Page 1

0^

fY^

Part No. 83874

OWNER’S

Manual

SERIES NP-80D

LIQUiD-COOLED

RECREATIONAL VEHICLE

GENERATOR

Model 9344-1

Revision 0(8/18/92)

CORPORATION

Printed in U.S.A.

Page 2

GENERAL SAFETY RULES

THE MANUFACTURER SUGGESTS THAT THESE "RULES" FOR SAFE OPERATION BE COPIED AND

POSTED IN POTENTIAL HAZARD AREAS OF THE RECREATIONAL VEHICLE. SAFETY SHOULD BE

STRESSED TO ALL OPERATORS AND POTENTIAL OPERATORS OF THIS EQUIPMENT.

Study these SAFETY RULES carefully before operating

or servicing applicable equipment. Become familiar

with this Owner’s Manual and with your generator.

Safe, efficient and reliable operation can only be

achieved if generator is properly installed, operated and

maintained. Many accidents are caused by failing to

follow simple and fundamental rules or precautions.

The manufacturer suggests that these GENERAL

SAFETY RULES be copied and posted in potential

hazard areas of the recreational vehicle. Stress safety

to all operators and potential operators of this equip

ment.

The manufacturer cannot possibly anticipate every pos

sible circumstance that might involve a hazard. The

warnings in this manual, therefore, are not all-inclusive.

If you use a procedure, work method or operating tech

nique that Generac does not specifically recommend,

you must satisfy yourself that it is safe for you and

others. You must also make sure the procedure, work

method or operating technique that you chose, does not

render the generator to be unsafe.

• For fire safety, the recreational vehicle generator

must be properly installed and maintained. Instal

lation must comply with applicable codes and stan

dards. Also, the generator must be installed to

conform to the manufacturer’s detailed installation

instructions. After installation, do nothing that might

render the generator in noncompliance with such

codes, standards and instructions.

• The recreational vehicle generator produces ex

tremely dangerous electrical voltages and can

cause dangerous, and possibly fatal, electrical

shock. Avoid contact with bare wires, terminals,

etc., while the unit is running. If you must work

around an operating generator, stand on an insu

lated, dry surface to reduce shock hazard.

• Never work on this equipment or handle any elec

trical device while standing in water, while barefoot,

or while hands or feet are wet. Dangerous electrical

shock will result.

• Have the generator properly grounded (bonded)

during installation onto the vehicle, either by solid

mounting to the vehicle frame or chassis or by

means of an approved bonding conductor, if so

equipped. DO NOT reconnect the bonding conduc

tor to any generator part that might be removed or

disassembled during routine maintenance. If the

grounding conductor must be replaced, use only a

flexible conductor that is of No. 8 AWG copper wire

minimum.

Inspect fuel system frequently for leaks or damage.

Repair or replace any damaged or leaking compo

nent immediately. Never attempt to change, alter

or modify the generator fuel system in any way that

might affect safety or compliance with applicable

codes and standards.

In case of accident caused by electric shock, shut

down the source of electrical power at once. If you

cannot do this, free the victim from live conductor.

AVOID DIRECT CONTACT WITH THE VICTIM.

Use a dry board, dry rope, or other non-conducting

tool to free the victim from live conductor. If victim

is unconscious, apply CPR (cardio-puimonary re

suscitation) and get medical help.

The generator engine gives off DEADLY carbon

monoxide gas through its exhaust system. This

dangerous gas, if breathed in sufficient concentra

tions, can cause unconsciousness or even death.

This exhaust system must have been properly in

stalled, complying strictly with applicable codes and

standards. After installing the unit, do nothing that

might render the unit unsafe or in non-compliance

with such codes and standards. The generator

compartment must be completely vapor-seaied

from vehicle interior. There must be no possibility

of exhaust fumes entering the vehicle interior.

Never operate this equipment with a leaking or

defective exhaust system.

Never use the generator or any of its parts as a step.

Stepping on the unit can stress and break parts and

may result in dangerous operating conditions from

leaking exhaust gases, leaking fuel, leaking oil or

leaking coolant.

The generator compartment needs adequate venti

lation to expel toxic fumes and diesel fuel vapors.

Do not alter the installation in any way that might

obstruct air and ventilation openings. Keep such

openings clear and unobstructed.

Keep hands, feet, clothing away from drive belts,

fans and other moving parts of this equipment.

Never remove a drive belt or fan guards while the

unit is operating.

Although diesel fuel is not as volatile as gasoline or

LP gas (liquid propane), it is still dangerous. Com

ply strictly with all laws and regulations regarding

the handling of diesel fuel.

Inspect the generator periodically. Repair or re

place all damaged or defective parts immediately.

Before performing any maintenance on the gener

ator set, disconnect its battery cables to prevent

accidental starting. First disconnect the cable from

the battery post indicated by a NEGATIVE, NEG or

(-)• Reconnect that cable last.

Page 3

IDENTIFICATION RECORD

Please record the following information. Find this information on the Model/Seria! Number Plate and on the

Generator Data Plate, affixed to your generator.

Model Number

Rated kW

Rated Hertz

Serial Number

Rated Volts

Rated RPM

1 -

Page 4

READ THIS MANUAL THOROUGHLY

If you don’t understand any portion of this manual,

contact Generac for a demonstration of actual starting,

operating and servicing procedures.

Throughout this publication and on tags and decals

affixed to the generator, DANGER and CAUTION

blocks are used to alert you to special instructions about

a particular operation that may be hazardous if per

formed incorrectly or carelessly. Observe them care

fully.

These safety warnings cannot eliminate the hazards

they indicate. Complying strictly with the special in

structions while servicing the unit plus "common sense"

are major measures for preventing accidents.

The following definitions apply to DANGER, CAUTION

and NOTE blocks found throughout the manual.

DANGER! AFTER THIS HEADING YOU CAN

READ INSTRUCTIONS FOR HANDLING, IN

STALLING OR SERVICING THAT, IF NOT COM

PLIED WITH STRICTLY, MAY RESULT IN PER

SONAL INJURY.

the generator. This prepares them if they need to oper

ate the equipment in an emergency.

OPERATION AND MAINTENANCE

The operator is responsible for performing all safety

checks: to be sure that all maintenance for safe opera

tions is performed promptly; and to have the equipment

checked by an Authorized Dealer periodically. Normal

maintenance service and replacement of parts are the

responsibility of the Owner/Operator and, as such, are

not considered defects in materials or workmanship

within the terms of the warranty. Individual operating '

habits and usage contribute to the need for maintenance

service.

Proper maintenance and care of your recreational vehi

cle generator keeps the number of problems to a

minmum and keeps your operating expenses low. See

your authorized Dealer/Distributor for service aids and

accessories.

CAUTION! After this heading you can read instruc

tions for handling, installing or servicing that, if not

complied with strictly, may result in damage to

equipment and/or property.

NOTE: After this heading you can read explanatory

statements that require special emphasis.

The operator (driver) is responsible for proper and safe

use of the vehicle, equipment of the vehicle and the

safety of all vehicle occupants. We strongly recom

mend that the operator read this Owner’s Manual and

thoroughly understand ail instructions before using this

equipment. We strongly recommend instructing other

occupants in the vehicle to properly start and operate

HOW TO OBTAIN SERVICE

When your recreational vehicle generator set requires

servicing or repairs, simply contact an authorized Ser

vice Station for assistance. Service technicians are

factory-trained and are capable of handling all of your

service needs.

When contacting an Authorized Service Facility of the

factory about parts and service, always supply the com

plete model number and serial number of your unit as

given on its data plate.

The warranty of your generator is included in this

Owner’s Manual as are listing for repair parts.

-2-

Page 5

GENERATOR FEATURES

1. Engine Pre-heat Switch

2. Engine Start/Stop Switch

3. 10 amp DC Circuit Breaker

4. 35 amp AC Circuit Breaker

5. 30 amp Battery Chargingn Fuse

6. Generator AC Output Leads

7. Remote Leads

8. Hourmeter

9. Generator

10. Fuel Return Connection

11. Air Cleaner

12. Oil Drain Hose

13. Oii Filter

14. Oil Dipstick

15. Oil Filler Opening and Cap

16. Fuel Filter

17. 14 amp Fuse

-i-

Page 6

G F r-J E n AT 1 ■ R_ Mì „ ? A R i/

GENti^.Al Jrt APPLÍCAbi'_r,'¡

These gr^nerators have been designer and rranuiac

tured ior he purpose of suppi'/ing elcetn^ai f^ower for

recreational vehicle You chouLi not modify * *ne gen

erator or L sp n f:' ally appiif atiuh oin- tfian fa wha' is

was detiyiibC. 1 ^sie-e are inv ouesi- n.- pe"*-inii o to

its application wri.>- or ''iH Tie r iciogc Do -a esc tne

unit until cl comnpifcni a'of'of'D r.ar “jv.sf*nv<t

DANGEn FOF FiRE 3ÄFE1 . i HL

MUST HAVE SEEK' FROPERLf iNSlALLED IK

COMPLIANCE W\lh AFPLrOAPLE TCCES AND |

ST ^NDARD" TEE GENERATOR ALSO MOST

hA/E SEEN iNSfAuLED IN STRiCT GOMPLin

ANCE mdTh THE MANÖFACTPi^Efl S DFTAIlSO i

INSTALLATION iWSTF.OCTlC NS FOLLGWiNG IN- j

STAuI^fiTIOM. NOTHiYG MUST EE DONE ThA^ |

M^GKT RENDER TNE JHll IN NON-OOMFLiANCe |

WiTh AuCh OD^ .S**ANr'^FOS A!4D Os-i

STRIjCJjf^liS.

