Generac GP6500E-5941-0, GP6500-5940-0, 5940-0, 005941-0, 005939-0 Owner’s Manual

r|Owne s IVlanual

G ®

- •

GPSeriesPortableGefl

br

introduction.............................................................1

ReadthisiVlanualThoroughly.................................1

Safety Rules ...........................................................1

StandardsIndex.............................................................3

Generalinformation................................................4

1.1 Unpacking......................................................................4

1.1.1 Accessory Box..................................................4

1.2 Assembly.......................................................................4

1.2.1 Assemblingthe Accessory Kit............................4

1.2.2 StarterConnection(ElectricStart Only)..............4

Operation................................................................4

2.1 Knowthe Generator.......................................................4

2.2 Hourmeter......................................................................5

2.3 CordSets andConnectionPlugs....................................6

2.3.1 120 VAC,20 Amp, DuplexReceptacle...............6

2.3.2 120/240 VAC,30 Amp, Receptacle....................6

2.4 Howto Usethe Generator..............................................6

2.4.1 Groundingthe Generator....................................6

2.4.2 ConnectingElectricalLoads...............................7

2.5 Don'tOverloadthe Generator..........................................7

2.6 WattageReferenceGuide...............................................7

2.7 BeforeStartingtheGenerator.........................................8

2.7.1 AddingEngineOil..............................................8

2.7.2 AddingGasoline.................................................8

2.8 Starting Pull Start Engines..............................................8

2.9 Starting ElectricStart Engines........................................9

2.10 Stoppingthe Engine.....................................................10

2.11 LowOil LevelShutdownSystem..................................10

2.11.1 SensingLow Oil Level......................................10

2.12 Chargingthe Battery(Electric Start UnitsOnly).............10

Maintenance.........................................................10

3.1 MaintenanceSchedule.................................................10

3.2 ProductSpecifications..................................................10

3.2.1 GeneratorSpecifications..................................10

3.2.2 EngineSpecifications.......................................11

3.2.3 EmissionsInformation.....................................11

3.3 GeneralRecommendations...........................................11

3.3.1 GeneratorMaintenance....................................11

3.3.2 ToCleanthe Generator.....................................11

3.3.3 EngineMaintenance......................................... 11

3.3.4 CheckingOil Level...........................................11

3.3.5 Changingthe Oil..............................................11

3.3.6 Replacingthe SparkPlug.................................12

3.3.7 Battery Replacement........................................12

3.4 ServiceAir Filter...........................................................12

3.5 ValveClearance............................................................13

3.6 General........................................................................13

3.7 Long TermStorage....................................................... 13

3.8 OtherStorageTips.......................................................13

Troubleshooting....................................................14

4.1 TroubleshootingGuide..................................................14

Notes....................................................................15

Warranty...............................................................16

Manualdel propietario.............................19

Manueld'entretien....................................39

iNTRODUCTiON

Thankyou for purchasingthis model by GeneracPowerSystems,

Inc. This model is a compact, high performance, air-cooled,

engine driven generatordesigned to supply electrical power to

operateelectrical loads where no utility power is availableor in

placeof utility dueto apoweroutage.

BEADTHiSMANUALTHOROUGHLY

If any portion of this manual is not understood, contact the

nearest Authorized Dealerfor starting, operating and servicing

procedures.

The operator is responsible for proper and safe use of the

equipment.We strongly recommend that the operator read this

manualandthoroughlyunderstandall instructionsbeforeusingthe

equipment.Wealsostronglyrecommendinstructingother usersto

properlystart andoperatethe unit.This preparesthem ifthey need

to operatetheequipmentin an emergency.

Thegeneratorcan operate safely,efficiently and reliably only if it

is properly located,operatedand maintained.Beforeoperatingor

servicingthe generator:

• Becomefamiliar with and strictly adhereto all local, state and

nationalcodes and regulations.

• Study all safety warnings in this manual and on the product

carefully.

• Becomefamiliarwith this manualandthe unit beforeuse.

Themanufacturercannot anticipateevery possible circumstance

that might involvea hazard.Thewarnings in this manual,and on

tags and decals affixedto the unit are,therefore,not all inclusive.

If usinga procedure,work method or operatingtechniquethat the

manufacturerdoes not specifically recommend,ensure that it is

safe for others. Also make sure the procedure,work methodor

operatingtechniqueutilizeddoes not renderthe generatorunsafe.

THE INFORMATIONCONTAINEDHEREIN WAS BASED ON

MACHINESIN PRODUCTIONAT THE TIME OF PUBLICATION.

GENERACRESERVESTHERIGHTTOMODIFYTHISMANUALAT

ANYTIME.

SAFETYRULES

Throughoutthis publication,and on tags and decals affixedto the

generator,DANGER,WARNING,CAUTIONand NOTEblocks are

usedto alert personnelto special instructions about a particular

operation that may be hazardous if performed incorrectly or

carelessly.Observethemcarefully.Theirdefinitionsareasfollows:

INDICATES A HAZARDOUS SITUATION OR ACTION

WHICH, iF NOT AVOIDED, WILL RESULT iN DEATH

OR SERIOUS INJURY.

Indicates a hazardous situation or action which, if

not avoided, could result in death or serious injury.

,ACAUTION!

Indicates a hazardous situation or action which,

if not avoided, could result in minor or moderate

injury.

NOTE:

Notes containadditional informationimportantto a procedure

and will be found withinthe regulartextbody of thismanual.

These safety warnings cannot eliminate the hazards that they

indicate. Common sense and strict compliancewith the special

instructionswhileperforming theaction or serviceareessentialto

preventingaccidents.

Four commonly used safety symbols accompany the BANGER,

WARNINGand CAUTIONblocks. The type of information each

indicatesis asfollows:

,_This symbol points out important safety

information that, if not followed, could

endanger personal safety and/or property of

others.

This symbol points out potential explosion

hazard.

//_This symbol points out potential fire hazard.

This symbol points out potential electrical

shock hazard.

GENERAL HAZARDS

• NEVERoperatein an enclosed area, in a vehicle, or indoors

EVENIFdoors and windows areopen.

• For safety reasons, the manufacturer recommends that the

maintenanceof this equipmentis carried out by an Authorized

Dealer.Inspectthe generatorregularly,and contactthe nearest

AuthorizedDealerfor parts needingrepairor replacement.

• Operategeneratoronly on levelsurfacesandwhereit will notbe

exposedto excessivemoisture,dirt, dust or corrosive vapors.

• Keephands, feet, clothing, etc., away from drive belts, fans,

and other moving parts. Neverremoveany fan guardor shield

whilethe unit isoperating.

• Certain parts of the generator get extremely hot during

operation. Keep clear of the generator until it has cooled to

avoidsevereburns.

• Do NOToperategeneratorinthe rain.

• Do not alter the construction of the generator or change

controlswhich might createan unsafeoperatingcondition.

• Neverstart or stop the unit with electrical loads connected

to receptaclesAND with connecteddevicesturned ON. Start

the engine and let it stabilize before connecting electrical

loads. Disconnect all electricalloads beforeshutting downthe

generator.

• Do notinsert objectsthrough unit's cooling slots.

• When working on this equipment, remain alert at all times.

Never work on the equipment when physically or mentally

fatigued.

• Neverusethegeneratororanyofitspartsasastep.Stepping

ontheunitcanstressandbreakparts,andmayresultin

dangerousoperatingconditionsfromleakingexhaustgases,

fuelleakage,oilleakage,etc.

• Onelectricstartmodels,disconnectthePOSITIVE(+)battery

cablefromtheenginestarterORtheNEGATIVE(-)battery

cablefromthebatteryterminal,whicheveriseasier,before

transportingthegenerator.

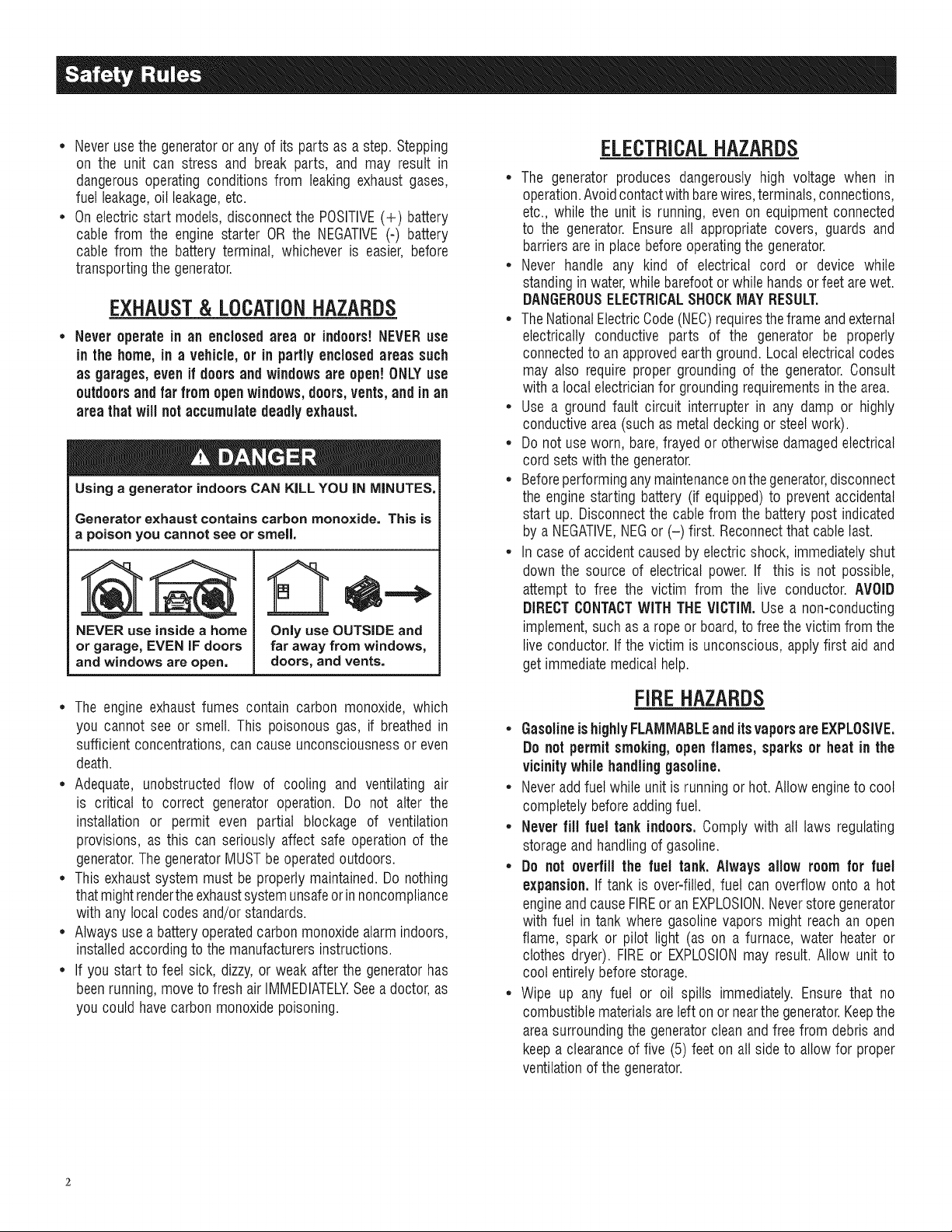

EXHAUST& LOCATIONHAZARDS

• Never operate in an enclosed area or indoors!NEVERuse

in the home, in a vehicle,or in partly enclosed areas such

as garages,evenif doors and windowsare open! ONLYuse

outdoors and far from openwindows,doors,vents,andinan

areathatwill notaccumulatedeadly exhaust.

Using a generator indoors CAN KILL YOU IN MINUTES,

Generator exhaust contains carbon monoxide. This is

a poison you cannot see or smell,

NEVER use insidea home

or garage,EVEN IF doors

and windows are open.

Only use OUTSIDE and

far away from windows,

doors, and vents=

ELECTRICALHAZARDS

• The generator produces dangerously high voltage when in

operation.Avoidcontactwithbarewires,terminals,connections,

etc., while the unit is running,even on equipmentconnected

to the generator.Ensureall appropriate covers, guards and

barriersarein placebeforeoperatingthegenerator.

