Page 1

NP Series and Q Series

AIR-COOLED

Manual No. 91355

INSTALLATION

Manual

RECREATIONAL VEHICLE

GENERATORS

For Models Powered by Gasoline and LP GAS

CORPORATION

Revision 6 (10/6/97)

Printed in U.S.A.

Page 2

GENERAL SAFETY RULES

THE MANUFACTURER SUGGESTS THAT THESE “RULES” FOR SAFE OPERATION BE

COPIED AND POSTED IN POTENTIAL HAZARD AREAS OF THE RECREATIONAL VEHICLE.

SAFETY SHOULD BE STRESSED TO ALL OPERATORS AND POTENTIAL OPERATORS OF

THIS EQUIPMENT.

WARNING:

The engine exhaust from this product

contains chemicals known to the State

of Caiifornia to cause cancer, birth

defects, or other reproductive harm.

NOTICE TO INSTALLER

The Installation Instructions have been published by

Generac Corporation to aid in the installation of the

products described in this manual. Generac assumes

that installation personnel are familiar with the proce

dures for installing such products, or similar products

that Generac manufactures. Generac also assumes

that personnel have been trained in the recommended

installation procedures for these products and that

such training includes (a) use of common hand tools,

(b) use of special Generac tools, and (c) use of any

tools and/or equipment from other suppliers.

We could not possibly know of and advise the recre

ational vehicle trade of all conceivable methods, proce

dures or techniques by which to perform an installation.

We could not know of the possible hazards that might

result from each installation method, procedure or

technique. We have not undertaken any such wide

evaluation. Therefore, people who use a method, pro

cedure or technique that Generac does not specifically

recommend must first completely satisfy themselves

that their safety, the safety of the vehicle's occupants

and the products's safety is not endangered by the

method, procedure or technique selected.

Information, illustrations, specifications, etc., contained

in this Installation Manual are based on the latest infor

mation available at the time of publication. Every effort

has been expended to be sure that such data is both

accurate and current. However, the manufacturer

reserves the right to change, alter or otherwise improve

his product at any time without prior notice.

Gasoline is extremely FLAMMABLE and its vapors are

EXPLOSIVE. Do not permit smoking, open flame,

A

sparks or any source of heat in the vicinity while han

dling gasoline. Comply with all regulations governing

the storage and handling of gasoline.

Fuel lines must be properly installed, properly fas

tened and free of leaks. There must be no possibility

of gasoline vapors entering vehicle interior.

You are required to install an approved, flexible,

non-conductive fuel line between the generator fuel

connection point and rigid fuel lines.

If the generator can be equipped with a liquid

propane (LP) gas fuel system, install the unit so it

complies with all codes, standards and regulations

pertaining to such systems. LP gas is highly explosive.

The gas tends to settle in low areas where even the

slightest spark can ignite it and cause an explosion.

Do not allow gas vapors to enter the vehicle.

SAFETY RULES

Engine exhaust gases contain DEADLY carbon

monoxide gas. This dangerous gas, if breathed in suf

ficient concentrations, can cause unconsciousness or

even death. Install the exhaust system in strict compli

ance with applicable codes, standards and regula

tions. There must be no possibility for exhaust gases

entering the vehicle interior and endangering people

or animals.

The generator set produces dangerously high electri

A

cal voltage. Contact with bare wires, bare terminals,

etc., will result in extremely hazardous and possibly

lethal electrical shock.

All applicable electrical codes, standards and regula

tions must be strictly complied with in the installation

and use of this equipment.

The generator must be properly grounded (bonded)

to the vehicle chassis or frame.

If the vehicle electrical circuits can be powered by any

other source of electricity (such as a "dockside"

A

power receptacle), there must be no possibility of

connecting the different power sources to the vehicle

circuits at the same time. The "dockside" (utility)

power source must be positively isolated from the

vehicle circuits whenever the generator is operating.

Failure to isolate the vehicle circuits from the dockside power supply when the generator is running

may result in damage to the generator or serious

injury or death to dockside (utility) power workers

due to backfeed of electrical energy.

Never work on the equipment while standing in

water, while barefoot, or while hands or feet are

wet. Dangerous electrical shock will result.

Jewelry conducts electricity, which can cause danger

ous electrical shock. Remove all jewelry (such as rings,

watches, or bracelets) before working on this equip

ment.

The generator requires an adequate flow of air for

cooling and ventilation. Without sufficient cooling air

flow, the engine-generator quickly overheats, which

causes serious damage to the generator, a fire or an

explosion. Generator air inlet and outlet openings

must be provided in strict compliance with the manu

facturer's recommendations.

Never work on this equipment while physically or

mentally fatigued. Stay alert at all times.

Storage batteries give off EXPLOSIVE hydrogen gas

while charging. The battery used for cranking and

starting this generator should be installed in its own

ventecT compartment. Provide adequate ventilation

for the battery, to prevent explosive hydrogen gas

from accumulating.

Never insert any tool or other object through open

ings in the generator interior, even if the unit is not

running. You might seriously injure yourself or dam

age the equipment.

Staying alert and using "common sense" are major

measures for preventing accidents.

Page 3

TABLE OF CONTENTS

GENERAL SAFETY RULES

....................

inside cover

GENERAL INFORMATION

Purpose and Scope of Manual..................................... 2

Safety......................................................................... 2

Standards Booklets

.............

......................................... 2

Equipment Description ;............................................... 2

Engine Generator Operating Speed

Reconnection for Dual Voltage

...............................

.......................................

2

SPECIFICATIONS

Generator Specifications.............................................. 4

Engine Specifications................................................... 4

Recommended Fuel..................................................... 4

Fuel Consumption........................................................ 4

Recommended Engine Oil

...........................................

4

LOCATION AND SUPPORT

Generator Location

Generator Support

Suspended Mounting

......................................................

.........

............................................. 5

..................................................

5

5

Generator Restraint...................................................... 6

Swing Mount Generator Tray

.....

.................................

6

GENERATOR COMPARTMENTS

Compartment Size

Compartment Construction

Sound Insulation Materials

Compartment Roor Cutouts

.......................................................

..........................................

...........................................

.........................................

7

7

8

8

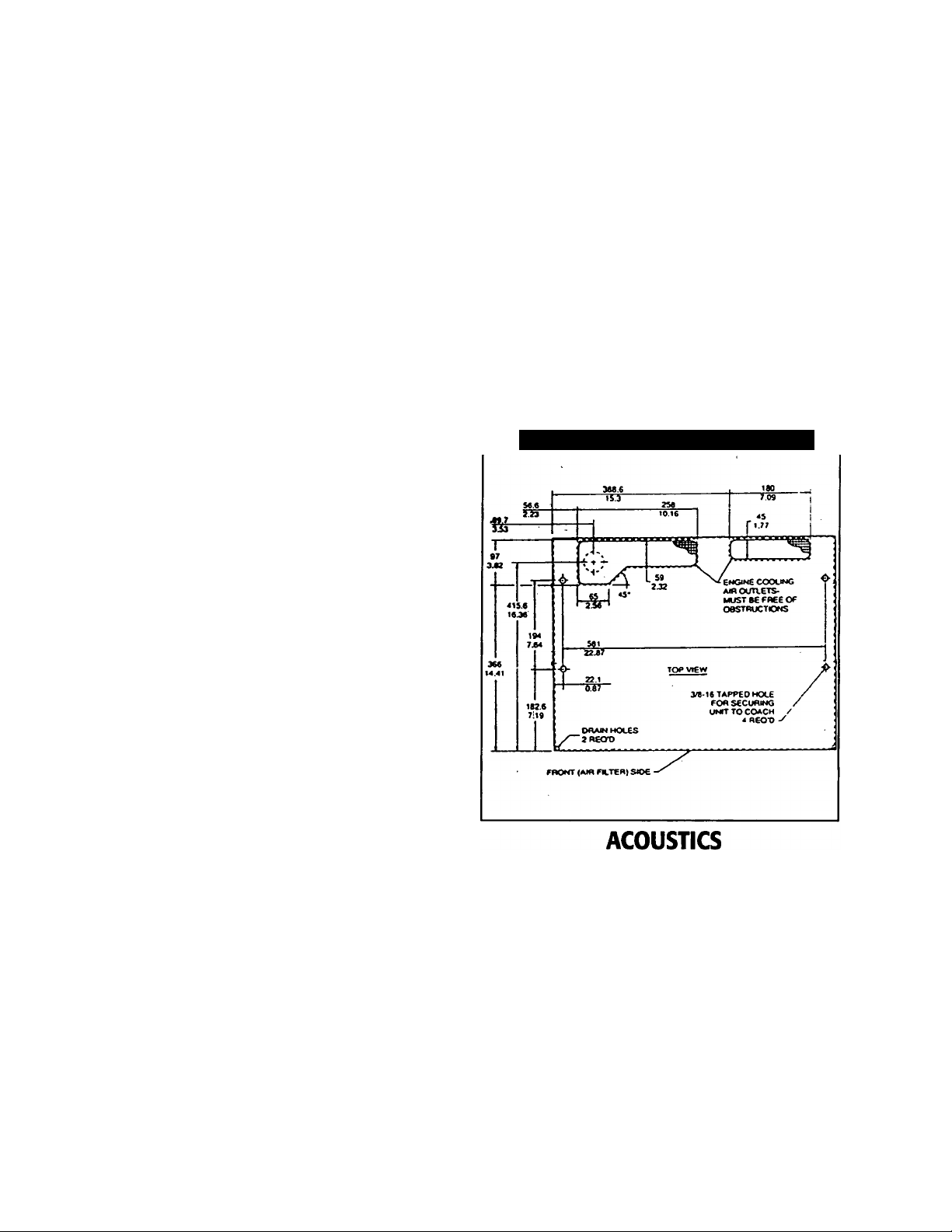

Acoustics’................................................................. 8-9

COOLING AND VENTILATION AIR

Generator Air Flow

.....................................................

10

Cooling Air Inlet Openings...........................................10

Compensating for Restrictions

......................

..............

11

Testing the Installation................................................11

GASOLINE FUEL SYSTEM..................................... 12

Fuel Tank....................................................................12

Generator Fuel Supply Line...,

....................................

12

PROPANE GAS FUEL SYSTEM

Parts Not Included in Fuel System

Some Important Considerations

Vapor Withdrawal

Primary Regulator..................................................................... 14

Gaseous Carburetion................................................................ 14

Fuel Supply Lines.......................................................................15

Excess Flow Valve

3

Leakage Tests.............................................................................15

EXHAUST SYSTEM

Mufflers and Spark Arrestors

Type of Exhaust System

Exhaust System Safety....................................................16-17

.......................................................................

.....................................................................

.................................................

...........................................................

..............................

.........................................

.............................................

..................................................

13

13

13

14

15

16

16

16

ELECTRICAL CONNECTIONS

Electrical Junction Box

Wiring............................................................................................18

Generator AC Connections

Conduit

.........................................................................................

Ground Fault Circuit Interrupters

Power Supply Cord....................................................................19

Isolating Different Power Sources

...........

..................................................18

......................................................

...........................................

................................

18

19

19

19-20

DUAL VOLTAGE RECONNECTION

Reconnection Procedure

.........................................................

21

BATTERY INSTALLATION

Recommended Battery

Battery Cables.............................................................................22

Battery Cable Connections

Battery Compartment

............................................................

......................................................

..............................................................

22

22

22

POST INSTALLATION TESTS

Before Initial Start Up

Initial Start....................................................................................23

Checking No-Load Voltage and Frequency

Testing Under-load............................................................23 - 24

Adjusting No-Load Frequency....^.........................

Voltage Regulator Adjustment

INSTALLATION CHECK LIST

.............

................................................. 23

................................................

