Generac Power Systems CorePower?/ES Generators, CorePower/ES Generator Installation Manuallines

Page 1

INSTALLATION

GUIDELINES

CorePower/ES Generators

THIS MANUAL MUST BE USED IN

CONJUNCTION WITH THE OWNERS

MANUAL.

www.generac.com or 1-888-GENERAC

NOT INTENDED FOR USE IN CRITICAL LIFE

SUPPORT APPLICATIONS.

ONLY QUALIFIED ELECTRICIANS OR CONTRACTORS

SHOULD ATTEMPT INSTALLATION!

DEADLY EXHAUST FUMES! OUTDOOR

INSTALLATION ONLY!

Page 2

Introduction .........................................................Inside Front Cover

Read this Manual Thoroughly ..............................................IFC

Contents ................................................................................1

Operation and Maintenance ....................................................1

How to Obtain Service ............................................................1

Safety Rules ...................................................................................1

Standards Index .....................................................................2

Unpacking/Inspection .....................................................................3

Before You Begin ............................................................................3

Unit Handling .................................................................................3

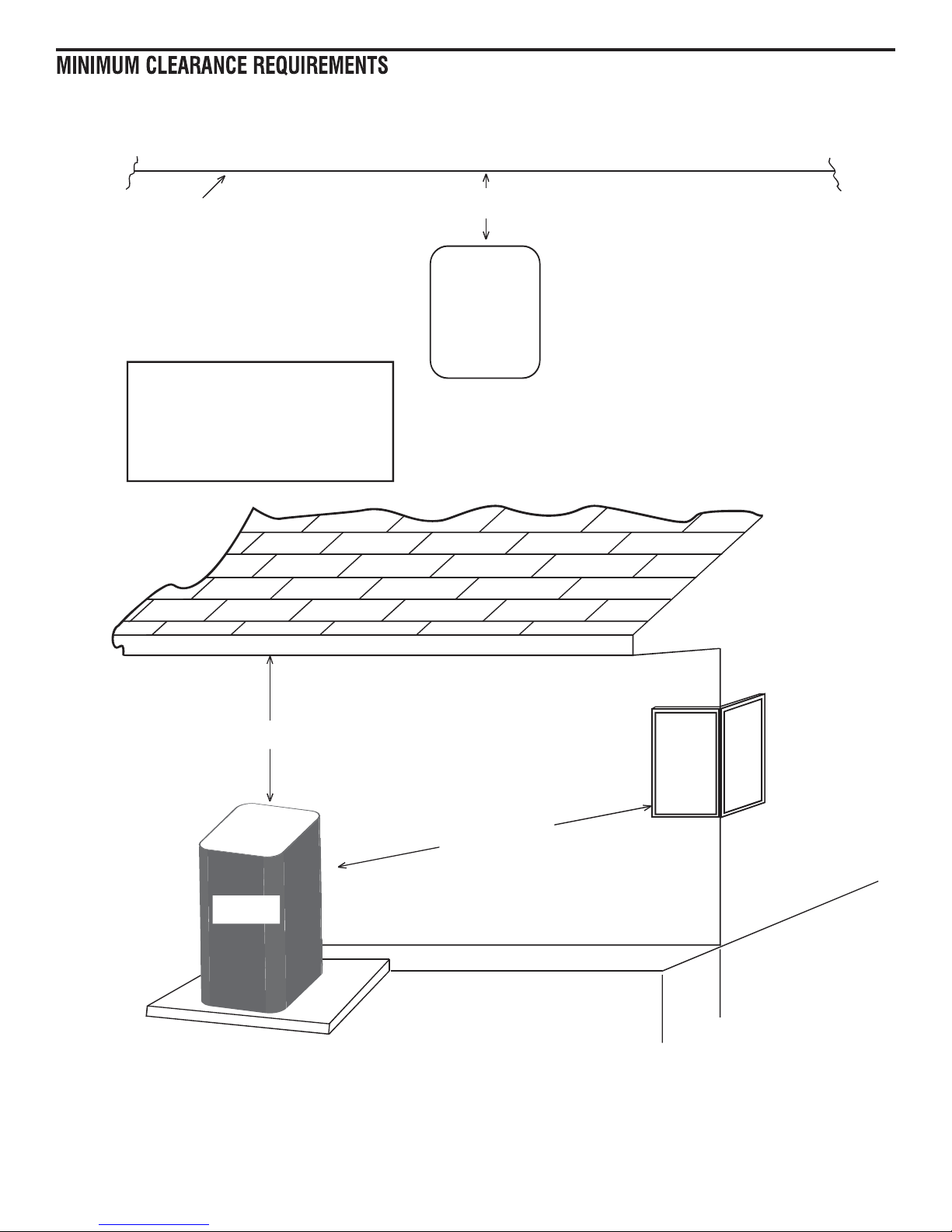

Minimum Clearance Requirements .................................................4

