Page 1

-------------------

GENERAC®

Model: 13694330200

Type:

SDI00

Engine: D6.

7.1

Owner's

Manual

Stationary

Emergency

Generator

c@us

LISTED

This

manual

should

remain

with

the

unit.

Page 2

Table of Contents

Safety

Rules

2

Introduction

1

Read

This

Manual

Thoroughly

1

Operation

and

Maintenance

1

HowtoObtain

Service

1

Authorized

Service

Dealer

Locator

Number

..'

...

1

Warranty

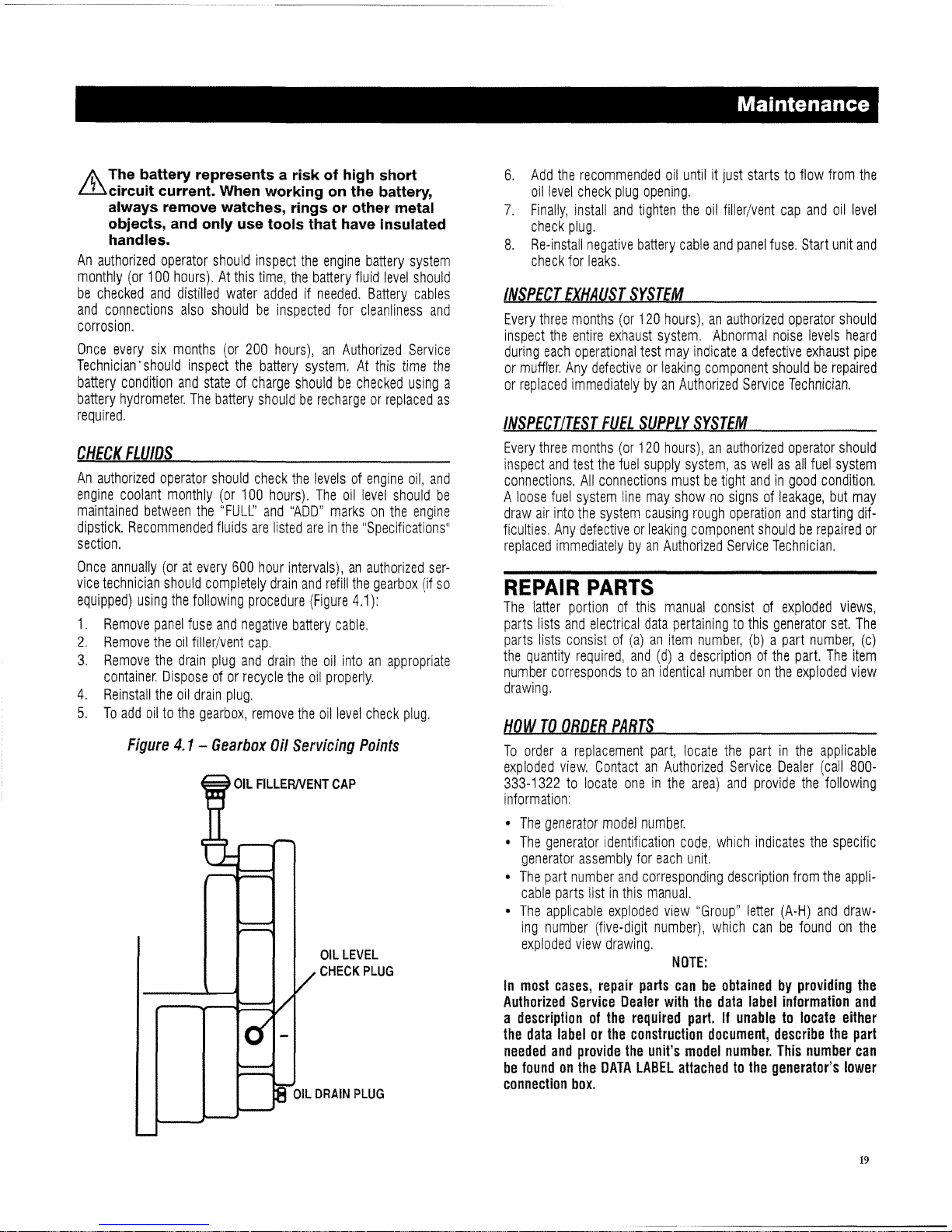

29

Notes

27

Maintenance

17

SERVICE

SCHEDULE..............

.

17

Authorized

Operator

Maintenance

Functions

17

Authorized

Service

Technician

Maintenance

Functions

.

17

PERIODIC

MAINTENANCE

18

Test

Stationary

Emergency

Generator

System

Operation

and

Components..

.. ..

.

18

Inspect

Battery...

..

18

Check

Fluids.

..

19

Inspect

Exhaust

System..

.

19

Inspect/Test

Fuel

Supply

System..

19

REPAIR

PARTS........

.

19

HowtoOrder

Parts..

. . 19

500

I\VV

TO

600

I\VV

STATIONARY

EMERGENCY

DIESEL

ENGINE

DRIVEN

GENERATOR

SETS..

.

..

20

SERVICE

MAINTENANCE

INTERVAL

INFORMATION

..

,,20

Operation

16

GENERATOR

CONTROL

AND

OPERATION

16

OPERATING

UNIT

WITH

MANUAL

TRANSFER

SWITCH

...16

Start-up

and

Transfer...

16

Retransfer

and

Shutdown..

.,..17

OPERATING

UNIT

WITH

AUTOMATIC

TRANSFER

SWITCH

....

17

Installation

13

STATIONARY

EMERGENCY

GENERATOR

INSTALLATION

.13

NFPA

Standards...

.

13

Other

Published

Standards..

...13

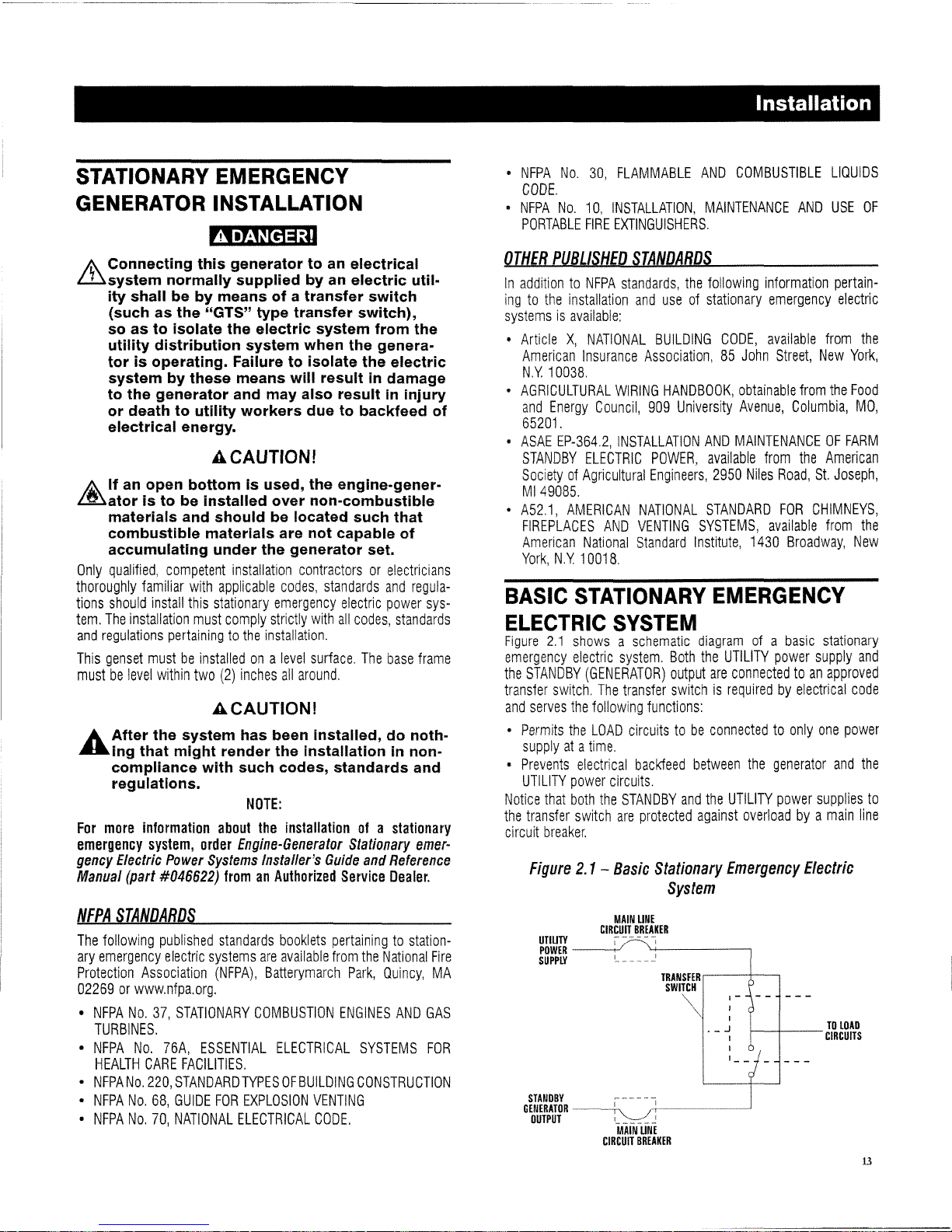

BASIC

STATIONARY

EMERGENCY

ELECTRIC

SYSTEM..

.

13

EMERGENCY

CIRCUIT

ISOLATION

METHOD

..

14

TOTAL

CIRCUIT

ISOLATION

METHOD

...14

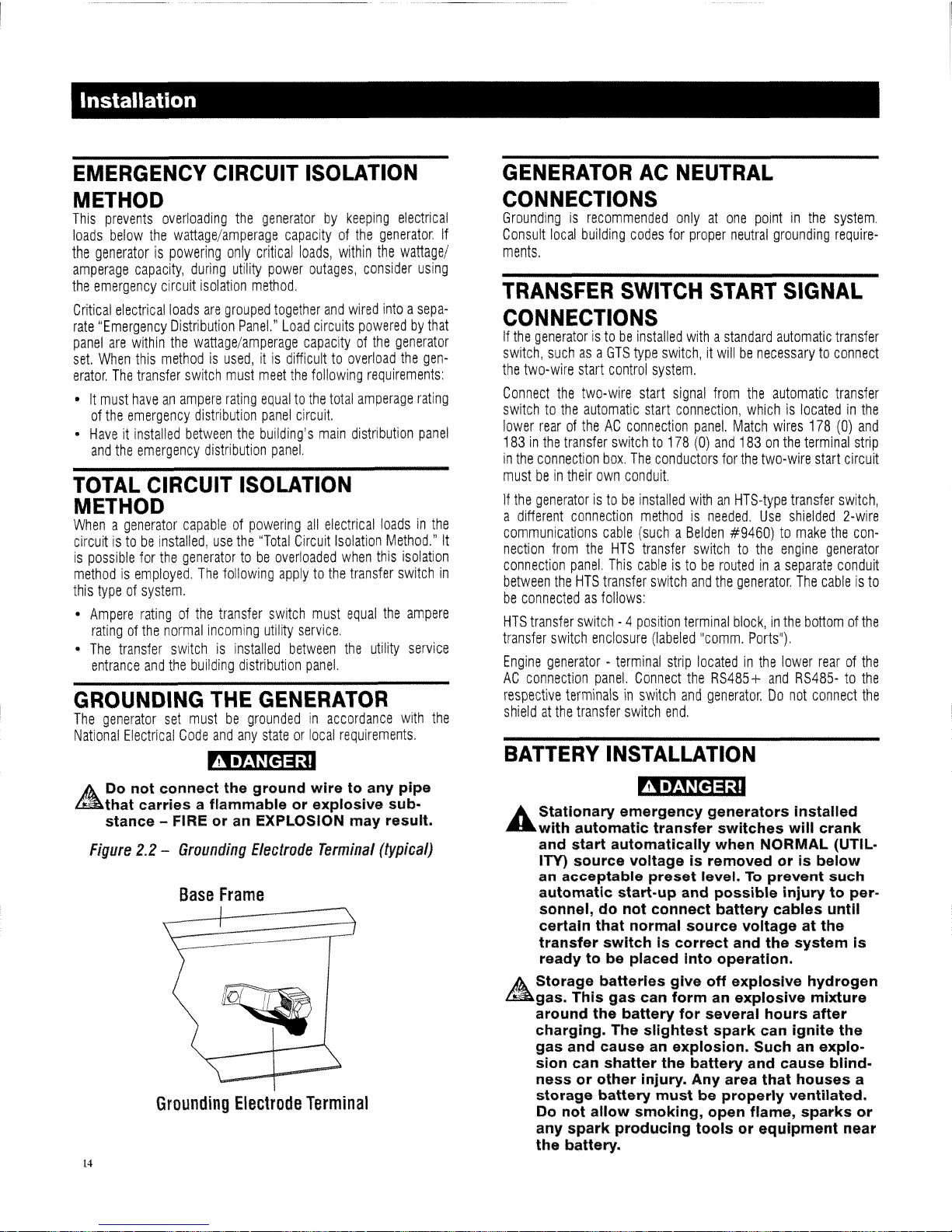

GROUNDING

THE

GENERATOR...

