Page 1

Page 2

FOREWORD

This manual has been written and published by GENERAC

POWER SYSTEMS, INC. to aid our dealers’ mechanics, company service personnel and general consumers when servicing the products

described herein.

It is assumed that these personnel are familiar with the servicing

procedures for these products, or like or similar products, manufactured and marketed by GENERAC® POWER SYSTEMS, INC. It is also

assumed that they have been trained in the recommended servicing

procedures for these products, which includes the use of mechanics

hand tools and any special tools that might be required.

Proper service and repair is important to the safe, economical and

reliable operation of the products described herein. The troubleshooting, testing, service and repair procedures recommended by

GENERAC® POWER SYSTEMS, INC. and described in this manual are

effective methods of performing such operations. Some of these

operations or procedures may require the use of specialized equipment. Such equipment should be used when and as recommended.

We could not possibly know of and advise the service trade of all

conceivable procedures or methods by which a service might be performed, nor of any possible hazards and/or results of each procedure or method. We have not undertaken any such wide evaluation.

Therefore, anyone who uses a procedure or method not recommended by the manufacturer must first satisfy himself that neither

his safety, nor the product’s safety, will be endangered by the service or operating procedure selected.

®

All information, illustrations and specifications contained in this

manual are based on the latest product information available at the

time of publication. However, GENERAC® POWER SYSTEMS, INC.

reserves the right to change, alter or otherwise improve the product

at any time without prior notice.

Some components or assemblies of the product described in this

manual may not be considered repairable. Disassembly, repair and

reassembly of such components may not be included in this manual.

The engines described herein may be used to power a wide variety

of products. Service and repair instructions relating to any such

products are not covered in this manual. For information pertaining

to use of these engines with other products, refer to any owner’s or

service manuals pertaining to said products.

Page 3

TABLE OF CONTENTS

DIMENSIONS AND FEATURES ............................ 3-7

4-CYCLE ENGINE THEORY...................................... 8

SECTION 1: GENERAL ...................................... 9-12

PURPOSE AND SCOPE OF MANUAL ................................ 9

LARGE FRAME ENGINES .................................................. 9

LONG BLOCK .................................................................. 9

ENGINE I.D. NUMBER/SERIAL NUMBER ............................ 9

ENGINE CARE ................................................................ 10

Recommended Fuels .................................................. 10

Recommended Engine Oil .......................................... 10

Change Oil Filter ........................................................ 10

STORAGE INSTRUCTIONS .............................................. 10

TUNE-UP PROCEDURE .............................................. 10-11

OVERSIZE PARTS ............................................................ 12

SECTION 2: AIR CLEANERS AND CARBURETION 14-17

AIR CLEANER ................................................................ 14

Servicing .................................................................... 14

Foam Pre-Cleaner ...................................................... 14

Paper Filter ................................................................ 14

Air Cleaner Box Removal............................................ 14

Air Cleaner Box Installation ........................................ 15

CARBURETION .......................................................... 15-16

General...................................................................... 15

Common Carburetor Problems .................................. 15

Carburetor Removal .................................................. 15

Carburetor Disassembly ........................................ 15-16

Carburetor Cleaning and Inspection .......................... 16

Carburetor Reassembly .............................................. 16

Carburetor Installation .............................................. 16

CARBURETOR ADJUSTMENT .......................................... 17

Initial Adjustment ...................................................... 17

Final Adjustment........................................................ 17

SECTION 3: MECHANICAL GOVERNOR.......... 18-20

GOVERNOR OPERATION ................................................ 18

GOVERNOR INTERNAL PARTS ........................................ 18

GOVERNOR EXTERNAL PARTS .................................. 18-19

Without Automatic Idle Control ................................ 18

With Automatic Idle Control ...................................... 19

Removal of Governor External Parts .......................... 19

Installation of Governor External Parts ........................ 19

GOVERNOR GEAR SHAFT REPLACEMENT ...................... 19

Inspection .................................................................. 19

Removal .................................................................... 19

Installation ................................................................ 19

LINKAGE INSTALLATION ................................................ 20

GOVERNOR ADJUSTMENT ........................................ 20-21

Initial Adjustment ...................................................... 20

Running Adjustment ............................................ 20-21

SECTION 4: OPTIONAL IDLE CONTROL .......... 22-23

GENERAL ...................................................................... 22

OPERATING INSTRUCTIONS............................................ 22

Before Start-up .......................................................... 22

Engine Running.......................................................... 22

CIRCUIT OPERATION ...................................................... 22

IDLE CONTROL ADJUSTMENT .................................. 22-23

General...................................................................... 22

Initial Adjustment.................................................. 22-23

Final Adjustment........................................................ 23

SECTION 5: REWIND STARTERS...................... 24-25

GENERAL ...................................................................... 24

REWIND ASSEMBLY REMOVAL ...................................... 24

DISASSEMBLY (OLD STYLE) ............................................ 25

REASSEMBLY.................................................................. 25

DISASSEMBLY (NEW STYLE)............................................ 25

SECTION 6: ELECTRIC STARTERS AND BATTERIES ..26-28

INTRODUCTION ............................................................ 26

STARTER CONTACTOR SYSTEM...................................... 26

HEAVY DUTY SWITCH SYSTEM...................................... 26

STARTER MOTOR OPERATING PRINCIPLES...................... 26

THE BENDIX DRIVE ........................................................ 26

STARTER MOTOR REPAIRS ........................................ 26-27

Starter Motor Removal .............................................. 26

Starter Motor Installation ...................................... 26-27

TESTING THE STARTER MOTOR ...................................... 27

Checking the Pinion .................................................. 27

Tools for Starter Performance Test .............................. 27

Starter Performance Test ............................................ 27

BATTERY MAINTENANCE .............................................. 27

General...................................................................... 27

Inspecting the Battery ................................................ 27

Electrolyte Level ........................................................ 27

TESTING A BATTERY ................................................ 27-28

SECTION 7: COVERS AND SHROUDS .................. 29

GENERAL ...................................................................... 29

Installation of Covers and Shrouds ............................ 29

1

Page 4

TABLE OF CONTENTS

GENERAC

SECTION 8: IGNITION SYSTEM ...................... 30-31

GENERAL ...................................................................... 30

MAJOR COMPONENTS .................................................. 30

IGNITION COIL ASSEMBLY.............................................. 30

SPARK PLUG .................................................................. 30

FLYWHEEL ................................................................ 30-31

Checking Flywheel Magnet ........................................ 30

Flywheel Key.............................................................. 30

Flywheel Removal ................................................ 30-31

Flywheel Installation .................................................. 31

TESTING THE IGNITION SYSTEM .................................... 31

SECTION 9: VALVE TRAIN .............................. 32-36

MAJOR COMPONENTS .................................................. 32

DISASSEMBLY .......................................................... 32-33

VALVE SERVICE .............................................................. 33

Valves ........................................................................33