______

_____ ______

_______

_ J

Yolljii c ihi£ ue ' r:ur-titucupDyw'

fof s'Prraliiiy iOjE-^'j ^ ills Jncle chase r '

ek Cl If '*'f ,ii< juifirg id'o ‘''C0v*,i:e/ - fVd !

pr)we Y -• T aac .anr-a • >i com: "

a - uDr “f . fit r i IPO‘'Of' i"“, . ^ '"OCf fc

cl oo V' k'

The owner/operaior should be sure the unit has been

installed to allow adequate ventillation for cooling and

exhaust air.

SAFETY

Before attempting to use the generator set, carefully

read GENERAL SAFETY RULES inside the cover of

this Manual. Comply stricly with these RULES to pre

vent accidents and damage to aauipment and/or prope’~y. r-ne-r-c Ciijaesio that copy. g and posting GEN

ERAL S-FFT RL re n peteriO* hazard areas of the.

vapirie 'ire:, sarnty ^ ^ ope ators and potential

'perah • 1 fOO 'Vi.'nfrji

GENErATSiP A^C CONNECTION SYSTEM

"h' per b pjr (: ^ win a -mal stator AC power

vcs.dingc rn- i- ' c . UvV wind res supply electrical

• G ce" T curtemH-r u' ci' jc 'oacm by means of a dual

d '/r I' ,i-mh{yfi /"if M Uc-e, .loweverOhe neutral

c QiijMm-h

■“ht mtm h . '-ij'k*, s > that units power

r/j/'* -0 -Of . ‘,,a! y aiurf i): c r you can rewire

'hs n ffu(Iir~ on / lO'v !’c k( !f ctrical loads. Be

jff r Un ^ nrki"f n ci'mjif breakers (C.B.

ji ~ lum . ) Alb ' -.1 I. -U> tj io' L 'olts

i ounON. Oc TUI ove"ioacJ the q t n t tn h i ^ero^IriStakaA&rT!-.'j row|uite inai n eoc

die r'’uceo'o 0'a-itiii ov*-f|:cd'ng feoriciCic »'

• v'^i ' Of h ' .f 1. |, 1 ,-f

I '» c^fien f .!>' ' s<n "rh

•n. ’ ( .al '“ir III mi * -I-. *i mi s c ^ ‘ '

T ' i' m^- r fi- ,'0'j‘ "*** , I"» if"t 1 Of » 3<.»

“h

r- 5 im C» - »1 -jouc . Oí '

«' '-rk m- n Í ' il/ ^

I! ‘ - . p, C'Ok- Hi (.íuíí, ,f .Í ’ f

should not be areale

-, i Or t ’ / ,

if ;i,< !. i< L

i V

Ou >i2 iuun t n-c/ egufro si’t.o /«.m f

p.wef iOr Ä.i pa m. ' ut cml mn 'm * m.,* Ii ' :cm

Í viiursouua - tt

IhOTALL.O.OOrv

Ì hi T/ -I ' fdac -I " c i-t it -cr. fr!''''iio 'jinm

'Ui.ffm-p iimh-a u if t;r ni '“.ri. ./„!! j

mr- iPtc r-_cr-:5aur,, ,0 v'/v dice csct r^r-

.C'npiic J ,vkh O'COaDle C'^nec c'ar ,a'' L a d ~

u'Ci ' '-'C Dtrre'ntny ÍC- n'iaiia''i.jn

An k4‘'TMLi_AT‘Aju HANUA* wm- <ri!pD“ö *"c

^mcf-rarnr T*ri¿.| Mnuii emmne nertmOn'" c •“

orjcffcr"- and reLorT.mpnriai'crn c¡ I'^oaJina ..*m rt

rtic a r-creOicnni cehi'ie rollovxsnq .nomiia:r-r ,r

cjii„ a sneuid 'erma'-d tne incmliaron Oa .uri

Awner/Operaiors Or ihsi. .normakoo r-r-Cc''!'

- !• rCSO'^o. ÌO

JCP' Oidi m.ght Ibi.de^'--mon'r msem rcy; /^¡¡i im

m\ V iih -upOcLie c ano'* ca -^tn if-on¡ -

j 1/ 0 0 i) <) ' G

T2 (WHITE)

-120 V,

-240 vC

T1 (RED)

Figure 1 — Connections for 120/240 Volts

Figure 2 — Connections for 120 Volts Only

44

öCn

cm

J

T3 (BLACK)

4 -

Page 7

OPERATION

GENERATOR CONTROL PANEL

See Figure 3 to identify the following components:

Hourmeter: Provides continous indication of engine

operating time, in hours and tenths of hours. Use the

hourmeter with the periodic maintenance schedule, to

make sure that required periodic maintenance tasks are

completed on a timely basis.

Engine-Stop/Start Switch: To crank the engine, hold

switch at START position. Release the switch when the

engine starts. To shut down an operating engine, set

the switch to STOP.

10-Amp Circuit Breaker: Protects the DC control cir

cuit against overload. If the circuit breaker has opened

due to an overload, engine preheat and start functions

cannot occur. The breaker is a "push to reset" type.

G E N E R A C

N P 8 0 D

R V GENERATOR

•MAr.'.iAL fOP COMh

E CC 0« ^ '

Preheat Switch: The diesel engine is equipped with

glow plugs, one for each cylinder. When you press the

preheat switch (Figure 3), the glow plugs heat the

engine combustion chamber for quicker starts in cold

weather. To preheat the combustion chamber for

quicker starts in cold weather. Press the switch and

between 15 and 30 seconds. Continue holding in the

preheat switch while cranking the engine until it starts.

NOTE: Refer to THE GENERATOR A-C CONNEC

TION SYSTEM on Page 4. Individual installations will

differ. If an overload occurs, the dual breakers will open

the hot stator leads (11 and 44). When the generator

has been connected for 120 volts only, one of the dual

circuit breakers will open stator AC output lead No. 11

(hot lead).

REMOTE START/STOP PANEL

A remote mounted Start/Stop Panel is available, which

allows you to start and stop the generator engine con

veniently from inside the vehicle.

You can also order a remote panel that includes meters

and gauges for monitoring low oil pressure, high coolant

temperature and low coolant level (Figure 5), in addition

to a start/stop switch. The panel also includes an am

meter, a voltmeter and an hourmeter.

Figure 3 — Generator Control Panel

Dual AC Circuit Breaker: Rated at 35 AC amps, the

circuit breaker (Figure 4) protects the generator’s AC

output circuit against overload and provides a method

of turning OFF the generator’s 120/240 volts AC output

to vehicle circuits.

Figure 4 — Dual 35-amp Circuit Breakers

1 mEM PREMEC WHTCH KM Sfl sec

L AFTEW SO sec Of WOHMr l»R£8S rcW »»ffTCH,

corrwue TO ewiTM mEHSJu mnc» *<hile cfWiWHO

UKTw. swrri.

GEN.

RUN

LiJ

STOP START

PREHEAT

LJJ

30 SEC. MAX

GENERAC R.V. GENERATOR “

Figure 5 — Remote Start/Stop & Gauge Panel

BEFORE STARTUP

• Check Engine Crankcase Oil Level: Refer to

SPECIFICATIONS and MAINTENANCE sections

for procedures and recommendations.

CAUTION! Any attempt to crank or start the engine

before properly servicing it with recommended oil

will result in an engine failure.

NOTE: Engine was factory serviced with a high quality

oil classified "For Service CD" or "For Service CC" and

having a viscosity rating of SAE 30. The installer may

have refilled the crankcase with an oil more suitable for

ambient temperature ranges in your area.

Page 8

® Check Coolant Level: Check coolant level prior to

initial use and at recommended intervals. Refer to

SPECIFICATIONS and MAINTENANCE sections

for procedures and recommendations.

® Check Fuel Supply: Make sure an adequate sup

ply of clean fuel is available to the engine. Many

installations include a Fuel Shutoff Valve, which you

must open before starting the engine.

NOTE: On some installations, the generator may have

been provided with its own fuel tank. On other installa

tions, the generator may "share" with the vehicle’s fuel

tank. When the vehicle’s tank is shared, some installers

may have installed a generator fuel pick up tube in the

shared tank that is shorter than the vehicle’s pick up

tube. When a shorter generator fuel pickup tube is

installed in the tank, the generator will run out of gas

while sufficient fuel remains in the tank for vehicle

engine operation.

START THE GENERATOR

To start the generator from either the generator control

panel or from the optional Remote Panel, proceed as

follows:

1. Turn OFF electrical loads, using whatever means

provided.

NOTE: If starting from the generator panel, turn OFF

loads by setting the generator’s main circuit breaker to

OFF or OPEN. If starting from a Remote Panel, turn

OFF loads using whatever means is provided in the

vehicle (such as a main circuit breaker.)

