Page 1

MODELS: 005796-0 (XG6500), 005797-0 (XG7000),

005798-0 (XG7000E), 005800-0 (XG8000),

005747-0 (XG8000E)

Owner's Manual

XG Series 6,500-8,000 Watt Portable Generator

www.generac.com or 1-888-436-3722

Page 2

Table of Contents

Introduction ............................................................. 1

Read this Manual Thoroughly ................................. 1

Safety Rules ........................................................... 1

Standards Index .............................................................3

General Information ................................................ 4

1.1 Unpacking ......................................................................4

1.1.1 Accessory Box ..................................................4

1.2 Assembly .......................................................................4

1.2.1 Assembling the Wheel Kit and Frame Foot ..........4

Operation ................................................................ 5

2.1 Know the Generator .......................................................5

2.1.1 Battery Connection (XG7000E & XG8000E) .......6

2.2 Hourmeter ......................................................................6

2.3 Cord Sets and Connection Plugs ....................................6

2.3.1 120 VAC, 20 Amp, GFCI Duplex Receptacle .......6

2.3.2 120/240 VAC, 30 Amp Receptacle .....................6

2.4 How to Use the Generator ..............................................7

2.4.1 System Ground ..................................................7

2.4.2 Grounding the Generator ....................................7

2.4.3 Neutral to Frame Grounding ...............................8

2.4.4 Connecting Electrical Loads ...............................8

2.5 Don’t Overload the Generator ..........................................8

2.6 Wattage Reference Guide ...............................................8

2.7 Before Starting the Generator .........................................9

2.7.1 Adding Engine Oil ..............................................9

2.7.2 Adding Gasoline .................................................9

2.8 To Start the Engine .......................................................10

2.8.1 Manual (Recoil) Starting ..................................10

2.8.2 Electric Star ting (XG7000E & XG8000E) ..........11

2.9 Stopping the Engine .....................................................11

2.10 Low Oil Pressure Shutdown System .............................11

2.10.1 Restarting ........................................................11

2.11 Charging a Battery .......................................................11

Maintenance ......................................................... 11

3.1 Maintenance Schedule .................................................11

3.2 Product Specifications ..................................................11

3.2.1 Generator Specifications ..................................11

3.2.2 Engine Specifications .......................................12

3.2.3 Emissions Information .....................................12

3.3 General Recommendations ...........................................12

3.3.1 Generator Maintenance ....................................12

3.3.2 To Clean the Generator .....................................13

3.3.3 Engine Maintenance .........................................13

3.3.4 Checking Oil Level ...........................................13

3.3.5 Changing the Oil and Oil Filter ..........................13

3.3.6 Replacing the Spark Plug .................................13

3.4 Service Air Cleaner .......................................................13

3.5 Clean Spark Arrestor Screen.........................................14

3.6 General ........................................................................14

3.7 Long Term Storage .......................................................14

3.8 Other Storage Tips .......................................................15

Battery Service ..................................................... 15

4.1 Battery Replacement (XG7000E & XG8000E) ...............15

Troubleshooting .................................................... 16

5.1 Troubleshooting Guide ..................................................16

Notes .................................................................... 17

Warranty ............................................................... 18

Page 3

Introduction

Thank you for purchasing this model by Generac Power Systems,

Inc. This model is a compact, high performance, air-cooled,

engine driven generator designed to supply electrical power to

operate electrical loads where no utility power is available or in

place of utility due to a power outage.

If any portion of this manual is not understood, contact the

nearest Authorized Dealer for star ting, operating and servicing

procedures.

The operator is responsible for proper and safe use of the

equipment. We strongly recommend that the operator read this

manual and thoroughly understand all instructions before using the

equipment. We also strongly recommend instructing other users to

properly start and operate the unit. This prepares them if they need

to operate the equipment in an emergency.

The generator can operate safely, efficiently and reliably only if it

is properly located, operated and maintained. Before operating or

servicing the generator:

Become familiar with and strictly adhere to all local, state and

national codes and regulations.

Study all safety warnings in this manual and on the product

carefully.

Become familiar with this manual and the unit before use.

The manufacturer cannot anticipate every possible circumstance

that might involve a hazard. The warnings in this manual, and on

tags and decals affixed to the unit are, therefore, not all inclusive.

If using a procedure, work method or operating technique that the

manufacturer does not specifically recommend, ensure that it is

safe for others. Also make sure the procedure, work method or

operating technique utilized does not render the generator unsafe.

THE INFORMATION CONTAINED HEREIN WAS BASED ON

MACHINES IN PRODUCTION AT THE TIME OF PUBLICATION.

GENERAC RESERVES THE RIGHT TO MODIFY THIS MANUAL AT

ANY TIME.

Throughout this publication, and on tags and decals affixed to the

generator, DANGER, WARNING, CAUTION and NOTE blocks are

used to alert personnel to special instructions about a particular

operation that may be hazardous if performed incorrectly or

carelessly. Observe them carefully. Their definitions are as

follows:

INDICATES A HAZARDOUS SITUATION OR ACTION WHICH, IF

NOT AVOIDED, WILL RESULT IN DEATH OR SERIOUS INJURY.

Indicates a hazardous situation or action which, if not

avoided, could result in death or serious injury.

Indicates a hazardous situation or action which, if not

avoided, could result in minor or moderate injury.

NOTE:

Notes contain additional information important to a procedure

and will be found within the regular text body of this manual.

These safety warnings cannot eliminate the hazards that they

indicate. Common sense and strict compliance with the special

instructions while performing the action or service are essential to

preventing accidents.

Four commonly used safety symbols accompany the DANGER,

WARNING and CAUTION blocks. The type of information each

indicates is as follows:

This symbol points out important safety

information that, if not followed, could

endanger personal safety and/or property of

others.

This symbol points out potential explosion

hazard.

This symbol points out potential fire hazard.

This symbol points out potential electrical

shock hazard.

GENERAL HAZARDS

Never operate in an enclosed area or indoors.

For safety reasons, the manufacturer recommends that the

maintenance of this equipment is carried out by an Authorized

Dealer. Inspect the generator regularly, and contact the nearest

Authorized Dealer for parts needing repair or replacement.

Operate generator only on level surfaces and where it will not be

exposed to excessive moisture, dirt, dust or corrosive vapors.

Keep hands, feet, clothing, etc., away from drive belts, fans,

and other moving parts. Never remove any fan guard or shield

while the unit is operating.

Certain parts of the generator get extremely hot during

operation. Keep clear of the generator until it has cooled to

avoid severe burns.

Do NOT operate generator in the rain.

Do not alter the construction of the generator or change

controls which might create an unsafe operating condition.

Never start or stop the unit with electrical loads connected

to receptacles AND with connected devices turned ON. Star t

the engine and let it stabilize before connecting electrical

loads. Disconnect all electrical loads before shutting down the

generator.

Do not insert objects through unit’s cooling slots.

When working on this equipment, remain aler t at all times.

Never work on the equipment when physically or mentally

fatigued.

1

Page 4

Safety Rules

Never use the generator or any of its parts as a step. Stepping

on the unit can stress and break parts, and may result in

dangerous operating conditions from leaking exhaust gases,

fuel leakage, oil leakage, etc.

On electric start models, disconnect the POSITIVE (+) battery

cable from the engine star ter OR the NEGATIVE (-) battery

cable from the battery terminal, whichever is easier, before

transporting the generator.

NOTE:

This generator is equipped with a spark arrestor muffler. The

spark arrestor must be maintained in effective working order

by the owner/ operator. In the State of California, a spark

arrestor is required by law (Section 4442 of the California

Public Resources Code). Other states may have similar laws.

Federal laws apply on federal lands.