.

14

GENERATORACNEUTRAL

CONNECTIONS..............

..14

TRANSFER

SWITCH

START

SIGNAL

CONNECTIONS.

.

14

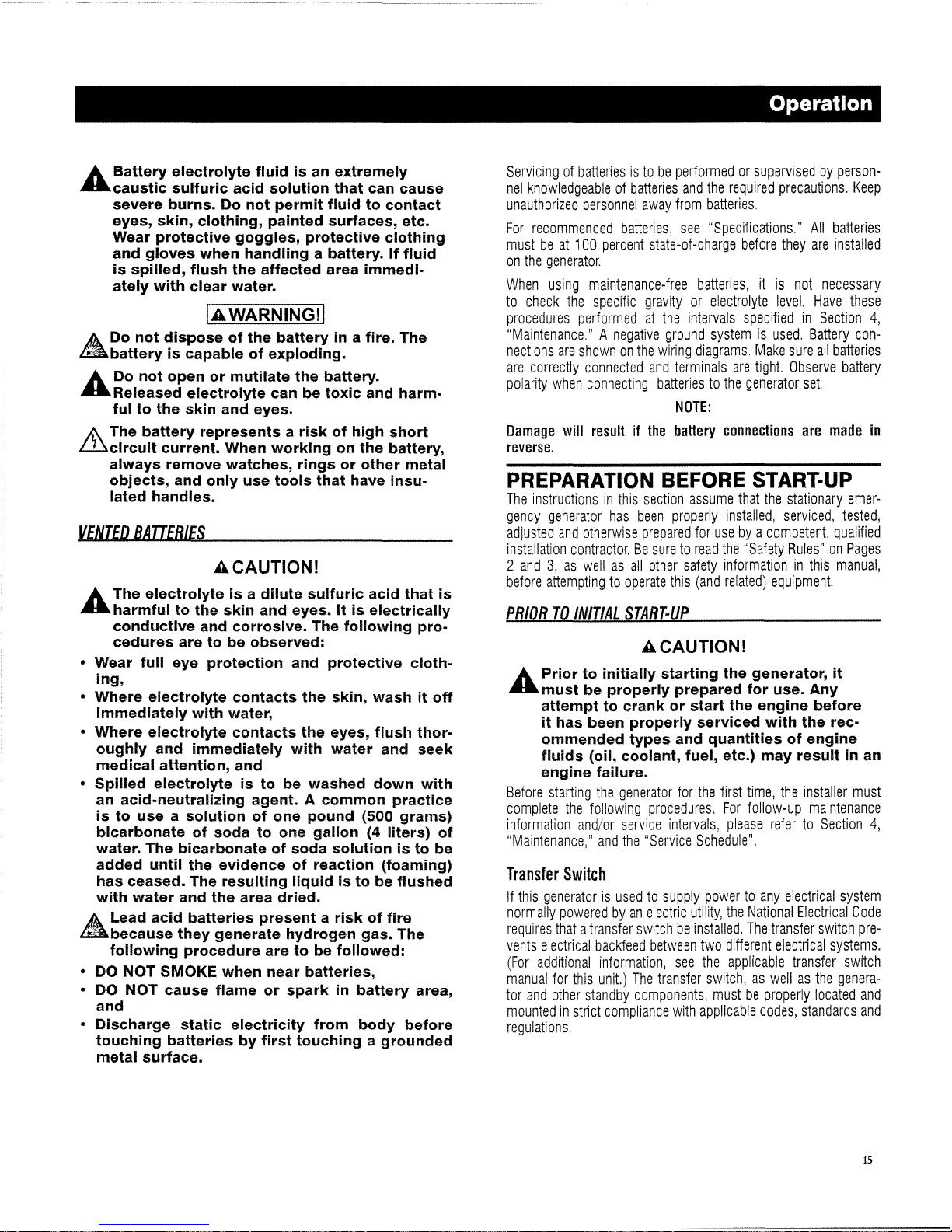

BATTERY

INSTALLATION.....

. .

14

Vented

Batteries.....

.

.15

PREPARATION

BEFORE

START-UP

..

..

15

PriortoInitial

Start-up..

...15

Start-up

Inspection

..

16

. 5

ENGINE

PROTECTIVE

DEViCES..

5

Coolant

Temperature

Sender

5

Low

Coolant

Level

Sensor...

. 5

Oil

Pressure

Sender

0

Overs

peed

Shutdown

;)

Overcrank

Shutdown

5

RPM

Sensor

Loss

Shutdown...

. 5

DC

FUSES..

5

FUEL

SYSTEM

6

Diesel

Fuel

System...

. 6

SPECIFICATIONS

6

Generator

6

Engine

Oil

Recommendations

6

Coolant. 6

Gearbox

Lubrication..

. 6

Fuel

System

Requirements

and

Recommendations.....

. 7

BATTERY

INSTALLATION..

. 7

THE

BATTERY...

8

GENERATORACLEAD

CONNECTIONS

8

Four-lead,

Single-phase

Stator..

. 8

12-lead,

Broad

Range

Stators

9

Six-lead,

600

VAC,

Three-phase

Stator

.....

10

FIELD

WIRING

CONNECTIONS

REQUIREMENTS

10

Field

Wiring

ConnectionstoBuss

Bars..

.

11

GENERATOR

AND

LOAD

COMPATIBILITY

11

STARTING

AIDS

.

11

Engine

Coolant

Heaters..

..

.

11

Engine

Oil

Heater

(Optional)

..

.

11

Battery

Warmers

(Optional)..

.

12

Battery

Chargers..

. .

12

Generallnformation

4

IDENTIFICATION

RECORD

.4

Data

Label

...

Generator

Set

XPL

Label

.

EQUIPMENT

DESCRIPTION

;)

Standard

Generator

Features

.

Page 3

INTRODUCTION

Thank

you

for

purchasing

this

modelofthe

stationary

emergency

generator

set

product

linebyGenerac

Power

Systems,

Inc"

Every

effort

was

expendedtomake

sure

that

the

information

and

instructionsinthis

manual

were

both

accurate

and

currentatthe

time

the

manual

was

written.

However,

the

manufacturer

reserves

the

righttochange,

alterorotherwise

improve

this

product(s)

at

any

time

without

prior

notice.

READ

THIS

MANUAL

THOROUGHLY

If

any

portionofthis

manualisnot

understood,

contact

the

near-

est

Authorized

Service

Dealer

for

starting,

operating

and

servicing

procedures.

Throughout

this

publication,

andontags

and

decals

affixedtothe

generator,

DANGER,

WARNING,

CAUTION

and

NOTE

blocks

are

usedtoalert

personneltospecial

instructions

aboutaparticular

serviceoroperation

that

maybehazardousifperformed

incor-

rectlyorcarelessly.

Observe

them

carefully.

Their

definitions

are

as

follows:

~

INDICATESAHAZARDOUS

SITUATIONORACTION

WHICH,

IF

NOT

AVOIDED,

WILL

RESULTINDEATHORSERIOUS

INJURY.

IAWARNING!I

Indicatesahazardous

situationoraction

which,ifnot

avoided,

could

resultindeathorserious

injury.

ACAUTIONI

Indicatesahazardous

situationoraction

which,ifnot

avoided,

could

resultinminorormoderate

injury.

NOTE:

Notes

contain

additional

information

importanttoa

procedure

and

willbefound

within

the

regular

text

bodyofthis

manual.

These

safety

warnings

cannot

eliminate

the

hazards

that

they

indicate.

Common

sense

and

strict

compliance

with

the

special

instructions

while

performing

the

actionorservice

are

essential

to

preventing

accidents.

Four

commonly

used

safety

symbols

accompany

the

DANGER,

WARNING

and

CAUTION

blocks.

The

typeofinformation

each

indicatesisas

follows:

A

This

symbol

points

out

important

safety

information

that,

....ifnot

followed,

could

endanger

personal

safety

and/or

propertyofothers.

A

This

symbol

points

out

potential

explosion

hazard.

£

This

symbol

points

out

potential

fire

hazard.

Lh

This

symbol

points

out

potential

electrical

shock

hazard.

Introduction

The

operatorisresponsible

for

proper

and

safe

useofthe

equip-

ment.

The

manufacturer

strongly

recommends

that

the

operator

read

this

Owner's

Manual

and

thoroughly

understand

all

instruc-

tions

before

using

this

equipment.

The

manufacturer

also

strongly

recommends

instructing

other

userstoproperly

start

and

operate

the

unit.

This

prepares

themifthey

needtooperate

the

equipment

inanemergency.

OPERATION

AND

MAINTENANCE

Itisthe

operator's

responsibilitytoperform

all

safety

checks,

to

make

sure

that

all

maintenance

for

safe

operationisperformed

promptly,

andtohave

the

equipment

checked

periodically

by

an

Authorized

Service

Dealer.

Normal

maintenance

service

and

replacementofparts

are

the

responsibilityofthe

owner/operator

and,assuch,

are

not

considered

defectsinmaterialsorworkman-

ship

within

the

termsofthe

warranty.

Individual

operating

habits

and

usage

contributetothe

need

for

maintenance

service.

Proper

maintenance

and

careofthe

generator

ensureaminimum

numberofproblems

and

keep

operating

expensesata

minimum.

SeeanAuthorized

Service

Dealer

for

service

aids

and

acces-

sories.

Operating

instructions

presentedinthis

manual

assume

that

the

stationary

emergency

electric

system

has

been

installedbyan

Authorized

Service

Dealerorother

competent,

qualified

contractor.

Installationofthis

equipmentisnota"do-it-yourself"

project.

HOWTOOBTAIN

SERVICE

When

the

generator

requires

servicingorrepairs,

contact

an

Authorized

Service

Dealer

for

assistance.

Service

technicians

are

factory-trained

and

are

capableofhandling

all

service

needs.

When

contactinganAuthorized

Service

Dealer

about

parts

and

service,

always

supply

the

complete

model

numberofthe

unit

as

givenonthe

front

coverofthis

manualoron

the

DATA

LABEL

affixedtothe

unit.

AUTHORIZED

SERVICE

DEALER

LOCATION

To

locate

the

nearest

AUTHORIZED

SERVICE

DEALER,

please

call

this

number:

1·800·333·1322

DEALER

LOCATION

INFORMATION

CANBEOBTAINEDATTHIS

NUMBER

or

visit

the

website

at

www.generac.com.

Page 4

Safety Rules

It..

SAVE

THESE INSTRUCTIONS - The manufacturer suggests that these rules for safe operation be

...

copied and posted In potential hazard areas. Safety should be stressed to all operators, potential

operators, and service and repair technicians for this equipment.

It..

SAVE

THESE INSTRUCTIONS - This manual contains Important Instructions that should be followed

"'durlng

Installation and maintenance of the generator and batteries.

Study

these

SAFETY

RULES

carefully

before

installing,

operating

or

servicing

this

equipment.

Become

familiar

with

this

Owner's

Manual

and

with

the

unit.

The

generator

can

operate

safely,

effi-

ciently

and

reliably

onlyifitisproperly

installed,

operated

and

maintained.

Many

accidents

are

causedbyfailingtofollow

simple

and

fundamental

rulesorprecautions.

The

manufacturer

cannot

anticipate

every

possible

circumstance

that

might

involveahazard.

The

warningsinthis

and

on

tags

and

decals

affixedtothe

unit

are,

therefore,

not

all-inclusive.

If

usingaprocedure,

work

methodoroperating

technique

that

the

manufacturer

does

not

specifically

recommend,

ensure

thatitis

safe

for

others.