Site Preparation and Generator Placement ......................................5

Coverting to LP Vapor ....................................................................6

Installing & Connecting Gas Lines ..................................................6

External Electrical Connections .......................................................8

Battery Installation..........................................................................9

Automatic Transfer Switch Electrical Connections .........................10

Operational Testing .......................................................................12

Notes ...........................................................................................13

Installation Diagrams ....................................................................16

Thank you for purchasing this compact, high performance, aircooled, engine-driven generator. It is designed to automatically

supply electrical power to operate critical loads during a utility

power failure.

This unit is factory installed in an all-weather, composite enclosure

that is intended exclusively for outdoor installation. This

generator will operate using either vapor withdrawn liquid propane

(LP) or natural gas (NG).

NOTE:

This generator is suitable for supplying typical residential loads

such as Induction Motors (sump pumps, refrigerators, air conditioners, furnaces, etc.), Electronic Components (computer,

monitor, TV, etc.), Lighting Loads and Microwaves.

If any portion of this manual is not understood, contact the

nearest Dealer for starting, operating and servicing procedures.

Throughout this publication, and on tags and decals affixed to the

generator, DANGER, WARNING, CAUTION and NOTE blocks are

used to aler t personnel to special instructions about a particular

operation that may be hazardous if performed incorrectly or

carelessly. Observe them carefully. Their definitions are as follows:

INDICATES A HAZARDOUS SITUATION OR

ACTION WHICH, IF NOT AVOIDED, WILL RESULT

IN DEATH OR SERIOUS INJURY.

Indicates a hazardous situation or action which,

if not avoided, could result in death or serious

injury.

Indicates a hazardous situation or action which,

if not avoided, could result in minor or moderate

injury.

NOTE:

Notes contain additional information important to a procedure

and will be found within the regular text body of this manual.

These safety warnings cannot eliminate the hazards that they

indicate. Common sense and strict compliance with the special

instructions while performing the action or service are essential to

preventing accidents.

Four commonly used safety symbols accompany the DANGER,

WARNING and CAUTION blocks. The type of information each

indicates is as follows:

This symbol points out important safety information that,

if not followed, could endanger personal safety and/or

property of others.

This symbol points out potential explosion hazard.

This symbol points out potential fire hazard.

Page 3

This symbol points out potential electrical shock hazard.

The operator is responsible for proper and safe use of the

equipment. The manufacturer strongly recommends that

the operator read and thoroughly understand all instructions

before using this equipment. The manufacturer also strongly

recommends instructing other users to properly start and operate

the unit. This prepares them if they need to operate the equipment

in an emergency.

This manual contains pertinent installation information for model:

• 6 kW NG, 7 kW LP, single-cylinder OHV 432 Engine

It is the operator’s responsibility to perform all safety checks, to

make sure that all maintenance for safe operation is performed

promptly, and to have the equipment checked periodically by a

Dealer. Normal maintenance service and replacement of parts

are the responsibility of the owner/operator and, as such, are not

considered defects in materials or workmanship within the terms

of the warranty. Individual operating habits and usage contribute to

the need for maintenance service.

Proper maintenance and care of the generator ensures a minimum

number of problems and keep operating expenses at a minimum.

See a Dealer for service aids and accessories.

When the generator requires servicing or repairs, contact a Dealer

for assistance. Service technicians are factory-trained and are

capable of handling all service needs.

The manufacturer cannot anticipate every possible circumstance

that might involve a hazard. The warnings in this manual, and on

tags and decals affixed to the unit are, therefore, not all-inclusive.

If using a procedure, work method or operating technique the

manufacturer does not specifically recommend, ensure that it is

safe for others. Also make sure the procedure, work method or

operating technique utilized does not render the generator unsafe.

Despite the safe design of this generator,

operating this equipment imprudently,

neglecting its maintenance or being careless

can cause

possible injury or death. Permit only responsible and capable persons to install, operate

and maintain this equipment.

Potentially lethal voltages are generated by

these machines. Ensure all steps are taken to

render the machine safe before attempting to

work on the generator.

Parts of the generator are rotating and/or hot

during operation. Exercise care near running

generators.

Installation must always comply with applicable codes, standards, laws and regulations.

A running generator gives off carbon monoxide, an odorless, colorless poison gas.

Breathing in carbon monoxide can cause

headaches, fatigue, diziness, nausea, vomitting, confusion, fainting, siezures or death.

