Page 1

GENERAC® GUARDIAN® SERIES

STANDBY GENERATORS

25 kW

Liquid-Cooled Engine Generator Sets

INCLUDES:

• Generac Naturally Aspirated

Gaseous Fueled 1.5L Engine

• Two Line LCD Tri-lingual

Digital Nexus™ Controller

• Isochronous Electronic Governor

• Sound Attenuated Enclosure

• Closed Coolant Recovery System

• Smart Battery Charger

• UV/Ozone Resistant Hoses

• ±1% Voltage Regulation

• Natural Gas or LP Operation

• 2 Year Limited Warranty

• UL 2200 Listed

Standby Power Rating

Model QT025 (Bisque) - 25 kW 60Hz

Meets EPA Emission Regulations

CA/MA emissions Compliant

FEATURES

¡ INNOVATIVE DESIGN & PROTOTYPE TESTING are key components of

GENERAC’S success in “IMPROVING POWER BY DESIGN.” But it

doesn’t stop there. Total commitment to component testing, reliability

testing, environmental testing, destruction and life testing, plus testing

to applicable CSA, NEMA, EGSA, and other standards, allows you to

choose GENERAC POWER SYSTEMS with the confidence that these

systems will provide superior performance.

¡ TEST CRITERIA:

PROTOTYPE TESTED NEMA MG1-22 EVALUATION

SYSTEM TORSIONAL TESTED MOTOR STARTING ABILITY

¡ SOLID-STATE, FREQUENCY COMPENSATED VOLTAGE REGULATION.

This state-of-the-art power maximizing regulation system is standard on

all Generac models. It provides optimized FAST RESPONSE to changing

load conditions and MAXIMUM MOTOR STARTING CAPABILITY

by electronically torque-matching the surge loads to the engine. An

unequalled ±1% voltage regulation.

¡ SINGLE SOURCE SERVICE RESPONSE from Generac’s extensive dealer

network provides parts and service know-how for the entire unit, from the

engine to the smallest electronic component.

¡ GENERAC TRANSFER SWITCHES. Long life and reliability are

synonymous with GENERAC POWER SYSTEMS. One reason for this

confidence is that the GENERAC product line includes its own transfer

systems and controls for total system compatibility.