Also

make

sure

the

procedure,

work

method

or

operating

technique

utilized

does

not

render

the

generator

unsafe.

~

It..

Despite the safe design of this genera·

...

tor, operating this equipment Imprudently,

neglecting Its maintenance or being careless

can cause possible Injury or death. Permit

only responsible and capable persons to

Install, operate or maintain this equipment.

~

Potentially lethal voltages are generated by

~these

machines. Ensure all steps are taken to

render the machine safe before attempting to

work on the generator.

It..

Parts of the generator are rotating and/or hot

...

during operation. Exercise care near running

generators.

GENERAL

HAZARDS

•

For

safety

reasons,

the

manufacturer

recommends

that

this

equipmentbeinstalled,

serviced

and

repairedbyan

Authorized

Service

Dealerorother

competent,

qualified

electrician

or

installation

technician

whoisfamiliar

with

applicable

codes,

standards

and

regulations.

The

operator

also

must

comply

with

all

such

codes,

standards

and

regulations.

•

Installation,

operation,

servicing

and

of

this

(and

related)

equipment

must

always

comply

with

applicable

codes,

stan-

dards,

laws

and

regulat'lons.

Adhere

strictlytolocal,

state

and

national

electrical

and

building

codes.

Comply

with

regulations

the

Occupational

Safety

and

Health

Administration

(OSHA)

has

established.

Also,

ensure

that

the

generatorisinstalled,

operat-

ed

and

servicedinaccordance

with

the

manufacturer's

instruc-

tions

and

recommendations.

Following

installation,donothing

that

might

render

the

unit

unsafeorin

noncompliance

with

the

aforementioned

codes,

standards,

laws

and

regulations.

2

•

The

engine

exhaust

fumes

contain

carbon

monoxide

gas,

which

canbeDEADLY.

This

dangerous

gas,ifbreathed

in

sufficient

concentrations,

can

cause

unconsciousnessoreven

death.

For

that

reason,

adequate

ventilation

mustbeprovided.

Exhaust

gases

mustbepiped

safely

away

from

any

building

or

enclosure

that

houses

the

generatortoan

area

where

people,

animals,

etc.,

will

notbeharmed.

This

exhaust

system

must

be

installed

properly,instrict

compliance

with

applicable

codes

and

standards.

•

Keep

hands,

feet,

clothing,

etc,

away

from

drive

belts,

fans,

and

other

movingorhot

parts.

Never

remove

any

drive

belt

or

fan

guard

while

the

unitisoperating.

•

Adequate,

unobstructed

flowofcooling

and

ventilating

air

is

criticalinany

roomorbuilding

housing

the

generatortoprevent

buildupofexplosive

gases

andtoensure

correct

generator

operation.Donot

alter

the

installationorpermit

even

partial

blockageofventilation

provisions,asthis

can

seriously

affect

safe

operationofthe

generator.

•

Keep

the

area

around

the

generator

clean

and

uncluttered.

Remove

any

materials

that

could

become

hazardous.

•

When

workingonthis

equipment,

remain

alertatall

times.

Never

workonthe

equipment

when

physicallyormentally

fatigued.

•

Inspect

the

generator

regularly,

and

promptly

repairorreplace

all

worn,

damagedordefective

parts

using

only

factory-

approved

parts.

•

Before

performing

any

maintenanceonthe

generator,

discon-

nect

its

battery

cablestoprevent

accidental

start-up.

Disconnect

the

cable

from

the

battery

post

indicatedbya

NEGATIVE,

NEG

or

first.

Reconnect

that

cable

last.

•

Never

use

the

generatororanyofits

partsasa

step.

Stepping

on

the

unit

can

stress

and

break

parts,

and

may

resultindan-

gerous

operating

conditions

from

leaking

exhaust

gases,

fuel

leakage,

oil

leakage,

etc.

Page 5

ELECTRICAL

HAZARDS

•

All

generators

coveredbythis

manual

produce

dangerous

elec-

trical

voltages

and

can

cause

fatal

electrical

shock.

Utility

power

delivers

extremely

high

and

dangerous

voltagestothe

transfer

switchaswellasthe

stationary

emergency

generator.

Avoid

contact

with

bare

Wires,

terminals,

connections,

etc.,onthe

generatoraswellasthe

transfer

switch,ifapplicable.

Ensure

all

appropriate

covers,

guards

and

barriers

areinplace

before

oper-

ating

the

generator.Ifwork

mustbedone

aroundanoperating

unit,

standonan

insulated,

dry

surfacetoreduce

shock

hazard.

•

Do

not

handle

any

kindofelectrical

device

while

stand-

inginwater,

while

barefoot,orwhile

handsorfeet

are

wet.

DANGEROUS

ELECTRICAL

SHOCK

MAY

RESULT.

•Ifpeople

must

standonmetalorconcrete

while

installing,

operating,

servicing,

adjustingorrepairing

this

equipment,

place

insulative

mats

overadry

wooden

platform.

Workonthe

equipment

only while

standingonsuch

insulative

mats.

•

The

generator

set

mustbegroundedinaccordance

with

the

National

Electrical

Code

and

any

stateorlocal

requirements.

•

Wire

gauge

sizesofelectrical

wiring,

cables

and

cord

sets

mustbeadequatetohandle

the

maximum

electrical

current

(ampacity)towhich

they

willbesubjected.

See

the

Field

Wiring

Requirements

Table.

•

Before

installingorservicing

this

(and

related)

equipment,

make

sure

that

all

power

voltage

supplies

are

positively

turned

off

at

their

source.

Failuretodosowill

resultinhazardous

and

pos-

sibly

fatal

electrical

shock.

•

Connecting

this

unittoan

electrical

system

normally

supplied

byanelectric

utility

shallbeby

meansofa

transfer

switchsoas

to

isolate

the

generator

electric

system

from

the

electric

utility

distribution

system

when

the

generatorisoperating.

Failure

to

isolate

the

two

electric

system

power

sources

from

each

other

by

such

means

will

resultindamagetothe

generator

and

may

also

resultininjuryordeathtoutility

power

workers

due

to

backfeedofelectrical

energy.

•

Generators

installed

withanautomatic

transfer

switch

will

crank

and

start

automatically

when

NORMAL

(UTILITY)

source

voltageisremovedoris

belowanacceptable

preset

level.

To

prevent

such

automatic

start-up

and

possible

injurytoperson-

nel,

disable

the

generator's

automatic

start

circuit

(battery

cables,

etc.)

before

workingonor

around

the

unit.

Then,

place

a

"Do

Not

Operate"

tagonthe

generator

control

panel

and

on

the

transfer

switch.

•Incaseofaccident

causedbyelectric

shock,

immediately

shut

down

the

sourceofelectrical

power.Ifthisisnot

pos-

sible,

attempttofree

the

victim

from

the

live

conductor.

AVOID

DIRECT

CONTACT

WITH

THE

VICTIM.

Useanonconducting

implement,

suchasa

dry

ropeorboard,tofree

the

victim

from

the

live

conductor.Ifthe

victimisunconscious,

apply

first

aid

and

get

immediate

medical

help.

•

Never

wear

jewelry

when

workingonthis

equipment.

Jewelry

can

conduct

electricity

resultinginelectric

shock,ormay

get

caughtinmoving

components

causing

injury.

Safety Rules

FIRE

HAZARDS

•

Keepafire

extinguisher

near

the

generatoratall

times,DoNOT

use

any

carbon

tetra-chloride

type

extingUisher,

Its

fumes

are

toxic,

and

the

liquid

can

deteriorate

wiring

insulation.

Keep

the

extinguisher

properly

charged

andbefamiliar

with

its

use.

If

there

are

any

questions

pertainingtofire

extinguishers,

consult

the

local

fire

department.

EXPLOSION

HAZARDS

•

Properly

ventilate

any

roomorbuilding

housing

the

generator

to

prevent

bUild-Upofexplosive

gas,

•

Do

not

smoke

around

the

generator,

Wipeupany

fueloroil

spills

immediately.

Ensure

thatnocombustible

materials

are

left

in

the

generator

compartment,oronornear

the

generator,

as

FIREorEXPLOSION

may

result.

Keep

the

area

surrounding

the

generator

clean

and

free

from

debris.

•

All

fuel

types

are

potentially

FLAMMABLE

and/or

EXPLOSIVE

and

shOUldbehandled

with

care,

Comply

with

all

laws

regulat-

ing

the

storage

and

handlingoffuels,

Inspect

the

unit's

fuel

system

frequently

and

correct

any

leaks

immediately,

Fuel

supply

lines

mustbeproperly

installed,

purged

and

leak

tested

accordingtoapplicable

fuel-gas

codes

before

placing

this

equipment

into

service,

•

Diesel

fuels

are

highly

FLAMMABLE.

CALIFORNIA

PROPOSITION65WARNING

Engine

exhaust

and

someofits

constituents

are

known

to

the

StateofCaliforniatocause

cancer,

birth

defects

and

other

reproductive

harm.

CALIFORNIA

PROPOSITION65WARNING

This

product

containsoremits

chemicals

knowntothe

StateofCaliforniatocause

cancer,

birth

defects

and

other

reproductive

harm

3

Page 6

General

Information

IDENTIFICATION

RECORD

DATA

LABEL

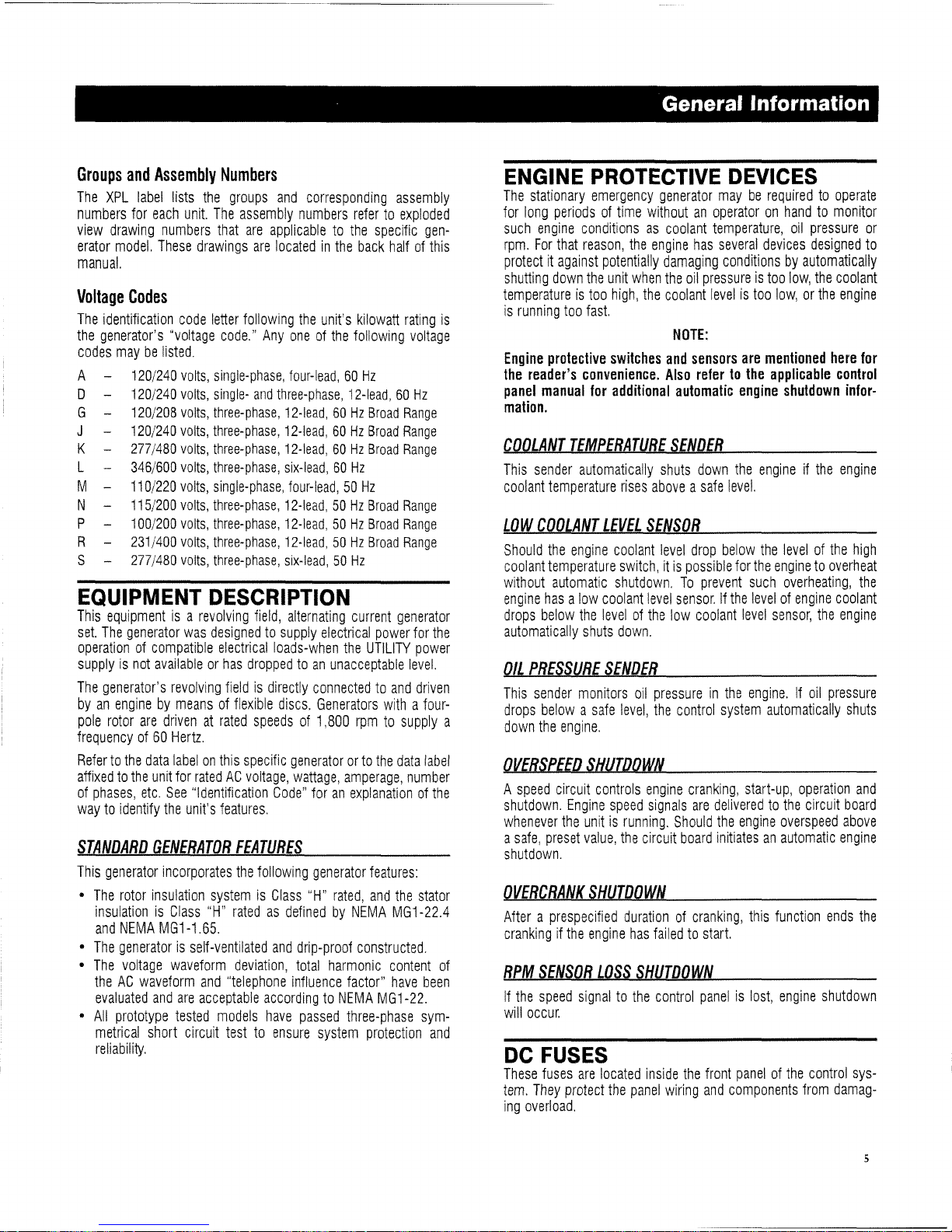

Figure

1.2

-

XPL

Label

GENERAC

POWER

SYSTEMS

WHEN

ORDERING

REPAIR

PARTS,

ALWAYS

GIVE

THE

ABOVE

INFORMATION

NOTE:

The

aboveisa

generic

representationofan

XPllabel.