GENERAL HAZARDS

When contacting a Dealer about parts and service, always supply

the complete model number and serial number of the unit as given

on its data decal, which is located on the generator. See section

“The Generator” in the Owner’s Manual for decal location.

Model No.__________________ Serial No. ______________

Save These Instructions The manufacturer

suggests that these rules for safe operation

be copied and posted near the units installation site. Safety should be stressed to all

operators and potential operators of this

equipment.

Study these SAFETY RULES carefully before installing, operating

or servicing this equipment. Become familiar with this Owners

Manual and with the unit. The generator can operate safely,

efficiently and reliably only if it is properly installed, operated and

maintained. Many accidents are caused by failing to follow simple

and fundamental rules or precautions.

• Adequate, unobstructed flow of cooling and ventilating air

is critical to correct generator operation. Do not alter the

installation or permit even partial blockage of ventilation

provisions, as this can seriously affect safe operation of the

generator. The generator MUST be installed and operated

outdoors only.

• Keep hands, feet, clothing, etc., away from drive belts, fans,

and other moving or hot parts. Never remove any drive belt or

fan guard while the unit is operating.

CALIFORNIA PROPOSITION 65 WARNING

Engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects

and other reproductive harm.

CALIFORNIA PROPOSITION 65 WARNING

This product contains or emits chemicals known to the

State of California to cause cancer, birth defects and

other reproductive harm.

1

Page 4

• When working on this equipment, remain alert at all times.

Never work on the equipment when physically or mentally

fatigued.

• Inspect the generator regularly, and contact the nearest Dealer

for parts needing repair or replacement.

• Before performing any maintenance on the generator,

disconnect its battery cables to prevent accidental start up.

Disconnect the cable from the battery post indicated by a

NEGATIVE, NEG or (–) first, then remove the POSITIVE, POS

or (+) cable. When reconnecting the cables, connect the

POSITIVE cable first, the NEGATIVE cable last.

• Never use the generator or any of its parts as a step. Stepping

on the unit can stress and break parts, and may result in

dangerous operating conditions from leaking exhaust gases,

fuel leakage, oil leakage, etc.

CARBON MONOXIDE HAZARDS

• The engine exhaust fumes contain carbon monoxide, which

can be DEADLY. This dangerous gas, if breathed in sufficient

concentrations, can cause unconsciousness or even death.

Do NOT alter or add to the exhaust system or do anything that

might render the system unsafe or in noncompliance with

applicable codes and standards.

• Install a battery operated carbon monoxide alarm indoors,

according to manufacturer’s instructions/recommendations.

ELECTRICAL HAZARDS

• All generators covered by this manual produce dangerous

electrical voltages and can cause fatal electrical shock. Utility

power delivers extremely high and dangerous voltages to

the transfer switch as does the standby generator when it

is in operation. Avoid contact with bare wires, terminals,

connections, etc., while the unit is running. Ensure all

appropriate covers, guards and barriers are in place, secured

and/or locked before operating the generator. If work must

be done around an operating unit, stand on an insulated, dry

surface to reduce shock hazard.

• Do not handle any kind of electrical device while standing

in water, while barefoot, or while hands or feet are wet.

DANGEROUS ELECTRICAL SHOCK MAY RESULT.

• The National Electrical Code (NEC) requires the frame and external

electrically conductive parts of the generator to be connected to

an approved earth ground. Local electrical codes also may require

proper grounding of the generator electrical system.

• After installing this home standby electrical system, the

generator may crank and start at any time without warning.

When this occurs, load circuits are transferred to the STANDBY

(generator) power source. To prevent possible injury if such

a start and transfer occur, always set the generator’s AUTO/

OFF/MANUAL switch to its OFF position before working on

equipment and remove the 7.5A fuse from the generator control

panel.

• In case of accident caused by electric shock, immediately shut

down the source of electrical power. If this is not possible,

attempt to free the victim from the live conductor. AVOID DIRECT

CONTACT WITH THE VICTIM. Use a nonconducting implement,

such as a dry rope or board, to free the victim from the live

conductor. If the victim is unconscious, apply first aid and get

immediate medical help.

2

• Never wear jewelry when working on this equipment. Jewelry

can conduct electricity resulting in electric shock, or may get

caught in moving components causing injury.

FIRE HAZARDS

• For fire safety, the generator must be installed and maintained

properly. Installation must always comply with applicable

codes, standards, laws and regulations. Adhere strictly

to local, state and national electrical and building codes.

Comply with regulations the Occupational Safety and Health

Administration (OSHA) has established. Also, ensure that the

generator is installed in accordance with the manufacturer’s

instructions and recommendations. Following proper

installation, do nothing that might alter a safe installation and

render the unit in noncompliance with the aforementioned

codes, standards, laws and regulations.

