Generac XG4000-5778-2, XG4000-5778-1, 005778-2, 005778-1 Owner’s Manual

GENERAC

Owner'sIVlanual

SeriesPortabJeGenerator

introduction..............................................................................1

Readthis IVlanualThoroughly..................................................1

Safety Rules ............................................................................1

StandardsIndex.......................................................................3

Generalinformation.................................................................4

1.1 Unpacking................................................................................4

1.1.1 AccessoryBox............................................................4

1.2 Assembly.................................................................................4

1.2.1 AssemblingtheWheelKitandFrameFoot...................4

Operation................................................................................. 5

2.1 Knowthe Generator................................................................. 5

2.2 Hourmeter- No Reset.............................................................. 6

2.3 Hourmeter- With Reset............................................................6

2.4 CordSets andConnectionPlugs..............................................6

2.4.1 120VAC,20Amp, GFCIDuplexReceptacle..................6

2.4.2 120/240 VAC,20 Amp Receptacle..............................7

2.5 Howto Usethe Generator........................................................7

2.5.1 Groundingthe GeneratorWhenUsedas a Portable......7

2.5.2 Connecting the Generatorto a Building's

ElectricalSystem......................................................... 8

2.5.3 Neutralto FrameGrounding.........................................8

2.5.4 ConnectingElectrical loads.......................................... 8

2.6 Don'tOverloadthe Generator...................................................8

2.7 WattageReferenceGuide......................................................... 9

2.8 BeforeStarting the Generator................................................... 9

2.8.1 Adding EngineOil........................................................9

2.8.2 Adding Gasoline........................................................ 10

2.9 ToStartthe Engine................................................................. 10

2.10 Stoppingthe Engine............................................................... 11

2.11 Low Oil PressureShutdownSystem....................................... 11

2.11.1 Restarting.................................................................. 11

Maintenance.......................................................................... 11

3.1 Performing ScheduledMaintenance....................................... 11

3.2 MaintenanceSchedule........................................................... 11

3.3 ProductSpecifications........................................................... 11

3.3.1 GeneratorSpecifications.............................................11

3.3.2 EngineSpecifications ................................................. 11

3.3.3 EmissionsInformation................................................ 12

3.4 GeneralRecommendations.................................................... 12

3.4.1 GeneratorMaintenance............................................... 12

3.4.2 ToCleanthe Generator............................................... 12

3.4.3 EngineMaintenance................................................... 12

3.4.4 CheckingOil Level...................................................... 12

3.4.5 Changingthe Oiland OilFilter.....................................12

3.4.6 ReplacingtheSparkPlug............................................ 13

3.5 ServiceAir Filter..................................................................... 13

3.6 CleanSparkArrestor Screen.................................................. 13

3.7 General.................................................................................. 14

3.8 Long TermStorage................................................................. 14

3.9 OtherStorageTips................................................................. 14

Troubleshooting.....................................................................1,5

4.1 TroubleshootingGuide............................................................15

Notes.....................................................................................16

Warranty................................................................................18

MANUALDELUSUARIO....................................23

MANUELDEL'UTILISATEUR.............................45

iNTRODUCTiON

Thankyou for purchasingthis model by GeneracPowerSystems,

Inc. This model is a compact, high performance, air-cooled,

engine driven generatordesigned to supply electrical power to

operateelectrical loads where no utility power is availableor in

placeof utility dueto a poweroutage.

READTHiSMANUALTHOROUGHLY

If any portion of this manual is not understood, contact the

nearest Authorized Dealerfor starting, operating and servicing

procedures.

The operator is responsiblefor proper and safe use of the

equipment.We strongly recommend that the operator read this

manualandthoroughlyunderstandallinstructions beforeusingthe

equipment.Wealsostronglyrecommendinstructingother usersto

properlystart andoperatethe unit.This preparesthemifthey need

to operatethe equipmentin an emergency.

Thegeneratorcan operatesafely,efficiently andreliably only if it

is properlylocated, operatedandmaintained.Beforeoperatingor

servicingthe generator:

• Becomefamiliar with and strictly adhereto all local, stateand

nationalcodes and regulations.

• Study all safety warnings in this manual and on the product

carefully.

• Becomefamiliarwith this manualandthe unit beforeuse.

Themanufacturercannot anticipateevery possible circumstance

that might involvea hazard.The warnings inthis manual,and on

tags and decals affixedto the unit are, therefore,not all inclusive.

If using a procedure,work method or operatingtechniquethat the

manufacturerdoes not specifically recommend,ensurethat it is

safe for others. Also make sure the procedure,work method or

operatingtechniqueutilizeddoes not renderthe generatorunsafe.

THE INFORMATIONCONTAINEDHEREIN WAS BASED ON

MACHINESIN PRODUCTIONAT THE TIME OF PUBLICATION.

GENERACRESERVESTHERIGHTTO MODIFYTHISMANUALAT

ANYTIME.

SAFETYRULES

Throughoutthis publication,and on tags and decals affixedto the

generator,DANGER,WARNING,CAUTIONand NOTEblocks are

usedto alert personnelto special instructionsabout a particular

operation that may be hazardous if performed incorrectly or

carelessly. Observe them carefully. Their definitions are as

follows:

iNDICATESA HAZARDOUSSiTUATiONORACTIONWHICH,IF

NOTAVOIDED,WiLLRESULTiN DEATHORSERIOUSiNJURY.

Indicatesa hazardoussituationor actionwhich,if not

avoided, couldresultin deathor seriousinjury.

,ACAUTION!

Indicatesa hazardoussituationor action which,if not

avoided, couldresultin minoror moderateinjury.

NOTE:

Notescontainadditionalinformationimportantto a procedure

and will be foundwithin the regulartextbodyof thismanual.

These safety warnings cannot eliminate the hazardsthat they

indicate. Common sense and strict compliancewith the special

instructionswhile performing the action or service areessentialto

preventingaccidents.

Four commonly used safety symbols accompany the DANGER,

WARNINGand CAUTIONblocks. The type of information each

indicatesis as follows:

,_This symbol points out important safety

information that, if not followed, could

endanger personal safety and/or property of

others.

This symbol points out potential explosion

hazard.

i/_This symbol points out potential fire hazard.

i/_This symbol points out potential electrical

shock hazard.

GENERAL HAZARDS

• NEVERoperatein an enclosed area, in a vehicle, or indoors

EVENIFdoors and windows areopen.

• For safety reasons, the manufacturer recommendsthat the

maintenanceof this equipmentis carried out by anAuthorized

Dealer.Inspectthe generatorregularly,and contactthe nearest

AuthorizedDealerfor parts needingrepairor replacement.

• Operategeneratoronly on levelsurfacesandwhereit will notbe

exposedto excessivemoisture,dirt, dust or corrosivevapors.

• Keephands, feet, clothing, etc., awayfrom drive belts, fans,

and othermoving parts. Neverremoveany fan guardor shield

whilethe unit is operating.

• Certain parts of the generator get extremely hot during

operation. Keep clear of the generator until it has cooled to

avoidsevereburns.

• Do NOToperategeneratorinthe rain.

• Do not alter the construction of the generator or change

controlswhich might createan unsafeoperatingcondition.

• Neverstart or stop the unit with electrical loads connected

to receptaclesAND with connected devicesturned ON. Start

the engine and let it stabilize before connecting electrical

loads. Disconnectall electricalloads beforeshutting downthe

generator.

• Do not insert objectsthrough unit's cooling slots.

• When working on this equipment, remain alert at all times.

Never work on the equipment when physically or mentally

fatigued.

* Neverusethe generatoror anyof its parts as a step. Stepping

on the unit can stress and break parts, and may result in

dangerousoperating conditions from leaking exhaust gases,

fuel leakage,oil leakage,etc.

NOTE:

This generatoris equipped with a spark arrestormuffler. The

spark arrestor must bemaintained in effective working order

by the owner/operator. In the State of California, a spark

arrestor is requiredby law (Section4442 ofthe California

PublicResourcesCode).Otherstates may havesimilarlaws.

Federal lawsapply on federallands.

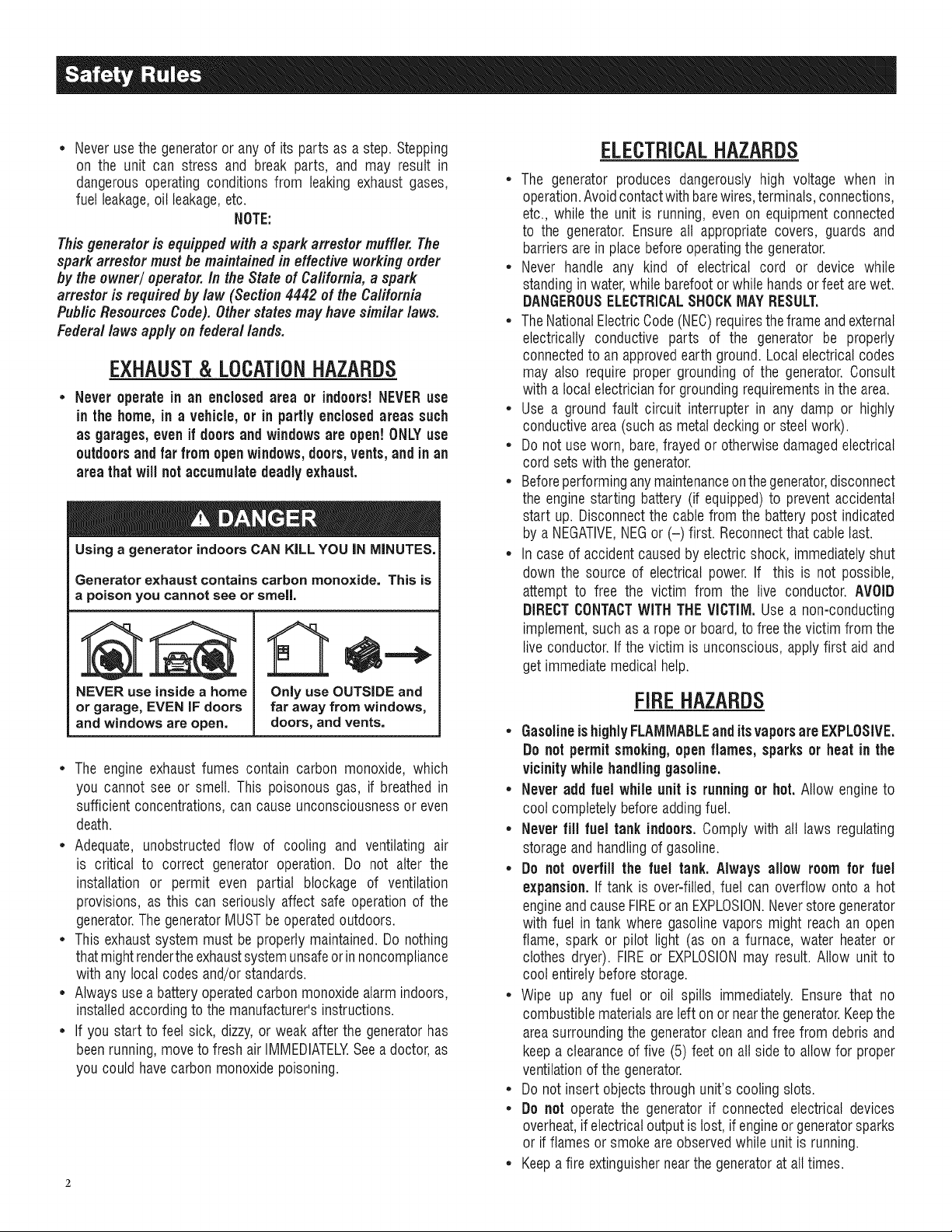

EXHAUST & LOCATIONHAZARDS

• Never operate in an enclosed area or indoors!NEVERuse

in the home,in a vehicle,or in partlyenclosedareas such

as garages, even if doors and windowsare open! ONLYuse

outdoors and far from openwindows,doors,vents,andinan

areathat will notaccumulatedeadly exhaust.

Using a generator indoors CAN KiLL YOU JN MINUTES.

Generator exhaust contains carbon monoxide. This is

a poison you cannot see or smell.

NEVER use insidea home

or garage, EVEN JFdoors

and windows are open.

* The engine exhaustfumes contain carbon monoxide, which

you cannot see or smell. This poisonous gas, if breathedin

sufficientconcentrations,can causeunconsciousnessor even

death.

* Adequate, unobstructed flow of cooling and ventilating air

is critical to correct generator operation. Do not alter the

installation or permit even partial blockage of ventilation

provisions, as this can seriously affect safe operationof the

generator.ThegeneratorMUSTbeoperatedoutdoors.

* This exhaustsystemmust be properly maintained.Do nothing

that mightrendertheexhaustsystemunsafeorinnoncompliance

with any localcodes and/orstandards.