For

actu-

al

information

relatedtothis

particular

model,

please

refer

to

the

"construction

document"

locatedatthe

endofthis

manual,

ortothe

data

cards

affixedtothe

unit.

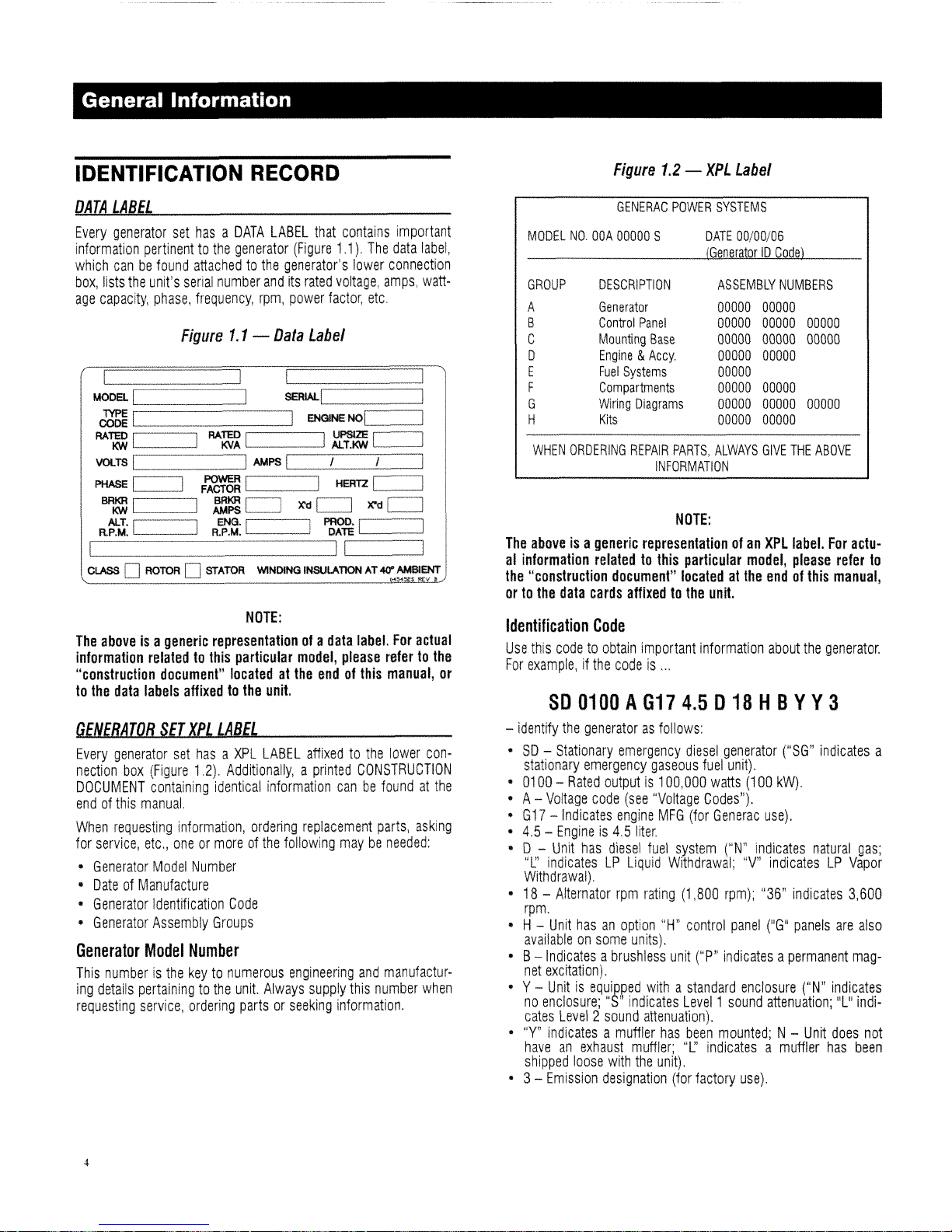

Every

generator

set

hasaDATA

LABEL

that

contains

important

information

pertinenttothe

generator

(Figure

1,1),

The

data

label,

which

canbefound

attachedtothe

generator's

lower

connection

box,

lists

the

unit's

serial

number

and

its

rated

voltage,

amps,

watt-

age

capacity,

phase,

frequency,

rpm,

power

factor,

etc

Figure

1.1

-

Data

Label

MODELNOOOA

00000

S

GROUP

DESCRIPTION

A

Generator

B

Control

Panel

C

Mounting

Base

D

Engine&Accy,

E

Fuel

Systems

F

Compartments

G

Wiring

Diagrams

H

Kits

DATE

00/00/05

ASSEMBLY

NUMBERS

00000 00000

00000 00000

00000

00000 00000 00000

00000 00000

00000

00000 00000

00000

00000 00000

00000

00000

NOTE:

The

aboveisa

generic

representationofa

data

label.

For

actual

information

relatedtothis

particular

model,

please

refertothe

"construction

document"

locatedatthe

endofthis

manual,

or

to

the

data

labels

affixedtothe

unit.

GENERATOR

SET

XPL

LABEL

Every

generator

set

hasaXPL

LABEL

affixedtothe

lower

con-

nection

box

(Figure

1,2),

Additionally,aprinted

CONSTRUCTION

DOCUMENT

containing

identical

information

canbefoundatthe

endofthis

manual.

When

requesting

information,

ordering

replacement

parts,

asking

for

service,

etc"

oneormoreofthe

following

maybeneeded:

•

Generator

Model

Number

•

DateofManufacture

•

Generator

Identification

Code

•

Generator

Assembly

Groups

Generator

Model

Number

This

numberisthe

keytonumerous

engineering

and

manufactur-

ing

details

pertainingtothe

unit

Always

supply

this

number

when

requesting

service,

ordering

partsorseeking

information,

4

Identification

Code

Use

this

codetoobtain

important

information

about

the

generator,

For

example,ifthe

codeis'"

SO

0100A617

4.5018

HBYY3

-

identify

the

generatorasfollows:

•

SO-Stationary

emergency

diesel

generator

("58"

indicates

a

stationary

emergency

gaseous

fuel

unit),

•

0100-Rated

outputis100,000

watts

(100

kW),

• A-

Voltage

code

(see

"Voltage

Codes"),

•

G17

-Indicates

engine

MFG

(for

Generac

use).

•

4,5-Engineis4,5

liter.

• 0 -

Unit

has

diesel

fuel

system

("N"

indicates

natural

gas;

'T'

indicatesLPLiquid

Withdrawal;

"v"

indicatesLPVapor

Withdrawal),

•18-

Alternator

rpm

rating

(1,800

rpm);

"36"

indicates

3,600

rpm.

• H-

Unit

hasanoption

"H"

control

panel

("G"

panels

are

also

availableonsome

units).

• B-

Indicatesabrushless

unit

("P"

indicatesapermanent

mag-

net

excitation).

• Y-

Unitisequipped

withastandard

enclosure

("N"

indicates

no

enclosure;

"5'

indicates

Level1sound

attenuation;

"L"

indi-

cates

Level2sound

attenuation),

•

"Y"

indicatesamuffler

has

been

mounted;N-Unit

does

not

haveanexhaust

muffler;

"L:'

indicatesamuffler

has

been

shipped

loose

with

the

unit),

• 3-

Emission

designation

(for

factory

use),

Page 7

Groups

and

Assembly

Numbers

The

XPL

label

lists

the

groups

and

corresponding

assembly

numbers

for

each

unit.

The

assembly

numbers

refertoexploded

view

drawing

numbers

that

are

applicabletothe

specific

gen-

erator

model.

These

drawings

are

locatedinthe

back

halfofthis

manual.

Voltage

Codes

The

identification

code

letter

following

the

unit's

kilowatt

rating

is

the

generator's

"voltage

code."

Anyoneofthe

following

voltage

codes

maybelisted.

A -

120/240

volts,

single-phase,

four-lead,60Hz

o -

120/240

volts,

single-

and

three-phase,

12-lead,60Hz

G -

120/208

volts,

three-phase,

12-lead,60Hz

Broad

Range

J

120/240

volts,

three-phase,

12-lead,60Hz

Broad

Range

K -

277/480

volts,

three-phase,

12-lead,60Hz

Broad

Range

L

346/600

volts,

three-phase,

six-lead,60Hz

M -

110/220

volts,

single-phase,

four-lead,50Hz

N -

115/200

volts,

three-phase,

12-lead,50Hz

Broad

Range

P -

100/200

volts,

three-phase,

12-lead,50Hz

Broad

Range

R -

231/400

volts,

three-phase,

12-lead,50Hz

Broad

Range

S

277/480

volts,

three-phase,

six-lead,50Hz

EQUIPMENT

DESCRIPTION

This

equipmentisa

revolving

field,

alternating

current

generator

set.

The

generator

was

designedtosupply

electrical

power

for

the

operationofcompatible

electrical

loads-when

the

UTILITY

power

supplyisnot

availableorhas

droppedtoan

unacceptable

level.

The

generator's

revolving

fieldisdirectly

connectedtoand

driven

byanenginebymeansofflexible

discs.

Generators

withafour-

pole

rotor

are

drivenatrated

speedsof1,800

rpmtosupply

a

frequencyof60

Hertz.

Refertothe

data

labelonthis

specific

generatororto

the

data

label

affixedtothe

unit

for

ratedACvoltage,

wattage,

amperage,

number

of

phases,

etc.

See

"Identification

Code"

foranexplanationofthe

waytoidentify

the

unit's

features.

STANDARD

GENERATOR

FEATURES

This

generator

incorporates

the

following

generator

features:

•

The

rotor

insulation

systemisClass

"H"

rated,

and

the

stator

insulationisClass

"H"

ratedasdefinedbyNEMA

MG1-22.4

and

NEMA

MG1-1.65.

•

The

generatorisself

-ventilated

and

drip-proof

constructed.

•

The

voltage

waveform

deviation,

total

harmonic

content

of

theACwaveform

and

"telephone

influence

factor"

have

been

evaluated

and

are

acceptable

accordingtoNEMA

MG1-22.

•

All

prototype

tested

models

have

passed

three-phase

sym-

metrical

short

circuit

testtoensure

system

protection

and

reliability.

General Information

ENGINE

PROTECTIVE

DEVICES

The

stationary

emergency

generator

mayberequiredtooperate

for

long

periodsoftime

withoutanoperatoronhandtomonitor

such

engine

conditionsascoolant

temperature,

oil

pressure

or

rpm.

For

that

reason,

the

engine

has

several

devices

designed

to

protectitagainst

potentially

damaging

conditionsbyautomatically

shutting

down

the

unit

when

the

oil

pressureistoo

low,

the

coolant

temperatureistoo

high,

the

coolant

levelistoo

low,orthe

engine

is

running

too

fast.

NOTE:

Engine

protective

switches

and

sensors

are

mentioned

here

for

the

reader's

convenience.

Also

refertothe

applicable

control

panel

manual

for

additional

automatic

engine

shutdown

infor-

mation.

COOLANT

TEMPERATURE

SENDER

This

sender

automatically

shuts

down

the

engineifthe

engine

coolant

temperature

rises

aboveasafe

level.

LOW

COOLANT

LEVEL

SENSOR

Should

the

engine

coolant

level

drop

below

the

levelofthe

high

coolant

temperature

switch,itis

possible

for

the

enginetooverheat

without

automatic

shutdown.Toprevent

such

overheating,

the

engine

hasalow

coolant

level

sensor.Ifthe

levelofengine

coolant

drops

below

the

levelofthe

low

coolant

level

sensor,

the

engine

automatically

shuts

down.

