Page 1

ULS-1 Single Point Level Switches

IP65 ingress protection

Stocked items highlighted.

Compact 1/4˝ and 1/2˝ NPT versions

All-Stainless Steel wetted materials

IP68 construction for tanks or sumps

Gems ultrasonic switches are an excellent choice for a broad range of liquids

including those with light coating or scaling type characteristics.

A:K:AHL>I8=:HÄH>C<A:ED>CI

Relay output provides a reliable switch interface with remote devices such as a PLC,

SCADA or alarm.

Specifications

Wetted Material 316L Stainless Steel

Repeatability 2 mm (or better)

Protection Transient Reverse Polarity

Leakage Current <50μA

Delay 0.5 seconds

Input Power 5 VDC to 30 VDC

Output See Ordering Table

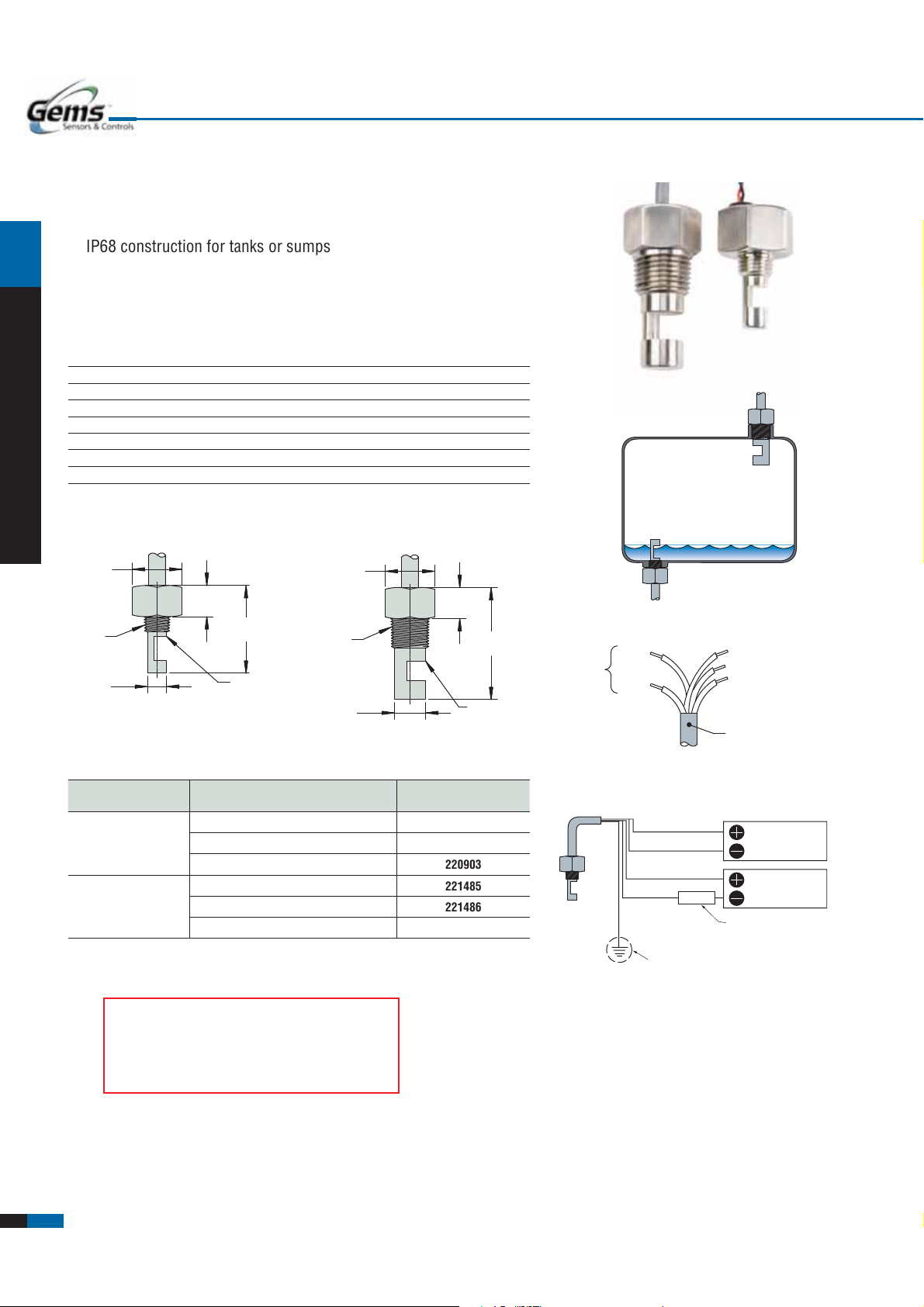

Dimensions

1/4˝ NPT Mounting

1/2˝ NPT Mounting

HIGH LEVEL

1/4˝ NPT

1˝

(25.4)

3/8˝

(9.5)

5/8˝

(15.88)

1.76˝

(44.7)

SWITCH POINT

1/2˝ NPT

(15.9)

5/8˝

1˝

(25.4)

How To Order

Select a Part Number based on Mounting Size and Output.

Mounting Size Electronic Output Part Number

Wet Sink 220901

1/4˝ NPT

1A SPST Relay, Normally Closed 220903

1/2˝ NPT

1A SPST Relay, Normally Closed 221487

Note: Other Electronic Output options are available. Please contact Gems.

Wet Source 220902

Wet Sink 221485

Wet Source 221486

- Standard units suitable for use up

to 80°C.

- High temperature versions also

available - up to 100°C.