* Always usea batteryoperatedcarbonmonoxidealarmindoors,

installedaccordingto themanufacturer'sinstructions.

* If you start to feet sick, dizzy,or weak after the generatorhas

beenrunning,moveto fresh air IMMEDIATELYSeea doctor,as

you couldhave carbonmonoxidepoisoning.

Only use OUTSIDE and

far away from windows,

doors, and vents.

ELECTRICALHAZARDS

* The generator produces dangerously high voltage when in

operation.Avoidcontactwith barewires,terminals,connections,

etc., while the unit is running,even on equipmentconnected

to the generator. Ensureall appropriate covers, guards and

barriersarein placebeforeoperatingthe generator.

* Never handle any kind of electrical cord or device while

standinginwater,while barefootorwhile handsor feet arewet.

DANGEROUSELECTRICALSHOCKMAYRESULT.

* TheNationalElectricCode(NEC)requirestheframe andexternal

electrically conductive parts of the generator be properly

connectedto an approvedearth ground.Local electricalcodes

may also require proper grounding of the generator.Consult

with a localelectricianfor groundingrequirementsin thearea.

* Use a ground fault circuit interrupter in any damp or highly

conductivearea(such as metaldecking or steelwork).

* Do not useworn, bare,frayed or otherwise damagedelectrical

cord setswith the generator.

* Beforeperforminganymaintenanceonthegenerator,disconnect

the enginestarting battery (if equipped)to preventaccidental

start up. Disconnectthe cablefrom the batterypost indicated

by a NEGATIVE,NEGor (-) first. Reconnectthatcable last.

* In caseof accident causedby electricshock, immediatelyshut

down the source of electrical power.If this is not possible,

attempt to free the victim from the live conductor. AVOID

DIRECTCONTACTWITH THEVICTIM, Use a non-conducting

implement,such asa rope or board,to freethevictim fromthe

live conductor.If the victim is unconscious, applyfirst aidand

getimmediatemedical help.

FiREHAZARDS

• GasolineishighlyFLAMMABLEand itsvaporsare EXPLOSIVE.

Do not permitsmoking,open flames, sparksor heat in the

vicinitywhilehandlinggasoline.

• Never add fuel while unit is runningor hot.Allow engineto

cool completelybeforeaddingfuel.

• Never fill fuel tankindoors, Comply with all laws regulating

storageand handlingof gasoline.

• Do not overfill the fuel tank. Always allow roomfor fuel

expansion. If tank is over=filled,fuel can overflow onto a hot

engineandcauseFIREor an EXPLOSION.Neverstoregenerator

with fuel in tankwhere gasolinevapors might reach an open

flame, spark or pilot light (as on a furnace, water heateror

clothes dryer). FIREor EXPLOSIONmay result. Allow unit to

cool entirelybeforestorage.

• Wipe up any fuel or oil spills immediately. Ensure that no

combustiblematerialsareleft on or nearthe generator.Keepthe

areasurroundingthe generatorcleanandfree from debrisand

keepa clearanceof five (5) feet on all side to allow for proper

ventilationof the generator.

• Do not insert objectsthrough unit's cooling slots.

• Do not operatethe generator if connected electrical devices

overheat,if electricaloutputislost,if engineor generatorsparks

or if flames or smoke are observedwhile unit is running.

• Keepafire extinguishernearthe generatoratall times.

STANDARDS/#DEX

Inthe absenceof pertinentstandards,codes,regulationsandtaws,

the publishedinformation listedbelowmay be usedas a guideline

foroperationofthis equipment.Alwaysreferencethelatestrevision

availablefor the standardslisted.

1. NationalFireProtectionAssociation(NFPA)70:TheNATIONAL

ELECTRICCODE(NEC)availablefrom www.nfpa.org

2. NationalFire ProtectionAssociation(NFPA)5000: BUILDING

CONSTRUCTIONAND SAFETYCODEavailablefrom www.

nfpa.org

3. InternationalBuildingCodeavailablefrom www.iccsafe.org

4. Agricultural Wiring Handbookavailablefrom www.rerc.org ,

Rural ElectricityResourceCouncil P.O.Box 309 Wilmington,

OH45177-0309

5. ASAEEP-364.2InstallationandMaintenanceof FarmStandby

Electric Power available from www.asabe.org, American

Society of Agricultural & Biological Engineers2950 Niles

Road,St. Joseph,MI 49085

This list is not all inclusive.Checkwith theAuthority HavingLocal

Jurisdiction (AHJ)for any localcodes or standardswhich maybe

applicableto your jurisdiction.

MODELNO:

SERIALNO:

CALIFORNIAPROPOSITION55 WARNING

Engineexhaustandsomeof its constituentsareknown

to theStateof Californiato causecancer,birth defects

and otherreproductiveharm.

CALIFORNIAPROPOSITION55 WARNING

This productcontainsor emitschemicalsknown tothe

Stateof Californiato causecancer,birth defects and

otherreproductiveharm.

UnitID

Locations

1.1 UNPACKING

• Removeall packagingmaterial.

• Removeseparateaccessorybox.

• Removecarton off the generator.

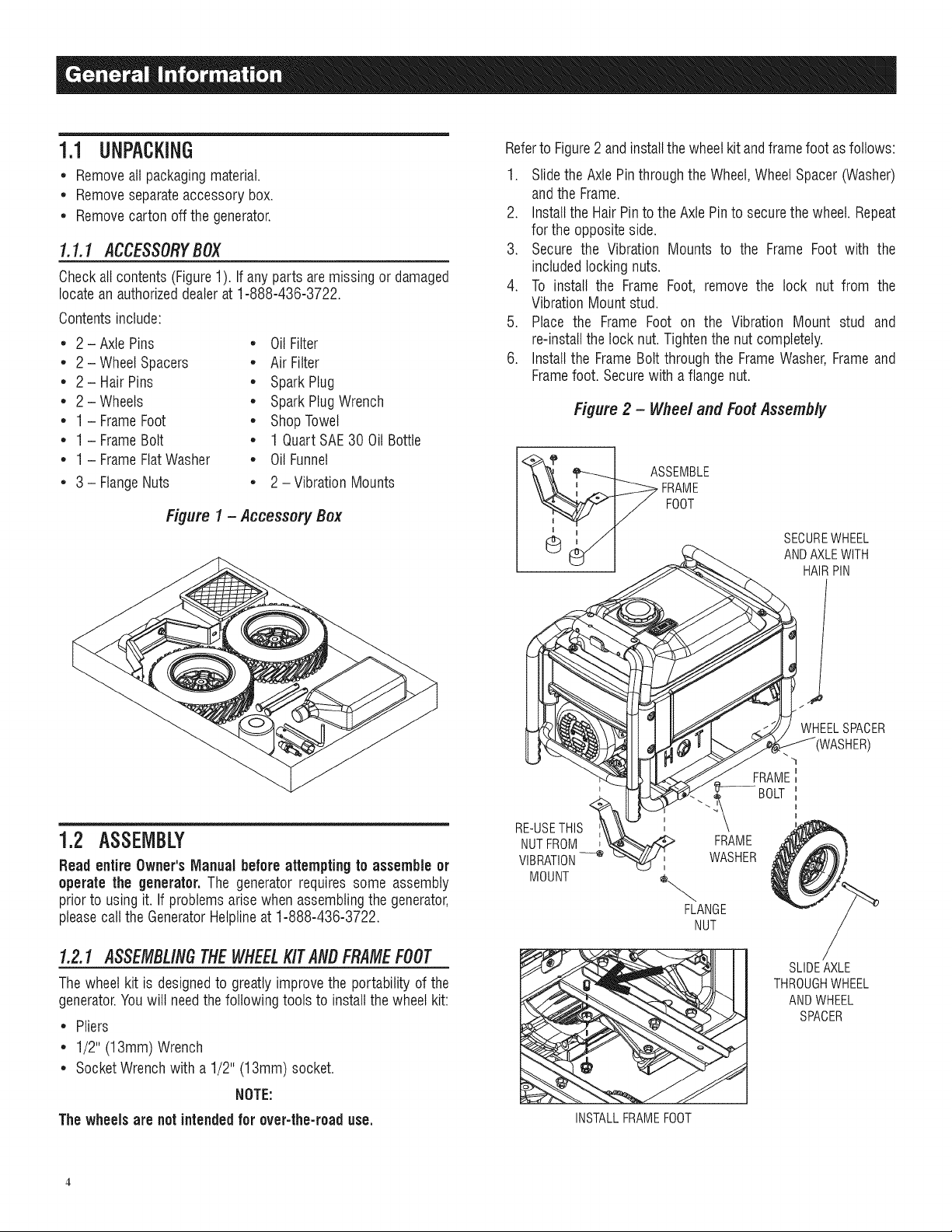

1.1.1 ACCESSORYBOX

Checkall contents(Figure1). If anyparts aremissingor damaged

locatean authorizeddealerat1-888-436-3722.

Contentsinclude:

• 2-Axle Pins • OilFilter

• 2- WheelSpacers • Air Filter

• 2- HairPins • SparkPlug

• 2- Wheels • SparkPlugWrench

• 1- FrameFoot • ShopTowel

• 1- FrameBolt • 1 QuartSAE30Oil Bottle

• 1- FrameFlatWasher • OilFunnel

• 3- FlangeNuts • 2 - VibrationMounts

Figure 1 - Accessory Box

Referto Figure2andinstallthe wheelkit andframefoot asfollows:

1. Slidethe AxlePinthroughthe Wheel,WheelSpacer(Washer)

andthe Frame.

2. Installthe Hair Pintothe AxlePinto securethewheel. Repeat

for the oppositeside.

3. Secure the Vibration Mounts to the Frame Foot with the

includedlocking nuts.

4. To install the Frame Foot, remove the lock nut from the

VibrationMount stud.

5. Place the Frame Foot on the Vibration Mount stud and

re-installthelock nut.Tightenthe nutcompletely.

6. Installthe FrameBolt through the FrameWasher,Frameand

Framefoot. Securewith a flangenut.

Figure 2 - Wheel and Foot Assembly

ASSEMBLE

FRAME

FOOT

SECUREWHEEL

ANDAXLEWITH

HAIRPIN

1.2 ASSEMBLY

Readentire Owner's Manual beforeattemptingto assemble or

operatethe generator. The generatorrequires some assembly

priorto usingit. If problems arise whenassemblingthegenerator,

pleasecall the GeneratorHelplineat 1-888-436-3722.

1.2.1 ASSEMBLINGTHEWHEELKITANBFRAMEFOOT

Thewheel kit is designedto greatly improvethe portability of the

generator.Youwilt needthe following tools to installthewheel kit:

• Pliers

• 1/2" (13mm)Wrench

• SocketWrenchwith a1/2" (13mm)socket.

NOTE:

The wheelsare notintendedfor over-the-roaduse.