Valve Seats ................................................................ 33

Valve Tappets ............................................................ 34

Valve Springs.............................................................. 34

Valve Guides.............................................................. 34

INSTALLATION .......................................................... 34-35

ADJUSTING VALVE CLEARANCE .................................... 36

INSTALL ROCKER ARM COVER ........................................36

SECTION 10: PISTON, RINGS AND ROD ........ 38-41

GENERAL ...................................................................... 38

REMOVAL ...................................................................... 38

PISTON .................................................................... 38-39

Removal from Connecting Rod .................................. 38

Check Piston for Wear .......................................... 38-39

PISTON RINGS .......................................................... 39-40

General...................................................................... 39

Description .......................................................... 39-40

Ring End Gap ............................................................ 40

CONNECTING ROD ........................................................ 40

ASSEMBLY AND INSTALLATION ...................................... 41

Assembly .................................................................. 41

Installation ................................................................ 41

CYLINDER SERVICE ........................................................ 41

Inspection .................................................................. 41

Reboring the Cylinder ................................................ 41

SECTION 11: CRANKSHAFT, CAMSHAFT

AND BALANCER .............................................. 42-45

CRANKCASE COVER REMOVAL .................................... 42

CRANKSHAFT, CAMSHAFT AND BALANCER REMOVAL .. 42

BALANCER INSPECTION ................................................ 42

CAMSHAFT INSPECTION ................................................ 43

CRANKSHAFT INSPECTION........................................ 43-44

Crankshaft Proper...................................................... 43

Crankshaft Sleeve Bearing.......................................... 44

COMPRESSION RELEASE .......................................... 44-45

CRANKSHAFT INSTALLATION ........................................ 45

CAMSHAFT INSTALLATION ............................................ 45

BALANCER INSTALLATION .............................................. 45

SECTION 12: LUBRICATION ............................ 46-51

GENERAL ...................................................................... 46

OIL FLOW ...................................................................... 46

OIL PICKUP ASSEMBLY .............................................. 46-47

Description ................................................................ 46

Inspection .................................................................. 47

OIL PUMP ...................................................................... 47

Description ................................................................ 47

Inspection .................................................................. 47

PRESSURE RELIEF VALVE ................................................ 48

Description ................................................................ 48

Inspection .................................................................. 48

CRANKSHAFT OIL SEALS ................................................ 48

Description ................................................................ 48

Seal Replacement ...................................................... 48

BREATHER ASSEMBLY .................................................... 49

Description ................................................................ 49

Inspection .................................................................. 49

CRANKCASE COVER ................................................ 49-50

Description ................................................................ 49

Inspection .................................................................. 49

Governor Gear Installation ........................................ 49

Crankcase Cover Installation ................................ 49-50

OPTIONAL OIL FILTER...................................................... 51

LOW OIL PRESSURE SYSTEM .......................................... 51

SECTION 13: TROUBLESHOOTING ................ 52-54

SPECIFICATIONS .............................................. 55-61

2

Page 5

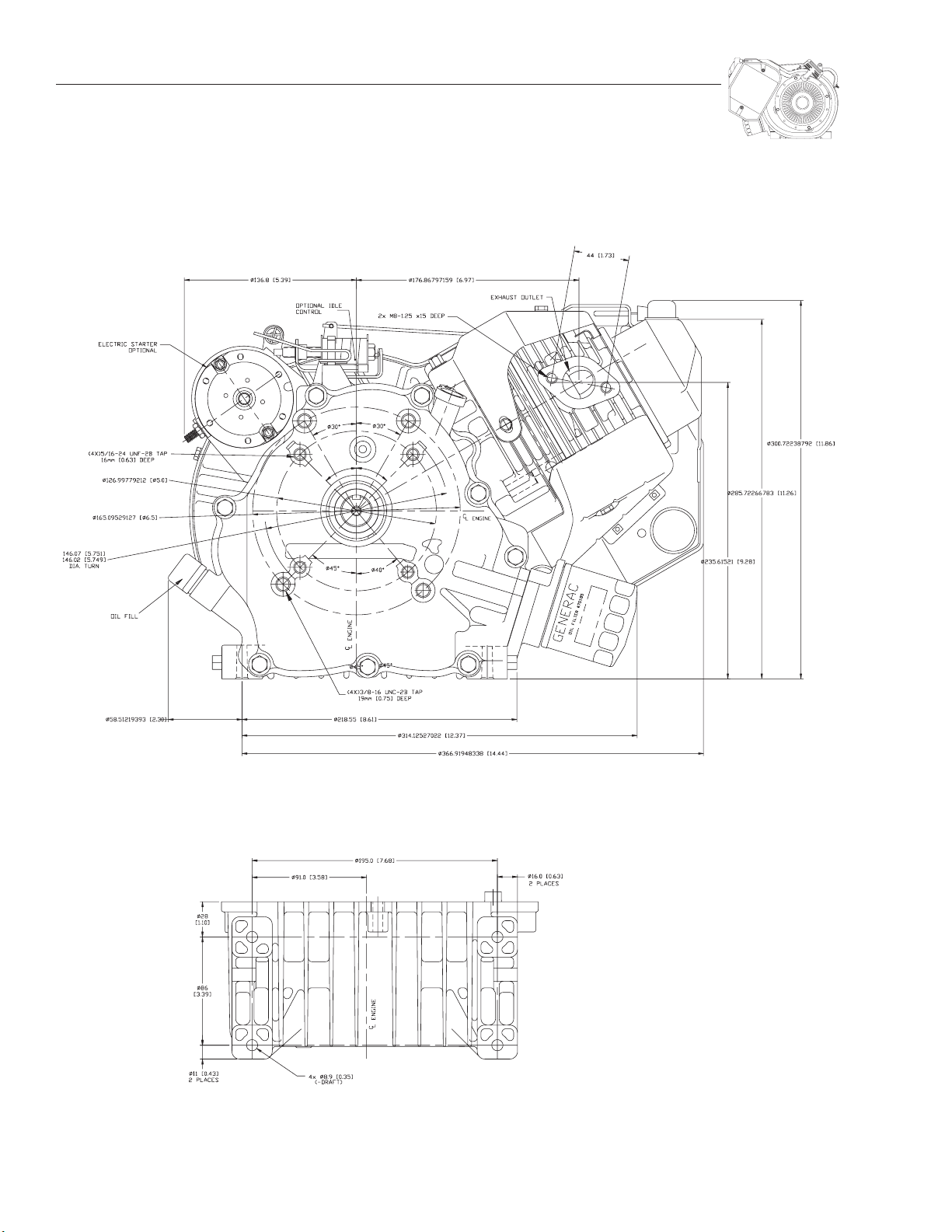

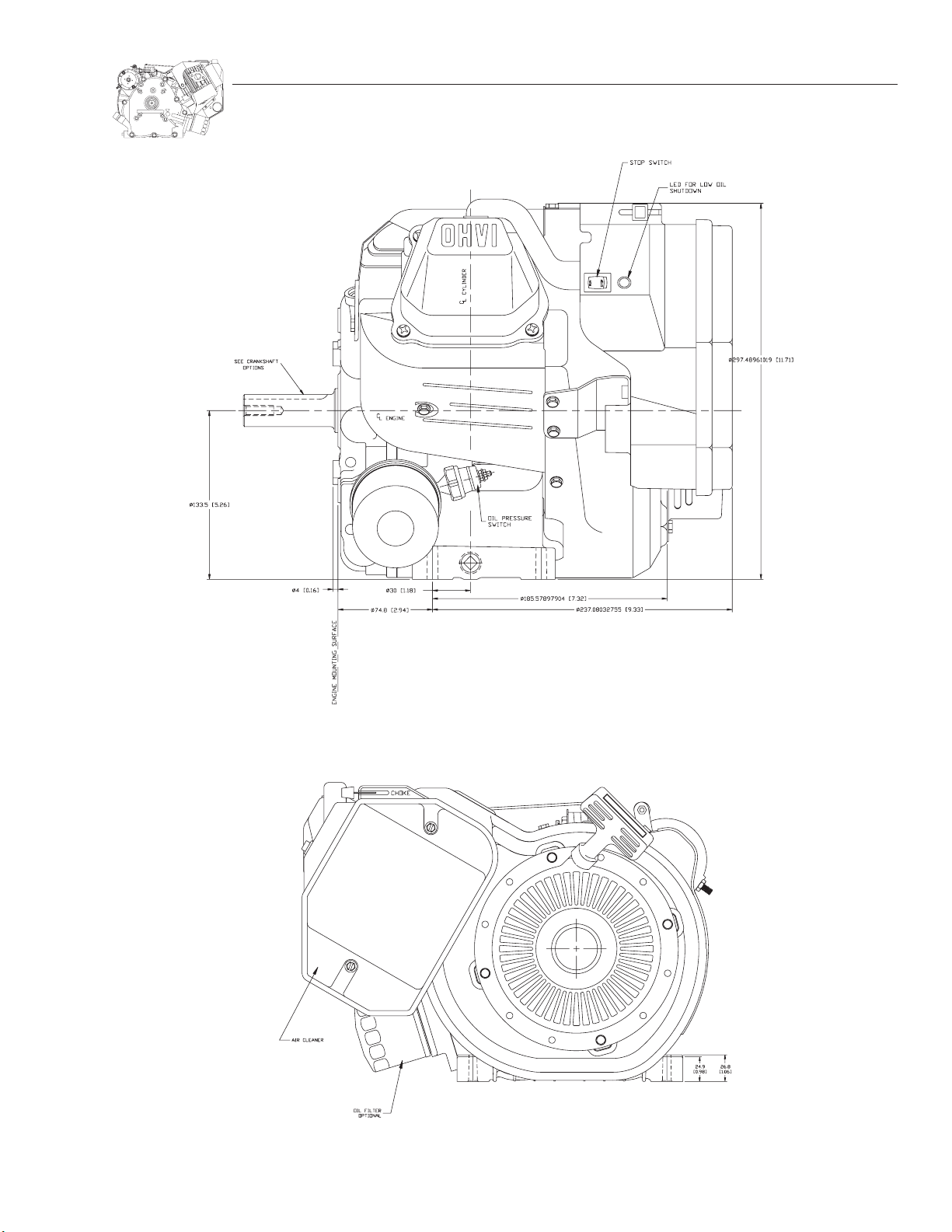

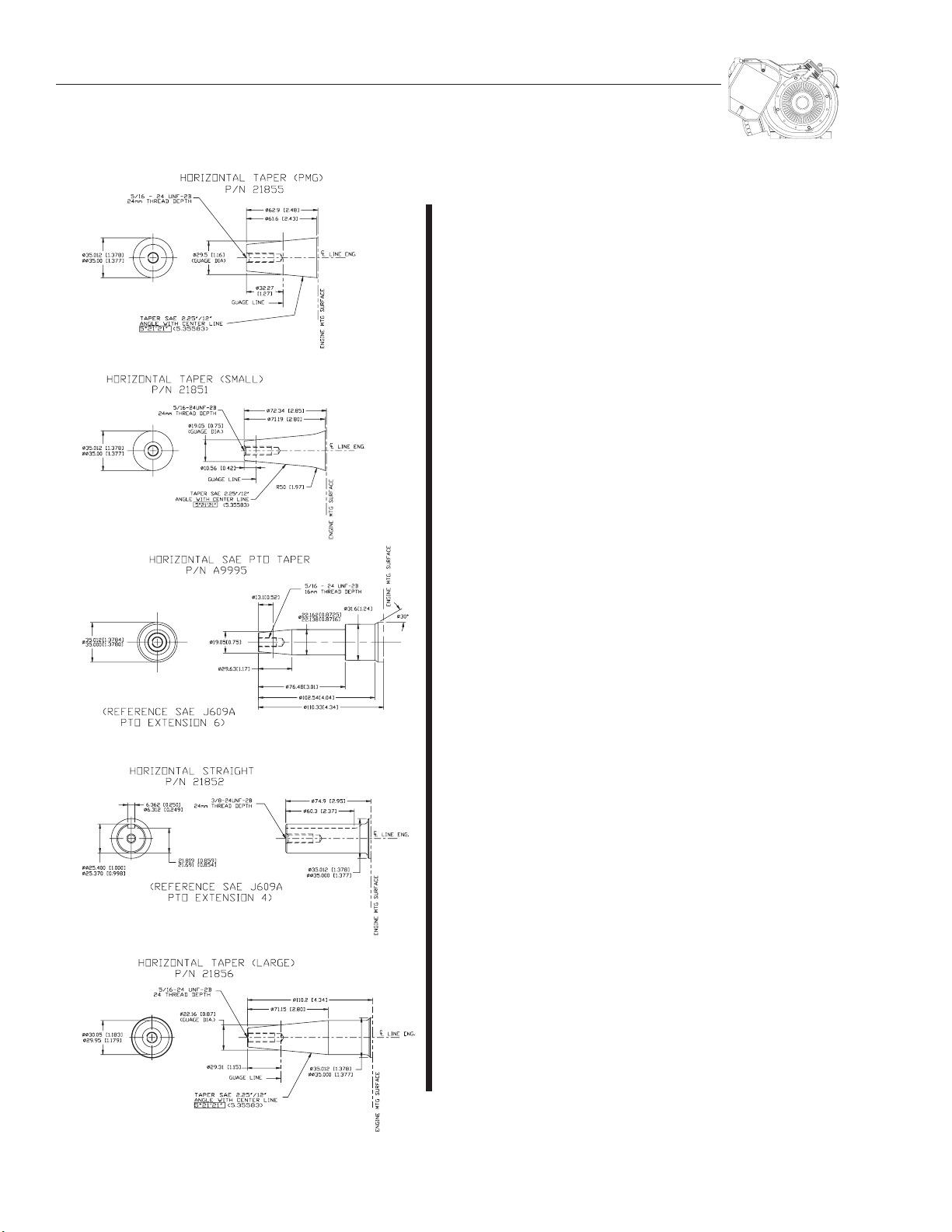

DIMENSIONS AND FEATURES

If you don't understand any portion of this manual, con-

tact an authorized Generac service dealer.

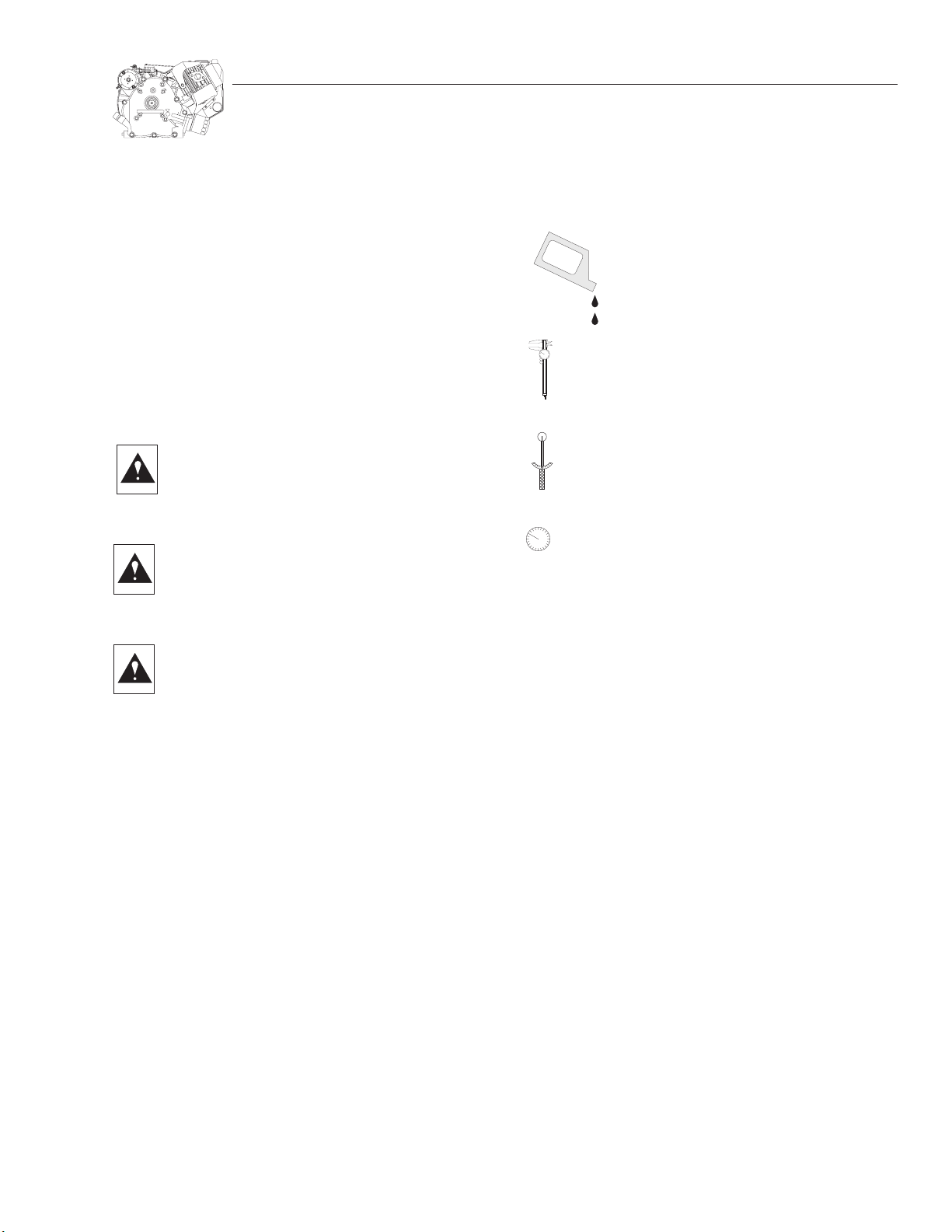

Throughout this publication, DANGER, WARNING and CAUTION blocks are used to alert you to special instruction about

a particular operation that may be hazardous if performed

incorrectly or carelessly. Observe them carefully.

These safety warnings cannot eliminate the hazards that

they indicate. Strict compliance with the special instructions

while performing the service plus "common sense" are major

measures to prevent accidents.

The following definitions apply to DANGER, WARNING,

CAUTION and NOTE blocks found throughout the manual.

DANGER: After this heading you can read handling, installing, operating or servicing instructions

that, if not strictly complied with, will result in personal injury.

WARNING: After this heading you can read handling, installing, operating or servicing instructions

that, if not strictly complied with, may result in personal injury.

In addition to the DANGER, WARNING, CAUTION and

NOTE blocks, the following blocks indicate specifications or

capacities as noted.

Indicates a fluid capacity.

Indicates a measurement.

Indicates a torque specification.

Indicates a load specification.

CAUTION: After this heading you can read instructions for handing, installing, operating or servicing

the engine that, if not strictly complied with, may

result in damage to equipment and/or property.

NOTE: After this heading you can read explanatory

statements that require special emphasis.

