Page 1

POWER SYSTEMS, INC.

®

Operator’s Manual

“C” Option Control Panel

This manual should remain with the unit.

NOT IN AUTOMATIC

START MODE

OVER

CRANK

OVER

SPEED

TEST

RESET

PREHEAT

30 SEC

MAX

PRE ALARM

LOW

OFF

HIGH

COOL

V

TEMP.

LOW

OIL

PRESS.

RPM

SENSOR

LOSS

150

200

100

25

TEMP

START

STOP

300

200

100

50

0

100

L

OI

AUTO

MANUAL

OFF

FUSE

15-A

AG

A

200

150

100

50

0

40

40

AMPS

C

0

3

1

Hz

0000 1

TOTAL HOURS

60

INCREASE

VO LTAG E

ADJUS

65

T

PRESS

PRE ALARM

HIGH

COOL

TEMP

LOW

COOL

TEMP

ALARM

HORN

ON - OFF

HIGH

BATT

VOLTA G E

LOW

BATT

VOLTAGE

RUPTURE

BASIN

FILLING

LOW

FUEL

HIGH

FUEL

Page 2

Generac®Power Systems, Inc.

Important Safety Instructions

“C” Option Control Panel

SAVE THESE INSTRUCTIONS – The manufacturer suggests that these rules for safe

operation be copied and posted in potential hazard areas. Safety should be stressed to all

operators and potential operators of this equipment.

!

!

Study these SAFETY RULES carefully before

installing, operating, or servicing this equipment.

Become familiar with this manual and all literature

pertaining to the generator set and related equipment. This equipment can operate safely, efficiently,

and reliably only if it is properly installed, operated,

and maintained. Many accidents are caused by failing

to follow simple and fundamental rules or precautions.

Generac cannot possibly anticipate every possible circumstance that might involve a hazard. The warnings in this manual, and on tags and decals

affixed to the equipment, are, therefore, not all-inclusive. If using a procedure, work method, or operating

technique Generac does not specifically recommend,

you must satisfy yourself that it is safe for you and others. Also must make sure the procedure, work method,

or operating technique that is used does not render the

equipment unsafe.

GENERAL HAZARDS

• For safety reasons, Generac recommends that this

equipment be installed and serviced by a Generac

Authorized Service Dealer or other qualified electrician or installation technician who is familiar with

applicable codes, standards, and regulations. The

operator also must comply with all such codes, standards, and regulations.

• When working on this equipment, remain alert at all

times. Never work on the equipment when physically or mentally fatigued.

• Inspect the equipment regularly, and promptly repair

or replace all worn, damaged or defective parts,

using only factory-approved parts.

• Before performing any maintenance on the generator

or any related equipment, disconnect the generator’s

battery cables and remove panel fuse to prevent accidental startup. Disconnect the cable from the battery

post, indicated by a NEGATIVE, NEG, or (–) first.

Reconnect that cable last.

ELECTRICAL HAZARDS

• Generators produce dangerous electrical voltages

and can cause fatal electrical shock. Avoid contact

with bare wires, terminals, connections, etc., while

the generator and related equipment are running.

Ensure all appropriate covers, guards, and barriers are in place before operating the equipment. If

working around an operating unit, stand on an

insulated, dry surface to reduce potential shock

hazards.

• Do not handle any kind of electrical device while

standing in water, while barefoot, or while hands or

feet are wet. DANGEROUS ELECTRICAL SHOCK

MAY RESULT.

• If people must stand on metal or concrete while

installing, operating, servicing, adjusting, or repairing this equipment, place insulative mats over a dry

wooden platform. Work on the equipment only while

standing on such insulative mats.

• Wire gauge sizes of electrical wiring, cables, and cord

sets must be adequate to handle the maximum electrical current (amperage) to which they will be subjected to.

• Before installing or servicing this equipment, make

sure that all power voltage supplies are positively

TURNED OFF at their source. Failure to do so will

result in hazardous and possibly fatal electrical

shock.

• When installed with an automatic transfer switch, the

generator may crank and start anytime, without

warning. To prevent injuries caused by sudden startup, disable the generator’s automatic start circuit

before working on, or around, the unit. Then, place

a “Do Not Operate” tag on the generator control

panel and on the transfer switch.

• In case of an accident caused by electric shock,

immediately shut down the source of electrical

power. If this is not possible, attempt to free the victim from the live conductor. AVOID DIRECT CONTACT WITH THE VICTIM. Use a nonconducting

implement, such as, a rope or board, to free the victim from the live conductor. If the victim is unconscious, apply first aid and get immediate medical

help.

• Never wear jewelry when working on this equipment.

Jewelry can conduct electricity, resulting in electric

shock, or may get caught in moving components,

causing injury.

F

IRE HAZARDS

• For fire safety, the generator and related equipment

must be installed and maintained properly.

Installation always must comply with applicable

codes, standards, laws, and regulations. Adhere

strictly to local, state, and national electrical and

building codes. Comply with regulations the

Occupational Safety and Health Administration

(OSHA) has established. Also, ensure that the

equipment is installed in accordance with the manufacturer’s instructions and recommendations.

Following proper installation, do nothing that

might alter a safe installation and render the unit

in noncompliance with the aforementioned codes,

standards, laws, and regulations.

!!

Page 3

Table of Contents

“C” Option Control Panel

Generac®Power Systems, Inc. 1

Part I - C Option Control Panel

Safety Rules ....................................Inside Front Cover

Section 1 — General Information ................................2

1.1 Overview ..............................................................2

1.2 Control Panel Components ..................................2

1.3 Optional Equipment ............................................2

1.3.1 Remote Annunciator Panel......................2

1.3.2 Remote Relay Panel ................................2

1.3.3 Additional Options..................................2

1.4 Panel Face Components ......................................2

1.4.1 AC Voltmeter ..........................................2

1.4.2 AC Ammeter ..........................................2

1.4.3 Frequency Meter ....................................2

1.4.4 Line-Phase Selector Switch ....................3

1.4.5 Voltage Adjust Potentiometer ..................3

1.4.6 Coolant Temperature Gauge ..................3

1.4.7 Oil Pressure Gauge ................................3

1.4.8 DC Voltmeter ..........................................3

1.4.9 Hourmeter ..............................................3

1.4.10 Start/Stop Switch....................................4

1.4.11 Auto/Off/Manual Switch ..........................4

1.4.12 Panel Fuse ..............................................4

1.5 Engine Monitor Panel ..........................................4

1.5.1 Not in Automatic Start Mode Lamp ........4

1.5.2 Overcrank Lamp ....................................4

1.5.3 High Coolant Temperature Lamp............4

1.5.4 Overspeed Lamp ....................................4

1.5.5 Low Oil Pressure Lamp ..........................5

1.5.6 RPM Sensor Loss Lamp..........................5

1.5.7 Test/Reset Switch....................................5

1.6 Optional Annunciator Panel ................................5

1.7 Optional Remote Annunciator..............................6

1.8 Optional Alarm Relay ..........................................6

1.9 Preparation Before Startup ..................................6

1.9.1 Prior to Initial Startup ............................6

1.9.2 Startup Inspection ..................................7

Section 2 — Operation ....................................................7

2.1 Operating Unit with Manually-Operated

Transfer Switch ..................................................7

2.2 Operating Unit with Automatic Transfer Switch ..7

2.2.1 Manual Startup and Transfer ................7

2.2.2 Manual Retransfer and Engine

Shutdown ..............................................7

2.2.3 Preventing Automatic Startup ................8

Appendix 1 – Electrical Data ........................................9

Appendix 2 – Exploded Views and Parts Lists ......16

Appendix 3 – Interconnection Diagrams ................24

P

art II - Remote Annunciator Panels

Section 1 — General Information ..............................29

1.1 Three Light Remote Annunciator ......................29

1.1.1 Installation............................................29

1.2 Five Light Remote Annunciator..........................29

1.2.1 Operation..............................................30

1.2.2 Customer Connections..........................30

1.2.3 Parts Included with Remote Panel ........30

1.3 18 Light Remote Annunciator ............................30

1.3.1 Generator Stop Signals ........................31

1.3.2 Latchable Signals..................................31

1.3.3 Other Lamps ........................................31

1.3.4 Panel Wiring Interconnections ..............31

1.4 Troubleshooting ................................................31

1.5 Annunciated Signals ..........................................32

1.6 Pre-Alarms ........................................................32

Appendix 4 — Electrical Data......................................33

Appendix 5 — Exploded Views and Parts Lists ......41

Appendix 6 — Notes ......................................................47

AUTHORIZED SERVICE

DEALER LOCATION

To locate the nearest GENERAC AUTHORIZED

SERVICE DEALER, please call this number:

1-800-333-1322

DEALER LOCATION INFORMATION

CAN BE OBTAINED AT THIS NUMBER.

Page 4

1.1 OVERVIEW

The “C” option control panel is an analog generator

set control panel designed for Generac’s range of

standby generators. It allows for either manual or

automatic startup and shutdown.

The panel is housed in a steel sheet metal enclosure

that meets NEMA 1 specifications. The front face of

the panel includes a number of analog meters and

gauges that indicate generator operating conditions,

several indicator lamps for annunciation of engine

fault shutdowns, and various other generator set controls.

1.2 CONTROL PANEL COMPONENTS

The control panel contains one main printed-circuit

board (PCB), the automatic voltage regulator (AVR),

optional components, such as battery monitor, dry

contact boards, run relay, etc., and terminal blocks

for external connections.

To find locations of the circuit board, refer to

Appendix 2 for the control panel exploded view.

Remove the 15-amp fuse from the front of the

panel during all engine maintenance to guard

against accidental or remote startup.

1.3 OPTIONAL EQUIPMENT

1.3.1 REMOTE ANNUNCIATOR PANEL

When connected to the generator via a 19 wire connection link, this multi-light remote indicator panel will

display the generator’s status.