2. Press the preheat switch (if engine is cold) for

. between 15 and 30 seconds.

3. At the same time, hold the Engine-Start/Stop

Switch at START and press the preheat switch to

crank engine. Release the switch when the engine

starts.

4. Let the engine stabilize and warm up.

5. Turn ON electrical loads, using whatever means

provided.

SHUTTING DOWN THE GENERATOR

1. Turn OFF electrical loads, using whatever means

provided.

2. Let the engine run at no-load for a few minutes to

stabiize internal temperatures.

3. Set the Engine-Run/Stop Switch to STOP position.

-6

Page 9

AUTOMATIC LOW OIL PRESSURE

SHUTDOWN

The engine is equipped with a normally-closed (N.C.)

oil pressure switch (Figure 6). Engine oil pressure holds

the switch open during cranking and operation. Should

oil pressure drop below about 15 psi, the switch contacts

close and the engine automatically shuts down.

HIGH COOLANT TEMPERATURE

SHUTDOWN

This switch (Figure 7) is a normally open (N.O.) thermo

static device which is immersed in engine coolant.

Should engine coolant temperature exceed about

230°F (110°C), the switch contacts close and the en

gine shuts down.

ADDITIONAL INFORMATION

Figure 8 — Engine Controller Circuit Board

NOTE: After an overspeed shutdown, the engine may

be cranked and re-started. However, if the engine

overspeeds again, the engine shuts down again.

ENGINE GOVERNED SPEED

The generator is equipped with a 4-pole revolving field

(rotor) which must be driven at 1500 rpm to produce the

unit’s rated a-c frequency of 50 Hz. The diesel engine

governor was factory set to about 52 Hz. (1560) at

no-load. After installing it, the installation technician

should check and adjust the governed speed. Setting

the no-load frequency slightly high helps prevent exces

sive frequency, rpm and voltage droop under heavy

electrical loading.

DANGER; DO NOT TAMPER WITH THE ENGINE

GOVERNOR SETTINGS. EXCESSIVELY HIGH

ENGINE SPEEDS ARE DANGEROUS AND IN

CREASE THE RISK OF PERSONAL INJURY AND

DAMAGE TO EQUIPMENT AND/OR PROPERTY.

EXCESSIVELY LOW SPEEDS IMPOSE A HEAVY

LOAD ON THE ENGINE WHEN ADEQUATE EN

GINE POWER IS NOT AVAILABLE AND MAY

SHORTEN ENGINE LIFE. THE GENERATOR SUP

PLIES CORRECT RATED FREQUENCY AND

VOLTAGE ONLY AT THE PROPER SPEED.

SOME ELECTRICAL DEVICES MAY BE DAM

AGED BY INCORRECT FREQUENCY AND/OR

VOLTAGE. IF ENGINE SPEED APPEARS TO BE

INCORRECT, CONTACT YOUR NEAREST AU

THORIZED SERVICE FACILITY.

Figure 7 — High Coolant Temperature Switch

OVERSPEED SHUTDOWN

The generator control panel houses an Engine Control

ler circuit board (Figure 8). That circuit board receives

a-c frequency signals from generator stator leads 11

and 22. Should a-c frequency exceed about 72 Hz

(2160 rpm), circuit board action initiates an automatic

shutdown after a few seconds.

25-HOUR BREAK-IN PERIOD

The first 25 hours of operation is the break-in period for

the generator. Properly breaking in the generator is

essential to reducing oil consumption and enhancing

engine performance. During the break-in period, ob

serve the following rules:

• For the first 25 hours, run the generator at varying

electrical loads, to help set the enaine piston rings

properly.

- 7

Page 10

Following the initial 25-hour break-in period, avoid

light electrical loads for the next 75 hours of opera

tion. The unit should be loaded at 50% (or more) of

its capacity during those 75 hours. Repeated light

loads during break-in period may improperly seat

the piston rings, resulting in blowby and high oil

consumption.

Check oil level frequently during the break-in period.

Add oil if needed. It is natural for the generator

engine to consume much oil until the piston rings

have seated properly.

When the 25-hour break-in period is done, complete

the tasks recommended under 25-HOUR CHECK

UP PERIOD.

25-HOUR CHECK-UP PERIOD

After the first 25 hours of operation have been com

pleted, contact an Authorized Service Facility for the

following maintenance. The Owner/Operator is respon

sible for any changes.

Change engine crankcase oil and oil filter.

Check all fluid levels.

Check all cooling system hoses and fittings for

damage, deterioration, looseness, etc. Check all

hose clamps for tightness and security.

Check engine for proper operation.

Inspect the diesel engine fuel system for leaks,

tightness and security of fuei fittings and hoses.

Inspect drive belts for condition and proper tension.

Inspect the exhaust system for damage, deteriora

tion, leaks, proper operation.

Inspect the electrical system.

Inspect the installation for safety violations, compli

ance with codes and standards.

FREEZING TEMPERATURE OPERATION

The engine cooling system should have been properly

filled with a 50-50 mixture of ethylene glycol base anti

freeze and soft water. When adding coolant to the

radiator or to the coolant recovery bottle, add only the

recommended 50-50 mixture. Refer to SPECIFICA

TIONS section. If the recommended 50-50 mixture is

added to the system consistently, the unit adequately

protects against freezing temperatures.

ATTENTION REQUIRED AFTER

SUBMERSION

If the generator has been submerged in water, it must

NOT be started and operated. Following any submer

sion in water, have an authorized Generac Service

Facility thoroughly clean and dry the generator.

OPERATING PRECAUTIONS

Never operate the generator set while the vehicle is

parked over dry leaves, dry grass or any other combus

tible substance. The generator’s exhaust sytem be

comes extremely hot and can cause fire if it is too close

to combustible materials.

The generator’s exhaust system gives off DEADLY

carbon monoxide gas. This dangerous gas, if breathed

in sufficient concentrations can cause unconsciousness

and even death. Never operate the generator set with

the vehicle inside any garage or other enclosed area.

Never operate the generator with a leaking exhaust

system. Close windows in the vicinity of the generator

exhuast outlet and take any other steps that may be

necessary to prevent exhaust gases from entering

rooms or areas occupied by people or animals.

EFFECTS OF MOISTURE AND DIRT

Keep the generator set as clean and dry as possible.

Protect the unit against excessive dust, dirt, corrosive

vapors, road splash, etc. Permitting dirt and moisture

to accumulate on generator windings wii! have an ad

verse affect on the insulation resistance of those wind

ings.

When moisture is allowed to remain in contact with

windings, some of that moisture will be retained in voids

and cracks in the insulation. This causes a reduced

insuiation resistance and will eventually cause prob

lems. Dirt will make the problem worse, since dirt tends

to hold moisture in contact with the windings. Salt (as

from sea air) will also worsen the problem since it tends

to absorb moisture from the air. Salt and moistsure,

when combined, form a good electrical conductor.

- 5

Page 11

_________

SPECIFICATIONS

FUEL REQUIREMENTS

Recommended fuel is any high quality, automotive type

diesel fuel conforming to JIS No. 2D diesel fuel. Keep

the fuel clean.

RECOMMENDED FLUIDS

Engine Oil; Use a high quality detergent oil classified

"For Service CC or CD." Detergent oils keep the engine

cleaner and reduce carbon deposits. Use oil having the

following SAE viscosity rating, based on the ambient

temperature range anticipated before the next oil

change:

Temperature Oil Grade (recommended)

Above 100°F

40°-l00°F

Below 40°F

Coolant: Use a mixture of half low silicate, ethylene

glycol base anti-freeze and half soft water. Coolant

system capacities may vary, depending on the specific

installation, length of system hoses, radiator use, etc.

Use only soft water and low silicate anti-freeze. If

desired, a high quality rust inhibitor may be added to the

recommended coolant mixture. When adding coolant,

always add the recommended 50-50 mixture.

CAUTION! Do not use any chromate base rust in

hibitor with ethylene glycol base anti-freeze or chro

mium hydroxide ("green slime") forms and causes

overheating. You must chemically clean engines

the have operated with a chromate base inhibitor

before adding ethylene glycol base anti-freeze.

Using any high silicate anti-freeze boosters or addi

tives will also cause overheating. In addition, using

any soluable oil inhibitor is not recommended for

this equipment.

SAE10W-30 or SAE 30 j

SAE 5W-20 or 5W-30

SAE 40 !

GENERATOR SPECIFICATIONS

Series........................................NP-80D

Model Number

Rated Maximum Continuous

a-c Power

Rated Volts

Rated Maximum Continuous Load Current

At 120 Volts .............................62.5 amps

At 240 Volts.............................31.25 amps

Rated a-c Frequency

Phase........................................1-Phase

Power Factor

Number of Rotor Poles

Rotor Speed at No-Load........... 1860 rpm

Engine Type

Displacement.............................58.2 inches (954cc)

Cooling Method

Combustion Chamber

Cylinders and Arrangement

Bore...........................................2.95 inches (75mm)

Stroke

.......................................

Compression Ratio....................23 to 1

No. of Main Bearings

Break Mean

Effective Pressure....................

..........................

..................................

...............................

................

............................

.............

9344-1

7500 watts (7.5 kW)

120/240*

60 Hz. at 1800 rpm

1.0

4

ENGINE SPECIFICATIONS

..............................