• Keep a fire extinguisher near the generator at all times.

Extinguishers rated “ABC” by the National Fire Protection

Association are appropriate for use on the standby electric

system. Keep the extinguisher properly charged and be

familiar with its use. Consult the local fire depar tment with any

questions pertaining to fire extinguishers.

EXPLOSION HAZARDS

• Do not smoke around the generator. Wipe up any fuel or oil

spills immediately. Ensure that no combustible materials are left

in the generator compartment, or on or near the generator, as

FIRE or EXPLOSION may result. Keep the area surrounding the

generator clean and free from debris.

• Gaseous fluids such as natural gas and liquid propane (LP)

gas are extremely EXPLOSIVE. Install the fuel supply system

according to applicable fuel-gas codes. Before placing the

home standby electric system into service, fuel system

lines must be properly purged and leak tested according to

applicable code. After installation, inspect the fuel system

periodically for leaks. No leakage is permitted.

In the absence of pertinent standards, codes, regulations and

laws, the published information listed below may be used as

installation guide for this equipment.

1. NFPA No. 37, STATIONARY COMBUSTION ENGINES AND GAS

TURBINES, available from the National Fire Protection Association,

470 Atlantic Avenue, Boston, MA 02210.

2. NFPA No. 76A, ESSENTIAL ELECTRICAL SYSTEMS FOR HEALTH

CARE FACILITIES, available same as Item 1.

3. NFPA No. 54, NATIONAL FUEL GAS CODE, available same as Item

1.

4. NFPA No. 58, AMERICAN NATIONAL STANDARD FOR STORAGE

AND HANDLING OF LIQUEFIED PETROLEUM GAS, available same

as Item 1.

5. NFPA No. 70, NFPA HANDBOOK OF NATIONAL ELECTRIC CODE,

available same as Item 1.

6. Article X, NATIONAL BUILDING CODE, available from the American

Insurance Association, 85 John Street, New York, N.Y. 10038.

7. AGRICULTURAL WIRING HANDBOOK, available from the Food and

Energy Council, 909 University Avenue, Columbia, MO 65201.

Page 5

8. ASAE EP-3634, INSTALLATION AND MAINTENANCE OF FARM

STANDBY ELECTRICAL SYSTEMS, available from the American

Society of Agricultural Engineers, 2950 Niles Road, St. Joseph, MI

49085.

9. NFPA No. 30, FLAMMABLE AND COMBUSTIBLE LIQUIDS CODE,

available same as Item 1.

Fully comply with all relevant NEC, NFPA and OSHA standards

as well as all federal, state and local building and electric codes.

As with any generator, this unit must be installed in accordance

with current NFPA 37 and NFPA 70 standards as well as any other

federal, state, and local codes for minimum distances from other

structures.

Only qualified electricians or contractors

should attempt such installations, which must

comply strictly with applicable codes, standards and regulations.

After unpacking, carefully inspect the contents for damage.

• This standby generator set is ready for installation with a factory

supplied and pre-mounted base pad and has a weather protective

enclosure that is intended for outdoor installation only.

• This UL listed standby generator set is packaged with an

automatic transfer switch with built in load center.

• This UL listed, 2-pole transfer switch is rated at 50A AC

amperes at 250 volts maximum.

If this generator is used to power electrical load

circuits normally powered by a utility power

source, it is required by code to install a transfer switch. The transfer switch must effectively

isolate the electrical system from the utility distribution system when the generator is operating (NEC 700, 701 & 702). Failure to isolate an

electrical system by such means will result in

damage to the generator and also may result in

injury or death to utility power workers due to

backfeed of electrical energy.

If any loss or damage is noted at time of delivery, have the

person(s) making the delivery note all damage on the freight bill

or affix their signature under the consignor’s memo of loss or

damage.