1.3.2 DRY CONTACTS

This panel is similar to the remote annunciator, but, in

addition to indicator lights, it provides relay contact

closures for status (e.g., alarms). The dry contact

boards are form C rated contacts. The five function dry

contacts are normally open (N.O.). The six function dry

contacts are either normally open (N.O.) or normally

closed (N.C.).

1.3.3 ADDITIONAL OPTIONS

The following are some of the more frequently requested optional accessories for the “C” option control panel:

• Emergency stop button

• Oil temperature gauge

• Engine run relay

• 100 dBa alarm horn

• Over/Under voltage relay

• Pre-alarm kit

• Control panel heater(s)

• Voltage change over switch (special)

• Battery monitor

• Over/Under frequency relay

• Over/Under current relay

1.4 PANEL FACE COMPONENTS

(FIGURE 1.1, PAGE 3)

1.4.1 AC VOLTMETER

This meter indicates the generator AC output voltage.

(Also see “Line-phase Selector Switch” and “Voltage

Adjust Potentiometer” in this section). To determine

the nominal rated AC voltage of the unit, refer to the

unit’s data plate.

NOTE:

Some generators are reconnectable to a variety of

voltages. Some units may be equipped with a

rotary “Voltage Selector Switch.” Be sure to read

the “Generator AC Lead Connections” section in

the Owner’s Manual.

1.4.2 AC AMMETER

This meter indicates the current draw of connected

electrical loads, in amps. (Also see “Line-phase

Selector Switch”). For continuous operation, never

exceed the rated maximum continuous current

capacity of the generator.

1.4.3 FREQUENCY METER

This meter indicates the generator’s AC output frequency in “Hertz” (cycles per second).

◆

◆

◆

!

Section 1 — General Information

“C” Option Control Panel

2 Generac®Power Systems, Inc.

Page 5

Generac®Power Systems, Inc. 3

1.4.4 LINE-PHASE SELECTOR SWITCH

This four-position switch permits selection of either

line-to-line or line-to-neutral readings on the panel

voltmeter and ammeter. Switch positions are as follows:

1.4.5 VOLTAGE ADJUST POTENTIOMETER

This potentiometer permits the operator to “fineadjust” the generator’s AC output voltage. Adjustment

range is plus or minus five percent from the midpoint. Turn the knob clockwise to increase voltage,

counterclockwise to decrease voltage.

1.4.6 COOLANT TEMPERATURE GAUGE

This gauge indicates the engine coolant temperature.

Normal operating temperature should read between

185° to 215°F (85° to 102°C). If coolant temperature

exceeds a safe level, the engine shuts down automatically.

NOTE:

Actual coolant temperature reading may vary due

to variables, such as, ambient temperature,

applied load, or cooling system condition.

1.4.7 OIL PRESSURE GAUGE

This gauge indicates oil pressure during operation.

After warm-up, oil pressure should be about 25-90

psi. Generac recommends that the operator record

the normal oil pressure during initial startup.

Sudden changes in oil pressure after first starting

indicate a possible engine problem.

NOTE:

Engine oil pressure may vary, depending on oil

viscosity, oil temperature, engine speed, ambient

temperature, etc. The engine automatically shuts

down if oil pressure drops below a safe level.

(10 psi.)

1.4.8 DC AMMETER

The engine is equipped with a belt-driven DC alternator, which charges the battery while the unit is running. This ammeter indicates the rate of charge to the

battery during operation. If the needle drops to the

left of zero, the battery is discharging. Investigate and

correct this problem immediately. Erratic movement

of the needle should also be corrected immediately.

1.4.9 HOURMETER

The hourmeter provides a continuous indication of

engine/generator operating time, in hours and tenths

of hours. Use the hourmeter with the periodic maintenance schedule.

◆

◆

◆

Section 1 — General Information

“C” Option Control Panel

Figure 1.1 – “C” Option Panel Components

Switch Single-phase Units Three-phase units

1 Line E1 to Neutral Line E1 to E2

2 Line E3 to Neutral Line E2 to E3

3 Line E1 to E3 Line E3 to E1

O No Reading No Reading

0

1

2

Page 6

4 Generac®Power Systems, Inc.

1.4.10 START/STOP SWITCH

Use this switch to crank and start the engine manually, or to shut down an operating engine.

• To crank and start engine, first set the

Auto/Off/Manual switch to its “Manual” position.

• Hold the Start/Stop switch at “Start.” When the

engine starts, release the switch to its center (run)

position.

• To shut engine down, move the switch to its “Stop”

position.

1.4.11 AUTO/OFF/MANUAL SWITCH

This safety switch should be used to prevent automatic startup of the engine when working on the

engine/generator. Use the switch as follows:

Auto Position

Always set switch to AUTO for automatic system

operation. This means that, when this generator is

installed with a GTS-type automatic transfer switch,

the generator automatically cranks and starts when

the utility source voltage drops below a preset level,

or the unit exercises, if programmed to do so.

Off Position

The engine cannot be started either automatically or

manually. Always set switch to OFF before working

on, or around, the engine-generator.

Manual Position

The engine can be cranked and started manually

using the panel Start/Stop switch. The engine will not

start automatically.

NOTE:

Also see “Engine Monitor Panel.” With switch set

to either OFF or MANUAL, a “Not in Automatic

Start Mode” lamp lights up on the panel.

1.4.12 PANEL FUSE

This fuse protects the control console’s DC circuits

against overload. If the fuse element melts open due

to an overload, engine cranking and startup will not

be possible. Should fuse replacement become necessary, use only an identical fuse (part number

022676).

1.5 ENGINE MONITOR PANEL

This panel has five advisory shutdown lamps for separate engine fault conditions, plus a “Not in

Automatic Start Mode” lamp. Cranking and starting

will not be possible while any one, or more, of engine

fault conditions lamps is lit, with the exception of

“Not in Auto” illuminated in the manual mode. The

following apply:

• A “lamp ON” condition indicates that fault condition has been “latched” by DC control/latch-crank

circuit board.

• If any one of the lamps is ON (fault condition

latched), the engine cannot be cranked either manually or automatically.

• To unlatch a fault (that is, to turn a lamp OFF) and

permit cranking, push the Test/Reset switch in.

The lamp will then go OFF, allowing for additional

cranking.

1.5.1 NOT IN AUTOMATIC START MODE

LAMP

This lamp comes ON to indicate that automatic startup of the engine is not possible. The lamp lights up

whenever the Auto/Off/Manual switch is set to OFF or

MANUAL.

1.5.2 OVERCRANK LAMP

The control console houses a DC control/latch-crank

circuit board (the “C” board) that controls engine

startup and shutdown. During automatic startup, the

engine cranks for about 14 seconds, rests for about

eight seconds, and so on, until eight crank-rest cycles

have occurred. At the end of eight attempts, cranking

stops, and the overcrank lamp goes ON.

1.5.3 HIGH COOLANT TEMPERATURE LAMP

This lamp comes ON if coolant temperature is too

high or coolant level is too low. The engine shuts

down automatically when such unsafe conditions

occur. The following apply:

• If the engine is started with an existing high coolant

temperature or low coolant level condition, the

engine shuts down, and the lamp comes ON when

engine speed reaches about 1000 rpm.

• If the engine starts normally but high temperature/low coolant level develops later, the engine

shuts down, and the light comes ON immediately.

1.5.4 OVERSPEED LAMP

An engine overspeed above a safe limit causes the

engine to automatically shut down, which turns ON

the indicator lamp. The overspeed lamp comes on

when the unit is run at a 15% faster rpm than rated.

◆

◆

◆

◆

◆

▼ ▼ ▼

◆

◆

Section 1 — General Information

“C” Option Control Panel

Page 7

Generac®Power Systems, Inc. 5

1.5.5 LOW OIL PRESSURE LAMP

This lamp lights up (latches) to indicate low oil pressure in the engine as follows:

• During cranking, after engine has reached 800 to

1000 rpm, the circuit allows four seconds for oil

pressure to build.

• In auto mode, if the unit runs above 800-1000 rpm

for more than four seconds, and oil pressure is

below a safe level, the engine shuts down, but the

lamp does NOT go ON. The system then actuates

eight restart attempts; the engine shuts down, and

the lamp goes ON.

• If the engine starts normally with good oil pressure, but oil pressure drops later, the system waits

five seconds for oil pressure to be restored. If pressure is still low after a five-second delay, the engine

shuts down, and the lamp goes ON immediately.

1.5.6 RPM SENSOR LOSS LAMP

Units with the “C” Option console are equipped with

an rpm sensor, which is mounted directly over the

engine flywheel gear teeth. This sensor is a magnetic

pickup that emits an electrical pulse at the passage of

each flywheel gear tooth. Sensor electrical signals are

used by the DC control/latch-crank circuit board as

engine speed (rpm) signals. The circuit board uses

these rpm signals (a) to establish a starter lockout

speed, and (b) to shut down the engine if the engine

runs too fast (overspeed). If the rpm signals to the

circuit board are lost, engine shutdown occurs, but

the lamp will not light, (i.e., the condition will not

latch), then, depending on whether the sensor signal

loss occurred during a manual or an automatic start

attempt, the following events occur:

Manual Startup

If the engine starts within two seconds after cranking

begins, shutdown occurs as soon as the Start/Stop

switch is released, but without a lamp ON condition

(latching does not occur). If engine does not start

within two seconds after cranking begins, which disables starting, the rpm sensor loss light goes ON.

Automatic Startup

The engine recranks within about one second after it

has stopped. If sensor loss persists, engine shuts

down, and lamp lights about two seconds after

cranking has restarted.

If engine starts within two seconds after recrank has

begun, the starter remains engaged until the two-second delay is over.

1.5.7 TEST/RESET SWITCH

To test all lamps, push this switch in. Following any

fault shutdown with any monitor panel lamp illuminated, engine cranking is inhibited. To reset the system (unlatch a fault) and crank the engine again,

push the switch in (lamp must go out). If the switch

is actuated with the engine running, only the lamps

will be tested. The engine will not shut down.