............

............

...............

................ 5

4-cycie diesel

Water Cooled

Swirl Type

......

3

2.83 inches (72mm)

97

. 9-

Page 12

MAINTENANCE

PERIODIC MAINTENANCE SCHEDULE

* Performed by Authorizied Service Facility

** Performed by Owner/Operator

A. After the first 25 Operating Hours*

1. Change Oil and Oil Filter.

2. Check engine coolant level.

3. Inspect cooling system.

4. Check engine operation.

5. Inspect drive belts.

6. Inspect exhaust system.

7. Inspect electrical system.

8. Inspect battery.

9. Check governed speed setting.

10. Check engine valve clearance.

11. Inspect air cleaner/flame arrestor.

12. Clean the generator.

B. Every 8 Hours of Operation**

1. Check coolant level in coolant recovery bottle.

2. Check fuel level.

3. Check engine oil level.

C. Once Each Week**

1. Inspect the generator set.

2. Inspect the generator battery.

_____________

_________

________

______

_____

_____

OVERLOAD PROTECTION FOR ENGINE

D-C ELECTRICAL SYSTEM

Engine cranking, start up and running are controlled by

a solid state Engine Controller circuit board. Battery

voltage is delivered to that circuit board via 10 amp

circuit breaker and 14 amp in-line fuse. These overcurr

ent protection devices will open if circuit is overloaded.

CAUTION! If a circuit breaker opens or a fuse ele

ment melts, you should find the cause of the over

load before resetting the circuit breaker or replacing

the fuse.

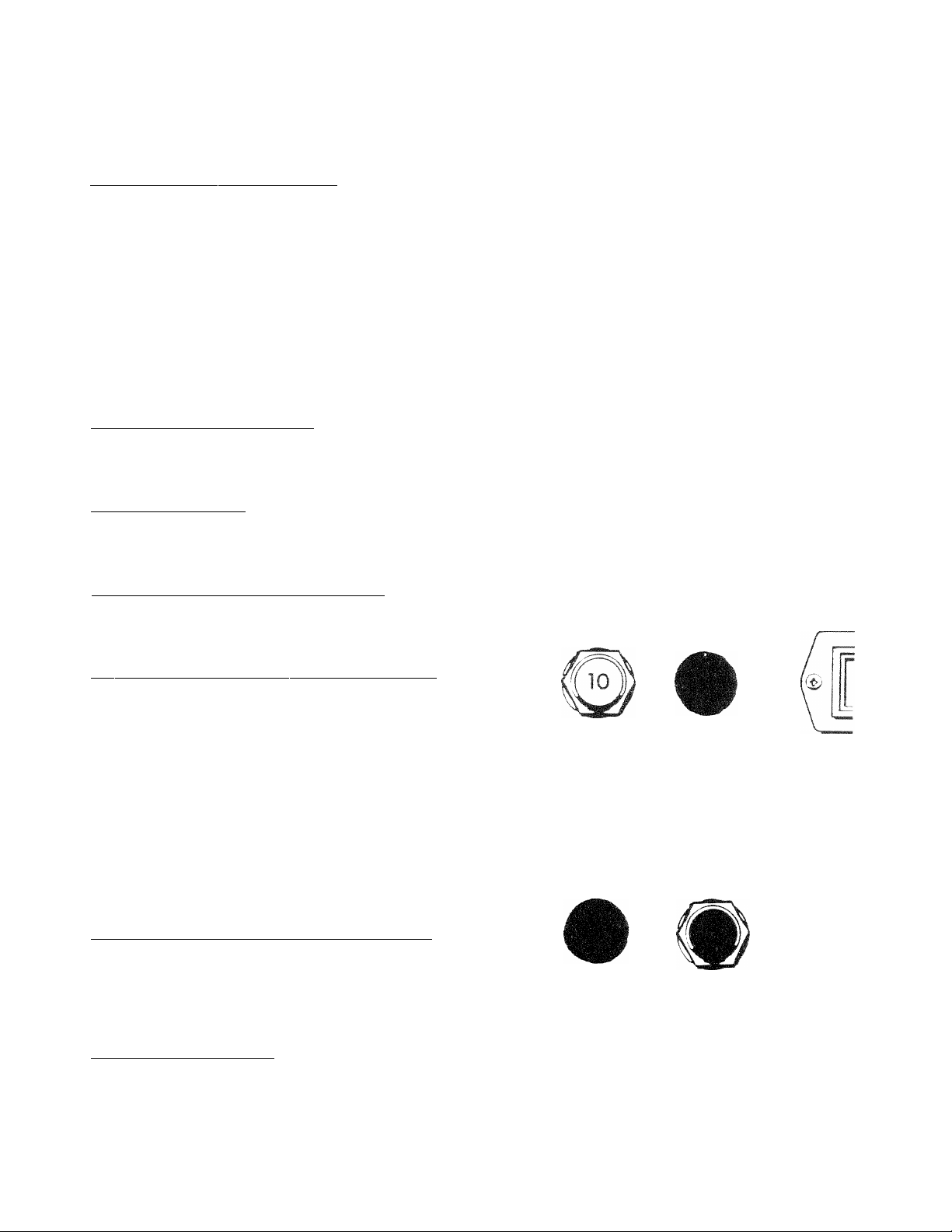

10 amp Circuit Breaker: If the circuit breaker opens

due to an overload, you cannot crank or start the engine.

The circuit breaker is a "push-to-reset“ type. For emer

gency shutdown, pull the circuit breaker open. Also see

"Generator Control Panel" on Page 5.

_

14 Amp Fuse: If the fuse element melts open, you

cannot crank or start the engine. If you must replace

the fuse, use only identical 14 amp fuse (Figure 9).

30 amp Fuse: The generator set battery is charged

during operation by a d-c alternator, driven by the en

gine. This 30 amp fuse protects the charging circuit

against overload. Should you need to replace the fuse,

use only an identical 30 amp fuse (Figure 10).

D. Every 100 hours or Once Each Month**

(whichever comes first)

1. Inspect cooling system.

2. Inspect exhaust system.

E. Every 6 months or Every 250 Operating Hours"

(whichever comes first)

1. Change engine oil and filter.

2. Check engine operation.

3. Inspect drive belts.

4. inspect electrical system.

5. Inspect and check battery.

6. Check engine governor setting.

7. Clean or replace fuel filters.

8. Inspect air cleaner/flame arrestor.

9. Clean the generator.

10. Check cooling system and coolant level.

11. Inspect exhaust system.

12. Inspect fuel system.

F. Once Annually or Every 500 Operating Hours"

(whichever comes first)

1. Check engine valve clearance.

2. Check engine compression and condition.

3. Check fuel injection timing.

4. Check/test fuel injection nozzles.

G. Once Every Two Years

____________________

________

STAR n.NG

C ! K C U i I

10 AMP

Figure 9 — 14 amp Fuse

batter'T'

CHARGING pre-heat

30 AMP 30 SEC. MAX

ENGINE

CON TROLlEFV

14 AM

ST/

1. Drain, flush and refill cooling system.

Figure 10 — 30 amp Fuse for Battery Charge Circuit

-10-

Page 13

CHECKING FLUID LEVELS

Check Engine Oil: Check the engine crankcase oil

level at least every 8 hours that you operate the unit, or

before every time you use it (Figure 11).

Make sure the generator is as level as possible.

Remove oil dipstick and wipe dry with a clean,

lintfree cloth.

Install oil dipstick, then remove again.

Oil should be at dipstick FULL mark. Never operate

the generator with oil level below dipstick ADD

mark. DO NOT FILL CRANKCASE ABOVE DIP

STICK FULL MARK.

Battery Fluid: Check battery electrolyte fluid at least

once weekly. Fluid should cover separators in all bat

tery cells. If fluid level is low, add distilled water to cover

tops of separators. DO NOT USE TAP WATER IN

BATTERY.

Engine Coolant: Check coolant level in coolant recov

ery bottle.

• Add the recommended coolant mixture as neces

sary.

• Periodically remove radiator pressure cap to make

sure the coolant recovery system is functioning

properly. Coolant should be at bottom of radiator

filler neck. If coolant level is low, inspect gasket in

radiator pressure cap. Replace cap, if necessary.

To have pressure cap tested, contact an authorized

Generac Service Facility. Inspect cooling system

and coolant recovery system for leaks.

INSPECT GENERATOR SET

Once each week inspect the generator set. Look for

fuel, oil coolant leaks. Check for missing or loose nuts,

bolts and other fasteners. Check for damage. If unitis

dirty, it may be cleaned with a damp cloth or soft brush.

Inspect the exhaust system. NEVER operate the gen

erator with a defective exhaust.

INSPECT COOLING SYSTEM

Inspect the entire cooling system once each month or

every 100 operating hours, whichever occurs first.

Check for leaks, condition of hoses, tightness of clamps.

CHANGING ENGINE OIL

Refer to PERIODIC MAINTENANCE SCHEDULE for

engine oil and filter change frequencies. You should

also change generator engine oil before placing the

vehicle into storage.

