Page 1

m

Miinual Part No. 05580

SERVICE

MANUAL

NP and IM Series

RECREATIONAL

VEHICLE &

NDUSTRIAL

MOBILE

AC GENERATORS

Liquid-Cooled

Diesel Engine Models

CORPORATION

Issued- 01A>4/93

*P. O. Box 8 *Waukesha, Wisconsin 53187

Printed in U.S.A.

Page 2

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, economicai and reliabie operation

of ali recreationai vehicie and industrial mobile generators. Troubleshooting, testing

and servicing procedures recommended by Generac and described in this manual are

effective methods of performing such operations. Some of these operations or proce

dures may require the use of specialized equipment. Such equipment should be used

when and as recommended.

It is important to note that the manual contains various DANGER, CAUTION and

NOTE blocks. These should be read carefully in order to minimize the risk of personal

injury or to prevent improper methods or practices from being used which could damage

equipment or render it unsafe. These DANGER, CAUTION and NOTE blocks are not

exhaustive. Generac could not possibly know, evaluate and advise the recreational

vehicle trade of all conceivable ways in which operations described in this manual might

be accomplished, or the possible hazardous consequences of each way. Consequently,

Generac has not taken any such broad evaluation. Accordingly, anyone who uses any

troubleshooting, testing or service procedure that is not recommended by Generac must

first satisfy himself that neither his nor the equipment’s safety will be jeopardized by the

procedure or method he selects.

Page 3

TABLE OF CONTENTS

#

SERVICE

MANUAL

NP and IM Series

RECREATIONAL

VEHICLE &

INDUSTRIAL

MOBILE

AC

PART

TITLE

THE REVOLVING FIELD AC GENERATOR

ENGINE MECHANICAL

ENGINE LUBRICATION AND COOLING

SYSTEM

ENGINE FUEL SYSTEM

ENGINE ELECTRICAL SYSTEM

ELECTRICAL DATA

GENERATORS

Liquid-Cooled

Diesel Engine Models

Page 4

Parti

THE REVOLVING

FIELD

AC

GENERATOR

NP and IM Series

RECREATIONAL

VEHICLE &

INDUSTRIAL

MOBILE

SECTION

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

TABLE OF CONTENTS

TITLE

Introduction

How a Generator Works

Major Components

(Units with 15 inch Stator)

Major Components

(Units with 10 Inch Stator)

Introduction to Troubleshooting

Troubleshooting

(Units with 15 Inch Stator)

Troubleshooting

(Units with 10 Inch Stator)

Insulation Resistance Tests

Operational Tests & Adjustments

AC GENERATORS

Liquid-Cooled Diesel Engine Models

Page 5

PARTI

THE REVOLVING FIELD AC GENERATOR

INTRODUCTION

SECTION 1.1

INTRODUCTION

Section 1.1

Service Manual Familiarization

This SERVICE MANUAL is divided into six (6)

PARTS. Each PART consists of two or more SEC

TIONS. In turn, each SECTION is divided into SUB

SECTIONS.

At the front of the manual is a main TABLE OF

CONTENTS divider page which lists the titles of Parts

1 through 6.

Each PART of the manual is also identified by a

divider page which Identifies the SECTIONS that make

up that PART.

PMes are numbered so as to identify the PART

and SECTION, as well as the specific page number.

For example, "Page 2.1-3" indicates Page 3 of Part 2,

Section 1. This type of numbering system permits indi

vidual Sections of the manual to be kept current without

affecting the entire manual.

Contents of Manual

Part 1 - The Revolving Field AC Generator

Section 1.1- Introduction

Section 1.2- How a Generator Works

Section 1.3- Major Components (Units with 15 inch

Stator)

Section 1.4- Major Components (Units with 10 inch

Stator)

Section 1.5- Introduction to Troubleshooting

Section 1.6- Troubleshooting (Units with 15 inch

Stator)

Section 1.7- Troubleshooting (Units with 10 inch

Stator)

Section 1.8- Insulation Resistance Tests

Section 1.9- Operational Tests & Adjustments

Part 2- Engine Mechanical

Section 2.1- Engine Specifications & Charts

Section 2.2- General Information

Section 2.3- Engine Disassembly

Section 2.4- Disassembly and Inspection

Section 2.5- Engine Reassembly

Part 3- Engine Lubrication & Cooling System

Section 3.1- Engine Lubrication System

Section 3.2- Water Pump and Thermostat

Section 3.3- Cooling and Ventilating Air

Section 3.4- Periodic Maintenance

Part 4- Engine Fuel System

Section 4.1- Introduction to the Diesel Fuel System

Section 4.2- Fuel Pump

Section 4.3- Governor

Section 4.4- Fuel Injection Pump

Section 4.5- Fuel Nozzles and Holders

Part 5- Engine Electrical System

Section 5.1- Introduction to DC Control Systems

Section 5.2- Engine Cranking System

Section 5.3- Battery Charge System

Section 5.4- Preheat System

Section 5.5- Engine Protective Systems

Section 5.6- Remote Radiator Fan (Model 9319)

Section 5.7- Remote Panels

Section 5.8- Troubleshooting Row Charts

Section 5.9- Troubleshooting Test Procedures

Part 6- Electrical Data

Page 6.1-1- Resistances of Rotors & Stators

Page 6.1-1- Index to Wiring Diagrams and Eiectrical

Schematics

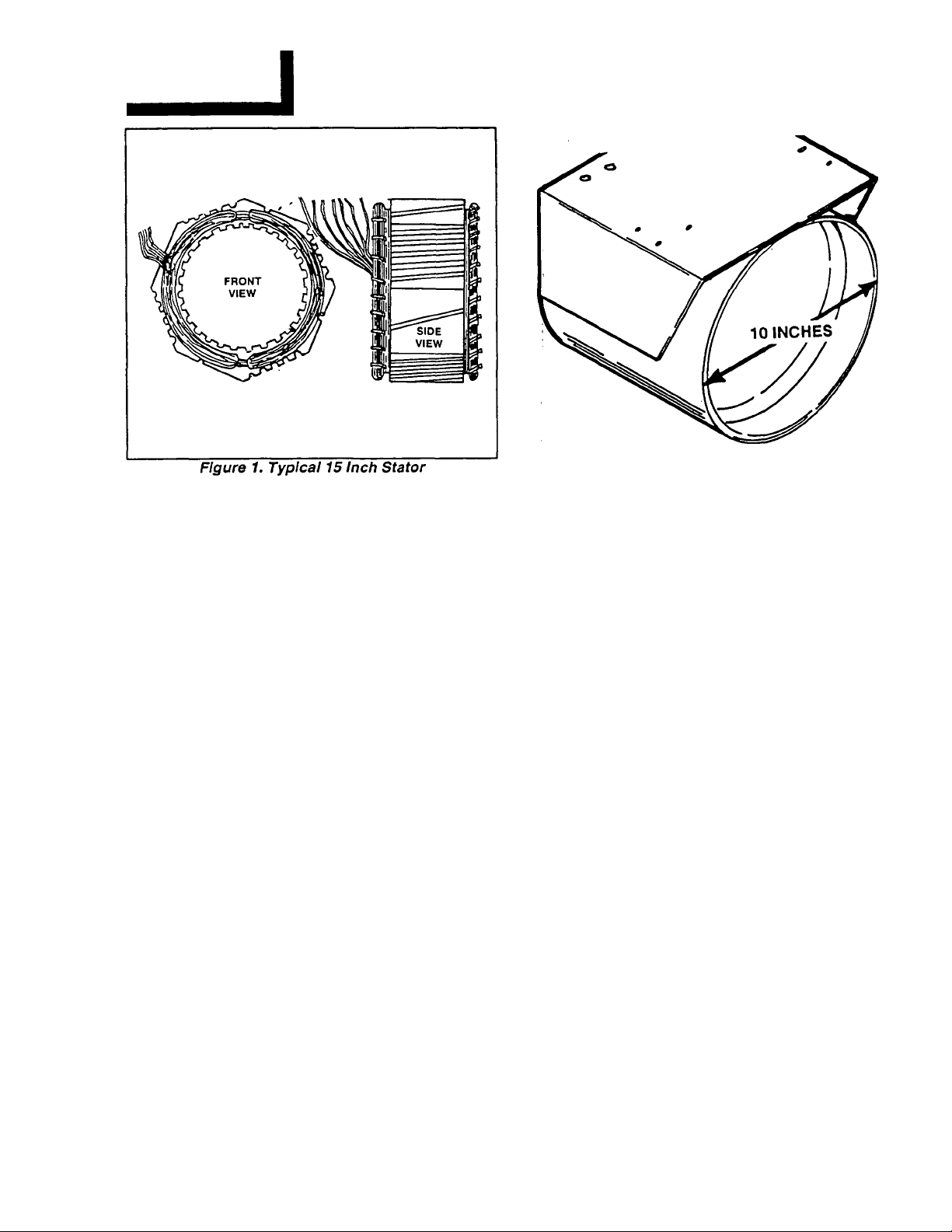

Identifying Units By Stator Diameter

Throughout the Manual, generators are identified

as having either a "15 inch" ora "10 inch" stator. These

numbers refer to the DIAMETER of the stator can

laminations. See Figures 1 and 2 on next page.

In addition to the diameter and construction of the

stator assembly, the following differences exist be

tween units with 10 inch stator and those having a 15

inch stator:

1. Units with 15 inch stator laminations are equipped

with a Part No. 67680 Voitage Regulator.

a. This type of Voltage Regulator mounts three advi

sory lamps (LED’s) which greatly simplify trouble

shooting.

b. The 67680 R^ulator requires a sensing voltage

of 240 volts AC. To provide the required 240 volts, a

step-up transformer (120 to 240 VAC) is used.

2. Units with 10 inch stator laminations are equipped

with a Part No. 81918 Voltage Regulator.

a. The 81918 Regulator mounts a single lamp (LED)

which remains on as long as sensing voltage is

available.

b. The 81918 Regulator requires a sensing voitage

of 120 volts AC and the step-up transformer is NOT

required.

Three Different Engine DC Control Sys

tems

The NP/IM series generators maybe equipped with

any one of three different kiinds of engine DC control

systems. For convenience, the three different DC sys

tems have been arbitrarily identified as Type 1, Type 2

and Type 3.

Refer to Part 5. "ENGINE ELECTRICAL SYS

TEM", for a description Type 1, 2 and 3 DC control

systems.

PAGE 1.1-1

Page 6

SECTION 1.1

INTRODUCTION

PARTI

THE REVOLVING FIELD AC GENERATOR

Figure 2. Typical 10 Inch Stator

PAGE 1.1-2

Page 7

PARTI

THE REVOLVING FIELD AC GENERATOR

HOW A GENERATOR WORKS

SECTION 1.2

HOW A GENERATOR WORKS

1

Section i.2

It has long been known that a relationship exists

General

between magnetism and electricity. The revolving field

generator (or alternator) depends on this relationship

for its operation. In order to diagnose problems and

repair a generator, the service technician must under

stand this relationship.

Why Generators Produce Electricity.

Generators produce an electrical current flow be

cause of the following laws of magnetic induction:

□ When a magnetic field is moved so that it cuts across

a conductor, a voltage and current flow are induced

into the conductor.

□ When current flows through a conductor, a magnetic

field is created around that conductor.

MAGNETIC FIELD CREATES A VOLTAGE;

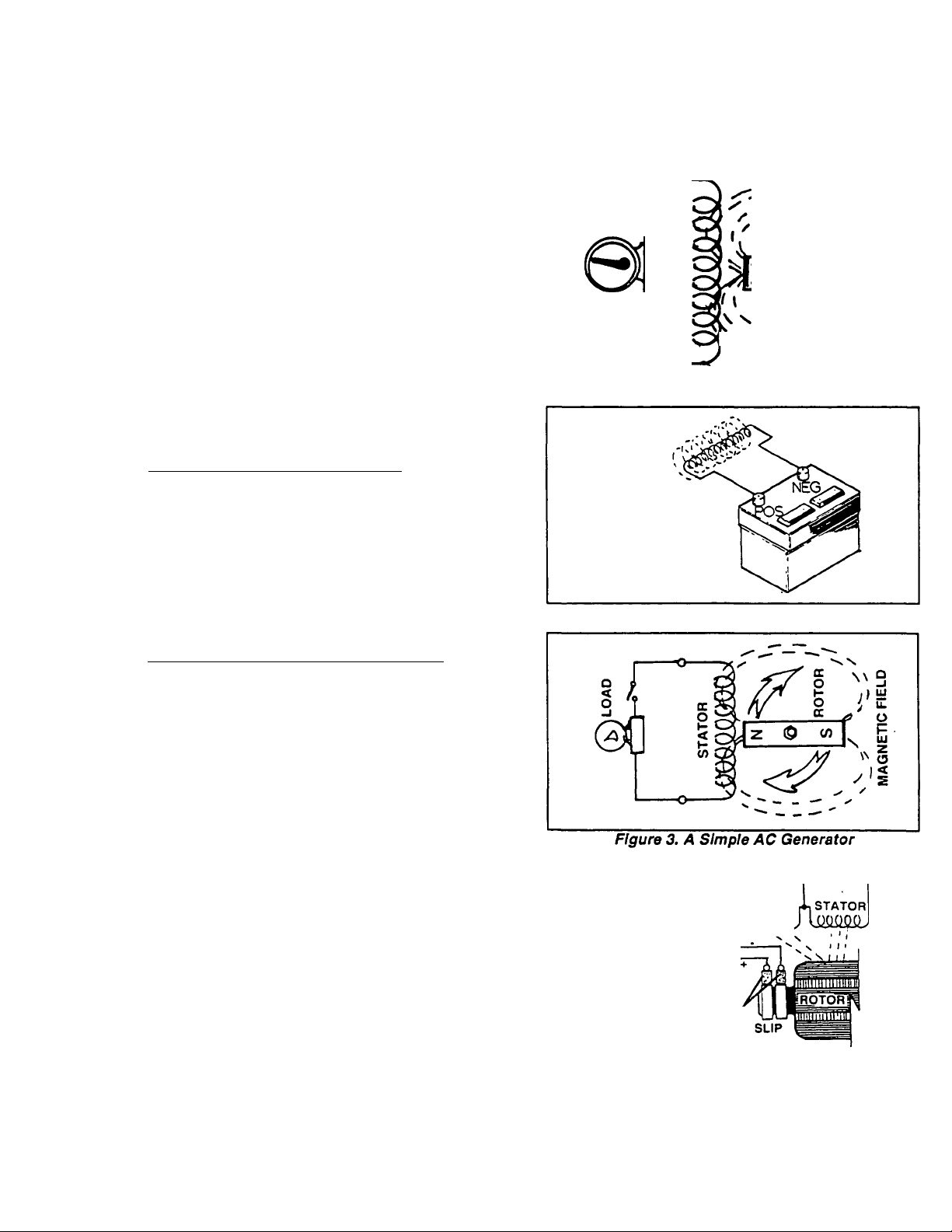

See Figure 1. When a wire, or coil of wire, is moved

through a magnetic field, an electromotive force (EMF)

or voltage is induced into the wire. Conversely, move

ment of the magnetic field so that its lines of flux cut

across the wire will induce a voltage into the wire. If the

ends of the wire are connected to form a complete

circuit, current will flow in the wire. The direction in

which the current flows depends on the polarity of the

magnetic field and the direction in which the magnet is

moved.

11

Z-

oCOIi

K

11

Figure 1. Magnetism Creates Electricity

Figure 2. Current Flow Creates a Magnetic Field

------

CURRENT FLOW CREATES A MAGNETIC FIELD:

See Rgure 2. Current flow through a wire or coil of

wire will create a magnetic field around the wire. The

strength of the magnetic field depends on the amount

of current flow and the number of loops or coils in the

wire. The direction (polarity) of the magnetic field de

pends on the direction of current flow through the wire.

A Simple AC Generator

See Figure 3. In the simple generator shown, the

revolving magnetic field (Rotor) is a permanent mag

net. As the magnet rotates, its magnetic lines of flux cut

across a stationary coil of wire called a STATOR. If the

stator circuit is completed (by adding a load such as the

light bulb), current will flow through the circuit.

A More Sophisticated Generator

In Figure 4, direct current (DC) is delivered to the

ROTOR coil through CARBON BRUSHES and SLIP

RINGS, to create a magnetic field around the ROTOR.

The greater the current flow through the ROTOR wind

ings, the stronger the magnetic field around the

ROTOR. The ROTOR’S magnetic field cuts across the

stationary STATOR windings, to induce a voltage into

those windings, with the induced voltage proportional

to the strength of the ROTOR’S magnetic field.

STATOR

Û. T 1«V.

üэ”r^

¿»V.

< o

z

UJ-

a.

oc

u 3

ou

Figure 4. A More Sophisticated Generator

BRUSHES

RINGS

PAGE 1.2-1

Page 8

SECTION 1.2

HOW A GENERATOR WORKS

Operational Analysis- Units with 10 inch Stator Laminations

NOTE: See "IDENTIFYING UNITS BY STATOR DIAMETER" on Page 1.1-1.