NOTE:

If engine shuts down due to some unmonitored

problem (such as, out of fuel or failed ignition system), none of the lamps will come ON. If such an

unmonitored shutdown occurs with the

Auto/Off/Manual switch set to AUTO, engine

recranks and attempts to start for any of the cycles

remaining in the eight-crank limit. After all eight

crank cycles have been used, the engine shuts

down, and the OVERCRANK lamp goes ON.

1.6 OPTIONAL ANNUNCIATOR PANEL

Some units may come equipped with a factoryinstalled annunciator panel having up to nine annunciated fault conditions displayed (Figure 1.2). This

optional panel is often called a “prealarm” panel,

since it warns of impending problems before an actual fault shutdown occurs.

The panel is designed to monitor various engine condition-sensing devices having normally-open (N.O.) or

normally-closed (N.C.) contacts.

Figure 1.2 — Optional Annunciator (Prealarm)

Panel

◆

▼

▼

◆

◆

Section 1 — General Information

“C” Option Control Panel

PRE-ALARM

LOW OIL

PRESSURE

PRE-ALARM

HIGH COOL

TEMP

LOW COOL

TEMP

LOW

FUEL

ALARM HORN

ON/OFF

HIGH

BATTERY

VOLTAG E

LOW

BATTERY

VOLTAG E

HIGH

OIL TEMP

SHUTDOWN

HIGH

OIL TEMP

PRE-ALARM

Page 8

6 Generac®Power Systems, Inc.

1.7 OPTIONAL REMOTE

ANNUNCIATOR

An optional 18-light REMOTE annunciator panel that

can be mounted on a wall (Figure 1.3) is also available. For information on the remote annunciator panels, ask the local dealer/distributor or consult the factory. Ask for information on the Models 9555 and

9556 remote annunciator panels. The following apply

to the remote annunciator panels:

• It is designed for use with installation having a

Generac Power Systems GTS-type transfer switch

and a “C” Option control panel.

• The panel is available in both flush-mounted

(Model 9556) and surface-mounted (Model 9555)

configurations.

• The panel has a built-in audible alarm horn, with a

reset switch to turn off the horn without disturbing

the lighted indication.

• Remote monitoring of the standby generator set

provides enough information to avoid unnecessary

maintenance trips to the generator site.

Figure 1.3 — Optional 18-Light Remote

Annunciator

1.8 STANDARD ALARM RELAY

The generator’s DC control/latch-crank circuit board

is equipped with an alarm relay “driver”. All units

with “C” Option control panels are equipped with an

alarm relay that is connected to the circuit board

driver (Figure 1.4). If any one or more of the five

annunciated shutdown faults occur, the circuit board

driver energizes the optional alarm relay.

A remote-mounted alarm or annunciator device may

be connected across the relay contacts so that a failure will turn on the remote alarm or device. The connected alarm device may range from an alarm horn

to a warning light to a telephone dialer with a prerecorded message. The alarm relay normally-open,

normally-closed, and common contacts are shown in

Figure 1.4.

Figure 1.4 — Standard Alarm Relay

1.9 PREPARATION BEFORE STARTUP

The instructions in this section assume that the

standby generator has been properly installed, serviced, tested, adjusted, and otherwise prepared for

use by a competent, qualified installation contractor.

Be sure to read RULES FOR SAFE OPERATION on

the inside of the front cover carefully, before attempting to operate this (and related) equipment.

1.9.1 PRIOR TO INITIAL STARTUP

Before starting the generator for the first time, the

installer must complete the following:

• Properly locate and properly mount the generator,

transfer switch, and other standby system components, in strict compliance with applicable codes,

standards, and regulations.

• Make sure the fuel supply system to the generator

(a) delivers the correct fuel at the correct pressure,

and (b) is properly purged and leak-tested according to code. No fuel leakage is permitted.

• Have the engine crankcase properly filled to the

correct level with the recommended oil.

• Have engine cooling system properly filled with recommended coolant mixture. Check the system for

leaks and other problems.

• If engine is equipped with a mechanical governor,

make sure the governor is properly filled with oil.

Use crankcase oil to fill.

• Check engine v-belt tension and belt condition.

• Make sure the generator is properly connected to

an approved earth ground.

• The generator battery must be fully charged, properly installed and interconnected, and ready for

use.

◆

Section 1 — General Information

“C” Option Control Panel

Page 9

Generac®Power Systems, Inc. 7

1.9.2 STARTUP INSPECTION

A standard, three-part form entitled “Startup

Inspection for Standby Power Systems” (Part No.

67377) must be completed by the installation technician or engineer in order to activate warranty. As stated on the form, inspections are to be performed only

by factory-trained personnel. The installer must complete the form and distribute copies as follows:

• White copy: Mail to Generac Service Department,

P.O. Box 310, Eagle, WI 53119.

• Pink copy: For service file of installing dealer.

• Yellow copy: For the customer’s records.

2.1 OPERATING UNIT WITH MANUALLY

OPERATED TRANSFER SWITCH

If the generator was installed with a transfer switch

capable of manual operation only, the following

applies: A manually-operated transfer switch is one

that will not provide automatic startup and does not

include the intelligence circuit, which comprises of a

utility voltage sensor PCB, an inphase monitor PCB,

a seven day exerciser PCB, or other type of sensing

circuits found in a Closed Transition Transfer Switch

(CTTS) or a Bypass Isolation Switch (BIS).

2.2 OPERATING UNIT WITH

AUTOMATIC TRANSFER SWITCH

If the generator has been installed with a Generac

“GTS”-type automatic transfer switch, the engine may be

started and stopped either automatically or manually.

IMPORTANT: BE SURE TO READ THE APPLICABLE AUTOMATIC TRANSFER SWITCH MANUAL

CAREFULLY. DIFFERENCES EXIST BETWEEN

TRANSFER SWITCHES.

2.2.1 MANUAL STARTUP AND TRANSFER

To crank and start the engine and to transfer electrical loads to the STANDBY power source, proceed as

follows:

• See applicable transfer switch instructions. If so

equipped, set the Safety Disconnect Switch to

MANUAL.

• On the generator’s Meter and Control Panel, set the

Auto/Off/Manual switch to MANUAL.

The safety disconnect switch and the

Auto/Off/Manual switches must be set as

instructed above, or the generator will crank

and start as soon as the utility power to the

transfer switch is turned OFF.

• Turn OFF both the NORMAL (utility) and EMERGENCY (standby) power supplies to the transfer

switch, using whatever means is provided (such as

the main-line circuit breaker(s).

DO NOT attempt manual operation until all

power voltage supplies to the transfer switch

have been positively turned OFF; otherwise,

extremely dangerous---possibly lethal--- electrical shock will result.

• Refer to the instructions that correspond to the

installed transfer switch. Manually actuate the

switch main contacts to their STANDBY (emergency) position, as outlined in the corresponding

manual. LOAD circuit must be connected to the

STANDBY power supply before proceeding.

• On the generator console, hold the Start/Stop

switch START to crank the engine. Hold it until it

begins running, then release the switch to its centered (RUN) position.

• Let the engine warm up and stabilize at no-load.

• Turn ON the STANDBY power supply to the transfer switch, using whatever means provided (such

as STANDBY source main-line circuit breaker).

• The generator will now power the load circuits.

2.2.2 MANUAL RETRANSFER AND ENGINE

SHUTDOWN

To retransfer LOAD circuits back to the NORMAL

(utility) power source and to stop the engine, proceed

as follows:

• Turn OFF both the UTILITY and STANDBY power

supplies to the transfer switch, using whatever

means provided, such as the main-line circuit

breaker(s).

DO NOT attempt manual operation until all

power voltage supplies to the transfer switch

have been positively turned OFF; otherwise,

extremely dangerous---possibly lethal---electrical shock will result.

• Refer to the applicable transfer switch instructions. Manually actuate the transfer switch main

contacts to their utility position (LOAD connected

to UTILITY power supply).

• Turn ON the UTILITY power supply to the transfer

switch, using whatever means are provided (such

as the UTILITY main-line circuit breaker(s).

• Check that the UTILITY voltage is available to the

transfer switch (see appropriate transfer switch

instructions).

• Let the generator engine run at no-load for a few

minutes. Then, set the generator Start/Stop switch

to STOP. Wait for the engine to come to a complete

stop.

• Reset the system for fully automatic operation.

◆

◆

◆

Section 2 — Operation

“C” Option Control Panel

DANGER

DANGER

DANGER

!

Page 10

8 Generac®Power Systems, Inc.

2.2.3 PREVENTING AUTOMATIC STARTUP

When installed with an automatic transfer

switch, Generac standby generators can crank

and start suddenly, without warning, when

UTILITY source voltage drops below a preset

value. To prevent possible injuries caused by

such sudden starts, disable the automatic

transfer switch before working on, or around,

the generator. Use any one, or more, of the following methods to disable the automatic start

function:

• Set the generator’s Auto/Off/Manual switch to OFF.

Neither a manual nor an automatic start can be

accomplished with this switch set to OFF.

• Remove the fuse from the generator control panel.

To remove the fuse, push fuse holder cap in and

turn cap counterclockwise. Remove cap and fuse

element.

• Refer to the automatic transfer switch instructions.

If the transfer switch is so equipped, set its Safety

Disconnect switch to MANUAL position to prevent

automatic startup and transfer.

• Disconnect battery cable from generator battery

post, indicated by a negative, NEG, or (-).

!