RE-USETHIS

NUTFROM

VIBRATION--_

MOUNT

t

WHEELSPACER

FRAME

BOLT

FRAME

WASHER

FLANGE

NUT

SLIDEAXLE

THROUGHWHEEL

ANDWHEEL

SPACER

INSTALLFRAMEFOOT

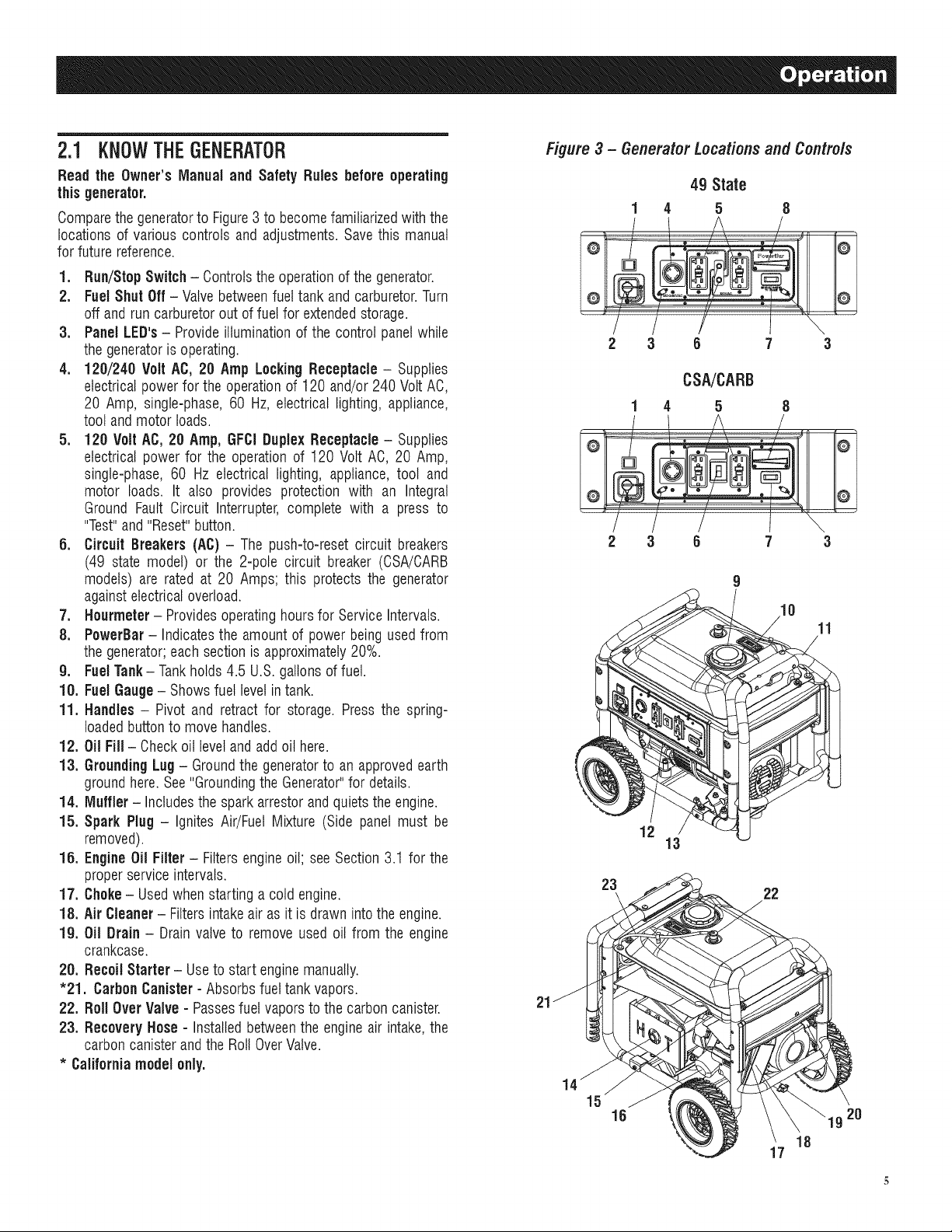

2.1 KNOWTHEGENERATOR

Read the Owner'sIVlanualand Safety Rules before operating

thisgenerator.

Comparethegeneratorto Figure3to becomefamiliarizedwith the

locations of various controls and adjustments.Savethis manual

for future reference.

1. Run/StopSwitch - Controlsthe operationof the generator.

2. FuelShut Off - Valvebetweenfueltank andcarburetor.Turn

off and run carburetoroutof fuelfor extendedstorage.

3. Panel LED's- Provideilluminationof the control panelwhile

thegeneratoris operating.

4. 120/240 Volt AC, 20 Amp LockingReceptacle- Supplies

electricalpower for the operationof 120 and/or 240 VoltAC,

20 Amp, single-phase,60 Hz, electrical lighting, appliance,

tool andmotor loads.

5. 120 Volt AC,20 Amp, GFCiDuplexReceptacle - Supplies

electrical power for the operationof 120 Volt AC, 20 Amp,

single-phase, 60 Hz electrical lighting, appliance,tool and

motor loads. It also provides protection with an Integral

Ground Fault Circuit Interrupter, complete with a press to

"Test"and "Reset"button.

6. CircuitBreakers(AC) - The push-to-reset circuit breakers

(49 state model) or the 2-pole circuit breaker (CSA/CARB

models) are rated at 20 Amps; this protects the generator

againstelectricaloverload.

7. Hourmeter- Providesoperatinghours for Service Intervals.

8. PowerBar- Indicatesthe amountof power being used from

thegenerator;each section is approximately20%.

g. FuelTank- Tankholds4.5 U.S.gallonsof fuel.

10. FuelGauge- Showsfuel levelin tank.

11. Handles - Pivot and retractfor storage. Press the spring-

loadedbuttonto move handles.

12. Oil Fill- Checkoil level andadd oil here.

13. Grounding Lug- Groundthe generatorto an approvedearth

groundhere.See"GroundingtheGenerator"for details.

14. Muffler - Includesthe sparkarrestor andquietsthe engine.

15. Spark Plug- Ignites Air/Fuel Mixture (Side panel must be

removed).

15. EngineOil Filter- Filtersengineoil; seeSection 3.1 for the

properservice intervals.

17. Choke- Usedwhenstarting a cold engine.

18, AirCleaner- Filtersintakeair as it is drawn intothe engine.

19. Oil Drain- Drain valveto remove used oil from the engine

crankcase.

20. RecoilStarter - Useto start enginemanually.

"21. CarbonCanister- Absorbs fuel tank vapors.

22. Roll OverValve - Passesfuel vaporsto the carboncanister.

23. Recovery Hose- Installedbetweenthe engineair intake,the

carboncanister andthe RollOverValve.

* Californiamodelonly,

Figure 3 - Generator Locations and Controls

49 State

1 4 5 8

@ @

2 3 6 7 3

CSA/CARB

1 4 5 8

2 3 6 7 3

12

13

23

21

22

11

15

16 20

18

17

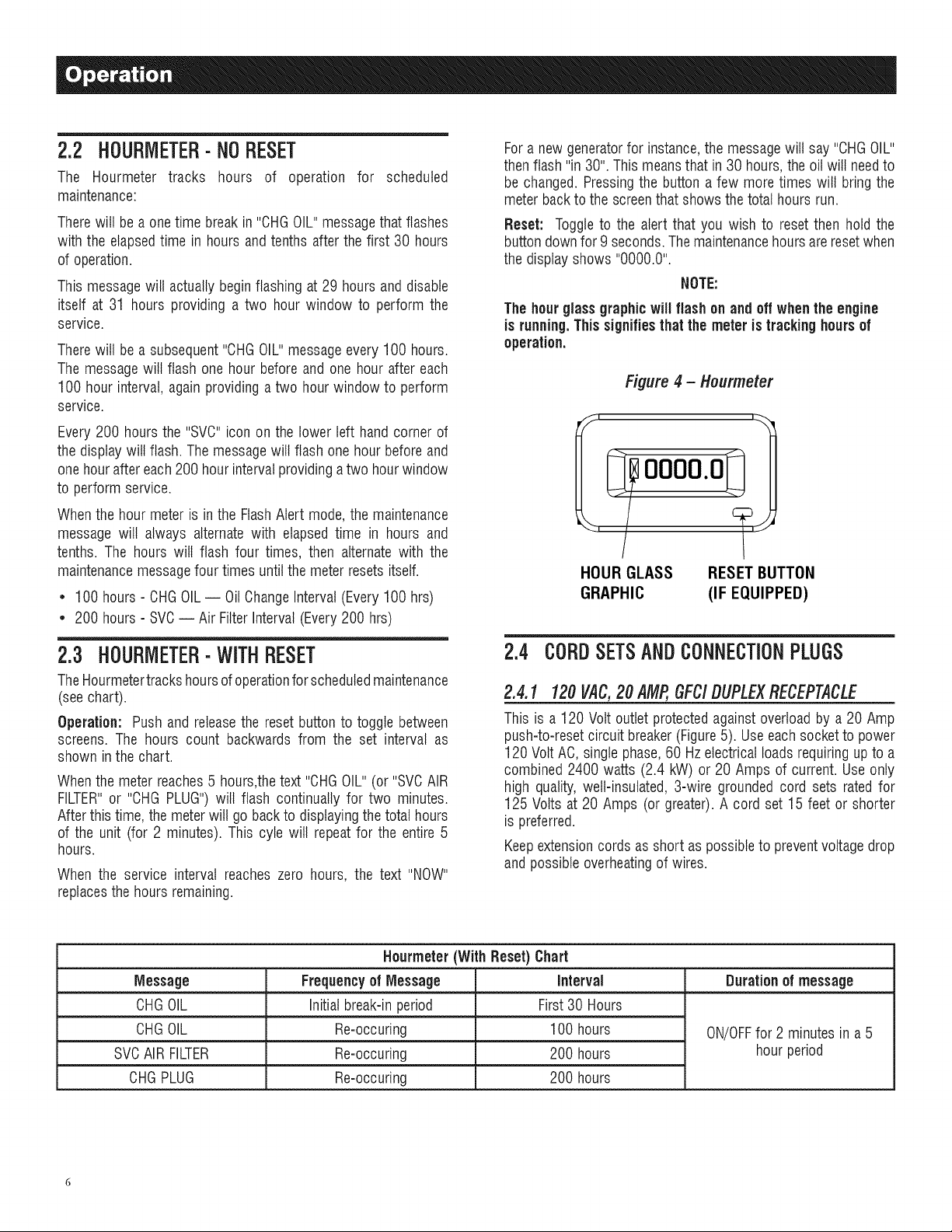

2.2 HOURMETER=NORESET

The Hourmeter tracks hours of operation

maintenance:

Therewill be a onetime breakin "CHGOIL"messagethat flashes

with the elapsedtime in hours and tenths after thefirst 30 hours

of operation.

This messagewill actuallybeginflashing at 29 hoursand disable

itself at 31 hours providing a two hour window to perform the

service.

Therewill be a subsequent"CHGOIL"messageevery 100 hours.

Themessage wilt flash one hour before and onehour after each

100 hour interval,again providinga two hour window to perform

service.

Every200 hours the "SVC"icon on the lower left hand corner of

the display will flash. Themessagewill flash one hourbefore and

onehourafter each200 hourintervalprovidingatwo hourwindow

to perform service.

Whenthe hour meter is inthe FlashAlert mode, the maintenance

message will always alternate with elapsedtime in hours and

tenths. The hours wilt flash four times, then alternate with the

maintenancemessagefour times untilthe meter resets itself.

,, 100 hours - CHGOIL-- Oil ChangeInterval(Every100 hrs)

* 200 hours- SVC-- Air FilterInterval(Every200 hrs)

for scheduled

Fora newgeneratorfor instance,the messagewill say "CHGOIL"

thenflash "in30". This meansthat in 30 hours, the oil wilt needto

be changed. Pressingthe button a few more times will bring the

meter backto the screenthat shows the total hoursrun.

Reset: Toggleto the alert that you wish to reset then hold the

buttondownfor 9 seconds.Themaintenancehoursareresetwhen

thedisplay shows "0000.0".

NOTE:

Thehourglass graphic willflashon and off whenthe engine

is running.Thissignifiesthatthe meter is trackinghours of

operation.

Figure 4 - Hourmeter

OOOO'O

HOUR GLASS RESETBUTTON

GRAPHIC (IF EQUIPPED)

2.3 HOURMETEB=WITHRESET

TheHourmetertrackshoursof operationforscheduledmaintenance

(seechart).

Operation: Pushand releasethe reset button to toggle between

screens. The hours count backwards from the set interval as

shown in the chart.

Whenthe meter reaches5 hours,thetext"CHGOIL"(or"SVCAIR

FILTER"or "CHG PLUG")will flash continually for two minutes.

Afterthis time, the meterwill go backto displayingthe total hours

of the unit (for 2 minutes). This cyle will repeatfor the entire 5

hours.

When the service interval reacheszero hours, the text "NOW"

replacesthe hours remaining.

Nourmeter(With Reset) Chart

Message Frequencyof Message Interval Duration of message

CHGOIL Initialbreak-inperiod First30 Hours

CHGOIL Re-occuring 100 hours ON/OFFfor 2 minutes in a 5

SVCAIR FILTER Re-occuring 200 hours hour period

CHGPLUG Re-occuring 200 hours

2.4 CORDSETSANDCONNECTIONPLUGS

2.4.1 120VAC,20AMP,GFC/DUPLEXRECEPTACLE

This is a 120 Volt outlet protectedagainst overloadby a 20 Amp

push-to-resetcircuitbreaker (Figure5). Useeach socketto power

120 VoltAC, singlephase,60 Hzelectrical loadsrequiringupto a

combined 2400 watts (2.4 kW) or 20 Amps of current.Use only

high quality, welt-insulated,3-wire groundedcord sets ratedfor

125 Volts at 20 Amps (or greater).A cord set15 feet or shorter

is preferred.

Keepextensioncords as short as possibleto preventvoltagedrop

and possibleoverheatingof wires.

Figure 5 - 120 Vo/t AC, 20 Amp, GFC/ Duplex Receptac/e

2.4.2 120/240 VAC,20 AMPRECEPTACLE

Use a NEMA L14-20 plug with this receptacle (rotate to lock!

unlock). Connecta suitable4-wire groundedcord set to the plug

andto thedesiredtoad.Thecordset should be ratedfor 250 Volts

ACat 20 Amps (or greater)(Figure6).

_t he engine exhaust fumes contain carbon

monoxide, which can you cannot see or smell.

This poisonous gas, if breathed in sufficient

concentrations, can cause unconsciousness or

even death.

_t Adequate, unobstructed flow of cooling and

ventilating air is critical to correct generator

operation. Do not alter the installation or permit

even partial blockage of ventilation provisions,

as this can seriously affect safe operation

of the generator. The generator MUST be

operated outdoors.