PARTI

THE REVOLVING FIELD AC GENERATOR

1

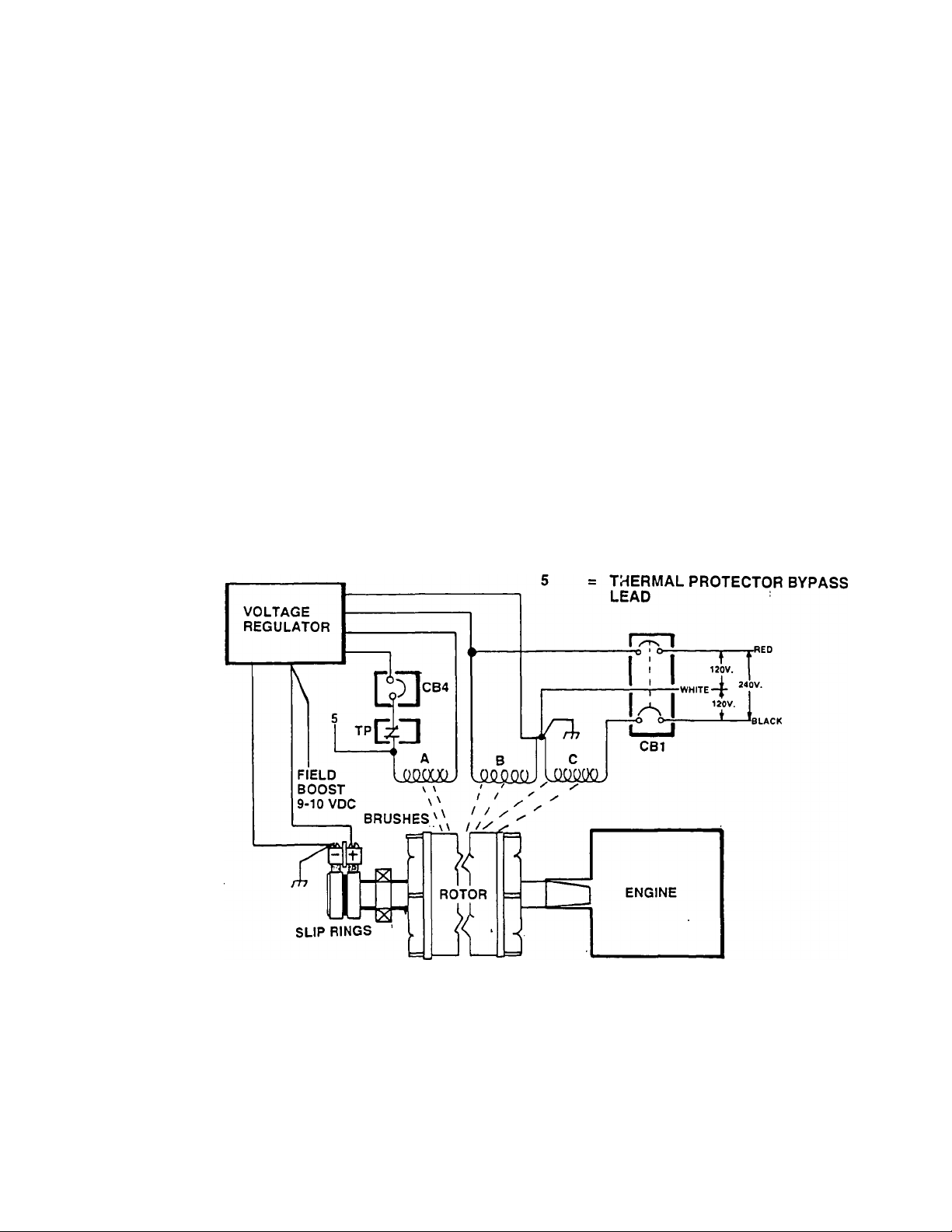

Generator Operation may be briefly described as

follows:

CZl The ROTOR is attached to the engine PTO shaft

and rotates at the same speed as the engine.

□ As the Rotor turns, its magnetic lines of flux cut

across the stationary coils of (a) a stator excitation

winding and (b) dual stator AC power windings. A

voltage is induced into these stationary windings.

□ Current flow from the Stator excitation winding is

delivered to the Voltage Regulator as unregulated

alternating current.

□ Current flow from the Stator AC power windings is

delivered to connected electrical loads.

□ Sensing leads deliver a signal of ACTUAL power

winding output voltage to the Voltage Regulator,

from the Stator AC power windings.

□ The Voltage Regulator electronically compares the

ACTUAL power winding voltage to a REFERENCE

voltage which was pre-set.

□ If the ACTUAL power winding voltage is less than the

Regulator’s REFERENCE voltage. Regulator action

will (a) change the excitation winding output to direct

current (DC), and (b) increase the excitation current

flow to the Rotor.

□ If the ACTUAL power winding voltage is more than

the Regulator’s REFERENCE voltage, regulator ac

tion will (a) change the excitation current to direct

current, and (b) decrease excitation current to the

Rotor.

□ The regulated direct current flow to the Rotor is

delivered via brushes and slip rings.

□ A regulated voltage is induced into the Stator AC

power windings as the Voltage Regulator acts to

maintain an ACTUAL voltage as close as possible to

an adjusted REFERENCE voltage.

A = EXCITATION WINDING

B = STATOR AC POWER WINDING

C = STATOR AC POWER WINDING

CB1 = MAIN CIRCUIT BREAKERS

CB4 = EXCITATION CIRCUIT BREAKER

TP = THERMAL PROTECTOR

PAGE 1.2-2

Figure 5. Operating Diagram- Units with 10 Inch Stator Laminations

Page 9

PART 1

THE REVOLVING FIELD AC GENERATOR

Operational Analysis- Units with 15 Inch Stator Laminations

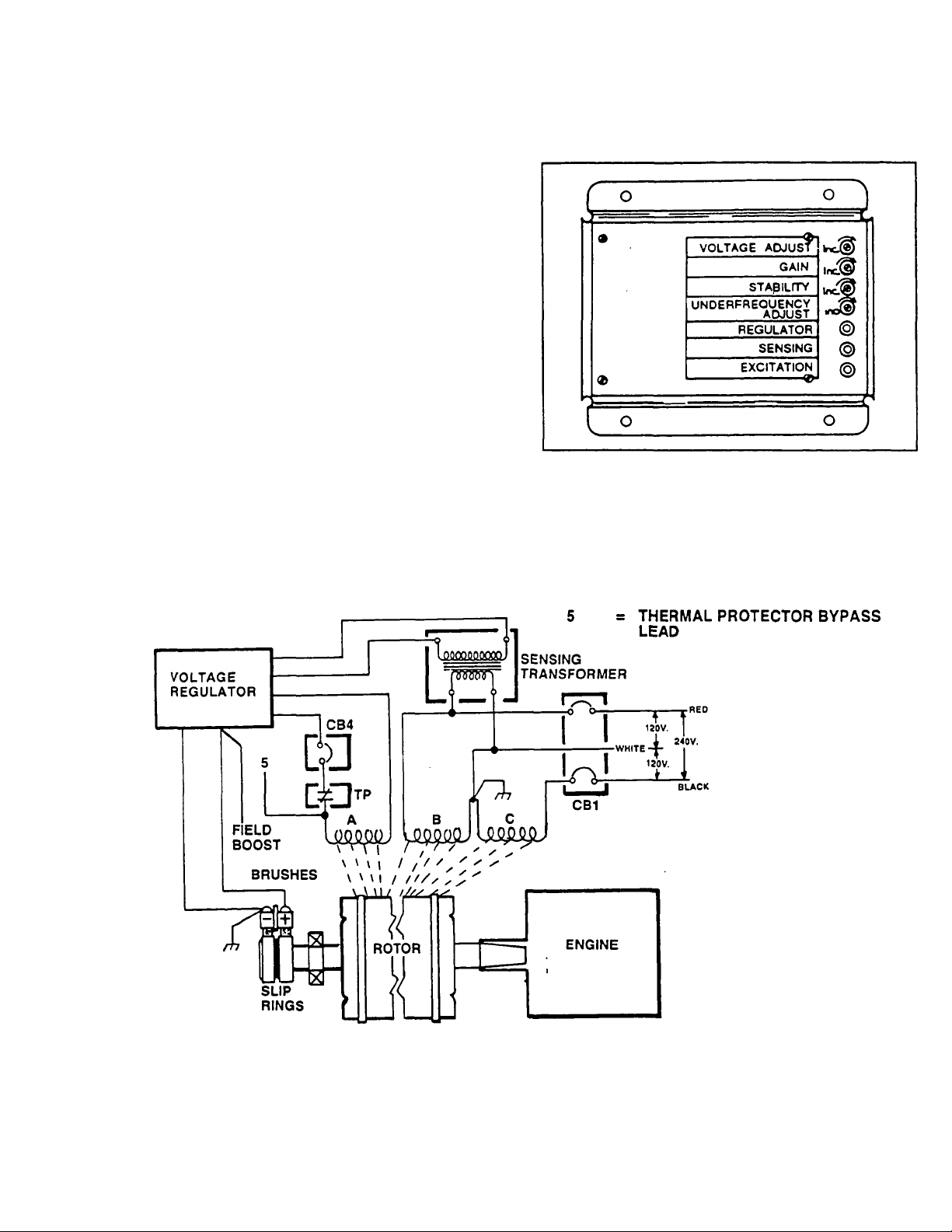

Some differences exist between generator models

having a 10 inch diameter stator and those with a 15

inch diameter Stator. You may wish to review "IDENTI

FYING UNITS BY STATOR DIAMETER" on Page 1:1-

1.

Figure 6 is an Operating Diagram for NF eries

generators with a 15* inch diameter stator. T units

are equipped with a Part No. 67680 voltagi n rewhich requires 240 volts AC sensing. Tf ram,

SENSING TRANSFORMER serves to itor’s

stator’s line-to-neutral sensing voltage to 24 ts.

SECTION 1.2

HOW A GENERATOR WORKS

1

Figure 7. Voltage Regulator Part No. 67680

m

A = EXCITATION WINDING

B = STATOR AC POWER WINDING

C = STATOR AC POWER WINDING

CB1 = MAIN CIRCUIT BREAKERS

CB4 = EXCITATION CIRCUIT BREAKER

TP = THERMAL PROTECTOR

Operating Diagram- Units with 15 Inch Diameter Stator Laminations

PAGE 1.2-3

Page 10

SECTION 1.2

HOW A GENERATOR WORKS

PARTI

THE REVOLVING FIELD AC GENERATOR

1

PAGE 1.2-4

Page 11

PARTI

THE REVOLVING FIELD AC GENERATOR

MAJOR COMPONENTS

(UNITS WITH 15 INCH DIAMETER STATOR)

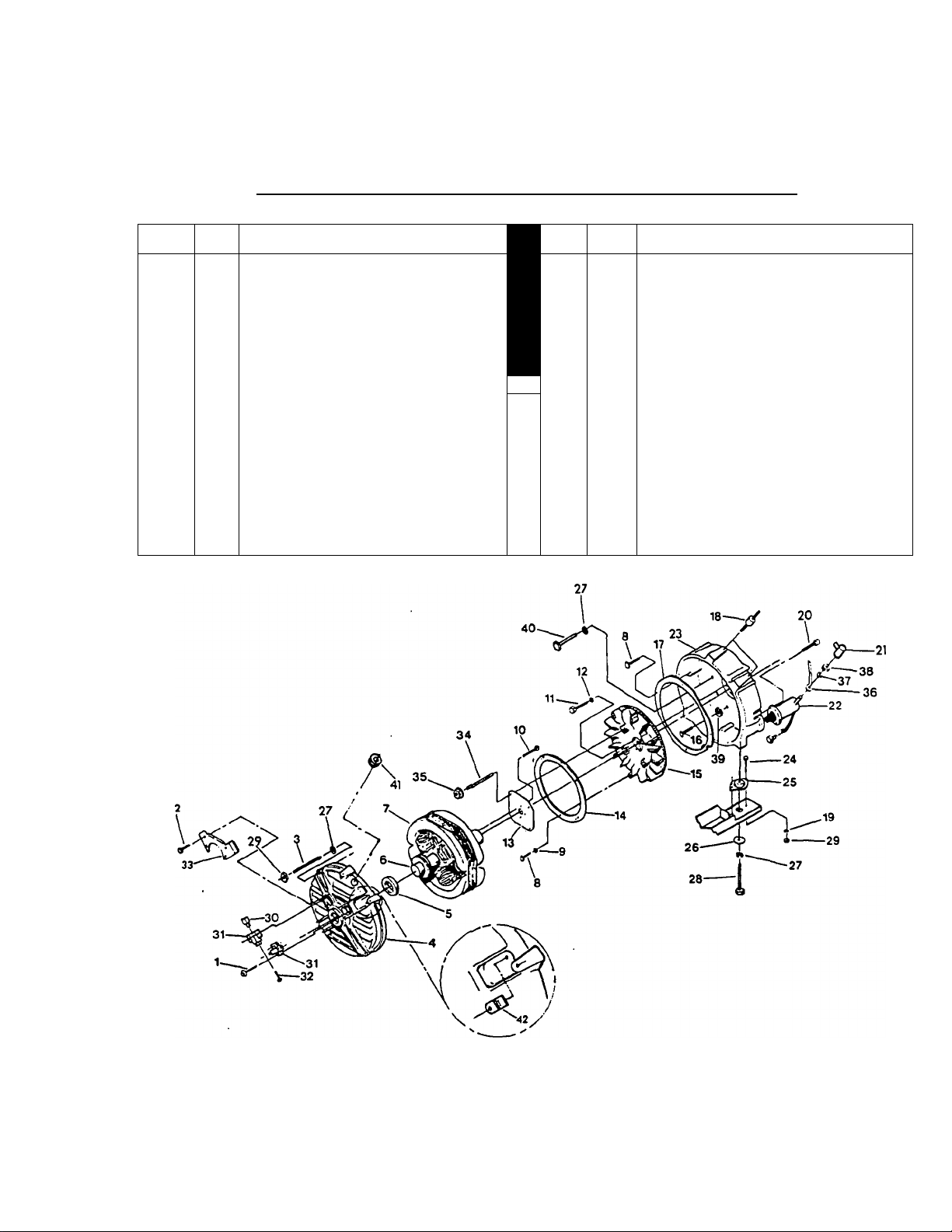

SECTION 1.3- MAJOR COMPONENTS

(UNITS WITH 15 INCH STATOR)

1

Section 1.3

ITEM

QTY DESCRIPTION

1

2 4

3

4 1 Rear Bearing Carrier

5

6 1

7 1

8 10

9 6

10 4 Hex Head Flanged Bolt

11 4 Screw

12

13 1 Flexible Coupling

14

15 1 Flywheel

16

17 1 Air Ring Baffle

18 4 Vibration Mount

19 6

20 2 Socket Head Capscrew

4 Taptite Screw

4 Stud

1

4

1

4 Hex Head Capscrew

Taptite Screw

Rotor Bearing

Rotor Assembly

Stator Assembly

Hex Head Capscrew

Lockwasner

Lockwasher

Fan Ring

Flatwasher

»

2®

ITEM

21

22

23

24

25

26

27 8 Lockwasher

28

29

30

31

32 4

33

34 4

35

36

37 1

38

39

40

QTY

■ 1

DESCRIPTION

1

1

4'

2

2

2

6

4

2

2

4

1

1

4

2

Battery Cable Boot

Starter Motor

Engine Adapter

Hex Head Capscrew

Vibration Isolator

Flatwasher

Hex Head Screw

Hex Nut

Brush

Brush Holder

Screw

Brush Cover

stud

Flanged Nut

Red Starter Cable

Lockwasher

Hex Nut

Lockwasher

Hex Head Capscrew

Figure 1. Exploded View of AC Generator with 15 Inch Stator

PAGE 1.3-1

Page 12

SECTION 1.3- MAJOR COMPONENTS

(UNITS WITH 15 INCH STATOR)