• Never handle any kind of electrical cord or device while

standinginwater,while barefootorwhile handsor feet arewet.

DANGEROUSELECTRICALSHOCKMAYRESULT.

• TheNationalElectricCode(NEC)requirestheframe andexternal

electrically conductive parts of the generator be properly

connectedto an approvedearthground.Local electricalcodes

may also require proper grounding of the generator.Consult

with a localelectricianfor groundingrequirementsin the area.

• Use a ground fault circuit interrupter in any damp or highly

conductivearea(such as metaldecking or steelwork).

• Do not useworn, bare,frayed or otherwisedamagedelectrical

cord setswith the generator.

• Beforeperforminganymaintenanceonthegenerator,disconnect

the enginestarting battery (if equipped)to prevent accidental

start up. Disconnectthe cable from the batterypost indicated

by a NEGATIVE,NEGor (-) first. Reconnectthat cable last.

• In caseof accident causedby electricshock, immediatelyshut

down the source of electrical power. If this is not possible,

attempt to free the victim from the live conductor. AVOID

DIRECTCONTACTWITH THEVICTIM, Use a non-conducting

implement,such as a rope or board,to freethevictim from the

live conductor.If the victim is unconscious,applyfirst aidand

getimmediatemedical help.

• The engine exhaustfumes contain carbon monoxide, which

you cannot see or smell. This poisonous gas, if breathed in

sufficientconcentrations,can causeunconsciousnessor even

death.

• Adequate, unobstructed flow of cooling and ventilating air

is critical to correct generator operation. Do not alter the

installation or permit even partial blockage of ventilation

provisions, as this can seriously affect safe operationof the

generator.ThegeneratorMUSTbeoperatedoutdoors.

• Thisexhaustsystemmust be properlymaintained.Do nothing

that mightrendertheexhaustsystemunsafeorinnoncompliance

with any local codes and/orstandards.

• Alwaysuse a batteryoperatedcarbonmonoxidealarmindoors,

installedaccordingto the manufacturersinstructions.

• If you start to feet sick, dizzy,or weak after the generatorhas

beenrunning,moveto fresh air IMMEDIATELYSeea doctor,as

you couldhavecarbonmonoxidepoisoning.

FIREHAZARDS

• GasolineishighlyFLAMMABLEand itsvaporsareEXPLOSIVE.

Do not permitsmoking,open flames, sparksor heat in the

vicinitywhilehandling gasoline.

• Neveraddfuel whileunit isrunning or hot. Allow engineto cool

completelybeforeaddingfuel.

• Never fill fuel tank indoors.Comply with all laws regulating

storageand handlingof gasoline.

• Do not overfill the fuel tank. Always allow roomfor fuel

expansion.If tank is over=filled,fuel can overflow onto a hot

engineandcauseFIREor an EXPLOSION.Neverstoregenerator

with fuel in tank where gasolinevapors might reachan open

flame, spark or pilot light (as on a furnace, water heateror

clothes dryer). FIREor EXPLOSIONmay result. Allow unit to

cool entirelybeforestorage.

• Wipe up any fuel or oil spills immediately. Ensure that no

combustiblematerialsareleft on or nearthe generator.Keepthe

areasurroundingthe generatorclean andfree from debrisand

keepa clearanceof five (5) feet on all side to allow for proper

ventilationof the generator.

* Do notinsert objectsthrough unit's cooling slots.

* Do not operatethe generator if connected electrical devices

overheat,if electricaloutputislost, if engineor generatorsparks

or ifflames or smoke are observedwhileunit is running.

* Keepafire extinguishernearthe generatorat all times.

STANDARDS/#DEX

Intheabsenceof pertinentstandards,codes,regulationsandtaws,

the publishedinformation listedbelowmay be usedas a guideline

foroperationof this equipment.Alwaysreferencethe latestrevision

availablefor the standardslisted.

1. NFPANo. 70, NFPAHANDBOOKOF NATIONALELECTRIC

CODE.

2. Article X, NATIONALBUILDINGCODE,available from the

American InsuranceAssociation, 85 John Street, New York,

N.Y 10038.

3. AGRICULTURALWIRINGHANDBOOK,availablefrom the Food

and EnergyCouncil, 909 UniversityAvenue, Columbia, MO

65201.

4. ASAE EP-3634, INSTALLATIONAND MAINTENANCEOF

FARMSTANDBYELECTRICALSYSTEMS,availablefrom the

AmericanSocietyof AgriculturalEngineers,2950 NilesRoad,

St. Joseph, MI 49085.

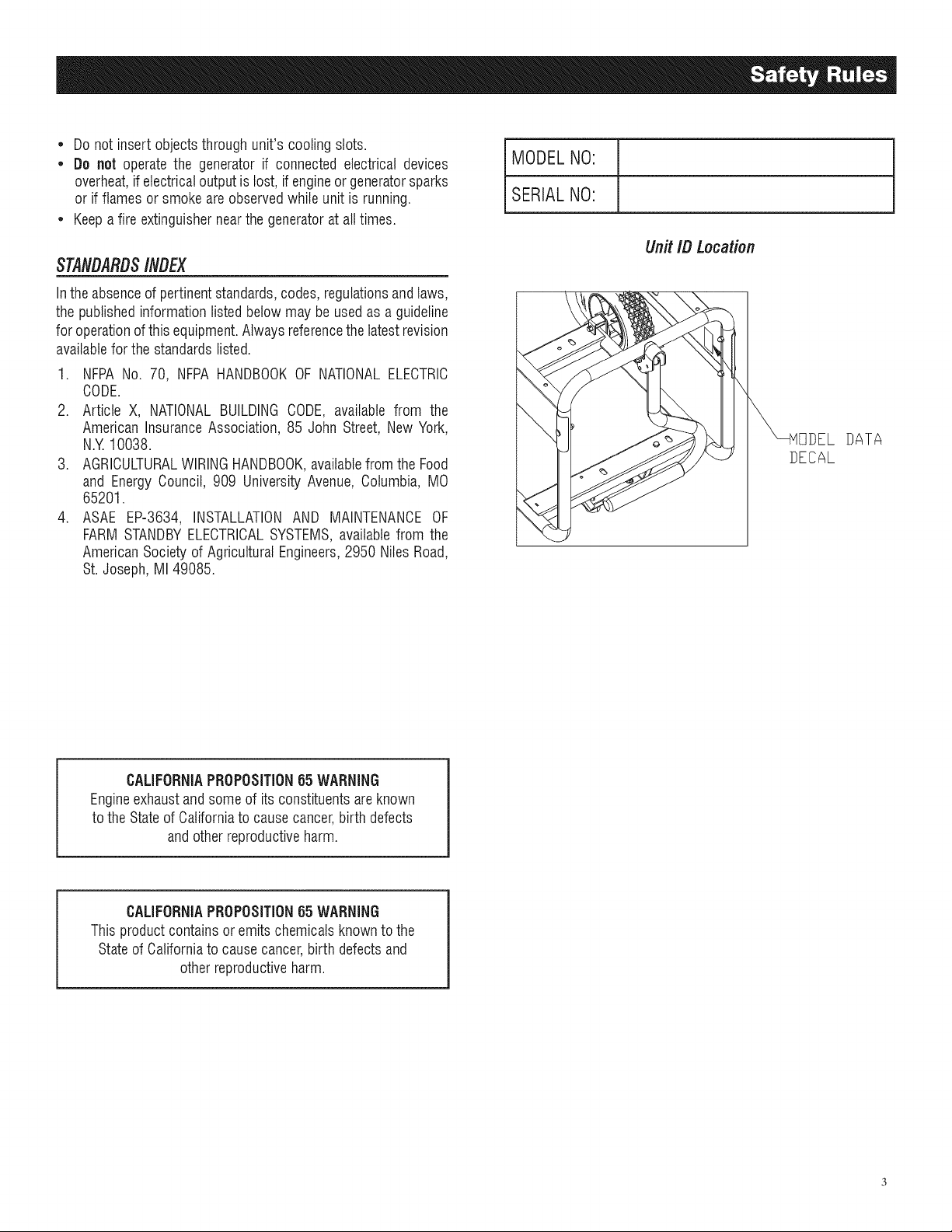

MODELNO:

SERIALNO:

Unit ID Location

DATA

DECAL

CALIFORNIAPROPOSITION65 WARNING

Engineexhaustandsomeof its constituentsareknown

to theStateof Californiato causecancer,birth defects

andotherreproductiveharm.

CALIFORNIAPROPOSITION65 WARNING

This productcontains or emitschemicalsknown tothe

Stateof Californiato causecancer,birth defectsand

otherreproductiveharm.

1.1 UNPACKING

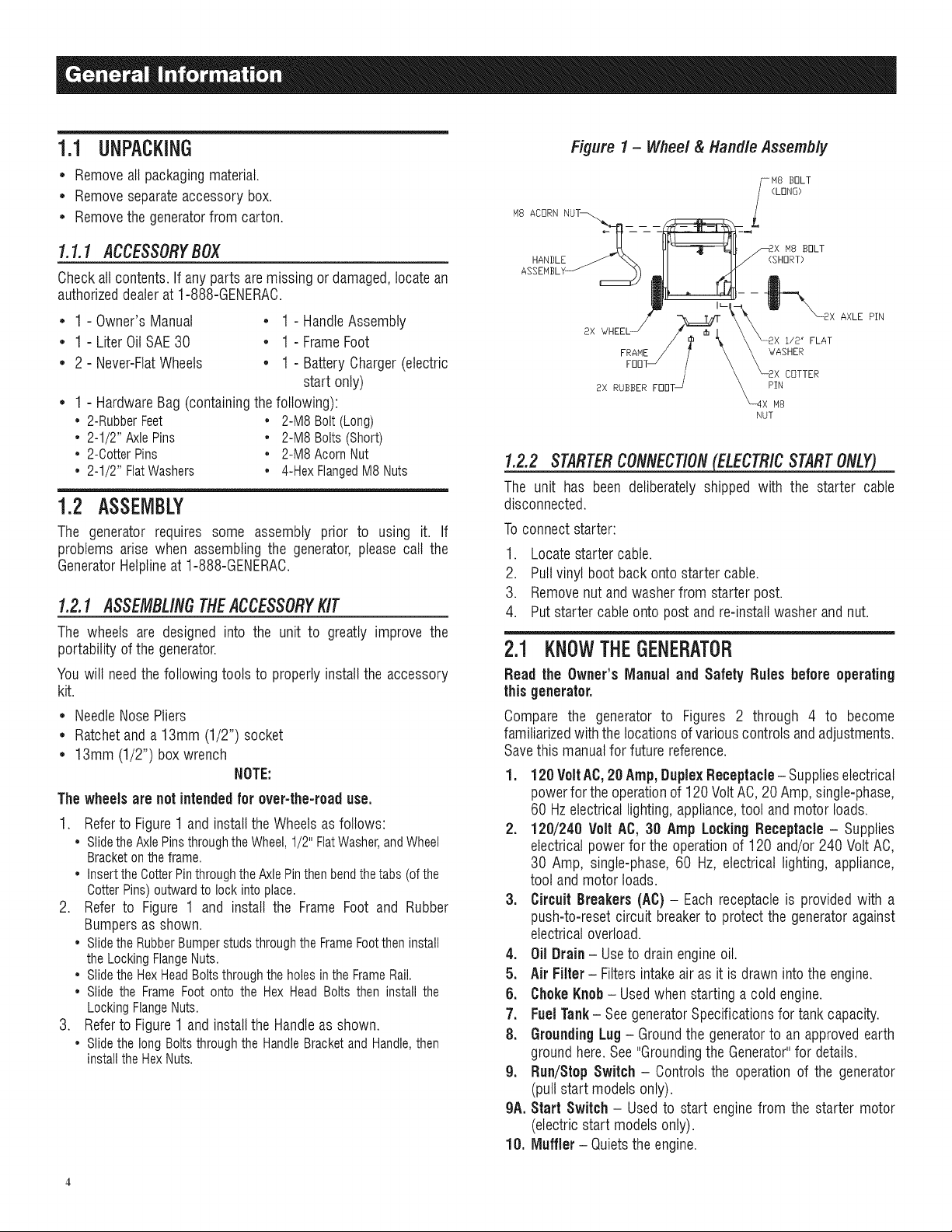

Figure 1 - Wheel & Handle Assembly

• Removeall packagingmaterial.