..............

..........................

.........

24 -25

...................

23

25

26

ELECTRICAL FORMULAS.......................................27

MAJOR FEATURES AND DIMENSIONS

.........

28 - 29

Page 4

GENERAL INFORMATION

PURPOSE AND SCOPE OF MANUAL

These instâllation Instructions have been prepared

especially for the purpose of familiarizing installers

and owners of the applicable equipment with the pro

duct's installation requirements. Give serious consid

eration to all information and instructions in the

Manual, both for safety and for continued reliable

operation of the equipment.

Because of the different recreational vehicle models

and the variations between the models, it would be

extremely difficult, if not impractical, to provide

detailed instructions on every installation possibility.

For that reason, instructions and illustrations in this

manual are general in nature. Illustrations are not

intended to serve as detailed installation blueprints. .

The installation should comply strictly with all applica

ble codes, standards and regulations pertaining to the

installation and use of this product. If any portion of this

manual appears to be in conflict with such codes, stan

dards or regulations, the applicable codes, standards

or régulations must take precedence over the manual.

SAFETY

Before handling, installing, operating or servicing this

equipment, be sure to read carefully the “Notice to

Installer” and “Safety Rules” at front of this manual;

Comply with all SAFETY RULES to prevent death,

personal injury or damage to equipment and/or prop

erty. Stress safety to all installers, operators and ser

vice technicians who work on this equipment.

STANDARDS BOOKLETS

Installation, use and servicing of this equipment

should comply strictly with published standards, as

well as the manufacturer's recommendations. The fol

lowing standards booklets (latest révision) are avail

able from the sources indicated;

1. NFPA Standard 501C, “Standard for Recreational

Vehicles", available from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269.

2. NFPA 70, “NFPA Handbook of the National Electric

Code", obtained from same address as Item 1.

3. ANSI Cl-1975 and ANSI 119.2-1975, available from the

American National Standards Institute, 1430 Broadway,

New York, NY 10018.

4. ANSI A119.2/NFPA 501C, available from the

Recreational Vehicle Association, 1896 Preston White

Drive, Reston, VA 22090.

EQUIPMENT DESCRIPTION

Instructions and information in this section pertain to

Generac “NP and “Q” air-cooled generators, more

specifically as listed below. These generators are

designed specifically for installing in recreational vehi

cles. They operate 120 volts, 1-phase, 60 Hertz, AC

electrical loads.

NOTE; All units, except the Q40G, may be recon

nected for a dual voltage output of 120/240 volts AC.

Series

Q-40G 4200 35.0

Q-55G/LP

Q-70G/LP 7000 58.3

NP-50G 5000 41.6

NP-50LP 4500 37.5

NP-66G/LP

Power (wattage) Max. Rated Current

at 120V

5500 45.8

6600

55

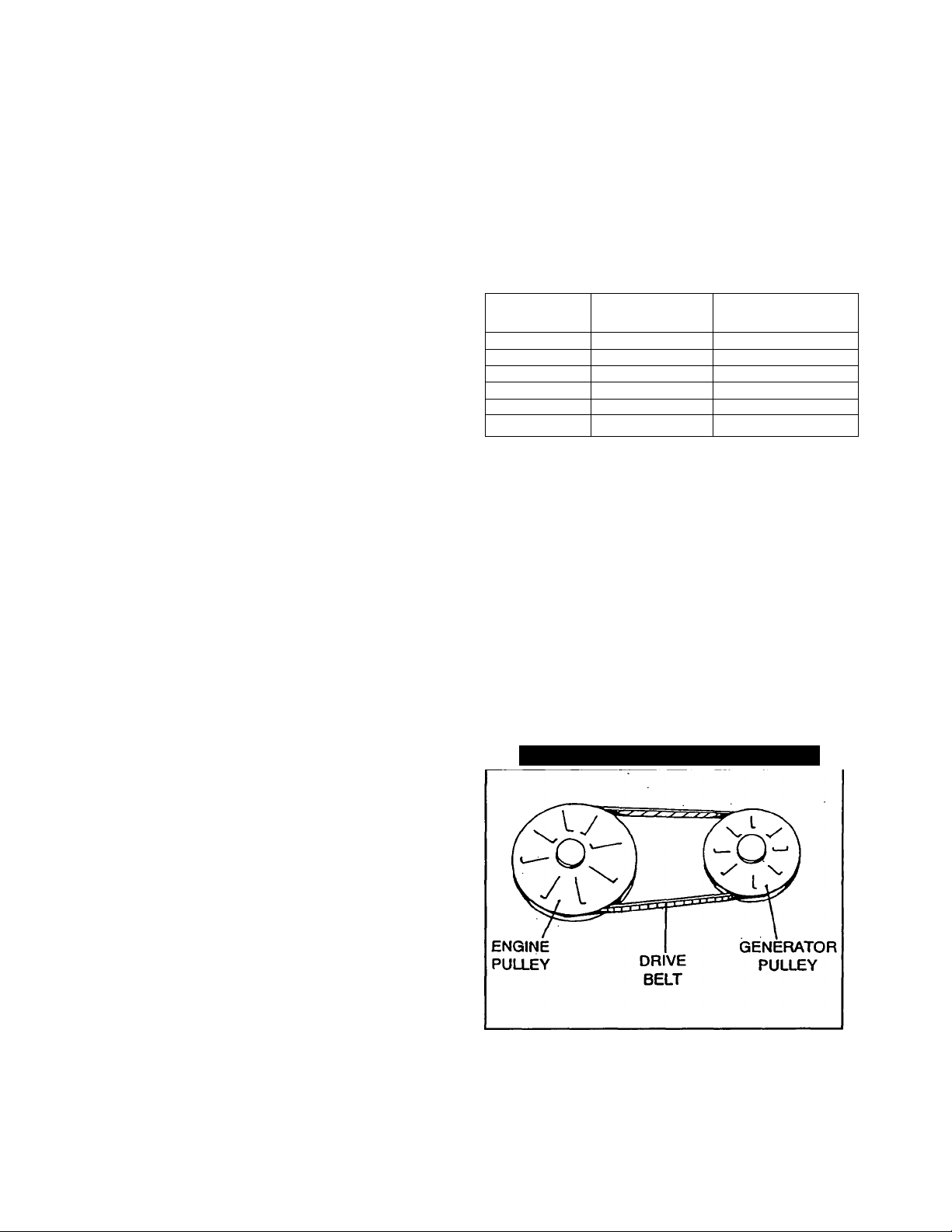

ENGINE GENERATOR

OPERATING SPEED

The generator’s revolving field (rotor) is driven by a 4cycle engine through a pulley and drive train arrange

ment (Figure 1). The generator supplies 120/240

volts AC at 60 Hertz when the rotor is operating at

3600 rpm. The drive train arrangement allows the

engine to operaté at a lower speed than the rotor.

Engine speed is held nearly constant by a mechani

cal, fixed speed governor as follows;

Series Q-40G

Series Q-55G/LP ......................

Series NP-50G/LP

Series NP-66G/LP

Series Q-70G/LP

Figure 1 — Typical Pulley and Drive Train

...........................

....................

....................

......................

2570 rpm

2570 rpm

2570 rpm ,

2700 rpm

.2570 rpm

5. California Administrative Code, Title 25, available from

the State of California, Documents Section, P.O. Box

1015, North Highlands, CA 95660.

6. CSA Electrical Bulletin 946, available from the Canadian

Standards Association, Housing and Constructions

Materials Section, 178 Rexdale Boulevard, Rexdale,

Ontario, Canada, M9W1R3.

— 2 —

Page 5

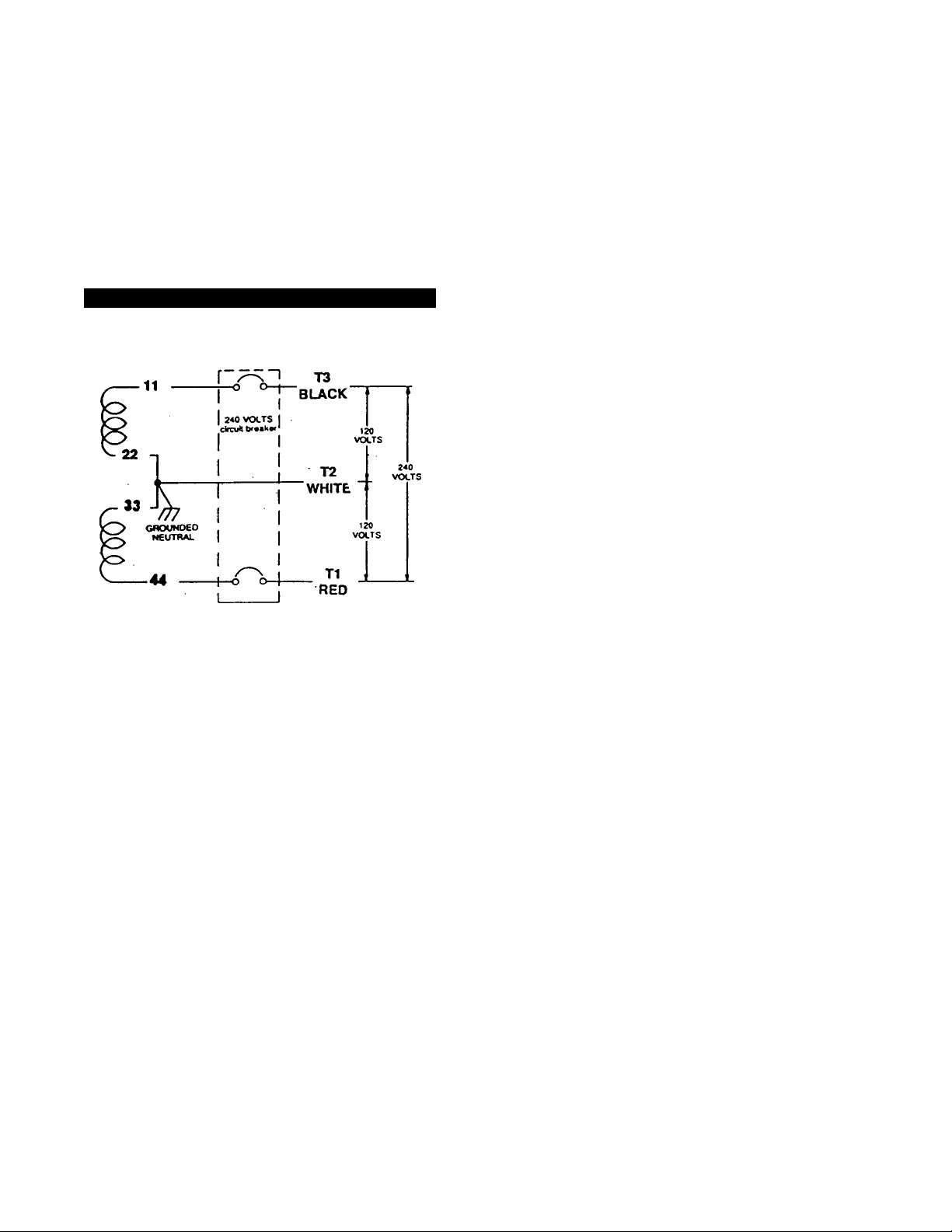

RECONNEaiON FOR DUAL VOLTAGE

You can reconnect the generators to supply a dual

voltage AC output, if desired. That is, units may be

reconnected to operate 120 and/or 240 volts, 1-

phase, 60 Hertz, AC loads. This is done by connect

ing the hwo stator AC power windings in series as it is

shown in Figure 2.

IMPORTANT: UNITS RECONNECTED FOR

120/240 VOLTS DUAL VOLTAGE OUTPUT WILL

NOT BE LISTED PER RVIA.