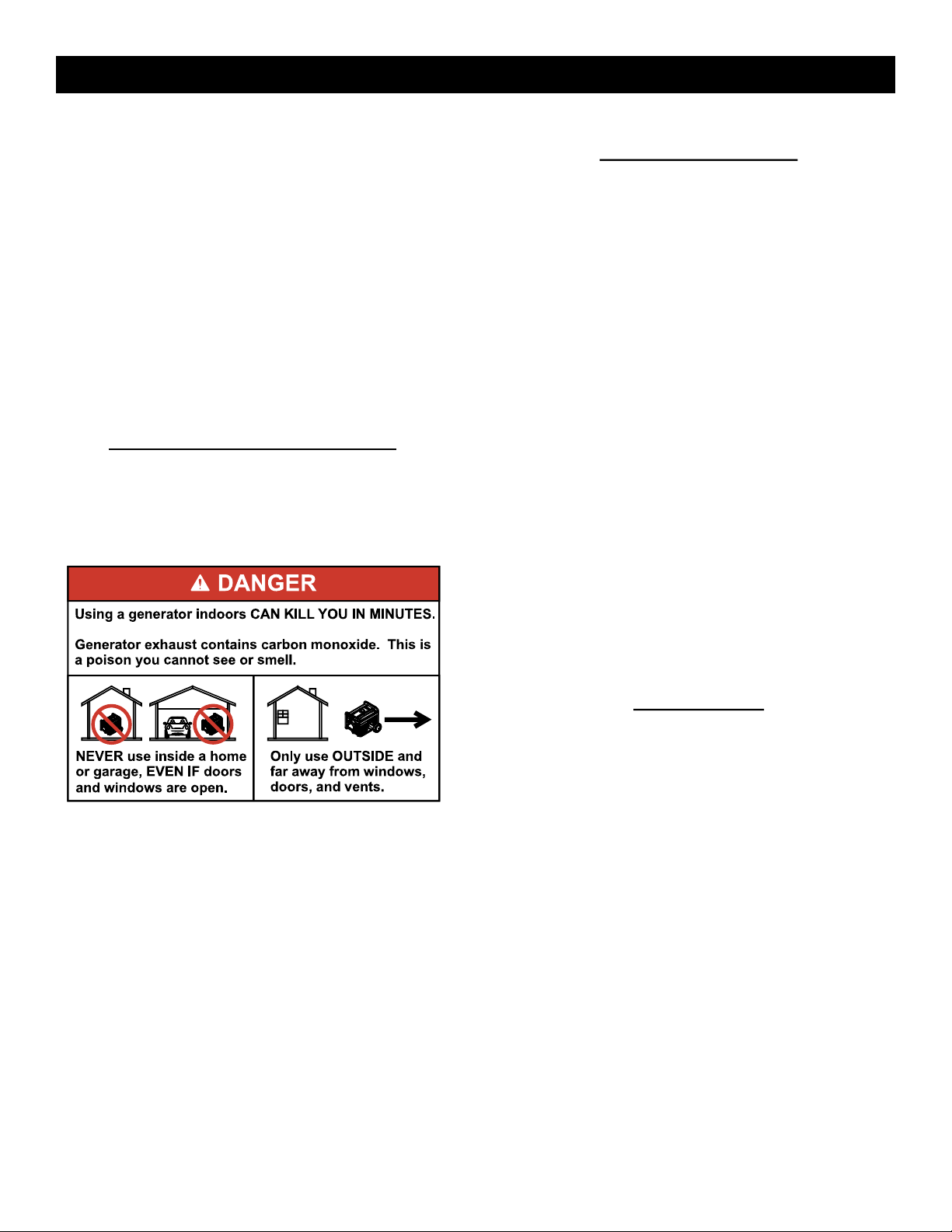

EXHAUST & LOCATION HAZARDS

Never operate in an enclosed area or indoors! • NEVER use in

the home, or in partly enclosed areas such as garages, even

if doors and windows are open! ONLY use outdoors and far

from open windows, doors, vents, and in an area that will not

accumulate deadly exhaust.

The generator produces dangerously high voltage when in

operation. Avoid contact with bare wires, terminals, connections,

etc., while the unit is running, even on equipment connected

to the generator. Ensure all appropriate covers, guards and

barriers are in place before operating the generator.

Never handle any kind of electrical cord or device while

standing in water, while barefoot or while hands or feet are wet.

DANGEROUS ELECTRICAL SHOCK MAY RESULT.

The National Electric Code (NEC) requires the frame and external

electrically conductive par ts of the generator be properly

connected to an approved earth ground. Local electrical codes

may also require proper grounding of the generator. Consult

with a local electrician for grounding requirements in the area.

Use a ground fault circuit interrupter in any damp or highly

conductive area (such as metal decking or steel work).

Do not use worn, bare, frayed or otherwise damaged electrical

cord sets with the generator.

Before performing any maintenance on the generator, disconnect

the engine starting battery (if equipped) to prevent accidental

start up. Disconnect the cable from the battery post indicated

by a NEGATIVE, NEG or (–) first. Reconnect that cable last.

In case of accident caused by electric shock, immediately shut

down the source of electrical power. If this is not possible,

attempt to free the victim from the live conductor. AVOID

DIRECT CONTACT WITH THE VICTIM. Use a non-conducting

implement, such as a rope or board, to free the victim from the

live conductor. If the victim is unconscious, apply first aid and

get immediate medical help.

ELECTRICAL HAZARDS

The engine exhaust fumes contain carbon monoxide, which

can you cannot see or smell. This poisonous gas, if breathed

in sufficient concentrations, can cause unconsciousness or

even death.

Adequate, unobstructed flow of cooling and ventilating air

is critical to correct generator operation. Do not alter the

installation or permit even partial blockage of ventilation

provisions, as this can seriously affect safe operation of the

generator. The generator MUST be operated outdoors.

This exhaust system must be properly maintained. Do nothing

that might render the exhaust system unsafe or in noncompliance

with any local codes and/or standards.

Always use a battery operated carbon monoxide alarm indoors,

installed according to the manufacturers instructions.

If you start to feel sick, dizzy, or weak after the generator has

been running, move to fresh air IMMEDIATELY. See a doctor, as

you could have carbon monoxide poisoning.

FIRE HAZARDS

Gasoline is highly FLAMMABLE and its vapors are EXPLOSIVE• .

Do not permit smoking, open flames, sparks or heat in the

vicinity while handling gasoline.

Never add fuel while unit is running or hot. Allow engine to cool

completely before adding fuel.

Never fill fuel tank indoors. • Comply with all laws regulating

storage and handling of gasoline.

Do not overfill the fuel tank. Always allow room for fuel •

expansion. If tank is over-filled, fuel can overflow onto a hot

engine and cause FIRE or an EXPLOSION. Never store generator

with fuel in tank where gasoline vapors might reach an open

flame, spark or pilot light (as on a furnace, water heater or

clothes dr yer). FIRE or EXPLOSION may result. Allow unit to

cool entirely before storage.

Wipe up any fuel or oil spills immediately. Ensure that no

combustible materials are left on or near the generator. Keep the

area surrounding the generator clean and free from debris and

keep a clearance of five (5) feet on all side to allow for proper

ventilation of the generator.

2

Page 5

Do not insert objects through unit’s cooling slots.

Do not • operate the generator if connected electrical devices

overheat, if electrical output is lost, if engine or generator sparks

or if flames or smoke are observed while unit is running.

Keep a fire extinguisher near the generator at all times.

In the absence of per tinent standards, codes, regulations and

laws, the published information listed below may be used as a

guideline for operation of this equipment. Always reference the

latest revision available for the standards listed.

1. NFPA No. 70, NFPA HANDBOOK OF NATIONAL ELECTRIC

CODE.

2. Article X, NATIONAL BUILDING CODE, available from the

American Insurance Association, 85 John Street, New York,

N.Y. 10038.

3. AGRICULTURAL WIRING HANDBOOK, available from the Food

and Energy Council, 909 University Avenue, Columbia, MO

65201.

4. ASAE EP-3634, INSTALLATION AND MAINTENANCE OF

FARM STANDBY ELECTRICAL SYSTEMS, available from the

American Society of Agricultural Engineers, 2950 Niles Road,

St. Joseph, MI 49085.

Safety Rules

MODEL NO:

SERIAL NO:

Generator Identification

CALIFORNIA PROPOSITION 65 WARNING

Engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects

and other reproductive harm.

CALIFORNIA PROPOSITION 65 WARNING

This product contains or emits chemicals known to the

State of California to cause cancer, birth defects and

other reproductive harm.