_t This exhaust system must be properly

maintained. Do nothing that might render the

exhaust system unsafe or in noncompliance

with any local codes and/or standards.

AIways use a battery operated carbon

monoxide alarm indoors, installed according to

the manufacturers instructions.

Figure 6 - 120/240 VoRAC, 20 Amp Receptac/e

Use this receptacleto operate120 Volt AC, 60 Hz, singlephase

loads requiringup to 2400 watts (2.4 kW) of power at 20 Amps

or 240 Volt AC, 60 Hz,single phase loads requiring up to 4000

watts (4.0 kW) of powerat 16.6 Amps. The outletis protectedby

a circuit breaker.

2,5 HOWTOUSETHEGENERATOR

Seethe "ToStart the Engine"sectionfor howto safelystart and

stop the generator and how to connect and disconnect loads. If

there are any problems operatingthe generator,pleasecall the

generatorhelplineat 1-888-436-3722.

Never operate in an encJosed area or indoors!

NEVER use in the home, in a vehicJe, or in

partly encJosed areas such as garages, EVEN

iF doors and windows are open! ONLY use

outdoors and far from open windows, doors,

vents, and in an area that will not accumulate

deadly exhaust.

Using a generator indoors CAN KiLL YOU iN MINUTES.

Generator exhaust contains carbon monoxide. This is

a poison you cannot see or smell.

NEVER use inside a home

or garage, EVEN iF doors

and windows are open.

Only use OUTSIDE and

far away from windows,

doors, and vents.

2.5.1 GROUNDINGTHEGENERATORWHENUSEDASA

PORTABLE

This generator has an equipment ground that connects the

generatorframe componentsto the groundterminals on the AC

output receptacles (see NEC 250.34 (A) for explanation).This

allows the generatorto be used as a portable without grounding

theframe ofthe generatoras specifiedin NEC250.34.

SpecialRequirements

There may be Federalor State Occupational Safety and Health

Administration(OSHA)regulations,localcodes, or ordinancesthat

applyto the intendeduse ofthe generator.

Pleaseconsult a qualified electrician, electrical inspector, or the

local agencyhavingjurisdiction:

* In someareas,generatorsarerequiredtoberegisteredwith local

utilitycompanies.

* If the generatoris used at a construction site, there may be

additionalregulationswhich mustbe observed.

2.5.2 CONNECTINGTHEGENERATORTOA BU/LD/NG'S

ELECTRICALSYSTEM

Connectionsfor standby power to a building's electrical system

must be made by a qualifiedelectricianand in strict compliance

with all national and local electrical codes and laws. The

connectionmust isolatethe generatorpowerfrom utility power or

otheralternativepowersources.

NOTE:

Becausethe generatorequipment groundis bondedto the AC

neutral wires in thegenerator(see Figure8), either a 3-pole

transferswitchor a 2 pole transferswitchwith a switching

neutralkit is requiredto connectthisgenerator to a building

load. Inthis application the generator becomes a separately

derived system(seeNEC250.20 (D)), and mustbegrounded

in accordancewith thenationalorlocalelectrical code

requirements.

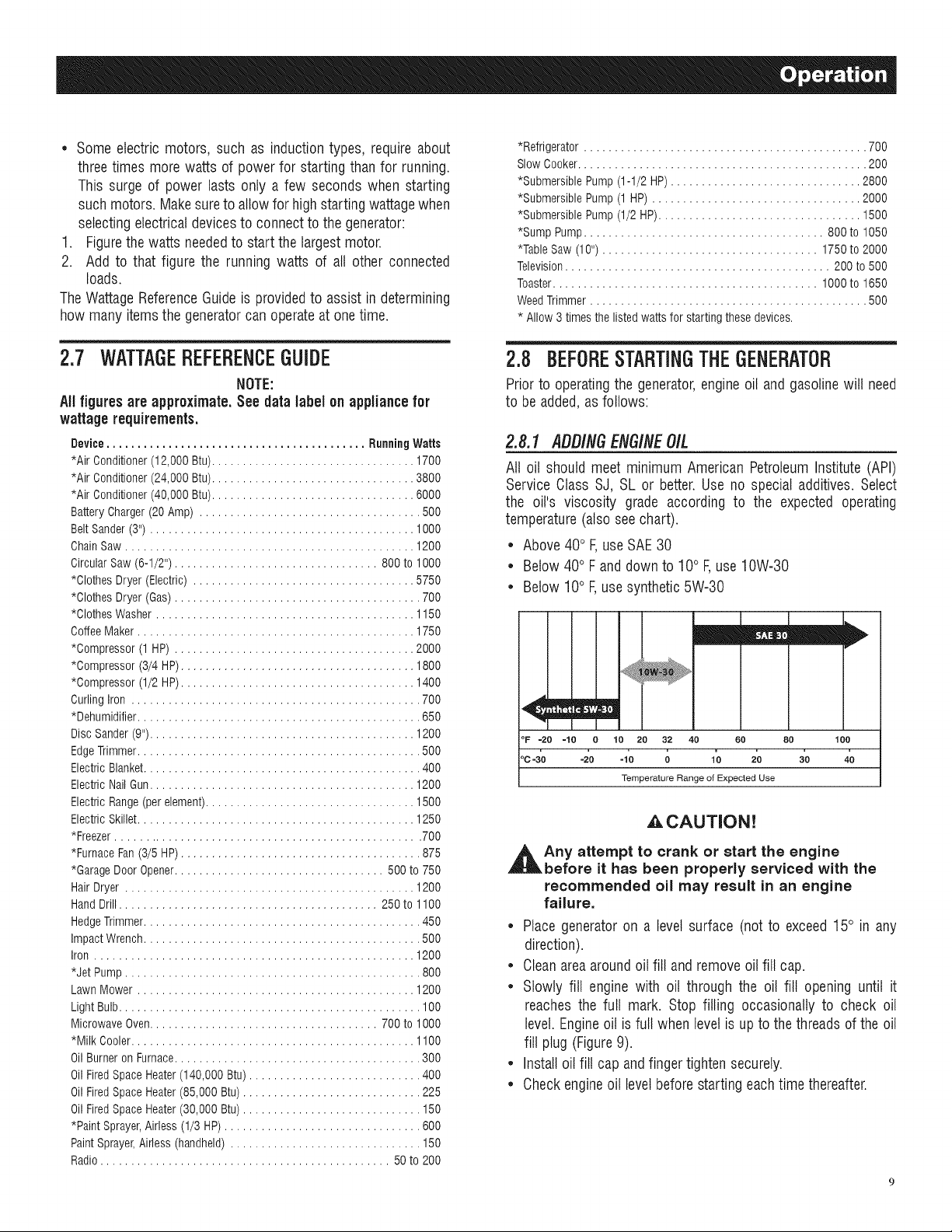

GroundingtheGeneratorina BuildingStandbyApplication

The National Electrical Code requires that the frame and

external electrically conductiveparts of this generator be

properlyconnectedto an approvedearth ground (Figure 7).

Local electrical codes also require grounding of the unit. For

that purpose,connecting a No.10 AWG (AmericanWire Gauge)

strandedcopperwire to the groundinglug and to an earth-driven

copper or brass grounding rod (electrode) provides adequate

protection against electrical shock. However, local codes may

vary widely. Consultwith a local electrician for grounding

requirementsin the area.

Proper grounding of the generator will help preventelectrical

shockin the event of a ground fault condition in the generator

or in connectedelectrical devices. Proper grounding also helps

dissipate static electricity, which often builds up in ungrounded

devices.

Figure7 - Groundingthe Generator

Figure8 - Neutral to FrameGroundWires

DONOTDISCARD

THESEWIRES!

NEUTRALTO

FRAMEGROUND

//_Failure to reconnect these wires may create a

potential shock hazard when the generator is

running!

2.5.4 CONNECtiNGELECTR/CALLOADS

DONOTconnect 240 Volt loadsto 120 Voltreceptacles.

DONOTconnect 3 phaseloadsto the generator.

DONOTconnect 50 Hzloadsto the generator.

* Let engine stabilize and warm up for a few minutes after

starting.

* Plug in and turn on the desired 120 or 240 Volt AC, single

phase,60 Hzelectrical loads.

* Add up the ratedwatts (or amps)of all loadsto be connected

at one time. This total should no be greaterthan (a)the rated

wattage/amperagecapacity of the generator or (b) circuit

breakerratingofthe receptaclesupplyingthepower.See"Don't

OverloadtheGenerator

CONNECTGENERATORGROUNDHERE

2.5.3 NEUTRALTOFRAMEGROUNDING

If service work is performed on the alternator,DO NOTdiscard

the white jumper wires from the terminal blockto the alternator

ground, located on the rear bearing carrier. Always make sure

the wires are properlyconnected beforeusingthe generatorafter

alternatorservicework is done (Figure8).

2.6 DON'TOVERLOADTHEGENERATOR

Overloadinga generatorin excess of its ratedwattage capacity

can result in damageto the generatorandto connectedelectrical

devices.Observethefollowing to preventoverloadingthe unit:

* Addupthetotal wattageofallelectricaldevicesto be connected

at one time. This total should NOT be greater than the

generator'swattagecapacity.

* The ratedwattageof lights can betaken from light bulbs. The

ratedwattage of tools, appliancesand motors can usually be

foundon a data labelor decal affixedto the device.

* If the appliance,tool or motor does not give wattage,multiply

voltstimes ampereratingto determinewatts (voltsx amps =

watts).

• Some electric motors, such as inductiontypes, requireabout

threetimes more watts of powerfor starting than for running.

This surge of power lasts only a few seconds when starting

such motors. Makesureto allowfor highstarting wattagewhen

selectingelectricaldevicesto connectto the generator:

1. Figurethewatts neededto start thelargest motor.

2. Add to that figure the running watts of all other connected

loads.

TheWattageReferenceGuideis providedto assist in determining

howmany itemsthe generatorcan operateat onetime.

*Refrigerator .............................................. 700

Slow Cooker............................................... 200

*Submersible Pump (1-1/2 HP)............................... 2800

*Submersible Pump (1 HP) .................................. 2000

*Submersible Pump (1/2 HP)................................. 1500

*Sump Pump....................................... 800to 1050

*Table Saw (10") ................................... 1750 to 2000

Television........................................... 200 to 500

Toaster........................................... 1000 to 1650

WeedTrimmer ............................................. 500

* Allow 3 times the listed watts for starting these devices.

2.7 WATTAGEREFERENCEGUIDE

NOTE:

Allfigures are approximate. Seedata labelon appliancefor

wattage requirements.

Device.......................................... RunningWatts

*Air Conditioner(12,000 Btu)................................. 1700

*Air Conditioner(24,000 Btu)................................. 3800

*Air Conditioner(40,000 Btu)................................. 6000

Battery Charger(20 Amp) .................................... 500

Belt Sander (3") ........................................... 1000

Chain Saw............................................... 1200

Circular Saw (6-1/2") ................................. 800 to 1000

*Clothes Dryer (Electric) .................................... 5750

*Clothes Dryer (Gas) ........................................ 700

*Clothes Washer .......................................... 1150

CoffeeMaker ............................................. 1750

*Compressor (1HP) ....................................... 2000

*Compressor (3/4 HP)...................................... 1800

*Compressor (1/2 HP)...................................... 1400

OurlingIron ............................................... 700

*Dehumidifier.............................................. 650

Disc Sander (9")........................................... 1200

EdgeTrimmer.............................................. 500

Electric Blanket............................................. 400

Electric NailGun........................................... 1200

Electric Range(per element).................................. 1500

Electric Skillet............................................. 1250

*Freezer.................................................. 700

*Furnace Fan(3/5 HP)....................................... 875

*Garage Door Opener.................................. 500 to 750

Hair Dryer ............................................... 1200

HandDrill .......................................... 250to 1100

HedgeTrimmer............................................. 450

Impact Wrench............................................. 500

Iron .................................................... 1200

*Jet Pump ................................................ 800

Lawn Mower ............................................. 1200

Light Bulb................................................. 100

Microwave Oven..................................... 700 to 1000

*Milk Cooler.............................................. 1100

OilBurner on Furnace........................................ 300

OilFired Space Heater(140,000 Btu)............................ 400

OilFired Space Heater(85,000 Btu)............................. 225

OilFired Space Heater(30,000 Btu)............................. 150

*Paint Sprayer,Airless (1/3 HP)................................ 600

PaintSprayer,Airless (handheld) ............................... 150

Radio ............................................... 50 to 200

2.8 BEFORESTARTINGTHEGENERATOR

Prior to operatingthe generator,engineoil and gasolinewill need

to beadded,as follows:

