Page 1

GENERAC _

0

erator'sIVianual

I

Page 2

introduction.............................................................1

Safety Rules...........................................................1

SafetySymbols and Meanings.......................................1

Generalinformation................................................4

KnowYourPowerWasher.........................................................4

ProductSpecifications..............................................................5

Unpacking.................................................................................5

Set-up.....................................................................5

Assembly..................................................................................5

Add EngineOil..........................................................................6

Add Fuel...................................................................................6

ConnectHoseand WaterSupplyto Pump.................................7

How to Use Nozzles..................................................................8

CleaningandApplying Detergent....................................9

PowerWasherRinsing.................................................10

CleaningDetergentSiphoningTube...............................10

Operation..............................................................11

Operation................................................................................11

PowerWasherLocation..........................................................11

ChecklistBefore StartingEngine..............................................11

How to Start YourPowerWasher............................................11

AutomaticCoolDown System (ThermalRelief).......................13

How to Stop YourPowerWasher.............................................13

Maintenance.........................................................14

MaintenanceRecommendations..............................................14

MaintenanceSchedule............................................................14

PumpOil.................................................................................14

EmissionsControl...................................................................14

PowerWasherMaintenance....................................................14

Checkand CleanInletScreen..................................................14

CheckHigh PressureHoses....................................................14

CheckDetergentSiphoningTube.............................................15

CheckSpray Gun....................................................................15

NozzleMaintenance................................................................15

EngineMaintenance................................................................15

EngineOil Recommendations..................................................15

CheckOil Level............................................................16

AddingEngineOil.........................................................16

ChangingEngineOil.....................................................16

ServiceAir Cleaner.................................................................16

ServiceSparkPlug..................................................................17

InspectMufflerand SparkArrestor..........................................17

After EachUse........................................................................17

WinterStorage........................................................................18

LongTermStorage..................................................................18

ProtectFuelSystem.....................................................18

ChangeOil...................................................................18

Protectingthe Pump.....................................................18

OtherStorageInstructions.......................................................18

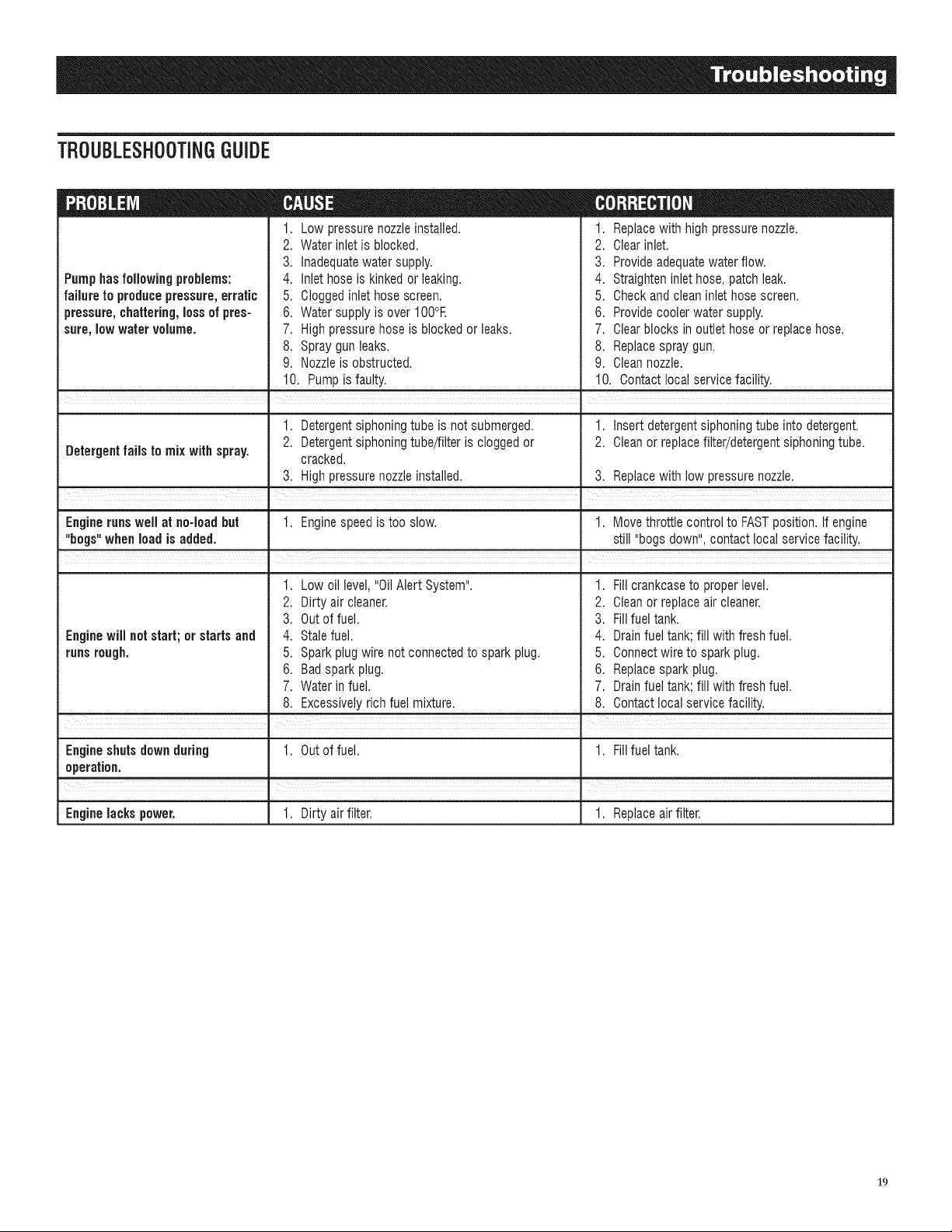

Troubleshooting....................................................19

TroubleshootingGuide.............................................................19

Warranty...............................................................20

-- m

lVlanueldel propietario..........................................23

lVlanueld'entretien................................................47

Page 3

iNTRODUCTION

Thank you for purchasing this power washer manufactured by

GeneracPower Systems, Inc.This modelis a high performance,

air-cooled, engine-driven power washer that operatesbetween

2500 and 3000 psi dependingon which model you purchased.

The units feature custom designed wheels, axial cam pump

with stainless steel pistons, automatic cool down system, quick

connect nozzles, high pressure hose, detergentsiphoning hose

and chemicaltank(s) dependingon unit model.

Commonsenseandstrictcompliancewiththespecialinstructions

are essentialto preventingaccidents. The operatormust read

this manual and thoroughly understand all of the instructions

and warnings before usingthe equipment.If any portion of the

manualis not understood, contact the nearestAuthorizedDealer

for starting, operating and servicing procedures.The owner is

responsiblefor properandsafe use of the equipment.

Thepowerwashercanoperatesafely,efficientlyandreliablyonly if

it is properly located,operatedand maintained. Beforeoperating,

servicingor storing:

• Studyall warnings in this manualand on the productcarefully.

• Becomefamiliar with this manual andthe unit beforeuse.

• Referto theAssemblysection of the manualfor instructionson

final assembly procedures.Followthe instructions completely.

Themanufacturercannot anticipateevery possible circumstance

that might involvea hazard.The warnings in this manual,and on

tags and decals affixedto the unit are,therefore,not all inclusive.

If usingaprocedure,workmethodoroperatingtechniquethat the

manufacturerdoes not specifically recommend,ensurethat it is

safe for others. Also make sure the procedure,work methodor

operatingtechnique utilized does not render the power washer

unsafe.

THE INFORMATIONCONTAINEDHEREIN WAS BASED ON

MACHINESIN PRODUCTIONAT THE TIME OF PUBLICATION.

GENERACRESERVESTHERIGHTTO MODIFYTHIS MANUALAT

ANYTIME.

Save these instructionsfor future reference. If you loan this

device to someone,ALWAYSloan these instructionsAND the

Owner's Manualto the individualas well.

WHERETOFiNDUS

You can contact GeneracCustomerService by phone at 1-888-

436-3722, or on the internet at www.generac.com.Recordthe

important information of the unit in the following chart for future

referenceand/orservice inquiries.

SAFETYRULES

Throughoutthis publication,and on tags and decalsaffixedto the

generator,DANGER,WARNING,CAUTIONand NOTEblocks are

usedto alert personnelto special instructionsabout a particular

operation that may be hazardous if performed incorrectly or

carelessly. Observe them carefully. Their definitions are as

follows:

Indicatesa hazardoussituationor action which,if notavoided,

will resultin death or seriousinjury.

Indicatesa hazardoussituationor actionwhich, if not avoided,

couldresultin deathor seriousinjury.

_CAUTION!

Indicatesa hazardoussituationor actionwhich, if not avoided,

couldresultin minoror moderateinjury.

NOTE:

Notescontainadditional informationimportanttoa procedure

and will be found withinthe regulartextbody of thismanual.

These safety warnings cannot eliminate the hazards that they

indicate. Common sense and strict compliancewith the special

instructionswhile performingtheaction or serviceareessentialto

preventingaccidents.

SAFETYSYMBOLSANDMEAN/NGS

ToxicFumes Kickback ElectricalShock

Slippery Surface Fall Fluid injection

D

Fire

Explosion Operator's Manual

ModelNumber

Serial Number

DatePurchased

MovingParts

Flying Objects Hot Surface

Page 4

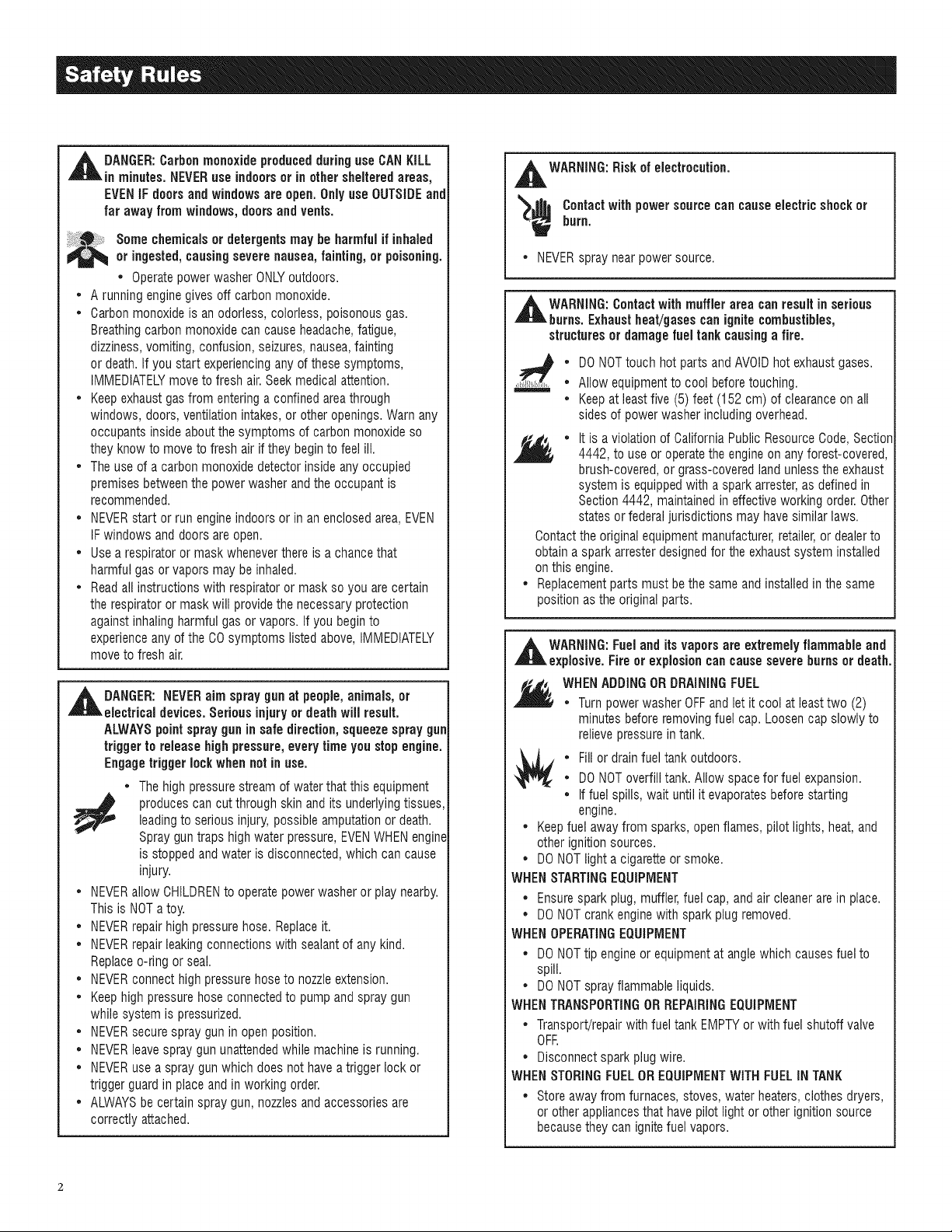

,_ DANGER:CarbonmonoxideproducedduringuseCANKiLL

inminutes.NEVERuseindoorsorinothershelteredareas,

EVENiFdoorsandwindowsare open.DrilyuseOUTSIDEand

farawayfromwindows,doorsandvents.

Somechemicalsor detergents may be harmfulif inhaled

oringested,causingseverenausea, fainting, or poisoning.

• Operatepowerwasher ONLYoutdoors.

• A runningenginegivesoff carbon monoxide.

• Carbonmonoxide is an odorless, colorless, poisonousgas.

Breathingcarbonmonoxidecan causeheadache,fatigue,

dizziness,vomiting, confusion,seizures,nausea,fainting

or death.If you start experiencingany of these symptoms,

IMMEDIATELYmoveto fresh air. Seekmedicalattention.

• Keepexhaustgasfrom enteringa confined areathrough

windows, doors, ventilationintakes,or other openings.Warnany

occupantsinside aboutthe symptoms of carbon monoxideso

they know to move to fresh air if they beginto feel ill.

• Theuse of a carbon monoxidedetector insideany occupied

premisesbetweenthe powerwasher andthe occupant is

recommended.

• NEVERstart or run engineindoors or in an enclosedarea,EVEN

IFwindows and doors areopen.

• Usea respiratoror maskwheneverthere is achance that

harmful gas or vapors may beinhaled.

• Readall instructions with respiratoror mask so you arecertain

the respiratoror mask will providethe necessaryprotection

againstinhalingharmful gasor vapors. Ifyou beginto

experienceany ofthe COsymptoms listedabove,IMMEDIATELY

moveto fresh air.

,_DANGER: spray gun people, or

electrical devices.Serious injuryor deathwill result.

ALWAYSpointspraygunin safedirection, squeezespraygun

trigger to release highpressure,every time you stopengine.

Engagetrigger lockwhen not in use.

• NEVERallow CHILDRENto operatepowerwasheror playnearby.

This is NOTa toy.

• NEVERrepairhigh pressure hose.Replaceit.

• NEVERrepairleaking connectionswith sealantof any kind.

Replaceo-ring or seal.

• NEVERconnecthigh pressurehose to nozzleextension.

• Keephigh pressurehoseconnectedto pump and spraygun

while system is pressurized.

• NEVERsecurespray gun in openposition.

• NEVERleavespray gununattendedwhile machineis running.

• NEVERuse a spray gunwhich does not havea trigger lock or

triggerguard in placeandin working order.

• ALWAYSbe certain spraygun, nozzlesandaccessories are

correctly attached.

NEVERaim at

• Thehigh pressurestream ofwater that this equipment

produces cancut through skin andits underlyingtissues,leadingto serious injury,possible amputationor death.

Spray guntraps high water pressure,EVENWHENengine

is stoppedandwater is disconnected,which can cause

injury.

animals,

,_WARNING: Riskofelectrocution.

burn.

'_ Contactwithpowersourcecancauseelectricshockor

• NEVERspray nearpower source.

,_WARNING: Contactwith muffler area canresult in serious

burns. Exhaustheat/gasescanignitecombustibles,

structuresor damage fuel tank causing a fire.

• DONOTtouch hot parts and AVOIDhot exhaustgases.

• Allowequipmentto cool beforetouching.

• Keepat leastfive (5) feet (152 cm) of clearance on all

sidesof powerwasherincluding overhead.

• Itis a violation of CaliforniaPublicResourceCode,Section

4442, to use or operatethe engineon anyforest-covered,

brush-covered,or grass-coveredland unlessthe exhaust

systemis equippedwith a sparkarrester,as definedin

Section4442, maintainedin effectiveworking order.Other

statesor federaljurisdictions may havesimilar laws.

Contactthe original equipmentmanufacturer,retailer,or dealerto

obtaina sparkarrester designedfor the exhaustsystem installed

onthis engine.

• Replacementparts must bethe same and installedin the same

position as the originalparts.

,_ WARNING:Fueland its vaporsare extremelyflammable and

explosive. Fire or explosion cancausesevere burns or death.

WHENADDINGDR DRAININGFUEL

• Turnpower washerOFFandlet it cool at leasttwo (2)

minutes beforeremovingfuel cap. Loosencap slowly to

relievepressurein tank.

• Fillor drainfuel tank outdoors.

• DONOToverfilltank.Allow spacefor fuel expansion.

• Iffuel spills, wait until it evaporatesbeforestarting

engine.