• Removeseparateaccessorybox.

• Removethegeneratorfrom carton.

1.1.1 ACCESSORYBOX

Checkall contents.If any parts aremissing or damaged,locatean

authorizeddealerat 1-888-GENERAC.

• 1 - Owner'sManual • 1 - HandleAssembly

• 1-LiterOiISAE30 • 1-FrameFoot

• 2 - Never-FlatWheels • 1 - BatteryCharger(electric

start only)

• 1 - HardwareBag (containingthefollowing):

• 2-RubberFeet • 2-M8Bolt(Long)

• 2-1/2" AxlePins • 2-M8Bolts(Short)

• 2-CotterPins • 2-M8AcornNut

• 2-1/2" FlatWashers • 4-HexFlangedM8Nuts

1.2 ASSEMBLY

The generator requires some assembly prior to using it. If

problems arise when assemblingthe generator,please call the

GeneratorHetplineat 1-888-GENERAC.

1.2.1 ASSEMBLINGTHEACCESSORYKIT

The wheels are designed into the unit to greatly improve the

portability ofthe generator.

You will needthe following tools to properlyinstall the accessory

kit.

• NeedleNosePliers

• Ratchetanda 13mm (1/2") socket

• 13mm (1/2") box wrench

NOTE:

The wheels are net intendedfor over-the-road use.

1. Refer to Figure 1 and install the Wheels as follows:

• Slidethe AxlePinsthroughthe Wheel, 1/2" FlatWasher,and Wheel

Bracketon the frame.

• Insertthe CotterPinthroughthe Axle Pinthenbend thetabs (ofthe

OotterPins) outward to lock into place.

2. Refer to Figure 1 and install the Frame Foot and Rubber

Bumpers as shown.

• Slidethe RubberBumperstuds throughthe FrameFootthen install

the Locking FlangeNuts.

• Slidethe HexHeadBoltsthrough the holes in the FrameRail.

• Slide the Frame Foot onto the Hex Head Bolts then install the

LockingFlangeNuts.

3. Refer to Figure 1 and install the Handle as shown.

• Slidethe long Bolts through the HandleBracketand Handle,then

installthe HexNuts.

Y_ H8 ]3r]LT

(LONG)

M8 ACORN NUT--,..,. -- -- -- L

\_ _ /_2x M8 BOLT

HANBLE _ _%, II II/ (SHORT)

.

FRAHE / 7" \ \ WASHER

FOOTJ / _ _2X COTTER

8X RUBBER FOOTJ _xPI:8

NUT

1.2.2 STARTERCONNECTION(ELECTRICSTARTONLY)

The unit has been deliberately shipped with the starter cable

disconnected.

Toconnectstarter:

1. Locatestarter cable.

2. Pullvinyl boot backonto startercable.

3. Removenut and washerfrom starter post.

4. Putstarter cableontopost and re-installwasher and nut.

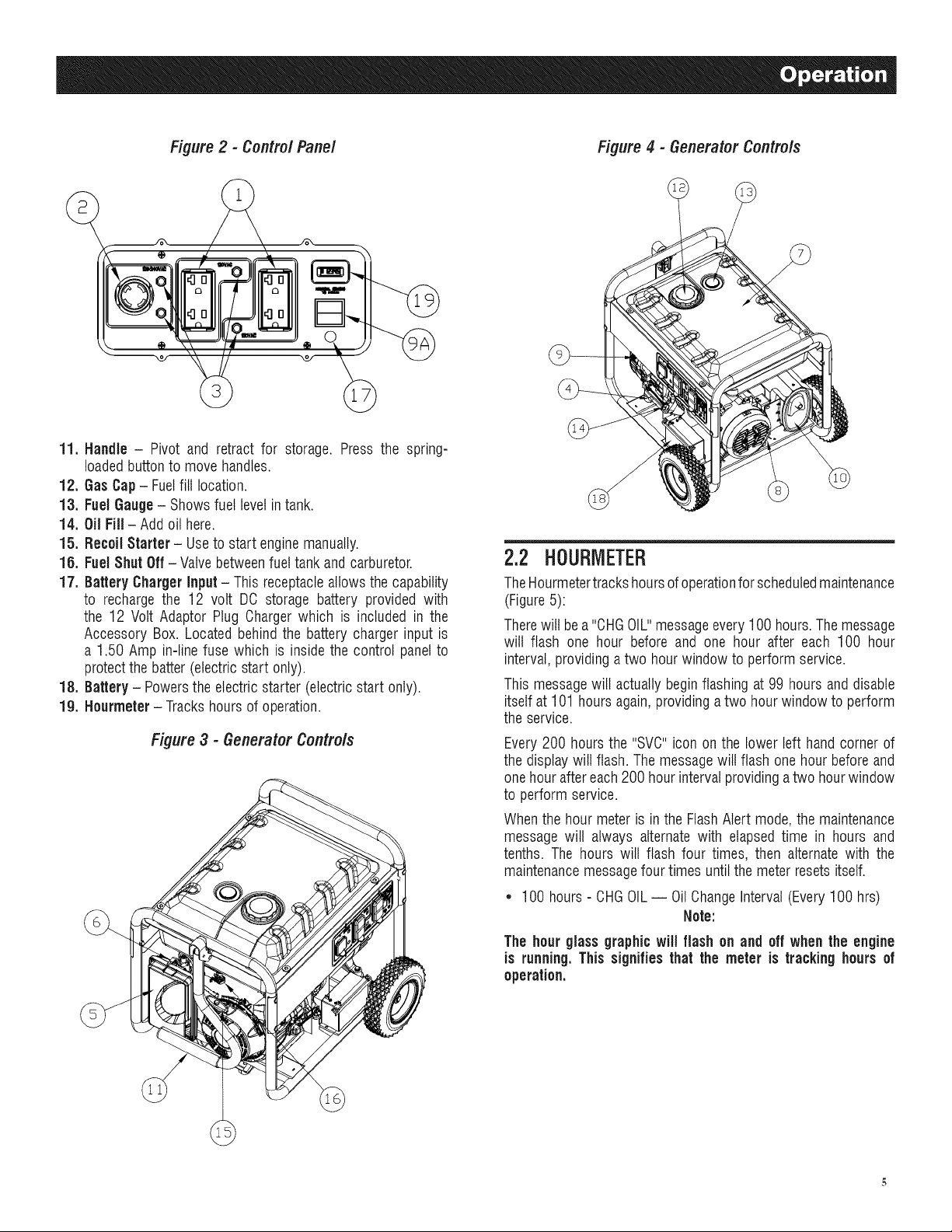

2.1 KNOWTHEGENERATOR

Read the Owner'sManual and Safety Rules before operating

this generator.

Compare the generator to Figures 2 through 4 to become

familiarizedwiththelocations of variouscontrolsandadjustments.

Savethis manualfor future reference.

1. 120 VoltAC,20 Amp, DuplexReceptacle- Supplieselectrical

powerfor theoperationof 120VoltAC,20 Amp,single-phase,

60 Hzelectricallighting,appliance,tool and motor loads.

2. 120/240 Volt AC, 30 Amp LockingReceptacle - Supplies

electricalpowerfor the operationof 120 and/or240 VoltAC,

30 Amp, single-phase, 60 Hz, electrical lighting, appliance,

tool andmotor loads.

3. CircuitBreakers(AC) - Eachreceptacleis providedwith a

push-to-reset circuit breakerto protectthe generatoragainst

electricaloverload.

4. Oil Drain- Useto drainengineoil.

5. Air Filter - Filters intakeair as it isdrawn into the engine.

6. ChokeKnob- Usedwhen starting a cold engine.

7. FuelTank- SeegeneratorSpecificationsfor tank capacity.

8. Grounding Lug - Groundthe generatorto an approvedearth

groundhere.See"Groundingthe Generator"for details.

g. Run/Step Switch - Controls the operation of the generator

(pullstart models only).

gA. Start Switch - Used to start enginefrom the starter motor

(electricstart modelsonly).

10. Muffler - Quietsthe engine.

Figure 2 - Contro/ Pane/ Figure 4 - Generator Contro/s

11. Handle - Pivot and retract for storage. Press the spring-

loadedbuttonto movehandles.

12. GasCap- Fuelfill location.

13. FuelGauge- Showsfuel levelin tank.

14. OilFill - Add oil here.

15. Recoil Starter - Useto start enginemanually.

15. Fuel Shut Off- Valvebetweenfuel tank and carburetor.

17. Battery Charger Input - This receptacleallowsthe capability

to recharge the 12 volt DC storage battery provided with

the 12 Volt Adaptor PlugChargerwhich is included in the

Accessory Box. Located behindthe battery charger input is

a 1.50 Amp in-line fuse which is inside the control panelto

protectthe batter(electricstart only).

18. Battery - Powersthe electricstarter (electricstart only).

19. Hourmeter - Trackshours of operation.

Figure3 - GeneratorControls

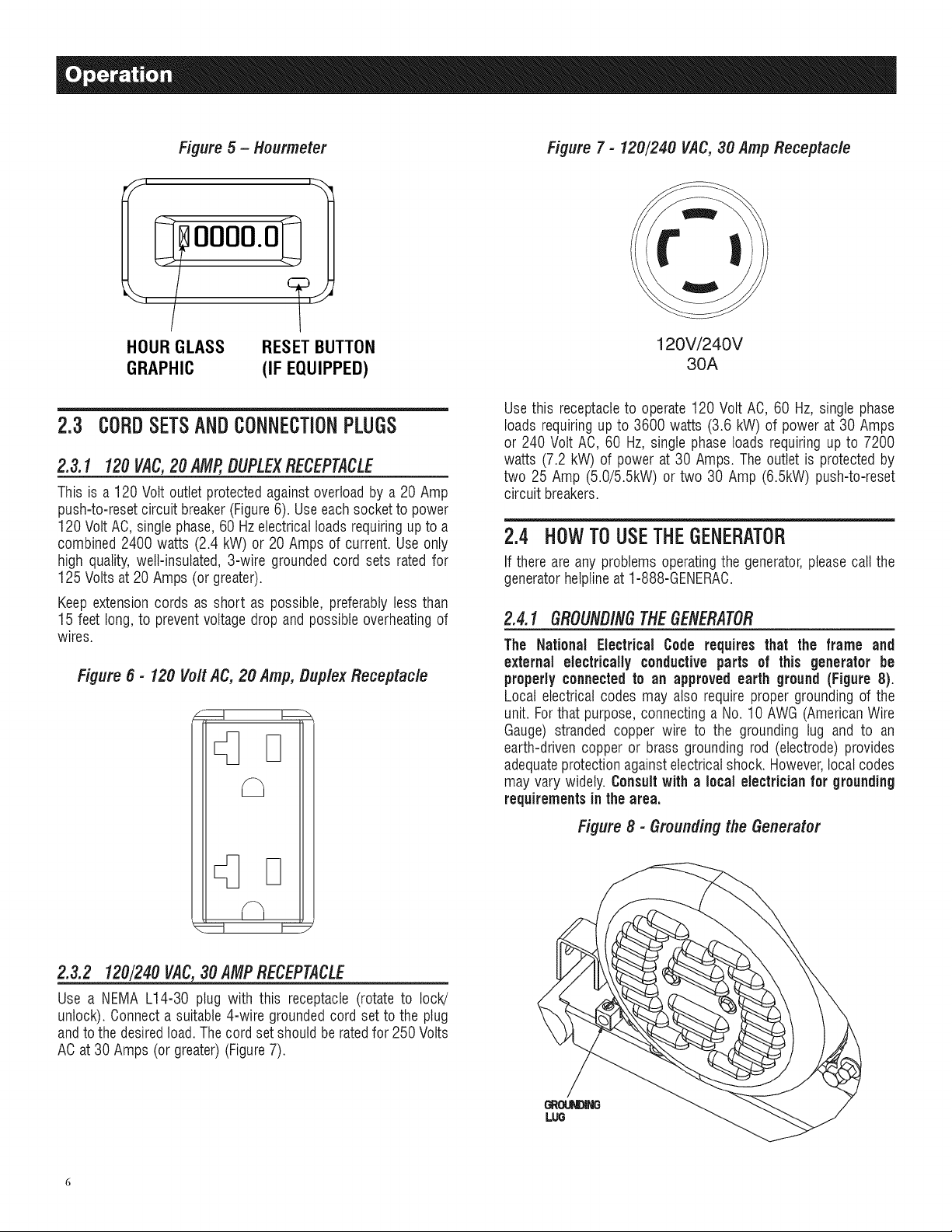

2.2 HOURIVIETER

TheHourmetertrackshoursofoperationforscheduledmaintenance

(Figure5):

Therewill be a"CHGOIL"messageevery100 hours.Themessage

will flash one hour before and one hour after each 100 hour

interval,providinga two hourwindow to performservice.