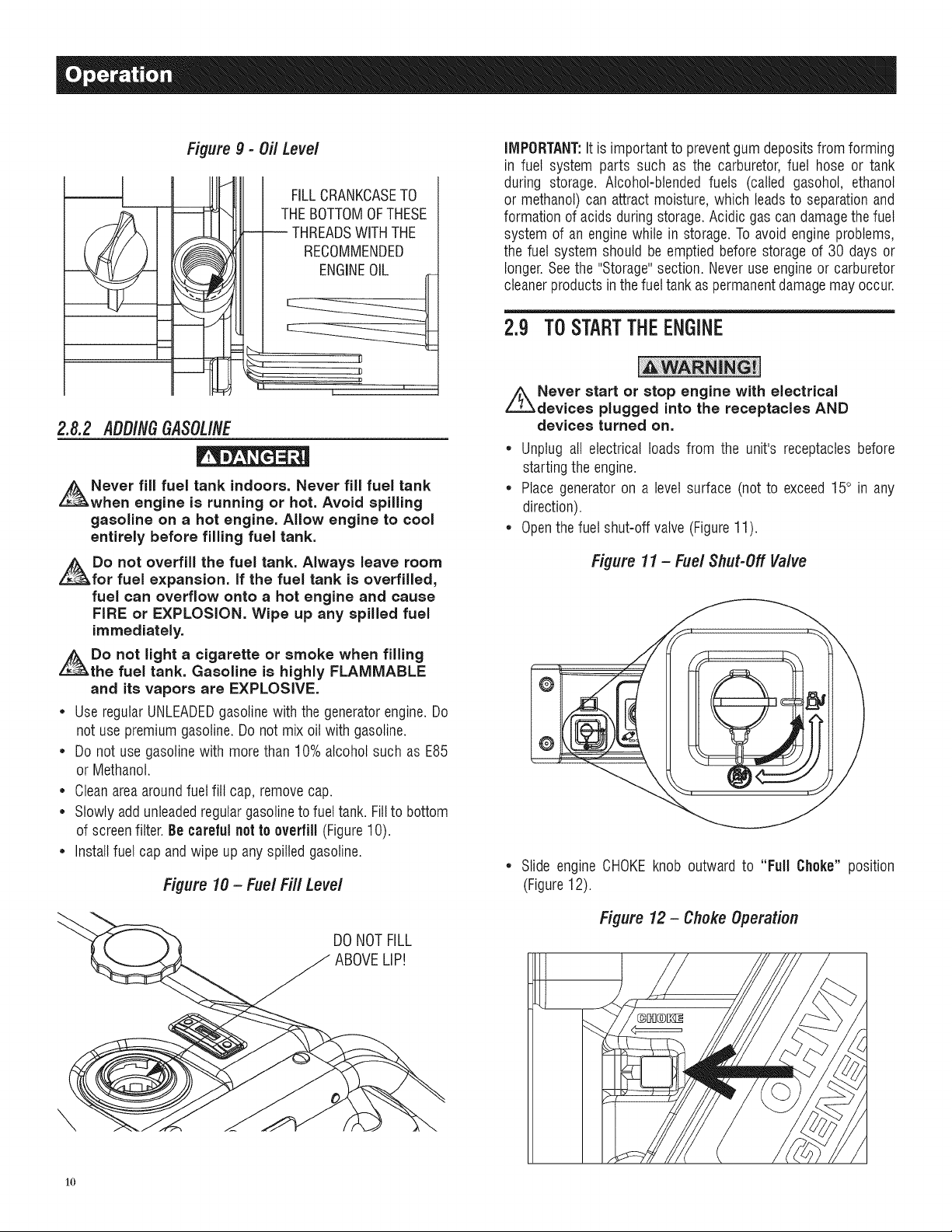

2.8.1 ADD/NGENG/NEO/L

All oil should meet minimum American PetroleumInstitute (API)

Service Class SJ, SL or better.Useno special additives. Select

the oil's viscosity grade according to the expected operating

temperature(also seechart).

• Above40° F,useSAE30

• Below40° Fand downto 10° F,use10W-30

• Below 10° F,usesynthetic5W-30

mEm

7I

°F -20 -!0 O 10 20 32 40 60 80 leo

oc-3'o -_o -;o ; 1'0 2'0 3'o 4?

Temperature Range of Expected Use

,&,CAUTION!

_t ny attempt to crank or start the engine

before it has been properly serviced with the

recommended oil may result in an engine

failure.

• Place generatoron a level surface (not to exceed15° in any

direction).

• Cleanareaaroundoil fill and removeoil fill cap.

• Slowly fill engine with oil through the oil fill opening until it

reaches the full mark. Stop filling occasionally to check oil

level. Engineoil isfull when levelis up to thethreadsof the oil

fill plug (Figure9).

• Installoil fill cap andfinger tightensecurely.

• Checkengineoil levelbeforestarting eachtime thereafter.

Figure g - Oil Level

m

THEBOTTOMOFTHESE

- -- THREADSWITHTHE

FILLCRANKCASETO

RECOMMENDED

ENGINEOIL

IMPORTANT:Itis important to preventgum depositsfromforming

in fuel system parts such as the carburetor,fuel hose or tank

during storage. Alcohol-blendedfuels (called gasohol, ethanol

or methanol)can attract moisture, which leadsto separationand

formationof acids duringstorage.Acidic gascandamagethefuel

system of an enginewhile in storage.Toavoid engineproblems,

the fuel system should be emptiedbefore storage of 30 days or

longer.Seethe "Storage"section. Neveruseengineor carburetor

cleanerproducts inthefueltank aspermanentdamagemay occur.

m

m

V ,

2.8,2 ADD/fiGGASOLINE

Never fill fuel tank indoors. Never fill fuel tank

when engine is running or hot. Avoid spilling

gasoline on a hot engine. Allow engine to cool

entirely before filling fuel tank.

z_Do not overfill the fuel tank. Always leave room

for fuel expansion. If the fuel tank is overfilled,

fuel can overflow onto a hot engine and cause

FiRE or EXPLOSION. Wipe up any spilled fuel

immediately.

Do not light a cigarette or smoke when filling

the fuel tank. Gasoline is highly FLAMMABLE

and its vapors are EXPLOSIVE.

• UseregularUNLEADEDgasofinewith the generatorengine.Do

not usepremiumgasoline.Do not mix oilwith gasoline.

• Do not use gasolinewith more than 10% alcohol such as E85

or Methanol.

• Cleanareaaroundfuel fill cap, removecap.

• Slowlyaddunleadedregulargasolineto fueltank. Fillto bottom

of screenfilter.Be carefulnotto overfill (Figure10).

• Installfuel cap andwipe up any spilled gasoline.

Figure 10 - Fuel Fill Level

2.9 TOSTARTTHEENGINE

//_Never start or stop engine with electrical

devices plugged into the receptacles AND

devices turned on.

• Unplug all electrical loads from the unit's receptaclesbefore

startingthe engine.

• Place generatoron a levelsurface (not to exceed15° in any

direction).

• Openthefuel shut-off valve (Figure11).

Figure 11 - Fuel Shut-Off Valve

Slide engine CHOKEknob outward to "FullChoke"position

(Figure12).

Figure 12- Choke Operation

DONOTFILL

ABOVELIP!

\

1o

NOTE:

The engine switchmustbe in the ONposition.

* Tostart manually,firmly grasp therecoil handleand pull slowly

until increasedresistance is felt. Pull rapidly up and away to

start engine. Then follow the same choke sequence listed

above.

* When the engine starts, slide choke knob to "1/2 Choke"

position untilthe engine runssmoothly andthenfully in to the

"Run" position. If enginefalters, slide chokeknob backout to

"1/2 Choke"position until the engine runs smoothly and then

to "Run" position.

NOTE:

If engine fires,but doesnot continuetorun,pull chokeknobto

"Full Choke"and repeatstartinginstructions.

A, CAUTION!

,_Do not overload the generator. Also, do

not overload individual panel receptacles.

These outlets are protected against overload

with push=to=reset=type circuit breakers, if

amperage rating of any circuit breaker is

exceeded, that breaker opens and electrical

output to that receptacle is lost. Read "Don't

Overload the Generator" carefully.

3.1 PEBFOBIVlINGSCHEDULEDMAINTENANCE

It is importantto performserviceas specified in the Maintenance

Schedulefor proper generatoroperation, and to ensure that the

generatorcomplieswith the applicableemissionstandardsfor the

durationof its usefullife. Serviceand repairsmaybe performedby

anycapable personor repairshop. Additionally,emissionscritical

maintenancemust be performed as scheduled in order for the

Emissions Warrantyto be valid. Emissions critical maintenance

consists of servicingthe air filter and spark plugs in accordance

with the MaintenanceSchedule.

3.2 MAINTENANCESCHEDULE

Follow the calendar intervals. More frequent service is required

whenoperatingin adverseconditions notedbelow.

CheckOilLevel AtEachUse

ChangeOilandOilFilters *EverySeason/Every100Hours

CleanSparkArrestorScreen EverySeason/Every100Hours

ServiceAirFilter **EverySeason/Every200Hours

ReplaceSparkPlug EverySeason/Every200Hours

:i: Changeoil after first 30 hours of operationthen every season.

* Changeoil and oilfilter every monthwhen operatingunderheavyload or in high

temperatures.

** Clean more often under dirty or dusty operating conditions. Replace air filter

parts if verydirty.

2.10STOPPINGTHEENGINE

1. Shut off all loads, then unplug the electrical loads from

generatorpanel receptacles.Never start or stop the engine

with electricaldevicespluggedin andturnedon.

2. Let enginerun at no-load for severalminutesto stabilizethe

internaltemperaturesof engineand generator.

3. Move Run/Stopswitch to "Off" position.

4. Closefuelvalve.

2.11LOW01LPRESSURESHUTDOWNSYSTEM

Theengineis equippedwith a low oil pressuresensorthat shuts

downthe engineautomaticallywhenthe oil pressuredropsbelow

5 psi. A delay built into the low oil shutdown system allows oil

pressureto build during starting. The delay allows the engineto

run for about10 secondsbeforesensingoil pressure.If theengine

shutsdown by itself andthe fueltank hasenoughgasoline,check

engineoil level.

2.1I.IRESTARTING

If trying to restart the engine within 10 seconds after a low oil

pressureshut down, theenginemay NOTstart. Thesystemneeds

5 to 10 secondsto reset.

If the engine is restarted after such a shutdown and the low oil

pressure has not been corrected (i.e. adding oil), the enginewill

run for about10secondsas describedabove andthen stop.

3.3 PBODUCTSPECIFICATIONS

3.3.1GENERATOR SPEC/F/CAT/ON$

RatedMax. Power................................................................... 3.6 kW**

SurgePower............................................................................... 4.5 kW

RatedACVoltage...................................................................... 120/240

RatedMax ACLoad

Current@ 240V............................................................. 15.0 Amps**

Current@ 120V............................................................. 30.0 Amps**

RatedFrequency.................................................... 60 Hz@ 3600 RPM

Phase................................................................................ SinglePhase

** Maximumwattageandcurrentaresubjectto,andlimitedby,suchfactors

asfuelBtucontent,ambienttemperature,altitude,enginecondition,etc..

Maximumpowerdecreasesabout3.5%foreach1,000feetabovesealevel;

andwillalsodecreaseabout1%foreach6° C(10° F)above16° C(60°F)

ambienttemperature.

3.3.2 ENG/NESPECIFICATIONS

RatedHorsepower@ 3600 RPIVl......................................................... 6

Displacement............................................................................ 216.5cc

SparkPlugType...................................ChampionRC14YCor Equivalent

SparkPlug Gap............................................... 0.030 inch or (0.76 ram)

GasolineCapacity......................................................... 4.5 U.S. gallons

OilType.................................... SeeChart in "Adding EngineOil"Section

OilCapacity................................................ w/Filter Change= 0.8 Qts.

RunTime/FuelConsumption-l/2 Load

3.6 kW .............................................. 14 Hours/ .35 gallons per hour

ClassI Emission Certified

11

3.3.3 EMISSIONSINFORMATION

TheEnvironmentalProtectionAgency(and CaliforniaAir Resource

Board for generators certified to CA standards) require(s) that

this generator comply with exhaust and evaporative emission

standards.Locate the emissions compliance decalon the engine

to determinewhat standards the generatormeets. This generator

is certified to operateon gasoline.The emission control system

consists ofthe following:

* Air InductionSystem

- IntakePipe/Manifold

- AirCleaner

, FuelSystem

- Carburetor

- FuelTanWCap

- FuelLines

- EvaporativeVentLines

- CarbonCanister(forCAenginesonly)

, IgnitionSystem

- SparkPlug

- IgnitionModule

, ExhaustSystem

- ExhaustManifold/Muffler

3.4 GENERALRECOMMENDATIONS

Thewarranty of thegeneratordoesnotcoveritemsthat havebeen

subjectedto operator abuseor negligence.To receivefull value

from the warranty, the operator must maintain the generatoras

instructed inthis manual.