• Keepfuel awayfrom sparks, openflames,pilot lights, heat, and

other ignitionsources.

• DONOTfighta cigaretteor smoke.

WHENSTARTINGEQUIPMENT

• Ensurespark plug, muffler,fuel cap, andair cleanerare in place.

• DONOTcrankenginewith spark plug removed.

WHENOPERATINGEQUIPMENT

• DONOTtip engineor equipment at anglewhich causesfuel to

spill.

• DONOTsprayflammable liquids.

WHENTRANSPORTINGORREPAIRINGEQUIPMENT

• Transport/repairwithfuel tank EMPTYor with fuel shutoff valve

OFF.

• Disconnectsparkplug wire.

WHENSTORINGFUELDREQUIPMENTWITH FUELiN TANK

• Storeaway from furnaces, stoves, waterheaters,clothes dryers,

or otherappliancesthat havepilot light or otherignition source

becausetheycan ignitefuel vapors.

Page 5

,_ll WARNING:Useofpowerwashercancreatepuddlesand

slipperysurfaces.Kickbackfromsprayguncancauseyouto

fail.

Useonly on a levelsurface.

The cleaning area should have adequate slopes and

drainageto reducethe possibility of afall due to slippery

surfaces.

Donot useon elevatedsurfaceswhere chanceof kickback

could resultin a seriousfall.

®

Firmlygrasp spraygun with both handswhen using high

pressure spray to avoid injury when spray gun kicks

back.

,_WARNING: Starter and otherrotatingpartscan

entangle hands,hair,clothing,or accessories.

or covers.

• NEVERoperatepowerwasherwithoutprotectivehousing

• DONOTwearlooseclothing,jewelryoranythingthat

maybecaughtinthestarterorotherrotatingparts.

• Tieuplonghairandremovejewelry.

,_ WARNING:Starter cordkickback(rapid retraction) canresult

in bodilyinjury.Kickbackwill pull handand arm toward

engine faster than you can let go. Brokenbones,fractures,

bruises,or sprains couldresult.

• NEVERpull starter cord withoutfirst relievingspray gun

pressure.

• Torelievetrappedpressure, point gunin safe directionand

releasepressureby pulling/actuatingtrigger on spraygun.

• Whenstartingengine, pull cord slowly until resistanceis felt and

then pull rapidlyto avoidkickback.

• After eachstarting attempt,where enginefailsto run, always

pointspray gun in safedirection, and squeezespray gun trigger

to releasehigh pressure.

• Firmlygrasp spraygun with both handswhenusing high

pressuresprayto avoid injurywhen spraygun kicks back.

,_ WARNING:Unintentionalsparking canresult in fire or electric

shock.

WHENADJUSTINGORMAKINGREPAIRSTO YOURPOWER

WASHER.

• Disconnectthe sparkplug wire from the spark plug and

place the wire whereit cannotcontact sparkplug.

,_WARNING: The engine exhaust from this productcontains

chemicalsknownto the State of Californiato causecancer,

birthdefects, or otherreproductive harm.

,_ll WARNING:This containslead and lead

knownto the State of Californiato causebirth defects or

otherreproductive harm.Wash your handsafterhandlingthis

product.

product compounds,

NOTE:

Highpressurespraymay damage fragile itemsincluding

glass.

DO NOTpoint spray gun at glass when using red (0°) MAX

nozzle.

NEVERaim spray gun at people,animals,electricaldevicesor

plants.

NOTE:

Impropertreatmentof powerwashercandamageit and

shortenits life.

• If you havequestionsaboutintendeduse,ask dealeror contact

qualifiedservice center.

• NEVERoperateunits with brokenor missing parts, or without

protectivehousingor covers.

• DONOTby-passanysafetydeviceonthismachine.

• DONOToperatepowerwasheraboveratedpressure.

• DONOTmodify power washerin anyway.

• Beforestartingpowerwasherincold weather,checkallparts of

the equipmentto be sure icehas notformed there.

• NEVERmovemachinebypullingon hoses.Usehandleprovided

on unit.

• Checkfuel system for leaks or signs of deterioration,such as

chafed or spongy hose, looseormissing clamps, or damaged

tank or cap. Correctall defectsbefore operatingpowerwasher.

• Thisequipmentisdesignedto be usedwith Generacauthorized

parts ONLY.If equipment is used with parts that DO NOT

comply with minimum specifications, user assumesall risks

and liabilities.

• Useapprovedsparkplug tester.

_ WHENTESTINGFORENGINESPARK

• DONOTcheck for spark with spark plug removed.

,_ WARNING:Risk of eye injury.Spray cansplash back or

propelobjects.

0 • Always wear safety goggleswhenusing this equipmentor

•. in vicinity of where equipmentis in use.

• Beforestartingthepower washer,be sureyou are

wearing adequatesafetygoggles.

• NEVERsubstitute safety glassesfor safety goggles.

Page 6

KNOWYOURPOWERWASHER

Readthis owner's manual and safety rules before operatingyour

high powerwasher.

Ifyou loanthis deviceto someone,ALWAYSloantheseinstructions

ANDthe owner's manualto the individual as well. Comparethe

illustrations with your high power washer to familiarize yourself

with the locations of variouscontrols (Figure1). Savethismanual

for future reference.Replacementowner's manualscan beprinted

from the GeneracWebsite.

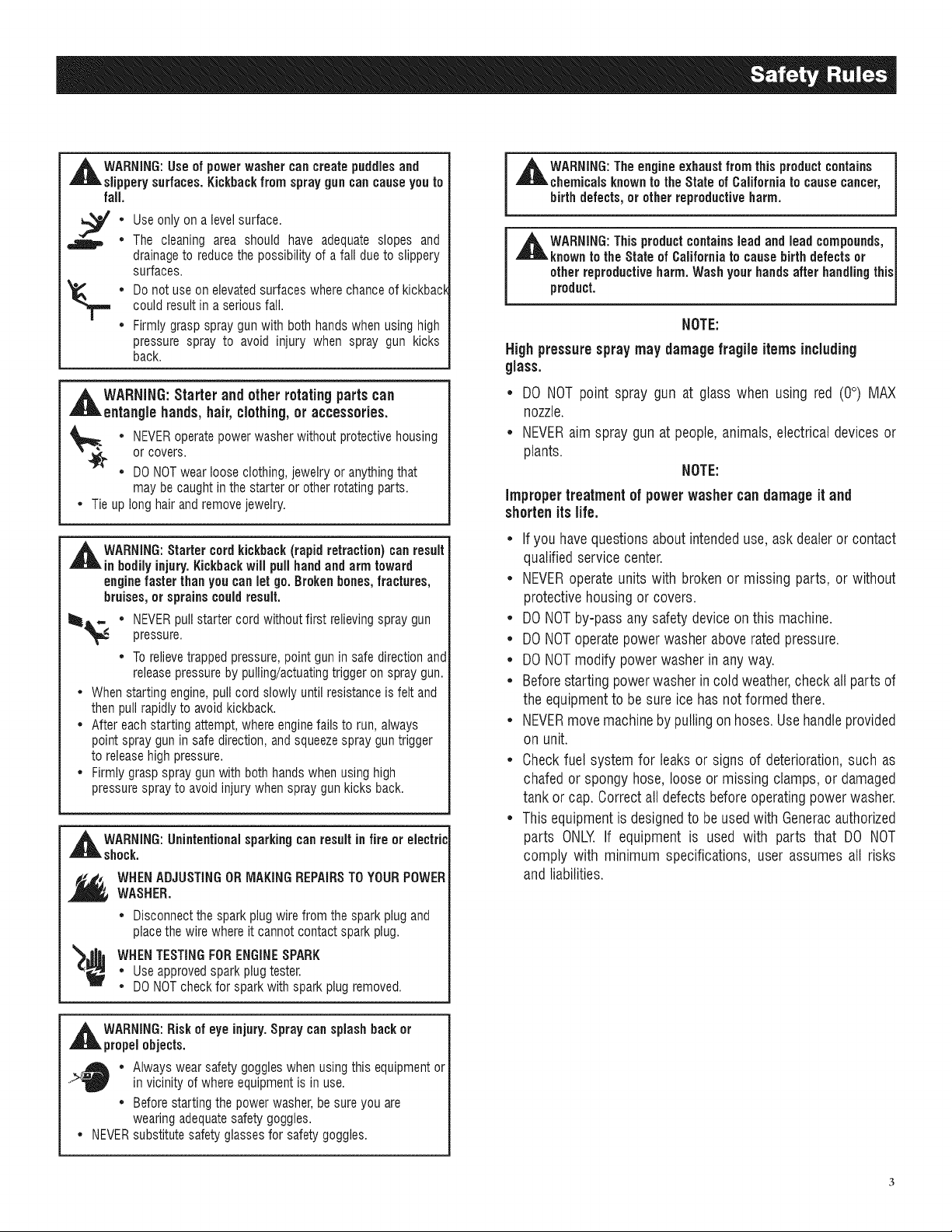

A- Spray Gun- Controls the application of water onto the cleaning

surface withtrigger device. Includesa trigger lock.

B- LancewithQuickConnect- Allowsyou to switch betweendifferent

nozzles

C- HighPressure Hose - Connectoneendto water pump andthe other

to the spraygun.

D - Recoil Starter - Usefor starting the engine.

E- Oil Fill - Checkandadd engineoil.

F - Air Filter - Protects engine by filtering dust and debris out of the

intakeair.

G - Pump- Developshigh pressure.

tt - Thermal Relief Valve- Cycleswaterthrough the pump when water

reaches125°F warm water will discharge from pump onto ground.

This preventsinternal pump damage.

I - Engine On/Off Switch - Turnthis switch to "ON" before using the

recoil starter. Turn theswitch to "OFF"to stop the engine.

J - UnloaderValve- Controlsthe highpressure output.

K- High Pressure Outlet- Connectionfor high pressure hose.

L - Water Inlet - Connectionfor GardenHose.

IVl- FuelTank- Filltank with regularunleadedfuel. Always leaveroom

forfuel expansion.

N - Fuel On/Off Switch- Turnsfuel supply to the engineon and off.

O - Choke- Preparesa cold enginefor starting.

P- Throttle Lever - Increases or decreases engine speed. Throttle

shouldbe at maximumtravel whenthe powerwasher is inuse.

Q- Nozzles - Chemicalinjection, 0°, 15°, 25°, 40° for various high

pressurecleaningapplications.

R- Chemical Tank- Usedto hold power washer safe detergentsto

be siphonedinto the low pressurestream. (some units may not be

equippedwith tanks or may only have onetank).

S- Warning/OperationInstruction - Identifies proper procedure to

start!stop powerwasher.

T - Brain Plug - Used to drain engine oil.

ITEMSNOTSHOWN

• IdentificationLabel (on engineblower housing)- Providesmodel and

serial numberof power washer. Pleasehavethese readilyavailableif

callingfor assistance.

• DetergentSiphoning Tube/Filter- Use to siphon power washer safe

detergentsinto the low pressurestream

T

Figure 1 - Features & Controls

A

C

K

H

D

R

P

Page 7

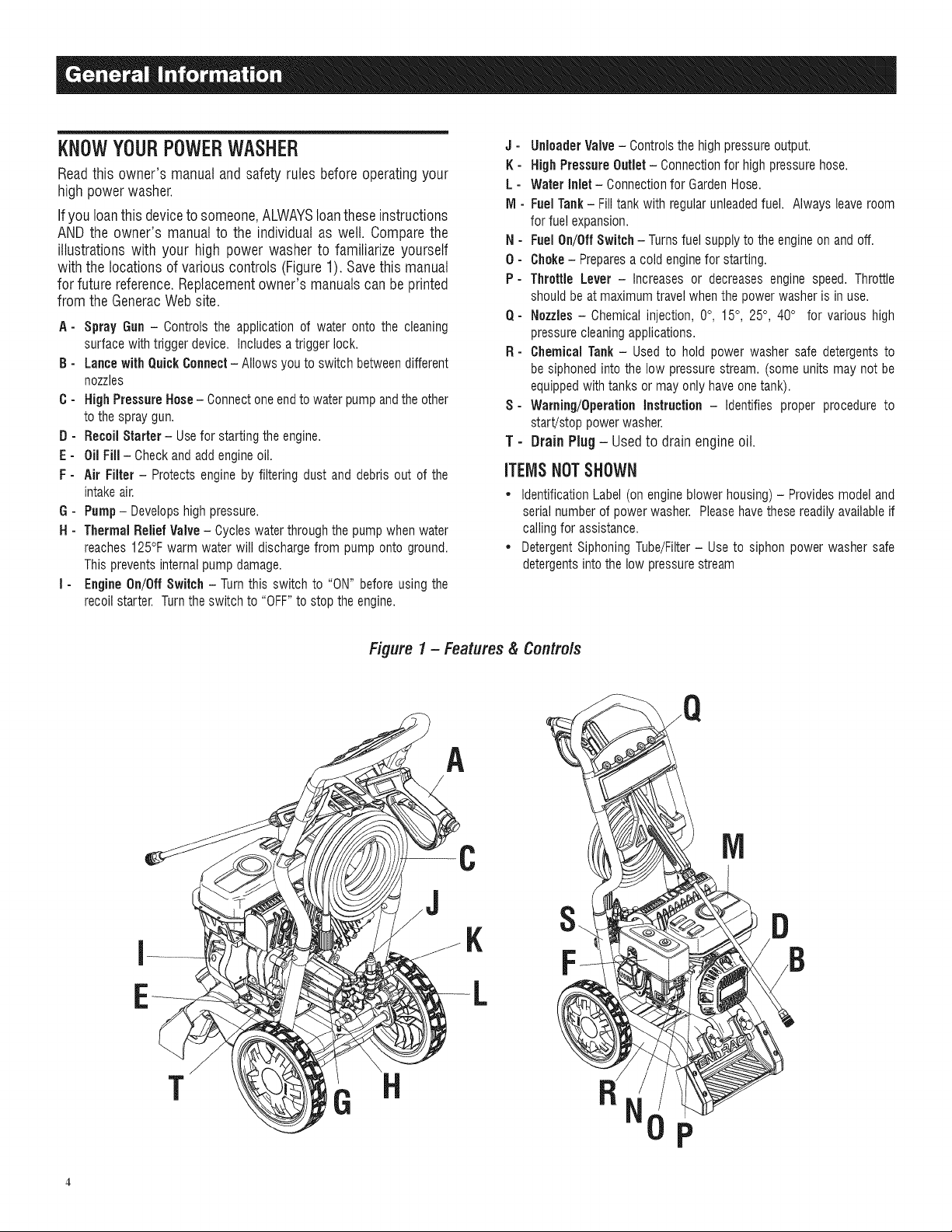

PRODUCTSPECiFiCATiONS

CONSUMER

OutletPressure- (PSI/BAR) 2500/172 j 2700/186 3000/207

FlowRate- (GPM/ LPM) 2.3/7.6 2.7/10.2

Watersupplytemperature- (°F/ C°) 100/38 Max

Hoselength- (Feet/Meters) 25/7.6 25/7.6 30/9.1

ChemicalTank(s)- Numberper unit 0 1 2

ChemicalTank- Capacity(Gal) N/A 0.75 0.75

Nozzles- Numberperunit 3 4 5

LanceLength (Inches/ cm) 20/51

Gun Standard Deluxe

EngineDisplacement- (Cubic Inch/ cc) 11.9/196 12.9/212

SparkPlugType F7RTCor equivalent

SparkPlugGap- (Inches/ mm) 0.028-0.031/0.70-0.80

Fuel 3.2/3.0

Capacity- (Quarts/ Liters) 3.8/3.6 1

OilCapacity- (Oz/ Liters) 20/0.6

Low OilShut Down System Yes

On/OffSwitch Yes

UNPACKING

1. Removethe parts bag,accessories,andinserts includedwith

powerwasher.

2. Open carton completely by cutting each corner from top to

bottom.

3. Ensureyou haveall includeditemspriorto assembly.

• MainUnit

• HandleAssembly

• HighPressureHose

• SiphonHose& Filter

• SprayGun

• LancewithQuickConnectFitting

• OilBottle

• HoseHookWireform

• PartsBag(whichincludesthefollowing):

ChemicalTankCapwith hole if modelis equippedwith a

ChemicalTank

Operator'sManual

Owner'sRegistrationCard

BagcontainingColor-codedNozzles

4. If you are missing any items from your carton, pleasecall

GeneracCustomerService at 1-888-436-3722. Whencalling

for assistance,pleasehavethe modeland serial numberfrom

thedata tag available.

5. Fill out and send in registrationcard. Write Model number,

Serial number& dateof purchase in the table located in the

"Whereto FindUs"section.

ASSEMBLY

Readentireoperator'smanualbeforeyouattemptto assembleorIf

you have anyproblems with the assembly of your power washer,

pleasecall GeneracCustomerService at 1-888-436-3722. When

calling for assistance, please havethe model and serial number

from the datatag available.

1. Place handle (A) onto handle supports (B). Push in latch

buttonsand allow handleto slide intoposition(C).Buttonwill

lock handleinto place(Figure2).

Figure 2 - Attach Handle

Page 8

NOTE:

it may be necessaryto movethe handle supportsfrom sideto

side in order to align the handlesoit will slideover the handle

supports.