NOTE: The Q-40G can NOT be reconnected for a

dual voltage output of 120/240 volts AC.

Figure 2 — Reconnection for Dual Voltage Output

When reconnecting for dual voltage output, the

installer should replace the main circiut breakers

(CB1 and CB2) with a single adequately rated circuit

breaker. Rated maximum continuous load currents

are listed below:

• NP-50LP —18.8 AC amperes

• NP-50G — 20.8 AC amperes

• Q-55G/LP — 22.9 AC amperes

• NP-66G/LP — 27.5 AC amperes

• Q-70G/LP — 29.1 AC amperes

NOTE: This option is unavailabe on the Q40 model.

— 3 —

Page 6

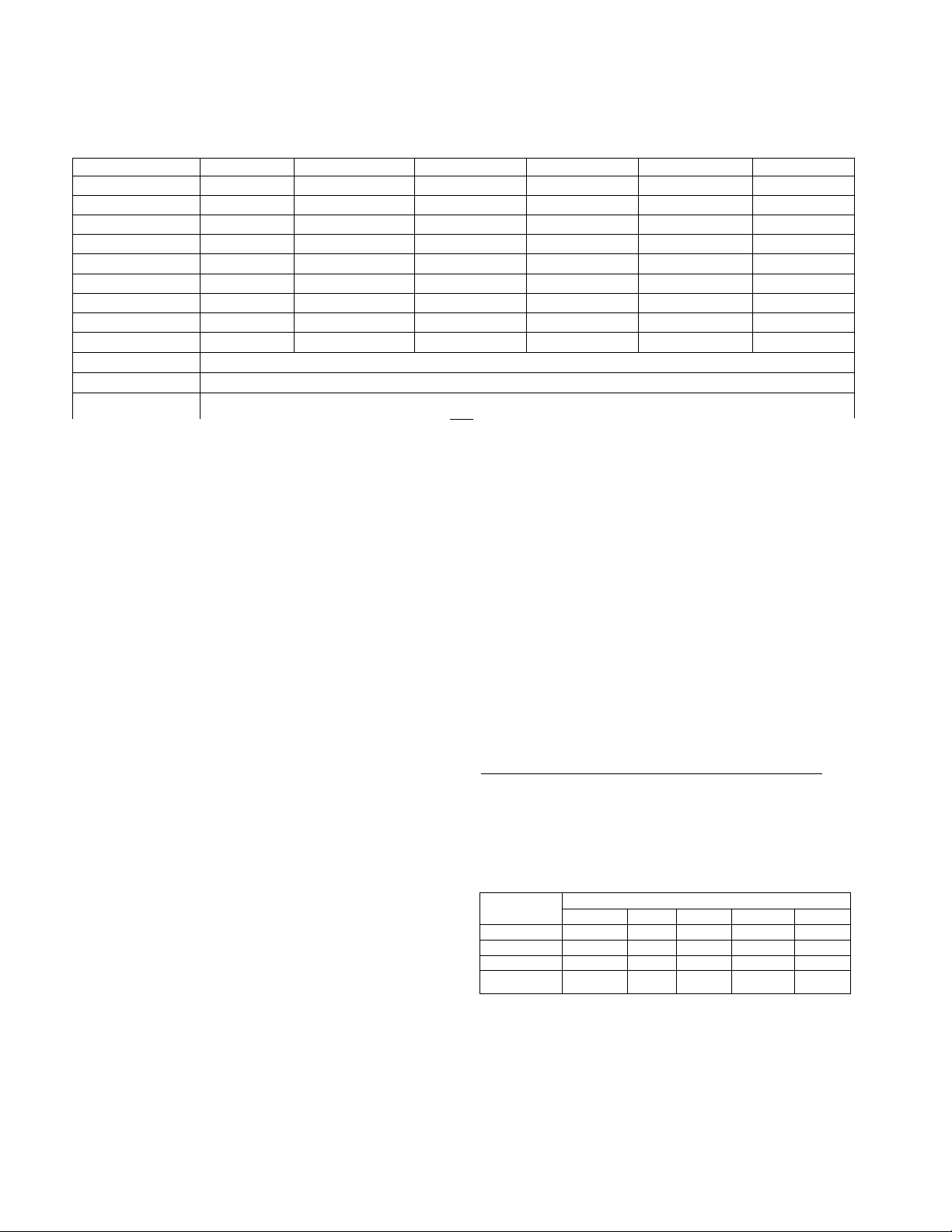

GENERATOR SPECIFICATIONS

SERIES Q-40G NP-50G

Rotor RPM 3600 3600 3600

Rotor Poles 2 2

Engine RPM

Wattage*

Voltage*

Rated Amps*

Phase 1

Frequency

Weight 215 lbs.

Length

Width

Height

All units, except Q-40G, are reconnectable to

120/240 volts, dual voltage output. When reconnect

ed for dual voltage, units are not listed per RVIA.

V Rated maximum continuous current at 240 volts is

20.8 amps.

t Rated maximum continuous current at 240 volts is

22.9 amps.

t Rated maximum continuous current at 240 volts is

27.5 amps.

A Rated maximum continuous current at 240 volts is

29.1 amps.

* Rated maximum continuous current at 240 volts is

18.8 amps.

2570 2570 2570

4200 5000

120 120

35

60 60

41.6V 37.5* 45.8*

1 1 1 -

207 lbs. 207lbs.

ENGINE SPECIFICATIONS

Type of Engine

NP-50G/LP.......................................1 Cylinder, 4 Cycle OHVI

NP-66G/LP, Q-70G/LP

Q-40G, Q-55G/LP..................................V-Twin, 4 Cycle OHVI

Number of Cylinders

Q-40G, Q-55G/LP, NP-66G/LP, Q-70G/LP

NP-50G/LP ..................................................................................1

Valve Configuration...........................................Overhead Valves

Cooling Method

Rated Horsepower

NP-50G/LP

Q-40G

Q-55G/LP ...........................................................16 at 3600 RPM

NP-66G/LP

Q-70G/LP ...........................................................19 at 3600 RPM

Displacement

NP-50G/LP .........................................................................363CC

Q-40G

Q-55G/LP

NP-66G/LP .........................................................................480CC

Q-70G/LP

Compression Ratio................................................................8.6 tol

Cylinder Block

Type of Governor

Air Cleaner.....................Paper element with foam pre-cleaner

Starter...............................................................12 volts DC electric

.............................................................

.......................................................

................................................................

........................................................

.................................................................................

............................................................................

............................................................................

..........................

................................

Aluminum with cast iron sleeve

..............................

Air-Cooled

13 at 3600 RPM

16 at 3600 RPM

16 at 3600 RPM

480CC

480CC

570CC

Mechanical, fixed speed

2

SPECIFICATIONS

NP-50LP

2

4500

120

60 60 Hertz

18.5 inches

16.68 inches ■

Ignition

Recommended Spark Plugs

Spark Plug Gap.............................................0.030 inch (0.8mm)

Oil Filter ................................................Generac Part No. 70185

Crankcase Oil Capacity..!.'...................................1.5 U.S. quarts

Battery Voltage............................................................12 volts DC

Recommended Battery§

Amp-Hour Rating

Cold Cranking Amperes

Cranking Current,

Battery Ground

§ If ambient temperature is usually below 32“F (0°C),

use a battery rated at 95 amp-hours and 450 cold

cranking amperes.

For the gasoline-powered units: Use clean, fresh

UNLEADED gasoline with a minimum octane rating of

87. Leaded REGULAR grade gasoline is an accept

able substitute.

■ FOR GASEOUS FUEL-POWERED UNITS

Use clean, fresh commercial propane gas. The

optional LP gas system was designed for a VAPOR

WITHDRAWAL type system.

Gasoline fuel system in U.S. gallons per hour:

OF WATTS

Use oil classified “For Service SP and having an SAE

viscosity rating of 10W-30. Engine crankcase oil

capacity is 1.5 U.S. quarts (1.6 liters).

C3-55G/LP NP-66G/LP Q-70GA.P

3600 3600 3600

2 2

2570 2700 2570

5500 6600 7000

120 120 120

,55t

60 Hertz 60 Hertz

215 lbs. 213 lbs. 222 lbs.

25 inches

..................................

........................................................

Solid state with flywheel magneto

......................

..................................................

.......................................................

..........................................

RECOMMENDED FUEL

FUEL CONSUMPTION

% '

25% 0.16

50%! 0.32

75% 0.46

100%

NP-50G Q-40G Q-55G NP-66G Q-70G

0.63

SERIES

0.16 0.21 0.25

0.32 0.42

0.47 0.62 0.74 0.81

0.63

0.83

RECOMMENDED ENGINE OIL

1

Champion RC12YC

100 DC amperes

0.50

0.99 1.08

2

58.3A

1

70 amp-hour

360.

Negative (-)

0.27

0.54

_4_

Page 7

LOCATION AND SUPPORT

GENERATOR LOCATION

The most desirable location for the generator set is

between the vehicle's main frame members However,

this is seldom possible. Most units must be installed

on the side of the vehicle and are difficult to reinforce.

Many recreational vehicles have been factory

equipped with an area for the generator set. Some

vehicles may even have a generator compartment,

provided by the vehicle manufacturer.

Plan the generator location based on the following:

• The generator set must be installed on a framework that

is part of the recreational vehicle, as outlined in the para

graph entitled “Generator Support.”

• The location must provide an access opening that is iarge

enough to permit generator removal (unless the genera

tor is to be removed from underneath the supporting

framework.

• The location must provide easy access to frequently ser

viced components, such as filters, oii drains, spark plugs

and other common maintenance parts.

• The location must provide sufficient room to allow mini

mum clearance of at least 1 inch between all sides and 1-

1/2 inches on top of the generator. If sound insulation is

to be used on compartment walls and ceiling, the mini

mum recommended applies to the space between the

generator and such insulation.

• The location must provide adequate cooling and ventilat

ing air flow for the generator without a great deal of work

and expense.