9RMX-(

0SGEXMSRW

3

Page 6

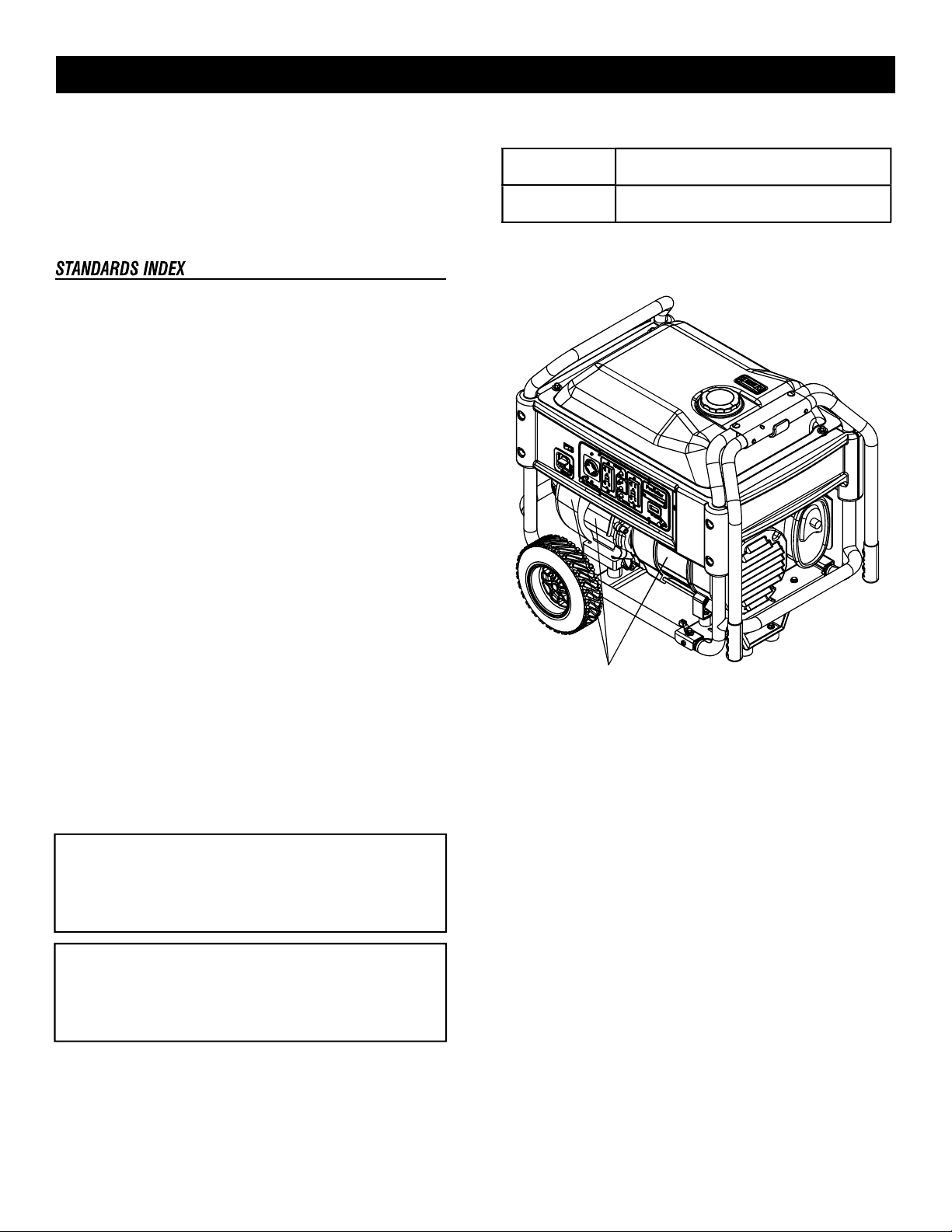

General Information

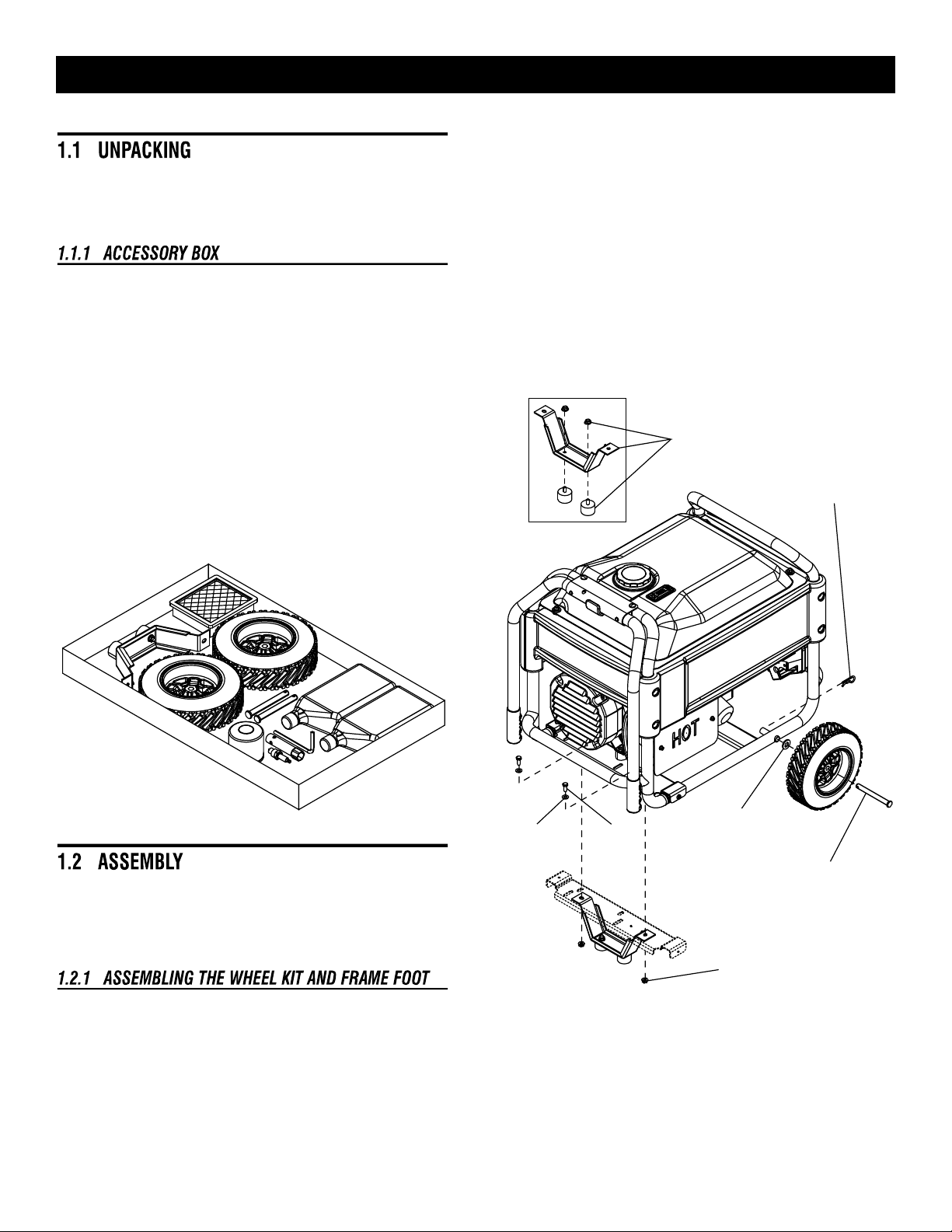

Remove all packaging material.

Remove separate accessory box.

Remove carton off the generator.

Check all contents (Figure 1). If any parts are missing or damaged

locate an authorized dealer at 1-888-775-6937.

Contents include:

2 – Axle Pins Oil Filter

2 – Wheel Spacers Air Filter

2 – Hair Pins Spark Plug

2 – Wheels Spark Plug Wrench

1 – Frame Foot Shop Towel

2 – Frame Bolts 2 – Frame Washers

2 – Vibration Mounts Oil Funnel

4 – Flange Nuts 12 Volt Adaptor Plug Charger

2 – 1 Quart SAE 30 Oil Bottles

Refer to Figure 2 and install the wheel kit and frame foot as

follows:

Slide the Axle Pin through the Wheel, Wheel S pacer (Washer)

and the Frame.

Install the Hair Pin to the Axle Pin to secure the wheel. Repeat

for the opposite side.

Secure the Vibration Mounts to the Frame Foot with the included

locking nuts.

To install the Frame Foot, install the Frame Bolts though the

Frame Washers, Frame and Frame foot. Secure with the locking

nuts.

Figure 2 Wheel and Foot Assembly

%77)1&0)

*6%1)

*338

7)'96);,))0

%2(%<0);-8,

,%-64-2

Figure 1 Accessory Boxes

Read entire Owner's Manual before attempting to assemble or

operate the generator. The generator requires some assembly

prior to using it. If problems arise when assembling the generator,

please call the Generator Helpline at 1-888-775-6937.

*6%1)

;%7,)6

*6%1)

&308

;,))074%')6

;%7,)6

70-()%<0)

8,639+,;,))0

%2(;,))0

74%')6

*0%2+)

298

The wheel kit is designed to greatly improve the portability of the

generator. You will need the following tools to install the wheel

kit: Pliers, 1/2" (13mm) wrench and a socket wrench with a 1/2"

(13mm) socket.

NOTE:

The wheel kit is not intended for over-the-road use.

4

Page 7

Read the entire Owner’s Manual and Safety Rules before

operating this generator.

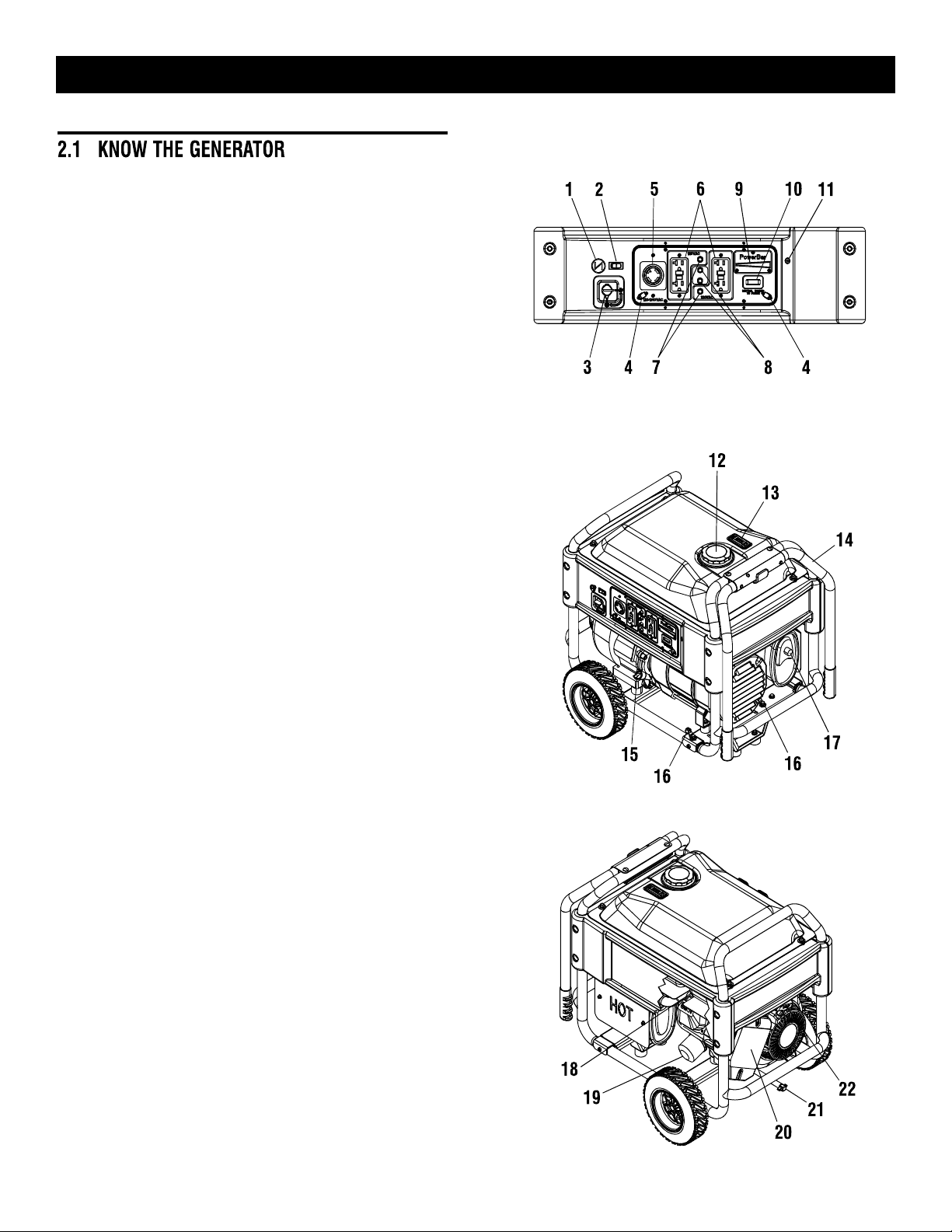

Compare the generator to Figures 3 through 6 to become

familiarized with the locations of various controls and adjustments.