◆

Section 2 — Operation

“C” Option Control Panel

DANGER

Page 11

Generac®Power Systems, Inc. 9

Appendix 1 — Electrical Data

“C” Option Control Panel 24 Volt, 400 kW and Larger

Interconnection Diagram — Drawing No. A7296-B

Page 12

10 Generac®Power Systems, Inc.

Appendix 1 — Electrical Data

“C” Option Control Panel 24 Volt, 400kW and Larger

Electrical Schematic — Drawing No. A4722-A

Page 13

Generac®Power Systems, Inc. 11

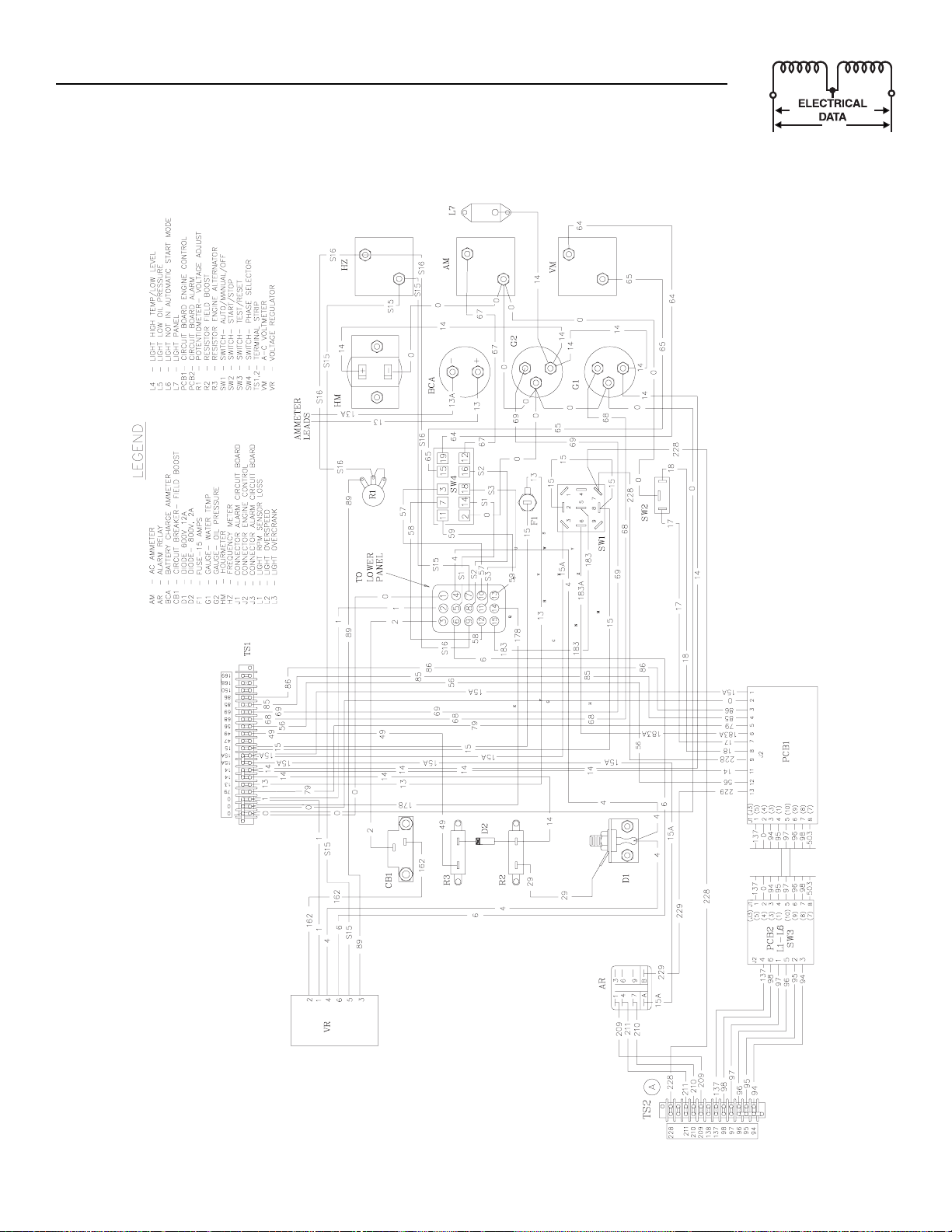

Appendix 1 — Electrical Data

“C” Option Control Panel 24 Volt, 400 kW and Larger

Wiring Diagram – Drawing No. A4723-B

Page 14

12 Generac®Power Systems, Inc.

Appendix 1 — Electrical Data

“C” Option Control Panel 24 Volt Diesel, Less than 400 kW

Control Panel Electrical Schematic – Drawing No. 84850-C

Page 15

Generac®Power Systems, Inc. 13

Appendix 1 — Electrical Data

“C” Option Control Panel 24 Volt Diesel, Less than 400 kW

Control Panel Wiring Diagram – Drawing No. 84849-C

Page 16

14 Generac®Power Systems, Inc.

Appendix 1 — Electrical Data

“C” Option Control Panel 12 Volt Gas

Control Panel Electrical Schematic – Drawing No. 85023-A

Page 17

Generac®Power Systems, Inc. 15

Appendix 1 — Electrical Data

“C” Option Control Panel 12 Volt Gas

Control Panel Wiring Diagram – Drawing No. 85024-A

Page 18

C

3

-

+

0

0

16 Generac®Power Systems, Inc.

Appendix 2 — Exploded Views and Parts Lists

“C” Option Control Panel 24 Volt Diesel

Control Panel – Drawing No. 84851-J

4

7

4

2

1

1

7

7

7

2

1

7

A

4

I

Page 19

Generac®Power Systems, Inc. 17

ITEM PART NO. QTY. DESCRIPTION

1 070023 1 CONTROL PANEL BOTTOM

2 070026 1 SLKSCRND PANEL FRONT

3 070028 1 COVER CON PNL SIDE

4 067680 1 ASSY VOLTAGE REGULATOR 60HZ

092952 1 ASSY VOLTAGE REGULATOR 50HZ

5 039271 1 FITTING 90 DEGREE 3/4

6 034616 1 FITTING STRAIGHT 3/4

7 1 CIRCUIT BREAKER

8 082985 1 RES 100R 5% 5W ASSY=55405

9 082984 1 RES 120R 10% 2W ASSY 55406

10 086266 1 RES WW LUG 75R 5% 25W

11 055444 1 HEATSINK

12 030468 1 WASHER STEP NYLON .20

13 049939 1 RECTIFIER MSC 12A 600V 1N1206R

14 083089 1 ASSY PCB "C" CONTROL 12/24V

15 033147 1 SCREW HHM #10-32 X 1

16 024469 2 SCREW HHTT #10-32 X 3/8 CZ_

17 084853A 1 HARNESS F/<100KW 24V C DIESEL

084853B 1 HARNESS F/>101KW 24V C DIESEL

084853C 1 HARNESS F/12LMITS 24V C DIESEL

18 029333 6 TIE WRAP 7.4"X.19" NATL UL

19 084875 1 DECAL TERMINAL STRIP

20 055920 1 SWITCH SPST SPADE PNL MNT

21 055867 1 SWITCH TOG SPDT 15A SPD MOM

22 067625 1 SWITCH TOGGLE 3P3T 15/10A

23 032300 1 HOLDER FUSE

24 022676 1 FUSE 15A X AGC15

25 040213 4 PCB SUPPORT SNAP-IN 1/4"

26 0C2428 14 SCREW PHTT #6-32 X 1/2 ZYC

27 061945 1 SWITCH SELECTOR 6A AMP/V

28 071361 1 POT 5K 10% 2.25W PNL

29 050123 1 KNOB PLASTIC .25 SHAFT

30 055349 1 INSULATOR

31 070030 1 COVER GENERAC SILKSCREENED

33 070042 1 FREQUENCY METER 240V 55-65HZ

070042-A 1 FREQUENCY METER 240V 45-55HZ

34 1 AC AMMETER

35 1 AC VOLTMETER

36 083287 1 LIGHT HLDR CLR LNS W/O BULB

ITEM PART NO. QTY. DESCRIPTION

37 070081 1 HOURMETER

38 062304 1 AMMETER 40-0-40 DC

39 055405 1 GAUGE OIL PRESSURE

40 055406 1 GAUGE COOLANT TEMPERATURE

41 070083 1 ASSY PCB ENGINE MONITOR

42 055089 1 CONN PLUG PNL 15P AMP M-N-L

43 070082 1 BLOCKER LIGHT

44 053247 1 LUG RNGTNG INS 22-18 X10 X.322

45 029187 2 SPACER .19 X .31 X .50 PL

46 077043B 1 FLEX CONDUIT .50 ID

50 036904 4 SCREW PPHM #6-32 X 3/4 (NOT SHOWN)

51 036908 2 SCREW PPHM #6-32 X 1-1/4

52 022155 2 WASHER LOCK #6

53 022985 6 WASHER FLAT #6 ZINC

54 022188 2 NUT HEX #6-32 STEEL

55 036918 4 SCREW PPHM #8-32 X 1/2

56 022264 4 WASHER LOCK #8-M4

57 033121 16 SCREW HHC #10-32 X ½

58 022152 26 WASHER LOCK #10

59 023897 14 WASHER FLAT #10 ZINC

60 022158 20 NUT HEX #10-32 STEEL

61 038150 4 WASHER FLAT #8 ZINC

62 022471 4 NUT HEX #8-32 STEEL

63 084787 1 CABLE RIBBON 16"

64 070370 2 WASHER MICA .203

65 083288 1 LIGHT 28VDC .17A MIN BAYNT MNT

66 023762 4 WASHER SHAKEPROOF EXT #10 STL

68 081767 2 RELAY PNL 24VDC DPDT 10A

70 064000 1 CONTROL PNL SIDE

71 064008 1 COVER CON PNL TOP

72 098940 1 HARNESS C-OPT CTRL PNL

73 066040 1 DECAL - TERM STRIP

77 0C2323 4 SCREW PHTT #6-32 X 5/8 ZYC

78 0C1229 1 DECAL CUST CONN BOX

79 022507 4 SCREW HHC 1/4-20 X 1/2 G5 (NOT

SHOWN)

80 022097 8 WASHER LOCK M6-1/4 (NOT SHOWN)

81 040479 4 VIB MNT 1.0 X 1.0 X 1/4-20 (NOT SHOWN)

Appendix 2 — Exploded Views and Parts Lists

“C” Option Control Panel 24 Volt Diesel

Control Panel – Drawing No. 84851-J

Page 20

18 Generac®Power Systems, Inc.

5

5

3

6

3

0

0

9

9

5

9

625

9

3

0

3

9

0

S

O

O

SS

S

.