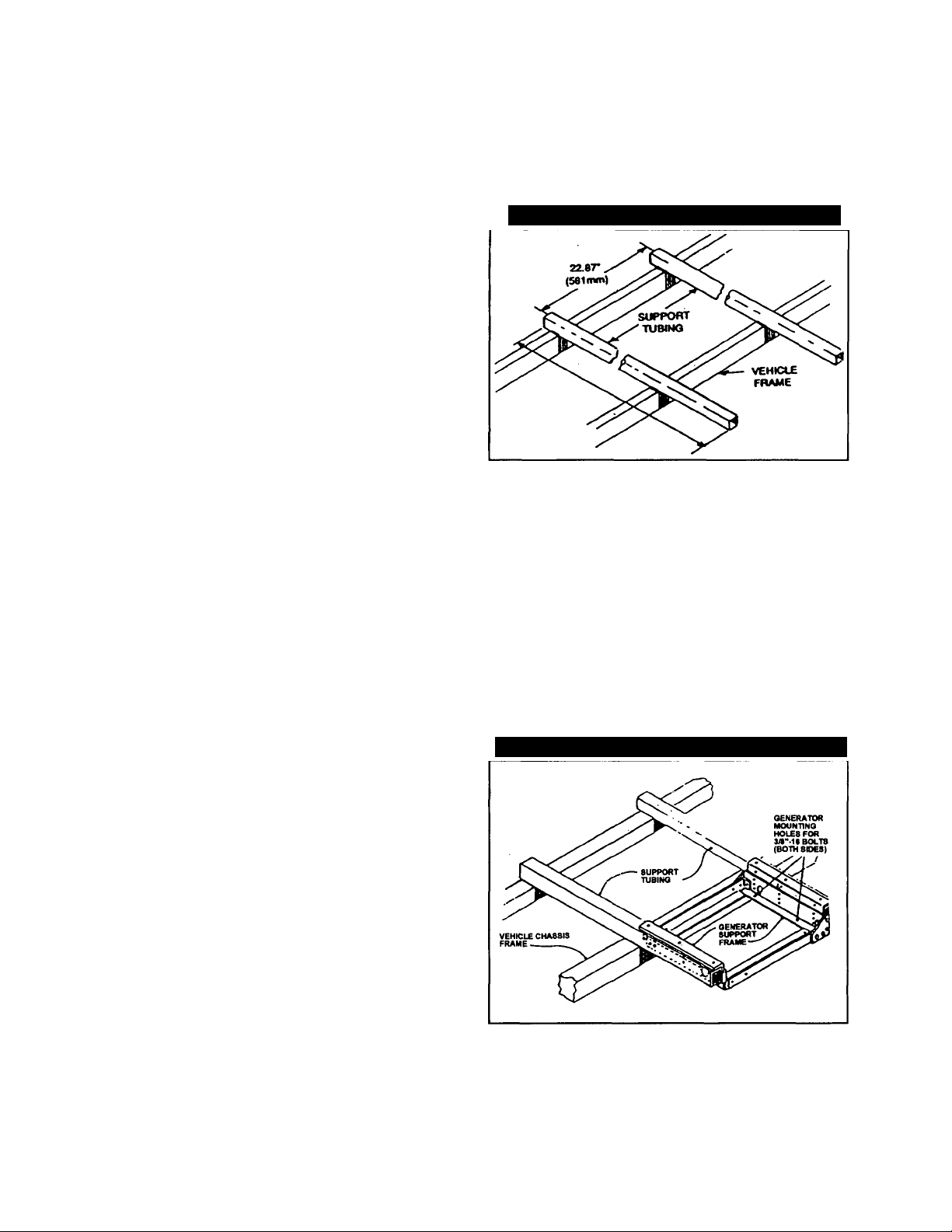

GENERATOR SUPPORT

The generator must be securely attached to a metal

framework that has been made part of the vehicle

frame structure by bolting or welding. The metal

framework on which the generator will rest and which

will restrain the generator set should consist of at

least two horizontal beams. These beams should con

sist of (a) 1-1/2 inch square, 11 gauge steel tubing

OR (b) 1-1/2 inch, 11 gauge angle iron. A typical sup

porting frame with horizontal support tubing, is shown

in Figure 3.

The generator can be installed so that it sits on top of

the horizontal support tubing, if the vehicle design

permits. Another method is to suspend the generator

below the horizontal support tubing by means of suit

able, structurally sound metal framework. The follow

ing general rules apply:

• Vehicle construction MUST be capable of supporting the

weight of the generator.

• Whether the generator is mounted above the horizontai

support tubing or suspended below the tubing, the sup

porting frame used must be structurally sound.

If the generator cannot be bolted directly to the support

ing frame or support tubing, consider using additional

tubing, angle brackets or other supports to give the sup

porting frame sufficient strength.

Figure 3 — Typical Horizontal Support Frame

SUSPENDED MOUNTING

If you are going to suspend the generator below the

horizontal support tubing, the suspension method you

use with the vehicle frame members must have the

following: (a) be able to support the weight of the gen

erator; and (b) provide sufficient restraint for the gen

erator. One typical suspended mounting system is

shown in Figure 4. The location of a suspended

mounting system must be carefully planned, keeping

the following general rules in mind:

• Protect the generator against road splash and debris.

Baffles or splash guards may be required to protect cer

tain areas of the generator. To make sure the generator is

adequately protected, road test the installation through

mud, water and slush.

Figure 4 — Typical Suspended Mounting System

• The installer must make certain the selected location will

permit adequate cooling and ventilating air flow to be

supplied.

— 5 —

Page 8

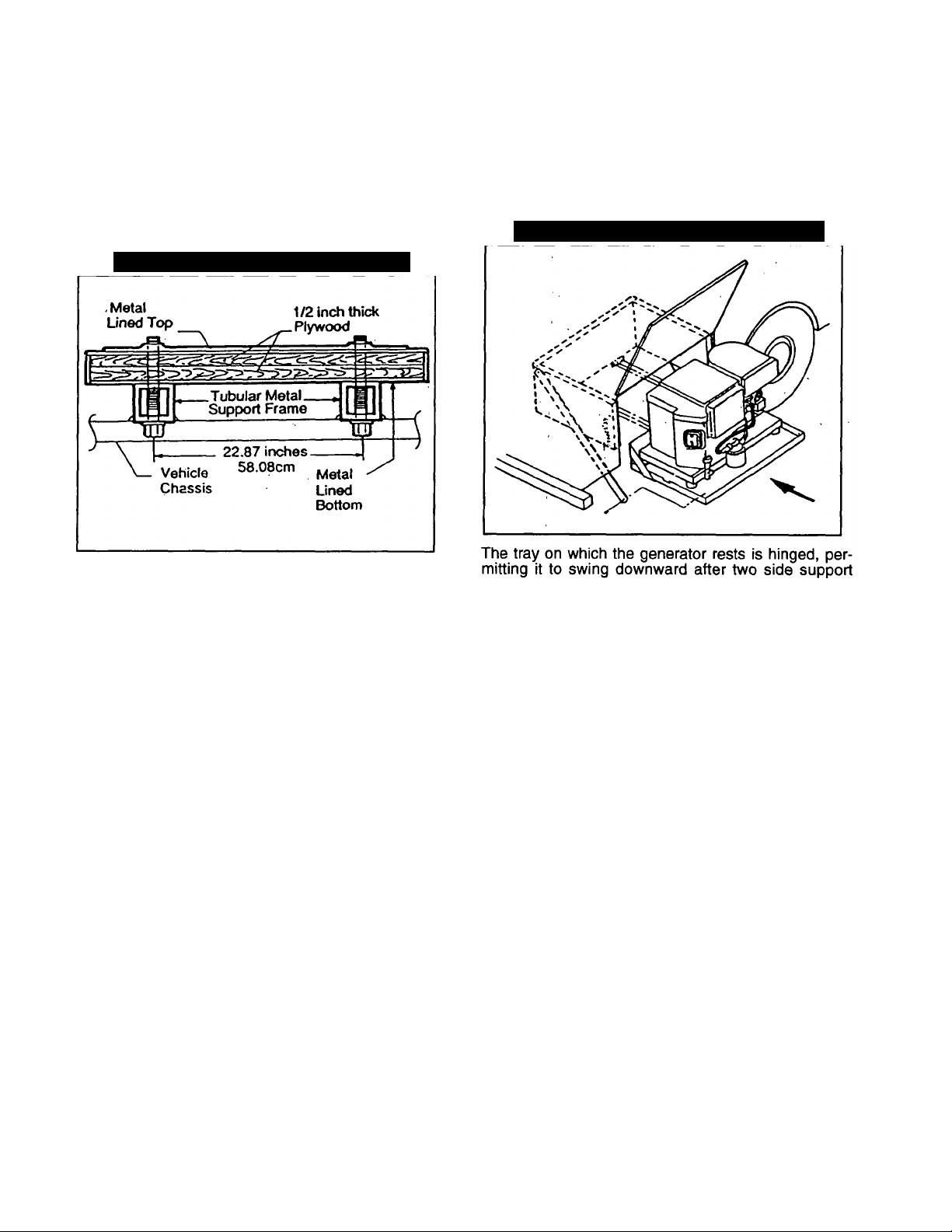

GENERATOR RESTRAINT

Use four 3/8"-16 hardened steel bolts (Grade 5) to

fasten the generator to the supporting frame or the

support tubing. These bolts must pass through (a) the

generator mounting base, (b) the compartment floor,

if a compartment is used, and (c) the supporting

framework (Figure 5). All bolts must be long enough

so that when tight, at least 3 threads are visible past

the retaining lock nuts. Refer to “COMPARTMENT’

section for location of generator mounting holes.

Figure 5 — Generator Restraint (typical)

SWING MOUNT GENERATOR TRAY

If you use a suspended mounting system, the installer

may wish to consider using the Generac Model 9164

Swing Mount Generator Tray, The Model 9164 tray

allows you to swing the generator downward and

away from the vehicle frame. This makes it simple to

remove the unit and have easy access to parts

(Figure 6).'

Figure 6 — Generator on Model 9164 Tray

rails and a center support rail are unbolted.

Instructions for tray installation are included with the

tray mounting kit.

— 6 —

Page 9

GENERATOR COMPARTMENTS

The generator set may or may not be installed inside

a compartment that is constructed specifically for

housing a generator. This section applies to generator

compartments when they are installed. The following

general rules apply to compartments:

• The generator compartment should be either

constructed of, or lined with, 26 gauge galvanized

steel.

IMPORTANT: ALUMINUM IS NOT AN ACCEPT

ABLE ALTERNATIVE TO GALVANIZED STEEL,

DUE TO ALUMINUM'S LOW MELTING POINT.

• If the compartment is lined with galvanized steel,

it may be constructed of any material. Generac

recommends that the compartment be construct

ed of 1/2-inch thick plywood, with the floor made

of a double thickness of plywood for added

strength.

• All seams, splices and joints of the compartment

walls (unless vapor tight by design) should be

caulked.

IMPORTANT: CAULKING MUST BE DONE SO

THAT THE CAULKING MATERIAL WILL STAY IN

PLACE PERMANENTLY. PRESSING SUCH MATE

RIALS AS PUTTY TAPE ONTO JOINTS AND

SEAMS WILL NOT MEET THAT REQUIREMENT. A

HIGH QUALITY SILICONE RUBBER SEALANT IS

RECOMMENDED.

• Holes and openings through the compartment

walls for passage of electrical conduit, conduc

tors, etc, into vehicle living area must be sealed

vapor-tight with silicone rubber base sealant.

• If you use flexible metal conduit, seal the conduit

at the end where it terminates inside the junction

box. Flexible metal conduit is NOT vapor tight

along its entire length.

• Seams and joints of the galvanized steel

(whether used as a liner or the compartment

itself) must be lapped and mechanically secured.

Such seams may be manufactured, welded, bolt

ed, riveted, or screwed. Manufactured lock

seams are shown in Figure 7.

