Generac 005993-0 Owner’s Manual

GENERAC _

0

erator'sIVianual

introduction.............................................................1

Safety Rules...........................................................1

SafetySymbols and Meanings.......................................1

Generalinformation................................................4

KnowYourPowerWasher.........................................................4

ProductSpecifications..............................................................5

Unpacking.................................................................................5

Set-up.....................................................................5

Assembly..................................................................................5

Add EngineOil..........................................................................6

CheckPumpOil........................................................................6

Add Fuel...................................................................................7

ConnectHoseand WaterSupplyto Pump.................................7

How to Use Nozzles..................................................................9

CleaningandApplying Detergent..................................10

PowerWasherRinsing.................................................10

CleaningDetergentSiphoningTube...............................10

Operation..............................................................11

Operation................................................................................11

PowerWasherLocation..........................................................11

ChecklistBefore StartingEngine..............................................11

How to Start YourPowerWasher............................................11

AutomaticCoolDown System (ThermalRelief).......................13

AdjustabelPressureSetting.....................................................13

How to Stop YourPowerWasher.............................................13

Maintenance.........................................................14

MaintenanceRecommendations..............................................14

MaintenanceSchedule............................................................14

EmissionsControl...................................................................14

PowerWasherMaintenance....................................................14

Checkand CleanInletScreen..................................................14

CheckHigh PressureHoses....................................................14

CheckDetergentSiphoningTube.............................................14

CheckSpray Gun....................................................................15

NozzleMaintenance................................................................15

PumpOilMaintenance............................................................15

EngineMaintenance................................................................15

EngineOil Recommendations..................................................16

CheckingOilLevel........................................................16

AddingEngineOil.........................................................16

ChangingEngineOil.....................................................16

ServiceAir Cleaner.................................................................17

ServiceSparkPlug..................................................................17

InspectMufflerand SparkArrestor..........................................17

After EachUse........................................................................17

WinterStorage........................................................................18

LongTermStorage..................................................................18

ProtectFuelSystem.....................................................18

ChangeOil...................................................................18

Protectingthe Pump.....................................................18

OtherStorageInstructions.......................................................18

Troubleshooting....................................................lg

TroubleshootingGuide.............................................................19

Warranty...............................................................20

MANUALDELPROPIETARIO.............................23

MANUELDEL'OPI_RATEUR...............................47

INTRODUCTION

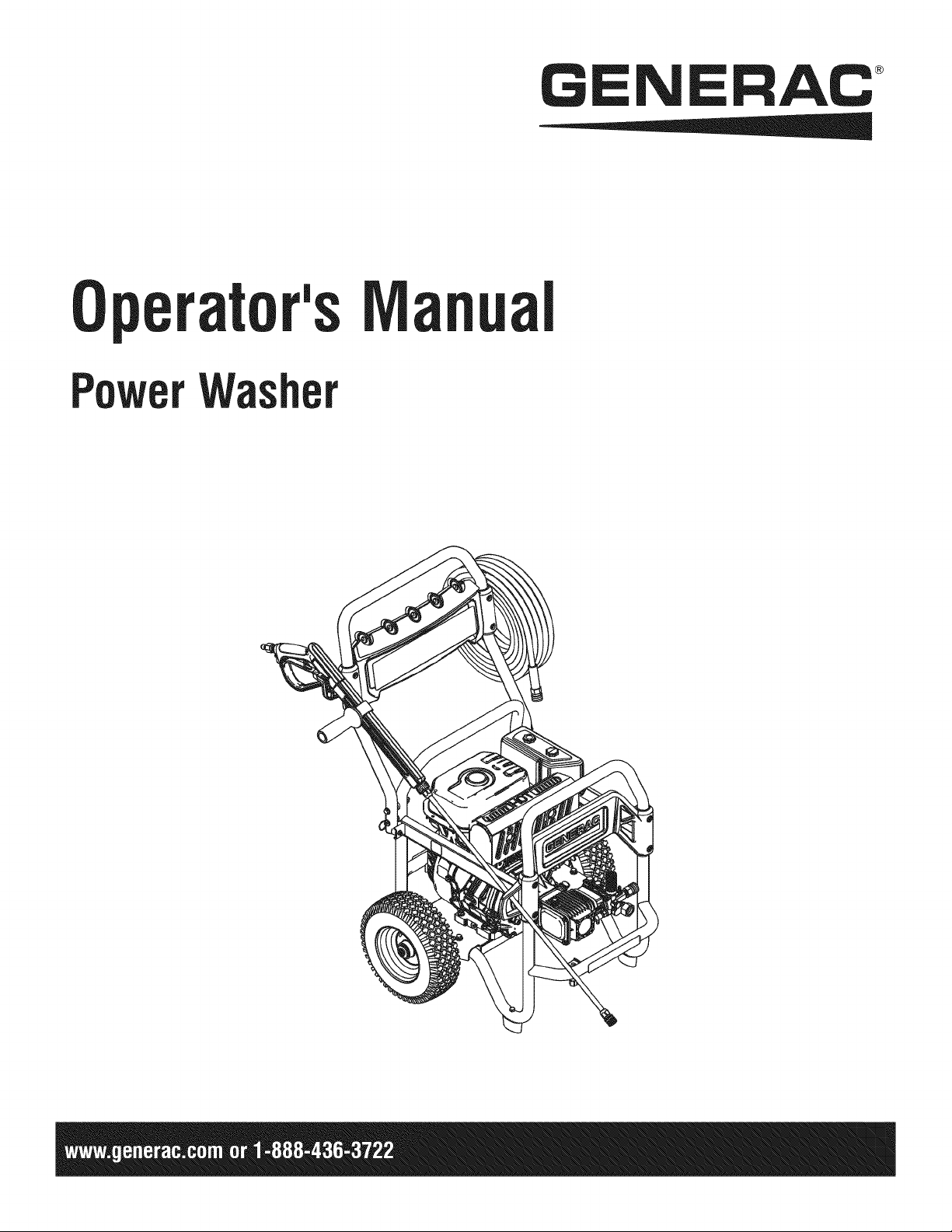

Thank you for purchasing this power washer manufactured by

GeneracPower Systems, Inc.This modelis a high performance,

air-cooled, engine-driven power washer that operatesbetween

3000 and 4000 psi dependingon which model you purchased.

Theseunitsfeaturepowerful Generacengines,atriplex pumpwith

ceramic coated pistons, a pressure control valve, an automatic

thermal relief system, a professional grade spray gun with

vibrationisolationfor reducedfatigue,astainlesssteellance,quick

connect nozzles, steel reinforcedhigh pressure rubber hose for

long life andmaximumflexibility and a detergentsiphoning hose.

Commonsenseandstrictcompliancewiththespecialinstructions

are essentialto preventing accidents. The operatormust read

this manual and thoroughly understand all of the instructions

and warnings before usingthe equipment. If any portion of the

manualis not understood, contact the nearestAuthorizedDealer

for starting, operating and servicing procedures.The owner is

responsiblefor properandsafe use of the equipment.

Thepower washer can operatesafely,efficientlyand reliably only

if it is properlylocated,operatedandmaintained.Beforeoperating,

servicingor storing:

• Studyall warnings in this manualand on the productcarefully.

• Becomefamiliar with this manual andthe unit beforeuse.

• Referto theAssemblysection of the manualfor instructionson

final assembly procedures.Followthe instructions completely.

Themanufacturercannot anticipateevery possible circumstance

that might involvea hazard.The warnings in this manual,and on

tags and decals affixedto the unit are,therefore,not all inclusive.

If usingaprocedure,workmethodoroperatingtechniquethat the

manufacturerdoes not specifically recommend,ensurethat it is

safe for others. Also make sure the procedure,work method or

operatingtechnique utilized does not render the power washer

unsafe.

THE INFORMATIONCONTAINEDHEREIN WAS BASED ON

MACHINESIN PRODUCTIONAT THE TIME OF PUBLICATION.

GENERACRESERVESTHERIGHTTO MODIFYTHIS MANUALAT

ANYTIME.

Save these instructionsfor future reference. If you loan this

device to someone,ALWAYSloanALL instructionalmaterialsto

theindividualas well.

SAFETYRULES

Throughoutthis publication,and on tags and decalsaffixedto the

generator,DANGER,WARNING,CAUTIONand NOTEblocks are

usedto alert personnelto special instructionsabout a particular

operation that may be hazardous if performed incorrectly or

carelessly. Observe them carefully. Their definitions are as

follows:

Indicatesa hazardoussituationor action which,if notavoided,

will resultin death or seriousinjury.

Indicatesa hazardoussituationor actionwhich,if notavoided,

couldresultin deathor seriousinjury.

ACAUTION!

Indicatesa hazardoussituationor actionwhich,if notavoided,

couldresultin minoror moderateinjury.

NOTE:

Notescontainadditional informationimportanttoa procedure

and will be found withinthe regulartextbody of thismanual.

These safety warnings cannot eliminate the hazards that they

indicate. Common sense and strict compliancewith the special

instructionswhile performingtheaction or serviceareessentialto

preventingaccidents.

SAFETYSYMBOLSANDMEAN/NGS

ToxicFumes Kickback ElectricalShock

Slippery Surface Fall Fluid injection

WHERETOFINDUS

You can contact GeneracCustomerService by phone at 1-888-

436-3722, or on the internet at www.generac.com. Record the

important information of the unit in the following chart for future

referenceand/orservice inquiries.

ModelNumber

Serial Number

DatePurchased

Fire

MovingParts

D

Explosion Operator's Manual

Flying Objects Hot Surface

,_ DANGER:CarbonmonoxideproducedduringuseCANKiLL

inminutes.NEVERuseindoorsorinothershelteredareas,

EVENiFdoorsandwindowsare open.DrilyuseOUTSIDEand

farawayfromwindows,doorsandvents.

Somechemicalsor detergents may be harmfulif inhaled

oringested,causingseverenausea, fainting, or poisoning.

• Operatepowerwasher ONLYoutdoors.

• A running enginegivesoff carbon monoxide.

• Carbonmonoxide is an odorless, colorless, poisonousgas.

Breathingcarbonmonoxidecan causeheadache,fatigue,

dizziness,vomiting, confusion,seizures,nausea,fainting

or death.If you start experiencingany of these symptoms,

IMMEDIATELYmoveto fresh air. Seekmedicalattention.

• Keepexhaustgasfrom enteringa confined areathrough

windows, doors, ventilationintakes,or other openings.Warnany

occupantsinside aboutthe symptoms of carbon monoxideso

they know to move to fresh air if they beginto feel ill.

• Theuse of a carbon monoxidedetector insideany occupied

premisesbetweenthe powerwasher andthe occupant is

recommended.

• NEVERstart or run engineindoors or inan enclosedarea,EVEN

IFwindows and doors areopen.

• Usea respiratoror maskwheneverthere is achance that

harmful gas or vapors may beinhaled.

• Readall instructions with respiratoror mask so you arecertain

the respiratoror mask will providethe necessaryprotection

againstinhalingharmful gasor vapors. Ifyou beginto

experienceany ofthe COsymptoms listedabove,IMMEDIATELY

moveto fresh air.

,_DANGER: spray gun people, or

electrical devices.Serious injuryor deathwill result.

ALWAYSpointspraygunin safedirection, squeezespraygun

trigger to release highpressure,every time you stopengine.

Engagetrigger lockwhen not in use.

• NEVERallow CHILDRENto operatepowerwasher or playnearby.

This is NOTa toy.

• NEVERrepairhigh pressure hose. Replaceit.

• NEVERrepairleaking connectionswith sealantof any kind.

Replaceo-ring or seal.

• NEVERconnecthigh pressurehoseto nozzleextension.

• Keephigh pressurehoseconnectedto pump and spraygun

while system is pressurized.

• NEVERsecurespray gun in openposition.

• NEVERleavespraygun unattendedwhile machineis running.

• NEVERusea spraygun which does not haveatrigger lock or

triggerguard in placeandin working order.

• ALWAYSbe certain spraygun, nozzlesandaccessories are

correctly attached.

NEVERaim at

• Thehigh pressurestream ofwater that this equipment

produces cancut through skin andits underlyingtissues,leadingto serious injury,possible amputationor death.

Spray guntraps high water pressure,EVENWHENengine

is stoppedandwater is disconnected,which can cause

injury.

animals,

,_WARNING: Riskofelectrocution.

burn.

'_ Contactwithpowersourcecancauseelectricshockor

• NEVERspraynearpower source.

,_WARNING: Contactwith muffler area canresult in serious

burns. Exhaustheat/gasescanignitecombustibles,

structuresor damage thefuel tank causinga fire.

• DONOTtouch hot parts and AVOIDhot exhaustgases.

• Allowequipmentto cool beforetouching.

• Keepat leastfive (5) feet (152 cm) of clearance on all

sidesof powerwasherincluding overhead.

• Itis aviolation of California PublicResourceCode,Section

4442, to use or operatethe engineon anyforest-covered,

brush-covered,or grass-coveredland unlessthe exhaust

systemis equippedwith a sparkarrester,as definedin

Section4442, maintainedin effectiveworking order.Other

statesor federaljurisdictions may havesimilar laws.

Contactthe original equipmentmanufacturer,retailer,or dealerto

obtaina sparkarrester designedfor the exhaustsystem installed

onthis engine.

• Replacementparts must bethe sameand installedinthe same

position as the originalparts.

,_ WARNING:Fueland its vaporsare extremelyflammable and

explosive. Fire or explosion cancausesevere burns or death.

WHENADDINGDR DRAININGFUEL

• Turnpower washer OFFandlet it cool at leasttwo (2)

minutes beforeremovingfuel cap. Loosencap slowly to

relievepressurein tank.

• Fillor drainfuel tank outdoors.

• DONOToverfill tank.Allow spacefor fuel expansion.

• Iffuel spills, wait until it evaporatesbeforestarting

engine.

• Keepfuel awayfrom sparks, openflames,pilot lights, heat, and

other ignitionsources.

• DONOTfighta cigaretteor smoke.

WHENSTARTINGEQUIPMENT

• Ensurespark plug, muffler,fuel cap, andair cleanerare in place.

• DONOTcrankenginewith spark plug removed.

WHENOPERATINGEQUIPMENT

• DONOTtip engineor equipment at anglewhich causesfuel to

spill.

• DONOTsprayflammable liquids.

WHENTRANSPORTINGORREPAIRINGEQUIPMENT

• Transport/repairwithfuel tank EMPTYor with fuel shutoff valve

OFF.

• Disconnectsparkplug wire.

WHENSTORINGFUELDREQUIPMENTWITH FUELiN TANK

• Storeaway from furnaces, stoves, waterheaters,clothes dryers,

or otherappliancesthat havepilot light or otherignition source

becausetheycan ignitefuel vapors.

,_ll WARNING:Useofpowerwashercancreatepuddlesand

slipperysurfaces.Kickbackfromsprayguncancauseyouto

fail.

Useonly on a levelsurface.

The cleaning area should have adequate slopes and

drainageto reducethe possibility of afall due to slippery

surfaces.

Donot useon elevatedsurfaceswhere chanceof kickback

could resultin a seriousfall.

®

Firmlygrasp spraygun with both handswhen using high

pressure spray to avoid injury when spray gun kicks

back.

,_WARNING: Starter and otherrotatingpartscan

entangle hands,hair,clothing,or accessories.

or covers.

* NEVERoperatepowerwasherwithoutprotectivehousing

* DONOTwearlooseclothing,jewelryoranythingthat

maybecaughtinthestarterorotherrotatingparts.

* Tieuplonghairandremovejewelry.