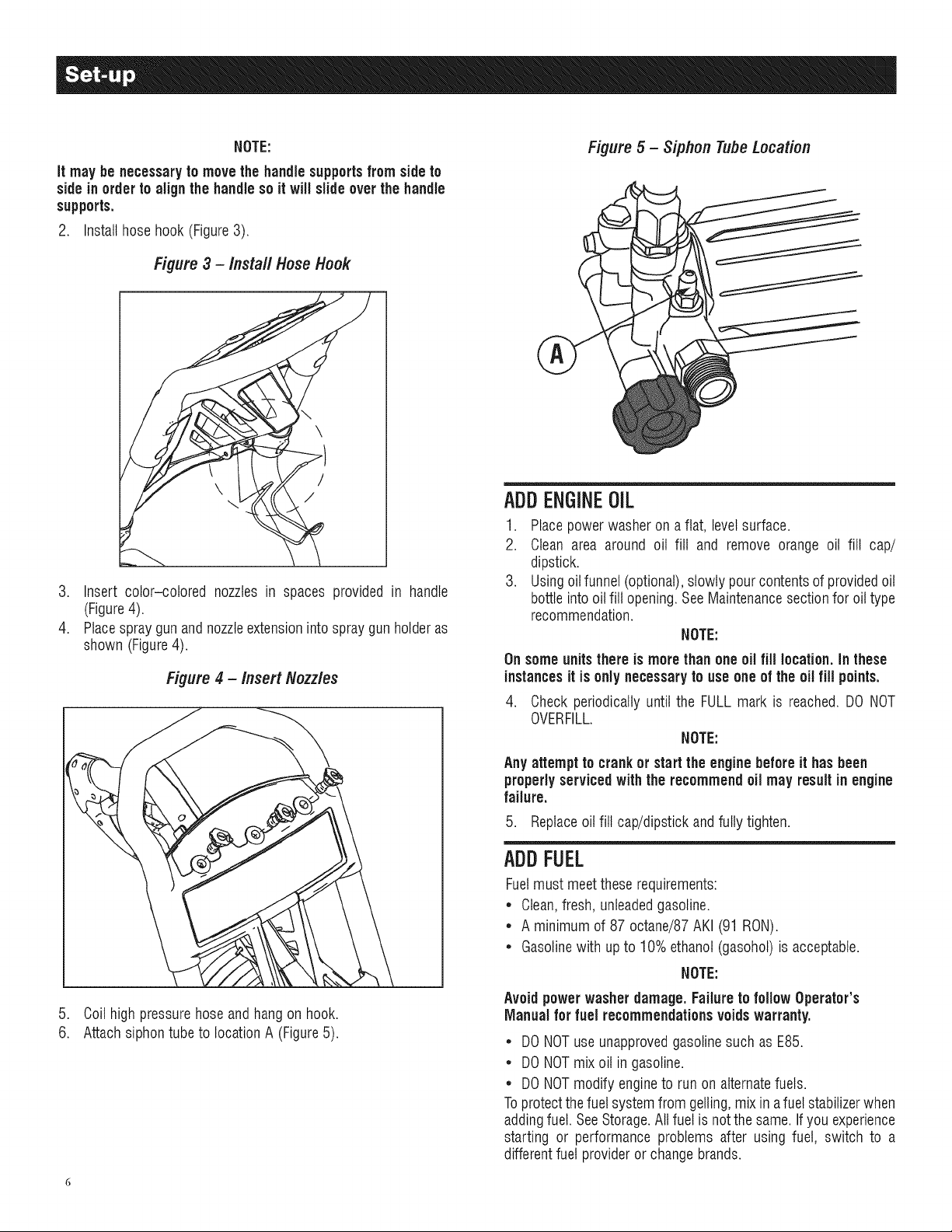

2. Installhose hook(Figure3).

Figure3 - InstallHoseHook

3. Insert color-colored nozzles in spaces provided in handle

(Figure4).

4. Placespraygunand nozzleextensionintospray gunholderas

shown (Figure4).

Figure4 - InsertNozzles

Figure5 - SiphonTubeLocation

ADDENGINEOIL

1. Placepowerwasher on a flat, level surface.

2. Clean area around oil fill and remove orange oil fill cap/

dipstick.

3. Usingoilfunnel(optional),slowly pour contentsof providedoil

bottle intooilfill opening.SeeMaintenancesectionfor oil type

recommendation.

NOTE:

Onsomeunits there is morethan one oil fill location.Inthese

instancesitis only necessaryto use one of the oil fill points.

4. Check periodicallyuntil the FULL mark is reached. DONOT

OVERFILL.

NOTE:

5. Coilhigh pressurehose and hangon hook.

6. Attachsiphon tubeto locationA (Figure5).

Any attempttocrankor startthe engine before it hasbeen

properlyservicedwith the recommendoil may resultin engine

failure.

5. Replaceoil fill cap/dipstickand fully tighten.

ADDFUEL

Fuelmust meettheserequirements:

• Clean,fresh, unleadedgasoline.

• A minimum of 87 octane/87AKI (91 RON).

• Gasolinewith up to 10% ethanol (gasohol)is acceptable.

NOTE:

Avoid powerwasherdamage. Failure to follow Operator's

Manualfor fuel recommendationsvoidswarranty.

• DONOTuse unapprovedgasolinesuch asE85.

• DONOTmixoilin gasoline.

• DONOTmodify engineto run on alternatefuels.

Toprotectthefuel systemfrom gelling,mix in afuelstabilizerwhen

addingfuel. SeeStorage.All fuel is notthe same.Ifyou experience

starting or performance problems after using fuel, switch to a

differentfuel provideror changebrands.

Page 9

and explosive. Fireor explosioncan cause

Fueland itsvaporsare extremelyflammable

severeburnsor death.

WHEN ADDING FUEL

* Turn power washer OFFand let it cool at least two (2) minutes

beforeremovingfuel cap. Loosen capslowly to relieve3ressurein

tank.

* Fillfuel tank outdoors.

* DONOToverfill tank. Allow spacefor fuel expansion.

* If fuel spills, wait until it evaporatesbeforestarting engine.

* Keepfuel awayfrom sparks, open flames, pilot lights, heat, and

other ignitionsources.

* DONOTlight acigarette orsmoke.

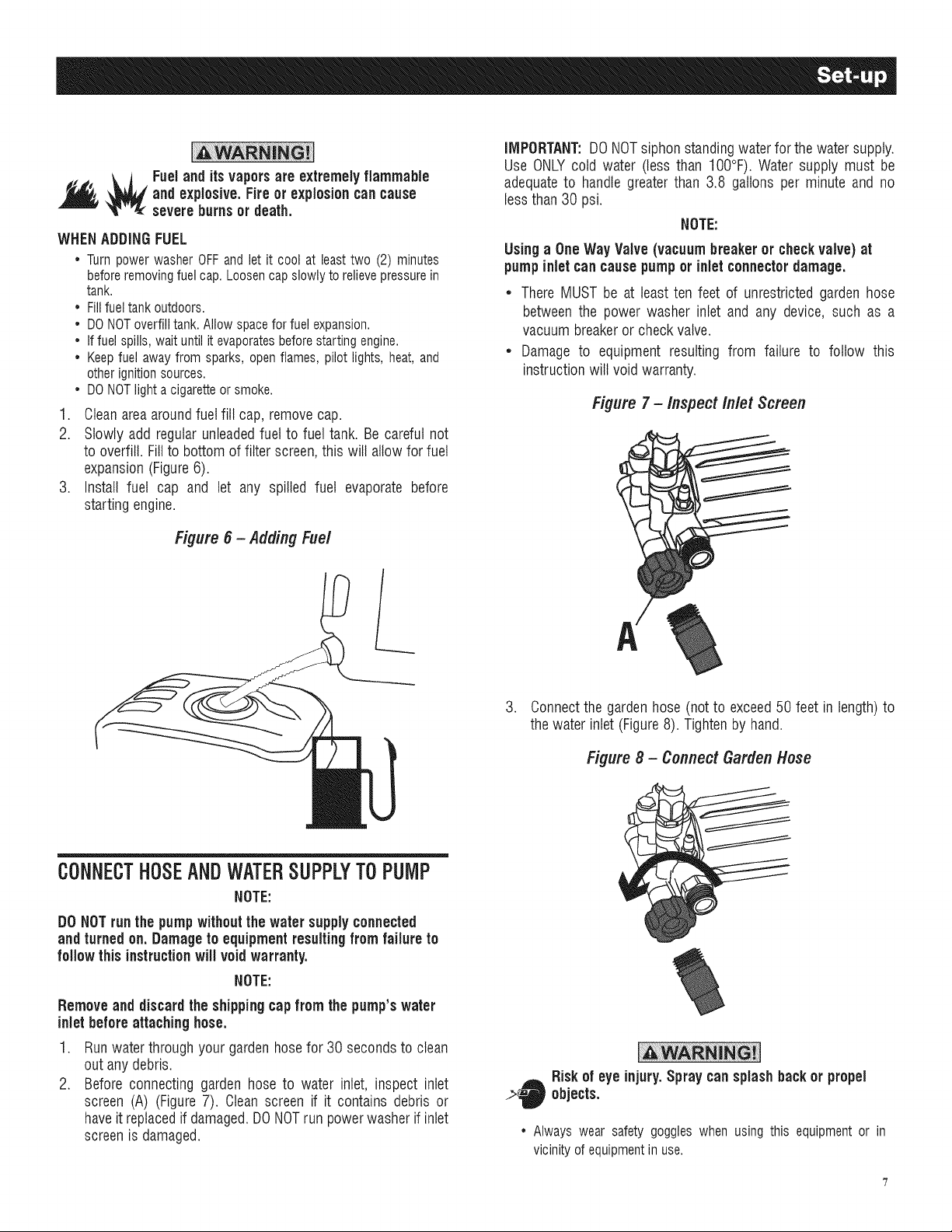

1. Clean area around fuel fill cap, remove cap.

2. Slowly add regular unleaded fuel to fuel tank. Be careful not

to overfill. Fillto bottom of filter screen, this will allow for fuel

expansion (Figure 6).

3. Install fuel cap and let any spilled fuel evaporate before

starting engine.

Figure 6 - Adding Fuel

iMPORTANT:DONOTsiphon standingwater forthe watersupply.

Use ONLYcold water (tessthan IO0°F).Water supply must be

adequateto handle greaterthan 3.8 gallons per minute and no

less than30 psi.

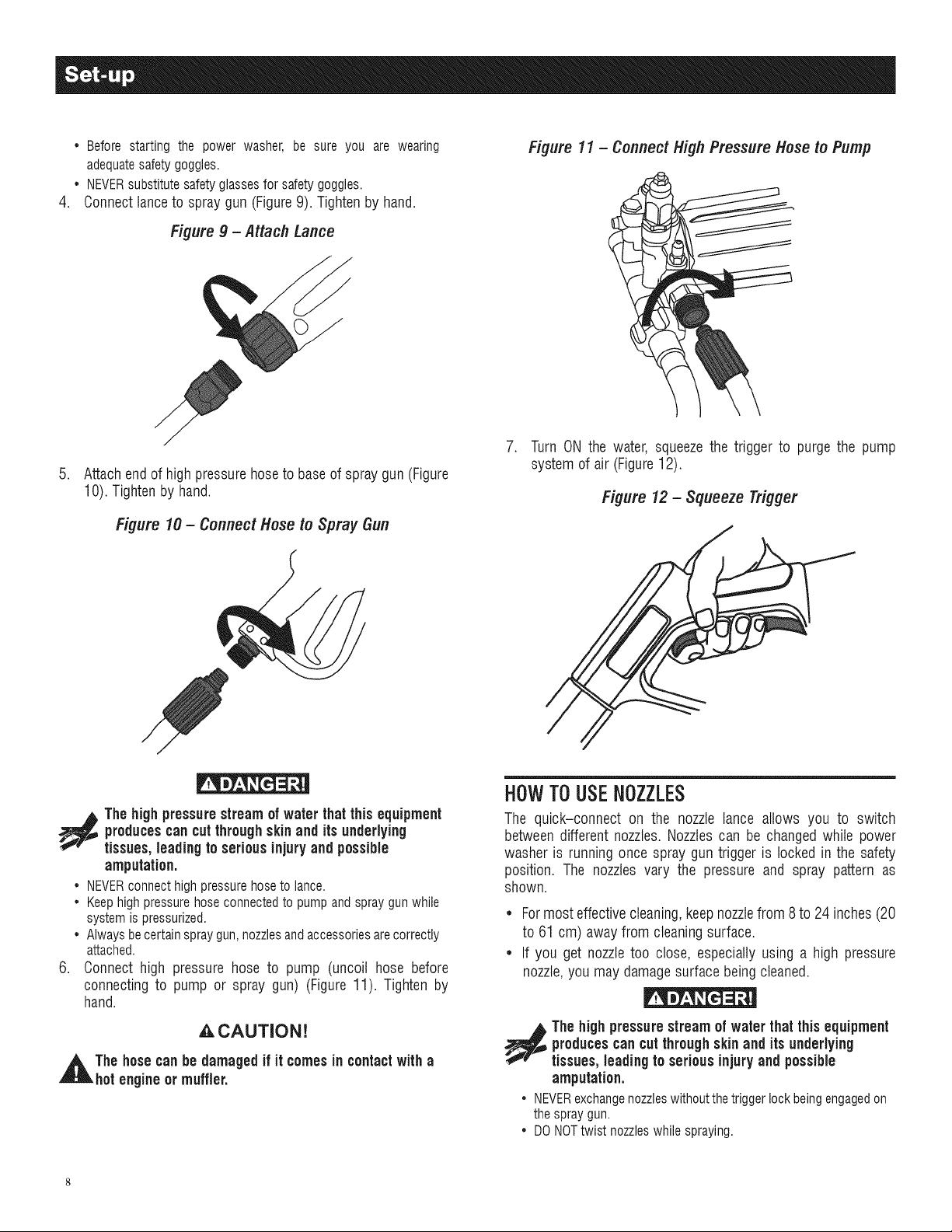

NOTE:

Usinga OneWay Valve(vacuumbreaker or checkvalve) at

pumpinlet cancausepumpor inletconnectordamage.

* ThereMUST be at least ten feet of unrestricted garden hose

between the power washer inlet and any device, such as a

vacuumbreakeror checkvalve.

* Damage to equipment resulting from failure to follow this

instructionwill voidwarranty.

Figure 7 - Inspect Inlet Screen

CONNECTHOSEANDWATERSUPPLYTOPUMP

NOTE:

DONOTrun the pumpwithoutthe water supplyconnected

andturned on. Damageto equipment resulting from failure to

follow this instructionwill voidwarranty.

NOTE:

Removeand discard the shippingcapfrom the pump'swater

inletbeforeattachinghose.

.

Runwaterthrough your gardenhose for 30 secondsto clean

out any debris.

2.

Before connecting garden hose to water inlet, inspect inlet

screen (A) (Figure7). Cleanscreen if it contains debris or

haveit replacedif damaged.DONOTrun powerwasher if inlet

screenis damaged.

.

Connectthe gardenhose (not to exceed50 feet in length)to

thewater inlet (Figure8). Tightenby hand.

Figure8 - Connect GardenHose

Riskof eye injury.Spray can splash backor propel

.._4_ objects.

* Alwayswearsafetygoggleswhenusingthis equipmentor in

vicinityof equipmentin use.

Page 10

• Beforestartingthe powerwasher,be sure you are wearing

adequatesafetygoggles.

• NEVERsubstitutesafetyglassesforsafetygoggles.

.

Connectlanceto spraygun (Figure9). Tightenby hand.

Figure g -Attach Lance

.

Attachend of high pressurehoseto baseof spraygun (Figure

10). Tightenby hand.

Figure 10- Connect Hose to Spray Gun

Figure 11- Connect High Pressure Hose to Pump

7. Turn ON the water, squeezethe trigger to purge the pump

system of air (Figure12).

Figure 12- Squeeze Trigger

producescancut throughskinand its underlying

Thehighpressurestreamof waterthat thisequipment

tissues,leadingto seriousinjuryand possible

amputation.

• NEVERconnecthighpressurehosetolance.

• Keephighpressurehoseconnectedto pumpandspraygunwhile

systemispressurized.

• Alwaysbecertainspraygun,nozzlesandaccessoriesarecorrectly

attached.

6. Connect high pressure hose to pump (uncoil hose before

connectingto pump or spray gun) (Figure 11). Tighten by

hand.

A.CAUTION!

,_The hosecanbe damagedif it comesin contactwitha

hotengineor muffler.

HOW TOUSENOZZLES

The quick-connect on the nozzle lance allows you to switch

between different nozzles.Nozzlescan be changed while power

washer is runningonce spray gun trigger is locked in the safety

position. The nozzles vary the pressure and spray pattern as

shown.

Formost effectivecleaning,keepnozzlefrom 8to 24 inches(20

to 61 cm) awayfrom cleaningsurface.

If you get nozzletoo close, especially using a high pressure

nozzle,you may damagesurfacebeing cleaned.

producescancut throughskinand itsunderlying

The highpressurestreamof water thatthis equipment

tissues,leadingto serious injuryand possible

amputation.