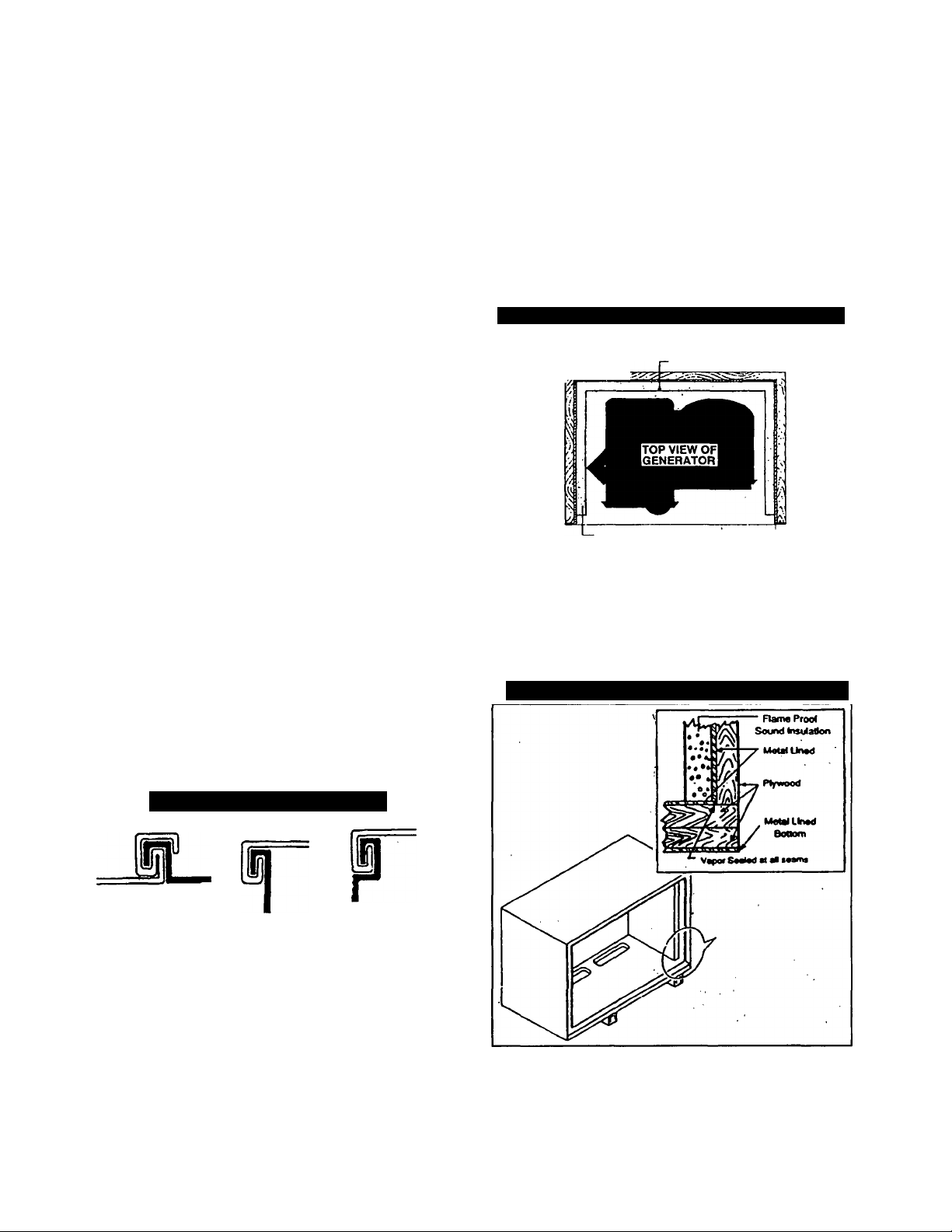

COMPARTMENT SIZE

Plan the compartment size carefully. Provide a mini

mum of at least 1 inch of clearance between the gen

erator and compartment walls and 1-1/2 inch of clear

ance between the generator and the ceiling AFTER

you have lined the compartment with metal, and

AFTER you have installed sound insulation (Figure

8).

NOTE: Refer to the “Dimensions and Features” draw

ing in the back of this manual.

Figure 8 — Provide Clearance Around Generato

plywood

COMPARTMENT,

" INSULATION MSTAL LINING

1 INCH (2.S4CM)

MINIMUM CLEARANCE

ON ALL SIDES

------

000*9

'

P

COMPARTMENT CONSTRUaiON

The generator compartment should be constructed of 1/2

inch thick plywood. Make the compartment floor a double

thickness of 1/2 inch plywood with the grain of the wood

at cross section for added strength (Figure 9).

Figure 9 — Typical Compartment Construction

Figure 7 — Types of Lock Seams

Fold Locked

Standing

Acme Lock

Offset

Double Lock

Double Seam

Gordon Seam Lock Seam

Line the entire compartment interior with 26 gauge galva

nized steel as described above.

— 7-

Page 10

• Line the exterior (underside) of the compartment floor

with 26 gauge galvanized steel.

• Vapor seal all compartment seams and joints, to prevent

poisonous, flammable or explosive vapors from entering

the vehiclef interior.

NOTE: Silicone rubber base sealant is an acceptable

caulking material. Pressing putty tape onto compart

ment joints and seams is NOT acceptable.

• After the compartment has been metal lined and vapor

sealed, line the compartment interior walls and ceiling

with an approved, non-flammable sound insulating mater

ial. See “Sound Insulating Materials.”

DANGER: DO NOT INSTALL SOUND INSULATION

OR ANY ABSORBENT MATERIAL ON THE COM

A

PARTMENT FLOOR INTERIOR. SUCH MATERIALS

WILL BECOME SOAKED WITH COMBUSTIBLE OR

EXPLOSIVE VAPORS AND LIQUIDS AND WILL

BECOME A FIRE HAZARD.

• Openings in compartment walls for passage of electrical

conduit, conductors, hoses, cables, etc., must be made

vapor tight with suitable caulking material.

• Flexible conduit must be sealed internally at the end

where it terminates inside a compartment's electrical

junction box.

NOTE: The preceding is required because flexible

conduit, due to its unique construction, is not vaportight along its entire length.

Using a combination of sound insulating materials can

often reduce noise more effectively than a single

material. For example, a sheet of lead or visco-elastic

material, along with a layer of other acoustical materi

al, is more effective than when a single material is

used.

COMPARTMENT FLOOR CUTOUTS

You nriust provide openings in the generator compart

ment for the following items (Figure 10):

• Engine exhaust and cooling air outlets

• Generator cooling air inlet

• Four holes for passage of generator mounting bolts. See

“Generator Restrainf on Page 6.

DANGER: FUEL UNES AND EXHAUST PIPING

MUST NOT PENETRATE INTO VEHICLE LIVING

AREA.

Figure 10 — Compartment Floor Cutout

DANGER: DO NOT INSTALL ANY FLAMMABLE

MATERIAL DIRECTLY ABOVE OR AROUND THE

A

COMPARTMENT. HEAT, TRANSFERRED THROUGH

THE COMPARTMENT STRUCTURE, MAY BE SUF

FICIENT TO IGNITE, CHAR OR DISCOLOR SEAT

CUSHIONS, FIBERBOARD AND OTHER FLAMMA

BLE MATERIALS. YOU MAY NEED TO USE

APPROVED NON-FLAMMABLE INSULATING

MATERIALS IN HIGH TEMPERATURE AREAS.

SOUND INSULATING MATERIALS

Once installers have determined that compartments

are properly constructed and metal lined, they can

add acoustical material. This may include additional

sealant or insulating material, to reflect noise away

from the vehicle interior.

Sound insulating materials should be of a non-flam

mable type. One excellent insulating material is a 1

inch thick fiberglass having a 2-pound density. When

fiberglass is used, its coated side should face toward

the compartment interior.

If excessive noise levels should become a problem,

the installer may wish to consider the following:

• Using special sound insulating materials.

• Construction of a special noise abatement compartment.

IMPORTANT: ANY METHOD USED TO REDUCE

NOISE MUST NOT ADVERSELY AFFECT THE

FLOW OF COOLING AND VENTILATING AIR INTO

OR OUT OF THE COMPARTMENT.

Page 11

In addition to the effective use of sound insulatingmaterials, construction of a special noise abatement

compartment might be considered to reduce noise

levels. Such a compartment might be constructed as

follows (Figure 11):

DANGER; DO NOT INSTALL ANY INSULATION OR

OTHER ABSORBENT MATERIALS ON THE INTERI

OR OR UNDERSIDE OF THE COMPARTMENT

FLOOR.

Figure 11 — Typical Noise Abatement

Compartment

EXTERIOR

PLYWOOD

5/8” THICK

SOUND

INSULATION

METAL LINER

FIBERGLASS

INSULATION

PLYWOOD

5/8" THICK

Use 5/8-inch thick or 3/4-inch thick plywood in the com

partment.

Construct the compartment floor of a double thickness of

5/8-inch or 3/4-inch plywood.

Line the compartment interior walls and floor, as well as

the underside of the floor, with 26-gauge galvanized

steel.

Vapor seal all compartment seams and joints.

Over the galvanized steel lining, install a selected combi

nation of acoustical materials as mentioned in “Sound

Insulating Materials."

Seal all compartment door edges to prevent noise leak

age around the door perimeter.

Line the compartment door interior (except for air open

ings) with suitable, fire proof sound insulation (such as 1 inch thick fiberglass with a 2-pound density) See Figue

12.

Figure 12 — Typical Compartment

Door Construction

A TIMES B MUST EQUAL_AT LEAST

100 IN.'OF FREE AIR OPENING

— 9 —

Page 12

COOLING AND VENTILATING AIR

It is absolutely essential that an adequate flow of air

for cooling, ventilating and engine combustion be sup

plied to the generator set. Without sufficient air flow,

the engine-generator quickly overheats. Such over

heating can cause serious operating difficulties and

may also cause fire and personal injury. The installer

must make sure that sufficient air is available to the

generator for cooling, ventilating and combustion. The

installer must also provide for a path for exhausting

the cooling air to the exterior of a compartment, if so

equipped.

DANGER: NEVER USE DISCHARGED

COOLING AIR FOR HEATING OR PERMIT

SUCH AIR TO ENTER THE VEHICLE INTE

RIOR. THIS AIR CONTAINS DEADLY CAR

BON MONOXIDE GAS AND OTHER POISO

NOUS, FLAMMABLE OR EXPLOSIVE

GASES.

GENERATOR AIR FLOW

Engine operation drives cooling fans for the 2-stage

cooling air system. A pressure fan draws cooling air

into the top of generator and into the side of the con

trol panel (Figure 13). This air flow cools the enginegenerator and electronic .components. The second

part of cooling system, a suction fan, draws air that is

heated from a hot engine into a collector pan at the

base of the unit. This heated air (although cooler than

exhaust muffler) is directed across the muffler to cool

it. The heated air flow is then deflected out the bottom

toward the ground.

Figure 13 — Air Flow Through Engine-Generator

For conventional compartment mounted units, the air

inlet is generally provided in the compartment door.

IMPORTANT: IF YOU PLAN TO INSTALL THE GEN

ERATOR IN A COMPARTMENT, BE SURE TO

LEAVE AT LEAST ONE AND A HALF (1-1/2") INCH

ES OF CLEARANCE BETWEEN THE GENERATOR

AND COMPARTMENT CEILING. INCLUDE 26

GAUGE GALVANIZED STEEL LINING AND SOUND

INSULATION WHEN YOU MEASURE FOR THIS 1-

1/2 INCH CLEARANCE. ALLOW 1” ON ALL SIDE

WALLS.

Figure 14 — Air Inlet in Compartment Door

MINIMUM FREE INLET

AREA =100 INCHES^

When the unit is installed on a suspended mounting

system, one of several different methods of supplying

air flow may be used as follows:

• Provide a door in the vehicle skirt having an air

inlet opening (Figure 15).

COOLING AIR INLET OPENING

Minumum size of the air inlet opening, whether the

generator is housed in a conventional compartment or

not, is at least 100 square inches. This rule applies

whether inlet air is brought in through an opening in

the compartment door (Figure 14) or other means.

NOTE: Screening, louvers, or expanded metal that

cover air openings restrict air flow that you must com

pensate for by making the actual air opening propor

tionately larger. See “Compensating for Restnctions."

— 10 —

Figure 15 — Suspended Mount: Inlet Door

MINIMUM FREE I

INLET AREA

100 INCHES’ Em?

f

• IL.

Using ductwork (Figure 16 on Page 11). The

instailer must be sure air is available to the top of

the generator since air inlets are located at the

top.

By providing an opening in the vehicle skirt and

space above the generator for cooling air flow

(Figure 17 on Page 11). Recommended clear

ance above the top of the generator is at least 1 -

1/2 inches.

L

Page 13

Figure 16 — Air Inlet Using Ductwork

Figure 17 — Air Inlet in Vehicle Skirt

COMPENSATING FOR

RESTRiaiONS

Such materials as screening, louvers, or expanded

metal can restrict the free flow of air. Compensate for

this restriction by making the actual air opening pro

portionately larger.