This messagewill actually beginflashing at 99 hours and disable

itselfat 101 hoursagain,providing atwo hourwindow to perform

theservice.

Every200 hoursthe "SVC"icon on the lower left hand corner of

thedisplay will flash. Themessagewill flash one hourbefore and

onehour aftereach200 hourintervalprovidingatwo hourwindow

to perform service.

Whenthe hour meter is inthe FlashAlert mode, the maintenance

message will always alternatewith elapsedtime in hours and

tenths. The hours wilt flash four times, then alternatewith the

maintenancemessagefourtimes untilthe meter resetsitself.

* 100 hours - CHGOIL-- OilChangeInterval(Every100 hrs)

Note:

The hour glassgraphicwill flash on and off when the engine

is running.This signifiesthat the meter is tracking hours of

operation.

Figure 5 - Hourmeter Figure 7 - 120/240 VAC,30 Amp Receptacle

0000.0

HOURGLASS

GRAPHIC

RESETBUTTON

(IF EQUIPPED)

2.3 CORDSETSANDCONNECTIONPLUGS

2.3.1 120VAC,20 AMP,DUPLEXRECEPTACLE

This is a120 Volt outlet protectedagainst overloadby a20 Amp

push-to-resetcircuitbreaker(Figure6). Useeachsocketto power

120 Volt AC, singlephase,60 Hzelectricalloadsrequiringup to a

combined 2400 watts (2.4 kW) or 20 Amps of current. Useonly

high quality,well-insulated, 3-wire groundedcord sets ratedfor

125 Volts at 20 Amps (or greater).

Keep extensioncords as short as possible, preferablyless than

15 feet long, to preventvoltagedrop and possibleoverheatingof

wires.

Figure 6 - 120 Vo/t AC, 20 Amp, Duplex Receptac/e

120V/240V

30A

Use this receptacleto operate120 Volt AC, 60 Hz, single phase

loads requiringup to 3600 watts (3.6 kW) of powerat 30Amps

or 240 Volt AC, 60 Hz,single phaseloads requiring up to 7200

watts (7.2 kW) of power at 30 Amps. The outlet is protected by

two 25 Amp (5.0/5.5kW) or two 30 Amp (6.5kW) push-to-reset

circuit breakers.

2.4 HOW TOUSETHEGENERATOR

If thereare any problems operatingthe generator,pleasecall the

generatorhelplineat 1-888-GENERAC.

2.4.1 GROUNDINGTHEGENERATOR

The National Electrical Code requires that the frame and

external electrically conductiveparts of this generator be

properlyconnectedto an approved earth ground (Figure 8).

Local electrical codes may also require proper grounding of the

unit. Forthat purpose, connectinga No. 10 AWG (AmericanWire

Gauge) stranded copper wire to the grounding lug and to an

earth-driven copper or brass grounding rod (electrode) provides

adequateprotectionagainstelectricalshock. However,local codes

may vary widely. Consultwith a localelectricianfor grounding

requirementsin the area.

D

2.3.2 120/240VAC,30 AMPRECEPTACLE

Use a NEMA L14-30 plug with this receptacle (rotate to lock!

unlock). Oonnecta suitable4-wire groundedcord set to the plug

andto thedesiredtoad.Thecordset should be ratedfor 250 Volts

ACat30 Amps (or greater)(Figure7).

Figure8 - Groundingthe Generator

Propergroundingofthe generatorwill help preventelectrical

shockin the event of a ground fault condition in the generator

or in connectedelectrical devices. Proper grounding also helps

dissipate static electricity, which often builds up in ungrounded

devices.

2.4.2 CONNECTINGELECTR/CALLOADS

DONOTconnect240 Volt loadsto 120Volt receptacles.DONOT

connect 3-phaseloads to the generator.DONOTconnect 50 Hz

loadsto thegenerator.

* Let engine stabilize and warm up for a few minutes after

starting.

* Plug in and turn on the desired 120 or 240 Volt AO, single

phase,60 Hzelectricalloads.

* Add up the ratedwatts (or amps) of all loadsto be connected

at onetime. This total should not be greaterthan (a) the rated

wattage/amperagecapacity of the generator or (b) circuit

breakerratingof thereceptaclesupplyingthe power.See"Don't

Overloadthe Generator".

2.5 DON'TOVEBLOADTHEGENEBATOB

Overloadinga generator in excess of its ratedwattage capacity

can result in damageto the generatorandto connectedelectrical

devices.Observethefollowing to preventoverloadingthe unit:

* Addupthetotal wattageofall electricaldevicesto be connected

at one time. This total should NOT be greater than the

generator'swattage capacity.

* The ratedwattage of lights can be takenfrom light bulbs. The

ratedwattageof tools, appliancesand motors can usually be

found on a data labelor decalaffixedto the device.

* If the appliance,toot or motor does not givewattage, multiply

voltstimes ampereratingto determinewatts (voltsx amps =

watts).

* Some electric motors, such as induction types, require about

threetimes morewatts of powerfor startingthan for running.

This surge of power lasts only a few seconds when starting

such motors.Makesureto allowfor high startingwattagewhen

selectingelectrical devicesto connectto the generator:

1. Figurethe watts neededtostart the largestmotor.

2. Add to that figure the running watts of all other connected

loads.

TheWattageReferenceGuideis providedto assist in determining

how many items the generatorcan operateatonetime.

NOTE:

All figuresare approximate. See data label on appliance for

wattage requirements.

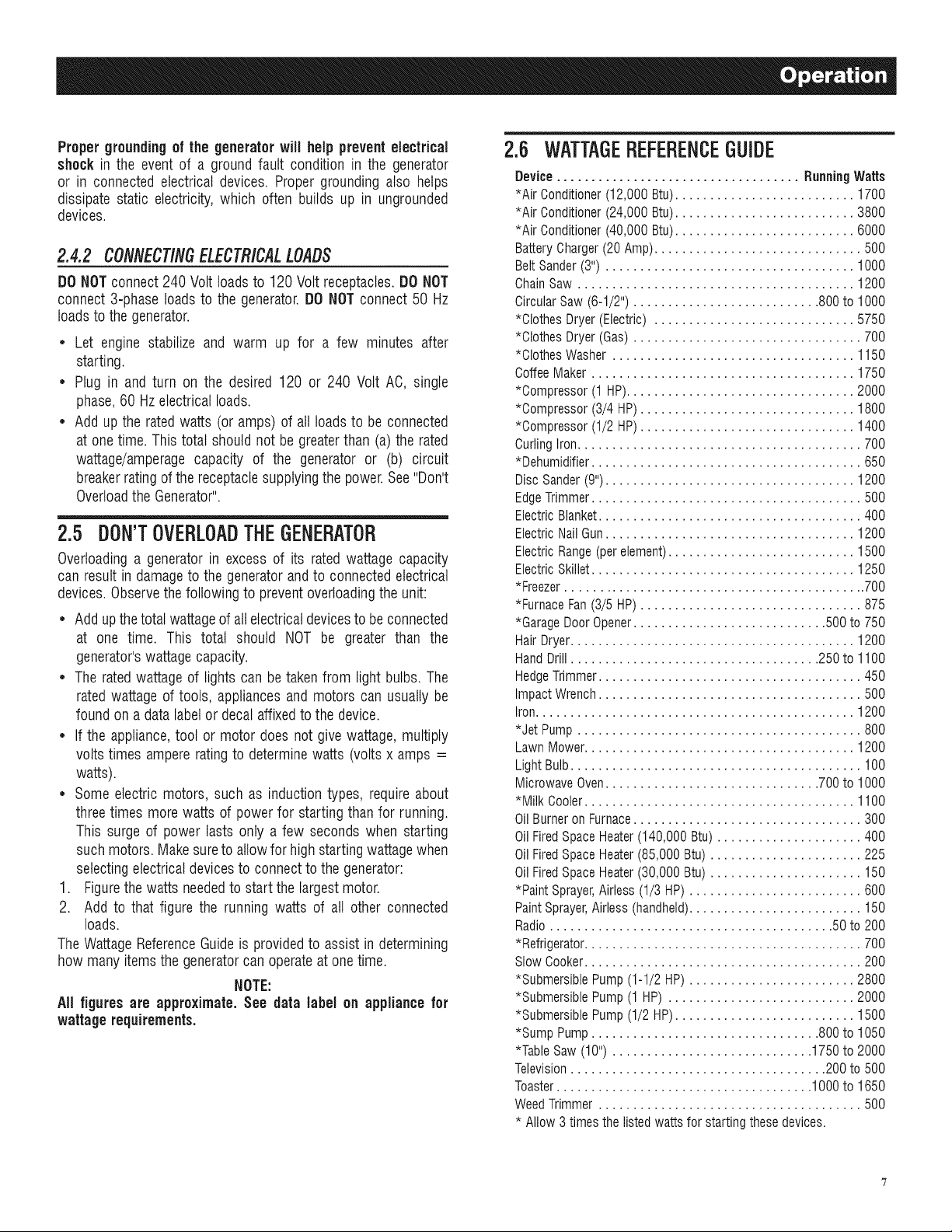

2.6 WATTAGEBEFEBENCEGUIDE

Device ................................... RunningWatts

*Air Conditioner(12,000 Btu).......................... 1700

*Air Conditioner(24,000 Btu).......................... 3800

*Air Conditioner(40,000 Btu).......................... 6000

BatteryCharger(20 Amp).............................. 500

BeltSander(3") .................................... 1000

ChainSaw ........................................ 1200

CircularSaw (6-1/2") ........................... 800to 1000

*Clothes Dryer (Electric) ............................. 5750

*Clothes Dryer (Gas) ................................. 700

*Clothes Washer ................................... 1150

CoffeeMaker ...................................... 1750

*Compressor (1 HP)................................. 2000

*Compressor (3/4 HP)............................... 1800

*Compressor (1/2 HP)............................... 1400

CurlingIron......................................... 700

*Dehumidifier....................................... 650

Disc Sander(9").................................... 1200

EdgeTrimmer....................................... 500

Electric Blanket...................................... 400

Electric NailGun.................................... 1200

Electric Range(per element)........................... 1500

Electric Skillet...................................... 1250

*Freezer............................................ 700

*FurnaceFan(3/5 HP) ................................ 875

*GarageDoor Opener............................ 500 to 750

Hair Dryer......................................... 1200

HandDrill .................................... 250to 1100

HedgeTrimmer...................................... 450

Impact Wrench...................................... 500

Iron.............................................. 1200

*Jet Pump ......................................... 800

Lawn Mower....................................... 1200

LightBulb.......................................... 100

Microwave Oven............................... 700to 1000

*Milk Cooler....................................... 1100

OilBurneron Furnace................................. 300

OilFiredSpace Heater(140,000 Btu) ..................... 400

OilFiredSpace Heater(85,000 Btu) ...................... 225

OilFiredSpace Heater(30,000 Btu) ...................... 150

*Paint Sprayer,Airless (1/3 HP) ......................... 600

PaintSprayer,Airless (handheld)......................... 150

Radio ......................................... 50 to 200

*Refrigerator........................................ 700

SlowCooker........................................ 200

*Submersible Pump(1-1/2 HP) ........................ 2800

*SubmersiblePump (1 HP) ........................... 2000

*Submersible Pump(1/2 HP).......................... 1500

*Sump Pump................................. 800to 1050

*Table Saw (10") ............................. 1750to 2000

Television..................................... 200 to 500

Toaster..................................... 1000to 1650

WeedTrimmer ...................................... 500

* Allow3 times the listedwatts for starting these devices.