5/8˝

(15.88)

2 1/4˝

(57.15)

SWITCH POINT

LOW LEVEL

Wiring

POWER

WHITE

OUTPUT

BROWN

(+) RED, 5VDC TO 30VDC

(-) BLK, GROUND

GREEN, CHASSIS GND

24 AWG PVC JACKET,

12˝ (305 MM) LENGTH

Wiring Direct to a Load

N.C. Operation (Relay Signal Output)

RED

BLACK

BROWN

WHITE

GREEN

SHIELD

GROUND

LOAD

CONTROLLED DEVICE

(RELAY, LAMP, VALVE, ETC.)

1A MAXIMUM

12 - 36 VDC

POWER SUPPLY

(SENSOR)

60 VAC/ VDC

MAXIMUM

POWER SUPPLY

6"(+

Visit www.GemsSensors.com for most current information.

Page 2

Ultrasonic Switches Monitor the Toughest Applications

Operates in a wide variety of liquids

Handles pressures to 1000 psi

Unaffected by foam, vapors, particulate or turbulence

Lengths to 121 inches (307.3 cm)

Can be side, top or bottom mounted

A:K:AHL>I8=:HÄH>C<A:ED>CI

Sized and priced for most applications

Easy to install — simple to use

GEMS ULS Series of ultrasonic switches are designed for a broad

spectrum of viscous to light liquids; including some of the most

challenging liquids you may deal with: acids, freon, paints, lacquers,

etc. Stainless steel units are built to withstand high temperatures and

pressures with welded stainless steel sensor probes that have no

seals to leak and no moving parts to wear out. ULS Series switches

are unaffected by variation in temperature, pressure, density or type of

liquid. ULS-10 and ULS-100 electronics are housed in cast aluminum,

NEMA 4/NEMA 7 explosion proof and water tight enclosures.

Ultrasonic Switch

ULS-100

ULS-10

Selection Guide

Single Point Sensing

Input Power:

115 VAC / 230 VAC

12/24 VDC

9-36 VDC

12-36 VDC

Output:

10 Amp DPDT

1 Amp SPDT

5 mA (dry), 10 mA (wet)

4 mA / 20 mA Single 2-Wire

FM-Approved Explosion Proof Option

Sensor Material Options:

316 Stainless Steel (standard)

316L Stainless Steel

®

Monel

Hastelloy B

Hastelloy C

Teflon

Kynar

CPVC

Polypropylene

®

®

®

®

ULS-1

ULS-10

ss

s

s

s

s

s

s

s

s

s

s

ULS-100 ULS-11

ss

s

s

s

s

s

s

ss

s

s

s

s

s

s

s

ULS-1

ULS-11

6"()

Visit www.GemsSensors.com for most current information.

Page 3

General Operating Principle

ULS Series switches operate using ultrasonic

sound wave propagation. Ultrasonic sound

waves are greatly attenuated when transmitted

through air. Conversely, when liquid is

present, transmission of the sound waves is

greatly enhanced. The electronic control unit

generates electrical signals that are converted

to bursts of ultrasonic energy at the sensor.

The ultrasonic bursts are transmitted across

the liquid sensing gap. Upon receipt of a valid

signal, the solid-state electronics generate

a data enable condition, indicating liquid is

present. This signal energizes a relay and

provides an output condition.

TRANSMITTING

CRYSTAL

RECEIVING

CRYSTAL

JAIG6HDC>8INE:

Switch actuates when level

reaches halfway point of gap.

Typical Installation

1. Drill a suitable hole in the vessel or pipe wall

and tap for 3/4˝ NPT. In thin walled vessel

or material not suitable for threading, weld

or braze a bushing to accept the sensor.

2. Screw the sensor in the threaded section

and make sure that there is a good seal. Use

a pipe compound or sealing tape to avoid

excessive tightening. Do not overtighten.

3. Run the power and control wiring cables to

the electronics control unit.

Vertical or Horizontal Mounting

HIGH LEVEL ALARM

PUMP CONTROL

LOW LEVEL ALARM

Advantages of GEMS ULS-10 2-Wire Output Switches

1. No A.C. Power

2. No Coaxial Cable Required

3. Up to 1000 ft. or Longer Distance

4. Reduces Installation Cost

Secondary Containment Tanks and Piping Systems

Maintenance

Electronics are

constructed with solidstate components

and epoxy-potted.

Periodically, check

and clean the sensor

when used with liquids

which cause a coating

build-up on the sensor. No

other maintenance is required.

If the pipe or vessel to which

the unit is mounted is to be

steam-cleaned or cleaned with

abrasive detergents, remove

the entire unit before cleaning

by:

(1) Disconnecting the power

at source.

(2) Opening the housing cover.

(3) Removing power and control wiring cables.

(4) Unthreading the sensor.

To reinstall, follow installation procedures.

CARRIER

PIPE

SECONDARY

CONTAINMENT

PIPE

SECONDARY CONTAINMENT

(1/2" NPT OPTIONAL)

SECONDARY CONTAINMENT TANK

3/4" NPT FITTING

3/4" NPT

FITTING

A:K:AHL>I8=:HÄH>C<A:ED>CI

COMPUTER INTERFACE

OR

REMOTE CURRENT

DETECTOR CIRCUIT

Contents Page Start

ULS-1 Low Power Steel

ULS-10 & ULS-100 10 Amp Switches

ULS-11 Low Power Steel

Visit www.GemsSensors.com for most current information.

......................................

...........

....................................

A-34

A-35

A-37

6"(*

Loading...

Loading...