• NEVERexchangenozzleswithoutthetriggerlockbeingengagedon

thespraygun.

• DONOTtwistnozzleswhilespraying.

Page 11

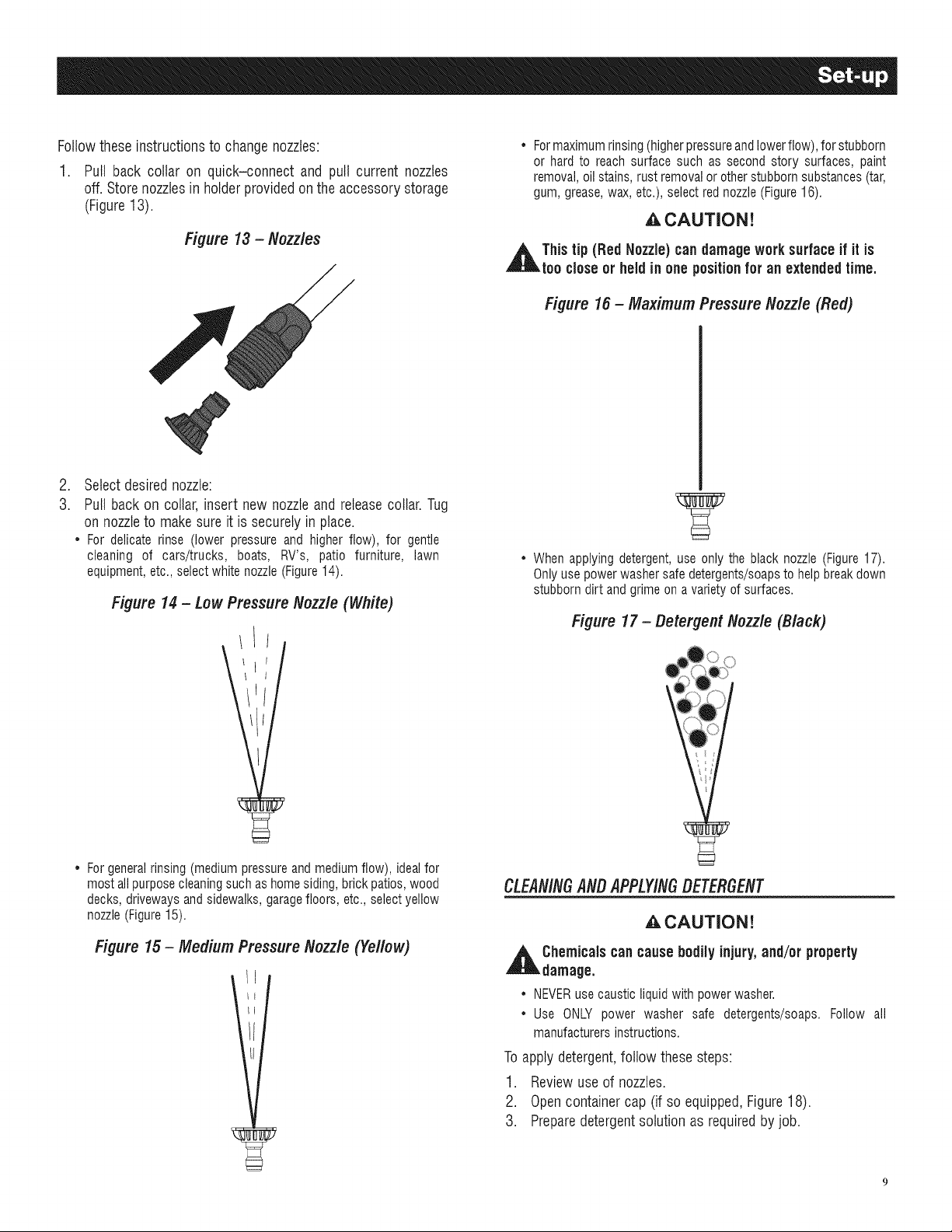

Followtheseinstructionstochangenozzles:

1. Pullbackcollaronquick-connectandpullcurrentnozzles

off.Storenozzlesinholderprovidedontheaccessorystorage

(Figure13).

Figure 13- Nozzles

.

Selectdesirednozzle:

3.

Pull backon collar, insert new nozzleand releasecollar.Tug

on nozzleto makesureit is securelyin place.

• Fordelicaterinse (lowerpressureandhigherflow), for gentle

cleaningof cars/trucks, boats, RV's, patio furniture, lawn

equipment,etc.,selectwhitenozzle(Figure14).

Figure 14- Low PressureNozzle(White)

Formaximumrinsing (higherpressureandlowerflow), for stubborn

or hard to reach surface such as second story surfaces, paint

removal,oilstains, rust removalor otherstubborn substances (tar,

gum, grease,wax, etc.), selectred nozzle(Figure16).

_CAUTION!

,l& Thistip (RedNozzle)can damageworksurface if it is

too closeor heldinonepositionfor an extendedtime.

Figure15- MaximumPressureNozzle(Red)

• When applying detergent,use only the black nozzle (Figure17).

Onlyuse powerwasher safe detergents/soapsto helpbreakdown

stubborn dirt andgrime on avariety of surfaces.

Figure 17 - Detergent Nozzle (Black)

• Forgeneralrinsing (medium pressureand mediumflow), idealfor

mostall purposecleaningsuch as homesiding, brickpatios,wood

decks, drivewaysand sidewalks,garagefloors, etc., selectyellow

nozzle(Figure15).

Figure 15- Medium Pressure Nozzle (Yellow)

CLEANINGANDAPPLYINGDETERGENT

_,CAUTION!

,l& Chemicals cancause bodilyinjury,and/orproperty

damage.

• NEVERusecausticliquidwithpowerwasher.

• Use ONLYpower washer safe detergents/soaps.Follow all

manufacturersinstructions.

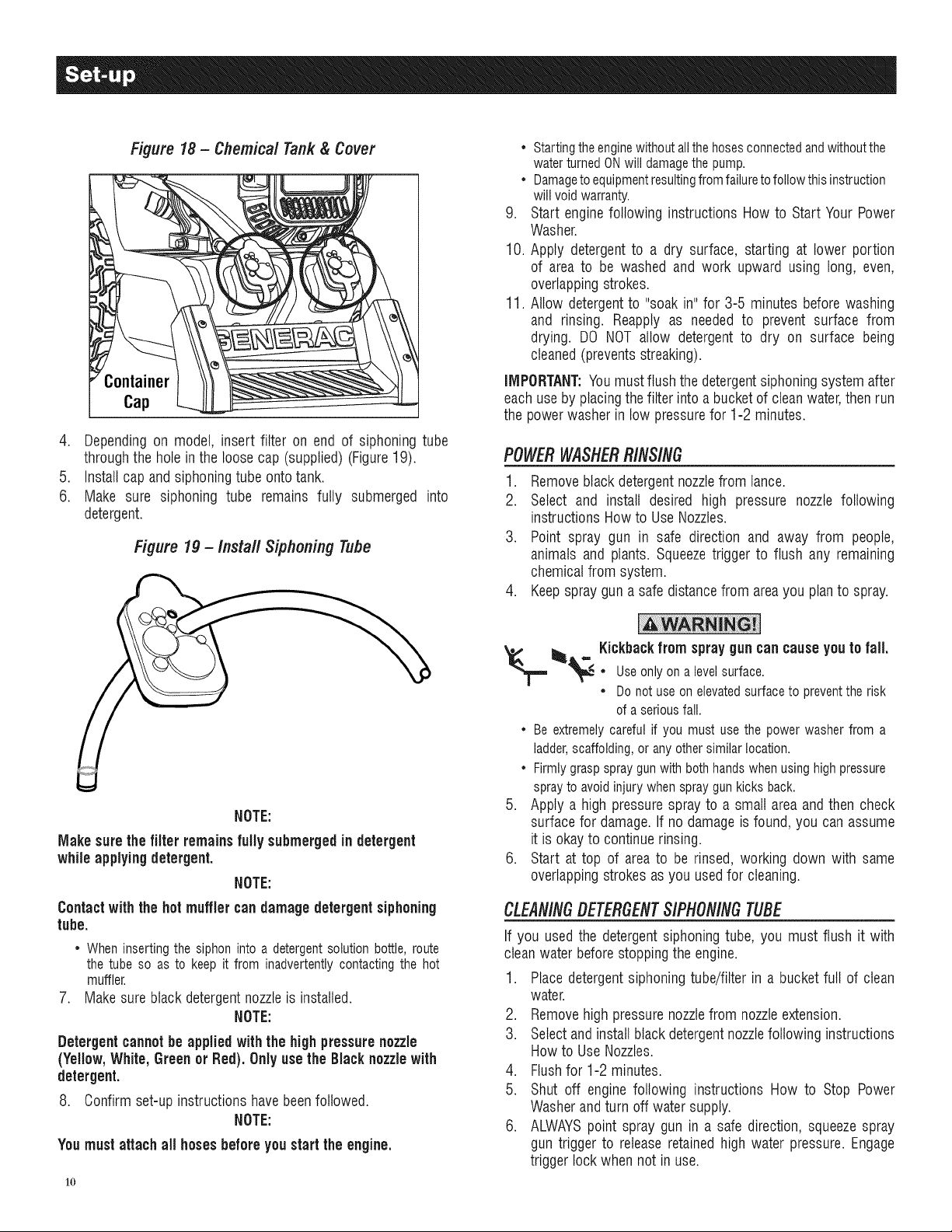

Toapply detergent,followthese steps:

1. Reviewuse of nozzles.

2. Opencontainercap (if so equipped,Figure18).

3. Preparedetergentsolutionas requiredby job.

Page 12

Figure 18 - Chemical Tank & Cover

Container

Cap

4. Dependingon model, insert filter on end of siphoningtube

throughthe hole in the loosecap (supplied)(Figure19).

5. Installcap andsiphoningtube ontotank.

6. Make sure siphoning tube remains fully submerged into

detergent.

Figure lg - Install Siphoning Tube

* Startingtheenginewithoutallthehosesconnectedandwithoutthe

waterturnedONwilldamagethe pump.

* Damagetoequipmentresultingfromfailuretofollowthisinstruction

willvoidwarranty.

9. Start enginefollowing instructions How to Start Your Power

Washer.

10. Apply detergentto a dry surface, starting at lower portion

of areato be washed and work upward using long, even,

overlappingstrokes.

11. Allow detergentto "soak in" for 3-5 minutes beforewashing

and rinsing. Reapply as neededto prevent surface from

drying. DO NOT allow detergent to dry on surface being

cleaned(preventsstreaking).

IMPORTANT:Youmustflush the detergentsiphoningsystem after

eachuse byplacing thefilter into a bucketof cleanwater,then run

the powerwasher in low pressurefor 1-2 minutes.

POWERWASHERRINSING

1. Removeblackdetergentnozzlefrom lance.

2. Select and install desired high pressure nozzle following

instructions Howto UseNozzles.

3. Point spray gun in safe direction and away from people,

animals and plants. Squeezetrigger to flush any remaining

chemicalfrom system.

4. Keepspraygun a safe distancefrom areayou planto spray.

NOTE:

Makesurethe filter remainsfully submergedin detergent

whileapplying detergent.

NOTE:

Contactwith the hotmuffler can damage detergent siphoning

tube.

* When inserting the siphon into a detergentsolution bottle, route

the tube so as to keep it from inadvertently contacting the hot

muffler.

.

Make sure black detergent nozzle is installed.

NOTE:

Detergentcannotbe applied withthe highpressurenozzle

(Yellow,White,Greenor Red). Only usethe Black nozzlewith

detergent.

8. Confirmset-up instructions havebeenfollowed.

NOTE:

Youmustattachall hosesbefore youstartthe engine.

1o

_ _ Kickback from spraygun cancauseyouto fall.

* Useonlyona levelsurface.

* Donot useonelevatedsurfaceto preventtherisk

ofa seriousfall.

* Beextremelycarefulif youmust usethe powerwasherfroma

ladder,scaffolding,or anyothersimilarlocation.

* Firmlygraspspraygunwithbothhandswhenusinghighpressure

sprayto avoidinjurywhenspraygunkicksback.

5. Apply a high pressurespray to a small area andthen check

surfacefor damage.If no damageis found,you can assume

it is okay to continuerinsing.

6. Start at top of areato be rinsed, working down with same

overlappingstrokesas you usedfor cleaning.

CLEANINGDETERGENTSIPHONINGTUBE

If you used the detergentsiphoningtube, you must flush it with

cleanwater beforestoppingthe engine.

1. Placedetergentsiphoning tube/filter in a bucketfull of clean

water.

2. Removehigh pressurenozzlefrom nozzleextension.

3. Selectandinstall blackdetergentnozzlefollowing instructions

How to Use Nozzles.

4. Flushfor 1-2 minutes.

5. Shut off engine following instructions How to Stop Power

Washerand turn off water supply.

6. ALWAYSpoint spray gun in a safe direction, squeezespray

gun trigger to release retainedhigh water pressure.Engage

triggerlock when not inuse.

Page 13

IMPORTANT:Sprayguntrapshighwaterpressure,evenwhen

engineisstoppedandwaterisdisconnected.

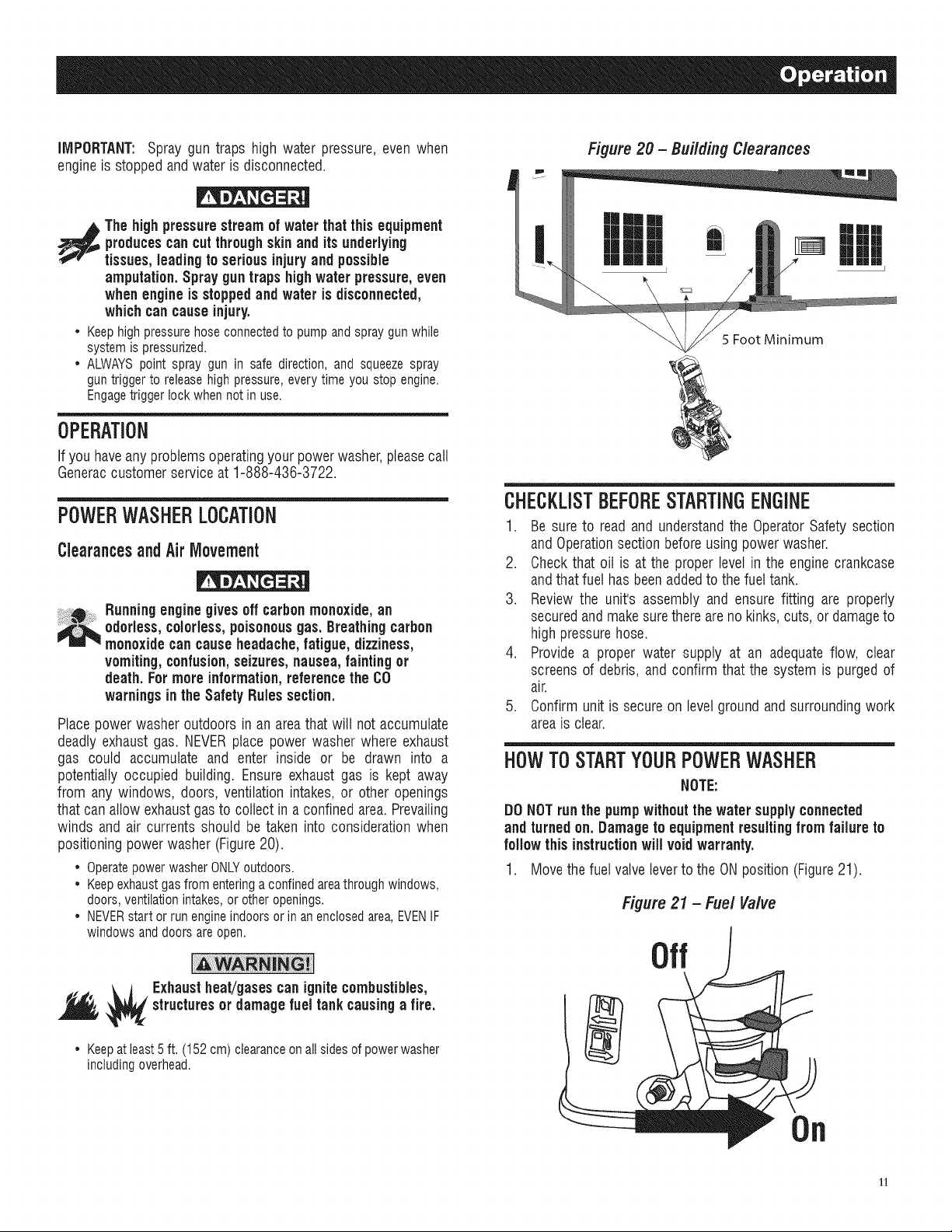

Figure20 - Building Clearances

:_ The highpressurestreamof water thatthis equipment

producescancutthroughskinand its underlying

tissues,leadingto seriousinjuryand possible

amputation.Spray guntrapshighwaterpressure,even

whenengineis stoppedandwater is disconnected,

whichcan causeinjury.

• Keephighpressurehoseconnectedto pumpandspraygunwhile

systemispressurized.