G

G

8

6

3

O

+

-

)

CA

Appendix 2 — Exploded Views and Parts Lists

“C” Option Control Panel 24 Volt Gas

Control Panel – Drawing No. 84711-N

4

1

2

282

4

1

1

4

4

2

2

4

1

M

A

R

F

7

4

RAM #

F WIRE HARNE

N

DIA

TALLATI

EE WIRIN

IN

4

4

1

7

MI

2-PLCS

7

Page 21

Generac®Power Systems, Inc. 19

ITEM PART NO. QTY. DESCRIPTION

1 070023 1 CONTROL PANEL BOTTOM

2 070026 1 CONTROL PANEL FRONT

3 070028 1 CONTROL PANEL SIDE

4 067680 1 REGULATOR ASSEMBLY VOLTAGE B&D

5 039271 1 FITTING 90 DEGREE 3/4

6 034616 1 FITTING STRAIGHT 3/4

7 057159 1 CIRCT BRK 2 X 1 ETA 46-500-P

053623 1 CIRCT BRK 2.5 X 1 ETA 46-500-P

054502 1 CIRCT BRK 3 X 1 ETA 46-500-P

056247 1 CIRCT BRK 3.5 X 1 ETA 46-500-P

049350 1 CIRCT BRK 4 X 1 ETA 46-500-P

048476 1 CIRCT BRK 4.5 X 1 AUT30KW CNT45K

048512 1 CIRCT BRK 5 X 1 ETA 46-500-P

054450 1 CIRCT BRK 5.5 X 1 ETA 46-500-P

048505 1 CIRCT BRK 6 X 1 ETA 46-500-P

048467 1 CIRCT BRK 7 X 1 ETA 46-500-P

048468 1 CIRCT BRK 8 X 1 ETA 46-500-P

048470 1 CIRCT BRK 9 X 1 ETA 46-500-P

8 057335 1 BLOCK TERM 20A 20 X 6 X 1100V

9 046669 7 BLOCK TERM JUMPER FOR S141

10 ** 081767 1 RELAY PNL 24VDC DPDT 10A

11 070042 1 METER FREQUENCY 55-65HZ

070042A 1 METER FREQUENCY 240V 45-55HZ

12 070054 1 AMMETER AC 0 TO 50

070055 1 AMMETER AC 0 TO 100

070056 1 AMMETER AC 0 TO 150

070045 1 AMMETER AC 0 TO 200

070057 1 AMMETER AC 0 TO 300

070058 1 AMMETER AC 0 TO 400

070059 1 AMMETER AC 0 TO 600

070060 1 AMMETER AC 0 TO 800

13 070043 1 METER VOLT AC 0-300

070044 1 METER VOLT AC 0-600

14 083089 1 ASSY BOARD "C" CONTROL 12/24V

15 0C2428 8 SCREW TAPTITE PH #6-32 X 1/2 ZYC

17 064000 1 CONTROL PANEL SIDE

18 064008 1 COVER CONTROL PANEL TOP (NOT

SHOWN)

19 084736 1 DECAL TERMINAL STRIP

20 026536 1 PLUG STEEL 0.5

21 055867 1 SWITCH SPDT 15A SPD TGGL MOM

22 067625 1 SWITCH 3P TRIP THR 15/10A TGGL

23 032300 1 HOLDER FUSE

24 022676 1 FUSE 15A X AGC15

25 040213 4 PCB SUPPORT SNAP-IN 1/4

26 024469 2 SCREW TAPTITE #10-32 X 3/8 BP

27 061945 1 SWITCH 6A AMP/V SELECTOR

28 071361 1 POTENTIOMETER 5K +/-10% 2.25W PNL

29 050123 1 KNOB PLASTIC .25 SHAFT

30 055349 1 INSULATOR

31 070030 1 COVER GENERAC SILKSCREEN

ITEM PART NO. QTY. DESCRIPTION

32 * 084717 1 ASSEMBLY TIME RELAY

33 084733 1 HARNESS CONTROL PANEL C

34 083287 1 LIGHT HLDR CLR LNS W/O BULB

35 083288 1 LIGHT 28V DC .17A MIN BAYNT MNT

37 070081 1 METER HOURS

38 062304 1 AMMETER 40-0-40 DC

39 055405 1 GAUGE OIL PRESSURE

40 055406 1 GAUGE COOLANT TEMPERATURE

41 066040 1 DECAL TERMINAL STRIP

42 055089 1 CONN ELEC AMP M-N-L 15 PLUG PNL

43 070082 1 BLOCKER LIGHT

44 053247 1 LUG RNGTNG INS 22-18 X 10 X .322

45 029187 2 SPACER .19 X .31 X .50 ST/ZNC

46 077043B 16" FLEX CONDUIT .50 ID

47 029333 6 TIE WRAP 7" WHITE

49 0C2323 10 SCREW PHM SWAGE 6-32 X 5/8 Z/YC

50 036904 2 SCREW PPHM #6-32 X 3/4 (NOT SHOWN)

51 036908 2 SCREW PPHM #6-32 X 1-1/4

52 022155 2 WASHER LOCK #6

53 022985 6 WASHER FLAT #6-M4

54 022188 2 NUT HEX #6-32 STEEL

55 036918 4 SCREW PPHM #8-32 X 1/2

56 022264 11 WASHER LOCK M4

57 033121 14 SCREW HHM 10-32 X 1/2

58 022152 22 WASHER LOCK #10

59 023897 15 WASHER FLAT #10 ZINC

60 022158 11 NUT HEX #10-32 STEEL

61 038150 8 WASHER FLAT #8 ZINC

62 022471 4 NUT HEX #8-32 STEEL

63 084787 1 CABLE RIBBON 16"

64 070083 1 ASSEMBLY ENGINE MONITOR

65 082985 1 ASSEMBLY RESISTER 68 OHM 5W

66 082984 1 ASSEMBLY RESISTER 120 OHM 2W

67 098940 1 HARNESS C-OPT CTRL PNL

69 023762 3 WASHER SHAKEPROOF EXT #10 STL

70 055444 1 SINK HEAT

71 030468 1 WASHER STEP NYLON .20

72 049939 1 RECTIFIER MSC 12A 600V 1N1206R

73 070370 2 WASHER MICA .203

75 086266 1 RESISTOR WW LUG 75R 5% 25W

76 022507 4 SCREW HHC 1/4-20 X 1/2 G5 (NOT

SHOWN)

77 022097 8 WASHER LOCK M6-1/4 (NOT SHOWN)

78 040479 4 MOUNT VIBR 1.0 X 1.0 X 1/4-20 (NOT

SHOWN)

79 0441140156 1 WIRE ASSY 18AWG #0 (NOT SHOWN)

80 033147 1 SCREW HHM #10-32 X 1 (NOT SHOWN)