2.7 BEFORESTARTINGTHEGENERATOR

Priorto operatingthe generator,engineoil and gasolinewill need

to be added,as follows:

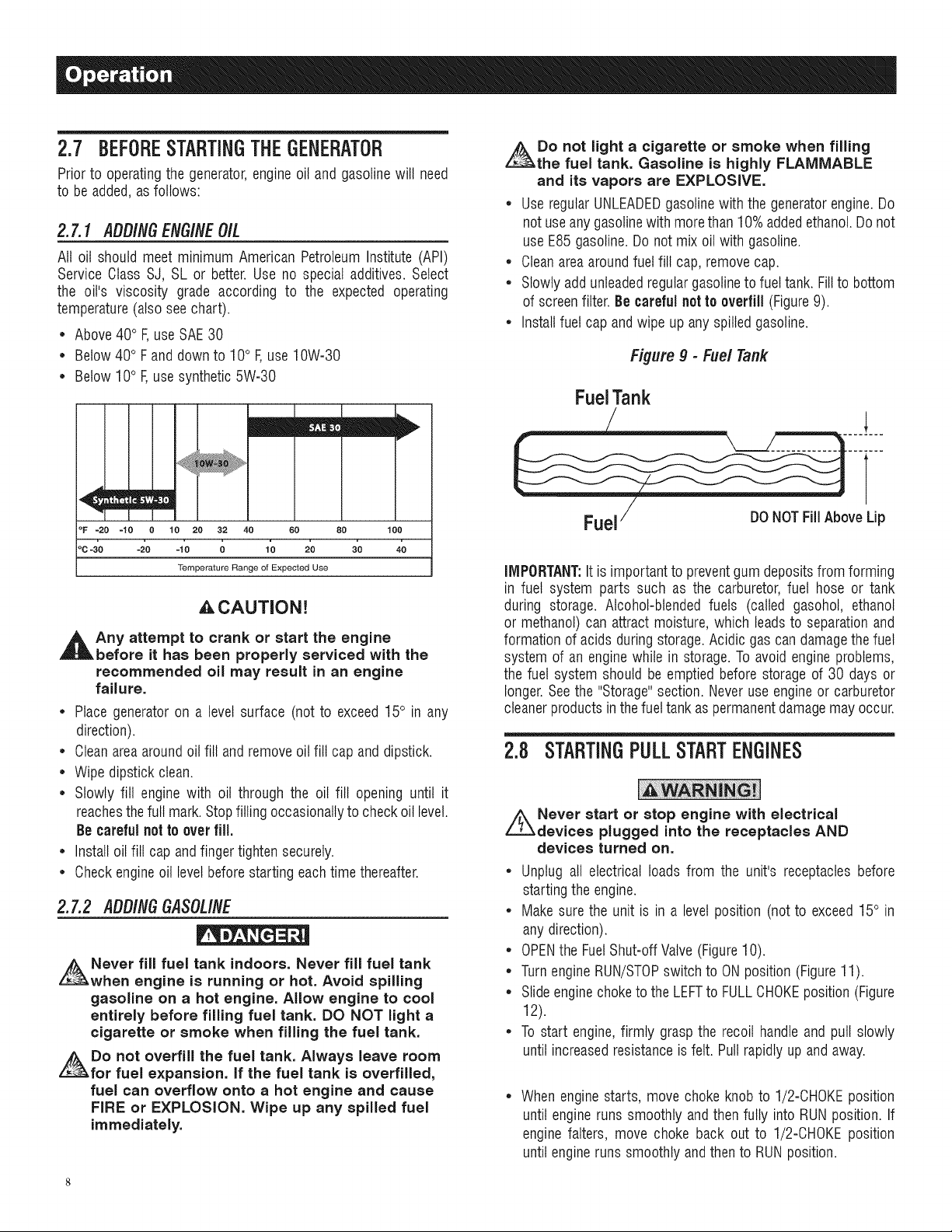

2.7.1 ADD/NGENG/NEO/L

All oil should meet minimum American PetroleumInstitute (API)

Service Class SJ, SL or better.Use no special additives. Select

the oil's viscosity grade according to the expected operating

temperature(also seechart).

* Above40° F,use SAE30

* Below 40° F and downto 10° F,use 10W-30

* Below 10° F,use synthetic 5W-30

mEm!

ZEn

°F =20 =10 0 10 20 32 40 60 80 100

oc-3'0 -_o -;0 o 1'0 2'0 3'0 4o

Temperature Range of Expected Use

_,CAUTION!

,_t Any attempt to crank or start the engine

before it has been properly serviced with the

recommended oil may result in an engine

failure.

* Place generator on a levelsurface (not to exceed15° in any

direction).

* Cleanareaaroundoil fill andremoveoil fill cap anddipstick.

* Wipe dipstick clean.

* Slowly fill engine with oil through the oil fill opening until it

reachesthefull mark.Stopfilling occasionallyto checkoil level.

Becarefulnotto overfill.

* Install oil fill cap andfinger tightensecurely.

* Checkengineoil levelbeforestarting eachtime thereafter.

2.7.2 ADDINGGASOLINE

Never fill fuel tank indoors. Never fill fuel tank

when engine is running or hot. Avoid spilling

gasoline on a hot engine. Allow engine to cool

entirely before filling fuel tank. DO NOT light a

cigarette or smoke when filling the fuel tank.

Do not overfill the fuel tank. Always leave room

for fuel expansion. If the fuel tank is overfilled,

fuel can overflow onto a hot engine and cause

FIRE or EXPLOSION. Wipe up any spilled fuel

immediately.

Do not light a cigarette or smoke when filling

the fuel tank. Gasoline is highly FLAMMABLE

and its vapors are EXPLOSIVE.

* Use regularUNLEADEDgasolinewith the generatorengine.Do

notuseany gasolinewith more than 10%addedethanol.Do not

useE85 gasoline.Do not mix oil with gasoline.

* Cleanareaaroundfuel fill cap,removecap.

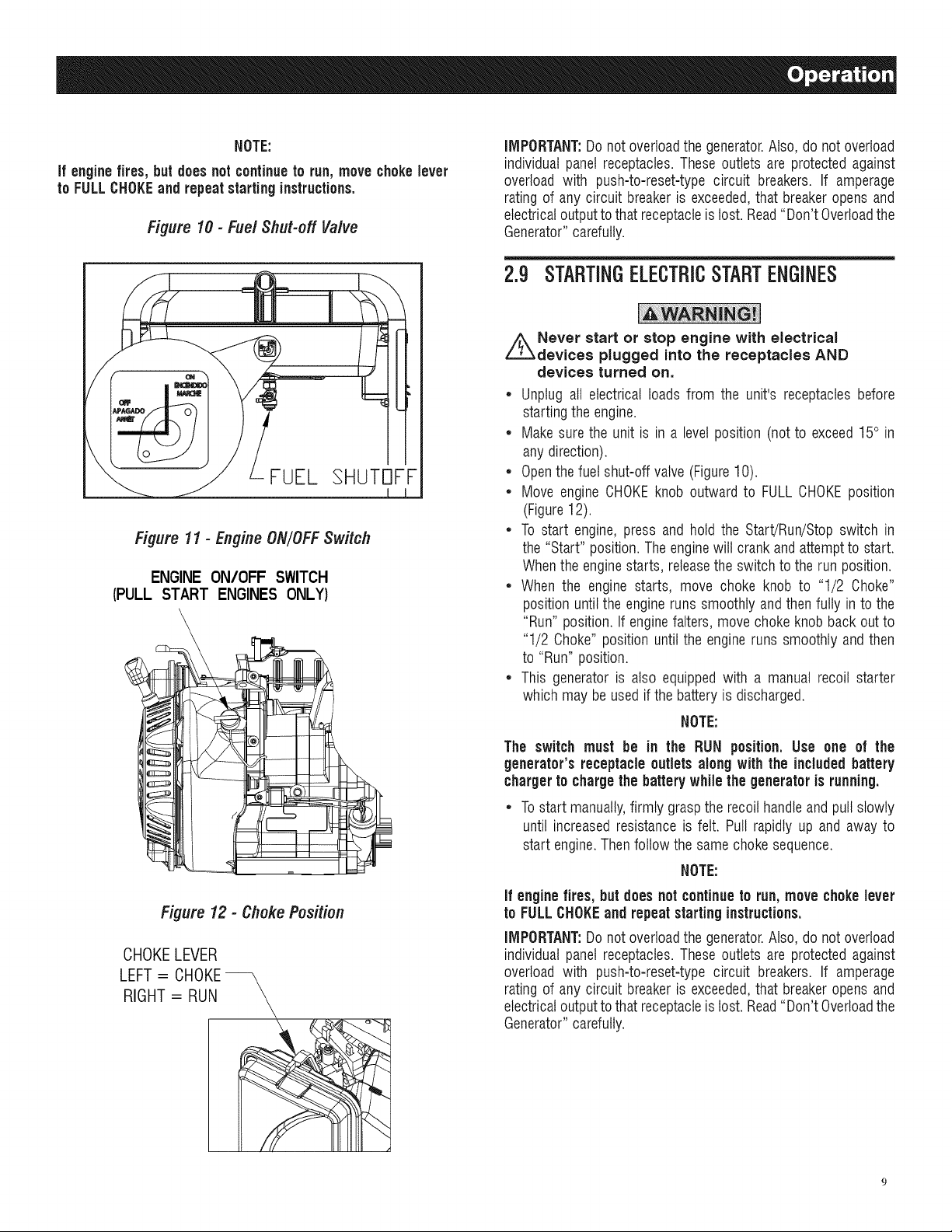

* Slowly addunleadedregulargasolineto fueltank. Fillto bottom

of screenfilter.Be carefulnot to overfill (Figure9).

* Install fuel cap andwipe up any spilledgasoline.

Figure9 - Fuel Tank

FuelTank

Fuel/ DONOTFillAbove Lip

IMPORTANT:It is important to preventgum depositsfrom forming

in fuel system parts such as the carburetor,fuel hose or tank

during storage. Alcohol-blendedfuels (called gasohol, ethanol

or methanol)can attract moisture, which leadsto separationand

formationof acids duringstorage.Acidic gascandamagethefuel

system of an enginewhile in storage. To avoid engineproblems,

the fuel system should be emptiedbefore storage of 30 days or

longer.Seethe "Storage"section. Neveruseengineor carburetor

cleanerproducts inthe fuel tank aspermanentdamagemay occur.

2.8 STARTINGPULLSTARTENGINES

Never start or stop engine with electrical

devices plugged into the receptacles AND

devices turned on.

* Unplug all electrical loads from the unit's receptaclesbefore

startingthe engine.

* Make surethe unit is in a levelposition (notto exceed15° in

anydirection).

* OPENthe FuelShut-offValve(Figure10).

* TurnengineRUN/STOPswitch to ON position(Figure11).