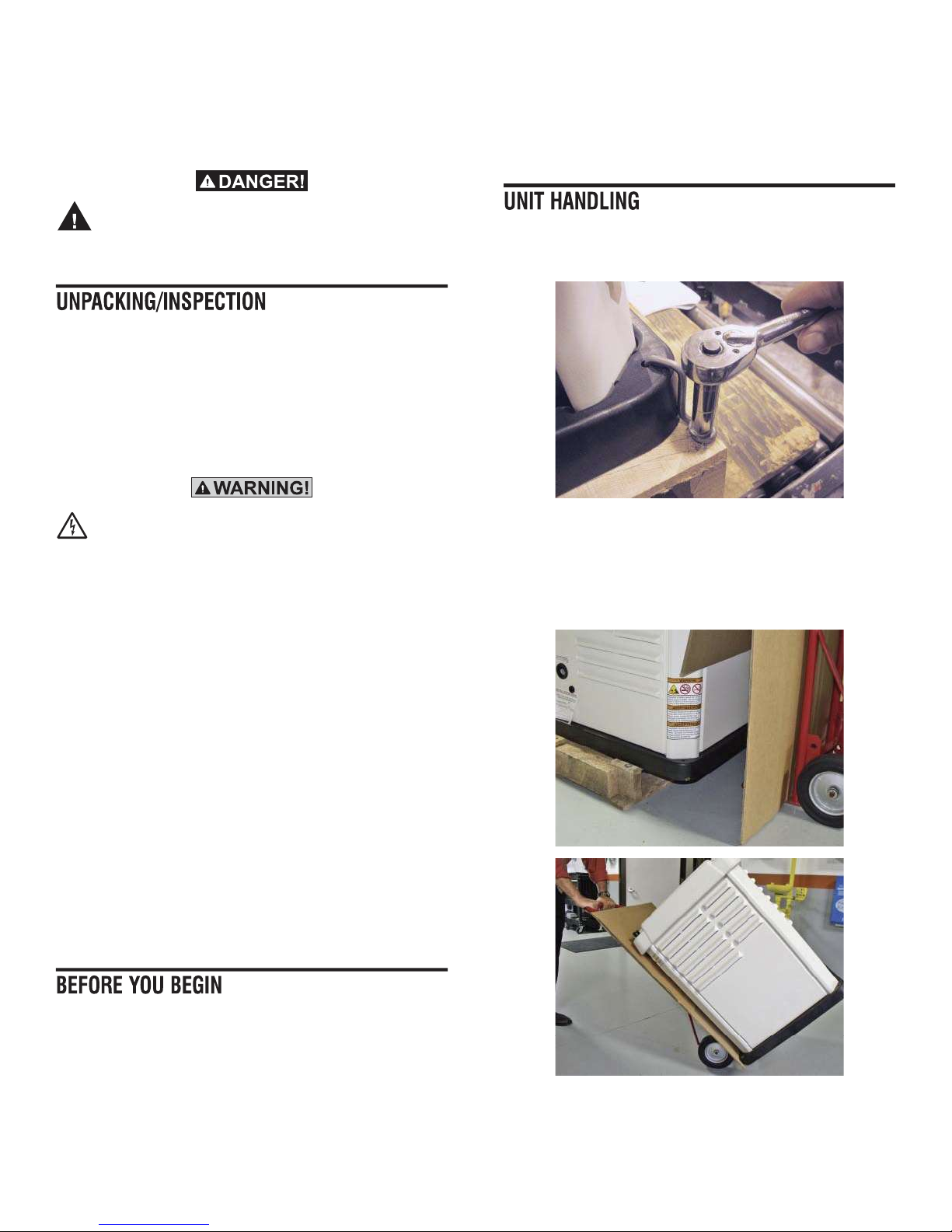

1. Once the generator has been unpacked. To remove it from

the wooden shipping pallet, remove the four lag bolts and

shipping brackets from the four corners of the base.

2. DO NOT ATTEMPT TO MOVE THE UNIT BY PULLING OR

LIFTING ON THE ROOF OF THE ENCLOSURE.

3. Using the sides of the enclosure slide the generator to one

edge of the wooden pallet.

4. Cut off one side panel of the shipping carton to use as a

protective barrier.

If a loss or damage is noted after delivery, separate the damaged

materials and contact the carrier for claim procedures.

“Concealed damage” is understood to mean damage to the

contents of a package that is not in evidence at the time of

delivery, but is discovered later.

To properly open the roof, press down on the center top lip and

release the latch. If pressure is not applied from the top, the roof

may appear stuck. Always verify that the side lock is unlocked

before attempting to lift the roof.

Contact the local inspector or City Hall to be aware of all federal,

state and local codes that could impact the installation. Secure all

required permits before starting the job.

Carefully read and follow all of the procedures and safety

precautions detailed in the installation guide. If any portion of the

installation manual, technical manual or other factory-supplied

documents is not completely understood, contact a dealer for

assistance.

5. Using a 2 wheeled hand truck place the cardboard between

the hand truck and the generator enclosure. Slide the

generator off the wooden pallet onto the hand truck. Wheel

the generator to the installation location.

3

Page 6

No windows or openings in the wall permitted

within 5 feet from any point of the generator.

Existing Wall

36” if the surface has a fire resistant rating of at least one hour per NFPA 37

These guidelines are based upon the

requirements of NFPA 37 and the

manufacturer’s requirement for air flow

for proper operation. Local codes may

be different and more restrictive than

what is described here.