3

Page 6

DIMENSIONS AND FEATURES

GENERAC

PTO SIDE VIEW

BOTTOM VIEW — MOUNTING HOLES

4

Page 7

FRONT VIEW

DIMENSIONS AND FEATURES

STARTER SIDE VIEW

5

Page 8

DIMENSIONS AND FEATURES

GENERAC

PTO CRANKSHAFT OPTIONS VIEW

55. DOWEL PIN

56. DOWEL PIN

57. SPRING PIN

58. OIL PUMP INNER ROTOR SHAFT

59. CAMSHAFT GEAR

60. ROCKER ARM

61. COMPRESSION RELIEF SPRING

62. COMPRESSION RELIEF FLYWEIGHT

63. COMPRESSION RELIEF LIFT SHAFT

64. O-RING

65. VALVE SPRING RETAINER

66. VALVE SPRING KEEPER

67. EXHAUST VALVE

68. INTAKE VALVE

69. DOWEL PIN

70. VALVE SPRING WEAR WASHER

71. VALVE SPRING

37. CRANKSHAFT GEAR

38. CRANKSHAFT OIL SEAL

39. PIVOT BALL STUD

40. JAM NUT

41. CRANKSHAFT GEAR

42. OIL PRESSURE RELIEF SCREW

43. OIL FILL PLUG

44. TAPER PLUG

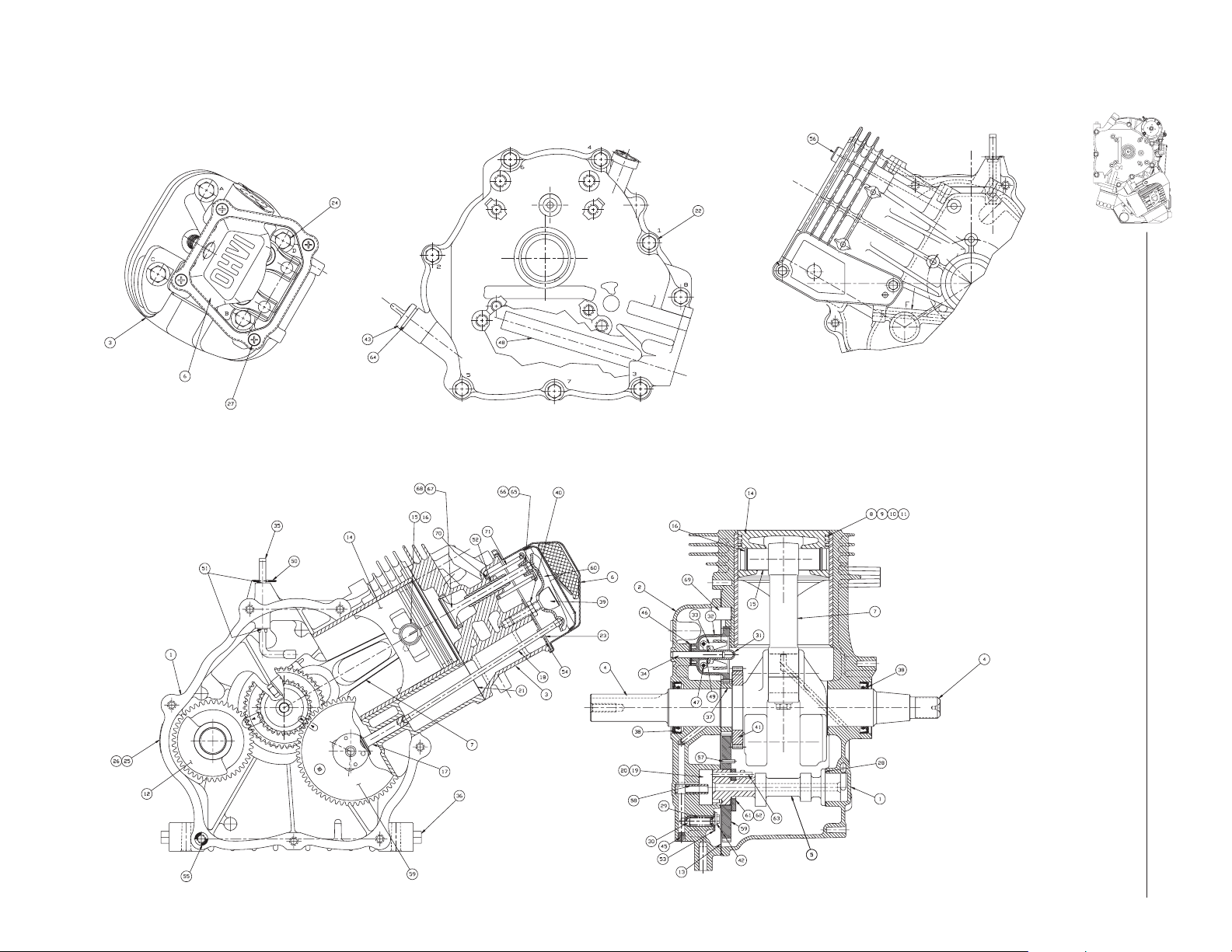

CUTAWAY VIEWS DESCRIPTIONS

19. OIL PUMP OUTER ROTOR

20. OIL PUMP INNER ROTOR

21. CYLINDER HEAD GASKET

22. CRANKCASE COVER BOLT

23. ROCKER ARM COVER GASKET

24. CYLINDER HEAD BOLT

25. DATA DECAL

26. OVERLAMINATE

45. TAPER PLUG

46. GOVERNOR GEAR THRUST WASHER

47. GOVERNOR FLYWEIGHT PIN

48. OIL PICKUP ASSEMBLY

49. GOVERNOR RETAINER CLIP

50. GOVERNOR ARM “R” PIN

51. GOVERNOR ARM THRUST WASHER

52. VALVE STEM SEAL

27. ROCKER ARM COVER SCREW

28. SPRING WASHER

29. OIL PRESSURE RELIEF VALVE SPRING

30. OIL PRESSURE RELIEF VALVE BALL

31. GOVERNOR SPOOL

32. GOVERNOR GEAR

33. GOVERNOR FLYWEIGHT

34. GOVERNOR SHAFT

53. OIL PRESSURE RELIEF RETAINER

54. PUSH ROD GUIDE PLATE

35. GOVERNOR ARM

36. PIPE PLUG

6

1. CRANKCASE

2. CRANKCASE COVER

3. ASSEMBLY

4. CRANKSHAFT

5. CAMSHAFT

6. ROCKER ARM COVER

7. CONNECTING ROD

8. PISTON RING TOP

9. PISTON RING, SECOND

10. OIL RING, RAIL

11. OIL RING, SPACER

12. BALANCER

13. CRANKCASE COVER GASKET

14. PISTON

15. PISTON PIN

16. SNAP RING

17. TAPPET

18. PUSH ROD

Page 9

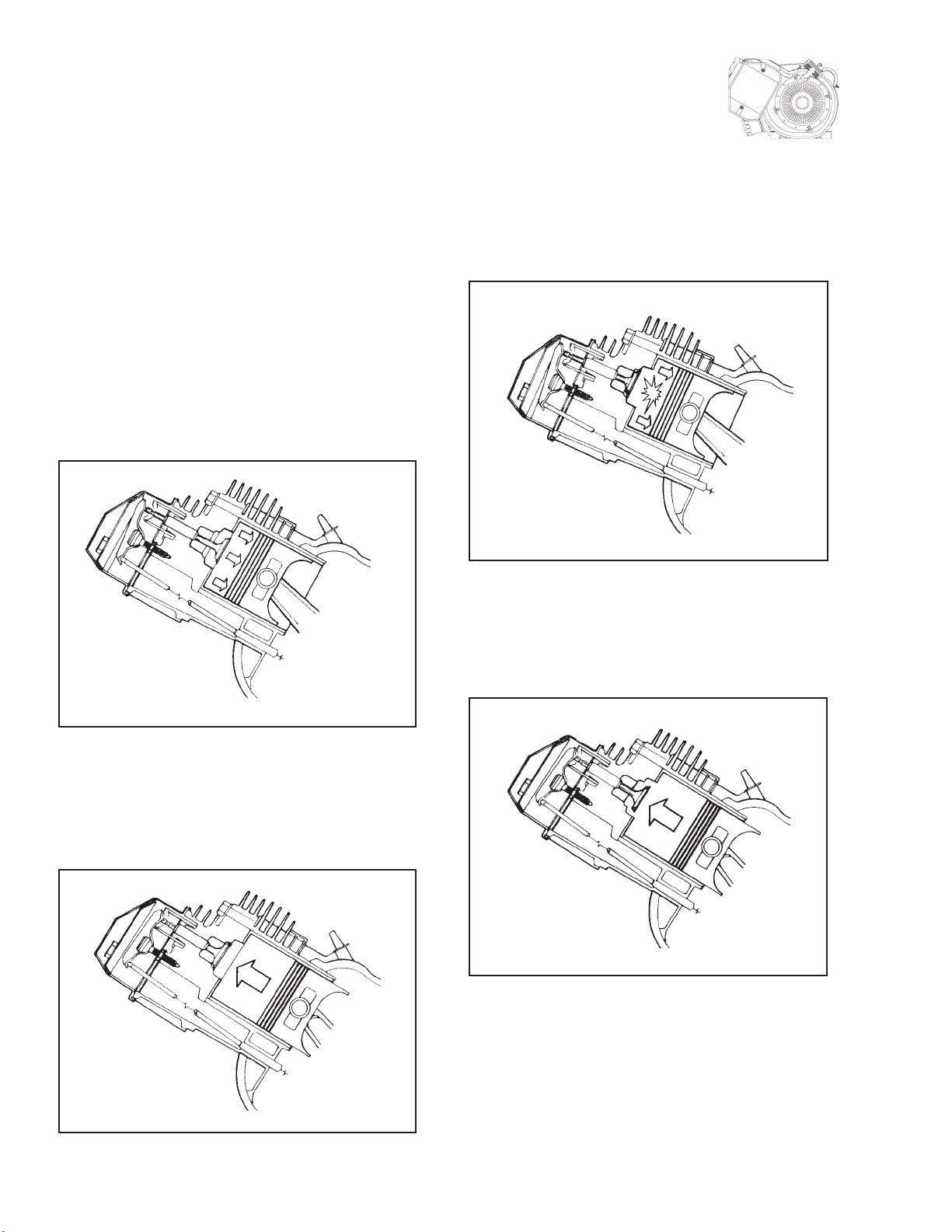

CUTAWAY VIEWS

7

DIMENSIONS AND FEATURES

Page 10

4-CYCLE ENGINE THEORY

GENERAC

If the engine Is to run properly, four (4) events must occur

in the proper sequence and at the correct time. These

events are (a) intake, (b) compression, (c) ignition and

power, and (d) exhaust.

A INTAKE

The piston is travelling from top dead center (TDC) to

bottom dead center (BDC). The cam has opened the intake

valve. The piston's downward movement in the cylinder

creates a partial vacuum In the cylinder. Air at atmospheric pressure is drawn into the cylinder through the

carburetor and is mixed with fuel in the carburetor. The

fuel-air mixture flows through the open intake valve into

the cylinder. When the piston reaches BDC, the intake

stroke is over.

IGNITION AND

C

By the time the piston reaches TDC, combustion is already

in progress. The intake and exhaust valves remain closed

as the expanding gases of combustion force the piston

downward.

POWER

D EXHAUST

The exhaust stroke begins when the piston has reached

BDC and has started its upward movement. The intake

valve is closed. The exhaust valve is open to let gases

escape.

B COMPRESSION

As the piston reaches bottom dead center (BDC), both the

intake and exhaust valves are closed. The piston moves

upward toward TDC and the fuel-air mixture is compressed. Just before the piston reaches TDC, ignition

occurs.

8

Page 11

PURPOSE AND SCOPE OF MANUAL

This manual contains all information normally required to

service or repair the Models GN-320, GN-360 and GN-410

horizontal shaft engines. Repair procedures are carefully

explained and illustrated.

LARGE FRAME ENGINES

Engine Models GN-320, GN-360 and GN-410 are designated as "large frame" engines. Some of the differences

between specific engine models are as follows:

1.Differences in the type of crankshaft.

a. Some engine models are equipped with a tapered crank-

shaft.

b. Some engine models may be equipped with a 1-inch

straight shaft.

2.Some engine models are equipped with automatic idle

control, other models are not.

3.Some engine models are equipped with an OPTIONAL oil

filter assembly.

4.Some engines may be equipped with electric start, others

are manual start.

5.Some engine models are "vertical shaft" for use in specific

applications (such as recreational vehicle generators).

6.Some engines are "horizontal shaft" type.

7.Some have an LOS (Low Oil Shutdown) module.

8.Some have an oil fill tube.

SECTION 1: GENERAL

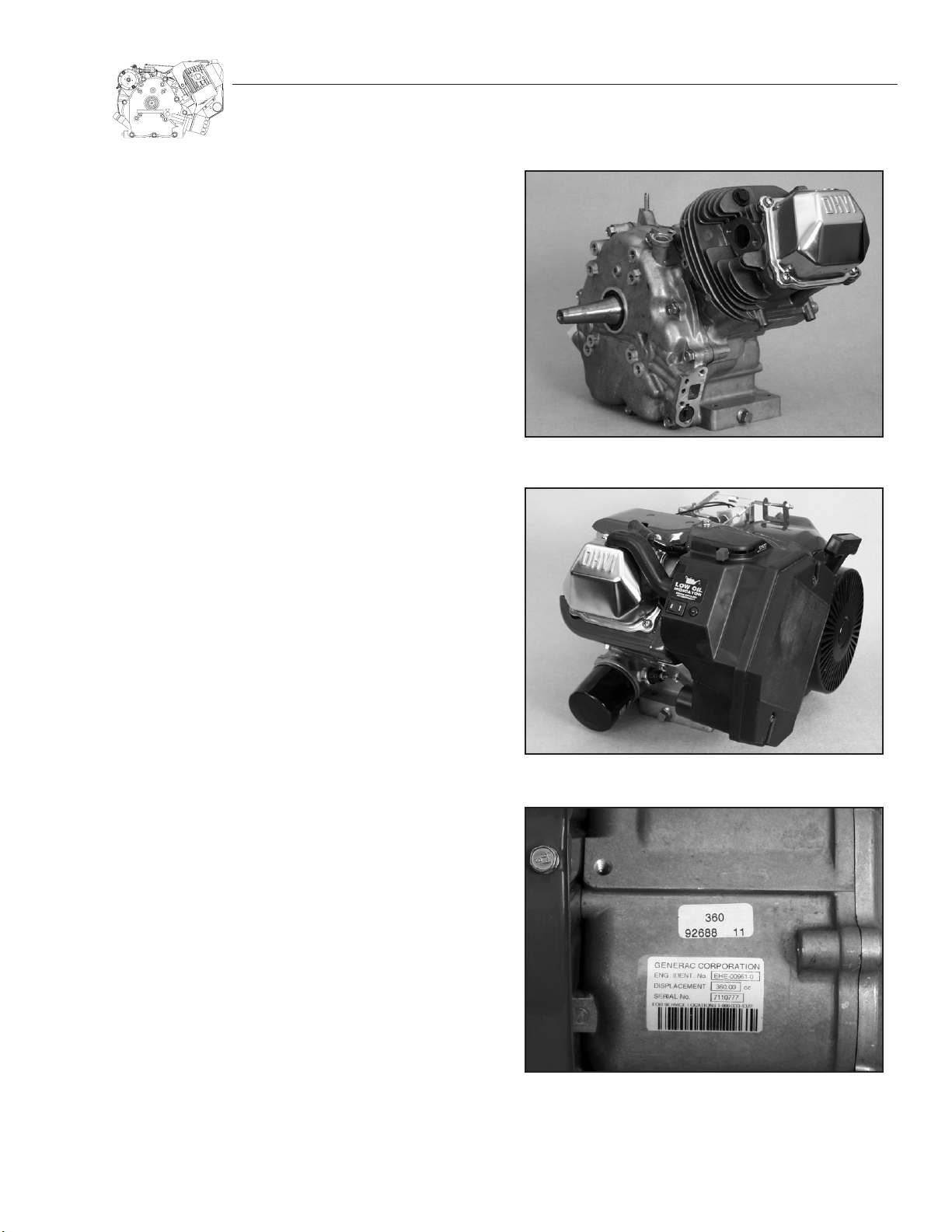

Figure 1.1 — Typical Long Block

LONG BLOCK

The term "long block" refers to a basic engine which does

not have such items as a blower housing, air cleaner, carburetor, etc. Figure 1.1 shows a typical long block.