,_ WARNING:Starter cordkickback(rapid retraction) canresult

in bodilyinjury.Kickbackwill puffhandand arm toward

engine faster than you can let go. Brokenbones,fractures,

bruises,or sprains couldresult.

• NEVERpullstarter cord without first relieving spraygun

pressure.

• Torelievetrappedpressure,point gun in safe directionand

releasepressureby pulling/actuatingtrigger on spraygun.

• Whenstartingengine, pull cord slowly until resistanceis felt and

then pull rapidlyto avoidkickback.

• After eachstarting attempt,where enginefails to run, always

pointspray gun in safedirection, and squeezespray gun trigger

to releasehigh pressure.

• Firmlygrasp spraygun with both hands whenusing high

pressuresprayto avoid injurywhen spraygun kicks back.

,_ WARNING:Unintentionalsparking canresult in fire or electric

shock.

WHENADJUSTINGORMAKINGREPAIRSTO YOURPOWER

WASHER.

* Disconnectthe sparkplug wire from the spark plug and

place the wire whereit cannotcontact sparkplug.

CALIFORNIAPROPOSITION65 WARNING

Engineexhaustandsome of its constituentsareknown

to the Stateof Californiato causecancer,birth defects

andotherreproductiveharm.

CAUFORNIAPROPOSITION65 WARNING

This productcontainsor emits chemicalsknownto the

Stateof Californiato causecancer,birth defectsand

otherreproductiveharm.

NOTE:

Highpressurespraymay damage fragile itemsincluding

glass.

DO NOTpoint spray gun at glass when using red (0°) MAX

nozzle.

NEVERaim spray gun at people,animals,electricaldevicesor

plants.

NOTE:

Impropertreatmentof powerwashercandamageit and

shortenits life.

* If you havequestionsabout intendeduse,ask dealeror contact

qualifiedservice center.

* NEVERoperateunits with brokenor missing parts, or without

protectivehousingor covers.

* DONOTby-pass anysafety deviceon this machine.

* DONOToperate powerwasher above ratedpressure.

* DONOTmodify power washerinanyway.

* Beforestarting powerwasher incold weather,checkallparts of

the equipmentto be sure icehas notformed there.

* NEVERmovemachineby pullingon hoses.Usehandleprovided

on unit.

* Checkfuel system for leaks or signs of deterioration,such as

chafed or spongy hose, looseormissing clamps, or damaged

tank or cap. Correctall defectsbefore operatingpowerwasher.

* Thisequipmentisdesignedto be usedwith Generacauthorized

parts ONLY.If equipment is used with parts that DO NOT

comply with minimum specifications, user assumesall risks

and liabilities.

* Useapprovedsparkplug tester.

_ WHENTESTINGFORENGINESPARK

* DONOTcheckfor spark with spark plug removed.

,_ WARNING:Risk of eye injury.Spray cansplashback or

propelobjects.

•. in vicinity of where equipmentis in use.

* Always wear safetygoggleswhen using this equipmentor

• Beforestarting the power washer,be sure you are

wearing adequatesafetygoggles.

• NEVERsubstitutesafety glassesfor safetygoggles.

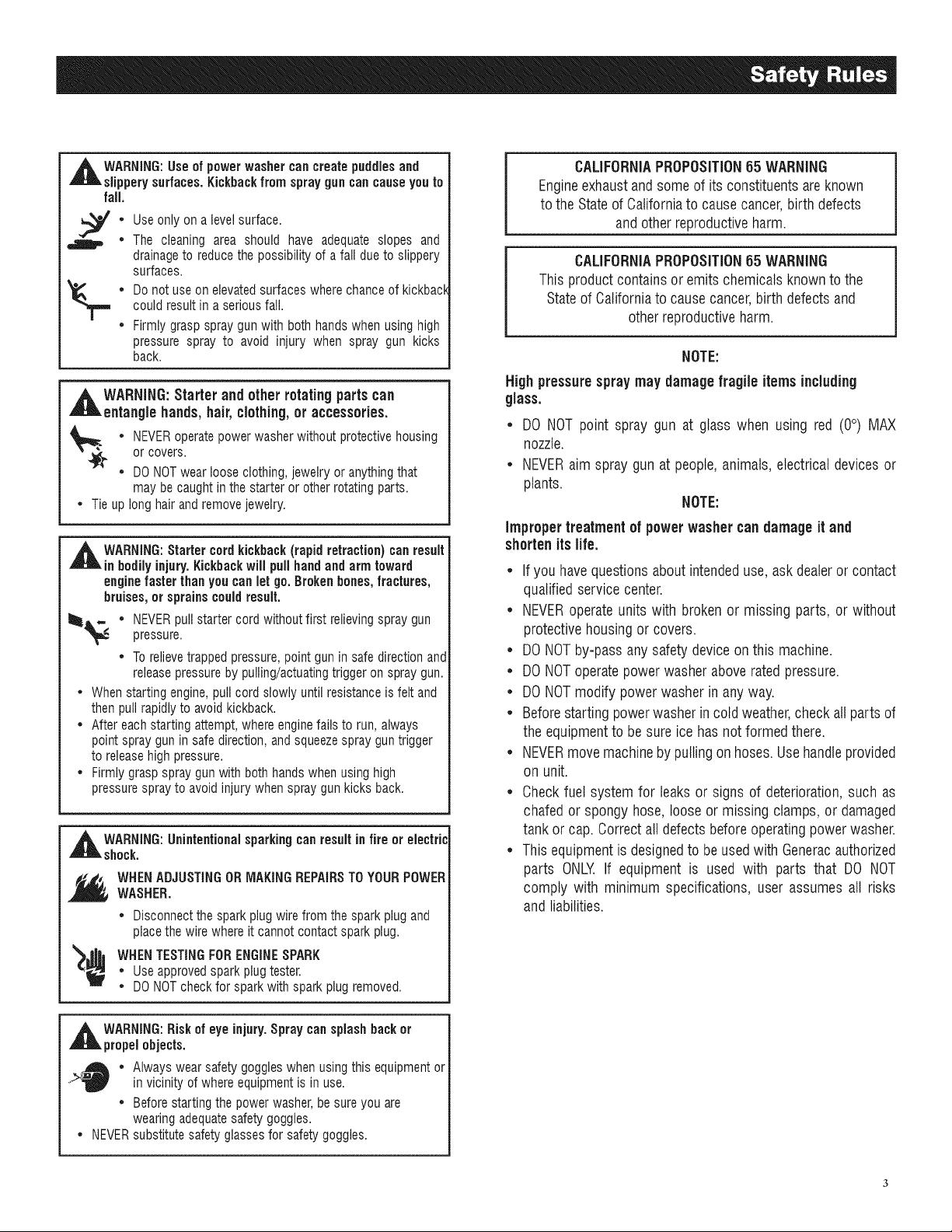

KNOWYOURPOWERWASHER

Readthis owner's manual and safety rules before operatingyour

high powerwasher.

If you loanthis deviceto someone,ALWAYSloanALL instructional

documentationto the individualas well. Comparethe illustrations

with your high power washer to familiarize yourself with the

locationsof variouscontrols(Figure1). Savethis manualfor future

reference.Replacementowner'smanualscan be printedfrom the

GeneracWebsite.

A = Spray Gun - Controls the application of water onto the

cleaningsurface with triggerdevice.Includesa trigger lock.

B - Lancewith QuickConnect- Allows you to switch between

four different nozzles.

C - High PressureHose- Connect one end to water pump and

theother to the spraygun.

D - Recoil Starter - Usefor starting the engine.

E - Oil Fill- Checkand add engineoil here.

F - Air Filter- Protectsenginebyfiltering dust, anddebrisout of

the intakeair.

G - Pump- Developshigh pressure.

H - ThermalRelief Valve- Cycle'swaterthroughthepumpwhen

water reaches 125°EWarm water will dischargefrom pump

ontoground. This preventsinternalpumpdamage.

I - Engine On/OffSwitch - Runthis switch to "ON" beforeusing

therecoil starter.Turnthe switch to "OFF"to stop the engine.

J - PressureControl/UnloaderValve- Controlsthe highpressure

output.

K- HighPressureOutlet - Connectionfor high pressurehose.

L - Water Inlet - Connectionfor GardenHose.

M - FuelTank- Filltank with regularunleadedfuel. Always leave

roomfor fuel expansion.

N - FuelOn/Off Switch - Turnsfuel supply to the engineon and

off.

0 - Choke- Preparesa cold enginefor starting.

P - ThrottleLever- Increasesor decreasesenginespeed.Throttle

shouldbe at maximumtravel whenthe pressurewasher is in

use.

Q - Nozzles- Chemicalinjection,0°, 15°, 25°, 40° (white,yellow,

redand black)forvarious highpressurecleaningapplications.

R - Pull Pin - Pullthe ring to unlock the handle.This allows the

handleto be collapsedfor storage.

S - Adjustable Side Handle- Adjustablebyturning counterclock-

wise to loosen, adjust to comfortable position and tighten

clock-wise. This allowsfor a firm operatinggrip of the spray

gun.

T - OilDrain- Drain engineoil here.

ITEMSNOTSHOWN

IdentificationLabel (near rear of base plate) - Providesmodel

and serial number of pressurewasher.Pleasehavethese readily

availableif callingfor assistance.

DetergentSiphoningTube/Filter- Useto siphonpressurewasher

safe detergentsintothe low pressurestream.

Figure 1 - Features & Controls

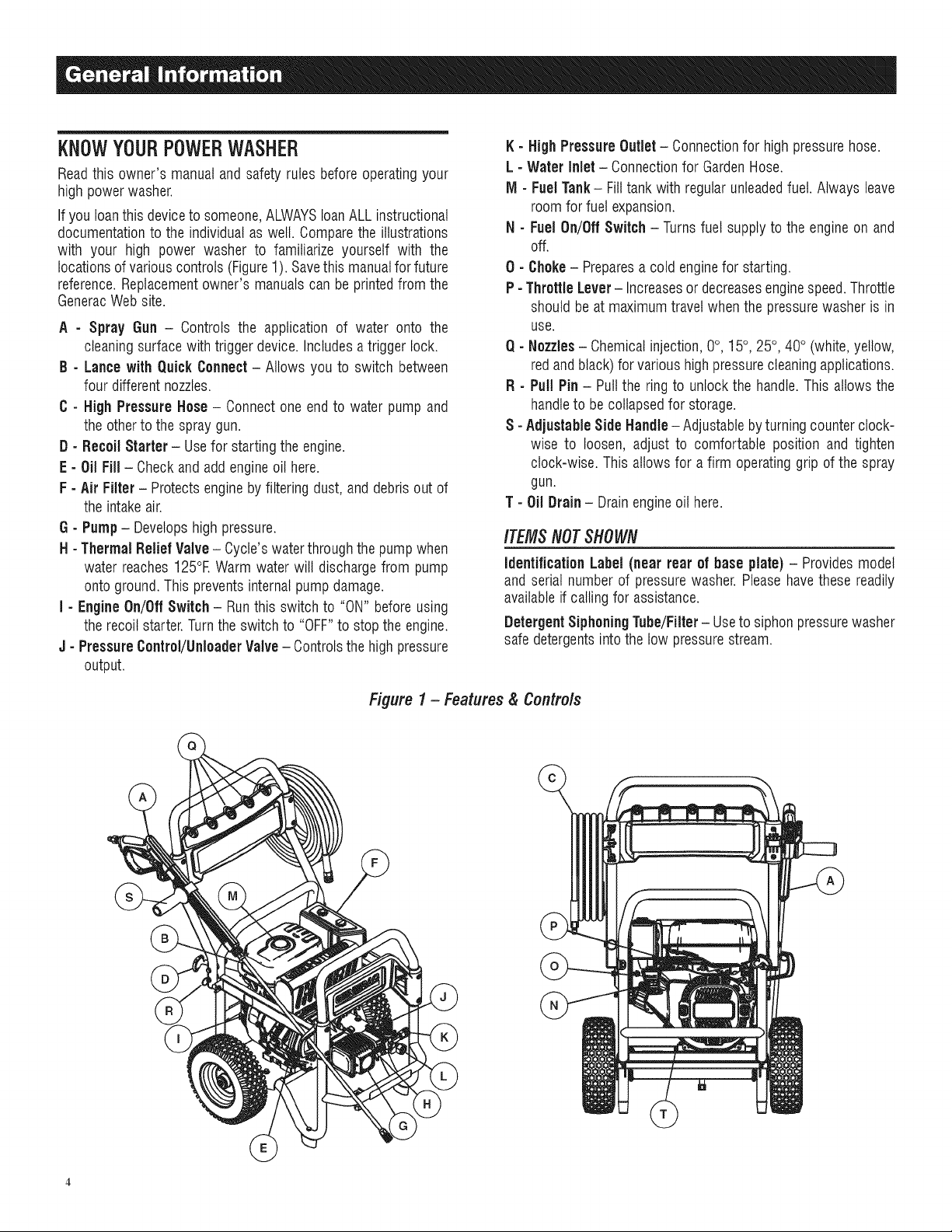

PRODUCTSPECiFiCATiONS

Pressure- (PSI/ BAR) 3000 / 207 3300/ 228 4000 / 276

FlowRate- (GPM/LPM) 2.8/10.6 3.2/12.1 4.0/15.1

WaterSupplyTemperature- (°F/ C°) 100 / 38 Max

HoseLength- (Feet/ Meters) 35 / 10.7 50 / 15.2

Nozzles- NumberperUnit 5

LanceLength (Inches/ cm) 20 / 51 33 / 84 33 / 84

Gun Professional

EngineDisplacement- (Cubic Inch/ cc) 12.9/ 212 18.4/ 302 25.6 / 420

SparkPlugType F7RTCor equivalent

SparkPlugGap- (Inches/ mm) 0.028-0.031 / 0.70-0.80

FuelCapacity- (Quarts/ Liters) 3.2/ 3.0 4.9/ 4.63 6.3 / 6.0

EngineOilCapacity- (Oz/ Liters) 20 / 0.6 37 / 1.1 37 / 1.1

Low OilShut Down System Yes

On/ Off Switch Yes

UNPACKING

1. Removethe parts bag,accessories,andinserts includedwith

powerwasher.

2. Open carton completely by cutting each corner from top to

bottom.

3. Ensureyou haveall includeditemspriorto assembly.

• MainUnit

• HighPressureHose

• SiphonHose& Filter

• SprayGun

• LancewithQuickConnectFitting

• OilBottle

• PartsBag(whichincludesthefollowing):

HoseHookWireformwithScrewsandAllenWrench

Operator'sManual

Owner'sRegistrationCard

BagcontainingColor-codedNozzles

FilterScreen

4. If you are missing any items from your carton, please call

GeneracCustomerService at 1-888-436-3722. Whencalling

for assistance,pleasehavethe modeland serial numberfrom

thedata tag available.

5. Fill out and send in registrationcard. Write Model number,

Serial number& dateof purchase in the table locatedin the

"Whereto FindUs"section.