60 inches Minimum Distance All Around

Top of Generator

Clearance from the ends and front of the generator

should be 36” minimum per NFPA 37. This would

include shrubs, trees and any kind of vegetation.

Clearance at the top should be a minimum of 60

inches from any structure, overhang or projections

from the wall. The generator should not be placed

under a deck or other structure that is closed in and

would limit or contain air flow.

60” Minimum

60” Recommended

Minimum From Ends

Generator

NOTE:

Failure to follow these minimum clearance guidelines may result in the generator failing inspection by the local

building, electrical or fire inspector requiring the generator be reinstalled in the correct location.

4

Page 7

1. Locate the mounting area as close as possible to the transfer

switch and fuel supply.

Leave adequate room around the area for service access

(check local code), and place high enough to keep rising

water from reaching the generator.

Choose an open space that will provide adequate and

unobstructed airflow. Do not install under or too close to

partially enclosed spaces including, but not limited to, decks

or buildings.

3. Set the generator onto the pad so that the gravel bed extends

several inches beyond the generator on all sides.

Make sure the generator is level within ½ inch.

4. The engine generator is to be grounded in accordance with

the NEC and local electrical codes.

Oil Dipstick

and Fill

Oil Drain

Hose

2. Place the unit so air vents won’t become clogged with leaves,

grass, snow or debris. Make sure exhaust fumes will not enter

the building through eaves, windows, ventilation fans or other

air intakes.

Dig a rectangular area approximately five inches deep and

about six inches longer and wider than the footprint of the

generator. Cover with polyurethane film and fill with pea gravel

or crushed stone. Compact and level the stone. A concrete

pad can be poured, or a Gen-Pad can be purchased if desired.

5. Check the engine oil and, if necessary, add enough of the

recommended oil to bring the level up to the FULL mark on

the dipstick. Be careful not to overfill the crankcase.

5

Page 8

1. Remove the generator enclosure roof by turning the four

quarter turn latches on the roof top. Push down slightly on the

latch then turn 90 degrees to release. The latch should pop up

as shown.

5. To change the fuel selection, remove the hose clamp and

hose from the throttle assembly.

6. Remove the Natural Gas (Larger ID) fuel jet from the fuel inlet.

7. Obtain the fuel jet for Propane (Smaller ID that has been

supplied loose with the owners manual).

8. Verify that the O-ring, supplied loose with the owners manual

is installed, into the groove of the fuel jet.

9. Insert the Propane fuel jet into the end of the fuel inlet.

10. Reinstall the hose and clamp onto the fuel inlet and secure.

11. Verify the hose has not been kinked in any way.

\2. Remove the two side panels of the enclosure by lifting the

panels straight up until they are clear.

3. Carefully place the roof and side panels to one side.

4. Locate the fuel throttle assembly mounted to the engine

intake.

*YIP-RPIX

36MRKMRWXEPPIH

8LVSXXPI

%WWIQFP]

*YIP.IX

6IKYPEXSV

,SWI

,SWI'PEQT

12. The generator is now ready to run on LP Vapor fuel.

Remove Clamp

and Hose

6

1. Both natural gas and LP Vapor are highly volatile substances,

so strict adherence to all safety procedures, codes, standards

and regulations is essential.

Gas line connections should be made by a certified plumber

familiar with local codes. Always use AGA-approved gas pipe

and a quality pipe sealant or joint compound.

Verify the capacity of the natural gas meter or the LP tank in

regards to providing sufficient fuel for both the generator and

other operating appliances.

Page 9

2. Most applications will require an external manual full flow

shutoff valve on the fuel line.

3. Where the gas line is to enter the generator enclosure. Install

a 3 - 5“ long piece of ½” black iron pipe threaded at both

ends (Not provided). Thread one end into the generator fuel

regulator using the reducing bushing provided. On the other

end of the pipe thread a ½” standard pipe Tee as shown (Not

provided).

6. When connecting the gas line to the generator, use the

provided section of UL Listed or AGA-approved flexible fuel

line in accordance with local regulations. The purpose of the

flexible fuel line is to ensure that vibration from the generator

does not cause a gas leak at one of the connection points, so

it’s important that the line be installed with as few bends as

possible.

7. Never bend the flexible fuel line to avoid using an elbow.

Bending the flexible line decreases its ability to absorb

vibrations and defeats its purpose as well as constricts the

actual fuel flow.

8. After checking for leaks, check the gas pressure at the

regulator to make sure there’s enough pressure for proper

generator operation.

The local gas supplier is responsible for ensuring adequate

pressure, so if the pressure is too low, or if it’s greater than

14 inches of water column, contact the gas supplier.