Some materials may offer only a 60 percent “free air

inlet area.” Other more efficient materials may provide

up to a 90 percent free air inlet area. The percentage

of free air inlet opening is usually available from the

material supplier or manufacturer.

TO DETERMINE THE ACTUAL AIR INLET OPEN

ING SIZE REQUIRED, DIVIDE 100 SQUARE INCH

ES BY THE PERCENTAGE OF FREE AIR INLET

AREA FOR THE MATERIAL YOU WILL USE.

For example: If you plan to use screening with an

80% free air inlet area, divide 100 by 0.8, which

results in 125 square inches. Minimum actual size of

air inlet opening in this casé is 125 square inches. An

opening that measures 8 inches wide by 16 inches

long provides the required air flow (8 x 16 = 128

square inches).

RECOMMENDED CLEARANCE • 1-1/2 IN. (38.1 MM) ^

MINIMUM CLEARANCE - 1 IN. (25.4MM)

VEHICLE FLOOR

.-L

ENGINE

SIDE

VIEW

J

VEHICLE

.SKIRT

TESTING THE INSTALLATION

Generac recommends testing the installation to be

sure adequate cooling air flow is available to the unit

before placing the unit into service. If the unit shows

signs of overheating, you will need to enlarge the air

openings. Never place a unit into service until

absolutely certain that cooling and ventilation is ade

quate.

IMPORTANT: YOU MUST TEST THE INSTALLA

TION ESPECIALLY IF YOU BRING IN AIR FROM

BELOW THE GENERATOR SET.

11 —

Page 14

GASOLINE FUEL SYSTEM

Installing a gasoline fuel system (Figure 18) for recre

ational vetiicle generator sets must comply with

applicable codes, standards and regulations. The

entire fuel system must be completely free of leaks.

There must be no possibility of gasoline vapors enter

ing the vehicle interior.

Figure 18 — Generator Fuel System

DANGER: GASOLINE IS HIGHLY FLAMMABLE

AND ITS VAPORS ARE EXPLOSIVE. COMPLY

A

WITH ALL CODES, STANDARDS AND REGULA

TIONS PERTAINING TO GASOLINE FUEL SYS

TEMS USED IN INDUSTRIAL MOBILE GENERA

TORS. PROPERLY INSTALL AND MAINTAIN THE

FUEL SYSTEM AND KEEP IT ENTIRELY FREE OF

LEAKS. GASOUNE VAPORS MUST NOT ENTER

THE VEHICLE INTERIOR.

Factory installed generator fuel system components

include (a) fuel filter, (b) 12-volt DC electric pump, (c)

engine carburetor, and (d) interconnecting lines and

fittings. Connect a fuel supply line to the fuel filter inlet.

Use a flexible length of approved fuel hose between

the fuel filter inlet connection and rigid fuel lines.

FUEL TANK

Either the generator must share the vehicle engine's

fuel tank, or you must install a separate fuel tank for

the generator set. All fuel tanks installed on the vehi

cle must be constructed, installed, restrained so it

complies with applicable codes, standards and regu

lations.

If the generator is to share the vehicle engine's tank,

separate fuel pickup tubes are required for the engine

and the generator. Generac recommends that you

make the fuel pickup tube about 2 to 3 inches shorter

than the vehicle engine's pickup tube. This prevents

the generator from depleting the entire fuel supply

during prolonged generator operating periods.

CAUTION: Do NOT tee the generator fuel supply

line into the vehicle engine fuel supply line. If this

is done, the generator will be starved of fuel when

both engines are operating at the same time. Also,

while the vehicle engine is not running, generator

operation may drain the vehicle engine supply line,

making it difficult to start the vehicle engine.

GENERATOR FUEL SUPPLY LINE

RIGID FUEL LINES

Those lines used to supply fuel from a tank to the

generator must comply with ac applicable codes, standards and regulations.' The following generator rules

apply to rigid fuel lines:

• Rigid lines should be of annealed, seamless, drawn alu

minum or steel.

• Lines and fittings must comply with SAE J512F,

“Standard Automotive Fittings”, or with ANSI B126.26

(latest edition).

• Route the fuel line so that at least 2 inches of clearance

is maintained between the line and any exhaust system

parts.

• Do not attach electrical wiring to fuel lines. Route the

wiring so it cannot come into contact with any fuel line.

• Route fuel lines so if they leak, fuel does not drip onto

any electrical or exhaust system parts.

• Use non-ferrous metal straps without sharp edges to

secure fuel lines.

I fu

■ FLEXIBLE FUEL LINE

Use an approved flexible length of fuel hose between

the generator fuel inlet connection and rigid fuel lines.

This prevents breaking of the line caused by vibration,

shifting, settling or movement. The following rules

apply:

• The flexible hose must comply with SAE J30B, “Standard

for Fuel and Oil Hose”. It must be approved for use with

gasoline.

• The hose should be at least 6 inches longer than is need

ed to prevent the hose from rupturing if the generator

shifts or settles.

with

iliowir

__________________

12 —

Page 15

PROPANE GAS FUEL SYSTEM

DANGER: LP (PROPANE) GAS IS HIGHLY EXPLO

SIVE. THE GAS IS HEAVIER THAN AIR AND

TENDS TO SEHLE IN LOW AREAS, WHERE EVEN

THE SLIGHTEST SPARK CAN IGNITE IT AND

CAUSE AND EXPLOSION. ONLY COMPETENT,

QUALIFIED PERSONS SHOULD BE ALLOWED TO

INSTALL, TEST, ADJUST OR SERVICE AN LP GAS

FUEL SYSTEM. INSTALL THE OPTIONAL FUEL

SYSTEM IN COMPLIANCE WITH APPLICABLE

CODES, STANDARDS AND REGULATIONS. AFTER

THE INSTALLATION, DO NOTHING THAT MIGHT

RENDER THE SYSTEM IN NON-COMPLIANCE

WITH APPLICABLE CODES AND STANDARDS.

The LP powered range of Gensets are fitted with nonadjustable factory set system. These systems are

tamper-proof to meet 1997 California Air Resources

Board for Engine Emmissions.

PARTS NOT INCLUDED IN FUEL SYSTEM

The propane fuel system does NOT include such

items as (a) gas tank, (b) gas piping, (c) fittings, (d)

valves, and (e) primary regulator, used to store the

gaseous fuel and deliver it to the gaseous fuel sole

noid (Figure 19).

DANGER: USE ONLY APPROVED COMPONENTS

IN THE GAS SUPPLY SYSTEM. ALL COMPONENTS

MUST BE PROPERLY INSTALLED IN ACCOR

DANCE WITH APPLICABLE CODES. IMPROPER

INSTALLATION OR USE OF UNAUTHORIZED COM

PONENTS MAY RESULT IN FIRE OR AN EXPLO

SION. FOLLOW APPROVED METHODS TO TEST

THE SYSTEM FOR LEAKS. NO LEAKAGE IS PERMIHED. DO NOT ALLOW FUEL VAPORS TO

ENTER THE VEHICLE INTERIOR.

SOME IMPORTANT CONSIDERATIONS

When installing an LP gas system, consider seriously

the following items:

• All fittings, lines, hoses and clamps must be tight and free

of leaks. Apply a pipe sealant to threads when assem

bling threaded connections. This reduces the possibility

of leakage.

• Test the entire fuel system for leaks, using approved test

methods.

Figure 19 — Typical Propane Gas Fuel System

Page 16

• Optimum gas pressure at the inlet to the gaseous fuel

solenoid valve and secondary regulator is 11 inches

water column.

• The instaljer’s fuel supply connection point is at the

gaseous fuel solenoid valve. This is a 3/4 inch (female)

connection. Provide a suitable 3/4 inch NPT (male) con

nector to attach to the fuel supply line.

• Use a length of approved flexible fuel hose between

gaseous fuel solenoid valve and rigid gas piping. The

flexible line should be at least six (6) inches longer than

necessary.

VAPOR WITHDRAWAL

Liquid propane (LP) gas is stored in pressure tanks

as a liquid. The gas systems used with these genera

tors were designed only for “vapor withdrawal” type

systems. Vapor withdrawal systems use the gas

vapors that form above the liquid fuel in the tank. Do

NOT attempt to use the generator with any “liquid

withdrawal” type system.

PRIMARY REGULATOR

Gas pressure delivered to the solenoid valve must be

properly regulated by means of a primary gas regula

tor. Mount the primary regulator at the gas tank outlet

or in the supply line from the gas tank. The following

rules apply:

• For best results, the primary regulator supplies gaseous

fuel to the secondary regulator at 11 inches water col

umn. Do NOT exceed 14 inches water column.

• The installer must be sure the primary regulator is rated

at sufficient gas flow to operate the generator plus all

other gas appliances in the circiut.

NOTE: Recommended MINIMUM gas flow rate for all

air-cooled NP or Q series generators is 67 cubic feet

per hour.

IMPORTANT: IF AN EXISTING PRIMARY GAS

REGULATOR DOES NOT HAVE A SUFFICIENT

FLOW CAPACITY FOR THE GENERATOR AND

OTHER GAS APPLIANCES IN THE CIRCUIT, (a)

INSTALL A PRIMARY REGULATOR WITH ADE

QUATE FLOW RATE, OR (b) INSTALL A SEPA

RATE REGULATOR ONLY AND RATED AT LEAST

67 CUBIC FEET PER HOUR. THE INLET SIDE OF

ANY PRIMARY REGULATOR THAT SUPPLIES THE

GENERATOR MUST CONNECT DIRECTLY TO

GAS TANK PRESSURE. DO NOT TEE THE GEN

ERATOR LINE INTO A GAS CIRCUIT FEEDING

OTHER AREAS.

GASEOUS CARBURETION

LP gas vapors should be supplied to the secondary

regulator inlet at about 11 inches water column (posi

tive pressure). The engine pistons draw air in during

the intake stroke (Figure 20). This air passes through

a carburetor venturi which creates a low pressure that

is proportional to the quantity of air being pumped.

The low pressure from the carburetor venturi acts on

the regulator diaphragm, to pull the diaphragm toward

the source of low pressure. A lever attached to the

diaphraghn opens a valve to permit gas glow through

the carburetor.

The greater the air flow through the carburetor ven

turi, the lower the presure at the venturi throat. The

lower the pressure at the venturi throat, the greater

the diaphragm movement and the greater the move

ment of the regulator valve. The more the regulator

valve opens, the greater the gas flow that is propor

tional to air flow through the generator.

AIR

Figure 20 — Propane Gas Carburetion Diagram

GAS AT

AREA

— 14 —

Page 17

The following facts about the secondary regulator

must be emphasized;

• The regulator must be sensitive to venturi throat pressure

changes throughout the operating range.

• The regulator must be properly adjusted so it will stop the

flow of gas when the engine is not running (no air flow

through the carburetor).

• The slightest air flow (and vacuum in the venturi throat

should move the regulator valve off its seat and permit

gas to flow.

LEAKAGE TESTS

Do not place the generator into service untii you have

properly tested the gas system for leaks. To test the

system, you need a separate source of 12 volts DC to

open the gaseous fuel solenoid valve.

The leak test must comply fully with NFPA, Paragraph

318. All connections, hoses, valves regulators, fit

tings, and other fuel system parts must be tested

under gas or air pressure of not less than 90 psi

(620kPa), while using soap and water or equivalent

solution to check for leaks. Other approved methods

of testing for leaks may be used, if appropriate. DO

NOT USE ANY FLAME TO TEST FOR LEAKS.

FUEL SUPPLY LINES

• Propane gas lines must be accessible, but protected

against possible damage.

• Do NOT connect electrical wiring to any propane gas fuel

line or run wiring alonside the lines.

• Route gas lines away from hot engine exhausts.

• Retain gas lines with metal clamps that do not have

sharp edges.