Some adjustmentswilt need to be made periodically to properly

maintainthegenerator.

All adjustmentsin the Maintenancesectionof this manual should

be madeat leastonce eachseason.Followthe requirementsinthe

"MaintenanceSchedule".

NOTE:

Oncea year replacethe spark plugand replace the air filter.

A new sparkplugand cleanair filter assure properfuel-air

mixture andhelpthe engine run better andlast longer.

NOTE:

DONOTuse a garden hose to cleangenerator.Water can

enter the engine fuel system and cause problems.In addition,

if water entersthe generator through coolingair slots,some

waterwill be retained in voidsand crevicesof the rotor

and stator windinginsulation.Water anddirt buildup on the

generatorinternalwindingswill eventually decreasethe

insulationresistanceof these windings.

3.4.2 TOCLEANTHEGENERATOR

* Usea dampcloth to wipe exteriorsurfaces clean.

* A soft, bristlebrushmaybe usedto loosencakedon dirt, oil, etc.

* A vacuumcleanermay be usedto pick up loose dirt anddebris.

* Low pressure air (not to exceed 25 psi) may be used to

blow away dirt. Inspect cooling air slots and openingson the

generator.Theseopeningsmustbekeptcleanandunobstructed.

3.4.3 ENGINEMAINTENANCE

When working on the generator, always

disconnect spark plug wire from spark plug and

keep the wire away from the spark plug.

3.4.4 CHECKINGOILLEVEL

See the "BEFORESTARTINGTHE GENERATOR"section for

information on checking the oil level. The oil level should be

checkedbeforeeachuse,or at leasteveryeighthoursof operation.

Keepthe oil levelmaintained.

3.4.5 CHANGINGTHEOILANDOILFILTER

Changethe oil and filter after the first 30 hours of operation.

Changethe oil every 100 hours or every season thereafter. If

running this unit under dirty or dusty conditions, or in extremely

hotweather,changethe oil moreoften.

ACAUTION!

3.4.1 GENERATORMAINTENANCE

Operateandstorethe unit in a cleandry environmentwhereit will

not be exposedto excessivedust,dirt, moistureor any corrosive

vapors.Coolingair slotsin thegeneratormustnot becomeclogged

with snow, leaves,or anyotherforeign material.

Checkthe cleanlinessof the generatorfrequentlyand cleanwhen

dust, dirt, oil, moisture or otherforeign substancesarevisible on

its exteriorsurface.

,_ CAUTION!

,l_ Never insert any object or tool through the air

cooling slots, even if the engine is not running.

12

,_ Hot oil may cause burns. Allow engine to

cool before draining oil. Avoid prolonged

or repeated skin exposure with used oil.

Thoroughly wash exposed areas with soap.

Usethe followinginstructionsto changethe oil afterthe engine

coolsdown:

1. Cleanareaaroundoil drainplug.

2. Removeoil drain plugfrom engineand oil fill plug to drainoil

completelyinto a suitablecontainer.

3. When oil has completely drained, install oil drain plug and

tightensecurely.

4. Placea suitable containerbeneaththe oil filter and turn filter

counterclockwise to remove. Discard according to local

regulations.

5. Coat gasket of new filter with clean engine oil. Turn filter

clockwise untilgasketcontacts lightlywith filter adapter.Then

tightenan additional3/4 turn.

6. Fill engine with recommendedoil. (See "Before Starting the

Generator"for oil recommendations).

7. Wipeup anyspilledoil.

8. Disposeof usedoil at a propercollectioncenter.

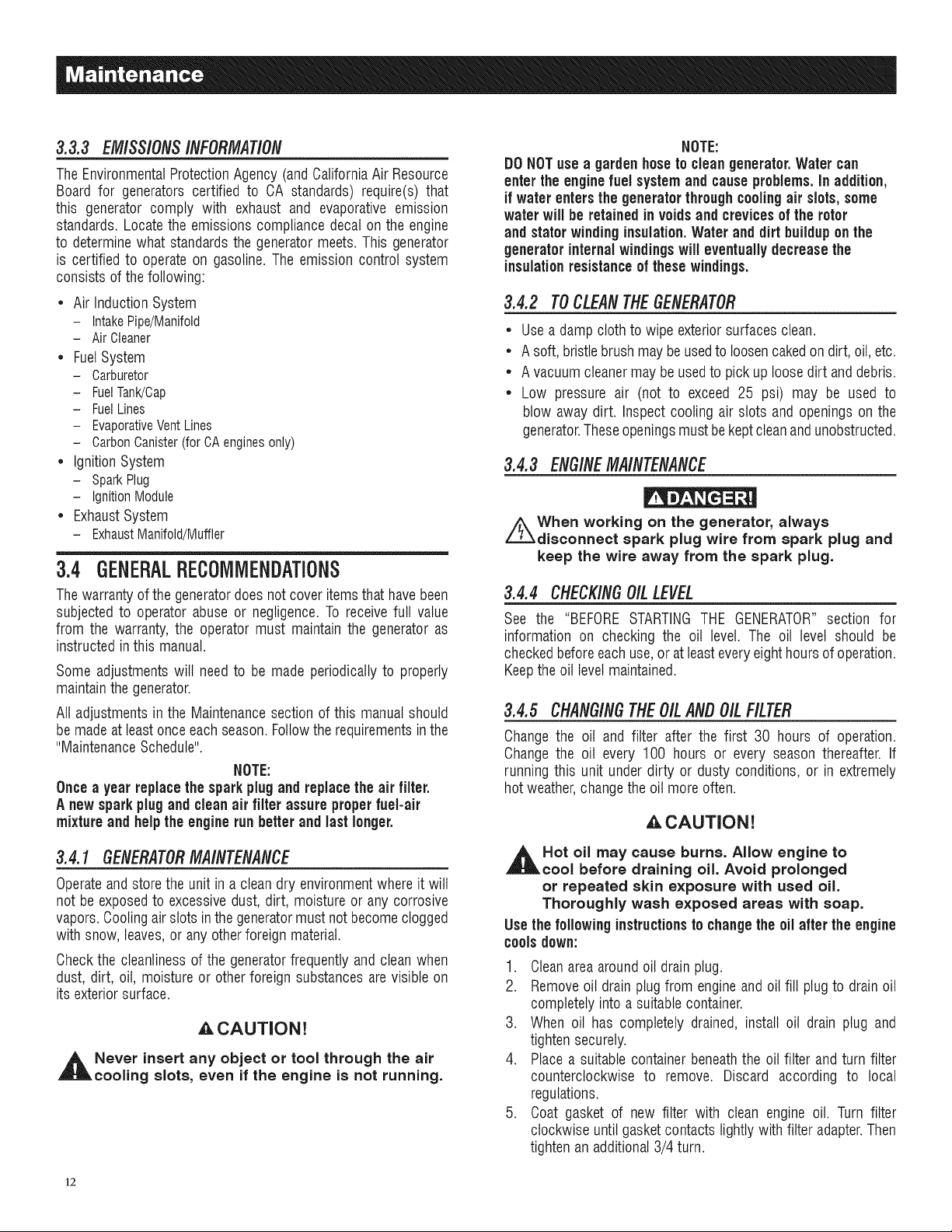

Figure 14- Air Filter

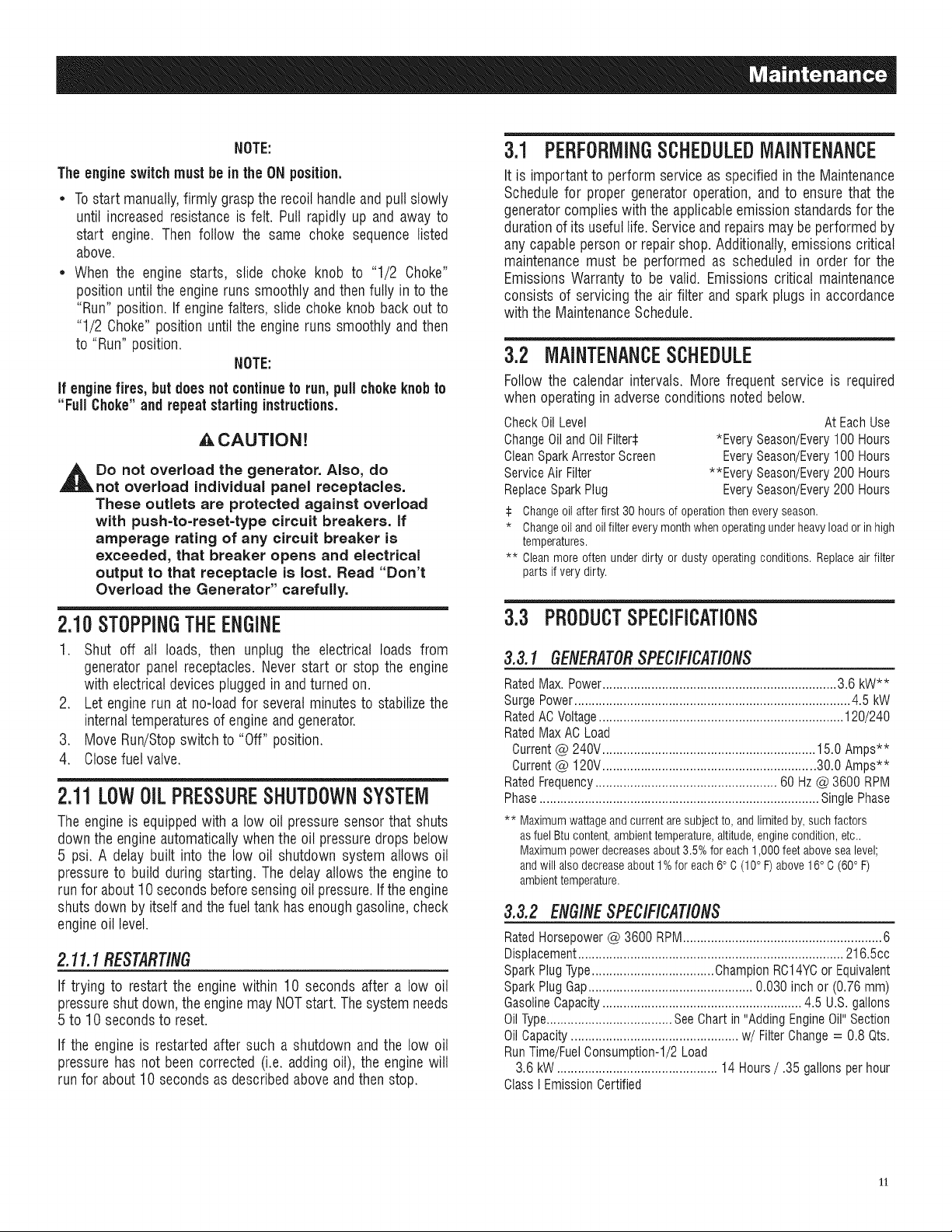

3.4.6 REPLACINGTHESPARKPLUG

Use Champion RC14YCspark plug or equivalent. Replace the

plugevery 200 hours.This wilt help the engine start easierand

run better.

1. Stopthe engineand pull the spark plug wire off of the spark

plug.

2. Togain access, removethe four (4) screws and removethe

side panel.

3. Cleanthe area aroundthe spark plug and remove it from the

cylinder head.

4. Set the spark plug's gap to .76 mm (0.030 in.). Install the

correctly gappedsparkplug intothe cylinderhead(Figure13).

5. Pushthe bootfirmly on the sparkplug and install side panel.

Figure 13 - Spark Plug Gap

3.5 SERVICEAIRFILTER

Theenginewilt not run properlyand may be damaged if usinga

dirty air filter. Cleanor replacethe air filter paperfilter every 200

hours or once a year (Figure14). Cleanor replace more often if

operatingunderdusty conditions.

Tocleanor replacepaperair filter:

1. Removeairfilter cover;then removethe paperfilter.

2. Cleanpaperfilter bytappingit gentlyon a solid surface. If the

filter is too dirty, replaceit with a newone. Disposeof theold

filter properly.

3. Cleanairfilter cover,then insert new paperfilter into the base

of the airfilter.Re-installair filter cover.