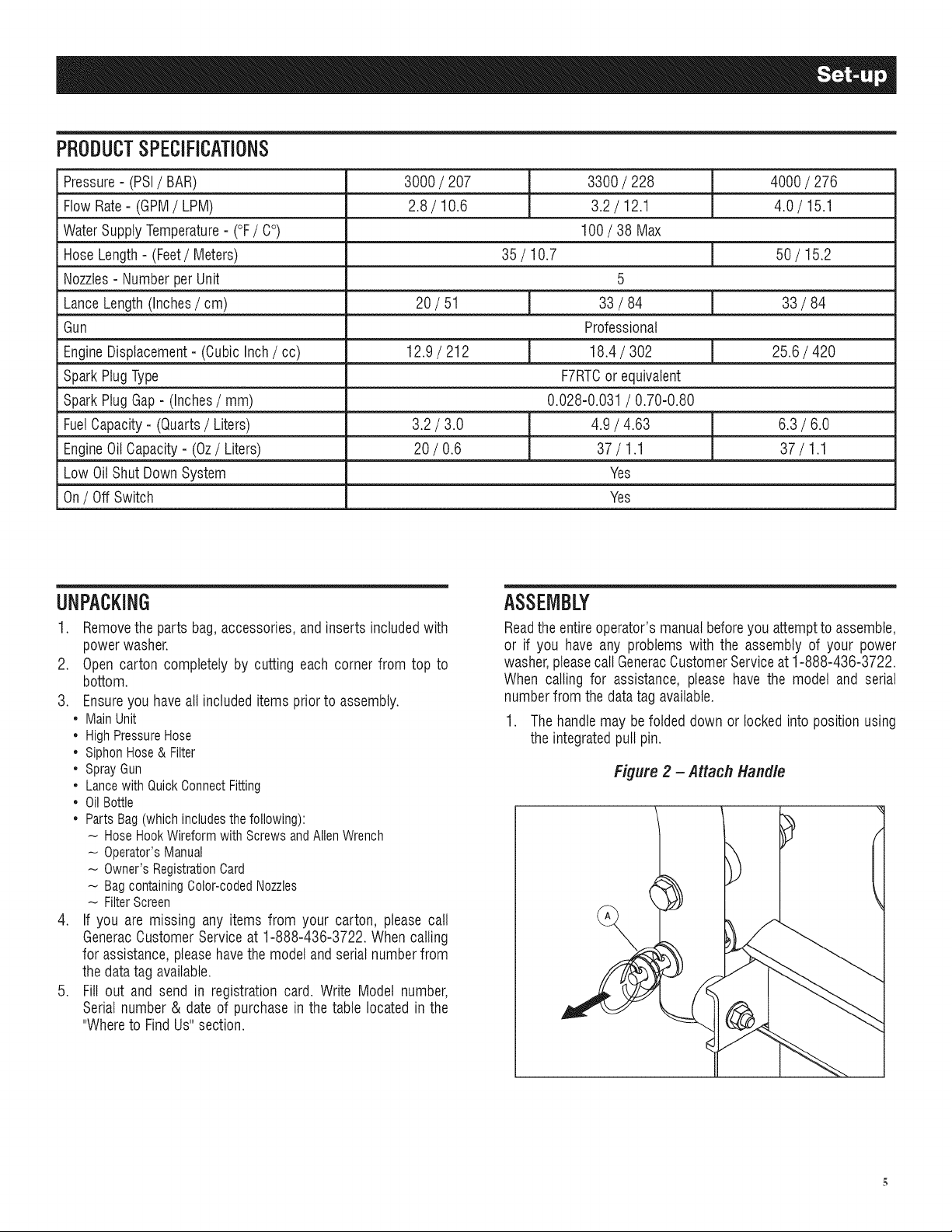

ASSEMBLY

Readthe entireoperator'smanualbeforeyou attemptto assemble,

or if you have any problems with the assembly of your power

washer,pleasecallGeneracCustomerServiceat 1-888-436-3722.

When calling for assistance, please have the model and serial

numberfrom thedata tag available.

1. Thehandlemay be folded down or locked into position using

theintegratedpull pin.

Figure 2 - Attach Handle

.

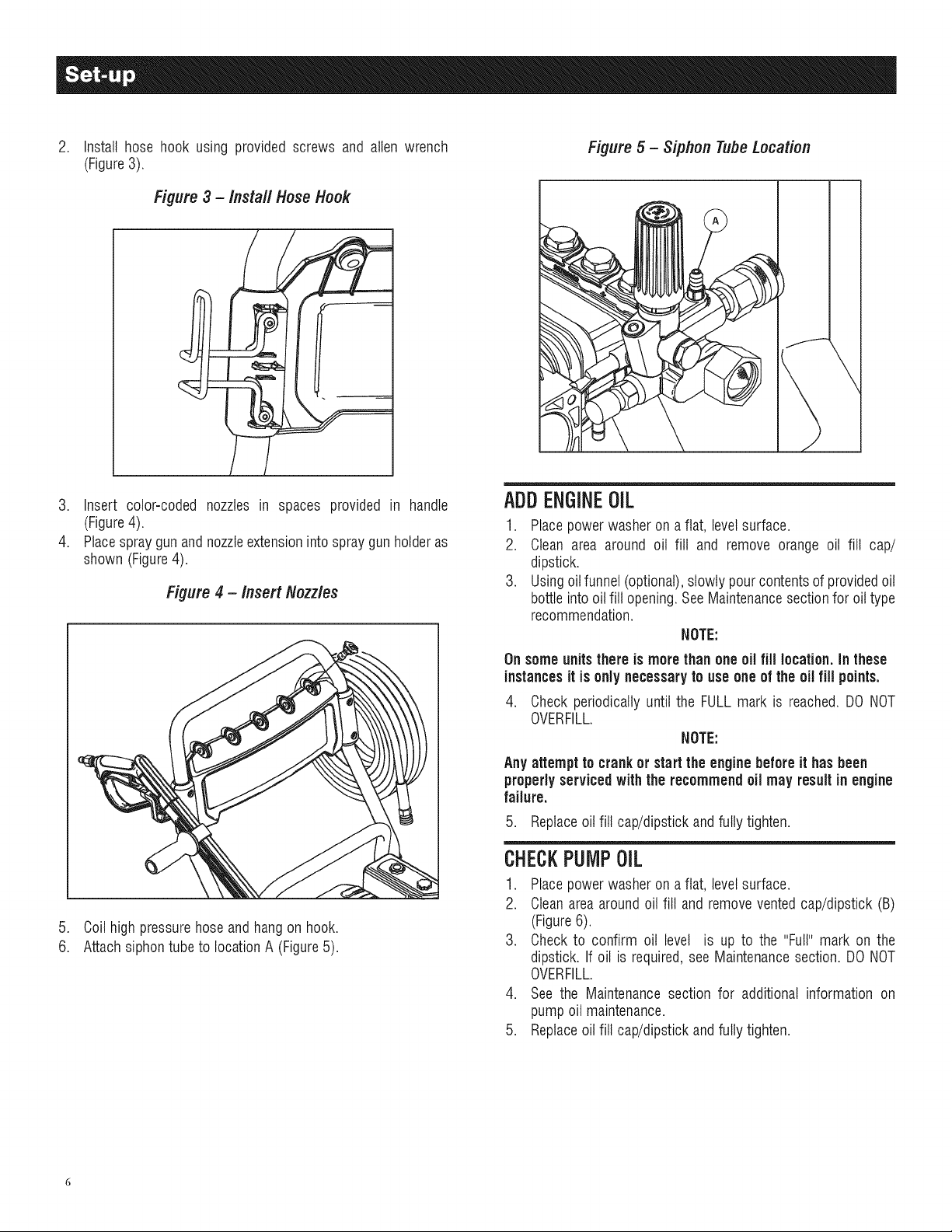

Install hose hook using provided screws and allen wrench

(Figure3).

Figure 3 - Instal/Hose Hook

Figure5 - Siphon TubeLocation

3. Insert color-coded nozzles in spaces provided in handle

(Figure4).

4. Placespraygunand nozzleextensionintospray gunholderas

shown (Figure4).

Figure4 - InsertNozzles

5. Coilhigh pressurehoseand hangon hook.

6. Attachsiphon tubeto locationA (Figure5).

ADDENGINEOIL

1. Placepowerwasher on a flat, level surface.

2. Clean area around oil fill and remove orange oil fill cap/

dipstick.

3. Usingoilfunnel(optional),slowly pour contentsof providedoil

bottle intooilfill opening.SeeMaintenancesectionfor oil type

recommendation.

NOTE:

Onsomeunitsthere ismore than one oil fill location.Inthese

instancesitis only necessaryto use one of the oil fill points.

4. Check periodicallyuntil the FULL mark is reached. DONOT

OVERFILL.

NOTE:

Any attemptto crankor startthe engine before it hasbeen

properlyservicedwith the recommendoil may resultin engine

failure.

5. Replaceoil fill cap/dipstickand fully tighten.

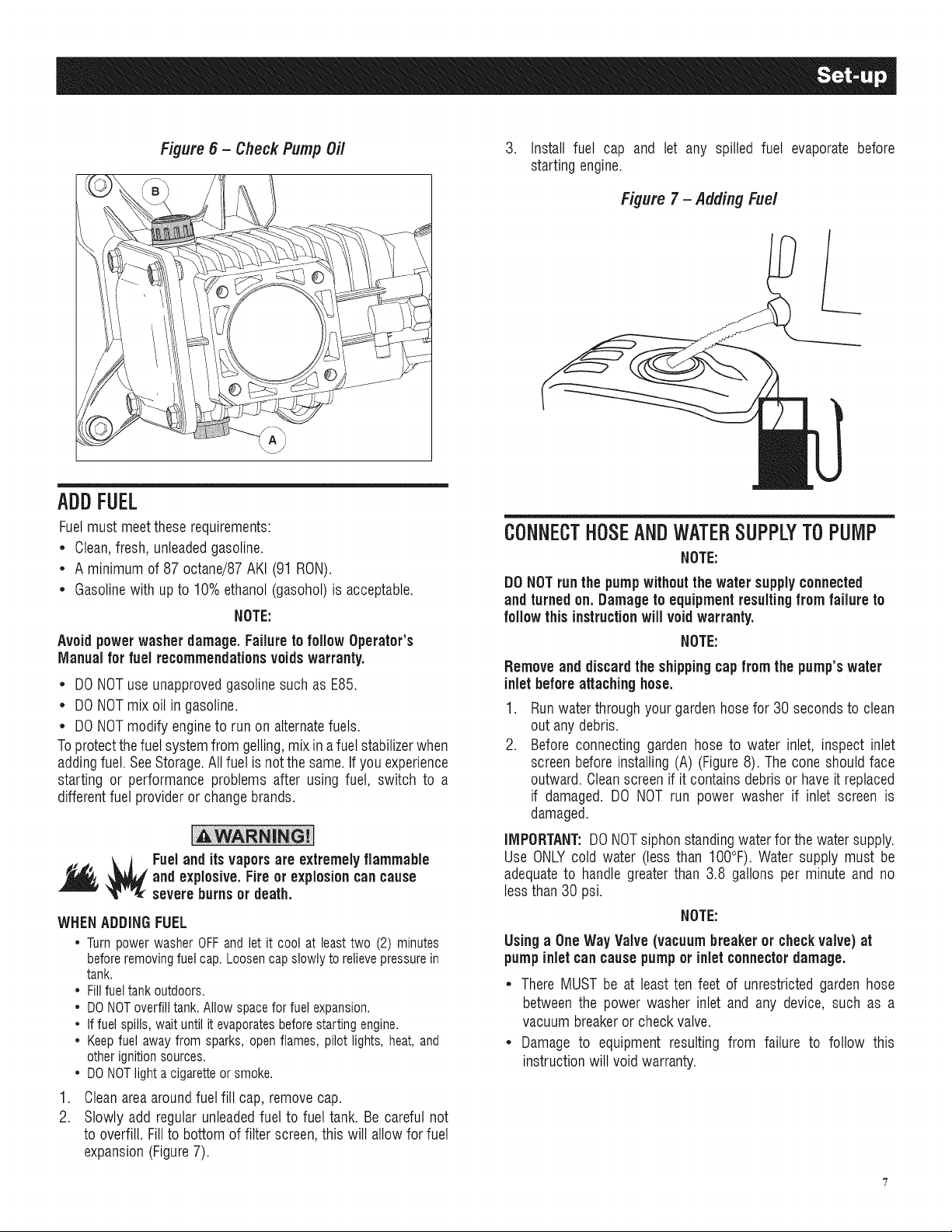

CHECKPUMPOIL

1. Placepowerwasher on a flat, level surface.

2. Cleanarea aroundoil fill and removevented cap/dipstick (B)

(Figure6).

3. Checkto confirm oil level is up to the "Full" mark on the

dipstick. If oil is required,seeMaintenancesection.DO NOT

OVERFILL.

4. See the Maintenancesection for additional information on

pumpoil maintenance.

5. Replaceoil fill cap/dipstickand fully tighten.

Figure 6 - Check Pump Oi/ 3. Install fuel cap and let any spilled fuel evaporate before

ADDFUEL

Fuelmust meetthese requirements:

* Clean,fresh, unleadedgasoline.

* A minimum of 87 octane/87AKI (91 RON).

* Gasolinewith up to 10%ethanol (gasohol)is acceptable.

NOTE:

Avoid powerwasherdamage.FailuretofollowOperator's

Manualfor fuel recommendationsvoidswarranty.

* DONOTuse unapprovedgasolinesuch as E85.

* DONOTmix oil in gasoline.

* DONOTmodify engineto run on alternatefuels.

Toprotectthefuel systemfrom gelling,mix in afuel stabilizerwhen

addingfuel. SeeStorage.All fuel isnotthesame.If youexperience

starting or performance problems after using fuel, switch to a

differentfuel provideror changebrands.

and explosive. Fire or explosion cancause

Fueland itsvaporsare extremely flammable

severeburns or death.

WHEN ADDING FUEL

* Turn power washer OFFand let it cool at least two (2) minutes

beforeremovingfuel cap. Loosen capslowly to relievepressurein

tank.

* Fillfuel tank outdoors.

* DONOToverfill tank. Allow spacefor fuel expansion.

* If fuel spills, wait until it evaporatesbeforestarting engine.

* Keepfuel awayfrom sparks, open flames, pilot lights, heat, and

other ignitionsources.

* DONOTlight acigarette or smoke.

1. Clean area around fuel fill cap, remove cap.

2. Slowly add regular unleaded fuel to fuel tank. Be careful not

to overfill. Fillto bottom of filter screen, this will allow for fuel

expansion (Figure 7).

starting engine.

Figure 7- Adding rue/

/

CONNECTHOSEANDWATERSUPPLYTOPUMP

NOTE:

DONOTrunthe pumpwithoutthewater supplyconnected

and turnedon. Damage to equipment resultingfrom failure to

follow this instructionwiil voidwarranty.

NOTE:

Removeand discard the shippingcapfrom the pump'swater

inletbefore attachinghose.

1. Runwaterthrough your gardenhose for 30 secondsto clean

out any debris.

2. Before connecting garden hose to water inlet, inspect inlet

screen beforeinstalling (A) (Figure8). The coneshouldface

outward.Cleanscreenif it containsdebrisor have it replaced

if damaged. DO NOT run power washer if inlet screen is

damaged.

iMPORTANT:DONOTsiphon standingwater forthe watersupply.

Use ONLYcold water (tessthan IO0°F).Water supply must be

adequateto handle greater than 3.8 gallons per minute and no

less than30 psi.

NOTE:

Using a OneWayValve (vacuumbreaker or checkvalve)at

pumpinlet cancausepumpor inletconnectordamage.

* ThereMUST be at least ten feet of unrestricted garden hose

between the power washer inlet and any device, such as a

vacuumbreakeror checkvalve.

* Damage to equipment resulting from failure to follow this

instructionwill voidwarranty.

Figure 8 - Inspect Inlet Screen

.

Connectthe gardenhose (not to exceed50 feet in length)to

the water inlet (Figure9). Tightenby hand.

Figure 9 - Connect Garden Hose

.