Drain the oil while engine is still warm from running,

which means warm up the engine, shut it dov^n and

drain immediately as follows (Figure 12 ):

1. Remove OIL DRAIN HOSE from its retaining dip.

2. Loosen and remove OIL DRAIN HOSE CAP. Drain

oil completely into suitable container.

Figure 12 — Changing Engine Oil

-11 -

Page 14

3. When all oil has drained, insiail and tighten OIL

DRAIN HOSE CAP.

4. Turn OIL FILTER counterclockwise and remove.

Dispose of old filter.

5. Apply a light coating of engine oil to seal of new oil

filter, install FILTER and tighten bv hand only. DO

NOT OVERTIGHTEN.

6. Remove OIL FILLER CAP. Add recommended oil

(see SPECIFICATIONS). DO NOT OVERFILL

ABOVE THE DIPSTICK "FULL" MARK. Crank

case oil capacity is 3.7 U.S. quarts (3.5 liters).

CAUTION! After refilling the crankcase with oil,

always check oil level on dipstick. NEVER OPER

ATE ENGINE WITH OIL BELOW THE DIPSTICK

"ADD" MARK.

7. Start engine and check for oil leaks.

COOLANT CHANGE

Every two years, the cooling system should be drained,

flushed and refilled by an Authorized Service Facilty.

See SPECIFICATIONS for cooling system recommen

dations.

MISCELLANEOUS MAINTENANCE

Cleaning the Generator: Keep your standby genera

tor as dean and as dry as possible. Dirt and moisture

that is allowed to accumulate on internal generator

windings have an adverse effect on insulation resis

tance.

Periodically clean generator exterior surfaces. A soft

brush may be used to loosen caked on dirt. You can

use a vacuum system or dry, low pressure air to remove

any accumulations of dirt, if the generator is housed

inside an all-weather enclosure, clean the enclosure

with a soft, damp cloth or sponge and water.

Once each year have the generator cleaned and in

spected by an Authorized Service Facility. That facility

will use dry, low pressure air to clean internal windings.

Parts inside the control console should be cleaned and

inspected at this time as well.

Finally, have the insulation resistance of stator and rotor

windings checked. If insulation resistances are exces

sively low, the generator may require drying.

Battery: All lead-acid storage batteries discharge when

not in use. Refer to specific instructions and warnings

that accompany your battery. If such information is not

available, observe the following precautions when han

dling a battery:

• DO NOT use jumper cables and a booster battery

to crank or start the generator engine.

• DO NOT recharge a weak batter/ while it is installed

in the generator. Remove battery from generator

and recharge in a well-ventilated area, away from

fuel vapors, sparks, heat or flames.

• Battery electrolyte fluid is an extremely caustic sul

furic solution that can cause severe burns. DO NOT

permit fluid to contact eyes, skin, clothing, painted

surfaces, wiring insulation, etc. If you spill any

battery fluid, flush the affected area with clear water

immediately.

• Always wear safety glasses, rubber apron and

gloves when handling a battery.

• Batteries give off explosive hydrogen gas while

charging. The gas can form an explosive mixture

around the battery for several hours after charging.

Any spark, heat or flames can ignite the gas'^and

cause an explosion which can shatter the battery,

causing blindness or other serious Injury.

PERIODIC REPLACEMENT PARTS

Part Name

Oil Filter

Radiator Cap

Air Cleaner Element

Fuel Filter

Generac Part No.

127-70939

46627

70941

69858

-12

Page 15

TROUBLESHOOTING

PROBLEM

Engine won’t crank.

POSSIBLE CAUSES REMEDY

1. 10 amp circuit breaker tripped.

2. 14 amp fuse blown.

3. Loose corroded or defective

battery cables.

4. Defective engine Start/Stop switch.

5. Defective starter contactor.

6. Defective starter motor.

Engine cranks but won't start.

1. Vehicle fuel shutoff valve is closed.

2. Out of fuel.

3. Fuel solenoid (FS) is defectcive

4. Fuel pump (FP) is defective.

5. Open Wire #14 from Engine Control C.B.

6. Clogged fuel filter or fuel line.

7. Engine mechanical parts failure.

8. Spark plugs defective.

Engine starts hard, runs rough.

1. Flame arrestor (air cleaner) plugged or

damaged.

2. Defective fuel pump.

3. Plugged fuel filter or fuel line.

4. Water in fuel.

Engine starts, shuts down

when Start/Stop switch is

released.

1. Engine oil level is low.

2. Engine is overheated.

3. Defective Low Oil Pressure Switch

4. Defective Coolant Temperature Switch

5. Defective Engine Controller circuit board.

1. Reset circuit breaker

2. Replace fuse.

3. Tighten dean or replace

as necessary.

4. Replace Start/Stop switch.

5. Replace contactor.

6. Replace starter motor.

1. Open valve.

2. Replenish fuel tank.

3. Refplace solenoid.

4. Repair or replace fuel pump.

5. Reconnecfwire.

6. Replace if clogged.

7. Repair or replace parts.

8. Clean, regap or replace plugs.

1. Clean or replace as needed.

2. Replace or repair fuel pump.

3. Replace filter; unclog fuel line.

4. Drain tank and refill.

1. Check oil and add oil as needed,

2. Check cooling system for leaks.

3. Replace switch.

4. Replace switch

5. Replace circuit board.

Start/Stop Switch at STOP,

engine continues to run

1. Defective Start/Stop switch.

2. Open/disconnected wire #18 between

Start/Stop switch & Engine Controller C.B.

3. Open/disconnected wire #0 between

Start/Stop switch & Engine Controller C.B.

4. Defective Engine Controller circuit board

No a-c output from generator.

1. Check 15-amp circuit breaker.

2. Check vehicle circuit breaker & fuses.

3. Transfer switch set to NORMAL position

4. Generator internal failure.

1. Replace switch.

2. Reconneci/close wire.

3. Reconnect/close wire.

4. Replace board.

1. Reset to ON or CLOSED.

2. Reset and replace, if necessary,

3. Set to GENERATOR position.

4. Take generator to Authorized

Generac service facility.

- 13 -

Page 16

- CIRCUÍ г BREAKER 30A.3SA

- CiRCUíT BREAKER (iOA)

- CiRCUir BREAKER (5A)

- RELAY 02v) ТРОТ

relay (12v) DPOT

- DIODE 600V, 6АЫР

- DiOOE 600V, 6AMP

“ DC alternator

FUSE И AMP SEE

FUSE 30A

FUEL PUMP

FUEL SOlENOlD

GROUND

HIGH WATER TEMP SWITCH

HOURME TER

LOW OIL PRESSURE SWITCH

preheat contactor

RESISTOR 10 OHM, 5 WATT

STARIER

START contactor

PREHEAT SWITCH

SWITCH START/STOP

SENSE transformer

id

О

P

Z2

00

OJ

o>

tvi

CO

2

z

о

g

>

Q

33

>

T3

I

Ш

о

о

Q

m

z

m

WIRE POSITION 1

IS GROUND.

WIRE POSITION 2

TO 1 WILL START

UNIT.

WIRE POSITION 6

TO 1 WILL LIGHT

A RUN LAMP.

WIRE POSITION 3

TO 1 WILL STOP

UNITWIRE POSITION 4

TO 5 WILL START

PREHEAT.

>

О

Page 17

ELECTRICAL SCHEMATIC — NP-80D GENERATOR

DCA-DC ALTERNATOR

DP£ -EXCiTATiON WINDING

n -FUSE UAMP SFE

F2 -FUSE 30A

FS -FUEL SOLENOiD

FP -FUEL PUMP

HM -HOURMETER

HWT-HiGH water temp switch

LOS-LOW Oil PRESSURE SWITCH

PHC -preheat contactor

R2 -resistor 10 OHM. 5W

s -starter

SC -START contactor

Sw -PREHEAT S'WITCH

SW] -SWITCH, START/STOP

T1 -SENSE transformer

TP -thermal PROTECTOR

CONNECTION OPTIONS

- 15 -

Page 18

EXPLODED VIEW — ENGINE COMMON PARTS

Drawing No. 81982

-16

Page 19

_______

Drawing No. 81982

REPAIR PARTS LIST — ENGINE COMMON PARTS

ITEM

PART NO.QTY.

1 81932

2

3

4

5

6

35586

81946

81947

55934

22302

7 51755

8

9

10

72501

43107

81942

11 49813

12

13

14

15

16

17

18

19

20

21

22

23

24 72573

25

26

27

28

29

30

75674

81975

357-70939

42909

81936

70941

42574

60108

26208

25507

42568

81951

70928

51716

22152

81939

65852

71912

DESCRIPTION

1 1.0 Liter Diesel Engine

6

1

1

1

1 -3/4" Hose Clamp 32 69860-B

Upper Radiator Hose

Lower Radiator Hose

Hose Retainer 35 70936

4 M10 Lock Washer

2

Ml 0-1.5 X 16mm Capscrew37

2 Engine Support

4

1

6

1

1

1

1

1

M8-1.25 X 25mm Capscrew

Exhaust Manifold

M6-1.0 Hex Nut

Exhaust Outlet Gasket42

Flex Exhaust Outlet 43

Manifold Gasket

M8-1.25 X 30mm Capscrew

Air Intake Chamber

1 Air Filter

1

1/8" NPT-1/8-28 Adaptor

1 Oil Pressure Switch

1

1

1

1

M8 Shakeproof Washer50

Ml 0 Washer

M8-1.25 X 20mm Capscrew

Engine Wire Harness

1 Oil Drain Fitting

1

1

5

1

1

1

Hose Clamp

M5-0.8 Hex Nut

M5 Lock Washer

Oil Drain Bracket 58

Oil Drain Hose Clip

M5-0.8 X 8mm Screw

ITEM

PART NO.