Figure 1.2 shows a typical complete engine, with all the parts

needed to adapt the engine for a particular use. The typical

complete engine shown is a horizontal shaft model, for use

with AC generators.

ENGINE I.D. NUMBER/SERIAL NUMBER

The engine ID number and serial number of the engine long

block can be found on a nameplate, located on the engine

crankcase. (See Figure 1.3).

NOTE: Have the engine model and serial number when

ordering parts. This number is located on the back of

the cylinder block on the identification tag.

Figure 1.2 — Typical Complete Engine

Figure 1.3. — Location of Engine I.D. and Serial Numbers

9

Page 12

SECTION 1: GENERAL

GENERAC

ENGINE CARE

RECOMMENDED FUELS:

Use clean, fresh, UNLEADED regular grade gasoline.

Unleaded gasoline burns cleaner, extends engine life and

promotes easier starting by reducing combustion chamber

deposits.The use of gasohol is NOT recommended. If gasohol must be used, it should contain not more than 10 percent

ethanol. If gasohol containing ethanol is used, special care

is required when preparing the engine for storage (see "Storage Instructions").

• DO NOT USE GASOLINE CONTAINING METHANOL.

• DO NOT MIX OIL WITH THE GASOLINE.

DANGER! GASOLINE IS EXTREMELY FLAMMABLE

AND ITS VAPORS ARE EXPLOSIVE. DO NOT PERMIT

SMOKING, OPEN FLAME OR HEAT IN THE VICINITY

WHILE HANDLING GASOLINE. AVOID SPILL AGE

OF GASOLINE ON A HOT ENGINE. COMPLY WITH

ALL LAWS PERTAINING TO THE STORAGE AND

HANDLING OF GASOLINE.

RECOMMENDED ENGINE OIL:

Use a clean, high quality, detergent oil classified "For Service SC, SD, SE, SF or SG." No special additives should be used

with the recommended oil. Detergent oils keep the engine

cleaner and retard the formation of gum and varnish deposit.

Synthetic oil can be used in place of petroleum base oils.

During summer months (above 32F or 0C), use SAE 30 oil.

SAE 10W-30 oil is an acceptable substitute.

During winter (below 32F or 0C) use SAE 5W-20 or 5W30 oil.

DO NOT USE SAE 10W-4O OIL.

CRANKCASE OIL CAPACITY

GN-320, GN-360, GN-410 ENGINES

WITHOUT OIL FILTER CHANGE —

46 ounces (1350 ml)

WITH OIL FILTER CHANGE —

51 ounces (1500 ml)

CHANGE OIL FILTER:

Replace oil filter with every oil change. Before installing new

oil filter, put a light coat of clean oil on rubber o-ring on filter

base. Screw filter on by hand until o-ring touches filter

adapter base, then tighten 3/4 turn. Check for leaks after starting engine.

Check engine oil level each time the equipment is used.

When checking oil level, make sure the equipment is level .

Change oil after the first eight hours of operation on a new

engine. Thereafter, change oil and filter every 50 hours of

operation. Change oil ever

y 25 hours if operating under

extremely dusty or dirty conditions, or in very hot weather.

NOTE: Engine may be equipped with automatic low oil

shutdown capability. If so equipped, it will not start

when oil level is low. See Section 12, "Lubrication."

STORAGE INSTRUCTIONS

The engine should be started at least once every seven days

and allowed to run for at least 30 minutes. If this cannot be

done and the engine is to remain unused longer than 30 days,

it must be prepared for storage.

DANGER! NEVER STORE THE ENGINE WITH FUEL IN

TANK INDOORS OR IN ANY ENCLOSED, POORLY

VENTILATED AREA WHERE FUEL VAPORS MIGHT

REACH AN OPEN FLAME (AS ON A FURNACE,

WATER HEATER, DRYER, ETC.). FIRE OR AN EXPLOSION COULD RESULT.

To prepare an engine for storage, proceed as follows:

1.Run the engine for about five minutes to warm it up.

a. If gasohol was used, drain the fuel tank, then run the

engine until it shuts down due to lack of fuel.

b. Use of a good fuel stabilizer will prevent gum deposits

from forming in the engine fuel system.

2.While engine is still warm from running, drain oil from

crankcase and refill with new oil.

3.Remove the spark plug and pour about 1/2 ounce (15ml)

of clean, fresh engine oil into cylinder. Crank the engine

over slowly to distribute the oil. Then, install the spark plug

but do not connect the spark plug wire.

4.Clean dirt, oil, grease, etc., from the engine.

5.Store the engine in a clean, dry area.

TUNE-UP PROCEDURE

Following is a minor tune-up procedure. When the procedure has been completed, either the engine will run properly

or further repairs may be required.

1.Service or replace engine air cleaner as needed.

2.Check level and condition of oil. Add or change oil

as necessary.

3. Remove the blower housing. Clean dirt from intake screen,

head and cylinder cooling fins. Also, remove dirt from carburetor and governor lever(s) and linkage.

4.Clean fuel tank, fuel filter(s) and fuel lines.

5.Replace any damaged governor springs.

6.If required, adjust the carburetor and governor.

10

Page 13

SECTION 1: GENERAL

7.Replace the spark plug. Use a Champion RC12YC (or

equivalent) spark plug.

a. Set spark plug gap to 0.030 inch (0.76mm).

b. Install new plug, tighten to 13 ft-lbs (156 in-lbs).

c. If torque wrench is not available, tighten plug with fin-

gers. Then, tighten NEW plug 1/2 turn further; or USED

plug 1/4 turn further.

8.Check that ignition wires are free of breaks and abrasions

and are properly routed.

9.Install the blower housing.

10. Run engine and adjust engine speed.

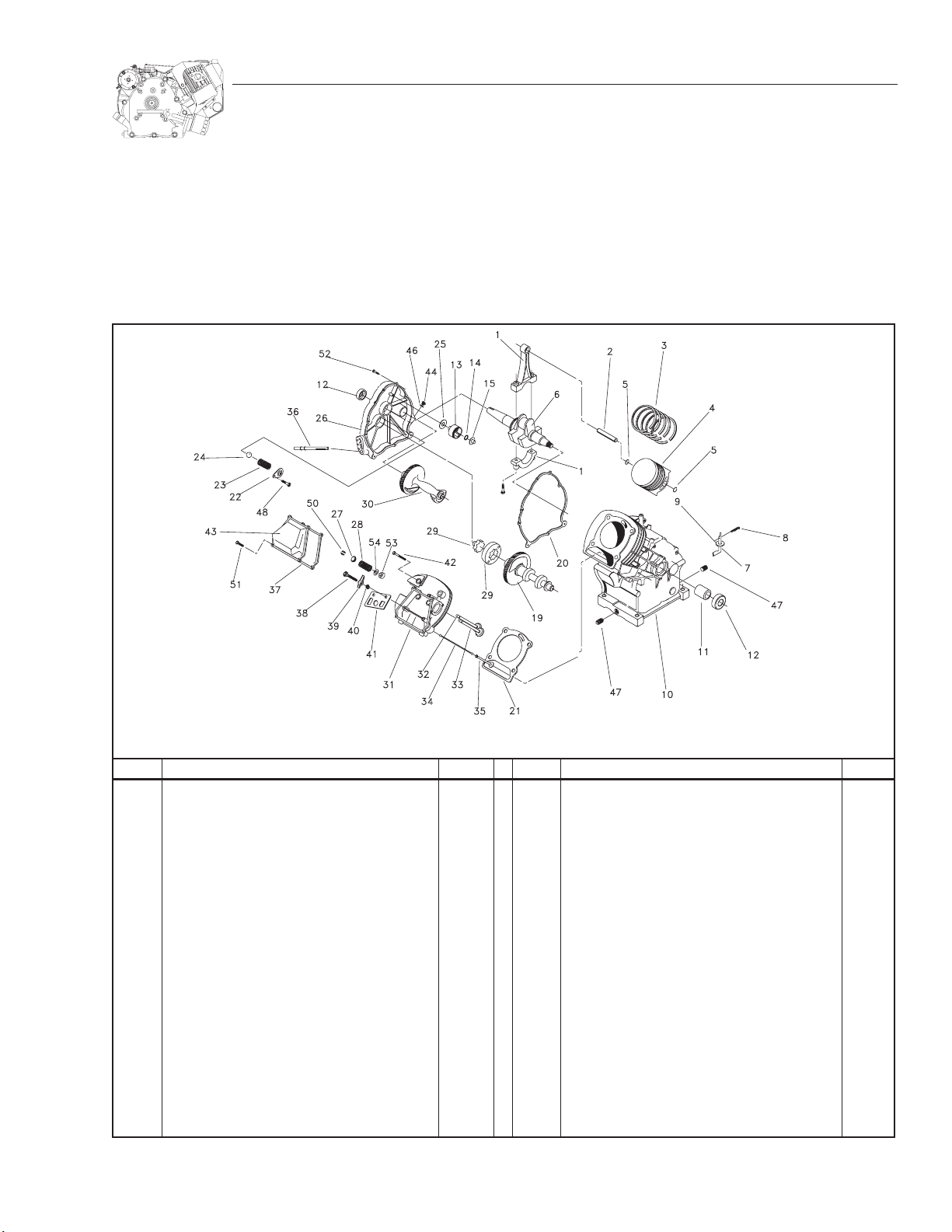

Figure 1.4 — Exploded View — Typical Horizontal Shaft Long Block

ITEM DESCRIPTION QTY ITEM DESCRIPTION QTY

1 Connecting Rod Assembly 1

2 Piston Pin 1

3 Piston Ring Set 1

4 Piston 1

5 Snap Ring 2

6 Crankshaft Assembly 1

7 Governor Arm 1

8 Governor Arm “R” Pin 1

9 Governor Arm Washer 1

10 Crankcase Assembly 1

11 Sleeve Bearing 1

12 Crankshaft Oil Seal 2

13 Governor Gear Assembly 1

14 Governor Gear Retainer 1

15 Governor Spool 1

19 Camshaft Assembly 1

20 Crankcase Gasket 1

21 Cylinder Head Gasket 1

22 Oil Pressure Relief Retainer 1

23 Oil Pressure Relief Spring 1

24 Oil Pressure Relief Ball 1

25 Governor Thrust Washer 1

26 Crankcase Cover 1

27 Valve Spring Retainer 2

28 Valve Spring 2

29 Gerotor Set 1

30 Balancer 1

31 Cylinder Head Assembly 1

32 Exhaust Valve 1

33 Intake Valve 1

34 Push Rod 2

35 Tappet 2

36 Oil Pick-up Assembly 1

37 Rocker Cover Gasket 1

38 Pivot Ball Stud 2

39 Rocker Arm 2

40 Rocker Arm Jam Nut 2

41 Push Rod Guide Plate 1

42 Cylinder Head Bolt 4

43 Rocker Cover/Breather Assembly 1

44 Oil Fill Plug 1

46 “O” ring 1

47 Pipe Plug 2

48 Oil Pressure Relief Screw 1

50 Valve Spring Keeper 4

51 Rocker Cover Screw 4

52 Crankcase Cover Bolt 8

53 Valve Stem Seal 1

54 Valve Spring Wear Washer 2

11

Page 14

SECTION 1: GENERAL

GENERAC

OVERSIZE PARTS

GENERAL:

At the time this Manual was published, oversize pistons,

rings, valves, etc., were not available. Worn or damaged

parts must be replaced.

OVERSIZE PISTONS AND RINGS:

Oversize pistons and rings are not available at this time. The

engine cylinder cannot be rebored to an oversize dimension.

If the cylinder is worn excessively or damaged, the crankcase

must be replaced. A standard size piston and rings can then

be used.

OVERSIZE VALVES:

Oversize valves are not available at this time. Valve guides

cannot be rebored to an oversize dimension. If valve guides

are worn or damaged, the cylinder head must be replaced.

Standard size valves can then be used. Valve guides cannot

be replaced.

NOTE: Always use original GENERAC® replacement

parts.