Page 2

Application & Engineering Data

QT025

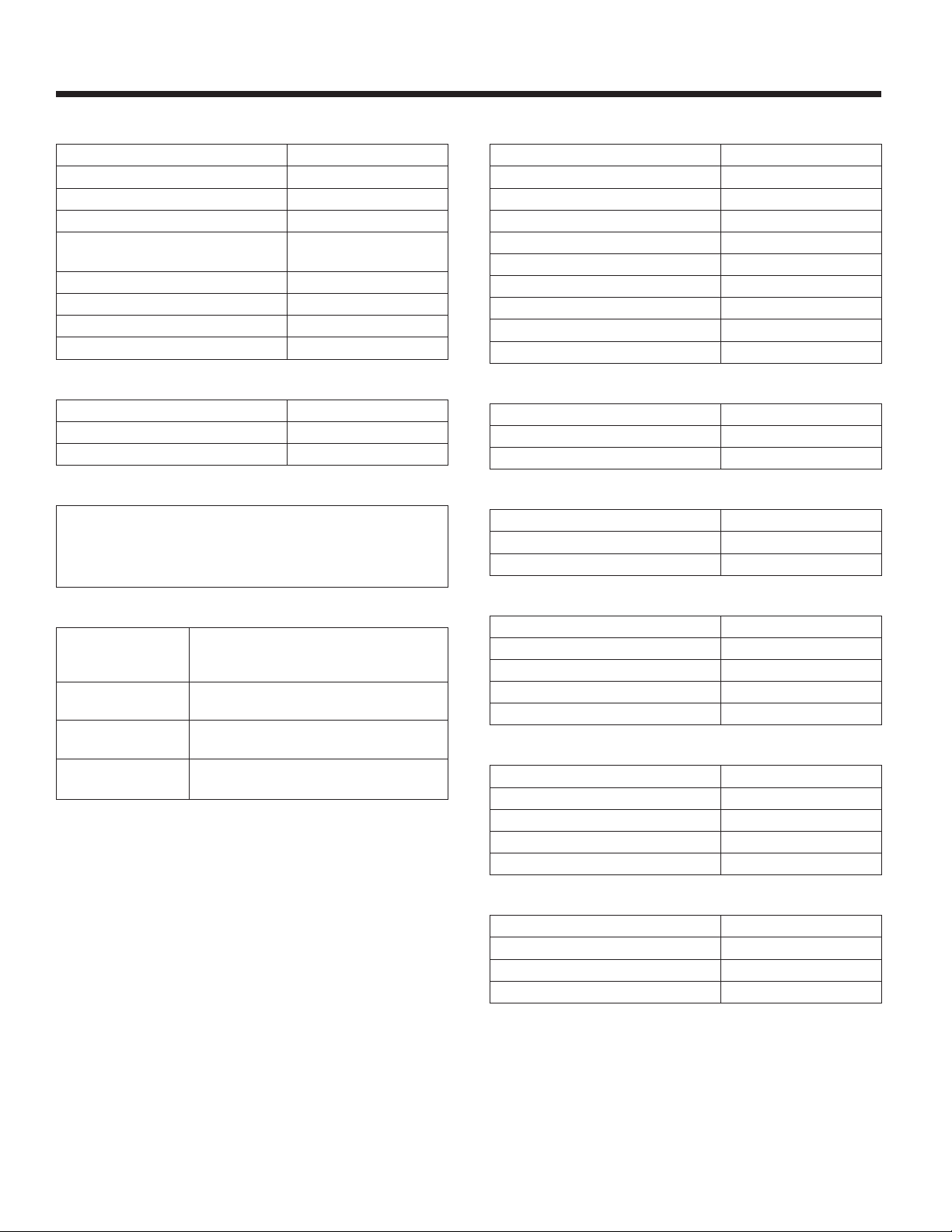

GENERATOR SPECIFICATIONS

TYPE Synchronous

ROTOR INSULATION Class H

STATOR INSULATION Class H

TELEPHONE INTERFERENCE FACTOR (TIF) <50

ALTERNATOR OUTPUT LEADS 1-PHASE

ALTERNATOR OUTPUT LEADS 3-PHASE

BEARINGS Sealed Ball

COUPLING Flexible Disc

LOAD CAPACITY (STANDBY RATING) 25 kW

EXCITATION SYSTEM Direct

4 wire

6 wire

VOLTAGE REGULATION

TYPE Electronic

SENSING Single Phase

REGULATION ± 1%

GENERATOR FEATURES

Revolving field heavy duty generator

Directly connected to the engine

Operating temperature rise 120°C above a 40°C ambient

Insulation is Class H rated at 150°C rise

All models are fully prototyped tested

ENGINE SPECIFICATIONS

MAKE Generac

MODEL In line

CYLINDERS 4

DISPLACEMENT 1.5 Liter

BORE (mm) 77.4

STROKE (mm) 79.52

COMPRESSION RATIO 11:1

INTAKE AIR SYSTEM Naturally Aspirated

VALVE SEATS Replaceable

LIFTER TYPE Hydraulic

GOVERNOR SPECIFICATIONS

TYPE Electronic

FREQUENCY REGULATION Isochronous

STEADY STATE REGULATION ± 0.25%

ENGINE LUBRICATION SYSTEM

OIL PUMP Gear

OIL FILTER Full flow spin-on cartridge

CRANKCASE CAPACITY 4 Quarts

ENCLOSURE FEATURES

Galvanized steel weather

protective enclosure

Enclosed critical grade

muffler

Small, compact,

attractive

SAE Sound attenuated enclosure ensures quiet

Ensures protection against mother nature.

Electrostatically applied textured epoxy paint for

added durability.

Quiet, critical grade muffler is mounted inside

the unit to prevent injuries.

Makes for an easy, eye appealing installation.

operation.