1

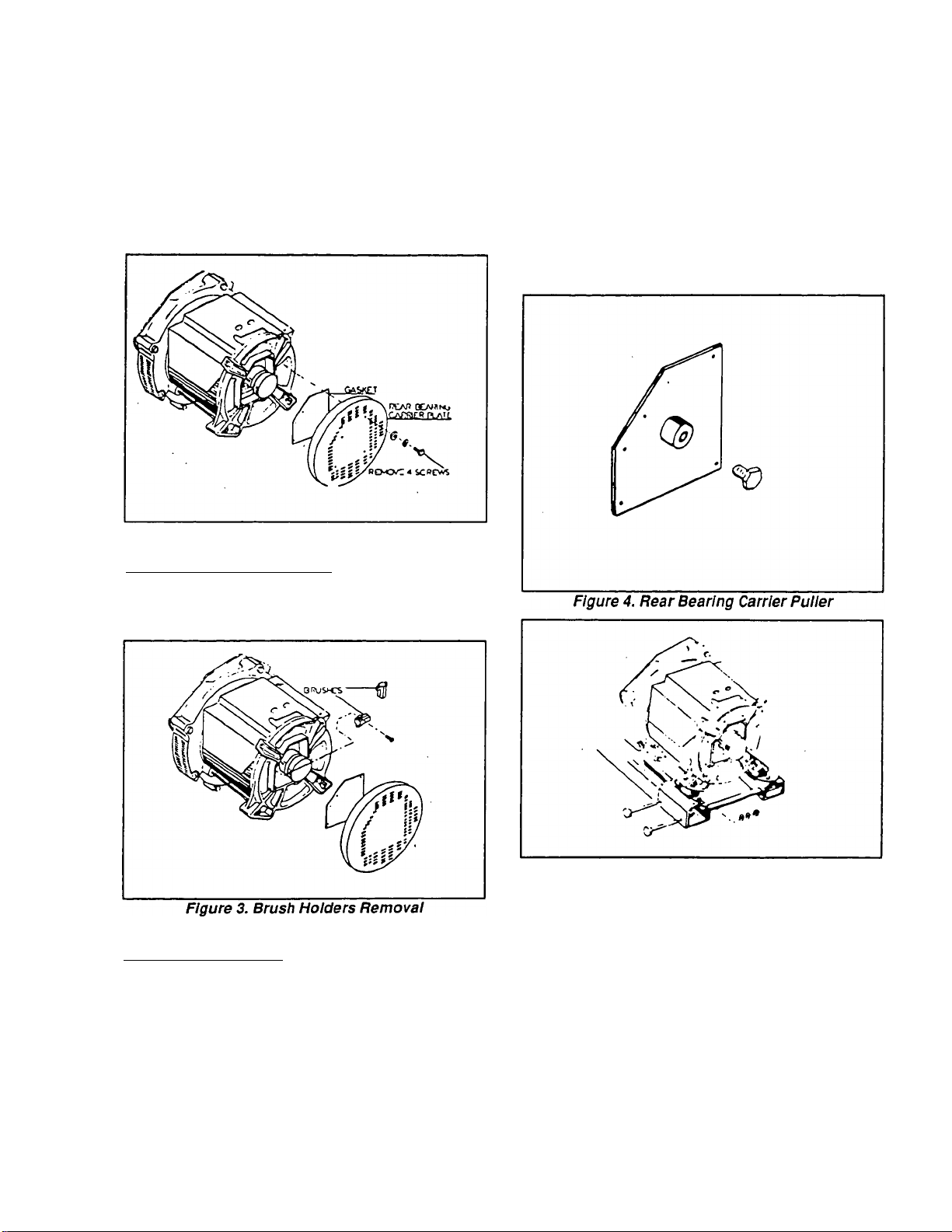

AC Generator Disassembly

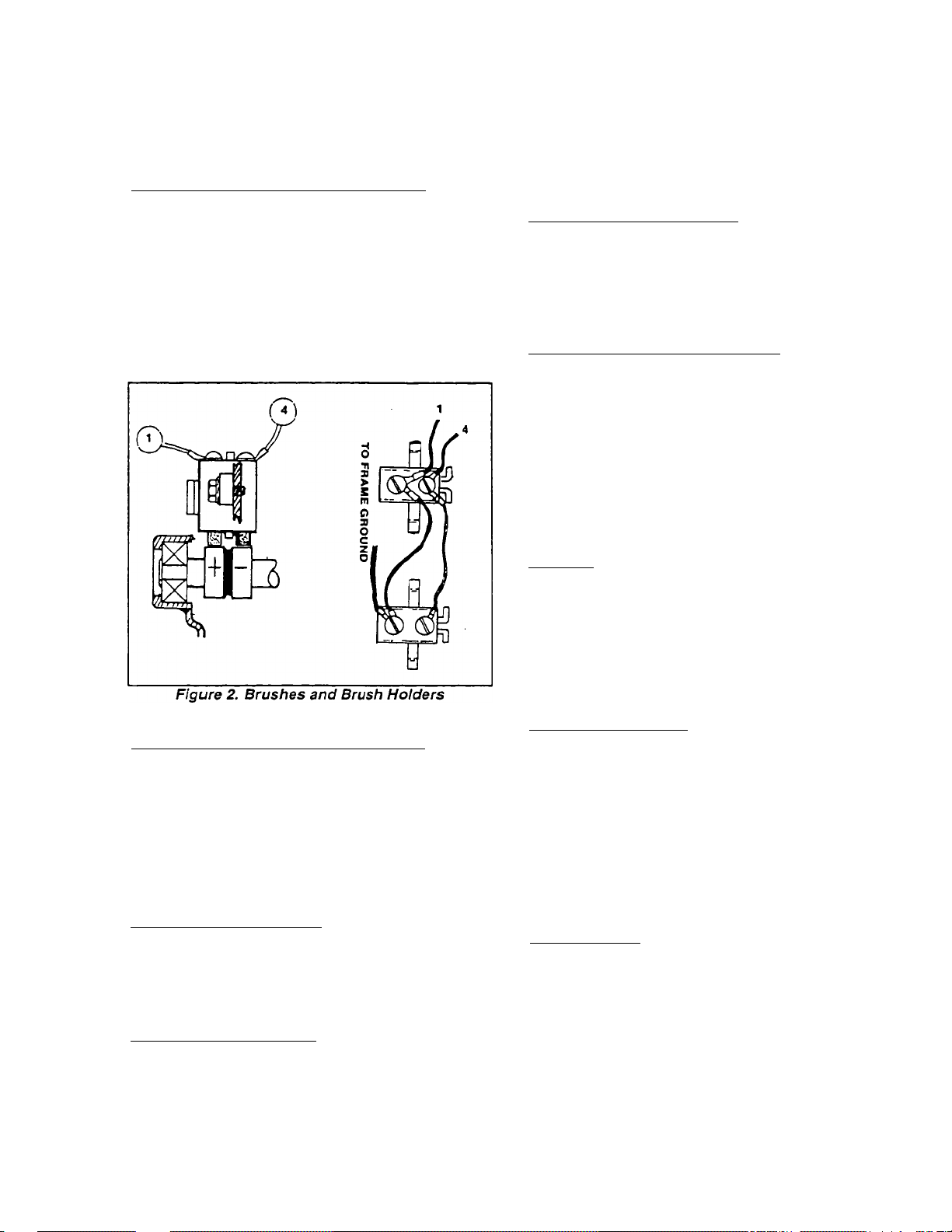

BRUSH ACCESS AND REMOVAL Figures 1 & 2);

See Rgure 1. Remove the TAPTITE SCREWS

(Item 2) that retain the two BRUSH COVERS (Item 33)

to the REAR BEARING CARRIER (Item 4). Remove

the BRUSH COVERS (Item 33) to gain access to the

BRUSH HOLDERS (Item 31).

See Figure 2, below. Remove Wires No. 1 and 4

from the BRUSHES in both BRUSH HOLDERS. Re

move the TAPTITE SCREWS that retain the BRUSH

HOLDERS to the REAR BEARING CARRIER. Re

move both BRUSH HOLDERS, along with the

BRUSHES

PARTI

THE REVOLVING FIELD AC GENERATOR

To remove the FLEXIBLE COUPLING (Item 13)

from the ROTOR (Item 6), remove four HEX HEAD

FLANGED BOLTS (Item 10).

FLYWHEEL REMOVAL (Figure 1):

Remove four SCREWS (Item 11) and

LOCKWASHERS (Item 12). Then, remove FLY

WHEEL (Item 15). If desired, the FAN RING (Item 14)

can be removed by removing HEX HEAD

CAPSCREWS (Item 8) and LOCKWASHERS (Item 9).

ENGINE ADAPTER REMOVAL (Figure 1);

To remove AIR RING BAFFLE (Item 17), remove

CAPSCREWS (Item 8) that retain It to the ENGINE

ADAPTER (Item 23).

Support the engine and remove all fasteners that

retain the ENGINE ADAPTER to the BASE ASSEM

BLY. Remove HEX HEAD CAPSCREWS (Item 40) and

LOCKWASHERS (Item 27). Finally, remove the EN

GINE ADAPTER.

Components Inspection and Testing

REAR BEARING CARRIER REMOVAL (Figure 1):

Remove HEX NUTS (Item 29), LOCKWASHERS

(Item 27) and STUDS (Item 3) that retain the REAR

BEARING CARRIER (Item 4). To free the REAR

BEARING CARRIER (Item 4) from the ROTOR BEAR

ING (Item 5), use a soft mallet to tap around the outer

periphery of the BEARING CARRIER. Continue tap

ping until the BEARING CARRIER is free of the bear

ing.

STATOR REMOVAL (Figure 1):

The STATOR (Item 7) is "sandwiched" between the

ENGINE ADAPTER (Item 23) and the REAR BEARING

CARRIER (Item 4). Carefully remove the STATOR

(Item 7). DO NOT PERMIT THE STATOR TO DROP

OR BUMP THE ROTOR DURING REMOVAL.

ROTOR REMOVAL (Figure 1):

Remove the four FLANGED NUTS (Item 35) from

STUDS (Item 34). The ROTOR (Item 6), with FLEXI

BLE COUPLING (Item 13) attached, can now be pulled

free of the FLYWHEEL (Item 15).

GENERAL;

Following disassembly, generator components

should be cleaned, dryed and inspected or tested.

Never reassemble a generator having defective parts.'

Keep major parts separated and keep the mounting

hardware along with the parts they are used with. Store

parts in a clean, dry area where condensation, dirt, or

moisture will not damage them.

REAR BEARING CARRIER:

The Rear Bearing Carrier (Figure 1, Item 4) is an

aluminum casting. Clean the casting and blow dry with

air. Inspect carefully for cracks, obvious damage. An

insert has been pressed into the Carrier center bore, to

accommodate the Rotor Bearing. Replace the Rear

Bearing Carrier if the center bore diameter is not within

the following dimensions:

BEARING CARRIER CENTER BORE

2.9527-2.9533 Inches (74.999-75.014mm)

ROTOR BEARING:

The rotor bearing is a prelubricated and sealed ball

bearino that requires no additional lubrication for the

life of the bearing. Spin the Rotor bearing by hand and

check it for binding, seizing, roughness, etc. If the

bearing is defective, it must be replaced.

The bearing may be removed from the Rotor shaft

using a bearing puller. A new bearing can then be

pressed onto the shaft. Exert pressing force on the

bearing inner race only- NEVER on the bearing outer/'"~^^

race.

PAGE 1.3-2

Page 13

PART 1

THE REVOLVING FIELD AC GENERATOR

SECTION 1.3- MAJOR COMPONENTS

(UNITS WITH 15 INCH STATOR)

1

Components Inspection and Testing

(Continued)

ROTOR ASSEMBLY;

Clean the Rotor with dry, low pressure air (25 psi

or less). If the slip rings are dirty or tarnished, clean

them with fine sandpaper. Inspect the Rotor for dam

age.

Check the resistance of Rotor windings with a

volt-ohm-milliammeter (VOM). Refer to Section 1.6,

"TROUBLESHOOTING (UNITS WITH 15 INCH STA

TOR)".

Use an Insulation resistance tester, megohmmeter,

or Hi-Pot tester to test the resistance of Rotor insula

tion. See Section 1.8,

TESTSr.

If the Insulation resistance is low, dry the Rotor with

warm, dry air. DO NOT EXCEED 185* F. (85’ C.). If

resistance is still low after drying, replace the Rotor

Assembly.

STATOR ASSEMBLY:

Clean the Stator Assembly in the same manner as

the Rotor was cleaned. Inspect ther Stator for damage.

Use a VOM to check Stator windings resistance

(see Section 1.6).

Check the insulation resistance of Stator windings,

as outlined in Section 1.8.

FLEXIBLE COUPLING:

Carefully inspect the Flexible Coupling (Figure 1,

Item 13) for damage, cracking. Check mounting holes

on couplino for elongation and damage. Replace the

Coupling, if it is damaged.

FAN RING AND AIR RING BAFFLE:

Inspect the Fan Ring (Figure 1, Item 14) and the

Air Ring Baffle (Item 17) for damage, cracking. Re

place, if damaged.

•INSULATION RESISTANCE

Reassemble the generator In the reverse order of

Generator Reassembly

disassembly. The reassembly process requires a great

deal of care. Components must be properly aligned and

retained. Tighten all fasteners to the recommended

torque values (see Part 6, "SPECIFICATIONS AND

CHARTS"). Following reassembly, perform an opera

tional test of the unit (Section 1.9).

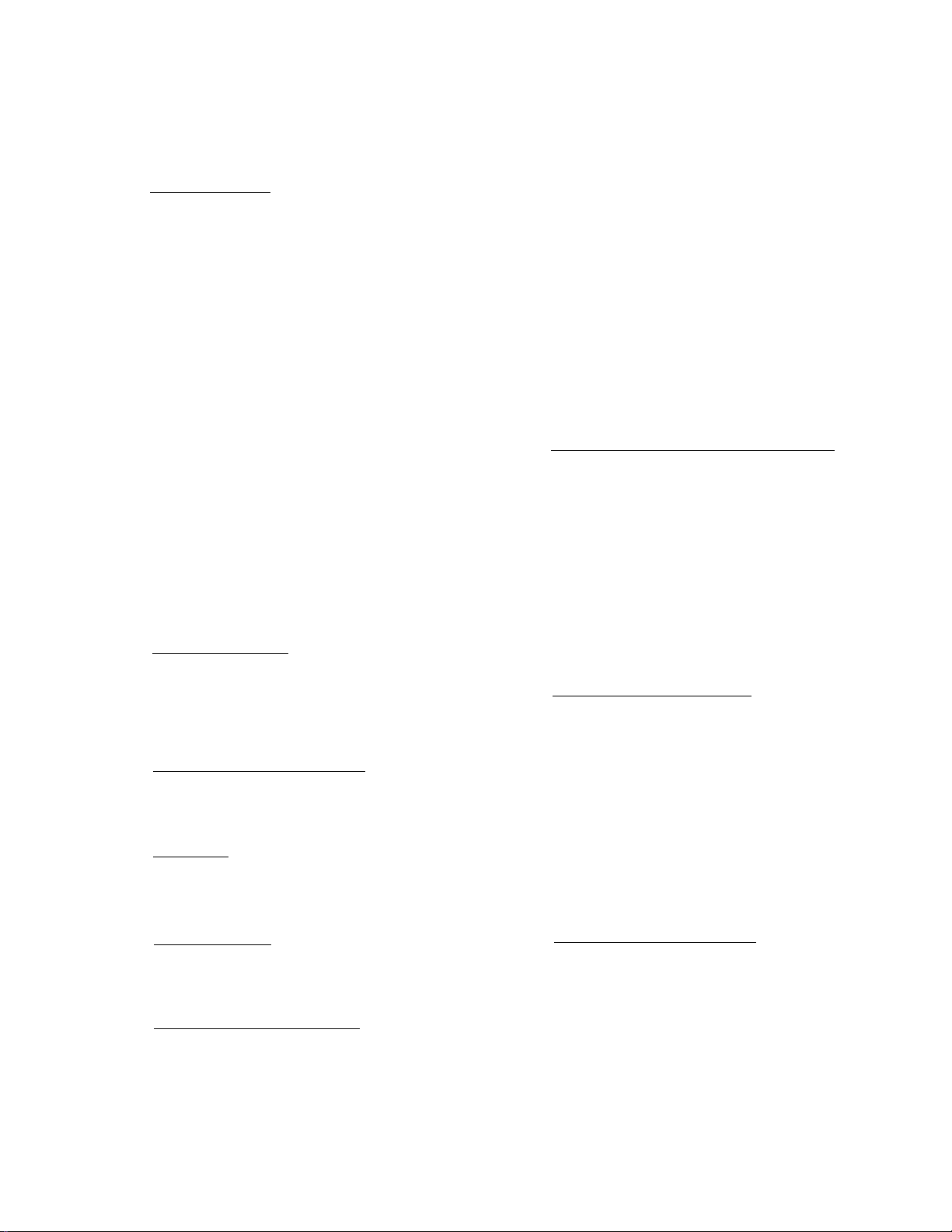

Components In Generator Control Panel

INTRODUCTION:

Rgure 3 (next page) Is an exploded view of the

generator control panel. The Panel houses or mounts

several Important AC generator components, as well

as components that are part of the engine DC electrical

systems.

ENGINE ELECTRICAL SYSTEM COMPONENTS;

The Control Panel houses the following compo

nents that are part of the engine electrical system. For

Information on these components, refer to Part 5 of this

Manual, "ENGINE ELECTRICAL SYSTEM".

□ The 14 and 30 amp Fuses (Items 4 and 5).

□ The 10 amp DC Circuit Breaker (Item 6).

□ The two 12 volts DC Relays (Items 7 and 8).

□ The DC Voltage Regulator (Item 13).

□ Engine Control Circuit Board (Item 39).

□ Hourmeter (Item 23).

□ Start-Stop Switch (Item 24).

□ Preheat Switch (Item 25).

AC GENERATOR COMPONENTS:

The following components, housed in the control

panel, are major generator components and will be

discussed in this Section and Sub-Section.

□ Excitation Circuit Breaker (Item 11).

□ AC Voltage Regulator (Item 14).

□ The Sensing Transformer (Item 15).

□ AC Circuit Breaker (Item 16).

FLYWHEEL;

Clean the flywheel. Inspect for damage, cracks,

wear, etc. Replace, if necessary.

ENGINE ADAPTER;

Clean the Engine Adapter (Figure 1, Item 23).

Inspect the Adapter carefully for damage, wear, crack

ing, etc. Replace, if necessary.

BRUSH HOLDERS AND BRUSHES:

Inspect Brush Holders and Brushes for damage,

cracking, chipping, excessive wear, etc. Replace any

defective or damaged part. Brushes must always be

replaced in complete sets.

In addition to the above components, a THERMAL

PROTECTOR is physically imbedded in the wire wind

ings of the Stator Assembly. A discussion of this com

ponent will also be included in this Section.

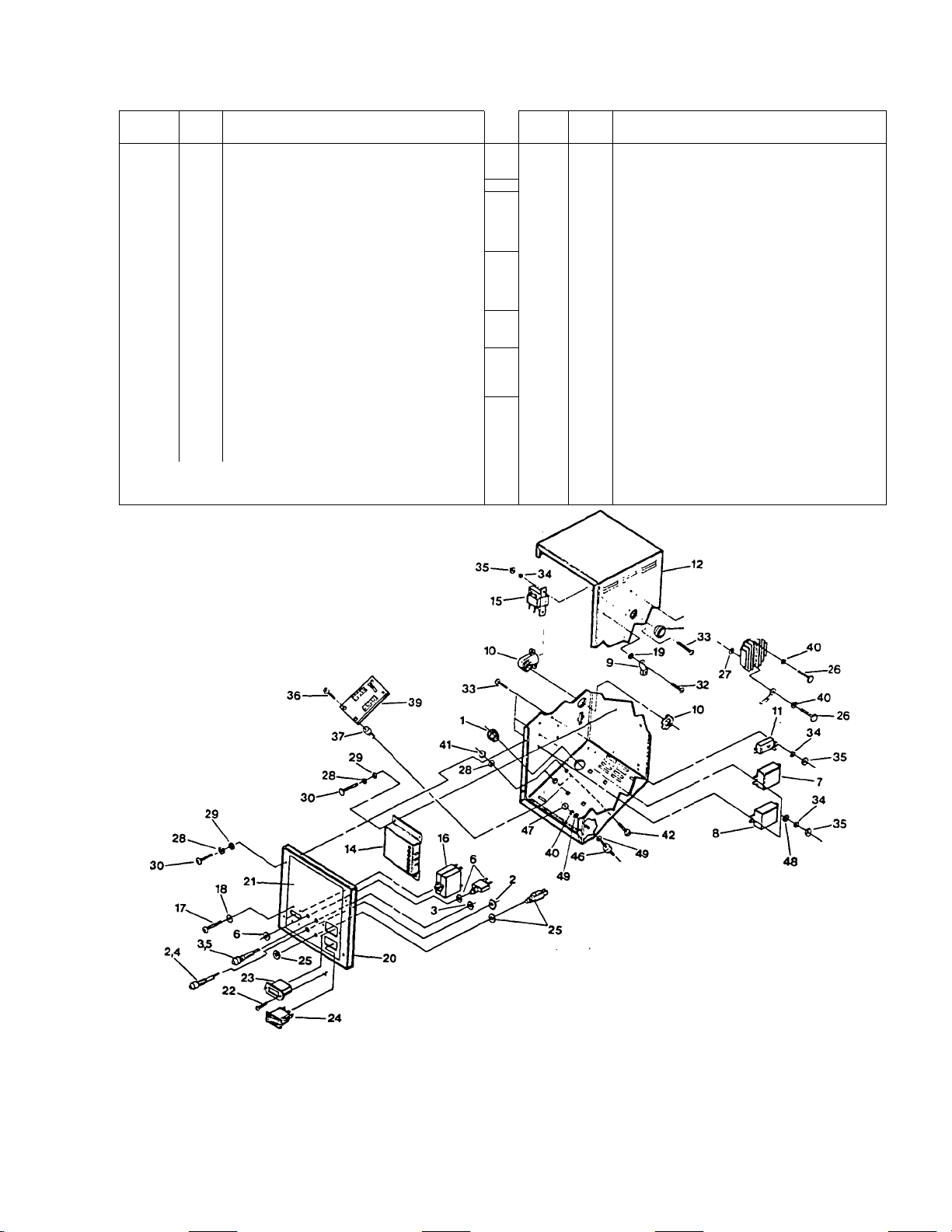

EXCITATION CIRCUIT BREAKER;

The excitation circuit breaker is housed in the con

trol panel and connected in series with .the Stator

Excitation winding output to the Voltage Regulator.