• Install an approved length of flexible hose between the

gaseous fuel solenoid valve and rigid fuel supply lines.

The flexible line must be non-metallic, non-organic and

non-conductive. It must be approved for use with LP gas.

EXCESS FLOW VALVE

Propane gas tanks should have an excess flow valve,

according to NFPA 501C, Paragraph 3-4.4. This valve

and the gas lines must be carefully sized so the valve

will close when a fuel line is severed or broken.

Consult the Natural-LP Gas Association for informa

tion and limitations of excess flow valves.

Manual shutoff valves on the supply tank and else

where in the system must be fully open when operat

ing the generator. The excess flow valve functions

properly only if all valves are fully open.

DANGER; GASEOUS FUEL LINES BETWEEN THE

TANK AND THE SECONDARY REGULATOR ARE

A

UNDER A POSITIVE PRESSURE (ABOUT 11 INCH

ES WATER COLUMN). GAS PRESSURE AT THE

OUTLET SIDE OF THE SECONDARY REGULATOR,

HOWEVER, IS A NEGATIVE PRESSURE AND CAN

DRAW FLAME INSIDE A LINE OR FIHING AND

CAUSE AN EXPLOSION.

— 15 —

Page 18

EXHAUST SYSTEM

The generator exhaust system must be safely and

properly installed. Only approved mufflers and other

exhaust system parts must be used. A properly

installed exhaust system must be vapor tight, quiet

and completely safe.

CAUTION: Never tee the generator engine exhaust

pipe into the vehicle engine exhaust piping. This

causes excessive back pressure on the generator

engine. Also, water from one engine can damage

the other engine.

DANGER: THE GENERATOR ENGINE GIVES OFF

DEADLY CARBON MONOXIDE GAS THROUGH ITS

EXHAUST SYSTEM. THIS DANGEROUS GAS, IF

BREATHED IN SUFRCIENT CONCENTRATIONS, CAN

CAUSE UNCONSCIOUSNESS OR EVEN DEATH. SYMP

TOMS OF CARBON MONOXIDE POISONING ARE (a)

INABILITY TO THINK COHERENTLY, (b) VOMITING, (c)

TWITCHING MUSCLES, (d) THROBBING IN TEMPLES,

(e) DIZZINESS, (f) HEADACHE, (g) WEAKNESS AND

SLEEPINESS. IF ANY OF THESE SYMPTOMS ARE

EXPERIENCED, MOVE INTO FRESH AIR IMMEDIATELY.

IF SYMPTOMS PERSIST, GET MEDICAL ATTENRON.

DO NOT OPERATE THE GENERATOR UNTIL ITS

EXHAUST SYSTEM HAS BEEN INSPECTED AND

REPAIRED.

MUFFLERS AND SPARK ARRESTORS

If the generator is not equipped with a spark arrestor

exhaust muffler and is to be used on any forest cov

ered, brush covered or grass covered unimproved

land, you may have to install a spark arrestor. The

spark arrestor must be maintained in effective work

ing order by the vehicle owner/operator.

For assistance in ordering, installing and maintaining

spark arrestor exhaust mufflers, contact your nearest

authorized service facility.

Exhaust mufflers supplied by Generac are spark

arrestor types. Generac exhaust mufflers for NP and

Q series generators do not have a spark arrestor

screen, but are of the more efficient “toroid” or “swirl”

type. To remove carbon and combustion deposits

from such mufflers, remove the PLUG from muffler

and run engine for about 15 minutes. Shut down, let

the muffler cool and install the plug.

WARNING: BE SURE TO RE-INSTALL THE PLUG

FROM THE MUFFLER TIGHTLY. ENGINE VIBRA

A

TION COULD CAUSE A LOOSE PLUG TO FALL OUT.

WITHOUT THE PLUG IN PLACE, HOT ENGINE

EXHAUST IS DIRECTED OUT THE OPENING. THIS

HOT EXHAUST, DEPENDING ON THE INSTALLA

TION, COULD BE DIRECTED TO AREAS NOT ABLE

TO WITHSTAND THE EXTREME HEAT SUCH AS

WOODEN FLOOR BOARDS OR OTHER FLAMMA

BLE MATERIALS. THIS COULD RESULT IN A FIRE.

TYPE OF EXHAUST SYSTEM

Two types of exhaust systems for “NP” and “Q” series

generators are available from Generac. They include

these;

• “Out-the-bottom” exhaust system, Model 9742 (Figure

21). '

• “Out-the-side” exhaust system, Model 9743 (Figure 22 on

Page 17).

NOTE: No matter what type of exhaust kit best fits

your recreational vehicle, the mounting base has

openings for either “bottom-ouf or “side-out exhaust

systems. Use the cover plate provided with the gen

erator to cover the opening you do NOT use.

Figure 21 — Model 9742 Exhaust System

ITEM PART NO. DESCRIPTION QTY

52108 Rinffler r

2 46591 Hanger 1

28238

3

28237 Clamp, Saddle

4

5 22129

22259 5/16”Hex Nut

6

7

75238 Pipe

75411 Elbow 1

8

9 77643 Gasket 2

77642 Adaptor, Bottom Out 1

10

11 68527

U-Bolt 3

Lock\Vasher

M6-1.0 X 20mm Screw 2

3

6

6

1

16-

Page 19

EXHAUST SYSTEM SAFETY

• Maintain a clearance of at least 3 inches (76mm)

between exhaust system parts and any combustible

material (such as wood, felt, cotton, organic fibers or

other like material). If you cannot maintain the 3-inch

clearance, locate, insulate or shield the exhaust part(s)

so that the temperature of any combustible material is not

raised more than 117°F (65“C) above the ambient air

temperature.

• Terminate the exhaust tailpipe such that exhaust gases

will not be drawn back into the generator compartment

and recirculated.

• If there is any possibility of the tailpipe or muffler being

damaged, protect these damage prone areas by means

of a protective device (such as a “skid baf).

• Install the generator exhaust system according to safe

automotive practices.

• Use enough exhaust system hangers to prevent

any part of the system from being dislocated.

Figure 22 — Model 9743 Exhaust Kit

Use exhaust system parts recommended by

Generac. Using unapproved exhaust mufflers

and exhaust system parts is the responsibility of

the person(s) installing such unauthorized parts.

Do not terminate the exhaust system under the

vehicle.

. Do not terminate the exhaust system under any

opening, window or vent which can be opened or

is not permanently sealed from the vehicle interi

or.

Exhaust piping must be large enough to prevent

excessive back pressure on the generator

engine.

Never tee the generator engine exhaust pipe into

the vehicle engine exhaust piping. This causes

excessive back pressure on the generator

engine. Also, water from one engine can damage

the other engine.

Plan exhaust system installation carefully.

Comply with all applicable codes, standards and

regulations.

ITEM

1 .22129

2

3

4 81107

5

6

7 76508

PART NO.

42907

45771

92675A

94670

DESCRIPTION

5/16”-M8 Lockwasher

M8-1.25 X 16 Screw

M8-1.25 Hex Nut

Exhaust Pipe Extension

Exhaust Muffler

1.120 Exhaust Clamp

. Muffler Bracket

QTY. ITEM

4

4

2 10

1 11 92676

1 12

2

1

— 17 —

8

9

13

PART NO. DESCRIPTION QTY.

77643 Gasket

90863 Adaptor 1

79246 M6-1.0 X 20mm Capscrew 2

95277

56893

Muffler Adaptor 1

Outlet Adaptor Gasket

#10-24 X 1/2 Crimptite

2

1

3

Page 20

ELECTRICAL CONNECTIONS

The following general rules apply to electrical connec

tions in a recreational vehicle:

• Qualified electricians who are familiar with applicable

codes, standards and regulations should install electrical

wiring.

• The wiring should comply with codes, standards and reg

ulations. The National Electric Code (NFPA 70), as well

as state and local codes, apply.

• Switches and circuit breakers should be of a type

approved for use in recreational vehicles and must be

mounted and installed to prevent damage from road

shock.

• Wiring must be of adequate size, with approved insulative

qualities, and properly supported.

Conduit and wire openings into generator compartment

(if used) must be vapor-sealed, to prevent entry of flam

mable, explosive or poisonous gases into the vehicle.

ELEamCAL JUNQION BOX

Install an approved, square electrical junction box that

has a blank cover on the interior or exterior wall of the

area you plan to install the generator (NOT on the

generator). Route the generator's AC output leads

into this junction box through approved flexible con

duit, and into this junction box. This is the point of first

termination for generator AC output leads.

• From the junction box route power supply wires through

approved conduit to either (a) double-pole, double-throw

transfer switch, or (b) approved isolation receptacle.

Connecting to a transfer switch or isolation receptacle

must prevent vehicle electrical circuits from being con

nected to two different power supplies at the same time

(such as generator and dockside power).

• Conductors must be rated 221°F (105“C) or must be of a

larger conductor size.

GENERATOR AC CONNEaiONS

Generator AC output leads T1 (red) and T2 (white)

and T3 (black) come out of the generator as shown in

Figure 23. Leads T1 (red) and T3 (black) are “hot,”

while T2 (white) is the grounded “neutral”. There is

also a green lead that connects to ground in the junc

tion box of the recreational vehicle.

Figure 23 — Generator AC Output Leads

WIRING

• Wiring should be of stranded copper to reduce chance

that vibration may cause breakage.

• Wire gauge size of wires should be large enough to han

dle at least 115% of the installed generator's rated maxi

mum current.

• If neutral conductors are used, they must be the same

size as other leg wires.

• Route power supply conductors from generator AC output

leads T1 (red) and T2 (white), T3 (black) and the green

ground wire through approved flexible conduit to the elec

trical junction box on the compartment wall.

If flexible metal conduit is used between the generator

and the compartment junction box, the conduit end that

terminates the compartment junction box, must be vaporsealed. Flexible metal conduit is NOT vapor tight along its

entire length.

Line T1 (red) to T2 (white) is protected against over

load by the circuit breaker (CB1). Use this line-to-neutral connection separately to operate 120 volts, 1phase, 60 Hz, AC loads requiring up to 3600 watts

(3.6 kW) of power. Line T3 (black) to T2 (white) is

also protected against overload by a circuit breaker

(CB2). Use this line-to neutral connection separately

to operate similar loads. However, be sure the total

unit load does NOT exceed the maximum rating of

the generator. The neutral line (T2, white) on all units

is a grounded neutral.

NOTE: The generator may be reconnected for dual

voltage AC output. (See “Dual Voltage Reconnection

on page 3).”

CAUTION: Do NOT connect electrical loads in

excess of any circuit breaker rating or you will

A

develop problems with circuit breaker tripping,

which causes a loss of AC output Also, do NOT

exceed the generator's rated wattage capacity. Add

the watts or amperes of all lighting, appliance, tool

and motor loads the generator will operate at one

time. This total should be less than the unit's rated

wattage/amperage capacity.

— 18 —

Page 21

CONDUIT

Route the conductors between the generator and the

junction box through approved, flexible conduit. The

following general rules apply:

• Cut wiring to the required length and allow extra wire for

junction box connections.

• Carefully prepare conduit ends, to prevent sharp edges

from cutting through wiring insulation.

• Route conduit so it does not interfere with generator

movement.

• If you use metallic conduit, vapor seal the end of the con

duit where it enters the junction box. Do this because

flexible metallic conduit is not vapor proof along its entire

length.

ISOLATING DIFFERENT POWER

SOURCES

Conductors from the junction box must terminate in a

double pole, double throw transfer switch (Figure 24).

An alternate method for isolating different power

sources is by using an isolating receptacle (Figure 25

on Page 20). Whichever method you use, you must

be certain that both power sources are NOT connect

ed at the same time.