ENGINE COOLING SYSTEM

TYPE Closed

WATER PUMP Belt driven

FAN SPEED 2484

FAN DIAMETER 17.7 inches

FAN MODE Pusher

FUEL SYSTEM

FUEL TYPE Natural gas, propane vapor

CARBURETOR Down Draft

SECONDARY FUEL REGULATOR Standard

FUEL SHUT OFF SOLENOID Standard

OPERATING FUEL PRESSURE 5” - 14” H2O

ELECTRICAL SYSTEM

BATTERY CHARGE ALTERNATOR 12V 30 Amp

STATIC BATTERY CHARGER 2 Amp

RECOMMENDED BATTERY Group 26, 525CCA

SYSTEM VOLTAGE 12 Volts

Rating definitions - Standby: Applicable for supplying emergency power for the duration of the utility power outage. No overload capability is available for this rating. (All ratings in accordance with BS5514,

ISO3046 and DIN6271). (All ratings in accordance with BS5514, ISO3046, ISO8528, SAE J1349 and DIN6271).

Page 3

Generac® Guardian® Series Standby Generator - 25 kW

OPERATING DATA

KW RATING (LP/NG) 25/25

ENGINE SIZE 1.5 Liter 4 cyl. inline

GENERATOR OUTPUT VOLTAGE/KW - 60Hz KW AMP CB Size

®

120/240V, 1-phase, 1.0 pf

120/208V, 3-phase, 0.8 pf

120/240V, 3-phase, 0.8 pf

ENGINE FUEL CONSUMPTION (Natural Gas) (Propane)

25

25

25

104

87

75

Natural Gas

(ft3/hr.)

Exercise cycle

25% of rated load

50% of rated load

75% of rated load

100% of rated load*

For Btu content, multiply ft3/hr x 2520 (LP) or ft3/hr x 1000 (NG)

60

220

297

362

430

ENGINE COOLING

Air flow (inlet air including alternator and combustion air) ft3/min.

System coolant capacity US gal.

Heat rejection to coolant BTU/hr.

Max. operating air temp. on radiator °C (°F)

Max. ambient temperature °C (°F)

112,000

60 (150)

50 (140)

COMBUSTION AIR REQUIREMENTS

Flow at rated power 60 Hz cfm 62

SOUND EMISSIONS IN DBA

Exercising at 7 meters

Normal operation at 7 meters

EXHAUST

Exhaust flow at rated output 60 Hz cfm

Exhaust temp. at muffler outlet °F

ENGINE PARAMETERS

125

100

90

Propane

(gal/hr.) ft

0.7 24

2.9 88

3.3 119

4 145

4.7 172

1,800

2.0

59

72

203

1100

3

/hr

Rated synchronous RPM 60 Hz 3600

POWER ADJUSTMENT FOR AMBIENT CONDITIONS

Temperature Deration

3% for every 10 °C above - °C

1.65% for every 10 °F above - °F

25

77

Altitude Deration

1% for every 100 m above - m

3% for every 1000 ft. above - ft.

* Refer to "Emissions Data Sheets" for maximum fuel flow for EPA and SCAQMD permitting purposes.

RATING: All three phase units are rated at 0.8 power factor. All single phase units are rated at 1.0 power factor. STANDBY RATING: Standby ratings apply to installations served by a

reliable utility source. The standby rating is applicable to varying loads for the duration of a power outage. There is no overload capability for this rating. Ratings are in accordance with

ISO-3046-1. Design and specifications are subject to change without notice.

kW rating is based on LPG Fuel and may derate with natural gas.