If this Breaker should open, loss of unregulated

excitation current to the Regulator will occur. The Reg

ulator will then shut down and loss of regulated excita

tion current to the Rotor will occur. Generator AC output

will then be proportional to Rotor residual magnetism

only (about 2-7% of rated voltage).

PAGE 1.3-3

Page 14

SECTION 1.3- MAJOR COMPONENTS

(UNITS WITH 15 INCH STATOR)

PARTI

THE REVOLVING FIELD AC GENERATOR

1

ITEM

QTY

1

2*

3* 1

4*

5*

6*

r 1

8*

9

10 1

11** 1

12

13*

14“

15“

16

17

18

19

20 1

21 1

22 2

* See Part 5,

2

1

1

1

1

1

1

EXCITATION CIRCUIT BREAKER

1

1

1

1

1

4

4

1

'* Part of AC generator circuit, Included in this Section.

"ENGINE ELECTRICAL SYSTEM".

DESCRIPTION

Snap Bushing

FUSE HOLDER- 30 amp

FUSE HOLDER-14 amp

30 AMP FUSE

14 AMP FUSE

10 amp DC Circuit Breaker

12 volts DC RELAY

12 volts DC RELAY

Solderless Lug

90 Conduit Clamp

Control Panel Box

DC VOLTAGE REGULATOR

AC VOLTAGE REGULATOR

SENSING TRANSFORMER

AC CIRCUIT BREAKER

Pan Head Screw

Lockwasher

Lockwasher

Control Panel

Panel Decal

Pan Head Screw

ITEM

23* 1

24* 1

25*

26 2

27

28

29

30

31

32 1

33

34

35

36

37 4

39*

40

41

42 2

44 1

45

46

47

48

QTY

1

2

10

8

8

•

8 Pan Head Screw

8

8

4

1

6

2

1

4

4

4

DESCRIPTION

HOURMETER

START-STOP SWITCH

PREHEAT SWITCH

Hex Head Capscrew

External Lockwasher

Lockwasher

Flatwasher

Hex Head Capscrew

Customer Leeds (Not Shown).

Pan Head Screw

Lockwasher

Hex Nut

Self Tapping Screw

ENGINE CONTROL CIRCUIT

Spacer Tlut

BOARD

Lockwasher

Hex Nut

Hex Head Capscrew

Panel Wiring Harness

Engine Wire Harness

Vibration Dampener

Hex Nut

Flatwasher

Figure 3. Exploded View of Control Panel

/ 13

PAGE 1.3-4

Page 15

PARTI

THE REVOLVING FIELD AC GENERATOR

Components In Generator Control Panel (Continued)

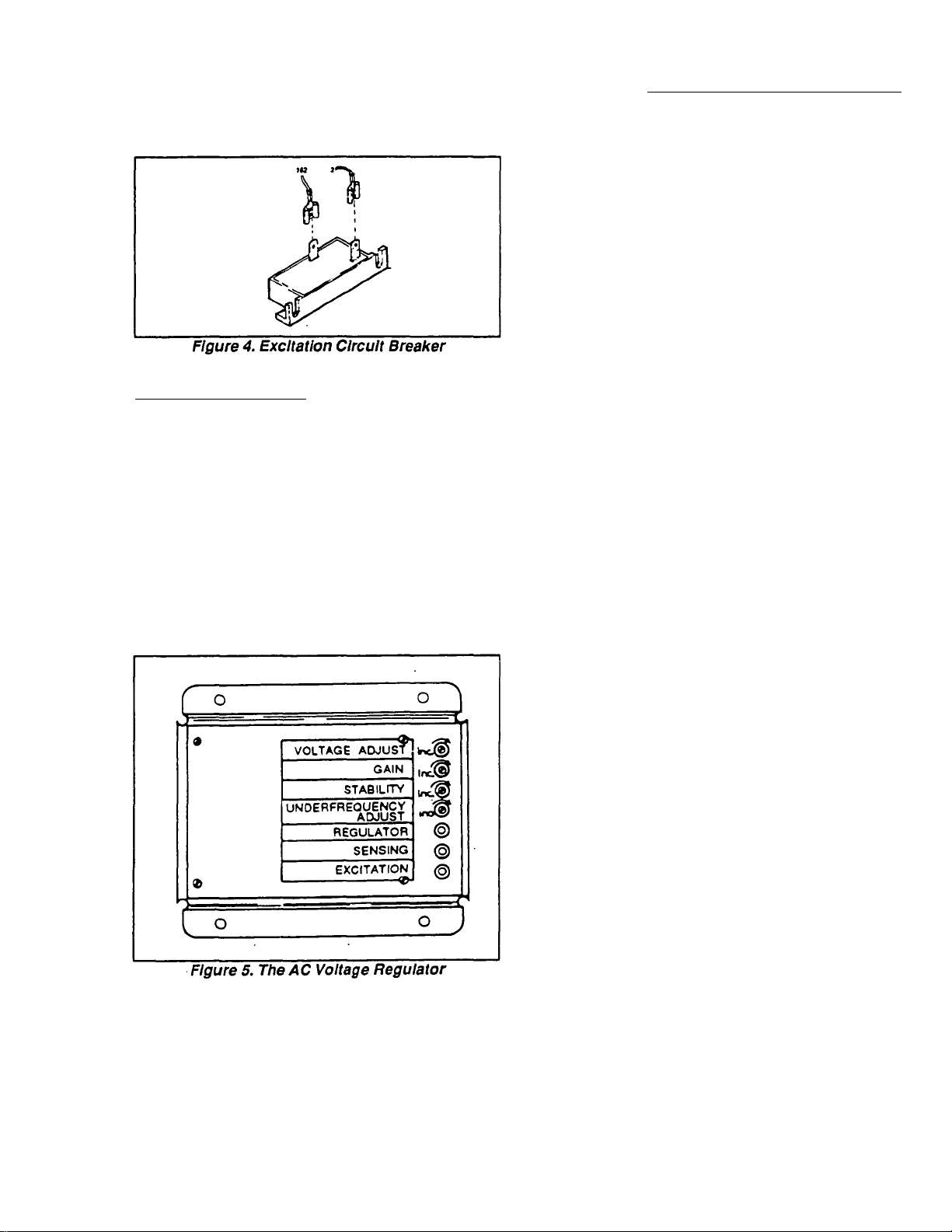

AC VOLTAGE REGULATOR:

The Voltage Regulator is powered by stator excitation

winding AC output. Approximately 4 to 8 volts is required

from that power source to turn the regulator on.

The Regulator is equipped with three (3) lamps

(LED’s or "light emitting diodes). See Figure 5. These

lamps are normally on during operation with no faults in

the system. The green EXCITATION lamp and the red

REGULATOR lamp are both turned on by stator excita

tion winding output. If, for any reason, stator excitation

winding output were to be reduced, the two lamps would

begin to dim. Finally, at some mid-point voltage and

current, the two lamps will no longer glow visibly.

SECTION 1.3- MAJOR COMPONENTS

(UNITS WITH 15 INCH STATOR)

1

NOTE: Sensing input to the Regulator Is actually taken

from Hne-to-neutra! stator leads and Is about 120 volts

AC. However, this voltage Is boosted to about 240 volts

AC by the action of a sensing transformer.

The following facts apply to Voltage Regulator opera

tion:

1. The Regulator will shut down on occurence of one or

more of the following conditions:

a. Loss of sensing voltage.

b. Loss of stator excitation voltage Input to the

Regulator.

c. Loss of circuit reference.

NOTE: The term "circuit reference" refers to voltage

regulator settings. The Regulator "regulates" excitation

winding current flow to the Rotor windings in order to

maintain a sensing (actual) voltage that Is commen

surate with a preset "reference" voltage. The reference

voltage is adjustable within a 20 percent range at the

Regulator. Voltage regulation Is accomplished by

electronically maintaining an ACTUAL voltage that Is

very close to the Regulator's preset REFERENCE volt

age.

The yellow SENSING lamp Is powered by sensing

input to the Regulator from the stator AC power wind

ings. The brightness of this lamp (LED) will depend on

available sensing voltage.

2. During generator operation, all three Regulator lamps

should be ON.

a. REGULATOR lamp ON Indicates the Regulator is

functioning normally.

b. SENSING lamp ON indicates that normal sensing

voltage Is available to the Regulator.

c. EXCITATION lamp ON Indicates that unregulated

excitation winding output Is available to the

Regulator.

3. If the red REGULATOR lamp is OUT, a Voltage

Regulator fault exists or the Regulator has shut down

due to occurence of one or more Regulator shutdown

conditions. See Step 1 above for conditions that will

result in Regulator shutdown.

a. Expect to see a generator AC output voltage that

is commensurate with the Rotor’s residual mag

netism.

b. Rotor residual magnetism will supply approximate

ly 2 to 7 percent of the unit’s rated voltage.

NOTE: "Residual" magnetism Is that magnetism that Is

normally always present In the Rotor. The Rotor may be

considered a "permanent magnet".

PAGE 1.3-5

Page 16

SECTION 1.3- MAJOR COMPONENTS

(UNITS WITH 15 INCH STATOR)

1

Components In Generator Control Panel (Continued)

AC VOLTAGE REGULATOR (CONT’D):

4. If the green EXCITATION lamp goes out, loss of

stator excitation winding output to the Regulator has

occured.

a. Loss of excitation winding output will result in

Regulator shutdown. The red REGULATOR lamp will

then go out, as well.

b. Under this condition, look for a generator AC output

voltage that is commensurate with residual Rotor

magnetism (about 2-7% of rated volts).

c. When the REGULATOR and EXCITATION lamps

are both out, the excitation circuit from the stator

excitation windings to the voltage regulator Is suspect

(inclusive).

5. Should the yellow SENSING lamp go out, loss of

sensing voltage to the Regulator has occured.

a. Loss of sensing may cause the Regulator to shut

down. Both the SENSING lamp and the

REGULATOR lamp will then go out.

b. Generator AC output voltage will then be commen

surate with Rotor residual magnetism (2-7% of rated

volts).

c. Look for a fault in the sensing circuit.

6. If all three lamps go out, look for a fault that might

cause both sensing and excitation to fail.

a. Look for dirty or corroded slip rings, bad brushes,

defective Rotor.

b. Look for open circuit in Wires No. 1 and/or 4.

7. If the red REGULATOR lamp flashes, the

Regulator’s STABILITY potentiometer requires ad

justment.

PART 1

THE REVOLVING FIELD AC GENERATOR

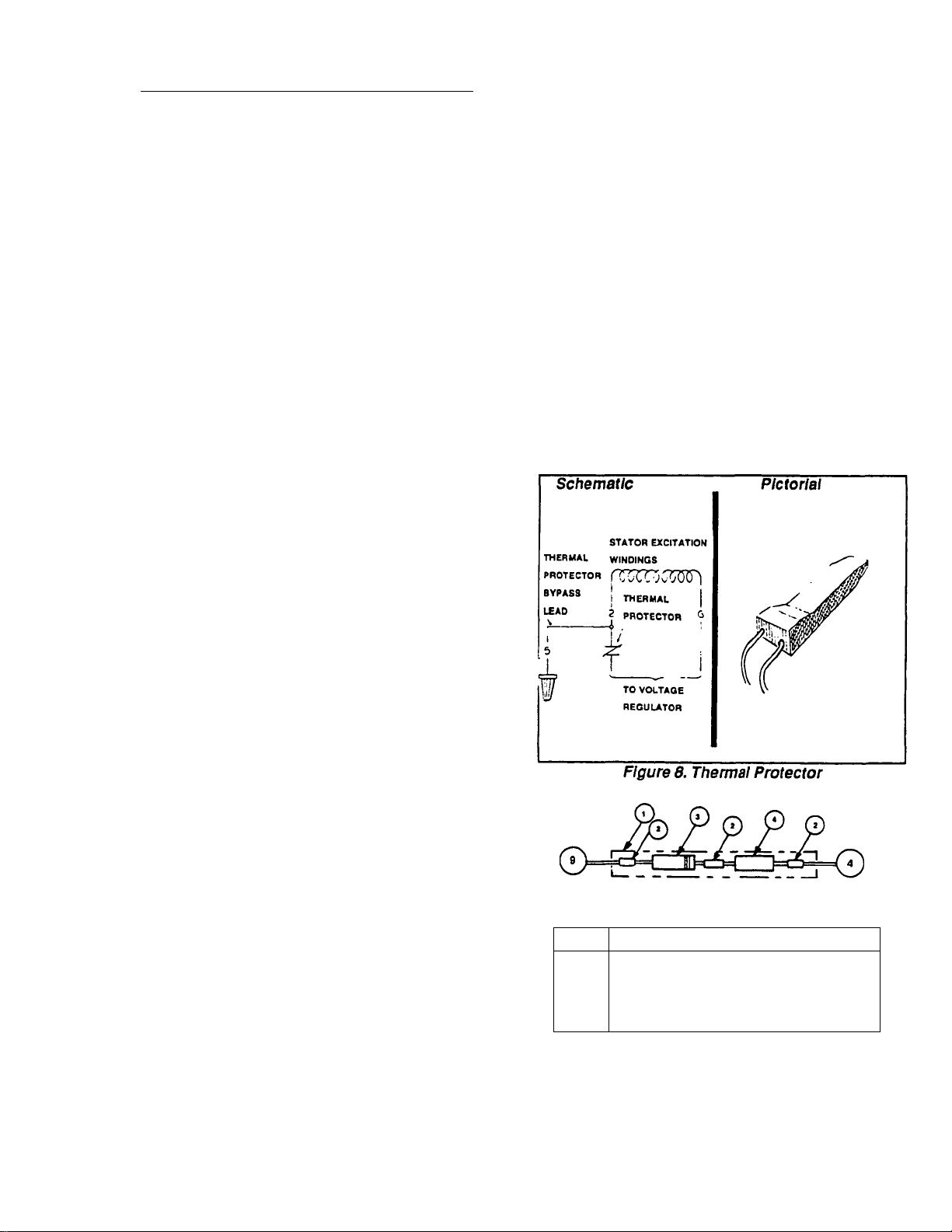

AC CIRCUIT BREAKER:

The AC circuit breaker protects the unit against cur

rent overload by opening the AC output circuit in the

event the generator’s current (amperage) capacity is,/'”^

exceeded. The amperage at which the breaker will trip

(open) is the breaker’s trip rating.

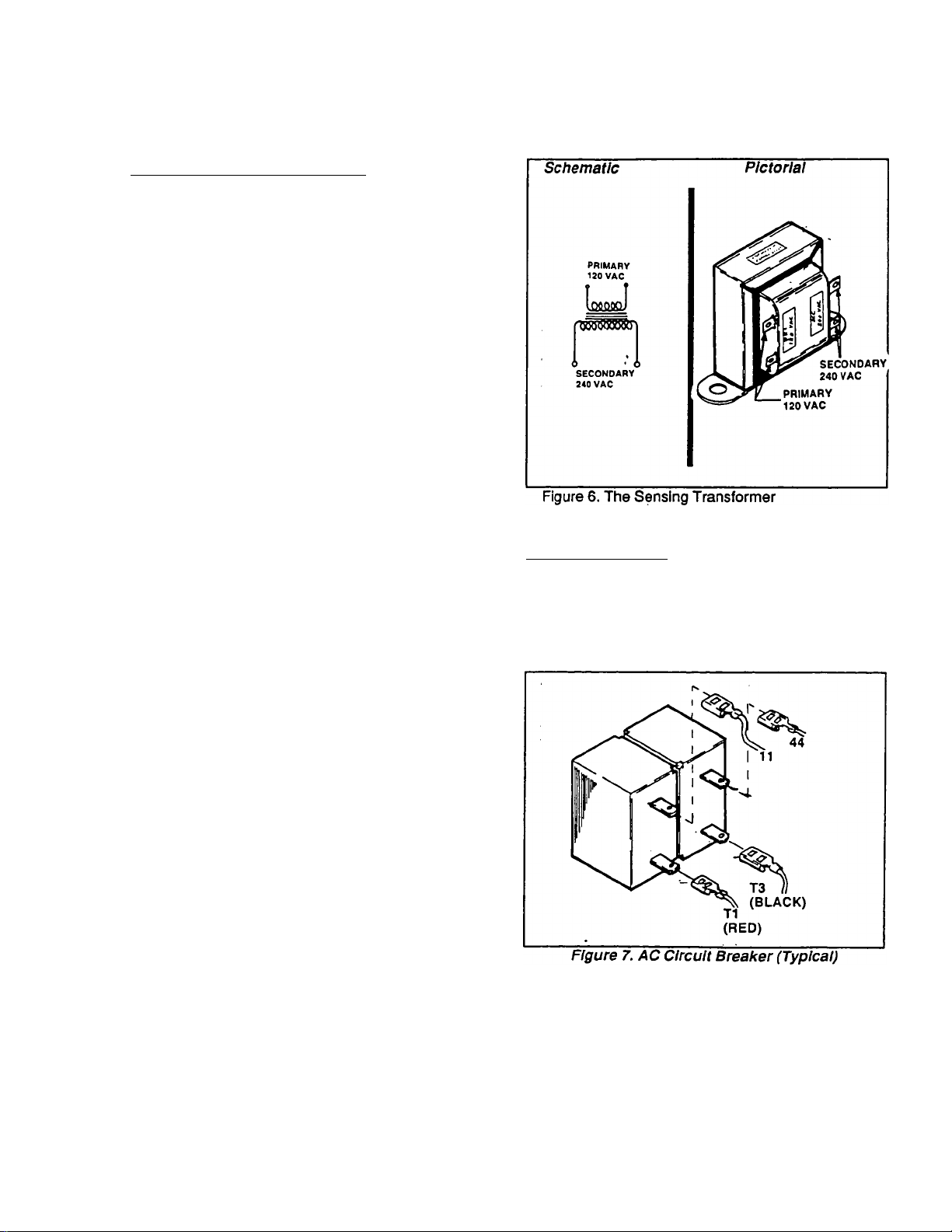

SENSING TRANSFORMER:

The Part No. 67680 Voltage Regulator requires a

"line-to-line" sensing voltage (240 volts) for proper

operation. However, the sensing Is taken from "line-toneutral" Wires No. 11 and 22 (120 volts). For that

reason, the primary coil of a sensing transformer is

connected in series with the sensing leads. The sensing

transformer is a "step-up" type. That is, 120 volts AC in

its primary coil will induce 240 volts into its secondary

coil. It is the secondary coil voltage that is delivered to

the regulator as sensing voltage.