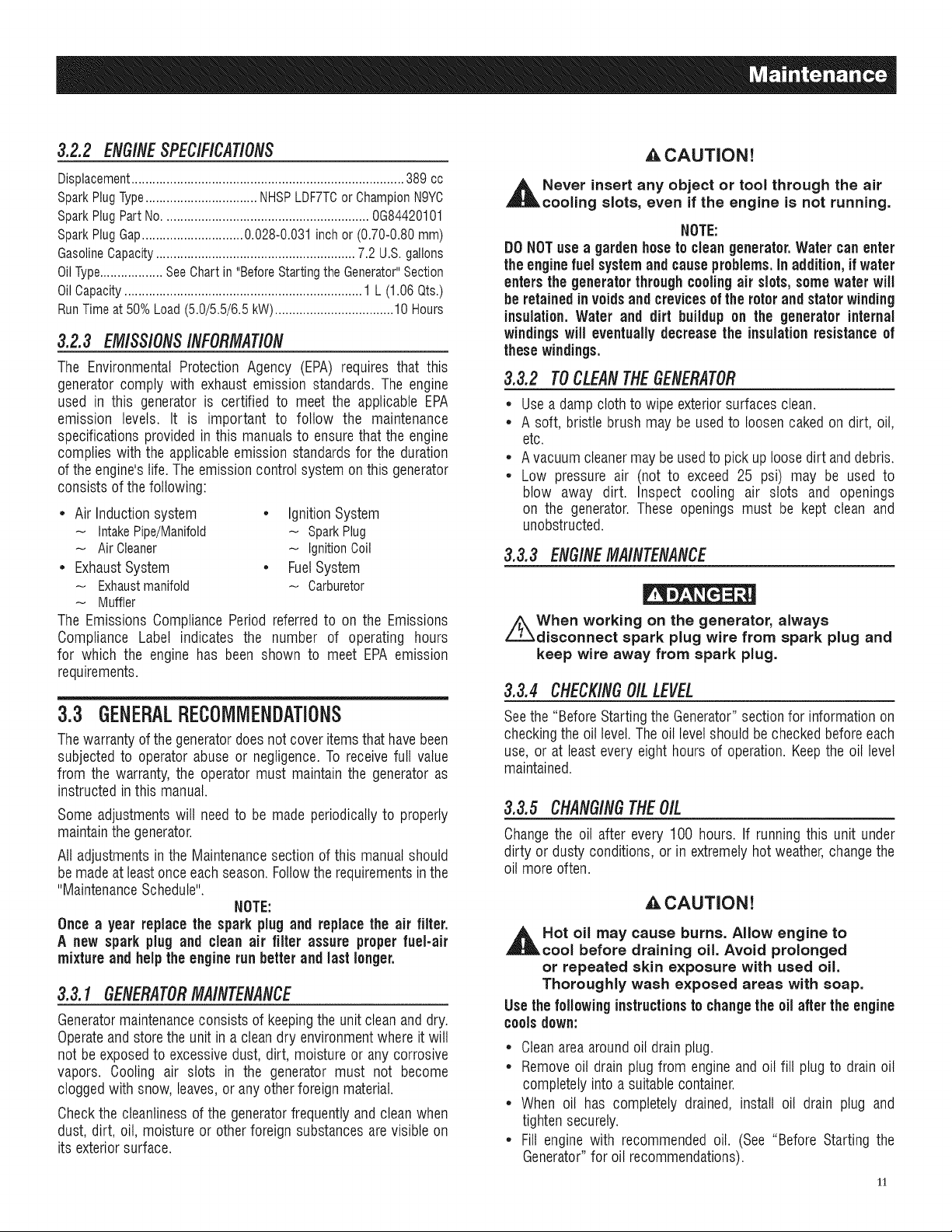

* Slideenginechoketo the LEFTto FULLCHOKEposition(Figure

12).

. To start engine,firmly graspthe recoil handleand pull slowly

until increasedresistanceisfelt. Pullrapidly up and away.

Whenenginestarts, move choke knobto 1/2-CHOKEposition

until engineruns smoothly andthen fully into RUNposition.If

engine falters, move choke back out to 1/2-CHOKEposition

untilengineruns smoothly andthento RUNposition.

NOTE:

if enginefires, butdoesnot continueto run, movechokelever

to FULLCHOKEand repeatstartinginstructions.

Figure 10 - FuelShut-offVaNe

FUEL SHUTOFF

Figure 11 - Engine ON/OFF Switch

ENGINE ON/OFF SWITCH

(PULL START ENGINES ONLY)

IMPORTANT:Donotoverloadthe generator.Also,do not overload

individual panel receptacles.These outlets are protectedagainst

overload with push-to-reset-type circuit breakers. If amperage

rating of any circuit breakeris exceeded,that breakeropensand

electricaloutputtothat receptacleis lost.Read"Don't Overloadthe

Generator"carefully.

2.9 STARTINGELECTRICSTARTENGINES

Never start or stop engine with electrical

devices plugged into the receptacles AND

devices turned on.

• Unplug all electrical loads from the unit's receptaclesbefore

startingthe engine.

• Makesurethe unit is in a levelposition (notto exceed15° in

anydirection).

• Openthefuel shut-off valve (Figure10).

• Move engine CHOKEknob outward to FULLCHOKEposition

(Figure12).

• To start engine, press and hold the Start/Run/Stopswitch in

the"Start" position. The enginewill crankand attemptto start.

Whenthe enginestarts, releasethe switch to the runposition.

• When the engine starts, move choke knob to "1/2 Choke"

position until the engine runssmoothly and thenfully in to the

"Run" position.If enginefalters, move chokeknob back outto

"1/2 Choke"position until the engine runs smoothly and then

to "Run" position.

• This generator is also equippedwith a manual recoil starter

which may be usedif the batteryis discharged.

NOTE:

Figure 12 - Choke Position

CHOKELEVER

LEFT = CHOKE--

RIGHT = RUN

The switch must be in the RUN position. Use one of the

generator's receptacle outlets along with the includedbattery

chargerto chargethe battery while the generator is running.

• Tostart manually,firmly grasp the recoil handleand pull slowly

until increasedresistance is felt. Pull rapidly up and away to

start engine.Thenfollow the samechoke sequence.

NOTE:

if enginefires, but does not continueto run,move chokelever

to FULLCHOKEand repeatstartinginstructions.

IMPORTANT:Donot overloadthe generator.Also,do not overload

individual panel receptacles.These outlets are protectedagainst

overload with push-to-reset-type circuit breakers. If amperage

rating of any circuit breakeris exceeded,that breakeropensand

electricaloutputtothat receptacleis lost.Read"Don't Overloadthe

Generator"carefully.

2.10STOPPINGTHEENGINE

• Shutoff all loads,then unplugtheelectricalloadsfrom generator

panelreceptacles.Neverstart or stop theenginewith electrical

devicespluggedin andturnedon.

• Let engine run at no-loadfor several minutes to stabilizethe

internaltemperaturesof engineandgenerator.

• MoveRun/Stopswitch to OFFposition.

• Closefuelvalve.

2.11LOWOiLLEVELSHUTDOWNSYSTEM

Theengineis equippedwith a low oil levelsensorthat shutsdown

the engineautomaticallywhenthe oil leveldropsbelow a specified

level. If the engine shuts down by itself and the fuel tank has

enoughgasoline,checkengineoil level.

2. Unplugbattery chargerfrom wall outlet andcontrol paneljack

whengeneratoris goingto be in use.

NOTE:

Do not use the battery chargerfor more than 48 hoursat one

charge.

Figure 13 - Battery Charger Jack

BATTERY

CHARGER

2.11.1 SENSINGLOWOILLEVEL

If the system senses a low oil level during operation,the engine

shuts down. The enginewill not run until the oil has beenrefilled

to the properlevel.

2.12CHARGINGTHEBATTERY(ELECTRICSTART

UNITSONLY)

Storage batteries give off explosive hydrogen

gas while recharging. An explosive mixture will

remain around the battery for a long time after

it has been charged. The slightest spark can

ignite the hydrogen and cause an explosion.

Such an explosion can shatter the battery and

cause blindness or other serious injury.

,_Do not permit smoking, open flame, sparks

or any other source of heat around a battery.

Wear protective goggles, rubber apron and

rubber gloves when working around a battery.

Battery electrolyte fluid is an extremely

corrosive sulfuric acid solution that can cause

severe burns, if spill occurs flush area with

clear water immediately.

NOTE:

The battery shipped withthe generator has been fully charged.

A battery may lose some of its charge when not in use for

prolongedperiodsof time. If the battery isunable to crankthe

engine, plugin the 12V chargerincludedin the accessory box

(seesection"Chargingthe Battery").RUNNINGTHEGENERATOR

DOESNOTCHARGETHEBATTERY.

Usebatterychargerplugto keepthebattery chargedandreadyfor

use. Batterychargingshouldbe done in a dry location.

1. Plugchargerinto "BatteryChargerInput" jack, locatedon the

control panel.Plugwall receptacleendof the batterycharger

into a 120 VoltACwalt outlet(Figure13).

1o

INPUT

3.1 MAINTENANCESCHEDULE

Follow the calendar intervals. More frequent service is required

whenoperatingin adverseconditionsnotedbelow.

CheckOil Level

ChangeOil:_

CheckValveClearance

ServiceAir Filter

ReplaceSparkPlug

$ Changeoil after first 30 hours of operationthen every season.

* Changeoiland oilfilter every monthwhen operatingunderheavyload or in high

temperatures.

** Cleanmore often under dirty or dusty operatingconditions. Replaceair filter

parts if they cannot beadequatelycleaned.

*** Check valve clearance and adjust if necessary after first 50 hours of

operationand every 100 hours thereafter.

*Every 100 hoursor EverySeason

** Every200 hoursor EverySeason

3.2 PRODUCTSPECIFICATIONS

3.2.1 GENERATORSPECIFICATIONS

RatedPower............................................................... 5.0/5.5/6.5 kW**

SurgePower...............................................................6.25/6.88/8.0 kW

RatedACVoltage...................................................................... 120/240

RatedAC Load

Current@ 240V (5.0/5.5/6.5 kW) ..................20.8/22.9/27.1 Amps**

Current@ 120V (5.0/5.5/6.5 kW) ..................41.6/45.8/54.2 Amps**

RatedFrequency.................................................... 60 Hz@ 3600 RPM

Phase................................................................................ SinglePhase

** Maximumwattageandcurrentaresubjectto,andlimitedby,suchfactors

asfuelBtucontent,ambienttemperature,altitude,enginecondition,etc..

Maximumpowerdecreasesabout3.5%foreach1,000feetabovesealevel;

andwillalsodecreaseabout1%foreach6°C (10°F)above16° C(60°F)

ambienttemperature.

At EachUse

***Every Season

EverySeason

3.2.2 ENG/NESPEC/F/CAT/ONS

Displacement.............................................................................. 389 cc

SparkPlugType................................ NHSPLDF7TCor ChampionN9YC

SparkPlug PartNo........................................................... 0G84420101

SparkPlug Gap.............................0.028-0.031 inch or (0.70-0.80 mm)

GasolineCapacity......................................................... 7.2 U.S. gallons

OilType.................. SeeChart in "Before Starting the Generator"Section

OilCapacity.................................................................... 1 L (1.06 Qts.)

RunTime at 50% Load (5.0/5.5/6.5 kW)..................................10 Hours

3.2.3 EMISSIONSINFORMATION

The Environmental Protection Agency (EPA) requires that this

generatorcomply with exhaustemission standards. The engine

used in this generator is certified to meet the applicable EPA

emission levels. It is important to follow the maintenance

specifications provided in this manualsto ensurethat the engine

complies with the applicableemission standardsfor the duration

of theengine'slife. The emissioncontrol system onthis generator

consists ofthe following:

* Air Induction system * Ignition System

IntakePipe/Manifold - SparkPlug

Air Cleaner _ Ignition Coil

* Exhaust System * Fuel System

Exhaustmanifold _ Carburetor

Muffler

The Emissions Compliance Period referredto on the Emissions

Compliance Label indicates the number of operating hours

for which the engine has been shown to meet EPA emission

requirements.

3.3 GENERALRECOMMENDATIONS

Thewarranty of the generatordoesnotcover itemsthathave been

subjectedto operatorabuse or negligence.To receive full value

from the warranty, the operatormust maintainthe generatoras

instructed inthis manual.

Some adjustmentswill needto be made periodicallyto properly

maintainthegenerator.

All adjustments in the Maintenancesection of this manualshould

bemadeat leastonceeachseason.Followthe requirementsinthe

"MaintenanceSchedule".

NOTE:

Once a year replace the sparkplug and replace the air filter.

A new spark plug and clean air filter assure properfuel-air

mixture and helpthe engine runbetter and last longer.

3.3.1 GENERATORMAINTENANCE

Generatormaintenanceconsists of keepingthe unit clean and dry.

Operateandstorethe unitin a clean dry environmentwhere it will

not be exposedto excessivedust, dirt, moisture or any corrosive

vapors. Cooling air slots in the generator must not become

cloggedwith snow, leaves,or anyother foreign material.

Checkthe cleanlinessof the generatorfrequently andclean when

dust, dirt, oil, moisture or other foreign substancesarevisible on

its exteriorsurface.

A.CAUTION!

_h Never insert any object or tool through the air

cooling slots, even if the engine is not running.