81 0C1299 1 DECAL WARNING

* USED ON 13.3L SPARK IGNITED ONLY

** USED ON 13.3L TURBO SPARK ONLY

Appendix 2 — Exploded Views and Parts Lists

“C” Option Control Panel 24 Volt Gas

Control Panel – Drawing No. 84711-N

Page 22

20 Generac®Power Systems, Inc.

Appendix 2 — Exploded Views and Parts Lists

“C” Option Control Panel 12 Volt Diesel

Control Panel – Drawing No. 85027-H

Page 23

Generac®Power Systems, Inc. 21

ITEM PART NO. QTY. DESCRIPTION

1 070023 1 CONTROL PANEL BOTTOM

2 070026 1 CONTROL PANEL FRONT

3 070028 1 CONTROL PANEL SIDE

4 067680 1 REGULATOR VOLT 60HZ

092952 1 REGULA TOR VOLT 50HZ

5 039271 1 FITTING 90 DEGREE 3/4

6 034616 1 FITTING STRAIGHT 3/4

7 057159 1 CIRCT BRK 2 X 1 ETA 46-500-P

053623 1 CIRCT BRK 2.5 X 1 ETA 46-500-P

054502 1 CIRCT BRK 3 X 1 ETA 46-500-P

056247 1 CIRCT BRK 3.5 X 1 ETA 46-500-P

049350 1 CIRCT BRK 4 X 1 ETA 46-500-P

048476 1 CIRCT BRK 4.5 X 1 AUT 30KW CNT45K

048512 1 CIRCT BRK 5 X 1 ETA 46-500-P

054450 1 CIRCT BRK 5.5 X 1 ETA 46-500-P

048505 1 CIRCT BRK 6 X 1 ETA 46-500-P

048467 1 CIRCT BRK 7 X 1 ETA 46-500-P

048468 1 CIRCT BRK 8 X 1 ETA 46-500-P

048470 1 CIRCT BRK 9 X 1 ETA 46-500-P

8 044213 1 RESIST MISC 10R X 12W

9 025192 1 RECTIFIER MSC 2A 600V 1N5062

10 048352 1 RESIST MISC 5R X 25W

057907 1 RESISTOR WW LUG 10R 10% 25W

057405 1 RESIST MISC 25R X 25W

11 055444 1 HEAT SINK 13.3L

12 030468 1 WASHER STEP NYLON .20

13 049939 1 RECTIFIER MSC 12A 600V 1N1206R

14 083089 1 BOARD "C" CONTROL 12/24V

15 024469 2 SCREW TAPTITE #10-32X3/8 BP

17 085058 1 HARNESS 12 VOLT DIESEL

18 029333 6 TIE WRAP 7" WHITE

19 070097 1 DECAL TERMINAL STRIP

20 055920 1 SWITCH 1PST PSADE PNL MNT

21 055867 1 SWITCH SPDT 15A SPD TGGL MOM

22 067625 1 SWITCH 3P TRIP THR 15/10A TGGL

23 032300 1 HOLDER FUSE

24 022676 1 FUSE 15A X AGC15

25 040213 4 CONN PCB SUP SNAP-IN

26 0C2428 8 SCREW TAPTITE PH #6-32 X 1/2 ZYC

27 061945 1 SWITCH 6A AMP/V SELECTOR

28 071361 1 POTENTIO PNL 5K +/-10% 2.25W

29 050123 1 KNOB PLASTIC .25 SHAFT

30 055349 1 INSULATOR

31 070030 1 COVER SILKSCREEN

32 070080 2 INSULATOR

33 070042 1 METER FREQUENCY 55-65HZ

070042A 1 METER FREQUENCY 240V 45-55HZ

34 070054 1 AMMETER AC 0 TO 50

070055 1 AMMETER AC 0 TO 100

070056 1 AMMETER AC 0 TO 150

070045 1 AMMETER AC 0 TO 200

ITEM PART NO. QTY. DESCRIPTION

070057 1 AMMETER AC 0 TO 300

070058 1 AMMETER AC 0 TO 400

070059 1 AMMETER AC 0 TO 600

070060 1 AMMETER AC 0 TO 800

35 070043 1 METER VOLT AC 0 TO 300

070044 1 METER VOLT AC 0 TO 600

36 070202 1 LIGHT PANEL

37 070081 1 METER HOURS

38 062304 1 AMMETER 40-0-40 DC

39 055405 1 GAUGE OIL PRESSURE

40 055406 1 GAUGE COOLANT TEMPERATURE

41 070083 1 ASSY ENGINE MONITOR

42 055089 1 CONN ELEC AMP M-N-L 15PLUG PNL

43 070082 1 BLOCKER LIGHT

44 053247 1 LUG RNGTNG INS 22-18 X 10 X .322

45 029187 2 SPACER .19 X .31 X .50 ST/ZNC

46 077043B 16" FLEX CONDUIT .50 ID

49 0C2323 12 SCREW PHM SWAGE 6-32X5/8 Z/YC

51 036908 2 SCREW PPHM #6-32 X 1-1/4

52 022155 2 WASHER LOCK #6

53 022985 2 WASHER FLAT #6

54 022188 2 NUT HEX #6-32 STEEL

55 036918 4 SCREW HHM #8-32 X 1/2

56 022264 6 WASHER LOCK M4

57 033121 14 SCREW HHM 10-32 X 1/2

58 022152 20 WASHER LOCK #10

59 023897 12 WASHER FLAT #10

60 022158 9 NUT HEX #10-32 STEEL

61 038150 4 WASHER FLAT #8 ZINC

62 022471 4 NUT HEX #8-32 STEEL

63 084787 1 CABLE RIBBON 16"

64 070370 2 WASHER MICA .203

65 063617 1 RELAY PNL 12VDC DPDT 10A @ 240VA

66 023762 1 WASHER SHAKEPROOF EXT #10 STL

67 057335 1 BLOCK TERM 20A 20 X 6 X 1100V

68 046669 5 JUMPER TERMINAL BLOCK

69 098940 1 HARNESS C-OPTION CONTROL PANEL

70 064000 1 SIDE CONTROL PANEL

71 064008 1 COVER CONTROL PANEL TOP

(NOT SHOWN)

72 066040 1 DECAL TERMINAL STRIP

73 022507 4 SCREW HHC 1/4-20 X 1/2 G5

(NOT SHOWN)

74 022097 8 WASHER LOCK M6-1/4 (NOT SHOWN)

75 040479 4 MOUNT VIBR 1.00X1.00X1/4-20

(NOT SHOWN)

76 036904 2 SCREW PPHM #6-32 X 3/4

(NOT SHOWN)

77 0441140156 1 ASSY WIRE 18AWG #15 (NOT SHOWN)

78 033147 1 SCREW HHM #10-32 X 1 (NOT SHOWN)

Appendix 2 — Exploded Views and Parts Lists

“C” Option Control Panel 12 Volt Diesel

Control Panel – Drawing No. 85027-H

Page 24

22 Generac®Power Systems, Inc.

3

9

5

9

9

0

8

9

3

9

0

5

5

3

6

0

6

9

G

G

850

OR

S

O

O

SS

S

.

)

CA

Appendix 2 — Exploded Views and Parts Lists

“C” Option Control Panel 12 Volt Gas

Control Panel – Drawing No. 085026-J

4

1

2

M

A

4

4

24 F

RAM #

F WIRE HARNE

N

DIA

TALLATI

EE WIRIN

IN

282

7

2

1

2

1

4

2

7

4

4

2

MI

2-PLCS

1

Page 25

Generac®Power Systems, Inc. 23

ITEM PART NO. QTY. DESCRIPTION

1 070023 1 PANEL BOTTOM CONTROL

2 070026 1 PANEL FRONT CONTROL

3 070028 1 PANEL SIDE CONTROL

4 067680 1 REGULATOR ASSY VOLTAGE 60HZ

092952 1 REGULATOR ASSY VOLTAGE 50HZ

5 039271 1 FITTING 90DEGREE ¾

6 034616 1 FITTING STRAIGHT ¾

7 057159 1 CIRCT BRK 2 X 1 ETA 46-500-P

053623 1 CIRCT BRK 2.5 X 1 ETA 46-500-P

054502 1 CIRCT BRK 3 X 1 ETA 46-500-P

056247 1 CIRCT BRK 3.5 X 1 ETA 46-500-P

049350 1 CIRCT BRK 4 X 1 ETA 46-500-P

048476 1 CIRCT BRK 4.5 X 1 AUT30KW CNT45K

048512 1 CIRCT BRK 5 X 1 ETA 46-500-P

054450 1 CIRCT BRK 5.5 X 1 ETA 46-500-P

048505 1 CIRCT BRK 6 X 1 ETA 46-500-P

048467 1 CIRCT BRK 7 X 1 ETA 46-500-P

048468 1 CIRCT BRK 8 X 1 ETA 46-500-P

048470 1 CIRCT BRK 9 X 1 ETA 46-500-P

8 044213 1 RESIST MISC 10RX12W

9 025192 1 RECTIFIER MSC 2A 600V 1N5062

10 044213 1 RESIST MISC 10RX12W

11 055444 1 HEAT SINK 13.3L

12 030468 1 WASHER STEP NYLON .20

13 049939 1 RECTIFIER MSC 12A 600V 1N1206R

14 083089 1 ASSY PCB "C" CONTROL 12/24V

15 024469 2 SCREW TAPTITE #10-32X3/8 BP

17 085025 1 HARNESS 12-V.GAS

18 029333 6 TIE WRAP 7" WHITE

19 070097 1 DECAL TERMINAL STRIP

20 026536 1 PLUG STEEL 0.5

21 055867 1 SWITCH SPDT 15A SPD TGGL MOM

22 067625 1 SWITCH 3P TRIP THR 15/10A TGGL

23 032300 1 FUSE HOLDER

24 022676 1 FUSE 15A X AGC15

25 040213 4 PCB SUPPORT SNAP-IN 1/4

26 0C2428 8 SCREW TAPTITE PH #6-32X1/2 ZYC

27 061945 1 SWITCH 6A AMP/V SELECTOR

28 071361 1 POTENTIO PNL 5K +/-10% 2.25W

29 050123 1 KNOB PLASTIC .25 SHAFT

30 055349 1 INSULATOR

31 070030 1 COVER GENERAC SILKSCREEN

32 070080 2 INSULATOR

33 070042 1 METER FREQUENCY 60HZ

070042A 1 METER FREQUENCY 50HZ

34 070054 1 AC AMMETER-0 TO 50

070055 1 AC AMMETER-0 TO 100

070056 1 AC AMMETER-0 TO 150

ITEM PART NO. QTY. DESCRIPTION

070045 1 AC AMMETER-0 TO 200

070057 1 AC AMMETER-0 TO 300

070058 1 AC AMMETER-0 TO 400

070059 1 AC AMMETER-0 TO 600

070060 1 AC AMMETER-0 TO 800

35 070043 1 AC VOLTMETER-0 TO 300

070044 1 AC VOLTMETER-0 TO 600

36 070202 1 LIGHT PANEL #26306C

37 070081 1 METER HOURS

38 062304 1 AMMETER 40-0-40 DC

39 055405 1 GAUGE OIL PRESSURE

40 055406 1 GAUGE COOLANT TEMPERATURE

41 070083 1 ASSY ENGINE MONITOR

42 055089 1 CONN ELEC AMP M-N-L 15PLUG PNL

43 070082 1 LIGHT BLOCKER

44 053247 1 LUG RNGTNG INS 22-18X10X.322

45 029187 2 SPACER .19X.31X.50 ST/ZNC

46 077043B 16" FLEX CONDUIT .50 ID

49 0C2323 12 SCREW PHM SWAGE 6-32X5/8 Z/YC

51 036908 1 SCREW PPHM #6-32 X 1-1/4

52 022155 2 WASHER LOCK #6

53 022985 2 WASHER FLAT #6

54 022188 2 NUT HEX #6-32 STEEL

55 036918 4 SCREW PPHM #8-32 X ½

56 022264 6 WASHER LOCK M4

57 033121 14 SCREW HHM 10-32 X ½

58 022152 22 WASHER LOCK #10

59 023897 14 WASHER FLAT #10 ZINC

60 022158 9 NUT HEX #10-32 STEEL

61 038150 4 WASHER FLAT #8 ZINC

62 022471 4 NUT HEX #8-32 STEEL

63 084787 1 CABLE RIBBON 16"

64 070370 2 WASHER MICA .203

65 063617 1 RELAY PNL 12VDC DPDT 10A@240VA

66 023762 1 WASHER SHAKEPROOF EXT #10 STL

67 057335 1 BLOCK TERM 20A 20 X 6 X 1100V

68 046669 5 BLOCK TERM JUMPER

69 098940 1 HARNESS "C" OPTION

70 064000 1 PANEL SIDE CONTROL

71 064008 1 PANEL TOP CONTROL (NOT SHOWN)