31 69811

33 74018

34

74070

36 71956

22129

38 72553

39

40

41

49813

26850

22158

42568

22097

44 24114

45 56739

46

47

48

49

75763

77745

40173

49340

74024

51 43146

52 45757

53

54

74069

74009

55 39253

56

57

72564

71910-A 1

45771 4

59

46233

60 50190

QTY. DESCRIPTION

1 Drain Cap

1 Oil Drain Hose

4

4

M12 Lock Washer

Ml2-1.25 X 40mm Capscrew

2 Vibrator Mount

2

Special Washer

12 M8 Lock Washer

2

4

M8-1.25 X 50mm Capscrew

M6-1.0 Hex Nut

2 M6 Shakeproof Washer

4 No. 10-32 Hex Nut

4

M6-1.0 X 20mm Capscrew

6 M6 Lock Washer

4

5/16"-18 Hex Nut

2 12 volts Solenoid

2 Red Vinyl Boot

2 Starter Cable

1

1

1

1

Hose Clamp

Elbow (barb to thread)

Fuel Pump Assembly

M6-1.0 X 10mm Capscrew

1 M10-1.0 x 25mm Capscrew

2

2

6

1

M10-1.5 X 40mm Capscrew

M10-1.5 Hex Nut

M8-1.25 X 20mm Capscrew

Fuel Filter Bracket

Lifting Bracket

M8-1.25 Hex Nut

1

1

3/8-30-1/8 V-Beit

Special M8 Fiat Washer

-17-

Page 20

EXPLODED VIEW — ENGINE BLOCK

Drawing No. 82961

18

Page 21

Drawing No. 82961

EXPLODED VIEW — ENGINE BLOCK

ITEM

1 139-70939

2

12

13

14

15

16

17

18

19

20

21

22

23

24

25

28

29

30

31

32

33

PART NO. QTY.

140-70939 20

143-70939

144-70939

145-70939 1

146-70939

182-70939

183-70939

184-70939

185-70939

186-70939 1

145-70939

168-70939 1

187-70939

188-70939

189-70939 1

26073-A 1

244-70939

245-70939

246-70939

145-70939

122-70939 1

DESCRIPTION

1

1 DIPSTICK TUBE

2 0-RING

1

1

1

1

1

2

3

1

1 0-RlNG

1

1

2

OIL PAN

BOLT

BOLT

DIPSTICK

ROCKER COVER GASKET

ROCKER COVER GASKET

ROCKER COVER

OIL STOPPER

SCREEN

BOLT

GASKET

NUT

CAP

O-RING

1/4" PIPE PLUG

TUBING

SUCTION FILTER

BOLT

GASKET

¡9-

Page 22

EXPLODED VIEW — CRANKSHAFT, PISTON & FLYWHEEL

Drawing No. 75679

ITEM

1

2 194-70939

3

4 196-709391

5

6

7

PART NO. QTY.

143-70939

195-70939

226-70939

197-709391 Bearing Holder

200-709391

8. 201-70939

9 198-709396

10

11 202-709393

199-709396 Dowel Pin 21

203-70939AR 0.25mm U.S. Bearing

204-70939AR

12 205-709393

206-70939AR 0.25mm U.S. Bearing

207-70939

13

208-709392

14 204-709392

15

210-709391 Bolt

DESCRIPTION ITEM

1 Crankshaft Assembly 16

1 Crankshaft Gear

1

1 Spring Pin

1

Key 216-70939

Dowel Pin

Bearing Holder

17

18 217-709393 Piston Pin

Bearing Holder 19

Bolt 20

Standard Bearing

22

23

0.50mm U.S. Bearing24

Standard Bearing

AR

0.50mm U.S. Bearing

28

Thrust Washer 30

Bolt

- 20-

PART NO.

QTY.

DESCRIPTION

214-709393 Standard Piston Assembly

215-70939

211-70939

212-70939

213-70939

218-70939

219-70939

220-709393

221-70939

222-70939

223-709396

224-70939

225-70939

230-70939

231-70939

AR

AR

3

AR

AR

6 Snap Ring

3 Connection Rod Assembly

6

6

AR

AR

1

1 Nut

Piston Assembly - 0.5mm O.S

Piston Assembly - 1.0mm O.S

Standard Piston Ring Set

Piston Ring Set - 0.5mm O.S.

Piston Ring Set - 1.0mm O.S.

Bushing

Connecting Rod Bolt

Nut, Connecting Rod Bolt

Standard Bearing

Bearing — 0.25mm U.S.

Bearing —0.50mm U.S.

Pulley

U.S. — UNDERSIZE

O.S .— OVERSIZE

Page 23

Drawing No. 75678

EXPLODED VIEW — CYLINDER HEAD

ITEM

1

2

3

4 149-70939

5

6

7

8

9

10

11 157-70939

12

13

14 161-70939

15

16

17

18

19

20

21

22

PART NO.

147-70939

148-70939 6

447-70939

150-70939

151-70939

152-70939

153-70939

154-70939 6

155-70939

156-70939

158-70939

159-70939

160-70939

162-70939

163-70939

164-70939

165-70939

60108

167-70939

168-70939

169-70939

QTY.

1

3

2

3

3

3

3

6

12

6

1

1

11

3

2

2

1

2

1

1

4

1

DESCRIPTION

Cylinder Head Assembly

Expansion Plug

Expansion Plug

Expansion Plug

intake Valve

Exhaust Valve

Valve Guide Seal (Exhaust)

Valve Guide Seal (Intake)

Spring

Retainer

Key

Cap

Cylinder Head Gasket, 1.2mm thick

Cylinder Head Gasekt, 1.3mm thick

Bolt

Bolt

Lifting Eye

Bolt

Tubing

Bolt

Oil Switch

Thermo-Switch

Gasket

Washer

21 -

Page 24

EXPLODED VIEW — CAM SHAFT

Drawing No. 75677

ITEM PART NO.

1 232-70939

2

3

4 234-70939

5

6

7 237-70939

8

9

10

11 241-70939

12 242-70939

13

233-70939 1 Camshaft Gear

195-70939 1 Key

235-70939 3 Spacer

236-70939

238-70939

239-70939

240-70939

243-70939

QTY.

1

1

1

1

1

1

1 Bolt

1

1

1 Nut

DESCRIPTION

Camshaft Assembly

Gear

Bail Bearing

Slider

Plate

Tachometer Shaft

Bolt

Gasket

r2 -

Page 25

Drawing No. 75676

EXPLODED VIEW — CYLINDER BLOCK

ITEM

1

2

3

PART NO.

100-70939

447-70939

101-70939

4 102-709392

5 103-70939

6 104-70939

7 105-70939

8 106-70939

9

10

11

107-70939

108-70939

109-70939

110-70939

111-70939

12 112-70939

13

14

15

16

113-70939

114-70939

115-70939

116-70939

QTY.

1

1

1

DESCRIPTION

Complete Cylinder Block

Expansion Plug 18

Expansion Plug

Expansion Plug

2

1

Expansion Plug 21 121-709391

Expansion Plug

4 Plug

4 Plug

1

1

1

1

1

1

1

1

2

2

Idle Gear Shari

Bushing

Bushing — Standard

0.25mm U.S. Bushing28 128-70939

0.50mm U.S.Bushing

Ball Bearing

Expansion Plug

Ball Bearing mm = millimeter

Dowel Pin U.S. = Undersize

Dowel Pin

ITEM PART NO.

17

117-709392 Dowel Pin

QTY. DESCRIPTK

118-709392 Spring Pin

19

20 120-70939

22 131-70939

23 123-70939

24

25 125-70939

26

119-709392

1

1

1

124-709391 Drain Cock

1

126-709391

27 127-709396 Tappet

6

29

129-70939

30 130-70939

1

1

- 2i

Stud

Stud

Stud

Snap Ring

Oil Seat

Connector

Oil Filter

Push Rod

Relief Valve

0-ring

Page 26

EXPLODED VIEW — OIL PUMP COMPONENTS

Drawing No. 75682^

■X

\

•) I.. \ ^.

I r-\ '

1 \ -7^

• ‘ 7 .x, (— f > V

H ■ \\ u A' ^ v'' ^X

.. 'i ^ Xf ■,X'' A"-i' A//A^

y \v73 Aa

Xv^^ 1: AA«

; •’"K

’ i r

A

A. I

ITEM

1 250-70939

2

3 251-70939

4 253-70939 1

5 254-7093S

6

7

8

9

10

11 263-70939

12 264-70939 3

PART NO.