NOTE:

DONOTuse a gardenhoseto cleangenerator. Water canenter

the enginefuel systemand causeproblems.In addition, if water

enters thegenerator throughcoolingair slots,some water will

be retainedinvoidsand crevicesof the rotorand statorwinding

insulation.Water and dirt buildup on the generator internal

windingswill eventually decreasetheinsulationresistanceof

these windings.

3.3.2 TOCLEANTHEGENERATOR

* Usea damp cloth to wipe exteriorsurfaces clean.

* A soft, bristle brush may be used to loosencaked on dirt, oil,

etc.

* Avacuumcleanermay beusedto pick uploosedirt anddebris.

* Low pressure air (not to exceed 25 psi) may be used to

blow away dirt. Inspect cooling air slots and openings

on the generator.These openings must be kept clean and

unobstructed.

3.3.3 ENGINEMAINTENANCE

/_When working on the generator, always

disconnect spark plug wire from spark plug and

keep wire away from spark plug.

3.3.4 CHECKINGOILLEVEL

Seethe "BeforeStartingthe Generator"sectionfor informationon

checkingthe oil level.The oil levelshouldbe checkedbeforeeach

use, or at leastevery eight hours of operation.Keepthe oil level

maintained.

3.3.5 CHANGINGTHEOIL

Changethe oil after every 100 hours. If runningthis unit under

dirty or dusty conditions, or in extremelyhotweather,changethe

oil moreoften.

,&CAUTION!

,_Hot oil may cause burns. Allow engine to

cool before draining oil. Avoid prolonged

or repeated skin exposure with used oil.

Thoroughly wash exposed areas with soap.

Use thefollowinginstructionsto changethe oil after the engine

coolsdown:

* Cleanareaaroundoil drainplug.

* Removeoil drain plug from engine and oil fill plug to drainoil

completelyinto a suitablecontainer.

* When oil has completely drained, install oil drain plug and

tightensecurely.

* Fill enginewith recommendedoil. (See "Before Starting the

Generator"for oil recommendations).

11

• Wipeup anyspilledoil.

• Disposeof usedoil at a propercollectioncenter.

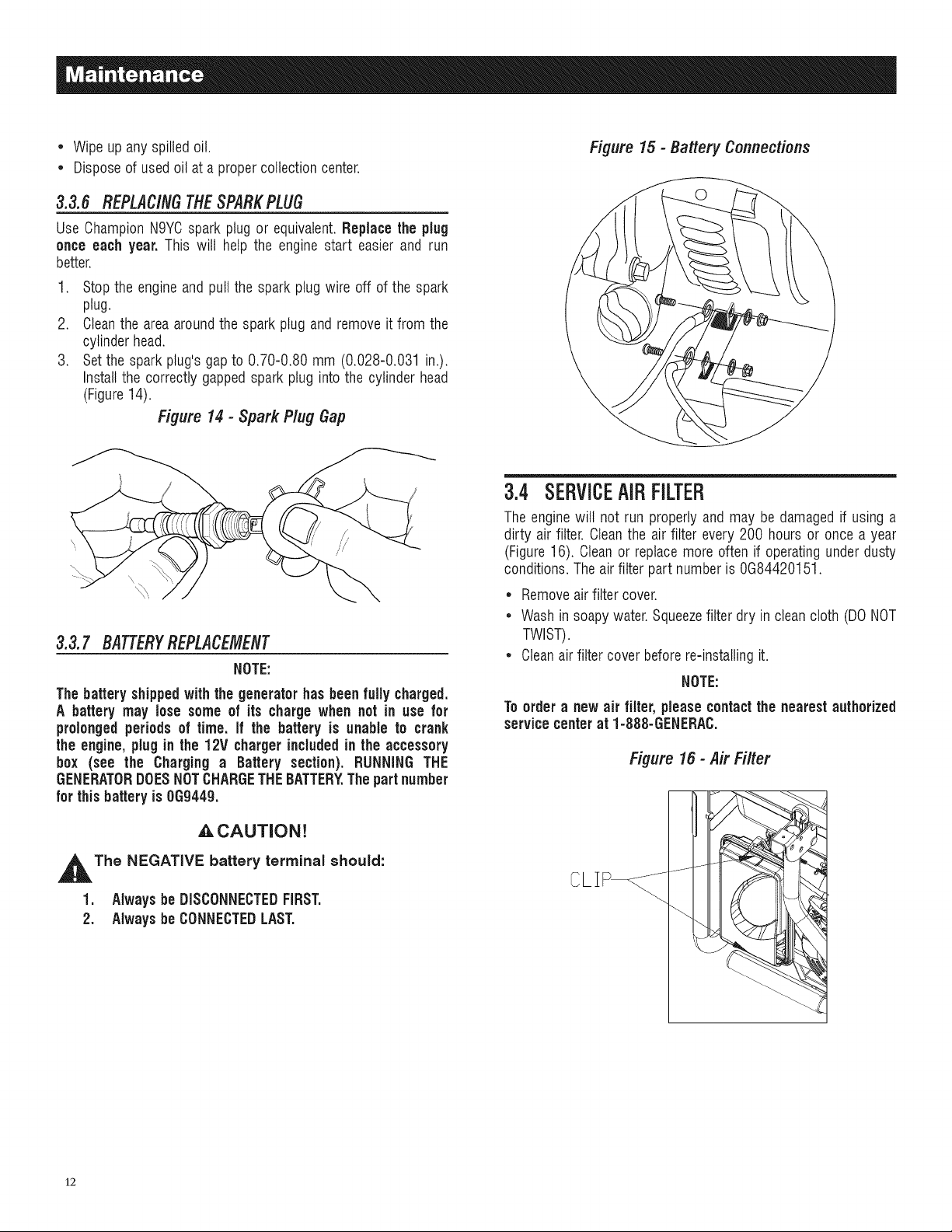

3.3.6 REPLACINGTHESPARKPLUG

Use ChampionN9YCspark plug or equivalent.Replace the plug

once each year. This will help the engine start easier and run

better.

1. Stopthe engineand pull the spark plug wire off of the spark

plug.

2. Cleanthe area aroundthe spark plug and remove it from the

cylinder head.

3. Setthe spark plug's gap to 0.70-0.80 mm (0.028-0.031 in.).

Installthe correctly gappedspark plug into the cylinderhead

(Figure14).

Figure 14 - Spark Plug Gap

3.3.7 BATTERYREPLACEMENT

NOTE:

Thebatteryshippedwith the generator hasbeen fully charged.

A battery may lose some of its charge when not in use for

prolongedperiodsof time. If the battery is unable to crank

the engine,plug in the 12V chargerincludedin the accessory

box (see the Charging a Battery section). RUNNING THE

GENERATORDOESNOTCHARGETHEBATTERY.Thepartnumber

for this battery is 069449.

Figure15 - Battery Connections

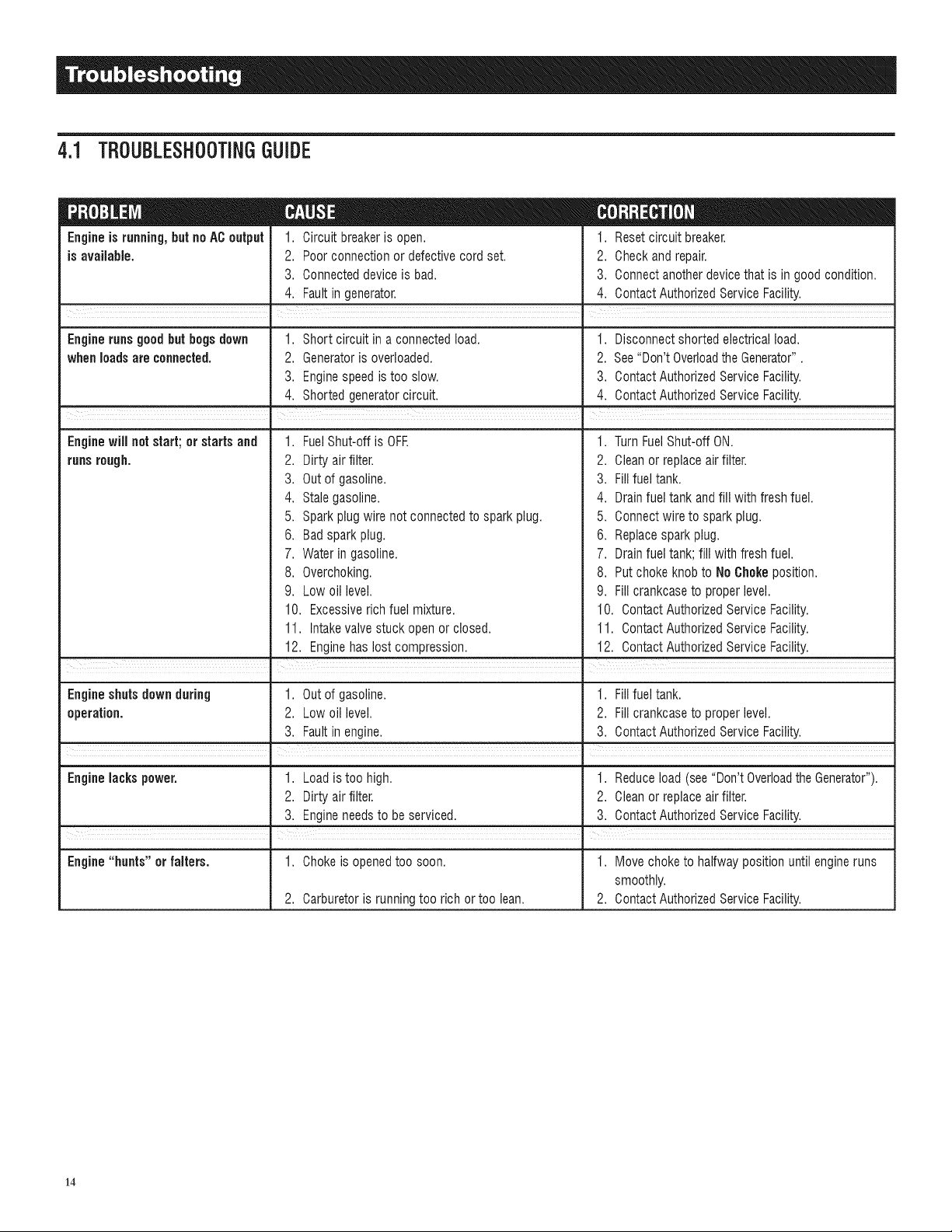

3.4 SERVICEAiRFILTER

Theenginewilt not run properlyand may be damagedif usinga

dirty airfilter. Cleanthe air filter every 200 hours or once a year

(Figure16). Cleanor replacemore often if operatingunderdusty

conditions.Theair filter part numberis 0G84420151.

• Removeairfilter cover.

• Washin soapy water.Squeezefilterdry in cleancloth (DONOT

TWIST).

• Cleanair filter cover beforere-installingit.

NOTE:

Toorder a new air filter, pleasecontactthe nearestauthorized

servicecenterat 1-888-GENERAC.

Figure 16- Air Filter

,_ CAUTION!

,_The NEGATIVE battery terminal should:

1. Always be DISCONNECTEDFIRST.

2. Alwaysbe CONNECTEDLAST.

12

CLIP_

3.5 VALVECLEARANCE

* Intake-- 0.15 __O.02mm (cold), (0.006" __0.0008" inches)

* Exhaust-- 0.20 _ O.02mm(cold) (0.008" _ 0.0008" inches)

Afterthefirst 50 hoursof operation,checkthevalveclearance

in the engineand adjustif necessary.

Important: If feelinguncomfortableabout doing this procedureor

theproper tools are not available,pleasetakethe generatorto the

nearestservicecenterto havethevalveclearanceadjusted.This is

a very importantstepto ensurelongestlife for theengine.

3.6 GENERAL

Thegeneratorshould be started at least once every 30 days and

be allowed to run at least 30 minutes. If this cannot be done and

the unit must be stored for morethan 30 days, use thefollowing

informationas a guideto prepareitfor storage.

NEVER store engine with fuel in tank indoors

or in enclosed, poorly ventilated areas where

fumes may reach an open flame, spark or pilot

light as on a furnace, water heater, clothes dryer

or other gas appliance.