• ALWAYSpointspraygunin safedirection,andsqueezespray

guntriggerto releasehighpressure,everytimeyou stopengine.

Engagetriggerlockwhennotinuse.

OPERATION

If youhaveany problemsoperatingyourpower washer,pleasecall

Generaccustomerservice at 1-888-436-3722.

POWERWASHERLOCATION

ClearancesandAir Movement

Runningenginegives off carbonmonoxide,an

odorless,colorless,poisonousgas. Breathing carbon

monoxidecan causeheadache,fatigue, dizziness,

vomiting,confusion,seizures,nausea,faintingor

death. Formore information,reference the CO

warnings in the SafetyRulessection.

Placepower washer outdoors in an areathat will not accumulate

deadly exhaust gas. NEVERplace power washer where exhaust

gas could accumulate and enter inside or be drawn into a

potentially occupied building. Ensure exhaustgas is kept away

from any windows, doors, ventilationintakes,or other openings

that canallow exhaustgasto collect inaconfinedarea.Prevailing

winds and air currents should be taken into considerationwhen

positioningpowerwasher (Figure20).

• OperatepowerwasherONLYoutdoors.

• Keepexhaustgasfromenteringaconfinedareathroughwindows,

doors,ventilationintakes,orotheropenings.

• NEVERstartorrunengineindoorsor inanenclosedarea,EVENIF

windowsanddoorsareopen.

||i

5 Foot Minimum

CHECKLISTBEFORESTARTINGENGINE

1. Be sure to read and understandthe OperatorSafety section

and Operationsectionbeforeusing powerwasher.

2. Checkthat oil is at the proper level in the enginecrankcase

andthat fuel has beenaddedto the fueltank.

3. Reviewthe unit's assembly and ensure fitting are properly

securedandmakesurethere are nokinks, cuts, or damageto

high pressurehose.

4. Provide a proper water supply at an adequateflow, clear

screensof debris, and confirm that the system is purged of

air.

5. Confirm unit is secureon levelgroundandsurroundingwork

areais clear.

HOW TOSTARTYOURPOWERWASHER

NOTE:

DONOTrun the pumpwithout the water supplyconnected

andturnedon. Damage to equipment resultingfrom failure to

follow this instructionwill voidwarranty.

1. Movethefuel valve leverto theONposition (Figure21).

Figure 21 - Fue/ Va/ve

Off

_ Exhaustheat/gases can ignitecombustibles,

• Keepatleast5 ft. (152 cm) clearanceon all sidesofpowerwasher

includingoverhead.

structuresor damage fuel tankcausinga fire.

11

Page 14

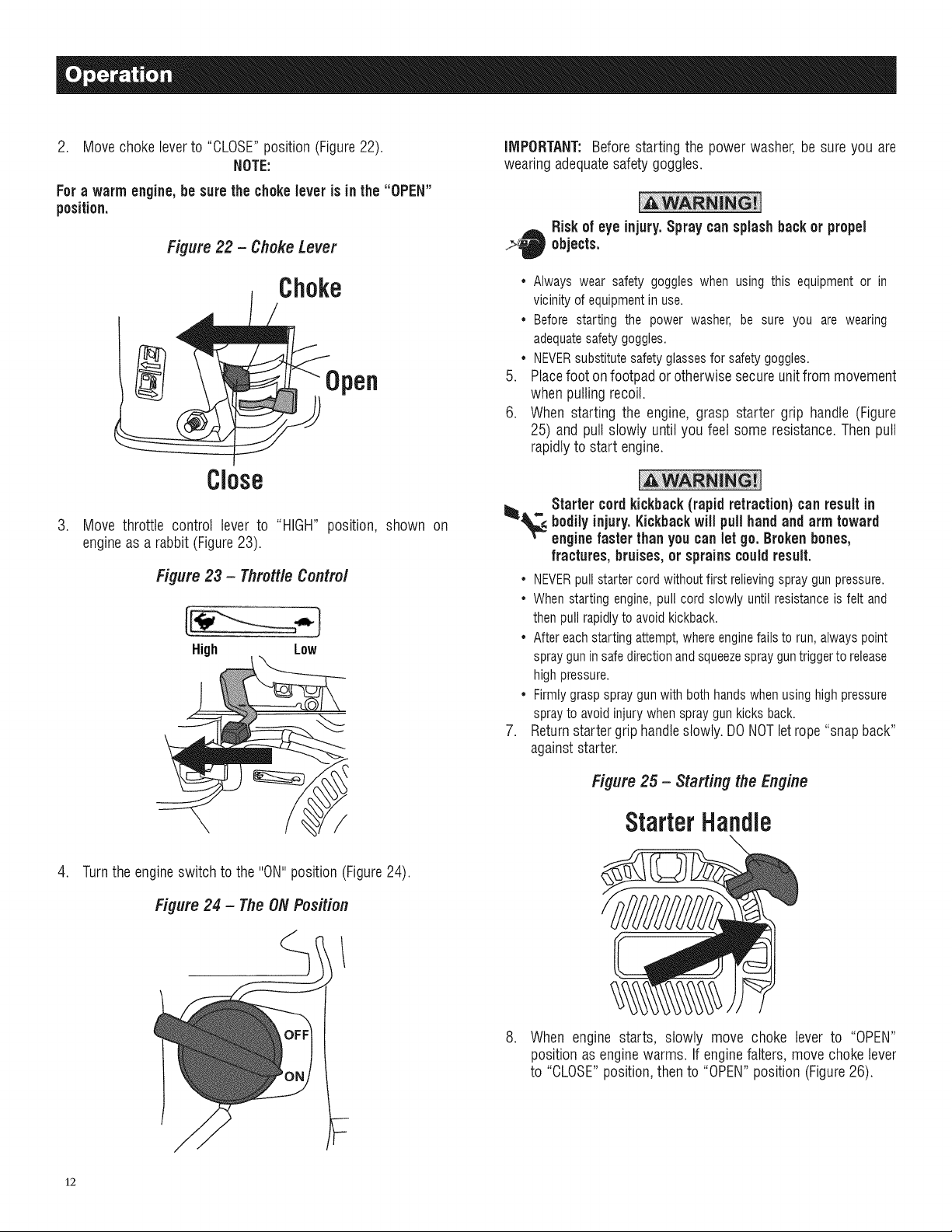

2. Move chokeleverto "CLOSE"position (Figure22).

NOTE:

Fora warm engine, be surethe chokeleveris inthe "OPEN"

position.

Figure22 - ChokeLever

Open

Close

.

Move throttle control lever to "HIGH" position, shown on

engineasa rabbit (Figure23).

Figure 23 - Throttle Control

High Low

IMPORTANT:Beforestarting the power washer,be sure you are

wearingadequatesafetygoggles.

Risk of eye injury.Spraycansplashbackor propel

'>_0 objects.

Alwayswear safetygoggleswhen usingthis equipmentor in

vicinityof equipmentin use.

Beforestarting the powerwasher,be sure you are wearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesfor safetygoggles.

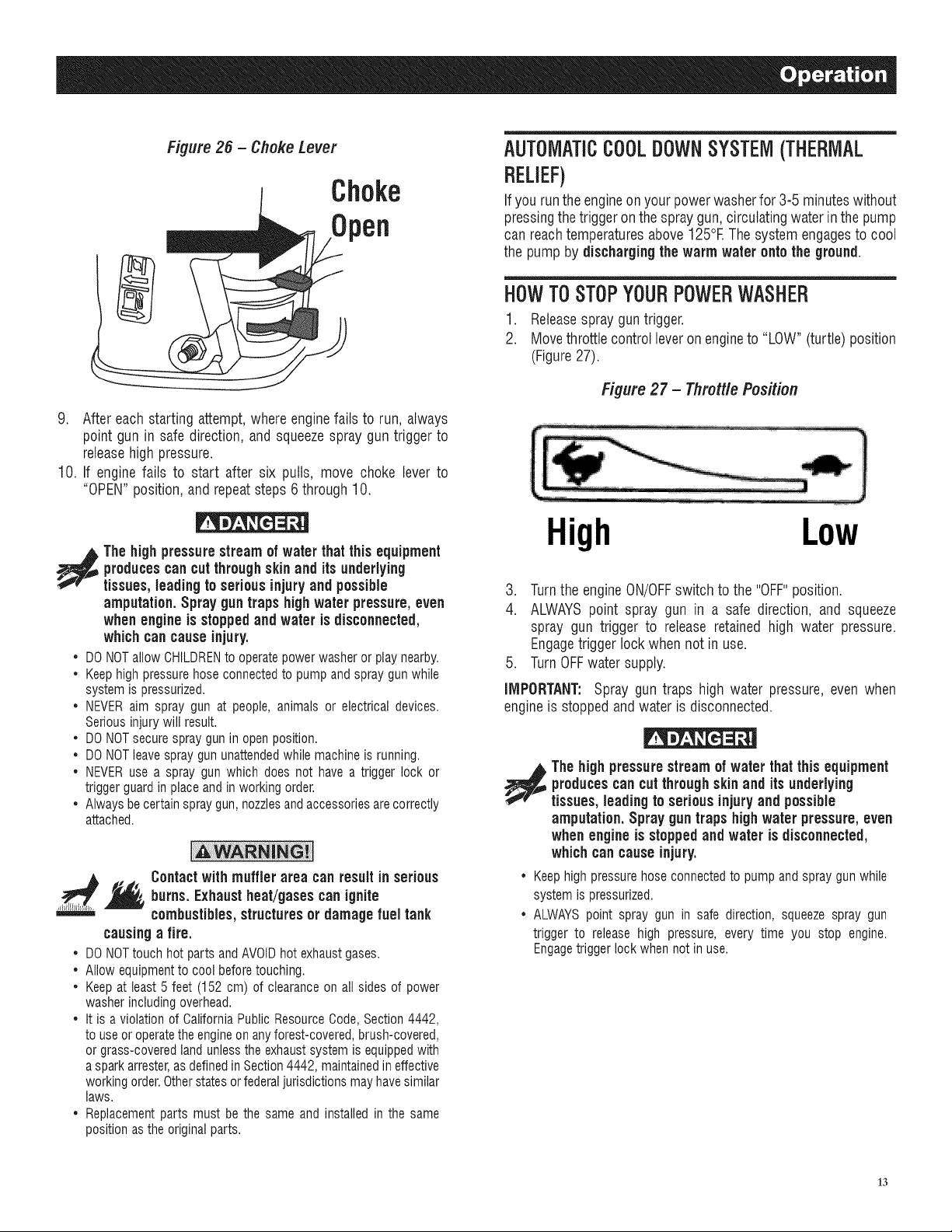

.

Placefoot onfootpador otherwise secureunitfrom movement

whenpulling recoil.

6.

When starting the engine, grasp starter grip handle (Figure

25) and pull slowly until you feel some resistance.Then pull

rapidlyto start engine.

Starter cordkickback (rapidretraction)canresult in

bodily injury.Kickback will pullhandand arm toward

enginefaster thanyoucan let go. Brokenbones,

fractures, bruises, or sprainscouldresult.

* NEVERpullstartercordwithoutfirstrelievingspraygunpressure.

* Whenstartingengine,pullcordslowlyuntilresistanceis felt and

thenpullrapidlyto avoidkickback.

* Aftereachstartingattempt,whereenginefailstorun,alwayspoint

sprayguninsafedirectionandsqueezesprayguntriggertorelease

highpressure.

®

Firmlygraspspraygunwithbothhandswhenusinghighpressure

sprayto avoidinjurywhenspraygunkicksback.

7.

Returnstartergrip handleslowly.DONOTletrope"snapback"

againststarter.

.

Turnthe engineswitch to the "ON"position (Figure24).

Figure24 - The ONPosition

12

Figure25 - Starting the Engine

StarterHandle

8. When engine starts, slowly move choke lever to "OPEN"

position asenginewarms. If enginefalters, move chokelever

to "CLOSE"position,thento "OPEN"position(Figure26).

Page 15

9. After eachstarting attempt,where enginefails to run, always

point gun in safe direction,andsqueezespray guntriggerto

releasehigh pressure.

10. If engine fails to start after six pulls, move choke leverto

"OPEN"position,and repeatsteps 6 through 10.

producescancutthroughskinand its underlying

The highpressurestreamof waterthat this equipment

tissues,leadingto seriousinjuryandpossible

amputation.Spray guntrapshighwaterpressure,even

whenengineisstoppedandwater is disconnected,

whichcan causeinjury.

, DONOTallowCHILDRENtooperatepowerwasherorplaynearby.

* Keephighpressurehoseconnectedtopumpandspraygunwhile

systemispressurized.

* NEVERaimspraygun at people,animalsor electricaldevices.

Seriousinjurywill result.

* DONOTsecuresprayguninopenposition.

* DONOTleavespraygununattendedwhilemachineisrunning.

* NEVERusea spraygunwhich doesnot havea triggerlockor

triggerguardinplaceandinworkingorder.

* Alwaysbecertainspraygun,nozzlesandaccessoriesarecorrectly

attached.

Contactwith mufflerarea canresultin seriousburns.Exhaustheat/gasescan ignite

combustibles,structuresor damagefuel tank

causinga fire.

* DONOTtouchhotpartsandAVOIDhotexhaustgases.

* Allowequipmenttocoolbeforetouching.

* Keepatleast5feet(152cm)of clearanceon allsidesof power

washerincludingoverhead.

* Itisa violationof CaliforniaPublicResourceCode,Section4442,

to useoroperatetheengineonanyforest-covered,brush-covered,

orgrass-coveredlandunlesstheexhaustsystemis equippedwith

asparkarrester,asdefinedinSection4442,maintainedineffective

workingorder.Otherstatesorfederaljurisdictionsmayhavesimilar

laws.

* Replacementpartsmustbethesameand installedinthe same

positionastheoriginalparts.

AUTOMATICCOOLDOWNSYSTEM(THERMAL

RELIEF)

If you run the engine on your power washer for 3-5 minutes without

pressing the trigger on the spray gun, circulating water inthe pump

can reach temperatures above 125°E The system engages to cool

the pump by discharging the warm water onto the ground.

HOWTOSTOPYOURPOWERWASHER

1. Release spray gun trigger.

2. Move throttle control lever on engine to "LOW" (turtle) position

(Figure 27).

Figure 27- ThmtUe Position

High Low

3. Turnthe engineON/OFFswitch to the "OFF"position.

4. ALWAYSpoint spray gun in a safe direction, and squeeze

spray gun trigger to release retained high water pressure.

Engagetrigger lock whennot in use.

5. TurnOFFwatersupply.

IMPORTANT:Spray gun traps high water pressure, evenwhen

engineis stoppedandwater is disconnected.

producescancutthroughskinand its underlying

The highpressurestreamof waterthat this equipment

tissues,leadingto seriousinjuryand possible

amputation. Spray guntrapshighwater pressure,even

whenengineisstoppedandwater is disconnected,

whichcan causeinjury.

* Keephigh pressurehose connectedto pump and spray gunwhile

systemis pressurized.

* ALWAYSpoint spray gun in safe direction, squeeze spray gun

trigger to release high pressure, every time you stop engine.

Engagetrigger lockwhen not in use.

13

Page 16

MAINTENANCERECOMMENDATIONS

Regularmaintenance wilt improve the performance and extend

the lifeof the powerwasher.Seeanyqualifieddealerfor service.

Thepowerwasher'swarrantydoesnotcover itemsthathavebeen

subjectedto operatorabuse or negligence.To receivefull value

from the warranty, the operator must maintainthe power washer

as instructed in this manual, includingproper storageas detailed

in WinterStorageand Long TermStorage.

NOTE:

Should youhavequestions aboutreplacingcomponents

on yourpowerwasher, pleasecall1-888-436-3722 for

assistance.

Some adjustmentswill needto bemade periodicallyto properly

maintainyour power washer.

All service and adjustmentsshould be madeat least once each

season. Follow the requirements in the MaintenanceSchedule

chart.

NOTE:

Oncea year youshouldcleanor replacethe sparkplug, clean

or replace the air filter, and checkthe spraygun and nozzle

extension assemblyfor wear.A new sparkplugand clean air

filter assure properfuel-air mixtureand help yourengine run

better and lastlonger.