252-70939

255-70939 AR

531-70939 AR 0.15mm Shim

532-70939 AR

258-70939 AR 0.50mm Shim

259-70939

260-70939

261-70939 1 Snap Ring

262-70939

AR — AS REQUIRED

DESCRIPTION

1

1

1

1 Oil Pump Cover

1

1 Collar

1 Front Plate

1 Gasket

Idler Gear Assembly

Spring

Thrust Washer

Rotor

0,1mm Shim

0.2mm Shim

Spring

Bolt

7

8

#

24

Page 27

__________

Drawing No. 75683

EXPLODED VIEW — ROCKER ARM ASSEMBLY

ITEM PART NO.

1

2

3

4

5

6

7

8

9

10

11

12

170-70939 1

171-70939

172-70939 3

174-70939 6

173-70939 6

175-70939

176-70939

177-70939

178-70939

179-70939

180-70939

181-70939

QTY.

3

3

1

2

2

1

3

3

DESCRIPTION

Rocker Arm Assembiy

intake Rocker Arm

Exhaust Rocker Arm

Nut

Stud

Rocker Arm Bracket

Rocker Arm Shaft

Spring

Screw

Spring Pin

Nut

Stud

25 -

Page 28

EXPLODED VIEW — FUEL SUPPLY

Drawing No. 75693

TO FUEL TANK

ITEM PART NO.

1

2

3 47290

661-70939

69858

4 52221

5

6

7

8 74808

9

40173

378-709392

379-709391

52233 2

10 39450

TO INJUCTION PUMP

TO FUEL FtiMP

QTY. DESCRIPTION ITEM PART NO. QTY. DESCRIPTION

1

1

Fuel Filter Support

Fuel Filter

1 3/8“ dia. X 12-1/2" Hose

1 5/16" dia. X 6-1/2" Hose

4 No. 5.5 Hose Clamp

Gasket 15

Banjo Fitting

1

Fuel Bleed Fitting

1/8" NPT Tee (brass)18

2

1/8" NPT X 3/16“ 90-degree

11

30096

12 68736 1 3/16" dia. X 1/2" Hose

13 68736 1 3/16" dia. X 7-3/4" Hose

14

74823

74819 1 Fuel Bleed Fitting

16

17

651-709395 Fuel Bleed Gasket

662-70939

663-709392 Banjo Type Fitting

2

1/8" NPT X 3/16" Barbed

Straight Fitting

4

Clamp

2 Hollow Bolt

Barbed Fitting

- 26

Page 29

Drawing No. 82962

EXPLODED VIEW — WATER PUMP

ITEM

1

2 266-70939

3

4

5

6 270-70939

7 271-70939 1 Bolt

8

9

10

11 275-70939

12

15

PART NO. QTY.

265-70939

267-70939

268-70939

269-70939 3 Gasket

272-70939

273-70939

274-70939

247-70939

284-70939

1 Water Pump Assembly

1

1 Thermostat

1

1

1 Gasket

1

1 Bolt

1

1

1

DESCRIPTION

Plug

Spring

Set Plate

Bolt

Nut

Pulley

Bolt

-27-

Page 30

EXPLODED VIEW — INJECTOR PUMP

Drawing No. 75686

ITEM PART NO.

1

316-70939

2

317-70939

318-70939

319-70939

320-70939

3

298-70939

4

321-70939

5

322-70939

6

323-70939

7

324-70939

8

9

10

11

12

13

14

325-70939

326-70939

327-70939

328-70939

329-70939

330-70939

331-70939

QTY.

1

AR

AR

AR

AR

2

2

3

3

DESCRIPTION ITEM

Injector Pump Assembly15

0.2mm Shim

0.3mm Shim 17

0.5mm Shim

1.0mm Shim

Nut

Bolt

Gasket

Insert

3 Cap

3

Injector

1 Tubing

1 Tubing

1 Tubing

1 Tubing

1

1 Bolt

Clamp

PART NO. QTY.

298-70939 1

16

332-70939 3

333-70939 1

18

334-70939

19

335-70939

20 264-70939

21

336-70939 1

22

337-70939 2 Washer

23338-70939

24

339-70939

25

240-709391

26341-70939

27

342-70939 1

28343-70939

29344-70939

AR — AS REQUIRED

28

DESCRIPT

Nut

Glow Plug

Connector

1

1

2

Gasket

Cover

Bolt

Sensor

2

1

Nut

Bolt

Lock Wire

1

Solenoid

Washer

1

1

Washer

Screw

Page 31

EXPLODED VIEW — TIMING GEAR HOUSING AND GOVERNOR

iTEM PART MO.

1 285-70939

2

3

286-70939

287-70939

4 307-70939

5

6

7 310-70939

8 314-70939

9

10

11

12 297-70939

13

14 299-70939

15

16 301-70939

17

18

19

20

21

22

23

24

308-70939

309-70939

315-70939

180-70939

296-70939

298-70939

300-70939

540-70939

282-709395 Bolt

288-70939

274-70939

311-70939

304-70939

305-70939

306-70939

QTY.

1

1

1

1 Spring

1 Washer

2

1 Stop Lever

2

1

4

1 Governor Lever

1

4

1

1 0-Ring

1

3

1

4

5 Bolt

1

1

1 0-Ring

DESCRIPTION

Timing Gear Housing

Spring Pin

Gasket 27

Nut 30

Cover 32

Gasket

Nut

Bolt

Nut 37

Shaft

Snap Ring

Bolt

Oil Seal

Bolt

Arm

Snap Ring

ITEM

25 289-70939

26

28

29

31

33

34

35

36

38 71944

39

40

41

42

43 537-70939

44

45

46

47

PART NO.

QTY.

290-70939

291-70939

136-70939

292-70939

313-70939

293-70939

294-70939

295-70939

291-709391

302-70939

271-70939

303-70939

660-70939

3 Boit

2 Bolt

1 Screw

1

534-709391

535-70939

1

536-70939

539-70939

1

1

188-709391

541-70939

538-70939

1

3

1

1

1

1 Washer

1

1

1

1

1

1

1

DESCRIPTION

Governor Lever Assembly

Tension Lever

Snap Ring

Cotter Pin

Spring

Spring

Arm

0-Ring

Snap Ring

Bracket

0-Ring

0-Ring

Spacer

Gasket

Holder

0-Ring

Cap

Bolt

Nut

Page 32

EXPLODED VIEW — RADIATOR

Drawing No. 83294

• INDICATES

UK'aTION of

WELD STUDS

ITEM PART NO. QTY.

1

2

3 80245

4

5 82603

6 83058

7 81977-A 2 FOAM PAD

8

9

10

83098

83057

81905

81947

81946

82605

11 22097

12 49813

13 66831

14

15

35586

45757 4

16 42568

17 56892

18

19

20

21

22

23

58442 2

46627

52250 5 ft. FOAM PAD - 3/4" X 1" WIDE

50832

81976

51787

1 ASSEMBLY, BASE

1 RADIATOR, CROSS FLOW

1

1

1

1

1

1

1

15

11

2 RIVET, POP

4

7

6 CRIMPTITE, No. 10-32 x 3/8"

1

1

1

6 CAPSCREW, HEX HEAD - M4-0.7 x 16mm

DESCRIPTION

BLOWER HOUSING

FAN, ENGINE

RING, FAN INLET

BRACKET, RADIATOR MOUNTING

HOSE, LOWER RADIATOR

HOSE, UPPER RADIATOR

PLATE, BLOWER HOUSING

LOCK WASHER - M6

NUT, HEX-M6-1.0

CLAMP (WORM TYPE)

CAPSCREW, HEX HEAD - M6-1.0 x 25mm

CAPSCREW, HEX HEAD - M6-1.0 x 20mm

CRIMPTITE, 1/4--20X 1/2"

CAP, RADIATOR

DRAIN COCK-V8 NPT

HUB, FAN

24 22152 6 LOCK WASHER - M4

25 22473

26

29451

11

5 ft.

FLAT WASHER-M6

FOAM TAPE - 1/8" X 1/2"

-30-

Page 33

_________________

Drawing No. 75685

EXPLODED VIEW — D-C ALTERNATOR

ITEM

1

2

3

4

5

6

8

9

10

11

12

PART NO.

QTY.

77909

74829

72545

74007

74069

51753

277-70939

345-70939

349-70939

346-70939

348-70939

DESCRIPTION

1

1

Adjusting Plate 13 349-70939

M8-1.25 X 30mm Bolt

ITEM PART NO. QTY. DESCRIPTION

14

352-70939

1 Lock Washer 15 353-70939

1

1

2

1

1

1

1

1

M10 Flat Washer

Ml 0-1.5 X 40mm Capscrew

M6-1.0 X 40mm Bolt 18 350-70939

Alternator Assembly 19 351-70939

Flywheel

Bearing

Plate Assembly

Stator

16 354-70939

17

355-70939

20 137-709391 Lock Washer

21

280-709391 Washer

22 356-709391

23 74827 1 M8 Flat Washer

24

70005 2

-31 -

1 Bearing

1

1

1

2

1

1

Coupler

Clamp

Screw

Screw

Cap

Nut

Collar

M6 Lock Washer

Page 34

J2

Page 35

_________________

Drawing No. 83699

REPAIR PARTS LIST — CONTROL BOX

ITEM PART NO.