Correct static fuel pressure should be:

• Natural Gas = 5-7 inches water column

• LP = 10-12 inches water column

Measure fuel

pressure here.

9. When finished checking the gas pressure, close the manual

shutoff valve.

4. Make sure the center leg of the Tee is pointing straight down

when fully tightened onto the pipe.

5. Thread a 3 – 4” long piece of ½” black iron pipe threaded

at both ends (not provided) into the Tee Fitting. Fully tighten.

Thread a ½” Pipe cap (not provided) to the other end of the

pipe. Fully tighten. This downward pointing pipe will serve as

a water and sediment trap and should be periodically emptied

once the generator is in service.

7

Page 10

1. Electrical Connections to the generator are to be made inside

the main output circuit breaker panel. The connections will

consist of the following:

• 2 x Ungrounded conductors – Minimum wire size use 75

Deg C, 300V wire, 10AWG Copper.

• 1 x Grounded Conductor - Minimum wire size use 75 Deg

C, 300V wire, 10AWG Copper.

• 1 x Equipment Grounding Conductor - Minimum wire size

use 75 Deg C, 300V wire, 10AWG Copper.

• 6 x Control Wires – Use 75 Deg C, 300V wire, 14AWG

Copper.

NOTE:

Either use different colored wires or identify both ends of the

wires for easy connection of all wires to the Transfer Switch.

NOTE:

Local codes may require the control wires to be run in a separate conduit than the power wires.

• Use Class 1 wiring methods.

• These conductors should be fed through ¾” Flexible Liquidtight conduit for easy connection to the generator.

2. Remove the dead front plate from the output circuit breaker

panel. Retain fastener and external tooth washer for

reassembly.

5. Support the conduit connector plate up towards the output

circuit breaker. Make all the required wiring connections to the

Circuit breaker, Neutral Bar, Ground bar and Terminal strips

as described on the decal on the back side of the dead front

plate.

NOTE:

In order to maintain separation of circuits, the DC control wires

must be separated from the AC control wires. A piece of fiberglass sleeving has been provided in the manual kit to achieve

this. Slide the sleeving over the AC wires OR the DC wires, but

not both. Sleeving should extend over the wires from the conduit

connector in the conduit plate up to the terminal blocks.

3. Remove the conduit connector plate from the output circuit

breaker panel. Remove the plastic hole plug from the conduit

connector plate.

4. Pass all wires through hole in conduit connector plate, insert

conduit connector, and place lock nut onto conduit connector.

Fully tighten locknut.

8

6. Once all connections are made, reattach the conduit

connector plate to the output circuit breaker panel making

sure no wires are trapped behind the panel.

Page 11

7. Reattach the dead front plate to the output circuit breaker

panel with hardware removed in Step 1. Make sure to

reconnect the grounding wire.

8. Insert the padlock hasp that is supplied loose with the

generator through the slot in the dead front plate. Push the

padlock hasp back until it clicks and locks into place.

The correct size battery for this generator that will fit easily and

provide the required star ting ability is any maintainable automotive

style group 26R with a minimum of 525 CCA @ 0 deg F.

Before attempting to install the battery make

sure the auto/off/manual switch is in the off

position. Remove the main fuse from the

control panel.

Remove fuse!

9. To complete the external electrical connections snap in the

output circuit breaker cover that is supplied loose with the

generator into the output circuit breaker panel. Allow the cover

to swing down providing weather protection for the circuit

breaker.

The padlock hasp will now protrude through the circuit

breaker cover and it is recommended that once installation

of the generator is completed a padlock be used to provide

suitable security to the generator.

2. Rest the battery on the base of the generator and make the

battery connections. Connect battery positive (red) first then

battery negative (black). Install the plastic battery covers

supplied loose with the generator.

9

Page 12

3. Slide the battery under the rubber air in duct until it drops into

the holding well in the generator base. It may be necessary

to gently lift up the bottom edge of the rubber air in duct to

allow the battery to pass underneath until it drops into its final

location.

4. Once the battery is in place double check that the rubber air in

duct has not been displaced and is still fully connected at both

ends.

2. Connect the utility supply from the 50A 2-pole circuit breaker

in the main distribution panel to the terminals in the transfer

switch marked – Utility Source Connection.

NOTE:

Make sure the 50A Circuit Breaker remains OPEN or OFF at this

time.

Utility voltage is potentially leathal. It is

strongly recommened that the electrical portion of this installation be performed by a

qualified electrician.

Local code enforcement may require that AFCI’s be incorporated

into the transfer switch distribution panel. The Transfer Switch

provided with this generator has a distribution panel that will

accept AFCI’s.