NOTE:

Filter

Base

Covel

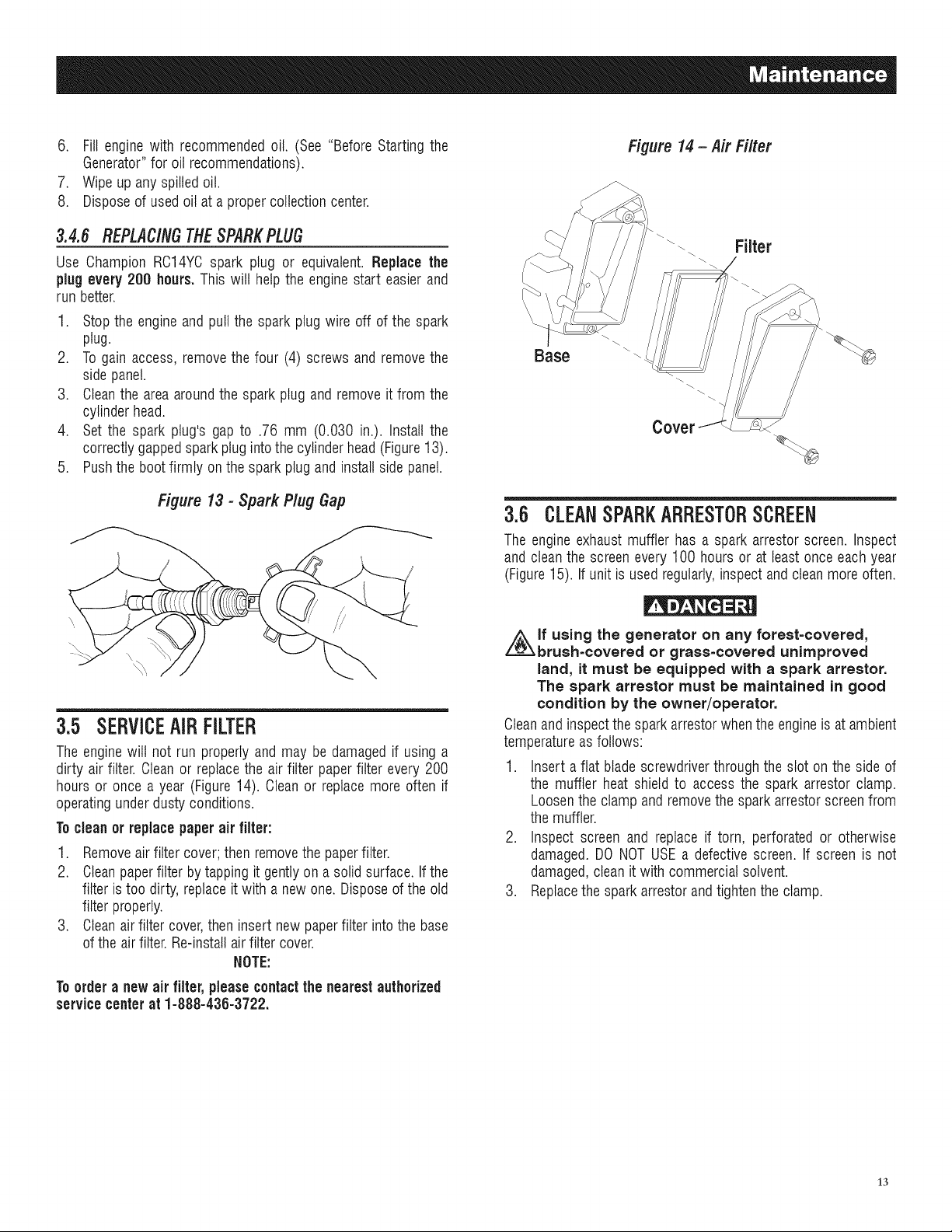

3.6 CLEANSPARKARRESTORSCREEN

The engineexhaustmuffler has a spark arrestor screen. Inspect

and cleanthe screen every 100 hours or at least onceeachyear

(Figure15). If unit is usedregularly,inspectand cleanmore often.

i_lf using the generator on any forest=covered,

brush=covered or grass=covered unimproved

land, it must be equipped with a spark arrestor.

The spark arrestor must be maintained in good

condition by the owner/operator.

Cleanandinspectthe sparkarrestorwhentheengineis at ambient

temperatureasfollows:

1. Insert a flat blade screwdriverthrough the slot on the side of

the muffler heat shield to access the spark arrestor clamp.

Loosenthe clamp and removethe spark arrestorscreenfrom

themuffler.

2. Inspect screen and replace if torn, perforated or otherwise

damaged. DONOT USEa defective screen. If screen is not

damaged,cleanit with commercialsolvent.

3. Replacethe spark arrestorandtightenthe clamp.

Toorder a new air filter, pleasecontactthe nearestauthorized

servicecenterat 1-888-436-3722.

13

Figure 15 -- Spark Arrestor Screen

Drain fuel into approved container outdoors,

away from open flame. Be sure engine is cool.

Do not smoke in the vicinity or light a cigarette.

2. Start and run engineuntilenginestopsfrom lack of fuel

3. Allow the engineto cool to the touch and then drain the oil

from the crankcase.Refillwith the recommendedgrade.

4. Removespark plug and pour about 1/2 ounce (15 mt) of

engineoil intothecylinder.Coversparkplug holewith rag. Putt

the recoil starter acouple times to lubricatethe piston rings

and cylinderbore.

CAUTION!

ARRESTOR

SCREENCLAMP

SPARK

ARRESTOR

SCREEN

INSERTSCREWDRIVER

THROUGHSLOTINHEAT

SHIELDTO ACCESS

ARRESTORSCREENCLAMP

3.7 GENERAL

Thegeneratorshould be started at leastonce every 30 days and

be allowedto run at least30 minutes.If this cannot be done and

the unit must be stored for morethan 30 days, use thefollowing

informationas a guideto prepareit for storage.

NEVER store engine with fuel in tank indoors

or in enclosed, poorly ventilated areas where

fumes may reach an open flame, spark or pilot

light as on a furnace, water heater, clothes

dryer or other gas appliance.

_t Allow unit to cool entirely before storage.

3.8 LONGTERMSTORAGE

It is importantto preventgum deposits from forming in essential

fuel systemparts such asthe carburetor,fuel hoseortank during

storage. Also, experience indicates that alcohol-blendedfuels

(calledgasohol,ethanol or methanol)can attract moisture,which

leadsto separationand formation of acids during storage.Acidic

gas candamagethefuel system of an enginewhile in storage.

To avoid engineproblems, the fuel system should be emptied

beforestorageof 30 days or longer,asfollows:

1. Removeallgasolinefrom thefuel tank.

_t void spray from the spark plug hole when

cranking engine.

5. Install and tighten the spark plug. Do not connect the spark

plug wire.

6. Cleanthe generatorouter surfaces. Check that cooling air

slots andopeningson generatorareopen andunobstructed.

7. Storethe unit in a clean, dry place.

3.9 OTHERSTORAGETiPS

* Do not store gasolinefrom oneseasonto another.

* Replacethe gasolinecan if it starts to rust. Rustand/or dirt in

the gasolinewill cause problems with the carburetorand fuel

system.

* If possible, store the unit indoors, in a garage or shed, and

cover it to give protectionfrom dust and dirt. BESURETO

EMPTYTHEFUELTANK.

* If it is not practical to emptythe fuel tank andthe unit is to

be stored for some time, use a commercially availablefuel

stabilizer added to the gasoline to increase the life of the

gasoline.

* Coverthe unit with a suitable protective cover that does not

retainmoisture.

i_NEVER cover the generator while engine and

exhaust area are warm. Allow unit to cool

entirely.

14

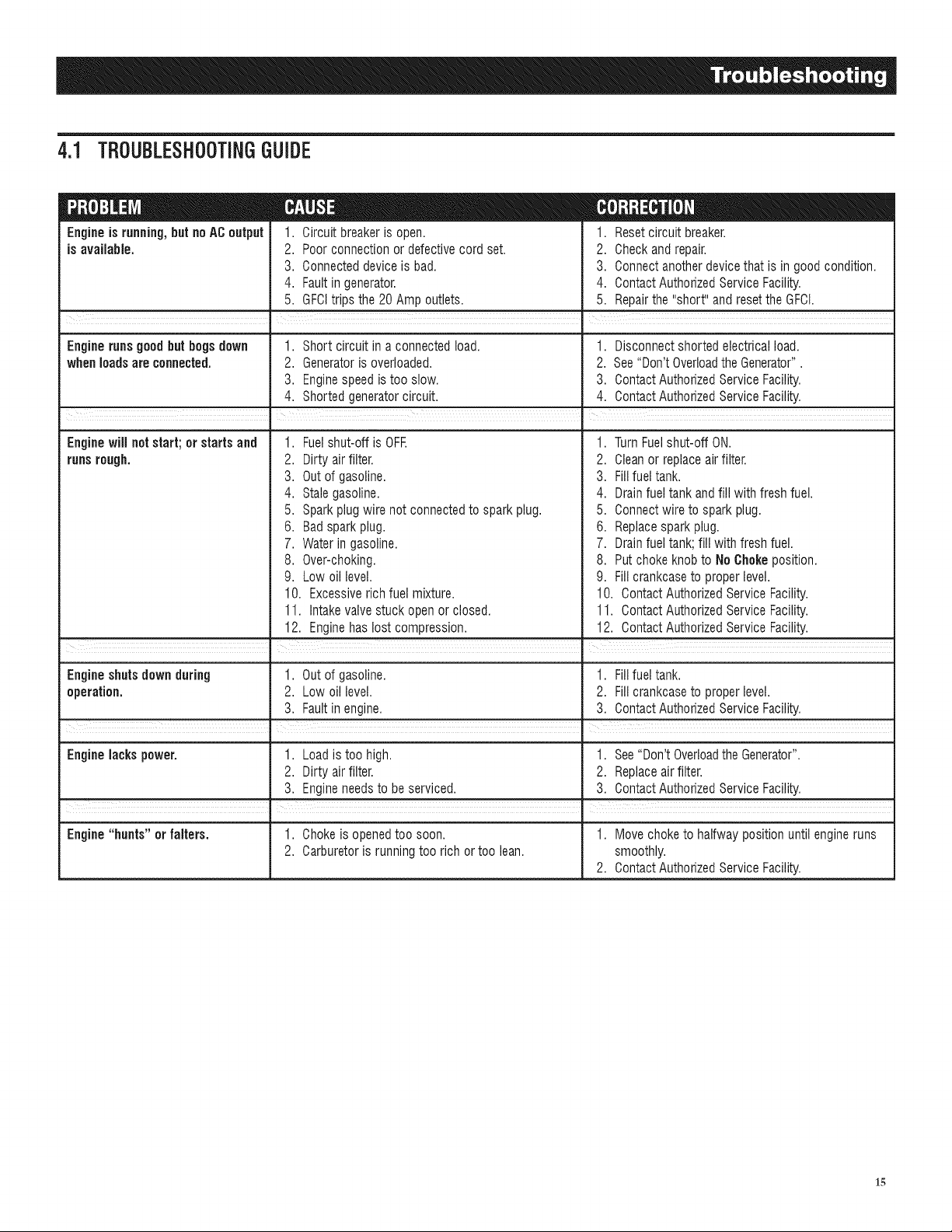

4.1 TBOUBLESHOOTINGGUIDE

Engineis running,but noAC output

is available.

1. Circuit breakeris open.

2. Poor connectionor defectivecord set.

3. Connecteddevice is bad.

4. Faultin generator.

5. GFCItrips the 20 Amp outlets.

! I

1. Resetcircuit breaker.

2. Checkand repair.

3. Connectanotherdevicethat is in good condition.

4. ContactAuthorizedService Facility.

5. Repairthe"short" and reset the GFCI.

Engine runs good but bogs down 1. Short circuit in a connectedload. 1. Disconnectshorted electricalload.

when loadsare connected. 2. Generatoris overloaded. 2. See"Don'tOverloadthe Generator".

3. Enginespeedis too slow. 3. ContactAuthorizedServiceFacility.

4. Shorted generatorcircuit. 4. ContactAuthorizedService Facility.

Enginewill not start; or starts and 1. Fuelshut-off is OFF. 1. TurnFuelshut-off ON.

runsrough. 2. Dirtyair filter. 2. Cleanor replaceairfilter.

3. Out of gasoline. 3. Fillfuel tank.

4. Stale gasoline. 4. Drainfuel tank andfill with fresh fuel.

5. Sparkplug wire not connectedto spark plug. 5. Connectwire to spark plug.

6. Badsparkplug.

7. Waterin gasoline.

8. Over-choking.

9. Low oil level.

10. Excessiverich fuel mixture.

11. Intakevalvestuck open or closed.

12. Enginehas lost compression.

6. Replacesparkplug.

7. Drainfuel tank; fill with fresh fuel.

8. Put choke knobto NoChokeposition.

9. Fill crankcaseto proper level.

10. Contact AuthorizedServiceFacility.

11. Contact AuthorizedServiceFacility.

12. Contact AuthorizedServiceFacility.

Engineshuts downduring 1. Out of gasoline. 1. Fillfuel tank.

operation. 2. Low oil level. 2. Fill crankcaseto proper level.

3. Faultin engine. 3. ContactAuthorizedService Facility.

Engine lacks power. 1. Load is too high. 1. See"Don'tOverloadthe Generator".

2. Dirty air filter. 2. Replaceairfilter.

3. Engineneedsto beserviced. 3. ContactAuthorizedServiceFacility.

.