Save this manual for future reference.

1. Choke Knob – Used when starting a cold engine (Pull/Push).

2. Engine Switch – Controls the operation of the generator. On

electric start models the switch is Start/Run/Stop. On recoil

start models the switch is On/Off.

3. Fuel Shut Off – Valve between fuel tank and carburetor. Turn

off and run carburetor out of fuel for extended storage.

4. Panel LED's – Provide illumination of the control panel while

the generator is operating.

5. 120/240 Volt AC, 30 Amp Locking Receptacle – Supplies

electrical power for the operation of 120 and/or 240 Volt AC,

30 Amp, single-phase, 60 Hz, electrical lighting, appliance,

tool and motor loads.

6. 120 Volt AC, 20 Amp, GFCI Duplex Receptacle – Supplies

electrical power for the operation of 120 Volt AC, 20 Amp,

single-phase, 60 Hz electrical lighting, appliance, tool and

motor loads. It also provides protection with an Integral

Ground Fault Circuit Interrupter, complete with a press to

"Test" and "Reset" button.

7. Circuit Breakers (AC) – Each 20 Amp receptacle is provided

with a push-to-reset circuit breaker to protect the generator

against electrical overload.

8. Circuit Breakers (AC) – The 30 Amp receptacle is protected

with a pair of push-to-reset circuit breakers to protect the

generator against electrical overload.

9. PowerBar – Indicates the amount of power being used from

the generator; each section is approximately 25%

10. Hourmeter – Provides operating hours for Service Intervals.

11. Battery Charger Input (Electric Start Models) – This

receptacle allows the capability to recharge the 12 VDC engine

starting battery with the 12 Volt Adaptor Plug Charger. The

battery is protected by a 1.50 Amp in-line fuse which is inside

the control panel.

12. Fuel Tank – Tank holds 9 U.S. gallons of fuel.

13. Fuel Gauge – Shows fuel level in tank.

14. Handles – Pivot and retract for storage. Press the spring-

loaded button to move handles.

15. Oil Fill – Check oil level and add oil here.

16. Grounding Lug – Ground the generator to an approved earth

ground here. See "Grounding the Generator" for details.

17. Muffler – Includes the spark arrestor and quiets the engine.

18. Spark Plug Location – The spark plug ignites the Air/Fuel

Mixture (Side panel must be removed).

19. Engine Oil Filter – Filters engine oil; see Section 3.1 for the

proper service intervals.

20. Air Cleaner – Filters intake air as it is drawn into the engine.

21. Oil Drain – Drain valve to remove used oil from the engine

crankcase.

22. Recoil Starter – Use to start engine manually.

Operation

Figure 3 Generator Locations

5

Page 8

Operation

NOTE:

The battery shipped with the generator has been fully charged.

A battery may lose some of its charge when not in use for

prolonged periods of time. If the battery is unable to crank

the engine, plug in the 12V charger included in the accessory

box (see the Charging the Battery section). RUNNING THE

GENERATOR DOES NOT CHARGE THE BATTERY.

The positive battery wire was deliberately left detached for

shipping. To operate the unit, attach this wire to the terminal on

the starter motor as shown. Do not overtighten. Slide the attached

rubber boot over the starter terminal. See Figure 4.

Figure 4 Battery Connection

437-8-:)

&%88)6='%&0)

When the hour meter is in the Flash Alert mode, the maintenance

message will always alternate with elapsed time in hours and

tenths. The hours will flash four times, then alternate with the

maintenance message four times until the meter resets itself.

100 hours - CHG OIL — Oil Change Interval (Every 100 hrs)

200 hours - SVC — Air Filter Interval (Every 200 hrs)

This is a 120 Volt outlet protected against overload by a 20 Amp

push-to-reset circuit breaker (Figure 5). Use each socket to power

120 Volt AC, single phase, 60 Hz electrical loads requiring up to a

combined 2400 watts (2.4 kW) or 20 Amps of current. Use only

high quality, well-insulated, 3-wire grounded cord sets rated for

125 Volts at 20 Amps (or greater).

Keep extension cords as short as possible, preferably less than

15 feet long, to prevent voltage drop and possible overheating of

wires.

)2+-2)

78%68)6

The Hourmeter tracks hours of operation for scheduled

maintenance:

There will be a one time break in "CHG OIL" message that flashes

with the elapsed time in hours and tenths after the first 30 hours

of operation.

This message will actually begin flashing at 29 hours and disable

itself at 31 hours providing a two hour window to perform the

service.

There will be a subsequent "CHG OIL" message every 100 hours.

The message will flash one hour before and one hour after each

100 hour interval, again providing a two hour window to perform

service.

Every 200 hours the "SVC" icon on the lower left hand corner of

the display will flash. The message will flash one hour before and

one hour after each 200 hour interval providing a two hour window

to perform service.

Use a NEMA L14-30 plug with this receptacle (rotate to lock/

unlock). Connect a suitable 4-wire grounded cord set to the plug

and to the desired load. The cord set should be rated for 250 Volts

AC at 30 Amps (or greater) (Figure 5).

Use this receptacle to operate 120 Volt AC, 60 Hz, single phase

loads requiring up to 3600 watts (3.6 kW) of power at 30 Amps

or 240 Volt AC, 60 Hz, single phase loads requiring 6,500 to 8000

watts of power, depending on the model. The outlet is protected by

a 30 Amp circuit breaker.

Figure 5 Generator Receptacles

:%'%

6)')48%'0)

:%'%

+*'-6)')48%'0)

6

Page 9

Operation

If there are any problems operating the generator, please call the

generator helpline at 1-888-436-3722.

Never operate in an enclosed area or indoors!

NEVER use in the home, or in partly enclosed

areas such as garages, even if doors and

windows are open! ONLY use outdoors and far

from open windows, doors, vents, and in an

area that will not accumulate deadly exhaust.

The engine exhaust fumes contain carbon

monoxide, which can you cannot see or smell.

This poisonous gas, if breathed in sufficient

concentrations, can cause unconsciousness or

even death.

Adequate, unobstructed flow of cooling and

ventilating air is critical to correct generator

operation. Do not alter the installation or permit

even partial blockage of ventilation provisions,

as this can seriously affect safe operation

of the generator. The generator MUST be

operated outdoors.

This exhaust system must be properly

maintained. Do nothing that might render the

exhaust system unsafe or in noncompliance

with any local codes and/or standards.

The manufacturer recommends installing

a battery operated carbon monoxide alarm

indoors, according to the manufacturers

instructions.

There may be Federal or State Occupational Safety and Health

Administration (OSHA) regulations, local codes, or ordinances that

apply to the intended use of the generator.

Please consult a qualified electrician, electrical inspector, or the

local agency having jurisdiction:

In some areas, generators are required to be registered with

local utility companies.

If the generator is used at a construction site, there may be

additional regulations which must be observed.

Connections for standby power to a building’s electrical system

must be made by a qualified electrician. The connection must

isolate the generator power from utility power or other alternative

power sources and must comply with all applicable laws and

electrical codes.

The National Electrical Code requires that the

frame and external electrically conductive parts

of this generator be properly connected to an

approved earth ground.

Local electrical codes may also require proper grounding of

the unit (Figure 6). For that purpose, connecting a No. 10 AWG

(American Wire Gauge) stranded copper wire to the grounding lug

and to an ear th-driven copper or brass grounding rod (electrode)

provides adequate protection against electrical shock. However,

local codes may vary widely. Consult with a local electrician for

grounding requirements in the area.

Proper grounding of the generator will help prevent electrical

shock in the event of a ground fault condition in the generator or in

connected electrical devices. Proper grounding also helps dissipate

static electricity, which often builds up in ungrounded devices.

The generator has a system ground that connects the generator

frame components to the ground terminals on the AC output

receptacles. The system ground is bonded to the AC neutral wire

in the generator control panel via a jumper wire.

Figure 6 Generator Ground Location

<+

+6392(

03' %8-32

<+<+

+6392(03'%8-32

7

Page 10

Operation

If service work is performed on the alternator, DO NOT discard

the white jumper wires from the terminal block to the alternator

ground, located on the rear bearing carrier. Always make sure

the wires are properly connected before using the generator after

alternator service work is done (Figure 7).

Failure to reconnect these wires may create a

potential shock hazard when the generator is

running!

Figure 7 Neutral to Frame Ground

(3238(-7'%6(

8,)7);-6)7

2)986%083*6%1)+6392(

<+

(3238(-7'%6(

8,)7);-6)7

Add up the rated watts (or amps) of all loads to be connected

at one time. This total should no be greater than (a) the rated

wattage/amperage capacity of the generator or (b) circuit

breaker rating of the receptacle supplying the power. See “Don’t

Overload the Generator

Overloading a generator in excess of its rated wattage capacity

can result in damage to the generator and to connected electrical

devices. Observe the following to prevent overloading the unit:

Add up the total wattage of all electrical devices to be connected

at one time. This total should NOT be greater than the

generator's wattage capacity.