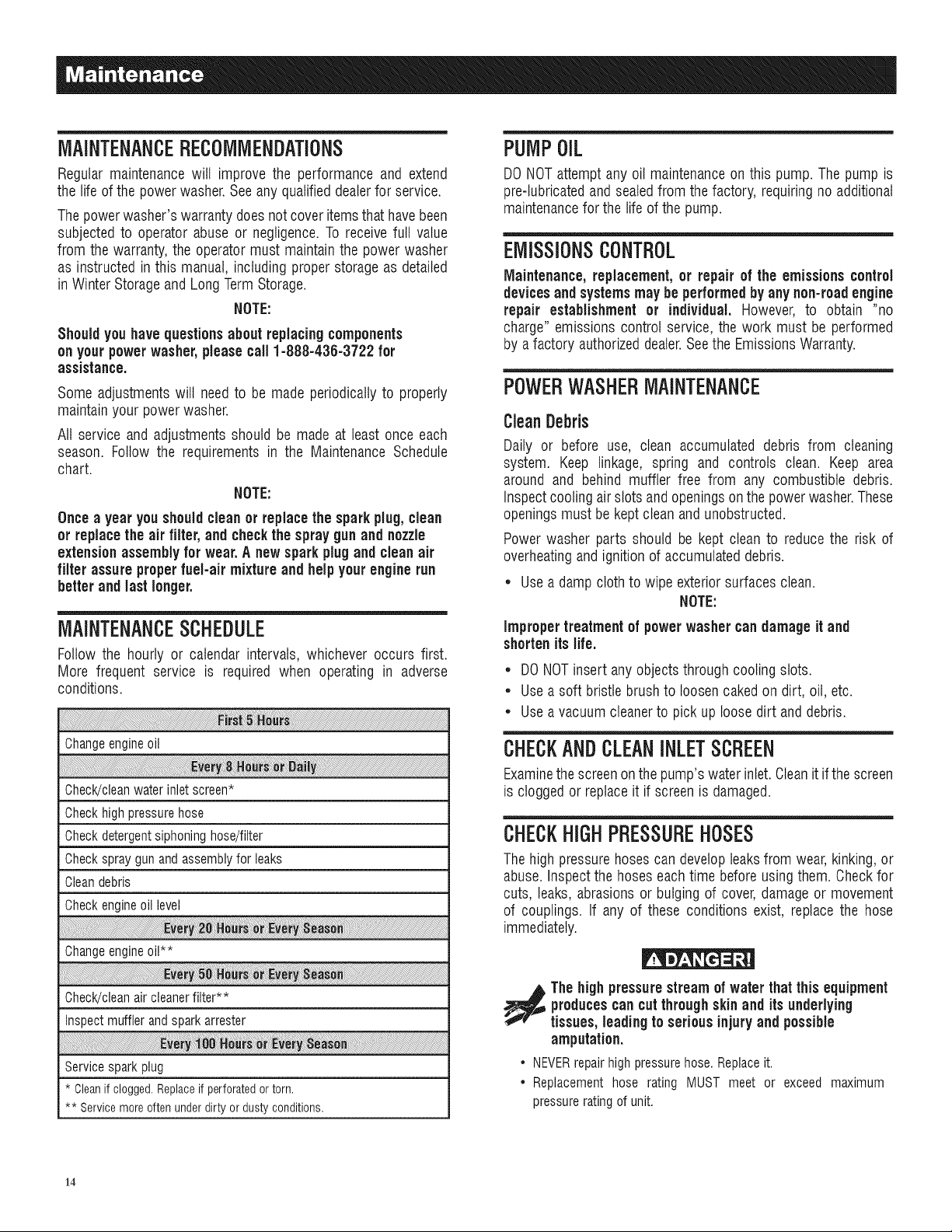

MAINTENANCESCHEDULE

Follow the hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in adverse

conditions.

PUMPOIL

DONOTattemptany oil maintenanceonthis pump. Thepump is

pre-lubricatedand sealedfrom the factory, requiringno additional

maintenancefor the life ofthe pump.

EMISSIONSCONTROL

Maintenance,replacement,or repair of the emissions control

devicesand systemsmaybe performedbyany non-roadengine

repair establishment or individual. However, to obtain "no

charge" emissions control service, the work must be performed

by afactory authorizeddealer.Seethe EmissionsWarranty.

POWERWASHERMAINTENANCE

CleanDebris

Daily or before use, clean accumulated debris from cleaning

system. Keep linkage, spring and controls clean. Keep area

around and behind muffler free from any combustible debris.

Inspectcoolingair slots and openingsonthe powerwasher.These

openingsmust be keptcleanand unobstructed.

Powerwasher parts should be kept clean to reducethe risk of

overheatingand ignition of accumulateddebris.

• Usea dampcloth to wipe exteriorsurfaces clean.

NOTE:

impropertreatment of powerwashercandamage it and

shortenits life.

• DONOTinsert anyobjects throughcooling slots.

• Usea soft bristlebrushto loosen cakedon dirt, oil, etc.

• Usea vacuumcleanerto pick up loosedirt anddebris.

Changeengineoil

Check!cleanwaterinletscreen*

Checkhighpressurehose

Checkdetergentsiphoninghose/filter

Checkspraygunandassemblyfor leaks

Cleandebris

Checkengineoil level

Changeengineoil**

Check/cleanaircleanerfilter**

Inspectmufflerand spark arrester

Servicespark plug

* Cleanif clogged.Replaceif perforated ortorn.

** Service more often under dirty or dusty conditions.

14

CHECKANDCLEANINLETSCREEN

Examinethe screenonthe pump'swaterinlet.Cleanitifthe screen

is clogged or replaceit if screenis damaged.

CHECKHIGHPRESSUREHOSES

Thehigh pressurehosescan developleaksfrom wear,kinking, or

abuse.Inspectthehoses each time beforeusingthem. Checkfor

cuts, leaks,abrasionsor bulgingof cover,damageor movement

of couplings. If any of these conditions exist, replace the hose

immediately.

producescancut throughskinand its underlying

Thehighpressurestream of water thatthisequipment

tissues,leadingtoseriousinjuryand possible

amputation.

• NEVERrepair high pressurehose.Replaceit.

• Replacement hose rating MUST meet or exceed maximum

pressure ratingof unit.

Page 17

CHECKDETERGENTSiPHONiNGTUBE

Examinethefilter on the detergenttube and cleanif clogged. The

tube should fit tightly on the barbedfitting. Examinethe tube for

leaks or tears.Replacethe filter or tube if eitheris damaged.

CHECKSPRAYGUN

Examinethe hoseconnectionto thespray gun andmakesureit is

secure.Test the trigger by pressingthe trigger,it "springs back"

into place whenyou releaseit. Replacespray gun immediatelyif

it fails to "springback".

NOZZLEMAINTENANCE

A pulsing sensation felt while squeezingthe spray gun trigger

may becaused by excessivepumppressure.Theprincipalcause

of excessive pump pressure is a nozzle clogged or restricted

with foreign materials,such as dirt, etc. Tocorrect the problem,

immediatelycleanthe nozzlefollowing these instructions:

1. Shutoff engineandturn off water supply.

2. ALWAYSpoint spray gun in a safe direction, squeezespray

gun triggerto releaseretainedhighwater pressure.

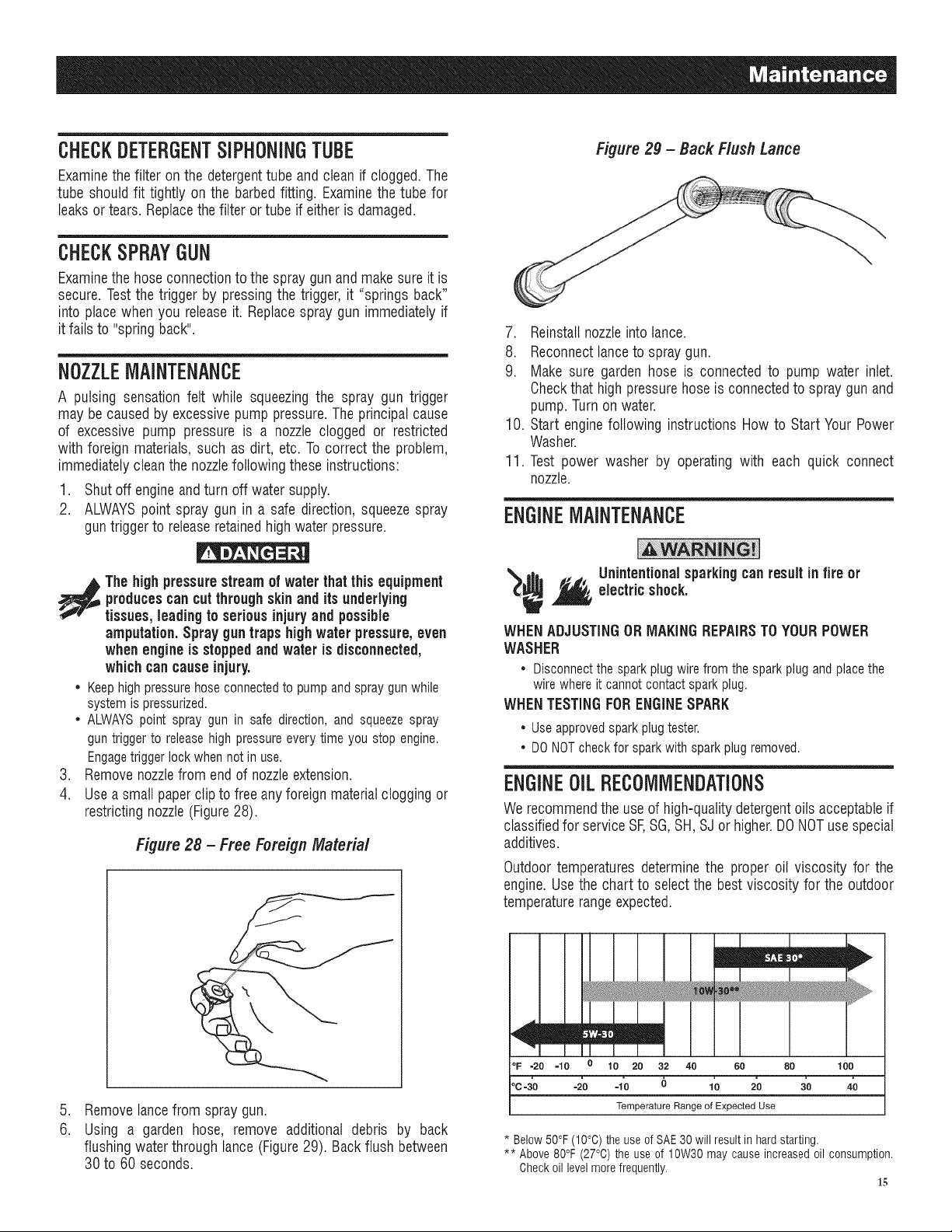

Figure29 - BackFlushLance

7. Reinstallnozzleinto lance.

8. Reconnectlanceto spraygun.

9. Make sure gardenhose is connectedto pump water inlet.

Checkthat high pressurehose is connectedto spray gunand

pump.Turnon water.

10. Start enginefollowing instructions How to Start Your Power

Washer.

11. Test power washer by operating with each quick connect

nozzle.

ENGINEMAINTENANCE

producescancutthroughskinand itsunderlying

The highpressurestream of water thatthis equipment

tissues,leadingto seriousinjuryand possible

amputation.Spray gun trapshighwaterpressure,even

whenengine isstoppedandwater isdisconnected,

whichcan causeinjury.

* Keephighpressurehoseconnectedto pumpandspraygunwhile

systemispressurized.

* ALWAYSpointspraygun in safedirection,andsqueezespray

guntriggerto releasehighpressureeverytimeyou stopengine.

Engagetriggerlockwhennotinuse.

3. Removenozzlefrom endof nozzleextension.

4. Use asmall paperclipto free anyforeignmaterialcloggingor

restricting nozzle(Figure28).

Figure 28 - Free Foreign Material

5. Removelancefrom spraygun.

6. Using a garden hose, remove additional debris by back

flushing waterthrough lance (Figure29). Backflush between

30 to 60 seconds.

_r Unintentional sparkingcanresultin fire or

WHENADJUSTINGORMAKINGREPAIRSTOYOURPOWER

WASHER

* Disconnectthesparkplugwirefromthe sparkplugandplacethe

wirewhereitcannotcontactsparkplug.

WHENTESTINGFORENGINESPARK

* Useapprovedsparkplugtester.

* DONOTcheckforsparkwithsparkplugremoved.

eJectricshock.

ENGINEOILRECOMMENDATIONS

Werecommendthe useof high-qualitydetergentoils acceptableif

classifiedfor service SF,SG,SH, SJor higher.DONOTuse special

additives.

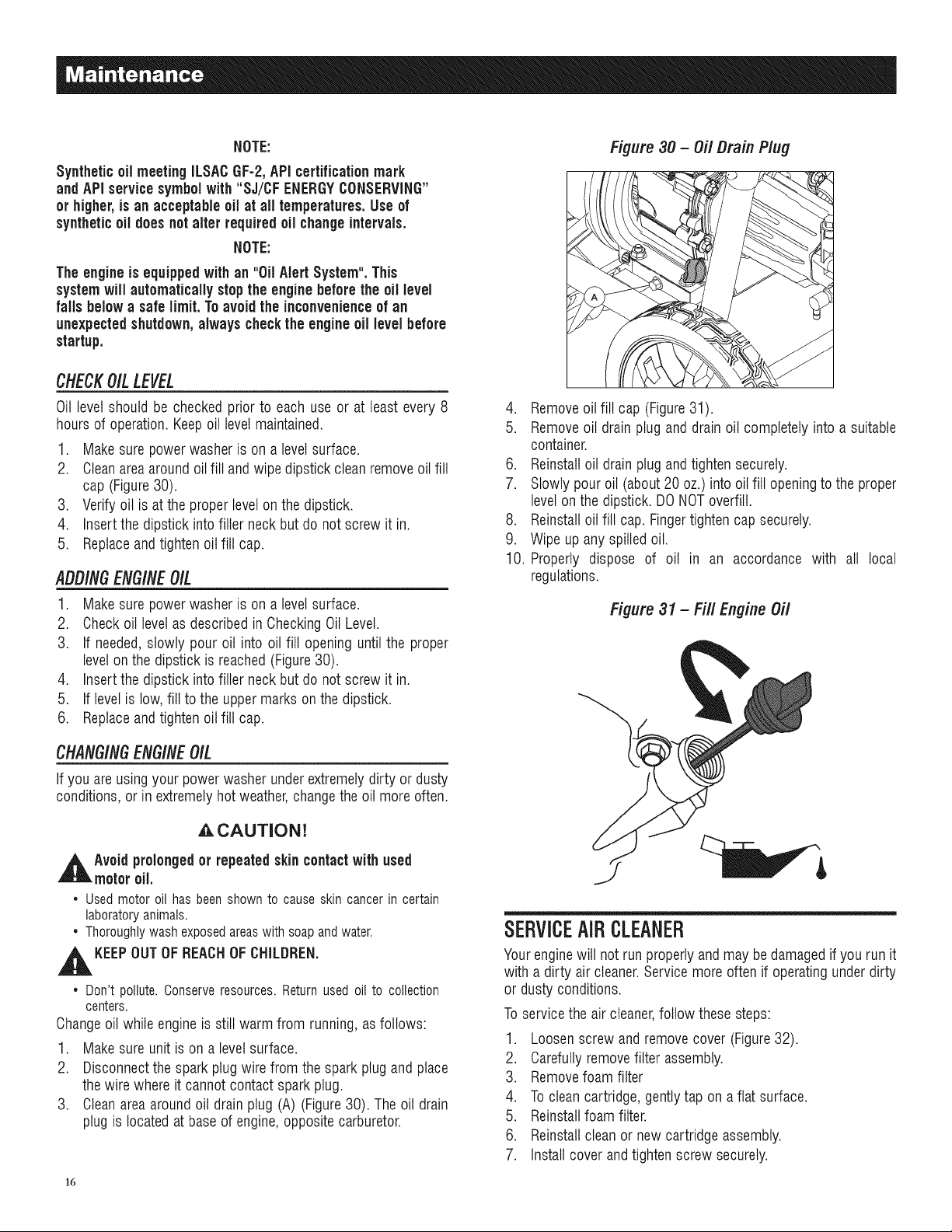

Outdoortemperaturesdeterminethe proper oil viscosity for the

engine.Usethe chart to selectthe best viscosity for the outdoor

temperaturerangeexpected.

| zmm

°F -20 =10 0 10 20 32 40 60

ocio -_'o -10 6 lo 2'o

Temperature Range of Expected Use

* Below 50°F (10°C) the use of SAE 30 will result in hardstarting.

** Above 80°F (27°C) the use of 10W30 may cause increased oil consumption.

Checkoil level morefrequently.

15

Page 18

NOTE:

Synthetic oil meetingiLSACGF-2,API certificationmark

and API servicesymbolwith "SJ/CFENERGYCONSERVING"

or higher,is an acceptable oil at all temperatures.Useof

syntheticoil doesnotalter requiredoil changeintervals.

NOTE:

Theengine is equippedwithan "0il Alert System". This

systemwill automatically stopthe engine beforethe oil level

falls below a safe limit.Toavoidtheinconvenienceof an

unexpectedshutdown,always checkthe engine oil levelbefore

startup.

CHECK OILLEVEL

Figure30 - OilDrain Plug

Oil level should be checkedprior to each use or at least every 8

hoursof operation.Keepoil level maintained.

1. Makesure powerwasher is on a levelsurface.

2. Cleanareaaroundoil fill and wipedipstickcleanremoveoil fill

cap (Figure30).

3. Verifyoil is atthe properlevelonthe dipstick.

4. Insertthe dipstick intofiller neck butdo not screw it in.

5. Replaceandtighten oil fill cap.

ADDINGENGINEOIL

1. Makesure powerwasher is on a levelsurface.

2. Checkoil levelas describedin CheckingOil Level.

3. If needed,slowly pour oil into oil fill opening untilthe proper

levelonthe dipstick is reached(Figure30).