72 066040 1 DECAL TERMINAL STRIP

73 036904 2 SCREW PPHM #6-32 X 3/4 (NOT SHOWN)

74 022507 4 SCREW HHC 1/4-20 X 1/2 G5

75 040479 4 MOUNT VIBR 1.00X1.00X1/4-20

76 022097 8 WASHER LOCK M6-1/4

77 0441140156 1 ASSY WIRE 18AWG #0 (NOT SHOWN)

78 033147 1 SCREW HHM #10-32 X 1 (NOT SHOWN)

79 0C1299 1 DECAL WARNING

Appendix 2 — Exploded Views and Parts Lists

“C” Option Control Panel 12 Volt Gas

Control Panel – Drawing No. 085026-J

Page 26

24 Generac®Power Systems, Inc.

3

O

CO

O

L

U

L

5

O

R

O

D

S

S

S

CH

O

5

O

C

CO

C

ON

/

S

T

09

5A

9

U

Y

C

S

O

3

O

1

5

5

5

G

O

E

U

C

OR

5

5

5

83

8

4

0

87

G

O

OR

CU

O

D

O

M

5

5

5

506

505

500

50

50

506

500

50

505

37

5

5

5

8

9

5

9

5

5

O

S:

,

,

S

Q

K

C

G

O

S

S

G

S

S

M

S

O

O

O

O

S

S

S

S

S

G

S

O

G

O

CO

O

.

O

U

S

OU

3

CO

C

S

500

U

506

C

O

O

U

C

OR

O

8

35

O

S

O

O

C

O

O

U

S.

S

09

0

CO

C

Y

209 NC CONTACTS OPEN ON ANNUNCIATED SHUTDOWN

211 NO CONTACTS CLOSE ON ANNUNCIATED SHUTDOWN

210 C CONNECT TO FUSE +12V DC CIRCUIT AS SHOWN

8

9

0

O

COO

T

S

CH

O

O

SS.

GH

.

O

U

L

CH

G

E

U

K

3

Y

Y

3

,

.

CH

U

/

U

O/O

F

Appendix 3 — Interconnection Diagram

“C” Option Control Panel 12 Volt Gas

Interconnection Diagram – Drawing No. 87625

TE

Y

ET "A"

LAN

WIT

IN

EN

1

1

2

1

1

2

IL PRE

W

W

L

TEMP.

L

1

1

4

2

LANT TEMP

PREALARM HI

1

1

1

EL LEVE

W F

WIT

L

1

EL TAN

F

1

T

IAT

N

HT - REM

ANN

LI

1

2

22

1

2

1

1

1

1

LE BATTERY

IN

EE IN

N

LT

3-PHASE TRANSFER SWITCHE

UIPPED WITH NEUTRAL BLOC

ER WITH 12 V

THER VARIATI

R

HAR

1-PHASE & 4-POLE

WN. F

TE

H

N

1. 3-POLE

GENERALLY NOT E

2. 2 AMP

1

F

T

A

AL

WIT

MAN

L PANEL

NTR

R

ENERAT

N

HT

"D" & "E"

ET

EE IN

.

PREALARM LI

BATTERY ALAR

HI-L

NIT

N

PTI

"-

IAT

SEE INSET "G"

R "

N

T TP ALARM RELA

T WIRE

WN F

NNE

TE ANN

H

NNE

RN

-211

REM

-21

T TB

TLY T

2

ALARM H

2

WITH

DIRE

NIT

DEL

N

. M

TB2 TERMINAL

THR

CONTACTS. FOR "A" & "B" OPTION UNITS

L PANE

NTR

R

ENERAT

TE

N

NIT

INE M

EN

AR

IT B

IR

2

#7

22

1

2

ME

A

T

L

E

WIT

FER

TE

N

TRAN

T

TE

-N

T

XILIAR

A

NTA

1

PPL

TILIT

2

TB

17

1

TI

TRA

TAR

NNE

NE

2-WIRE

R A

E

PANEL W

ENERAT

Page 27

Generac®Power Systems, Inc. 25

Appendix 3 — Interconnection Diagram

“C” Option Control Panel 12 Volt Gas

Interconnection Diagram – Drawing No. 87625

G

COO

T

O

L

CK

CK

N

0

O

S

C

G

BLAC

WHITE

2

8

9

OS

T

G

WHITE

BLAC

S

50

O

S

S

S

S

CH

S

"

S

"

S

S

CH

S

600

O

S

S

U

CO

C

S

5

C

OS

ON

C

S

S

S

C

OS

O

C

ON

O

8

G

O

U

C

OR

O

U

R

Y

O

U

R

O

S

9555

9556

8

G

O

E

U

C

OR

S

S

C

OS

O

C

ON

O

8

G

O

U

C

OR

O

G

G

OU

D

)

O

Y

)

D

O

O

O

N

S

G"

O

S

CH

O

E

5

O

5

N

CK

9

5

5

9

O

CO

O

O

D

9

G

E

T

0

AM

P

/

F

G

R

C

Y

0

C

Y

S

0

C

G

/

C

G

S

S

S

1

PPE

R

T

IAT

12M

12AF

E

HAR

12VD

TANDB

TEM

Y

INE

HT - REM

DEL

LI

M

1

N

ANN

2

1

EN

LAN

IN

EN

2

2

BLA

REE

K

REEN

12 VD

ER W

HAR

VA

TILIT

A.

12

ET "A"-1

IN

NL

ENERAT

T

NTA

ERIE

WIT

FER

LT "N"

XILIARY

V

TRAN

T

TANDARD A

ITI

H P

WIT

T

NTA

4-64-

ATI

IAT

N

N INDI

ITI

TE ANN

H P

WIT

HT REM

LI

"N"

1

T

T

ET "E

IN

PPE

R

ENERAT

ATI

IAT

N

N INDI

ITI

TE ANN

H P

HT REM

WIT

LI

"Y"

1

T

T

ET "D

IN

R

N ALARM H

PTI

"A" & "B"

N

R

INE

EN

BATTER

BATTERY NEGATIVE

POSITIVE TERMINAL

T

T

LAN

INE

EN

TA

THERM

A

LT

V

2

1

ERIE

WIT

FER

LT "Y"

V

TRAN

2

T

12

BLA

NA

REE

BLA

PTI

K

REEN

AR

L B

NTR

T

WIT

RN

H

22

TE

N

BLACK/RE

D

DI

1

ET "

IN

Page 28

26 Generac®Power Systems, Inc.

3

O

CO

O

L

U

L

0

9

O

R

O

D

S

S

S

CH

O

5

O

C

CO

C

ON

/

S

T

09

0A

9

U

Y

C

S

O

3

U

L

O

1

0

0

0

G

O

E

U

C

OR

0

0

9

0

9

83

8

O

4

8

6

G

O

OR

CU

O

D

O

M

0

0

0

506

505

500

50

505

37

0

0

0

9

8

S

S

OR

9

5

9

9

5

5

O

COO

T

S

CH

O

O

SS.

GH

.

O

U

L

CH

G

E

U

K

3

3

Y

Y

3

0220

C

O

C

O

S:

,

,

S

Q

K

Q

T

C"

S

S

S

"

G

S

O

G

O

CO

O

.

O

U

S

OU

3

CO

C

S

500

U

506

C

O

O

U

C

OR

O

8

35

O

S

O

O

C

O

O

U

S

S

09

0

CO

C

O

209 NC CONTACTS OPEN ON ANNUNCIATED SHUTDOWN

211 NO CONTACTS CLOSE ON ANNUNCIATED SHUTDOWN

210 C CONNECT TO FUSE +24V DC CIRCUIT AS SHOWN

,

.

CH

U

/

U

O/O

F

Appendix 3 — Interconnection Diagram

“C” Option Control Panel 24 Volt Diesel

Interconnection Diagram – Drawing No. 87624

LAN

WIT

IN

EN

IL PRE

W

W

L

TEMP.

L

21

22

LANT TEMP

PREALARM HI

22

22

EL LEVE

W F

WIT

L

22

EL TAN

F

21

22

3-PHASE TRANSFER SWITCHE

UIRE 120 VAC FOR ENGINE COOLAN

UIPPED WITH NEUTRAL BLOC

"D" & "E

ET

1-PHASE & 4-POLE

TE

N

EE IN

.

2. 4.0L & 6.4L UNITS RE

1. 3-POLE

GENERALLY NOT E

"B" & "

.

NIT

N

PTI

L PANEL

"-

IAT

ALARM RELAY

SEE INSET "G"

NTR

R "

N

T T

R

T WIRE

WN F

NNE

TE ANN

H

NNE

ENERAT

RN

-211

REM

N

-21

T TB

TLY T

2

HT

ALARM H

2

WITH

DIRE

NIT

DEL

N

. M

CONTACTS. FOR "A" & "B" OPTION UNITS

TB2 TERMINAL

PREALARM LI

THR

NIT

INE M

EN

AR

IT B

IR

T

IAT

21

22

22

22

2

1

21

2

1

4

22

22

ME

1

A

2

T

L

N

TE

PPL

TILIT

-N

T

XILIAR

A

NTA

TRA

NE

N

HT - REM

ANN

LI

22

22

22

22

2

22

1

471

#

E

WIT

FER

TE

N

TRAN

T

22

N

N

NON

22

BATTERY ALAR

HI-L

L PANE

NTR

T

I

F

T

A

AL

MAN

WIT

R

ENERAT

TE

N

TE

RE

N

TB

17

1

TI

TRA

TAR

NNE

NE

2-WIRE

R A

E

PANEL W

ENERAT

Page 29

Generac®Power Systems, Inc. 27

Appendix 3 — Interconnection Diagram

“C” Option Control Panel 24 Volt Diesel

Interconnection Diagram – Drawing No. 87624

G

E

T

0

C

Y

G

E

T

O

L

R

3

S

"

0

/

F

G

R

3

3

G

S

O

Y

0

C

CK

N

0

6

R

Y

OU

D

O

R

8

G

WHITE

8

G

WHITE

OS

T

G

R

OS

T

G

C

OR

OS

T

BLAC

G

D

N

CK

CK

0

C

Y

3

3

G

S

O

Y

O

S

C

G

R

S

C"

0

3A

O

L

T

G

E

Y

0

C

R

G

E

0

6

3

3

G

S

O

U

L

G

R

8

8

OS

T

OS

T

G

R

OS

T

8

S

50

O

S

S

S

S

CH

S

"

O

S

9555

9556

8

G

O

E

S

S

C

OS

O

C

ON

O

8

G

O

U

C

OR

O

U

R

9

5

S

"

S

S

CH

S

600

O

S

S

Y

O

U

R

S

S

C

OS

O

C

ON

O

8

G

O

U

C

OR

9

5

S

S

OR

O

5

0

O

E

O

S

CH

S

G"

O

O

O

N

C

/

D

O

CO

O

O

D

9

PPE

R

PPER PANE

T

V A

TILIT

24

NL

RANKIN

CONTACTO

GROUN

BLA

BLA

REE

INE

2

1

LITER EN

.