Attachendof high pressurehoseto baseof spray gun (Figure

11).

Figure 11 - Connect Hose to Spray Gun

producescancut throughskinand itsunderlying

The highpressurestreamof water thatthisequipment

tissues,leadingto seriousinjury,possibleamputation

or death.Spray guntrapshighwater pressure,even

whenengineisstoppedandwater is disconnected,

whichcan causeinjury.

• NEVERconnecthighpressurehosetolance.

• Keephighpressurehoseconnectedtopumpandspraygunwhile

systemispressurized.

• Always be certain spray gun, nozzlesand accessoriesare

correctlyattached.

6. Connect high pressure hose to pump (uncoil hose before

connectingto pump or spraygun) (Figure12).

Riskof eye injury.Spray cansplashbackor propel

..>40 objects.

• Always wear safety goggles when using this equipment or in

vicinity of equipmentin use.

• Before starting the power washer, be sure you are wearing

adequatesafetygoggles.

• NEVERsubstitute safety glassesfor safetygoggles.

.

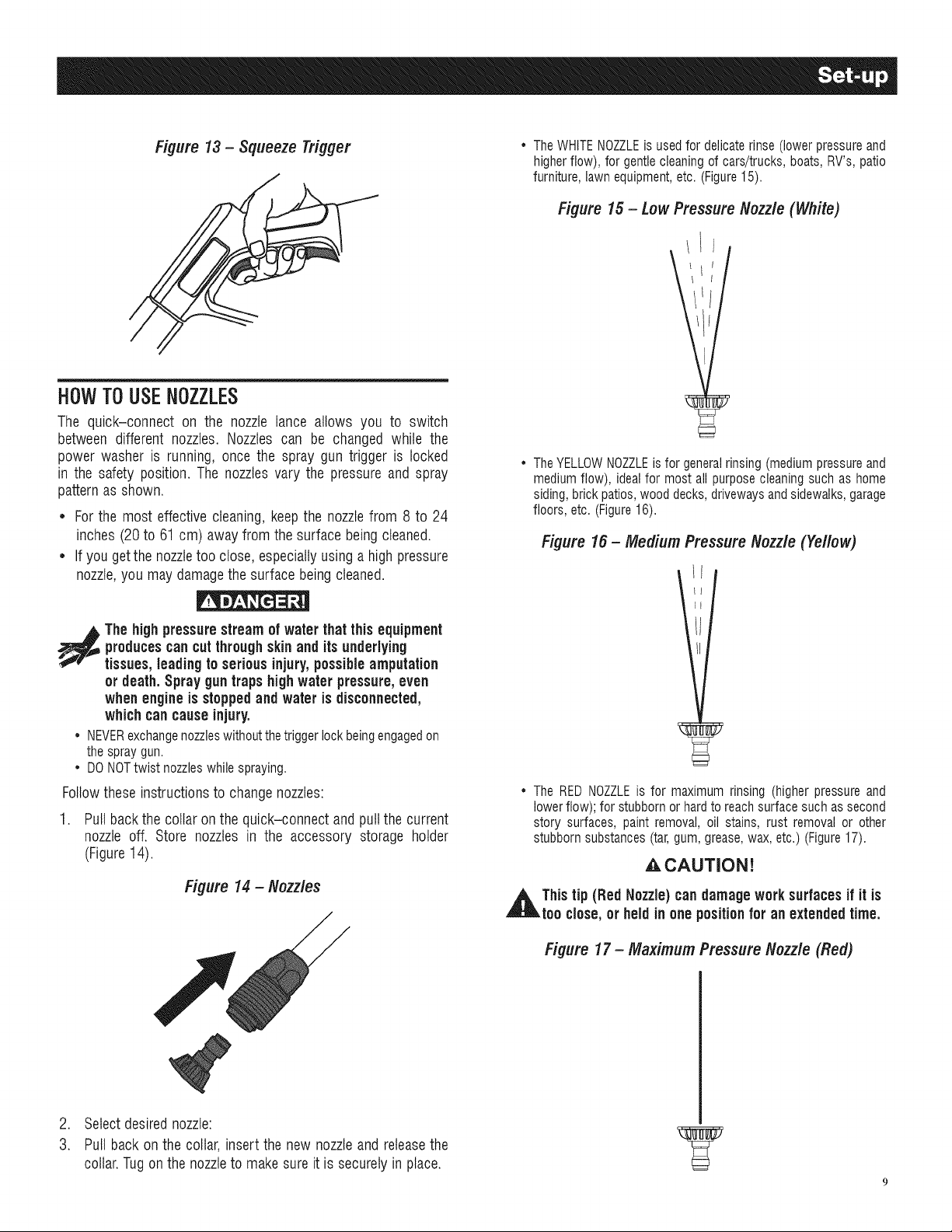

Connect lance to spray gun (Figure 10). Tighten by hand.

Figure10- Attach Lance

Figure 12- Connect High PressureHoseto Pump

7. Turn ON the water, squeezethe trigger to purge the pump

system of air (Figure13).

,A CAUTION!

,iA The hosecanbe damagedif it comesin contactwitha

hotengineor muffler.

Figure 13- Squeeze Trigger

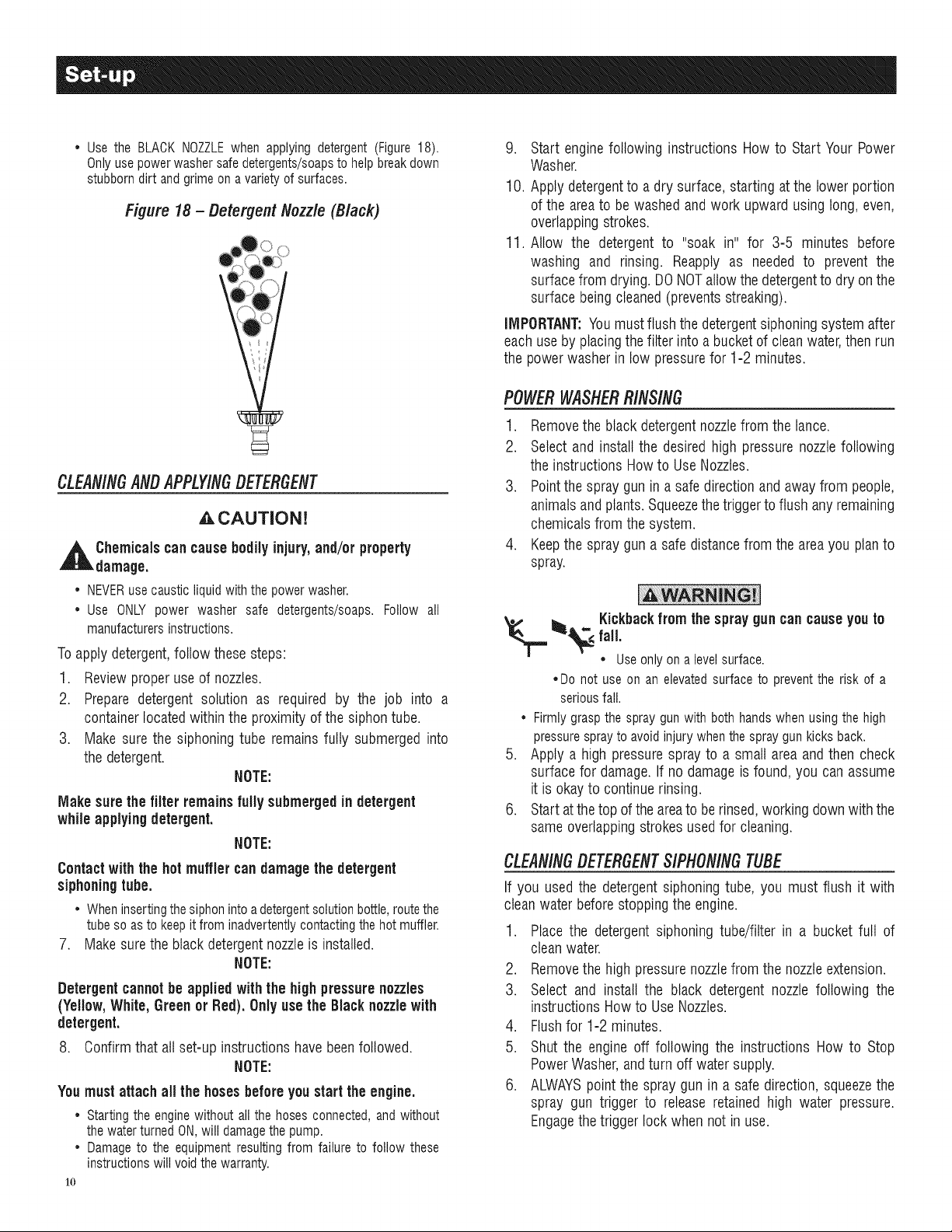

HOW TOUSENOZZLES

The quick-connect on the nozzle lance allows you to switch

between different nozzles. Nozzles can be changed while the

power washer is running, once the spray gun trigger is locked

in the safety position. The nozzles vary the pressure and spray

patternas shown.

* Forthe most effectivecleaning,keepthe nozzlefrom 8 to 24

inches (20 to 61 cm) awayfrom the surfacebeing cleaned.

* If you getthe nozzletoo close,especiallyusinga highpressure

nozzle,you may damagethe surfacebeingcleaned.

* TheWHITENOZZLEis usedfor delicaterinse (lower pressure and

higherflow), for gentlecleaningof cars/trucks, boats, RV's,patio

furniture, lawn equipment,etc. (Figure15).

Figure 15 - Low Pressure Nozzle (White)

• TheYELLOWNOZZLEis for generalrinsing (medium pressureand

mediumflow), idealfor most all purposecleaning such as home

siding, brickpatios,wood decks, drivewaysandsidewalks,garage

floors, etc. (Figure16).

Figure 16 - Medium Pressure Nozzle (Yellow)

producescancutthroughskinand its underlying

The highpressurestreamof waterthat this equipment

tissues,leadingto seriousinjury,possibleamputation

or death. Spray gun trapshighwaterpressure,even

whenengine is stoppedandwater is disconnected,

whichcan causeinjury.

* NEVERexchangenozzleswithoutthetriggerlockbeingengagedon

thespraygun.

* DONOTtwistnozzleswhilespraying.

Followthese instructionsto changenozzles:

1. Pull backthe collar on the quick-connect and pullthe current

nozzle off. Store nozzles in the accessory storage holder

(Figure14).

Figure 14- Nozzles

* The REDNOZZLEis for maximum rinsing (higher pressure and

lowerflow); for stubborn or hardto reachsurface such as second

story surfaces, paint removal, oil stains, rust removal or other

stubborn substances(tar,gum, grease,wax, etc.) (Figure17).

,&CAUTION!

,l_ Thistip (Red Nozzle)can damageworksurfacesif it is

too close,or heldin one positionfor an extendedtime.

Figure17- MaximumPressureNozzle(Red)

2. Selectdesirednozzle:

3. Pull back on the collar, insert the new nozzleand releasethe

collar.Tugon the nozzleto makesureit is securely in place.

• Use the BLACKNOZZLEwhen applying detergent (Figure 18).

Onlyusepower washer safe detergents/soapsto helpbreakdown

stubborn dirt andgrime on avariety of surfaces.

Figure 18- Detergent Nozzle(Black)

CLEANINGANDAPPLYINGDETERGENT

,A CAUTION!

,_ Chemicals cancause bodily injury,and/or property

damage.

• NEVERusecausticliquidwiththepowerwasher.

• Use ONLYpower washer safe detergents/soaps.Follow all

manufacturersinstructions.

9. Start enginefollowing instructions How to Start Your Power

Washer.

10. Applydetergentto a dry surface,starting atthe lowerportion

of the areato bewashed andwork upward usinglong, even,

overlappingstrokes.

11. Allow the detergent to "soak in" for 3-5 minutes before

washing and rinsing. Reapply as needed to prevent the

surfacefrom drying. DONOTallowthe detergentto dry onthe

surface beingcleaned(preventsstreaking).

IMPORTANT:Youmustflush the detergentsiphoningsystem after

eachuse byplacing thefilter into a bucketof cleanwater,then run

the powerwasher in low pressurefor 1-2 minutes.

POWERWASHERRINS/NG

1. Removethe black detergentnozzlefrom the lance.

2. Select and install the desiredhigh pressure nozzlefollowing

theinstructions Howto UseNozzles.

3. Pointthe spray gun in a safedirection andaway from people,

animalsandplants.Squeezethe triggerto flush anyremaining

chemicalsfrom the system.

4. Keepthe spray gun a safe distancefrom the areayou planto

spray.

Kickback from thespray guncancauseyouto

Toapply detergent,followthese steps:

1. Reviewproper use of nozzles.

2. Prepare detergent solution as required by the job into a

containerlocatedwithin the proximityof the siphontube.

3. Make sure the siphoning tube remains fully submergedinto

thedetergent.

NOTE:

Makesurethe filter remainsfully submergedin detergent

while applying detergent.

NOTE:

Contactwith the hotmuffler can damage the detergent

siphoningtube.

• Wheninsertingthesiphonintoadetergentsolutionbottle,routethe

tubeso asto keepitfrominadvertentlycontactingthehotmuffler.

7. Makesurethe blackdetergentnozzleis installed.

NOTE:

Detergentcannotbe applied withthe highpressurenozzles

(Yellow, White,Greenor Red). Only usethe Black nozzlewith

detergent.

8. Confirmthat all set-up instructions havebeenfollowed.

NOTE:

Youmustattachall the hosesbefore youstart the engine.

• Startingtheenginewithoutallthe hosesconnected,andwithout

thewaterturnedON,willdamagethepump.

• Damageto the equipmentresultingfrom failureto followthese

instructionswillvoidthewarranty.

1o

• Useonlyonalevelsurface.

•Donotuseon anelevatedsurfacetopreventthe riskof a

seriousfall.

• Firmlygraspthespraygunwith bothhandswhenusingthehigh

pressurespraytoavoidinjurywhenthespraygunkicksback.

5. Apply a high pressurespray to a small area andthen check

surfacefor damage.If no damageis found,you can assume

it is okay to continuerinsing.

6. Start atthe top of theareato be rinsed,workingdownwiththe

same overlappingstrokesusedfor cleaning.

CLEAN/NGDETERGENTS/PHON/NGTUBE

If you used the detergentsiphoningtube, you must flush it with

cleanwater beforestoppingthe engine.

1. Place the detergent siphoning tube/filter in a bucket full of

cleanwater.

2. Removethe high pressurenozzlefrom the nozzleextension.

3. Select and install the black detergent nozzle following the

instructions Howto UseNozzles.

4. Flushfor 1-2 minutes.

5. Shut the engine off following the instructions How to Stop

PowerWasher,andturn off water supply.

6. ALWAYSpointthe spray gun in a safe direction, squeezethe

spray gun trigger to release retained high water pressure.

Engagethe trigger lock when notin use.

IMPORTANT:Sprayguntraps highwater pressure,evenwhenthe

engineis stoppedandwater is disconnected.