OIL

PRESSURE

SENDER

This

sender

monitors

oil

pressureinthe

engine.Ifoil

pressure

drops

belowasafe

level,

the

control

system

automatically

shuts

down

the

engine.

OVERSPEED

SHUTDOWN

A

speed

circuit

controls

engine

cranking,

start-up,

operation

and

shutdown.

Engine

speed

signals

are

deliveredtothe

circuit

board

whenever

the

unitisrunning.

Should

the

engine

overspeed

above

a

safe,

preset

value,

the

circuit

board

initiatesanautomatic

engine

shutdown.

OVERCRANK

SHUTOOWN

Afteraprespecified

durationofcranking,

this

function

ends

the

crankingifthe

engine

has

failedtostart.

RPM

SENSOR

LOSS

SHUTDOWN

If

the

speed

signaltothe

control

panelislost,

engine

shutdown

will

occur.

DC

FUSES

These

fuses

are

located

inside

the

front

panelofthe

control

sys-

tem.

They

protect

the

panel

wiring

and

components

from

damag-

ing

overload.

5

Page 8

General Information

FUEL

SYSTEM

DIESR

FUEL

SYSTEM

Diesel

fuelissuppliedtothe

generator

set

fromabase-mounted

fuel

tankorexternal

source.

Diesel

fuels

are

less

volatile

than

gaseous

fuels,

however,

careless

installation

can

leadtosafety

hazards

and/or

serious

problems

with

engine/generator

performance

and

reliability.

NOTE:

Appropriate

care

shouldbetakeninapplications

where

extremely

low

ambient

temperatures

are

possibletoensure

the

temperatureofthe

diesel

fuelisnot

allowedtofall

below

levels

where

"gelling"

could

occur.

SPECIFICATIONS

GENERATOR

Refertothe

data

plateonthe

generator

for

rated

watts,

amperes,

frequency,

voltage,

phase

and

other

pertinent

information.

Refer

to

the

drawingsinthe

backofthis

manual

for

engine,

cooling

system,

and

exhaust

system

specifications.

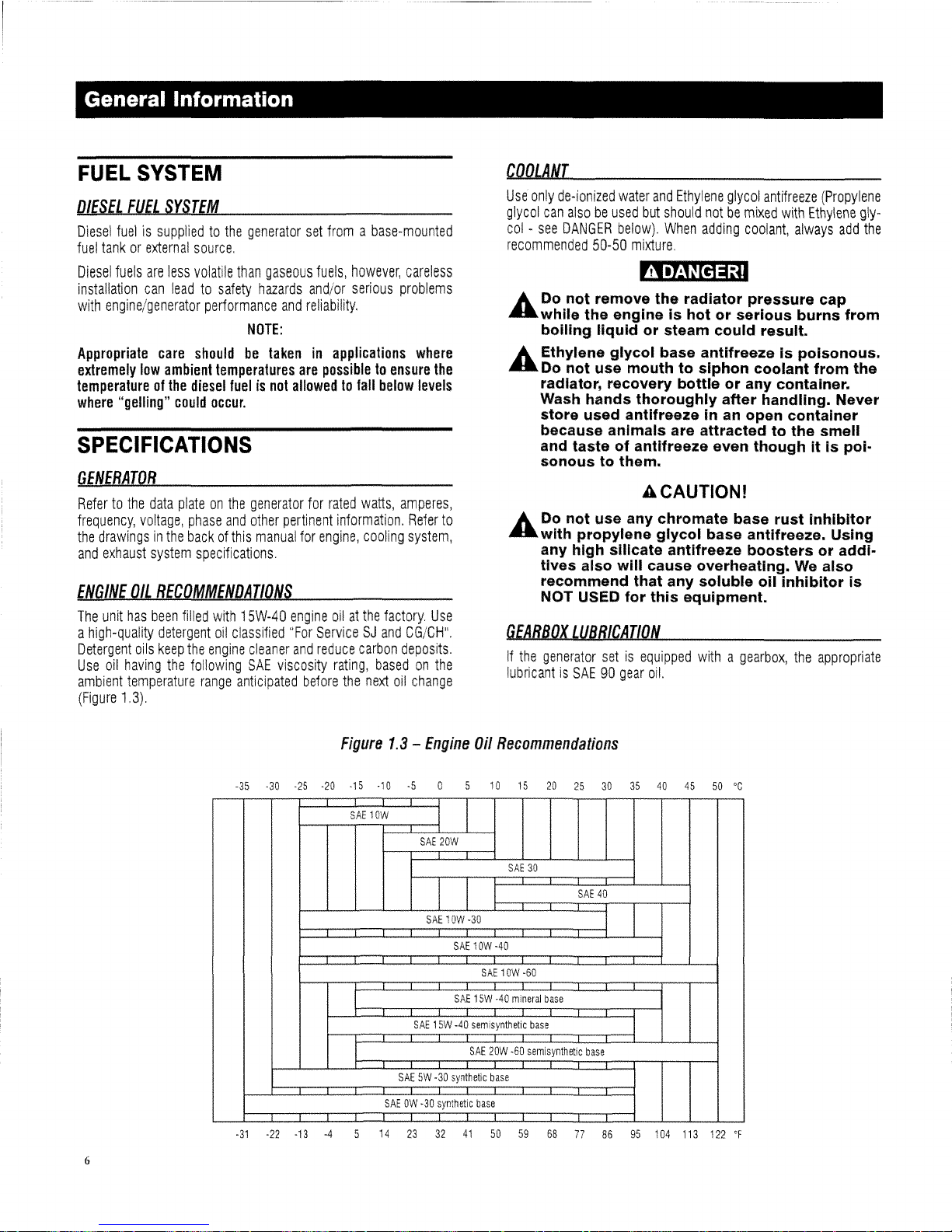

ENGINE

OIL

RECOMMENDATIONS

The

unit

has

been

filled

with

15W-40

engine

oilatthe

factory.

Use

a

high-quality

detergent

oil

classified

"For

ServiceSJand

CG/CH".

Detergent

oils

keep

the

engine

cleaner

and

reduce

carbon

deposits.

Use

oil

having

the

following

SAE

viscosity

rating,

basedonthe

ambient

temperature

range

anticipated

before

the

next

oil

change

(Figure

1.3).

COOLANT

Use

only

de-ionized

water

and

Ethylene

glycol

antifreeze

(Propylene

glycol

can

alsobeused

but

should

notbemixed

with

Ethylene

gly-

col-see

DANGER

below).

When

adding

coolant,

always

add

the

recommended

50-50

mixture.

~

A.

Do not remove the radiator pressure cap

....

while the engine is hot or serious burns from

boiling liquid or steam could result.

A.

Ethylene glycol base antifreeze Is poisonous.

....

Do not use mouth to siphon coolant from the

radiator, recovery bottle or any container.

Wash hands thoroughly after handling.

Never

store used antifreeze

in an open container

because animals are attracted to the smell

and taste of

antifreeze even though It is poi-

sonoustothem.

ACAUTIONI

A.

Do not use any chromate base rust Inhibitor

....

with propylene glycol base antifreeze. Using

any high silicate antifreeze boosters or additives also will cause overheating. We also

recommend that any soluble

011

Inhibitor Is

NOT USED for this equipment.

GEARBOX

LUBBICATION

If

the

generator

setisequipped

withagearbox,

the

appropriate

lubricantisSAE90gear

oil.