1

2

3

4

5

6

7 22220

8 22155

9

10

11

12 81903

13

14 67680

15

16

17

18

19

20

21

22 74076

23

24

25

26 42568

27 26850

28

29

30 45770

31

32

33

34

35

36

37

39

40

41

42 55440

44

45

46

47 49813

48

49

23484-F

32300

81904

22668

55927

75207-B

25433

39271

48512

71938-A

83635

74969

36900

22155

23762

81902

81884-D

77604

75208

55920

22152

23897

*77744

74041

51718

43184

51715

80882

72566

70325

22097

51716

*82617 1 Panel Wire Harness

*81951

82737

22188

22473

QTY.

2 SB-1000-12 Snap Bushing

1

1

1 30-amp AGC Fuse

1 14-amp SFE Fuse

1 10-amp DC Circuit Breaker

1 No. 6 X 7/8" long Round Head Machine Screw

1 No. 6 Lock Washer

1 No. 6-No. 14 AWG Solderless Lug

1

1

1 Control Box

1 DC Regulator

1 AC Regulator Assembly

1

1 35-amp Circuit Breaker

4 No. 6-32 X 1/4" Phillips Pan Head Machine Screw

4 No. 6 Lock Washer

1 No. 10 External Lock Washer

1

1 Control Pane! Decal

2

1

1

1

2

2

10

8

8

1

1 M5-0.8 X 20mm Phillips Pan Head Machine Screw

2

2

2

4 No. 6 X 5/8" Self-tapping Screw

4 Spacer Nut

1 Engine Controller Assembly

6

2

2

1 Engine Wire Harness

4

4

1

8

DESCRIPTION

30-amp AGC Fuse Hoider

14-amp SFE Fues Holder

3/4" Greenlee, 90-degree Conduit Clamp

5-amp Circuit Breaker

AC Transformer

Control Panel

M3-0.5 X 10mm Pan Head Machine Screw

Hour Meter

Start/Stop Switch

Preheat Switch

M6-1.0 X 20mm Hex Head Capscrew

M6 External Lock Washer

M5 Lock Washer

M5 Flat Washer

M5-0.8 X 10mm Hex Head Capscrew

Customer Leads

M4-0.7 X 10mm Pan Head Machine Screw

M4 Lock Washer

M4-0.7 Hex Nut

M6 Lock Washer

M5 Hex Nut

M5-0.8 X 25mm Hex Head Capscrew

Vibration Dampener

M6-1.0 Nut

No. 6 Hex Nut

M6 Flat Washer

NOT SHOWN

jj

Page 36

EXPLODED VIEW — GENERATOR

Drawing No. 81983

Qs CM

0^

34

CM

\ ,

\

/

^ / \

/

\

!

\/

CO

\

1

i-

o

F5

Page 37

Drawing No. 31983

REPAIR PARTS LIST — GENERATOR

ITEfyi

1 24488

2 24911

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34 BM45761

35

36

37

38

39

40

41

42

PART NO.

BN45761

81931

47248

81956

81955

45770

22152

81974

74066

22302

81952

81900

81192

42911

81901

82737

22145

59450

75763

70954

81929

39253

70936

71956

22129

72553

45771

A-24044-A

23877-D

25105

82626

52858

81991

22097

22127

22237

42909

29107

25155

QTY.

4

4

4

1

1 45M Ball Bearing

1

1

10

6

4

4

4

1

1 Ring Fan

1

4

1

4

4

2

1

1

1

4

2

2

8

2

8

4

2

4

1

4

4

1

1

1

4

2

1

1

DESCRIPTION

No. 8 X 5/8“ Taptite Screw

No. 8 X 3/8" Taptite Screw

M8-1.25 X 160mm Stud

15" RV Rear Bearing Carrier

15" RV, 2.5L ASM Rotor

15" RV, 2.5L ASM Stator

M5-0.8 X 10mm Hex Head Capscrew

No. 10 Lock Washer

M8 X 20mm Hex Flange Bolt

M10-1.25 X 30mm Hex Screw

M10 Lock Washer

15" RV, 15M Flex Plate

15" ISM Flywheel Mach.

M10-1.5 X 30mm Hex Head Capscrew

Air Ring Baffle

Vibration Mount

5/16-M8 Fiat Washer

5/16-18 X 1-1/4" Hex Head Capscrew

Battery Cable Boot

Starter Motor

15", ISM 1L Engine Adaptor

M8-1.25 X 20mm Hex Head Capscrew

Vibration Isolator

5/16-M8 Flat Washer

5/16-M8 Lock Washer

M8-1.25 X 60mm Hex Head Screw

M8-1.25 Hex Nut

Brush

Brush Holder

No. 6-32 X 1/4" SIMS

Brush Cover

M8-1.25 X 30mm Stud

M8-1.25 Hex Nut Flange

Red Wire Assembly

1/4" Lock Washer

1/4-20 Hex Nut

M10 Lock Washer

M8-1.25 X 30mm Hex Head Capscrew

Rubber Grommet

Clamp

-35

Page 38

NOTES

36

Page 39

ELECTRICAL FORMULAS

TO FIND

KILOWATTS (kW)

KVA

AMPERES

WATTS

NO. OF ROTOR

POLES

FREQUENCY

RPM

KNOWN VALUES

Volts, Current, Power Factor

Volts, Current

kW, Volts, Power Factor

Volts, Amps, Power Factor

Frequency, RPM

RPM, No. of Rotor Poles

Frequency, No. of Rotor Poles

1-PHASE

ExI

1000

ExT !

E X T X 1.71 X PF

1000

E.xIa L73

1000 ; 1000

kWxlOOO

kWx 1000

E i Ex 1.73 xPF

Volts X Amps

E X I X 1.73 X PF

.

2 X 60 X Frequency

RPM

RPM X Poles

2x60 i

2 X 60 X Frequency

Rotor Poles :

2 X 6flxFie,quency

RPM X Poles

2x60

2 X 60 X Frequency

Rotor Poles

3-PHASE

RPM

kW (required for

Motor)

RESISTANCE

VOLTS

AMPERES

E = VOLTS

Motor Horsepower, Efficiency

Volts, Amperes

Ohm, Amperes

Ohms, Volts

I = AMPERES

HP X 0.746 :

Efficiency

E :

I

IxR

1 ^

1 R

HP X 0.746

Efficiency

E

I

IxR

E

R

1

R = RESISTANCE (OHMS) PF = POWER FACTOR

Page 40

GENERAC’S 3-YEAR LIMITED WARRANTY

FOR NP SERIES RECREATIONAL VEHICLE GENERATORS

Generac warrants to the original purchaser that its generators will be free from defects in materials or

workmanship for the period set forth below from date of original purchase. During said warranty period,

Generac will, at its option, repair or replace any part which, upon examination by Generac or Generac

Authorized Distributors and/or Dealers, is found to be defective under normal use and service.

3-YEAR WARRANTY SCHEDULE

1. All NP Series generators used in a recreational vehicle shall be warranted from date of purchase

for a period of three (3) years or 2000 hours of operation, whichever occurs first. All parts, labor,

removal and reinstallation shall be covered for the first two years. Parts and labor on selected

generator and engine parts shall be covered during the third year or 2000 hours.

2. The drive train, belt and pulleys on NP series air-cooled generators shall be warranted against failure

due to defective materials or normal usage for the life of the generator. For the original owner, this

drive train warranty shall include parts and labor plus a $50.00 payment upon return of the failed

belt or pulley by the original owner. For succeeding owners, this power train warranty shall cover

belt or pulley parts only.

3. Rental units, demonstrators or commercial applications, such as construction or utility, are warranted

for one year or 2000 hours, whichever comes first.

All warranty expense allowances are subject to the conditions defined in the published

POLICIES AND PROCEDURES" manual.

THIS WARRANTY DOES NOT COVER;

Costs of maintenance, installation and startup.

Failures due to normal wear, accident, misuse, abuse, negligence or improper installation.

Products which are modified or altered in a manner not authorized by the manufacturer in

writing.

Incidental, consequential or indirect damages caused by defects in materials or workman

ship, or any delay in repair or replacement of defective parts.

Failure due to misapplication.

Telephone, telegraph, teletype or other communications expenses.

Living or travel expenses of persons performing service.

All transportation/travel expenses.

Rental equipment used while warranty repairs are being performed.

Overtime labor.

Starting batteries, fuses, light bulbs and engine fluids.

THIS WARRANTY IS IN PLACE OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED. SPECIF

ICALLY, GENERAC MAKES NO OTHER WARRANTIES AS TO MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. Some states do no allow limitations on how long an implied warranty

lasts, so the above limitation may not apply to you. GENERAC'S ONLY LIABILITY SHALL BE THE

REPAIR OR REPLACEMENT OF PARTS AS STATED ABOVE. IN NO EVENT SHALL GENERAC BE

LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF SUCH DAMAGES ARE

A RESULT OF GENERAC’S NEGLIGENCE. Some states do not allow the exclusion or limitation of

incidental or consquential damages, so the above limitation may not apply to you. Buyeragrees to make

no claims against generac based on negligence.

‘GENERAC

This warranty gives you specific legal rights, and you may also have other rights, which vary from state

to state.

GENERAC CORPORATION, P.O. Box 8, Hwy 59 and Hillside Road, Waukesha, Wl 53187

Telephone (414) 544-4811 FAX (414) 544-4851

Loading...

Loading...