The sensing transformer is housed in the generator

control panel and is used on generator’s with the Part

No. 67680 Voltage Regulator and with 15 inch diameter

stator laminations.

The sensing transformer Is shown pictorially and

schematically in Figure 6.

PAGE 1.3-6

The AC circuit breaker used on any specific generator

model will depend on the rated current (amperage)

capacity of that model.

Page 17

PART 1

THE REVOLVING FIELD AC GENERATOR

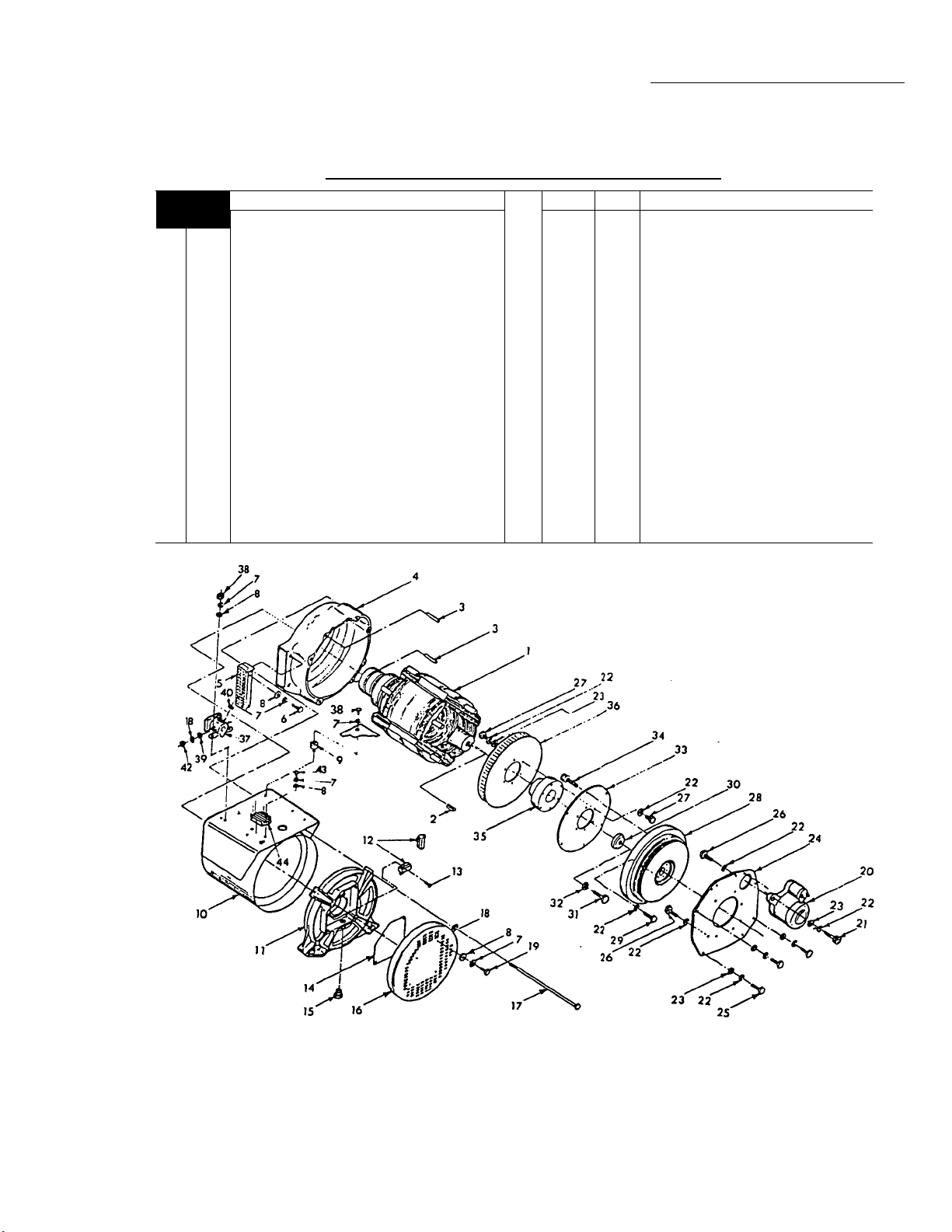

Thermal Protector !

A Thermal Protector is physically imbedded in the

wire windings of the Stator and electrically connected In

series with the excitation winding output leads to the

Regulator. The device is a normally-closed (N.C.),

temperature sensitive switch. The switch contacts will

open when stator temperatures exceed a safe level. The

switch is self resetting. That Is, it will re-dose when

stator temperatures decrease to a safe level.

If the switch contacts should op>en, excitation winding

AC output to the Voltage Regulator will be terminated

and the Regulator’s green EXCITATION lamp will go

out. Since the Regulator cannot op>erate without excita

tion winding output, the red REGULATOR lamp will also

go out. Generator AC output voltage will then drop to a

value commensurate with the Rotor’s residual mag

netism.

If the Thermal Protector contacts open during opera

tion due to a stator overtemperature condition, the

cause of the overtemperature condition must be found

and corrected. High Internal stator temperatures can be

caused by any one of the following:

SECTION 1.3- MAJOR COMPONENTS

(UNITS WITH 15 INCH STATOR

1

rings. The direct current (approximately 9-10 volts DC)

flows through the Rotor windings, the negative (-) slip

ring and brush, and to ground.

Field boost current creates a magnetic field strength

that is additive to the Rotor’s residual magnetism. The

Increased magnetic field strength during engine crank

ing provides an early "pickup* voltage In the stator. The

Regulator is turned on more quickly and AC output

occurs sooner. In effect, field boost current "flashes the

field" on every startup.

Failure of the field boost system nr^y or may not result

In a reduction of AC output to that produced by residual

Rotor magnetism. If residual magnetism Is adequate to

turn the Regulator on and provide the required pickup

voltage, the generator will operate normally with or

without field boost. However, if residual magnetism Is

not adequate, generator AC output will not build and will

be comrr^nsurate with Rotor residual magnetism.

D Insufficient cooling air flow into the generator

interior. Look for blockage of cooling air inlet/outlet openings, air openings that are too small,

ambient temperatures that are too high, etc.

□ Exceeding the wattage/amperage capacity of the

generator. If the unit is overloaded for a period of

time, internal stator temperatures can rise quickly

and cause the Thermal Protector contacts to

open.

D A shorted condition in the generator stator wind

ings or in an electrical load connected to the

generator’s AC output.

The Thennal Protector is not accessible and cannot

be removed and replaced. If the device has failed open,

it can be bypassed by connecting excitation lead No. 2

to a bypass lead (Wire No. 5). Once the device has been

bypassed, stator overtemperature protection Is no

longer available.

Field Boost

When the generator engine Is cranked, direct current

(DC) Is delivered to the Rotor windings. The cunent flow

is provided by the action of an Engine Control circuit

board housed In the control panel and Is delivered to the

Rotor via Wire No. 9, a Field Boost Resistor (R2), a Field

Boost Diode (D2), Wire No. 4, and the brushes and slip

PART OF CONTROL PANEL

WIRING HARNESS

rrSM

1

• 2

3

4

Figure 9. The Field Boost Circuit

DIODE-600V., 6 AMP

RESISTOR-5 WATT. 10 OHMS

DESCRIPTION

HEAT SHRINK

BARREL LUG

PAGE 1.3-7

Page 18

SECTION 1.3- MAJOR COMPONENTS

(UNITS WITH 15 INCH STATOR)

PARTI

THE REVOLVING FIELD AC GENERATOR

1

PAGE 1.3-8

Page 19

PARTI

THE REVOLVING FIELD AC GENERATOR

MAJOR COMPONENTS

(UNITS WITH 10 INCH STATOR)

SECTION 1.4- MAJOR COMPONENTS

(UNITS WITH 10 INCH STATOR)

1

Section 1.4

l~47.ir>r« description

■ n Rotor Assembly

n

2

3 2

4 1

5

6

7

8

9

10

11

12 2

13

14

15 1

16 1

17

18 6

19

20 1

21

22

1

1

4

16

12

4 Vibration Dampener

1 Stator Assembly

1 Rear Bearing Carrier

4

1

4

4 Capscrew

2

33

Drive Key

Dowel Pin

Blower Housing

Air Outlet Screen

Hex Head Capscrew

Lock Wasner

Flat Washer

Brush Holder

Hex Head Capscrew

Bearing Carrier Gasket

Rame Arrestor 37

Bearing Carrier Cover

Bolt

Lock Washer

Starter Assembly

Socket Head Capscrew

Lock Washer

•i'" -W'

TUFT

23

24

25

26 10

27 12

28

29

30 1

31

32

33 1

34

35

36

38 6

39 2

40 2

42

43 2

44 1

45 1

QTY

9

1

3

1

8

1

1

6 Socket Head Capscrew

1

1 Cooling Fan

1

2 Hex Nut

DESCRIPTION

Ratwasher

Engine Plate

Hex Head Capscrew

Hex Head Capscrew

Hex Head Capscrew

Flywheel

Hex Head Capscrew

Spacer

Hex Head Capscrew

Lock Washer

Flexible Coupling

Drive Hub

Starter Solenoid

Hex Head Capscrew

Rat Wasner

Hex Nut

Hex Head Capscrew

DC Voltage Regulator

Starter to Starter Solenoid Ci

Figure 1. Exploded View of Generator with 10 Inch Diameter Stator

PAGE 1.4-1

Page 20

SECTION 1.4- MAJOR COMPONENTS

^UNnrewmjno^mc^T^OR^^^

1

AC Generator Disassembly

BEARING CARRIER COVER:

Remove four (4) CAPSCREWS (Item 19), FLAT

WASHERS (Hem 8), and LOCK WASHERS (Item 7).

Then, remove the BEARING CARRIER COVER (Item

16) and the BEARING CARRIER GASKET (Item 14).

PARTI

THE REVOLVING FIELD AC GENERATOR

Remove all four long stator bolts along with washers.

Turn the large boH at center of Bearing Carrier puller

until end of bolts is flush wHh the puller. Retain the puller

to the Bearing Carrier with original Carrier Cover

screws. Turn the large center bolt of puller until the

bearing carrier Is free of the Rotor Bearing. Completely

remove the Bearing Carrier.

Figure 2. Bearing Carrier Cover Removal

BRUSH HOLDERS AND BRUSHES:

Remove wires from BRUSHES (Item 12). Remove

SCREWS (Item 13) and remove BRUSH HOLDERS

(Item 12) with brushes.

REAR BEARING CARRIER:

A bearing carrier puller (Figure 4) can be used to

remove the Rear Bearing Carrier. Retain the puller to

the Bearing Caller using the same saews that original

ly held the Bearing Carrier Cover.

Remove fasteners that retain the Bearing Carrier to

the mounting rail.

Figure 5. Removal of Mounting Rail Fasteners and

Stator Bolts

STATOR REMOVAL:

CAUTION. Use care when removing the Stator. Do

NOT allow It to drop or bump the Rotor during

removal.

Free the Stator from the Blower Housing and remove.

See Figure 6.

PAGE 1.4-2

Page 21

I

PARTI

THE REVOLVING FIELD AC GENERATOR

Figure 6. Stator Removal

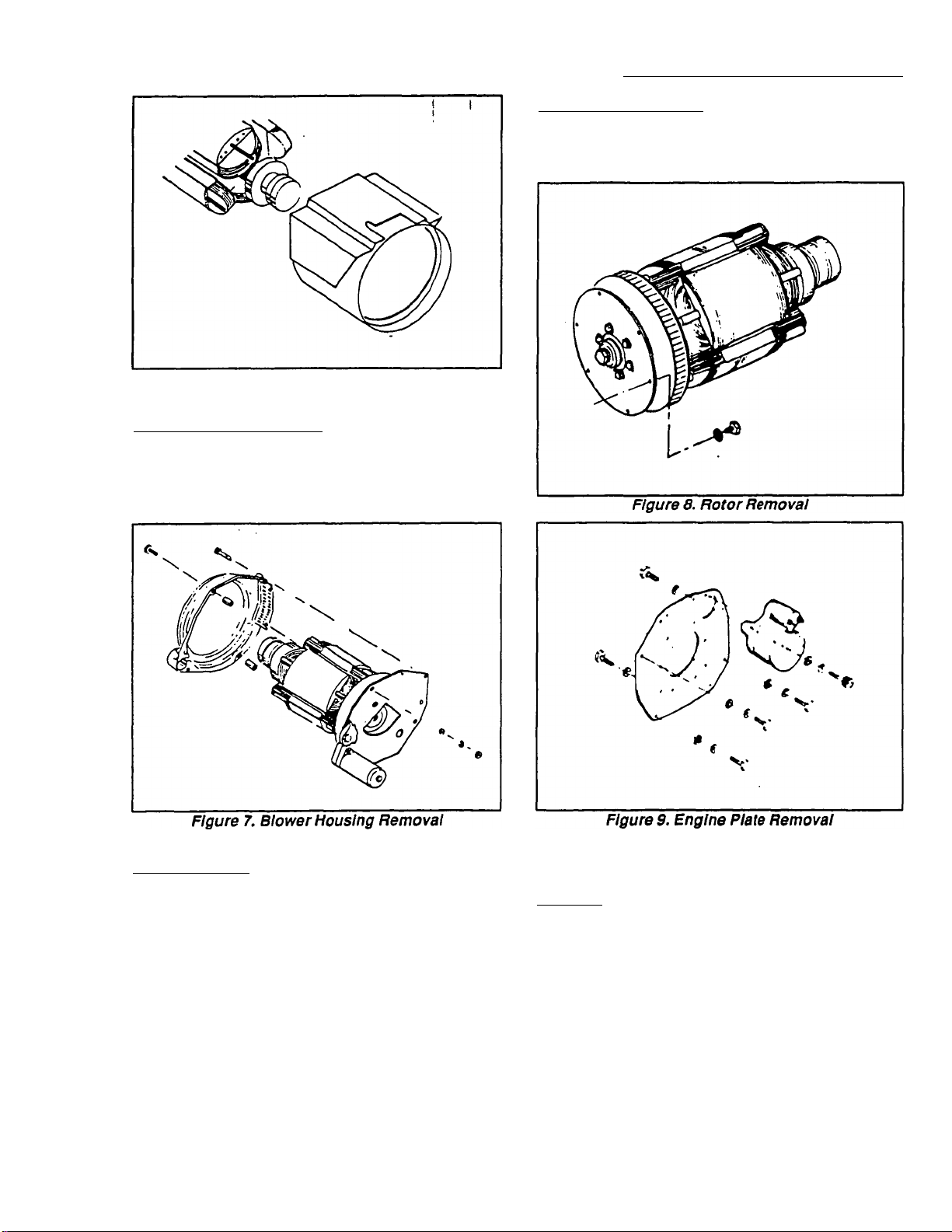

BLOWER HOUSING REMOVAL:

Remove the capscrews that retain the Blower Hous

ing to the Engine Plate, along with flat washers, lock

washers and hex nuts. Note positions of longer and

shorter screws, for reassembly.

SECTION 1.4- MAJOR COMPONENTS

(UNITS WITH 10 INCH STATOR)

1

ENGINE PLATE REMOVAL:

Remove starter retaining bolts and remove starter.

Remove bolts that retain the engine plate. Remove the

engine plate.

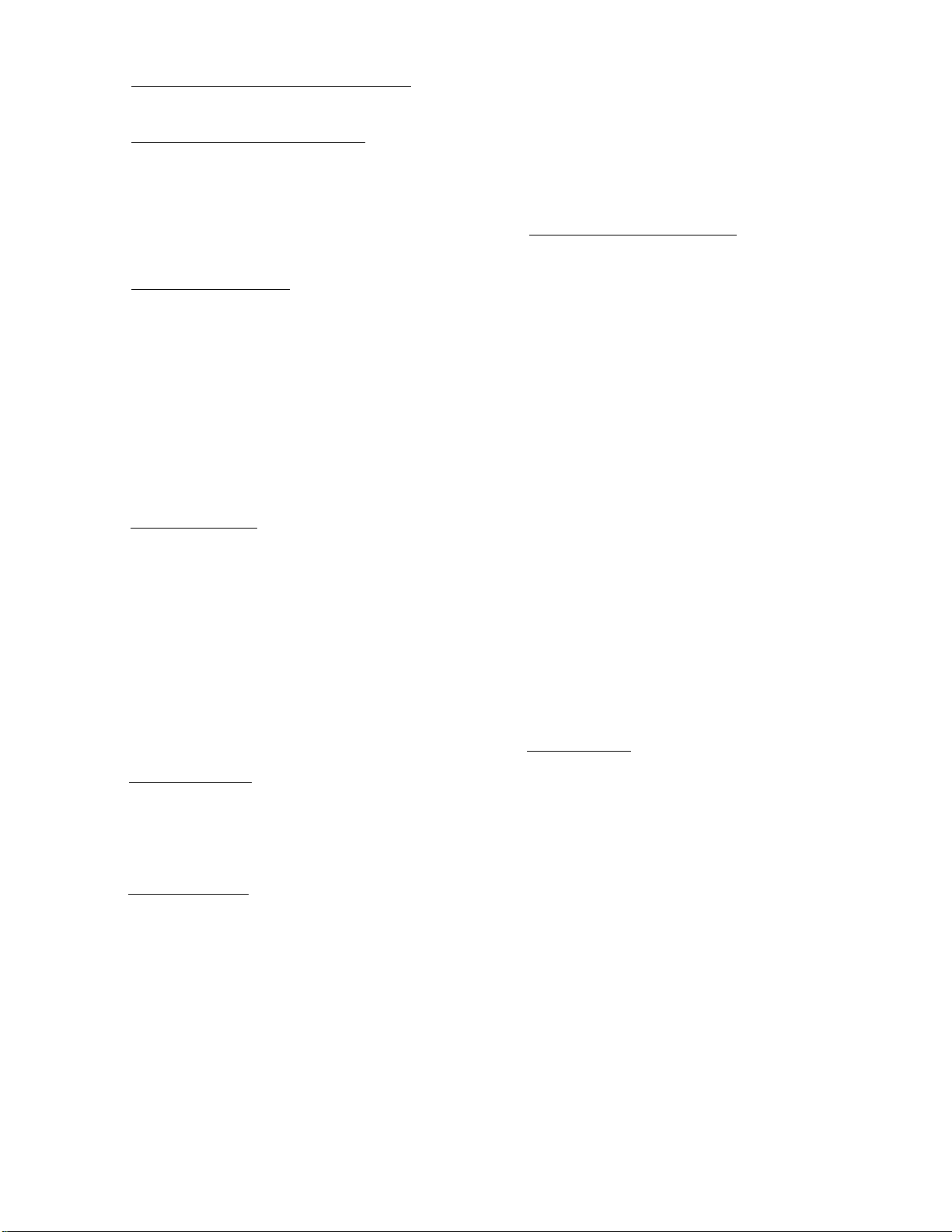

ROTOR REMOVAL;

Remove capscrews and washers that retain the Cou

pling Plate to the Ring Gear. Remove Rotor, Cooling

Fan, Drive Hub and Coupling Plate as a unit.