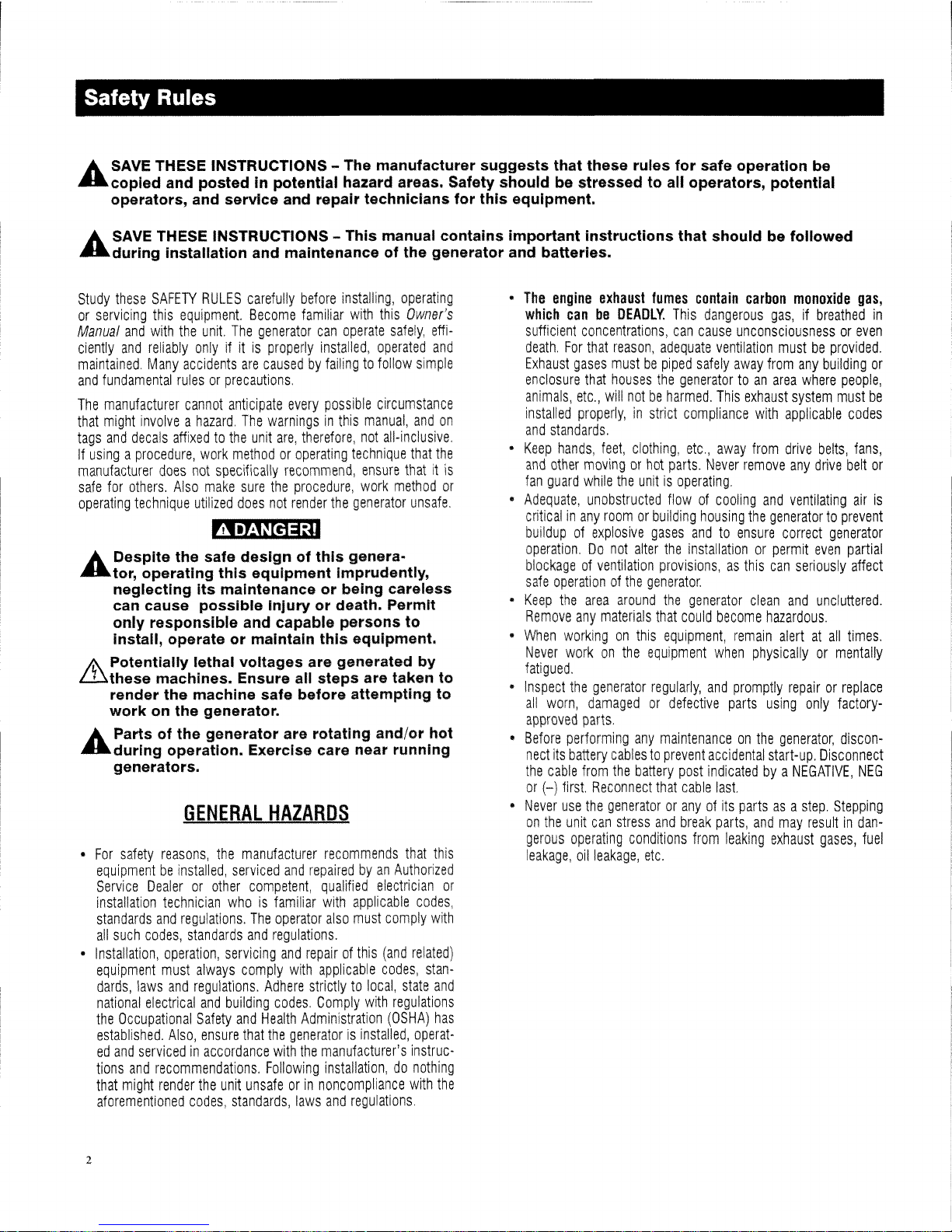

Figure

1.3

-

Engine

Oil

Recommendations

-35

-30

-25

-20

-15

-10

·5

15

20

25

30

35

40

45

50'C

SAE

lOW

I

I

SAE

20W

SAE

30

I I

SAE

40

SAE1OW

-30

SAE

lOW

-40

SAE

10W

·60

SAE

l5W

-40

mineral

base

SAE

15W

-40

semisynthetic

base

SAE

20W

·60

semisynthetic

base

SAE5W-30

synthetic

base

SAEOW·30

synthetic

base

6

-31

-22 -13

14

23

32

41

50

59

68

77

86

95

104

113 122

'F

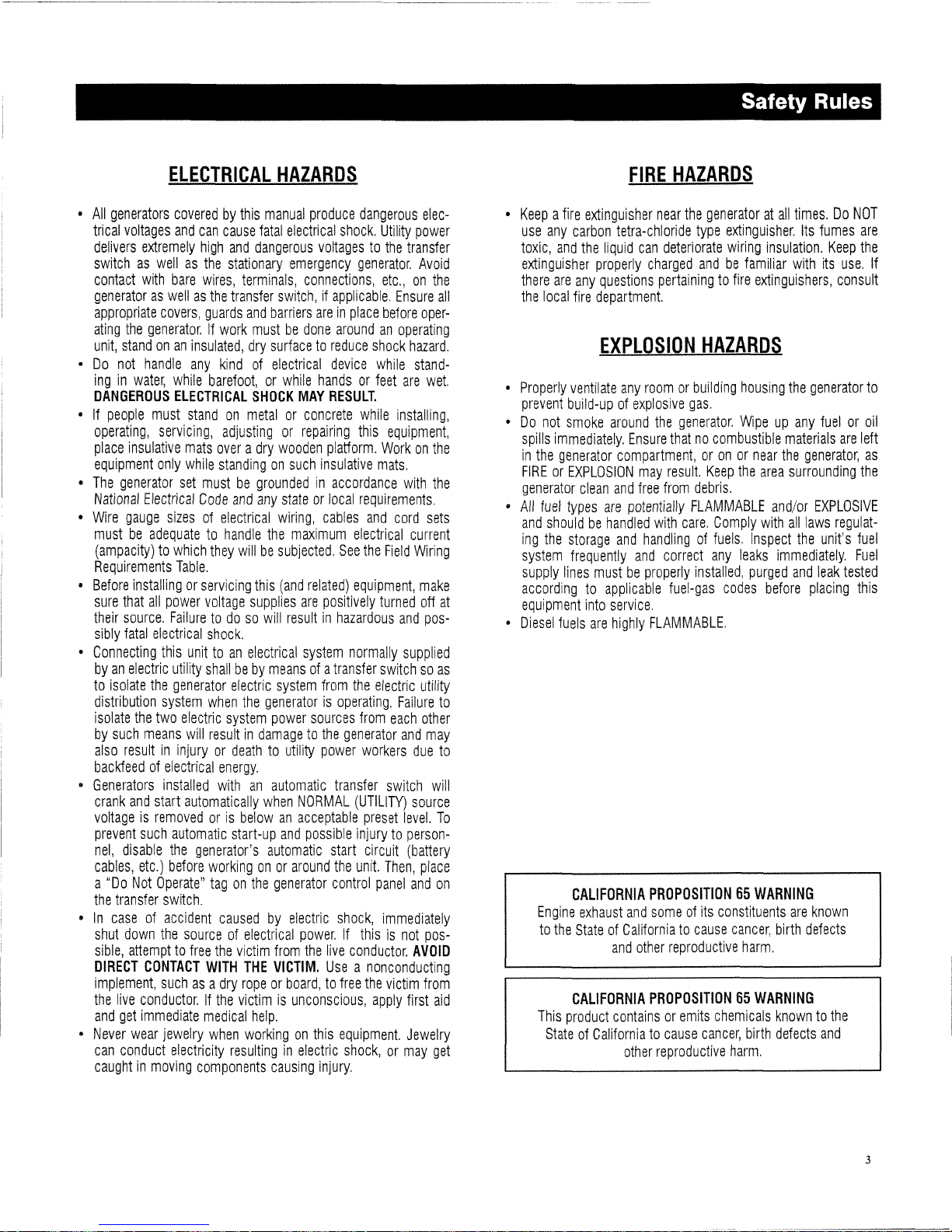

Page 9

General

Information

BLACK

___________

RED

LEAD

(FROM

STARTER

CONTACTOR)

BLACK

LEAD

~

(FROM

FRAME)

---<~~

+

BATTERY

4.

Connect

the

red

battery

cable

(from

starter

contactor)tothe

battery

post

indicatedbya

positive,

pas

or

(+).

5.

Connect

the

black

battery

cable

(from

frame

ground)tothe

battery

post

indicatedbya

negative,

NEGor(-).

NOTE:

Damage

will

resultifbattery

connections

are

madeinreverse.

NOTE:

The

generatorisequipped

withabattery

trickle

charger

that

is

active

when

the

unitissetupfor

automatic

operation.

With

the

battery

installed

and

utility

power

source

voltage

available,

the

battery

receivesatrickle

charge

while

the

engineisnot

run-

ning,toprevent

self-discharge.

The

trickle

chargerisdesigned

to

help

extend

the

lifeofthe

batterybymaintaining

the

battery

when

the

unitisnot

running.

The

trickle

charge

feature

cannot

be

usedtorechargeadischarged

battery.

Before

installing

and

connecting

the

battery,

complete

the

follow-

ing

steps:

1.

Set

the

generator's

AUTO/OFF/MANUAL

switchtoOFF.

2.

Turn

off

utility

power

supplytothe

transfer

switch.

3.

Remove

the

10A

and

15A

fuses

from

the

generator

control

panel.

Battery

cables

were

factory

connectedatthe

generator

(Figure

1.4).

Connect

cablestobattery

postsasfollows:

Figure

1.4

-

Battery

Cable

Connections

Diesel

Engine

Battery

Size

Minimum

CCA

2.4L

3.4L

GRP27or

GRP

31

650or925

4.5L

GRP31or

GRP

925

31E

6.7L

(100,

130Kw)1or2XGRP

31

925

6.7L

(150,

175Kw)

2X

GRP

31

925

8.7L

10.3L

12.9L

13.0L

2x

GRP31or

2x

16.0L

GRP

80

925or1155

18.0L

22.0L

Fill

the

battery

with

the

proper

electrolyte

fluidifnecessary

and

have

the

battery

fUlly

charged

before

installing

it.

BATTERY

INSTALLATION

Whenaunitissupplied

with

outabatteryorduring

replacement

use

the

following

tabletoproperly

select

the

battery

size

and

mini-

mum

Cold

Cranking

Ampere

required

foraparticular

unit.

FUEL

SYSTEM

REDUIREMENTS

AND

RECOMMENDATIONS

Diesel

Fuel

System:

See

Chapter8of

Engine-Generator

Stationary

Emergency

Electric

Power

Systems

Installer's

Guide

and

Reference

Manual

(part

no.

046622).

1.

Beginning

October1,2007,

owners

and

operators

that

use

diesel

fuel

must

use

diesel

fuel

that

meets:

A.

Sulfur

contentof500

parts

per

million

(ppm)

maximum.

B.

Cetane

indexoraromatic

contentasfollows:

• A

minimum

cetane

indexof40

or;

• A

maximum

aromatic

contentof35

volume

percent.

2.

Beginning

October1,2010,

owners

and

operators

that

use

diesel

fuel

must

use

diesel

fuel

that

meets:

A.

Sulfur

contentof15

parts

per

million

(ppm)

maximum.

B.

Cetane

indexoraromatic

contentasfollows:

• A

minimum

cetane

indexof40

or;

• A

maximum

aromatic

contentof35

volume

percent.

7

Page 10

General Information

THE

BATTERY

~

A Do

not

disposeofthe

battery

In a

fire.

The

tAbattery

Is

capableofexploding.

/r\ A

battery

presentsariskofelectrical

shock

illand

high

short

circuit

current.

The

following

precautions

aretobe

observed

when

work-

ingonbatteries:

• Remove

the

10A

and

15A

fuses

from

the

gen-

erator

control

panel.

• Remove

watches,

ringsorother

metal

objects;

• Use

tools

with

Insulated

handles;

• Wear

rubber

gloves

and

boots;

• Do

not

lay

toolsormetal

parts

on

topofthe

battery;

and

• Disconnect

charging

source

priortoconnecting

or

disconnecting

battery

terminals.

IA

WARNING!1

Jt..

Do

not

openormutilate

the

battery.

Released

....

electrolyte

has

been

knowntobe

harmful

to

the

skin

and

eyes,

andtobe

toxic.

A The

electrolyteIsa

dilute

sulfuric

acid

that

Is

....

harmfultothe

skin

and

eyes.Itis

electrically

conductive

and

corrosive.

The

following

procedures

aretobe

observed:

• Wear

full

eye

protection

and

protective

clothing;

•

Where

electrolyte

contacts

the

skin,

washItoff

Immediately

with

water;

•

Where

electrolyte

contacts

the

eyes,

flush

thoroughly

and

Immediately

with

water

and

seek

medical

attention;

and

•

Spilled

electrolyteIstobewashed

down

with

an

acid

neutralizing

agent.Acommon

practice

Istouseasolutionof1

pound

(500

grams)

bicarbonateofsodato1

gallon(4liters)

of

water. The

bicarbonateofsoda

solutionisto

be

added

until

the

evidenceofreaction

(foam-

ing)

has

ceased.

The

resulting

liquidIsto

be

flushed

with

water

and

the

area

dried.

&.

lead-acid

batteries

presentariskoffire

Lmbecause

they

generate

hydrogen

gas.

The

following

procedures

aretobe

followed:

• DO NOT SMOKE

when

near

the

battery;

• DO NOT

cause

flameorsparkinbattery

area;

and

•

Discharge

static

electricity

from

body

before

touching

the

batterybyfirst

touchingaground-

ed

metal

surface.

A Be

sure

the

AUTO/OFF/MANUAL

switchisset

....

to

the

OFF

position

before

connecting

the

battery

cables.Ifthe

switchissettoAUTO

or

MANUAL,

the

generator

can

crank

and

startassoonasthe

battery

cables

are

con-

nected.

8

A Be

sure

the

utility

power

supplyisturned

off

tAand

the

10A

and

15A

fuses

are

removed

from

the

generator

control

panel,orsparking

may

occuratthe

battery

postsasthe

cables

are

attached

and

causeanexplosion.

Servicingofthe

batteryistobeperformedorsupervisedbyper-

sonnel

knowledgeableofbatteries

and

the

required

precautions.

Keep

unauthorized

personnel

away

from

batteries.

A

negative

ground

systemisused.

Battery

connections

are

shown

on

the

wiring

diagrams.

Make

sure

the

batteryiscorrectly

con-

nected

and

terminals

are

tight.

Observe

battery

polarity

when

con-

necting

the

batterytothe

generator

set.

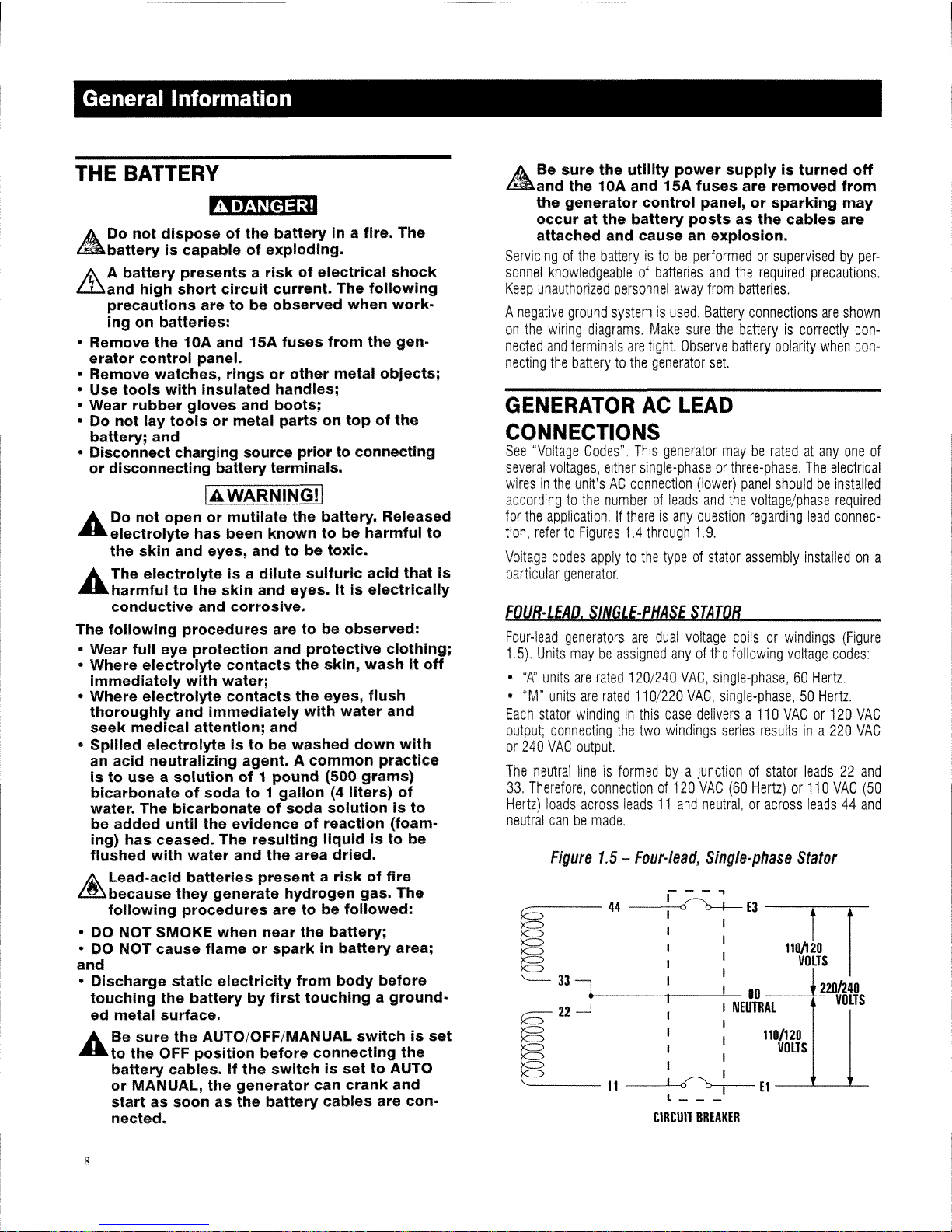

GENERATOR

AC

LEAD

CONNECTIONS

See

"Voltage

Codes".