1

TA

IN

21

21

21

LAN

EN

& THERM

NL

ENERAT

ERIE

LT "N"

V

T

WIT

FER

TRAN

ATI

IAT

N

N INDI

ITI

TE ANN

H P

WIT

HT REM

LI

"N"

1

T

T

ET "E

IN

NA

TA

TA

THERM

HEATE

IN

EN

REEN

LAN

TA

INE HEATE

EN

THERM

.4 LITE

-

4.

PTI

THERM

VA

E

INE

TILIT

12

HAR

LITER EN

LT

.

.4-1

-

V A

24

TILIT

2 AMP 24 V

ET "

IN

WITH 4.

T

-

HT - REM

DEL

LI

M

1

2

1

K

REEN

N

R

BLACKBLA

REE

NLY

INE

PPE

R

ENERAT

ERIE

LT "Y"

V

2

T

WIT

FER

TRAN

ATI

N INDI

ITI

H P

WIT

"Y"

T

IAT

N

TE ANN

HT REM

LI

1

T

ET "D

LITER EN

.

1

TA

IN

LAN

EN

& THERM

T

TE

I

N

WIT

E

VA

12

TILIT

24M

HAR

AMP 24AF

1

NA

NL

TA

PTI

HEATE

THERM

AR

L B

NTR

T

RN

H

RE

RE

K

BLA

REEN

ET "B

IN

22

D

DI

22

IN

R

N ALARM H

PTI

"A" & "B"

ET "

IN

IN

1

1

T

PPE

1

EN

T

NTA

RANKIN

21

21

INE HEATE

EN

Page 30

28 Generac®Power Systems, Inc.

Part II

Remote Annunciator

Panels

Page 31

Generac®Power Systems, Inc. 29

Section 1 — General Information

Remote Annunciator Panels

1.1 THREE LIGHT REMOTE

ANNUNCIATOR

The Generac Three Light Remote Annunciator

(Figure 1.1) provides a valuable reference when used

with the Generac automatic transfer switch and

standby generator with a C option control panel.

This equipment is designed to be mounted remotely

from the standby generator set. The panel, when

properly interconnected with a Generac standby generator system and transfer switch, annunciates up to

three (3) standby electric system operating parameters.

• Utility Power Supply: This light comes ON when

customer electric loads are being powered by the

NORMAL (utility) power source.

• Emergency Power Supply: This light comes ON

when customer electric loads are being powered by

the EMERGENCY (standby) power source.

• Generator Fault Light: This light comes ON when

the generator engine has shut down automatically

due to a fault condition (such as low oil pressure,

high coolant temperature, overcrank, overspeed,

or RPM sensor loss). Fault conditions that will

result in an automatic engine shutdown are discussed in the INSTRUCTIONS AND PARTS MANUAL for the applicable generator set.

Figure 1.1 — Model 8848 Annunciator Panel

Lights

1.1.1 INSTALLATION

Mount the annunciator at any convenient location

near or remote from the standby generator. Mounting

dimensions are shown in Appendix ???. Holes are

provided for fastening the panel to a desk, wall or

other convenient object. Four 7/8” (22mm) holes are

also provided for routing of required wiring into the

panel. Installation must comply with all applicable

codes and regulations.

Required wiring between the Model 8848 annunciator, the Generac generator meter and control (upper)

panel, and transfer switch auxiliary contacts are

shown in Appendix ???, Interconnection Diagram.

NOTE:

Two different types of auxiliary contacts may be

encountered on Generac transfer switches.

1.2 FIVE LIGHT REMOTE

ANNUNCIATOR

The Model 8617 Remote Annunciator Panel (Figure

1.2), when properly interconnected with a Generac

standby generator equipped with an Option C control

panel, will provide remote annunciation of the same

five engine operating parameters as the generator

panel. The remote panel mounts five advisory lamps.

On occurrence of one or more of the panel monitored

faults, the applicable lamp will illuminate and the

horn will sound. Both the lamp(s) and the Alarm

Horn can be turned OFF by depressing the Reset

switch. All five lamps may be tested by actuating the

Test switch. The following engine fault conditions will

be indicated on the annunciator panel:

• Low Engine Oil Pressure

• High Engine Coolant Temperature/Low Coolant

Level

• Overcrank Condition

• Overspeed Condition

• RPM Sensor Loss Condition

Figure 1.2 — Model 8617 Remote Annunciator

Page 32

30 Generac®Power Systems, Inc.

Section 1 — General Information

Remote Annunciator Panels

1.2.1 OPERATION

Both the remote and generator panel advisory lamps

are controlled by a single DC CONTROL-LATCHCRANK circuit board housed in the generator control

console. Engine mounted, normally open (N.O.)

switches and sensors provide the necessary signal to

the circuit board on occurrence of a monitored

engine fault. should any one (or more) of the monitored faults occur, an automatic engine shutdown,

illumination of the applicable lamp(s), and sounding

of the Alarm Horn will occur. circuit board action will

then “latch” the fault. That is, the applicable lamp(s)

will remain ON after engine shutdown. While any

lamp remains lighted (latched), further attempts at

generator cranking and startup are inhibited. A 12

volt DC input is required to operate the panel.

NOTE:

See applicable standby generator owner’s manual

for more detailed operational description of

remote and generator panel lamps.

1.2.2 CUSTOMER CONNECTIONS

Suitable, approved wiring must be purchased for

interconnection of the Remote Annunciator Panel

with Terminal block TB2. Connect each wire to a

numbered terminal block screw and to an identically

numbered terminal in the remote annunciator panel.

A total of nine wires are required. Numbered terminals may be identified as follows:

• #94 — Low Oil Pressure Shutdown

• #95 — High Coolant Temperature/Low Coolant

Level Shutdown

• #96 — Overcrank Shutdown

• #97 — Overspeed Shutdown

• #98 — RPM Sensor Loss Shutdown

• #137 — Test Switch Connections

• #138 — Reset Switch Connections

• #209 — Alarm Relay Normally Closed Contacts*

• #210 — Alarm Relay Common Contacts*

• #211 — Alarm Relay Normally Open Contacts*

* DO NOT EXCEED ONE (1) AMPERE OF CURRENT

ACROSS ALARM RELAY CONTACTS.

1.2.3 PARTS INCLUDED WITH REMOTE

PANEL

Factory shipment of any standby generator set which

includes the optional Remote Annunciator Panel will

include a WIRING HARNESS (Part No. 70287). The

WIRING HARNESS includes the following parts:

1. Terminal Block TB2 (Part No. 55911)

2. Terminal Block Decal (Part No. 66040)

3. Alarm Relay (Part No. 63617)

4. The Wiring Harness proper

1.3 18 LIGHT REMOTE ANNUNCIATOR

The Model 9555 Remote Annunciator Panel is a self

contained system, utilizing solid state circuits to

annunciate up to sixteen (16) engine-driven generator

operating parameters (Figure 1.3). The system meets

NFPA (National Fire Protection Association) specifications for standby electric power systems.

The system will monitor any sensing device having

normally-open (N.O.) contacts which provide a +DC

signal to the applicable panel lamp on contacts closure. On contacts closure, both an alarm lamp and

an alarm horn are activated and latched in to manual reset. The alarm horn may be silenced without disturbing the visual indication and with any subsequent alarm re-activating the horn. The system

includes a test circuit.

NOTE:

The one exception to the normally-open (N.O.)

contacts rule is the LOW BATTERY VOLTAGE

lamp. This lamp must be connected to normallyclosed (N.C.) contacts on the battery monitor circuit board, located in the generator control panel.

Figure 1.3 — Model 9555 Remote Annunciator

Panel

Page 33

Generac®Power Systems, Inc. 31

1.3.1 GENERATOR STOP SIGNALS

All signals occur when generator shutdown occurs as a

result of the failure indicated by the illuminated

lamp(s).

1. High Water Temperature/Low Water Level: This

lamp comes ON and the horn sounds when the generator’s high temperature alarm is active.

2. Low Oil Pressure: This lamp illuminates and the

alarm horn sounds when the generator’s low oil

pressure alarm is active.

3. Overspeed: This lamp turns ON and the alarm

horn sounds when the generator’s overspeed alarm

is active.

4. Overcrank: This lamp turns on and the alarm horn

sounds when the generator’s overcrank alarm is

active.

5. Sensor Loss: This lamp illuminates and the alarm

horn sounds when the generator’s rpm sensor loss

alarm is active.

1.3.2 LATCHABLE SIGNALS

The following signals can be individually selected by

means of miniature rocker switch on the Remote

Panel’s monitor circuit board. The available switch

positions are “Latch On” and “Latch Off”. “Latch Off ”

indicates the lamp will turn ON only when the signal is