The rated wattage of lights can be taken from light bulbs. The

rated wattage of tools, appliances and motors can usually be

found on a data label or decal affixed to the device.

If the appliance, tool or motor does not give wattage, multiply

volts times ampere rating to determine watts (volts x amps =

watts).

Some electric motors, such as induction types, require about

three times more watts of power for star ting than for running.

This surge of power lasts only a few seconds when starting

such motors. Make sure to allow for high starting wattage when

selecting electrical devices to connect to the generator:

1. Figure the watts needed to start the largest motor.

2. Add to that figure the running watts of all other connected

loads.

The Wattage Reference Guide is provided to assist in determining

how many items the generator can operate at one time.

NOTE:

All figures are approximate. See data label on appliance for

wattage requirements.

2)986%083*6%1)+6392(<+

DO NOT connect 240 Volt loads to 120 Volt receptacles.

DO NOT connect 3 phase loads to the generator.

DO NOT connect 50 Hz loads to the generator.

Let engine stabilize and warm up for a few minutes after

starting.

Plug in and turn on the desired 120 or 240 Volt AC, single

phase, 60 Hz electrical loads.

8

Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Running Watts

*Air Conditioner (12,000 Btu). . . . . . . . . . . . . . . . . . . . . . . . . . 1700

*Air Conditioner (24,000 Btu). . . . . . . . . . . . . . . . . . . . . . . . . . 3800

*Air Conditioner (40,000 Btu). . . . . . . . . . . . . . . . . . . . . . . . . . 6000

Battery Charger (20 Amp). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500

Belt Sander (3") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1000

Chain Saw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200

Circular Saw (6-1/2") . . . . . . . . . . . . . . . . . . . . . . . . . . .800 to 1000

*Clothes Dryer (Electric) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5750

*Clothes Dryer (Gas) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 700

*Clothes Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1150

Coffee Maker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1750

*Compressor (1 HP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000

*Compressor (3/4 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1800

*Compressor (1/2 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1400

Curling Iron. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 700

*Dehumidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 650

Disc Sander (9") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200

Edge Trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500

Electric Blanket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

Page 11

Electric Nail Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200

Electric Range (per element) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1500

Electric Skillet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1250

*Freezer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..700

*Furnace Fan (3/5 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 875

*Garage Door Opener . . . . . . . . . . . . . . . . . . . . . . . . . . . .500 to 750

Hair Dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200

Hand Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250 to 1100

Hedge Trimmer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 450

Impact Wrench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500

Iron. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200

*Jet Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800

Lawn Mower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200

Light Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Microwave Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .700 to 1000

*Milk Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1100

Oil Burner on Furnace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Oil Fired Space Heater (140,000 Btu) . . . . . . . . . . . . . . . . . . . . . 400

Oil Fired Space Heater (85,000 Btu) . . . . . . . . . . . . . . . . . . . . . . 225

Oil Fired Space Heater (30,000 Btu) . . . . . . . . . . . . . . . . . . . . . . 150

*Paint Sprayer, Airless (1/3 HP) . . . . . . . . . . . . . . . . . . . . . . . . . 600

Paint Sprayer, Airless (handheld). . . . . . . . . . . . . . . . . . . . . . . . . 150

Radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 to 200

*Refrigerator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 700

Slow Cooker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

*Submersible Pump (1-1/2 HP) . . . . . . . . . . . . . . . . . . . . . . . . 2800

*Submersible Pump (1 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000

*Submersible Pump (1/2 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . 1500

*Sump Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .800 to 1050

*Table Saw (10") . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1750 to 2000

Television . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200 to 500

Toaster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1000 to 1650

Weed Trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500

* Allow 3 times the listed watts for starting these devices.

Operation

8)14)6%896)-2()+6))7*%,6)2,)-8*

8)14)6%896)-2()+6))7')07-97'

Place generator on a level surface.

Clean area around oil fill and remove oil fill cap.

Slowly fill engine with oil through the oil fill opening until it

reaches the full mark. Stop filling occasionally to check oil level.

(Engine oil is full when level is up to the threads of the oil fill

plug, see Figure 8)

Install oil fill cap and finger tighten securely.

Check engine oil level before starting each time thereafter.

Figure 8 Oil Level

Prior to operating the generator, engine oil and gasoline will need

to be added, as follows:

All oil should meet minimum American Petroleum Institute (API)

Service Class SJ, SL or better. Use no special additives. Select

the oil's viscosity grade according to the expected operating

temperature (also see char t).

Above 40° F, use SAE 30

Below 40° F and down to 10° F, use 10W-30

Below 10° F, use synthetic 5W-30

Any attempt to crank or start the engine before it has

been properly serviced with the recommended oil may

result in an engine failure.

DO NOT light a cigarette or smoke when filling the fuel

tank.

Never fill fuel tank indoors. Never fill fuel tank when

engine is running or hot. Avoid spilling gasoline on a hot

engine. Allow engine to cool entirely before filling fuel

tank.

9

Page 12

Operation

Do not overfill the fuel tank. Always leave room for fuel

expansion. If the fuel tank is overfilled, fuel can overflow

onto a hot engine and cause FIRE or EXPLOSION. Wipe

up any spilled fuel immediately.

Use regular UNLEADED gasoline with the generator engine. Do

not use premium gasoline. Do not mix oil with gasoline.

Do not use gasoline with more than 10% alcohol such as E85

or Methanol.

Clean area around fuel fill cap, remove cap.

Slowly add unleaded regular gasoline to fuel tank. Fill to bottom

of screen filter. Be careful not to overfill (Figure 9).

Install fuel cap and wipe up any spilled gasoline.

Figure 9 Fuel Fill Level

(3238*-00

%&3:)0-4

Figure 10 Fuel Shut-off Valve

Figure 11 Choke Operation

IMPORTANT: It is important to prevent gum deposits from forming

in fuel system parts such as the carburetor, fuel hose or tank

during storage. Alcohol-blended fuels (called gasohol, ethanol

or methanol) can attract moisture, which leads to separation and

formation of acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine problems,

the fuel system should be emptied before storage of 30 days or

longer. See the "Storage" section. Never use engine or carburetor

cleaner products in the fuel tank as permanent damage may

occur.

Never start or stop engine with electrical devices plugged into

the receptacles AND devices turned on.

Unplug all electrical loads from the unit's receptacles before

starting the engine.

Make sure the unit is in a level position.

Open the fuel shut-off valve (Figure 10).

Pull engine CHOKE knob outward to “Full Choke” position

(Figure 11).

To start the generator, put the on/off switch in the ON position.

Firmly grasp the recoil handle and pull slowly until increased

resistance is felt. Pull rapidly up and away to start engine.

When the engine starts, push choke knob to “1/2 Choke”

position until the engine runs smoothly and then fully in to the

“Run” position. If engine falters, pull choke knob back out to

“1/2 Choke” position until the engine runs smoothly and then

to “Run” position.

NOTE:

If engine fires, but does not continue to run, pull choke knob

to Full Choke and repeat starting instructions.

IMPORTANT: Do not overload the generator. Also, do not overload

individual panel receptacles. These outlets are protected against

overload with push-to-reset-type circuit breakers. Read “Don’t

Overload the Generator” carefully.

10

Page 13

To start the engine, press and hold the Start/Run/Stop switch in

the “Start” position. The engine will crank and attempt to start.

When the engine star ts, release the switch to the run position.

When the engine starts, push choke knob to “1/2 Choke”

position until the engine runs smoothly and then fully in to the

“Run” position. If engine falters, pull choke knob back out to

“1/2 Choke” position until the engine runs smoothly and then

to “Run” position.

This generator is also equipped with a manual recoil starter

which may be used if the battery is discharged.

NOTE:

The engine Start/Run/Stop switch must be in the RUN

position when using the manual recoil starter.

Shut off all loads, then unplug the electrical loads from generator

panel receptacles. Never start or stop the engine with electrical

devices plugged in and turned on.

Let engine run at no-load for several minutes to stabilize the

internal temperatures of engine and generator.

Move Start/Run/Stop or On/Off switch to the “Off” position.

Close fuel valve.

The engine is equipped with a low oil pressure sensor that shuts

down the engine automatically when the oil pressure drops below

5 psi. A delay built into the low oil shutdown system allows oil

pressure to build during starting. The delay allows the engine to

run for about 10 seconds before sensing oil pressure. If the engine

shuts down by itself and the fuel tank has enough gasoline, check

engine oil level.

Maintenance

Storage batteries give off explosive hydrogen

gas while recharging. An explosive mixture will

remain around the battery for a long time after

it has been charged. The slightest spark can

ignite the hydrogen and cause an explosion.

Such an explosion can shatter the battery and

cause blindness or other serious injury.

Use battery charger plug to keep the battery charged and ready

for use. Battery charging should be done in a dry location.

1. Plug charger into “Battery Charger Input” jack, located on the

control panel. Plug wall receptacle end of the battery charger

into a 120 Volt AC wall outlet.

2. Unplug battery charger from wall outlet and control panel jack

when generator is going to be in use.

NOTE:

Do not use the battery charger for more than 48 hours at one

charge.

Follow the calendar intervals. More frequent service is required

when operating in adverse conditions noted below.