12

Page 15

SECTION 2: AIR CLEANERS AND CARBURETION

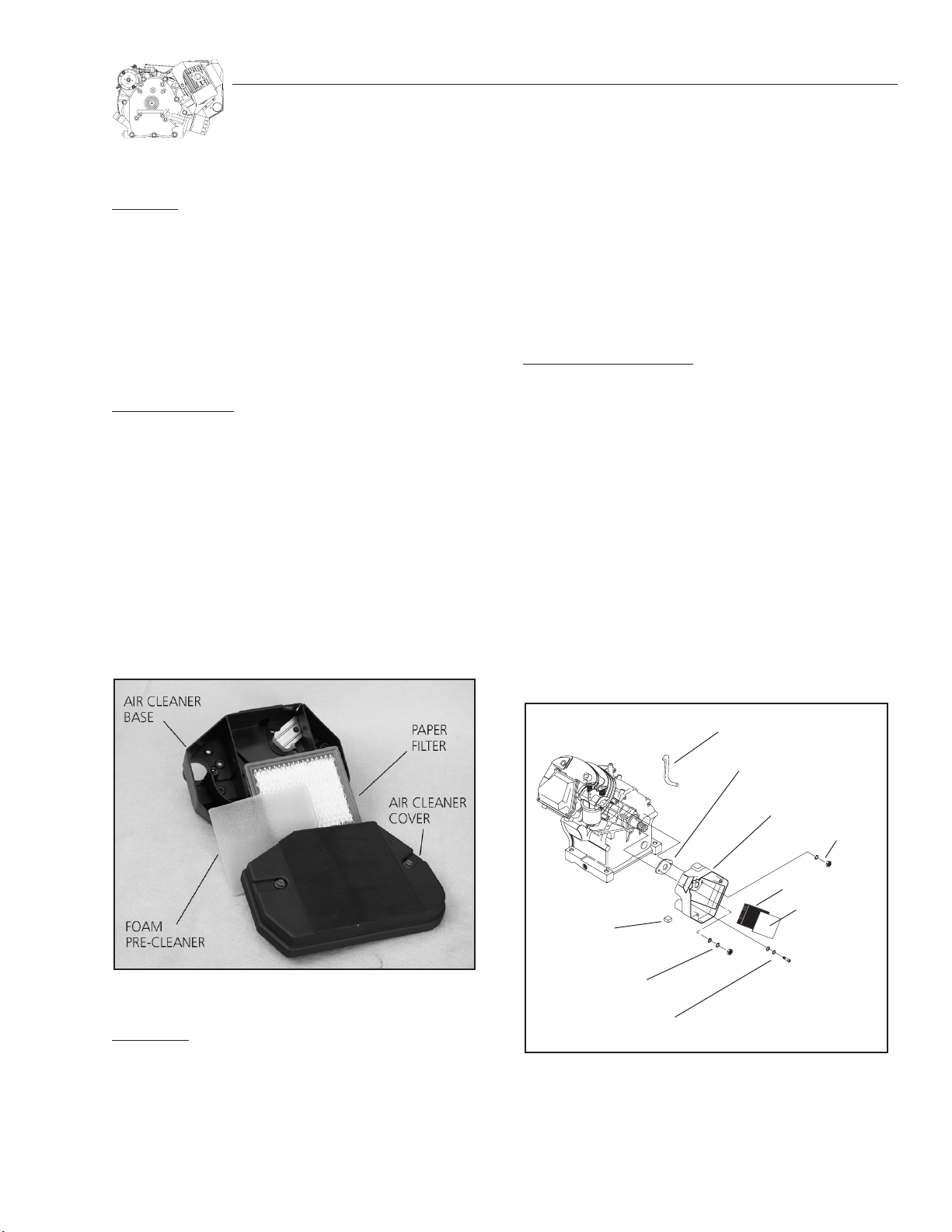

AIR CLEANER

SERVICING:

The engine will not run properly and may be damaged if it

is run with a dirty air cleaner.

Clean or replace the paper filter every 25 hours of operation or once annually, whichever occurs first. Clean or replace

the paper filter more often if operating in extremely dusty or

dirty conditions.

Clean or replace the foam pre-cleaner every 25 hours of

operation; more frequently under dirty or dusty conditions.

FOAM PRE-CLEANER:

To clean or replace the foam pre-cleaner:

1.Remove the air cleaner cover, then remove the foam pre-

cleaner.

2.Wash the foam pre-cleaner in soapy water.

3. Squeeze the pre-cleaner dry with a clean cloth. DO NOT

TWIST.

NOTE: If the pre-cleaner is still dirty after washing and

drying it, replace it with a new filter

4.Apply enough clean engine oil to saturate the pre-cleaner.

5.Wrap the pre-cleaner in a clean dry cloth and squeeze out

excess oil. DO NOT TWIST. Set the pre-cleaner aside.

4.Clean the paper filter by tapping gently on a flat surface.

If it is very dirty, replace it.

5.Clean the air cleaner cover. Then, install the foam precleaner into the cover.

6.Insert the paper filter into the cover so it holds the precleaner in place.

7.Assemble the pre-cleaner, paper filter and cover to the air

cleaner base.

AIR CLEANER BOX REMOVAL:

If the air cleaner box must be removed for further engine

disassembly, do the following (see Figure 2.2):

1.Remove the air cleaner cover.

2.Remove the foam pre-cleaner and paper filter.

3. Remove the choke knob.

4.Remove the breather hose.

5. Remove the two nuts and corresponding washers from the

carburetor mounting bolts.

6.Remove the two capscrews and corresponding washers

from the lower part of the air cleaner box.

NOTE: The carburetor will be loose after removal of the

air cleaner box. Do not allow the carburetor to drop.

Note: Be careful not to stretch or bind the wires connected to the Low Oil Indicator and Start/Stop switch.

Figure 2.1. Typical Air Cleaner

APER FILTER:

P

1.Remove the air cleaner cover.

2.Remove the foam pre-cleaner and service it, if necessary.

3.Remove the paper filter.

13

BREATHER HOSE

GASKET

AIR CLEANER BOX

NUT AND WASHER

PAPER FILTER

FOAM

CHOKE KNOB

NUT, WASHER

AND LOCK WASHER

CAPSCREW

AND WASHERS

PRE-CLEANER

Figure 2.2 — Exploded View of Air Cleaner Box

Page 16

SECTION 2: AIR CLEANERS AND CARBURETION

GENERAC

AIR CLEANER BOX INSTALLATION:

Install the air cleaner box to the engine and carburetor as

follows:

1.Using a new gasket, place the air cleaner box on the carburetor, line up the holes and install the two nuts and

corresponding washers to the carburetor mounting bolts

(see Figure 2.2). Refer to “Torque Specifications” on page

59 for proper torque.

Note: The nut on the right side (toward the rear of the

engine) uses only a flat washer. The nut on the left side

(toward the front of the engine) uses a lock washer and

a flat washer (see Figure 2.2).

2. Install the two capscrews in the lower part of the air cleaner

box (see Figure 2.2). Refer to Torque Specifications on page

61 for proper torque.

3.Reinstall the breather hose.

4. Reinstall the choke knob.

5. Install the filters and cover as stated in the preceding sections

on filter maintenance.

CARBURETION

GENERAL:

Proper engine performance depends on the carburetion

system. The use of clean, fresh fuel and a well maintained

air cleaner is extremely important to engine operation, as well

as engine reliability and power.

COMMON CARBURETOR PROBLEMS:

Most causes of carburetor problems are related to the use

of stale, gummy fuel and the ingestion of dirt. Prior to servicing any carburetor, be sure to check for evidence of these

conditions.

Gasoline that is left in the system for long periods can form

gum or varnish deposits that will adversely affect carburetor

operation.

NOTE: Use of a good fuel stabilizer will minimize the

formation of gum deposits during storage. Add the

stabilizer to the gasoline in the fuel tank or in the storage container. Follow the mix ratio recommended on

the stabilizer container. After adding the stabilizer to

the engine fuel tank, run the engine for about ten (10)

minutes so it will enter the carburetor. A brand name

stabilizer can be purchased in most automotive repair

facilities or in lawn and garden centers.

SERVICE TIP:

Carefully inspect the carburetor choke and throttle shafts

for wear. Grasp each shaft and attempt to move it horizontally and vertically. Maximum allowable end play for choke

and throttle shafts is 0.004 inch (0.1mm). Replace if excessive play is evident.

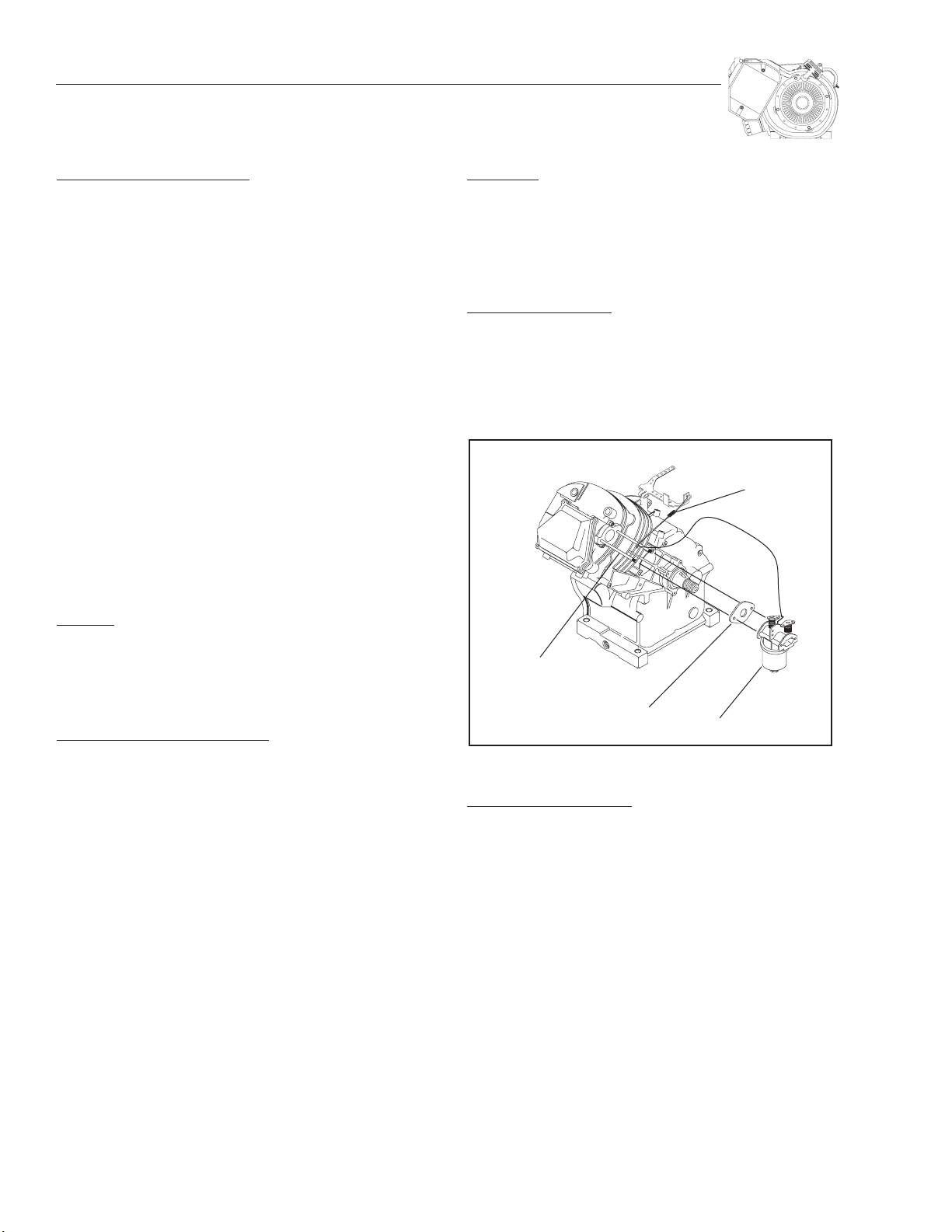

CARBURETOR REMOVAL:

1.Remove the air cleaner box as outlined in “AIR CLEANER

BOX REMOVAL.”

2.Disconnect the governor rod and anti-lash spring from the

throttle arm of the carburetor.

3.Slide the carburetor off of its mounting bolts.

GOVERNOR

ROD AND

ANTI-LASH SPRING

CARBURETOR

MOUNTING

BOLT

CARBURETOR

GASKET

CARBURETOR

Figure 2.3 — Removal of Carburetor

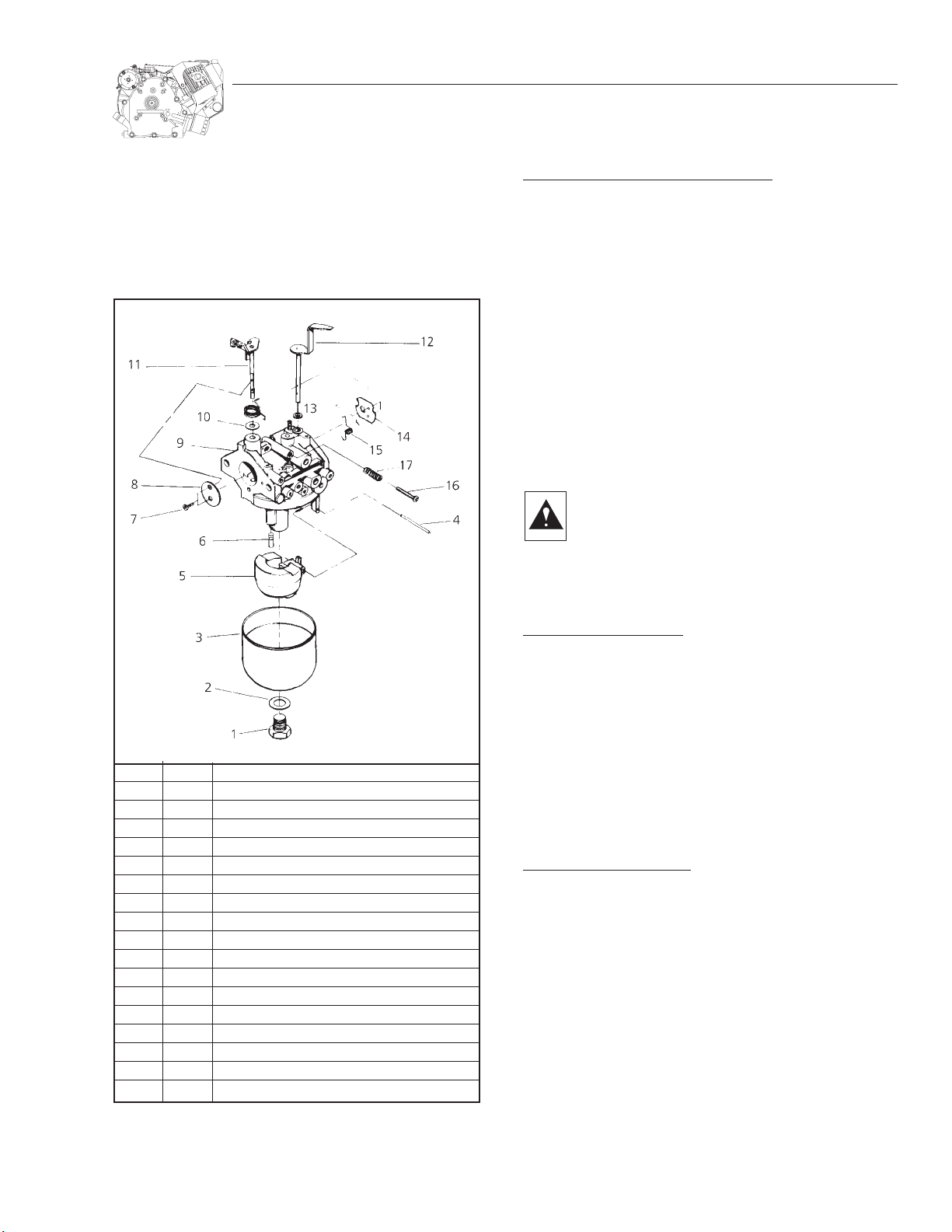

CARBURETOR DISASSEMBL

Y:

To disassemble the carburetor, proceed as follows (See

Figure 2.4):

1.Remove the FLOAT BOWL NUT (Item 1) and the FIBER

WASHER (Item 2). Then remove the FLOAT BOWL (Item 3).