If desired, the Cooling Fan, Drive Hub and Coupling

Plate may be removed from the Rotor.

Components Inspection and Testing

GENERAL;

Follovving disassembly, generator components

should be cleaned, dryed and inspected or tested.

Never reassemble a generator with defective or

damaged parts. Store parts In a dean, dry area.

PAGE 1.4-3

Page 22

SECTION 1.4- MAJOR COMPONENTS

(UNITS WITH 10 INCH STATOR)

Components Inspection

REAR BEARING COVER AND GASKET:

Clean the Beeuing Cover in a suitable non-flammable

commercial cleaner. Blow dry with compressed air.

Inspect the Cover for obvious damage, clogged air slots,

etc. Replace, if necessary. Inspect gasket, replace if

damaged or defective.

REAR BEARING CARRIER;

The Rear Bearing Carrier is an aluminum casting.

Clean the casting and blow dry with air. Inspect carefully

for cracks, damage. An insert is pressed into the Bear

ing Carrier center bore, to accommodate the Rotor

bearing. Use an inside micrometer to check the inside

diameter of the insert. Replace the Bearing Carrier if the

insert inside diameter is not within the following:

PARTI

THE REVOLVING FIELD AC GENERATOR

J

and Testing (Continued)

the Rotor with dry, heated airfor several hours. DO NOT

EXCEED 185* F. (85* C.). if Insulation resistance is still

low after drying, replace the Rotor Assembly.

FAN AND RING GEAR ASSEMBLY:

The FAN, DRIVE HUB, COUPLING PLATE and

RING GEAR are assembled and balanced as a unit.

Clean and inspect parts, replace the entire assembly if

necessary.

BRUSH HOLDER AND BRUSHES:

Inspect both brush holders and both sets of brushes.

Look for cracks, excessive wear, cracks, chipping, etc.

Replace any damaged brush holder. Brushes should be

replaced as a complete set

2.834-2.836 inches (71.996-72.012mm)

STATOR ASSEMBLY:

Clean the stator can exterior surfaces with a soft

brush or cloth. Use clean, dry low pressure air (25 psi

maximum) to clean the stator. Use an ohmmeter to test

the resistance of Stator AC power and excitation wind

ings. Use an insulation resistance tester (megohmmeter

or Hi-Pot tester) to check condition of Stator insulation

(see Section 1.8). If Stator insulation fails the test, the

Stator may be dried by blowing warm, dry air across it

for several hours. DO NOT EXCEED 185* F. (85* C.). If

insulation resistance is still low after drying, replace the

Stator.

BLOWER HOUSING:

Clean with a commercial solvent that is suitable for

use with aluminum. Inspect the Housing carefully for

cracks, damage, etc. Replace, if necessary.

ROTOR ASSEMBLY:

Clean with dry, low pressure air (25 psi maximum).

Test Rotor winding resistance with an ohmmeter. Check

Rotor bearing for binding, seizing, roughness. If the

bearing is defective, replace the Rotor assembly. In

spect the keyway in the tapered shaft for wear, damage.

If slip rings are dull or tarnished, clean with fine

sandpaper. Use an insulation resistance tester

(megohmmeter or Hi-Pot tester) to test for insulation

breakdown (see Section 1.8). If resistance is low, dry

Inspect brush leads No. 1 and 4. Replace any

damaged or defective brush lead.

Generator Reassembly

Reassemble the generator in the reverse order of

disassembly. The reassembly process requires a great

deal of care. All components must be properly aligned

and retained. Tighten all fasteners to the recommended

torque values. Following reassembly, perform an opera

tional test of the unit.

Components In Generator Control Panel

INTRODUCTION:

The following AC generator components are

mounted on or housed in the generator control panel:

□ Voltage Regulator Assembly.

□ An AC Circuit Breaker (CB1 and CB2).

□ Exdtation Circuit Breaker (CB4).

□ A field boost circuit.

In addition to the above AC generator components

housed in the control panel, aTHERMAL PROTECTOR

is physicaliy imbedded in the wire windings of the Stator

Assembly.

Other components are housed in the control panel,

as well. However, these components are part of the

engine's DC control system and will be discussed in

PART 5, "ENGINE ELECTRICAL SYSTEM".

PAGE 1.4-4

Page 23

PARTI

THE REVOLVING FIELD AC GENERATOR

Components in Generator Control Panel (Continued)

SECTION 1.4- MAJOR COMPONENTS

1

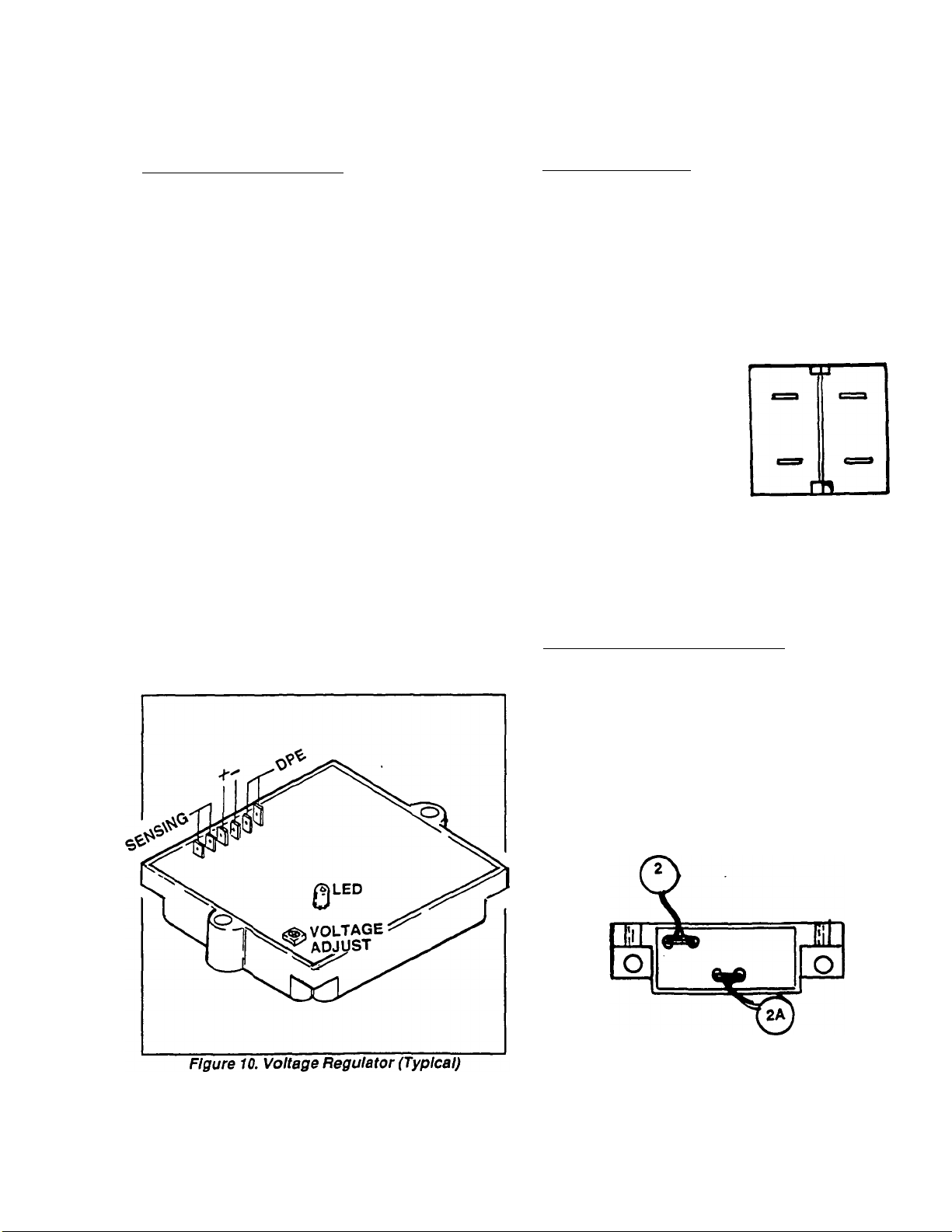

THE AC VOLTAGE REGULATOR:

The VoKage Regulator used on units with 10 inch

stator is shown In Figure 10. The Regulator has a single

red lamp (LED) which will remain on during operation

as long as stator AC power winding "sensing* voitage is

avaiiabie. Three sets of leads connect to the Regulator

terminals as follows:

D Unregulated AC output from the stator excitation

winding connect to the two terminals indicated by

"DPE*.

□ Sensing (actual) voltage signals from the stator

AC power windings are delivered to the

Regulator terminals indicated by "SEN".

□ Rectified and regulated (DC) current Is delivered

to the Rotor winding from Regulator terminals

Indicated by a"+" and

The Regulator provides over-voltage protection. On

loss of "sensing", the Regulator will shut down and

regulated excitation current to the Rotor will terminate.

A single adjustment potentiometer permits the gener

ator's AC output voltage to be adjusted. Perform this

adjustment with the engine running at no-load and with

AC frequency at 62 Hertz (1860 rpm). At 62 Hertz, set

the line-to-neutral AC output voltage to 124 volts AC; or

the line-to-line AC output voltage to 248 volts AC.

AC CIRCUIT BREAKERS:

Two AC output circuit breakers (CB1 and CB2) are

provided, one for each line of the 240 volts AC output

circuit. The trip rating of these breakers depends on the

rated maximum amperage capacity of the generator.

Units rated at 8000 watts (8.0 kW) are equipped with AC

breakers rated at 35 amperes.

Schematic

Pictorial

11

SEE FIGURES 4 & 5 ON

PAGE 1.5-2 FOR WIRING

CONNECTIONS

Figure 11. AC Output Circuit Breakers

EXCITATION CIRCUIT BREAKER (CB4):

An AC circuit breaker, rated 5 amperes, is electrically

connected in series with Wires No. 2 and 2A betwen the

stator excitation winding and the Voltage Regulator. If

the breaker should trip (open) due to an overload, loss

of excitation current to the Rotor will occur. Generator

AC output voltage will then decrease to a value that is

commensurate with Rotor residual magnetism (about 2

to 7% of the unit's rated voltage). The breaker is self

resetting and cannot be reset manually.

Figure 12. Excitation Circuit Breaker

PAGE 1.4-5

Page 24

SECTION 1.4- MAJOR COMPONENTS

(UNITS WITH 10 INCH STATOR)

1

Components In Generator Control Panel (Continued)

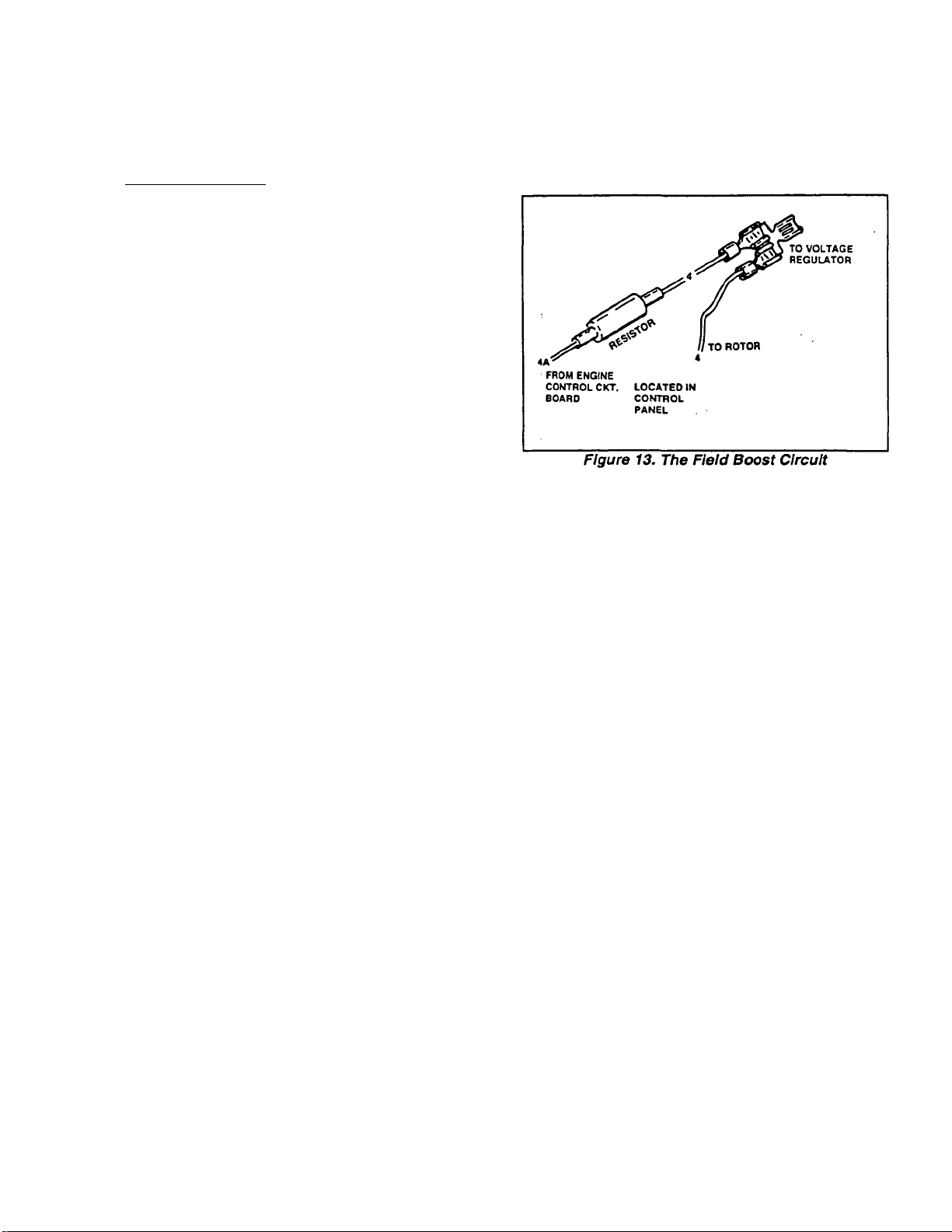

FIELD BOOST CIRCUIT

During engine cranking, an engine controi circuit

board deiivers battery voltage to the Rotor windings.

This "Field Boost" current is delivered to the Rotor via

Wire 4A, a field boost resistor, and Wire 4. The Field

Boost feature provides the following benefits:

□ In effect, field boost current "flashes the field" on

every engine startup. Thus, if Rotor residual magne

tism was lost for any reason, it would be restored by

the act of "flashing the field" during cranking.

□ Approximately 4-8 volts AC output from the stator

excitation winding is needed to turn the voltage reg

ulator on. Reid boost current builds Rotor magnetism

early which, in turn, develops voltage early during

startup. The result of field boost is an early "pickup"

voltage in the stator windings.

THERMAL PROTECTOR:

Refer to " THERMAL PROTECTOR' on Page 1.3-7.

PARTI

THE REVOLVING FIELD AC GENERATOR

PAGE 1.4-6

Page 25

PARTI

THE REVOLVING FIELD AC GENERATOR

Section 1.5

INTRODUCTION TO TROUBLESHOOTING

DANGER: GENERATORS PRODUCE EXTREMELY

HIGH AND DANGEROUS VOLTAGES. CONTACT

WITH LIVE WIRES OR TERMINALS WILL RESULT

IN HAZARDOUS AND POSSIBLY FATAL ELECTRI-

<CAL SHOCK. ONLY PERSONNEL WHO HAVE

BEEN TRAINED IN THE SERVICING AND REPAIR

OF RV GENERATORS SHOULD ATTEMPT TO

TROUBLESHOOT, TEST OR REPAIR THESE GEN

ERATORS.

Tools and Test Equipment

An RV generator service technician shouid have a

weii stocked tool box that is fiiied with a good seiection

of common hand tools. The tool box should contain

combination wrenches and socket wrenches in both

standard and metric sizes. Also, a good nut driver set is

recommended.

SECTION 1.5

INTRODUCTION TO TROUBLESHOOTING

1

Figure 1. Typical Volt-Ohm-Mllllamm eter (VOM)

The following test equipment is recommended:

□ An accurate volt-ohm-milliammeter (VOM),

preferably a precise digital type.

□ A good AC frequency meter.

D An insulation resistance tester (megohmmeter or

Hi-Pot tester).

O A load bank or some means of applying a known

electrical load to the generator.

Volt-Ohm>Milllammeter (VOM)

If desired, three separate meters may be used, i.e., a

voltmeter, ohmmeter and ammeter. Recommended is

an accurate digital type VOM having a ’Diode Check'

mode.

The service technician must be familiar with his VOM

and must know how to use it. He must also be familiar

with generator electrical circuits and must be able to

read electrical vriring diagrams and schematics.