Check Oil Level At Each Use

Change Oil and Oil Filter *Every Season/Every 100 Hours

Clean Spark Arrestor Screen *Every Season/Every 100 Hours

Service Air Cleaner **Every Season/Every 200 Hours

Replace Spark Plug Every Season

Change oil after first 30 hours of operation then every season.

* Change oil and oil filter every month when operating under heavy load or in

high temperatures.

** Clean more often under dirty or dusty operating conditions. Replace air

cleaner parts if very dirty.

If trying to restart the engine within 10 seconds after it shuts down,

the engine may NOT start. The system needs 5 to 10 seconds to

reset.

If the engine is restarted after such a shutdown and the low oil

pressure has not been corrected, the engine will run for about 10

seconds as described above and then stop.

Do not permit smoking, open flame, sparks

or any other source of heat around a battery.

Wear protective goggles, rubber apron and

rubber gloves when working around a battery.

Battery electrolyte fluid is an extremely

corrosive sulfuric acid solution that can cause

severe burns. If spill occurs flush area with

clear water immediately.

Model # ...............................................................005800-0, 005747-0

Rated Max. Power ...................................................................8.0 kW**

Surge Power ................................................................................10 kW

Rated AC Voltage ......................................................................120/240

Rated Max AC Load

Current @ 240V .............................................................33.3 Amps**

Current @ 120V .............................................................66.7 Amps**

Rated Frequency .................................................... 60 Hz @ 3600 RPM

Phase ................................................................................Single Phase

Rated DC Voltage ......................................................................12 Volts

Battery Type .................................................................... 10 AH, 12VDC

11

Page 14

Maintenance

Model # ...............................................................005797-0, 005798-0

Rated Max. Power ...................................................................7.0 kW**

Surge Power .............................................................................8.75 kW

Rated AC Voltage ......................................................................120/240

Rated Max AC Load

Current @ 240V .............................................................29.2 Amps**

Current @ 120V .............................................................58.3 Amps**

Rated Frequency .................................................... 60 Hz @ 3600 RPM

Phase ................................................................................Single Phase

Rated DC Voltage ......................................................................12 Volts

Battery Type .................................................................... 10 AH, 12VDC

Model # ................................................................................ 005796-0

Rated Max. Power ...................................................................6.5 kW**

Surge Power .............................................................................8.13 kW

Rated AC Voltage ......................................................................120/240

Rated Max AC Load

Current @ 240V .............................................................27.1 Amps**

Current @ 120V .............................................................54.2 Amps**

Rated Frequency .................................................... 60 Hz @ 3600 RPM

Phase ................................................................................Single Phase

Rated DC Voltage ......................................................................12 Volts

** Maximum wattage and current are subject to, and limited by, such factors

as fuel Btu content, ambient temperature, altitude, engine condition, etc..

Maximum power decreases about 3.5% for each 1,000 feet above sea level;

and will also decrease about 1% for each 6° C (10° F) above 16° C (60° F)

ambient temperature.

Fuel System Air Induction System

Fuel Tank ~ Intak e pip e/manif old

Fuel Cap ~ Air cleaner

Carburetor

Fuel Line s ~ Spark plug

Ignition System

Evaporative Control System ~ Ignition module

Carbon Canister Exhaust System

Vap or Ho se s ~ Pulse Air Injection Valve

~ Muffler

The Emissions Compliance Period referred to on the Emissions

Compliance Label indicates the number of operating hours for

which the engine has been shown to meet Federal and California

emission requirements. See the table below to determine the

compliance period for your generator. The displacement of your

generator is listed on the Emissions Compliance Label.

Displacement Category Compliance Period

A500 Hours

66 cc - < 225 cc

B 250 Hours

C 125 Hours

A 1000 Hours

225 cc

B 500 Hours

C 250 Hours

Rated Horsepower @ 3600 RPM ....................................................14.5

Displacement ...............................................................................410cc

Spark Plug Type ...................................Champion RC14YC or Equivalent

Spark Plug Gap ............................................... 0.030 inch or (0.76 mm)

Gasoline Capacity ............................................................ 9 U.S. gallons

Oil Type....................................See Chart in "Adding Engine Oil" Section

Oil Capacity ................................................ w/ Filter Change = 1.5 Qts.

w/o Filter Change = 1.2 Qts.

Run Time/Fuel Consumption-1/2 Load .. 10 Hours / .73 gallons per hour

Class II Emission Certified

The Environmental Protection Agency (EPA) and California Air

Resource Board (CARB) require that your generator comply with

exhaust and evaporative emission standards. This generator is

certified to meet the applicable EPA and CARB emission levels.

Additional information regarding the requirements set by EPA and

CARB is as follows:

It is important that you follow the maintenance specifications

provided in this manual to ensure that your engine complies with

the applicable emission standards for the duration of the engine’s

life. This engine is certified to operate on gasoline. The emission

control system on your generator consists of the following:

The warranty of the generator does not cover items that have been

subjected to operator abuse or negligence. To receive full value

from the warranty, the operator must maintain the generator as

instructed in this manual.

Some adjustments will need to be made periodically to properly

maintain the generator.

All adjustments in the Maintenance section of this manual should

be made at least once each season. Follow the requirements in the

"Maintenance Schedule".

NOTE:

Once a year replace the spark plug and replace the air filter.

A new spark plug and clean air filter assure proper fuel-air

mixture and help the engine run better and last longer.

Generator maintenance consists of keeping the unit clean and dry.

Operate and store the unit in a clean dry environment where it will

not be exposed to excessive dust, dirt, moisture or any corrosive

vapors. Cooling air slots in the generator must not become clogged

with snow, leaves, or any other foreign material.

Check the cleanliness of the generator frequently and clean when

dust, dirt, oil, moisture or other foreign substances are visible on

its exterior surface.

Never insert any object or tool through the air cooling

slots, even if the engine is not running.

12

Page 15

Maintenance

NOTE:

DO NOT use a garden hose to clean generator. Water can

enter the engine fuel system and cause problems. In addition,

if water enters the generator through cooling air slots, some

water will be retained in voids and crevices of the rotor

and stator winding insulation. Water and dirt buildup on the

generator internal windings will eventually decrease the

insulation resistance of these windings.

Use a damp cloth to wipe exterior surfaces clean.

A soft, bristle brush may be used to loosen caked on dirt, oil,

etc.

A vacuum cleaner may be used to pick up loose dirt and

debris.

Low pressure air (not to exceed 25 psi) may be used to blow

away dirt. Inspect cooling air slots and openings on the generator.

These openings must be kept clean and unobstructed.

When working on the generator, always disconnect

negative cable from battery. Also disconnect spark plug

wire from spark plug and keep wire away from spark

plug.

Coat gasket of new filter with clean engine oil. Turn filter

clockwise until gasket contacts lightly with filter adapter. Then

tighten an additional 3/4 turn.

Fill oil sump with recommende d oil and replace the oil fill pl ug. (See

“Before Starting the Generator” for oil recommendations).

Wipe up any spilled oil.

Dispose of used oil at a proper collection center.

Use Champion RC14YC spark plug or equivalent. Replace the

plug once each year. This will help the engine start easier and

run better.

1. Stop the engine and pull the spark plug wire off of the spark

plug.

2. To gain access, remove the four (4) socket head screws and

take off the side panel.

3. Clean the area around the spark plug and remove it from the

cylinder head.

4. Set the spark plug's gap to .76 mm (0.030 in.). Install the

correctly gapped spark plug into the cylinder head (Figure

12).

5. Push the boot firmly on the spark plug and install side panel.

Figure 12 Spark Plug Gap

See the “BEFORE STARTING THE GENERATOR” section for

information on checking the oil level. The oil level should be

checked before each use, or at least every eight hours of operation.

Keep the oil level maintained.

Change the oil and filter after the first 30 hours of operation. Change

the oil every 100 hours or every season thereafter. If running this

unit under dirty or dusty conditions, or in extremely hot weather,

change the oil more often.

Hot oil may cause burns. Allow engine to cool before

draining oil. Avoid prolonged or repeated skin exposure

with used oil. Thoroughly wash exposed areas with soap.

Use the following instructions to change the oil:

Clean area around oil drain cap.

Remove oil drain cap from the drain hose and oil fill plug to drain

oil completely into a suitable container.

When oil has completely drained, install oil drain cap and tighten

securely.

Place a suitable container beneath the oil filter and turn

filter counterclockwise to remove. Discard according to local

regulations.

The engine will not run properly and may be damaged if using a

dirty air cleaner. Clean or replace the air cleaner paper filter every

200 hours or once a year (Figure 15). Clean or replace more often

if operating under dusty conditions. To clean or replace paper air

filter:

Remove air cleaner cover and remove paper filter (Figure 13).

Clean paper filter by tapping it gently on a solid surface. If the

filter is too dirty, replace it with a new one. Dispose of the old

filter properly.

Clean air cleaner cover. Next insert new paper filter into the base

of the air cleaner. Re-install air cleaner cover.

NOTE:

To order a new air filter, please contact the nearest authorized

service center at 1-888-GENERAC.

13

Page 16

Maintenance

Figure 13 Air Filter

'3:)6

%-6*-08)6

The engine exhaust muffler has a spark arrestor screen. Inspect

and clean the screen at least once each year (Figure 14). If unit is

used regularly, inspect and clean more often.

The generator should be star ted at least once every seven days

and be allowed to run at least 30 minutes. If this cannot be done

and the unit must be stored for more than 30 days, use the

following information as a guide to prepare it for storage.

NEVER store engine with fuel in tank indoors

or in enclosed, poorly ventilated areas where

fumes may reach an open flame, spark or pilot

light as on a furnace, water heater, clothes

dryer or other gas appliance.