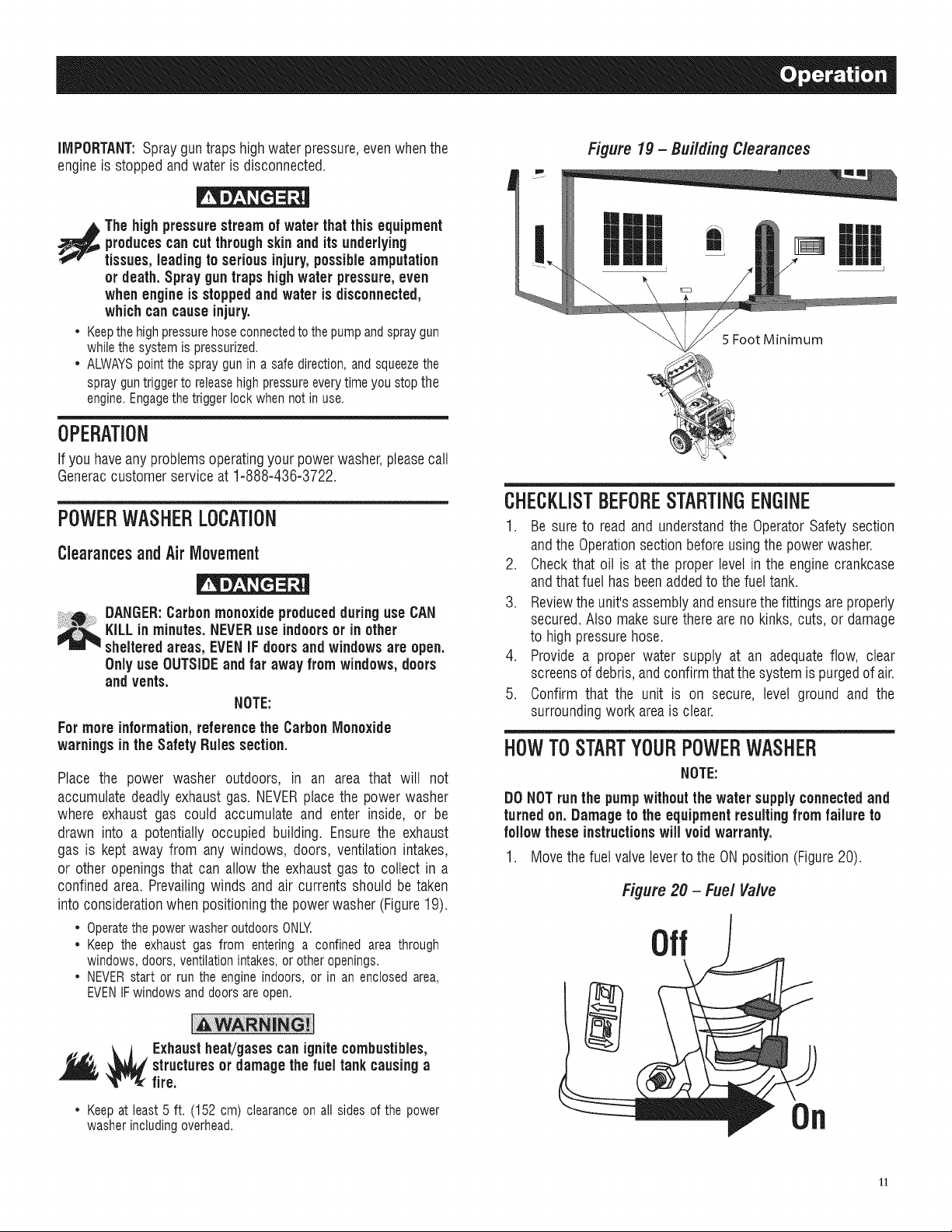

Figure19 - Building Clearances

:_ The highpressurestreamof water thatthisequipment

producescancutthroughskinand its underlying

tissues,leadingto seriousinjury,possibleamputation

or death.Spray guntrapshighwaterpressure,even

whenengineis stoppedandwater is disconnected,

whichcan causeinjury.

• Keepthehighpressurehoseconnectedtothepumpandspraygun

whilethesystemis pressurized.

• ALWAYSpointthespraygunin a safedirection,andsqueezethe

sprayguntriggerto releasehighpressureeverytimeyoustopthe

engine.Engagethetriggerlockwhennotinuse.

OPERATION

If youhaveany problemsoperatingyourpower washer,pleasecall

Generaccustomerservice at 1-888-436-3722.

POWERWASHERLOCATION

ClearancesandAir Movement

_ ANGER:Carbonmonoxide producedduringuse CAN

For moreinformation,reference the CarbonMonoxide

warningsinthe Safety Rules section.

Place the power washer outdoors, in an area that wilt not

accumulatedeadly exhaustgas. NEVERplacethe power washer

where exhaust gas could accumulate and enter inside, or be

drawn into a potentially occupied building. Ensurethe exhaust

gas is kept away from any windows, doors, ventilation intakes,

or other openingsthat can allow the exhaustgas to collect in a

confined area. Prevailingwinds and air currents should be taken

into considerationwhenpositioningthe powerwasher (Figure19).

KILLin minutes.NEVERuseindoorsor in other

shelteredareas, EVENIFdoorsand windowsare open.

Onlyuse OUTSIDEand far awayfromwindows,doors

andvents.

NOTE:

• OperatethepowerwasheroutdoorsONLY.

• Keepthe exhaustgasfrom enteringa confinedareathrough

windows,doors,ventilationintakes,or otheropenings.

• NEVERstartor run theengineindoors,or in an enclosedarea,

EVENIFwindowsanddoorsareopen.

5 Foot Minimum

CHECKLISTBEFORESTARTINGENGINE

1. Be sure to read and understandthe OperatorSafety section

andthe Operationsectionbefore usingthe power washer.

2. Checkthat oil is at the proper level in the enginecrankcase

andthat fuel has beenaddedto the fueltank.

3. Reviewtheunit'sassemblyandensurethefittings areproperly

secured.Also make surethere areno kinks, cuts, or damage

to high pressurehose.

4. Provide a proper water supply at an adequateflow, clear

screensof debris,andconfirmthat the systemis purgedof air.

5. Confirm that the unit is on secure, level ground and the

surroundingwork areais clear.

HOW TOSTARTYOURPOWERWASHER

NOTE:

DONOTrun the pumpwithoutthe water supplyconnectedand

turnedon. Damageto the equipment resultingfrom failure to

follow theseinstructionswill voidwarranty.

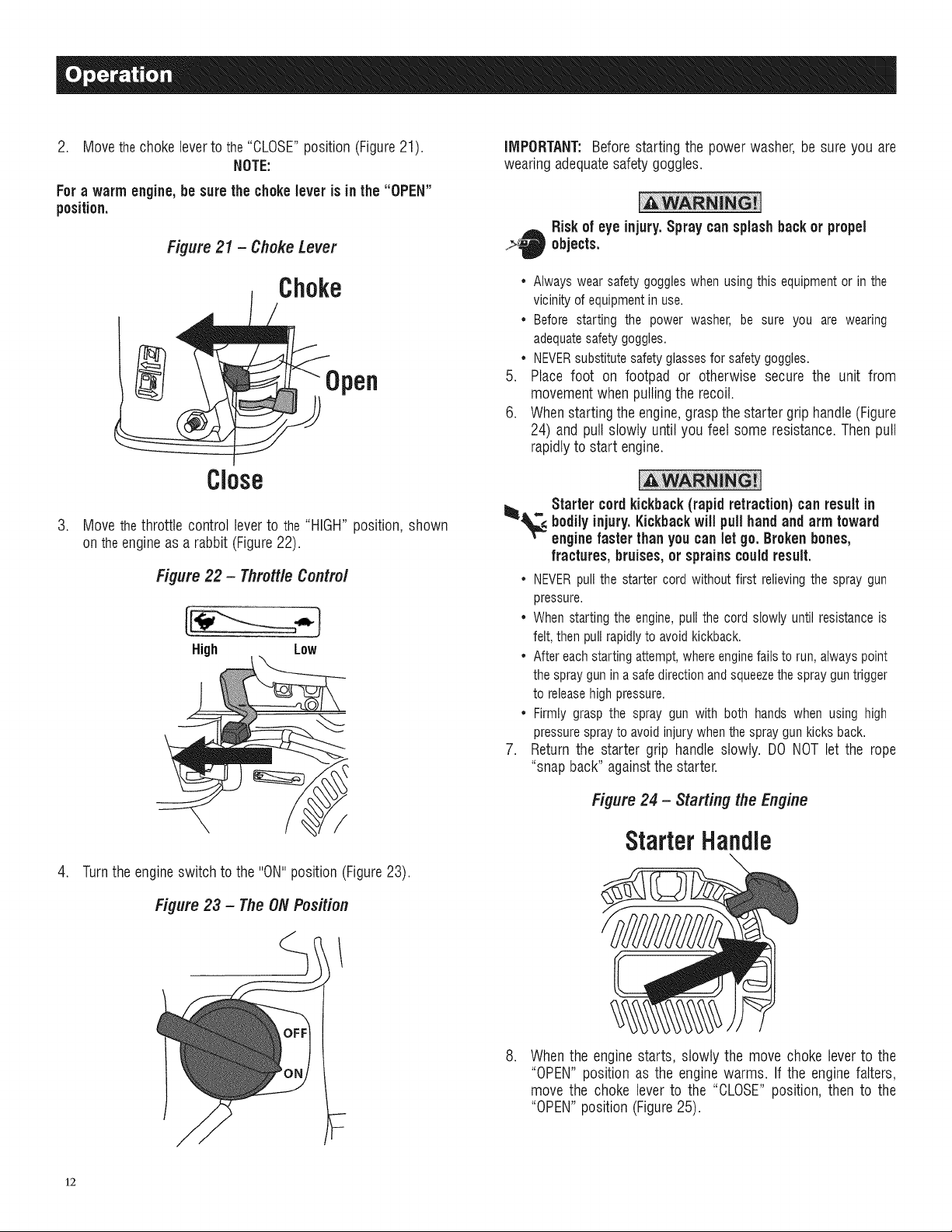

1. Movethefuel valve leverto theONposition (Figure20).

Figure20- Fue/Va/ve

Off

structuresor damagethe fuel tankcausinga

_1_ Exhaustheat/gasescan ignitecombustibles,

fire.

• Keepat least 5 ft. (152 cm) clearanceon all sides of the power

washerincludingoverhead.

11

2. Movethechokeleverto the "CLOSE"position (Figure21).

NOTE:

Fora warm engine, be surethe chokeleveris inthe "OPEN"

position.

Figure21 - ChokeLever

Open

Close

.

Move thethrottle control lever to the"HIGH" position, shown

on theengineas a rabbit(Figure22).

Figure 22 - Throttle Centre/

High Low

IMPORTANT:Beforestarting the power washer,be sure you are

wearingadequatesafetygoggles.

Risk of eye injury.Spraycansplashbackor propel

'>_0 objects.

Alwayswearsafetygoggleswhenusingthisequipmentor inthe

vicinityof equipmentin use.

Beforestarting the powerwasher,be sure you are wearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesfor safetygoggles.

.

Place foot on footpad or otherwise secure the unit from

movementwhenpullingthe recoil.

6.

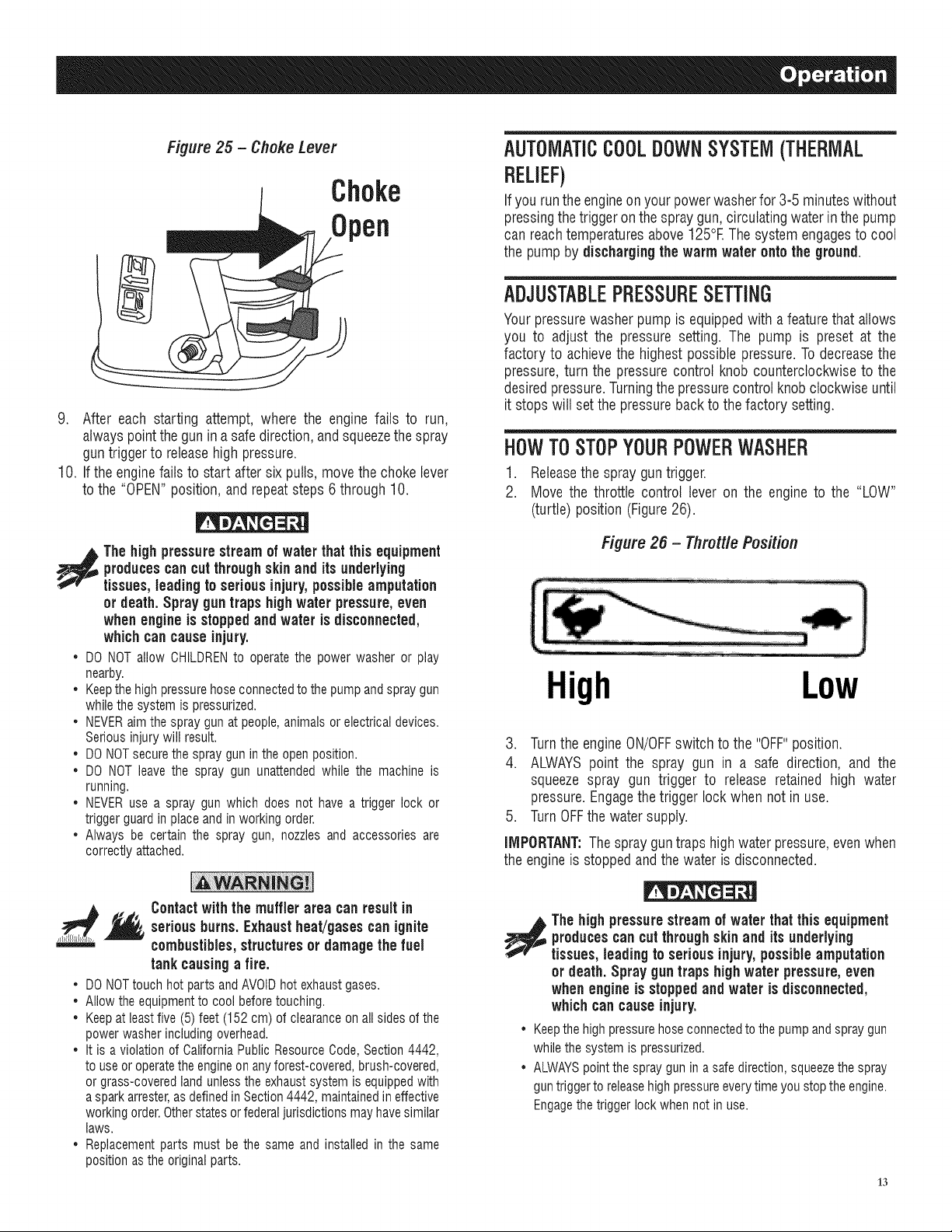

Whenstarting the engine,graspthe startergrip handle(Figure

24) and pull slowly until you feel some resistance.Then pull

rapidlyto start engine.

Starter cordkickback (rapidretraction)canresult in

bodily injury.Kickback will pullhandand arm toward

enginefaster thanyoucan let go. Brokenbones,

fractures, bruises, or sprainscouldresult.

* NEVERpullthe startercordwithoutfirst relievingthespraygun

pressure.

* Whenstartingthe engine,pullthecord slowlyuntilresistanceis

felt,thenpullrapidlyto avoidkickback.

* Aftereachstartingattempt,whereenginefailstorun,alwayspoint

thesprayguninasafedirectionandsqueezethesprayguntrigger

to releasehighpressure.

®

Firmlygraspthe spraygun with both handswhenusing high

pressurespraytoavoidinjurywhenthespraygunkicksback.

7.

Return the starter grip handle slowly. DO NOTlet the rope

"snap back" againstthe starter.

.

Turnthe engineswitch to the "ON"position (Figure23).

Figure 23- The ON Position

12

Figure24 - StartingtheEngine

StarterHandle

.

Whenthe engine starts, slowly the move choke leverto the

"OPEN" position as the engine warms. If the enginefalters,

move the choke leverto the "CLOSE"position, then to the

"OPEN"position (Figure25).