4. Insertthe dipstick intofiller neck butdo not screw it in.

5. If levelis tow,fill to the uppermarks onthe dipstick.

6. Replaceandtighten oil fill cap.

CHANG/NGENG/NEOIL

If you are usingyour power washer underextremelydirty or dusty

conditions,or in extremelyhot weather,changethe oil moreoften.

ACAUTION!

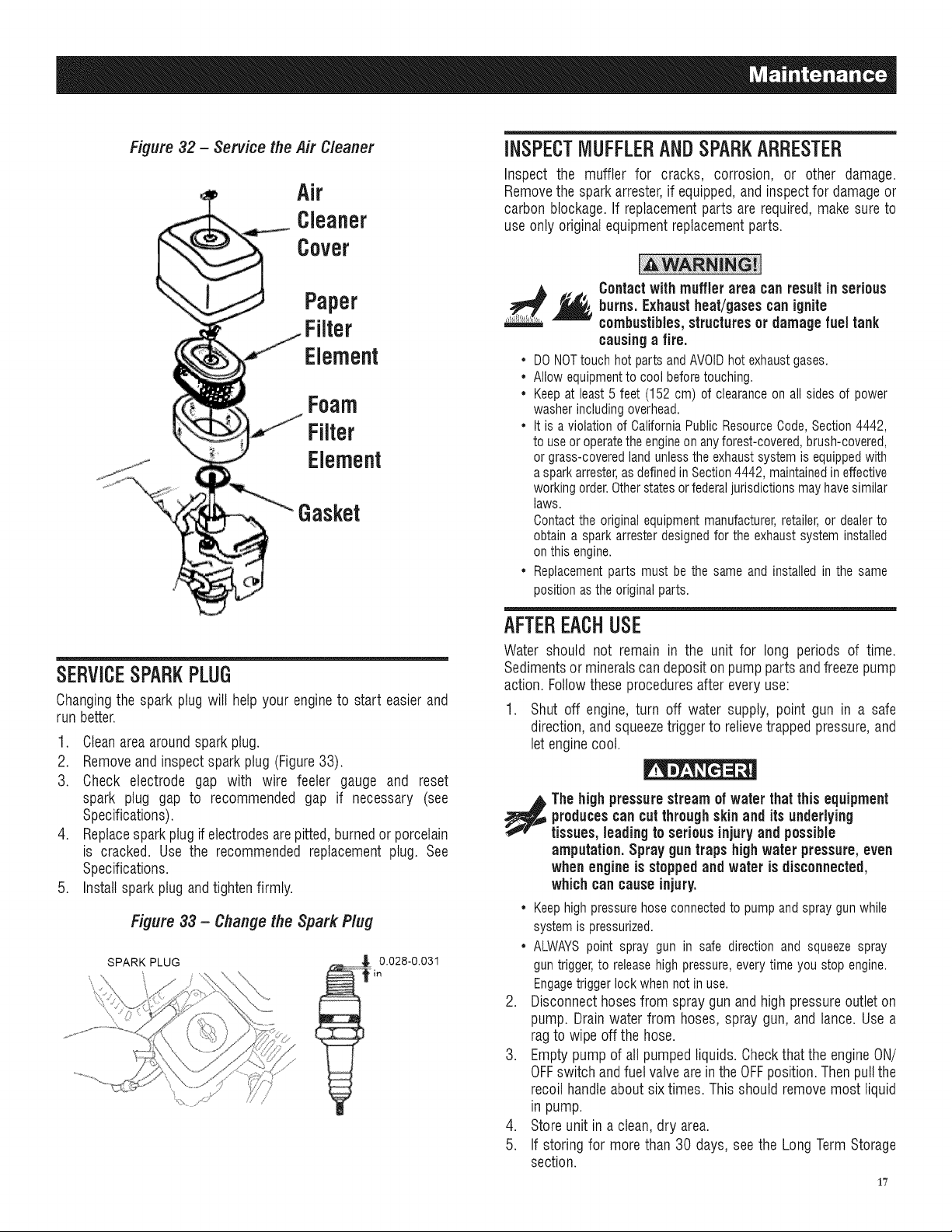

4. Removeoil fill cap (Figure31).

5. Removeoil drain plug anddrain oil completely intoa suitable

container.

6. Reinstalloil drain plug andtighten securely.

7. Slowly pour oil (about20 oz.) into oilfill openingto the proper

levelonthe dipstick. DONOToverfill.

8. Reinstalloil fill cap. Fingertighten capsecurely.

9. Wipeup any spilledoil.

10. Properly dispose of oil in an accordance with all local

regulations.

Figure31 - FillEngineOff

,_ Avoid prolongedor repeatedskincontactwith used

motoroil.

• Usedmotoroil hasbeenshownto causeskincancerincertain

laboratoryanimals.

• Thoroughlywashexposedareaswithsoapandwater.

,_ KEEPOUT OF REACH OF CHILDREN,

• Don'tpollute.Conserveresources.Returnusedoil to collection

centers.

Changeoil while engineis still warm from running,asfollows:

1. Makesure unit is on a levelsurface.

2. Disconnectthe sparkplug wirefrom the spark plugand place

thewire whereit cannot contactspark plug.

3. Cleanareaaround oil drain plug (A) (Figure30). The oildrain

plug is locatedat baseof engine,oppositecarburetor.

16

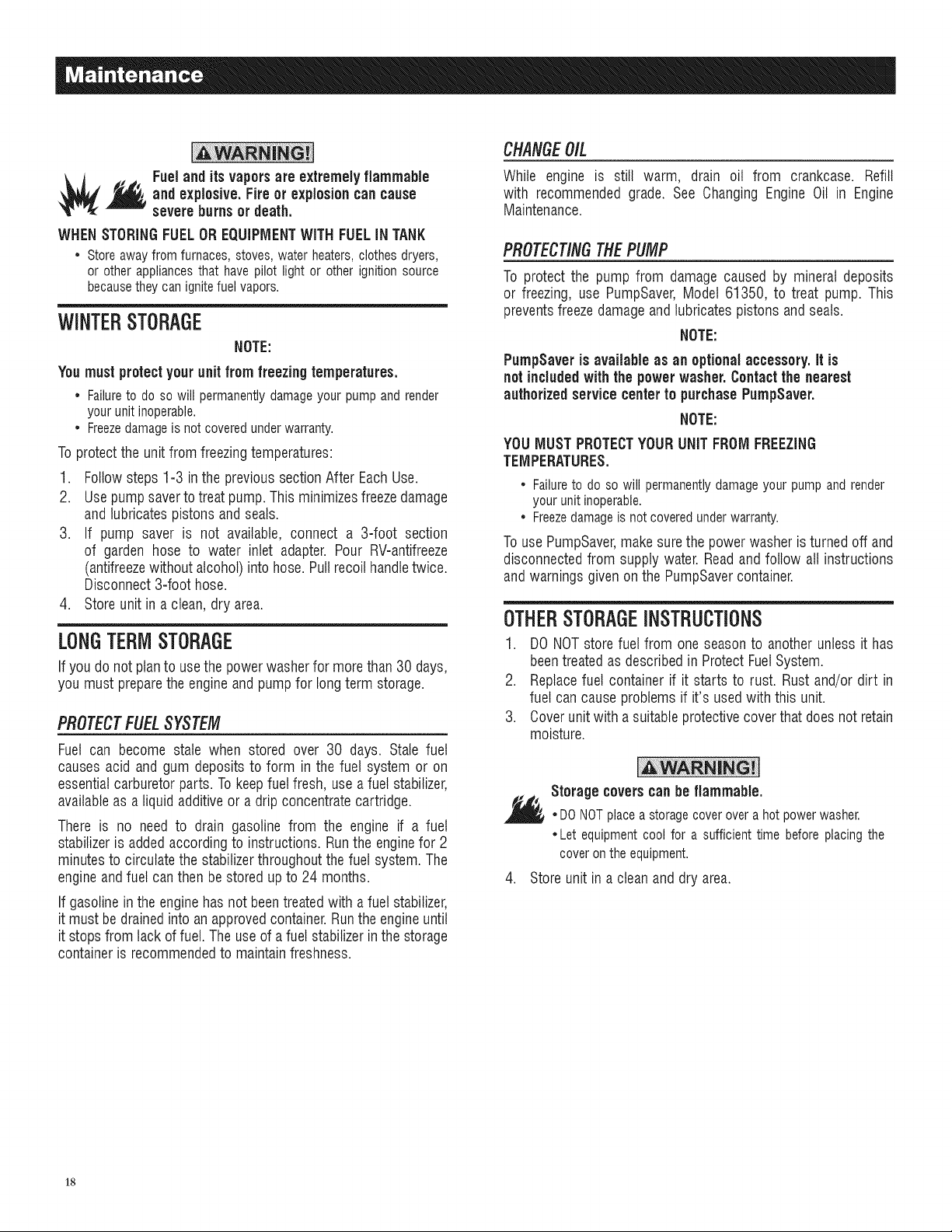

SERVICEAIRCLEANER

Yourenginewill notrun properly andmay bedamagedif you runit

with a dirty air cleaner.Servicemoreoftenif operatingunderdirty

or dustyconditions.

Toservicethe air cleaner,follow these steps:

1. Loosenscrew and removecover (Figure32).

2. Carefullyremovefilter assembly.

3. Removefoamfilter

4. Tocleancartridge,gentlytap on a flat surface.

5. Reinstallfoamfilter.

6. Reinstallclean or new cartridgeassembly.

7. Installcover andtightenscrew securely.

Page 19

Figure 32 - Service the Air Cleaner

Air

Cleaner

Cover

iNSPECTMUFFLERANDSPARKARRESTER

Inspect the muffler for cracks, corrosion, or other damage.

Removethe sparkarrestor,if equipped,andinspect for damageor

carbon blockage.If replacementparts are required,make sure to

useonly originalequipmentreplacementparts.

Paper

Filter

Element

Foam

Filter

Element

Gasket

SERVICESPARKPLUG

Changingthe spark plug will helpyour engineto start easierand

run better.

1. Cleanareaaroundspark plug.

2. Removeandinspect spark plug (Figure33).

3. Check electrode gap with wire feeler gauge and reset

spark plug gap to recommended gap if necessary (see

Specifications).

4. Replacespark plugif electrodesarepitted,burnedor porcelain

is cracked. Use the recommended replacementplug. See

Specifications.

5. Installspark plugand tightenfirmly.

Figure 33 - Change the Spark Plug

SPARKPLUG

burns.Exhaustheat/gasescan ignite

Contactwith muffler area can resultin serious

combustibles,structuresor damagefuel tank

causinga fire.

, DONOTtouchhotpartsandAVOIDhotexhaustgases.

* Allowequipmenttocoolbeforetouching.

* Keepatleast5feet(152cm)of clearanceon allsidesof power

washerincludingoverhead.

* Itisa violationof CaliforniaPublicResourceCode,Section4442,

to useoroperatetheengineonanyforest-covered,brush-covered,

orgrass-coveredlandunlesstheexhaustsystemis equippedwith

asparkarrester,asdefinedinSection4442,maintainedineffective

workingorder.Otherstatesorfederaljurisdictionsmayhavesimilar

laws.

Contactthe originalequipmentmanufacturer,retailer,or dealerto

obtainasparkarresterdesignedforthe exhaustsysteminstalled

onthisengine.

* Replacementpartsmustbethesameand installedinthe same

positionastheoriginalparts.

AFTEREACHUSE

Water should not remain in the unit for long periods of time.

Sedimentsormineralscan depositon pumpparts andfreezepump

action. Followthese proceduresafter every use:

1. Shut off engine, turn off water supply, point gun in a safe

direction,andsqueezetriggerto relievetrappedpressure,and

let enginecool.

producescancutthroughskinand its underlying

The highpressurestreamof waterthat this equipment

tissues,leadingto seriousinjuryand possible

amputation.Spray guntrapshighwaterpressure,even

whenengineisstoppedandwater is disconnected,

whichcan causeinjury.

, Keephighpressurehoseconnectedtopumpandspraygunwhile

systemispressurized.

* ALWAYSpointspraygun in safe directionand squeezespray

guntrigger,to releasehighpressure,everytimeyoustopengine.

Engagetriggerlockwhennotinuse.

2. Disconnecthosesfrom spray gunandhighpressureoutleton

pump. Drainwater from hoses,spraygun, and lance. Usea

ragto wipeoff the hose.

3. Emptypump of all pumpedliquids. Checkthat the engineON/

OFFswitch andfuel valvearein theOFFposition.Thenpullthe

recoil handleabout six times. Thisshould removemost liquid

in pump.

4. Storeunit in a clean,dry area.

5. If storing for morethan 30 days, seethe LongTerm Storage

section.

17

Page 20

CHANGEOIL

Fueland itsvaporsare extremelyflammable

and explosive. Fireor explosioncancause

severeburnsor death.

WHENSTORINGFUELOREQUIPMENTWiTH FUELiNTANK

• Storeawayfromfurnaces,stoves,waterheaters,clothesdryers,

or otherappliancesthat havepilotlightor otherignitionsource

becausetheycanignitefuelvapors.

WINTERSTORAGE

NOTE:

Youmustprotectyourunitfrom freezing temperatures.

• Failureto doso will permanentlydamageyourpumpandrender

yourunitinoperable.

• Freezedamageis notcoveredunderwarranty.

Toprotectthe unit from freezingtemperatures:

1. Followsteps 1-3 inthe previoussection After EachUse.

2. Usepumpsaverto treat pump.This minimizesfreezedamage

and lubricatespistons andseals.

3. If pump saver is not available,connect a 3-foot section

of garden hose to water inlet adapter. Pour RV-antifreeze

(antifreezewithoutalcohol)into hose. Pullrecoilhandletwice.

Disconnect3-foot hose.

4. Storeunit in a clean,dry area.

LONGTERM STORAGE

If you do not planto use thepower washerfor morethan 30 days,

you must preparetheengineandpump for longtermstorage.

PROTECTFUELSYSTEM

Fuel can become stale when stored over 30 days. Stale fuel

causes acid and gum depositsto form in the fuel system or on

essentialcarburetorparts. Tokeep fuelfresh, useafuel stabilizer,

availableas a liquidadditiveor a drip concentratecartridge.

There is no need to drain gasoline from the engine if a fuel

stabilizeris addedaccording to instructions. Runthe enginefor 2

minutesto circulatethe stabilizerthroughoutthe fuel system.The

engineandfuel can then bestored up to 24 months.

If gasolinein theenginehas notbeentreatedwith a fuel stabilizer,

it must bedrainedintoanapprovedcontainer.Runtheengineuntil

it stops from lack offuel.Theuseof a fuelstabilizerin thestorage

containeris recommendedto maintainfreshness.

While engine is still warm, drain oil from crankcase. Refill

with recommended grade. See Changing Engine Oil in Engine

Maintenance.

PROTECtiNGTHEPUMP

To protect the pump from damage caused by mineral deposits

or freezing, use PumpSaver,Model 61350, to treat pump. This

preventsfreezedamageand lubricatespistons andseals.

NOTE:

PumpSaveris available as anoptional accessory,it is

notincludedwiththe power washer.Contactthe nearest

authorized service centerto purchasePumpSaver.

NOTE:

YOUMUSTPROTECTYOURUNiT FROMFREEZING

TEMPERATURES.

• Failureto do sowill permanentlydamageyourpumpandrender

yourunitinoperable.

• Freezedamageis notcoveredunderwarranty.

Touse PumpSaver,makesurethe powerwasheristurnedoff and

disconnectedfrom supply water. Readand follow all instructions

andwarnings givenonthe PumpSavercontainer.

OTHERSTORAGEiNSTRUCTiONS

1. DONOTstore fuel from one seasonto anotherunlessit has

beentreatedas describedin Protect FuelSystem.

2. Replacefuel container if it starts to rust. Rustand/or dirt in

fuel can cause problemsif it's usedwith this unit.

3. Coverunitwith a suitableprotectivecoverthat doesnot retain

moisture.

Storage coverscan be flammable.

•DONOTplaceastoragecoveroverahotpowerwasher.

•Letequipmentcoolfor a sufficienttime beforeplacingthe

coveronthe equipment.

.

Storeunit in a cleanand dry area.

18

Page 21

TBOUBLESHOOTiNGGUIDE

1. Low pressurenozzleinstalled. 1. Replacewith high pressurenozzle.

2. Waterinletis blocked. 2. Clearinlet.

3. Inadequatewatersupply.

Pumphasfollowingproblems:

failuretoproducepressure,erratic

pressure,chattering,lossofpres-

sure,lowwatervolume.

Detergent fails to mix with spray, cracked.

Engineruns well at no-load but 1. Enginespeedistoo slow. 1. Movethrottlecontrolto FASTposition.If engine

"bogs" when load isadded, still "bogs down", contact local servicefacility.

4. Inlet hoseis kinked or leaking.

5. Cloggedinlethose screen.

6. Watersupplyis over lO0°E

7. Highpressurehose is blockedor leaks.

8. Spray gunleaks.

9. Nozzleis obstructed.

10. Pumpis faulty.

1. Detergentsiphoningtube is not submerged. 1. Insertdetergentsiphoningtube into detergent.

2. Detergentsiphoningtube/filteris cloggedor 2. Cleanor replacefilter/detergentsiphoningtube.

3. Highpressurenozzleinstalled. 3. Replacewith low pressurenozzle.

! I

3. Provideadequatewaterflow.

4. Straighteninlethose,patch leak.

5. Checkand cleaninlet hose screen.

6. Providecoolerwater supply.

7. Clearblocks in outlethose or replacehose.

8. Replacespray gun.

9. Cleannozzle.

10. Contact local servicefacility.

1. Low oil level,"OilAlert System".

2. Dirty air cleaner.

3. Outof fuel.

Enginewill notstart;orstartsand

runsrough.