This

generator

mayberatedatanyone

of

several

voltages,

either

single-phaseorthree-phase.

The

electrical

wiresinthe

unit'sAGconnection

(lower)

panel

shouldbeinstalled

accordingtothe

numberofleads

and

the

voltage/phase

required

for

the

application.Ifthereisany

question

regarding

lead

connec-

tion,

refertoFigures

1.4

through

1.9

.

Voltage

codes

applytothe

typeofstator

assembly

installedona

particular

generator

.

fOUR-LEAD,

SINGLE-PHASE

STATOR

Four-lead

generators

are

dual

voltage

coilsorwindings

(Figure

1.5).

Units

maybeassigned

anyofthe

following

voltage

codes:

•

"{:>:.'

units

are

rated

120/240

VAG,

single-phase,60Hertz.

•

"M"

units

are

rated

110/220

VAG,

single-phase,50Hertz.

Each

stator

windinginthis

case

deliversa110

VAGor120

VAG

output;

connecting

the

two

windings

series

resultsina

220

VAG

or

240

VAC

output.

The

neutral

lineisformedbya

junctionofstator

leads22and

33.

Therefore,

connectionof120

VAG

(60

Hertz)or110

VAC

(50

Hertz)

loads

across

leads11and

neutral,oracross

leads44and

neutral

canbemade.

Figure

1.5

-

Four-lead,

Single-phase

Stator

E

44~EJ

I I

I

II

110/120

I

VOLTS

JJ ] I :

00

b20h40

I I

NEUTRAL:lloLTS

E

22

I

I :

110/120

I

VOLTS

I I

I

11~E1

l _

CIRCUIT

BREAKER

Page 11

General Information

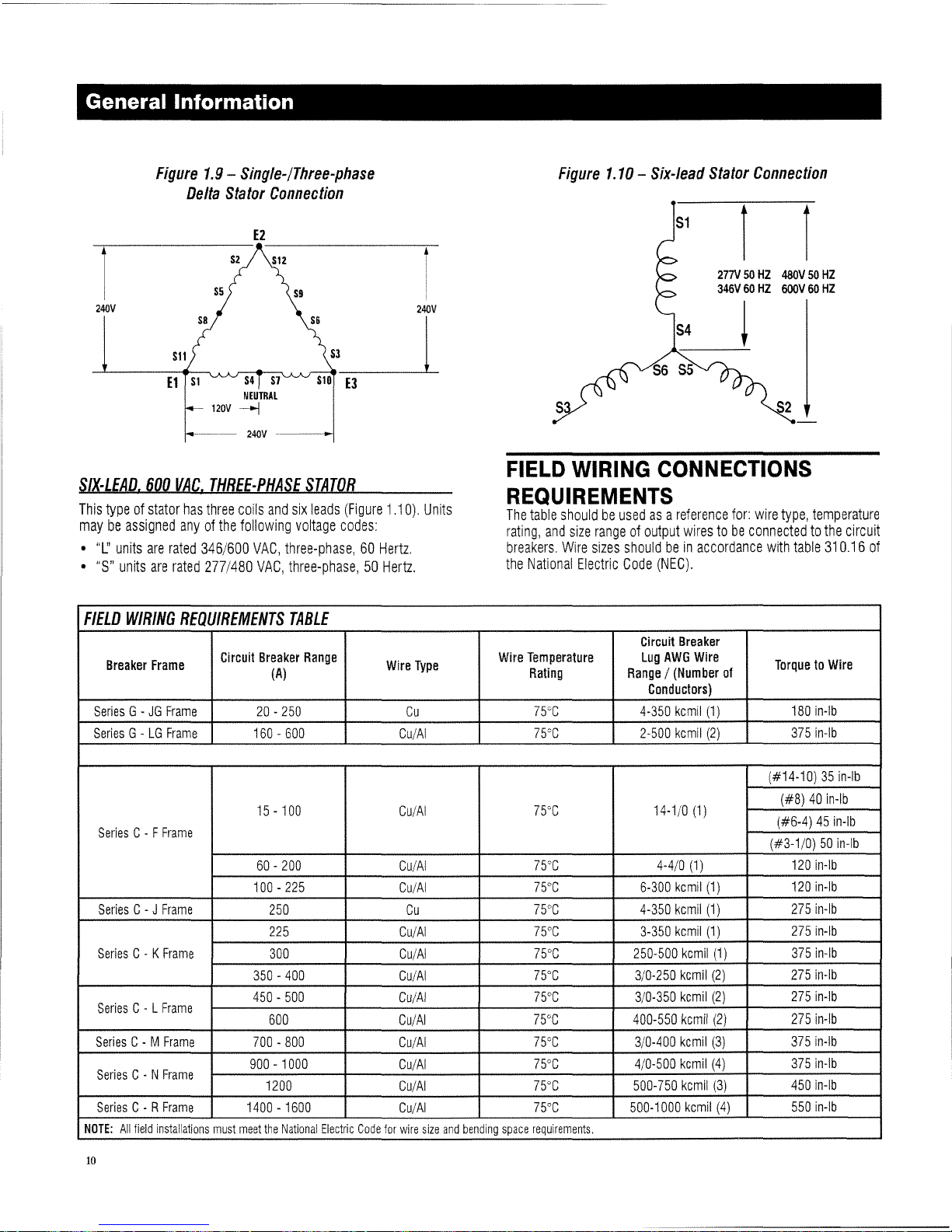

Figure

1.9

-

Single-/Three-phase

Delta

Stator

Connection

Figure

1.10-Six-lead

Stator

Connection

240V

SII

E2

240V

S6

I

S3~

--

240V

----J

51

1 1

277V

50HZ

480V50HZ

346V60HZ

600V60HZ

!

S2

SIX-LEAD.

600

VAG,

THREE-PHASE

STATOR

This

typeofstator

has

three

coils

and

six

leads

(Figure

1.10).

Units

maybeassigned

anyofthe

following

voltage

codes:

•

"1.:'

units

are

rated

346/600

VAG,

three-phase,60Hertz.

•

"5"

units

are

rated

277/480

VAG,

three-phase,50Hertz.

FIELD

WIRING

CONNECTIONS

REQUIREMENTS

The

table

shouldbeusedasa

reference

for:

wire

type,

temperature

rating,

and

size

rangeofoutput

wirestobe

connectedtothe

circuit

breakers.

Wire

sizes

shouldbein

accordance

with

table

310.16

of

the

National

Electric

Gode

(NEG).

FIELD

WIRING

REQUIREMENTS

TABLE

Circuit

Breaker

Breaker

Frame

Gircuit

Breaker

Range

Wire

Type

Wire

Temperature

Lug

AWG

Wire

TorquetoWire

(A)

Rating

Range/(Number

of

Gonductors)

SeriesG-JG

Frame

20-250

Cu

75cC

4-350

kemil

(1)

180

in-Ib

SeriesG-LG

Frame

160-600

Cu/AI

75CC

2-500

kemil

(2)

3751n-lb

(#14-10)35In-Ib

15-100

Cu/AI

75cC

14-1/0

(1)

(#8)40In-Ib

Series

C- F

Frame

(#6-4)45in-Ib

(#3-1/0)50in-Ib

60-200

CulAl

75cC

4-4/0

(1)

120

in-Ib

100-225

Cu/AI

75°C

6-300

kemll

(1)

120

in-Ib

Series

C-J

Frame

250

Cu

75°C

4-350

kemll

(1)

275

in-Ib

225

CulAl

75°C

3-350

kemll

(1)

275

in-Ib

Series

C- K

Frame

300

CulAl

75DC

250-500

kemll

(1)

375

In-Ib

350-400

Cu/AI

75DC

3/0-250

kemil

(2)

2751n-lb

450-500

Cu/AI

75°C

3/0-350

kemil

(2)

275

in-Ib

Series

C- L

Frame

600

Cu/AI

75°C

400-550

kemll

(2)

275

in-Ib

Series

C- M

Frame

700-800

Cu/AI

WC

3/0-400

kemll

(3)

3751n-lb

900-1000

Cu/AI

75°C

4/0-500

kemll

(4)

375

In-Ib

Series

C- N

Frame

1200

Cu/AI

WC

500-750

kemil

(3)

450

In-Ib

Series

C- R

Frame

1400-1600

Cu/AI

75°C

500-1000

kemil

(4)

550

in-Ib

NOTE:

All

field

installations

must

meet

the

National

Electric

Code

for

wire

size

and

bending

space

requirements.

10

Page 12

General

Information

FIELD

WIRING

CONNECTIONSTOBUSS

BARS

ENGINE

COOLANT

HEATERS

500Kw

Volvo

and

500/600Kw

Doosan

powered

units

supplied

with

Series

C- R

Frame

Breakers

rated

1400,

1600,

2000

and

2500A

have

Buss

Bars

suppliedinthe

connection

Module

for

the

connectionofthe

Field

Conductors.

The

following

information

shouldbefollowedinordertoobtainasuitable

electrical

connec-

tiontothe

Buss

Bars.

•

Conductor

Lugs

-

The

Buss

Bars

have

been

configured

to

accept

Aluminum

Compression

Lugs

suitable

for

copper

or

aluminum

stranded

wire

.

•

Suggested

Manufacturer

-

PENN

UNION

CORP

•

Manufacturers

Part

No.

-

BLUA060D2

•

Type

-

Dual

Rated

(Al/CU),

Two

Studs

spaced13/4"