9. After each starting attempt, where the engine fails to run,

alwayspointthegun in asafe direction,andsqueezethe spray

guntriggerto releasehigh pressure.

10. If the enginefails to start after six pulls, movethe chokelever

to the "OPEN"position,andrepeatsteps6through 10.

producescancutthroughskinand its underlying

The highpressurestreamof waterthat this equipment

tissues,leadingto seriousinjury,possibleamputation

or death.Spray guntraps highwater pressure,even

whenengineisstoppedandwater is disconnected,

whichcan causeinjury.

, DONOTallow CHILDRENto operatethe powerwasheror play

nearby.

* Keepthehighpressurehoseconnectedtothepumpandspraygun

whilethesystemis pressurized.

* NEVERaimthespraygunatpeople,animalsorelectricaldevices.

Seriousinjurywill result.

* DONOTsecurethe spraygunintheopenposition.

* DONOTleavethe spraygun unattendedwhilethe machineis

running.

* NEVERuse a spraygunwhich doesnot havea triggerlockor

triggerguardinplaceandinworkingorder.

* Alwaysbe certainthe spray gun,nozzlesand accessoriesare

correctlyattached.

AUTOMATICCOOLDOWNSYSTEM(THERMAL

RELIEF)

If yourunthe engineon yourpowerwasherfor 3-5 minuteswithout

pressingthetrigger onthe spraygun, circulatingwater inthe pump

can reachtemperaturesabove125°EThesystemengagesto cool

the pump by discharging thewarm waterontotheground.

ADJUSTABLEPRESSURESETTING

Yourpressurewasher pumpis equippedwith a featurethat allows

you to adjust the pressure setting. The pump is preset at the

factory to achievethe highest possible pressure.Todecreasethe

pressure,turn the pressurecontrol knob counterclockwiseto the

desiredpressure.Turningthe pressurecontrolknobclockwise until

it stops will setthe pressureback to thefactory setting.

HOWTOSTOPYOURPOWERWASHER

1. Releasethe spray guntrigger.

2. Move the throttle control lever on the engine to the "LOW"

(turtle) position (Figure26).

Figure 26 - Throttle Position

High Low

3. Turnthe engineON/OFFswitch to the "OFF"position.

4. ALWAYSpoint the spray gun in a safe direction, and the

squeeze spray gun trigger to release retained high water

pressure.Engagethe triggerlock when not inuse.

5. TurnOFFthe watersupply.

iMPORTANT:Thesprayguntraps highwater pressure,evenwhen

theengineis stoppedand thewater is disconnected.

serious burns, Exhaust heat/gasescanignite

Contact with the muffler area can result in

combustibles,structures or damagethe fuel

tank causinga fire,

• DONOTtouch hot parts and AVOIDhot exhaustgases.

• Allowthe equipmentto cool beforetouching.

• Keepat leastfive (5)feet (152 cm) of clearance on allsides ofthe

powerwasher including overhead.

• It is a violation of CaliforniaPublic ResourceCode,Section 4442,

to useor operatethe engineon anyforest-covered,brush-covered,

or grass-coveredland unlessthe exhaustsystemis equippedwith

aspark arrester,asdefinedin Section4442, maintainedin effective

workingorder.Otherstatesorfederaljurisdictions mayhavesimilar

laws.

• Replacementparts must be the same and installed in the same

positionas the originalparts.

producescancutthroughskinand its underlying

The highpressurestreamof waterthat this equipment

tissues,leading to seriousinjury,possibleamputation

or death,Spray guntraps highwater pressure,even

whenengineisstoppedandwater is disconnected,

whichcan causeinjury,

* Keepthehigh pressurehoseconnectedtothe pump andspray gun

while thesystemis pressurized.

* ALWAYSpointthe spray gunin a safedirection,squeezethe spray

guntrigger to releasehigh pressureeverytime youstop the engine.

Engagethetrigger lock when not in use.

13

MAINTENANCERECOMMENDATIONS

Regularmaintenancewillimprovetheperformanceandextendthe life

ofthe powerwasher.Seeanyqualifieddealerforservice.

Thepowerwasher'swarrantydoesnotcover itemsthathavebeen

subjectedto operator abuseor negligence.To receivefull value

from the warranty,the operatormust maintainthe power washer

as instructedin this manual,includingproperstorageas detailedin

WinterStorageandLongTermStorage.

NOTE:

Shouldyouhavequestionsaboutreplacingcomponentson your

powerwasher,pleasecall1-888-436-3722for assistance.

Some adjustmentswill need to be made periodicallyto properly

maintainyour powerwasher.

All service and adjustmentsshould be made at least once each

season.Followtherequirementsinthe MaintenanceSchedulechart.

NOTE:

Oncea yearyoushouldcleanor replacethesparkplug,clean

or replacetheair filter, andcheckthespraygun andnozzle

extensionassemblyfor wear.Anewsparkplugandcleanair filter

assureproperfuel-air mixture and helpyourenginerunbetter

and lastlonger.

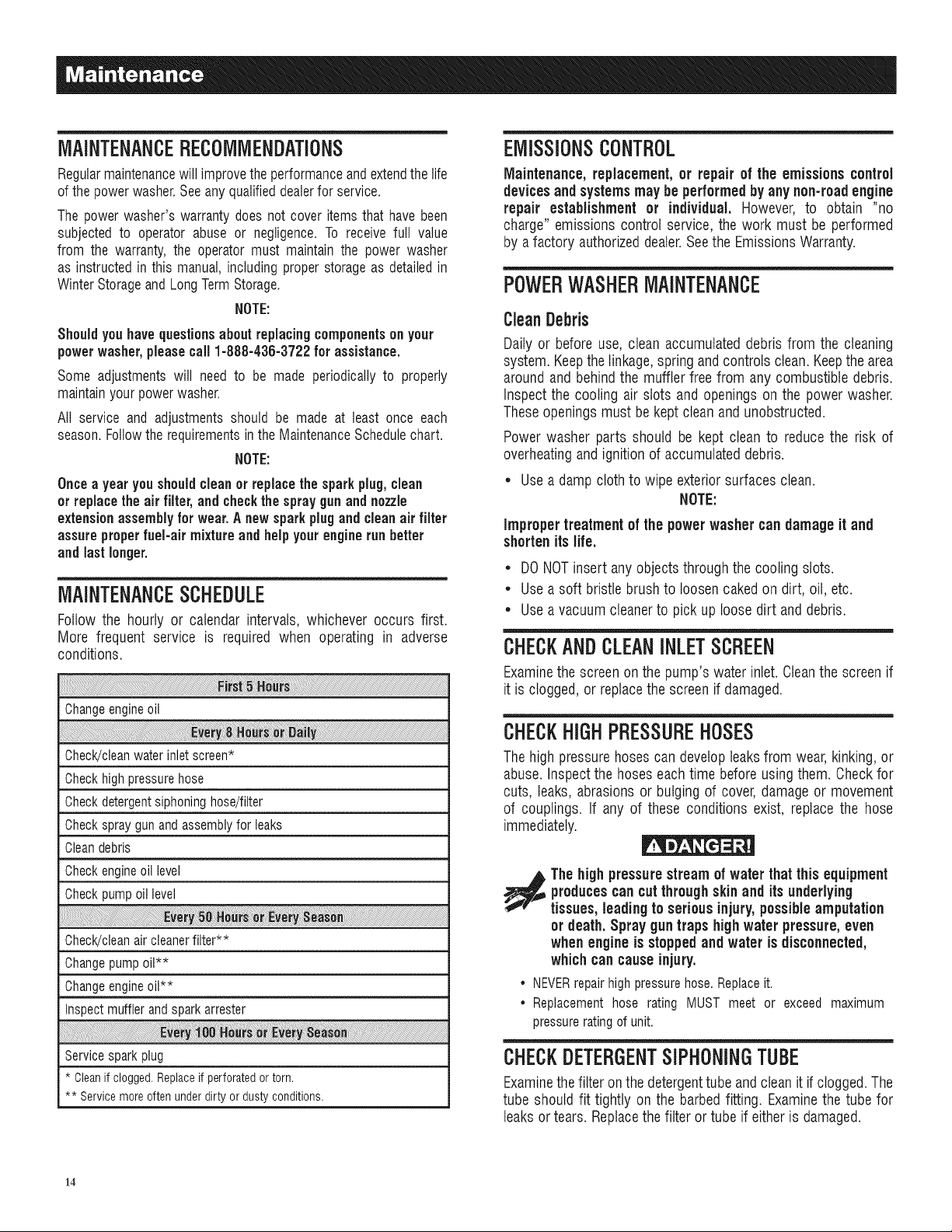

MAINTENANCESCHEDULE

Follow the hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in adverse

conditions.

Changeengineoil

Check!cleanwaterinletscreen*

Checkhighpressurehose

Checkdetergentsiphoninghose/filter

Checkspraygunandassemblyfor leaks

Cleandebris

Checkengineoil level

Checkpumpoillevel

Check/cleanaircleanerfilter**

Changepumpoil**

Changeengineoil**

Inspectmufflerandsparkarrester

EMISSIONSCONTROL

Maintenance,replacement,or repair of the emissions control

devicesand systemsmaybe performedbyany non-roadengine

repair establishment or individual, However, to obtain "no

charge" emissions control service, the work must be performed

by afactory authorizeddealer.Seethe EmissionsWarranty.

POWERWASHERMAINTENANCE

CleanDebris

Daily or beforeuse, cleanaccumulateddebris from the cleaning

system.Keepthelinkage,spring and controlsclean.Keepthe area

aroundand behindthe muffler freefrom anycombustible debris.

Inspectthe cooling air slots and openings on the power washer.

Theseopeningsmust be kept cleanandunobstructed.

Powerwasher parts should be kept clean to reducethe risk of

overheatingand ignition of accumulateddebris.

• Usea dampclothto wipe exteriorsurfaces clean.

NOTE:

Improper treatmentof the powerwasher candamageit and

shortenits life.

• DONOTinsert anyobjects throughthe cooling slots.

• Usea soft bristlebrushto loosen cakedon dirt, oil, etc.

• Usea vacuumcleanerto pick up loosedirt anddebris.

CHECKAND CLEANINLETSCREEN

Examinethe screen on thepump's water inlet. Cleanthe screen if

it is clogged,or replacethe screen if damaged.

CHECKHIGHPRESSUREHOSES

Thehigh pressurehosescan developleaksfrom wear,kinking, or

abuse.Inspectthehoses each time beforeusingthem. Checkfor

cuts, leaks,abrasionsor bulgingof cover,damageor movement

of couplings. If any of these conditions exist, replace the hose

immediately.

producescancut throughskinand its underlying

Thehighpressurestream of water thatthisequipment

tissues,leadingto seriousinjury,possibleamputation

or death.Spray gun trapshighwaterpressure,even

whenengine is stoppedand water is disconnected,

whichcan causeinjury.

• NEVERrepairhigh pressurehose.Replaceit.

• Replacement hose rating MUST meet or exceed maximum

pressure ratingof unit.

Servicesparkplug

* Cleanif clogged.Replaceif perforated ortorn.

** Service moreoften under dirty or dusty conditions.

14

CHECKDETERGENTSIPHONINGTUBE

Examinethe filter on thedetergenttube andcleanit if clogged.The

tube should fit tightly on the barbedfitting. Examinethe tube for

leaksor tears.Replacethe filter or tube if eitheris damaged.

CHECKSPRAYGUN

Examinethe hoseconnectionto thespray gun andmakesure itis

secure.Test the trigger by pressingthe trigger,it "springs back"

into placewhenyou releaseit. Replacethe spraygun immediately

if itfails to "springback".

NOZZLEMAINTENANCE

A pulsing sensation felt while squeezingthe spray gun trigger

may becaused by excessivepumppressure.Theprincipalcause

of excessive pump pressure is a nozzle clogged or restricted

with foreign materials,such as dirt, etc. Tocorrect the problem,

immediatelycleanthe nozzlefollowing these instructions:

1. Shutoff the engineandturn off thewater supply.

2. ALWAYSpointthe spray gun in a safe direction, squeezethe

spray guntriggerto releaseretainedhighwater pressure.

producescancutthroughskinand itsunderlying

The highpressurestream of water thatthis equipment

tissues,leadingto seriousinjury,possibleamputation

or death.Spray gun trapshighwaterpressure,even

whenengine isstoppedandwater is disconnected,

whichcan causeinjury.

* Keepthehighpressurehoseconnectedtothepumpandspraygun

whilethesystemispressurized.

* ALWAYSpointthespraygunin a safedirection,andsqueezethe

sprayguntriggerto releasehighpressureeverytimeyoustopthe

engine.Engagethetriggerlockwhennotinuse.

3. Removethe nozzlefrom theendof nozzleextension.

4. Use asmall paperclipto free anyforeignmaterialcloggingor

restrictingthe nozzle(Figure27).

5. Removethe lancefrom the spray gun.

6. Using a garden hose, remove additional debris by back

flushing water through the lance (Figure28) for 30 to 60

seconds.

7. Reinstallthe nozzleintothe lance.

8. Reconnectthe lanceto the spray gun.

9. Make surethe gardenhose is connectedto the pump water

inlet. Checkthat the high pressurehose is connectedto the

spray gun and pump.Turnon the water.

Figure28 - BackFlushLance

10. Start the enginefollowing the instructions Howto Start Your

PowerWasher.

11. Testthepowerwasher by operatingit with eachquickconnect

nozzle.

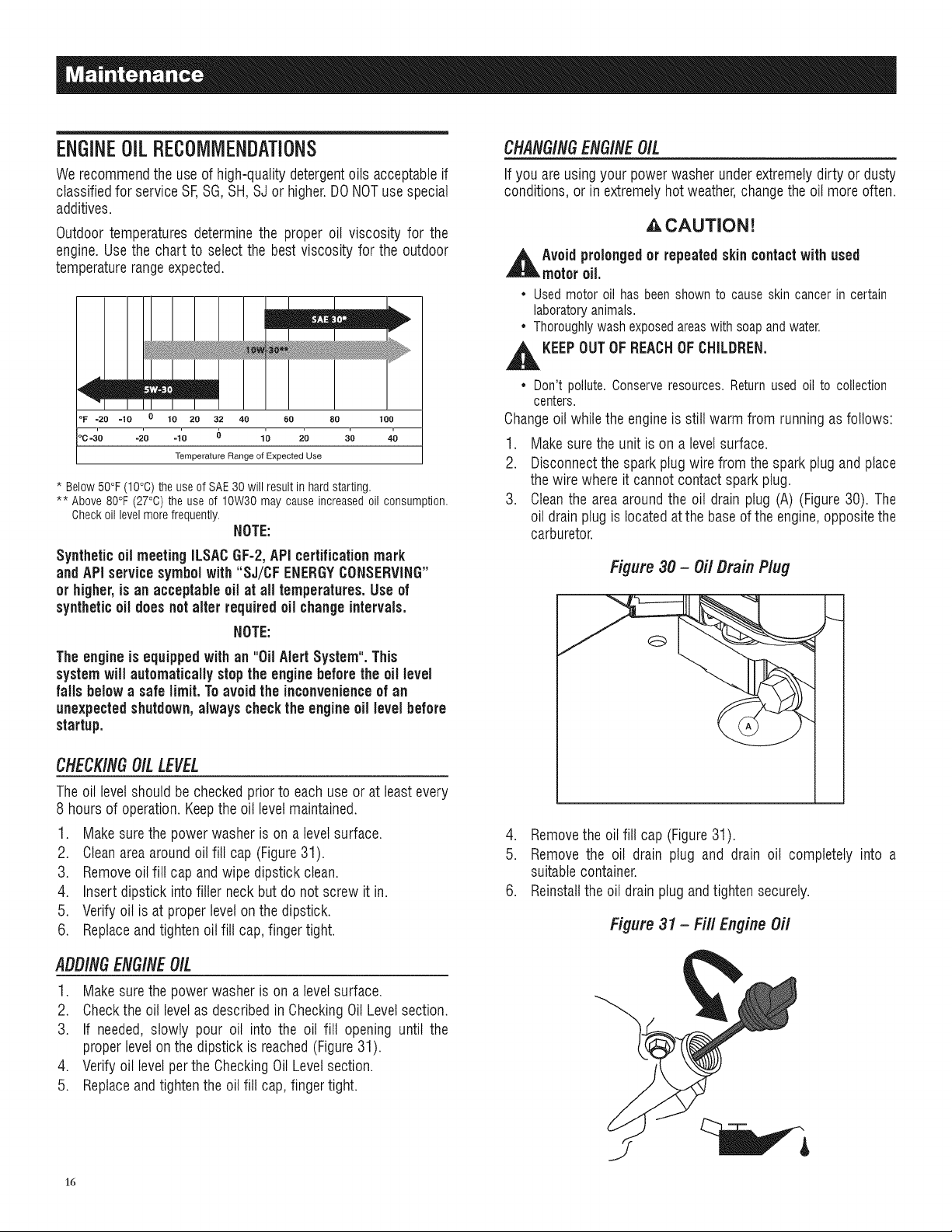

PUMPOILMAINTENANCE

Changepump oil every 50 hours of operation.