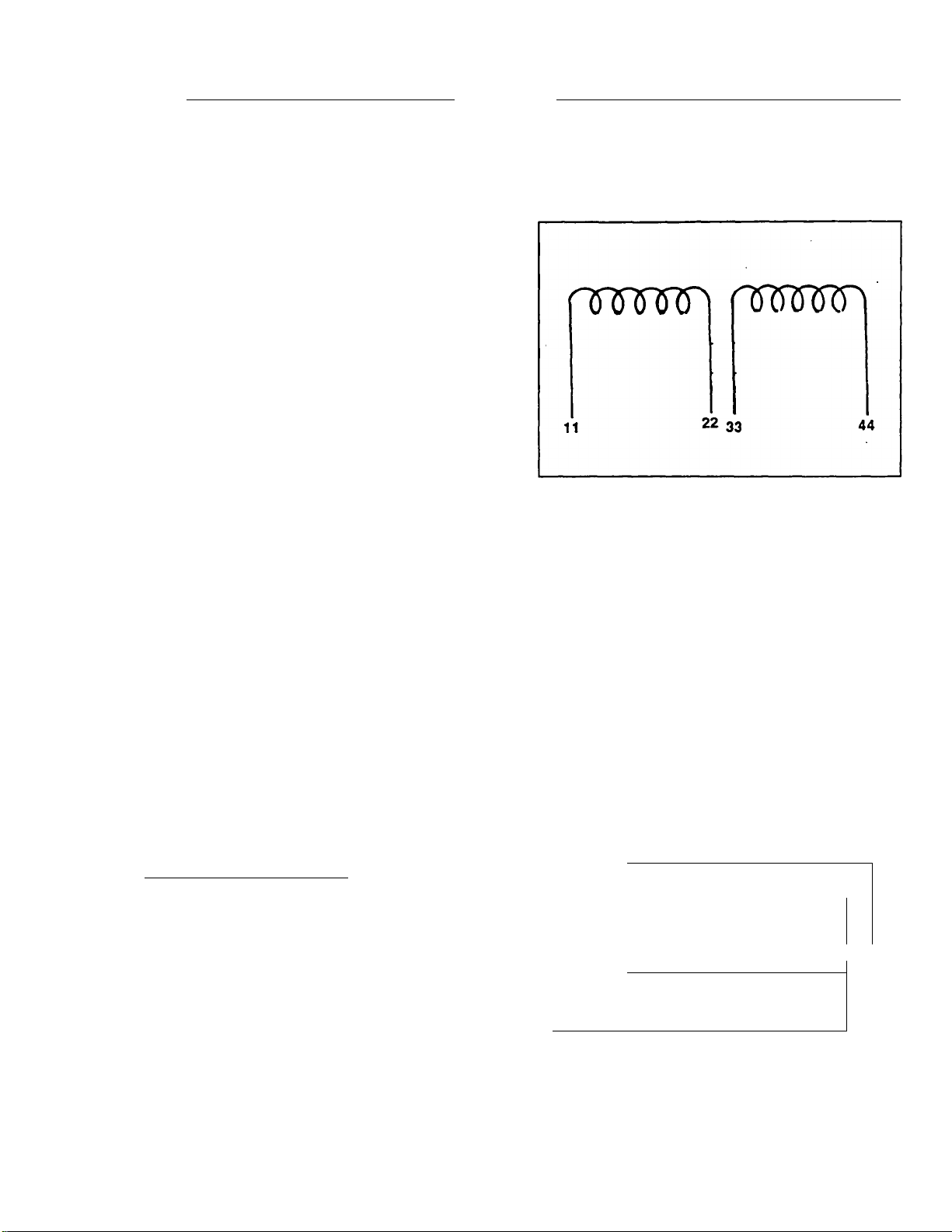

Frequency Meter

The generator’s AC output frequency must be known

if engine governed speed Is to be property adjusted. See

"ROTOR ROTATIONAL SPEED’ in this section.

Figure 2. One Kind of AC Frequency Meter

Testing Insulation Resistance

Insulation resistance Is a measurement of the In

tegrity of the Insulating materials that separate the

electrical windings from the generator’s steel core. This

resistance can degrade over time due to contaminants

such as dust, dirt, grease and especially moisture.

Information on Insulation resistance test can be found

in Section 1.8, "INSULATION RESISTANCE TESTS'.

PAGE 1.5-1

Page 26

SECTION 1.5

INTRODUCTION TO TROUBLESHOOTING

Rotor Rotational Speed

"NP" series generators are equipped with a 4-pole

Rotor. That is, the Rotor has two south magnetic poles

and two north magnetic poles. A 4-pole Rotor must be

operated at 1800 rpm to obtain a 60 Hertz AC output

frequency. The following formulas apply when calculat

ing frequency, rpm and number of Rotor poles:

Hertz = RPM X No. of Rotor Poles

2x 60

RPM = 2 X 60 X Hertz

No. of Rotor Poles

PART 1

THE REVOLVING FIELD AC GENERATOR

L

A second alternative Is to connect the wiring to supply

120 volts AC only (Figure 5). When this connectior

method Is used, a jumper wire must be connected

between the two main circuit breakers (CB1 and CB2),

as shown.

No. of =

Poles

2 X 60 X Hertz

RPM

Voltage and Frequency

The generator's solid state Voltage Regulator will

maintain an AC output voltage that is at a fixed ratio to

frequency. For example, at a frequency of 60 Hertz, AC

output voltage will be maintained at about 120/240 volts

(plus or minus 2%). Should frequency drop to 30 Hertz,

voltage will decrease proportionally to about 60/120

volts.

For generators rated 120/240 volts, the engine gover

nor should be set to maintain a NO-LOAD frequency of

about 60.5-63.5 Hertz. The Voltage Regulator should

then be set to maintain a voltage of about 121-127 volts

(line-to-neutral); or 242-254 volts (line-to-line).

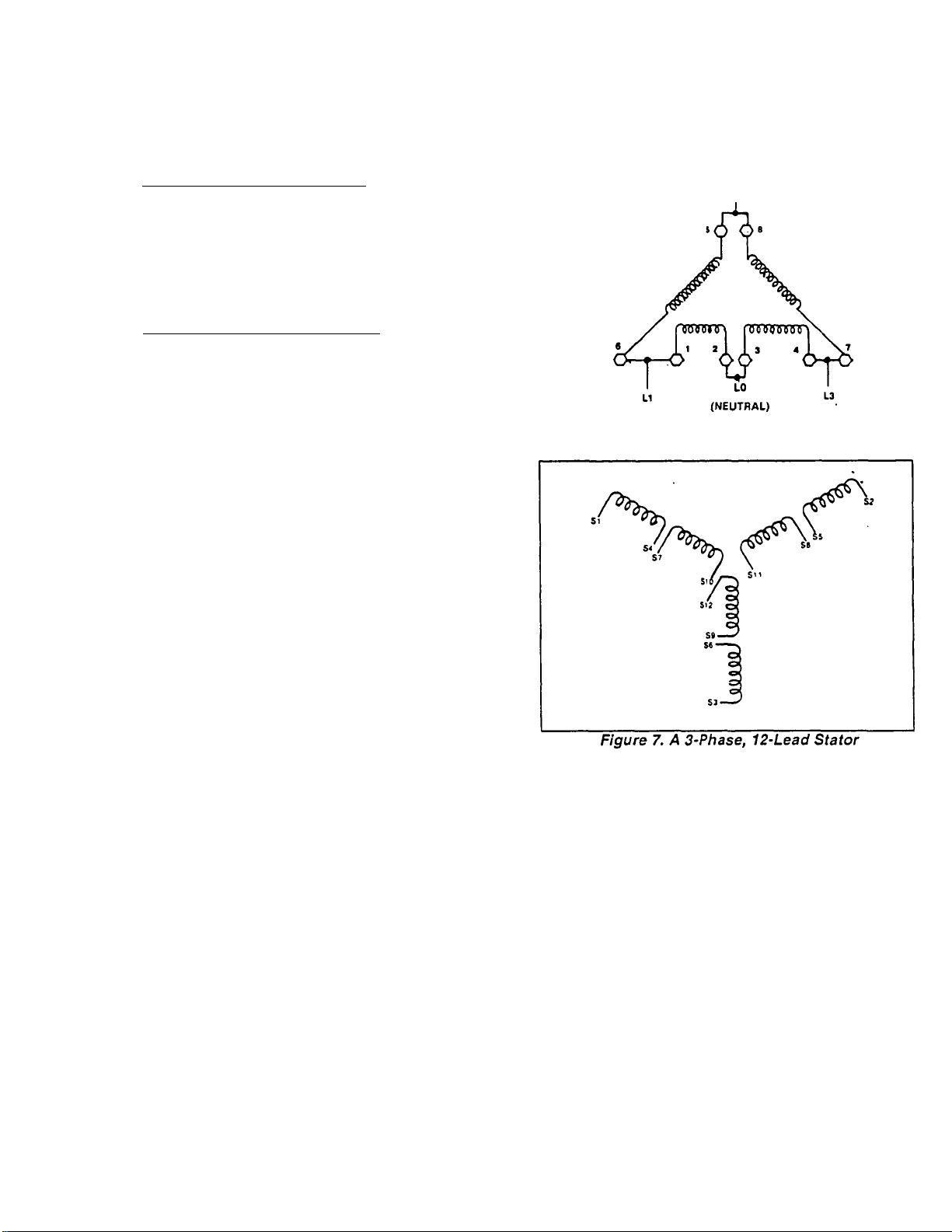

Stator AC Connection Systems

1-PHASE, DUAL WINDING TYPE:

Some NP/IM series generators have dual AC

power windings (Figure 3). Each winding supplies a

120 volts AC output. When the two windings are con

nected in series (Figure 4), a 240 volts AC output

results.

When installed, the unit may have ben connected to

supply a dual voltage output (120 and/or 240 volts). This

is shown In Figure 4. A 3-wire connection system Is

used. Stator leads No. 11 and 44 form the two "hot"

leads; the Junction of stator leads 22 and 33 form the

"Neutral" lead. Notice the "Neutral" line is grounded.

Figure 3. The Dual Stator AC Power Windings

nnrowi fWtrCPi

,, 22 33 44

)CB. ‘f CBzS

T2

-120 V.----------------^

T1

(RED)

Figure 4. Connected for Dual Voltage AC Output

11

(WHnE)

■ 24-3V.

22 33 1

------------------------------------

L 1

K—

T

-------------

T3

(BLACK)

I«

-----------------

120V.

---------------------------------

1

1

T1

(RED)

^

-----------------

Figure 5. Connected for 120 Volts AC Output

■ 120V.-

120 V.

---------

T3

(BLACK)

44

------

T2

-------

-------

(WHITE)

P

»

/

r

PAGE 1.5-2

Page 27

PART1 I SECTION 1.5

THE REVOLVING FIELD AC GENERATOR ■ INTRODUCTION TO TROUBLESHOOTING

Stator AC Connection Systems (Continued)

3-PHASE DELTA STATOR WINDING:

Some units may be equipped with a 3-phase delta

type stator winding, shown in Figure 6. Phase rotation

is L1-L2-L3. The ^Neutral* line is designated as "LO’.

Generator Model No. 9422 uses this type of stator to

deliver 120 volts AC (line-to-neutral); or 240 volts AC

(line-to-line).

3-PHASE. WYE-CONNECTED SYSTEM:

Figure 7 shows a 3-phase Wye-Type stator which

has 12 AC output leads that are reconnectable to

supply several voltages. Generator Model 9318 uses

this type of statorto supply 220/380 volts AC at 50 Hertz

(i.e., 220 volts AC line-to-neutral; 380 volts AC line-toline).

Figure 6. A 3-Phase Delta Stator

PAGE 1.5-3

Page 28

SECTION 1.5

INTRODUCTION TO TROUBLESHOOTING

PARTI

ITHE REVOLVING FIELD AC GENERATOR

PAGE 1.5-4

Page 29

PARTI

THE REVOLVING FIELD AC GENERATOR

SECTION 1.6- TROUBLESHOOTING

(UNITS WITH 15 INCH STATOR)

1

Section 1.6

TROUBLESHOOTING

(UNITS WITH 15 INCH STATOR)

Introduction

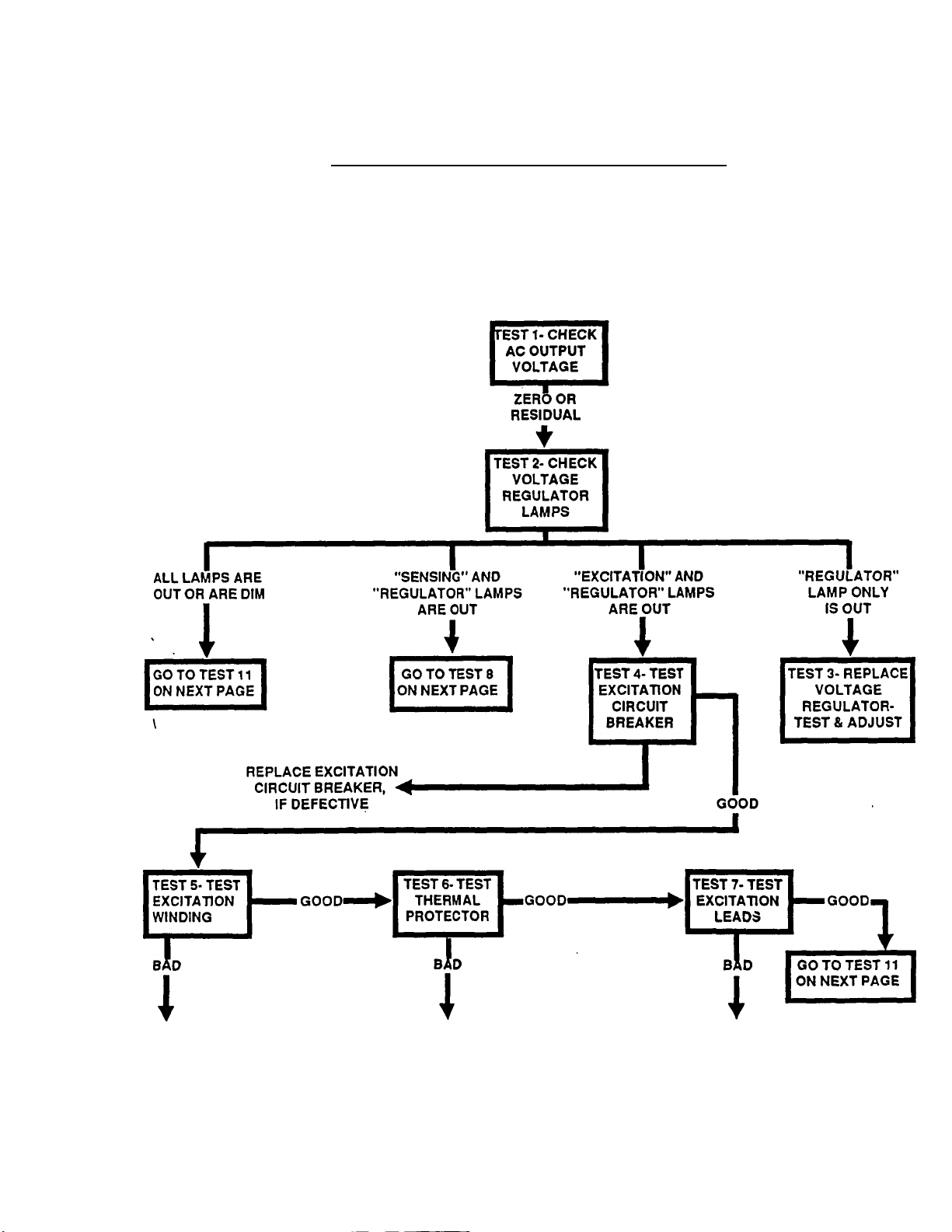

The 'Troubleshooting Flow Charts' that follow have been carefully formulated to help the technician find the

cause of problems quickly and easily. Use the Charts as a guide In troubleshooting RV generator problems, to help

avoid the unnecessary labor and expense of replacing parts needlessly. Test numbers in the Charts correspond to

the numbered tests In the 'DETAILED INSTRUCTIONS' that follow the Flow Charts.

Problem 1- Generator Produces Zero or Residual Voltage at No-Load

REPLACE

STATOR

BYPASS

THERMAL PROTECTOR

RECONNECT,

REPAIR OR REPLACE

PAGE 1.6-1

/•.'3c

Page 30

SECTION 1.6- TROUBLESHOOTING

(UNITS WITH 15 INCH STATOR)

Problem 1 - Generator Produces Zero or Residual Voltage at No-Load (Continued)

PART 1

THE REVOLVING FIELD AC GENERATOR

1

TEST 8- CHECK

SENSING LEADS

BAD

AT/M3

i

RECONNECT, REPAIR OR

REPLACE BAD LEADS AS

NECESSARY

TEST 11-TEST

ROTOR

WINDINGS

BAD

I

REPLACE ROTOR

---------

O.K._^ BRUSHES AND

r\ 1/ w

TEST 9-TEST

TRANSFORMER

REPLACE BAD

TRANSFORMER

TEST 12- CHECK

REPLACE BRUSHES

OR CLEAN SLIP RINGS,

AS NECESSARY

CCKICIAI/^

BAD

J

SLIP RINGS

I

I

--

rsr\r\r\^

«O.K.^

TEST 10- TEST

CTATnn An

POWER

WtNniNnft

BAD

\

REPLACE

STATOR

ASSEMBLY

TEST 13- CHECK

WIRES NO.

1 AND 4

T

BAD

I

RECONNECT,

REPAIR OR REPLACE

BADWIRE(S)

TEST 14- TEST

FIELD

BOOST

BAD

»

REPAIR BAD

WIRE(S) OR

REPLACE BAD

PART(S)

Problem 2- Generator Produces Low Voltage and Frequency at No-Load

(Greater than Residual Voltage)

TESTIS- CHECK

VOLTAGE AND

FREQUENCY

FREQUENCY GOOD,

VOLTAGE IS LOW

NOTE: A shorted stator winding can cause rpm, frequency and voltage to droop excessively In the same

manner as when the unit’s wattage/amperage capacity Is exceeded.

BOTH

__ AREbh^

LOW

TEST 17-CHECK

AND ADJUST

VOLTAGE

REGULATOR

TEST 16-ADJUST

ENGINE

GOVERNOR

LOW VOLTAGE

, AND/OR LOW FREQUENCY!