Siemens Par t No. Q115AF - 15A or Q120AF - 20A can be

obtained from a local electrical wholesaler and will simply replace

any of the single pole circuit breakers supplied in the Transfer

Switch distribution panel.

1. Install the Automatic Transfer Switch as close to the home

main distribution panel as possible. The Automatic Transfer

Switch requires to be electrically supplied from the main

distribution panel via a 50A 2-pole branch circuit breaker (Not

Provided).

3. The automatic transfer switch incorporates the emergency

load distribution panel. These are the circuits that will be

powered by the generator during a power outage.

4. The home owner must determine which circuits in the main

distribution panel should be powered by the generator. The

chosen circuit wires both Hot and Neutral should be moved

from the main distribution panel to the emergency load

distribution panel.

NOTE:

Only identically rated circuits can be moved; i.e move a 15A

circuit to a 15A circuit. DO NOT move a 20A circuit to a 15A

circuit.

10

Page 13

1. Remove one of the ¾” knockouts from the side or bottom of

the transfer switch enclosure.

2. Feed the power and control wires from the generator into

the transfer switch enclosure and secure the conduit using a

suitable conduit connector and locknut.

5. Cut to length, strip, identify and attach transfer switch

control wires marked 23, 15B & 0 to XFER, BAT + and

BAT – terminals respectively on the transfer switch control

mechanism.

XFER

BAT+

BAT -

3. Cut to length, strip and attach generator power wires to

Generator source connections in the Transfer Switch

4. Cut to length, strip, identify and attach generator sensing

wires marked N1, N2 & T1 to correspondingly marked Fuses

in the Transfer Switch.

6. Cut to length, strip and attach remaining neutral and ground

wires to the loadcenter grounding bars.

7. Move all the circuit breakers in the load center to the OFF or

OPEN position.

11

Page 14

8. Manually move the transfer switch mechanism into the stand

by or generator position. i.e Circuit breaker connected to

generator should be closed.

1. Turn on fuel supply.

2. Attach fuel pressure gauge to test point on fuel regulator.

3. Replace the fuse in the generator control panel and place the

switch into the manual position which will start the engine.

4. Allow the generator to warm up. Move the generator main

circuit breaker to the ON or CLOSED position. Generator

power is now being supplied to the transfer switch.

5. Check voltage and frequency of generator output at the

transfer switch terminals. Line to Line voltage should be

240V (+/- 10 VAC) and line to neutral voltage should be

approximately120V. Frequency should be 62 – 63Hz. If either

the voltage or frequency are incorrect refer to the owners

manual for instructions on how to adjust.

6. Once the voltage and frequency of the generator output have

been confirmed and are correct move the generator main

output breaker to the OFF or OPEN position and move the

control panel switch to the off position.

7. Manually move the transfer switch mechanism into the utility

position. i.e Circuit breaker connected to 50A utility breaker

should be closed.

10. One by one move each circuit breaker in the load center to

the ON or CLOSED position. Once all the circuit breakers are

closed and the Generator is powering all the priority loads.

Check the fuel pressure at the fuel regulator. When powering

the loads the fuel pressure should NOT be less than:

• Nat Gas Fuel = 5 inches W.C

• LP Vapor Fuel = 10 inches W.C

11. Move the 2-pole 50A circuit breaker mounted in the main

distribution panel to the ON or CLOSED position. The Transfer

Switch mechanism should automatically move to the utility

position. The Generator will continue to run for a pre set cool

down period then will automatically shut down.

12. The operational tests are complete. Refer to the owners

manual for instructions on setting the generator exercise

function.

8. Move the 2-pole 50A circuit breaker mounted in the main

distribution panel to the ON or CLOSED position. Move

the generator control panel switch to the Auto position. To

indicate that the generator control panel is able to identify the

presence of utility voltage the GREEN system ready light will

be illuminated on the generator control panel. (Disregard the

flashing RED lights at this time.) The engine should NOT start.

Move the generator main output circuit breaker to the ON or

CLOSED position.

9. Move the 2-pole 50A circuit breaker mounted in the main

distribution panel to the OFF or OPEN position. After a short

delay the generator will start. The transfer switch mechanism

should automatically move from the Utility position to the

Stand By position.

12

Page 15

Notes

13

Page 16

Installation Diagrams Drawing No. 0H9267-B

14

Page 17

Drawing No. 0H9267-B Installation Diagrams

15

Page 18

Installation Diagrams Drawing No. 0J1064-C

16

Page 19

Drawing No. 0J1064-C Installation Diagrams

17

Page 20

Part No. 0J0193 Revision G (01/30/13) Printed in U.S.A.

Loading...

Loading...