2.Remove the FLOAT PIN (Item 4). Then remove the FLOAT

(Item 5), and FUEL INLET VALVE (Item 6).

3.Remove the IDLE SPEED STOP SCREW (Item 16) along with

its SPRING (Item 17).

4.Rotate the THROTTLE PLATE (Item 8) to it's closed position

and remove two THROTTLE PLATE SCREWS (Item 7).

14

Page 17

SECTION 2: AIR CLEANERS AND CARBURETION

5.Rotate the CHOKE PLATE (Item 14) to its closed position

and remove the CHOKE RETAINER SPRING (Item 15).

6.Remove the CHOKE SHAFT (Item 12) and the CHOKE

SHAFT SEAL (Item 13).

7.Remove the THROTTLE SHAFT (Item 11) and the THROTTLE SHAFT SEAL (Item 10).

CARBURETOR CLEANING AND INSPECTION:

1.Separate out all nonmetallic parts. Then, clean metallic

parts with solvent or commercial carburetor cleaner. DO

NOT PERMIT NONMETALLIC PARTS TO CONTACT SOLVENT OR CLEANER.

2.Inspect the THROTTLE SHAFT (Item 11) Replace if worn or

damaged.

3. Inspect the CHOKE SHAFT (Item 12) Replace if worn or damaged.

4.Inspect the FLOAT BOWL (Item 3). It must be free of dirt

and corrosion.

5.Inspect the FLOAT (Item 5) Replace if damaged.

6.After all metallic parts have been cleaned, blow out carburetor passages with compressed air.

Generac recognizes that there are spray type carburetor cleaners on the market, however Generac

does not authorize the use of carburetor cleaners.

Also, Generac does not recommend soaking a carburetor in any cleaners since the carburetor might

be damaged.

ITEM QTY DESCRIPTION

1 1 Float Bowl Nut

2 1 Fiber Washer

3 1 Float Bowl

4 1 Float Pin

5 1 Float

6 1 Fuel Inlet Valve

7 2 Throttle Plate Screw

8 1 Throttle Plate

9 1 Carburetor Body

10 1 Throttle Shaft Seal

11 1 Throttle Shaft

12 1 Choke Shaft

13 1 Choke Shaft Seal

14 1 Choke Plate

15 1 Choke Retainer Spring

16 1 Idle Speed Stop Screw

17 1 Spring

Figure 2.4 — Exploded View of Carburetor

CARBURETOR REASSEMBLY:

Reassemble the carburetor in the reverse order of disas-

sembly. The following rules apply:

1.Blow metallic parts dry with compressed air.

2.A notch on the FUEL INLET VALVE mates with the FLOAT

(See Figure 2.4).

3.The FLOAT SETTING is FIXED and NONADJUSTABLE.

4. Before tightening the FLOAT BOWL NUT (Item 1), make sure

the FLOAT BOWL is properly aligned with the GASKET and

the CARBURETOR BODY.

CARBURETOR INST

ALLATION:

Using a new gasket, reinstall the carburetor as follows:

1. Slide the new carburetor gasket over the carburetor mounting bolts followed by the carburetor.

2.Connect the governor rod and anti-lash spring.

3.Install the air cleaner box, filters and air cleaner cover as

described in “AIR CLEANER BOX INSTALLATION.”

15

Page 18

SECTION 2: AIR CLEANERS AND CARBURETION

GENERAC

CARBURETOR ADJUSTMENT

INITIAL ADJUSTMENTS:

(See Figures 2.4 and 2.5)

1.The IDLE SPEED STOP SCREW is located at top of the carburetor and contacts the THROTTLE SHAFT. After

reassembling the carburetor, complete an initial adjustment of the STOP SCREW as follows:

a. Close the THROTTLE PLATE.

b. Hold the throttle plate in its closed position and back out

the idle speed stop screw.

c. Turn the idle speed stop screw until it just contacts the

stop tang of the throttle shaft. Then turn the idle speed

stop screw in one turn further.

NOTE: Final adjustment of idle speed can be accomplished with the engine running. Engines equipped with

optional automatic idle control require a special procedure for idle speed adjustment. See Section 4,

"Optional Idle Control."

NOTE: The carburetor is equipped with a fixed main jet,

which requires no adjustment.

FINAL ADJUSTMENT:

The following instructions apply to engines NOT equipped

with automatic idle control. If the unit has an automatic idle

control, refer to the Section 4, "Optional Idle Control."

If the engine is used to drive an AC generator set, use an

AC frequency meter to measure engine speed/frequency.

Connect the AC frequency meter across one of the generator’s AC output receptacles or across the generator’s AC

power winding output leads. Read the AC output frequency

in HERTZ (cycles per second).

If the engine is used in some other application (pressure

washer, pump, air compressor, etc.), use a tachometer to read

the engine rpm.

1.Start the engine and allow a sufficient warm-up period.

2. Hold the carburetor throttle lever against the idle speed stop

screw, then turn the idle speed stop screw until the correct idle speed is obtained.

a. If the driven unit is an AC generator and an AC frequency

meter is used, the correct idle speed is between 62-63

Hertz. (3720-3780 rpm).

b. If the unit is not a generator, adjust the idle speed stop

screw to obtain about 3750 rpm.

Figure 2.5 — Idle Speed Stop Screw

16

Page 19

NOTES

17

Page 20

SECTION 3: MECHANICAL GOVERNOR

GENERAC

GOVERNOR OPERATION

1.The GOVERNOR SPRING tends to pull the LEVER and GOVERNOR ROD toward the "INC. RPM" direction.

2. As engine speed increases, centripetal force acts on the FLYWEIGHT. When FLYWEIGHT centripetal force exceeds

SPRING force, the governor SPOOL is moved axially by FLYWEIGHT force. This causes the GOVERNOR ARM to rotate,

which then moves the LEVER and GOVERNOR ROD toward

a "DEC. RPM" direction.

3.As engine speed decreases, a point is reached where governor SPRING force is greater than FLYWEIGHT centripetal

force. SPRING force then moves the LEVER and GOVERNOR

ROD toward "INC. RPM."

4. Governor action consists of a series of small rpm overshoots

and undershoots, as SPRING force increases rpm and FLYWEIGHT centripetal force decreases rpm.

5.The point at which SPRING tension and FLYWEIGHT force

are equal is the governed speed of the engine.

SPEED

ADJUST

INC. RPM

CENTRIPETAL

FORCE

FLYWEIGHT

CRANKSHAFT

(PTO END)

SHAFT

GOVERNOR

GEAR

SPRING

TO THROTTLE LINK

DEC. RPM

SPOOL

CRANKSHAFT

GEAR

GOVERNOR

GEAR SHAFT

THRUST

WASHER

GOVERNOR

GEAR ASSEMBLY

LOCK PIN

SNAP

RING

WASHER

GOVERNOR

SPOOL

GOVERNOR

ARM

Figure 3.2 — Internal Governor Parts

GOVERNOR EXTERNAL PARTS

WITHOUT AUTOMATIC IDLE CONTROL:

External governor parts for units without automatic idle control are shown in Figure 3.3. Parts include (a) a GOVERNOR

LEVER, (b) a GOVERNOR ROD, (c) ANTI-LASH SPRING, (d) a

SPEED ADJUST BOLT, (e) a SPEED ADJUST NUT, and (f) a

GOVERNOR SPRING.

The governor lever is clamped to the governor arm, so that

arm rotation is imparted to the lever. The governor rod connects to the governor lever at one end and to the carburetor

throttle arm at it's other end. Governor spring tension is

adjustable by means of the speed adjust bolt and nut.

Engine speed can be adjusted by changing the tension of

the governor spring. Governor spring tension can be changed

by turning a locknut on the governor adjusting bolt.

Figure 3.1 — Governor Operating Diagram

GOVERNOR INTERNAL PARTS

See Figure 3.2. A governor gear shaft is pressed into a bore

in the engine crankcase cover. Internal governor components

include (a) a THRUST WASHER, (b) GOVERNOR GEAR ASSEMBLY, (c) SNAP RING, (d) GOVERNOR SPOOL, and (e) GOVERNOR

ARM. A lock pin and washer retain the governor arm in the

crankcase cover.

The governor gear assembly houses the governor flyweights.

Flyweight movement causes the spool to move axially. In

turn, axial movement of the spool results in rotation of the

governor arm.

Figure 3.3 — External Governor Parts

(Units without Idle Control)

18

Page 21

SECTION 3: MECHANICAL GOVERNOR

WITH AUTOMATIC IDLE CONTROL:

Models equipped with automatic idle control (Section 4)

have the same external governor parts as shown in Figure

3.3 with the addition of an idle control solenoid as shown

in Figure 3.4.

Figure 3.4 — External Governor Parts

(Units with Idle Control)

4. Reinstall the GOVERNOR SPRING to the GOVERNOR LEVER

and SPEED ADJUST SCREW, then tighten the SPEED ADJUST

NUT accordingly.

5. Reinstall the CAPSCREW into the IDLE CONTROL BRACKET

if equipped with automatic idle control (Figure 3.4). See

BLOWER HOUSING SCREW under “TORQUE SPECIFICATIONS,” page 61, for proper tightness.

For proper governor adjustment, refer to “GOVERNOR

ADJUSTMENT” on this page.

GOVERNOR GEAR SHAFT REPLACEMENT

CAUTION! DO NOT TWIST THE GEAR SHAFT WITH

A VISE GRIP OR ANY OTHER TOOL. THIS COULD

RESULT IN ENLARGEMENT OF THE SHAFT BOSS.

INSPECTION:

If the governor gear shaft is scored, damaged or worn, it

should be replaced.

GOVERNOR GEAR SHAFT DIAMETER

GN-320, GN-360, GN-410

0.236-0.237 inch (6.004-6.012mm)

AL OF GOVERNOR EXTERNAL PARTS:

REMOV

Before any covers and shrouds can be removed from the

engine, the governor external parts must be removed. Refer

to Figures 3.3 and 3.4 for identification of the parts described

in the following procedure.

1. Remove the CAPSCREW from the IDLE CONTROL BRACKET

if equipped with automatic idle control (Figure 3.4).

2.Loosen the GOVERNOR LEVER CLAMP BOLT (Figure 3.3).

3.Loosen SPEED ADJUST NUT until the GOVERNOR SPRING

can be removed (Figure 3.3).

4.Lift the GOVERNOR LEVER from the GOVERNOR ARM

(Figure 3.3).

5.Disconnect the GOVERNOR ROD and ANTI-LASH SPRING

from the GOVERNOR LEVER (Figure 3.3).

Set the governor external parts aside.

INSTALLATION OF GOVERNOR EXTERNAL PARTS:

AFTER the installation of the engine shrouds and covers,

reinstall the governor external parts as follows (refer to

Figure 3.3):

1.Reattach the GOVERNOR ROD and ANTI-LASH SPRING to

the GOVERNOR LEVER.

2.Slide the GOVERNOR LEVER onto the GOVERNOR ARM.

3. Tighten the GOVERNOR LEVER CLAMP BOLT.

REMOVAL:

If it becomes necessary to replace the governor gear shaft,

remove the crankcase cover (See Section 11). Use care to avoid

damage to the shaft boss area of the crankcase cover. Clamp

the shaft in a vise, then tap the flange with a wooden or plastic mallet to remove the shaft.

INSTALLATION:

Start the new shaft into the shaft boss by tapping lightly

with a soft mallet. Add red Loctite®to the shaft. Then, use

a press or vise to press the shaft into the boss. The shaft is

properly positioned when its end is just flush with the external boss of the crankcase cover. Be sure to wipe away any

excess Loctite®from the flange.

CRANKCASE COVER

SHAFT

INSTALL SHAFT

FLUSH WITH

OUTER BOSS

Figure 3.5 — Governor Gear Shaft

19

Page 22

SECTION 3: MECHANICAL GOVERNOR

GENERAC

LINKAGE INSTALLATION

Differences may exist between governor/carburetor linkages,

depending on the type of equipment on which the engine is used.

The best method for installation of linkage and springs is

to record the attachment points prior to disassembly. Reinstall the governor rod, link and spring(s) in the same manner.