1. Cleanareaaroundoil drain plug (A).

2. Removeoil drain plug. Drainoil completely.

3. Installoil drain plug. Do not overtighten.

4. CleanAreaaroundoil dipstick (B).

5. Fill pump with SAE 30 non-detergentoil to "Full" mark on

dipstick.

6. Installoil dipstick until fingertight.

7. Cleanup any spilledoil.

Figure2g - Drain PumpOil

Figure 27 - Free Foreign Material

ENGINEMAINTENANCE

'_f Unintentionalsparkingcanresultin fire or

WHENADJUSTINGORMAKINGREPAIRSTOYOURPOWER

WASHER:

* Disconnectthesparkplugwirefromthesparkplugandplacethe

wirewhereitcannotcontactsparkplug.

WHENTESTINGFORENGINESPARK:

* Useanapprovedsparkplugtester.

* DONOTcheckforsparkwithsparkplugremoved.

electric shock.

15

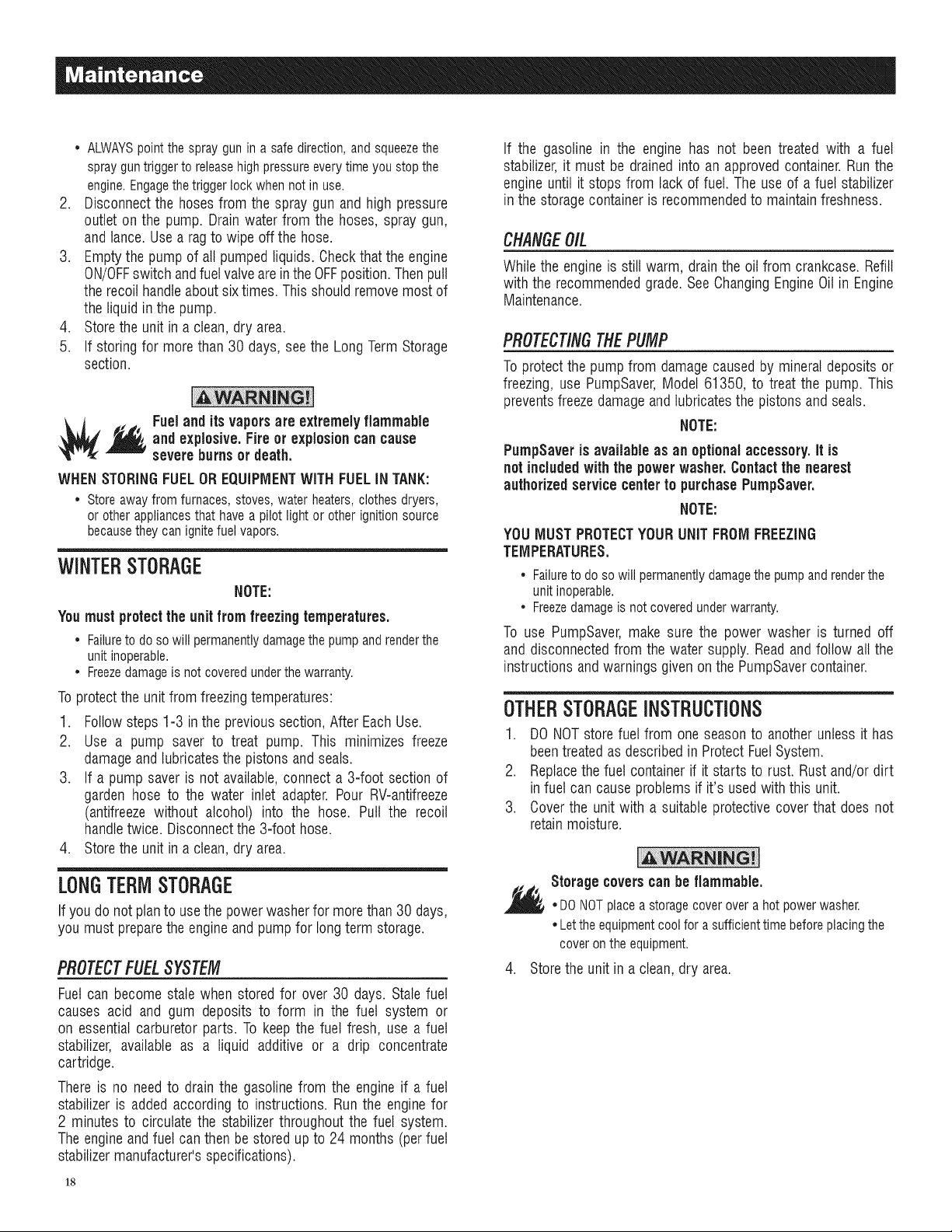

ENGINEOiLBECOIVlIVIENDATIONS

Werecommendthe use of high=qualitydetergentoils acceptableif

classifiedfor service SF,SG,SH,SJor higher.DONOTusespecial

additives.

Outdoortemperatures determinethe proper oil viscosity for the

engine.Usethe chart to select the best viscosity for the outdoor

temperaturerangeexpected.

, lm| zmm

°F =20 -10 0 10 20 32 40 60 80 100

oc-3'o -2'o -I'o 6 1'o 2'0 3'o 40

Temperature Range of Expected Use

* Below 50°F (10°C) the use of SAE 30 will result in hard starting.

** Above 80°F (27°C) the use of 10W30 may causeincreased oil consumption.

Checkoil levelmore frequently.

NOTE:

Synthetic oil meetingILSACGF-2,API certificationmark

and API servicesymbolwith "SJ/CFENERGYCONSERVING"

or higher,is an acceptableoil at all temperatures.Useof

syntheticoil doesnotalter requiredoil changeintervals.

NOTE:

CHANG/NGENG/NEOIL

If you are usingyour power washer underextremelydirty or dusty

conditions,or in extremelyhot weather,changethe oil moreoften.

,_ CAUTION!

,_ Avoid prolongedor repeatedskincontactwith used

motoroil.

* Usedmotoroil hasbeenshownto causeskincancerin certain

laboratoryanimals.

* Thoroughlywashexposedareaswithsoapandwater.

,_ KEEP OUT OF REACH OF CHILDREN,

* Don'tpollute.Conserveresources.Returnusedoil to collection

centers.

Changeoil while the engineis still warm from running as follows:

1. Makesurethe unitis on a levelsurface.

2. Disconnectthe sparkplug wirefrom the spark plugand place

thewire whereit cannot contactspark plug.

3. Cleanthe area aroundthe oil drain plug (A) (Figure30). The

oil drain plugis locatedat the baseof the engine,oppositethe

carburetor.

Figure30 - OilDrain Plug

Theengineis equipped withan "OilAlert System". This

systemwill automaticallystopthe engine beforethe oil level

fails below a safe limit.Toavoidtheinconvenienceof an

unexpectedshutdown,alwayscheckthe engine oil levelbefore

startup.

CHECK/NGO/LLEVEL

Theoil levelshould be checkedprior to eachuse or at leastevery

8 hoursof operation.Keepthe oillevelmaintained.

1. Makesurethe powerwasherison a levelsurface.

2. Cleanareaaroundoil fill cap (Figure31).

3. Removeoil fill cap andwipedipstick clean.

4. Insert dipstick into filler neck but do notscrew it in.

5. Verifyoil is at properlevelonthe dipstick.

6. Replaceandtighten oil fill cap,fingertight.

ADDINGENG/NEOIL

1. Makesurethe powerwasherison a levelsurface.

2. Checkthe oil levelasdescribedin CheckingOilLevelsection.

3. If needed, slowly pour oil into the oil fill opening until the

proper levelon the dipstick is reached(Figure31).

4. Verifyoil levelperthe CheckingOilLevelsection.

5. Replaceandtightenthe oil fill cap,finger tight.

4. Removethe oil fill cap (Figure31).

5. Removethe oil drain plug and drain oil completely into a

suitablecontainer.

6. Reinstallthe oil drainplug andtighten securely.

Figure 31 - Fi// Engine Oil

16

7. Slowly pour oil (about 20 oz.) into the oil fill openingto the

proper levelon the dipstick. DO NOToverfill.

8. Reinstallthe oil fill cap. Fingertightencap securely.

9. Wipeup any spilledoil.

10. Properly dispose of oil in an accordance with all local

regulations.

SERVICEAIRCLEANER

Yourenginewill notrun properly andmay bedamagedif you runit

with a dirty air cleaner.Servicemoreoftenif operatingunderdirty

or dustyconditions.

Toservicethe air cleaner,follow these steps:

1. Loosenthe screw andremovecover (Figure32).

2. Carefullyremovethe filter assembly.

3. Removethe foam filter.

4. Tocleanthe cartridge, gentlytap it on a flat surface.

5. Reinstallthe foam filter.

6. Reinstalla clean or newcartridgeassembly.

7. Installthe cover andtighten screwsecurely.

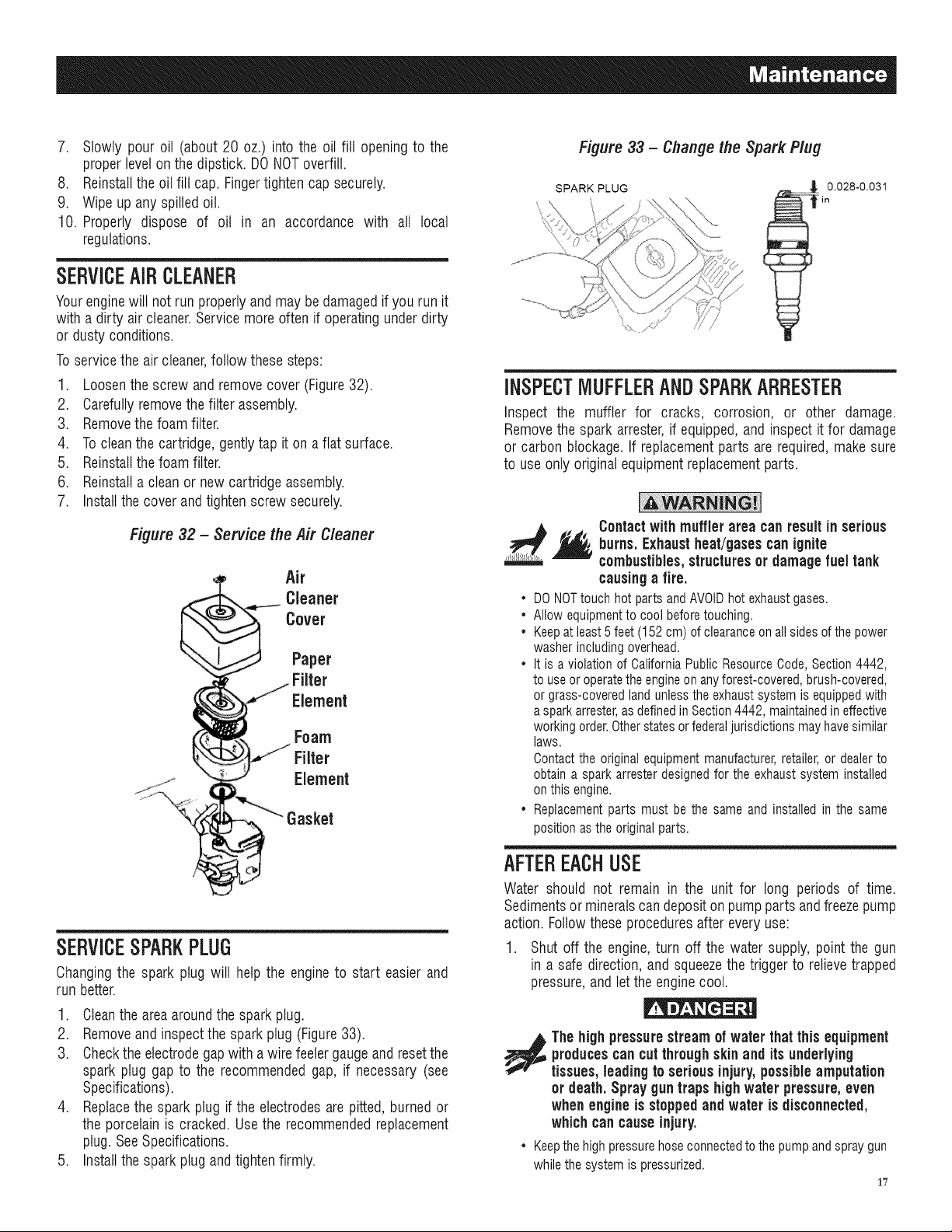

Figure 33 - Change the Spark Plug

SPARKPLUG

0.028-0.031

INSPECTMUFFLERANDSPARKARRESTER

Inspect the muffler for cracks, corrosion, or other damage.

Removethe spark arrester,if equipped,and inspectit for damage

or carbon blockage.If replacementparts are required,makesure

to use only originalequipmentreplacementparts.

Figure 32 - Service the Air Cleaner

Air

Cleaner

Cover

Paper

Filter

Element

Foam

SERVICESPARKPLUG

Changingthe spark plug will help the engineto start easier and

run better.

burns.Exhaustheat/gasescan ignite

Contactwith muffler area can result in serious

combustibles,structuresor damagefuel tank

causinga fire.

* DONOTtouchhotpartsandAVOIDhotexhaustgases.

* Allowequipmenttocoolbeforetouching.

* Keepatleast5feet(152cm)ofclearanceonallsidesofthepower

washerincludingoverhead.

* It isa violationof CaliforniaPublicResourceCode,Section4442,

to useoroperatetheengineonanyforest-covered,brush-covered,

orgrass-coveredlandunlesstheexhaustsystemis equippedwith

asparkarrester,asdefinedinSection4442,maintainedineffective

workingorder.Otherstatesorfederaljurisdictionsmayhavesimilar

laws.

Contactthe originalequipmentmanufacturer,retailer,or dealerto

obtainasparkarresterdesignedforthe exhaustsysteminstalled

onthisengine.

* Replacementpartsmust bethesameand installedin the same

positionastheoriginalparts.