Apart

•

Wire

Size

-

600

kcmil

Required

Hardware

Belowisthe

recommended

hardware

requiredtoattach

the

Lugs

to

the

Buss

Bars,

•

M12x65mm

Grade

8,8

Hex

Head

Cap

Screw,

M12

Flat

Washers,

Lock

Washer

and

Nut

or

If

the

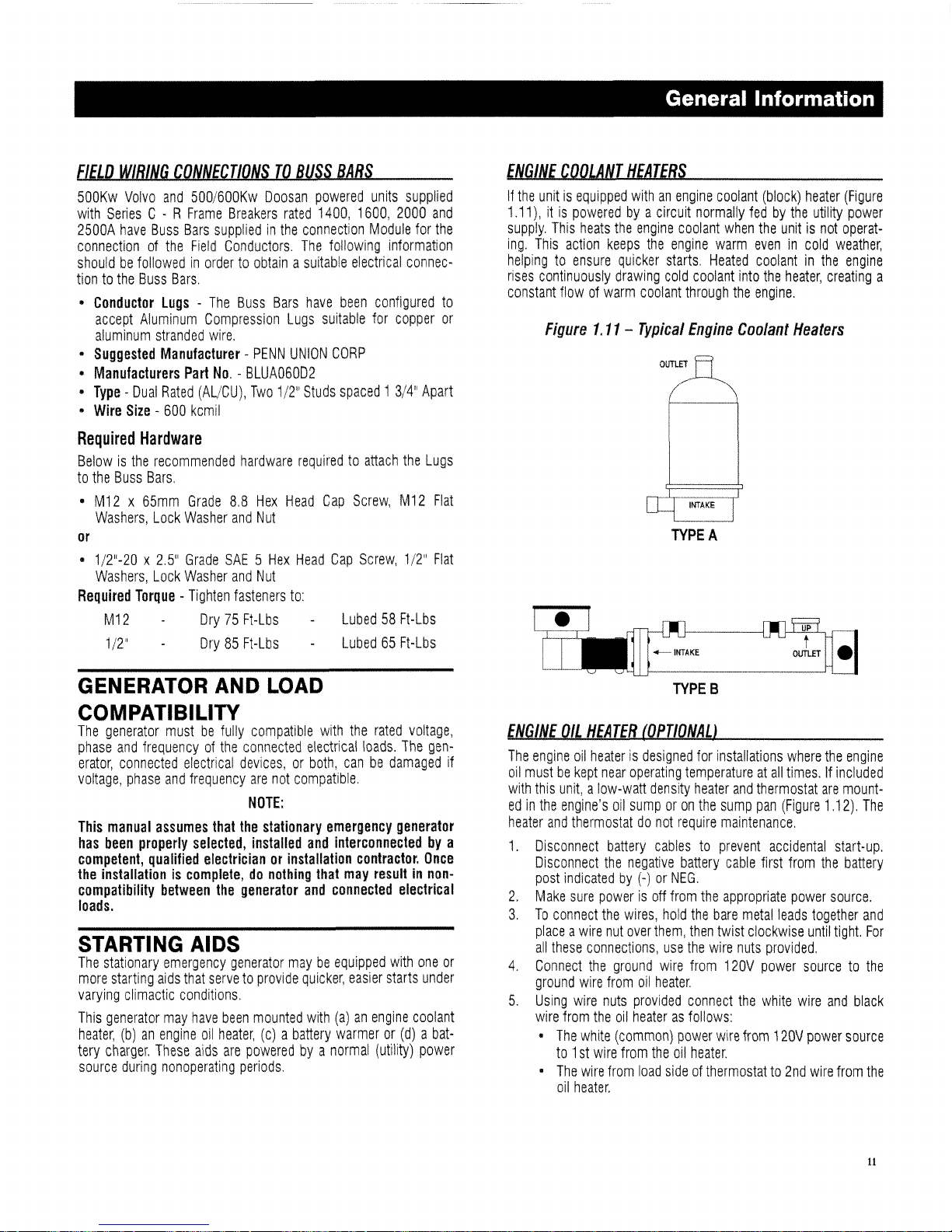

unitisequipped

withanengine

coolant

(block)

heater

(Figure

1.11),itis

poweredbya

circuit

normally

fedbythe

utility

power

supply.

This

heats

the

engine

coolant

when

the

unitisnot

operat-

ing,

This

action

keeps

the

engine

warm

evenincold

weather,

helpingtoensure

quicker

starts,

Heated

coolantinthe

engine

rises

continuously

drawing

cold

coolant

into

the

heater,

creating

a

constant

flowofwarm

coolant

through

the

engine

.

Figure

1.11-

Typical

Engine

Coolant

Heaters

OUTLET

TYPE

A

Lubed58FHbs

Lubed65FHbs

STARTING

AIDS

The

stationary

emergency

generator

maybeequipped

with

one

or

more

starting

aids

that

servetoprovide

quicker,

easier

starts

under

varying

climactic

conditions.

This

generator

may

have

been

mounted

with

(a)anengine

coolant

heater,

(b)anengine

oil

heater,

(c)abattery

warmeror(d)abat-

tery

charger.

These

aids

are

poweredbya

normal

(utility)

power

source

during

nonoperating

periods.

GENERATOR

AND

LOAD

COMPATIBILITY

The

generator

mustbefully

compatible

with

the

rated

voltage,

phase

and

frequencyofthe

connected

electrical

loads.

The

gen-

erator,

connected

electrical

devices,orboth,

canbedamaged

if

voltage,

phase

and

frequency

are

not

compatible,

NOTE:

This

manual

assumes

that

the

stationary

emergency

generator

has

been

properly

selected,

installed

and

interconnectedbya

competent,

qualified

electricianorinstallation

contractor.

Once

the

installationiscomplete,donothing

that

may

resultinnon-

compatibility

between

the

generator

and

connected

electrical

loads.

TYPES

The

engine

oil

heaterisdesigned

for

installations

where

the

engine

oil

mustbekept

near

operating

temperatureatall

times.Ifincluded

with

this

unit,alow-watt

density

heater

and

thermostat

are

mount-

edinthe

engine's

oil

sumporon

the

sump

pan

(Figure

1.12).

The

heater

and

thermostatdonot

require

maintenance.

1.

Disconnect

battery

cablestoprevent

accidental

start-up.

Disconnect

the

negative

battery

cable

first

from

the

battery

post

indicatedby(-)orNEG,

2.

Make

sure

powerisoff

from

the

appropriate

power

source.

3.

To

connect

the

wires,

hold

the

bare

metal

leads

together

and

placeawire

nut

over

them,

then

twist

clockwise

until

tight.

For

all

these

connections,

use

the

wire

nuts

provided.

4.

Connect

the

ground

wire

from

120V

power

sourcetothe

ground

wire

from

oil

heater,

5.

Using

wire

nuts

provided

connect

the

white

wire

and

black

wire

from

the

oil

heaterasfollows:

•

The

white

(common)

power

wire

from

120V

power

source

to1st

wire

from

the

oil

heater.

•

The

wire

from

load

sideofthermostatto2nd

wire

from

the

oil

heater.

ENGINE

OIL

HEATER

(OPTIONAL)

Flat

•

1/2"-20x2.5"

Grade

SAE5Hex

Head

Cap

Screw,

Washers,

Lock

Washer

and

Nut

Required

Torque

-

Tighten

fasteners

to:

M12

Dry75Ft-Lbs

1/2"

Dry85FHbs

11

Page 13

Lubed58Ft-Lbs

Lubed65Ft-Lbs

-------_.

__

_--_

..

_-------

FIELD

WIRING

CONNECTIONSTOBUSS

BARS

Units

supplied

with

Series

C- R

Frame

Breakers

rated

1600,

2000

and

2500A

have

Buss

Bars

suppledinthe

connection

Module

for

the

connectionofthe

Field

Conductors.

The

following

information

shouldbefollowedinordertoobtainasuitable

electrical

connec-

tiontothe

Buss

Bars.

•

Conductor

lugs

-

The

Buss

Bars

have

been

configured

to

accept

Aluminum

Compression

Lugs

suitable

for

copper

or

aluminum

stranded

wire.

•

Suggested

Manufacturer

-

PENN

UNION

CORP

•

Manufacturers

Part

No.

-

BLUA060D2

•

Type

-

Dual

Rated

(AL/CU),

Two

1/2"

Studs

spaced13/4"

Apart

•

Wire

Size

-

600

kcmil

Required

Hardware

Belowisthe

recommended

hardware

requiredtoattach

the

Lugs

to

the

Buss

Bars.

•

M12x65mm

Grade

8.8

Hex

Head

Cap

Screw,

M12

Flat

Washers,

Lock

Washer

and

Nut

or

•

1/2"-20x2.5"

Grade

SAE5Hex

Head

Cap

Screw,

1/2"

Flat

Washers,

Lock

Washer

and

Nut

Required

Torque

-

Tighten

fasteners

to:

M12

Dry75Ft-Lbs

1/2"

Dry85Ft-Lbs

GENERATOR

AND

LOAD

COMPATIBILITY

The

generator

mustbefully

compatible

with

the

rated

voltage,

phase

and

frequencyofthe

connected

electrical

loads.

The

gen-

erator,

connected

electrical

devices,orboth,

canbedamaged

if

voltage,

phase

and

frequency

are

not

compatible.

NOTE:

This

manual

assumes

that

the

stationary

emergency

generator

has

been

properly

selected,

installed

and

interconnectedbya

competent,

qualified

electricianorinstallation

contractor.

Once

the

installationiscomplete,donothing

that

may

resultinnon-

compatibility

between

the

generator

and

connected

electrical

loads.

STARTING

AIDS

The

stationary

emergency

generator

maybeequipped

with

one

or

more

starting

aids

that

servetoprovide

quicker,

easier

starts

under

varying

climactic

conditions.

This

generator

may

have

been

mounted

with

(a)anengine

coolant

heater,

(b)anengine

oil

heater,

(c)abattery

warmeror(d)abat-

tery

charger.

These

aids

are

poweredbya

normal

(utility)

power

source

during

nonoperating

periods.

General

Information

ENGINE

COOLANT

HEATERS

If

the

unitisequipped

withanengine

coolant

(block)

heater

(Figure

1.11),itis

poweredbya

circuit

normally

fedbythe

utility

power

supply.

This

heats

the

engine

coolant

when

the

unitisnot

operat-

ing.

This

action

keeps

the

engine

warm

evenincold

weather,

helpingtoensure

quicker

starts.

Heated

coolantinthe

engine

rises

continuously

drawing

cold

coolant

into

the

heater,

creating

a

constant

flowofwarm

coolant

through

the

engine.

Figure

1.11-

Typical

Engine

Coolanl

Healers

OUTLET

TYPE

A

1~'_KE

__

~

TYPEB

ENGINE

OIL

HEATER

(OPTIONALl

The

engine

oil

heaterisdesigned

for

installations

where

the

engine

oil

mustbekept

near

operating

temperatureatall

times.Ifincluded

with

this

unit,alow-watt

density

heater

and

thermostat

are

mount-

edinthe

engine's

oil

sumporon

the

sump

pan

(Figure

1.12).

The

heater

and

thermostatdonot

require

maintenance.

1.

Disconnect

battery

cablestoprevent

accidental

start-up.

Disconnect

the

negative

battery

cable

first

from

the

battery

post

indicatedby(-)orNEG.

2.

Make

sure

powerisoff

from

the

appropriate

power

source.

3.

To

connect

the

wires,

hold

the

bare

metal

leads

together

and

placeawire

nut

over

them,

then

twist

clockwise

until

tight.

For

all

these

connections,

use

the

wire

nuts

provided.

4.

Connect

the

ground

wire

from

120V

power

sourcetothe

ground

wire

from

oil

heater.

5.

Using

wire

nuts

provided

connect

the

white

wire

and

black

wire

from

the

oil

heaterasfollows:

•

The

white

(common)

power

wire

from

120V

power

source

to1st

wire

from

the

oil

heater.

•

The

wire

from

load

sideofthermostatto2nd

wire

from

the

oil

heater.

11

Page 14

General Information

ACAUTIONI

A.

Be

surenobare wire or wire strands are vis-

~Ible

after making connections.

6.

Push

all

wires

and

wire

nuts

into

junction

box.

7.

Assemble

junction

box

covertojunction

box

8.

Reconnect

battery

cablestobattery

posts.

Connect

the

posi-

tive

cable

firsttothe

battery

post

indicated

by

(+)

or

POS.

Figure

1.12

-

Oil

Heater

Kit

BATTERY

WARMERS

(OPTIONAL)

When

usedinconjunction

withacoolant

(block)

heater,

battery

warmers

(Figure

1.13)

aidinensuring

that

the

engine

will

reach

maximum

cranking

speed.

1,

Disconnect

battery

cablestoprevent

accidental

start-up.

Disconnect

the

negative

battery

cable

first

from

the

battery

post

indicatedby(-)orNEG,

2.

Make

sure

powerisoff

from

the

appropriate

power

source,

3,

To

connect

the

wires,

hold

the

bare

metal

leads

together

and

placeawire

nut

over

them,

then

twist

clockwise

until

tight.

For

all

these

connections,

use

the

wire

nuts

provided.

4,

Connect

the

ground

wire

from

120V

power

sourcetothe

ground

wire

from

battery

heater.

5,

Using

wire

nuts

provided

connect

the

white

wire

and

black

wire

from

the

battery

heaterasfollows:

•

The

white

(common)

power

wire

from

120V

power

source

to1st

wire

from

the

battery

heater,

•

The

wire

from

load

sideofthermostatto2nd

wire

from

the

battery

heater,

12

ACAUTIONI

A.

Be

surenobare wire or wire strands are vis-

~

Ible after making connections.

6.

Push

all

wires

and

wire

nuts

into

junction

box,

7.

Assemble

junction

box

covertojunction

box,

8,

Reconnect

battery

cablestobattery

posts,

Connect

the

posi-

tive

cable

firsttothe

battery

post

indicated

by

(+)

or

POS,

Figure

1.13

-

Battery

Warmer

Kit

BATTERY

CHARGERS

There

are

two

typesofbattery

chargers

available:

2,5-amp

and

10-amp

(nine-amp

UL)

rated,

The

2,5-amp

chargeris12

VDC

only.

The1Q-ampisavailableas12

VDCor24

VDC,asappropri-

ate

for

the

engine'sDCsystem

voltage,

These

chargers

are

UL

component

recognized