Engineshutsdownduring 1. Outof fuel. 1. Fillfuel tank.

operation.

Enginelacks power. 1. Dirty air filter. 1. Replaceairfilter.

4. Stalefuel.

5. Sparkplugwire not connectedto spark plug.

6. Badspark plug.

7. Waterinfuel.

8. Excessivelyrich fuel mixture.

1. Fillcrankcaseto proper level.

2. Cleanor replaceair cleaner.

3. Fillfuel tank.

4. Drainfuel tank;fill with fresh fuel.

5. Connectwire to spark plug.

6. Replacespark plug.

7. Drainfuel tank;fill with fresh fuel.

8. Contactlocal servicefacility.

19

Page 22

U,S, EPA EMiSSiON CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLiGATiONS

TheUnited StatesEnvironmentalProtectionAgency (EPA)and GeneracPowerSystems, Inc. (Generac)arepleasedto explainthe Emission Control

SystemWarranty (ECSWarranty)on yournew 2011 and laterequipment.New equipmentthat use smallspark-ignitedenginesmust bedesigned,built,

andequipped to meetstringentanti-smog standardsfor the federal government.Generacwill warrant the emission control system on your equipment

for the periodof time listed belowprovided therehas beenno abuse, neglect,unapprovedmodificationor impropermaintenanceof your equipment.

Theemission control systemon this equipmentincludesall componentswhose failurewould increasethe emissionsof anyregulatedpollutant.These

componentsare listed in the EmissionsInformation section ofthis manual.

MANUFACTURER'S WARRANTY COVERAGE:

This ECSWarranty is validfor two years, orfor the same periodas specifiedin the GeneracLimitedWarranty,whicheveris longer. Forequipmentwith

hourmeters,the warranty period is a number of hours equalto halfthe Useful Lifeto which the equipmentis certified, or the warrantyperiod specified

abovein years,whicheveris less.The UsefulLife can befound on the EmissionControl Labelon the engine.If, during suchwarranty period, any

emission-relatedpart on yourequipment isfound to be defectivein materialsor workmanship, repairs orreplacementwill be performedby a Generac

AuthorizedWarrantyServiceDealer.

OWNER'S WARRANTY RESPONSiBiLiTiES:

Asthe equipmentowner,you areresponsiblefor the completion of all requiredmaintenanceaslisted inyour factory suppliedOwner'sManual.For

warranty purposes,Generacrecommendsthat you retainall receiptscovering maintenanceon your generator,butGeneraccannotdenywarranty

solelydueto the lack of receipts.

Youshould beawarethat Generacmay deny anyand/or all warrantycoverageor responsibility if your equipment,or apart!component thereof,has

failed dueto abuse,neglect, impropermaintenance,or unapprovedmodifications.

Youare responsible for contactingaGeoeracAuthorized Warranty Dealer as soonas a problemoccurs.Thewarranty repairsshouldbe

completed in a reasonable amount of time, not to exceed 30 days.

Warrantyservice can bearrangedby contacting eitheryour sellingdealeror a GeneracAuthorizedWarrantyServiceDealer.Tolocatethe Generac

AuthorizedWarrantyServiceDealernearestyou, call our toll free numberbelow, oremail emissions@generac.com.

1-800-333-1322

IMPORTANTNOTE:Thiswarranty statementexplainsyour rights and obligationsunderthe Emission ControlSystemWarranty,which is providedto

you by Generacpursuantto federal law. Seealso the "GeneracLimitedWarrantiesfor GeneracPowerSystems,Inc.," which is enclosedherewith on a

separatesheet,also providedto you by Generac.Notethat this warranty shallnot apply to any incidental,consequentialor indirect damagescaused

bydefects in materialsor workmanship or any delayin repairor replacementof the defectivepart(s). This warranty is in place of all other warranties,

expressedor implied.Specifically,Generacmakes no other warrantiesasto the merchantabilityor fitness for aparticular purpose.Any implied

warrantieswhich areallowed by law, shallbe limited indurationto the terms of the expresswarranty providedherein.Somestatesdo not allow

limitationson how long an implied warrantylasts, so the abovelimitation may not applyto you.

TheECSWarrantyappliesonly to the emissioncontrol system of your newequipment. Boththe ECSWarrantyandthe GeneracWarrantydescribe

importantrights and obligationswith respectto your new engine.

Warrantyservice can beperformed onlyby a GeneracAuthorizedWarrantyService Facility.When requestingwarranty service,evidencemust be

presentedshowingthe dateof the saleto the originalpurchaser/owner.

Ifyou haveany questionsregardingyour warranty rights andresponsibilities,you should contact Generacatthe following address:

ATTENTION WARRANTY DEPARTMENT

GENERAC POWER SYSTEMS, INC.

P.O. BOX 297 * WHITEWATER, WI 53190

PartI of 2

PartNo. 0J3335 Rev.C 11/11

20

Page 23

EMiSSiON CONTROL SYSTEM WARRANTY

EmissionControl SystemWarranty(ECSWarranty)for equipmentusing small spark-ignitedengines:

(a) Applicability:This warrantyshall applyto equipmentthat uses small off-road engines.TheECSWarrantyperiodshall beginon the date the new

equipmentis purchasedby/deliveredto its original, end-usepurchaser/ownerand shall continuefor the lesserof:

(1) The periodof time specifiedin the GeneracLimited Warrantyenclosedherewith,but not lessthan24 months, or

(2) Forenginesequippedwith hour meters, a numberof operatinghours equal to half of the engine'suseful life.The usefullife is specifiedon the

EmissionsControl Labelon the engine.

(b) GeneralEmissionsWarrantyCoverage:Generacwarrantsto the original,end-usepurchaser/ownerof the newengineor equipment andto each

subsequentpurchaser/ownerthat the ECSwhen installed was:

(1) Designed,built and equippedso as to conform with all applicableregulations;and

(2) Freefrom defectsin materialsand workmanshipwhich causethe failureof a warrantedpart at anytime duringthe ECSWarrantyPeriod.

(c) Thewarranty on emissions-relatedparts will be interpretedas follows:

(1) Any warrantedpart that is not scheduledfor replacementas requiredmaintenancein the Owner'sManualshall bewarrantedfor the ECS

WarrantyPeriod.If any such partfails during the ECSWarrantyPeriod, it shallbe repairedor replacedby Generacaccordingto Subsection

(4) below. Any such part repairedor replaced underthe EOSWarranty shallbewarranted for the remainderof the ECSWarranty Period.

(2) Any warrantedpart that is scheduled onlyfor regularinspection as specifiedin the Owner'sManualshallbe warrantedfor the EOSWarranty

Period.A statementin the Owner's Manualtothe effectof "repair or replaceas necessary"shall not reducethe ECSWarrantyPeriod.Any

such part repairedor replacedundertheECSWarranty shallbewarranted for the remainderof the ECSWarrantyPeriod.

(3) Any warrantedpart that is scheduledfor replacementasrequired maintenancein the Owner'sManualshallbe warrantedfor the periodof time

priorto first scheduledreplacementpoint for that part. If the part fails prior to thefirst scheduled replacement,the part shall be repairedor

replacedby Generacaccording to Subsection(4) below.Any such emissions-relatedpart repairedor replaced underthe ECSwarranty shall

bewarrantedfor the remainderof the period prior to thefirst scheduledreplacementpointfor that part.

(4) Repairor replacementof anywarranted,emissions-relatedpart underthis ECSWarrantyshall beperformed at no charge tothe ownerat a

GeneracAuthorizedWarrantyService Facility.

(5) Notwithstandingtheprovisions of subsection (4) above,warranty services or repairsmust beprovided at GeneracAuthorizedService

Facilities.

(6) Whenthe engineis inspectedby a GeneracAuthorizedWarranty ServiceFacility,the purchaser/ownershall not beheld responsiblefor

diagnosticcosts if the repair is deemedwarrantable.

(7) ThroughouttheECSWarrantyPeriod, Generacshall maintainasupply of warrantedemission-relatedparts sufficient to meetthe expected

demandfor such parts.

(8) Any Generacauthorizedandapprovedemission-relatedreplacementparts may beused inthe performance of any ECSWarrantymaintenance

or repairsandwill beprovided without chargeto the purchaser/owner.Such useshall not reduce Generac'sEOSWarrantyobligations.

(9) No modifications,other than those explicitlyapprovedby Generac,may be madeto the generator.Unapprovedmodificationsvoid this ECS

Warrantyand shall be sufficientgroundfor disallowingan EOSWarrantyclaim.

(10) Generacshall not be heldliablehereunderfor failures of any non-authorizedreplacementparts, or failures of anyauthorizedparts causedby

the use of non-authorizedreplacementparts.

EMiSSiON RELATED PARTS MAY iNCLUDE THE FOLLOWING (iF EQUIPPED):

1) FUELMETERINGSYSTEM 3) IGNITIONSYSTEM

A. CARBURETORANDINTERNALPARTS A. SPARKPLUGS

B. FUELTANK/CAP B. IGNITIONCOILS/MODULE

C. FUELLINES 4) AIR INJECTIONSYSTEM

D. EVAPORATIVEVENTLINES A. PULSEAIRVALVE

E. REGULATOR(GASEOUSFUELS) 5) EXHAUSTSYSTEM

2) AIR INDUCTIONSYSTEM A. CATALYST

A. INTAKEMANIFOLD B. EXHAUSTMANIFOLD

B. AIRFILTER

Part2 of 2

PartNo. 0J3335 Rev.C 11/11

21

Page 24

GENERAC POWER SYSTEMS "TWO YEAR" LiMiTED WARRANTY

FOR POWER WASHERS

Foraperiodoftwo yearsfromthedateof originalsale,GeneracPowerSystems,Inc.(Generac)warrantsitsPowerWasherswill befreefrom defectsinmaterials

andworkmanshipfor theitemsandperiodsetforth below.Generacwill, at itsoption,repairorreplaceanypartwhich, uponexamination,inspectionandtesting

byGeneracor a GeneracAuthorizedWarrantyServiceDealer,isfoundto bedefective.Repairorreplacementpursuantto thislimitedwarrantyshallnot renewor

extendthe originalwarrantyperiod.Any repairedproductshallbewarrantedforthe remainingoriginalwarrantyperiodonly.Any equipmentthatthepurchaser/

ownerclaimsto bedefectivemustbe returnedto andexaminedbythe nearestGeneracAuthorizedWarrantyServiceDealer.Alltransportationcosts underthe

warranty,includingreturntothefactory,areto beborneandprepaidby the purchaser/owner.Thiswarrantyappliesonlyto GeneracPowerWashersandis not

transferablefrom originalpurchaser.Saveyourproof-of-purchasereceipt.Ifyou donotprovideproofofthe initial_urchasedate,themanufacturer'sshippingdate

oftheproductwill be usedto determinethewarrantyperiod.

WARRANTY SCHEDULE

Consumerapplicationsarewarrantedfortwo (2) years.

CONSUMEBAPPLICATION

YEARONE- LimitedcomprehensivecoverageonLaborand Part(s)(proofof purchaseandmaintenanceisrequired):

• All Components

YEARTWO- Limitedcomprehensivecoverageon Part(s)(proofofpurchaseandmaintenanceis required):

• Engineonly- Majorcomponentsincluding: Block,head,crank,cam, rodsandpistons.

NOTE:Forthepurposeof thiswarranty"consumeruse"meanspersonalresidentialhouseholdorrecreationaluseby originalpurchaser.Anyuseof the Power

Washerina commercialor rentalapplicationwill voidthe warranty.

GUiDELiNES

* Thecustomeris responsibleto readandfollowall operatinginstructions.

, Productsthataredamageddueto improperoperation,will notbecoveredby warranty. Thisincludeswaterpumpcomponentsthatare startedwithoutthe

requiredwaterflow andpressure.

, Thecustomerwill beresponsibletotransportthe productto anauthorizedGeneracrepairfacilityfor all WarrantyAll Components.

, Verificationof maintenancemay berequestedfor coverageofWarrantyRepairs.

, WarrantyLaborRatesarebasedon normalworkinghours.Additionalcostsfor overtime,holidayor emergencylaborcostsfor repairsoutsidenormalbusiness

hourswill bethe responsibilityof thecustomer.

, WarrantyPartsshipmentcostsarereimbursedatgroundshipmentrates.Costsrelatedto requestsfor expeditedshippingwill bethe responsibilityof the

customer.

THIS WARRANTY SHALL NOT APPLY TO THE FOLLOWING:

• GeneracPowerWashersthat utilizenon-Generacreplacementparts.

• Costsof normalmaintenanceandadjustments.

• Failurescausedbyanycontaminatedor improperfuels,oils or lackof properoillevels,or contaminatedwater.

• Repairsor diagnosticsperformedby individualsotherthanGuardian/Generacauthorizeddealersnot authorizedin writingby GeneracPowerSystems.

• Failuresdue, butnot limited,to normalwearandtear,accident,misuse,abuse,negligenceor improperuse.Aswith allmechanicaldevices,theGenerac

enginesneedperiodicpart(s)serviceandreplacementto performasdesigned.Thiswarrantywill notcoverrepairwhennormalusehasexhaustedthelife of a

part(s)or engine.

• Failurescausedbyanyact of Godand/orotherforcemajeureeventsbeyondthe manufacturer'scontrol.

• Waterfreezingin thepump(watermustbedrainedfromthe pumpatthe endof theseasoninfreezingclimates).

• Damagerelatedto rodentand/orinsectinfestation.

• Productsthat aremodifiedor alteredina mannernot authorizedbyGeneracin writing.

• Anyincidental,consequentialor indirectdamagescausedby defectsin materialsor workmanship,or anydelayin repairor replacementofthedefectivepart(s).

• Failuredueto misapplication.

• Expensesrelatedto "customerinstruction"ortroubleshootingwherenomanufacturingdefectisfound.

• Rentalequipmentusedwhilewarrantyrepairsarebeingperformed.

• Startingbatteries,fuses,filters,lightbulbsandenginefluids.

THISWARRANTYISIN PLACEOFALLOTHERWARRANTIES,EXPRESSEDORIMPLIED,SPECIFICALLY,GENERACPOWERSYSTEMSMAKESNOOTHER

WARRANTIESASTOTHEMERCHANTABILITYORFITNESSFORA PARTICULARPURPOSE.Anyimpliedwarrantieswhichareallowedbylaw,shallbelimitedin

durationto theterms oftheexpresswarrantyprovidedherein.Somestatesdo notallowlimitationsonhow longanimpliedwarrantylasts,sotheabovelimitation

maynotapplyto purchaser/owner.

GENERACPOWERSYSTEMSONLYLIABILITYSHALLBETHEREPAIRORREPLACEMENTOFPART(S)ASSTATEDABOVE.INNOEVENTSHALLGENERAC

POWERSYSTEMSBELIABLEFORANYINCIDENTAL,ORCONSEQUENTIALDAMAGES,EVENIFSUCHDAMAGESAREADIRECTRESULTOFGENERACPOWER

SYSTEMS,INC.NEGLIGENCE.Somestatesdonot allowtheexclusionorlimitationof incidentalorconsequentialdamages,sothe abovelimitationsmaynot apply

to purchaser/owner.Purchaser/owneragreesto makenoclaimsagainstGeneracPowerSystems,Inc. basedon negligence.Thiswarrantygivespurchaser/owner

specificlegalrights.Purchaser/owneralsomayhaveotherrightsthatvaryfrom stateto state.

GENERACPOWERSYSTEMS,INC. • RO.BOX8 • Waukesha,Wl 53187 • Ph: (888) GENERAC(436-3722) • Fax:(262) 544-4851

Tolocate thenearest AuthorizedDealervisit ourwebsite www.generac.com

PartNo.0J3020 RevisionF(12/11)

Manual PartNo. 0H9700 RevisionD (12/09/11) Printedin U.S.A.

Page 25

GENERAC _

IVianualdelProietario

I

23

Page 26

Introducci6n..........................................................25

Dondenos encuentran.................................................25

ReglasdeSeguridad............................................25

Simbolosde seguridady su significado........................25

Informaci6n general..............................................28

Conozcasu hidrolavadora.......................................................28

Especificacionesdet producto.................................................29

Desempaque...........................................................................29

Ensamblar.............................................................29

Ensambtar...............................................................................29

Agregueaceitepara motor......................................................30

Agregadode combustible........................................................30

Conexi6nde la mangueray etsuministrodeaguaalabomba...31

Como usarlas boquillas..........................................................32

Limpiezay aplicacionde detergente.............................33

Enjuaguede la hidrolavadora........................................34

Limpiezadeltubo de descargade detergente...............34

Operaci6n.............................................................35

Operaci6n...............................................................................35

Localizacionde la hidrolavadora..............................................35

Lista de verificacionantesde encenderet motor.....................35