AFTEREACHUSE

Water should not remain in the unit for long periods of time.

Sedimentsormineralscan depositon pumpparts andfreezepump

action. Followthese proceduresafter every use:

1. Shut off the engine,turn off the water supply, point the gun

in a safe direction,andsqueezethe triggerto relievetrapped

pressure,and let the enginecool.

1. Cleanthe areaaroundthe sparkplug.

2. Removeandinspect the spark plug (Figure33).

3. Checkthe electrodegapwith a wirefeelergaugeandresetthe

spark plug gap to the recommendedgap, if necessary (see

Specifications).

4. Replacethe spark plug if the electrodesarepitted, burnedor

the porcelain is cracked. Usethe recommendedreplacement

plug.SeeSpecifications.

5. Installthe spark plug andtightenfirmly.

producescancutthroughskinand its underlying

The highpressurestreamof waterthat this equipment

tissues,leadingto seriousinjury,possibleamputation

or death.Sprayguntrapshighwater pressure,even

whenengineisstoppedandwater is disconnected,

whichcan causeinjury.

* Keepthehigh pressurehoseconnectedtothe pump andspray gun

while thesystemis pressurized.

17

* ALWAYSpointthespraygunin a safedirection,andsqueezethe

sprayguntriggerto releasehighpressureeverytimeyoustopthe

engine.Engagethetriggerlockwhennotinuse.

2. Disconnectthe hosesfrom the spray gun and high pressure

outlet on the pump. Drainwaterfrom the hoses, spray gun,

and lance.Use a ragto wipe off the hose.

3. Emptythe pump of all pumped liquids. Checkthat the engine

ON/OFFswitch andfuel valveareintheOFFposition.Thenpull

therecoil handleaboutsixtimes. This should removemost of

the liquidin the pump.

4. Storethe unit inaclean,dry area.

5. If storing for morethan 30 days,seethe LongTermStorage

section.

Fueland itsvaporsare extremelyflammable

and explosive.Fireor explosioncan cause

severeburnsor death.

WHENSTORINGFUELOREQUIPMENTWiTH FUELiNTANK:

* Storeawayfromfurnaces,stoves,waterheaters,clothesdryers,

or otherappliancesthathaveapilotlightor otherignitionsource

becausetheycanignitefuelvapors.

WINTERSTORAGE

NOTE:

Youmustprotectthe unitfrom freezing temperatures.

* Failuretodosowillpermanentlydamagethepumpandrenderthe

unitinoperable.

* Freezedamageisnotcoveredunderthewarranty.

Toprotectthe unit from freezingtemperatures:

1. Followsteps 1-3 inthe previoussection, After EachUse.

2. Use a pump saver to treat pump. This minimizes freeze

damageand lubricatesthe pistons andseals.

3. If a pump saver is not available,connect a 3-foot sectionof

garden hose to the water inlet adapter. Pour RV-antifreeze

(antifreeze without alcohol) into the hose. Pull the recoil

handletwice. Disconnectthe 3-foot hose.

4. Storethe unit inaclean,dry area.

If the gasoline in the engine has not been treated with a fuel

stabilizer,it must be drainedinto an approvedcontainer.Runthe

engineuntil it stops from lack of fuel. Theuse of a fuel stabilizer

in thestoragecontaineris recommendedto maintainfreshness.

CHANGEO/L

Whilethe engineis still warm, drain the oil from crankcase. Refill

with the recommendedgrade.SeeChangingEngineOil in Engine

Maintenance.

PROTECT/NGTHEPUMP

Toprotect the pump from damagecausedby mineral depositsor

freezing, use PumpSaver,Model 61350, to treat the pump. This

preventsfreezedamageand lubricatesthe pistonsandseals.

NOTE:

PumpSaveris available as anoptional accessory,it is

notincludedwiththe powerwasher.Contactthenearest

authorizedservicecenterto purchasePumpSaver.

NOTE:

YOUMUSTPROTECTYOURUNiT FROMFREEZING

TEMPERATURES.

• Failureto dosowill permanentlydamagethe pumpandrenderthe

unitinoperable.

• Freezedamageis notcoveredunderwarranty.

To use PumpSaver,make sure the power washer is turned off

and disconnectedfrom the water supply.Read andfollow all the

instructionsandwarnings given on the PumpSavercontainer.

OTHERSTORAGEINSTRUCTIONS

1. DONOTstore fuel from one seasonto anotherunlessit has

beentreatedas describedin Protect FuelSystem.

2. Replacethe fuel containerif it starts to rust. Rustand/ordirt

infuel can causeproblems if it's usedwiththis unit.

3. Coverthe unit with a suitable protectivecover that does not

retainmoisture.

LONGTERM STORAGE

If you do not planto use thepower washerfor morethan 30 days,

you must preparetheengineandpump for longtermstorage.

PROTECTFUELSYSTEM

Fuelcan become stale when stored for over 30 days. Stalefuel

causes acid and gum deposits to form in the fuel system or

on essentialcarburetor parts. To keepthe fuel fresh, use afuel

stabilizer, available as a liquid additive or a drip concentrate

cartridge.

Thereis no needto drain the gasoline from the engineif a fuel

stabilizeris added according to instructions. Run the enginefor

2 minutes to circulatethe stabilizerthroughout the fuel system.

Theengineandfuel canthen bestored up to 24 months (perfuel

stabilizermanufacturer'sspecifications).

18

Storage coverscan beflammable.

*DONOTplaceastoragecoveroverahotpowerwasher.

*Lettheequipmentcoolforasufficienttimebeforeplacingthe

coveronthe equipment.

.

Storethe unitin a clean,dry area.

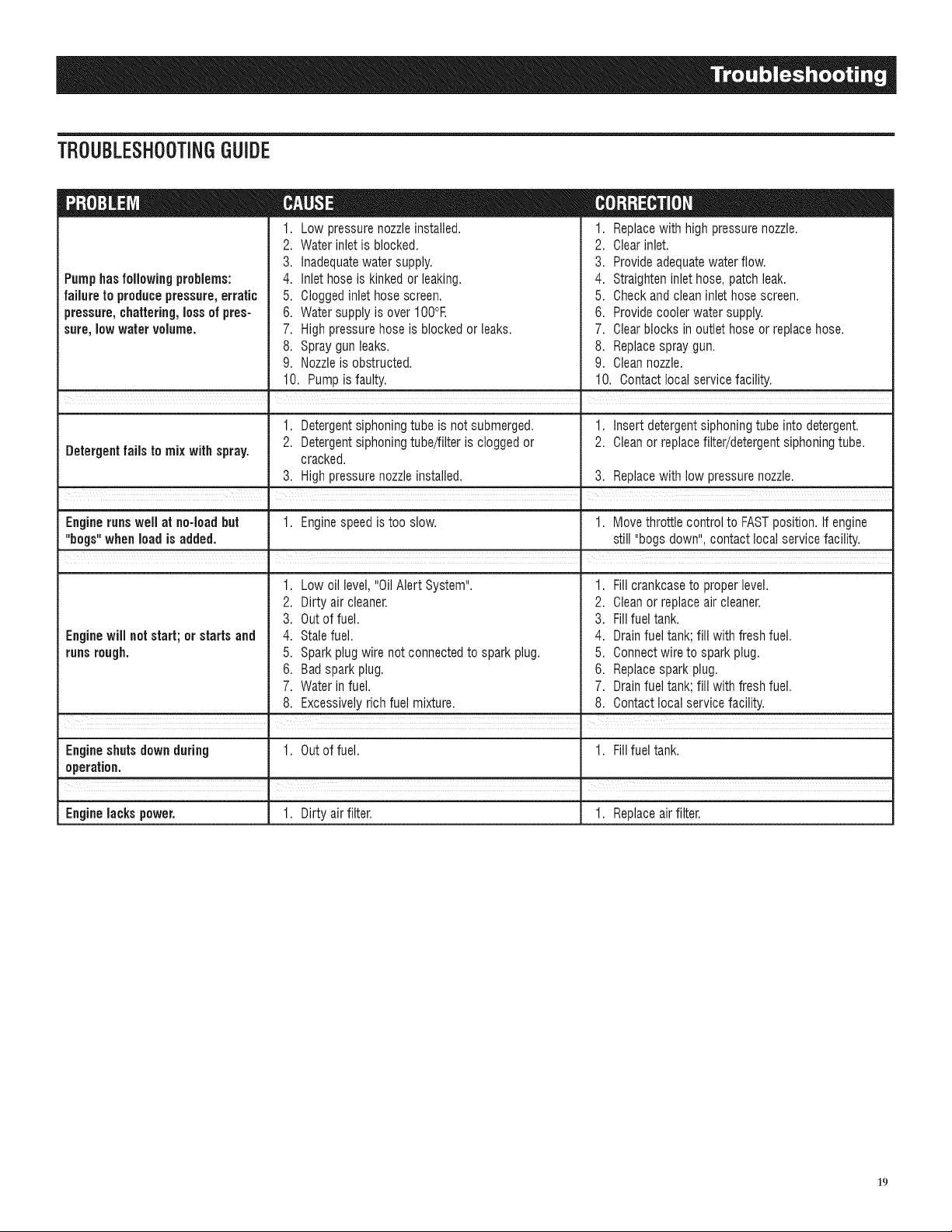

TBOUBLESHOOTiNGGUIDE

1. Low pressurenozzleinstalled. 1. Replacewith high pressurenozzle.

2. Waterinlet is blocked. 2. Clearinlet.

3. Inadequatewatersupply.

Pumphasfollowingproblems:

failuretoproducepressure,erratic

pressure,chattering,lossofpres-

sure,lowwatervolume.

Detergent fails to mix with spray, cracked.

Engineruns well at no-load but 1. Enginespeedistoo slow. 1. Movethrottle control to FASTposition.If engine

"bogs" when load isadded, still "bogs down", contact local servicefacility.

4. Inlet hoseis kinked or leaking.

5. Cloggedinlethose screen.

6. Watersupplyis overlO0°E

7. Highpressurehose is blocked orleaks.

8. Spray gunleaks.

9. Nozzleis obstructed.

10. Pumpis faulty.

1. Detergentsiphoningtube is not submerged. 1. Insert detergentsiphoning tubeinto detergent.

2. Detergentsiphoningtube/filteris cloggedor 2. Cleanor replacefilter/detergentsiphoningtube.

3. Highpressurenozzleinstalled. 3. Replacewith low pressurenozzle.

! I

3. Provideadequatewaterflow.

4. Straighteninlethose,patch leak.

5. Checkand cleaninlet hose screen.

6. Providecoolerwater supply.

7. Clearblocks in outlethose or replacehose.

8. Replacespray gun.

9. Cleannozzle.

10. Contact local servicefacility.

1. Low oil level,"OilAlert System".

2. Dirty air cleaner.

3. Outof fuel.

Enginewill notstart;orstartsand

runsrough.

Engineshutsdownduring 1. Outof fuel. 1. Fillfuel tank.

operation.

Enginelacks power. 1. Dirty air filter. 1. Replaceairfilter.

4. Stalefuel.

5. Sparkplug wire not connectedto spark plug.

6. Badspark plug.

7. Waterinfuel.

8. Excessivelyrich fuel mixture.

1. Fillcrankcaseto proper level.

2. Cleanor replaceair cleaner.

3. Fillfuel tank.

4. Drainfuel tank;fill with fresh fuel.

5. Connectwire to spark plug.

6. Replacespark plug.

7. Drainfuel tank;fill with fresh fuel.

8. Contactlocal servicefacility.

19

U,S, EPA EMiSSiON CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLiGATiONS

The UnitedStatesEnvironmentalProtectionAgency (EPA)and GeneracPowerSystems, Inc. (Generac)are pleasedto explainthe Emission Control

SystemWarranty(ECSWarranty)on your new 2011 and laterequipment.New equipmentthat use smallspark-ignited enginesmust be designed,built,

andequippedto meet stringentanti-smogstandardsfor the federal government.Generacwill warrant the emissioncontrol system on your equipment

for the periodof time listed below providedtherehas been no abuse,neglect,unapprovedmodificationor impropermaintenanceofyour equipment.

The emissioncontrolsystemon this equipmentincludesall components whose failurewould increasethe emissions of anyregulatedpollutant. These

componentsare listedin the EmissionsInformation section ofthis manual.

MANUFACTURER'S WARRANTY COVERAGE:

This ECSWarrantyis valid fortwo years,or for the same periodas specified inthe GeneracLimitedWarranty,whicheveris longer.Forequipmentwith

hour meters,the warranty period is a number of hours equalto halfthe Useful Lifeto which the equipmentis certified, or thewarranty period specified

abovein years,whicheveris less. TheUseful Life can befound onthe EmissionControl Labelon theengine.If, during suchwarranty period, any

emission-relatedpart on your equipmentis foundto be defectivein materialsor workmanship, repairsor replacementwill be performedby a Generac

AuthorizedWarrantyServiceDealer.

OWNER'S WARRANTY RESPONSiBiLiTiES:

As the equipmentowner,you are responsiblefor thecompletion of all requiredmaintenanceas listedin your factory suppliedOwner'sManual. For

warranty purposes,Generacrecommendsthat you retainall receiptscovering maintenanceon your generator,butGeneraccannot denywarranty

solelydueto the lack of receipts.

Youshould be awarethat Generacmaydeny anyand/or all warrantycoverageor responsibility if your equipment,or apart/component thereof,has

failed dueto abuse,neglect, impropermaintenance,or unapprovedmodifications.

Youare responsible for contactinga GeneracAuthorizedWarrantyDealeras soonas a problemoccurs.The warranty repairsshouldbe

completed in a reasonable amount of time, not to exceed30 days.

Warrantyservice can bearrangedby contacting eitheryour sellingdealeror a GeneracAuthorizedWarrantyService Dealer.Tolocate the Generac

AuthorizedWarrantyServiceDealernearestyou, call our toll free numberbelow, oremail emissions@generac.com.

1-800-333-1322

IMPORTANTNOTE:Thiswarranty statementexplainsyour rightsand obligations underthe Emission ControlSystemWarranty,which is providedto

you by Generacpursuantto federal law. Seealso the "GeneracLimitedWarrantiesfor GeneracPowerSystems, Inc.,"which is enclosed herewithon a

separatesheet,also providedto you by Generac.Notethat this warranty shallnot apply to any incidental,consequentialor indirect damagescaused

bydefects in materialsor workmanship or any delayin repairor replacementof the defectivepart(s). This warranty is in place of all other warranties,

expressedor implied. Specifically,Generacmakes no other warrantiesasto the merchantabilityor fitness for a particularpurpose. Anyimplied

warrantieswhich areallowedby law, shallbe limited indurationto the terms of the expresswarranty providedherein.Somestatesdo not allow

limitationson how long an implied warrantylasts, so the abovelimitation maynotapply to you.

The ECSWarrantyappliesonly to the emissioncontrol system of your newequipment. Boththe ECSWarrantyand the GeneracWarrantydescribe

importantrights and obligationswith respectto your new engine.

Warrantyservice can beperformed only by a GeneracAuthorizedWarrantyServiceFacility.Whenrequestingwarrantyservice, evidencemust be

presentedshowing the dateof the saleto the originalpurchaser/owner.

Ifyou haveany questionsregardingyour warranty rights andresponsibilities,you shouldcontact Generacatthe following address:

ATTENTION WARRANTY DEPARTMENT

GENERAC POWER SYSTEMS, INC.

RO. BOX 297 * WHITEWATER, Wi 53190

Part1 of 2

Part No.0J3335 Rev.C 11/11

20

Loading...

Loading...