In the typical connection system shown in Figure 3.3 (page

18), the governor rod connects to the governor lever at one

end; to the carburetor throttle arm at the opposite end.

In some applications, an anti-lash spring also will be connected at these two points.

GOVERNOR ADJUSTMENT

INITIAL ADJUSTMENT:

Before starting the engine, complete an initial adjustment

of th governor as follows:

1. Loosen the GOVERNOR LEVER CLAMP BOLT (see Figure 3.3).

2. While holding the GOVERNOR LEVER at its full "INC. RPM"

position, rotate the GOVERNOR ARM clockwise as far as it

will go. Then, tighten the GOVERNOR LEVER CLAMP BOLT.

TORQUE SPECIFICATION

GOVERNOR LEVER CLAMP BOLT

70 inch-pounds

3.For adjustable carburetors, turn the carburetor IDLE JET in

(clockwise) until it just bottoms. DO NOT FORCE. Then, back

the IDLE JET out (counterclockwise) about 1-1/2 turns (see

Figure 3.6).

4.Turn the MAIN JET (Figure 3.6) in (clockwise) until it just

bottoms. DO NOT FORCE. Then, back the MAIN JET out

(counterclockwise) about 1-1/2 turns.

RUNNING ADJUSTMENT:

After completing the INITIAL ADJUSTMENT, final adjustment can

be accomplished with the engine running. Proceed as follows:

NOTE: For AC generator applications, disconnect or

turn OFF all electrical loads. For nongenerator applications, turn OFF the equipment being powered. Initial

checks and adjustments will be accomplished with

engine at no-load.

1.If so equipped, set the idle control switch to OFF.

2.Start the engine, let it warm up and stabilize at no-load.

3.For AC generator applications, connect an AC frequency

meter to one of the generator's AC output receptacles.

a. If the generator is rated 60 Hertz, the no-load AC fre-

quency reading should be 61.5-63.5 Hertz.

b. If the generator is rated 50 Hertz, the no-load AC fre-

quency should be 50.5-51.5 Hertz.

4.For nongenerator applications (pumps, pressure washers,

etc.), refer to the product DATA PLATE for rated engine

speed. Use a tachometer to read engine speed.

NOTE: Several types of inexpensive tachometers are

commercially available.

5.If the frequency (or rpm) reading is incorrect, turn the

SPEED ADJUST NUT (Figure 3.3) on the governor until frequency or rpm is within limits.

6. If frequency or rpm is unstable, turn the IDLE SPEED SCREW

on carburetor until engine stabilizes.

IDLE SPEED STOP SCREW IN FURTHER THAN

DO NOT TURN THE

NECES-

SARY. Fine tune this adjustment after the engine has

warmed up and stabilized. Adjust it 1/8 turn at a time.

20

Page 23

SECTION 3: MECHANICAL GOVERNOR

7. When the no-load frequency or rpm is correct, apply a load

to the engine.

a. For AC generator applications, connect electrical loads

as close as possible to the unit's rated wattage/amperage capacity.

b. For nongenerator applications, turn on the equipment

being powered by the engine.

8.With a load applied to the engine, adjust the carburetor

as follows:

a. CARBURETOR WITH FIXED MAIN JET

IDLE SPEED STOP SCREW to obtain best operation and

highest rpm under load (see Figure 3.6). DO NOT EXCEED

RPM SPECIFICATION.

b. CARBURETOR WITH ADJUST

carburetor as follows:

(1) Slowly turn the MAIN JET counterclockwise ( richer)

until rpm or frequency starts to drop off.

(2) Turn the MAIN JET clockwise (leaner) until rpm or fre-

quency again starts to decrease.

(3) Turn the MAIN JET counterclockwise (richer) until the

best and most stable frequency or rpm is obtained.

ABLE MAIN JET: Adjust the

: Slowly adjust the

9.Turn off all loads and check the no-load governor setting.

Readjust governor no-load speed, if necessary.

Figure 3.6 — Adjustable Carburetor

21

Page 24

SECTION 4: OPTIONAL IDLE CONTROL

GENERAC

GENERAL

Some applications, such as AC generators, may be equipped

with an automatic idle control system. This type of system provides greatly improved fuel economy by running the engine at

a high governed speed only when electrical loads are connected

to the generator. When the electrical loads are disconnected,

engine speed will automatically be reduced to an idle.

OPERATING INSTRUCTIONS

BEFORE START UP

CAUTION! Before cranking and starting the engine,

always set the idle control switch to OFF. Set the

switch to its ON position only after the engine has

stabilized at high governed speed (see Figure 4.1).

ENGINE RUNNING:

To have the engine run at high governed speed only when

electrical loads are connected and turned on, set the idle control switch to ON.The engine will decelerate to idle speed when

loads are disconnected or turned off. If you wish to have the

engine run at high governed speed at all times (with or without loads connected), set the idle control switch to OFF.

ON

OFF

CIRCUIT OPERATION

1.With Idle Control switch set to ON:

a. AC power is delivered from the generator’s AC power

windings to a circuit board, for operation of the circuit

board.

b. With electrical loads connected to the generator, current

will flow through the primary windings of a sensing

transformer. A proportional voltage and current will then

be induced into the transformer’s secondary windings.

c. Current from the transformer secondary windings is

delivered to the circuit board. Circuit board action then

opens the circuit to an idle control solenoid.

d. The idle control solenoid de-energizes and engine speed

is established by the engine governor.

e. When electrical loads are disconnected or turned off, cur-

rent flow through the transformer primary windings will

terminate. Voltage and current cannot be induced into

the transformer secondary windings and the solenoid

energizes.

f. Zero current flow of the transformer secondary wind-

ings is sensed by the circuit board. The circuit board then

closes the circuit to the idle control solenoid.

g. The energized solenoid pulls the carburetor throttle arm

against its idle speed stop screw. The engine decelerates

to idle speed, about 2280-2400 rpm (38-40 Hertz).

2.Idle control switch set to OFF:

a. AC power is not available to the circuit board. The idle

control solenoid will then remain de-energized at all

times.

b. The engine will run at high governed speed.

Figure 4.1 — Idle Control Switch

STATOR POWER WINDINGS

11

44X

11X

11A 110

SWITCH

22

33

44X

TRANSFORMER

155

44

CIRCUIT

BOARD

156

44

22

COIL (MAGNET)

81

82

A. Schematic B. Pictorial

Figure 4.2 — Idle Control System (Typical AC Generator)

22

CIRCUIT

BOARD

155

156

TRANSFORMER

COIL

11X

44

SWITCH

22

11A

Page 25

SECTION 4: OPTIONAL IDLE CONTROL

IDLE CONTROL ADJUSTMENT

GENERAL:

Idle speed will be correct when (a) the idle control solenoid

is positioned to maintain an idle speed equal to about 15002100 rpm (25-35 Hertz), and (b) when the carburetor idle

speed stop screw is set to maintain an idle speed of approximately 2280- 2400 rpm (38-40 Hertz). Proper adjustment

consists of first positioning the idle control solenoid to obtain

an idle speed of 1500-2100 rpm. Fine adjustment can then

be obtained by setting the idle speed stop screw for an idle

speed of 2280-2400 rpm (38-40 Hertz).

INITIAL ADJUSTMENT:

1.Set the idle control switch to OFF.

2.Unplug all electrical loads from the generator.

3.Connect an AC frequency meter into one of the genera-

tors power receptacles.

4.Crank and start the engine as outlined in the appropriate

owner's manual.

a. For units rated 60 Hertz, the frequency meter should read

about 3,690-3,810 rpm (high governed speed). This is

about 61.5-63.5 Hertz.

b. For units rated 50 Hertz, the meter should read 3,030-

3,090 rpm (50.5-51.5 Hertz).

5.Let the engine stabilize and warm up.

6.Set the idle control switch to ON. The idle control solenoid

should energize, and engine speed should decelerate to

idle speed.

7.If necessary, back the carburetor's idle speed stop screw

out so that governor lever travel is limited by the solenoid

and not by the idle stop screw.

a. Check the frequency meter reading.

b. Meter should indicate about 1,500- 2,100 rpm (25-35

Hertz).

c. If reading is not within the stated range, adjustment of

the idle control solenoid is required.

8.To adjust the idle control solenoid, proceed as follows:

a. Loosen the solenoid JAM NUT, then turn the solenoid

BOLT clockwise (faster) or counterclockwise (slower).

b. When engine speed is 1500- 2100 rpm (25-35 Hertz), hold

that setting and tighten the solenoid JAM NUT.

c. When JAM NUT is tight, check that engine speed is still

1,500- 2,100 rpm (25-35 Hertz).

FINAL ADJUSTMENT:

On the carburetor, turn the idle speed stop screw clockwise

(faster speed) until engine speed increases to 2,280-2,400 rpm

(38-40 Hertz) (see Figure 4.4).

NOTE: Idle speeds less than about 38 Hertz could cause

the engine to stall when loads are suddenly applied.

Figure 4.3 — Initial Adjustment Points

Figure 4.4 — Final Adjustment Point

23

Page 26

SECTION 5: REWIND STARTERS

GENERAC

GENERAL

The rewind starter used on most GN series engines is a

manual starter that uses a spring to rewind the starter rope

after it has been pulled. Pulling the rope winds up a clocktype spiral spring in the starter housing. When the rope is

released, the spring unwinds and causes the rope to wind

around the pulley.

When the rope is pulled outward and away from the engine,

spring-loaded “starter dogs” engage the pulley, and the

engine is cranked.

When the rope is allowed to return, the starter dogs do not

engage the pulley.

RECOIL ASSEMBLY REMOVAL

The rewind starter assembly is retained to the engine blower

housing by screws and lock washers (see Figure 5.1). Remove the

screws and lock washers, then remove the complete starter

rewind assembly.

Figure 5.1 — Recoil Assembly Removal

1. Housing

2. Spring

3. Starter Dog

4. Dog Spring

5. Retainer Pawl

6. Screw

Figure 5.2 — Exploded View of Rewind Starter (Old Style)

7. Pulley

8. Spring and Spring

Keeper

24

9. Handle

10. Handle Insert

11. Rope

Page 27

SECTION 5: REWIND STARTERS

DISASSEMBLY (OLD STYLE)

1.Pry up the HANDLE INSERT, to expose knot in ROPE (see

Figure 5.2).

2. Untie knot in ROPE. Remove HANDLE INSERT and HANDLE.

3.Slowly release spring tension on the PULLEY, after the

ROPE has been drawn through the HANDLE.

4.Remove the SCREW. Then, remove the RETAINER PAWL,

STARTER DOGS, DOG SPRINGS, and SPRING.

5.Lift out the PULLEY.

REASSEMBLY

1. Place SPRING and SPRING KEEPER into position, turn to lock

into position (see Figure 5.2). The spring should be lightly

coated with grease.

2.Place the PULLEY, along with SPRING and SPRING KEEPER,

into the HOUSING. Install SPRING, STARTER DOGS and

DOG SPRINGS.

3.Install RETAINER PAWL and SCREW.

TORQUE SPECIFICATION

RETAINER PAWL SCREW

84 inch-pounds

4.Wind the PULLEY counterclockwise until tight. Then, allow

it to unwind until the hole in the PULLEY lines up with the

eyelet in the HOUSING.

5.Pull the ROPE up through the eyelet in the HOUSING, then

through the HANDLE and HANDLE INSERT. Tie a left-hand

knot in the rope.

6.Install the HANDLE INSERT into the HANDLE.

7.Test the starter for proper operation.

TORQUE SPECIFICATION

CAPSCREWS ON REWIND TO BLOWER COVER

inch-pounds

84

DISASSEMBLY (NEW STYLE)

Disassembly of new style rewind starter is not cost effec-

tive, except for ROPE or HANDLE replacement (see Figure 5.3)

Figure 5.3 — Exploded View of Rewind Starter (New Style)

25

Page 28

SECTION 6: ELECTRIC STARTERS AND BATTERIES

GENERAC

INTRODUCTION

Some GN series engine applications may be equipped with

a 12-volt DC electric cranking system. Such a system converts

electrical energy from a battery into mechanical energy at the

starter motor, for the purpose of turning the engine over for

starting.

Generally, two types of cranking systems are used in GN

series engine applications. These are (a) the starter contactor system and (b) the heavy duty cranking switch system.

NOTE: Cranking systems discussed in this manual are

typical systems. The actual cranking system used in

specific applications may differ. Refer to the wiring

diagram and/or electrical schematic in the Owner's

Manual for specific applications.

NOTE: Vertical crankshaft engines used in recreational

vehicle applications are equipped with a cranking and

starting system that is controlled by a solid-state circuit board. This system is a "starter contactor" type, with

the starter contactor energized by circuit board action.

For instructions and information order "DIAGNOSTIC

REPAIR MANUAL — RECREATIONAL VEHICLE GENERATORS" (Generac Part No. 94468).

STARTER CONTACTOR SYSTEM

When the start-stop switch is held at START, battery current

flows through the STARTER CONTACTOR coil and to ground

via the switch. The starter contactor energizes, its contacts

close, and battery output is delivered to the starter motor. The

motor energizes, and the engine is cranked (Figure 6.1).

STARTER MOTOR OPERATING PRINCIPLES

Closure of the circuit to the starter motor allows battery current to flow through a commutator, to the loops of wire in

the armature, and back to the battery. The interaction of the

magnetic fields causes the armature to revolve.

The armature rotates at a relatively high speed to provide

sufficient torque to crank the engine. The required engine

cranking speed is relatively slow, so the starter motor is

equipped with a small drive pinion that meshes with the teeth

of a flywheel ring gear to crank the engine. The large ring

gear and the small starter pinion gear results in a gear reduction that can vary in ratio up to 19-to-1. This reduction allows

the starter to rotate at high speeds while cranking the engine

at low speeds.