,_AIIow unit to cool entirely before storage.

3.7 LONGTERMSTORAGE

It is importantto preventgum depositsfrom forming in essential

fuel systemparts such as the carburetor,fuel hose or tank during

storage. Also, experience indicates that alcohol-blended fuels

(called gasohol,ethanolor methanol)can attract moisture,which

leadsto separationandformation of acids during storage.Acidic

gascan damagethe fuel systemof an enginewhile in storage.

To avoid engine problems, the fuel system should be emptied

beforestorageof 30 daysor longer,asfollows:

Drain fuel into approved container outdoors,

away from open flame. Be sure engine is cool.

Do not smoke.

* Start and run engineuntil enginestops from lack of fuel.

* While engineis still warm, drain oil from crankcase. Refillwith

recommendedgrade.

* Removespark plugandpour about 1/2 ounce (15 ml) of engine

oil into the cylinders. Coverspark plug hole with rag. Puttthe

recoil starter a couple times to lubricatethe piston rings and

cylinder bore.

ACAUTION!

,_Avoid spray from spark plug hole when

cranking engine.

* Install andtighten spark plug.Donot connectspark plugwire.

* Cleanthe generatorouter surfaces. Checkthat cooling air slots

and openingson generatorareopen andunobstructed.

* Storethe unit in a clean, dry place.

3.8 OTHERSTORAGETiPS

* Do notstore gasolinefrom oneseasonto another.

* Replacethe gasolinecan if it startsto rust. Rustand/ordirt in

the gasolinewill cause problems with the carburetor and fuel

system.

* If possible,storethe unit indoorsandcover it to giveprotection

from dust anddirt. BESURETOEMPTYTIdEFUELTANK.

* If it is not practicalto empty the fuel tank and the unit is to be

storedfor sometime, useacommerciallyavailablefuelstabilizer

addedto the gasolineto increasethe life of thegasoline.

* Cover the unit with a suitable protective cover that does not

retainmoisture.

* Removeall gasolinefrom the fueltank.

,_ NEVER cover the generator while engine and

exhaust areas are warm.

13

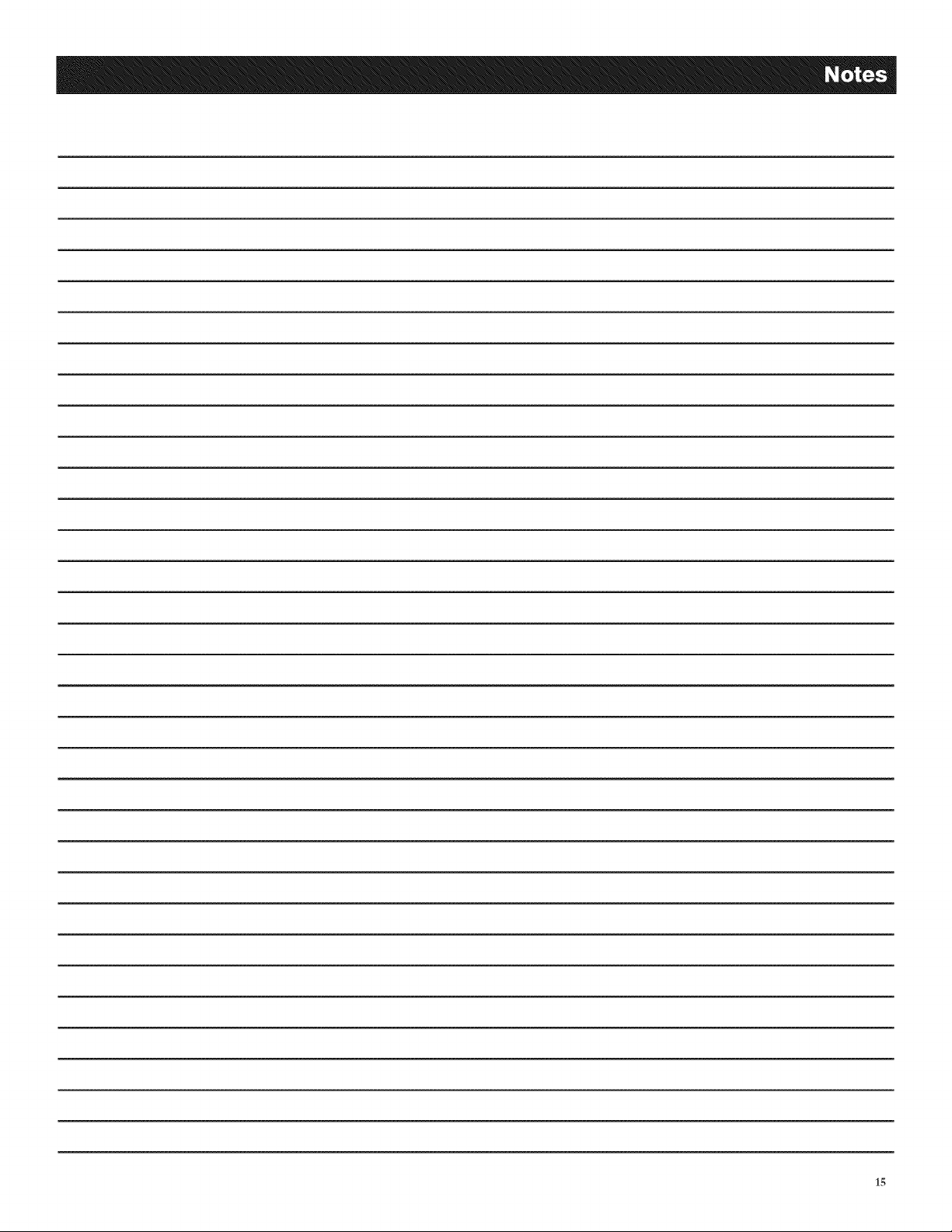

4.1 TROUBLESHOOTINGGUIDE

Engineis running,but no ACoutput

is available.

1. Circuit breakeris open.

2. Poorconnection or defectivecord set.

3. Connecteddevice is bad.

4. Faultin generator.

1. Resetcircuit breaker.

2. Checkand repair.

3. Connectanotherdevicethat is in good condition.

4. Contact AuthorizedService Facility.

Engine runs good but bogs down 1. Short circuit in a connectedload. 1. Disconnectshorted electricalload.

whenloadsare connected. 2. Generatoris overloaded. 2. See"Don'tOverloadtheGenerator".

3. Enginespeedis too slow. 3. ContactAuthorizedService Facility.

4. Shorted generatorcircuit. 4. Contact AuthorizedServiceFacility.

Enginewill notstart;orstartsand

runsrough.

FuelShut-offis OFF.

,

2.

Dirtyair filter.

3.

Out of gasoline.

4.

Stale gasoline.

5.

Sparkplug wire not connectedto sparkplug.

6. Badsparkplug.

7. Water in gasoline.

8. Overchoking.

9. Low oil level.

10. Excessiverich fuel mixture.

11. Intakevalvestuck open or closed.

12. Enginehas lost compression.

1. TurnFuelShut-off ON.

2. Cleanor replaceair filter.

3. Fillfuel tank.

4. Drainfuel tank and fill with fresh fuel.

5. Connectwire to spark plug.

6. Replacesparkplug.

7. Drainfuel tank;fill with freshfuel.

8. Put choke knobto NoChokeposition.

9. Fill crankcaseto proper level.

10. ContactAuthorizedServiceFacility.

11. ContactAuthorizedServiceFacility.

12. ContactAuthorizedServiceFacility.

Engineshuts down during 1. Out of gasoline. 1. Fillfuel tank.

operation. 2. Lowoil level. 2. Fill crankcaseto proper level.

3. Faultin engine. 3. ContactAuthorizedService Facility.

I I

Engine lacks power. 1. Loadis too high. 1. Reduceload (see"Don't Overloadthe Generator").

2. Dirty air filter. 2. Cleanor replaceair filter.

3. Engineneedsto be serviced. 3. ContactAuthorizedServiceFacility.

R

Engine "bunts" orfalters. 1. Chokeis openedtoo soon. 1. Movechoketo halfway position until engineruns

smoothly.

2. Carburetoris runningtoo rich or too lean. 2. ContactAuthorizedServiceFacility.

14

15

FEDERALEMiSSiONCONTROLWARRANTYSTATEMENT

YOURWARRANTYRIGHTSANDOBLiGATiONS

TheUnitedStates EnvironmentalProtectionAgency (EPA)andGeneracPowerSystems, Inc. (Generac)are pleasedto explainthe EmissionOontrol

Systemwarranty onyour new 2008 and later equipment.Newequipmentthat usesmall spark-ignitedenginesmust be designed,built, and equipped

to meetstringent anti-smog standardsfor the federalgovernment. Generacwill warrantthe emission control system on your generatorfor the period of

time listed below providedthere has been no abuse,neglect,unapprovedmodificationor improper maintenanceof your equipment.

Youremission control system may includeparts such as the: carburetor,ignitionsystem,fuel system,catalytic converter, andother associated

emission-relatedcomponents (if equipped).

MANUFACTURER'SWARRANTYCOVERAGE:

This emission control system is warrantedfor two years. If, during such warranty period,any emission-relatedpart on your equipmentis found to be

defectivein materials or workmanship,repairsor replacementwill beperformed by a GeneracAuthorizedWarrantyServiceDealer.

OWNER'SWARRANTYRESPONSiBiLiTiES:

Asthe generatorowner,you are responsiblefor the completion of all requiredmaintenanceas listed in your factory suppliedOwner'sManual.For

warrantypurposes, Generacrecommendsthat you retainall receipts covering maintenanceon your generator,but Generaccannot deny warranty

solelydueto the lack of receipts.

Asthe generatorowner,you should be awarethat Generacmay deny any and/orall warranty coverageor responsibilityif your generator,or a part!

componentthereof, hasfailed due to abuse,neglect, improper maintenanceor unapprovedmodifications,or the use of counterfeit and/or "grey market"

parts not made, suppliedor approvedby Generac.

Youare responsible for contactinga GeneracAuthorizedWarrantyDealer assoon as a problemoccurs.The warrantyrepairs should he

completed in a reasonable amount oftime, not to exceed 30 days.

Warrantyservice can be arrangedby contacting eitheryour sellingdealer or a GeneracAuthorizedWarrantyService Dealer.Tolocatethe Generac

AuthorizedWarrantyService Dealernearestyou, call our toll free number:

1-800-333-1322

IMPORTANTNOTE:Thiswarranty statementexplainsyour rightsand obligations underthe EmissionOontrolSystemWarranty(EOSWarranty),which

is providedto you by Generacpursuanttofederal law. See alsothe "GeneracLimitedWarrantiesfor GeneracPowerSystems, Inc.,"which is enclosed

herewith on aseparatesheet, also providedto you by Generac.Notethat this warrantyshall not applyto anyincidental,consequentialor indirect

damagescausedby defectsin materialsor workmanship or any delayin repairor replacementof the defectivepart(s). This warranty is in placeof all

other warranties,expressedor implied.Specifically,Generacmakes no otherwarranties as to the merchantabilityor fitness for aparticular purpose.

Any impliedwarrantiesallowedby law shall be limited in durationto theterms of the expresswarrantyprovidedherein. Some states do not allow

limitationson how long an implied warrantylasts, so the abovelimitationmay not applyto you.

TheEOSWarrantyapplies only to the emission control system of your new equipment.If thereis any conflict in terms betweenthe ECSWarranty and

the GeneracWarranty,the GeneracWarrantyshall apply.Both the EOSWarrantyandthe GeneracWarrantydescribe important rights and obligations

with respectto your new engine.

Warrantyservice can be performed only by a GeneracAuthorizedWarrantyService Facility.Whenrequestingwarranty service, evidencemust be

presentedshowing the dateof the saleto the original purchaser/owner.

If you haveany questions regardingyourwarranty rights and responsibilities,you should contact Generacat the following address:

ATTENTIONWARRANTYDEPARTMENT

GENERACPOWERSYSTEMS,iNC.

P.O.BOX297• WHITEWATER,Wl 53190

Part I

PartNo. 0H1911 Rev.C 03/12

16

Loading...

Loading...