=

Engine "hunts" or falters. 1. Chokeis openedtoo soon. 1. Move choke to halfway position until engineruns

2. Carburetoris runningtoo rich or too lean. smoothly.

2. ContactAuthorizedService Facility.

15

16

17

EM/$$/ONWARRANTYFOREPACERTIFIEDEQUIPMENT

U,S, EPA EMiSSiON CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLiGATiONS

TheUnited StatesEnvironmentalProtectionAgency (EPA)and GeneracPowerSystems,Inc. (Generac)are pleasedto explainthe Emission Control

SystemWarranty (ECSWarranty) on your new 2011 and laterequipment.New equipmentthat use small spark-ignitedenginesmust bedesigned,built,

andequipped to meet stringentanti-smog standardsfor the federal government.Generacwill warrantthe emission control system on your equipment

for the period of time listed belowprovidedthere has beenno abuse, neglect,unapprovedmodificationor improper maintenanceof your equipment.

Theemission control system on this equipmentincludes all components whose failurewould increasethe emissionsof anyregulatedpollutant.These

componentsare listed in the EmissionsInformation section ofthis manual.

MANUFACTURER'S WARRANTY COVERAGE:

This ECSWarranty is validfor two years,or for the same period as specifiedin the GeneracLimited Warranty,whicheveris longer.Forequipmentwith

hourmeters,the warranty period is anumber of hours equalto halfthe UsefulLifeto whichthe equipmentis certified, or the warrantyperiod specified

abovein years, whicheveris less.TheUseful Life can befound on the EmissionControlLabel on the engine.If, during suchwarranty period,any

emission-relatedpart on your equipmentisfound to be defectivein materialsor workmanship, repairs or replacementwill be performed by aGenerac

AuthorizedWarrantyServiceDealer.

OWNER'S WARRANTY RESPONSiBiLiTiES:

Asthe equipmentowner,you are responsiblefor the completion of all requiredmaintenanceas listed in your factory suppliedOwner'sManual.For

warranty purposes,Generacrecommendsthat you retainall receiptscovering maintenanceon your generator,butGeneraccannotdenywarranty

solelydueto the lack of receipts.

Youshould beaware that Generacmay denyanyand/or all warrantycoverageor responsibility if your equipment,or apart!component thereof,has

failed due to abuse,neglect, impropermaintenance,or unapprovedmodifications.

Youare responsible for contactingaGeoeracAuthorized Warranty Dealer as soonas a problemoccurs.Thewarranty repairsshouldbe

completed in a reasonableamount oftime, not to exceed 30 days.

Warrantyservice can bearrangedby contacting eitheryour sellingdealeror aGeneracAuthorizedWarranty ServiceDealer.Tolocate the Generac

AuthorizedWarrantyServiceDealernearestyou, call ourtoll free numberbelow, or email emissions@generac.com.

1-800-333-1322

IMPORTANTNOTE:This warranty statementexplainsyour rights and obligationsunderthe Emission ControlSystem Warranty,which is providedto

you by Generacpursuantto federal law. Seealsothe "GeneracLimitedWarrantiesfor GeneracPowerSystems,Inc.," which is enclosedherewith on a

separatesheet,also providedto you byGenerac.Notethat this warranty shall not apply to any incidental,consequentialor indirect damagescaused

bydefects in materials or workmanship or any delayin repairor replacementof the defectivepart(s). This warranty is in place of all other warranties,

expressedor implied.Specifically,Generacmakesno other warrantiesas to the merchantabilityor fitness for a particular purpose.Any implied

warrantieswhich areallowed by law, shallbe limited in durationto the terms of the expresswarranty providedherein.Somestates do not allow

limitationson how long an implied warrantylasts, so the abovelimitation may not applyto you.

TheECSWarrantyappliesonly to the emissioncontrol system of your newequipment. Boththe ECSWarrantyandthe GeneracWarrantydescribe

importantrights and obligationswith respectto your new engine.

Warrantyservice can beperformed onlyby a GeneracAuthorizedWarrantyServiceFacility.When requestingwarranty service, evidencemust be

presentedshowingthe date ofthe saleto the originalpurchaser/owner.

Ifyou have any questionsregardingyour warranty rights andresponsibilities,you should contact Generacatthe following address:

ATTENTION WARRANTY DEPARTMENT

GENERAC POWER SYSTEMS, INC.

P.O. BOX 297 * WHITEWATER, Wi 53190

PartI of 2

PartNo. 0J3335A Rev.A 11/11

18

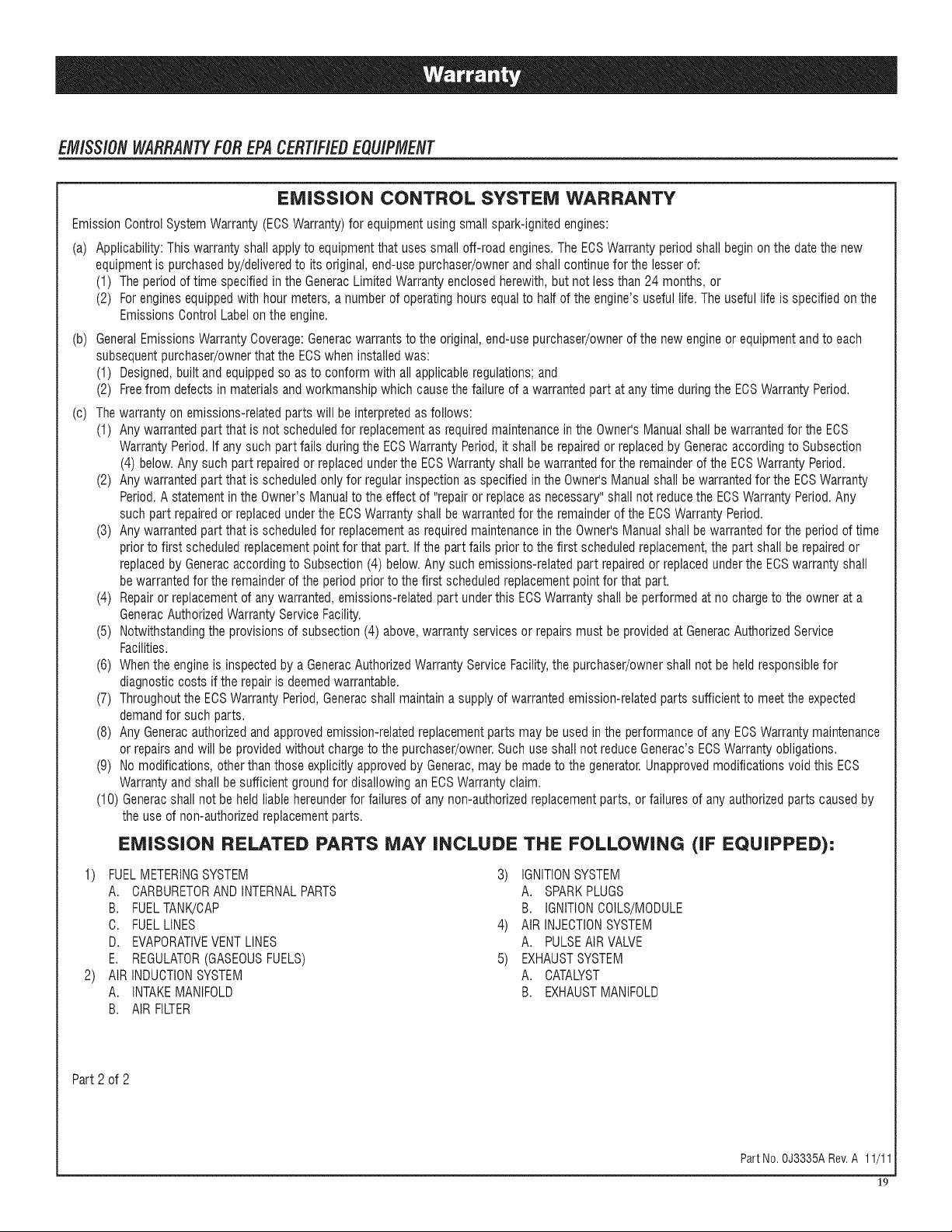

EM/SS/ONWARRANTYFOREPACERTIFIEDEQUIPMENT

EMiSSiON CONTROL SYSTEM WARRANTY

EmissionControl SystemWarranty (ECSWarranty)for equipmentusing small spark-ignited engines:

(a) Applicability:This warranty shall applyto equipmentthat usessmall off-road engines.The ECSWarrantyperiodshall beginon the datethe new

equipmentis purchasedby/deliveredto itsoriginal, end-usepurchaser/ownerandshall continue for the lesserof:

(1) Theperiodof time specified in the GeneracLimited Warrantyenclosedherewith,but notless than 24 months,or

(2) Forenginesequippedwith hour meters,a numberof operating hoursequal to half of the engine'suseful life. The usefullifeis specified on the

EmissionsControl Labelon the engine.

(b) GeneralEmissionsWarranty Coverage:Generacwarrantsto the original,end-usepurchaser/ownerof the new engineor equipment andto each

subsequentpurchaser/ownerthat the ECSwhen installedwas:

(1) Designed,built andequippedsoas to conform with all applicableregulations;and

(2) Freefrom defectsin materialsand workmanship which causethe failure of a warrantedpart at anytime duringthe ECSWarrantyPeriod.

(c) Thewarranty on emissions-relatedparts will be interpretedasfollows:

(1) Anywarranted part that is not scheduledfor replacementas requiredmaintenancein the Owner'sManual shall bewarranted forthe ECS

WarrantyPeriod.If any such partfails duringthe ECSWarranty Period,it shall be repairedor replacedby Generacaccordingto Subsection

(4) below.Any such part repairedor replacedunderthe ECSWarrantyshall bewarranted for the remainderofthe ECSWarranty Period.

(2) Anywarranted part that is scheduled onlyfor regularinspection asspecifiedin the Owner'sManualshall be warrantedfor the ECSWarranty

Period.A statementin the Owner's Manualto the effect of "repairor replace asnecessary"shall not reducethe ECSWarrantyPeriod.Any

such part repairedorreplacedunderthe ECSWarrantyshall be warrantedfor the remainderofthe ECSWarrantyPeriod.

(3) Anywarranted part that is scheduledfor replacementasrequired maintenancein the Owner'sManualshall be warrantedfor the period of time

priorto first scheduled replacementpointfor thatpart. Ifthe part fails prior to the first scheduled replacement,the part shall be repairedor

replacedby Generacaccordingto Subsection(4) below.Any such emissions-relatedpart repairedor replacedunderthe ECSwarranty shall

bewarrantedfor the remainderof the period prior to the first scheduledreplacementpoint for that part.

(4) Repairor replacementof any warranted,emissions-relatedpart underthis ECSWarranty shall beperformed atno charge to the owner ata

GeneracAuthorizedWarrantyServiceFacility.

(5) Notwithstandingthe provisions of subsection (4) above,warranty services or repairsmust be providedat GeneracAuthorizedService

Facilities.

(6) Whenthe engineis inspectedby a GeneracAuthorizedWarrantyServiceFacility,the purchaser/ownershall notbe heldresponsiblefor

diagnosticcosts if the repairis deemedwarrantable.

(7) Throughoutthe ECSWarrantyPeriod,Generacshall maintaina supply of warranted emission-relatedparts sufficient to meetthe expected

demandfor such parts.

(8) AnyGeneracauthorizedand approvedemission-relatedreplacementparts may beused in the performanceof any ECSWarrantymaintenance

or repairsandwill beprovidedwithout chargeto the purchaser/owner.Such useshall not reduceGenerac'sECSWarrantyobligations.

(9) No modifications,other than those explicitlyapproved by Generac,may be madeto the generator.Unapprovedmodificationsvoid this ECS

Warrantyand shall be sufficient groundfor disallowingan ECSWarrantyclaim.

(10) Generacshall not be heldliablehereunderforfailures of any non-authorizedreplacementparts, or failures of anyauthorizedparts caused by

the useof non-authorizedreplacementparts.

EMISSION RELATED PARTS MAY iNCLUDE THE FOLLOWING (IF EQUIPPED):

1) FUELMETERINGSYSTEM 3) IGNITIONSYSTEM

A. CARBURETORANDINTERNALPARTS A. SPARKPLUGS

B. FUELTANK!CAP B. IGNITtONCOILS/MODULE

C. FUELLINES 4) AIRINJECTIONSYSTEM

D. EVAPORATIVEVENTLINES A. PULSEAIRVALVE

E. REGULATOR(GASEOUSFUELS) 5) EXHAUSTSYSTEM

2) AIRINDUCTIONSYSTEM A. CATALYST

A. INTAKEMANIFOLD B. EXHAUSTMANIFOLD

B. AIRFILTER

Part 2 of 2

PartNo. OJ3335ARev.A 11/11

19

Loading...

Loading...