CONDITION

IS NOT CORRECTED

FREQUENCY AND

I VOLTAGE GOOD-

AFTER ADJUSTMENT

^1 STOP TESTS

GOTO

PROBLEM 1

PAGE 1.6-2

Page 31

PARTI

THE REVOLVING FIELD AC GENERATOR

Problem 3- Generator Produces High Voltage at No-Load

SECTION 1.6- TROUBLESHOOTING

(UNITS WITH 15 INCH STATOR)

1

TESTIS- CHECK BOTH

VULi AuiC MHil/

FREQUENCY

FREQUENCY GOOD,

VOLTAGE IS HIGH

TEST 17- CHECK

L

Problem 4- Voltage and Frequency Drop Low When Electrical Loads are Applied

TESTIS- CHECK

FOR OVERLOAD

CONDITION

1 la

HIGH

AND ADJUST

VOLTAGE

REGULATOR

TEST 16-ADJUST

GOVERNOR

UNIT IS NOT

HIGH VOLTAGE

CONDITION w

CORRECTED

W

O.K.

ADJUSTMENT

VOLTAGE REGULATOR,

TEST 16-ADJUST

ENGINE

GOVERNOR

TESTS- REPLACE

TEST AND ADJUST

.. NOWHii|

I O.K. NOW-

UNIT IS OVERLOADED

REDUCE LOAD TO UNIT’S

RATED WATTAGeAMPERAGE

CAPACITY

VOLTAGE/FREQUENCY

STILL DROP LOW

WHEN LOADS ARE

APPLIED

i

TEST 19- CHECK

CMr^lMC D/MAICn

AND CONDITION

r

I^STOPTIST^

REPAIR

NEEDED

PAGE 1.6-3

Page 32

SECTION 1.6- TROUBLESHOOTING

(UNITS WITH 15 INCH STATOR)

1

Detailed Instructions

INTRODUCTION:

The following diagnostic test instructions are num

bered to correspond with the numbered tests in the

troubleshooting 'Row Charts’ on Pages 1.6-1 through

1.6-3. Read the instructions carefully.

PARTI

THE REVOLVING FIELD AC GENERATOR

Results: Analyze the results of the AC output voltage

test as follows:

1. If the reading is zero volts or residual volts, perform

tests as indicated under Problem 1 of the Flow Charts.

TEST 1- CHECK AC OUTPUT VOLTAGE:

Discussion; In order to identify the specific probiem,

it is necessary to measure the generator’s AC output

voltage. Some Installations may Include an optional AC

meter package. Even when this is the case, it is a good

idea to verify the AC voltage with an external meter. In

some cases, the AC meter(s) on the optional package

may be reading incorrectly.

Remember, some installed units may be connected

for dual voltage AC output (120 and/or 240 volts). Some

units may be connected for 120 volts AC output only.

Also see "STATOR AC CONNECTION SYSTEM" on

Page 1.5-2.

Procedure; An AC voltmeter or a volt-ohm-milliammeter (VOM) may be used to measure voltage. If the

unit is installed in a vehicle, the meter may be connected

to a convenient receptacle. For uninstalled units, con

nect the VOM across Wires No. T1 (red) and T3 (black)

to obtain a line-to-line voltage reading (240 volts). For a

line-to-neutral reading (120 volts), connect the VOM

across line T1 (red) and T2 (white); or across line T3

(black) and T2 (white). With the unit runing at no-load,

read the AC voltage. Voltage should be 121-127 volts

(line-to-neutral): or 242-254 volts (line-to-line).

NOTE: "Residual" voltage Is that voltage produced

as a result of Rotor residual magnetism only. It Is

equal to approximately 2 to 7percent of the unit’s

rated voltage. For units rated 120/240 volts, residual

voltage will be approximately 2.4-0.4 volts (llne-to-

neutral); or 4.8-16.8 volts (llne-to-llne).

2. If the voltage is low, but greater than residual, go to

Problem 2 of the Flow Charts.

3. If AC output voltage is high, go to Problem 3 of the

Flow Charts.

4. If AC output voltage Is normal at no-load, but drops

excessively when electrical loads are applied, go to

Problem 4 of the Flow Charts.

Test 2- Check Voltage Regulator Lamps

Discussion: Refer to 'AC VOLTAGE REGULATOR'

on Pages 1.3-5 and 1.3-6.

Procedure: Gain access to the AC Voltage Regulator

in the control panel. With the generator running at

no-load, observe the condition of the Regulator lamps

(LED’s).

nrSMiTi nnrotRPi

1 22 33 44

CB1 CB2 )

)

Qy )—1

T2

(WHITE)

-120V

___________

T1

SHOWN CONNECTED FOR DUAL (BLACK)

VOLTAGE AC OUTPUT. FOR 120

VOLTS OUTPUT, SEE FIGURE 5

ON PAGE 1.5-2.

Figure 1. Stator AC Output Leads

NOTE: Line T1 (red) and T3 (black) are the two "hot''

lines. Line T2 (white) Is the "Neutral" line.

^ 4

• 240V. •

---------

120V.

■ K

T3

PAGE 1.6-4

The Voltage Regulator lamps are normally ON

during engine-generator operation. It is suggested that

■ AC VOLTAGE REGULATOR' on Pages 1.3-5 and

1.3-6 be read carefully. The REGULATOR lamp will go

out if (a) a Regulator fault exists, or (b) if the Regulator

has shut down due to occurence of one or more Reg

ulator shutdown conditions. The EXCITATION lamp

will go out on loss of stator excitation winding output to

the Regulator. The SENSING lamp will go out on loss

of sensing input to the Regulator.

Resülts:

1. if ail lamps are out, go to Test 11.

2. If the 'Sensing' lamp is out, go to Test 8.

3. If the ’Excitation* lamp is out, go to Test 4.

4. If the 'Regulator* lamp Is out, go to Test 3.

Page 33

PARTI

THE REVOLVING FIELD AC GENERATOR

Detailed Instructions

TEST 3- REPLACE REGULATOR, TEST/ADJUST;

Discussion: The Voltage Regulator lamps (LED’s)

are normally ON. If the 'Regulator* lamp is OUT, the

Voltage Regulator has shut down or has failed. A

'Regulator lamp ON condition indicates the

Regulator’s SCR’s (silicone controlled rectifiers) are

firing.

"U

---

" ^ .

----------------------------------

V

«

Figure 2. The Part No. 67680 Voltage Regulator

Procedure: Unplug the voltage regulator connec

tor plug. Remove the screws, flatwashers and

lockwasners that retain the regulator to the control

panel. Remove the regulator. Install the new regulator,

test and adjust as outlined in Section 1.9, ‘OPERA

TIONAL TESTS AND ADJUSTMENTS'.

NOTE: Before attempting to adjust the voltage reg

ulator, the engine governor must be properly ad

justed to maintain a no-load frequency of 60.5-63.5

Hertz (1815-1905 rpm). Correct no-load AC output

voltage setting Is 121-127 volts AC (llne-to-neutral),

or 242-257 volts AC (llne-to-llne).

Results: If problem is corrected, discontinue tests.

If problem still exists, continue troubleshooting as indi

cated in the 'Flow Charts".

TEST 4- TEST EXCITATION CIRCUIT BREAKER:

Discussion: See Figure 3. The excitation circuit

breaker is electrically connected in series with the

stator excitation winding AC output to the voltage reg

ulator. It is physically mounted in the control panel

interior. Should the breaker fail open, loss of excitation

winding output to the regulator will occur. Without exci

tation current, the regulator will shut down and gener

ator AC output will drop to a voltage commensurate with

Rotor residual magnetism. The breaker cannot be reset

manuaily (it is normally self-resetting). If it has failed

open, it must be replaced.

VOCTAQE ADJUST

UNOERFREOUENCY

— .. - 1 ^

OAIN

STABIUmr

ADJUST

REGULATOR

SENSING

EXCITATION

In^

Ine®

r«®

®

SECTION 1.6- TROUBLESHOOTING

(UNITS WITH 15 INCH STATOR)

1

from excitation grinding

to voltage regulator

Figure 3. Excitation Circuit Breaker

Procedure: To prevent interaction, disconnect

Wires No. 2 and 162 from the circuit breaker terminals.

Set a VOM to its "Rxl' scale and zero the meter.

Connect thè VOM test probes across the two circuit

breaker terminals. The meter should read "continuity*.

Resuits: •

1. If the meter displays any reading o(;her than "conti

nuity", replace the excitation circuit breaker.

2. If the VOM reads "continuity", go on to Test 5.

NOTE: When reading resistance across the circuit

breaker contacts, a very small resistance reading

Is acceptable. An oxide film can build up on circuit

breaker contact surfaces, causing the small resis

tance.

TEST 5- TEST STATOR EXCITATION WINDING:

Discussion: An open circuit in the stator excitation

(OPE) winding will result in loss of excitation current to

the Voltage Regulator. An excitation winding AC output

of approximately 4-8 volts AC is required to turn the

Voltage Regulator on. Thus, on loss of excitation wind

ing output, the Regulator will shut down and regulated

excitation current to the Rotor will terminate. Generator

AC ou^ut voltage will then drop to a value commensu

rate with Rotor residual magnetism plus field boost

current (about one-half normal no-load AC output volt

age). An open winding will be Indicated by a VOM

reading of 'infinity* or a very high resistance reading. A

shorted excitation winding will be Indicated by a veiy

low resistance reading. In the following 'Procedure*^,

the excitation winding will also be testedfor a grounded

condition.

Procedure: See Figure 4, next page. In the control

panel, locate unattached Wire No. 5. This is the thermal

protector bypass lead. Remove the wire nut from end

of Wire No. 5. Also locate Wire No. 6, connected to Pin

6 of the voltage regulator plug. On some units, a barrel

lug may be used to connect Wire No. 6 between the

voltage regulator and the stator excitation winding. Test

the stator excitation winding for an open, shorted or

grounded condition as follows:

PAGE 1.6-5

Page 34

SECTION 1.6- TROUBLESHOOTING

(UNITS WITH 15 INCH STATOR)

Detailed Instructions (Continued)

PART 1

THE REVOLVING FIELD AC GENERATOR

1

1. Set a VOM to Its ’Rxl ’ scale eind zero the meter.

2. Connect the VOM test probes across Wire No. 5 and

Pin 6 of the Voltage Regulator. The meter should read

the resistance of the stator excitation winding (about

0. 53.ohm).

3. Now, set the VOM to a very high resistance scale

such as ’Rx10,000" or "Rx1 K". Again, zero the meter.

a. Connect one VOM test lead to bypass Wire No. 5,

the other to a clean frame ground on the stator. The

meter should Indicate "infinity".

b. Any reading other than "infinity" indicates a shorted

condition and the stator should be replaced.

4. With the VOM still set to a high resistance scale,

connect one VOM test probe to stator Wire No. 5, the

other to stator ac output Wire No. 11 or 22. "Infinity"

should be Indicated.

5. Connect the VOM test probes across Wire No. 5 and

stator AC output Wire No. 33. "Infinity" should be indi

cated.

Results:

1. If the stator excitation winding fails any part of the test,

replace the stator assembly.

2. If the stator excitation winding checks good, go on to

Test 6.

Results:

1. If normal excitation winding resistance was indi

cated in Test 5, but "infinity" was Indicated in Test 6, the

thërmal protector is open and must be bypassed.

2. If normal excitation winding resistance was indi

cated in both Tests 5 and 6, the thermal protector is

good. Go on to Test 7.

TEST 7- TEST EXCITATION LEADS:

Discussion: An open or shorted condition in the

stator excitation winding's output leads to the Regulator

will cause complete or partial loss of the unregulated

excitation current to the Regulator.

Procedure: Inspect Wires No. 2,6 and 162, between

the stator and the Voltage Regulator. Make sure they

are properly connected and undamaged. Use a VOM to

test the wires tor "continuity".

Results:

1. Reconnect, repair or replace any damaged, discon

nected or shorted wire(s). /

2. If all excitation leads are good, go to Test 11.

Figure 4. Excitation Winding Test Points

TEST 6- TEST THERMAL PROTECTOR:

Discussion: You may wish to review the information

on the thermal protector. See Page 1.3-7.

Procedure: Set a VOM to its "Rxl" scale and zero

the meter. Connect the VOM test probes across stator

wires No. 2 and 6. See Table 1, Page 6.1-1 for nominal

resistances.

TEST 8- CHECK REGULATOR SENSING LEADS:

Discussion: An open or shorted condition in the

sensing leads to the Voltage Regulator will result in loss

of sensing (actual voltage) signals to the Voltage Reg

ulator. The Regulator’s "Sensing" lamp will then go out.

Procedure: Carefully inspect Wires SI 5 and SI6,

between the Regulator and the sensing transformer.

Also inspect Wires No. 11 and 22, between the sensing

transformer and the stator. Use a VOM to test all wires

for an open or shorted condition.

Results:

1. Reconnect, repair or replace any disconnected,

damaged or defective wire(s).

2. If the sensing leads are good, go on to Test 9.

TEST 9- TEST SENSING TRANSFORMER:

Discussion: The Part No. 67680 Voltage Regulator

requires a 240 volts AC sensing signal to operate

properly. You may wish to review the information on the

sensing transfonmer on Page 1.3-6.

PAGE 1.6-6

Page 35

PARTI

THE REVOLVING FIELD AC GENERATOR

Detailed Instructions (Continued)

SECTION 1.6- TROUBLESHOOTING

(UNITS WITH 15 INCH STATOR)

1

Procedure: Gain access to the sensing trans

former, inside the control panel. Use a volt-ohm-milli-

ammeter (VOM) to test the sensing transformer as

follows:

1. Disconnect Wires No. 11 and 22 from the

transformer’s PRIMARY terminals, to prevent interac

tion.

2. Connect the VOM test leads across the two PRI

MARY (120 volts) terminals. Resistance of this winding

should be approximately 120 ohms (plus or minus 2%).

3. Disconnect Wires No. SI5 and SI 6 from the trans

former SECONDARY (240 volts) terminals, to prevent

interaction.

4. Connect the VOM test leads across the two SEC

ONDARY (240 volts) terminals. Resistance should be

approximately 950 ohms (plus or minus 2%).

Results:

1. If the transformer fails the test, it should be replaced.

2. If the transformer checks good, go on to Test 10.

PRIMARY

120 VAC

[qooopI

oaoWflÒSbì

2. Set a VOM to its ■ Rxl’’ scale and zero the meter.

3. Test the windings as follows:

a. Connect the meter test leads across Wires No. 11

and 22. Resistance reading should be approximately

as listed in chart in Part 6.

b. Connect the meter test leads across Wires No. 33

and 44. Resistance reading should be approximately

as listed in chart in Part 6.

c. Set the VOM to a very high resistance scale, such

as 'Rxl 0,000" or "RxlK". Then, zero the meter.

d. Make sure none of the stator leads are touching

the generator or each other at any point. Connect

one VOM test probe to Wire No. 11, the other test

probe to Wire No. 33. The VOM should read "Infinity“.

Any reading other than "infinity" indicates a short

between the stator windings.

e. Connect one VOM test probe to Wire No. 11, the

other to a clean frame ground on the stator. VOM

should read "infinity".

f. Connect one VOM test probe to Wire No. 33, the

other to a clean frame ground. Reading should be

"infinity".

nmnrin

rWiRRTi

■ 6

SECONDARY

20 VAC

Figure 5. The Sensing Transformer

TEST 10- TEST STATOR AC POWER WINDINGS:

Discussion: An open condition in eitherof the dual

stator AC power windings will result In loss of AC output

from the affected winding. A shorted condition in those

windings will cause a reduction in AC voltage that is

commensurate with the number of shorted turns. A

shorted condition can also impose such a heavy load

on the engine that engine speed and AC frequency will

also drop sharply. This test will check the stator AC

power windings for (a) an open condition, (b) a shorted

condition, and (c) a grounded condition.

Procedure: To test 1-phase, dual winding stators,

proceed as follows:

1. Disconnect Wires No. 11, 22, 33 and 44 from the

main circuit breaker (CB1) and from the unit grounding

lug.

11 22 33 44

SEE SECTION 1.5, PAGE 1.5-3 FOR

SOME OTHER STATOR CONFIGURATIONS.

ALSO SEE PART 6, PAGE 6.1-1 FOR SOME

RESISTANCE VALUES.

Figure 6. Stator Windings Schematic

TEST 11- TEST ROTOR WINDINGS;

Discussion: An open circuit condition in the Rotor

windings means that excitation current cannot flow in

the circuit. Field boost current will be unable to flow in

an open circuit either.

Procedure: Use a VOM to check the resistance of

Rotor windings. Connect the positive (+) VOM test

probe to the positive (+) Rotor slip ring (nearest the

Rotor bearing). Connect the common (-) VOM test

probe to the negative (-) slip ring. The VOM should

indicate approximately as listed in the chart in Part 6

(Page 6.1-1).

Remove both brush holders to prevent interaction.

Set VOM to a high resistance scale and zero the meter.

Connect the positive (+) test probe to the positive (+1

slip ring (nearest the Rotor bearino); the common (•)

test probe to a clean frame ground. "Infinity" must be

indicated.

PAGE 1.6-7

Page 36

SECTION 1.6- TROUBLESHOOTING

(UNITS WITH 15 INCH STATOR)

Detailed Instructions (Continued)

Results:

1. Replace the Rotor if it fails test.

2. If Rotor checks good, go to Test 12.

PARTI

THE REVOLVING FIELD AC GENERATOR

1

ulated excitation current (DC) is delivered from the

Regulator to the Rotor via these wires.

Figure 7. Rotor Assembly Test Points

TEST 12- CHECK BRUSHES AND SLIP RINGS:

Discussion: The brushes and slip rings are de

signed for long life and dependability. Problems with

therse components are very infrequent. It is possible

that, after a prolonged non-operating period, the slip

rings can develop a corrossive film around their outer

periphery. This film can separate the brushes from the

slip rings and open the excitation circuit.

Procedure: Remove wires from the brushes. Re

move the brush holders from the rear bearing carrier.

Carefully inspect brushes, brush holders, wires and slip

rings. Replace brushes that are chipped, cracked, or

worn excessively. Replace brushes as complete sets.

Replace any damaged brush holders. If the slip rings

have a dull or tarnished appearance, they may be

cleaned with fine sandpaper. DO NOT USE ANY ME

TALLIC GRIT TO CLEAN SLIP RINGS. Polish the slip

rings until shiny.