, and disconnect unit from power source. Failure

to do so could result in death, serious injury, or

equipment damage.

(000586

CAUTION

Equipment Damage. Failure to perform a daily

inspection could result in damage to the unit.

(000306)

Daily Walk-Around Inspection

Perform a walk-around inspection of the unit every day

before starting the unit. Look for conditions that could

hinder performance or safety, such as (but not limited to)

damaged or missing parts and hardware, and loose or

broken electrical connections.

General Maintenance

Maintenance

Activity

Clean Unit

Rinse Nozzles

Empty Water Circuit

Clean Water Filter

Lubricate Unit

Clean Nozzles

Before

Each Use

After

Each Use

Semi-

Annually

Before servicing the unit, always follow the instructions

listed below.

1. Verify unit power switch is OFF.

2. Disconnect power.

3. Disconnect water supply.

4. Attach a DO NOT USE sign to the control panel.

This will notify everyone that the unit is being

serviced and will reduce the chance of someone

inadvertently trying to start the unit.

Inspecting the Unit

If the unit is stored outside, check for water inside

•

the cabinet and control panel cover before each

use. If wet, dry the unit thoroughly before starting.

• Inspect condition of electrical cords. DO NOT use

the unit if insulation is cut or worn through.

Cleaning the Unit

Always clean the unit after each use to remove dust,

grease, mud or spilled fuel or oil. fter each use, clean the

unit if dust, grease, or dirt. Use soft, clean rags to wipe

the cabinet exterior and control panel. Low-pressure

compressed air (less than 40 PSI [276 kPa]) can also be

used to remove dust and debris from control panel.

NOTE: Do not use a high pressure hose or power

washer to clean control panel or cabinet. Water could

damage the electronic components.

Rinsing nozzles

See

Figure 4-1

antilimestone solution to prevent nozzle fouling.

. After each use, rinse nozzles (A) with an

Poorly maintained equipment can become a safety

hazard. In order for the equipment to operate safely and

properly over a long period of time, periodic maintenance

and occasional repairs are necessary. DO NOT perform

routine service unless all electrical components are OFF.

Regular maintenance will improve performance and

extend engine/equipment life. Generac Mobile Products,

LLC recommends all maintenance work be performed by

an Generac Mobile Products Authorized Dealer (ASD).

Figure 4-1. Cleaning the Unit

Owner’s Manual for DF7500 Dust Suppression System 21

A

Page 22

Maintenance and Troubleshooting

Emptying Water Circuit

After each use, empty the water system must to remove

sediment from the inlet filter and to prevent fouling.

See

See

Figure 4-3

Figure 4-3

1.

2.

open inlet valve (C).

. Open nozzle valves (A).

A

008796

Figure 4-2. Open Valves

. Disconnect hose from inlet (B) and

B

A

Figure 4-4. Inlet Water Filter

Cleaning Nozzle Filter

1.

See

Figure 4-3. Remove nozzle filter plug (C).

2. Remove filter cartridge.

3. Tap cartridge on a solid surface and blow with com-

pressed air to remove sediment.

4. Install cartridge and replace inlet filter plug.

008957

B

C

008796

Figure 4-3. Disconnect Hose and Open Valve

3. Allow system to drain.

4. Close inlet valve.

5. Close nozzle valves.

Cleaning Water Filters

The unit is equipped with an inlet filter and nozzle filter.

Both must be cleaned semiannually or whenever

performing system maintenance.

Cleaning Inlet Filter

1.

See

Figure 4-5. Unscrew and remove water inlet (B).

2. Remove filter cartridge.

3. Tap cartridge on a solid surface and blow with com-

pressed air to remove sediment.

4. Install cartridge and replace inlet filter plug.

C

008957

Figure 4-5. Nozzle Water Filters

Nozzle Cleaning

Clean nozzles on a semiannual basis or whenever

clogged.

1.

See

Figure 4-1. Remove nozzles (A) from blower.

2. Soak nozzles in antilimestone solution over night.

3. Rinse nozzles.

4. Reinstall nozzles

Figure 4-6. Cleaning Nozzles

.

A

22 Owner’s Manual for DF7500 Dust Suppression System

Page 23

Maintenance and Troubleshooting

Lubrication

See

Figure 4-1. Lubricate transport support (A) and

thrust bearing (B) on a semiannual basis.

Trailer Maintenance (if equipped)

Jack Maintenance See the original equipment’s

operating manual for maintenance schedule and a

complete list of maintenance requirements.

IMPORTANT NOTE: Failure to comply with the procedures and requirements as described in the trailer

operators manual will nullify the warranty, decrease

A

A

B

performance, and cause equipment damage or premature equipment failure.

Figure 4-7. Lubrication

General Troubleshooting

This information is intended to be a check or verification for simple causes that can be located and fixed. It does not

cover all types of problems. See the engine operator’s manual for additional troubleshooting information. Procedures

that require in-depth knowledge or skills should be performed by a GMP ASD.

Problem

Water Pump Doesn’t

Work

Fan and Pump do Not

Work

Possible Cause Solution

Open main water tap.

Pump dry

Open water control valves.

Air in water system

Verify sufficient water supply. See for requirements

Insufficient water inlet

pressure

Plug not correctly connected

Emergency stop button is

pressed

Main switch set to OFF

Pump or fan circuit protection breakers switched to

off.

Disconnected cables in the

electrical system

Dirty or obstructed nozzles

Improper start up sequence. The pump must be started prior to

opening the water flow and stopped before closing the water flow

Verify the plug properly fits into socket seat and is fastened by the

locking ring.

Verify the stop button is in the out, armed postion. If not turn the

knob clockwise.

Switch main switch to ON

Switch circuit protection breakers to ON

Inspect electrical system for disconnected plug.

Clean nozzles.

Uneven Nebulization

Tilt, Rotation or

Stabilizer Regulation

Difficult

Owner’s Manual for DF7500 Dust Suppression System 23

Low water pressure

Lack of lubrication Lubricate using proper grease for sliding systems.

Verify water pressure is greater than

requirements

.

14.5 psi (1 bar). See for

Page 24

Maintenance and Troubleshooting

This page intentionally left blank.

24 Owner’s Manual for DF7500 Dust Suppression System

Page 25

Maintenance and Troubleshooting

This page intentionally left blank.

Owner’s Manual for DF7500 Dust Suppression System 25

Page 26

Maintenance and Troubleshooting

This page intentionally left blank.

26 Owner’s Manual for DF7500 Dust Suppression System

Page 27

Page 28

Part No. 10000037626 Rev. A 11/15/2018

©2018 Generac Mobile Products, LLC

All rights reserved.

Specifications are subject to change without notice.

No reproduction allowed in any form without prior written

consent from Generac Mobile Products, LLC.

Generac Mobile Products, LLC

215 Power Drive, Berlin, WI 54923

GeneracMobileProducts.com │800-926-9768 │920-361-4442

Loading...

Loading...