POWER SUPPLY CORD

The power supply cord must comply with all applica

ble codes, standards and regulations. It must be large

enough to handle the full amperage to which it will be

subjected.

GROUND FAULT CIRCUIT

INTERRUPTERS

The National Electric Code (NFPA 70, 551-7) requires

that you install ground fault circuit interrupters

(GFCIs) on all external and some internal electrical

receptacles. Contact your manufacturer or dealer for

recommendations.

FLEXIBLE

CONDUIT

1—1

I JlHiPÜ

Figure 24 — Transfer Switch Isolation Method

FROM

HACR BREAKER_____

VEHICLE

WIRING

b

-1

POWER SUPPLY CORD

2ND AIR

CONOITIONEB

VEHICLE A-C

DISTRIBUTION

PANEL

MAIN BREAKER

HACR

BREAKERS

FOR AIR

CONDITIONERS

GFCI

BREAKERS

— 19 —

Page 22

Figure 25 — Installation with Isolation Receptacle

DOCKSIDE

POWER

DISTRIBUTION

PANEL

— 20 —

Page 23

DUAL VOLTAGE RECONNECTION

NOTE: Be sure to read “Reconnection for Dual

Voltage: on page 3. Installers must be aware that if

they reconnect the generator for dual voltage AC out

put, the generator is not listed per RVIA.

When reconnecting these units for dual voltage,

replace the existing circuit breakers with a single suit

ably rated circuit breaker.

RECONNEQION PROCEDURE

NOTE: Not applicable to Q-40G model.

t.Gain access to the generator panel interior by removing

the generator cover and the front panel (Figure 26).

Figure 26 — Removing Cover and Panel

3. Disconnect stator, leads 11 and 33 from the 4-tab terminal

connector (TC).

4. Disconnect stator leads 22 and 44 from the grounding

terminal (GT).

5. Disconnect one of the two 12 (white) leads from the

grounding terminal.

6. Remove the existing circuit breakers CB1 and CB2.

Install new appropriately rated circuit breaker.

7. Connect stator leads 11 and 44 to the new circuit breaker

as shown in Figure 28. Also attach leads T1 (red) and T3

(black) to the circuit breaker as shown.

8. Connect stator leads 22 and 33 to the grounding terminal

(GT) as shown (Figure 28).

9. Be sure a neutral lead is installed and routed from the

grounding terminal for connection loads.

10. Routs leads T1 (red) and T3 (black) and the grounded

neutral lead through the conduit clamp and out of the

panel.

11 .Reassemble the panel and generator cover.

Loads may now be connected as follows (Figure 28):

• T3 (black) to Neutral — 120 volts

• T1 (red) to Neutral — 120 volts

• T1 to T3 — 240 volts

2. Disconnect stator leads 11 and 33, T1 (red) and T3

(black) from the main circuit breakers CB1 and CB2

(Figure 27). Set aside leads T1 (red) and T3 (black) for

later use.

Figure 27 — Existing

Wiring Connections — 120 Volts

Figure 28 — Reconnected for Dual Voltage

— 21 —

Page 24

BATTERY INSTALLATION

RECOMMENDED BAHERY

Install a battery that meets the following require

ments:

• Battery must be a 12 volt, automotive type storage bat

tery.

• For prevailing ambient temperatures above 32°F (0°C),

use a battery rated 70 amp-hours and capable of deliver

ing 360 cold cranking amperes.

• For prevailing ambient temperatures below 32°F (0°C),

use a battery rated 95 amp-hours and capable of deliver

ing 450 cold cranking amperes.

IMPORTANT: IF THE BATTERY IS TO BE USED TO

POWER OTHER VEHICLE ACCESSORIES, AS

WELL AS START THE GENERATOR, YOU MAY

NEED A BATTERY WITH A LARGER CAPACITY.

BAHERY CABLES

Using battery cables that are too long or too small in

diameter may cause a drop in voltage which causes

starting problems. For best cold weather starting, the

voltage drop between battery terminals and the gen

erator connection point should not exceed 0.12 volts

per 100 amperes of cranking current.

Q Series generators are rated at about 100 DC

amperes of cranking current.

Select battery cables based on (a) cable length, and

(b) prevailing ambient temperatures. Generally, the

longer the cable and the colder the weather, the larg

er the cable size must be (as shown in the chart in the

next column).

CABLELENGTH

in Feet (meters) CABLE SIZE

0to10(0to3) 2*

11 to 15 (3.4 to 4.5) 0

16 to 20 (4.5 to 6) 000

* For warm weather, use No. 2 cable up to 20 feet.

BAHERY CABLE CONNEaiONS

1. Connect the battery cable from the battery post or termi

nal indicated by a POSITIVE, POS or (+) to the large lug

on the starter contactor (Figure 29).

2. Connect the battery cable from the battery post indicated

by a NEGATIVE, NEG or (-) to the frame ground connec

tion (Figure 27).

3. Connect cables so the connectors are clean and tight.

NOTE: Check to be sure the battery cable boot for

the starter cable has been installed.

BAHERY COMPARTMENT

Install the generator battery in its own, vented com

partment. Place the battery compartment away from

any source of heat, sparks or flame.

Provide ventilation openings in the battery compart

ment. The minimum size of openings should be 2

square inches at the top of the compartment. Mount

the battery on a strong, rigid supporting structure,

where leaks and spills of battery fluid will not cause

damage.

Figure 29 — Connecting Battery Cables

ATTACH NEGATIVE BATTERY CABLE

TO ONE OF THESE LUGS

— 22 —

GROUND LUG

Page 25

POST INSTALLATION TESTS

The air cooled generator set was factory tested and

adjusted to provide maximum power. You should not

be required to adjust the unit any further except under

special circumstances.

WARNING: DO NOT MAKE ANY UNNECESSARY

ADJUSTMENTS. FACTORY SETTINGS ARE COR

RECT FOR MOST APPLICATIONS. WHEN MAKING

ADJUSTMENTS, HOWEVER, BE CAREFUL TO

AVOID OVERSPEEDING THE ENGINE.

BEFORE INITIAL START UP

Before starting, complete the following:

1. Check engine crankcase oil level and, if necessary, fill to

dipstick FULL mark with the recommended oil. Do not fill

above FULL mark.

2. Check the fuel supply. Gaseous fuel lines must have

been properly purged and leak tested in accordance with

applicable fuel-gas codes. All fuel shutoff valves in the

fuel supply lines must be open.

DANGER: IF AN LP (PROPANE) GAS FUEL SYS

TEM HAS BEEN INSTALLED, IT MUST HAVE BEEN

PROPERLY TESTED FOR LEAKS BEFORE OPER

ATING THE SYSTEM IN COMPLIANCE WITH ANSI

A119.2/NFPA 501C. NO LEAKAGE IS PERMIHED.

YOU MUST BE SURE NO GASEOUS FUEL

VAPORS ENTER THE VEHICLE INTERIOR.

INITIAL START

When absolutely certain that the unit has been prop

erly installed and prepared for use, start the engine as

follows:

1. Turn off all electrical loads. Do this by setting the generator

main circuit breakers to their “OFF or “OPEN” position.

2. Refer to the Owner's Manual shipped with unit for crank

ing and starting instructions. The engine may require

more cranking for initial starting since the fuel lines have

to be primed.

3. Let the engine warm up for about five minutes to allow

internal temperatures to stabilize.

4. Carefully inspect the engine-generator for fuel, oil and

exhaust system leaks. Before proceeding to the next

step, correct any leakage immediately.

5. When engine has stabilized and warmed up, check the

no-load voltage and frequency. See “Checking No-Load

Voltage and Frequency”. Initial tests and adjustments are

done at no-load condition.

6. When all tests and adjustments at no-load are completed,

apply electrical loads and check for proper operation

under load. See “Testing Under Load”. Run the unit at

least 30 minutes with loads applied.

7. Turn off all electrical loads by setting the generator main

circuit breakers to “OFF or “OPEN.”

8. Let the unit run at no-load for a few minutes to stabilize

internal engine-generator temperatures. Then, shut down

the engine.

IMPORTANT: THE GENERATOR SET WAS THOR

OUGHLY TESTED AND ADJUSTED AT THE FAC

TORY BEFORE SHIPPING. NO ADDITIONAL

ADJUSTMENT SHOULD BE NECESSARY. ONLY

QUALIFIED SERVICE TECHNICIANS WHO HAVE

BEEN TRAINED SHOULD PERFORM ADJUST

MENTS OUTLINED IN THIS MANUAL.

CHECKING NO’LOAD VOLTAGE

AND FREQUENCY

Connect an accurate AC voltmeter and an AC fre

quency meter across the generator’s AC output leads.

This can be done at a convenient point in the circuit

(such as the transfer switch terminals or isolating

receptacle). Connect the meters across lines T1 (red)

and T2 (white); or across line T3 (black and T2

(white). Line-to-neutral readings will be taken with

unit at no-load condition.

t.With generator running, stabilized and warm, check the

AC frequency and voltage. Frequency shoud be about 62

Hz; voltage about 122-126 volts AC.

2. After taking frequency and voltage readings, determine if

any adjustment is required as follows:

• If frequency and voltage are both good, no adjust

ment IS needed.

• If frequency is high or low, adjust the engine gov

ernor to obtain 62 Hertz at no-load. Then, recheck

voltage reading.

• If frequency is good but voltage is high or low,

adjust the voltage regulator to obtain 124 volts at

62 Hz (no-load).

NOTE: If the generator has been reconnected to pro

vide a dual voltage AC output (Page 18), line-to-line

frequency and voltage readings may be used.

Frequency at no-load should be about 62 Hz; line-toline voltage should be about 244-252 volts.

TESTING UNDER LOAD

After it has been determined that no-load frequency

and voltage are correct, apply electrical loads equal to

about 75-100% of the unit s rated wattage/amperage

capacity. Check frequency with electrical load

applied. The frequency should not drop below about

58 Hz under load.

Let the unit run at least 30 minutes with load applied.

During this part of the test, check that the unit is not

running excessively hot and that adequate cooling air

flow is available. You must not allow the unit to over

heat during prolonged operation.

23 —

Page 26

NOTE: The generator engine is equipped with a high

oil temperature switch. The switch has normally-open

(N.O.) contacts which will close at about 28A°F

(140°C). When the switch contacts close, engine

shuts down automatically.

IMPORTANT; GENERAC RECOMMENDS THAT

YOU TEST THE GENERATOR FOR ADEQUATE

COOLING.

ADJUSTING NO-LOAD FREQUENa

With engine stopped, visually inspect the ANTI-LASH

SPRING. Replace spring if broken or damaged;

attach if disconnected.

For Series Q-40G, NP-66G/LP, Q-55G/LP and Q-

70G/LP generators proceed as follows (Figure 30):

1. Loosen the GOVERNOR CLAMP NUT.

2. Push spring end of GOVERNOR LEVER all the way up to

its wide open throttle position.

• Hold the GOVERNOR LEVER at wide open throttle

and insert screwdriver into slotted end of GOVER

NOR SHAFT. Rotate the GOVERNOR SHAFT fully

counterclockwise (CCW).

• While holding the GOVERNOR SHAFT fully coun

terclockwise and the GOVERNOR LEVER at wide

open throttle, tighten the GOVERNOR CLAMP NUT

to 70 inch-pounds (8 N-m).

Figure 30 — Governor Adjustment

for NP-66G et.al.

IOLE STOP SCREW

3. Start engine, let it stabilize and warm up at no-load.

4. Turn the ADJUSTER NUT to obtain a frequency reading

of 62 Hertz.

5. Determine if the GOVERNOR SPRINGis properly located

In the notched teeth of the GOVERNOR ADJUSTMENT

BRACKET as follows:

• If droop is excessive, move the GOVERNOR SPRING