When the engine starts, its speed increases quickly. For

example, if the engine reaches 100 rpm and the starter

pinion remains meshed with the ring gear, the starter armature would spin at about 1,900 rpm (19-to-1 ratio). To prevent

damage to the armature, a "Bendix Drive" mechanism is used

to disengage the starter pinion from the ring gear when the

engine has started.

THE BENDIX DRIVE

When the field coils of the starter drive are energized, the

armature starts to turn. A loose fitting sleeve inside the pinion

gear is turned with the armature. This sleeve has large spiral

threads on its surface that match the pinion gear’s internal

threads. The sleeve turns with the armature, and the pinion

gear rotates on the threads to move outward on the sleeve.

Outward movement of the pinion gear causes that gear to

mesh with the flywheel ring gear. The pinion hits a stop on

the sleeve, and the pinion turns the ring gear and engine.

On start-up, the engine turns faster than the armature. This

causes the pinion to spin back on the spiral threads of the

sleeve and out of engagement with the ring gear.

Figure 6.1— Schematic of Typical Starter Contactor System

HEAVY DUTY SWITCH SYSTEM

The heavy duty switch contacts are closed manually to

deliver battery voltage to the starter motor.

STARTER MOTOR REPAIRS

If the starter motor is defective, it should be removed

and replaced. Disassembly and repair of the motor is not

cost effective.

STARTER MOTOR REMOVAL:

To remove the starter from the engine, loosen and disconnect the starter wire, then remove the two hex head

screws that hold the starter in place.

STARTER MOTOR INSTALLATION:

To install the starter motor, reverse the previous steps.

TORQUE SPECIFICATION

HEX HEAD SCREWS ON STARTER MOTOR

inch-pounds

216

26

Page 29

SECTION 6: ELECTRIC STARTERS AND BATTERIES

TORQUE SPECIFICATION

STARTER MOTOR WIRE NUT

inch-pounds

84

TESTING THE STARTER MOTOR

CHECKING THE PINION:

When the starter motor is activated, the pinion gear should

rise and engage the ring gear. If the pinion does not rise normally, inspect the large spiral threads of the sleeve and pinion

for binding or sticking.

TOOLS FOR STARTER PERFORMANCE TEST:

The following equipment may be used to complete a performance test of the starter motor:

• A digital multimeter (VOM).

• A tachometer capable of reading up to 1,500 rpm.

• A fully charged 12-volt battery.

ARTER PERFORMANCE TEST:

ST

1. Set the meter to read DC amps.

2. Connect the STARTER MOTOR, BATTERY and VOM as

shown in Figure 6.2.

STARTER MOTOR PERFORMANCE SPECIFICATIONS AT

12 VOLTS DC

MINIMUM MOTOR RPM = 800

MAXIMUM AMPS = 9

If the starter does not perform satisfactorily, it should be replaced.

BATTERY MAINTENANCE

GENERAL

Many of the batteries in use today are "maintenance free"

and require little or no maintenance. In most cases, battery

failure requires replacement of the battery. The lead-acid

cells found in many products, however, still require maintenance. Maintenance of lead-acid batteries falls into three

categories:

• Inspecting the battery.

• Maintaining proper electrolyte levels.

• Charging the battery properly.

INSPECTING THE BATTERY:

Inspect the battery case for cracks or signs of damage.

Inspect battery terminals periodically and keep them clean.

NOTE: Always make sure that the battery is fully

charged.

Figure 6.2 — Starter Performance Test

3. Insert the tachometer at end of the pinion gear and activate the starter motor. A starter motor in good condition

will be within the following specifications:

ELECTROLYTE LEVEL:

Check the battery electrolyte level regularly. When level is

low, add distilled water to the correct level.

NOTE: After adding distilled water, do not check electrolyte specific gravity until after the battery has been

recharged. Adding of sulfuric acid is NOT recommended.

If the battery has been recharged and specific gravity

is not correct, replace the battery.

TESTING A BATTERY

1.Visually inspect the battery case for cracks and other

defects. If damaged, replace the battery.

2.Check the electrolyte level in all battery cells.

a. If distilled water is added, recharge the battery before

taking a specific gravity reading.

b. Charge the battery until it is gassing freely, then take the

specific gravity reading.

3.Begin at one end of the battery and check the first cell,

using an automotive type battery hydrometer.

a. Take two or three samples from the cell to stabilize the

reading.

27

Page 30

SECTION 6: ELECTRIC STARTERS AND BATTERIES

GENERAC

b. Once stabilized, draw in the final sample.

c. Draw in only enough electrolyte to obtain a reading —

do not let the hydrometer float hit the suction bulb.

d. Hold the hydrometer vertically and shake it gently to

make sure the float is not sticking to the inside of the

glass barrel.

e. Read and record the specific gravity reading.

4.Check the temperature of the fluid. Add the required

points if temperature is above 80 F. Subtract the required

points if below 80 F (see Figure 6.3).

5.Check and record readings of the remaining cells in the

same manner.

6.When all cells have been checked, subtract the lowest

reading obtained from the highest reading. If there is more

than 30 points difference, the battery is probably defective and should be replaced.

In Figure 6.3, the highest reading is 1.260, and the lowest

reading is 1.225. Subtract 1.225 from 1.260 to obtain a 35

point difference.

Figure 6.3 — Using a Battery Hydrometer

28

Page 31

SECTION 7: COVERS AND SHROUDS

LOWER SHROUD

UPPER SHROUD

BLOWER HOUSING ASSEMBLY

BLOWER HOUSING

CAPSCREW

(TORQUE TO 84 INCH POUNDS)

UPPER SHROUD

CAPSCREW

(TORQUE TO 84 INCH POUNDS)

LOWER SHROUD

CAP SCREW

(TORQUE TO 84 INCH POUNDS)

GENERAL

In the course of tearing down a complete engine for service and repairs, the engine shrouds and covers may need to

be removed. The following section briefly describes the order

in which these items should be removed.

1.Remove air cleaner assembly and carburetor as described

in Section 2, “AIR CLEANERS AND CARBURETION.”

2.Disconnect the governor rod and anti-lash spring from the

carburetor.

3.Remove the five capscrews from the BLOWER HOUSING

ASSEMBLY (see Figure 7.1).

Carefully remove the blower cover, making sure not to

stretch the wires from the RUN/STOP switch and low oil indicator (LOS). When the cover is far enough away from the

engine, these wires may be unplugged.

4.Remove the capscrew from the LOWER SHROUD (see

Figure 7.1).

4.Remove the two capscrews from the UPPER SHROUD (see

Figure 7.1).

NOTE: The blower cover is notched at the point where

the governor rod and anti-lash spring pass through it.

This allows the cover to be removed without disconnecting the governor rod from the governor arm.

NOTE: It will be helpful to make note of the locations

of the screws that hold the covers in place.

INSTALLATION OF COVERS AND SHROUDS:

To reinstall the covers and shrouds, reverse the previous

steps. Make sure that the wires for the RUN/STOP switch and

low oil indicator (LOS) are not in the way of the covers during

reassembly.

Figure 7.1 — Exploded View of Engine Covers and Shrouds

29

Page 32

SECTION 8: IGNITION SYSTEM

GENERAC

GENERAL

The ignition system typically used on GN-320/GN-360/GN410 engines is a solid-state (breakerless) type. The system

utilizes a magnet on the engine flywheel to induce a relatively

low voltage into an ignition coil assembly. Ignition coil internal components increase the voltage and deliver the resulting

high voltage across the spark plug gap.

The ignition coil houses a solid-state circuit board that controls ignition timing. Timing is fixed, nonadjustable and spark

advance is automatic.

MAJOR COMPONENTS

Major components of the ignition system include (a) the

ignition coil assembly, (b) the spark plug, (c) the engine run

switch and (d) the engine flywheel (see Figures 8.1 and 8.4).

ENGINE

RUN SWITCH

SPARK PLUG

IGNITION COIL ASSEMBLY

SPARK PLUG

The spark plug should be cleaned and regapped periodically. The plug should be replaced every 100 hours of operation

or once annually, whichever comes first.

Recommended spark plug is a Champion RC12YC or equivalent. Set spark plug gap to 0.030 inch (0.76mm) (Figure 8.3).

NOTE: Always use original GENERAC®replacement

parts.

SET PLUG GAP AT 0.030 inch

(0.76 mm)

Figure 8.3 — Setting Spark Plug Gap

FLYWHEEL

Figure 8.1 — Ignition System Components

IGNITION COIL ASSEMBLY

Solid-state components encapsulated in the ignition coil are

not accessible and cannot be serviced. If the coil is defective,

the entire assembly must be replaced. The air gap between

the coil and the flywheel magnet is fixed and nonadjustable.

The ignition coil assembly (Figure 8.2) consists of (a) ignition coil, (b) spark plug high tension lead and (c) spark

plug boot.

Figure 8.2 — Ignition Coil Assembly

CHECKING FLYWHEEL MAGNET:

The flywheel magnet rarely loses its magnetism. If you suspect a magnet might be defective, a rough test can be

performed as follows:

1.Place the flywheel on a wooden surface.

2.Hold a screwdriver at the extreme end of its handle and

with its point down.

3.Move the tip of the screwdriver to about 3/4 inch (19mm)

from the magnet. The screwdriver blade should be pulled

in against the magnet.

FLYWHEEL KEY:

The flywheel’s taper is locked on the crankshaft taper by

the torque of the flywheel nut. A keyway is provided for alignment only and theoretically carries no load.

If the flywheel key becomes sheared or even partially

sheared, ignition timing can change. Incorrect timing can result

in hard starting or failure to start.

FLYWHEEL REMOVAL:

Use a strap wrench to prevent the flywheel from turning.

Remove the FLYWHEEL NUT. Then, remove the CONICAL

WASHER and the STARTER CUP.

30

Page 33

Use a commercially available flywheel puller to remove the

flywheel from the engine tapered shaft.

YWHEEL INSTALLATION:

FL

Align the keyway in the flywheel with the woodruff key on

the crankshaft. Install the flywheel, the conical washer and

the starter cup. Install the flywheel nut and tighten to the

proper torque.

NOTE: The conical washer must be installed in the

proper direction (see Figure 8.4) with the convex side

facing out (away from the flywheel).

TORQUE SPECIFICATION

FLYWHEEL NUT

90 foot-pounds

WOODRUFF

KEY

FLYWHEEL

STARTER

CUP

CONVEX SIDE OF CONICAL

WASHER FACING OUT

CONICAL

WASHER

FLYWHEEL

NUT

SECTION 8: IGNITION SYSTEM

Figure 8.5 — Testing Ignition System

NOTE: If the flywheel key is sheared or partially sheared,

spark can jump the tester gap. However, loss of correct

ignition timing may result in hard starting or no starting at all.

4. To determine if an engine miss is ignition related, connect

the spark tester in series with the high tension lead and the

spark plug (Figure 8.6). Then, test the system as follows:

a. Start the engine.

b. If spark jumps the tester gap regularly but the miss con-

tinues, the problem is in the spark plug or in the fuel

system. A spark miss will be readily apparent.

FLYWHEEL

NUT

FLYWHEEL

STARTER

CUP

Figure 8.4 — Exploded View of Flywheel Assembly

TESTING THE IGNITION SYSTEM

Use a spark tester to test the ignition system. Such spark

testers are commercially available. Test the system as follows:

1.Disconnect the high tension lead from the spark plug.

2.See Figure 8.5. Attach the spark tester clamp to the engine

cylinder head (frame ground). Attach the spark plug high

tension lead to the tester terminal.

3.Crank the engine rapidly. If spark jumps the gap of the

spark tester, you may assume the ignition system is operating satisfactorily.

Figure 8.6 — Checking for Engine Miss

NOTE: The ignition system described in this section is

typically used on horizontal shaft engines. The ignition

system used on all vertical shaft (RV) engines differs

from that of horizontal shaft engines. See "SERVICE

MANUAL COMPUTER CONTROLLED VARIABLE SPEED RV

GENERATORS," Manual Part No. 94468-A.

31

Page 34

SECTION 9: VALVE TRAIN

GENERAC

MAJOR COMPONENTS

Valve train components are shown in Figure 9.1 below.

8

7

6

5

4

3

ITEM QTY DESCRIPTION

1 2 Tappet

2 2 Push Rod

3 1 Push Rod Guide Plate

4 2 Rocker Arm Jam Nut

5 2 Rocker Arm

6 2 Pivot Ball Stud

7 4 Valve Spring Keeper

8 2 Valve Spring Retainer

9 2 Valve Spring

10 2 Wear Washer

11 1 Intake Valve Stem Seal

12 1 Exhaust Valve

13 1 Intake Valve

Figure 9.1 — Valve Train Components

9

10

11

12

13

2

1

DISASSEMBLY

1.Remove the oil breather tube. Remove the four M6-

1.00 x 12mm screws. Then, remove the rocker arm

cover (see Figure 9.2).

NOTE: Whenever the rocker arm cover is removed, the

cover gasket must be replaced to ensure a proper seal.

2.Loosen the rocker arm jam nuts on the pivot ball studs.

Then, loosen the pivot ball studs. Remove the two pivot

ball studs, rocker arms and jam nuts. Also, remove the push

rod guide plate.

NOTE: Always keep intake and exhaust valve parts separated. Intake and exhaust pivot ball studs, rocker arms

and push rods are identical. However, the wear patterns

will be different.

Figure 9.3 — Rocker Arms, Pivot Ball Studs, Push Rods and

Push Rod Plate

3.Remove the push rods (see Figure 9.3).

4. Remove the cylinder head bolts, then the cylinder head and

cylinder head gasket (see Figure 9.4).

CYLINDER

HEAD

CRANKCASE

CYLINDER

HEAD BOLT

CYLINDER

HEAD GASKET

Figure 9.2 — Removal of Rocker Arm Cover

Figure 9.4 — Cylinder Head Removal

32

Page 35