Allow unit to cool entirely before storage.

It is important to prevent gum deposits from forming in essential

fuel system parts such as the carburetor, fuel hose or tank during

storage. To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer, as follows:

Remove all gasoline from the fuel tank.

If using the generator on any forest-covered,

brush-covered or grass-covered unimproved

land, it must equipped with a spark arrestor.

The spark arrestor must be maintained in good

condition by the owner/operator.

Clean and inspect the spark arrestor when the engine is at ambient

temperature as follows:

Loosen the clamp and remove the spark arrestor screen from

the muffler.

Inspect screen and replace if torn, perforated or otherwise

damaged. DO NOT USE a defective screen. If screen is not

damaged, clean it with commercial solvent.

Replace the spark arrestor and secure with the clamp.

Figure 14 Spark Arrestor Screen

%66)7836

7'6))2

'0%14

74%6/

%66)7836

7'6))2

Drain fuel into approved container outdoors, away from

open flame. Be sure engine is cool. Do not smoke in the

vicinity or light a cigarette.

Start and run engine until engine stops from lack of fuel.

Allow the engine to cool, then drain oil from crankcase. Refill

with recommended grade.

Remove spark plug and pour about 1/2 ounce (15 ml) of engine

oil into the cylinder. Cover spark plug hole with rag. Pull the

recoil star ter a couple times to lubricate the piston rings and

cylinder bore.

Avoid spray from spark plug hole when

cranking engine.

Install and tighten spark plug. Do not connect the spark plug

wire.

Clean the generator outer surfaces. Check that cooling air slots

and openings on generator are open and unobstructed.

Store the unit in a clean, dry place.

14

Page 17

Do not store gasoline from one season to another.

Replace any gasoline can that starts to rust. Rust and/or dirt in

the gasoline will cause problems with the carburetor and fuel

system.

If possible, store the unit indoors and cover it to give protection

from dust and dirt. Cover the unit with a suitable protective

cover that does not retain moisture.

BE SURE TO EMPTY THE FUEL TANK. If it is not practical

to empty the fuel tank and the unit is to be stored for some

time, use a commercially available fuel stabilizer added to the

gasoline to increase the life of the gasoline.

NEVER cover the generator while engine and

exhaust area are warm.

NOTE:

The battery shipped with the generator has been fully charged.

A battery may lose some of its charge when not in use for

prolonged periods of time. If the battery is unable to crank

the engine, plug in the 12V charger included in the accessory

box (see the Charging a Battery section). RUNNING THE

GENERATOR DOES NOT CHARGE THE BATTERY.

The battery shipped with the generator has been provided fully

charged. To replace the battery (See Figure 16):

Remove the side panel as shown. Remove the four bolts

securing the fuel tank.

Turn the fuel valve on the control panel to the "OFF" position.

Pull the fuel tank back slightly and remove the fuel hose that

runs from the engine to the fuel valve.

7-()

4%2 ) 0

Battery Service

Figure 16 Battery Removal

*9)08%2/

%77)1&0=

)2+-2)

78%68-2+

&%88)6=

&%88)6=

&6%'/)8

Drain fuel into approved container outdoors, away from

open flame. Be sure engine is cool. Do not smoke in the

vicinity or light a cigarette.

Push the fuel valve from the control panel and remove the fuel

tank.

Remove the battery wire connections (black wire first) and the

battery hold-down bracket.

Replace the battery, connecting the RED wire to the POSITIVE

(+) terminal and the BLACK wire to the NEGATIVE (-) terminal

NOTE:

Start all four screws on the side panel before tightening or it

may not be possible to get all the screws in place.

15

Page 18

Troubleshooting

PROBLEM CAUSE CORRECTION

Engine is running, but no AC output

is available.

1. Circuit breaker is open.

2. Poor connection or defective cord set.

3. Connected device is bad.

4. Fault in generator.

5. GFCI trips the 20 Amp outlet.

1. Reset circuit breaker.

2. Check and repair.

3. Connect another device that is in good condition.

4. Contact Authorized Service Facility.

5. Repair the "short" and reset the GFCI.

Engine runs good but bogs down

when loads are connected.

Engine will not crank. 1. Battery weak or dead. 1. Recharge or replace battery (see "No Battery

Engine will not start; or starts and

runs rough.

Engine shuts down during

operation.

1. Shor t circuit in a connected load.

2. Generator is overloaded.

3. Engine speed is too slow.

4. Shorted generator circuit.

1. Fuel shut-off is OFF.

2. Dirty air cleaner.

3. Out of gasoline.

4. Stale gasoline.

5. Spark plug wire not connected to spark plug.

6. Bad spark plug.

7. Water in gasoline.

8. Over-choking.

9. Low oil level.

10. Excessive rich fuel mixture.

11. Intake valve stuck open or closed.

12. Engine has lost compression.

1. Out of gasoline.

2. Low oil level.

3. Fault in engine.

1. Disconnect shor ted electrical load.

2. See “Don’t Overload the Generator” .

3. Contact Authorized Service Facility.

4. Contact Authorized Service Facility.

Charger DC output" at bottom of guide).

2. Start engine manually using recoil starter.

1. Turn Fuel shut-off ON.

2. Clean or replace air cleaner.

3. Fill fuel tank.

4. Drain fuel tank and fill with fresh fuel.

5. Connect wire to spark plug.

6. Replace spark plug.

7. Drain fuel tank; fill with fresh fuel.

8. Put choke knob to No Choke position.

9. Fill crankcase to proper level.

10. Contact Authorized Service Facility.

11. Contact Authorized Service Facility.

12. Contact Authorized Service Facility.

1. Fill fuel tank.

2. Fill crankcase to proper level.

3. Contact Authorized Service Facility.

Engine lacks power. 1. Load is too high.

2. Dirty air filter.

3. Engine needs to be serviced.

Engine “hunts” or falters. 1. Choke is opened too soon.

2. Carburetor is running too rich or too lean.

No Battery Charger DC output. 1. Battery posts are corroded.

2. Battery cable is bad.

3. Battery is defective.

4. Receptacle is bad.

5. Battery Charger in-line fuse (1.5A) melted open.

16

1. See “Don’t Overload the Generator”.

2. Replace air filter.

3. Contact Authorized Service Facility.

1. Move choke to halfway position until engine runs

smoothly.

2. Contact Authorized Service Facility.

1. Clean battery posts.

2. Replace cable.

3. Check battery condition; replace if defective.

4. Contact Authorized Service Facility.

5. Replace fuse with identical 1.5A replacement fuse

only (located inside control panel).

Page 19

Notes

17

Page 20

Warranty

CALIFORNIA AND FEDERAL EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board (CARB) and the United States Environmental Protection Agency (EPA), together with Generac

Power Systems, Inc. (Generac), are pleased to explain the Emission Control System warranty on your new 2008 and later

generator. New equipment that use small spark-ignited engines must be designed, built, and equipped to meet stringent antismog standards for the state of California and the federal government. Generac will warrant the emission control system on your

generator for the period of time listed below provided there has been no abuse, neglect, unapproved modification or improper

maintenance of your equipment.

Your emission control system may include parts such as the: carburetor, ignition system, catalytic converter, fuel tank, fuel lines,

fuel cap, valves, carbon canister, filters, vapor hoses, clamps, connectors, and other associated emission-related components (if

equipped).

MANUFACTURERS WARRANTY COVERAGE:

This emission control system is warranted for two years. If, during such warranty period, any emission-related part on your

equipment is found to be defective in materials or workmanship, repairs or replacement will be performed by a Generac Authorized

Warranty Service Dealer.

OWNER'S WARRANTY RESPONSIBILITIES:

As the generator owner, you are responsible for the completion of all required maintenance as listed in your factory supplied

Owner's Manual. For warranty purposes, Generac recommends that you retain all receipts covering maintenance on your

generator, but Generac cannot deny warranty solely due to the lack of receipts.

As the generator owner, you should be aware that Generac may deny any and/or all warranty coverage or responsibility if your

generator, or a part/component thereof, has failed due to abuse, neglect, improper maintenance or unapproved modifications, or

the use of counterfeit and/or "grey market" parts not made, supplied or approved by Generac.

You are responsible for contacting a Generac Authorized Warranty Dealer as soon as a problem occurs. The warranty

repairs should be completed in a reasonable amount of time, not to exceed 30 days.

Warranty service can be arranged by contacting either your selling dealer or a Generac Authorized Warranty Service Dealer. To

locate the Generac Authorized Warranty Service Dealer nearest you, call our toll free number:

1-800-333-1322

IMPORTANT NOTE: This warranty statement explains your rights and obligations under the Emission Control System Warranty

(ECS Warranty), which is provided to you by Generac pursuant to California and federal law. See also the "Generac Limited

Warranties for Generac Power Systems, Inc.," which is enclosed herewith on a separate sheet, also provided to you by Generac.

Note that this warranty shall not apply to any incidental, consequential or indirect damages caused by defects in materials or

workmanship or any delay in repair or replacement of the defective part(s). This warranty is in place of all other warranties,

expressed or implied. Specifically, Generac makes no other warranties as to the merchantability or fitness for a particular purpose.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

The ECS Warranty applies only to the emission control system of your new equipment. If there is any conflict in terms between

the ECS Warranty and the Generac Warranty, the Generac Warranty shall apply. Both the ECS Warranty and the Generac Warranty

describe important rights and obligations with respect to your new engine.

Warranty service can be performed only by a Generac Authorized Warranty Service Facility. When requesting warranty service,

evidence must be presented showing the date of the sale to the original purchaser/owner.