183

600

Page 4

INTERCONNECTIONS

QT025

NOTE:

MATCH WIRE

NUMBERS TO

TERMINAL NUMBERS

QT SERIES ENGINE GENERATOR

CONNECTION PANEL

N1N1

T1/LINE

N2

NEU

ON

T1

N2

23

194

178

194

183

23

E1

E2

NEUT

0

GROUND

UTILITY SUPPLY FROM

SERVICE DISCONNECT

CUSTOMER SUPPLIED

NEUTRAL WIRE

LOAD SHED

MODULE

NEUTRAL BLOCK

GROUND

CUSTOMER CONNECTIONS

0

DC COMMON

194

23

NEUTRAL BLOCK

RTS TRANSFER SWITCH

0 GROUND

15B +12V

T1

23 TRANSFER

NEUTRAL

AIR 1

CONTACTOR

1

AIR 2

CONTACTOR

2

PRIORITY 1

CONTACTOR

3

PRIORITY 2

PRIORITY 3

CONTACTOR

4

PRIORITY 4

48850-T

0

194

+12VDC

23

TRANSFER

WARNING

NOTE WIRE ORIENTATION

T1N1 N2

UTILITY

(C1 & VR1)

STANDBY

(C2 & VR2)

0C4449A-T

N2

N1

N1

N2

E1

E2

T1

T2

T2

E1

E2

T1

NOTE:

POWER LEADS AND TRANSFER SWITCH LEADS

TO BE RUN IN TWO DIFFERENT CONDUITS.

CUSTOMER LOAD

(DISTRIBUTION PANEL)

LIQUID COOLED INSTALLATION

NEXUS™ CONTROL FEATURES

2-Line Plain Text LCD Display Simple user interface for ease of operation

Mode Switch

-Auto

-Off Stops unit. Power is removed. Control and charger still operate.

-Manual/Test (start) Start with starter control, unit stays on. If utility fails, transfer to load takes place.

Programmable start delay between 10-30 seconds Standard

Engine Start Sequence Cyclic cranking: 16 sec. on, 7 rest (90 sec. maximum duration)

Engine Warm-up 5 seconds

Engine Cool-Down 1 minute

Starter Lock-out Starter cannot re-engage until 5 sec. after engine has stopped.

Smart Battery Charger Standard

Automatic Voltage Regulation with Over and Under Voltage Protection Standard

Automatic Low Oil Pressure Shutdown Standard

Overspeed Shutdown Standard, 72Hz

High Temperature Shutdown Standard

Overcrank Protection Standard

Safety Fused Standard

Failure to Transfer Protection Standard

Low Battery Protection Standard

50 Event Run Log Standard

Future Set Capable Exerciser Standard

Incorrect Wiring Protection Standard

Internal Fault Protection Standard

Common External Fault Capability Standard

Governor Failure Protection Standard

Automatic Start on Utility failure. 7 day exerciser

*Single and three phase connections may vary , refer to the owner’s manual for specific connection information.

Page 5

INSTALLATION LAYOUT QT025

Page 6

AVAILABLE ACCESSORIES

Model # Product Description

If the temperature regularly falls below 32° F, install a cold weather kit to maintain

6175 Cold Weather Kit

optimal battery temperature. Kit consists of battery warmer with thermostat built into

the wrap.

QT025

6174 Extreme Cold Weather Kit

5651 Base Plug Kit Add base plugs to the base of the generator to keep out debris.

5703 Paint Kit Bisque Kit

6176 Scheduled Maintenance Kit

5928 Nexus Wireless Remote

5951

5937

Advanced Nexus Wireless

Remote

DLM Load Control Module

(50 Amps)

Recommended where the temperature regularly falls below 32° F for extended periods

of time. For liquid cooled units only.

The Liquid-Cooled Scheduled Maintenance Kits offer all the hardware necessary to

perform a complete maintenance on Generac liquidcooled generators.

Completely wireless and battery powered, Generac's Nexus wireless remote monitor

provides you with instant status information without ever leaving the house.

Remotely control generator functions with the advanced model's LCD display. In

addition to remote testing of the generator, set the excercise cycle and maintenance

interval reminders

DLM Modules are used in conjunction with the Nexus Smart Switch to increase

its load management capabilities. It gives the Nexus Smart Switch additional load

management flexibility not found in any other transfer switch.

®

Generac Power Systems, Inc. • S45 W29290 HWY. 59, Waukesha, WI 53189 • generac.com

©2011 Generac Power Systems, Inc. All rights reserved. All specifications are subject to change without notice. Bulletin 0187670SBY-F / Printed in U.S.A. 12/16/11

Loading...

Loading...