If you have any questions regarding your warranty rights and responsibilities, you should contact Generac at the following address:

ATTENTION WARRANTY DEPARTMENT

GENERAC POWER SYSTEMS, INC.

P.O. BOX 297 WHITEWATER, WI 53190

Part 1

Part No. 0H1913 Rev. A 01/09

18

Page 21

Warranty

EMISSION CONTROL SYSTEM WARRANTY

Emission Control System Warranty (ECS warranty) for equipment using small spark-ignited engines:

(a) Applicability: This warranty shall apply to equipment that uses small off-road engines. The ECS Warranty period shall begin

on the date the new equipment is purchased by/delivered to its original, end-use purchaser/owner and shall continue for 24

consecutive months thereafter.

(b) General Emissions Warranty Coverage: Generac warrants to the original, end-use purchaser/owner of the new engine or

equipment and to each subsequent purchaser/owner that the ECS when installed was:

(1) Designed, built and equipped so as to conform with all applicable regulations; and

(2) Free from defects in materials and workmanship which cause the failure of a warranted part at any time during the ECS

Warranty Period.

(c) The warranty on emissions-related parts will be interpreted as follows:

(1) Any warranted part that is not scheduled for replacement as required maintenance in the Owner's Manual shall be

warranted for the ECS Warranty Period. If any such part fails during the ECS Warranty Period, it shall be repaired or

replaced by Generac according to Subsection (4) below. Any such part repaired or replaced under the ECS Warranty shall

be warranted for the remainder of the ECS Warranty Period.

(2) Any warranted part that is scheduled only for regular inspection as specified in the Owner's Manual shall be warranted

for the ECS Warranty Period. A statement in the Owners Manual to the effect of "repair or replace as necessary" shall not

reduce the ECS Warranty Period. Any such part repaired or replaced under the ECS Warranty shall be warranted for the

remainder of the ECS Warranty Period.

(3) Any warranted part that is scheduled for replacement as required maintenance in the Owner's Manual shall be warranted

for the period of time prior to first scheduled replacement point for that part. If the part fails prior to the first scheduled

replacement, the part shall be repaired or replaced by Generac according to Subsection (4) below. Any such emissions-

related part repaired or replaced under the ECS warranty shall be warranted for the remainder of the period prior to the first

scheduled replacement point for that part.

(4) Repair or replacement of any warranted, emissions-related part under this ECS Warranty shall be performed at no charge to

the owner at a Generac Authorized Warranty Service Facility.

(5) Notwithstanding the provisions of subsection (4) above, warranty services or repairs must be provided at Generac

Authorized Service Facilities.

(6) When the engine is inspected by a Generac Authorized Warranty Service Facility, the purchaser/owner shall not be held

responsible for diagnostic costs if the repair is deemed warrantable.

(7) Throughout the ECS Warranty Period, Generac shall maintain a supply of warranted emission-related parts sufficient to

meet the expected demand for such parts.

(8) Any Generac authorized and approved emission-related replacement parts may be used in the performance of any ECS

warranty maintenance or repairs and will be provided without charge to the purchaser/owner. Such use shall not reduce

Generac ECS Warranty obligations.

(9) Unapproved, add-on, modified, counterfeit and/or "grey market" parts may not be used to modify or repair a Generac

engine. Such use voids this ECS Warranty and shall be sufficient grounds for disallowing an ECS Warranty claim. Generac

shall not be held liable hereunder for failures of any warranted parts of Generac equipment caused by the use of such an

unapproved, add-on, modified, counterfeit and/or "grey market" part.

EMISSION RELATED PARTS MAY INCLUDE THE FOLLOWING (IF EQUIPPED):

1) FUEL SYSTEM

A. FUEL TANK

B. FUEL CAP

C. FUEL LINE

D. FUEL LIN E FITTINGS

E. CLAMPS*

F. PRESSURE RELIEF VALVES*

2) EVAPORATIVE CONTROL SYSTEM

A. CARBON CANISTER

B. CANISTER MOUNTING BRACKETS

C. CARBURETOR PURGE PORT

D. C ONTR OL VALVES*

E. VAPOR HOSES

F. PU RG E VA L V E S

G. LIQUID / VAPOR SEPARATOR

H. VACUUM CONTROL DIAPHRAGMS*

*NOTE: As they relate to the Emission Control System.

Part 2

3) FUEL METERING SYSTEM

A. CARBURETOR AND INTERNAL PARTS

B. PRESSURE REGULATOR

4) AIR INDUCTION SYSTEM

A. INTAKE MANIFOLD

B. AIR FILTER

5) IGNITION SYSTEM

A. SPARK PLUGS

B. IGNITION COILS / MODULE

6) AIR INJECTION SYSTEM

A. PULSE AIR VALVE

7) EXHAUST SYSTEM

A. CATALYST

B. THERMAL REACTOR

C. EXHAUST MANIFOLD

Part No. 0H1913 Rev. A 01/09

19

Page 22

Warranty

GENERAC POWER SYSTEMS “TWO YEAR” LIMITED WARRANTY FOR

XG SERIES PORTABLE GENERATORS

For a period of two years from the date of original sale, Generac Power Systems, Inc. (Generac) warrants its XG Series generators will be free from defects in materials

and workmanship for the items and period set forth below. Generac will, at its option, repair or replace any part which, upon examination, inspection and testing by

Generac or a Generac Authorized Warranty Service Dealer, is found to be defective. Any equipment that the purchaser/owner claims to be defective must be returned to

and examined by the nearest Generac Authorized Warranty Service Dealer. All transportation costs under the warranty, including return to the factory, are to be borne and

prepaid by the purchaser/owner. This warranty applies only to Generac XG Series portable generators and is not transferable from original purchaser. Save your proof-ofpurchase receipt. If you do not provide proof of the initial purchase date, the manufacturer’s shipping date of the product will be used to determine the warranty period.

Consumer applications are warranted for two (2) years. Commercial and Rental applications are warranted for one (1) year or 1000 hours maximum, whichever comes

first.

CONSUMER APPLICATION

YEAR ONE - 100% (one hundred percent) coverage on Labor and Part(s) (proof of purchase and maintenance is required):

• All Components

YEAR TWO- 100% (one hundred percent) coverage on Part(s) (proof of purchase and maintenance is required):

• All Components

COMMERCIAL/RENTAL APPLICATION

YEAR ONE – 100% (one hundred percent) coverage on Labor and Part(s) (proof of purchase and maintenance is required):

•All Components

NOTE: For the purpose of this warranty “consumer use” means personal residential household or recreational use by original purchaser. This warranty does not apply

All warranty expense allowances are subject to the conditions defined in Generac’s Warranty Policies, Procedures and Flat Rate Manual.

to units used for Prime Power in place of utility where utility power service is present or where utility power service does not normally exist. Once a generator

has experienced commercial or rental use, it shall thereafter be considered a non-consumer use generator for the purpose of this warranty.

THIS WARRANTY SHALL NOT APPLY TO THE FOLLOWING:

Generac portable generators that utilize non-Generac replacement parts.•

Costs of normal maintenance and adjustments.•

Failures caused by any contaminated fuels, oils or lack of proper oil levels.•

Repairs or diagnostics performed by individuals other than Guardian/Generac authorized dealers not authorized in writing by Generac Power Systems.•

Failures due, but not limited, to normal wear and tear, accident, misuse, abuse, negligence or improper use. As with all mechanical devices, the Generac engines need •

periodic part(s) service and replacement to perform as designed. This warranty will not cover repair when normal use has exhausted the life of a part(s) or engine.

Failures caused by any act of God and other force majeure events beyond the manufactures control.•

Damage related to rodent and/or insect infestation.•

Products that are modified or altered in a manner not authorized by Generac in writing.•

Any incidental, consequential or indirect damages caused by defects in materials or workmanship, or any delay in repair or replacement of the defective part(s).•

Failure due to misapplication.•

Telephone, cellular phone, facsimile, internet access or other communication expenses.•

Living or travel expenses of person(s) performing service, except as specifically included within the terms of a specific unit warranty period.•

Expenses related to “customer instruction” or troubleshooting where no manufacturing defect is found.•

Rental equipment used while warranty repairs are being performed.•

Overnight freight or special shipping costs for replacement part(s).•

Overtime, holiday or emergency labor.•

Starting batteries, fuses, filters, light bulbs and engine fluids.•

WARRANTY SCHEDULE

THIS WARRANTY IS IN PLACE OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, SPECIFICALLY, GENERAC POWER SYSTEMS MAKES NO OTHER WARRANTIES

AS TO THE MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Any implied warranties which are allowed by law, shall be limited in duration to the terms

of the express warranty provided herein. Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to purchaser/

owner.

GENERAC POWER SYSTEMS ONLY LIABILITY SHALL BE THE REPAIR OR REPLACEMENT OF PART(S) AS STATED ABOVE. IN NO EVENT SHALL GENERAC POWER

SYSTEMS BE LIABLE FOR ANY INCIDENTAL, OR CONSEQUENTIAL DAMAGES, EVEN IF SUCH DAMAGES ARE A DIRECT RESULT OF GENERAC POWER SYSTEMS,

INC. NEGLIGENCE. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations may not apply to purchaser/

owner. Purchaser/owner agrees to make no claims against Generac Power Systems, Inc. based on negligence. This warranty gives purchaser/owner specific legal rights.

Purchaser/owner also may have other rights that vary from state to state.

GENERAC POWER SYSTEMS, INC.

P.O. BOX 8 • Waukesha, WI 53187

Ph: (888) GENERAC (436-3722) • Fax: (262) 544-4851